Patents

Literature

72 results about "Fluid migration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bi-phasic compressed porous reinforcement materials suitable for implant

ActiveUS8389588B2Efficient use ofHigh and low porosity zoneBone implantSkeletal disorderFluid migrationUltimate tensile strength

Owner:DSM IP ASSETS BV

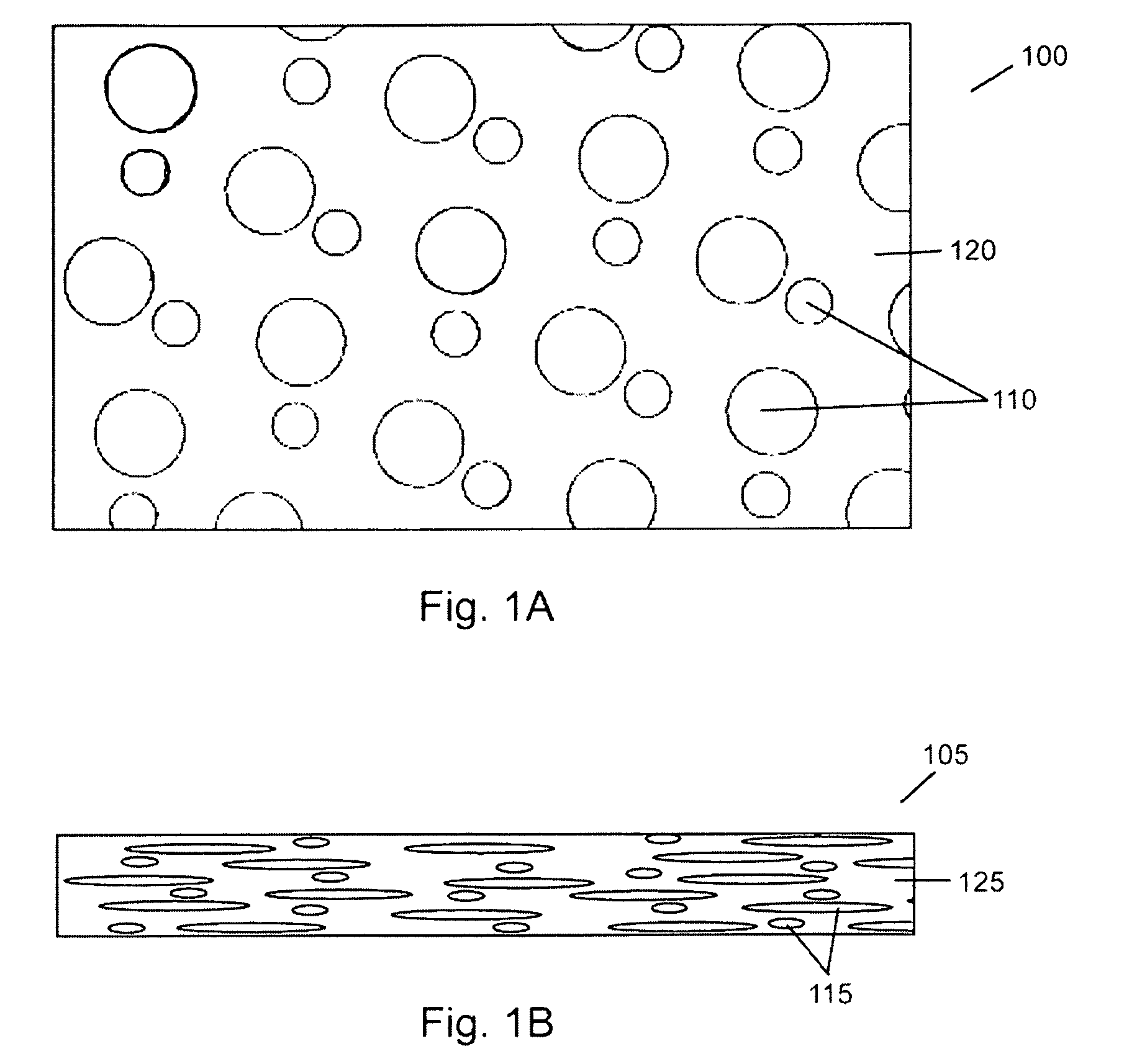

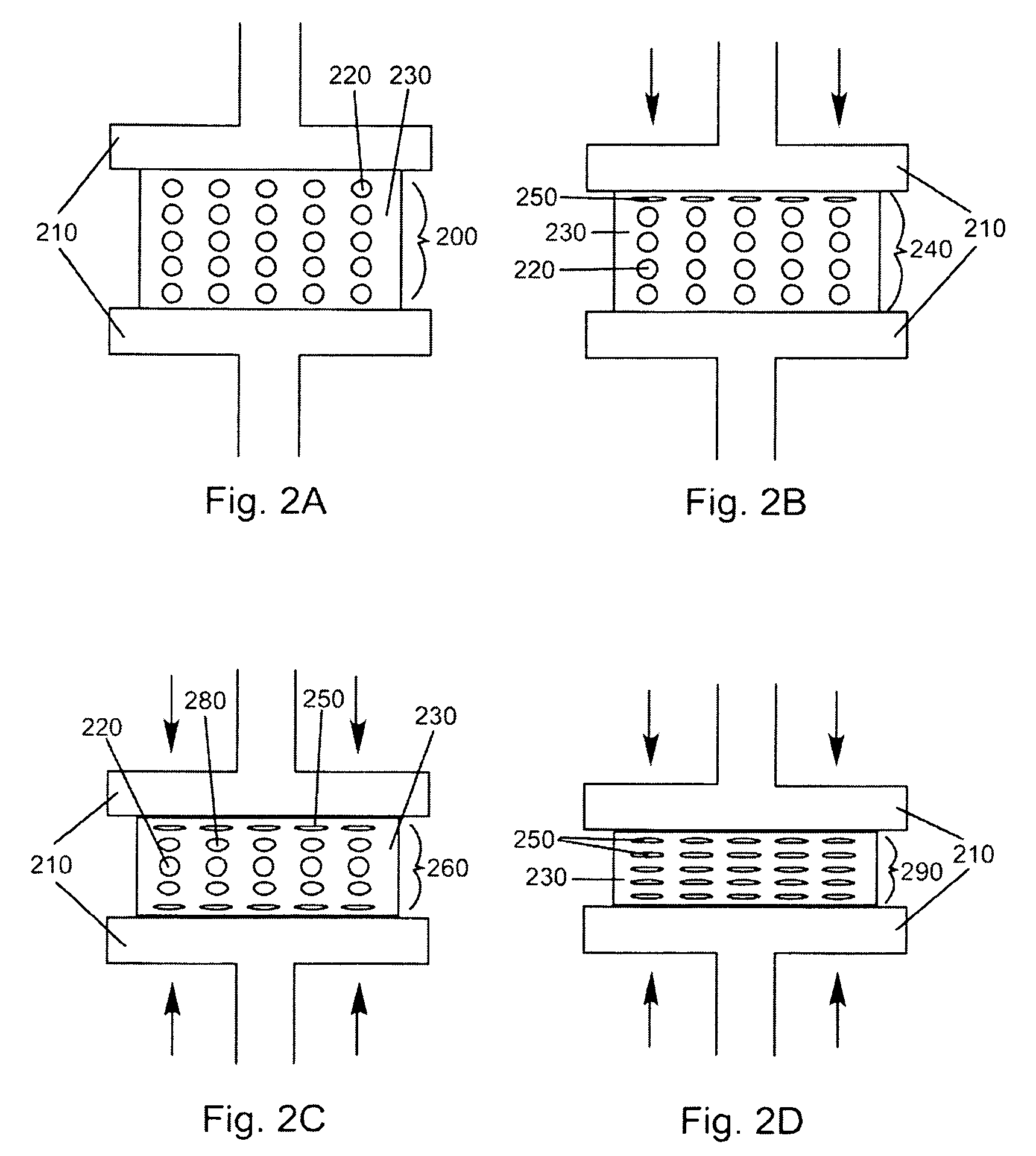

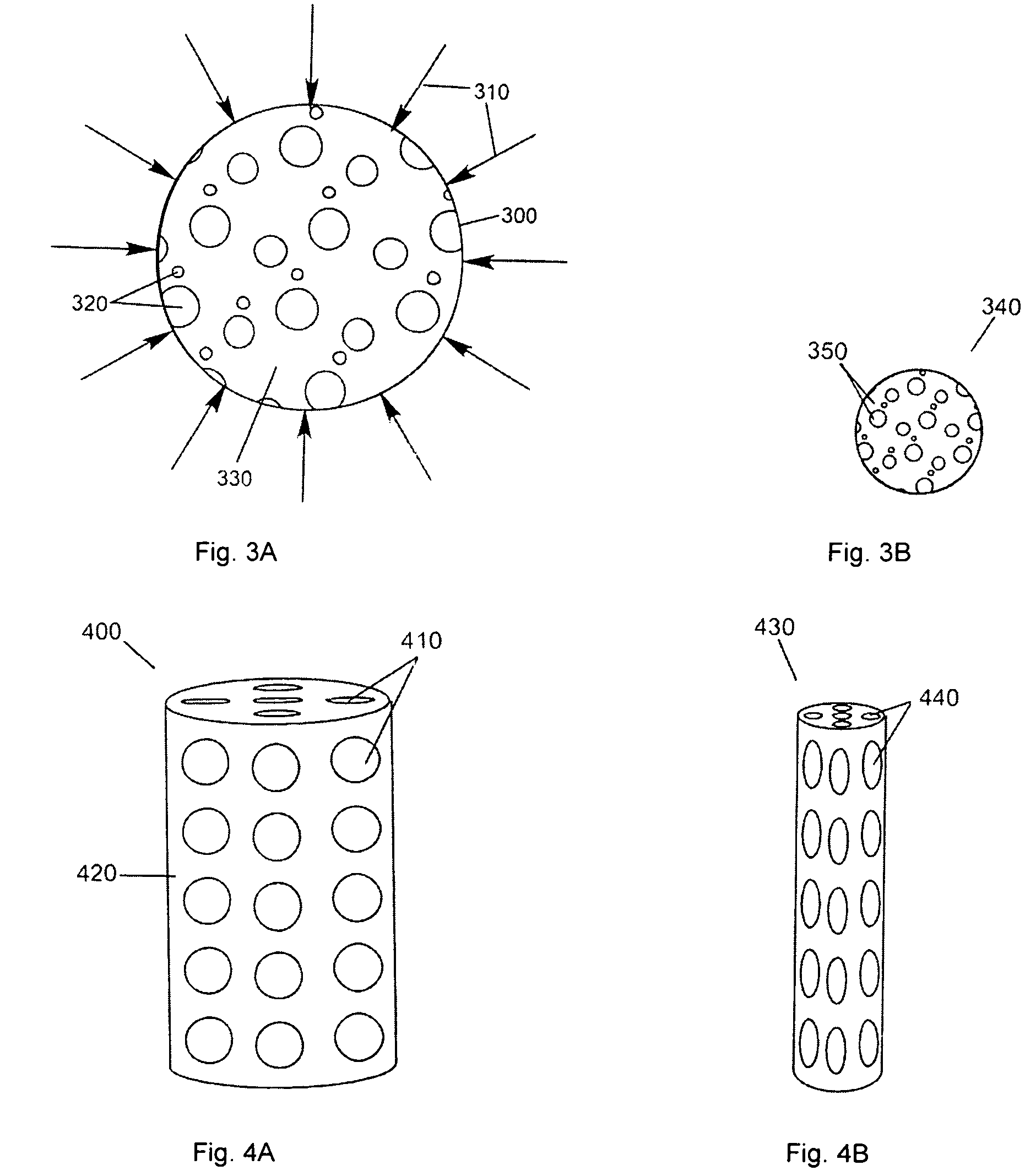

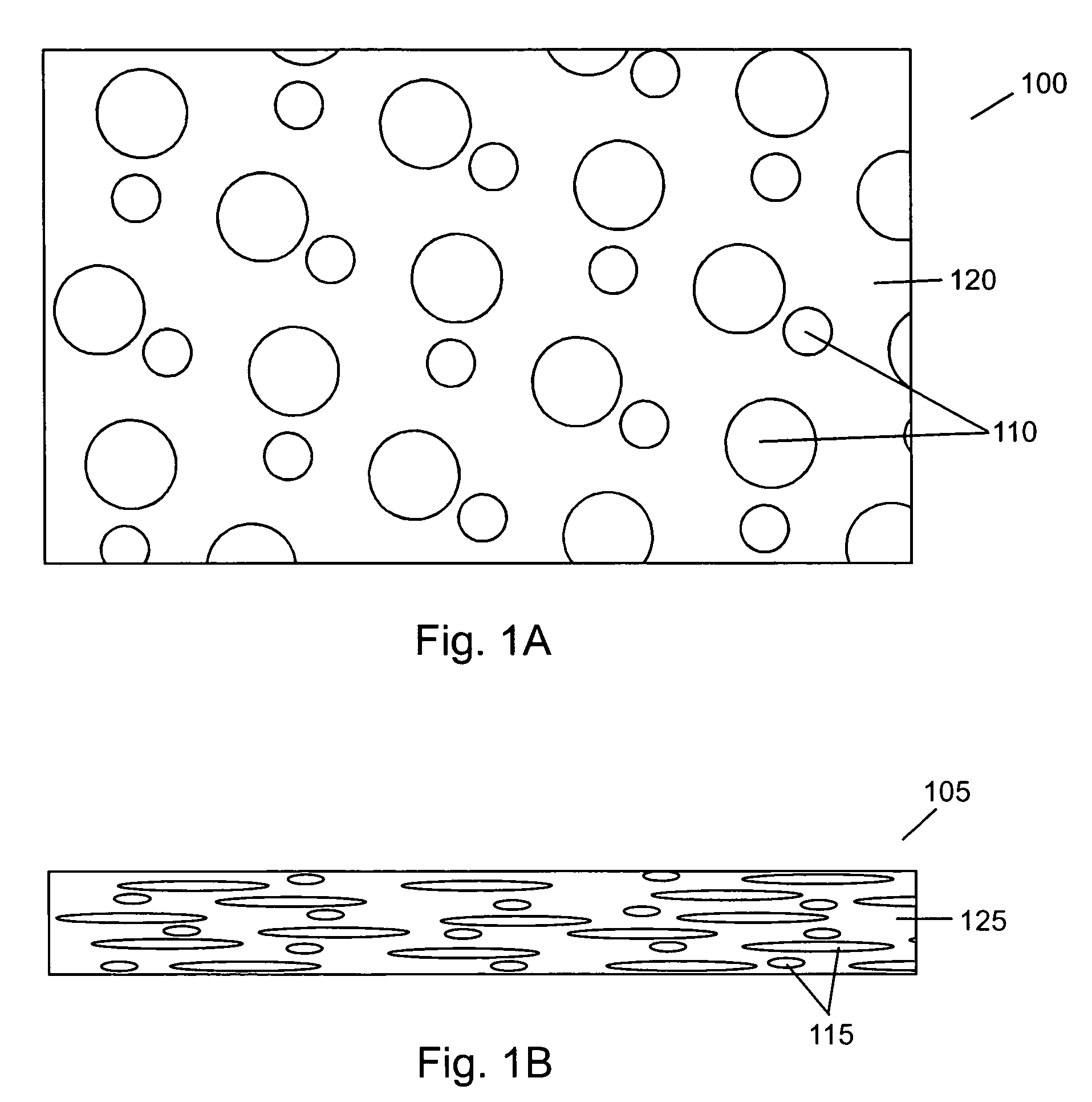

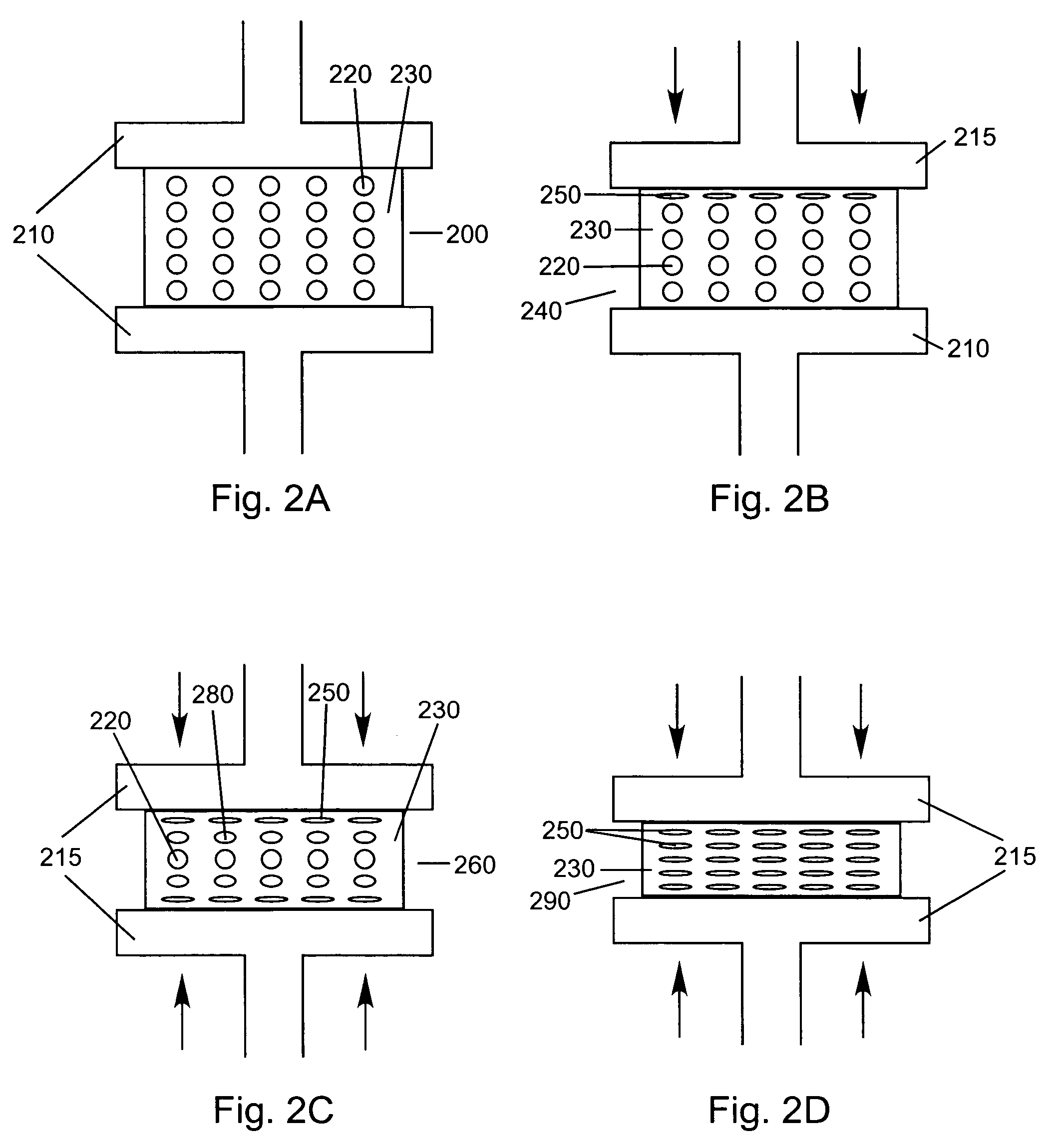

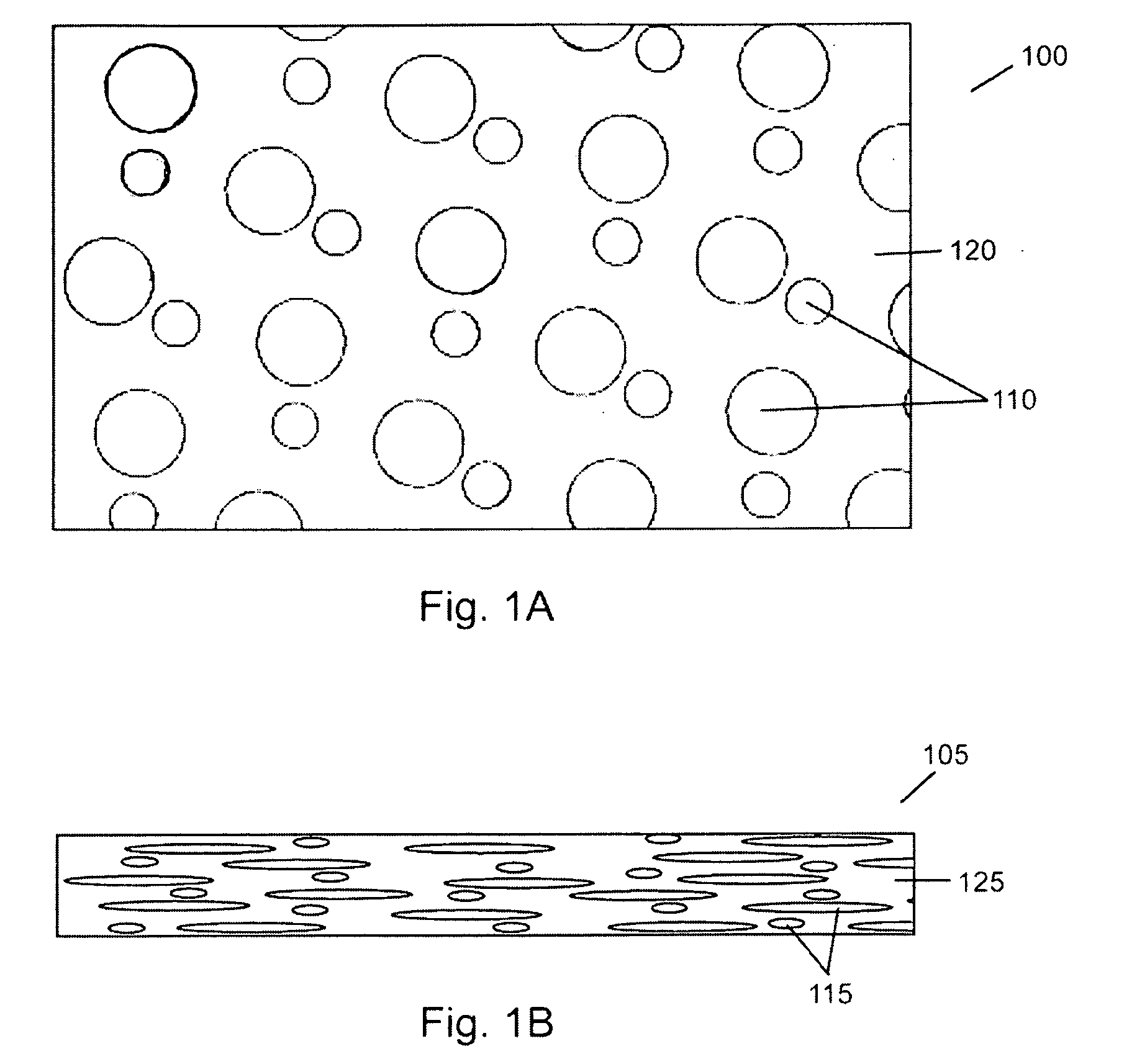

Compressed porous materials suitable for implant

ActiveUS7723395B2Increase surface areaReduce porosityInternal osteosythesisBone implantFluid migrationHigh intensity

A high strength porous polymeric material manufactured by a compression process is disclosed. The material results in a network of interconnected collapsed pores, which forces thin overlapping walls and passages to be created. The network provides permeable access for fluid migration throughout the material. The strength and / or permeability are advantageous for medical devices and implants.

Owner:DSM IP ASSETS BV

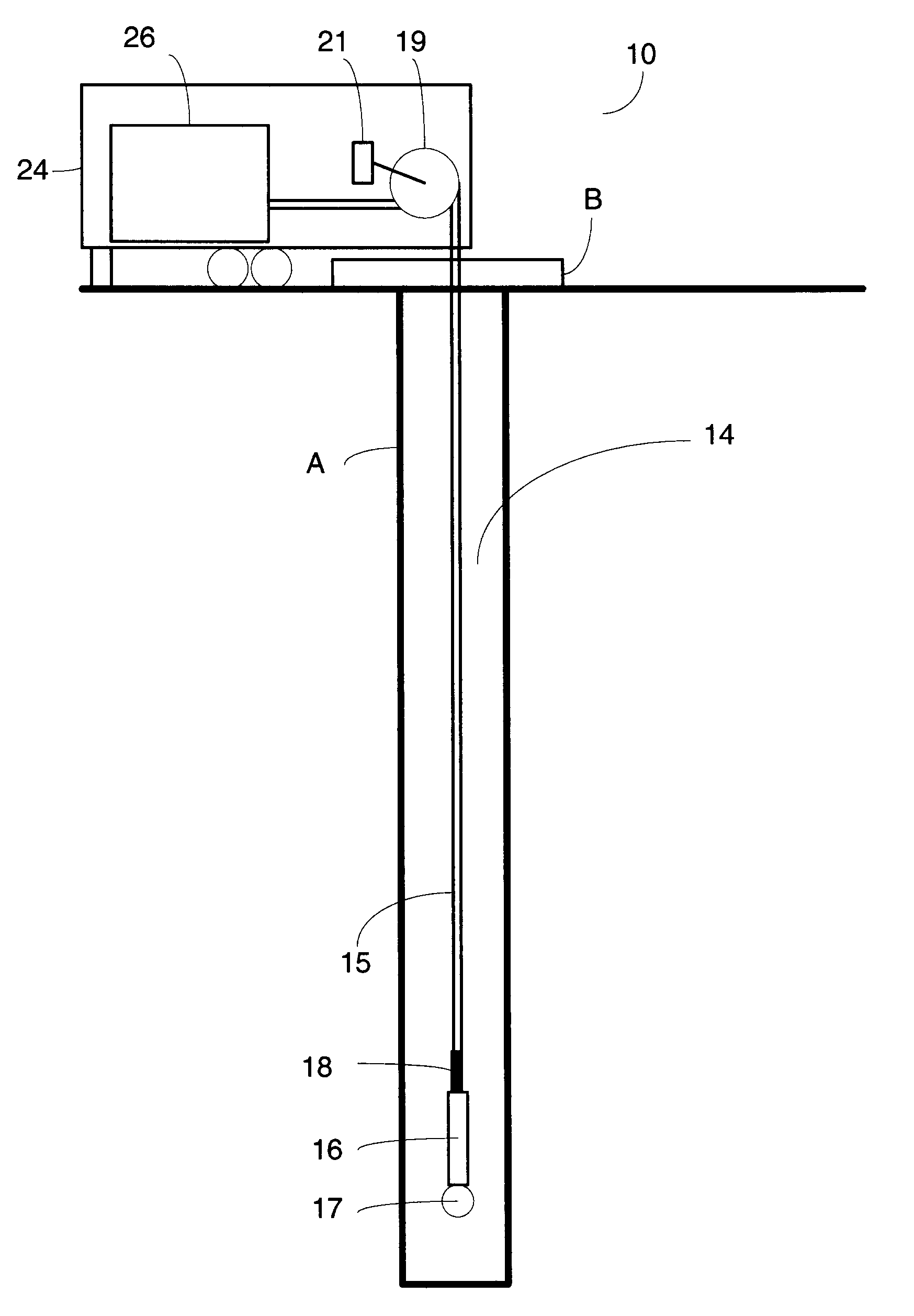

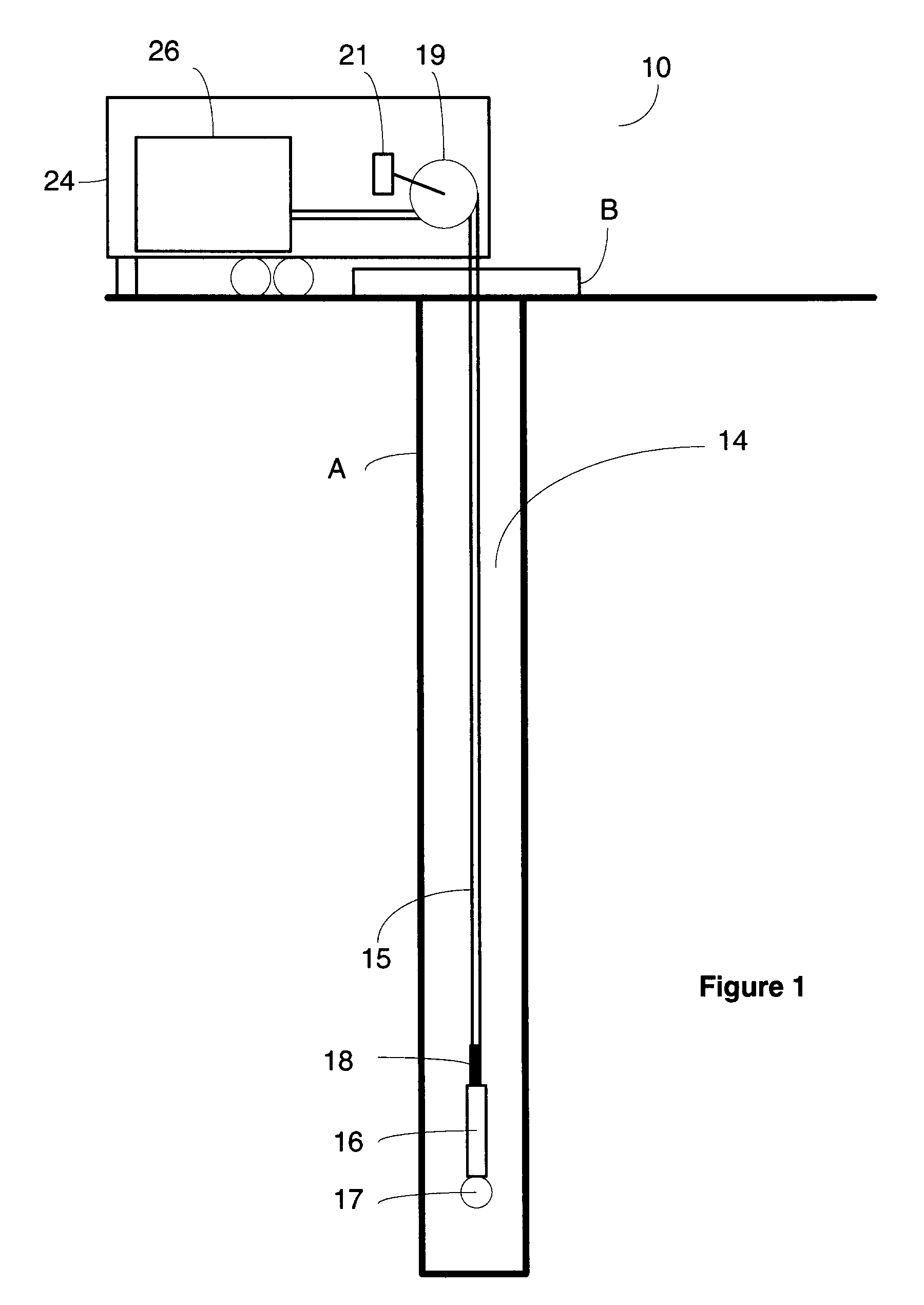

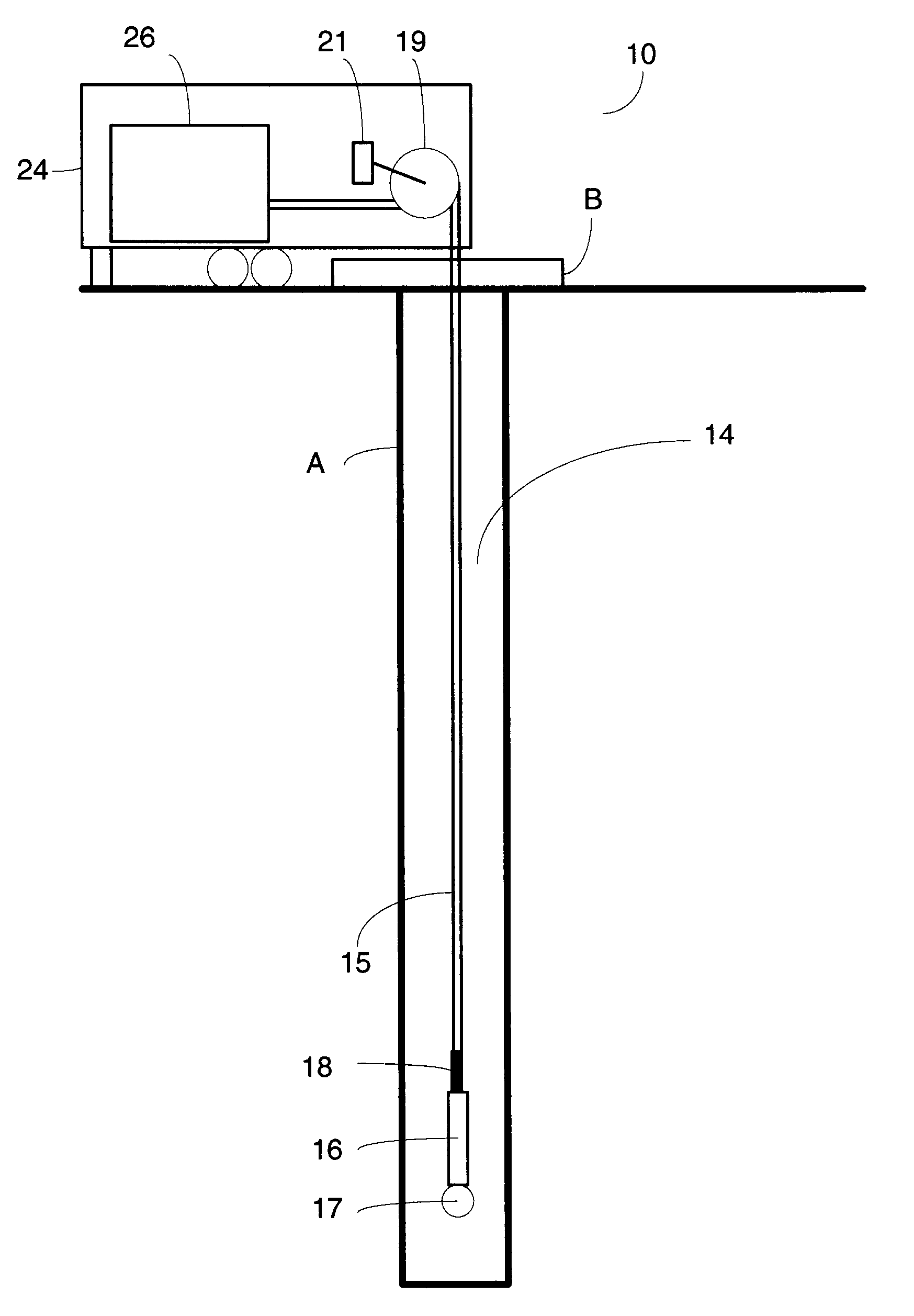

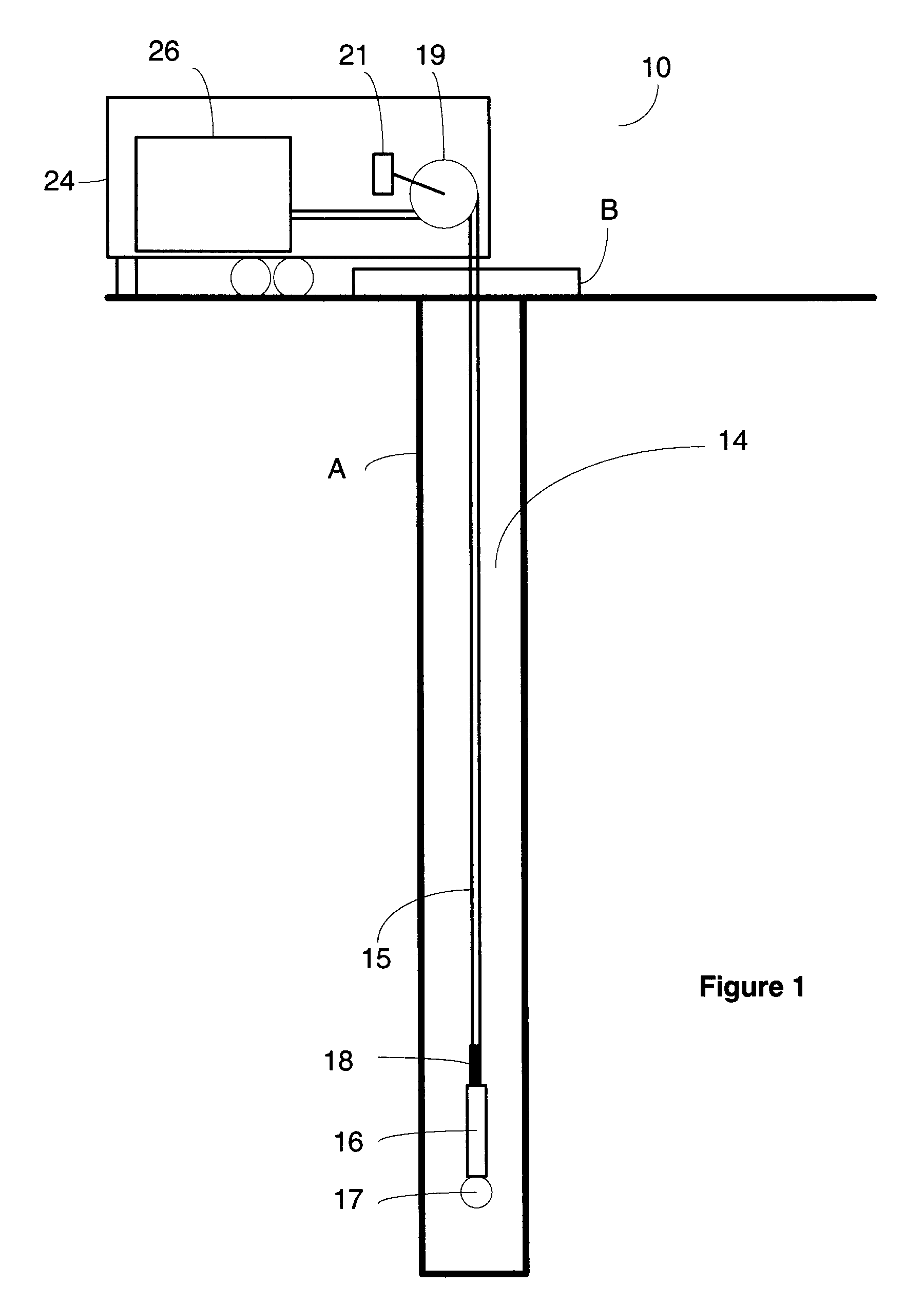

Method and apparatus for fluid migration profiling

ActiveUS20090326826A1Electric/magnetic detection for well-loggingConstructionsSection planeFluid migration

