Patents

Literature

1580 results about "Dc bus voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are two important DC bus voltage measurements you should take. The first is the actual DC bus voltage, which should be equal to the line-side peak voltage (rms voltage x 1.41). Once the capacitors are charged, the reading should remain constant. On a 480V system, the DC bus voltage will be about 676VDC.

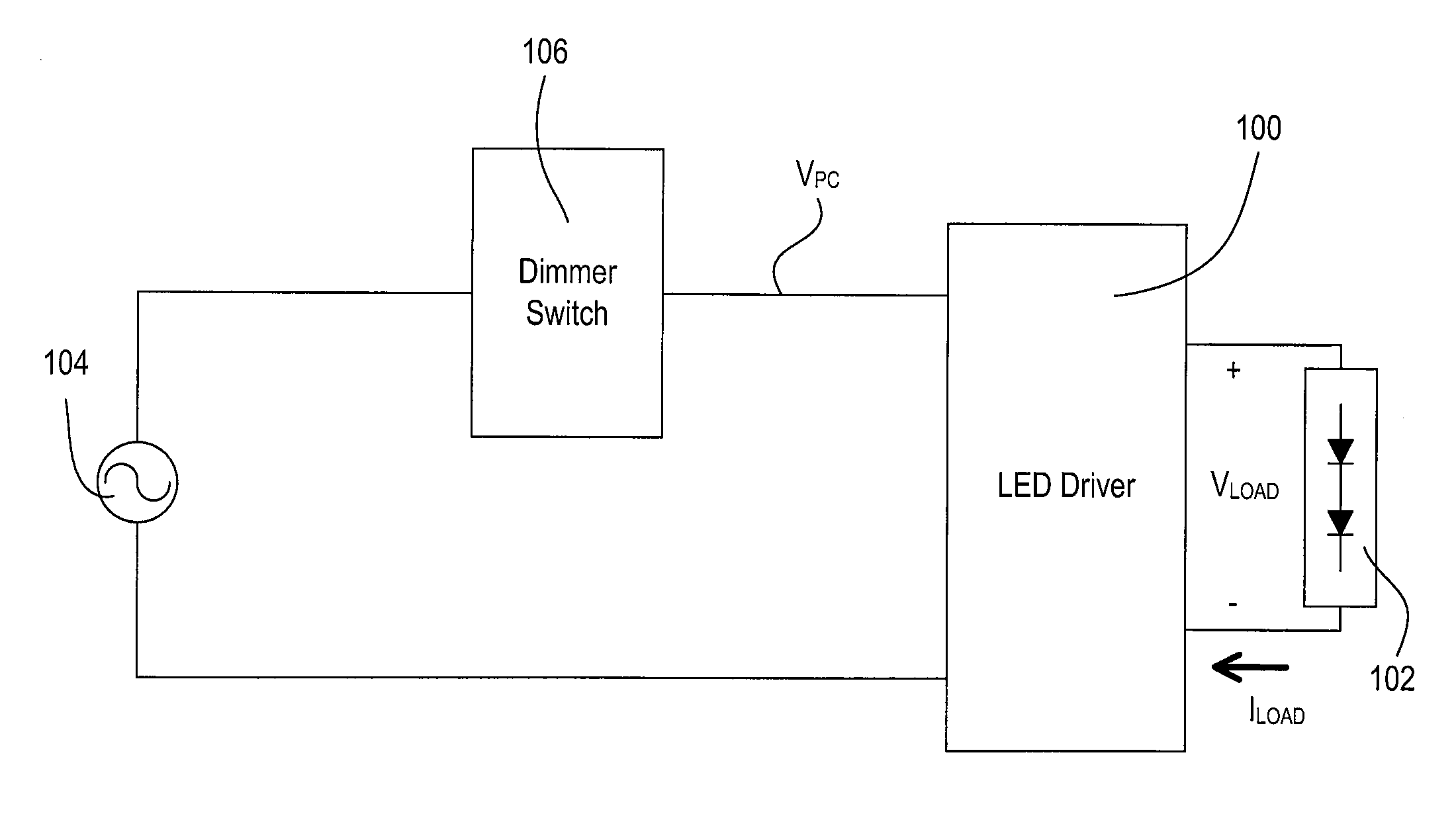

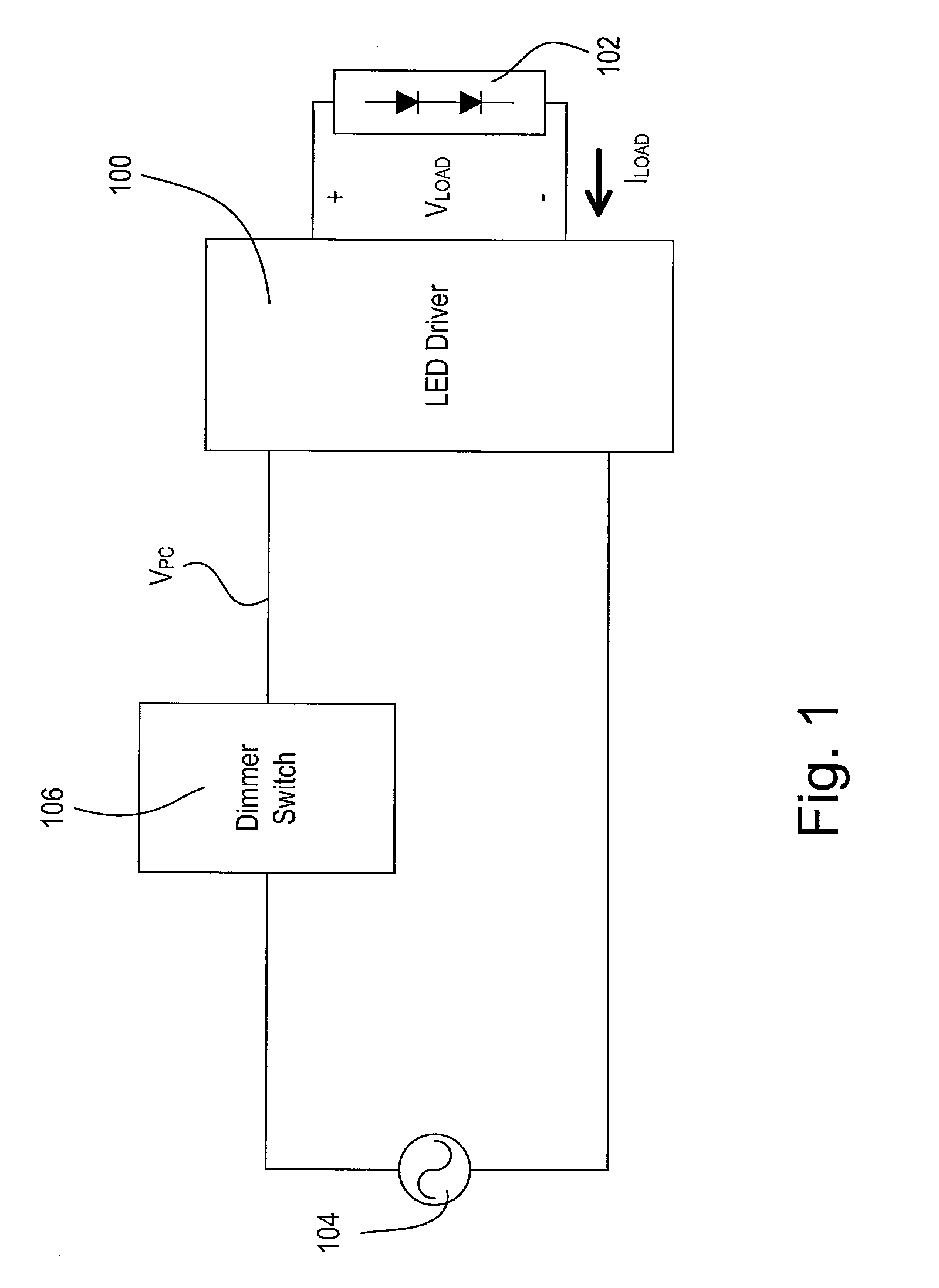

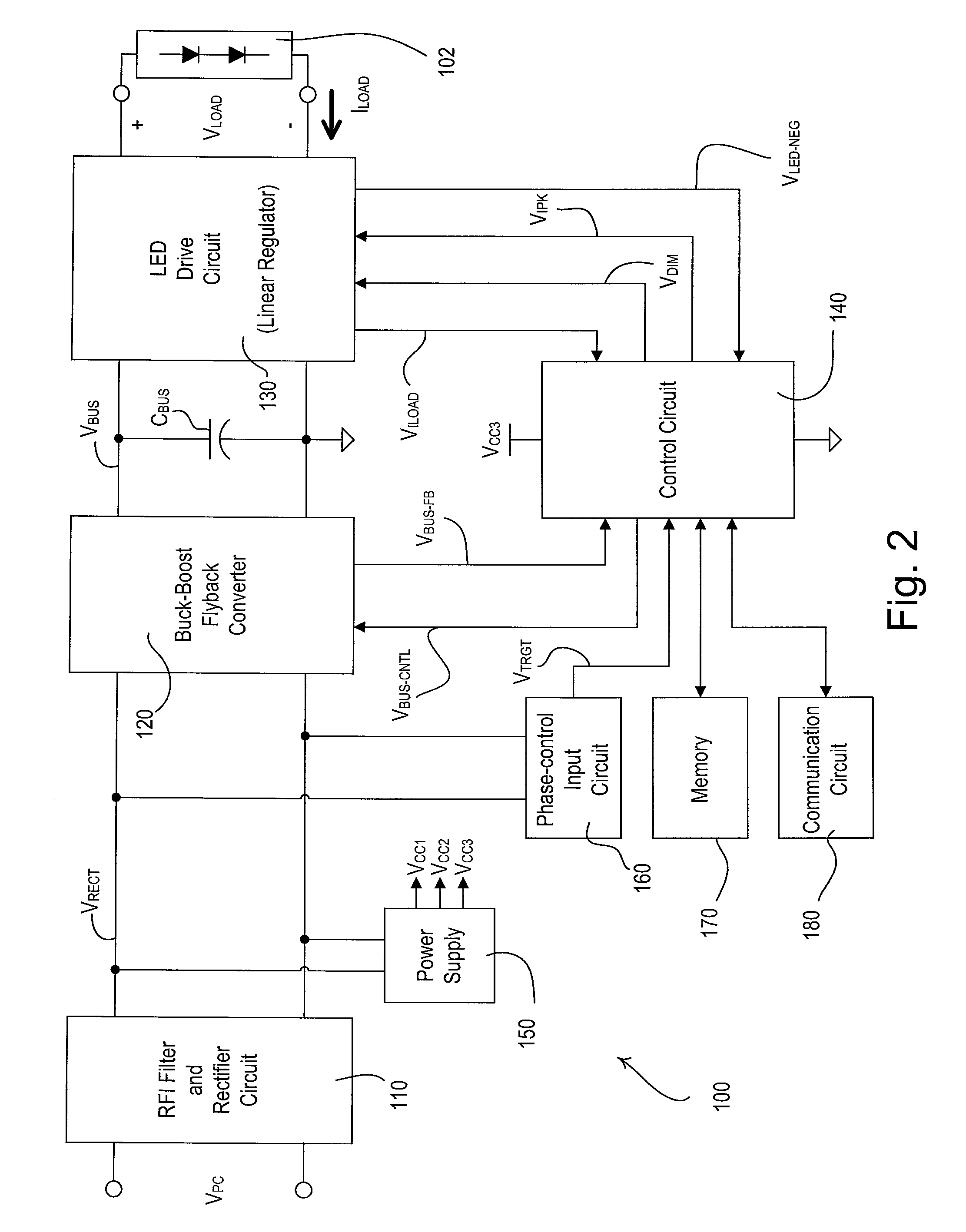

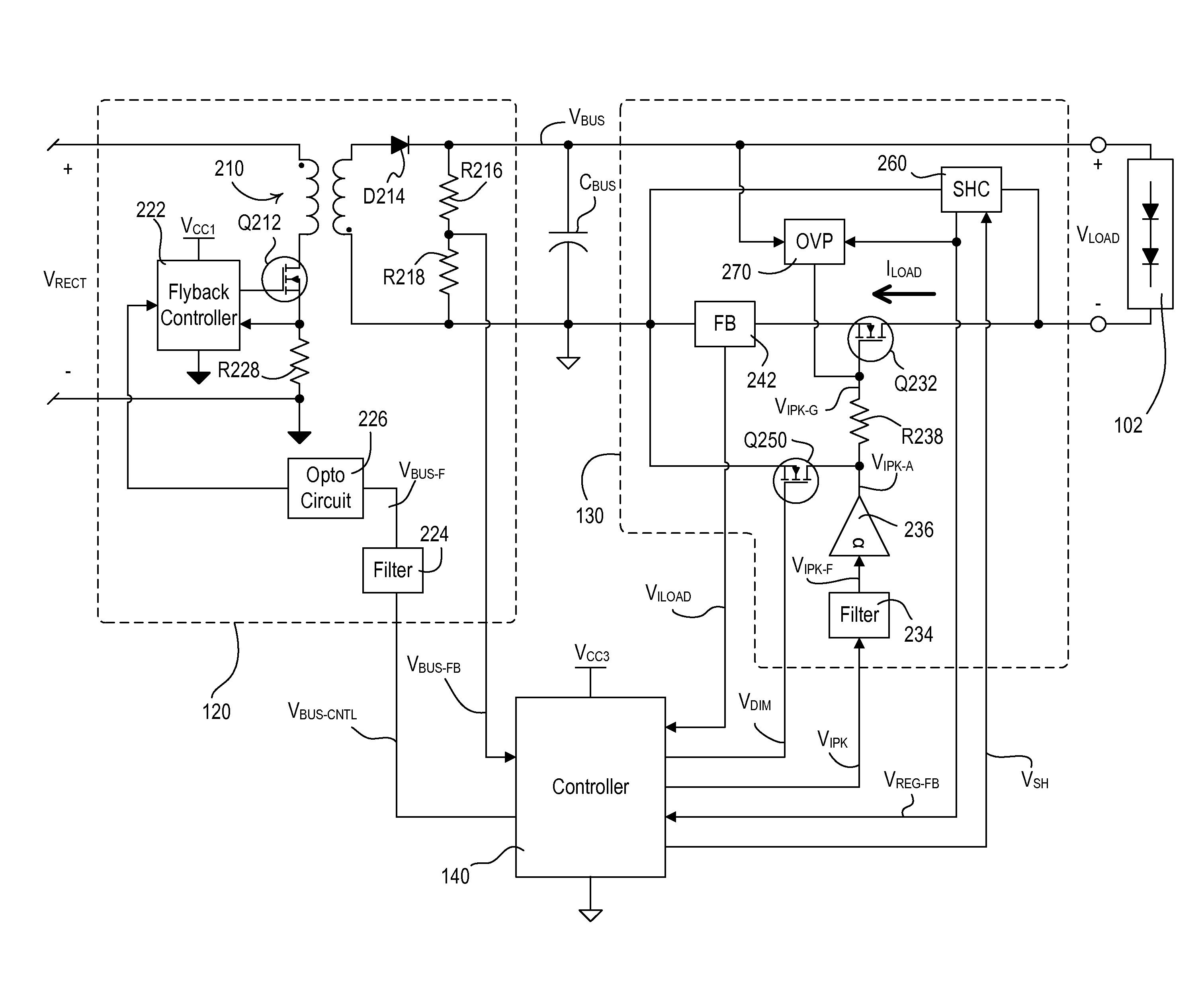

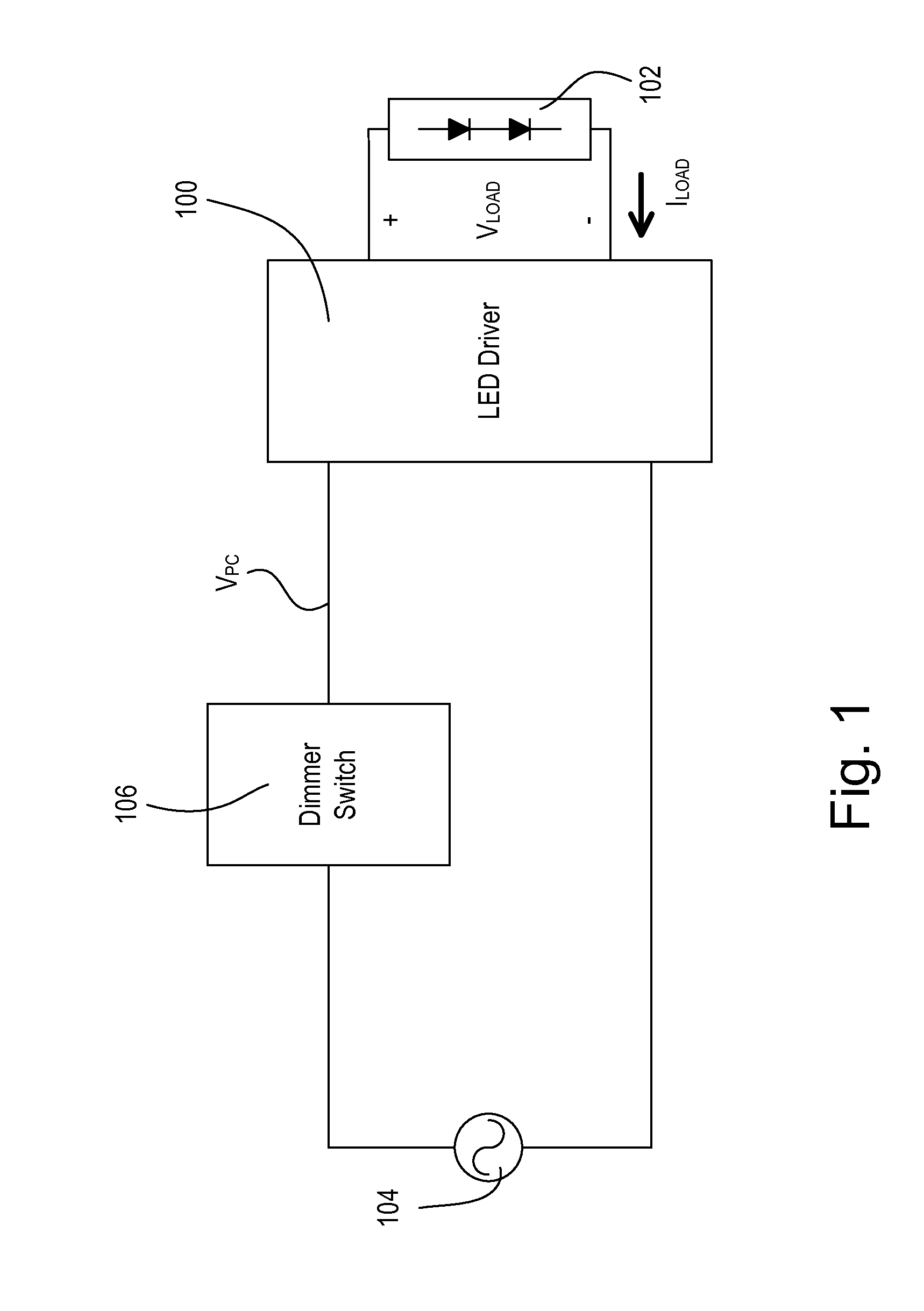

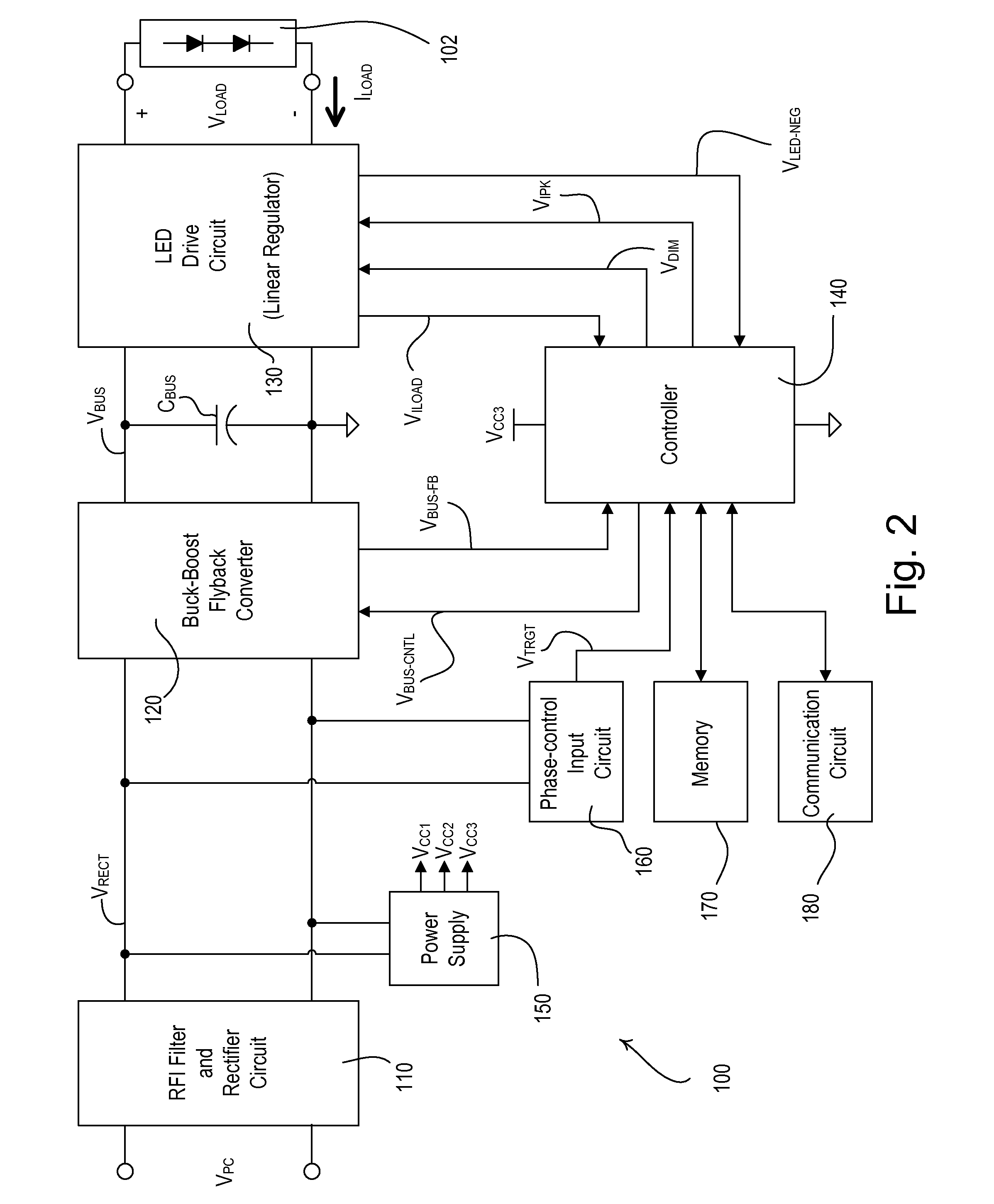

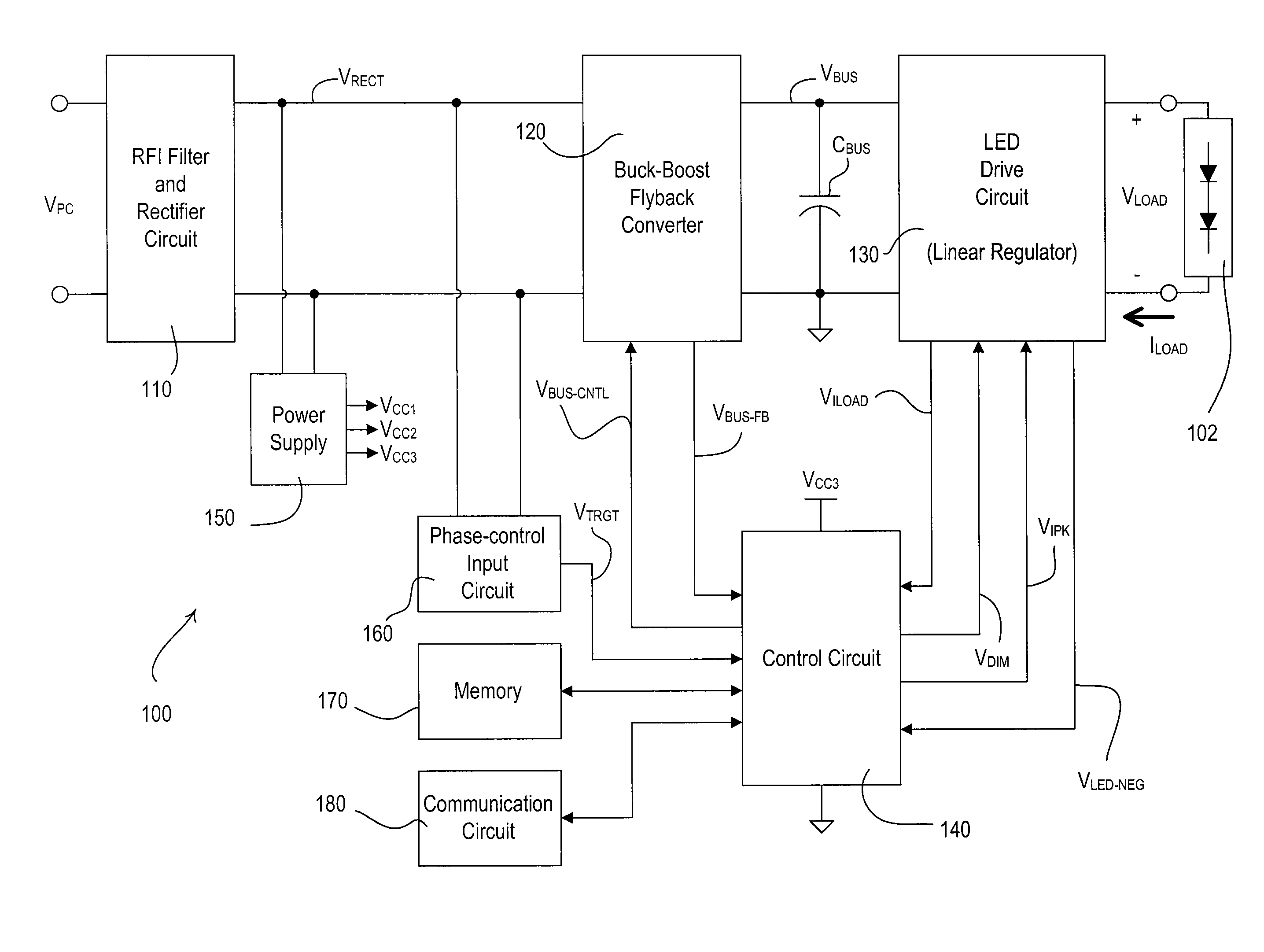

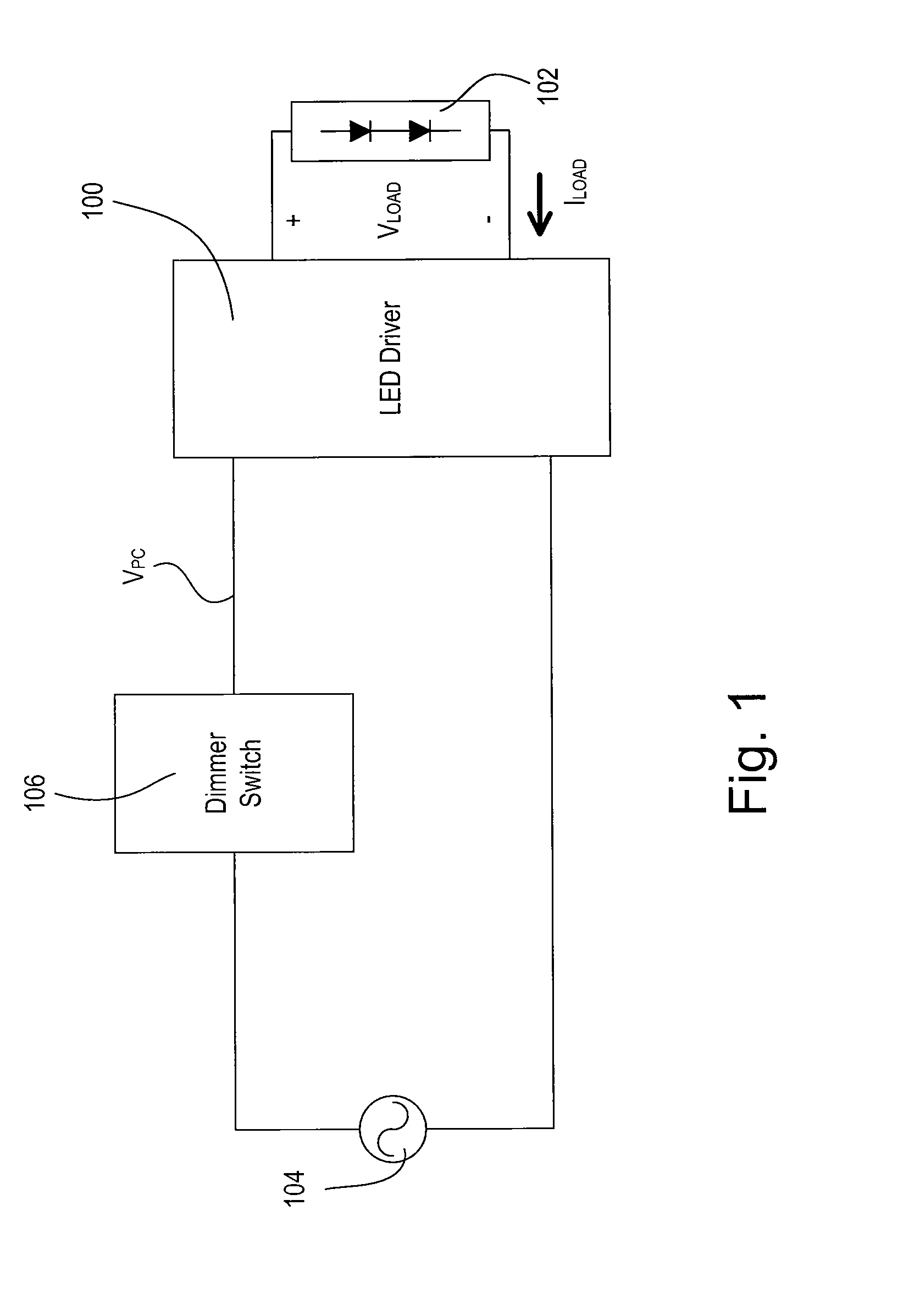

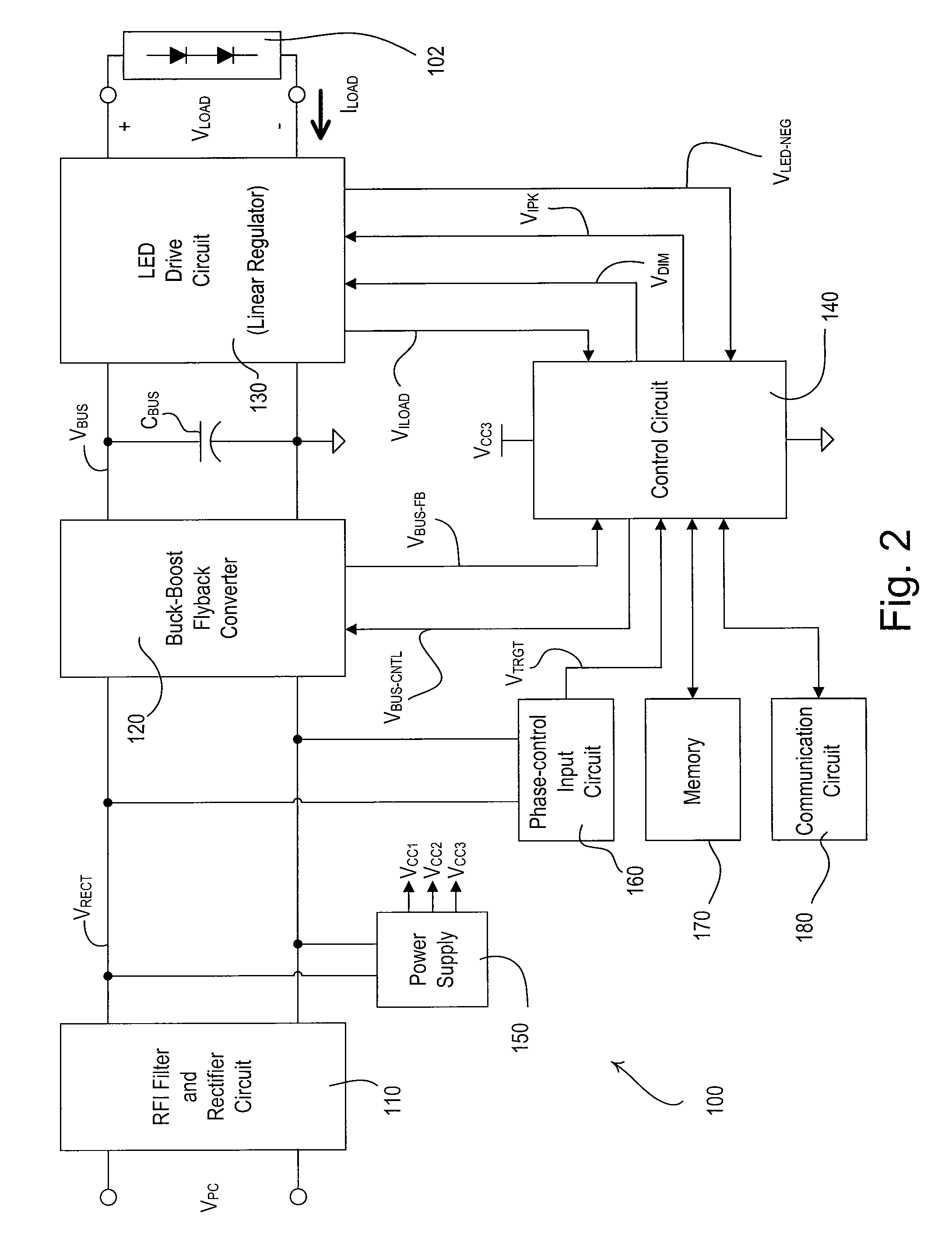

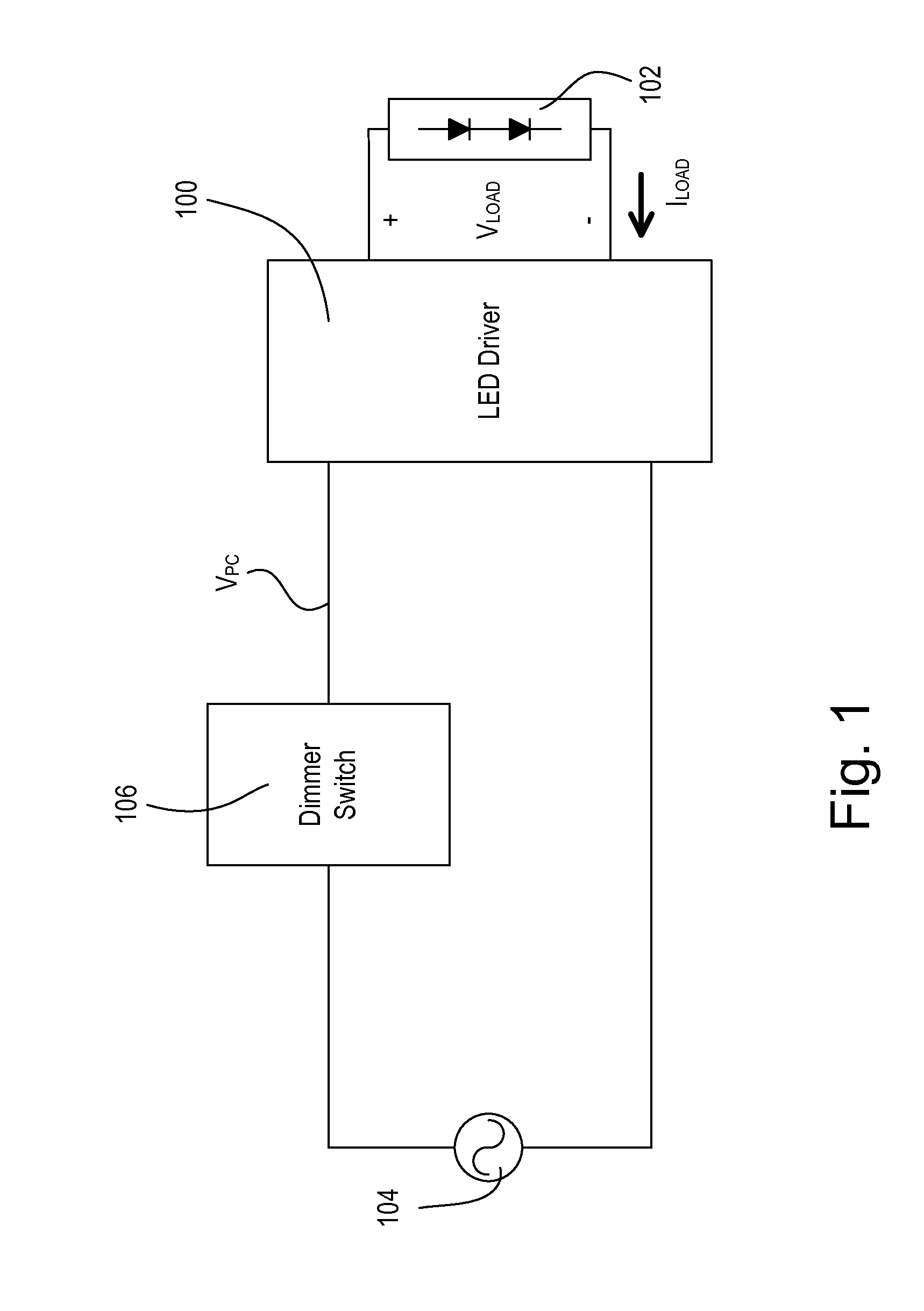

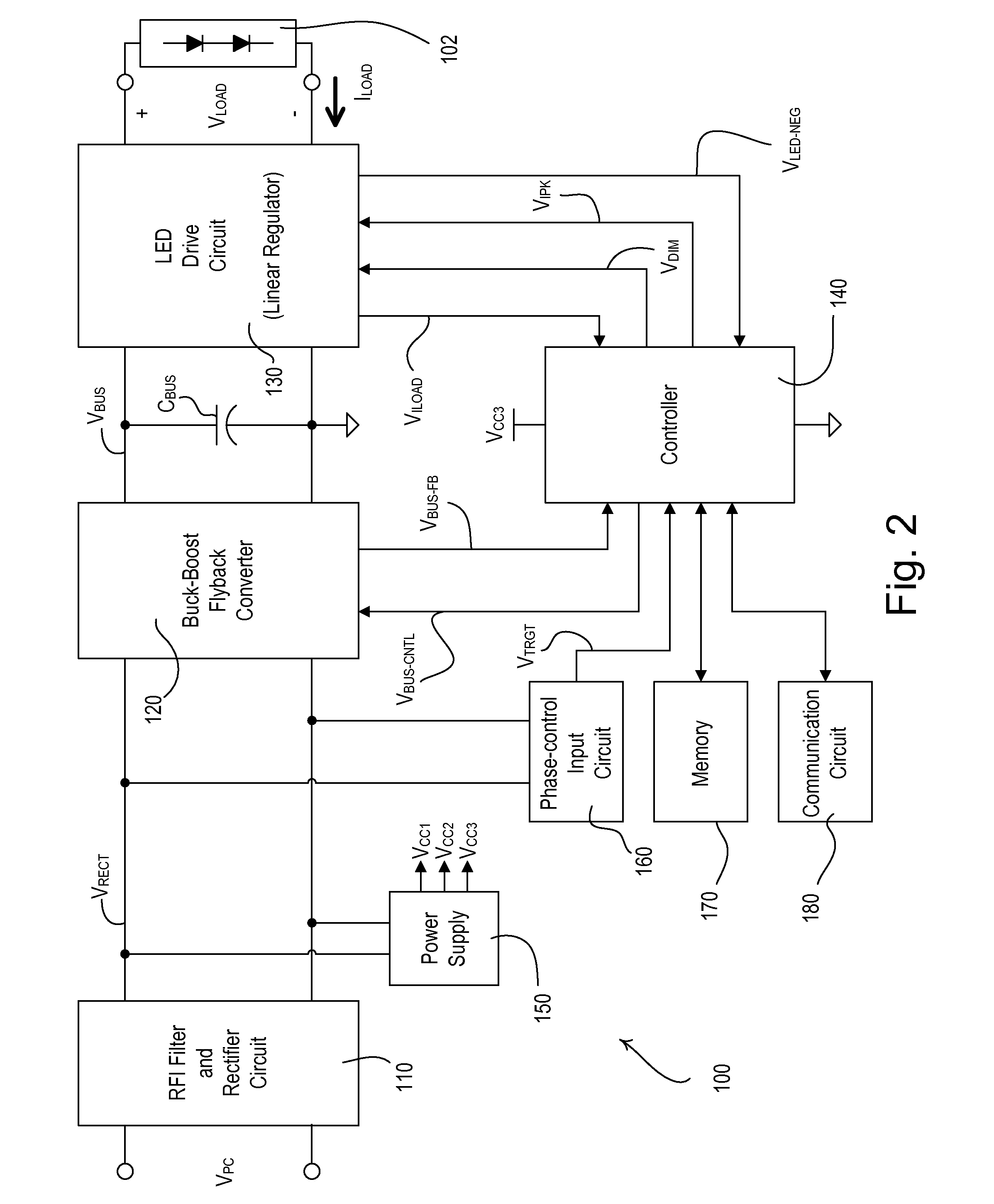

Load control device for a light-emitting diode light source

ActiveUS20110080110A1Reduce power consumptionControlling the magnitude of a load current conductedElectrical apparatusElectroluminescent light sourcesLinear regulatorEngineering

A light-emitting diode (LED) driver is adapted to control either the magnitude of the current conducted through a LED light source or the magnitude of a voltage generated across the LED light source. The LED driver comprises a power converter circuit for generating a DC bus voltage, and an LED drive circuit for receiving the bus voltage and adjusting the magnitude of the current conducted through the LED light source. The LED driver is operable to dim the LED light source using either a pulse-width modulation technique or a constant current reduction technique. The LED drive circuit may comprise a controllable-impedance circuit, such as a linear regulator. The LED driver may be operable to control the magnitude of the bus voltage to optimize the efficiency and reduce the power dissipation in the LED drive circuit, as well ensuring that the load voltage and current do not have any ripple.

