Patents

Literature

48results about "Speed/accelaration control with auxillary non-electric power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

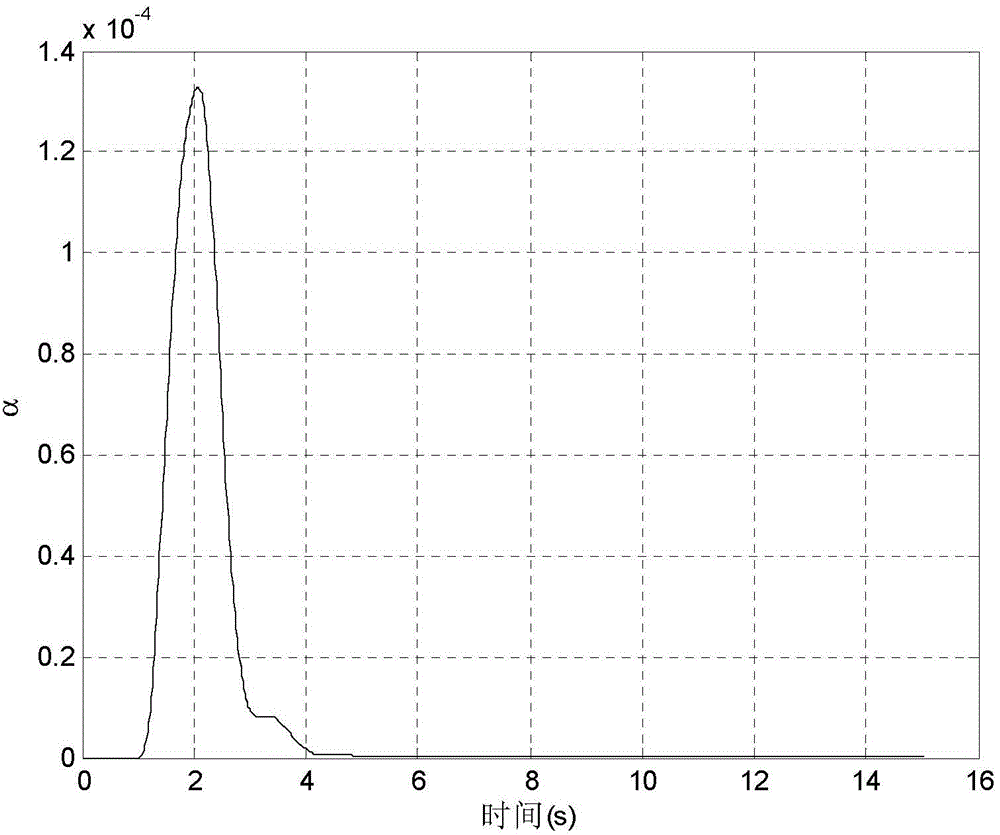

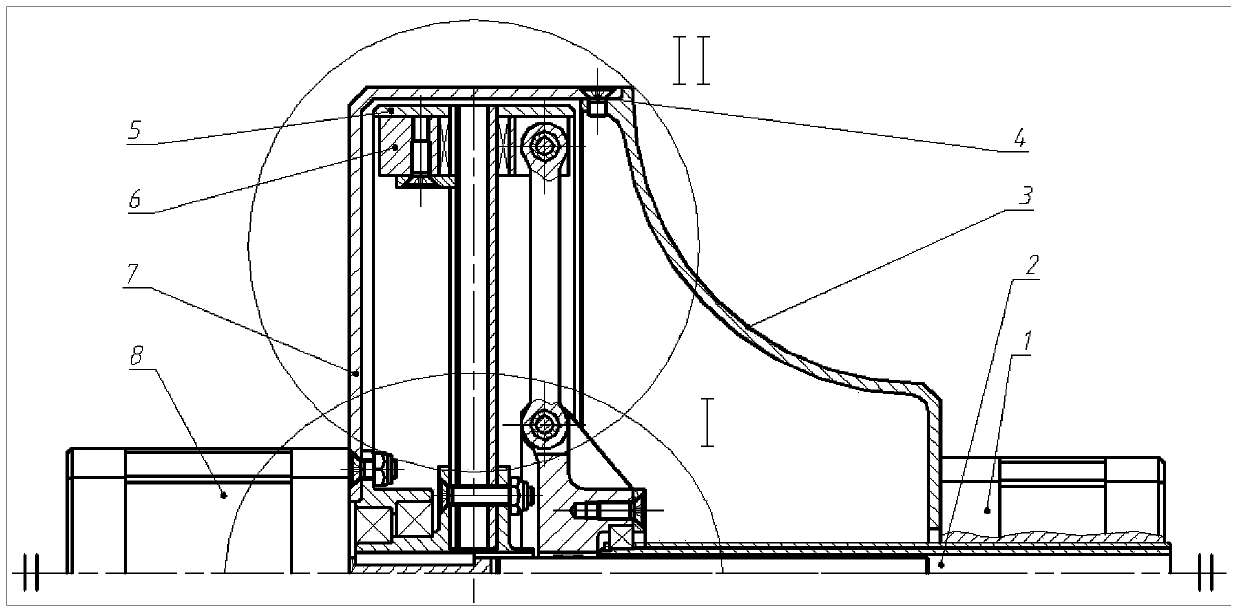

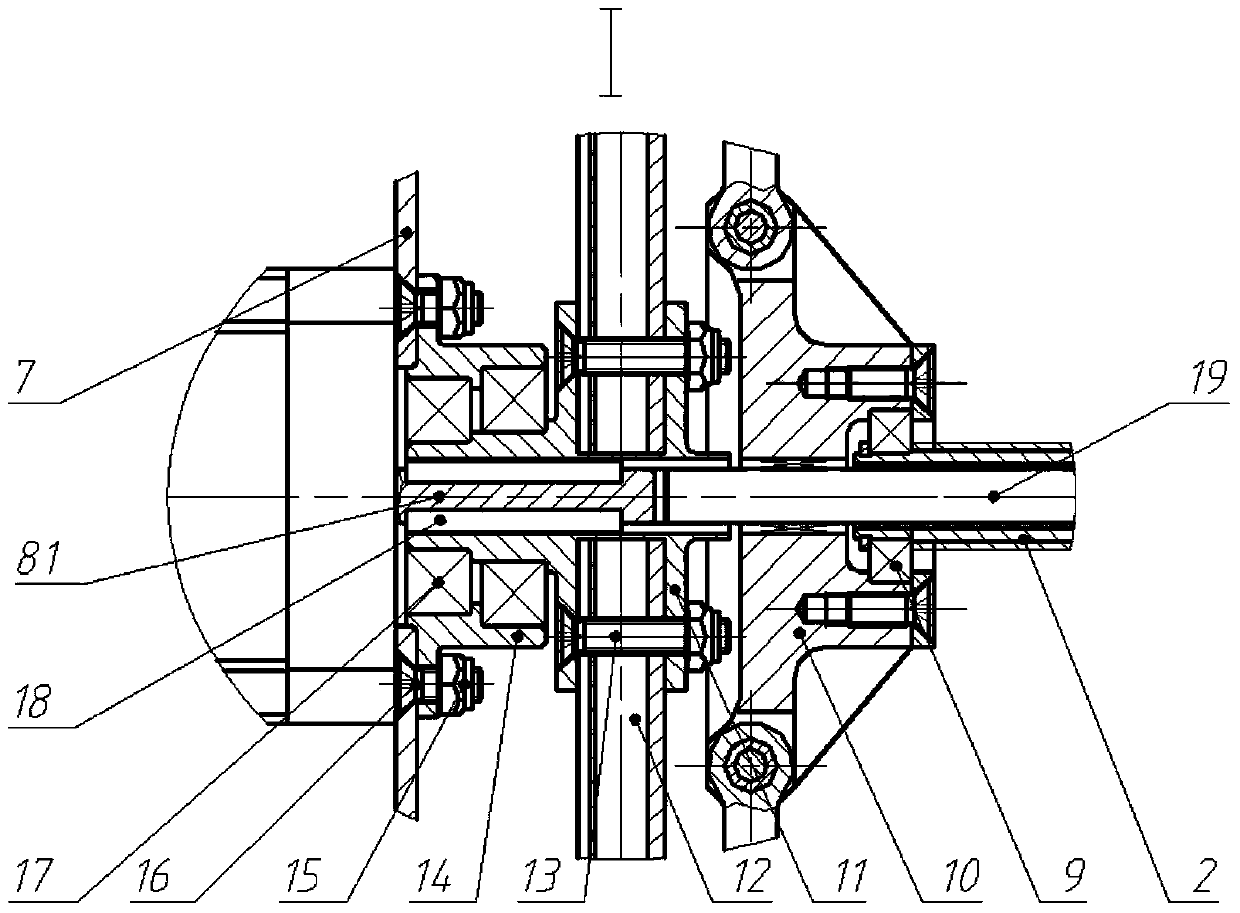

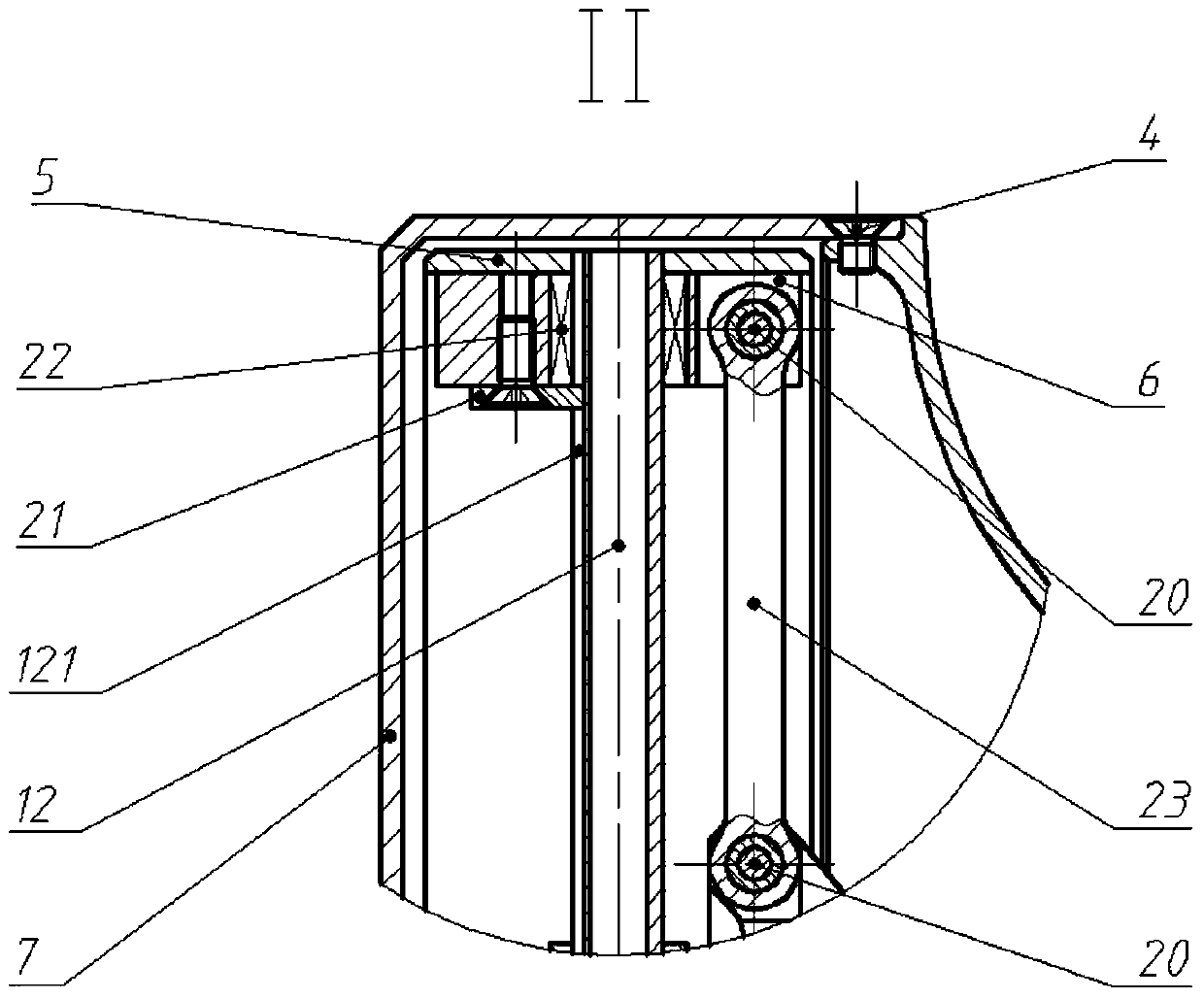

Control moment gyroscope framework control system and control moment gyroscope framework control method for restraining dynamic unbalance disturbance of rotor

ActiveCN105786036AGuaranteed dynamic performanceReduce the disturbing torqueSpeed/accelaration control with auxillary non-electric powerControl systemElectric machine

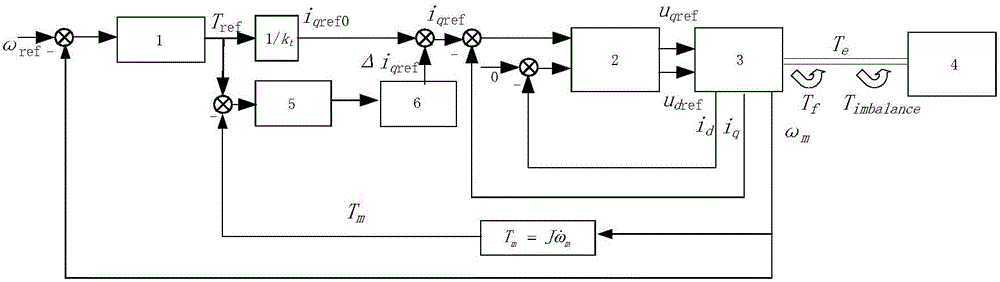

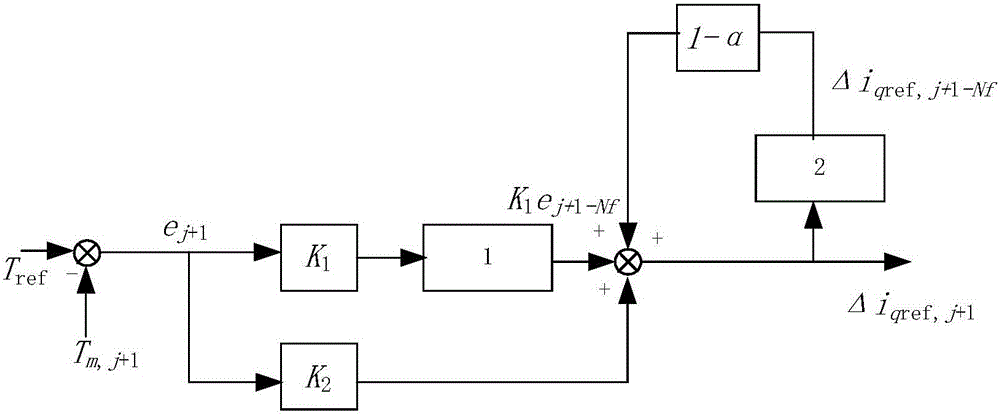

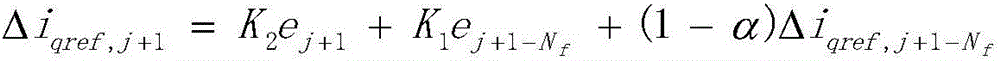

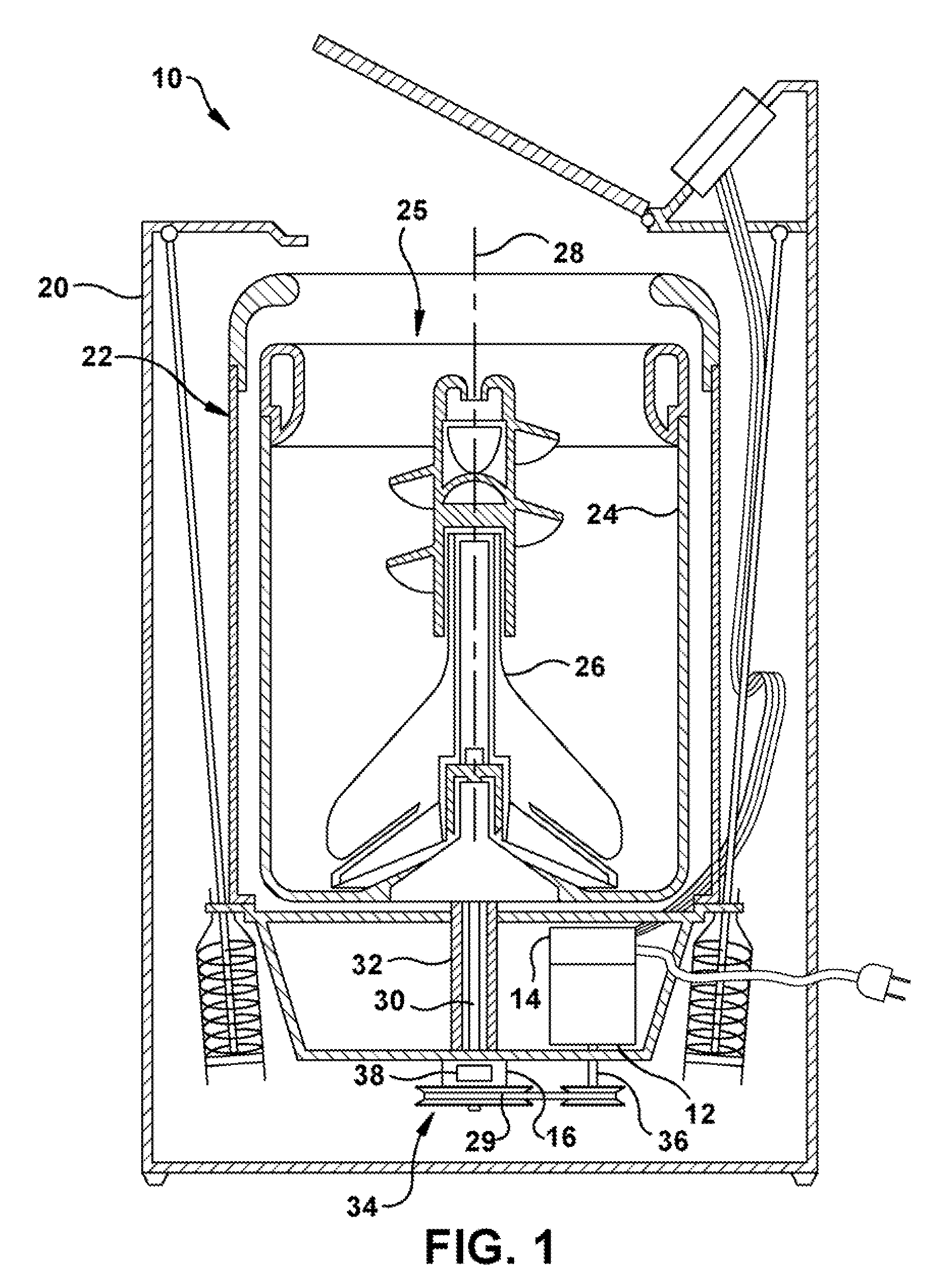

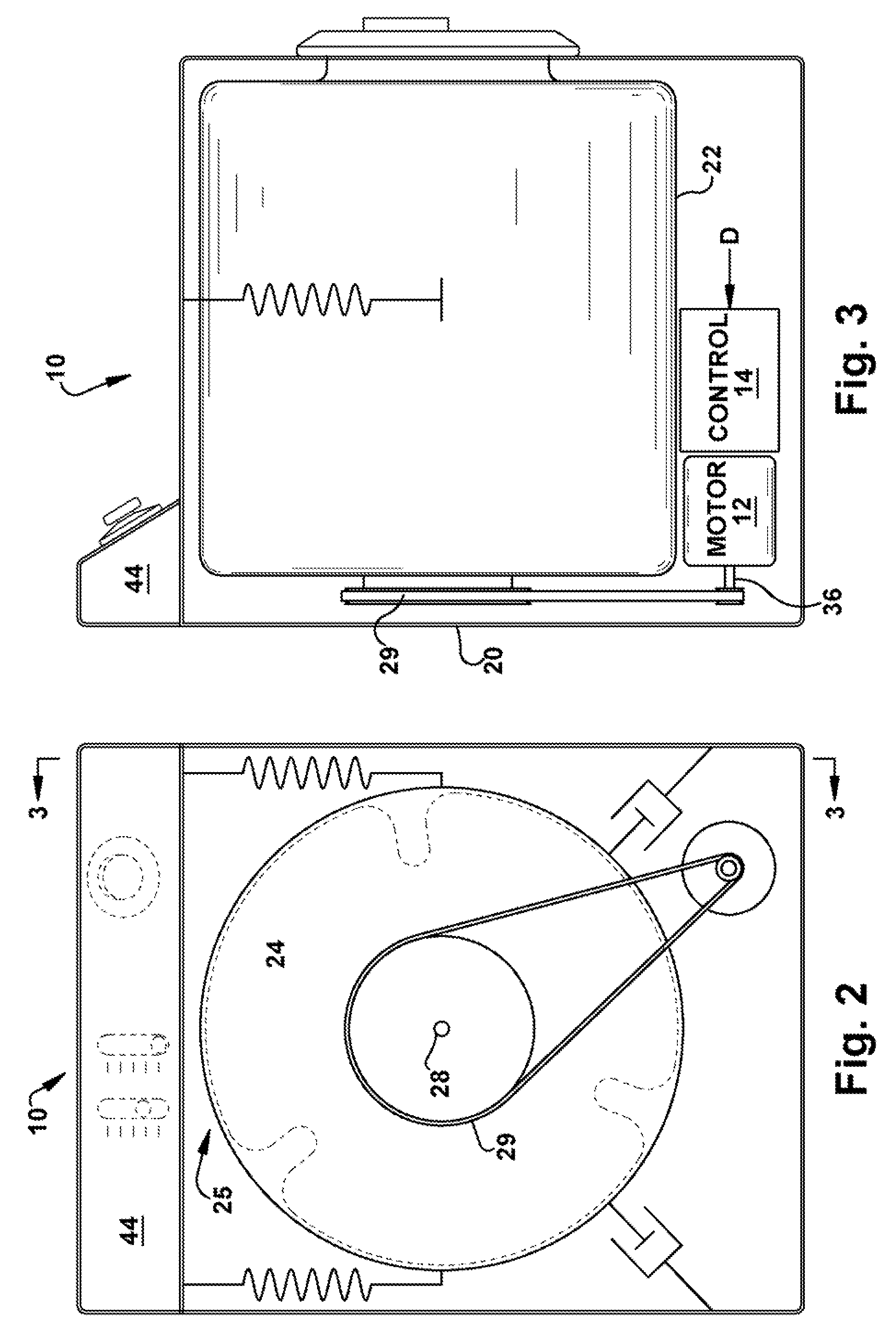

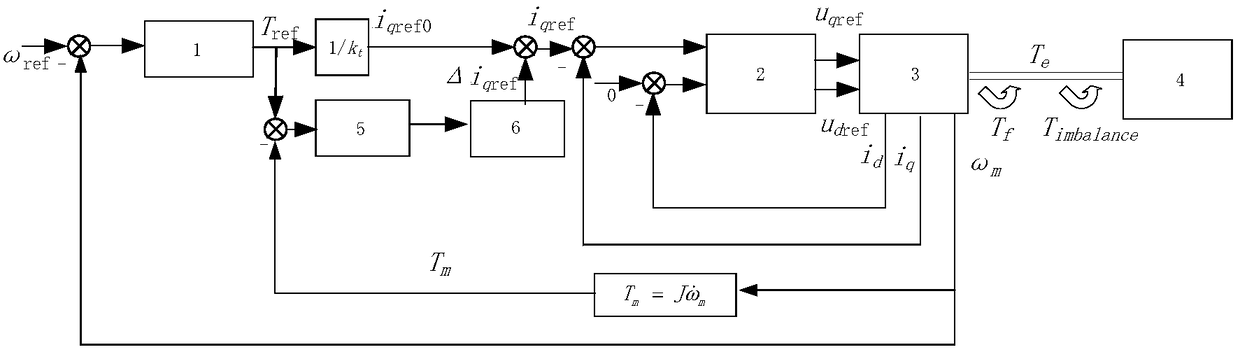

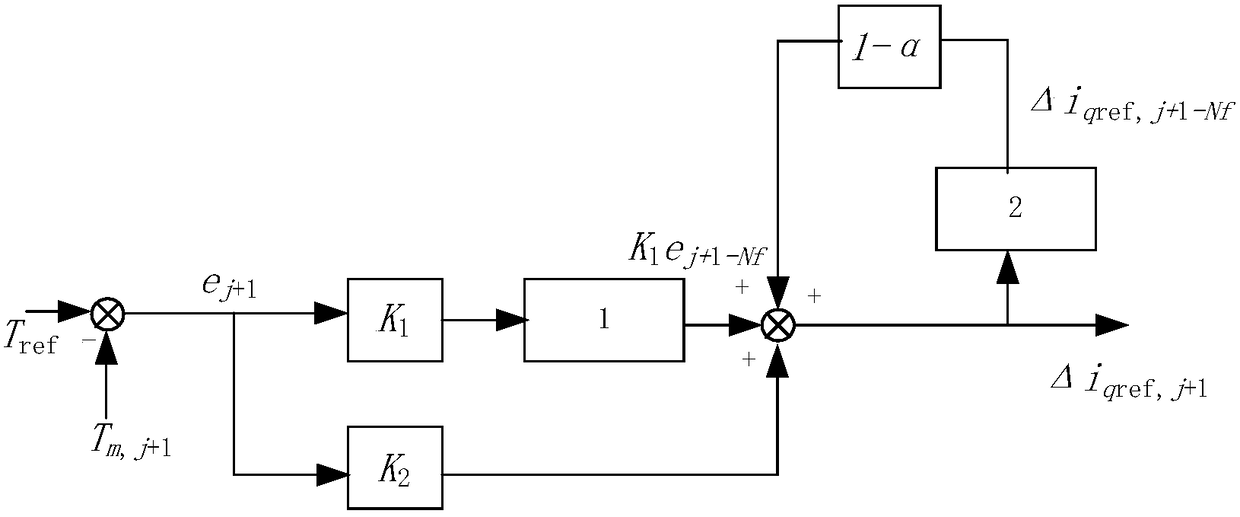

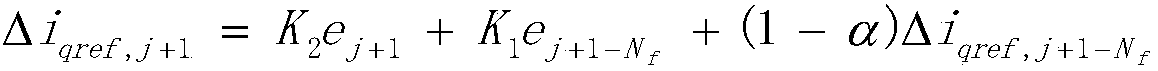

A control moment gyroscope (CMG) framework control system and a CMG framework control method for restraining dynamic unbalance disturbance of a rotor are provided. A feed-forward compensation module and an algorithm switching module are embedded on the basis of a double-loop PI control system. In preset Ng control cycles, the whole framework control system is set to a PI control mode; in each control cycle from the (Ng+1)th control cycle, the speed precision of a CMG framework in the current control cycle is calculated through the algorithm switching module, and whether there is a need to switch the control mode of the current control cycle is determined; if the control mode is a feed-forward compensation mode after switching, subtraction operation is carried out on a moment reference value output by a speed loop PI controller and a fed-back torque of a framework motor to get the mechanical torque error e(j+1) of the current control cycle, and the feed-forward compensation module calculates the current feed-forward compensation value Delta i(qref, j+1) of the current control cycle according to e(j+1) and adds Delta i(qref, j+1) to the double-loop PI control system; and if the control mode is a PI control mode after switching, current feed-forward compensation is blocked, and control is performed according to the double-loop PI control system.

Owner:BEIJING INST OF CONTROL ENG

Intelligent control system for automatic cutting formation of tunneling

InactiveCN101713975AGuaranteed forming qualityReduce excavation costsProgramme control in sequence/logic controllersSpeed/accelaration control with auxillary non-electric powerConstant powerCurrent sensor

The invention relates to an intelligent control system for automatic cutting formation of tunneling, comprising a space position detecting device of a cutting head, a current sensor of a cutting motor, a programmable controller, a proportional amplifier and a load-sensitive proportional multi-path reversing valve set, wherein the programmable controller is used for carrying out arithmetical operation on signals collected by the space position detecting device of the cutting head to control the cutting head to move along the set track in the stated range of a tunnel so that a regular section is cut. The current sensor of the cutting motor is used for collecting the current signals of the cutting motor to compare with rated current, the opening sizes of the valve ports of the load-sensitive proportional multi-path reversing valve set is controlled by the programmable controller to correspond to the constant-power pulling speed of the cutting motor with different coal properties so that the automatic formation control on the section of the tunnel and the intelligent control on the constant-power pulling speed of the cutting motor are realized. The invention is suitable for automatic cutting formation of the section when the tunnel of a coal mine and an engineering tunnel are tunneled by a cantilever type tunneling machine.

