Patents

Literature

57results about How to "Reduce Downhole Accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoelectric power generation type high-temperature drilling fluid cooling and circulating system

InactiveCN108457609ARapid cycle coolingReduce the temperatureMachines/enginesFlushingEngineeringHigh pressure

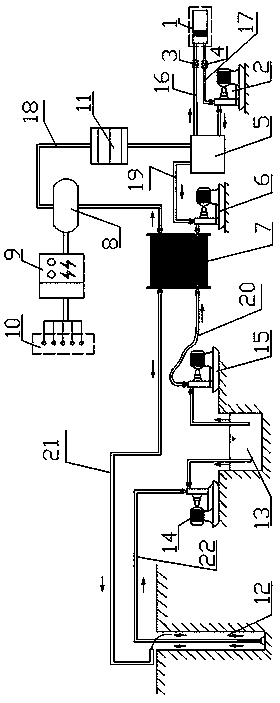

A thermoelectric power generation type high-temperature drilling fluid cooling and circulating system comprises a refrigerating unit, a refrigerating unit pump, a first valve, a second valve, a cooling fluid loading box, a cooling fluid delivering pump, a heat exchanger, a steam-turbine generator, an electricity storage box, electric equipment, a condenser, a well, a drilling fluid pond, a first drilling fluid delivering pump and a second drilling fluid delivering pump; the first drilling fluid delivering pump is positioned between the well and the drilling fluid pond, and pumps the high-temperature drilling fluid upwards returning from the well to the drilling fluid pond; and the second drilling fluid delivering pump is positioned between the drilling fluid pond and the heat exchanger, and delivers the high-temperature drilling fluid to the heat exchanger. By the heat exchanger, the high-temperature drilling fluid and the cooling fluid are subjected to heat exchange, the exchanged cooling fluid becomes high-temperature and high-pressure gas which enters the steam-turbine generator to drive the generator to generate power, and the generated electric energy is stored in the electricity storage box and supplies power for the electric equipment. After the high-temperature drilling fluid becomes low-temperature drilling fluid by exchange through the heat exchanger, the low-temperature drilling fluid enters the well through a sixth pipeline.

Owner:JILIN UNIV

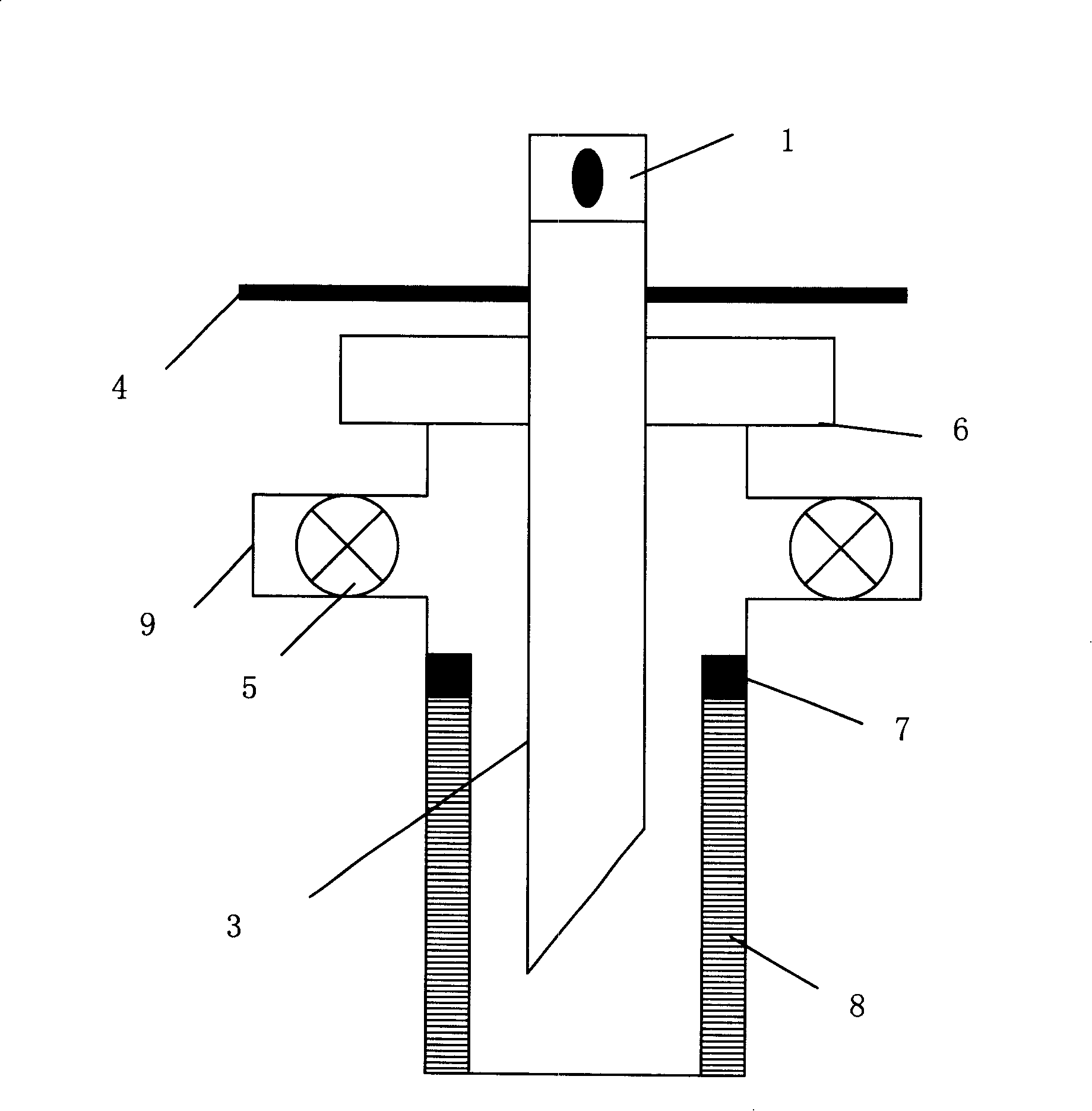

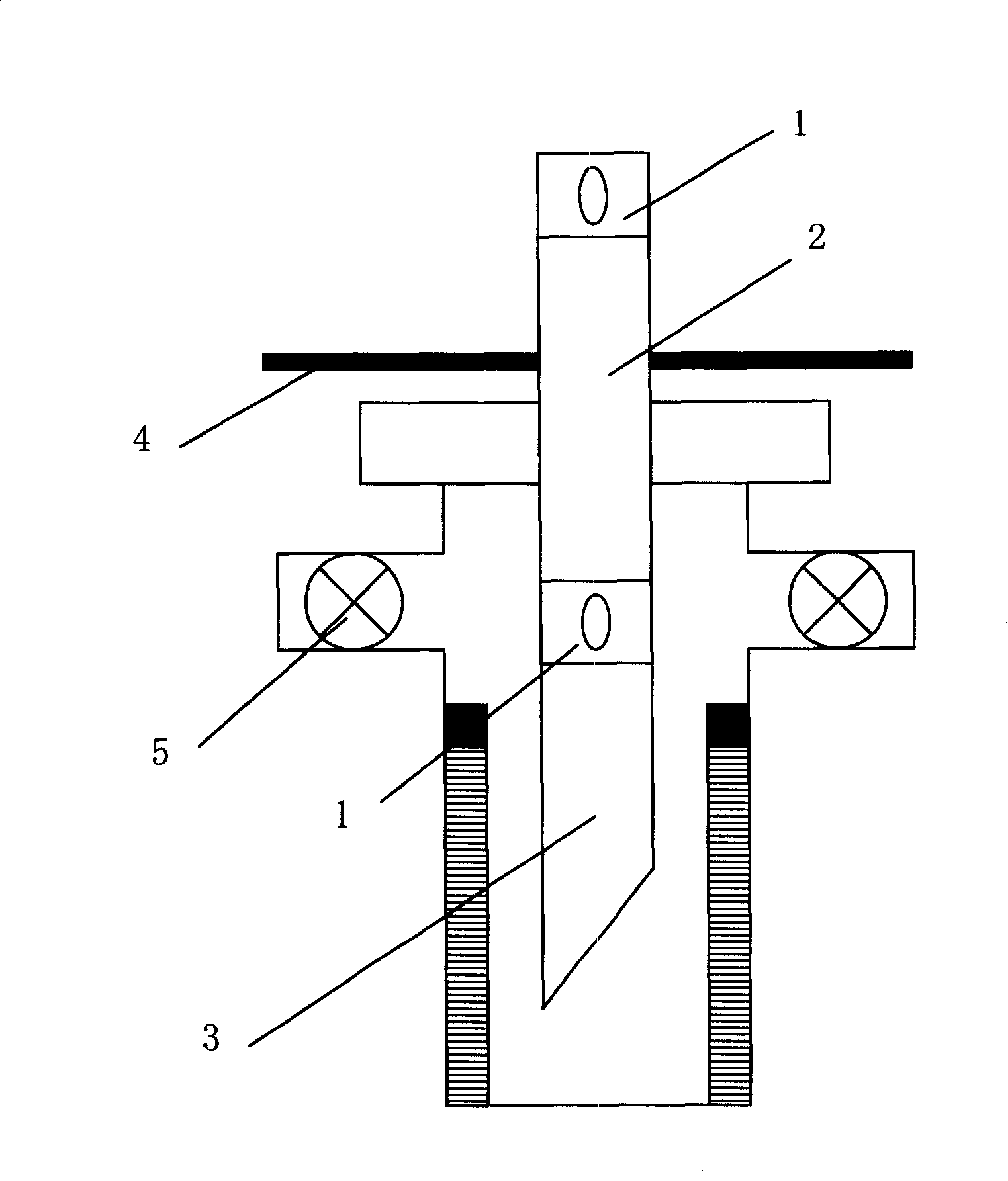

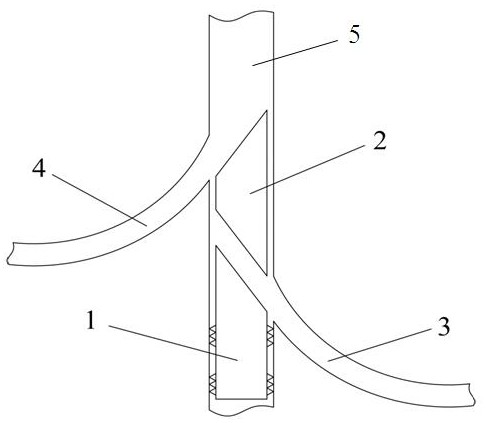

Pulse impact producing mechanism and center differential pressure drill comprising same

InactiveCN106703701ASimple structure and principleWide range of applicationsDrill bitsDrilling drivesDriven elementEngineering

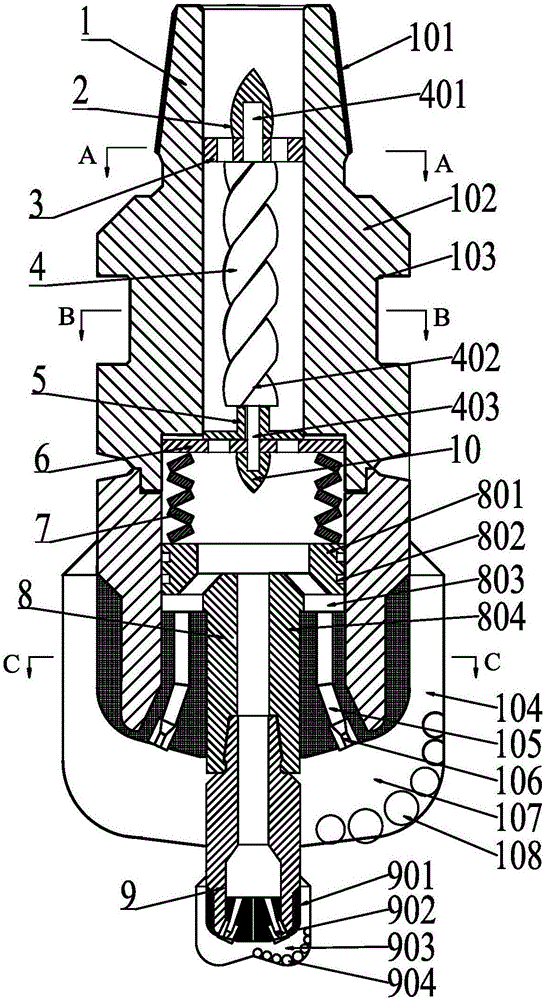

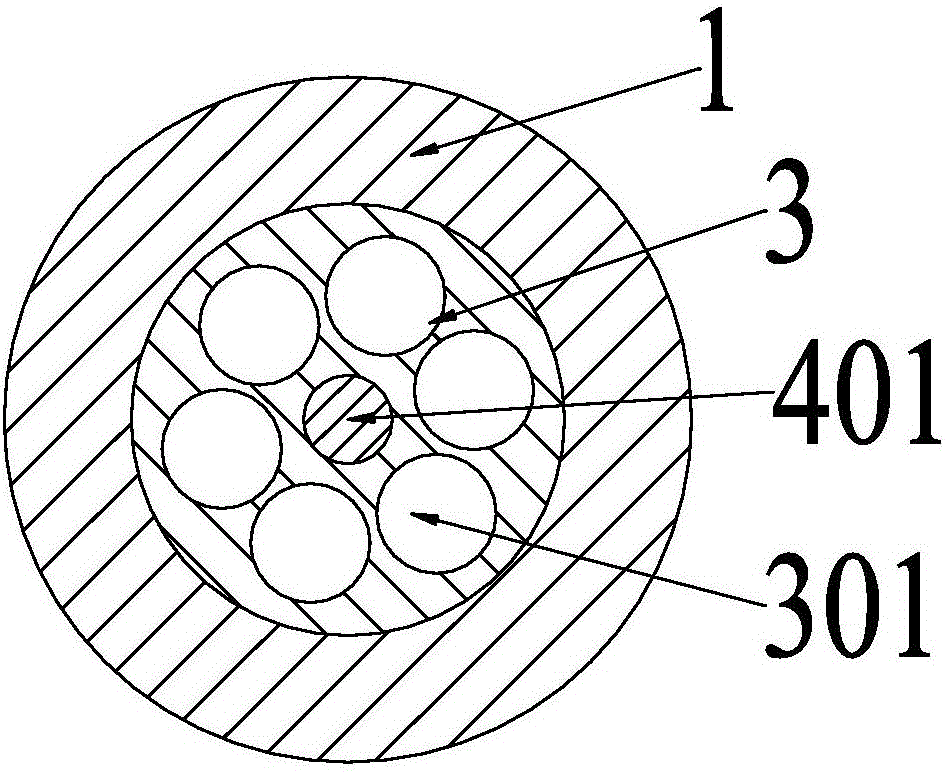

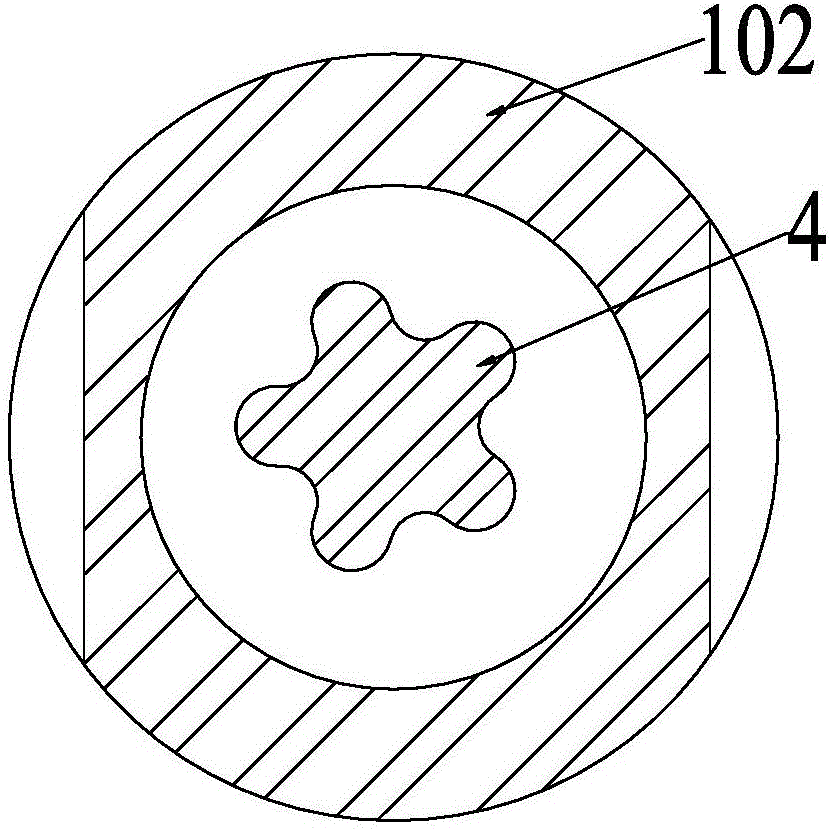

The invention relates to a pulse impact producing mechanism and a center differential pressure drill comprising the same. The pulse impact producing mechanism comprises a righting element, a driving element, a rotating element and a throttling element which are placed sequentially, the righting element, the driving element and the rotating element are connected sequentially, the throttling element and the rotating element are in clearance fit, overcurrent channels which are used for flowing of a drilling fluid are arranged on the righting element and the throttling element, the driving element drives the rotating element to rotate, and the overcurrent channels on the rotating element and the throttling element move relatively. The center differential pressure drill comprises a reaming bit, the pulse impact producing mechanism, a pressure regulating element, a transmission mechanism and a pilot bit, and the pressure regulating element, the transmission mechanism and the pilot bit are connected sequentially. Compared with the prior art, the cuttings hold-down effect of the pilot bit and the reaming bit is reduced while rotary impact drilling of the pilot bit can be realized, further the purposes of protecting the bits, prolonging the service lives and improving the drilling speed are realized, and the drilling effect is further improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

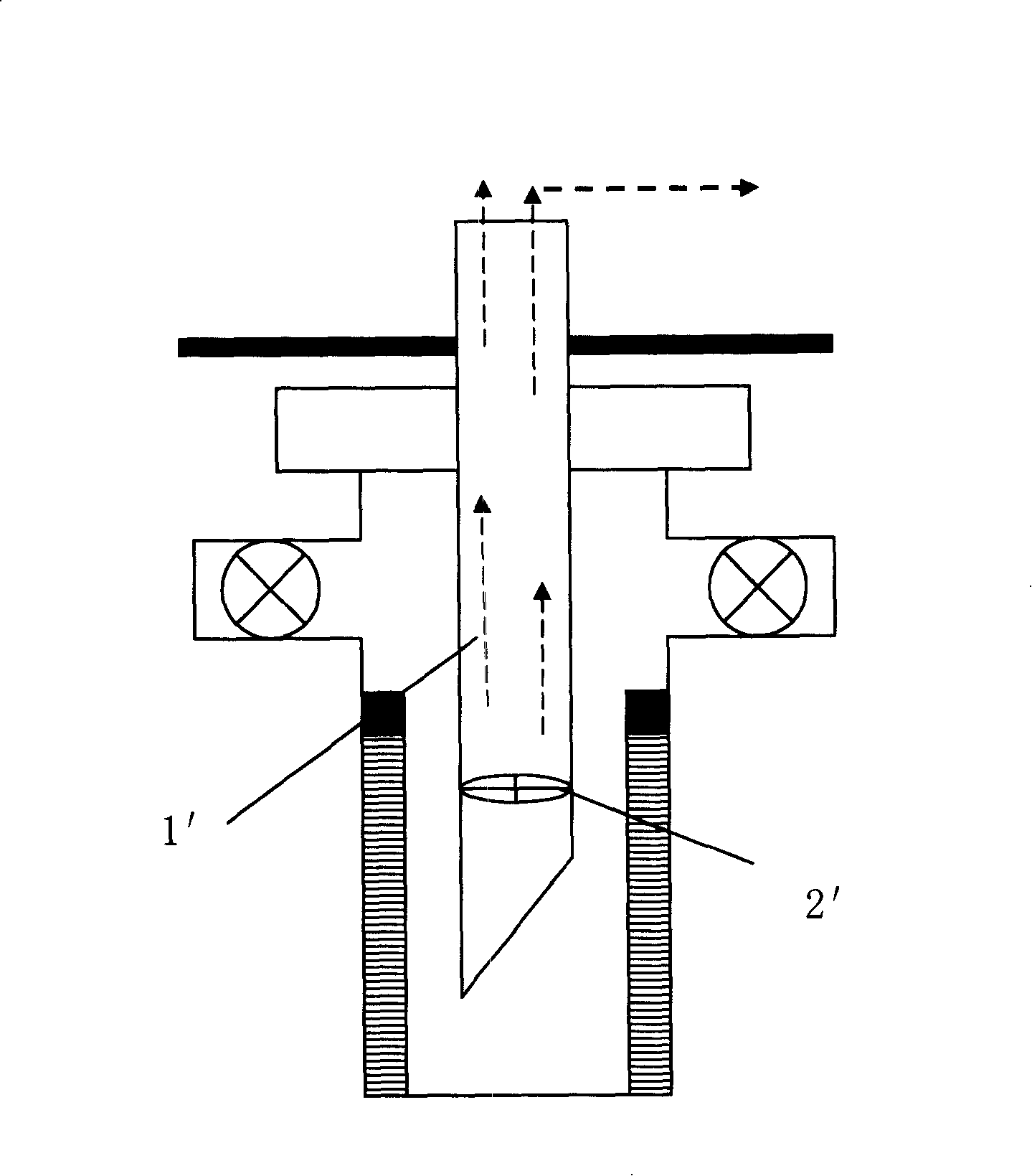

Continuous sand flushing technique and continuous sand flushing device thereof

The invention discloses a continuous sand-washing process and a continuous sand-washing device formed by, firstly, mounting control valves one by one on the upper port of a sand-washing pipe column and on the upper port of a single sand-washing pipe column. When the control valve is open, a regular sand-washing pipe column reaches down. When the sand-washing pipe column approaches or reaches the sand sediment or oil send at the bottom of a well, if extension is needed, single sand-washing pipe columns provided with control valves are connected one by one to establish sand-washing circulation channel, start a mud pump and carry out sand-washing operation; the control valve in open state allows double-way passage and offers such options as regular positive circulation operation and reverse circulation operation. Meanwhile, the control valve is started or closed manually to decouple from or couple with the single sand-washing pipe column. The invention is not subject to the restriction of sand medium and is particularly suitable for sand-washing operation by nitrogen foam under low-pressure well. The process saves the pressure-releasing time for connecting single sand-washing pipe column every time, realizes continuous sand washing, improves efficiency, prolongs the time of oil well production, and thus reduces cost and increases benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

