Patents

Literature

48results about How to "Shorten thickening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

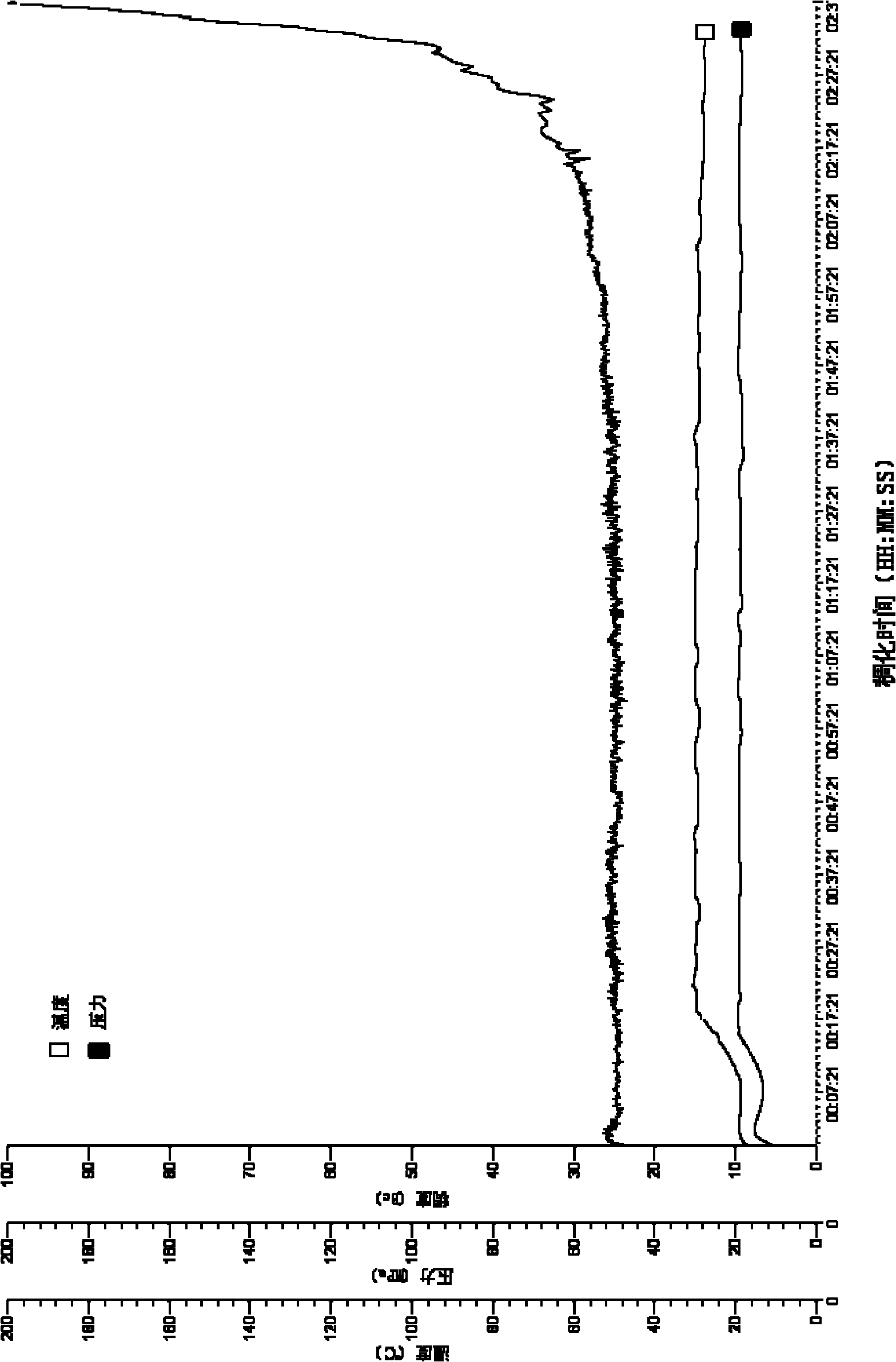

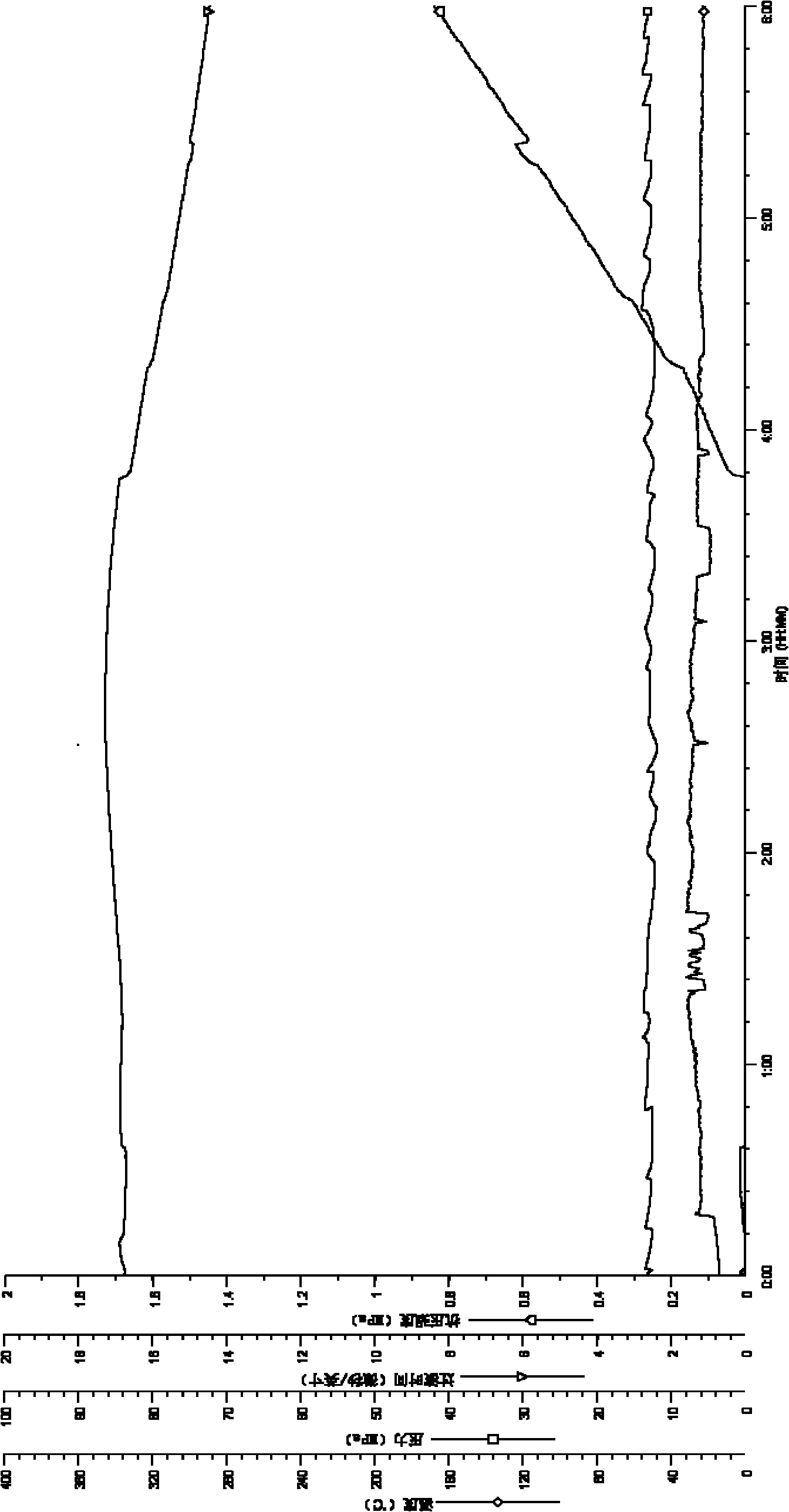

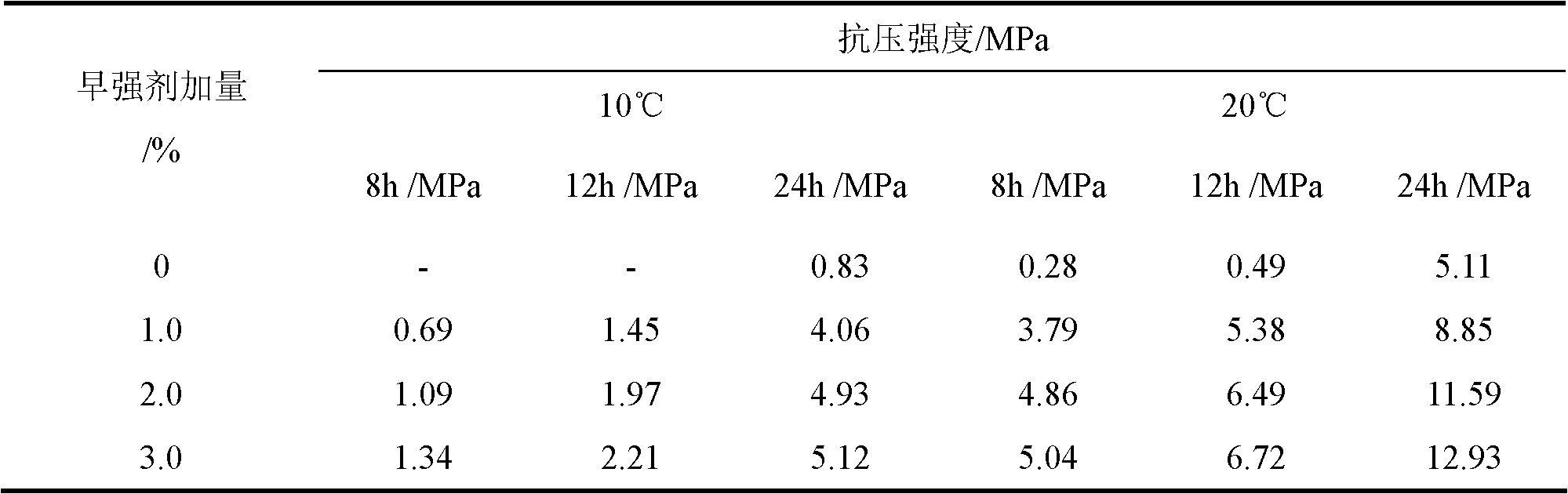

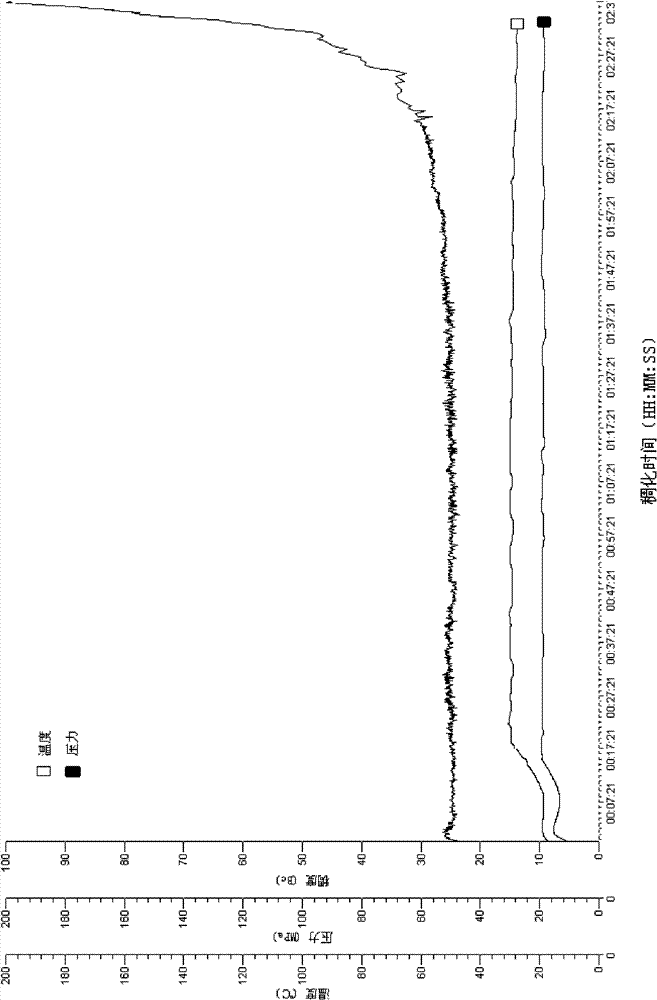

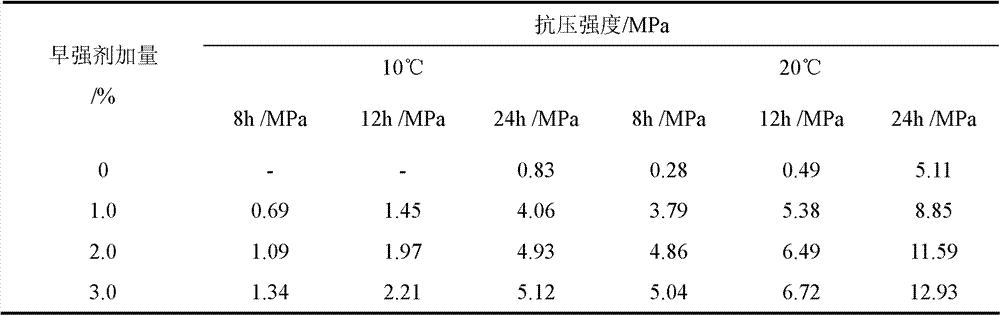

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

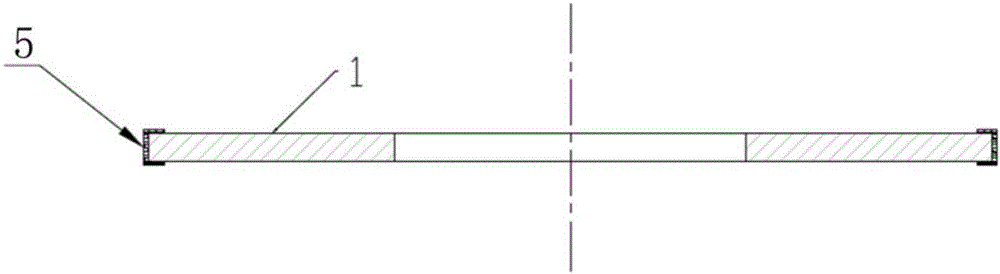

