Patents

Literature

81results about How to "Little impact on rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deepwater cementing low-temperature early strength agent

InactiveCN101864285APromotes hydration processImprove compactnessDrilling compositionTriisopropanolamineCement paste

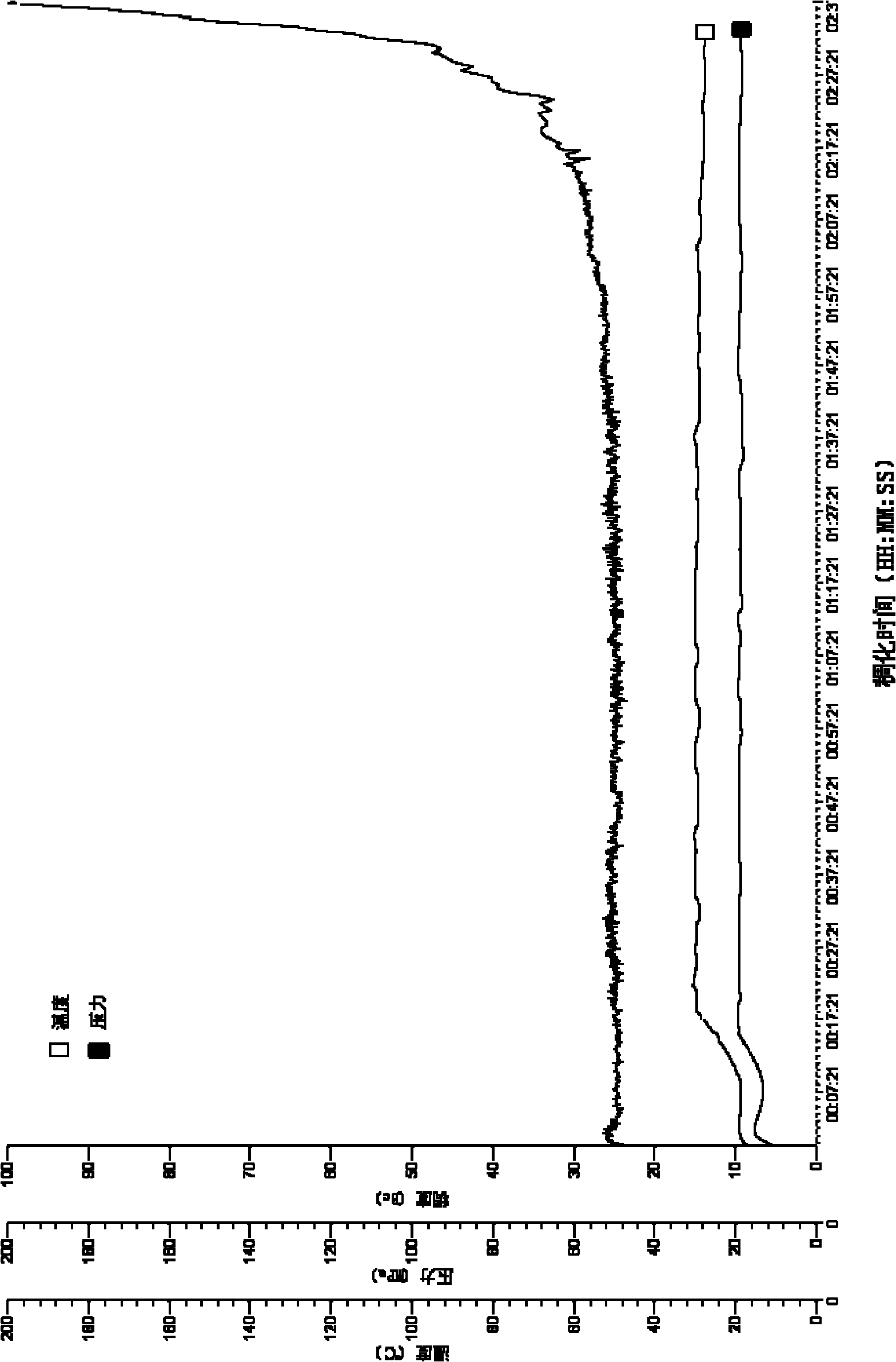

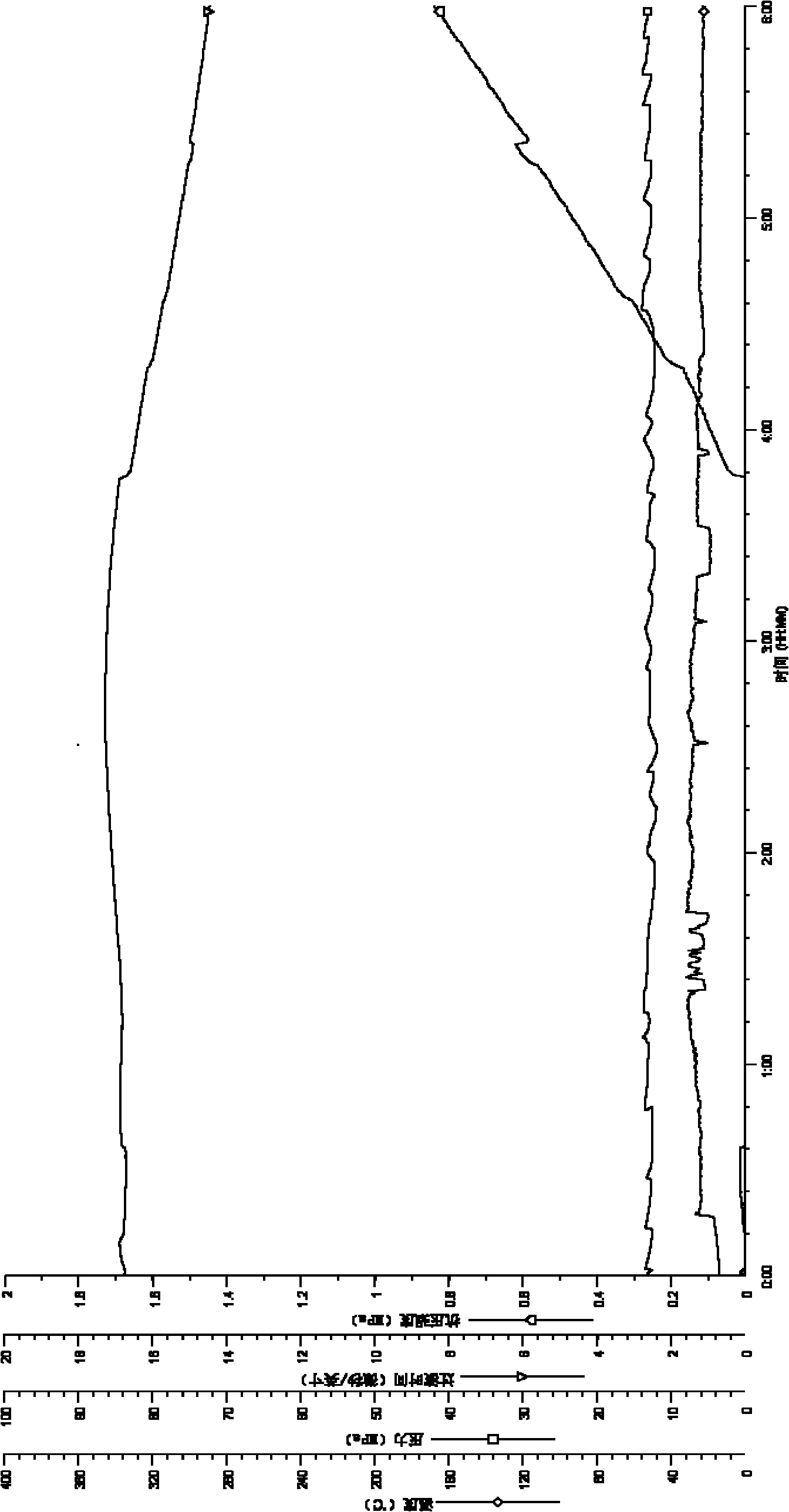

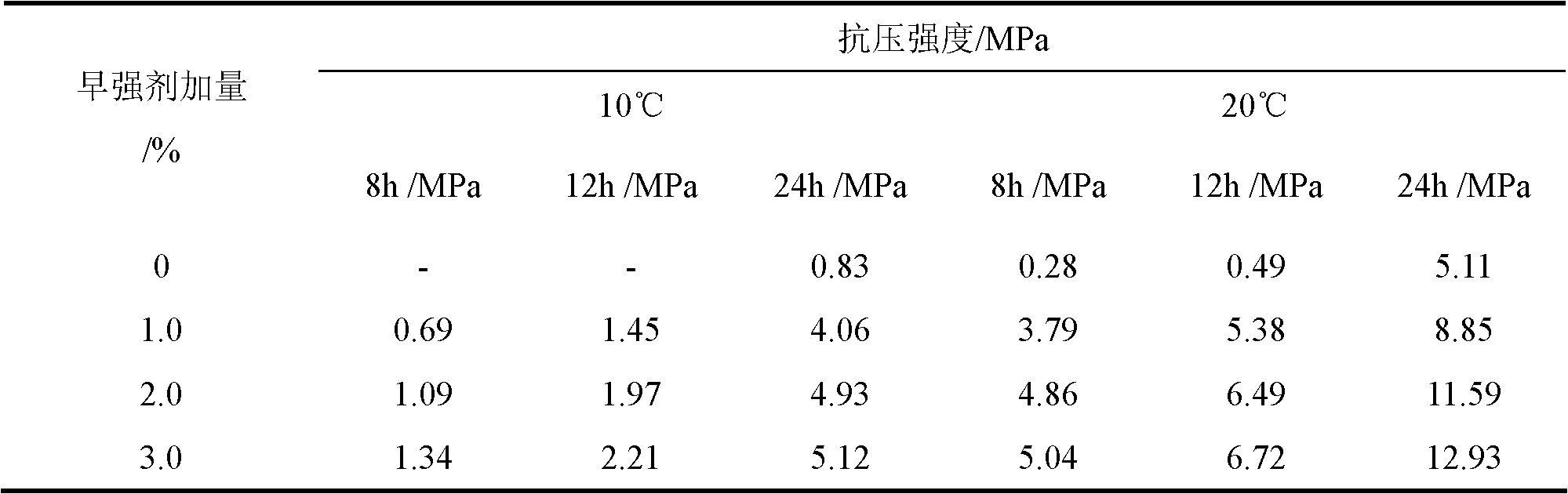

The invention relates to a deepwater cementing low-temperature early strength agent. The low-temperature early strength agent comprises the following components in percentage by weight: 33 to 66 percent of alkali metal bromides, 6 to 16 percent of sodium metaaluminate, 15 to 35 percent of alkali metal hydroxides, 8 to 15 percent of silicon dioxide and 0.8 to 1.5 percent of alcamines organics, wherein the alkali metal bromides are a mixture of one, two or more of NaBr, KBr and LiBr; the alkali metal hydroxides are NaOH, KOH or a mixture of the NaOH and KOH; and the alcamines organics are triethanolamine, triisopropanolamine or a mixture of the triethanolamine and triisopropanolamine. The deepwater cementing low-temperature early strength agent has small influence on rheological behaviour of cement paste at low temperature, can prompt the cement paste to be solidified rapidly at low temperature and reach higher early strength, shortens the thickening time of the cement paste at lower temperature and can well meet the requirements of the cementing construction of a surface casing under the conditions of low temperature, shallow gas and the like.

