Patents

Literature

3400results about How to "Low calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of barley seedling powder and product thereof

The invention relates to a production process of chewable tablets of barley shoot powder and a product thereof and belongs to the deep processing technology field of agricultural products. The production process is characterized in that the barley shoot powder is main base material, and the chewable tablets of the barley shoot powder with smooth appearance, green color and crispness and freshness is made after the processes of composite stabilizer, making soft material, granulation, drying, tabletting, sterilization and packing. The method has the advantages of simple process, higher industrialization degree, low production cost, realizing the full utilization of the barley shoot and promoting the added value of the barley shoot. The chewable tablets of the barley shoot powder produced by the invention which is leisure-base health care food can fully enhance physique and body immune, simultaneously has the function of catharsis, reducing blood lipid and preventing cerebral thrombosis and coronary heart disease.

Owner:NANJING AGRICULTURAL UNIVERSITY

Weight management beverage

InactiveUS20060121158A1Low calorific valueIncrease productionMilk preparationPre-extraction tea treatmentWeight managementEnergy expenditure

The present invention relates to a weight management beverage composition and methods of aiding in weight maintenance by promoting increased energy expenditure (“thermogenesis”) while simultaneously increasing satiety thereby decreasing overall energy intake of persons who consume these compositions. The compositions set forth herein include dry beverage mixes beverage concentrates as well as beverages in ready to drink form so that they can be used in a variety of settings.

Owner:NESTEC SA

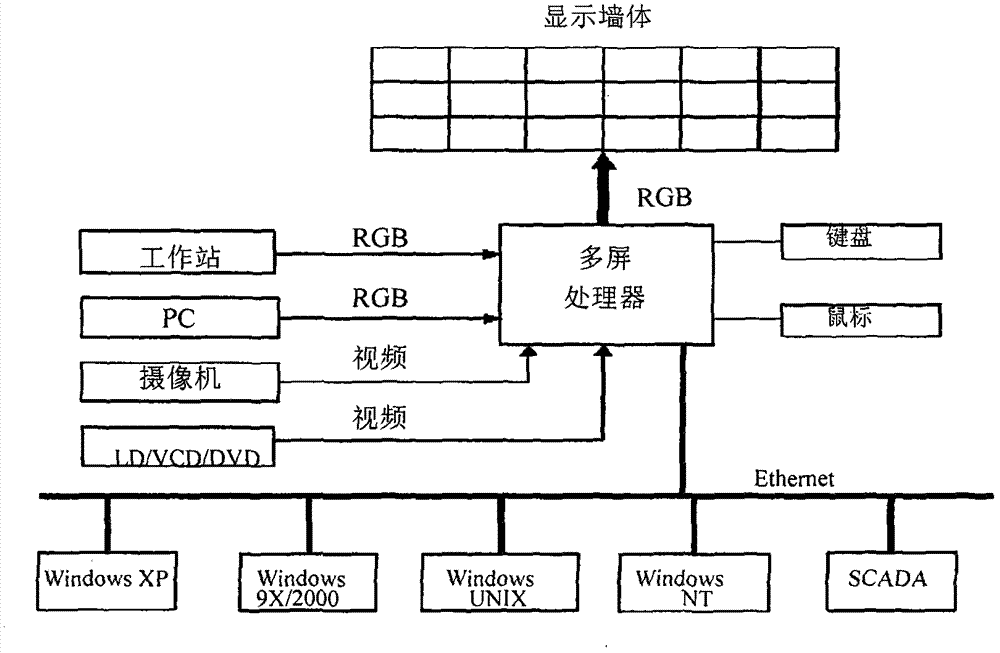

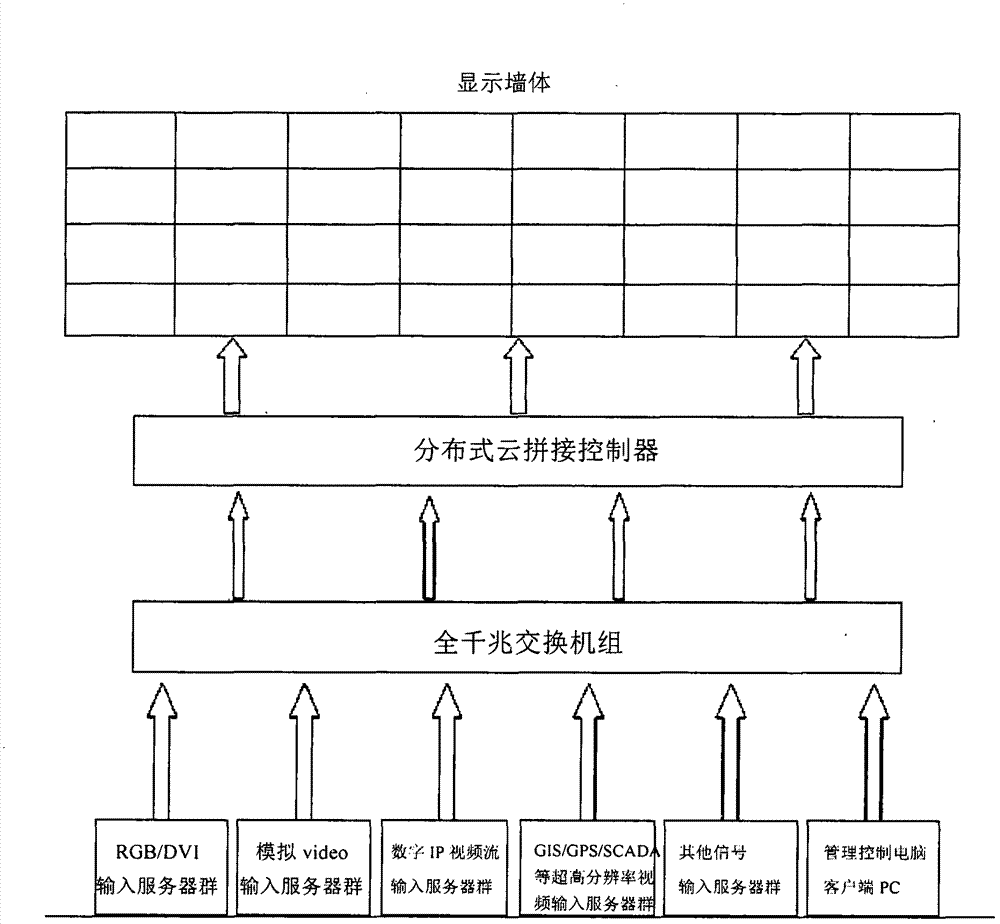

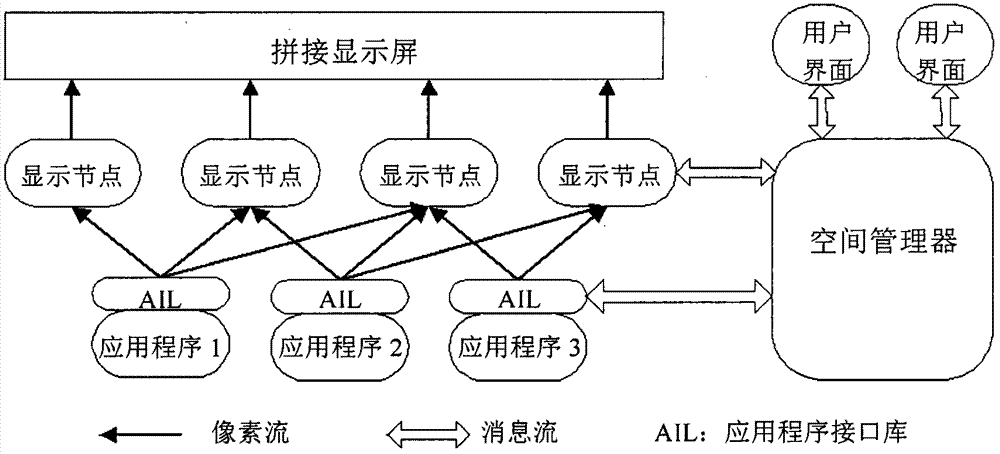

Tiled display control system based on cloud computing technology, image display method adopting system and application of system

InactiveCN104754305ARealize visualizationSupport real-time dynamic interactionTelevision system detailsTelevision conference systemsInformation processingDisplay device

The invention provides a tiled display control system based on a cloud computing technology, an image display method adopting the system and an application of the system. The system comprises a plurality of displays, a plurality of distributed cloud registration controllers, a plurality of exchangers and system software, wherein a jointing wall is formed by the plurality of displays; an LAN (Local Area Network) is formed by cascading the plurality of exchangers, and a framework core of an IP (Internet Protocol) network is formed by a transmission channel for providing data and control commands; the plurality of distributed cloud registration controllers are accessed into the exchangers of the corresponding levels, and are connected with the corresponding displays through video connecting wires, and the cloud registration controller adopts a PCI-E (PCI Express) base-plate and is provided with an Inter processor. A plurality of data (IE) windows can be displayed on an assembled display simultaneously by adopting the performance of a flexibly configured server and an output channel of the system, and can be interacted in real time; furthermore, the tiled display control system has the functions of video decoding, server memory and the like after the system is applied to a video conference system; compared with the traditional scheme, the system has the advantages of high performance, high reliability, high development, low cost, information processing, strong analysis and management capacities, high resolution ratio, high performance cost ratio, real-time display, green environmental protection and the like.

Owner:BEIJING DEPULL VIDEO TECH CO LTD

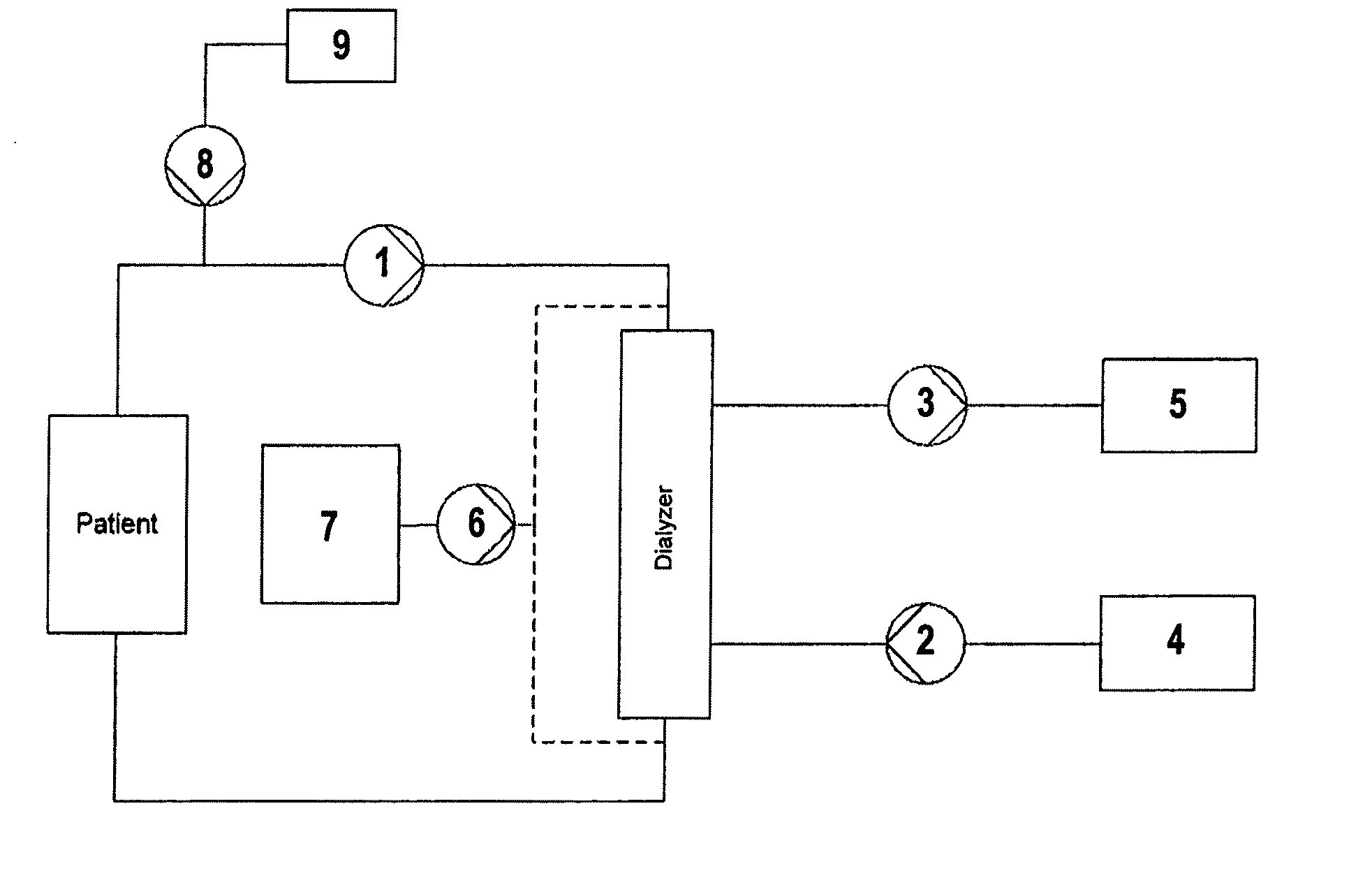

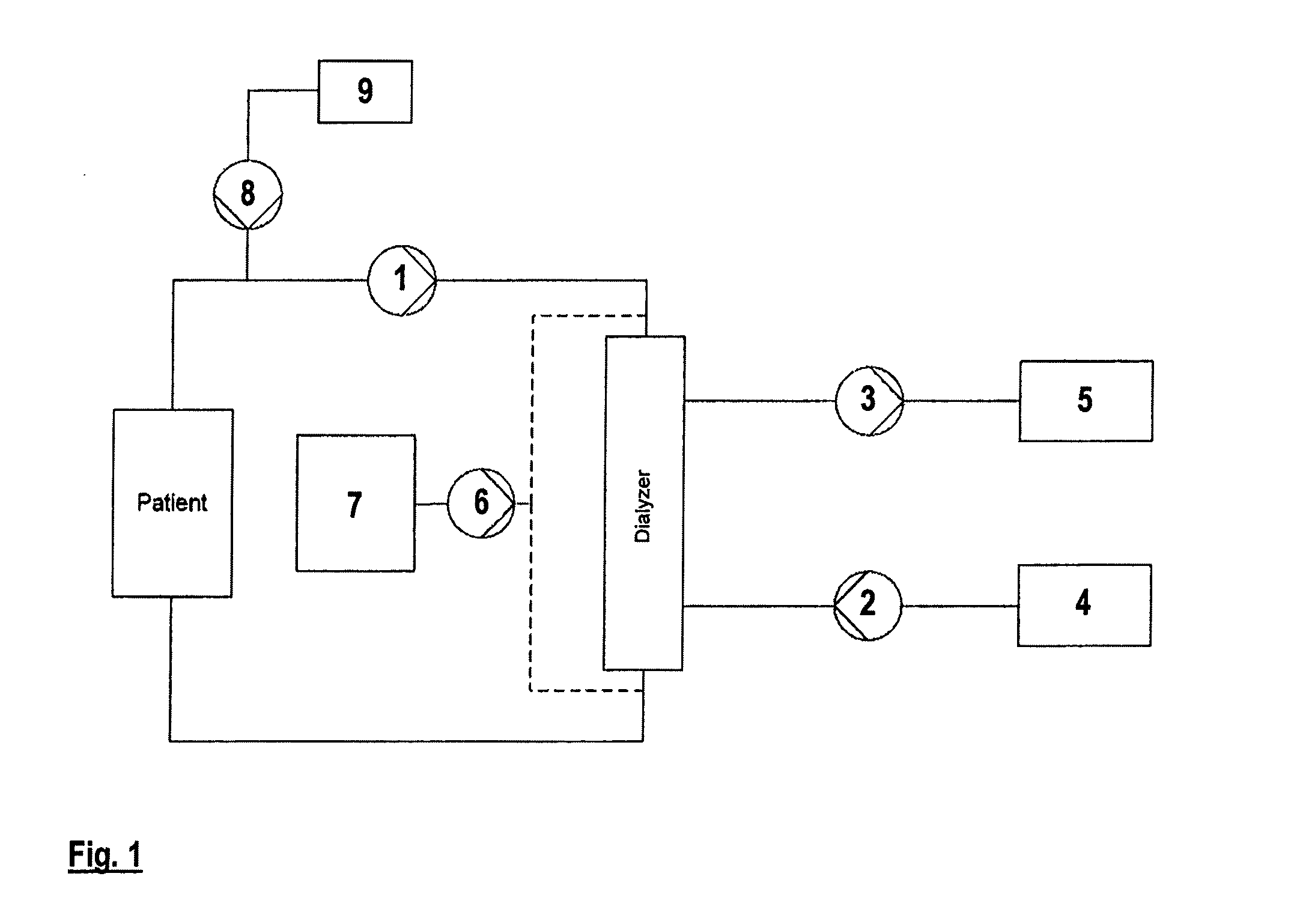

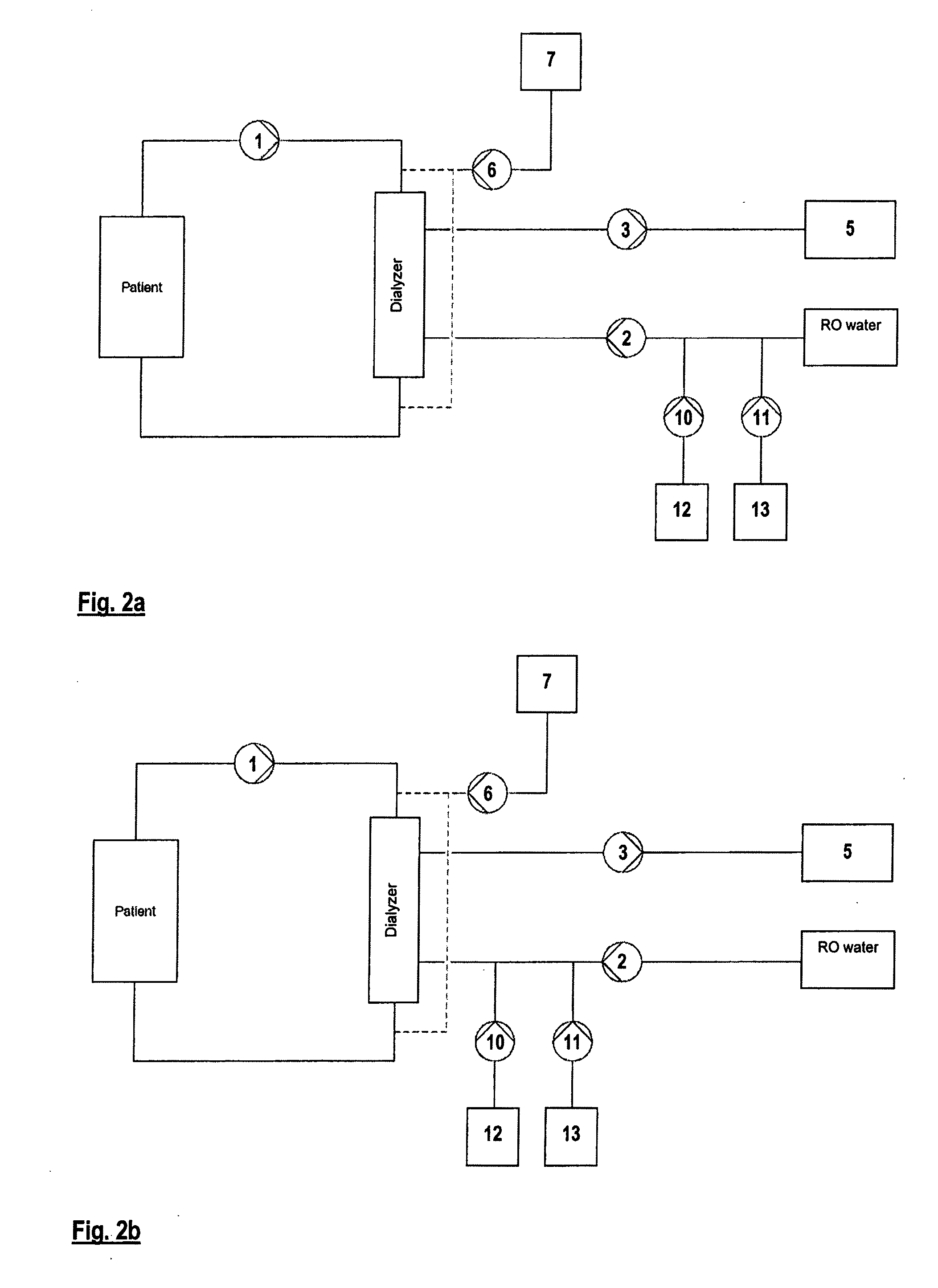

Dialysis device

InactiveUS20110105981A1Easy to replaceSmall installation sizeFlexible member pumpsBlood pumpsPeristaltic pumpPiezoelectric actuators

The present invention relates to dialysis devices comprising peristaltic pumps of linear build with piezoelectric actuators.