A method for obtaining a fluid migration profile for a wellbore, comprising the steps of obtaining a static profile for a logged region of the wellbore, obtaining a dynamic profile for the logged region of the wellbore, digitally filtering the dynamic profile to remove frequency elements represented in the static profile, to provide a fluid migration profile, and storing the fluid migration profile on a computer-readable memory.

Owner:HIFI ENG

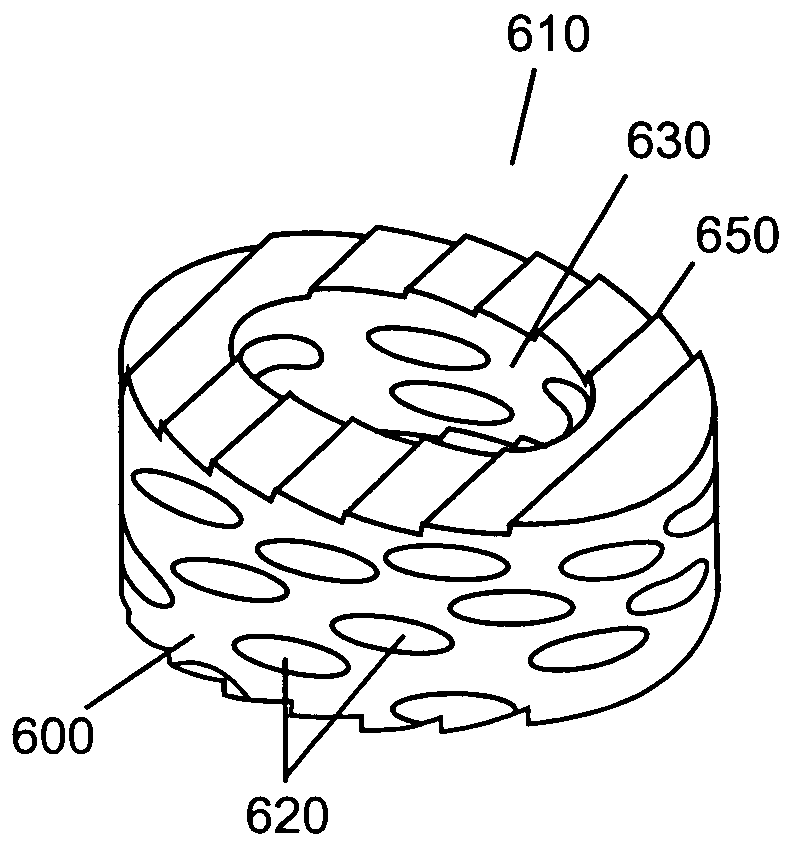

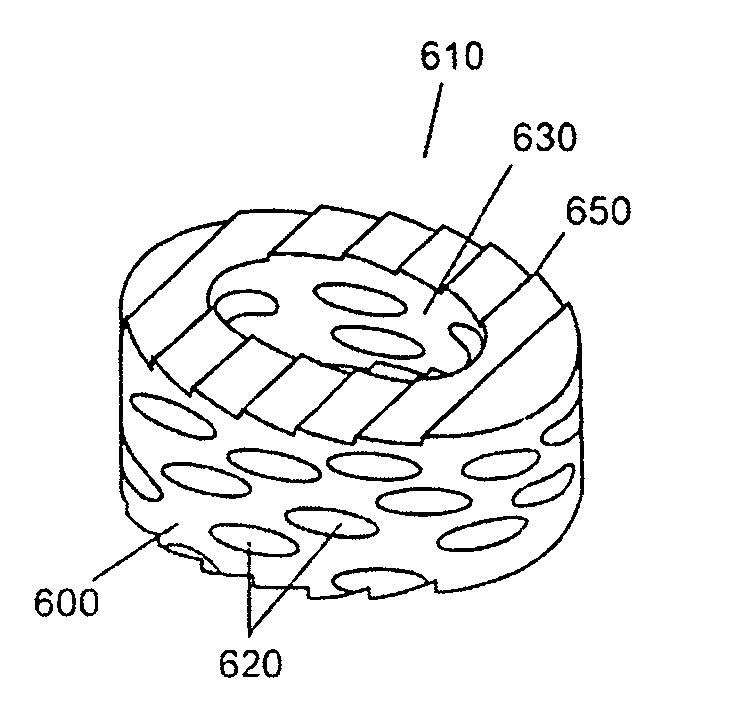

Implantable fistula closure device

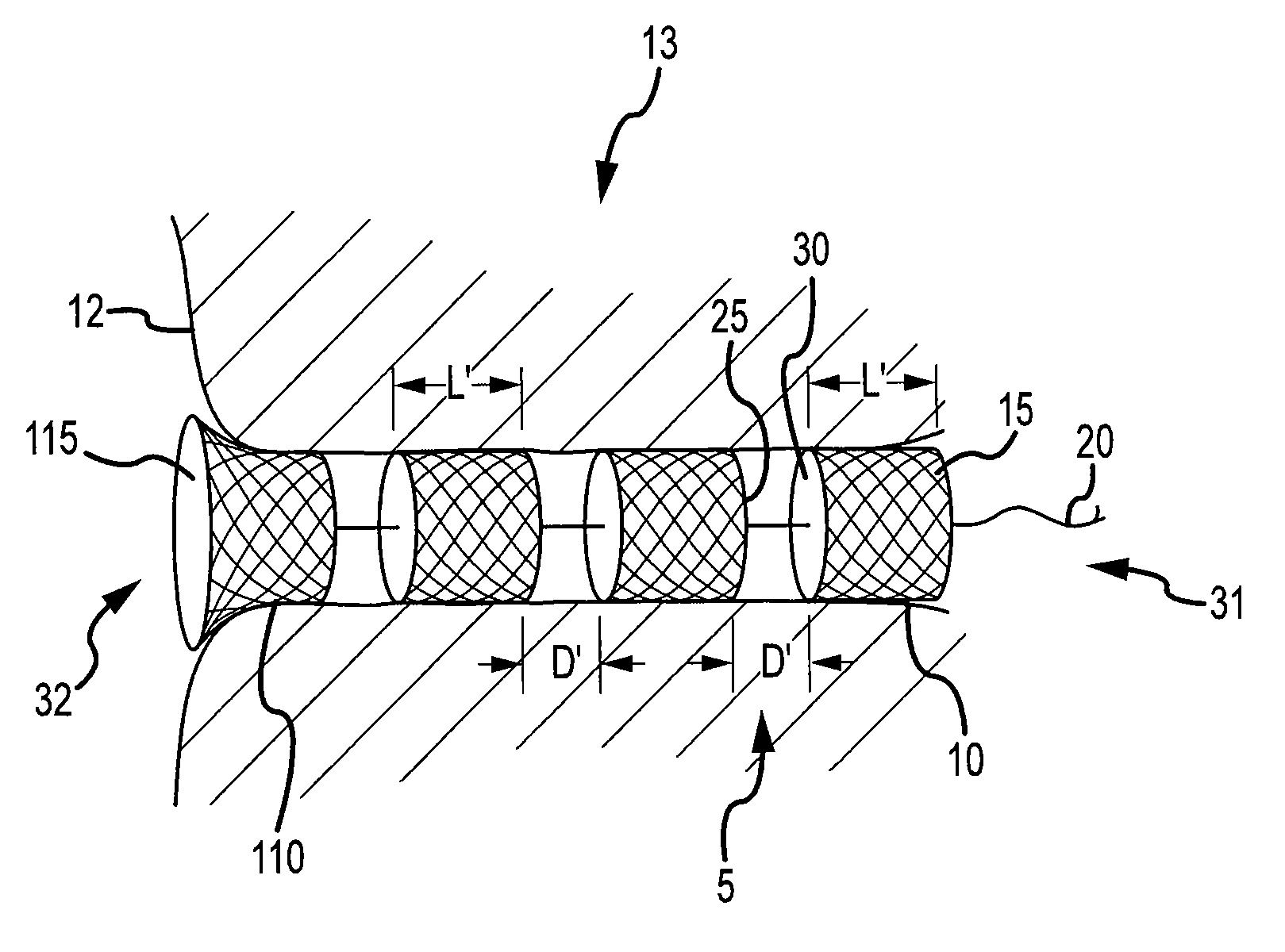

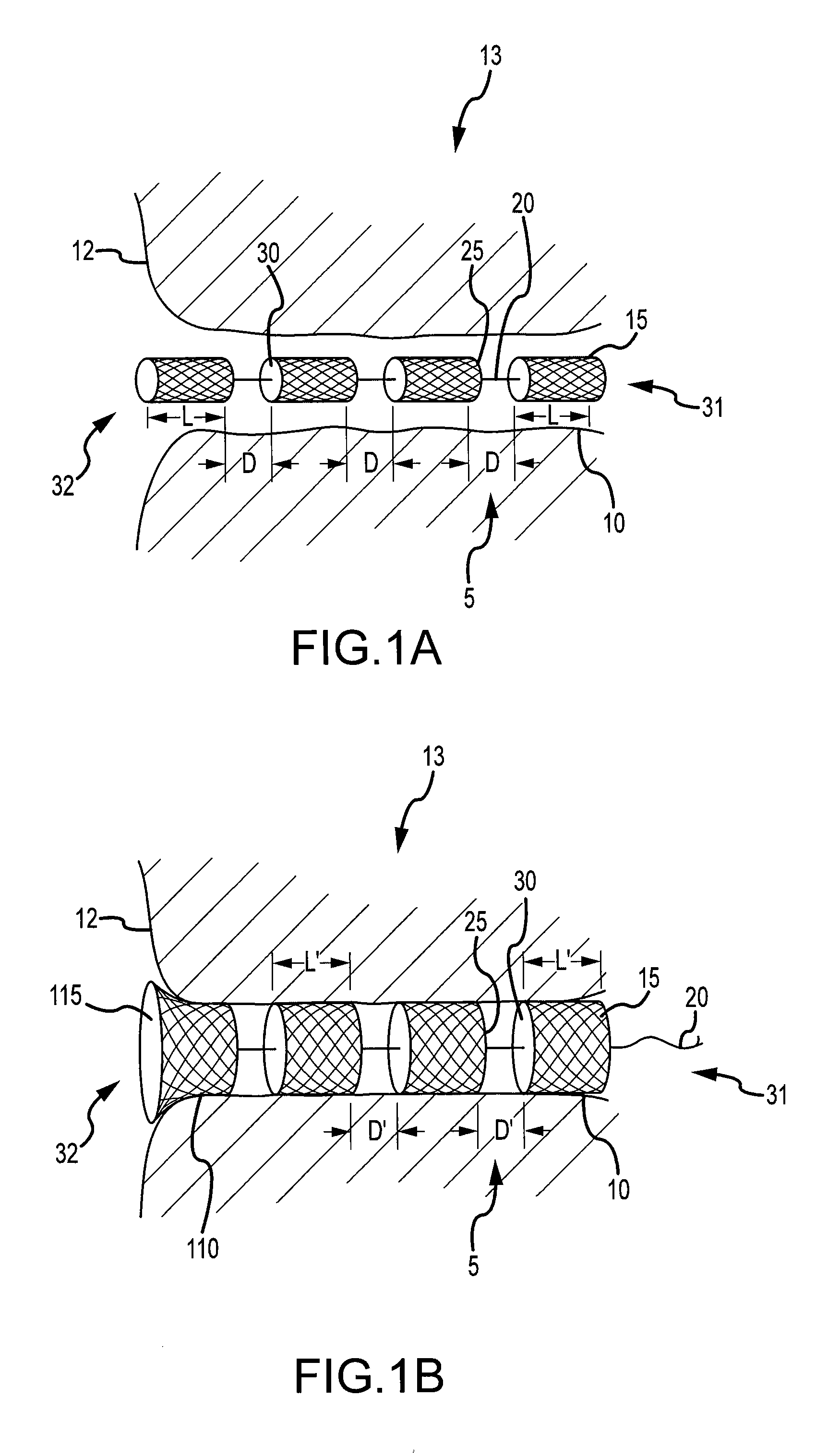

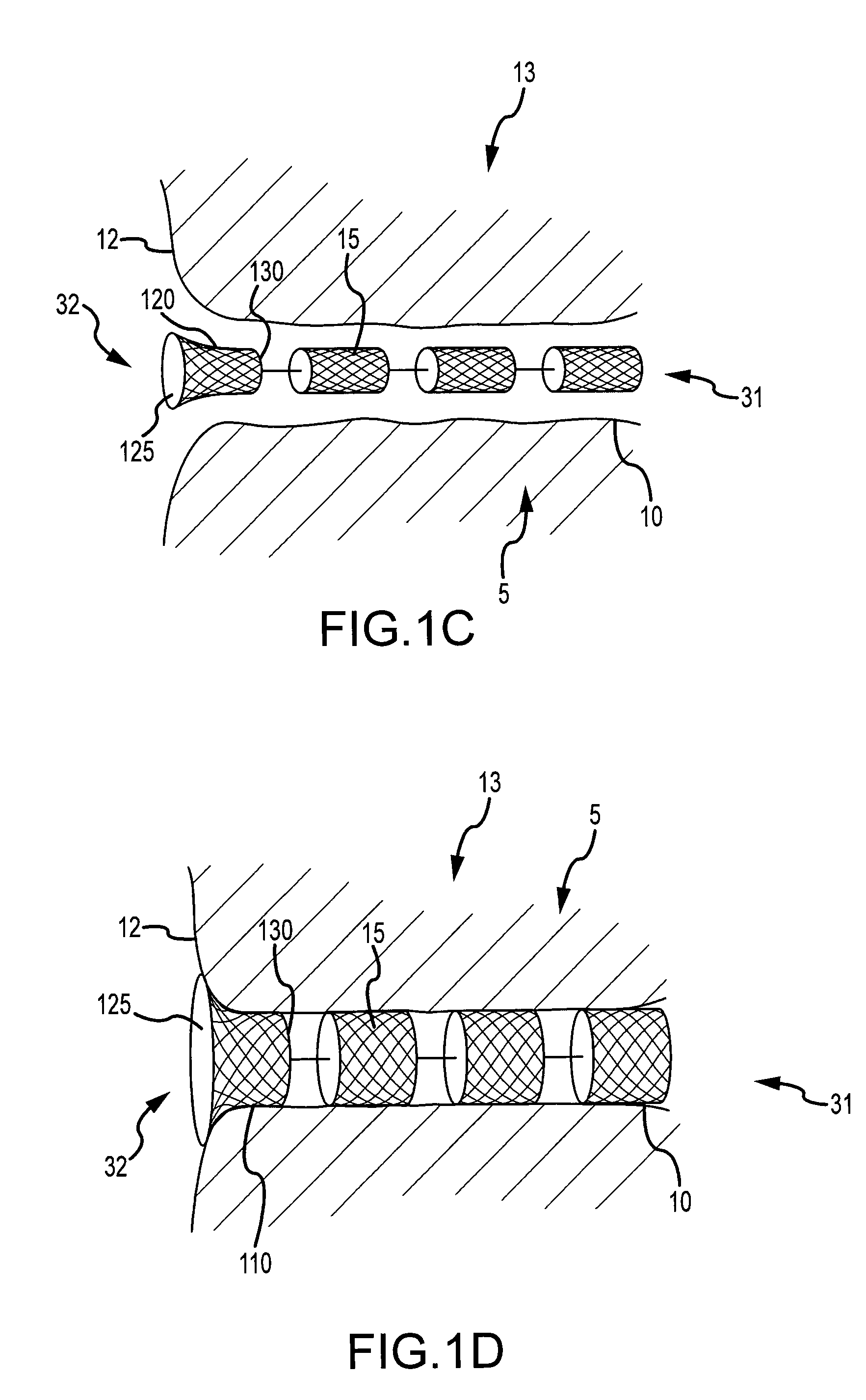

InactiveUS20100076463A1Prevent proximal displacementPrevent distal displacementStentsSurgical furnitureFluid migrationProximal point

Disclosed herein is a device for the treatment of a fistula tract having a distal opening and a proximal opening. In one embodiment, the device includes a distal anchor and a proximal anchor. The distal anchor is configured to provide a generally fluid tight seal in the tract in the vicinity of the distal opening and generally prevent proximal displacement of the device within the tract. The proximal anchor is operably coupled to the distal anchor and configured to generally prevent distal displacement of the device within the tract while allowing fluid migration at least one of through and past the proximal anchor when the proximal anchor is deployed in the vicinity of the proximal opening.