Owner:SOUTHWEST PETROLEUM UNIV

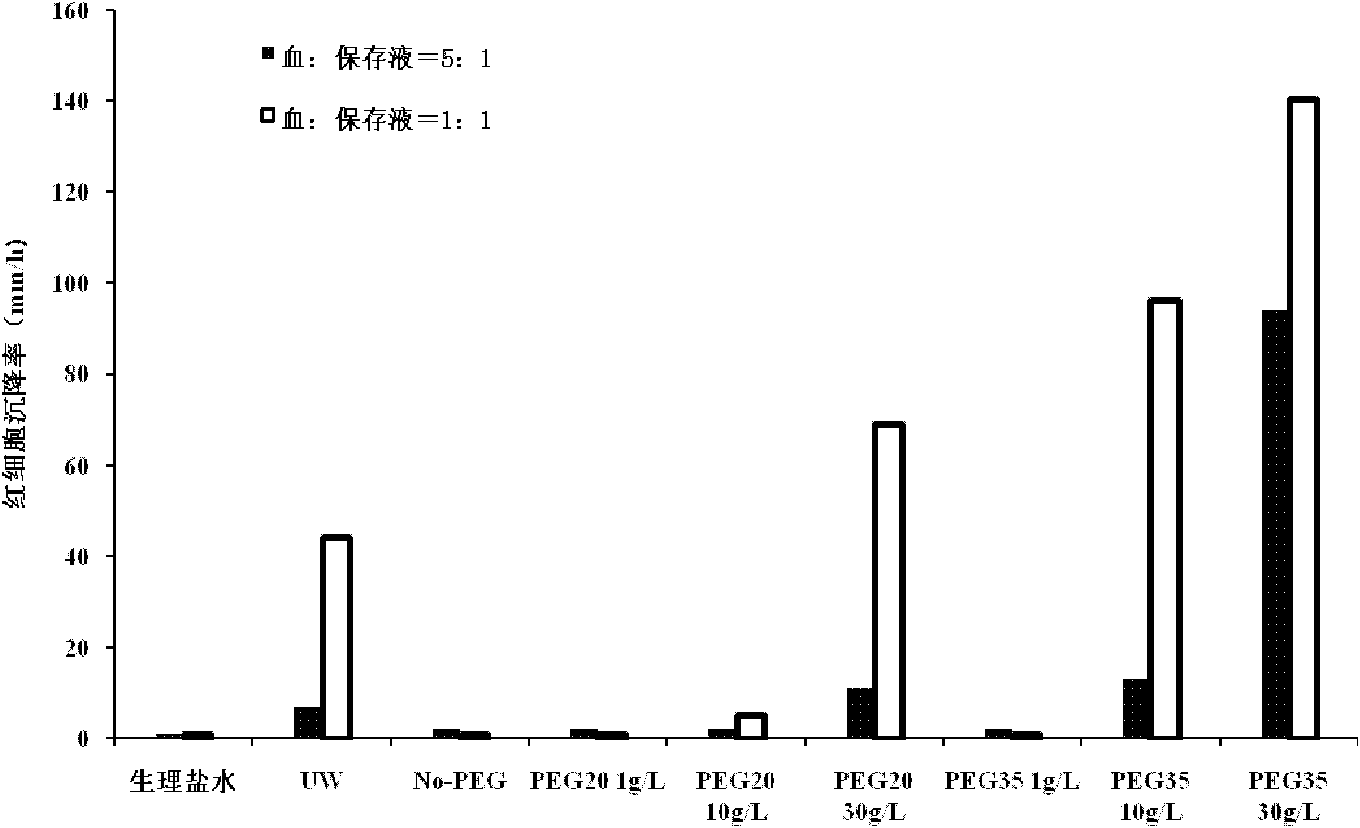

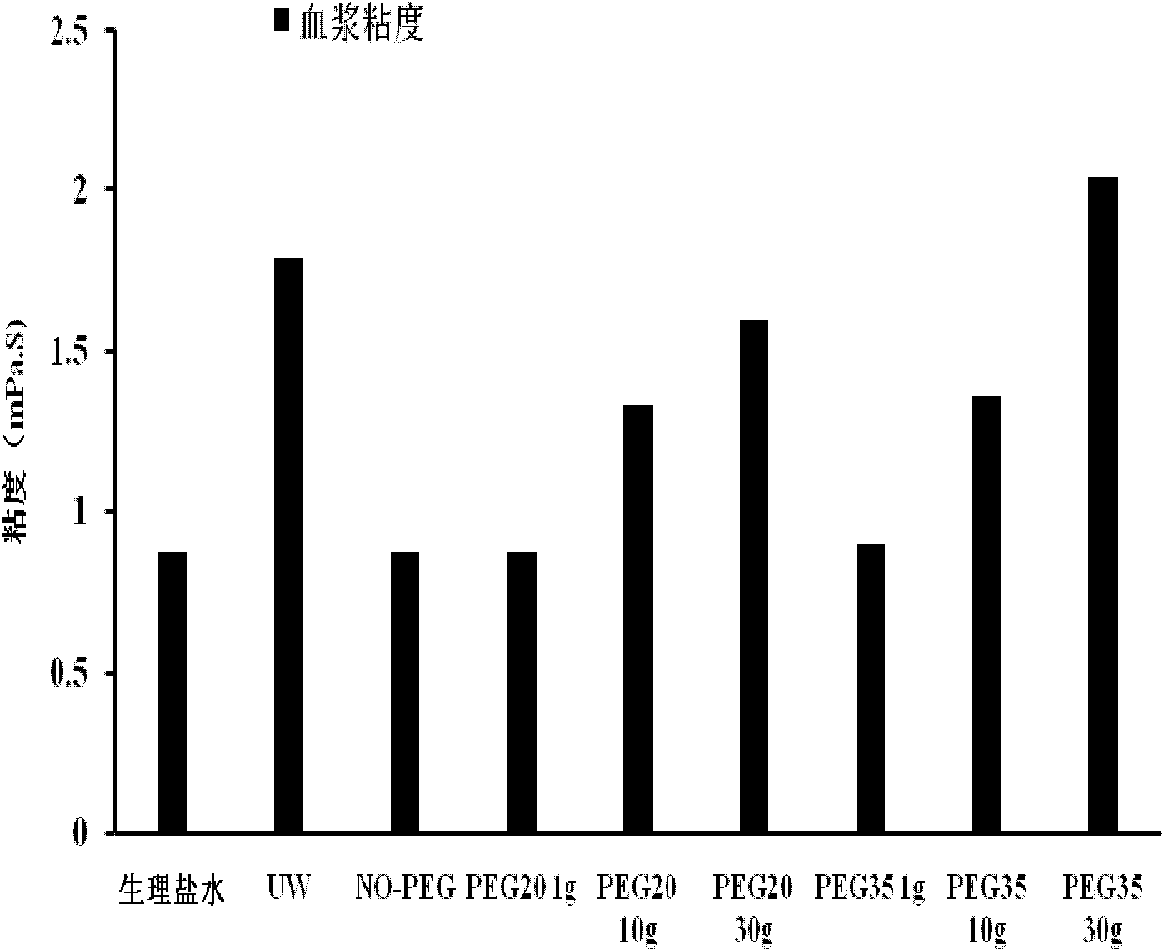

Organ preservation solution and method for preparing same

ActiveCN102726366AAvoid damageDisadvantages of Avoiding PrecipitationDead animal preservationPhosphateArginine

Owner:SHANGHAI GENEXT MEDICAL TECH

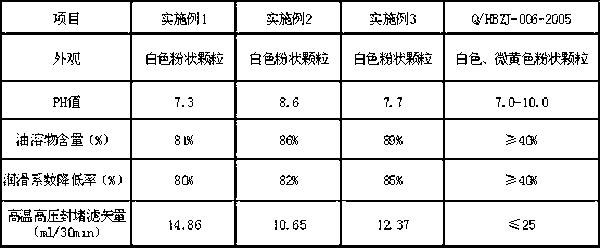

White asphalt for drilling fluid and method for preparing white asphalt for drilling fluid

ActiveCN103013461AGood sealing of cracksEasy to reverseDrilling compositionAlkylphenolPolyacrylamide

The invention discloses white asphalt for drilling fluid and a method for preparing the white asphalt for drilling fluid. The white asphalt is prepared from the following raw materials in parts by weight: 40 parts-50 parts of paraffin, 1 part-2 parts of alkylphenol polyoxyethylene ether, 4 parts-5 parts of polyethylene glycol, 4 parts-5 parts of polyacrylamide, 20 parts-30 parts of stearic acid and 20 parts-30 parts of light calcium carbonate. The method for preparing the white asphalt comprises the following steps: adding the paraffin, alkylphenol polyoxyethylene ether, polyethylene glycol and stearic acid into a reactor proportionally; raising the temperature of the reactor to 70 DEG C-100 DEG C, and then stirring for 20-40 minutes at constant temperature; adding polyacrylamide to be stirred for 30 minutes at constant temperature; and finally, uniformly adding light calcium carbonate to be stirred for 0.5-2 hours at constant temperature and then discharging, and carrying out spray granulation to obtain the white asphalt. The white asphalt does not damage a hydrocarbon reservoir, has good lubricating performance and prevents collapse and blockage, filtration can be effectively reduced, the capacity of oil-gas wells is improved, and the technical problems of easily generated loss, collapse and the like during a drilling process when stratums with complicated conditions are drilled are solved.

Owner:河北华运鸿业化工有限公司

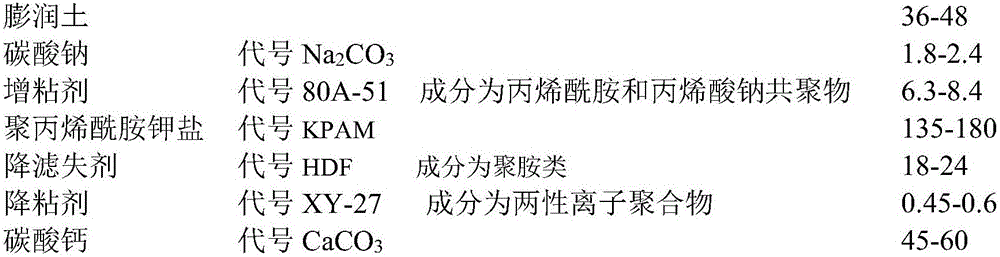

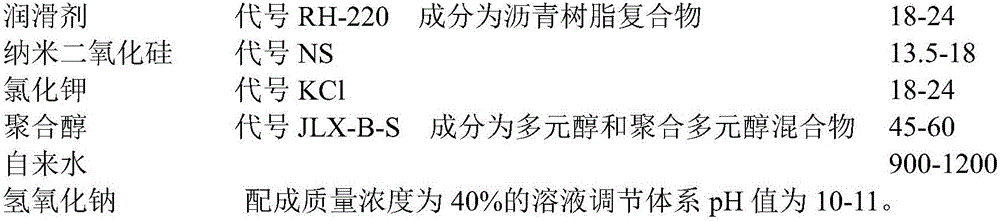

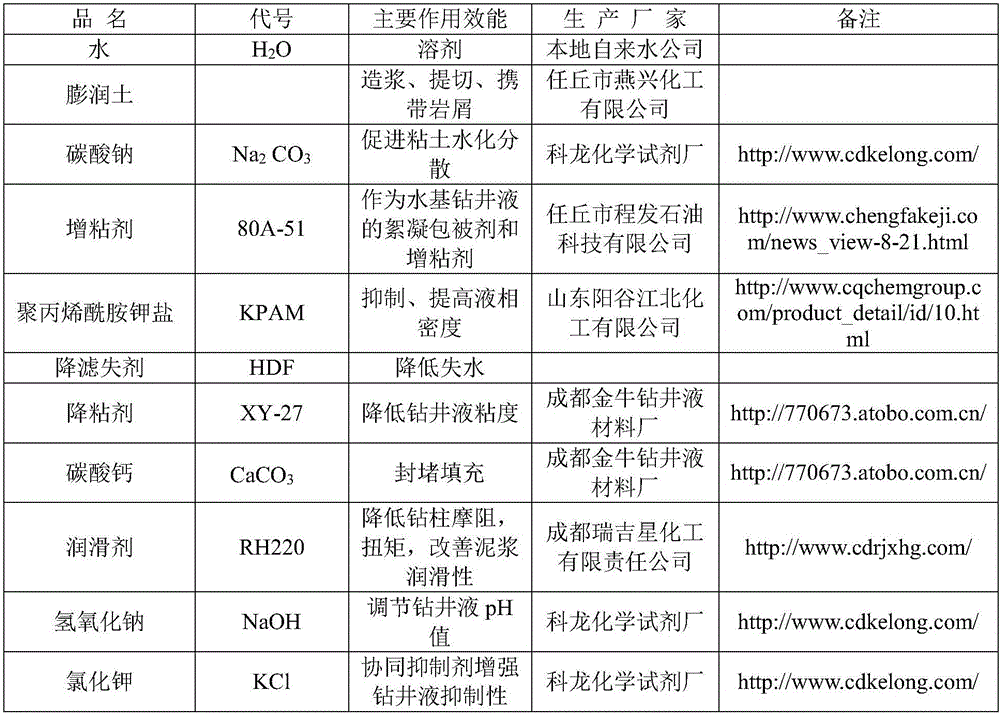

Shale strong-inhibition nano plugging water-based drilling fluid

ActiveCN106634900AReduce pollutionEnhanced inhibitory effectDrilling compositionWater basedSodium Bentonite

The invention relates to a shale strong-inhibition nano plugging water-based drilling fluid. The shale strong-inhibition nano plugging water-based drilling fluid is particularly applicable to drilling of long horizontal shale well sections with developing microfracture. The shale strong-inhibition nano plugging water-based drilling fluid is composed of, by weight part, 36-48 parts of bentonite, 1.8-2.4 parts of sodium carbonate, 6.3-8.4 parts of tackifier 80A-51, 135-180 parts of potassium polyacrylamide, 18-24 parts of filtrate reducer HDF, 0.45-0.6 part of viscosity reducer XY-270, 45-60 parts of calcium carbonate, 18-24 parts of lubricant RH-220, 45-60 parts of polymeric alcohol, 13.5-18 parts of nano silicon dioxide, 18-24 parts of potassium chloride and 900-1200 of tap water. The preparation method of the shale strong-inhibition nano plugging water-based drilling fluid comprises preparing clay basic mud; at a stirring speed of 500 r / min, adding in the tackifier and then sequentially adding in the other materials; adjusting the system pH at 10-11 and the density at 1.35 g / cm3 to obtained the shale strong-inhibition nano plugging water-based drilling fluid. The shale strong-inhibition nano plugging water-based drilling fluid is good in rheological property, capable of achieving strong-inhibition nano plugging and good in thermal stability, thereby being applicable to shale drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Polymer oil layer protective agent for drilling fluid and preparation method

ActiveCN103184035AInhibits hydration swellingAvoid hydrolysisDrilling compositionPolymer scienceNitrogen

The invention provides a polymer oil layer protective agent for a drilling fluid and a preparation method. The method is carried out according to the following steps of (1) adding 85-95 parts by volume of styrene, 5-65 parts by volume of butyl acrylate and 5-40 parts by volume of 2-acrylamido-2-methyl propanesulfonic acid to water, mixing uniformly, and then adding 5 parts by volume of an emulsifier to obtain a mixed liquid; (2) passing nitrogen into the mixed liquid obtained by the step (1) for 25-35 min, heating to a temperature of 70 DEG C, adding 0.01-0.2 part by weight of an initiator, and then reacting for 5-7 h by controlling the temperature at 70-80 DEG C to obtain a reaction liquid; (3) cooling the reaction liquid obtained by the step (2) to a room temperature, then adjusting a pH value of the liquid to 9-10 with a sodium hydroxide solution, putting the obtained solution in methanol with stirring, and precipitating to obtain a white precipitate; and (4) drying the white precipitate obtained by the step (3) at a temperature of 95-105 DEG C, and smashing the dried precipitate to obtain a product.

