Patents

Literature

3830 results about "LED circuit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, an LED circuit or LED driver is an electrical circuit used to power a light-emitting diode (LED). The circuit must provide sufficient current supply (either DC or AC, see below) to light the LED at the required brightness, but must limit the current to prevent damaging the LED. The voltage drop across an LED is approximately constant over a wide range of operating current; therefore, a small increase in applied voltage greatly increases the current. Very simple circuits are used for low-power indicator LEDs. More complex, current source circuits are required when driving high-power LEDs for illumination to achieve correct current regulation.

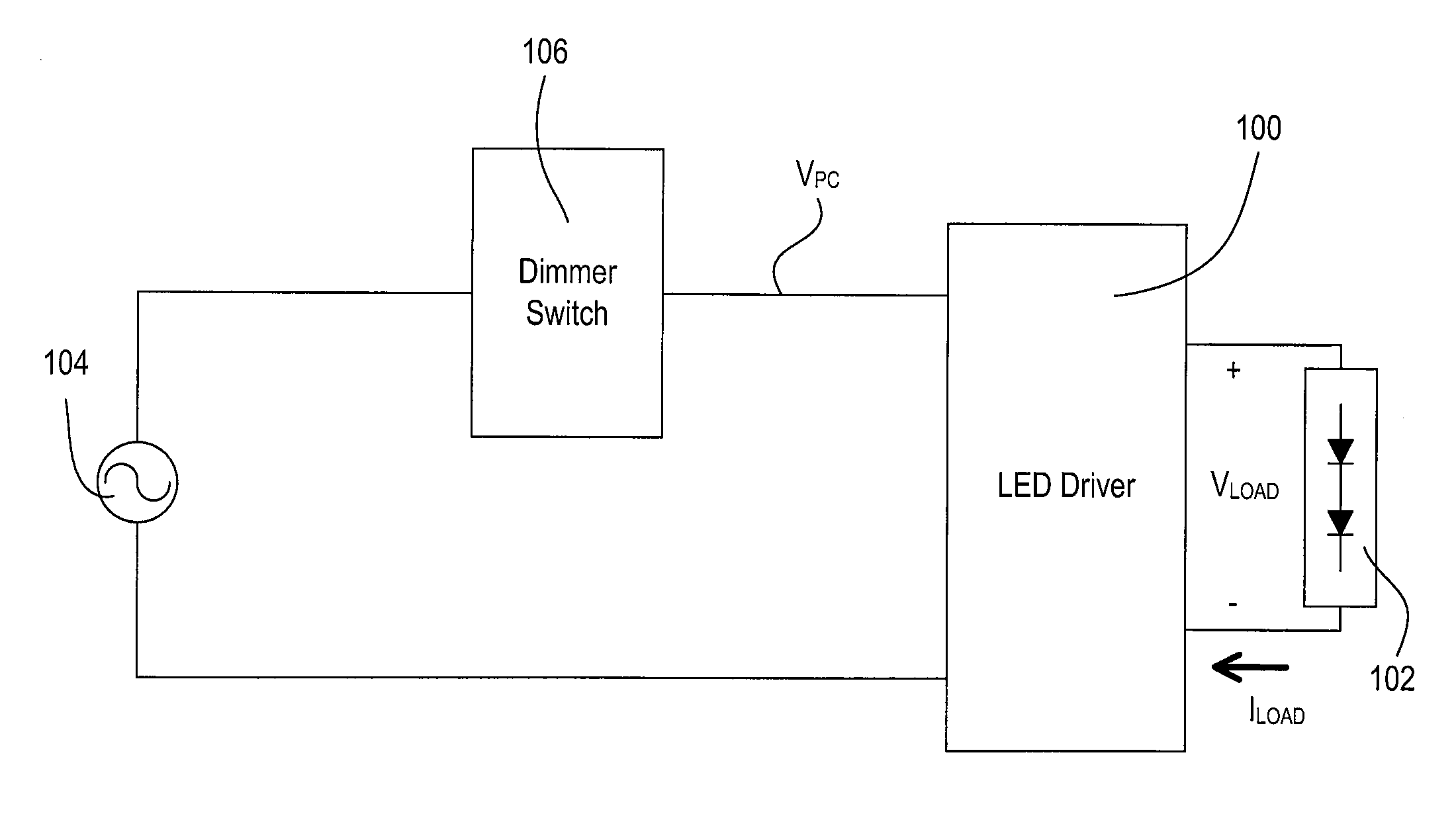

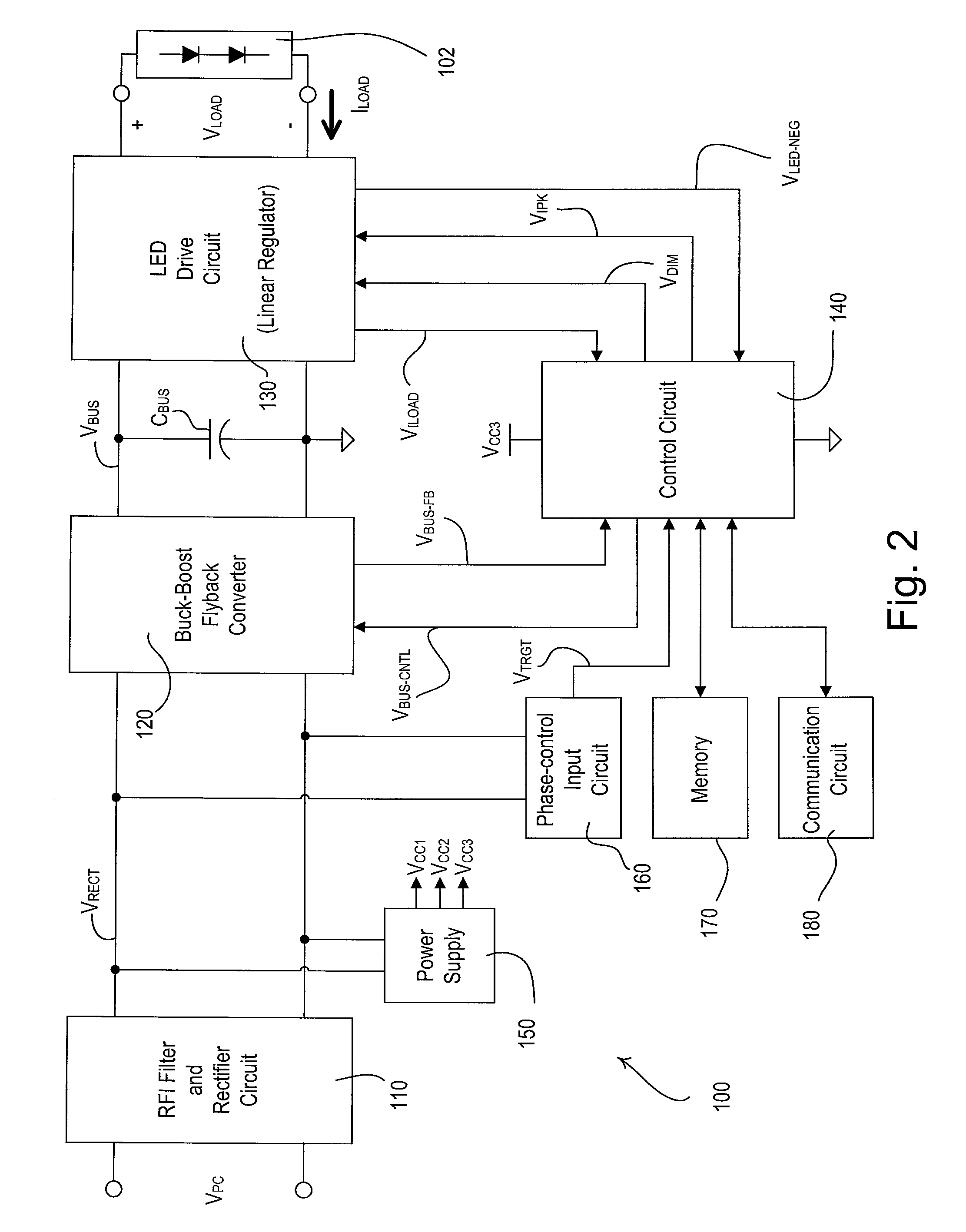

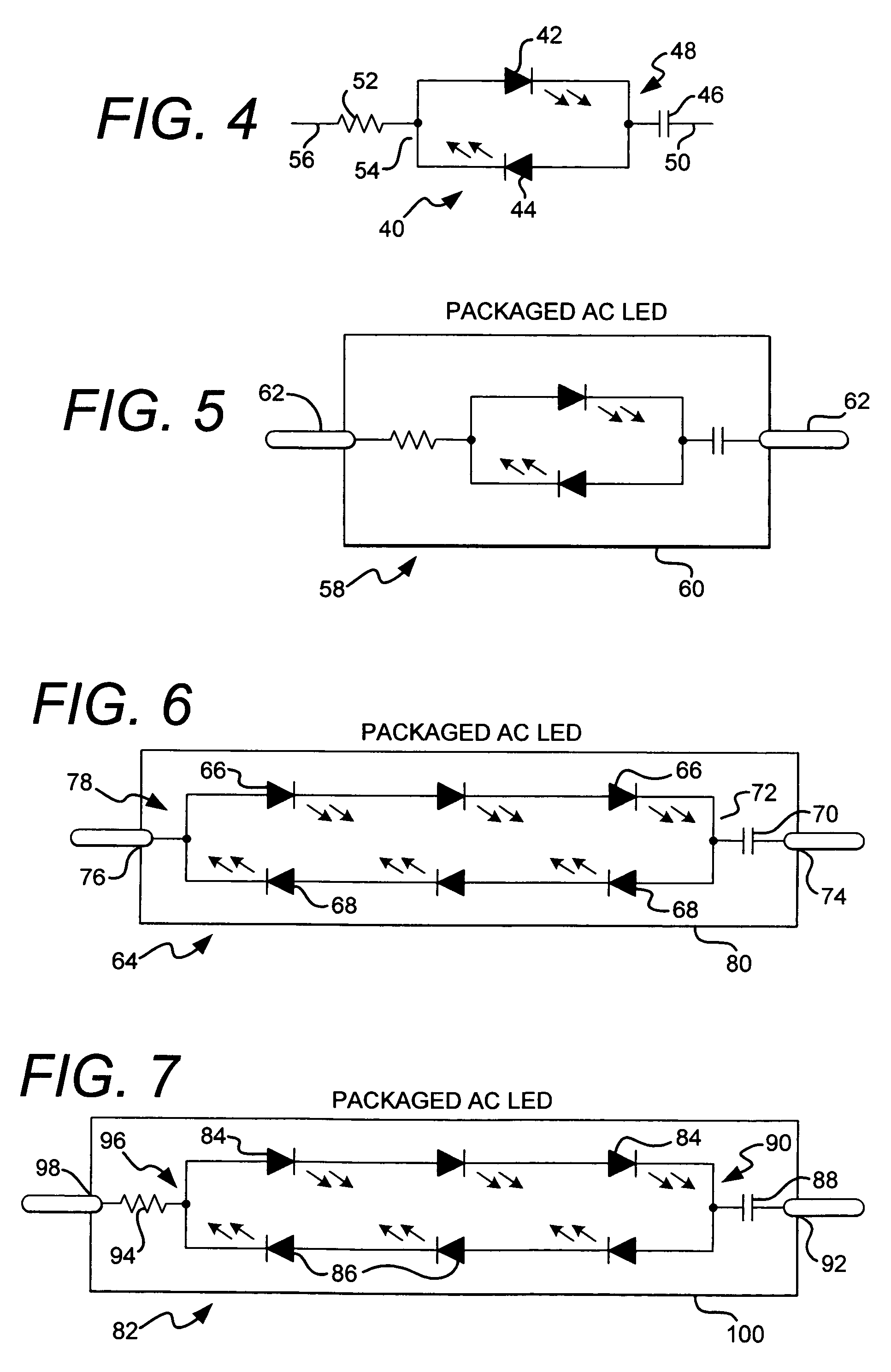

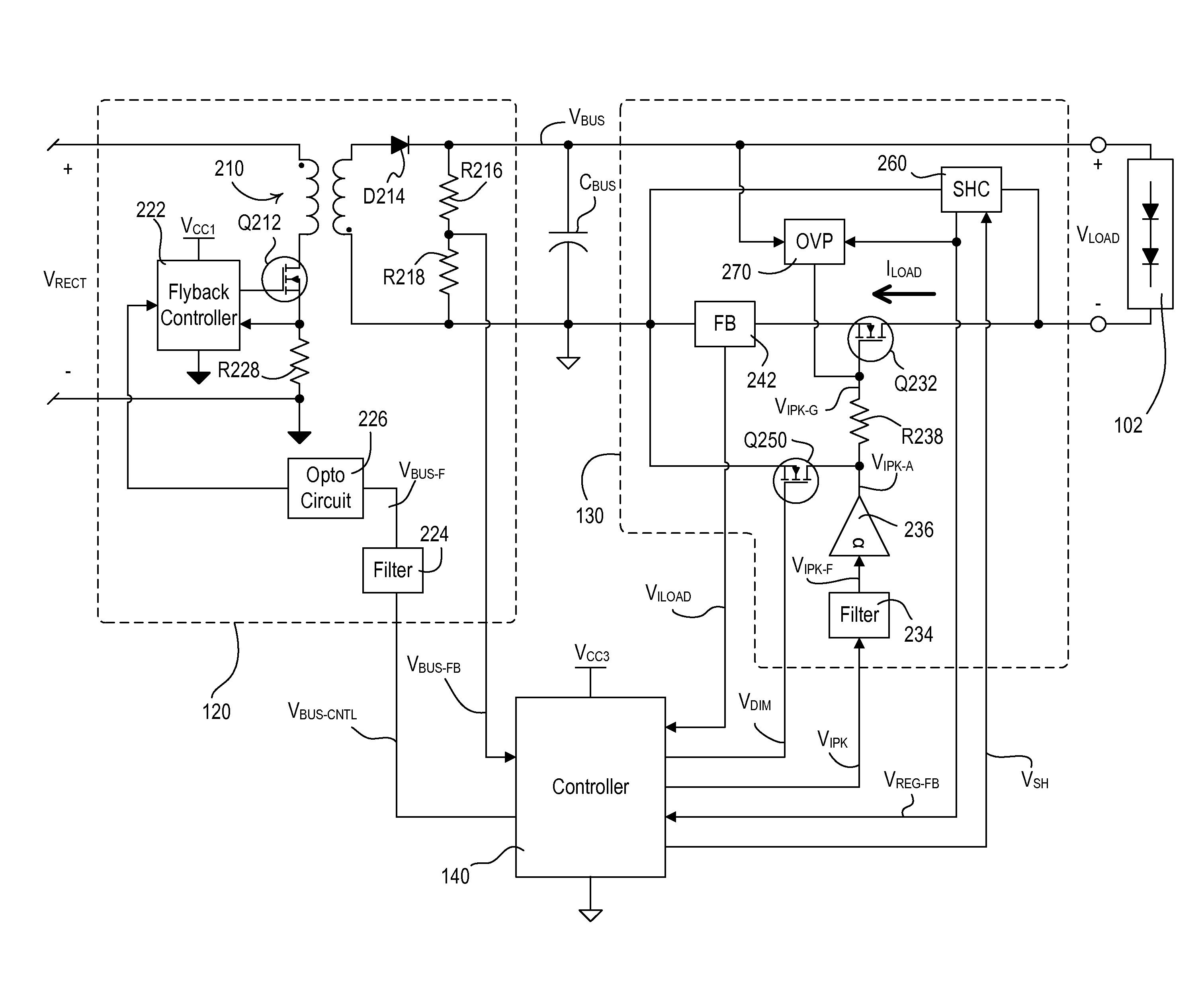

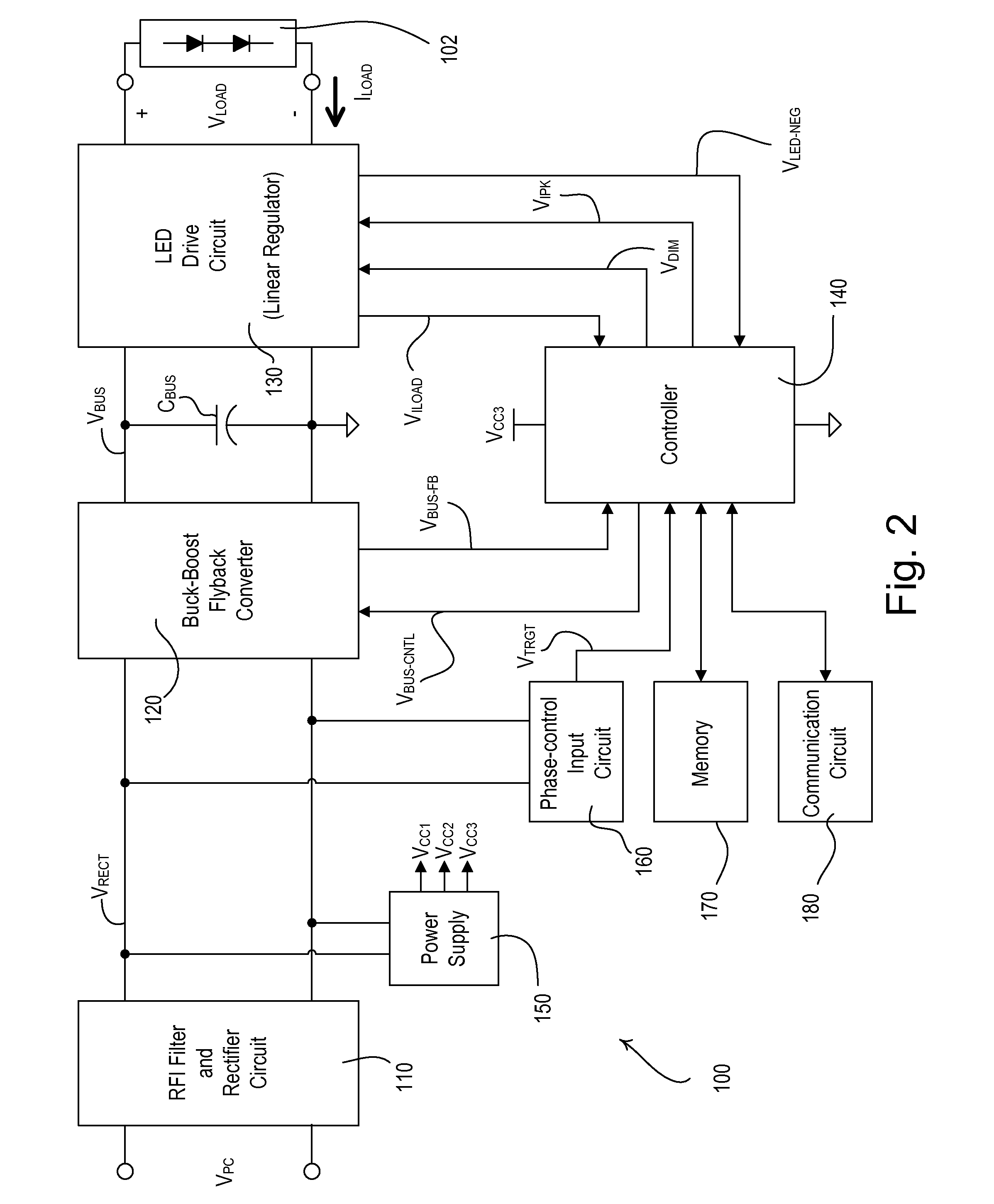

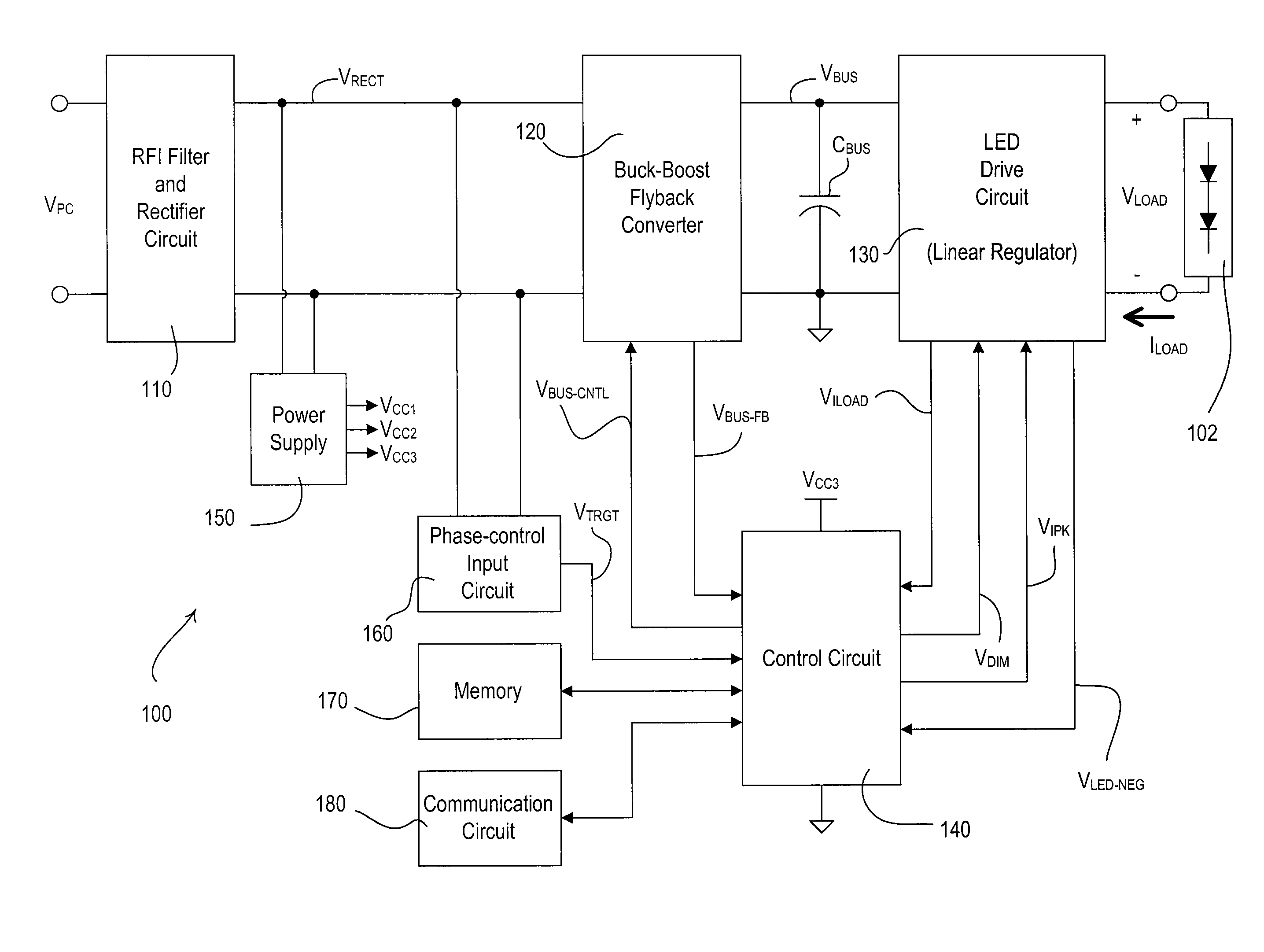

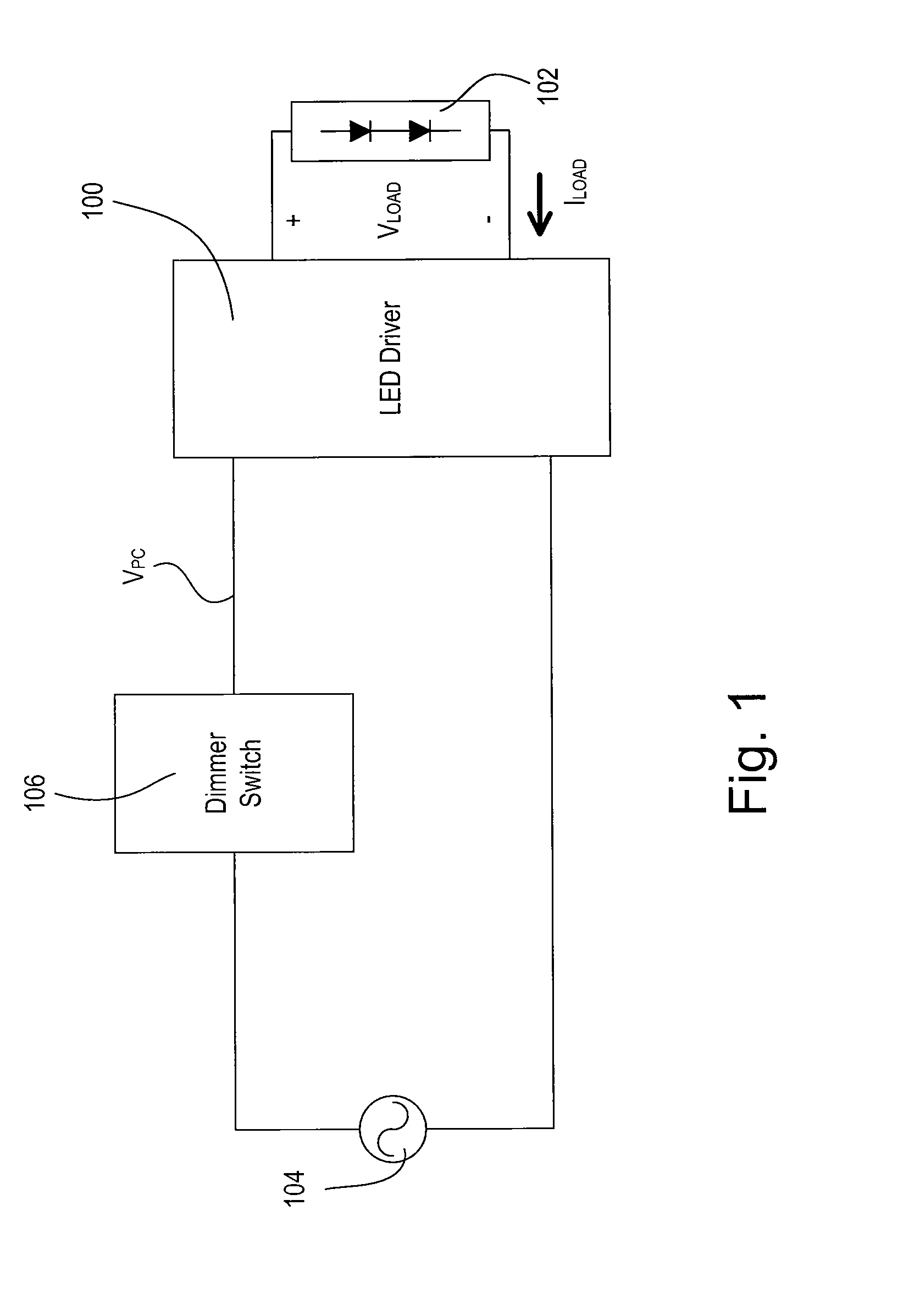

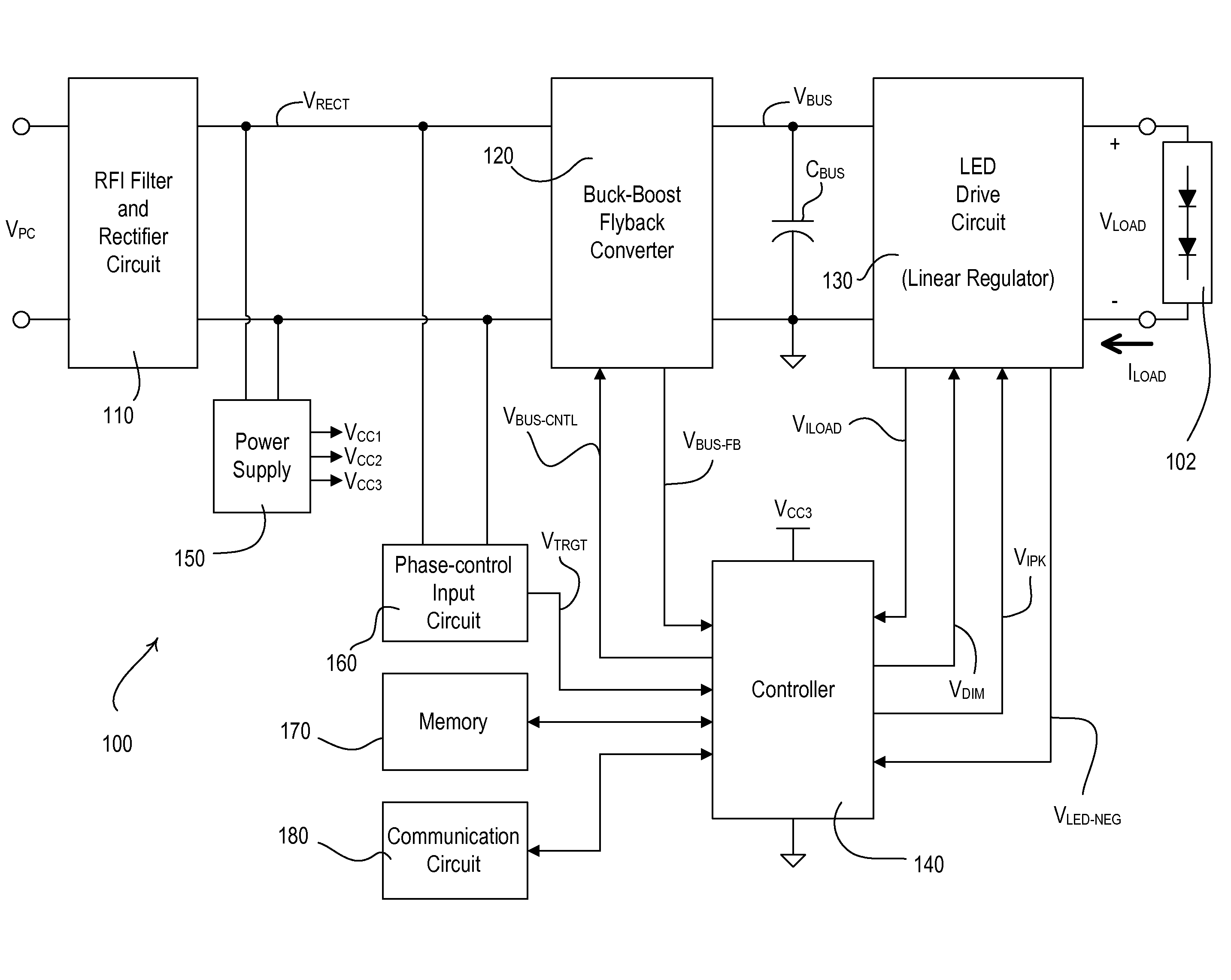

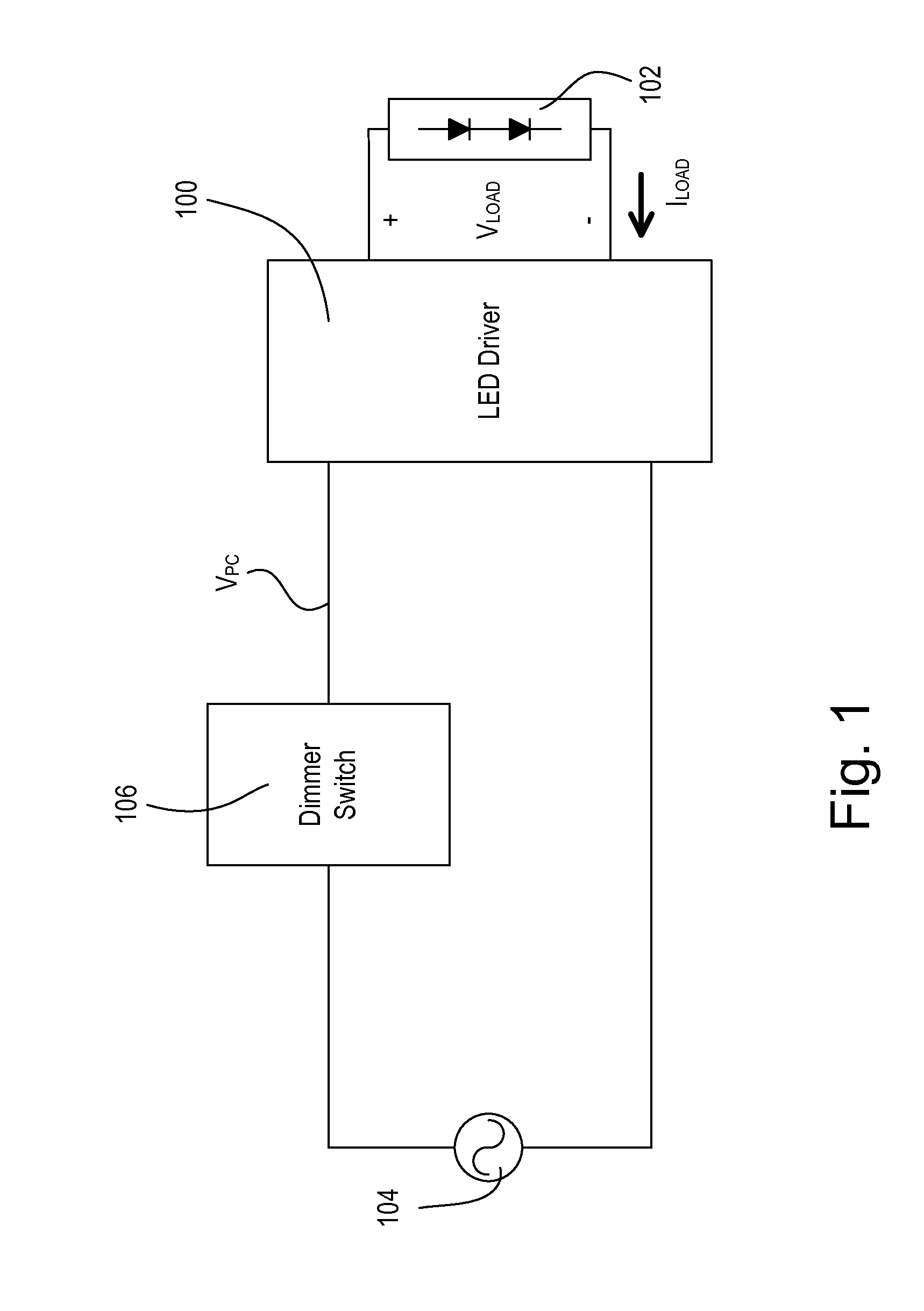

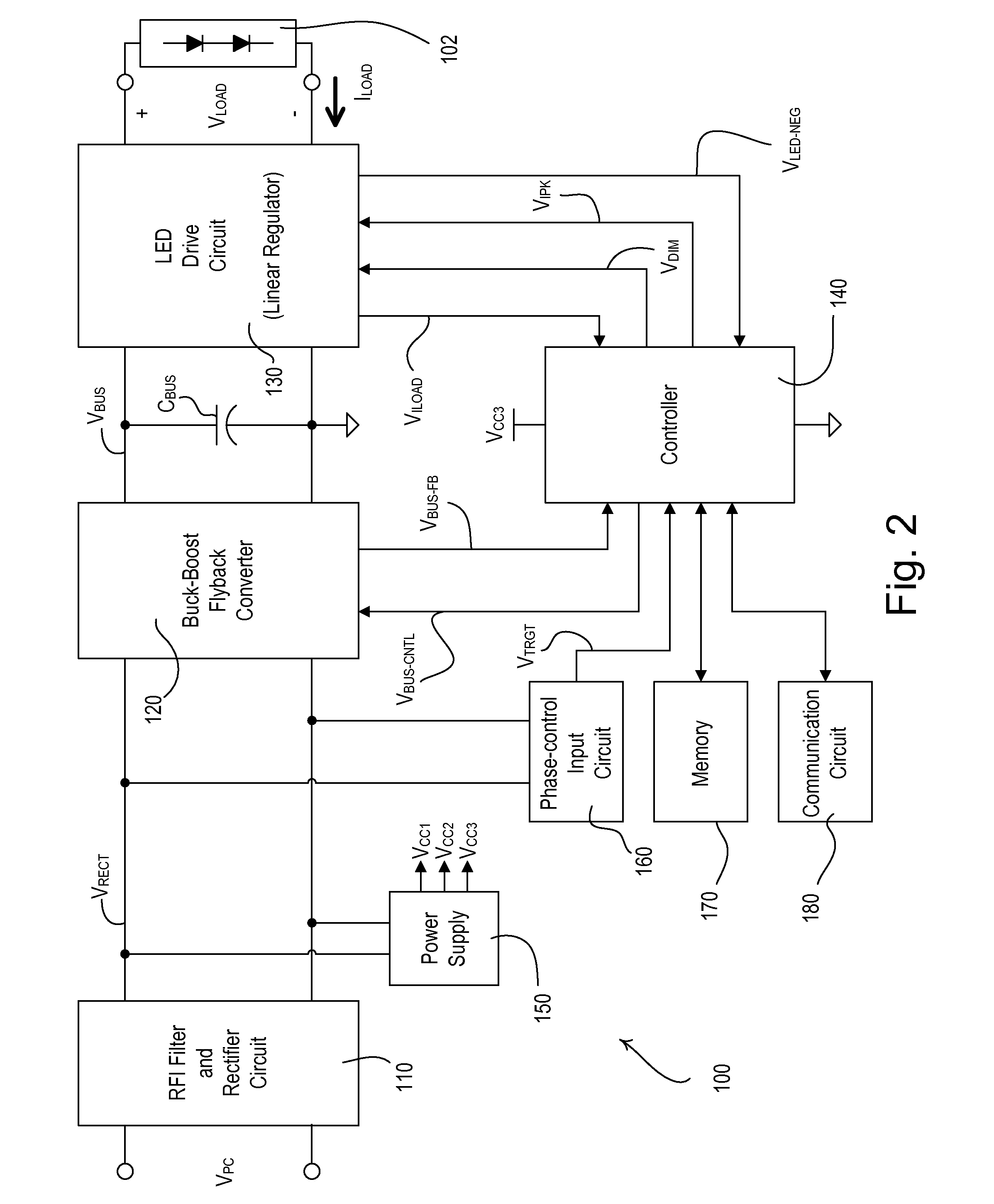

Load control device for a light-emitting diode light source

ActiveUS20110080110A1Reduce power consumptionControlling the magnitude of a load current conductedElectrical apparatusElectroluminescent light sourcesLinear regulatorEngineering

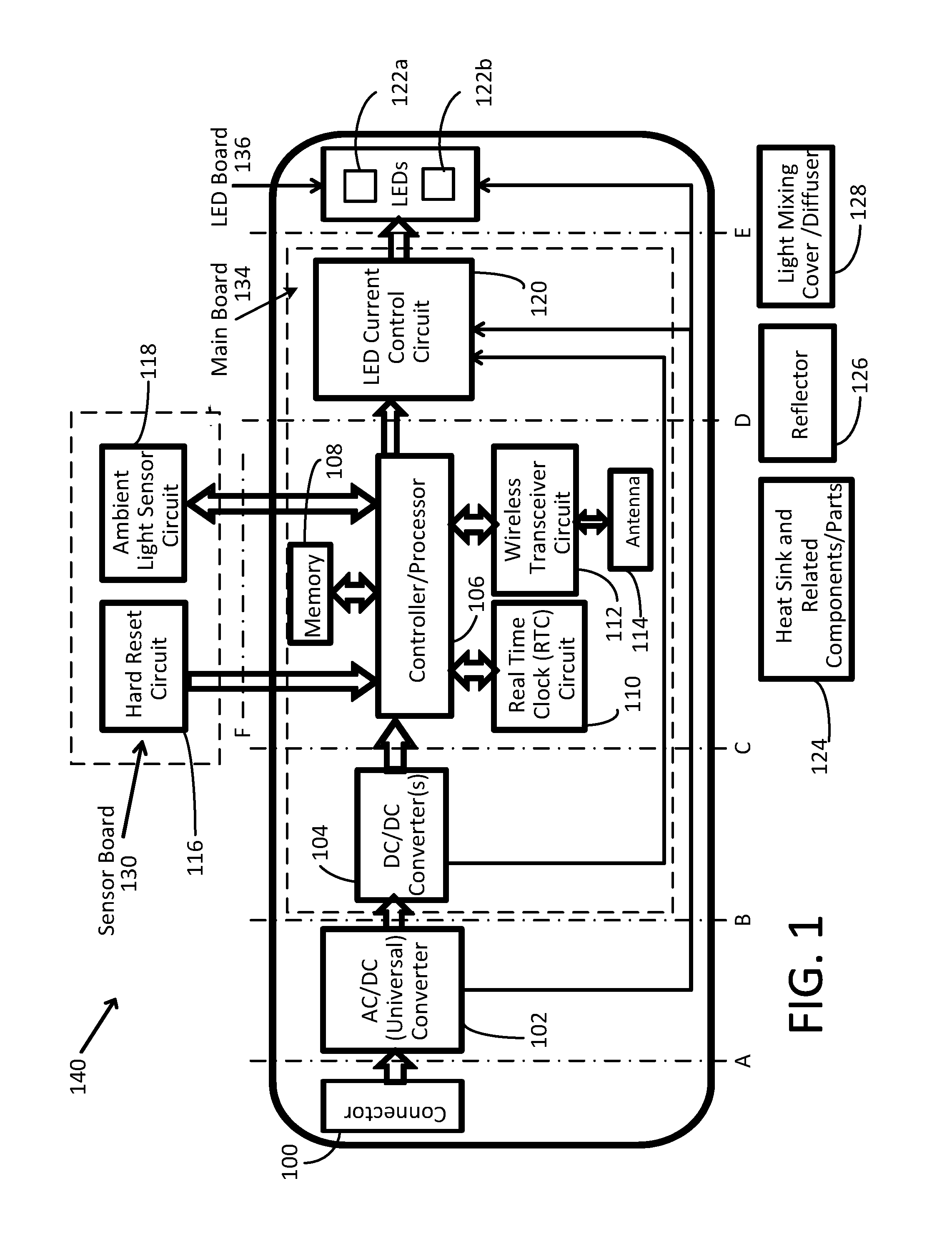

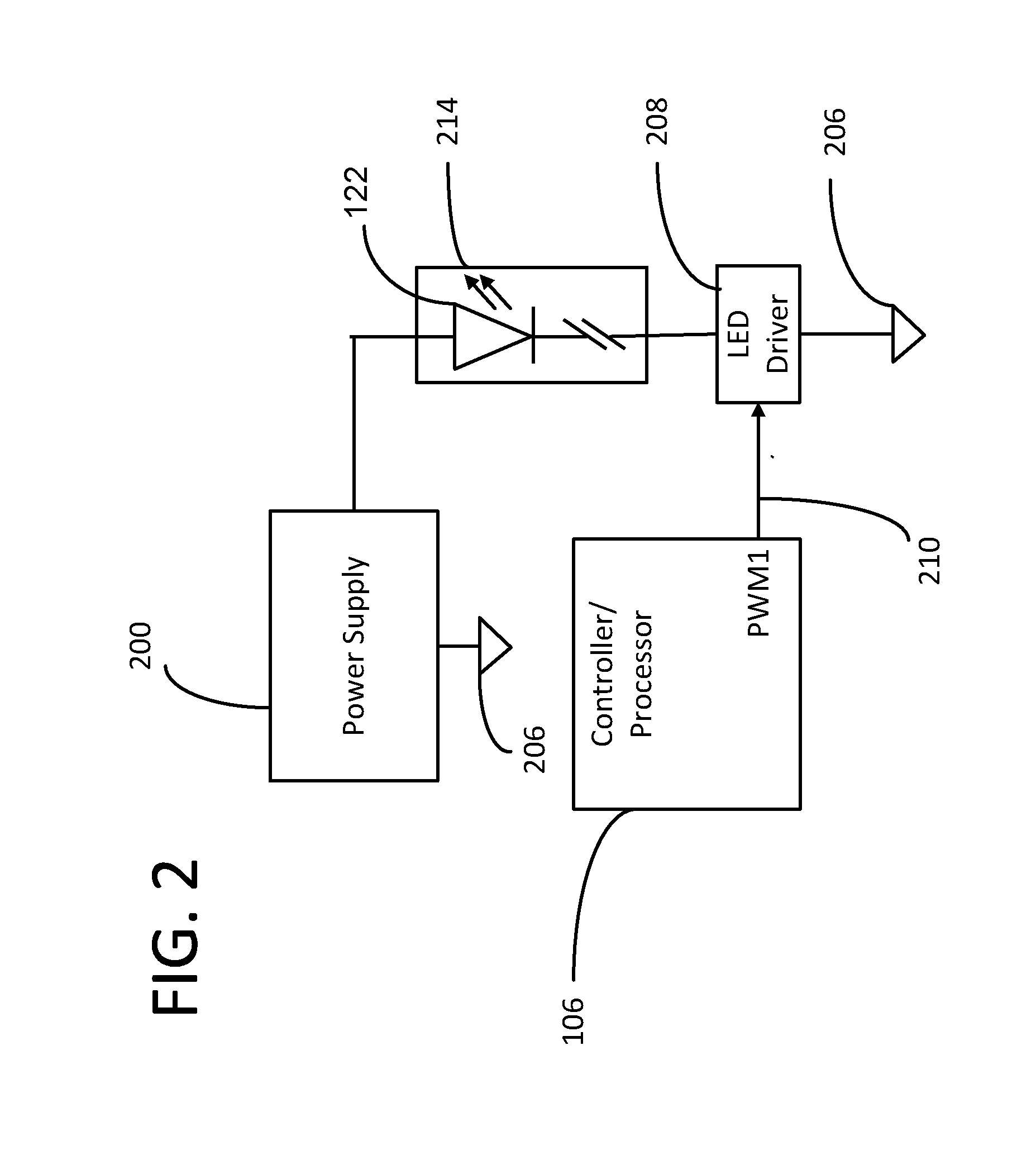

A light-emitting diode (LED) driver is adapted to control either the magnitude of the current conducted through a LED light source or the magnitude of a voltage generated across the LED light source. The LED driver comprises a power converter circuit for generating a DC bus voltage, and an LED drive circuit for receiving the bus voltage and adjusting the magnitude of the current conducted through the LED light source. The LED driver is operable to dim the LED light source using either a pulse-width modulation technique or a constant current reduction technique. The LED drive circuit may comprise a controllable-impedance circuit, such as a linear regulator. The LED driver may be operable to control the magnitude of the bus voltage to optimize the efficiency and reduce the power dissipation in the LED drive circuit, as well ensuring that the load voltage and current do not have any ripple.