Owner:LUTRON TECH CO LLC

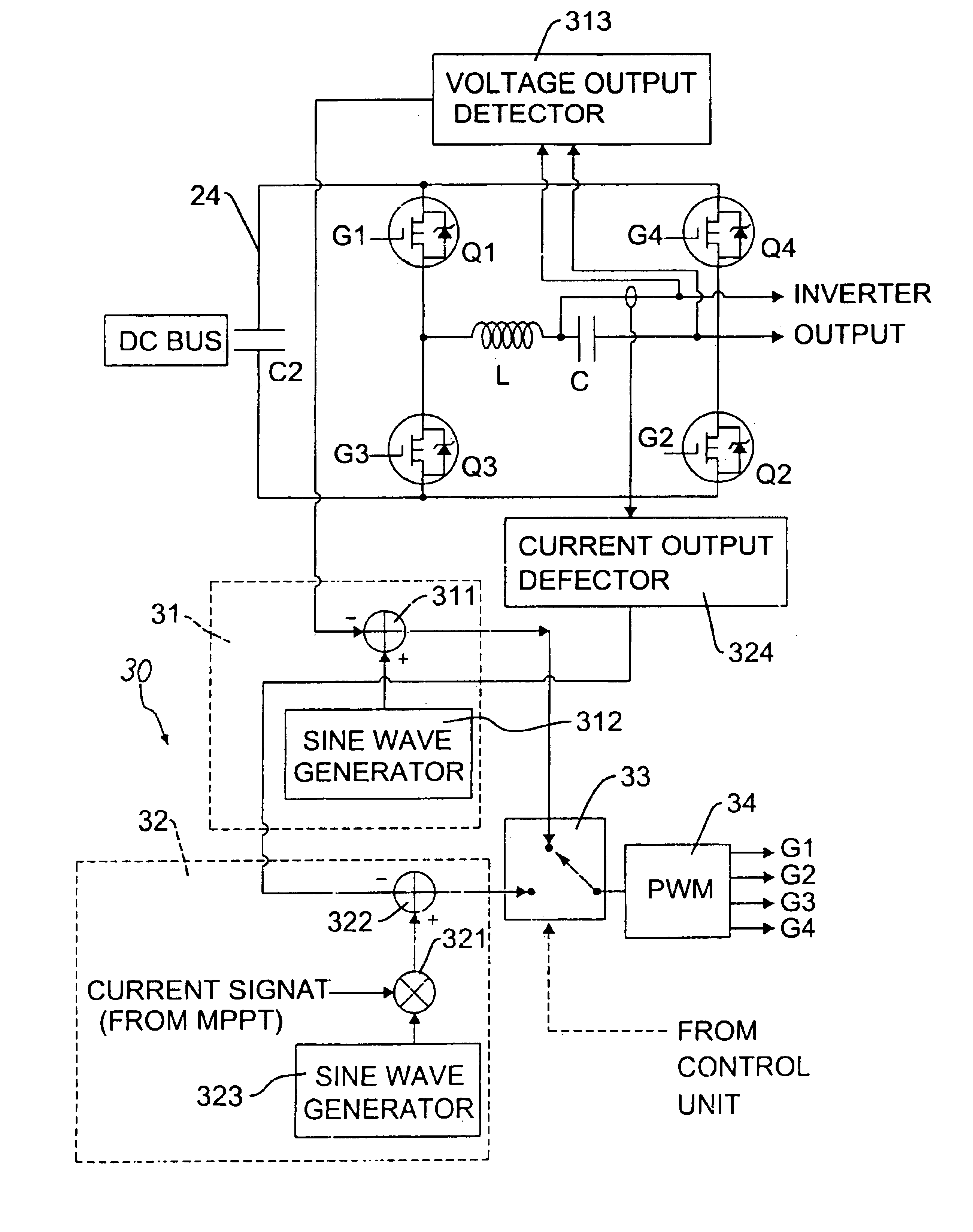

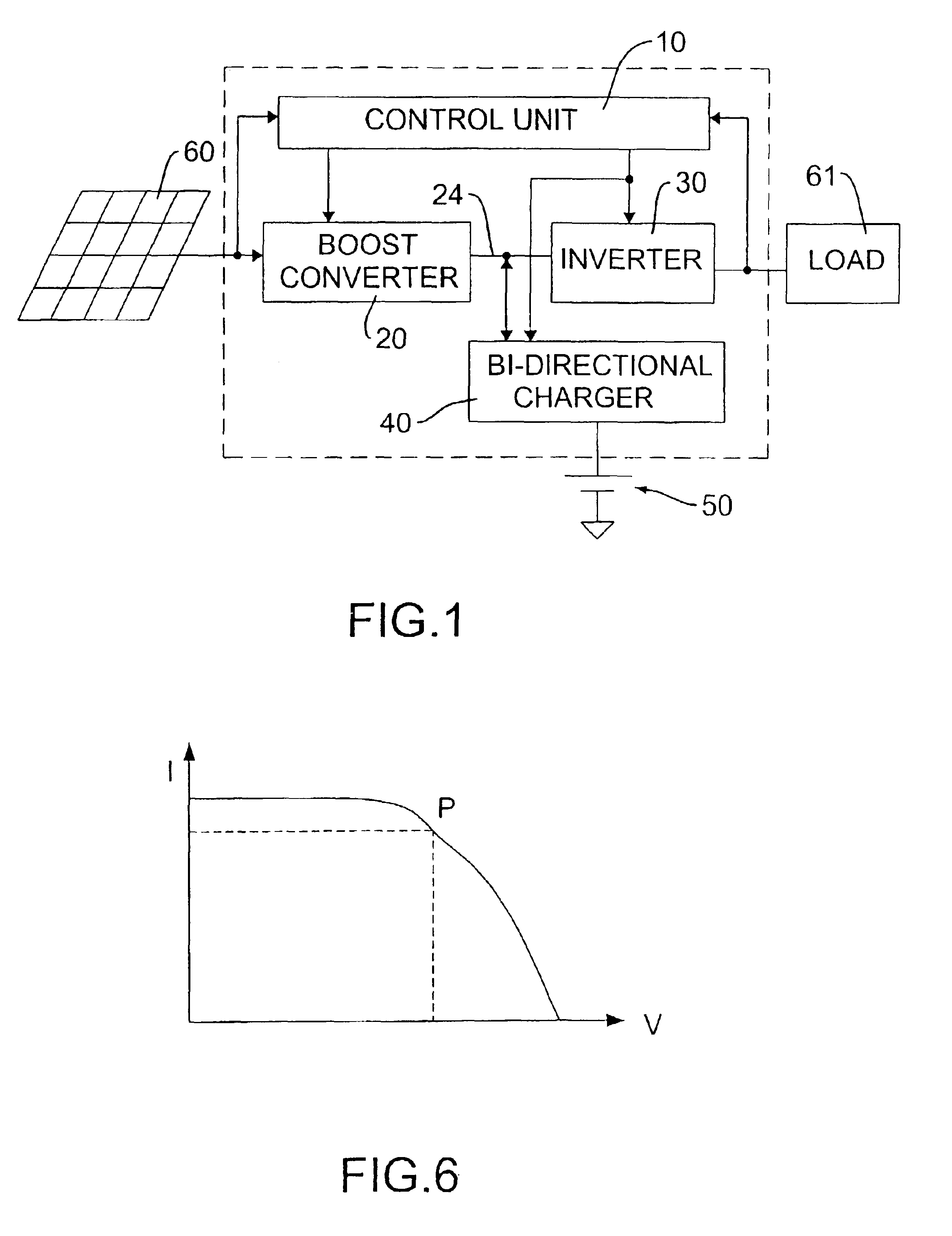

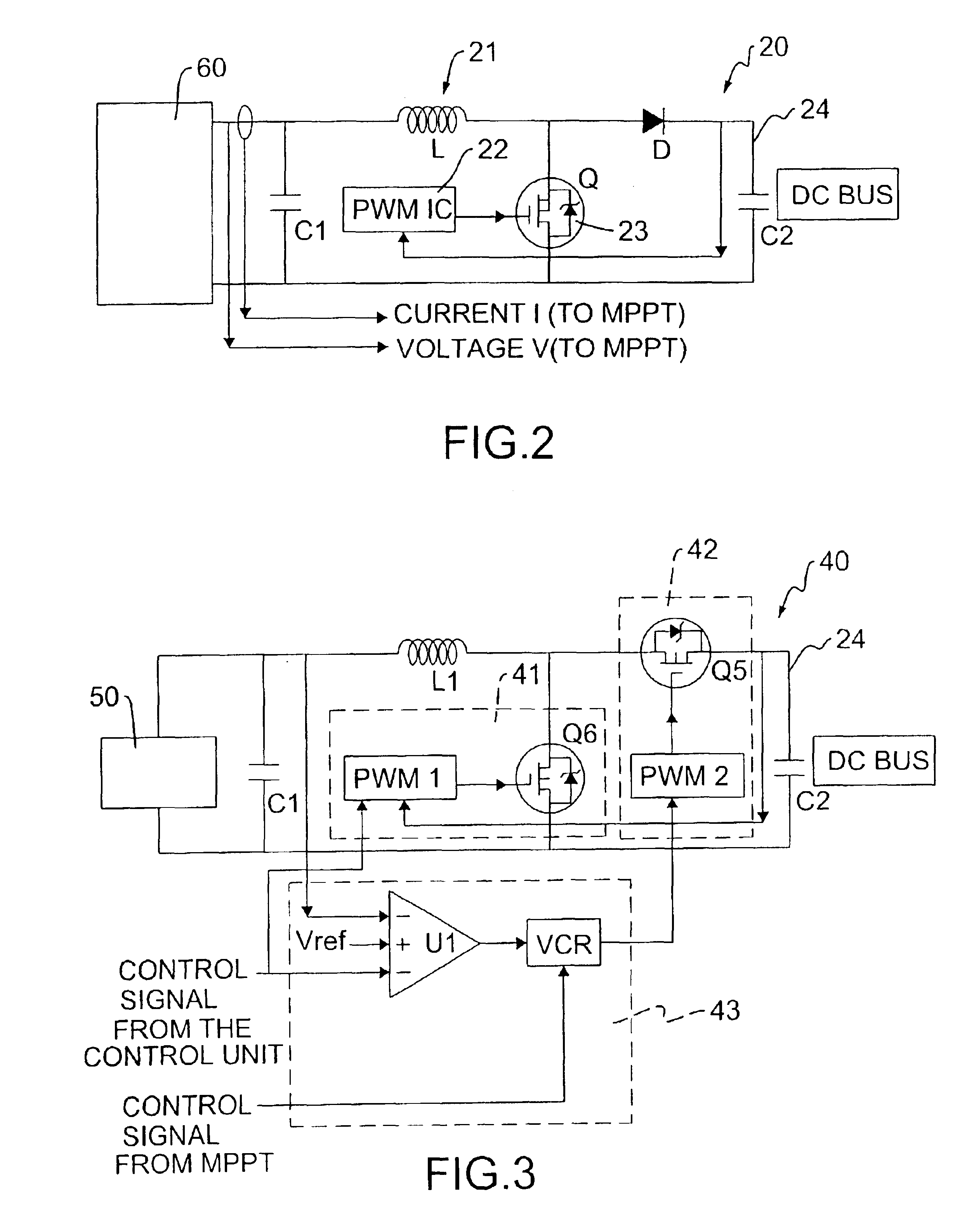

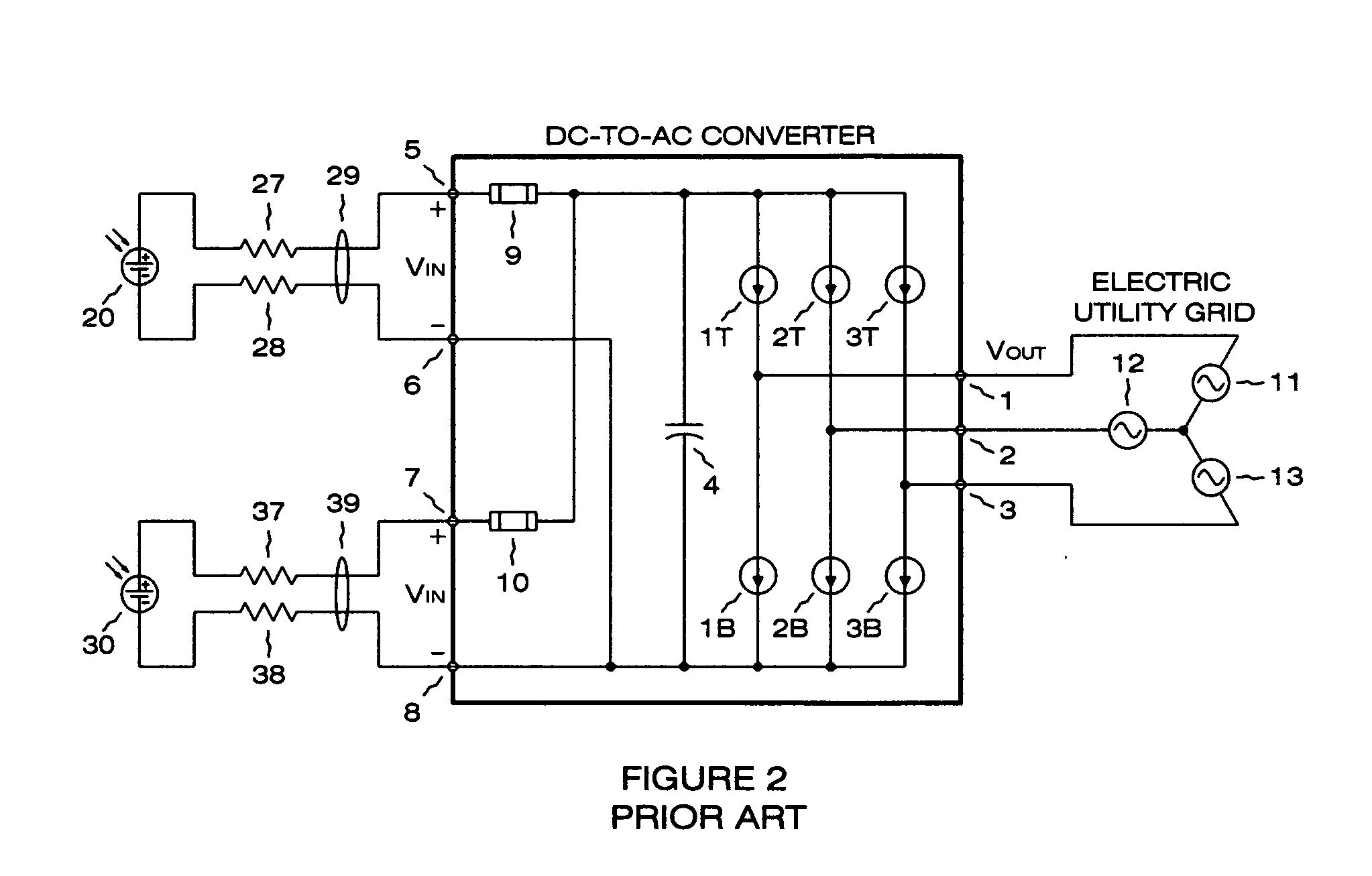

Multi-mode renewable power converter system

A multi-mode renewable power converter system is disclosed. The system includes a control unit, a boost converter, an inverter and optional bi-directional charger, wherein the boost converter converts DC output of a solar cell or a renewable source to high DC bus voltage, and the inverter converts this DC bus voltage to an AC output. This power converter can be used to support standalone load or grid-connected system with a dynamic maximum power point tracking (MPPT) circuit. The MPPT circuit detects the current and voltage from the solar cell and indicates to the inverter to provide power to the load connected. When the optional bi-directional charger is installed, the MPPT signal is also fed to this charger to make the power efficiency maximized for the system.

Owner:PHOENIXTEC POWER

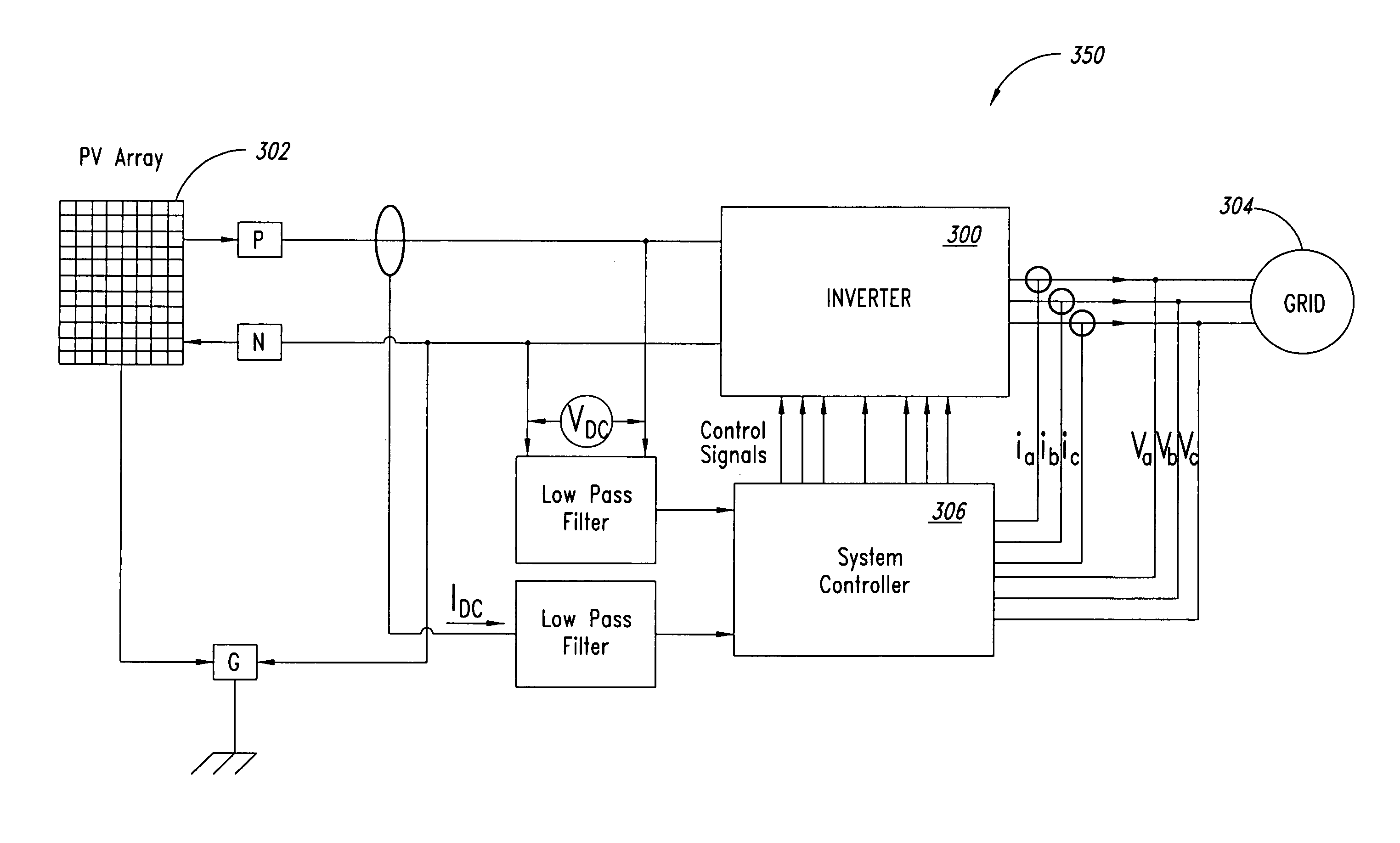

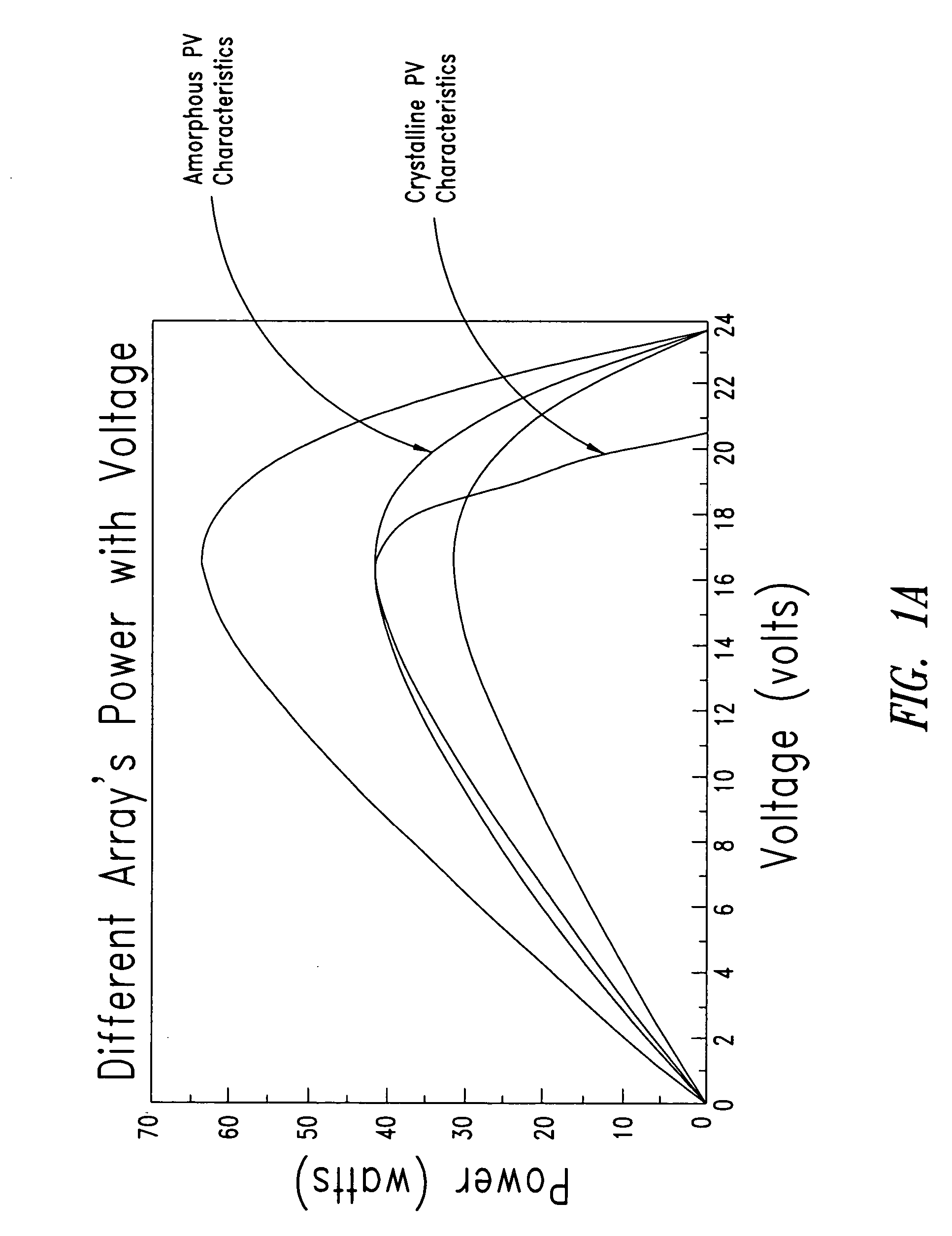

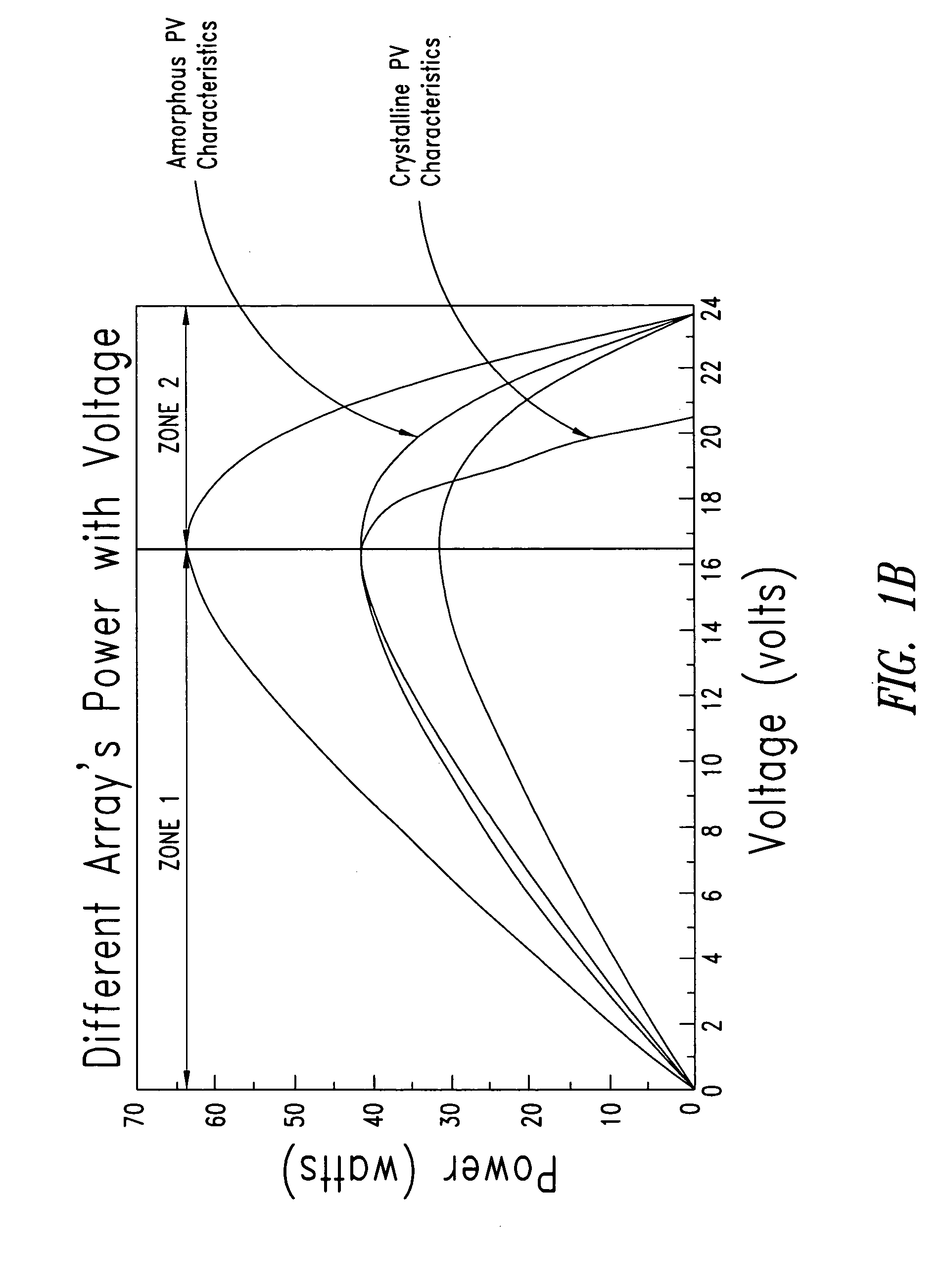

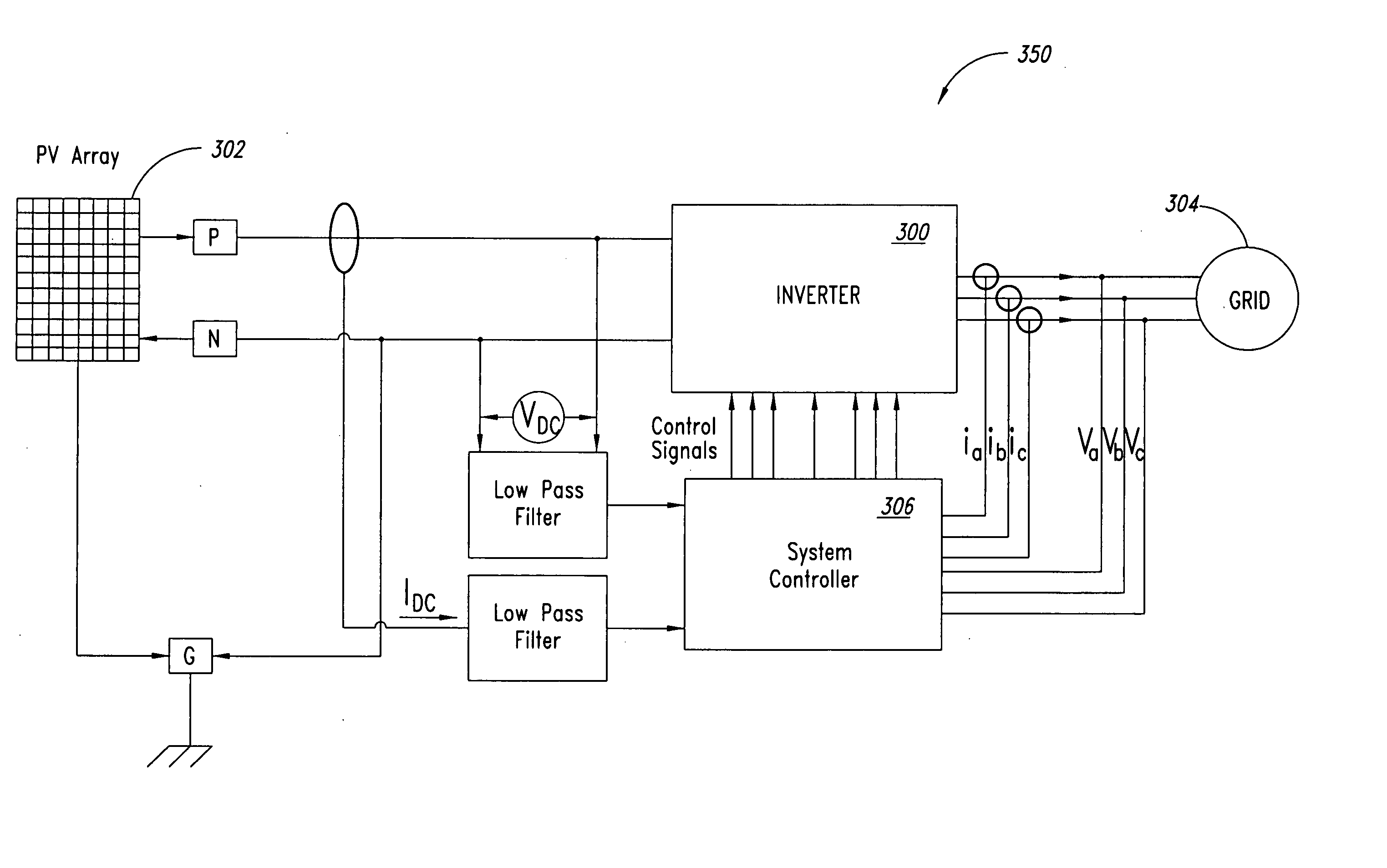

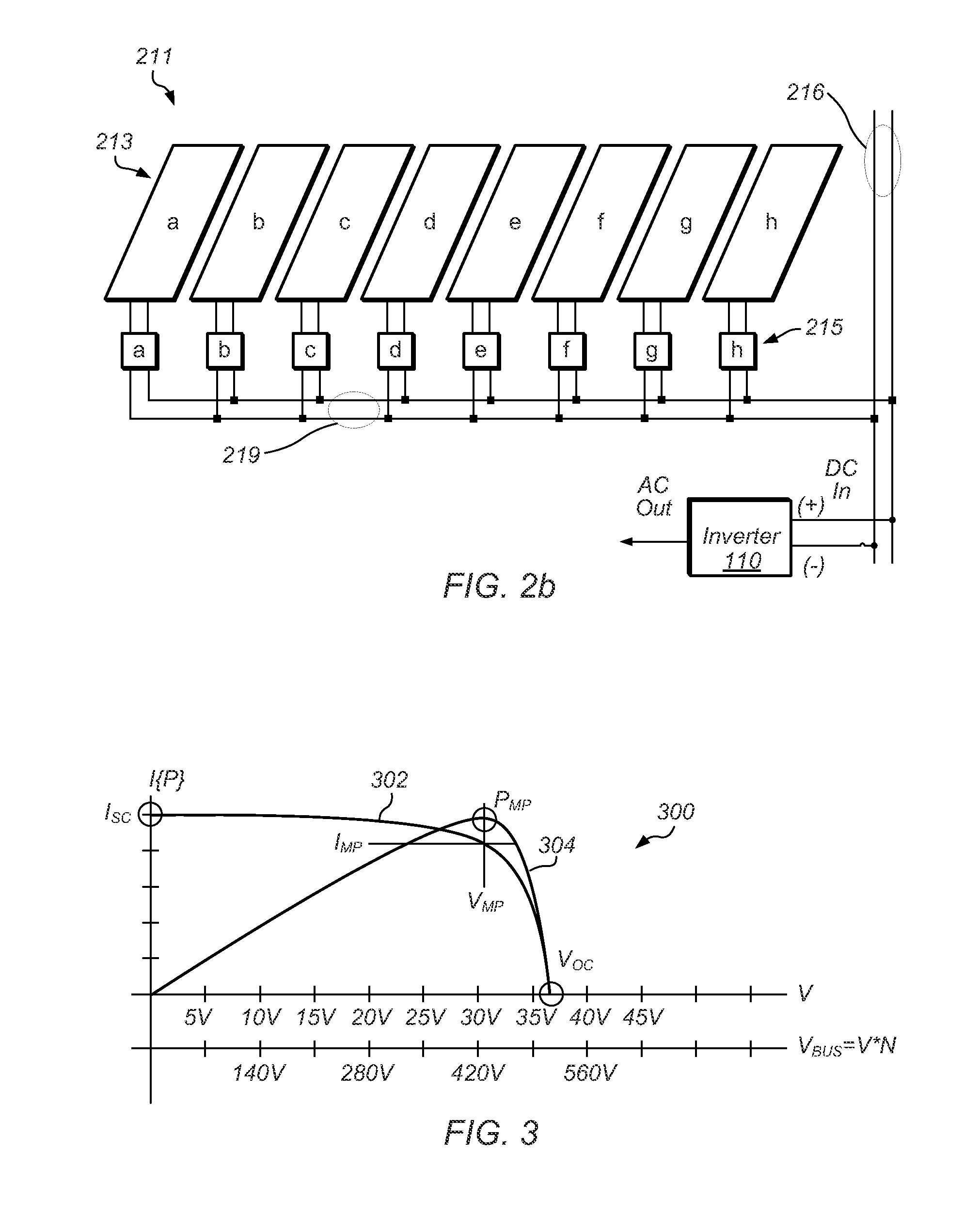

Method and apparatus for tracking maximum power point for inverters, for example, in photovoltaic applications

ActiveUS7158395B2Conversion with intermediate conversion to dcDc-dc conversionPower inverterElectric power system

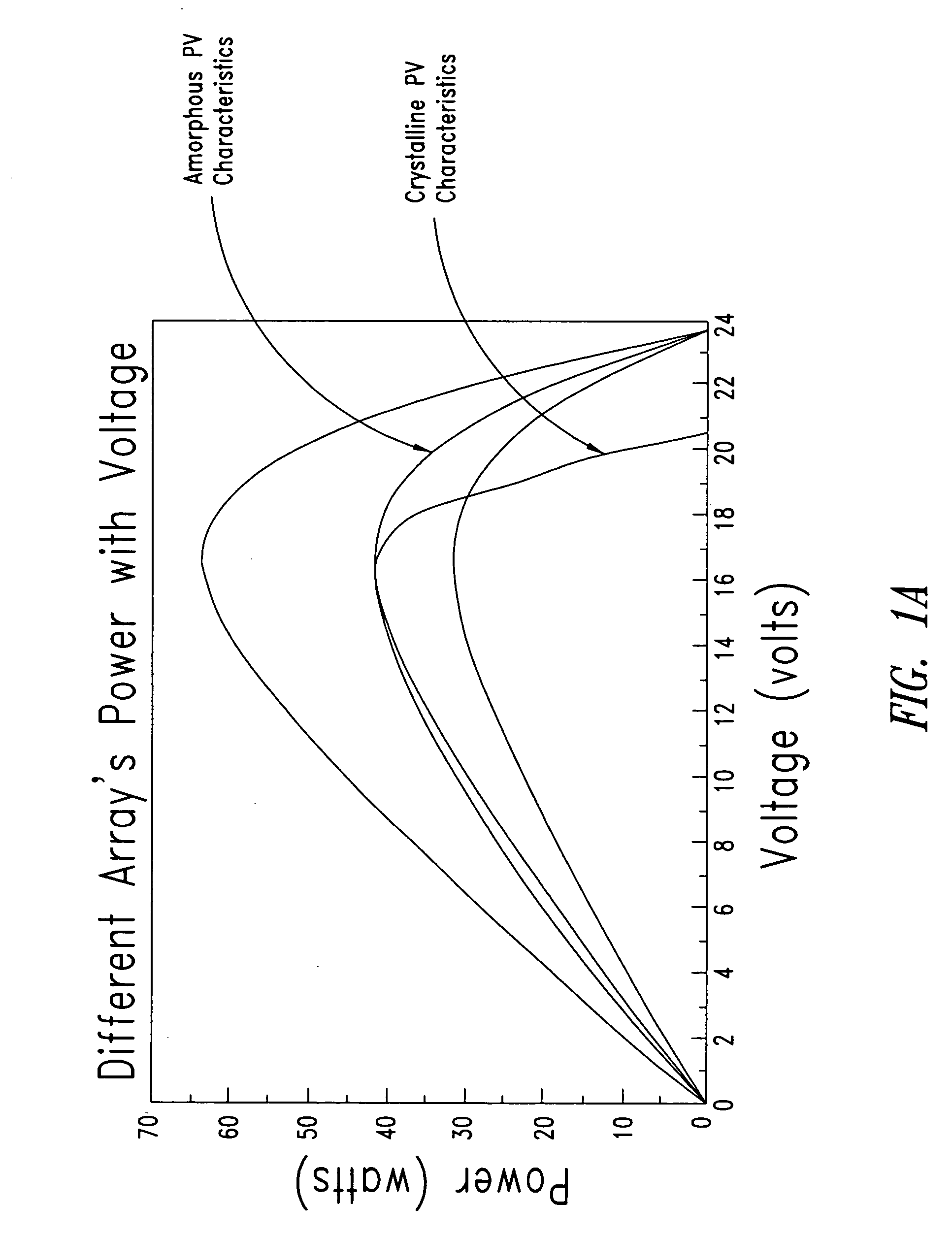

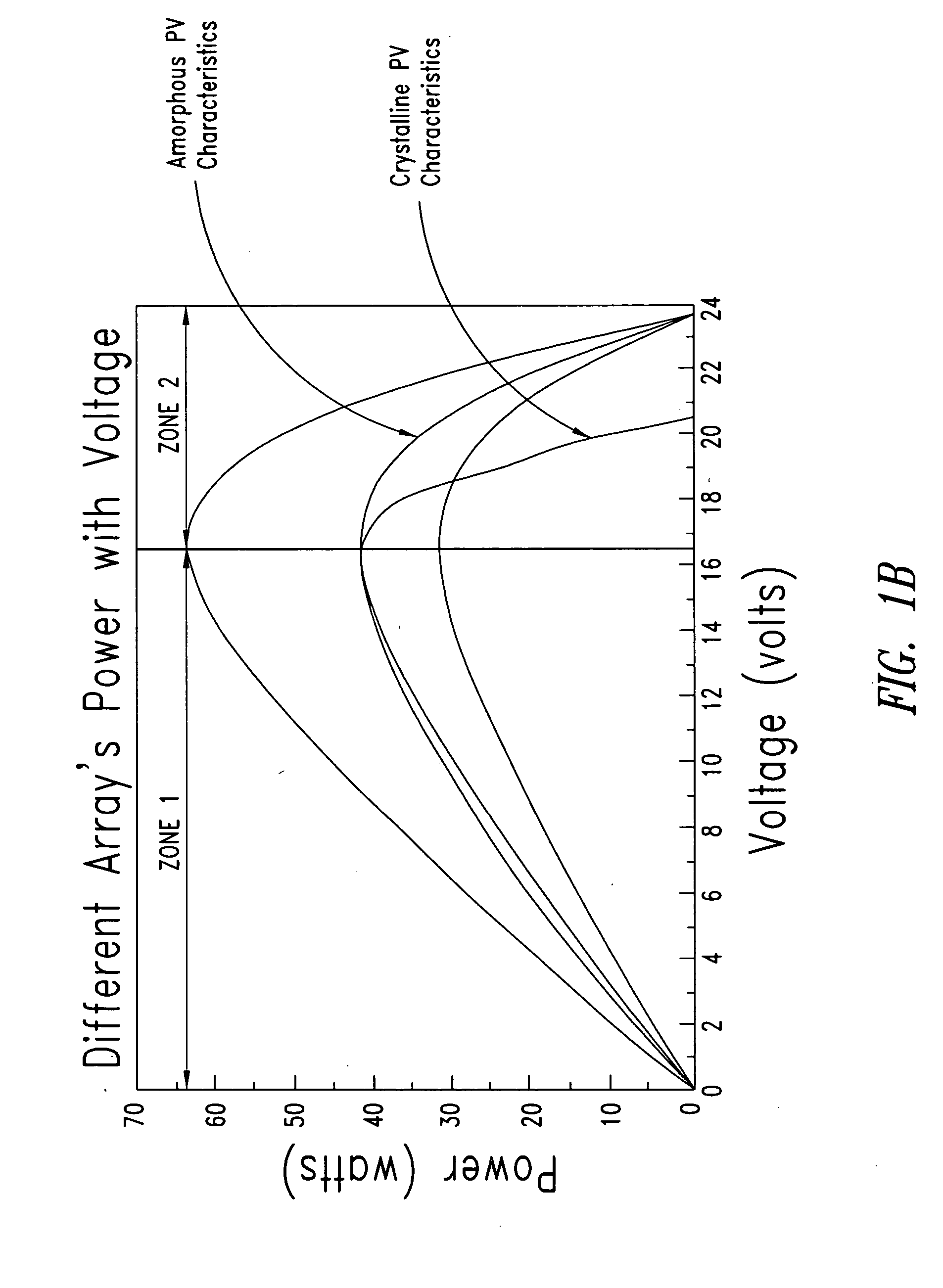

A power system employs an outer voltage feedback loop and an inner current feedback loop to control a power converter, such as a DC to AC inverter for transferring electrical power between a power source, for example a photovoltaic array, and a load, for example a power grid. The outer loop accommodates variations in the output of the power source, for example accommodating anomalies in IV characteristics such as IV droop characteristic associated with photovoltaic cells. The outer loop may employ a first control regime or a second control regime, for example, dependent on whether a DC bus voltage or power is smaller than a value corresponding to measurement resolution or expected noise.