Owner:SHIJIAZHUANG COAL MINING MACHINERY +1

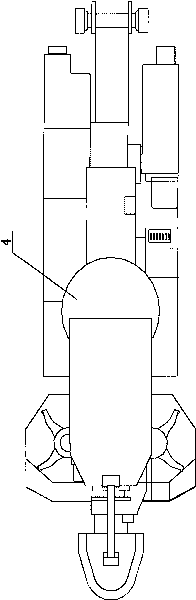

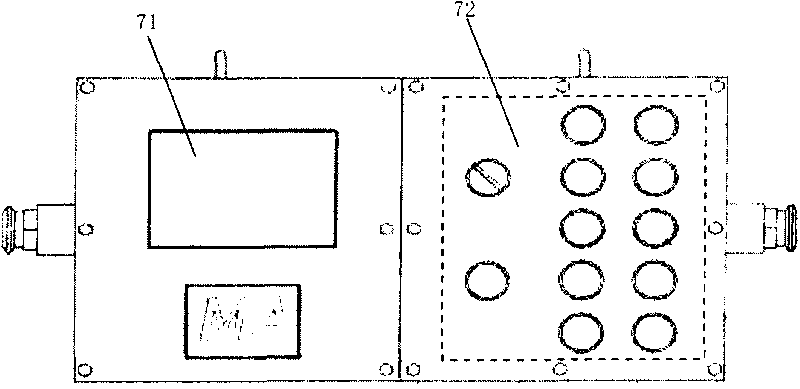

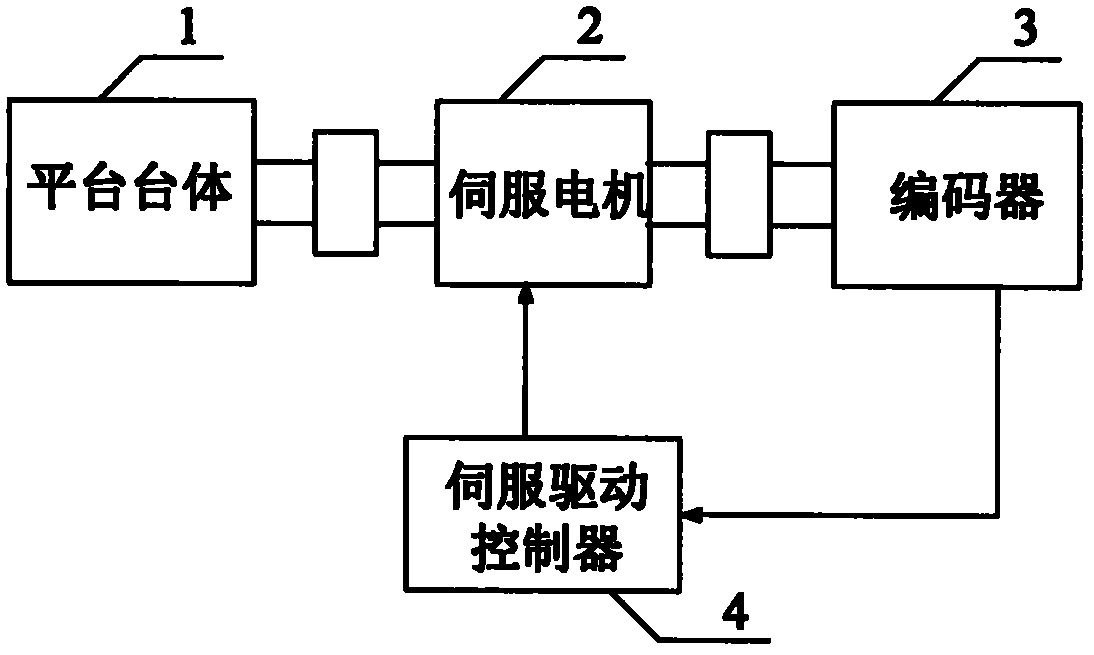

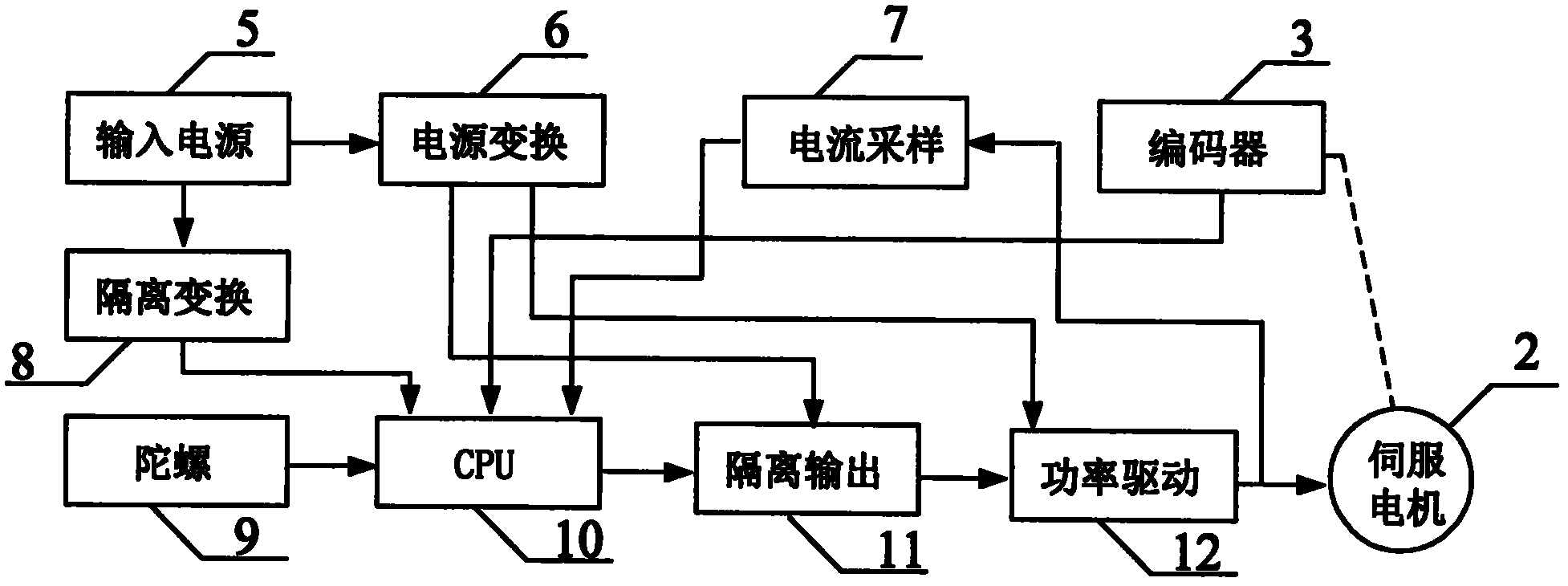

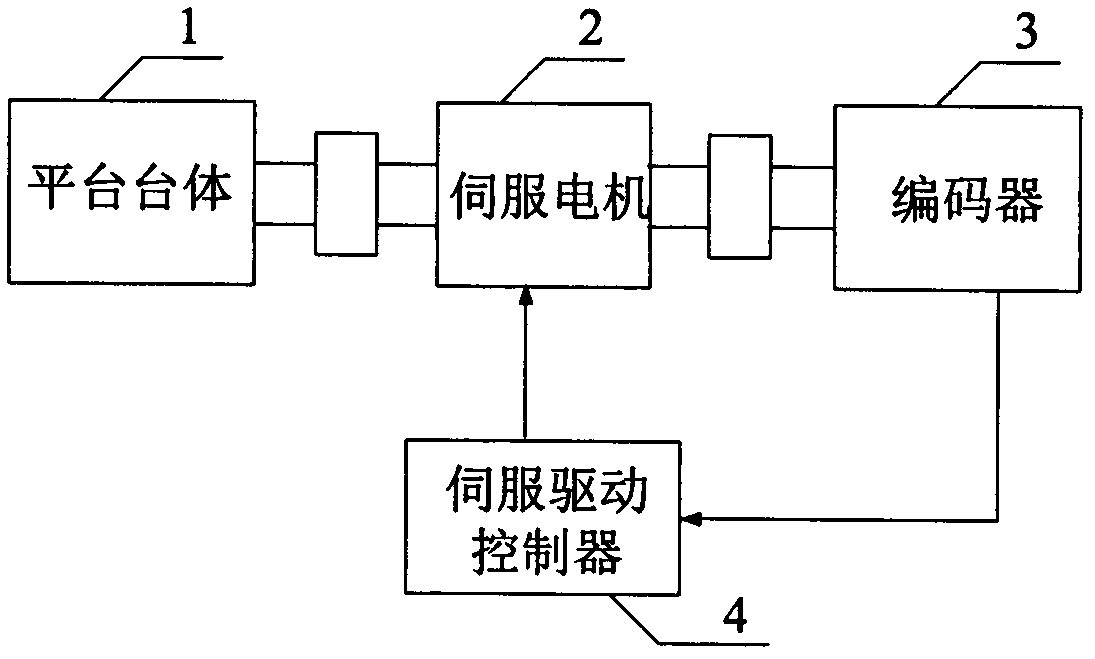

Gyro-stabilized platform for high-speed rolling carrier and control method thereof

InactiveCN102495645AHigh steady-state stability accuracyOvercome instant stuckNavigation by speed/acceleration measurementsSpeed/accelaration control with auxillary non-electric powerPhase currentsGyroscope

The invention discloses a gyro-stabilized platform for a high-speed rolling carrier and a control method thereof. The platform body is provided with a stabilized object and a gyroscope; the gyroscope measures the angular motion information of the platform body; an encoder measures the information of a rotor of a servo motor relative to a stator of the servo motor; and a servo drive controller analyzes the angular motion state of the platform body relative to a reference plane according to the angular motion information, performs space vector transformation on current by use of the angle information provided by the encoder and the phase current of the servo motor detected in real time according to a PID control strategy, and controls the output torque of the servo motor to counteract the corresponding rotation of the platform body. The gyro-stabilized platform disclosed by the invention is applied to a high-speed rolling carrier, and can accurately ensure the attitude reference in severe operation conditions.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

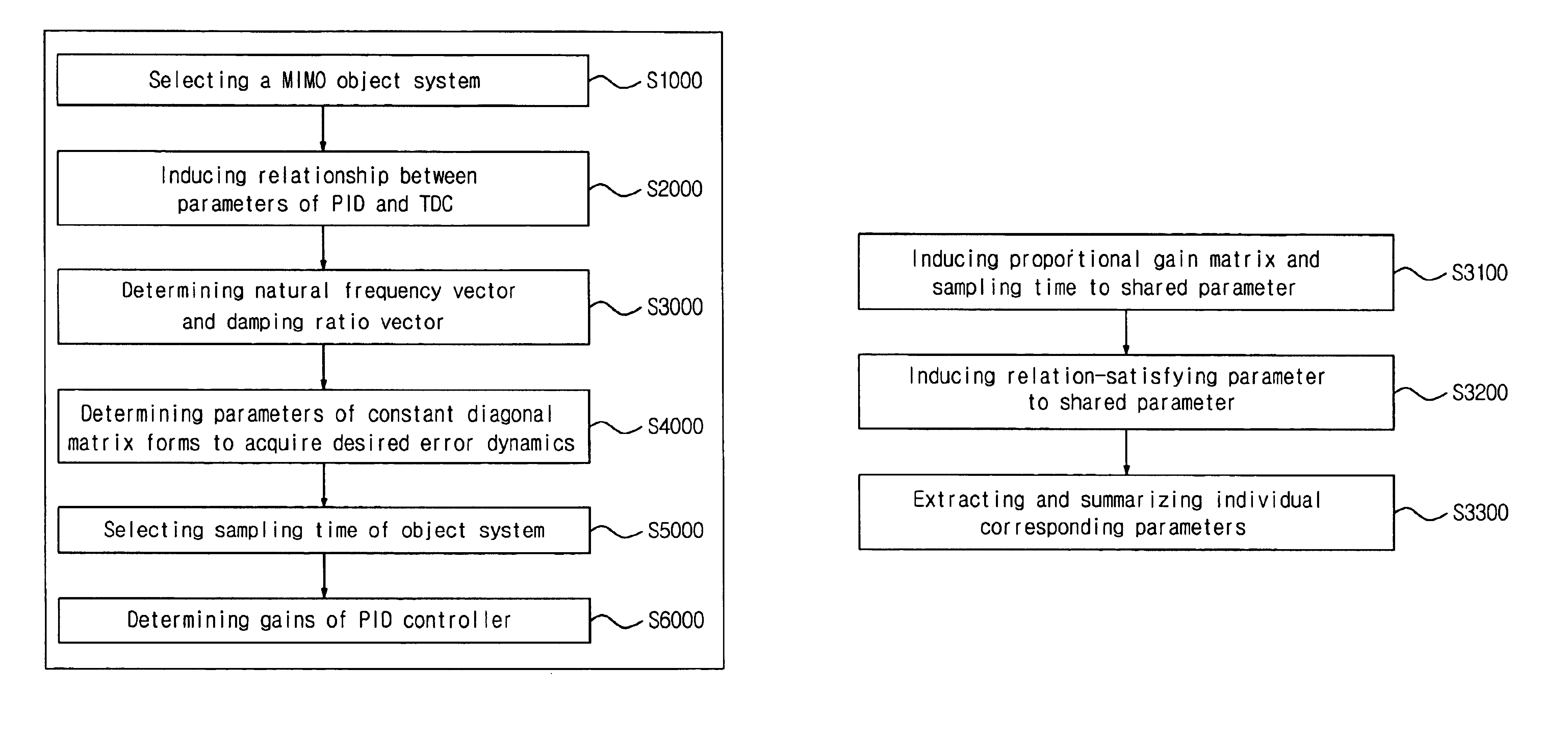

Method for tuning PID controllers applicable to nonlinear systems

InactiveUS6937908B2Ignition automatic controlControllers with particular characteristicsTime delaysClosed loop

A method for tuning a PID controller includes the steps of inducing equivalent relationships between PID gains of the PID controller and parameters of time delay control (TDC), selecting a natural frequency vector and a damping ratio vector so as to acquire a desired error dynamics of the closed PID control loop system, selecting a sampling time of the closed PID control loop system, determining the parameters of TDC on the basis of the natural frequency vector, the damping ratio vector and a closed loop stability condition for TDC, and selecting PID gains of the PID controller on the basis of the equivalent relationships.

Owner:KOREA ADVANCED INST OF SCI & TECH

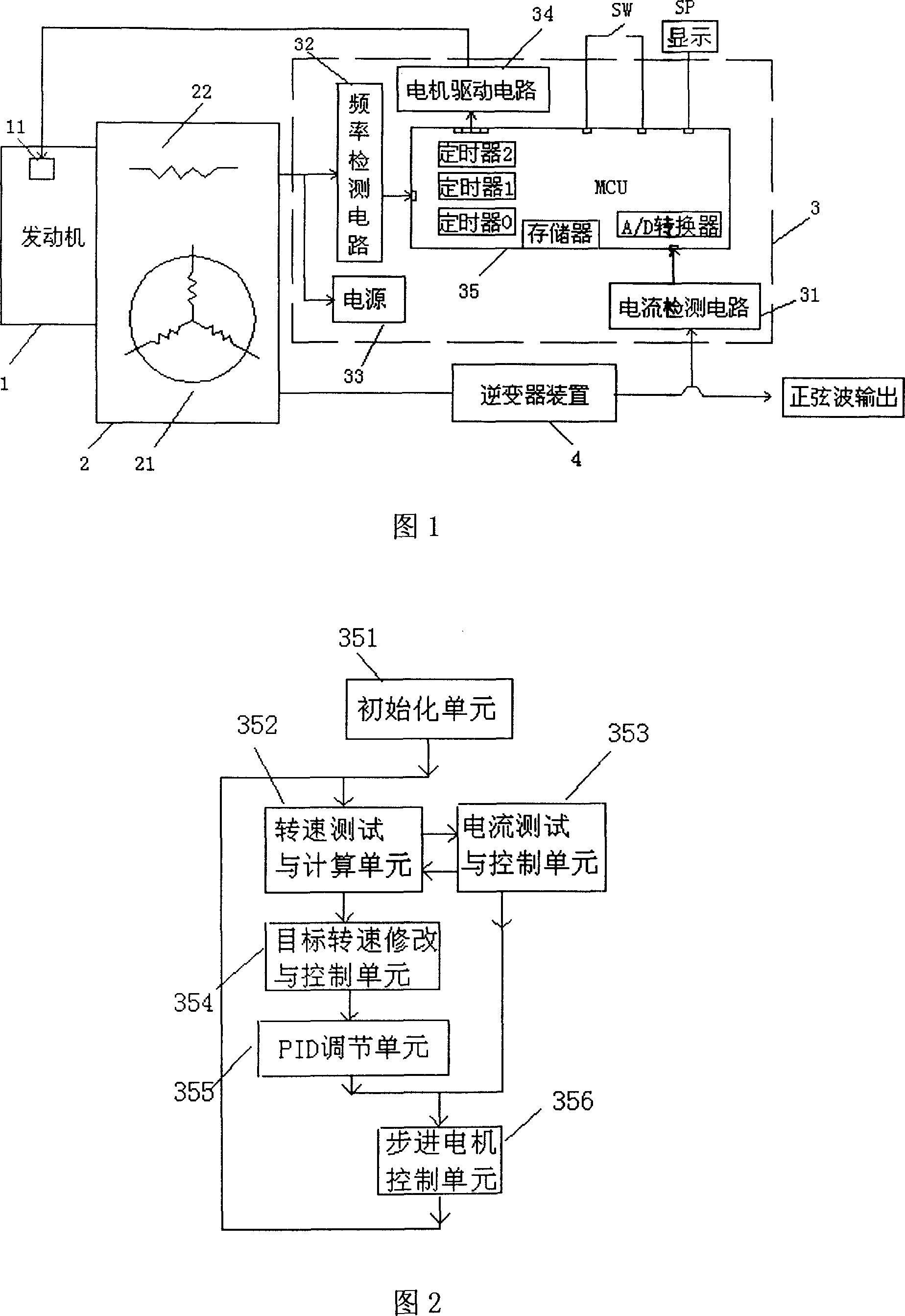

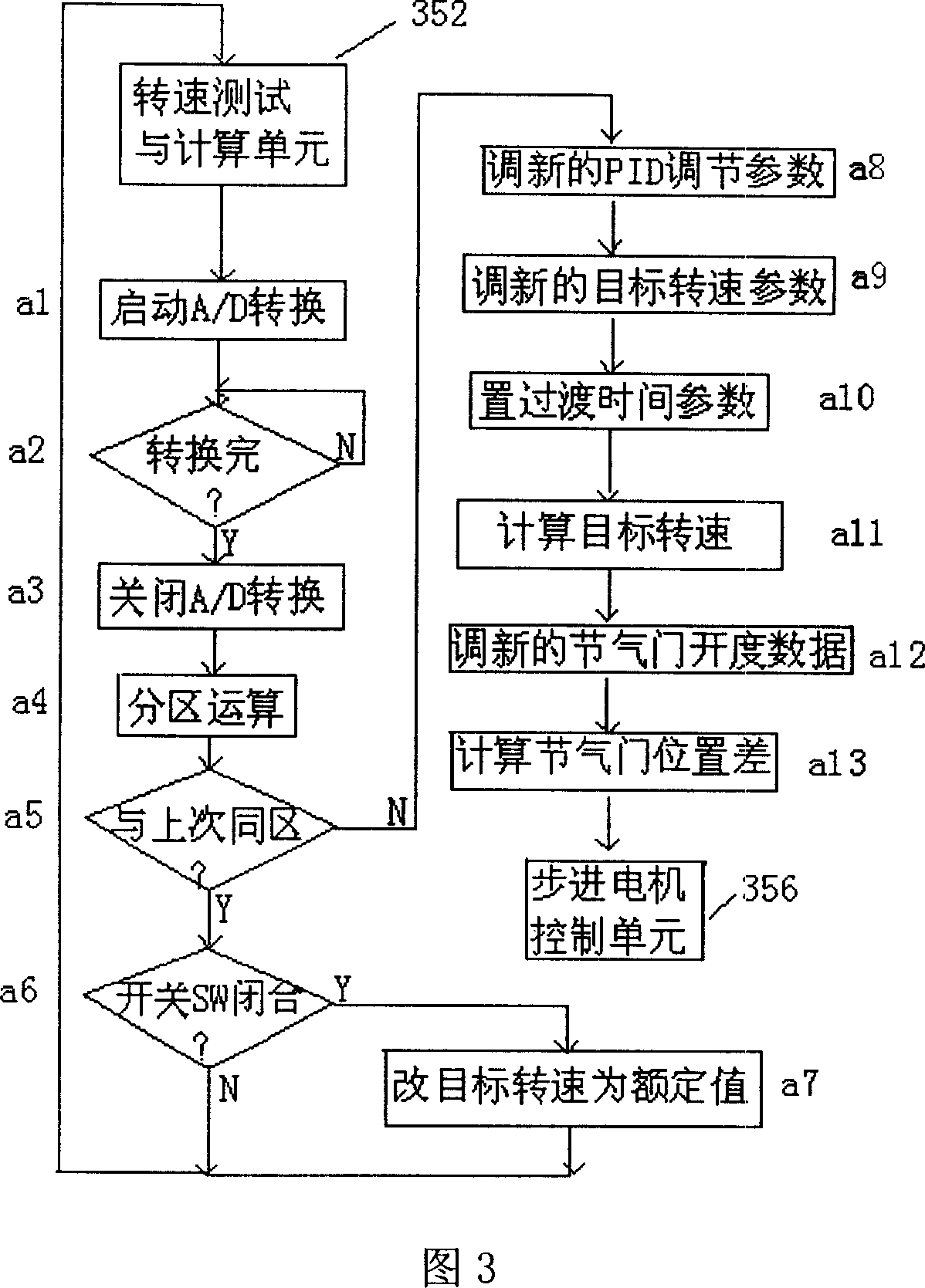

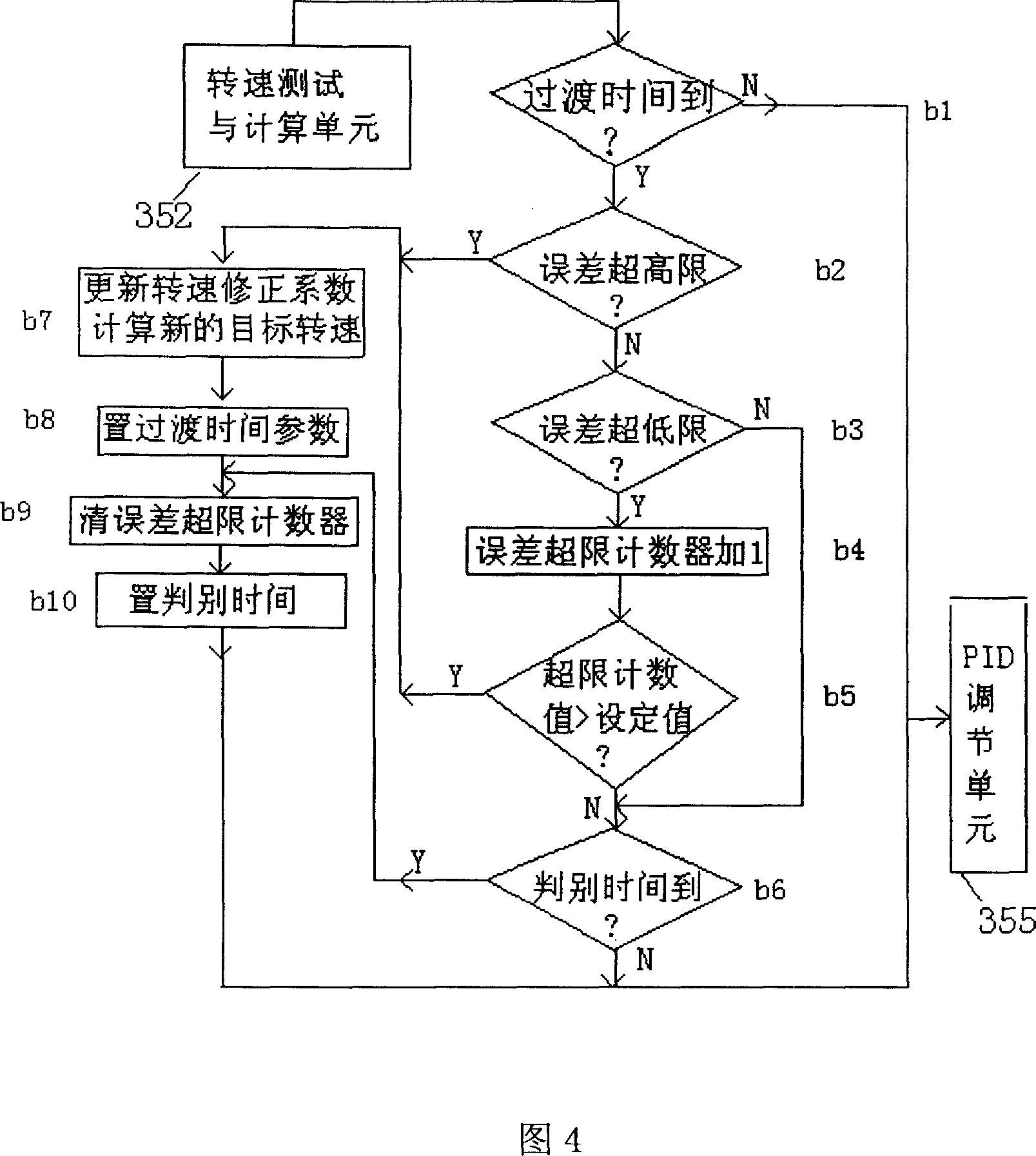

Converse speed regulation apparatus of generator and control method

InactiveCN101013873ASpeed adjustment in real timeReduce consumptionElectrical controlMachines/enginesControl theoryElectric generator