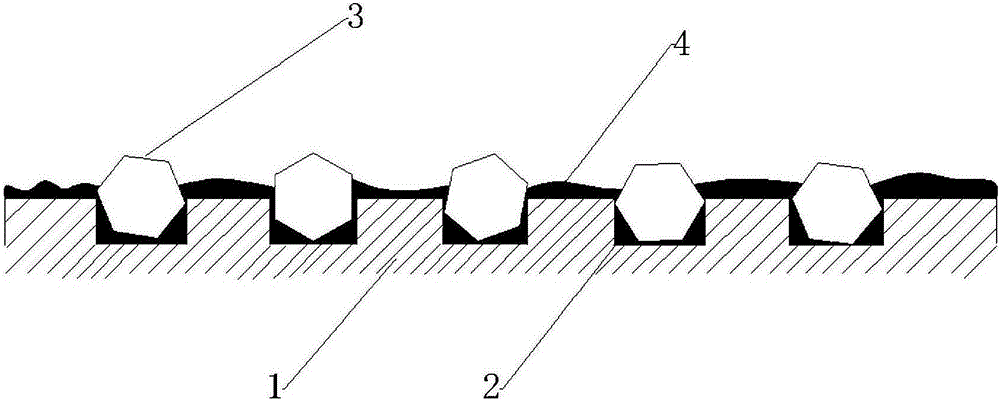

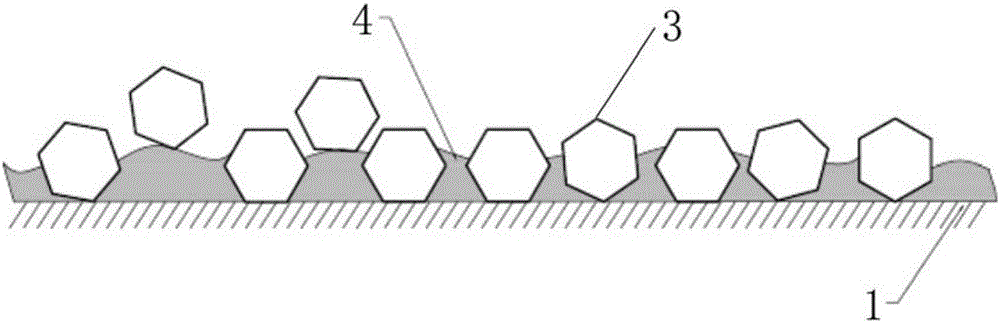

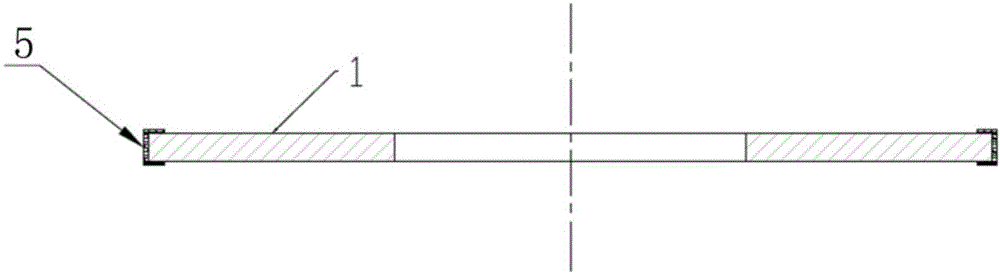

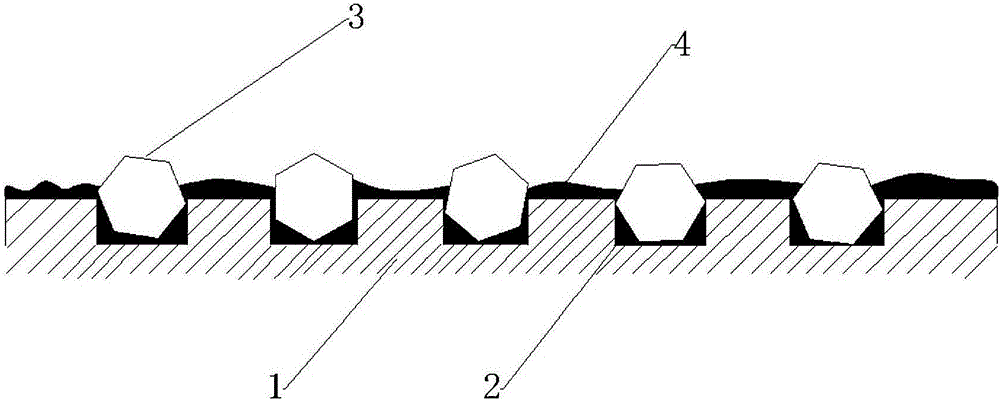

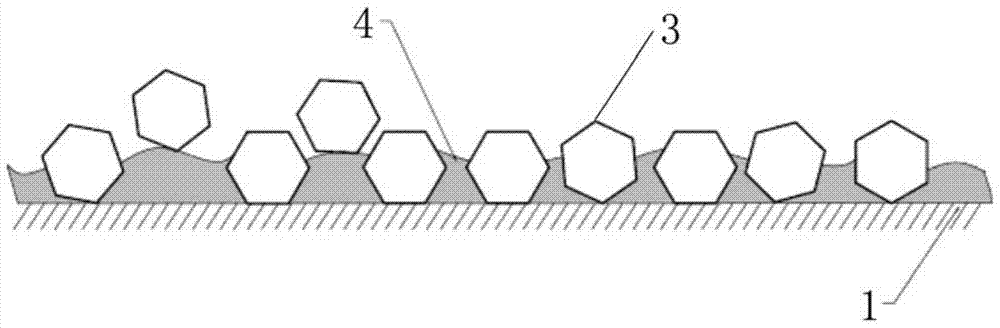

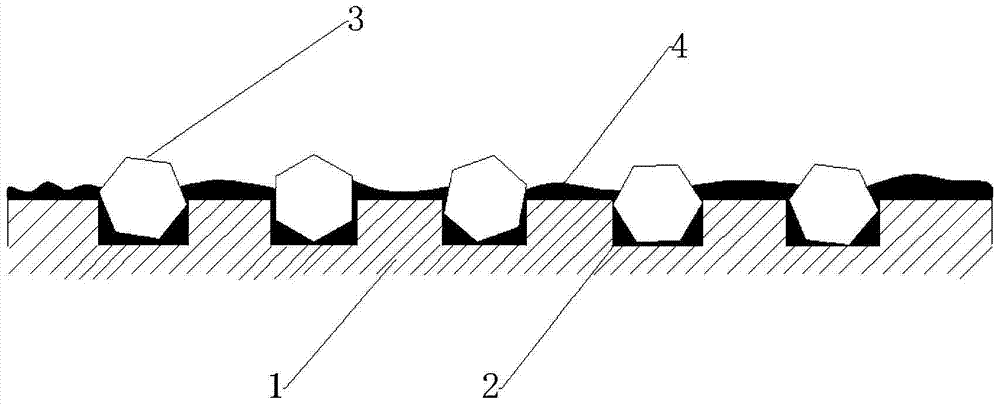

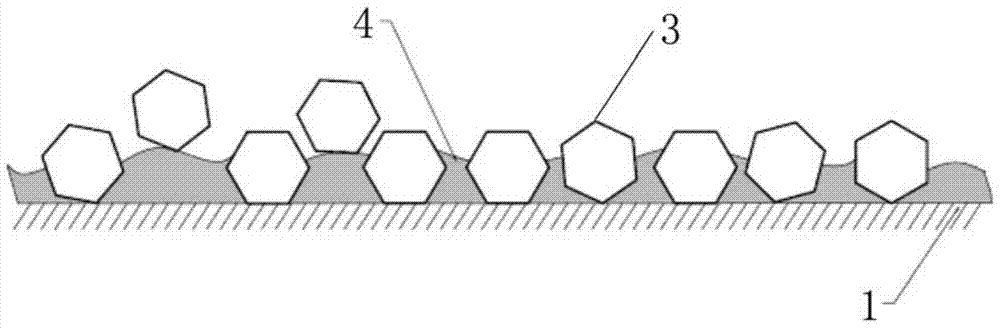

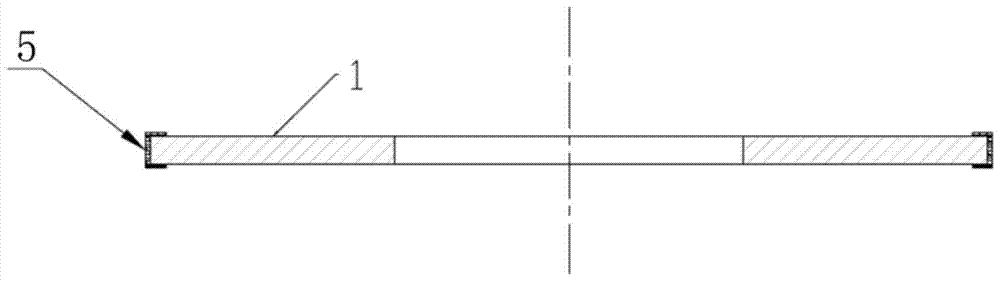

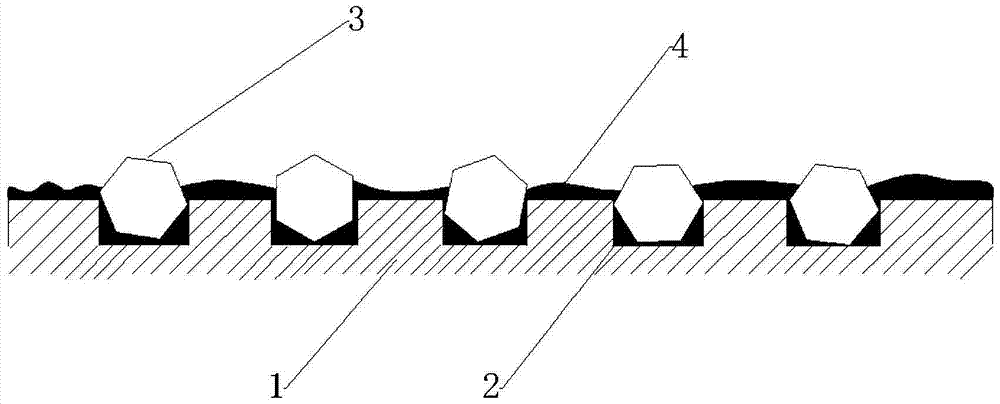

Electroplated diamond grinding wheel capable of orderly arranging abrasive materials