Owner:RHOMBUS ENERGY SOLUTIONS

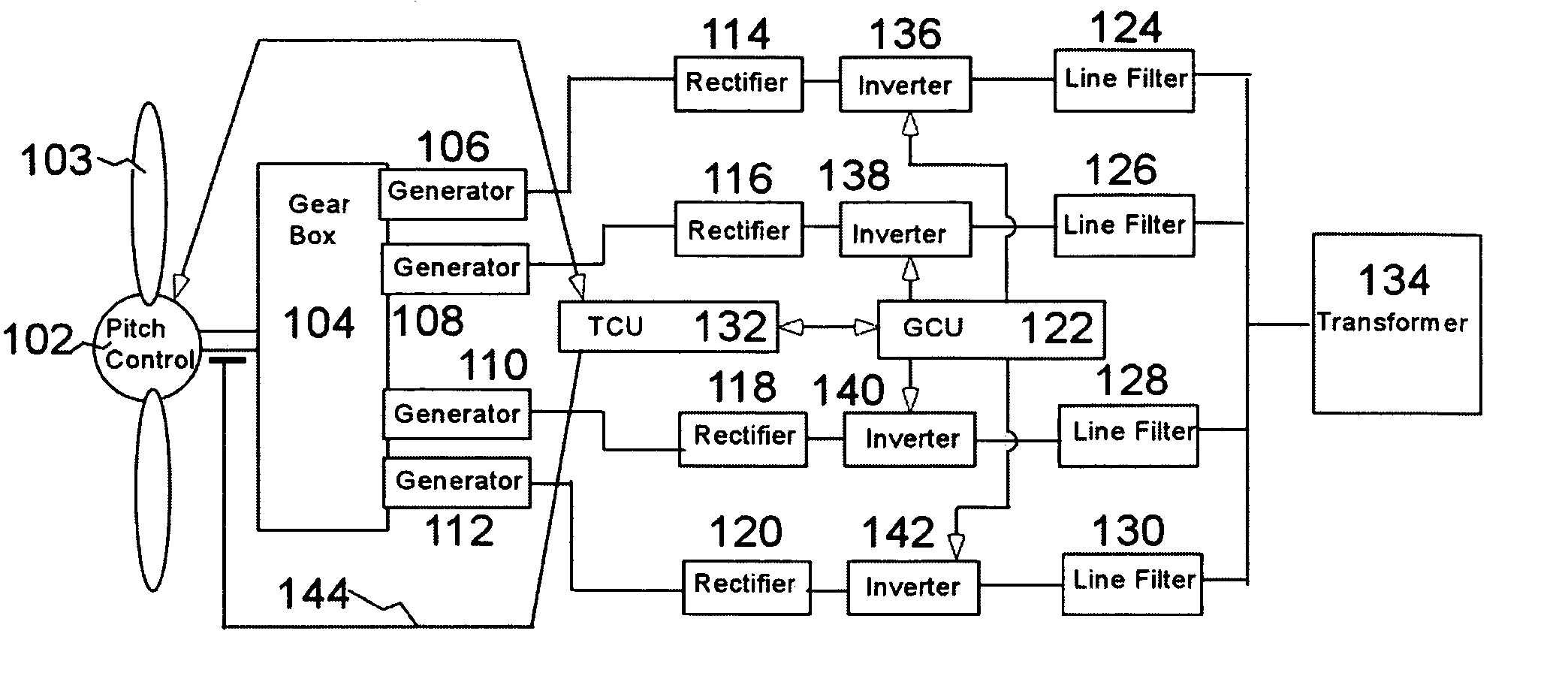

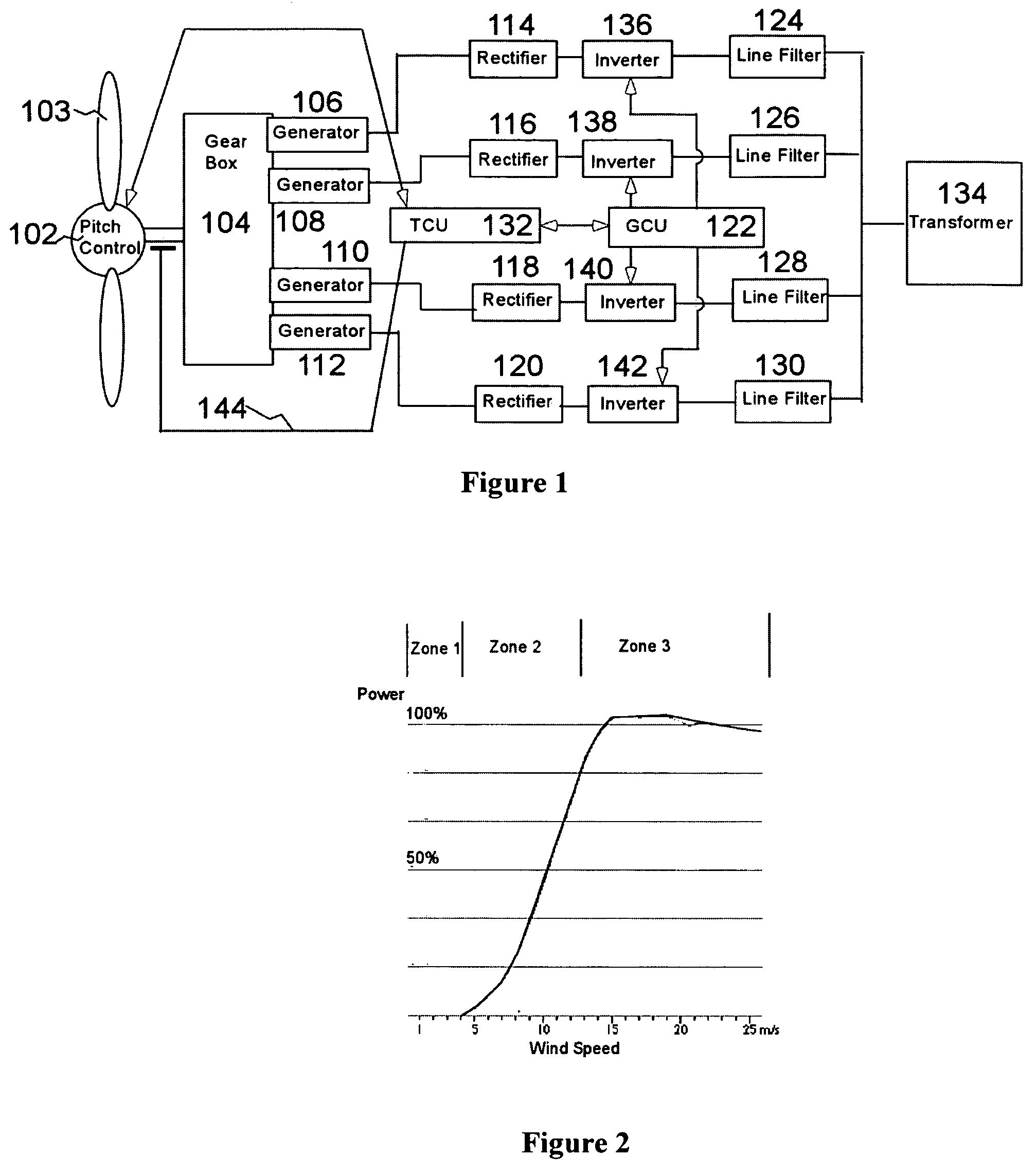

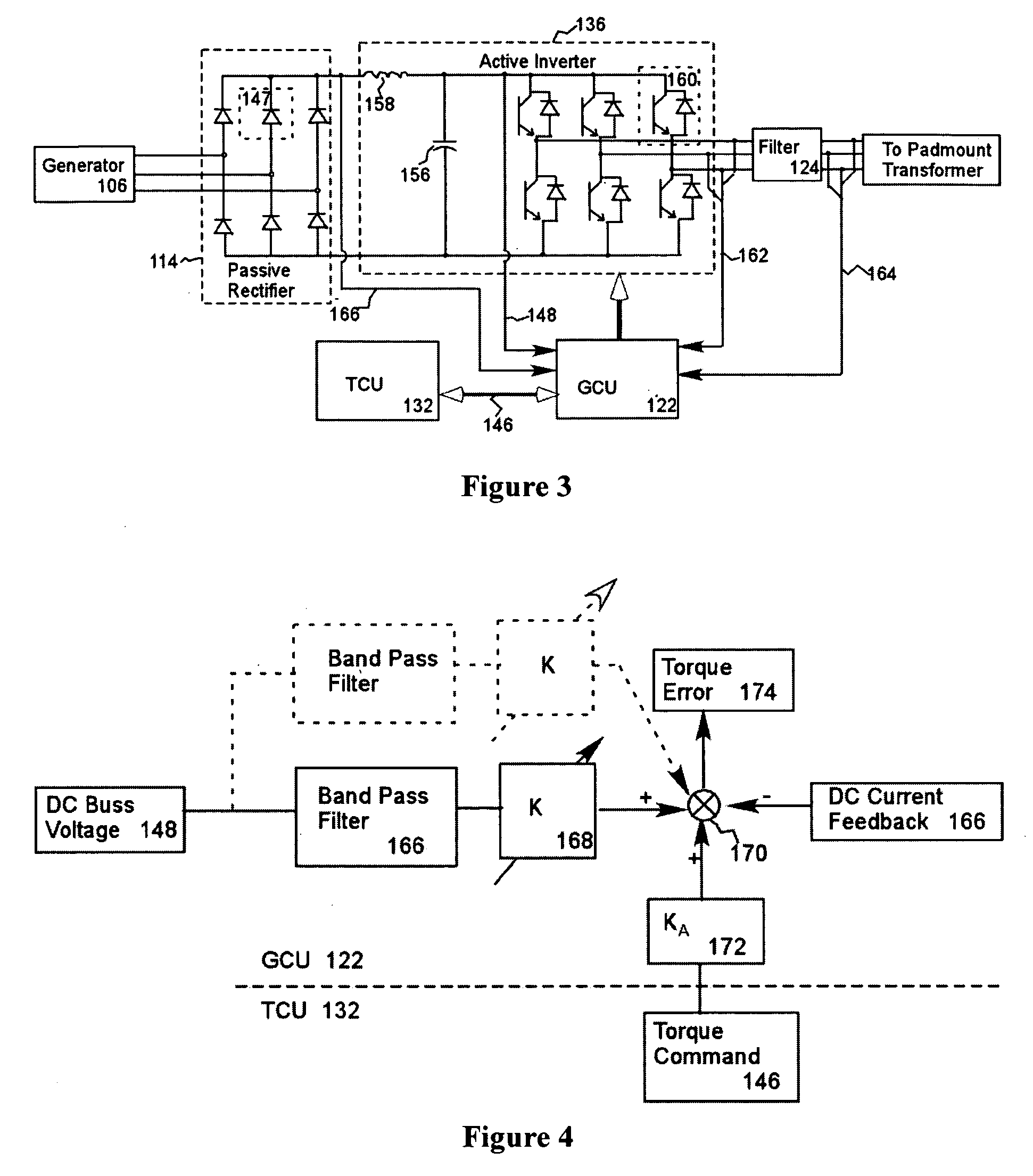

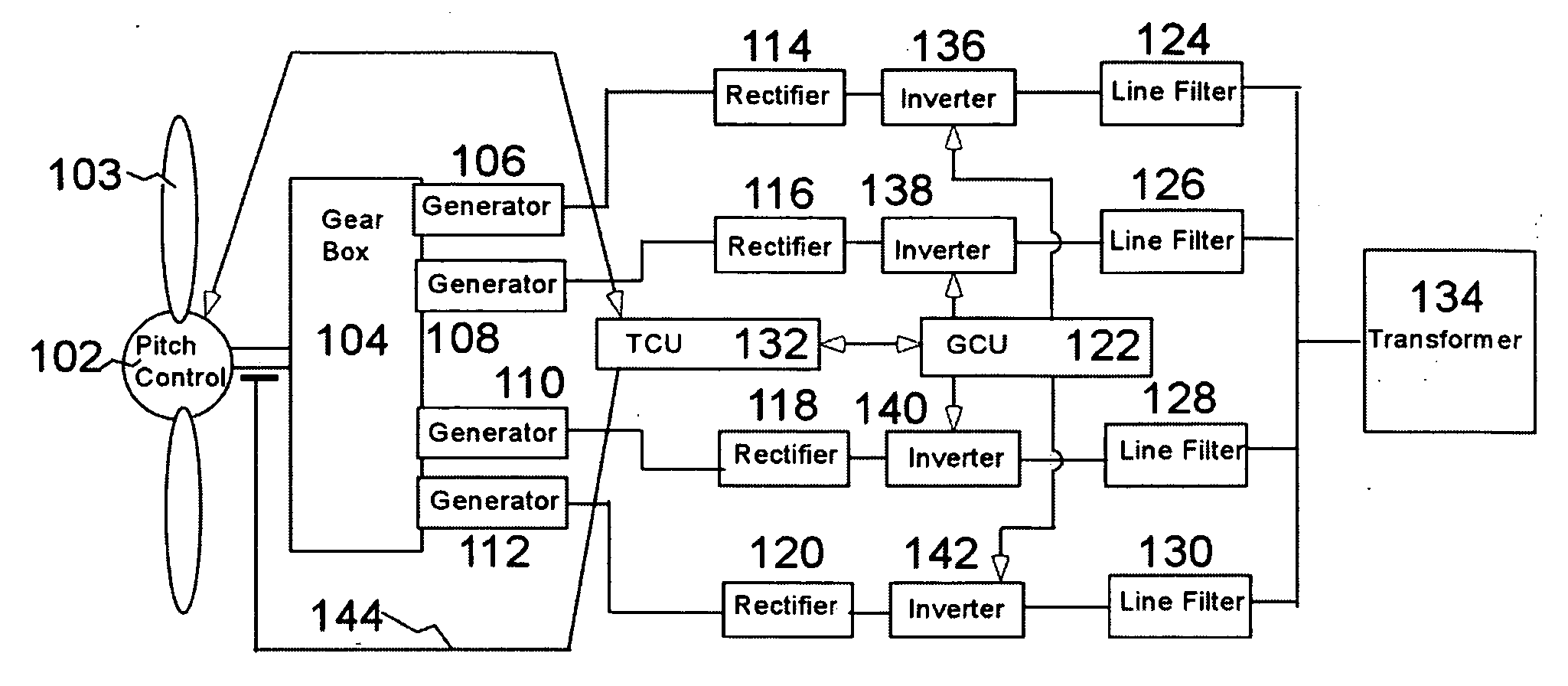

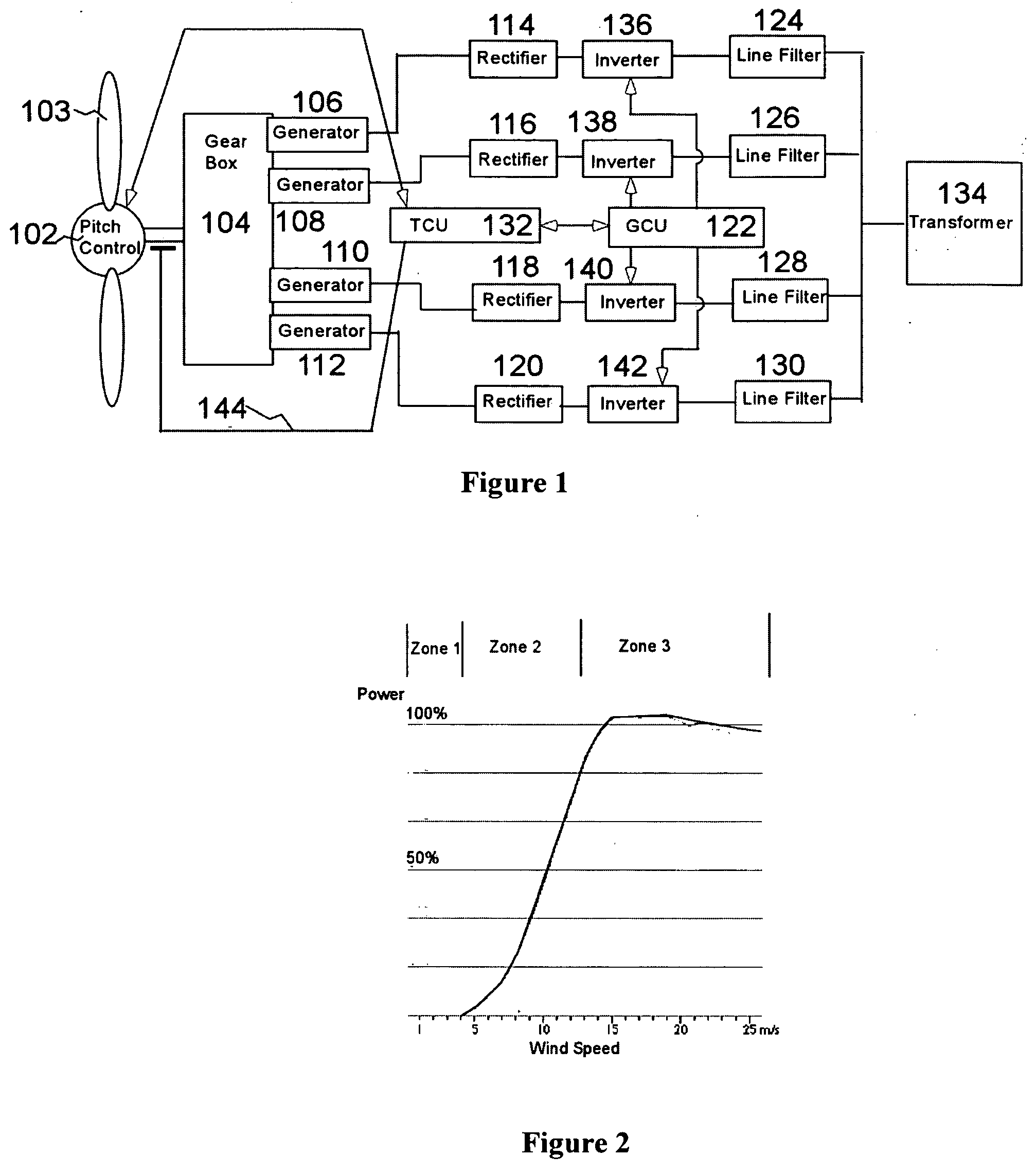

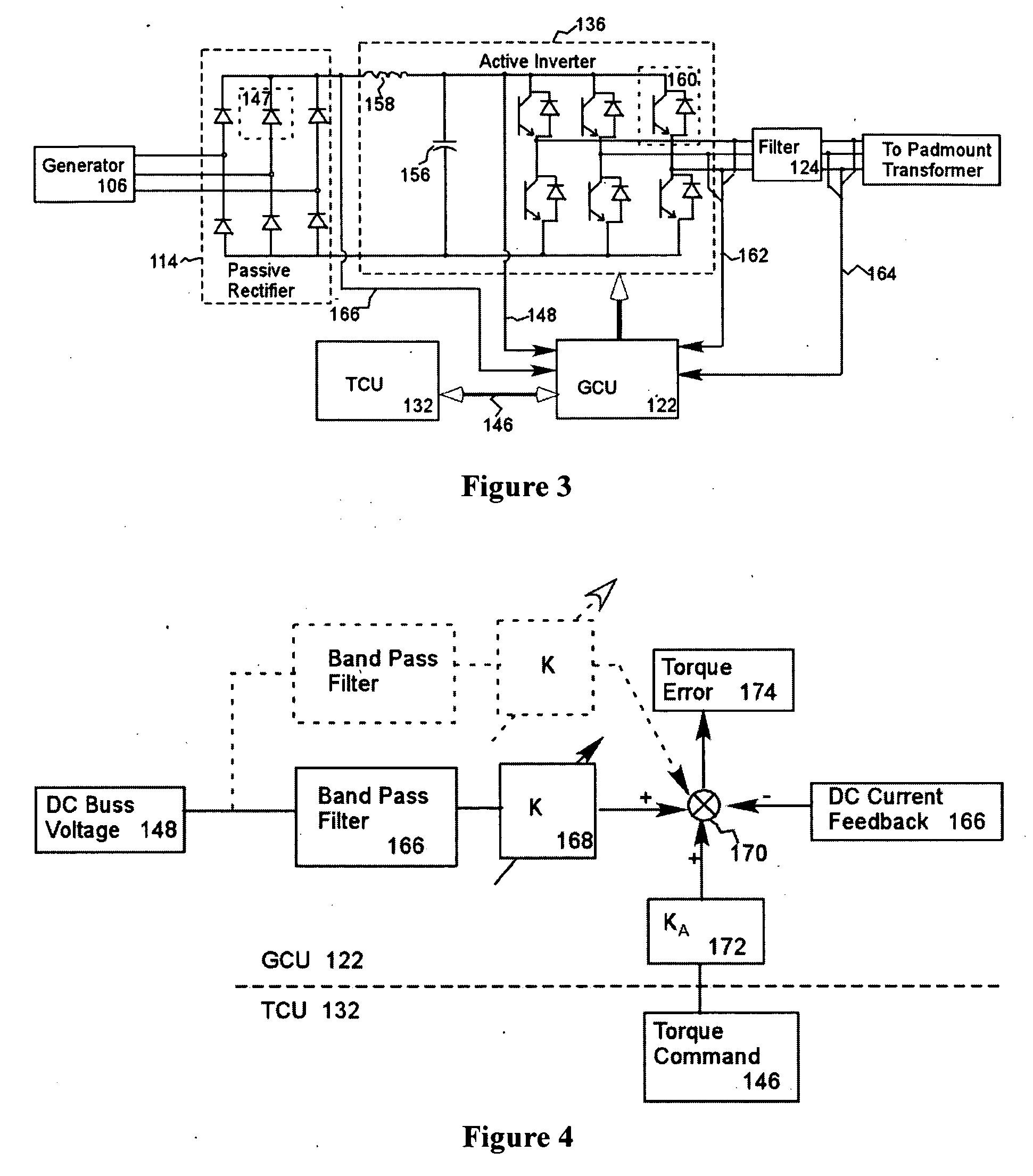

Variable speed distributed drive train wind turbine system

InactiveUS7042110B2Improve efficiencyImprove reliabilityWind motor controlEmergency protective circuit arrangementsPermanent magnet rotorDc current

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

Variable speed distributed drive train wind turbine system

InactiveUS20050012339A1Improve efficiencyImprove reliabilityWind motor controlWorking fluid for enginesElectric power transmissionPermanent magnet rotor

A variable speed wind turbine employing a rotor connected to a multiplicity of synchronous generators with wound field or permanent magnet rotors. A passive rectifier and an inverter are used for power transfer back to the grid. A Turbine Control Unit (TCU) commands a required generator torque based on rotor speed and power output of the turbine inverters. Torque is controlled by regulating the DC current by control of the inverter. A main-shaft-damping filter is provided by measurement of the DC bus voltage. In high winds the turbine remains at a constant average output power through a constant torque command and a varying pitch command to a rotor pitch servo system. A set point is fixed at the inverter output such that output VAR load is minimized running the turbine at very nearly unity power factor. Dynamic VAR and power factor control is provided by a separate VAR apparatus.

Owner:UNITED TECH CORP

Method and apparatus for tracking maximum power point for inverters, for example, in photovoltaic applications

ActiveUS20050002214A1Conversion with intermediate conversion to dcDc-dc conversionElectric power systemImage resolution

A power system employs an outer voltage feedback loop and an inner current feedback loop to control a power converter, such as a DC to AC inverter for transferring electrical power between a power source, for example a photovoltaic array, and a load, for example a power grid. The outer loop accommodates variations in the output of the power source, for example accommodating anomalies in IV characteristics such as IV droop characteristic associated with photovoltaic cells. The outer loop may employ a first control regime or a second control regime, for example, dependent on whether a DC bus voltage or power is smaller than a value corresponding to measurement resolution or expected noise.

Owner:RHOMBUS ENERGY SOLUTIONS

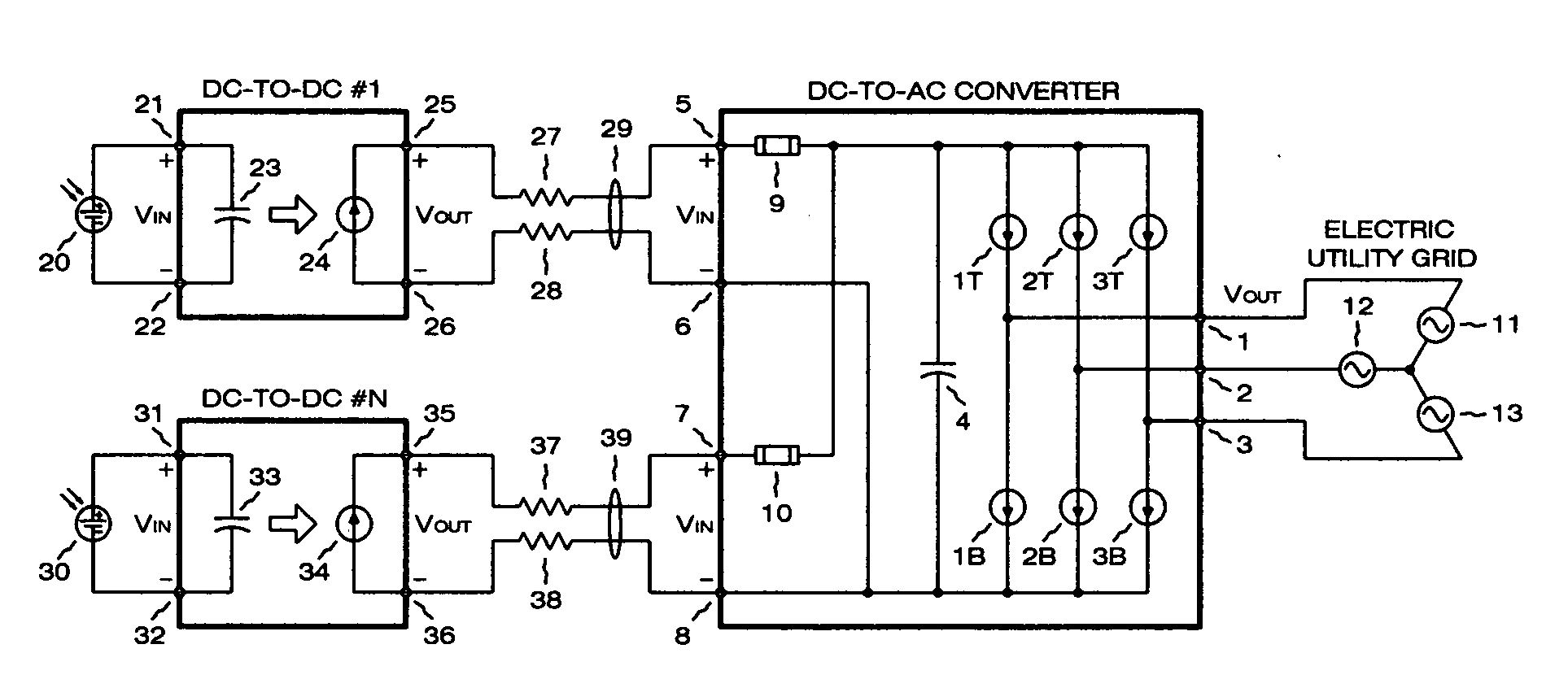

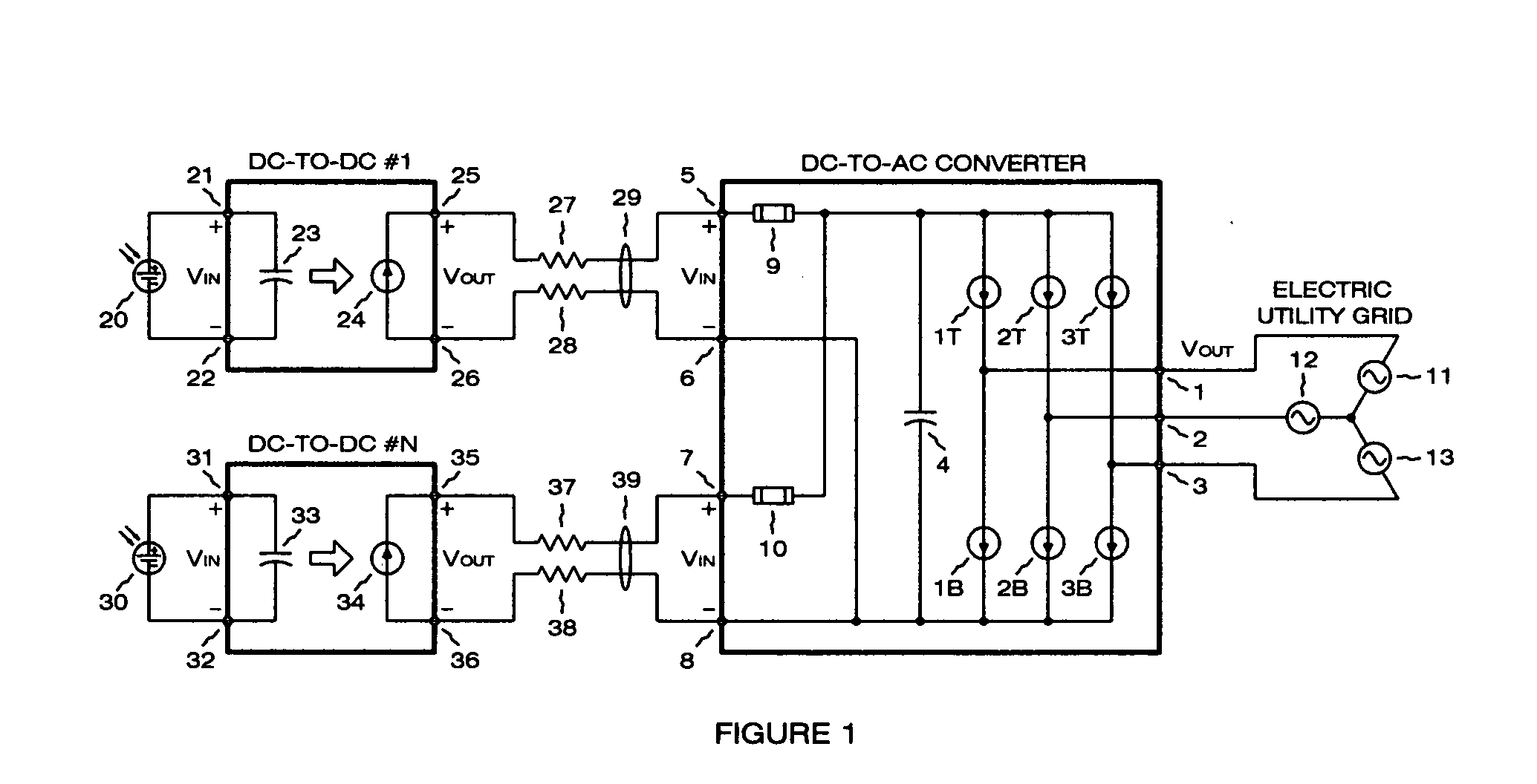

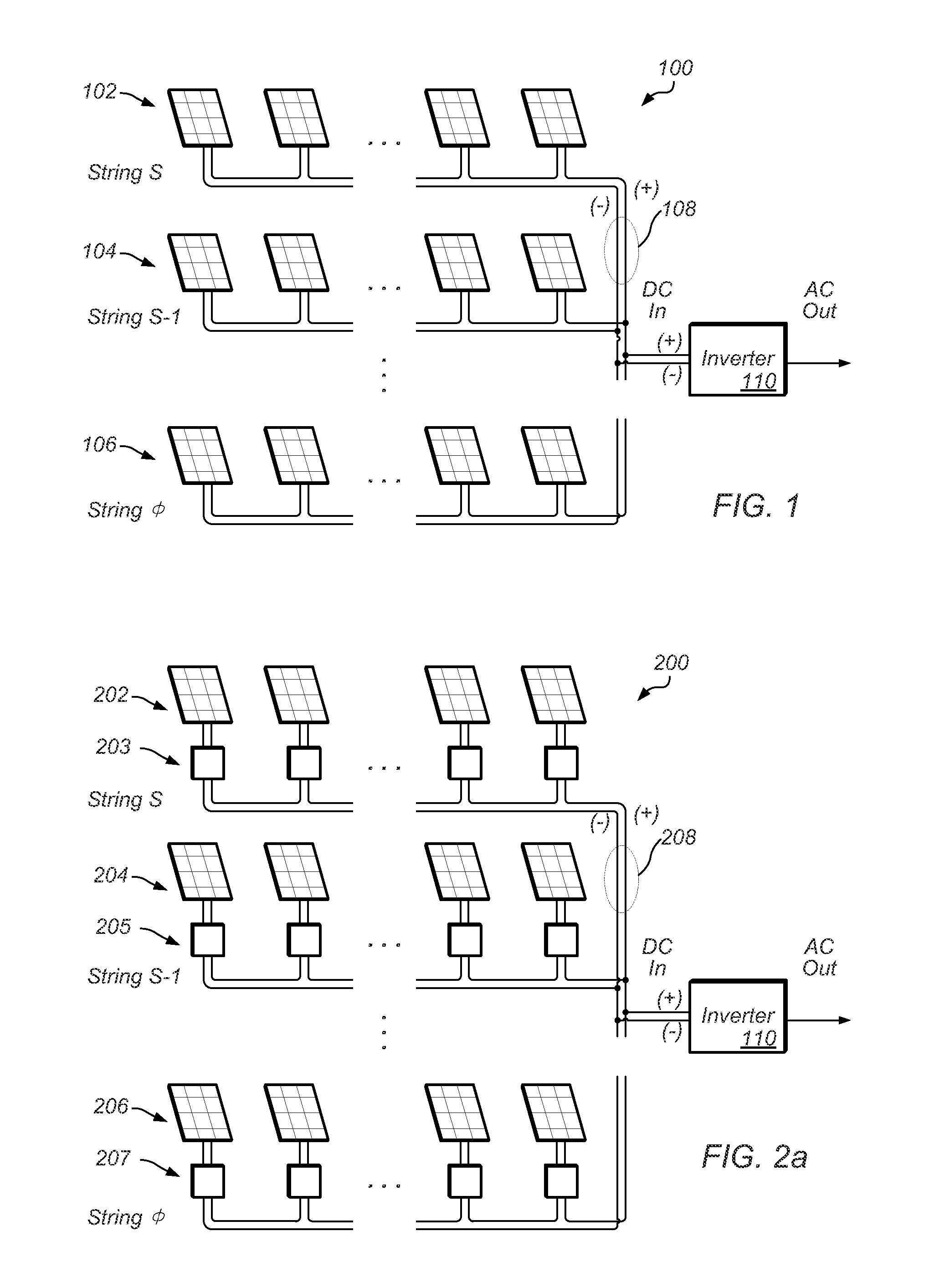

Photovoltaic power plant with distributed DC-to-DC power converters

A solar photovoltaic plant is disclosed where a number of distributed DC-to-DC converters are used in conjunction with a central DC-to-AC converter. Each DC-to-DC converter is dedicated to a portion of the photovoltaic array and tracks the maximum power point voltage thereof. The DC-to-DC converters also boost the photovoltaic voltage and regulate a DC output current for transmission to the central DC-to-AC converter. Five distinct advantages are had over the prior art. First, efficiencies in intra-field power collection are greatly improved by transferring power at higher DC voltages. Second, the number of independent photovoltaic maximum power point trackers in the power plant can be increased, in a cost effective manner, to optimize the overall photovoltaic array energy harvest. Third, each DC-to-DC converter output “looks” like a current source at the input of the DC-to-AC converter and therefore can be easily paralleled. Fourth, the current source nature of the DC-to-DC converter outputs enables the DC-to-AC converter to operate with a minimum, fixed DC bus voltage to provide maximum DC-to-AC power conversion efficiencies. And fifth, each distributed DC-to-DC converter can isolate a faulted portion of the photovoltaic array while the remainder of the array continues producing power.