Owner:LUTRON TECH CO LLC

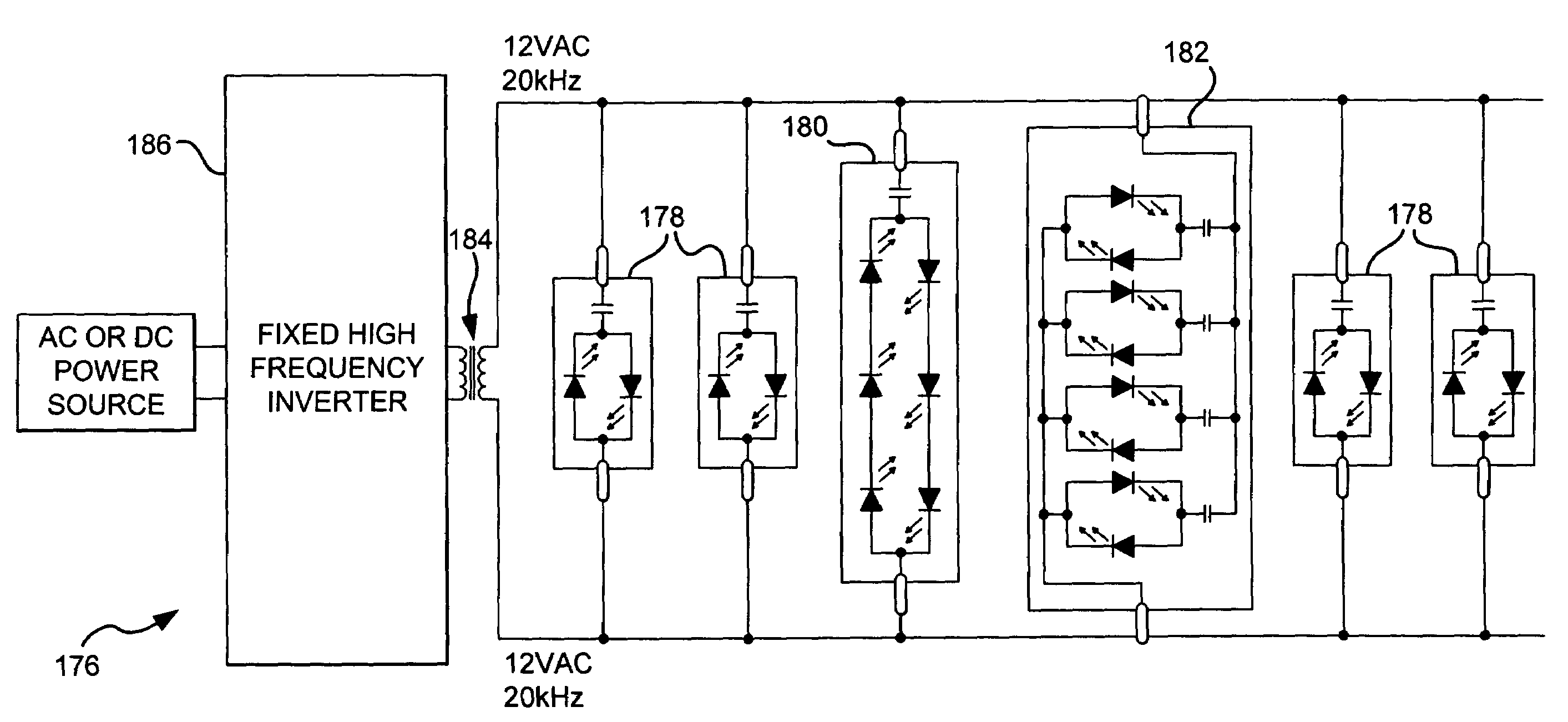

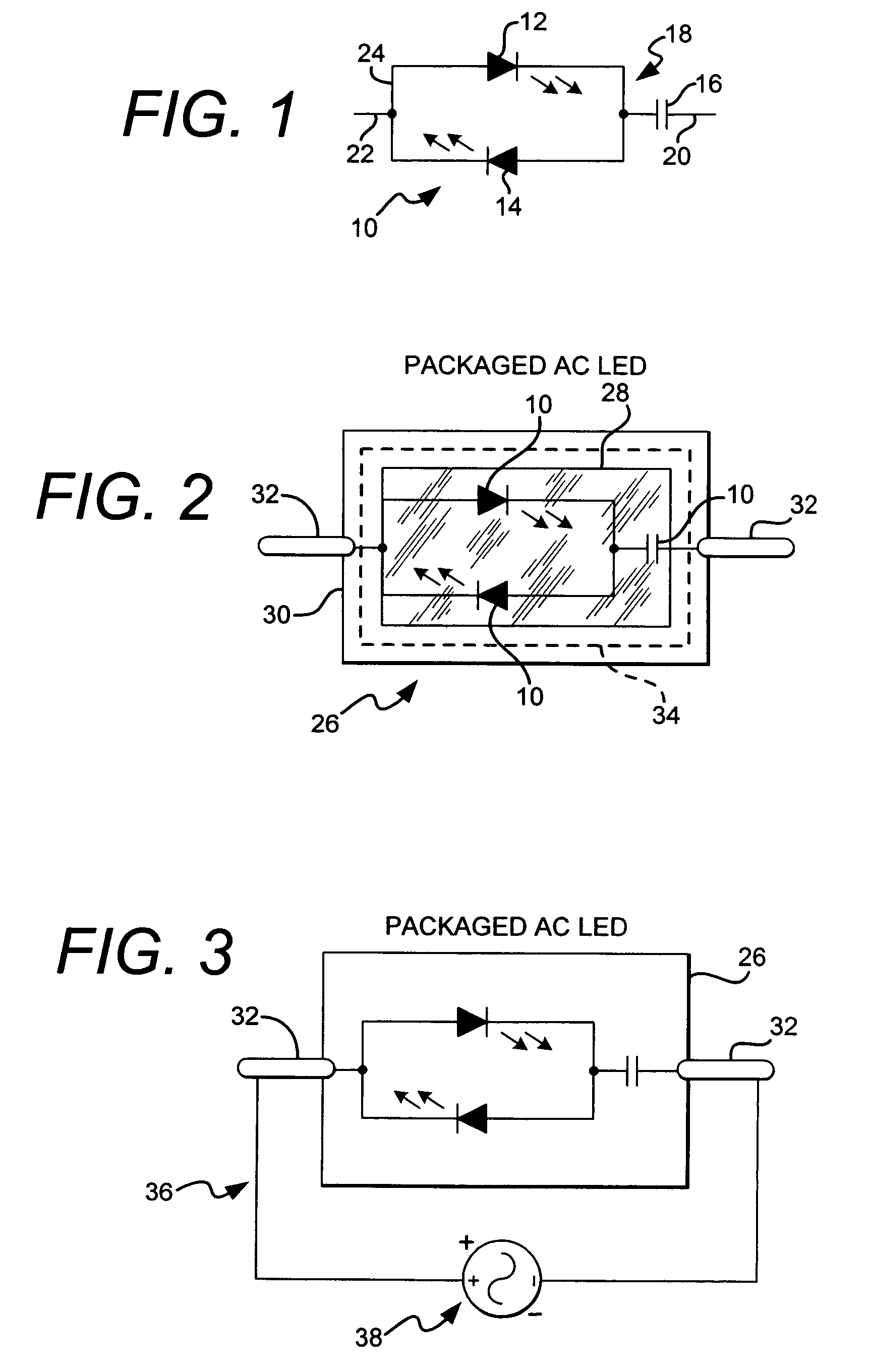

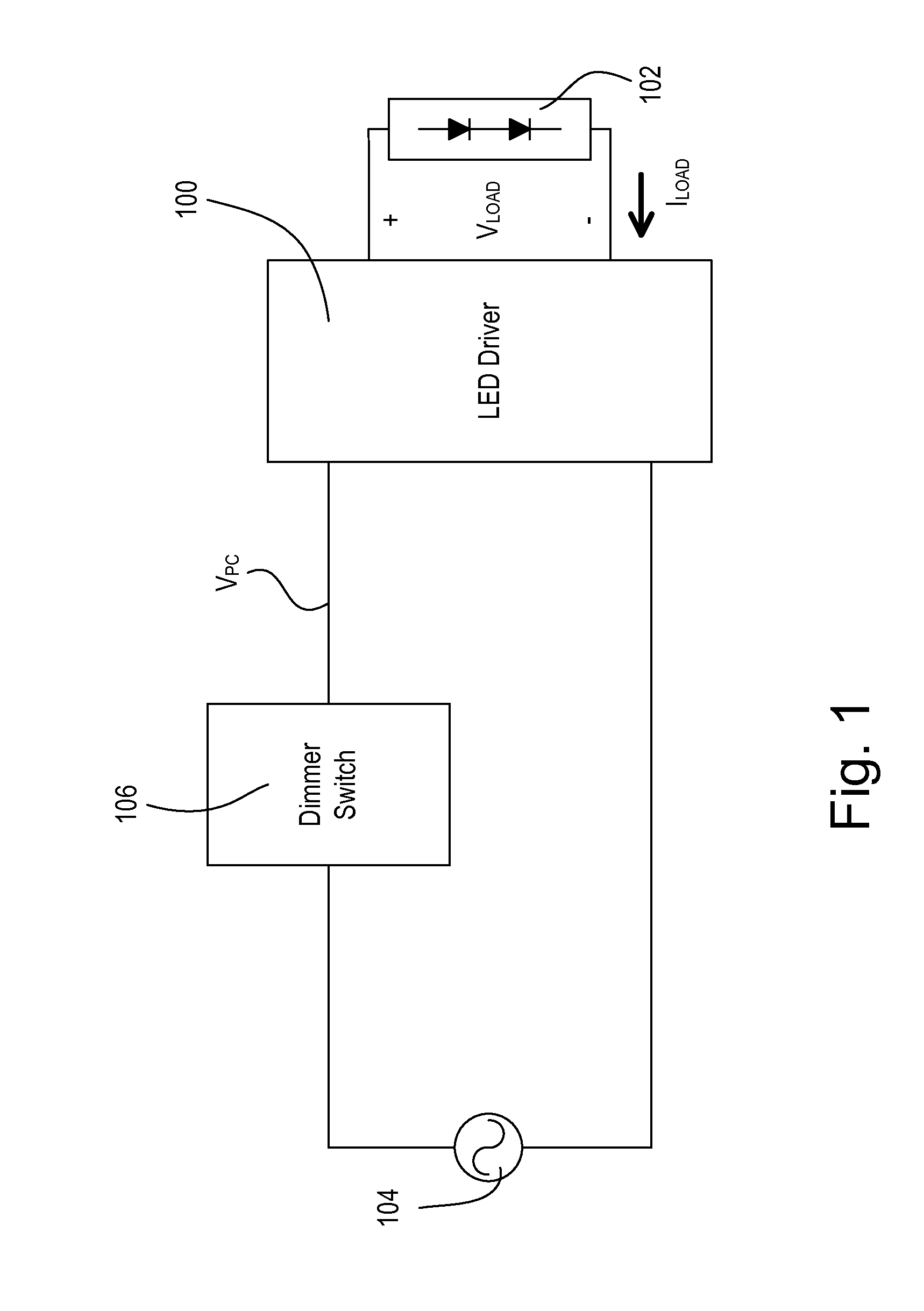

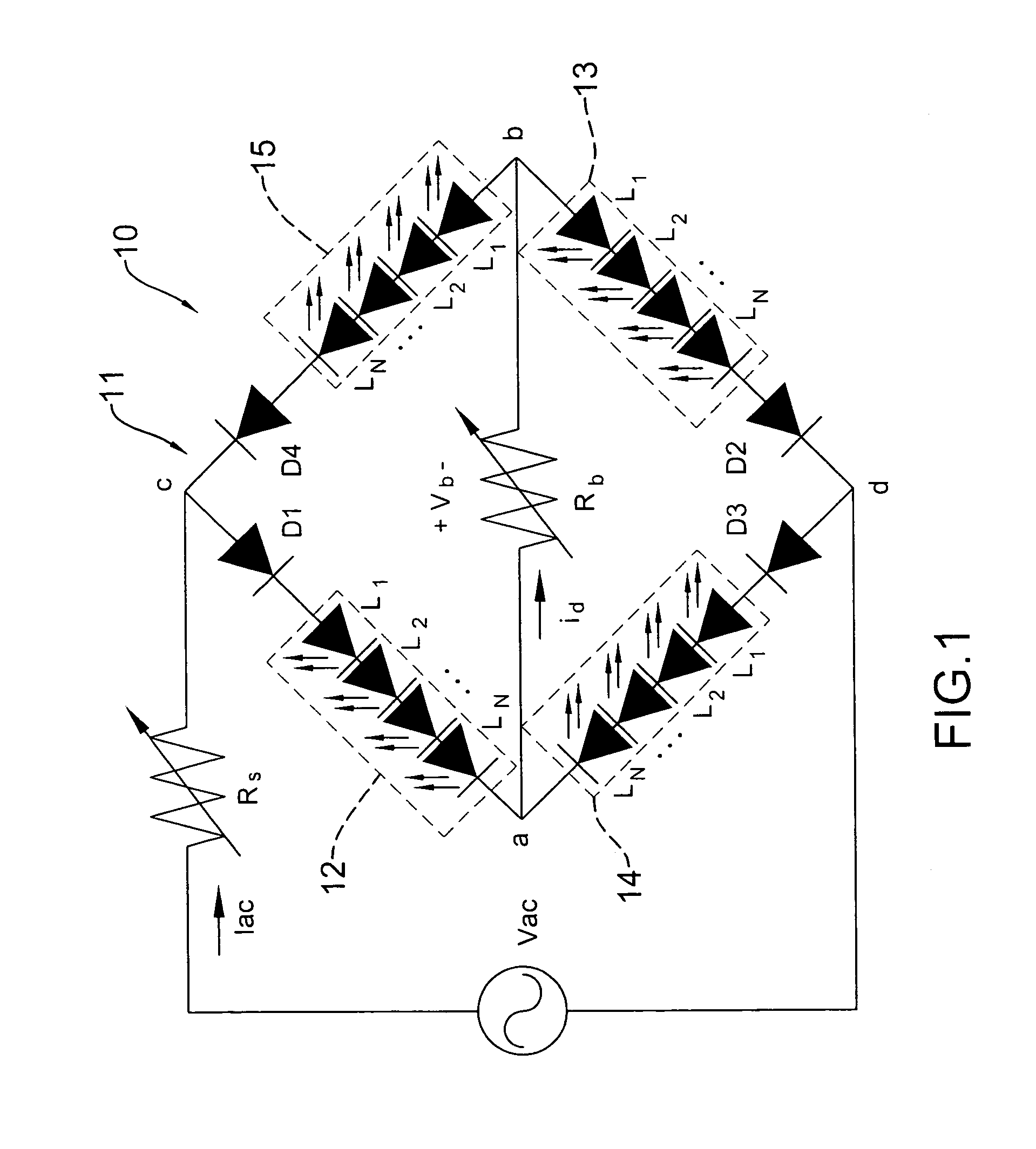

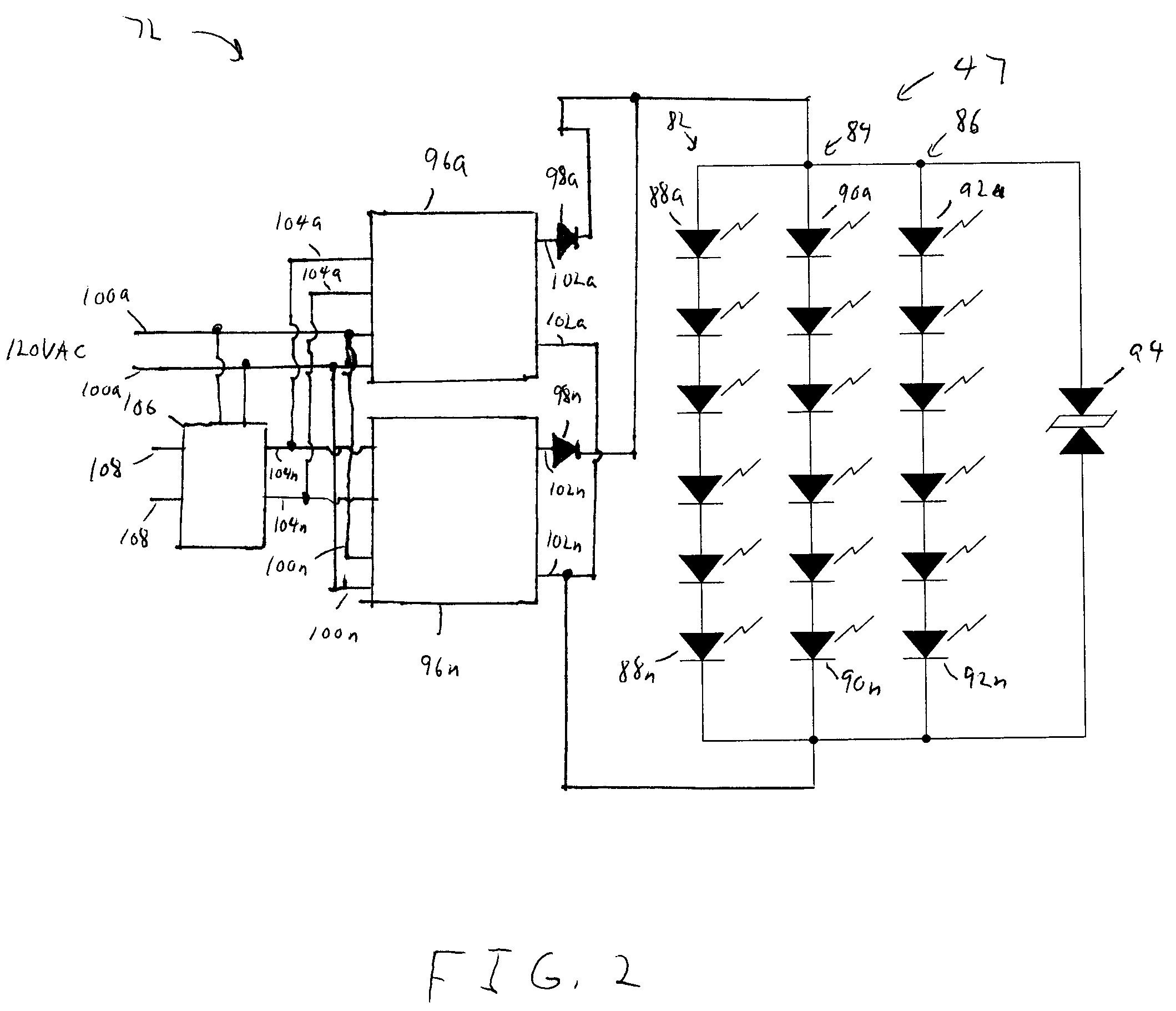

AC light emitting diode and AC LED drive methods and apparatus

ActiveUS7489086B2Small component sizeEasy to processElectroluminescent light sourcesSolid-state devicesEngineeringAlternating current

An AC LED package and circuits are disclosed along with an AC LED driver. The AC LED circuit may include as few as one LED or an array of anti-parallel LEDs driven with AC power sources and AC LED drivers at various voltages and frequencies. The AC LEDs are pre-packaged in various forms and materials and designed for mains or high frequency coupling in various forms to AC power sources, inverter type drivers or packages. The AC LED driver is a fixed frequency driver that provides a relatively constant voltage output to different size loads within the wattage limitation of the driver and in some cases is a direct mains power source.

Owner:LYNK LABS INC

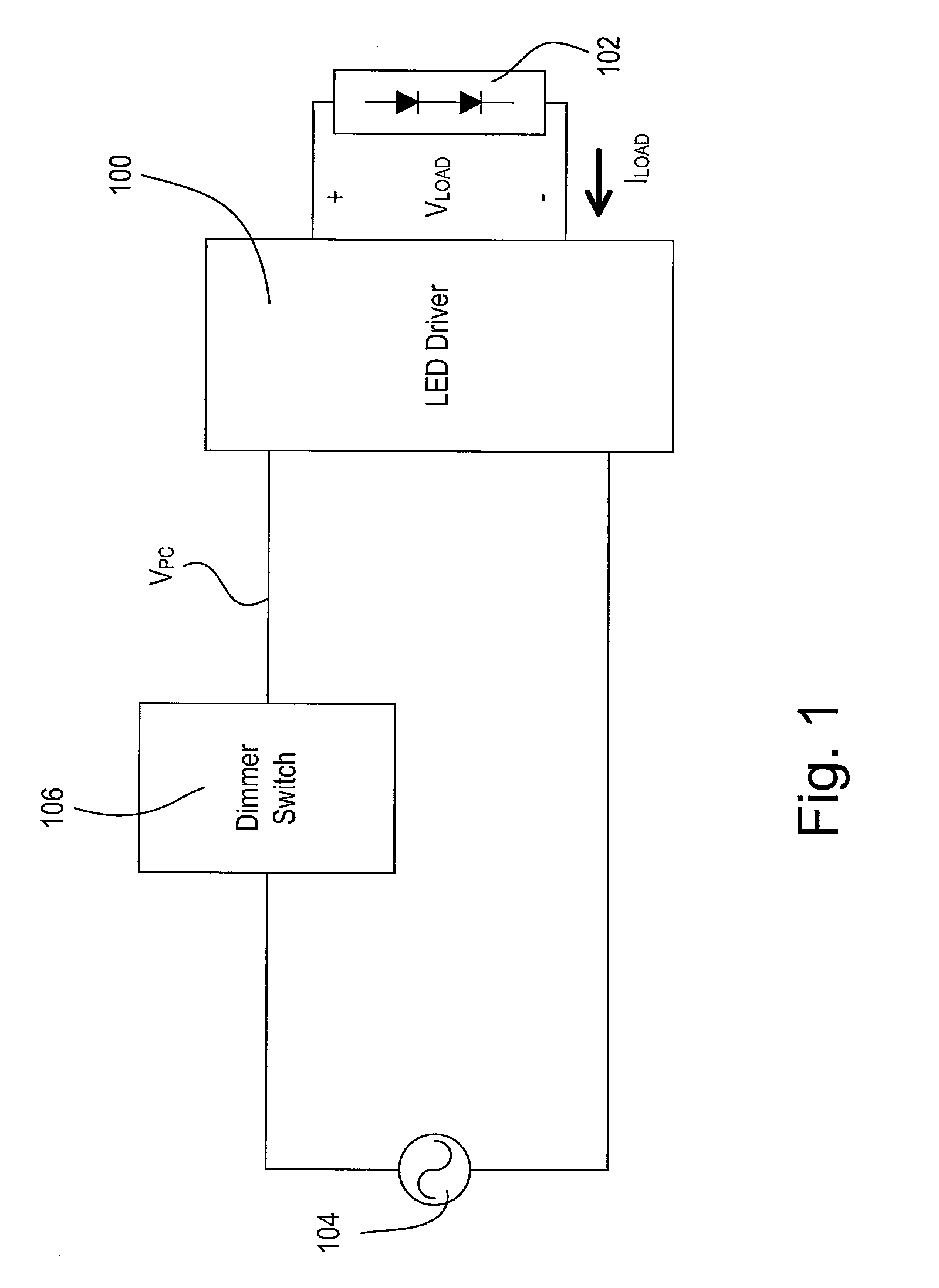

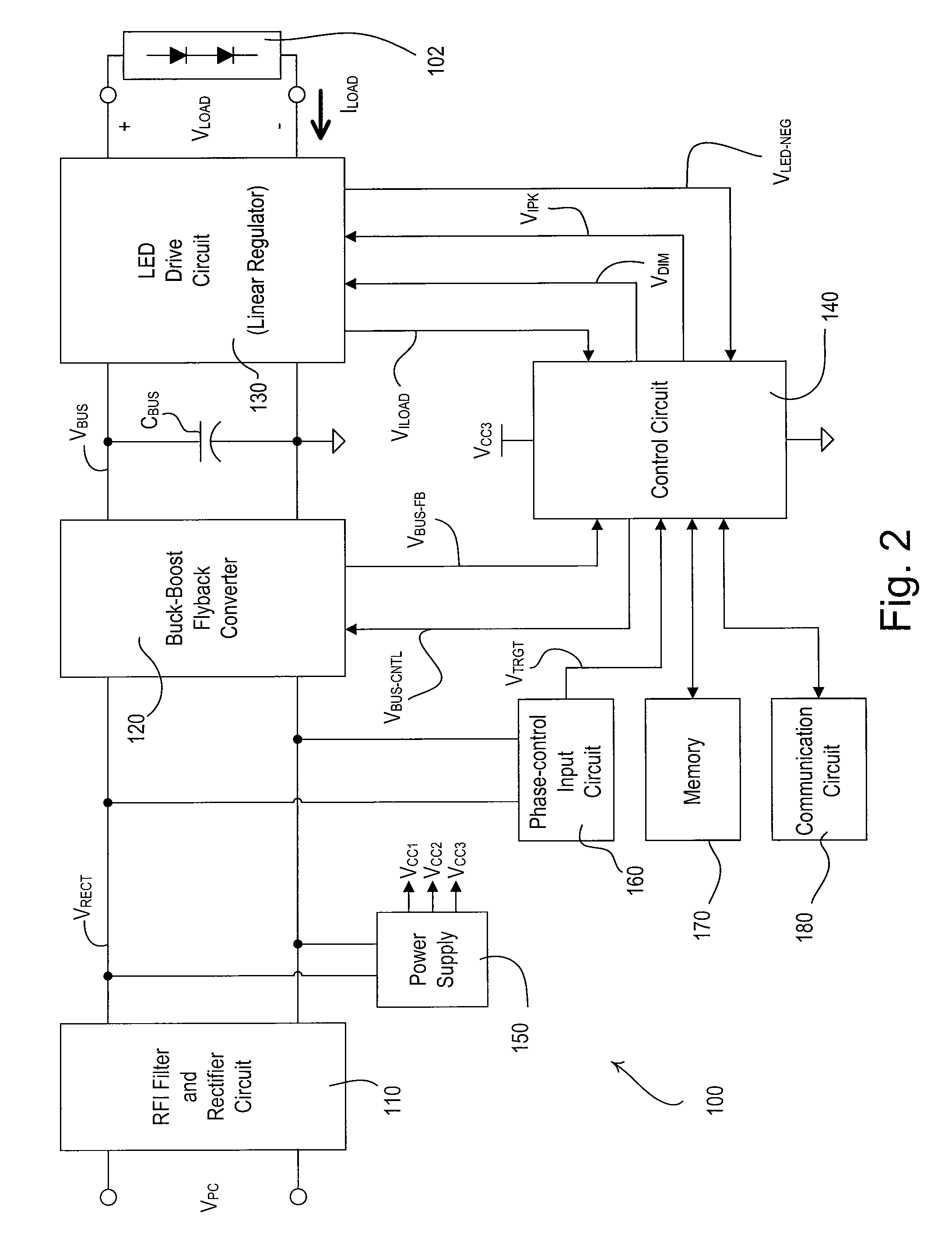

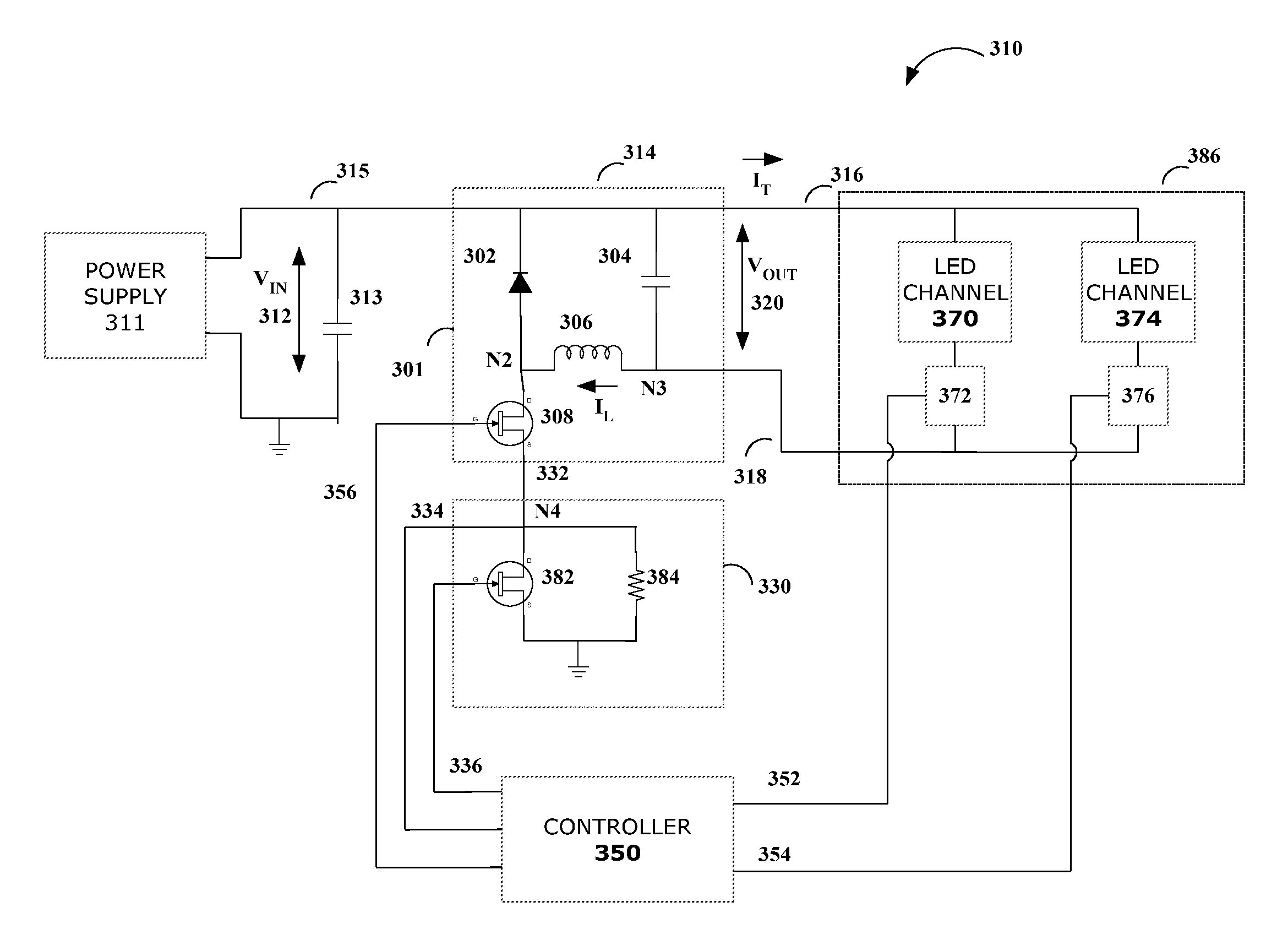

Load Control Device for a Light-Emitting Diode Light Source

ActiveUS20130063047A1Reducing bus voltageIncreases magnitudeElectrical apparatusElectroluminescent light sourcesEngineeringIntensity control

An LED driver for controlling the intensity of an LED light source includes a power converter circuit for generating a DC bus voltage, an LED drive circuit for receiving the bus voltage and controlling a load current through, and thus the intensity of, the LED light source, and a controller operatively coupled to the power converter circuit and the LED drive circuit. The LED drive circuit comprises a controllable-impedance circuit adapted to be coupled in series with the LED light source. The controller adjusts the magnitude of the bus voltage to a target bus voltage and generates a drive signal for controlling the controllable-impedance circuit. To adjust the intensity of the LED light source, the controller controls both the magnitude of the load current and the magnitude of the regulator voltage. The controller controls the magnitude of the regulator voltage by simultaneously maintaining the magnitude of the drive signal constant and adjusting the target bus voltage.