Owner:吴德峰 +1

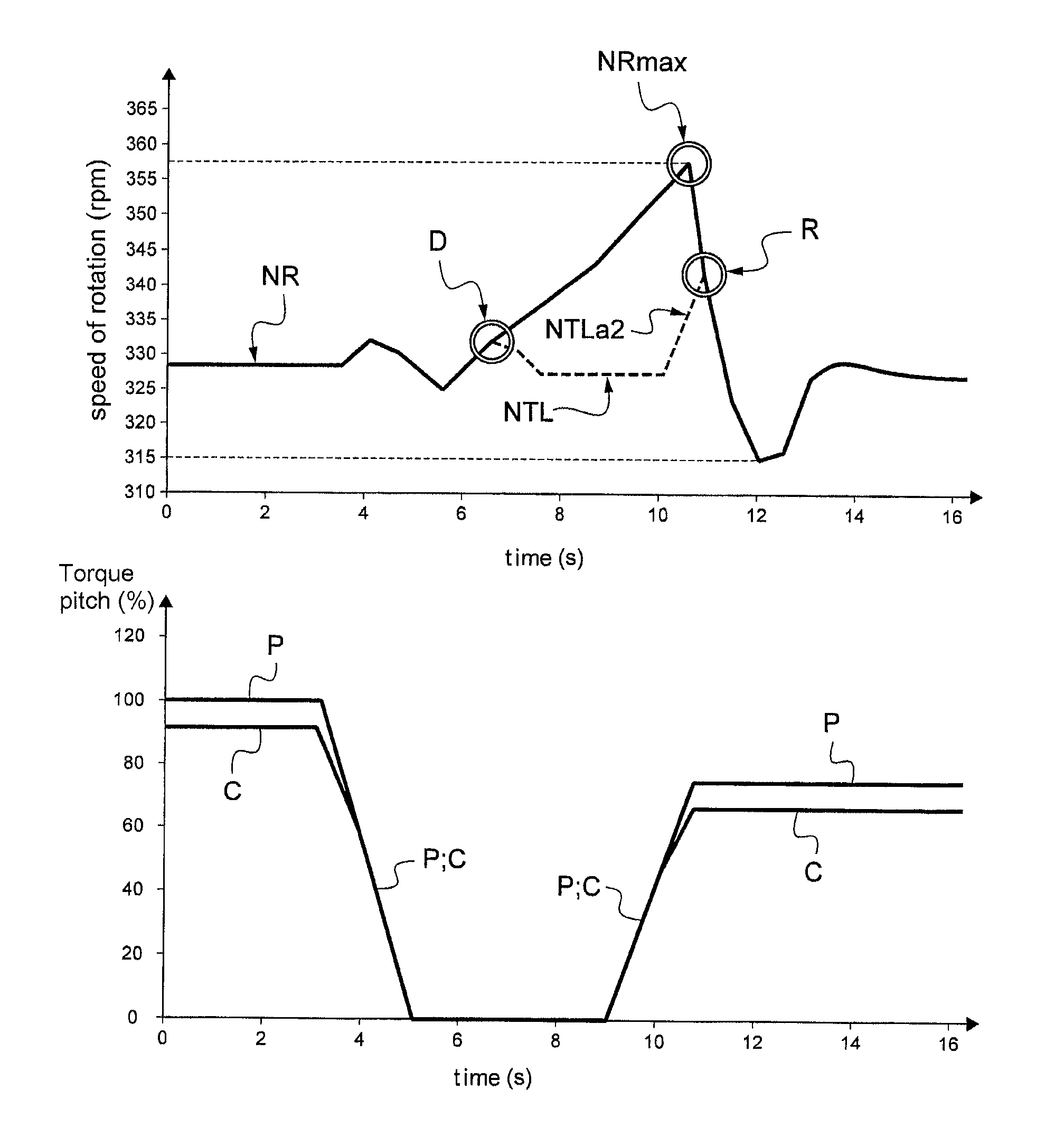

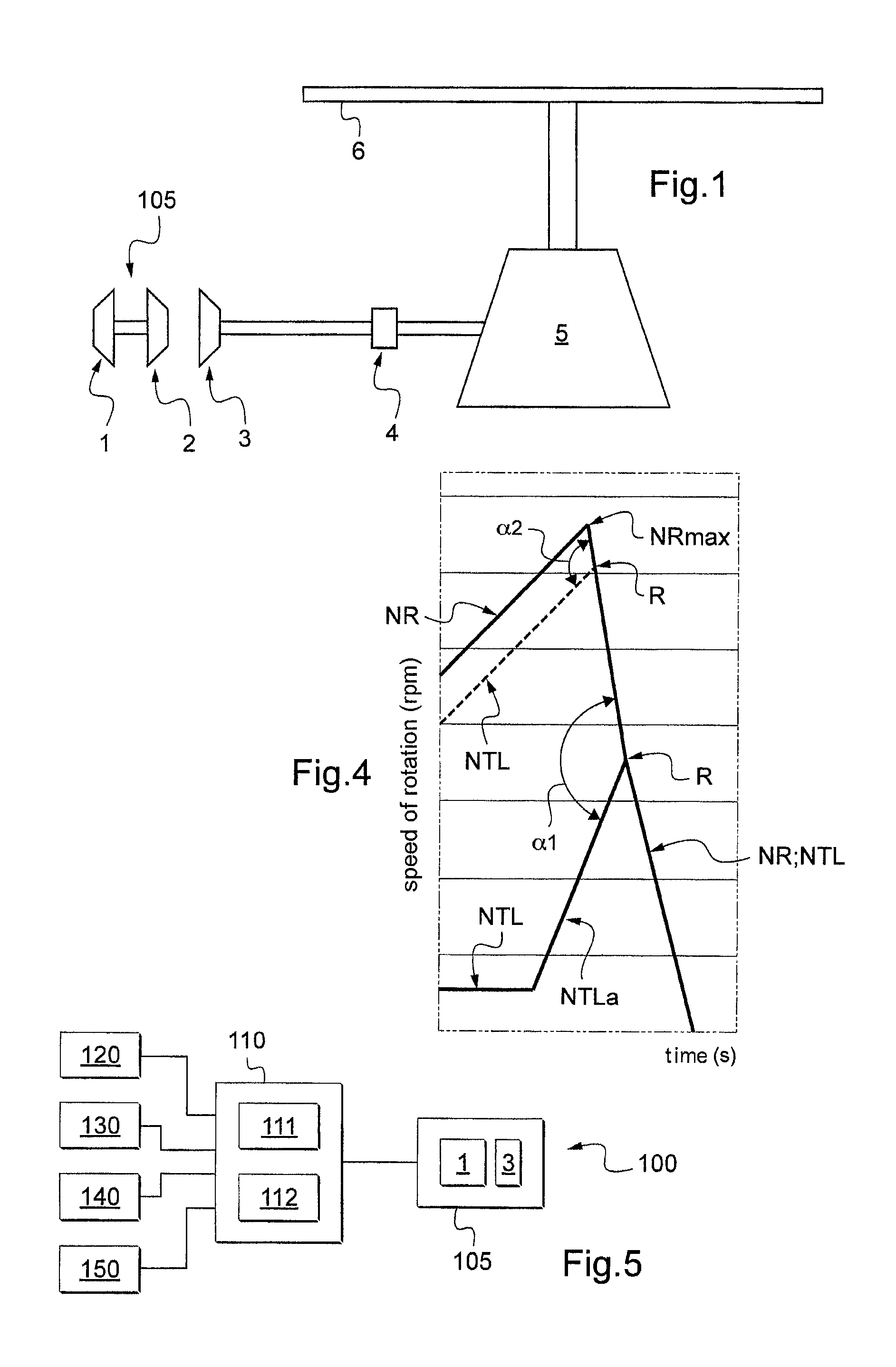

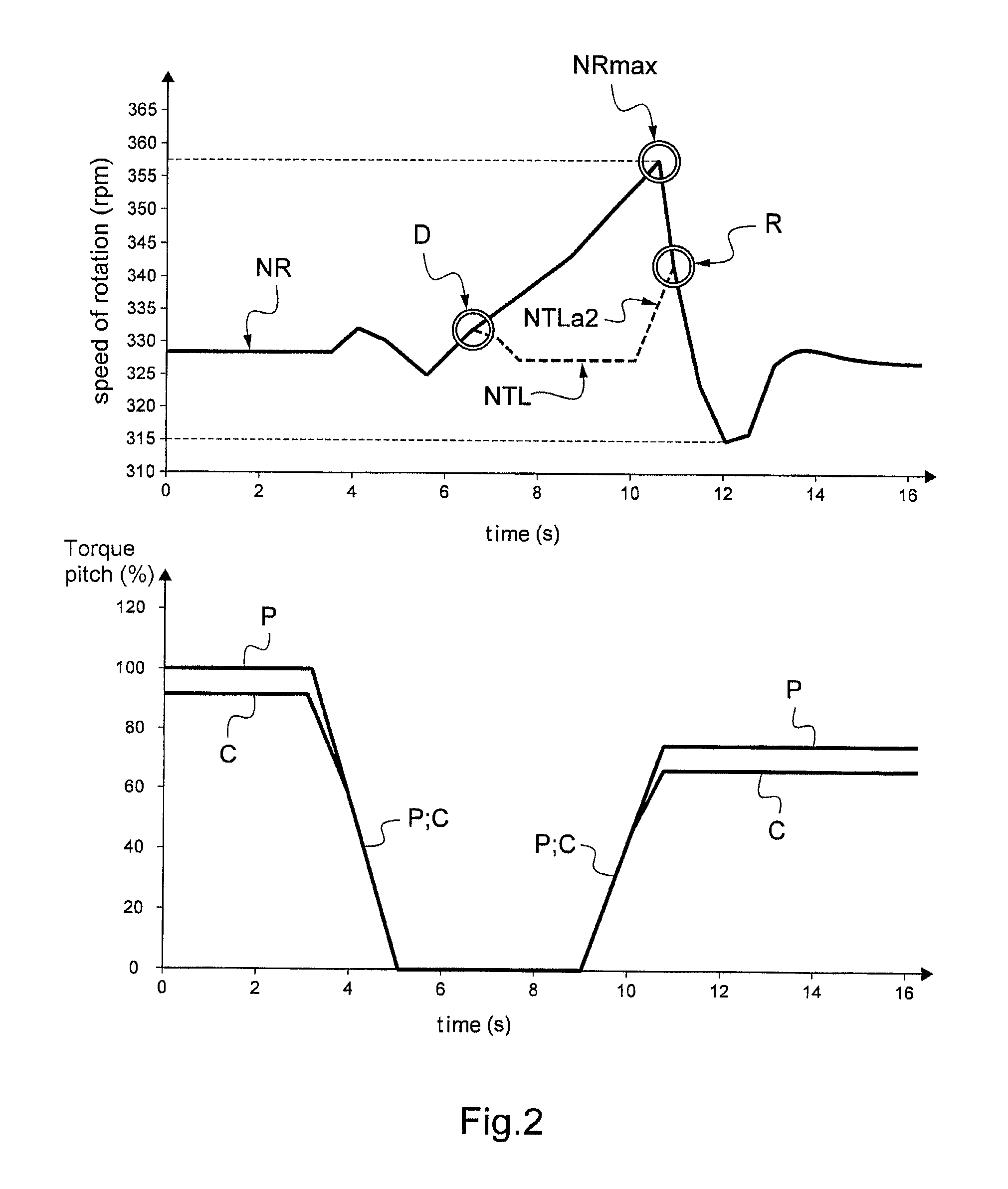

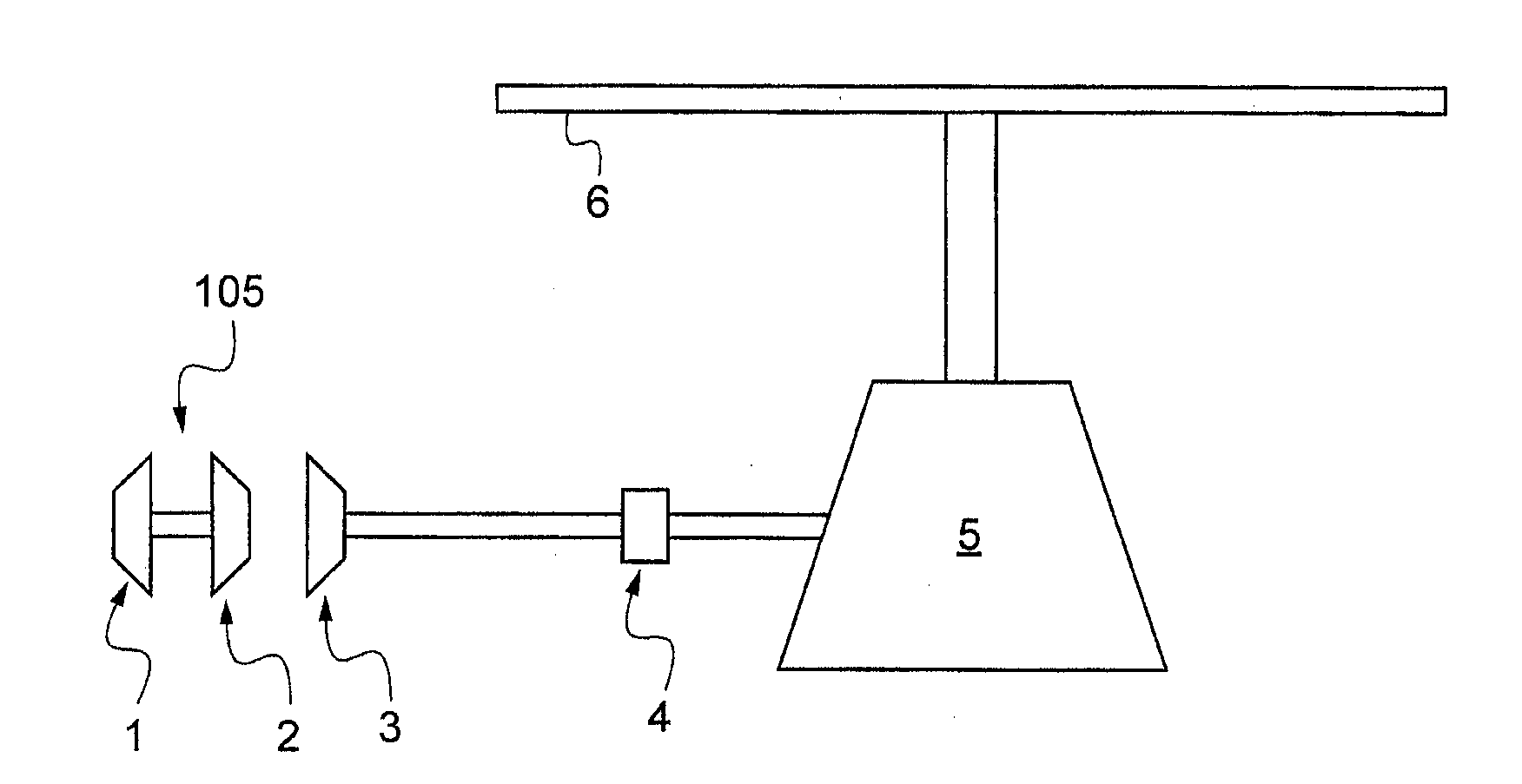

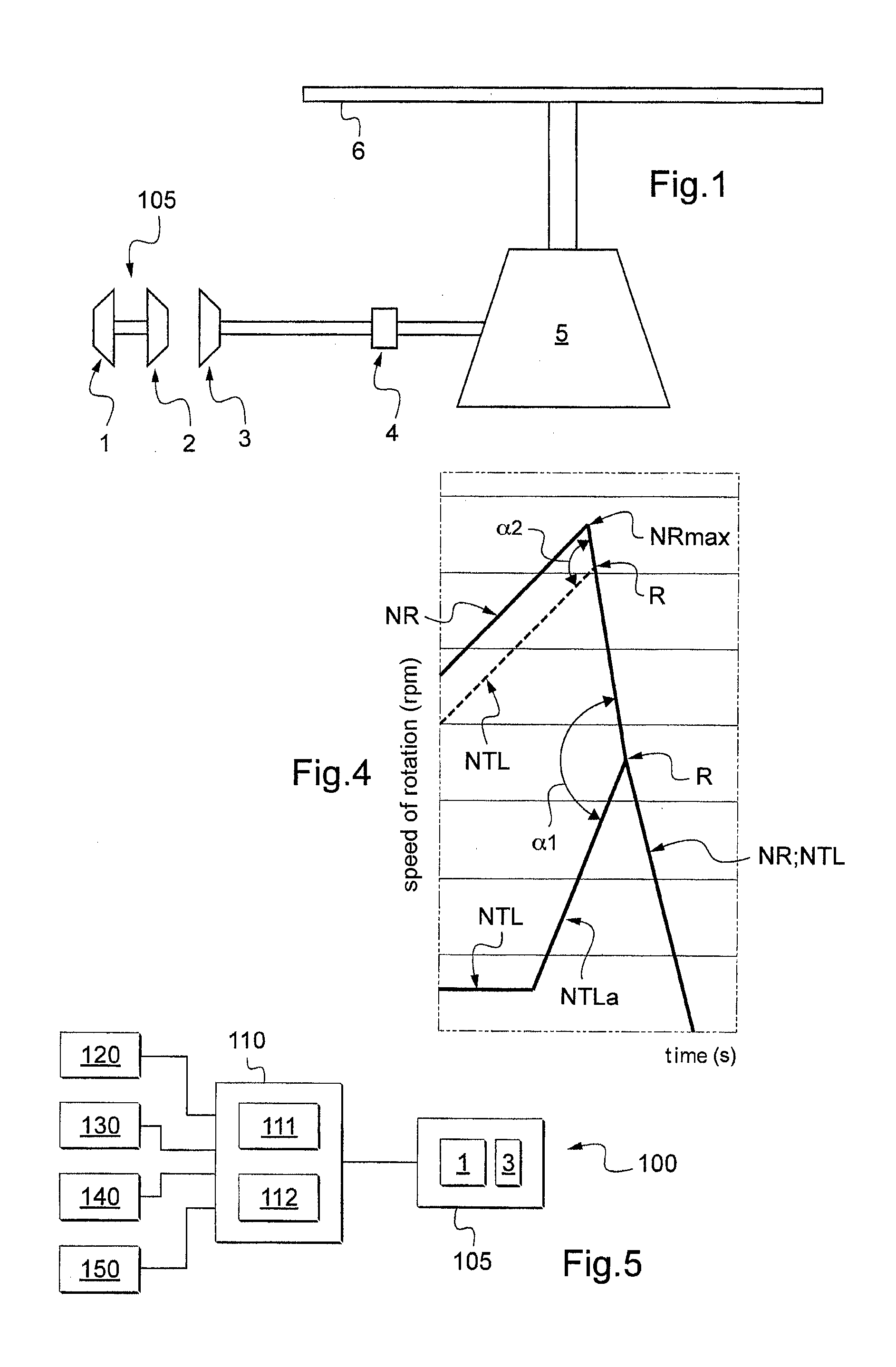

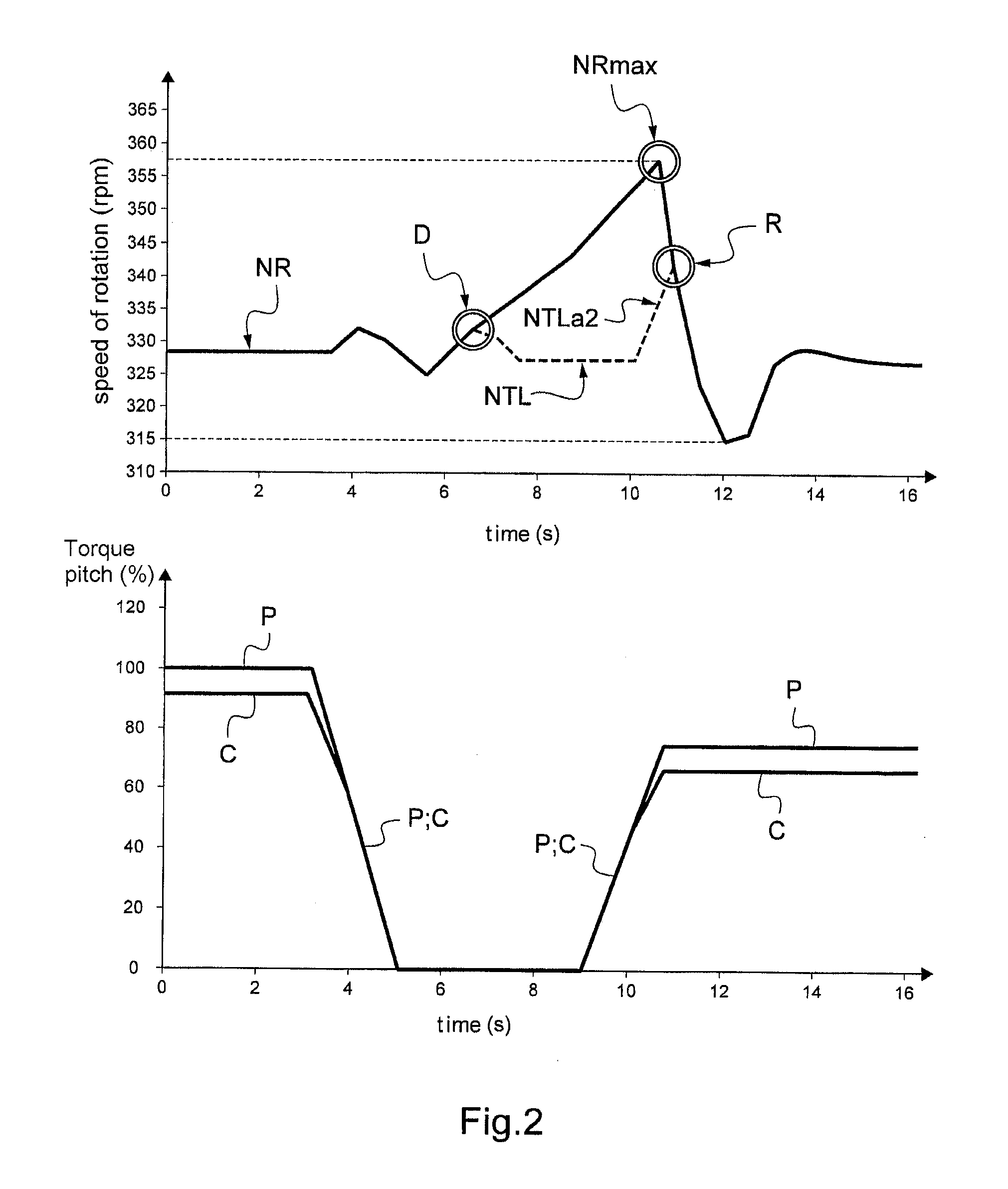

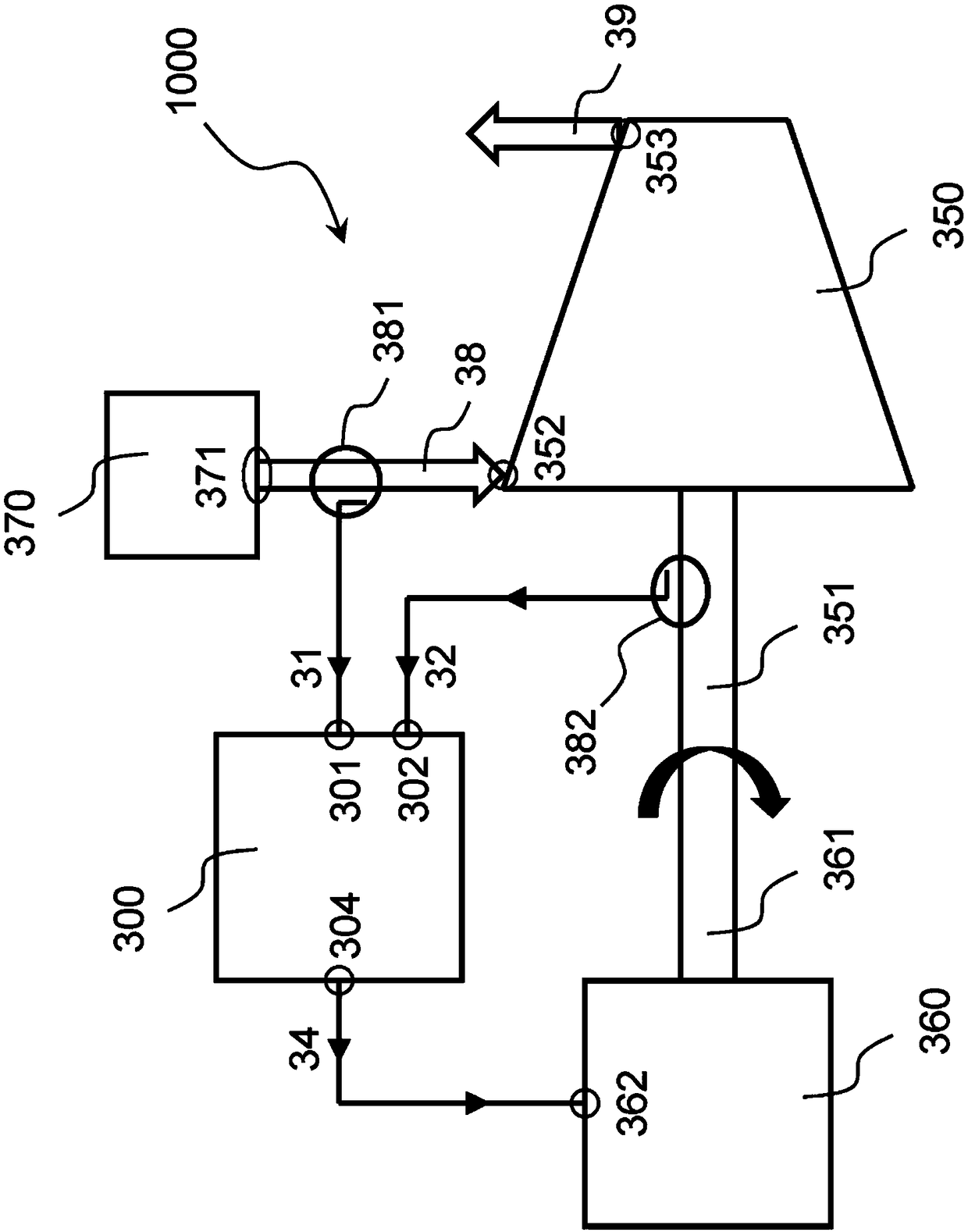

Passing from a non-synchronized state between an engine and a rotor to a synchronized state

ActiveUS8442740B2Reduce impactPremature agingAnalogue computers for vehiclesPropellersControl theoryTurbine

In order to regulate a power plant (105) having a gas generator (1) and a free turbine (3) to drive a rotary wing, a first speed of rotation (NTL) of the free turbine (3) is regulated on a first setpoint value (NTL*) equal either to a regulation term (NRc) or to a predetermined setpoint threshold (NTL*). The regulation term (NRc) is a function of a third speed of rotation (NR) of said rotary wing in accordance, where NRc=NR*(1−d), “d” representing a non-zero constant lying in the range 0 to 1.

