Patents

Literature

180 results about "Torque error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Error Code P0742 is defined as Torque Converter Clutch Circuit Stuck On. Meaning, the torque converter clutch circuit is performing abnormally, which usually happens due to dirty transmission fluid or valves.

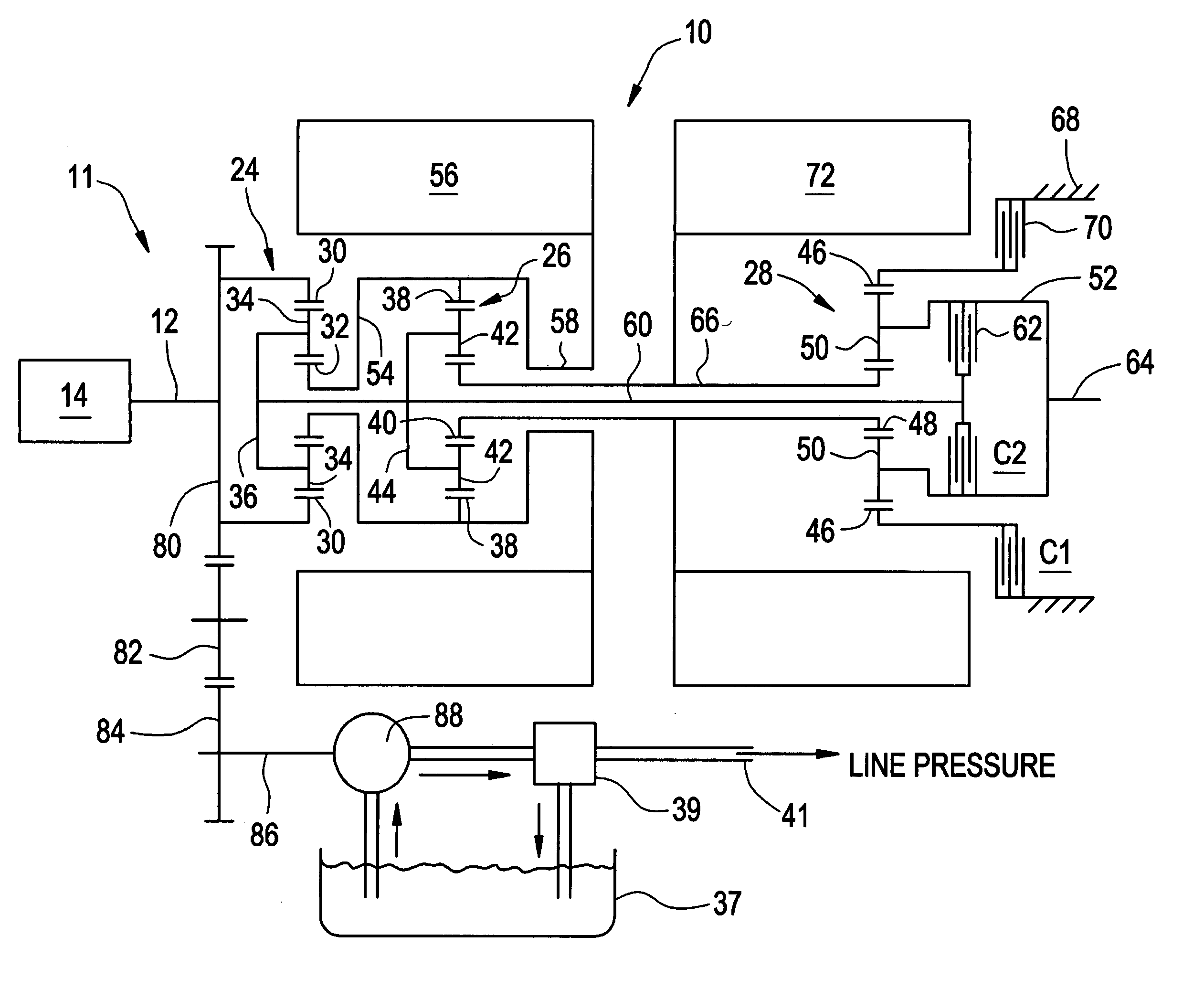

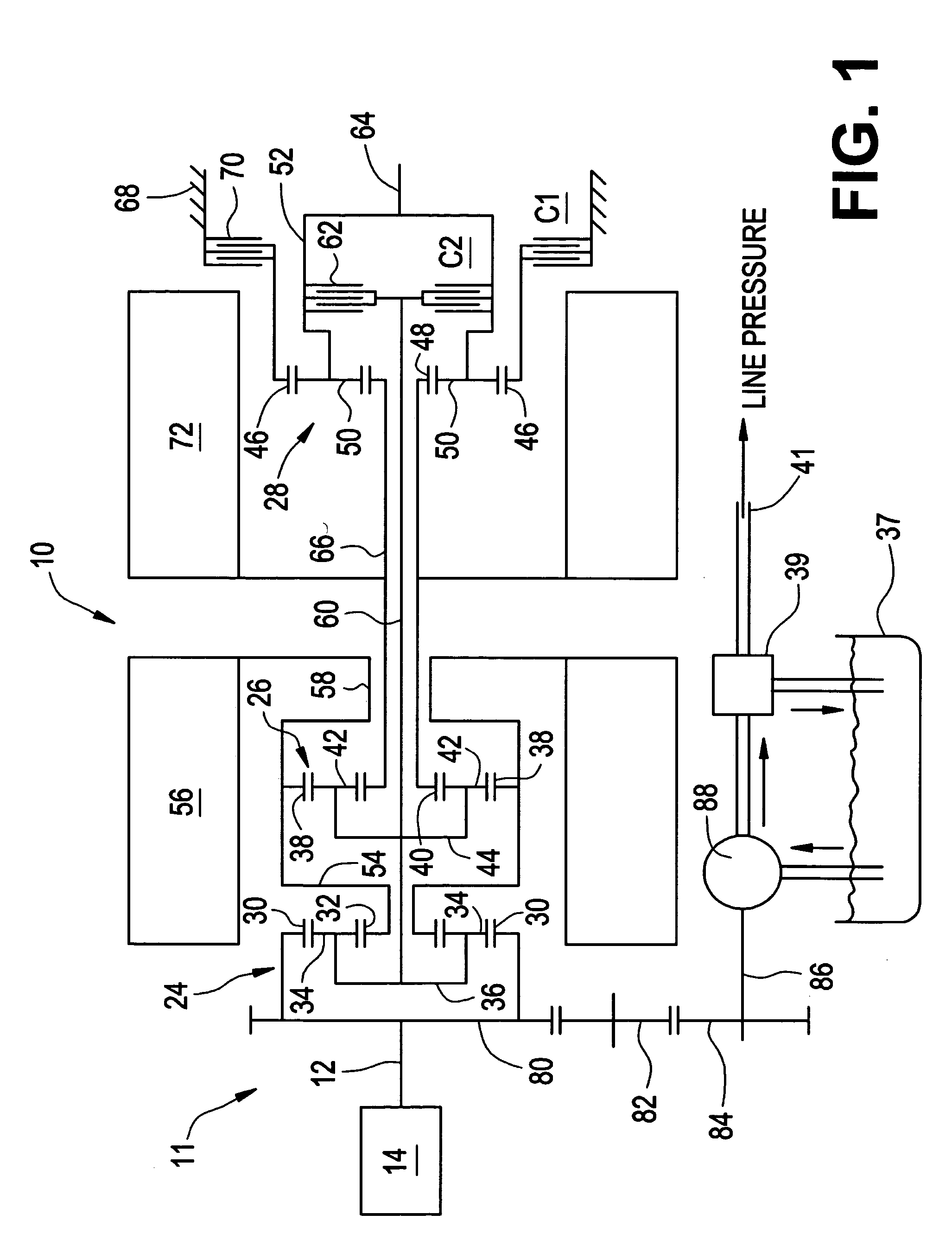

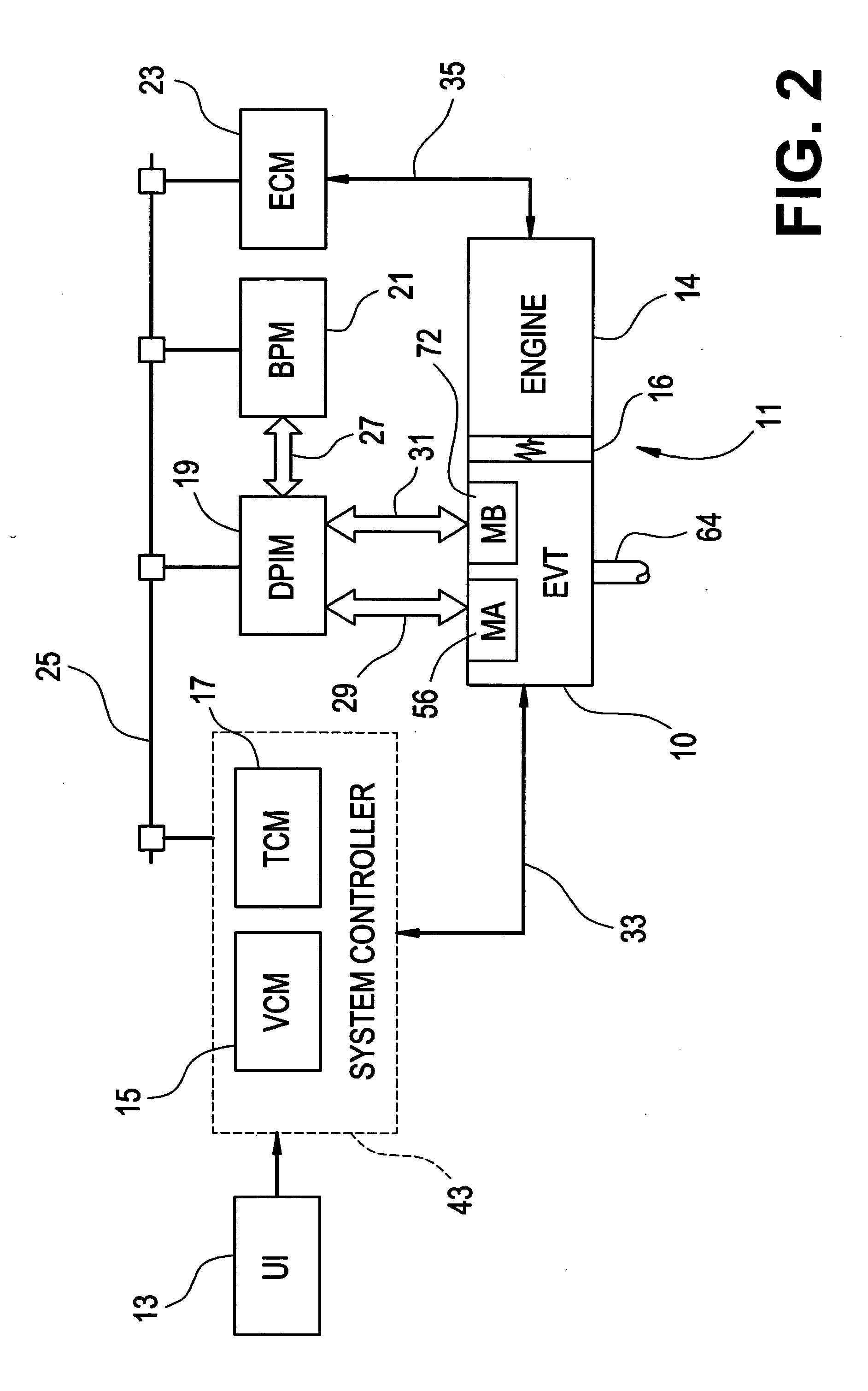

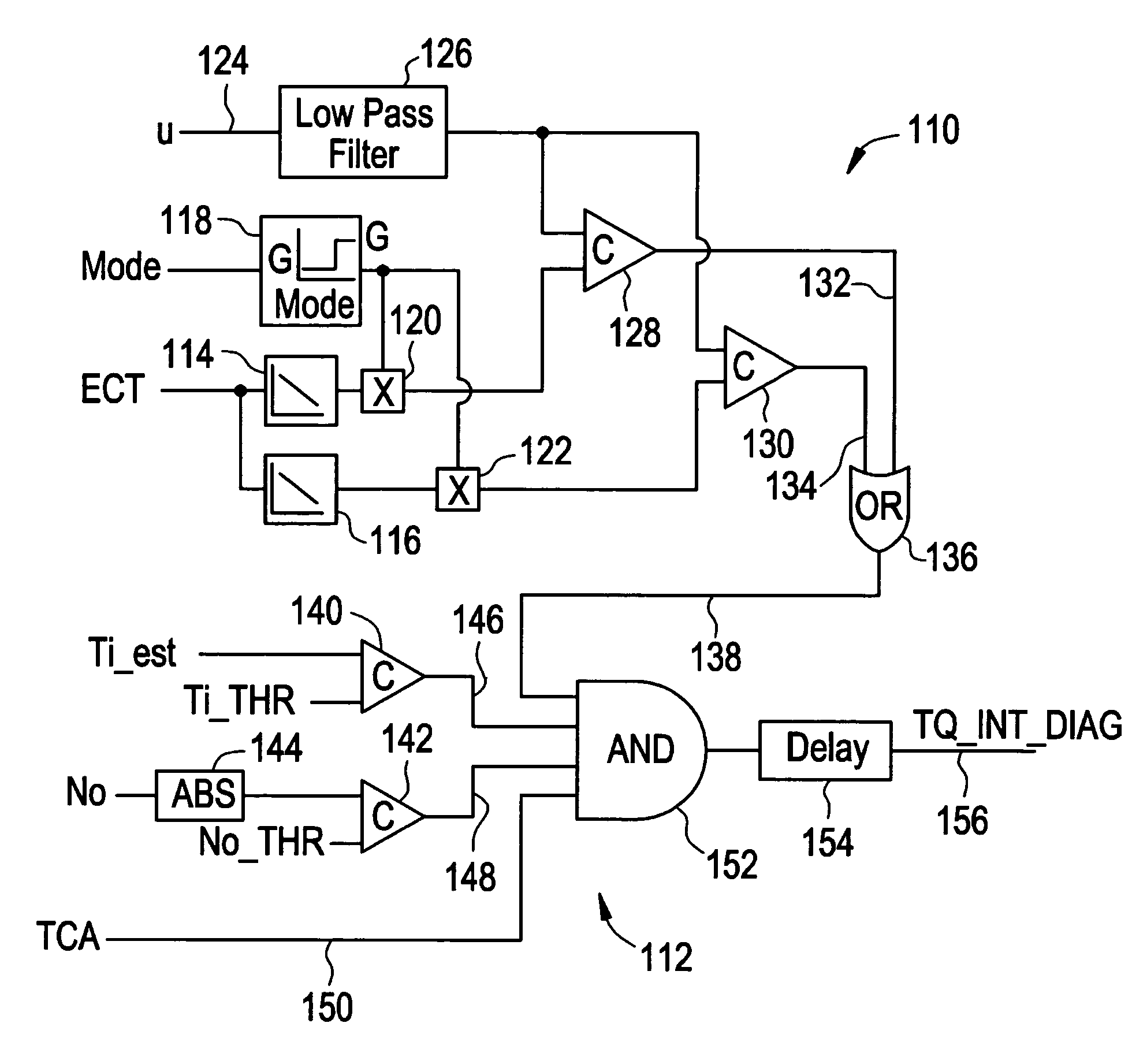

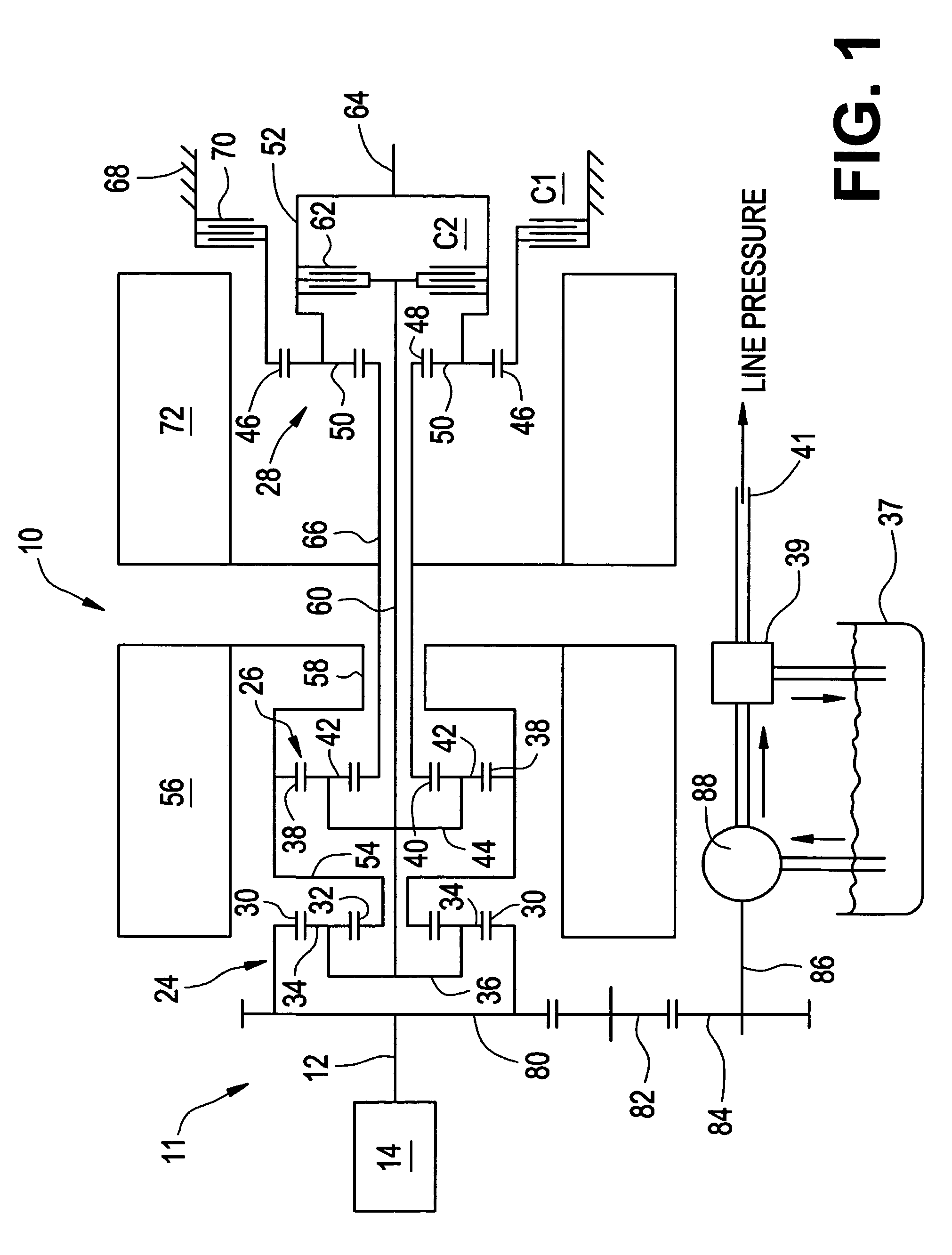

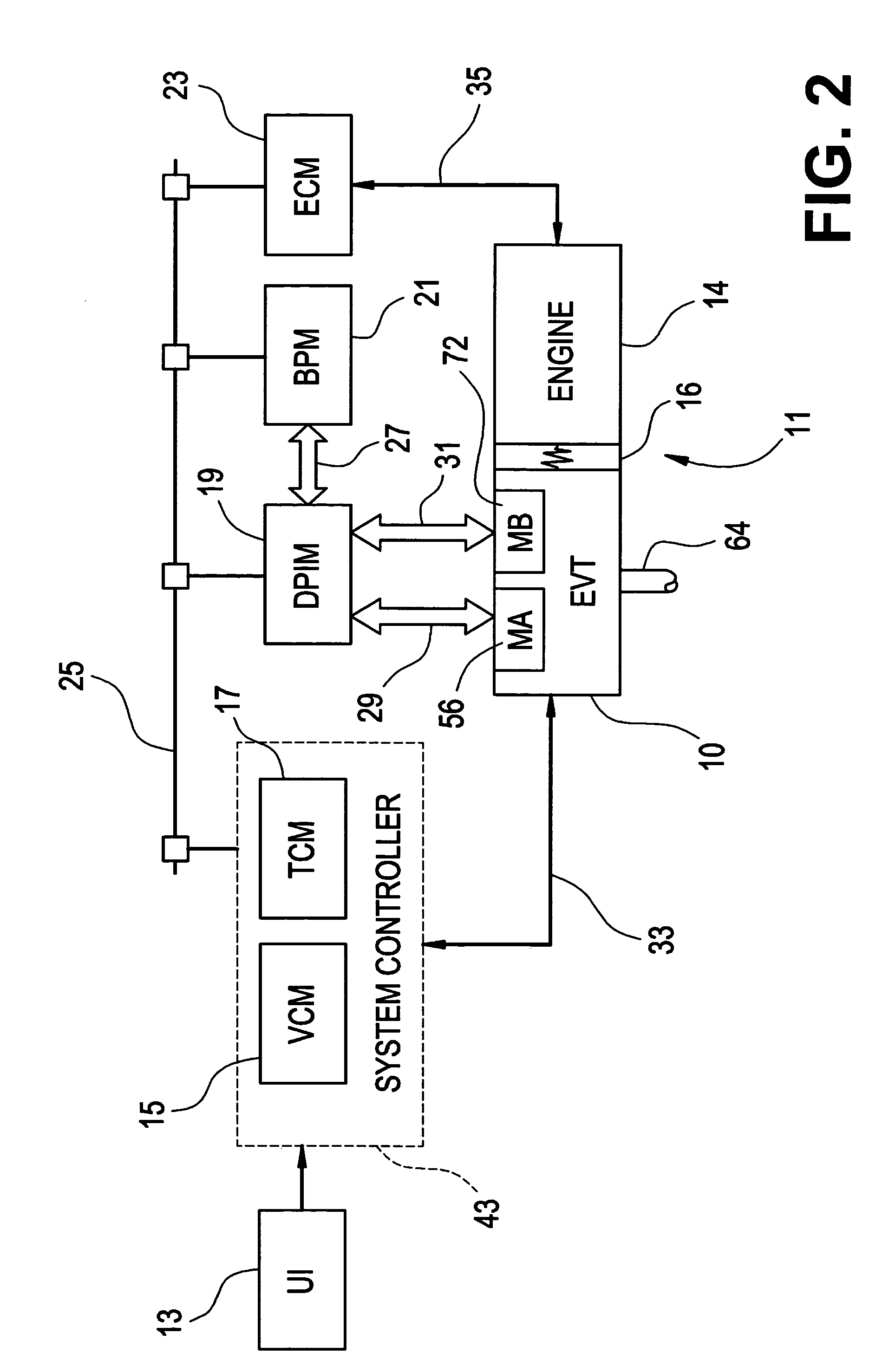

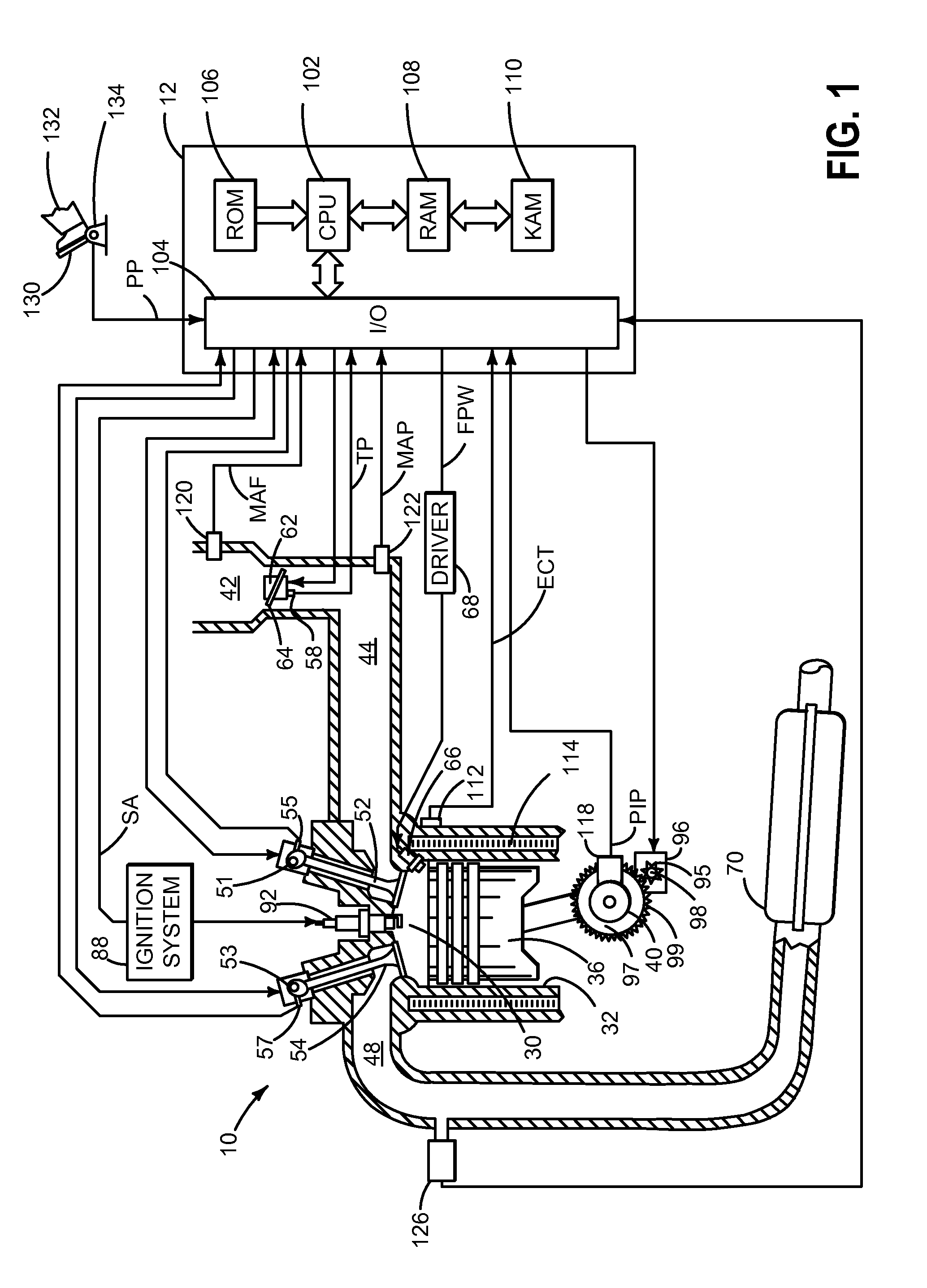

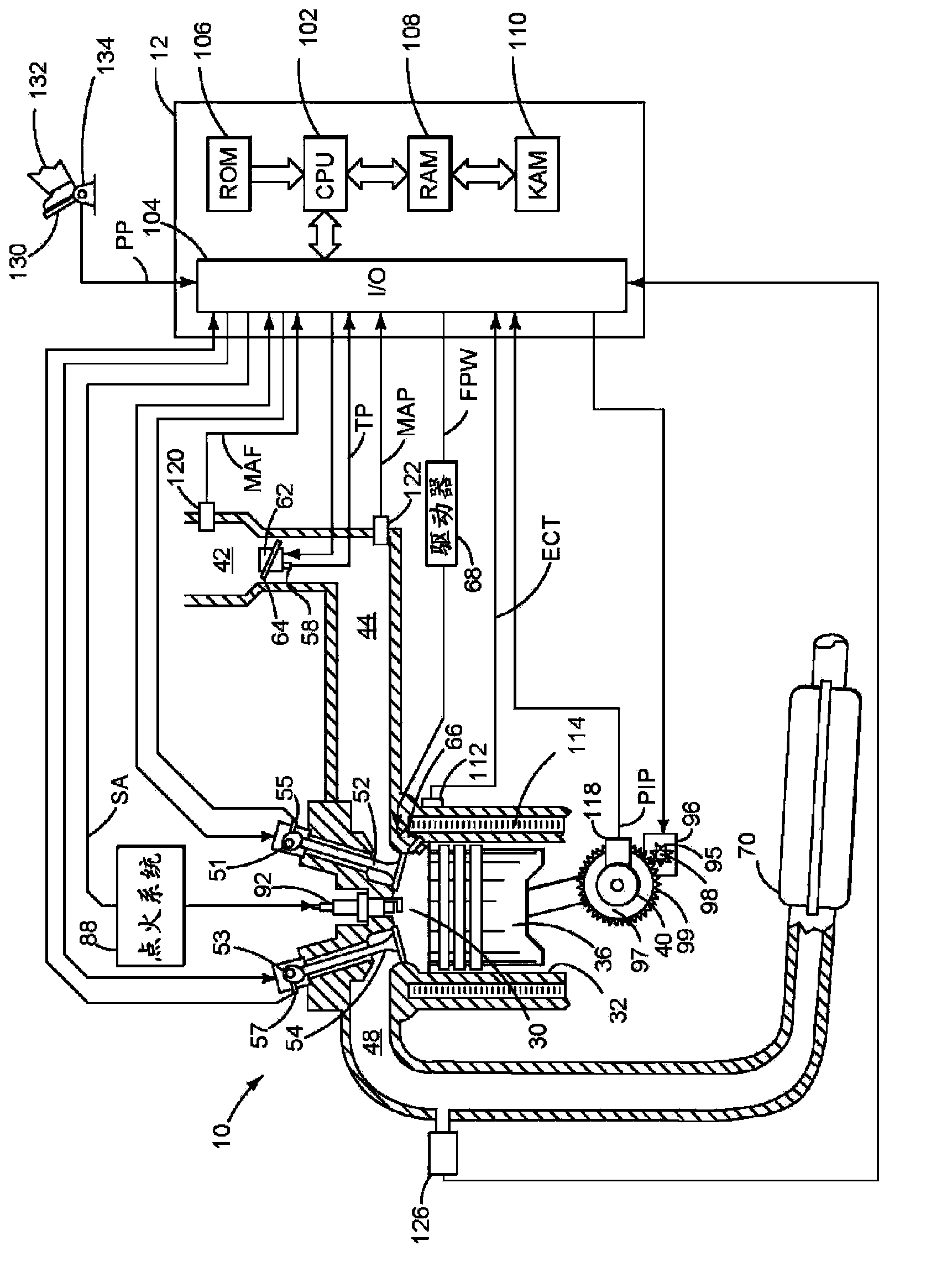

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS20050252283A1Impaired speed controlImpaired torque controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