Owner:CURASEAL

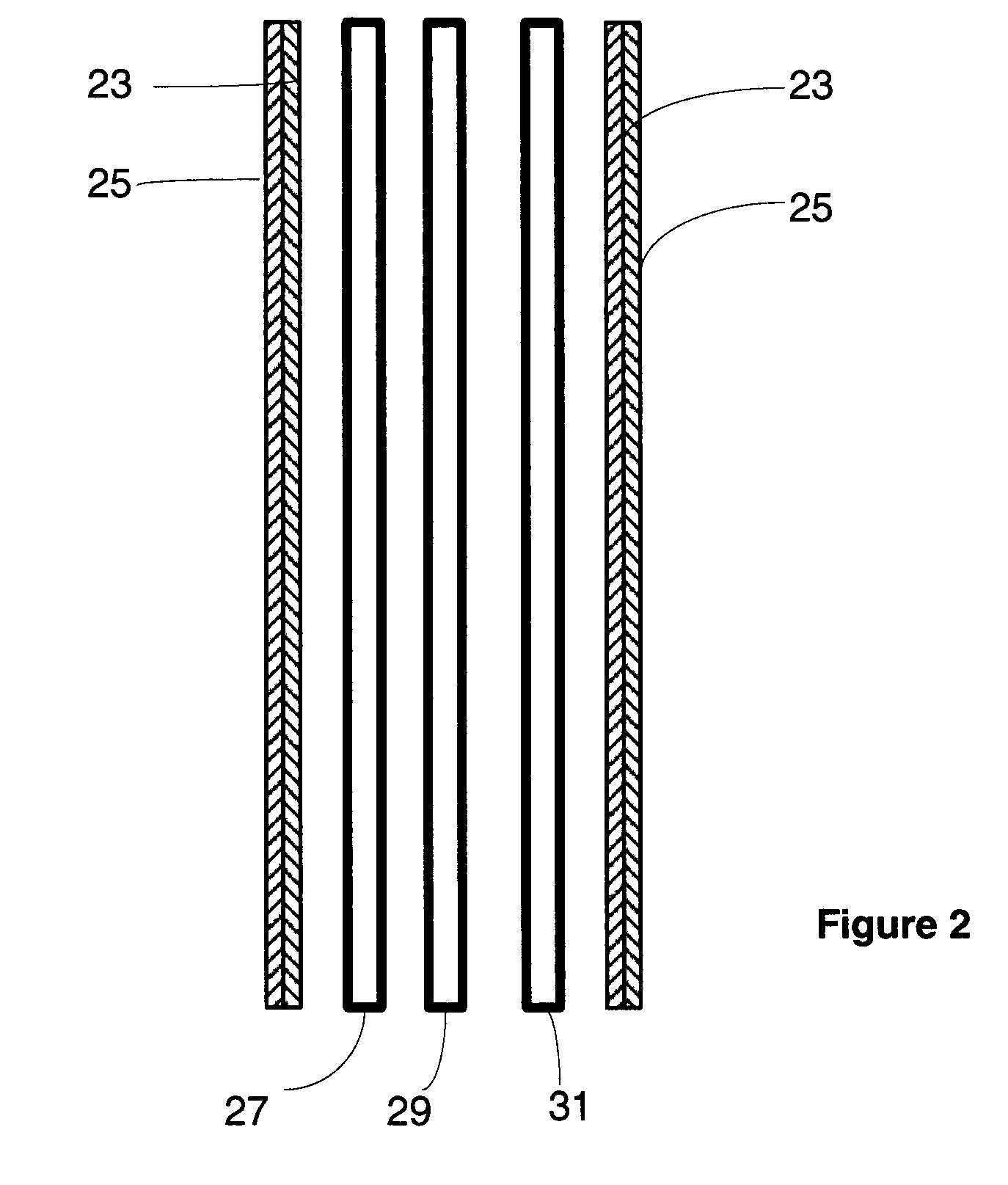

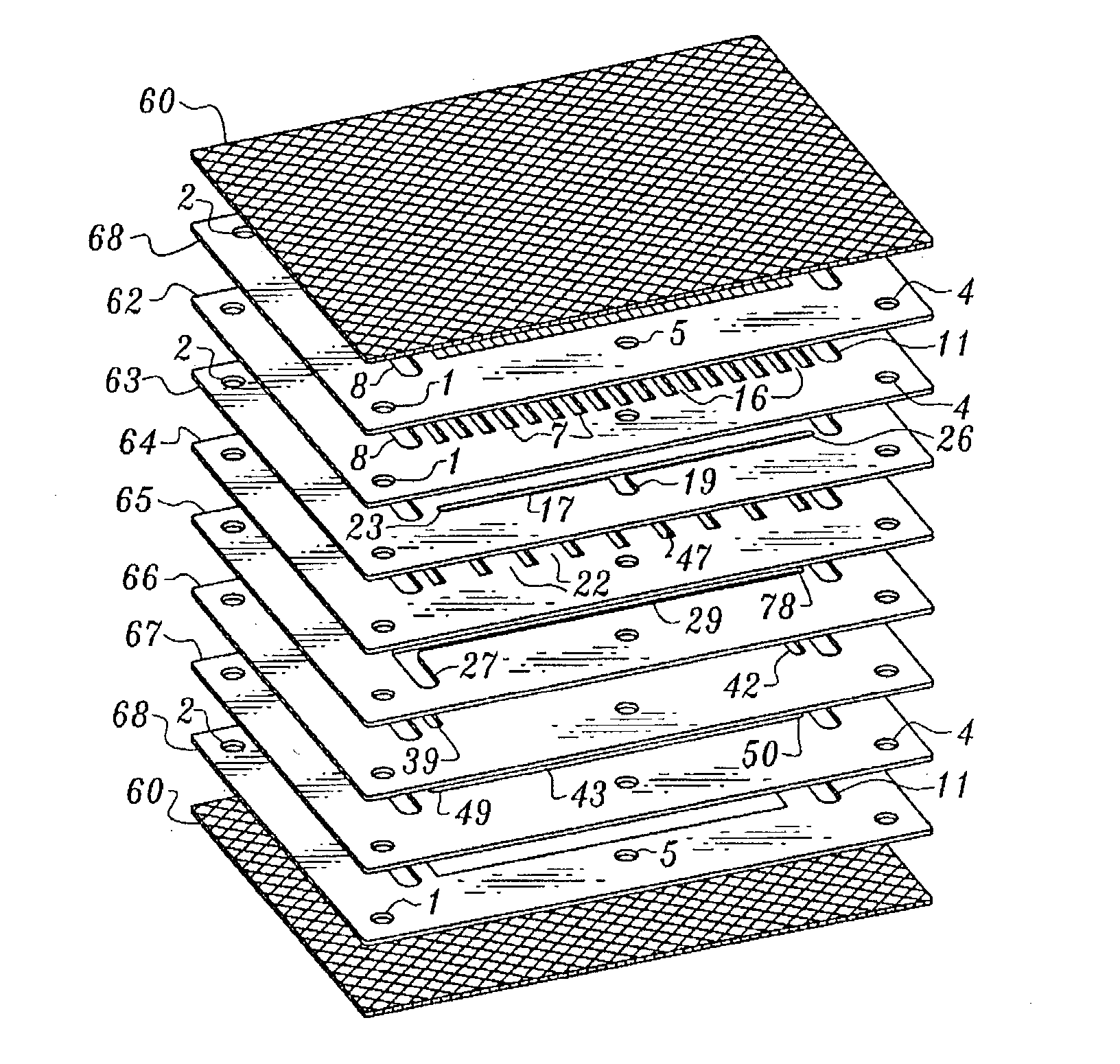

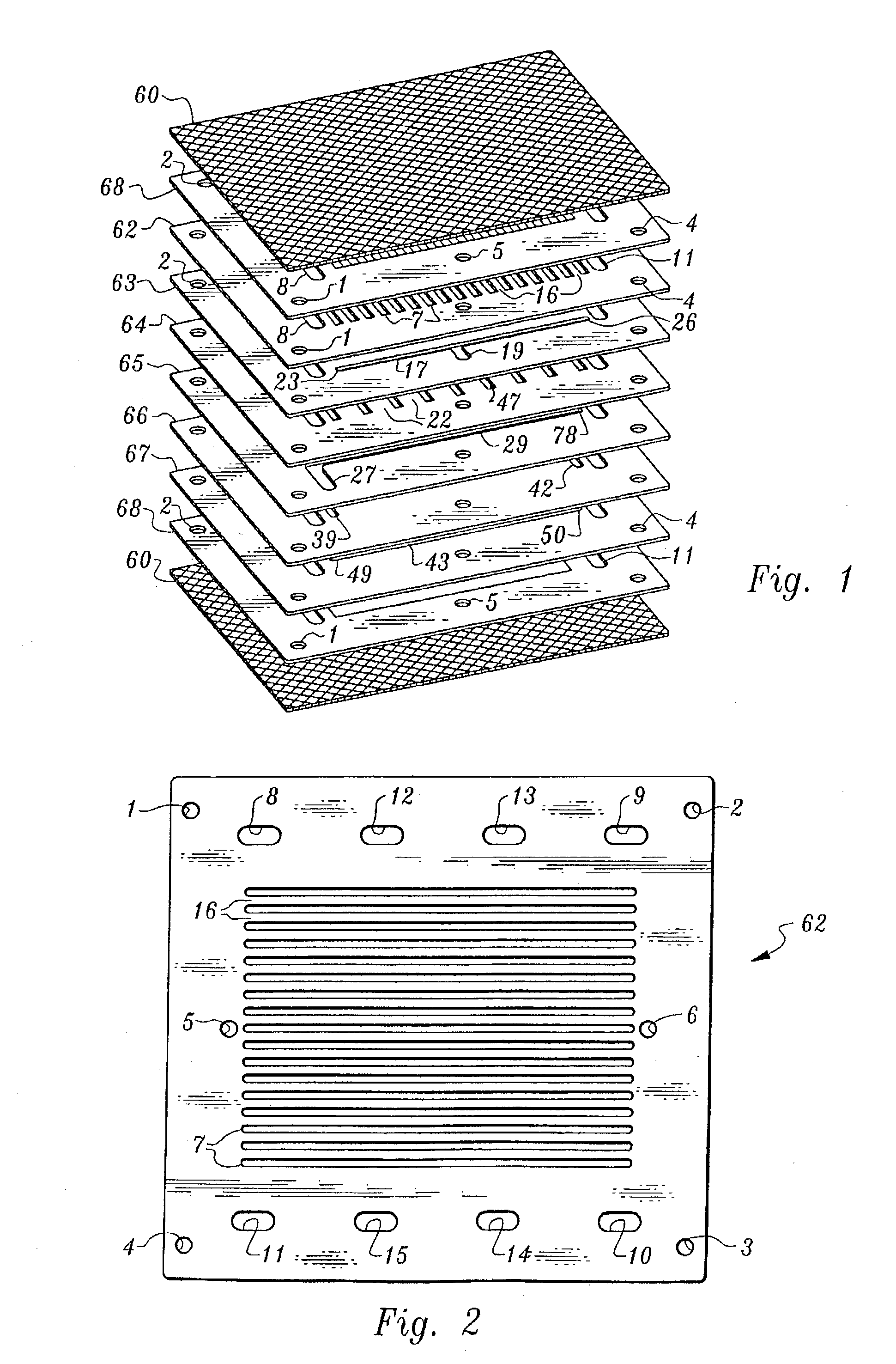

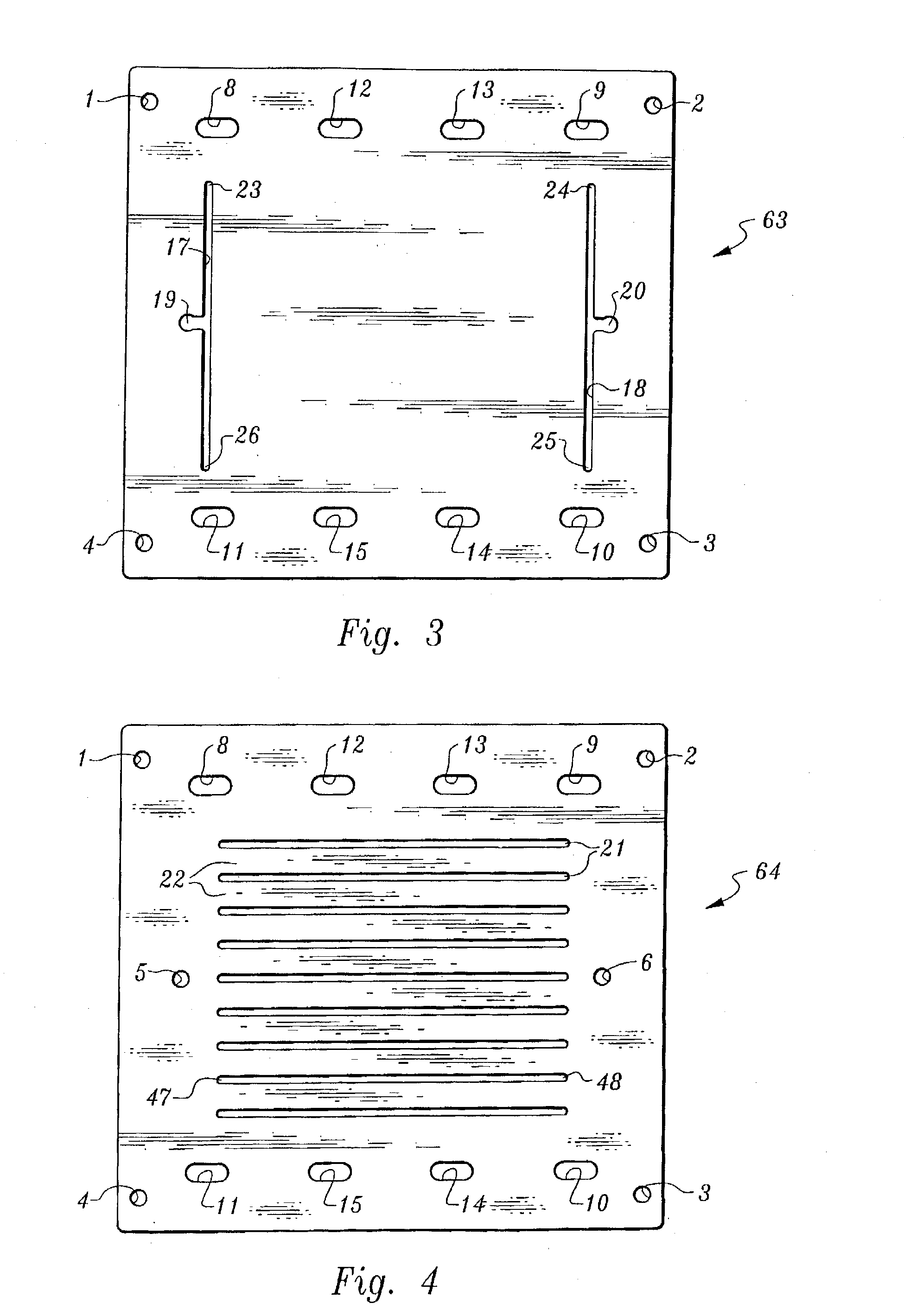

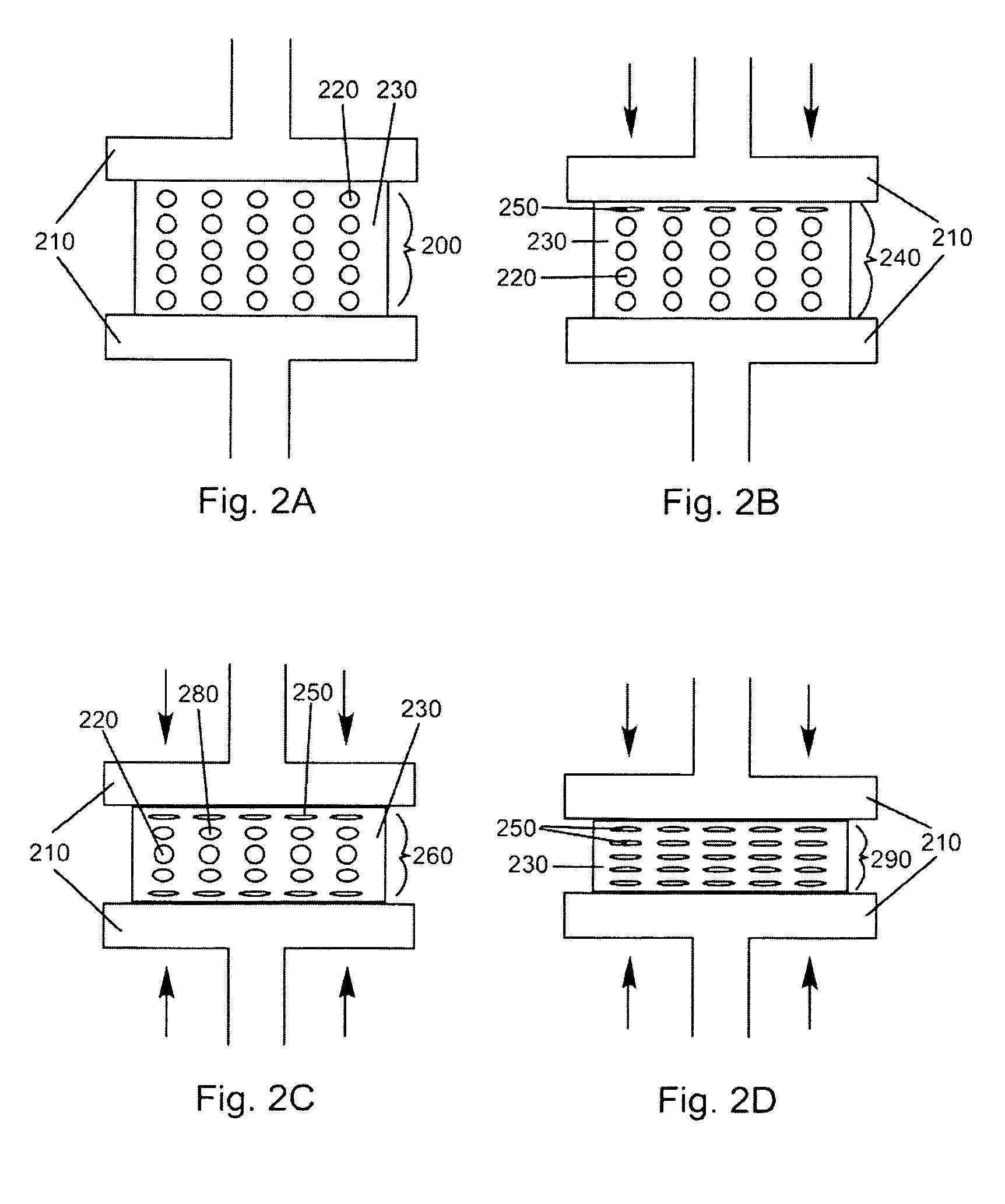

Electrochemical fuel cell comprised of a series of conductive compression gaskets and method of manufacture

InactiveUS20040018412A1Avoid Insufficient SealingEase of mass productionFuel cells groupingFinal product manufactureFluid migrationEngineering

A novel electrochemical fuel cell comprising at least one fuel cell assembly comprising a Membrane Electrode Assembly (MEA) interposed between an anode separator and a cathode separator. The Membrane Electrode Assembly comprises a solid polymer electrolyte or Proton Exchange Membrane (PEM) interposed between an anode and a cathode, each electrode comprising electrocatalyst. The anode separator contains the fuel flow field distribution features necessary to communicate the fuel to said anode. The cathode separator contains the oxidant flow field distribution features necessary to communicate the oxidant to said cathode. In addition, a Heat Transfer (HT) separator may be integrated into said fuel cell assembly. The Heat Transfer separator contains the flow field distribution features necessary to communicate Heat Transfer Fluid (HTF) through a Heat Transfer Zone (HTZ) in said fuel cell assembly in order to control the thermal conditions of the fuel cell assembly and stack. Each of the said anode, cathode and Heat Transfer separators are made up of a respective series of multiple conductive compression gaskets possessing inter-related fluid distribution channel and manifold features that form intra-communicating systems for the distribution of fuel, oxidant and Heat Transfer Fluid throughout the fuel cell separator and stack. Under sufficient mechanical load, the respective series of multiple compression gaskets are consolidated into fuel cell separators that demonstrate sufficient structural integrity to contain the PEMFC fluids under substantial pressure; that demonstrate sufficient electrical and thermal conductivity to enable the operation of a high-performing Proton Exchange Membrane Fuel Cell; that demonstrate sufficient material obduracy to bear the compressive load necessary to seal the fuel cell assembly and fuel cell stack; and that demonstrate sufficient fluid impermeability in order prevent fluid migration through the gasket material. Within the consolidated fuel cell separators, the inter-related channel and manifold features form an intra-communicating system for the distribution of fuel, oxidant and Heat Transfer Fluid throughout the fuel cell assembly and fuel cell stack. In addition, the present invention includes methods of manufacturing said electrochemical fuel cell.

Owner:TETROS INNOVATIONS LLC

Bi-phasic compressed porous reinforcement materials suitable for implant

ActiveUS20100278891A1Efficient use ofHigh and low porosity zoneBone implantSkeletal disorderFluid migrationHigh intensity

A high strength porous biphasic polymeric reinforcement material manufactured by a compression and / or sintering process is disclosed. The material results in a network of interconnected collapsed pores, which forces thin overlapping walls and passages to be created. The network provides permeable access for fluid migration throughout the material. The strength and / or permeability are advantageous for medical devices and implants.

Owner:DSM IP ASSETS BV

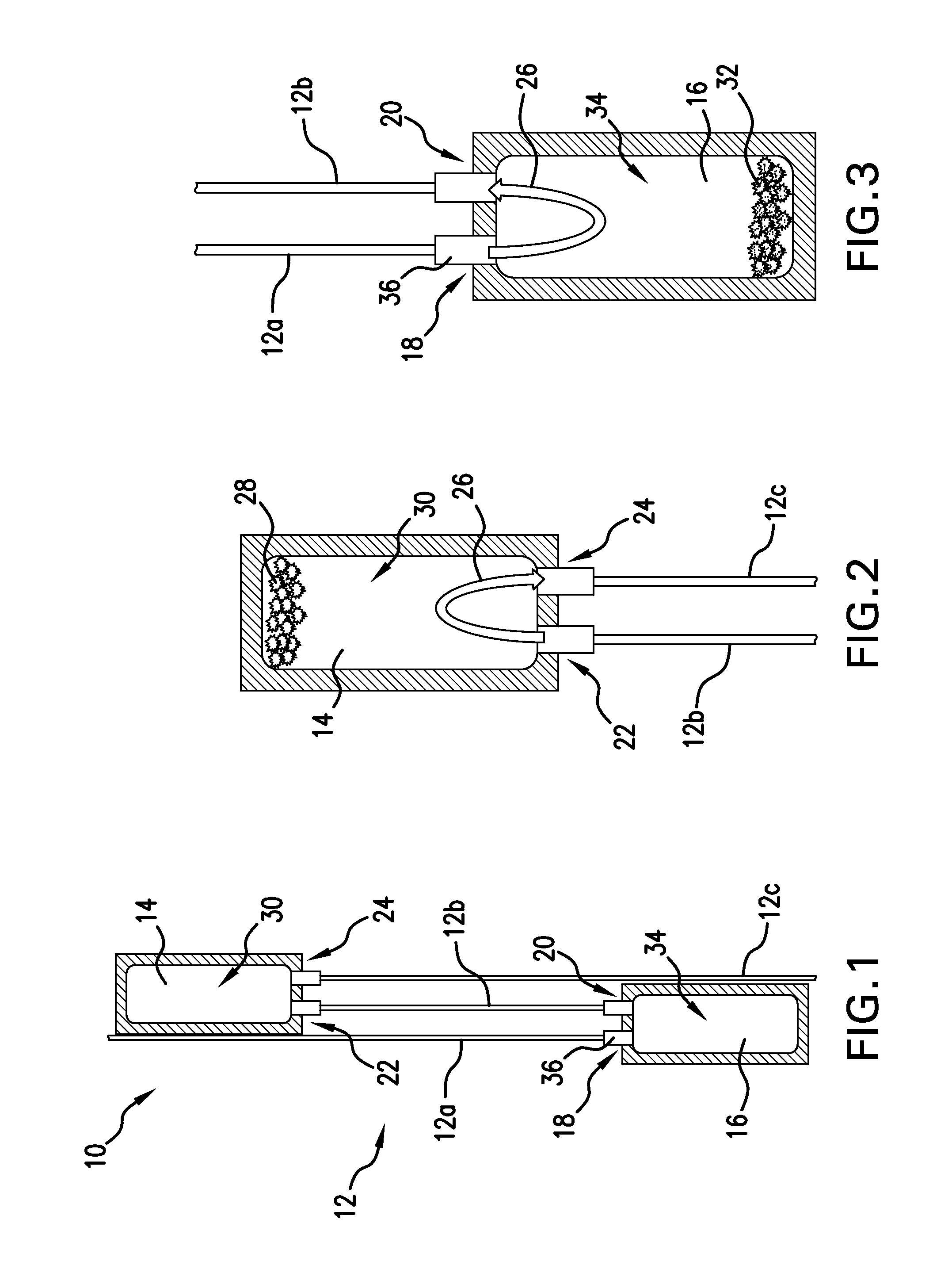

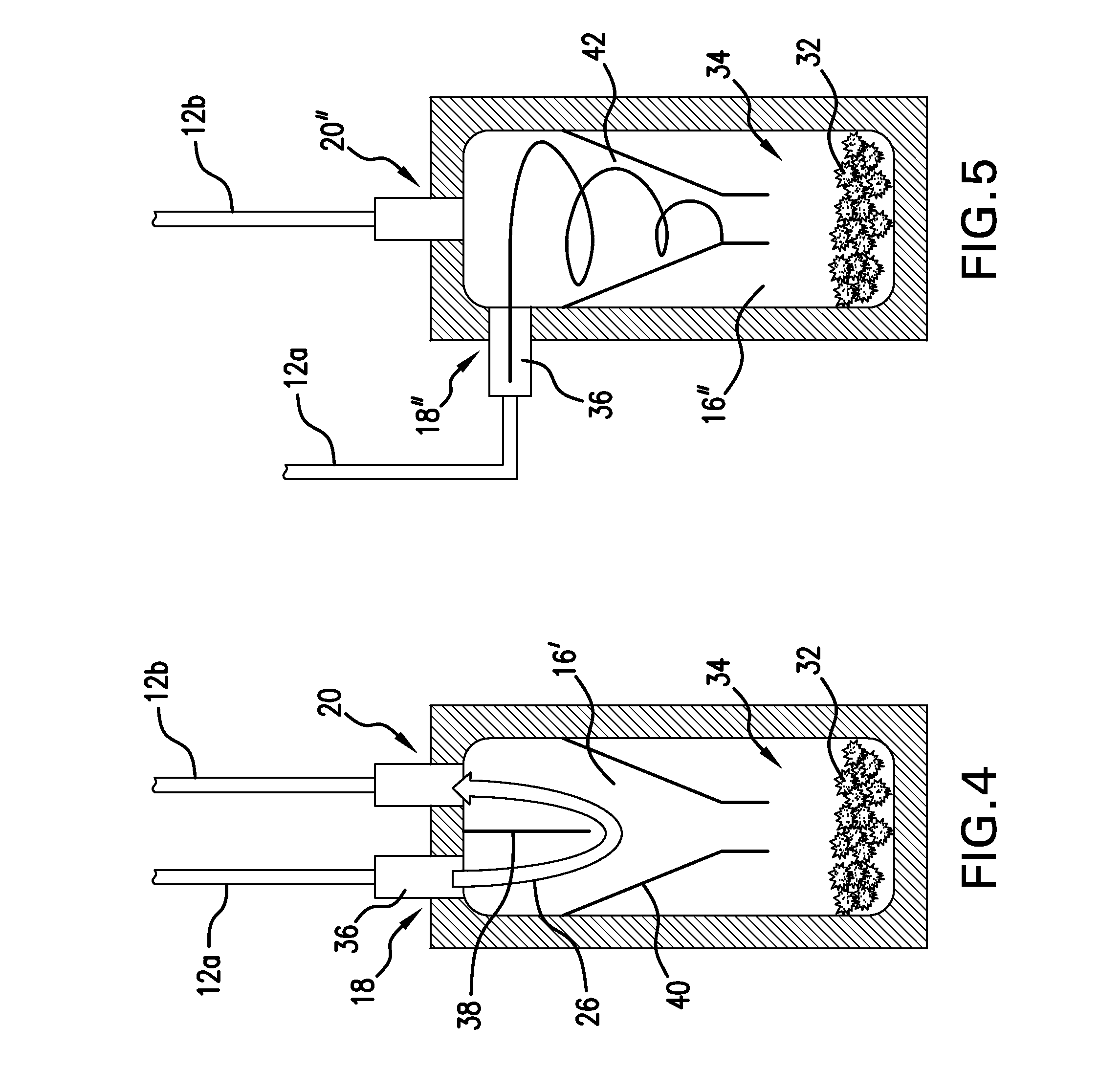

Multi-directional fluid dispenser

Owner:TABOR NORMAN W

Using noble gas geochemistry to evaluate fluid migration in hydrocarbon bearing black shales

InactiveUS20120134749A1Well formedHigh organic contentHydraulic engineering apparatusMarine site engineeringFluid migrationNoble gas

American energy costs steadily increase leading to increased unconventional energy use. However, scientific barriers prevent widespread and economic development of these resources. In gas shale plays, resource utilization is limited by the understanding of how hydrocarbons and other fluids migrate in fractured rock. This limits industry's ability to extract hydrocarbons with enhanced recovery methods; prevents exploration in areas where hydrocarbons do not collect in traditional traps; and could unfortunately lead to dangerous environmental consequences such as contaminated groundwater. To address these concerns, the present invention integrates geochemical and geostructural techniques in a novel method for evaluating and optimizing the placement and drilling strategies of extraction wells in hydrocarbon rich black shales. By correctly choosing hydrocarbon “sweet spots” companies can reduce the number of unprofitable wells, choose directional drilling and completion strategies to accurately reflect the subsurface, and better select prime small- and full-field reservoirs.

