Patents

Literature

224results about How to "Good filter loss reduction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

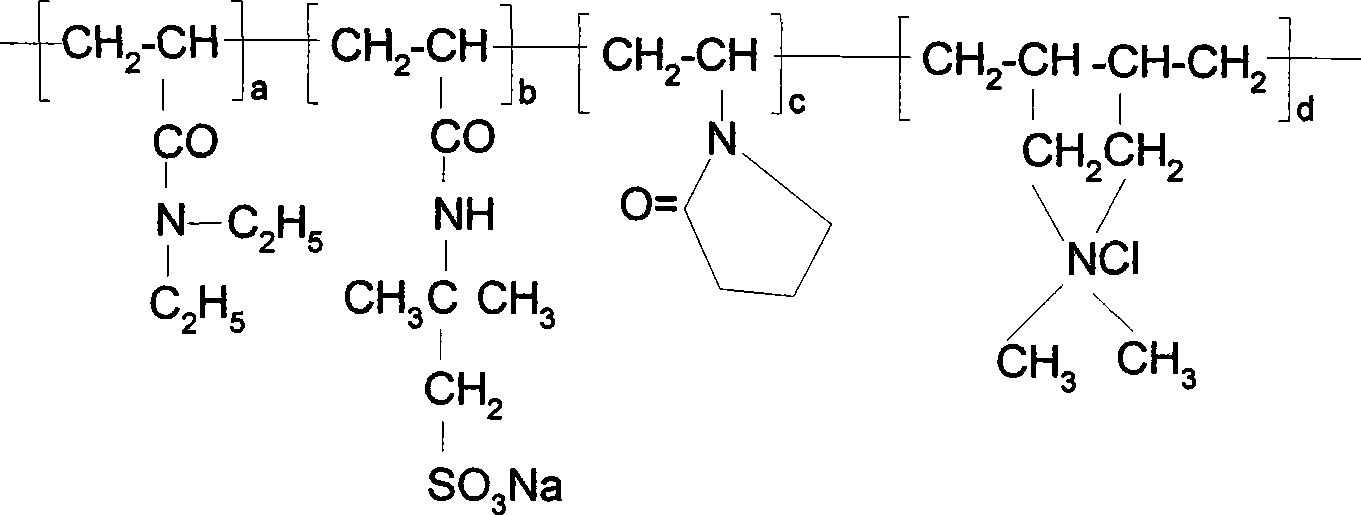

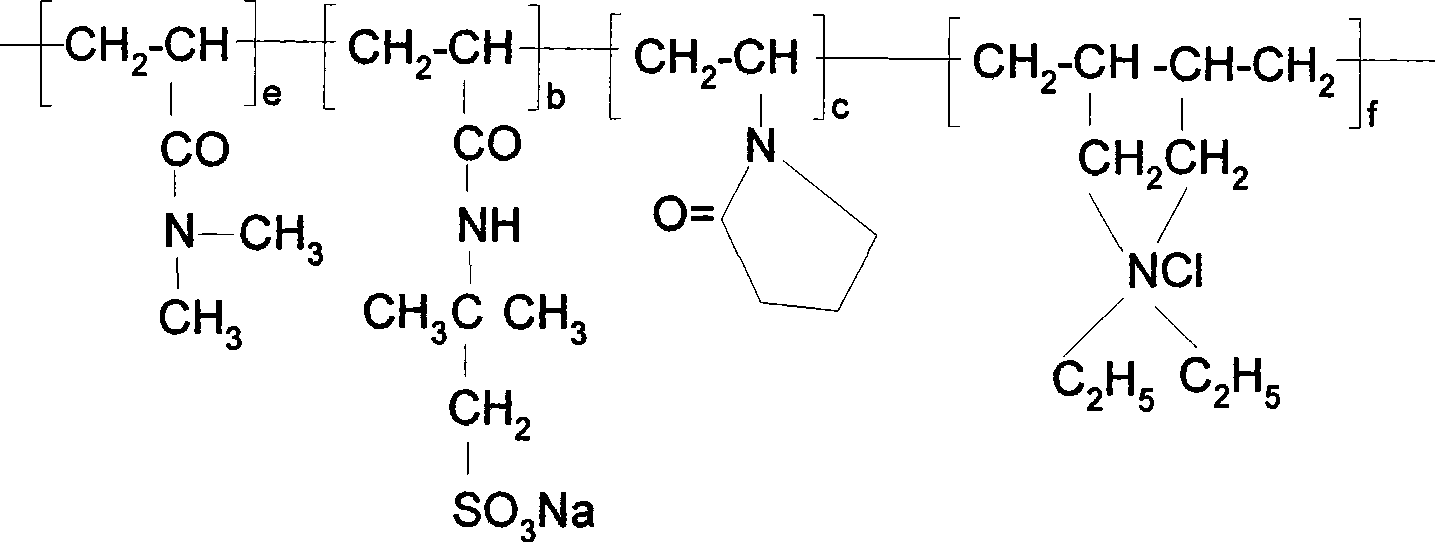

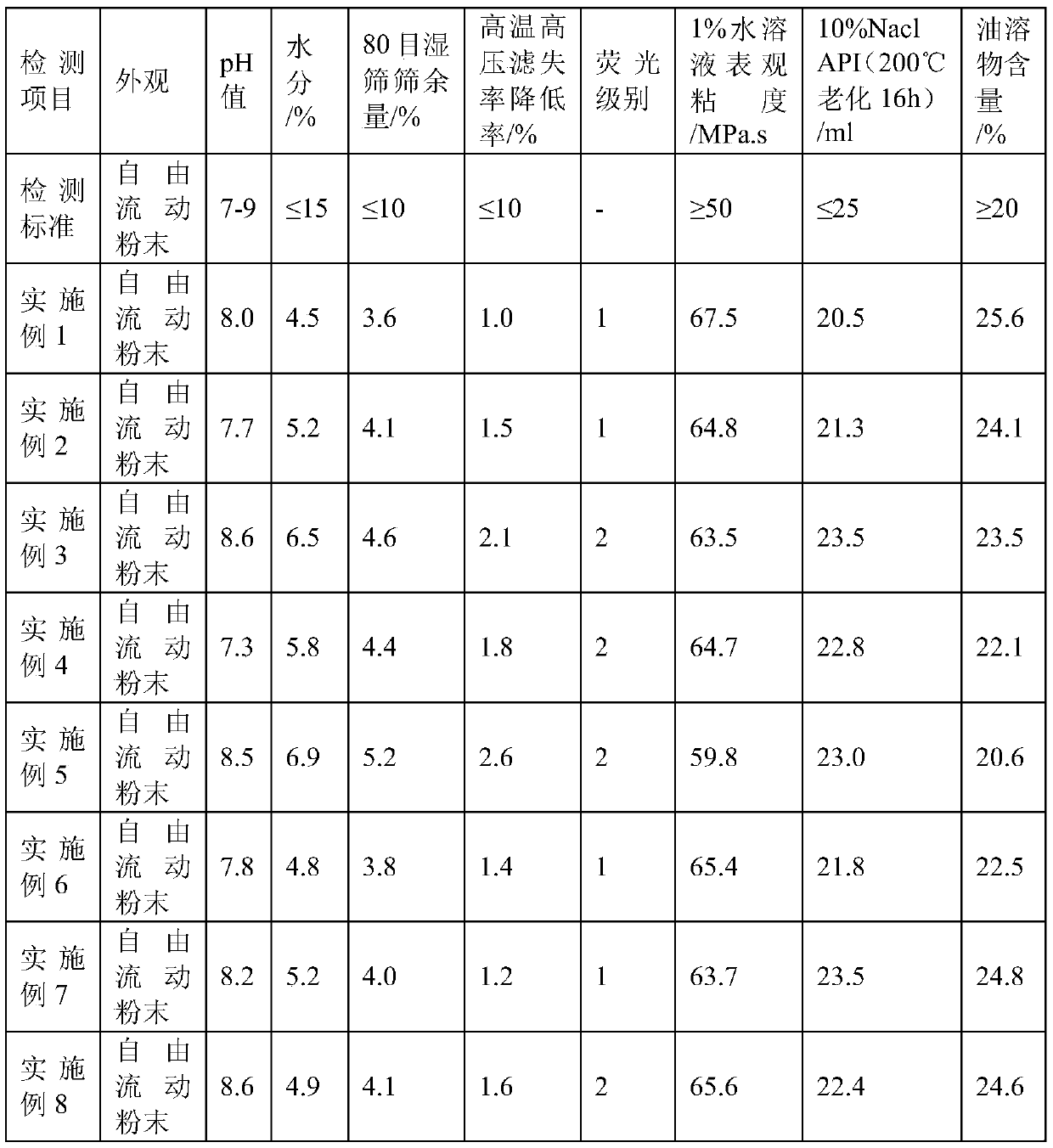

High-temperature resistant polymer fluid loss agent for drilling fluid and preparation method thereof

InactiveCN101531887AGood filter loss reduction effectInhibition of hydration dispersionDrilling compositionStructural unitSalt water

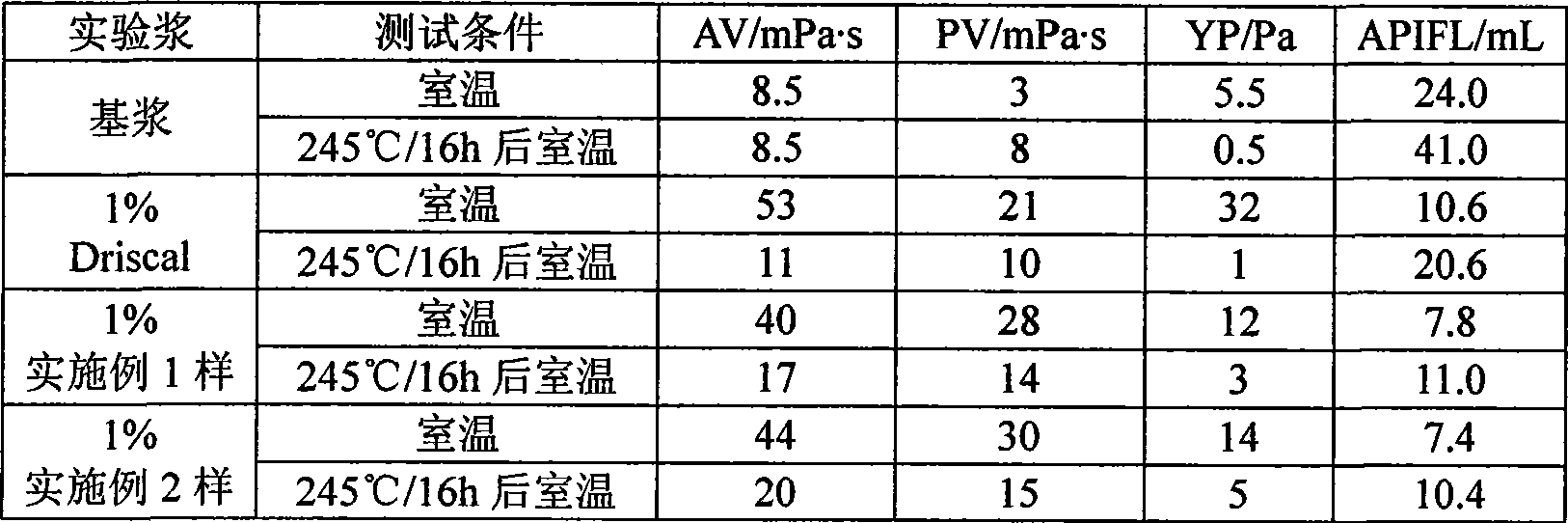

The invention discloses a high-temperature resistant polymer fluid loss agent for drilling fluid and a preparation method thereof. The polymer fluid loss agent is characterized in that the polymer fluid loss agent is a copolymer generated by olefine acid, alkenyl amide, alkenyl azululanone and alkenyl quaternary ammonium through reaction, molecules of the copolymer contain 800 to 1,800 structural units, and viscosity average molecular weight is 500,000 to 1,200,000. The polymer fluid loss agent can resist temperature of more than 245 DEG C in the drilling liquid, has good protective colloid performance to the drilling liquid, improves the quality of a filter cake, has good fluid loss reduction effect in fresh water, aggravated fresh water, salt water and the like, can simultaneously inhibit hydration and dispersion of clay and has good rheology.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