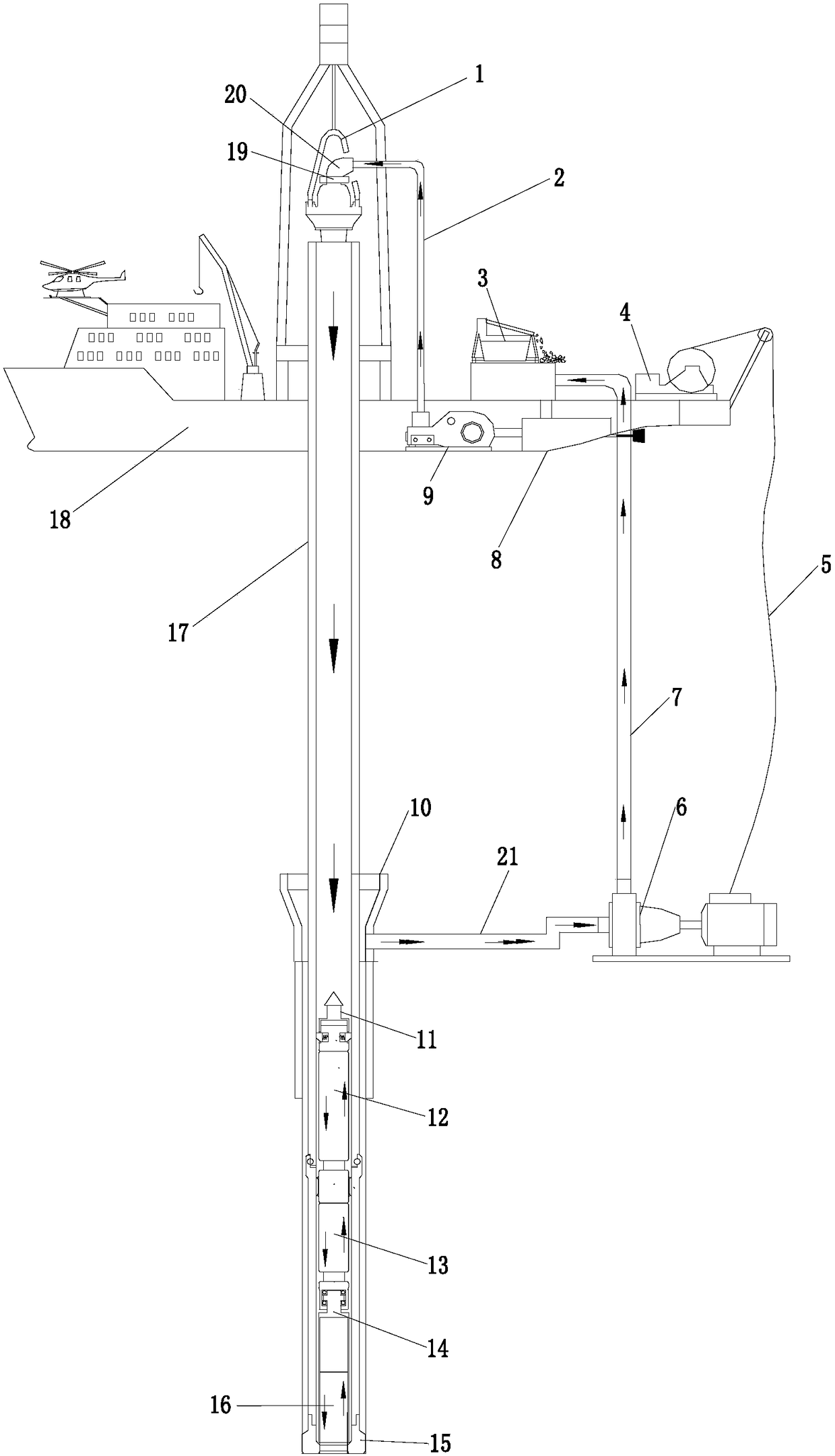

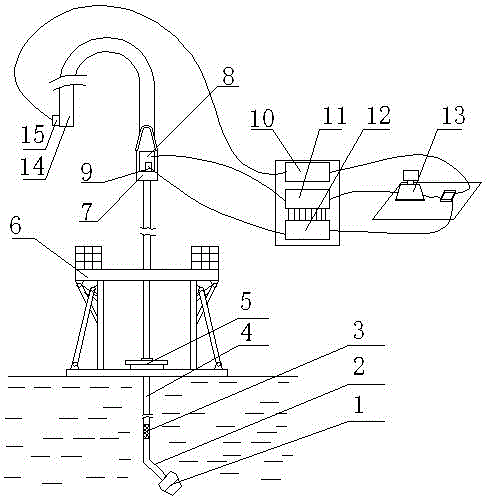

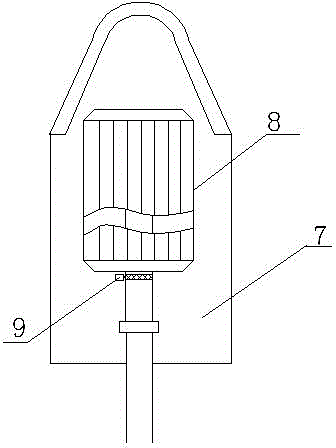

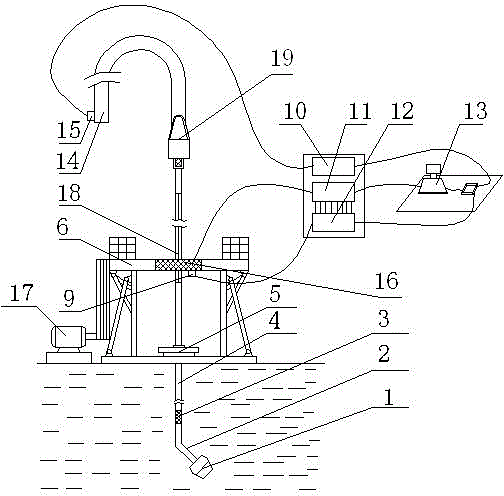

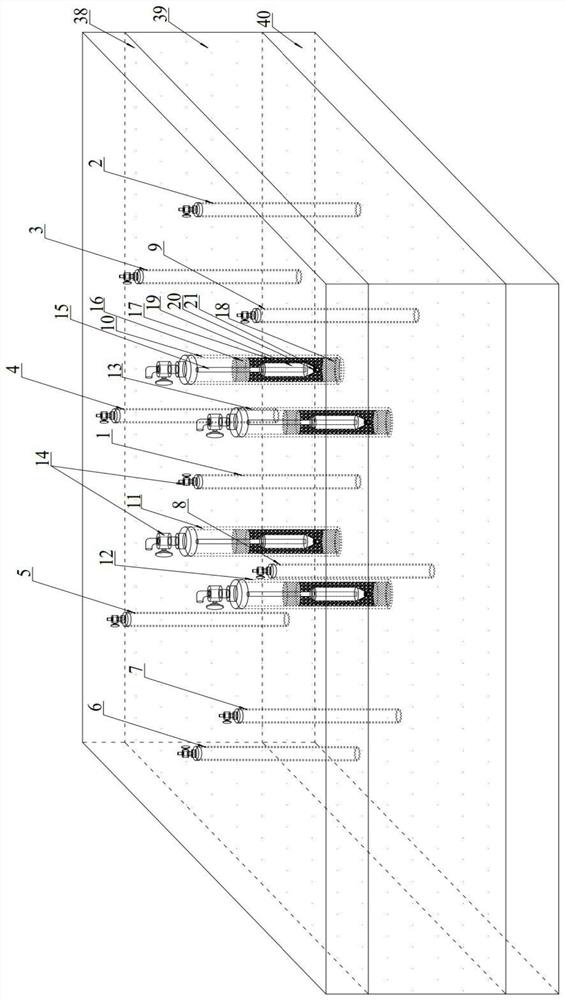

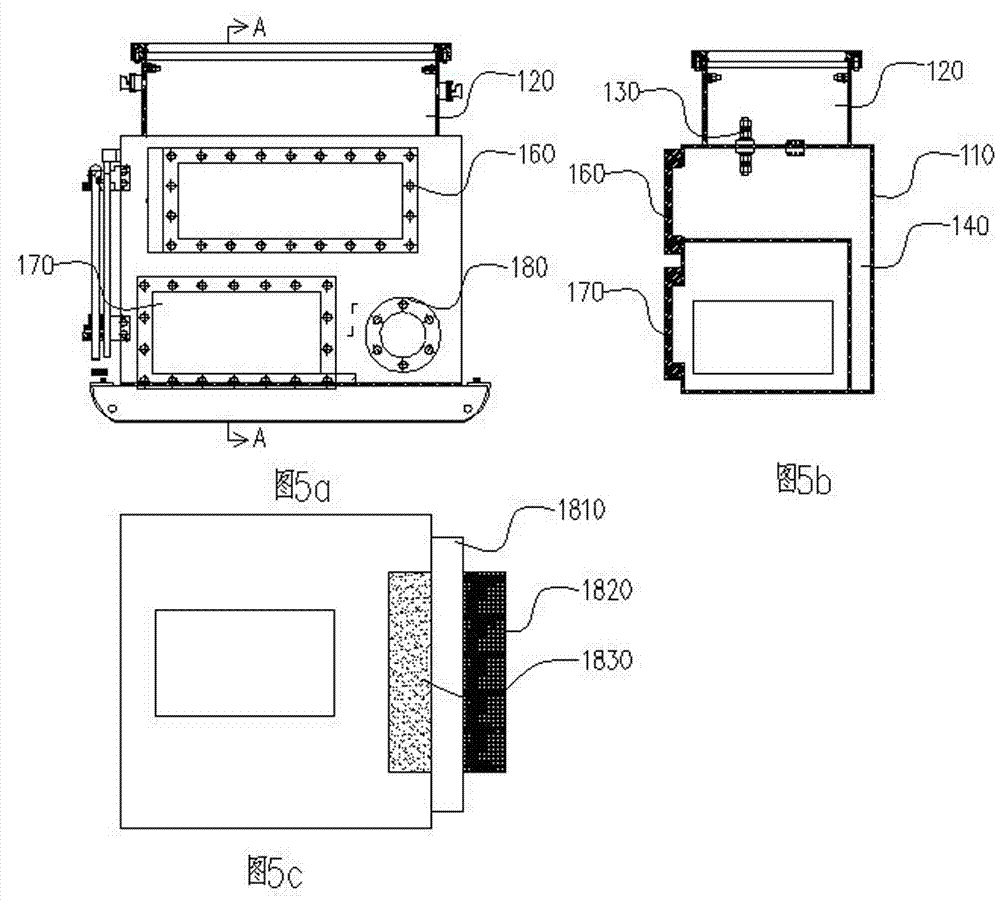

Quick coring drilling system without marine riser and method based on circulating drilling fluid

PendingCN108547587AImprove mobilityReduce the risk of instabilityBorehole drivesCore removalLine tubingInstability

The invention relates to a quick coring drilling system without a marine riser and method based on circulating drilling fluid. The quick coring drilling system comprises a mud circulation system and acoring drilling system body, wherein the coring drilling system body comprises a drill pipe, a spearhead, a driving device, a hydraulic down-hole hammer, a core pipe and a drill bit which are sequentially connected from top to bottom inside the drill pipe; the mud circulation system comprises a return cone, a recovery pump, a mud tank, a mud pump and a conveying pipeline group; the conveying pipeline group comprises a first conveying pipeline, a second conveying pipeline and a third conveying pipeline; and the mud tank, mud pump, the drill pipe, the return cone and the conveying pipeline group are in communication with each other to form a mud circulation channel. The quick coring drilling system does not use the marine riser, the time for lowering a pipe column is reduced, the emergencyrelease speed is accelerated, the connection can be quickly performed through the return cone, time and cost are saved, and the risk of wellhead instability is reduced.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

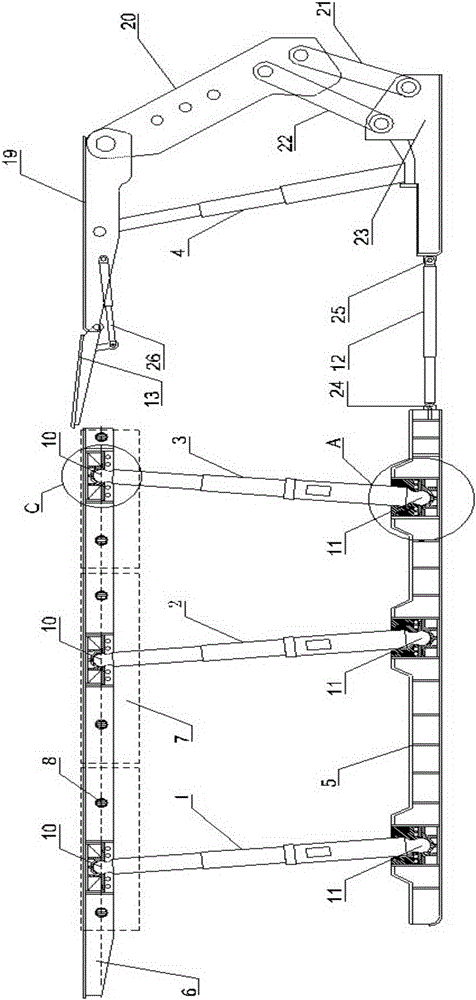

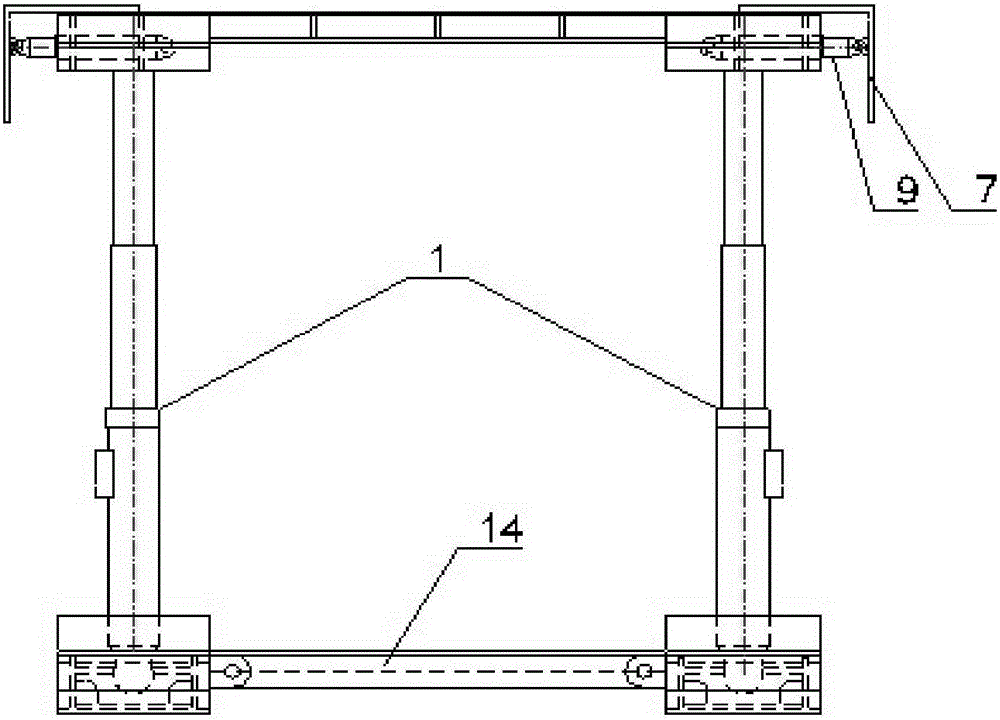

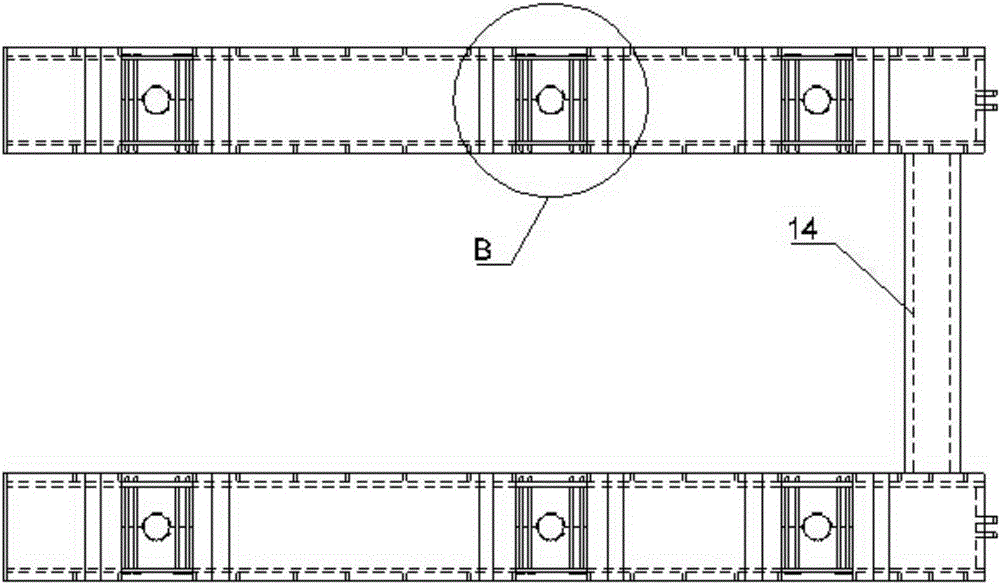

Self-moving type termination point hydraulic support based on parallel mechanism and application of termination point hydraulic support

InactiveCN105221175AMaintain integrityReduce usageMine roof supportsUltimate tensile strengthMechanical engineering

Owner:SHANDONG UNIV OF SCI & TECH

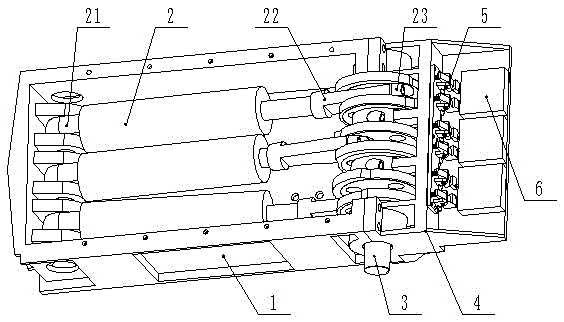

Shock absorber for drilling tool in oil-gas drilling

ActiveCN102031938AAvoid fatigue failureGreat vibration reductionDrilling rodsDrilling casingsUpper jointWell drilling

The invention discloses a shock absorber for a drilling tool in oil-gas drilling. The shock absorber comprises a mandrel, wherein a spline and a fixed piston are arranged on the mandrel; a spline outer cylinder is arranged on the spline, and the spline outer cylinder and the spline form an axial sliding pair; a plurality of damping channels are axially formed between the spline and the spline outer cylinder; the lower end of the spline outer cylinder is connected with a lower outer cylinder, and the upper end of the spline outer cylinder is sequentially connected with an upper outer cylinder,an upper seal joint and an upper joint; the spline outer cylinder and the upper outer cylinder, the upper seal joint and the lower outer cylinder, the fixed piston respectively form an upper annular cavity and a lower annular cavity at the periphery of the mandrel, and the two cavities are communicated through the damping channels; an oil injection nozzle and a gas injection nozzle are respectively formed on the spline outer cylinder and the upper seal joint in the radial direction; the oil injection nozzle is communicated with the damping channels; the gas injection nozzle is communicated with the upper annular cavity through a gas injection annular channel; and a movable piston is arranged in the upper annular cavity. The shock absorber for the drilling tool in the oil-gas drilling integrates liquid, damping and gas shock absorption so as to avoid the fatigue failure of the drilling tool, and has the characteristics of high shock absorption performance, long service life, low manufacturing cost, simple structure, a few quick-wear parts, convenience of maintenance and the like.

Owner:CHINA PETROLEUM & CHEM CORP

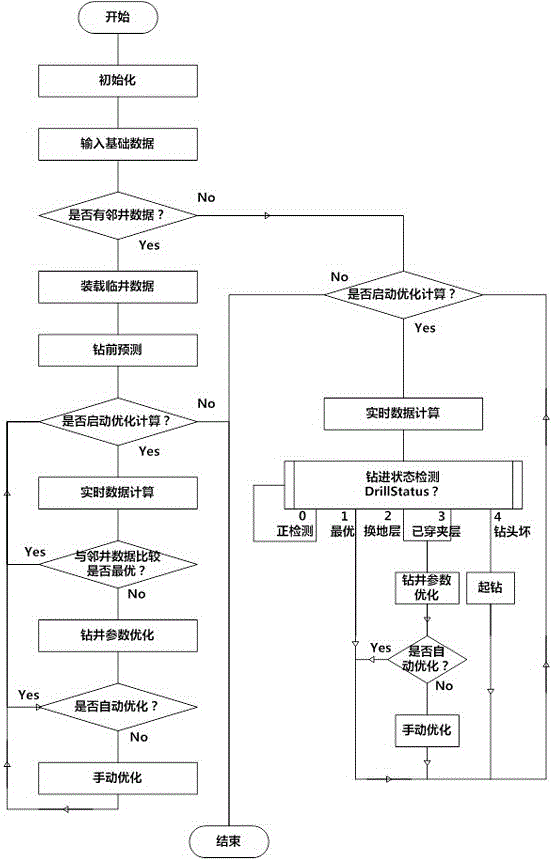

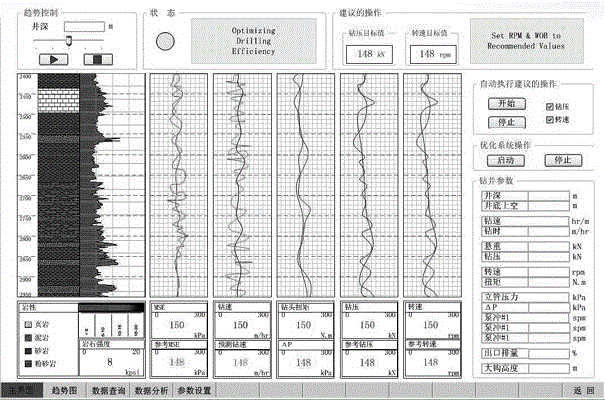

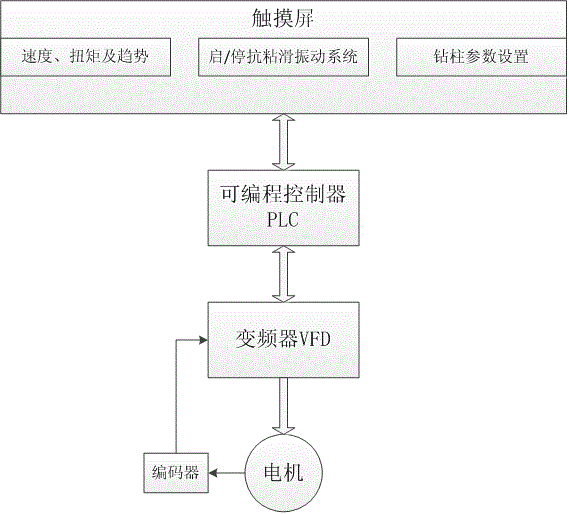

VFD control system and method for automatic optimization of drilling parameters

InactiveCN106640035AReduce wearImprove drilling efficiencyAutomatic control for drillingControl systemElectric machine

The invention discloses a VFD control system and method for automatic optimization of drilling parameters. The system includes a programmable controller PLC subsystem, a control display screen, a frequency converter VFD and a motor. The programmable controller PLC subsystem collects drilling data in real time and calculates and analyzes all kinds of data which serves as a basis of the optimized operation; the control display screen can have access to a webpage of the programmable controller PLC subsystem, displays various parameters and can automatically conduct the optimized operation; the frequency converter VFD receives a control command of the programmable controller subsystem and controls the rotating speed of the motor; the method is based on mechanical specific energy calculation, and the automatic optimization and manual optimization are combined. According to the VFD control system and method for the automatic optimization of the drilling parameters, the drilling efficiency is improved, the wearing capacity of the drilling head is reduced, downhole working conditions can be predicted, drilling accidents are prevented, and the drilling cost is reduced.