ActiveCN105196196AImprove gripExtended service lifeAbrasion apparatusGrinding devicesDiamond grindingDisorganized EEG

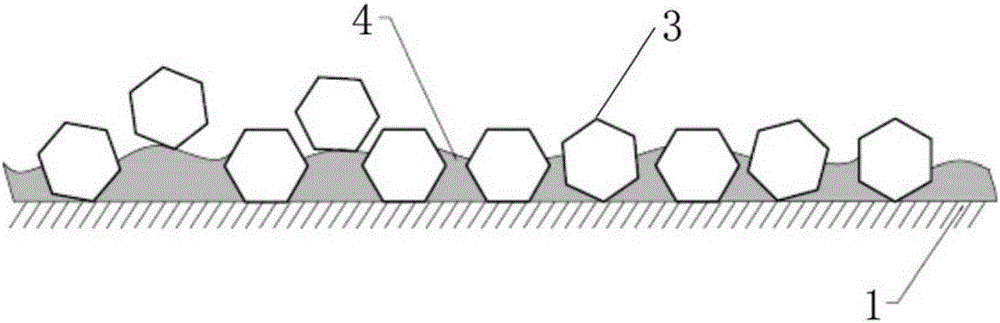

The invention discloses an electroplated diamond grinding wheel capable of orderly arranging abrasive materials, which comprises a grinding wheel base body and an abrasive material layer, wherein blind holes which are orderly arranged are arranged on the surface of the grinding wheel base body, the abrasive material layer comprises abrasive materials and a metal coating, the roots of the abrasive materials are embedded into the blind holes, and the metal coating is deposited on the surface of the grinding wheel base body and in the blind holes and is used to solidify the abrasive materials. The electroplated diamond grinding wheel capable of orderly arranging the abrasive materials achieves to regularly and orderly arrange the abrasive materials on the surface of the grinding wheel base body, and effectively solves the problems that the abrasive materials are rugged and chaotic to distribute in abrasive material layers of traditional diamond grinding wheels. The electroplated diamond grinding wheel capable of orderly arranging the abrasive materials improves holding force of coatings and base bodies to the abrasive materials by utilizing the squeezing and filling actions of diamond abrasive materials to the blind holes, and prolongs life 15%-20%. The abrasive materials are orderly arranged on the surface of the grinding wheel base body to form an excellent chip removal path, prevent having a phenomenon that process workpieces are burnt because of blocking of abrasive dusts, and improve grinding quality.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Method for preparing electroplated diamond grinding wheel with orderly arranged abrasive materials

InactiveCN105154958AImprove gripExtended service lifeElectrolytic coatingsLiquid/solution decomposition chemical coatingChemical platingElectroplating

The invention discloses a method for preparing an electroplated diamond grinding wheel with orderly arranged abrasive materials. The method comprises the following steps of forming orderly arranged blind holes in the surface of a grinding wheel substrate to obtain a processed substrate; subjecting the processed substrate to chemical plating to deposit a metal pre-plating layer on the bottoms and the side walls of the blind holes to obtain a pre-plated substrate; placing the diamond abrasive materials on the surface of the pre-plated substrate and carrying out rolling to embed the lower parts of the abrasive materials into the blind holes, so as to obtain a sanded substrate; activating the sanded substrate and electroplating the sanded substrate to deposit metal plating layers on the surface of the grinding wheel substrate and in the blind holes, thereby finally obtaining the electroplated diamond grinding wheel. According to the invention, the diamond abrasive materials can be regularly and orderly arranged on the surface of the grinding wheel substrate; the holding force of the plating layer to the diamond abrasive materials in the electroplating consolidation step is reinforced; the holding force of the diamond grinding wheel to the abrasive materials is strong; the service life is long; the abrasive materials are regularly and orderly arranged on the surface of the grinding wheel substrate; and the grinding quality and the grinding efficiency are increased. Compared with diamond abrasive materials of a same particle size, the abrasive materials in the invention are advantaged in that the electroplating time is shortened by 20-50% than that in the traditional technique, and the uniformity of the electroplating layer is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

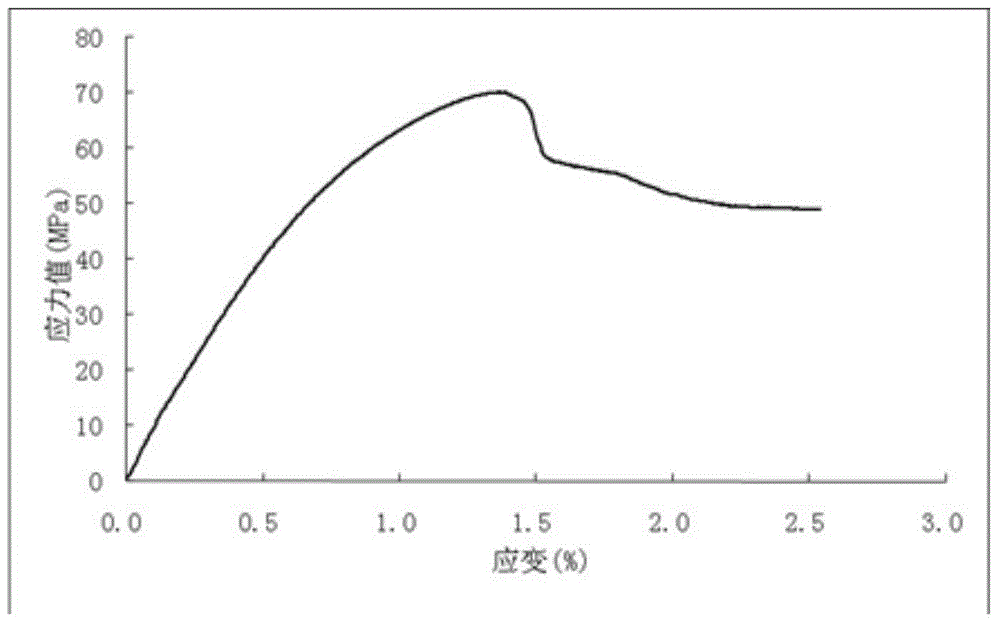

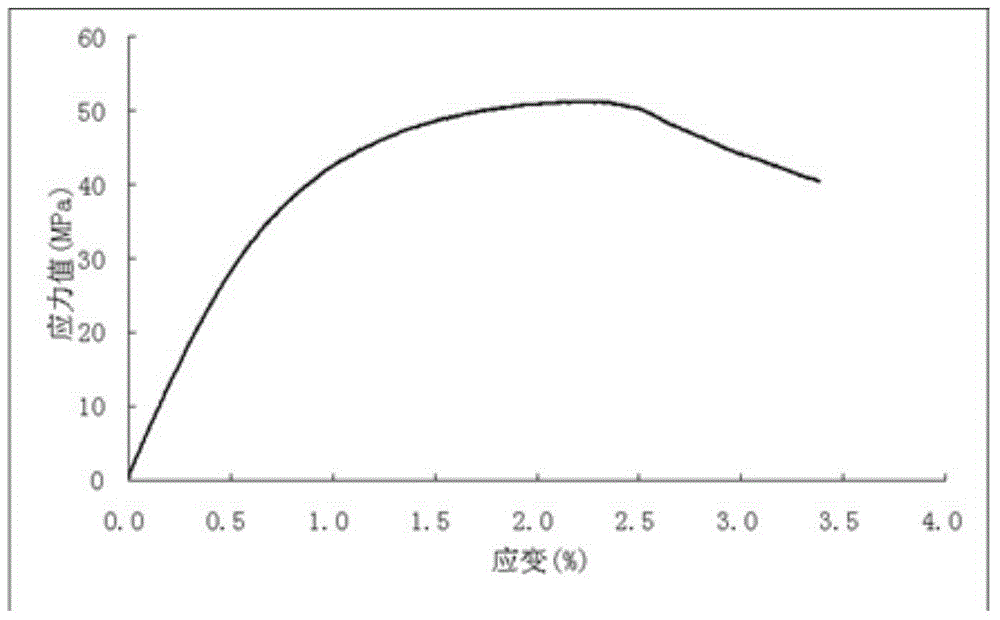

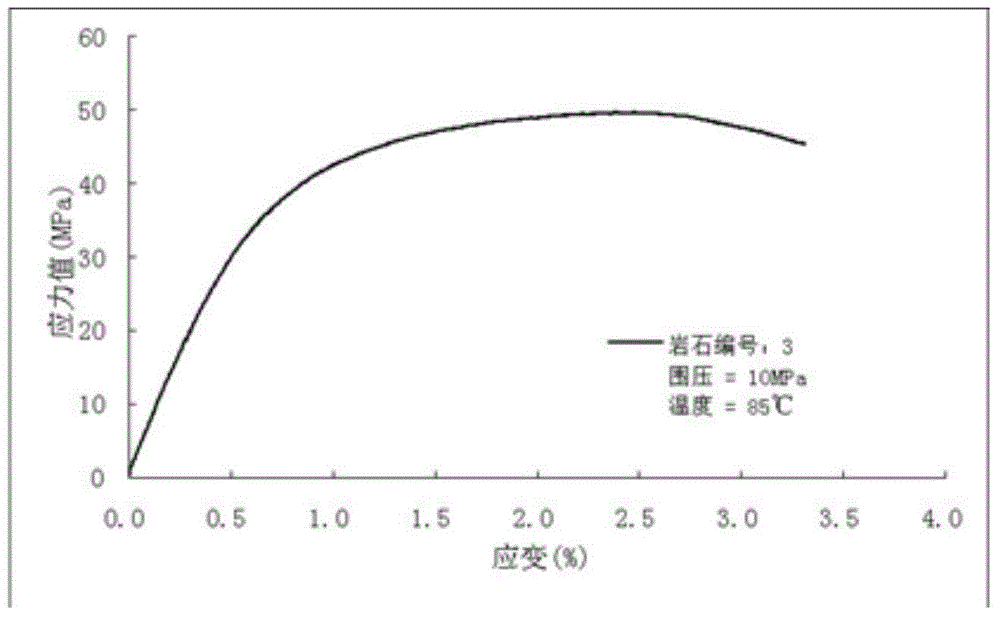

Horizontal well cement paste

ActiveCN104650836AZero analysis waterReduce dehydrationDrilling compositionStress–strain curveYoung's modulus

The invention provides a horizontal well cement paste, which comprises the following components in percentage by weight: 0.5%-2.5% of a flexibilizer GZR, 1%-3% of a GFC expansion agent, 0.04%-0.08% of a GH retarder and the balance of cement, zero free water and low-loss water, wherein the formed set cement does not shrink, and has a certain expansion rate and good mechanical property, and shows excellent tenacity. The set cement is high in breaking strength, and small in crumbly coefficient; the tenacity coefficient is increased; the young modulus of the set cement is decreased; the poisson ratio is increased; the bending radius of the set cement is reduced; a triaxial stress strain curve shows good elastoplasticity; the anti-channeling ability is improved; the thickening time is shortened; the time and the fluid channeling rate of a formation fluid intruding into the cement paste are reduced; the paste is uniform, stable and good in mobility; reduction of annular flow resistance is facilitated; and the displacement efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement

ActiveCN106186777AImprove anti-channeling abilityImprove top strengthDrilling compositionOXALIC ACID DIHYDRATEApatite

The invention relates to a wide spectrum chlorine-free coagulation accelerating early strength agent for oil field oil well cement. The early strength agent comprises the following raw materials in parts by weight: 1 to 1.5 parts of sodium salts, 1 to 1.5 parts of calcium salts, 1 to 1.5 parts of aluminum salts, and 1 to 1.5 parts of other materials, wherein other materials are one or more of hydroxyl apatite, meta-kaolin, magnesium trisilicate, magnesium oxide, strontium sulfate, strontium carbonate, strontium nitrate, lithium carbonate, and oxalic acid. The provided early strength agent is stable, and has an excellent coagulation accelerating performance and early strength property; the early strength is high, the strength development is fast, the thickening transition time and primary-final setting transition time are short; and the early strength agent is suitable for various cement slurry systems such as cement slurry system with a wide temperature range and large temperature difference, AMPS cement slurry system, and the like.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Oil well cement coagulation-accelerating early strength agent and preparation method thereof

InactiveCN105349126AShorten thickening timeFreeze fastDrilling compositionInorganic saltsPhysical chemistry

The invention relates to an oil well cement coagulation-accelerating early strength agent and a preparation method thereof, and belongs to the technical field of oil well cement additives. The early strength agent is prepared from, by weight, 10-50 parts of gypsum powder, 10-40 parts of quick lime and 10-50 parts of aluminum salt. The purposes that the agent is quite convenient to use, and the synergistic interaction of organic salt and inorganic salt is sufficiently utilized can be achieved, and cement paste can rapidly set at low temperature.