Owner:EUROCOPTER

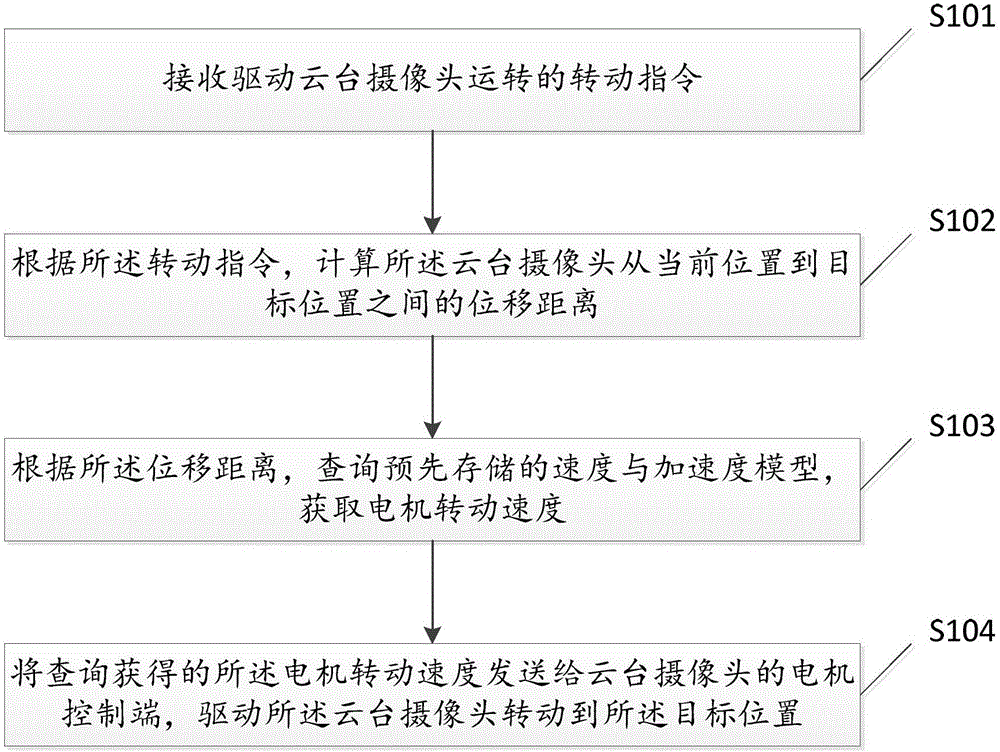

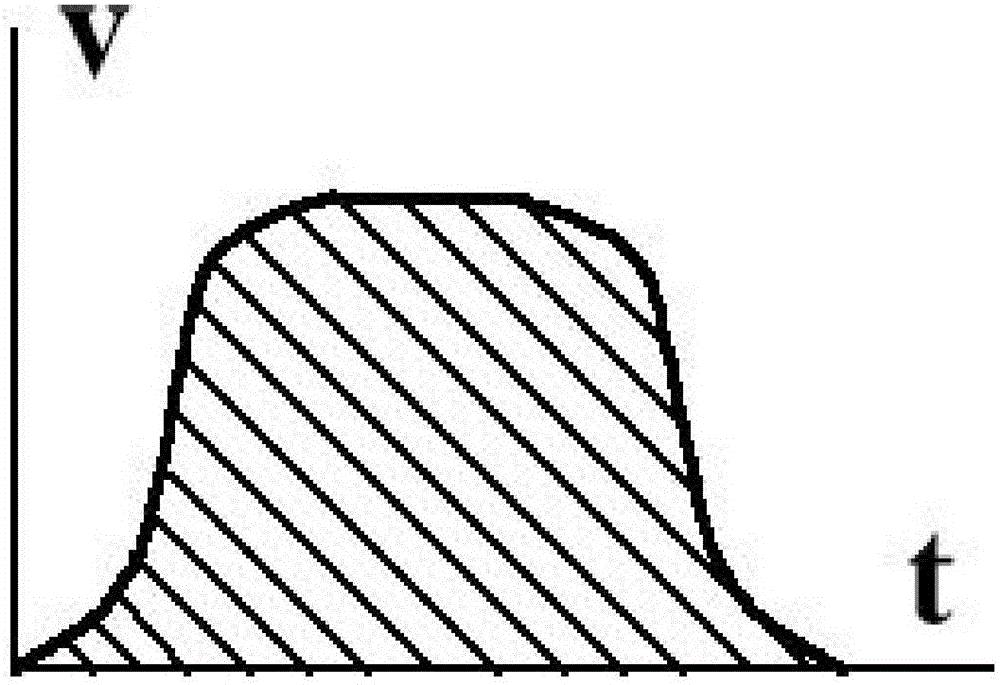

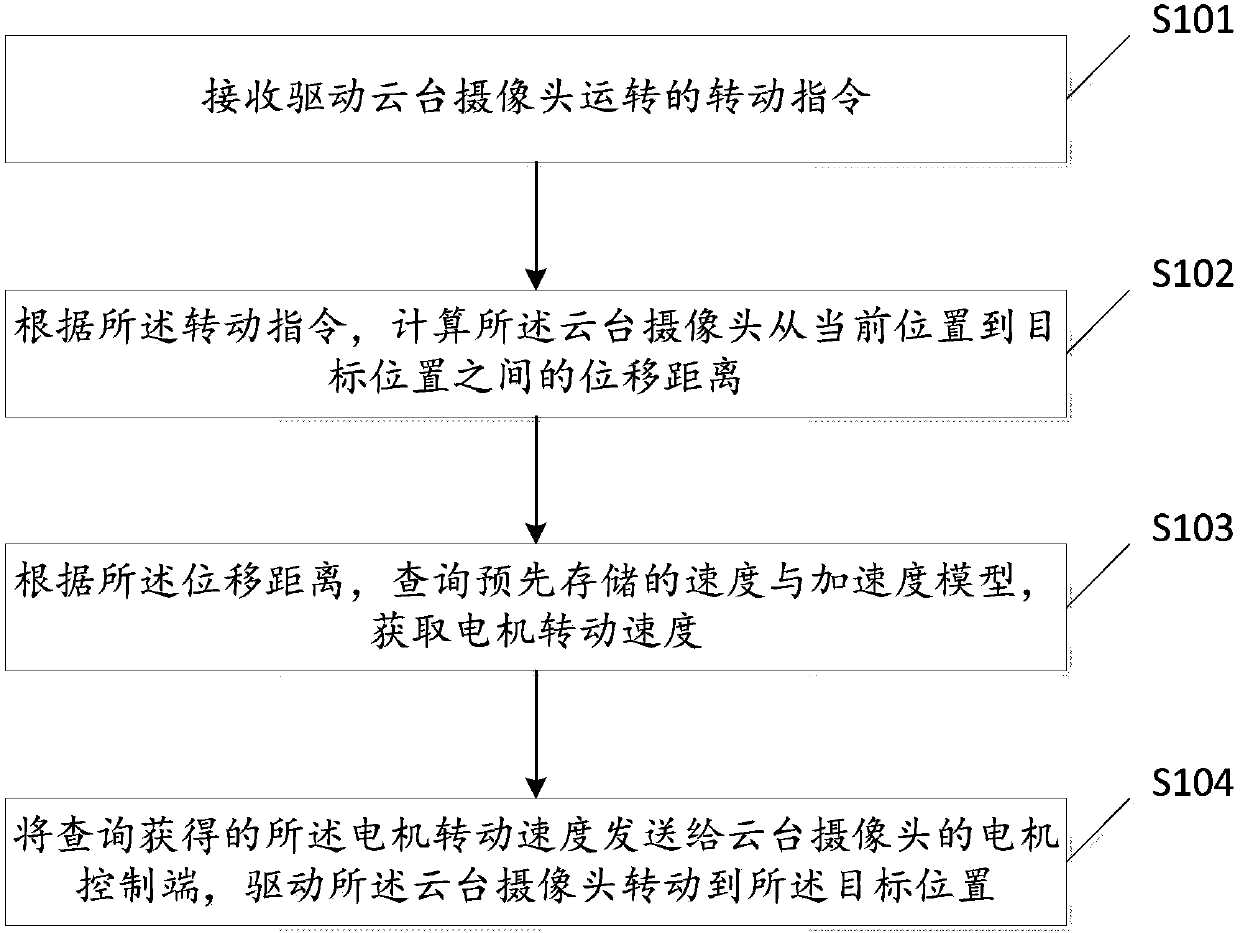

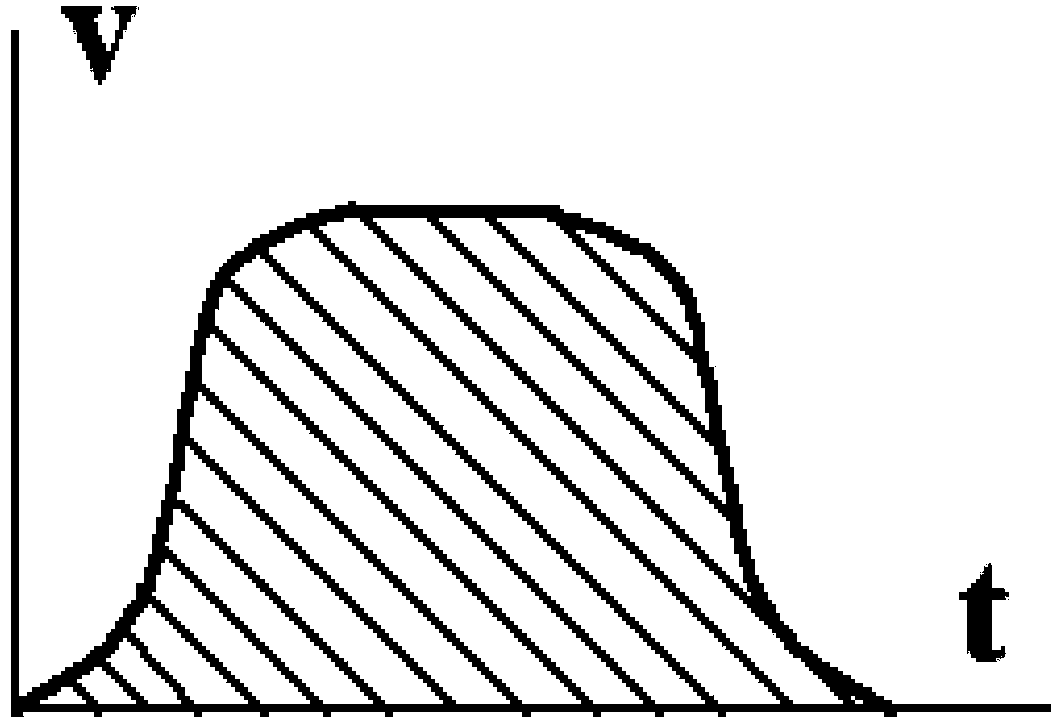

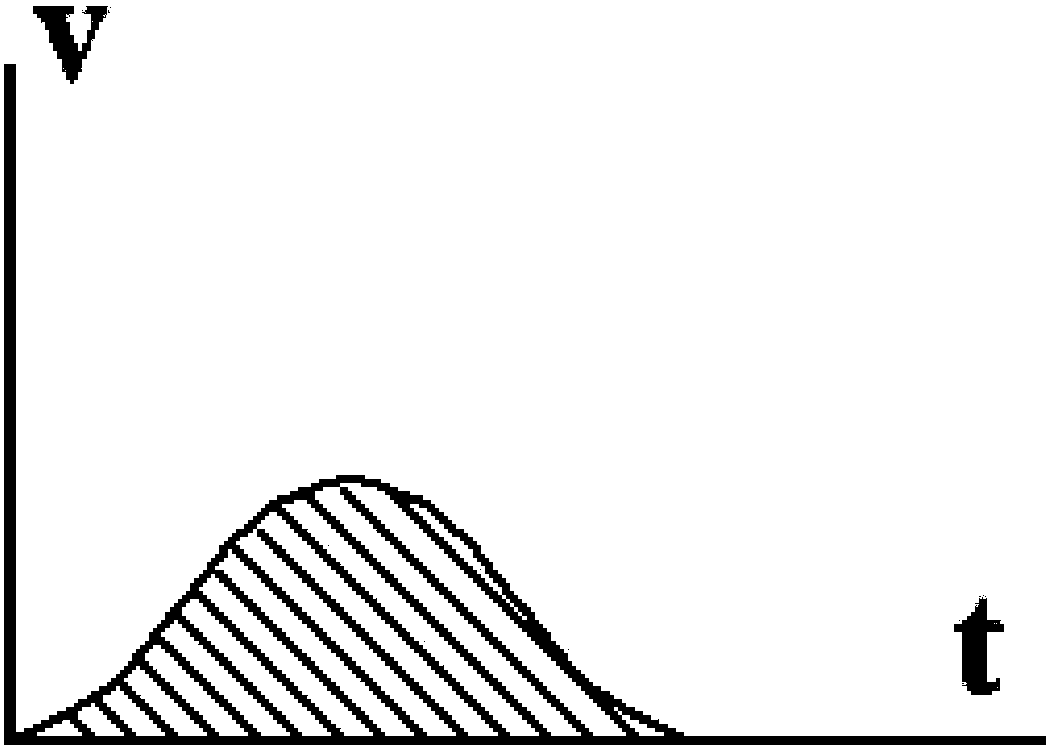

Holder camera speed control method and device

ActiveCN105955328AEliminate jitterSpeed/accelaration control with auxillary non-electric powerComputer hardwareMotor control

The invention discloses a speed control device for a holder camera. The device comprises an instruction reception unit used for receiving a rotation instruction for driving the holder camera to rotate, a displacement calculation unit used for calculating a displacement distance of the holder camera from the present position to a target position according to the rotation instruction, a speed querying unit used for querying a pre-stored speed and an acceleration model according to the displacement distance to acquire a motor rotation speed, and a driving control unit used for sending the motor rotation speed acquired through querying to a motor control end of the holder camera to drive the holder camera to rotate to the target position. Through the device, jittering of the holder camera can be eliminated to a great degree at relatively low cost.

Owner:成都全景智能科技有限公司

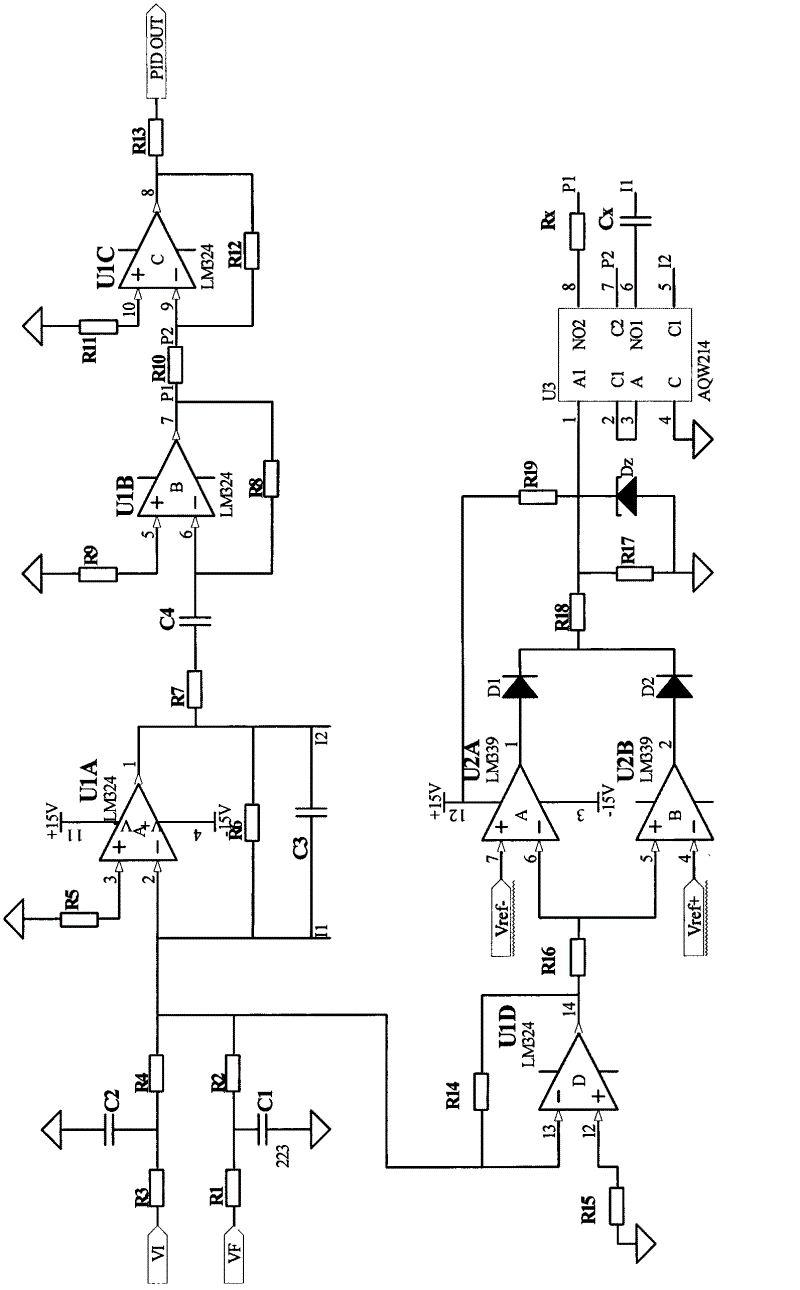

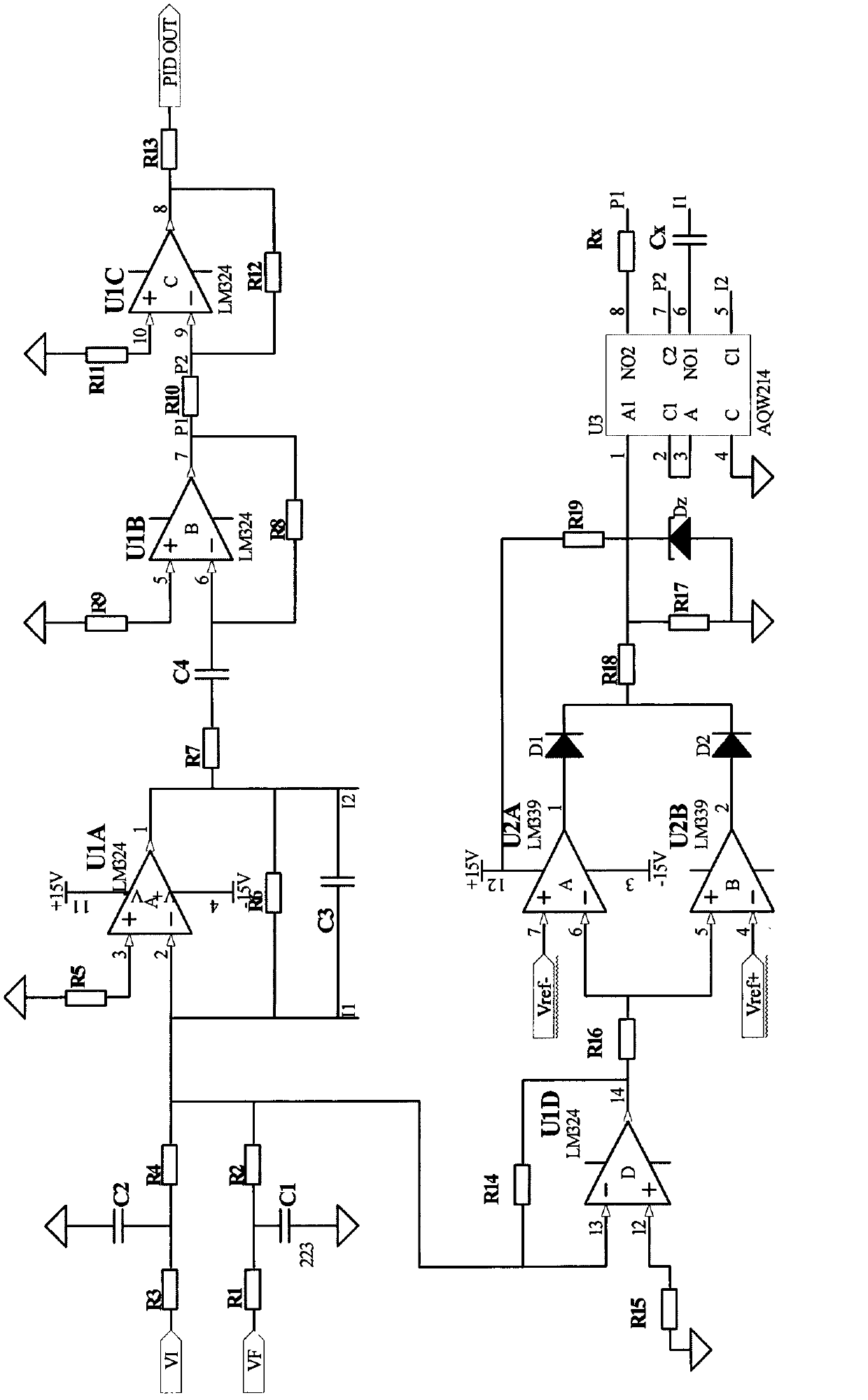

Variable-parameter PID (proportion-integration-differentiation) control circuit and variable-parameter PID control method for electric steering gear

ActiveCN102622001AReasonable designGood control effectSpeed/accelaration control with auxillary non-electric powerCapacitanceAviation

The invention relates to a variable-parameter PID (proportion-integration-differentiation) control circuit and a variable-parameter PID control method for an electric steering gear, which belong to the technical field of automatic control. The PID control circuit comprises a filtering circuit, a PID circuit, an adding circuit, a deviation judgment circuit and an on-off switching circuit, wherein the deviation judgment circuit is used for controlling on and off of two groups of output of an analog switch in the on-off switching circuit by means of a deviation value of input signals and feedback signals of an electric steering gear closed-loop system, so that whether a parallel resistor and a parallel capacitor are inputted into the PID circuit or not are controlled, and online adjustment of PID parameters is realized. By the aid of the variable-parameter PID control circuit and the variable-parameter PID control method, the problem that the electric steering gear of an aviation guided weapon is difficult to achieve good control effect with a group of preset PID parameters in the working environment of great inertia, nonlinearity, strong interference and the like. The variable-parameter PID control circuit is reasonable in design, simple and feasible, is capable of effectively weakening systematic buffeting, increasing systematic robustness and improving control precision, and can guarantee the system to have good control quality in different control phases.

Owner:HARBIN JIANCHENG GRP

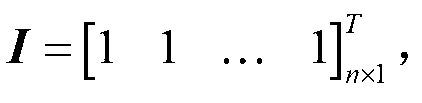

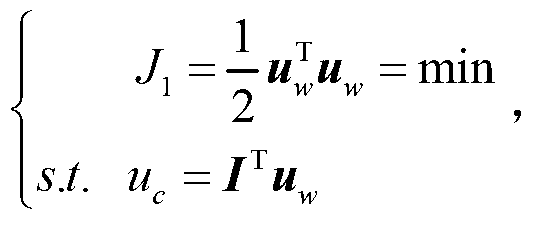

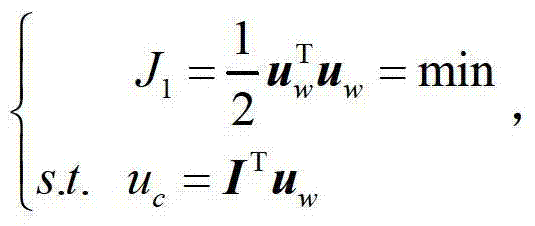

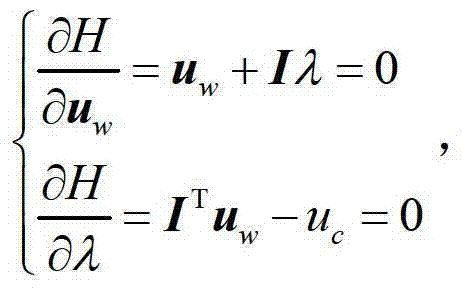

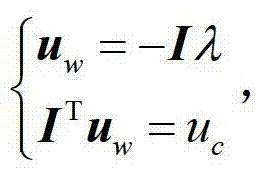

Single-shaft batch counteractive flywheel moment optimal distribution method based on angular momentum margin

ActiveCN103345275AReduce consumptionAvoid saturationSpeed/accelaration control with auxillary non-electric powerMomentumDistribution method

The invention discloses a single-shaft batch counteractive flywheel moment optimal distribution method based on an angular momentum margin, and belongs to the field of control distribution. The multi-objective optimization distribution method based on the angular momentum margin is designed for solving the problem that due to the fact that a traditional moment distribution method takes no account of self angular momentum of flywheels, the flywheels are saturated and cannot complete tasks. A weight coefficient optimization method is used, system energy consumption and output margins of the flywheels are integrally considered, a suitable weight coefficient is given to each item according to energy consumption and the output margin of each flywheel, the weight coefficients are adjusted in the process of moment distribution, therefore, energy consumption is reduced, and saturation of the flywheels is avoided. The single-shaft batch counteractive flywheel moment optimal distribution method based on the angular momentum margin is beneficial to improving flywheel system output capacity, can save fuel to a certain extent, and can be widely used for the field of rapid spacecraft attitude maneuver.