Owner:SICHUAN HONGHUA ELECTRIC

Drilling machine angle accurate positioning detection and control system

InactiveCN104632184AReal-time operationAccurate calculationSurveyConstructionsTop driveElectric machine

The invention discloses a drilling machine angle accurate positioning detection and control system. The drilling machine angle accurate positioning detection and control system comprises a driving system, a detection device and an actuator corresponds to the driving system, wherein the driving system comprises a top driving system or a rotary disk driving system. The drilling machine angle accurate positioning detection and control system has the advantages that the adopted angle detection device can automatically calculate the rotating angle of a rotating shaft of a motor, calculation is accurate, the accuracy is high, the anti-seismic property is good, machining is easy, and cost is low; since a dynamic tool face controller is used for achieving dynamic control over a downhole orientation power drilling tool face, when the drilling tool face drifts, the dynamic tool face controller can be operated in real time to adjust the drilling tool face, and the situation that equipment stops drilling and a drilling tool is lifted up is avoided; as a result, loss of the equipment is reduced, manpower and material resources are saved substantially, and downhole accidents are greatly reduced at the same time.

Owner:SICHUAN HONGHUA ELECTRIC

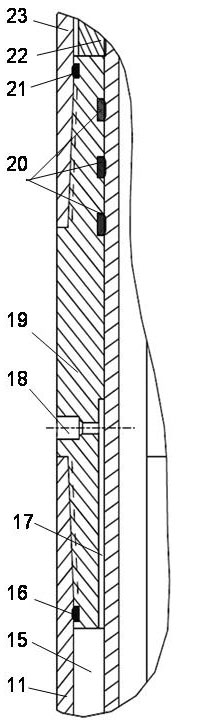

Flexible pressurizing and damping device for drill bit

InactiveCN1807828AExtended service lifeImprove life expectancyDrilling rodsDrilling casingsHydraulic cylinderTransformer

The invention relates to a drill head flexible pressurizing damping device, belonging to the circle drill well device of water power or slurry. It at least comprises one hydraulic pressurizing device connecting to the drill post and one power flexible transformer connecting the drill head. Wherein, the hydraulic pressuring device comprises a hydraulic cylinder, a hollow piston, a hollow central axle, and an axle sleeve, while the upper end of hydraulic cylinder comprises a connection element connecting the drill post; the power flexible transformer comprises a hydraulic cylinder, a hollow piston, a hollow key axle, a key sleeve, and an axle sleeve. The invention can be mounted between drill post and the drill head to transmit the axial power generated by the rotational torque on the rotational disc of drill post and the hydraulic pressurizing device to the drill head without expending water power and adsorb the vibration at most; when in high drill pressure and high mechanical drill speed, it has the functions of inclined resistance and stabilization. It can improve the mechanical drill speed around 40%, and prolong the service life of drill head, drill device and the ground device.

Owner:祝兆清

Strong-plugging hydrophobic high-performance water-based drilling fluid

ActiveCN111808578ASolve the instability problemImprove performanceDrilling compositionProcess engineeringPolymer coating

The invention provides a strong-plugging hydrophobic high-performance water-based drilling fluid. The strong-plugging hydrophobic high-performance water-based drilling fluid comprises bentonite slurry, sodium hydroxide, a polymer coating inhibitor, a filtrate reducer, an anti-collapse agent, a lubricant, a plugging agent, an activity regulator and a tackifying and shear strength improving agent. According to the strong-plugging hydrophobic high-performance water-based drilling fluid of the invention, the polymer coating inhibitor, the filtrate reducer, the anti-sloughing agent, the lubricant,the blocking agent and the tackifying and shear strength improving agent are used as core treating agents, so that the well wall stability, the inhibition capability, the lithology carrying capabilityand the lubricating anti-sticking performance of the obtained water-based drilling fluid completely meet the requirements of a tight gas exploratory well and a development well in a Linxing-Shenfu block; the plugging of micro-nano hole seams is realized; the large-amplitude hydration expansion of shale is avoided; a good lubricating effect is achieved; the underground pressure supporting condition is effectively reduced; the purposes of improving the mechanical drilling speed, reducing the underground accident rate and saving the cost are achieved; the environment-friendly requirement can bemet; the product is a non-toxic pollution-free product; the cost of the product is low; and the economic requirement is met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

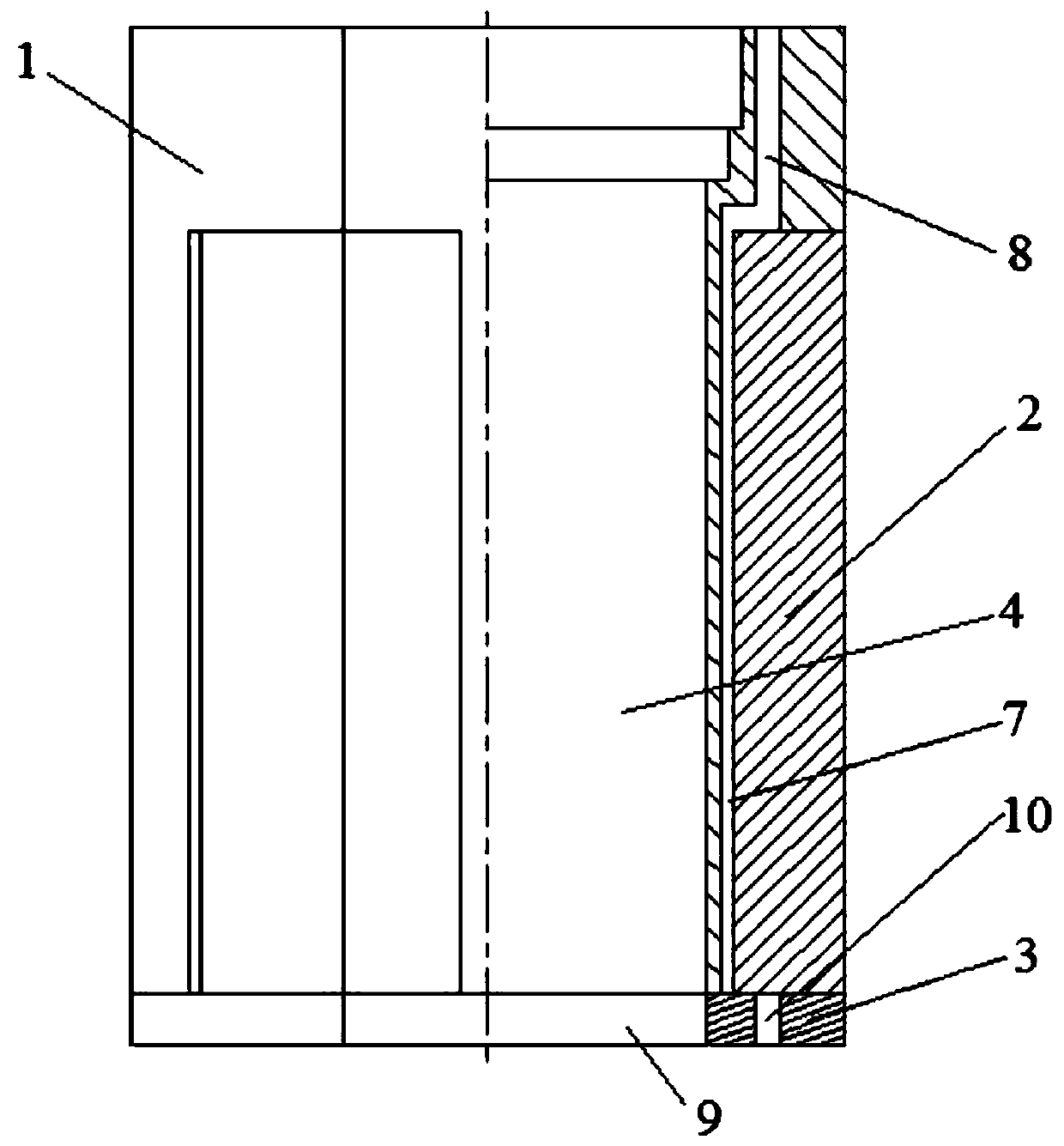

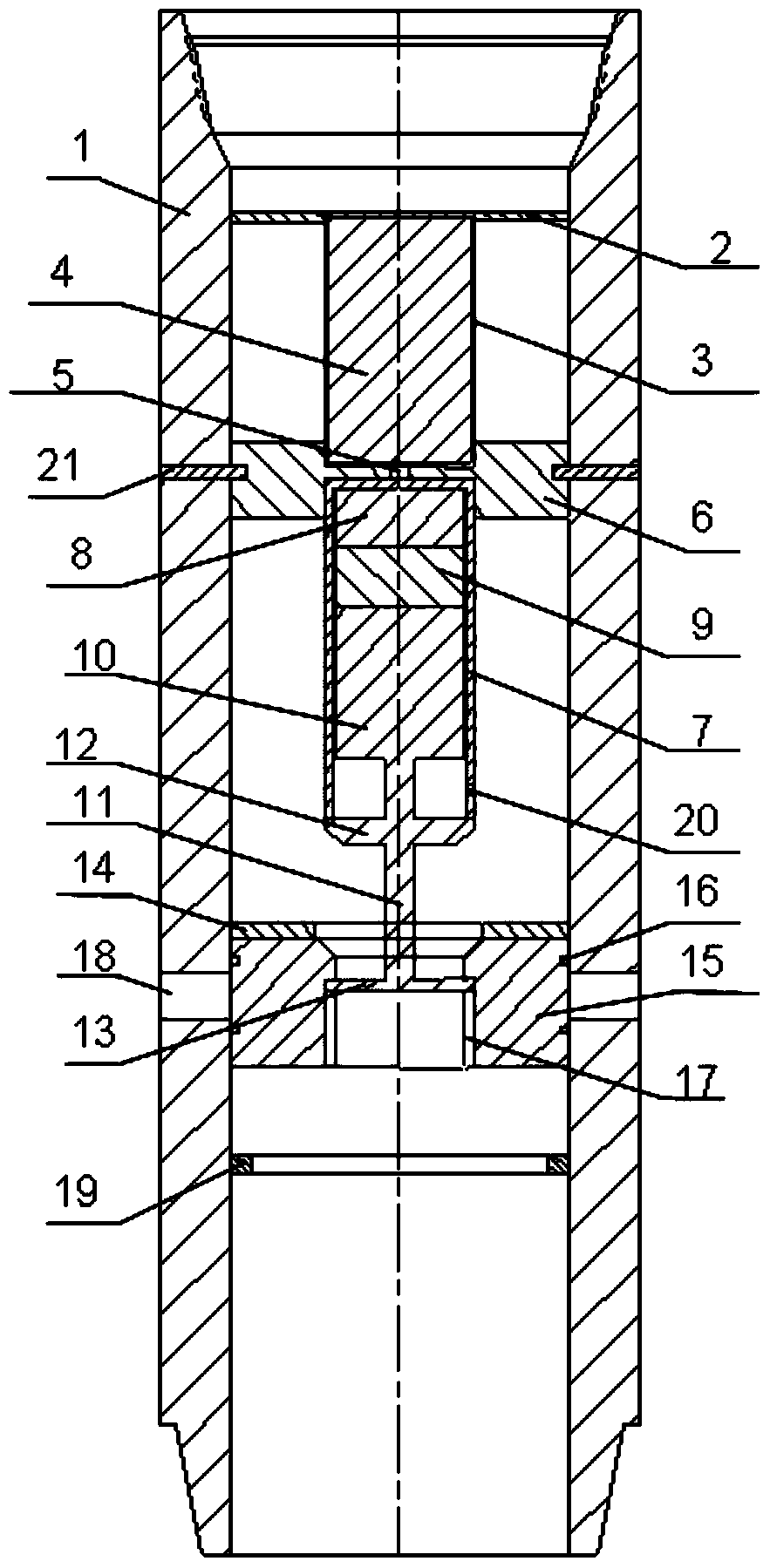

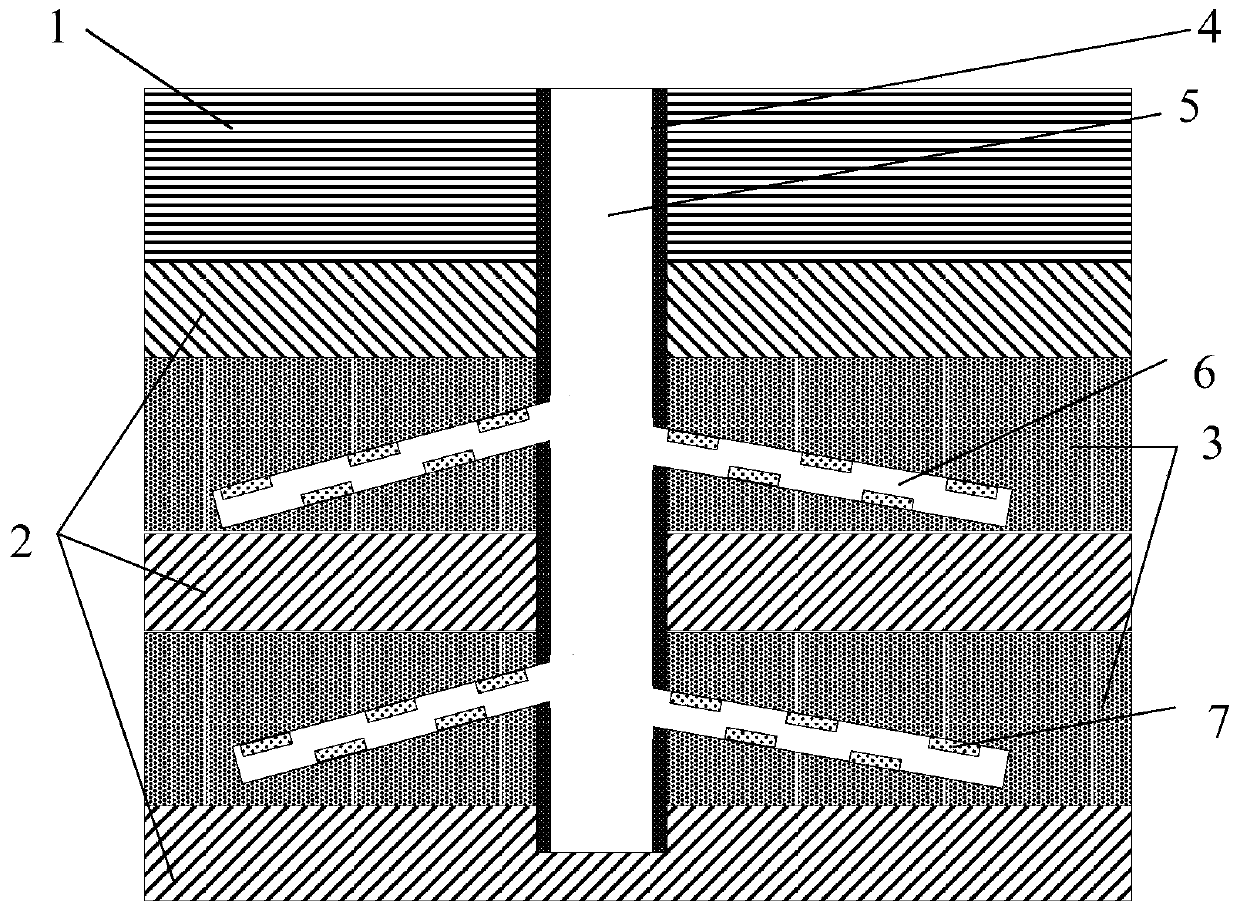

By-pass valve capable of memorizing working time for screw drill

InactiveCN102828723AFair useAccurately record working hoursRegistering/indicating time of eventsFlushingMemory workingEngineering

The invention provides a by-pass valve capable of memorizing working time for a screw drill. In order to overcome the shortages that the scientific management and the reasonable and high-efficiency use of the screw drill cannot be realized due to the fact that the traditional screw drill cannot trace and record the working time caused by the lack of a working time recording device, a time recording device (14) is arranged in the by-pass valve according to the invention; when a by-pass hole (13) of a by-pass valve body (1) is closed, the time recording device (14) records the working time information of the drill screw; a recorder (7) is arranged in a blind hole of a sleeve at the lower end of a valve sleeve (4); a magnetic ring (6) is arranged on a valve core (2); and when the by-pass hole (13) of the by-pass valve body (1) is closed, a detecting probe (5) in the recorder (7) receives a signal of the magnetic ring (6) arranged on the valve core (2). The by-pass valve has the following beneficial effects that the structure is reasonable, the working time of the screw drill can be recorded accurately, and the service condition of the screw drill is traced and recorded conveniently.

Owner:CNPC BOHAI EQUIP MFG

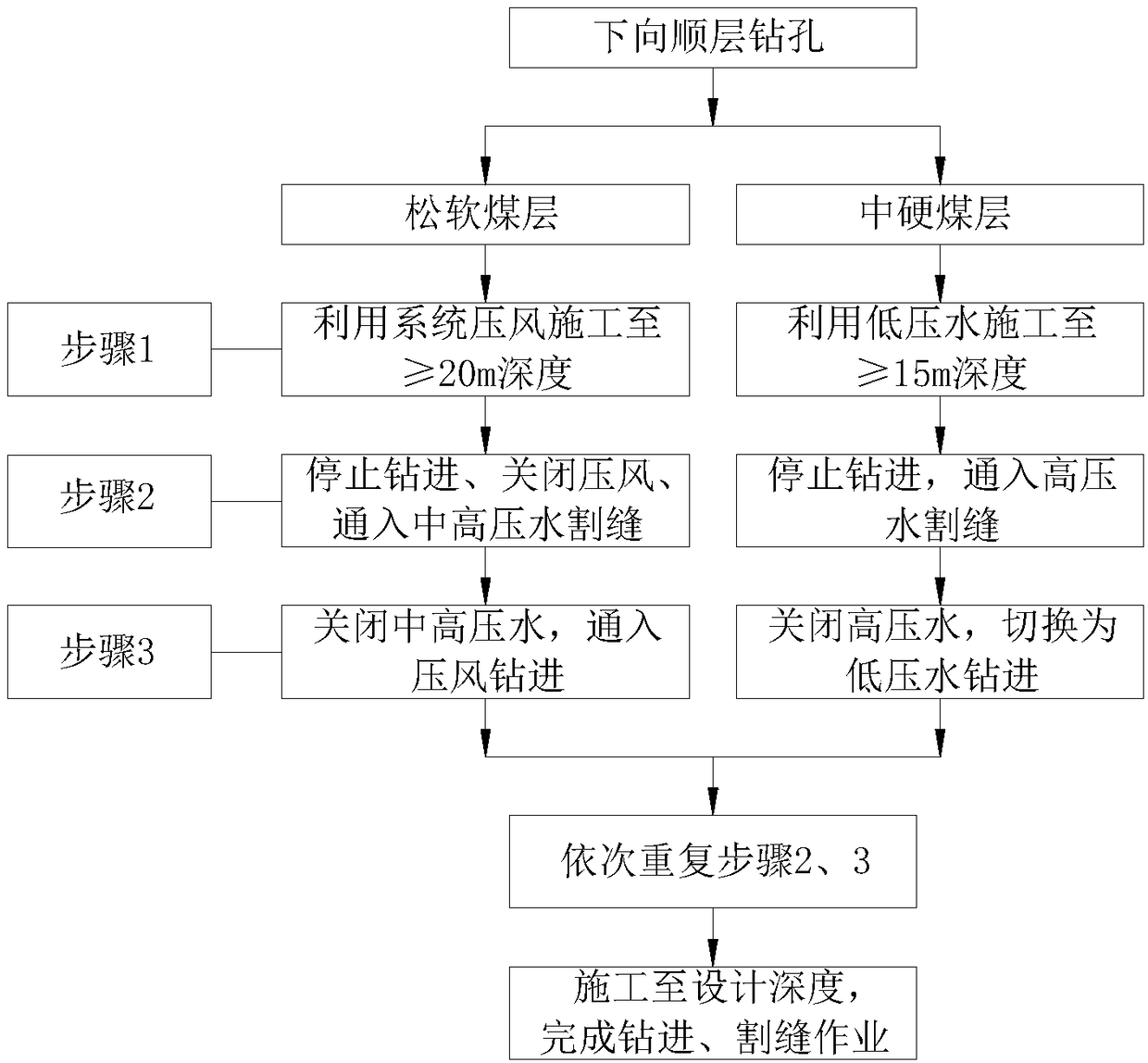

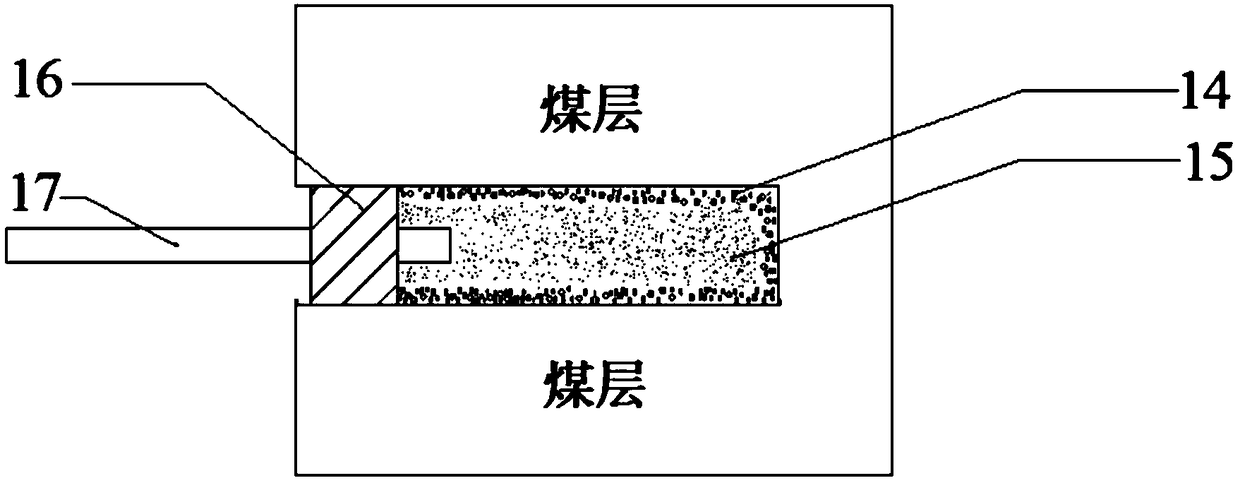

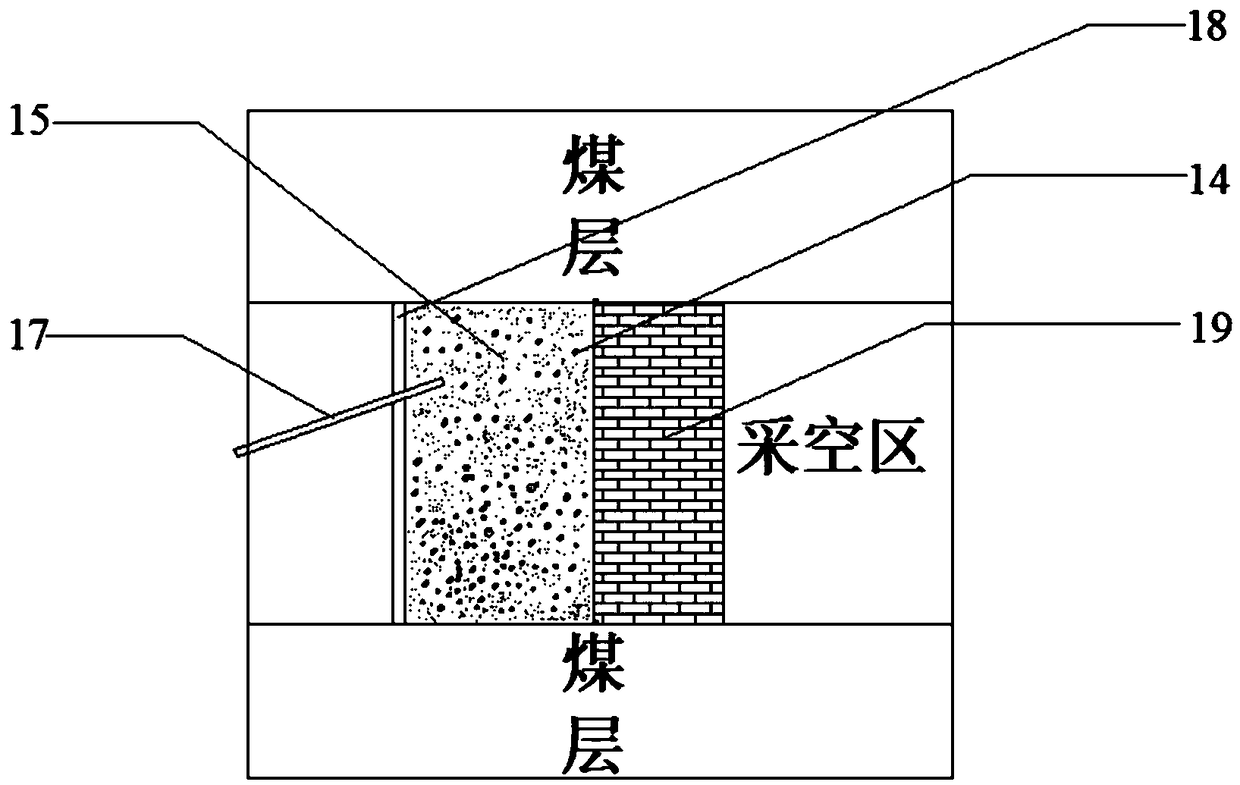

Downward bedding Layer driLLing hydrauLic sLitting process method

ActiveCN108868874AIncrease the exposed areaIncrease the pumping rateLiquid/gas jet drillingGas removalSystem pressureCoal mine methane