Owner:CHENGDU CHUANFENG CHEM ENG CO LTD

Chlorine-free fluid migration prevention early strength agent for oil well cement, and preparation method and application thereof

InactiveCN106554765AShorten thickening timeHigh strengthDrilling compositionFluid migrationWater source

The invention provides a chlorine-free fluid migration prevention early strength agent for oil well cement. The chlorine-free fluid migration prevention early strength agent comprises, by mass, 33-48% of a coagulation accelerator, 20-25% of an expanding agent, 1-2% of an organic early strength agent, and the balance of a filler. The chlorine-free fluid migration prevention early strength agent effectively improves the early strength of set cement, contains no chloride ions or other corrosive ions, has no corrosion effect on sleeves or the set cement, avoids catalytic corrosion of Cl<-> to the sleeves and pollution of the Cl<-> to an underground water source, prolongs the exploitation life of a single well, truly realizes harmlessness of cementing additives, greatly shortens the well cementation cement curing time, shortens the cement curing time, meets performance requirements of cement mortar and the set cement in well cementation construction process, effectively protects sleeves, protects oil and gas reservoirs, and improves the productivity of the single well.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG +1

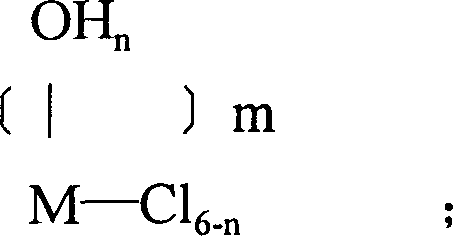

Early strength agent composition and preparation method thereof, cement composition and uses of above

The present invention relates to an early strength agent composition, which comprises the following materials, by weight, 15-40 parts of a soluble organic calcium compound, 5-25 parts of calcium metaaluminate (Ca(AlO2)2), 25-55 parts of a metal chloride, and 10-28 parts of an alkali metal carbonate (M2CO3), wherein M is an alkali metal. The present invention further relates to a preparation method for the early strength agent composition, a cement composition containing the early strength agent composition. The present invention further relates to uses of the compositions in cementing application.

Owner:CHINA UNITED COALBED METHANE +1

Well cementation material suitable for low-temperature environment and production method of well cementation material

ActiveCN110105030AImprove liquidity impactReduce the rate of hydrationDrilling compositionPortland cementUltimate tensile strength

The invention provides a well cementation material suitable for a low-temperature environment and a production method of the well cementation material. The well cementation material is prepared by mainly mixing 75-89% of portland cement clinker, 1-8% of sulphoaluminate cement clinker, 1-8% of high-alumina cement clinker, 2-4% of dihydrate gypsum, 0.5-1.2% of a dispersing agent and 1-4% of a retarder by weight. The well cementation material has the advantages that selected raw materials of raw meal cooperate with one another, on the basis of meeting the early strength, the later strength is ensured, the hydration rate is also slowed down to a certain extent, the setting time is prolonged, time guarantee is provided for radial grouting, and the risk ratio of blockage caused by the generationof cement plugs during grouting is reduced.

Owner:葛洲坝石门特种水泥有限公司

Aerated concrete blocks added with high chlorine silicon slag slurry

The invention relates to reuse of wastes, in particular relates to an application of waste residues in aerated concrete blocks and adjustment in production of the aerated concrete blocks. According to the invention, coal ash is replaced by high chlorine silicon slag slurry to provide strength subsidy after steam curing. Meanwhile, part of stone powder is replaced by the high chlorine silicon slag slurry, so that the dosage of limestones or quartz sand can be saved. The high chlorine silicon slag slurry mainly exists in form of fine silicon oxide and sodium chloride, and the specific surface area even can reach 300-350 sq / g, the use amount of the stone powder can be reduced since part of stone powder is partially replaced, and the energy consumption and the cost caused by a grinding process are reduced. By controlling the specific surface area (220+ / -10mm) of the mixed slurry and keeping a certain density, the problem of insufficient foaming or collapse as the slurry is too thick or too thin is solved. By taking an aluminum powder single product as a foaming agent, a compound foaming process of combining the aluminum powder with part of K12(lauryl sodium sulfate) or sodium dodecyl sulfate can be adopted. The mass fraction of the aluminum powder to K12 is 8: 2 or 9: 1. The uniformity and stability of bubbles are better. By adjusting the mass fraction, the foaming speed and controllability are higher. According to the invention, a foam stabilizer is also introduced, for example, resins, acacia gum, bone glue and the like, so that the production quality stability is guaranteed.

Owner:云南巧消渣科技有限公司

Clean fracturing fluid

ActiveCN106336862AEliminate water quality chemical treatment processReduce operating costsDrilling compositionChemical treatmentAcid fracturing

The invention provides a clean fracturing fluid, which comprises the following ingredients (by weight): 2-4% of a densifier, 0-8% of potassium chloride, 0-10% of a modifier, 2-5% of a temperature-resistant reinforcing agent and the rest of fluid preparation water. The fracturing fluid can adopt acidic or alkaline fresh water or highly saline acid fracturing backflow fluid. After mechanical impurity removal treatment, highly saline backflow fluid can be used in fracturing fluid preparation of the next well without adjusting fluid preparation water quality in advance. Then, water quality chemical treatment process is omitted, and operating cost is greatly reduced. During site operation, efficient sand-carrying of the fracturing fluid is realized through a continuous mixing mode. Therefore, acid fracturing modification of a reservoir stratum and no falling of spent liquor during the whole oil and gas testing process are achieved, and ''zero pollution'' of borehole operation site is realized. The invention is helpful for cleaning and efficient production.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Water absorption lightening material for cementing wells and application of material

The invention discloses a water absorption lightening material for cementing wells. The material comprises, in weight percent, 20-30% of fly ash with different particle diameters, 30-40% of volcanic ash with different particle diameters, 2-5% of inorganic gel, 1-4% of nano-silicon dioxide and 25-35% of sepiolite powder. The raw materials are mixed to form the material. The particle diameter ranging from 10 nanometers to 100 nanometers accounts for 1%-2%; the particle diameter ranging from 1 micrometer to 10 micrometers accounts for 10%-20%; the particle diameter ranging from 10 micrometers to50 micrometers accounts for 40%-60%; the particle diameter ranging from 50 micrometers to 150 micrometers accounts for 10%-30%. Cement paste prepared from the water absorption lightening material canform more compact cement stones, the strength of low-density cement paste can be remarkably improved, the cement paste has a certain suspension stability, and the sedimentation stability of the cementpaste is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Chloride-free coagulating early strength agent for oil well cement and preparation method and application of agent