Owner:CHINA PETROLEUM & CHEM CORP +1

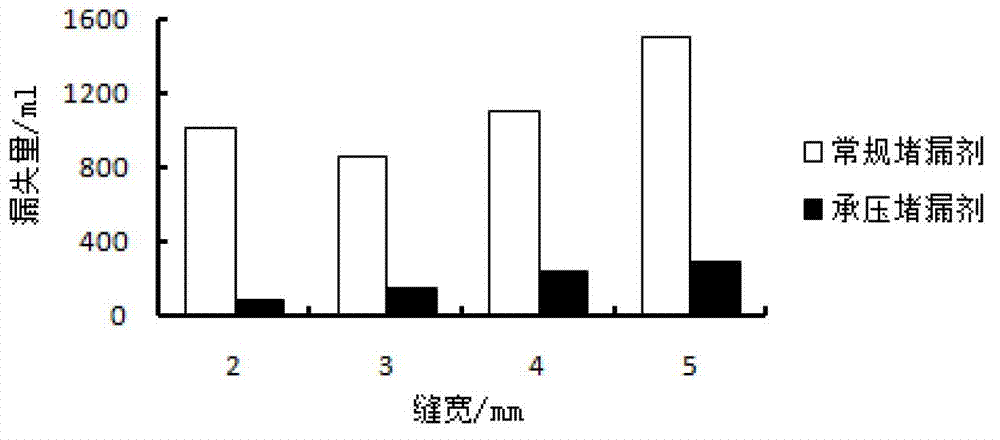

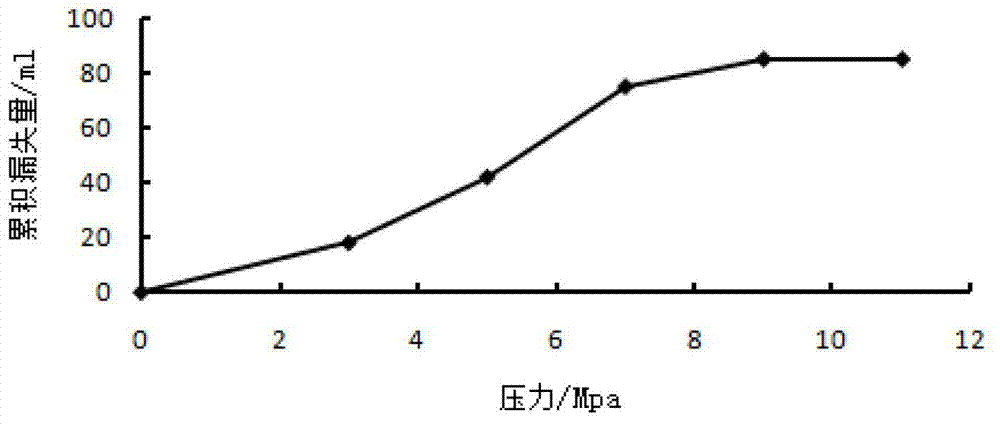

Pressure-bearing lost circulation additive for drilling fluid and for stably bearing pressure on smooth fracture leakage wall surface

InactiveCN102876303AIncrease bearing pressureIncrease internal frictionDrilling compositionBridge materialFilling materials

The invention relates to a pressure-bearing lost circulation additive for a drilling fluid and for stably bearing pressure on a smooth fracture leakage wall surface. The lost circulation additive is composed of 10%-20% of damping material, 45%-50% of bridging material and 35%-40% of filling material by weight, wherein the damping material is an industrial metal screen, having the size of the damping material is 1.0*1.0mm to 3.0*3.0 mm and the thickness of the damping material is about 0.5 mm; the bridging material is calcium carbonate particles, and the standard mesh number of the screening mesh product of the bridging material is lower than 20 meshes; the filling material is a mixture composed of calcium carbonate powder and flexible graphite powder; the calcium carbonate powder is further divided into three grades to realize multi-grade filling and to form a compact shielding layer; and the mesh number of the flexible graphite is greater than 150, and the anti-pressure ability of a bridge plug section is improved. With the pressure-bearing lost circulation additive for the drilling fluid and for stably bearing pressure on the smooth fracture leakage wall surface disclosed by the invention, leak stoppage success rate and bearing pressure for smooth fracture leakage can be improved, leakage stoppage failure due to complexity is reduced, the benefits of exploring and developing a bored well are improved; and the preparation process of the lost circulation additive is simple and convenient, the source of the materials of the lost circulation additive is broad, and the lost circulation additive is easy to spread and apply.

Owner:SOUTHWEST PETROLEUM UNIV

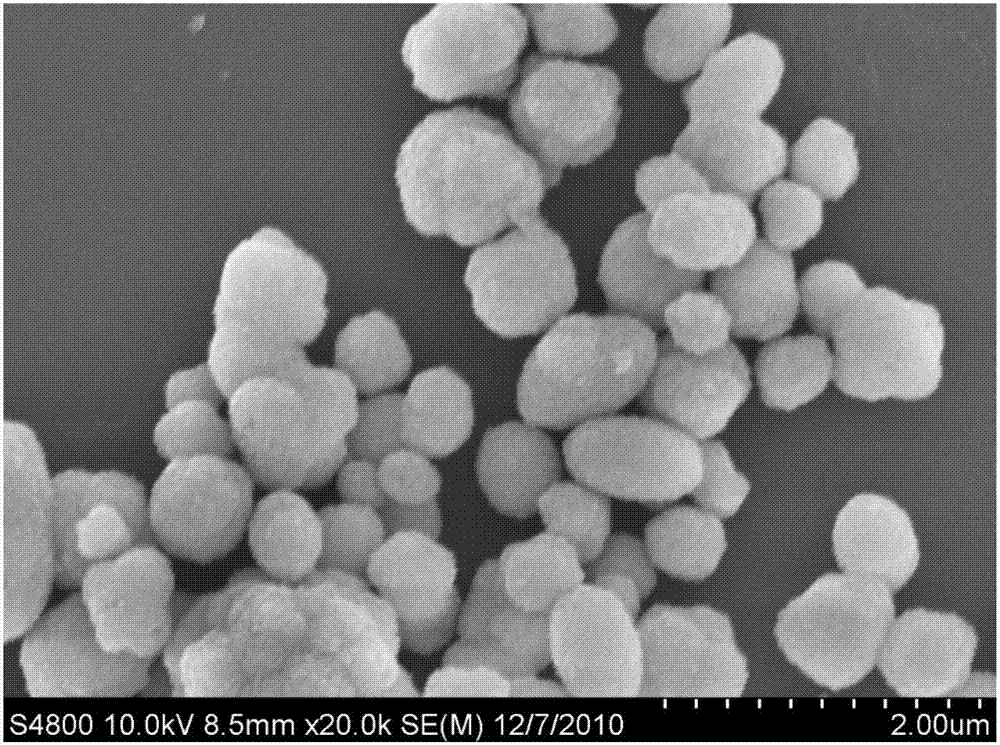

Plugging agent for environment-friendly water-based drilling fluid and preparation method of plugging agent

The invention discloses a plugging agent for environment-friendly water-based drilling fluid and a preparation method of the plugging agent. A product is obtained from a reaction of, by weight, 30-50 parts of carbon balls coated with AlOOH, 10-20 parts of acrylamide, 10-20 parts of N-isopropylacrylamide and 2-4 parts of hexamethylenetetramine under the action of 0.01-0.05 part of initiator, and the plugging agent for the environment-friendly water-based drilling fluid is obtained by mixing the product and 30-50 parts of vinyl acetate-ethylene copolymer emulsion under the action of 2-5 parts of dispersant. The plugging agent for the environment-friendly water-based drilling fluid has the advantages of good plugging effect, no toxic effect, certain compressive strength, high temperature-resistance capability and good compatibility with the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling fluid lubricating agent composition containing lubricating capsules, preparation method of drilling fluid lubricating agent composition, water-based drilling fluid and application thereof

InactiveCN109135690ALow costImproves oxidation stability and lubricityDrilling compositionGas industryPetroleum

The invention belongs to the technical field of drilling fluid in petroleum and natural gas industry and relates to a drilling fluid lubricating agent composition containing lubricating capsules, a preparation method of the drilling fluid lubricating agent composition, water-based drilling fluid and application thereof. The lubricating agent composition comprises the capsules, a dispersing agent,an anti-wear reagent at extreme pressure and a defoaming agent and is characterized in that each capsule comprises a capsule shell and a lubricating substance arranged in the capsule shell, the capsule shell is prepared by sulfonated polyimide, dimethyl diallyl ammonium chloride and ceric ammonium nitrate through polymerization reaction, and the lubricating substance is one or more of modified vegetable oil, biodiesel, surfactant and polyol non-ionic emulsifier. The lubricating agent composition has the advantages that the composition can achieve targeting release under pressure control, a drilling fluid lubricating agent can perform 'targeting positioning and lubricating according to needs' on underground high-friction-drag and high-torque parts, the efficient friction and resistance reducing effect of the lubricating agent is brought into full play, and the drilling fluid lubricating agent composition is good in friction resistance, good in turbidity point stability, easy in biodegradation, green, environmentally friendly and promising in application prospect.

Owner:SINOPEC SSC +2

Nanometer lubricant for drilling fluid and preparation method of nanometer lubricant

InactiveCN108753269AGood dispersionLarge specific surface areaMaterial nanotechnologyDrilling compositionWater in oil emulsionSURFACTANT BLEND

The invention discloses a nanometer lubricant for a drilling fluid and a preparation method of the nanometer lubricant in the petroleum industry. The lubricant is added to the drilling fluid to improve the lubricity of the drilling fluid, and then the friction and the torque in the drilling process are reduced. The nanometer lubricant for the drilling fluid comprises linear alpha-olefin, nanosilicon dioxide, sulfide fatty acid ester, a surfactant and water, the preparation method comprises putting the linear alpha-olefin into a stirring kettle, controlling the temperature of the kettle to 25-30 DEG C, then proportionally adding the surfactant, stirring for 4 hours, proportionally adding the nanosilicon dioxide, stirring for 2 hours, then proportionally adding the sulfide fatty acid ester,stirring for 2 hours, proportionally adding water, controlling the water addition speed to be lower than or equal to 2 m<3> / h, and continuously stirring for 4 hours until an even water-in-oil emulsionis formed, wherein the water-in-oil emulsion is the nanometer lubricant for the drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

Drilling fluid plugging agent while drilling

Owner:PETROCHINA CO LTD

Low-permeability plugging agent

The invention discloses a low-permeability plugging agent which is composed of the following components in percentage by mass: 60-70% of organic material, 15-25% of high-temperature-resistant fiber and 10-15% of surfactant. The low-permeability plugging agent does not have the polymer component, is still available under high-temperature conditions, and does not influence the rheological properties of the drilling fluid in a conventional environment under high-density conditions. By reasonably optimizing the particle size distribution, the low-permeability plugging agent can effectively plug various pore throats and cracks and enhance the stratum loading capacity.

Owner:ASTAR PETROTECH

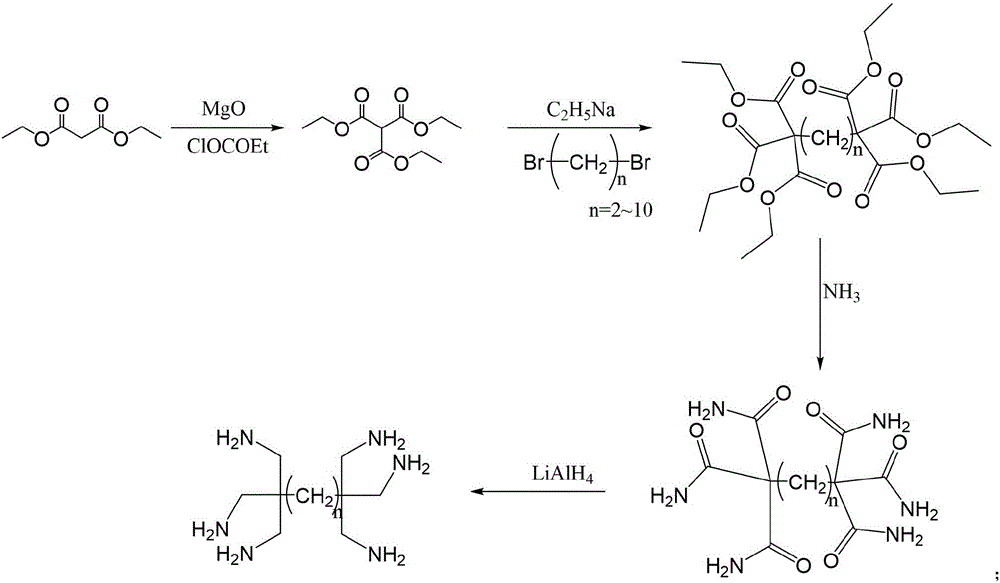

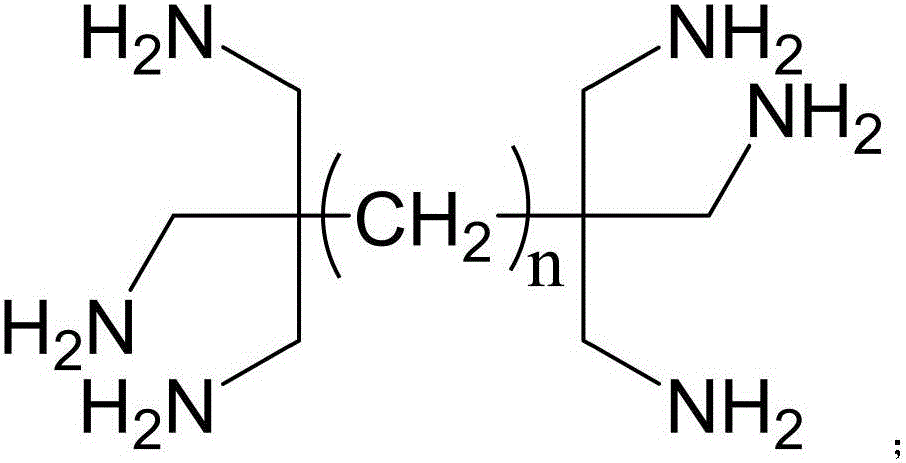

Ultralow molecular weight dendritic alkyl hexamine shale inhibitor and synthetic method thereof

InactiveCN106380407AReliable technologyLow priceOrganic compound preparationCarboxylic acid esters preparationSolubilityEnvironmental resistance

The invention relates to an ultralow molecular weight dendritic alkyl hexamine shale inhibitor and a synthetic method thereof. The synthetic method comprises the following steps: 1, synthesizing triethyl methanetricarboxylate; 2, synthesizing hexaester; 3, synthesizing hexaamide; and 4, synthesizing hexamine. The alkyl hexamine product prepared through the method has a molecular structure formula shown in the description, and 1-3% of the alkyl hexamine product is mixed with clear water to prepare a shale inhibitor. The synthetic method has the advantages of good reliability, high synthesis yield, low prices of raw materials, low production cost, safe and environmentally-friendly product, and suitableness for large-scale industrial production; and the alkyl hexamine product is nontoxic and harmless, has good water solubility, and has an obviously better inhibition performance than the same variety of products, and the addition amount of the alkyl hexamine has small influences on the rheological property of a drilling fluid, so the contradiction of the inhibition and the rheological property of the drilling fluid is effectively balanced, and the drilling fluid has high temperature resistance and is especially suitable for drilling ultrahigh temperature deep wells.