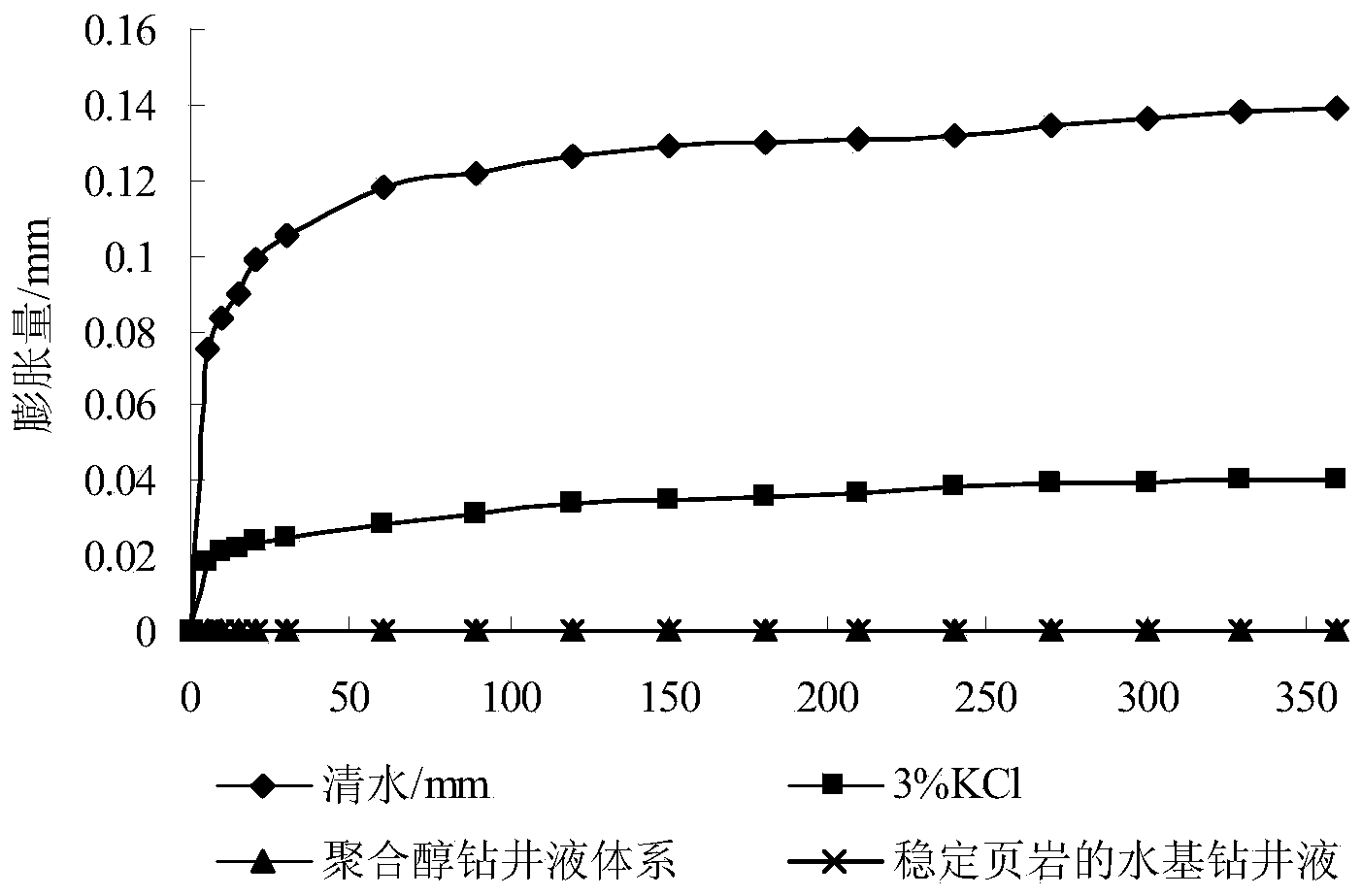

Water-based drilling fluid for stabilizing shale

ActiveCN103725272AImprove rheologyGood filter loss reduction effectDrilling compositionWater basedWell drilling

The invention provides water-based drilling fluid for stabilizing shale. The drilling fluid is formed by mixing sodium-based bentonite, a shale inhibitor, a tackifier, a flow-pattern adjusting agent, a filtrate reducer, a high-temperature-resisting processing agent, a bridging agent, bridging particle and an anti-collapse agent. Calculated by the addition quantity in every 100 parts of water, the water-based drilling fluid comprises the following components in parts by mass: 5 parts of sodium-based bentonite, 1.5 to 1.8 parts of shale inhibitor, 0.5 to 0.7 part of tackifier, 0.1 to 0.2 part of flow-pattern adjusting agent, 0.7 to 0.9 part of filtrate reducer, 2.3 to 2.5 parts of high-temperature-resisting processing agent, 9.33 to 10.67 parts of bridging agent, 1.8 to 2.2 parts of bridging particle and 1.1 to 1.3 parts of anti-collapse agent. The drilling fluid is good in rheological property, filtrate reduction property and lubricating property and strong in inhabitation property, so that the requirement of the shale gas horizontal well drilling cuttings carrying and wall stability requirement can be met, and the probability of drilling seizure can be reduced.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for preparing temperature-resistant anti-salt amphoteric polymer filtrate reducer

The invention relates to a method for preparing a temperature-resistant anti-salt amphoteric polymer filtrate reducer used for drilling fluid. In the filtrate reducer, C6 to C10 paraffin hydrocarbons are used as a continuous phase; Span and Tween are used as a compound non-ionic surface active agent, wherein the mass ratio of the Span to the Tween is 2-4:1-3; three monomers, namely acrylamide(AM), acrylic acid(AA) and styrene sulfonic sodium(SSS), are used as raw materials in a mass ratio of 10:3-6:1-4; and an initiator of ammonium persulphate or redox initiator of ammonium persulphate-sodium bisulphite is added for copolymerization by adopting an opposite micro-emulsion polymerization method to obtain the filtrate reducer. The filtrate reducer provided by the invention has the advantages of higher temperature resistance, salt resistance and filtrate-reducing property, simple preparation method, mild and controllable reaction conditions, high polymerization stability, high reaction speed and high conversion rate.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