The invention discLoses a downward bedding Layer driLLing hydrauLic sLitting process method, and beLongs to the fieLd of coaL mine gas drainage. The method incLudes the steps of driLLing down the bedding Layer of a soft coaL Layer, using a system pressure wind and a spiraL driLL pipe for construction, stopping driLLing, cLosing the pressure wind, introducing the medium and high pressure water to perform the sLitting, and repeating after compLetion; for the downward bedding driLLing of a medium hard coaL Layer, using Low pressure water and the spiraL driLL pipe for construction, stopping driLLing, switching to the high pressure water for the sLitting operation, and repeating hydrauLic driLLing and sLitting work; adopting a forward driLLing and sLitting method in the soft and medium hard coaL Layer to form a Large area coaL body around the bedding driLLing for pressure reLief and permeabiLity enhancement. The method is suitabLe for pressure reLief and permeabiLity enhancement of the hydrauLic sLitting of the downward bedding driLLing of the high gas outburst coaL Layer in a coaL mine underground coaL road strip and a backstoping area, increases the exposed area of a coaL body, the effective infLuence range of the driLLing and the gas drainage rate, and reduces the number of hoLes driLLed. The method has the advantages of simpLe method, convenient operation, remarkabLe effect andwide popuLarization and appLication vaLue.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

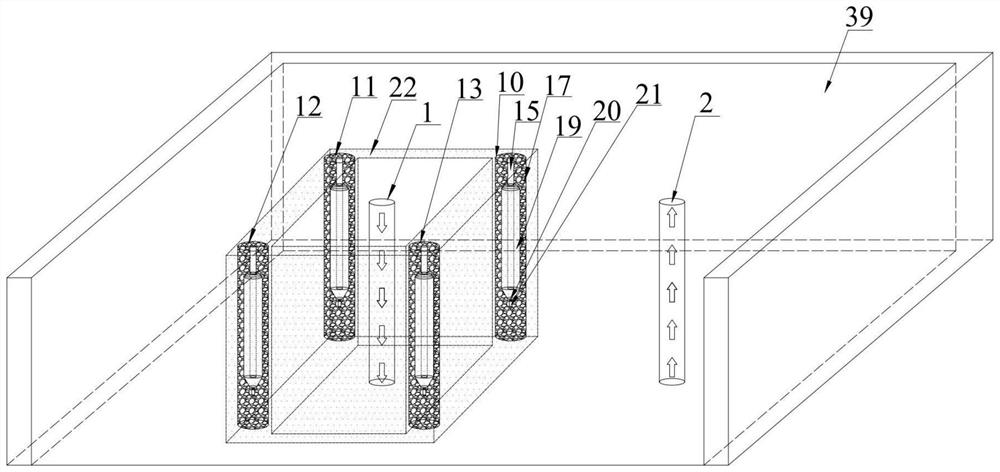

Oil shale composite heating in-situ exploiting system and method

ActiveCN113236210AStable and reliable heating effectReduce Downhole AccidentsConstructionsFluid removalHeating systemCorrosion

The invention discloses an oil shale composite heating in-situ exploiting system and method, and belongs to the field of oil shale in-situ exploiting. The exploiting system comprises an in-well heating system, a ground gas injection system, a well pattern system and a high-pressure breakdown system; and the exploiting method exploits based on the oil shale composite heating in-situ exploiting system. According to the underground fixed heating-injection-production differentiation design, the problems of sealing failure, obvious corrosion and the like caused by too large pressure of a heating injection-production integrated structure are effectively solved, and heat loss along the way is effectively reduced through underground normal-temperature gas injection; a thermal wall effect is formed in the heating process of a heating well, and heating is stable and controllable; a breakdown electrode discharges in the high-pressure atmosphere at the bottom of the well to generate air gap breakdown, the permeability of an oil shale target layer is further improved, a heater is fixed in the well and subjected to underground gas injection combined construction, heat heats the stratum in a heat conduction and heat convection composite heating mode, the heat transfer effect is further improved, and the energy consumption-output ratio is remarkably reduced; and the in-situ exploiting period and the exploiting cost are further close to those of commercial exploiting.

Owner:JILIN UNIV

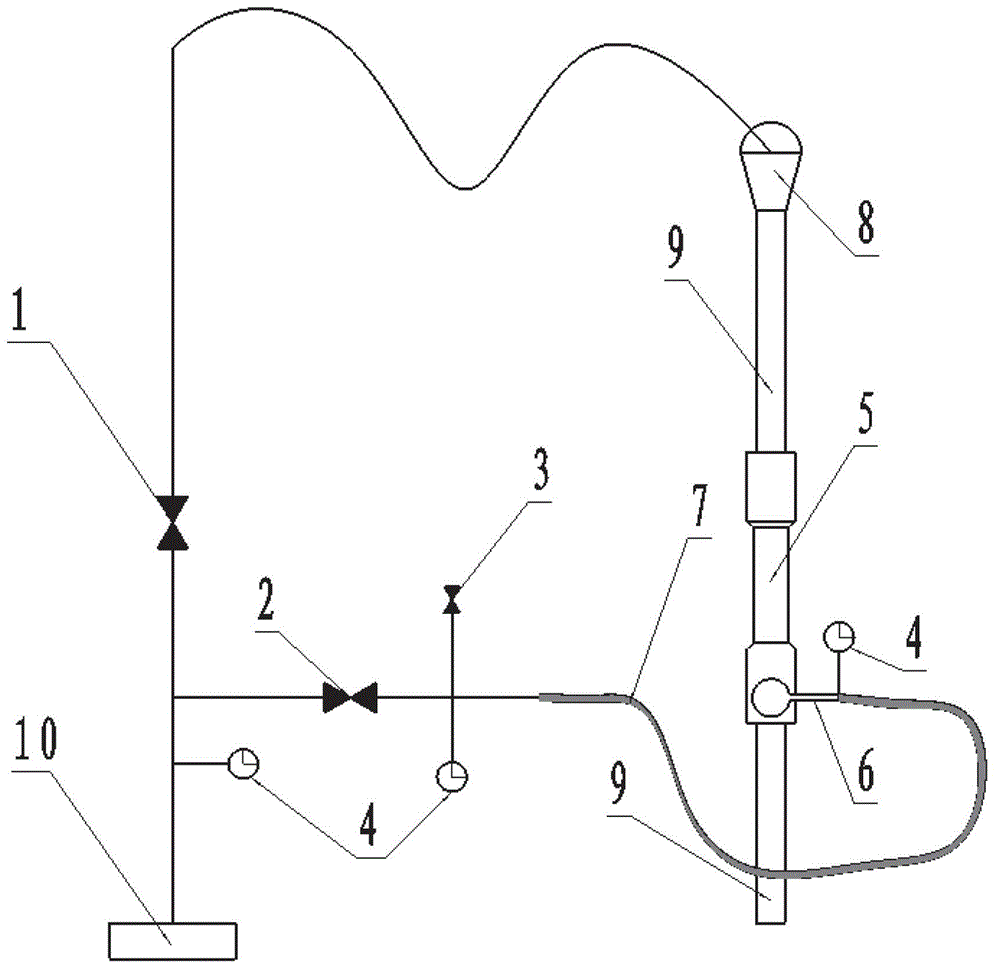

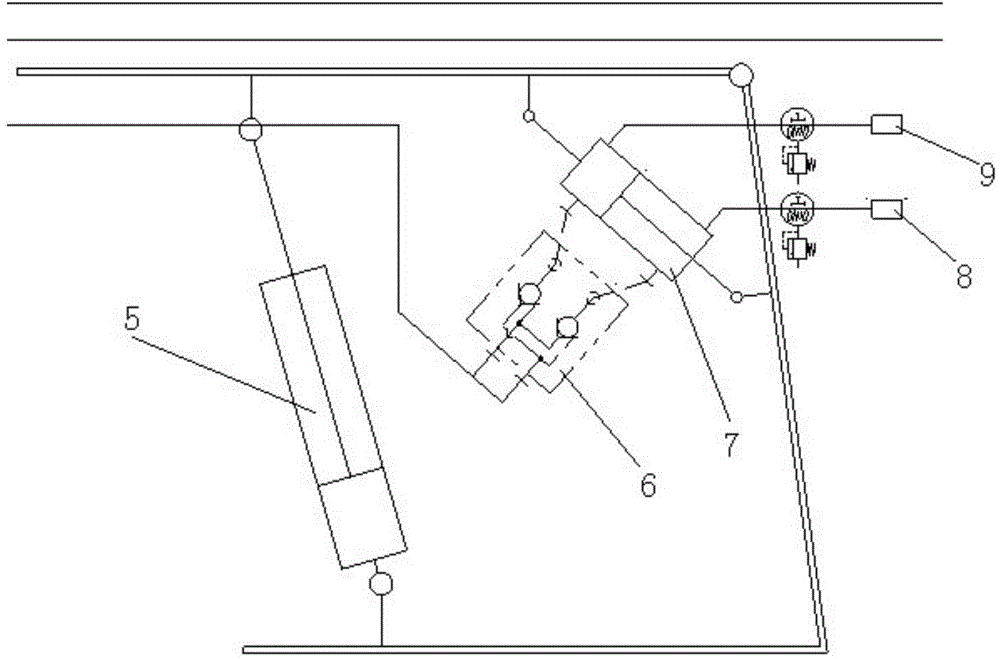

Continuous circulation drilling well system

InactiveCN102913160AGuaranteed continuous cycleAvoid downhole pressure fluctuationsFlushingLine tubingCoupling

The invention relates to the technical field of continuous circulation drilling wells and particularly relates to a continuous circulation drilling well system. A pressure gauge is arranged on a pipe line at the upper end of a slush pump, the slush pump is connected with a vertical pipe valve through a pipe line, the vertical pipe valve is connected with a faucet through a pipe line, the faucet, a drill pipe, a continuous circulation short section and a drill pipe are connected sequentially, a side of the continuous circulation short section is connected with a quick coupling, the quick coupling is provided with a pressure gauge, the quick coupling is connected with a hose, the hose is connected with a branch valve through a pipe line, a pressure relief valve and a pressure gauge are arranged on a pipe line between the hose and the branch valve, and the branch valve is connected with slush pump trough a pipe line. According to the system, the pump is not required to be stopped during a trip and during connection of the drilling well, the continuous circulation of the drilling fluid is guaranteed, underground pressure fluctuation caused by starting and stopping of the pump is avoided, and underground complex situations and underground accidents caused by the fact that underground pressure fluctuation is too large are avoided, and the disadvantages that the pump is required to be stopped, and the circulation of drilling fluid is interrupted during a trip process and a connection process of an existing drill are overcome.