Owner:LUTRON TECH CO LLC

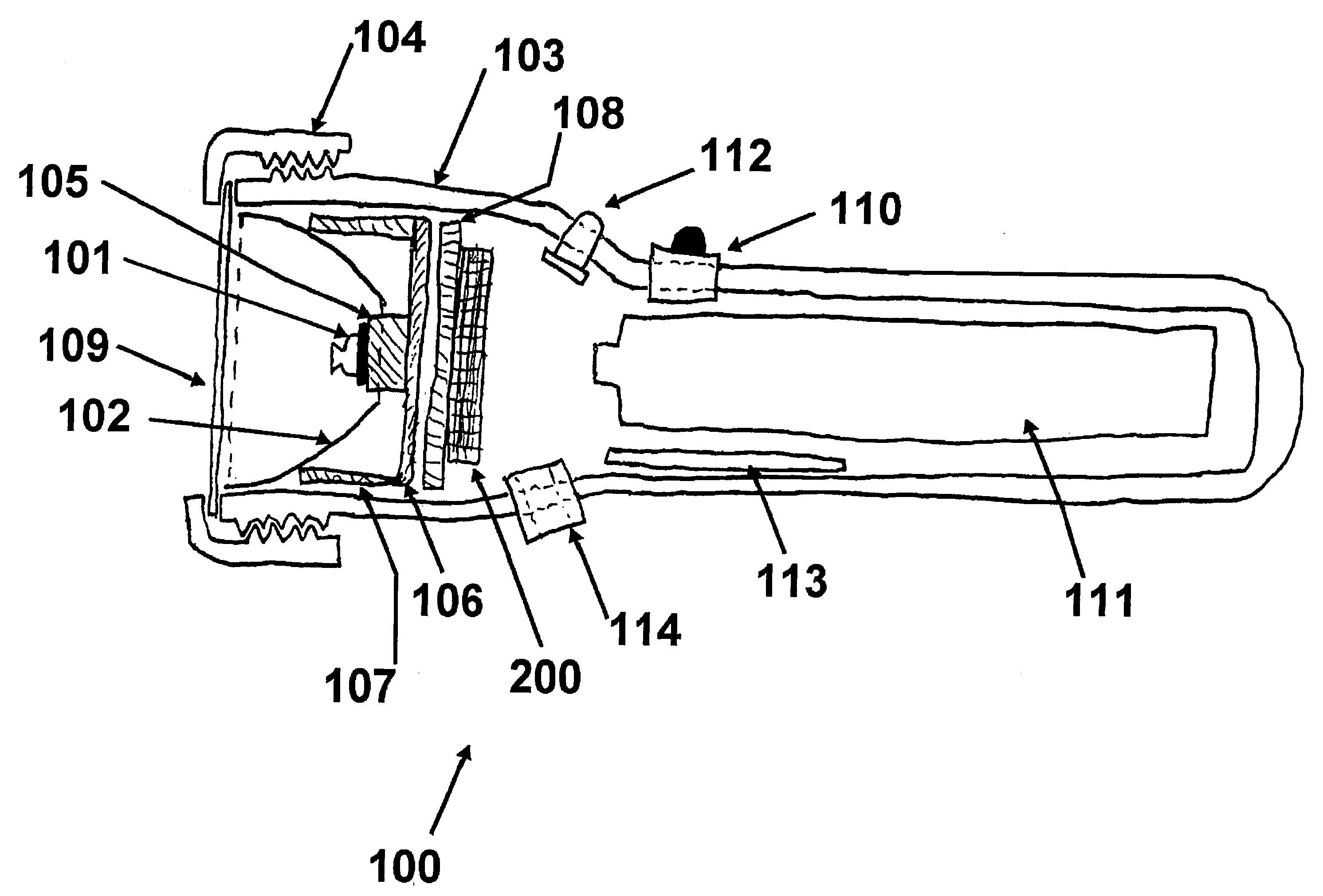

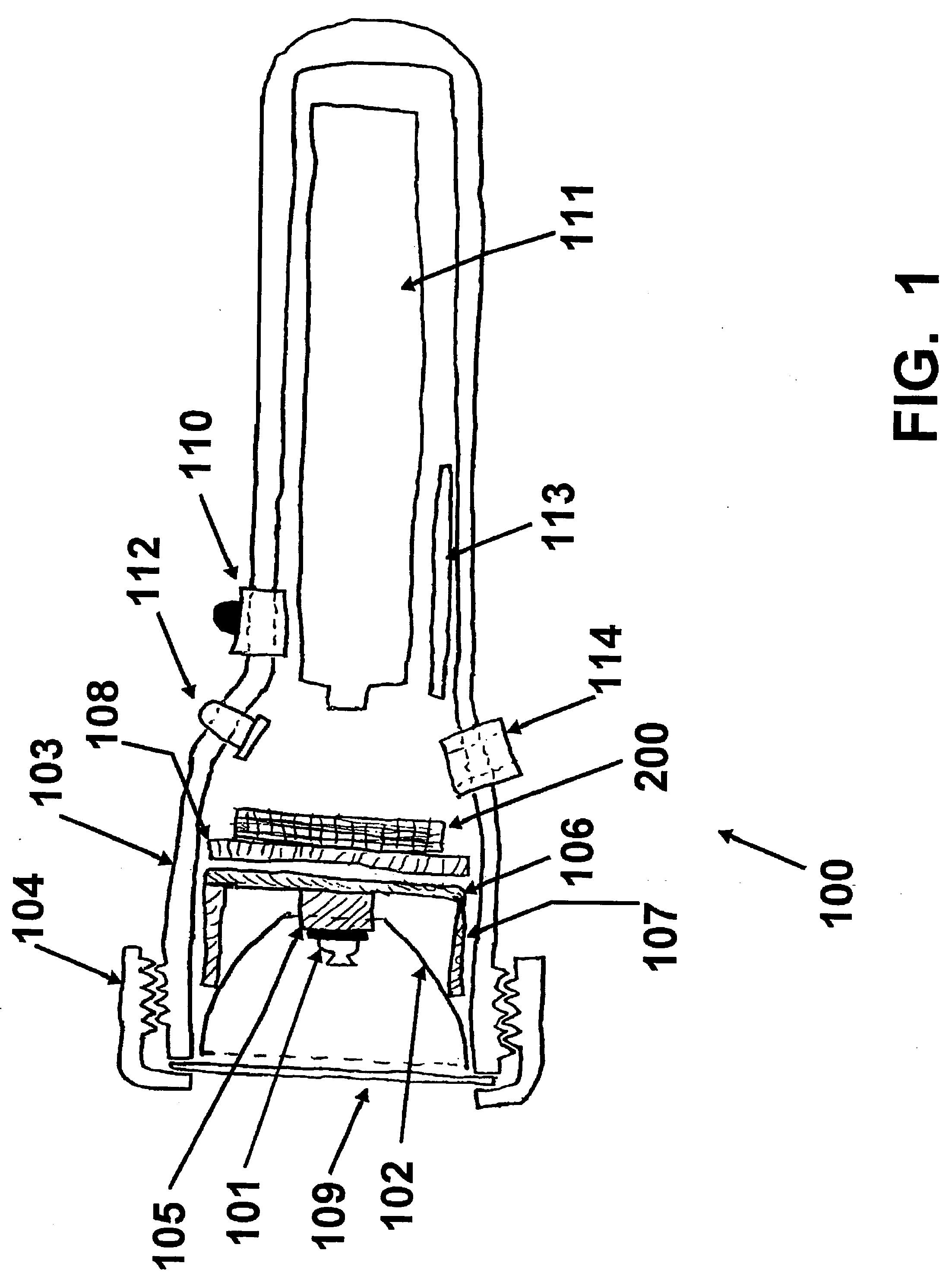

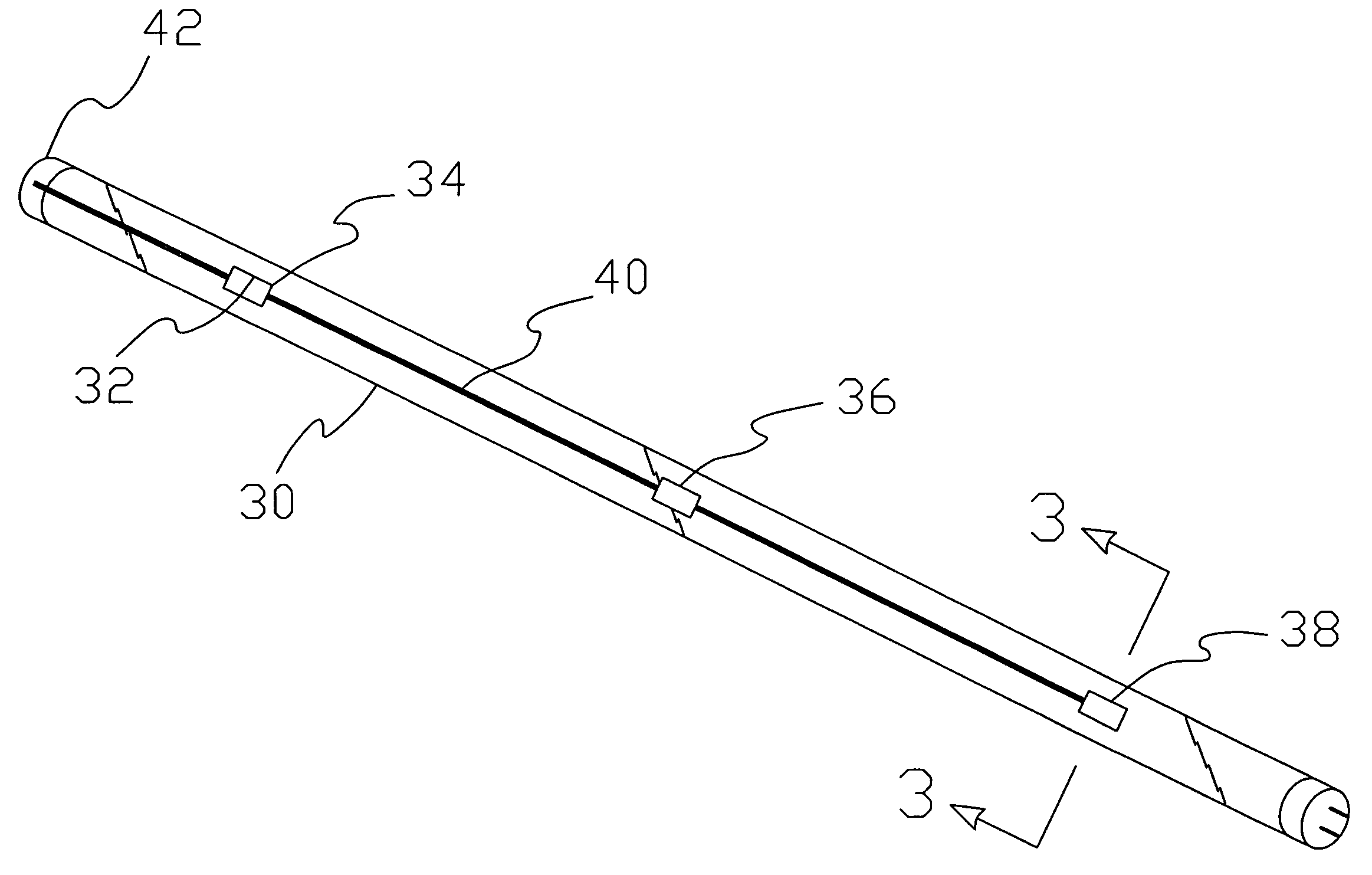

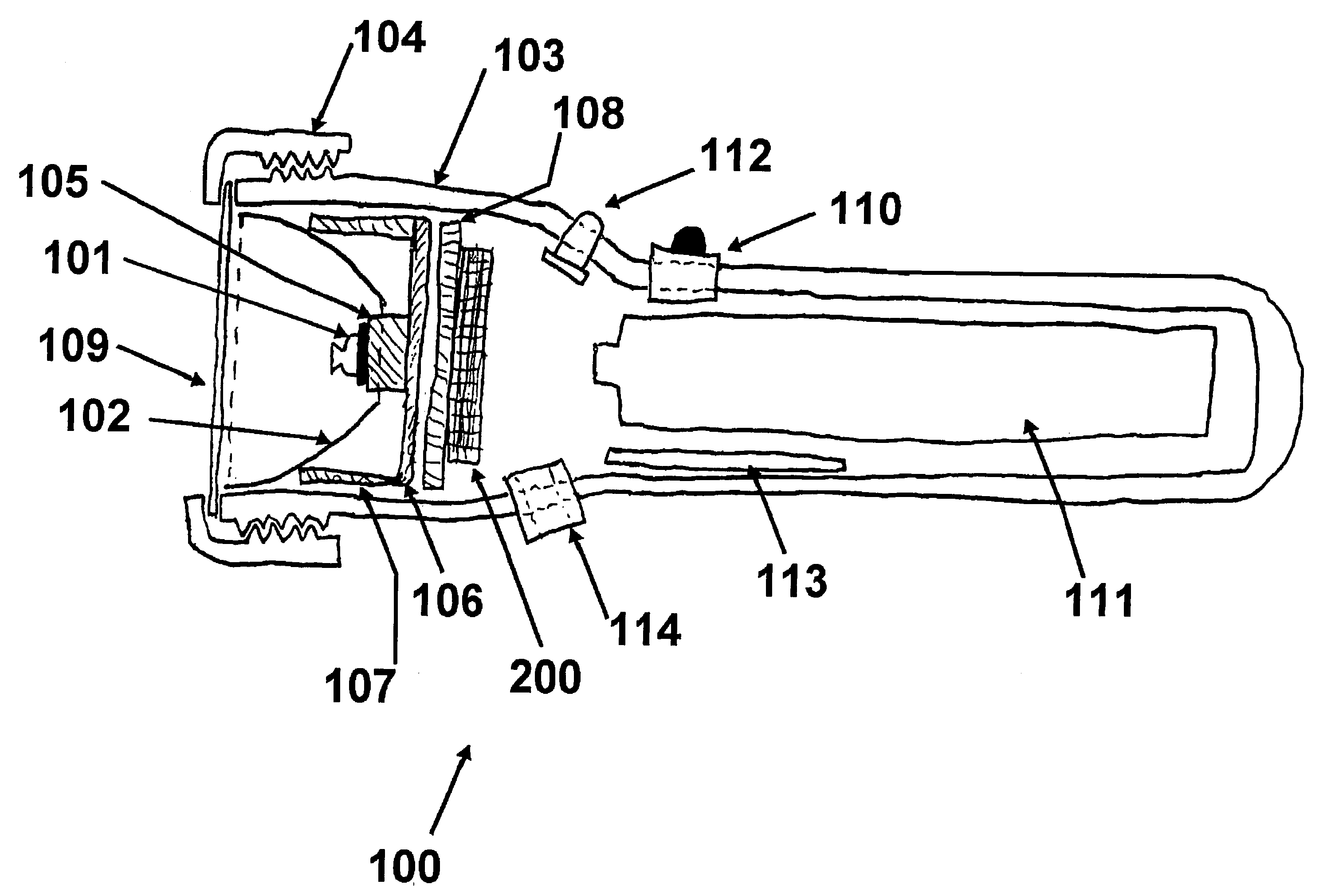

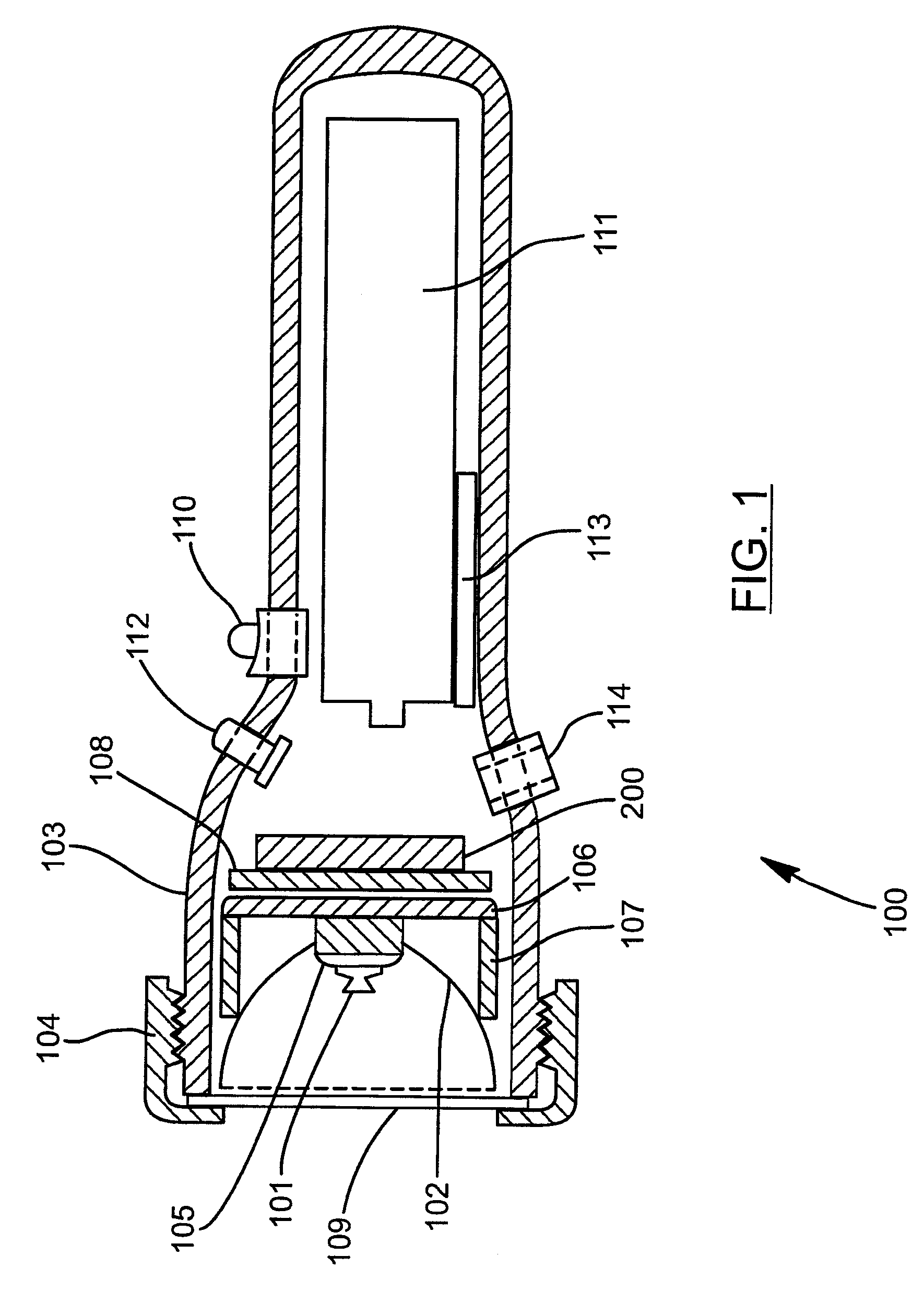

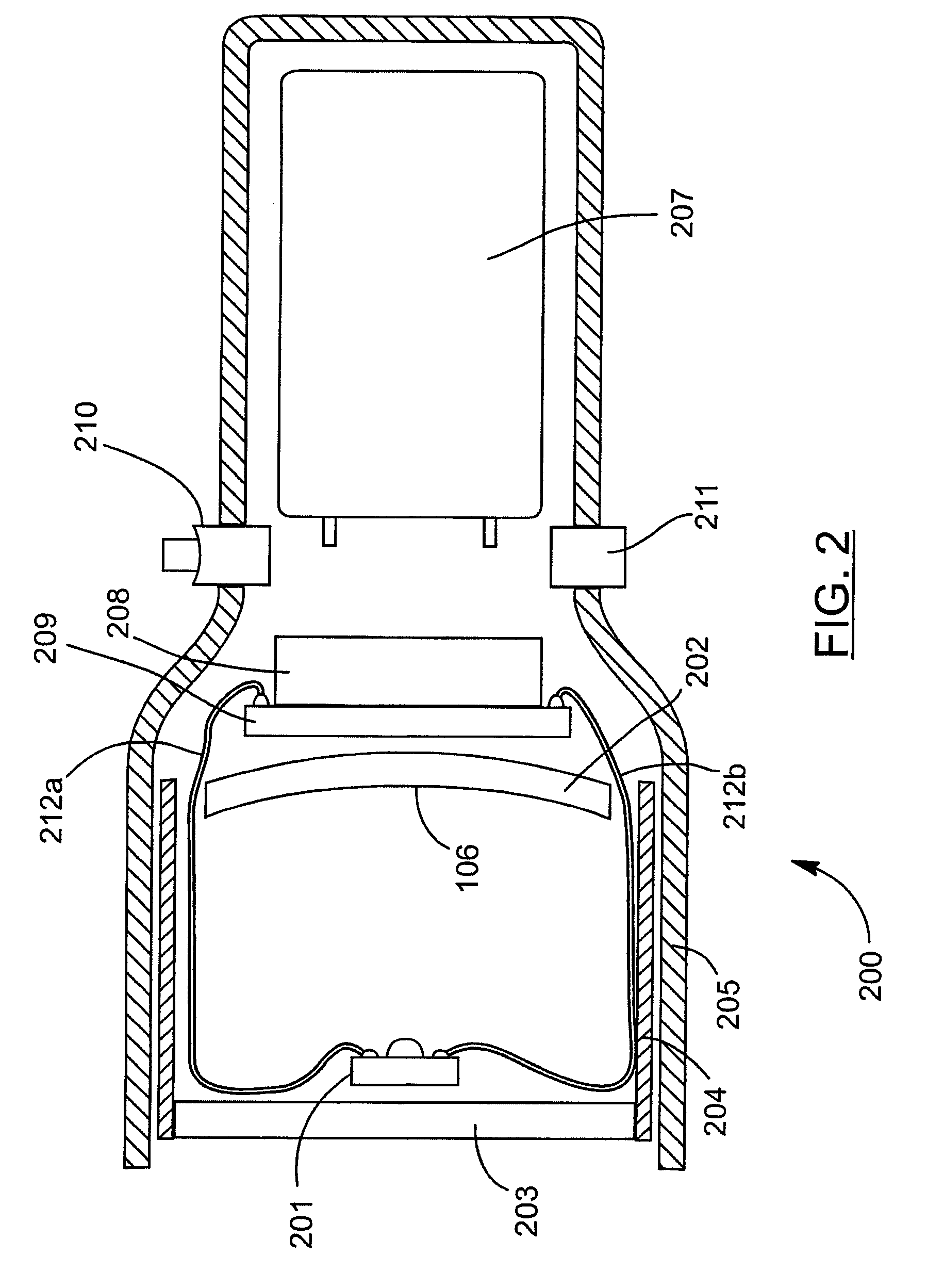

LED lamps and LED driver circuits for the same

ActiveUS20050007777A1Assist in detectingLight source combinationsPoint-like light sourceLight beamEngineering

LED lamp has LEDs aimed rearwards with either a concave mirror to the rear of each LED, or one concave mirror to the rear of two or more LEDs, collecting the light from the LEDs to form a forward projecting beam. LEDs may be high power types that require heatsinking. LED lamp may have a lens forward of each LED to collimate the radiation produced by the LEDs into a beam, where at least one lens has at least one aspheric curved surface. LED lamp may have a transparent reflective optic to collimate the radiation produced by each LED into a beam. For an inspection lamp, the LEDs typically have a peak wavelength of 395 to 415 naometers for seeing the area being irradiated but not so visible as to overwhelm fluorescence of fluorescent materials to be detected. Other wavelengths may be used. LED inspection lamp has a combination of LEDs of different wavelengths or a combination of at least one LED and at least one other light source such that the lamp produces radiation suitable for detection of materials to be detected and adequately illuminates the area being irradiated. LED lamp has LEDs that produce a beam of suitable radiation with a width of 10 degrees or less without additional optics. LED inspection lamp has head attached to a flexible member, with head serving as heatsink for one or more high power LEDs. Current regulator circuits are also disclosed.