Owner:DARRAH THOMAS

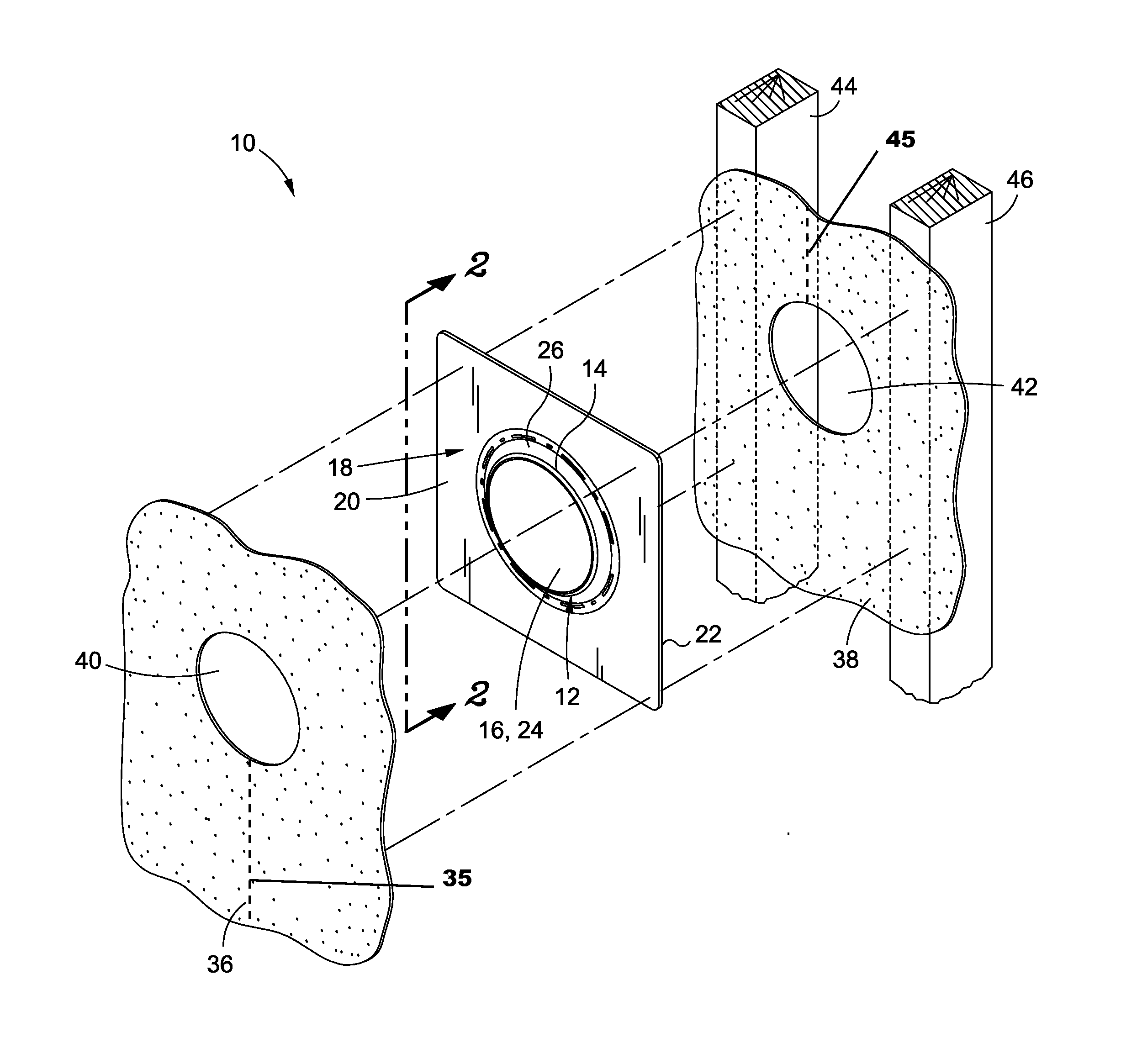

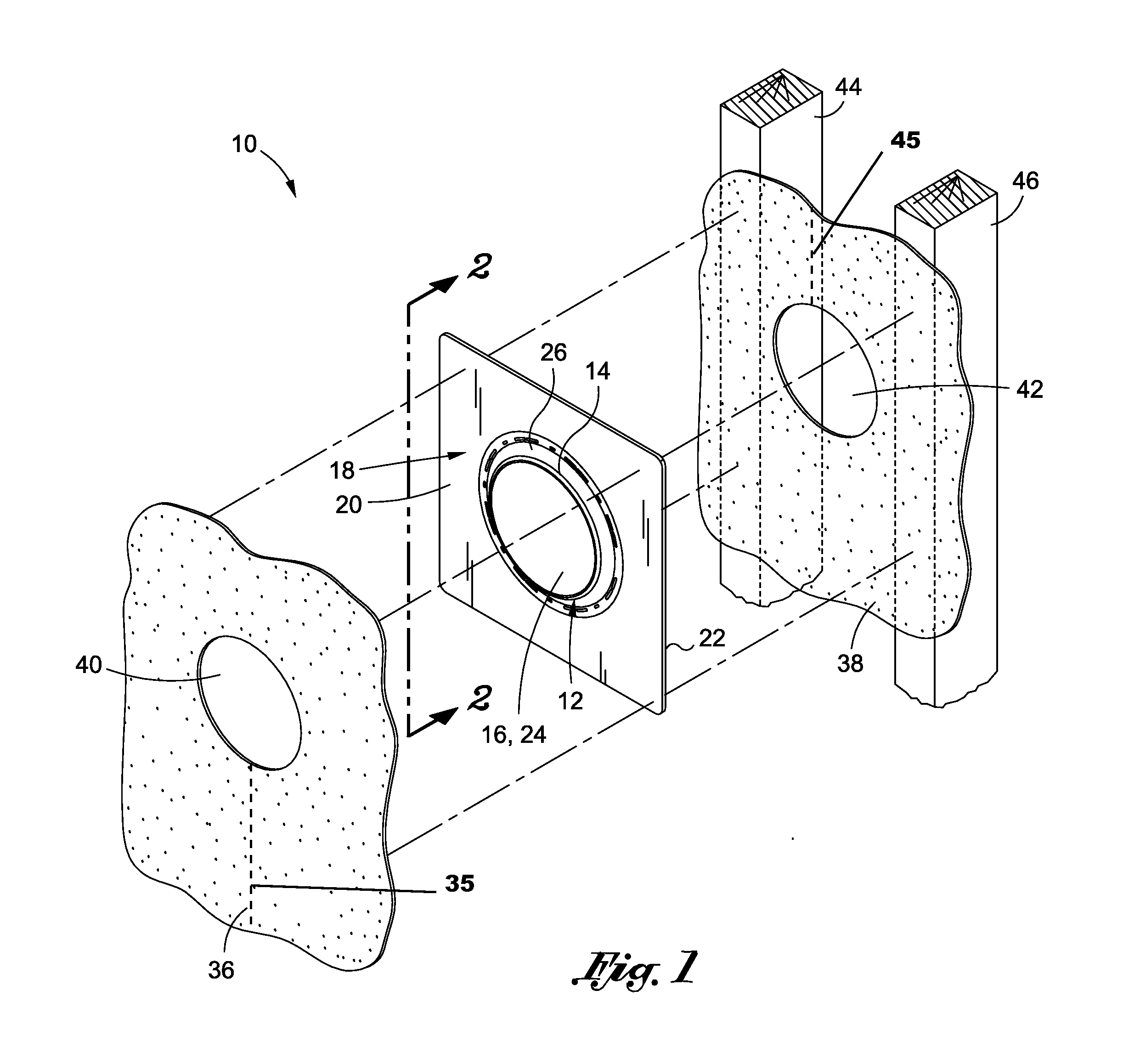

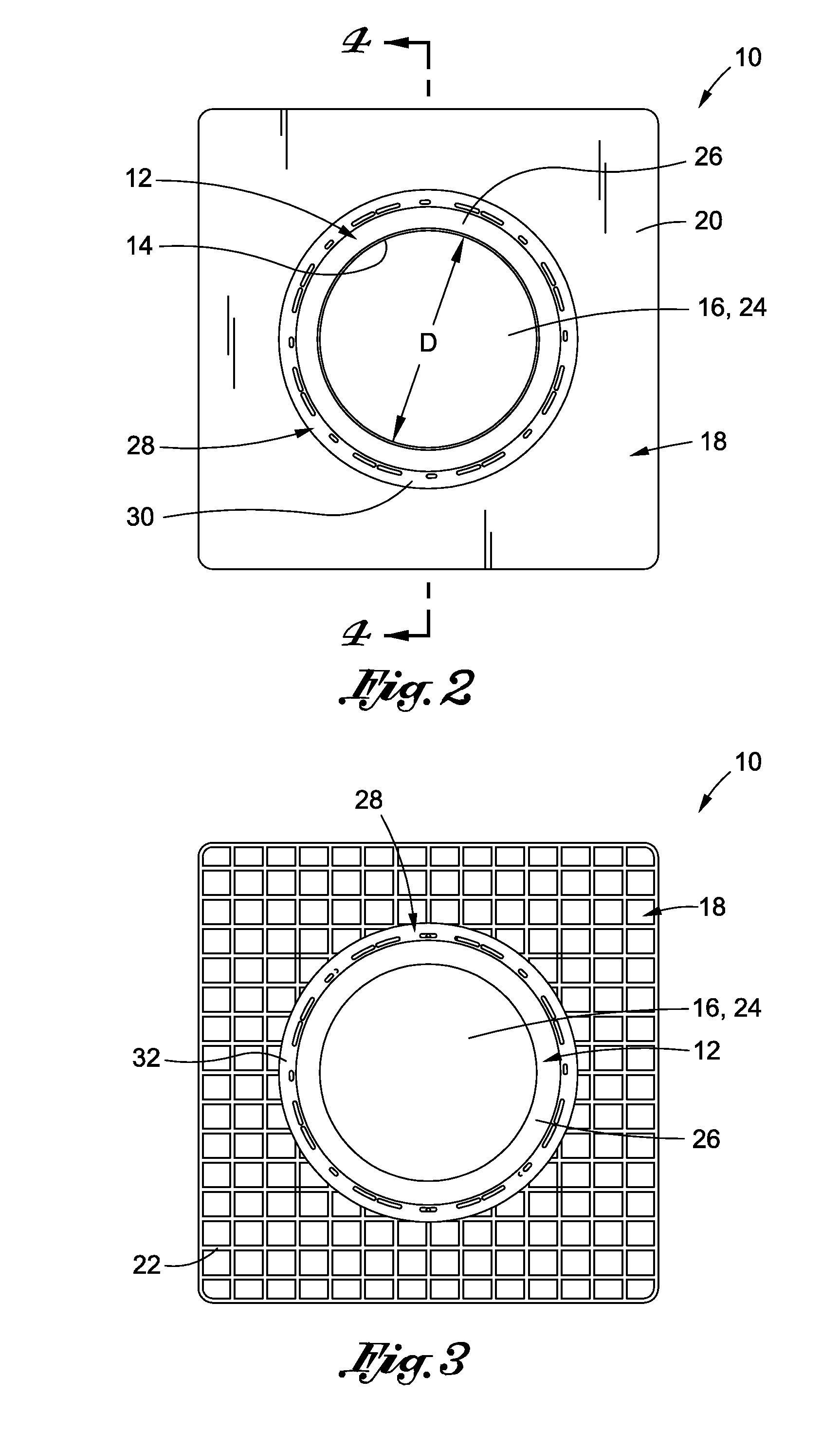

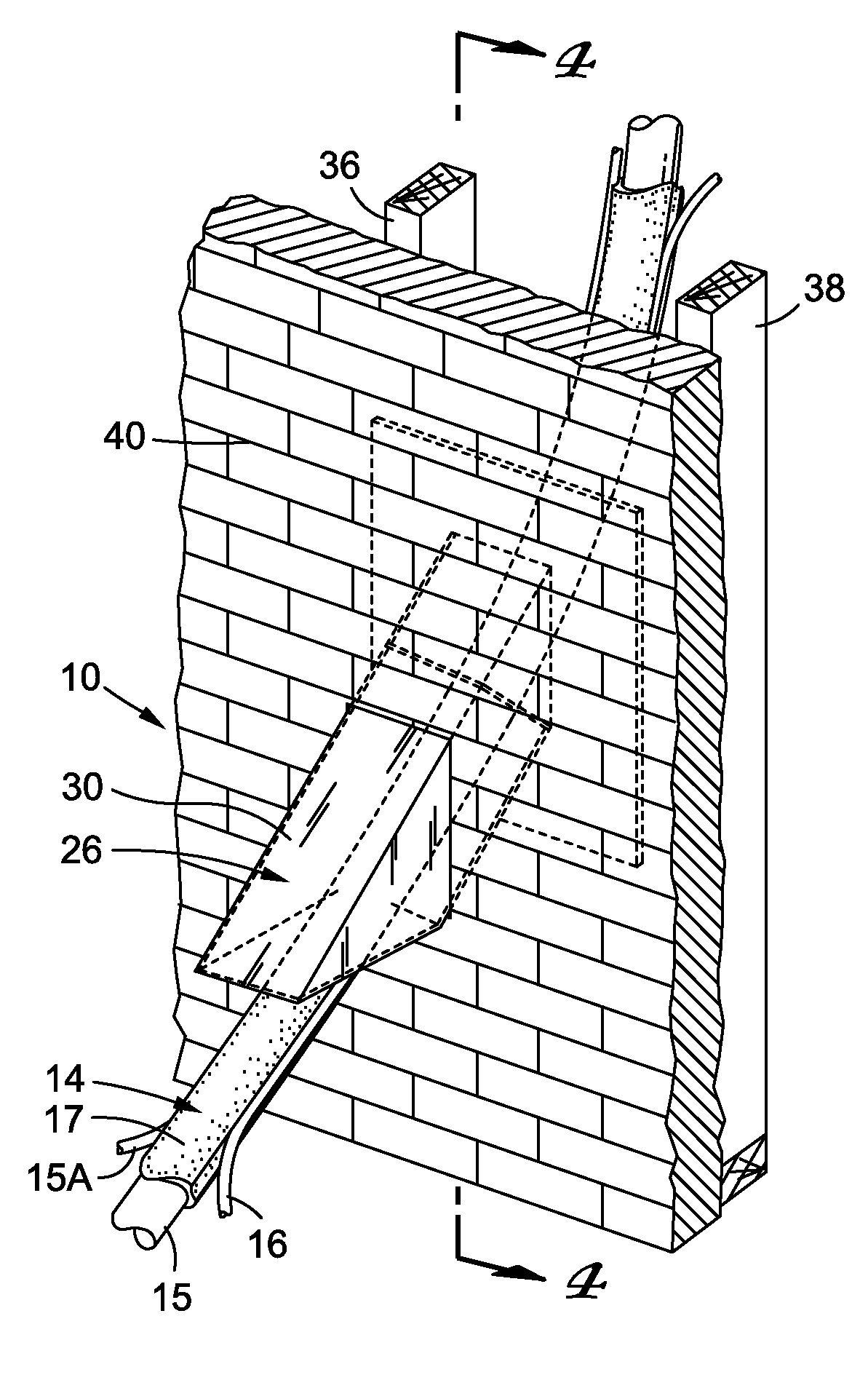

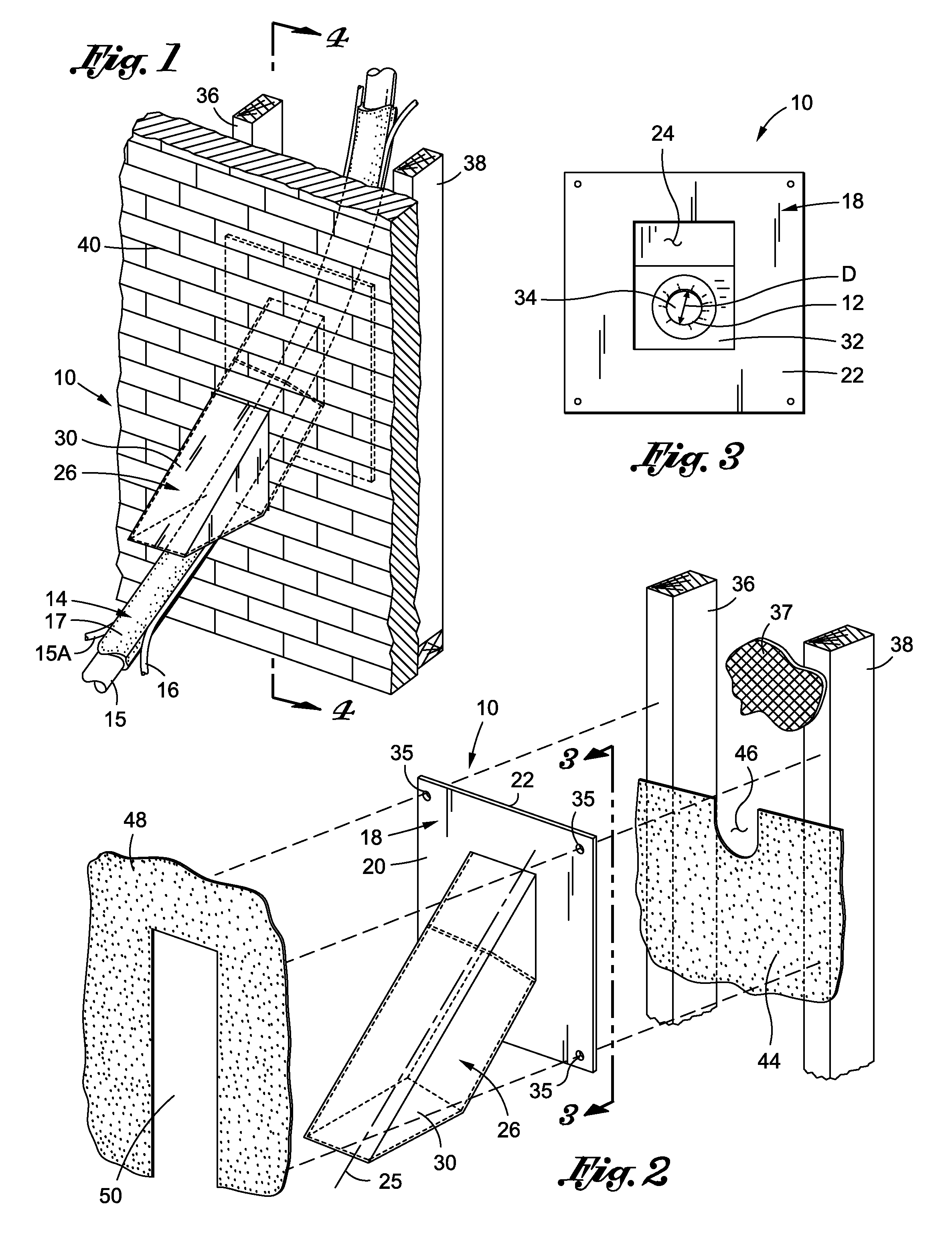

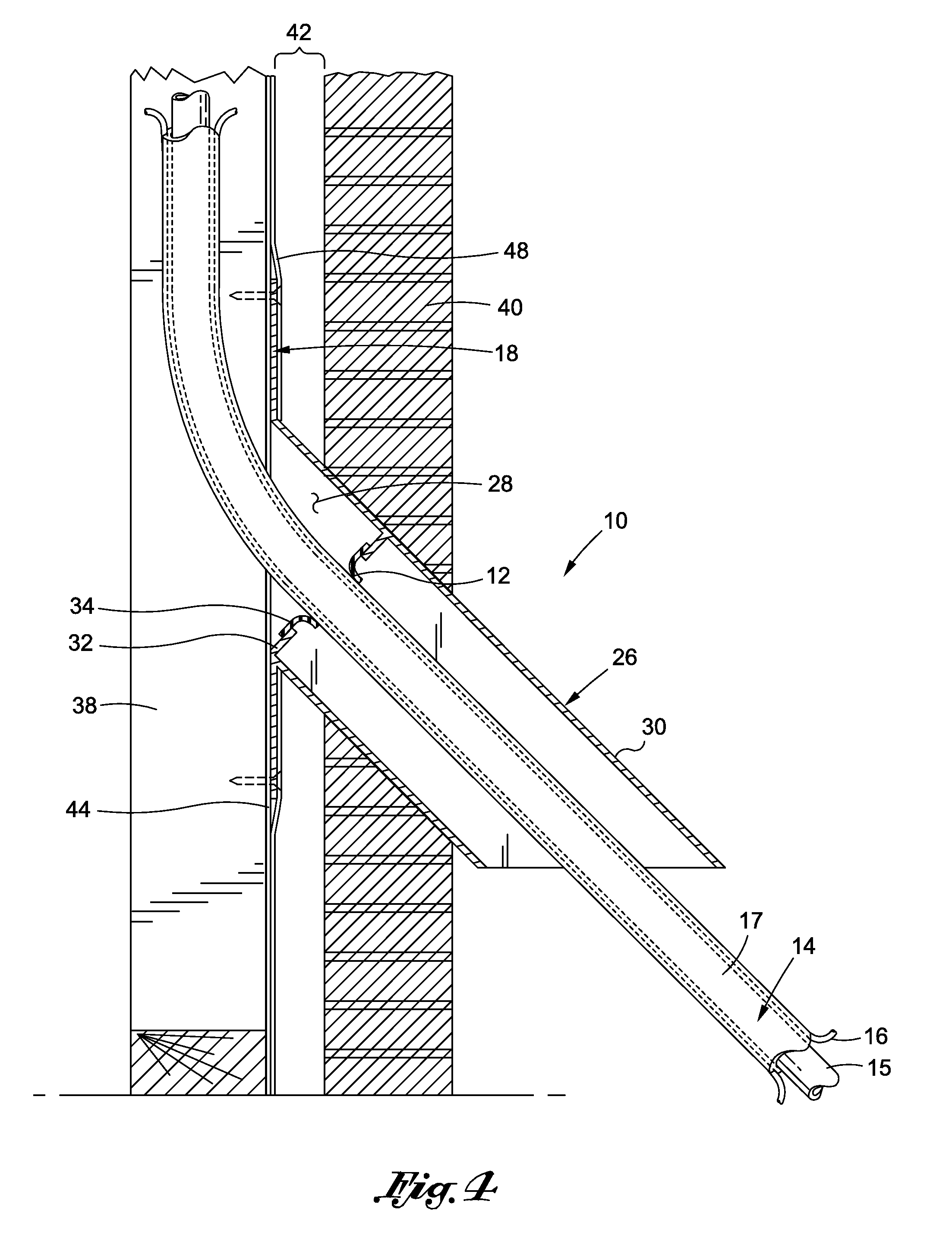

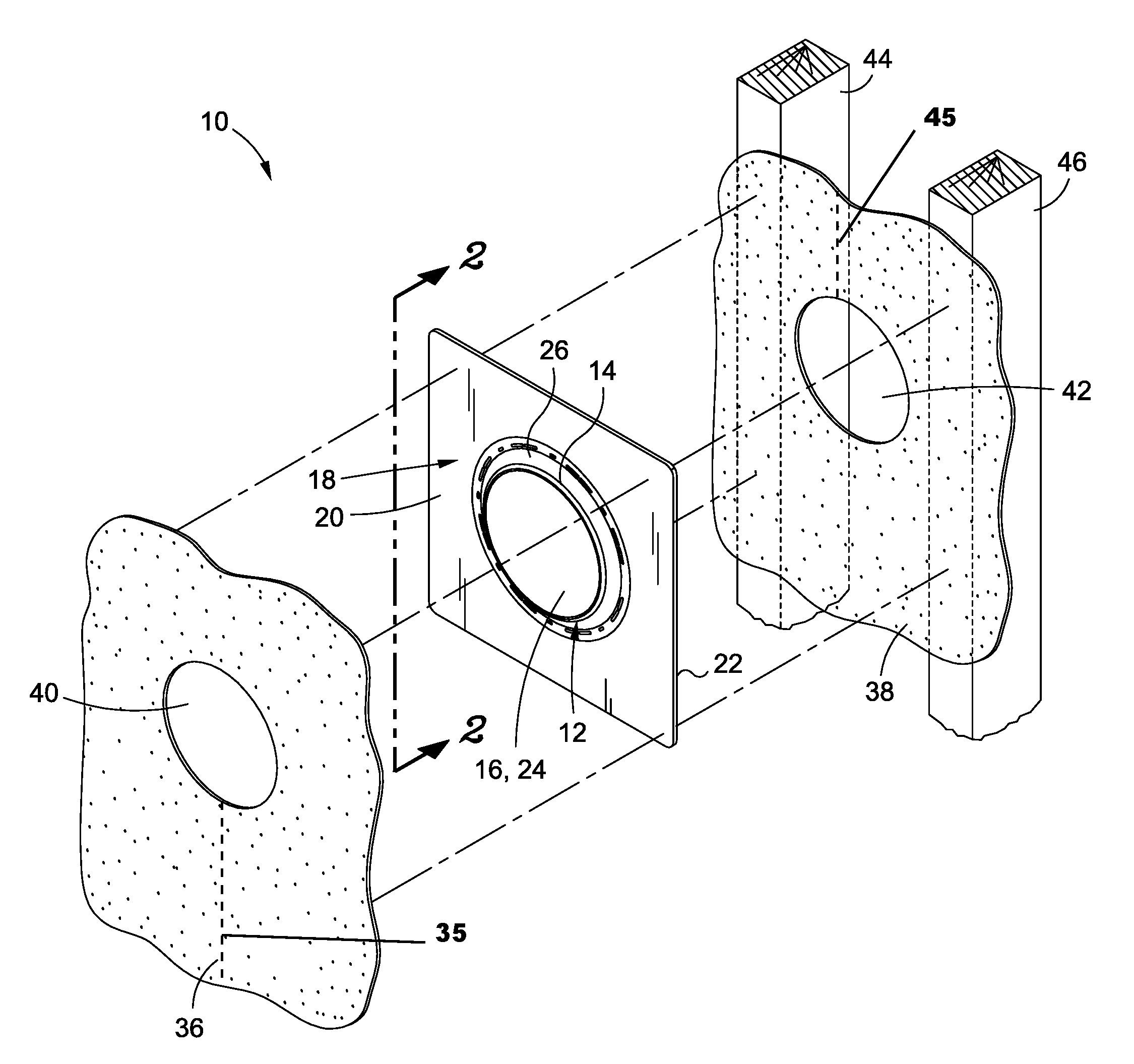

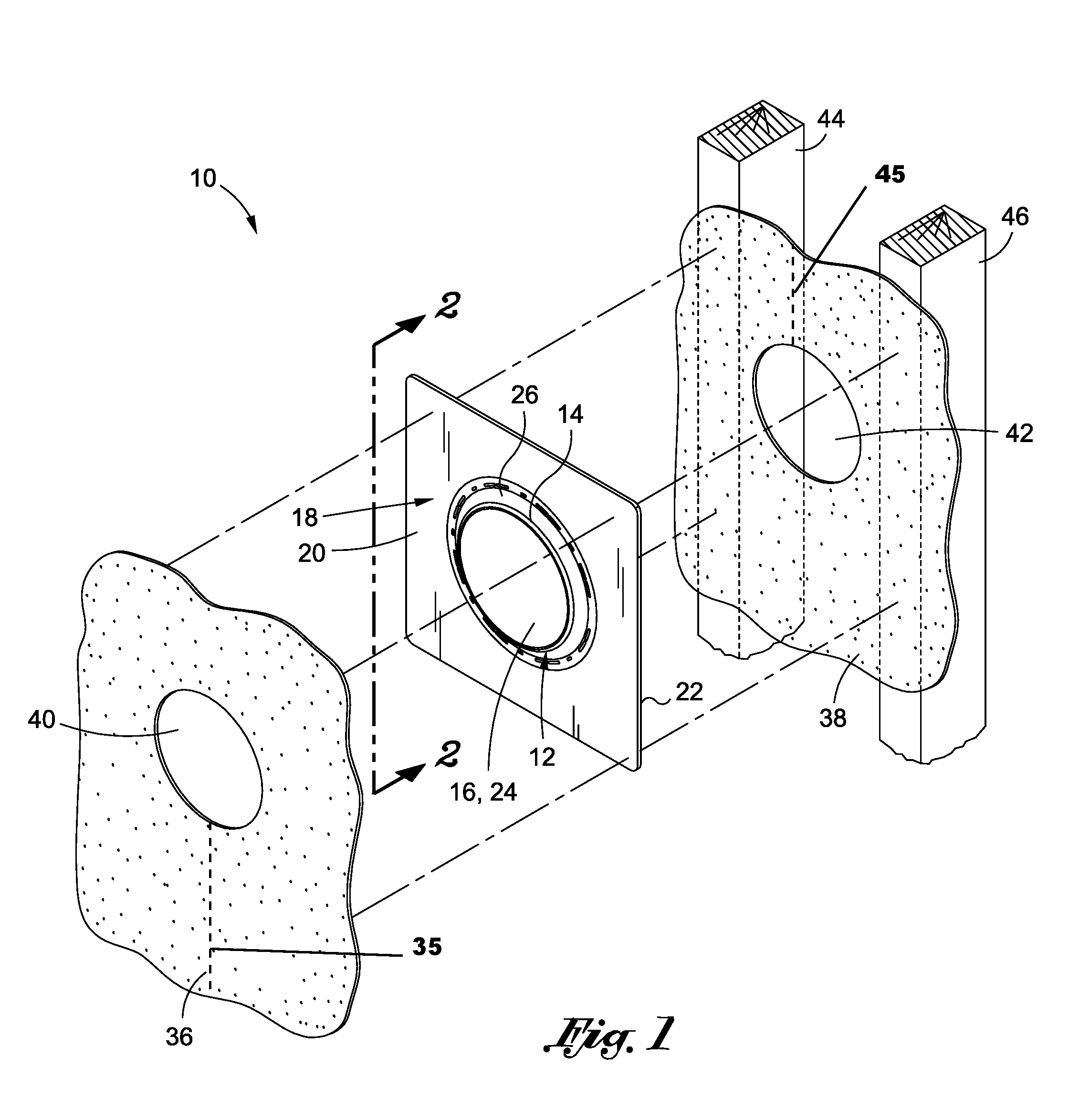

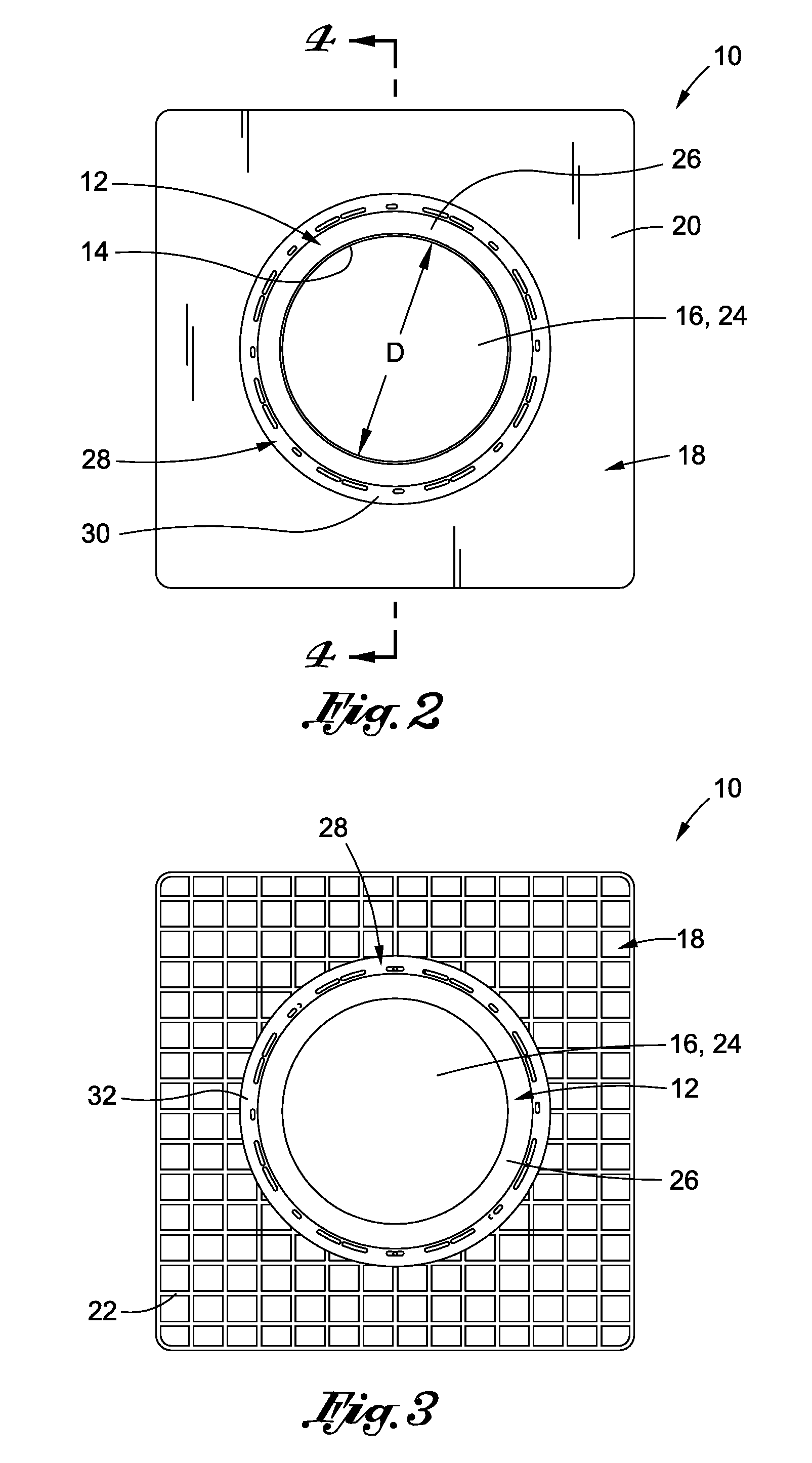

Single wall duct flashing panel

A duct flashing panel configured to provide weatherproofing for single wall ducts extending through the walls of a structure and having a terminal end extending outside of the structure. The duct flashing panel includes a panel body and an elastomeric collar sized and configured to circumferentially engage the exterior surface of the duct to form a fluid-tight seal between the duct and the collar to prevent fluid migration along the exterior of the duct. The collar includes an annular bead which provides rigidity and strength to the collar to urge the collar into compressive engagement with the exterior surface of the duct.

Owner:GILLERAN WILLIAM J

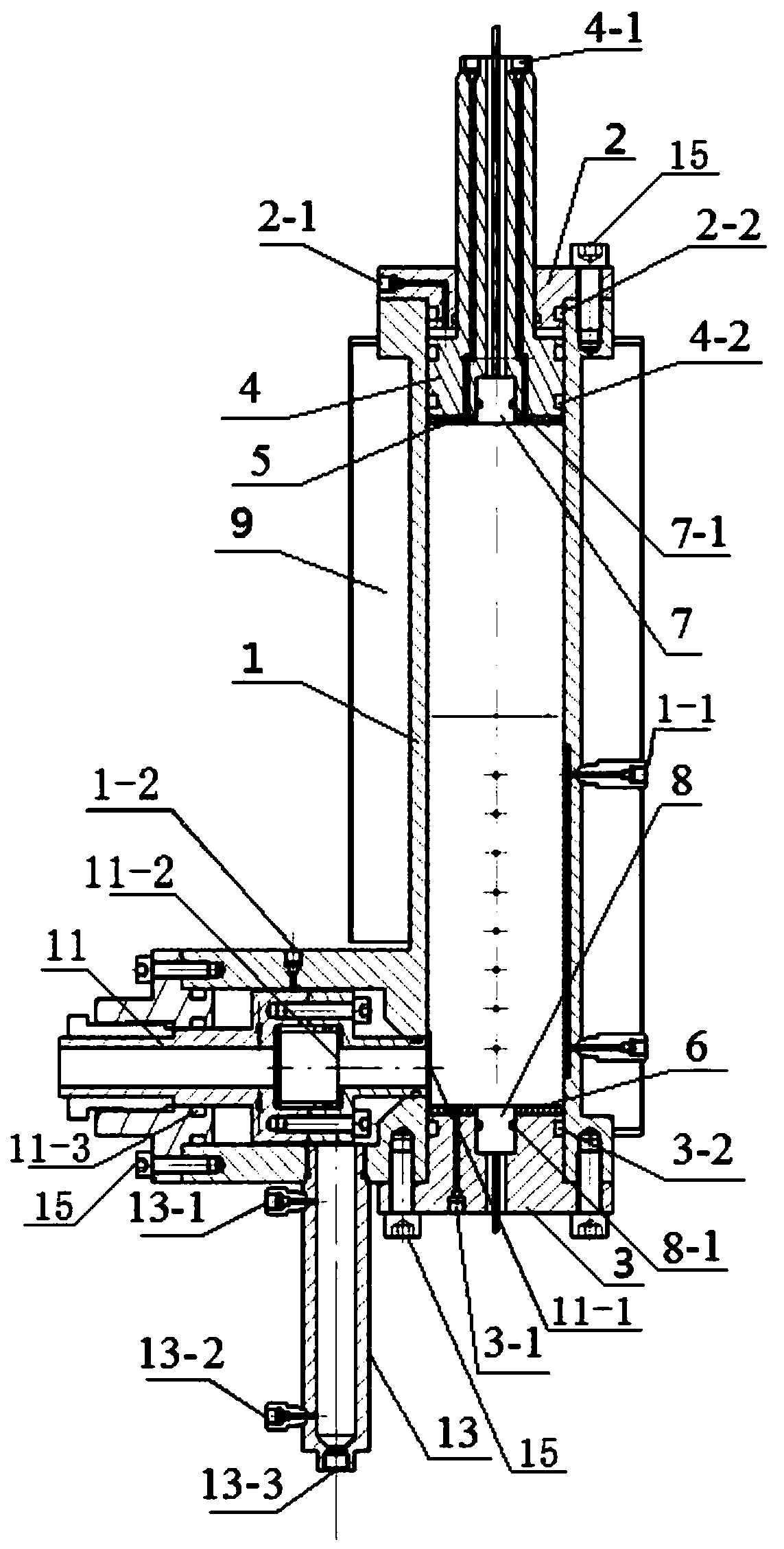

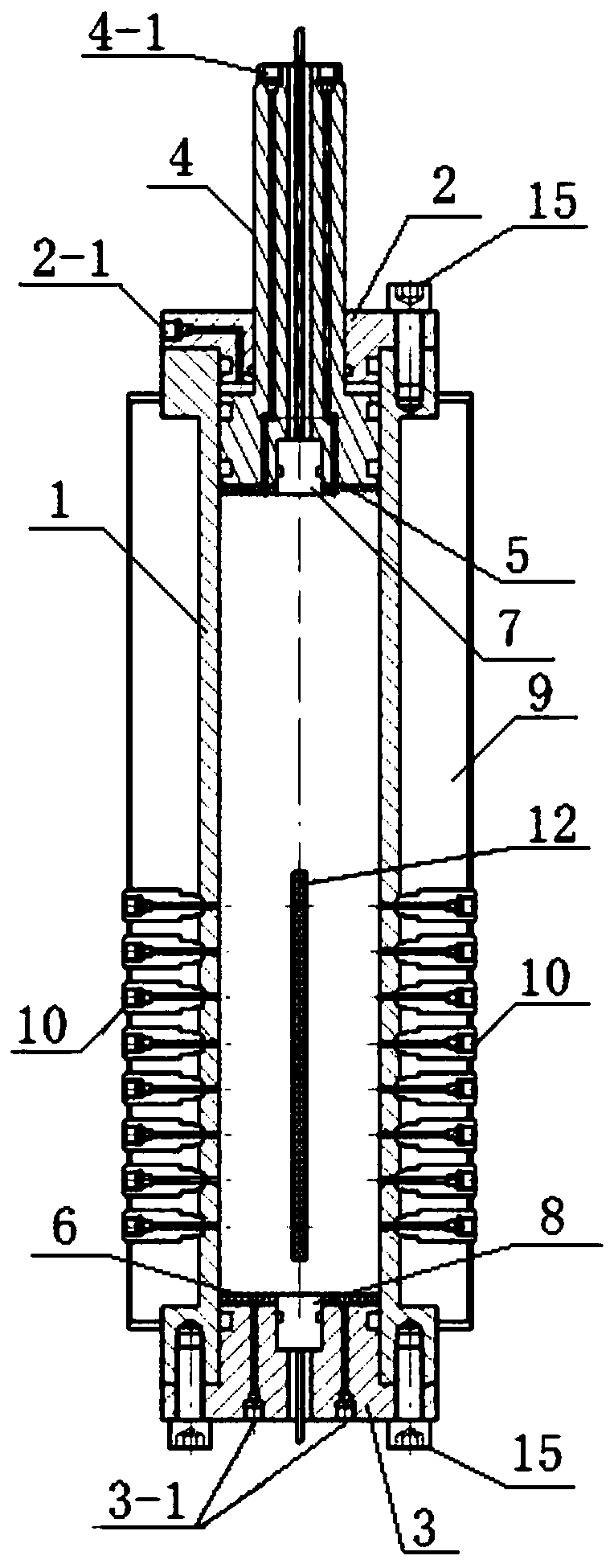

Dynamic shale pore pressure transmission tester

ActiveCN102706786AReasonable structureEasy to operatePermeability/surface area analysisPressure transmissionFluid migration

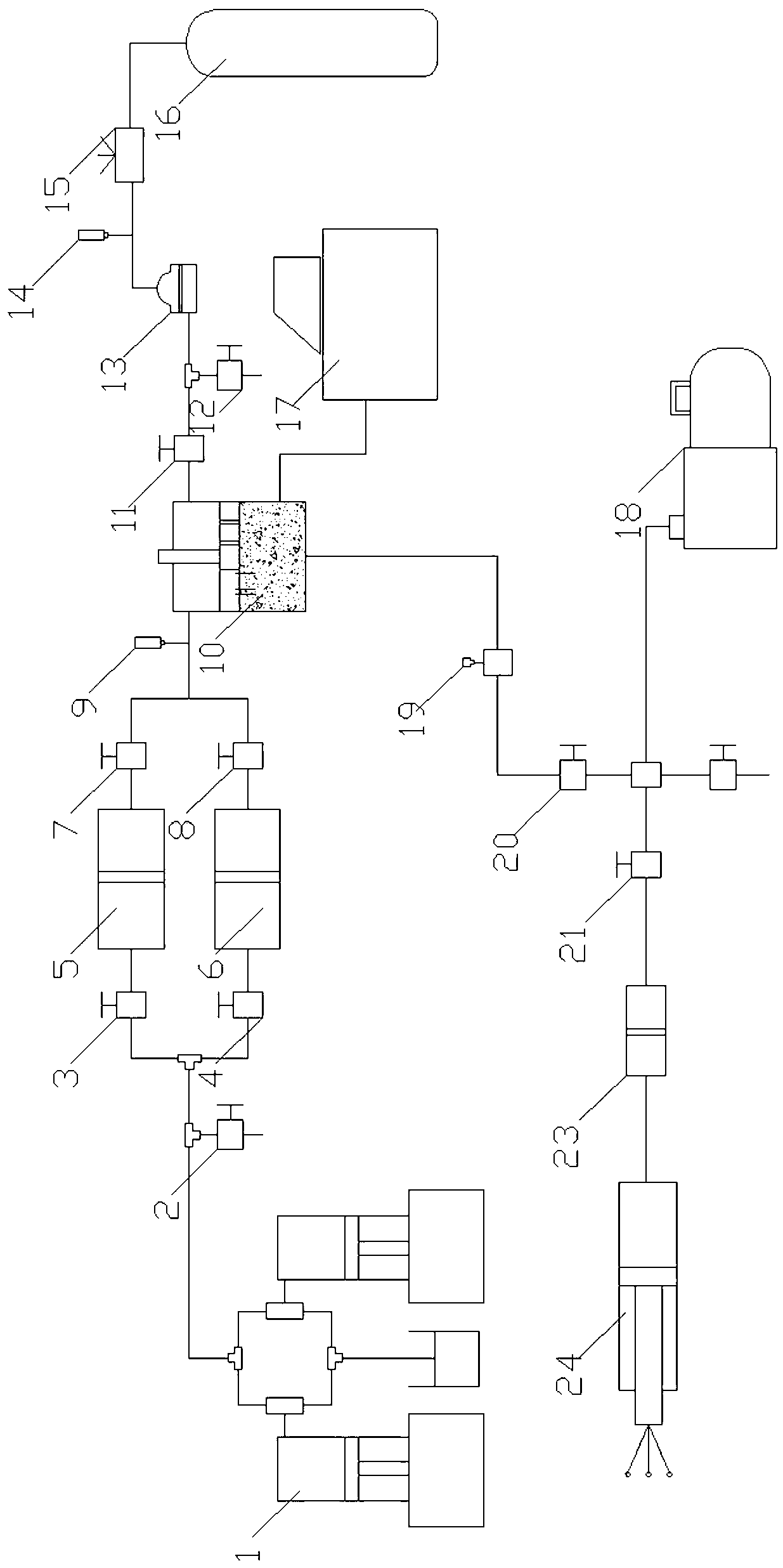

The invention discloses a dynamic shale pore pressure transmission tester, which overcomes the defect that physicochemical effects such as properties of drilling fluid and influences of shale permeability and the like on fluid migration are not effectively analyzed currently. In the tester, a core holding unit comprises an upstream workroom and a downstream workroom, a confining pressure automatic tracking pump is connected to the core holding unit through a pipeline, a downstream piston container and a vacuum pump are connected to the downstream workroom of the core holding unit through a shared pipeline, an outlet end of a first upstream piston container and an outlet end of a second upstream piston container are connected with the upstream workroom of the core holding unit through a shared pipeline, and return pressure is provided for an end surface of the core holding unit by a high pressure air source; and the downstream piston container is connected with a mechanical booster bump, and the vacuum pump is connected to a pipeline between the core holding unit and the downstream piston container. According to the device disclosed by the invention, the influence of fluid on the efficiency of shale semi-permeable membranes can be studied.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Control of fluid migration in wet-wipes

InactiveUS20090081269A1Improved fluid migration propertyBiocideCosmetic preparationsFluid migrationWet wipe

The present invention describes wet-wipe composition with a liquid portion that is impregnated in a substrate, wherein the liquid portion contains a binary pair of a thickening or gelling polymer along with a thickening or gelling agent which substantially reduces fluid migration of the liquid portion within a wet-wipes stack during storage.