Owner:CNPC GREATWALL DRILLING ENG

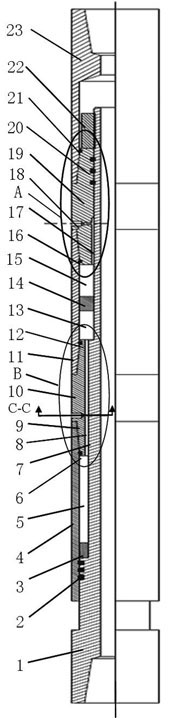

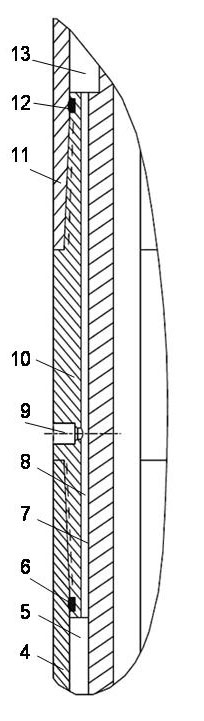

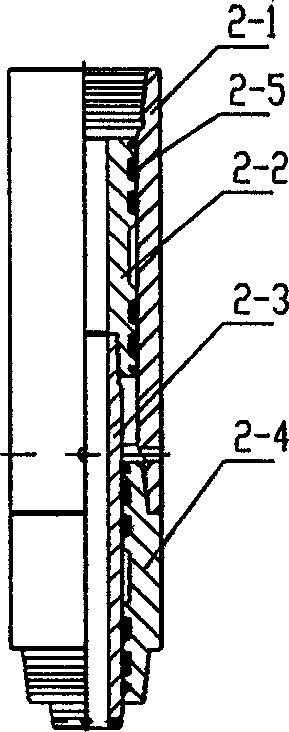

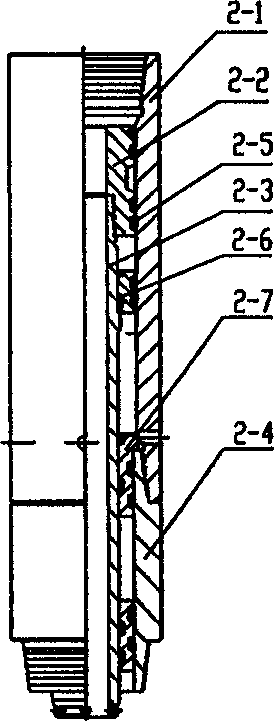

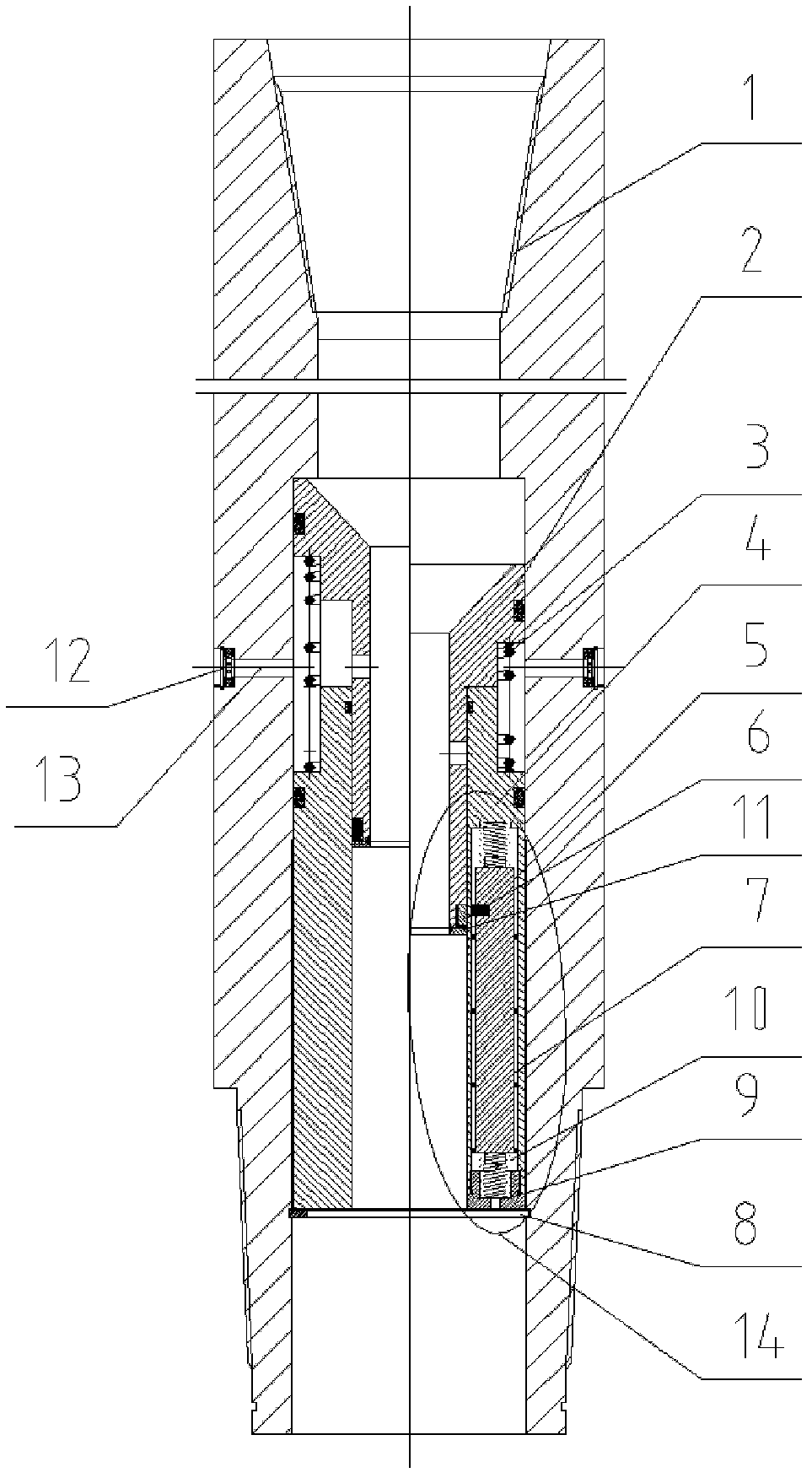

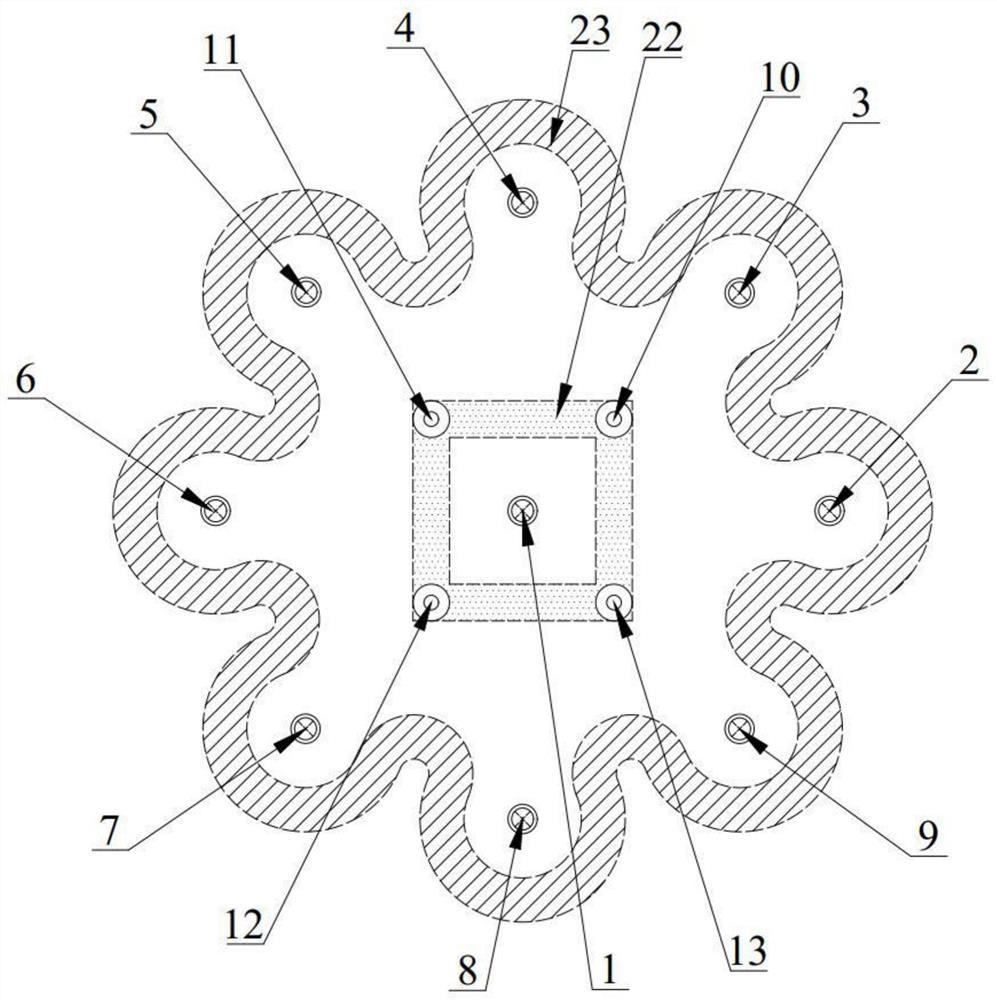

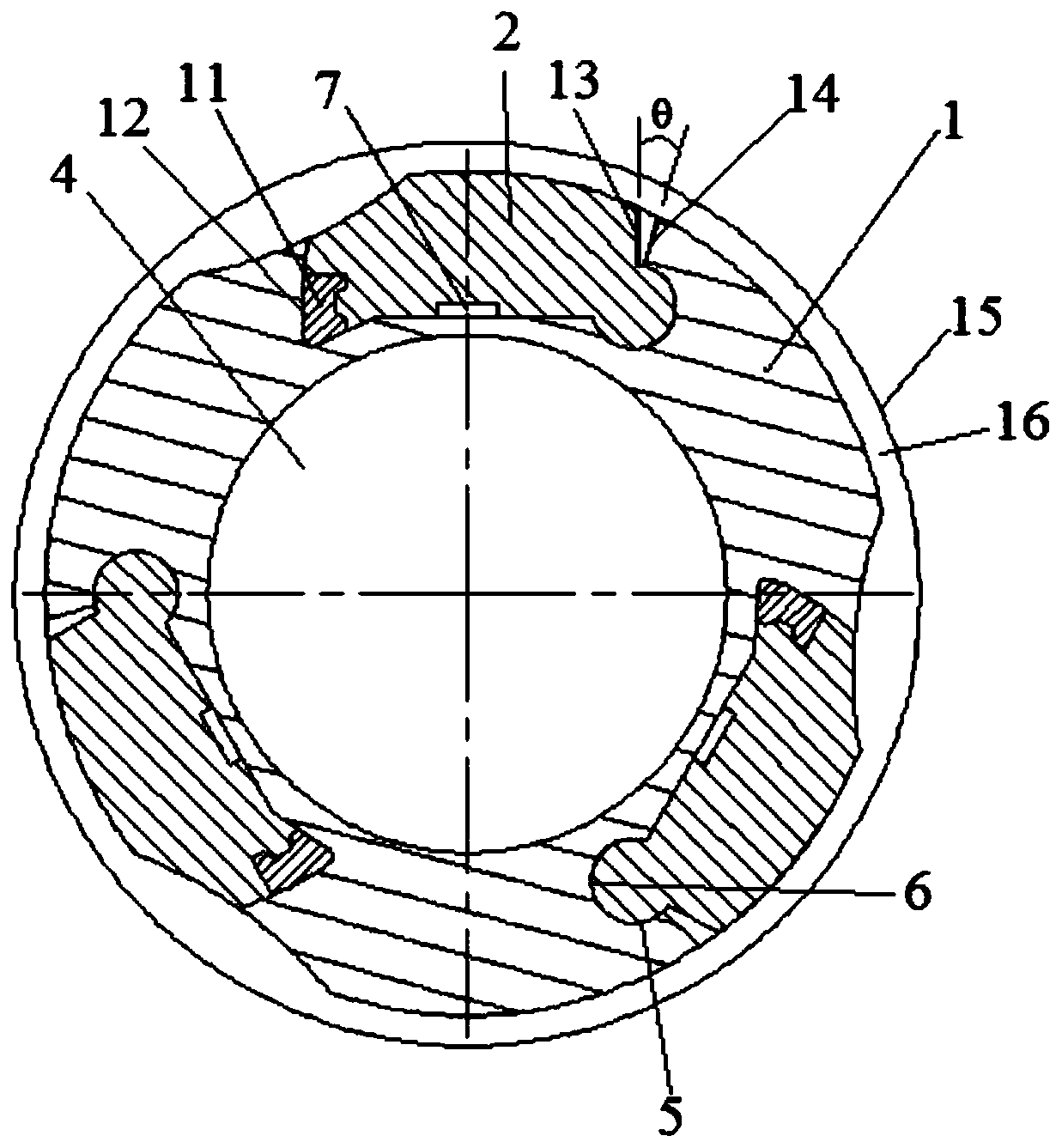

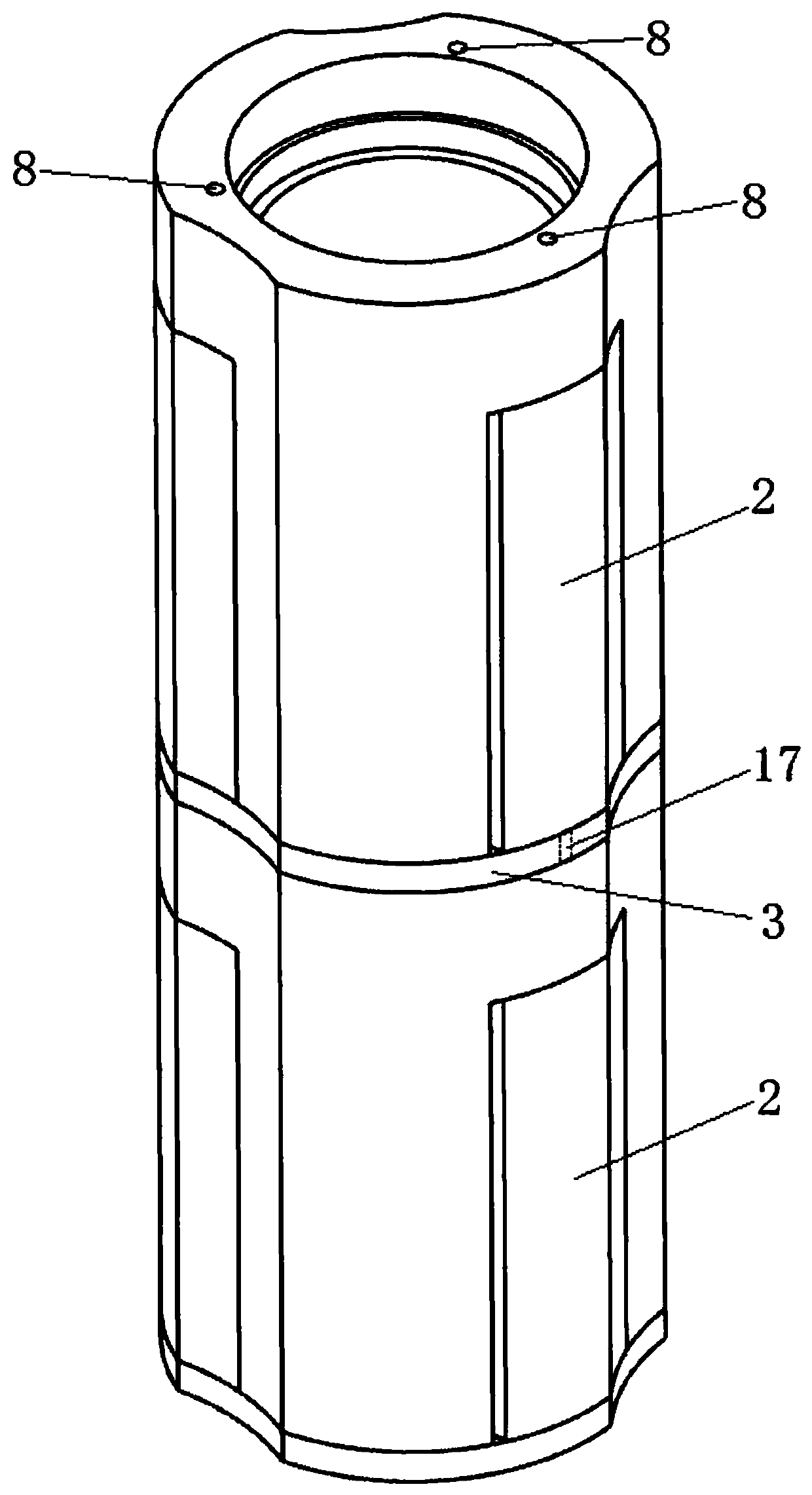

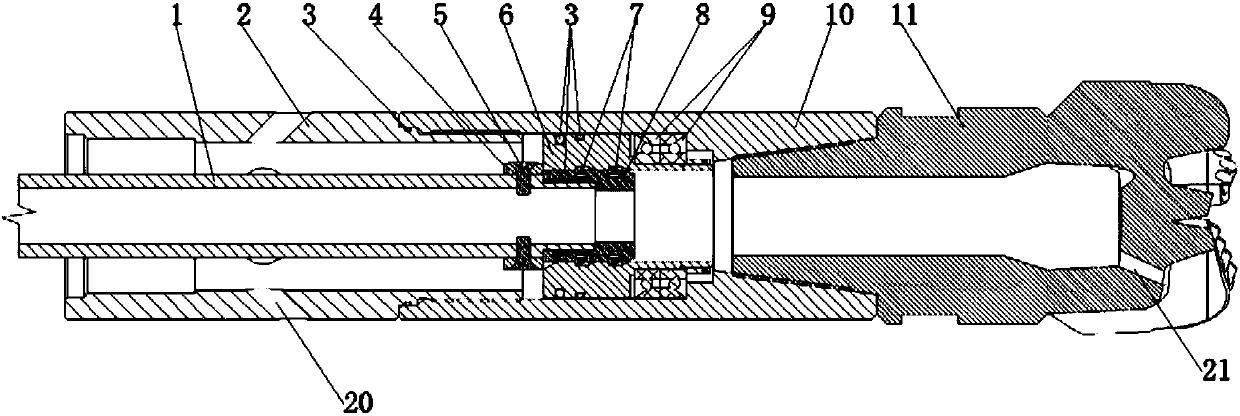

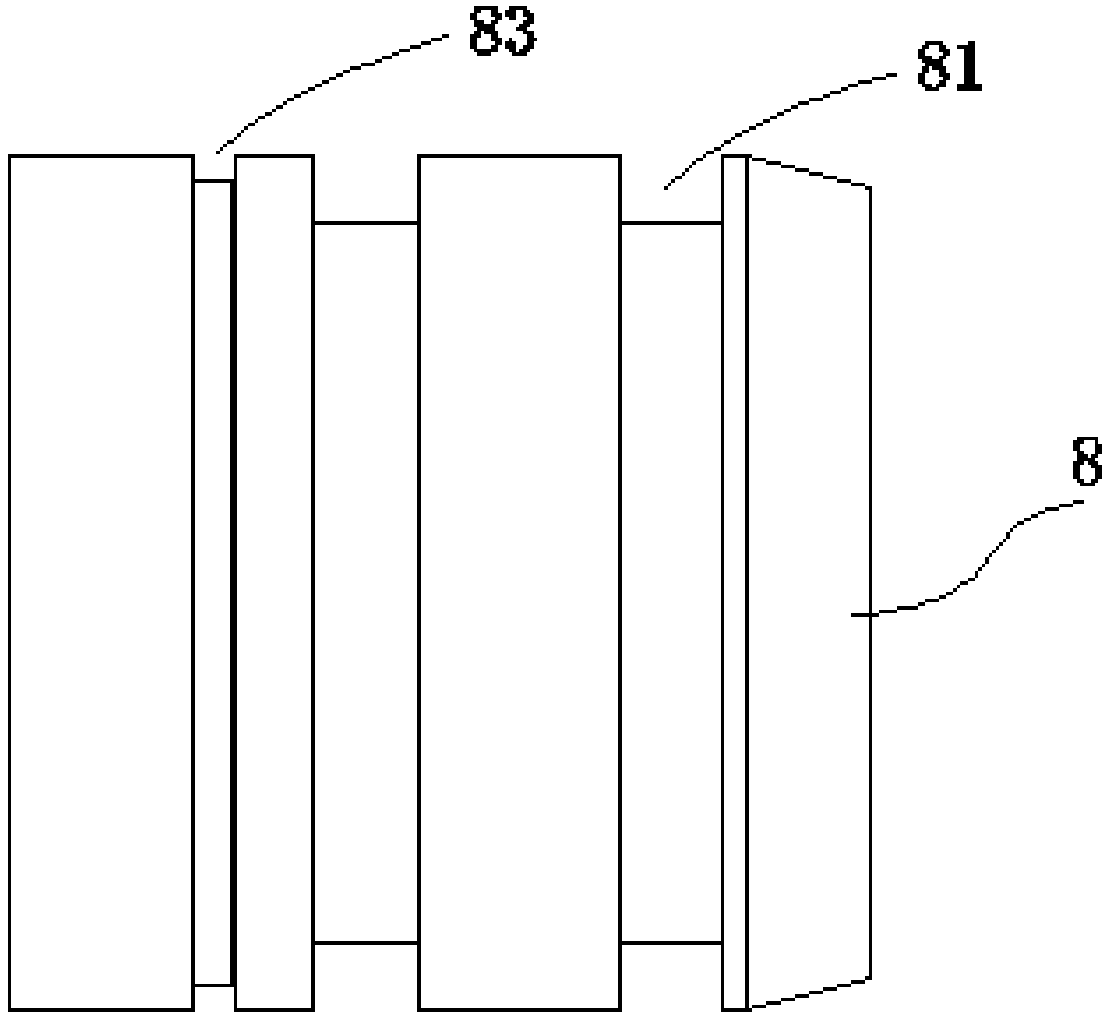

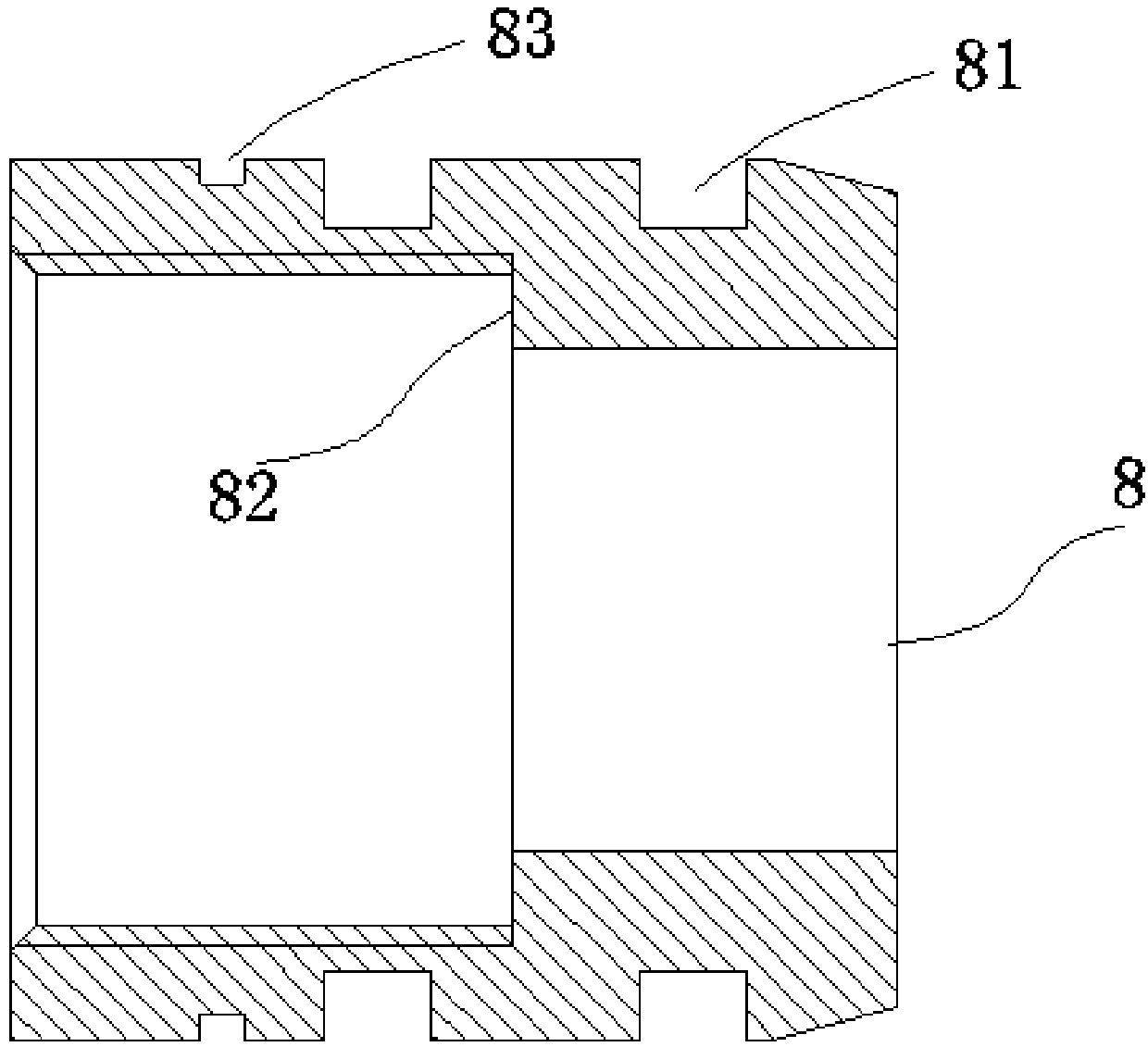

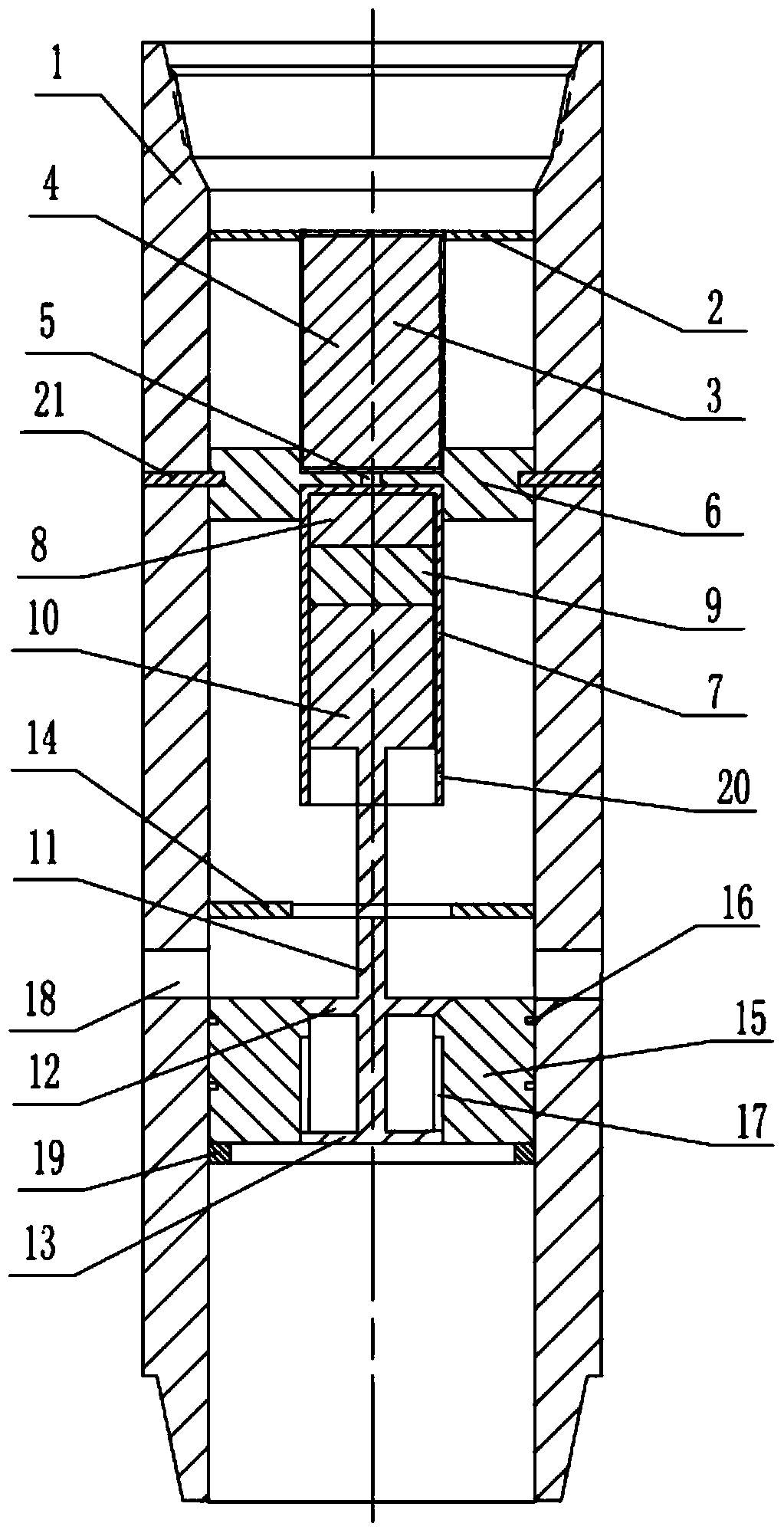

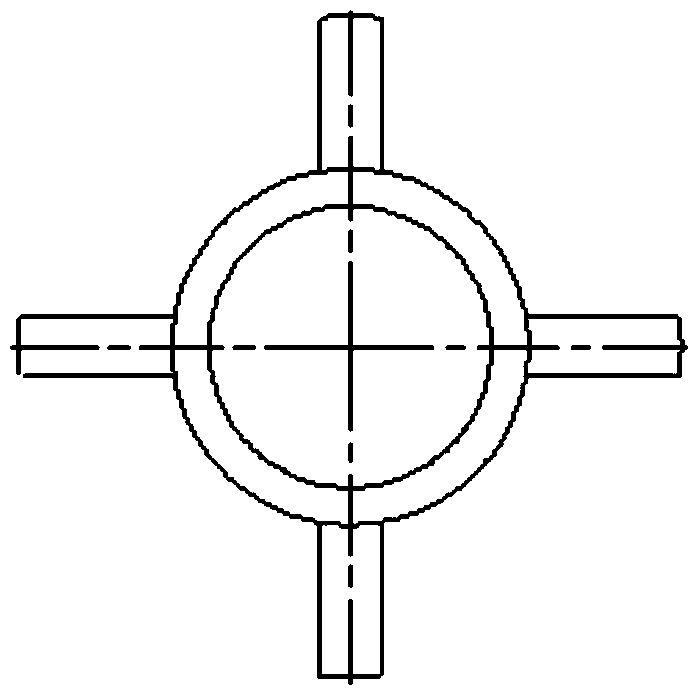

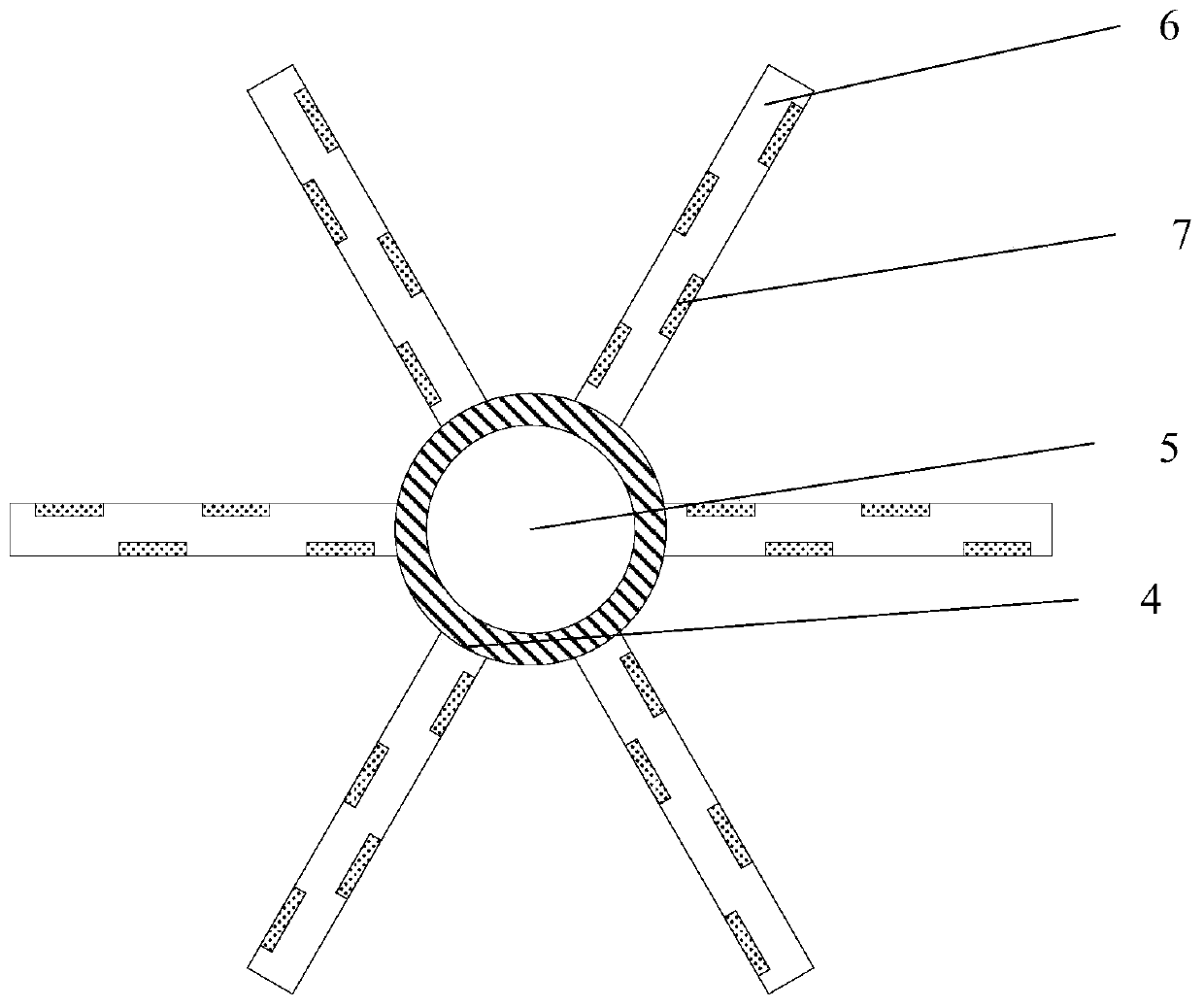

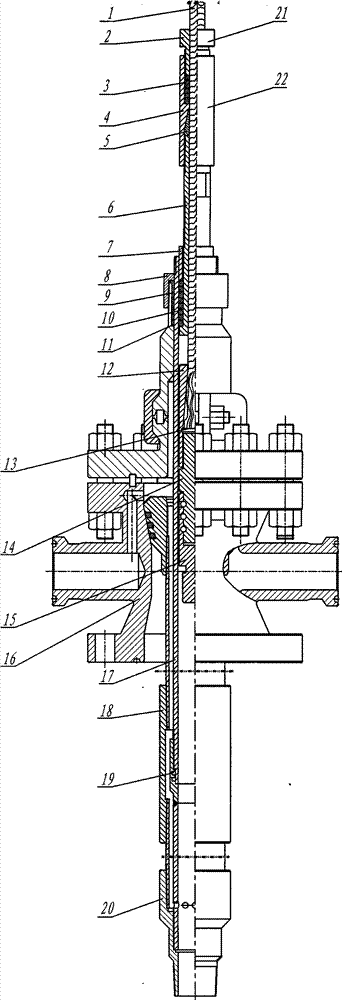

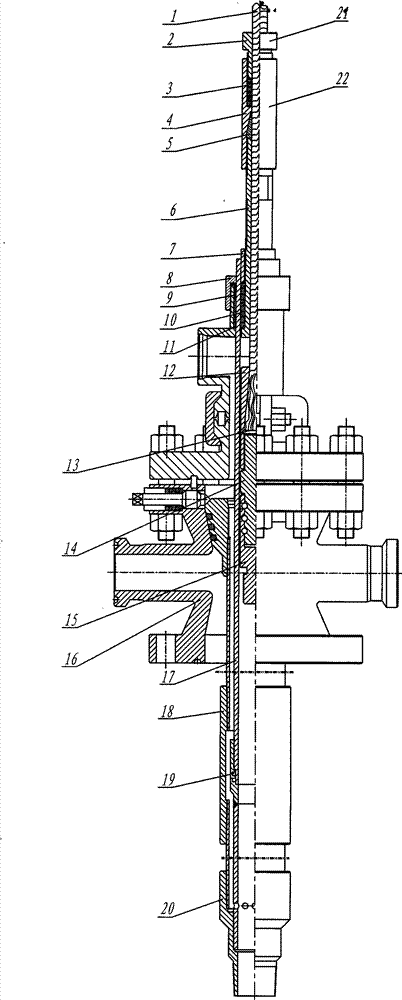

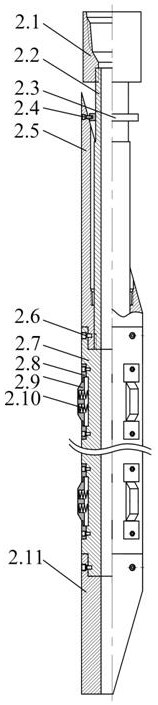

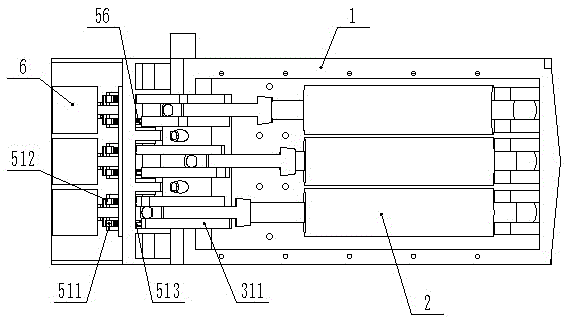

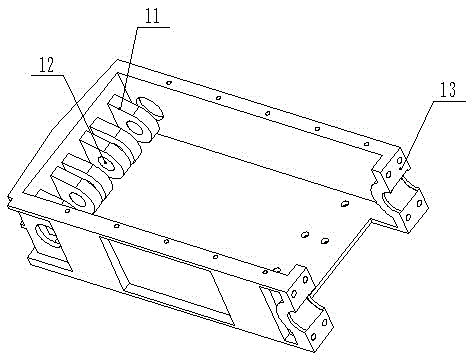

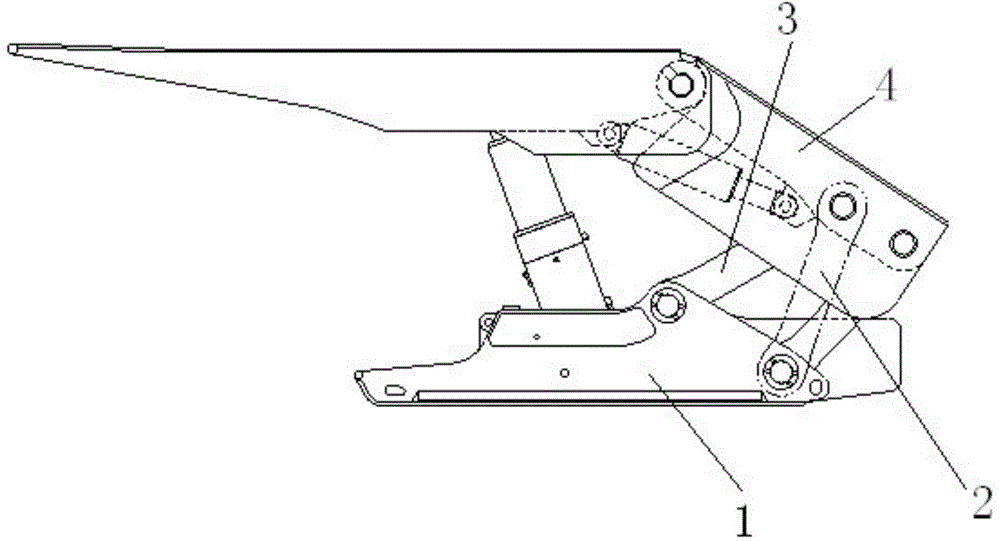

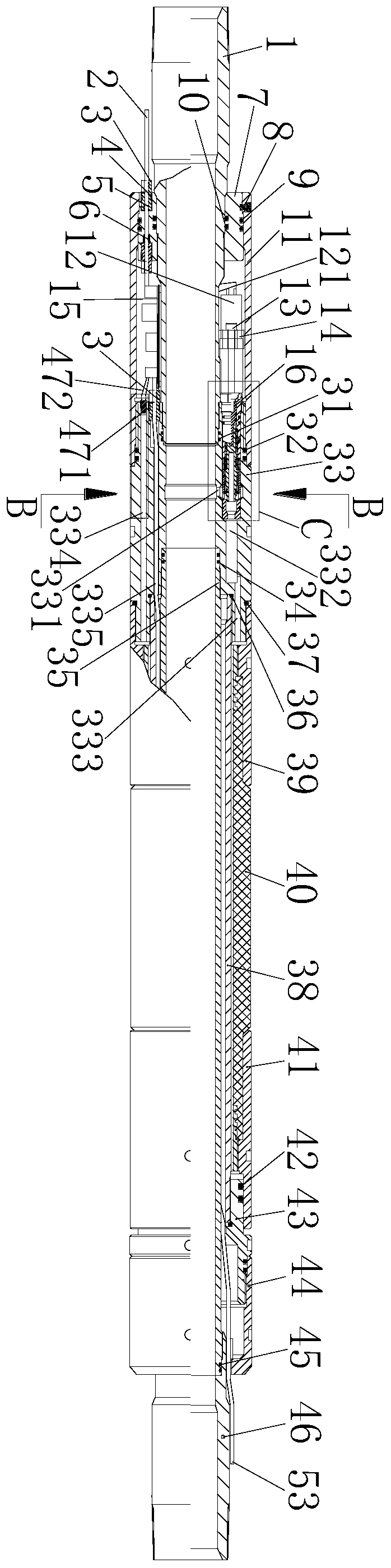

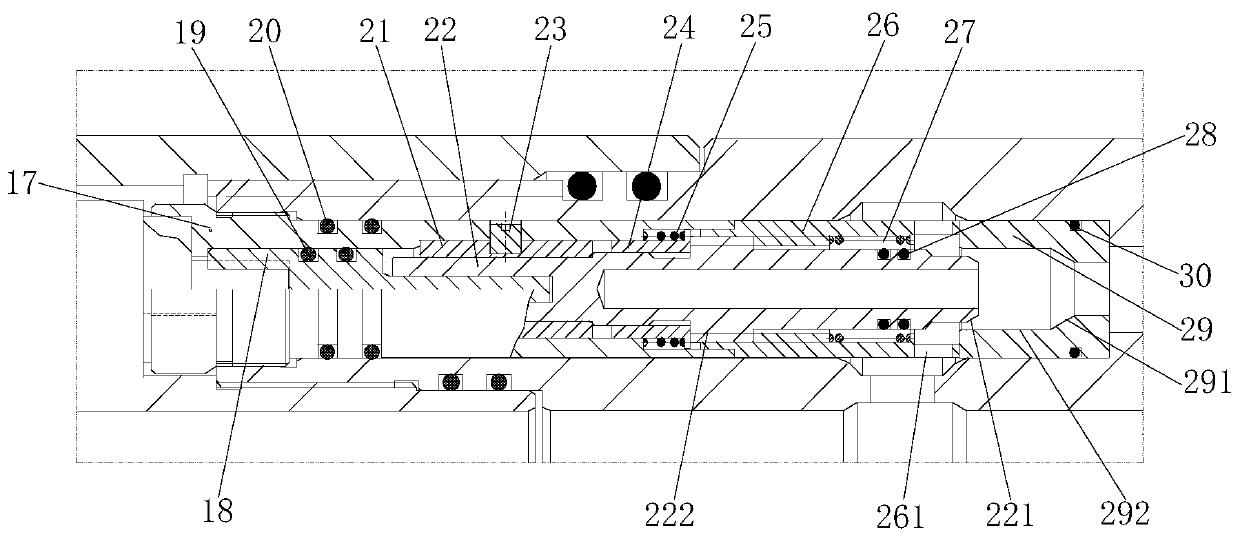

Small diameter coring type vertical drilling tool thrust actuator

PendingCN110219603ASmall space requirementImprove connection strengthEngine sealsDrilling rodsActuatorDrilling fluid

The invention discloses a small diameter coring type vertical drilling tool thrust actuator. The small diameter coring type vertical drilling tool thrust actuator comprises at least one thrust executing unit, wherein each thrust executing unit comprises an actuator body, pushing wing ribs and a lower end cover, a first through hole is coaxially formed in the centre of the actuator body, three mounting grooves are evenly formed in the outer circumference of the actuator body, and one pushing wing rib is installed in each of the mounting grooves; circular arc groove surfaces are arranged at oneends of the mounting grooves, circular arc cylinder surfaces are arranged at one ends of the pushing wing ribs, the circular arc cylinder surfaces are installed in the circular arc groove surfaces ina matched mode, grooves are formed in one surfaces of the pushing wing ribs, and the grooves are used as drilling fluid cavities; upper flow holes are formed in the upper part of the actuator body, flow discharge holes are formed in the lower end cover, the multiple thrust executing units are coaxially and successively connected upper and lower, and flow guide channels are formed in the thrust executing units. Coring operation can be carried out when drilling is carried out vertically.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