Owner:哈尔滨工大卫星技术有限公司

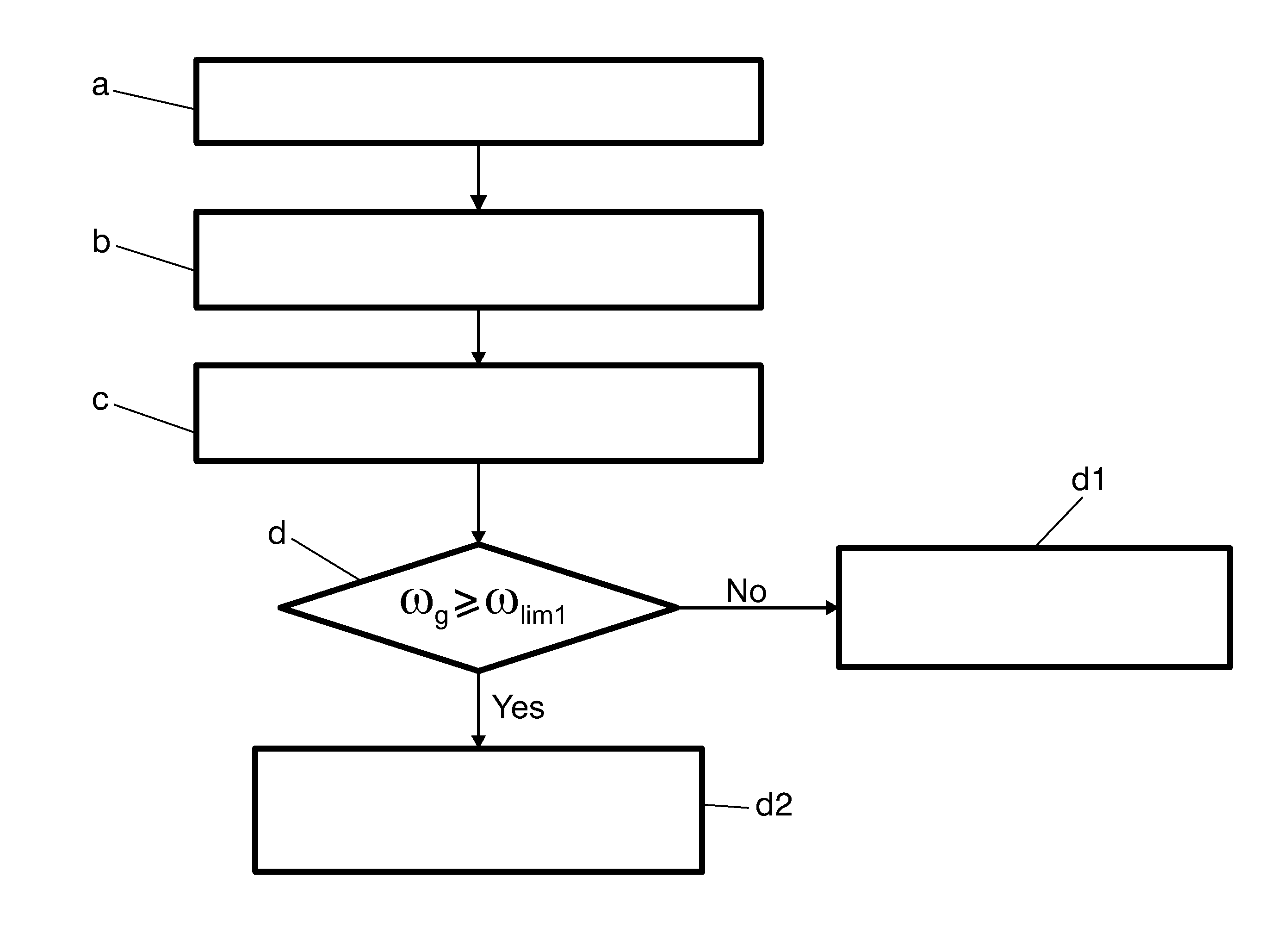

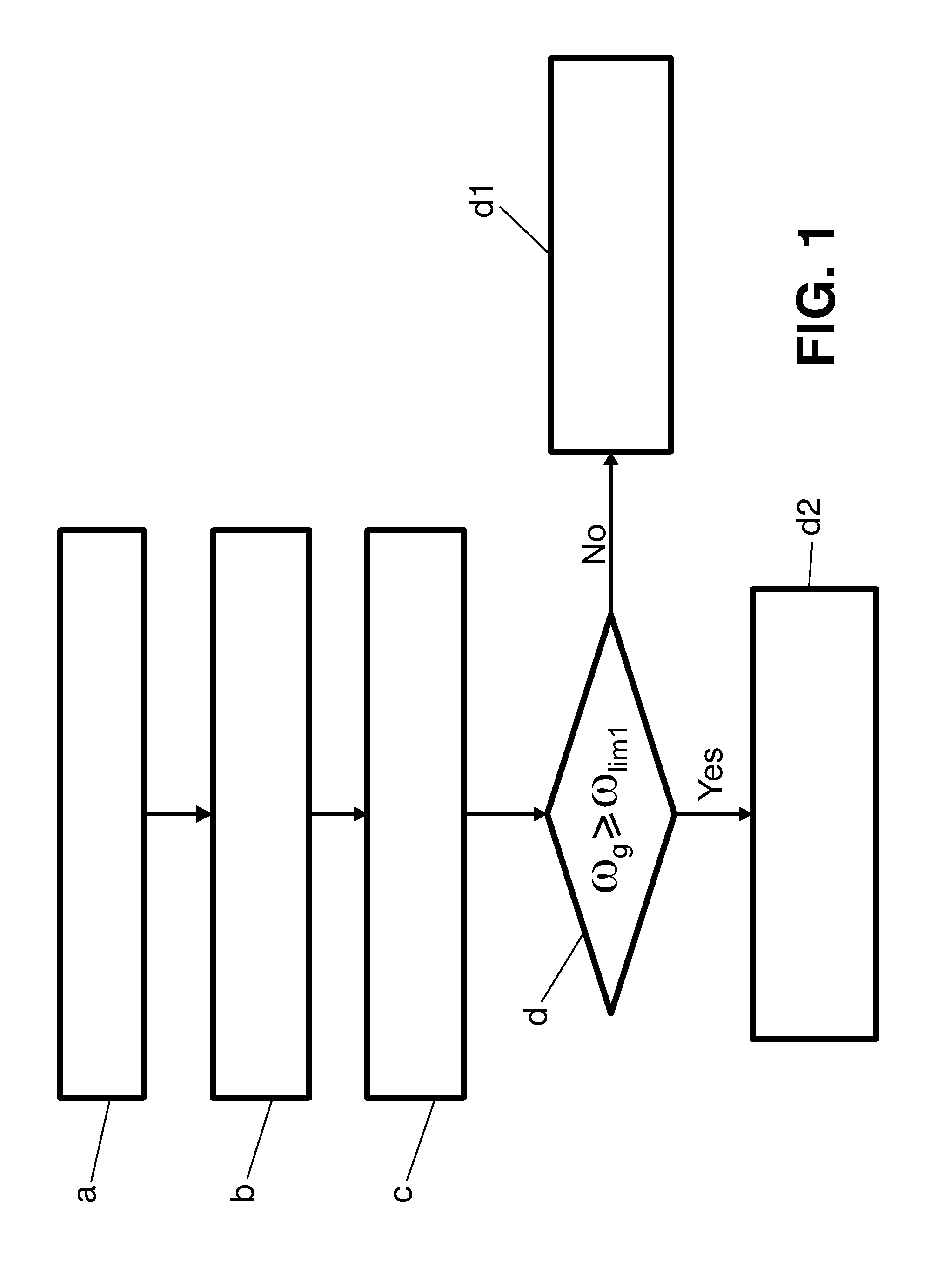

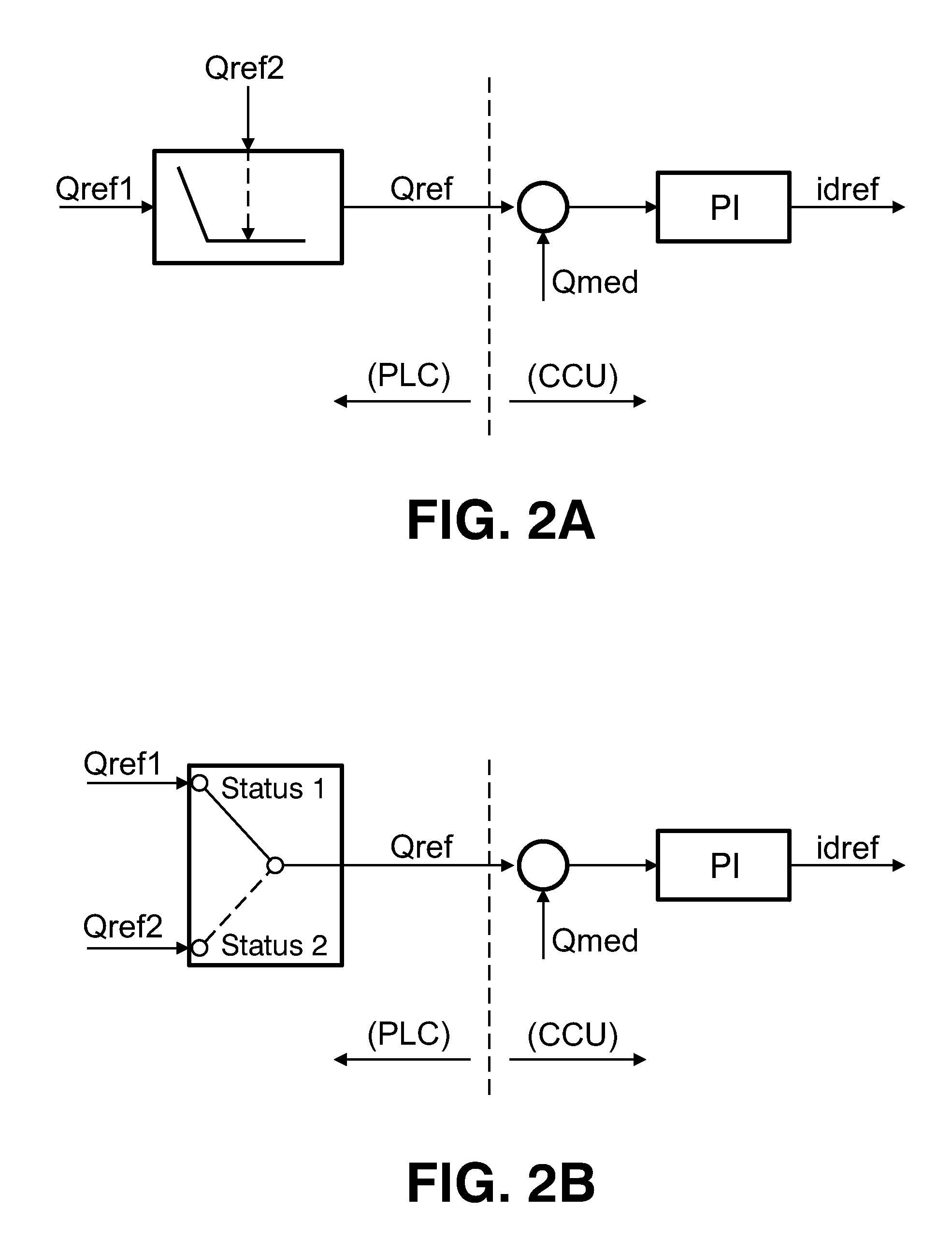

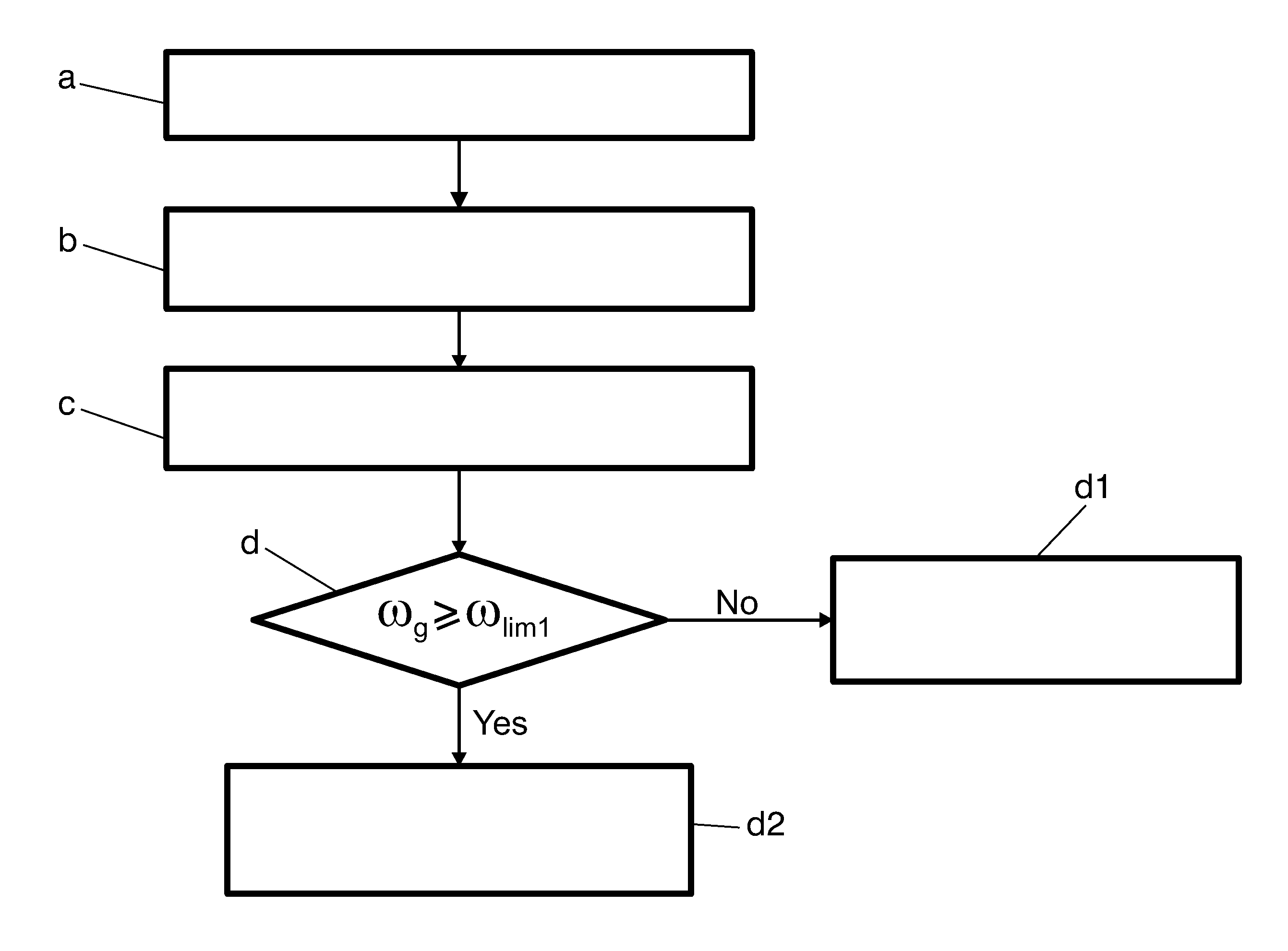

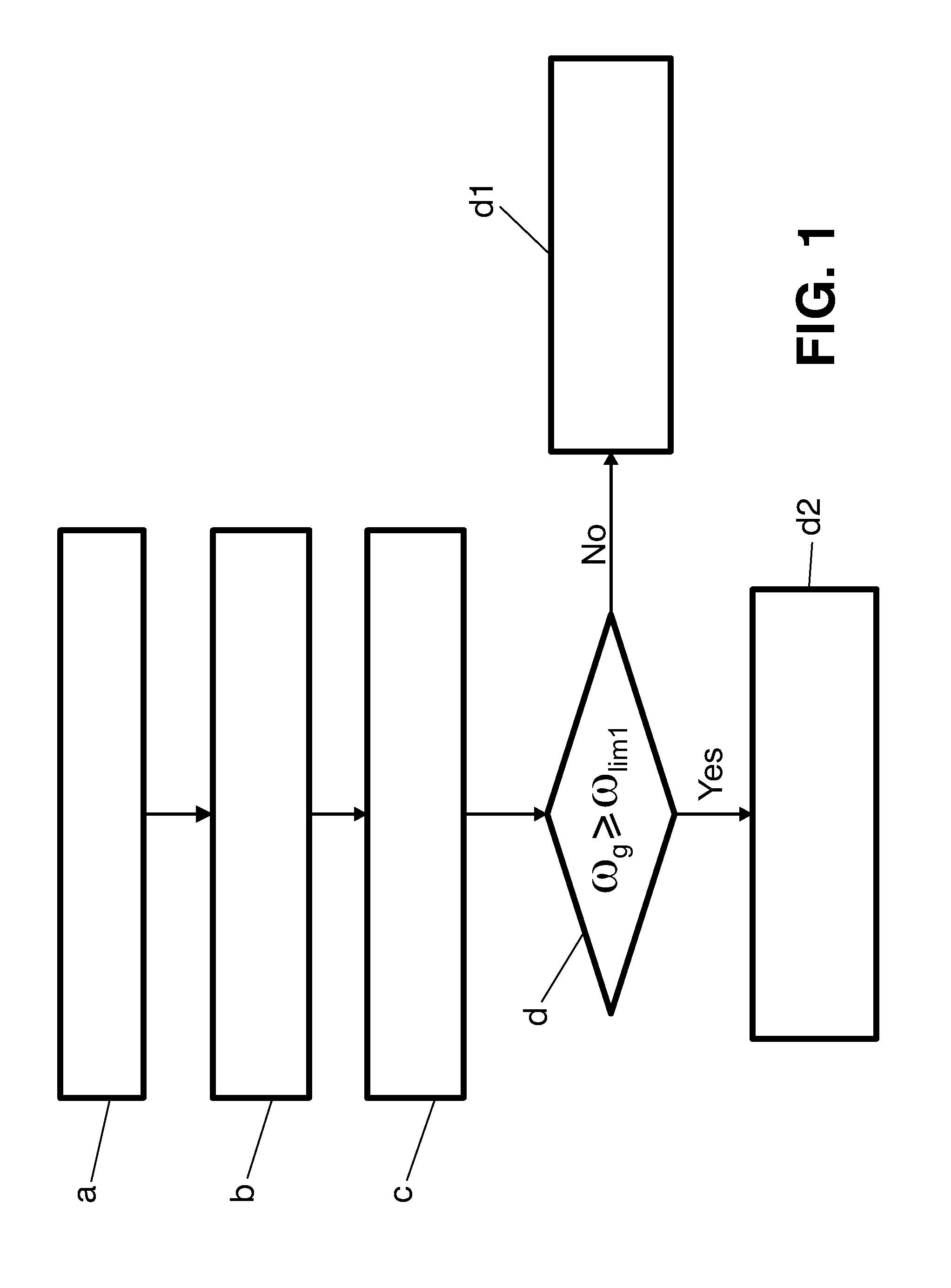

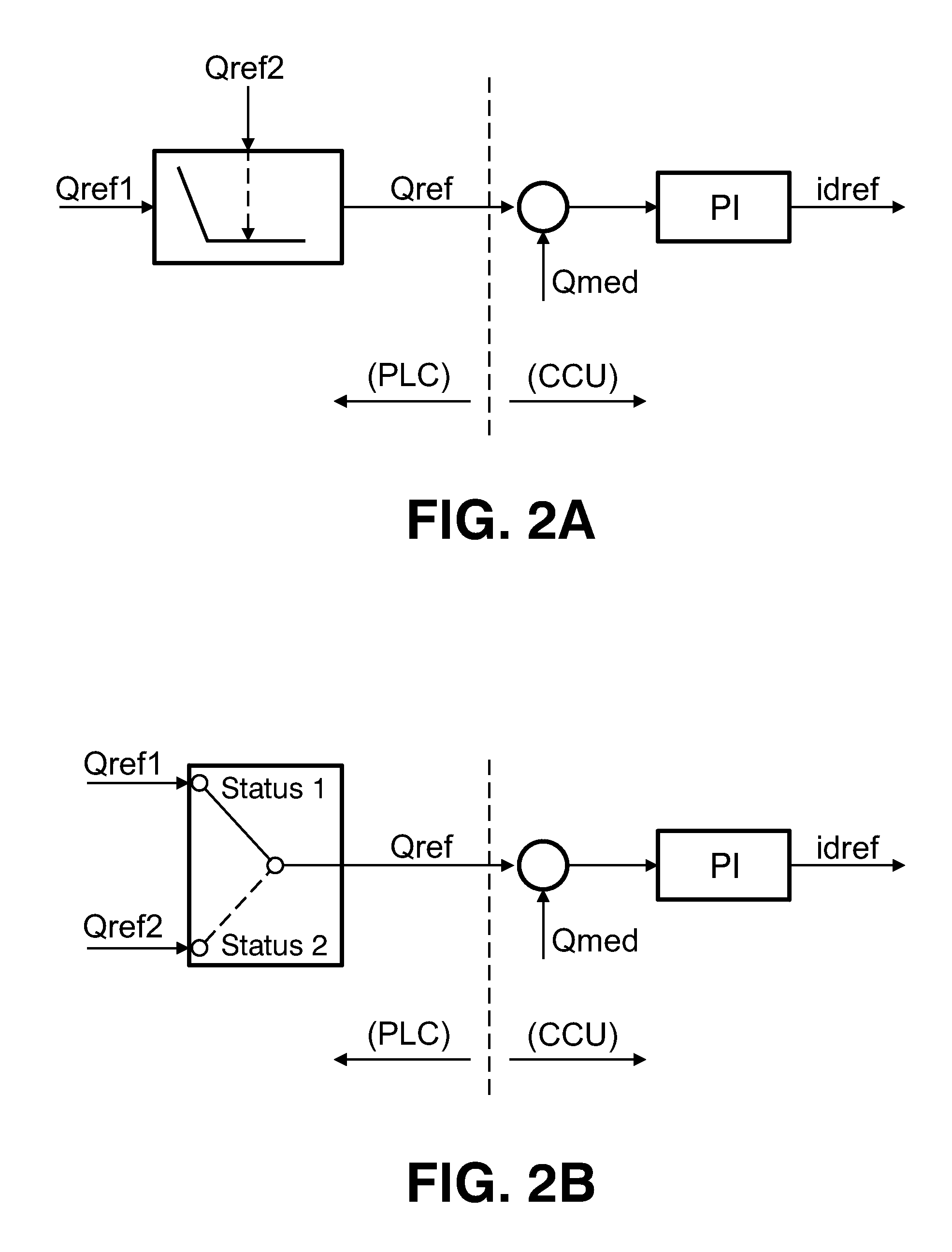

Control method of a wind turbine generator

ActiveUS20130169241A1Extends operation and efficiencyExtended speed rangeVector control systemsWind motor controlTurbineWind force

The control method of a wind turbine generator increases the speed range of wind turbine generators, maximising the operation and efficiency thereof, in addition to lengthening their service life, on minimising the extreme and fatigue loads to which the wind turbine generators are subject, and which are due mainly to the stops and disconnections thereof as a result of strong gusts of wind. More specifically, the control method of the present invention stands out essentially for being based on the control of the reactive current circulating through the electric generator, said reactive current control being carried out in accordance with the rotational speed (ωg) for the purpose of reducing the voltage at the converter terminals on the generator side, or rotor voltage (VR), which ultimately allows a transitional increase in the speed range of the wind turbine generator.

Owner:NORDEX ENERGY SPAIN SA

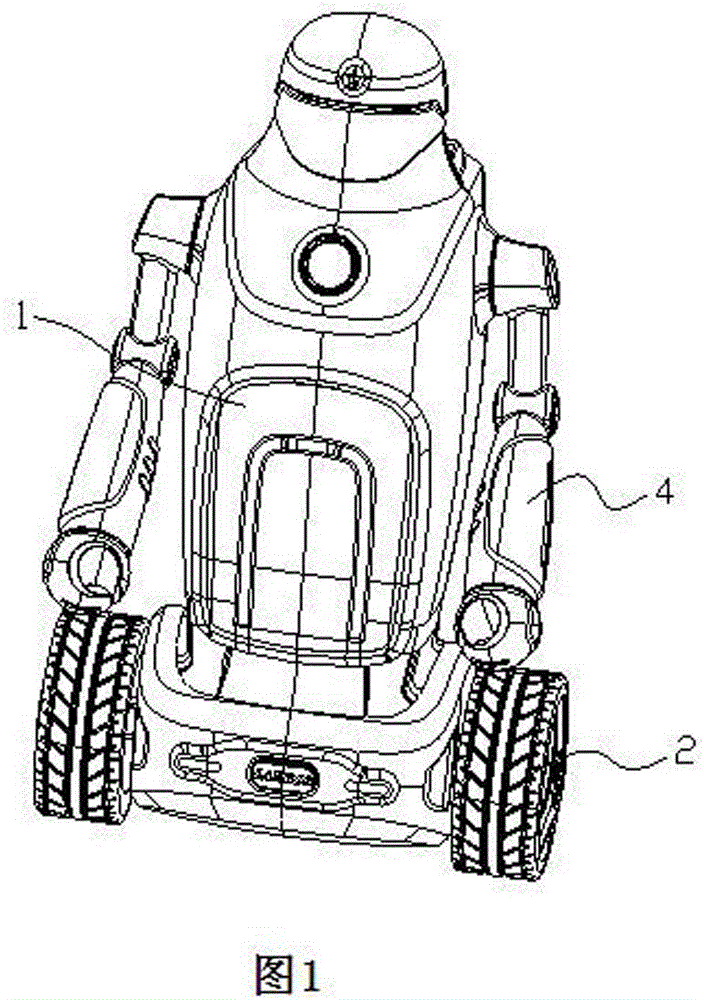

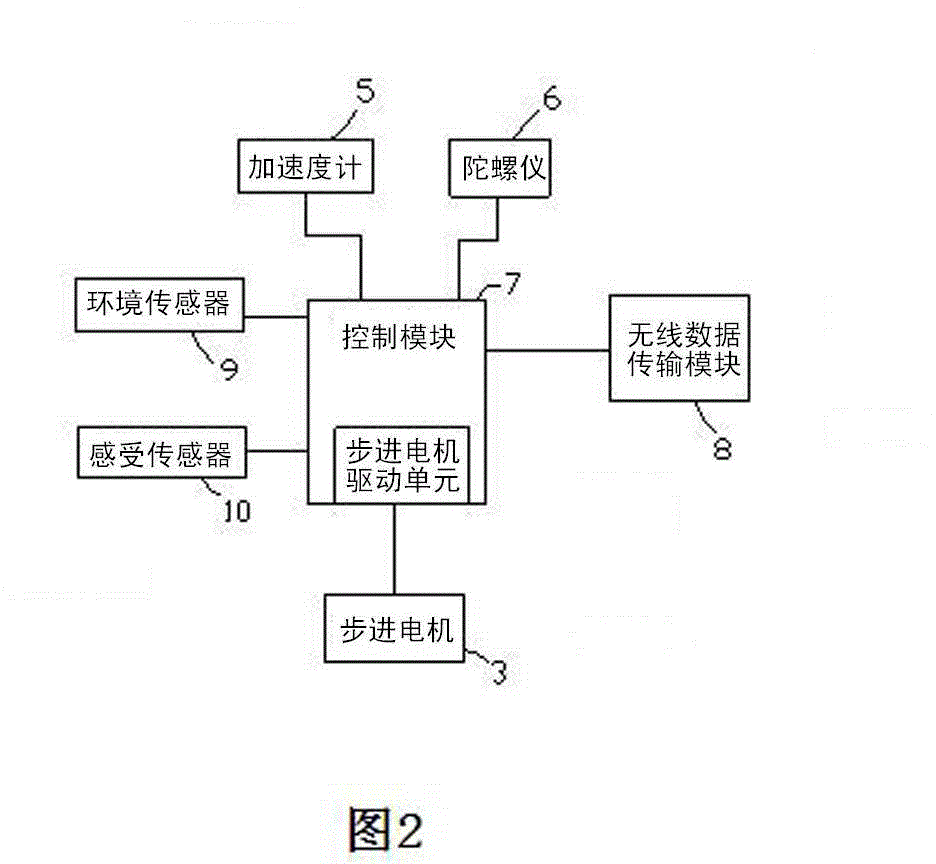

Vertical balanced robot

InactiveCN105094160AControl upright balanceReduce volumeSpeed/accelaration control with auxillary non-electric powerGyroscopeAccelerometer

The invention discloses a vertical balanced robot. The vertical balanced robot comprises a robot body. The robot body is internally provided with an accelerometer, a gyroscope and a control unit integrated with a stepping motor driving unit. Two wheels are arranged on two sides of the lower end of the robot body. The robot body is internally provided with two groups of stepping motors. Moving arms are arranged on two sides of the robot body. The control module obtains an angle value and an angular velocity value by carrying out filtering and calculation based on measured values of the accelerometer and the gyroscope. PD controlling is carried out based on the angle value and the angular velocity value so as to generate two output values used for controlling the rotation of the motors. The stepping motors are controlled by the stepping motor driving unit. According to the invention, the vertical balancing of the robot is precisely controlled by controlling the rotation of the two motors; the robot is integrally in a human shape, so that a bionic shape effect is achieved; the control module is integrated with the stepping motor driving unit, a conventional large motor driver is not needed, the size of the robot itself is reduced, and the power consumption is lowered; in addition, by means of further configuration, the robot can be provided with an entertainment function.

Owner:WUHU LANDZO ELECTRONICS TECH

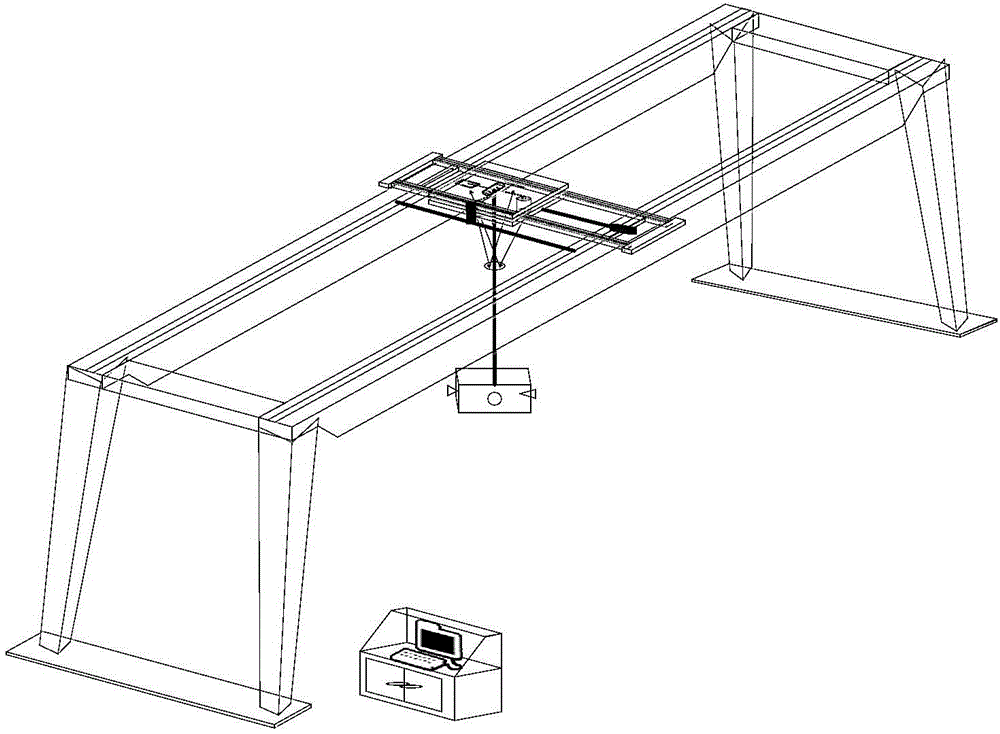

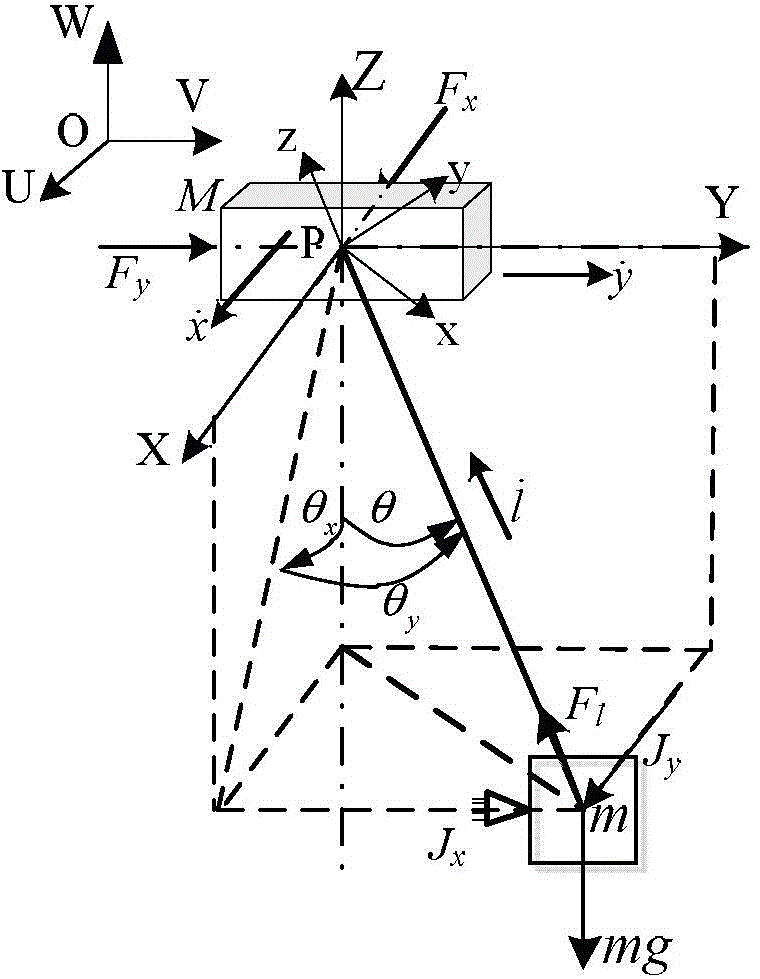

Acceleration compensation control method of suspension floating object follow-up system and mode-selection-based control method of suspension floating object follow-up system

InactiveCN104460722ASimplify the design processGuaranteed control effectSpeed/accelaration control with auxillary non-electric powerKinematicsMotor control

The invention discloses an acceleration compensation control method of a suspension floating object follow-up system and a mode-selection-based control method of the suspension floating object follow-up system, and belongs to the field of suspension floating object follow-up systems. The acceleration compensation control method and the mode-selection-based control method aim at solving the problem that a controller designed for follow-up platform driving with a traditional method can not be directly used for motor rotation speed control modes. The acceleration compensation control method of the suspension floating object follow-up system includes the four steps of firstly establishing kinematical and dynamical equations, determining a motor control mode of the suspension floating object follow-up system, designing a controller and adjusting parameters. The problems that in the traditional method, driving force F<x> and driving force F<y> serve as control items, only a torque model can be adopted for a motor, and the performance can not be sufficiently developed; the requirement of the motor for the control mode of the motor is lowered, the performance of the motor is better developed accordingly, and the control performance of the suspension floating object follow-up system is improved. The acceleration compensation control method and the mode-selection-based control method are suitable for the field of the suspension floating object follow-up systems.

Owner:HARBIN UNIV OF SCI & TECH

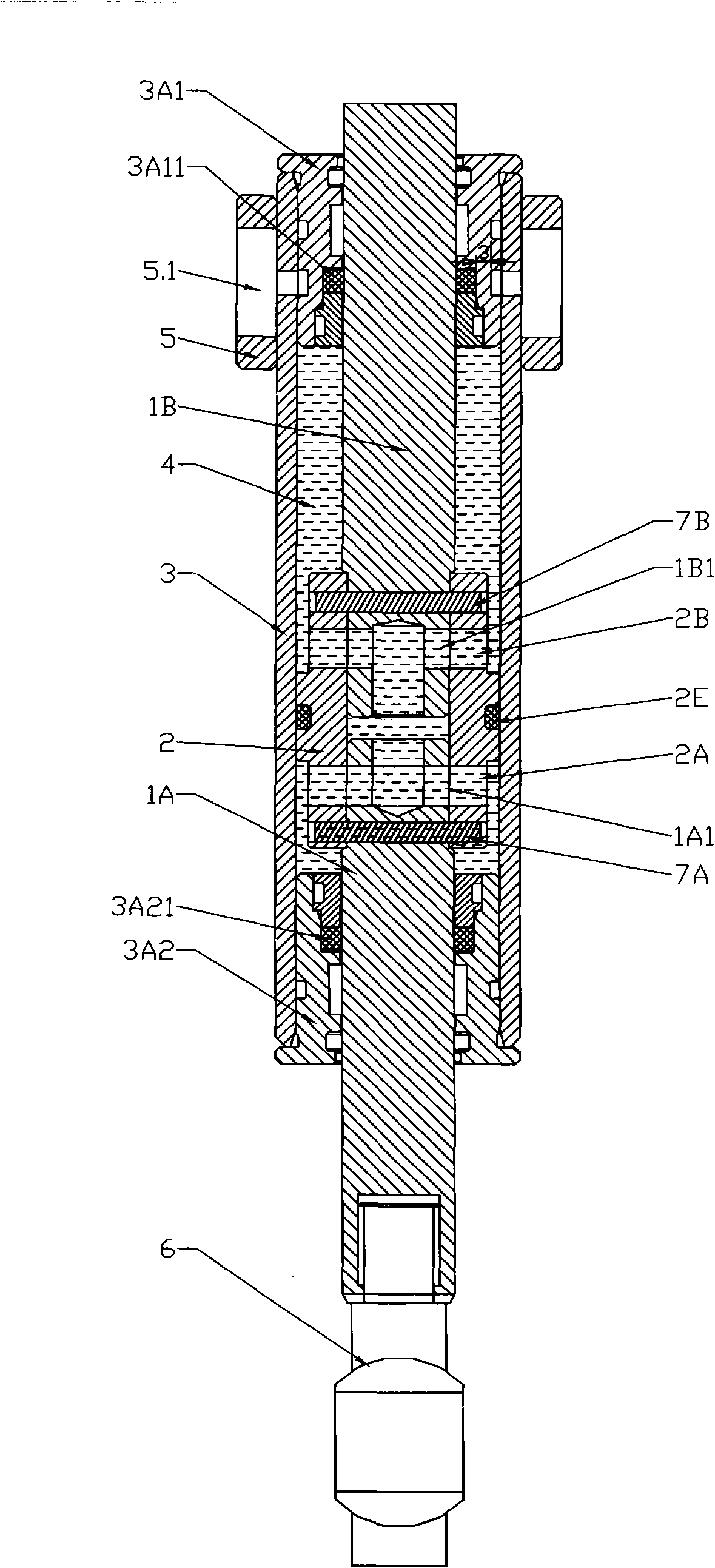

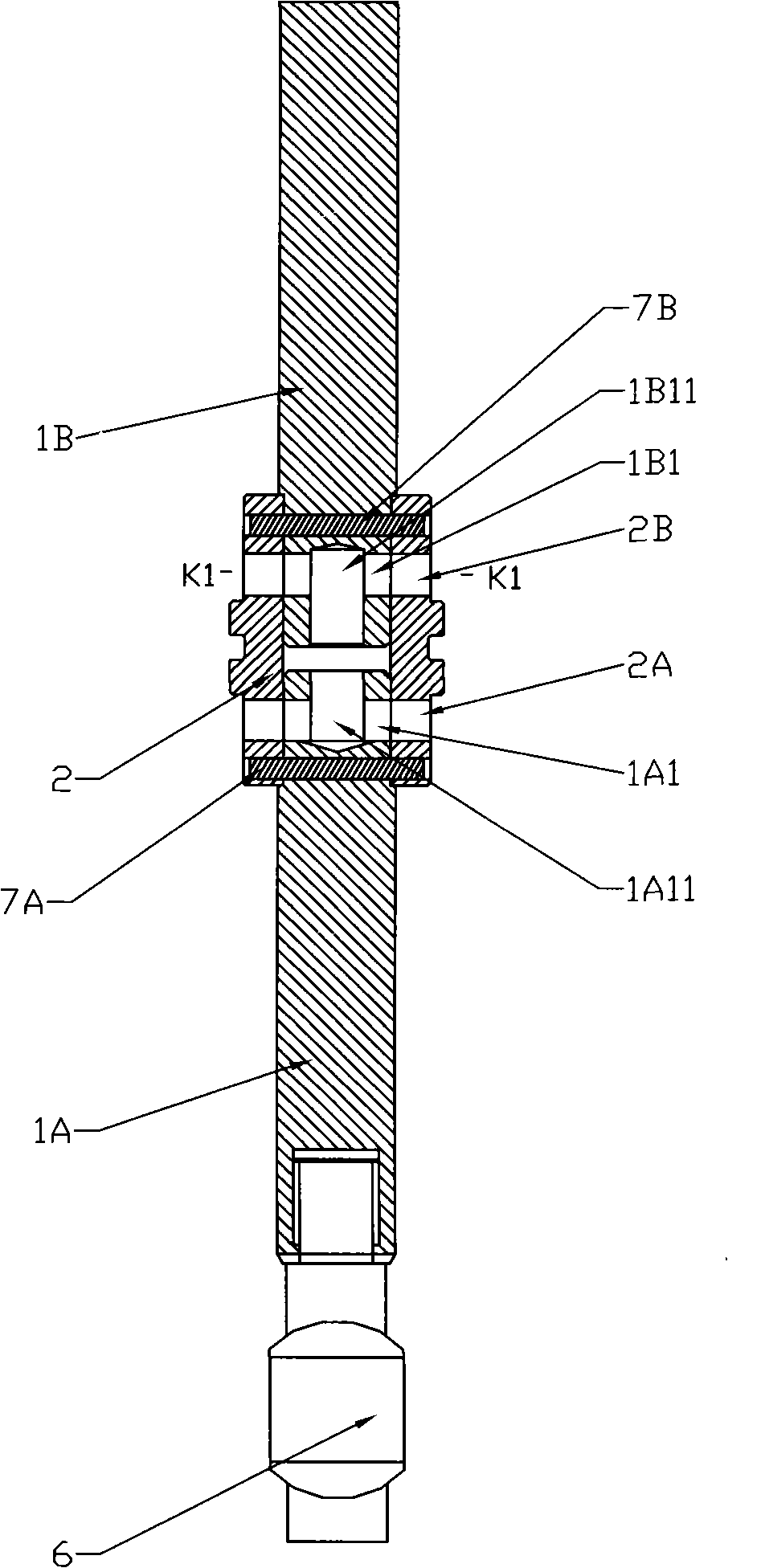

Variable inertia reaction flywheel

InactiveCN103631280ASimple structureCalculate moment of inertiaSpeed/accelaration control with auxillary non-electric powerBall bearingElectric machinery

The invention relates to a variable inertia reaction flywheel. A flywheel shaft is linked with a flywheel outer ring by virtue of a guide bar; the flywheel shaft is arranged on a support by virtue of a deep groove ball bearing; the support is fixed on a left shell; a drive motor is fixed on the left shell, and the shaft of the drive motor is linked with the flywheel shaft by virtue of a flat key, so as to drive the flywheel to rotate; the guide bar is provided with a balancing weight which can slide along the guide bar; the flywheel shaft is provided with a guide rod of which the axis is superposed with the axis of the flywheel; the guide rod is provided with a slide block; the slide block is linked with the balancing weight by virtue of a connecting rod; the other end of the slide block is linked with a lead screw by virtue of a deep groove ball bearing; a right shell and a left shell are oppositely fixed; a through screw rod motor is arranged on the right shell; the lead screw motor drives the lead screw to do spiral movement; the lead screw drives the slide block to slide along the guide rod, so as to drive the balancing weight to slide along the guide bar, and thus the rotary inertia of a flywheel mechanism is adjusted; the counter torque output by the variable inertia reaction flywheel is controlled by controlling the angular speed of the drive motor and the angle of revolution of the lead screw motor.