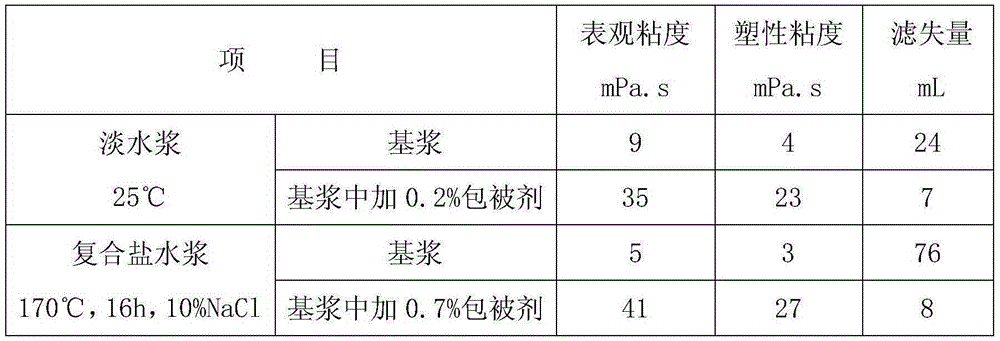

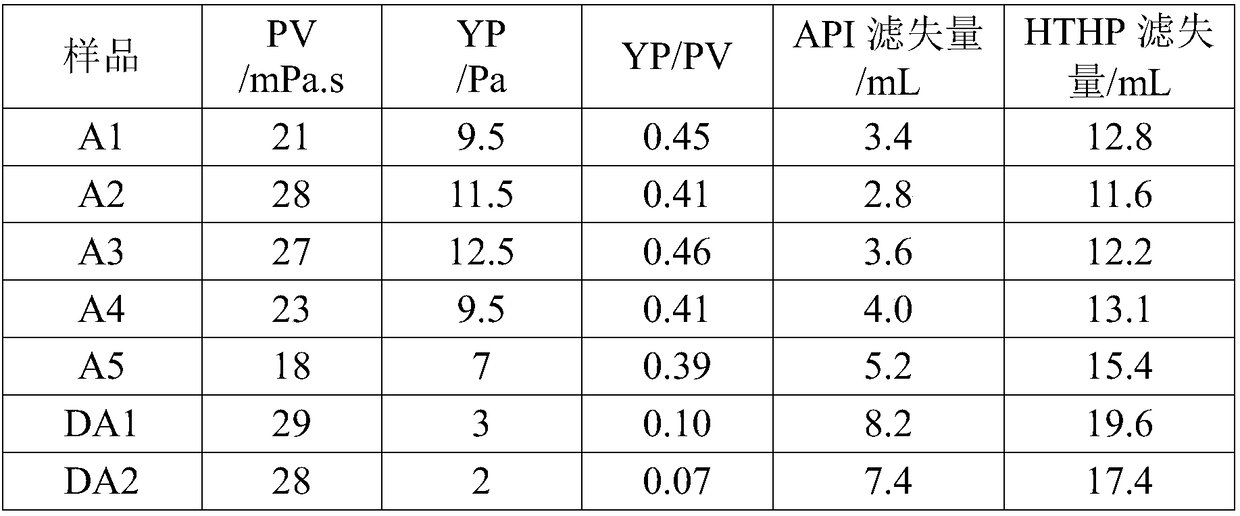

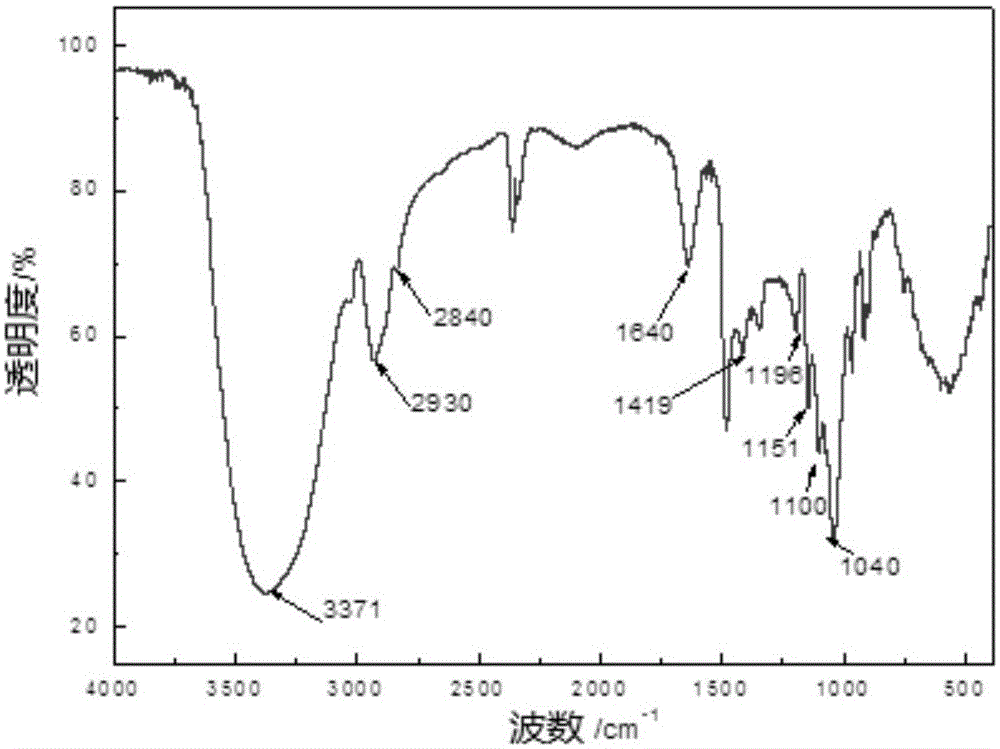

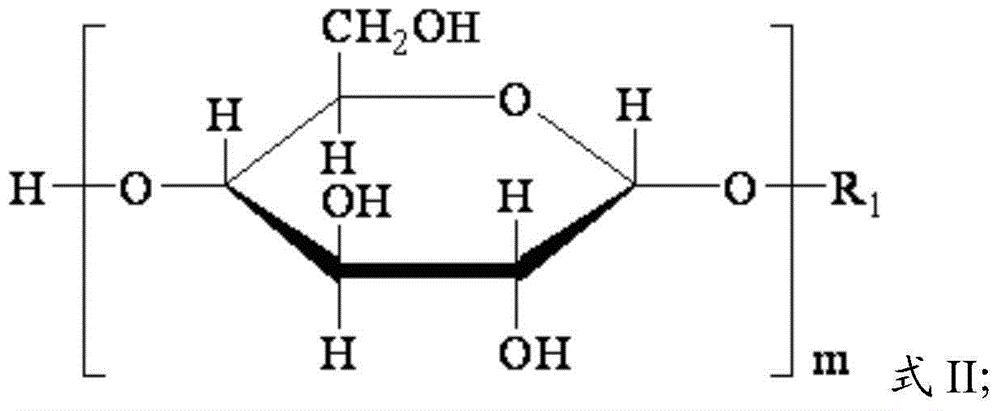

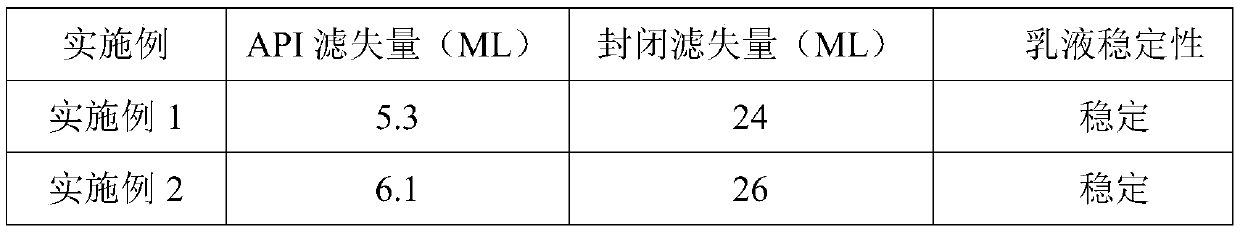

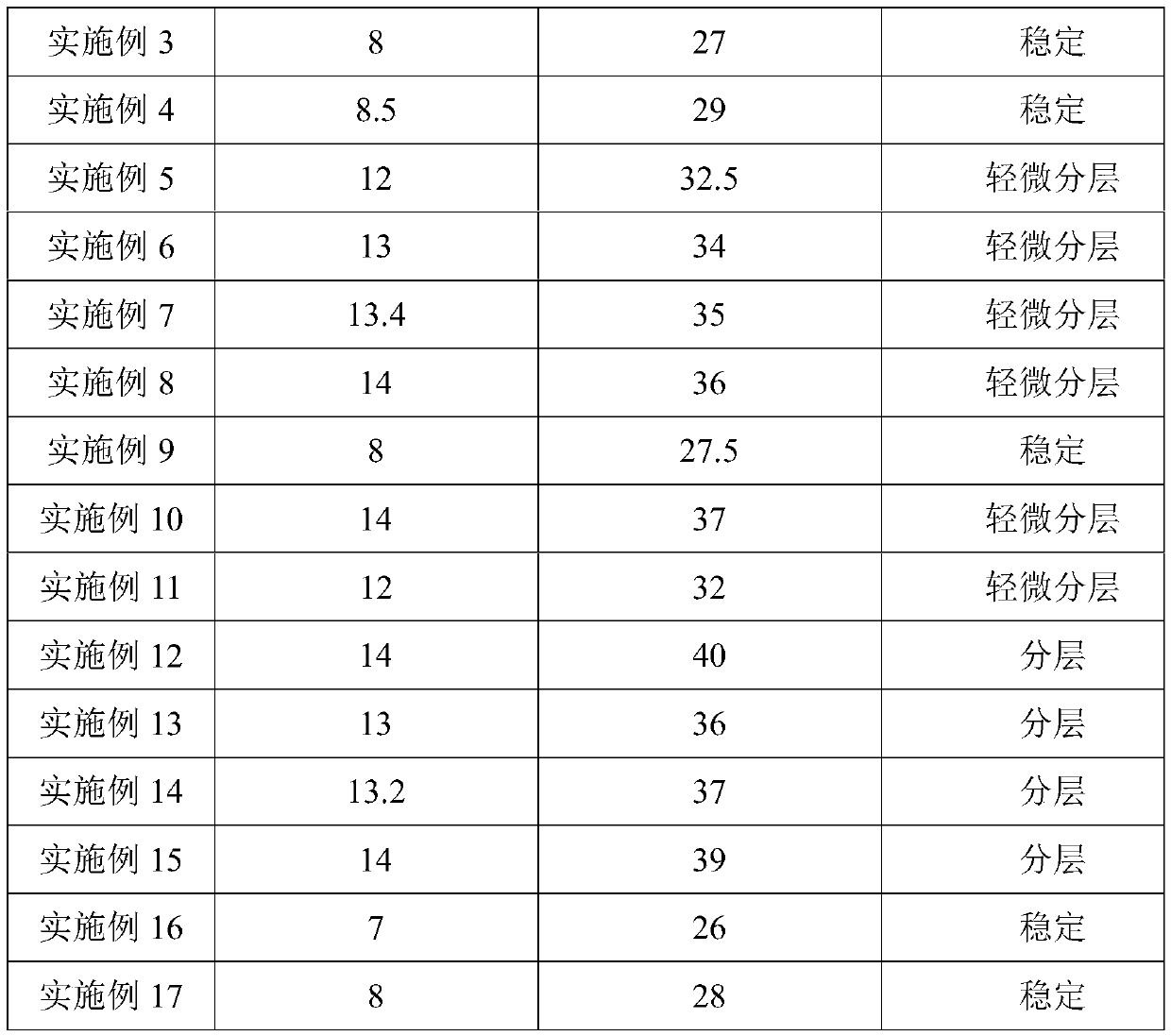

Aminoalkyl glucoside graft copolymer and preparation method thereof, and drilling fluid

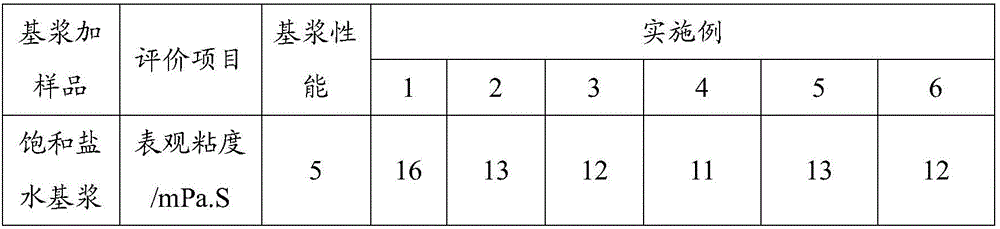

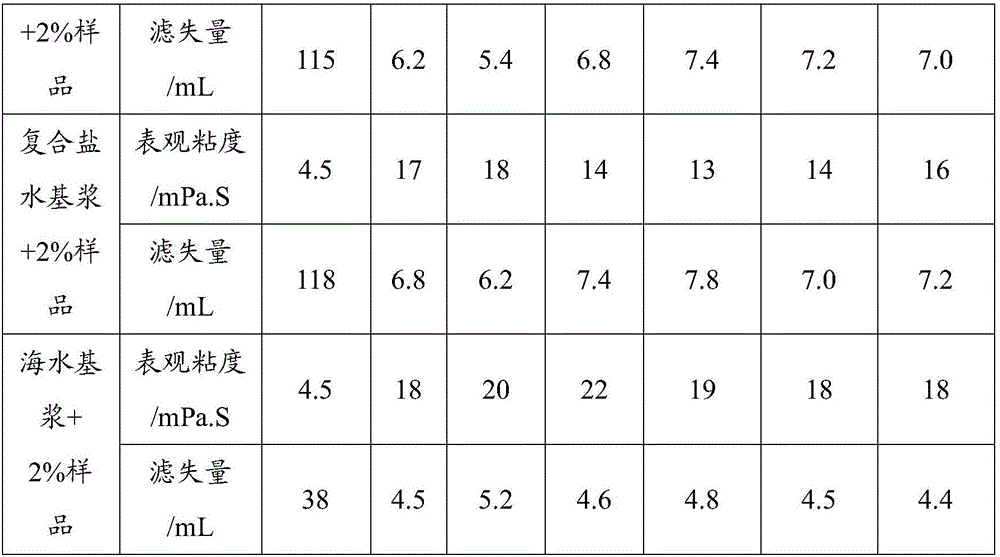

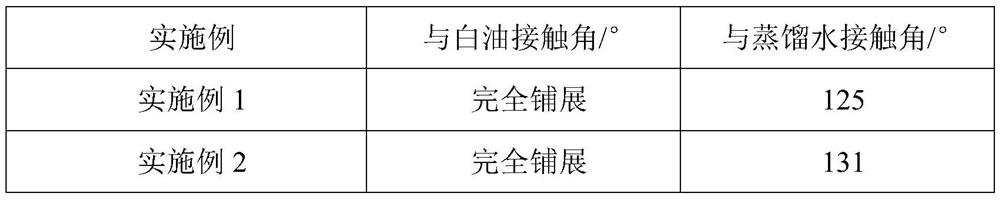

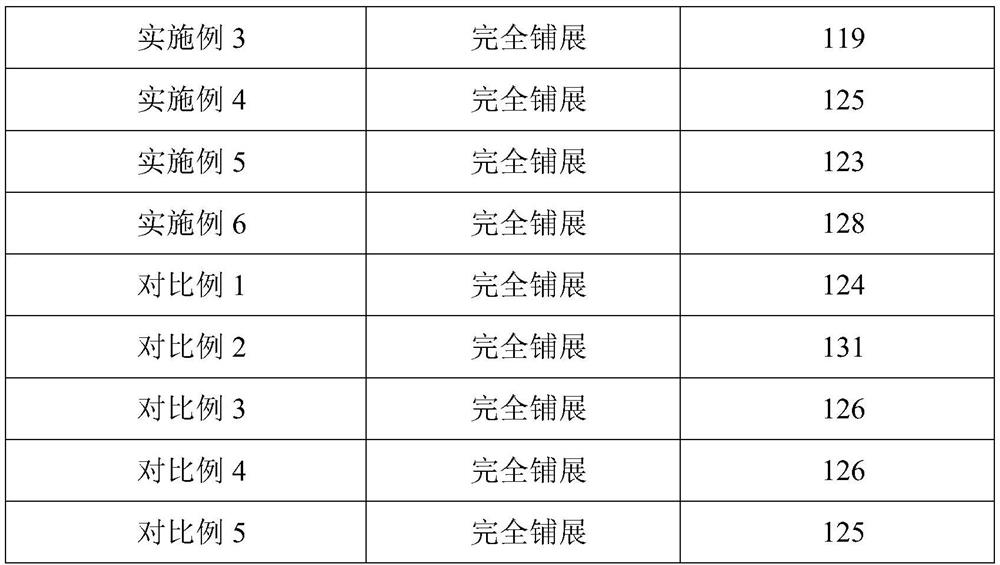

InactiveCN107973827AEnhanced inhibitory effectImprove the lubrication effectSugar derivativesDrilling compositionFatty amineAlkyl polyglycoside

The invention provides a preparation method for an aminoalkyl glucoside graft copolymer. The preparation method comprises the following steps: (1) subjecting alkyl glucoside, epoxide, chloride and anacidic catalyst to a reaction so as to obtain a first intermediate; (2) reacting the first intermediate with alicyclic amine so as to obtain a second intermediate; and (3) under the action of an initiator, subjecting the second intermediate, acrylamide and 2-acrylamide-2-methylpropanesulfonic acid to a reaction so as to obtain the aminoalkyl glucoside graft copolymer. With the method provided by the invention, the aminoalkyl glucoside graft copolymer with a specific structure is prepared and has good inhibition performance, lubrication performance, filtrate loss reducing performance, and resistance to contamination by saturated salts and composite salts. Moreover, the aminoalkyl glucoside graft copolymer is free of biological toxicity. The invention also provides the aminoalkyl glucoside graft copolymer and a drilling fluid.