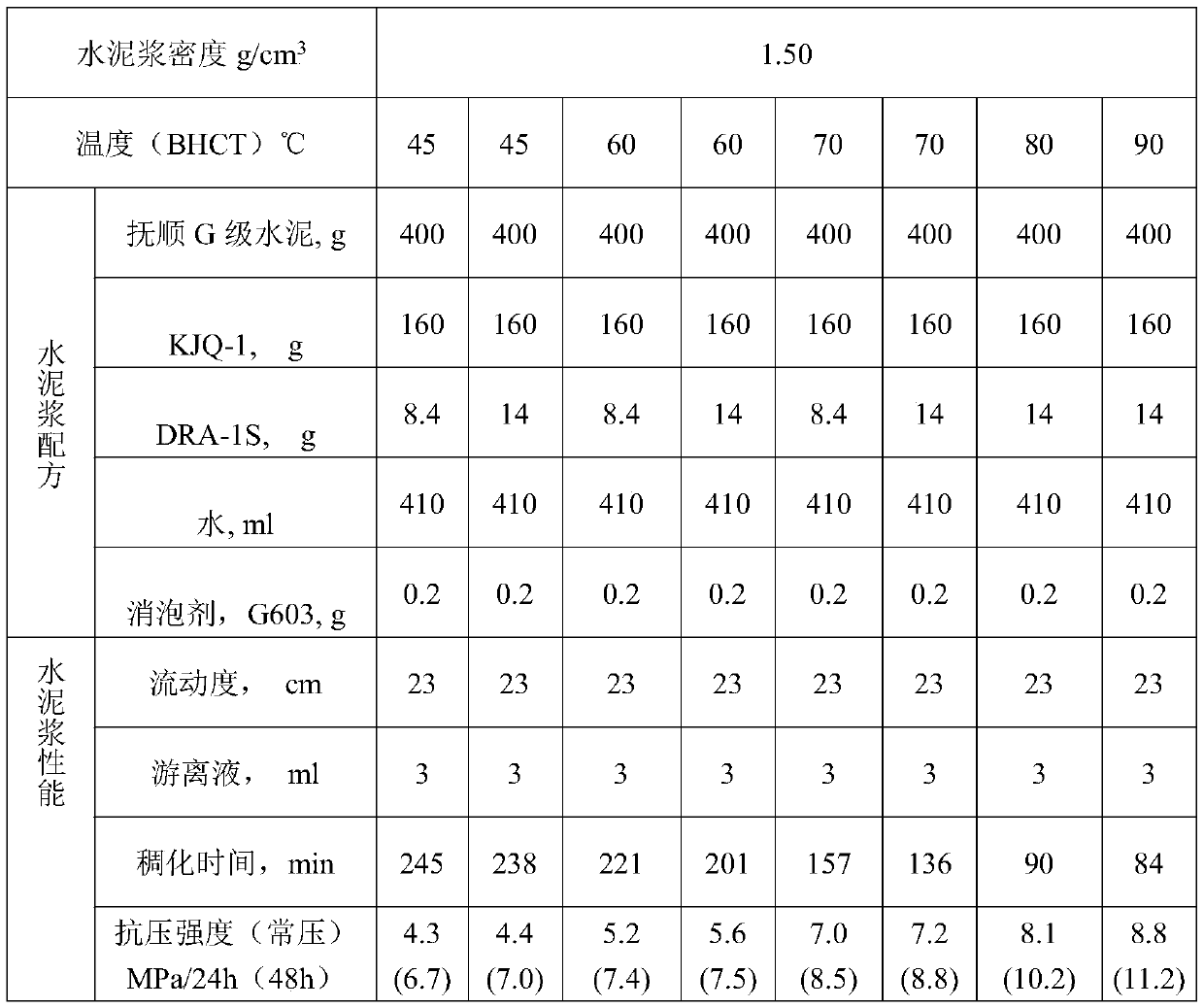

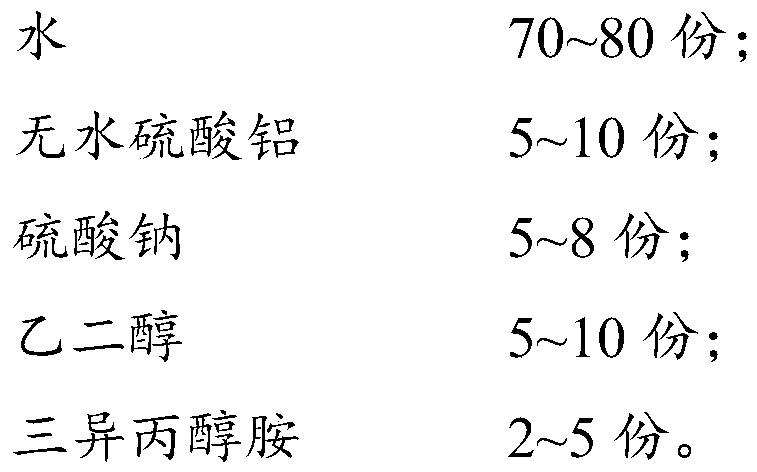

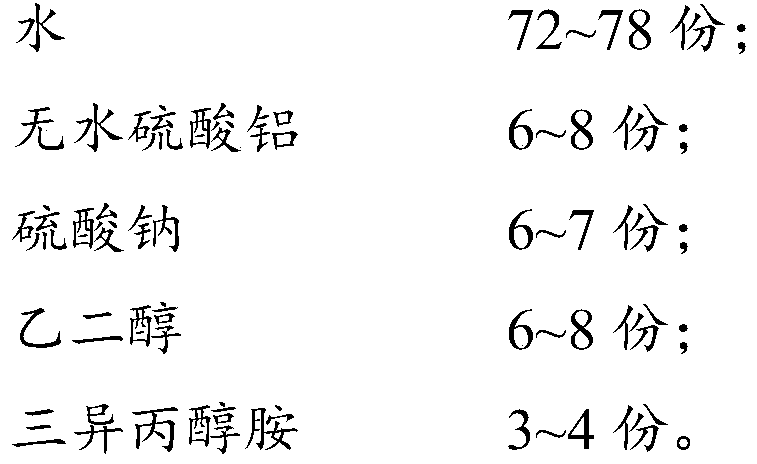

ActiveCN109943303AShorten thickening timeImprove early strengthDrilling compositionAluminium sulfateChloride

The invention relates to the technical field of additives for oil well cement and provides a chloride-free coagulating early strength agent for oil well cement and a preparation method and applicationof the agent. The coagulating early strength agent for the oil well cement is prepared from, by mass, 70-80 parts of water, 5-10 parts of anhydrous aluminium sulfate, 5-8 parts of sodium sulfate, 5-10 parts of ethylene glycol and 2-5 parts of triisopropanolamine. The chloride-free coagulating early strength agent for the oil well cement does not contain chlorine ions and is suitable for high-temperature-resistant cement paste, in the well cementation construction process, the thickening time of the high-temperature-resistant cement paste can be shortened at low temperature, the early strengthof high-temperature-resistant set cement is improved, and strength attenuation of the high-temperature-resistant set cement at high temperature can be effectively prevented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Biological ash portland cement with low probability of cracking and production method of biological ash portland cement

The invention discloses biological ash portland cement with low probability of cracking and a production method of the biological ash portland cement. The biological ash portland cement is prepared from the following components by weight percent: 55-75% of ordinary Portland cement clinker, 4-8% of flue gas desulfurization gypsum, 4.5-10.0% of humus, 7-15% of biological ash, 1-3% of polyvinyl alcohol, 5-10% of gravel powder, 5-8% of zeolite powder and 0.2-1.0% of a biological bacterium additive. The biological ash portland cement can permeate into fine seams among cement seams, stratum and a sleeve joint, has favorable cement squeezing, leakage stopping and tiny gap filling functions for easy-to-leak layers, vertically fractured stratum or porous stratum, and meets the actual application demands; and the compactness and the strength of cement paste are enhanced, and the cement paste based on biological ash is a very good culture medium of biological bacteria.

Owner:葛洲坝石门特种水泥有限公司

Tunnel grouting process in salt rock stratum

ActiveCN111577346APlay the role of reinforcementLarge particle sizeUnderground chambersTunnel liningMicrofine cementSaline water

The invention belongs to the technical field of tunnel waterproofness and impermeability, and provides a tunnel grouting process in a salt rock stratum. The tunnel grouting process in the salt rock stratum comprises the steps that grouting holes are formed, specifically, the grouting holes are formed in the periphery of a tunnel hole, and anti-corrosion grouting pipes are embedded; slurry is prepared, specifically, ordinary cement slurry and ultra-fine cement slurry are prepared with brine of certain concentration; the slurry is grouted, specifically, when the underground water volume is linear strand water or above, the ordinary cement slurry and the ultra-fine cement slurry are sequentially grouted; and when the underground water volume is drip water or below, the ultra-fine cement slurry is grouted. According to the tunnel grouting process, salt rocks are not dissolved in the grouting process, meanwhile the surrounding rock cracks can be effectively blocked, an effective sealing ring can be formed, the salt rock is prevented from being dissolved by underground water, and the intrusion of underground salt water into the tunnel structure is prevented.

Owner:中铁二局第二工程有限公司

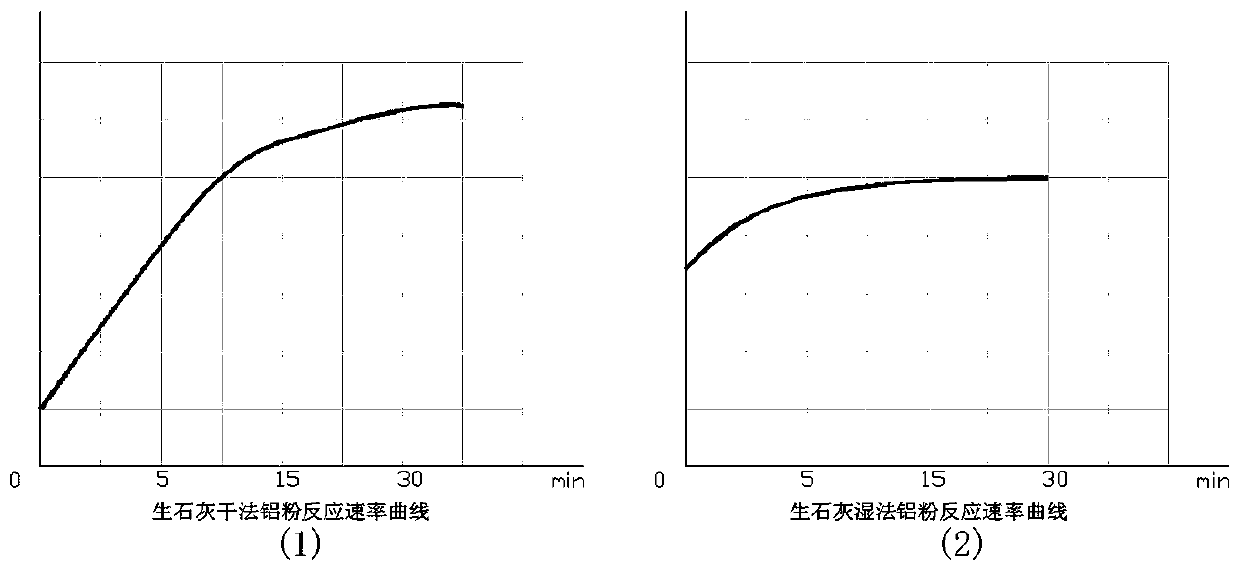

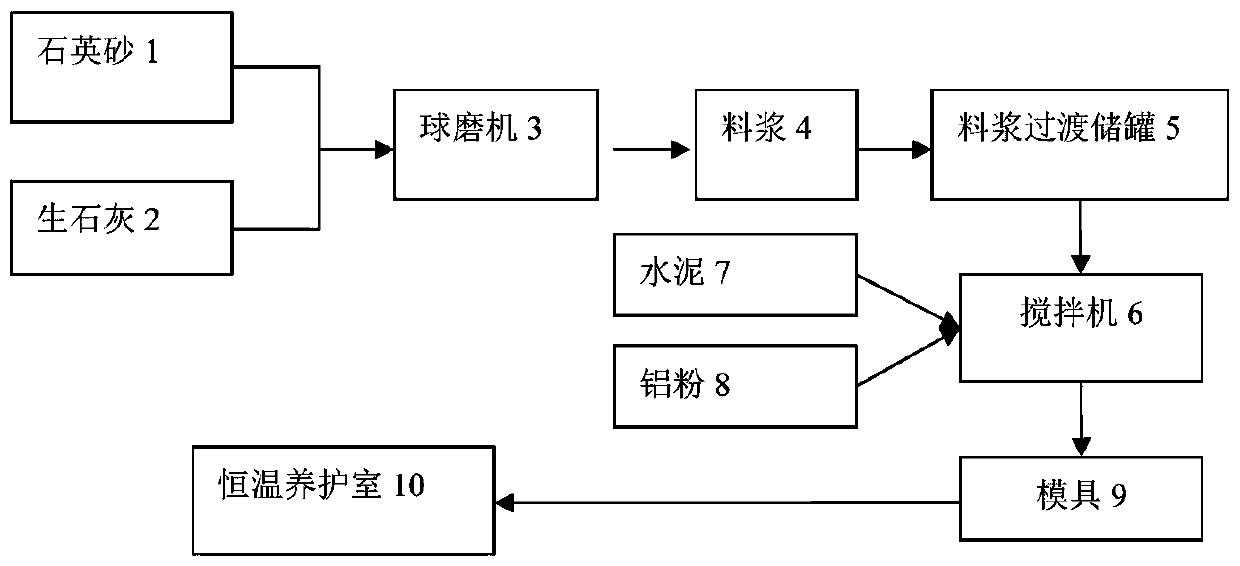

Method for producing aerated concrete blocks by lime wet pulping

InactiveCN111497008AIncrease thickening speedImprove water absorptionFeeding arrangmentsClay processing apparatusPortland cementSuperplasticizer

The invention provides a method for producing aerated concrete blocks by lime wet pulping. The method comprises the following steps of adding quartz sand and quicklime into a ball mill, adding water,mixing, and carrying out ball milling to prepare slurry at 38-40 DEG C; pumping slurry into a burdening stirrer, adding Portland cement, uniformly stirring, adding aluminum powder, a polycarboxylate superplasticizer and an oxidized paraffin soap bubble stabilizer, uniformly stirring and mixing components, discharging the slurry into a mold, and carrying out injection molding; and after injection molding, feeding the mixture and the mold into a constant-temperature chamber together, and obtaining the concrete block after gas generation, thickening and hardening. By adopting the method, in the thickening stage after gas generation is completed, the uniformly distributed calcium hydrate system reduces the existence of intermediate water and increases adsorbed water, so that the slurry thickening speed is increased, the pouring stability is improved, the thickening time is shortened, and the production efficiency is improved.

Owner:宜昌益通鹏程新型墙体材料有限公司

An electroplated diamond grinding wheel with abrasives arranged in order

ActiveCN105196196BImprove gripExtended service lifeAbrasion apparatusGrinding devicesEffective solutionGrip force

The invention discloses an electroplated diamond grinding wheel with abrasives arranged in order. The electroplated diamond grinding wheel comprises a grinding wheel base and an abrasive layer, and the surface of the grinding wheel base is provided with orderly arranged blind holes; the abrasive layer comprises abrasives and a metal coating, The root of the abrasive is embedded in the blind hole, and the metal coating is deposited on the surface of the grinding wheel substrate and in the blind hole for consolidating the abrasive. The electroplated diamond grinding wheel of the present invention realizes the regular and orderly arrangement of abrasives on the surface of the grinding wheel substrate, effectively solving the problem of uneven distribution and disorder of abrasives in the abrasive layer of traditional diamond grinding wheels; The filling effect increases the holding force of the coating and the substrate to the abrasive, which increases the life of the grinding wheel by 15% to 20%. The orderly arrangement of the abrasive on the surface of the substrate forms a good chip removal path and avoids machining due to abrasive debris blocking The phenomenon of workpiece burning improves the grinding quality.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Method for preparing corrosion-resistant anti-channeling agent for oil well cement

The invention discloses a method for preparing a corrosion-resistant anti-channeling agent for oil well cement. The method comprises the following steps: crushing calcium formate, sodium aluminate, mica and kaolinite separately, and then adding the crushed materials into a grinding machine for grinding; feeding a kiln with ground powder, carrying out calcining at 1200-1800 DEG C for 15-30 hours and then carrying out cooling so as to obtain a clinker; adding styrene-butadiene rubber emulsion, butadiene-styrene, phosphate, sulfonate and a defoaming agent into the clinker, carrying out calcining at 50-100 DEG C for 15 min and then carrying out cooling to room temperature; and adding slag in proportion, carrying out uniform mixing, and grinding the obtained mixture to a fineness of 400-500 meshes to obtain the anti-channeling agent for oil well cement.