Owner:PARKER INTANGIBLES LLC

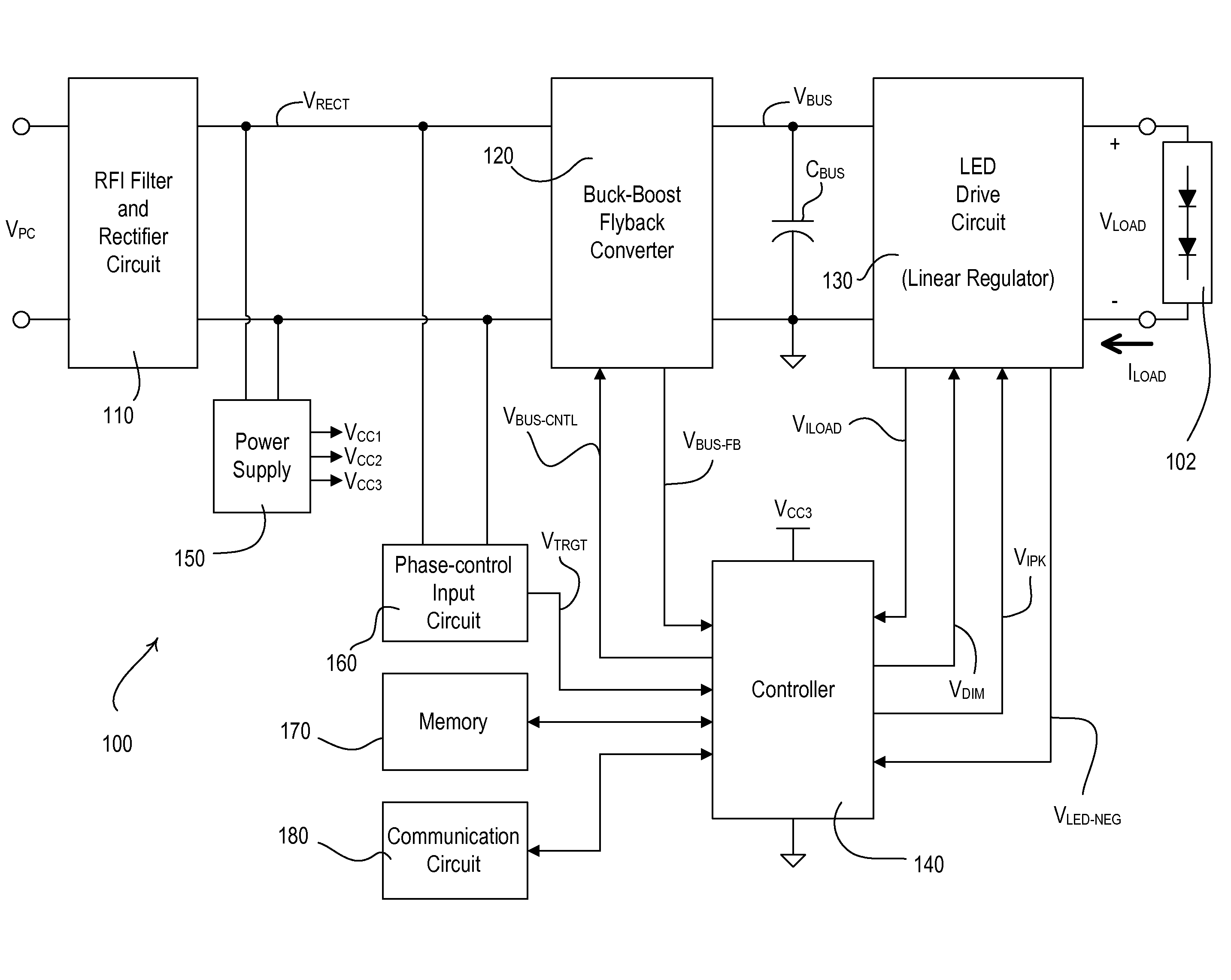

Load Control Device for a Light-Emitting Diode Light Source

ActiveUS20130063047A1Reducing bus voltageIncreases magnitudeElectrical apparatusElectroluminescent light sourcesEngineeringIntensity control

An LED driver for controlling the intensity of an LED light source includes a power converter circuit for generating a DC bus voltage, an LED drive circuit for receiving the bus voltage and controlling a load current through, and thus the intensity of, the LED light source, and a controller operatively coupled to the power converter circuit and the LED drive circuit. The LED drive circuit comprises a controllable-impedance circuit adapted to be coupled in series with the LED light source. The controller adjusts the magnitude of the bus voltage to a target bus voltage and generates a drive signal for controlling the controllable-impedance circuit. To adjust the intensity of the LED light source, the controller controls both the magnitude of the load current and the magnitude of the regulator voltage. The controller controls the magnitude of the regulator voltage by simultaneously maintaining the magnitude of the drive signal constant and adjusting the target bus voltage.

Owner:LUTRON TECH CO LLC

Configurable load control device for light-emitting diode light sources

ActiveUS20110080111A1Electrical apparatusElectroluminescent light sourcesEngineeringPersonal computer

A configurable light-emitting diode (LED) driver is adapted to control a plurality of different LED light sources, which may be rated to operate using different load control techniques, different dimming techniques, and different magnitudes of load current and voltage. The LED driver comprises a power converter circuit for generating a DC bus voltage, and an LED drive circuit for receiving the bus voltage and adjusting either the magnitude of the current conducted through the LED light source or the magnitude of the voltage across the LED light source. The LED driver is operable to dim the LED light source using either a pulse-width modulation technique or a constant current reduction technique, and may be configured using a programming device and a personal computer.

Owner:LUTRON TECH CO LLC

Load control device for a light-emitting diode light source

An LED driver for controlling the intensity of an LED light source includes a power converter circuit for generating a DC bus voltage, an LED drive circuit for receiving the bus voltage and controlling a load current through, and thus the intensity of, the LED light source, and a controller operatively coupled to the power converter circuit and the LED drive circuit. The LED drive circuit comprises a controllable-impedance circuit coupled in series with the LED light source. The controller adjusts the magnitude of the bus voltage to a target bus voltage and generates a drive signal for controlling the controllable-impedance circuit. To adjust the intensity of the LED light source, the controller controls the magnitudes of both the load current and the regulator voltage. The controller controls the magnitude of the regulator voltage by simultaneously maintaining the magnitude of the drive signal constant and adjusting the target bus voltage.

Owner:LUTRON TECH CO LLC

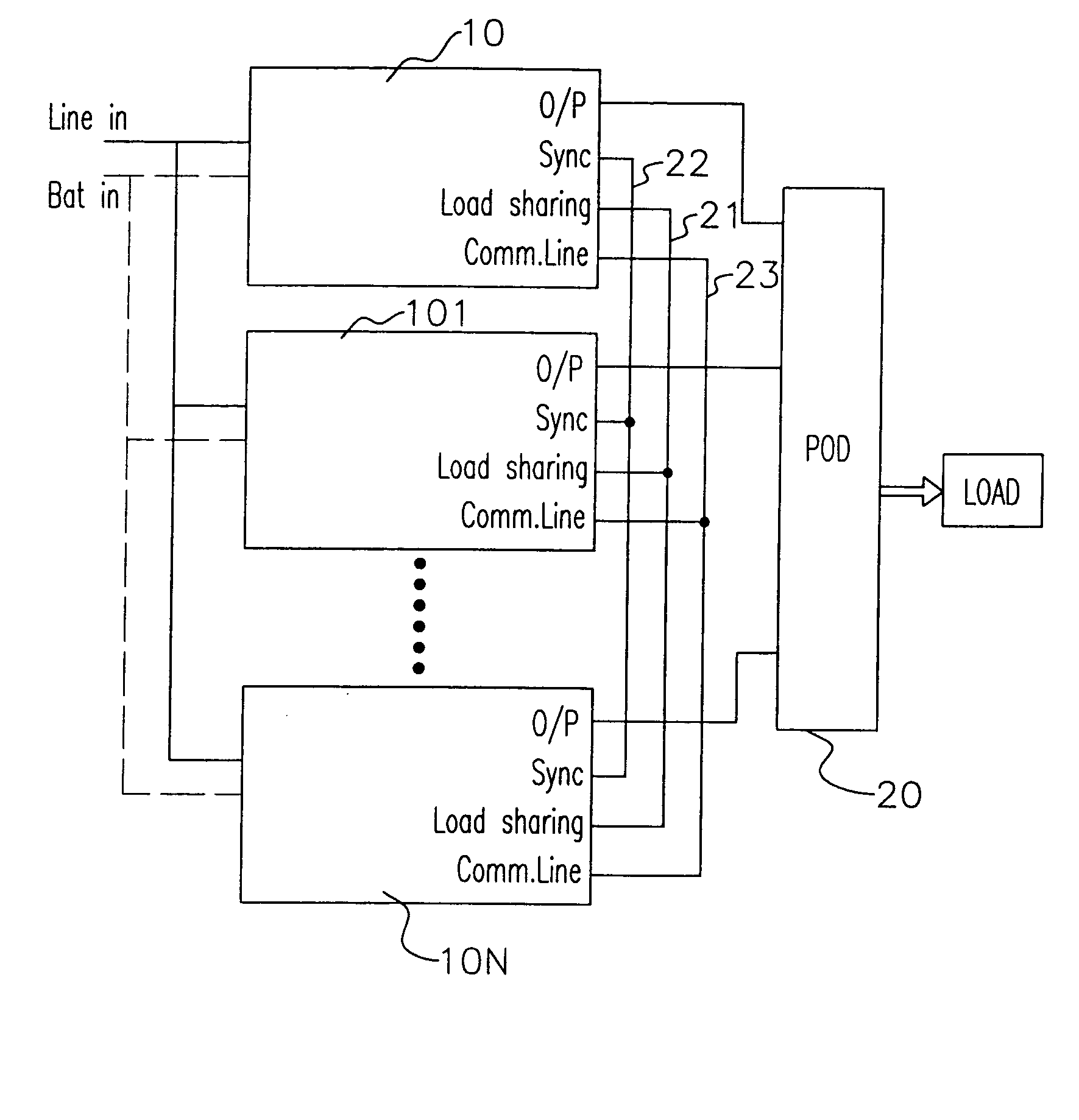

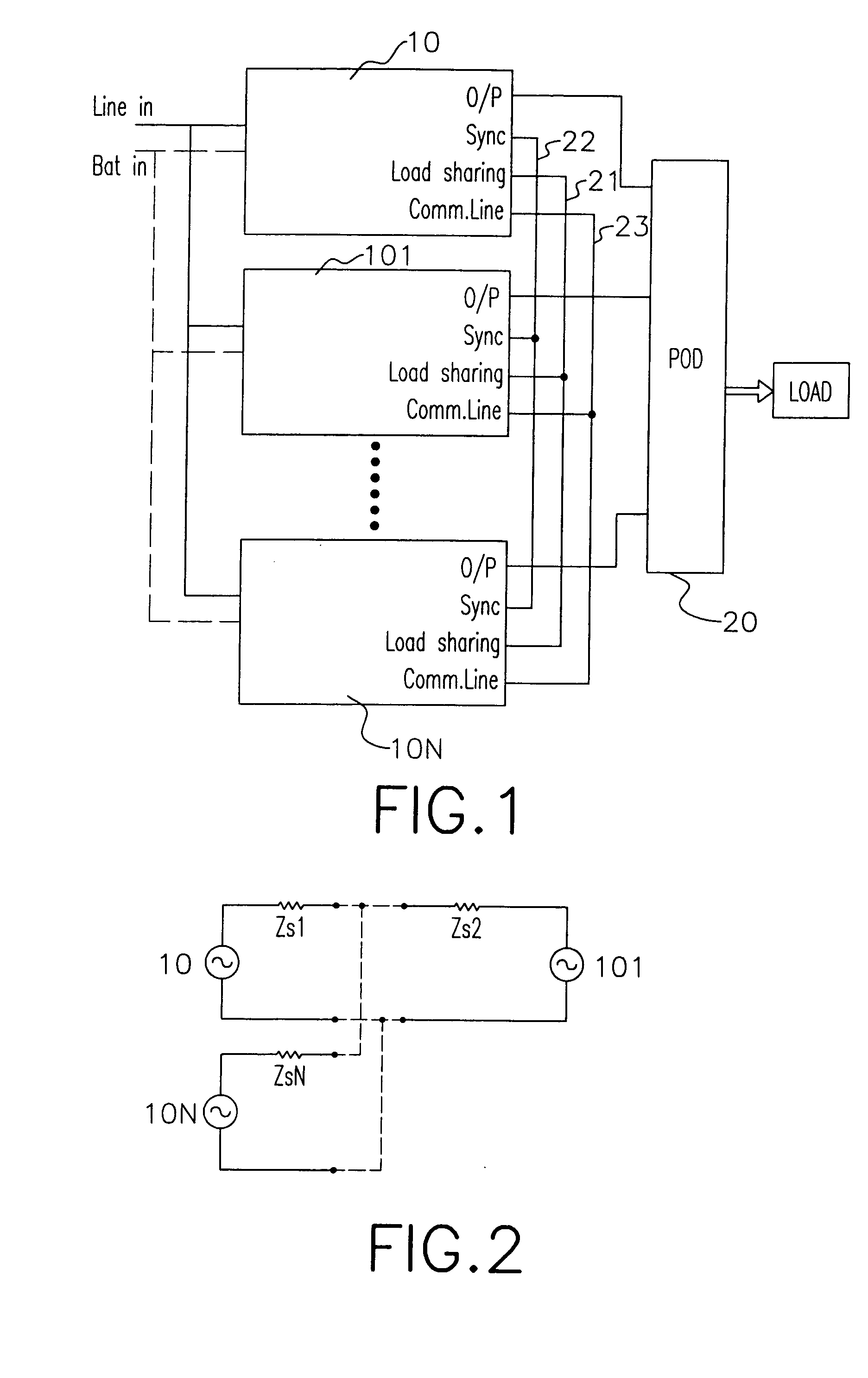

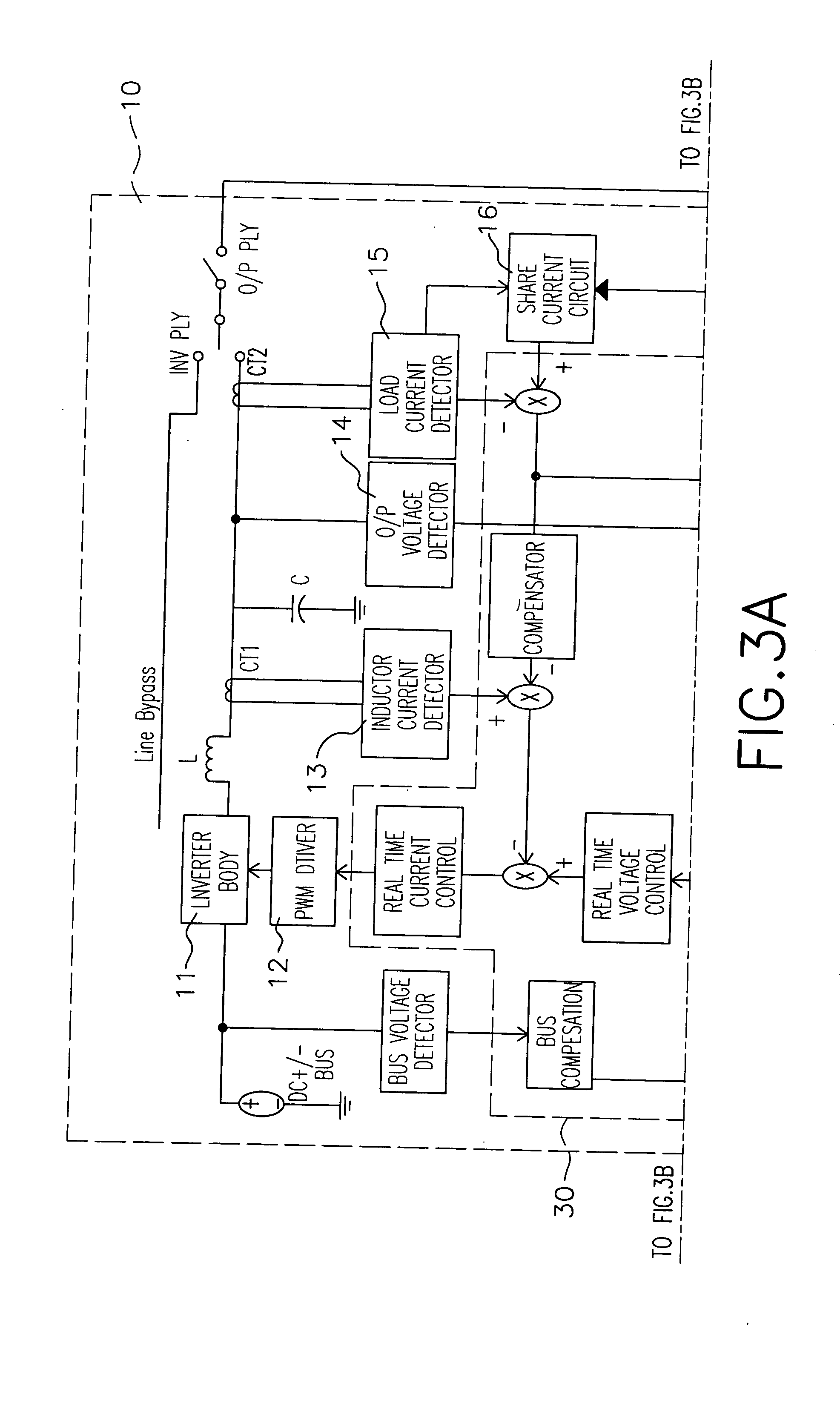

Parallel redundant power system and the control method for the same

InactiveUS20050073783A1Improve reliabilitySharing is limitedEmergency protective arrangements for automatic disconnectionDc-ac conversion without reversalElectric power systemEngineering

A power redundant power system and a method for controlling the power system are presented, wherein the power system is composed of at least one inverter for supplying AC power to a load through a bus, a phase lock system to synchronize all output voltages of the inverters and a current sharing circuit to properly distribute the load current among all inverters. Each inverter is controlled by an unbalanced power to limit the increase of its cross current. Moreover, the information related to DC bus voltage is further applied to control the inverters, whereby the cross current is mitigated and entire power system is operated steadily.