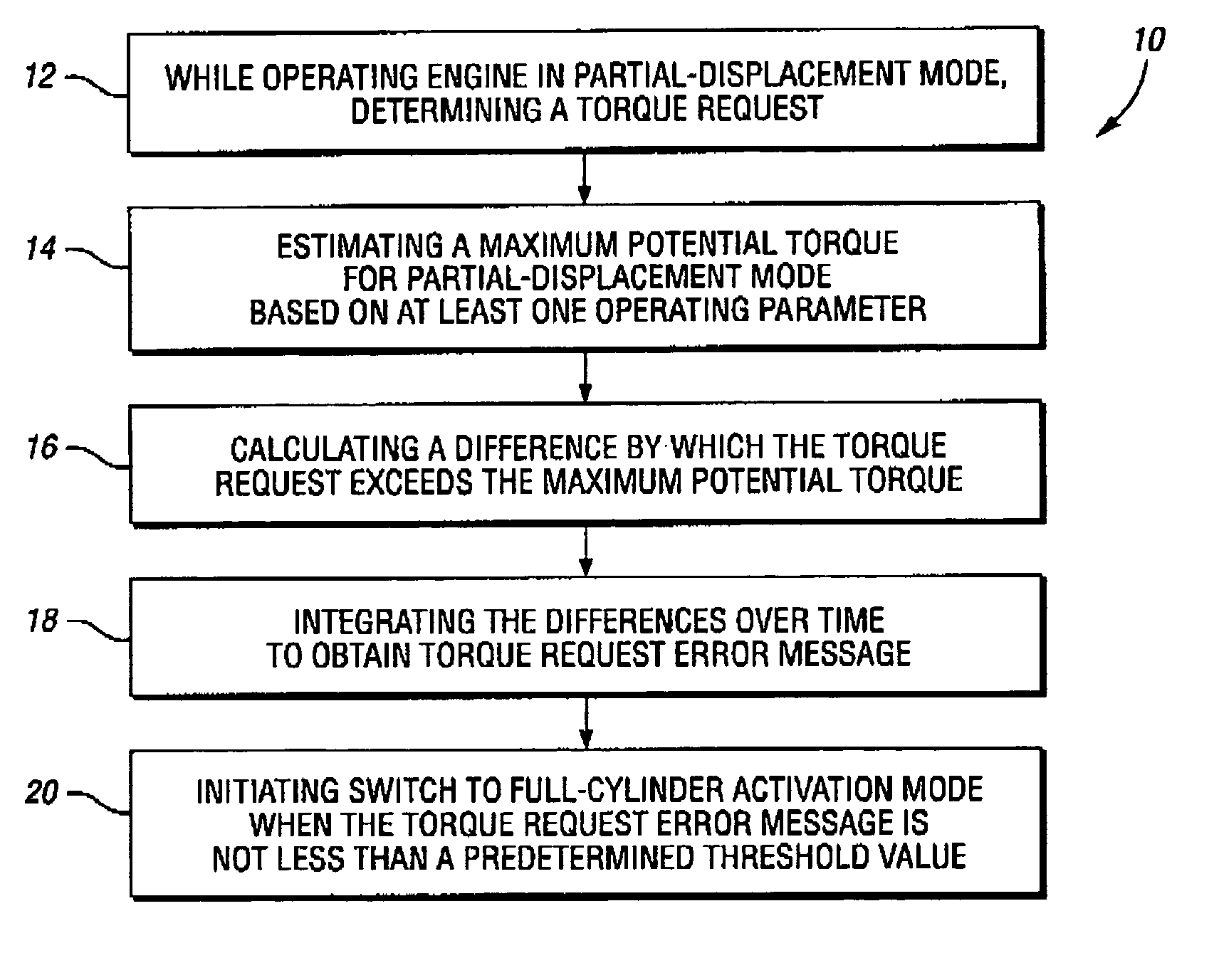

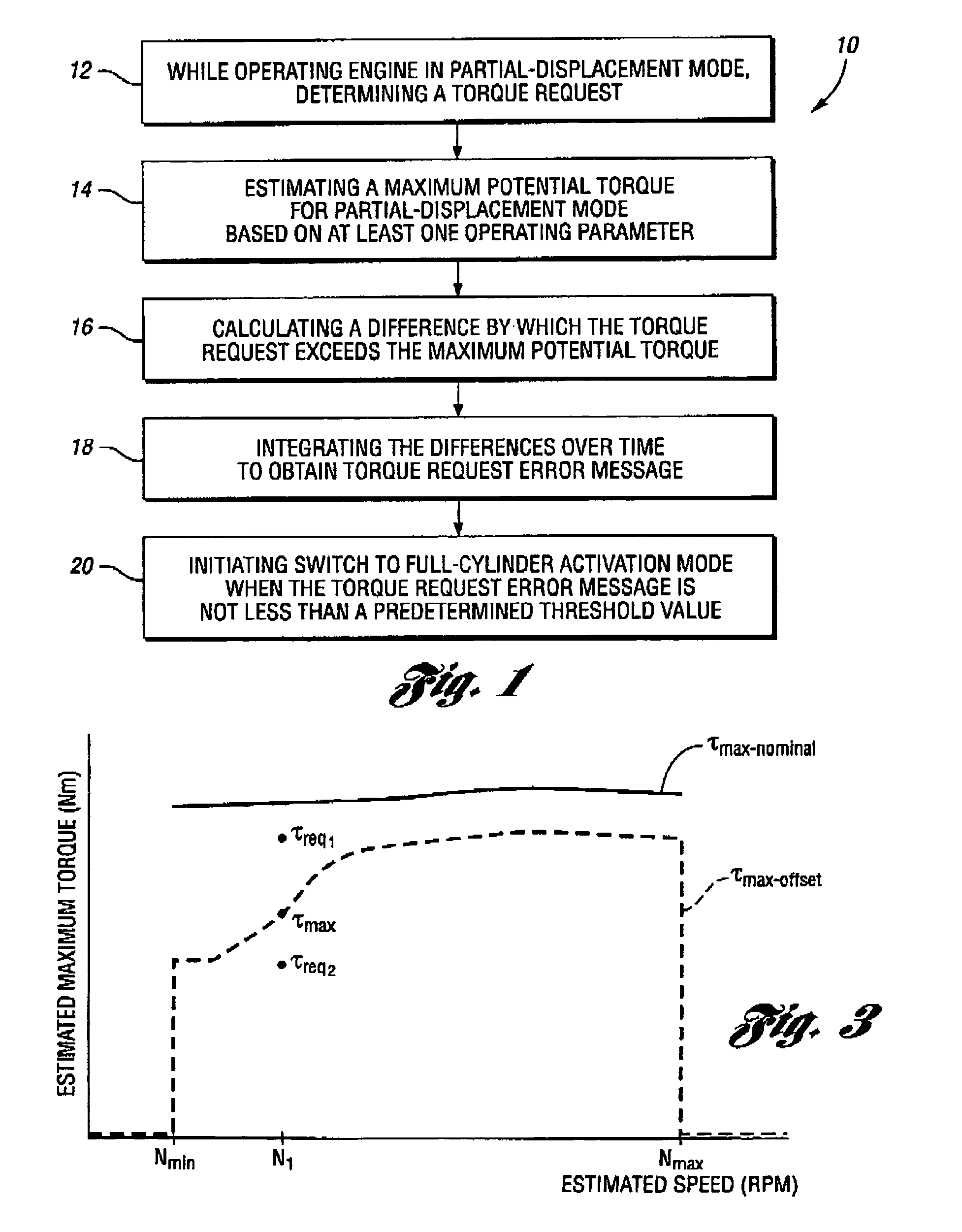

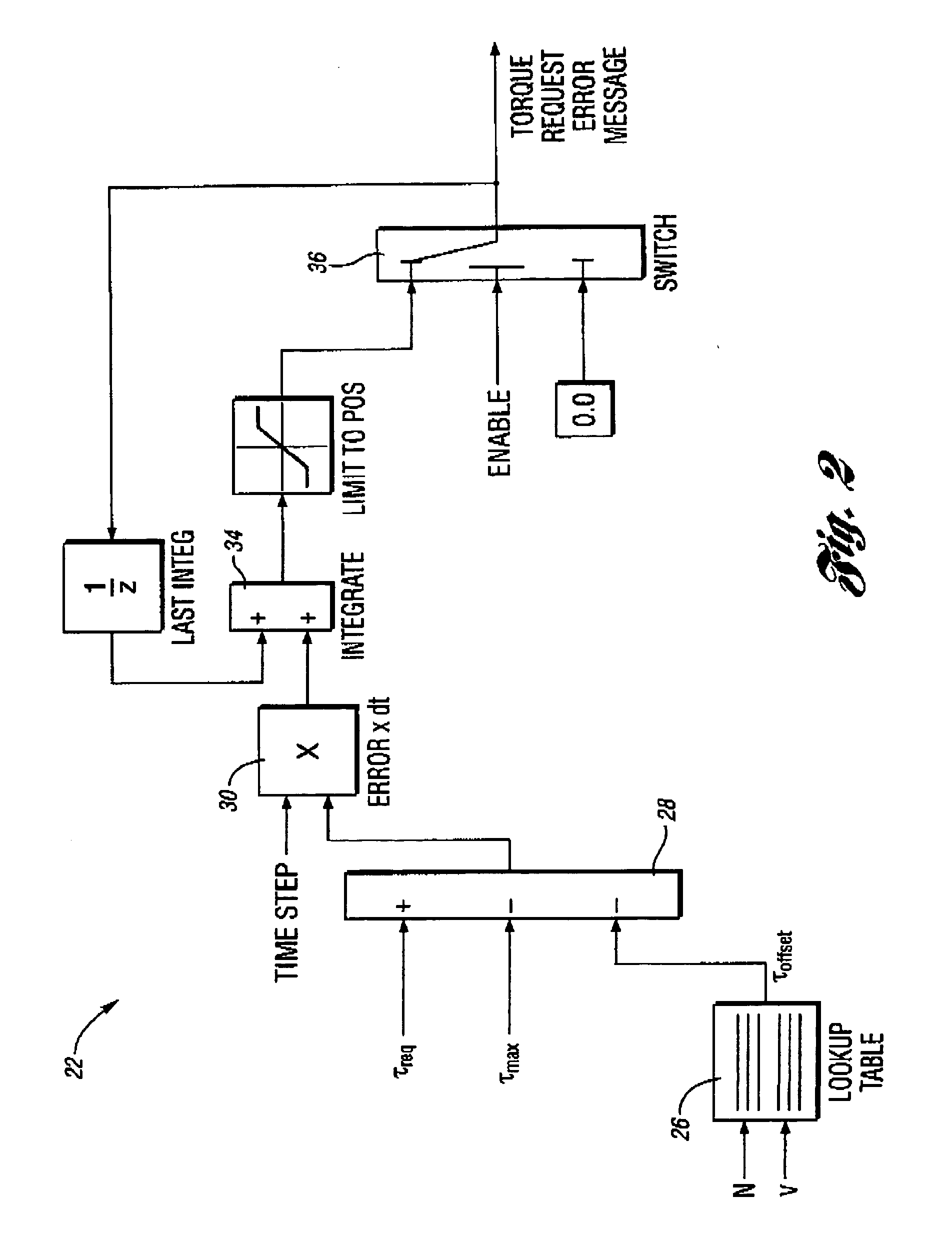

Method and code for controlling reactivation of deactivatable cylinder using torque error integration

In an internal combustion engine adapted to operate in a cylinder-deactivation mode, a method for controlling the reactivation of a deactivated cylinder includes determining a difference between a torque request from a vehicle operator, and an estimate of a maximum engine torque achievable in cylinder-deactivation mode based at least in part on a current engine speed. The difference is integrated over time to obtain a torque request “error.” A reactivation of the deactivated cylinder is triggered when the torque request error exceeds a first threshold value, which can be a calibrated value, a calibrated value adapted, for example, for driving style, or a value determined from a vehicle operating parameter such as vehicle speed. The use of the torque request error advantageously avoids reactivation of the deactivated cylinders in response to brief transients in the torque request signal that otherwise temporarily exceed the maximum achievable engine output torque.

Owner:FCA US

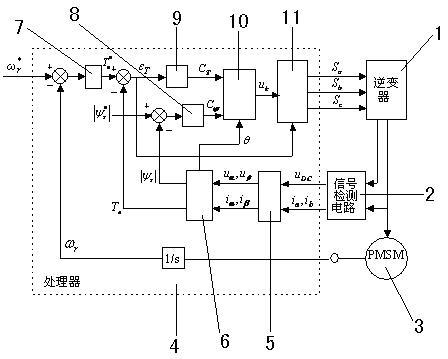

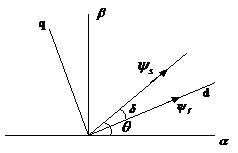

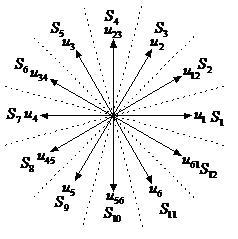

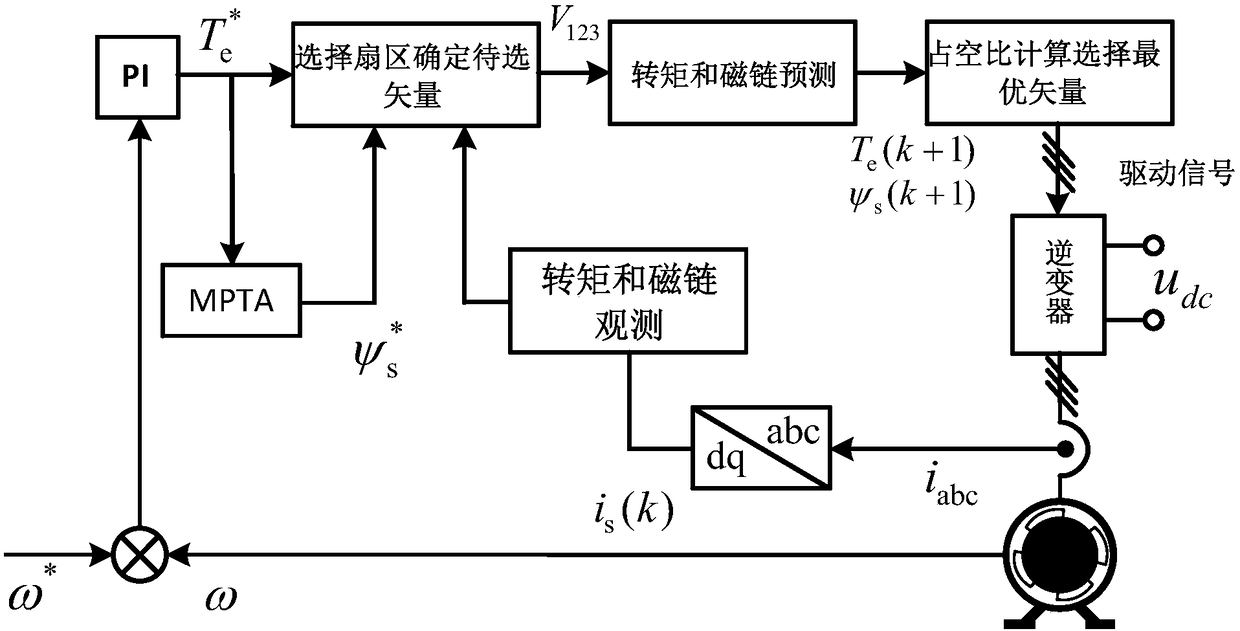

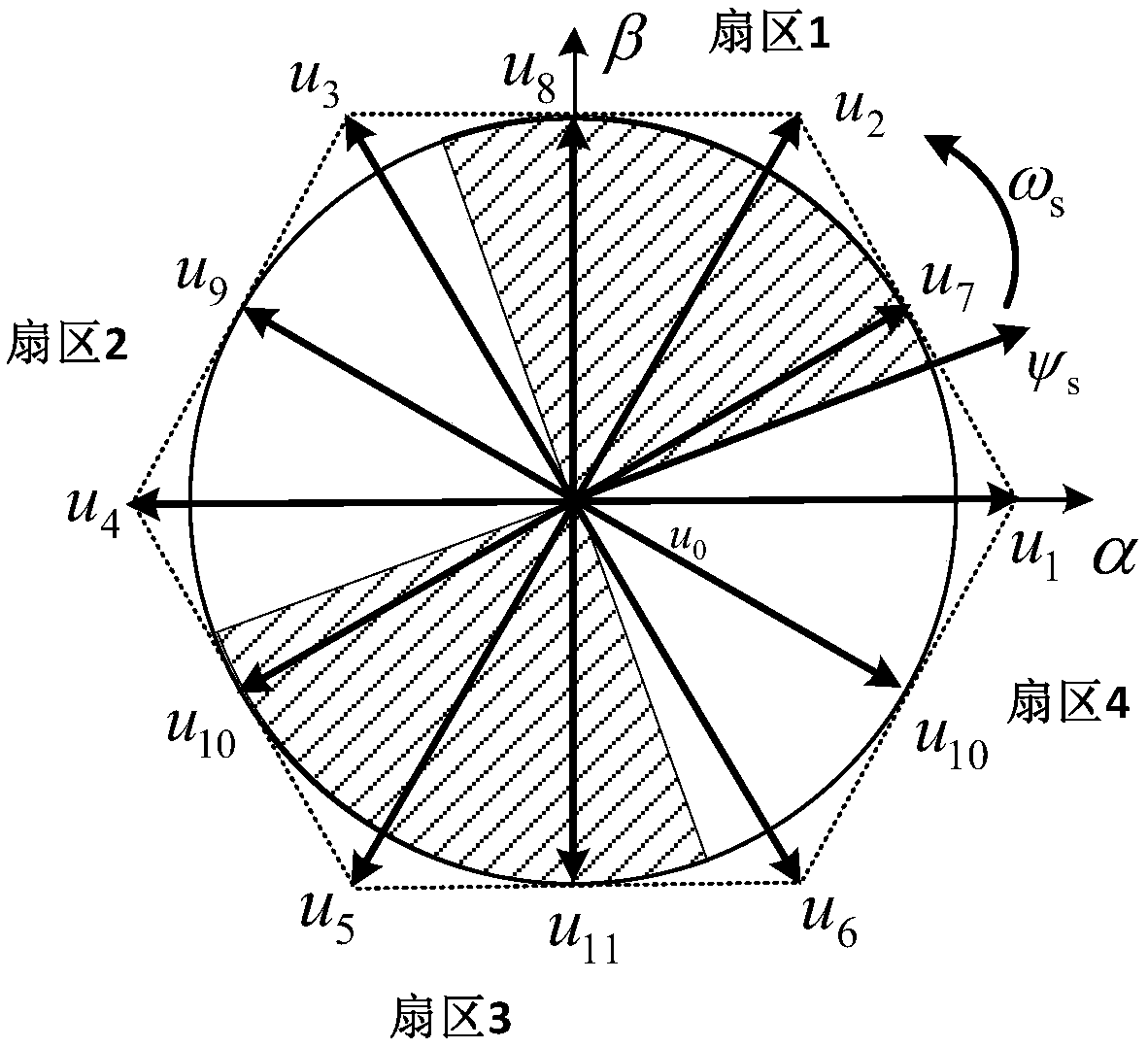

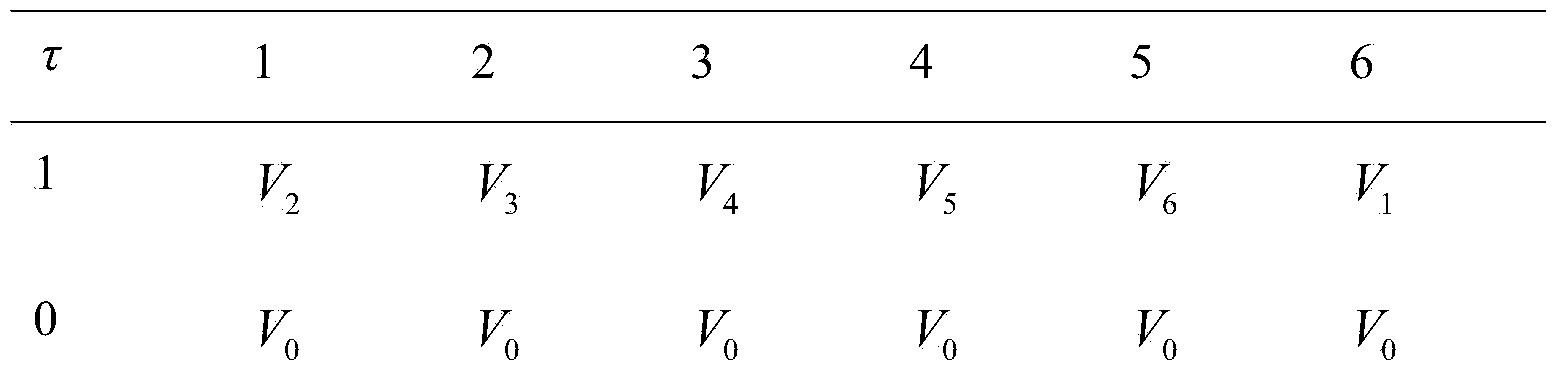

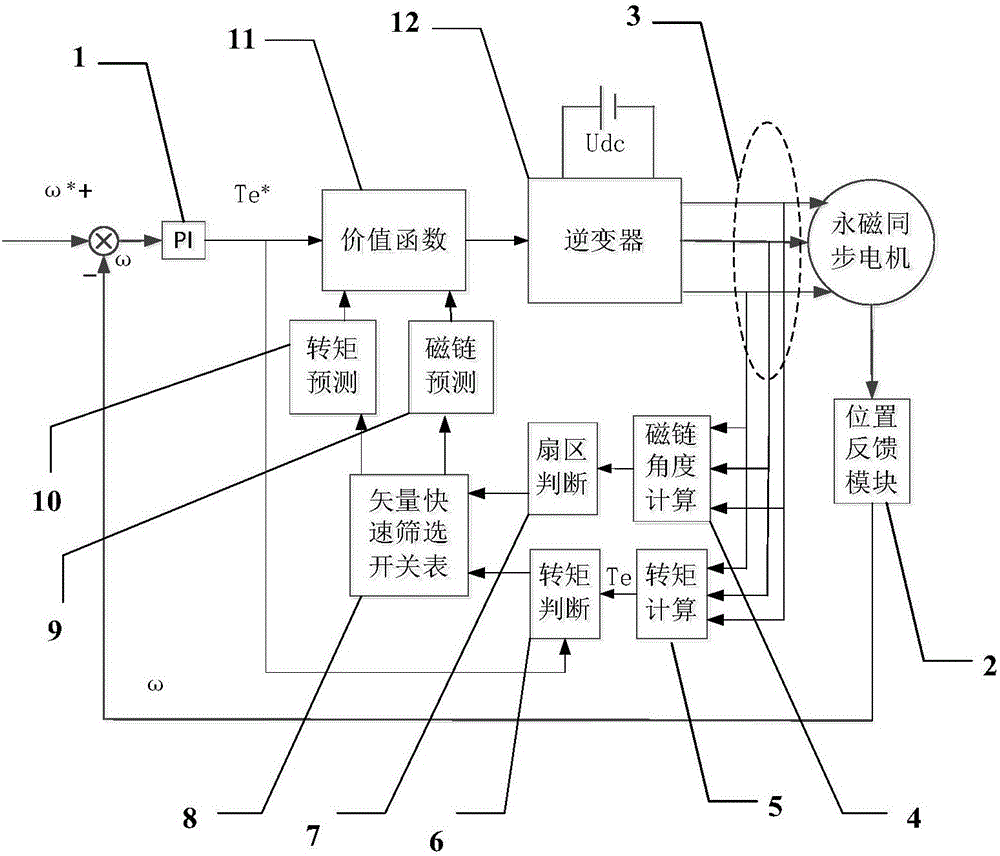

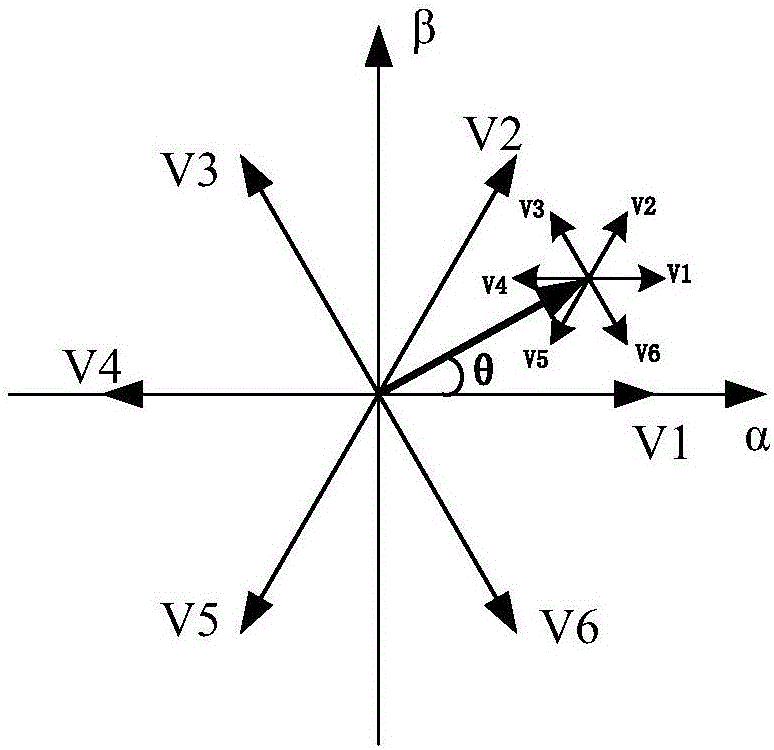

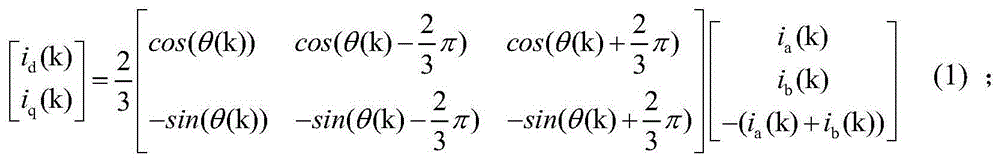

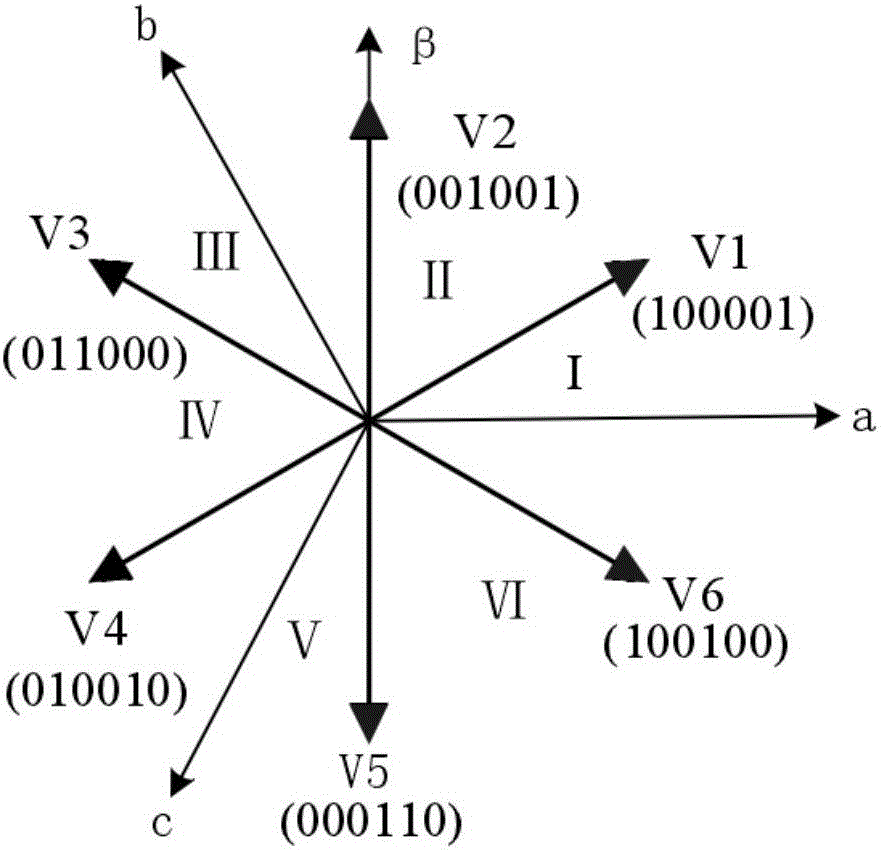

Direct torque control device and method for permanent magnet synchronous motor

InactiveCN101931362AIncrease the number of optional vectorsReduce torque rippleTorque ripple controlVector control systemsVoltage vectorPermanent magnet synchronous motor

The invention discloses a direct torque control device and a direct torque control method for a permanent magnet synchronous motor. The DC bus voltage of an inverter and a current signal of the permanent magnet synchronous motor are output to a signal detection circuit; the signal detection circuit outputs the DC bus voltage and the current signal to a processor; meanwhile, a rotating speed pulse signal of the permanent magnet synchronous motor is output to the processor and is processed by the processor to form a proper switch signal which is then output to the inverter so as to control the motor. A proper voltage vector is selected from twelve synthesized voltage vectors according to a flux linkage error and a torque error and the position of the flux linkage in twelve sectors, and the duty ratio of the selected voltage vector is determined in real time according to the torque error so as to generate a proper inverter switch signal for controlling the permanent magnet synchronous motor. The number of the selectable voltage vectors in the traditional direct torque control is increased, the duty ratio of an acting vector is adjusted in real time according to the torque error, and the torque pulsation in the traditional direct torque control can be effectively reduced.

Owner:XIAN UNIV OF TECH

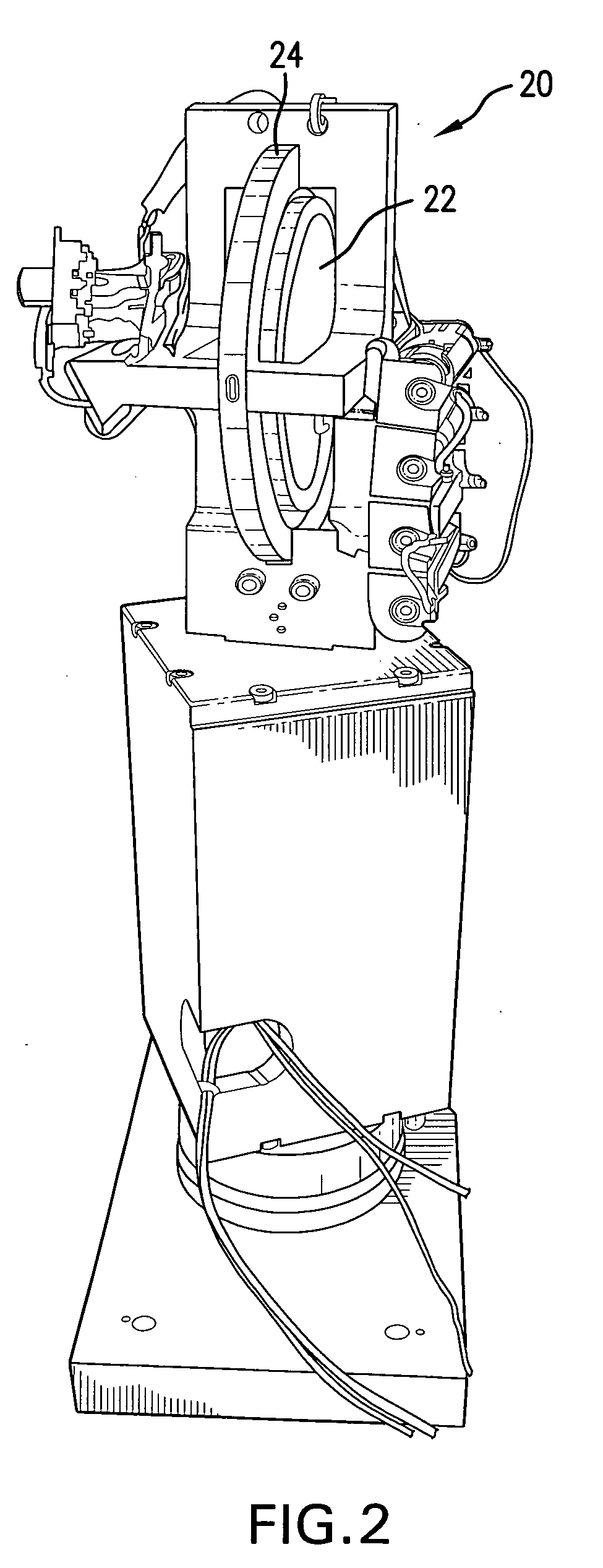

Diagnostic method for a torque control of an electrically variable transmission

ActiveUS6976388B2Easy to controlVehicle testingRegistering/indicating working of vehiclesLoop controlLow speed

A condition of impaired speed and torque control of a parallel electrically variable transmission due to factors beyond nominal modeling and estimation errors is diagnosed under low speed operation. The transmission includes at least one electric machine and a motor torque controller for regulating the transmission input speed and output torque. The motor torque controller includes an open-loop control path based on predetermined torques and accelerations and a closed loop control path based on input speed error. The presence of a larger than expected closed-loop correction magnitude, combined with low output speed and one or more other conditions is used to diagnose a condition of potential torque error, in which case the transmission control is altered to prevent unwanted operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