Owner:四川宏升石油技术开发有限责任公司

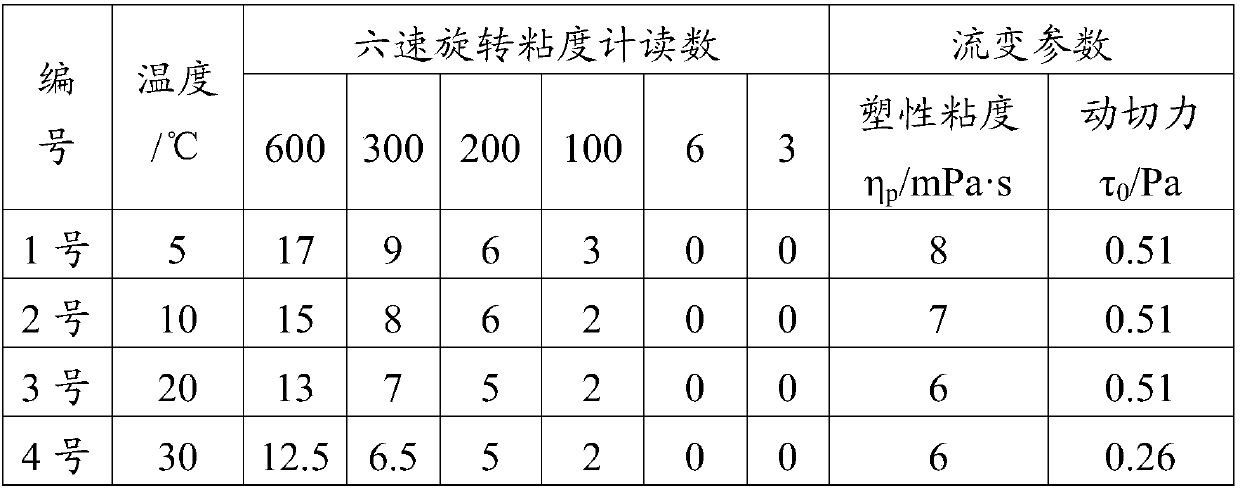

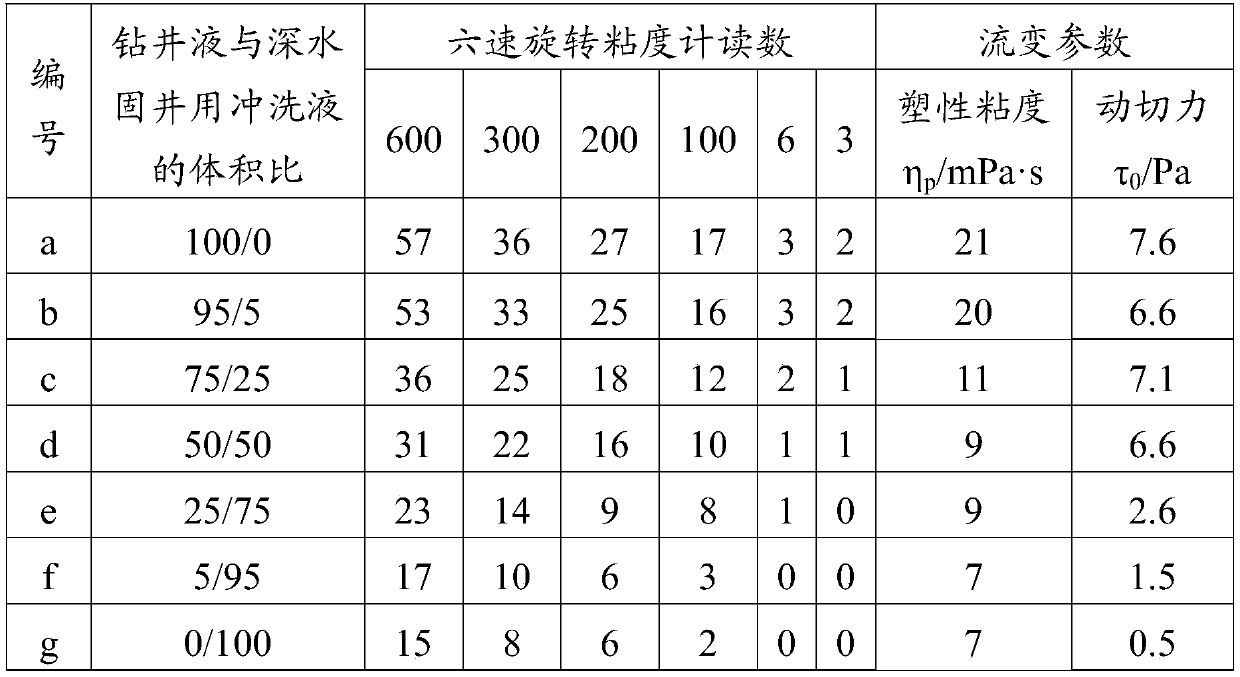

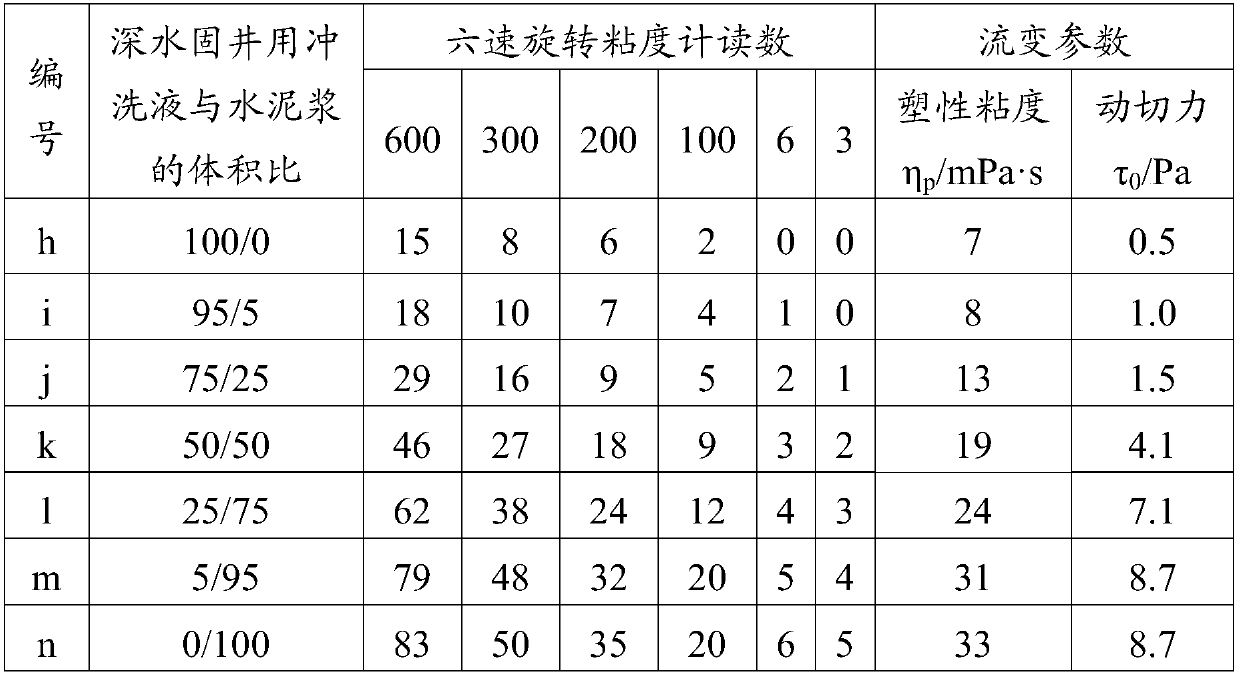

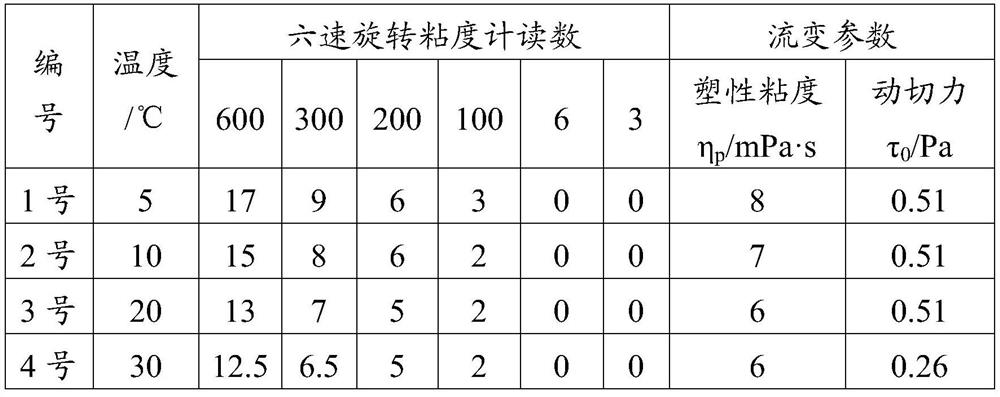

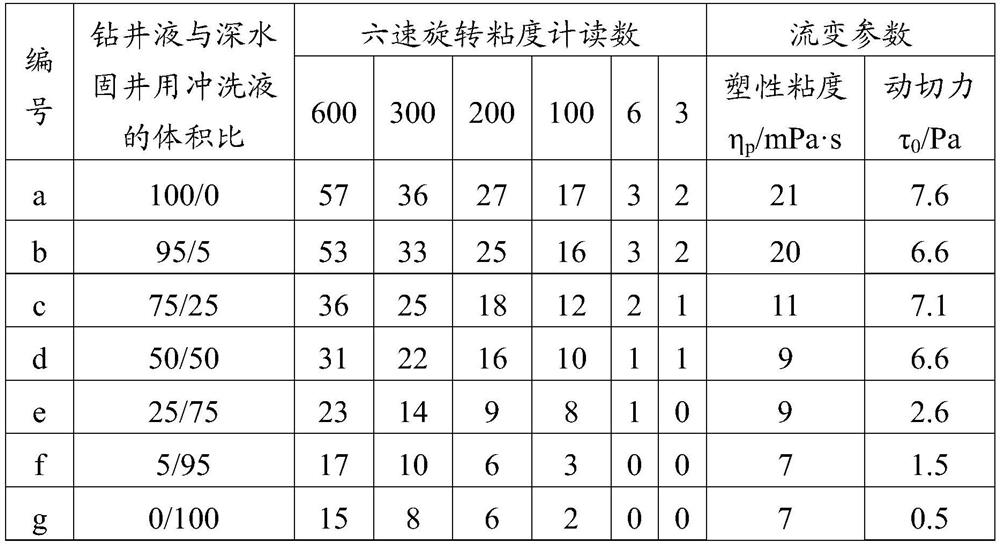

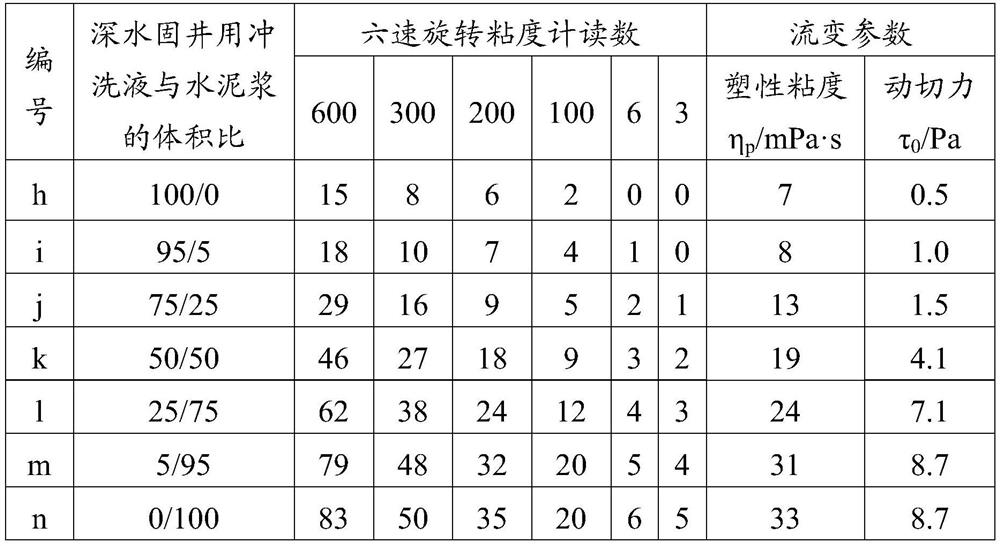

Flushing liquid, preparation method thereof, and flushing liquid for deepwater cementing