Owner:HERCULES INC

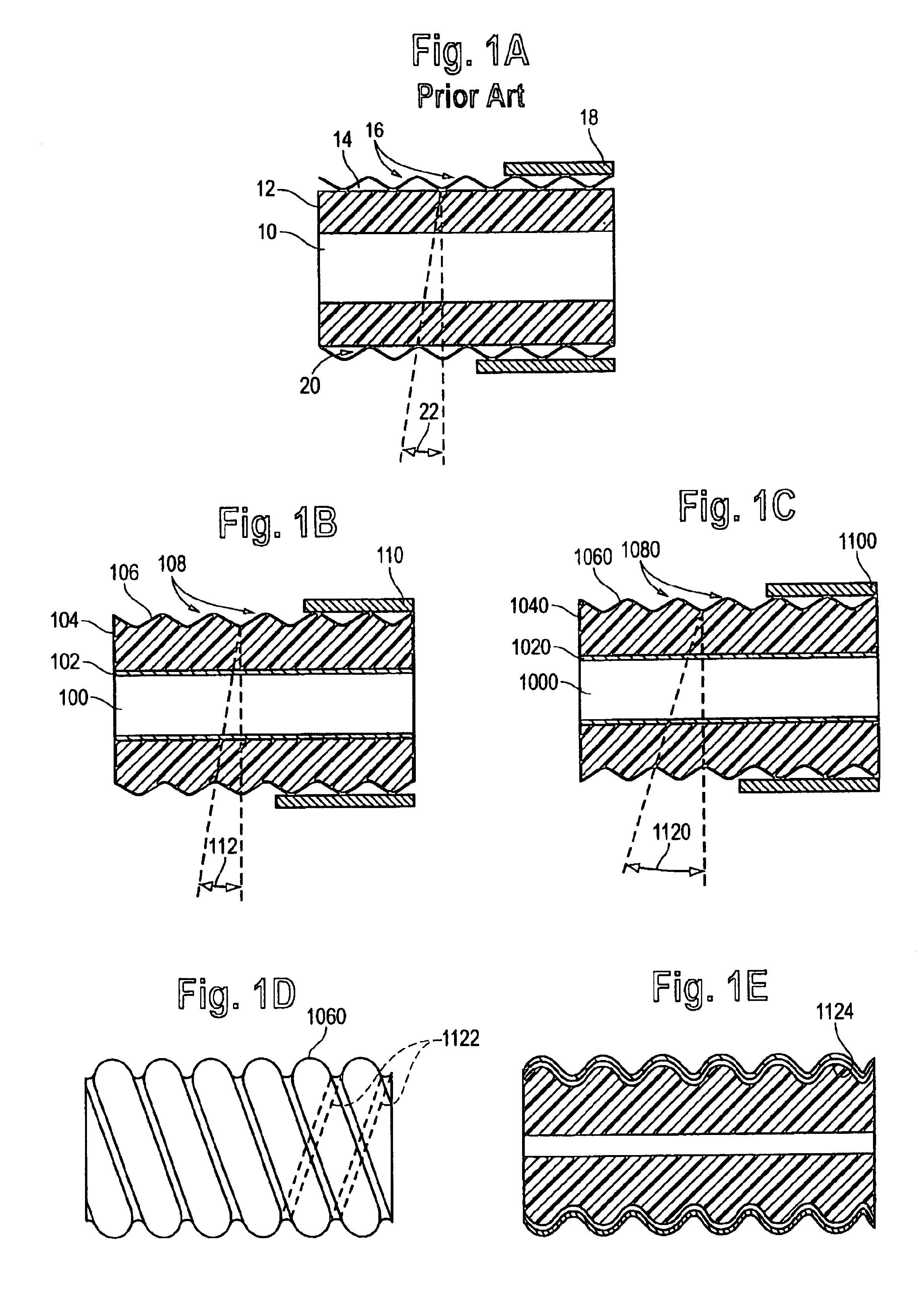

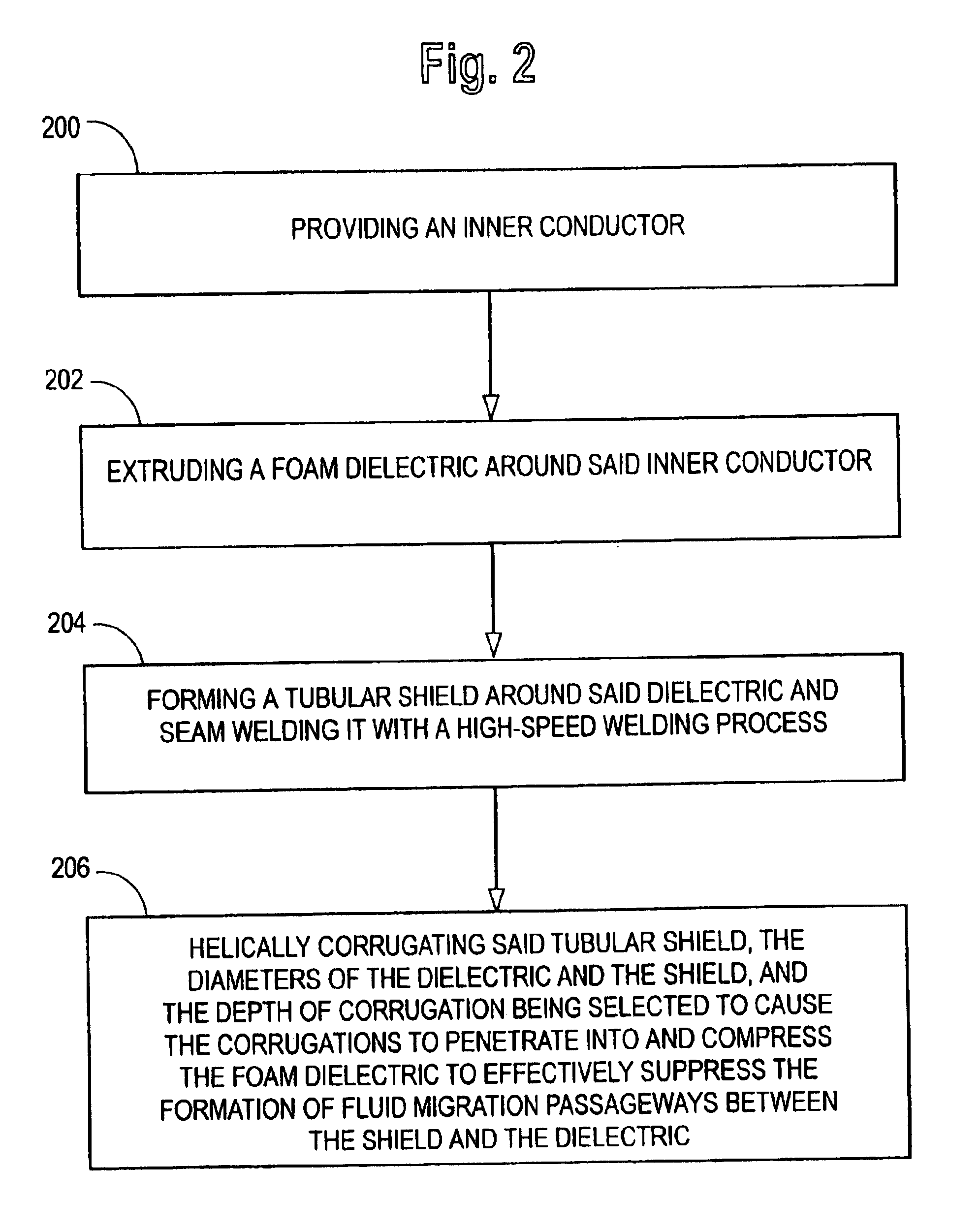

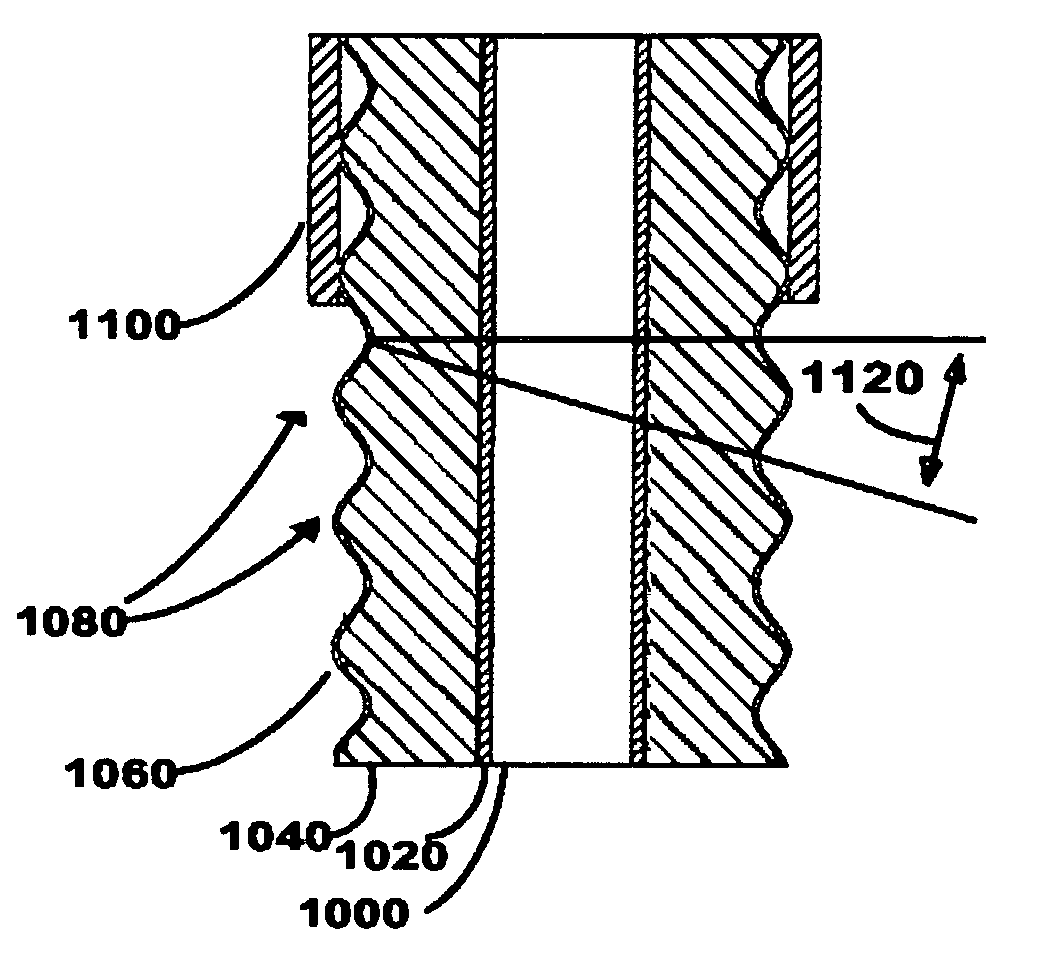

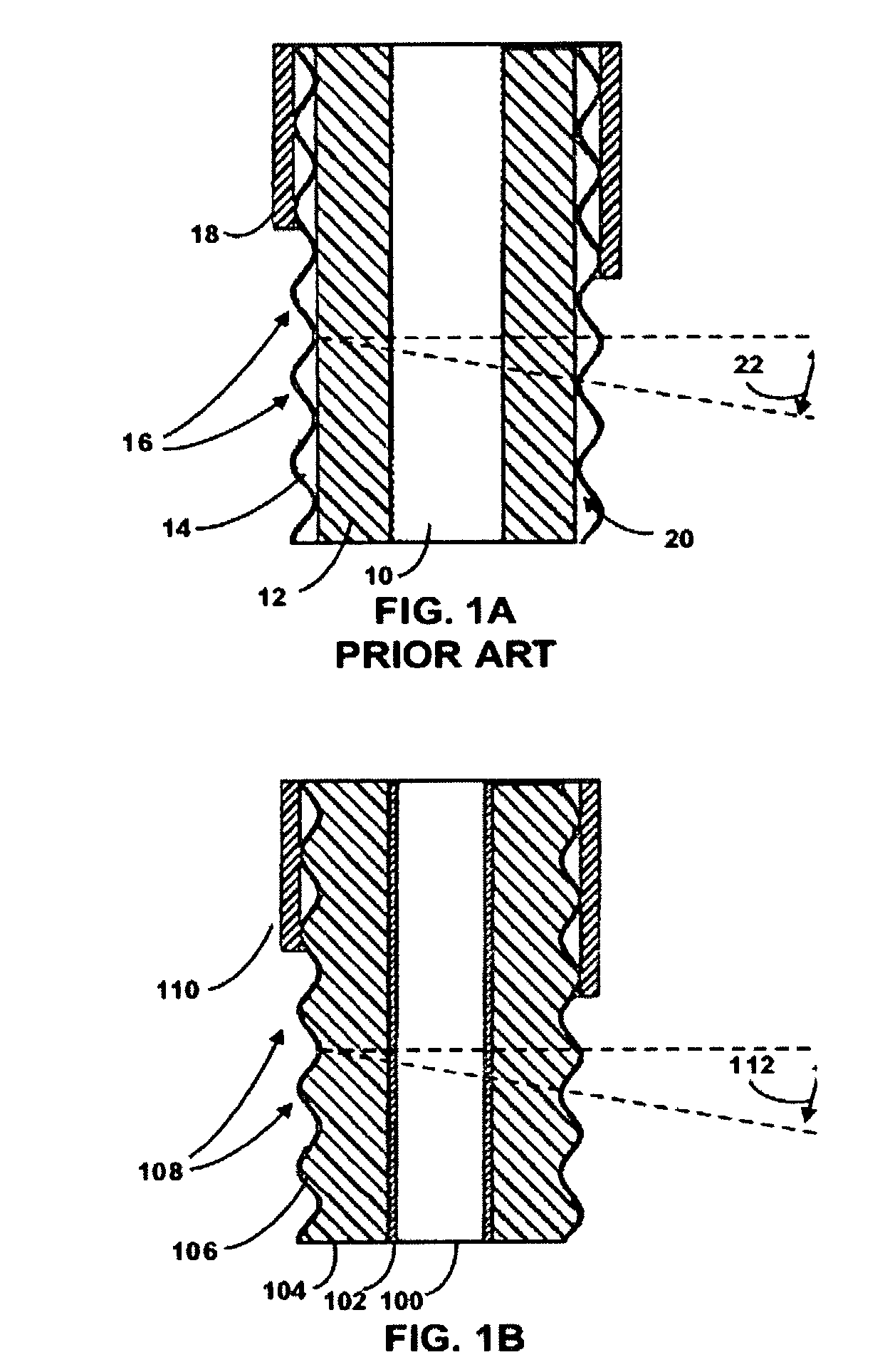

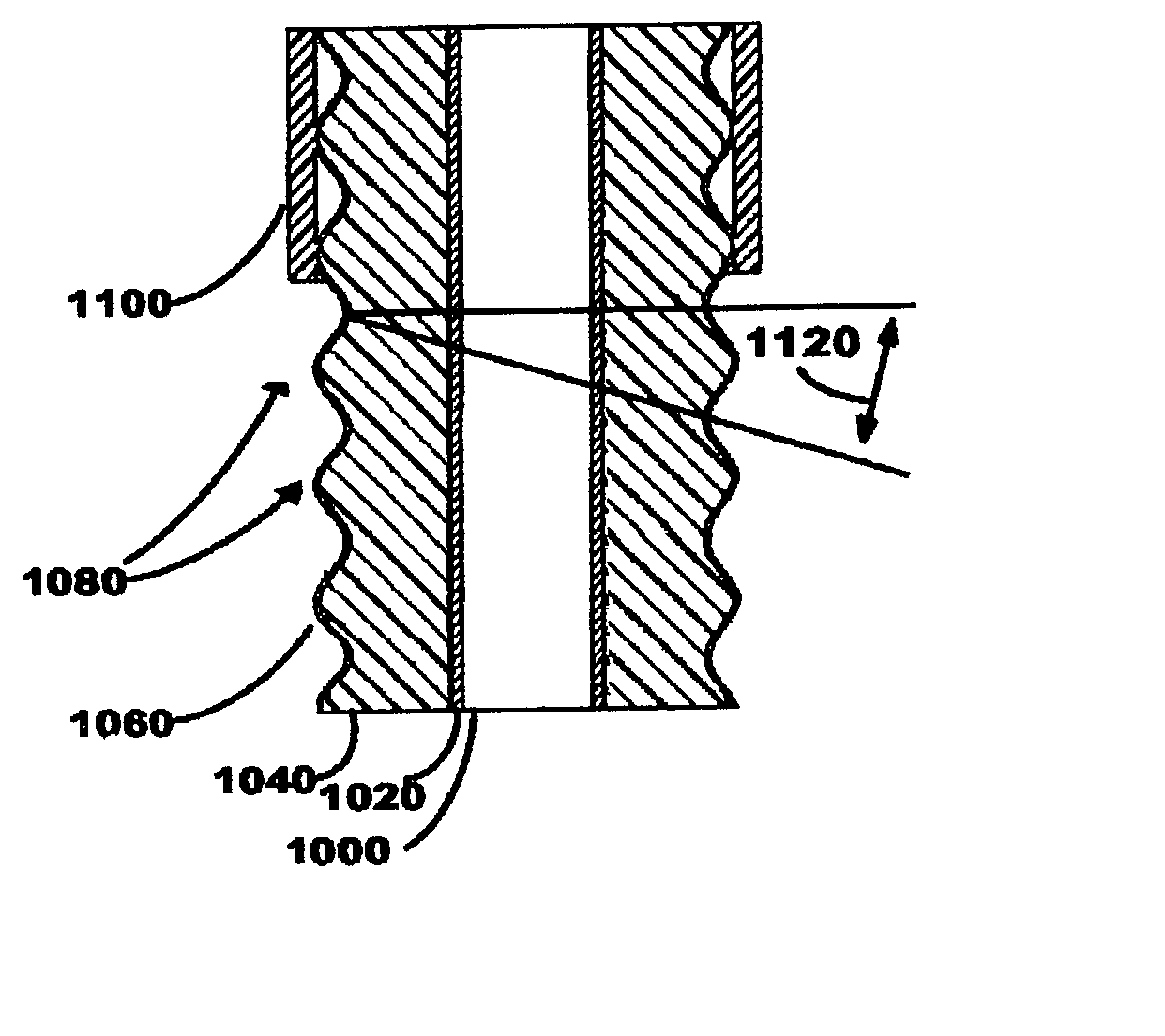

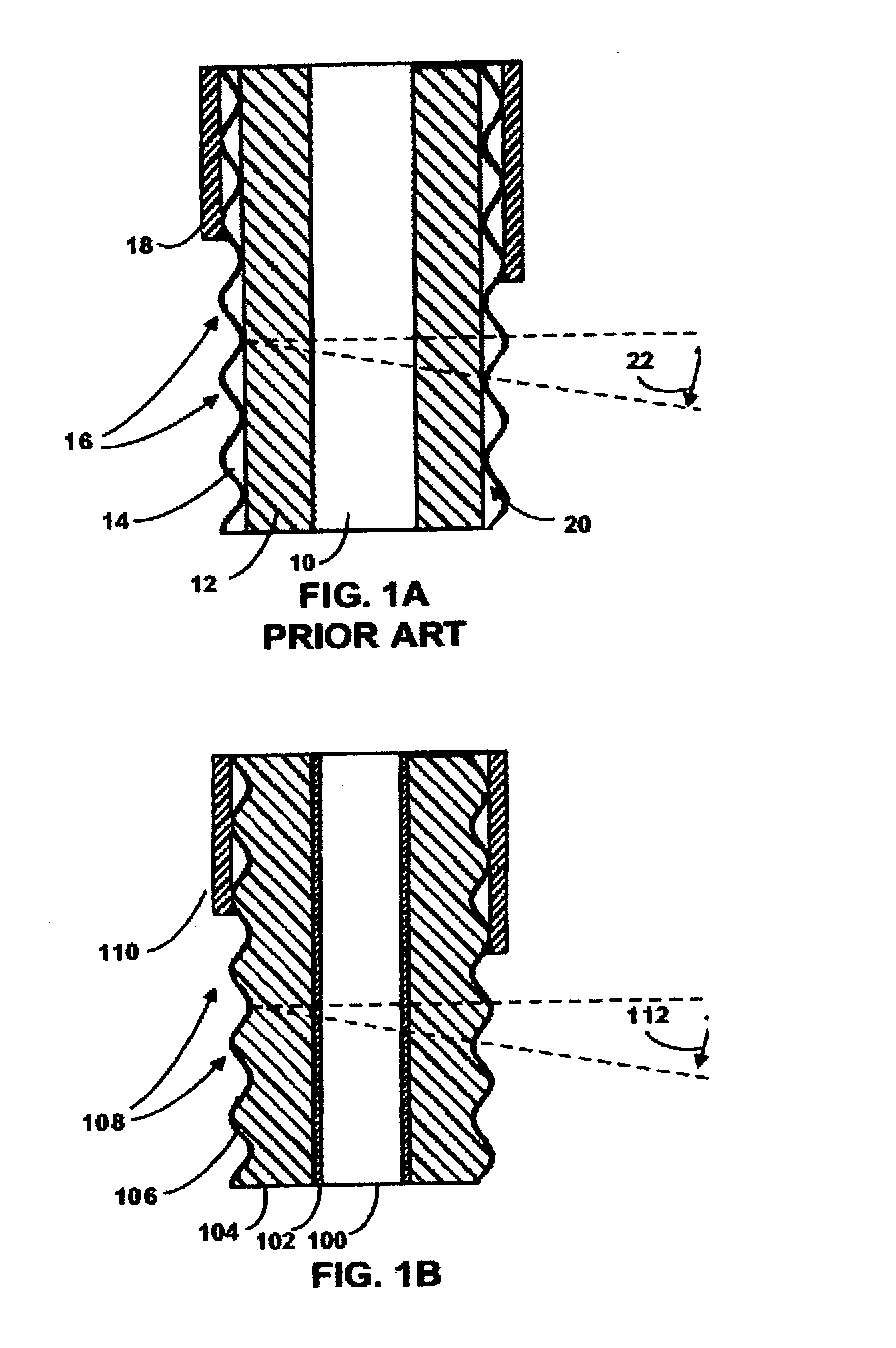

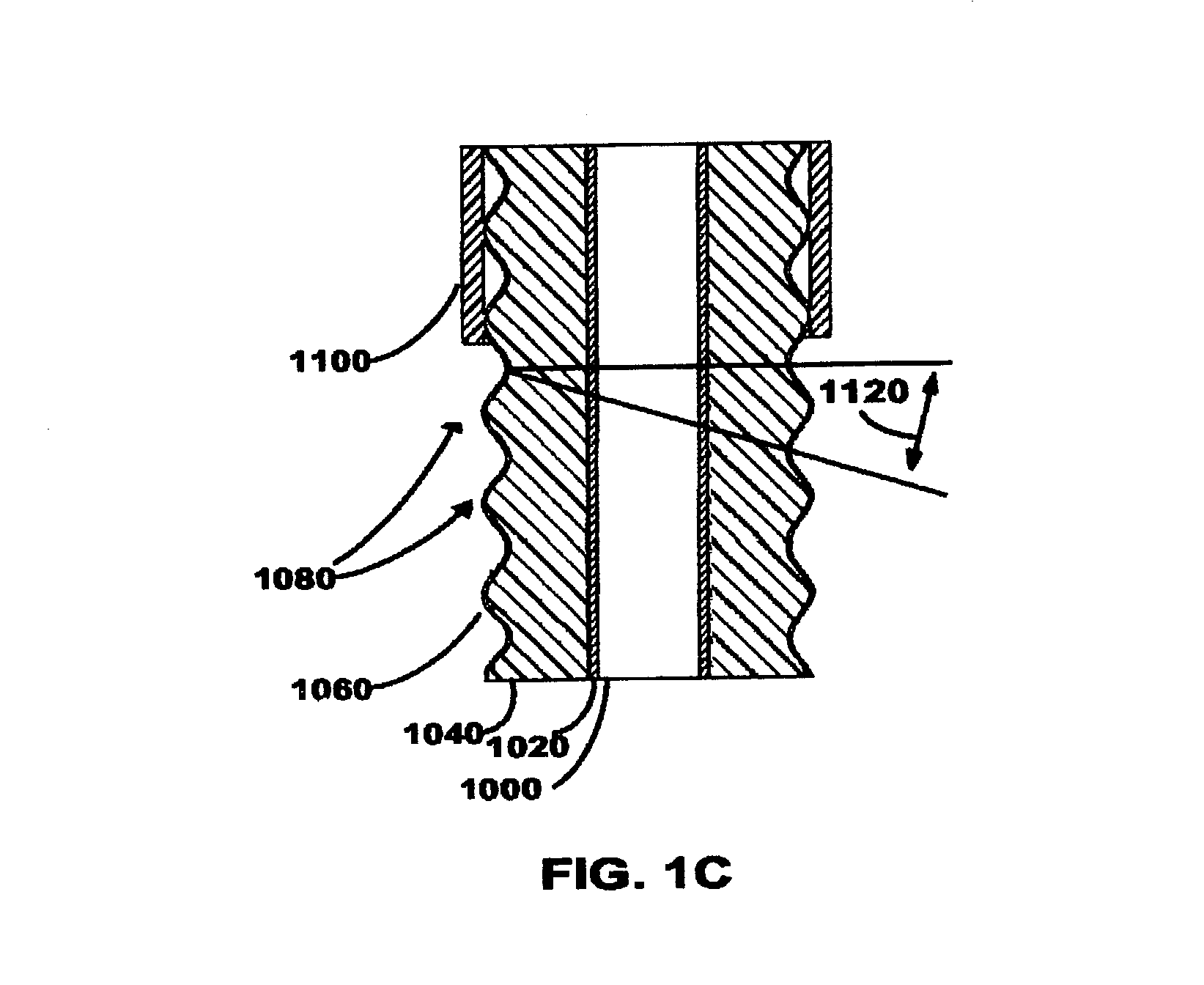

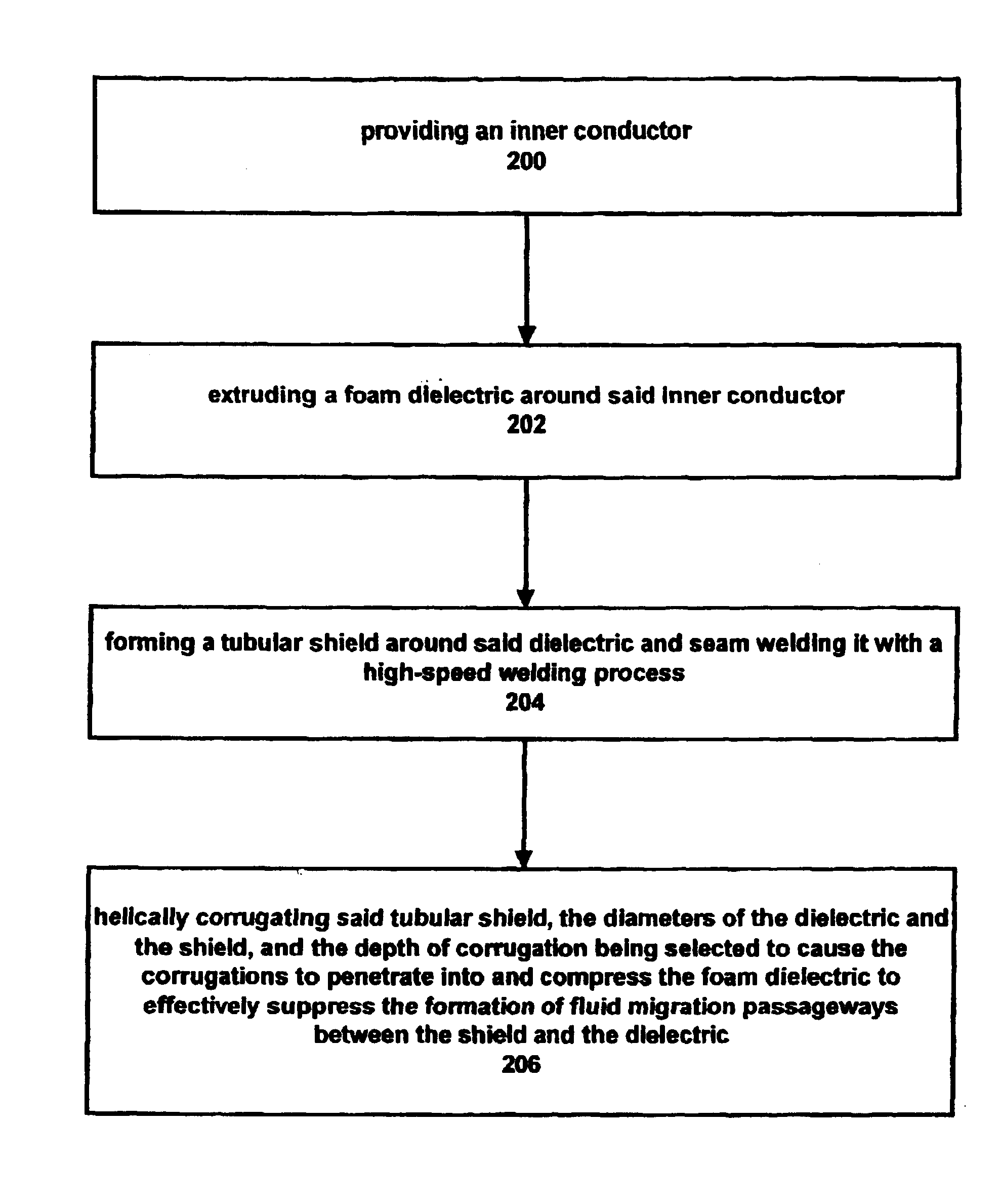

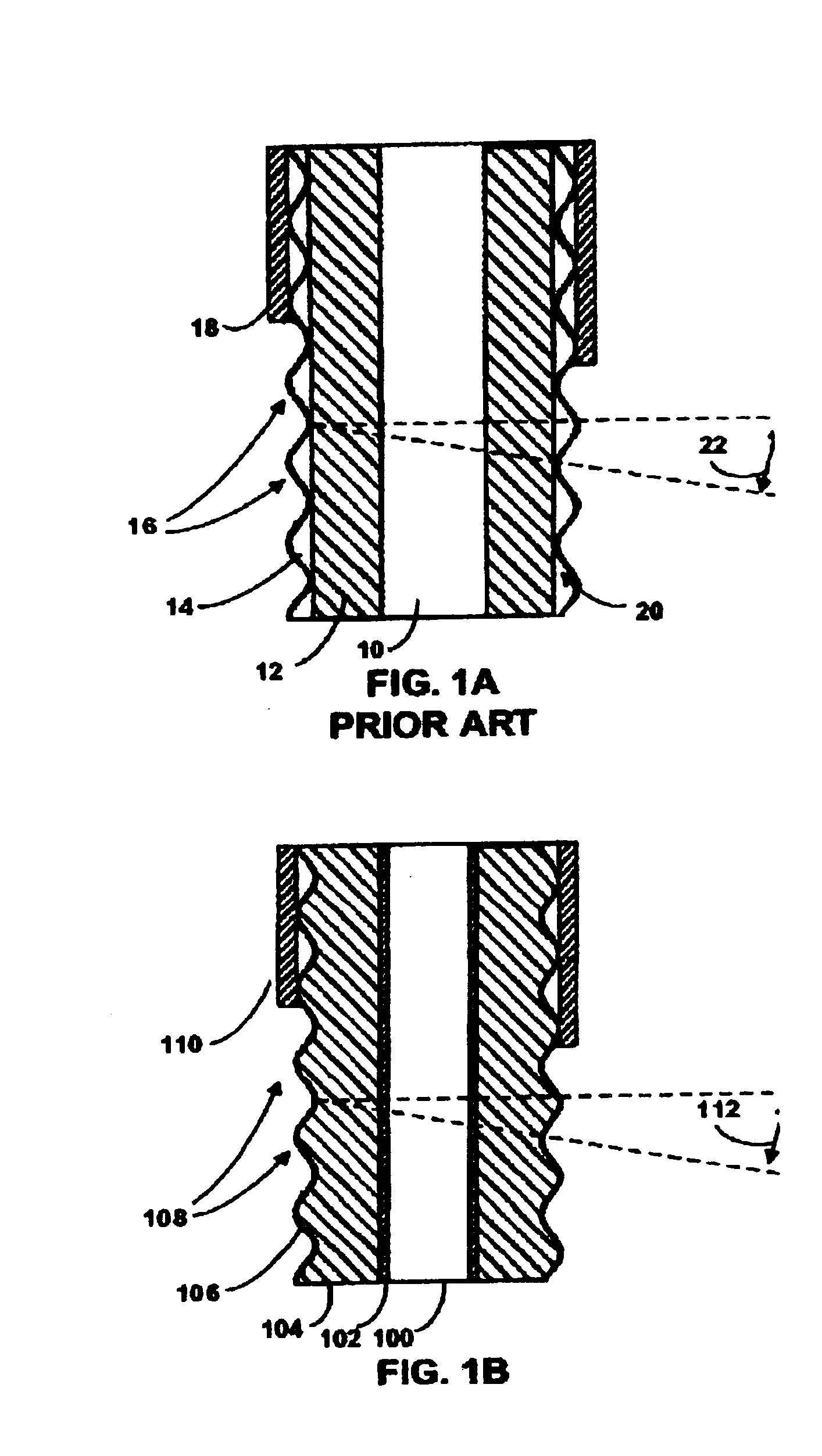

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS6693241B2Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