Owner:中石化石油工程技术服务有限公司 +1

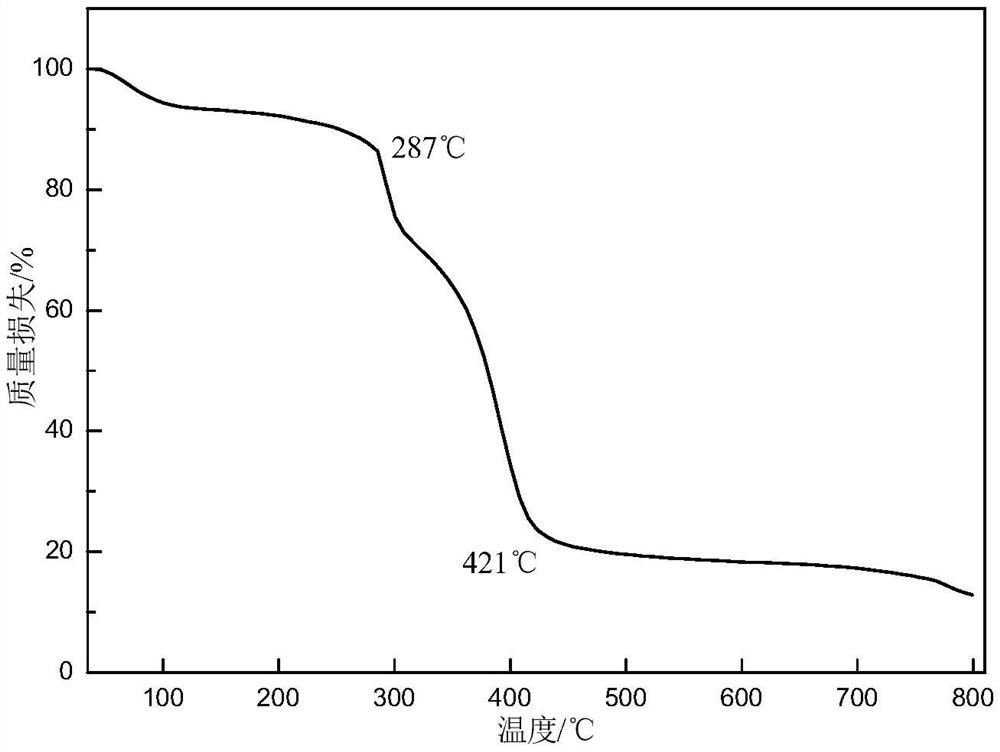

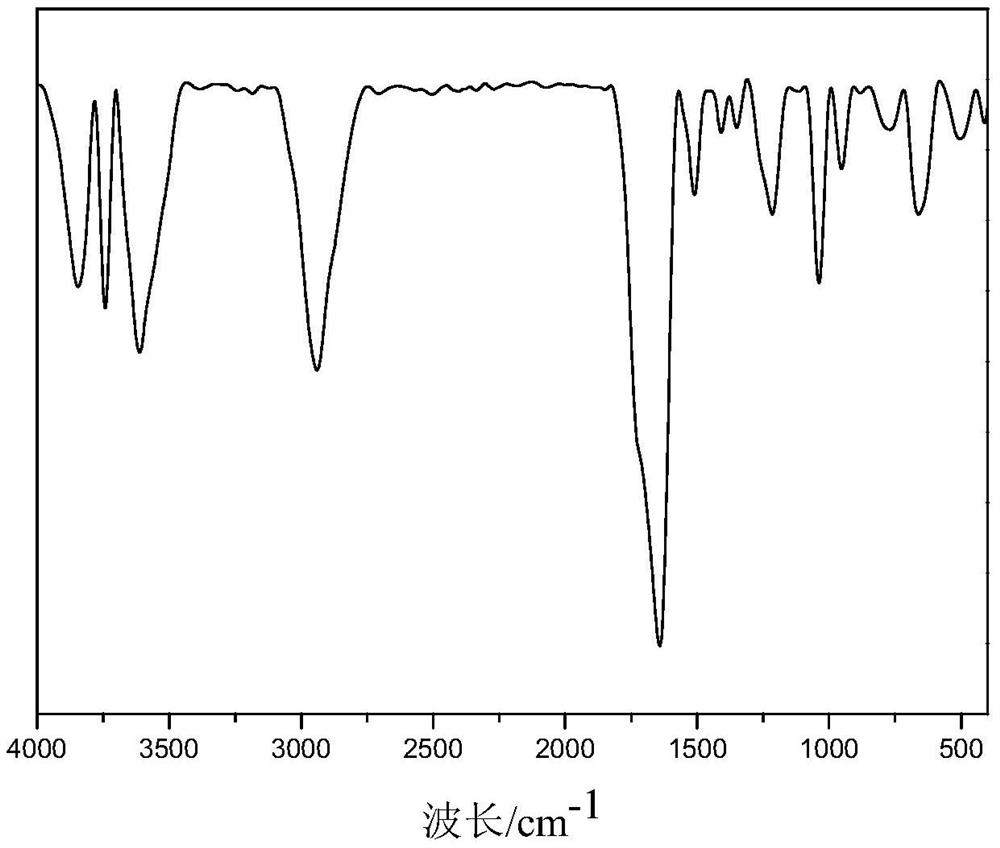

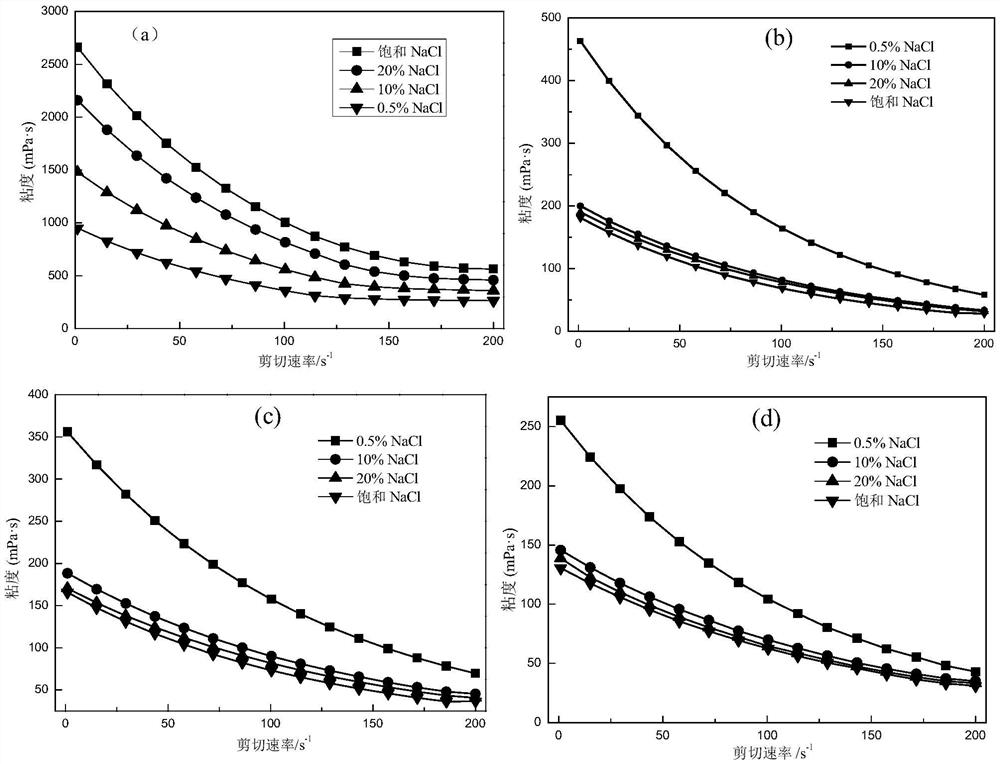

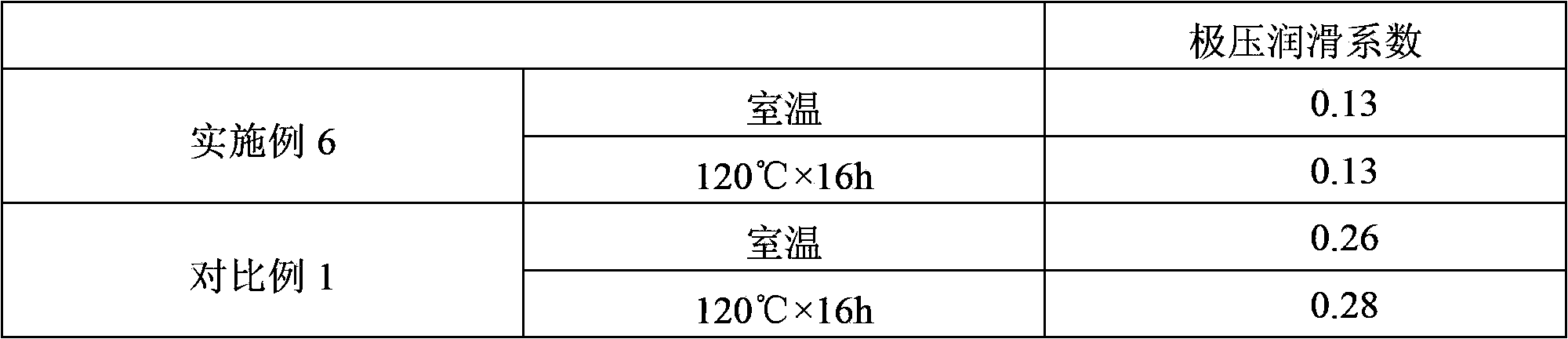

Salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and preparation method and application thereof

ActiveCN112011318AImprove salt toleranceImprove temperature resistanceDrilling compositionPolyelectrolyteMeth-

The invention provides a salt-responsive high-temperature-resistant zwitterionic polymer filtrate reducer and a preparation method and application thereof. The filtrate reducer is prepared from the following raw materials in parts by mass: 2 to 40 parts of N, N-dimethylacrylamide, 2 to 20 parts of methacryloxyethyl trimethyl ammonium chloride, 2 to 20 parts of 2-acrylamide-2-methylpropanesulfonicacid, 4 to 8 parts of nano oxide, 1.0 to 1.5 parts of silane modifier and 0.3 to 0.4 part of an initiator. The salt-responsive zwitterionic polymer provided by the invention has a special polyelectrolyte resistance effect and positive response to salt, essentially realizes conversion from salt resistance to salt response, and is essentially compatible with salt, the obtained filtrate reducer has excellent salt resistance, temperature resistance and filtrate loss reduction performance, and also has shear dilutability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Acid carboxymethyl guargum fracturing fluid and preparation method thereof

InactiveCN102391851AThe preparation process is simpleEasy to operateDrilling compositionBacteriocidesDemulsifier

The invention relates to the technical field of the fracturing of an oil field, and particular relates to an acid carboxymethyl guargum fracturing fluid and a preparation method of the fluid. The acid carboxymethyl guargum fracturing fluid comprises the following raw materials: carboxymethyl guargum power, discharge aiding agent, swelling-resistant agent, bactericide, demulsifier, acid cross-linking agent, cross-linking time delay action activator, gel breaker and water. The preparation method of the fluid comprises the following steps of: firstly preparing base liquid; secondly preparing cross-linking; and thirdly preparing the acid carboxymethyl guargum fracturing fluid. The invention has the beneficial effects of acidic crosslinking environment, simple technology, convenience of in-field operation, and good combination property; and the acid carboxymethyl guargum fracturing fluid has the advantages of being good in compatibility performance, delayed in crosslinking characteristic, good in fluid loss characteristic, good in swelling-resistant effect, low in residue, and thorough in gel breaking, and can meet the fracturing construction of a reservoir stratum under the temperature from 30 DEG C to 100 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

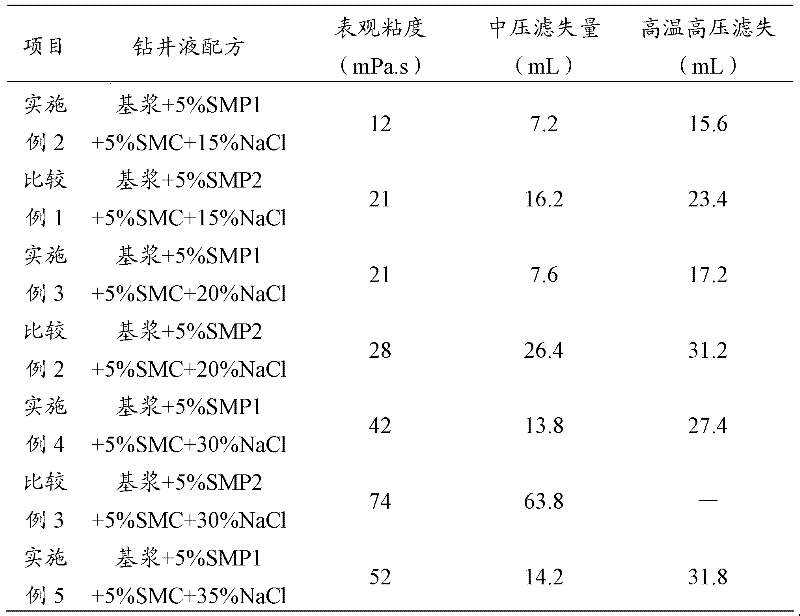

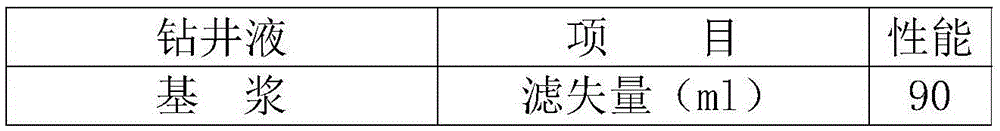

Method for preparing modified sulfomethal phenolaldehy resin for drilling liquid

ActiveCN102241803AGood filter loss reduction effectImprove salt resistanceDrilling compositionEpoxySalt resistance

The invention provides a method for preparing modified sulfomethal phenolaldehy resin for drilling liquid, comprising the following steps of: a) mixing a sodium hydroxide solution, molten phenol, epoxy chloropropane and trimethyl amine, and reacting to obtain a cationic intermediate; and b) mixing the cationic intermediate with sulfomethal phenolaldehy resin, and reacting to obtain the modified sulfomethal phenolaldehy resin for the drilling liquid. In the modified sulfomethal phenolaldehy resin for the drilling liquid, provided by the invention, a quaternary ammonium salt cationic group is added and is capable of improving the adsorption capacity of the sulfomethal phenolaldehy resin and clay, thus, the adsorption amount of the resin on the clay is increased greatly so that the sulfomethal phenolaldehy resin has a better filtration loss reduction effect and better salt resistance. Results from embodiments of the invention indicate that the drilling liquid consisting of basic slurry, 5% of the modified sulfomethal phenolaldehy resin prepared according to the method provided by the invention, 5% of sulfonated lignite and 35% of NaCl has the high-temperature / pressure filtration loss of 31.8mL.

Owner:河南金马石油科技有限责任公司

Saturated salt water drilling fluid for deep well salt mine drilling and preparation method of drilling fluid

ActiveCN104017550AImprove rheologyGood filter loss reduction effectDrilling compositionHigh concentrationWater based

The invention discloses a saturated salt water drilling fluid for deep well salt mine drilling and a preparation method of the drilling fluid. The saturated salt water drilling fluid comprises the following raw materials in parts by weight: 100 parts of water, 2-4 parts of bentonite, 1-2 parts of sepiolite, 0.5-1 part of hectorite, 1-4 parts of FT-1 sulfonated bitumen powder, 0.2-1 part of an inorganic salt recrystallization inhibitor, 0.4-2 parts of a GTQ salt-resistant copolymer, 0.3-0.5 part of KHm potassium humate, 0.1-0.5 part of a water-based defoaming agent, 0.2-1 part of sodium carbonate, 0.1-0.3 part of sodium hydroxide, 2-10 parts of magnesium chloride, 7-15 parts of potassium chloride and 20-35 parts of sodium chloride. According to the saturated salt water drilling fluid, the influence on the performance of the drilling fluid caused by complicated environments of high-concentration inorganic salt, high temperature and the like in deep well salt mine construction can be eliminated and a technical guarantee is provided for rock salt stratum coring operation; and the saturated salt water drilling fluid is relatively good in rheological property, is capable of effectively preventing corrosion on a salt well wall and a rock core in core drilling, and is stable in performance at a high temperature and suitable for deep well salt mine sampling drilling.

Owner:山东省鲁北地质工程勘察院 +2

White asphalt for drilling fluid and method for preparing white asphalt for drilling fluid

ActiveCN103013461AGood sealing of cracksEasy to reverseDrilling compositionAlkylphenolPolyacrylamide

The invention discloses white asphalt for drilling fluid and a method for preparing the white asphalt for drilling fluid. The white asphalt is prepared from the following raw materials in parts by weight: 40 parts-50 parts of paraffin, 1 part-2 parts of alkylphenol polyoxyethylene ether, 4 parts-5 parts of polyethylene glycol, 4 parts-5 parts of polyacrylamide, 20 parts-30 parts of stearic acid and 20 parts-30 parts of light calcium carbonate. The method for preparing the white asphalt comprises the following steps: adding the paraffin, alkylphenol polyoxyethylene ether, polyethylene glycol and stearic acid into a reactor proportionally; raising the temperature of the reactor to 70 DEG C-100 DEG C, and then stirring for 20-40 minutes at constant temperature; adding polyacrylamide to be stirred for 30 minutes at constant temperature; and finally, uniformly adding light calcium carbonate to be stirred for 0.5-2 hours at constant temperature and then discharging, and carrying out spray granulation to obtain the white asphalt. The white asphalt does not damage a hydrocarbon reservoir, has good lubricating performance and prevents collapse and blockage, filtration can be effectively reduced, the capacity of oil-gas wells is improved, and the technical problems of easily generated loss, collapse and the like during a drilling process when stratums with complicated conditions are drilled are solved.