Owner:ALLTEMP PROD CO LTD

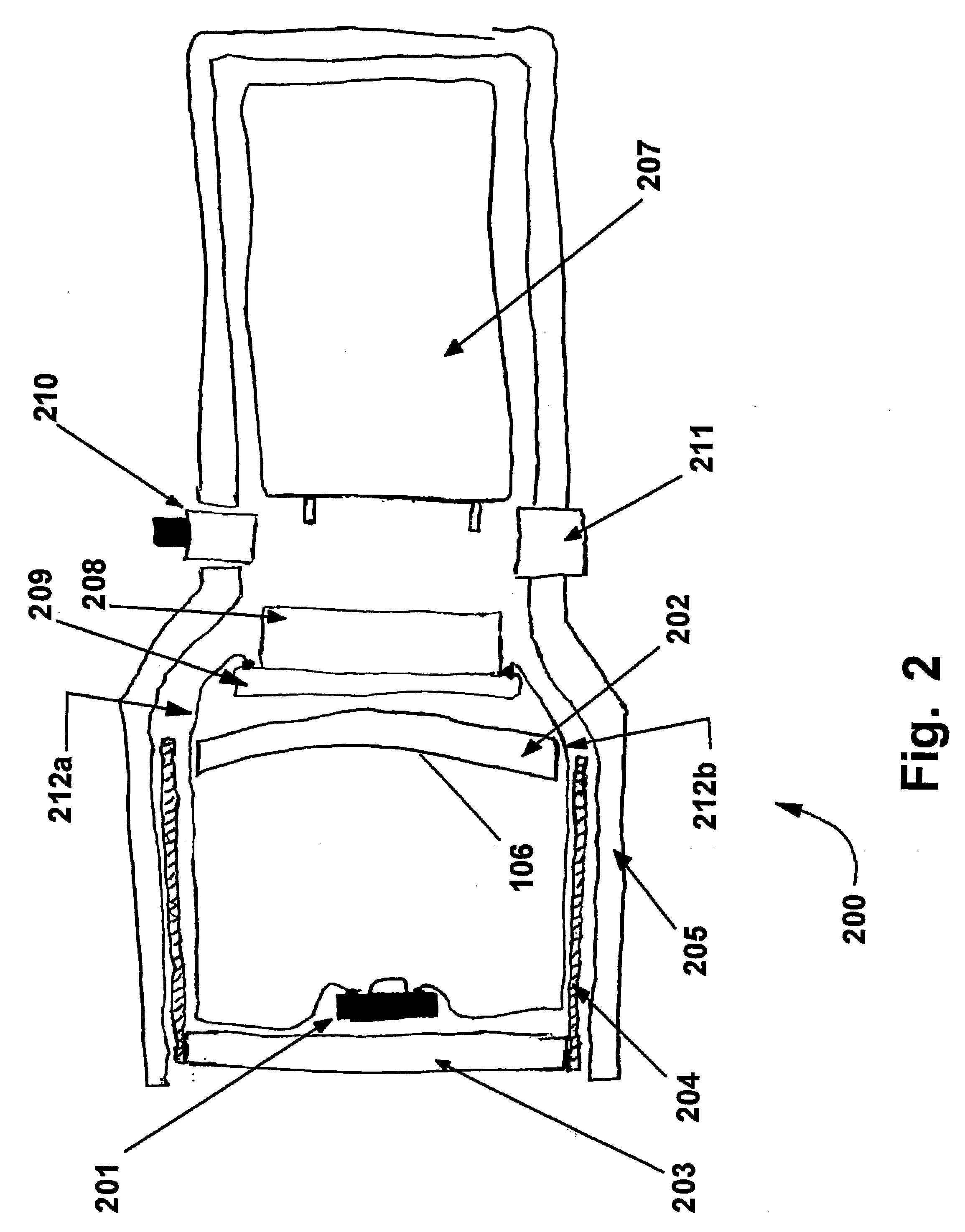

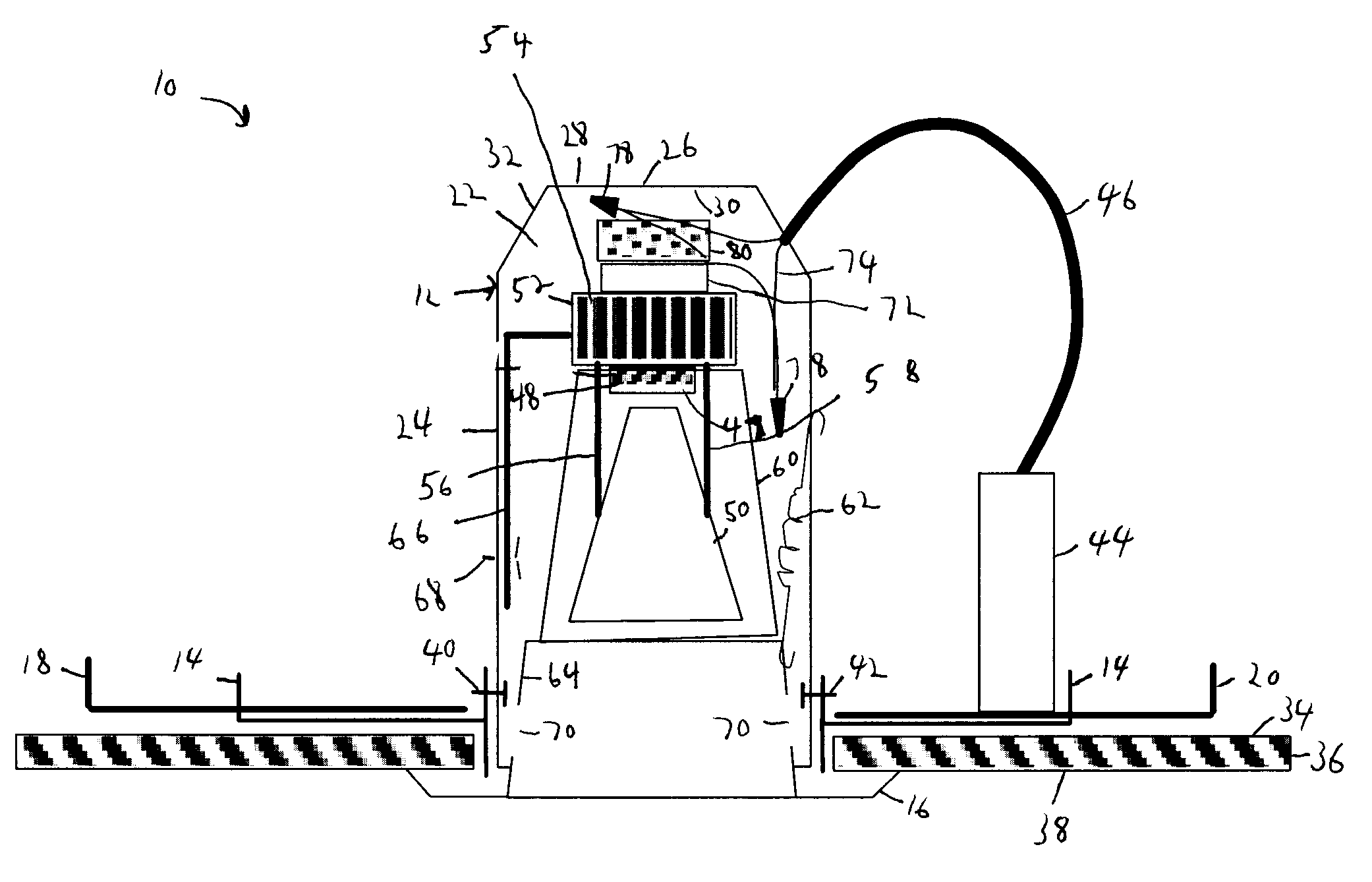

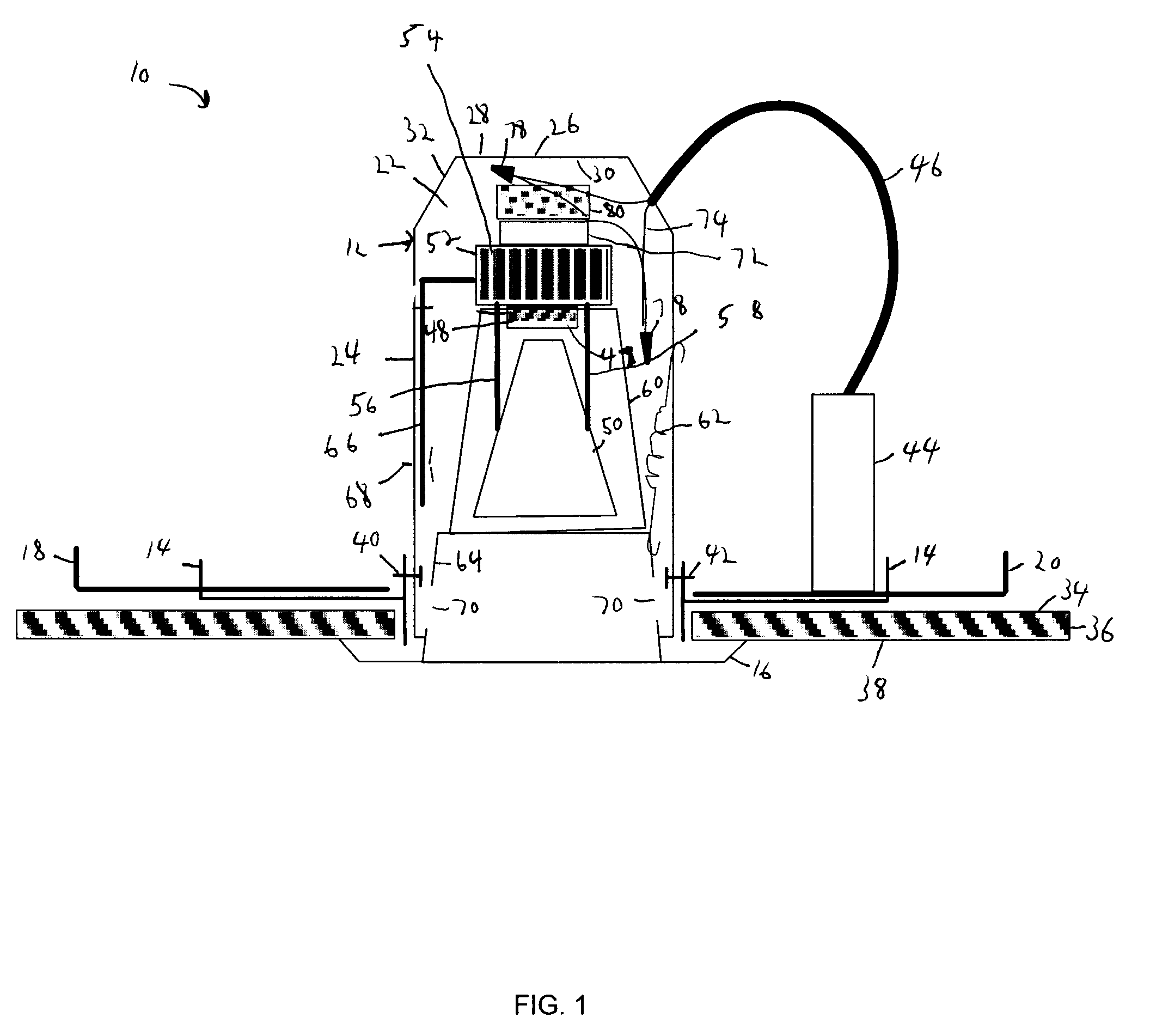

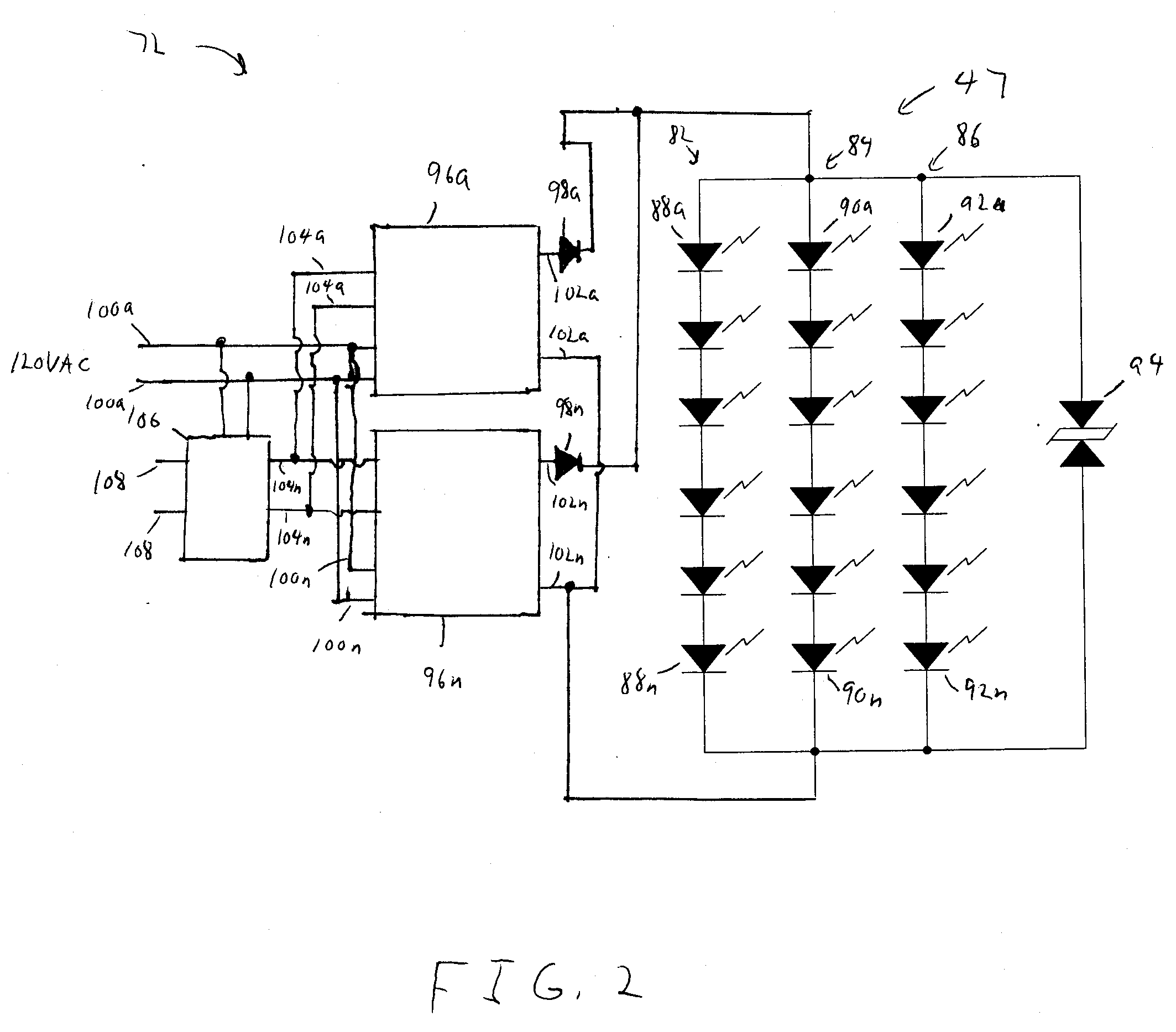

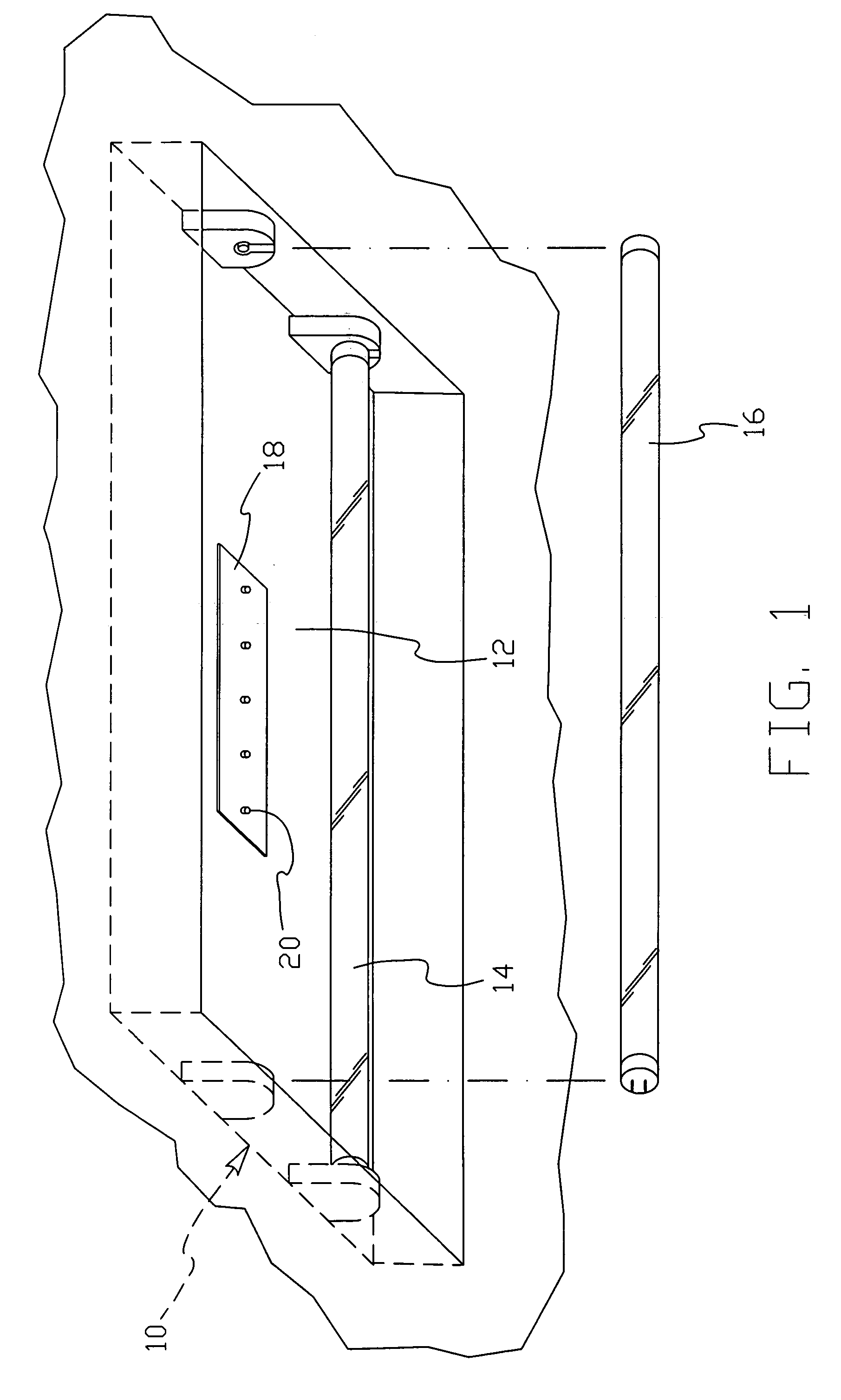

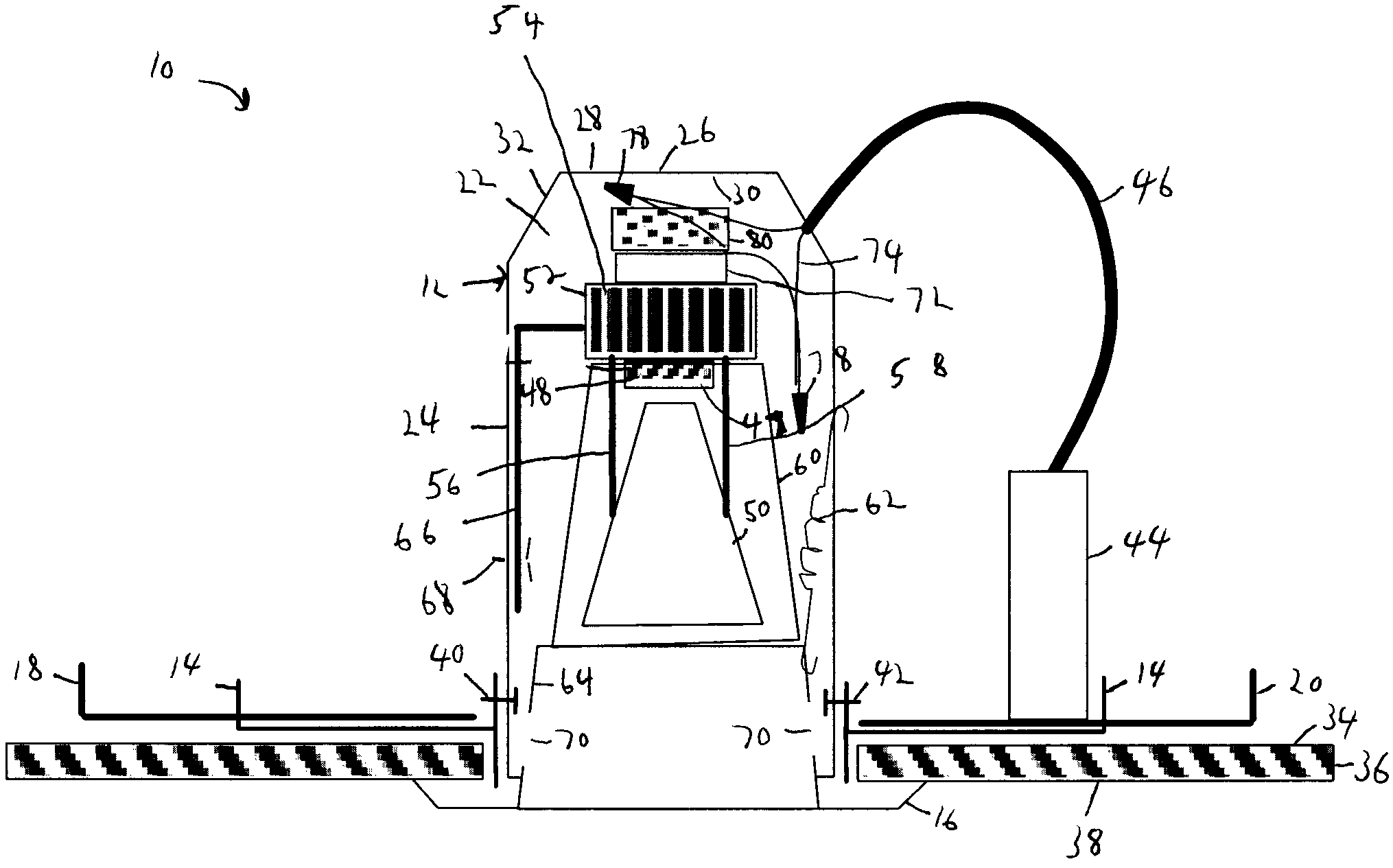

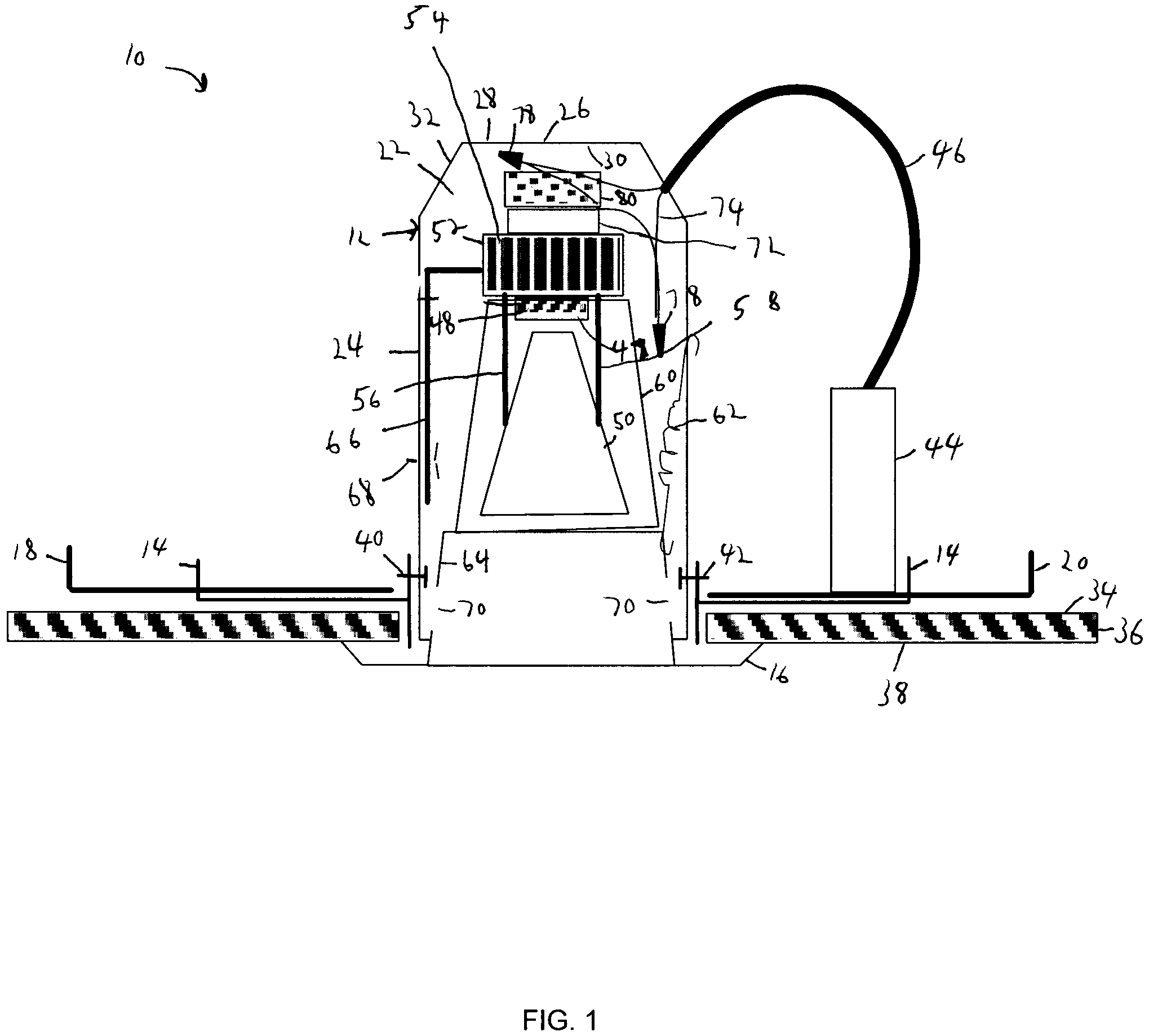

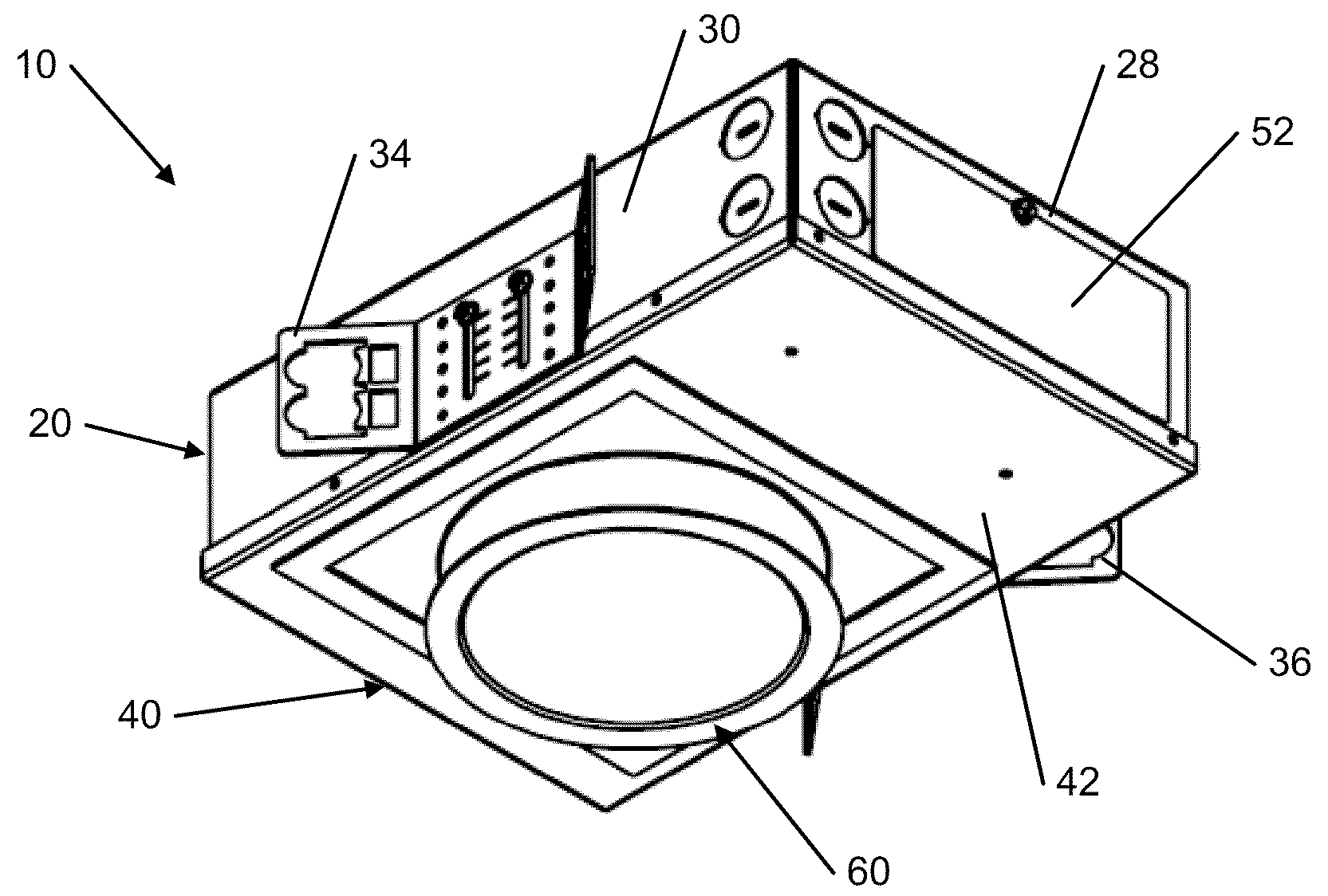

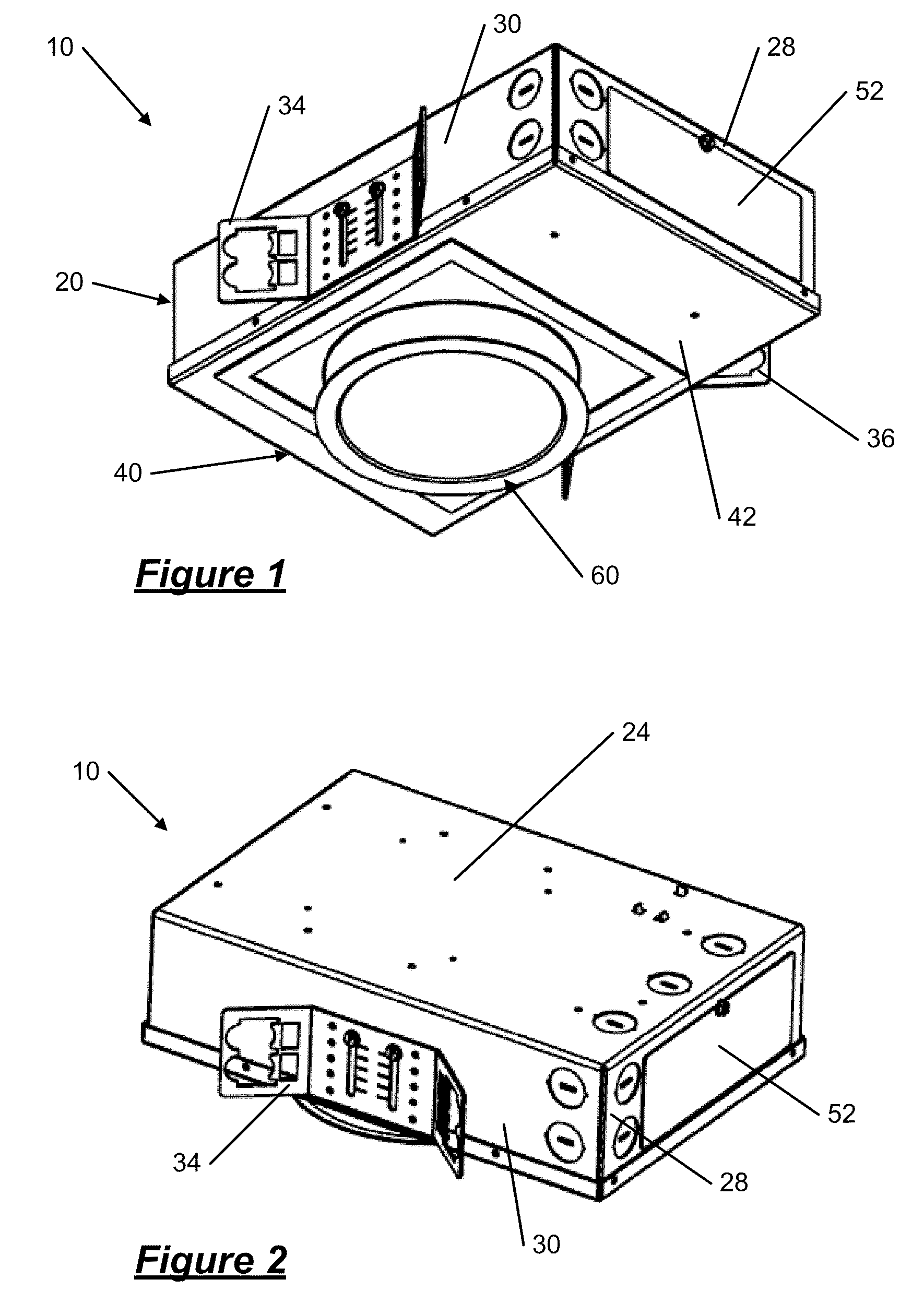

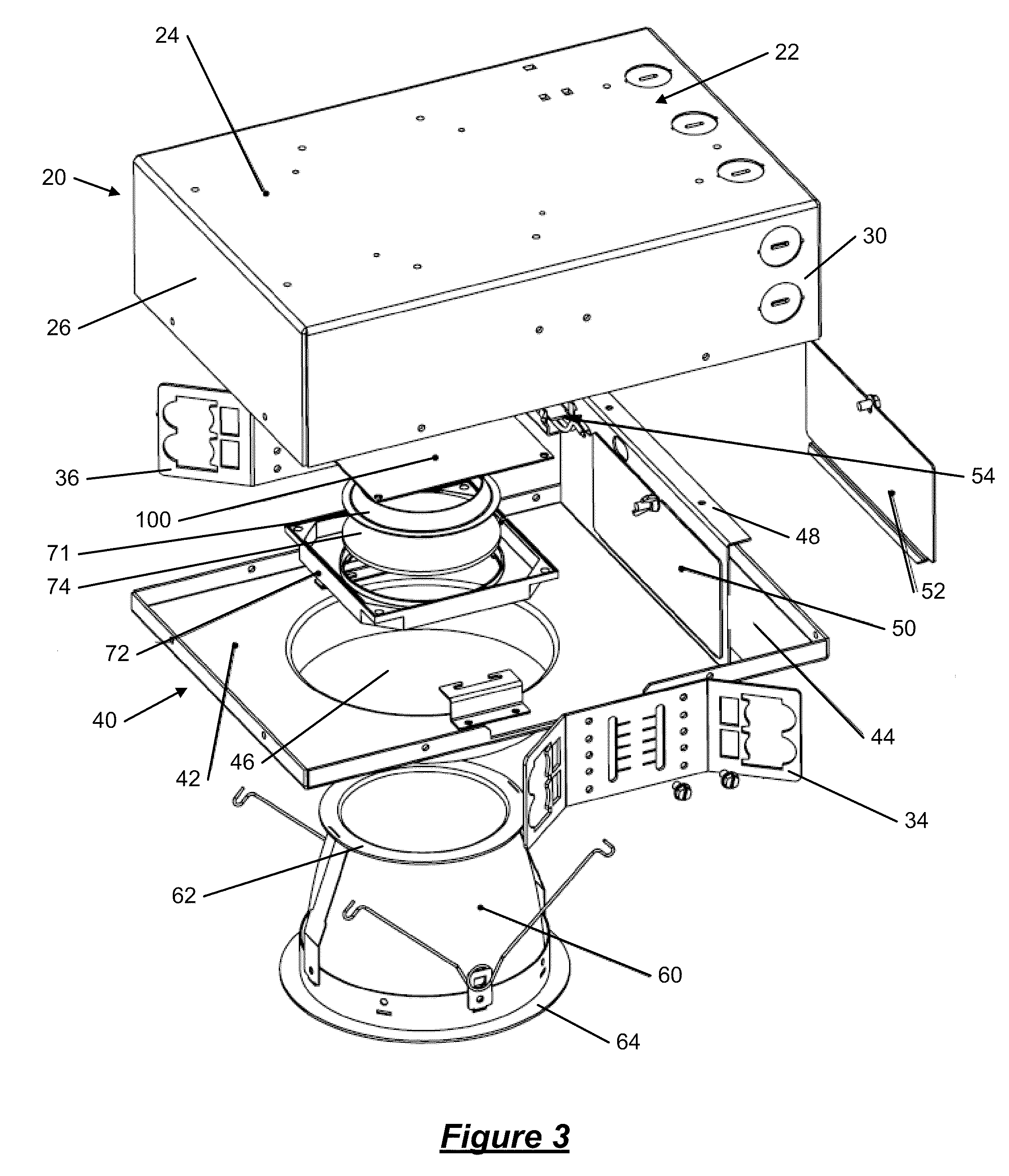

Thermally-Managed Led-Based Recessed Down Lights

An LED down light replacement apparatus is disclosed for insertion into a recessed-light housing can, which includes an LED light source, a means for mounting said LED light source within the housing can, an LED driver circuit electrically connected to the LED light source, a heat sink in thermal contact with the LED light source, and means for removing heat generated by the LED light source. The means for removing heat generated by the LED light source can include a fan and / or ventilation holes in the top of the housing can.

Owner:LIGHTING SCI GROUP

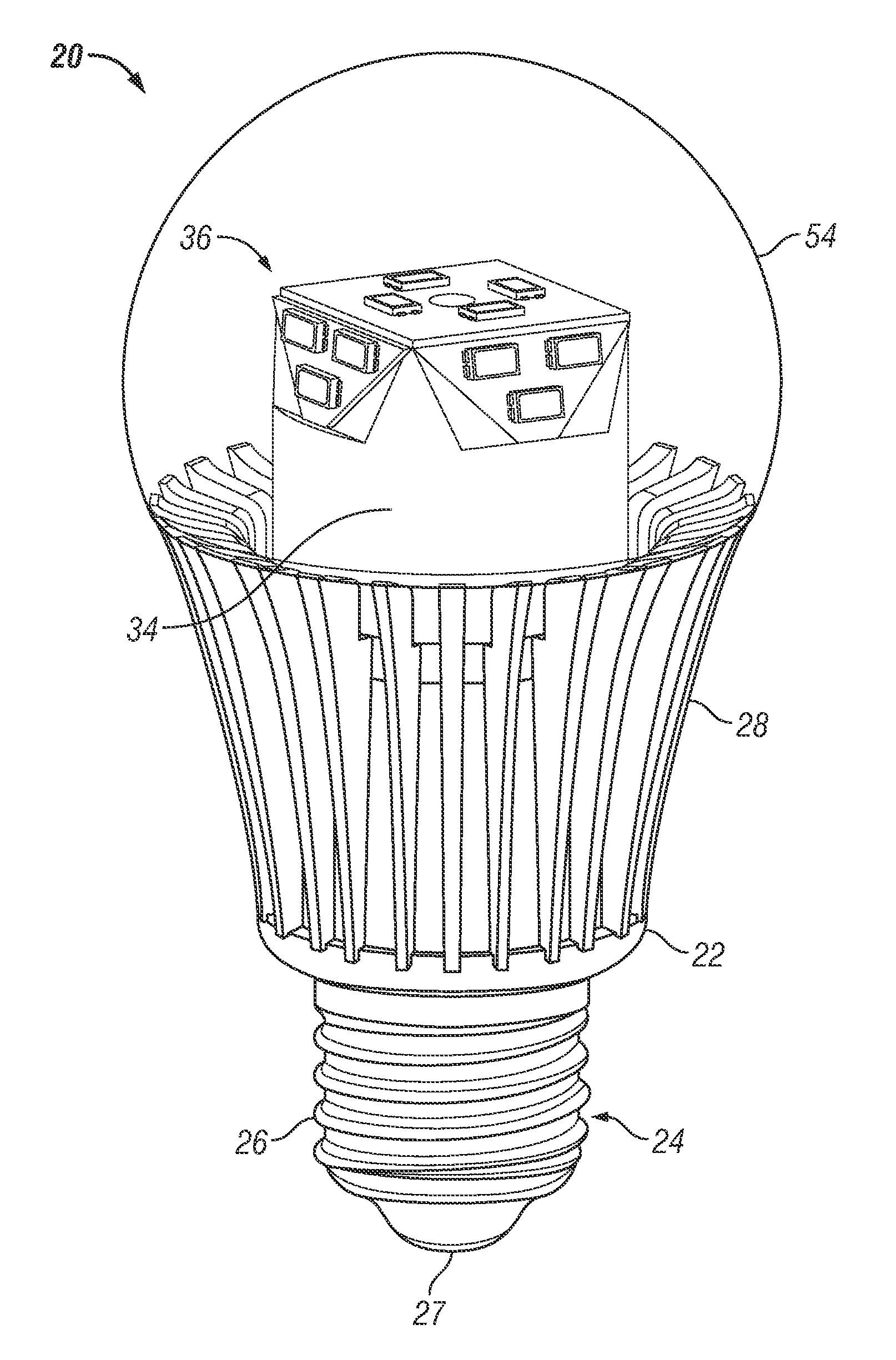

LED luminaire

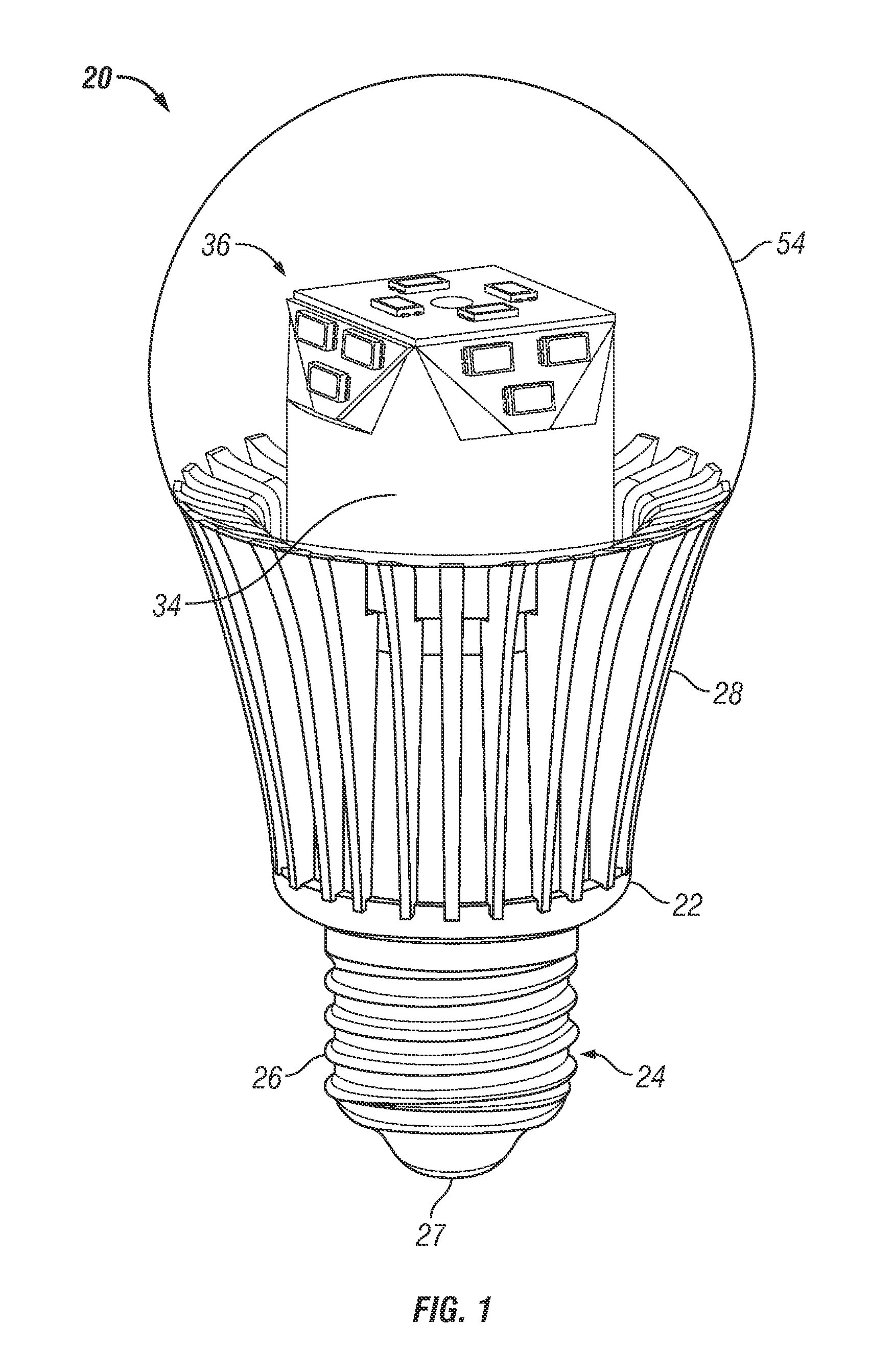

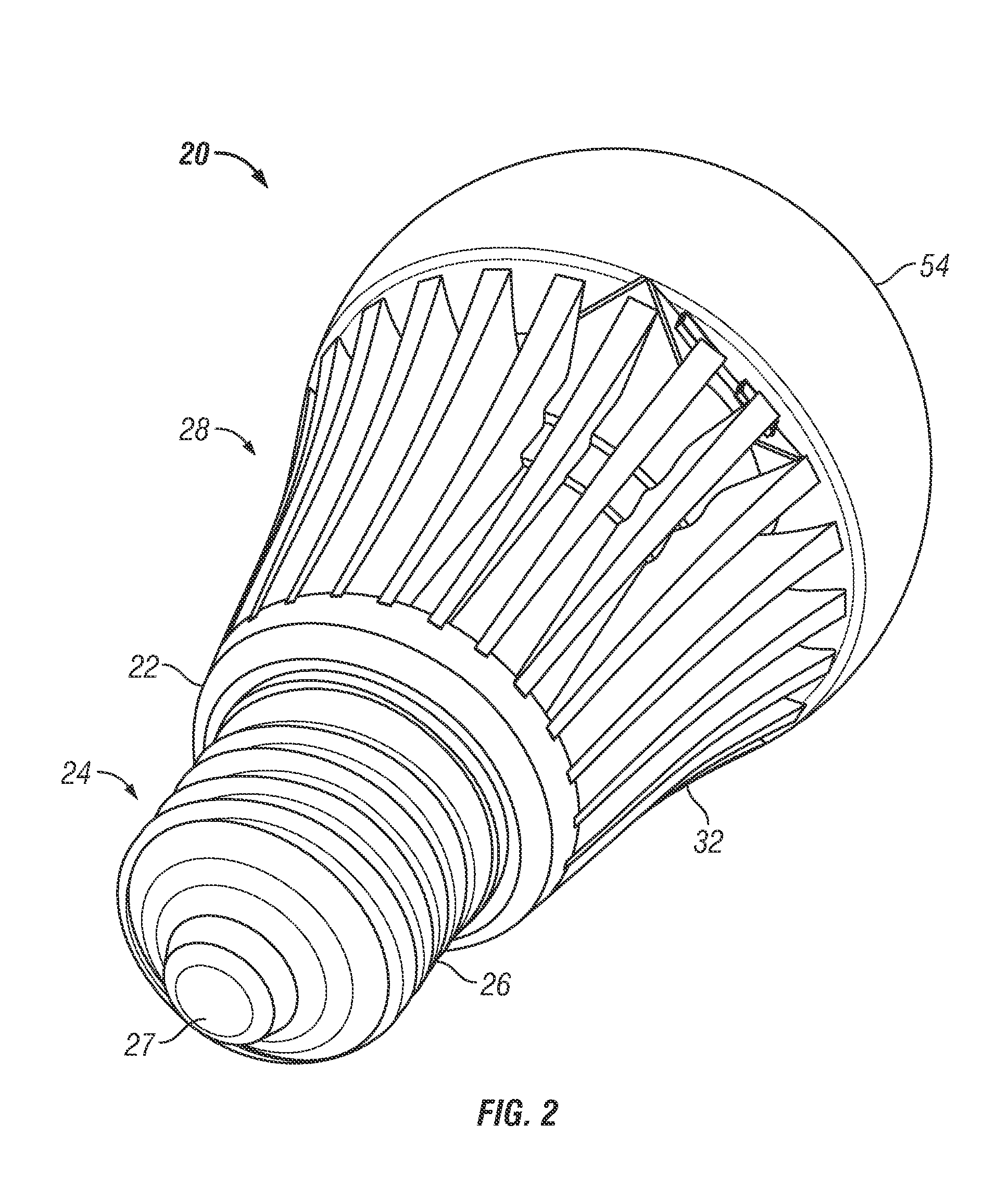

A luminaire includes an electrical base, an optic, and a heat sink disposed between the base and the optic. An LED driver circuit is disposed at least partially within the heat sink, and is disposed in electrical communication with the base. An LED light source is disposed in thermal communication with one or more surfaces of the heat sink, and in electrical communication with the driver circuit, the LED assembly includes an LED module. The light source includes a printed circuit board with a plurality of projections that are bendable such that the projections are arranged on an angle when assembled on the heat sink.

Owner:LIGHTING SCI GROUP

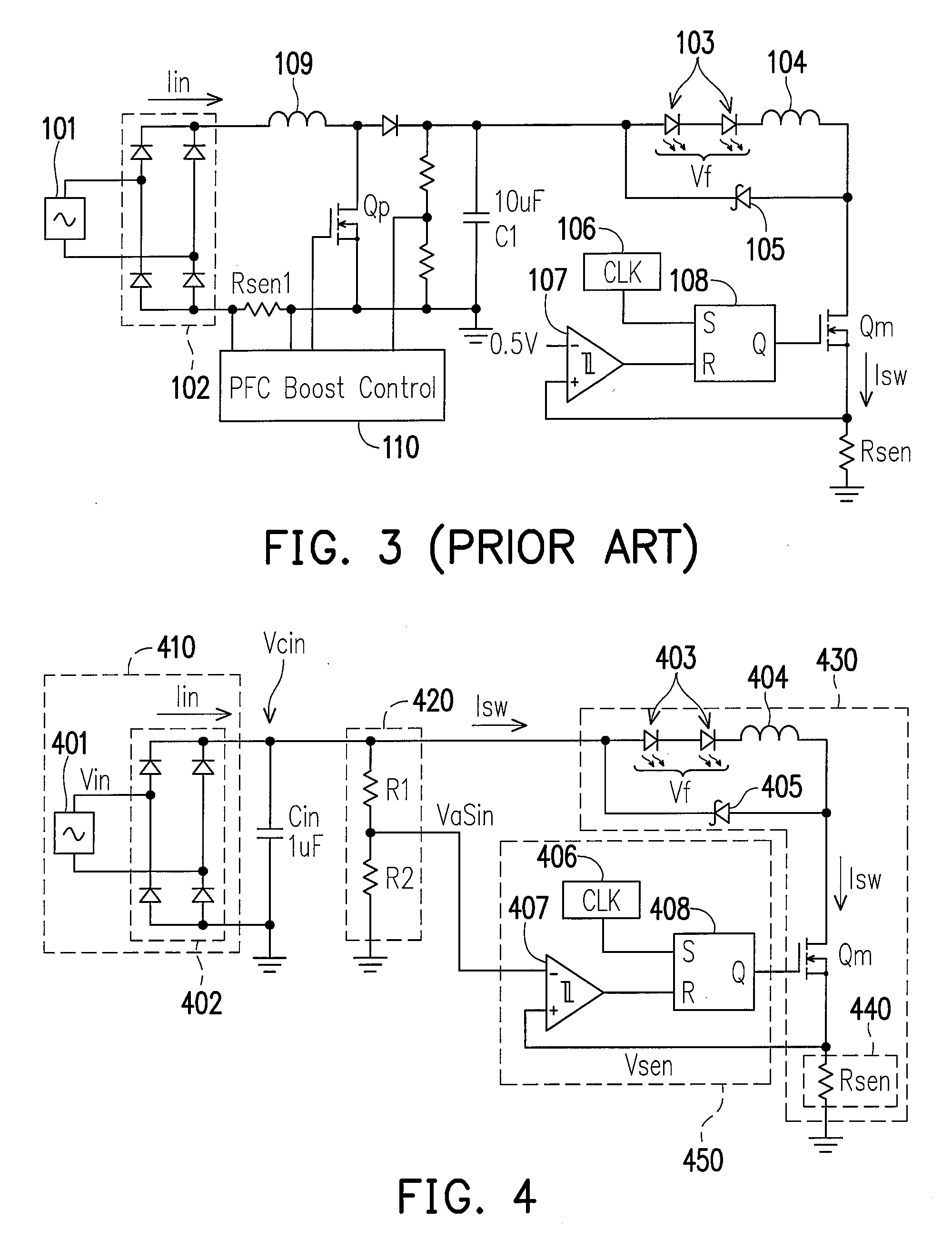

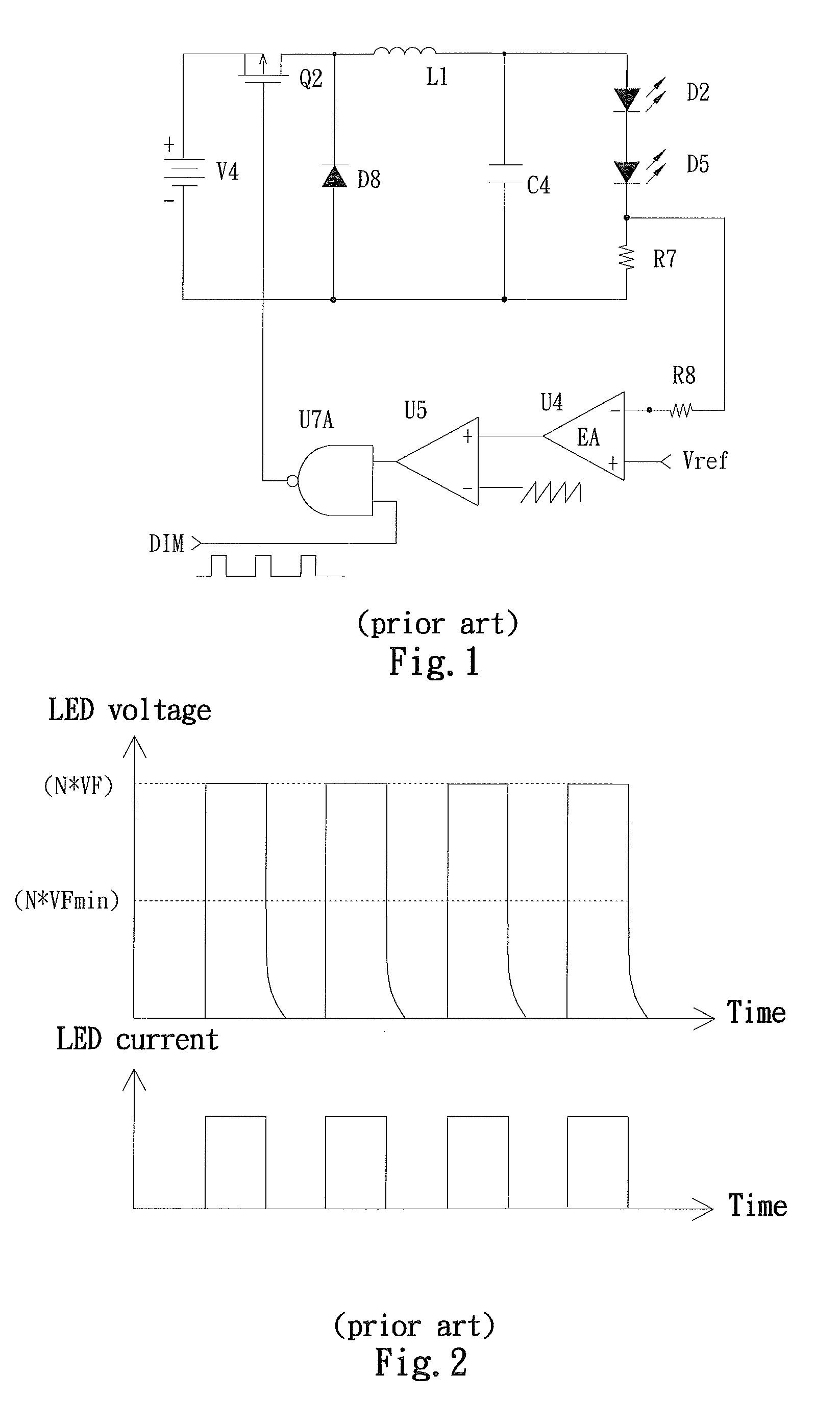

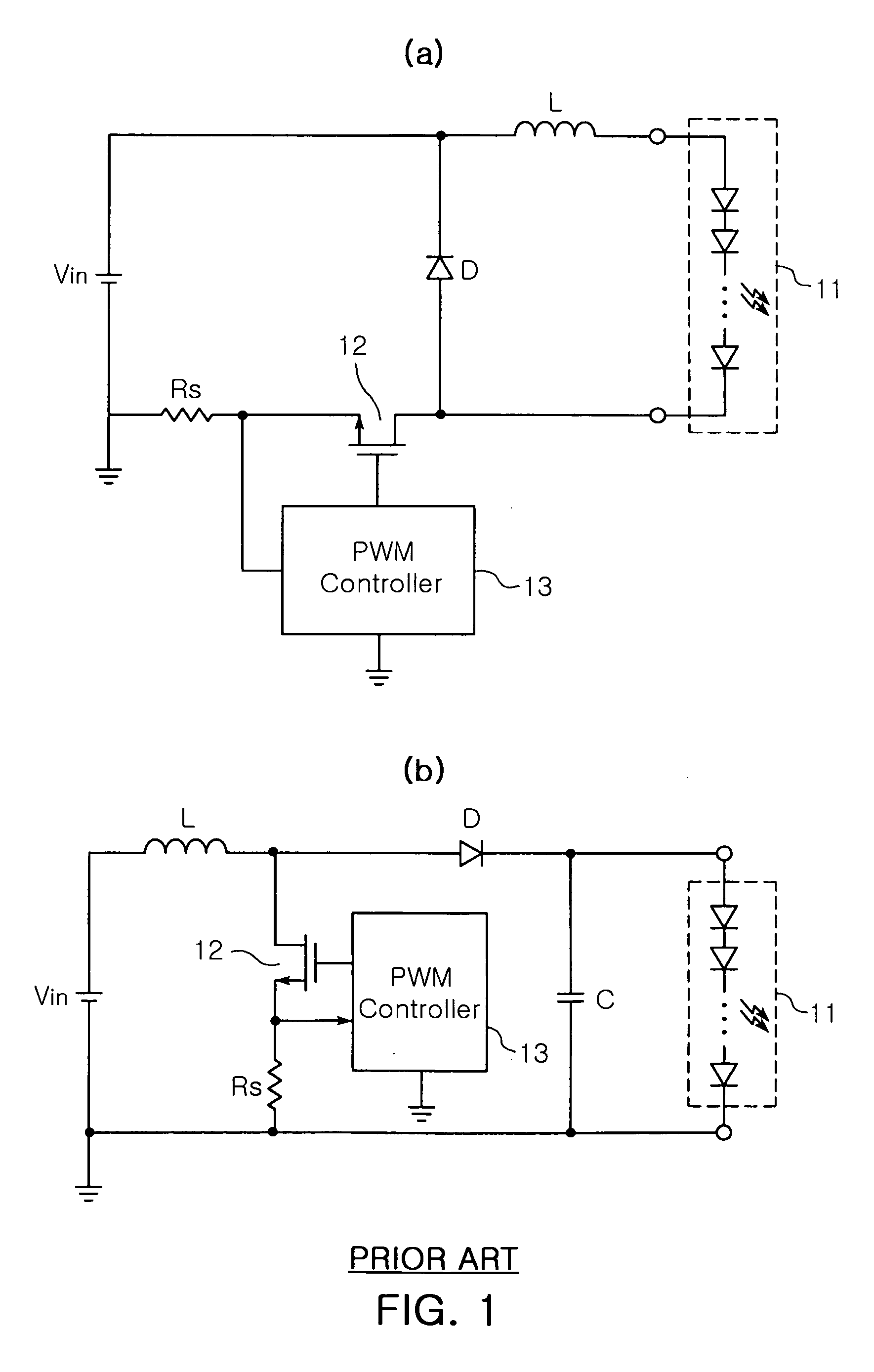

Buck converter LED driver circuit

InactiveUS20080316781A1Simple designHigh input power factorElectroluminescent light sourcesDc-dc conversionDriver circuitBuck converter

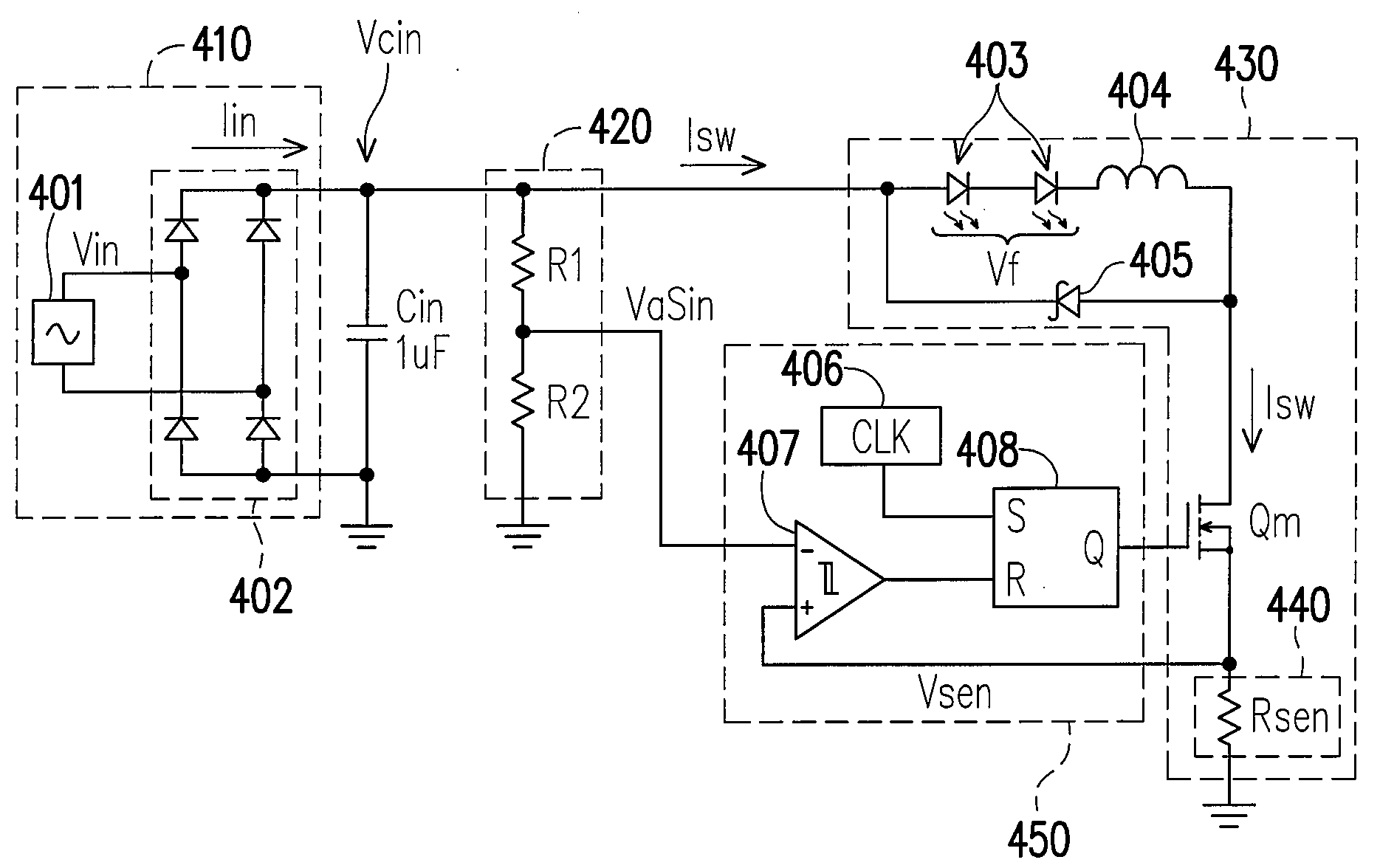

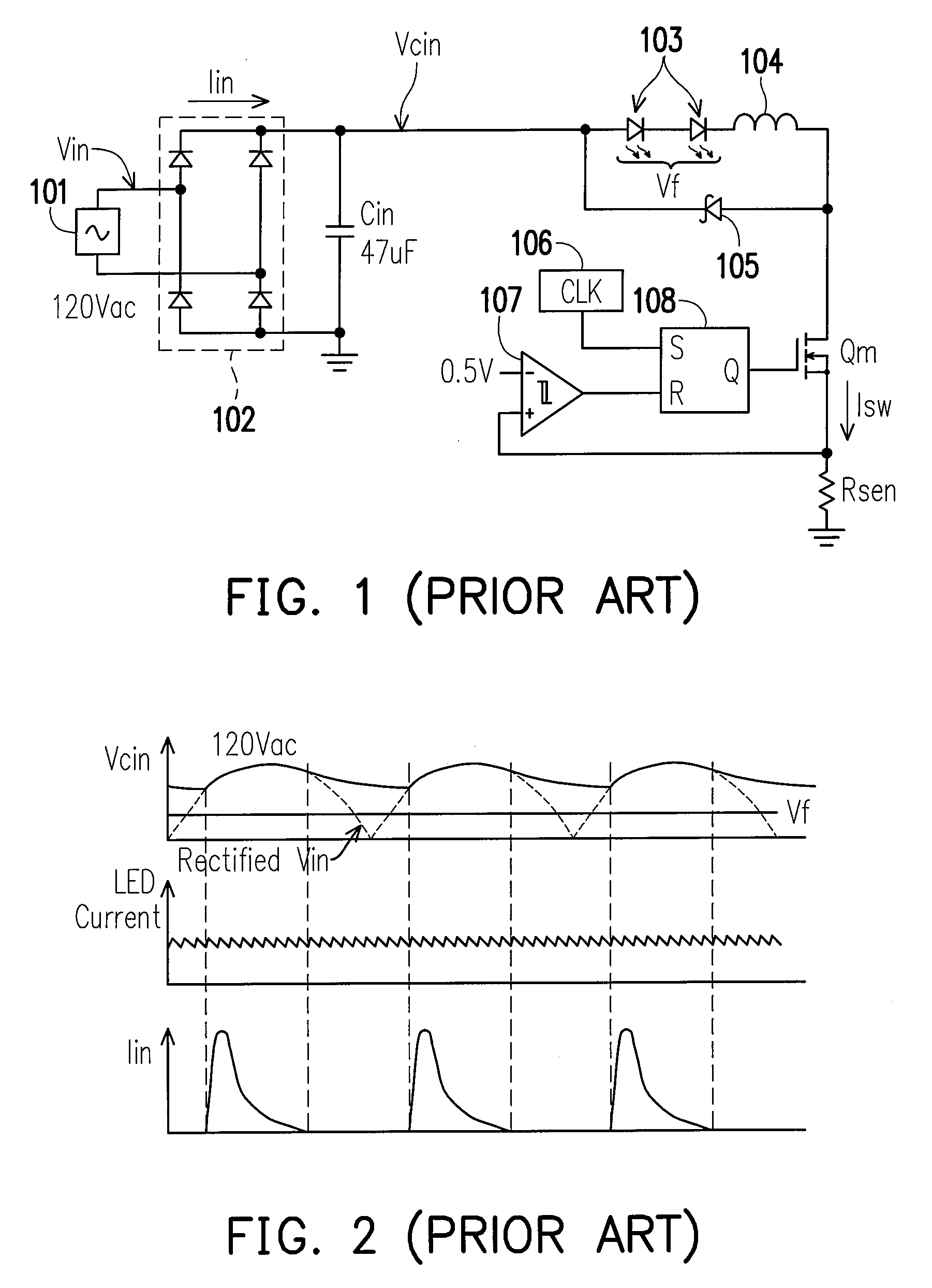

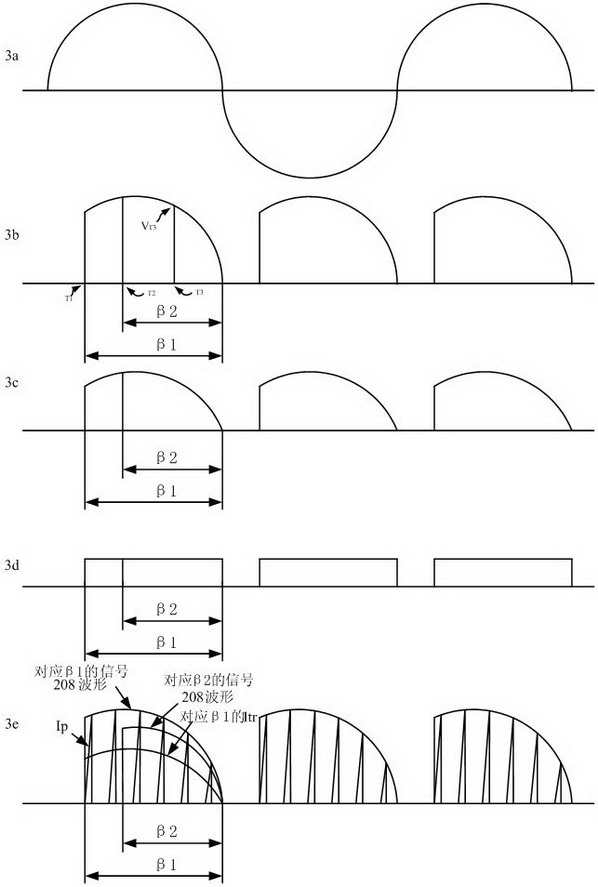

A buck converter LED driver circuit is provided. The driver circuit includes a buck power stage, a rectified AC voltage source, a voltage waveform sampler, and a control circuit. The buck power stage includes at least one LED and provides a first signal directly proportional to the current through the LED. The rectified AC voltage source is coupled to the buck power stage for driving the buck power stage. The voltage waveform sampler is coupled to the rectified AC voltage source for providing a second signal directly proportional to the voltage provided by the rectified AC voltage source. The control circuit is coupled to the voltage waveform sampler and the buck power stage for turning on and turning off the buck power stage according to a comparison between the first signal and the second signal.