Owner:GAMBRO LUNDIA AB

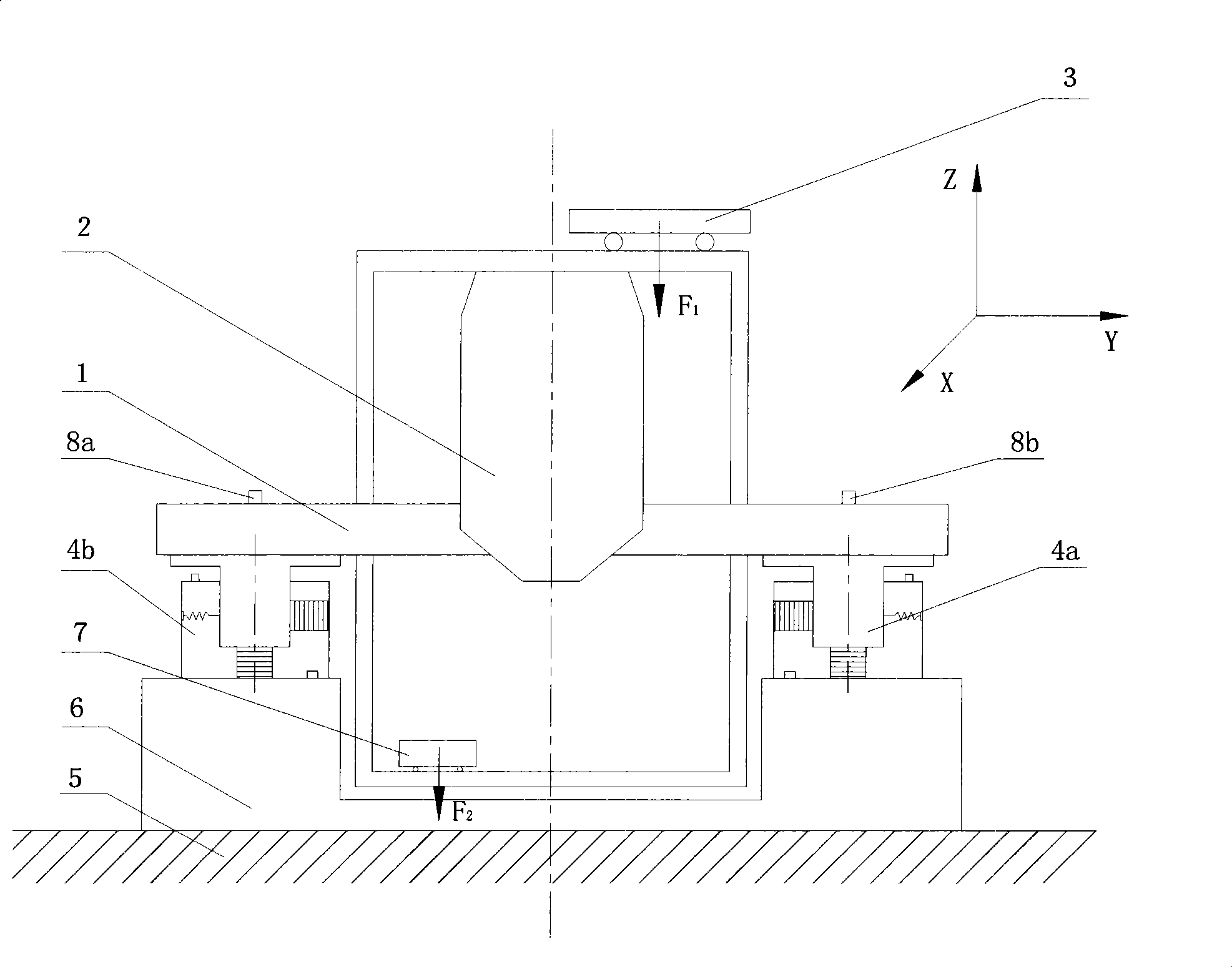

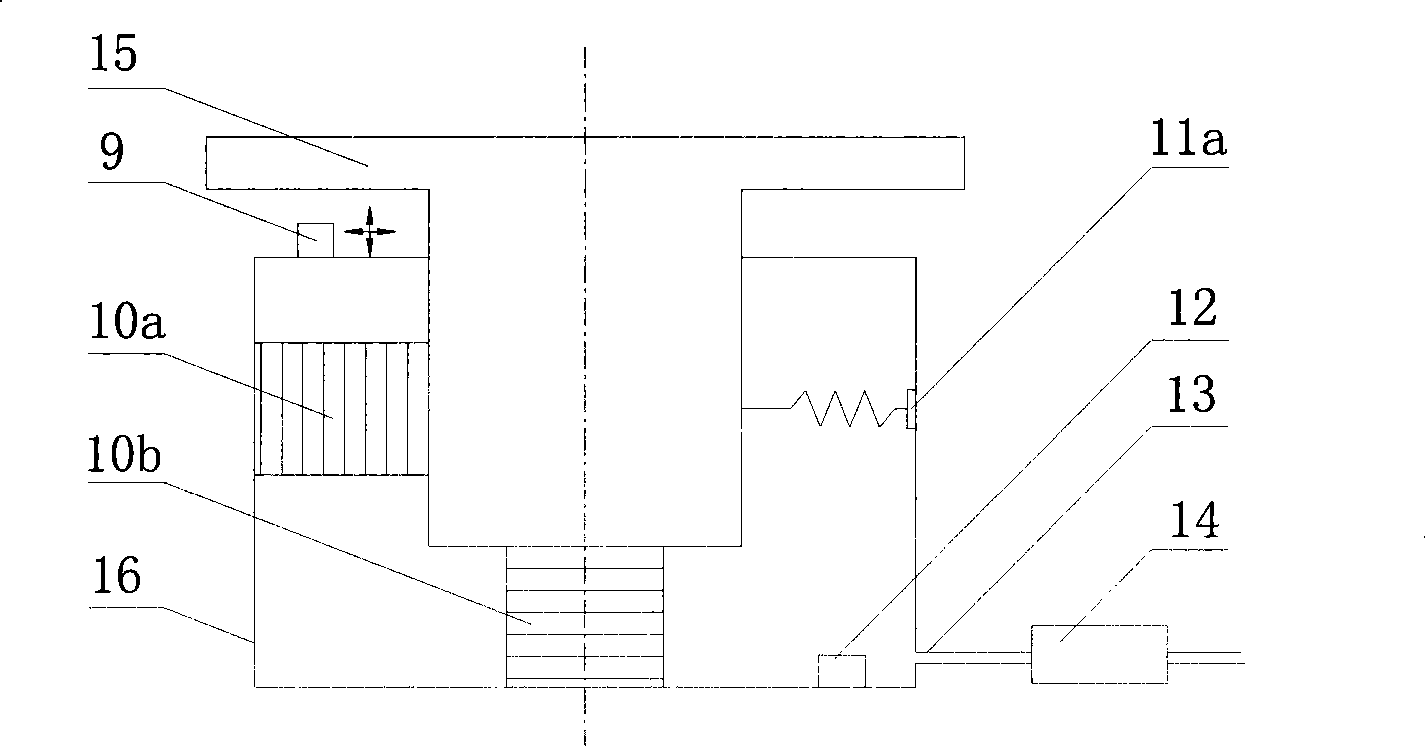

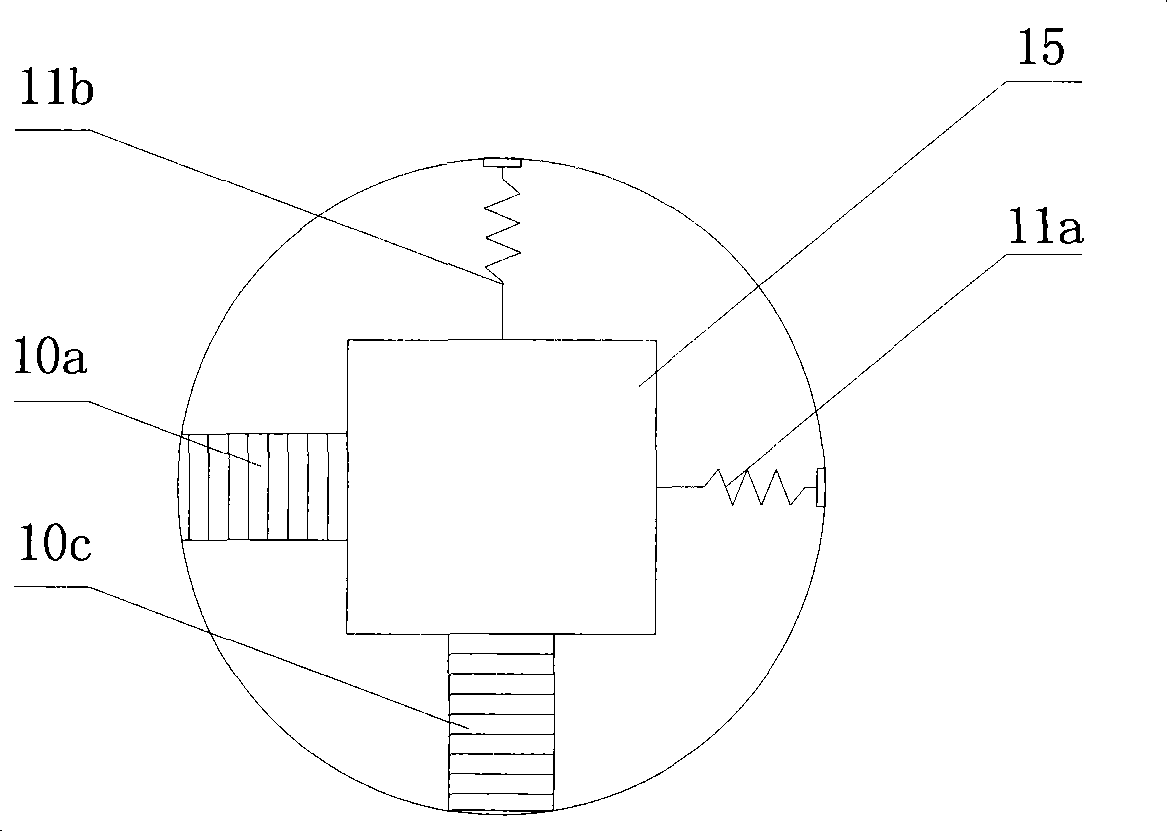

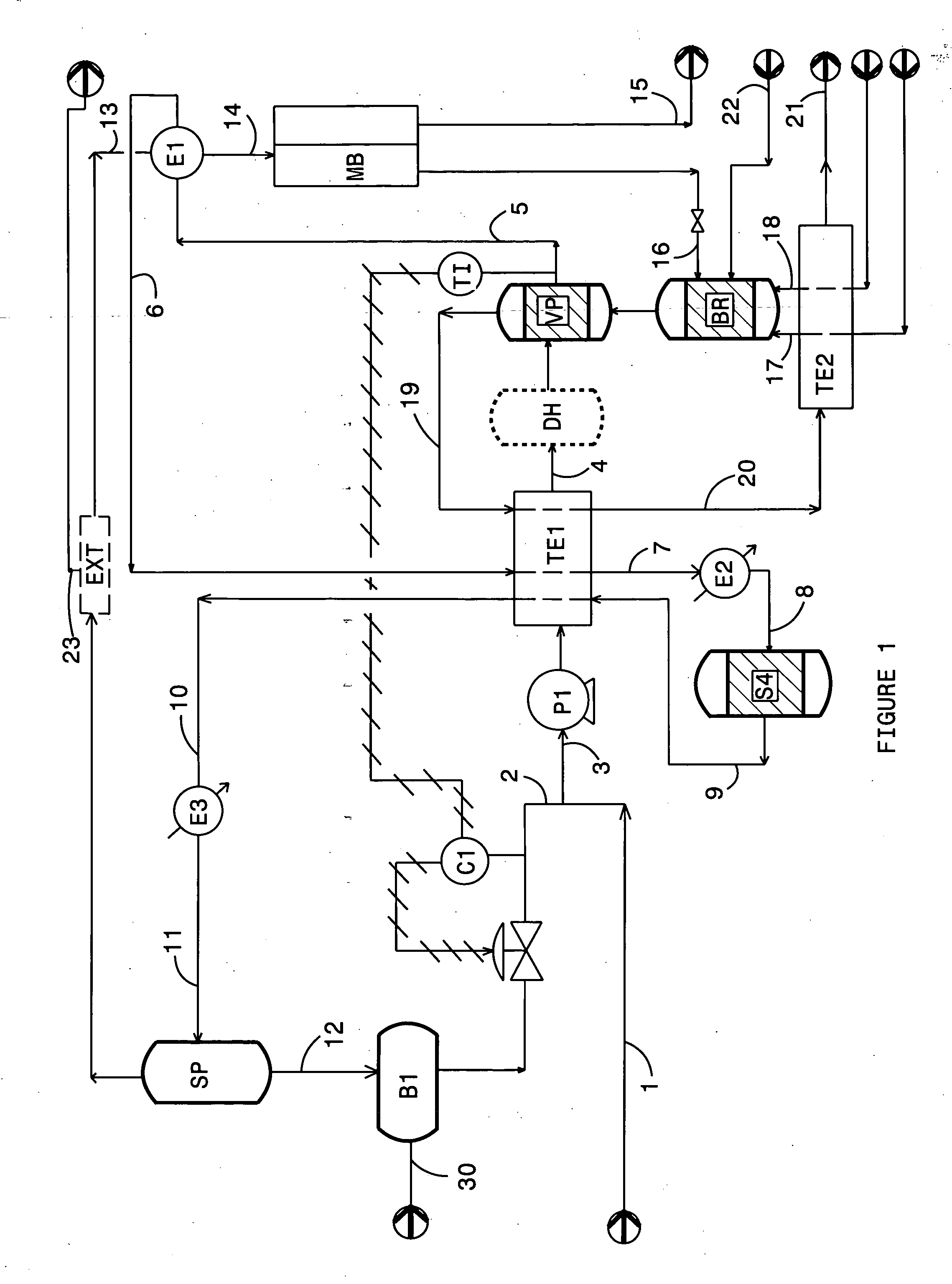

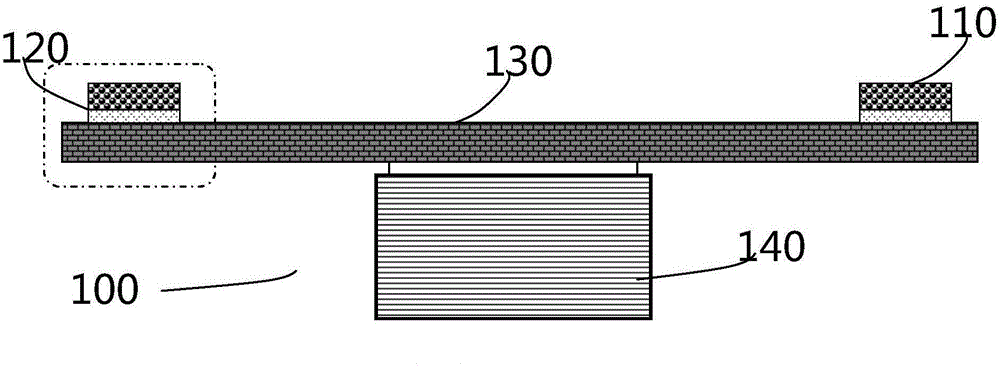

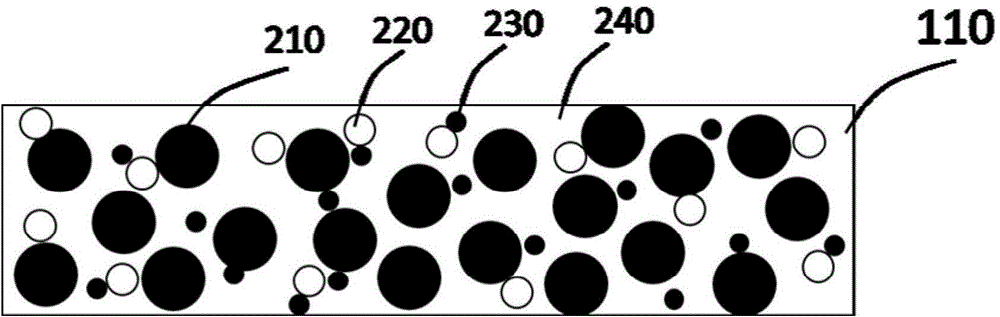

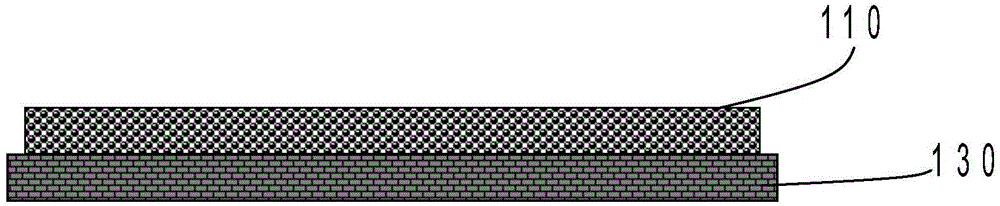

Active vibration damping system and forecast control method thereof

ActiveCN101364052AReduce overturning momentLow calorific valueMachine framesPhotomechanical exposure apparatusControl systemControl signal

The invention provides an active damping system which comprises a pedestal, a main substrate, damping units and a control system and which is characterized in that: the number of the damping units is at least three; the damping units are arranged at the same included angle around a center and uniformly distributed on the same circumference; the bottom ends of the damping units are positioned on the pedestal and the top ends of the damping units are positioned on the main substrate; the control system is connected with the damping units to receive vibration signals from the damping units and feedback a control signal. According to the path planning of the moving parts such as the mask table and the working table on the main substrate, the preview control module generates the position information of each moving part within a future time period; integrates the current position information and the position information within the future time period of each moving parts; calculates a preview compensation control signal by means of the preview control algorithm; superposes the preview compensation control signal to the damping feedback control signal; and actuates the active damping system. The active damping system has the advantages of small power, low energy consumption and high damping accuracy.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

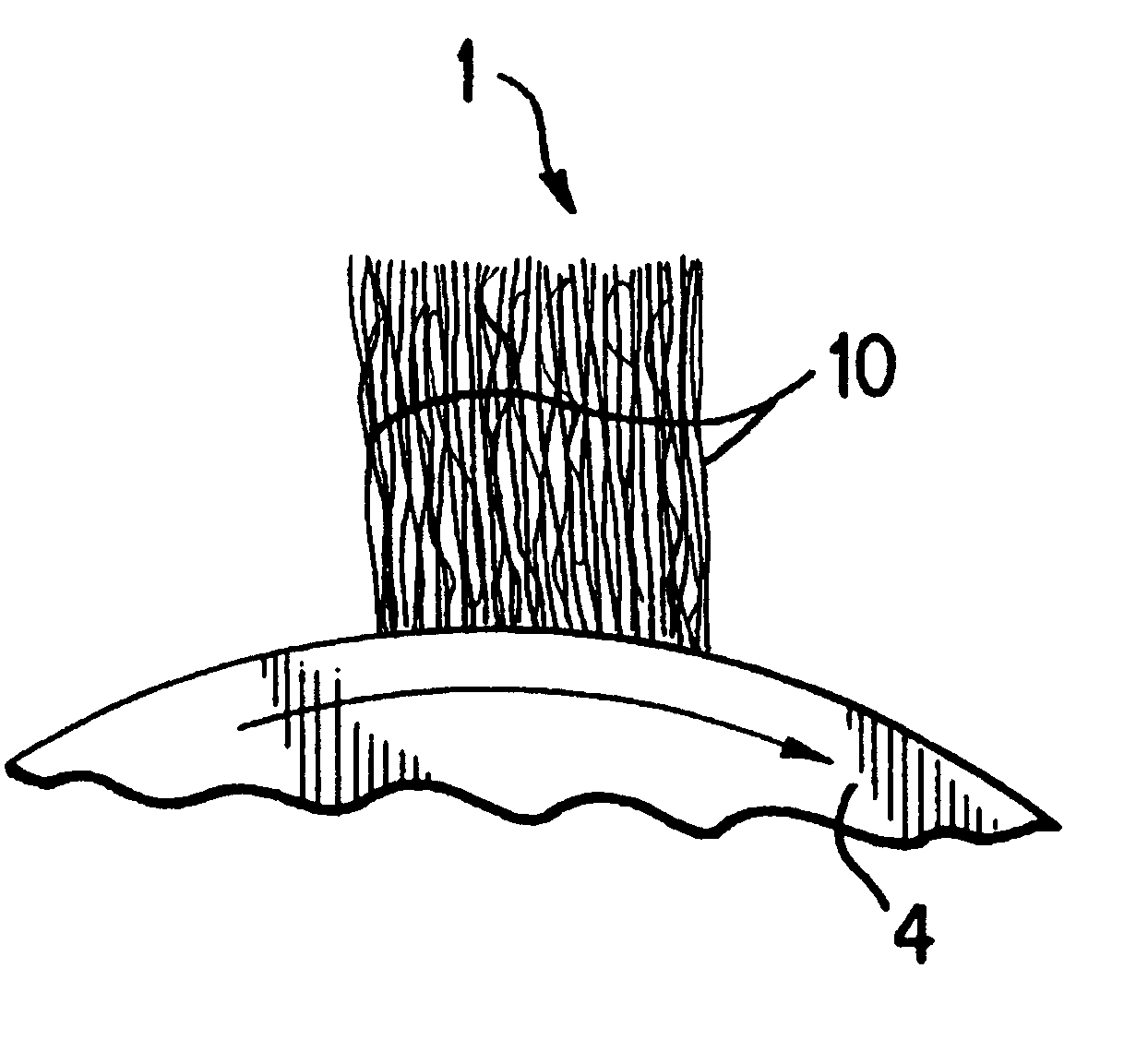

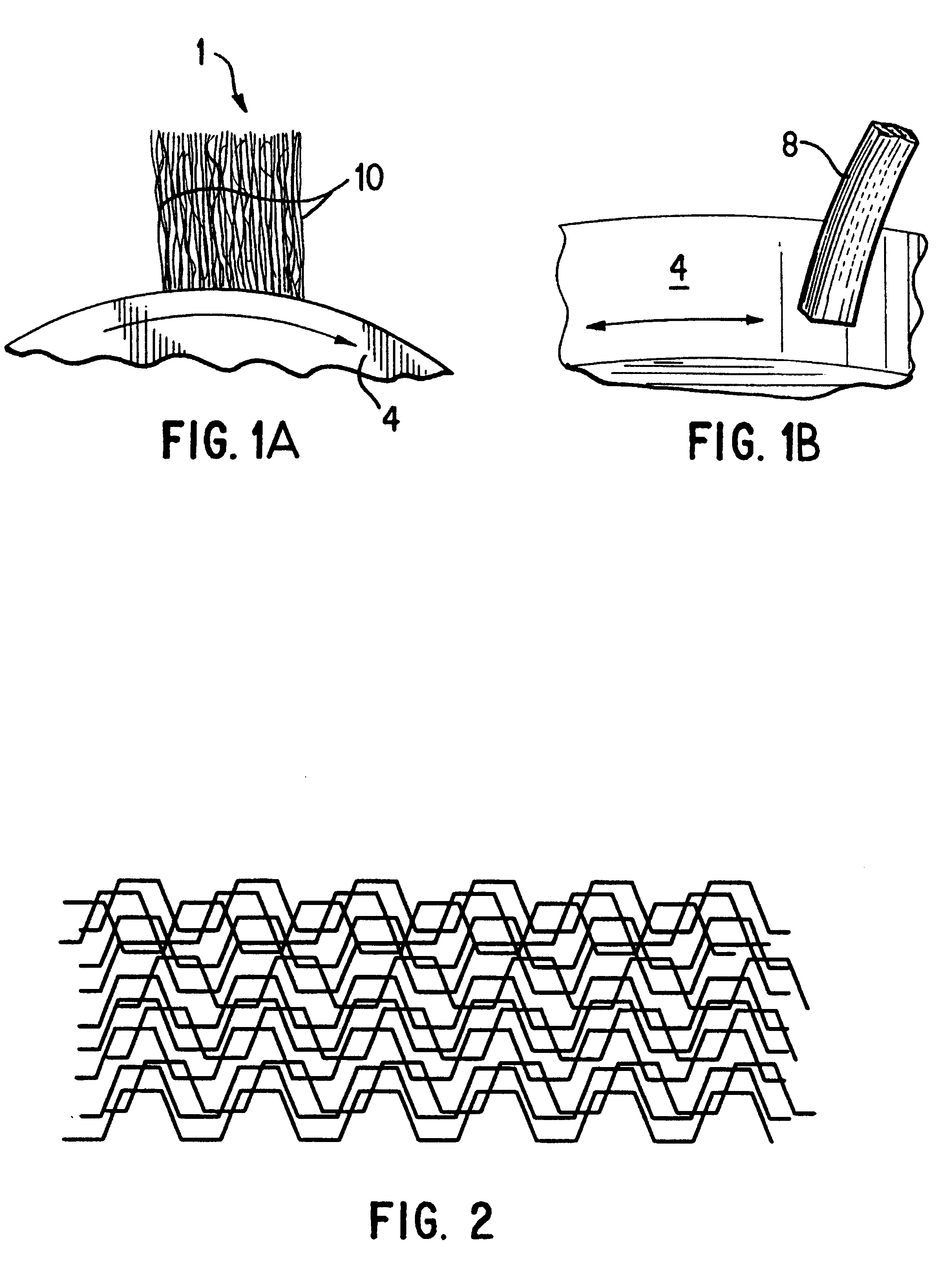

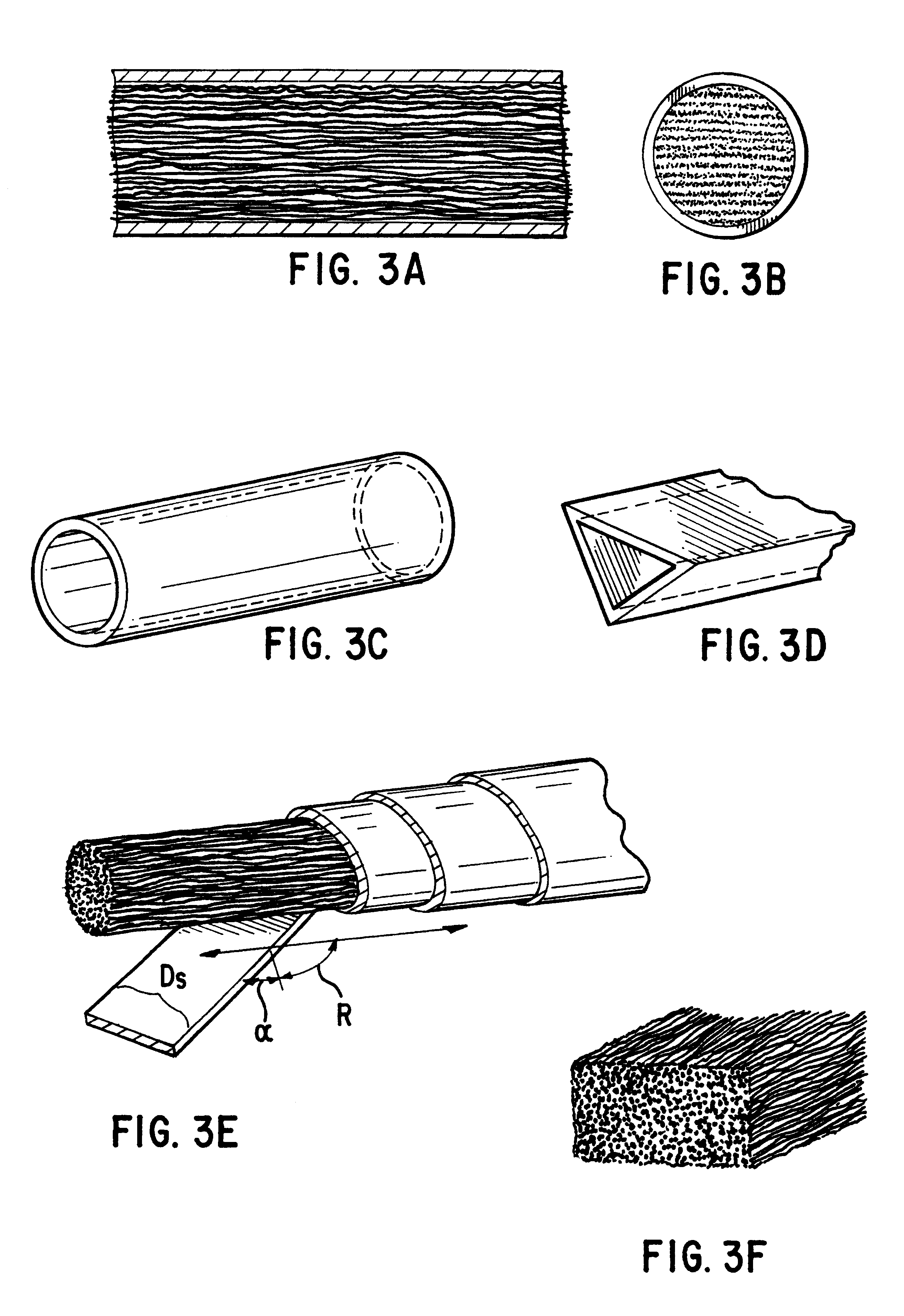

Continuous metal fiber brushes

InactiveUS6245440B1Avoid large gapsSuppressing advanceRotary current collectorMagnetic materialsMetal fiberLubrication

A conductive fiber brush including a brush stock composed of plural conductive fibers or strands of fibers at least some of which may have plural bends along the leg of the fibers or strands. The fibers may have a diameter less than 0.2 mm and are arranged in contacting engagement with each other with the touching points among the fibers or strands maintaining elastic tension between the fibers or strands and thereby maintaining voids between the fibers or strands to produce a packing fraction between 1 and 50% and in extreme cases up to 70% but generally between 10-20% depending on the various factors, including the materials used, the current densities to be conducted, and the sliding speeds under operation. The plural bends are implemented by producing fibers or strands having a regular or irregular spiral, wavy, saw-tooth, triangular, and / or rectangular pattern, or other undulating pattern. Optionally, the voids in brush stock may be partially filled with a strengthening, lubricating, abrasive, and / or polishing material, and may be wrapped in an outer sheath, slid into a casing, or provided with an other covering of all or part of the area of the brush stock, be infiltrated or sprayed at the surface with some material, have an increased packing fraction at the surface and / or have some or all of the touching points between the fibers or strands soldered, welded or otherwise thermally joined. Optionally also, the friction among the fibers may be reduced through light lubrication applied by rinsing the brush or brush stock in a lubricant. In one embodiment, the fiber brush is employed in a brush loading device having a hydrostatically controlled brush holder wherein the force exerted on the brush is controlled by a metallic or other conductive hydrostatic fluid which at the same time conducts the current to the brush.