Owner:河北华运鸿业化工有限公司

Coating agent for water-based drilling fluid

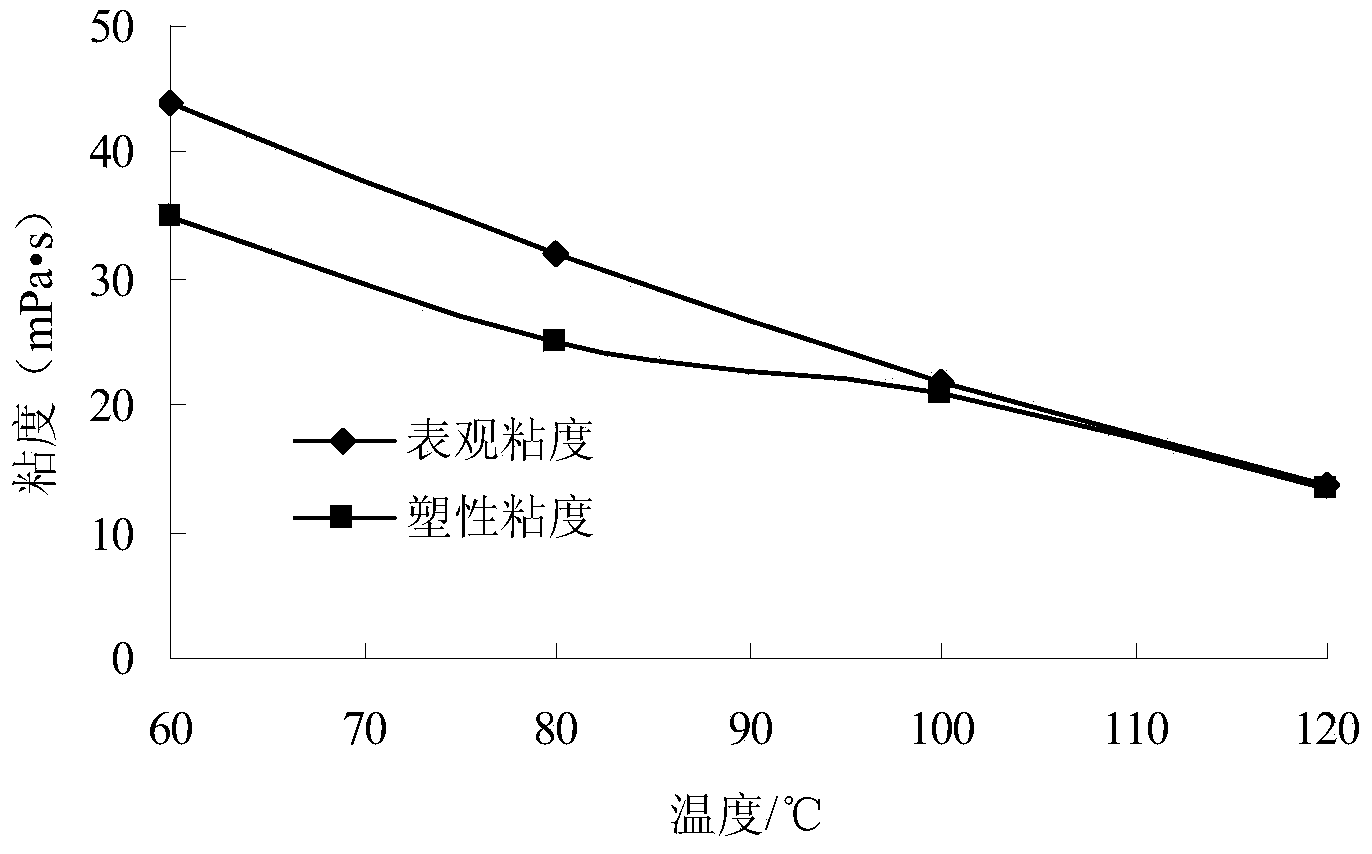

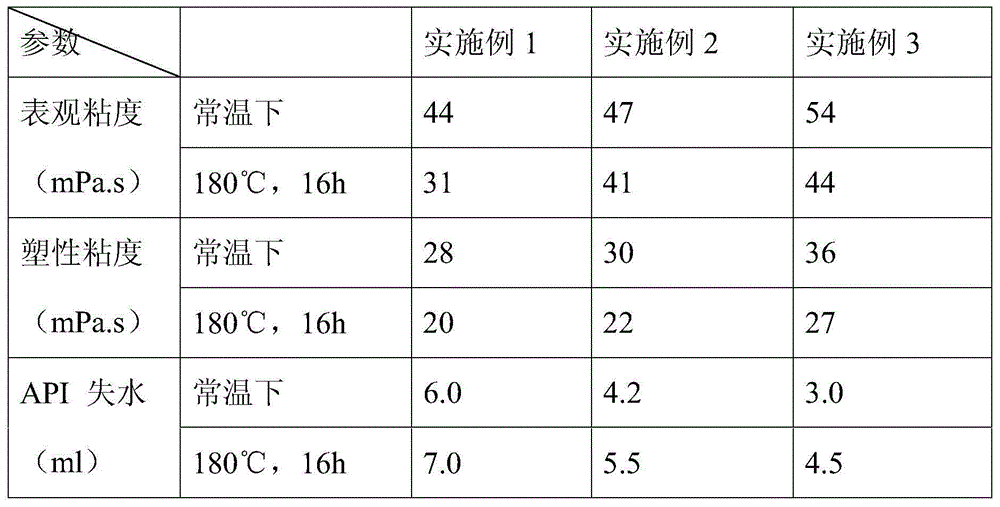

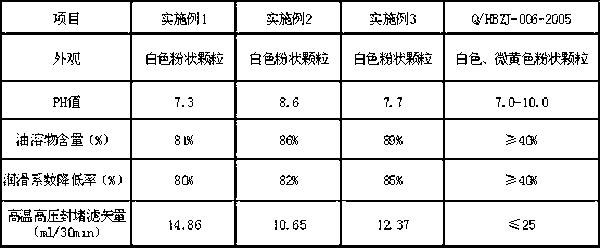

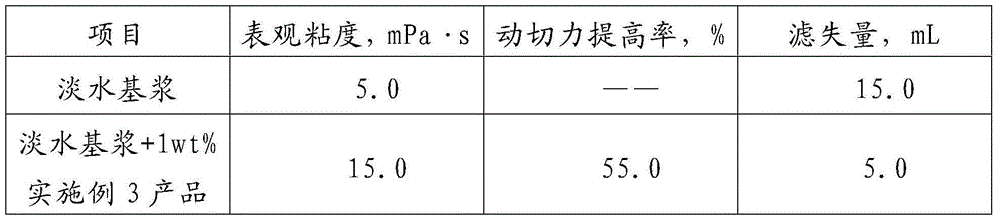

InactiveCN105294946AInhibition of hydrationPrevent collapseDrilling compositionApparent viscosityChemistry

The invention discloses a coating agent for a water-based drilling fluid. The coating agent is prepared from the following raw materials in parts by weight: 900-1100 parts of liquid polyacrylamide, 180-220 parts of AMPS, 170-190 parts of 1-methyl-2-pyrrolidinone, 75-85 parts of sodium carbonate, 180-220 parts of a co-solvent, 1.5-2.5 parts of sodium bisulfite and 1.5-2.5 parts of hydrogen peroxide. The coating agent can be added into the drilling fluid for controlling the filtration vector, and can be used in a salt water drilling fluid system for key control of the apparent viscosity, the plastic viscosity, the filtration vector and the like; drillings can be effectively coated by the coating agent, so as to protect the drillings and shale from hydration, protect a well wall from collapse, facilitate the stability of the well wall, and improve the drilling speed; meanwhile, the coating agent is capable of resisting high temperature, calcium, magnesium and salinity, has the characteristic of being good in filtrate loss effect, and is applicable to fresh water, sea water and saturated salt water slurry systems.

Owner:天津滨海新区普瑞德石油科技有限公司

Gelled acid for acid fracturing stimulation measures of oil-gas reservoir

ActiveCN105838348AReduce secondary damageImprove diversion capacityDrilling compositionAcid fracturingFiltration

The invention relates to a gelled acid for acid fracturing stimulation measures of an oil-gas reservoir. The gelled acid can be applied to cid fracturing stimulation measures of a medium-high temperature carbonate reservoir and has excellent acid-rock reaction retarding property, and filtration reduction property; the flow conductivity of an acid corrosion fracture and the penetration distance of an acid liquid can be effectively improved; deep penetration of the acid liquid can be effectively achieved; a remote reservoir is communicated to reach the target of deep acid fracturing transformation; meanwhile, the gelled acid generates a small amount of residues after acid fracturing; the secondary harm caused by the reservoir is extremely low; meanwhile, the acid liquid system is stable in performance; and field preparation is simple and convenient.

Owner:PETRO KING OILFIELD TECH +1

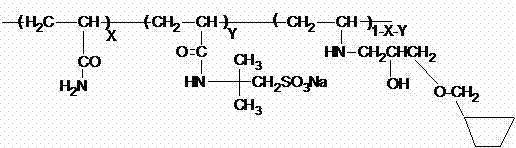

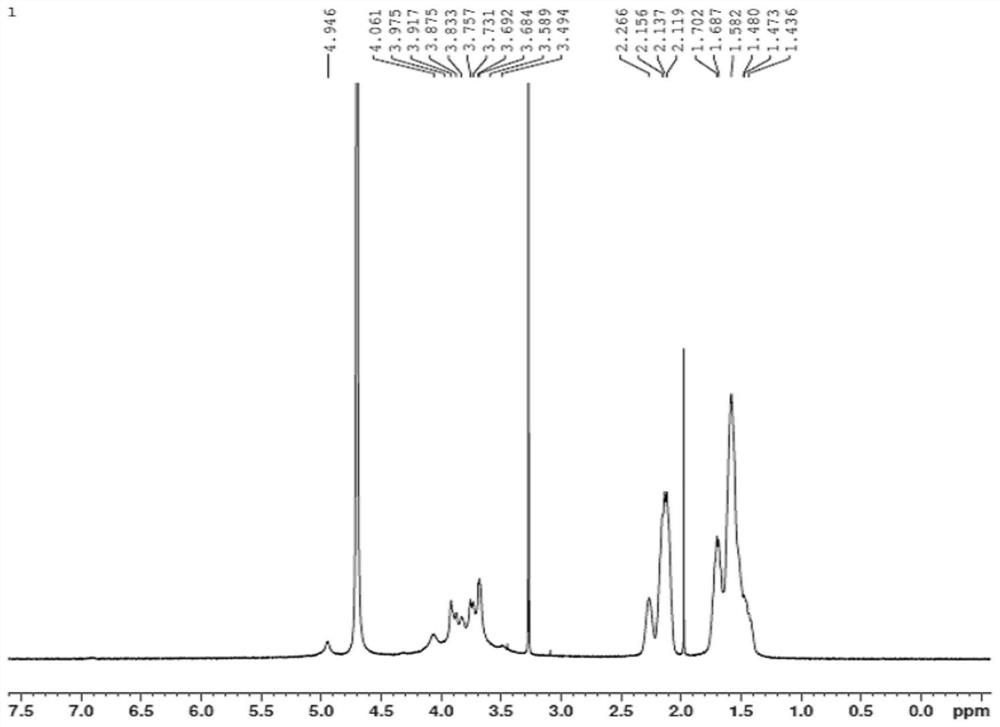

Acrylamide/2-acrylamido-2-methylpropane sulfonic acid sodium/cyclodextrin modified acrylamide (AM/AMPS-Na/MAM) copolymer and preparation method thereof

InactiveCN102199251AControl vectorThe preparation method is simple and feasibleDrilling compositionEthylenediamineAcetic acid

The invention discloses acrylamide / 2-acrylamido-2-methylpropane sulfonic acid sodium / cyclodextrin modified acrylamide (AM / AMPS-Na / MAM) copolymer serving as a fluid loss reducer for drilling fluid in oilfield, and a preparation method thereof, which can solve the problems of short cement paste thickening time, failure of an additive and high filter loss due to strata pressure and temperature rise. The technical scheme is that: the copolymer is prepared by polymerizing 83 to 85 percent of acrylamide AM, 15 to 16 percent of 2-acrylamido-2-methylpropane sulfonic acid sodium AMPS-Na and 1 to 2 percent of cyclodextrin modified acrylamide MAM. The preparation method comprises the following steps of: adding aqueous solution of the AM, solution of the MAM and solution of the AMPS-Na into a reaction container; adding ethylene diamine tetraacetic acid, potassium peroxydisulfate and sodium hydrogensulfite; and stirring uniformly, and reacting at the temperature of between 40 and 50DEG C for 5 to 6 hours under the protection of nitrogen to obtain the AM / AMPS-Na / MAM copolymer. The AM / AMPS-Na / MAM copolymer serving as a drilling fluid treating agent has high thermal stability, high temperature resistance, and better fluid loss reducing effect; the preparation method is simple and practicable, and the reaction conditions are mild; and the AM / AMPS-Na / MAM copolymer is used as the drilling fluid treating agent in the oilfield.