Owner:BEIJING UNIV OF TECH

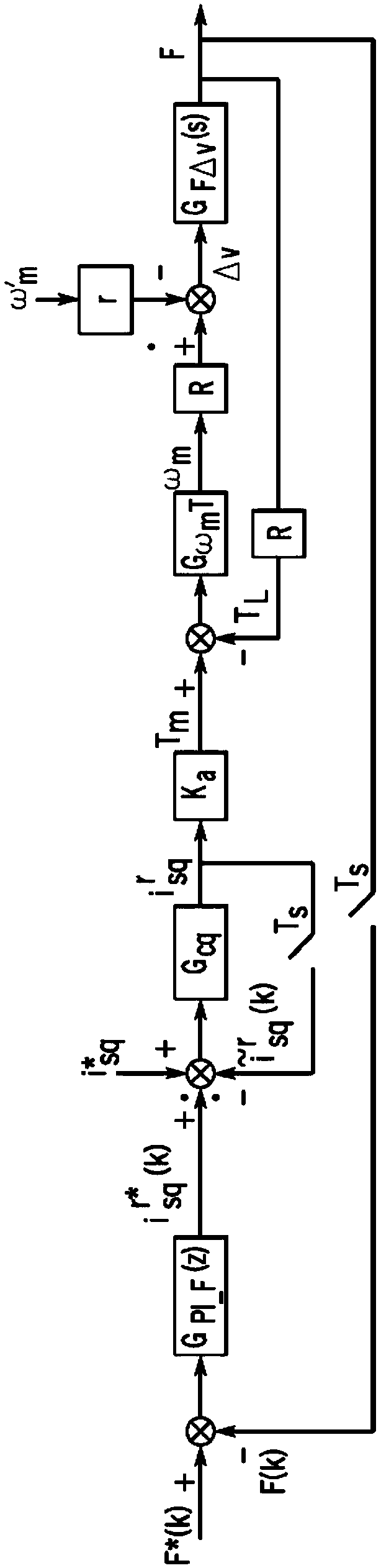

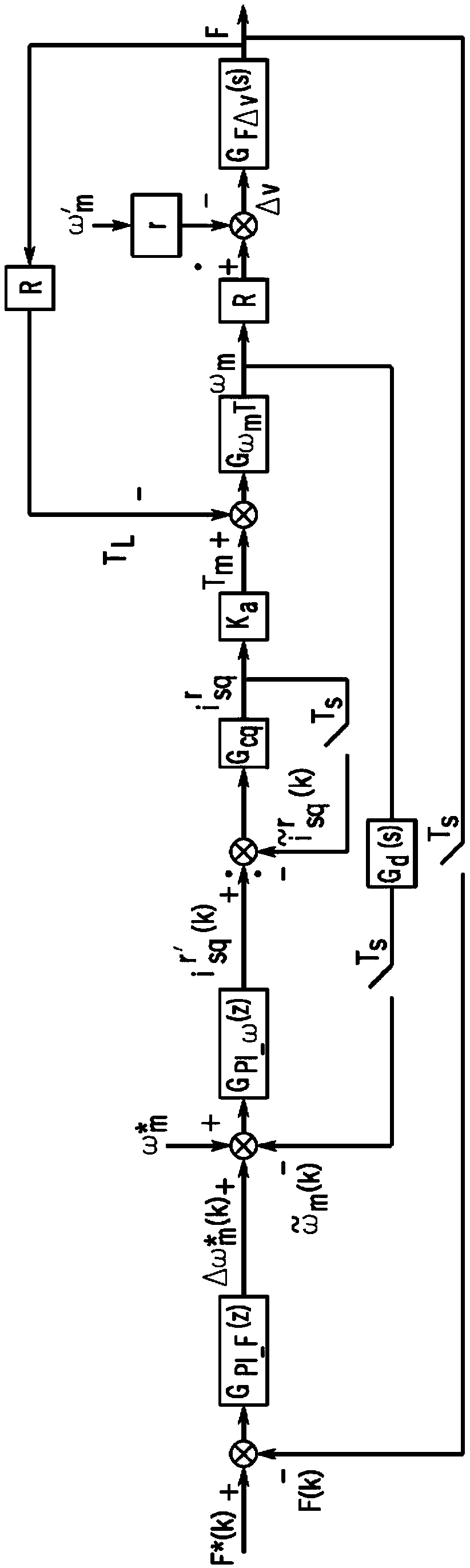

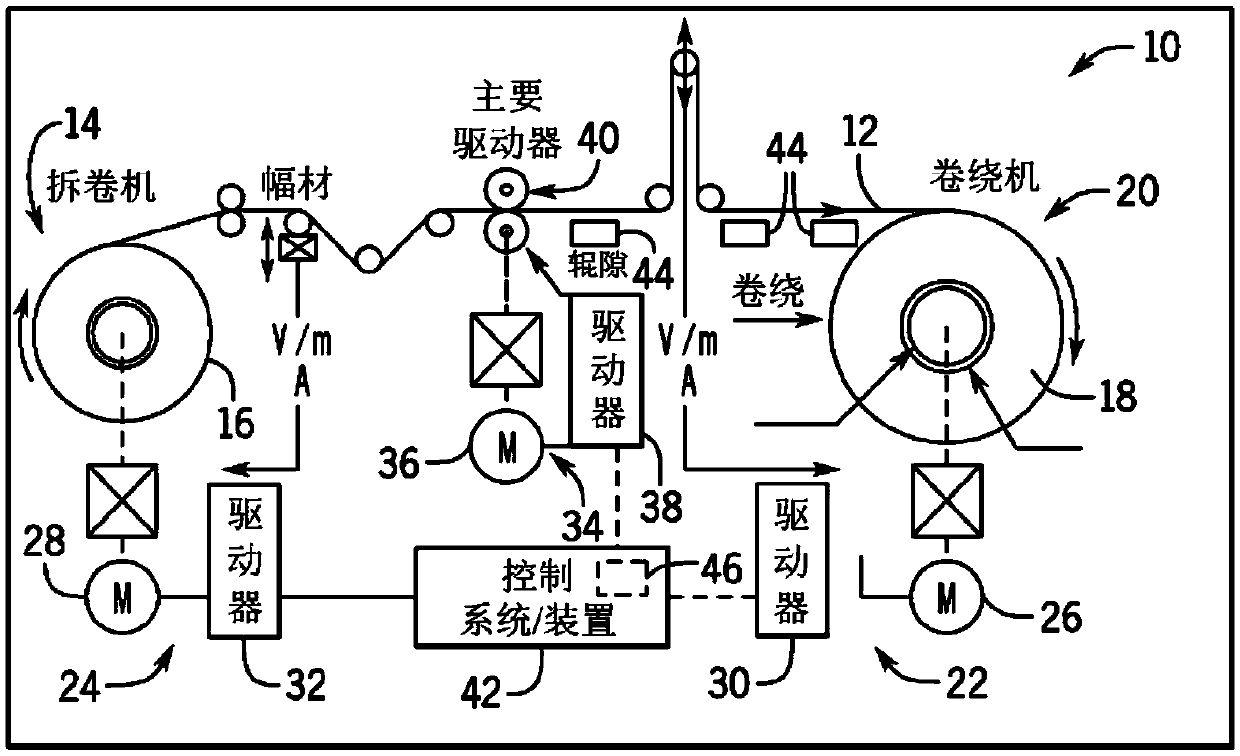

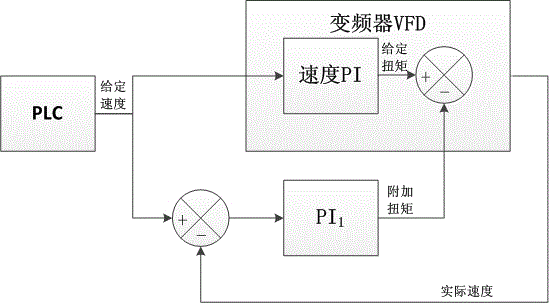

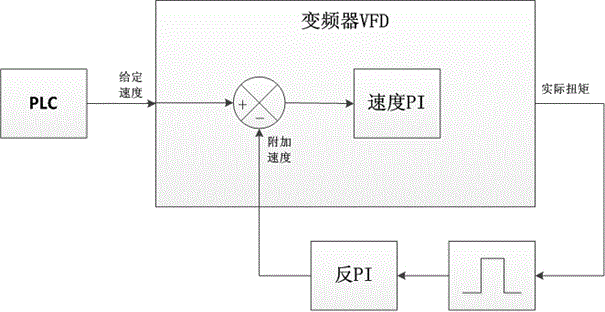

Dynamic performance and active damping method in web winding machine tension control system

PendingCN110502043ASpeed/accelaration control with auxillary non-electric powerWinding machineControl system

A control system is disclosed for controlling operations of a primary driving unit and a secondary driving unit in a web winding machine system to provide tension control over a continuous web of material. The control system enables the primary driving unit to operate in a speed mode to set a linear speed of the continuous web of material. The control system receives an input from a tension and speed detector in the web winding machine system, the tension and speed detector detects tension and a speed of the continuous web of material, and enables the secondary driving unit to operate in a modified torque-adjusted closed-loop tension control mode, so as to control the tension in the web of material. The control system enables the secondary driving unit to operate in the torque-adjusted closed-loop tension control mode and integrates a speed feedback loop into the torque-adjusted closed-loop tension control mode, so as to introduce active damping into tension control.

Owner:EATON CORP

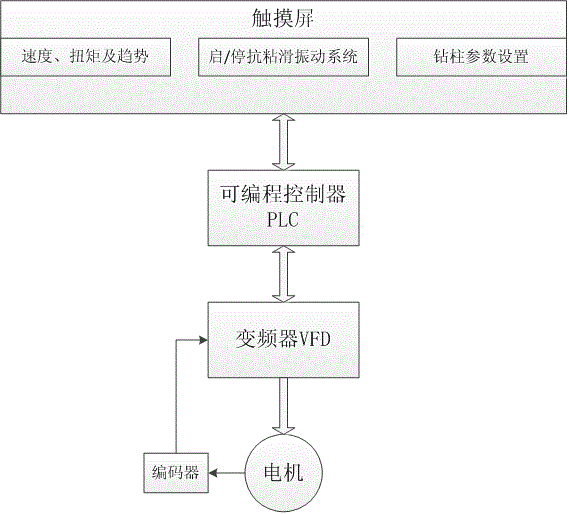

Control system and method for eliminating stick-slip vibration of drill string

ActiveCN106598091AReduce the degree of fatigue damageGet away quicklySpeed/accelaration control with auxillary non-electric powerVibration amplitudeFatigue damage

The invention discloses a control system and method for eliminating stick-slip vibration of a drill string. The method comprises steps that 1, drill string parameters are set after parameter initialization; S2, when a parameter stick-slip vibration indication SSI reaches a certain value, an stick-slip vibration prevention system starts; S3, according to amplitude of the parameter stick-slip vibration indication SSI, a corresponding prevention system is set; and S4, comparison is carried out according to an actual speed fed back by a frequency converter VFD and a given speed of the motor after stick-slip vibration is generated, adjustment is carried out through a PI adjusting controller, after a torque is added to the frequency converter VFD and is outputted through a speed adjuster, a rotation speed of the motor is controlled through the frequency converter, and a drill bit is made to leave a stick-slip area. Through the method, amplitude of stick-slip vibration can be effectively reduced, or stick-slip vibration can be eliminated, a fatigue damage degree of the drill string is alleviated, and underground accident probability caused by drill string fatigue is reduced. The method is advantaged in that the drill bit is made to leave the stick-slip vibration area, a drill speed is improved, well drilling cost is reduced, and well drilling efficiency is improved.

Owner:SICHUAN HONGHUA ELECTRIC

Piston type speed controller

InactiveCN102012707AEasy to processReduce manufacturing costSpringsLiquid based dampersControl theoryThrottle

The invention relates to a piston type speed controller. In order to overcome the defects of large processing difficulty and high manufacturing cost of parts of the traditional piston type speed controller, which are caused by needing to set an outer flow storage chamber, the invention provides a piston type speed controller comprising a flowing medium, a piston, piston rods, a piston cylinder, apiston cylinder tip and a sealing member. The piston type speed controller is characterized in that the piston is provided with two piston rods, through holes or through gaps are arranged on the piston rods, and the through holes or through gaps of the two piston rods are communicated with each other to form medium circulating throttle pipelines; and when the piston is moved, the flowing medium sequentially flows into the through hole or through gap of one piston rod and then flows out and enter the other side of the piston from the through hole or through gap of the other piston rod.

Owner:何少敦

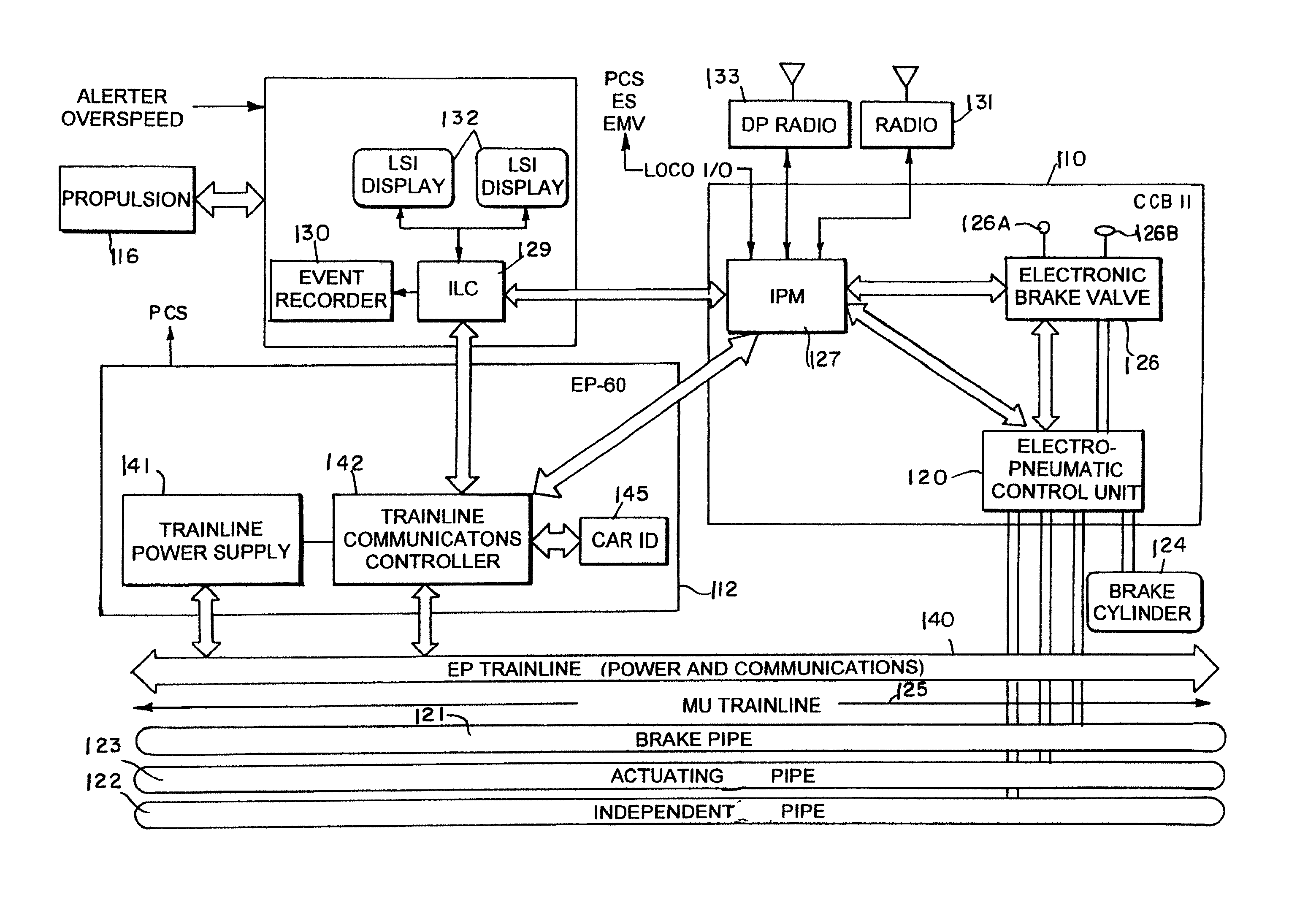

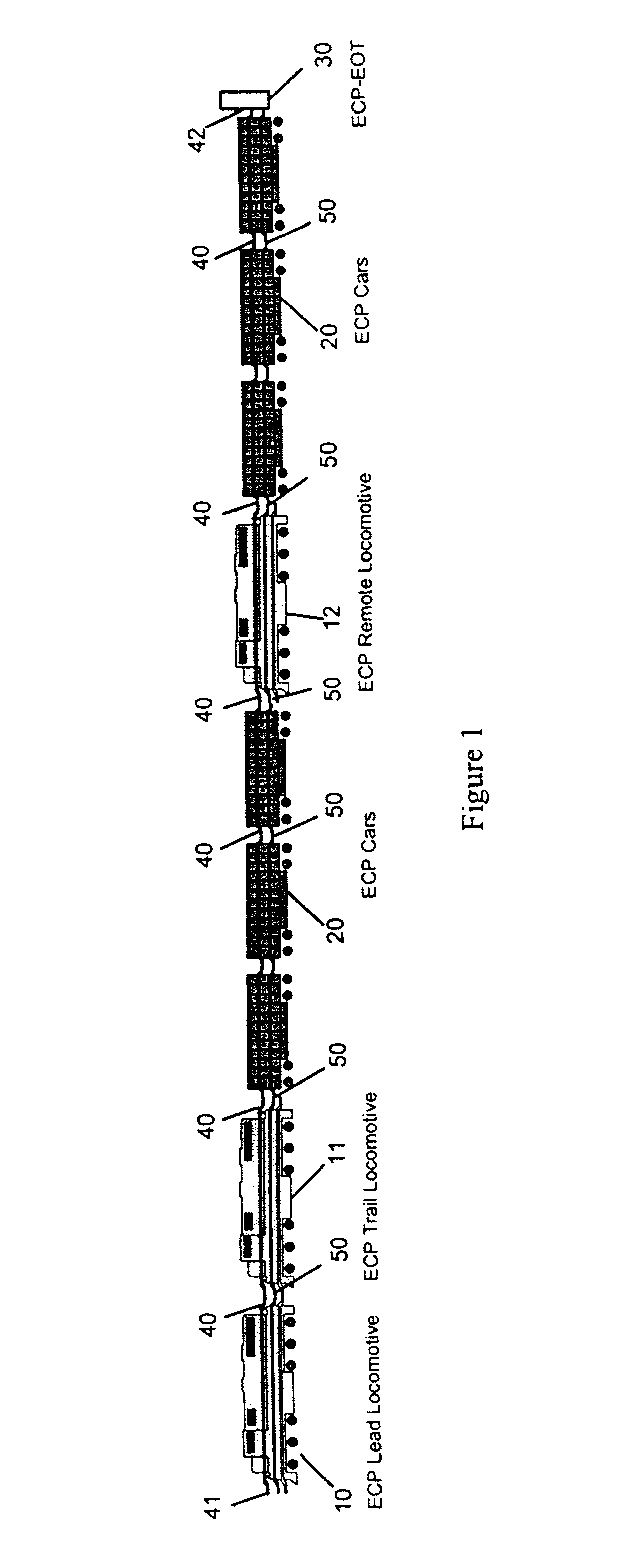

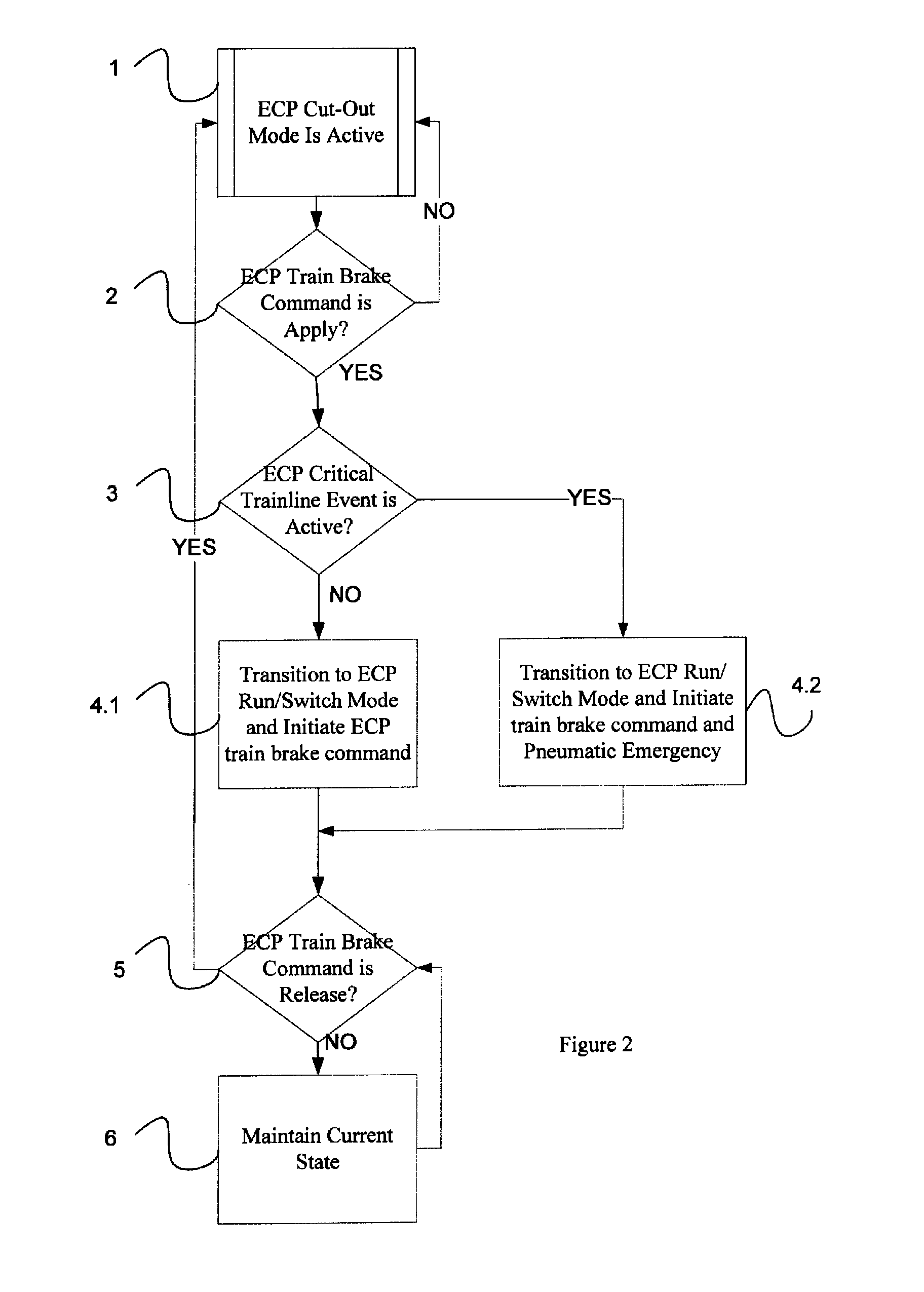

ECP terminal mode operation

ActiveUS8483894B2Improve performanceAnalogue computers for trafficBraking action transmissionSemi activePresent method