Owner:SOUTHWEST PETROLEUM UNIV

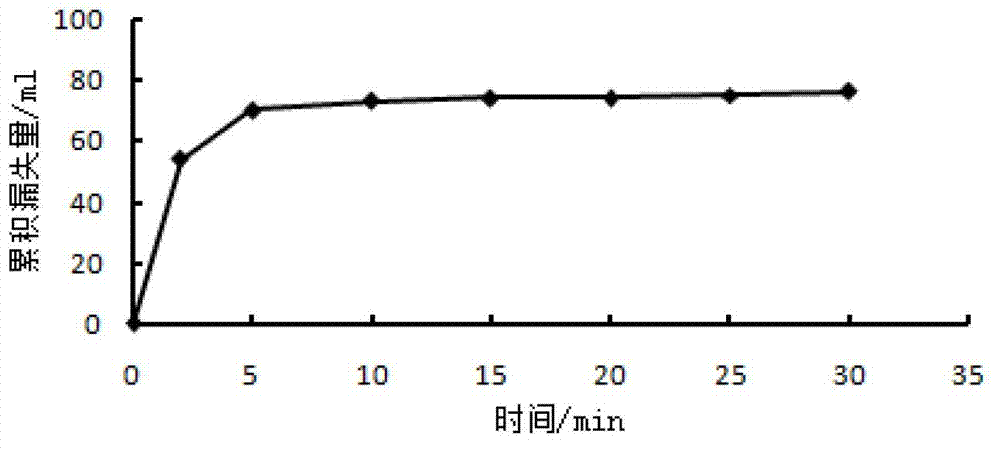

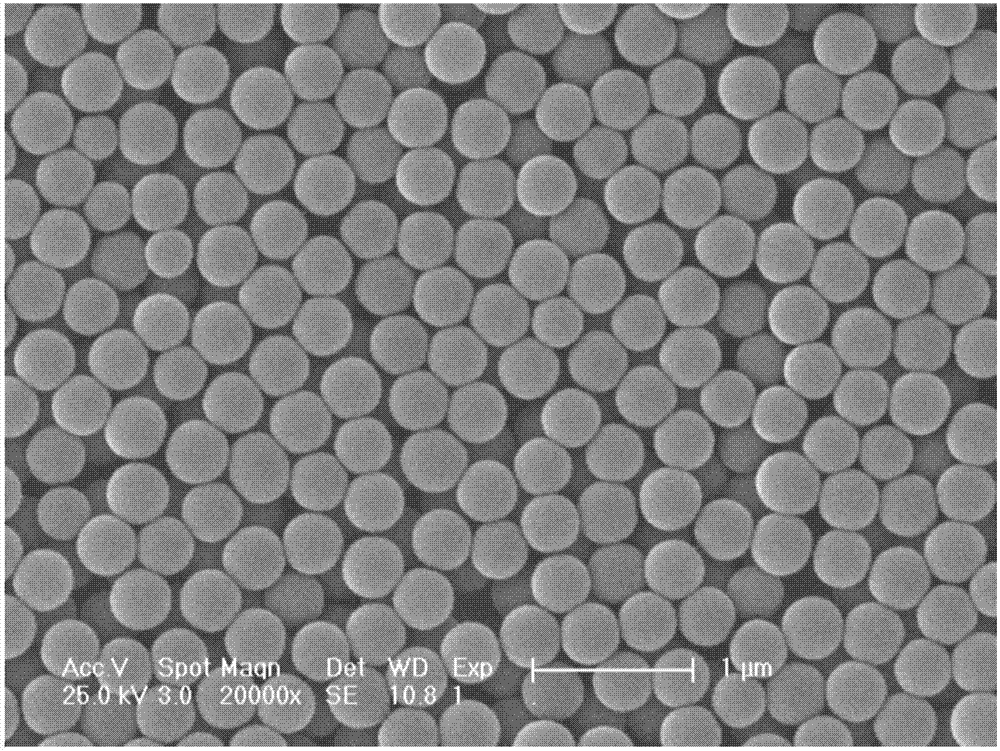

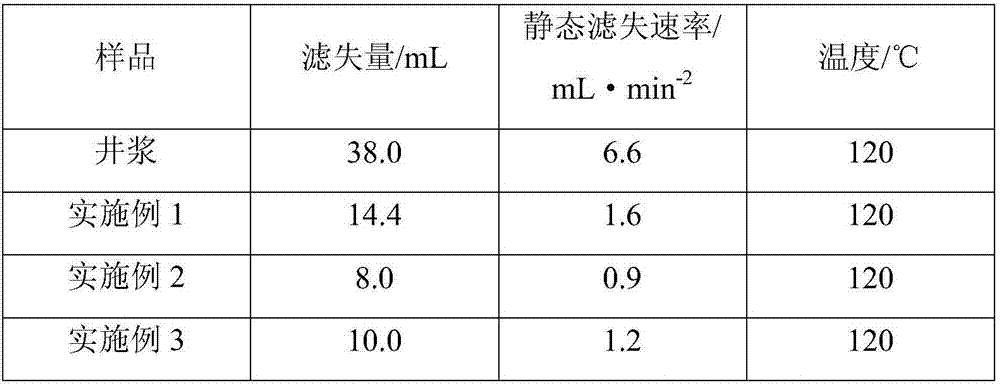

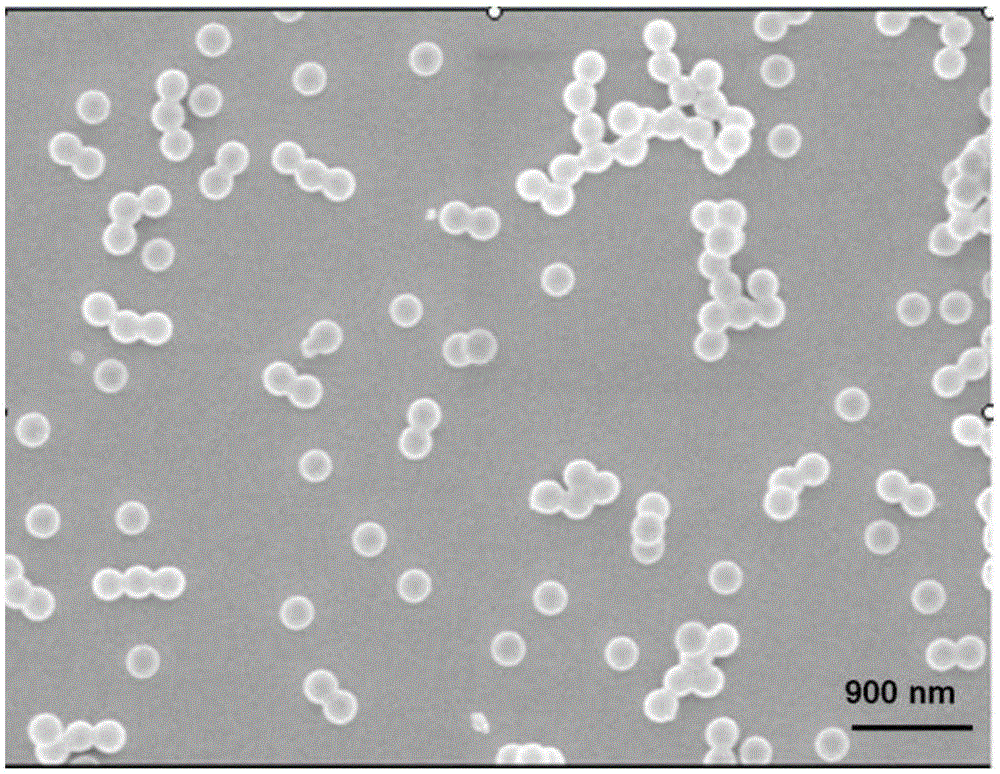

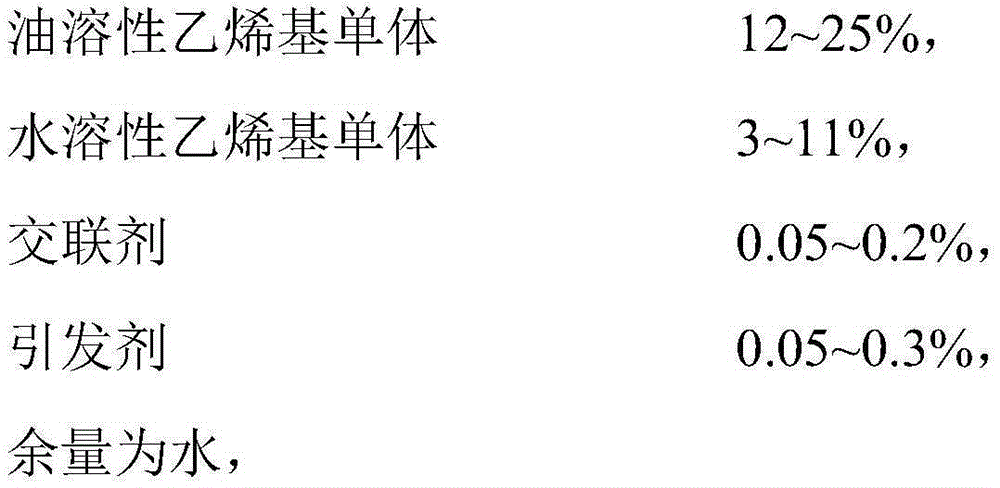

Temperature-resistant salt-resistant nano anti-collapse filtrate reducer for drilling fluid and preparation method thereof

ActiveCN105330785ALittle impact on rheologyFunction increaseDrilling composition2-Methyl propaneEmulsion

The invention discloses a temperature-resistant salt-resistant nano anti-collapse filtrate reducer and a preparation method thereof. The filtrate reducer is prepared by 12 to 25 percent by weight of oil-soluble vinyl monomer, 3 to 11 percent by weight of water-soluble vinyl monomer, 0.05 to 0.2 percent by weight of cross-linking agent, 0.05 to 0.3 percent by weight of initiator and balance of water in a polymerization method by virtue of soap-free emulsion, wherein the oil-soluble vinyl monomer is methyl acrylate or methyl methacrylate; the water-soluble vinyl monomer comprises 1 to 3 percent by weight of N-vinyl pyrrolidone and 2 to 8 percent by weight of 2-acrylamide-2-methyl propane sulfonic acid. The temperature-resistant salt-resistant nano anti-collapse filtrate reducer for the drilling fluid is applied to the drilling fluid and has an excellent filtration reduction function and an excellent anti-collapse function; moreover, the temperature resisting performance and the salt resisting performance are remarkably better than that of a material disclosed in patents Cn201410141841.4 and Cn201410142391.0, the resisting temperature can reach 240 DEG C, the concentration of the resisted calcium chloride is 0.5 percent by weight or more, the concentration of the resisted sodium chloride is saturated, and the rheology impact on the drilling fluid is relatively small.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A microemulsion type lubricant used for a drilling fluid and a preparing method thereof

InactiveCN106634877ASolve environmental problemsMeet the needs of industrial productionDrilling compositionChemistryMineral oil

The invention relates to a microemulsion type lubricant used for a drilling fluid and a preparing method thereof. The lubricant includes mineral oil or refined gutter oil, a surfactant, an inorganic salt, n-butanol and water. The method includes firstly adding water into a reaction kettle, slowly adding the surfactant into the reaction kettle with the stirring speed being 2000-3000 r / min; after the water and the surfactant are fully mixed, slowly adding the inorganic salt; after the inorganic salt is fully dissolved, adding the n-butanol and the mineral oil or refined gutter oil; and allowing the mixture to stand for 5-10 h. The lubricant and the method are advantageous in that industrial production of the lubricant can be achieved and the environment protection problem of the gutter oil is solved; the lubricant has good compatibleness with a water-based drilling fluid, has low influences on rheological properties of the drilling fluid, and can effectively reduce the frictional resistance coefficient and the mud cake adhesion coefficient; and by adding the lubricant into the drilling fluid, the mud cake adhesion coefficient can be effectively reduced. Experiment measurement shows that the highest reduction rate of the mud cake adhesion coefficient is 52.3%.

Owner:SINOPEC SSC +2

Drilling fluid lubricant composition and preparation method thereof and water-based drilling fluid and application thereof

InactiveCN109135691AImprove wear resistancePromote degradationDrilling compositionMicroballoon preparationWater basedBiodiesel

The invention belongs to the technical field of drilling fluid for the petroleum and natural gas industry, and relates to a drilling fluid lubricant composition and a preparation method thereof and awater-based drilling fluid and application thereof. The lubricant composition comprises modified vegetable oil, biodiesel, capsule particles, a first dispersant, an extreme pressure antiwear additiveand a defoaming agent, the capsule particles comprise internal materials and capsule materials covering the internal materials, the capsule materials are made of phenolic resin, and the internal materials include sulfonated polyimides, water and a second dispersant. The capsule particles are introduced to the drilling fluid lubricant composition, so that the composition in the drilling fluid is not affected by high temperature, is easy to degrade, has good cloud point, has low influence to rheological property of the drilling fluid, and can meet requirements on lubricating property of the drilling fluid better.