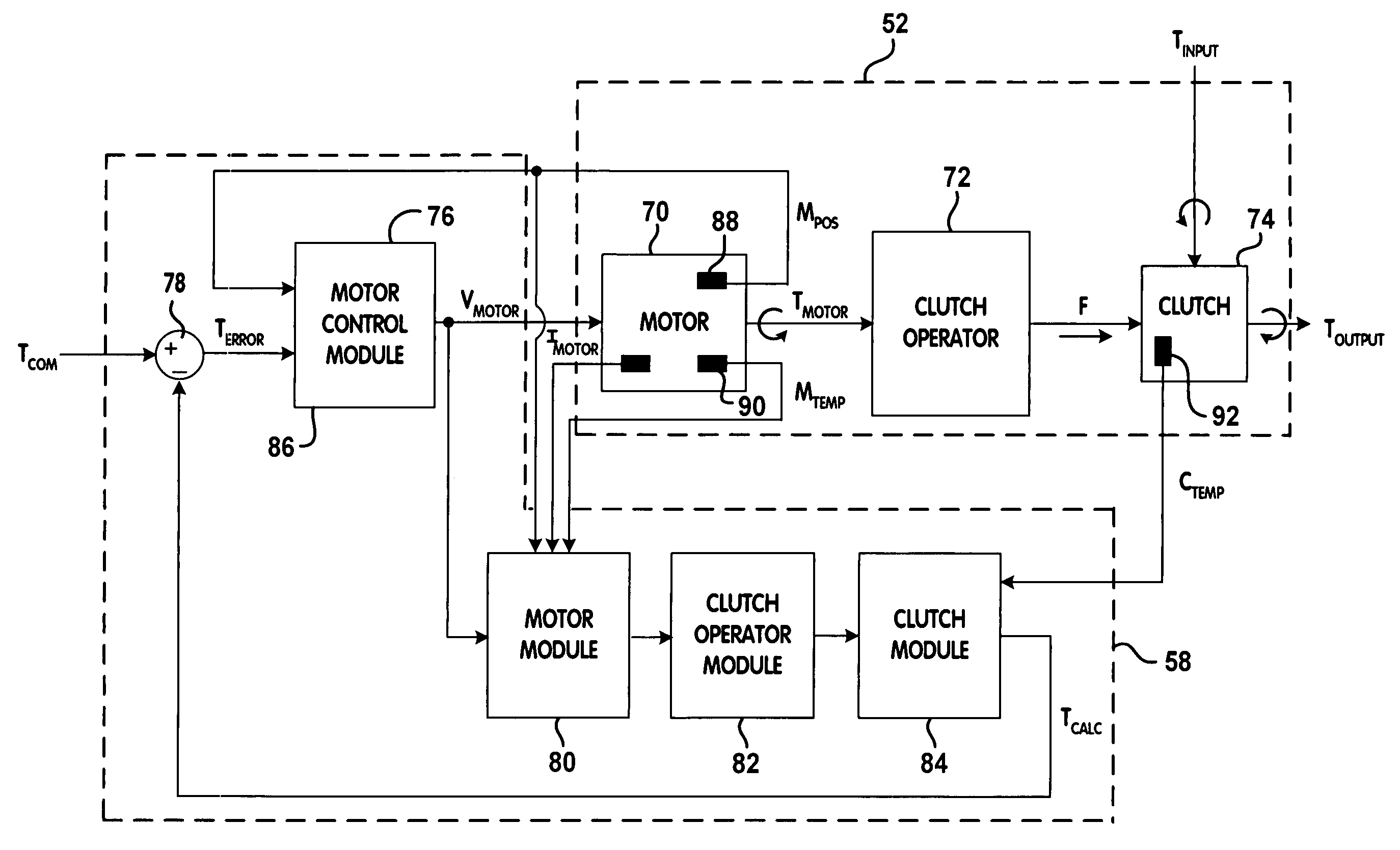

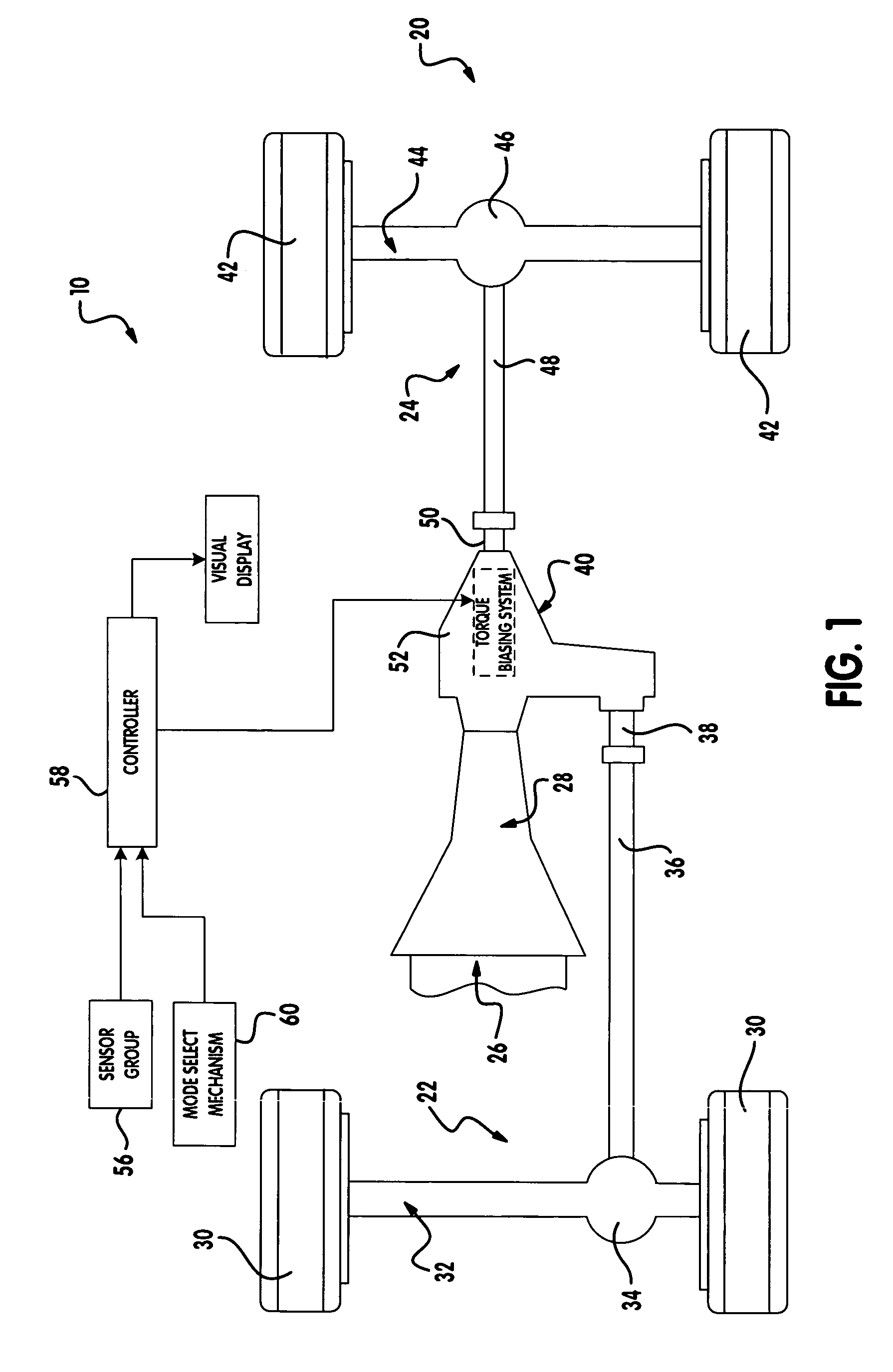

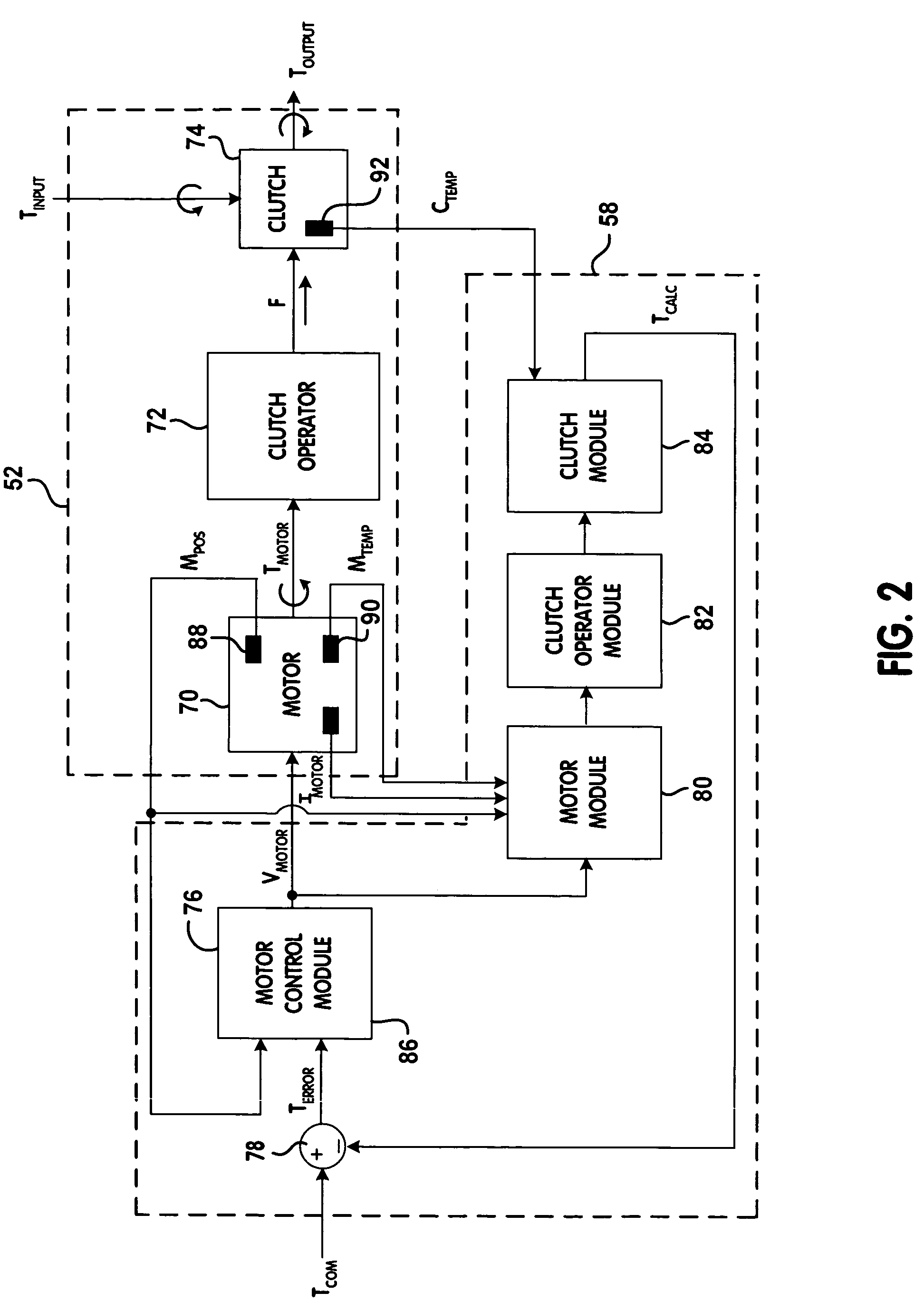

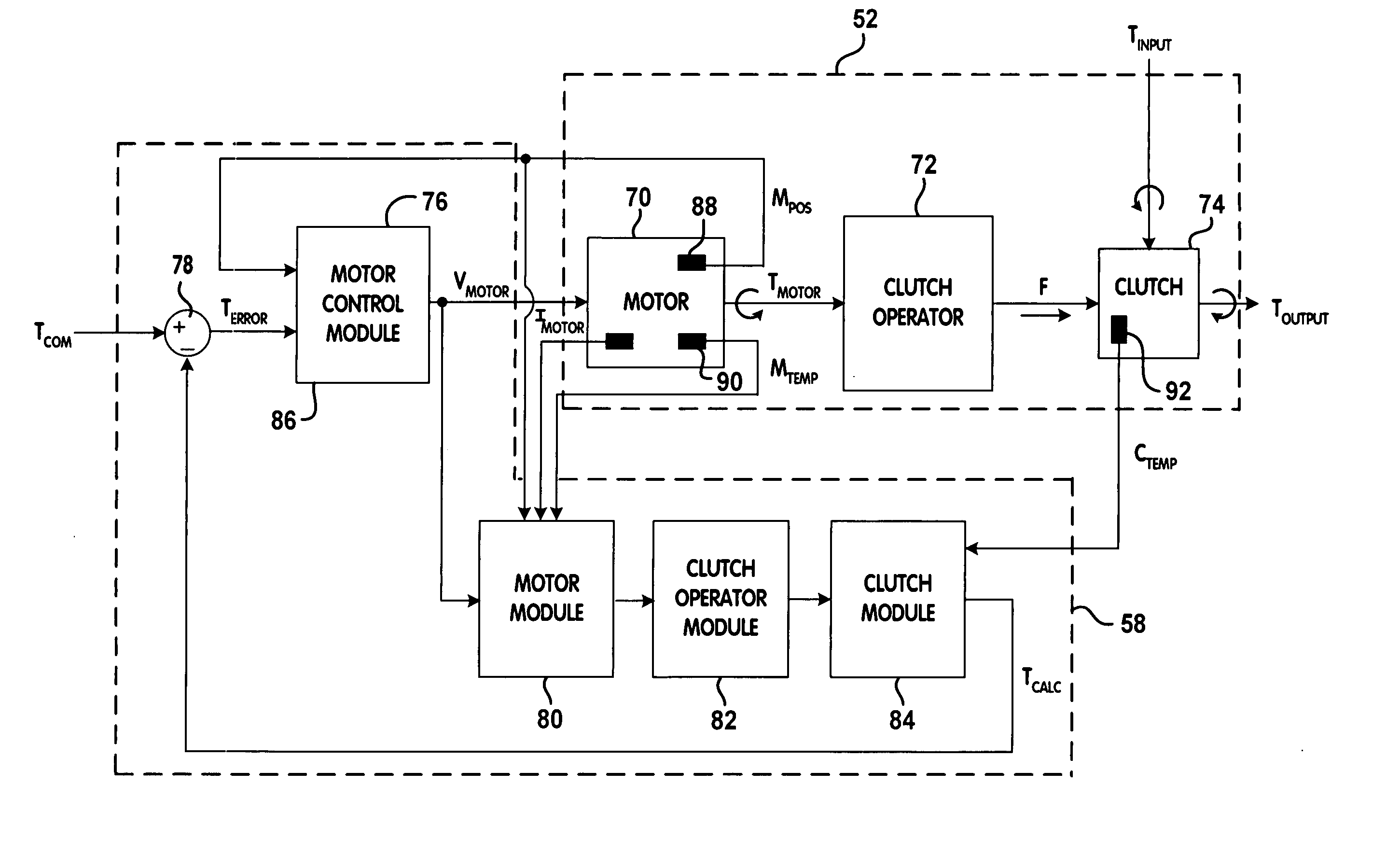

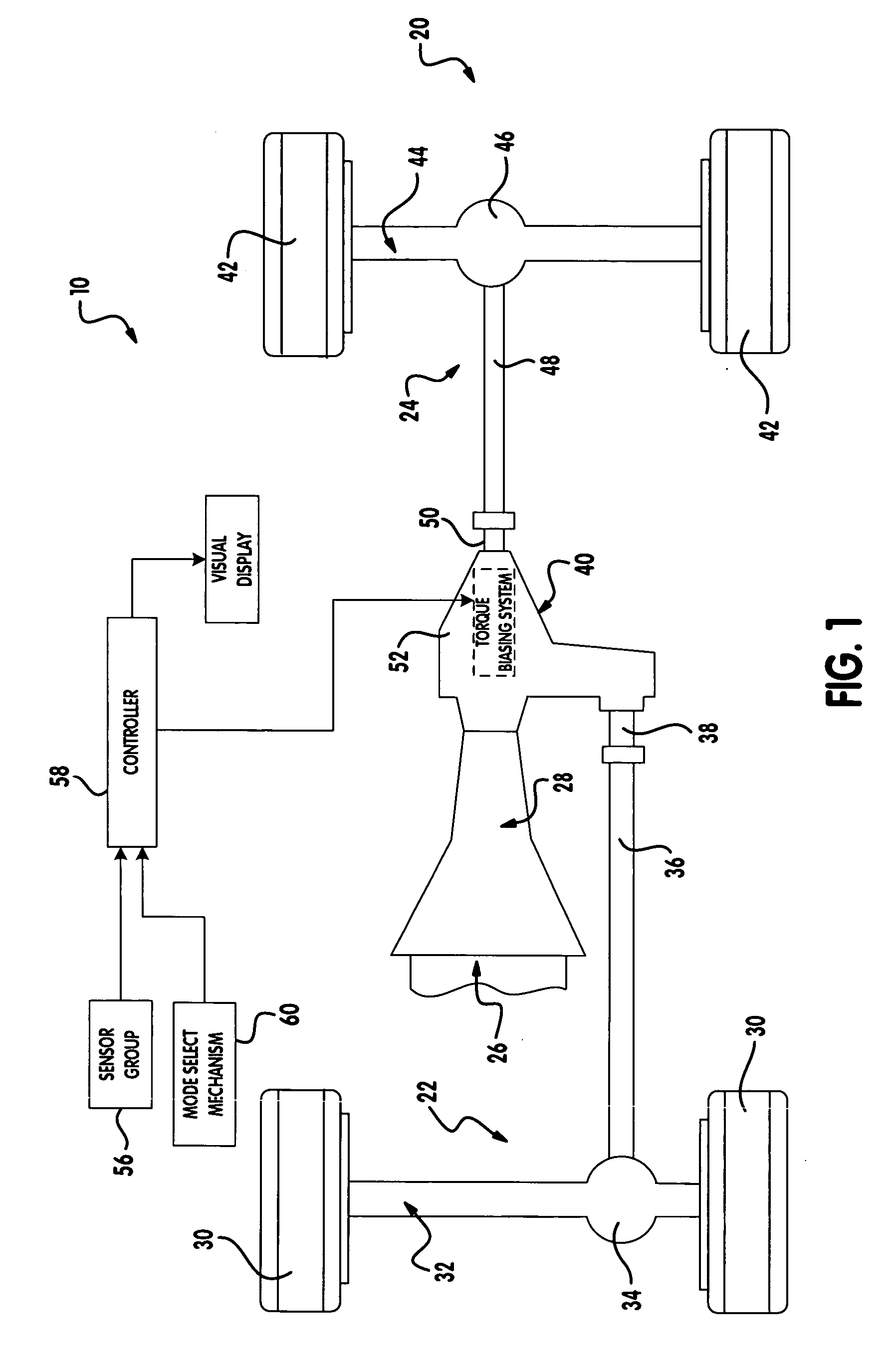

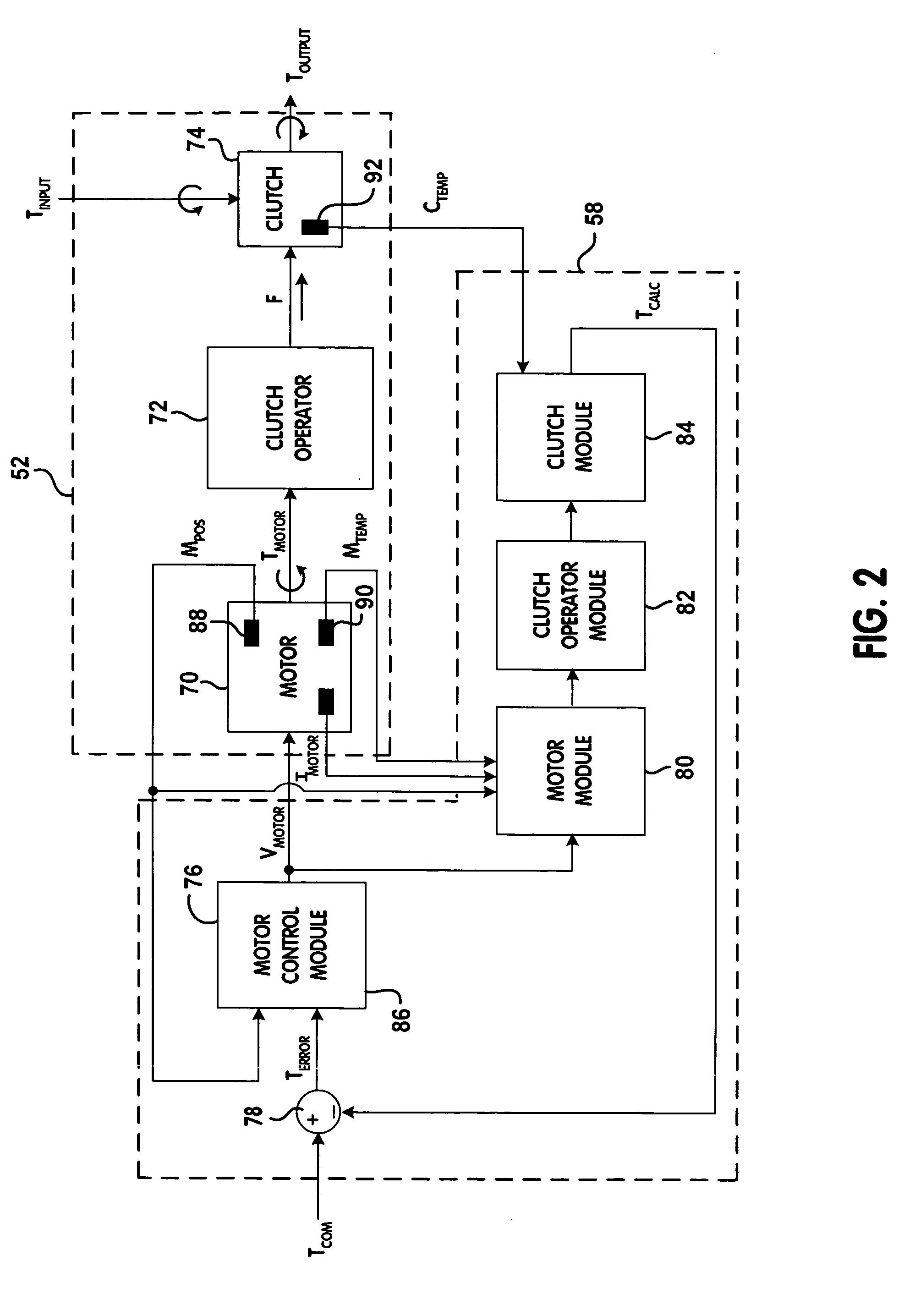

Model-based control for torque biasing system

A method of controlling a torque biasing system includes determining a torque command, calculating a torque error based on the torque command and a model-based torque. A control signal is generated based on the torque error and the torque biasing system is operated based on the control signal.

Owner:NEW VENTURE GEAR INC

Model-based control for torque biasing system

A method of controlling a torque biasing system includes determining a torque command, calculating a torque error based on the torque command and a model-based torque. A control signal is generated based on the torque error and the torque biasing system is operated based on the control signal.

Owner:NEW VENTURE GEAR INC

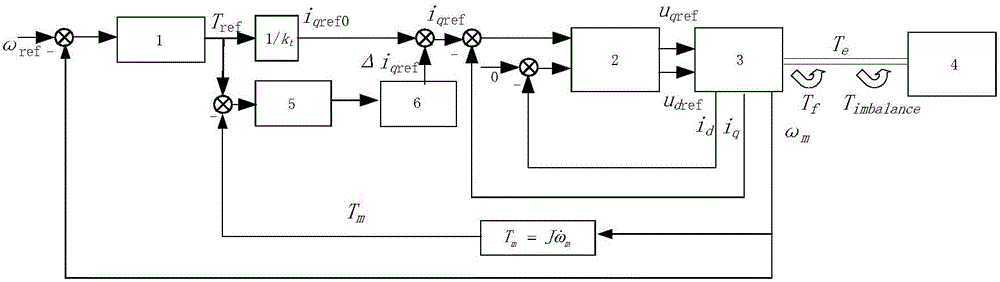

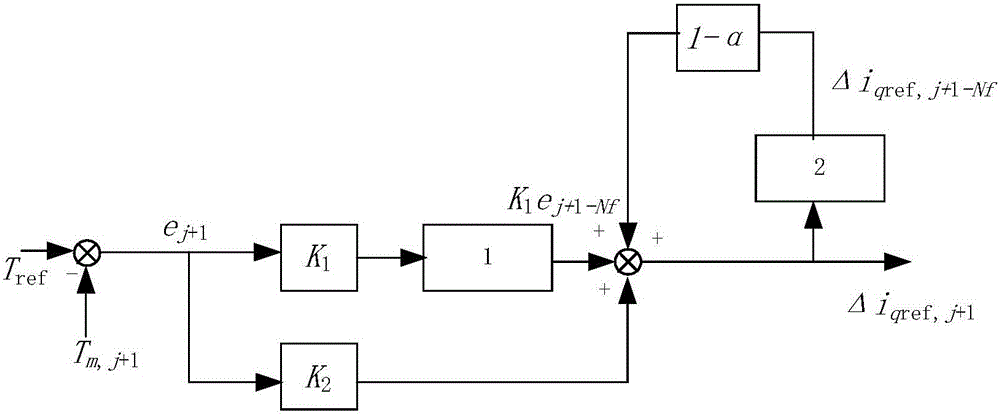

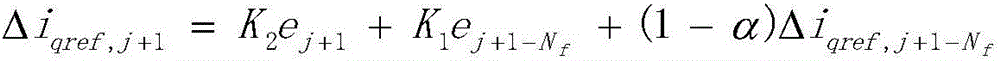

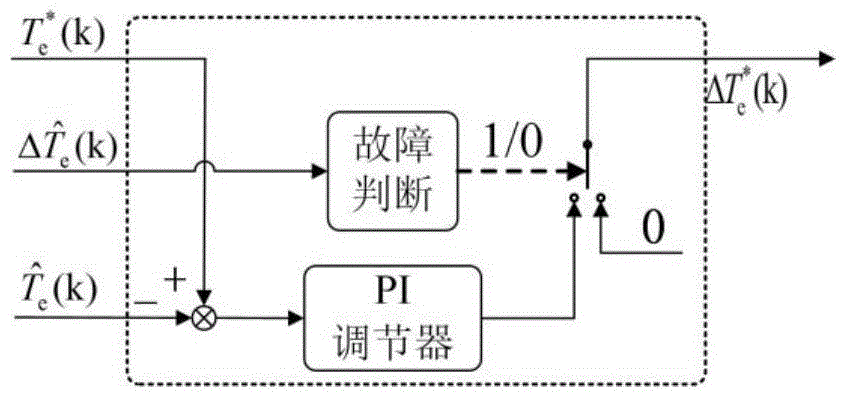

Control moment gyroscope framework control system and control moment gyroscope framework control method for restraining dynamic unbalance disturbance of rotor

ActiveCN105786036AGuaranteed dynamic performanceReduce the disturbing torqueSpeed/accelaration control with auxillary non-electric powerControl systemElectric machine

A control moment gyroscope (CMG) framework control system and a CMG framework control method for restraining dynamic unbalance disturbance of a rotor are provided. A feed-forward compensation module and an algorithm switching module are embedded on the basis of a double-loop PI control system. In preset Ng control cycles, the whole framework control system is set to a PI control mode; in each control cycle from the (Ng+1)th control cycle, the speed precision of a CMG framework in the current control cycle is calculated through the algorithm switching module, and whether there is a need to switch the control mode of the current control cycle is determined; if the control mode is a feed-forward compensation mode after switching, subtraction operation is carried out on a moment reference value output by a speed loop PI controller and a fed-back torque of a framework motor to get the mechanical torque error e(j+1) of the current control cycle, and the feed-forward compensation module calculates the current feed-forward compensation value Delta i(qref, j+1) of the current control cycle according to e(j+1) and adds Delta i(qref, j+1) to the double-loop PI control system; and if the control mode is a PI control mode after switching, current feed-forward compensation is blocked, and control is performed according to the double-loop PI control system.