Owner:VIRGINIA UNIV PATENT FOUND OF

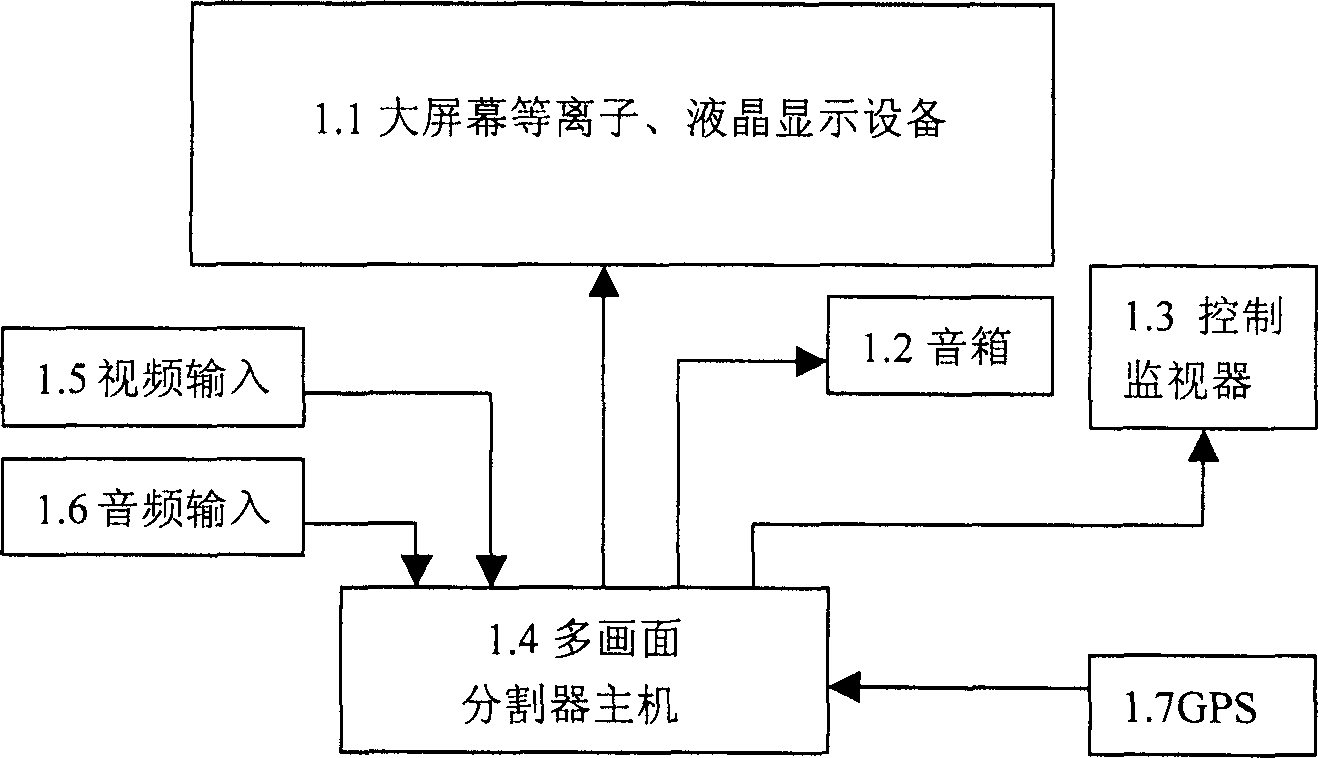

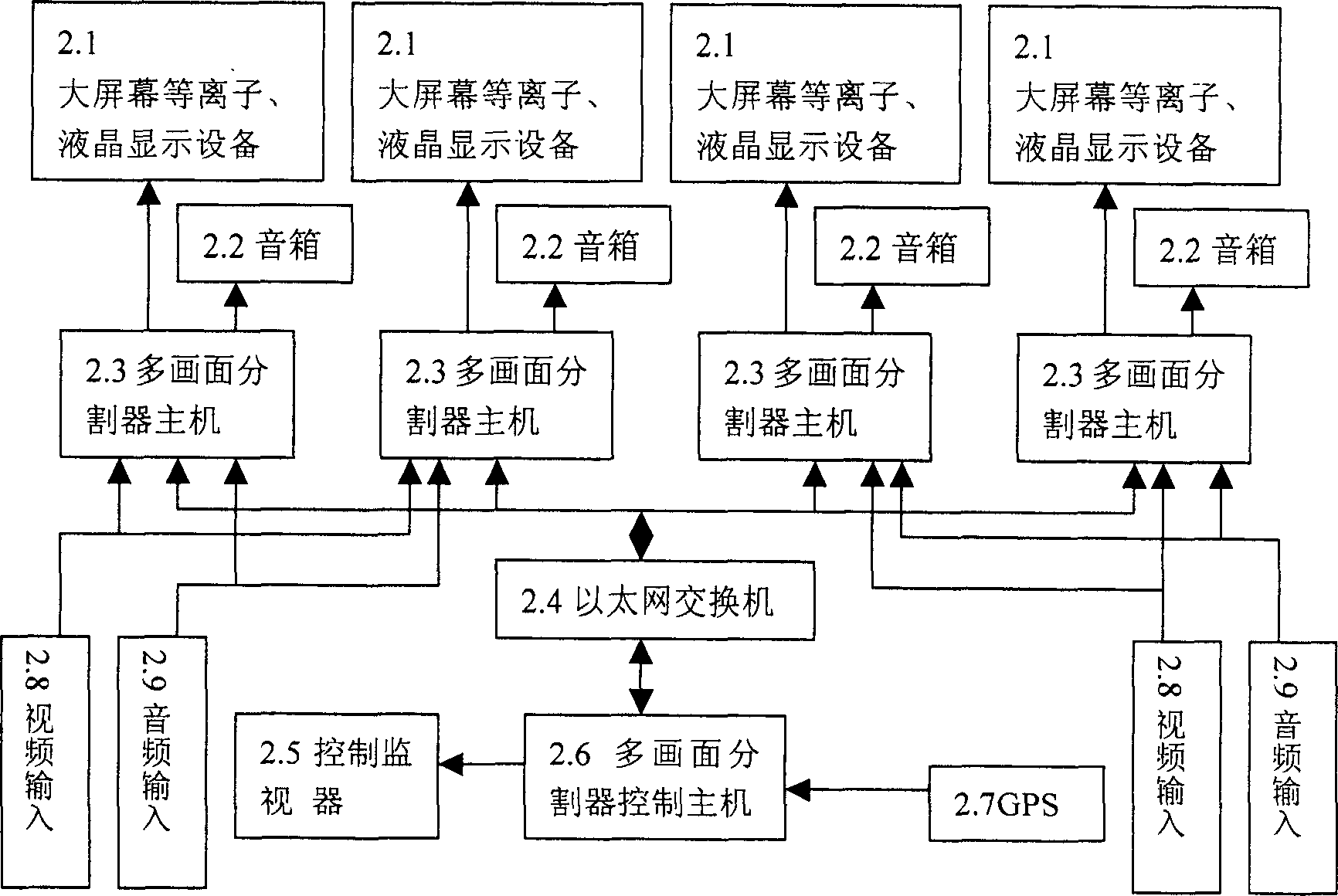

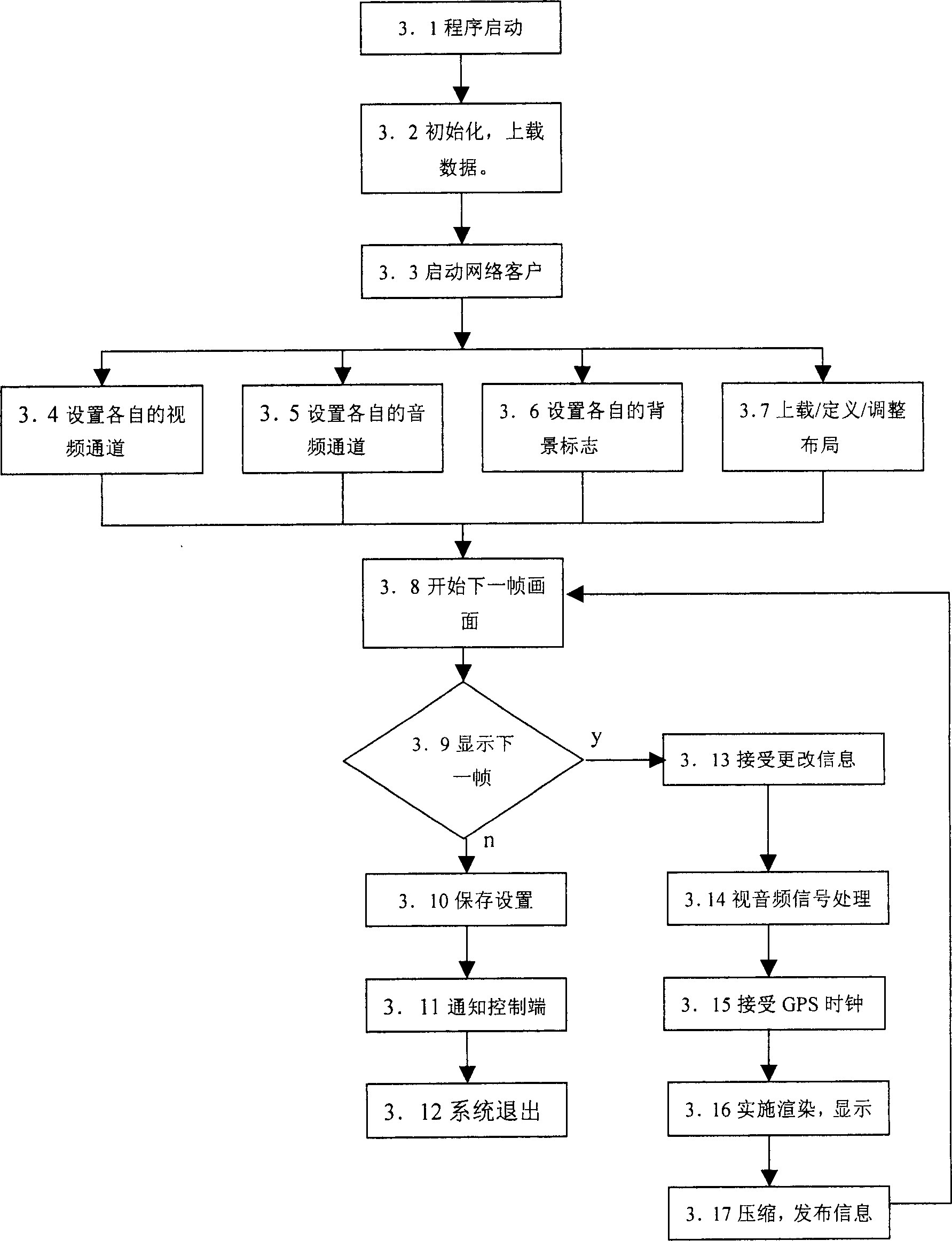

Multiple picture frame splitting system

InactiveCN1782984AAchieve arbitrary scalingLess investmentTelevision systemsDigital output to display deviceLarge screenDigital image

The multiple picture frames decollating system belongs to the field of video digital image treating technology, and is especially multiple picture frame great screen TV wall decollating display system. The present invention consists of two parts, including multiple picture frame decollator and large screen display equipment. The multiple picture frame decollator consists of a computer with video and audio treating card, operation system and control software, a control monitor and sound box. The large screen display equipment is large screen liquid crystal screen, plasma screen or large screen rear projecting TV with VGA / DVI interface. The present invention may be used in multiple picture frame monitoring in different fields. The present invention may be controlled in different modes.

Owner:BEIJING DAYANG TECH DEV

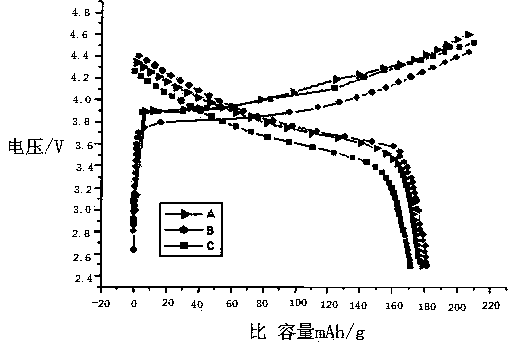

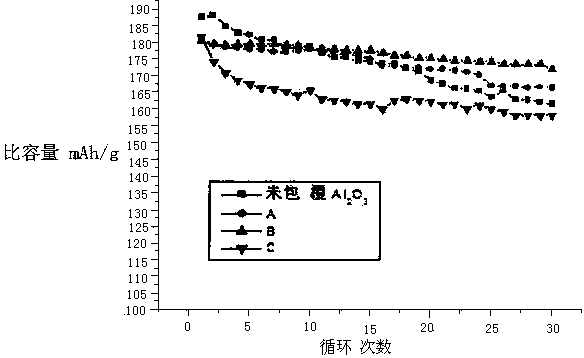

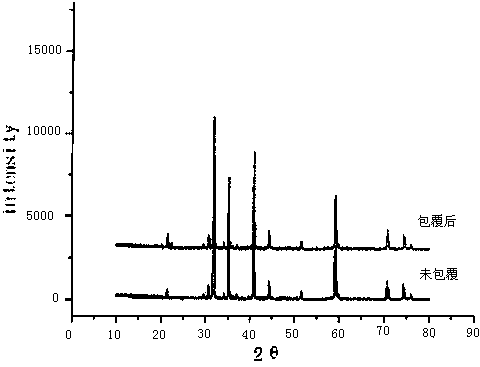

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

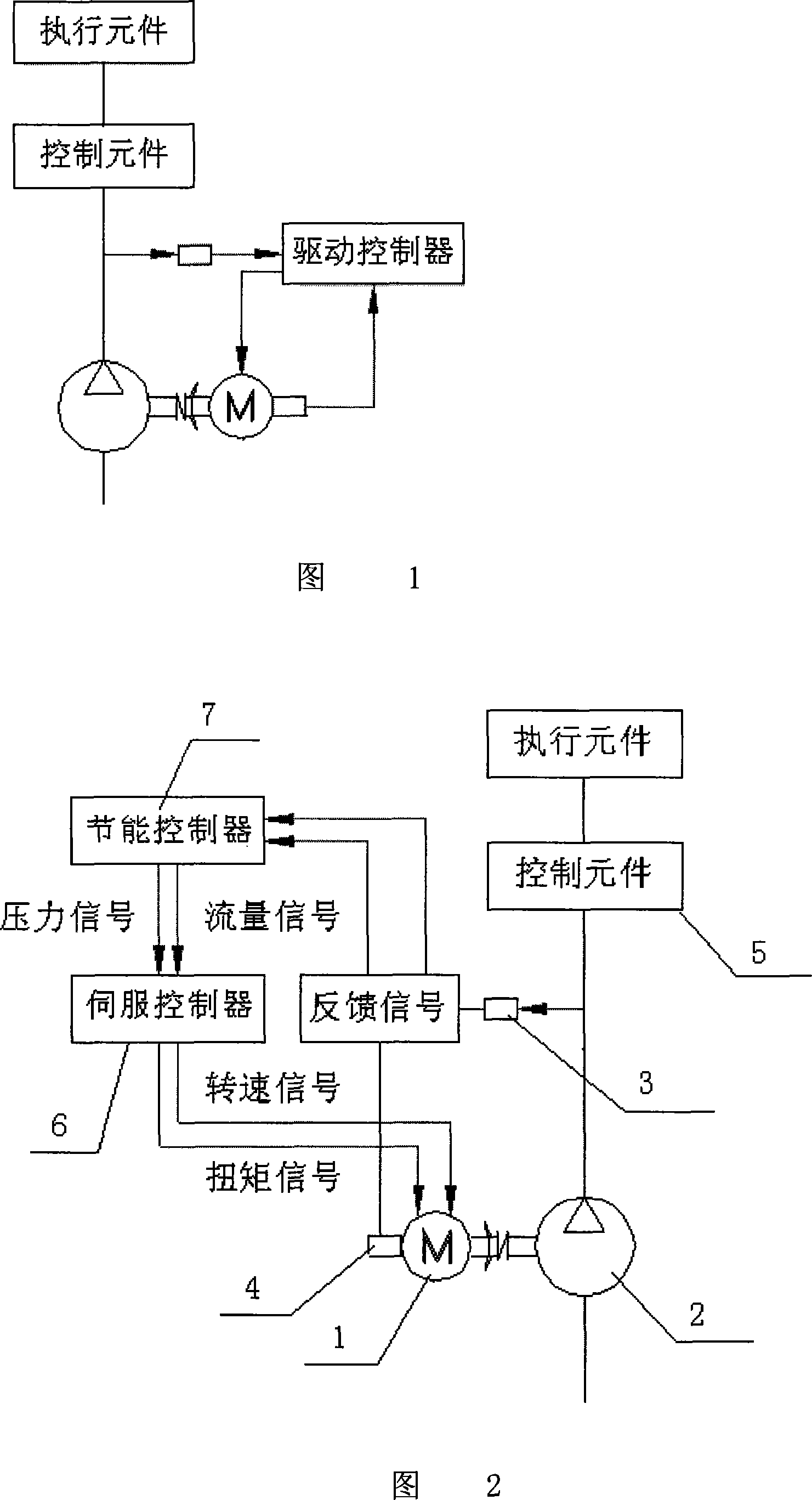

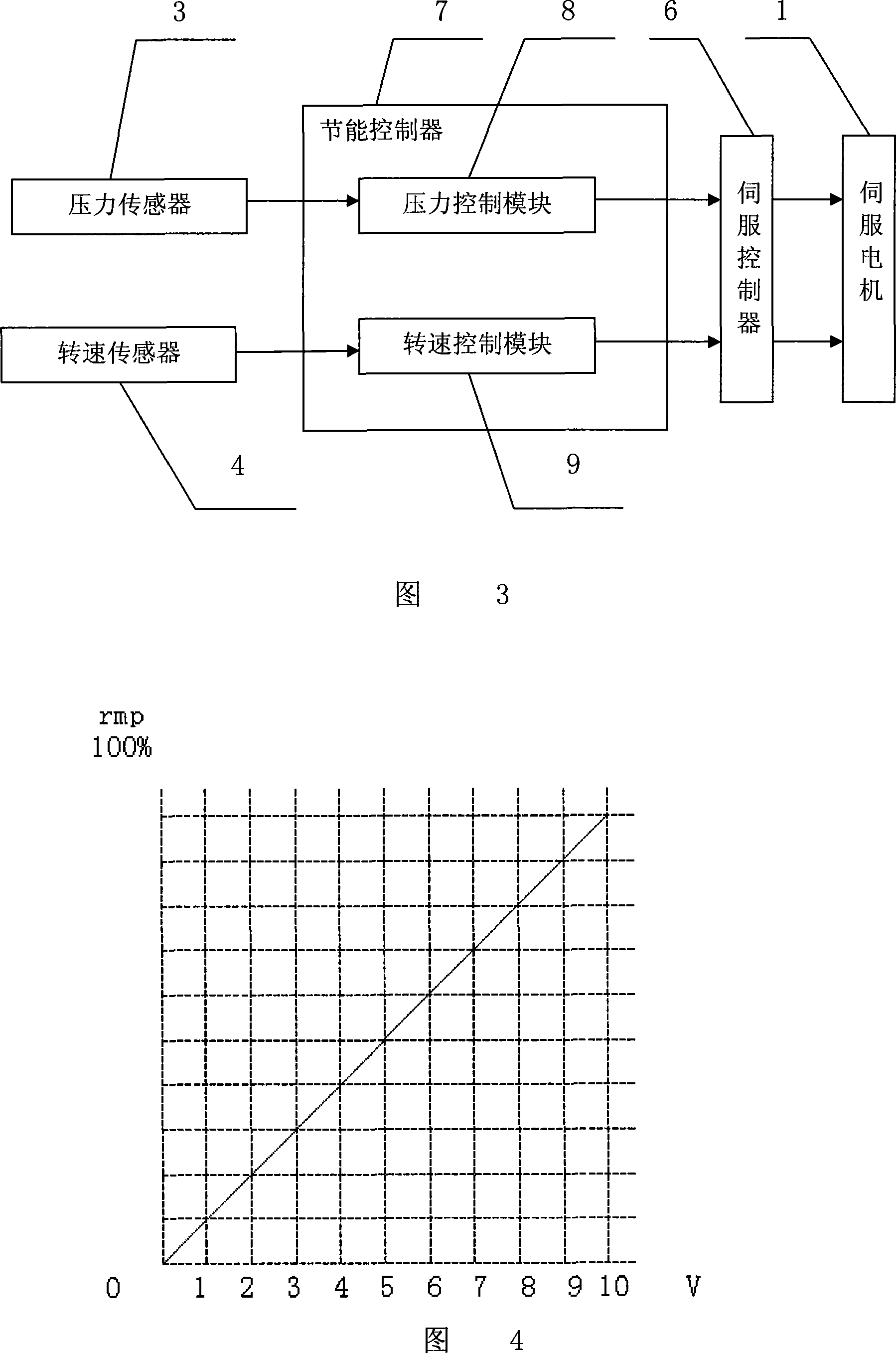

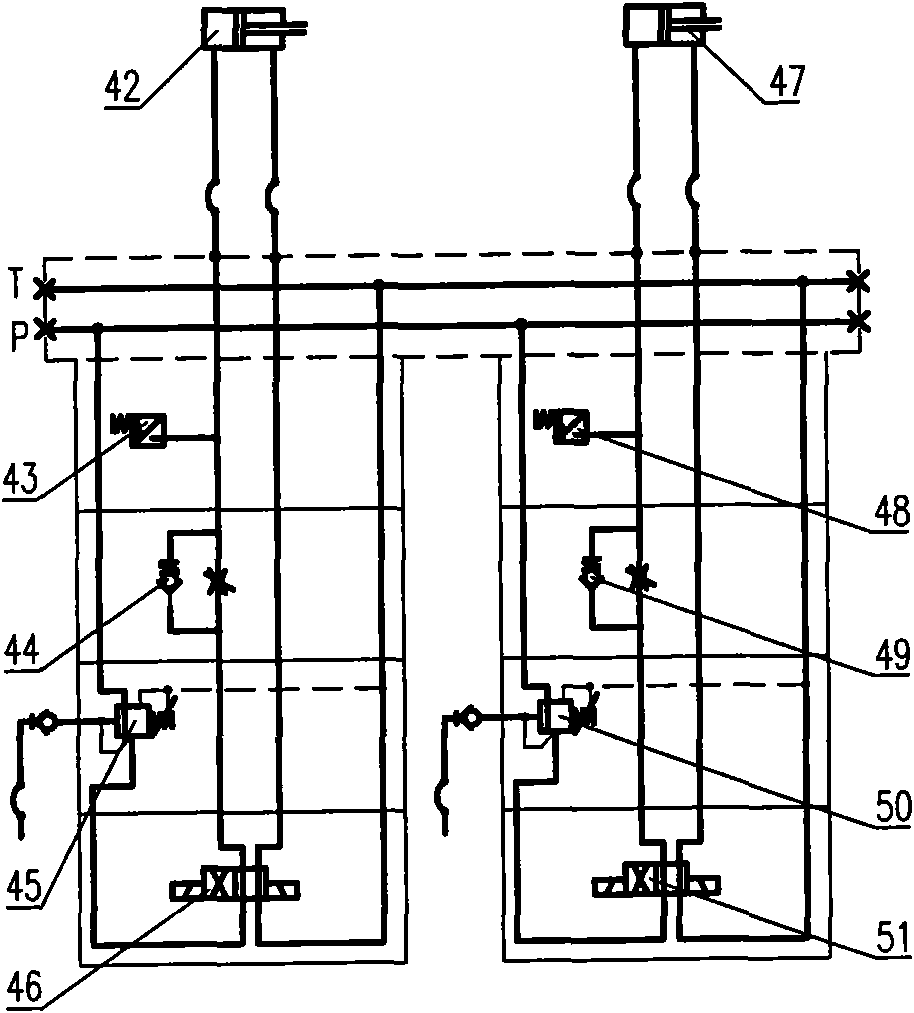

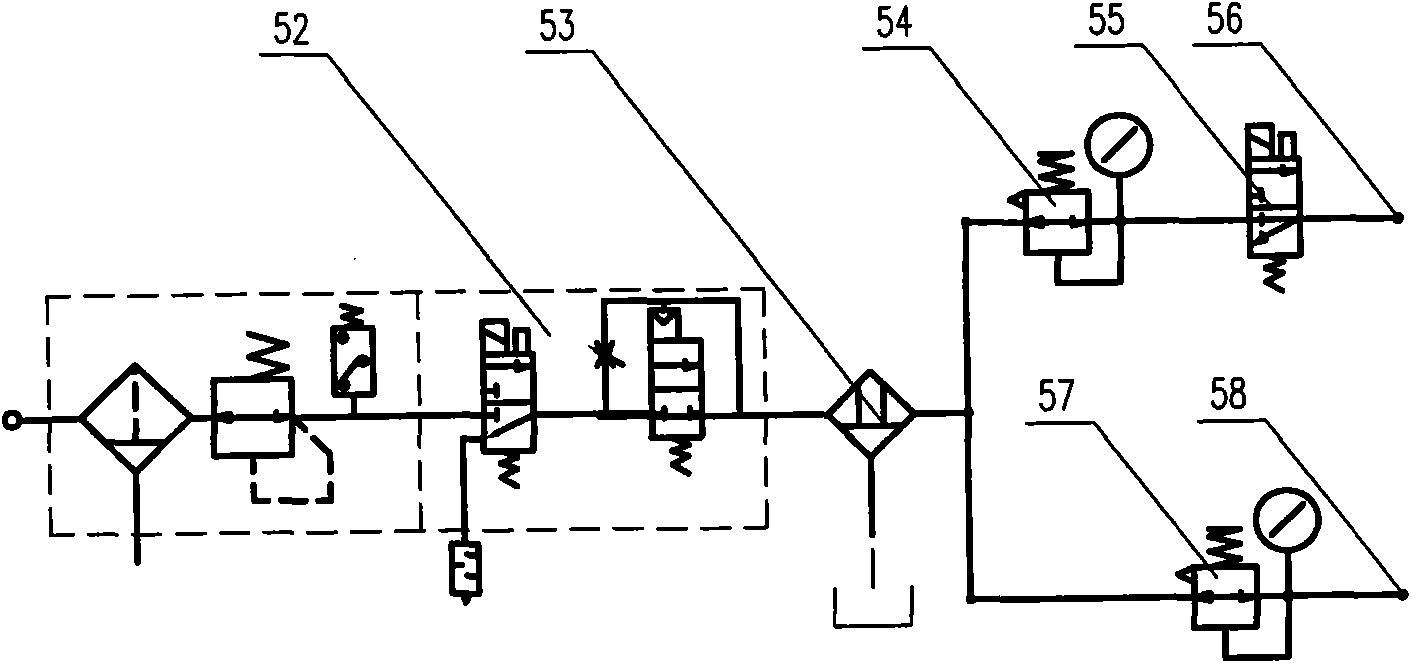

Injection moulding machine servo energy-saving control system

The energy-saving servo control system for injection molding machine includes one servo motor, one constant displacement oil pump providing pressure to the hydraulic system, one pressure sensor, one rotation speed sensor, and one control element, as well as one energy-saving controller connected to the outputs of the pressure sensor and the rotation speed sensor for automatic closed-loop regulation of pressure and flow rate. The servo motor includes one torque regulating input and one rotation speed regulating input; the energy-saving controller includes one pressure control module and one flow rate control module with outputs connected to the servo controller; the servo controller includes one torque driving unit and one rotation speed driving unit connected separately to the torque regulating input and the rotation speed regulating input of the servo motor. The energy-saving servo control system has high adaptability, high sensitivity, high accuracy and high energy-saving effect.