Owner:中石化石油工程技术服务有限公司 +2

Oil base drilling fluid wetting agent and application thereof

The invention discloses an oil base drilling fluid wetting agent and application thereof, belonging to the technical field of oil and gas filed chemical engineering. The wetting agent comprises the following components by weight percent: 60%-90% of pine tar and 10%-40% of oleic acid, wherein the pine tar is vegetable pine tar, oleic acid is vegetable oleic acid, and the adding amount of the wetting agent accounts for 1%-3% of the weight of the oil base drilling fluid. The components of the wetting agent have wide source of feed and are cheap; the wetting agent is easy to prepare, has good wetting effect on multiple weighting materials, and can be widely used for the base oil of the oil base drilling fluid; the oil base drilling fluid prepared by using the wetting agent can meet the well drilling and construction requirements of unconventionality oil and gas reservoirs.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

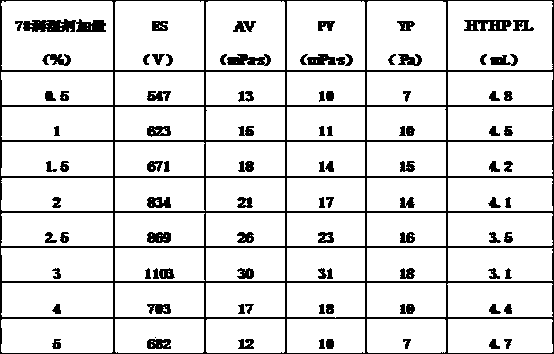

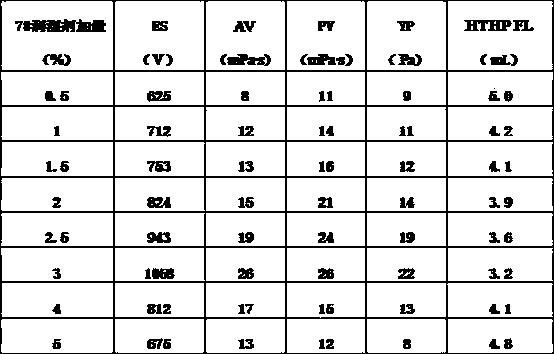

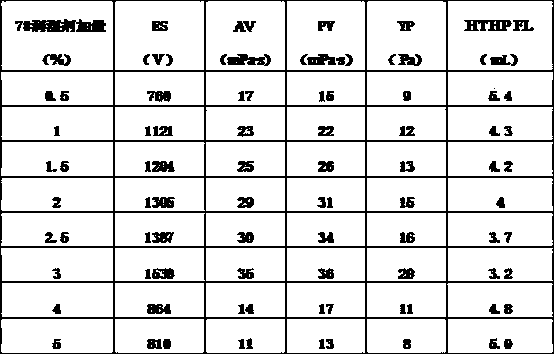

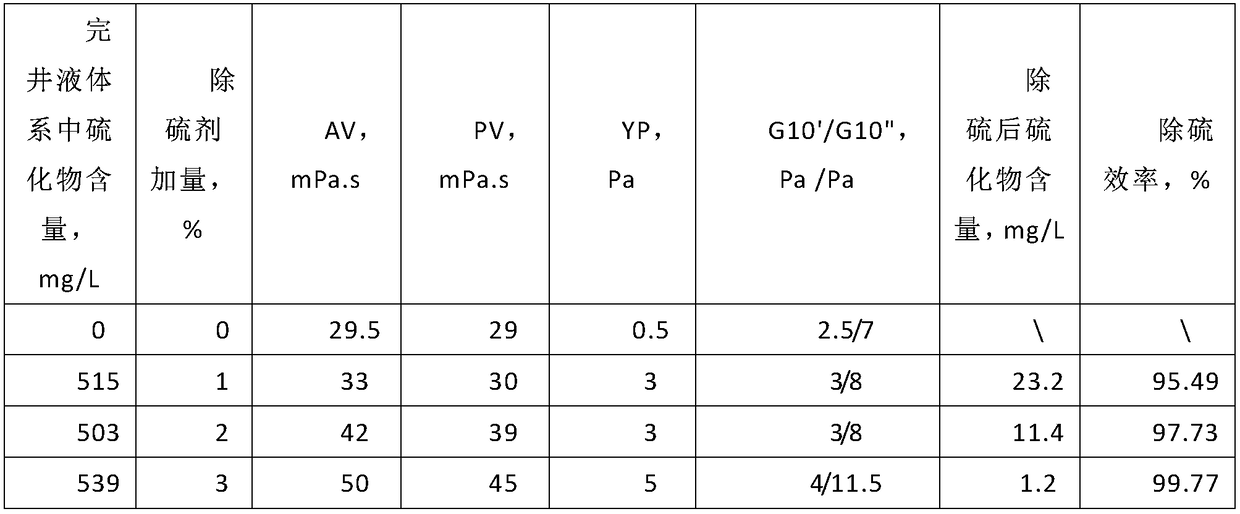

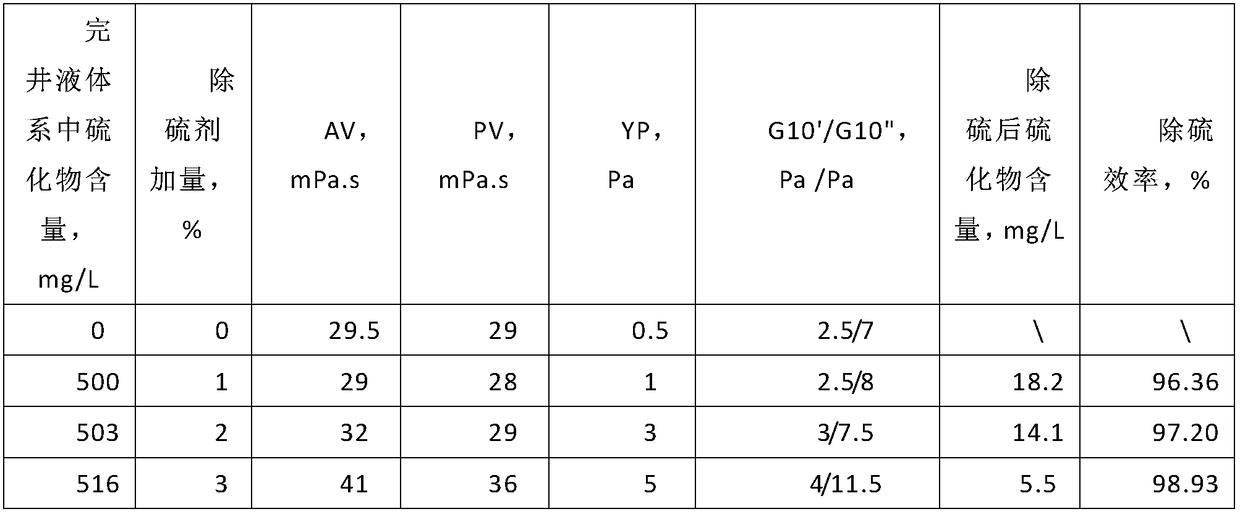

Preparation method of suspension liquid desulfurization agent for water-based oil testing well completion fluid system

ActiveCN108865094ALow viscosityLow sulfur removal efficiencyDrilling compositionBorehole/well accessoriesWater basedHydrogen

The invention discloses a preparation method of a suspension liquid desulfurization agent for a water-based oil testing well completion fluid system. The suspension liquid desulfurization agent is prepared from the following raw materials in parts by weight: 5 to 8 parts of a surface modifying agent, 0.8 to 1 part of an emulsifier, 1 to 3 percent of a dispersant and 10 to 30 parts of nano-powder;the preparation method comprises the following steps: adding the surface modifying agent into isopropyl alcohol in a container A; heating to 60 to 80 DEG C and stirring to form a uniform solution; adding the dispersant, the emulsifier and the nano-powder into a water solution with the pH (Potential of Hydrogen) of 9 to 10 in a container B; heating to 60 to 80 DEG C and stirring to form a uniform solution; under the action of rapid stirring, adding the uniform solution formed in the container A into the container B and stirring for 2h to form slurry which is uniformly dispersed; cooling to roomtemperature. According to the preparation method disclosed by the invention, the desulfurization agent and a well completion fluid system treatment agent are not gathered and consolidated under a high-temperature condition of 180 DEG C; the desulfurization agent does not influence the rheological property and sedimentation stability of the well completion fluid system under the high-temperature condition, and the aim of high desulfurization efficiency is realized.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

Environmentally-friendly microemulsion lubricant used for well drilling fluid and preparation method of lubricant

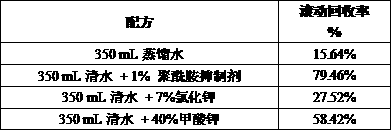

InactiveCN107459978ALittle impact on rheologySolve environmental problemsDrilling compositionEmulsionEnvironmental resistance

The invention relates to the technical field of well drilling industry chemical engineering, and especially relates to an environmentally-friendly microemulsion lubricant used for a well drilling fluid and a preparation method of the lubricant. The micro emulsion lubricant can match with the water-based well drilling fluid, and influences on a well drilling fluid rheological property is relatively small, so that a lubricating property of a well drilling fluid system is improved, frictional drag and a sticking coefficient are effectively reduced, and a drilling speed is improved. The environmentally-friendly microemulsion lubricant used for the well drilling fluid is composed of refined illegal cooking oil, a surfactant, an inorganic salt, n-butyl alcohol and water, wherein the weight content of the refined illegal cooking oil is 10%-30%, the weight content of the surfactant is 10%-15%, the weight content of the n-butyl alcohol is 10%-20%, the weight content of the inorganic salt is 2%-4%, and the balance of the water.

Owner:SINOPEC SSC +2

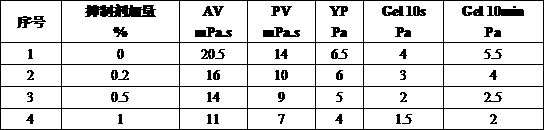

Preparation method of imidazoline inhibitor applicable to drilling fluid

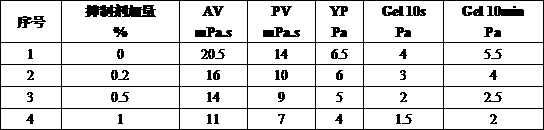

InactiveCN107699214AStable rheologyFiltration performance is stableOrganic chemistryDrilling compositionChemistryDrilling fluid

The invention discloses a preparation method of an imidazoline inhibitor applicable to drilling fluid. The preparation method comprises the following steps: a. adding a material A and a material B into a reaction kettle according to a molar ratio of 2 : (1 to 2), and continuously stirring for fully mixing; b. cooling reactants to 100 DEG C or below; c. then, reducing the pressure to 0.5-0.7kPa, heating up to 240 DEG C, maintaining the temperature, and reacting for 2-8h; d. stopping heating, cooling to 120 DEG C, pouring the cooled product into a crystallization kettle, and cooling and condensing into a brown yellow material which is the product. The inhibitor prepared by the method provided by the invention is good in compatibility with a conventional water-based treatment agent, has little impact on the properties of water-based drilling fluid, and can effectively strengthen the inhibition ability of the water-based drilling fluid, thus achieving the effect of inhibiting the hydrationdispersion of water sensitive formation minerals; therefore, the well drilling cost is lowered, and the well drilling safety and speed are guaranteed.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

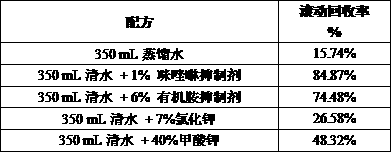

Preparation method of polyamide inhibitor for drilling fluid

InactiveCN107841298ARolling recovery rate (150°C) increasedStable rheologyDrilling compositionViscous liquidClay minerals

The invention discloses a preparation method of a polyamide inhibitor for drilling fluid. The preparation method comprises the following steps: (a) feeding a substance A and a substance B into a reactor according to the molar ratio of (0.5 to 2):1, heating to 60 DEG C, and stirring for 30 minutes till the materials are completely melted and mixed uniformly; (b) under the condition of nitrogen-gasprotection, carrying out insulating reaction for 5-8 hours at the temperature of 150-180 DEG C, and separating out water; (c) after the reaction is ended, cooling reactants to below 30 DEG C and obtaining yellow or brown-yellow viscous liquid, namely a final product; the substance A is dimer acid, trimer acid or a mixture of the dimer acid and the trimer acid. The polyamide inhibitor prepared by adopting the method has the characteristics of high-temperature resistance, obvious inhibition effect and slight influence on the rheological property and the like, is applicable to various water-baseddrilling fluid systems, not only can prevent the problem of well-wall instability caused by hydrous dispersion and expansion of clay minerals of the water-sensitive formation, but also can stabilizethe rheological property of the drilling-fluid system effectively and avoid the property from being out of control.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

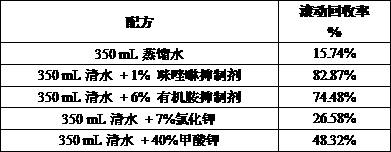

Preparation method of tetrahydroglyoxaline inhibitor applicable to drilling fluid

InactiveCN107721929AHigh recovery rateStable rheologyOrganic chemistryDrilling compositionWater basedViscous liquid

The invention discloses a preparation method of a tetrahydroglyoxaline inhibitor applicable to a drilling fluid. The preparation method comprises the following steps of a, adding 150mL of substance A,150mL of substance B and 26.8g of substance C in a beaker; b, using 8 to 12mL of water for dissolving 7.6g of substance D, and dropwise adding 1 to 2 drops of sodium hydroxide solution; c, using thesodium hydroxide solution for adjusting a pH value of a reaction mixture to 8, filtering for removing separated white solid, distilling off the substance A, the substance B and water, and obtaining apale yellow viscous liquid; d, using chloroform for extracting to obtain a product 1; e, adding 13.6g of product 1 and 7.4g of substance E in to a three-necked flask, and obtaining an orange-yellow viscous transparent liquid; f, using ethyl acetate as an eluent, and obtaining a product 2; g, adding 60mL of substance B and 5.8g of substance F into the three-necked flask, and obtaining a pale yellowviscous liquid; h, extracting with acetone, removing a solvent, using benzene for recrystallizing, and obtaining a white product. The polyamide inhibitor prepared by adopting the method has the characteristics of high temperature resistance, remarkable inhibitory effect, less influence on rheological property, and the like, and is applicable to various water-based drilling fluid systems.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

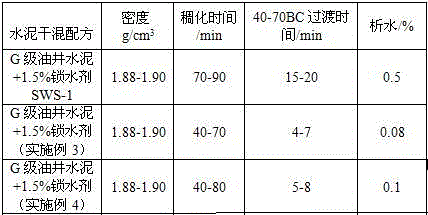

Non-chloride ion potassium salt water-locking agent for oil well cement, preparation method and application thereof

ActiveCN106517843AHigh normal sclerosisPromote rapid formationDrilling compositionPotassiumPetroleum

Belonging to the technical field of oil-gas well cementing additives for the petroleum industry, the invention provides a non-chloride ion potassium salt water-locking agent for oil well cement, a preparation method and application thereof. The non-chloride ion potassium salt water-locking agent is composed of the following materials by mass percentage: 40-60% of a potassium salt, 10-30% of alkali, and 20-40% of sodium silicate, can effectively improve the early strength of cement stone, greatly shortens the well cementing setting waiting time, is free of chlorine ions and other corrosive ions, has no corrosive effect on casing pipes and cement stone, is easy for dry blending, has obvious reinforcing effect on cement slurry, low hydration heat and small influence on the rheological properties of cement slurry, and is conducive to site construction operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of imidazoline inhibitor for drilling fluid

InactiveCN107698619AGood inhibitory effectGood compatibilityGroup 5/15 element organic compoundsDrilling compositionPolyamideAqueous solution