Owner:NEW YORK AIR BRAKE CORP

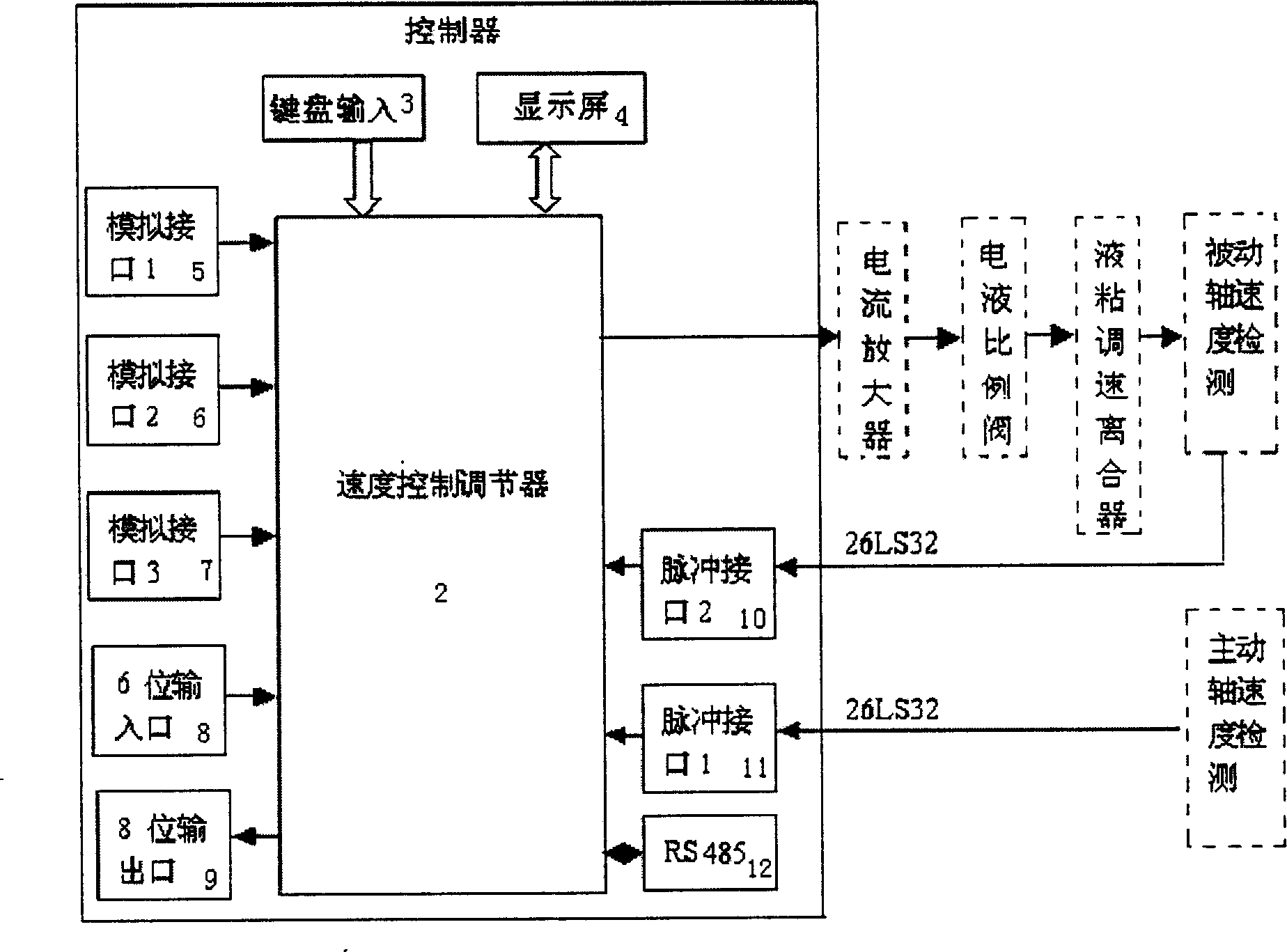

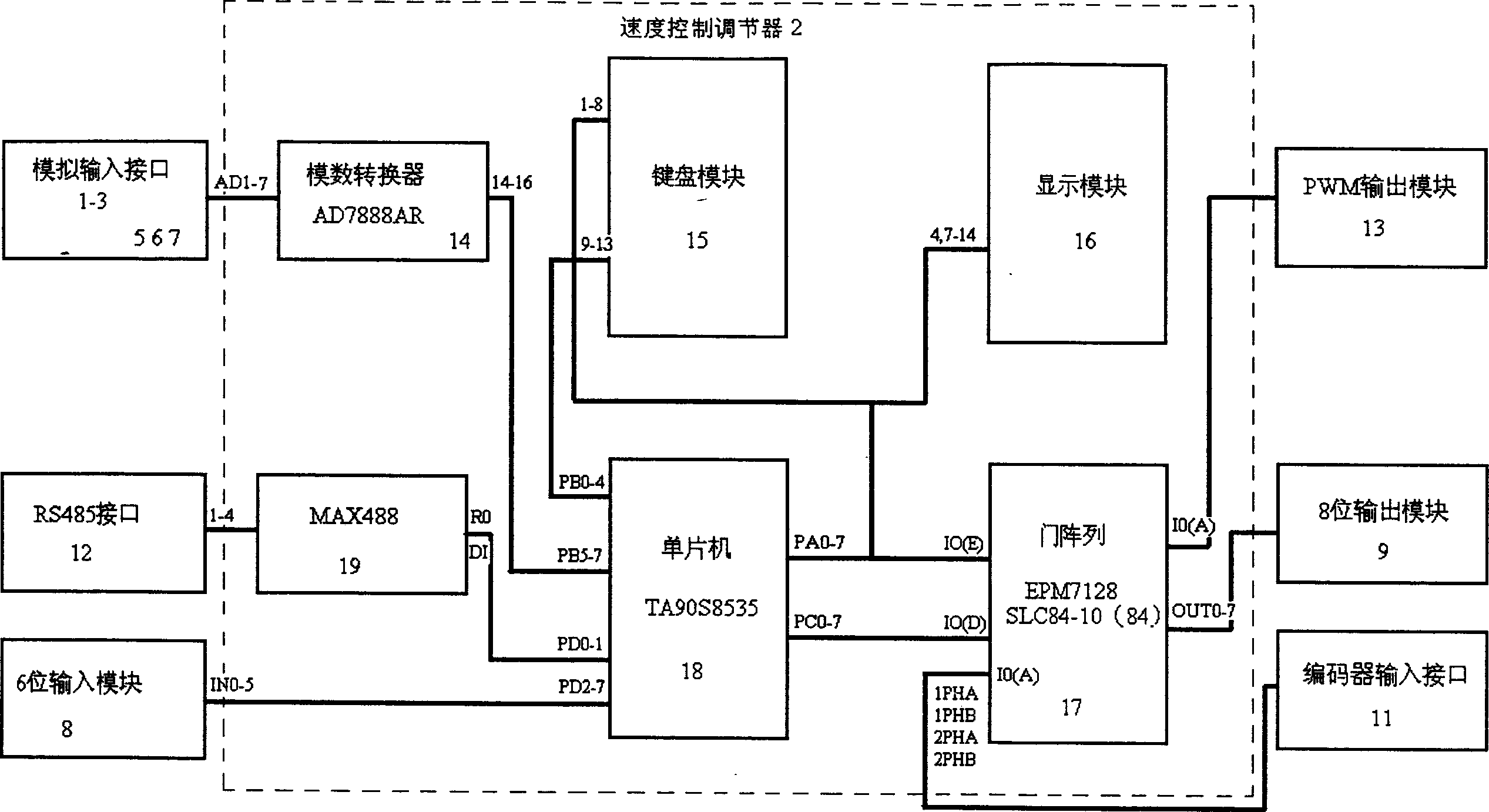

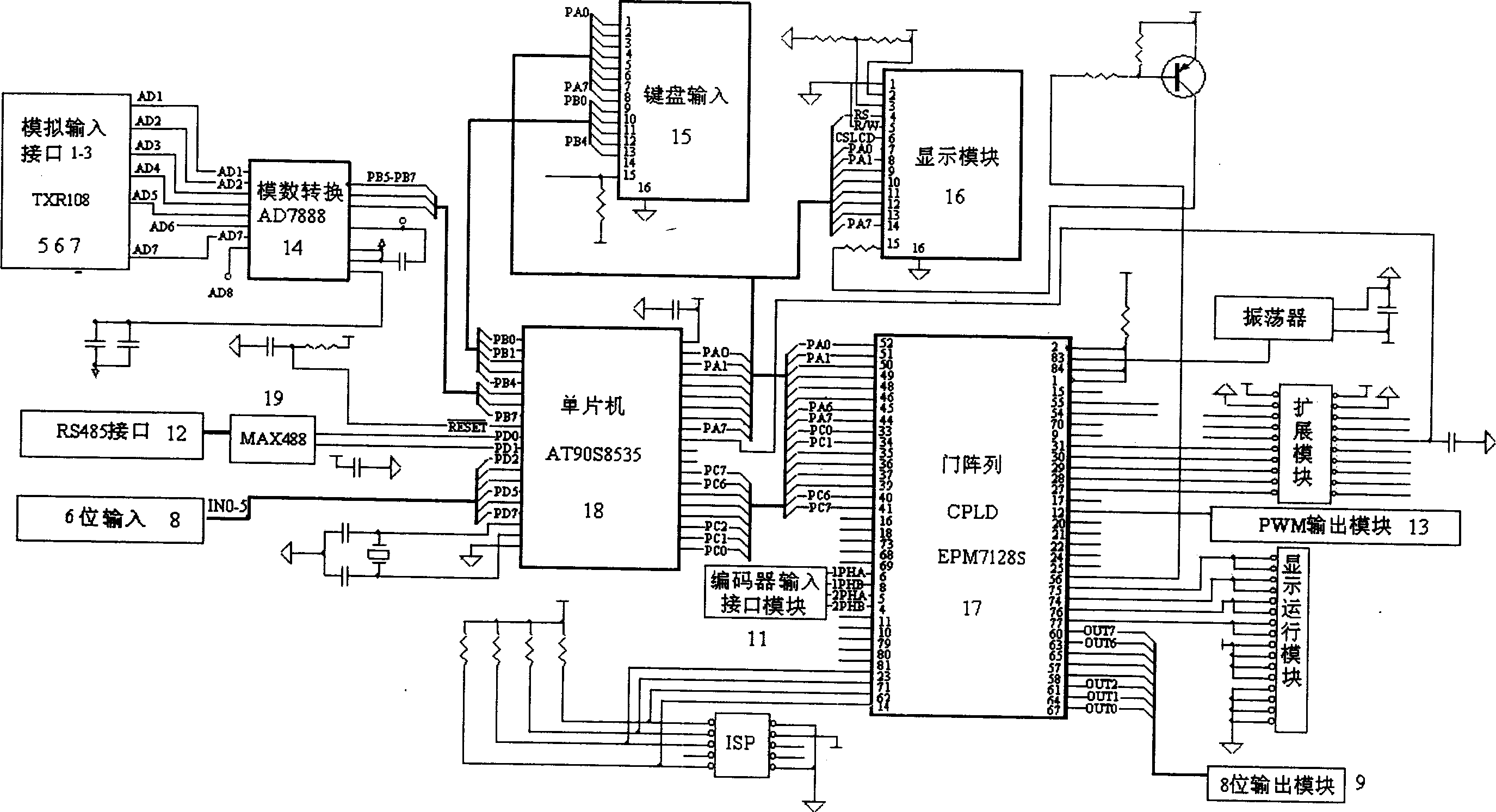

Digital fuzzy controller in use for variable speed clutch of viscous liquid

InactiveCN1728031AClear interfaceFacilitate man-machine dialogueFluid clutchesSpeed/accelaration control with auxillary non-electric powerViscous liquidAudio power amplifier

A digital fuzzy controller used on speed regulation clutch of viscous liquid is a speed regulator connected in external with three analog input interfaces, two digital interfaces, two pulse interfaces, RS485 interface, keyboard input and display screen. The said speed regulator uses one pulse interface to input speed signal detected out from driven shaft of speed regulation clutch and uses another pulse interface to input speed signal detected out from driving shaft of said clutch for applying photoelectric rotary coder to measure speed.

Owner:SHANGHAI UNIV

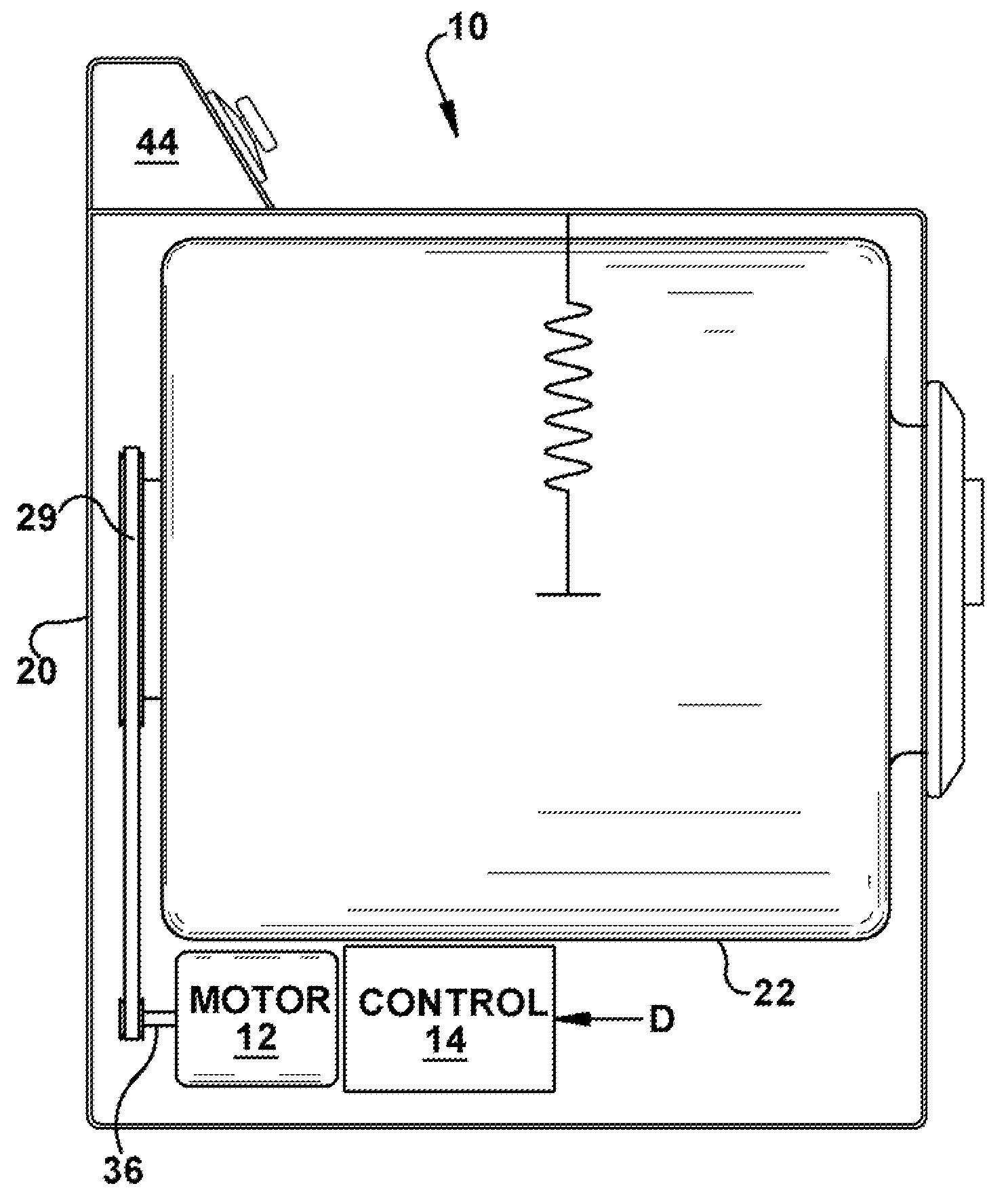

Motor apparatus and method

InactiveUS20090106912A1Consume energyAdditional hardwareSingle motor speed/torque controlControl devices for washing apparatusMotor speedConductor Coil

A method of operating a motor, the method comprising: operating a motor at a first speed; operating the motor in negative slip; imbalancing at least one phase of the motor to dissipate regeneration energy using windings of the motor; and wherein a next motor speed is decreased to a speed less than the first speed. An apparatus for carrying out the method is also presented.

Owner:GENERAL ELECTRIC CO

A Control Moment Gyro Frame Control System and Method for Suppressing Rotor Dynamic Unbalance Disturbance

ActiveCN105786036BGuaranteed dynamic performanceReduce the disturbing torqueSpeed/accelaration control with auxillary non-electric powerControl systemControl engineering

Owner:BEIJING INST OF CONTROL ENG

Passing from a non-synchronized state between an engine and a rotor to a synchronized state

ActiveUS20120277969A1Reduce the impactReduce impactAnalogue computers for vehiclesGas turbine plantsControl theoryTurbine

In order to regulate a power plant (105) having a gas generator (1) and a free turbine (3) to drive a rotary wing, a first speed of rotation (NTL) of the free turbine (3) is regulated on a first setpoint value (NTL*) equal either to a regulation term (NRc) or to a predetermined setpoint threshold (NTL*). The regulation term (NRc) is a function of a third speed of rotation (NR) of said rotary wing in accordance, where NRc=NR*(1−d), “d” representing a non-zero constant lying in the range 0 to 1.

Owner:EUROCOPTER

Speed control method and device for PTZ camera

ActiveCN105955328BEliminate jitterSpeed/accelaration control with auxillary non-electric powerMotor controlComputer science

The invention discloses a speed control device for a holder camera. The device comprises an instruction reception unit used for receiving a rotation instruction for driving the holder camera to rotate, a displacement calculation unit used for calculating a displacement distance of the holder camera from the present position to a target position according to the rotation instruction, a speed querying unit used for querying a pre-stored speed and an acceleration model according to the displacement distance to acquire a motor rotation speed, and a driving control unit used for sending the motor rotation speed acquired through querying to a motor control end of the holder camera to drive the holder camera to rotate to the target position. Through the device, jittering of the holder camera can be eliminated to a great degree at relatively low cost.

Owner:成都全景智能科技有限公司

Control method of a wind turbine generator

ActiveUS8759995B2Extends operation and efficiencyExtended speed rangeVector control systemsWind motor controlTurbineDynamo

The control method of a wind turbine generator increases the speed range of wind turbine generators, maximizing the operation and efficiency thereof, in addition to lengthening their service life, on minimizing the extreme and fatigue loads to which the wind turbine generators are subject, and which are due mainly to the stops and disconnections thereof as a result of strong gusts of wind. More specifically, the control method of the present invention stands out essentially for being based on the control of the reactive current circulating through the electric generator, said reactive current control being carried out in accordance with the rotational speed (ωg) for the purpose of reducing the voltage at the converter terminals on the generator side, or rotor voltage (VR), which ultimately allows a transitional increase in the speed range of the wind turbine generator.

Owner:NORDEX ENERGY SPAIN SA

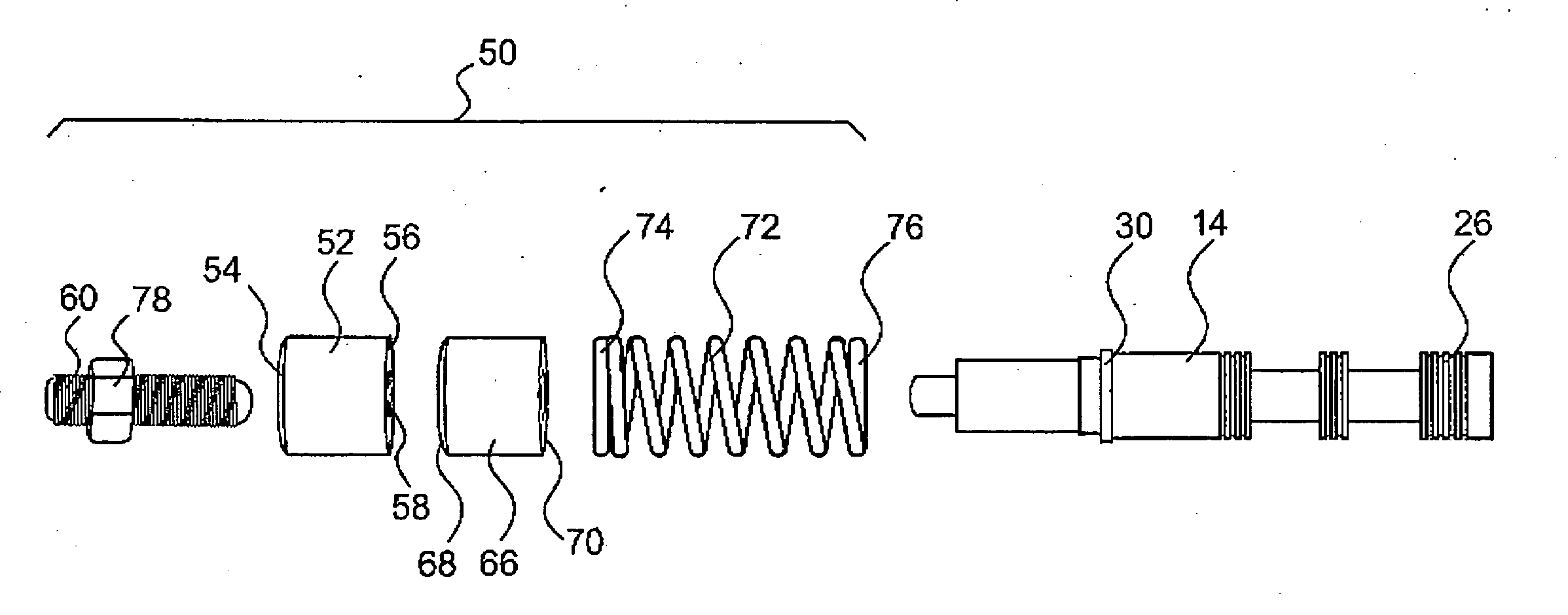

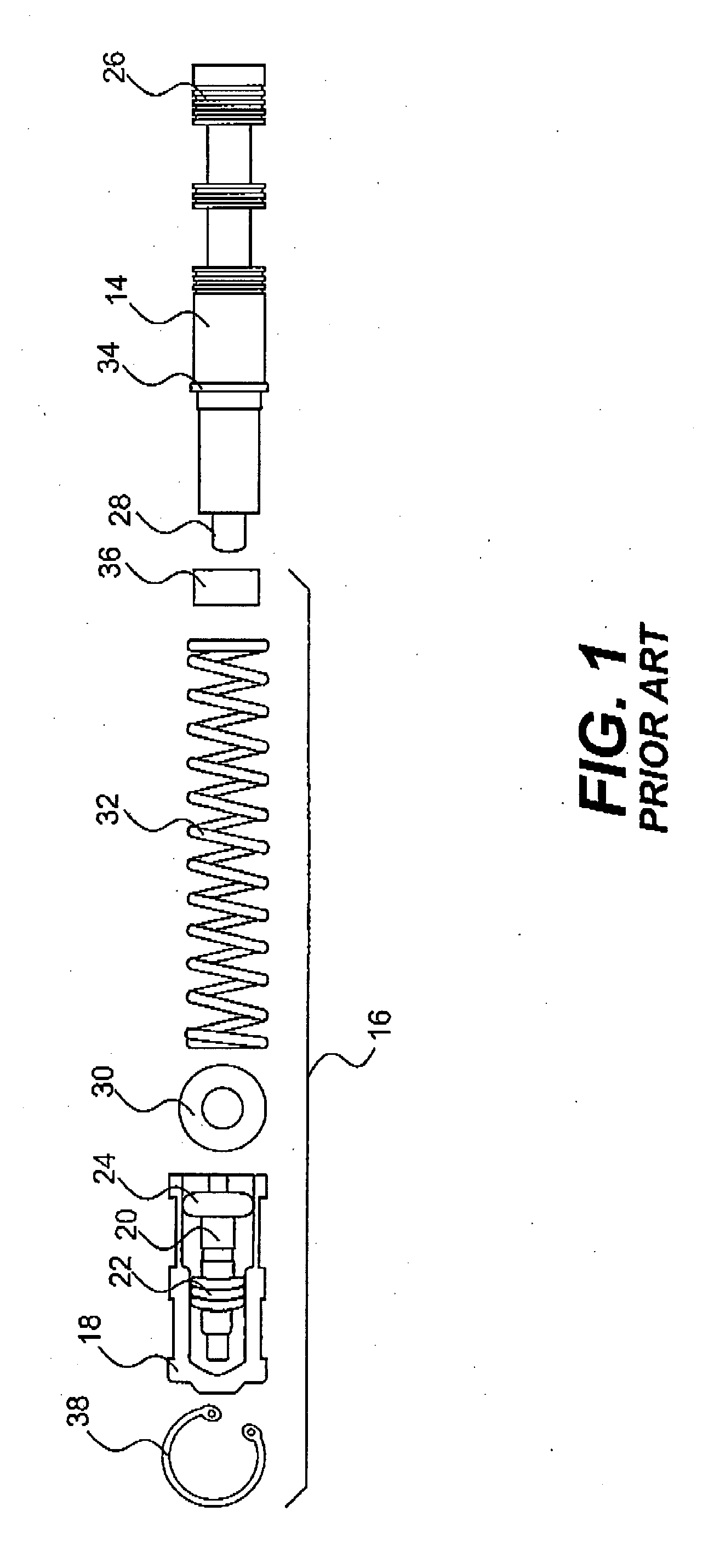

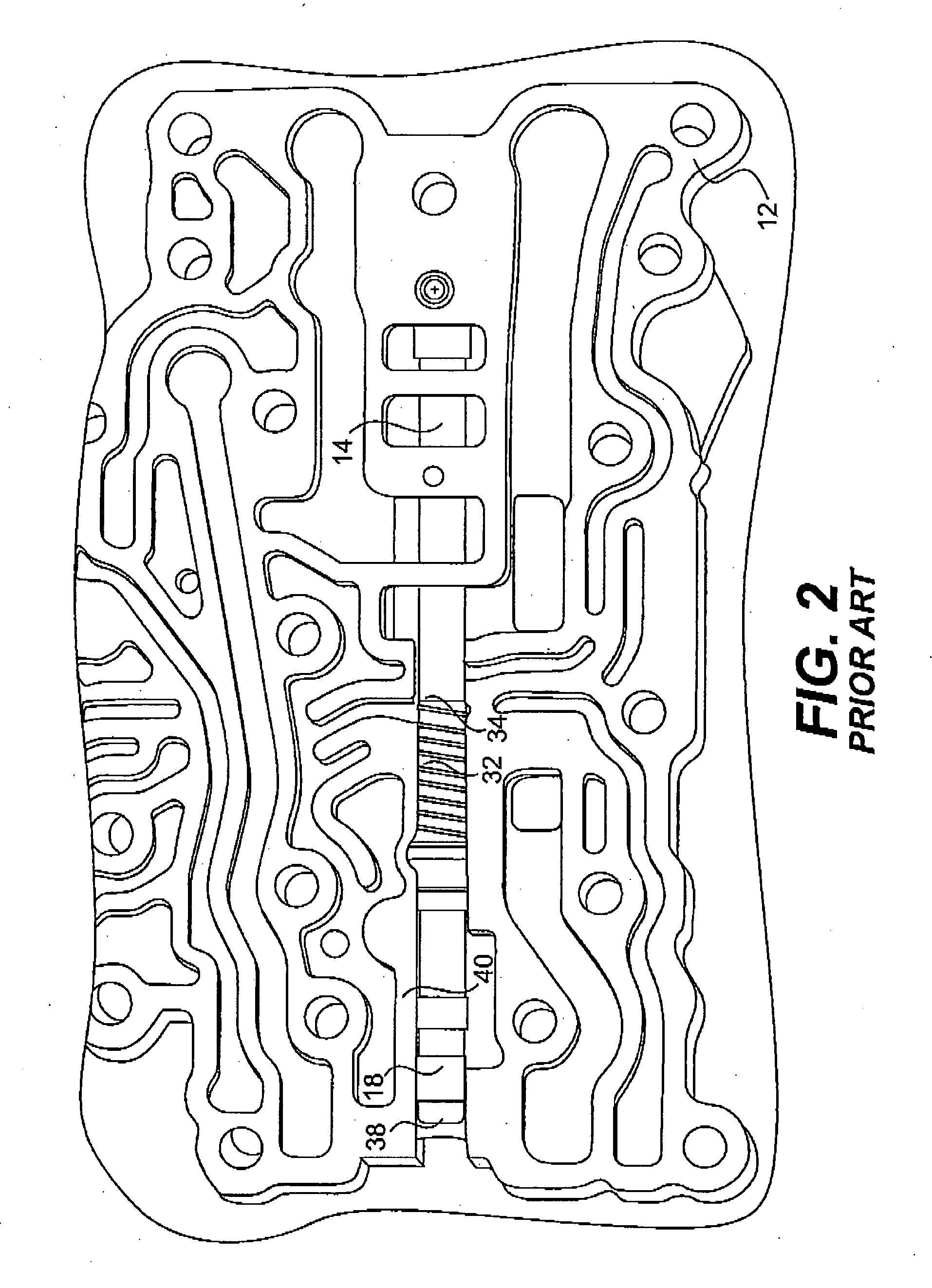

Automatic transmission hydraulic line pressure regulator

InactiveUS20080026912A1Increase pressureReduce line pressureGearingGearing controlAutomatic transmissionScrew thread

An automatic transmission line pressure regulator includes a first body for installation in a valve bore distant from a line pressure valve and having a threaded bore passing therethrough, a threaded adjuster axially engaged in the threaded bore and rotationally adjustable with respect to the first body, a second body for installation in the valve bore and engagement with the threaded adjuster and a spring for installation between and engagement with the second body and the line pressure valve. Rotation of the threaded adjuster with respect to the first body alters an axial position of the adjuster, the second body and a first end of the spring, thereby altering a pre-load on the spring to alter a resistive force against movement of the line pressure valve caused by line pressure, and thusly, regulates line pressure.

