High-efficiency energy-saving bridging channel full-coupling fiber proppant system and application method thereof

A proppant, fully coupled technology, used in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problem of failure to meet the needs of hydraulic fracturing in multiple wells, high prices of coated proppants, formation cracks and pores Damage and other problems, to achieve the effect of efficient suspension, low price, and little environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

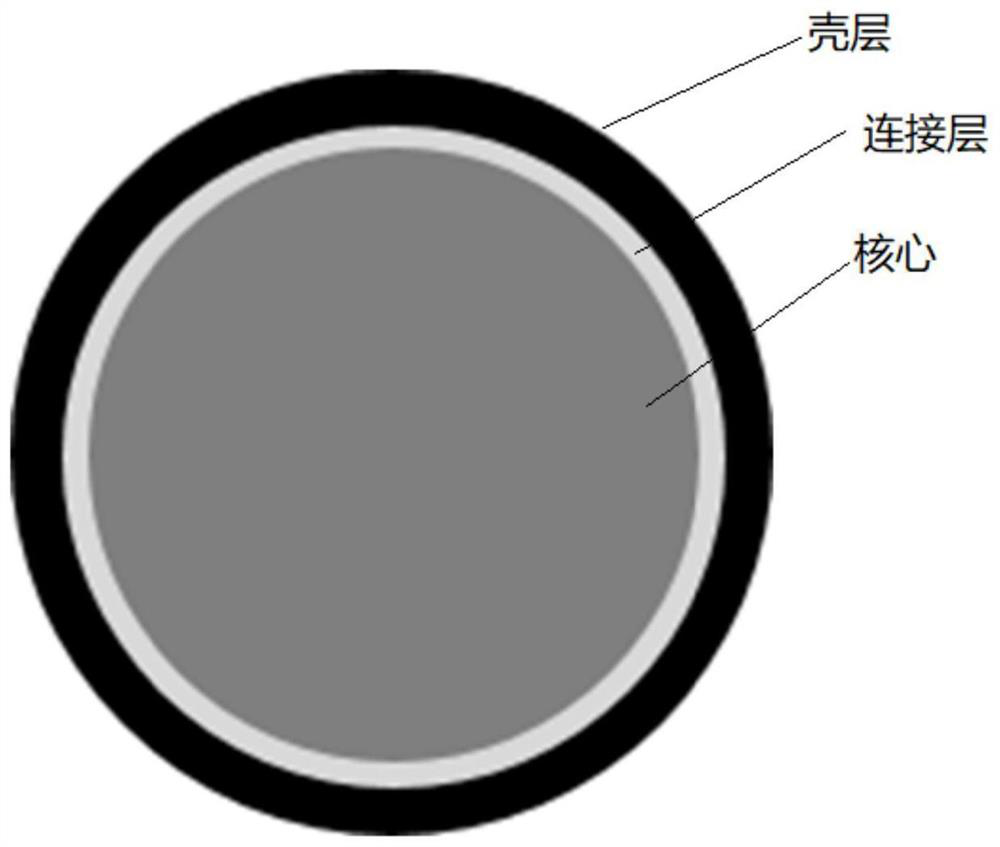

[0038] Such as figure 1 with 2 as shown, figure 1 is a schematic diagram of the structure of a conventional proppant. figure 2 It is a structural schematic diagram of the film-covered proppant of the present invention. It can be seen that the film-coated proppant of the present invention has a core-shell structure, the core of which is a conventional proppant, and the surface of the conventional proppant is sequentially wrapped with a connecting layer and a shell layer. The connecting layer is located between the core and the shell, and is used for fixedly connecting the core and the shell.

Embodiment 2

[0040] A kind of preparation of membrane proppant:

[0041] The film-covered proppant uses quartz sand as the core, 3-aminopropyltriethoxysilane and 3-chloro-1,2-propylene oxide as the connecting layer, and cocoamidosulfobetaine as the shell layer. All raw material formulations are as shown in Table 1:

[0042] Table 1 Raw materials used in film-coated proppants

[0043]

[0044] Preparation method steps:

[0045] (1) Select 20 / 40 mesh quartz sand and add it to the reaction vessel, soak it with 1wt% HCl solution for 30 minutes to remove the stains on the surface of the quartz sand; filter the liquid, wash with water to remove residual acid until neutral; After drying for 2 hours, set aside.

[0046] (2) Take 3-aminopropyltriethoxysilane and add it to the reaction vessel, add ethanol as a solvent, and stir at room temperature for 10mim; Mix well; raise the temperature of the reactor to 80°C, and react for 3h until the solvent is completely evaporated; continue to raise t...

Embodiment 3

[0050] A preparation method of film-coated proppant:

[0051] The film-covered proppant selects 40 / 70 mesh ceramsite as the core, N-(β-aminoethyl)-γ-aminopropyltriethoxysilane and glutaraldehyde as the connecting layer, and 10,000 molecular weight oil-soluble polymer as the shell Floor. All raw material formulations are as shown in Table 2:

[0052] Table 2 Raw materials used in film-coated proppants

[0053]

[0054] Preparation method steps:

[0055] (1) Select ceramsite of 40 / 70 mesh and add it to the reaction container, soak it with 1wt% HCl solution for 30 minutes to remove the stain on the surface of the quartz sand; filter the liquid, wash it with water to remove the residual acid until neutral; After drying for 2 hours, set aside.

[0056] (2) Take N-(β-aminoethyl)-γ-aminopropyltriethoxysilane into the reaction vessel, add ethanol as a solvent, and stir at room temperature for 10mim; then add step (1) to the reaction vessel to wash Clean and dry quartz sand, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com