The invention discloses a preparation method of an imidazoline inhibitor for drilling fluid. The preparation method comprises the following steps: (a) adding a substance A and a substance B in a molarratio of (1 to 2):1, and synthesizing an intermediate I; (b) adding water in a molar ratio of (1.1 to 2):1 of water to the substance A into the intermediate I synthesized in the step (a) at 50-100 DEG C; (c) dropwise adding a substance D with equal amount as the substance A into a hydrolysate generated in the step (b) at 50 to 100 DEG C, keeping the temperature and reacting for 1-5h to obtain anintermediate II; (d) adding, in batches, a substance E in a molar ratio of 1:2 of the substance E to the substance A into the intermediate II obtained in the step (c) at 40-100 DEG C to obtain an intermediate III; (e) adding alkali, water and an aqueous solution of the substance A into the intermediate III obtained in the step (d), in a ratio of 2:(40 to 70): 1 to obtain a yellow-brown substance which is the final product. By adopting the method disclosed by the invention, the prepared imidazoline inhibitor has the characteristics of resistance to high temperature, remarkable inhibiting effect, little impact on rheological property and the like, and is suitable for different water-based drilling fluid systems.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

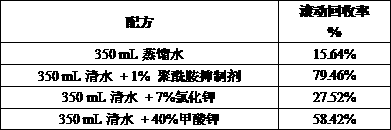

Soilless potassium formate water-based drilling fluid for drilling shale

InactiveCN105295865AReduce pollutionEasy to handleDrilling compositionWater basedPolyethylene glycol

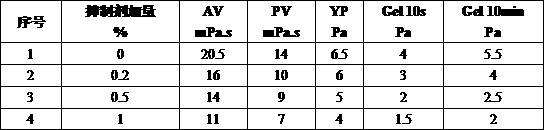

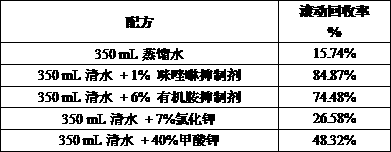

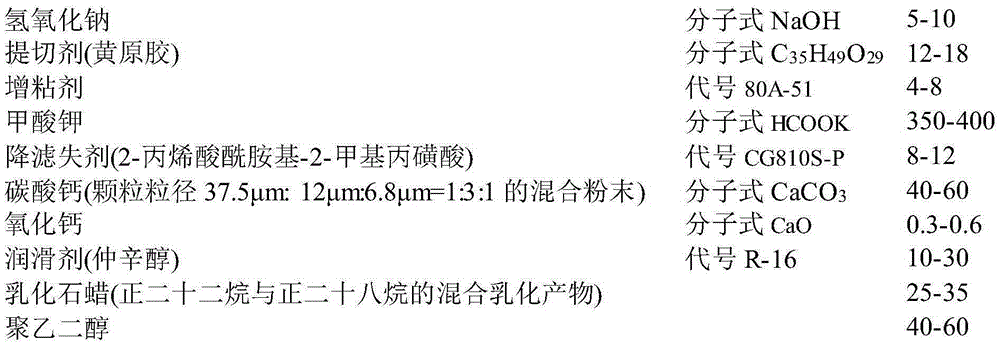

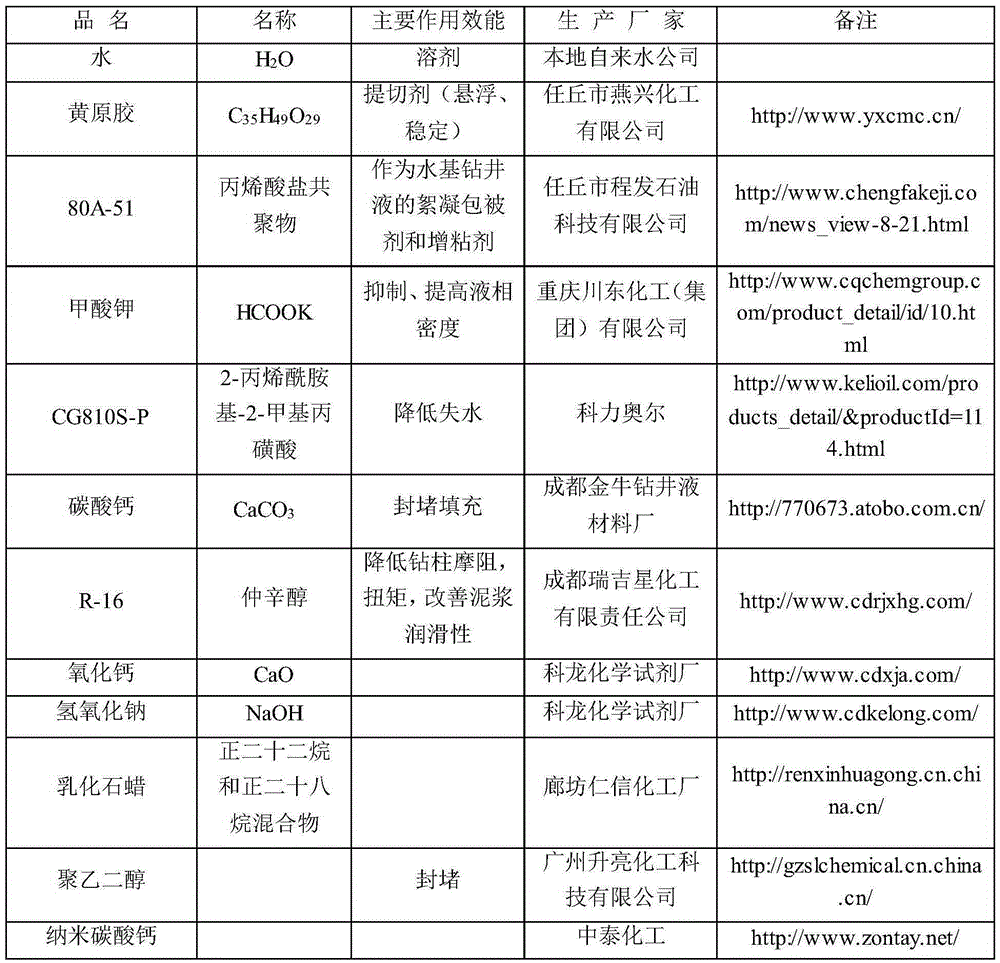

The invention relates to soilless potassium formate water-based drilling fluid for drilling shale which is used in long horizontal shale sections with developing microcracks. The soilless potassium formate water-based drilling fluid can inhibit the hydration collapse of shale formations, seal the nano-micropores and nano-microcracks of shale and solve the problem of stabilizing well walls. The technical solvent is that the materials for preparing the drilling fluid and contents (mass unit: gram) thereof are as follows: 12g to 18g of xanthan gum as a shear strength-improving agent; 4g to 8g of tackifier 80A-51; 350g to 400g of potassium formate; 8g to 12g of filtrate reducer CG810S-P; 0.3g to 0.6g of calcium oxide; 40g to 60g of calcium carbonate; 10g to 30g of lubricant R-16; 40g to 60g of polyethylene glycol; 25g to 35g of emulsified paraffin; 5g to 15g of nano calcium carbonate; 900g to 1200g of tap water; a sodium hydroxide solvent with the concentration of 40 percent. The tap water is first weighed and added with the xanthan gum while agitated under 500r / min, the treatment agents, such as the 80A-51, the potassium formate, the CG810S-P, the CaO, the CaCO3 and the R-16, are then sequentially added, the pH of the system is then regulated to 8.5, and thereby the drilling fluid is produced. The environment pollution of a drilling fluid system is little, and the drilling fluid system has good rheological property and strong inhibiting and sealing capabilities, and can be used in shale drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of polyamide inhibitor for drilling fluid

InactiveCN107699215AImproved rolling recoveryGood inhibitory effectDrilling compositionSolventPolyamide

The invention discloses a preparation method of a polyamide inhibitor for drilling fluid. The preparation method comprises the following steps: (a) dissolving a substance A in an alcohol solvent, andadding a substance B into the alcohol solution of the substance A, wherein the mass ratio of A to B is (1 to 1.5): 1, the reaction temperature is 45-70 DEG C, and the reaction time is 12-24h, so as toobtain an intermediate product; (b) adding a substance C and a catalyst into the intermediate product, wherein the mass ratio of C to A is (0.5 to 1.2): 1, and the dosage of the catalyst accounts for1% of the substance A; heating to a reflux temperature, and reacting for 4-12h at the reflux temperature; (c) distiling out the solvent alcohol to obtain a product. The polyamide inhibitor prepared by the invention has the characteristics of remarkable high-temperature resisting and inhibiting effect, and little impact on rheological property and the like, and is suitable for different water-based drilling fluid systems. The polyamide inhibitor can prevent the problem of borehole instability caused by hydration dispersion and expansion of clay minerals on water-sensitive formation, and also can effectively stabilize the rheological property of the drilling fluid system so as to avoid failure in performance control.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