Owner:PHOENIXTEC POWER

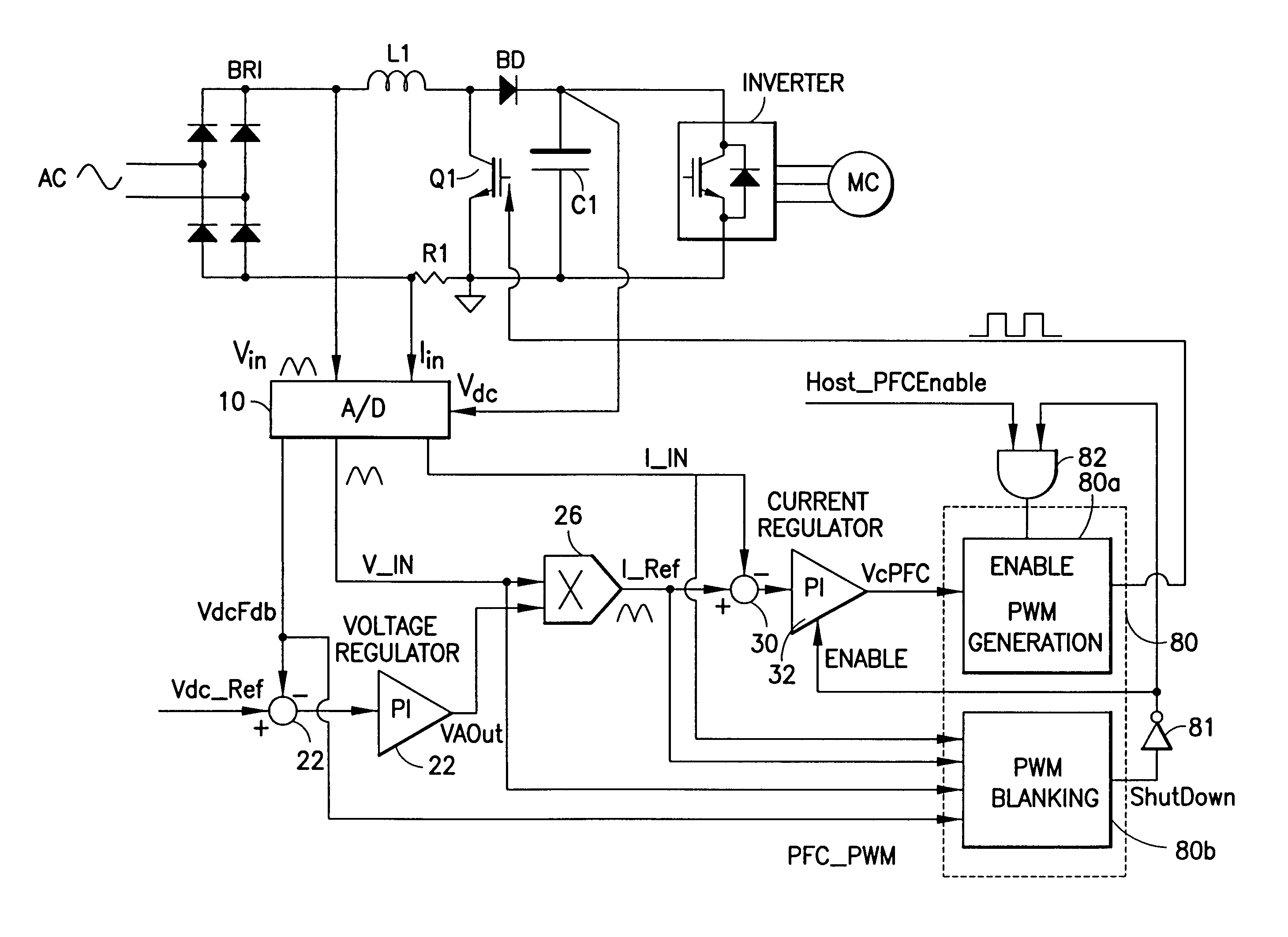

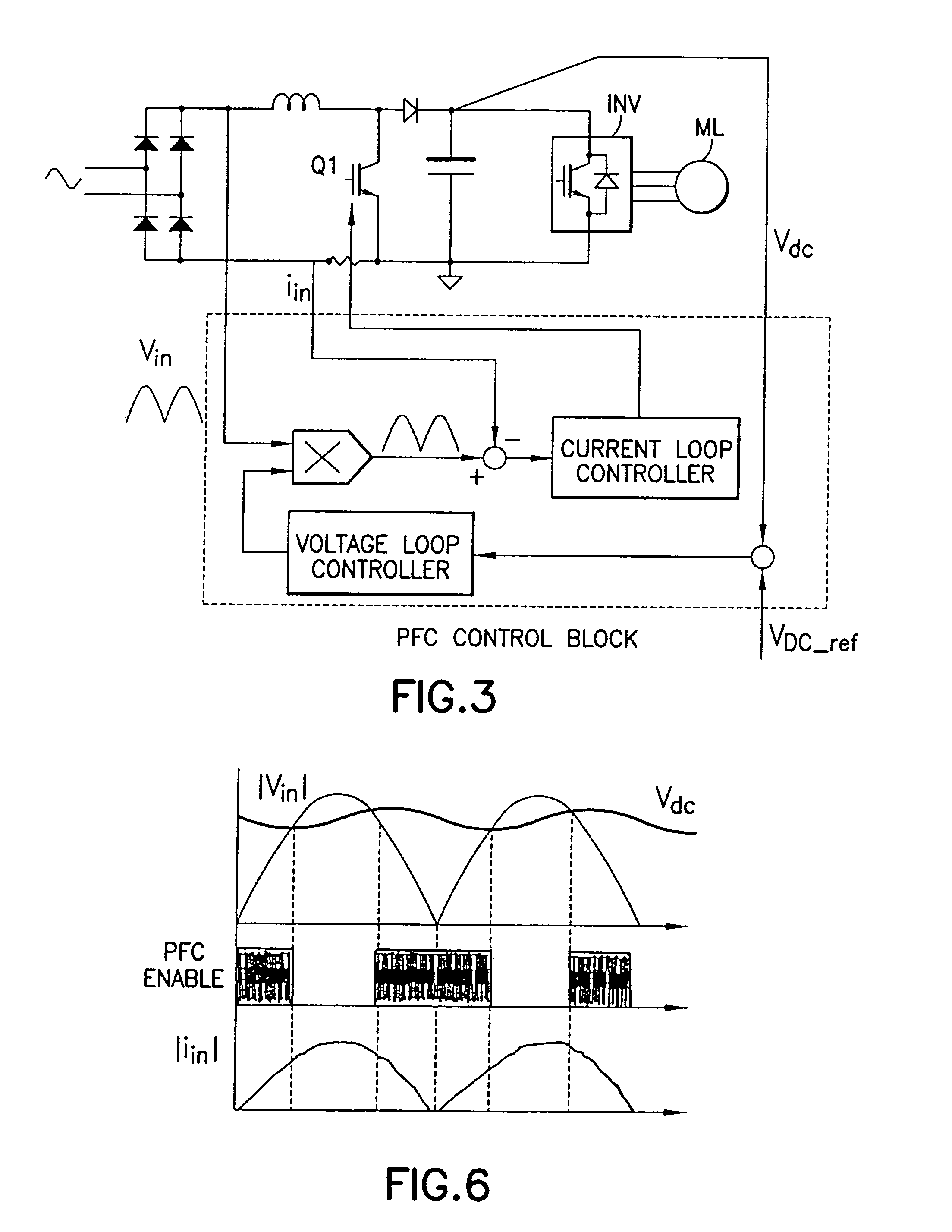

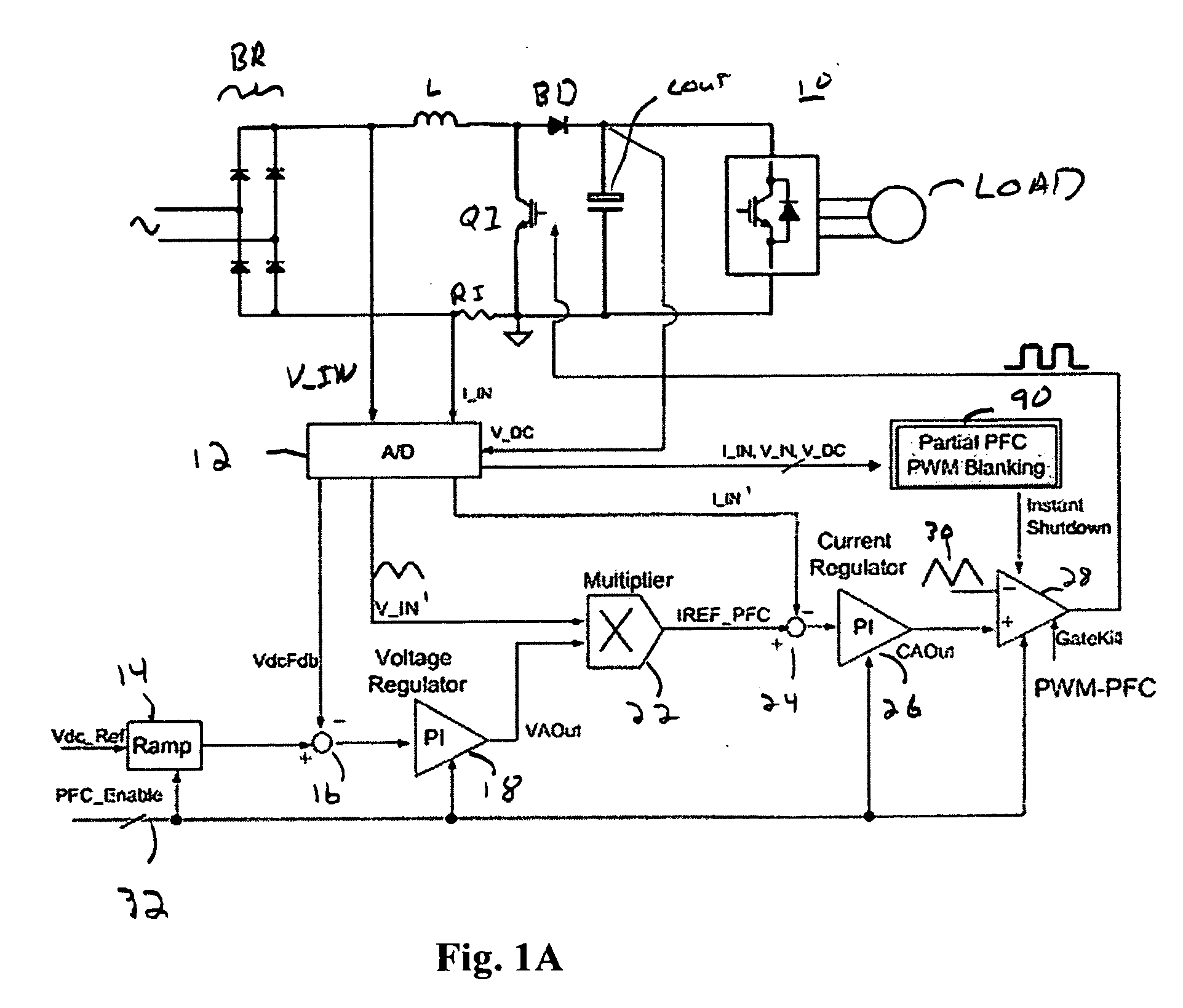

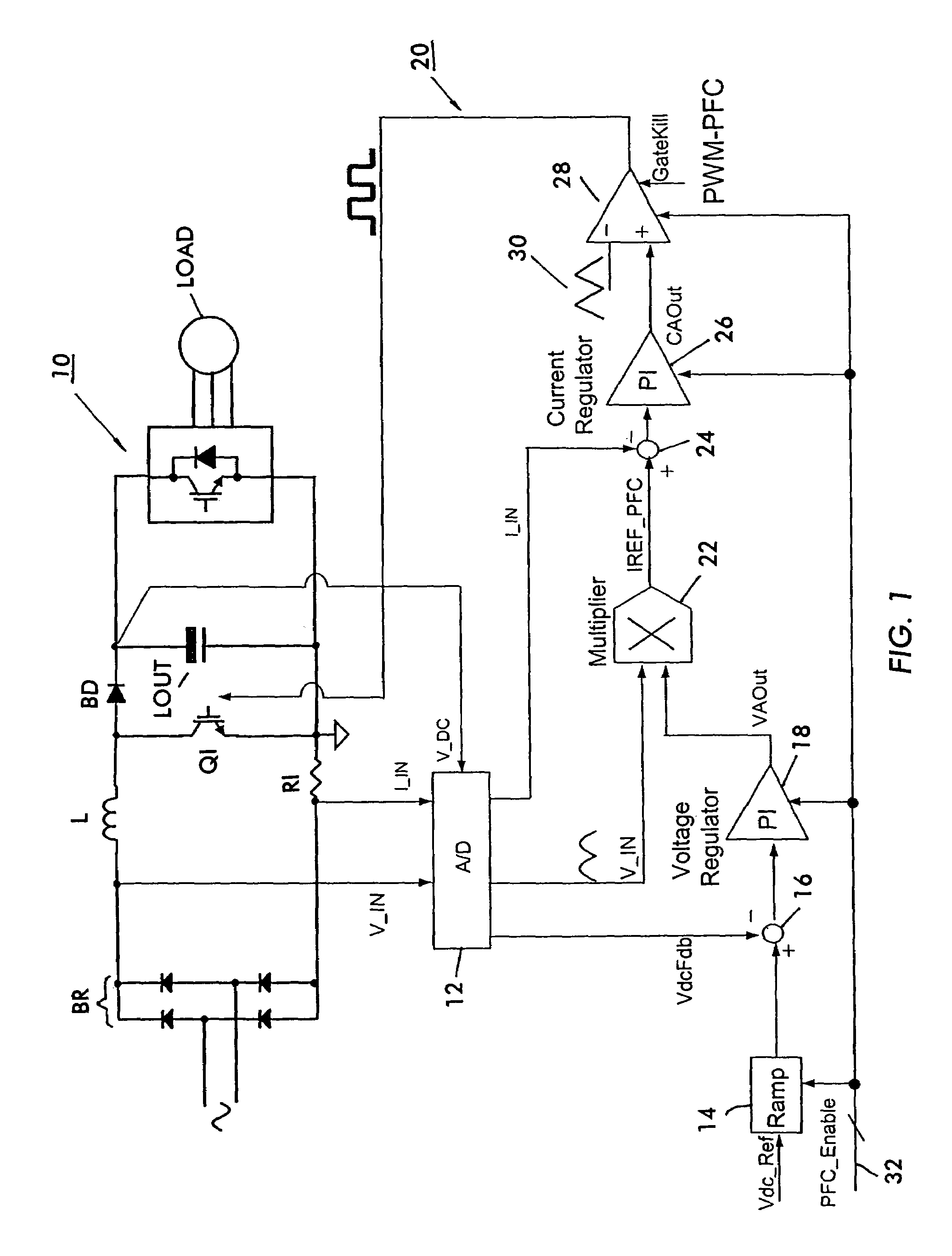

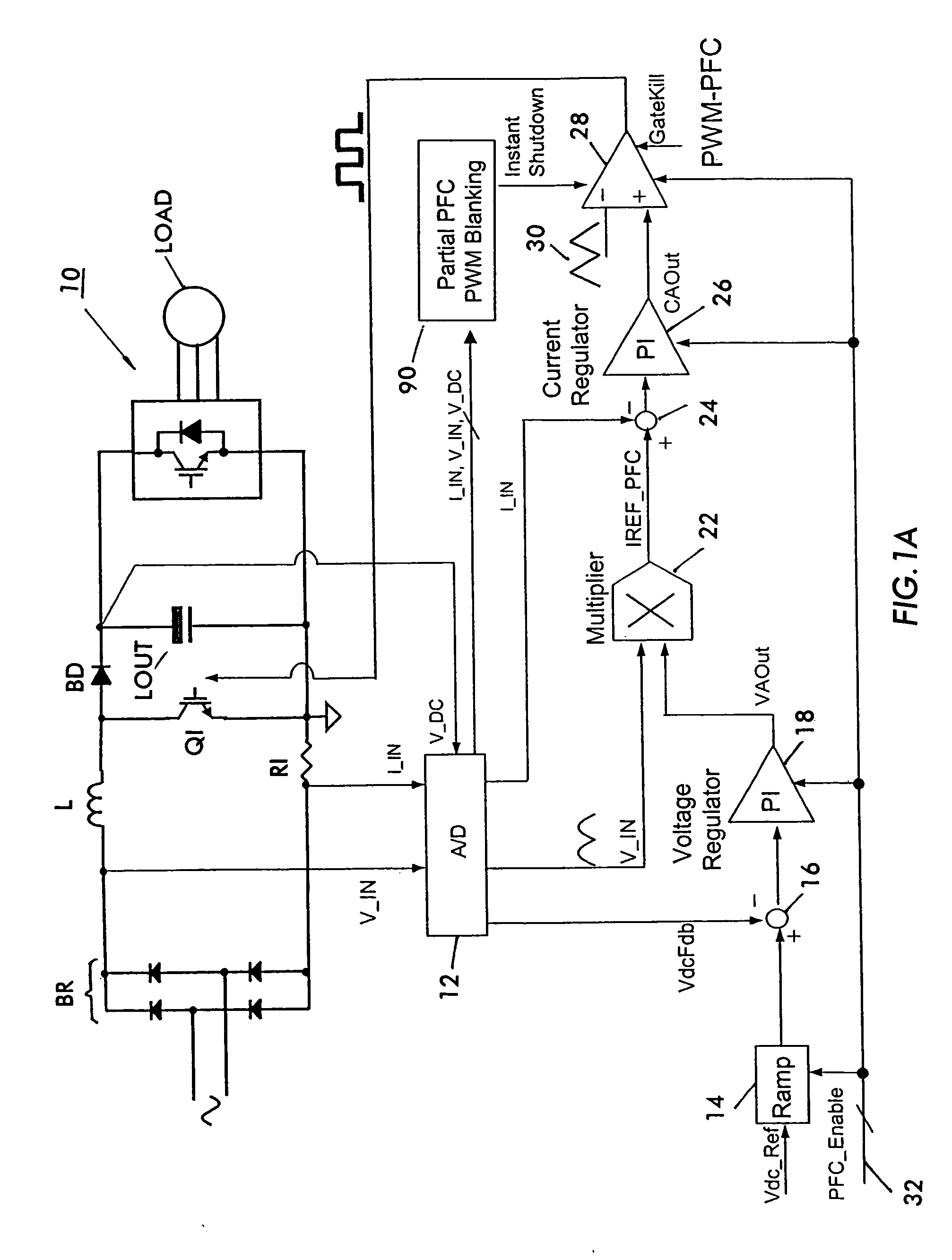

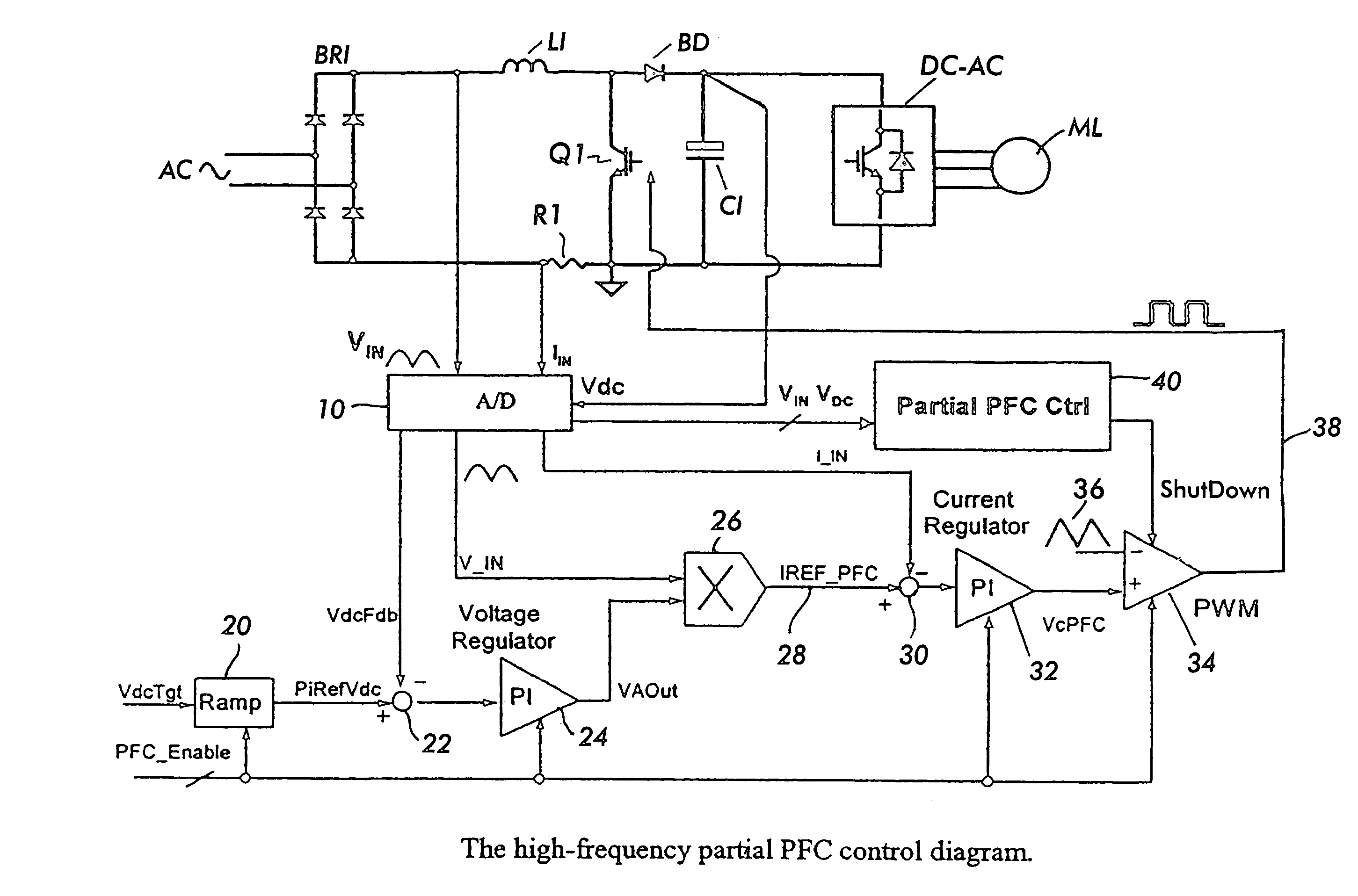

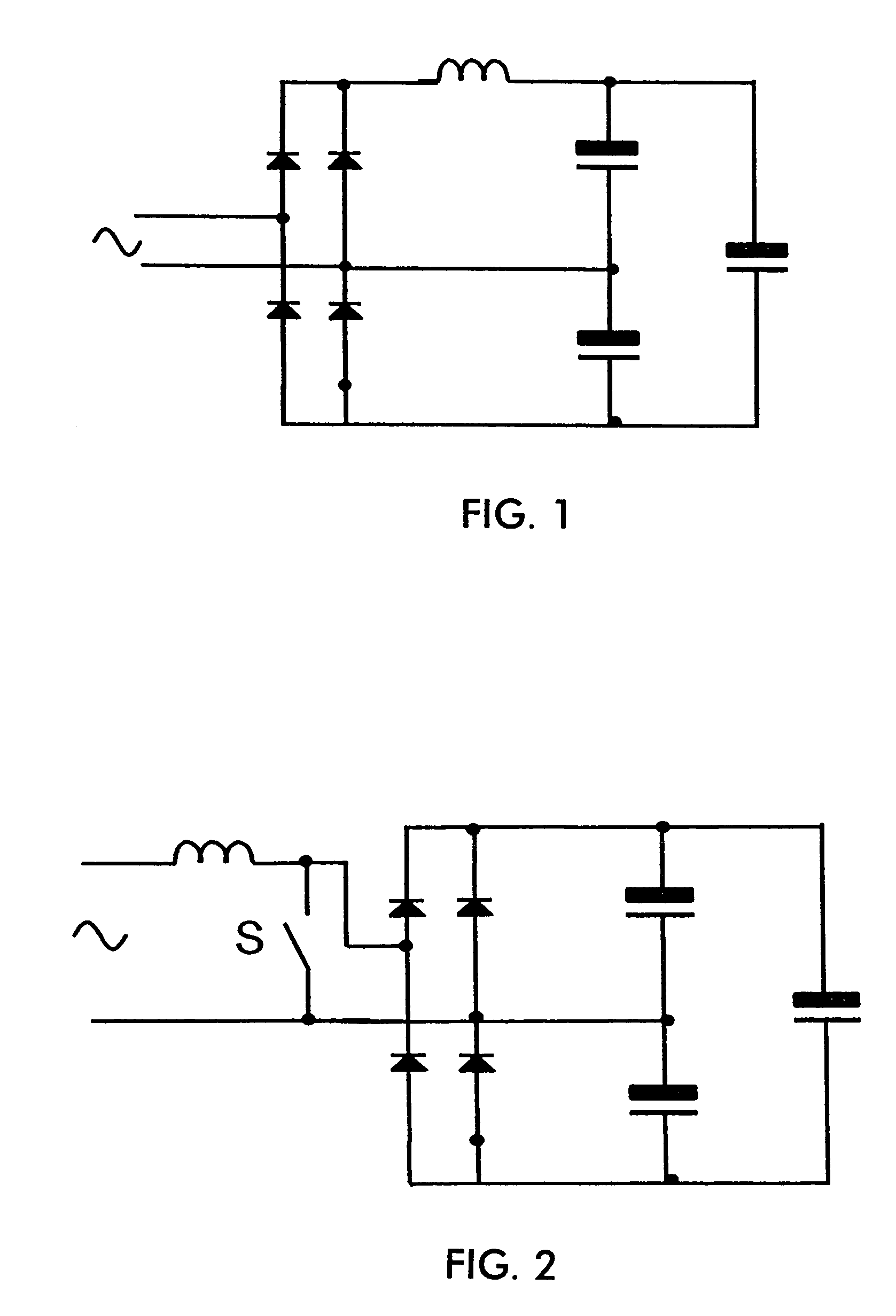

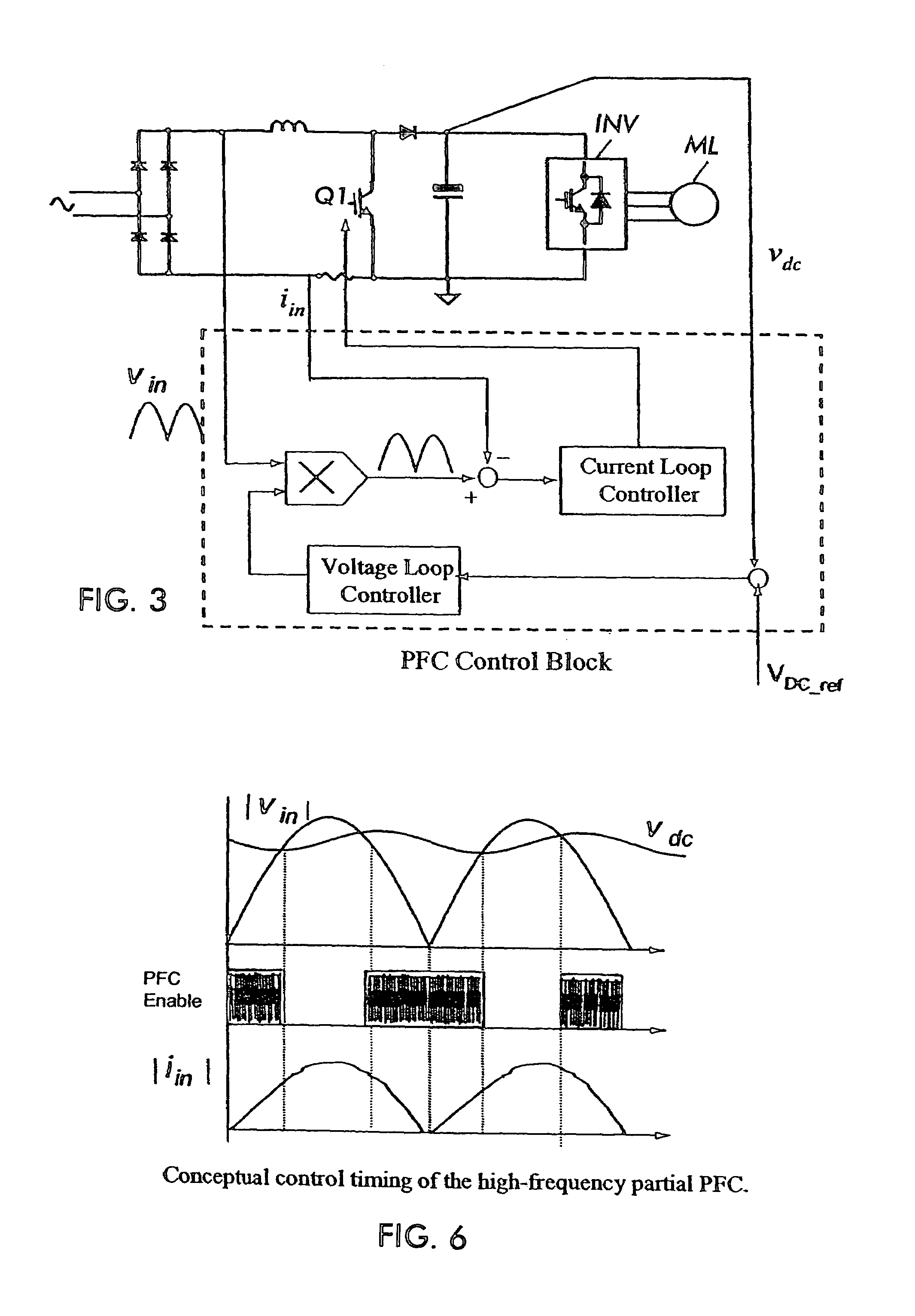

High frequency partial boost power factor correction control circuit and method

ActiveUS7148664B2Efficient power electronics conversionElectric variable regulationReference currentEngineering

A circuit for providing power factor correction includes a boost converter circuit with a boost inductance and a power factor correction switch and a control circuit. The control circuit provides a pulse width modulated signal to control the on time of a PFC switch, and also includes a power factor correction pulse width modulated device receiving as inputs a rectified AC input voltage, a DC bus voltage, a signal proportional to the current through the inductor and a reference current signal. The power factor correction pulse width modulated device also includes a pulse width modulated generator operable to provide the pulse width modulated signal to control the on time of the PFC circuit and a pulse width modulated blanking device operable to provide an enable / disable signal to disable the pulse width modulated generator when predetermined conditions are met.

Owner:INFINEON TECH AMERICAS CORP

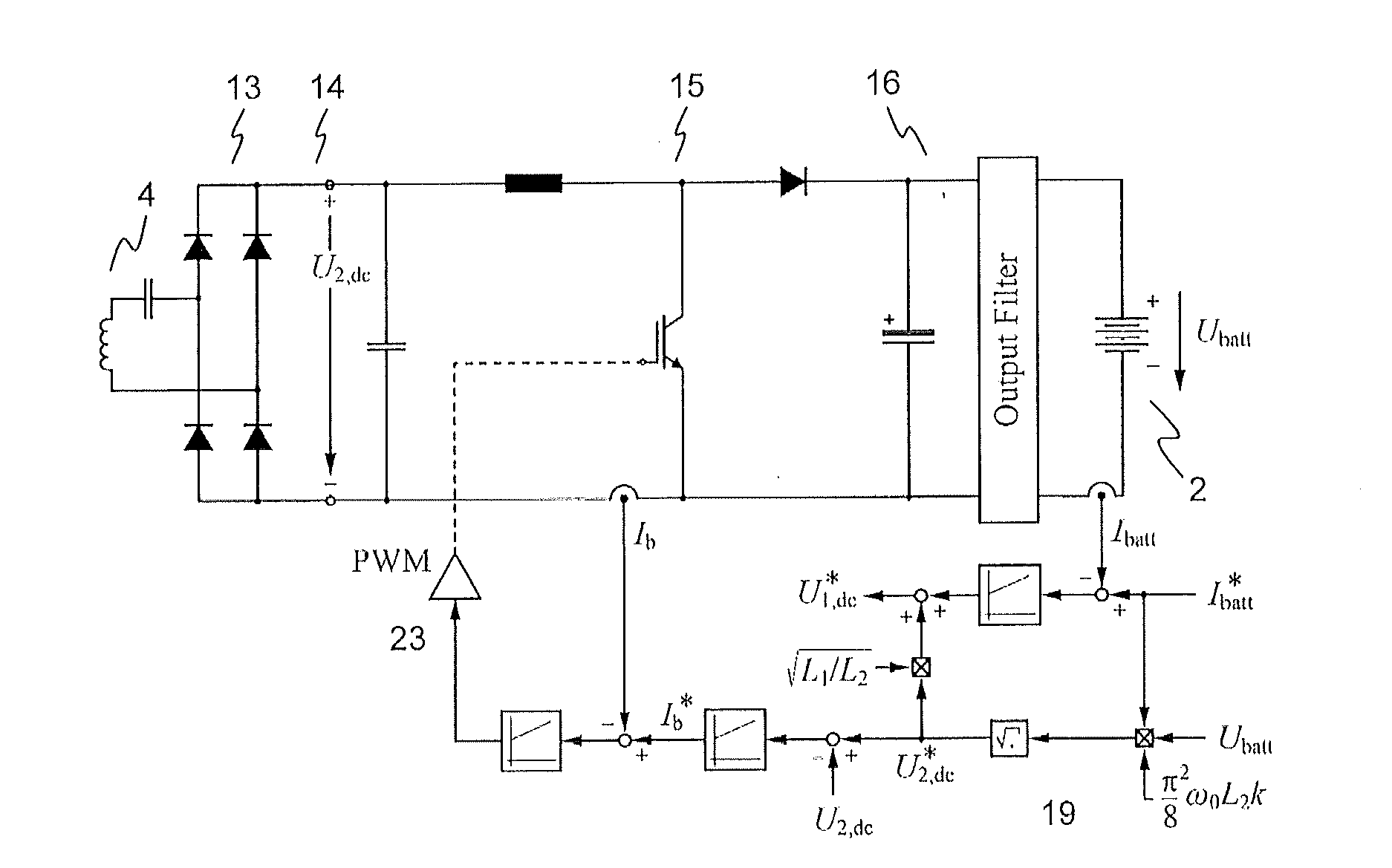

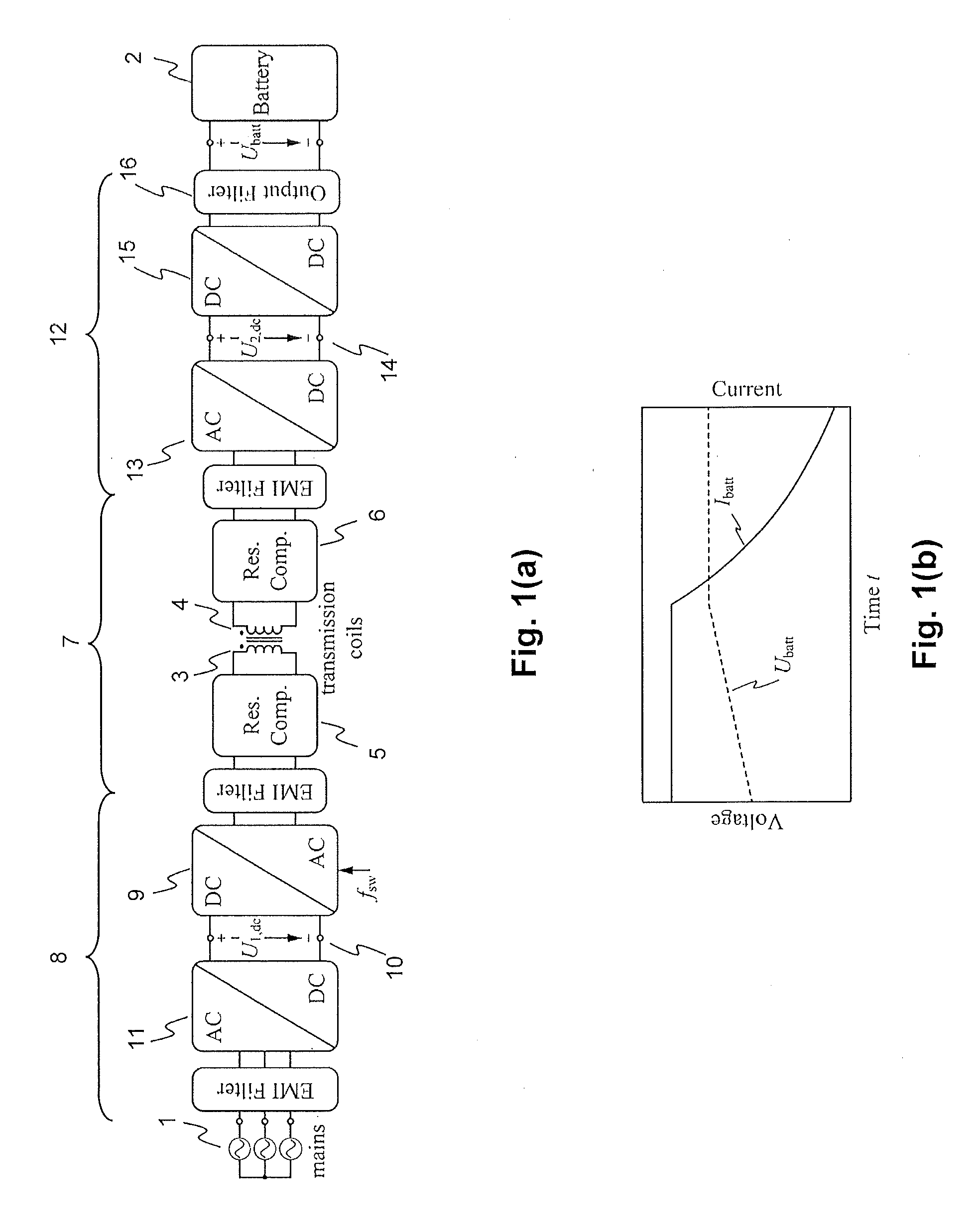

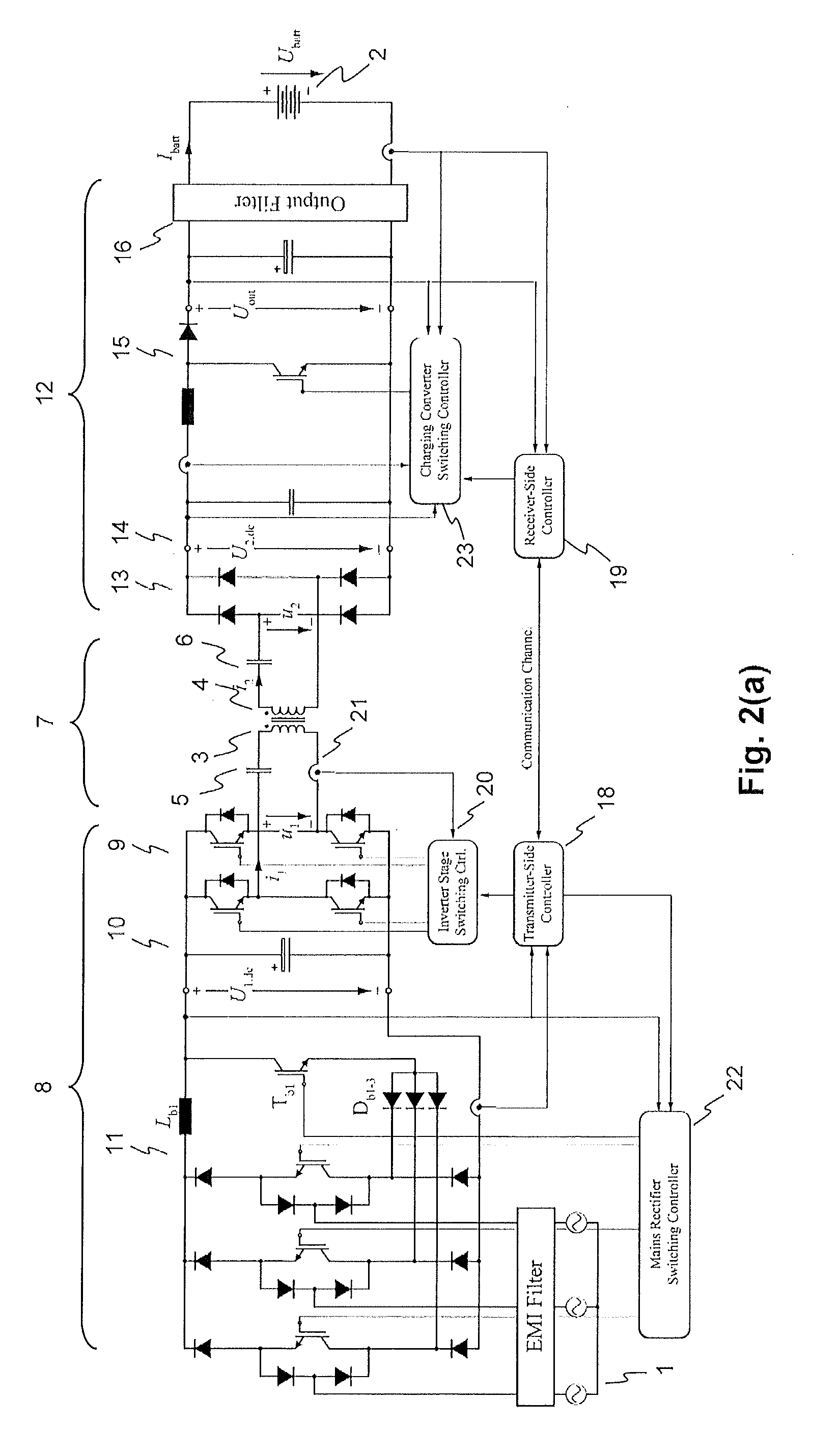

Inductive power transfer system and method for operating an inductive power transfer system

InactiveUS20150280455A1Minimize switching lossesBatteries circuit arrangementsCharging stationsTransmitter coilEngineering

An exemplary inductive power transfer system having a transmitter coil and a receiver coil. A transmitter-side power converter having a mains rectifier stage powering a transmitter-side dc-bus and controlling a transmitter-side dc-bus voltage U1,dc. A transmitter-side inverter stage with a switching frequency fsw supplies the transmitter coil with an alternating current. A receiver-side power converter having a receiver-side rectifier stage that rectifies a voltage induced in the receiver coil and powering a receiver-side dc-bus and a receiver-side charging converter controlling a receiver-side dc-bus voltage U2,dc. Power controllers that determine from a power transfer efficiency of the power transfer, reference values U1,dc*, U2,dc* for the transmitter and receiver side dc-bus voltages. An inverter stage switching controller controls the switching frequency fsw to reduce losses in the transmitter-side inverter stage.

Owner:ABB (SCHWEIZ) AG

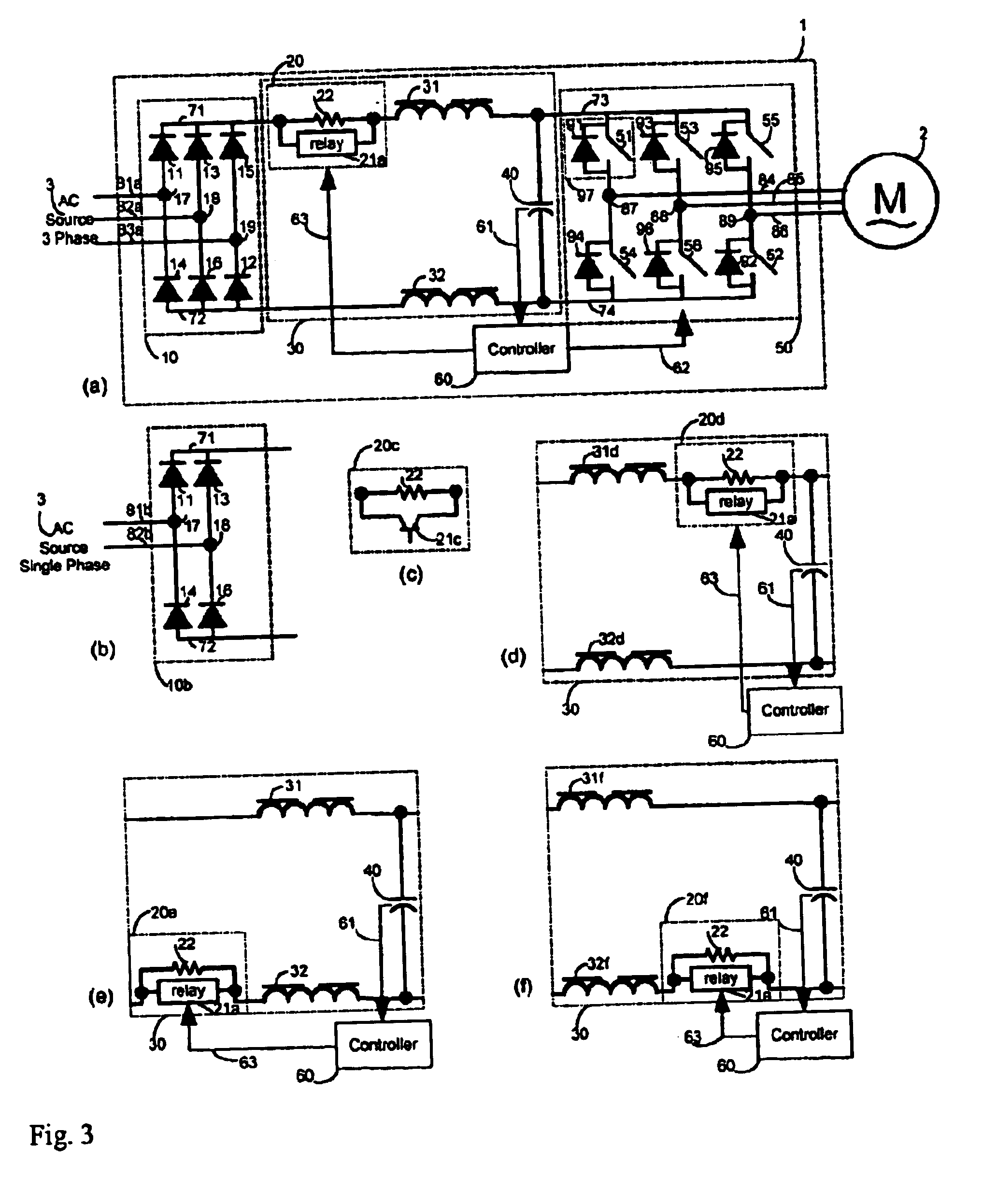

Reduced capacitance AC/DC/AC power converter

InactiveUS6804127B2Quick monitoringMore compact, durable and reliableEmergency protective circuit arrangementsAc-ac conversionCapacitanceElectrolytic capacitor

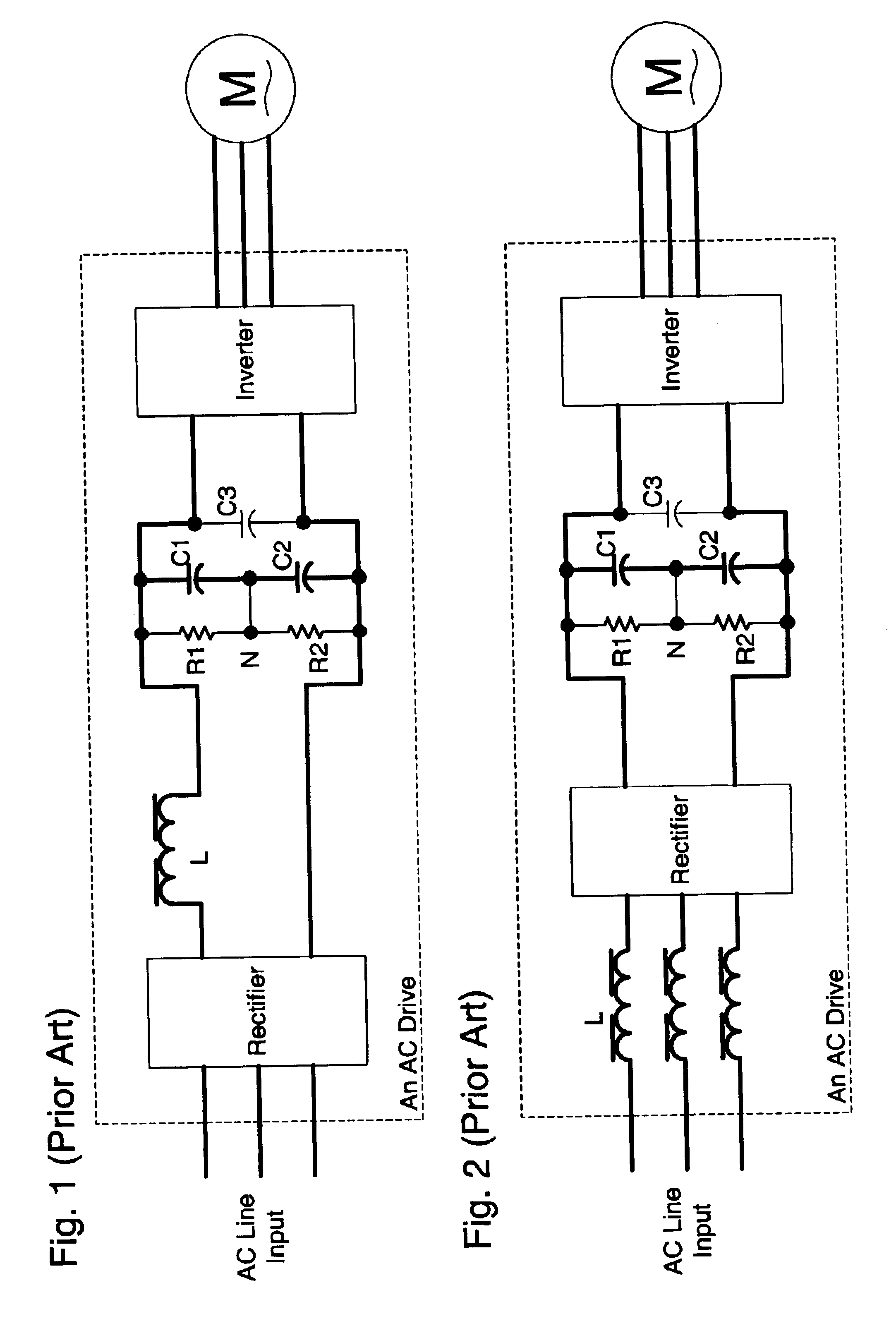

An AC / DC / AC power converter is constructed without using any electrolytic capacitor, such that it is more compact, durable and reliable. This converter only required a small capacitance for its DC link and this capacitor can be easily obtainable with other types of capacitors such as film or ceramic type. The system further includes means to disconnect both input and output to this DC bus capacitor. A controller capable of fast monitoring the DC bus voltage is also able of quickly disconnecting the capacitor out of either input or output energy path to prevent the capacitor from being charged to over-voltage. The controller also possesses capability of re-connecting the disrupted energy path once the DC bus voltage returns to normal.