Owner:GREEN MARK TECH

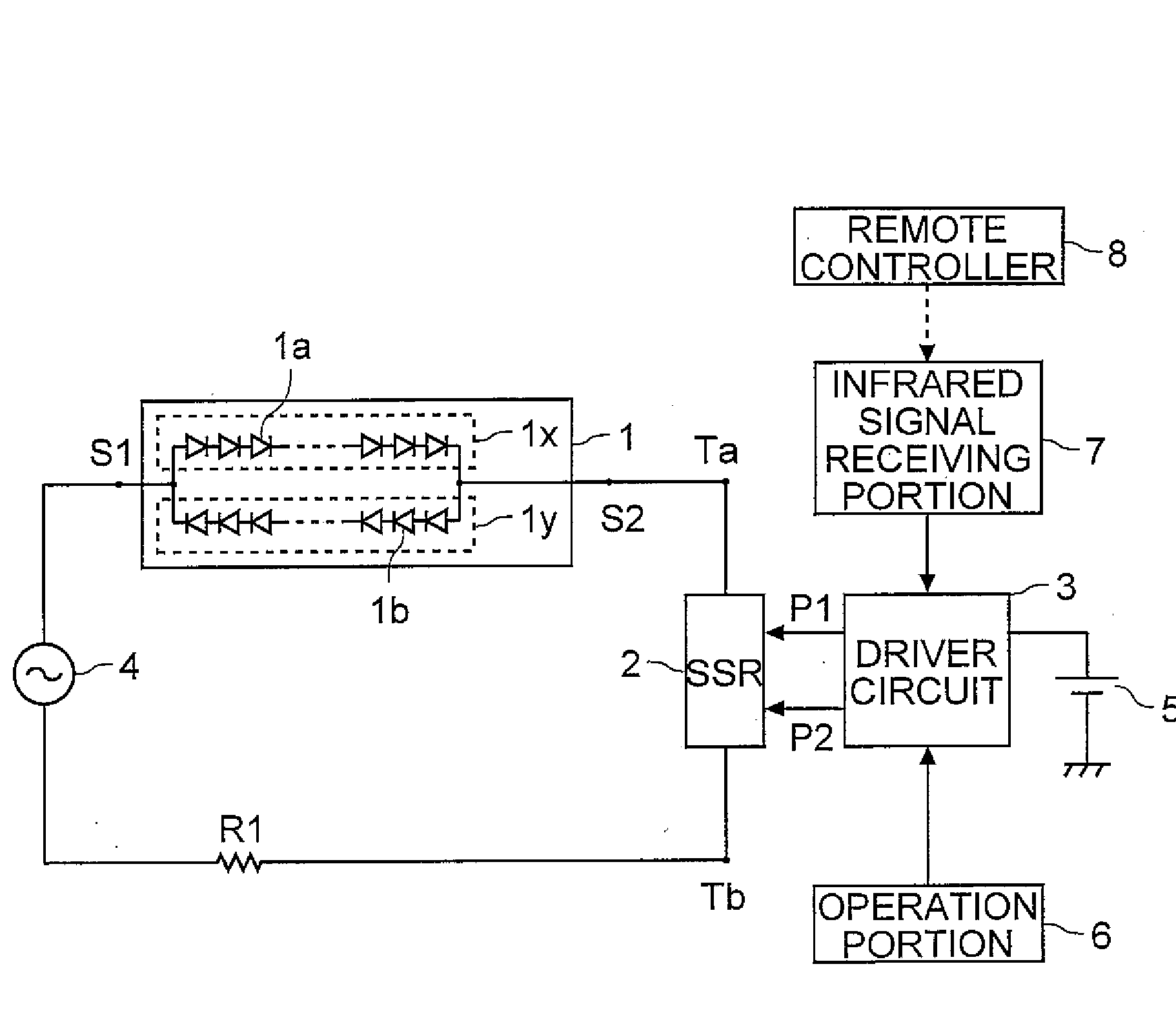

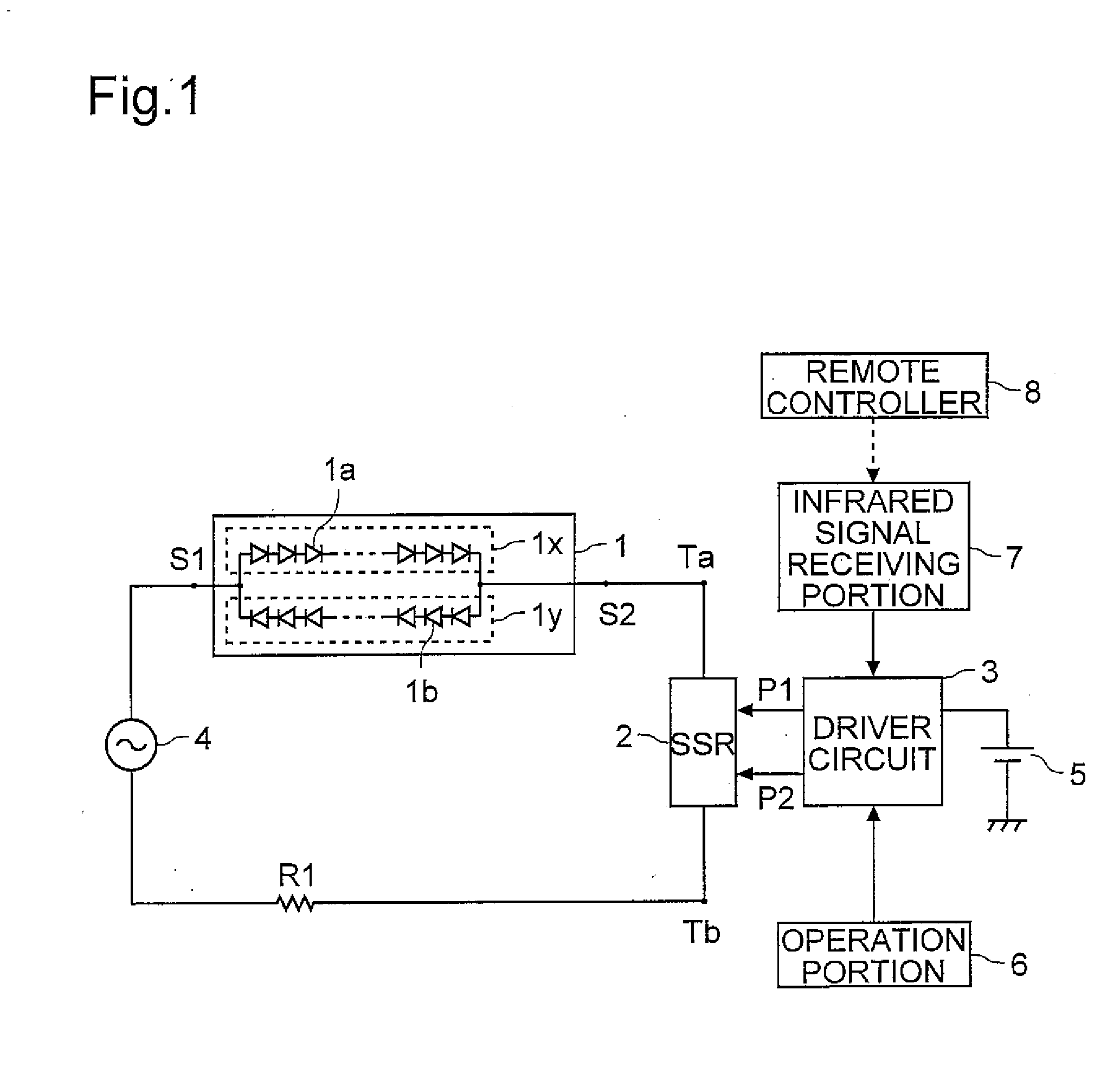

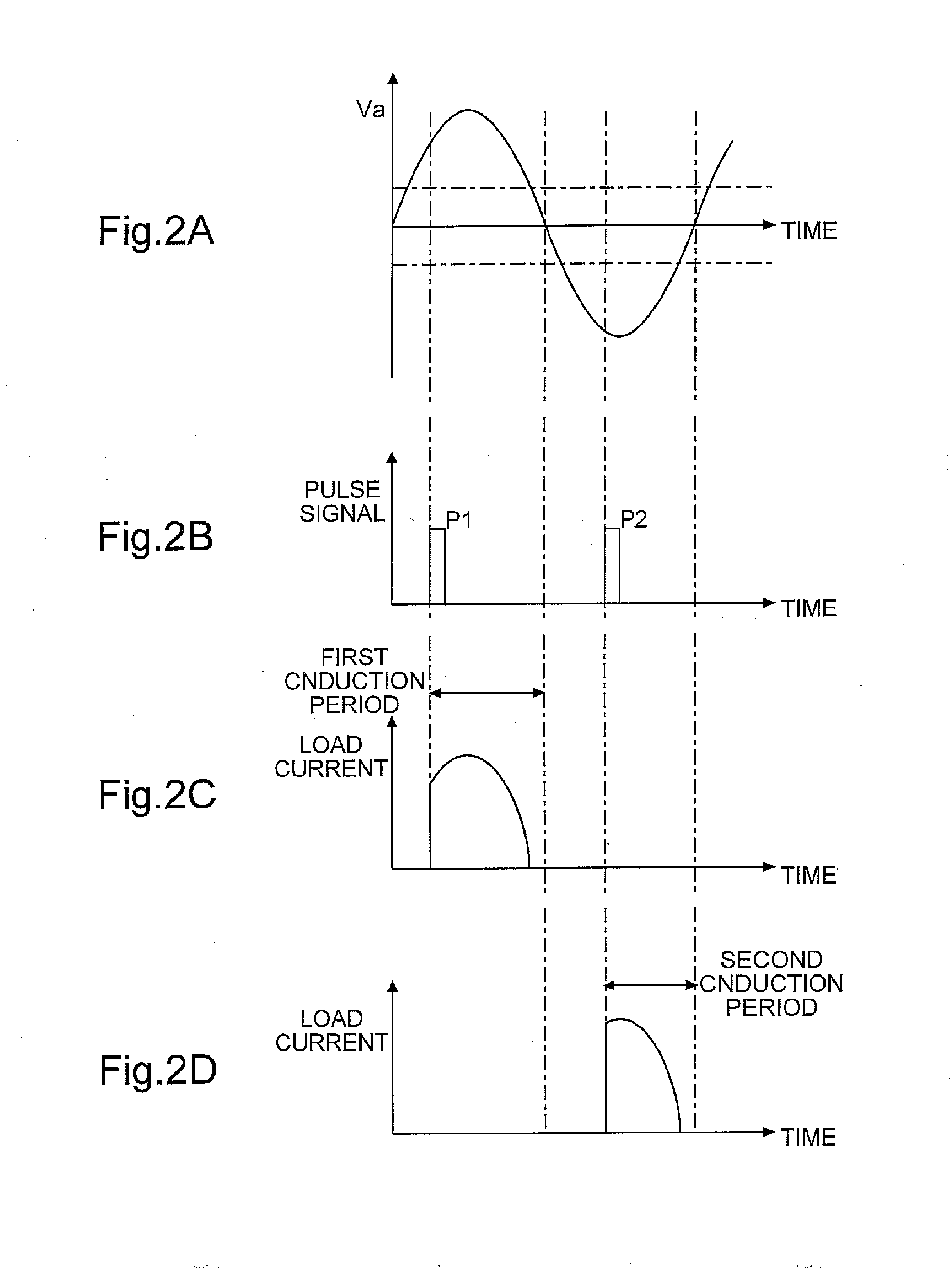

LED drive circuit and LED light-emitting device

InactiveUS20080203936A1Easy to changeSimple circuit configurationElectroluminescent light sourcesSemiconductor lamp usageDriver circuitEngineering

A driver circuit 3 feeds a pulse signal to an SSR 2 every half wave of alternating-current power from a commercial power source 4, and thereby separately controls the amounts of emitted light of LED groups 1x and 1y forming an LED unit 1, the LED groups 1x and 1y being connected in parallel in such a way as to point in different directions. That is, a first pulse signal for controlling the duration of light emission of the LED group 1x and a second pulse signal for controlling the duration of light emission of the LED group 1y are fed to the SSR 2 from the driver circuit 3.

Owner:SHARP KK

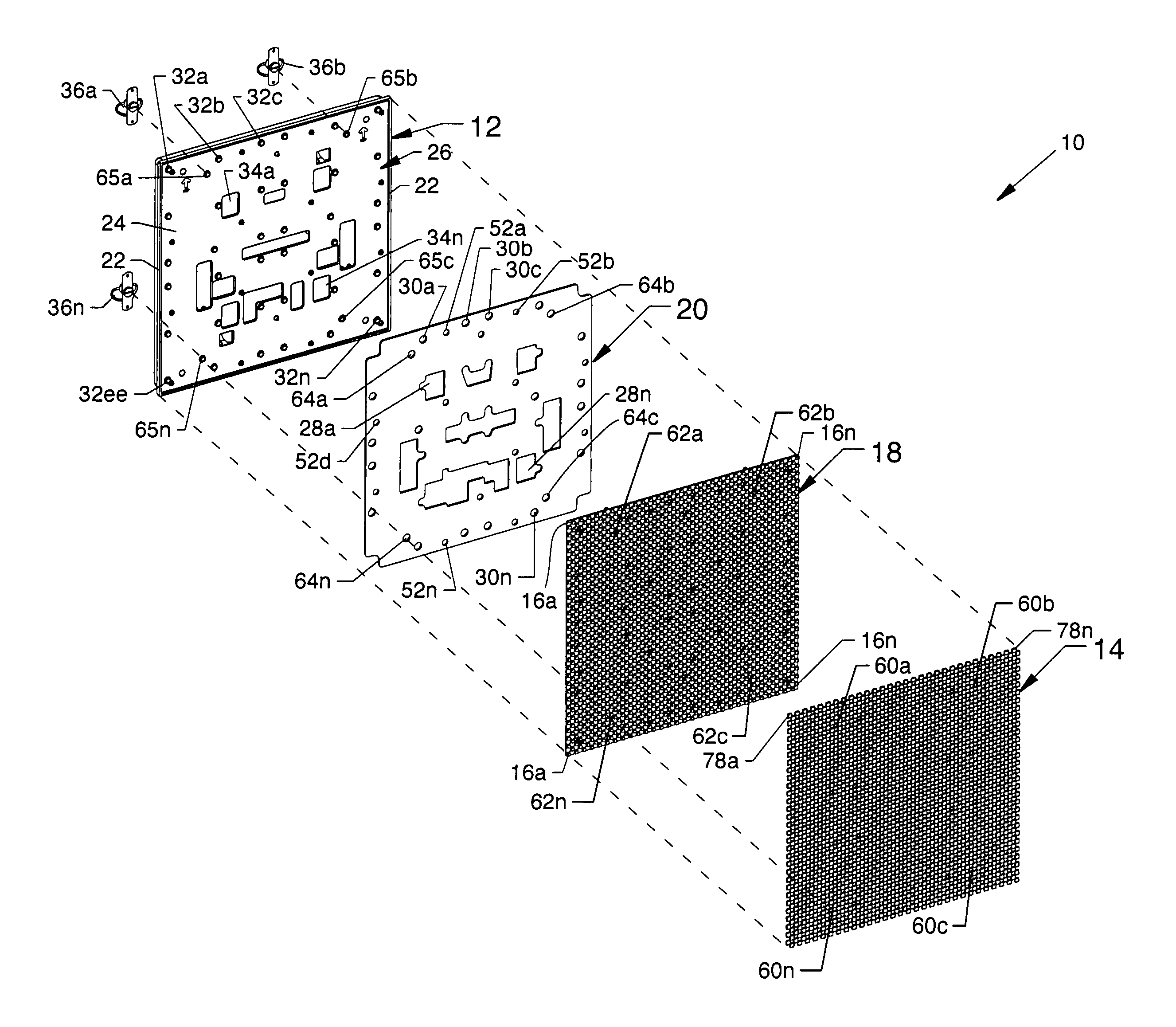

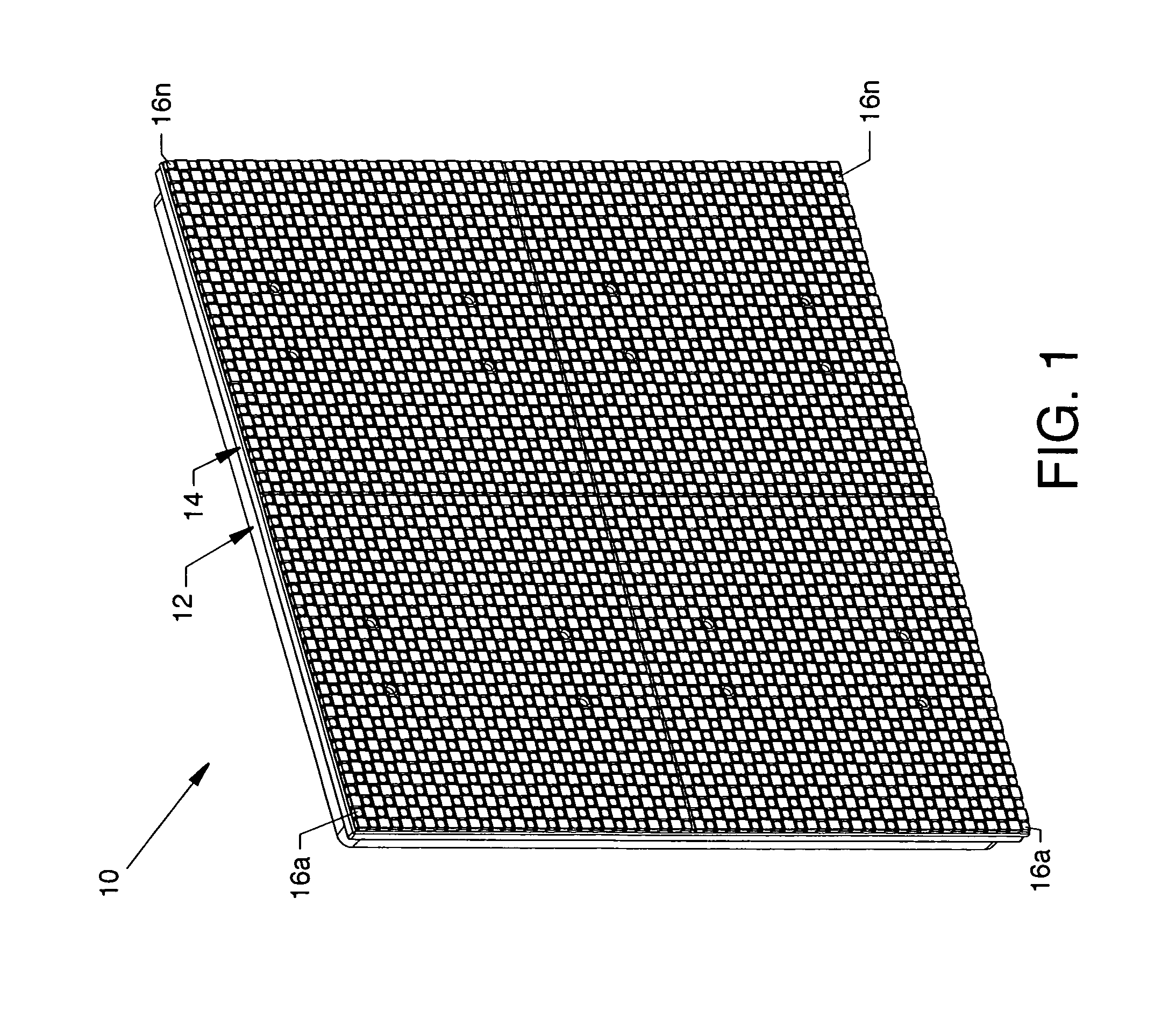

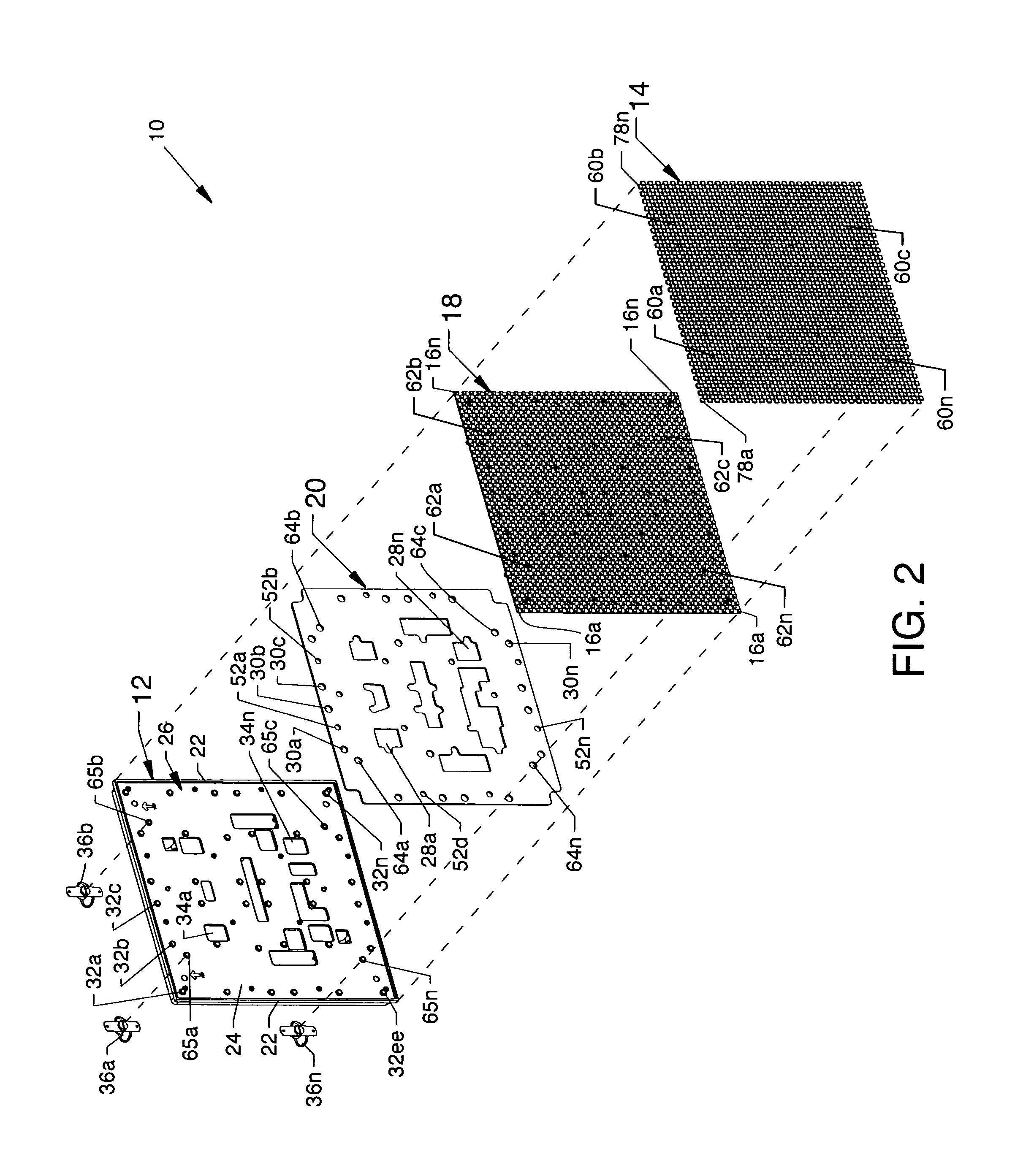

LED display module having a metallic housing and metallic mask

InactiveUS8154864B1Equally distributedReduce heatLighting support devicesDigital data processing detailsLED displayEngineering

The present invention is a robust LED display module for use in an electronic sign which display module includes a metallic housing, a heat conductive interface panel, an LED circuit board and LEDs, and a metallic mask arranged in intimate contact and association therewith, and which components operate synergistically in concert with each other in order to evenly distribute, reduce and dissipate heat along, about and within the structure of the present invention. Display uniformity is provided by the use of major metallic structures in order to prevent warpage and to protect the geometric integrity of the LED display module.

Owner:DAKTRONICS

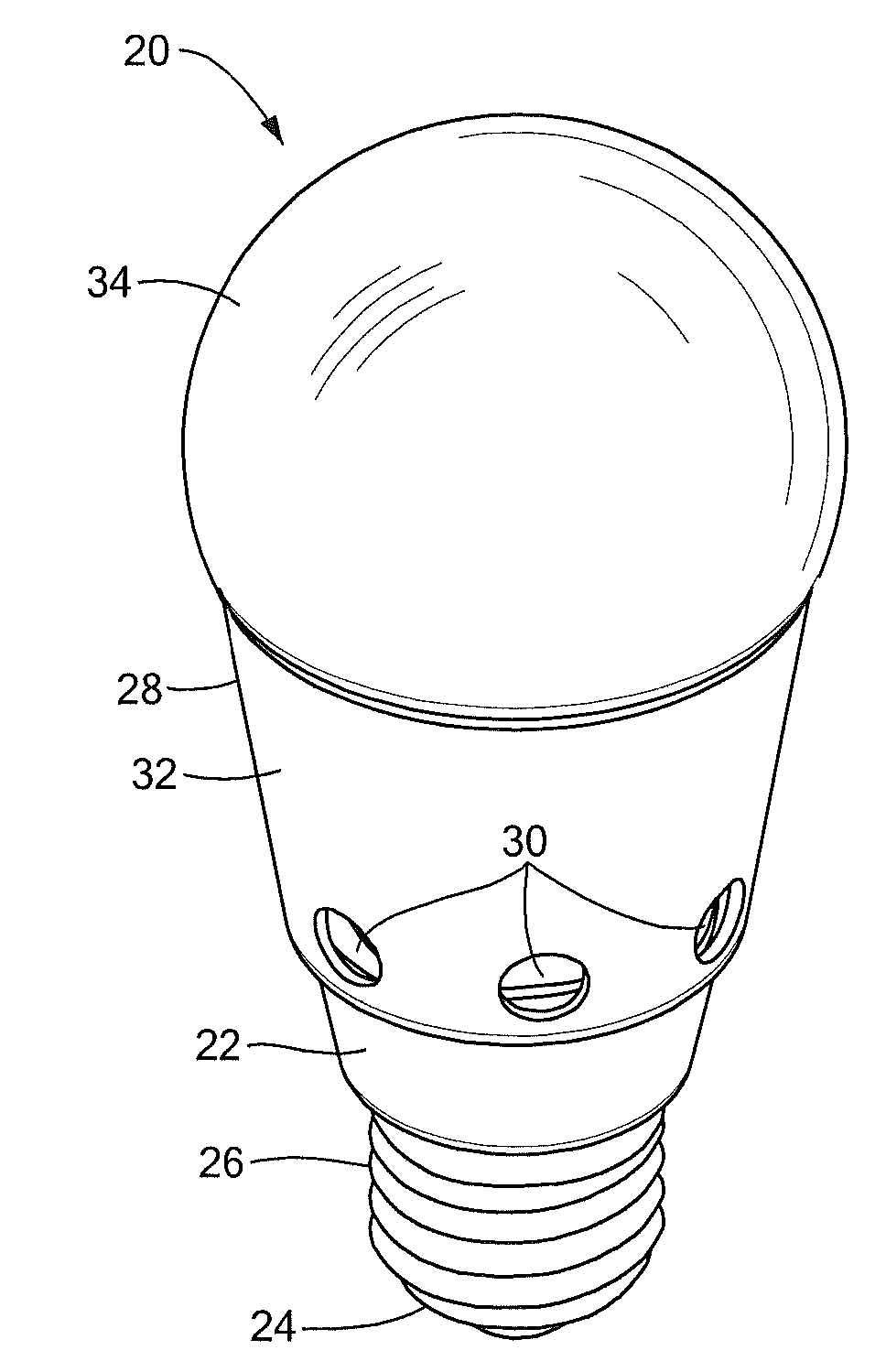

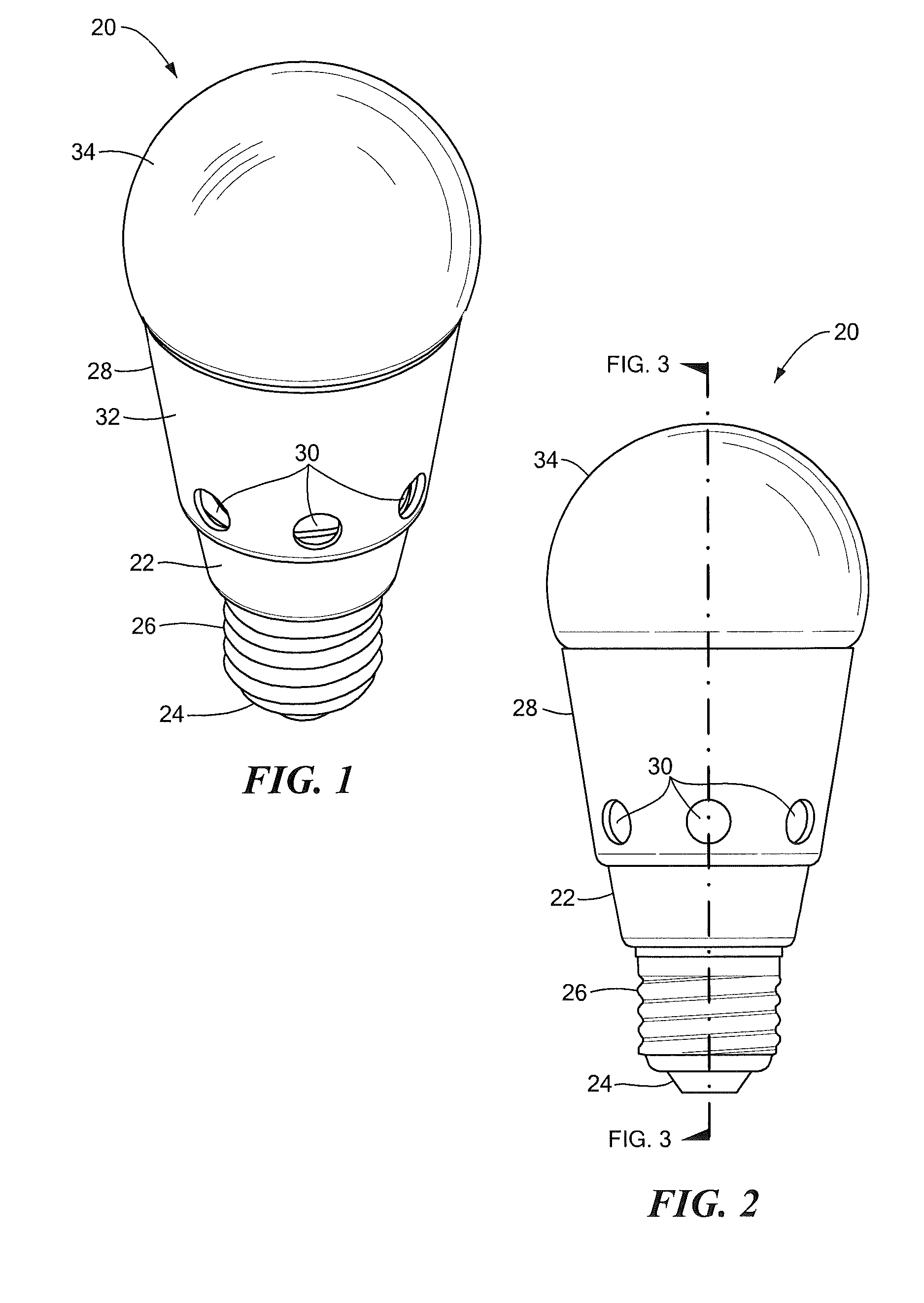

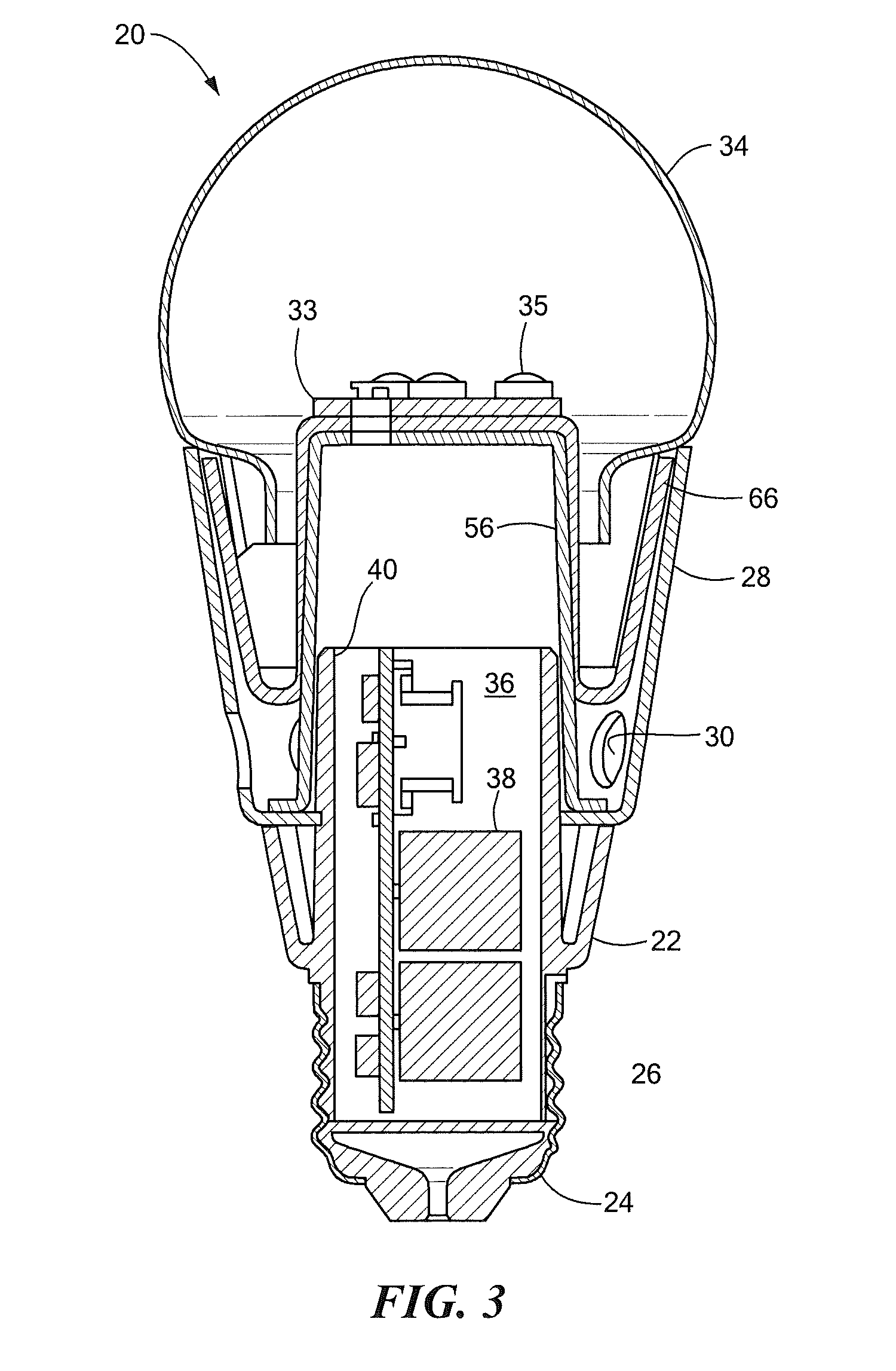

Dimmable LED luminaire

InactiveUS20100277067A1Point-like light sourceElectric circuit arrangementsElectricityDriver circuit

A luminaire includes an Edison type electrical base, an optic, and a heat sink disposed between the base and the optic. An LED driver circuit is disposed at least partially within the heat sink, and is disposed in electrical communication with the base. An LED assembly is disposed in thermal communication with a surface of the heat sink, and in electrical communication with the driver circuit, the LED assembly includes an LED. The driver circuit includes circuitry that converts an AC signal at the base to a DC signal and provides the DC signal to the LED assembly, the circuitry includes holding current circuitry that produces a holding current for an electrical dimmer disposed upstream of the base in response to a current to the LED assembly being reduced for light dimming purposes.

Owner:LIGHTING SCI GROUP

Combination fluorescent and LED lighting system

LEDs can be added to a conventional fluorescent lighting fixture by providing an LED circuit to the fluorescent lighting fixture pan, by adding LEDs to the fluorescent light tube with an indentation in the light tube rear to receive an LED to influence the apparent color of the the fluorescent light, or by adding an LED to either end cap of the fluorescent light tube to shine down the tube from the interior, added as an add-on band which could clip onto the tube, and could also include a circuit board based LED attached to the rear of the tube and alternatively have LED lighting within a charged fluorescent tube.

Owner:PLASTICS INVENTIONS & PATENTS INC

LED Lighting Device

A lighting device having a plurality of analog LEDs mounted on a substrate, a plurality of addressable digital LEDs mounted on the substrate, a first LED circuit connected to the plurality of analog LEDs, and a second LED circuit connected to the plurality of addressable digital LEDs. The plurality of analog LEDs and the plurality of addressable digital LEDs are arranged in an array or pattern on the substrate.

Owner:ILUMI SOLUTIONS

Configurable load control device for light-emitting diode light sources

ActiveUS20110080111A1Electrical apparatusElectroluminescent light sourcesEngineeringPersonal computer

A configurable light-emitting diode (LED) driver is adapted to control a plurality of different LED light sources, which may be rated to operate using different load control techniques, different dimming techniques, and different magnitudes of load current and voltage. The LED driver comprises a power converter circuit for generating a DC bus voltage, and an LED drive circuit for receiving the bus voltage and adjusting either the magnitude of the current conducted through the LED light source or the magnitude of the voltage across the LED light source. The LED driver is operable to dim the LED light source using either a pulse-width modulation technique or a constant current reduction technique, and may be configured using a programming device and a personal computer.

Owner:LUTRON TECH CO LLC

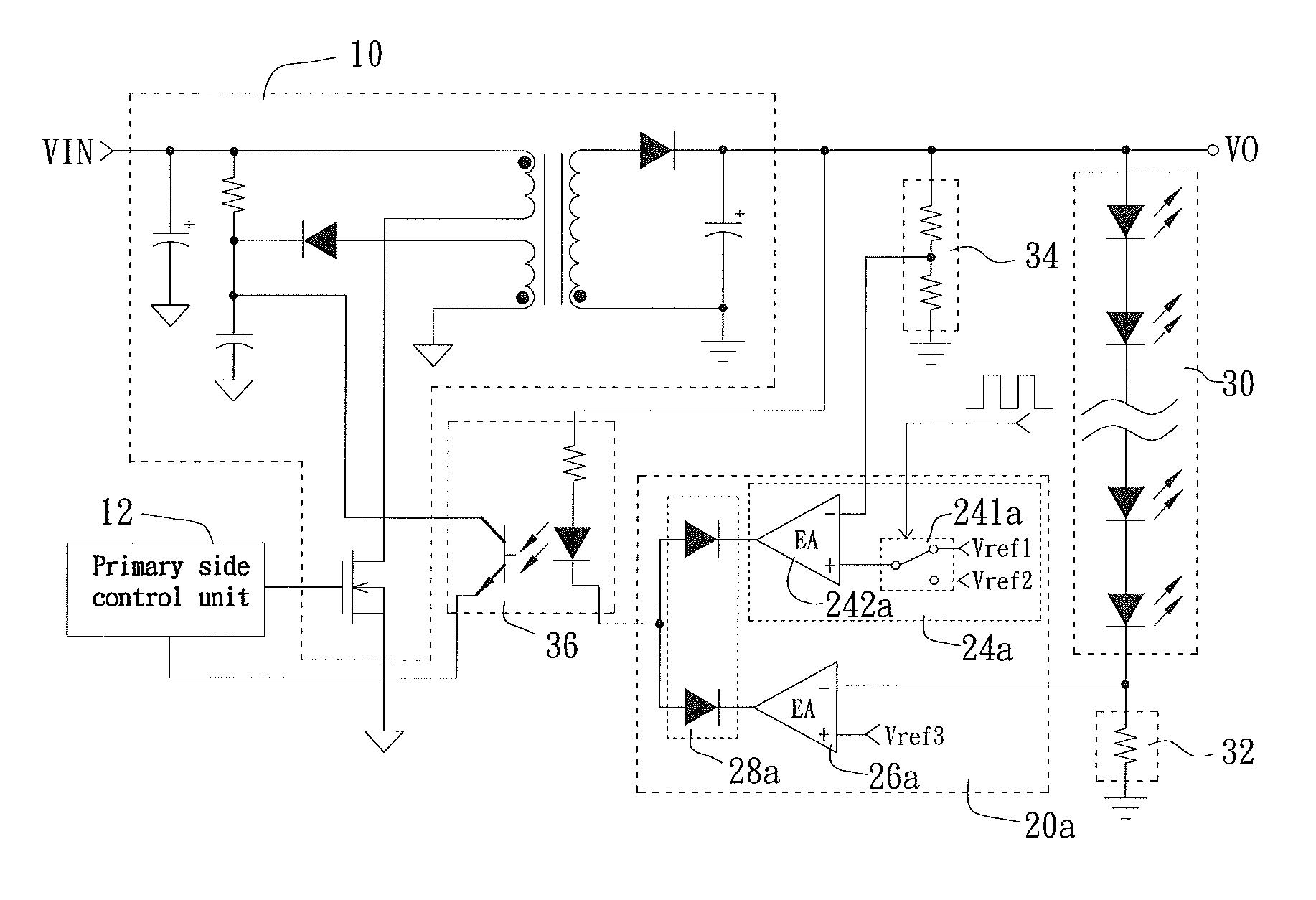

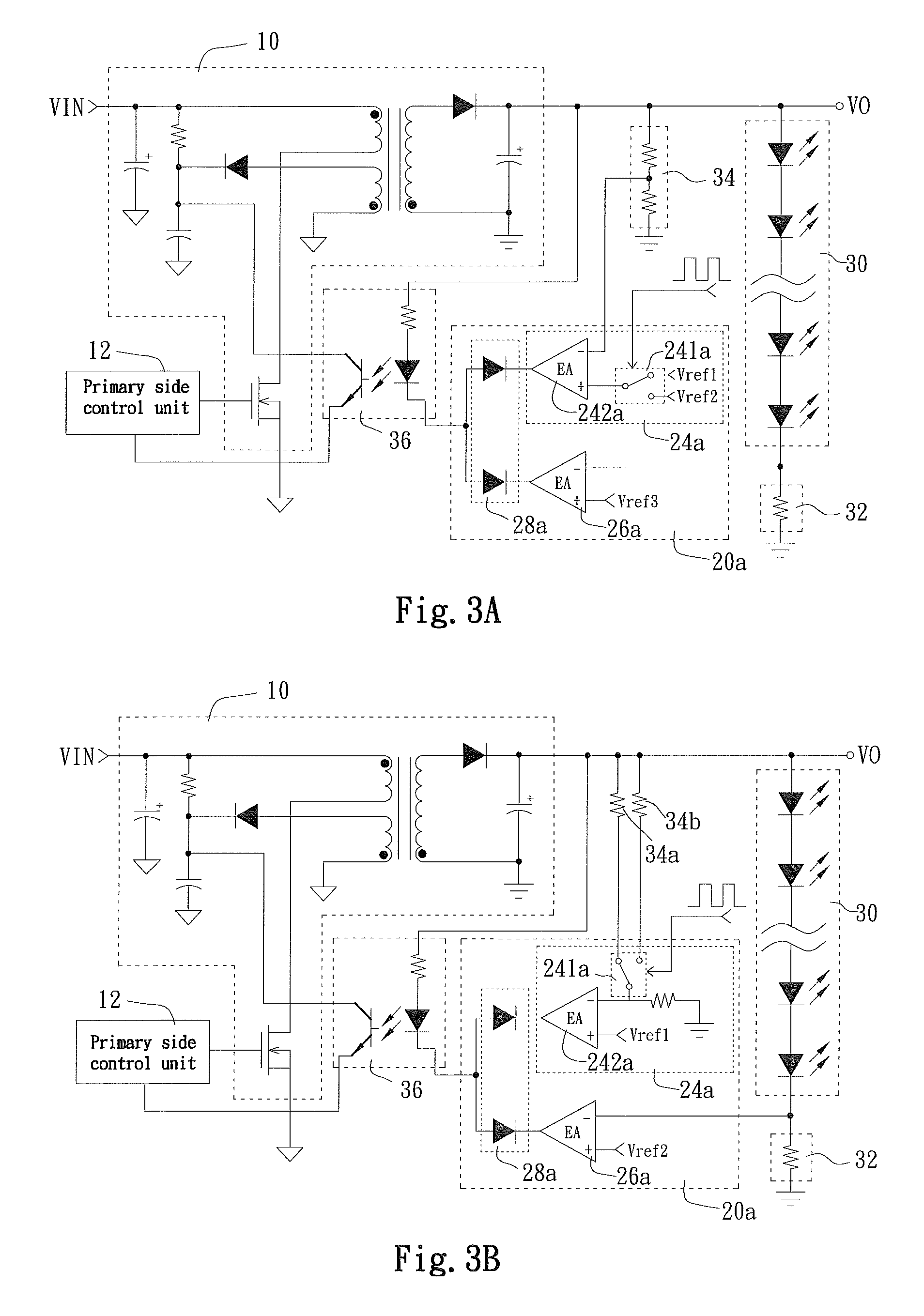

Light-emitting diode driving circuit and secondary side controller for controlling the same

InactiveUS7855520B2Low costLayout on a printed circuit board (PCB) may be simplifiedElectrical apparatusElectroluminescent light sourcesDriver circuitEffect light

Owner:NIKO SEMICON

Load control device for a light-emitting diode light source

An LED driver for controlling the intensity of an LED light source includes a power converter circuit for generating a DC bus voltage, an LED drive circuit for receiving the bus voltage and controlling a load current through, and thus the intensity of, the LED light source, and a controller operatively coupled to the power converter circuit and the LED drive circuit. The LED drive circuit comprises a controllable-impedance circuit coupled in series with the LED light source. The controller adjusts the magnitude of the bus voltage to a target bus voltage and generates a drive signal for controlling the controllable-impedance circuit. To adjust the intensity of the LED light source, the controller controls the magnitudes of both the load current and the regulator voltage. The controller controls the magnitude of the regulator voltage by simultaneously maintaining the magnitude of the drive signal constant and adjusting the target bus voltage.