Owner:CHANGSHENGDA MASCH ZHEJIANG CO LTD

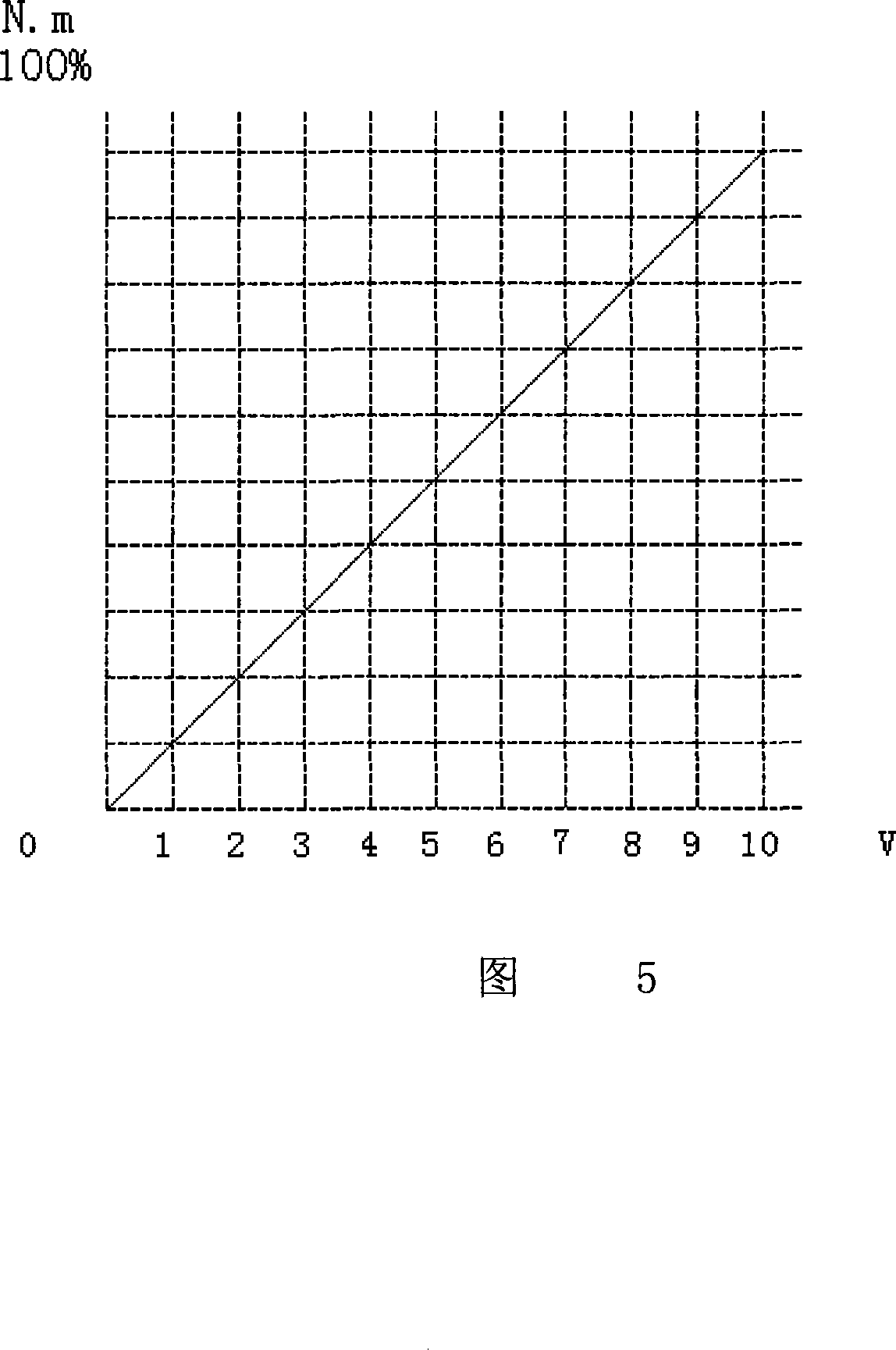

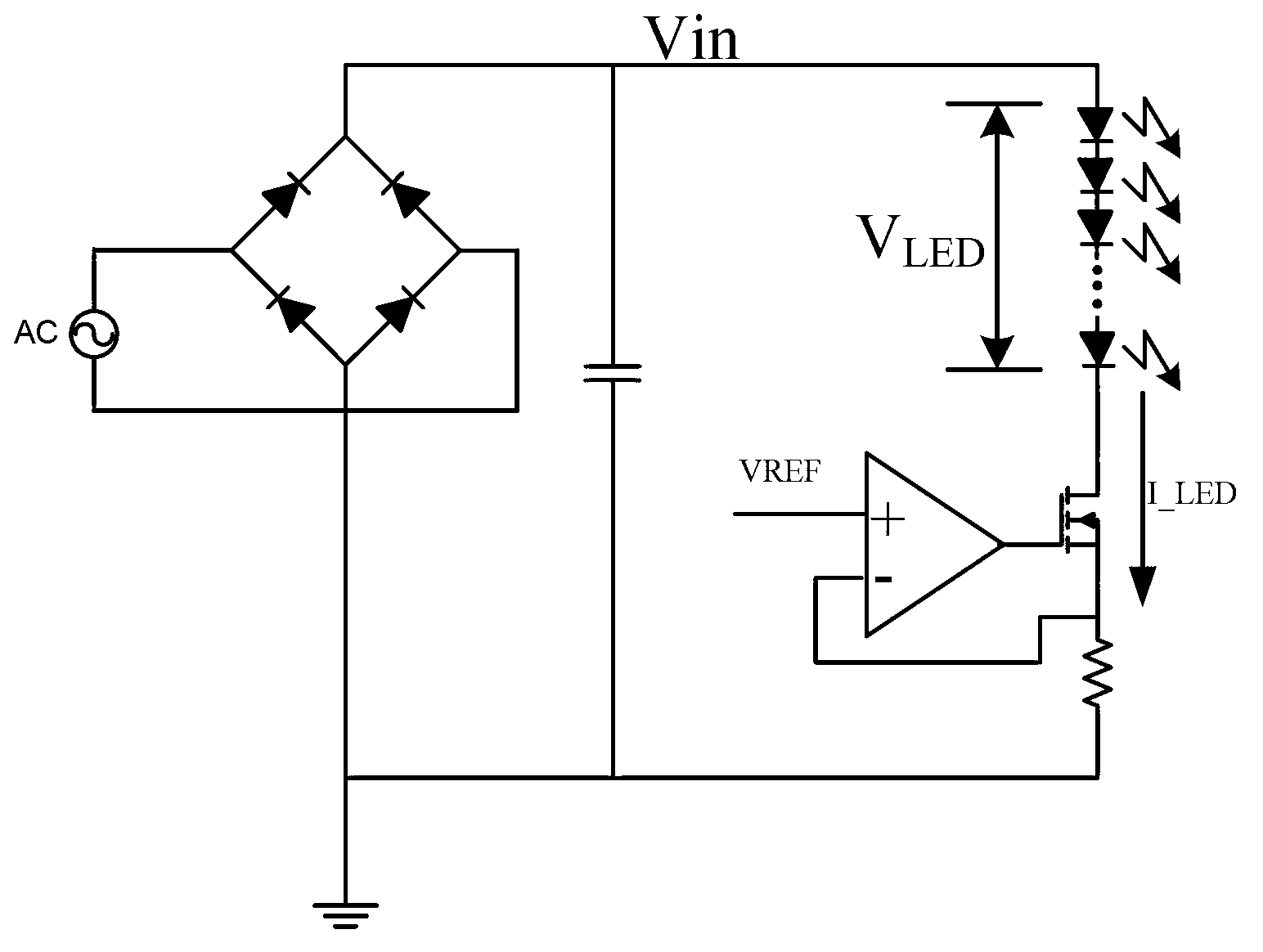

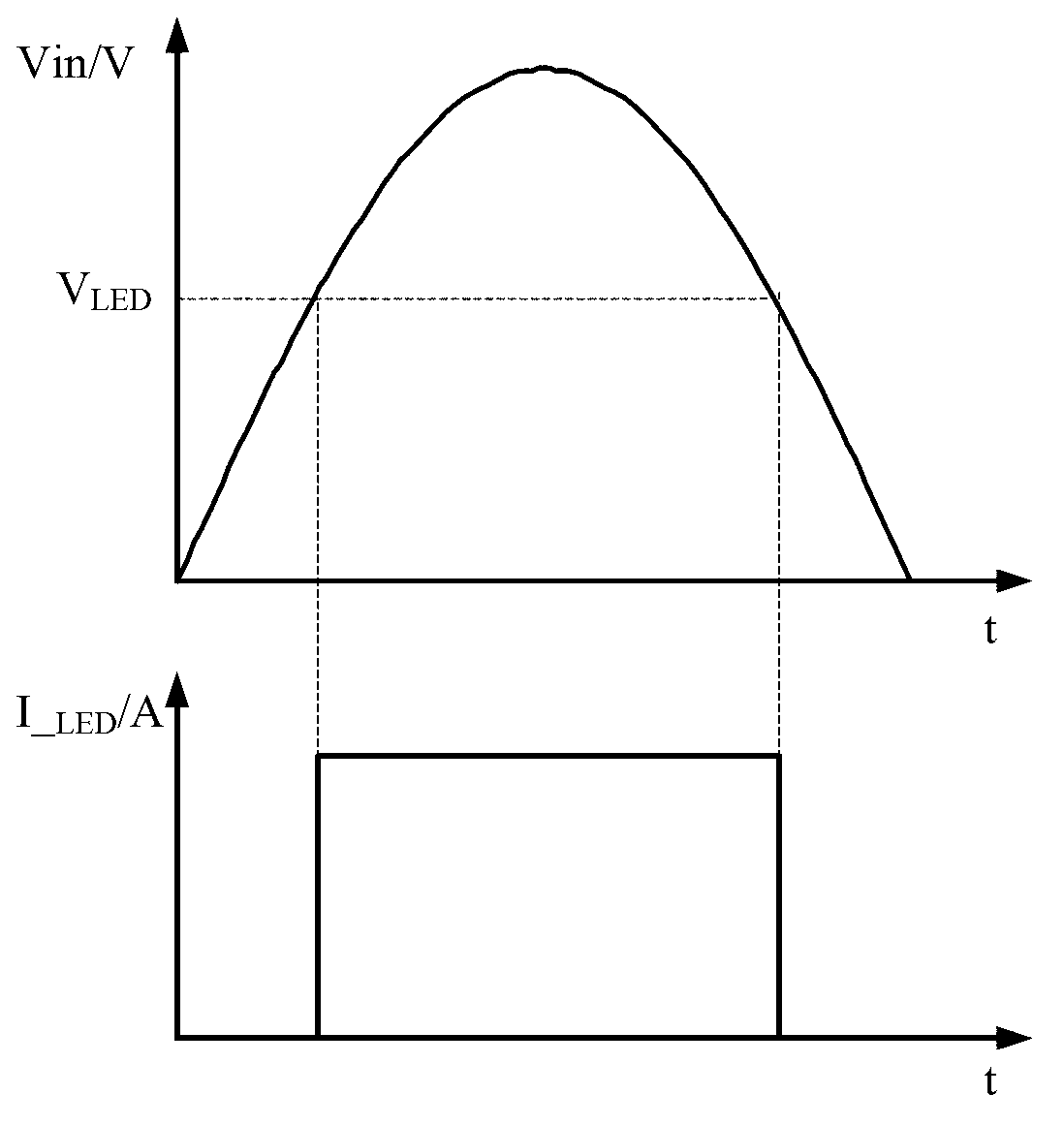

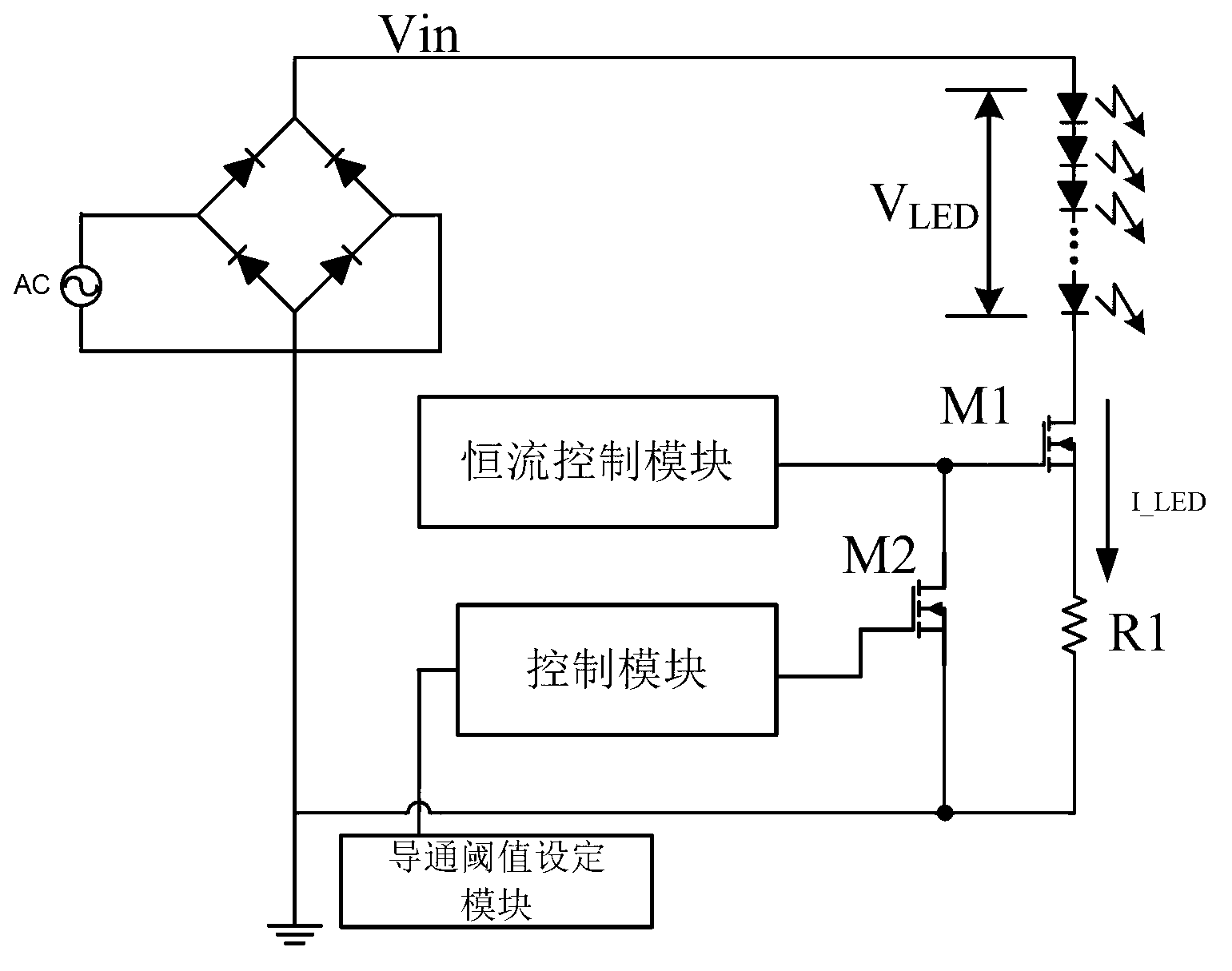

LED driver with adjustable conduction time

ActiveCN103260302AAvoid large pressure differenceImprove efficiencyElectric light circuit arrangementEnergy saving control techniquesLinear controlValue set

The invention relates to an LED driver with an adjustable conduction time. The LED driver with the adjustable conduction time comprises one way or multiple ways of LEDs, a conductive threshold value setting module and a controlling module, wherein the LEDs are conducted when power supply voltage rises to LED conduction voltage, the conductive threshold value setting module is used for setting the LED conductive time, and the controlling module is used for disconnecting the one way or the multiple ways of LEDs when the power supply voltage rises to exceed an LED conduction voltage setting threshold value, and connecting the one way or the multiple ways of LEDs when the power supply voltage reduces to exceed the LED conduction voltage setting threshold value according to the conduction time of the LEDs, wherein the setting threshold value is related to the LED conduction threshold value. Due to comparison of an input voltage and an LED voltage drop, conduction time of the LEDs is controlled, the problem that voltage differences of the input voltage and the LED voltage are too large is solved, efficiency of a linear LED driving circuit is improved, circuit heating value is reduced, and application reliability is enhanced. In addition, the LED driver with the adjustable conduction time flexibly achieves the compromising design of high efficiency of the linear controlling scheme and a PF value through controlling the LED conduction time.

Owner:MAXIC TECHNOLOGY CORPORATION

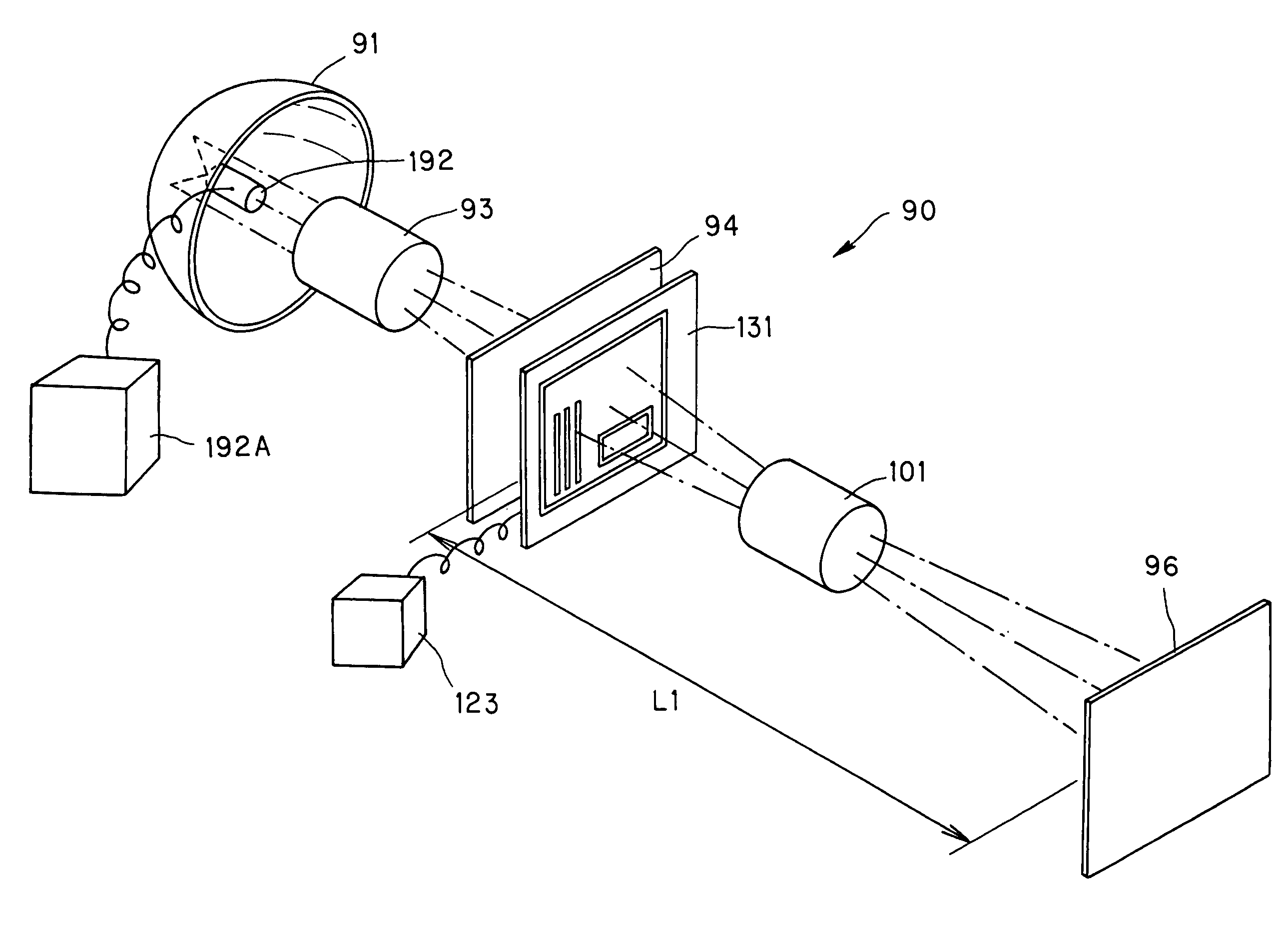

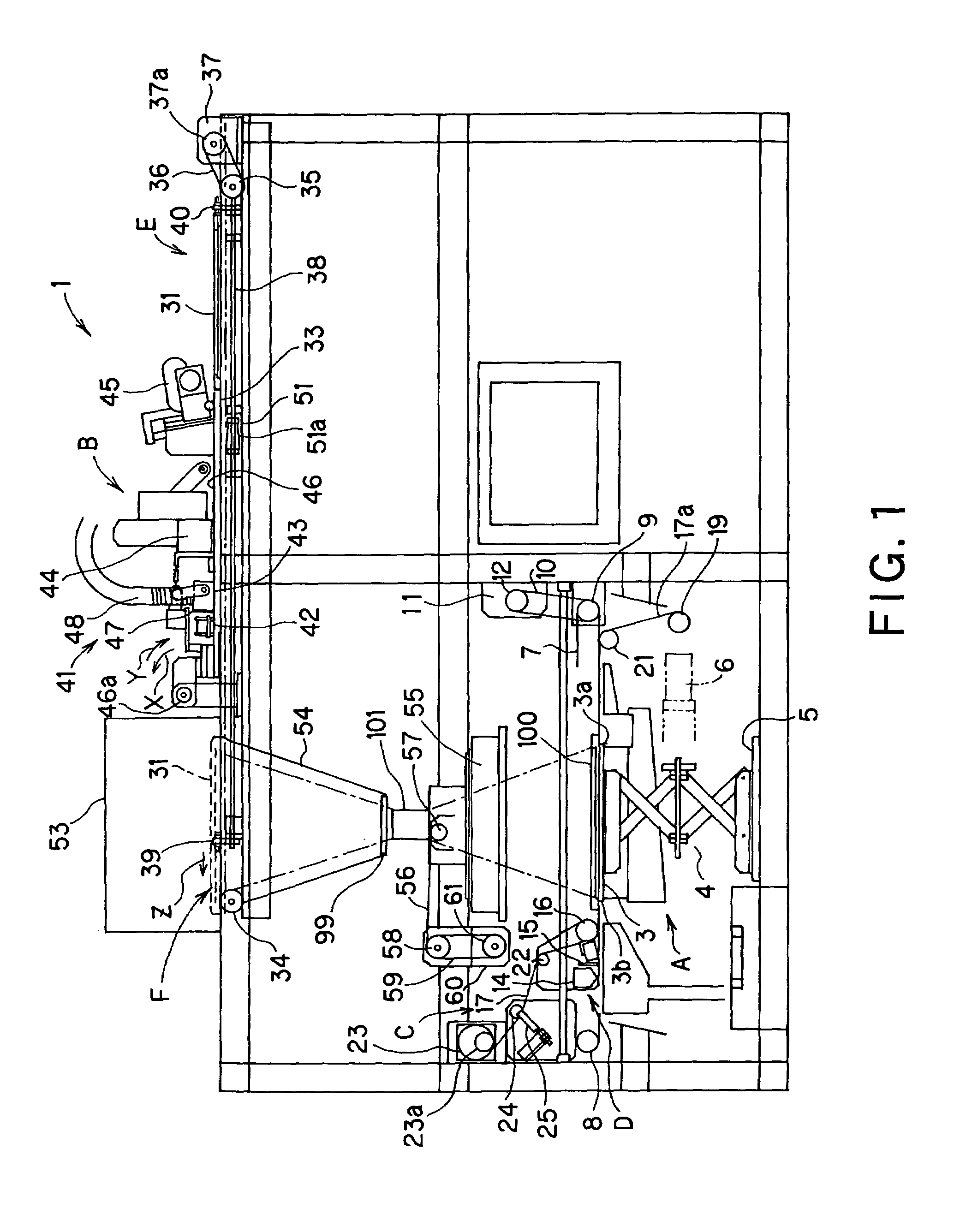

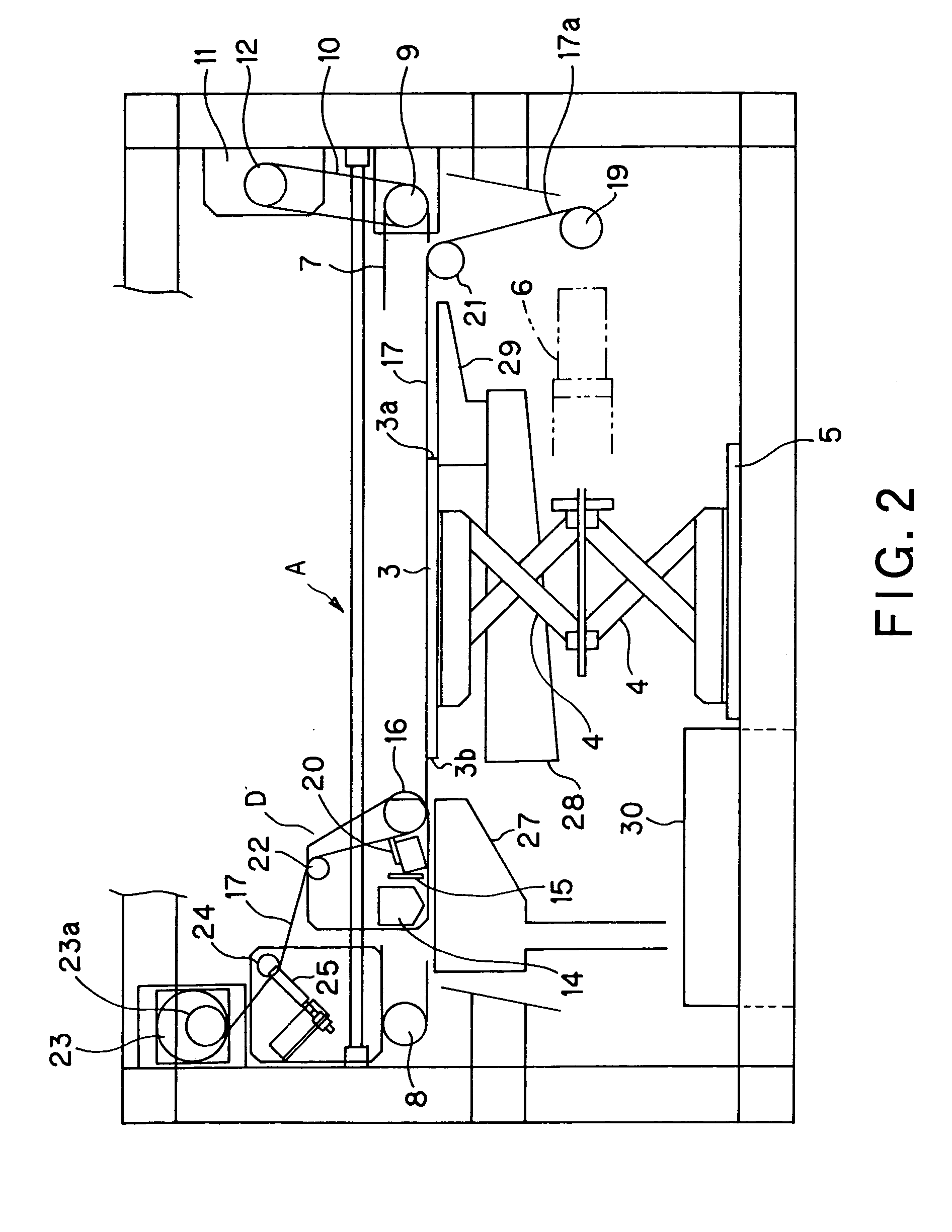

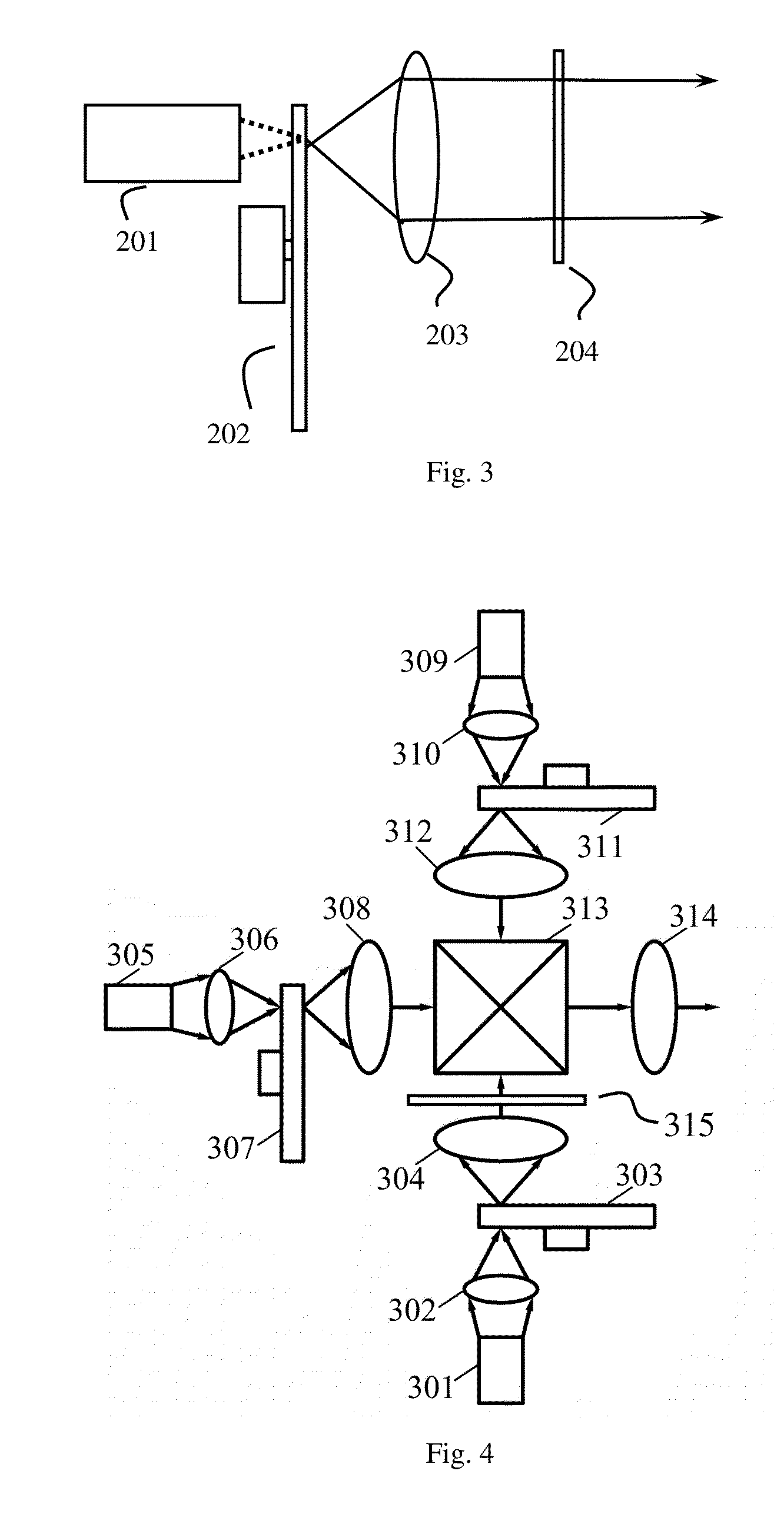

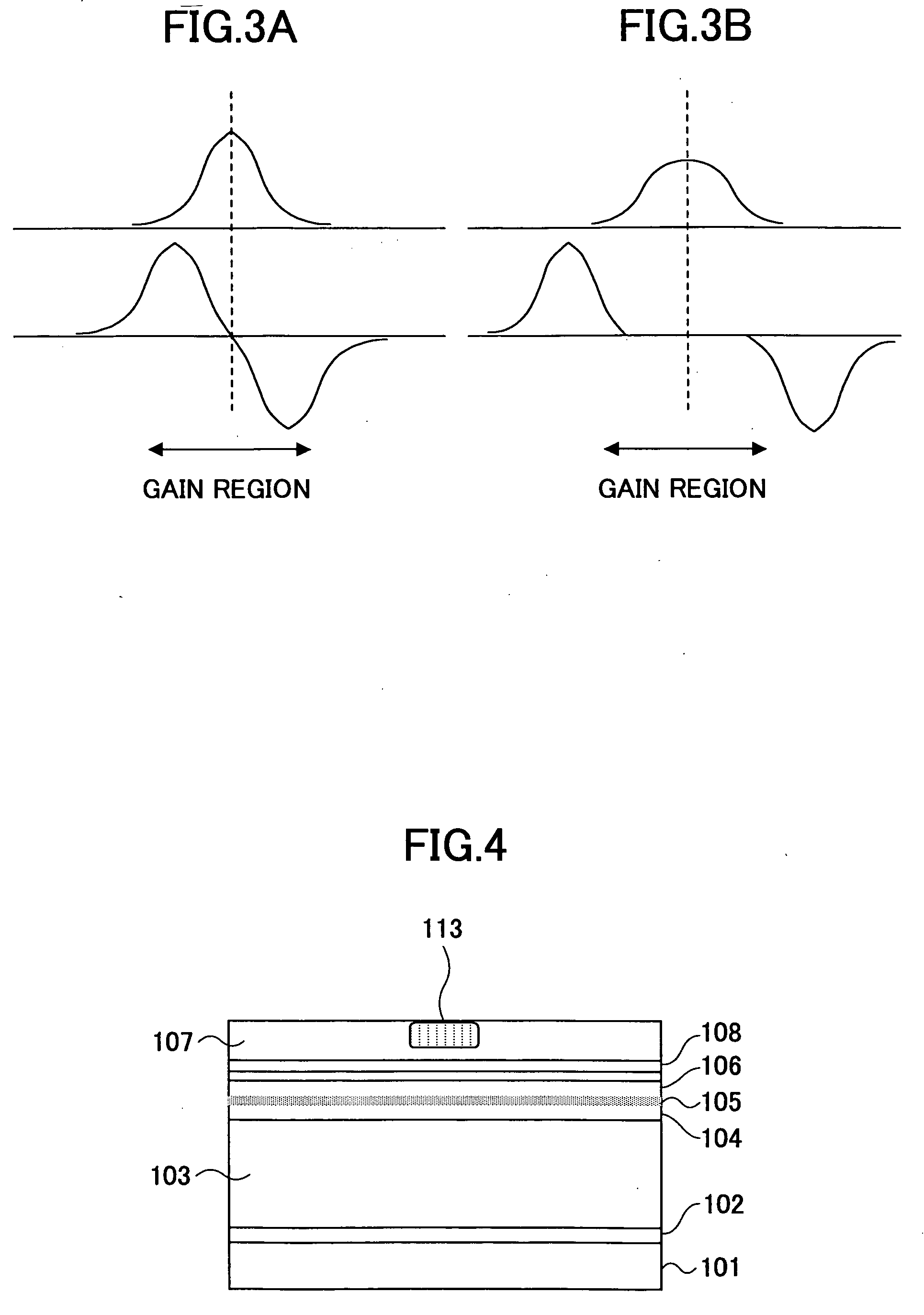

Stereolithographic apparatus and method for manufacturing three-dimensional object

InactiveUS7318718B2Low calorific valueDecrease in stereolithographic molding accuracyAdditive manufacturing apparatusElectric discharge tubesEngineeringStereolithography

An optical stereolithographic apparatus performs optical stereolithography by preparing a mask on a light-transmissible member (31) on the basis of data for one layer with respect to optical stereolithography, exposing an unhardened resin layer (96) of photohardenable resin to light through the mask, and repeating an exposure operation. The optical stereolithographic apparatus has an optical system in which the light-transmissible member (31) and the unhardened resin layer (96) are spaced from each other at a predetermined distance, and the unhardened resin layer (96) of the photohardenable resin is subjected to a projection exposure through the mask.