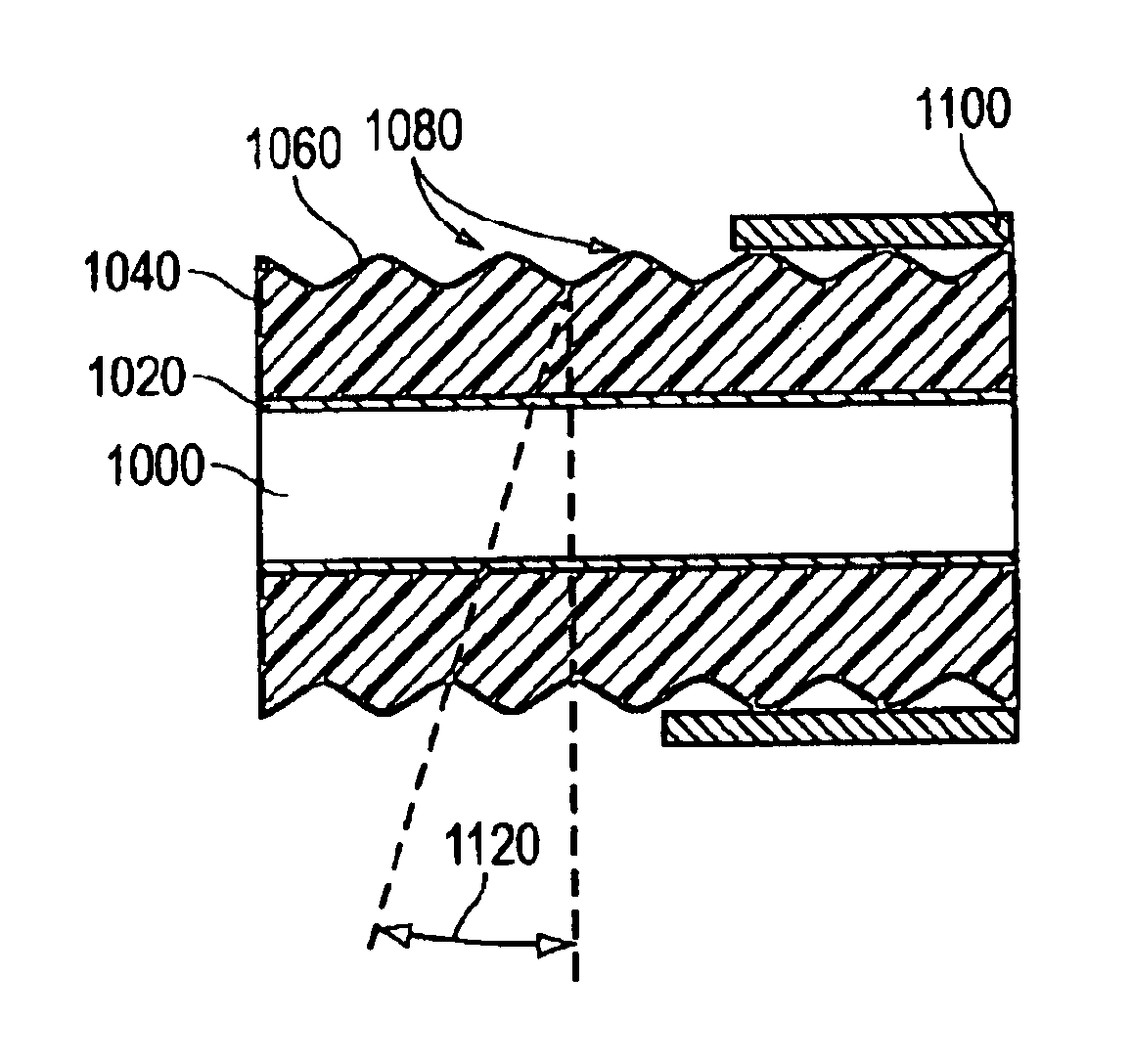

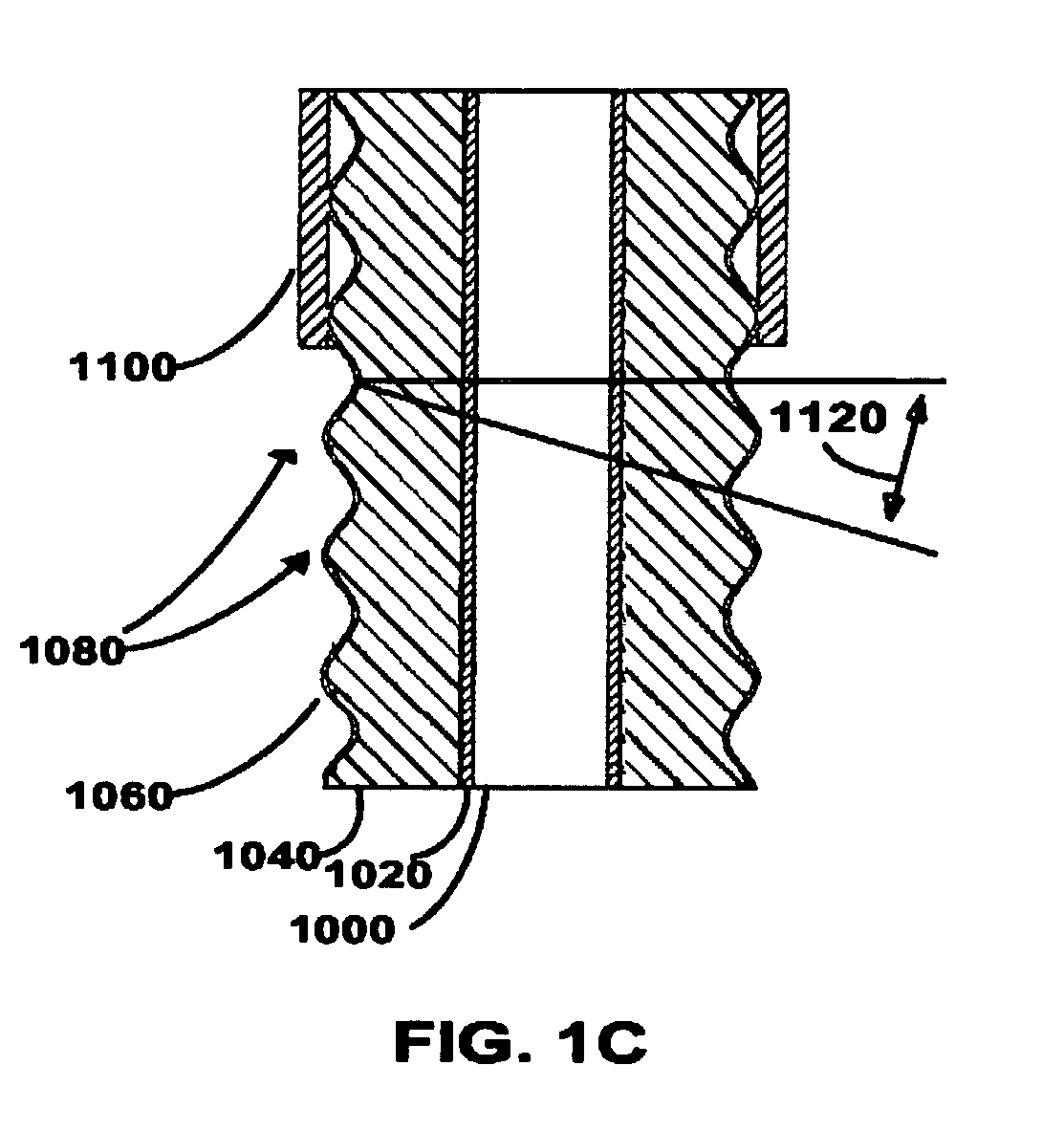

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201115A1Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Delayed, Swellable Particles for Prevention of Fluid Migration Through Damaged Cement Sheaths

InactiveUS20130105161A1Synthetic resin layered productsCellulosic plastic layered productsParticulatesFluid migration

A method includes providing a cementing composition that includes an aqueous fluid, a cementitious particulate, and a copolymer particulate which includes a monofunctional monomer, a water degradable first crosslinker, and a second crosslinker. The method further includes placing the cementing composition in a subterranean formation so as to form a set cement sheath and swelling the copolymer particulate in response to a void created in the set cement sheath. The copolymer particulate allows the cementing composition to set to form the cement sheath before substantial swelling of the copolymer particulate occurs.

Owner:HALLIBURTON ENERGY SERVICES INC

Control of fluid migration in non-latex bonded wet-wipes

InactiveUS20120121671A1Improved fluid migration propertyCosmetic preparationsBiocideFluid migrationWet wipe

The present invention describes wet-wipe composition with a liquid portion that is impregnated in a substrate, wherein the liquid portion contains a thickening or gelling polymer along with a thickening or gelling agent which substantially reduces fluid migration of the liquid portion within a wet-wipes stack during storage wherein the thickening or gelling agent is incorporated into the substrate through means of physical entanglement or thermal bonding.

Owner:THE BANK OF NOVA SCOTIA

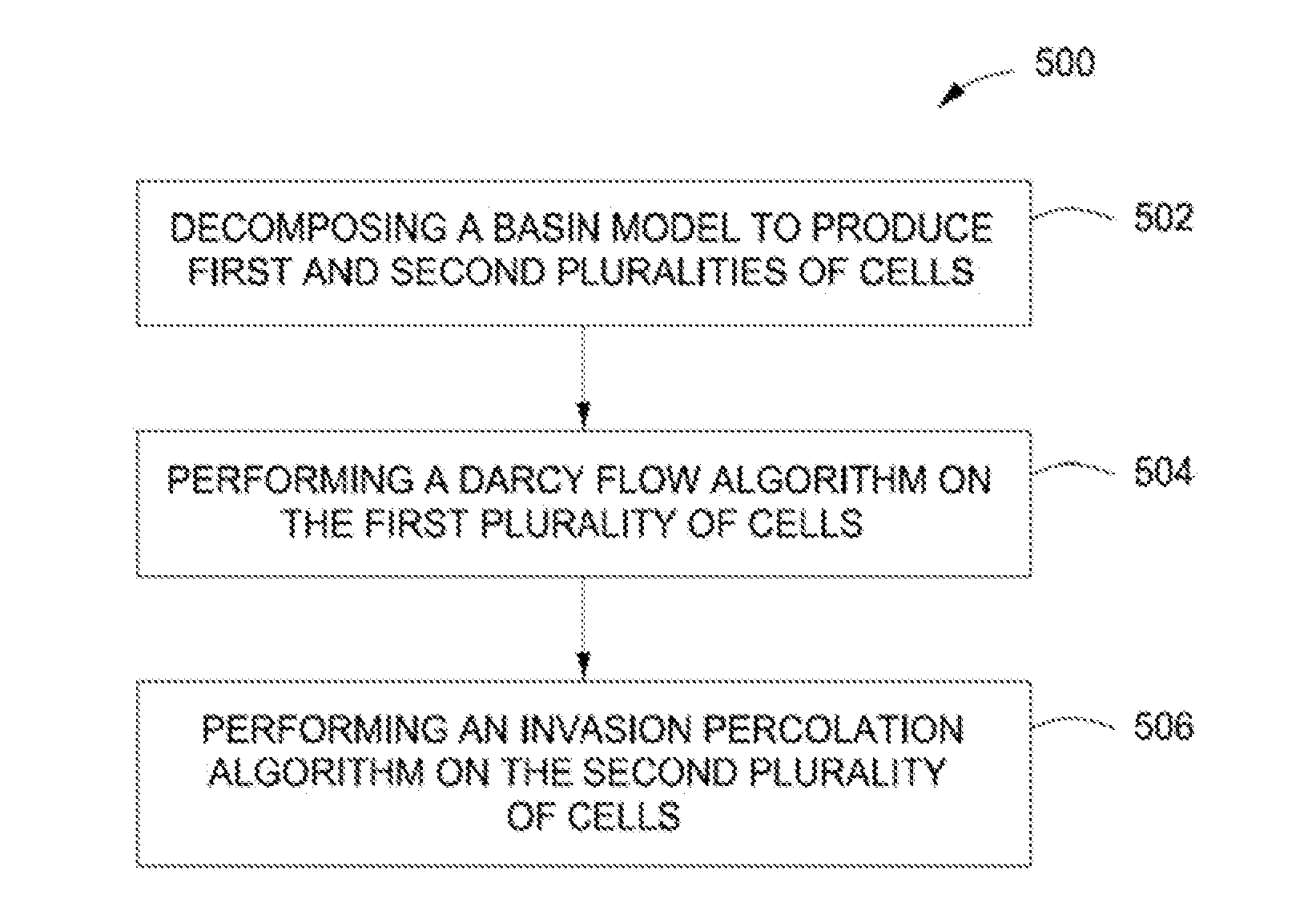

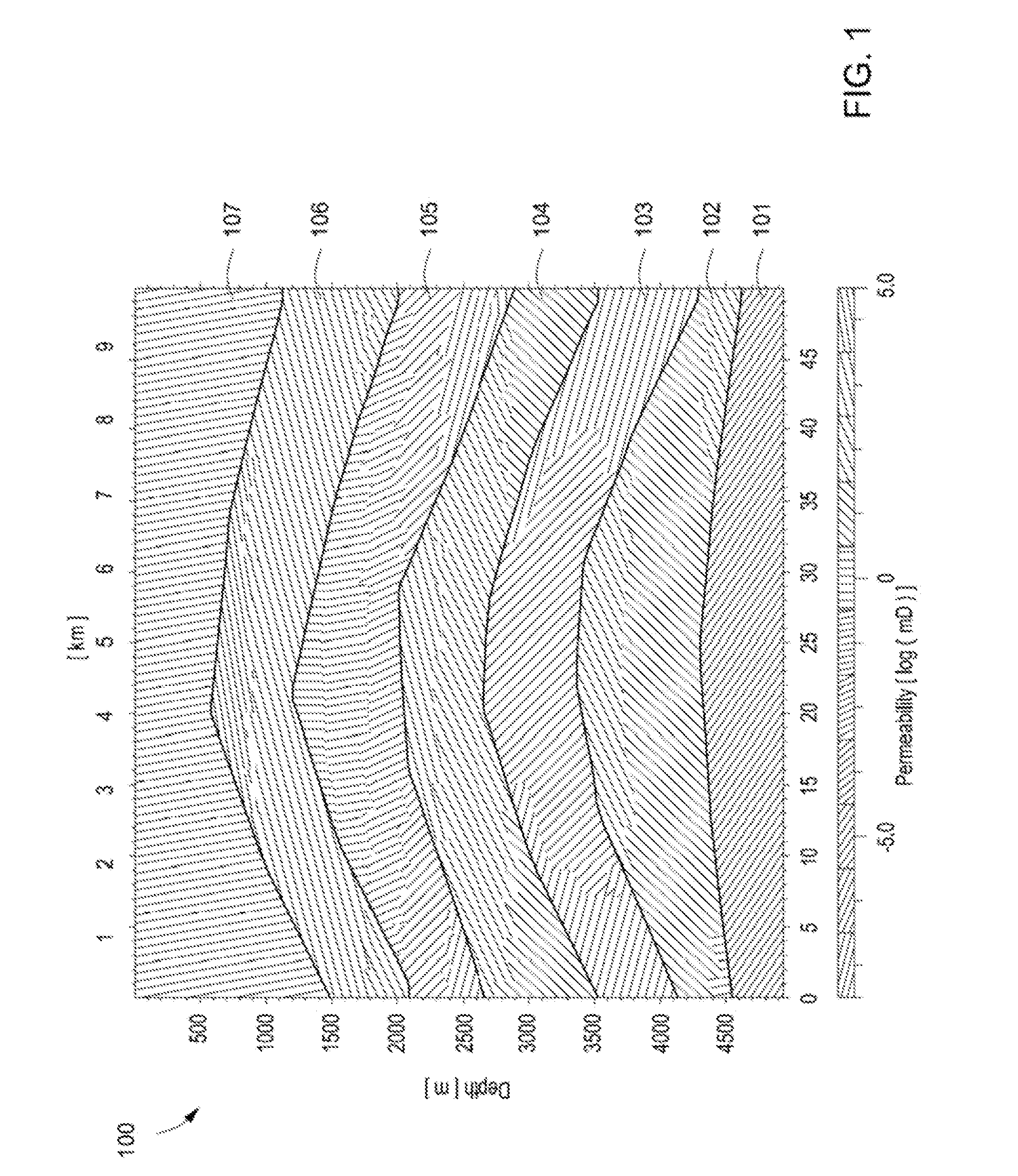

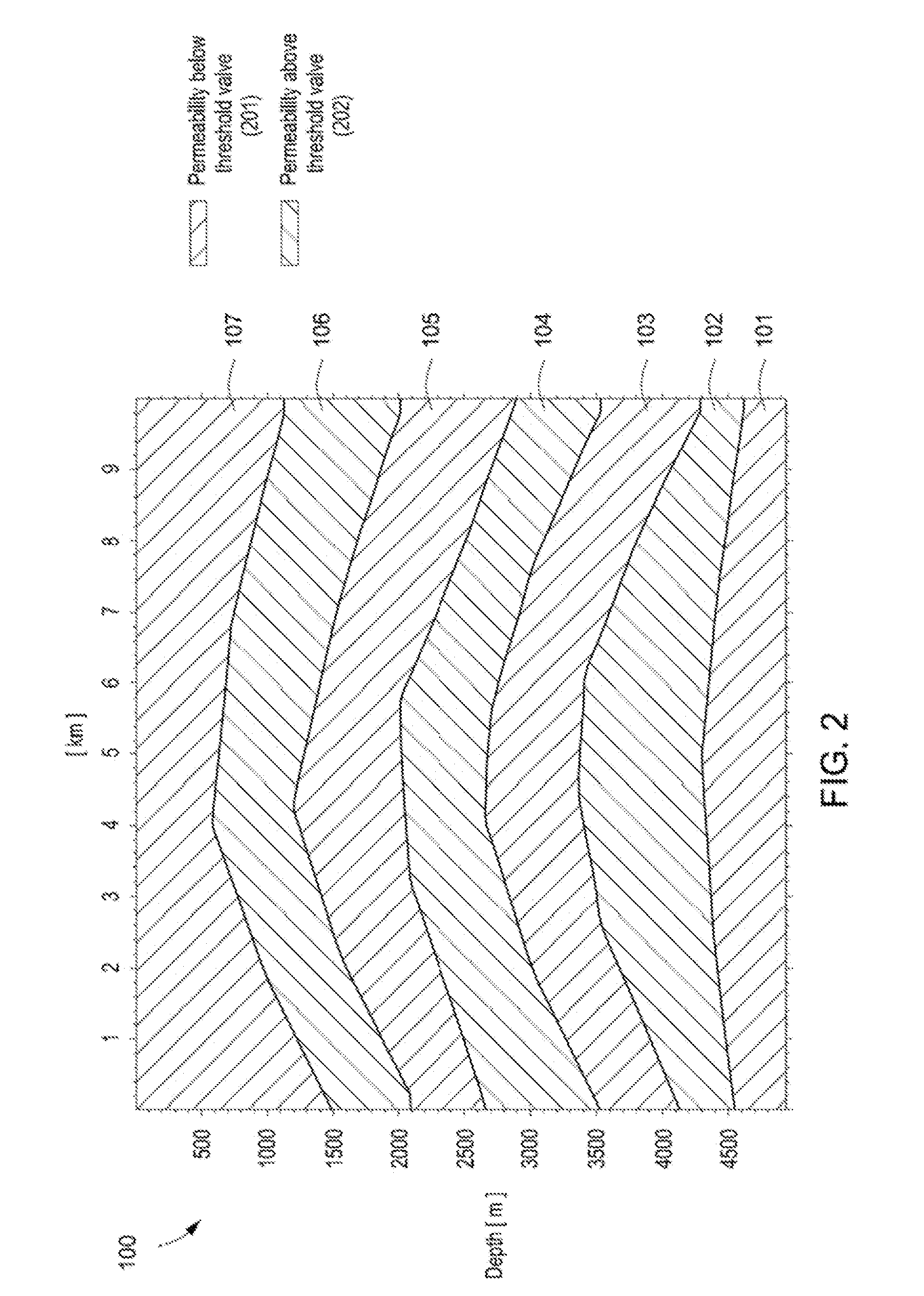

Combined migration method for basin modeling

A method for modeling a migration of hydrocarbon fluids. The method may include decomposing, by operation of a processor, a domain of a basin model to produce a first plurality of cells having a permeability below a threshold value and a second plurality of cells having a permeability above the threshold value. A first migration analysis may be performed to analyze a relatively slow migration starting in the first plurality of cells. A second migration analysis may be performed to analyze a relatively faster migration starting m the second plurality of cells.

Owner:SCHLUMBERGER TECH CORP

Air conditioning flashing hood

ActiveUS20140259974A1Mitigate fluid migrationPromote migrationRoof covering using slabs/sheetsRoof covering using tiles/slatesElectricityFluid migration

An air conditioning flashing hood adapted to be connected to the wall structure and extend through the exterior wall of the structure to provide a passage through which a refrigerant line and an electrical control line may extend to communicate with an external compressor. The air conditioning flashing hood includes an internal sealing element which compresses against the outer surface of the refrigerant line and the electrical control line to form a substantially weather-tight seal therebetween to mitigate fluid migration along the lines into the structure, as well as to provide a barrier for any bugs, debris or animals to keep such undesirable objects from entering the structure.

Owner:WJG

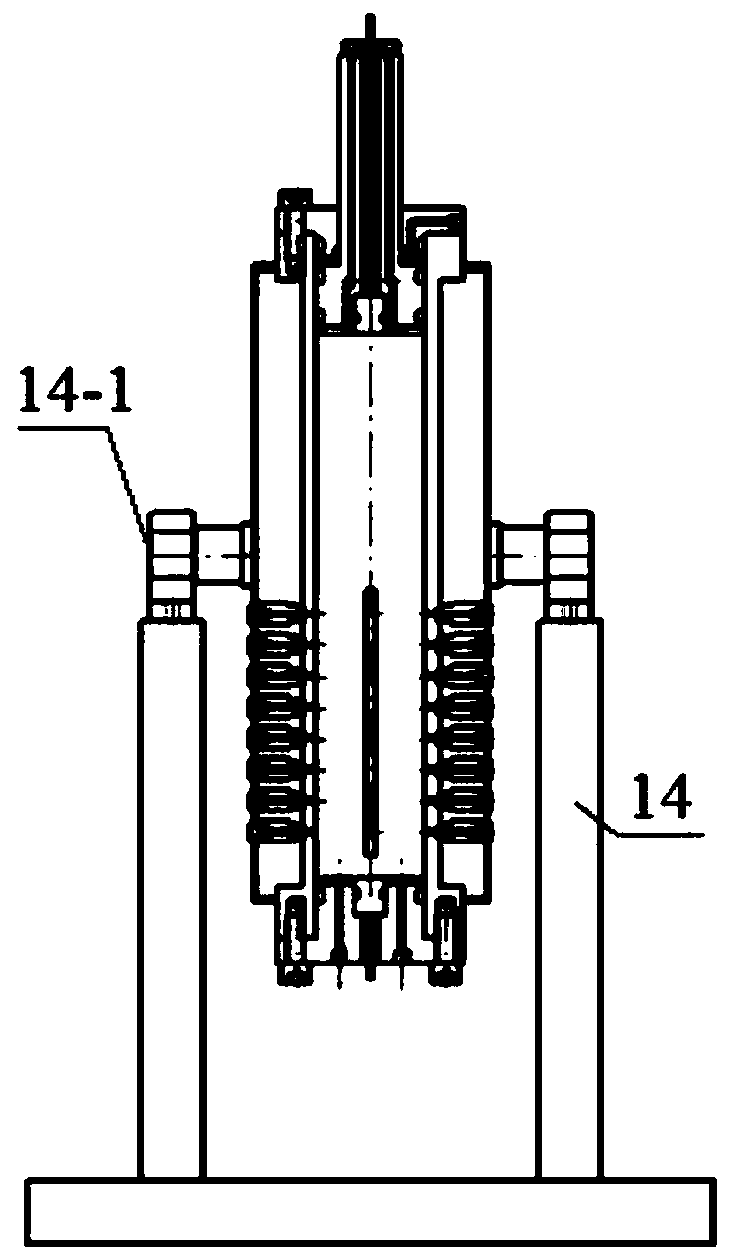

Multifunctional reaction kettle for reservoir response and sand production simulation in hydrate exploitation

PendingCN109696360AEasy to fillGuaranteed stable conditionsAnalysing solids using sonic/ultrasonic/infrasonic wavesResistance/reactance/impedenceFluid migrationTest sample

The invention discloses a multifunctional reaction kettle for reservoir response and sand production simulation in hydrate exploitation, which comprises a kettle body, an upper end cover, a lower endcover, a piston, a plug and a water-cooling jacket, wherein the kettle body is hollow for placing a test sample; the upper end cover is provided with an axial pressure injection hole, the piston is pushed to move by consolidation pressure provided by the axial pressure injection hole so as to conduct a consolidation test; the lower end cover and the piston are respectively provided with a fluid inlet and a fluid outlet so as to conduct a penetration test; the piston and the lower end cover are respectively provided with an acoustic wave transmitting probe and an acoustic wave receiving probe so as to conduct an acoustic wave test; the side wall of the kettle body is further provided with a plurality of resistivity probes so as to conduct a resistivity test; the plug is pulled out to enablethe kettle body to be communicated with a sand outlet so as to conduct a sand production test, and the lower part of the kettle body is further provided with a collection port. The multifunctional reaction kettle can conduct a synthesis and decomposition test of a hydrate, and monitor the stress consolidation, sand production settlement, fluid migration law, acoustic waves, the resistivity and the like of the test sample under the condition of maintaining the overlying formation pressure.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201116A1Low costMechanical working/deformationCable insulation constructionDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

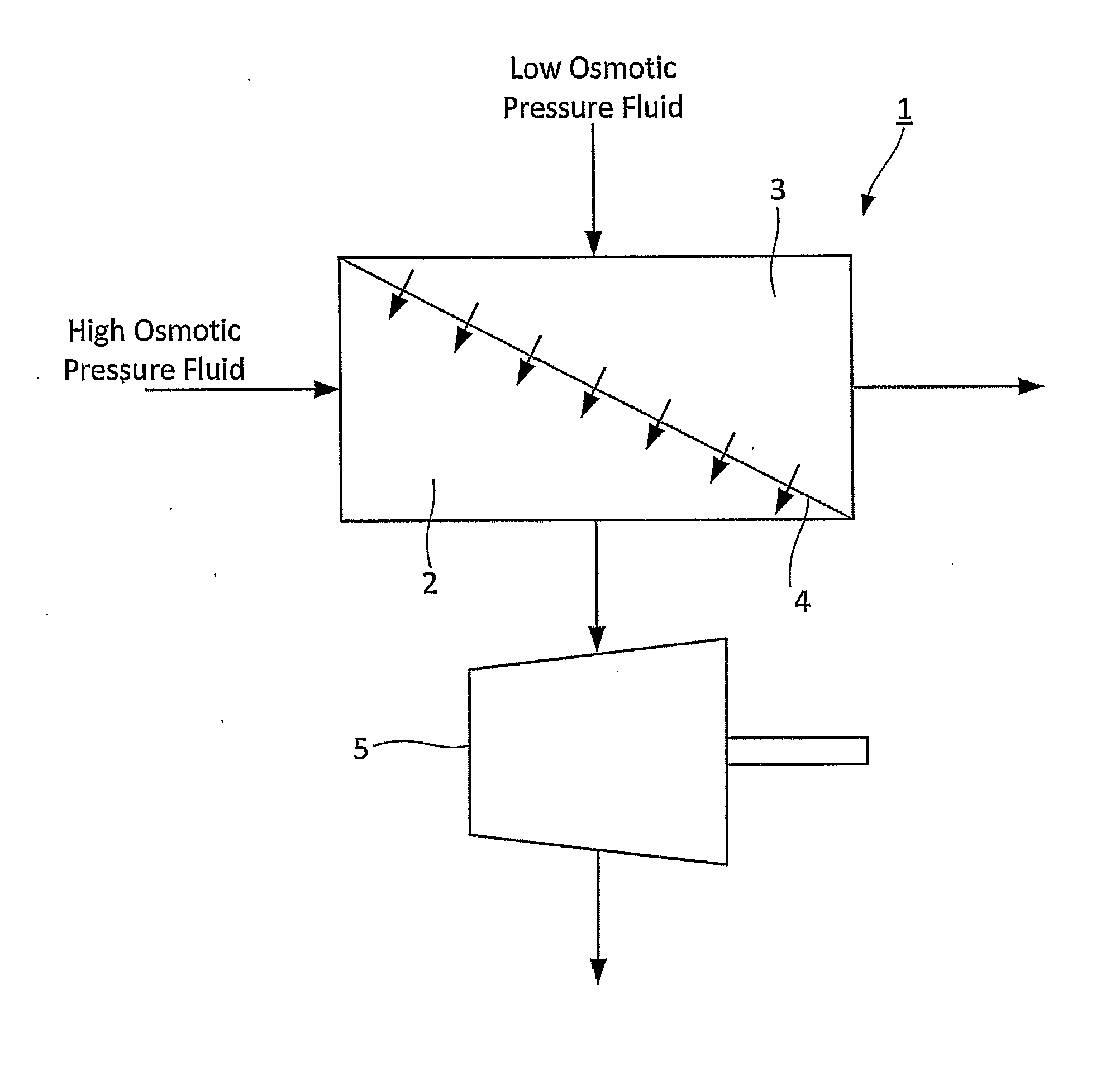

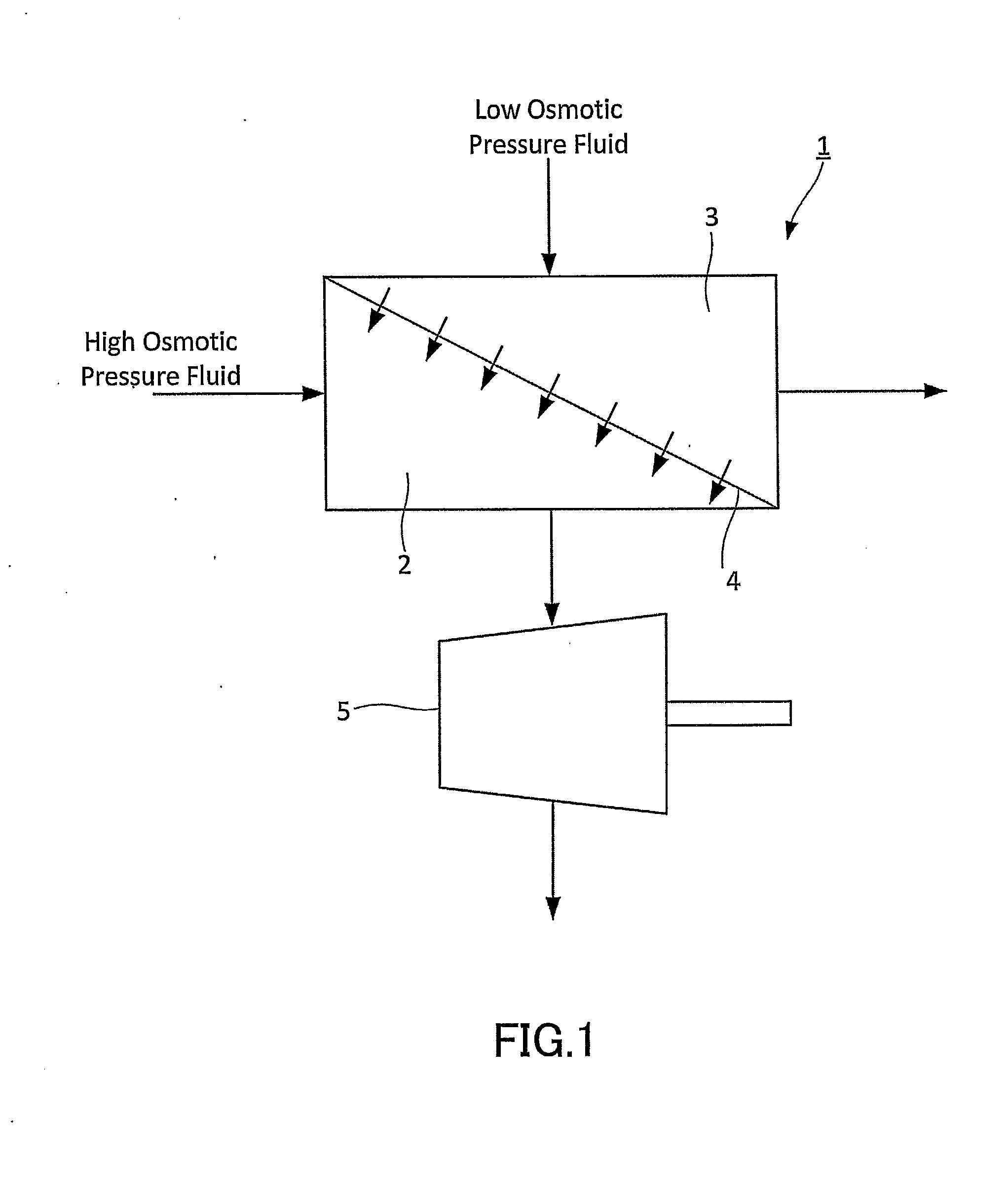

Forward osmosis membrane flow system and composite semipermeable membrane for forward osmosis membrane flow system

InactiveUS20140110328A1Improve efficiencyHigh permeation fluxSemi-permeable membranesHydro energy generationEpoxyFluid migration

The forward osmosis membrane flow system (1) includes a high osmotic pressure fluid flow section (2) to which a high osmotic pressure fluid is supplied, a low osmotic pressure fluid flow section (3) to which a low osmotic pressure fluid with a lower osmotic pressure than that of the high osmotic pressure fluid is supplied, and a semipermeable membrane (4) that separates the high osmotic pressure fluid flow section and the low osmotic pressure fluid flow section from each other. A flow rate in the high osmotic pressure fluid flow section (2) is increased by an occurrence of fluid migration from the low osmotic pressure fluid flow section (3) into the high osmotic pressure fluid flow section (2) through the semipermeable membrane (4). The semipermeable membrane (4) is a composite semipermeable membrane with a polyamide-based skin layer formed on a porous epoxy resin membrane.