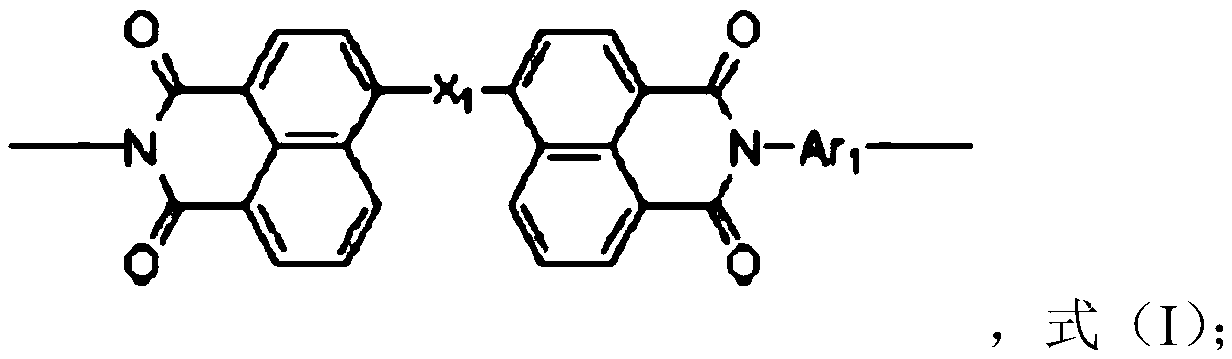

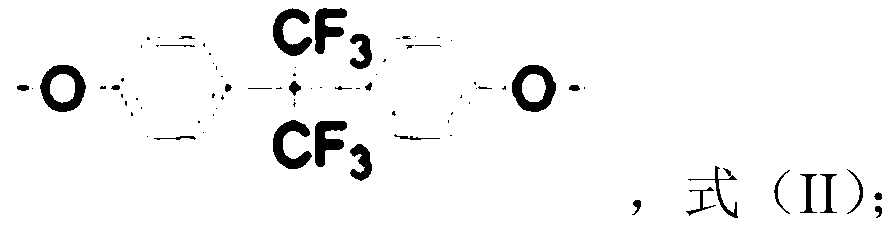

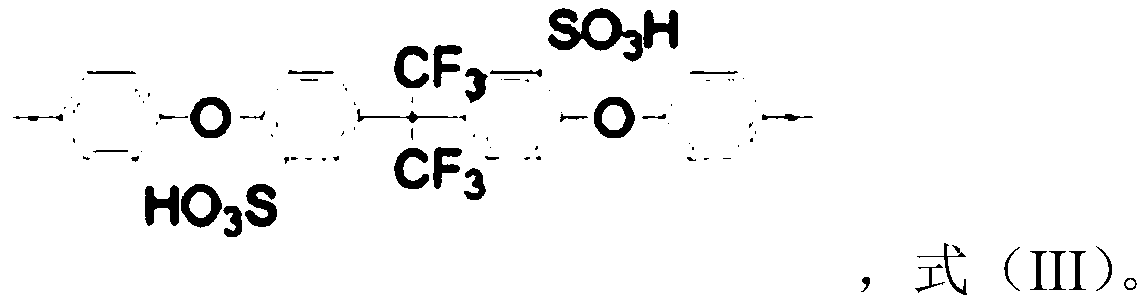

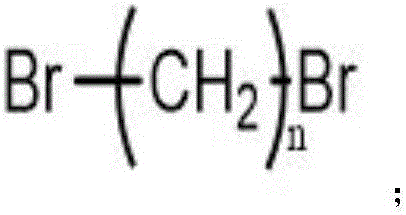

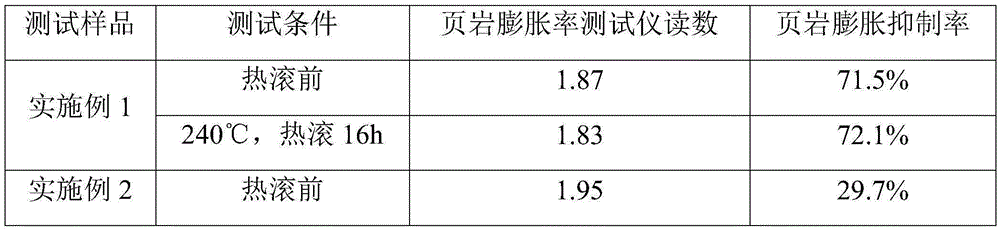

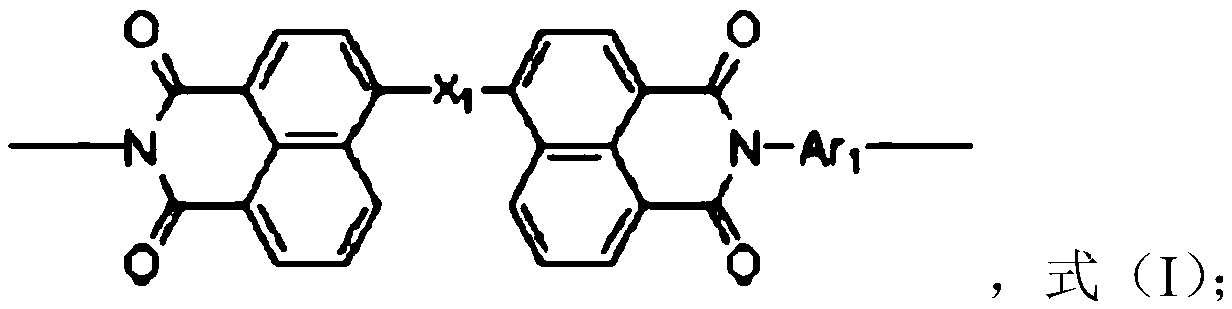

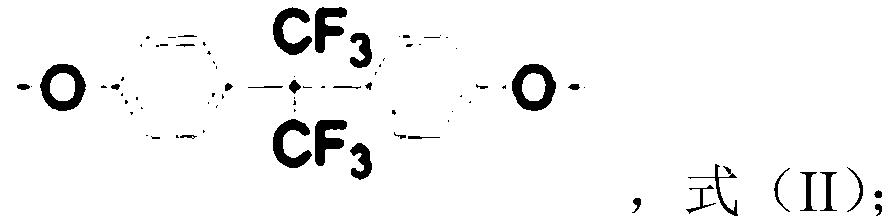

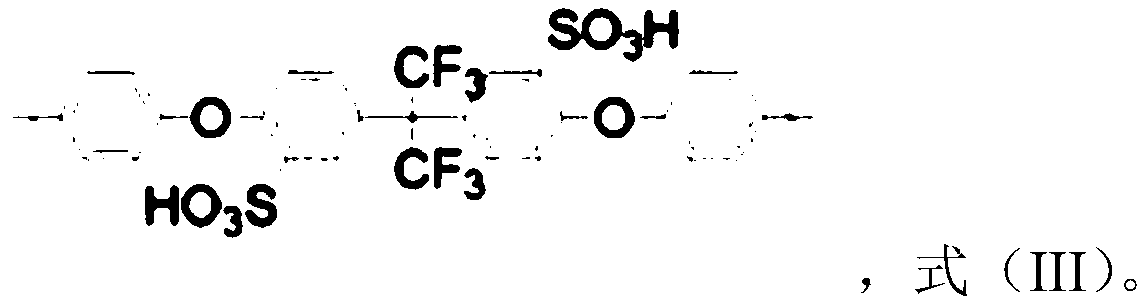

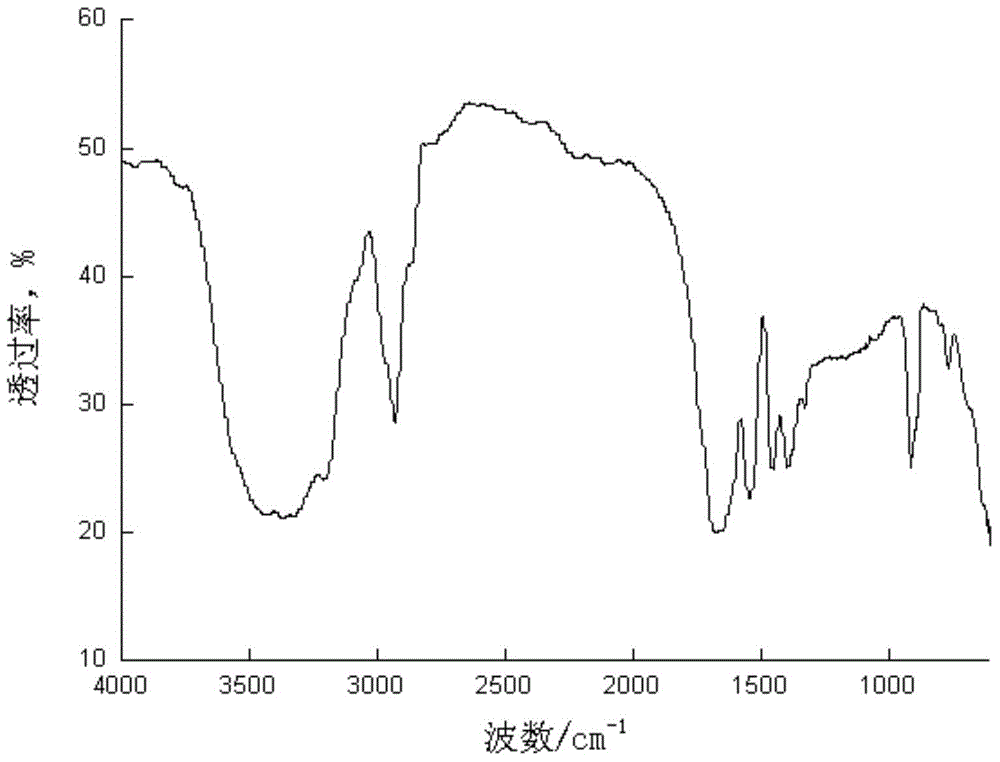

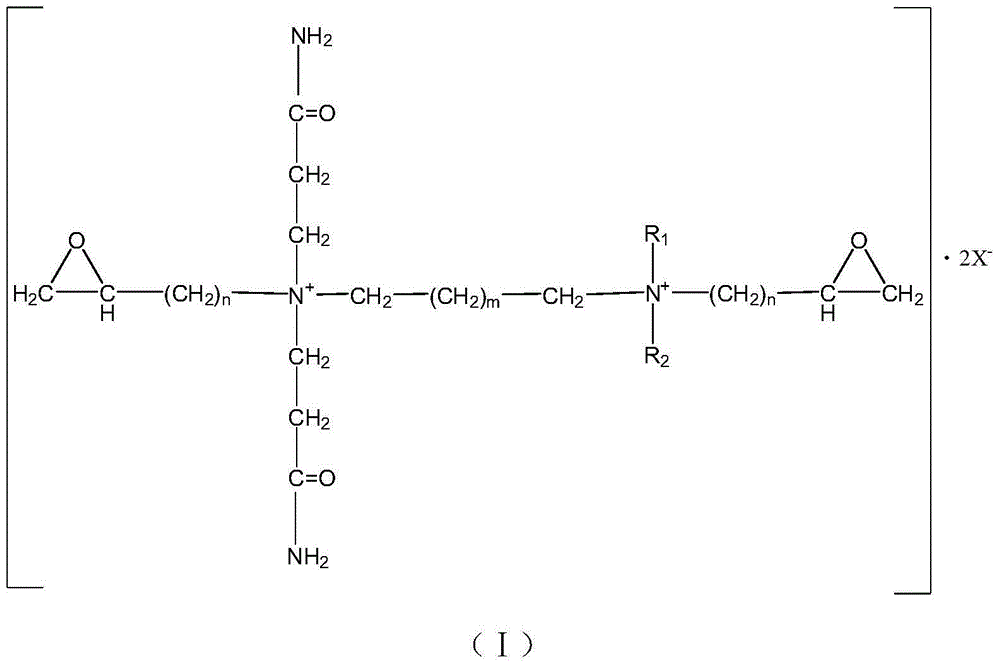

Biquaternary ammonium salt compound and application thereof in solid-phase chemical cleaning agent

ActiveCN105085441AImprove removal efficiencyEnhanced inhibitory effectOrganic chemistryDrilling compositionWater basedFiltration

The invention discloses a biquaternary ammonium salt compound and application thereof in a solid-phase chemical cleaning agent and belongs to the field of petroleum drilling. The biquaternary ammonium salt compound provided by the invention has a structural formula represented by a general formula (I) shown in the description. The biquaternary ammonium salt compound provided by the invention can play a dual role in flocculating and inhibiting in the solid-phase chemical cleaning agent. The invention also provides intermediates for preparing the solid-phase chemical cleaning agent and the solid-phase chemical cleaning agent containing at least one of the aforementioned intermediates. The solid-phase chemical cleaning agent provided by the invention is good in drilling fluid inhibiting capacity and high in harmful solid phase removal efficiency, has little influence on the filtration loss and rheological property of drilling fluid in an effective dose range, can achieve low-solid-phase rapid well drilling and meets the needs of different water-base drilling fluid systems.