Owner:SOUTHWEST PETROLEUM UNIV

High-temperature-resistant viscosity-reduction filtrate reducer for drilling fluid and preparation method of filtrate reducer

The invention relates to a high-temperature-resistant viscosity-reduction filtrate reducer for a drilling fluid and a preparation method of the filtrate reducer. The filtrate reducer comprises the raw materials of waste acrylon fibers, alkali, mineral acid, hydrogen peroxide, lignite, a sulfonating agent, formaldehyde, copperas and water, wherein the waste acrylon fibers and part of alkali are added in water for reaction at the temperature of 85-95 DEG C; the mineral acid and the hydrogen peroxide are added when the temperature is reduced to 80-85 DEG C, and then the temperature is increased to 85-95 DEG C for reaction for 1-3 h; the remained alkali, lignite, sulfonating agent and formaldehyde are added for reaction for 1-3 hours at the temperature of 85-95 DEG C; the temperature is reduced to 60-80 DEG C, and then ferrous sulfate is added for reaction for 10-30 min; and finally, the product is fetched for drying and smashing. The obtained filtrate reducer not only can reduce the drilling fluid viscosity, but also has a good de-filtration effect and is resistant to high temperature. The filtrate reducer takes the waste acrylon fibers and the lignite as main raw materials, is low in cost and simple in process.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

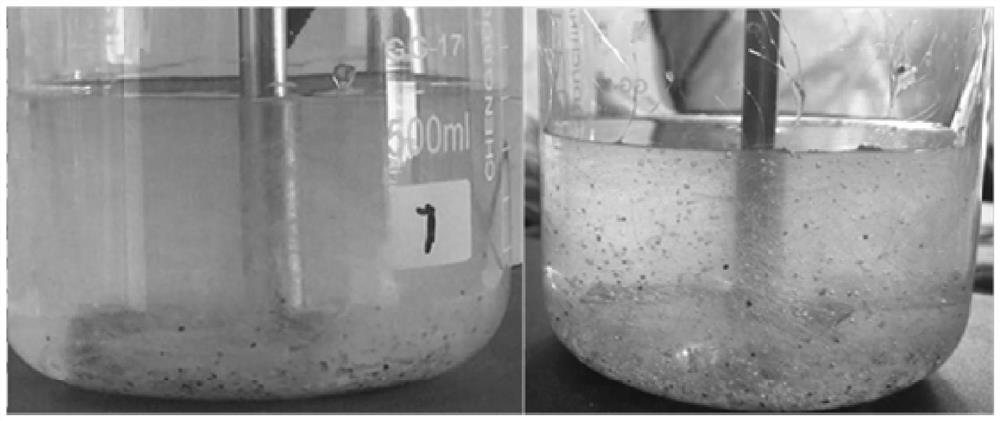

Solid-free drilling fluid

InactiveCN103509536ASimple system compositionSimple processing capacityDrilling compositionSalt resistanceFiltration

The invention provides solid-free drilling fluid. The solid-free drilling fluid comprises water and polymer swelling particles, and preferably, the solid-free drilling fluid also comprises alkali and / or salt. The solid-free drilling fluid provided by the invention can be formed by matching polymer swelling particles with different types, different swelling multiples and different particle sizes according to stratum requirements. The solid-free drilling fluid has the advantages of stable performance, high temperature resistance, high salt resistance, high rheological property, high lubricity and high filtration reducing property, and has simpler slurry matching and maintenance processes compared with conventional solid-free drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP +1

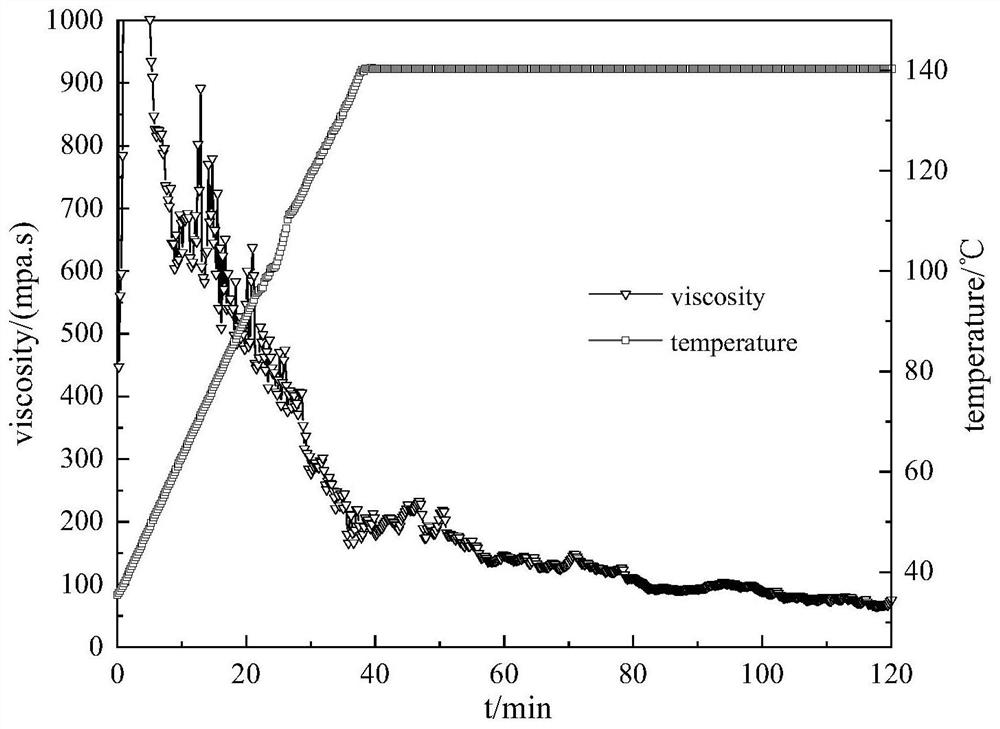

Water-based drilling fluid high-temperature-resistant tackifying rheology modifier, and preparation method thereof, and drilling fluid

ActiveCN109266318AExcellent carrying rockExcellent suspended weight material performanceDrilling compositionWater basedHorizontal wells

The invention relates to a water-based drilling fluid high-temperature-resistant tackifying rheology modifier, and a preparation method thereof, and a drilling fluid, and belongs to the technical field of oil field drilling fluids. According to the present invention, the water-based drilling fluid high-temperature-resistant tackifying rheology modifier is a starch micro-gel, and the starch micro-gel has an average particle size of 100-500 nm, preferably 100-300 nm, more preferably 100-200 nm, and is preferably a spherical particle; the high-temperature-resistant soilless phase water-based drilling fluid uses the starch micro-gel as the high-temperature-resistant tackifying rheology modifier, such that the problem of the insufficient temperature resistance of the tackifying rheology modifier commonly used in the existing soilless phase water-based drilling fluid is overcome; and the drilling fluid containing the tackifying rheology modifier can provide the good tackifying rheology effect at a high temperature of 150 DEG C, such that the soilless phase water-based drilling fluid system can be used for horizontal wells with a well temperature of about 150 DEG C, and the good application prospects can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gelatine drilling fluid additive and preparation method thereof

The invention discloses a gelatine drilling fluid additive and a preparation method thereof. The preparation method comprises the following steps of: performing the procedures of washing for removing impurities, flaking, drying, fine crushing and crude fiver removal on shaved nanmu materials, thus obtaining shaved nanmu gelatine; and then uniformly stirring and mixing the shaved nanmu gelatine with bentonite, sodium carbonate, polyacrylamide and carboxymethyl cellulose, thus obtaining the gelatine drilling fluid additive. The main material, namely the shaved nanmu gelatine, of the gelatine drilling fluid additive is easy to get, and thus the gelatine drilling fluid additive has good industrialization prospect, and can replace macro guar gum drilling fluid additives at present. When being applied to the field of drilling engineering, the gelatine drilling fluid additive provided by the invention is strong in inhibiting capability, good in de-filtration effect and excellent in lubricating performance, has the characteristics of being green, environment-friendly and reproducible, and has broad development and utilization prospect.

Owner:何洪城

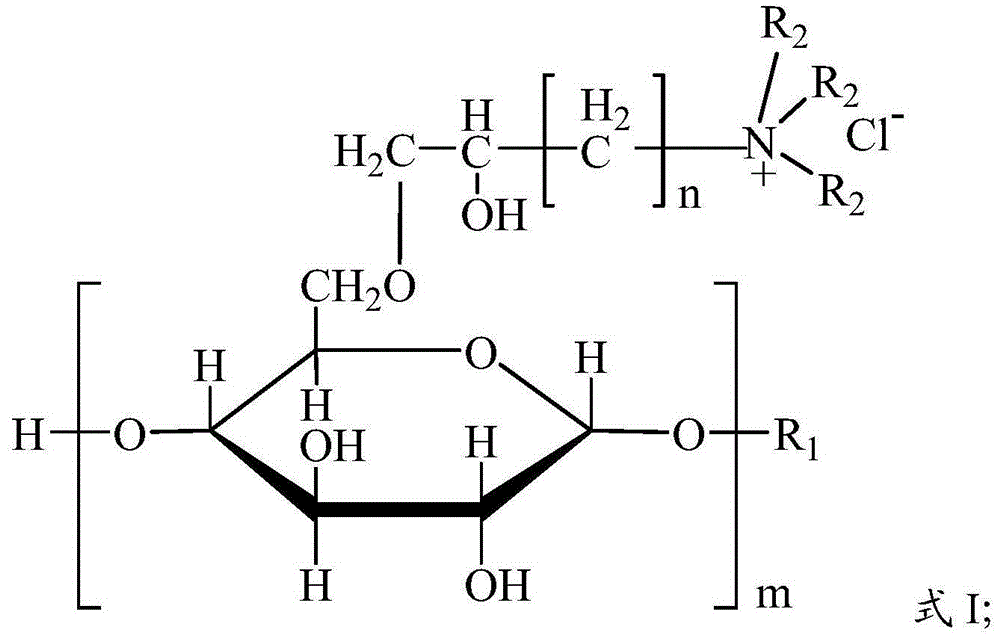

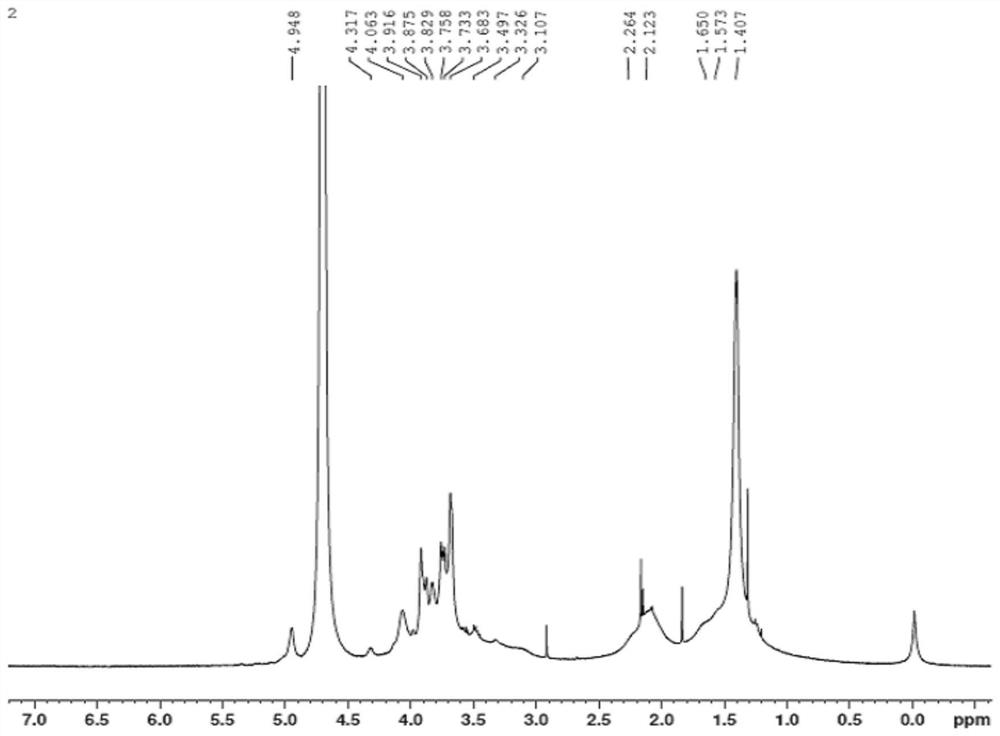

Glucoside, preparation method and applications thereof

ActiveCN106432377AEnhanced inhibitory effectImprove the lubrication effectSugar derivativesDrilling compositionGlucosidePhotochemistry

The present invention provides a cation alkyl glucoside, which has a structure represented by a formula I, wherein m is 1-3, n is 1-2, R1 is C1-C5 alkyl, and R2 is methyl, ethyl, propyl or butyl. The present invention provides a preparation method of the cation alkyl glucoside, wherein the preparation method comprises: carrying out a reaction on alkyl glucoside, a chlorinated epoxide, an acid catalyst and water to obtain an intermediate product, and carrying out a reaction on the intermediate product, an alkali compound and a tertiary amine hydrochloride to obtain the cation alkyl glucoside. According to the present invention, the cation alkyl glucoside has good inhibition performance, good lubricating property and good filtrate loss reduction performance; and with the application of the cation alkyl glucoside in the drilling fluid, the inhibition performance, the lubricating property and the filtrate loss reduction performance of the drilling fluid can be improved, and the cation alkyl glucoside is suitable for the drilling construction of the easily collapsible stratums such as the strong water sensitivity mudstone, the sand mud rock, and the like. The formula I is defined in the specification.