Owner:BEIJING INST OF CONTROL ENG

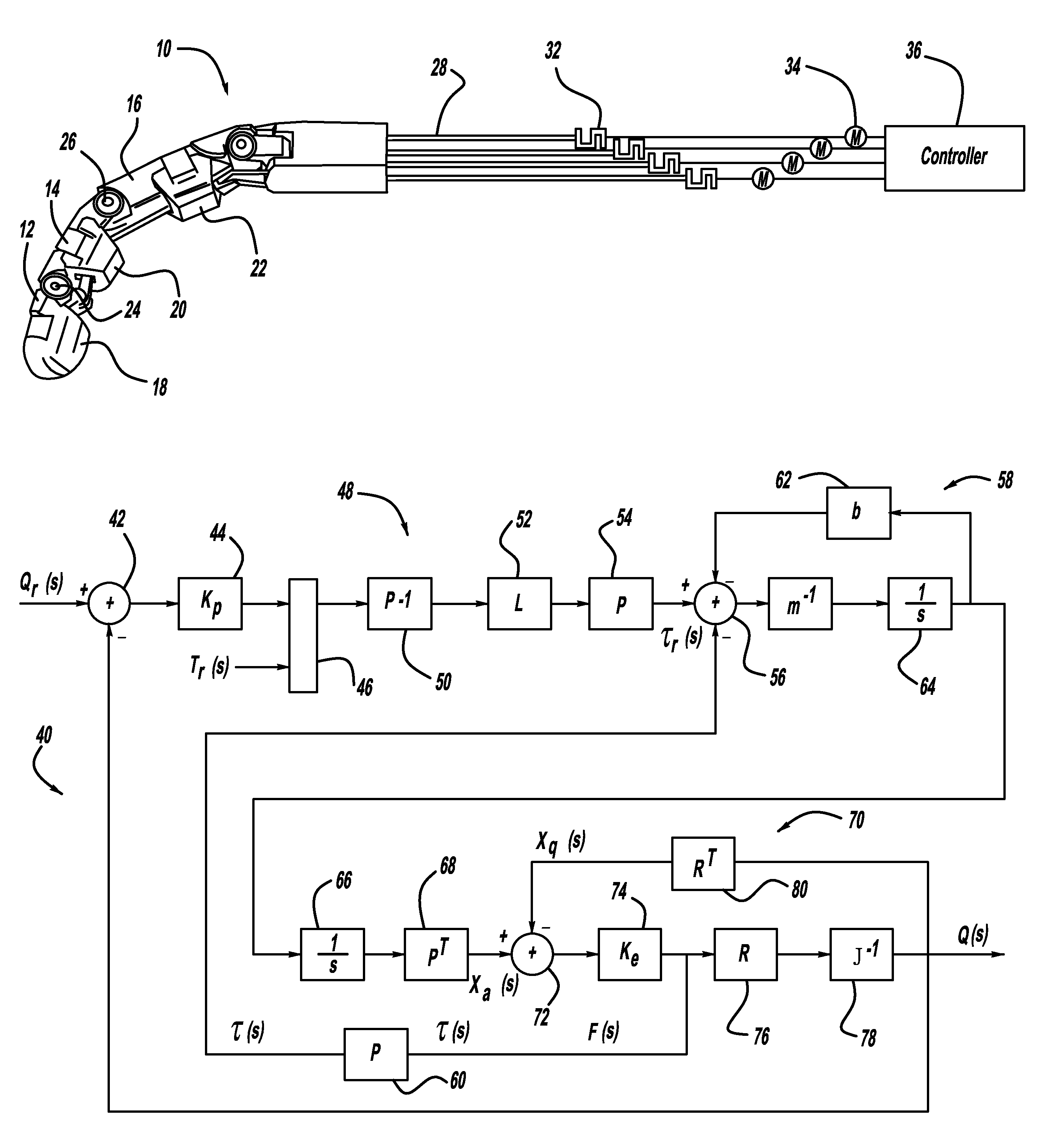

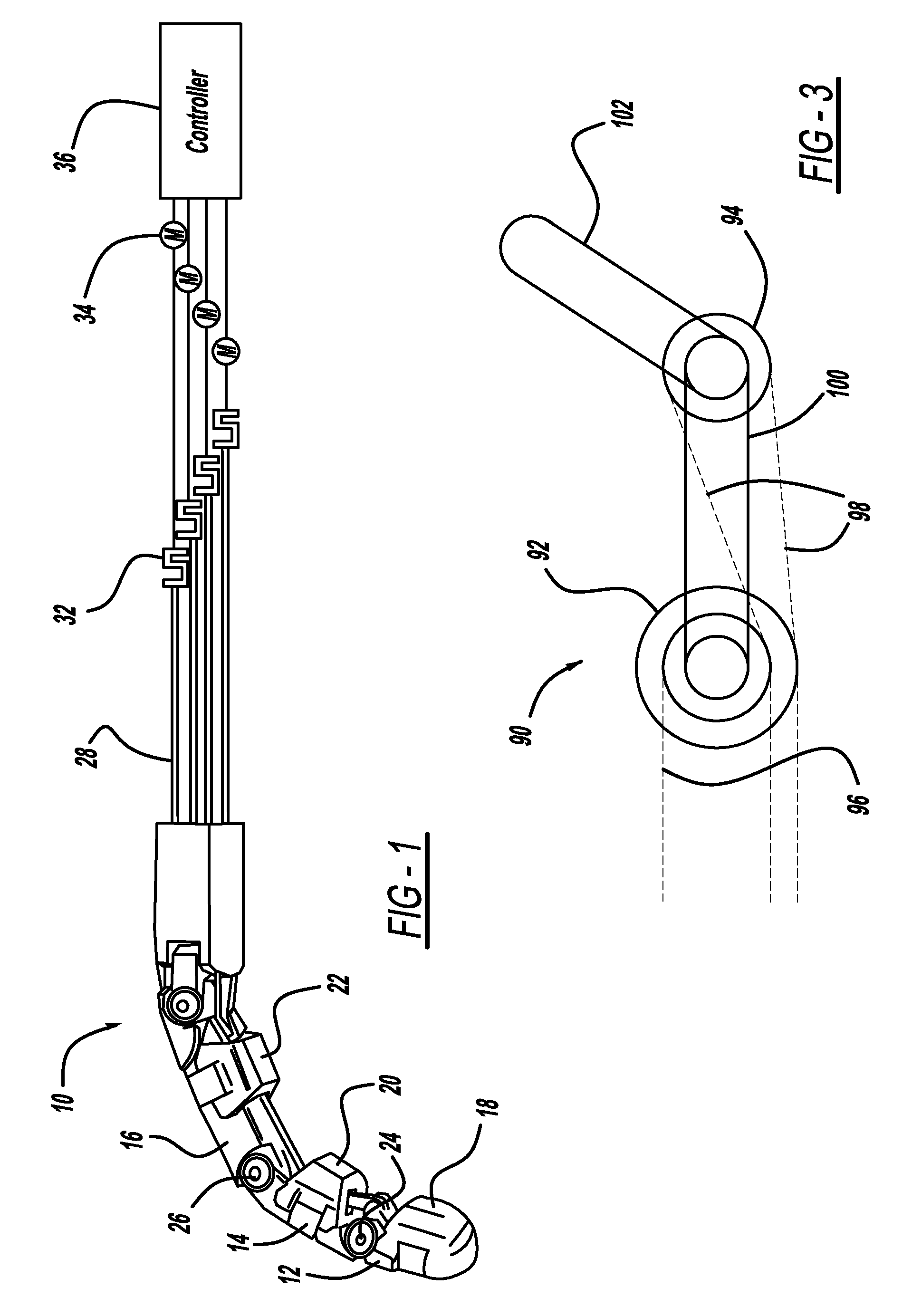

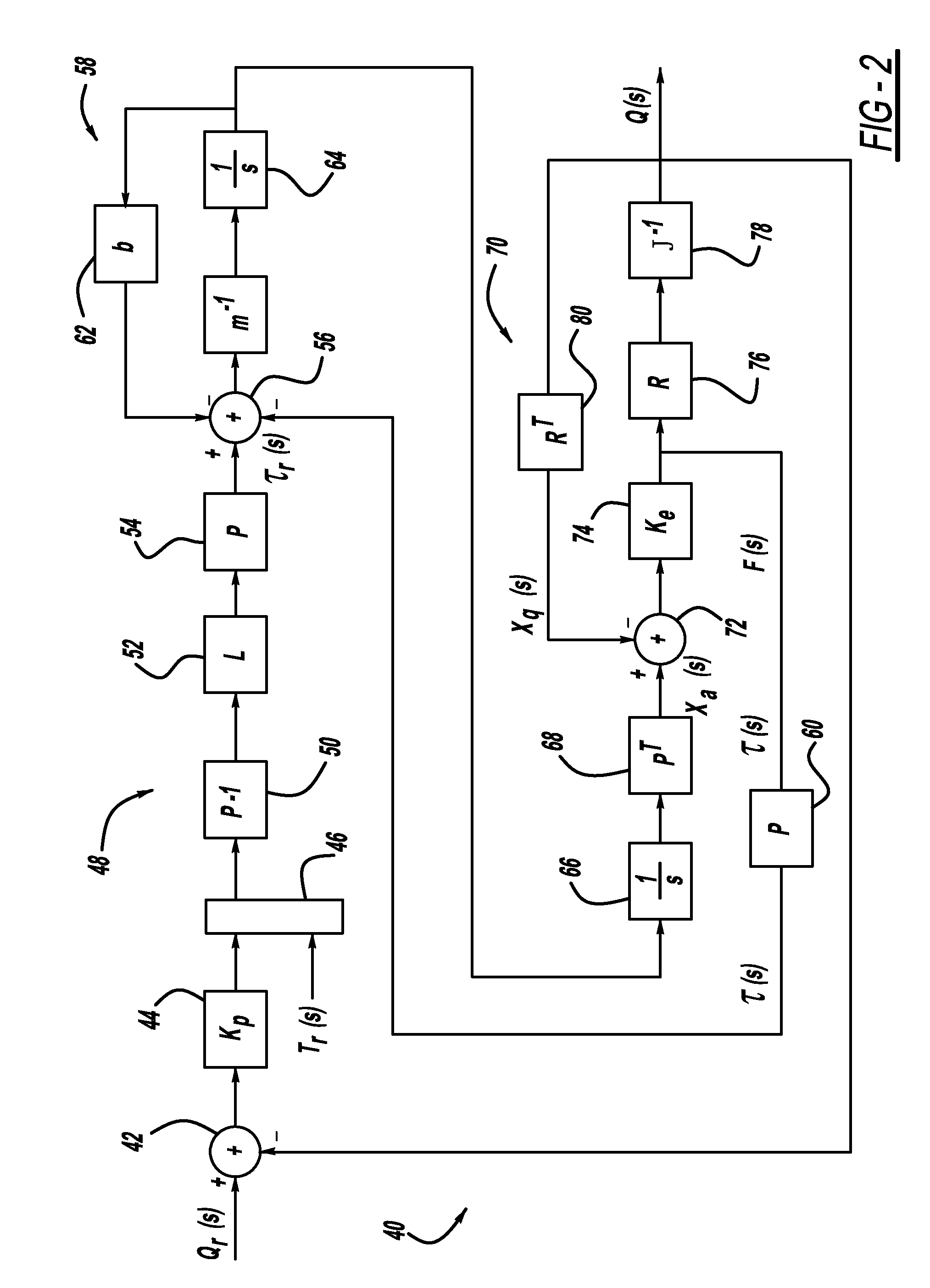

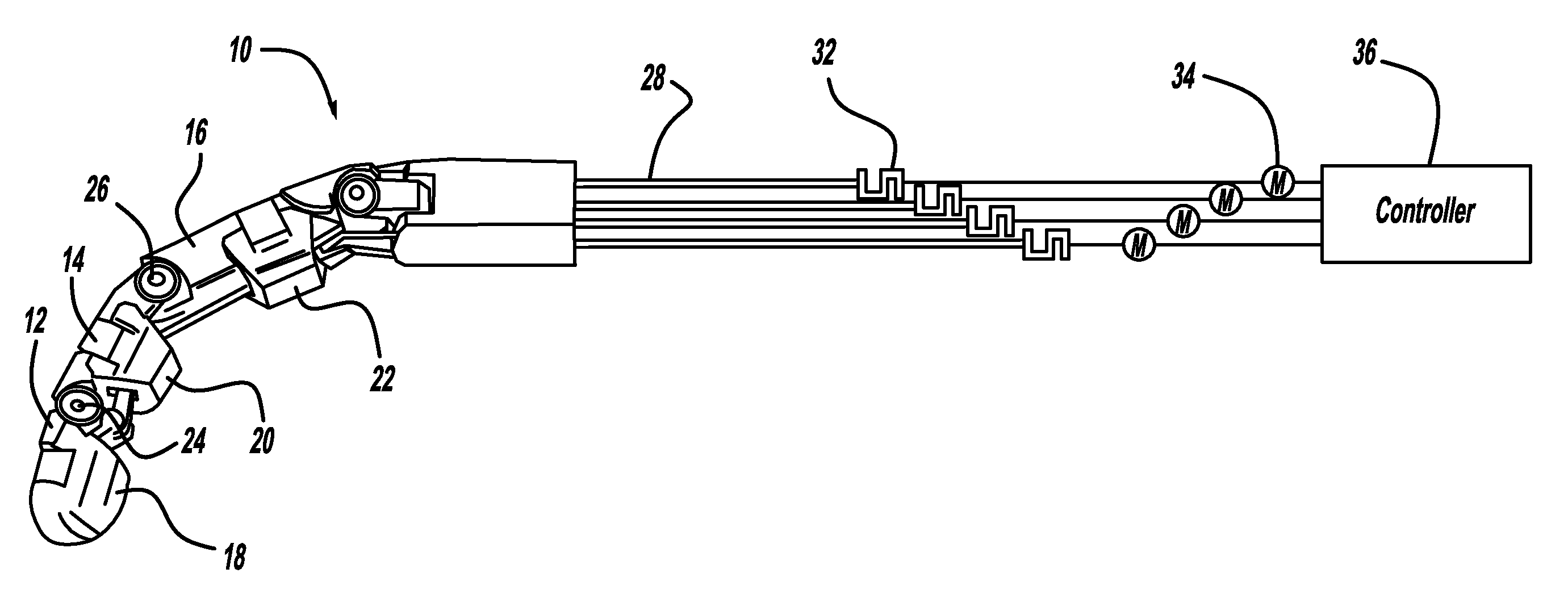

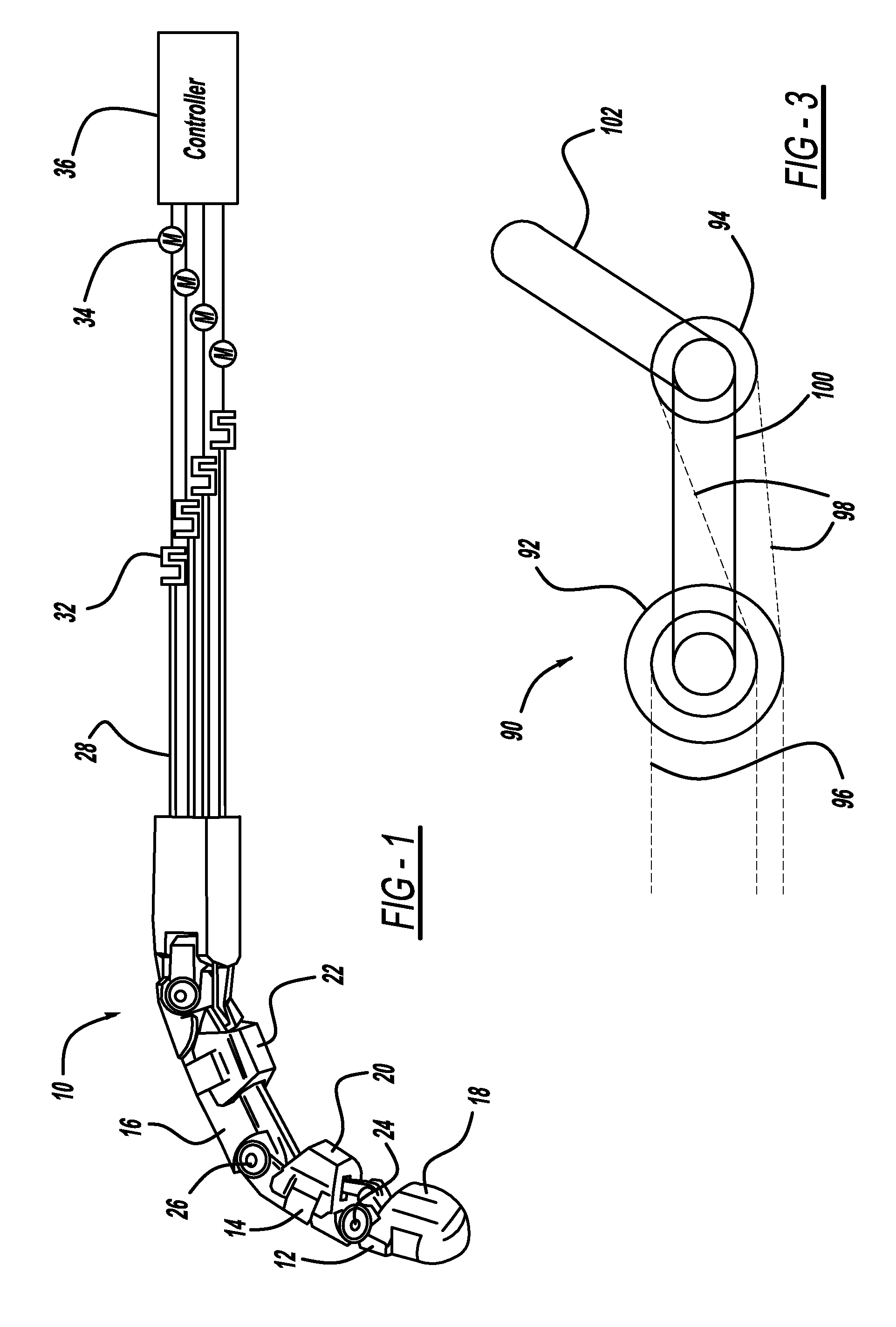

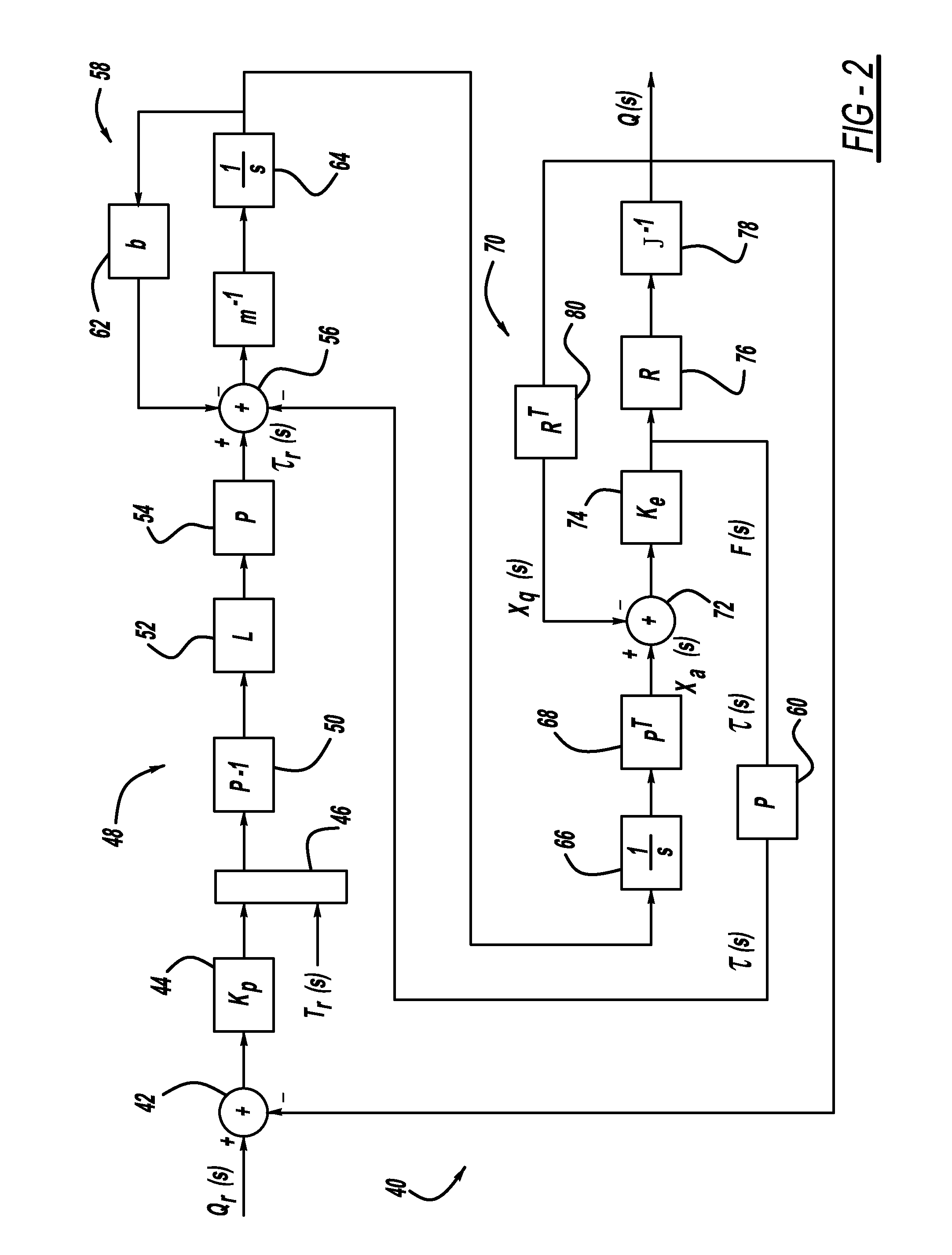

Joint-space impedance control for tendon-driven manipulators

A system and method for controlling tendon-driven manipulators that provide a closed-loop control of joint torques or joint impedances without inducing dynamic coupling between joints. The method includes calculating tendon reference positions or motor commands by projecting a torque error into tendon position space using a single linear operation. The method calculates this torque error using sensed tendon tensions and a reference torque and internal tension. The method can be used to control joint impedance by calculating the reference torque based on a joint position error. The method limits minimum and maximum tendon tensions by projecting the torque error into the tendon tension space and then projecting ii back into joint space.

Owner:NASA +1

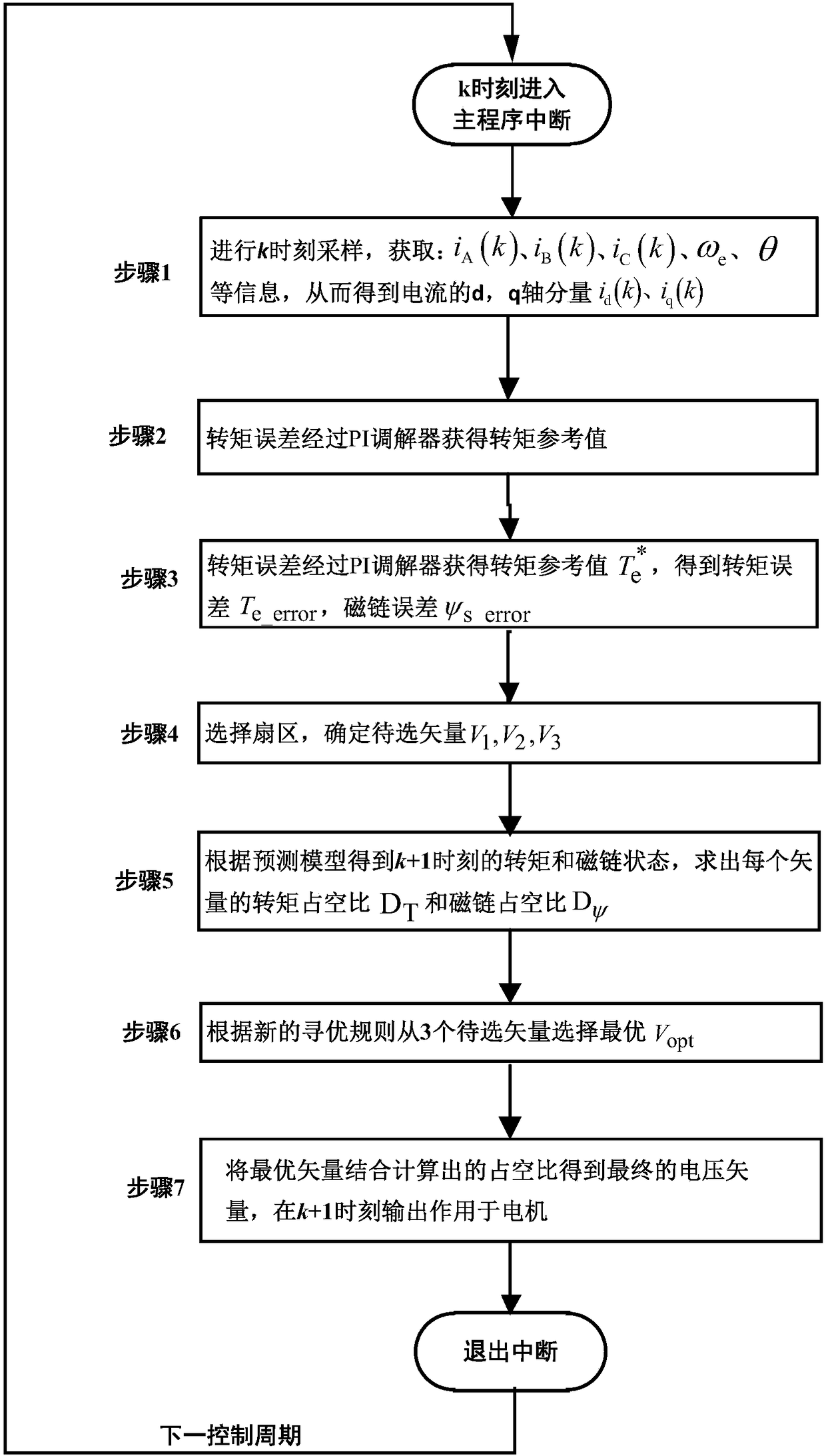

Model prediction torque control method based on duty ratio

ActiveCN108649855AImprove control effectReduce the numberElectronic commutation motor controlVector control systemsVoltage vectorWeight coefficient

The invention discloses a model prediction torque control method based on duty ratio. The method comprises the following steps: adding six virtual vectors on the basis of six basic effective vectors of the existing motor, and establishing a rotary coordinate system directed by a stator flux at the same time; dividing into four sectors according to the torque and flux increase-decrease demands, reducing the number of the candidate vectors and reducing the computing time if each sector in each control period comprises three candidate vectors; for three candidate voltage vectors, respectively computing the torque duty ratio with torque error as zero and the flux duty ratio with flux error as zero, at the end of this control period, of three candidate vectors according to the torque error andthe flux error, and providing a new optimal evaluation method according to the torque duty ratio and the flux duty ratio, wherein the optimal evaluation method does not need the evaluation function inthe tradition method, and the weight coefficient problem is eliminated; and the duty ratio algorithm is added to inhibit the torque pulse caused by the traditional single vector effect control at thesame time; the torque and the flux are simultaneously controlled when the weight factor problem is eliminated, and the torque and the flux have better control effect.

Owner:TIANJIN POLYTECHNIC UNIV

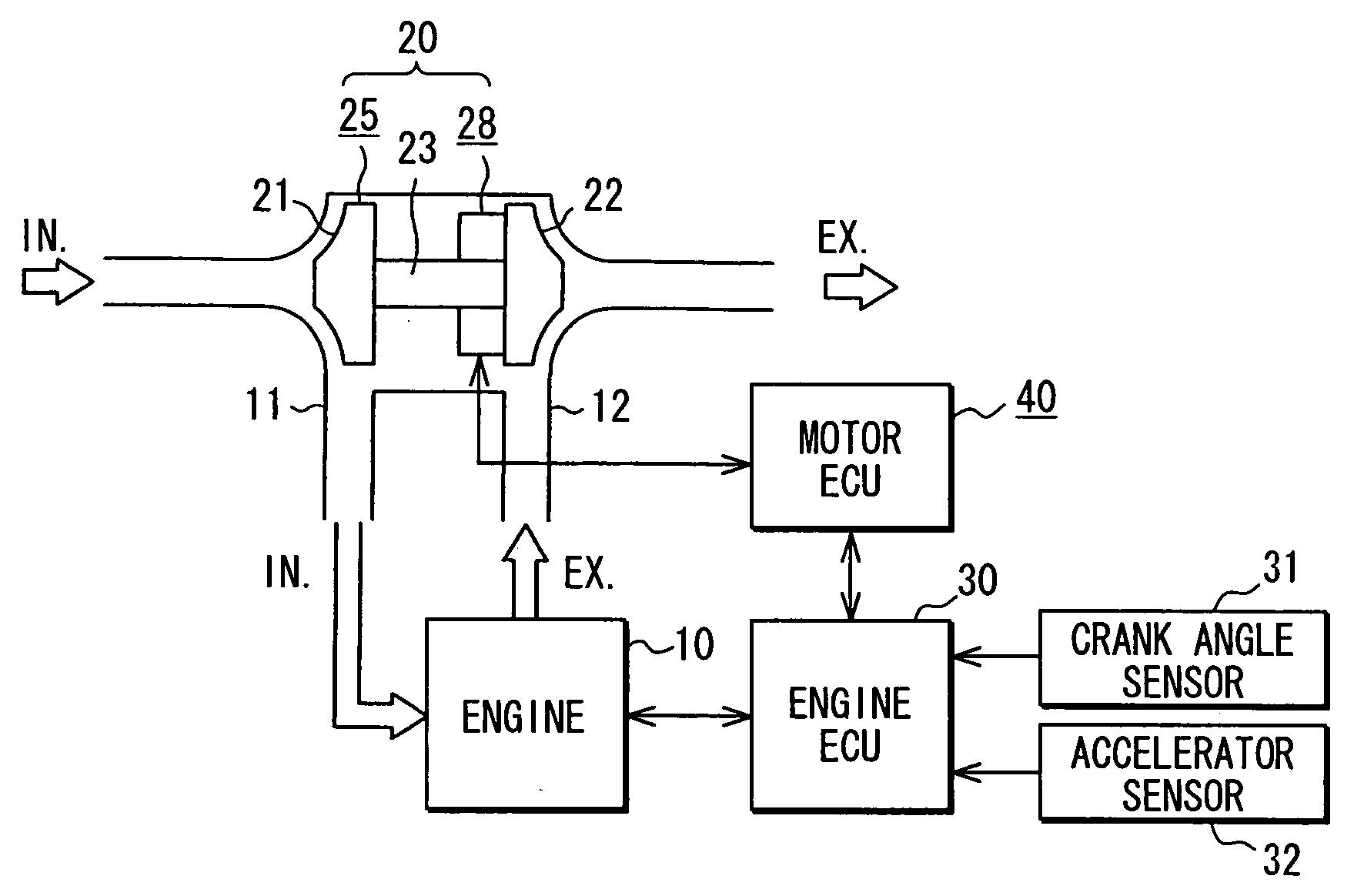

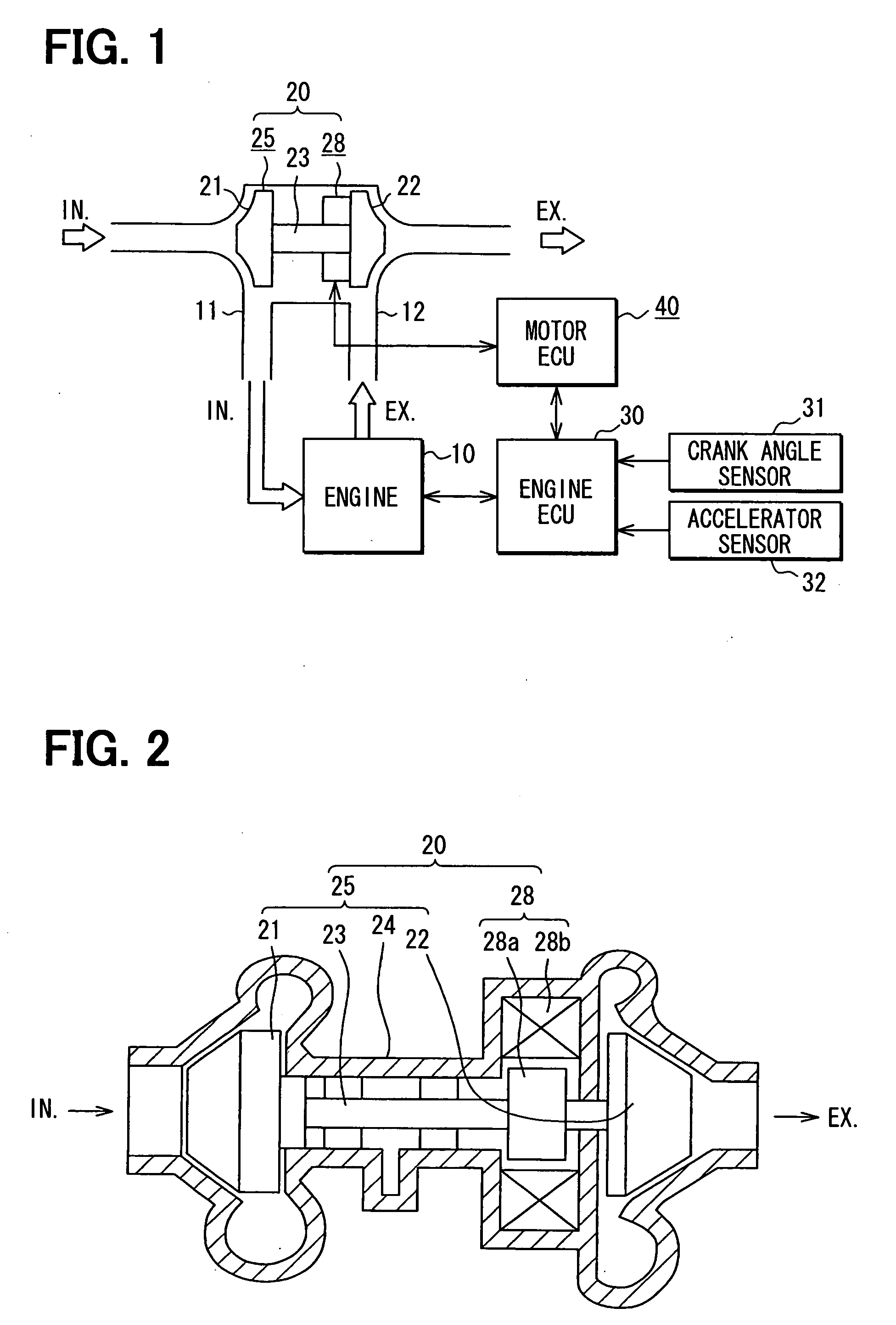

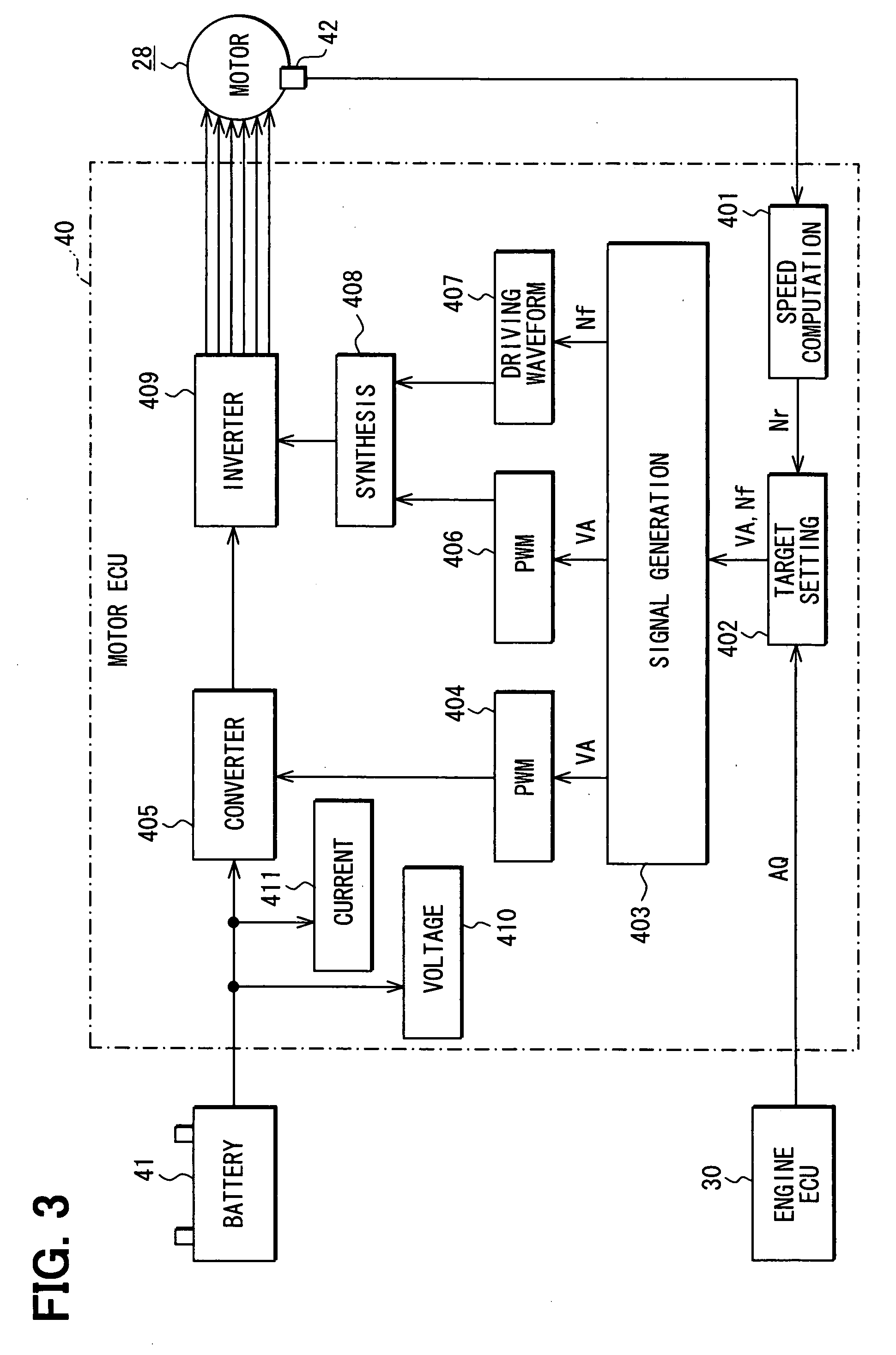

Controller for turbocharger with electric motor

InactiveUS20080047268A1Guaranteed uptimeReduce outputInternal combustion piston enginesEngine componentsElectricityTurbocharger

A controller controls an electrically assisted turbocharger including a turbocharger body and an assist electric motor for assisting the turbocharger body in driving. The controller controls the operation of the assist electric motor. The controller compares a target power value of the assist electric motor with an actual power value actually supplied to the assist electric motor, and computes the differential between them. The controller compensates a torque error of the assist electric motor due to the differential (updating a correction coefficient) based on the differential.

Owner:DENSO CORP

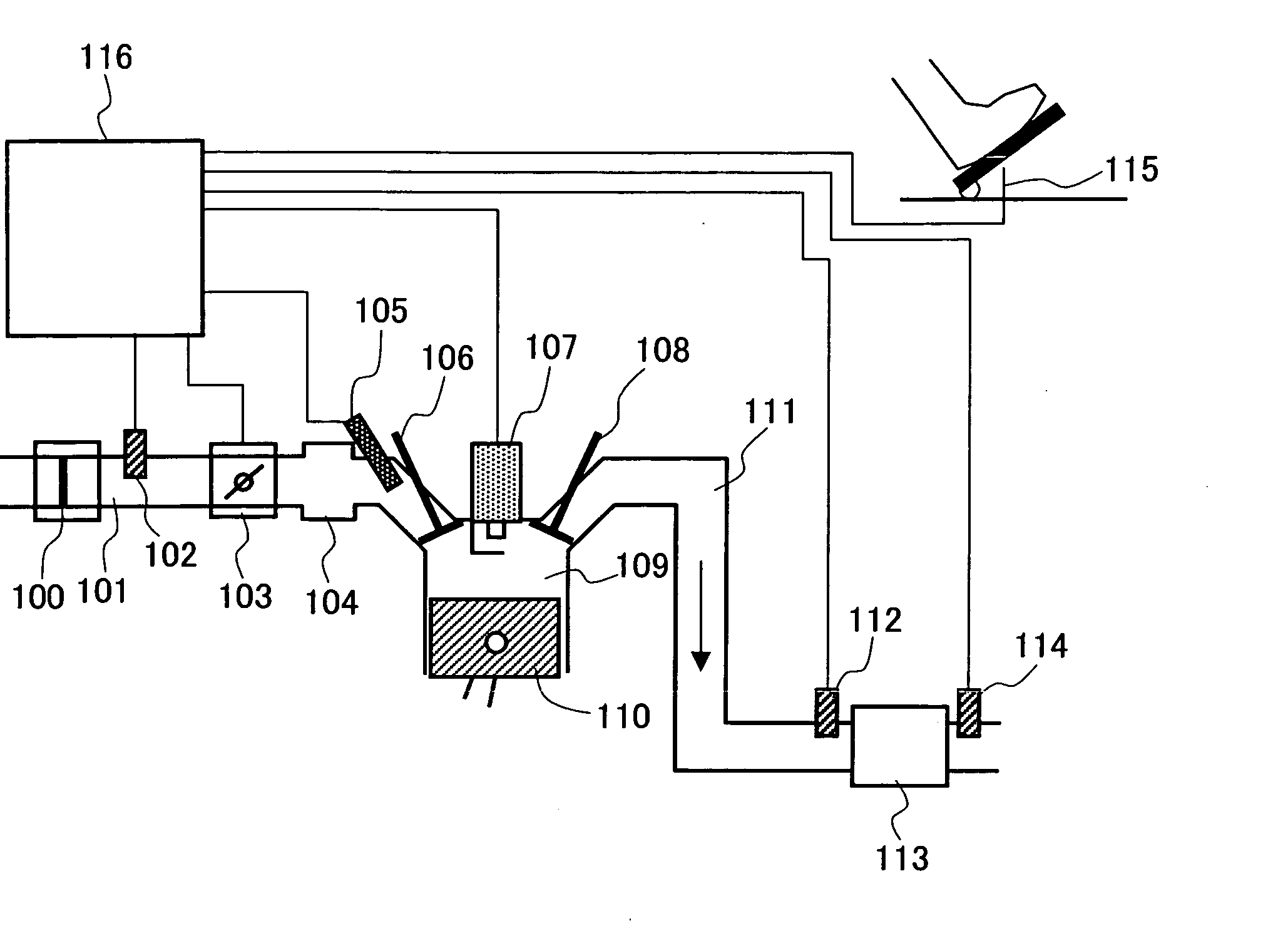

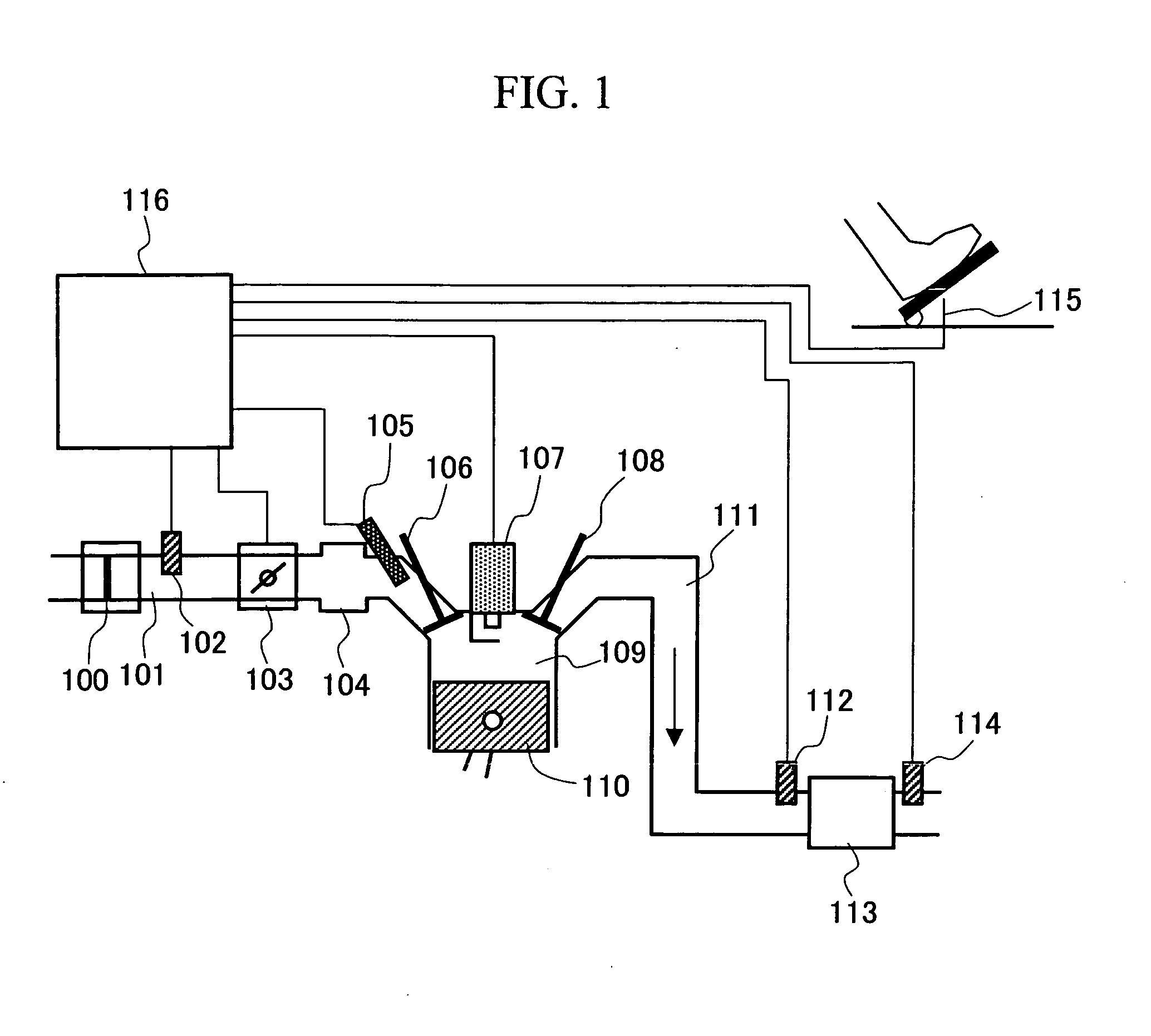

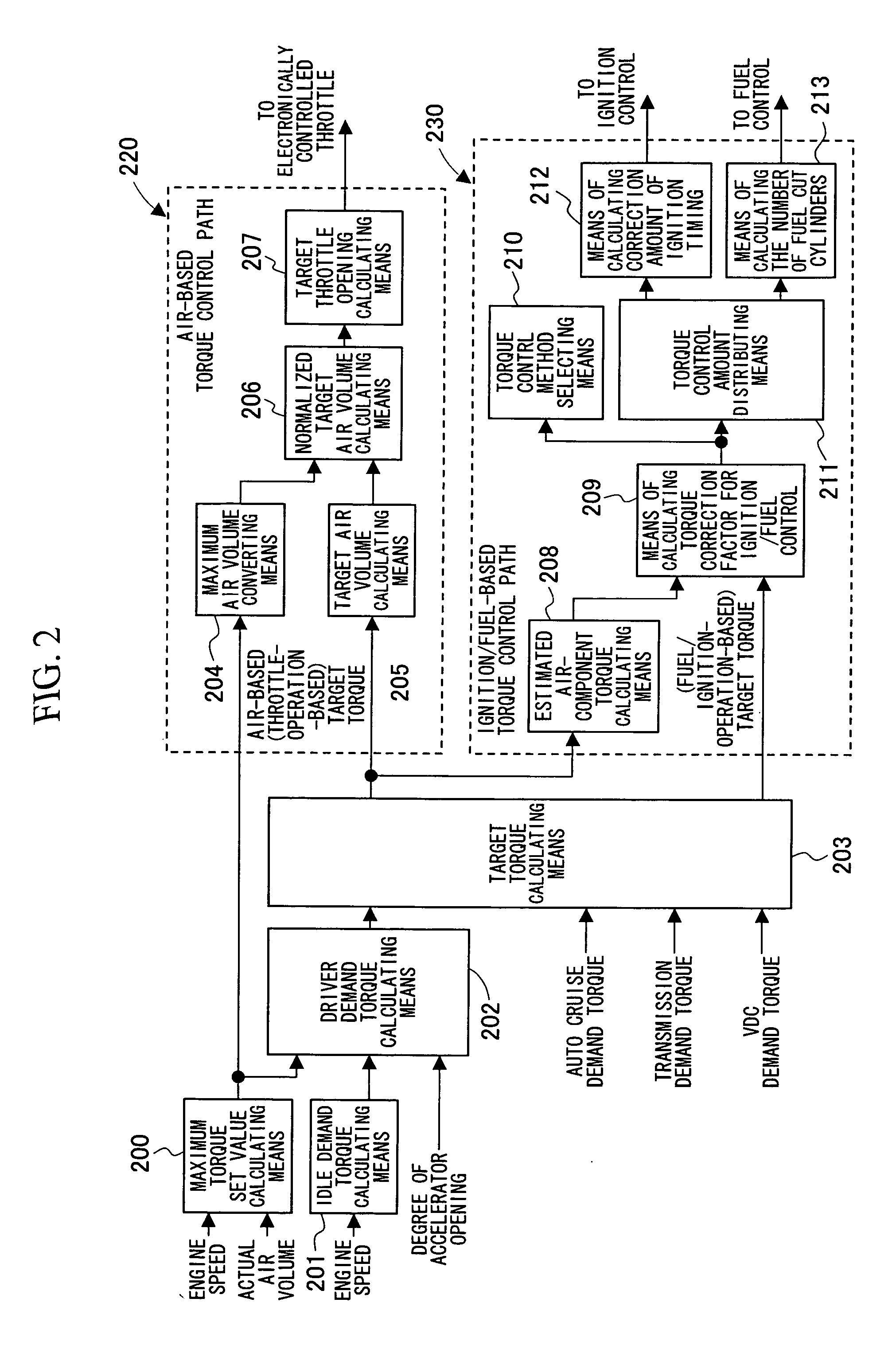

Engine Controller and Controlling Method

InactiveUS20080066718A1Increase opportunitiesAnalogue computers for vehiclesElectrical controlMaximum torqueAir volume

When a throttle is fully open, a maximum torque set value is corrected based on the ratio between the maximum air volume set value under fully-open throttle conditions and the actual maximum air volume detected by an intake air volume meter such as an air flow sensor. Based on the corrected maximum torque set value, both the relation between the degree of accelerator opening and target torque and the relation between the target torque (target air volume) and the degree target throttle opening are corrected. Thus, even when various types of disturbances relating to torque error are generated, such as variations in air density generated in association with variations in temperature or altitude, variations over time such as contaminations of throttle chambers, or difference between machines such as engine bodies or auxiliary machines, it is possible to generate actual torque with respect to a target torque with a high degree of accuracy, while maintaining a desired relation between the degree of accelerator opening and the throttle opening.