The invention discloses flushing liquid, a preparation method thereof, and flushing liquid for deepwater cementing, and belongs to the field of cementing operation. The flushing liquid is prepared from a diluent and a cleaning agent, wherein the mass ratio of the diluent to the cleaning agent is (75 to 95):(18 to 24); the diluent is prepared from water, sulfonated sodium tannin, sodium hexametaphosphate and hydroxyethyl cellulose, wherein the mass ratio of the water to the sulfonated sodium tannin to the sodium hexametaphosphate to the hydroxyethyl cellulose is (75 to 85):(8 to 12):(6 to 10):(1 to 4); and the cleaning agent is prepared from ethylene glycol, fatty alcohol-polyoxyethylene ether and octaphenyl polyoxyethyiene, and the mass ratio of the ethylene glycol to the fatty alcohol-polyoxyethylene ether to the octaphenyl polyoxyethyiene is (65 to 75):(15 to 25):(5 to 15). When being applied to the flushing liquid for deepwater cementing, the flushing liquid can dilute a mixed section of the flushing liquid for deepwater cementing and drilling liquid and / or cement slurry, slurry mixing of the cement slurry and the drilling liquid is effectively prevented, flocculation of the cement slurry is avoided, the thickening time is shortened, it is ensured that the mixed section has the good rheological property, false filter cakes of the drilling liquid, a casing and a well wall annulus are effectively flushed, and the flushing liquid can be applied to deepwater cementing operation at 0-30 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Friction-resistant thermal-insulation composite coating

The invention discloses a friction-resistant thermal-insulation composite coating. The friction-resistant thermal-insulation composite coating comprises, by weight, 50-80 parts of cement, 11-16 parts of polyethylene methyl ether methacrylate, 9-14 parts of Meretrix meretrix Linnaeus shell powder, 3-9 parts of ham shell powder, 5-6 parts of Mactra veneriformis shell powder, 3-7 parts of a bactericide, 3-9 parts of an organosilicon-modified epoxy resin, 10-16 parts of carbamate, 3-5 parts of thermoplastic resin, 5-8 parts of polyisoprene rubber, 3-8 parts of an antimony-based composite eco-friendly fire retardant and 5-9 parts of triisocyanurate. The friction-resistant thermal-insulation composite coating utilizes composite cement and lime, can shorten slurry thickening time, can fully keep foam produced by a foaming agent and aluminum powder so that material thermal insulation properties are guaranteed, simultaneously uses physical and chemical foaming agents and is conducive to slurry heat insulation performance improvement.

Owner:QINGDAO UWELL INFORMATION TECH

Environment-friendly foam building material

The invention discloses an environment-friendly foam building material. The environment-friendly foam building material comprises, by weight, 15-18 parts of cement, 18-23 parts of calcium carbonate, 1-3 parts of carbon celluloses, 2-3 parts of wetting agents, 0.1-0.8 part of silicon carbide, 10-14 parts of phenol, 1-3 parts of polyurethane, 22-25 parts of organic silicon-modified epoxy resin, 0.5-1.3 parts of preservatives, 20-25 parts of kaolin, 0.2-0.5 part of dispersing agents and 3-5 parts of pigment. The environment-friendly foam building material has the advantages that the kaolin, the cement and lime are combined with one another, accordingly, the slurry thickening time can be shortened, and the heat preservation and heat insulation performance of the environment-friendly foam building material can be advantageously improved; environment-friendly effects can be realized by the environment-friendly foam building material, other components are added into the environment-friendly foam building material, and accordingly the stability and the frost resistance of the environment-friendly foam building material can be effectively guaranteed in service procedures.

Owner:凡音环保科技(苏州)有限公司

A clean fracturing fluid

ActiveCN106336862BEliminate water quality chemical treatment processReduce operating costsDrilling compositionLiquid wasteChemical treatment

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Flushing fluid and preparation method thereof, flushing fluid for deep water well cementing

The invention discloses a flushing fluid, a preparation method thereof, and a flushing fluid for deep water well cementing, which belong to the field of well cementing operations. The flushing solution includes: diluent and cleaning agent; the mass ratio of diluent to cleaning agent is 75-95:18-24; the diluent includes: water, sulfonated tannin, sodium hexametaphosphate, and hydroxyethyl cellulose; The mass ratio of water, sulfonated tannin, sodium hexametaphosphate, and hydroxyethyl cellulose is 75-85:8-12:6-10:1-4; cleaning agents include: ethylene glycol, fatty alcohol polyoxyethylene Ether, octylphenol polyoxyethylene ether; mass ratio of ethylene glycol, fatty alcohol polyoxyethylene ether, octylphenol polyoxyethylene ether is 65-75:15-25:5-15. When the flushing fluid is applied to the flushing fluid for deepwater well cementing, it can dilute the mixing section with drilling fluid and / or cement slurry, effectively prevent cement slurry and drilling fluid from mixing, avoid cement slurry flocculation, shorten the thickening time, and ensure mixing The section has good rheological properties, effectively flushes the virtual mud cake of drilling fluid, casing and borehole wall annulus, and can be applied in deepwater cementing operations at 0-30°C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A preparation method of an electroplated diamond grinding wheel with ordered abrasives

InactiveCN105154958BImprove gripExtended service lifeElectrolytic coatingsLiquid/solution decomposition chemical coatingGrip forceBiological activation

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Compounding method of foamed silicon-calcium concrete wall building block

The invention provides a compounding method of a foamed silicon-calcium concrete wall building block, which comprises the following steps: in 100 parts of main body slurry formed by mixing fly ash, lime and water, based on the mass ratio, adding 10 parts of volcanic tuff powder and 10 parts of steel slag powder serving as filler, adding 1 part of polyvinyl formal and 0.5 part of carboxymethyl cellulose serving as thickener, adding 0.1 part of calcium stearate and 0.1 part of oleic acid-triethanolamine mixture serving as foaming stabilizer, sufficiently stirring, adding 3 parts of 5% sodium carbonate water solution serving as foaming aid into the slurry, and finally adding 50-60g of degreased aluminum powder serving as gas former; and adding the prepared slurry into a stirrer, stirring, performing injection molding, and performing steam curing to obtain the foamed silicon-calcium concrete wall material. The foamed silicon-calcium concrete wall building block prepared by the invention is high in strength and uniform in pore size distribution, and saves cement. The compounding method provided by the invention is suitable for being used as a foamed silicon-calcium concrete wall building block making method.

Owner:SUIZHONG GUANGYUAN NEW MATERIALS

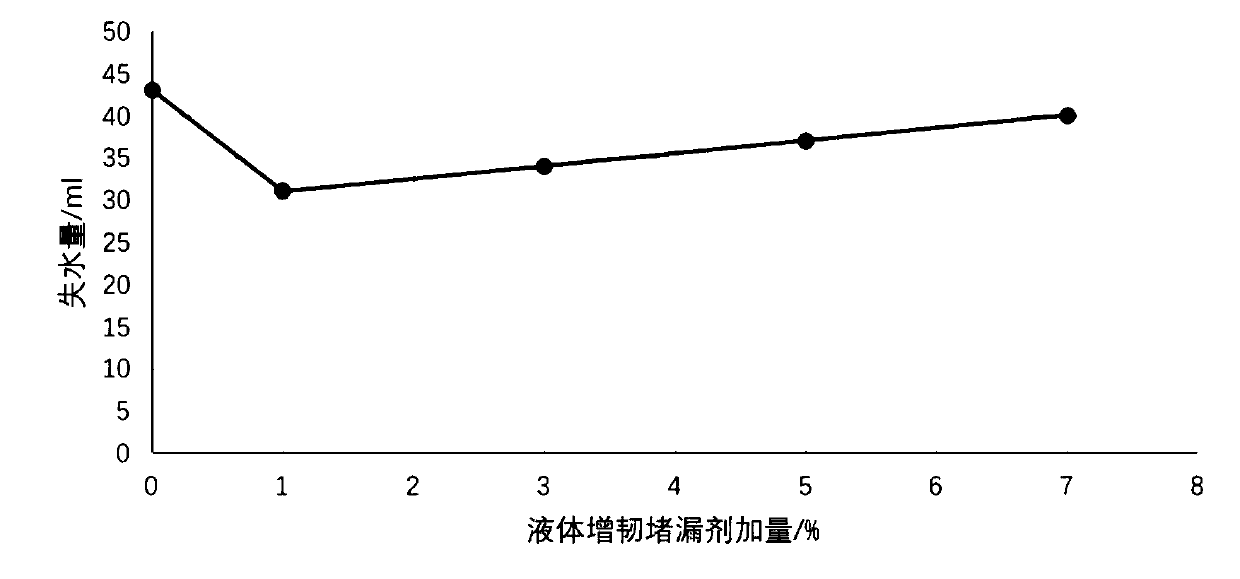

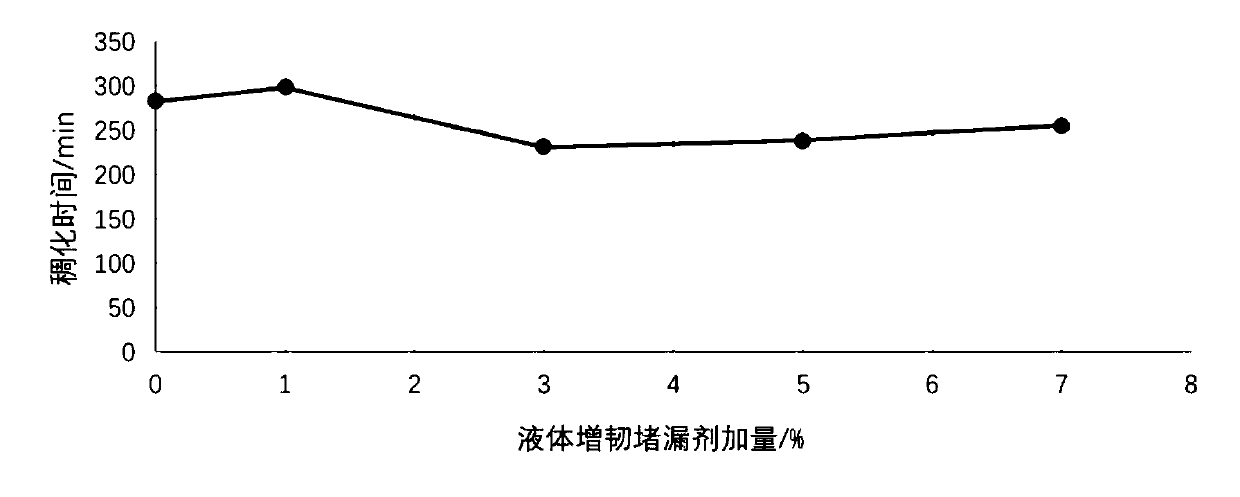

Liquid toughening leakage-blocking agent for well cementation

The invention relates to a liquid toughening leakage-blocking agent for well cementation. The liquid toughening leakage-blocking agent comprises a novel fiber material which is formed by stacking sheet graphite microcrystalline organic fiber along its axial direction, and a microcrystalline graphite material is obtained by carbonizing and graphitizing. The liquid toughening leakage-blocking agentcan reduce set cement microcrack and block macrocrack expansion, so that resistance to wear, cavitation erosion, scouring and freeze-thawing and anti-permeability can be improved to different degrees;rate of an erosion medium in invading a matrix is lowered, and gas channeling and oil channeling are prevented effectively.