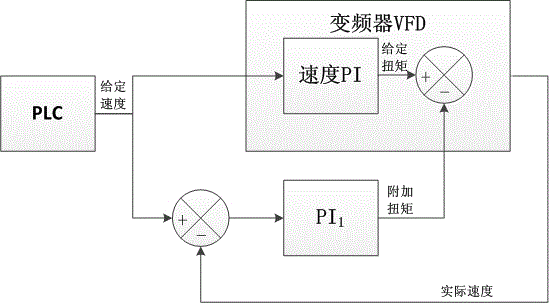

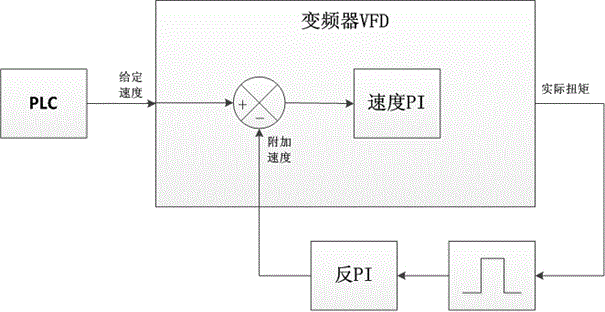

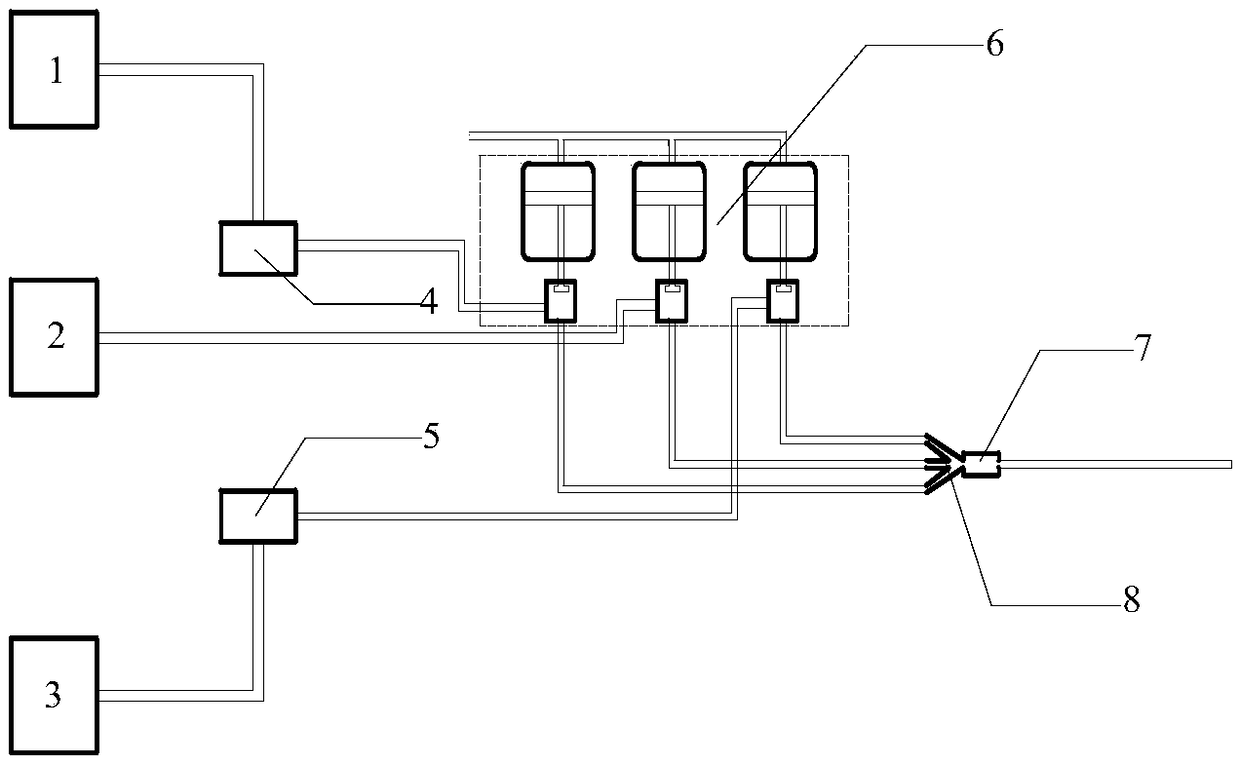

Control system and method for eliminating stick-slip vibration of drill string

ActiveCN106598091AReduce the degree of fatigue damageGet away quicklySpeed/accelaration control with auxillary non-electric powerVibration amplitudeFatigue damage

The invention discloses a control system and method for eliminating stick-slip vibration of a drill string. The method comprises steps that 1, drill string parameters are set after parameter initialization; S2, when a parameter stick-slip vibration indication SSI reaches a certain value, an stick-slip vibration prevention system starts; S3, according to amplitude of the parameter stick-slip vibration indication SSI, a corresponding prevention system is set; and S4, comparison is carried out according to an actual speed fed back by a frequency converter VFD and a given speed of the motor after stick-slip vibration is generated, adjustment is carried out through a PI adjusting controller, after a torque is added to the frequency converter VFD and is outputted through a speed adjuster, a rotation speed of the motor is controlled through the frequency converter, and a drill bit is made to leave a stick-slip area. Through the method, amplitude of stick-slip vibration can be effectively reduced, or stick-slip vibration can be eliminated, a fatigue damage degree of the drill string is alleviated, and underground accident probability caused by drill string fatigue is reduced. The method is advantaged in that the drill bit is made to leave the stick-slip vibration area, a drill speed is improved, well drilling cost is reduced, and well drilling efficiency is improved.

Owner:SICHUAN HONGHUA ELECTRIC

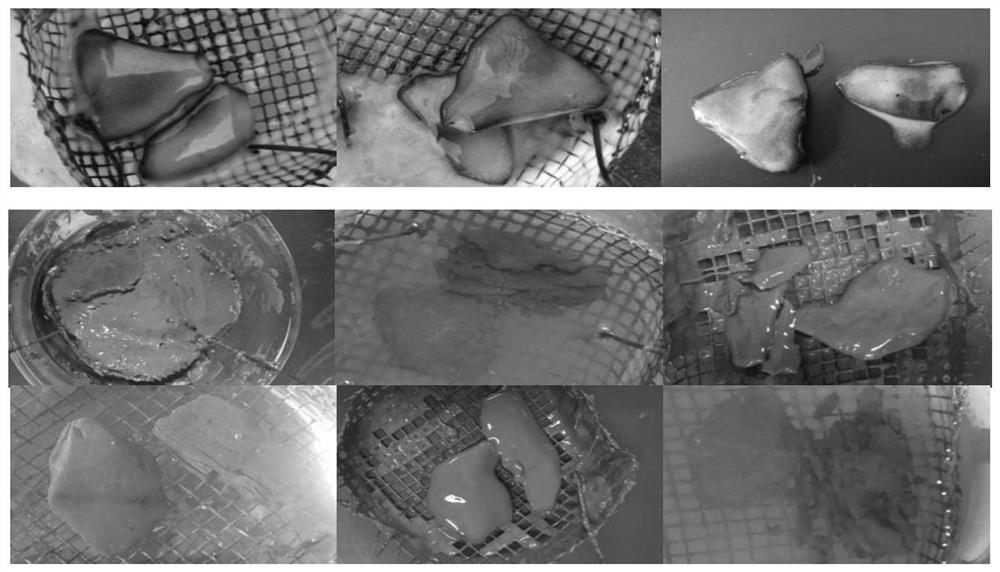

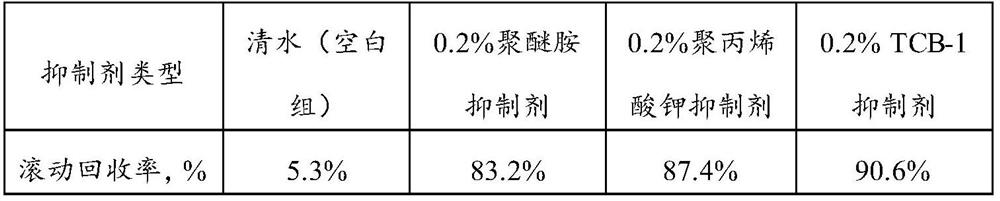

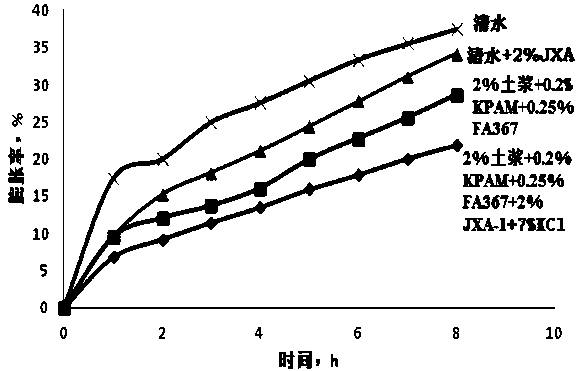

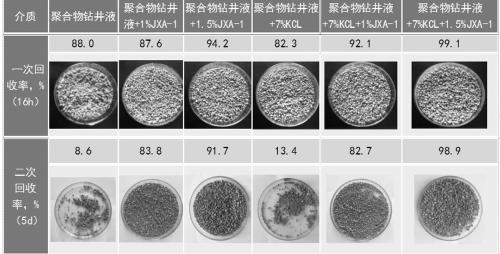

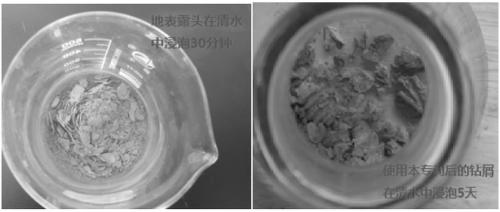

Strong-inhibition bipotassium amine-based ionic polymeric drilling fluid and preparation method thereof