Owner:中石化石油工程技术服务有限公司 +1

Nanometer polymer blocking agent for drilling fluid and preparation method thereof

ActiveCN110387016AReduce fluid lossImprove conversion rateDrilling compositionCross-linkPolymer science

The invention provides a nanometer polymer blocking agent for a drilling fluid and a preparation method thereof, belonging to the technical field of oil-gas exploration and development. The nanometerpolymer blocking agent for the drilling fluid comprises, by weight, 14-16 parts of a surfactant, 30-35 parts of a functional monomer, 40-46 parts of an oil-phase dispersion medium, 2-5 parts of a cross-linking agent, 0.05-0.1 part of an initiator and 50-60 parts of water. The functional monomer includes an acrylic monomer, an acrylamide monomer and a polyethylene glycol methyl ether acrylate monomer. Since the nanometer polymer of the invention is a high-molecular-weight polymer and has non-polar functional groups on the molecular chain, a hydrophobic film can be formed on a mud cake, so polarmolecules such as water cannot pass through the film composed of non-polar molecules; and at the same time, the nanometer polymer can be gathered in the mud cake to reduce the permeability of the mudcake, thereby achieving the purpose of reducing the fluid loss of the drilling fluid. At the same time, the nanometer polymer blocking agent also has certain lubrication and anti-collapse performance, does not damage a hydrocarbon reservoir, and is of important significance for oil-gas field development in the future.

Owner:黑龙江益瑞化工有限公司

Starch filtrate reducer for drilling fluid and preparing method thereof

The invention discloses a starch filtrate reducer for drilling fluid and a preparing method thereof. The starch filtrate reducer for the drilling fluid is prepared from, by mass, 90-99 parts of starch, 0-5 parts of high-temperature stabilizer and 1-5 parts of alkalinity modifier, wherein the starch comprises one or more of potato starch, tapioca starch, canna edulis ker starch and colocasia esculenta starch. The starch filtrate reducer for the drilling fluid has the advantages of being good in filtrate reducing effect, good in reservoir protection effect, capable of being liquefied and the like; a reservoir stratum section drilling fluid system prepared from the starch filtrate reducer has automatic flowback performance, liquefiable performance and the like, has no harm to a reservoir stratum, and is beneficial for protecting the reservoir stratum.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Filtrate loss reducer for drilling fluid and preparation method thereof

InactiveCN106256870AShorten the production cycleReduce workloadDrilling compositionCross-linkEmulsion polymerization

The invention provides a filtrate loss reducer for a drilling fluid and a preparation method thereof. The filtrate loss reducer is an inverse emulsion polymer prepared from a water phase and an oil phase through emulsification. The water phase comprises, by weight, 45-56 parts of a sulfonic monomer, 25-38 parts of an amide group monomer, 5-10 parts of a rigid structure monomer and 100-120 parts of water. The water phase also comprises a cross-linking agent and an initiator, a mass ratio of the cross-linking agent to the sulfonic monomer, the amide group monomer and the rigid structure monomer is 0.008-0.015%, and a mass ratio of the initiator to the sulfonic monomer, the amide group monomer and the rigid structure monomer is 0.05-0.15%. The oil phase comprises 80-110 parts by weight of base oil and 4-10% by mass of an emulsifier. The preparation method has simple processes, a fast dissolution rate and excellent filtrate loss reduction performances.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

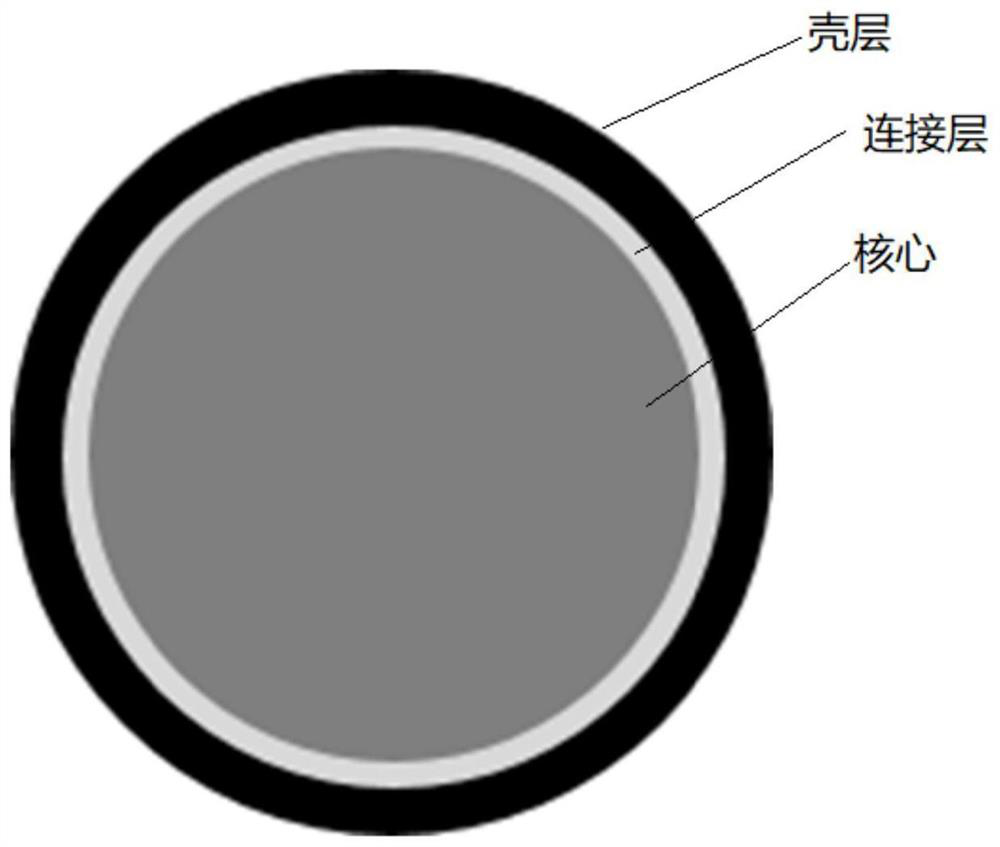

Inorganic/polymer composite plugging agent for ultrahigh-temperature-resistant oil-based drilling fluid, and preparation method and application thereof

ActiveCN112011315AImprove seal strengthAct as a bridgeDrilling compositionAcrylic resinPolymer composites

The invention provides an inorganic / polymer composite plugging agent for an ultrahigh-temperature-resistant oil-based drilling fluid, and a preparation method and application thereof. The plugging agent has a core-shell structure, the core is silane coupling agent modified quartz powder, and the shell is an acrylic resin material; the acrylic resin material is prepared from styrene, a vinyl-containing organic silicon monomer and a high-temperature-resistant monomer; and the high-temperature-resistant monomer comprises an oil-soluble hard monomer and an oil-soluble soft monomer. The invention also provides a preparation method of the plugging agent. The plugging agent disclosed by the invention is high in lipophilicity and has relatively good dispersity in an oil-based system; and the plugging agent has the advantages of good high-temperature resistance, good adaptability, good adsorption performance and excellent plugging capability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

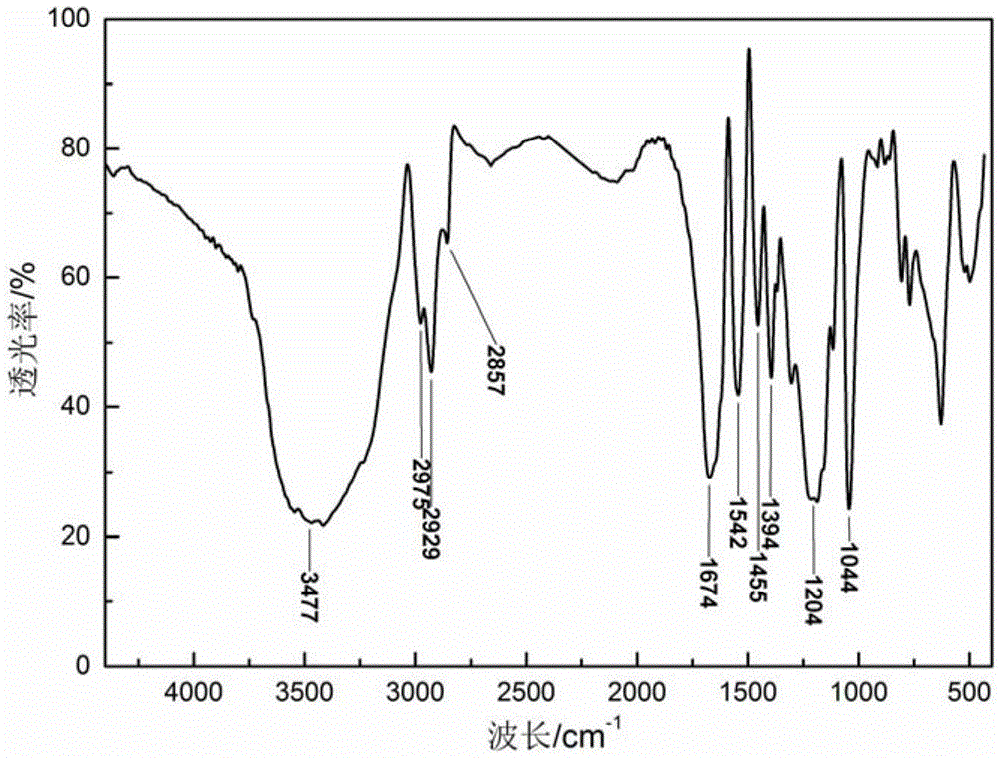

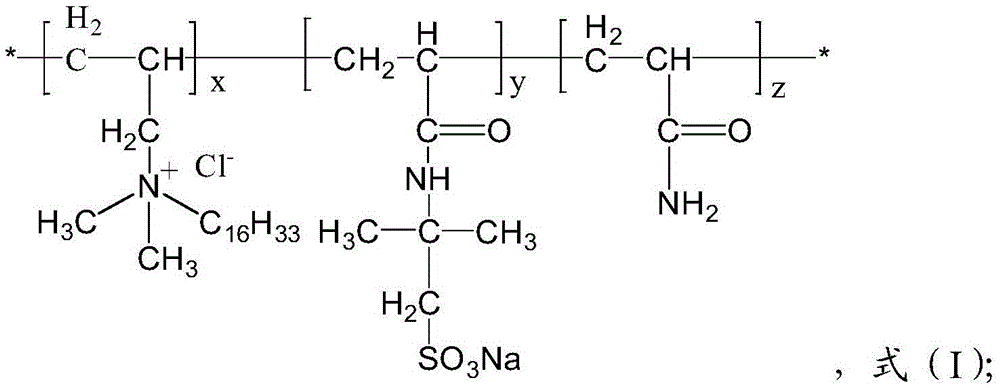

Filtrate reducer for drilling fluid and preparation method thereof

InactiveCN105670576AGood filter loss reduction effectGood temperature and salt resistanceDrilling compositionChemistryMethallyl chloride

The invention provides a filtrate reducer for drilling fluid. The filtrate reducer is characterized by being prepared from acrylamide, 2-acrylamido-2-methyl propyl sulfonic acid and hexadecyl dimethyl allyl ammonium chloride. According to the invention, the acrylamide, 2-acrylamido-2-methyl propyl sulfonic acid and hexadecyl dimethyl allyl ammonium chloride are taken as raw materials for preparing the filtrate reducer for the drilling fluid, and the filtrate reducer for the drilling fluid has relatively good filtration reducing property and also has relatively good temperature and salt tolerance.

Owner:SOUTHWEST PETROLEUM UNIV +1

High-efficiency energy-saving bridging channel full-coupling fiber proppant system and application method thereof

ActiveCN111961460AReduce pollutionEfficient suspensionFluid removalDrilling compositionActive agentSilane coupling

The invention discloses a high-efficiency energy-saving bridging channel full-coupling fiber proppant system for fracturing. The system comprises fracturing fluid, special fibers and a laminating proppant, wherein the special fibers are conventional fibers treated by a surface modifier; the laminating proppant takes a conventional proppant as a core, and the surface of the conventional proppant issequentially coated with a connecting layer and a housing layer, wherein the connecting layer is composed of a nitrogen-containing silane coupling agent and a cross-linking agent; and the material ofthe housing layer is a small molecular surfactant or an oil-soluble low-molecular-weight polymer, wherein the oil-soluble low-molecular-weight polymer is one or a combination of at least two of anionic polyacrylamide and derivatives thereof. According to the sand carrying system, through the mutual coupling effect of the laminating proppant and the special fibers, efficient suspension of the proppant, repeated cyclic utilization of reverse drainage liquid and an oil-gas high-speed channel formed in a unique self-bridging mode are finally achieved.

Owner:SOUTHWEST PETROLEUM UNIV +1

Organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system

ActiveCN109735314AImprove performanceImprove anti-slump performanceDrilling compositionSodium BentoniteReducer

The invention discloses an organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluid system, relates to drilling fluid, and belongs to the technical field of geological resource exploration and development. The drilling fluid system comprises bentonite base slurry, thickening agents, filtrate reducers, blocking agents, weighting agents, inorganic silicate and organic silicate, the dosage of raw materials is calculated according the weight of the bentonite base slurry, the weight percent of the bentonite base slurry is 1%-4%, the concentration of the organic silicate is 0.05mol / L-0.5mol / L, and the weight percent of the inorganic silicate is 0.1%-5%. According to the organic-inorganic composite silicate high-temperature-resistant film-forming drilling fluidsystem, the inhibition and anti-collapse ability of the drilling fluid is improved, the requirements of borehole stability and safe drilling are more effectively met, and inhibition, blocking and chemical wall fixation are achieved.