Owner:TEIJIN SEIKI CO LTD

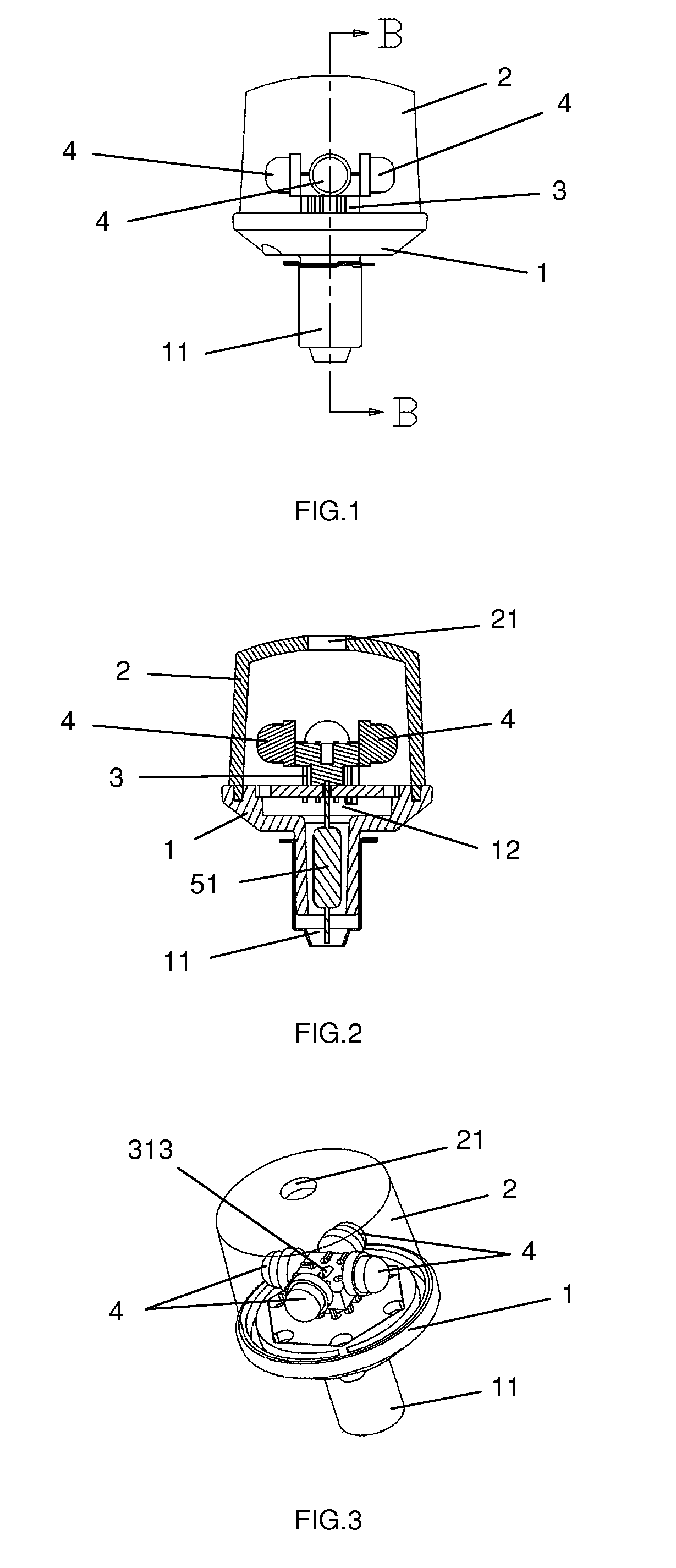

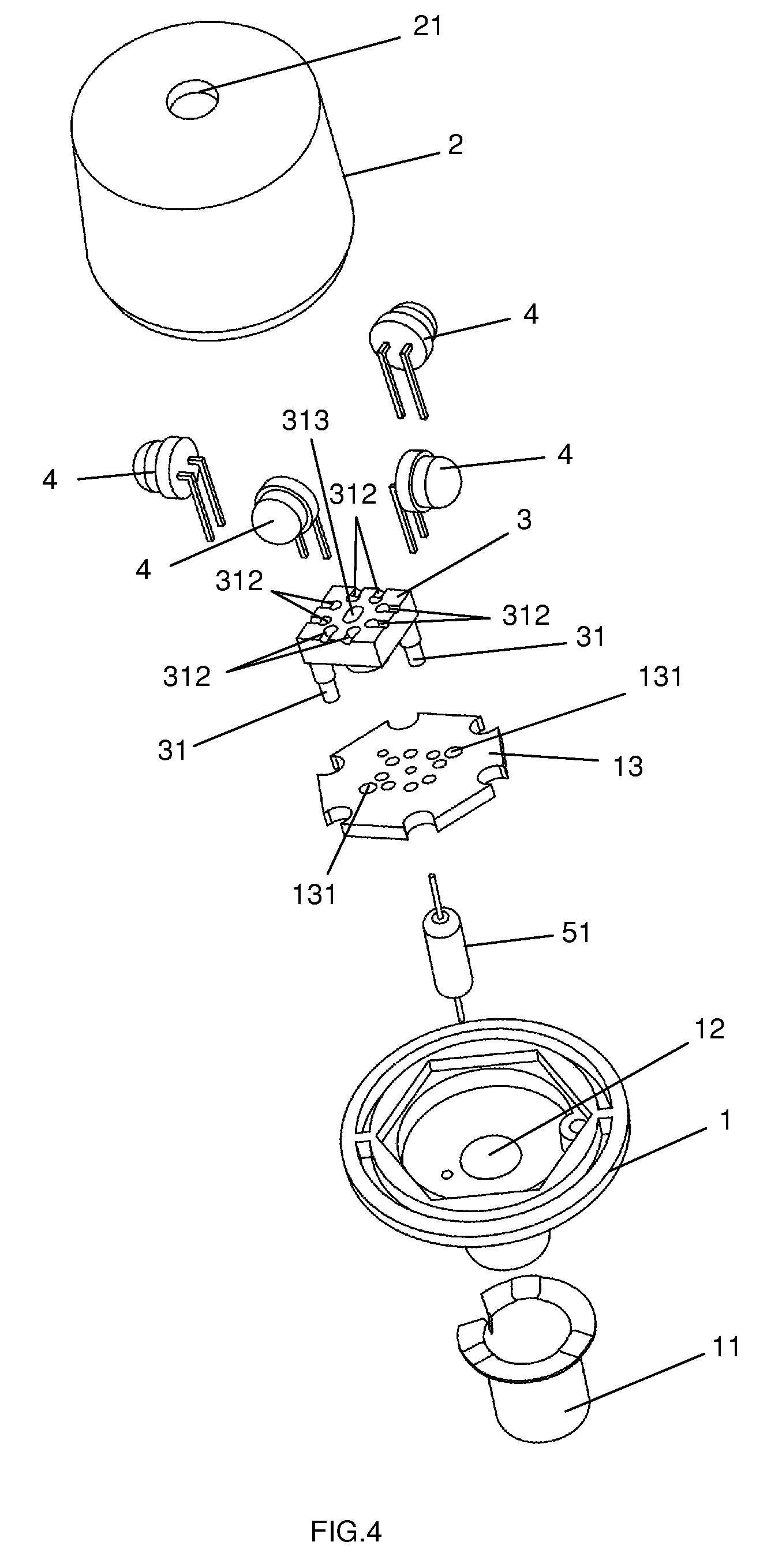

LED light module for portable lighting

InactiveUS20100097798A1Low production costSufficient light outputNon-electric lightingPoint-like light sourceElectricityEffect light

A LED light module for portable lighting which comprises a supporting base, a supporting plate, a diffusing cover, an electrical base, an axle, four round flat top single die miniature LEDs each with a light emitting angle of 100 degrees and a driving circuit disposed inside the axle and electrically connected to the LEDs. The present invention is more susceptible of low heat generation and low production costs. Moreover, since only four round flat top single die miniature LEDs are used to provide sufficient light output for an area in 360 degrees, it is more effective than the conventional portable lighting which provide spot lights only.

Owner:CALTRACO INT

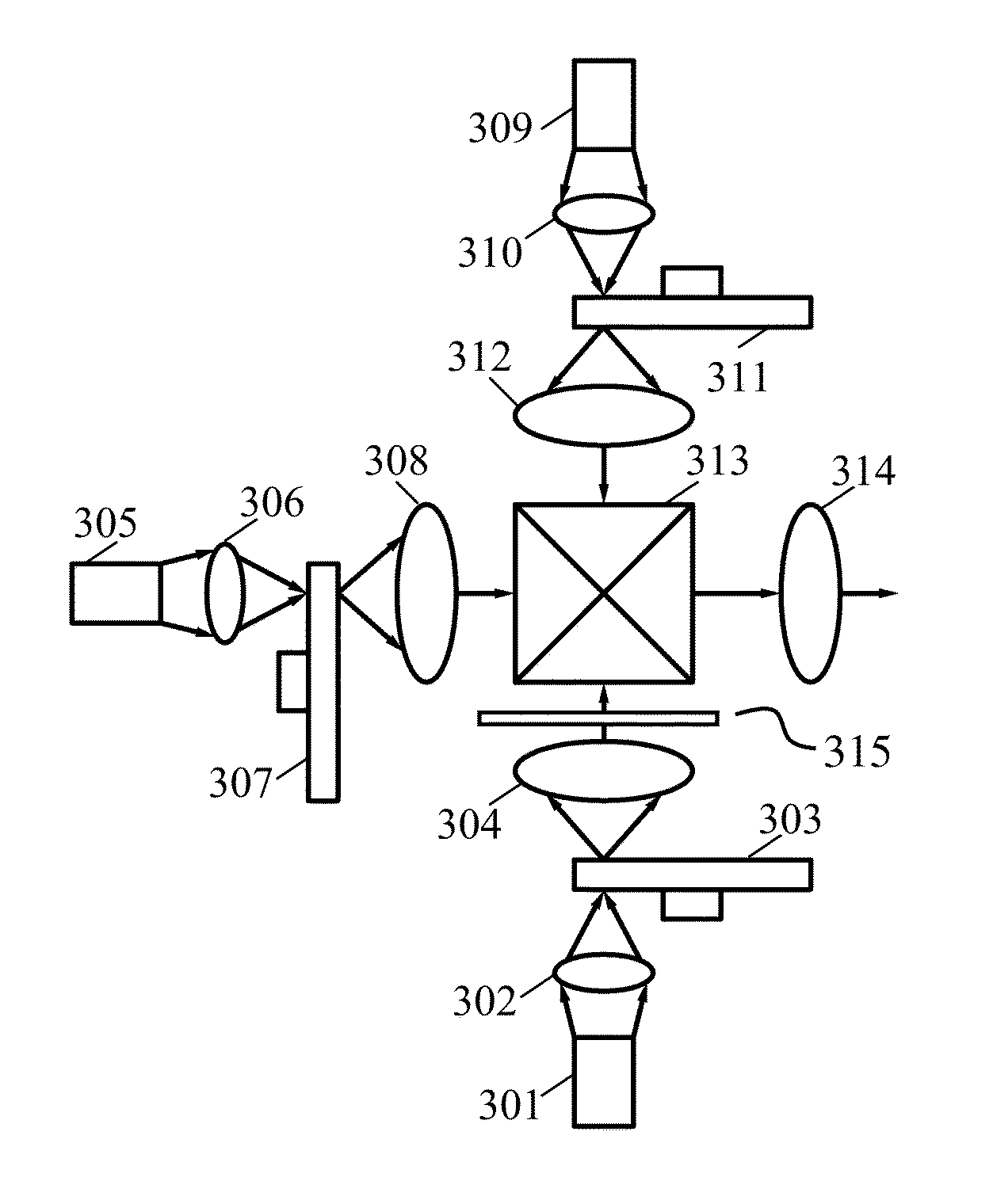

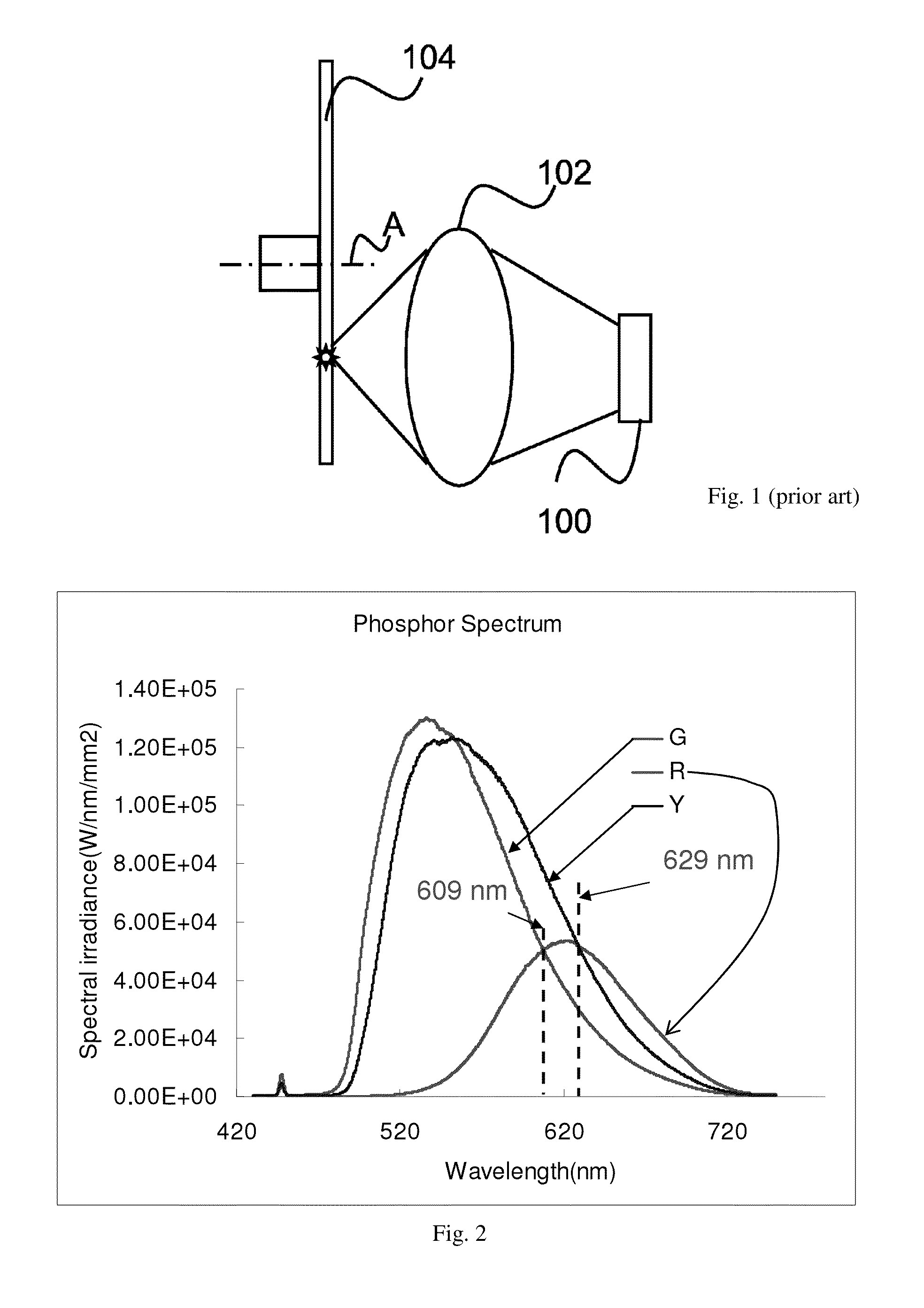

Method and apparatus for a solid state light source

ActiveUS20130229634A1Low heat generationValid conversionLighting applicationsMechanical apparatusPhosphorLength wave

A light source device uses a wavelength down conversion material for absorbing an excitation light and generating a converted light, and a color filter for filtering the converted light to generate a different color light as output. The wavelength conversion material is a yellow or green phosphor which absorbs blue or UV light and generates a yellow or green converted light, which has a sufficiently wide spectrum to cover some of the red color region. The color filter only allows the red component of the converted light to be output. This system is more energy efficient than using a red phosphor. This light source may be implemented as a moving phosphor wheel having multiple segments, one of which being the yellow or green phosphor with the corresponding color filter, the other segments being used to generate other colored lights such as green and blue lights.

Owner:APPOTRONICS CORP LTD

Process for the production of hydrogen with very high purity from alcohols that comprise at least two carbon atoms

InactiveUS20050244329A1High purityLow calorific valueHydrogen separation using liquid contactEnergy inputSteam reformingHydrogen

Process for the production of high-purity hydrogen from an ethanol or higher-alcohol feedstock, employing a vapor reforming unit, a carbon monoxide conversion unit and a membrane separation unit and comprising intense thermal integration that is obtained by combustion under the control of an effluent of the process so as to provide the calories that are necessary to the vapor reforming reaction.

