LED driver with adjustable conduction time

A technology of LED driver and conduction time, which is applied in the field of LED driving, can solve the problems of low efficiency of linear LED driving circuit, low efficiency of driving circuit, affecting application reliability, etc., achieve high PF value, improve efficiency, and enhance reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

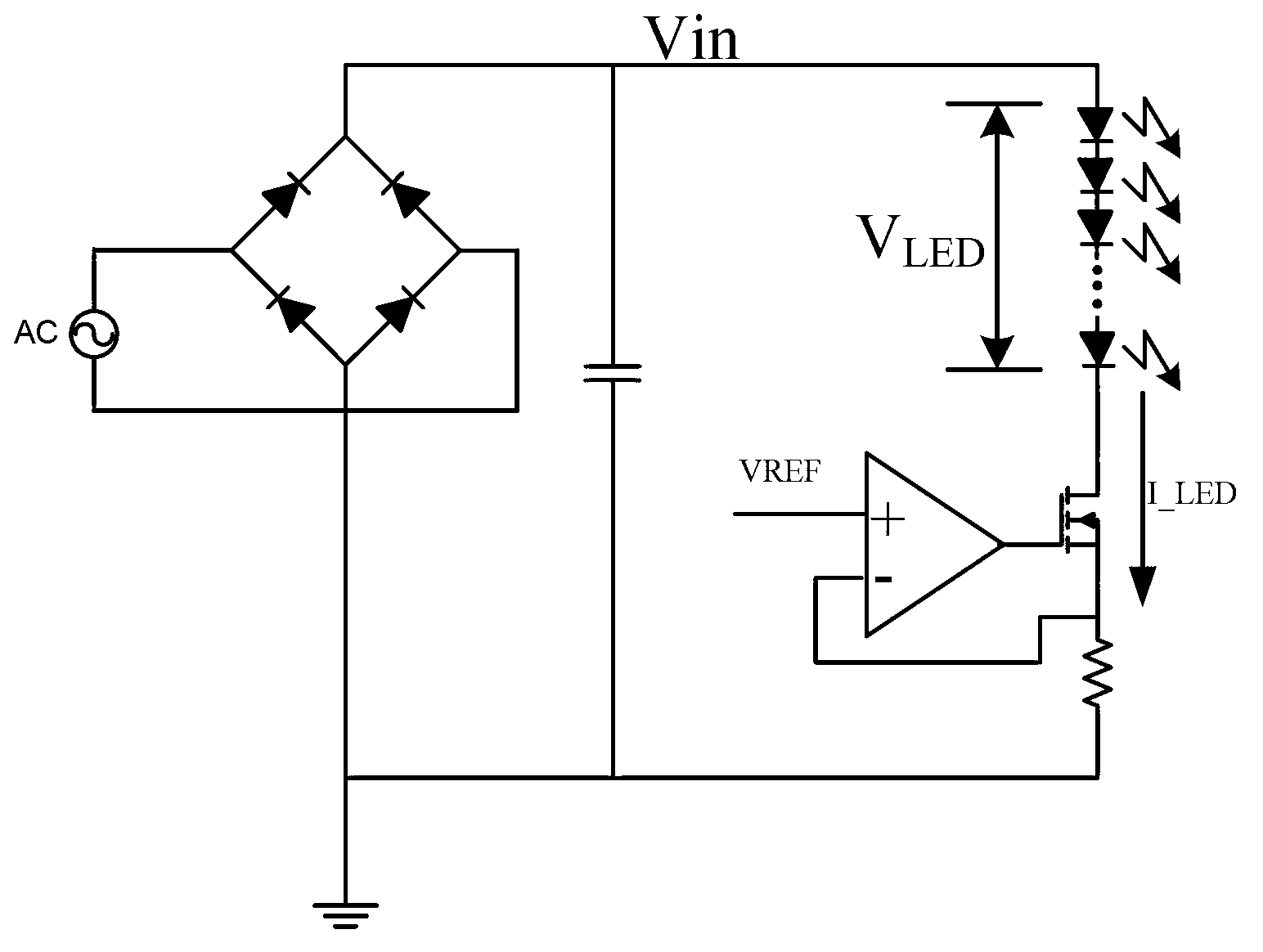

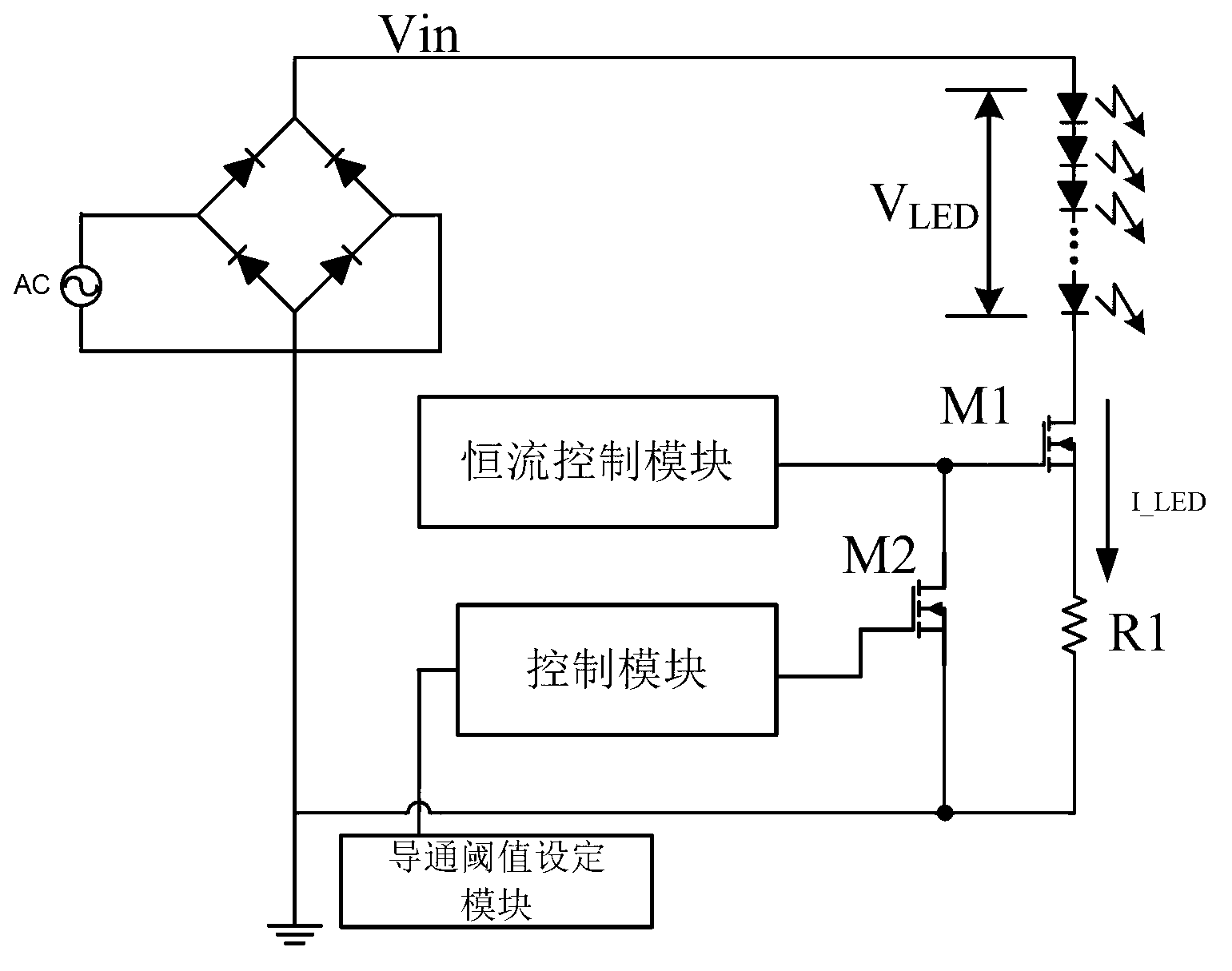