Owner:LUTRON TECH CO LLC

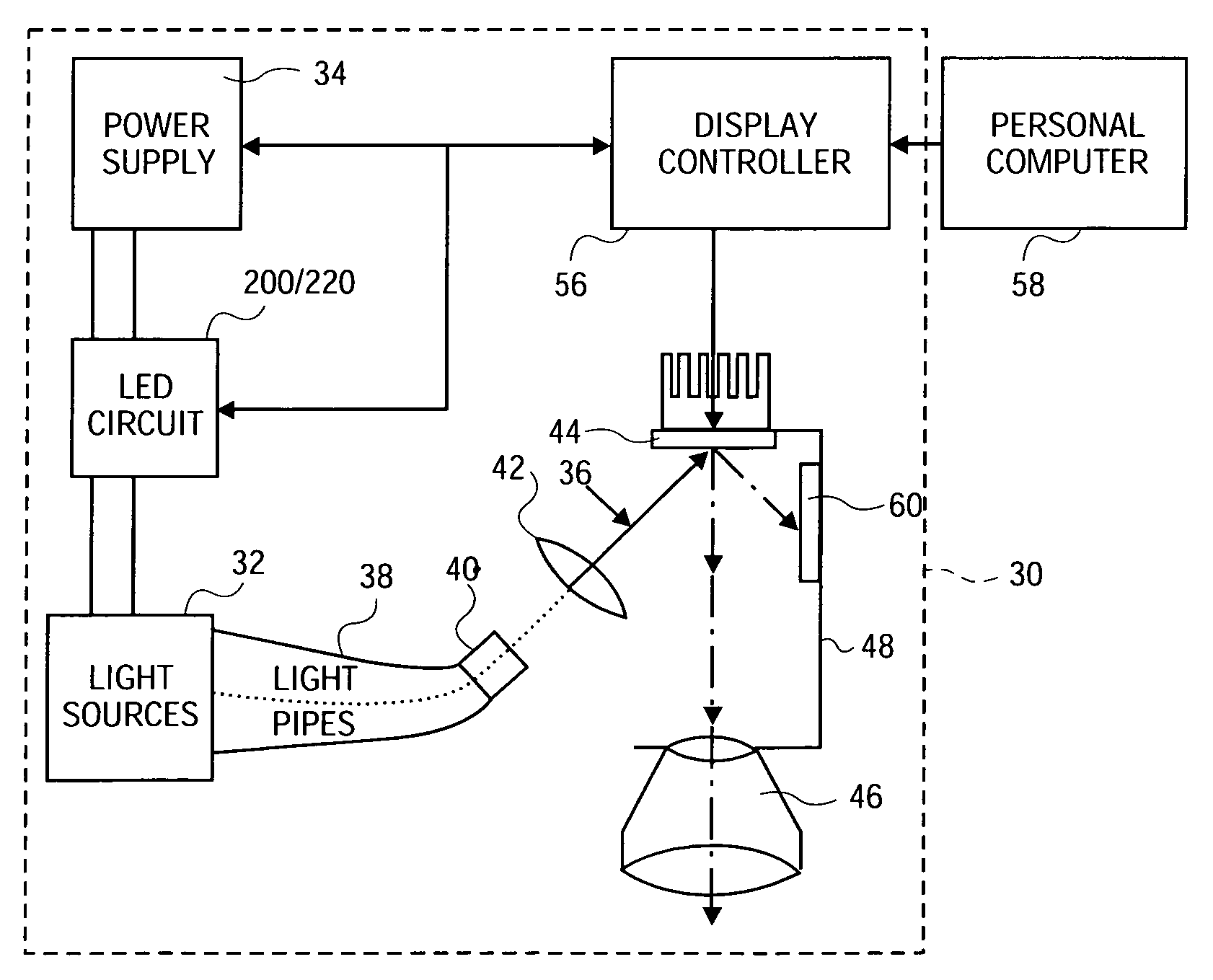

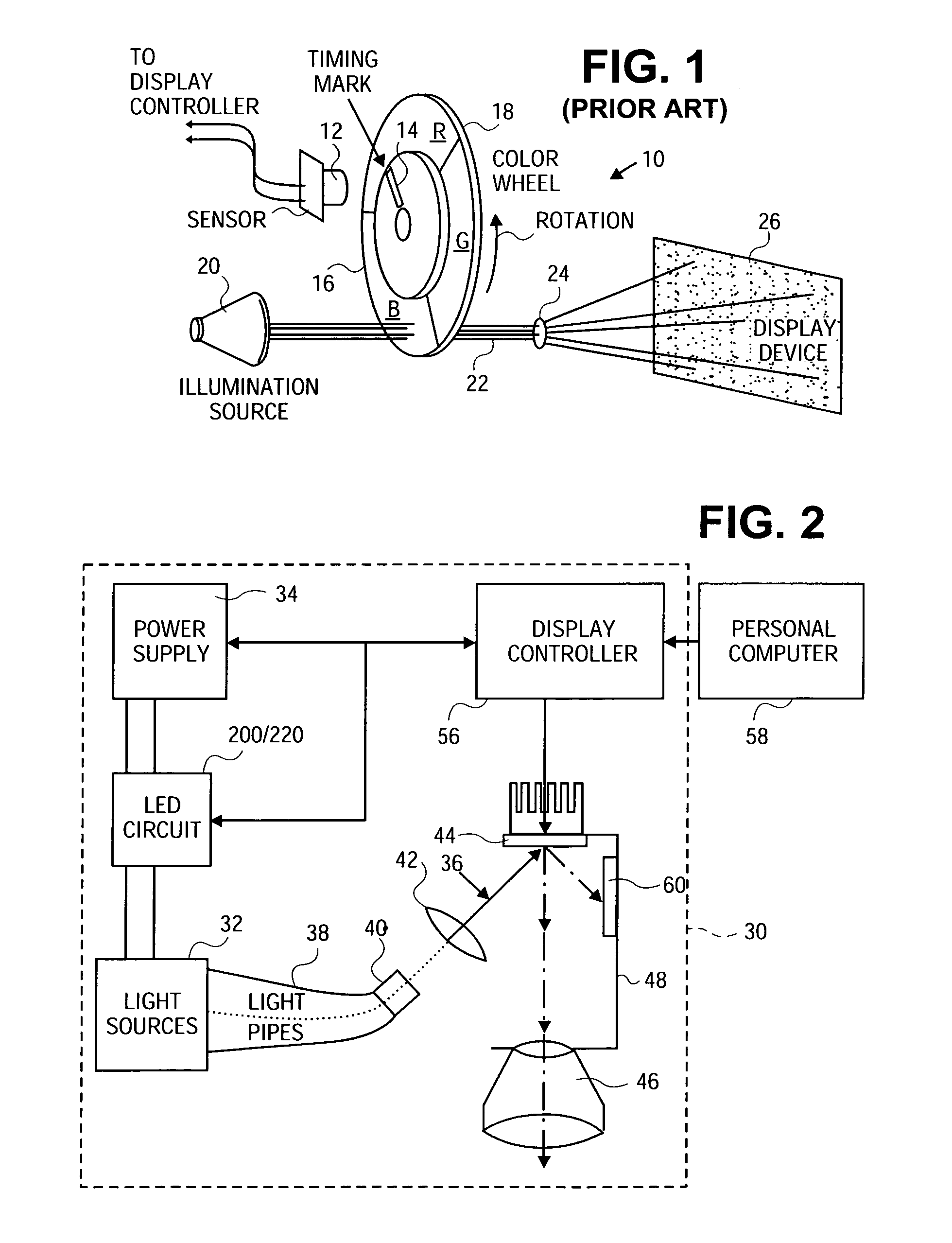

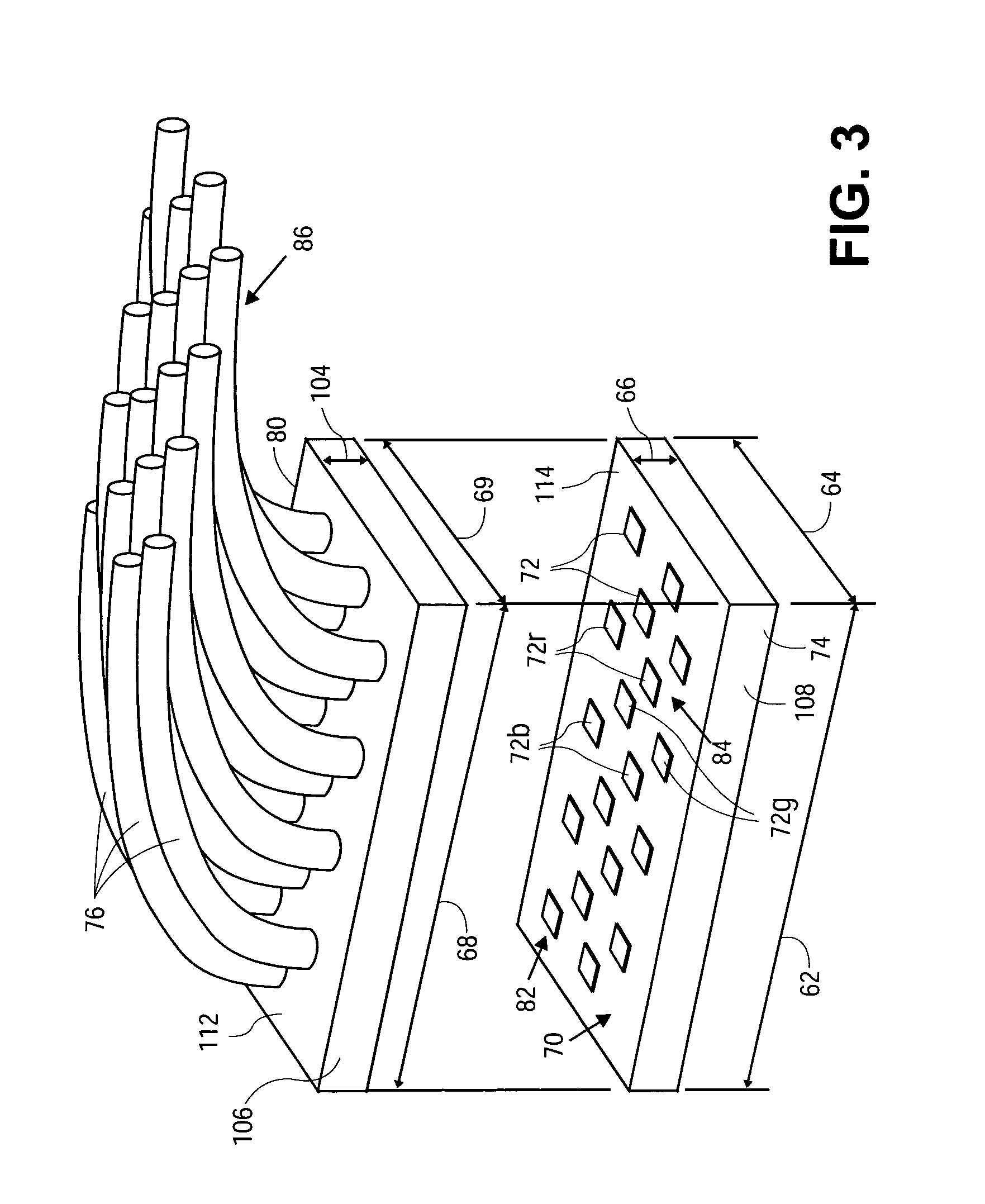

Method and apparatus for driving LED light sources for a projection display

InactiveUS7088321B1Reduce brightnessWithout reducing brightnessLaser detailsProjectorsData synchronizationControl signal

A circuit is provided to drive LEDs or diode lasers that emit light in desired wavelengths, such as the primary colors red, green, and blue, which serve as the light source for a projection display system. A display controller controls one or more series-parallel arrays of each color LED in the LED circuit with control signals to synchronize the color output of the light source with image data received from an image data source such as a personal computer. Synchronization is achieved by sending control signals to the power supply and circuit switches to sequence the color output in a single path system or adjust continuous color output in a triple path system with minimal or no reductions in the brightness of the projected image.

Owner:SEIKO EPSON CORP

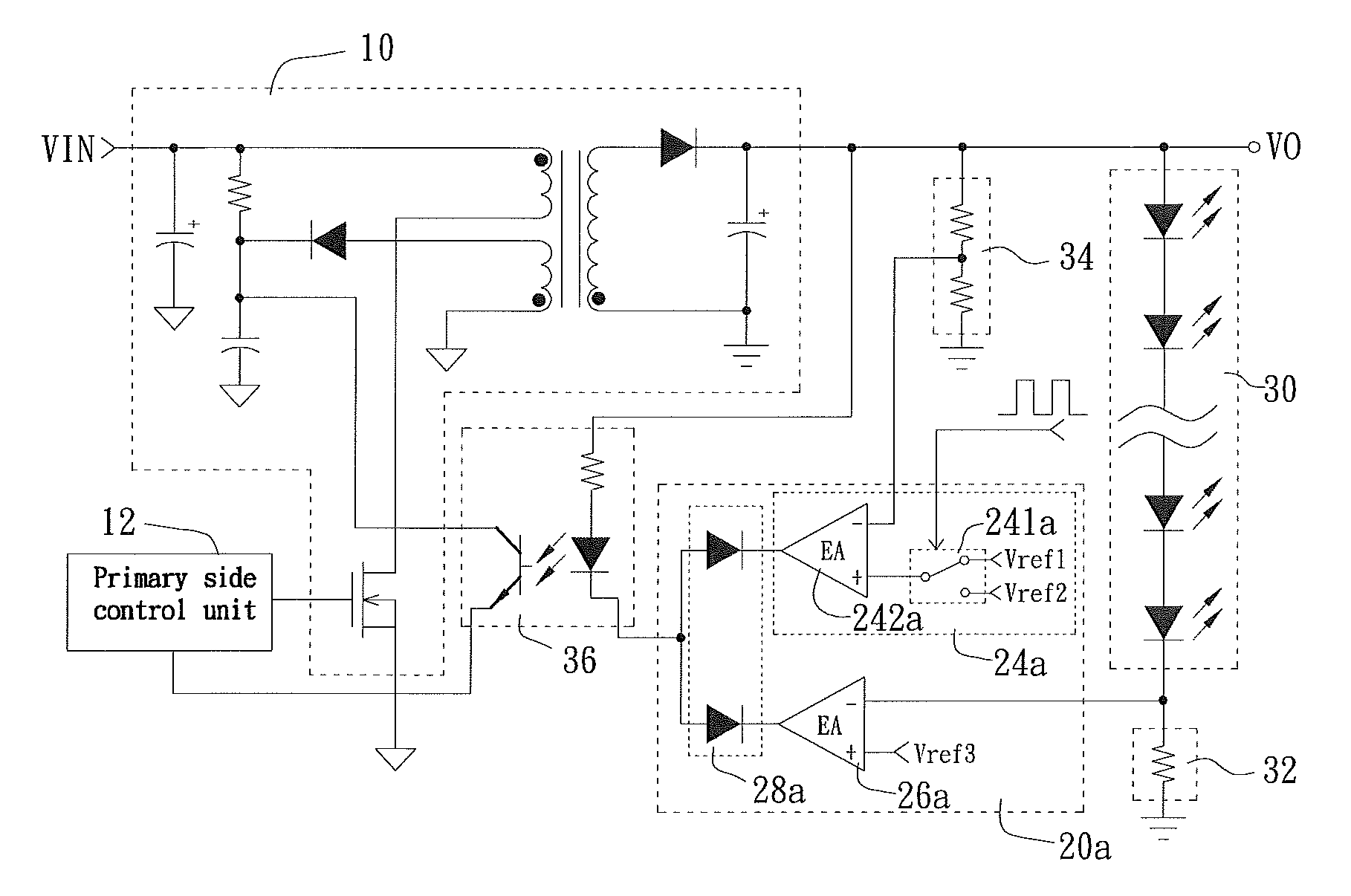

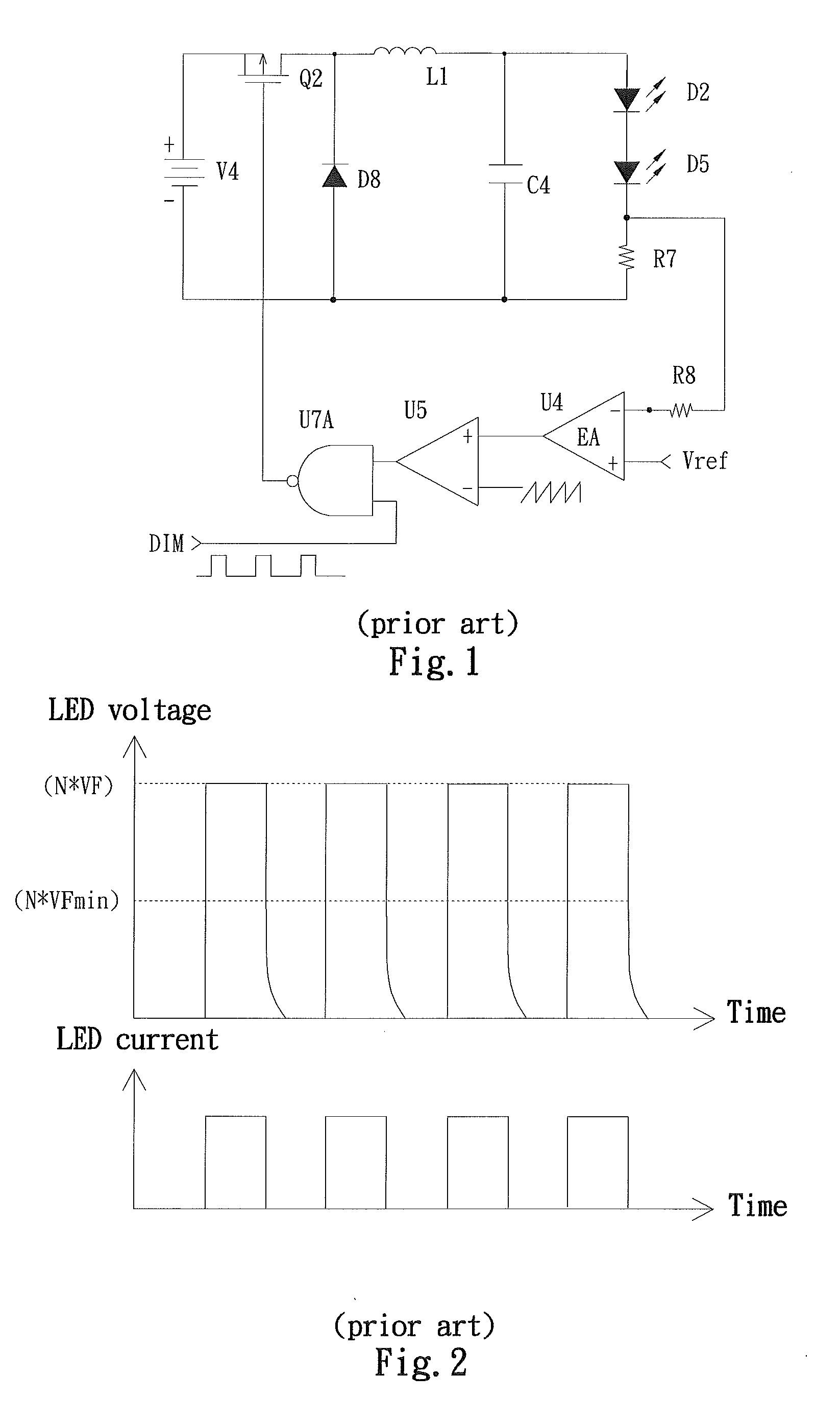

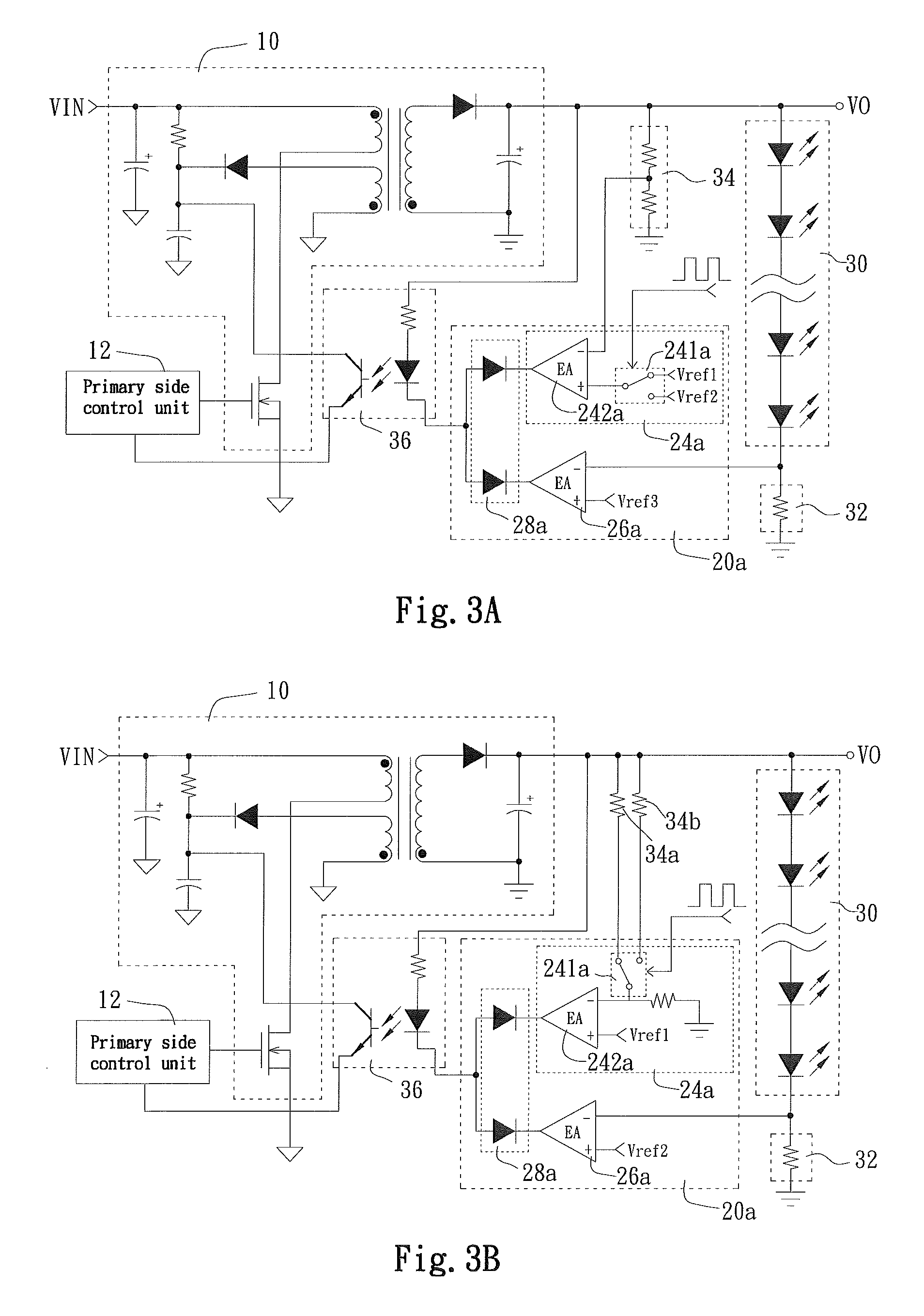

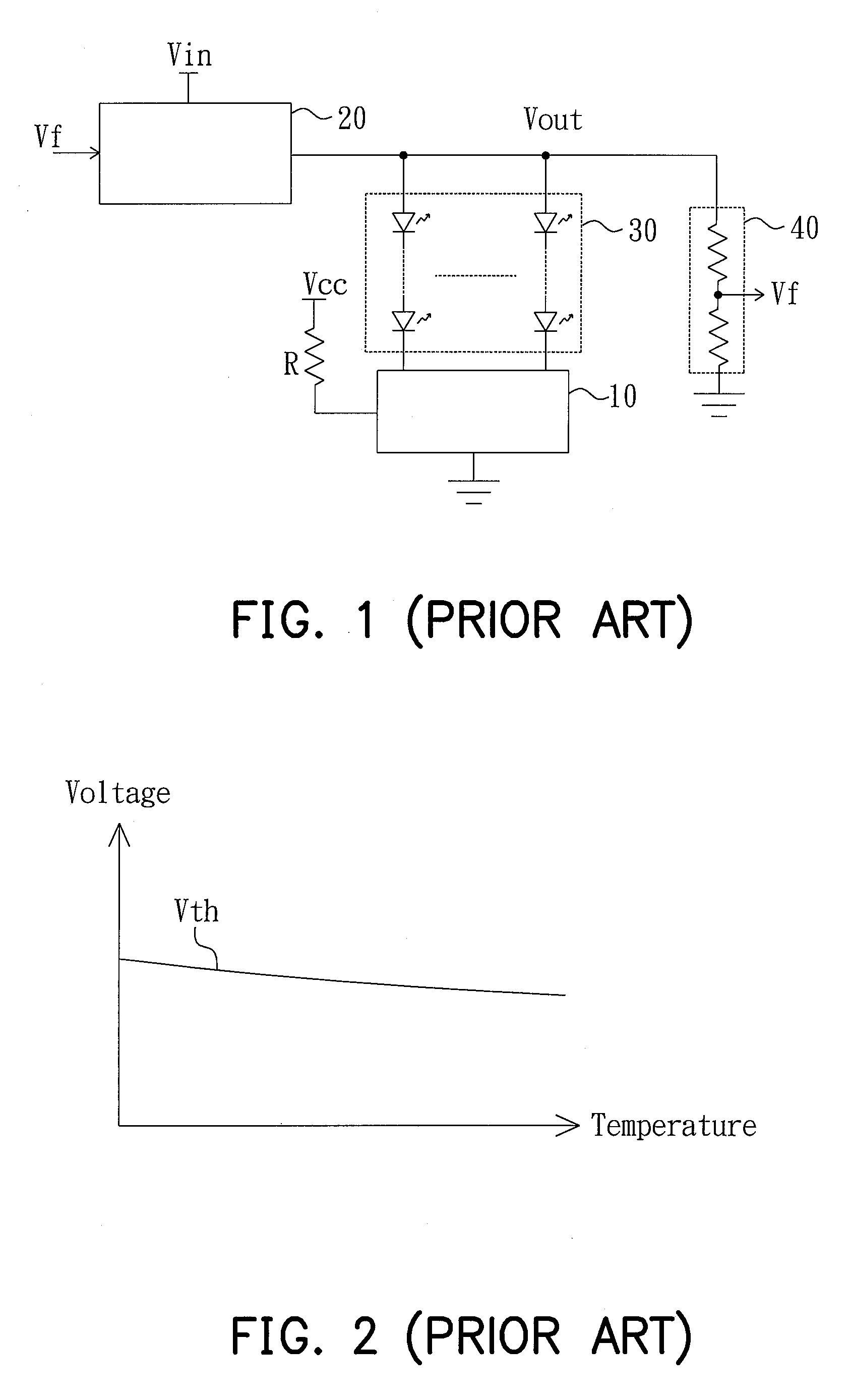

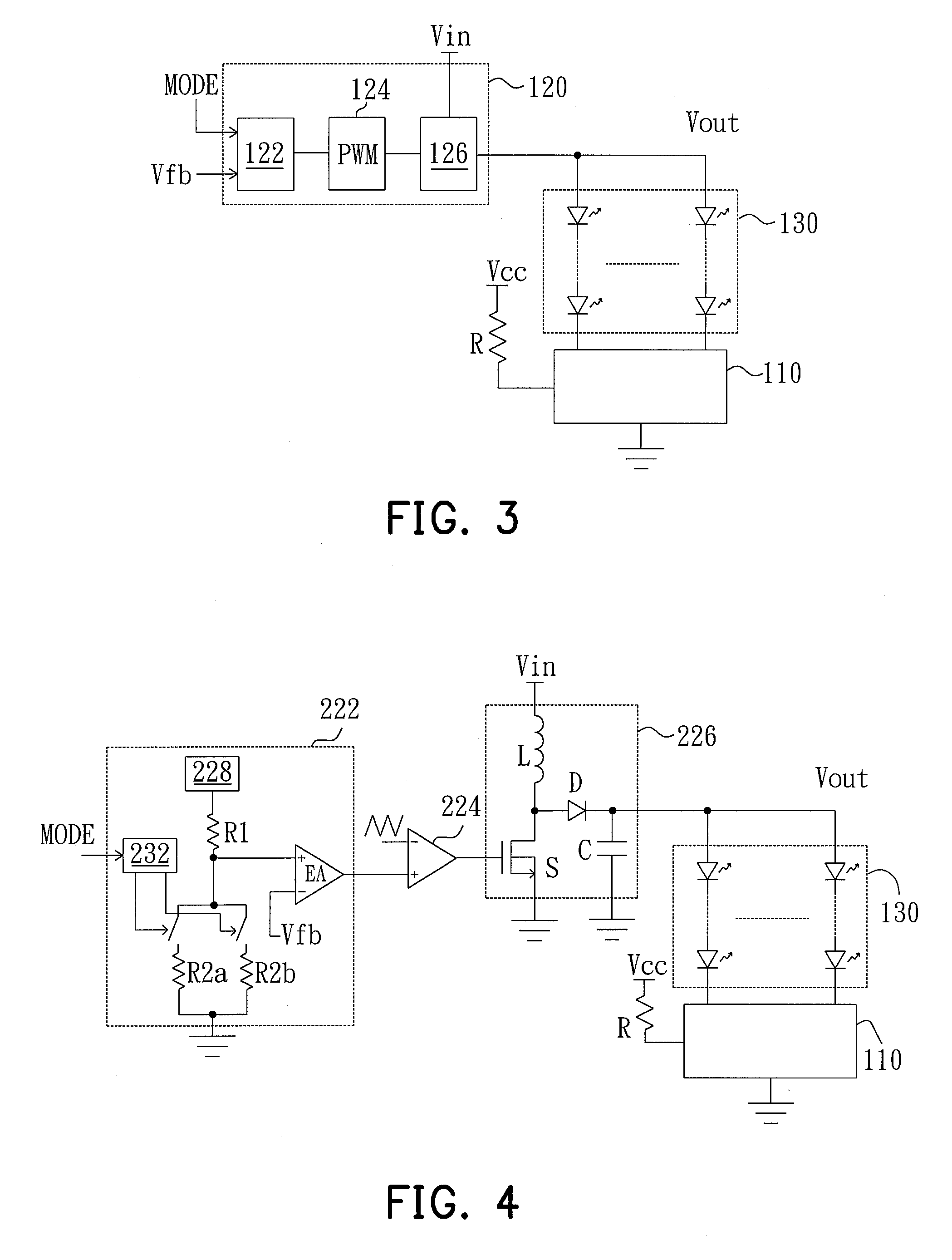

Light-emitting diode driving circuit and secondary side controller for controlling the same

InactiveUS20090237007A1Small voltage changeLow costElectrical apparatusElectroluminescent light sourcesDriver circuitEffect light

A light-emitting diode (LED) driving circuit and a secondary side controller for controlling the same control an output voltage of the LED driving circuit at a first driving voltage or a second driving voltage. When the output voltage is controlled at the first driving voltage, an LED module driven by the LED driving circuit is in a stably lighting state; and when the output voltage is controlled at the second driving voltage, the output voltage is approximately a threshold voltage of the LED module but higher than zero volt, so that the LED module is close to not emitting light. Therefore, in a dimming operation, the variation of voltage applied across the LED module is smaller than that in the conventional LED driving circuits to thereby protect the LED module against an excessive voltage stress and avoid the problem of inaccurate dimming.

Owner:NIKO SEMICON

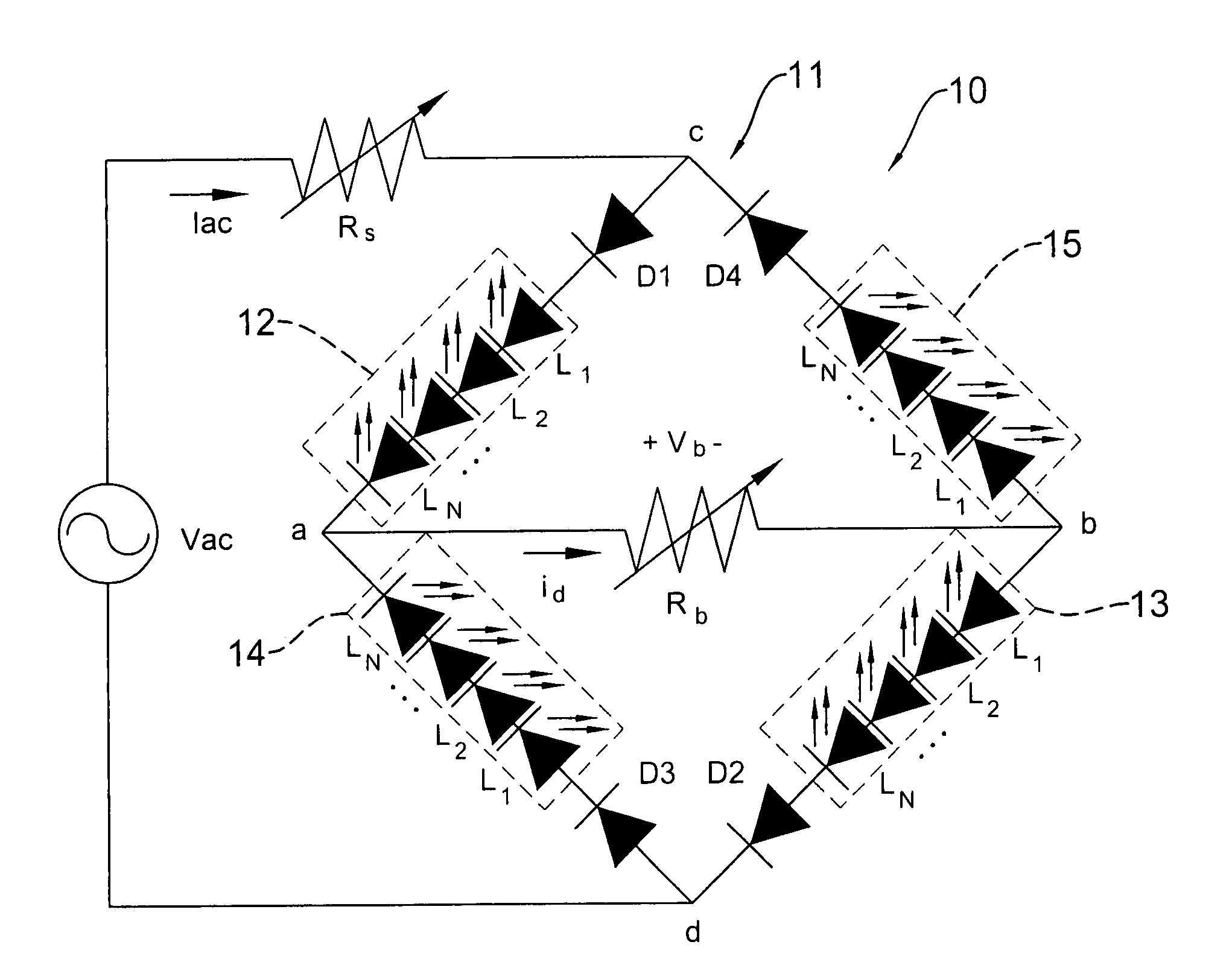

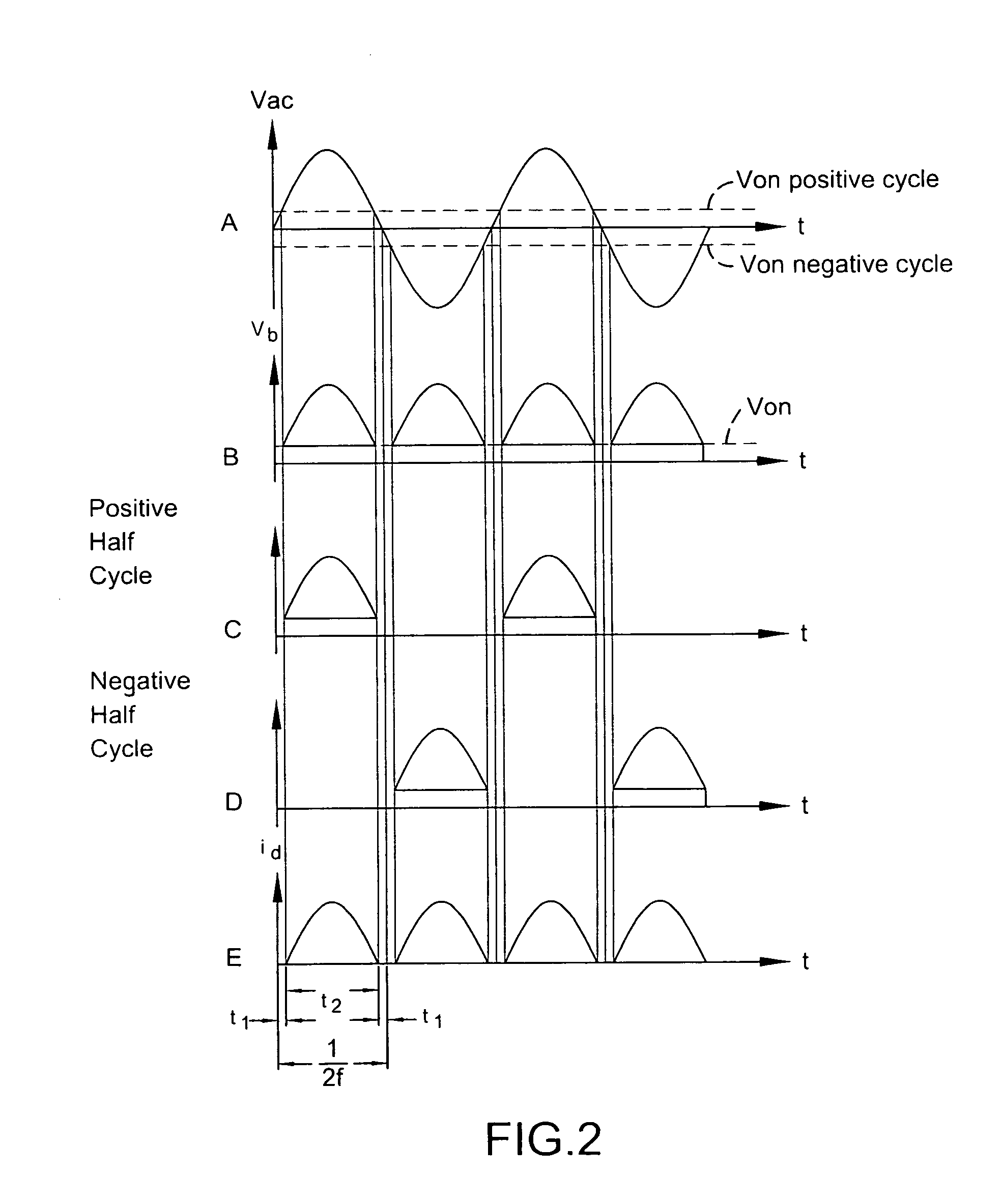

LED driving circuit

InactiveUS7138770B2Improve efficiencySimple circuit structureElectrical apparatusElectroluminescent light sourcesAC powerLED circuit

An LED driving circuit that is directly activated by an AC power supply is disclosed. A driving circuit has a first and second pair of opposite branches. The first pair of opposite branches operates in a positive half cycle of the AC power supply and the second pair of branches operates in a negative half cycle of the AC power supply, so the lighting time for each LED is less than a half cycle time, in other words, the time for heat dissipation is prolonged.