Owner:INST FR DU PETROLE

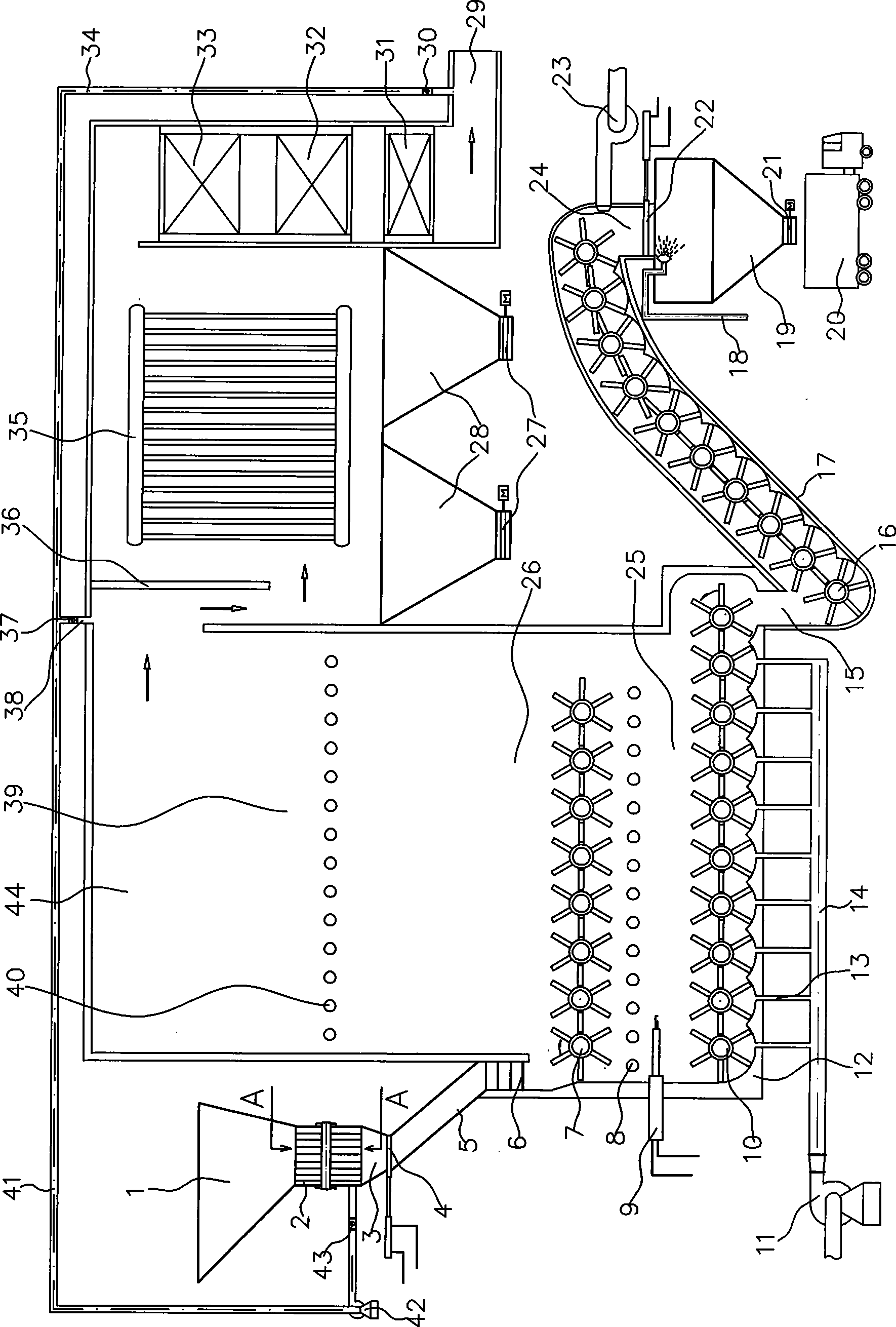

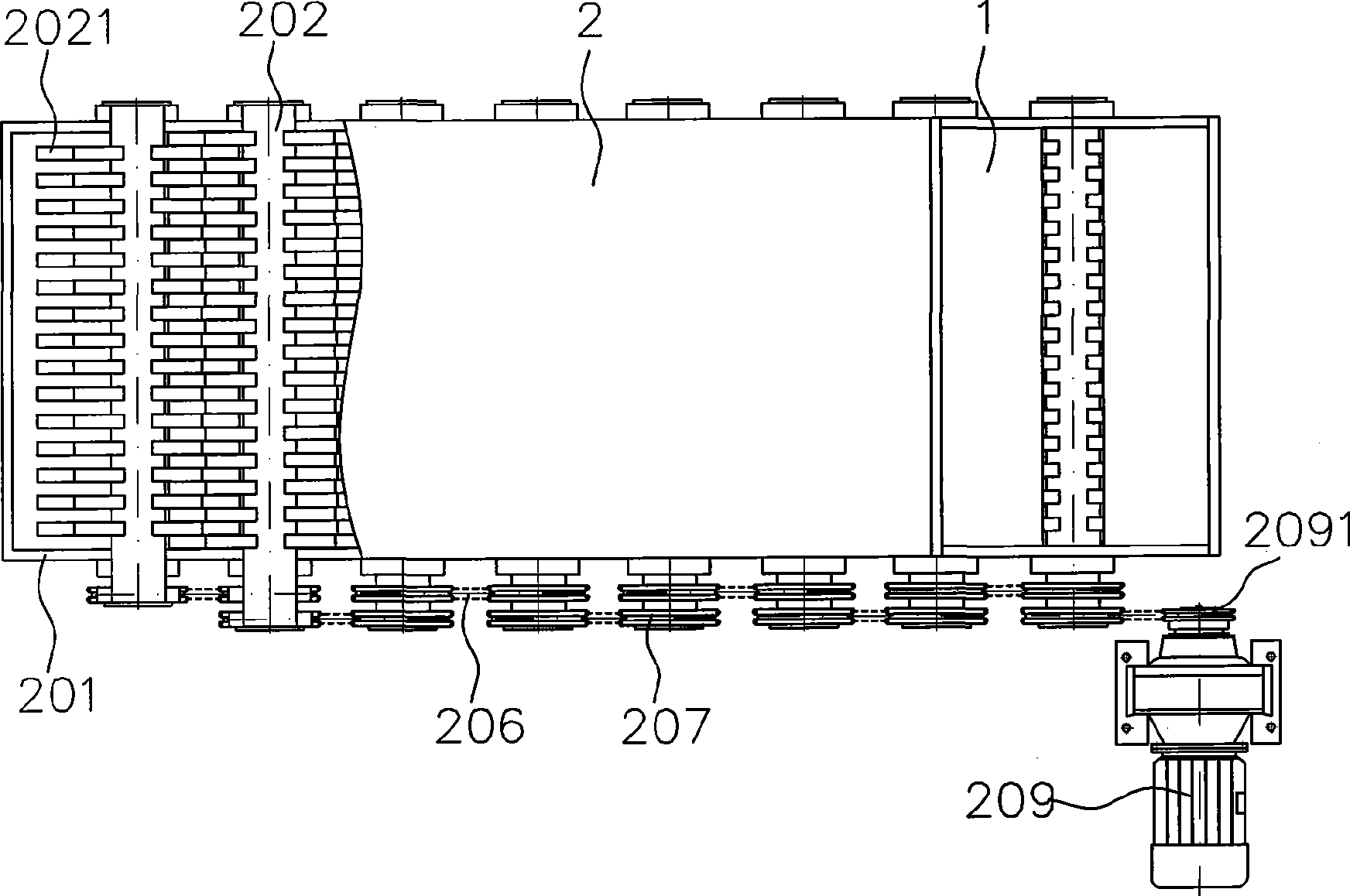

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

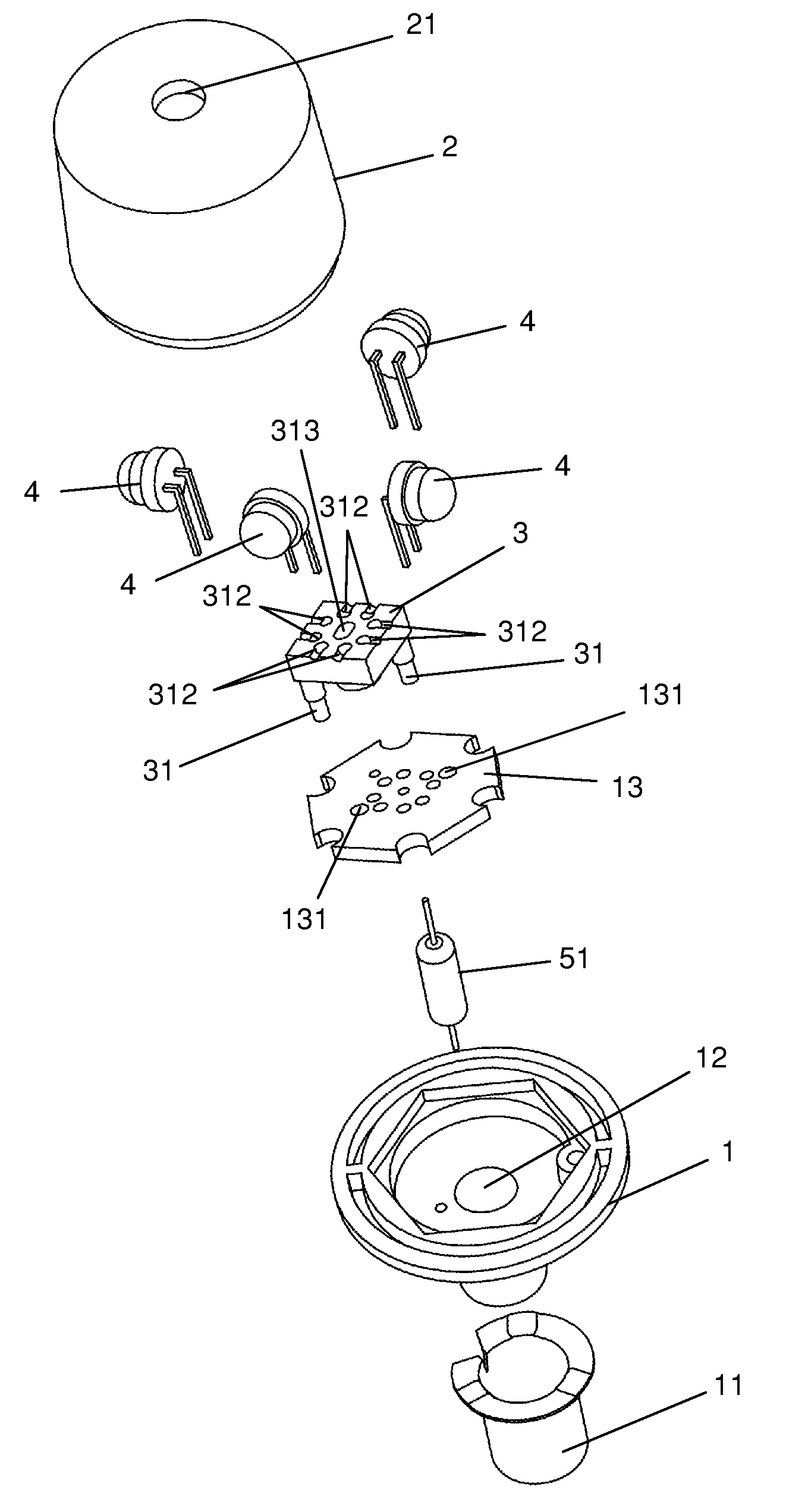

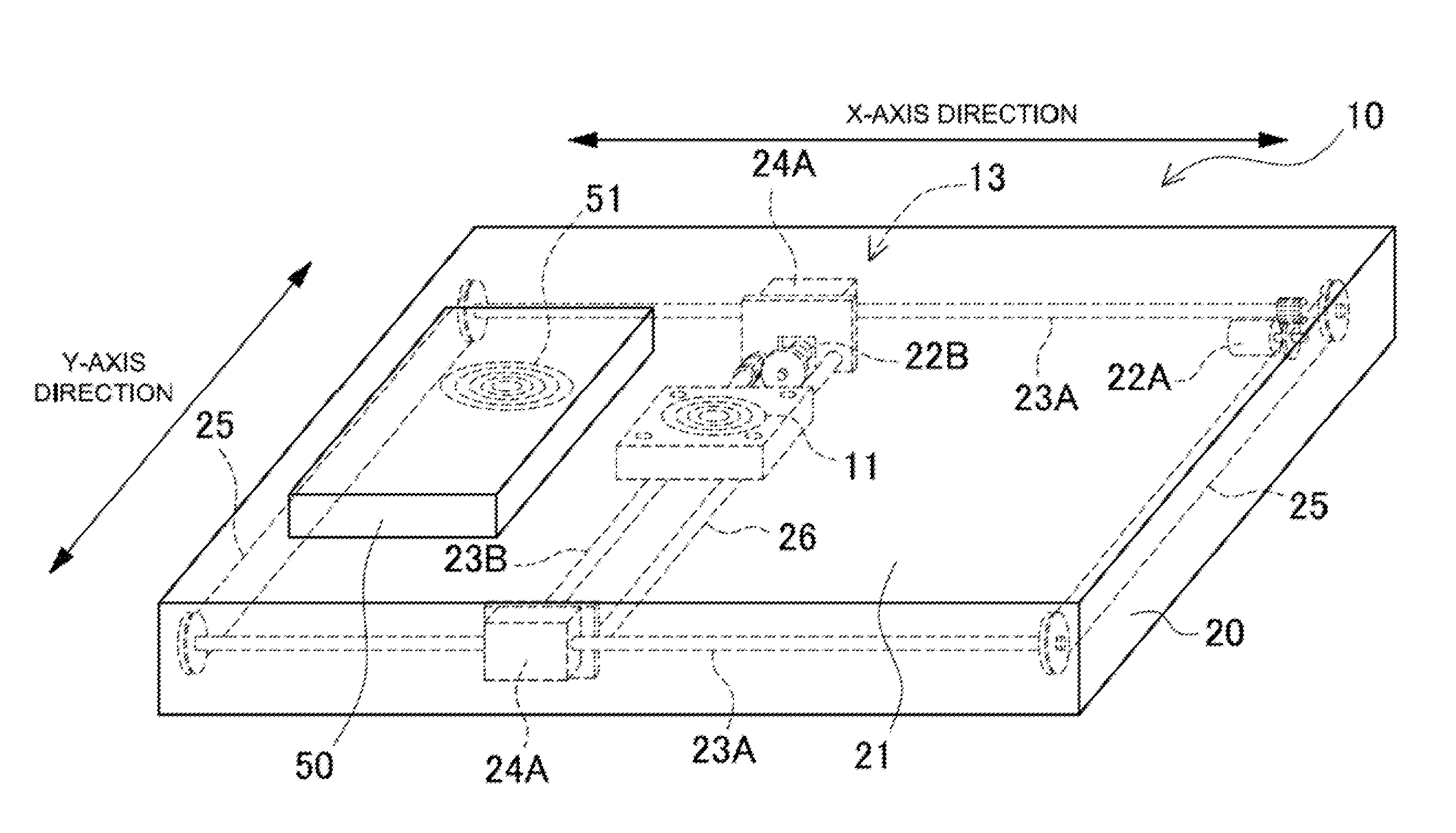

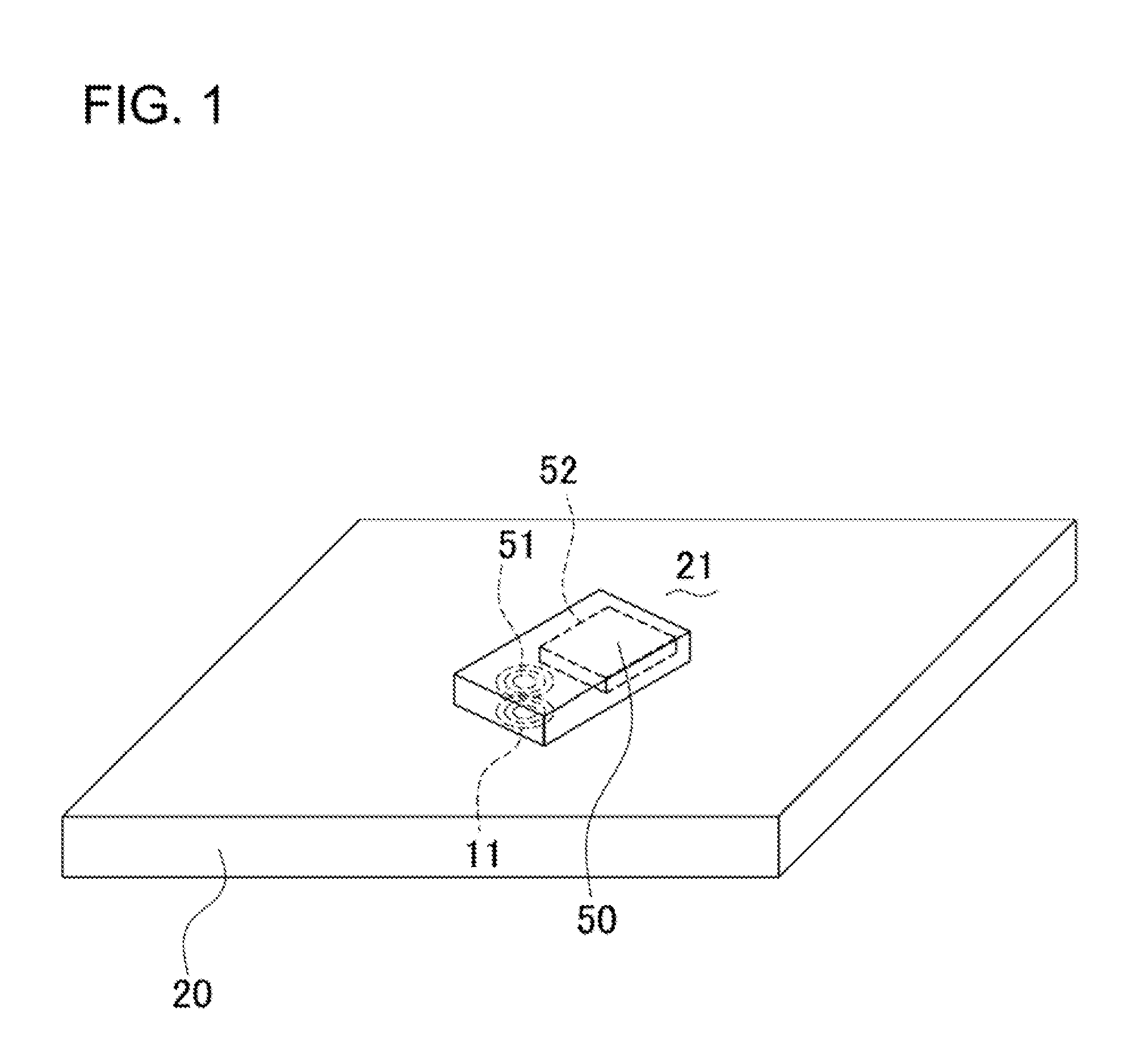

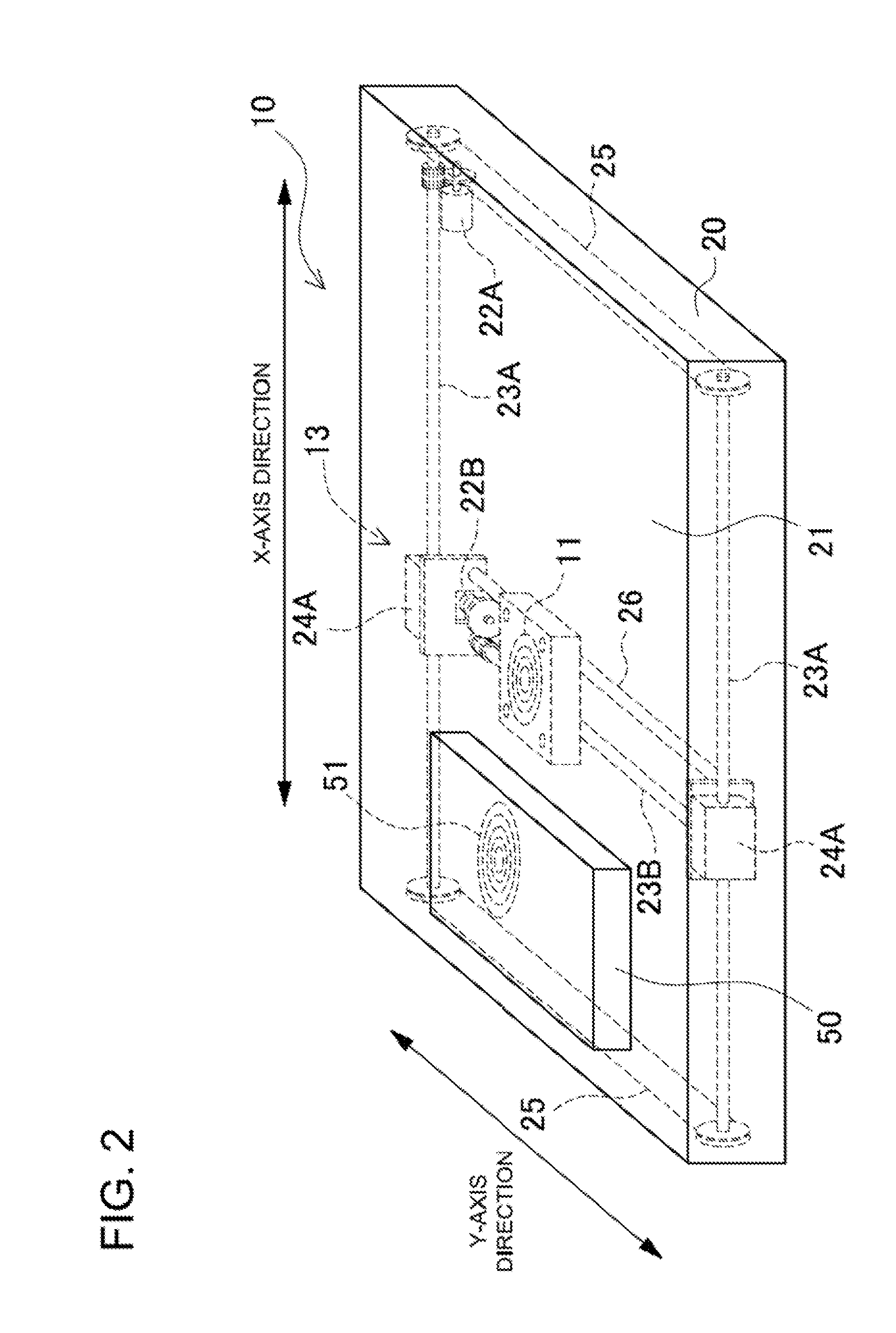

Device housing a battery and charging pad

InactiveUS20110128714A1Reduces rectifying circuit element ON-resistanceReduce voltage dropElectric powerBattery overcharge protectionElectric power transmissionControl circuit

A charging pad 10 is provided with a power supply coil 11, and a device housing a battery 50 containing an induction coil 51. A device housing a battery 50 is provided with a rectifying circuit 53 that rectifies AC power induced in the induction coil 51, a charging circuit 54 that charges the internal battery 52 with output from the rectifying circuit 53, a shorting circuit 56 that short circuits the terminals of the induction coil 51, and a control circuit 57 that controls the shorting circuit 56 ON when a charging abnormality is detected. If the control circuit 57 detects a charging abnormality during power transmission from the charging pad 10 power supply coil 11 to the device housing a battery 50 induction coil 51, it controls the shorting circuit 56 ON to cut-off the supply of power from the induction coil 51 to the rectifying circuit 53.

Owner:SANYO ELECTRIC CO LTD

Wavelength conversion device, fluorescent color wheel and light-emitting device

ActiveCN106206904AImprove compactnessImprove thermal conductivityNon-linear opticsSemiconductor devicesFluorescenceAdhesive

Owner:APPOTRONICS CORP LTD

Method for the treatment of obesity, overweight and fluctuations in blood insuline and/or glucose levels

InactiveUS20030113310A1Low calorific valueLowering indexPeptide/protein ingredientsMetabolism disorderIntestinal structureBlood insulin

The present invention relates to a method of treating or preventing obesity, overweight, fluctuations in blood insulin levels and / or fluctuations in blood glucose levels in mammals. The method acording to the invention comprises the enteral administration to a mammal of an effective amount of a preparation containing an enzyme capable of converting an ingested carbohydrate or digestion product thereof into one or more absorbable components, wherein the total metabolic caloric value of the absorbable component(s) is less than the metabolic caloric value of the ingested carbohydrate or digestion product thereof. Thus the present invention effectively provides a method that allows complete digestion of ingested digestible carbohydrates whilst at the same time reducing the actual metabolic caloric value of said ingested carbohydrates. Another aspect of the invention relates to a pill for oral administration provided with an enteric coating and containing 25 to 10.000 IU glucose isomerase per gram.

Owner:NV NUTRICIA

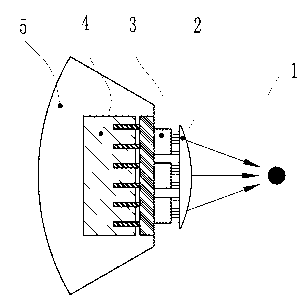

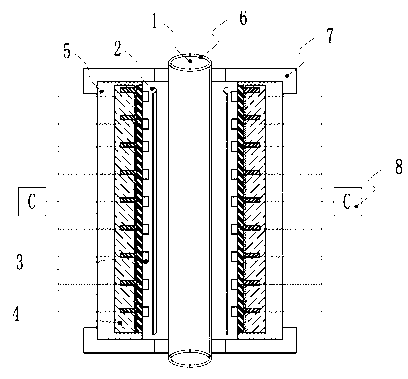

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

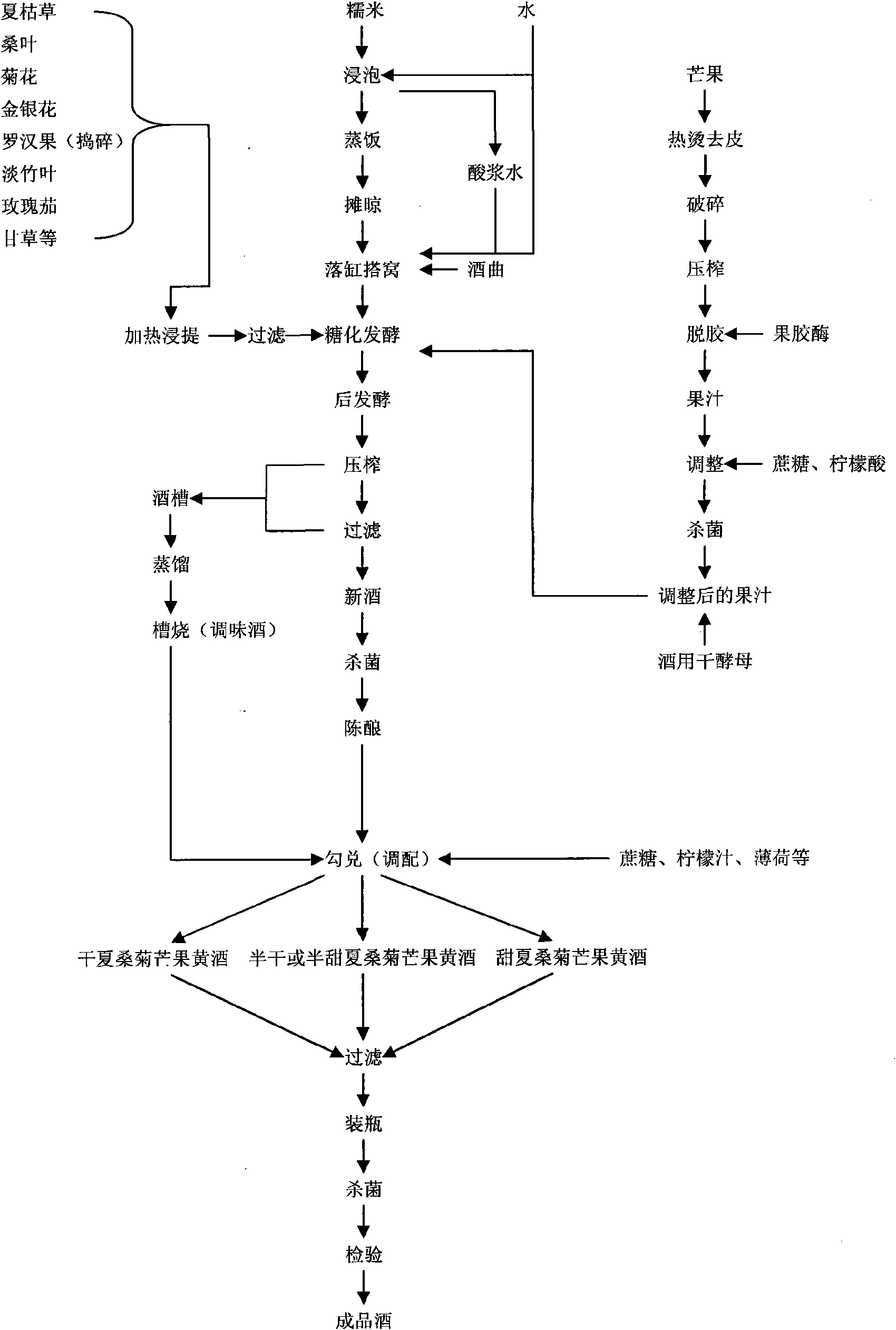

Herb-tea fruit/vegetable yellow wine and preparation method thereof

InactiveCN101649275AHigh nutritional valueEnhance heat-clearing and heat-relieving health functionAlcoholic beverage preparationMicroorganism based processesBiotechnologyMedicinal herbs

The invention discloses a herb-tea fruit / vegetable yellow wine and a preparation method thereof. Aiming at the problems of high alcoholic strength, strong flavor, high heat productivity, inadaptability to summer drink and the like of the common yellow wine, the method employs the technical proposal that: utilizing a plurality of raw and auxiliary materials having the advantages of nutritive characteristics and the like, such as Chinese medicinal herbs for herb tea, cool fruits (vegetables), glutinous rice and the like; using a pure saccharifying fermenting agent and an active dry yeast to carry out the compound fermentation with a plurality of raw and auxiliary materials; and using Chinese medicinal herb leaching liquor for herb tea and cool fruit (vegetable) juice instead of brewing waterso as to reduce the alcoholic strength and the heat value of the yellow wine, increase the content of the dry extractive, increase the nutrients and the content of the yellow wine, enhance the health-care functions for clearing away the heat and relieving the summer heat and improve the mouth feel. The yellow wine tastes, elegant, pure, sweet and thick, has peculiar flavor and has the characteristics of both yellow wines and fruit wines.

Owner:刘名汉

Device and method for inner bore type component brush plating

The invention provides a device and method for inner bore type component brush plating. The device comprises a workpiece to be plated, a workpiece clamping sealing device, a plating pen special for inner bore brush plating, and a plating pen rotary actuator. The workpiece to be plated and the clamping sealing device together form a container having an opening at the top; in plating process, the workpiece is the cathode, and the plating pen is the anode. The device and method realize that plating is prepared at the surface of the inner bore of the inner bore type component by using the technology of brush plating, thereby being applied to strengthening for new workpiece and also being applied to batch repair and remanufacturing for damaged pieces.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Surface-emission laser diode and surface-emission laser array, optical interconnection system, optical communication system, electrophotographic system, and optical disk system

InactiveUS20050147143A1High power operationIncrease speedOptical wave guidanceLaser cooling arrangementsSemiconductor materialsLaser array

A surface-emission laser diode includes an active layer, a pair of cavity spacer layers formed at both sides of the active layer, a current confinement structure defining a current injection region into the active layer, and a pair of distributed Bragg reflectors opposing with each other across a structure formed of the active layer and the cavity spacer layers, the current confinement structure being formed by a selective oxidation process of a semiconductor layer, the pair of distributed Bragg reflectors being formed of semiconductor materials, wherein there is provided a region containing an oxide of Al and having a relatively low refractive index as compared with a surrounding region in any of the semiconductor distributed Bragg reflector or the cavity spacer layer in correspondence to a part spatially overlapping with the current injection region in a laser cavity direction.

Owner:RICOH KK

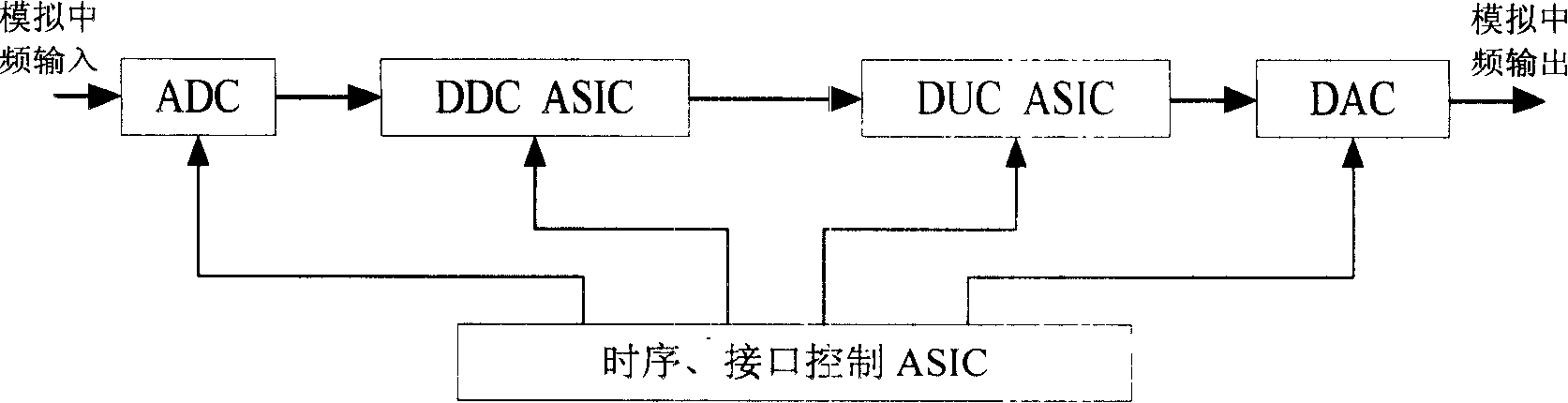

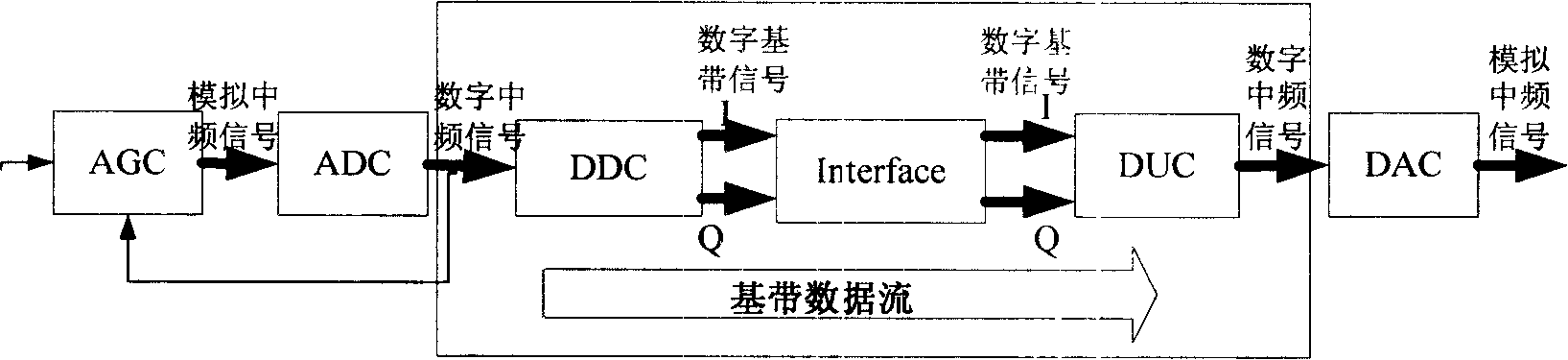

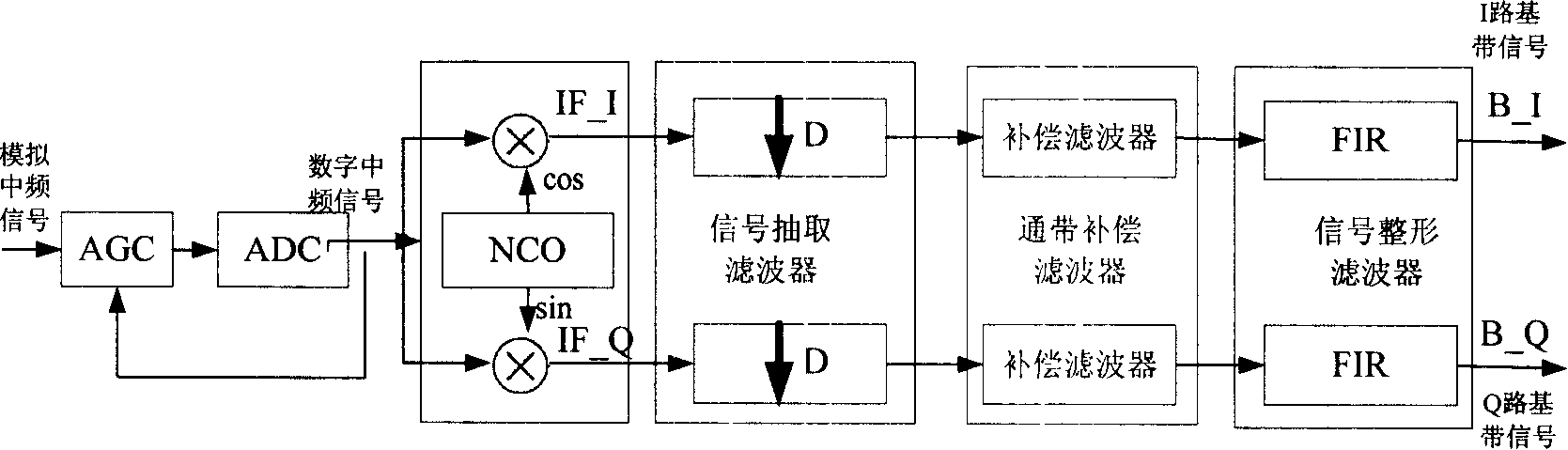

Digital intermediate frequency conversion method and system used in repeater

ActiveCN101197606AHigh degree of integrationReduce usageFrequency-modulated carrier systemsRadio relay systemsProgrammable logic deviceUp conversion

The invention discloses a frequency changing method of digital middle-frequency signals used in a repeater station system, which comprises two steps of an up frequency changing process and a down frequency changing process: in the down frequency changing process, the middle-frequency signals after digital analog conversion are processed by digital wave filtering processes such as an extraction process, a bandpass compensation, a signal shaping process, etc. after a digital frequency mixing process, the middle-frequency signals can be moved to a zero middle-frequency, a digital signal with the high speed rate can extracted as two-channel quadrature digital baseband I, Q signal with a low speed rate; in the up frequency changing process, the digital baseband I, Q signals acquired from the down frequency changing process are processed by an interpolation filtering process, then processed by I, Q modulation process and a secondary frequency mixing process, and the signals can be processed by a gain adjustment and control, finally high speed digital middle-frequency signals are outputted. Correspondingly, the invention also discloses a frequency changing system thereof. The invention can be achieved by using PLC units such as FPGA, CPLD, EPLD and DSP, etc., which can improve the integration degree of repeater station equipment; meanwhile, an ASIC chip is removed to decrease heating capacity and to improve the reliability.

