Control system and method for eliminating stick-slip vibration of drill string

A stick-slip vibration and control system technology, applied in the direction of auxiliary non-electric speed/acceleration control, etc., can solve the problems of reducing the working efficiency and life of the drill string, and the fatigue of the drill string, so as to reduce the probability of downhole accidents and reduce drilling costs. , the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

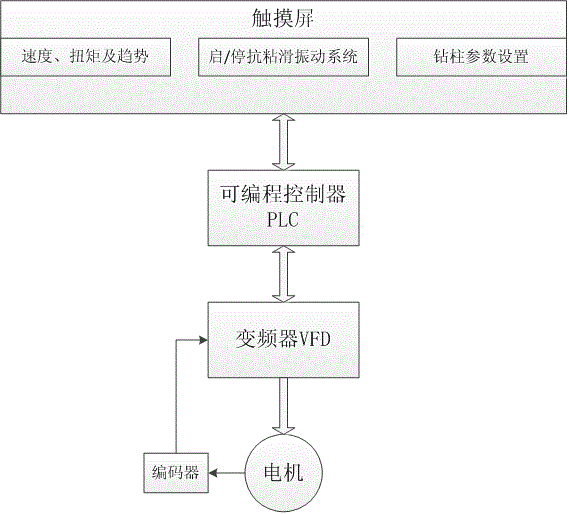

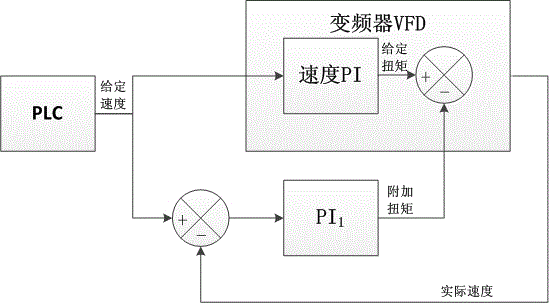

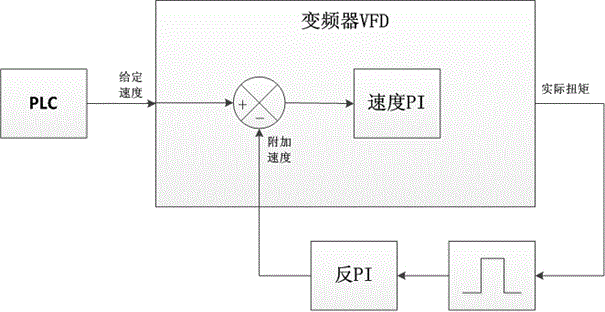

[0038] Such as figure 1 As shown, a control system for eliminating the stick-slip vibration of the drill string includes a touch screen, a programmable controller PLC and a motor with an encoder; the touch screen and the programmable controller PLC are connected to each other for displaying the motor speed The given value and actual value, motor torque actual value and limit value, motor speed, torque, operating status information and drill string setting parameters; the programmable logic controller PLC is used to eliminate drill string stickiness by controlling the speed of the motor slipping phenomenon; the motor is used to obtain the drill string system motion, and the motor speed and torque are controlled in real time by the programmab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com