Owner:WICON

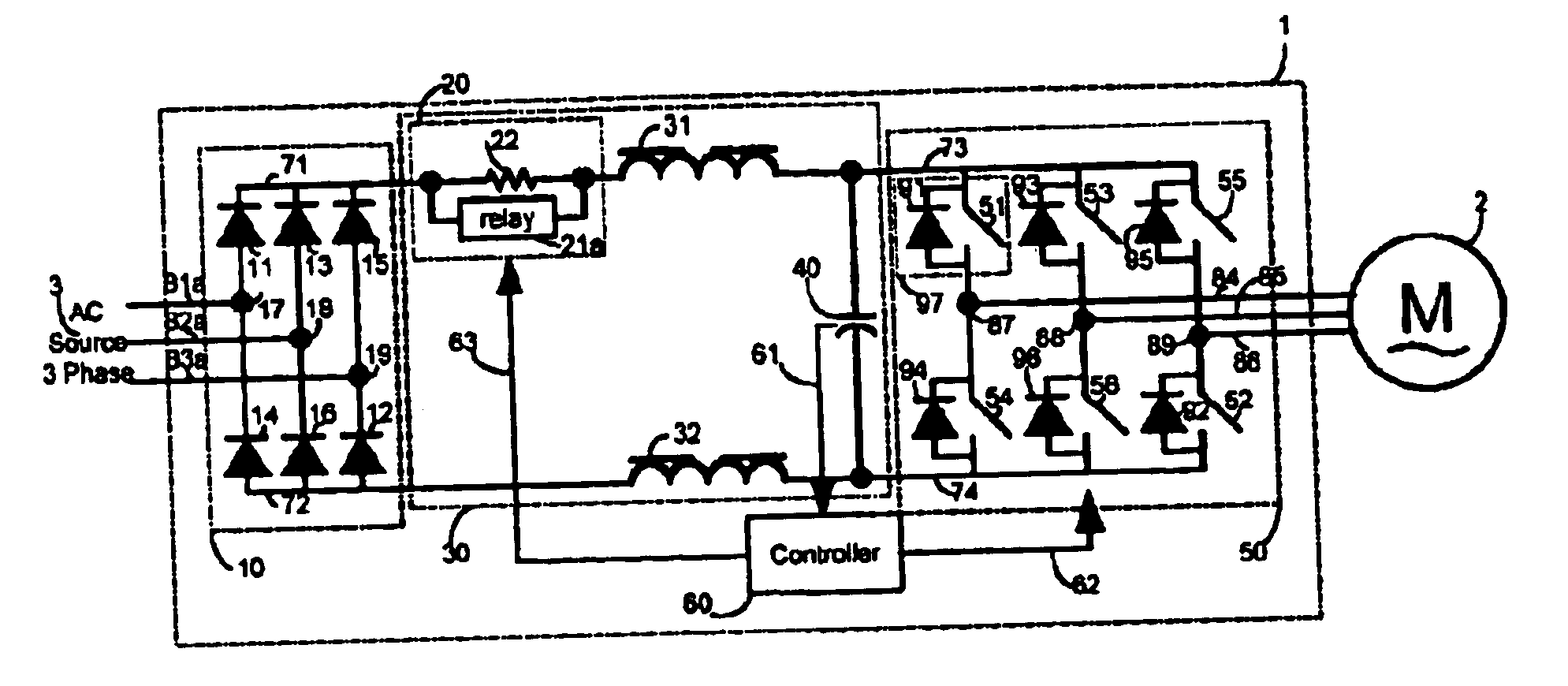

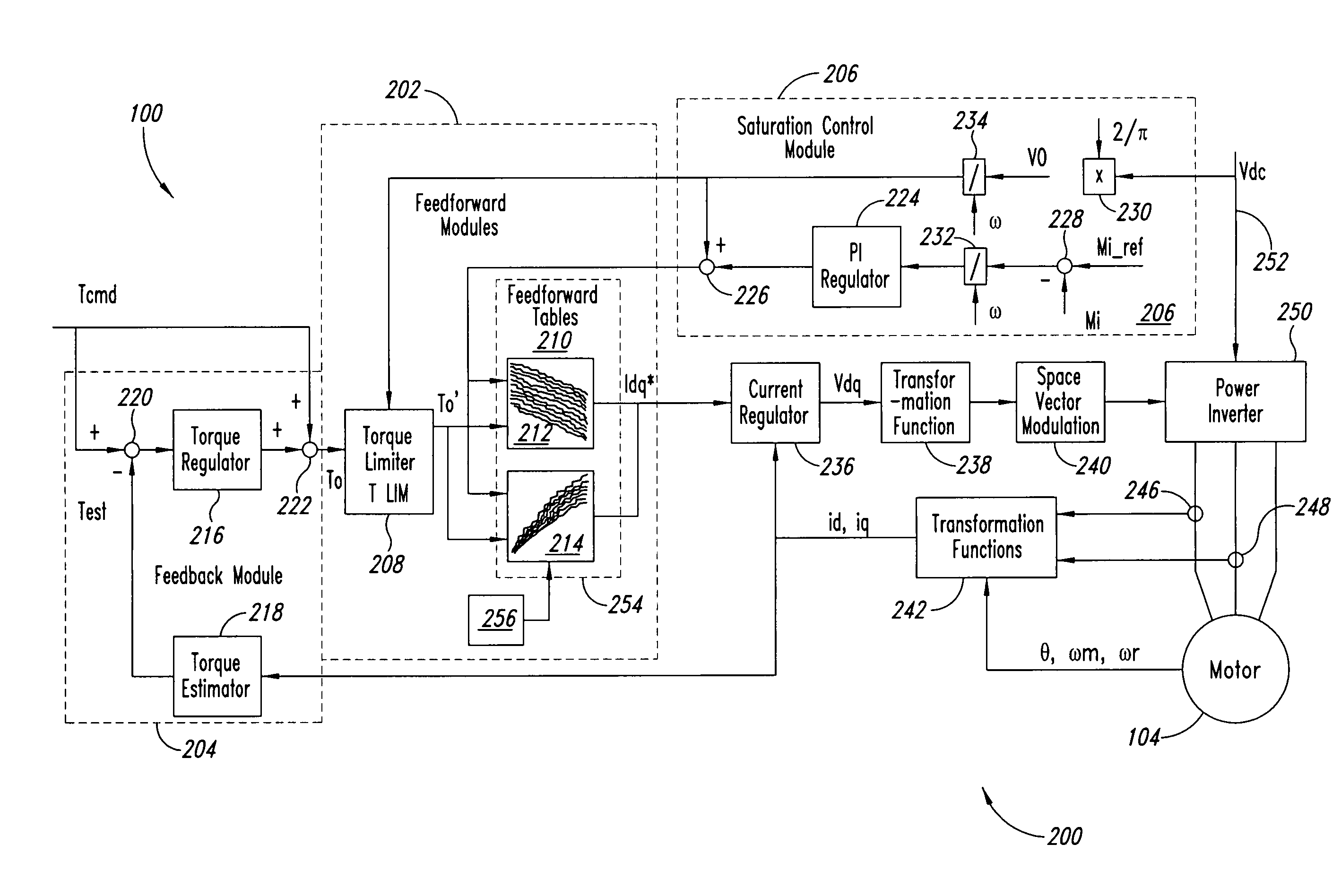

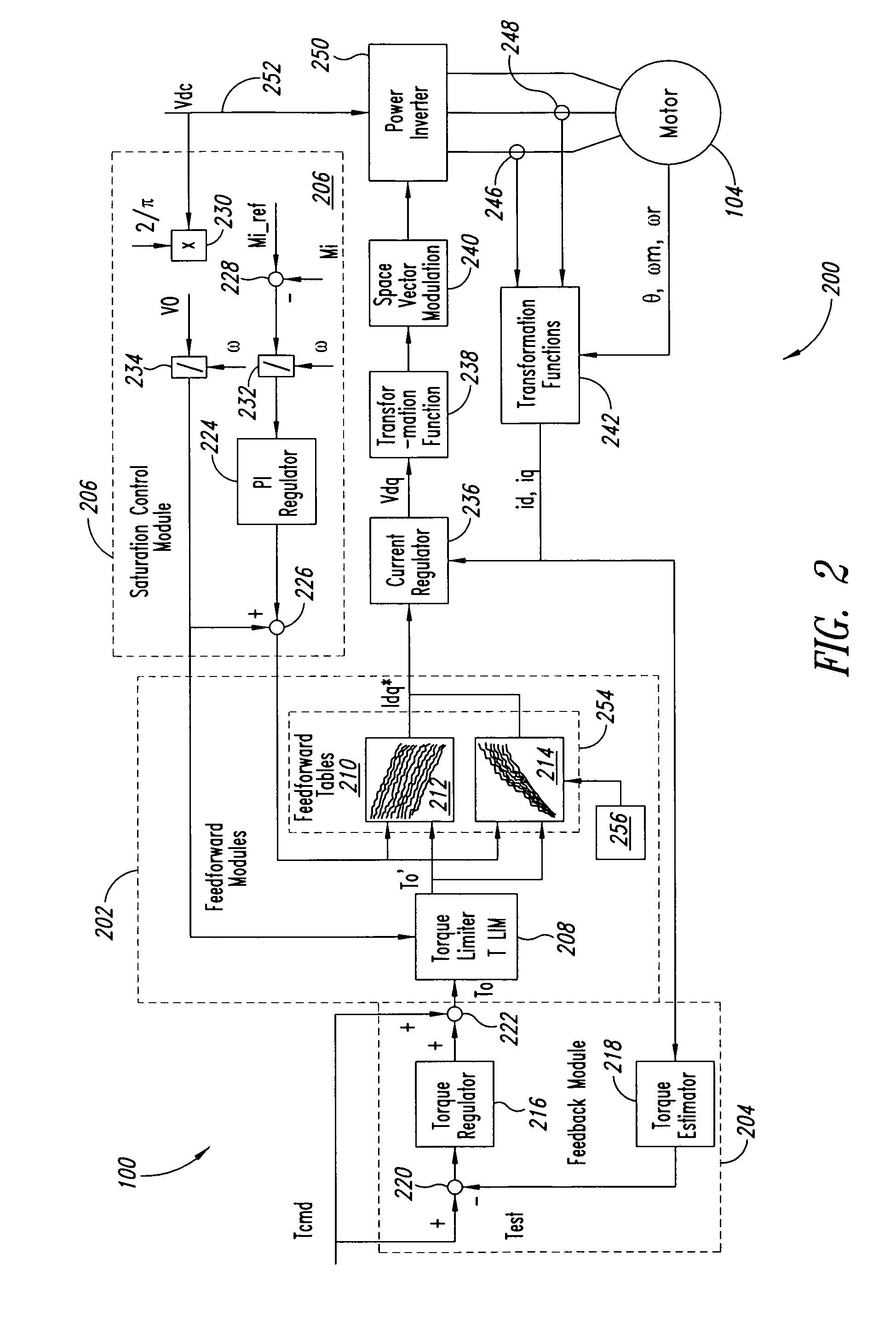

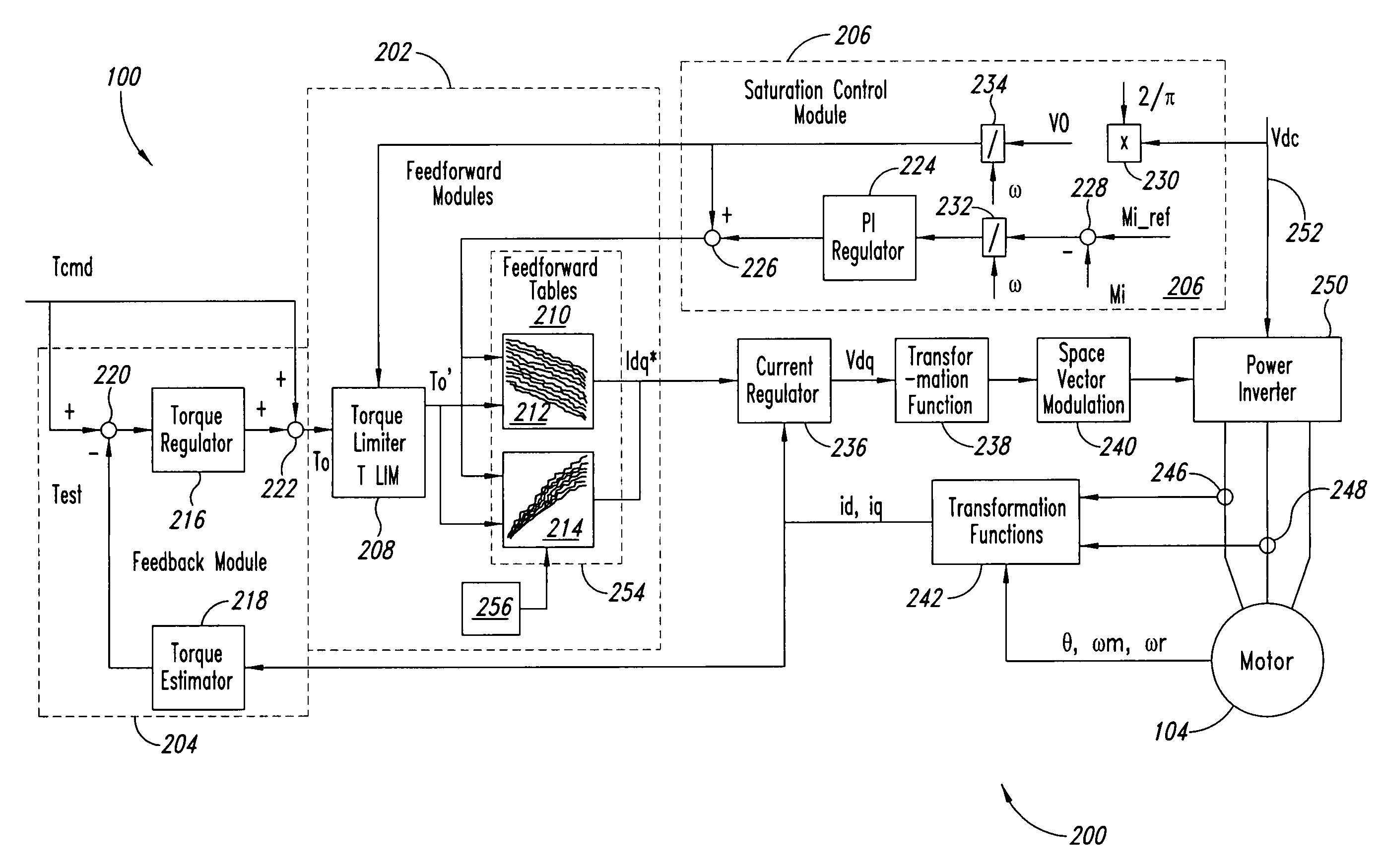

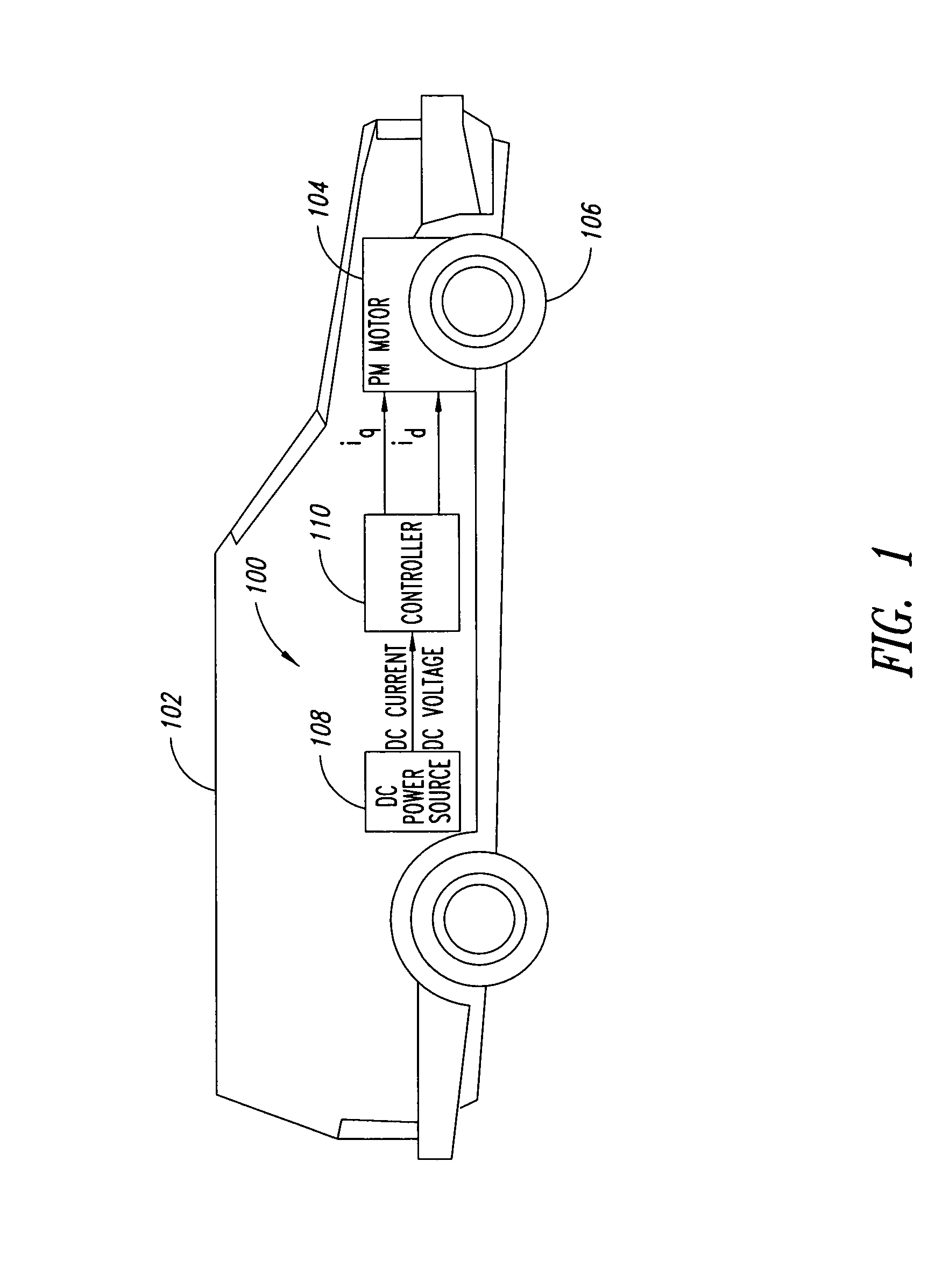

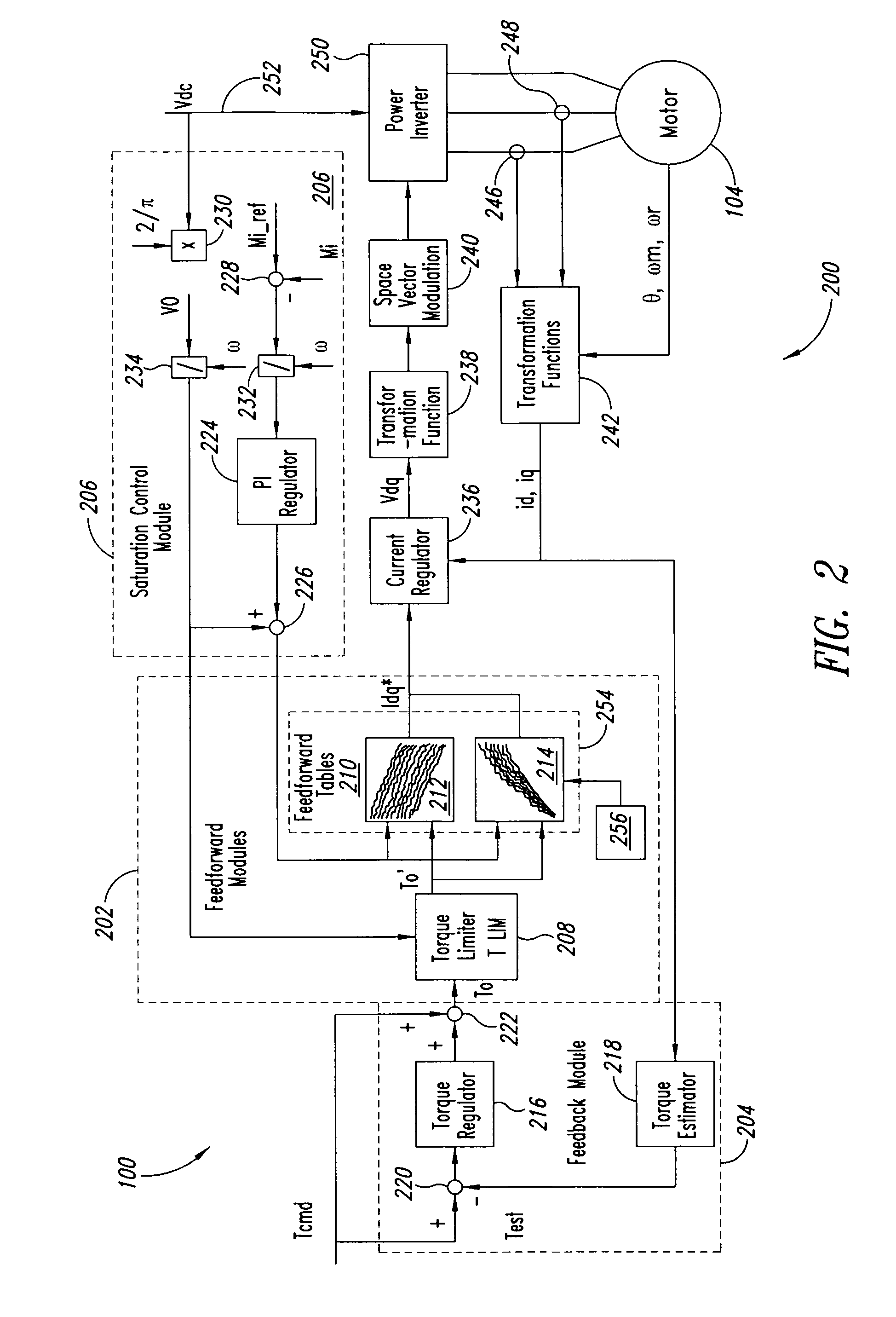

Method and apparatus for motor control

A system and method for controlling a permanent magnet motor are disclosed. Briefly described, one embodiment receives a torque command and a flux command; receives information corresponding to a direct current (DC) bus voltage and a motor speed; computationally determines feedforward direct-axis current information and feedforward quadrature-axis current information from a plurality of parameters associated with the permanent magnet motor; determines a current signal (idq*) based upon at least the requested torque command, the flux command, the DC bus voltage, the motor speed, the feedforward direct-axis current information, and the feedforward quadrature-axis current information; and controls a power inverter that converts DC power into alternating current (AC) power that is supplied to the permanent magnet motor, such that the permanent magnet motor is operated in accordance with the determined idq*.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

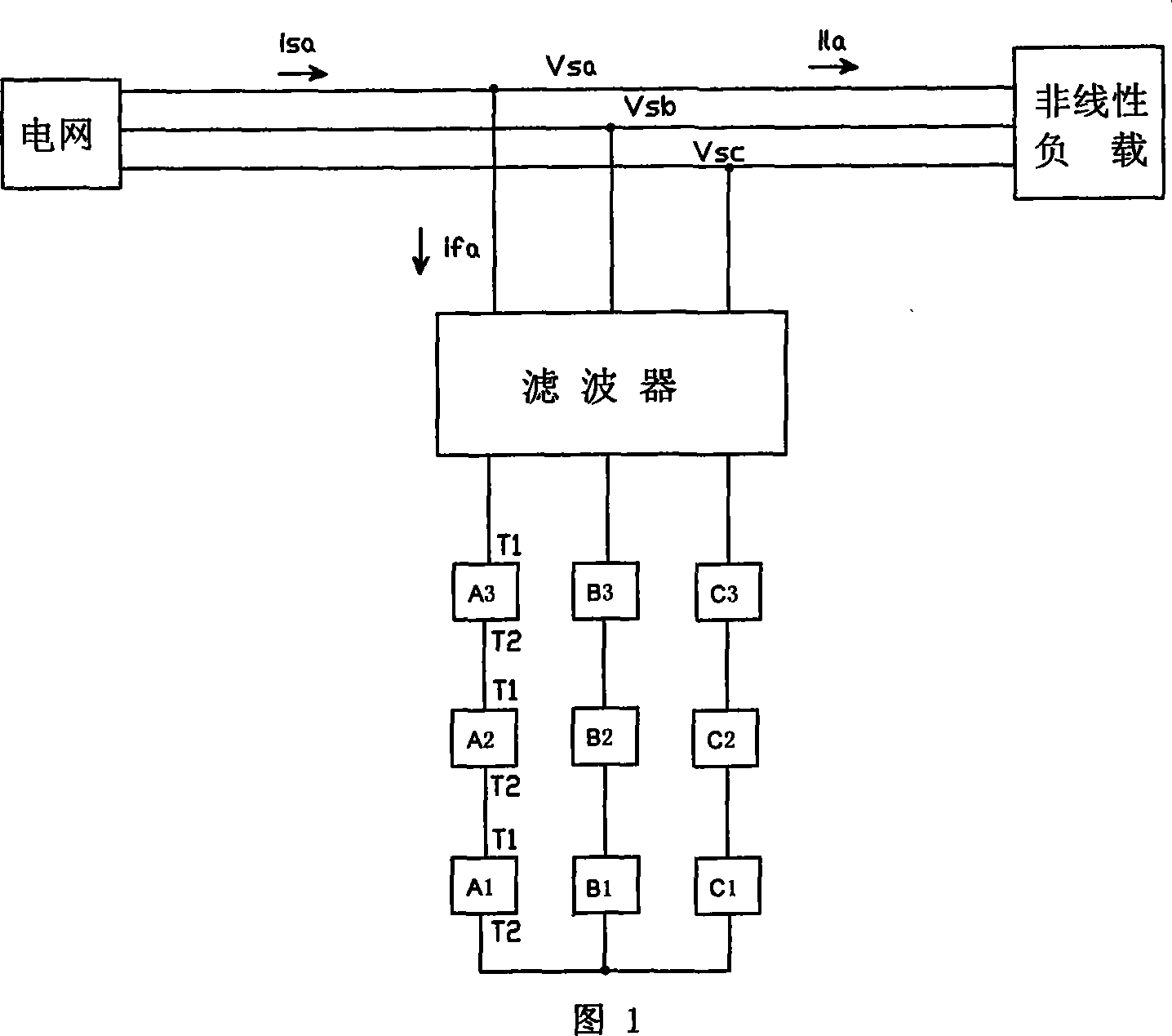

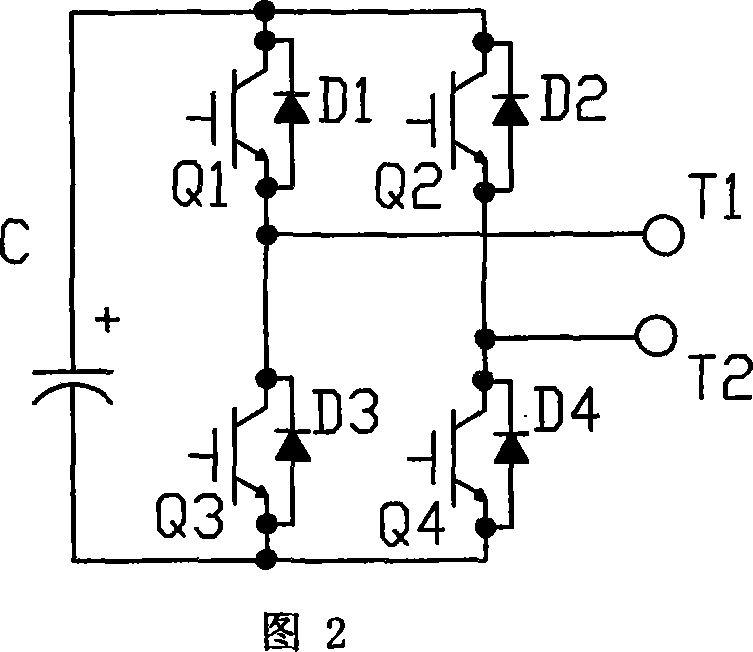

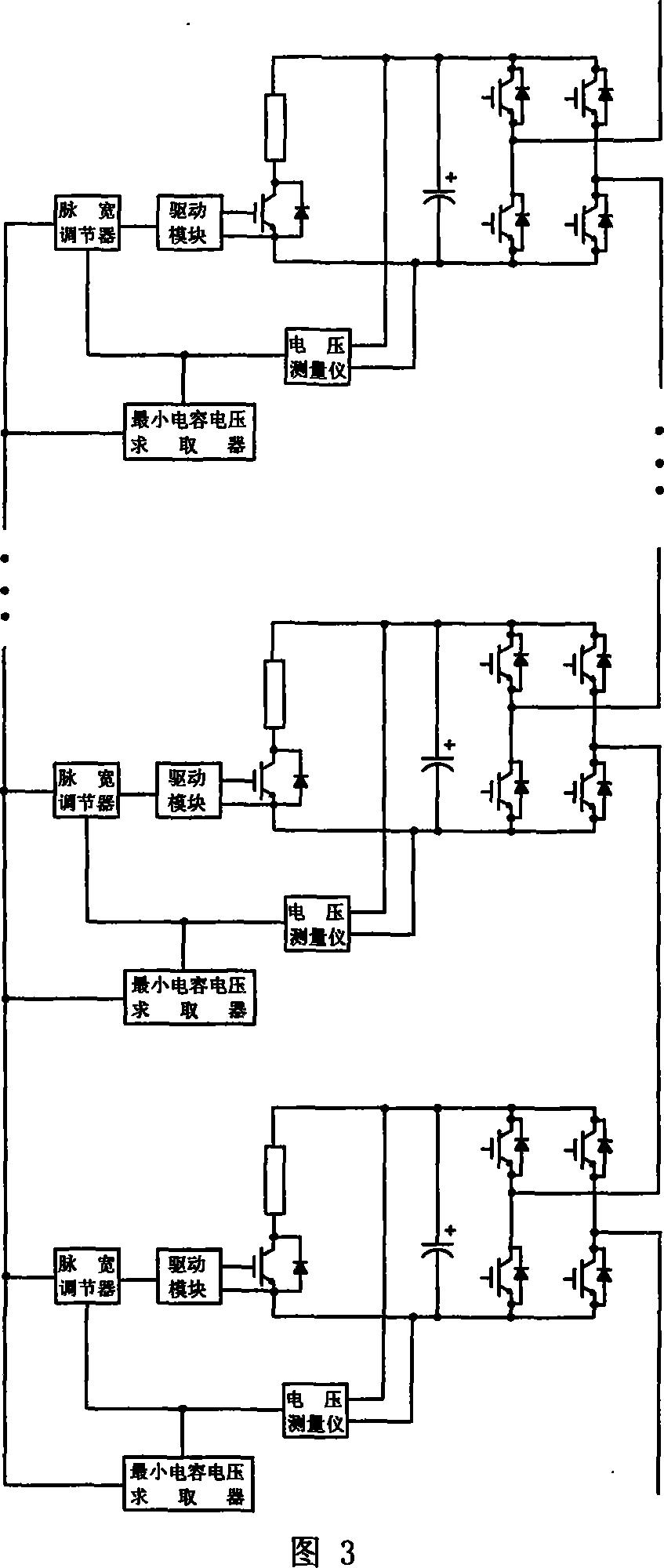

Active power filter including power unit and its control method

InactiveCN101051751ASolve control problemsSolve the inrush currentActive power filteringAc-dc conversionCapacitanceEngineering

The power unit includes H bridge inverter circuit, capacitance in DC section connected to DC bus in inverter circuit, and control circuit for controlling operation of the power unit. The power unit also includes a clipping energy consumption circuit. Combining a small quantity of active power absorbed by active electric power filter, the method realizes controlling DC bus voltage of power unit. The active electric power filter includes following parts: inverter with each phase including at least one power unit; voltage detection circuit, central control system, filtering circuit, precharge circuit, income line switch, interface and communication circuit, and cooling unit etc.

Owner:上海艾帕电力电子有限公司

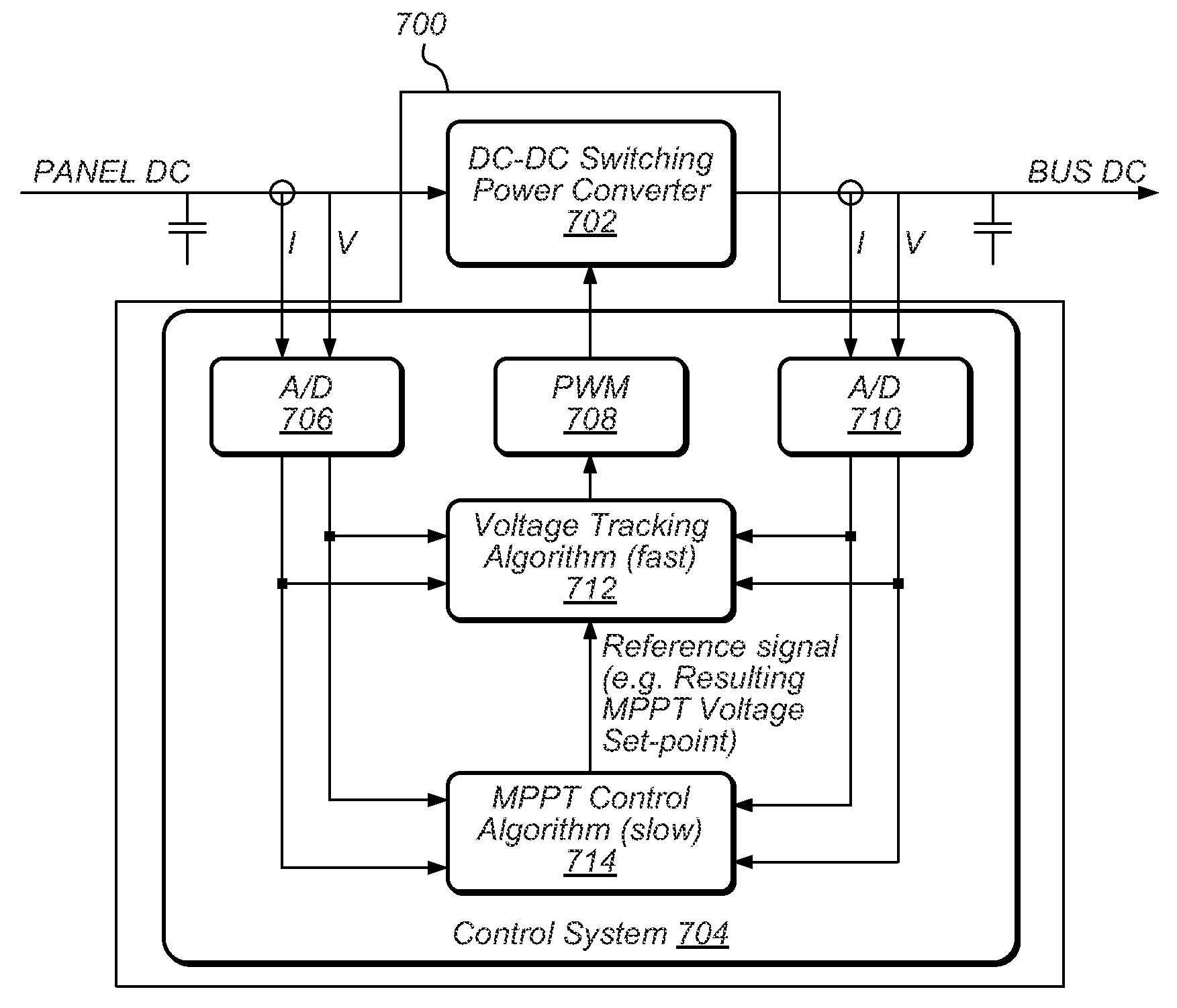

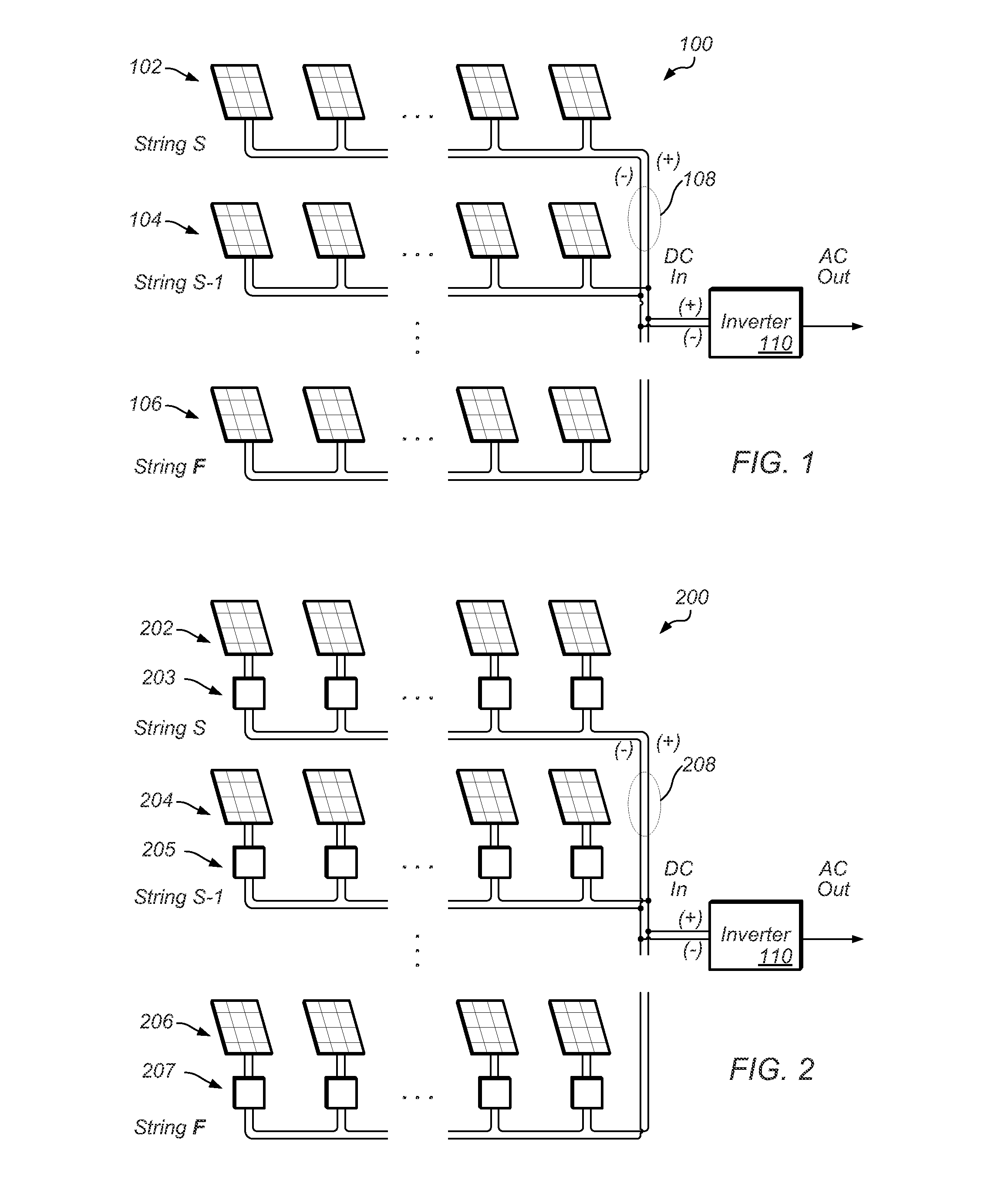

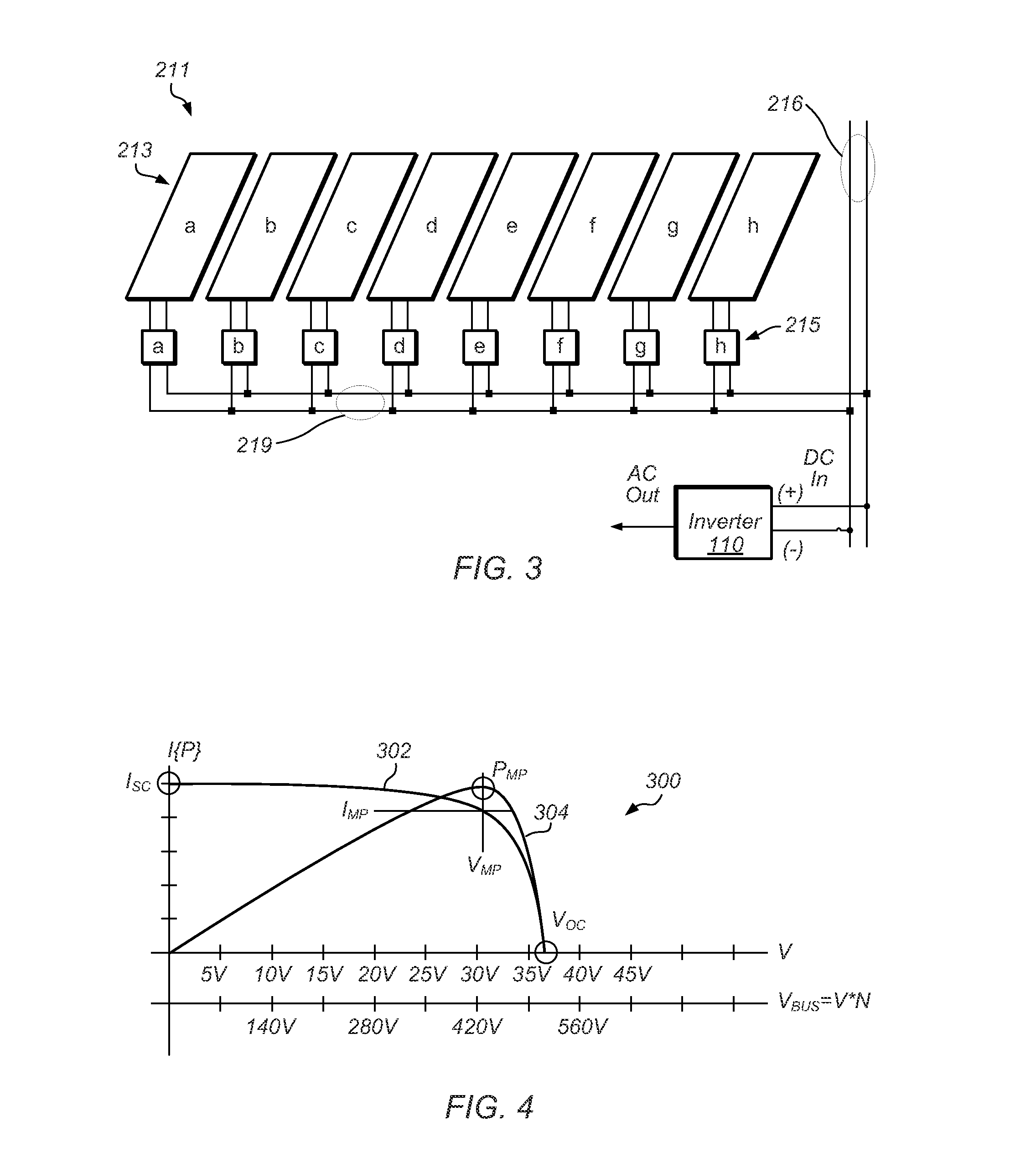

Regulation of Inverter DC Input Voltage in Photovoltaic Arrays

ActiveUS20120205974A1Batteries circuit arrangementsConversion with intermediate conversion to dcEngineeringDC-BUS

A converter unit configured to couple to a photovoltaic panel (PV) may include a controller to sense an output voltage and output current produced by the photovoltaic panel, and manage the output voltage of a corresponding power converter coupled to a DC bus to regulate the resultant bus voltage to a point that reduces overall system losses, and removes non-idealities when the panels are series connected. The controller may also adapt to output condition constraints, and perform a combination of input voltage and output voltage management and regulation, including maximum power point tracking (MPPT) for the PV. The output voltage and output current characteristic of the power converter may be shaped to present a power gradient—which may be hysteretically controlled—to the DC bus to compel an inverter coupled to the DC bus to perform its own MPPT to hold the DC-bus voltage within a determinate desired operating range.

Owner:BLUED ACQUISITION CORP

Method and apparatus for motor control

InactiveUS20080116842A1Electronic commutation motor controlSpeed controllerMotor speedPower inverter

A system and method for controlling a permanent magnet motor are disclosed. Briefly described, one embodiment receives a torque command and a flux command; receives information corresponding to a direct current (DC) bus voltage and a motor speed; computationally determines feedforward direct-axis current information and feedforward quadrature-axis current information from a plurality of parameters associated with the permanent magnet motor; determines a current signal (idq*) based upon at least the requested torque command, the flux command, the DC bus voltage, the motor speed, the feedforward direct-axis current information, and the feedforward quadrature-axis current information; and controls a power inverter that converts DC power into alternating current (AC) power that is supplied to the permanent magnet motor, such that the permanent magnet motor is operated in accordance with the determined idq*.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

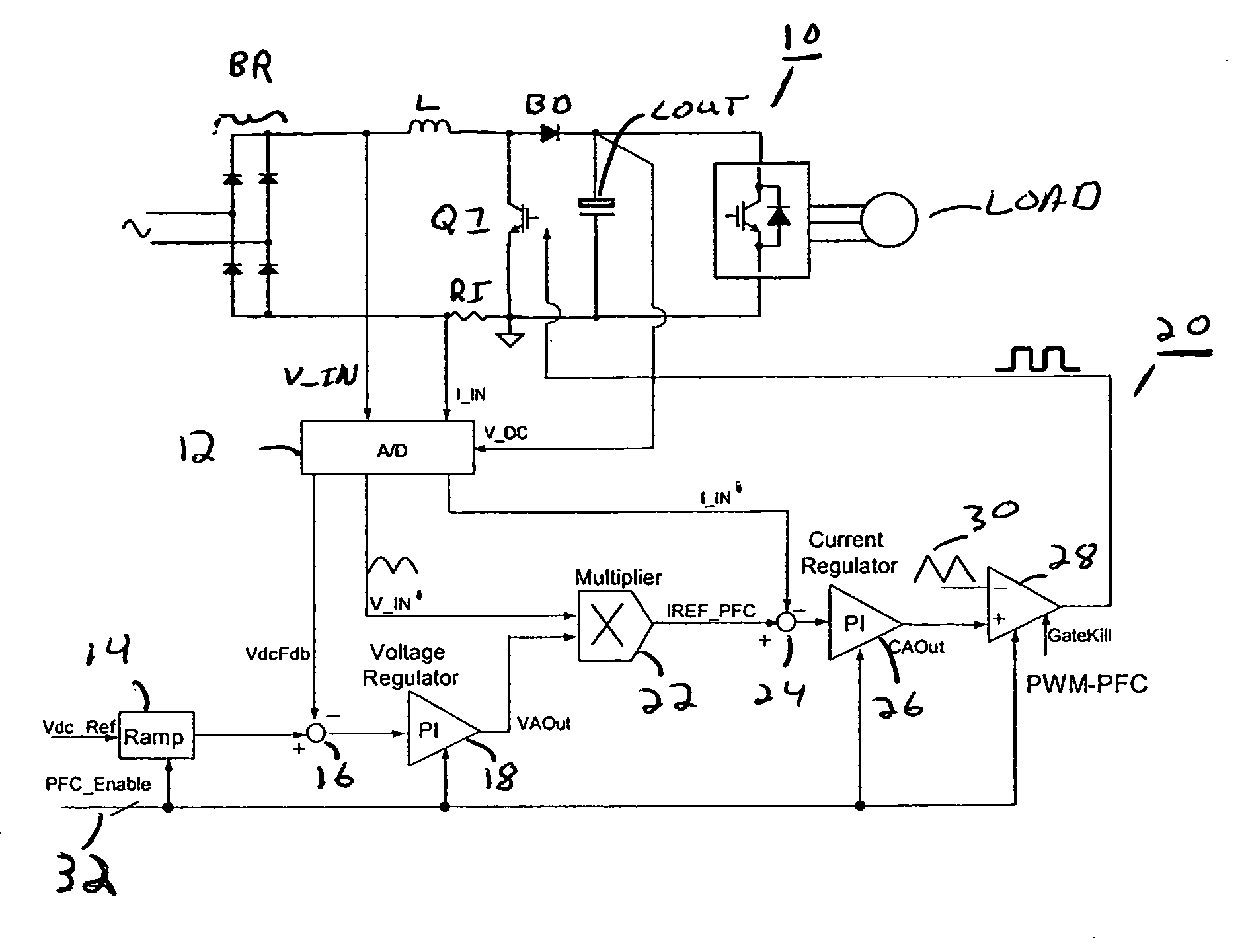

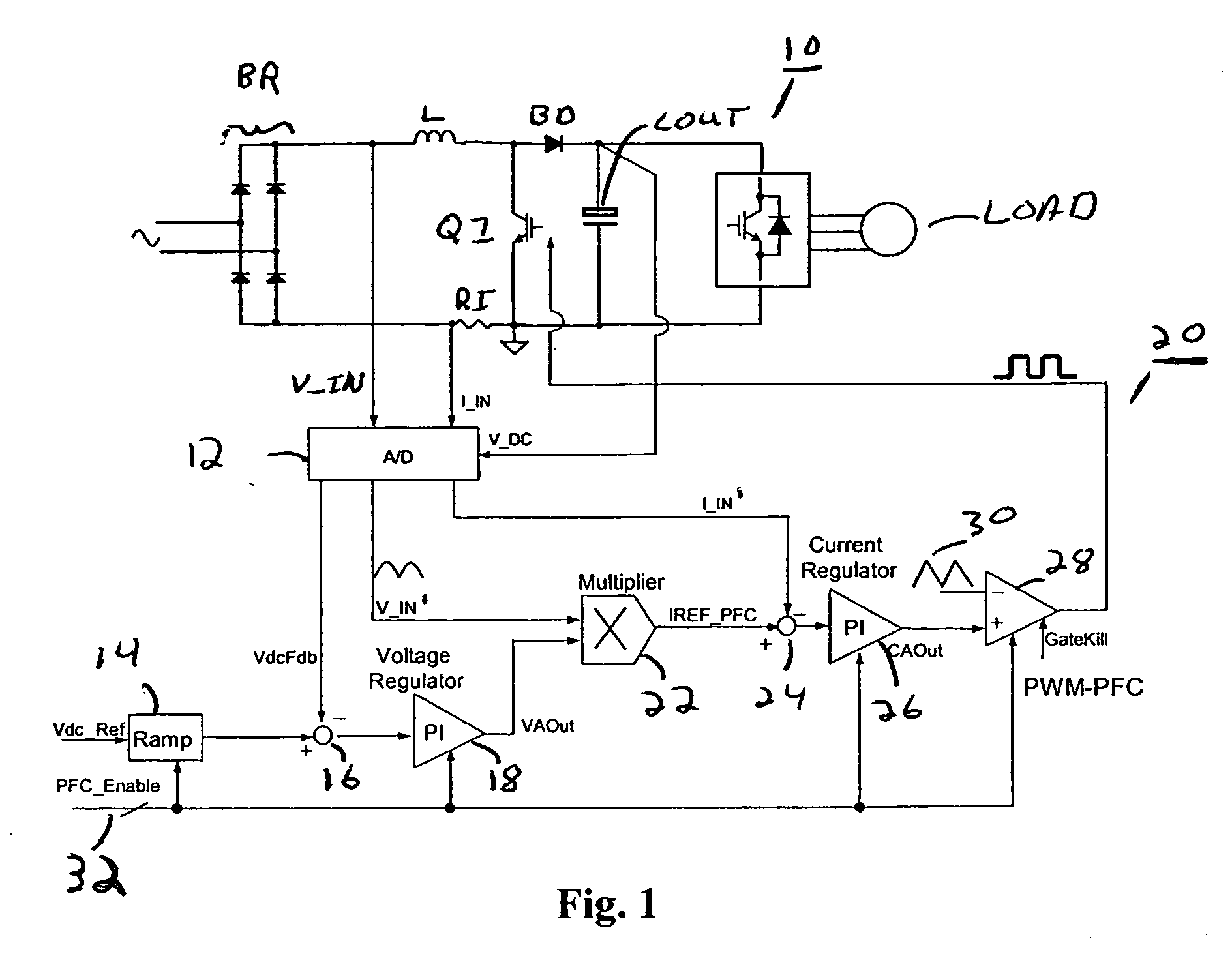

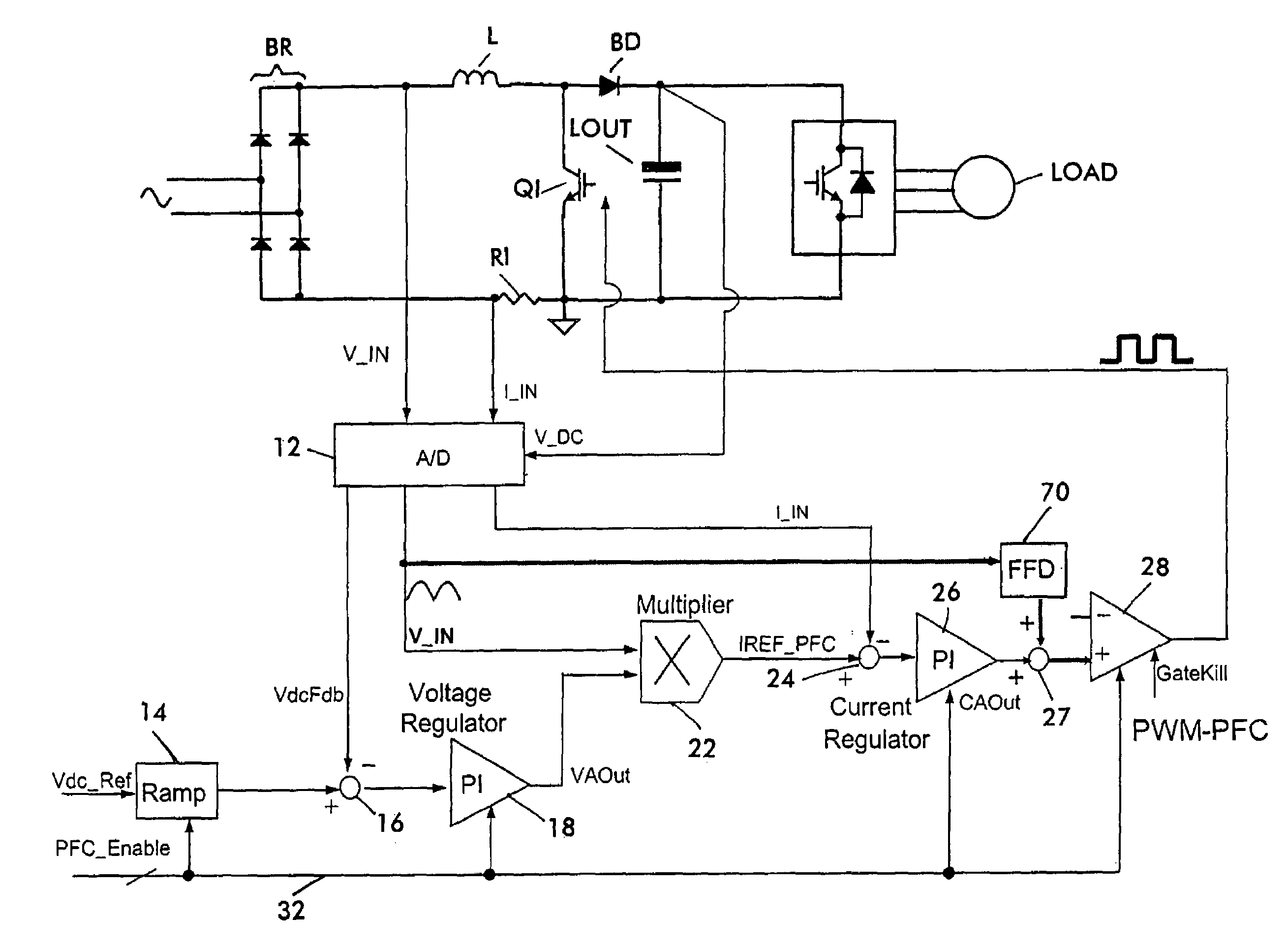

Digital implementation of power factor correction

InactiveUS20060245219A1Avoid problemsAc-dc conversion without reversalEfficient power electronics conversionControl signalEngineering

A circuit for providing power factor correction in accordance with an embodiment of the present application may include a boost converter circuit and a control circuit receiving as inputs a rectified AC input voltage from a rectifier, a signal proportional to current through the boost inductor and the DC bus voltage across the capacitor of the boost converter. The control circuit provides a pulse width modulated signal to control the on time of a PFC switch. The control circuit further includes a voltage regulator and a current regulator. The current regulator includes a difference device operable to subtract a signal proportional to the inductor current from the current reference signal, a PI controller adapted to receive the output of the difference device and provide a first control signal, a feed forward device operable to receive the rectified AC input voltage and to provide a second control signal with a smaller dynamic range than the AC input voltage, and an adder operable to add the first control signal to the second control signal to provide a PWM reference signal for generating the pulse width modulated signal. A zero crossing detector and vector rotator may be provided to provide a clean sinusoidal reference to the current regulator. A partial PFC regulator may be provide to provide partial mode PFC if desired.

