Plugging agent for environment-friendly water-based drilling fluid and preparation method of plugging agent

A water-based drilling fluid, an environmentally friendly technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of less environmentally friendly plugging agent products, achieve good compatibility, high compressive strength, and plugging good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

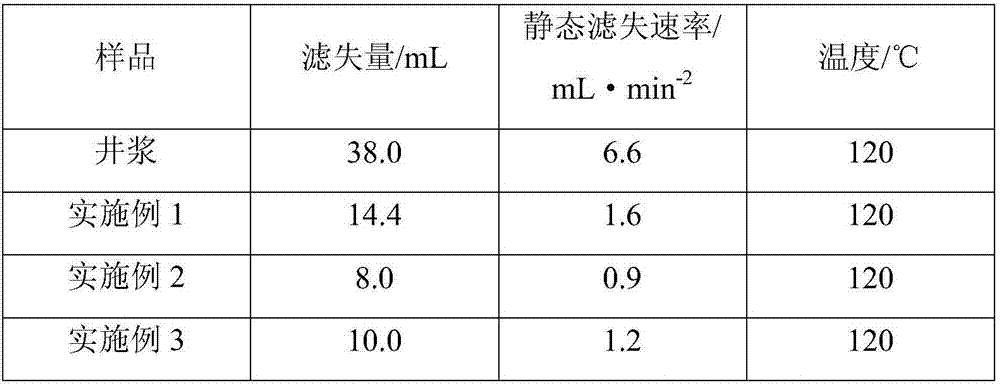

Examples

Embodiment 1

[0028] A preparation method for an environment-friendly water-based drilling fluid plugging agent, comprising the following steps:

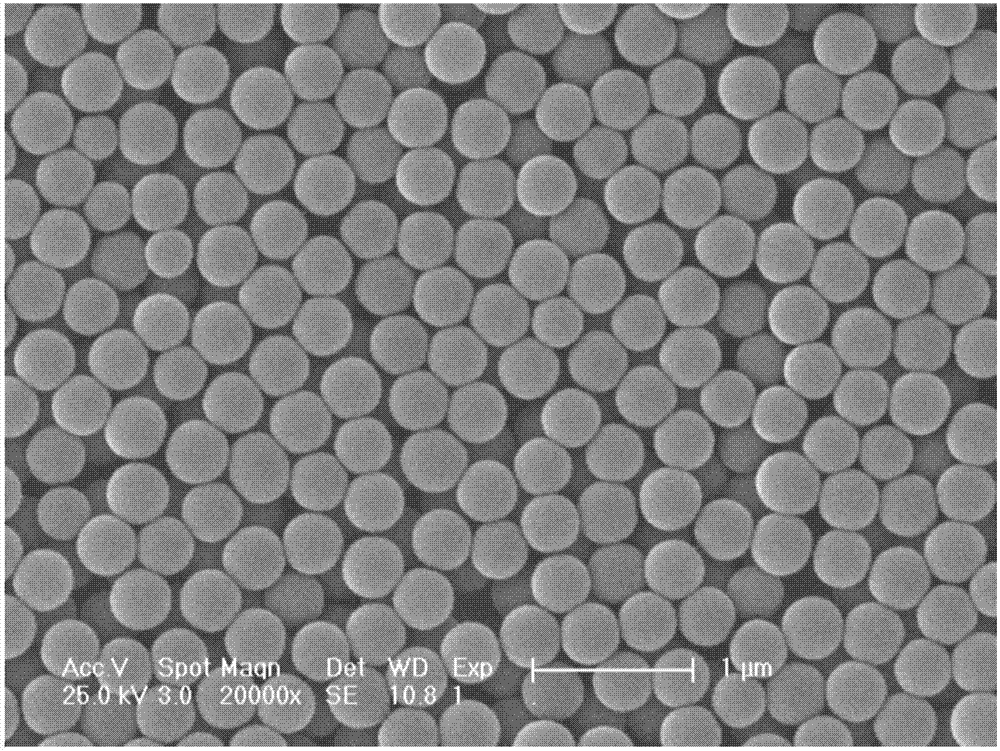

[0029] 1) Dissolve glucose in deionized water to make a glucose solution, then transfer the glucose solution to a tetrafluoroethylene-lined hydrothermal synthesis kettle, react at 160°C for 6 hours, cool to room temperature after the reaction, and centrifugally filter , washed three times with deionized water, and dried to obtain carbon spheres, such as figure 1 shown.