ActiveCN110028940AInhibits hydration swellingReduce osmotic pressureDrilling compositionClay mineralsPotassium

The invention relates to a strong-inhibition bipotassium ionic polymeric drilling fluid. The strong-inhibition bipotassium amine-based ionic polymeric drilling fluid comprises the following componentsin percent by mass: 2-5% of bentonite, 0.2-0.5% of caustic soda, 0.2-0.3% of soda ash, 0.2-0.5% of potassium polyacrylamide, 5-10% of potassium chloride, 0.2-1% of a zwitterionic polymeric coating agent, 0.5-2% of a shale inhibitor amide polymer, 0.5-1% of a fluid loss additive, 0.2-0.5% of a tackifier, 0.1-0.3% of a viscosity reducer and the balance of water, wherein the weighting density rangeof a weighting agent is 1.10-2.40g / cm<3>. The strong-inhibition bipotassium amine-based ionic polymeric drilling fluid has a very strong function of inhibiting the water-absorbing swelling and dispersion of a clay mineral, has a very good rheological property and proper fluid loss, and can significantly increase the drilling speed of mud shale and stabilize the borehole wall of the mud shale so asto reduce occurrence of downhole accidents.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

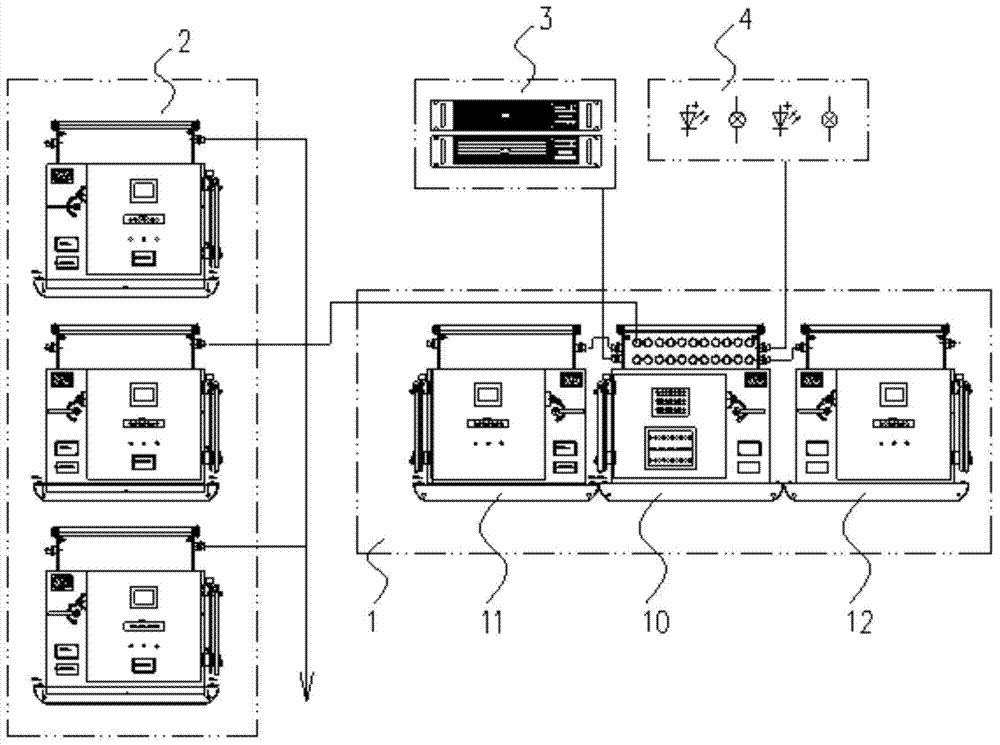

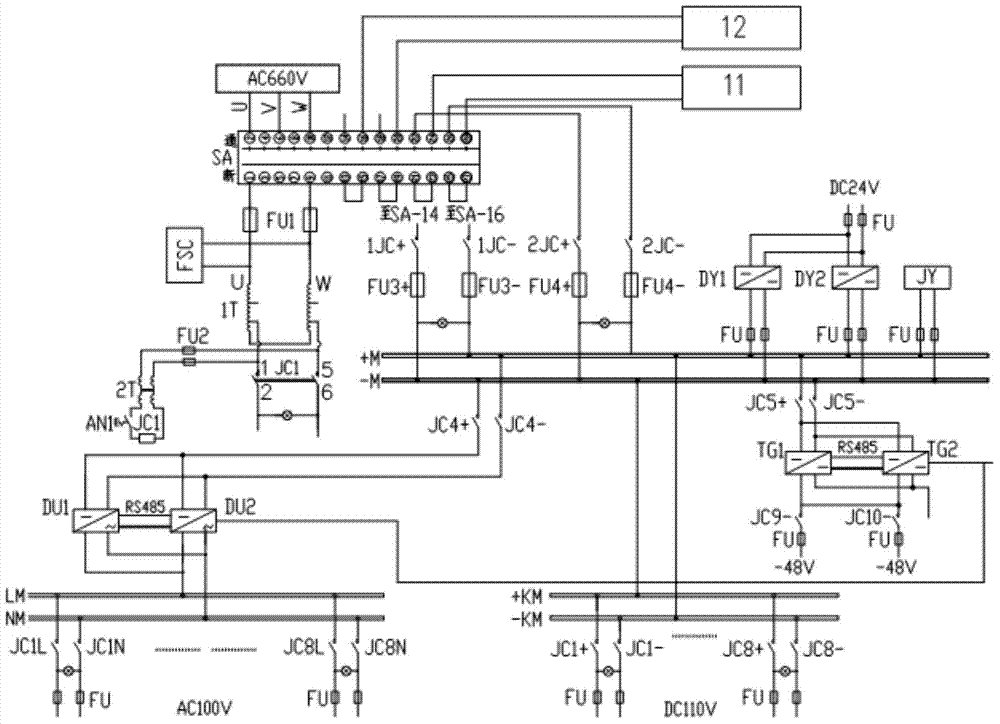

Mining explosion suppression type intelligent integrated power supply apparatus

ActiveCN104333232AImprove reliabilityReduce Downhole AccidentsBoards/switchyards circuit arrangementsSubstation/switching arrangement cooling/ventilationLight equipmentEngineering

The invention relates to the field of a mining power supply technology, and discloses a mining explosion suppression type intelligent integrated power supply apparatus. The integrated power supply apparatus comprises an explosion suppression type feed device and at least one storage battery power supply device connected with the explosion suppression type feed device, wherein the explosion suppression type feed device is also connected with an external underground distribution substation communication device, an external emergency illumination device, an external high-voltage switchgear and an external power supply device. According to the invention, AC or DC power supplies with different voltage grades and for different purposes can be provided, the power supply reliability is high, the power supply quality is good, the backup time is long, and the pressing problems can be well solved that conventional home and abroad coal mine underground backup power supplies are in short supply, or the management is chaotic and complex, the control power supply of an electric facility is unstable, the harmonic wave interference is severe, the voltage bounce is obvious, the backup time of communication equipment is short, and under the condition of power failure of an underground main power supply, accidents may be caused due to incapability of real-time monitoring of underground power supply equipment.

Owner:WUHAN RUIY POWER EQUIP CO LTD

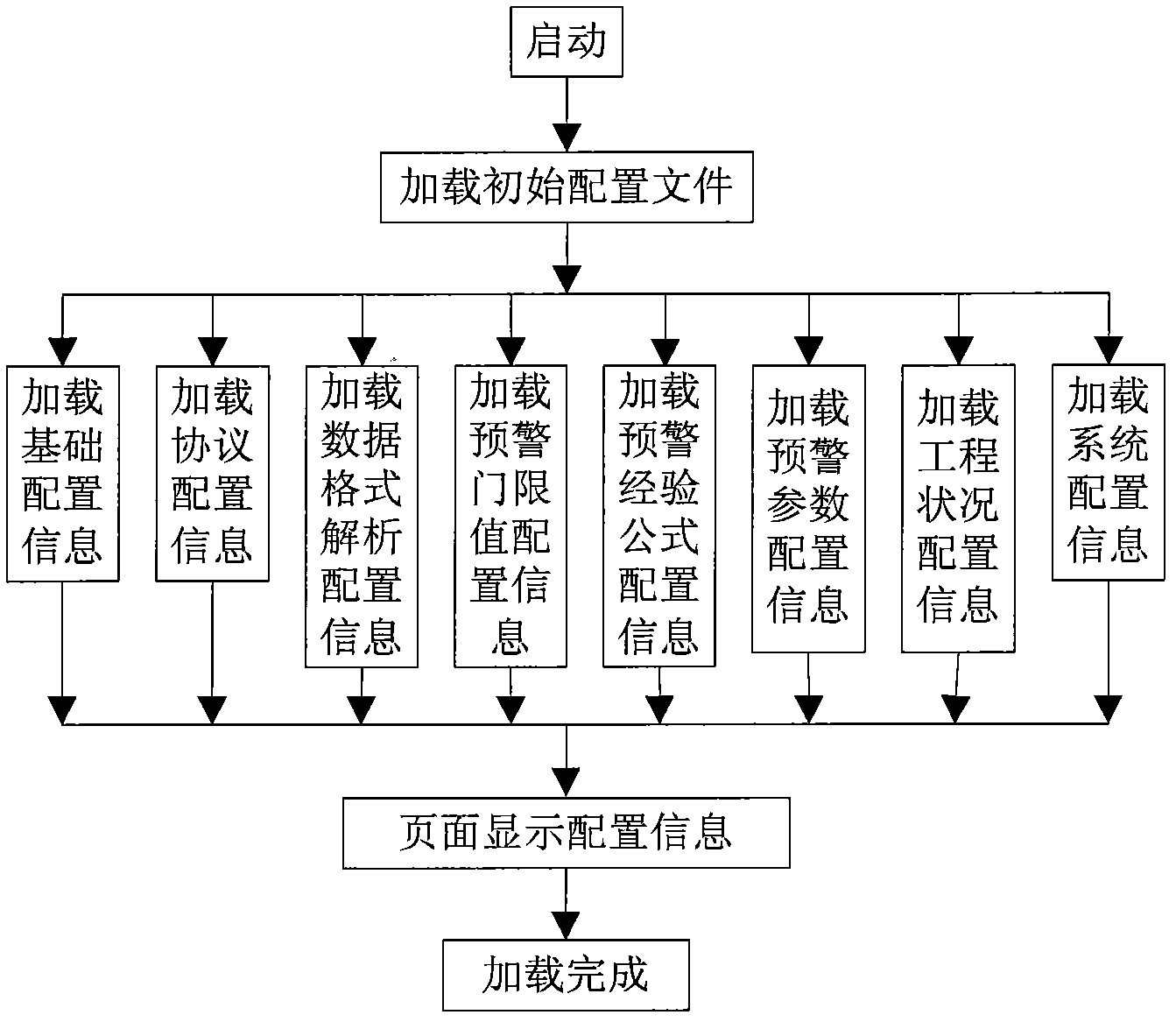

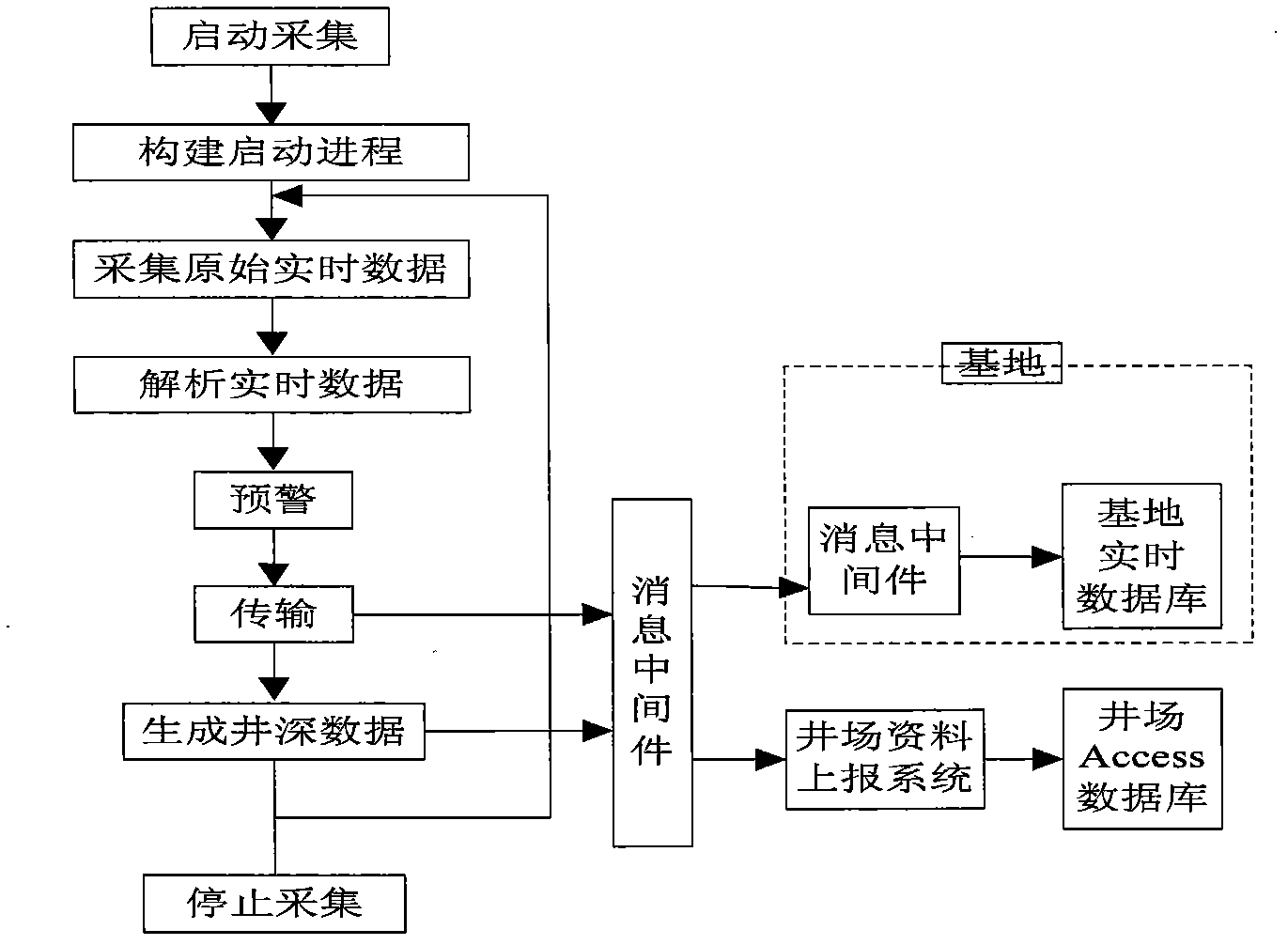

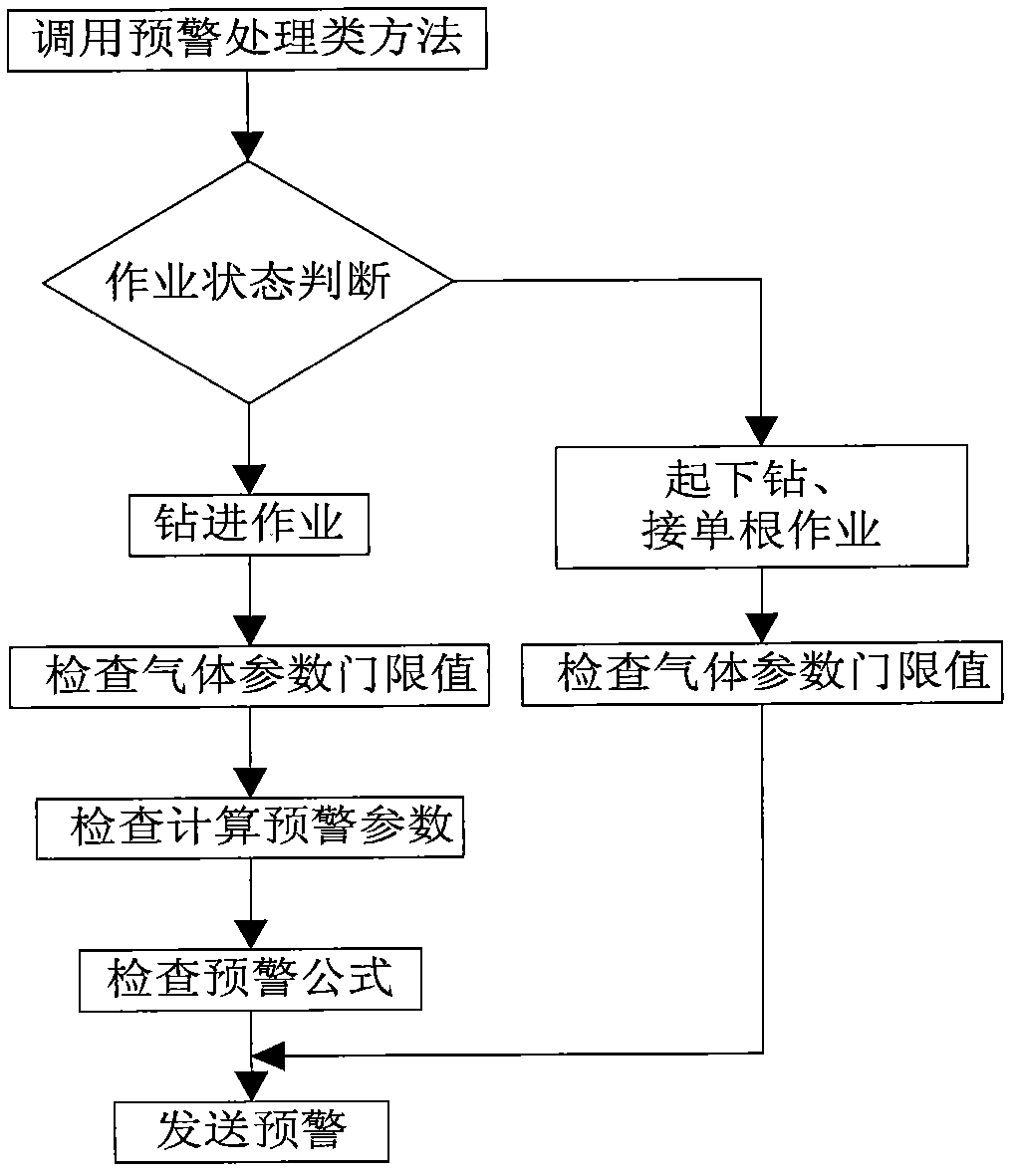

Real-time logging data acquisition and synchronous early-warning method

ActiveCN101976494BReduce Downhole AccidentsMeet the needs of safe drilling and productionSurveyAlarmsReal-time dataWell drilling

The invention discloses a real-time logging data acquisition and synchronous early-warning method, comprising the following steps: configuring data acquisition modules in well sites, configuring basic information of the well sites, and establishing an early-warning model; acquiring the real-time data of the well sites, and analyzing and formatting the real-time data; classifying and carrying out statistics on the real-time data according to the early-warning model for carrying out comprehensive analysis and judgment and early warning; and processing the formatted data and the abnormal information obtained based on the early-warning model into a standard format, sending to a base, and carrying out secondary early-warning. In the method, the real-time logging data of a site mud logging unitunder a plurality of operating conditions is acquired and then subject to intellectualized comprehensive analysis and judgment, and primary abnormal early warning is carried out; and meanwhile the data is processed into the standard format and then sent to the base so as to realize a synchronous secondary warning mechanism between the site and the logistical base, thus achieving the purposes of remote automatic monitoring and early warning during the well drilling process in a plurality of the well sites, reducing downhole accidents and meeting the demand for safety drilling production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

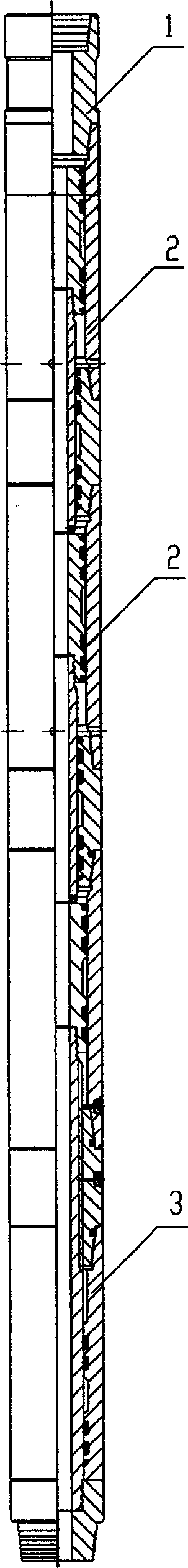

Local underbalanced drilling recycling device

The invention discloses a local underbalanced drilling recycling device. The local underbalanced drilling recycling device comprises coiled oil tubing, a coiled oil tubing connector, a coiled tubing connector, a top joint of a drill bit, the drill bit, and backflow pup joints; the coiled oil tubing connector is connected to the lower end of the coiled oil tubing; the coiled oil tubing connector issleeved with the coiled tubing connector, and the coiled tubing connector is connected with the coiled oil tubing connector in a clamping mode; the coiled tubing connector is sleeved with the top joint of the drill bit, a ring cavity is formed between the top joint of the drill bit and the coiled tubing connector, and bearings are disposed inside the ring cavity; the drill bit is connected to thelower end of the top joint of the drill bit, and a spray nozzle is formed in the drill bit; the backflow pup joints are connected to the upper end of the top joint of the drill bit; reflowing valvesare formed in the side walls of the backflow pup joints; drilling rods are connected to the upper end of the backflow pup joints; and a penetrating internal flow passage is formed between the coiled oil tubing and the drill bit. When drilling with the local underbalanced drilling recycling device, under the premise of local underbalanced drilling in the well bottom, microannular high-efficient solid-carrying is realized, the stability of the wellbore in the upper well section can be ensured, the well control is better achieved, and the drilling speed is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