Owner:ATI PERFORMANCE PRODS

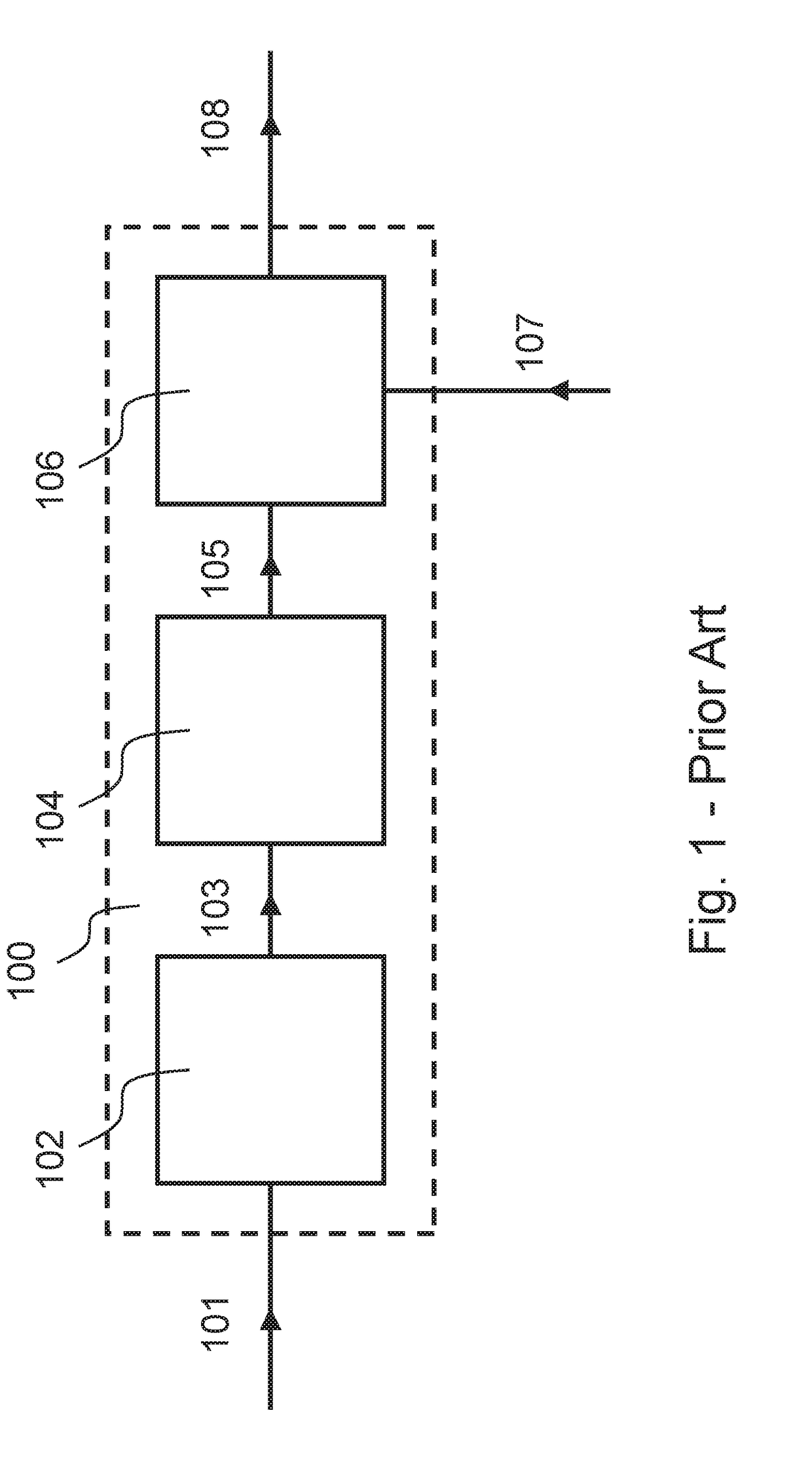

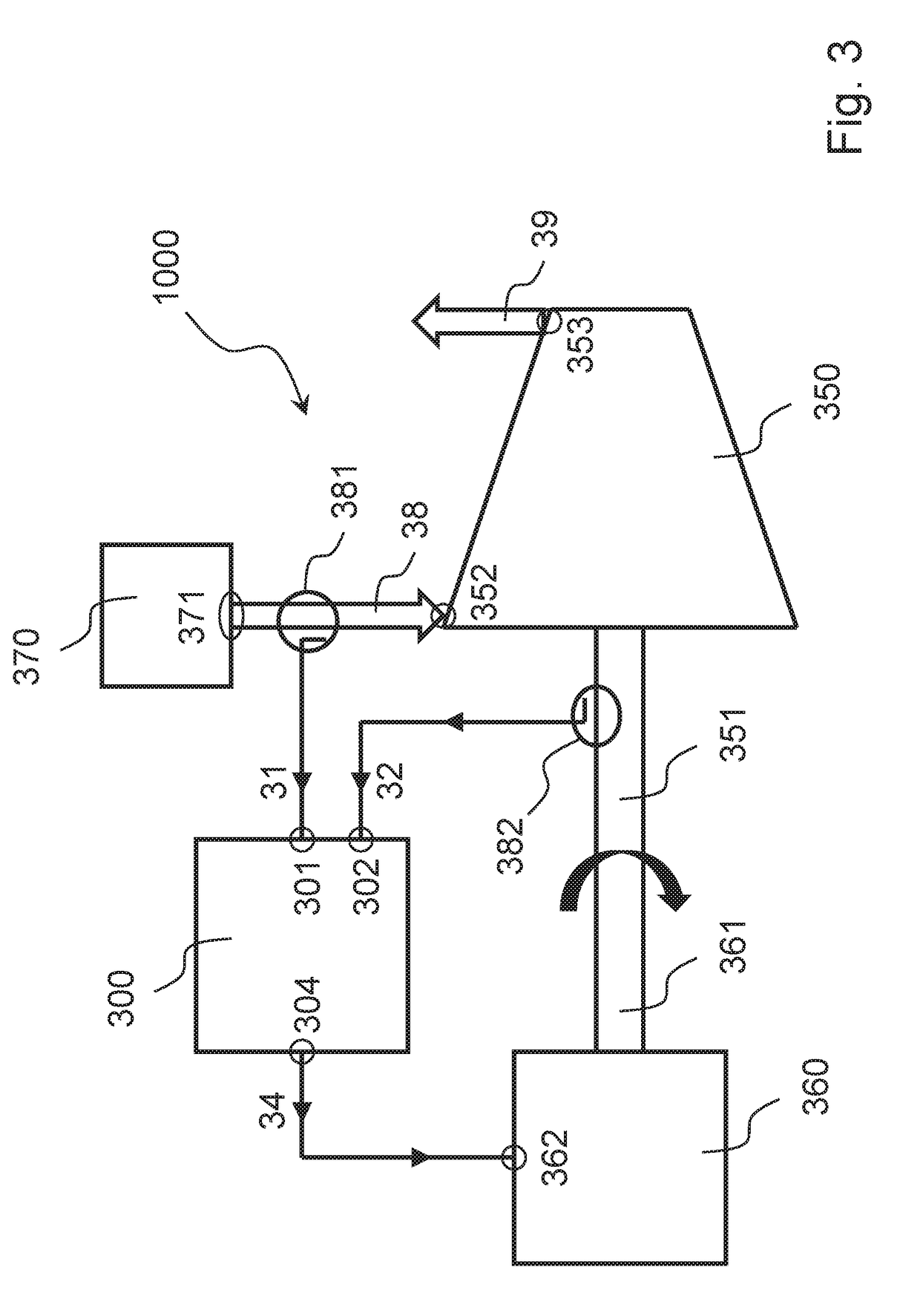

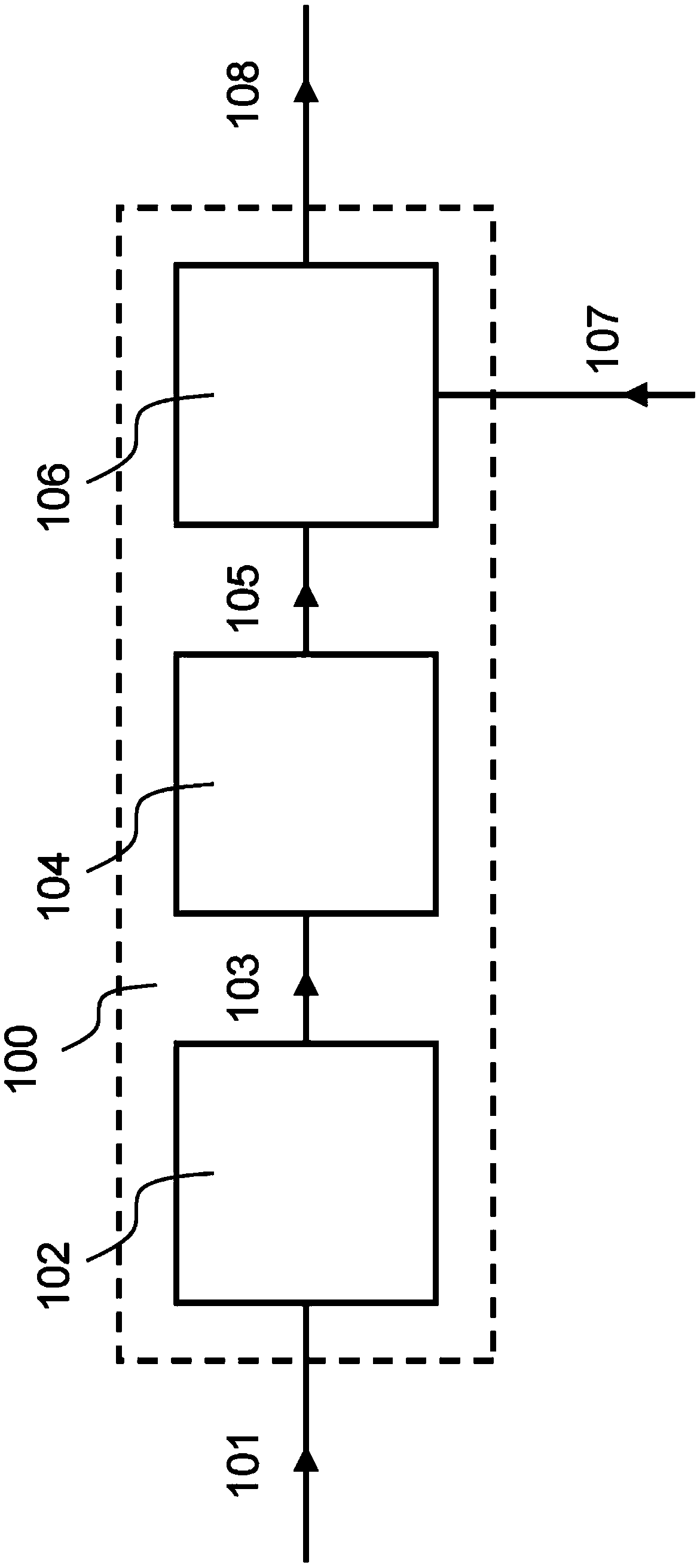

Control system for a compressor with speed-based subsystem, synthesis plant and control method

InactiveUS20190078575A1Efficient regulation technologiesTurbine/propulsion fuel controlControl signalControl system

Control system arranged for a rotary compressor driven by a rotary engine, and includes: a first control subsystem, a second control subsystem and a selector; the first control subsystem is arranged to provide a first control signal as a function of the performance of the compressor; the second control subsystem is arranged to provide a second control signal as a function of the speed of the compressor; the selector is arranged to select the first control signal or the second control signal as a third control signal to be provided to a power control input of the engine.

Owner:NUOVO PIGNONE TECH SRL

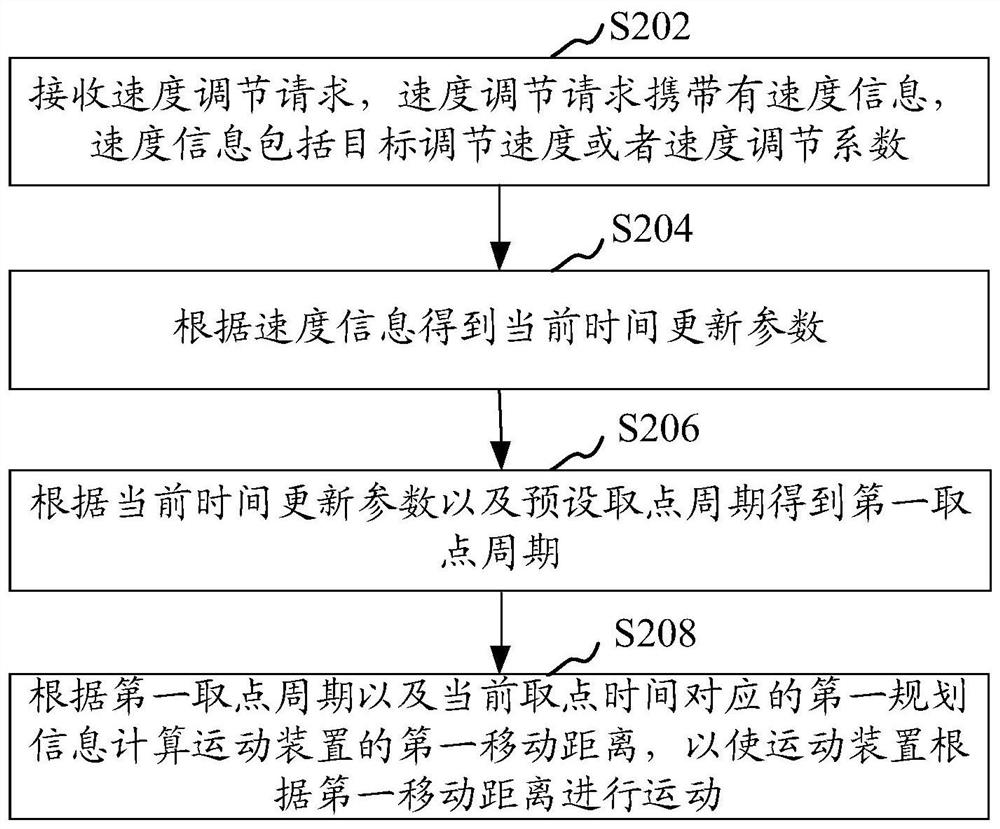

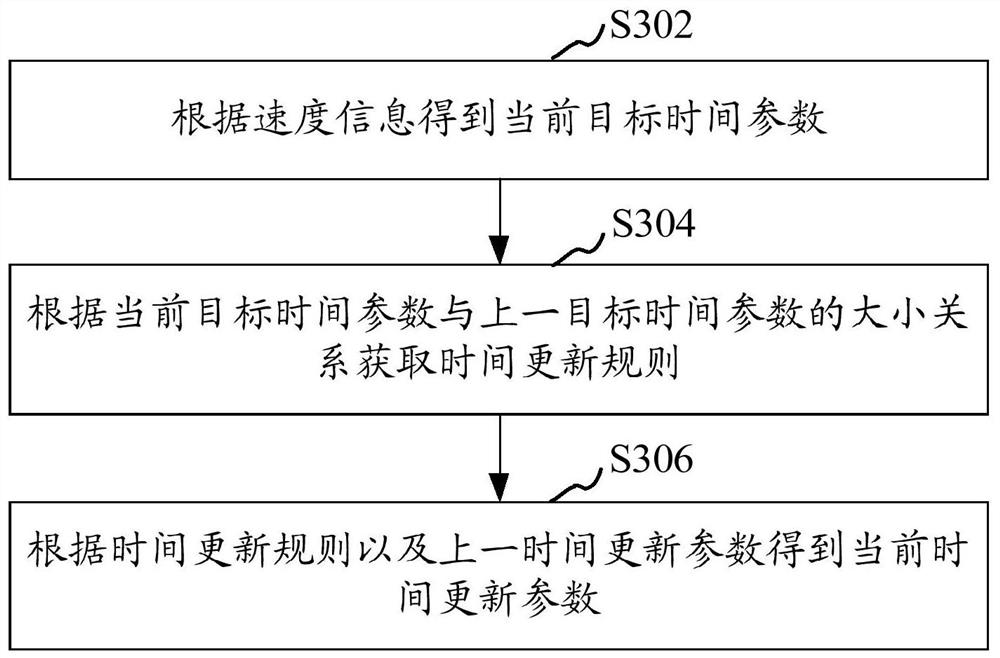

Speed adjustment method, device, computer equipment and storage medium

ActiveCN107561933BShorten the timeImprove real-time performanceProgramme-controlled manipulatorSpeed/accelaration control with auxillary non-electric powerSimulationReliability engineering

The present invention relates to a speed adjustment method, a speed adjustment device, a computer apparatus and a storage medium. The method includes the following steps that: a speed adjustment request is received, wherein the speed adjustment request carries speed information, wherein the speed information contains a target adjustment speed or a speed adjustment coefficient; a current time update parameter is obtained according to the speed information; a first point selection period is obtained according to the current time update parameter and a preset point selection period; and the firstmovement distance of a movement device is calculated according to the first point selection period and first planned information corresponding to a current point selection time, so that the movementdevice can be made to move according to the first movement distance, wherein the first planned information contains a first planned speed or a first planned distance. With the above method adopted, time for speed adjustment is decreased, and the real-time performance of the speed adjustment is improved.

Owner:SHENZHEN TONGCHUAN TECH

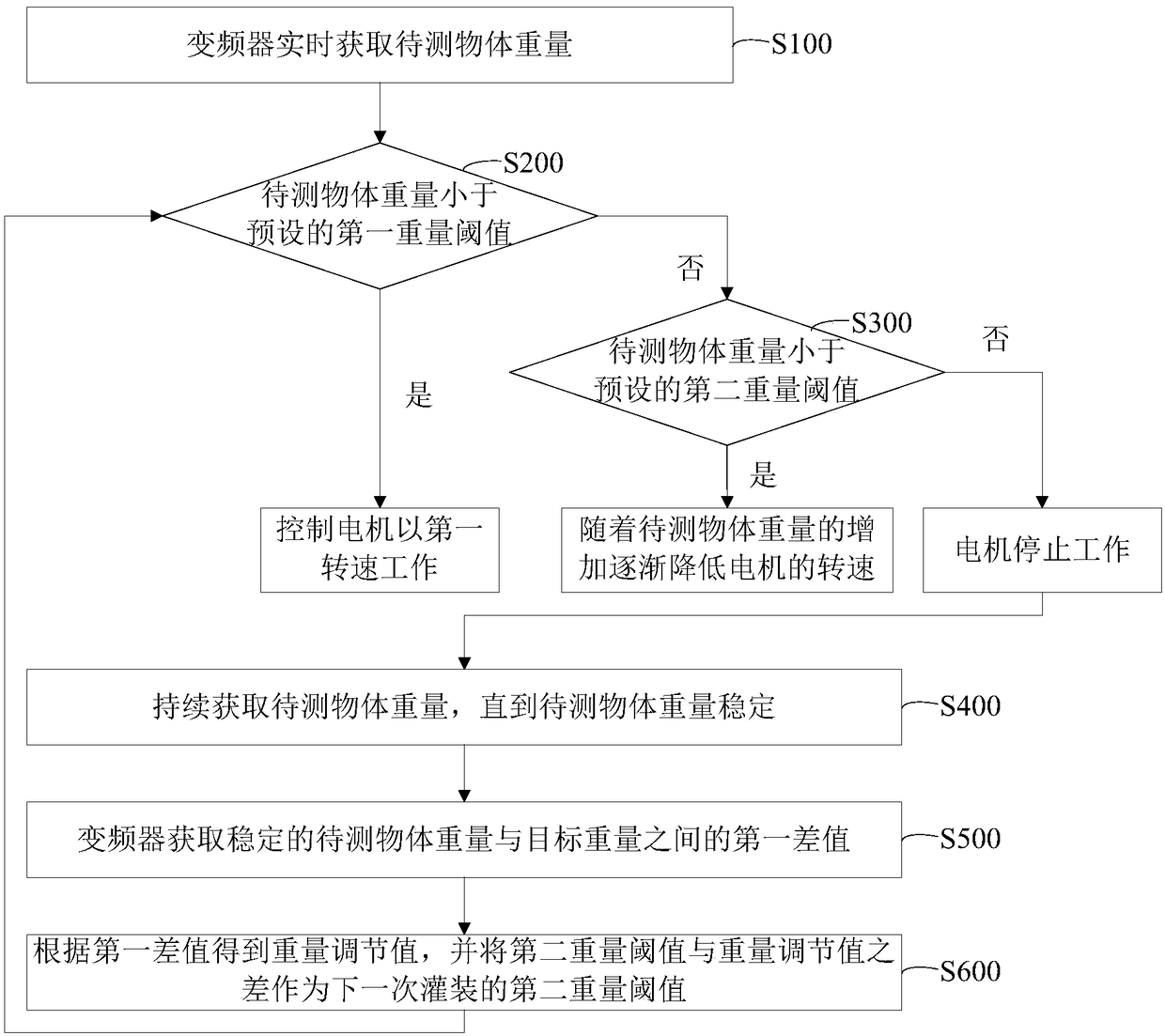

Frequency converter control method and frequency converter

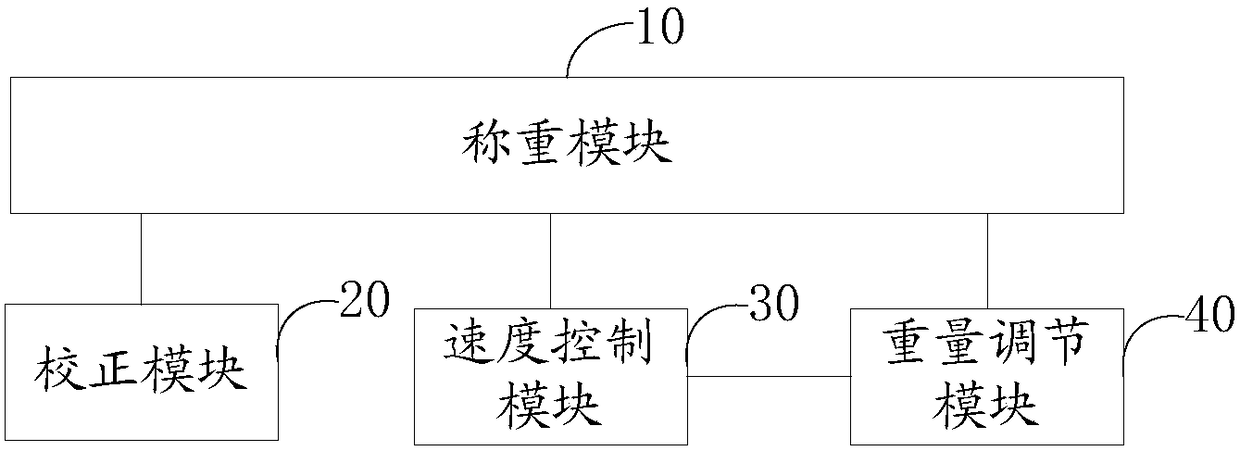

InactiveCN108508926AReduce manufacturing costControl weight errorBarrels/casks fillingSpeed/accelaration control with auxillary non-electric powerStopped workFrequency changer

The present invention relates to a frequency converter control method and a frequency converter. The frequency converter control method comprises the steps of: obtaining the weight of an object to bemeasured in real time; controlling the rotating speed of a motor of a filling device according to the weight of an object to be measured, if the weight of the object to be measured is smaller than a preset first weight threshold value, controlling the motor to work with a first rotating speed; if the weight of the object to be measured is larger than or equal to a preset first weight threshold value, or smaller than a second weight threshold value, gradually reducing the rotating speed of the motor with increasing of the weight of the object to be measured; if the weight of the object to be measured is equal to the second weight threshold value, controlling the motor to stop work; after the motor stops work, continuously obtaining the weight of the object to be measured until the weight ofthe object to be measured to be stable; and obtaining a first difference between the stable weight of the object to be measured and a target weight, obtaining a weight regulation value according to the first difference, and taking difference of the second weight threshold value and the weight regulation value as a second weight threshold value of next filling. The control method can effectively control weight errors and can effectively reduce the weight errors through multi-times cycle filling.

Owner:SHENZHEN HPMONT TECH

Optimal distribution method of uniaxial batch reaction flywheel torque based on angular momentum margin

ActiveCN103345275BReduce consumptionAvoid saturationSpeed/accelaration control with auxillary non-electric powerWeight coefficientFlywheel

The invention discloses a single-shaft batch counteractive flywheel moment optimal distribution method based on an angular momentum margin, and belongs to the field of control distribution. The multi-objective optimization distribution method based on the angular momentum margin is designed for solving the problem that due to the fact that a traditional moment distribution method takes no account of self angular momentum of flywheels, the flywheels are saturated and cannot complete tasks. A weight coefficient optimization method is used, system energy consumption and output margins of the flywheels are integrally considered, a suitable weight coefficient is given to each item according to energy consumption and the output margin of each flywheel, the weight coefficients are adjusted in the process of moment distribution, therefore, energy consumption is reduced, and saturation of the flywheels is avoided. The single-shaft batch counteractive flywheel moment optimal distribution method based on the angular momentum margin is beneficial to improving flywheel system output capacity, can save fuel to a certain extent, and can be widely used for the field of rapid spacecraft attitude maneuver.

Owner:哈尔滨工大卫星技术有限公司

Variable-parameter PID (proportion-integration-differentiation) control circuit and variable-parameter PID control method for electric steering gear

ActiveCN102622001BReasonable designGood control effectSpeed/accelaration control with auxillary non-electric powerCapacitanceAviation

The invention relates to a variable-parameter PID (proportion-integration-differentiation) control circuit and a variable-parameter PID control method for an electric steering gear, which belong to the technical field of automatic control. The PID control circuit comprises a filtering circuit, a PID circuit, an adding circuit, a deviation judgment circuit and an on-off switching circuit, wherein the deviation judgment circuit is used for controlling on and off of two groups of output of an analog switch in the on-off switching circuit by means of a deviation value of input signals and feedback signals of an electric steering gear closed-loop system, so that whether a parallel resistor and a parallel capacitor are inputted into the PID circuit or not are controlled, and online adjustment of PID parameters is realized. By the aid of the variable-parameter PID control circuit and the variable-parameter PID control method, the problem that the electric steering gear of an aviation guided weapon is difficult to achieve good control effect with a group of preset PID parameters in the working environment of great inertia, nonlinearity, strong interference and the like. The variable-parameter PID control circuit is reasonable in design, simple and feasible, is capable of effectively weakening systematic buffeting, increasing systematic robustness and improving control precision, and can guarantee the system to have good control quality in different control phases.

Owner:HARBIN JIANCHENG GRP

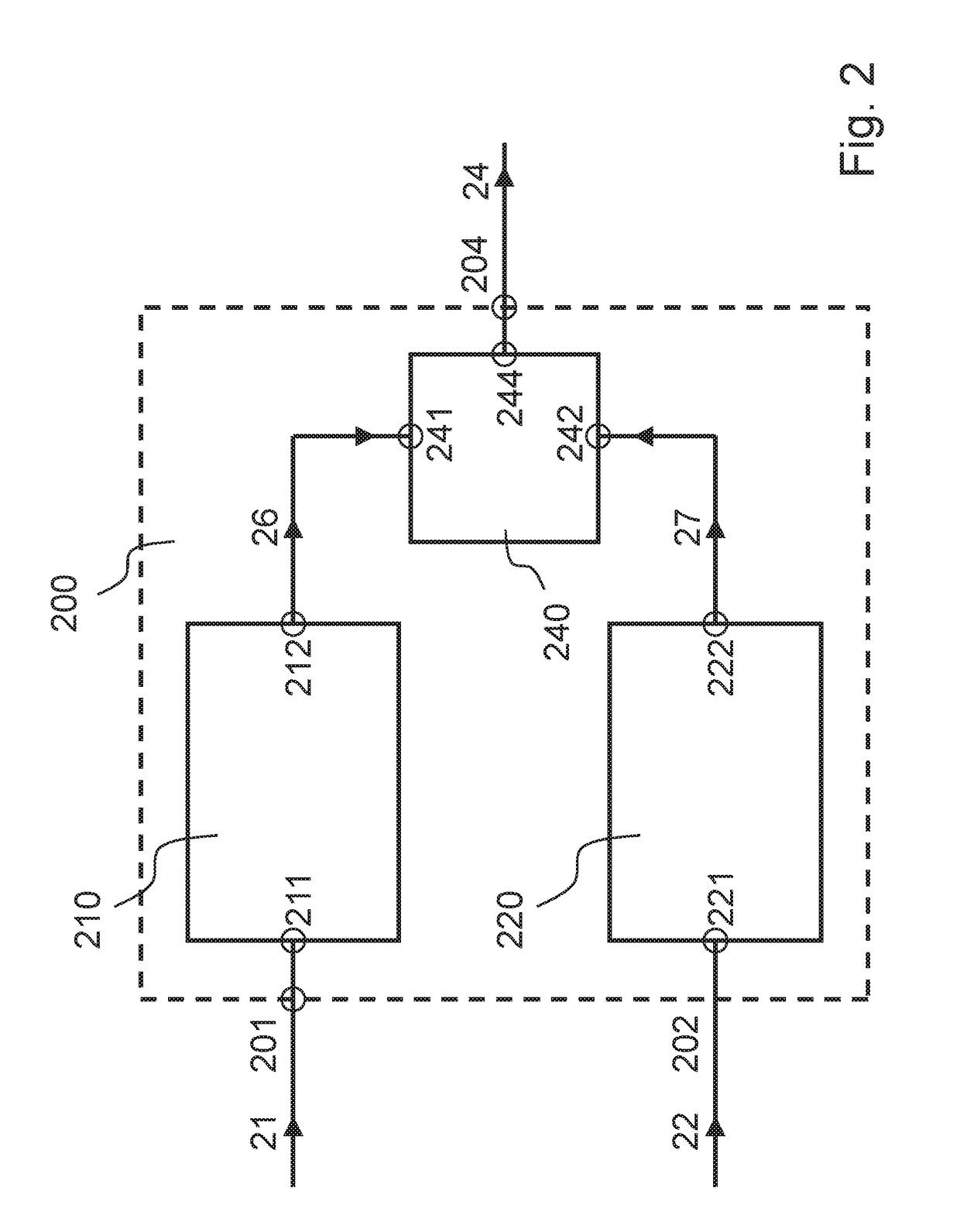

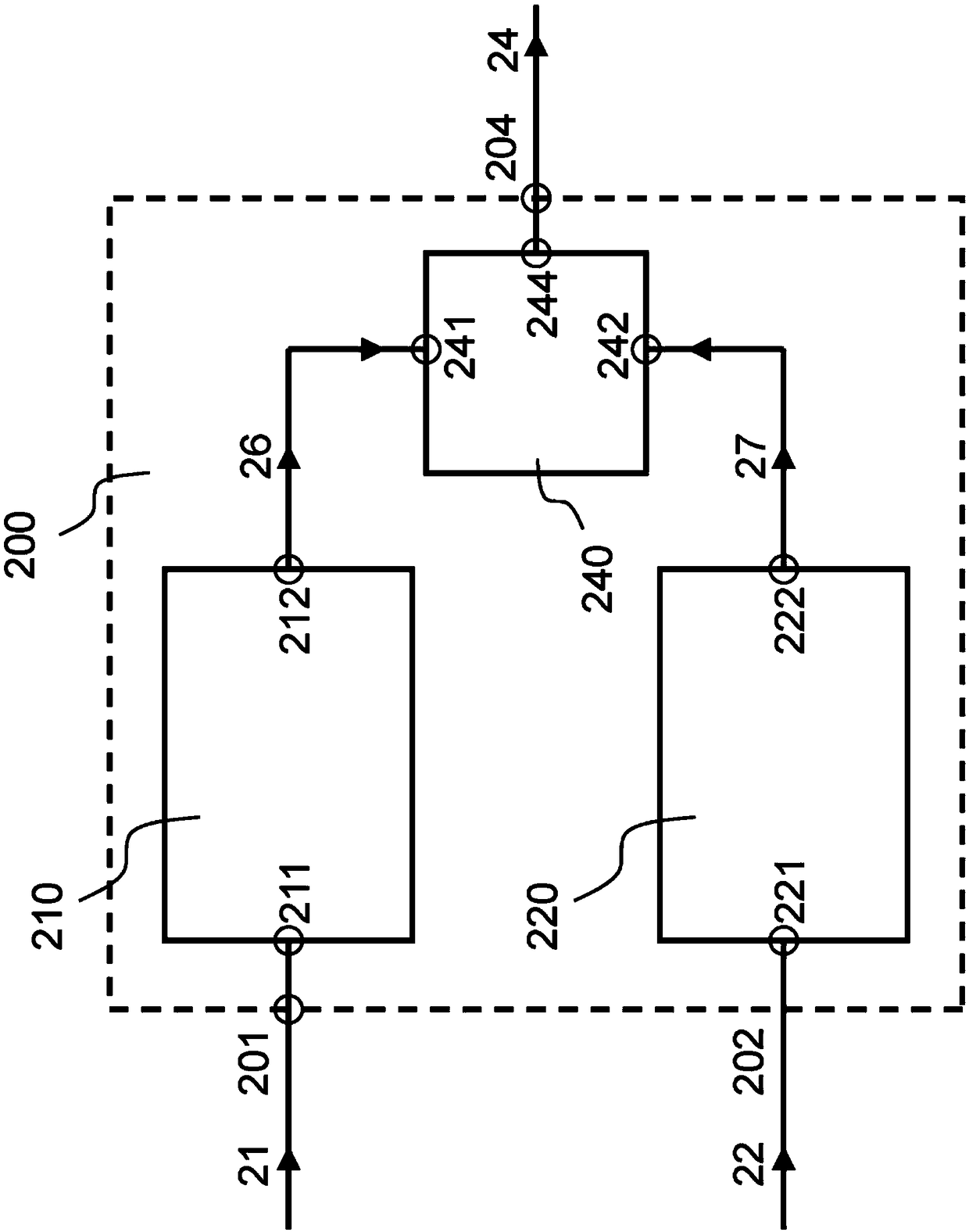

Control system for compressor with speed-based subsystem, synthesis plant and control method

ActiveCN109469639AEfficient regulation technologiesTurbine/propulsion fuel controlControl signalControl system

A control system (200) arranged for a rotary compressor driven by a rotary engine, and includes: a first control subsystem (210), a second control subsystem (220) and a selector (230); the first control subsystem (210) is arranged to provide a first control signal (26) as a function of the performance (21) of the compressor; the second control subsystem (220) is arranged to provide a second control signal (27) as a function of the speed (22) of the compressor; the selector (240) is arranged to select the first control signal (26) or the second control signal (27) as a third control signal (24)to be provided to a power control input of the engine.

Owner:NUOVO PIGNONE TECH SRL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com