[0021] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

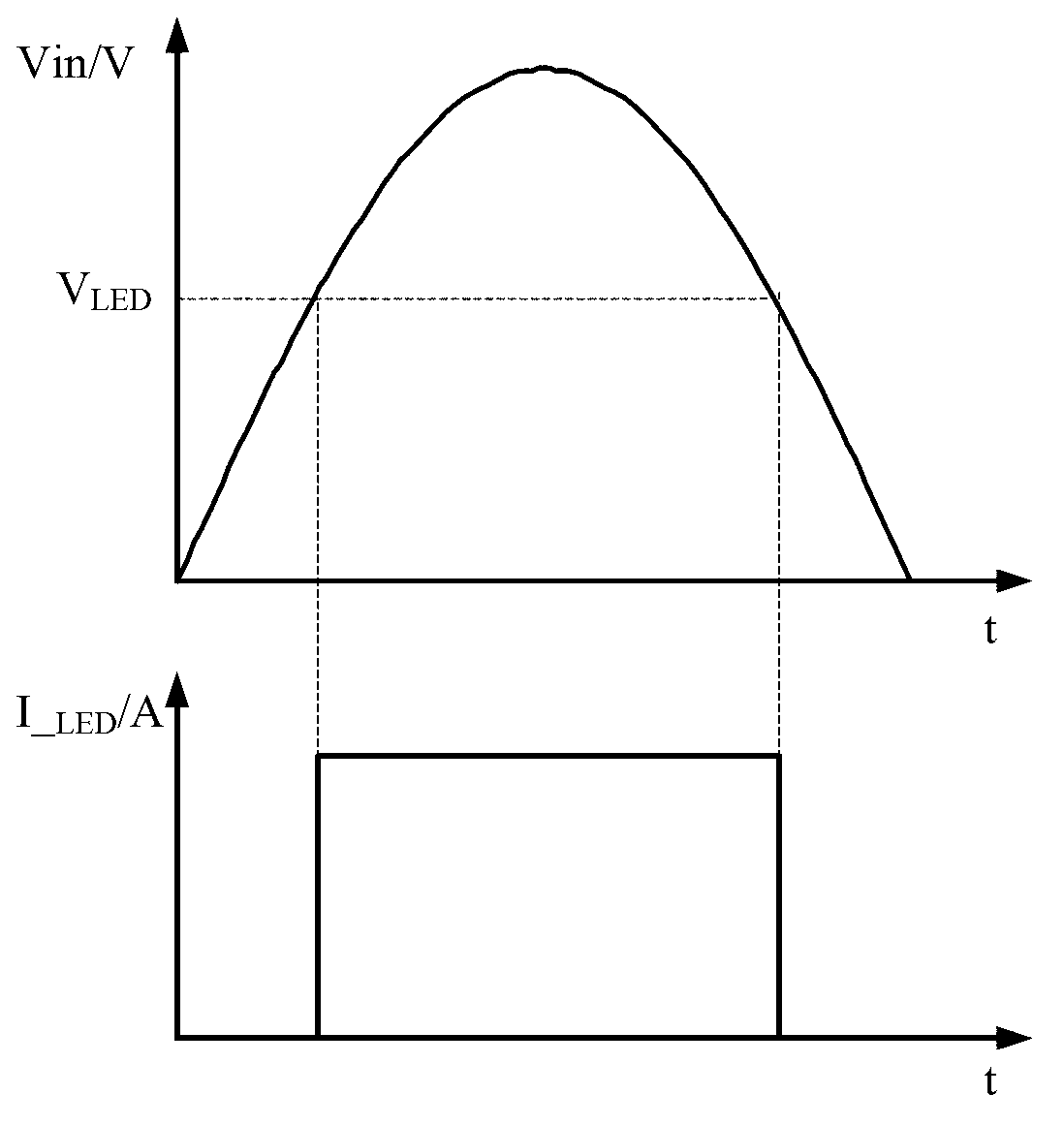

[0022] The present invention controls the conduction time of the LED current by comparing the power supply voltage Vin with the LED voltage drop, turns off the LED current when Vin is greater than a certain set value of the LED voltage, and turns on the LED current until Vin reaches the set value near the LED voltage again. LED current, and the on-time of the LED current is controlled by one or more voltages or currents. In this process, the LED current becomes a pulse waveform, and the average value of the LED current is kept constant through the constant current loop. In particular, when the LED is driven by the alternating current AC, the conduction time of the LED current is controlled by one or more voltages or currents, so as to achieve a compromise between the power factor PF and the efficiency. For application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com