Owner:NITTO DENKO CORP

Method of manufacturing a high-performance, water blocking coaxial cable

InactiveUS6912777B2Low costMechanical working/deformationCable insulation constructionShielded cableDielectric

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

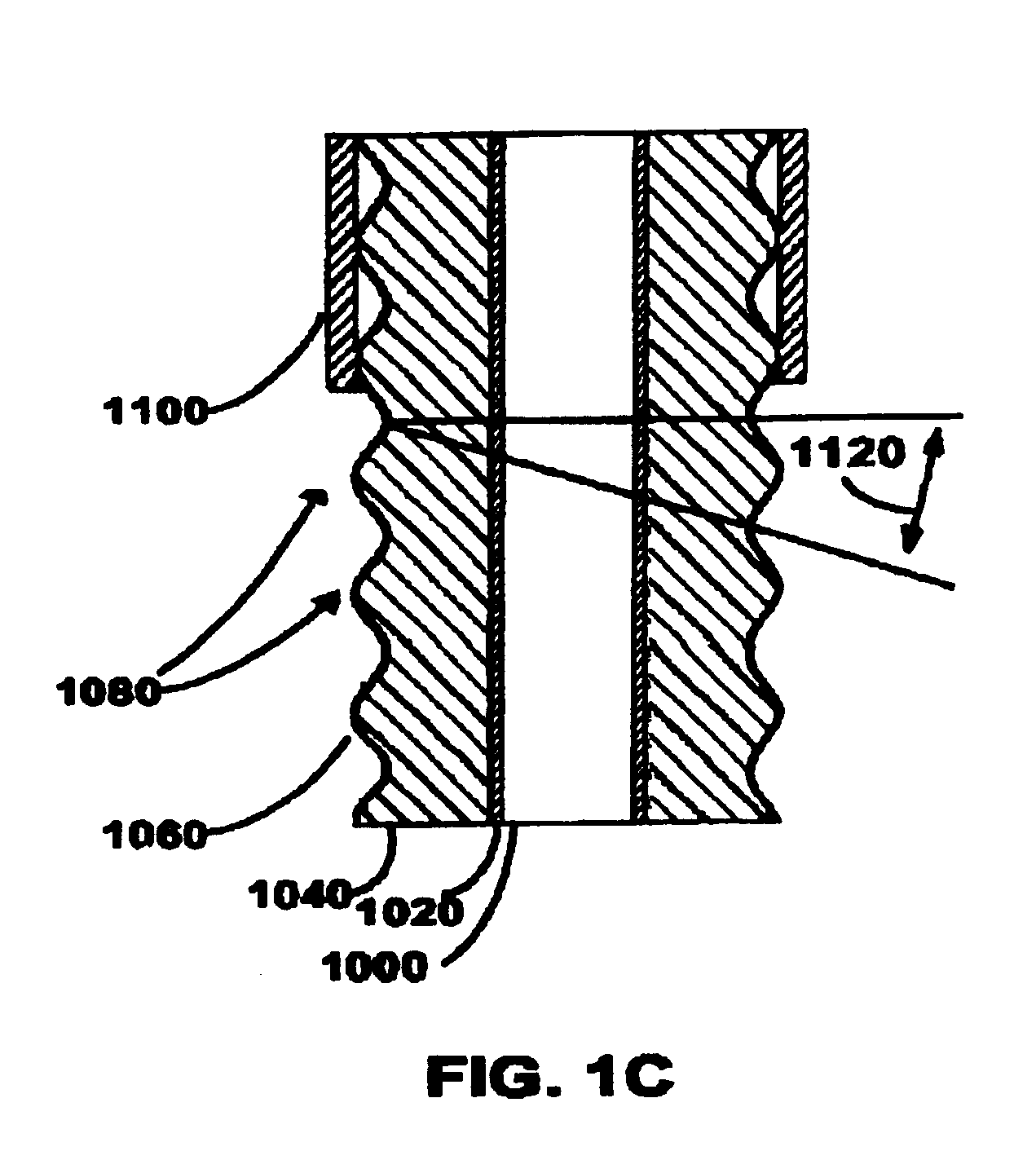

Chlorine-free fluid migration prevention early strength agent for oil well cement, and preparation method and application thereof

InactiveCN106554765AShorten thickening timeHigh strengthDrilling compositionFluid migrationWater source

The invention provides a chlorine-free fluid migration prevention early strength agent for oil well cement. The chlorine-free fluid migration prevention early strength agent comprises, by mass, 33-48% of a coagulation accelerator, 20-25% of an expanding agent, 1-2% of an organic early strength agent, and the balance of a filler. The chlorine-free fluid migration prevention early strength agent effectively improves the early strength of set cement, contains no chloride ions or other corrosive ions, has no corrosion effect on sleeves or the set cement, avoids catalytic corrosion of Cl<-> to the sleeves and pollution of the Cl<-> to an underground water source, prolongs the exploitation life of a single well, truly realizes harmlessness of cementing additives, greatly shortens the well cementation cement curing time, shortens the cement curing time, meets performance requirements of cement mortar and the set cement in well cementation construction process, effectively protects sleeves, protects oil and gas reservoirs, and improves the productivity of the single well.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG +1

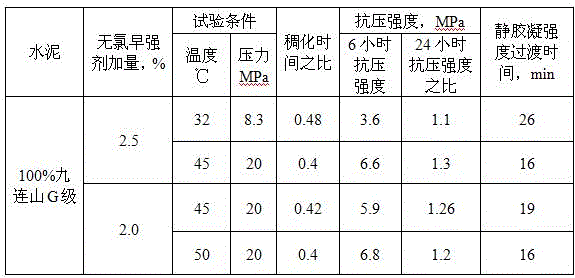

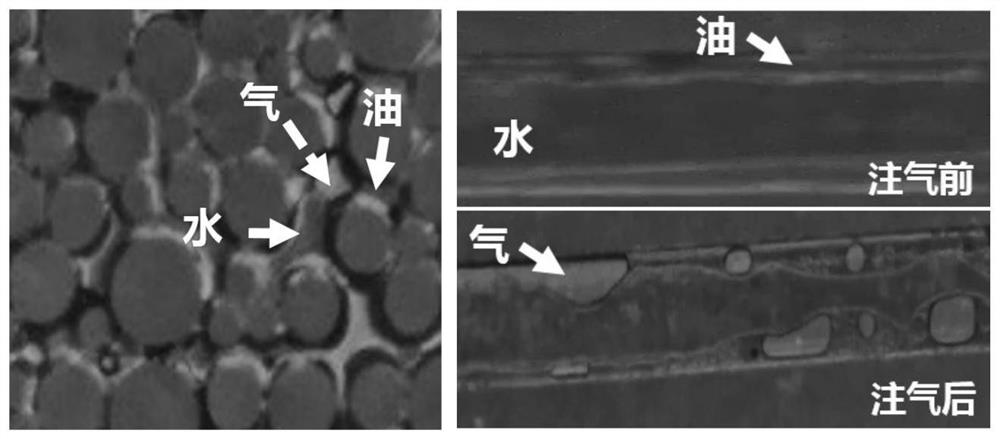

Deep oil reservoir high-temperature and high-pressure gas-displacing oil microcosmic visualization experiment method

ActiveCN112858113AAchieving Flow BehaviorQuantitativeTelevision system detailsHydrodynamic testingMicro nanoFluid migration

The invention discloses a deep oil reservoir high-temperature and high-pressure gas-displacing oil microcosmic visualization experiment method, which comprises the following steps of: installing a glass etching model for simulating a rock sample under an actual reservoir condition in a high-pressure sealed holder, and performing vacuumizing; injecting confining pressure liquid into a reservoir confining pressure annular cavity, and controlling the confining pressure through a confining pressure tracking pump; heating the confining pressure liquid in the reservoir confining pressure annular cavity through a high-temperature heating container; placing a glass etching model under a microscope; loading crude oil and a displacement fluid medium into a heating constant-temperature piston container, and adjusting a back pressure unit to a stratum simulation pressure; and carrying out a water and gas injection displacement experiment through a high-pressure injection pump and a gas pressurization system. The method can be used for simulating the oil-water-gas distribution state and fluid migration characteristics in a micro-nano pore structure, quantitatively characterizes the high-temperature and high-pressure water drive, gas drive and chemical drive microcosmic remaining oil starting mechanism, and has important guiding significance for judging the oil-water saturation distribution and size in the oil field reservoir development process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

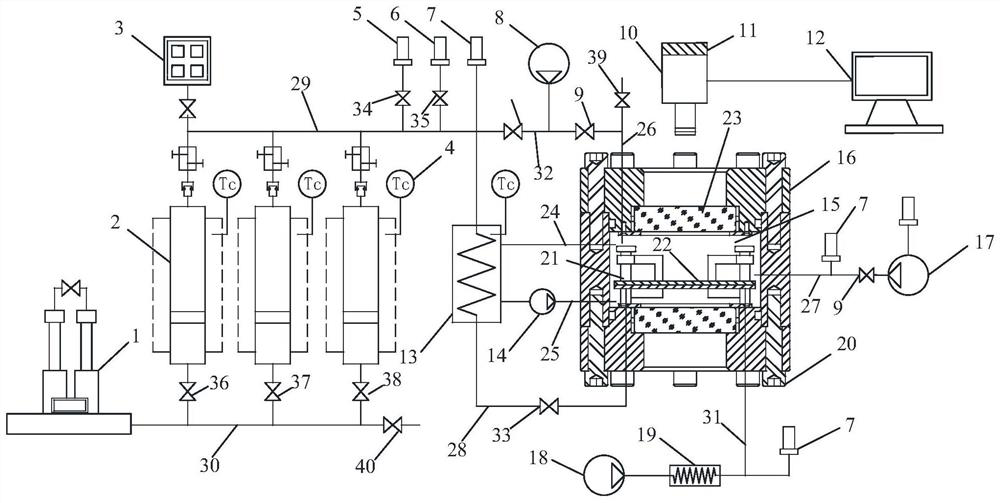

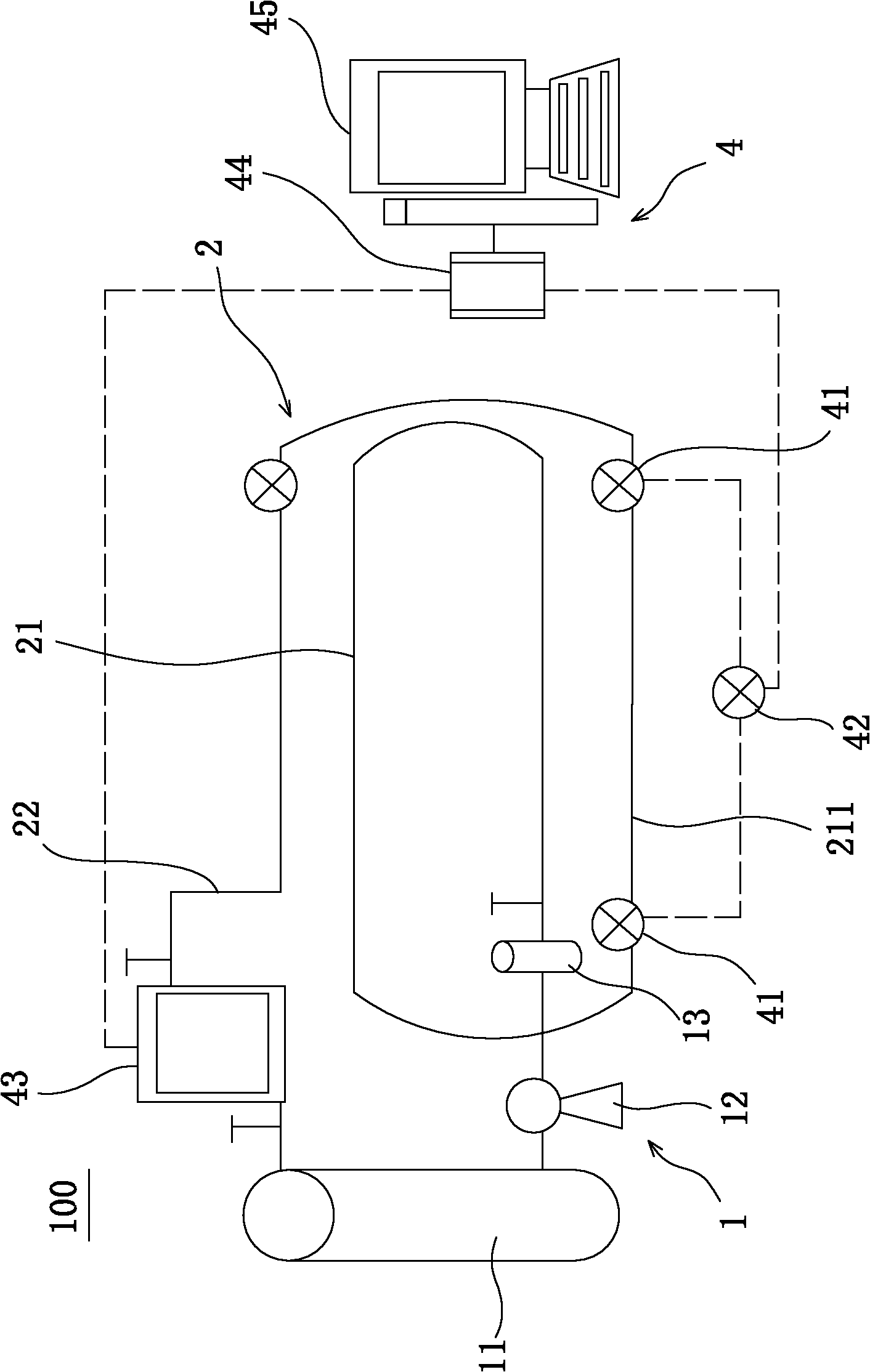

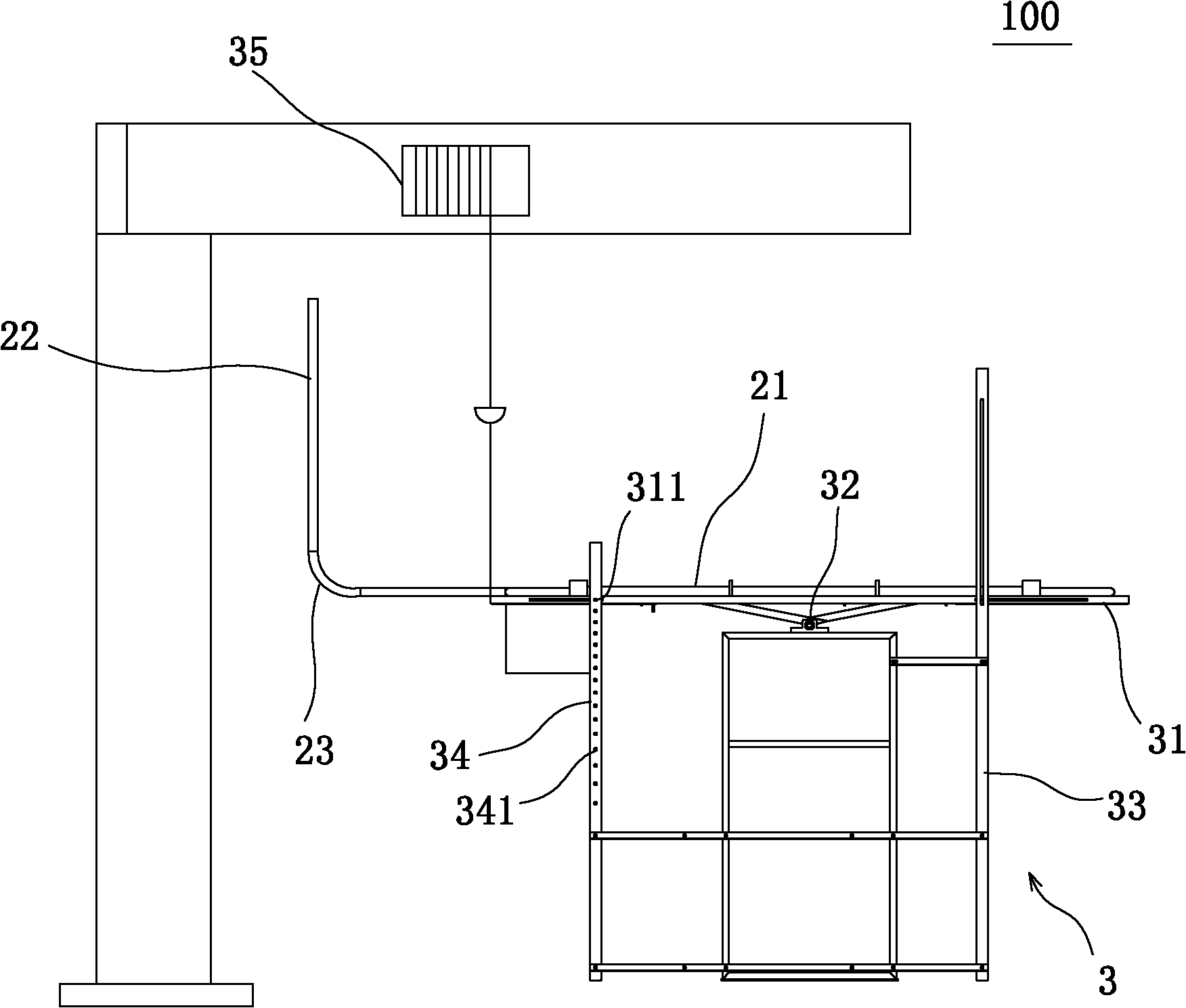

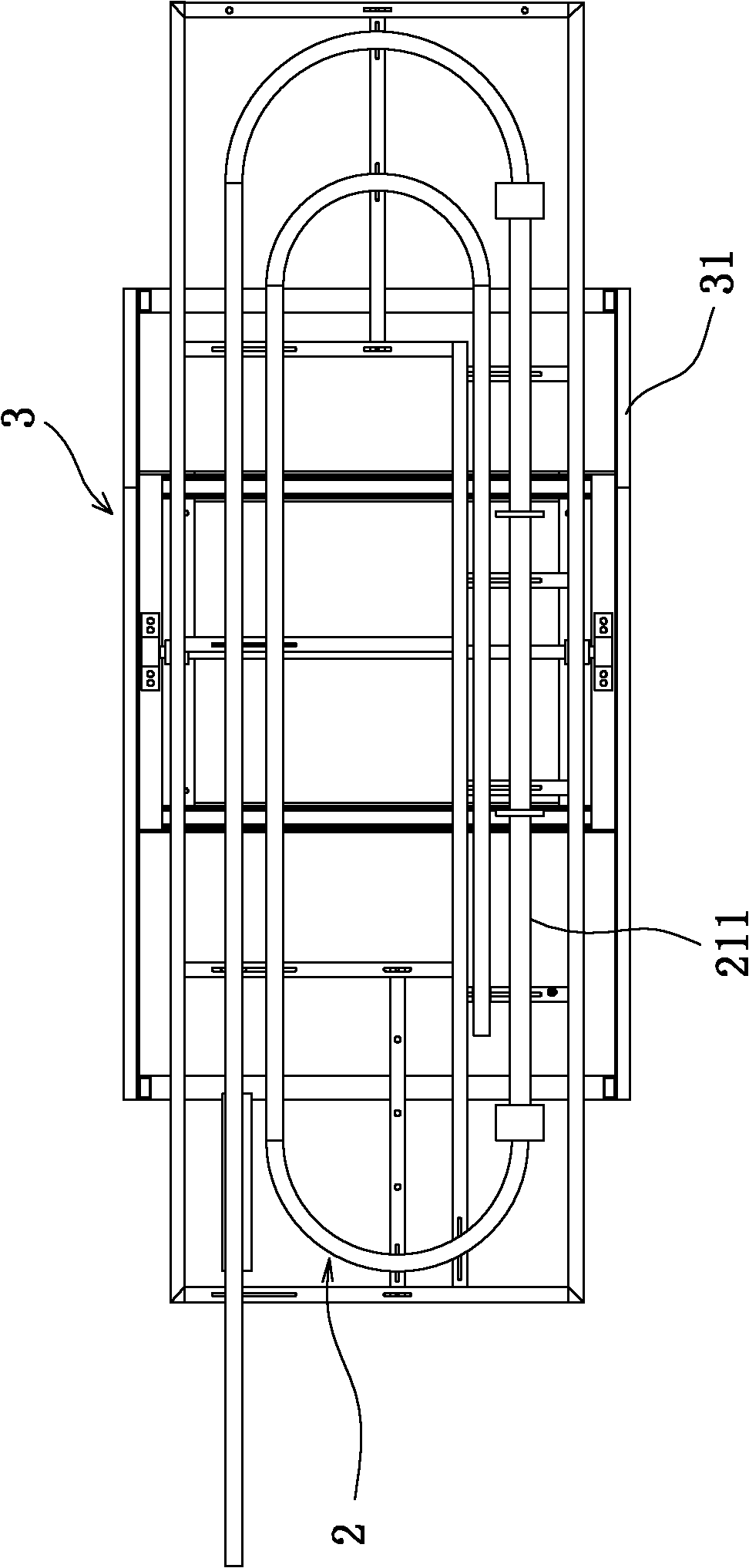

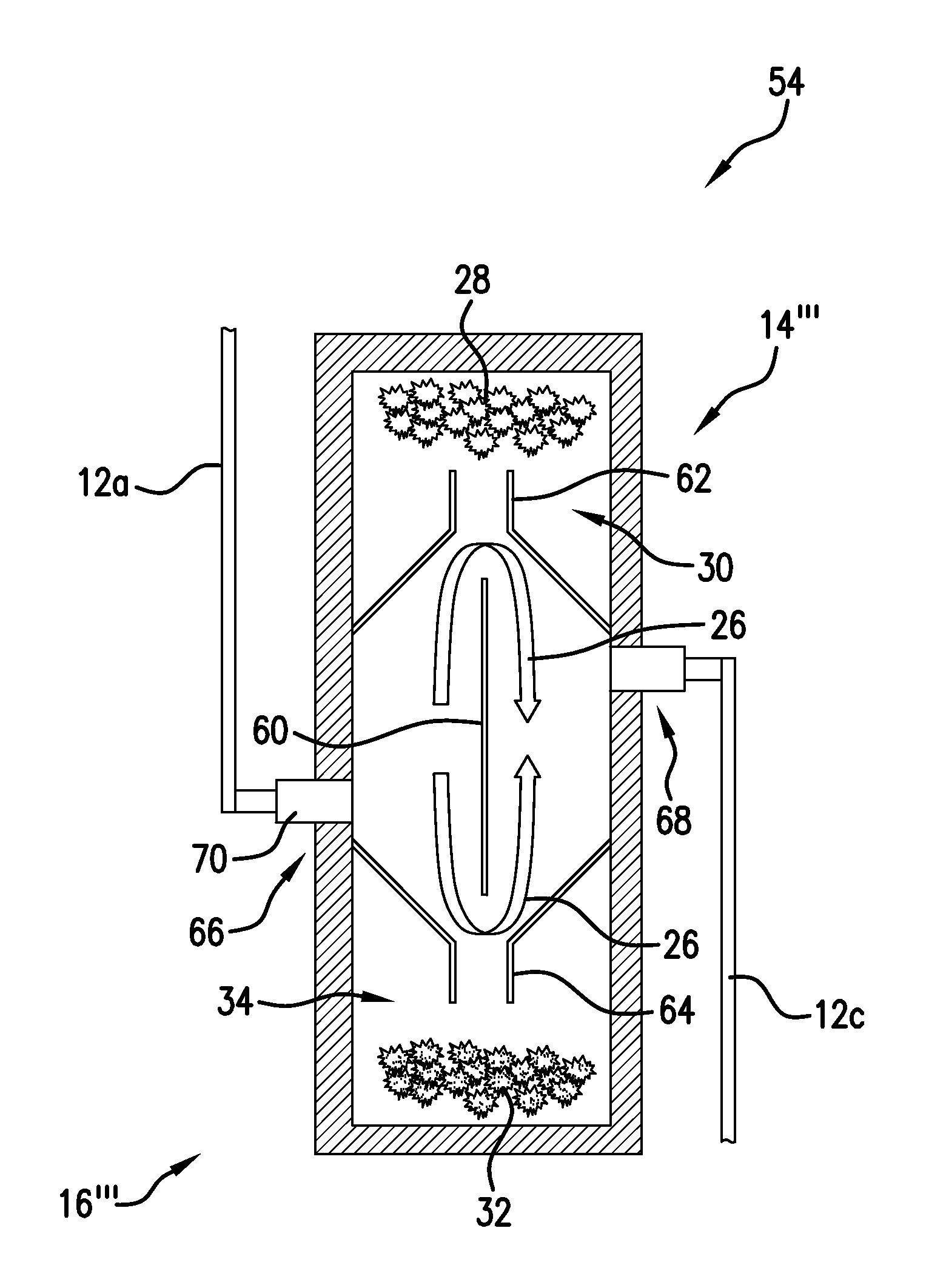

Fluid migration researching device

InactiveCN102032981AUnderstand and master featuresComprehensive data collectionHydrodynamic testingSupporting systemFluid migration

The invention discloses a fluid attribute parameter detecting device comprising a power system, a pipe flow system, a supporting system and a data collecting system, wherein the power system is used for supplying fluid and power to be detected; an input hole and an output hole of the pipe flow system are connected with the power system, and the fluid is subjected to parameter detection after flowing through the pipe flow system; the supporting system is positioned under the pipe flow system and is used for supporting the pipe flow system and regulating the multi-angle transformation of the supported pipe flow system; and the data collecting system is used for detecting the fluid in the pipe flow system and collecting and arranging attribute parameter detecting data. The fluid migration researching device provided by the invention is capable of detecting multiphase fluid attribute parameters with solids and realizing multi-angle fluid migration research and fluid migration research under the condition of coupling a horizontal pipe and a vertical pipe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method and apparatus for fluid migration profiling

ActiveUS8326540B2Electric/magnetic detection for well-loggingConstructionsFluid migrationComputer science

The method for obtaining a fluid migration profile for a wellbore, including the steps of obtaining a static profile for a logged region of the wellbore, obtaining a dynamic profile for the logged region of the wellbore, digitally filtering the dynamic profile to remove frequency elements represented in the static profile, to provide a fluid migration profile, and storing the fluid migration profile on a computer-readable memory.

Owner:HIFI ENG

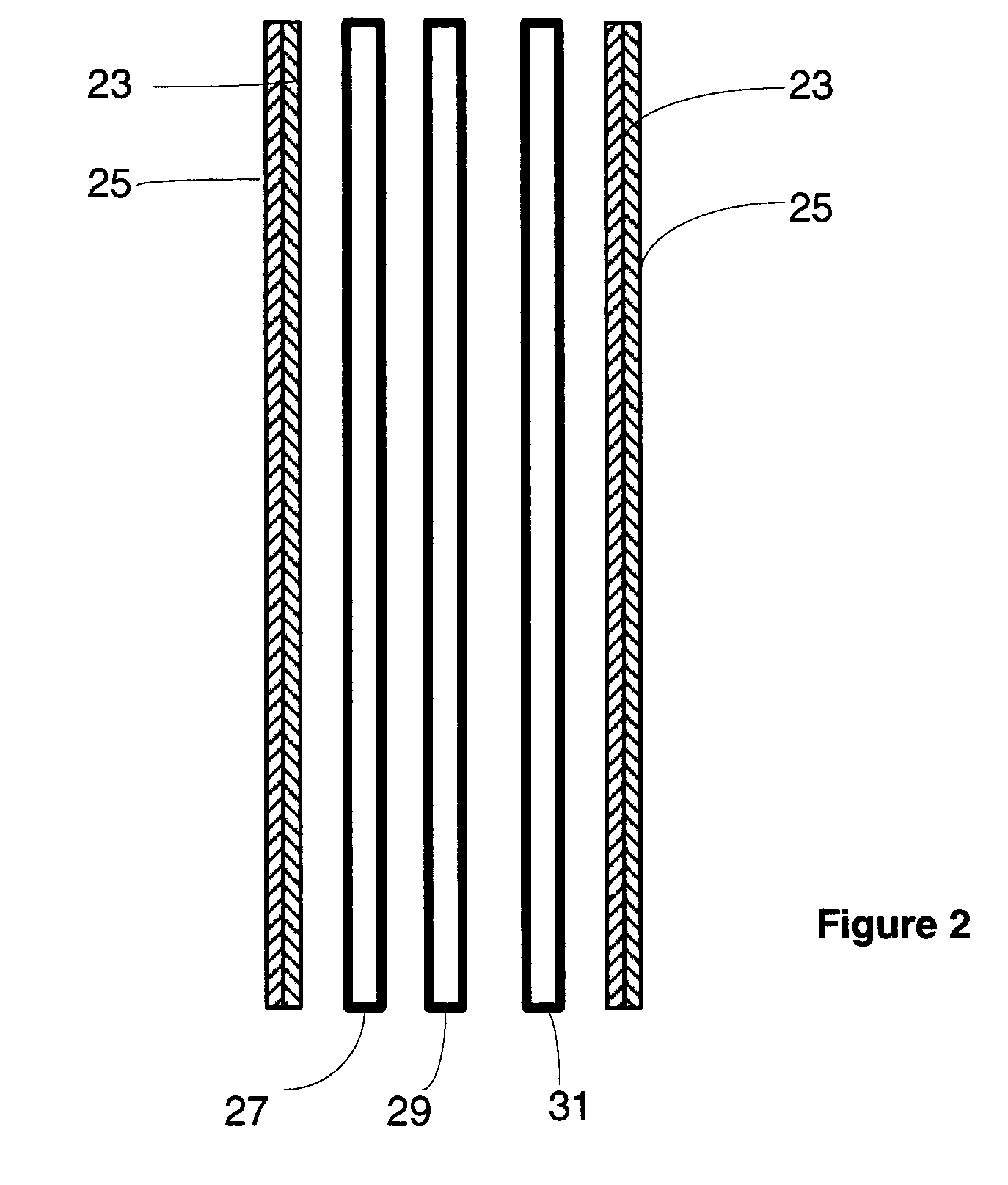

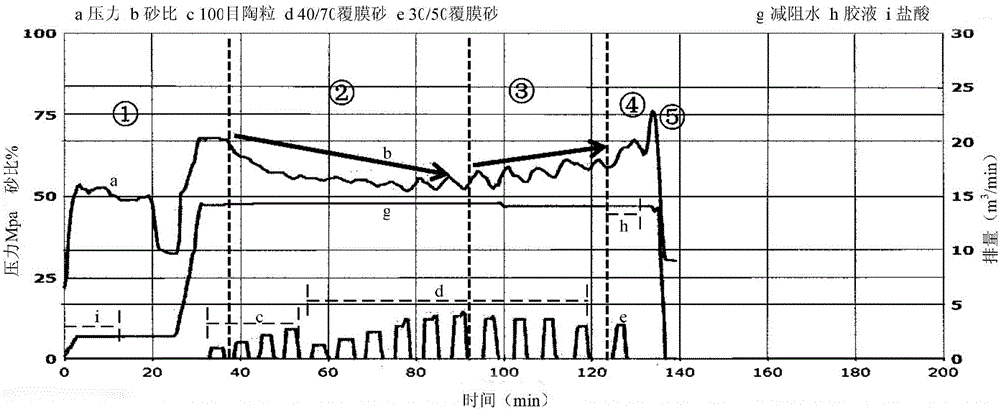

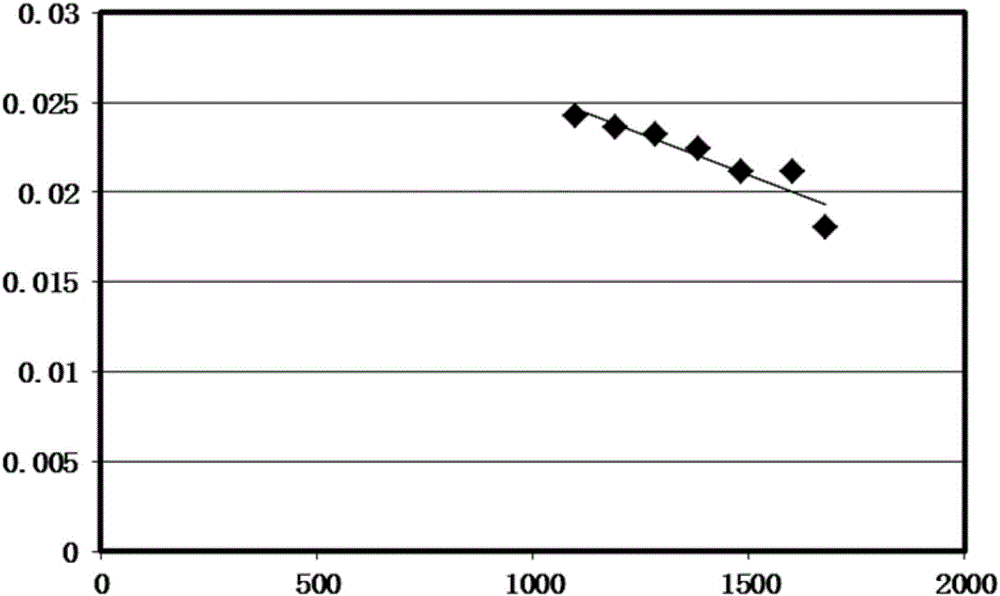

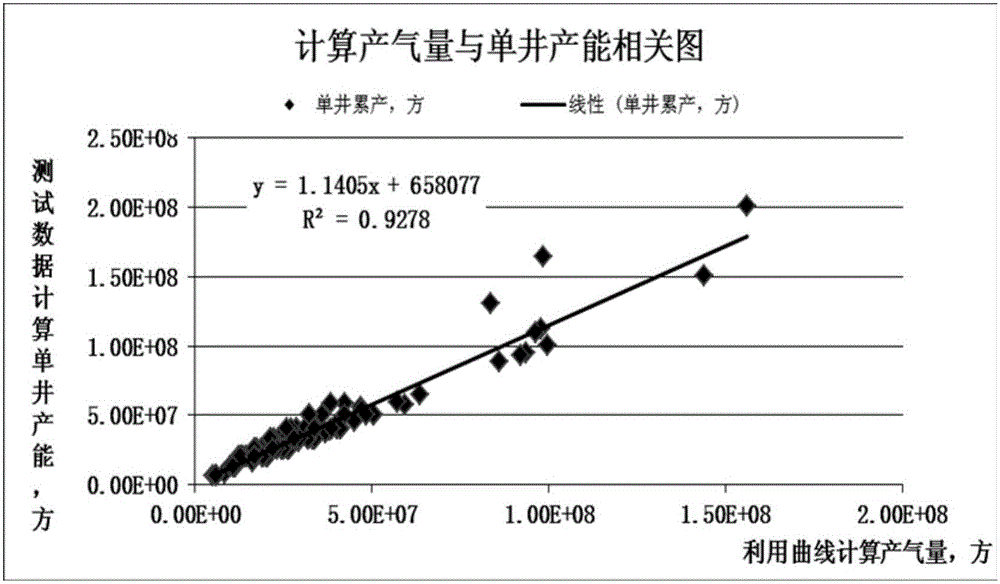

Shale gas reservoir single-well productivity calculation method

ActiveCN106227995ASolve the problem that the productivity of a single well cannot be accurately predictedAccurate calculationInformaticsSpecial data processing applicationsFluid migrationFracturing fluid

The invention relates to the technical field of shale gas and discloses a shale gas reservoir single-well productivity calculation method. The method includes: S1, according to a shale gas formation mechanism, fluid migration characteristics in a fracturing process and an ideal gas equation, deriving a gas-liquid displacement equation 1 / Pn=1 / Ps-1 / Pn*( Vi / Vs ), wherein Pn refers to well bottom gas pressure, Ps refers to well bottom liquid pressure, Vi refers to fracturing fluid compression volume, and Vs refers to fracturing fluid active volume; S2, according to a single-section fracturing construction curve and fracturing construction data of a horizontal shale gas well, drawing a linear regression curve of 1 / Pn and Vs, and working out a single-section productivity displacement factor Kj, a productivity coefficient Sj and a productivity index Dj; S3, according to the single-section productivity displacement factor Kj, the productivity coefficient Sj, the productivity index Dj and a well bottom pump stopping pressure Pj, calculating to obtain a single-section after-fracturing crack size SRVj and a single-section productivity Ej according to formulas as shown in the specification, and summing productivity of each single section to finally obtain the total productivity E of a single well. According to the shale gas reservoir single-well productivity calculation method, the total productivity of the single well can be calculated accurately.