Owner:CHINA PETROLEUM & CHEM CORP +1

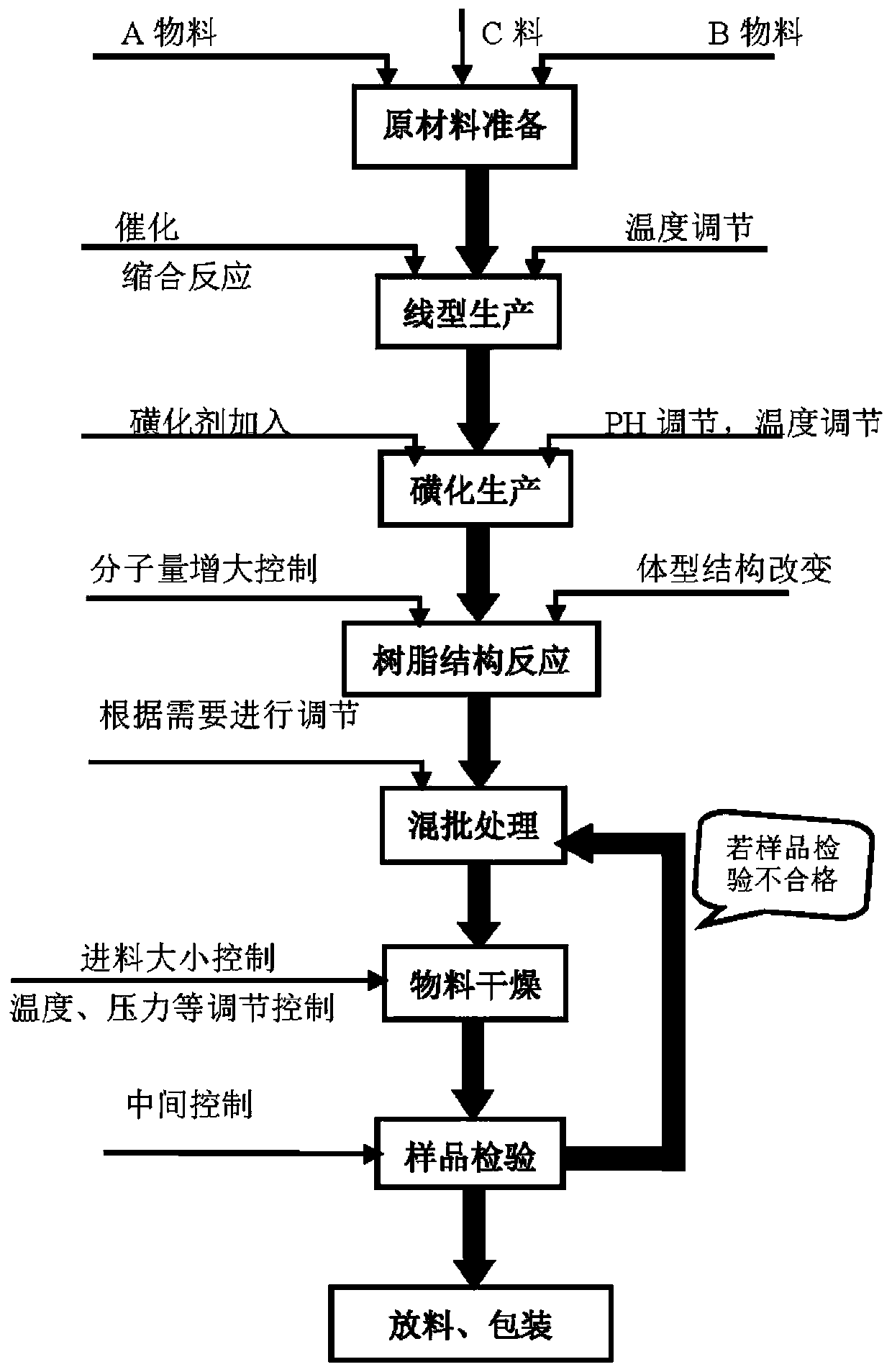

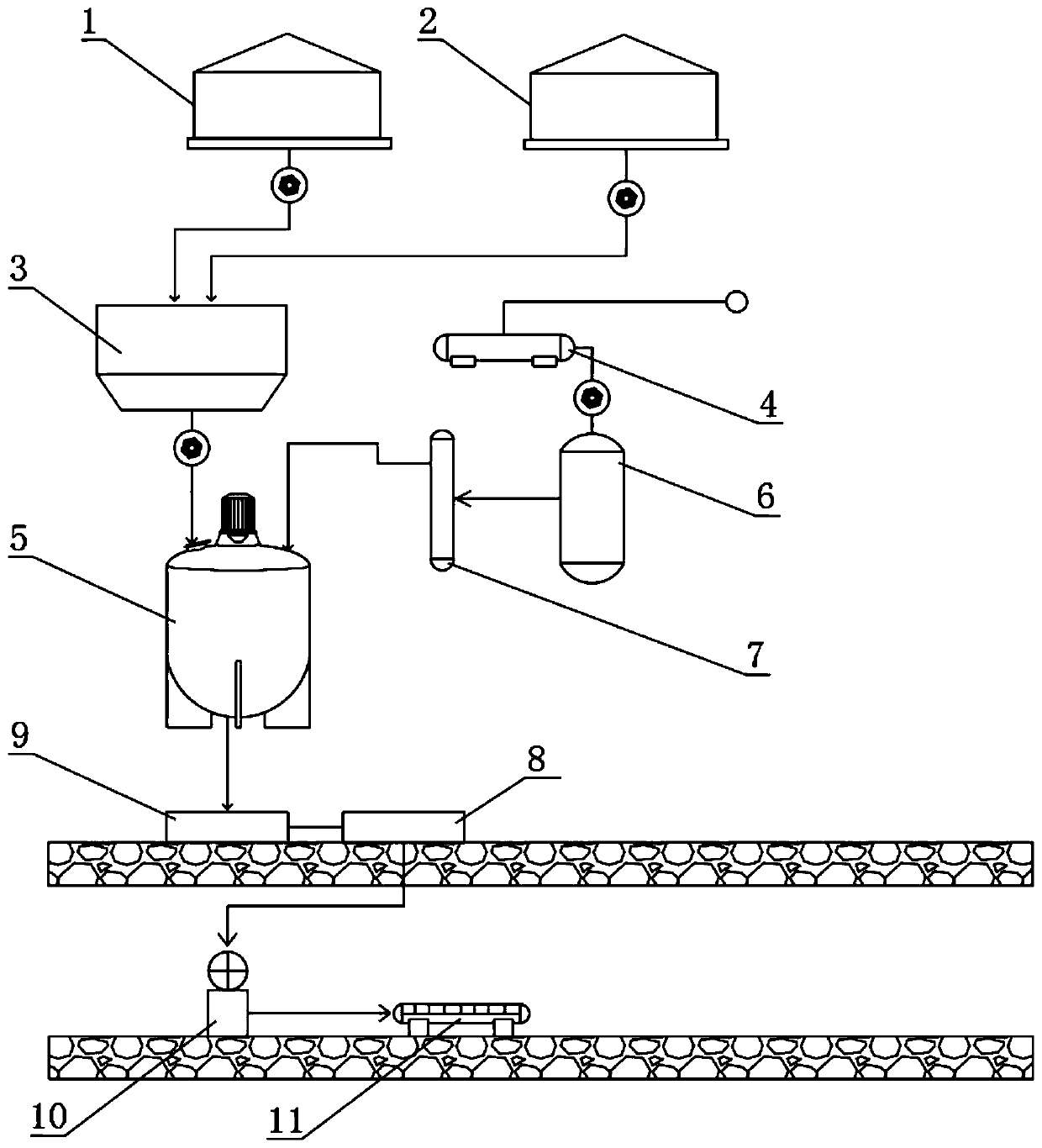

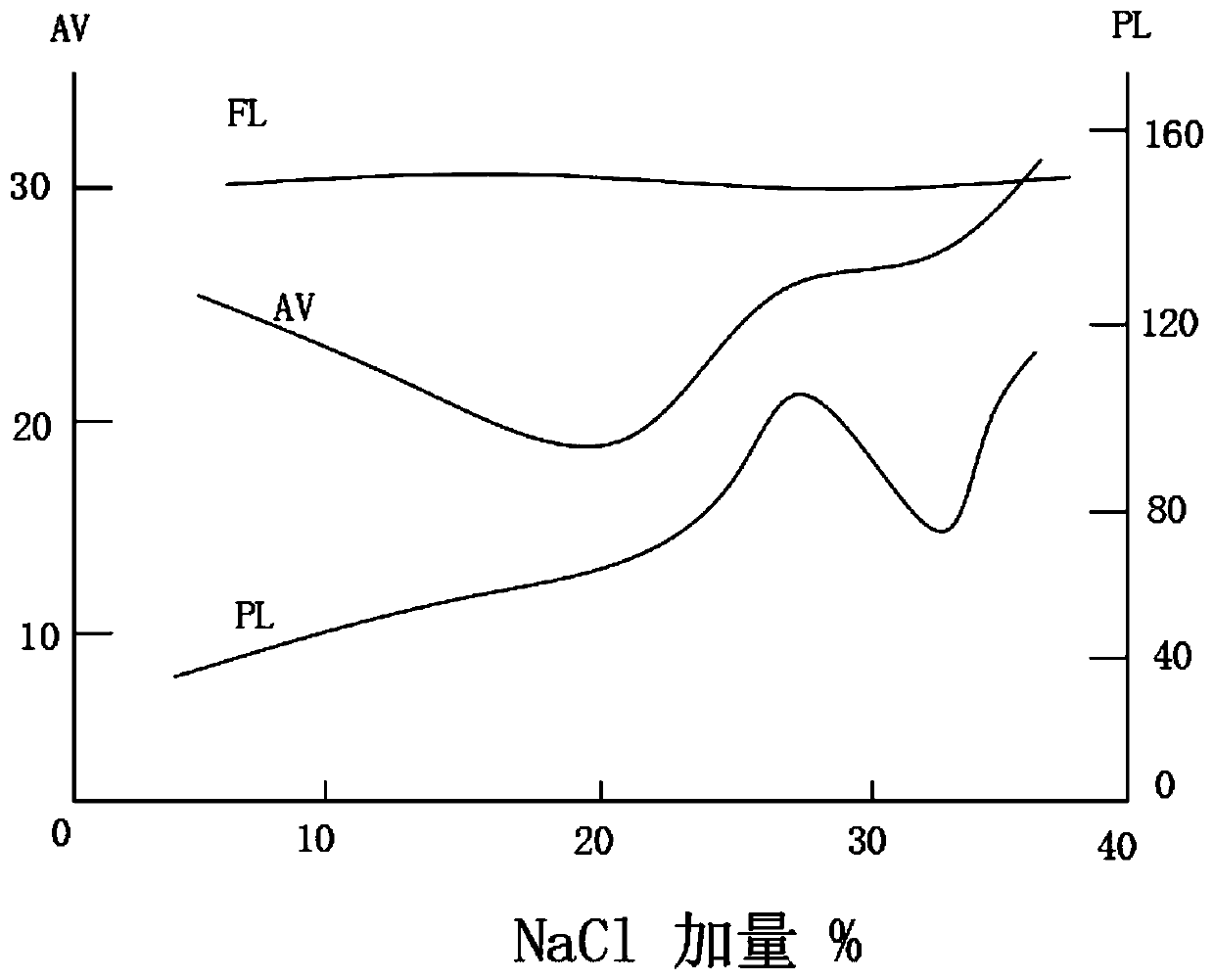

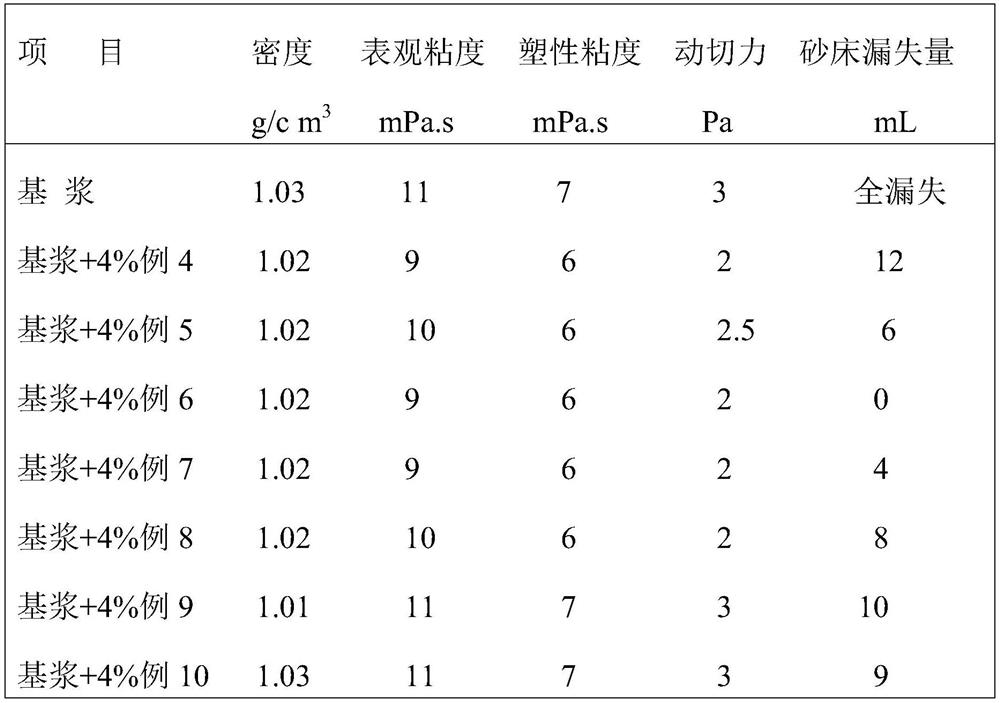

Preparation method of resin filtrate reducer

InactiveCN109912757AHigh temperature resistanceGood filter loss reduction effectDrilling compositionSulfite saltPerformance index

The invention relates to the technical field of filtrate reducers and discloses a preparation method of a resin filtrate reducer. The resin filtrate reducer comprises the following raw materials by weight percentage: 27%-33% of phenol, 47%-55% of formaldehyde, 10%-14% of sodium metabisulphite, 5%-10% of sodium sulfite, 0.5%-0.8% of propanesulfonic acid-based monomers and 0.3%-0.5% of a high temperature stabilizer. The resin filtrate reducer prepared with the preparation method is strong in temperature resistance; the resin filtrate reducer can resist saturated salt and compound salt in a drilling fluid system at the temperature of 220 DEG C, the product is strong in salt resistance, the resin filtrate reducer can still give play to excellent filtrate loss reduction performance in various complex conditions of saline, sylvite, calcium salt and the like, relevant performance indexes of drilling fluid can be greatly improved, the product is safe and environmentally-friendly and suitable for drilling fluid of various environmental protection systems under a new situation. Integrally, the product disclosed by the invention has the advantages of being strong in temperature resistance, good in filtrate loss reduction effect, less in dosage, small in influence on rheological property in the drilling fluid and the like.

Owner:广汉恒奕石油技术开发有限责任公司

Modified plant fiber plugging-while-drilling agent for drilling fluid and preparation method of plugging-while-drilling agent

The invention relates to a plugging-while-drilling agent for drilling fluid and a preparation method of the plugging-while-drilling agent, in particular to a preparation method of a modified plant fiber plugging agent. The plugging-while-drilling agent is prepared from the following components in percentage by weight: 40 to 80 percent of plant fiber, 10 to 40 percent of humic acid and 5 to 10 percent of hydrolyzed polyacrylonitrile colloid, wherein the hydrolyzed polyacrylonitrile colloid is floccule obtained by cross-linking hydrolyzed polyacrylonitrile salt. The preparation method of the modified plant fiber plugging-while-drilling agent comprises the following steps: adding the prepared hydrolyzed polyacrylonitrile salt cross-linked floccule solution into a mixture of plant fiber and humic acid according to a corresponding ratio, fully and uniformly mixing, drying into a solid, and grinding into powder, thereby obtaining the modified plant fiber plugging-while-drilling agent. The plugging-while-drilling agent has little influence on the performance of the drilling fluid, can effectively plug stratum micro-cracks and high-permeability pore leakage, and has the advantages of accessible raw materials, low cost, simple production technique and favorable popularization and application values.

Owner:DAQING HEZHENG CHEM

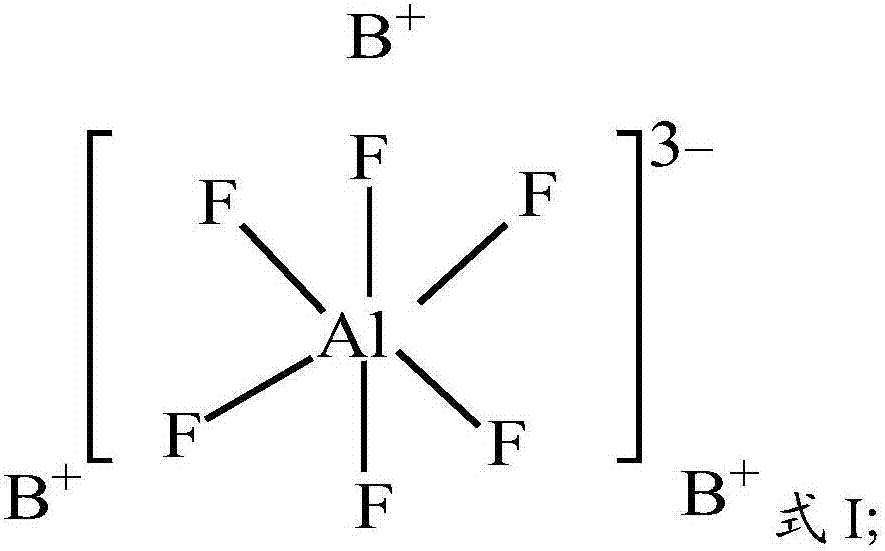

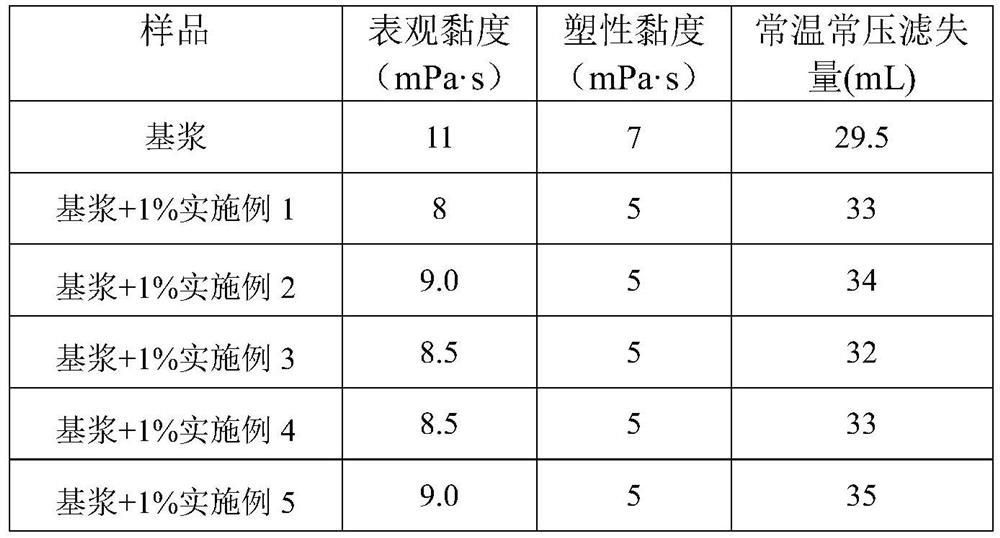

Applications of aluminum salt complex in preparation of drilling fluid, and drilling fluid

ActiveCN107312508ALittle impact on rheologyInhibits hydration swellingDrilling compositionRock coreSodium Bentonite

The present invention provides applications of an aluminum salt complex in preparation of a drilling fluid, wherein the aluminum salt complex has a general formula represented by a formula I. The invention provides a drilling fluid, which comprises a wall fixation material, wherein the wall fixation material is the aluminum salt complex having the general formula represented by the formula I, and B<+> is one or two selected from Na<+>, K<+> and NH4<+> in the formula I. According to the present invention, the aluminum salt complex having the general formula represented by the formula I exists in the complex ion form at the conventional drilling fluid pH value, and has little influence on the rheological property of the drilling fluid; after the Al<3+> enters the stratum along with the filtrate, the Al<3+> reacts with the stratum minerals at a certain temperature under a certain pH value to produce chemical cementation, such that the micro-crack is sealed so as to increase the stratum strength; Na<+>, K<+> or NH4<+> can inhibit the bentonite hydration expansion so as to further improve the wall stability; and the experimental results show that the aluminum salt complex has good wall fixation ability so as to significantly improve the compressive strength of the rock core. The formula I is defined in the specification.

Owner:中石化石油工程技术服务有限公司 +1

Modified polyol inhibitor and preparation method and application thereof in water-based drilling fluid

ActiveCN112175590AGood water solubilityImprove temperature resistanceDrilling compositionPolymer sciencePolyol

The invention provides a modified polyol inhibitor as well as a preparation method and an application thereof in water-based drilling fluid. The sulfonic acid monomers and sulfonated polyvinyl alcoholare subjected to a cross-linking reaction, an obtained product, high-temperature-resistant monomers and amide monomers are subjected to a double-cross-linking reaction, and the modified polyol inhibitor is obtained. The modified polyol inhibitor provided by the invention can significantly improve the tackifying negative effect of polyol, does not destroy the performance of the drilling fluid, haslittle influence on the rheological property of the drilling fluid, and has very strong inhibition property and excellent temperature resistance; the defects that an existing water-based drilling fluid polyhydric alcohol inhibitor has large influence on the rheological property of the drilling fluid and is insufficient in temperature resistance are overcome.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com