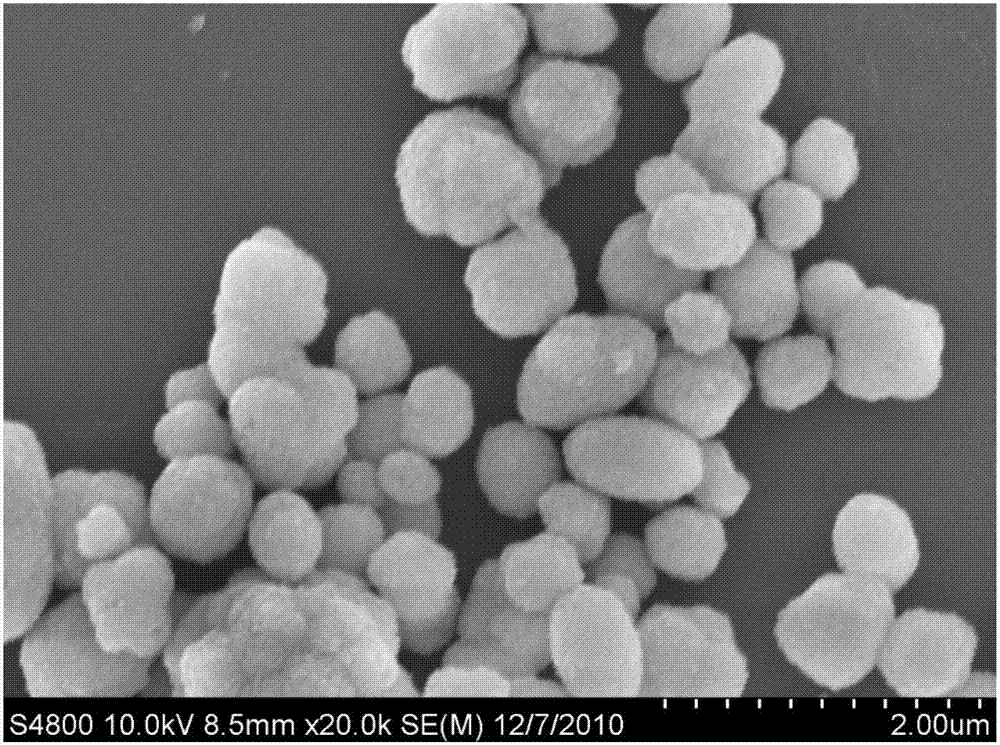

[0030] 2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dilute sulfuric acid to adjust the pH of the solution to be 4, then add urea and cetyltrimethylammonium bromide to the solution, Stir until the solution is clear, then add the prepared carbon spheres into the four-neck flask while stirring, heat at 90°C and stir for 5 hours, cool to room temperature, wash with deionized water three times, and dry to obtain AlOOH-coated c...

Embodiment 2

[0033] A preparation method for an environment-friendly water-based drilling fluid plugging agent, comprising the following steps:

[0034] 1) The difference from Example 1 is that the hydrothermal reaction condition is to react at 180° C. for 4 hours.

[0035] 2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dilute sulfuric acid to adjust the pH of the solution to be 4, then add urea and cetyltrimethylammonium bromide to the solution, Stir until the solution is clear, then add the carbon spheres prepared in step 1 into a four-necked flask while stirring, heat at 100°C and stir for 3 hours, cool to room temperature, wash with deionized water three times, and dry to obtain a coated Carbon spheres of AlOOH.

[0036] 3) Add deionized water, 50 parts of AlOOH-coated carbon spheres, 10 parts of acrylamide, 10 parts of N-isopropylacrylamide, 4 parts of hexamethylenetetramine into a four-neck flask equipped with a mechanical stir...

Embodiment 3

[0038] A preparation method for an environment-friendly water-based drilling fluid plugging agent, comprising the following steps:

[0039] 1) The difference from Example 1 is that the hydrothermal reaction condition is to react at 170° C. for 5 hours.

[0040] 2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dilute sulfuric acid to adjust the pH of the solution to be 4, then add urea and cetyltrimethylammonium bromide to the solution, Stir until the solution is clear, then add the carbon spheres prepared in step 1 into a four-neck flask while stirring, heat at 95°C and stir for 4 hours, cool to room temperature, wash with deionized water three times, and dry to obtain a coated Carbon spheres of AlOOH.

[0041]3) Add deionized water, 40 parts of AlOOH-coated carbon spheres, 9 parts of acrylamide, 9 parts of N-isopropylacrylamide, and 3 parts of hexamethylenetetramine into a four-neck flask equipped with a mechanical stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com