Owner:INFINEON TECH AMERICAS CORP

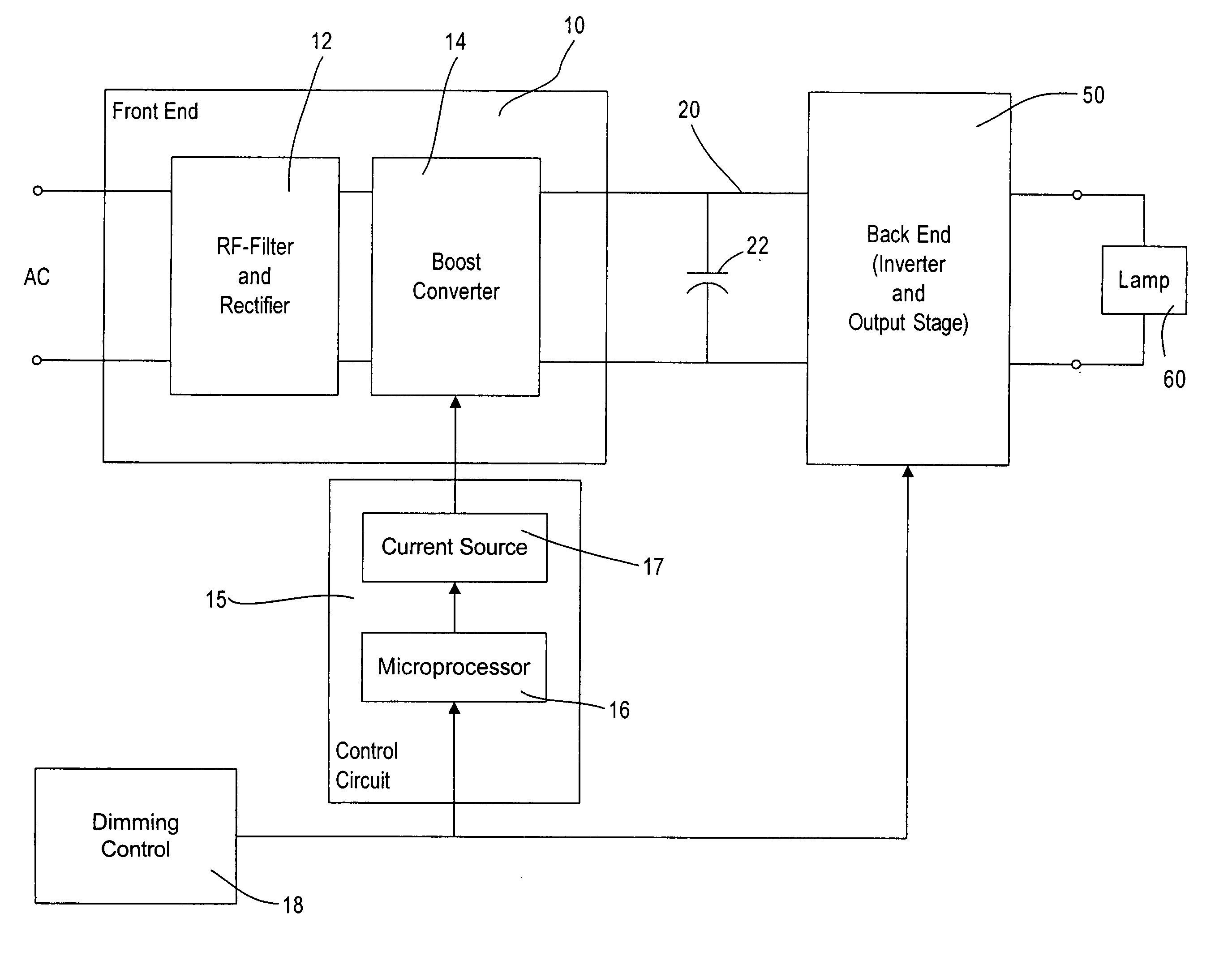

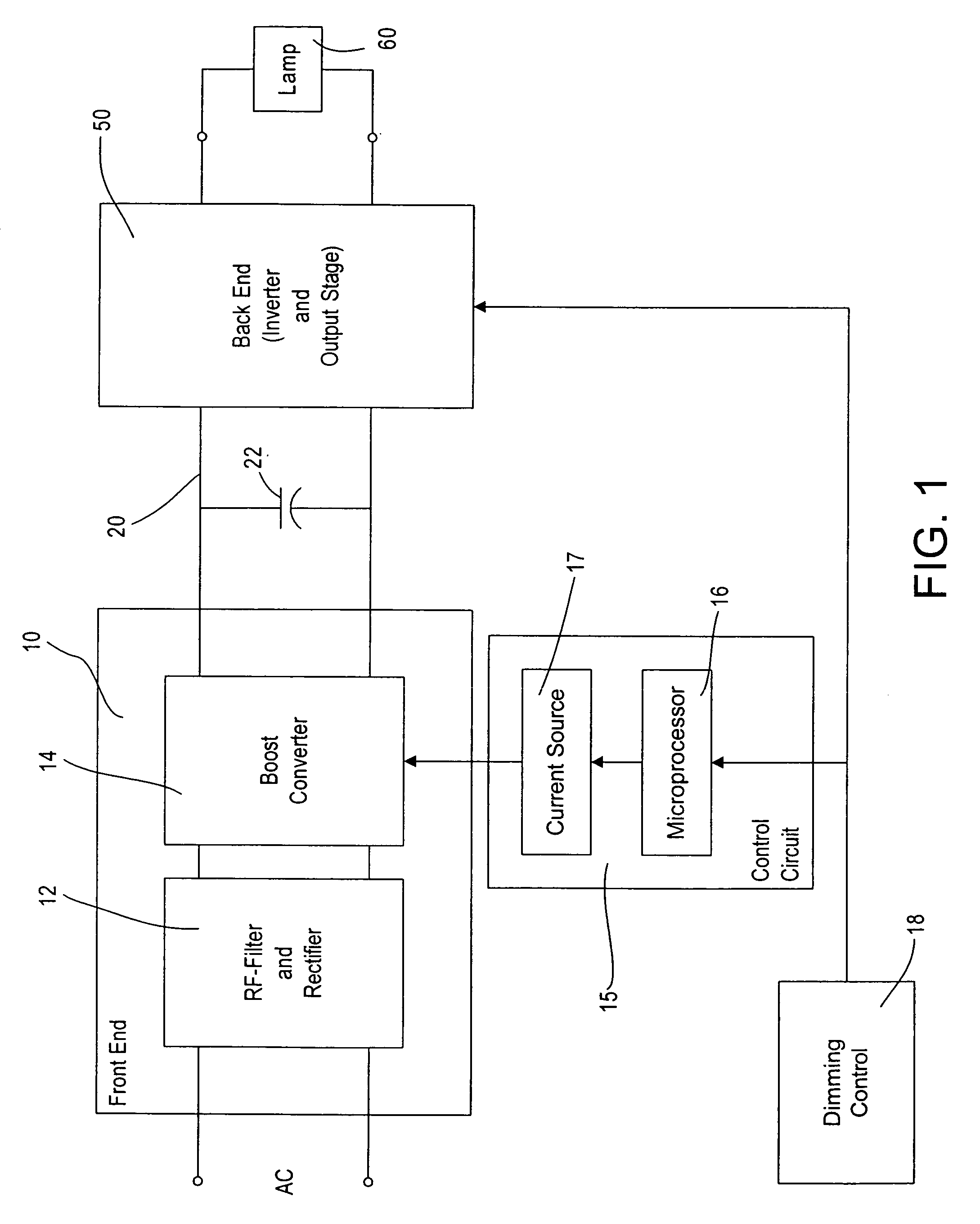

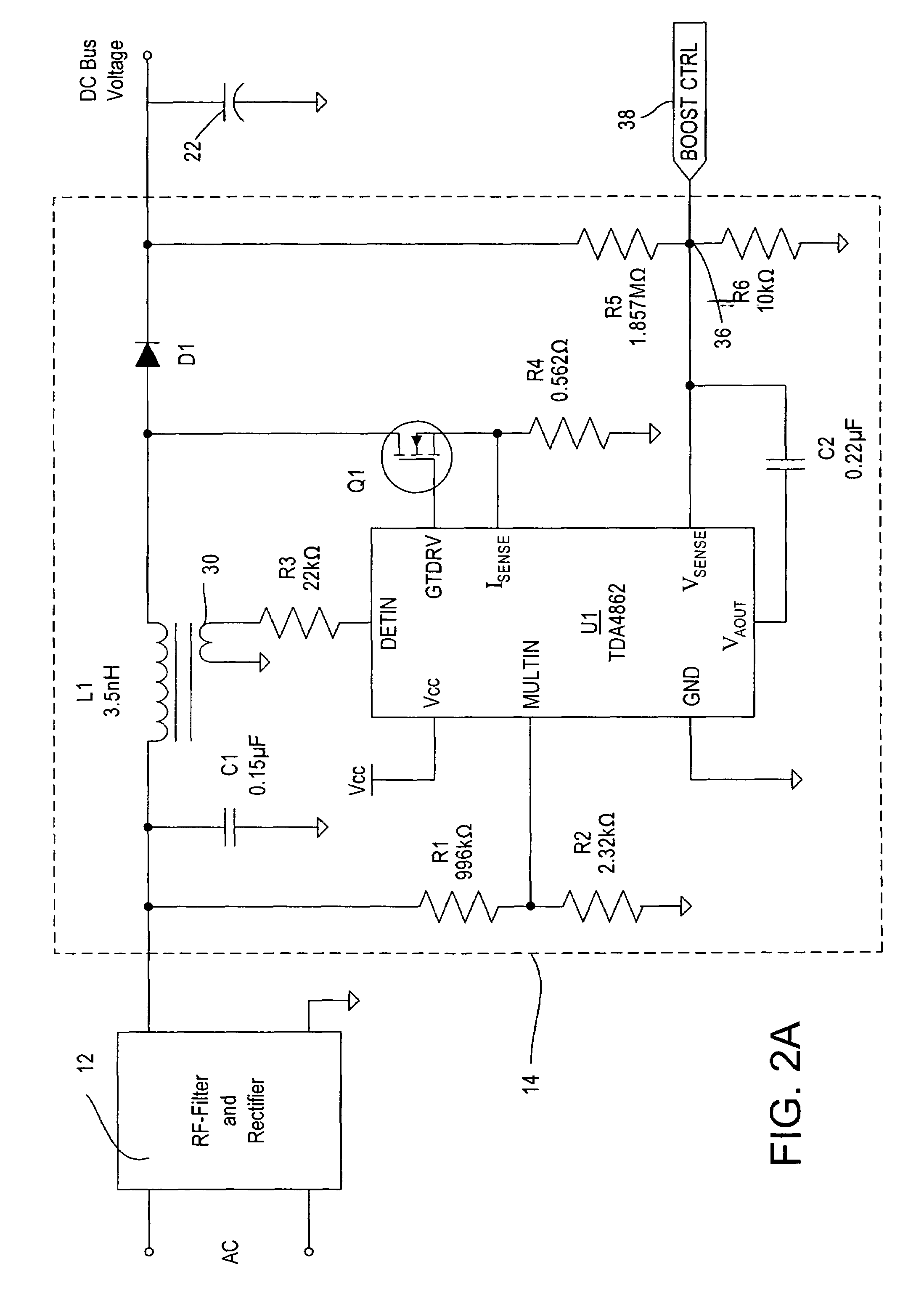

Lighting ballast having boost converter with on/off control and method of ballast operation

ActiveUS7075254B2Save energyLess powerElectric light circuit arrangementGas discharge lamp usageControl signalAlternating current

A ballast for driving a gas discharge lamp comprising a rectifier stage having an alternating current (AC) input and providing a rectified output voltage, a boost converter stage receiving the rectified output voltage as an input and providing a boosted direct current (DC) output voltage across a DC bus, an inverter output stage for converting the DC bus voltage to a high-frequency AC output voltage to drive the lamp, further comprising a control stage receiving a desired light level signal controlling the desired light level of the lamp and providing an output control signal for turning the boost converter stage on or off in dependency on the desired light level signal. The ballast thereby has reduced power consumption at low light levels for greater energy efficiency.

Owner:LUTRON TECH CO LLC

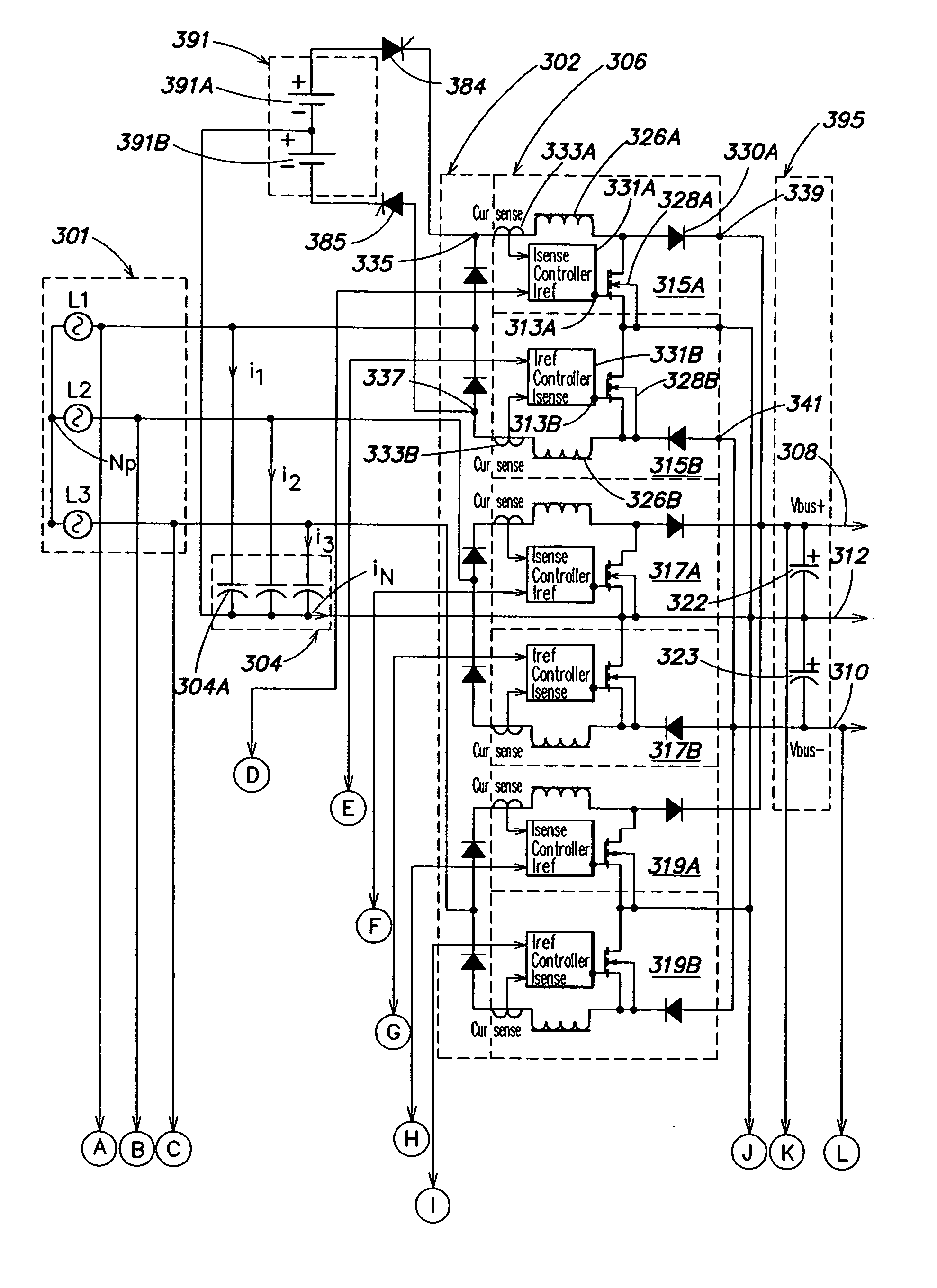

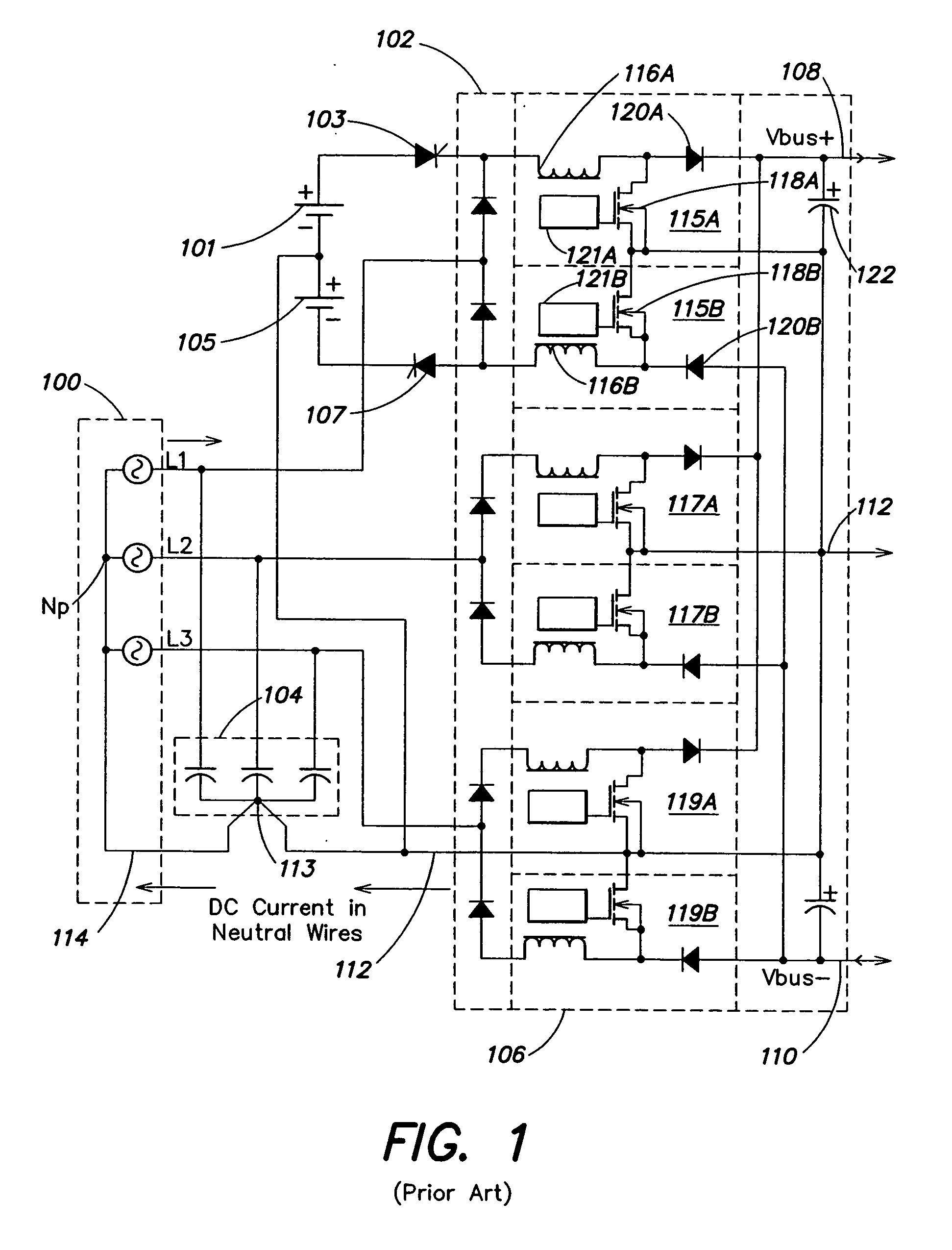

Apparatus for and method of UPS operation

A UPS is adapted to receive power from a polyphase AC source. The UPS includes power conversion circuitry adapted to convert the power supplied by the polyphase AC source to DC power. The power conversion circuitry includes phase conductors. The UPS also includes a neutral coupled to an output of the UPS, a plurality of input capacitors coupling the phase conductors to the neutral, a DC system including a positive DC bus with a positive DC bus voltage and a negative DC bus with a negative DC bus voltage, and a control system. The control system is adapted to control a difference between a magnitude of the positive DC bus voltage and a magnitude of the negative DC bus voltage by controlling a DC voltage across the input capacitors.

Owner:AMERICA POWER CONVERSION CORP

Digital implementation of power factor correction

InactiveUS7359224B2Ac-dc conversion without reversalEfficient power electronics conversionCapacitanceControl signal

A circuit for providing power factor correction in accordance with an embodiment of the present application may include a boost converter circuit and a control circuit receiving as inputs a rectified AC input voltage from a rectifier, a signal proportional to current through the boost inductor and the DC bus voltage across the capacitor of the boost converter. The control circuit provides a pulse width modulated signal to control the on time of a PFC switch. The control circuit further includes a voltage regulator and a current regulator. The current regulator includes a difference device operable to subtract a signal proportional to the inductor current from the current reference signal, a PI controller adapted to receive the output of the difference device and provide a first control signal, a feed forward device operable to receive the rectified AC input voltage and to provide a second control signal with a smaller dynamic range than the AC input voltage, and an adder operable to add the first control signal to the second control signal to provide a PWM reference signal for generating the pulse width modulated signal. A zero crossing detector and vector rotator may be provided to provide a clean sinusoidal reference to the current regulator. A partial PFC regulator may be provide to provide partial mode PFC if desired.

Owner:INFINEON TECH AMERICAS CORP

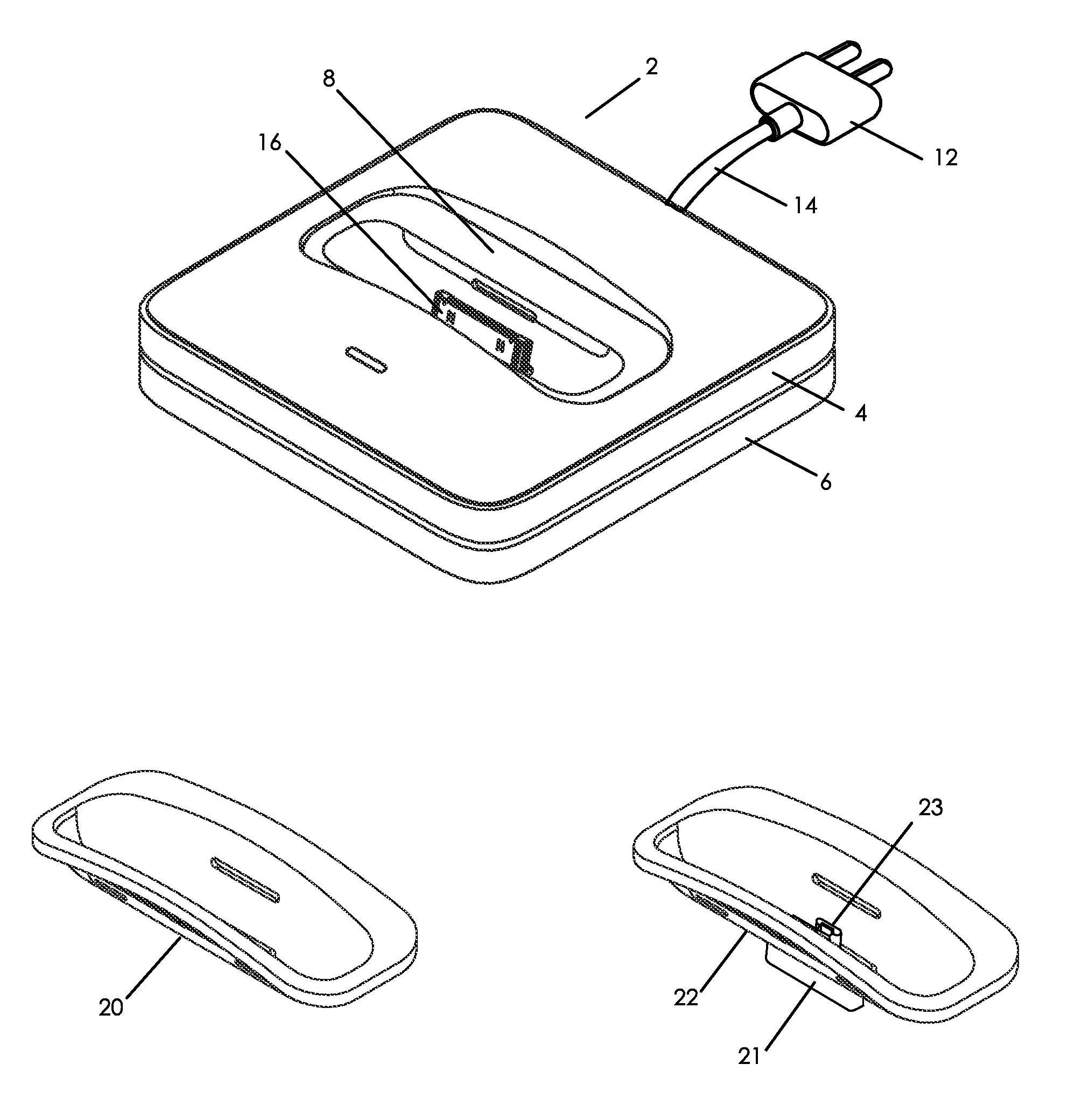

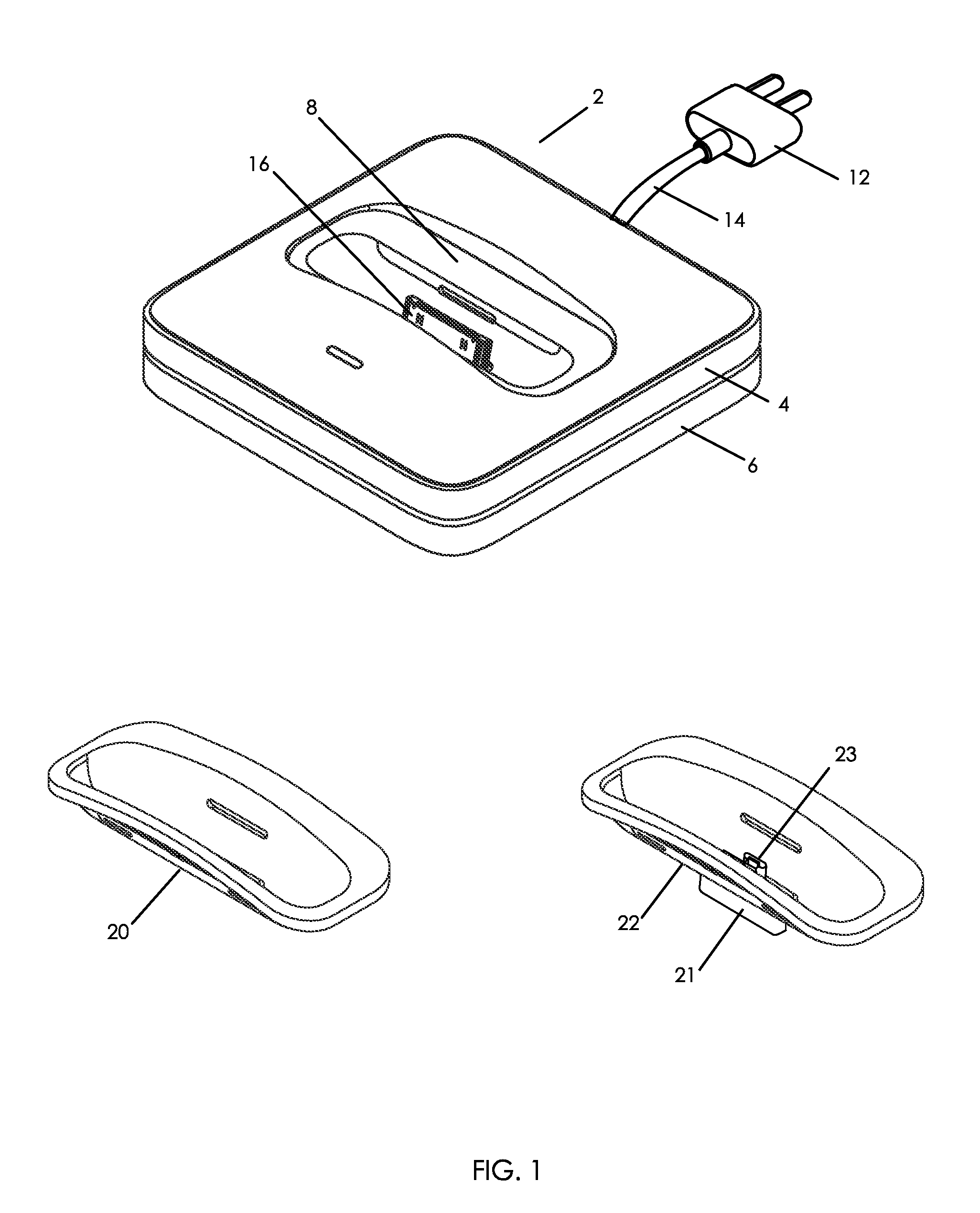

Modular power supply

InactiveUS20100033127A1Automatic call-answering/message-recording/conversation-recordingMobile unit charging stationsComputer moduleModularity

A modular power supply that can be adapted to receive and charge practically any type or number of portable electronic devices includes a power converter that receives an AC wall voltage and converts the wall voltage to DC bus voltage. Each charging module has a pair of conductive rails and magnets positioned around the exterior of the module. The power converter has a connector that is physically and electrically coupled to a charging module through a pair of magnets and conductive rails such that the DC bus voltage is applied to the conductive rails of the module. Each charging module has a dock that physically couples to a portable electronic device and supplies a charging voltage produced from the DC bus voltage to the device. Additional charging modules can be physically and electrically coupled together by simply placing the modules adjacent one another through the interaction of the module's conductive rails and magnets. Adapters can be inserted into the docks of the charging modules to reconfigure the docks stations to mate with different types of devices. An FM transmitter can be included in one of the modules to transmit audio from the charging device to a remote FM receiver.

Owner:VINCI BRANDS LLC

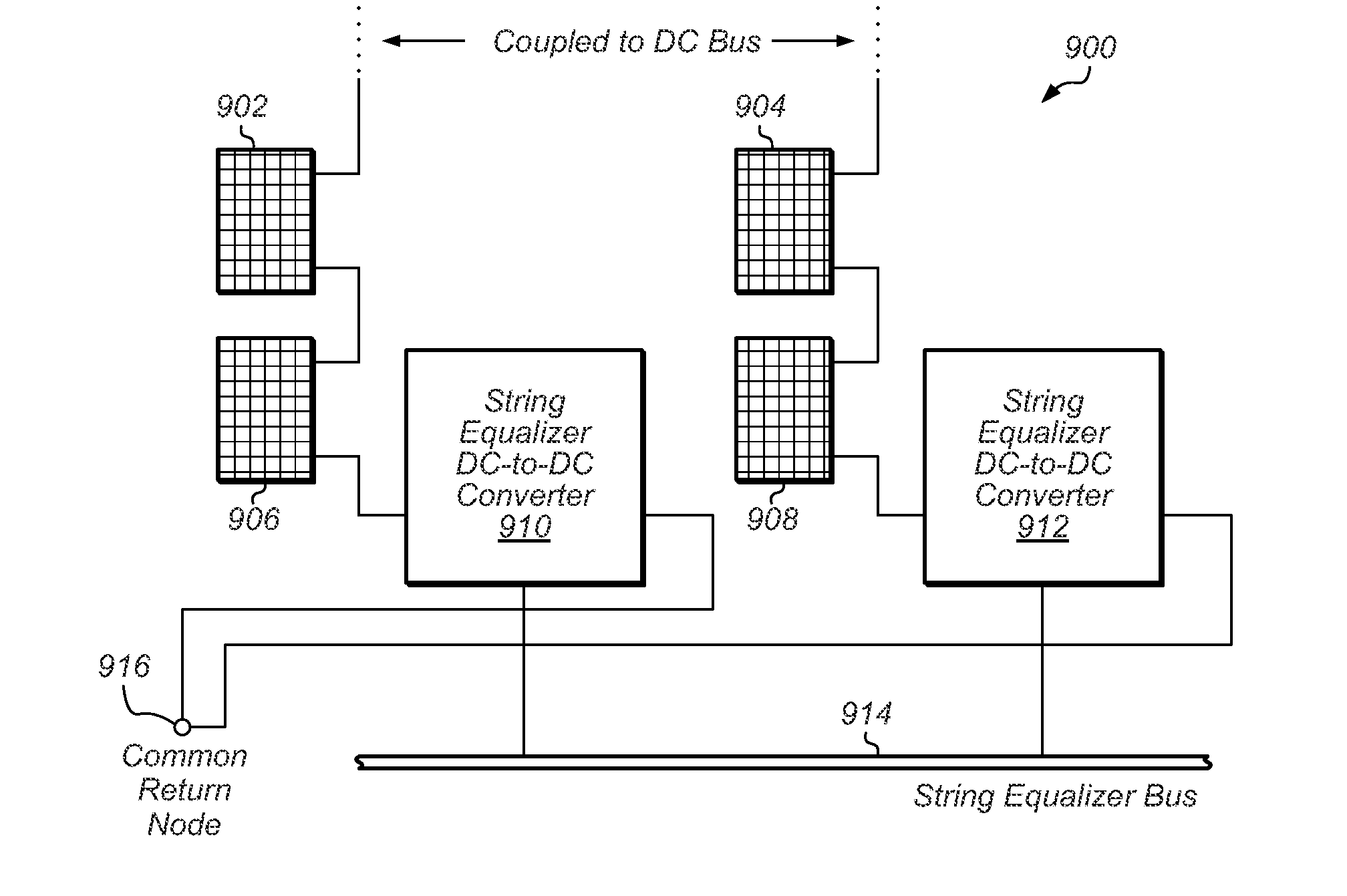

Power Shuffling Solar String Equalization System

InactiveUS20120319489A1Large pointEmergency protective arrangement detailsSingle network parallel feeding arrangementsEqualizationDC-BUS

A photovoltaic (PV) array system may include multiple PV strings, each PV string including respective PV panels coupled in series. Each PV string may be coupled in series with a first terminal of a respective string equalizer module. The string equalizer module may equalize a maximum power-point voltage (VMP) of the PV string before the PV strings combine to produce a single, composite DC bus voltage on a DC bus. To accomplish this, each string equalizer module may generate a respective adaptive string equalizer output voltage at its first terminal to tune a respective PV string voltage of its corresponding respective PV string to have the VMP of its corresponding PV string match respective VMP's of other PV strings. That is, PV strings may sink or source power from / to other PV strings, to equalize the VMP of each corresponding respective PV string.

Owner:DRAKER

High frequency partial boost power factor correction control circuit and method

A circuit for providing power factor correction comprising a boost converter circuit having a boost inductance and a power factor correction switch coupled in series with the boost inductance, the boost inductance and power factor correction switch being coupled across the output of a rectifier being supplied with AC power from an AC line, the boost converter circuit further comprising a boost diode coupled to a junction between the inductor and the switch, an output of the boost diode coupled to an output capacitor, a DC bus voltage being provided across the output capacitor, further comprising a control circuit receiving as inputs a rectified AC input voltage from the rectifier, a signal proportional to current through the inductor and the DC bus voltage across the capacitor, and wherein the control circuit provides a pulse width modulated signal to control the on time of the PFC switch, further comprising an enable / disable circuit receiving as inputs the rectified AC input voltage and the DC bus voltage, the circuit instantaneously comparing the rectified AC input voltage and the DC bus voltage and controlling the control circuit whereby the control circuit provides the pulse width modulated signal to control the PFC switch when the rectified AC input voltage is less than the DC bus voltage and disables the generation of the pulse width modulated signal to the PFC switch when the rectified AC input voltage is greater than DC bus voltage.