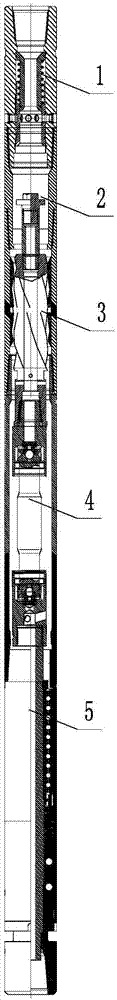

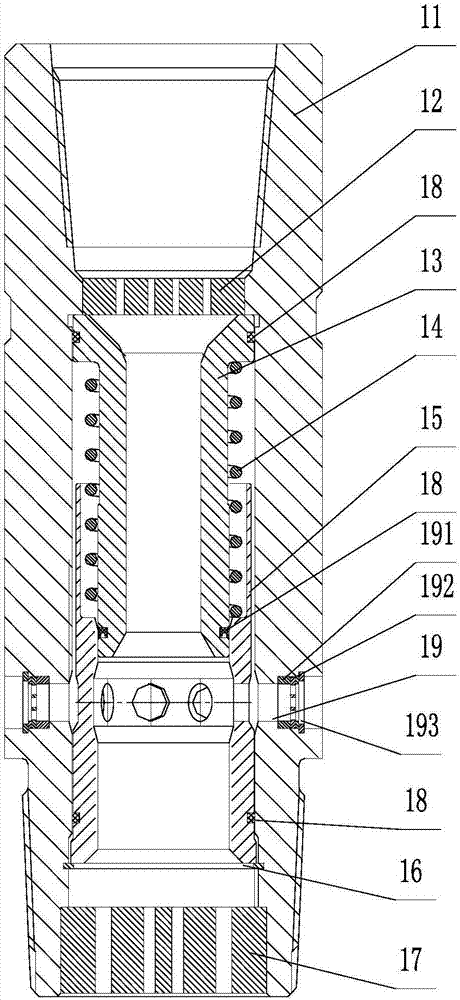

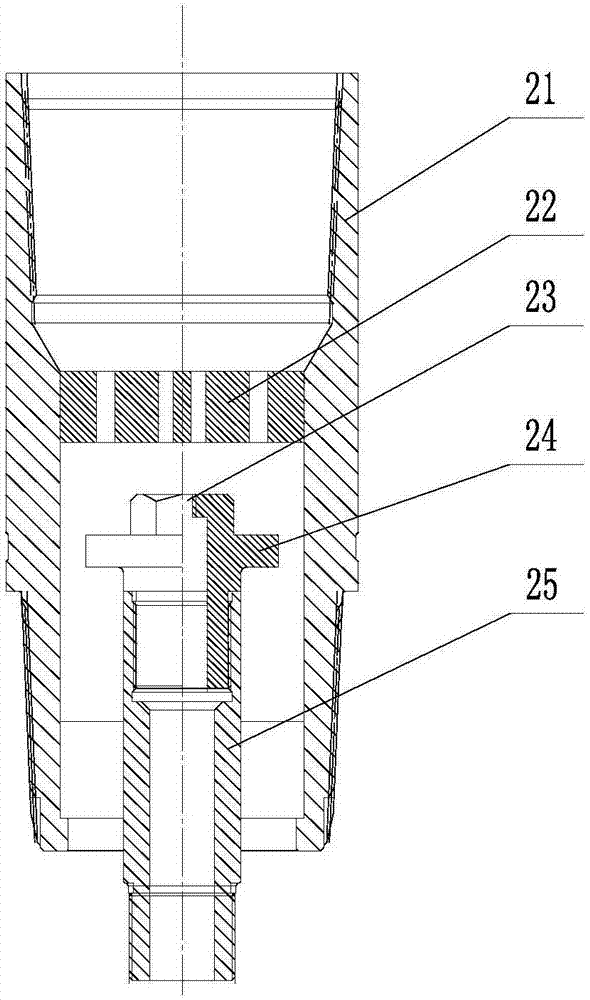

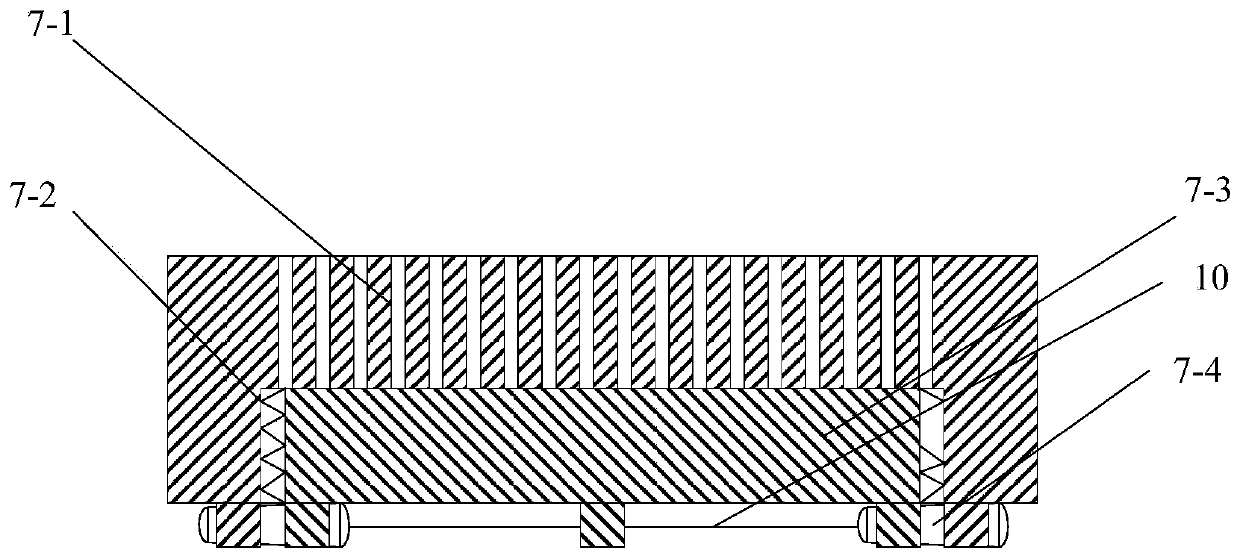

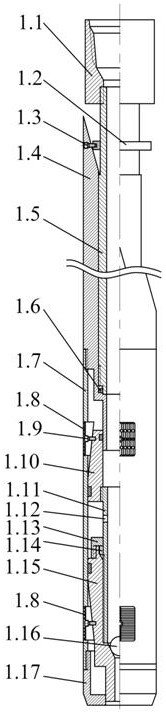

Single spiral spin micro-seismic emitter

The invention relates to drilling equipment, in particular to a single spiral spin micro-seismic emitter which comprises a filter bypass assembly, a filter safety assembly, a hydraulic drive assembly, a drive assembly and a spin micro-seismic emission assembly which are sequentially connected from top to bottom. The assemblies are connected with each other in a threaded manner and conveniently assembled and disassembled. When drilling fluids pass the emitter, solid particles are filtered in the filter bypass assembly, the filter safety assembly protects safe and efficient operation of the emitter, operating pressure drop of a motor is reduced, and rock crushing is assisted by a jet method. The spin micro-seismic emission assembly forms axial impact in an impact source emitting mode, reacting force of a spring is applied to an emission impact body, and an axial impact function is achieved. Impact frequency can be changed by adjusting the rotating speed of an emission connecting rod, and the emission connecting rod can be used with motors with different rotating speeds.

Owner:DONGYING WEIMA PETROLEUM DRILLING TOOLS

Bypass valve while drilling

ActiveCN105569609BHigh switching timesImprove reliabilityFlushingWell/borehole valve arrangementsElectricityControl signal

The invention discloses a while-drilling bypass valve comprising the following elements: a valve body; a power unit connected with the valve body; a control unit electrically connected with a ground controller, the control unit is electrically connected with the power unit, and used for receiving a ground control signal so as to control motions of the power unit; an execution unit arranged in the valve body and connected with the power unit, thus opening and closing the bypass valve. The while-drilling bypass valve is simpler in operation, less in quick wear parts, and can be opened / closed for more times.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling sleeve and large well -eye multi -branch well -branched well quickly drilled well

ActiveCN109236186BIncrease contact areaSimple structureConstructionsFluid removalMining engineeringWell drilling

The invention discloses a drilling casing, which comprises a casing wall and several sand control devices arranged at intervals on the casing wall, each sand control device includes a sand control net, a sealing steel sheet and a sealing rubber plug, and the sand control net is arranged with A plurality of sand control screen holes parallel to each other, the sand control screen holes are facing the sealing steel sheet, and the sand control mesh and the sealing steel sheet are connected by steel pins. The invention also discloses a fast drilling and completion method for multi-branch wells with large boreholes by using the drilling casing. The present invention uses a large-sized drill bit to drill to the target well depth at one time to form the main wellbore, and then uses the drilling casing to drill branch wellbores in the natural gas hydrate reservoir, and then takes out the drill bit to complete the well, which is suitable for various natural gas hydrate exploitation This method can greatly increase the production and recovery of hydrate wells, and integrate drilling and completion, shorten the drilling and completion cycle, save a lot of manpower and material resources, and effectively prevent sand at the same time.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

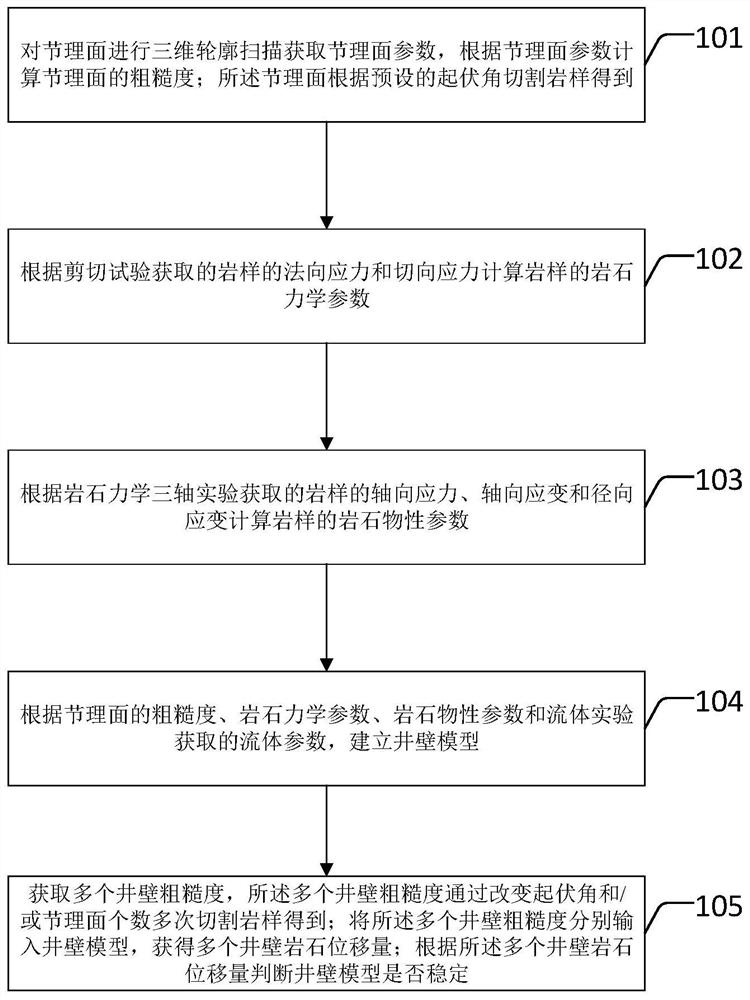

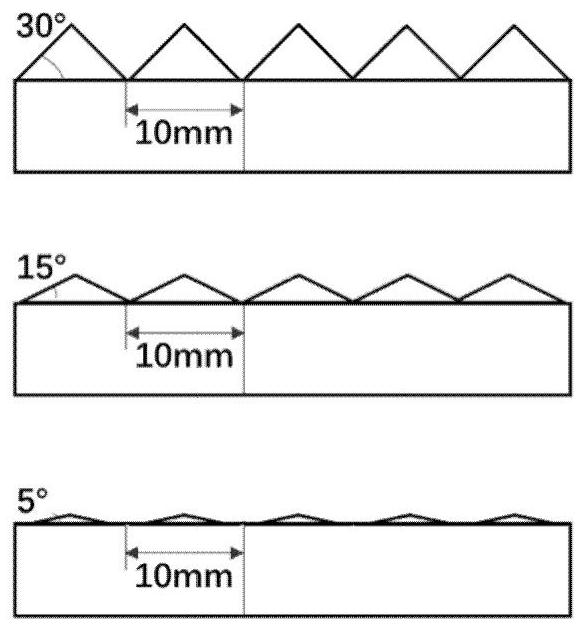

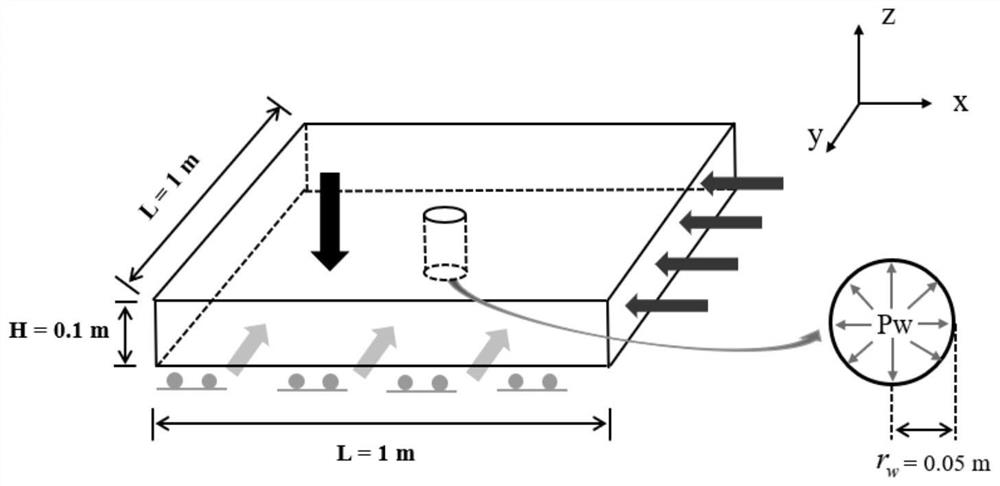

Well wall stability simulation method and device based on joint surface roughness

ActiveCN114460267AImprove accuracyReduce Downhole AccidentsEarth material testingDesign optimisation/simulationTangential stressClassical mechanics

The invention discloses a well wall stability simulation method and device based on joint surface roughness, and the method comprises the steps: carrying out the three-dimensional contour scanning of a joint surface, obtaining the parameters of the joint surface, and calculating the roughness of the joint surface; the joint surface is obtained by cutting the rock sample according to a preset fluctuation angle; calculating rock mechanical parameters of the rock sample according to the normal stress and the tangential stress of the rock sample obtained by the shear test; calculating rock physical property parameters of the rock sample according to the axial stress, the axial strain and the radial strain of the rock sample obtained by the rock mechanics triaxial experiment; according to the roughness of the joint surface, the rock mechanical parameters, the rock physical property parameters and fluid parameters obtained through a fluid experiment, a borehole wall stability model is established; cutting the rock sample for multiple times by changing the number of fluctuating angles and / or joint surfaces to obtain a plurality of well wall roughness; and inputting the plurality of well wall roughness into a well wall stability model to obtain a plurality of well wall rock displacements, and judging whether the well wall stability model is stable or not, so that the accuracy of well wall stability judgment can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Double-sealing packing box for oil field wellhead and wellhead double-sealing method

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Multi-branch borehole ultra-short radius windowing sidetrack drilling orientation tool and using method

PendingCN114790873ASimple and reliable designReduce downhole accidentsDrilling rodsDirectional drillingUpper jointClassical mechanics

The invention relates to a multi-branch borehole ultra-short radius windowing sidetrack drilling orientation tool and a using method, the windowing sidetrack drilling orientation tool comprises an oblique fixator, when an oblique device back-off rod and an oblique device centralizing ring in the oblique fixator are lifted out of a well, a guide slope of a guide slope body can be stacked with a recoverable positioner, and the recoverable positioner can be used for positioning the inclined slope of the guide slope body. The recoverable positioner is mainly composed of an upper positioning body, a centralizing body and a lower positioning body, the upper positioning body and the lower positioning body are respectively provided with a guide inclined face, the angle of the guide inclined face on the lower portion of the lower positioning body is the same as that of the guide inclined face of the guide inclined body in the inclined fixator, and a fishing thread is arranged in the upper positioning body. And the upper positioning body is sequentially connected with the positioner reversing rod and the positioner upper joint. And the guide inclined surface of the lower positioning body in the recoverable positioning device and the guide inclined body of the inclined fixer at the bottom of the windowing sidetrack drilling window can be stacked in a matched manner. According to the method, multi-window windowing can be achieved in the main borehole, the operation cost is reduced, and the remarkable development effect of reducing cost and improving efficiency can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Crankshaft for Equal Distribution Angle Hydraulic Cylinder Motor

Owner:NANTONG JUNQI MACHINERY

Hydraulic support balancing mechanism testing device and method

InactiveCN104533491AAuthentication strengthReduce Downhole AccidentsStructural/machines measurementMine roof supportsEngineeringUltimate tensile strength

The invention discloses a hydraulic support balancing mechanism testing device and method. A hydraulic support comprises a top beam, a caving shield, a base, a stand column, a front connecting rod, a rear connecting rod and a balancing jack. The front connecting rod on one side of the hydraulic support is detached first, and the hinge point of the upper end of the rear connecting rod on the same side and the caving shield is assembled at the hinge point of the upper end of the existing front connecting rod and the caving shield after being detached so that the hinge points can be fixed to each other; then, the stand column is lifted first so that the top beam can be lifted upwards, a rod cavity of the balance jack is pulled out by at least 30 mm till a safety valve is unloaded, then the stand column is lowered so that the head of the top beam can be lowered, and a piston cavity of the balance jack is pressed by at least 30 mm till the safety valve is unloaded; a cycle is completed after the stand column rises and falls one time, and at least 4000 cycles are completed. The telescopic amount of the balance jack is controlled through time, and the experiment shows that the average time for extending by 30 mm is set as the liquid supply time. The strength of a balance mechanism can be well verified, and downhole accidents are reduced.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

Double-aggregate composite polymer, and pouring method and application thereof

ActiveCN109206582AImproved particle size distributionReduce dosageUnderground chambersTunnel liningPolyolFire retardant

The invention provides a double-aggregate composite polymer, and relates to the technical field of coal mine safety materials, wherein the double-aggregate composite polymer includes the following rawmaterials by mass: 20-100 parts of polyether polyol, 20-100 parts of polymerized MDI, 5-10 parts of a dispersant, 5-10 parts of a catalyst, 5-10 parts of a chain extender, 3-10 parts of a flame retardant, 7-40 parts of a coarse aggregate, and 7-40 parts of a fine aggregate. The double-aggregate composite polymer is suitable for coal mine coal seam filling and reinforcing and leaked air blocking;the composite polymer has low manufacturing cost, and the probability of accidents in underground coal mine after the composite polymer is grouted for use can be effectively reduced.

Owner:SHANDONG UNIV OF SCI & TECH

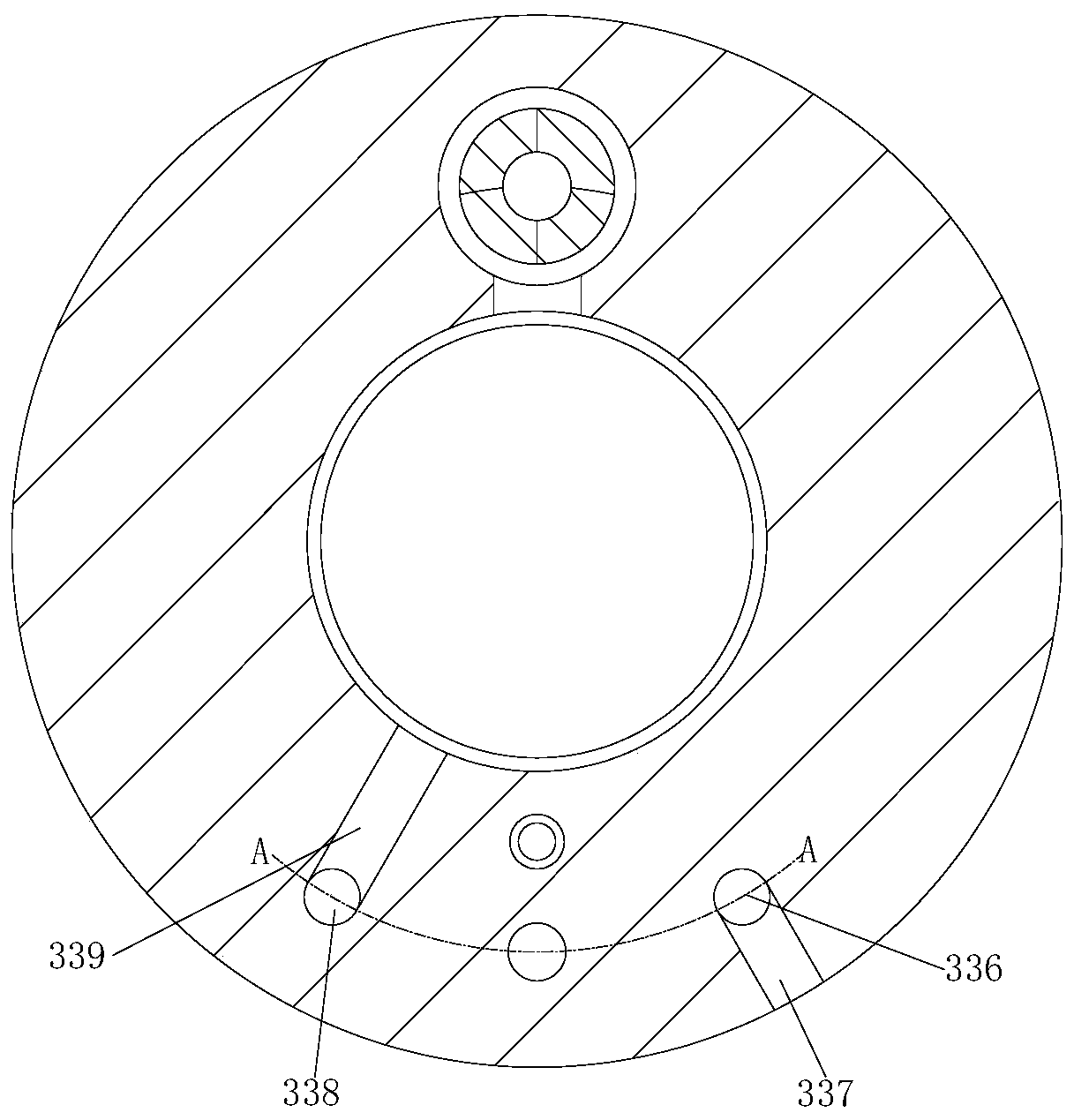

Downhole intelligent control expansion packer

ActiveCN107489395BSimplify the inspection and sealing processContain sand productionConstructionsWell/borehole valve arrangementsFluid migrationUpper joint

The invention discloses a downhole intelligent controlling type expansion packer. The downhole intelligent controlling type expansion packer comprises an upper joint and a lower joint; an intelligent controlling plate (15) is fixedly connected to the upper joint; an inner cavity pressure gauge (47), a sealing pressure gauge (54) and an in-pipe pressure gauge (55) which are connected with the intelligent controlling plate (15) are arranged on one side of a sealing main body (33); an electric switch is arranged in the sealing main body (33) and controls liquid inlet and liquid outlet of an inner cavity of a rubber barrel, steel pipe cables penetrate through a packer body, and locking and sealing mechanisms are arranged on the two extended ends of the steel pipe cables. According to the downhole intelligent controlling type expansion packer, the self power supply and data transmission problems are solved by utilizing the penetrating cables, a ground controlling system can control the packer to be set and unset and collect and upload data of the inner cavity, stratum and in-pipe pressure in time, the examining seal procedure of the packer is simplified, the accuracy of other downhole parameter admission is improved, fluid migration preventing pressure difference between layers during stopping injection is raised to over 15MPa, interlayer interference in an oil producing well is solved, and occurrence of downhole accidents is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com