Owner:中石化石油工程技术服务有限公司 +2

Lightweight building material

The invention discloses a lightweight building material which is characterized by comprising the following substances, by weight, 50-80 parts of cement, 5-9 parts of a mixed solvent, 6-8 parts of an inorganic thickening agent, 11-18 parts of clam shell powder, 2-8 parts of Scapharca subcrenata shell powder, 9-17 parts of white clamshell powder, 1-6 parts of polypropylene, 3-8 parts of nano-calcium sulfate, 3-9 parts of a titanate coupling agent, 2-8 parts of abietyl resin acid, 20-32 parts of organosilicone modified epoxy resin, 1-9 parts of laminated structured mica powder, 1-3 parts of hollow glass beads, 1-6 parts of linear low density polyethylene, 2-3 parts of white oil, 3-9 parts of fiber and 3-9 parts of a foaming agent. By the use of composite cement and lime, slurry thickening time can be shortened, and bubbles coming from the foaming agent and linear low density polyethylene can be fully maintained so as to guarantee thermal insulation property of the material; and by simultaneous application of two foaming agents, namely physical and chemical foaming agents, it helps to raise thermal insulation performance of the slurry.

Owner:黄艳

Jetting type foaming inorganic light energy-saving material

The invention provides a jetting type foaming inorganic light energy-saving material, consisting of the following components by weight percent: 50-70% of cement, 5-20% of siliceous dust, 5-20% of lime, 1-5% of plaster, 0.1-1% of fiber, 0.1-1% of cellulose ether, 0.5-3% of gelatine powder, 2-8% of protein foaming agent and 0.02-0.1% of aluminum powder. The jetting type foaming inorganic light energy-saving material disclosed by the invention has good non-flame property and can solve defects of slow construction speed, high labor occupancy ratio, repeated complex multiple construction and the like during production of the current coating type heat-insulating slurry.

Owner:武汉沃尔浦科技有限公司

Deepwater cementing low-temperature early strength agent

InactiveCN101864285BLittle impact on rheologyFreeze fastDrilling compositionTriisopropanolamineCement paste

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

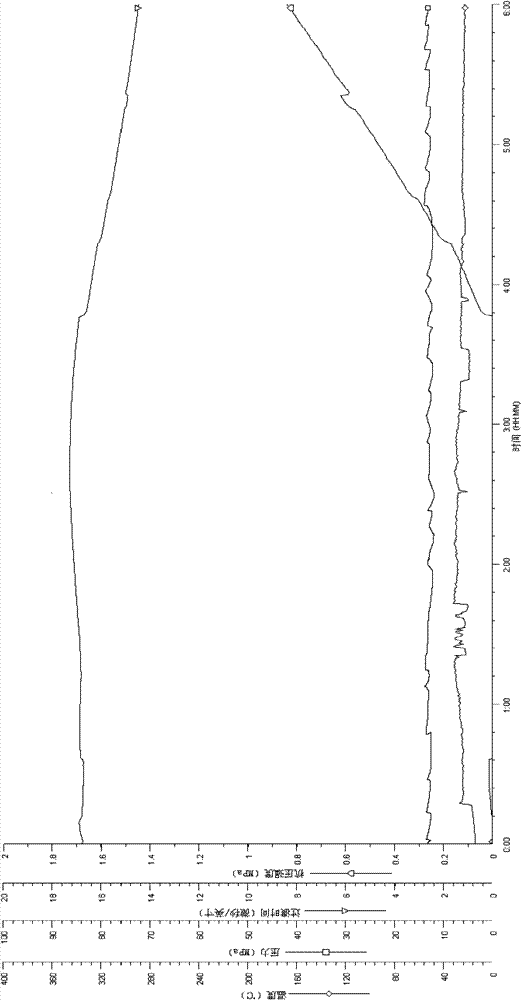

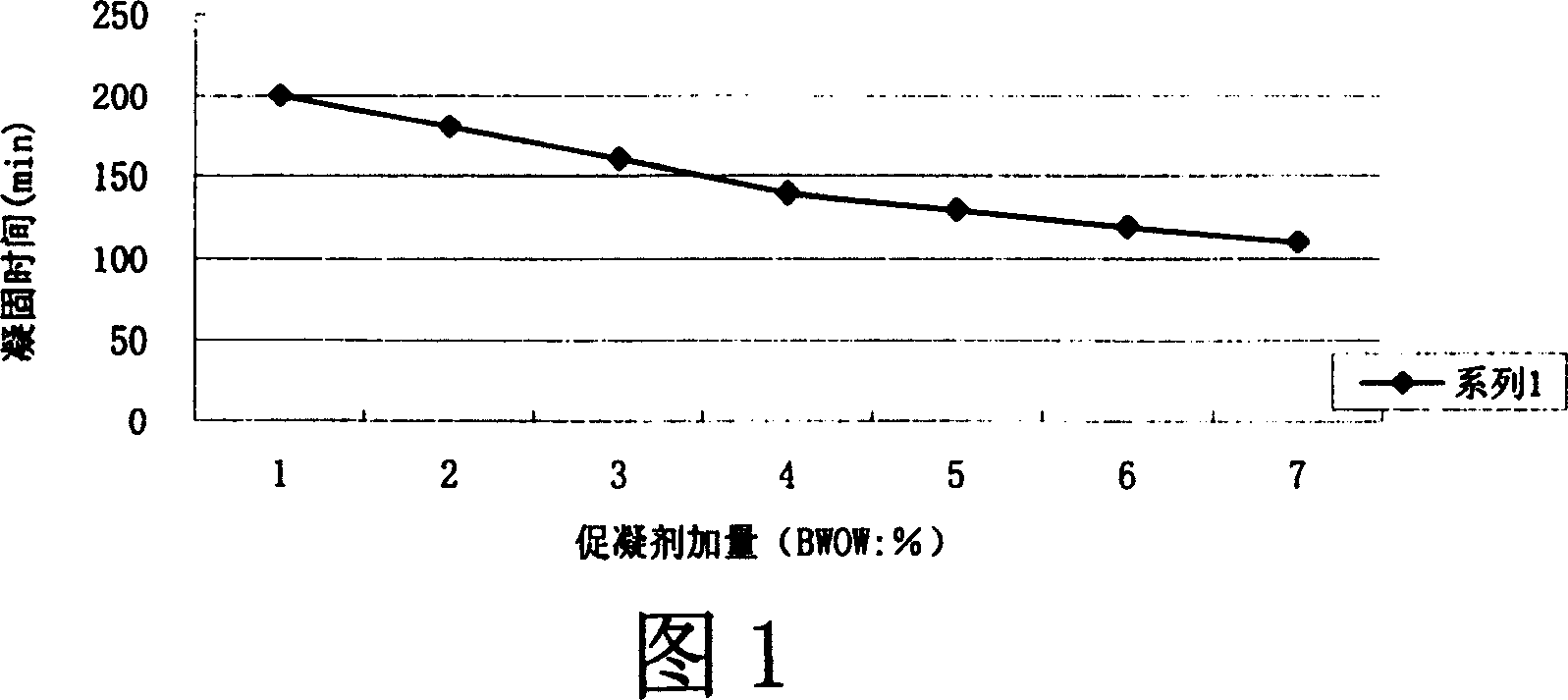

Low temperature early-strength coagulant agent

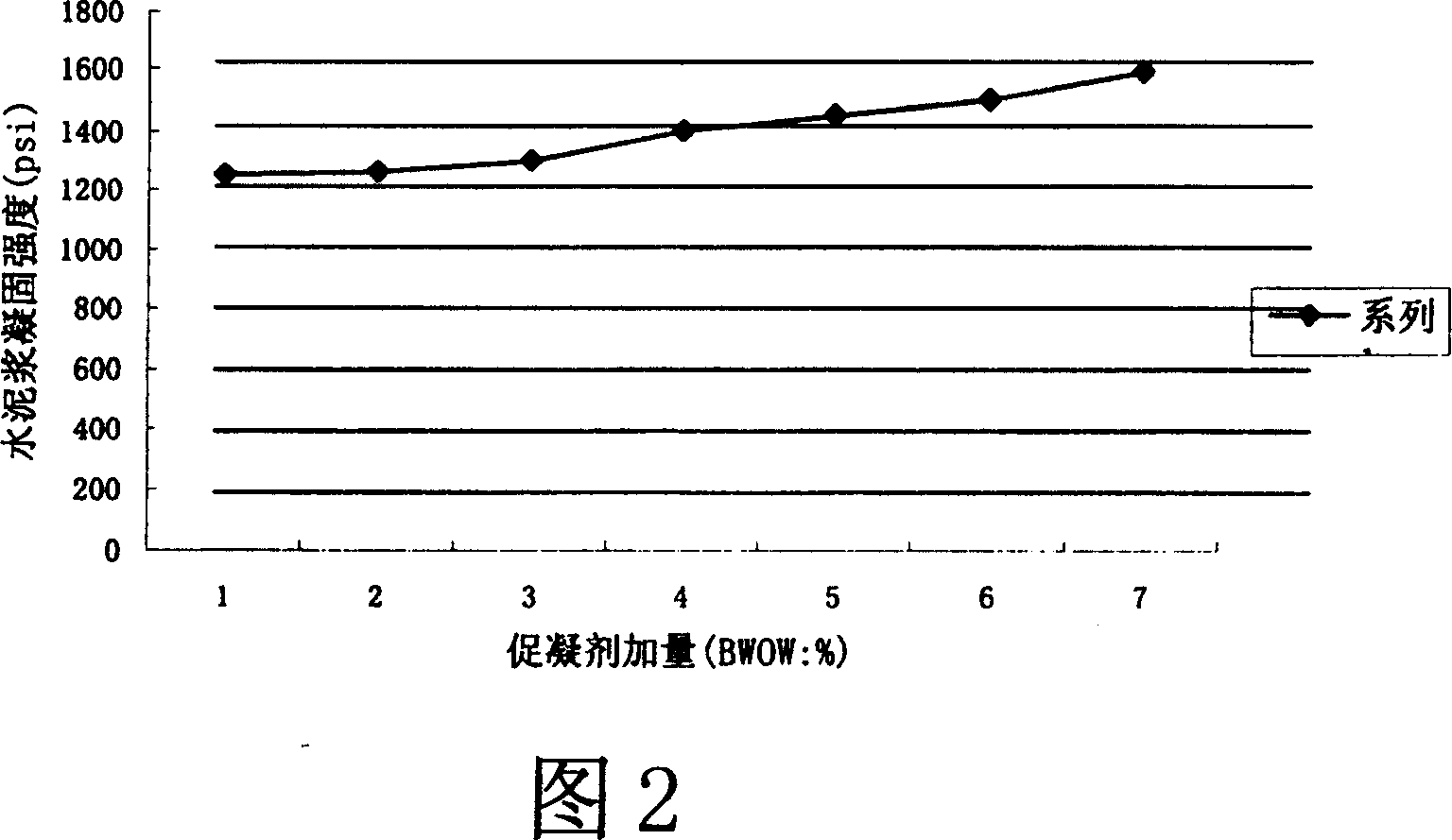

InactiveCN100340516CShorten thickening timeFreeze fastDrilling compositionSealing/packingOil fieldEngineering

This invention is related to that in the process of sea oil field exploration and drilling, we often adopt concentrated drilling and well fixing model. But in the operation of surface concentrated fixing, because there are too many wells, and the space between the wells is small, the surface tube is shallow to the field and the temperature is low in the winter, so it is bad for the surface fixing of well at a large scale and with close space between the wells. Adopting the high-early accelerant of this invention can shorten the densification time of cement paste under low temperature to freeze the cement in the low temperature quickly, and meet the demand of large scale of production and close drilling and the surface fixing of low temperature, shallow layer and filtering conditions.

Owner:CNOOC TIANJIN BRANCH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com