Owner:HITACHI LTD

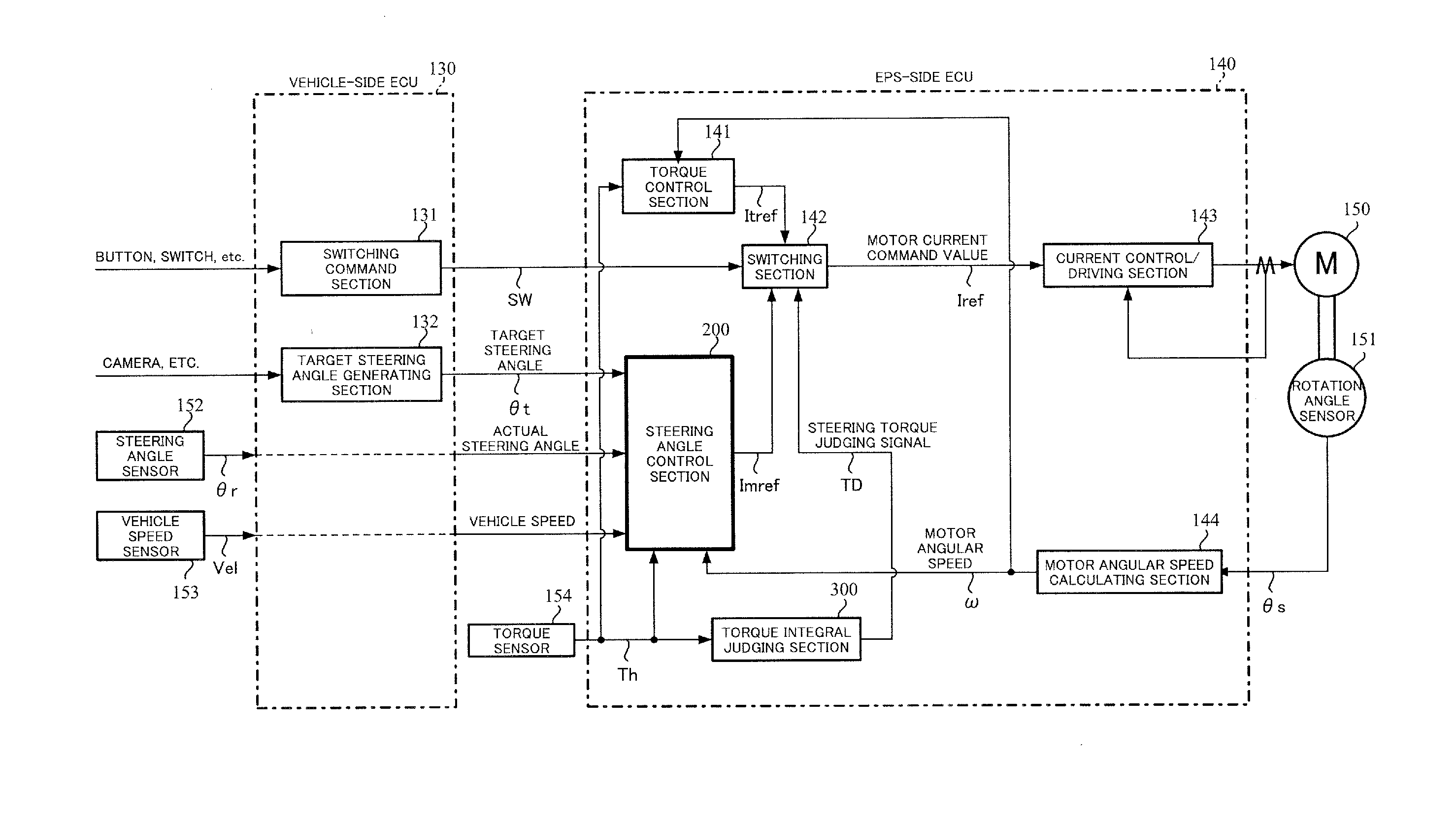

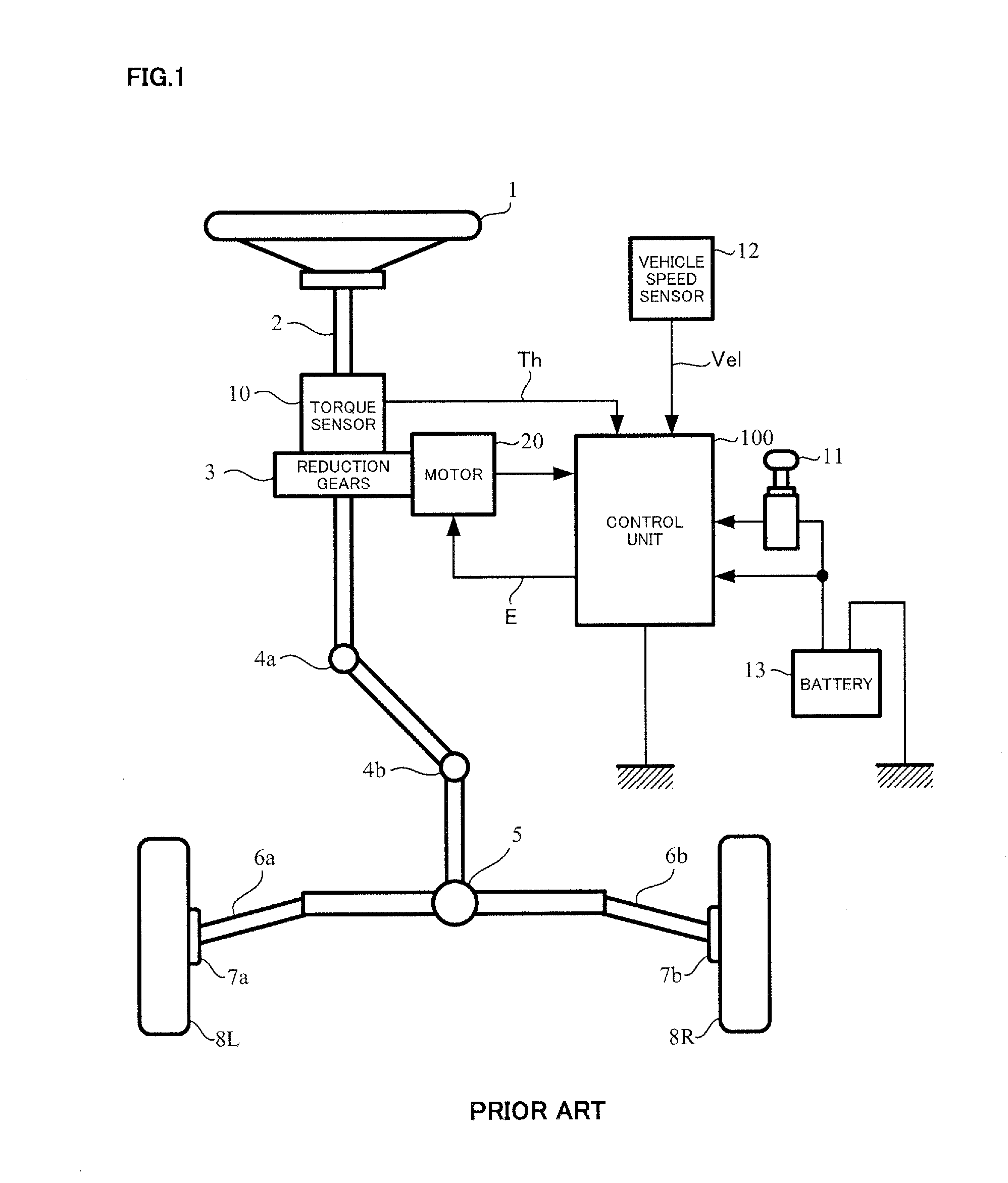

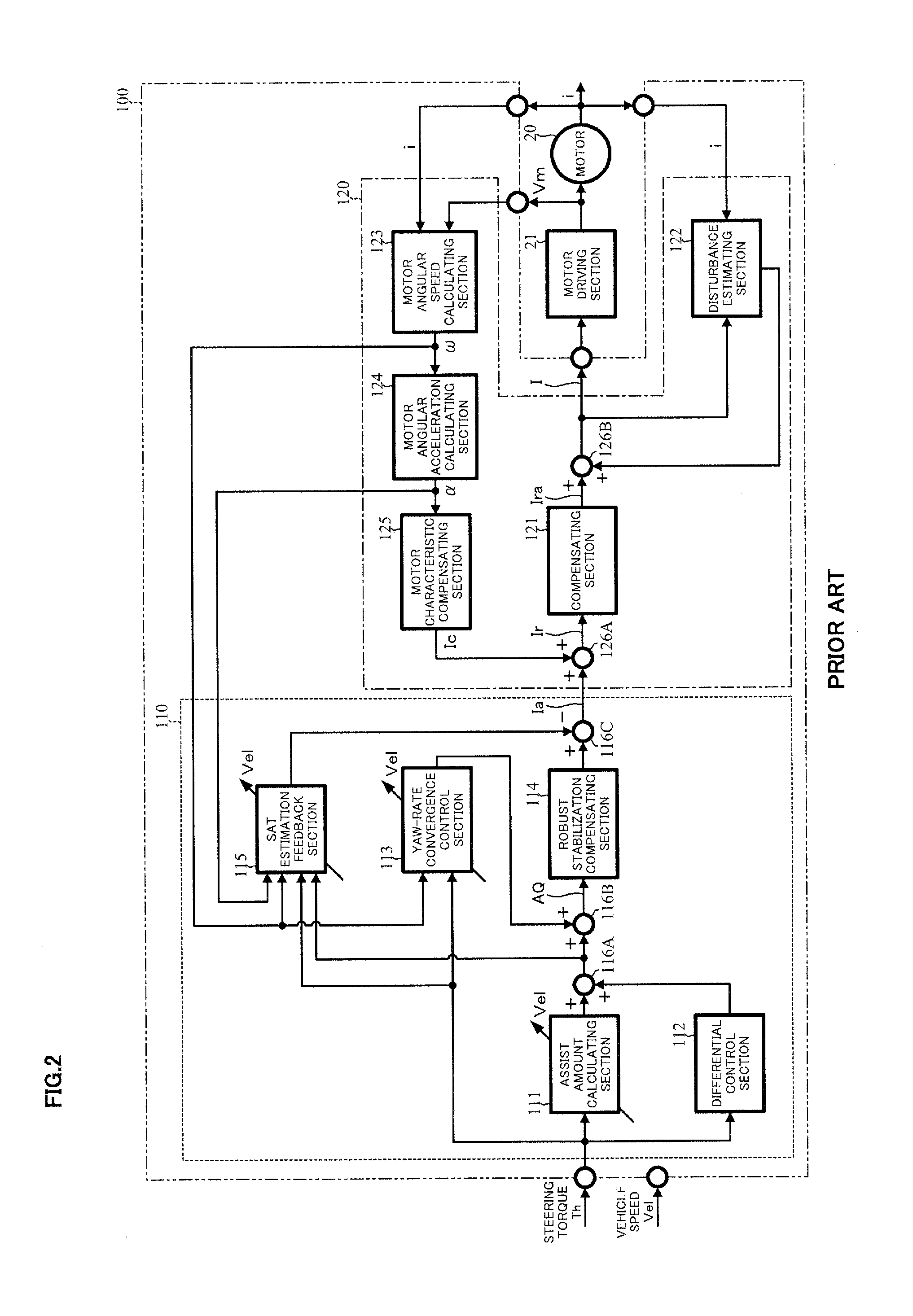

Electric power steering apparatus

ActiveUS20150353125A1Shorten the timeReduce computing loadSteering initiationsDigital data processing detailsElectric power steeringDriver/operator

[Problem]An object of the present invention is to provide an electric power steering apparatus that does not give uncomfortable feeling to a driver by detecting that the driver steers a steering wheel in an automatic steering mode by means of a steering torque from a torque sensor and switching to a manual steering mode by a capacity (an integrated value) corresponding to the occurring torque magnitude.[Means for solving the problem]The present invention comprises a steering angle control section that calculates a motor current command value 2, a torque integral judging section that outputs a steering torque judging signal by integrating a steering torque, which is compared with a threshold, and a switching section that inputs the motor current command value 1 and the motor current command value 2, and is switched in accordance with a switching signal or the steering torque judging signal; the torque integral judging section comprises a torque value comparing section, an integral calculating section and a switch judging section; and the switching section is switched depending on a switching command of an automatic steering mode and a manual steering mode or the steering torque judging signal.