Owner:TOP UNION GLOBALTEK

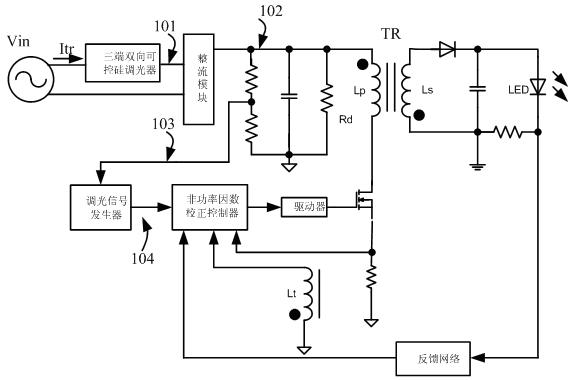

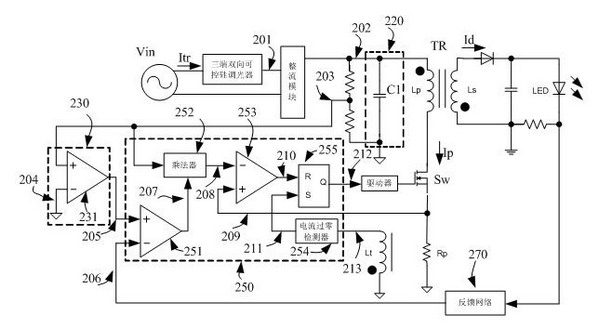

LED drive circuit with dimming function and lamp

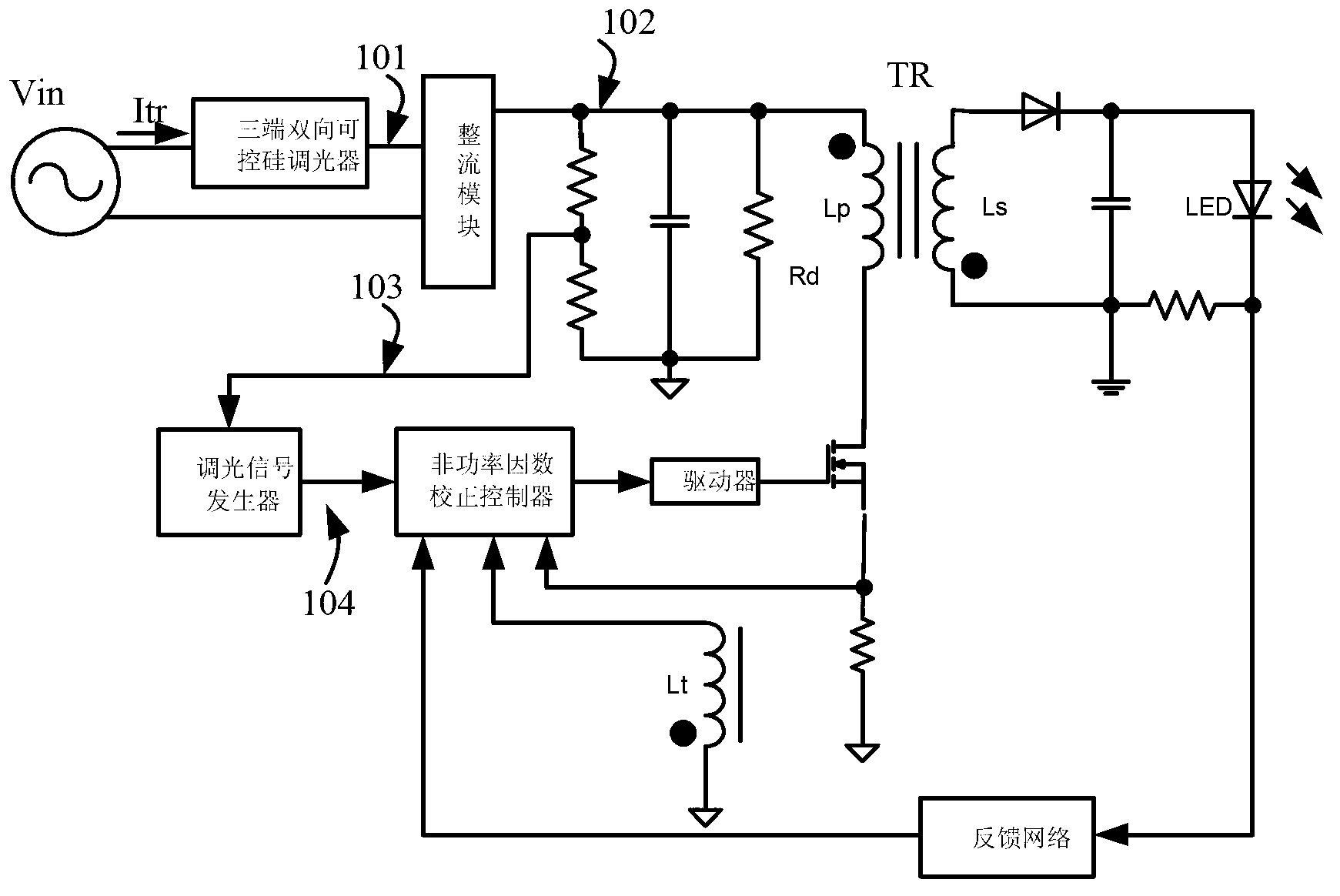

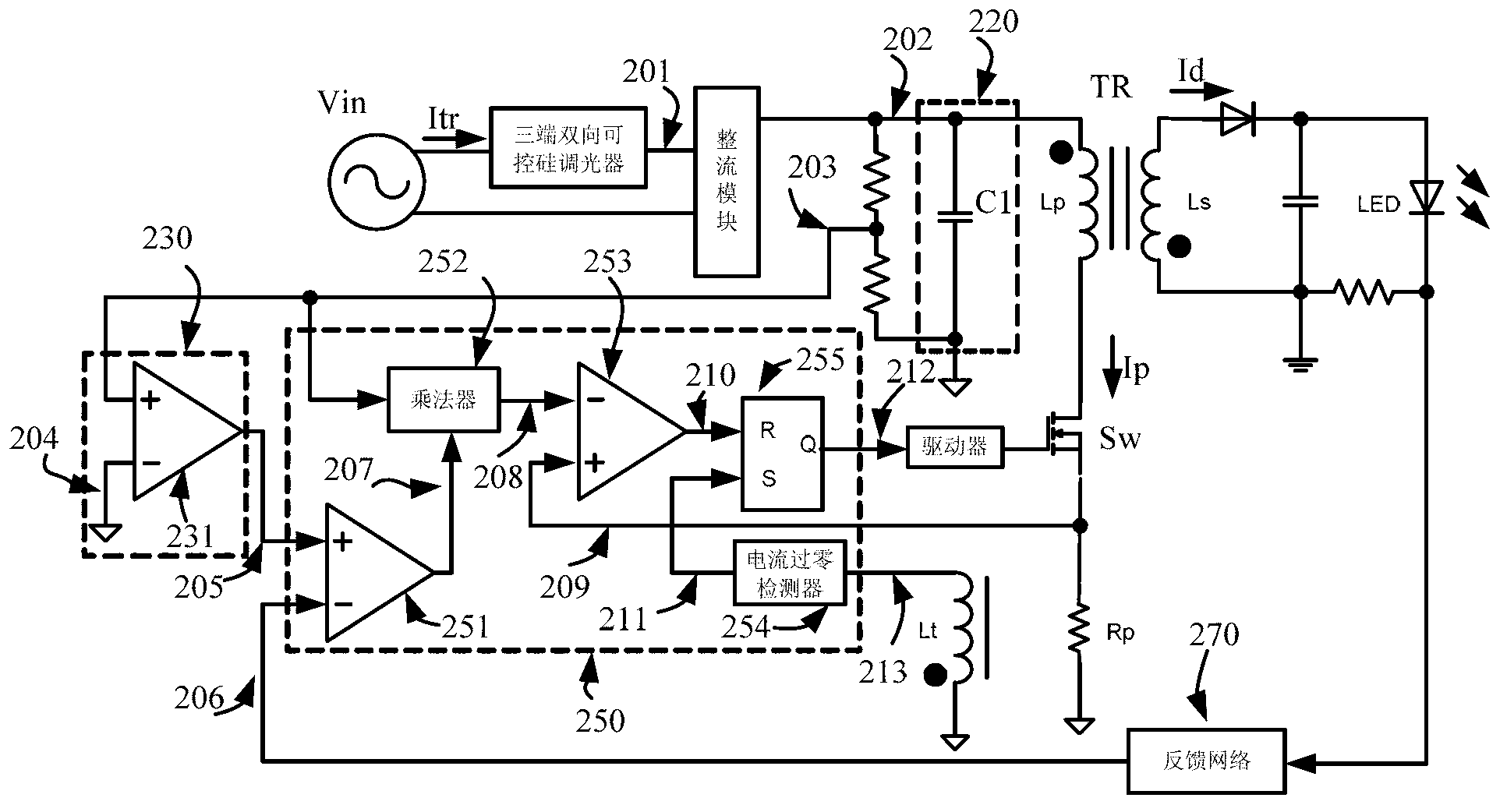

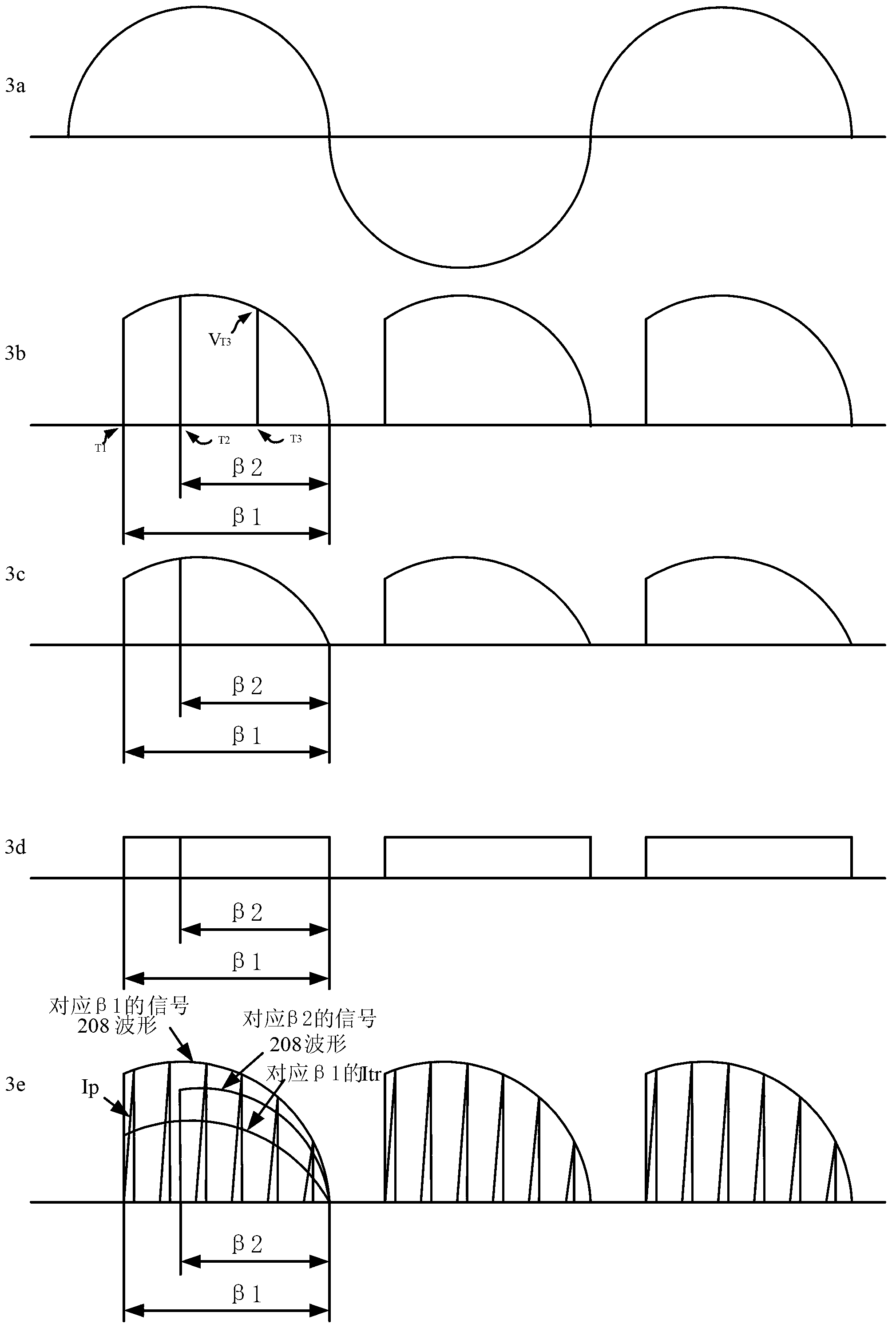

ActiveCN101835314ASolve the problem that the LED cannot be dimmed directlyElectroluminescent light sourcesElectric light circuit arrangementDIACControl signal

The invention discloses an LED drive circuit with dimming function and a lamp. The LED drive circuit comprises a TRIAC dimmer; the TRIAC dimmer receives an alternating-current input voltage and generates a cut phase voltage signal; the cut phase voltage signal is rectified by a rectifying module and then coupled to a dimming signal generator; and a power factor correcting controller receives an output signal of the dimming signal generator, reflects a feedback signal of LED brightness, and outputs a switching control signal to control the on and off of a switching tube so as to drive an LED. The dimming of the LED is implemented by adjusting a conduction angle of the TRIAC dimmer.

Owner:CHENGDU MONOLITHIC POWER SYST

LED drive circuit

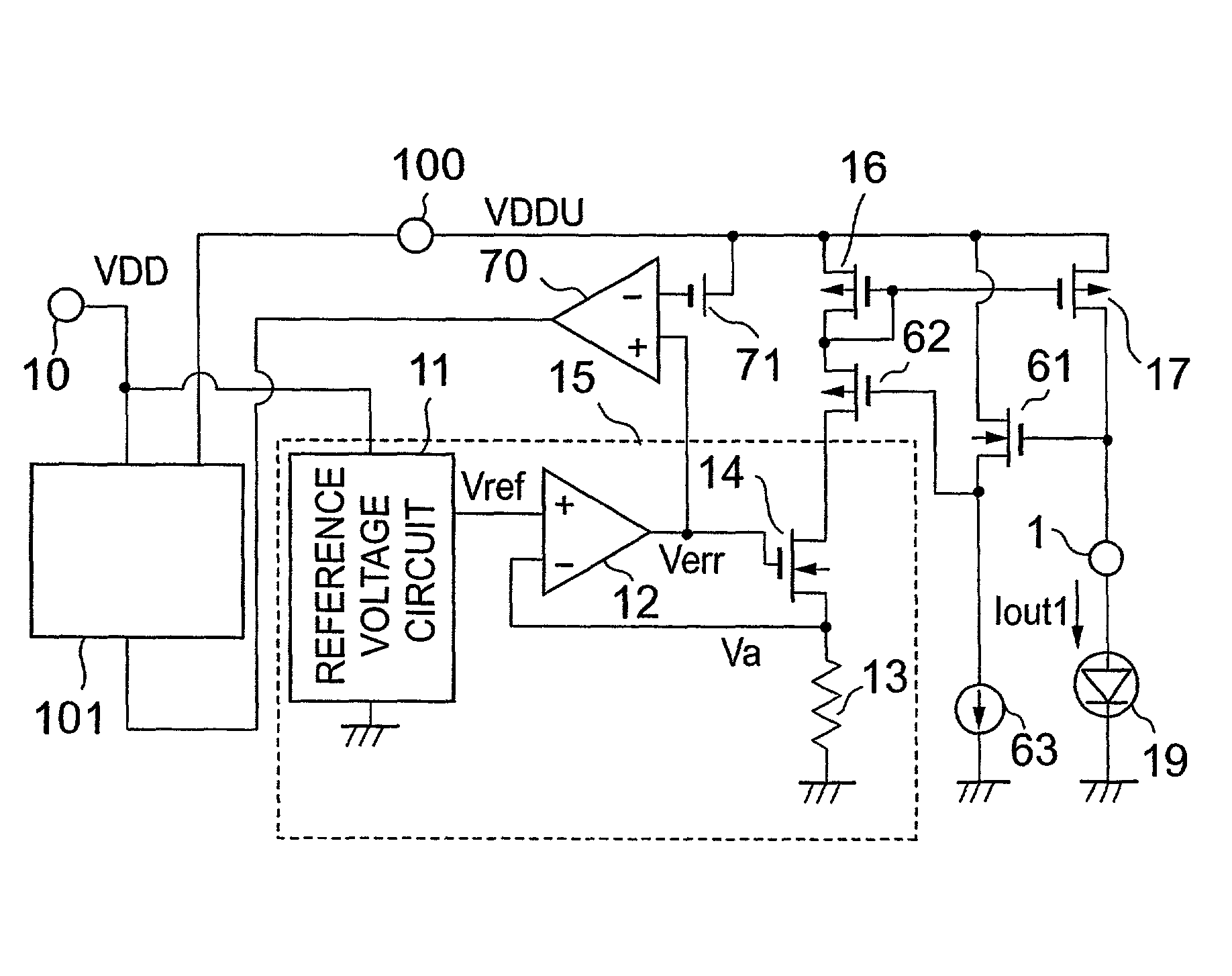

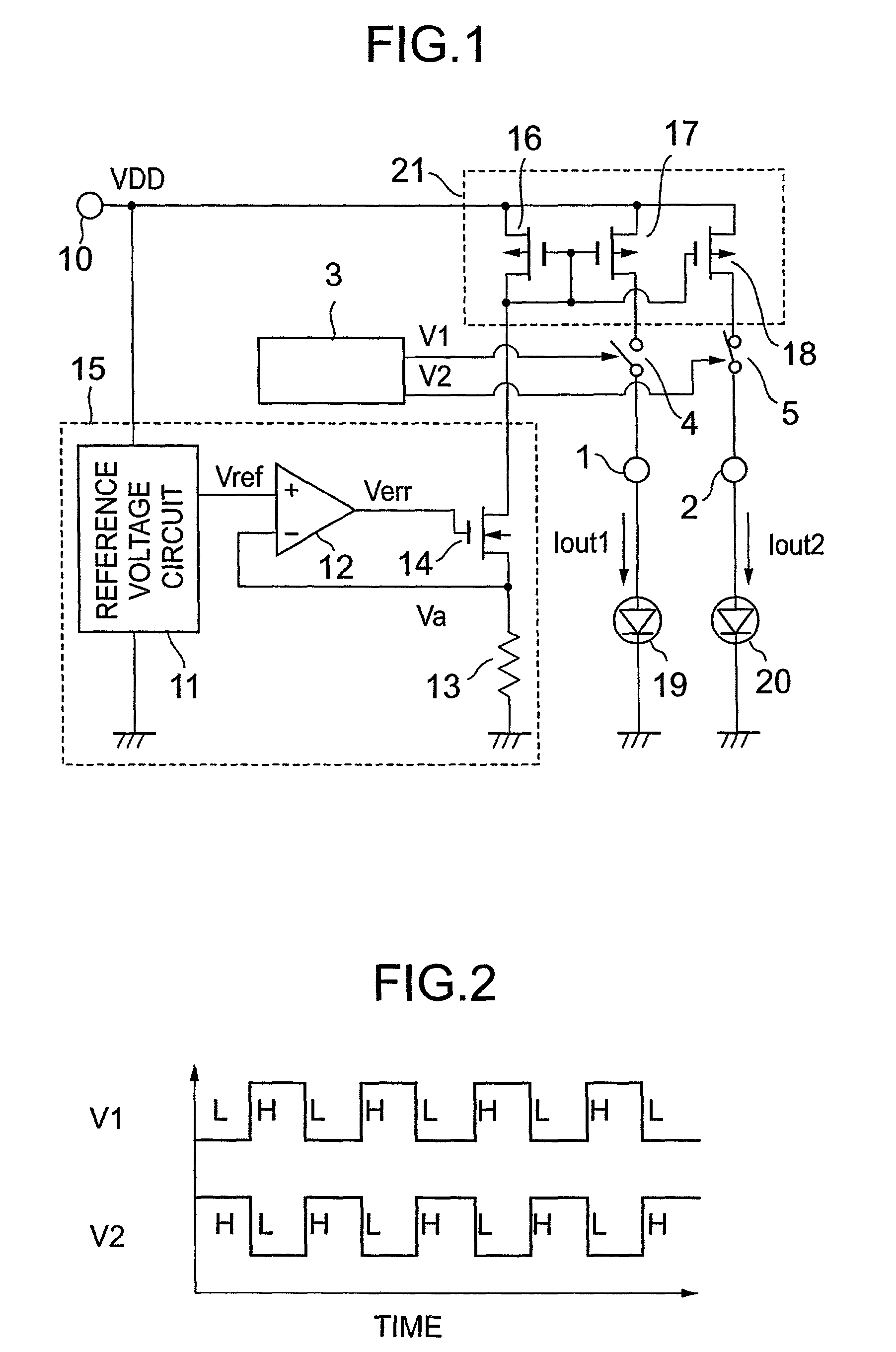

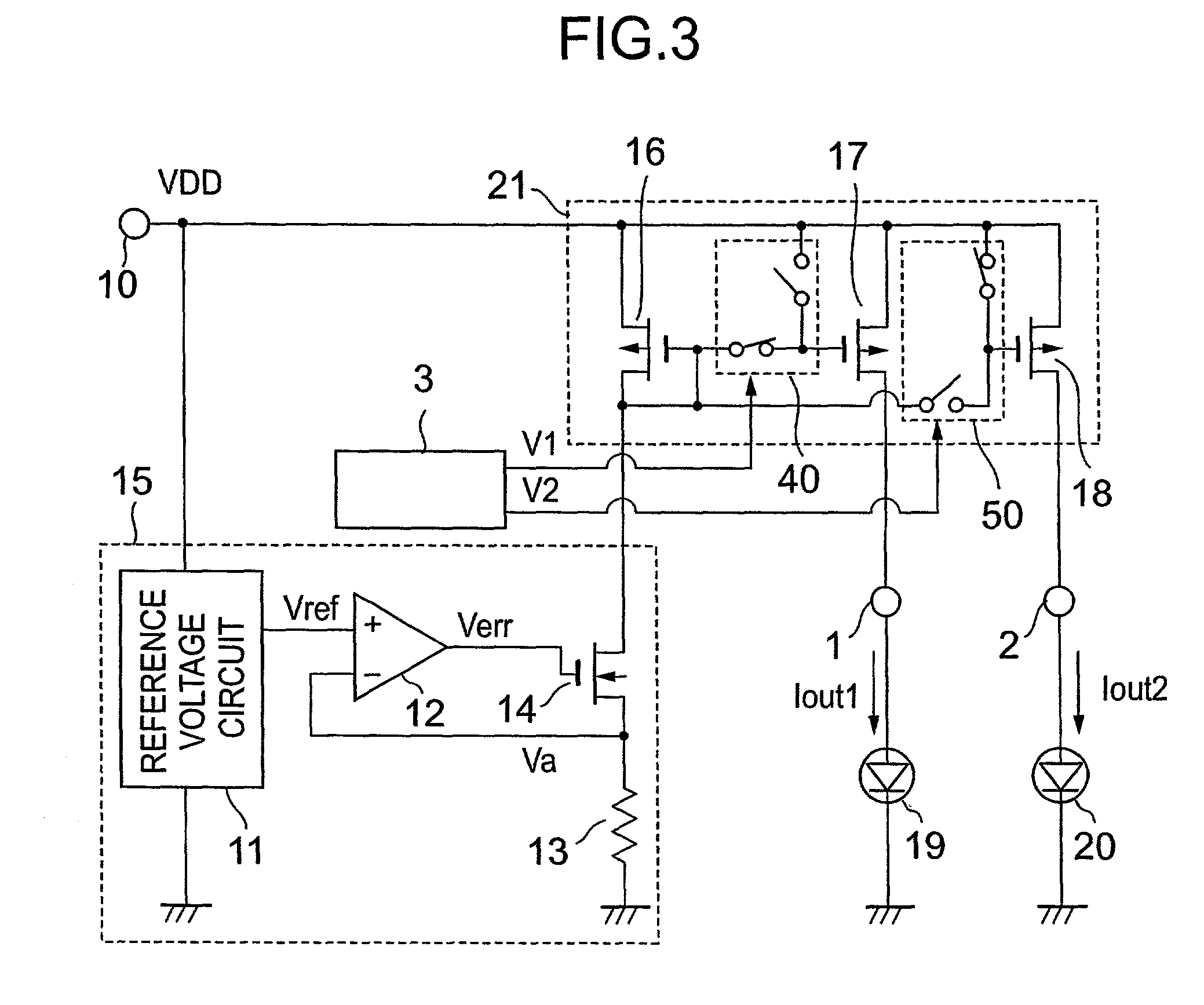

InactiveUS6980181B2Reduce power consumptionStatic indicating devicesElectroluminescent light sourcesLED circuitVisual perception

An LED drive circuit having reduced power consumption has a constant current generating circuit for driving a plurality of LEDs and at least one switch connected to a respective LED for periodically turning on and off the respective LED at a rate higher than a visual perception rate to reduce power consumption.

Owner:ABLIC INC

LED lamps and LED driver circuits for the same

LED lamp has LEDs aimed rearwards with either a concave mirror to the rear of each LED, or one concave mirror to the rear of two or more LEDs, collecting the light from the LEDs to form a forward projecting beam. LEDs may be high power types that require heatsinking. LED lamp may have a lens forward of each LED to collimate the radiation produced by the LEDs into a beam, where at least one lens has at least one aspheric curved surface. LED lamp may have a transparent reflective optic to collimate the radiation produced by each LED into a beam. For an inspection lamp, the LEDs typically have a peak wavelength of 395 to 415 naometers for seeing the area being irradiated but not so visible as to overwhelm fluorescence of fluorescent materials to be detected. Other wavelengths may be used. LED inspection lamp has a combination of LEDs of different wavelengths or a combination of at least one LED and at least one other light source such that the lamp produces radiation suitable for detection of materials to be detected and adequately illuminates the area being irradiated. LED lamp has LEDs that produce a beam of suitable radiation with a width of 10 degrees or less without additional optics. LED inspection lamp has head attached to a flexible member, with head serving as heatsink for one or more high power LEDs. Current regulator circuits are also disclosed.

Owner:ALLTEMP PROD CO LTD

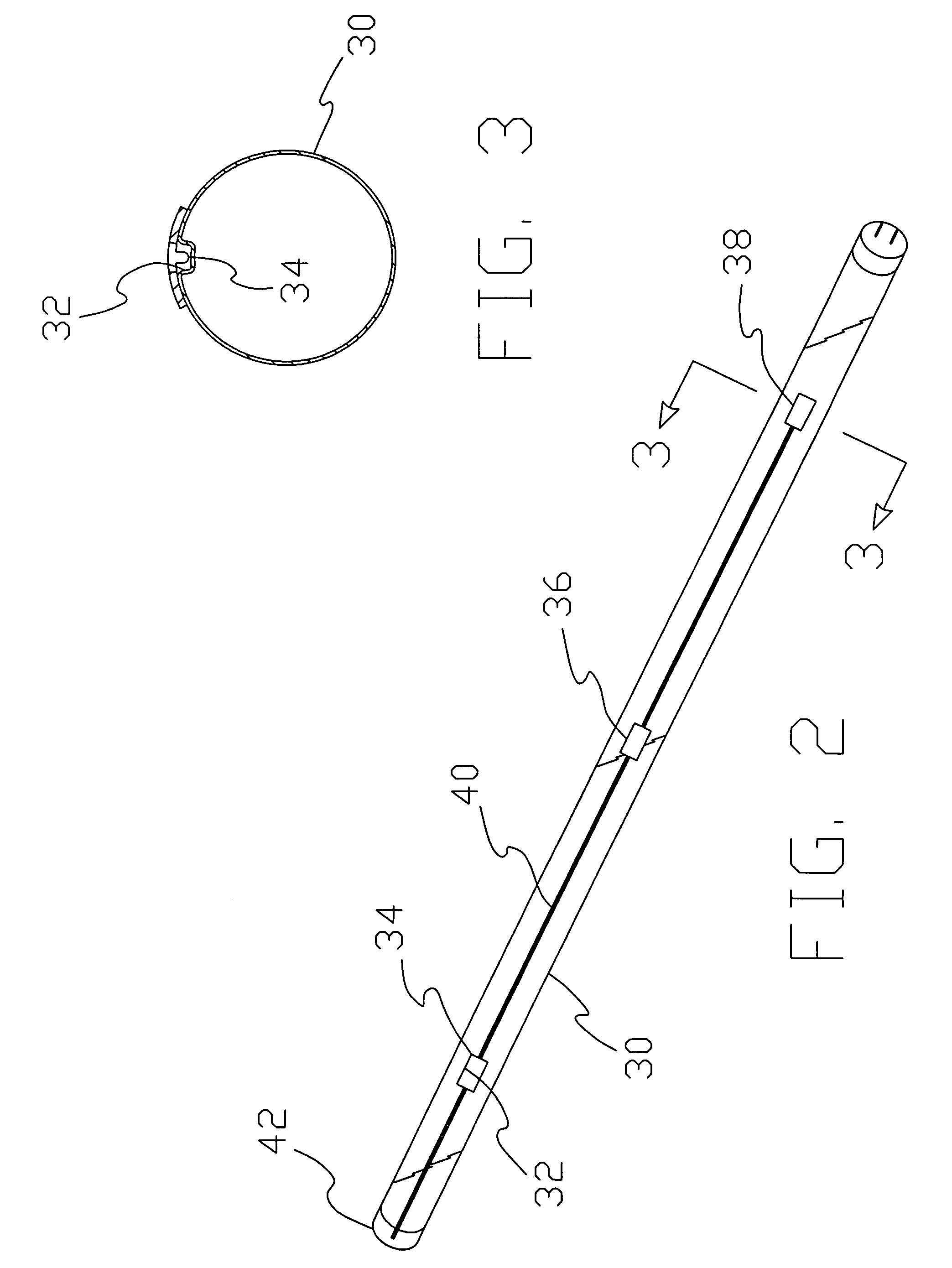

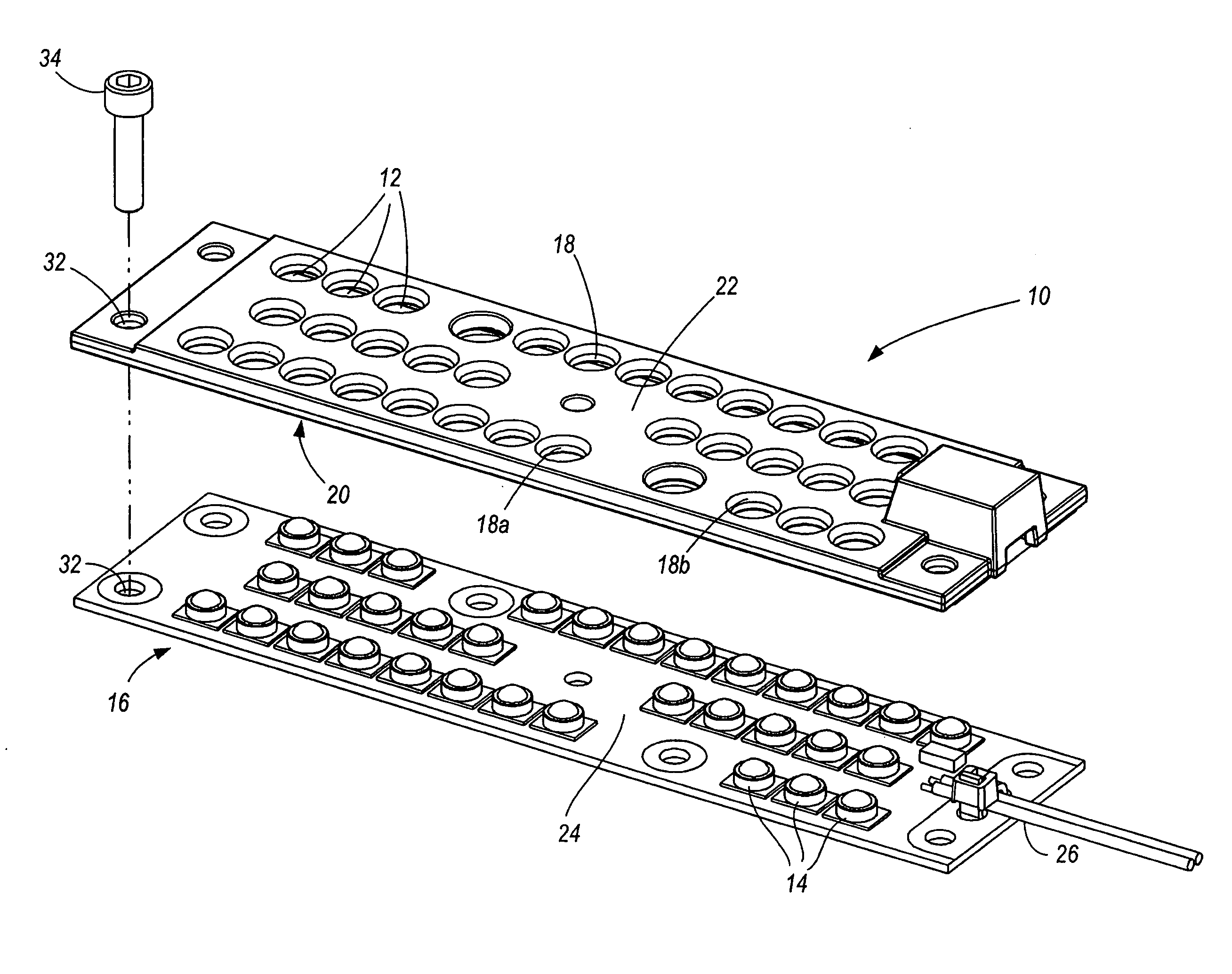

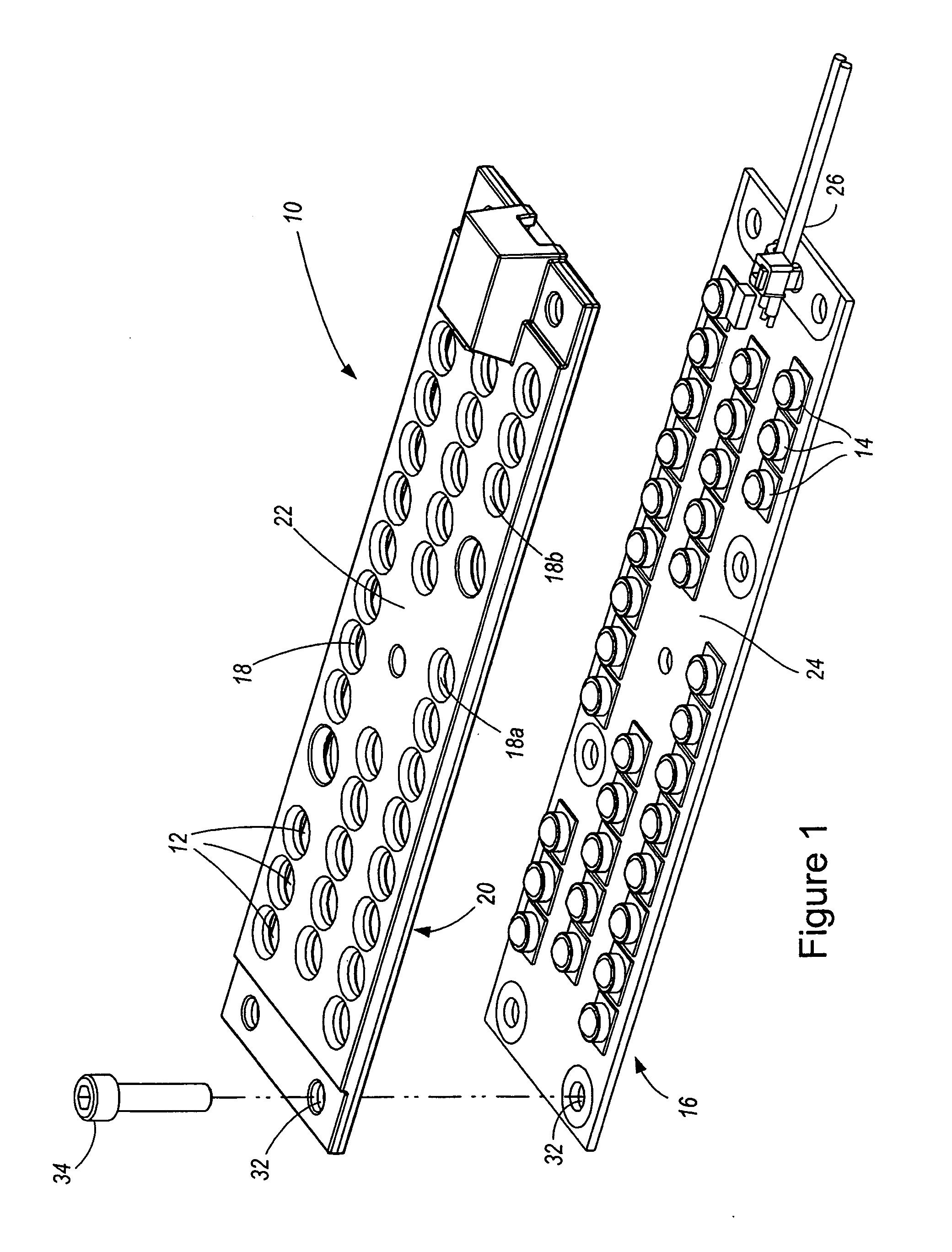

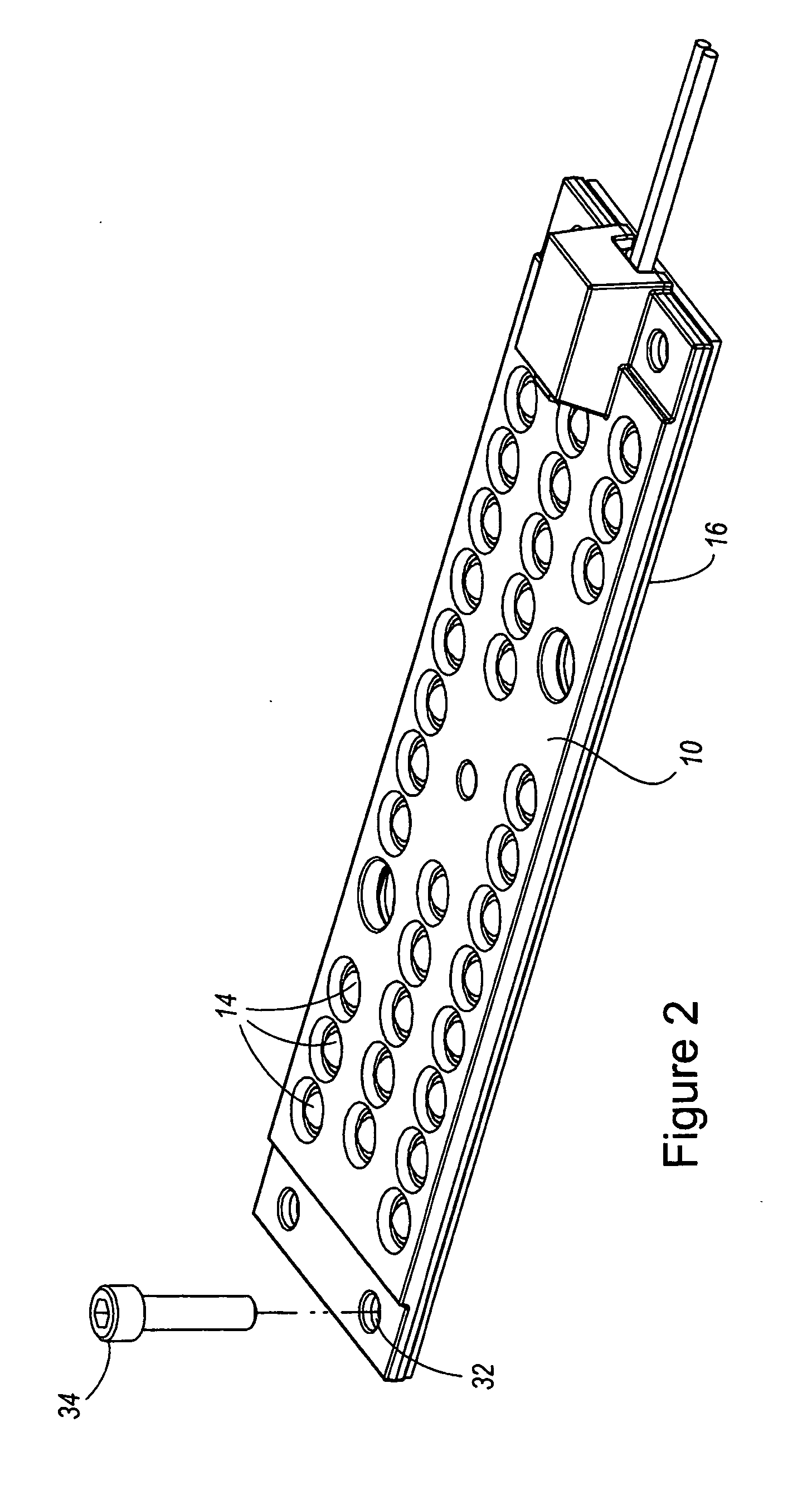

Enclosures for LED circuit boards

ActiveUS20090290345A1Easy to separateNon-electric lightingMechanical apparatusLED circuitPrinted circuit board

Embodiments of this invention provide an enclosure for an LED circuit board. The enclosure is manufactured from a flame resistant material and includes LED apertures through which LEDs mounted on an LED circuit board may pass. The enclosure is designed to be positioned on the LED circuit board so that, when so positioned, the LEDs extend at least partially through the LED apertures in the enclosure. When the enclosure is positioned on the board, portions of its lower surface contact the upper surface of the board. Various fixation / retention methods may be used to retain the enclosure in position relative to the circuit board. It is preferable that such methods allow for the separation of the enclosure from the board.