Owner:INTERNATIONAL RECTIFIER COEP

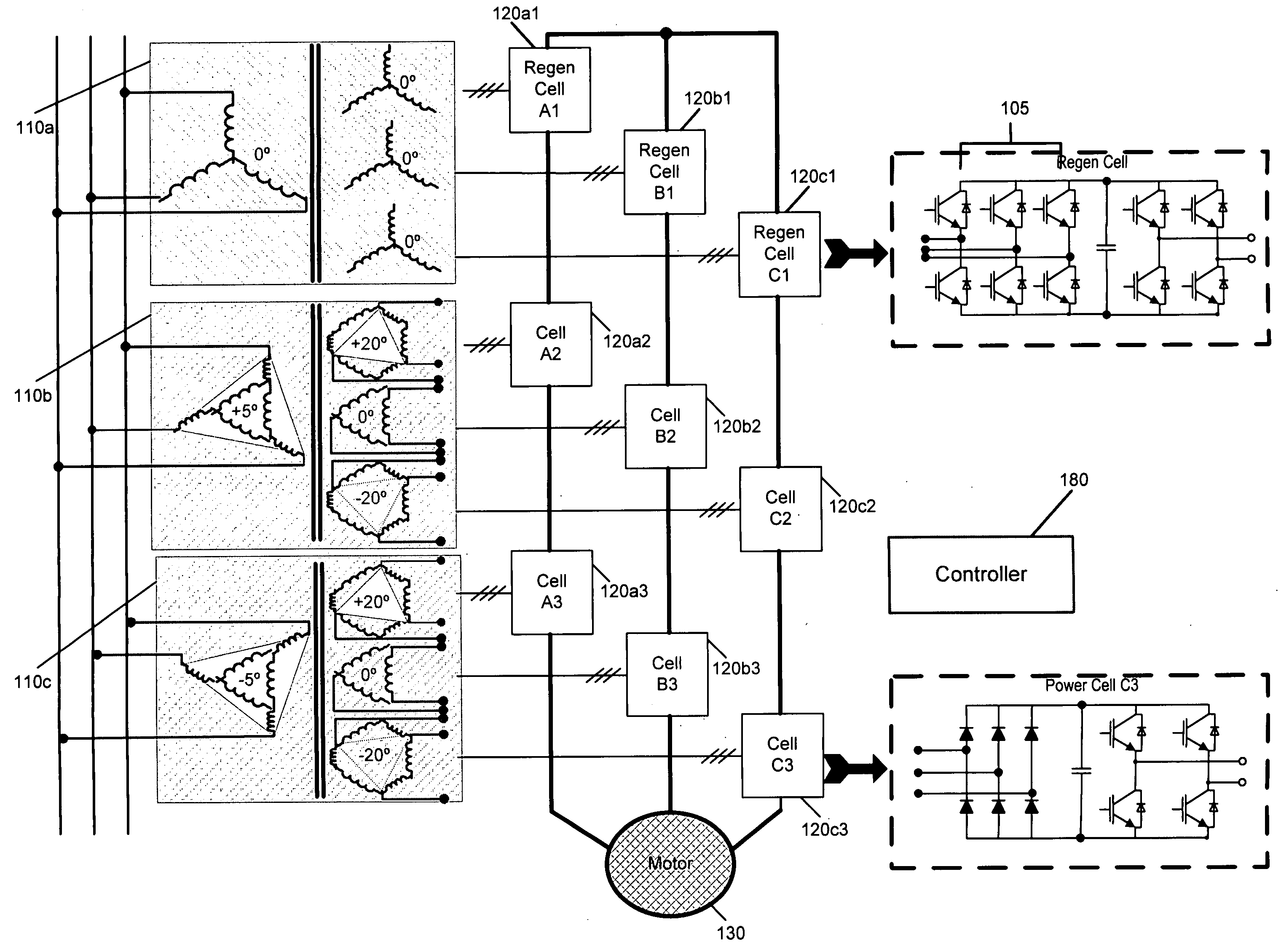

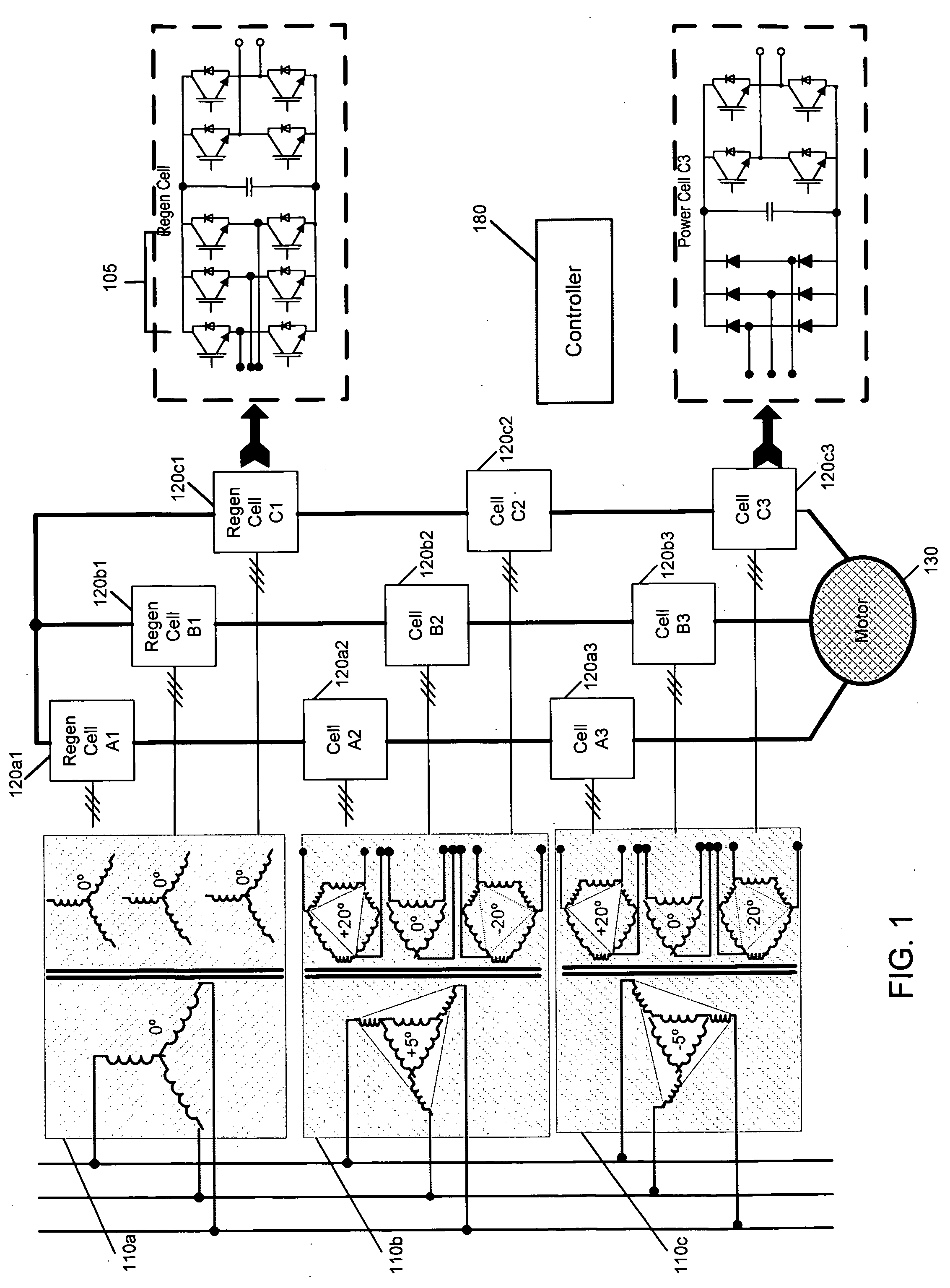

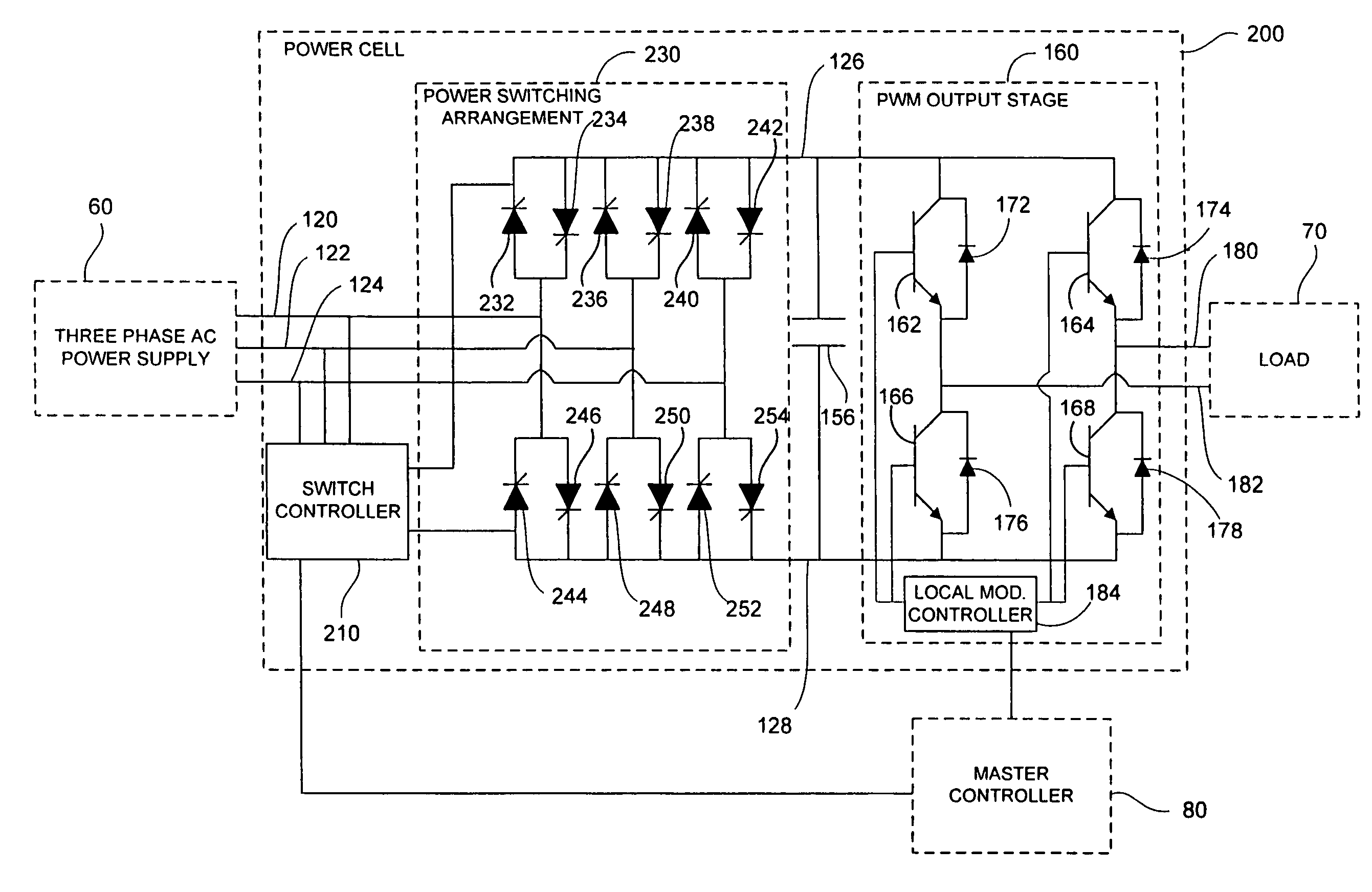

Partial regeneration in a multi-level power inverter

ActiveUS20100142234A1Corrected power factorDc source parallel operationAc-ac conversionPower inverterTransformer

In one embodiment, the present invention includes a medium voltage drive system having multiple power cells each to couple between a transformer and a load. A first subset of the power cells are configured to provide power to the load and to perform partial regeneration from the load, and a second subset of the power cells are configured to provide power to the load but not perform partial regeneration. A controller may be included in the system to simultaneously control a DC bus voltage of at least one of the first subset of the power cells, correct a power factor of the system, and provide harmonic current compensation for the system.

Owner:TECO WESTINGHOUSE MOTOR

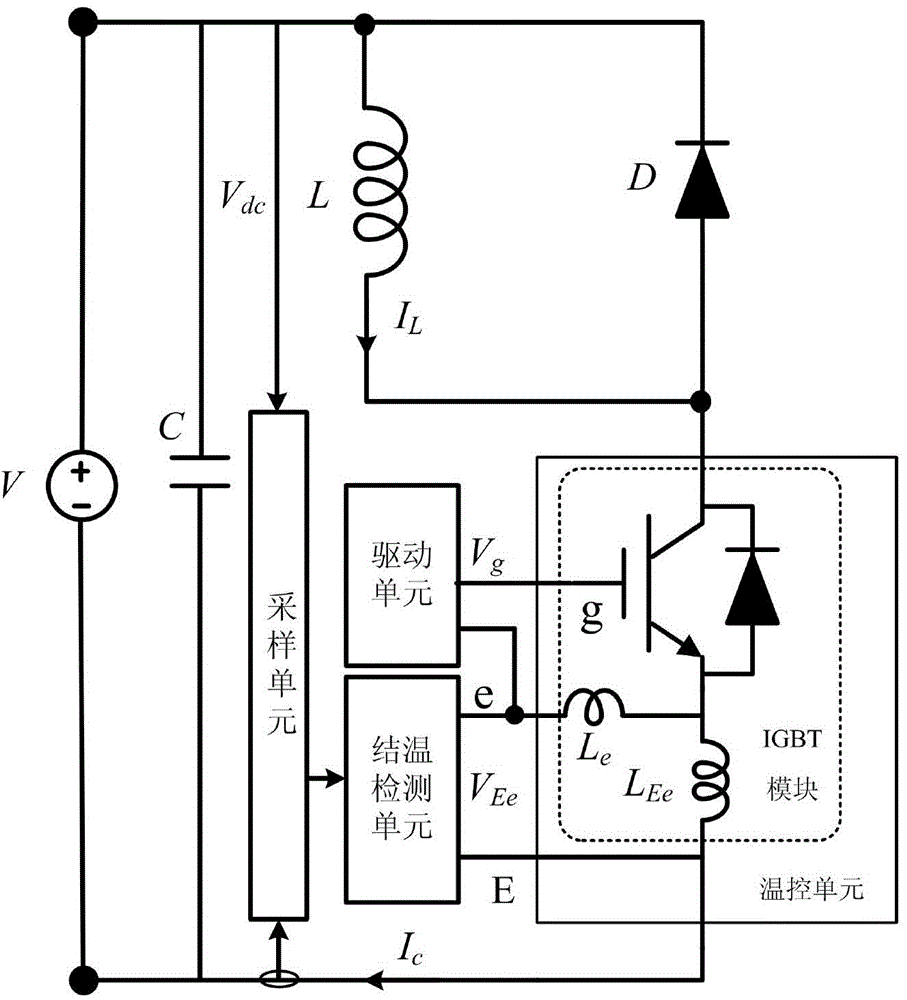

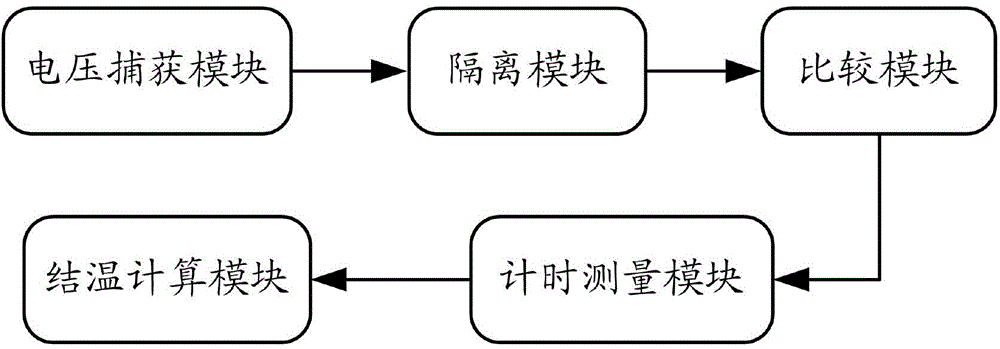

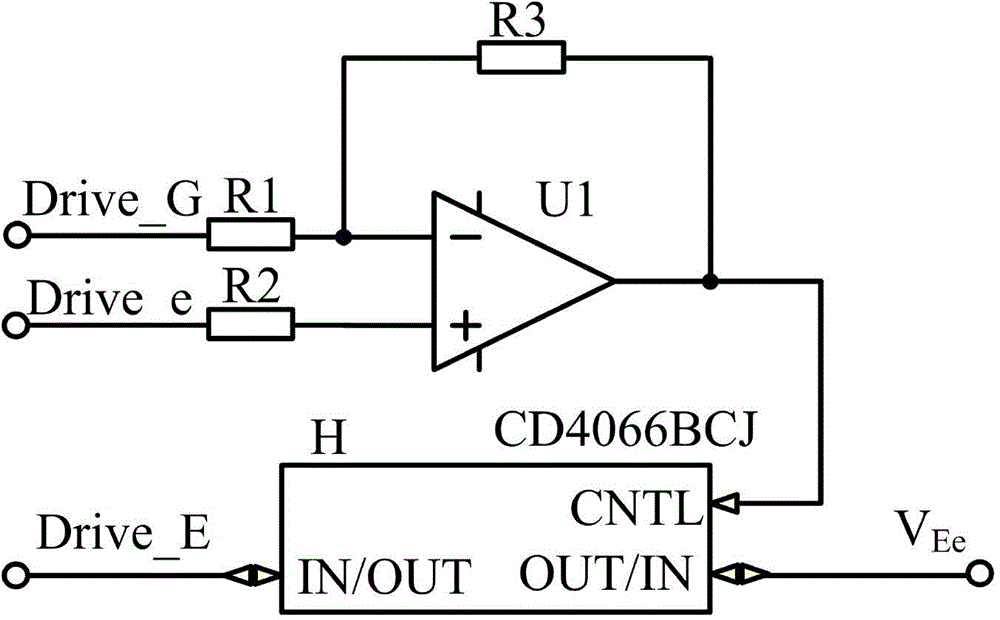

System and method for on-line detection of operating junction temperature of IGBT module

The invention discloses a system and a method for on-line detection of operating junction temperature of an IGBT module. Under an actually continuous on and off switching operate states of the IGBT module, changeable drive current and collector current generate induced voltage on stray inductance of the IGBT module; the induced voltage occurs twice voltage changes during turn-off, and the interval is recorded as the temperature-sensitive time which is closely related to the operating junction temperature of the IGBT module under a regular voltage and current turn-off condition. According to the system and the method, an IGBT test system is established to extract the temperature-sensitive time at different DC bus voltages, IGBT conducting currents and operating junction temperatures so as to establish an off-line reference database, voltage between a driving emitting electrode and a power emitting electrode of the IGBT module are monitored during the actual operation of an IGBT, and the temperature-sensitive time is extracted to calculate junction temperature on line. Compared with the conventional technology for monitoring the operating junction temperature of the IGBT, the method provided by the invention has higher real-time performance and integration.

Owner:ZHEJIANG UNIV

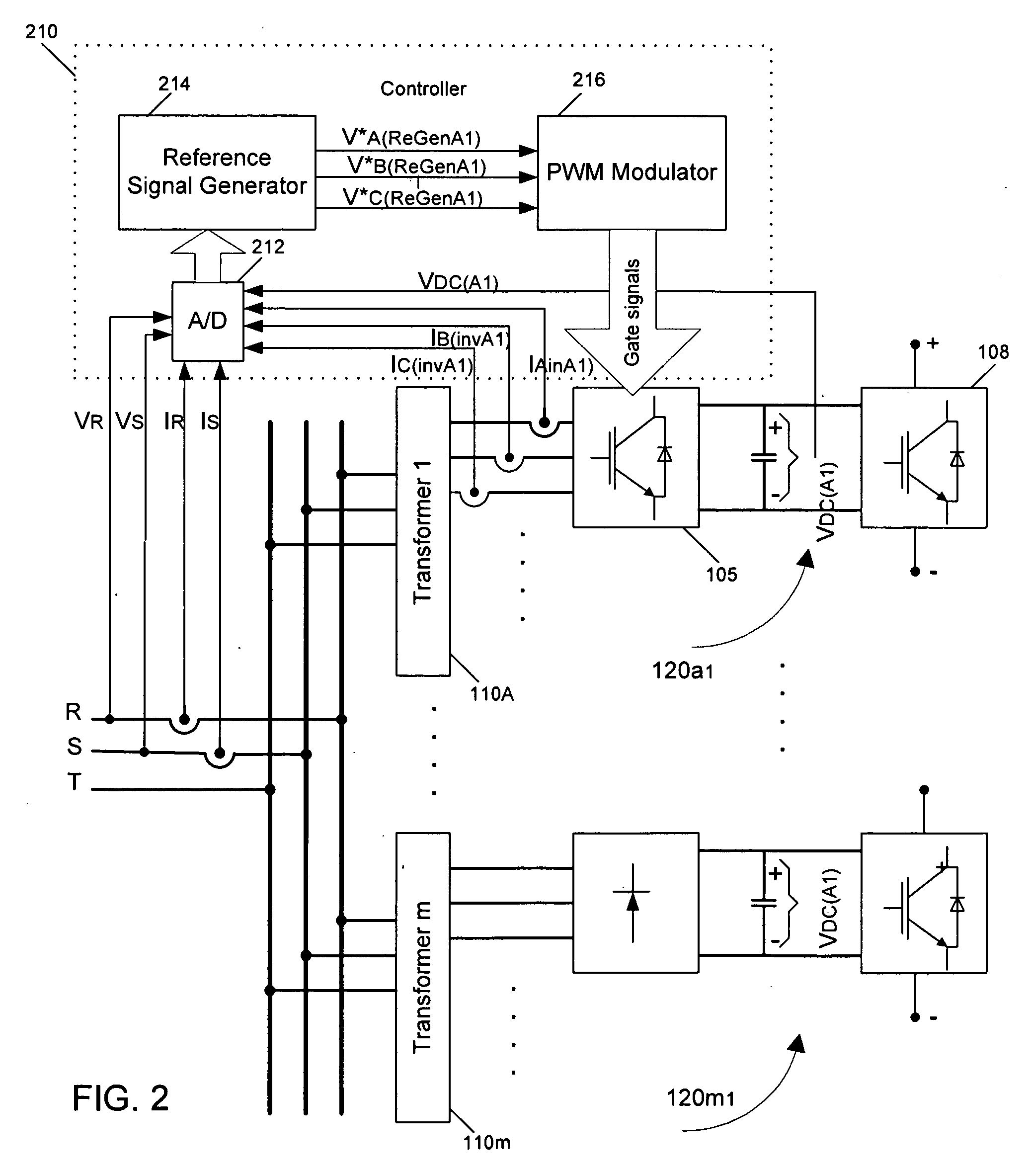

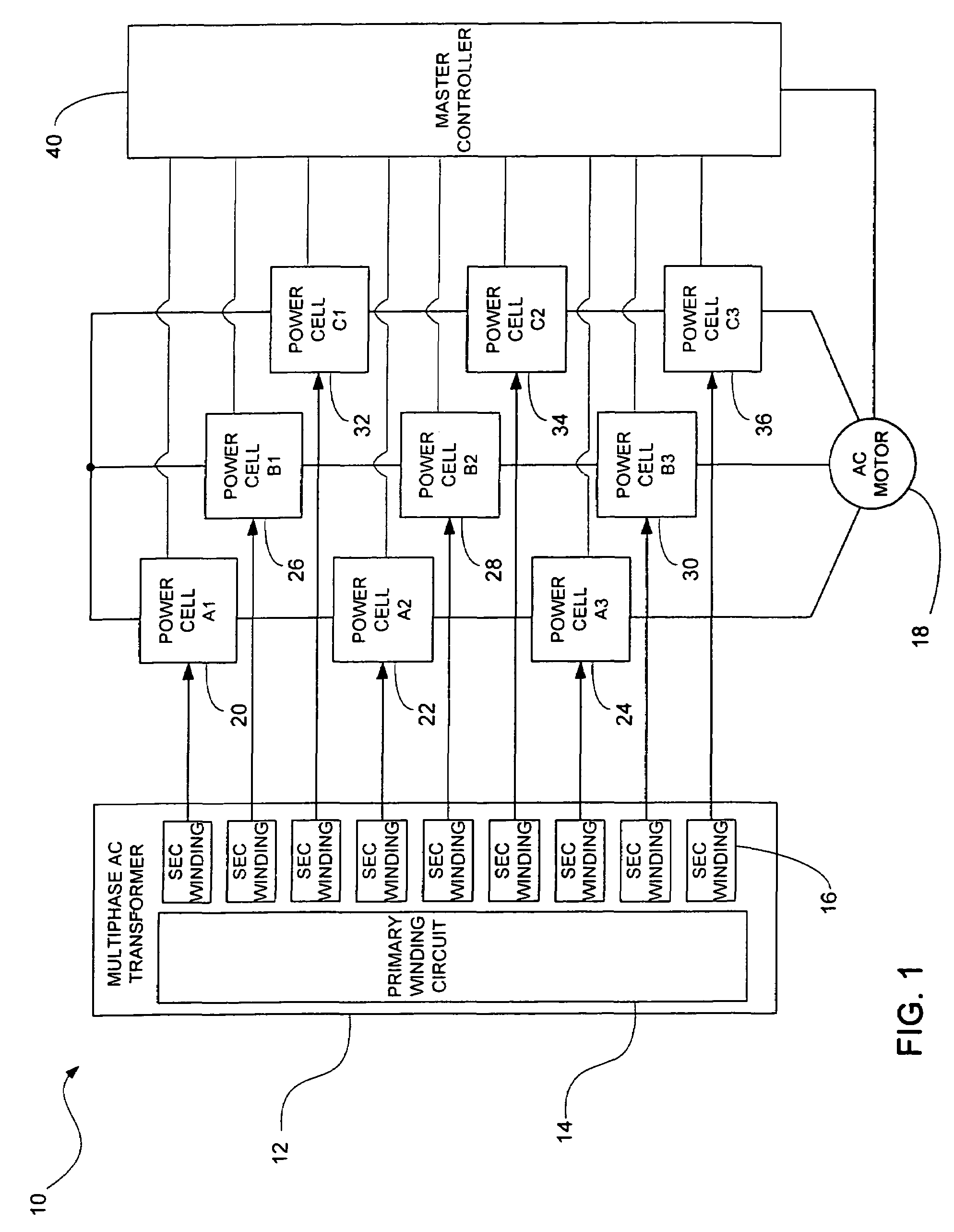

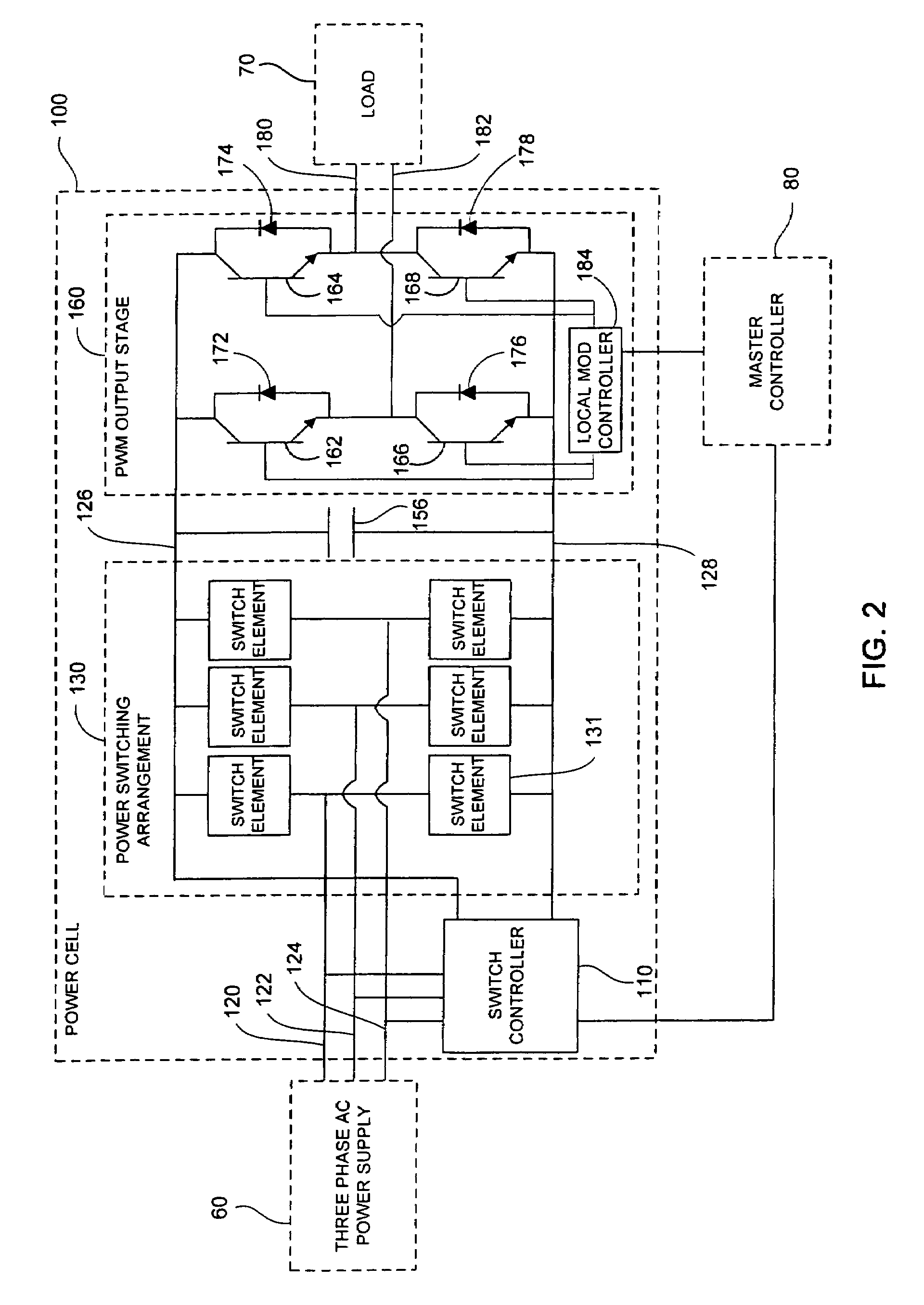

System and method for regenerative PWM AC power conversion

InactiveUS7170767B2Improve waveformBatteries circuit arrangementsAc-dc conversion without reversalElectricityPower flow

A power conversion system for driving a load is provided. The power conversion system comprises a power transformer having at least one primary winding circuit and at least one secondary winding circuit, the primary winding circuit being electrically connectable to an AC power source. The system further comprises at least one power cell, each of the at least one power cell having a power cell input connected to a respective one of the at least one secondary winding circuit. Each power cell also has a single phase output connectable to the load. A power switching arrangement including at least one power switch is connected to the power cell input and a DC bus, and a switch controller is connected to the power switching arrangement and the power cell input. The power cell also has a PWM output stage having a plurality of PWM switches connected to the DC bus and the single phase output. A local modulation controller is connected to the PWM output stage. The switch controller is adapted for monitoring and controlling a DC bus voltage according to a predetermined control methodology in both a motoring mode in which power from the AC power source is supplied to the load by the at least one power cell and a regeneration mode in which power from the load is supplied to the AC power source by the at least one power cell. The power conversion system also comprises a master controller in communication with the switch controller and the local modulation controller of each of the at least one power cell. The master controller is connectable to the load to monitor power flow thereto.

Owner:BIXEL PAUL S

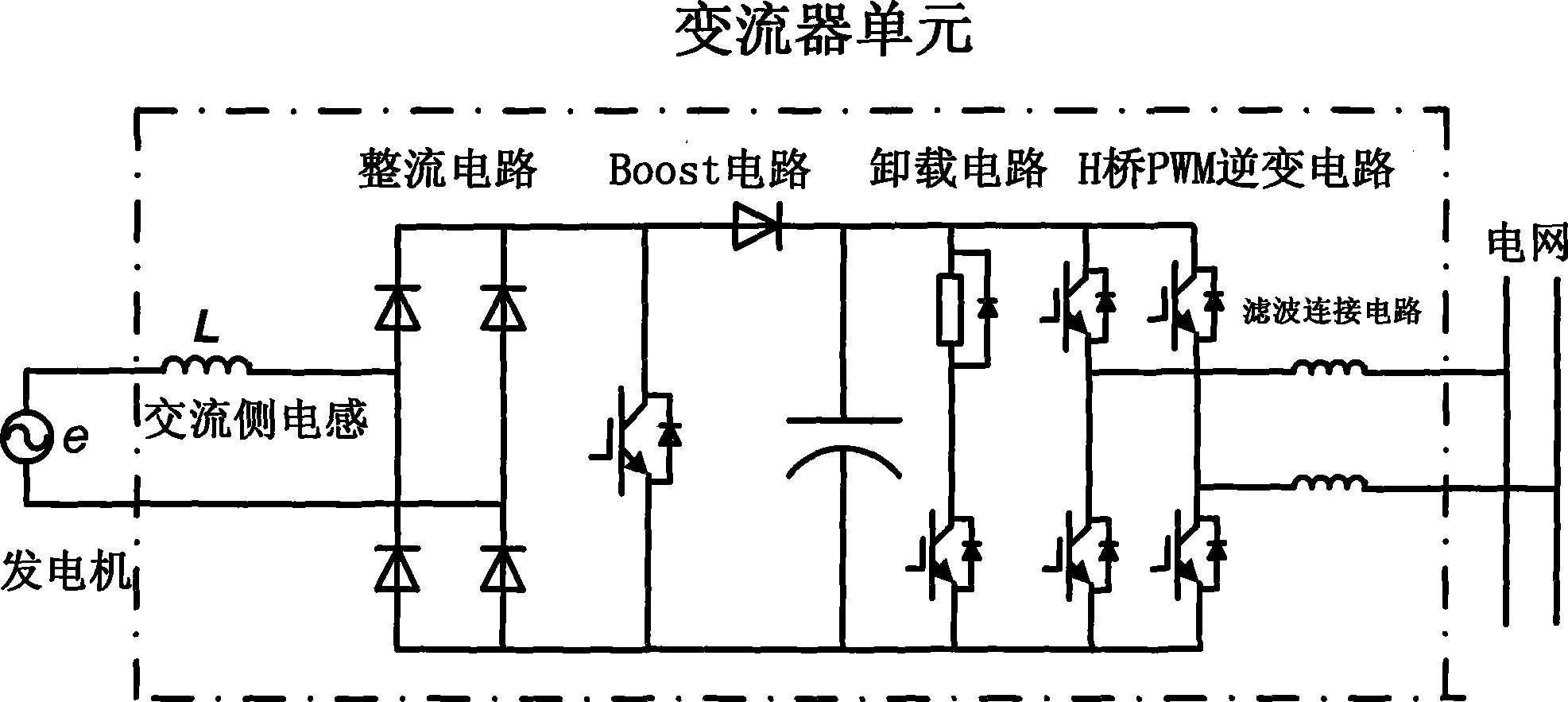

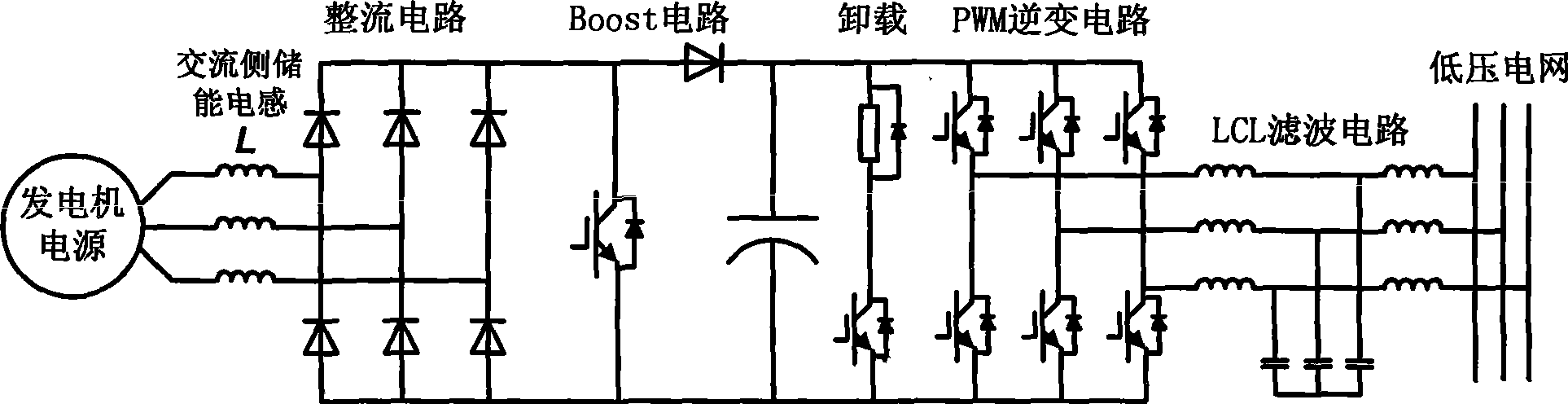

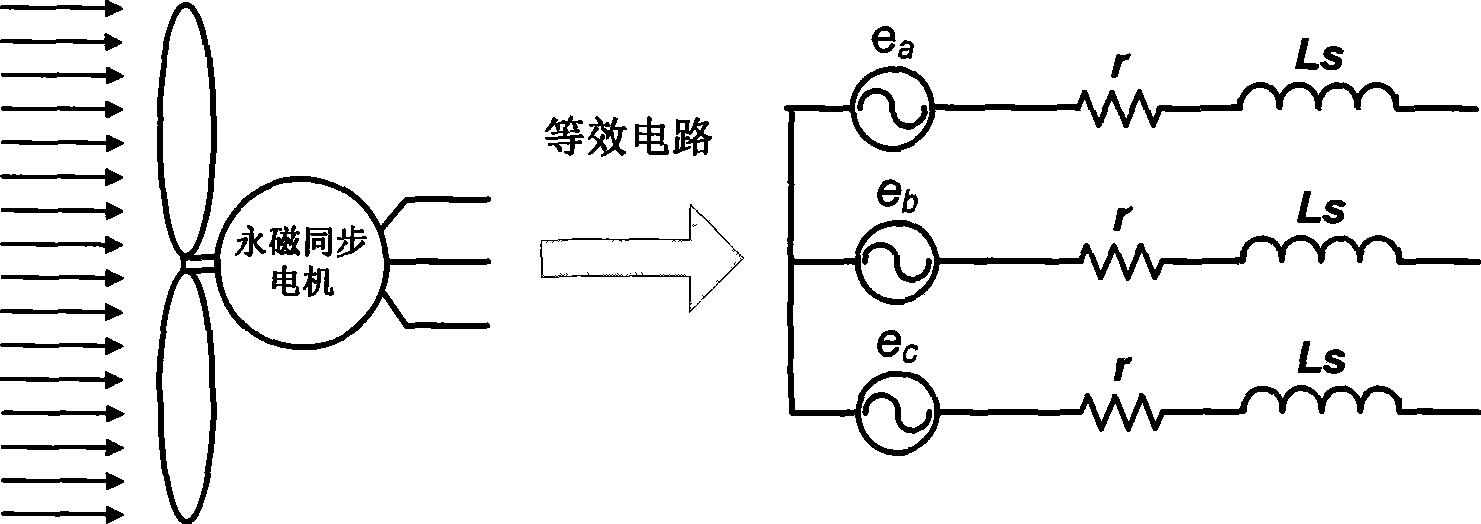

Parallel-in converter for directly-driving wind power generation system

InactiveCN101465606ALess energy storage linksReduce harmonic contentConversion with intermediate conversion to dcSingle network parallel feeding arrangementsĆuk converterEngineering

Disclosed are a grid-connected converter device of a direct-drive wind power system and a corresponding power coordination control method. The converter device is composed of basic converter units of a Boost circuit based on ac-side energy storage; the structure sufficiently utilizes the equivalent inductance of a power generator stator winding, avoids an external inductor in traditional dc voltage booster circuit, and reduces power loss and equipment cost. Two converter proposals, including a diode rectification mode and a PWM rectification mode are designed; converter topologies with two capacity grades, including medium and small power converter topology, megawatt grade high power converter topology, and relative extension structures are designed, such as a parallel connection converter and an H bridge cascade structure converter; wherein, the converter with the H bridge cascade structure is applicable to grids with high capacity and high voltage, and can obviously reduce the harmonic content in grid-connected current; meanwhile, the control method performing feedback through three closed loops is designed, so the input power and output power of the converter are balanced instantaneously, the dc bus voltage maintains stable, and the grid-connected current wave is sine.

Owner:刘建政

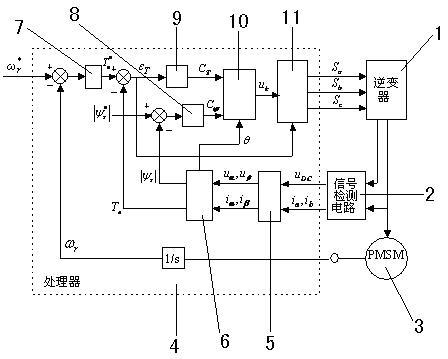

Direct torque control device and method for permanent magnet synchronous motor

InactiveCN101931362AIncrease the number of optional vectorsReduce torque rippleTorque ripple controlVector control systemsVoltage vectorPermanent magnet synchronous motor

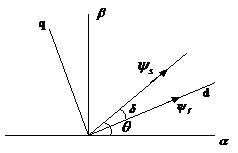

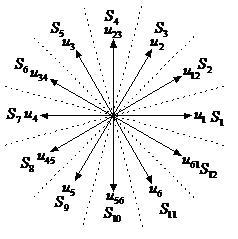

The invention discloses a direct torque control device and a direct torque control method for a permanent magnet synchronous motor. The DC bus voltage of an inverter and a current signal of the permanent magnet synchronous motor are output to a signal detection circuit; the signal detection circuit outputs the DC bus voltage and the current signal to a processor; meanwhile, a rotating speed pulse signal of the permanent magnet synchronous motor is output to the processor and is processed by the processor to form a proper switch signal which is then output to the inverter so as to control the motor. A proper voltage vector is selected from twelve synthesized voltage vectors according to a flux linkage error and a torque error and the position of the flux linkage in twelve sectors, and the duty ratio of the selected voltage vector is determined in real time according to the torque error so as to generate a proper inverter switch signal for controlling the permanent magnet synchronous motor. The number of the selectable voltage vectors in the traditional direct torque control is increased, the duty ratio of an acting vector is adjusted in real time according to the torque error, and the torque pulsation in the traditional direct torque control can be effectively reduced.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com