Owner:JILIN UNIV

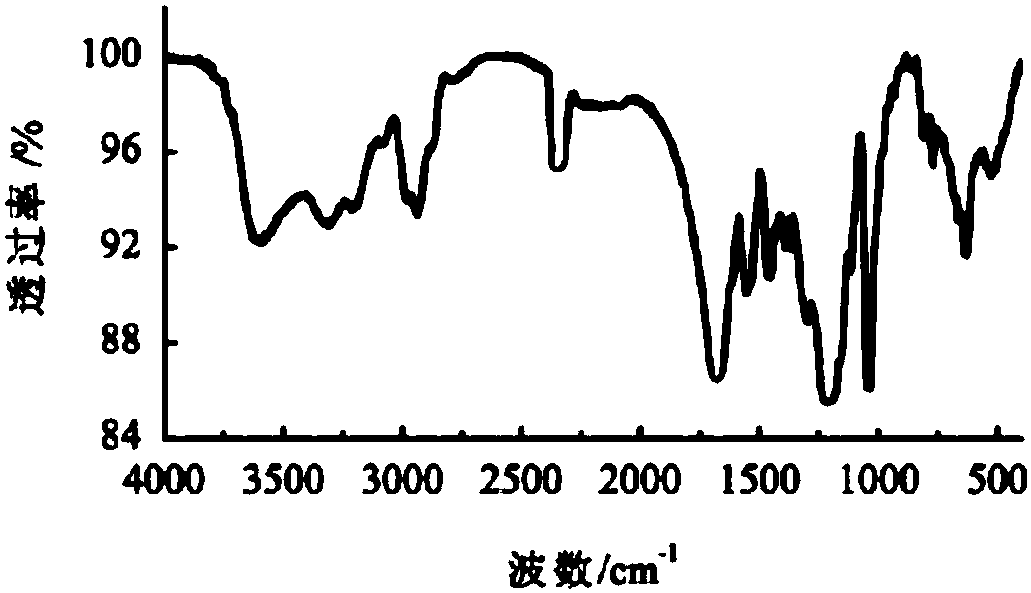

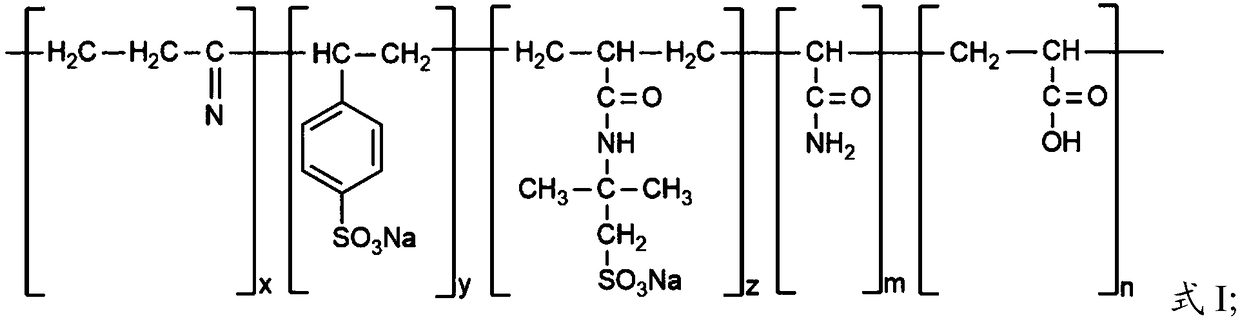

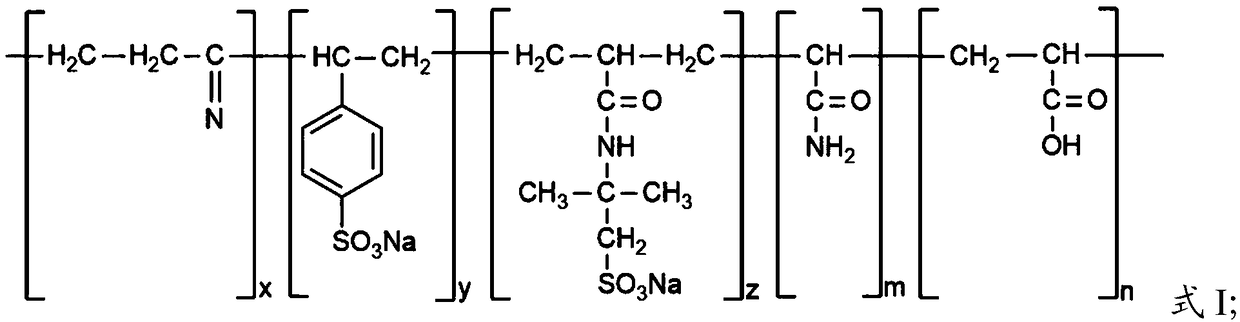

High-temperature-resistant fluid loss agent and preparation method thereof as well as water-based drilling fluid

InactiveCN108342188AImprove thermal stabilityImprove temperature resistanceDrilling compositionWater basedSalt resistance

The invention provides a high-temperature-resistant fluid loss agent and a preparation method thereof. According to the invention, the preparation conditions are strictly controlled to obtain a polymer formed by co-polymerization of various monomers, and due to statistical characteristics of the polymer in a formation process, a characteristic of non-uniform molecular weight of the fluid loss agent, i.e., polydispersity of the molecular weight, is formed, thus greatly improving the rheological property and temperature and salt resistance of the drilling fluid under high temperature conditions;in addition, the molecular structure of the high-temperature-resistant fluid loss agent also contains benzene rings which have stronger rigidity than linear molecular chains, enhance the rigidity ofmolecular chains, improve the thermal stability of the fluid loss agent, and improve the temperature resistance of the fluid loss agent in a drilling fluid. The invention also provides a water-based drilling fluid containing the high-temperature-resistant fluid loss agent. The fluid loss agent provided by the invention can still maintain good fluid loss reducing property under a high-temperature condition of 200 DEG C in a fresh water-based slurry and also can maintain good fluid loss reducing property under a high-temperature condition of 160 DEG C in a composite brine-based slurry.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Temporary plugging agent for drilling fluid

The invention discloses a temporary plugging agent for drilling fluid, and belongs to the technical field of petroleum drilling. The temporary plugging agent is prepared from the following raw materials in percentage by weight: 60 to 70 percent of hexadecane, 0.5 to 1 percent of catalyst persulfate, 10 to 20 percent of phenol, 10 to 20 percent of formaldehyde, and 1 to 2 percent of cationic surface active agent. The preparation method comprises the following steps of: 1, adding the hexadecane liquid into a reaction kettle, heating the reaction kettle to 50+ / -5 DEG C, adding the phenol, stirring the mixture, controlling the temperature to be 80+ / -5 DEG C and the pressure to 2+ / -0.5MPa, slowly adding the catalyst, adding the formaldehyde solution after 2 hours, stirring the mixed solution for 2 hours while continuously controlling the temperature to 40+ / -5 DEG C, adding the surface active agent, and stirring the mixed solution for 2 hours; and 2, relieving the pressure in the reaction kettle to normal pressure, extracting the mixture, drying the mixture at the temperature of 100+ / -5 DEG C, and then grinding the dried mixture to obtain the temporary plugging agent. The softening point temperature of the temporary plugging agent is within a wide range from 70 to 140 DEG C, so that the temporary plugging agent can almost meet the needs of all layers of earth.

Owner:CHENGDU DEDAO IND

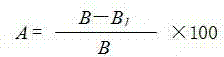

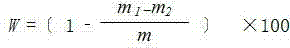

Shearing-force increase and filtrate loss reduction agent for drilling fluid and preparation method thereof

ActiveCN104559964AStrong stretch abilityNo significant increase in apparent viscosityDrilling compositionCross-linkSodium chloroacetate

The invention relates to a shearing-force increase and filtrate loss reduction agent for drilling fluid and a preparation method thereof. The shearing-force increase and filtrate loss reduction agent for drilling fluid is prepared with a method as follows: cross-linked starch, modified natural fiber and biological glue are subjected to graft copolymerization with comonomer under the action of an initiating agent A, wherein with the weight of the cross-linked starch as a reference, the weight fraction of other raw materials is as follows: biological glue accounts for 10-35%, natural fiber accounts for 10-35%, a basifier accounts for 2-8%, sodium chloroacetate accounts for 1-5%, epoxy chloropropane accounts for 0.5-3%, comonomer account for 20-60%, and the initiating agent accounts for 0.5-2%. The shearing-force increase and filtrate loss reduction agent for the drilling fluid can scientifically adjust apparent viscosity and static shearing force of the drilling fluid, has good filtrate loss reduction performance and shearing-force increase performance and is good in salt-resistant and temperature-resistant effect.

Owner:北京中科日升科技有限公司

Guar gum grafted copolymer nanocomposite gel fracturing fluid and preparation method thereof

The invention provides a guar gum grafted copolymer nanocomposite gel fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following components in percentage by mass:0.4-1.2% of a guar gum grafted copolymer thickening agent, 0.05-0.5% of a nanomaterial and 0.2-1% of a cross-linking agent, with the balance being water. According to the invention, guar gum or a derivative thereof and acrylamide monomers are used as raw materials to synthesize a guar gum graft copolymer, the guar gum graft copolymer is used as the thickening agent, a nanomaterial dispersion liquid is added, and the nanocomposite gel fracturing fluid is prepared under the action of the cross-linking agent. Hydrophilic flexible polymer branched chains are introduced to semi-rigid macromolecularchains of guar gum, so mutual entanglement and adsorption between the guar gum and the nanomaterial are facilitated, the compatibility of the guar gum and the nanomaterial can be greatly improved, and interaction between the nanomaterial and a polymer matrix is further improved; and the prepared nanocomposite gel fracturing fluid has better temperature resistance, shearing resistance, sand carrying property and filtrate loss reduction property.

Owner:SOUTHWEST PETROLEUM UNIV

Cellulose graft copolymer, and preparation method and application thereof

PendingCN109970916AImprove temperature resistance and heat resistanceImprove fluid loss controlDrilling compositionSodium carboxymethylcelluloseSide chain

The invention relates to the field of fluid loss agents, and discloses a cellulose graft copolymer, and a preparation method and an application thereof. The graft copolymer includes a carboxymethyl cellulose main chain and side chains, and the side chains include a structural unit represented by formula (1), a structural unit represented by formula (2), and a structural unit represented by formula(3); and a mass ratio of the carboxymethyl cellulose main chain to the structural unit of the formula (1) to the structural unit of the formula (2) to the structural unit of the formula (3) is (2-6):(1-4):(1-3):1. The cellulose graft copolymer can enhance the temperature resistance, the calcium resistance and the salt resistance of a drilling fluid and improve the fluid loss reduction effect of the drilling fluid when used in the drilling fluid as a fluid loss agent, and also can meet environmental protection requirements.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

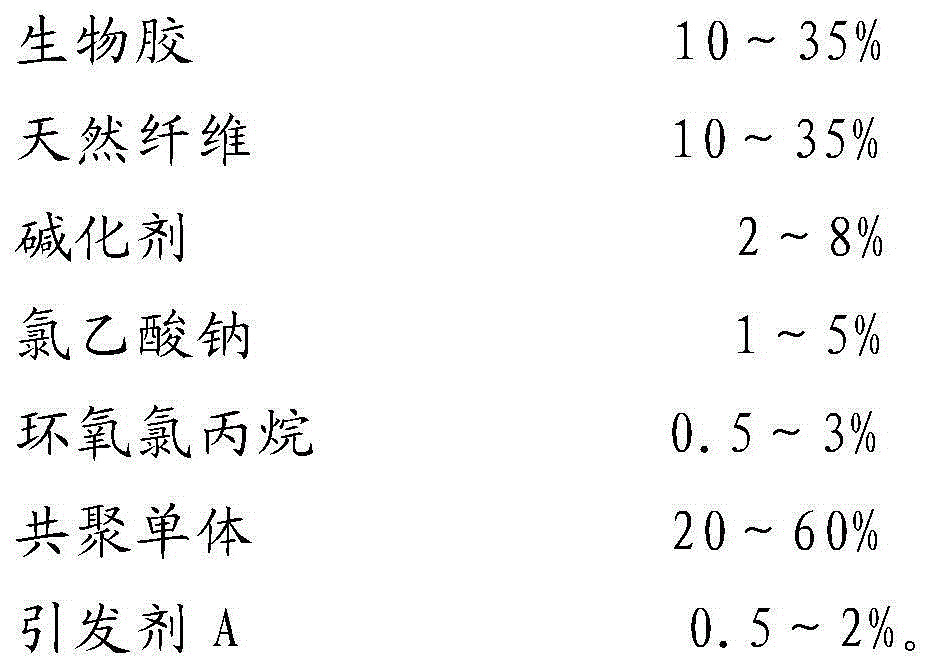

High-temperature-resistant filtrate reducer for drilling fluid and preparation method thereof

ActiveCN109852353AGood filter loss reduction effectStrong ability to seal cracksDrilling compositionPolymer scienceFiltration

The invention discloses a high-temperature-resistant filtrate reducer for drilling fluid. The high-temperature-resistant filtrate reducer is prepared from the following raw materials in parts by weight: 35-55 parts of synthetic resin, 15-25 parts of aldehyde ketone resin, 45-65 parts of sulfonated asphalt formed by sulfonating natural asphalt, 5-15 parts of an initiator B, 10-20 parts of nano calcium carbonate, and 60-80 parts of an alkene monomer polymer. The invention also discloses a preparation method of the high-temperature-resistant filtrate reducer. The preparation method comprises thefollowing steps: stirring the sulfonated asphalt and the alkene monomer polymer at 45-60 DEG C for 30-40 minutes; adding an initiator B, stirring the components for 2-3 hours, then adding nano calciumcarbonate, heating the mixture to 95-120 DEG C, then adding synthetic resin and aldehyde ketone resin, stirring the mixture, carrying out heat preservation reaction at 100-110 DEG C for 4-5 hours, and drying the reaction product to obtain the high-temperature-resistant filtrate reducer. The high-temperature-resistant filtrate reducer has the advantages of excellent filtration reduction performance, stronger crack plugging capability, stable mud rheological property, stable well wall and excellent high-temperature resistance and salt resistance.

Owner:北京宏勤石油助剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com