Owner:ABL IP HLDG

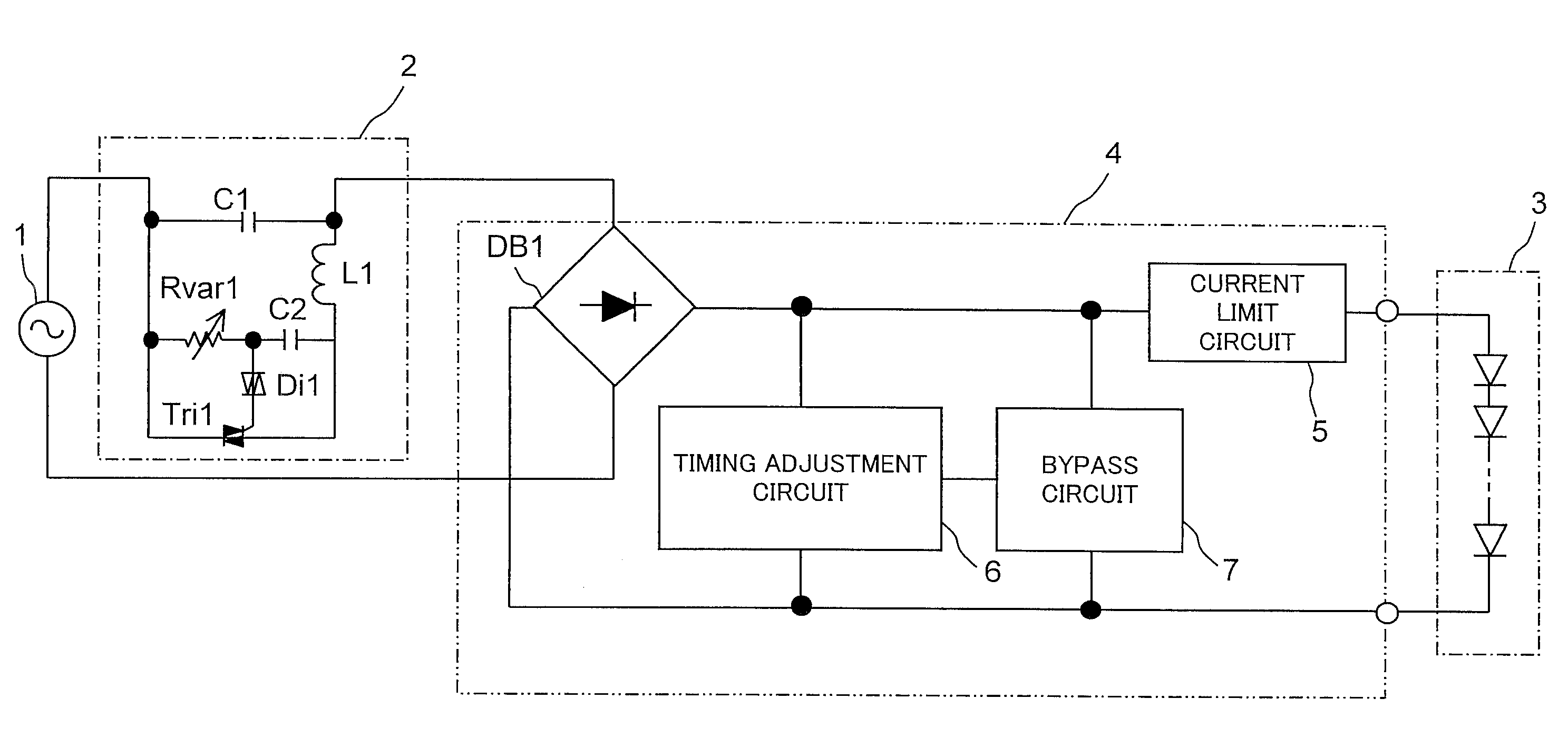

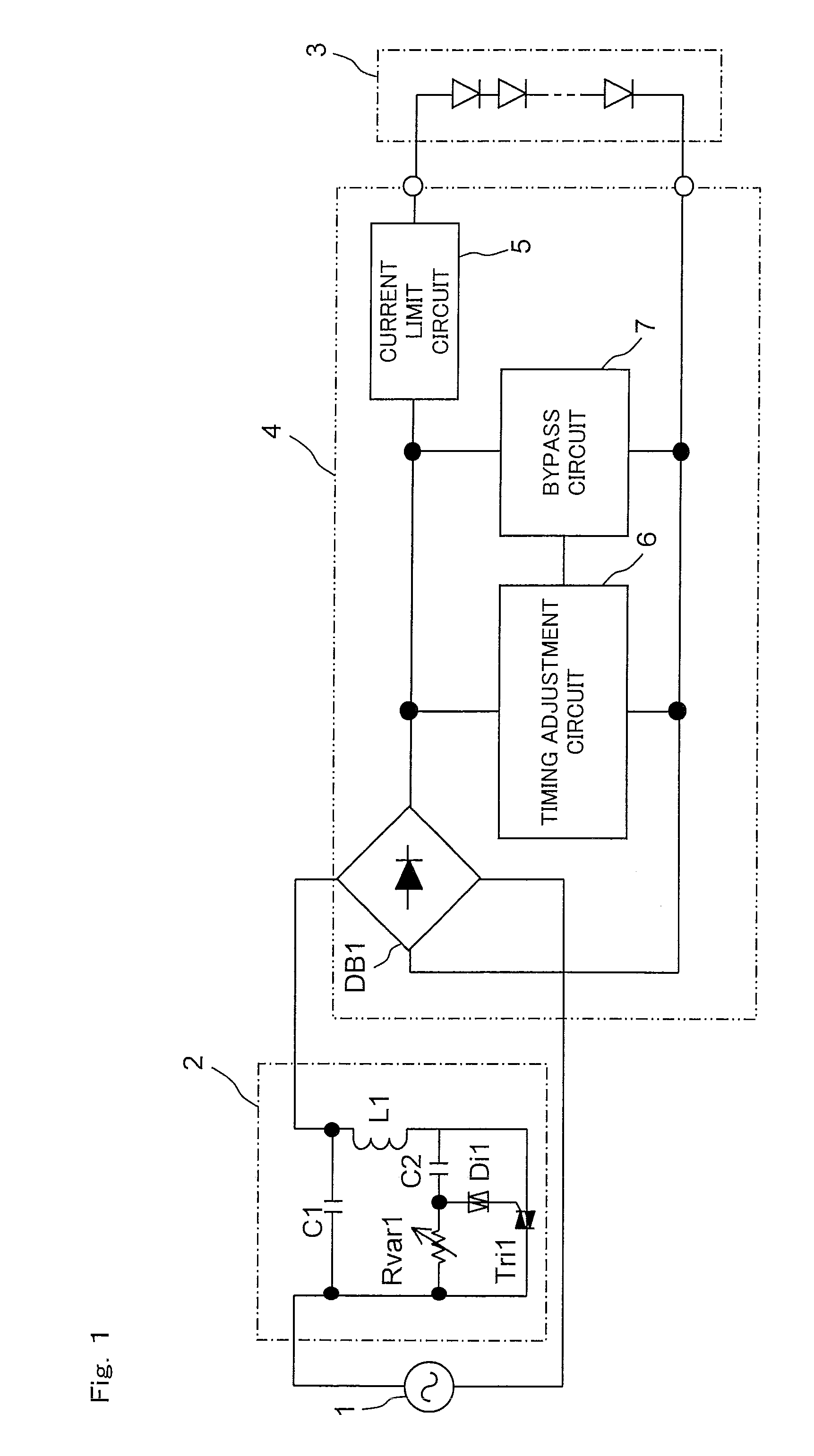

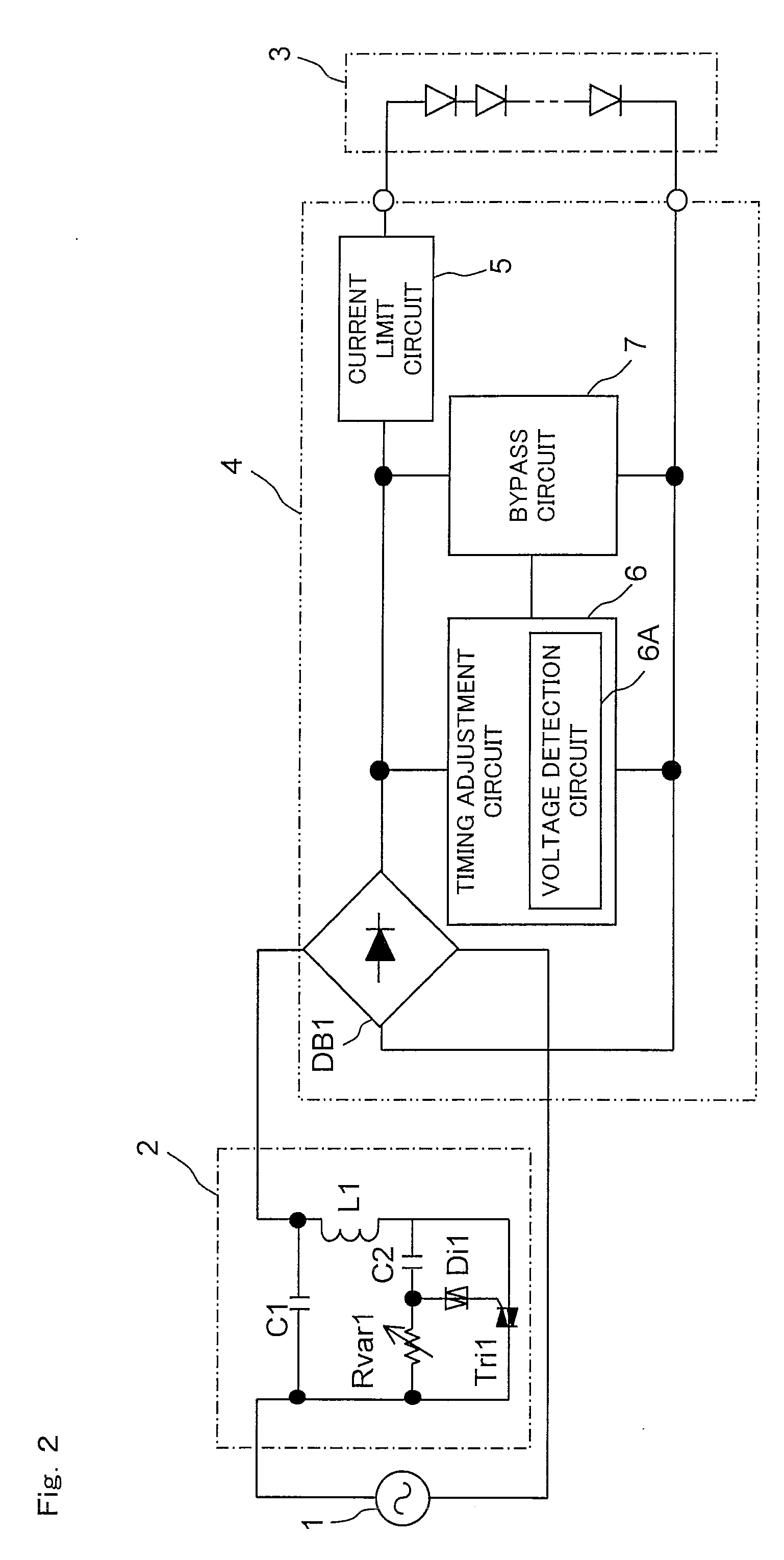

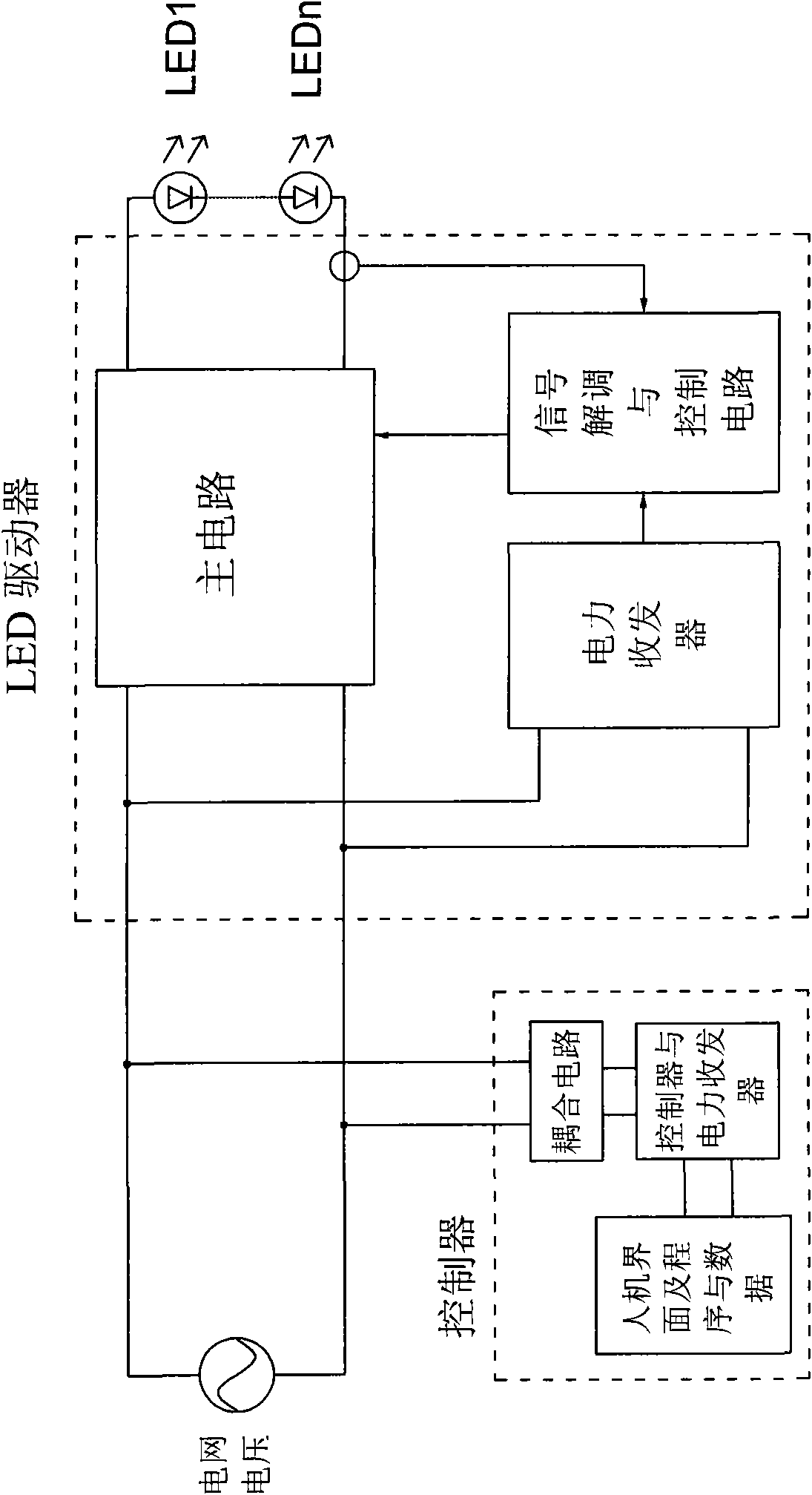

LED drive circuit, LED lamp, LED lighting appliance, and LED lighting system

An LED drive circuit receives an alternating-current voltage and drives an LED. The LED drive circuit has a current extractor which extracts a current from the current supply line through which an LED drive current is supplied to the LED, and a timing adjuster which adjusts the current extraction start timing and the current extraction duration in the current extractor.

Owner:SHARP KK

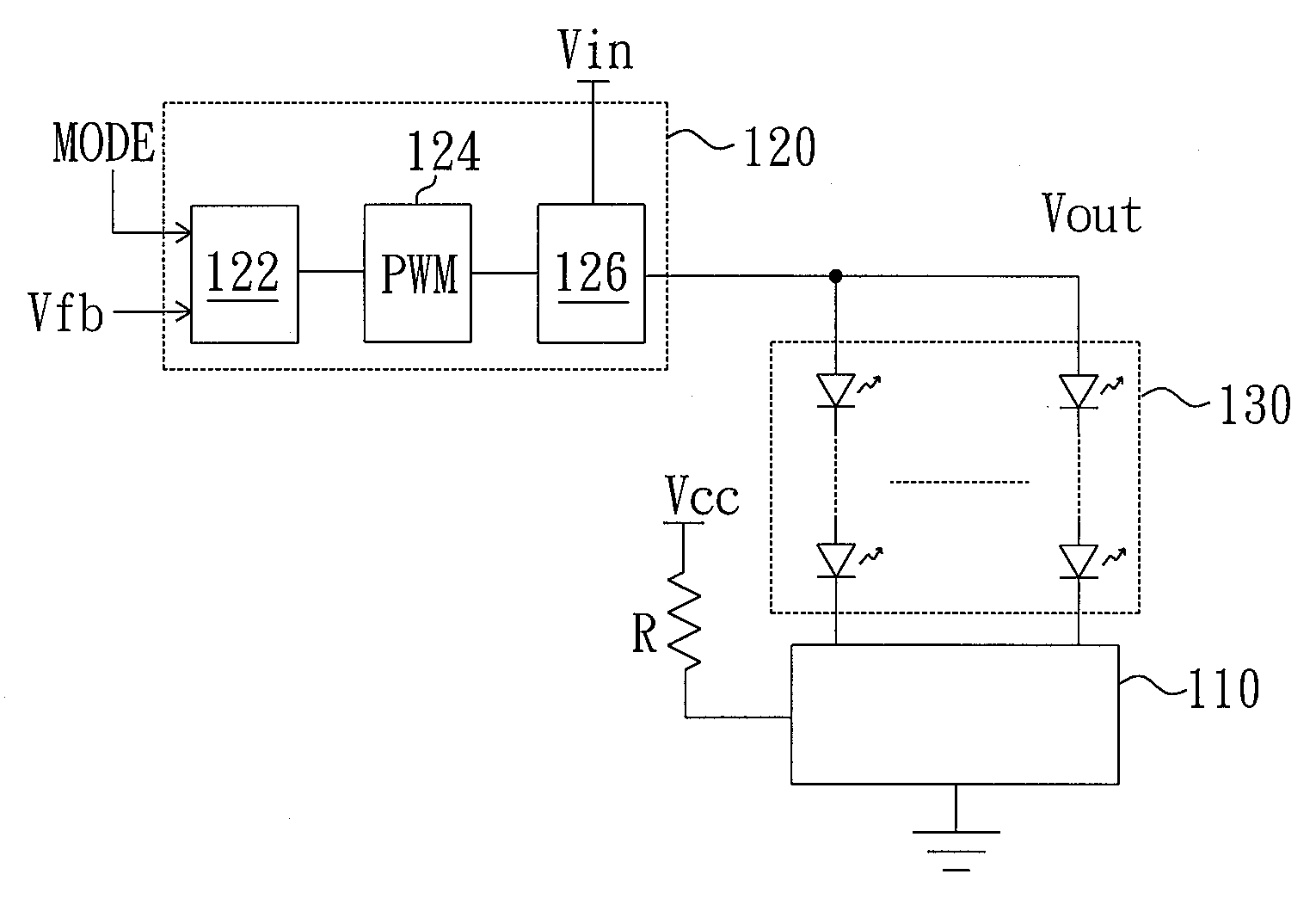

LED driving circuit and controller with temperature compensation thereof

InactiveUS20100141159A1Reduce output voltageIncrease working temperatureElectrical apparatusElectroluminescent light sourcesControl signalEngineering

The present invention provides an LED driving circuit with temperature compensation, comprising a power transforming circuit, an LED module and a controller. The transforming circuit receives an electrical power from an input power source and transforms it into an output voltage according to a control signal. The LED module is coupled to the transforming circuit. The controller generates the control signal according to an operation temperature and a voltage feedback signal indicative of the output voltage, and makes the output voltage decrease with increasing operation temperature. Therefore, the LED driving circuit of the present invention has an effect of temperature compensation that compensates the influence of the decreased driving voltage of the LED module due to temperature.

Owner:GREEN SOLUTION TECH CO LTD

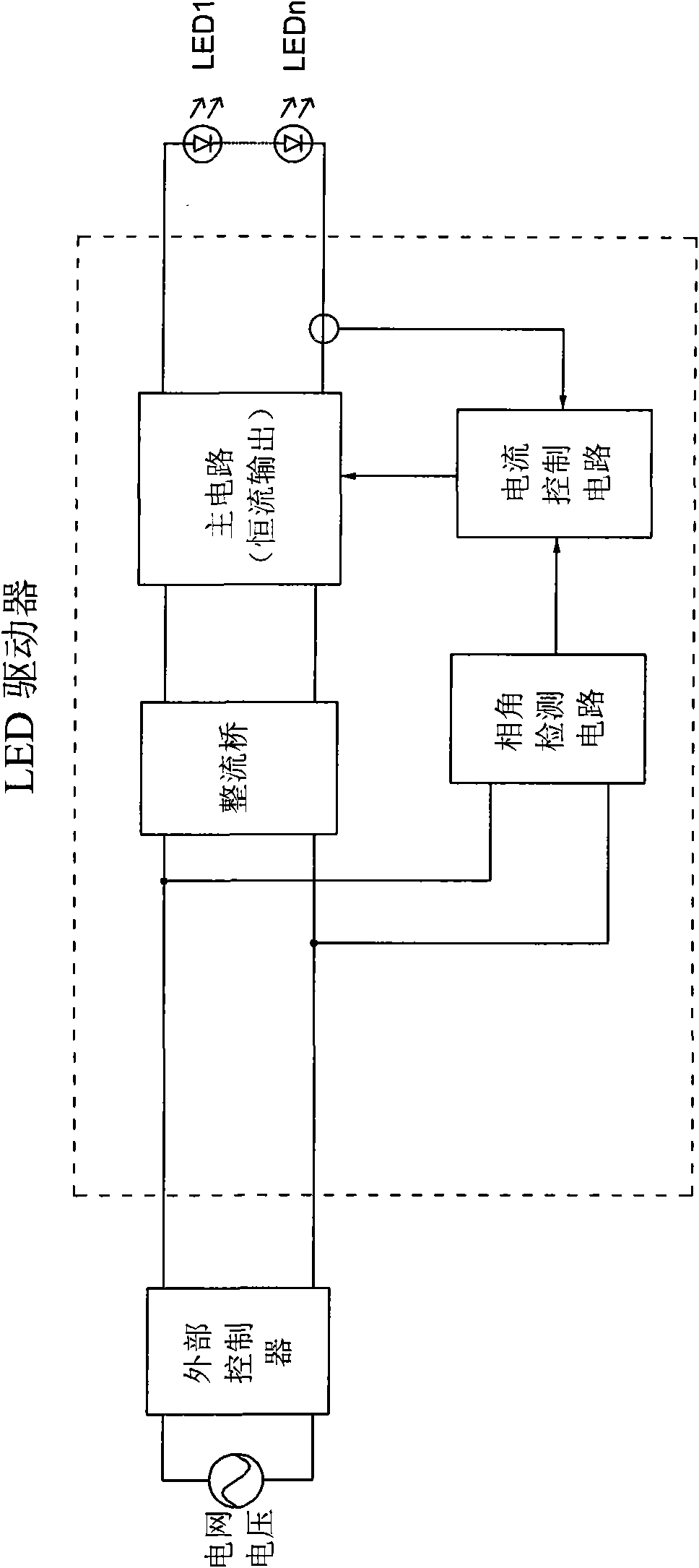

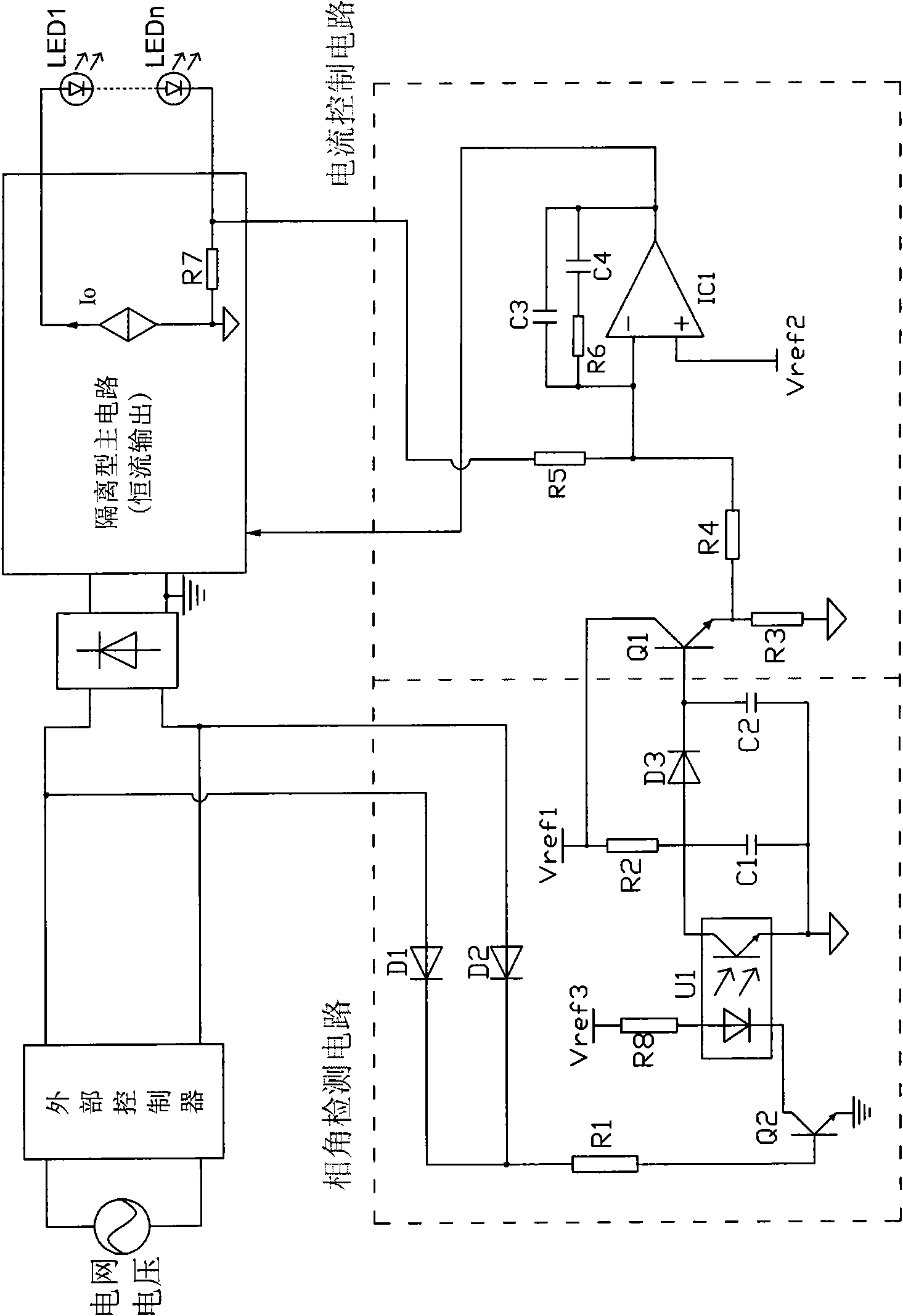

LED drive circuit suitable for controlled silicon light adjustment

The invention discloses an LED drive circuit suitable for controlled silicon light adjustment. The circuit comprises an outer controller and an LED driver, and is characterized in that the LED driver comprises a rectifier bridge, a main circuit, a phase angle detection circuit and a current control circuit. The LED drive circuit detects the phase of the trigger angle of a thyristor through the phase angle detection circuit and the current control circuit, and controls the brightness of an LED lamp through phase change; when the trigger angle of the thyristor is minimum, the LED lamp is brightest; when the trigger angle of the thyristor increases, the sawtooth wave peak value of the detection circuit increases and a level signal rises; the current control circuit feeds back the change to the main circuit and the output current of the main circuit decreases to darken the LED lamp, and vice versa. The LED drive circuit has simple structure and extremely low cost, and can obtain ideal light adjustment effect without a complicated modulation-demodulation circuit or a wireless transmission and receiving device; therefore, the circuit is suitable for light adjustment circuits controlled by any controlled silicon.

Owner:INVENTRONICS HANGZHOU

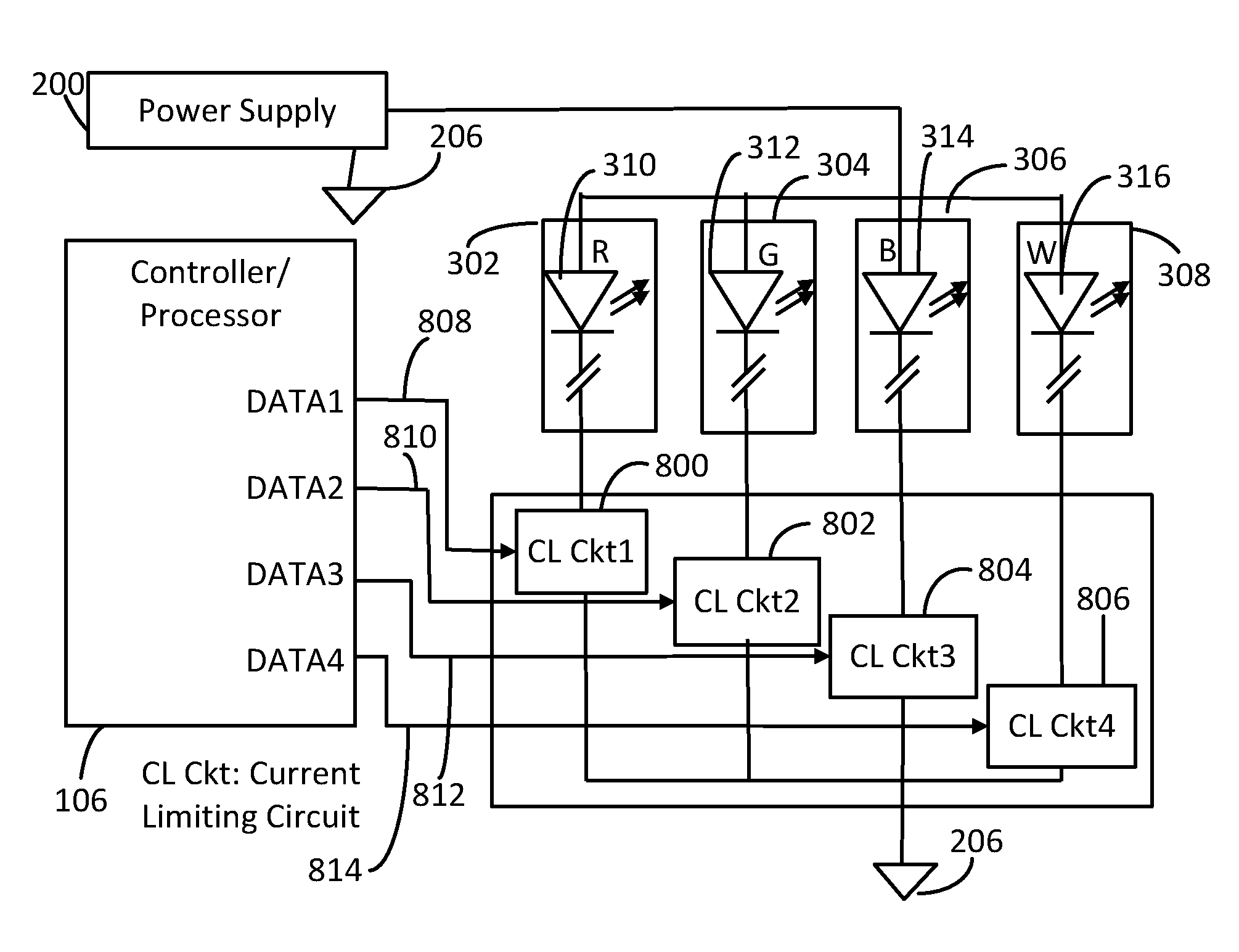

Thermally-managed LED-based recessed down lights

An LED down light replacement apparatus is disclosed for insertion into a recessed-light housing can, which includes an LED light source, a means for mounting said LED light source within the housing can, an LED driver circuit electrically connected to the LED light source, a heat sink in thermal contact with the LED light source, and means for removing heat generated by the LED light source. The means for removing heat generated by the LED light source can include a fan and / or ventilation holes in the top of the housing can.

Owner:LIGHTING SCI GROUP

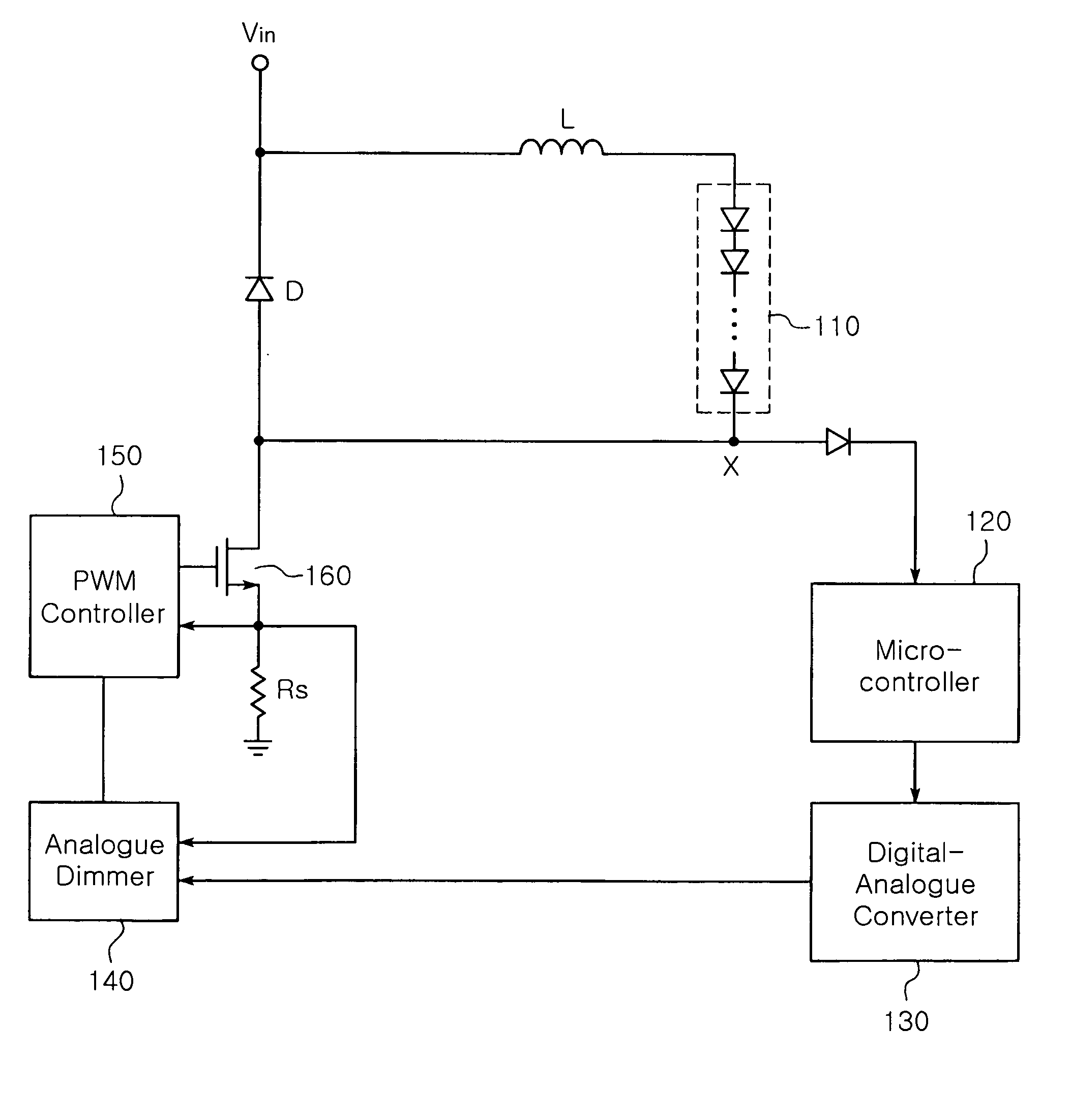

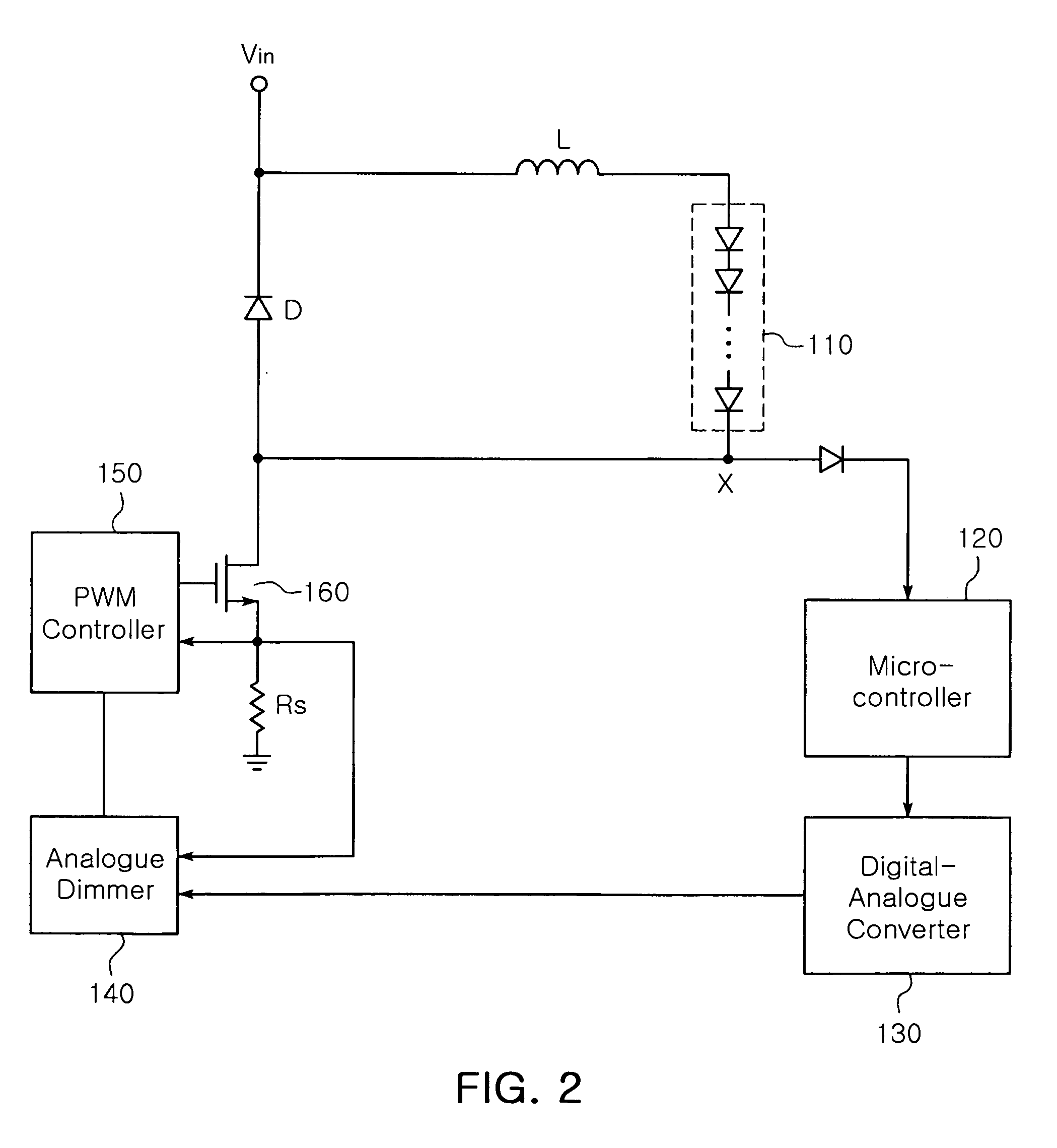

DC-DC converter having protective function of over-voltage and over-current and led driving circuit using the same

ActiveUS20060261752A1Avoid damageDischarge tube incandescent screensElectric discharge tubesMicrocontrollerDc dc converter

The invention relates to a DC-DC converter having over-current / over-voltage protection function and an LED driving circuit using the same. The DC-DC converter adjusts a width of a switching pulse outputted from a Pulse Width Modulation (PWM) controller to control on / off durations of a switch, thereby providing a controlled level of voltage to a load. The DC-DC converter includes a microcontroller for detecting a voltage, and if the detected voltage is greater than a reference voltage, generating an alarm signal. The DC-DC converter further includes a digital-analogue converter for outputting a voltage of 0V and an analogue dimmer for generating a control signal that changes an ‘on’ duration of the switching pulse outputted from the PWM controller to 0 and providing the control signal to the PWM controller.

Owner:SAMSUNG ELECTRONICS CO LTD

Recessed LED down light

In an embodiment of the present invention, a light emitting diode (LED) recessed down light fixture comprises a housing, a reflector assembly mounted to the housing, and an LED circuit board attached to the housing over the reflector assembly. The LED circuit board includes a plurality of resistors electrically connected to the LED circuit board, a bridge rectifier, and a plurality of at least 80 miniature LEDs electrically connected to the LED circuit board and configured to provide light. The plurality of miniature LEDs are separated into a plurality of LED clusters. Each cluster is electrically connected to at least one resistor. Further, the plurality of miniature LEDs are arranged in a configuration such that a voltage differential across any two proximate LEDs is less than 36 volts. The down light fixture further comprises a lens cover attached to the top end of the reflector assembly.

Owner:FOCAL POINT

LED (Light Emitting Diode) drive circuit with dimming function and lamp

ActiveCN103313472ASolve the problem that the LED cannot be dimmed directlyElectrical apparatusElectroluminescent light sourcesDIACControl signal

The invention discloses an LED (Light Emitting Diode) drive circuit with a dimming function and a lamp. The drive circuit comprises a triode AC (Alternating Current) semiconductor switch (TRIAC) light modulator which receives alternating current input voltage, and generates a phase-cut voltage signal which is rectified through a rectifier module to be coupled to a dimming signal generator; a power factor collection controller receives the output signal of the dimming signal generator and a feedback signal reflecting the brightness of an LED; and an output switch control signal controls the on and off of a switch tube so as to realize the drive of the LED. Through adjusting the conduction angle of the TRIAC light modulator, the dimming of the LED is realized.

Owner:CHENGDU MONOLITHIC POWER SYST

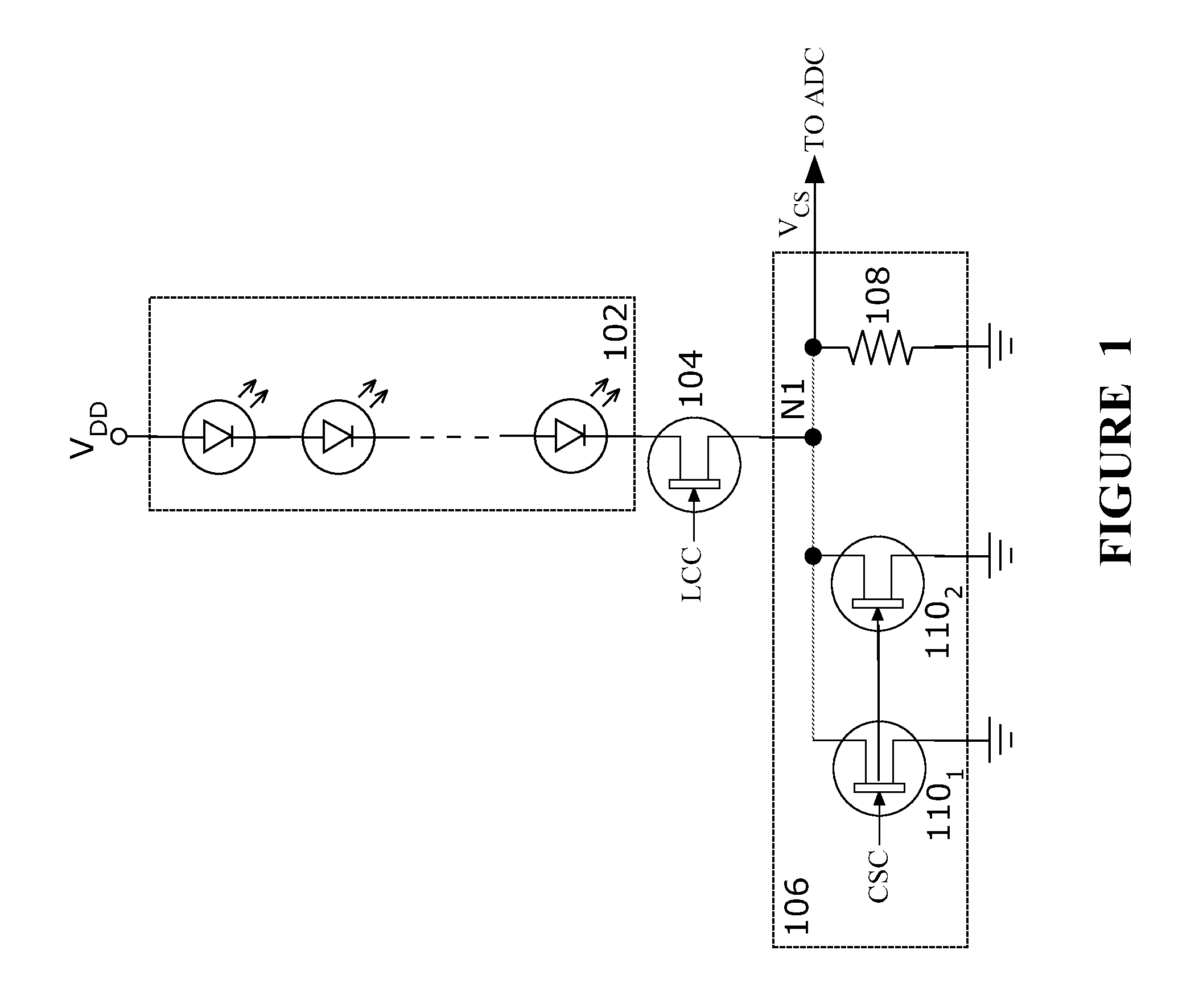

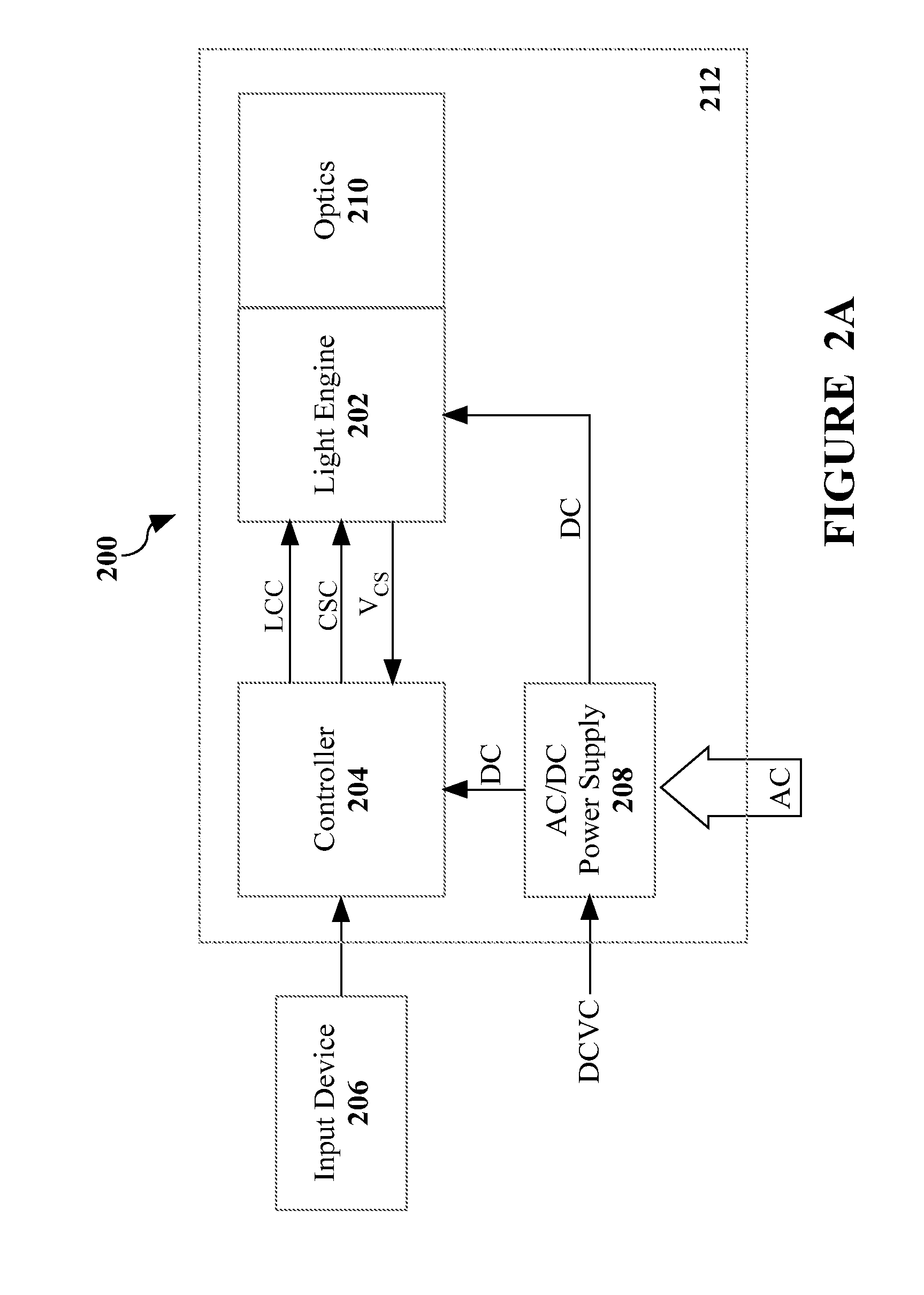

Circuits for sensing current levels within a lighting apparatus incorporating a voltage converter

ActiveUS20130009561A1Reduce resistanceElectrical apparatusElectrical measurement instrument detailsVoltage converterElectrical resistance and conductance

Circuits for sensing current levels within an apparatus are disclosed. In specific cases, a constant voltage power supply is used to power an LED lighting apparatus in which there are uncertainties within the forward voltages of the LEDs, which in turn creates uncertainty with respect to the current level flowing through the LEDs. To manage these uncertainties, the current flowing through the LEDs is measured by determining a voltage level across a known resistor and calculating the current level. To prevent the known resistor from causing a significant reduction in the efficiency of the overall light engine, the circuit includes one or more transistors in parallel with the known resistor to reduce the effective resistance in the LED circuit during times that the current is not being sensed.

Owner:ARKALUMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com