Owner:NSK LTD

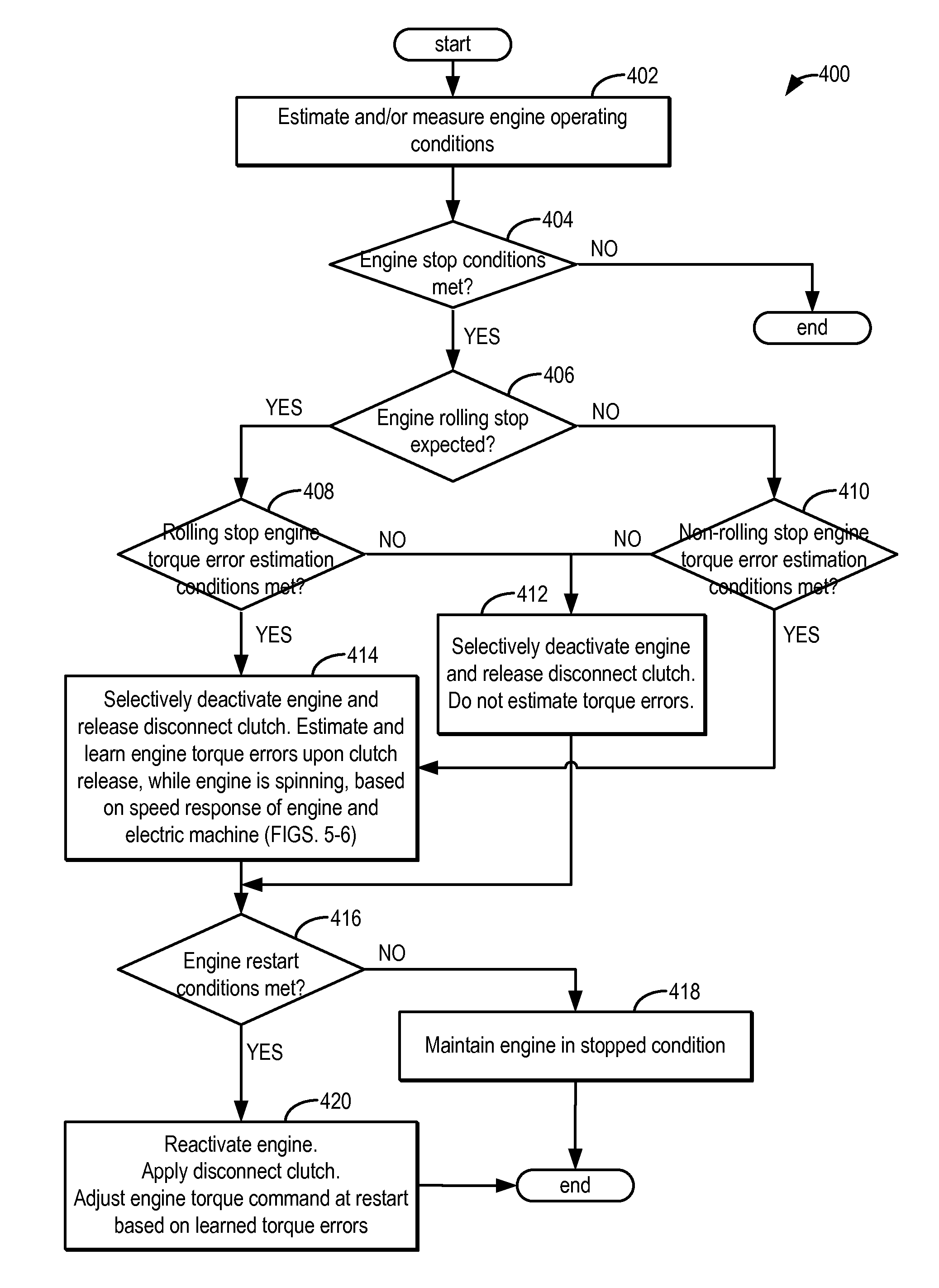

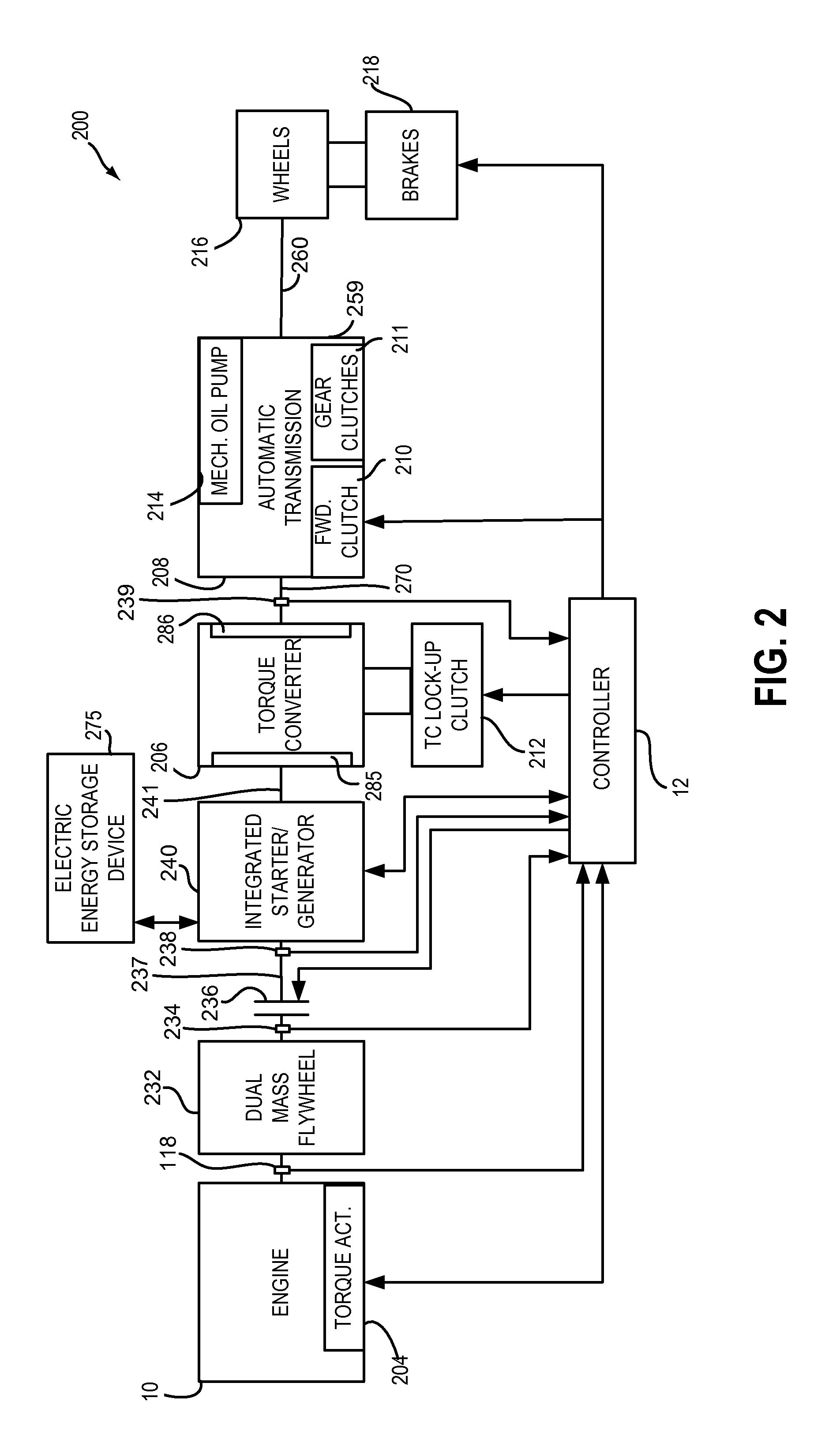

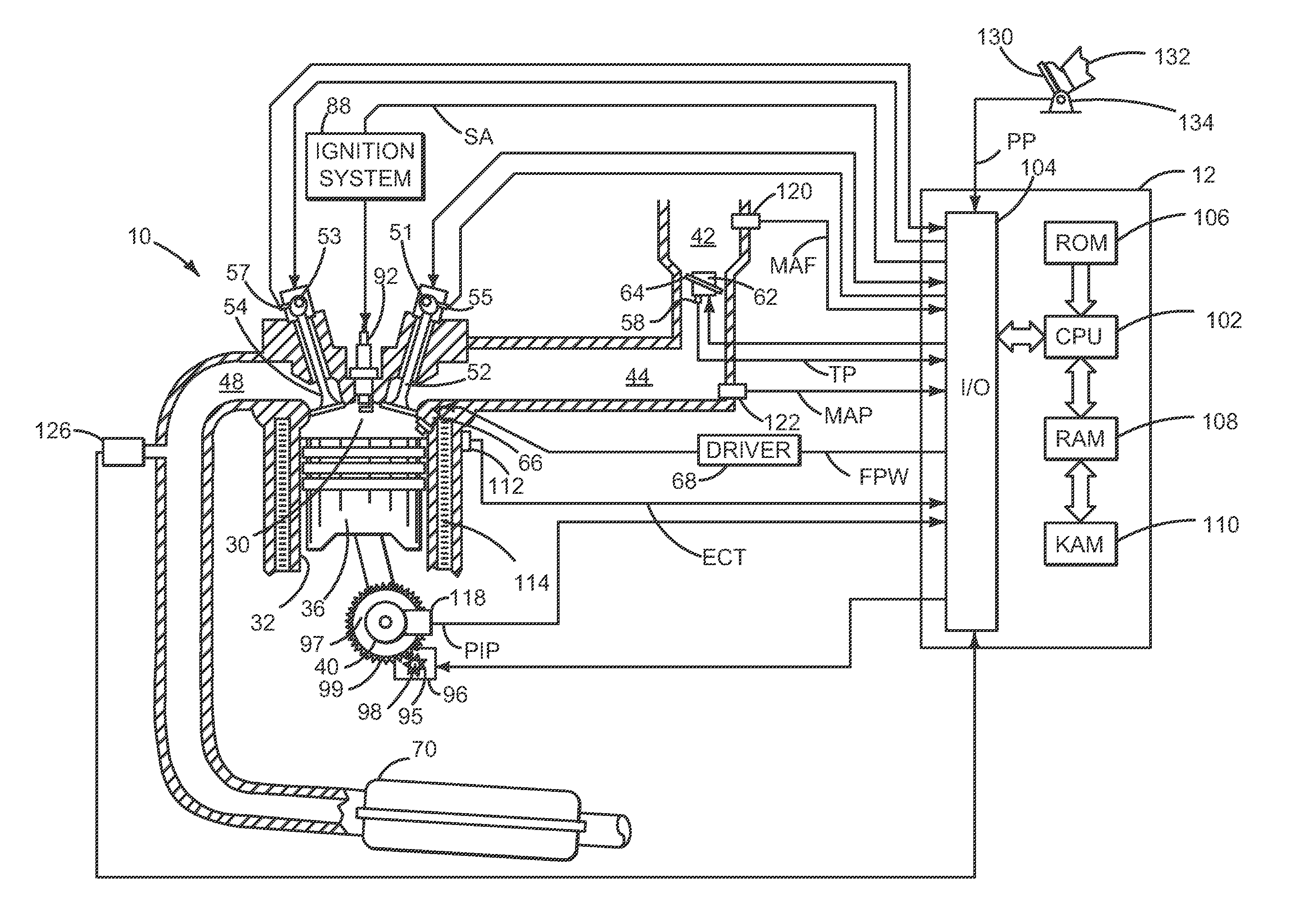

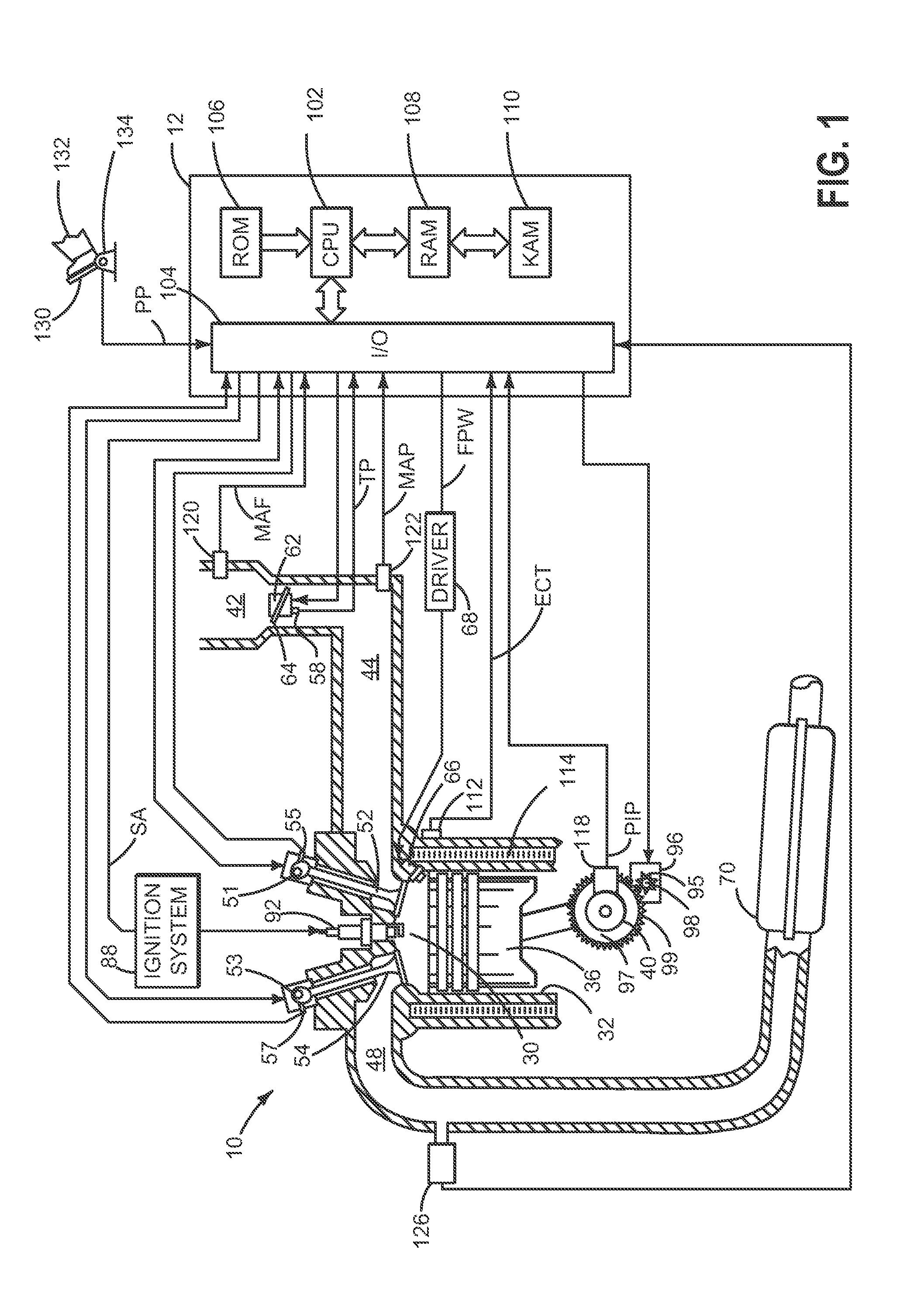

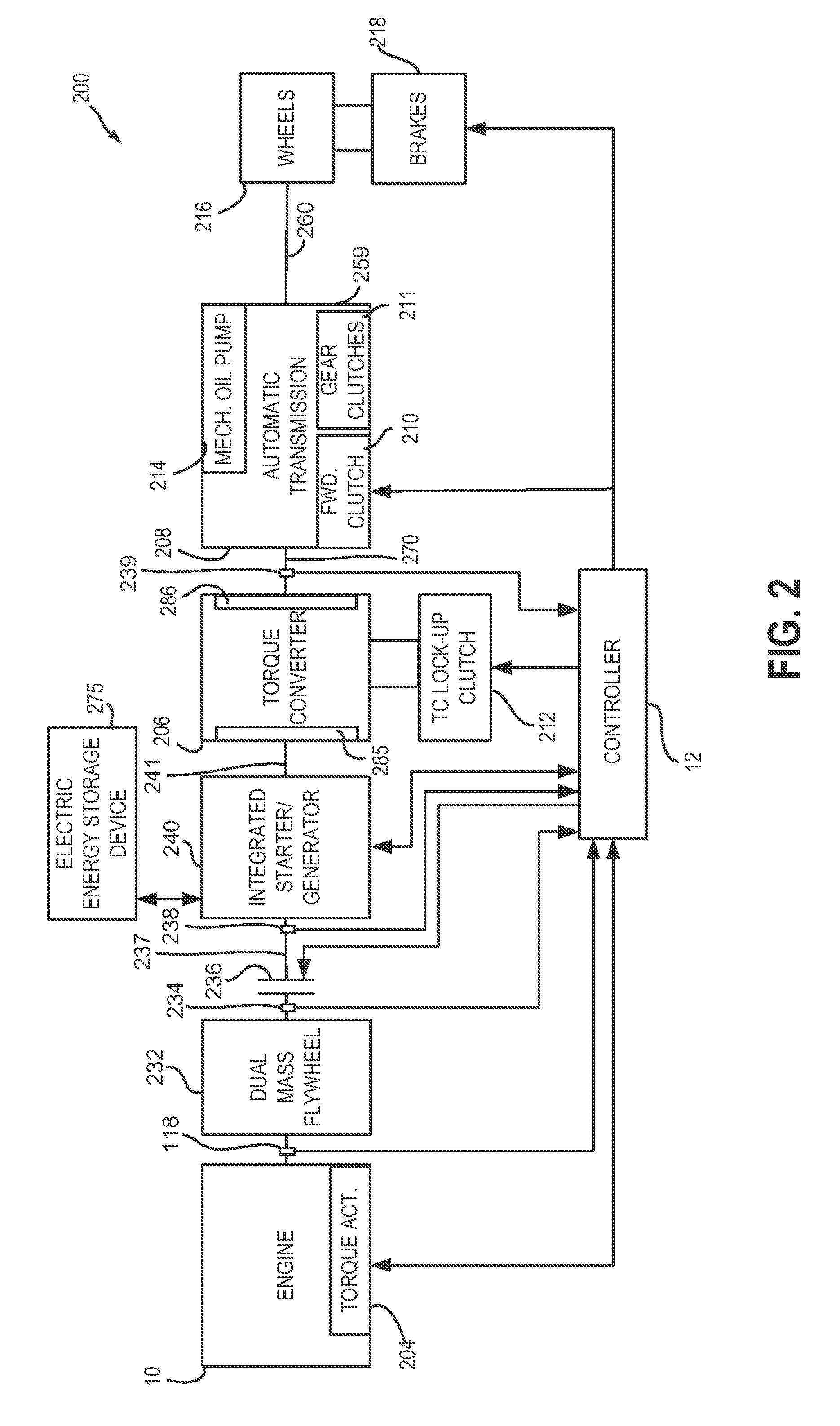

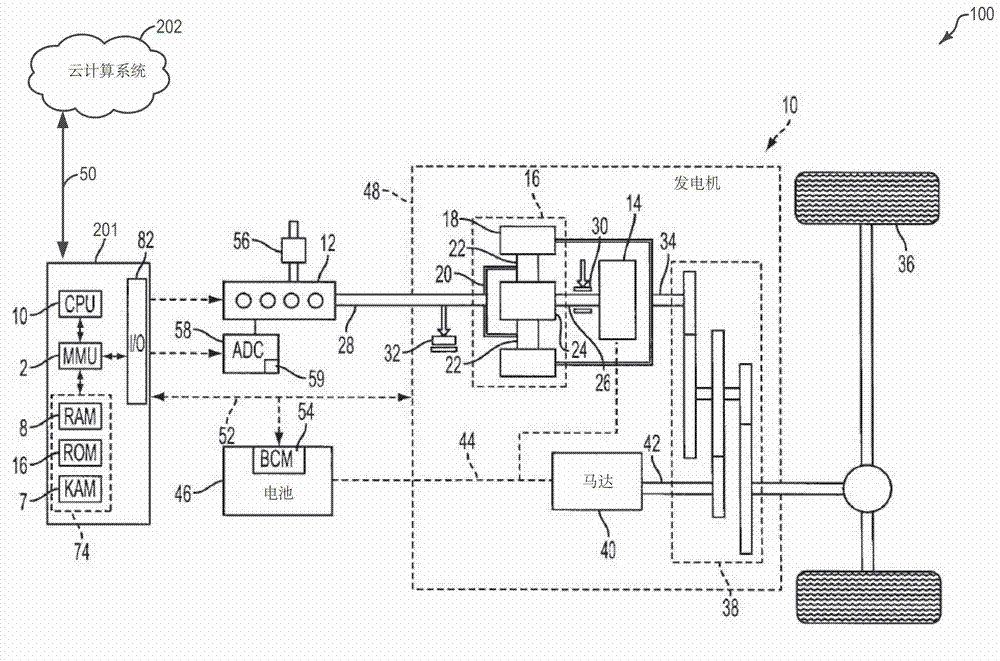

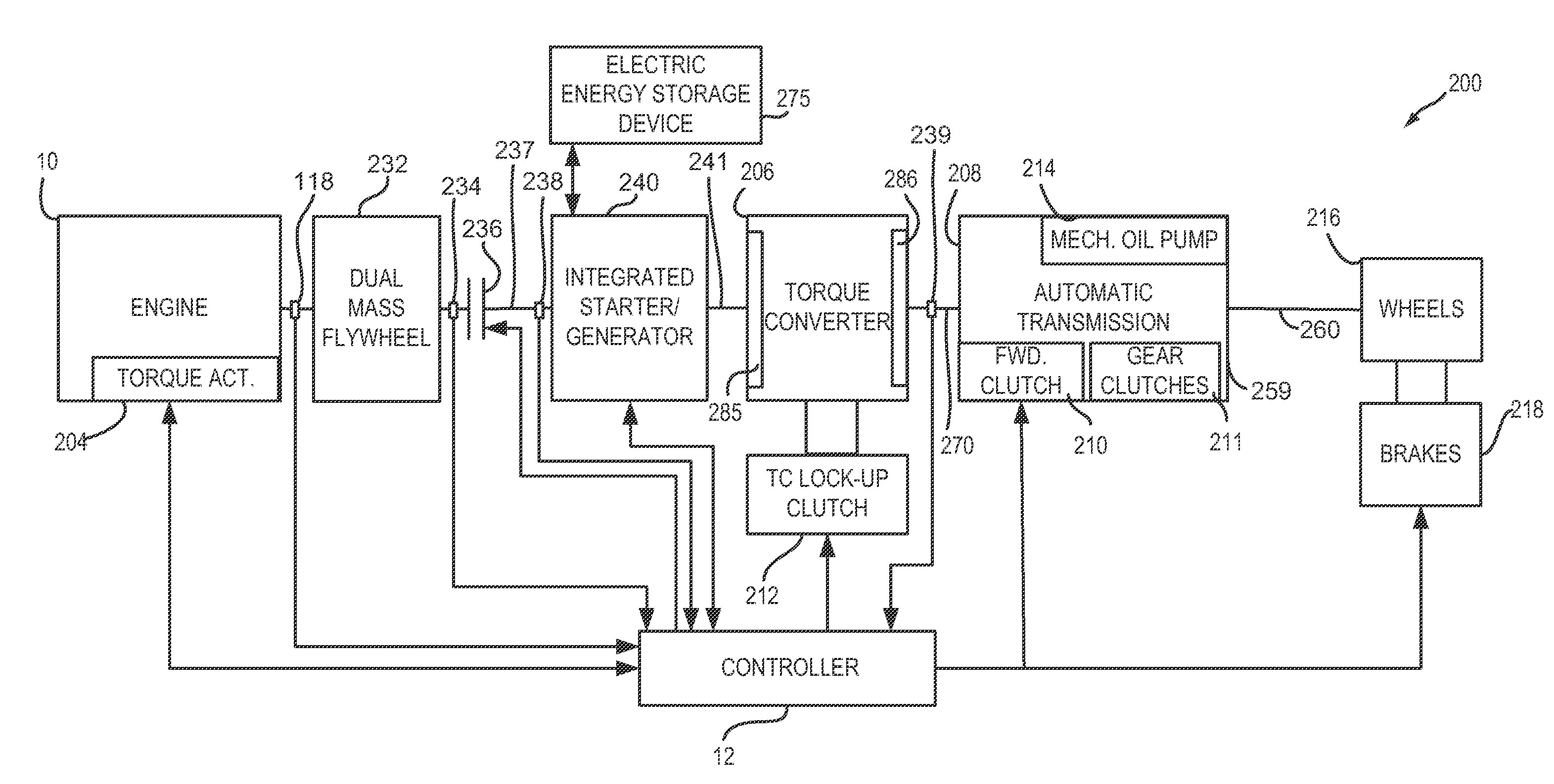

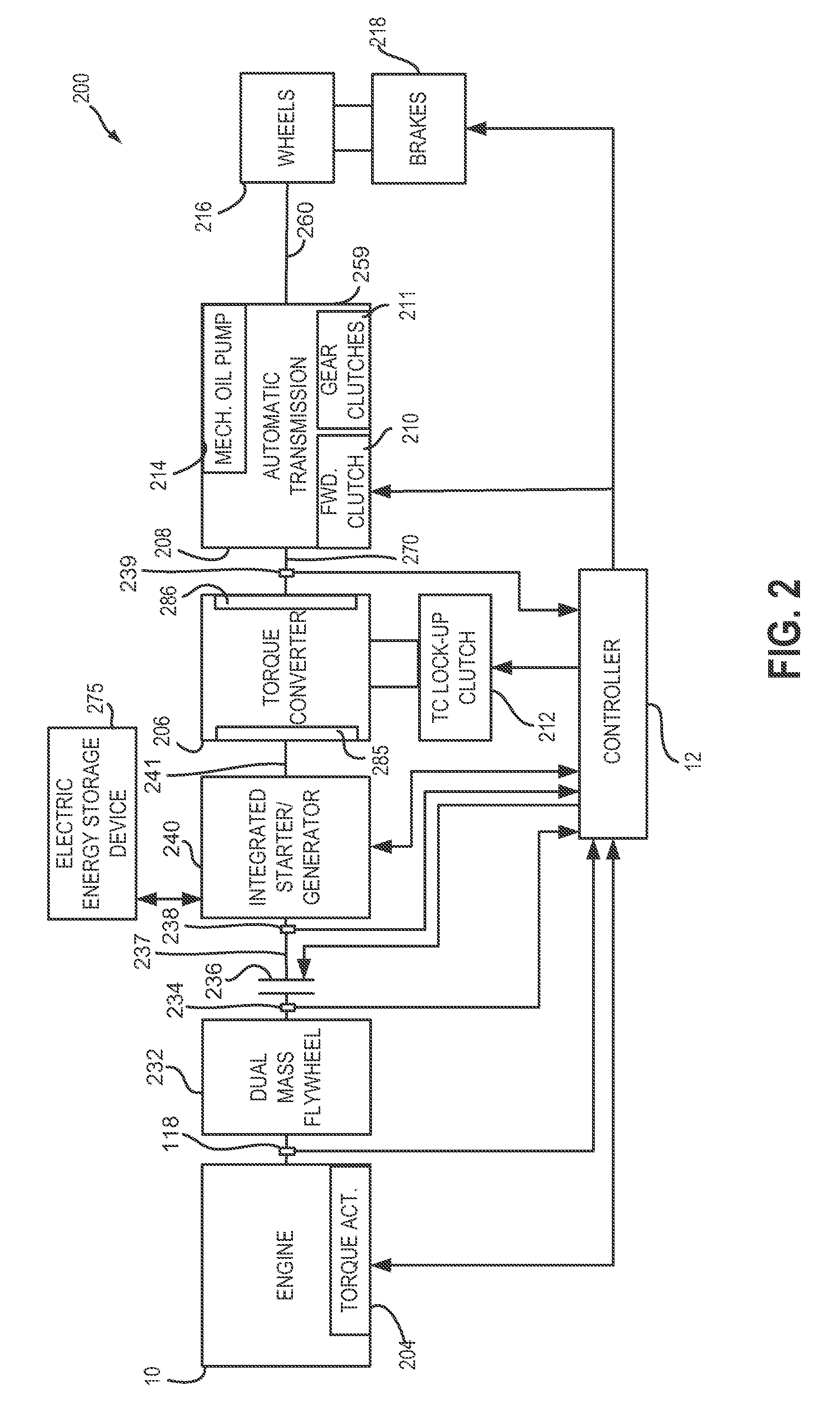

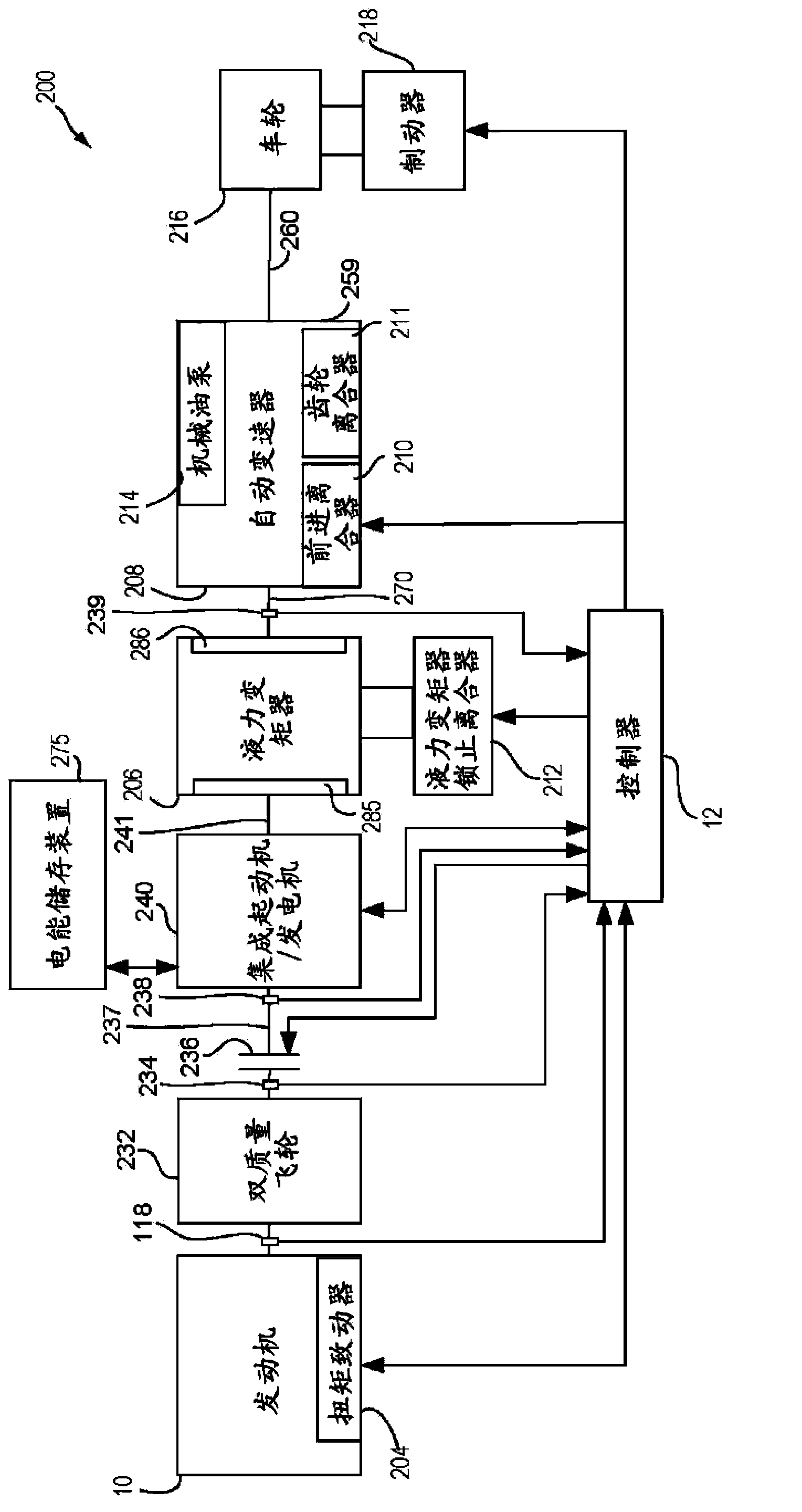

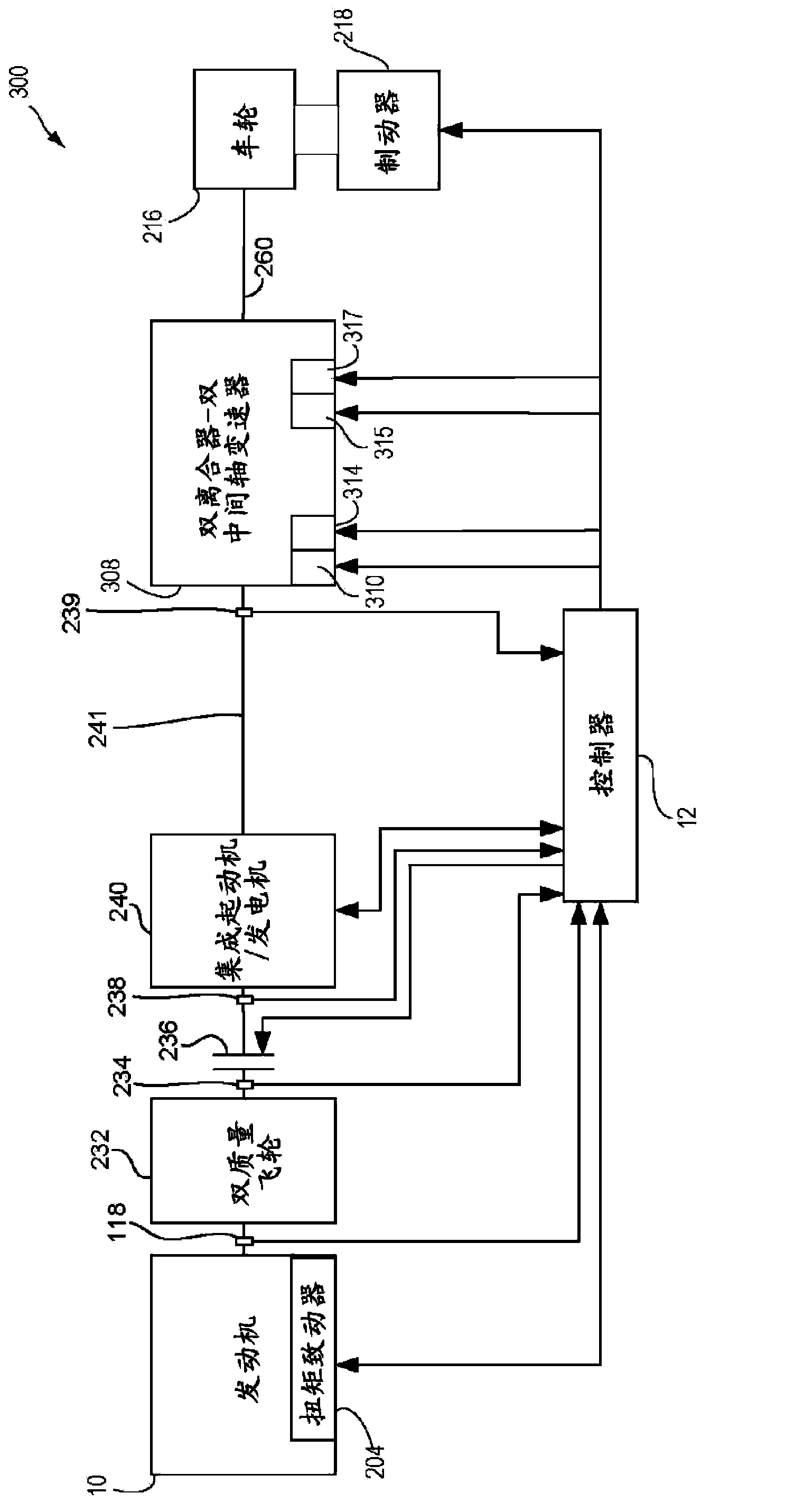

Methods and systems for a hybrid vehicle

ActiveUS20130297112A1Improve efficiencyIncrease rangeHybrid vehiclesElectrical controlElectric machineHybrid vehicle

Systems and methods for learning torque estimate errors and updating torque estimation models are presented. In one example, torque errors are learned during an engine shut-down, after a disconnect clutch coupled between an engine and an electric machine has been released. An updated torque estimation model is then used to control torque during subsequent engine operation to improve drive feel and vehicle performance.

Owner:FORD GLOBAL TECH LLC

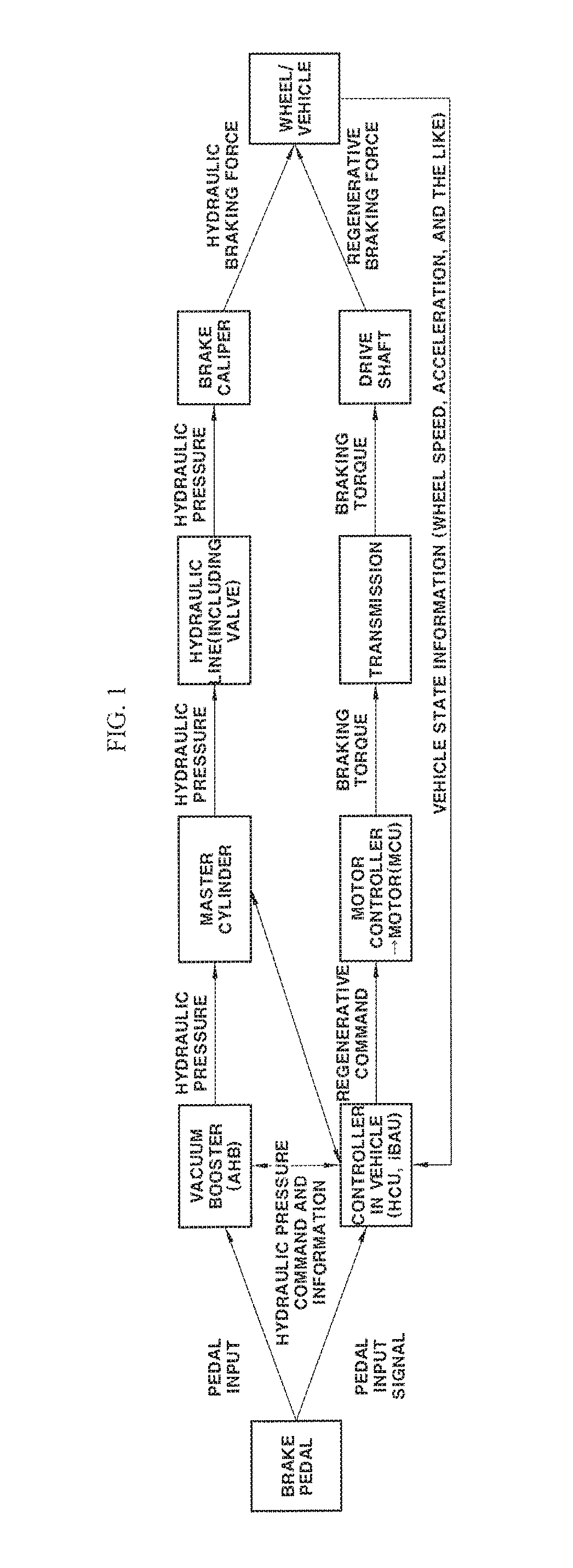

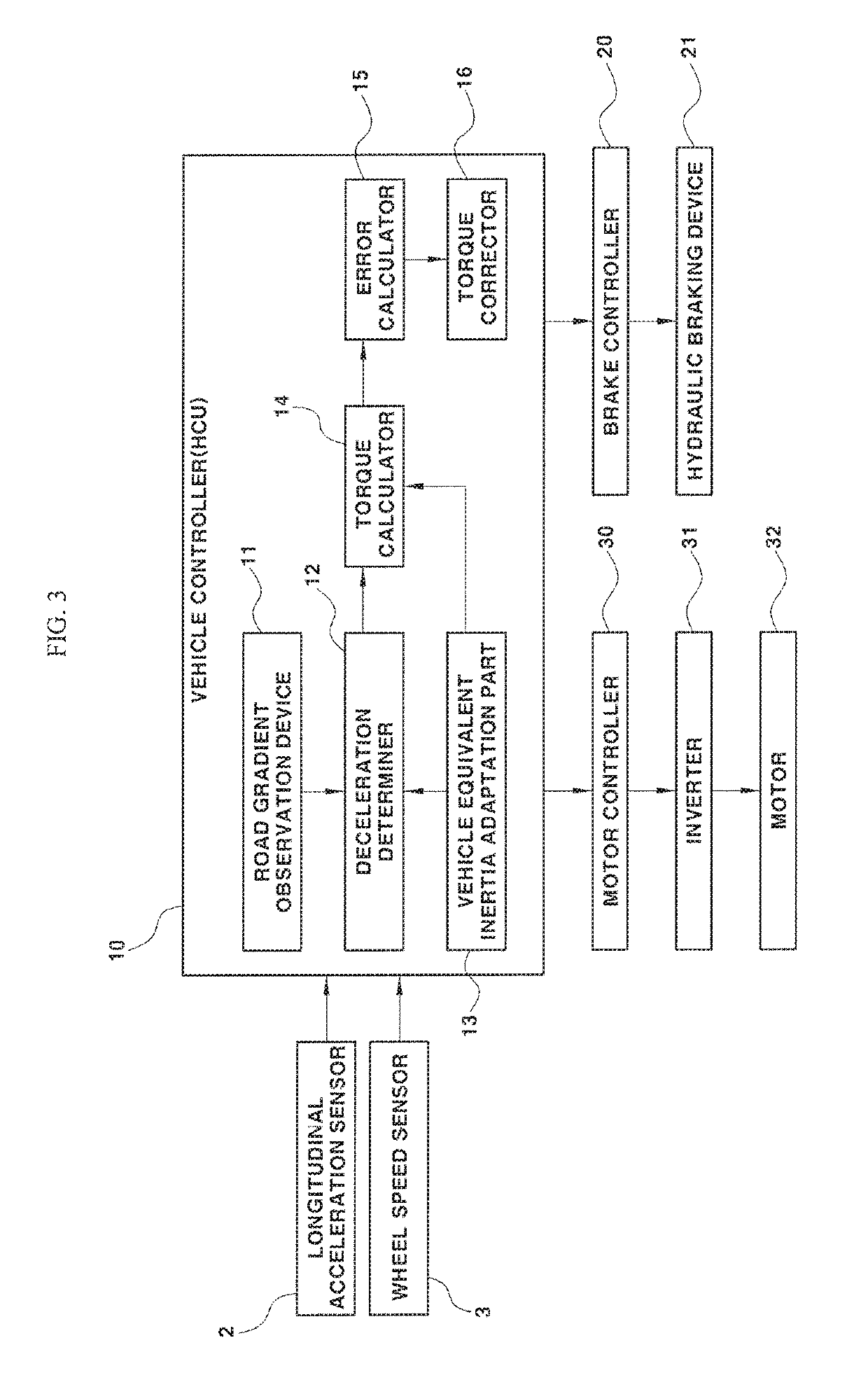

Braking control system and method for eco-friendly vehicle

ActiveUS20190193569A1Resolving discrepancy in braking force occurringHybrid vehiclesSpeed controllerRegenerative brakeControl system

A braking control system and a method for an eco-friendly vehicle are provided to resolve discrepancy in braking force occurring during switching between hydraulic braking and regenerative braking. The system includes a deceleration determiner that determines target and actual decelerations of the vehicle based on collected information when braking and a torque calculator that calculates target and actual deceleration torques from the determined target and actual decelerations of the vehicle using vehicle equivalent inertia information. An error calculator calculates a torque error and a torque corrector corrects a pre-correction target regenerative braking torque by the calculated torque error and calculates a post-correction target regenerative braking torque. A motor controller adjusts a regenerative braking torque of a motor according to the calculated post-correction target regenerative braking torque.

Owner:HYUNDAI MOTOR CO LTD +1

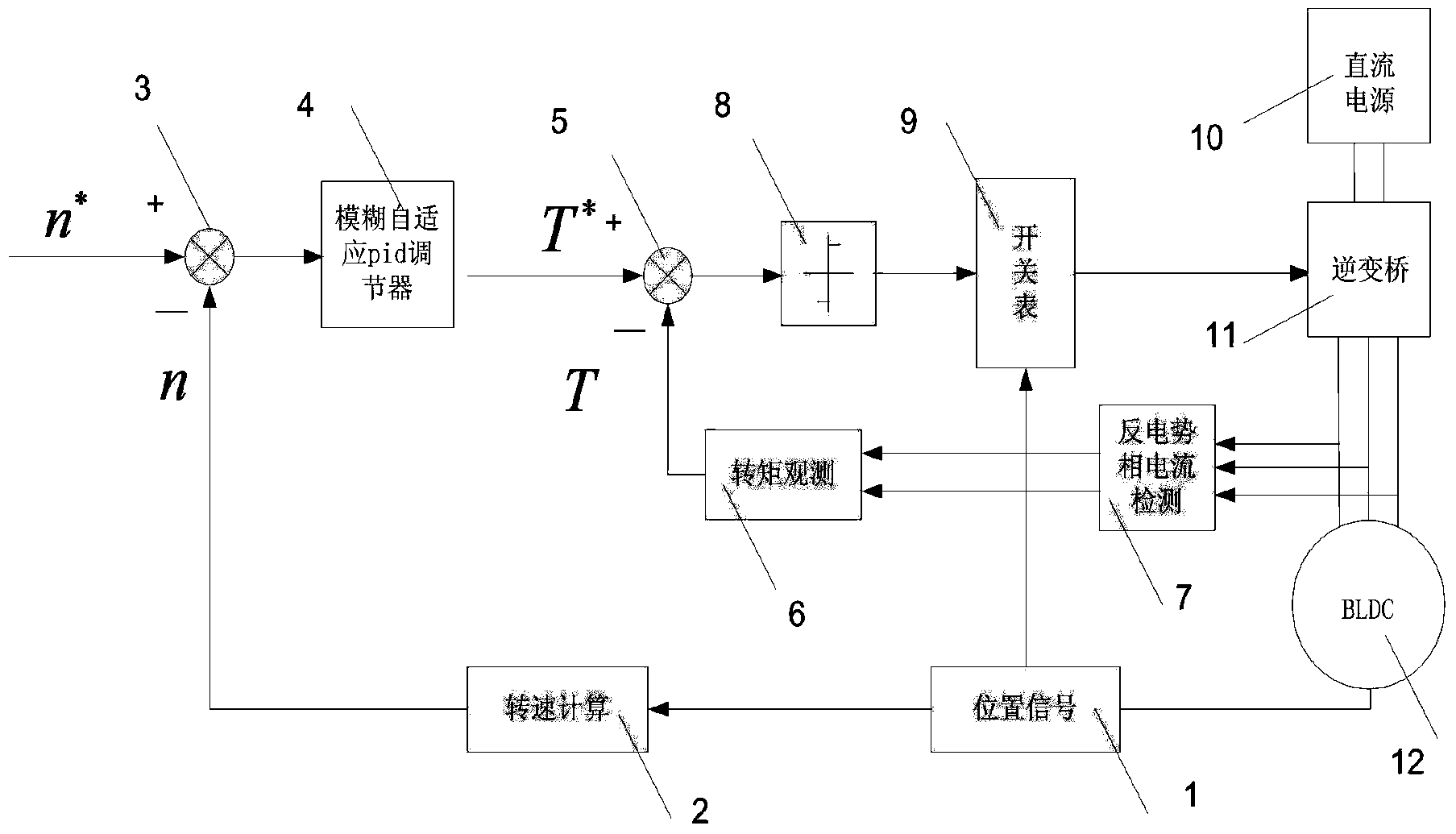

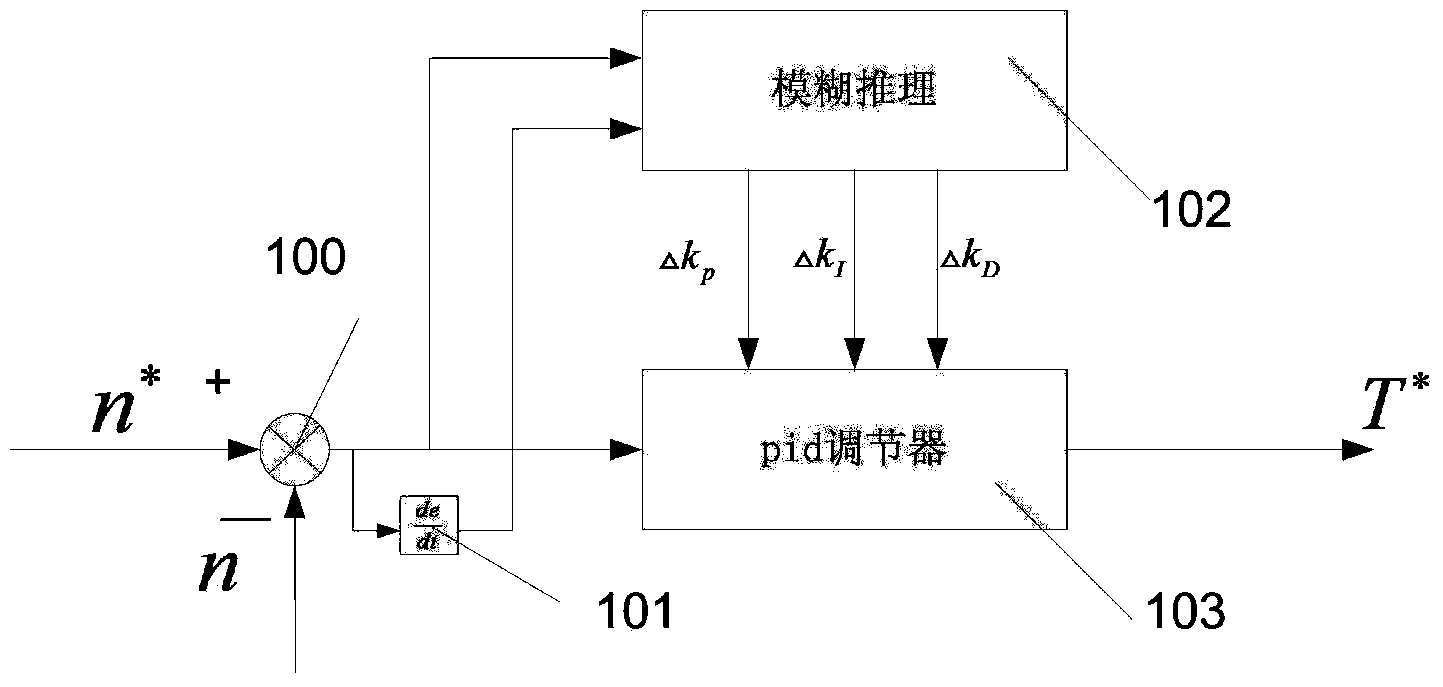

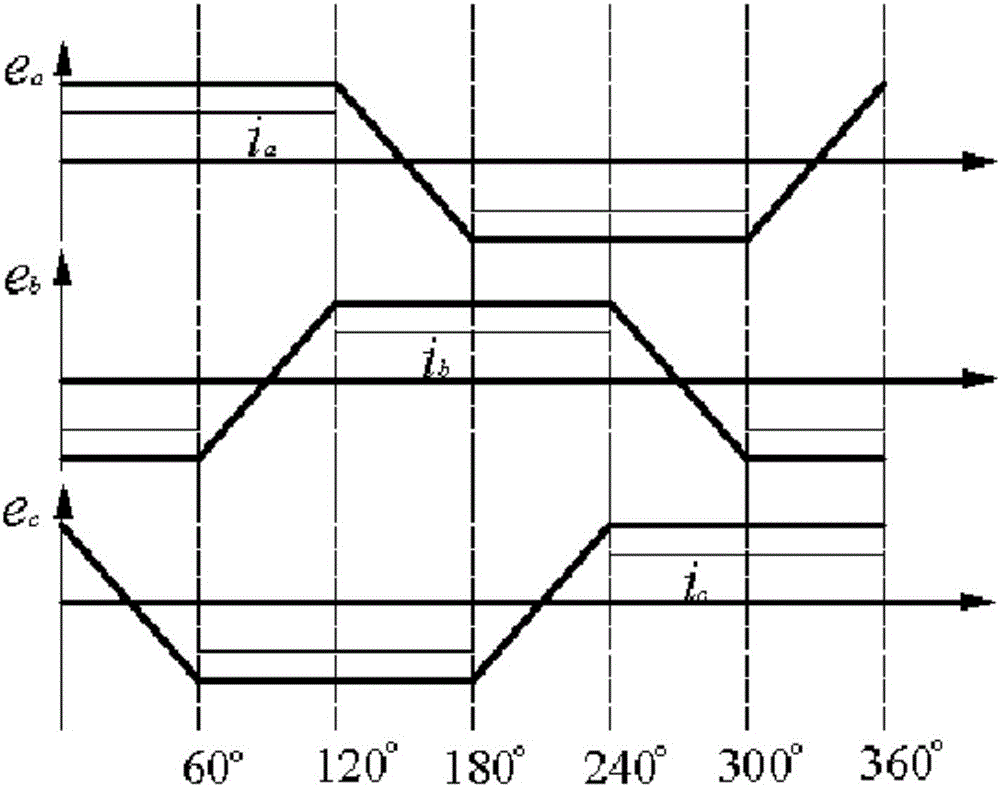

Direct torque control method for brushless direct current motor

InactiveCN104022699AOvercome precisionOvercoming interferenceElectronic commutation motor controlVector control systemsMotor speedPhase currents

The invention discloses a direct torque control method for a brushless direct current motor. By speed and torque double closed loop control, a rotating speed loop is used as an outer loop, and a torque loop is used as an inner loop; motor speed is calculated according to an output signal of a Hall sensor of the brushless direct current motor, and the motor speed is compared with reference speed to obtain speed error; an output value obtained after fuzzy self-adaptation adjustment is used as a torque expectation value; torque error is obtained by subtracting actual torque from expectation torque, wherein the actual torque is calculated by multiplying back-EMF (Electromotive Force) and phase current; the torque error is inputted into a hysteresis comparator; the hysteresis comparator outputs a position signal of a rotor; and an appropriate voltage vector is selected from a formulated switch list to control an inverter bridge connected with a DC power supply so as to make the brushless direct current motor output stable torque. By the method, the defect that current hysteresis control has a poor effect of inhibiting electromagnetic torque is avoided, and the problem that a traditional PID control method has low precision and poor anti-jamming capability in control of BLDCM is overcome.

Owner:江苏新绿能科技有限公司

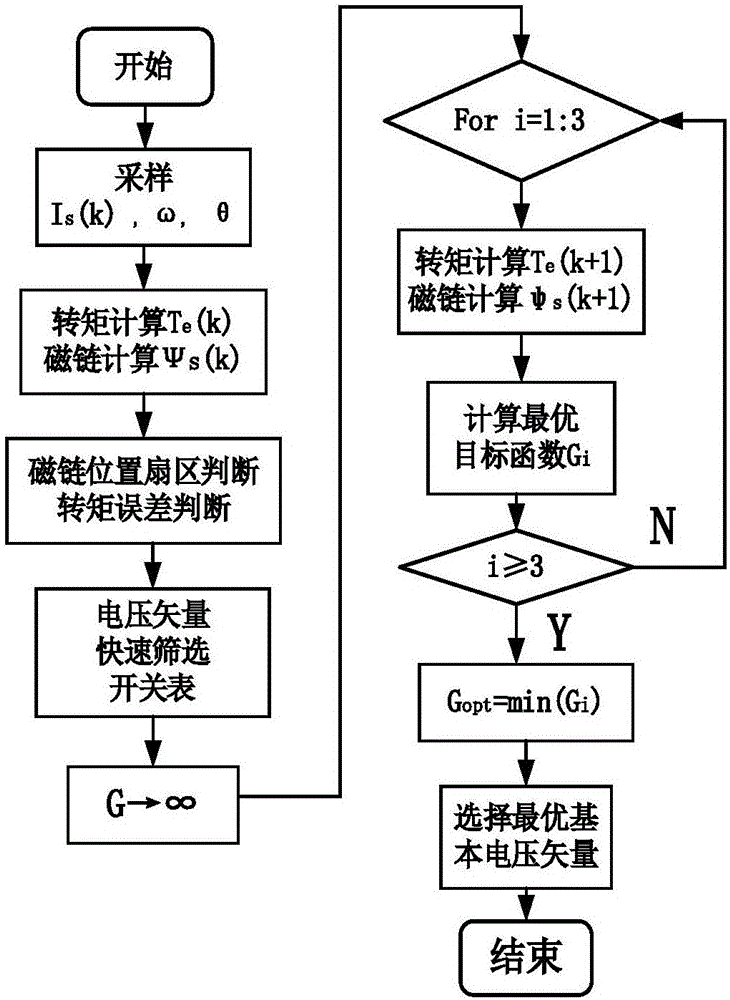

Improved eulerian method-based rapid vector screening and torque predicting control method

ActiveCN106788075ASmall amount of calculationHigh precisionElectronic commutation motor controlVector control systemsVoltage vectorPermanent magnet synchronous motor

The invention discloses an improved eulerian method-based rapid vector screening and torque predicting control method. The method comprises the following steps: calculating the angle of a stator magnetic chain at the current moment, determining a sector of the stator magnetic chain through a sector judgment module, calculating the electromagnetic torque at the current component, and comparing reference torque and actual torque to generate a torque error; rapidly screening out three optimized voltage vectors, and accurately predicting a stator magnetic chain value and a torque value at the next moment by using a two-order eulerian formula; and finally obtaining the optimal on-off state of an inverter through an optimal value function, converting the on-off state into voltage by the inverter, outputting the voltage to a permanent magnet synchronous motor and driving the motor to operate. By the method, the calculation of a processor is shortened, the predicting value is more accurate, the problems that the permanent magnet synchronous motor model torque predicting control is large in on-line calculation quantity and long in executing time are solved, the predicting results of current, torque and magnetic chain are more accurate.

Owner:SOUTHEAST UNIV

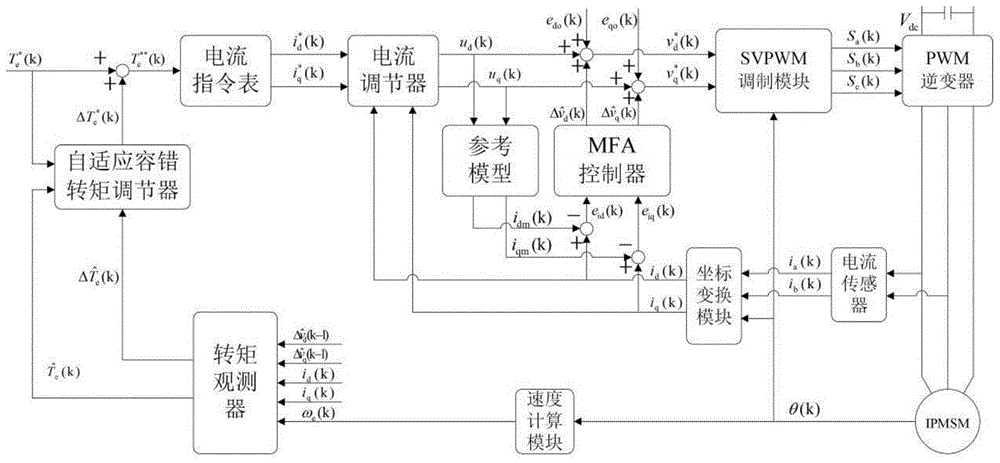

Adaptive fault tolerant control method with salient pole permanent magnet synchronous motor precise torque output

ActiveCN104836504AAchieve optimizationImprove torque dynamic response performanceElectronic commutation motor controlVector control systemsElectricityControl system

The present invention discloses an adaptive fault tolerant control method with salient pole permanent magnet synchronous motor precise torque output. The method is characterized in that based on a model free adaptive controller, the reference voltage disturbance quantity caused by parameter change of a motor is obtained, on one hand, the reference voltage disturbance quantity is compensated to a control system, a motor system of parameter change is stabilized to a motor system of a nominal parameter, the dynamic performance of a current loop is improved, on the other end, a torque disturbance estimation value is obtained and is compared with a given torque error threshold value, a failure judgment module is formed, when the appearance of a torque tracking failure is judged, a torque command correction amount is outputted through an adaptive fault-tolerant torque regulator and is stacked with a given torque command, a new correction torque command is generated, and the torque control precision of the system is improved. By using a torque feedback loop control structure, the precise torque output under a complex operation condition by an electric vehicle electric drive system can be realized according to the method.