Owner:COMBA TELECOM SYST CHINA LTD

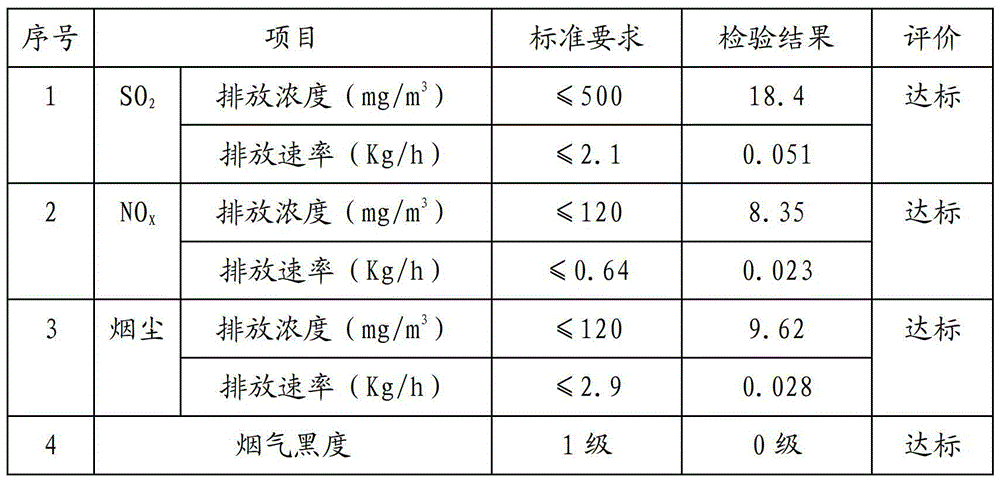

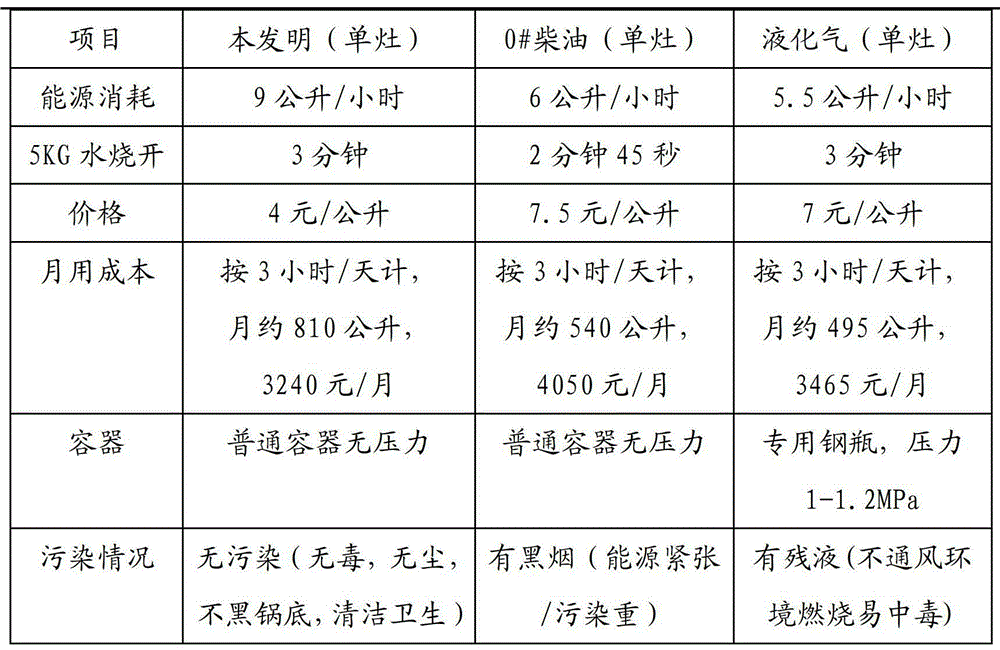

Alcohol-based fuel oil

ActiveCN103184081AProduct performance is stableClean and environmentally friendly oxygen contentLiquid carbonaceous fuelsSolventGlycerol

The invention discloses alcohol-based fuel oil which consists of the following components in part by weight: 70 to 75 parts of methanol, 4 to 6 parts of dimethylbenzene, 4 to 6 parts of No.200 solvent oil, 4 to 6 parts of paraffin oil, 4 to 6 parts of glycerol and 5 to 10 parts of water. Flame generated in the burning process of the alcohol-based fuel oil disclosed by the invention is stronger than that generated in the burning process of diesel oil and liquefied petroleum gas; the alcohol-based fuel oil is more completely and more sufficiently burnt; tail gas generated in the burning process of the alcohol-based fuel oil is cleaner and has no odor; and the alcohol-based fuel oil has the advantages of stable performance, high thermal efficiency, economy, safety and no pollution.

Owner:DONGGUAN CITY QUAN RAN TRADING

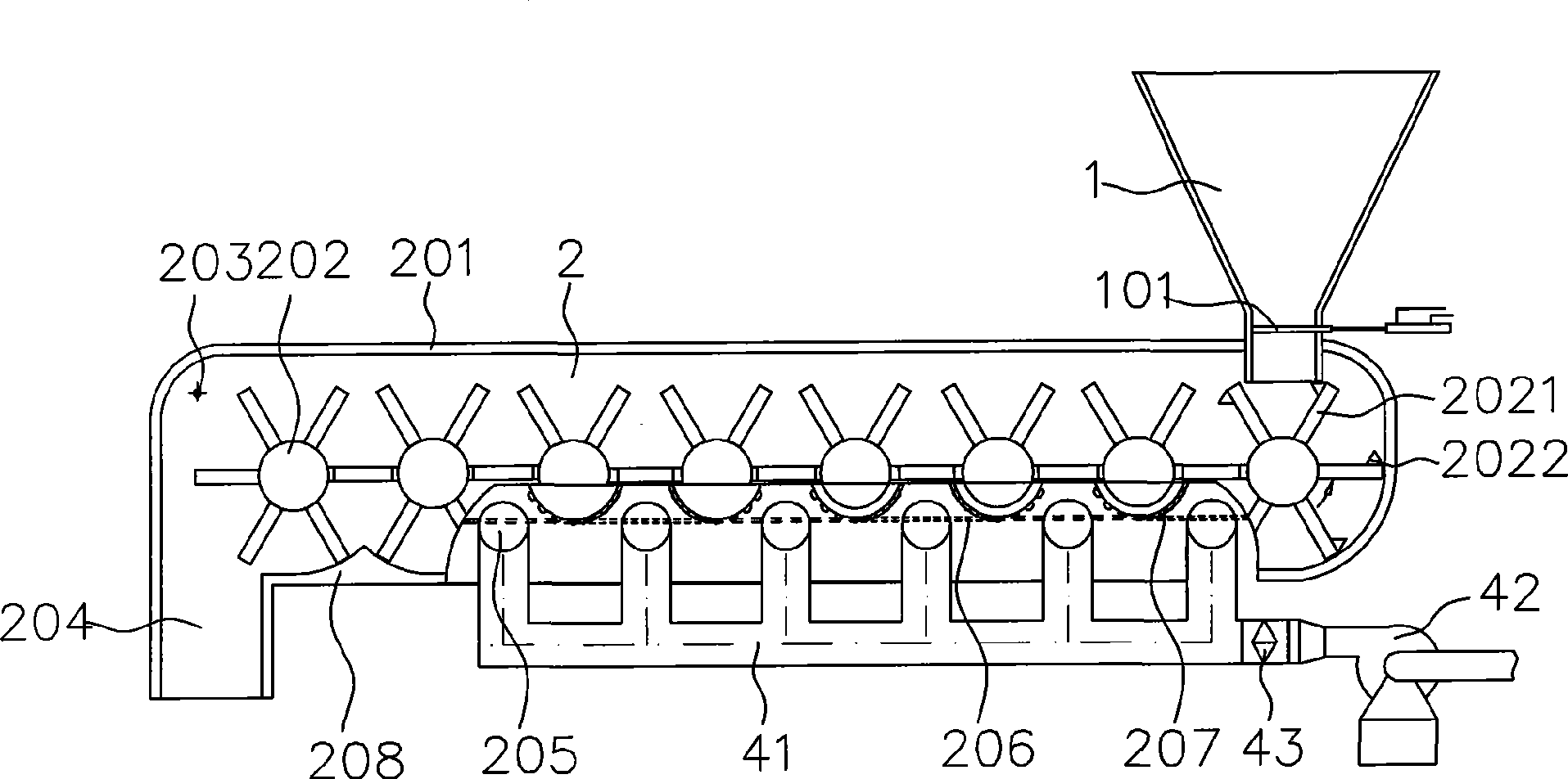

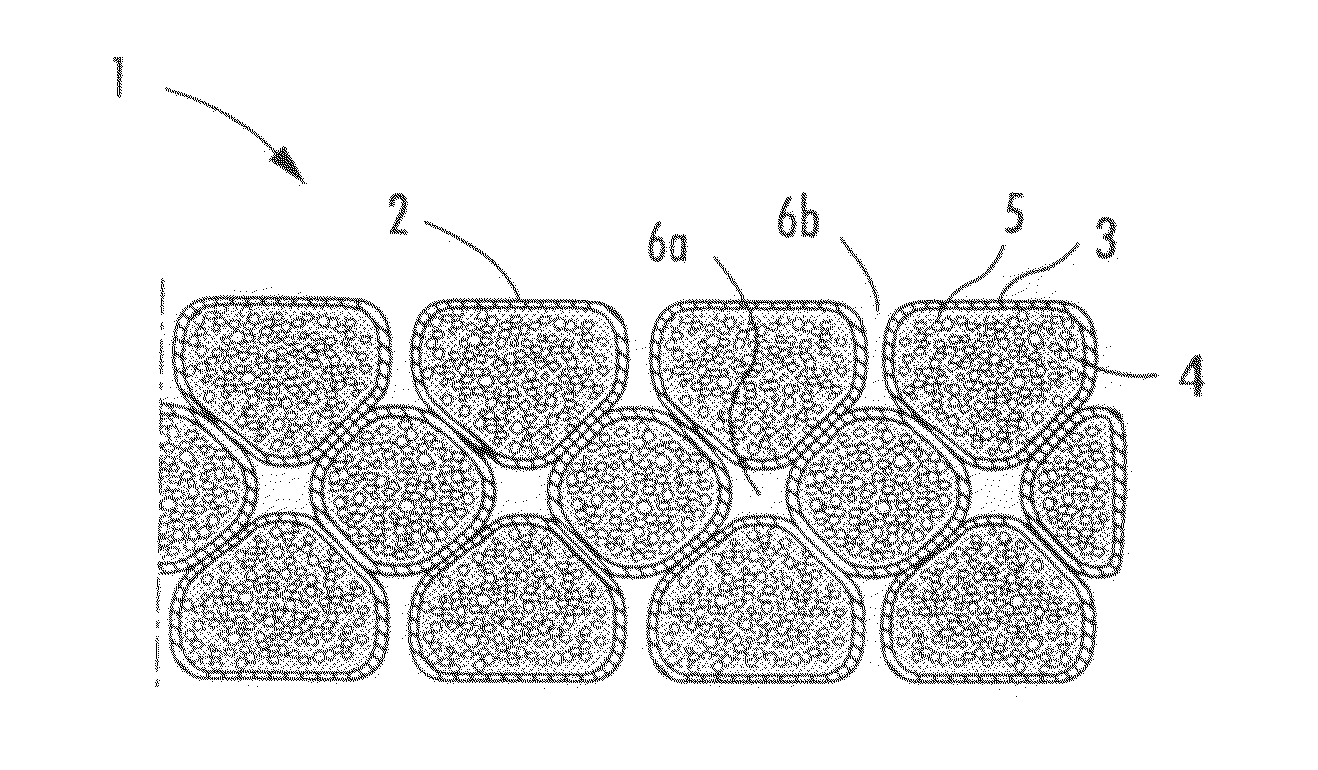

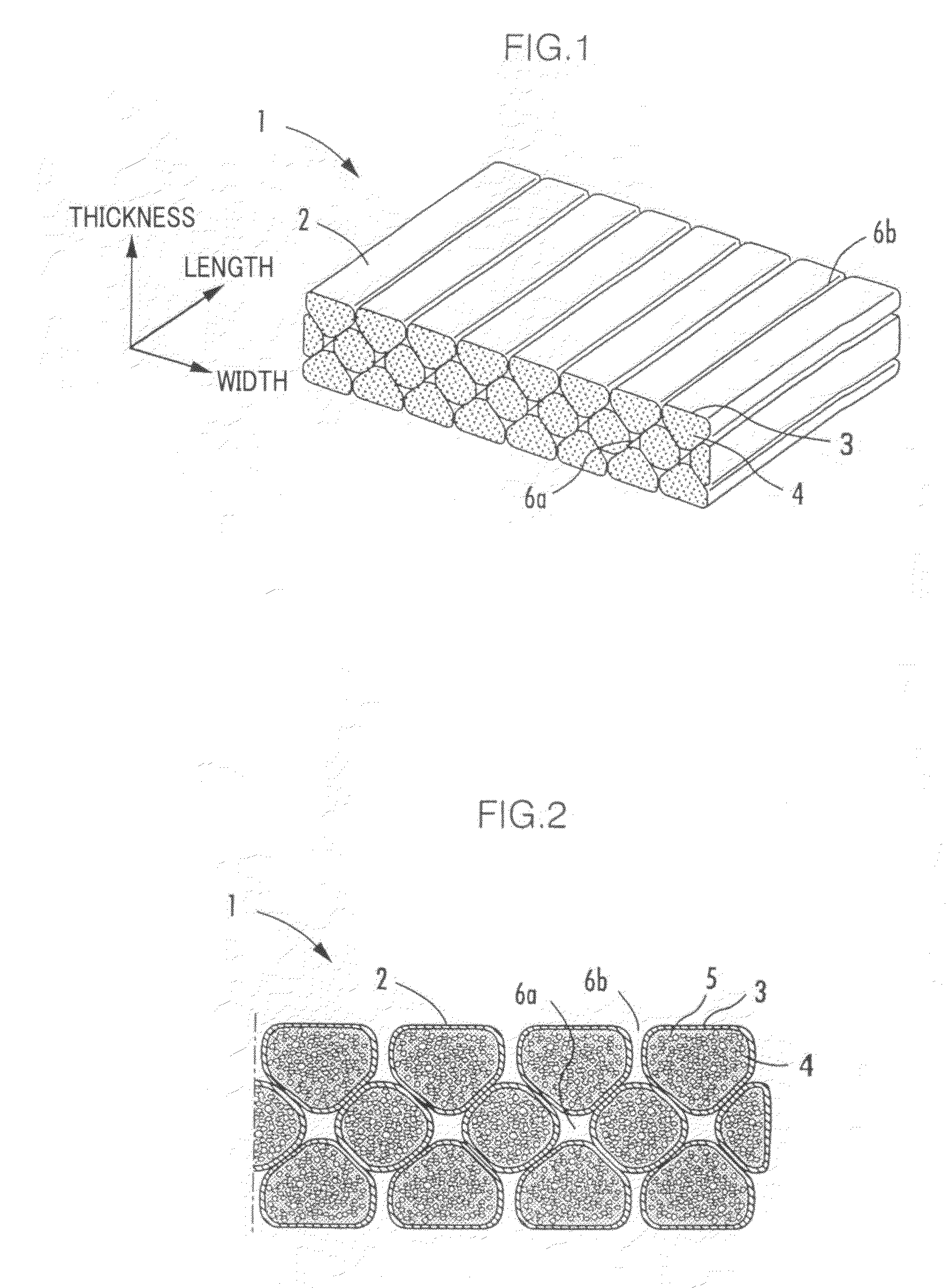

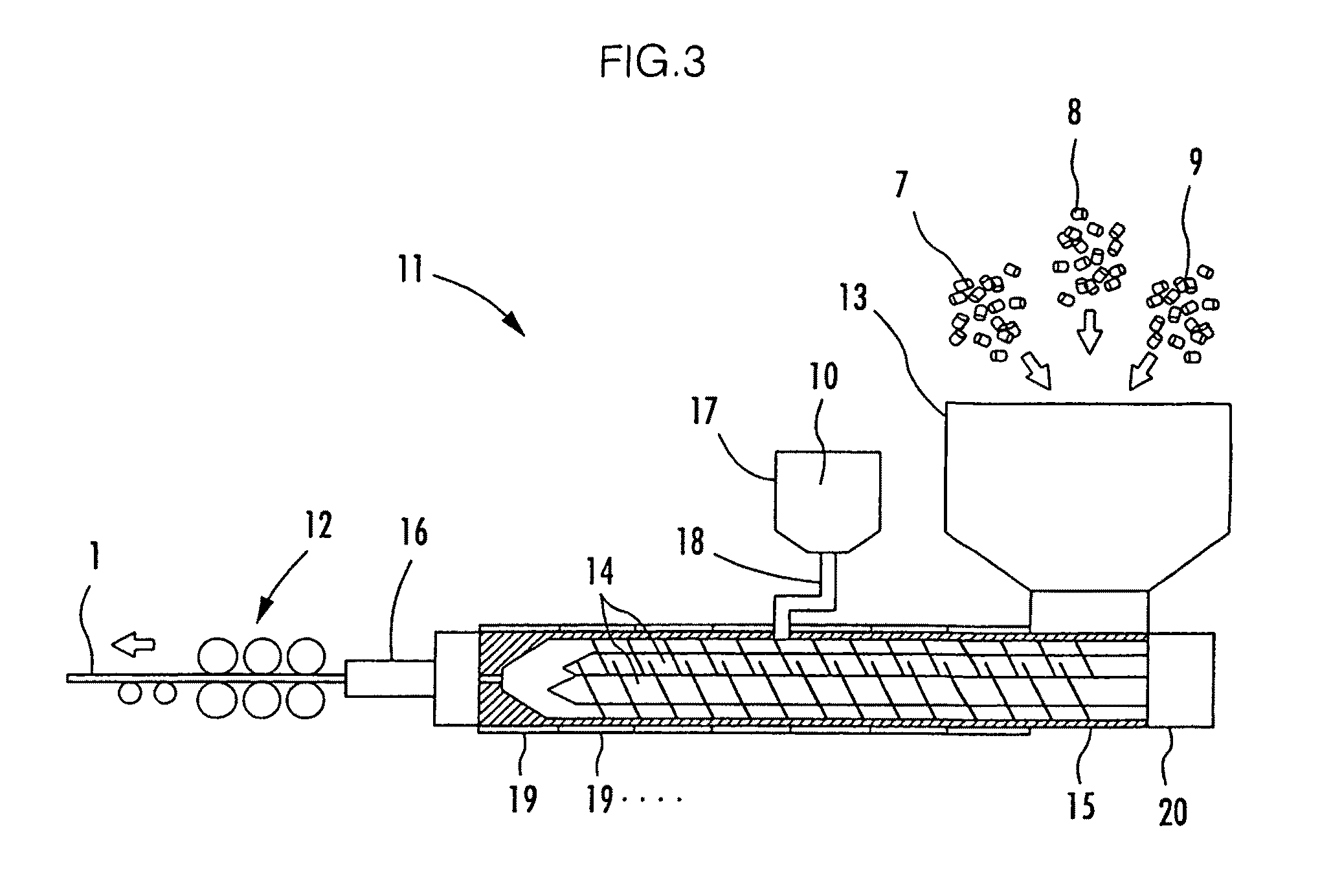

Foamed product and manufacturing method of the same

ActiveUS8227075B2Low calorific valueGenerates no smokeLaminationLamination apparatusThermal insulationPolystyrene

A foamed product that generates no smoke when incinerated, has a low calorific value, and achieves a desired dimension and thermal insulation performance is provided. A foamed product 1 is formed by heat-mixing, in an extruder 11, a paper pellet 7 that is a mixture of a fine paper powder having a particle diameter of 30 to 200 μm and starch, a container recycle pellet 8 that is a mixture of polypropylene, polyethylene, and polystyrene, foamable polypropylene 9, and water 10. A weight distribution is set so that the paper pellet 7 is 50 to 65% by weight, the container recycle pellet 8 is 15 to 25% by weight, the foamable polypropylene 9 is 10 to 30% by weight, and the water 10 is 10 to 20% by weight to these resins and other materials.

Owner:KANKYOKEIEISOGOKENKYUSHO CO INC

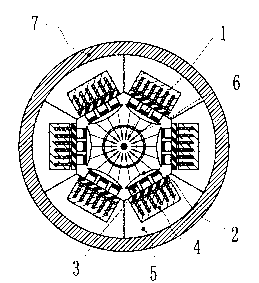

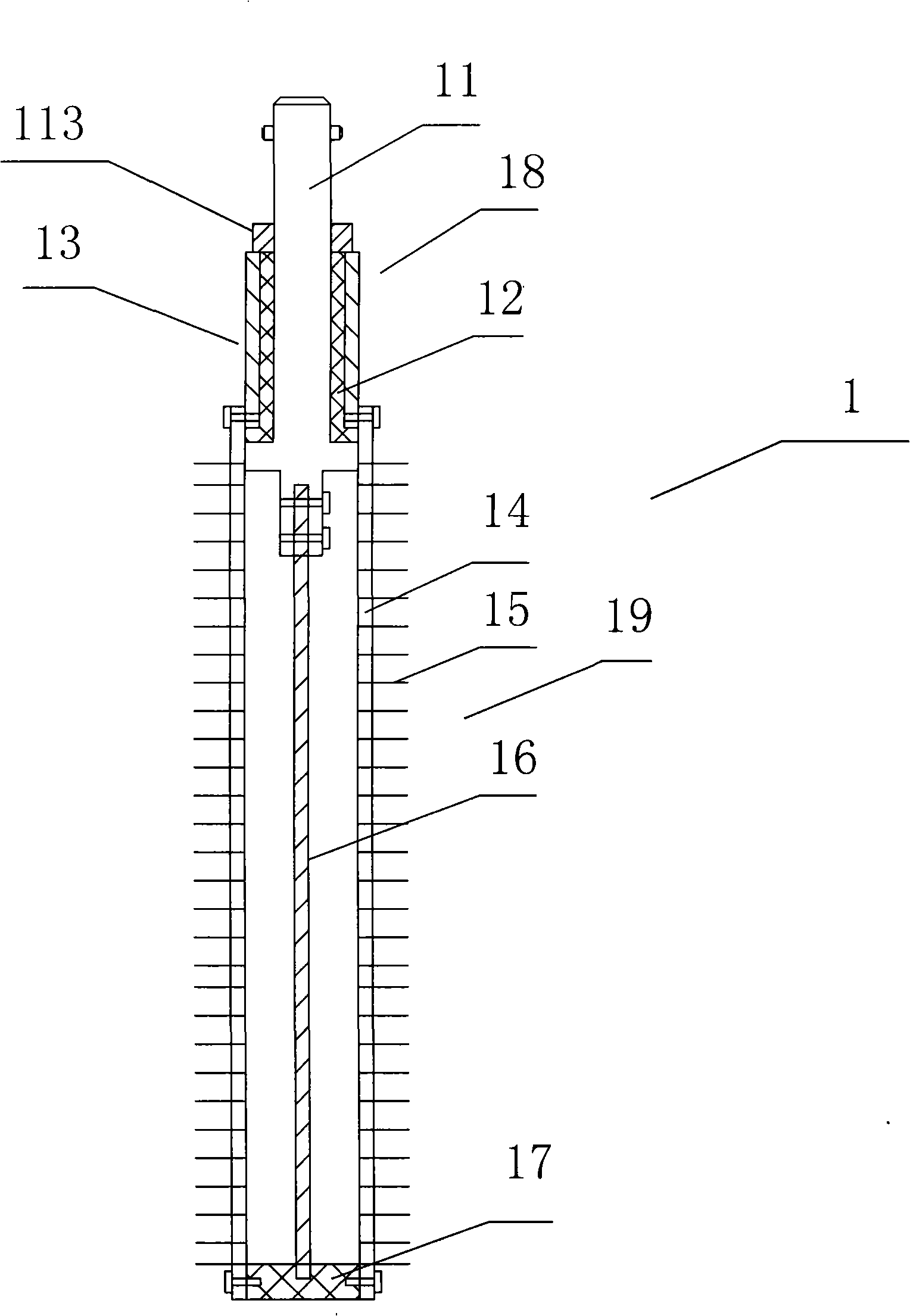

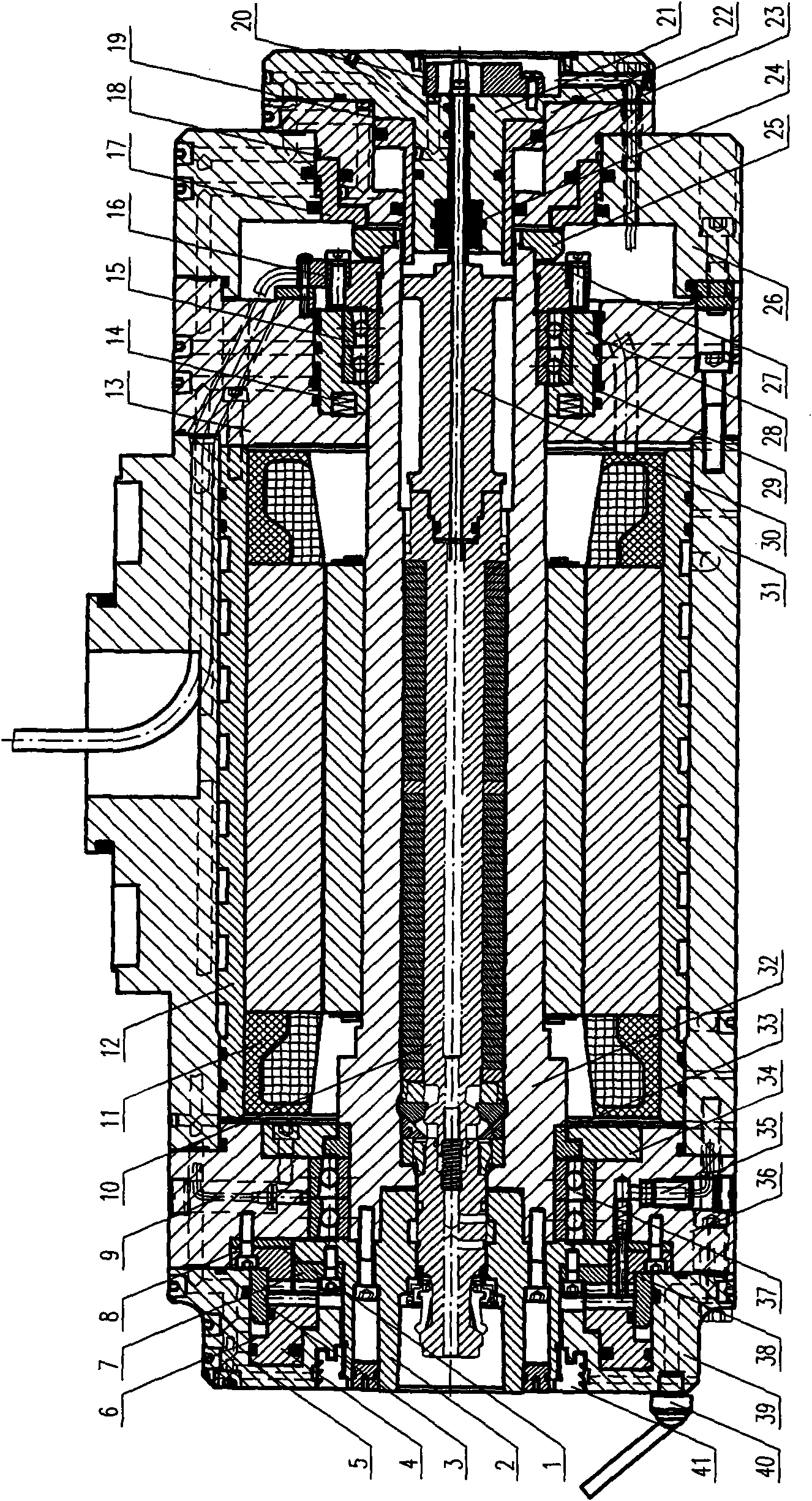

High-speed turn-milling combined machining power electric main shaft device and manufacturing method thereof

ActiveCN101941152AGuarantee working reliabilityAvoid shock loadsOther manufacturing equipments/toolsPositioning apparatusElectric machineryEngineering

The invention relates to a high-speed turn-milling combined machining power electric main shaft device and a manufacturing method thereof. The main shaft device is arranged on a high-speed five-shaft turn-milling combined machining machine tool, and assorted electric, hydraulic and control parts are correspondingly combined with a system on the machine tool. The high-speed turn-milling combined machining power electric main shaft device is characterized in that the inside of a main shaft box is concentrically provided with a water jacket, an in-built motor and a main shaft from the outside to the inside; the inner bore of the main shaft is provided with a broach mechanism; the front end of the broach mechanism is provided with a broach case, and the rear end thereof is connected with a connecting sleeve and a broach detaching mechanism; a front bearing and a rear bearing which are arranged on the outer walls of both ends of the main shaft respectively form a bearing variable pre-tightening structure; a three-fluted disc mechanism is arranged on the periphery of the broach case; a broach oil cylinder is formed by a sleeve; an unloading oil cylinder, the broach detaching oil cylinder and a broach forging oil cylinder which are arranged at the rear end of the main shaft are arranged on the main shaft box through a rear end cover and a big flange; and an oil inlet and an oil outlet are respectively connected with the hydraulic system of the machine tool. The invention can realize the combined machining, such as high-rigidity lathe machining, high-rotating speed milling and the like.