Owner:CHINA PETROLEUM & CHEM CORP +1

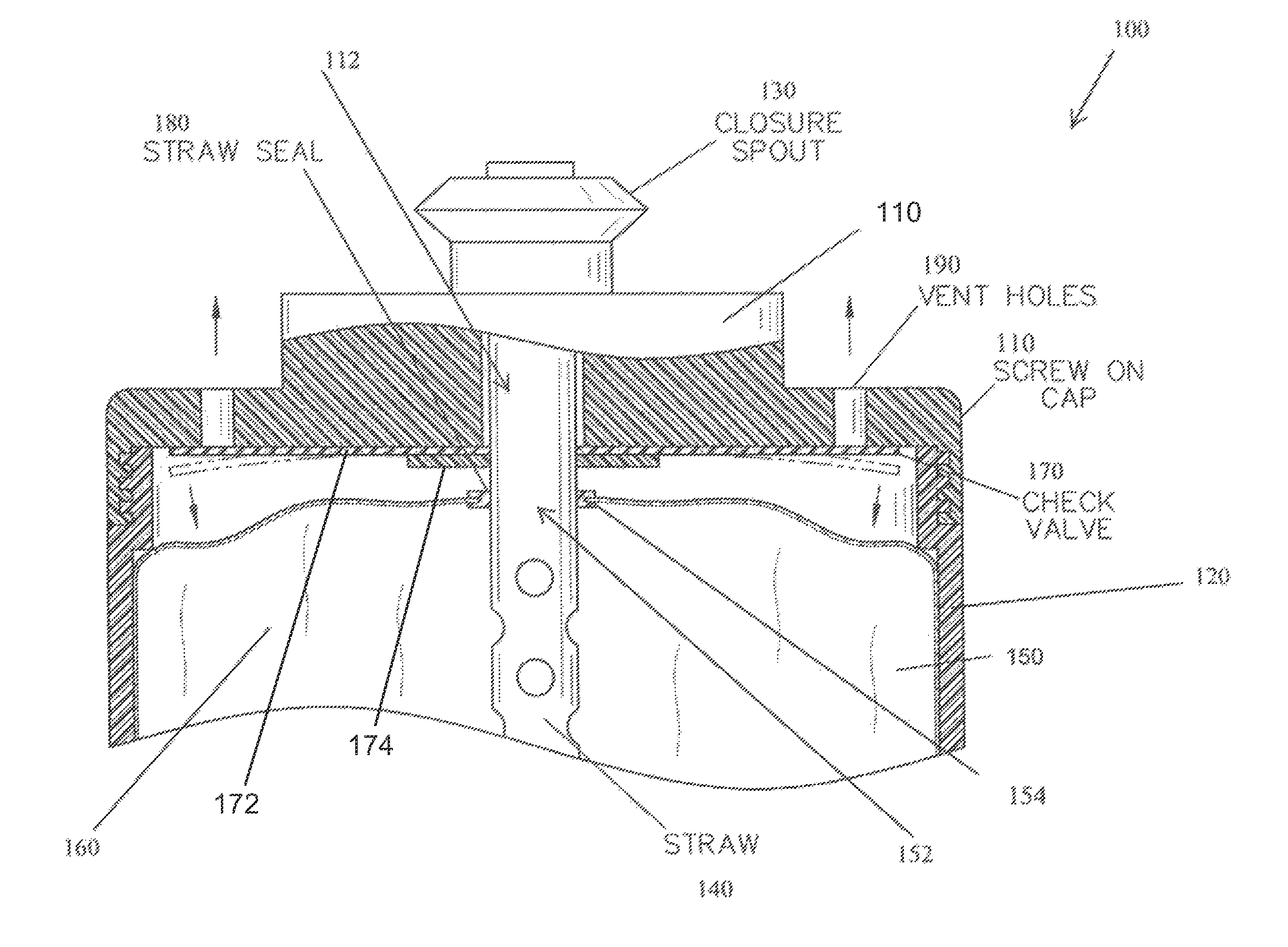

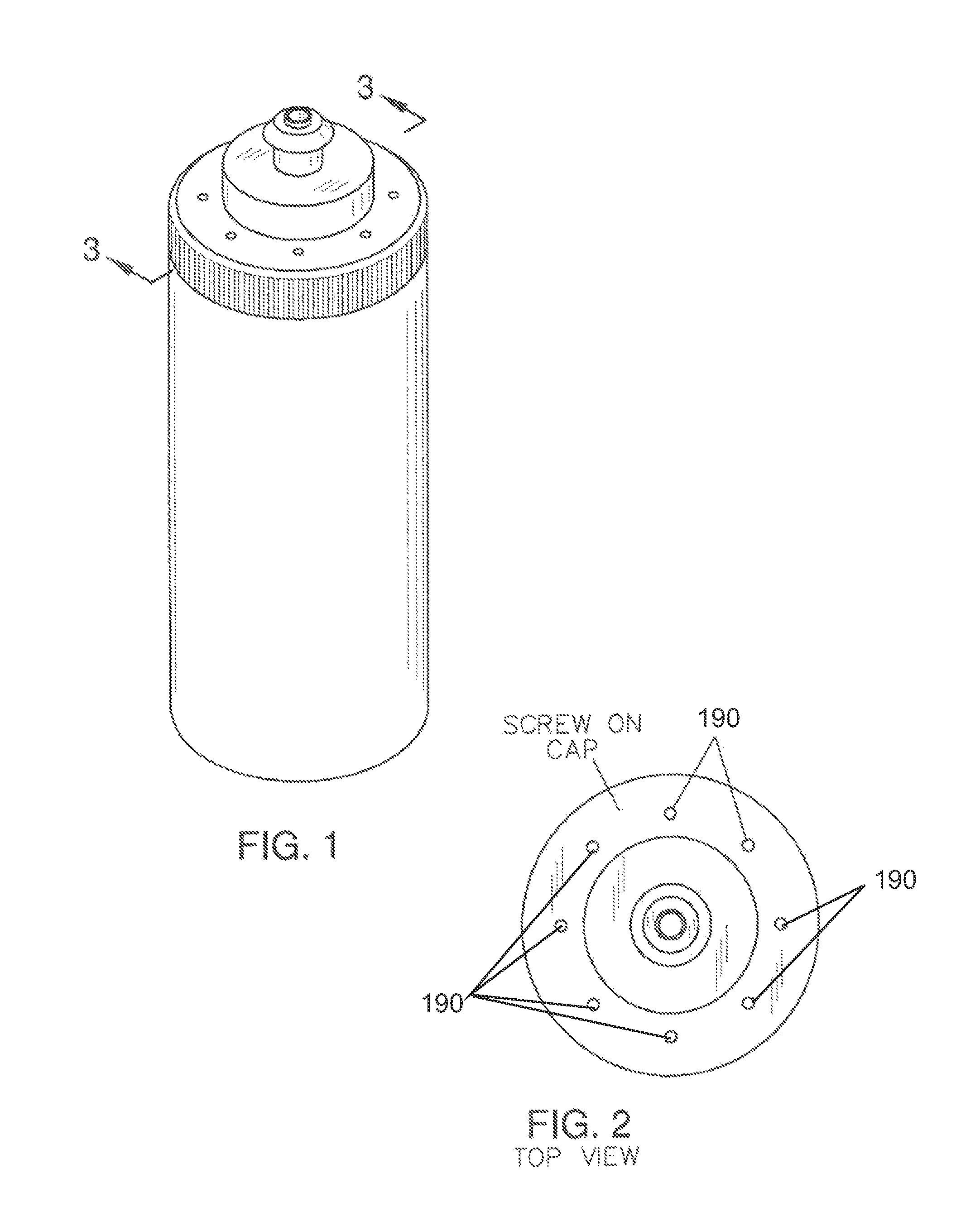

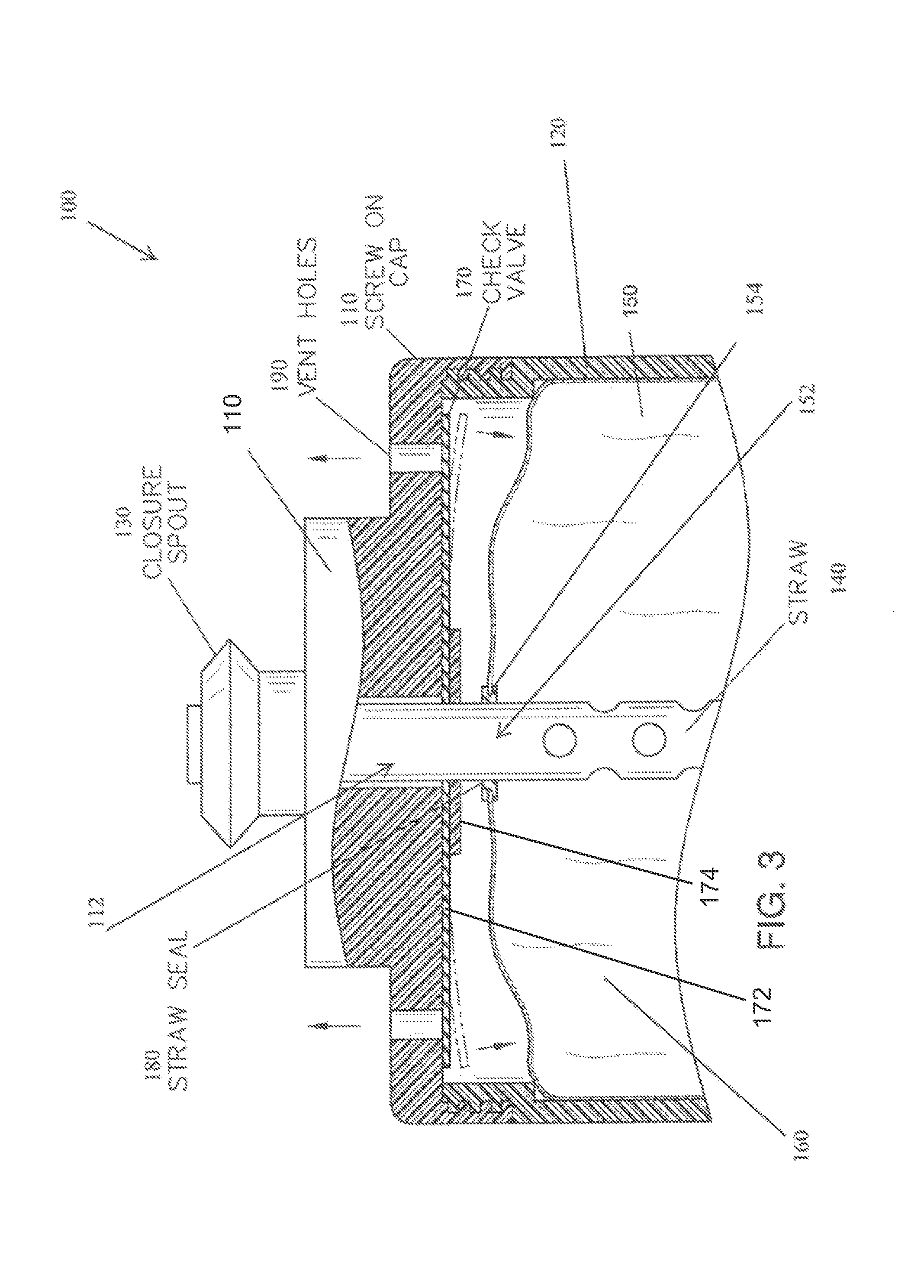

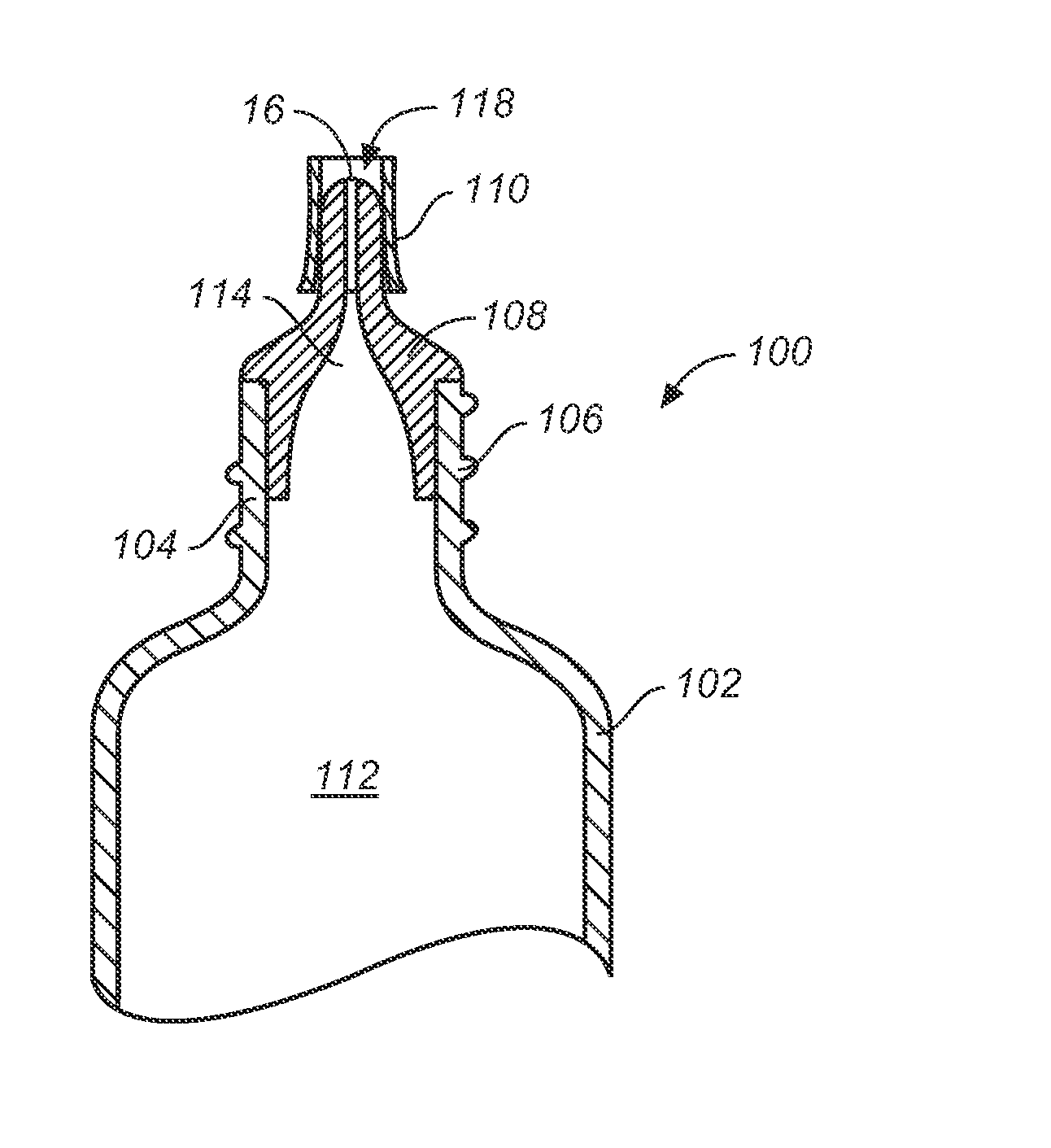

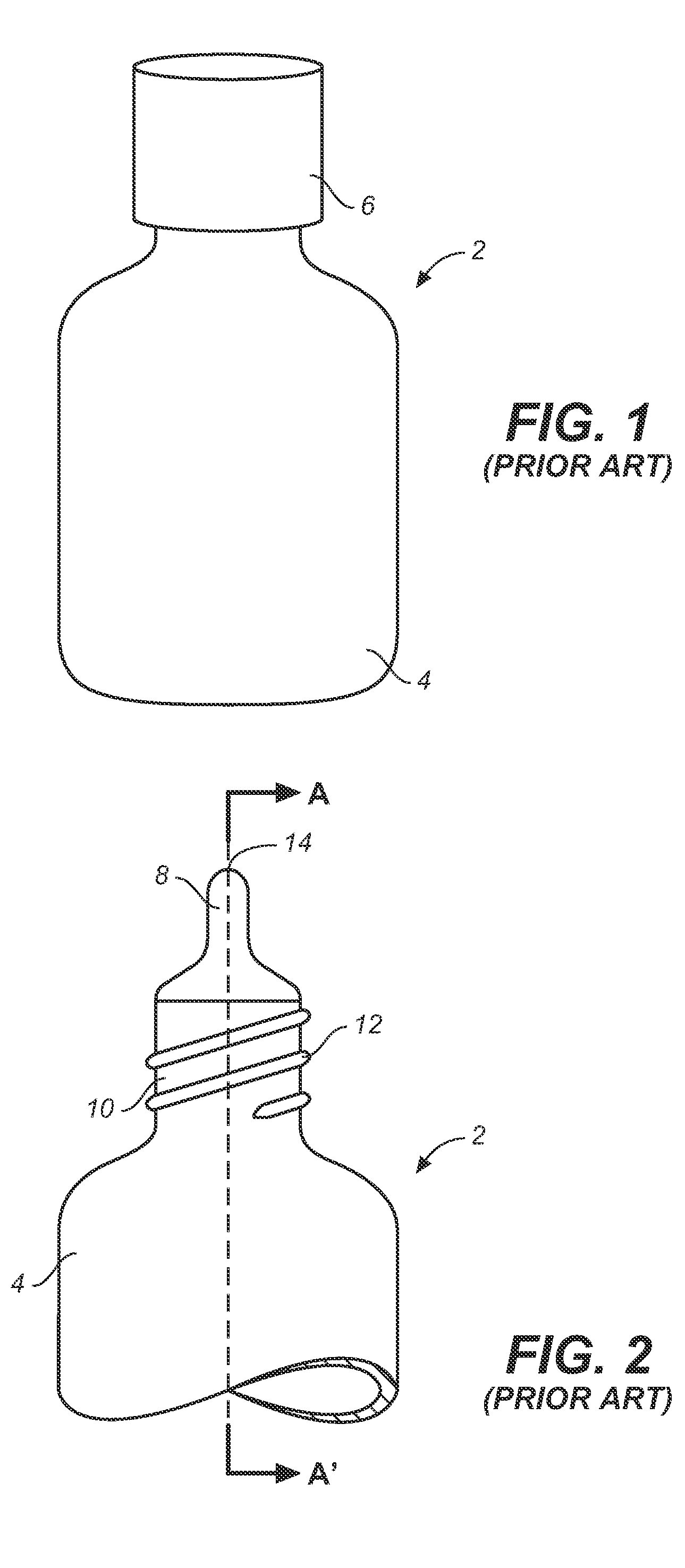

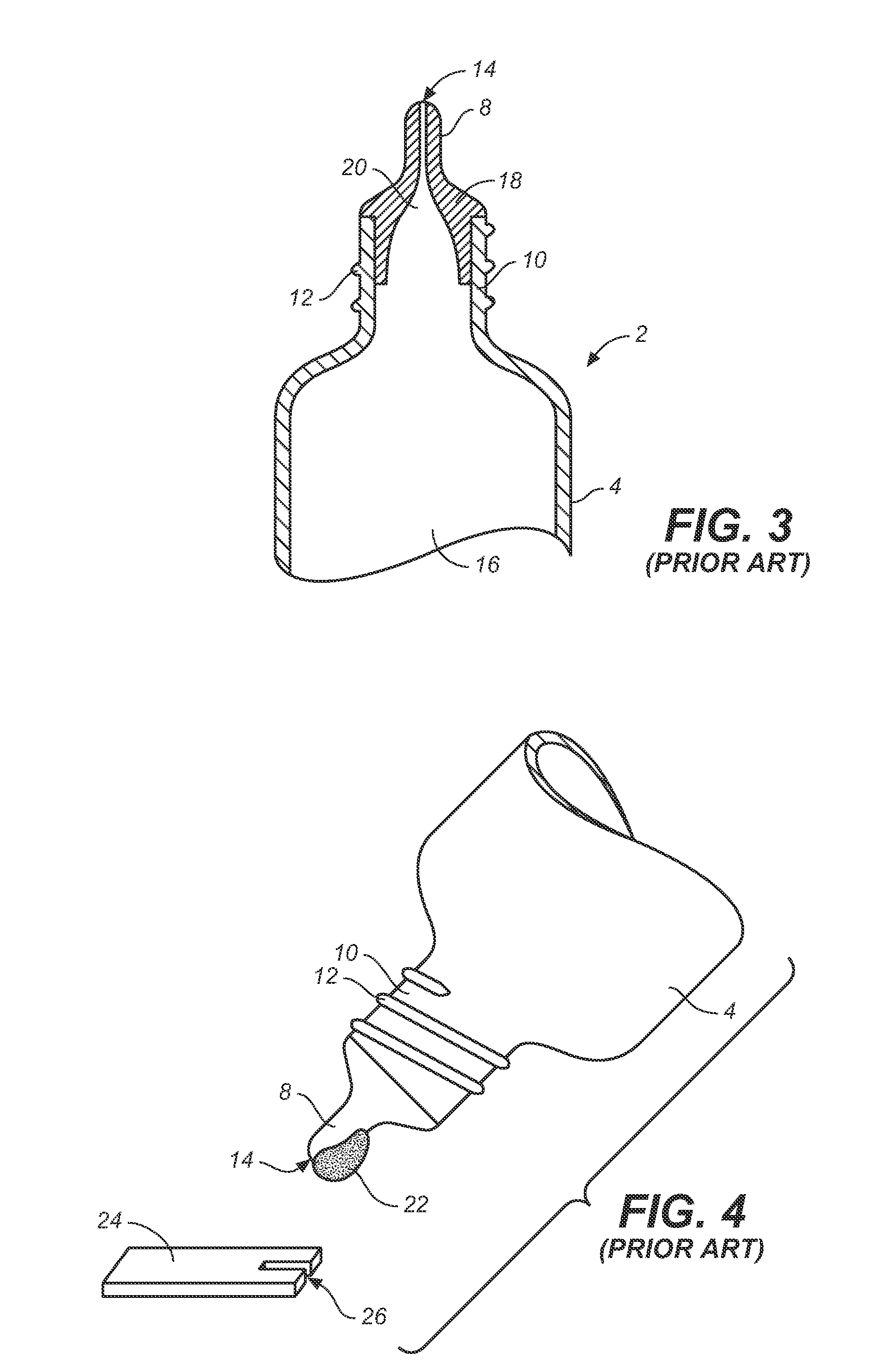

Liquid Dispensing Tip With Reservoir

InactiveUS20090101681A1Improve usabilityConfidenceClosuresLaboratory glasswaresFluid migrationEngineering

The present invention includes devices for containing and dispensing liquid solutions. The devices of the invention increase ease of sample volume control and, hence, application thereof while minimizing any sample spillage or fluid migration up the side of the dispensing tip. Furthermore, the devices provide ensure adequate sample volume.

Owner:LIFESCAN SCOTLAND

Single wall duct flashing panel

InactiveUS20160108611A1Inhibit migrationStrengthRoof covering using slabs/sheetsRoof covering using tiles/slatesFluid migrationEngineering

A duct flashing panel configured to provide weatherproofing for single wall ducts extending through the walls of a structure and having a terminal end extending outside of the structure. The duct flashing panel includes a panel body and an elastomeric collar sized and configured to circumferentially engage the exterior surface of the duct to form a fluid-tight seal between the duct and the collar to prevent fluid migration along the exterior of the duct. The collar includes an annular bead which provides rigidity and strength to the collar to urge the collar into compressive engagement with the exterior surface of the duct.

Owner:GILLERAN WILLIAM J

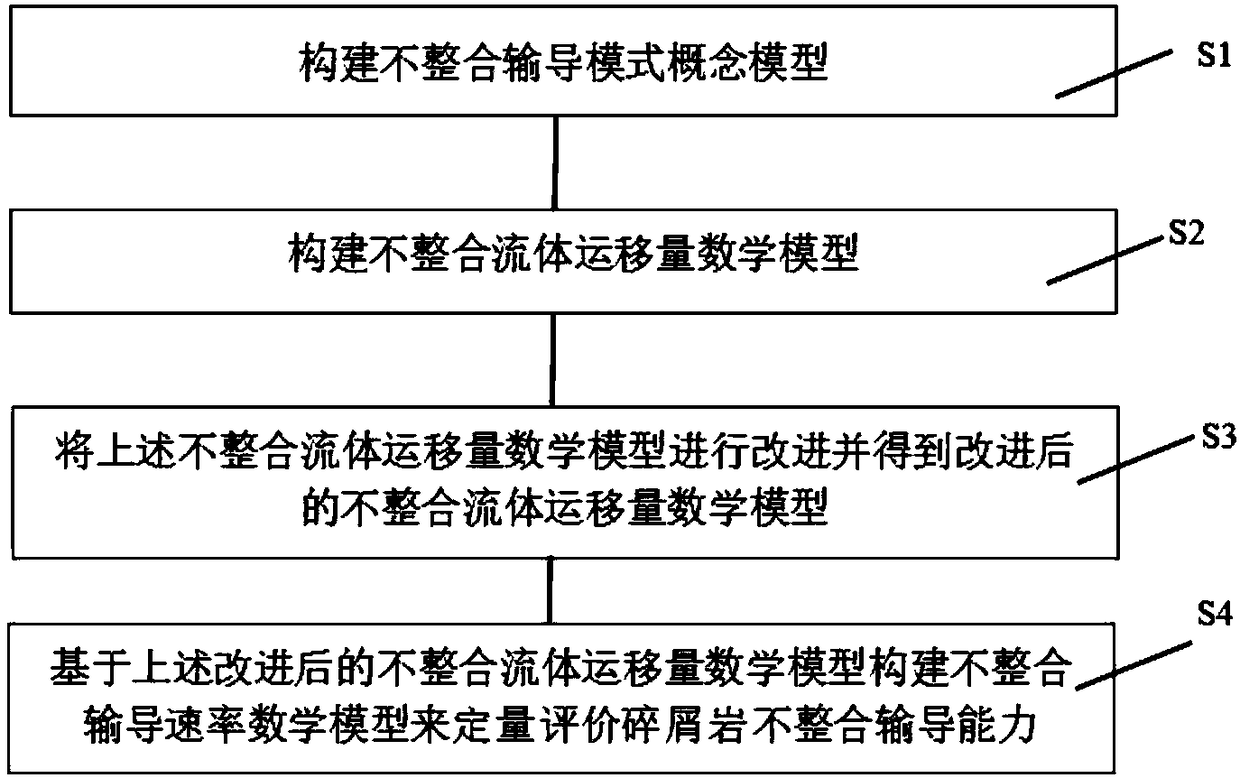

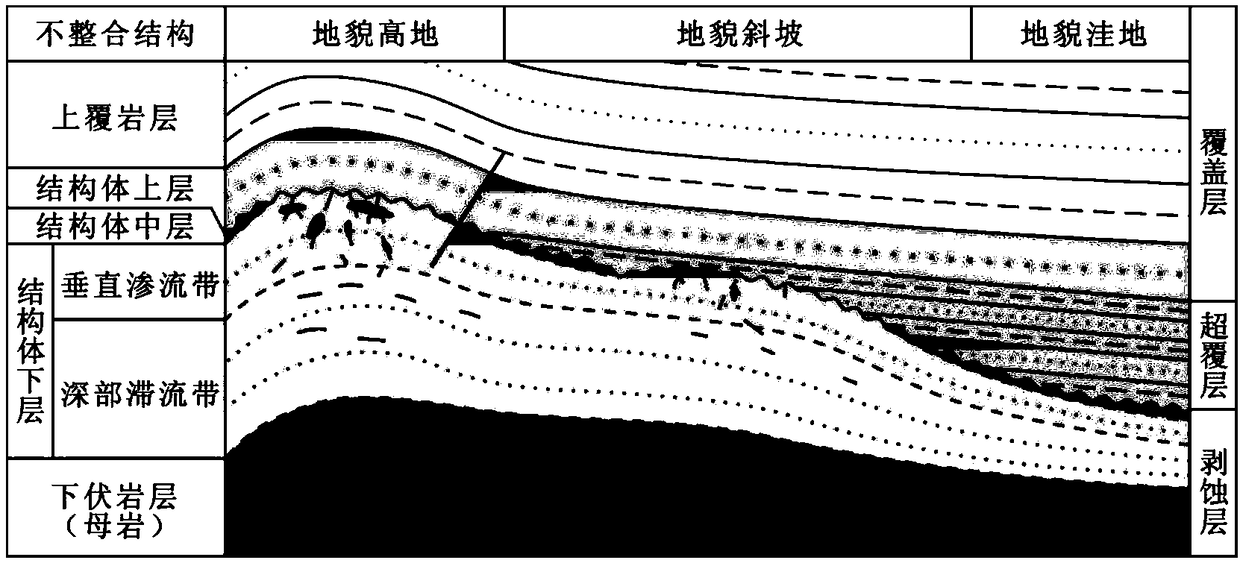

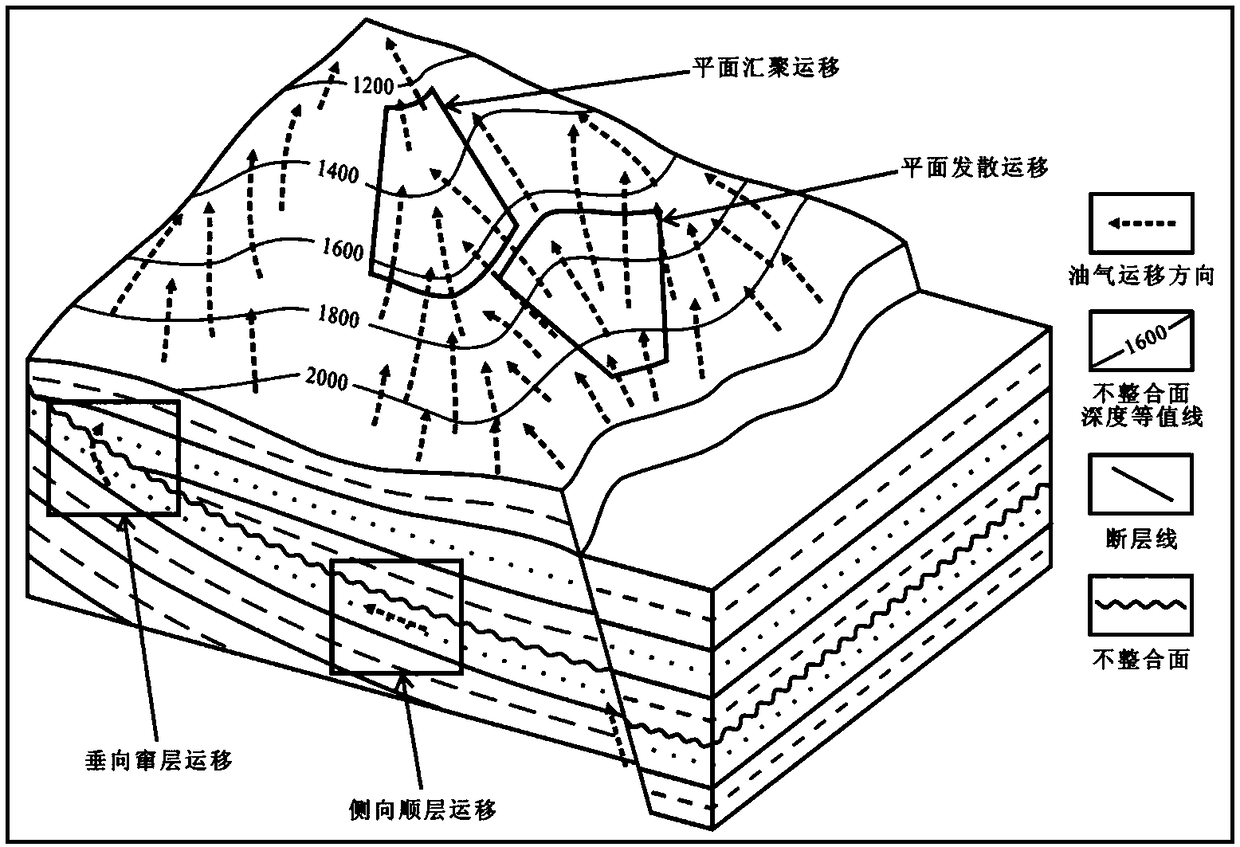

Quantitative evaluation method for unconformity conduction capability of clastic rock

InactiveCN108229089ASpecial data processing applicationsInformaticsFluid migrationGeological exploration

The invention discloses a quantitative evaluation method for unconformity conduction capability of clastic rock. According to the method, firstly, an unconformity conduction pattern concept model is constructed; secondly, an unconformity fluid migration amount mathematic model is constructed; thirdly, the unconformity fluid migration amount mathematic model is improved to obtain an improved unconformity fluid migration amount mathematic model; finally, on the basis of the improved unconformity fluid migration amount mathematic model, an unconformity conduction speed rate mathematic model is constructed to carry out quantitative evaluation on the unconformity conduction capability of the clastic rock. The method has the advantages that accurate requirements for the quantitative evaluation on the unconformity conduction capability of the clastic rock can be met, and the method can be widely applied to a geological exploration and development evaluation domain of oil and gas resources.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Fluid migration shut-off

A downhole assembly, including a line operatively arranged to carry a first fluid, and a trap arranged in fluid communication with the line, the trap operatively arranged to enable the first fluid to flow in a first direction, while capturing a second fluid in a compartment, thereby preventing migration of the second fluid through the line in a second direction opposite to the first direction.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com