Owner:HEFEI UNIV OF TECH

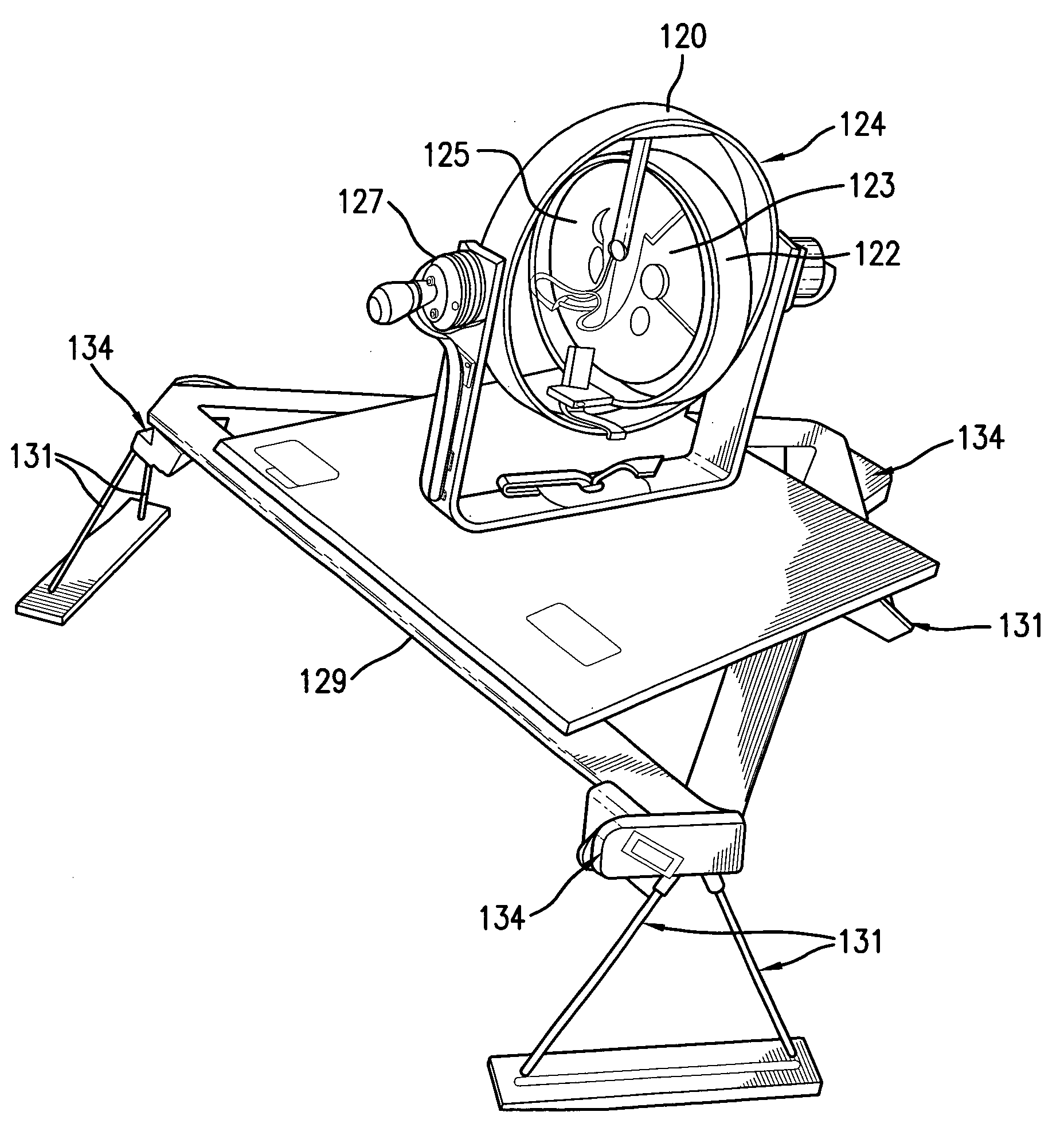

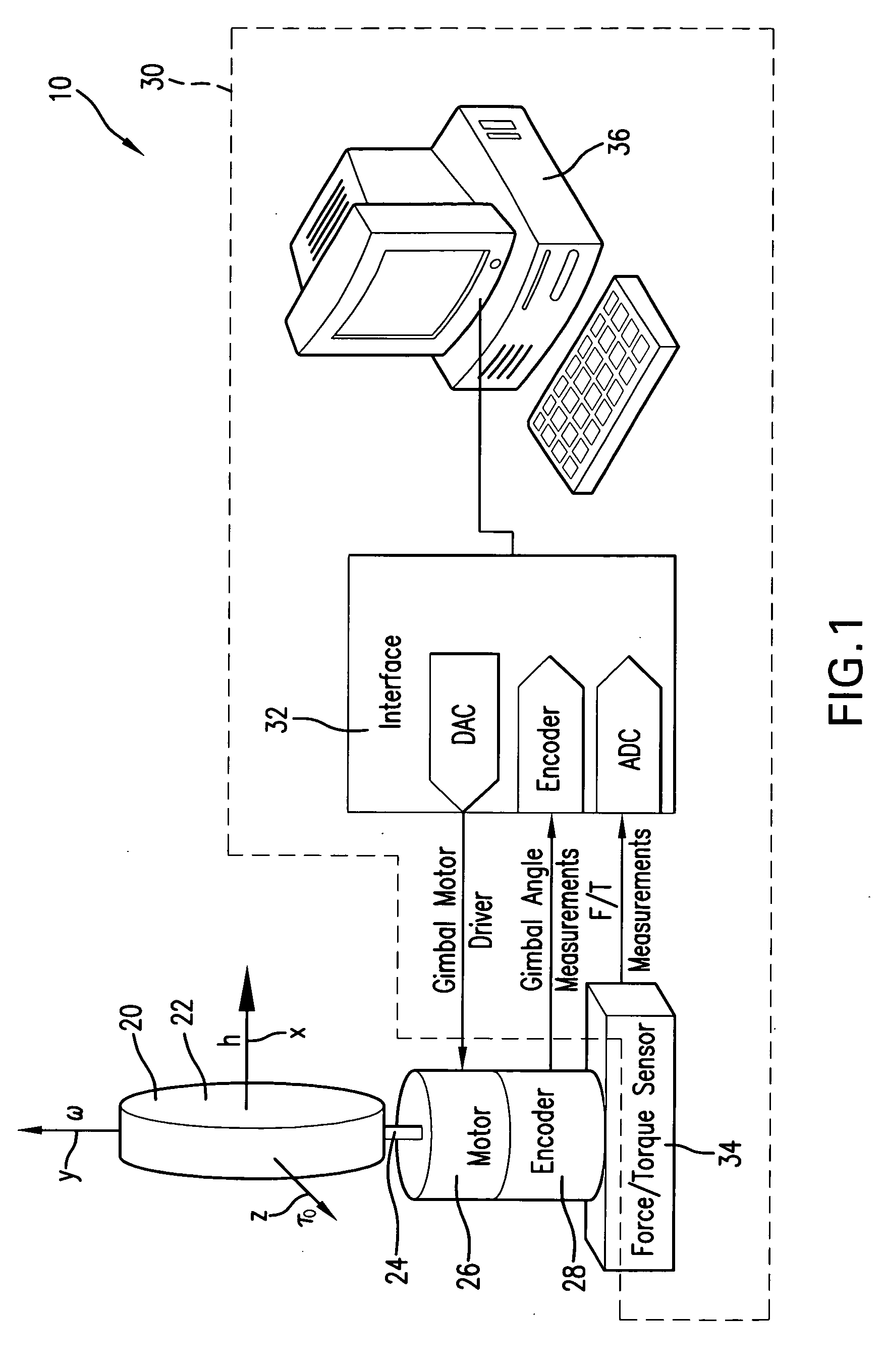

Direct torque actuator control for control moment gyroscope

InactiveUS20090001220A1Improve responsivenessReduce needMechanical apparatusCosmonautic vehiclesGyroscopeControl system

A control moment gyroscope system for delivering a target torque to a spacecraft including a rotor assembly having a rotor and a motor to spin the rotor about a rotor axis. A gimbal assembly has a gimbal for supporting the rotor assembly and a gimbal torque motor to rotate the gimbal about a gimbal axis, which is normal to the rotor axis, to generate an output torque. A control system has a sensor for determining the output torque and a processor in communication with the rotor assembly, the gimbal assembly and the sensor. The processor requests the target torque and establishes a feedback control loop to generate a torque error signal based on the output torque for bringing the output torque within a predetermined range of the target torque.

Owner:ITHACO SPACE SYST

Methods and systems for a hybrid vehicle

ActiveUS20130297113A1Improve efficiencyIncrease rangeHybrid vehiclesDigital data processing detailsElectric machineHybrid vehicle

Systems and methods for learning torque estimate errors and updating torque estimation models are presented. In one example, torque errors are learned during an engine shut-down, after a disconnect clutch coupled between an engine and an electric machine has been released. An updated torque estimation model is then used to control torque during subsequent engine operation to improve drive feel and vehicle performance.

Owner:FORD GLOBAL TECH LLC

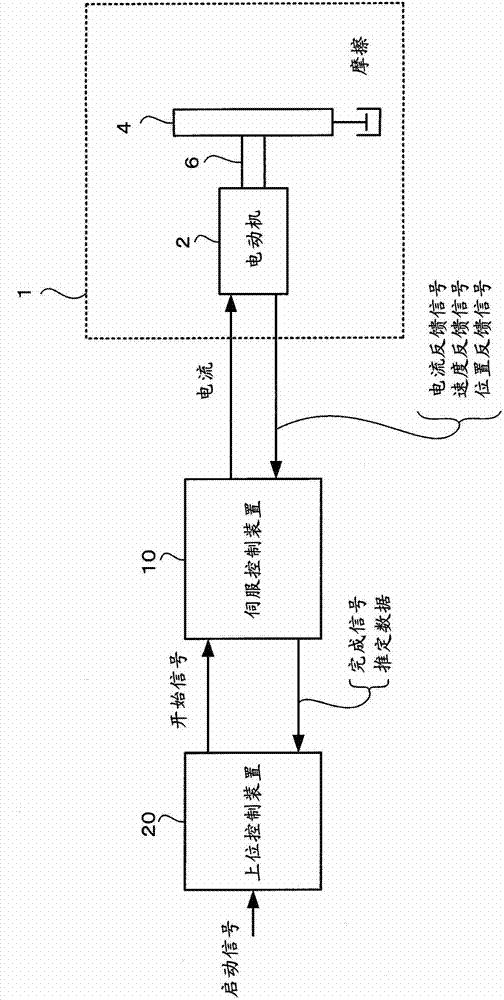

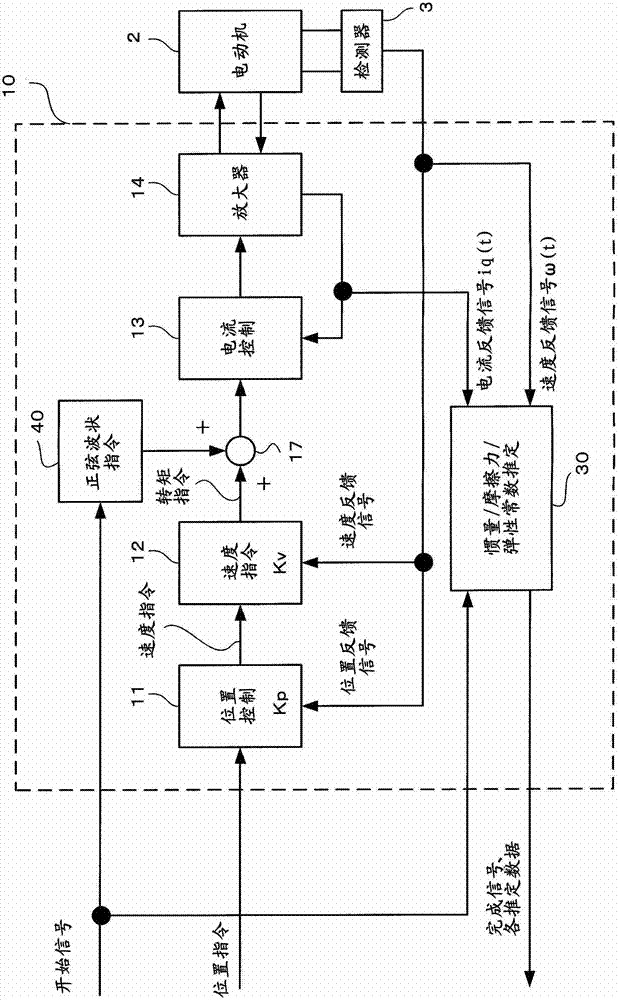

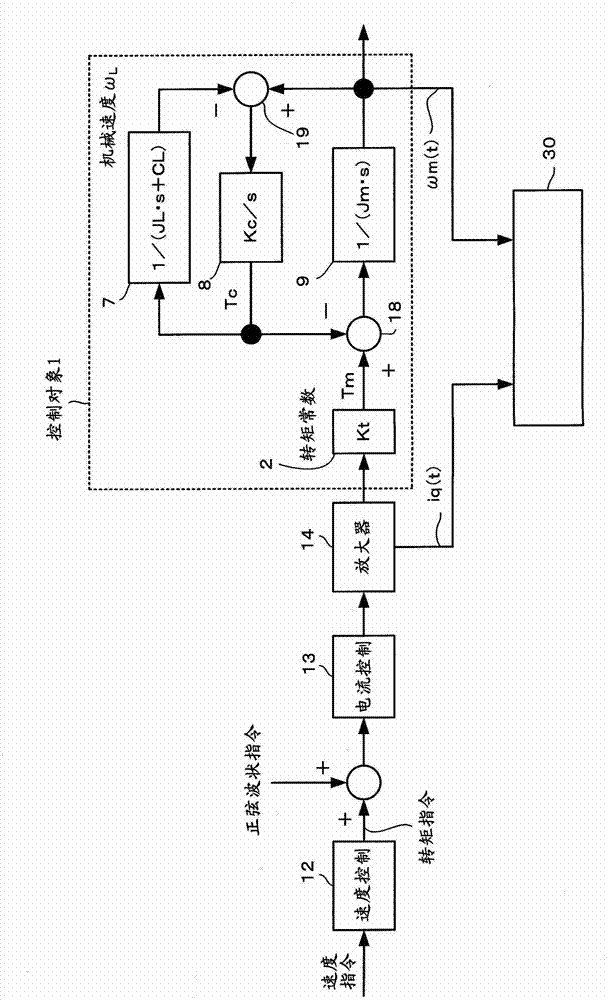

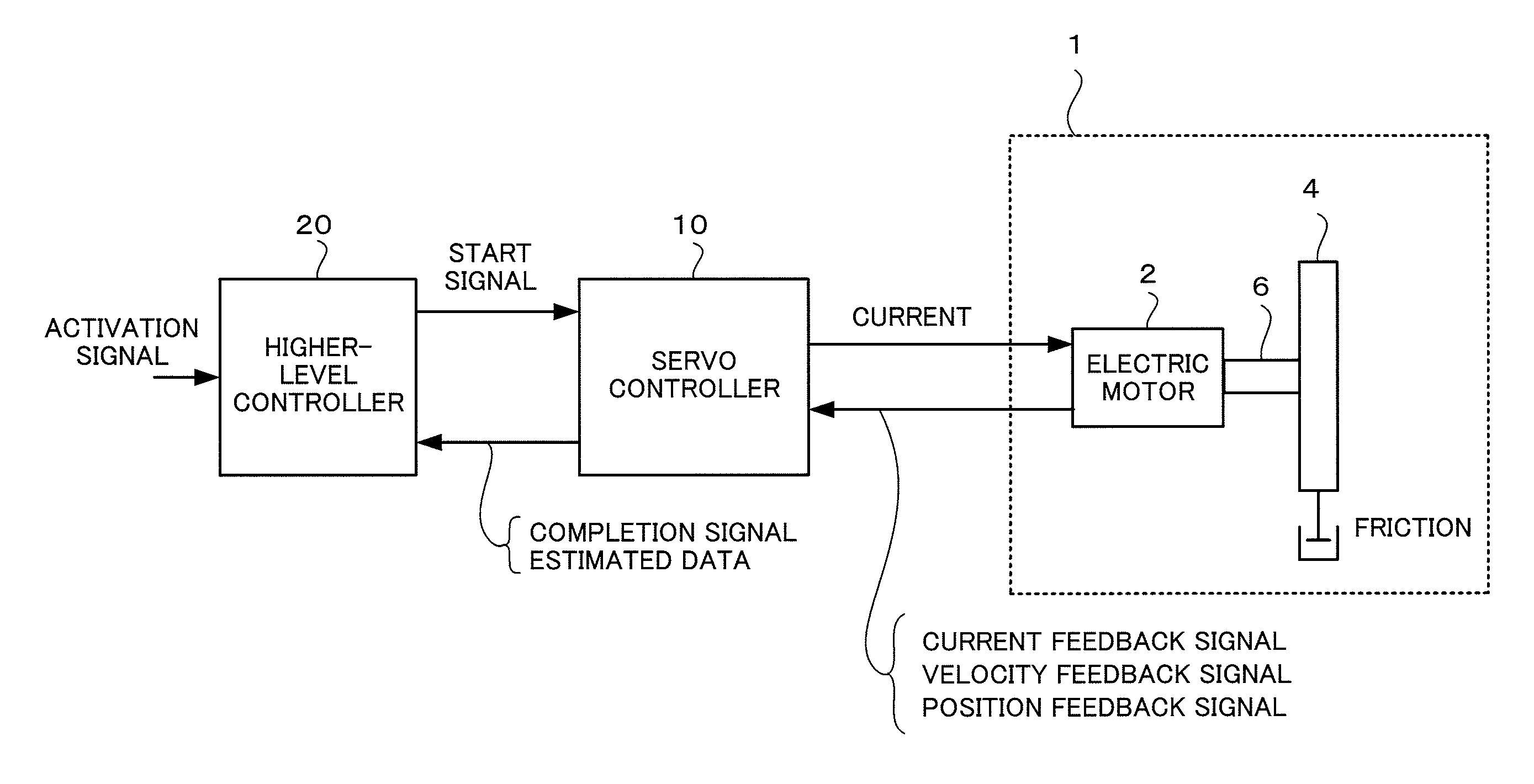

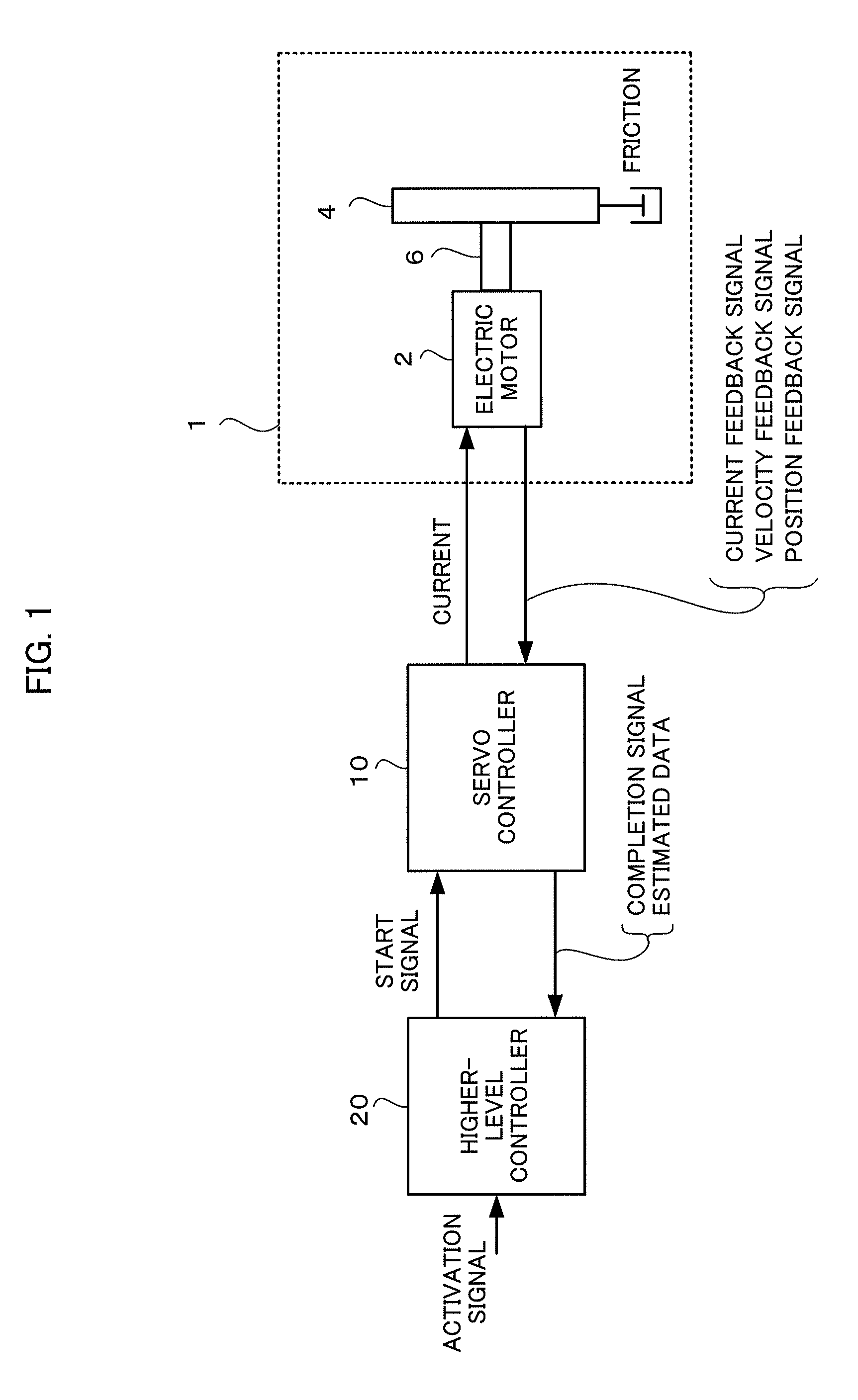

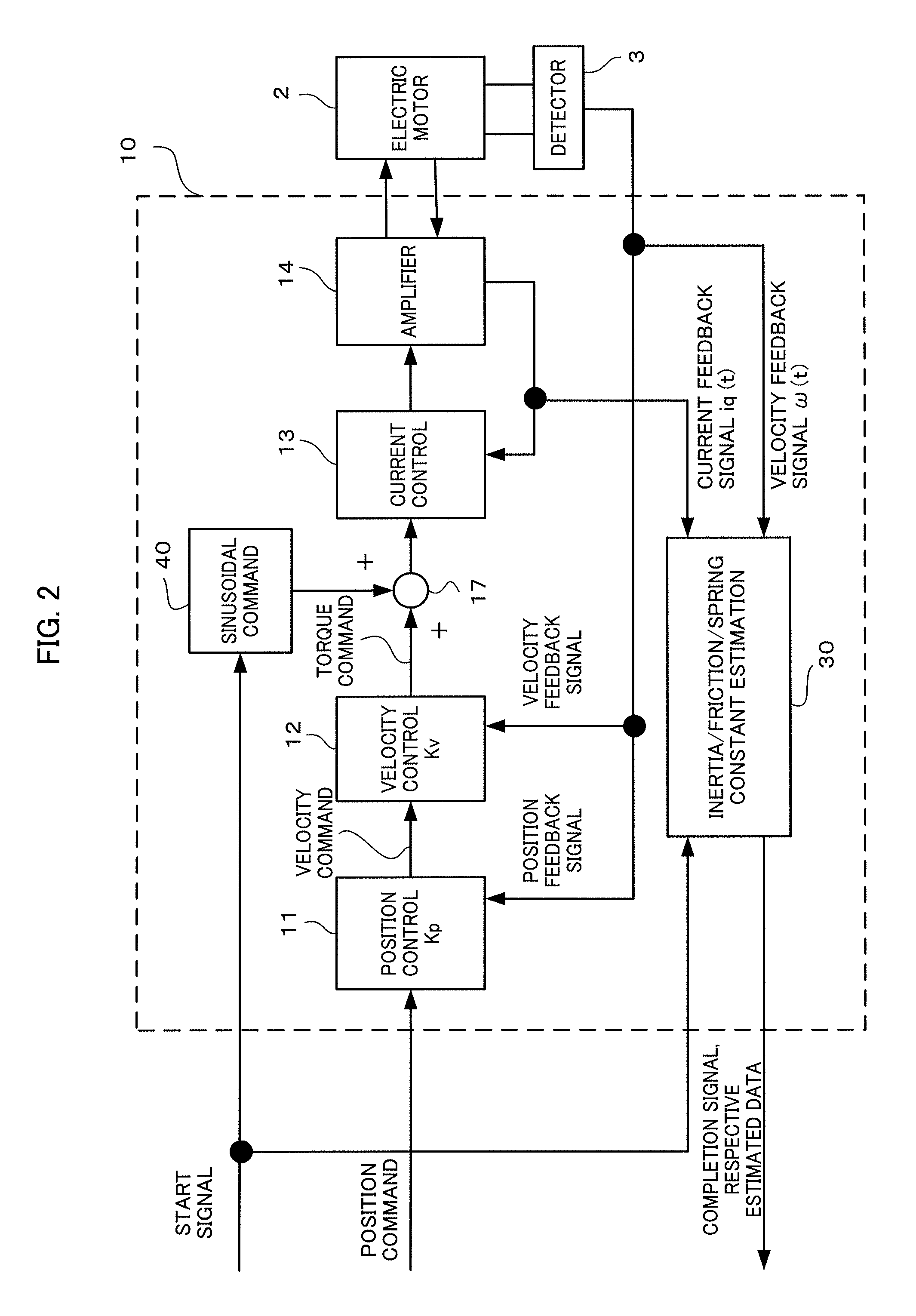

Electric motor controller comprising function for simultaneously estimating inertia, friction, and spring

ActiveCN102904521APresumed elasticityEstimated nonlinear frictionElectric motor controlVector control systemsCouplingControl theory

The invention provides an electric motor controller comprising functions for simultaneously estimating inertia, friction, and spring. A sinusoidal command is added to a torque command of a controller to acquire a velocity and a current value of an electric motor. An estimated coupling torque value is calculated by calculating an input torque value from the current value and a torque constant of the electric motor and further calculating a coupling torque value from a velocity difference, motor inertia, and the input torque. An estimated torque error is then calculated from the estimated coupling torque value and the coupling torque value, and inertia, friction, and a spring constant are estimated from the estimated torque error, the velocity, and the coupling torque value.

Owner:FANUC LTD

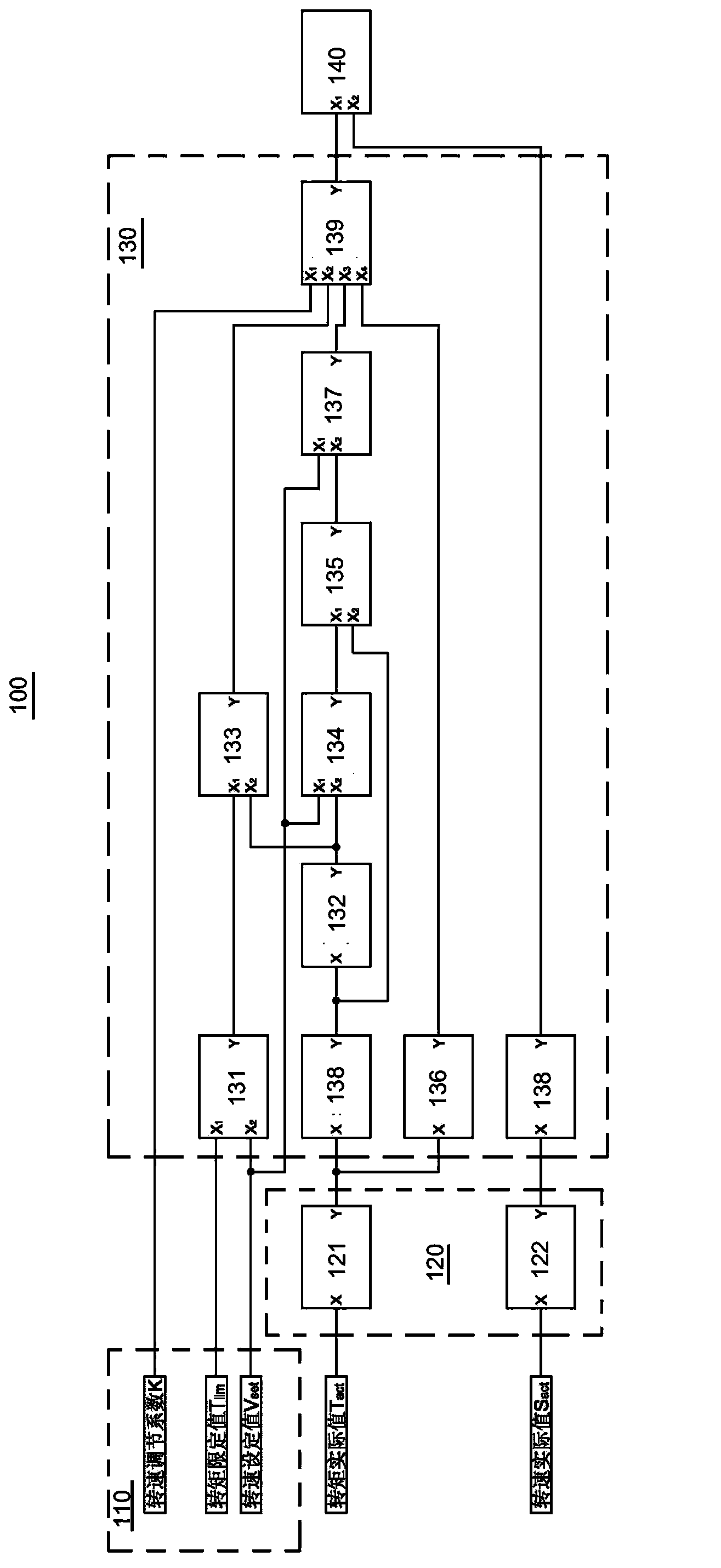

Load torque control system and load torque control method

The invention discloses a load torque control system which includes an input unit, through which a rotation speed set value of a motor is input; a detection unit which includes a torque sensor for detecting the torque actual value of the motor; a calculation unit which calculates a torque change rate according to the torque actual value detected by the detection unit and compares the torque change rate calculated by the calculation unit and a preset value and changes the rotation speed set value when the torque change rate is larger than the preset value and outputs the changed rotation speed set value to a speed controller of the motor. Through adoption of the load torque control system, the actual torque, rotation speed and speed transient fluctuation of a mechanical device can be monitored in a real-time manner and the system adjusts the speed automatically so that stable transmission and release of energy are realized and the security and service life of the system are improved.