Owner:通用技术集团沈阳机床有限责任公司

Lithium ion power battery with high safety performance

ActiveCN105470523ALow calorific valueImprove securityElectrode carriers/collectorsSecondary cellsCeramic coatingPole piece

The invention relates to the technical field of a lithium ion battery, in particular relates to a lithium ion power battery with high safety performance. The lithium ion power battery comprises a positive pole piece, a diaphragm, a negative pole piece, an electrolyte, an external connection terminal and a shell, wherein the positive pole piece comprises a positive temperature coefficient (PTC) aluminum foil current collector and a high-nickel positive electrode material, the double surfaces of the PTC aluminum foil current collector are coated with PTC coatings, the high-nickel positive electrode material is coated on the surface of the current collector, and the diaphragm is a double-sided ceramic coating diaphragm. A fabrication method of the positive pole piece comprises the following steps of firstly, mixing all constitutes of a PTC material, a conductive agent, a binding agent and a solvent which serve as raw materials of the PTC coatings to prepare a paste; secondly, uniformly applying the paste on the double surfaces of an aluminum foil and drying the paste to obtain the PTC aluminum foil current collector; and finally, uniformly applying the high-nickel positive electrode material paste on the PTC aluminum foil current collector, and then carrying out roasting, grinding, slitting and roasting to obtain the positive pole piece.

Owner:WANXIANG 123 CO LTD

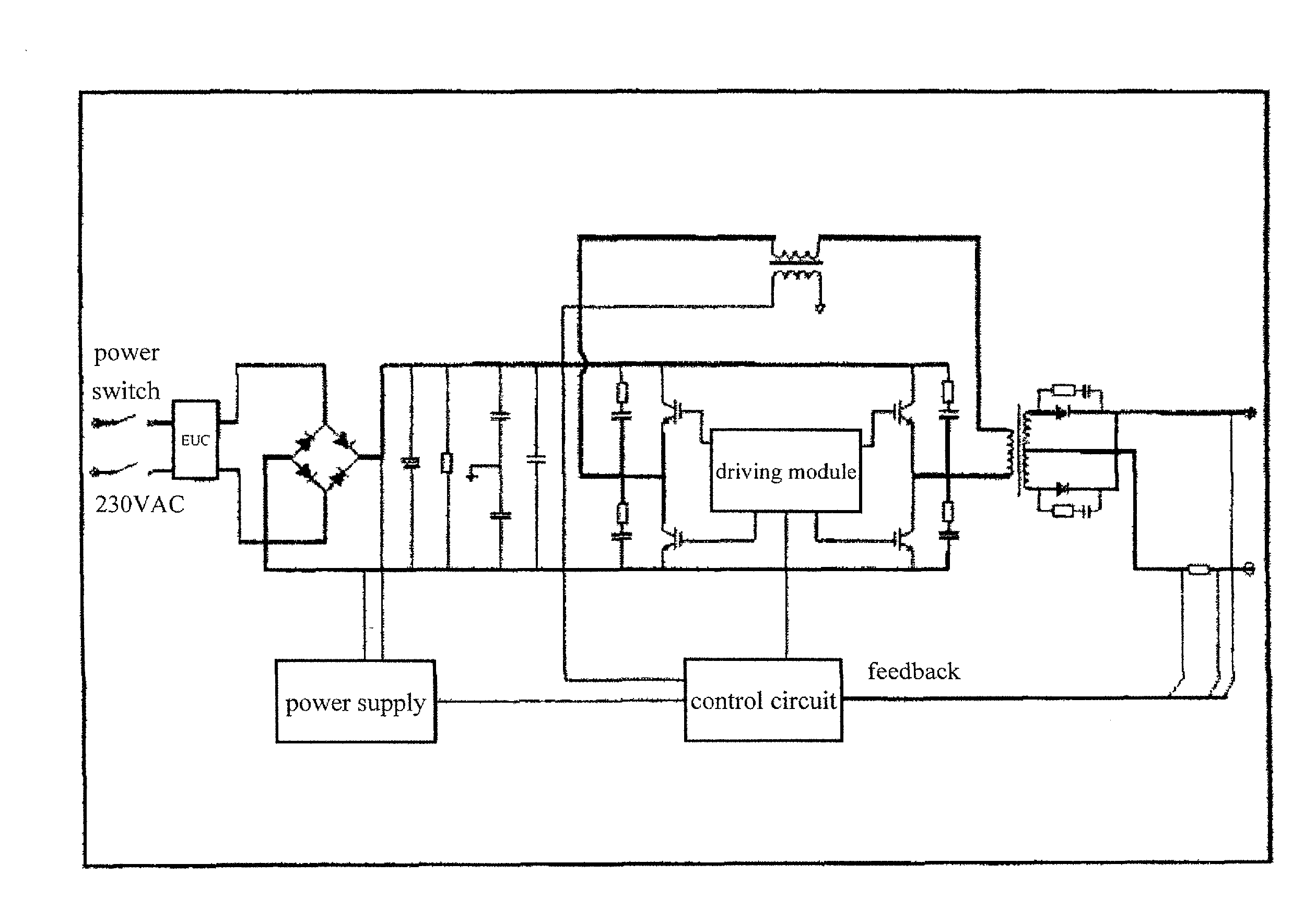

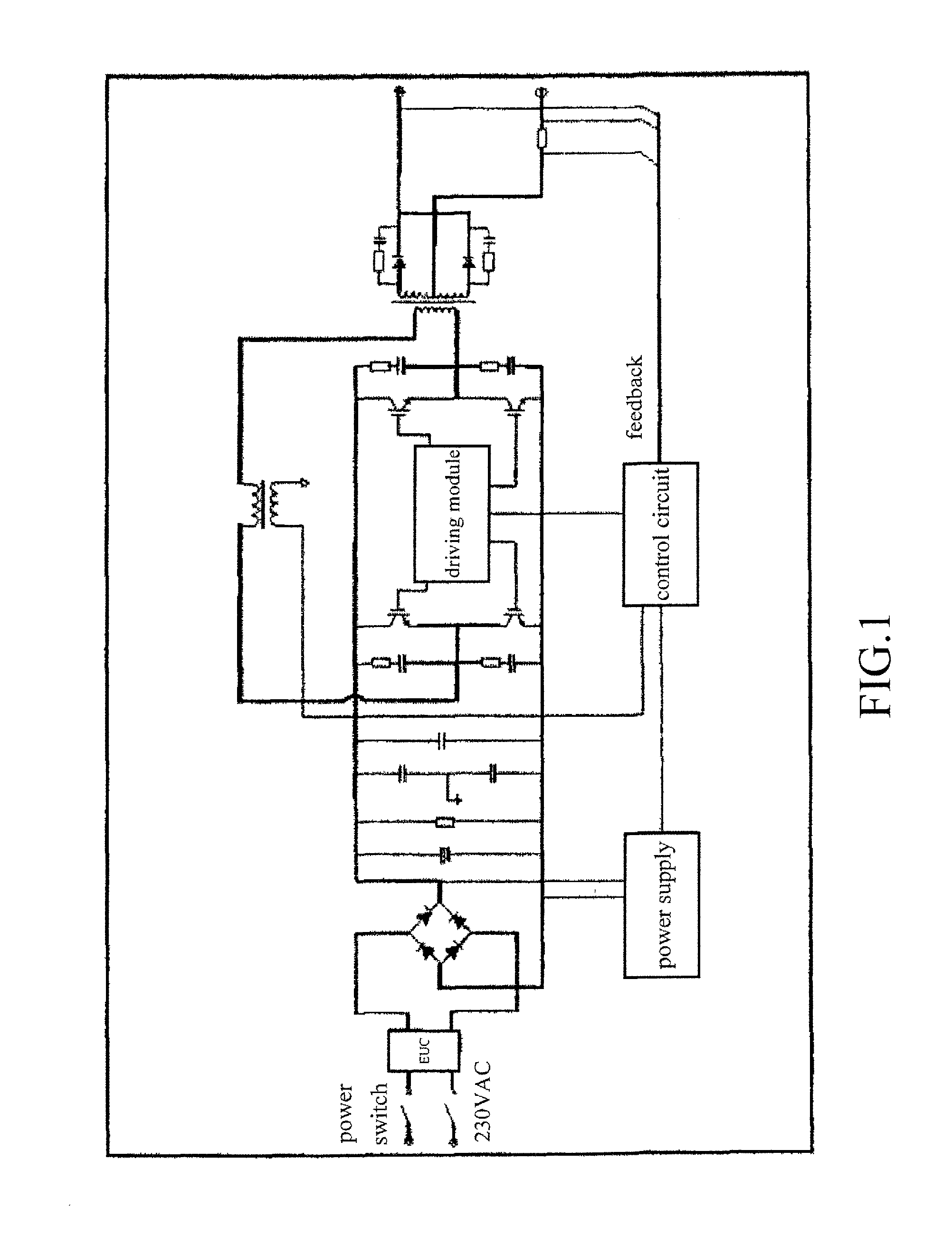

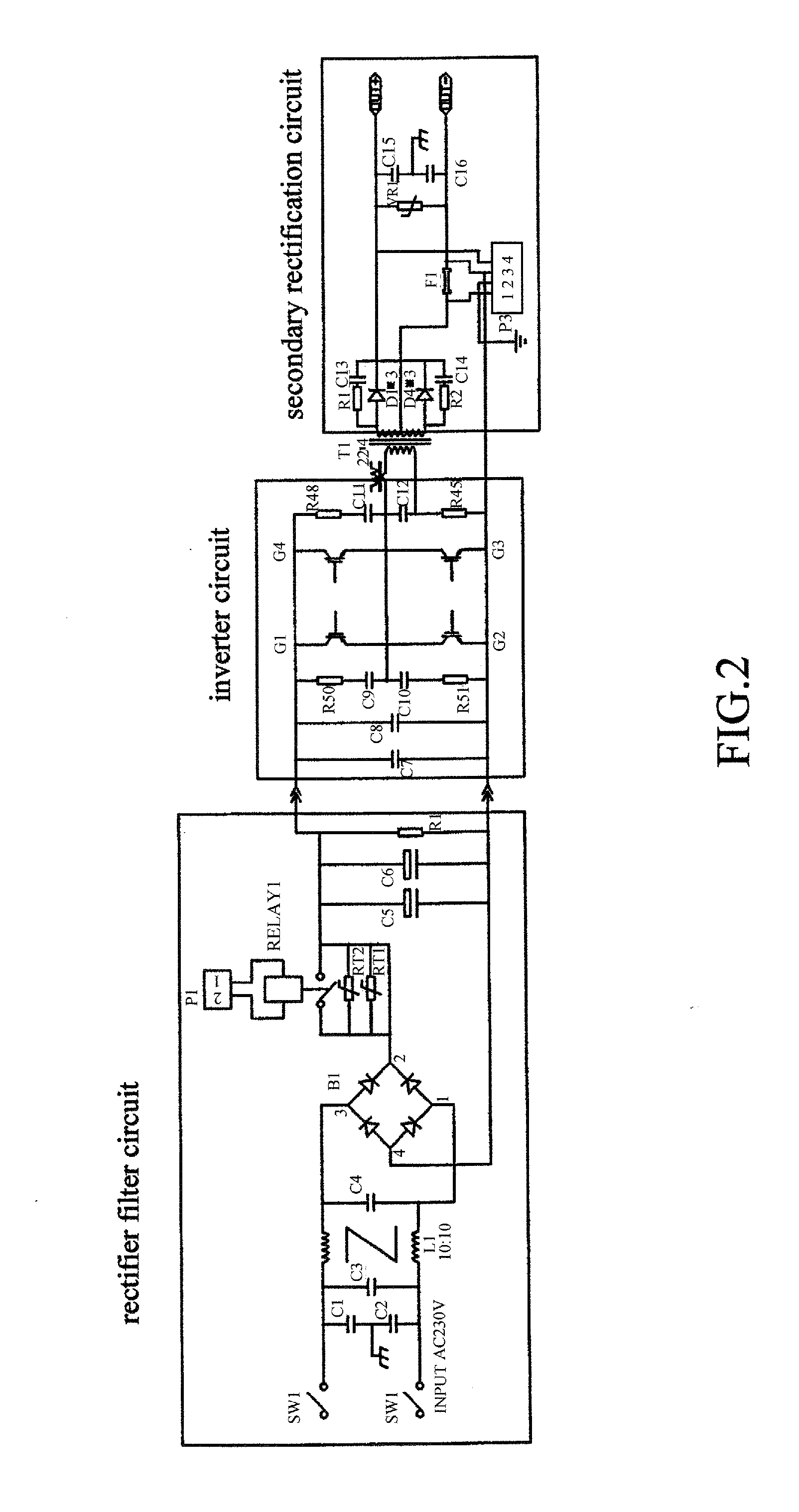

Portable IGBT arc welding machine

ActiveUS20140209586A1Large capacityLow calorific valueDc-dc conversionArc welding apparatusFull bridgeLow voltage

A portable IGBT (Insulated Gate Bipolar Transistor) of high reliability, compact size, and low cost includes a main circuit to which a control circuit and an auxiliary power supply circuit are connected. The main circuit includes, in sequence, an input rectifier filter circuit, an inverter circuit, a high-frequency primary transformer, and a secondary output rectifier circuit. The control circuit includes a PWM regulation circuit, an IGBT driving circuit, a current feedback circuit, and a current setup circuit. The inverter circuit includes a full-bridge hard switching structure, which has IGBTs constituting bridge arms that are sequentially conducted, so that their alternating conduction converts direct current into high frequency square wave alternating current, which flows through the high-frequency primary transformer and is then subjected to rectification to supply an output of low voltage direct current. Each IGBT is connected in parallel to resistor and capacitor, which constitute a peak voltage absorption circuitry.

Owner:SHENZHEN JASIC TECH

Phenolic resin composite material for manufacturing cable support and preparation method thereof

The invention relates to a phenolic resin composite material for manufacturing a cable support and a preparation method thereof. The preparation method comprises the following steps: adding zinc stearate into phenolic resin and stirring the mixture evenly; adding a fire retardant and a thickening agent in turn to prepare phenolic resin glue solution; passing reinforcing fibers through a phenolic resin glue solution steeping vat, then extruding out part of the resin, covering a polyethylene film on the upper surface and the lower surface of the resin, and coiling the resin into a coil; putting the resin into a baking oven to cure for 24 hours at a temperature of 50+ / -5 DEG C so as to prepare a one-way reinforced die pressing material of the phenolic resin composite material; cutting the one-way reinforced die pressing material of the phenolic resin composite material into corresponding sizes for weighing according to different regional sizes of a die structure; putting the one-way reinforced die pressing material into a die cavity when the temperature of the die cavity is between 130 and 150 DEG C until the die cavity is fully filled, and closing the die; and under the condition of a die pressing pressure of between 7 and 12 MPa, performing deflation twice in the die closing curing process, and taking the one-way reinforced die pressing material out of the die after 20 to 25 minutes to obtain the phenolic resin composite material cable support. The phenolic resin composite material has the advantages of low calorific value, high fire retardance, excellent insulating property, and high strength and corrosion resistance.

Owner:洛阳双瑞橡塑科技有限公司

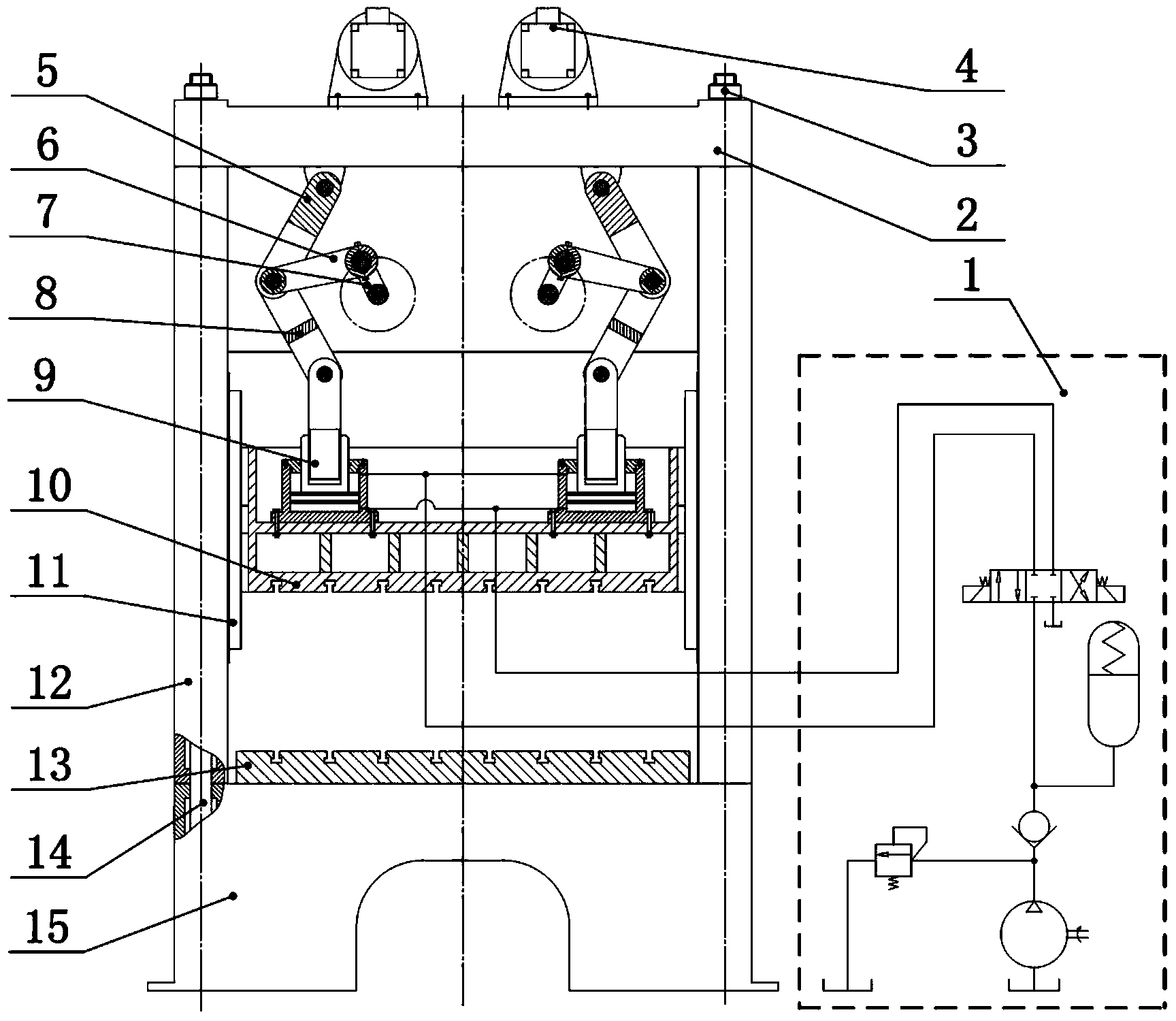

Mechanical-hydraulic composite energy-saving servo hydraulic machine with toggle rod mechanism

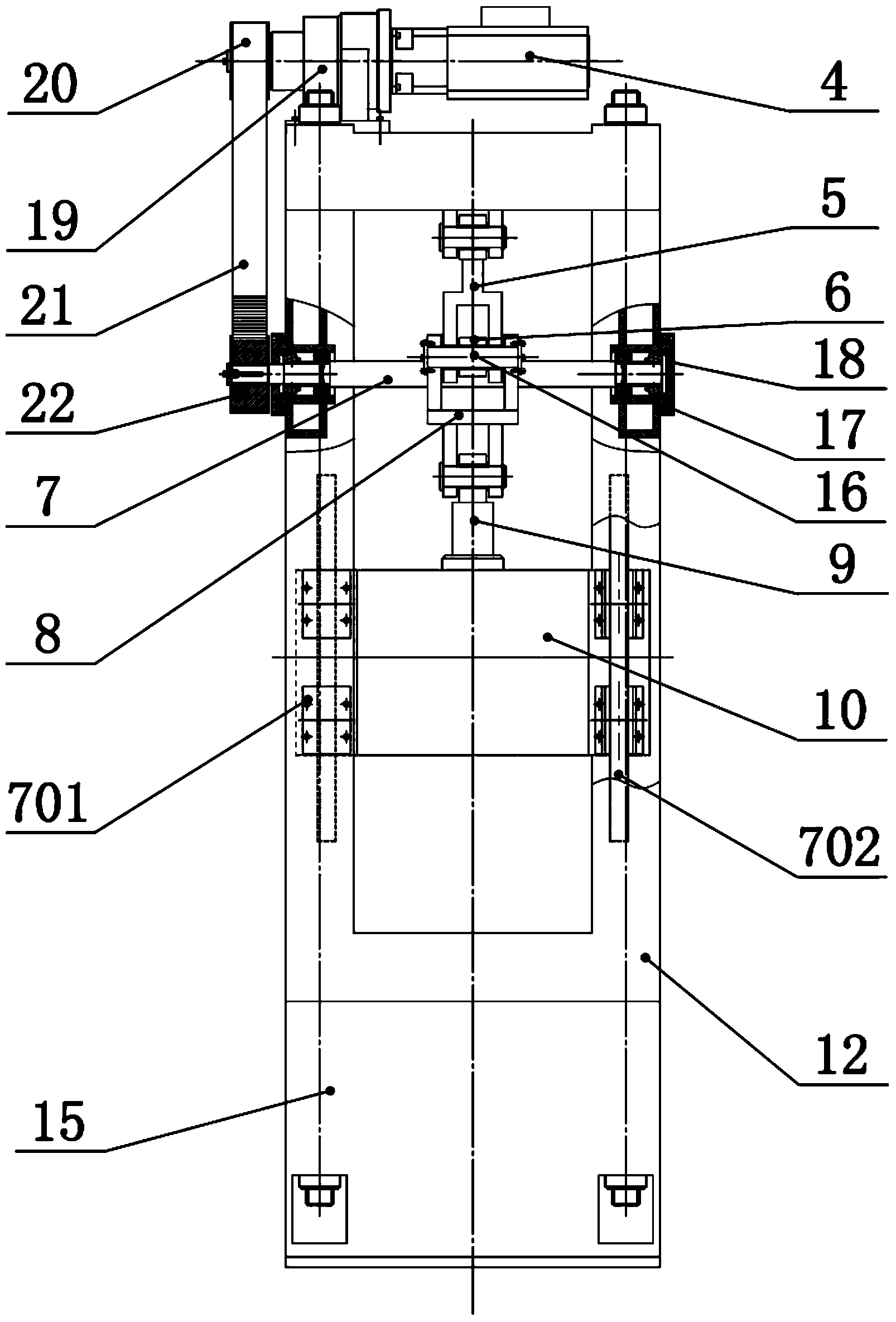

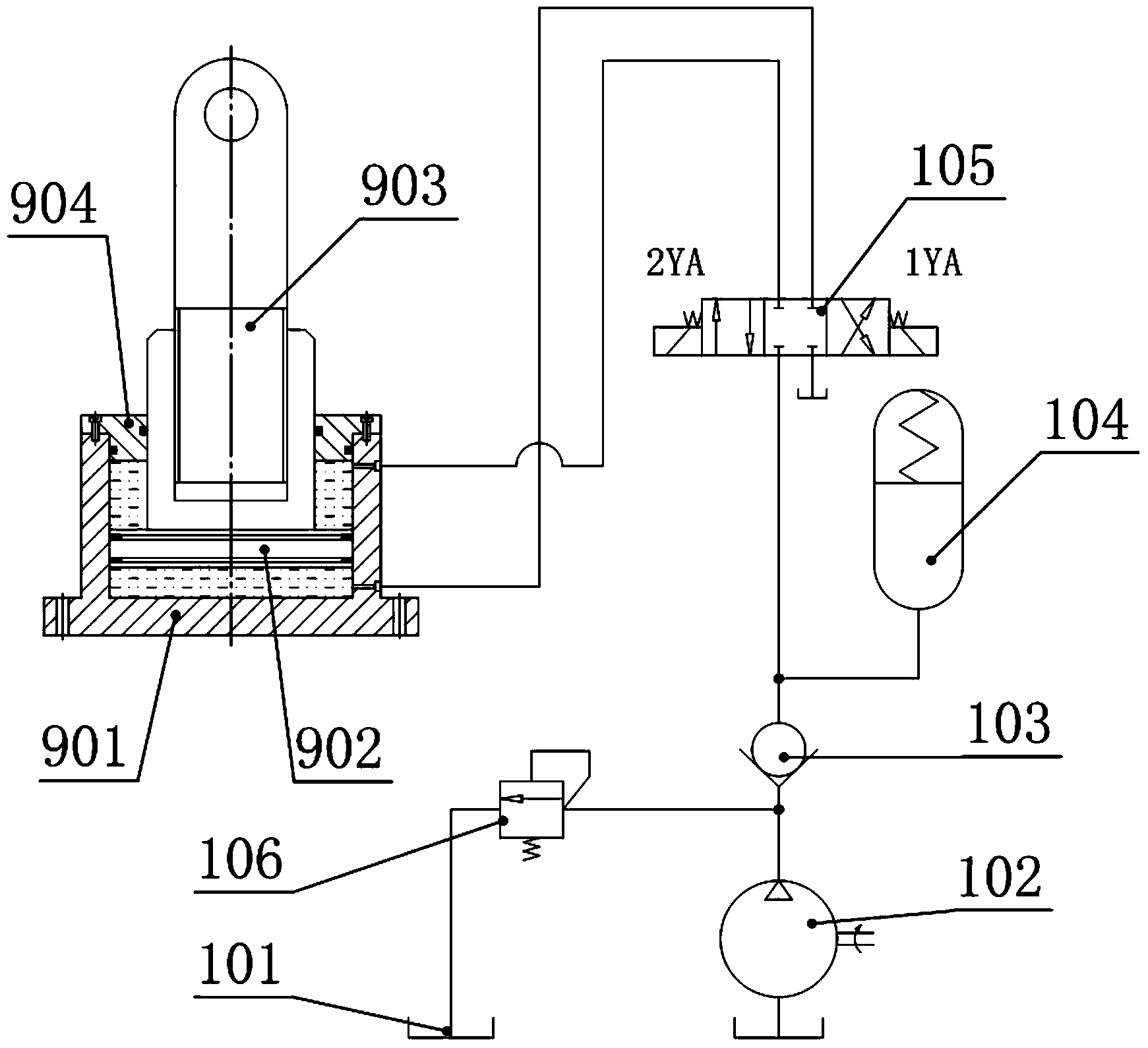

ActiveCN103963334ALow power requirementHigh control precisionPress ramHydraulic cylinderControl theory

A mechanical-hydraulic composite energy-saving servo hydraulic machine with a toggle rod mechanism comprises a work table which is fixed on a base. A machine body is of a three-beam and four-column structure, the four stand columns are hollow, pull rods penetrate through the inside of the stand columns, the two ends of each pull rod are fixed on an upper beam and the base respectively through tightening nuts, guide rails are fixed on the stand columns, and linear guide rail sliding blocks are fixed on the outer walls of press sliding blocks and slide up and down on the guide rails. By combining high control precision of a servo motor, high operation speed of a mechanical structure and large load of a hydraulic cylinder, idle stroke is driven by the independent servo motor and the mechanical structure, and work stroke is driven by a hydraulic system. The mechanical-hydraulic composite energy-saving servo hydraulic machine can lower power of the servo motor, improve the energy utilization rate and improve flexibility.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com