Owner:SIEMENS FACTORY AUTOMATION ENG

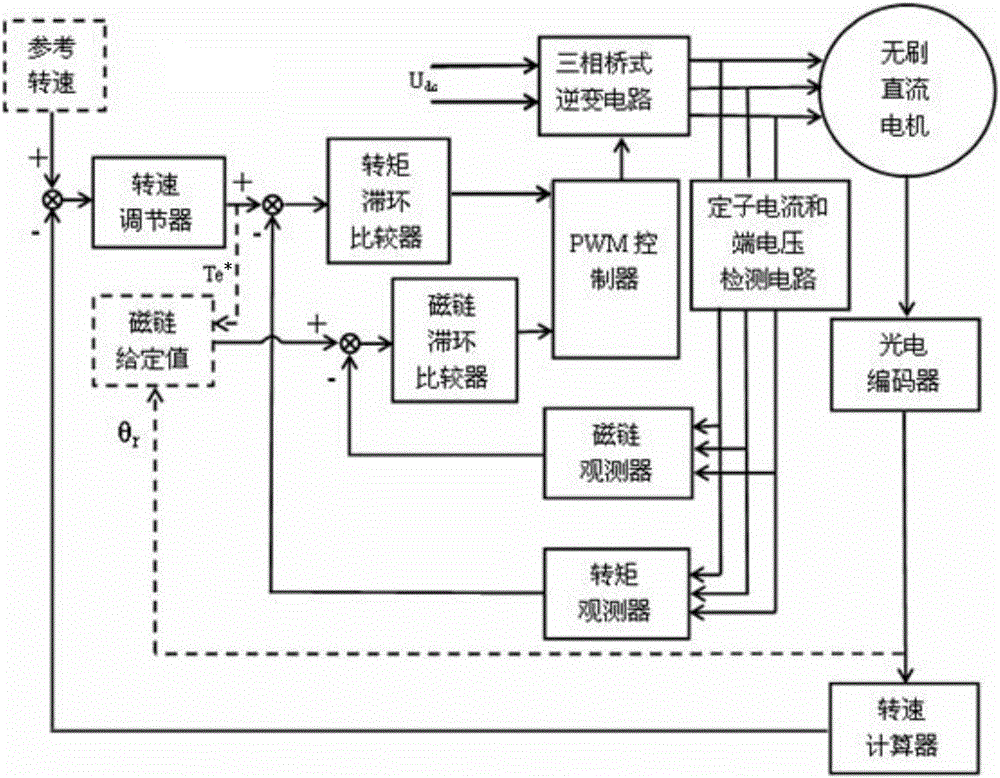

Brushless DC motor direct torque control system and control method

InactiveCN105846745AEasy to implementImprove operational efficiencyElectronic commutation motor controlVector control systemsVoltage vectorTorque observer

The invention discloses a brushless direct current motor direct torque control system and control method, the system includes a photoelectric encoder, a stator current and terminal voltage detection circuit, a speed calculator, a speed error comparator, a speed regulator, and a flux linkage observer , Flux linkage error comparator, flux linkage hysteresis comparator, torque observer, torque error comparator, torque hysteresis comparator, PWM controller and three-phase bridge inverter circuit. The photoelectric encoder collects the position information of the motor rotor, calculates the actual speed according to the rotor position information, calculates the given value of the stator flux linkage according to the rotor position information and the reference torque, and collects the three-phase current and terminal voltage of the stator to calculate the actual electromagnetic torque And the actual stator flux, the PWM controller generates a voltage vector according to the torque error and the flux error, and drives the inverter circuit through the voltage vector to realize the stable operation of the motor. The invention does not need to calculate the flux linkage in real time, simplifies the system program, and improves the control efficiency.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

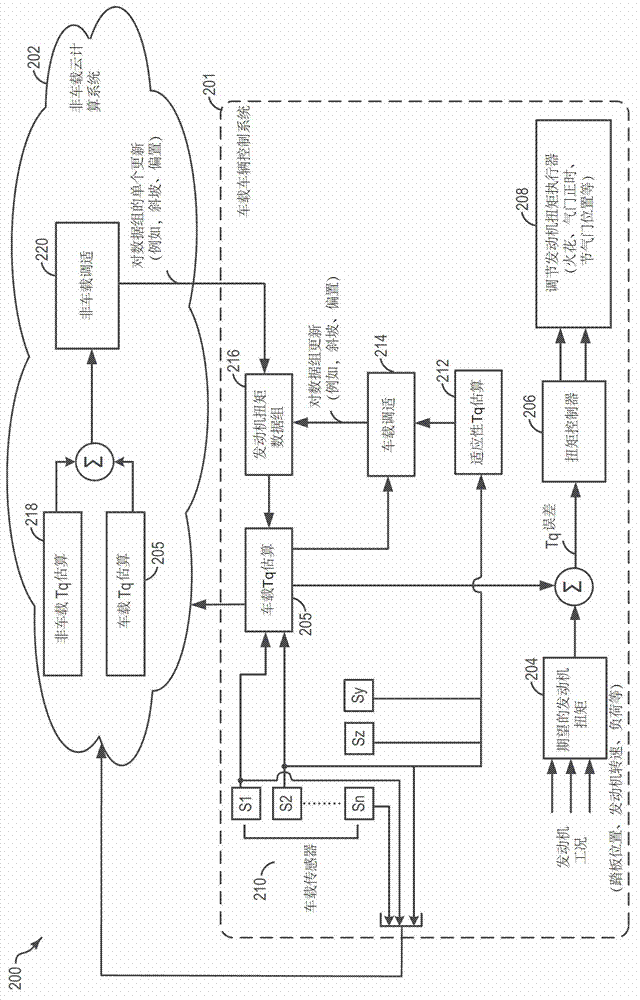

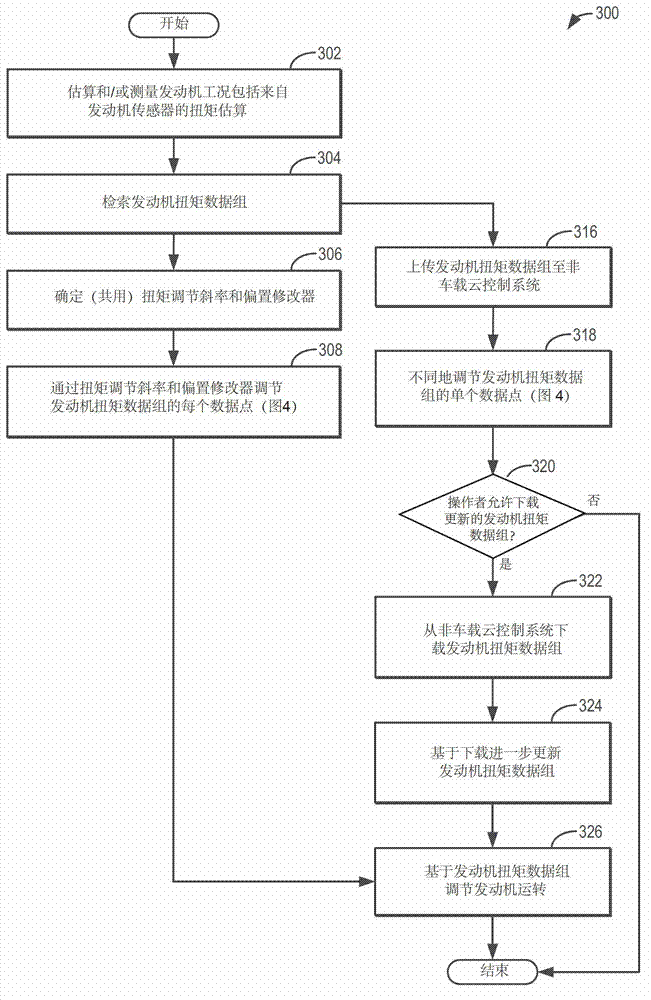

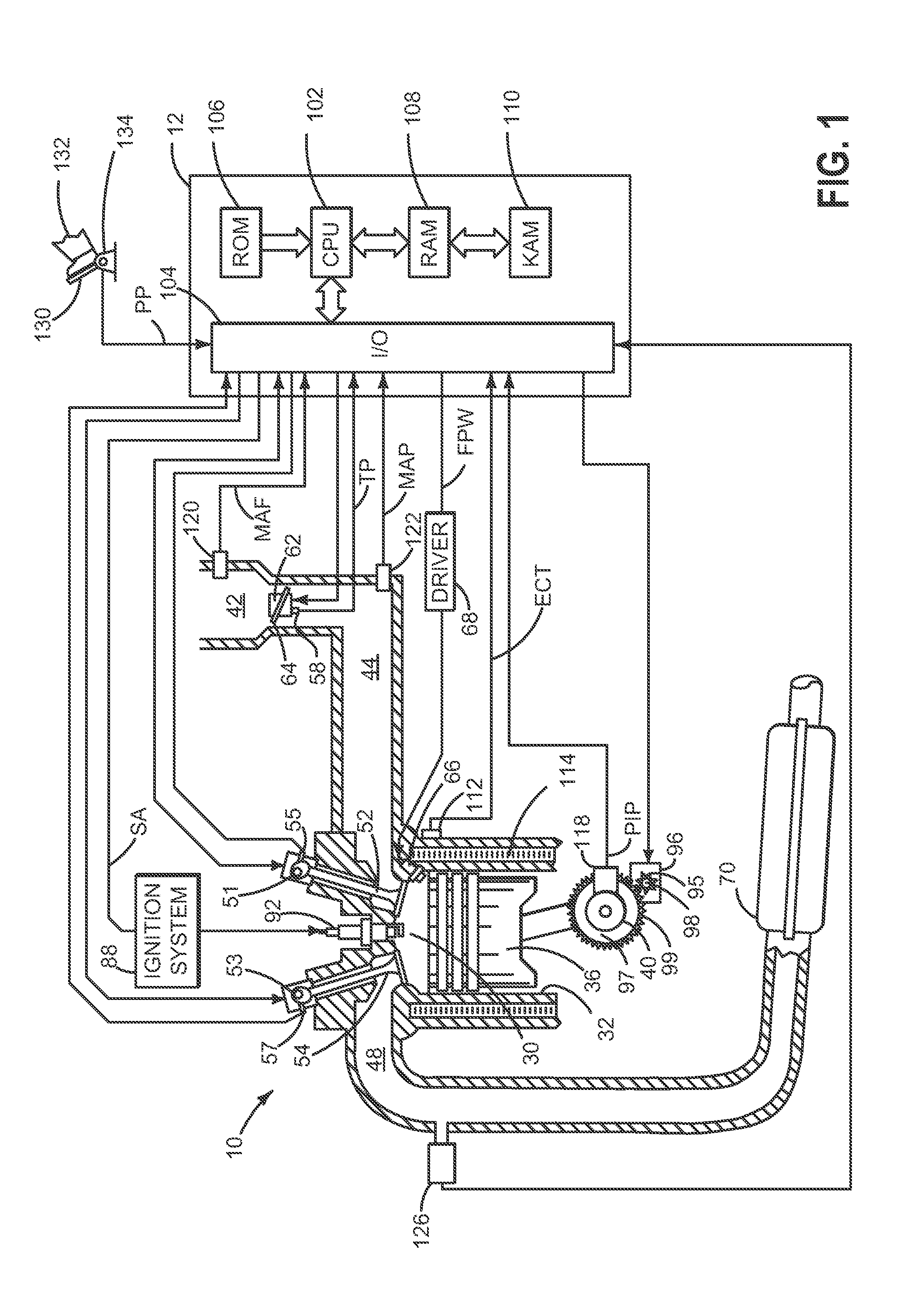

Method and system for engine torque control

ActiveCN103206309AEasy to handleImprove performanceHybrid vehiclesElectrical controlData setOn board

Methods and systems are provided for improving vehicle torque control accuracy. Data points of an engine torque data set are adjusted en masse by an on-board vehicle controller while also being adjusted individually by an off-board controller. By adjusting engine operation based on a torque data set that is updated by each of the on-board and off-board controllers, engine torque errors can be reliably determined and compensated for.

Owner:FORD GLOBAL TECH LLC

Methods and systems for a hybrid vehicle

ActiveUS8738217B2Improve efficiencyIncrease rangeHybrid vehiclesVehicle testingElectric machineHybrid vehicle

Systems and methods for learning torque estimate errors and updating torque estimation models are presented. In one example, torque errors are learned during an engine shut-down, after a disconnect clutch coupled between an engine and an electric machine has been released. An updated torque estimation model is then used to control torque during subsequent engine operation to improve drive feel and vehicle performance.

Owner:FORD GLOBAL TECH LLC

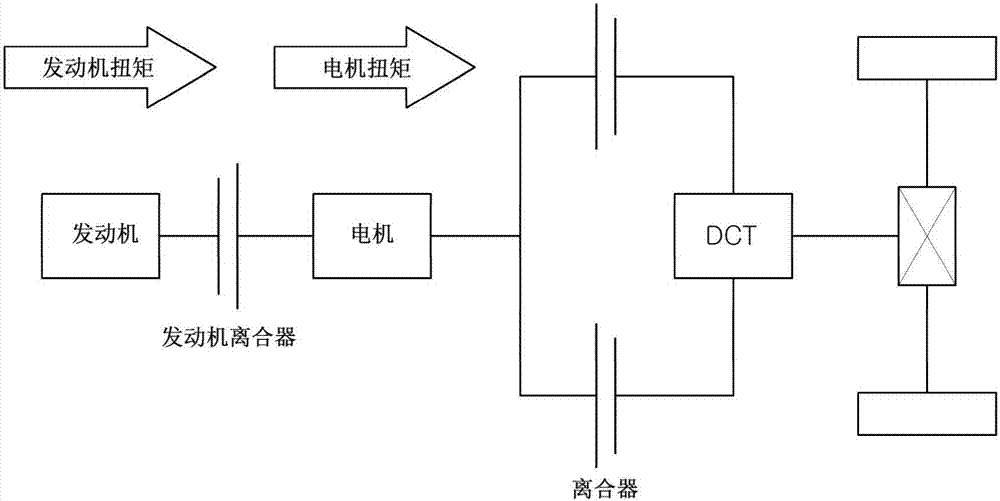

Method and system for hybrid vehicle

InactiveCN103381815AReduce estimation errorImproved Torque DisturbanceHybrid vehiclesInternal combustion piston enginesElectric machineHybrid electrical vehicle

The invention provides a system and a method for obtaining torque estimation faults and updating a torque estimation model. In one embodiment, the torque estimation faults are obtained during flame-out of the engine after a disengaging clutch connected between an engine and an electric machine is released. In the following engine operation period, the updated torque estimation module is used for controlling the torque and thus improving the driving feeling and vehicle performance.

Owner:FORD GLOBAL TECH LLC

Electric motor controller comprising function for simultaneously estimating inertia, friction, and spring

A sinusoidal command is added to a torque command of a controller to acquire a velocity and a current value of an electric motor. An estimated coupling torque value is calculated by calculating an input torque value from the current value and a torque constant of the electric motor and further calculating a coupling torque value from a velocity difference, motor inertia, and the input torque. An estimated torque error is then calculated from the estimated coupling torque value and the coupling torque value, and inertia, friction, and a spring constant are estimated from the estimated torque error, the velocity, and the coupling torque value.

Owner:FANUC LTD

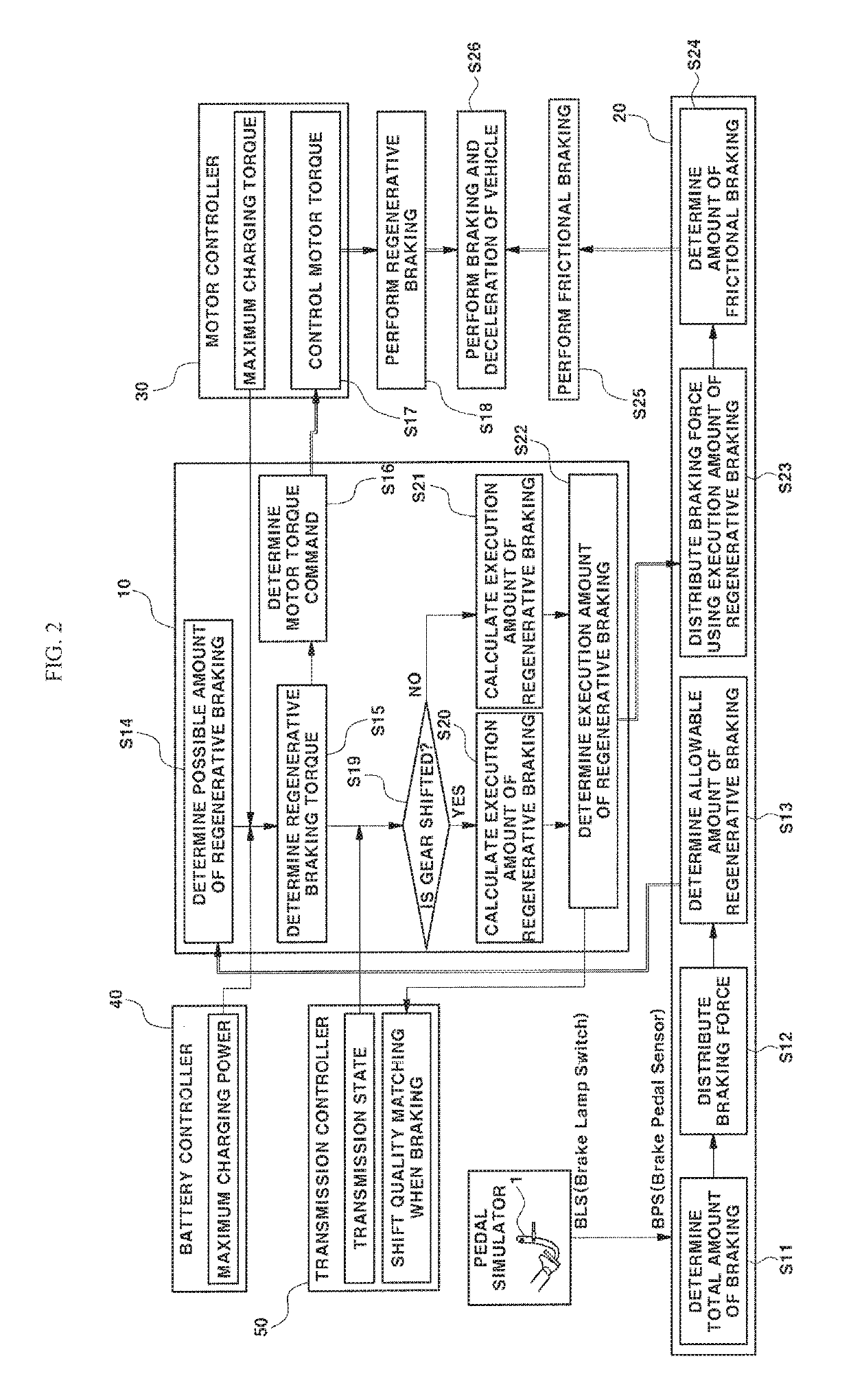

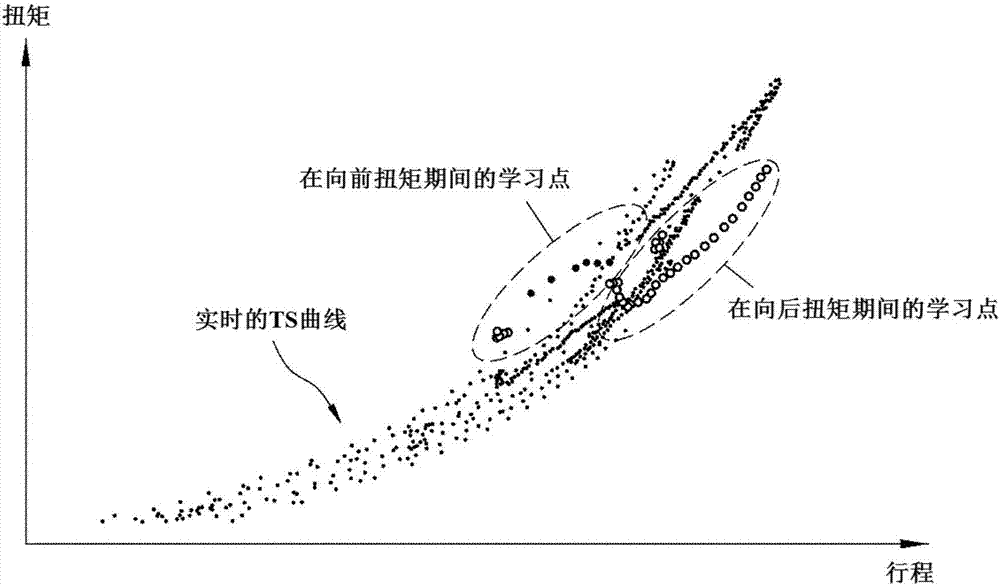

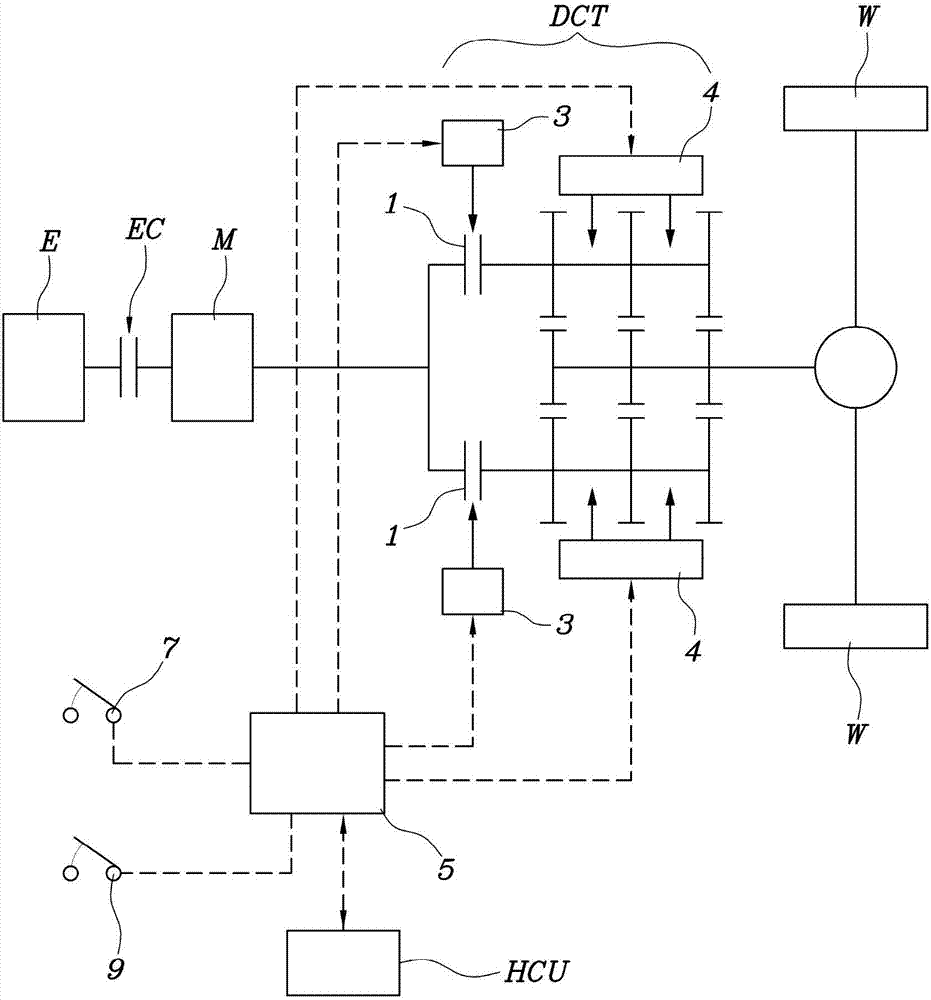

Clutch control method of hybrid vehicle

ActiveCN107401561APrevent or reduce variationPrevent or reduce shift vibrationHybrid vehiclesClutchesMotor speedClutch control

The present disclosure provides a clutch control method of a hybrid vehicle of the including an entering condition determining step in which a controller determines whether shifting is being performed during regenerative braking; an error calculating step in which the controller calculates a torque error by subtracting observer torque, which is clutch transfer torque calculated by a clutch torque estimator receiving transmission input torque and motor speed, from map torque, which is clutch transfer torque calculated based on a clutch transfer torque map for clutch actuator strokes learned in advance, when shifting is being performed during regenerative braking; a correcting step in which the controller corrects the clutch transfer torque map for the clutch actuator strokes using the torque error calculated in the error calculating step; and a clutch control step in which the controller controls a clutch using the map corrected in the correcting step.

Owner:HYUNDAI MOTOR CO LTD

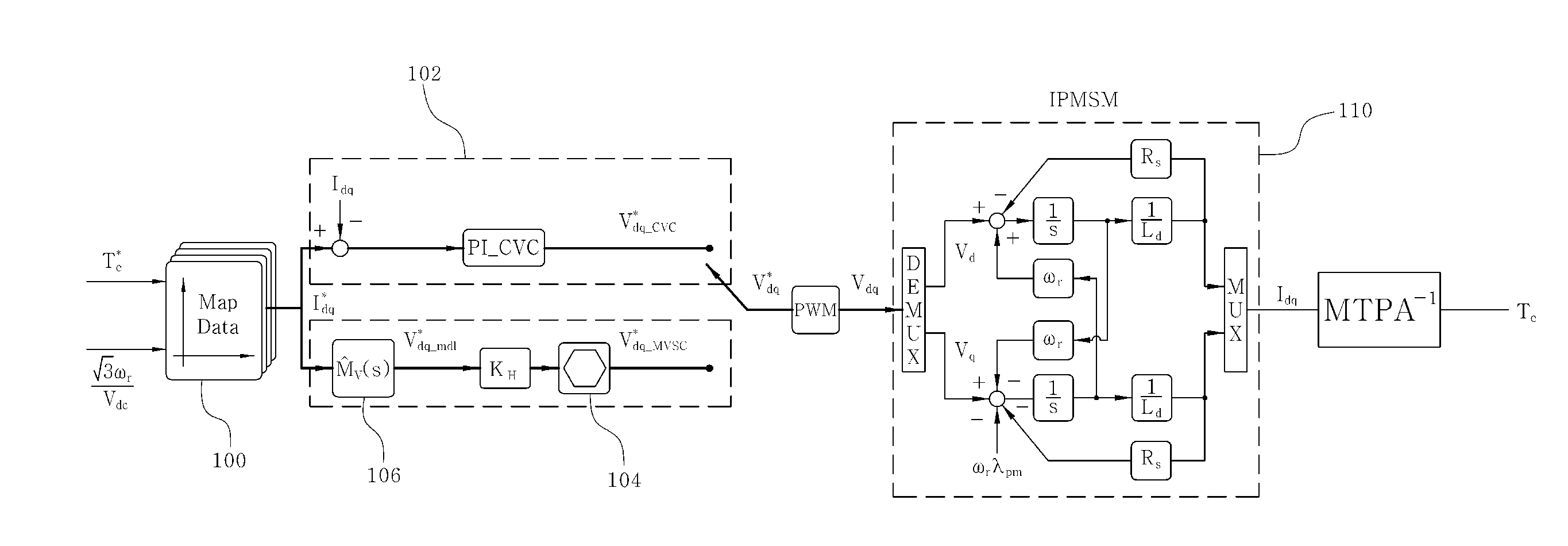

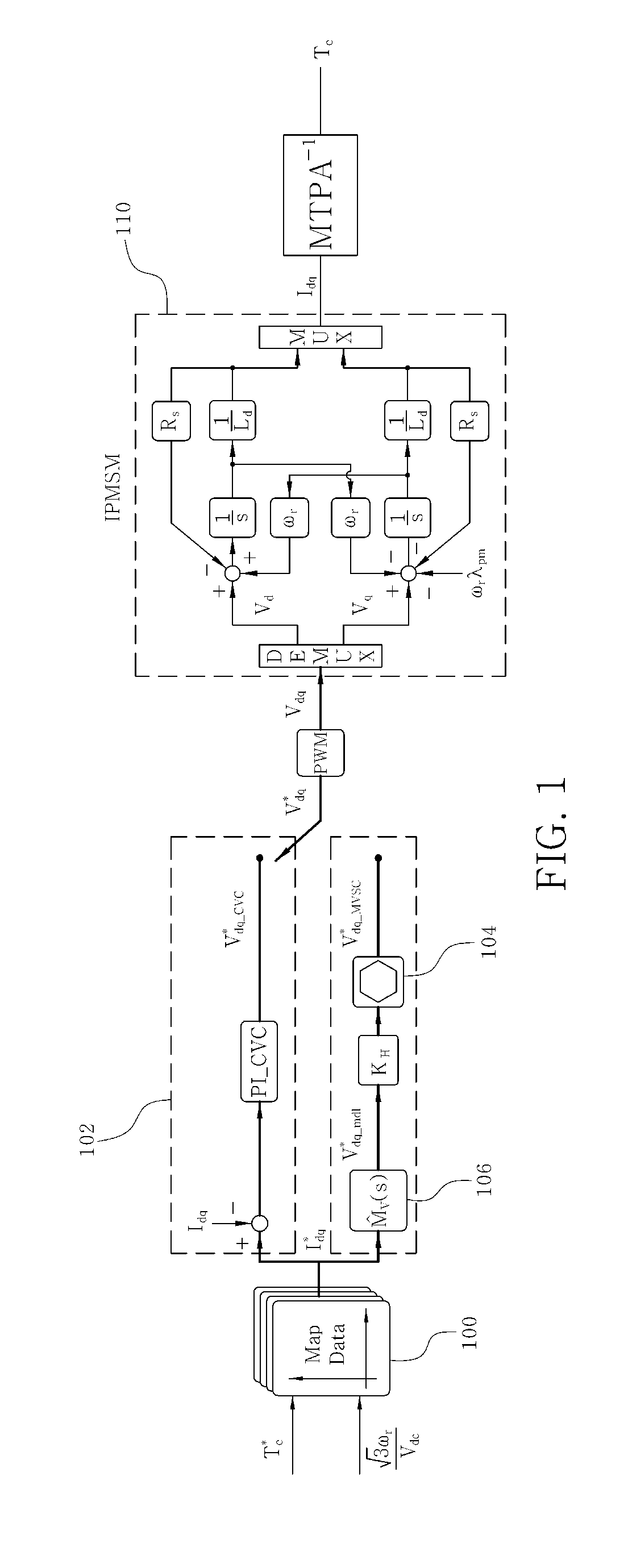

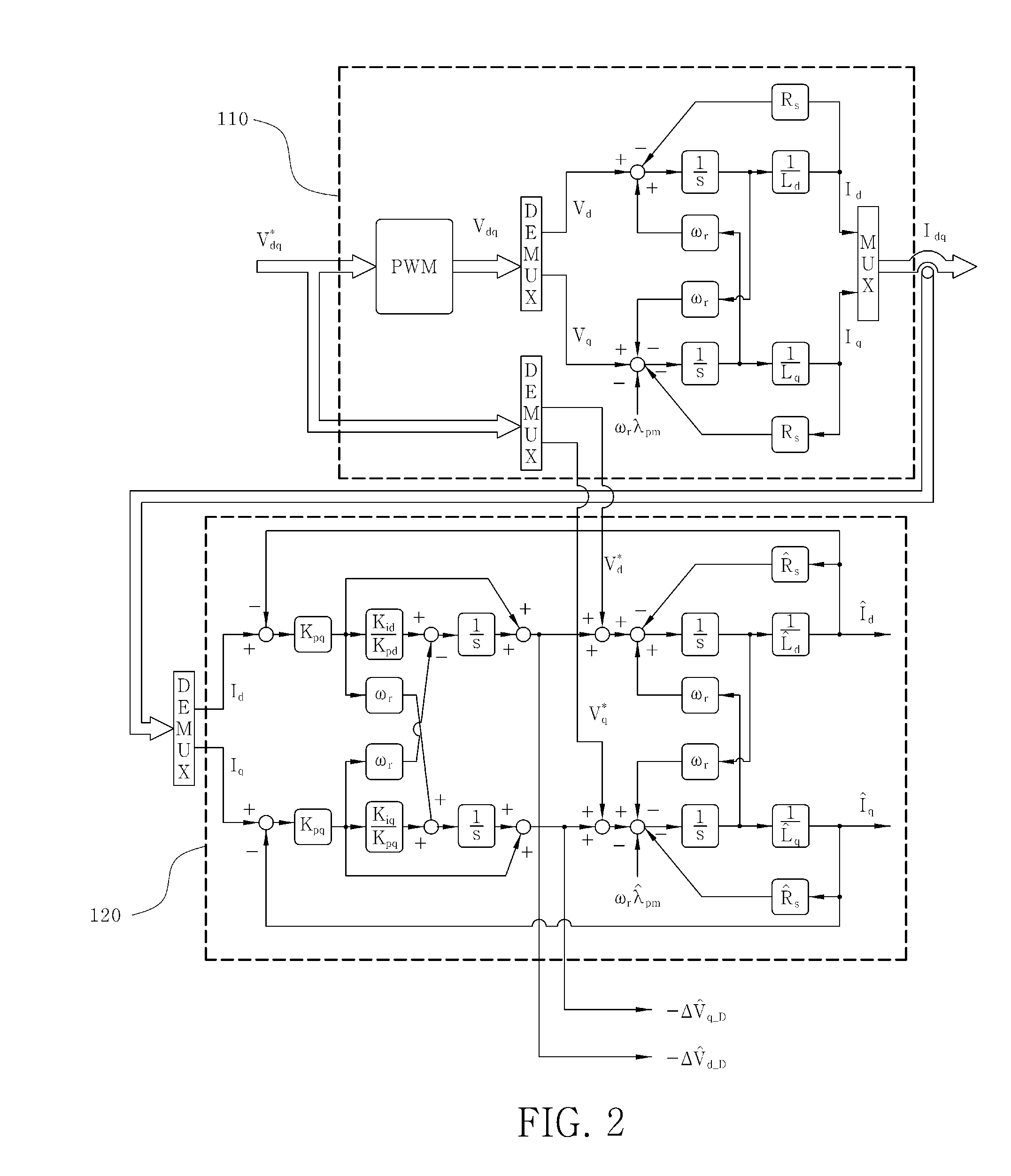

Method for controlling interior permanent magnet synchronous motor

ActiveUS20130328508A1Improved fuel ratioHigh outputHybrid vehiclesElectronic commutation motor controlMotor speedPermanent magnet synchronous motor

Disclosed is a method for controlling a permanent magnet synchronous motor to maximize use of voltages of a battery by voltage phase control within weak magnetic flux area and to achieve compensation for a torque error through a torque compensator when driving the permanent magnet synchronous motor for hybrid vehicles. In particular, the method controls a permanent magnet synchronous motor so that voltage use can be maximized in a weak magnetic flux area by using voltage near maximum voltage through voltage phase control utilizing magnetic flux-based map data receiving a torque command and motor speed / batter output voltage as inputs and torque error can be compensated using a torque compensation filter when a motor constant is changed in the weak magnetic flux by a circumstance parameter, when the permanent magnet synchronous motor mounted in a hybrid vehicle and an electric vehicle is driven.

Owner:HYUNDAI MOTOR CO LTD +2

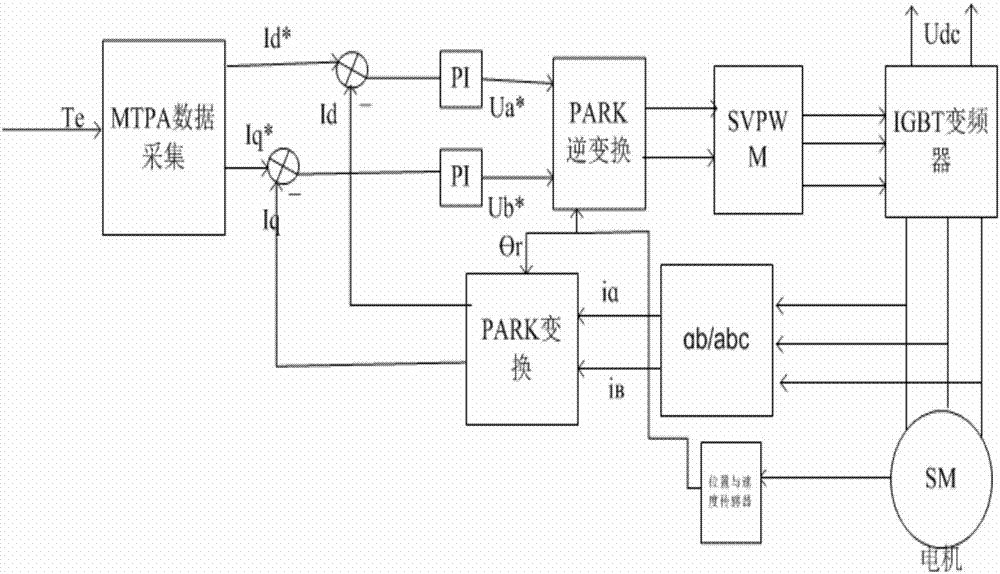

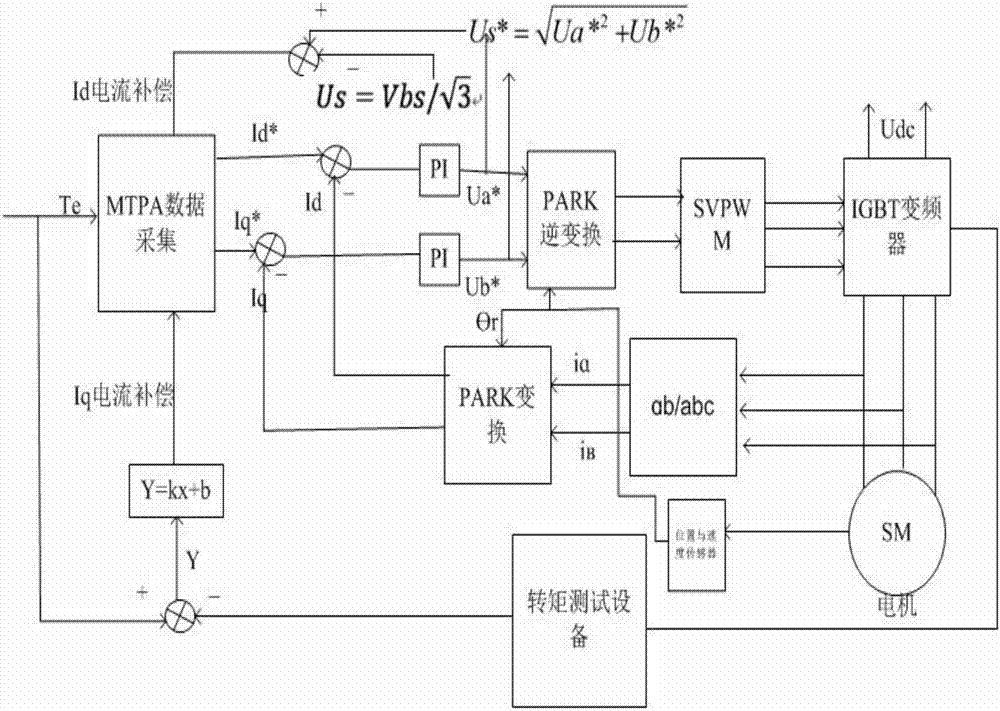

Novel method for flux weakening calibration of permanent-magnet synchronous motor controller for blade electric vehicle

ActiveCN107046386AIncrease flexibilityImprove practicalityElectronic commutation motor controlAC motor controlLow speedMotor controller

The invention discloses a novel method for flux weakening calibration of a permanent-magnet synchronous motor controller for a blade electric vehicle. The method comprises: (1), a data table look-up method is employed at a speed below a base speed; (2), at a high speed, when a flux weakening state is reached, MTPA data collected at a base speed are used and experiment testing is carried out to obtain a toque error between different situation; (3), an Id and Iq are added at the steps of (1) and (2) and PI controlling is carried out respectively; (4), when MTPA controlling at a speed below a base speed is employed, a table look-up method is used; (5), in flux weakening control, the difference between the high speed and the base speed is reflected by an iron loss and a rotational inertia and a compensation method based on a formula of y=kx+b is introduced; and (6), PI control is realized at three kinds of stages: a low-speed stage, a middle-speed stage, and a high-speed stage. The method has the following advantages: different speeds are decomposed into three parts and different PI parameters are set respectively for different parts, so that control flexibility and practicability are enhanced; and a torque error caused by flux weakening can be compensated linearly.

Owner:NANJING YUEBOO POWER SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com