Patents

Literature

2249 results about "Coalbed methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coalbed methane (CBM or coal-bed methane), coalbed gas, coal seam gas (CSG), or coal-mine methane (CMM) is a form of natural gas extracted from coal beds. In recent decades it has become an important source of energy in United States, Canada, Australia, and other countries.

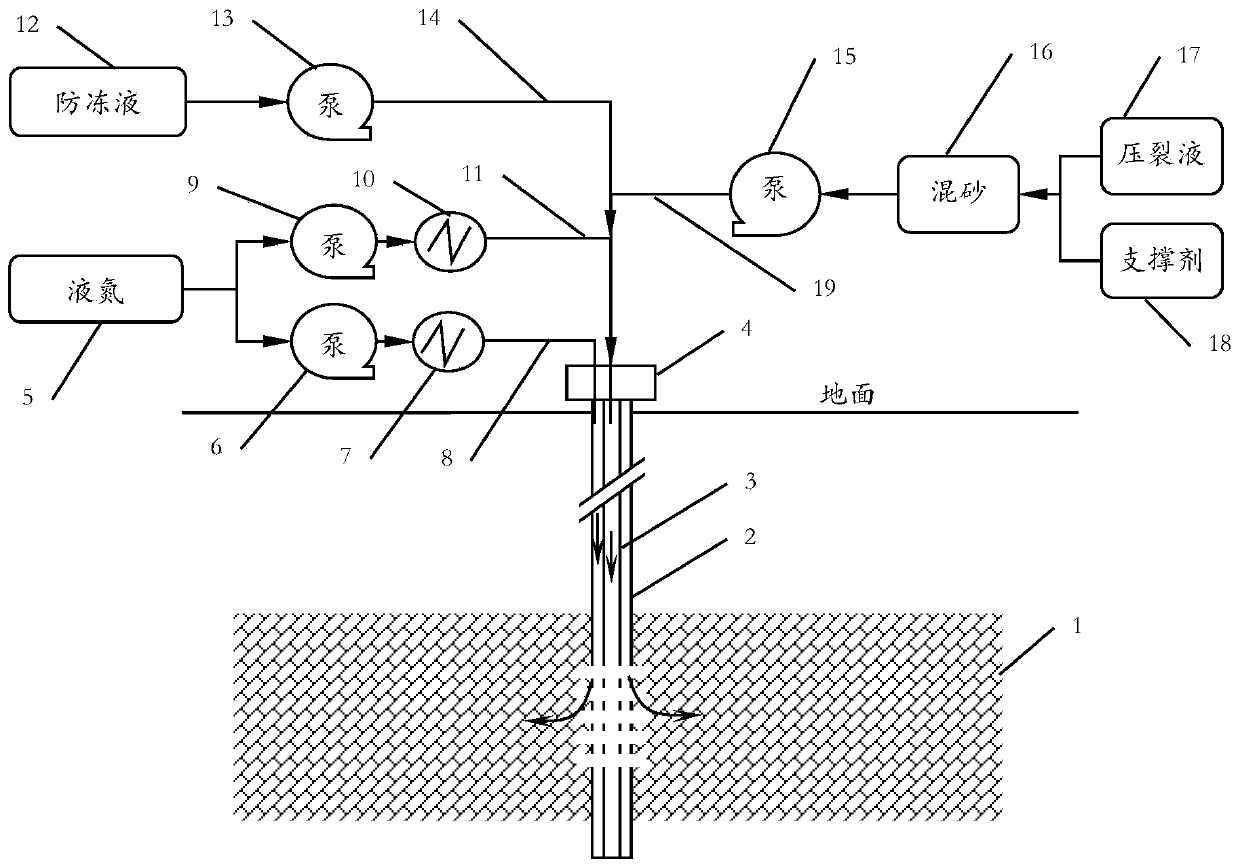

Method of low-temperature gas-assisted coalbed methane fracturing technology

InactiveCN103726819AImproved crack systemImprove mechanical propertiesInsulationFluid removalOil and natural gasIce formation

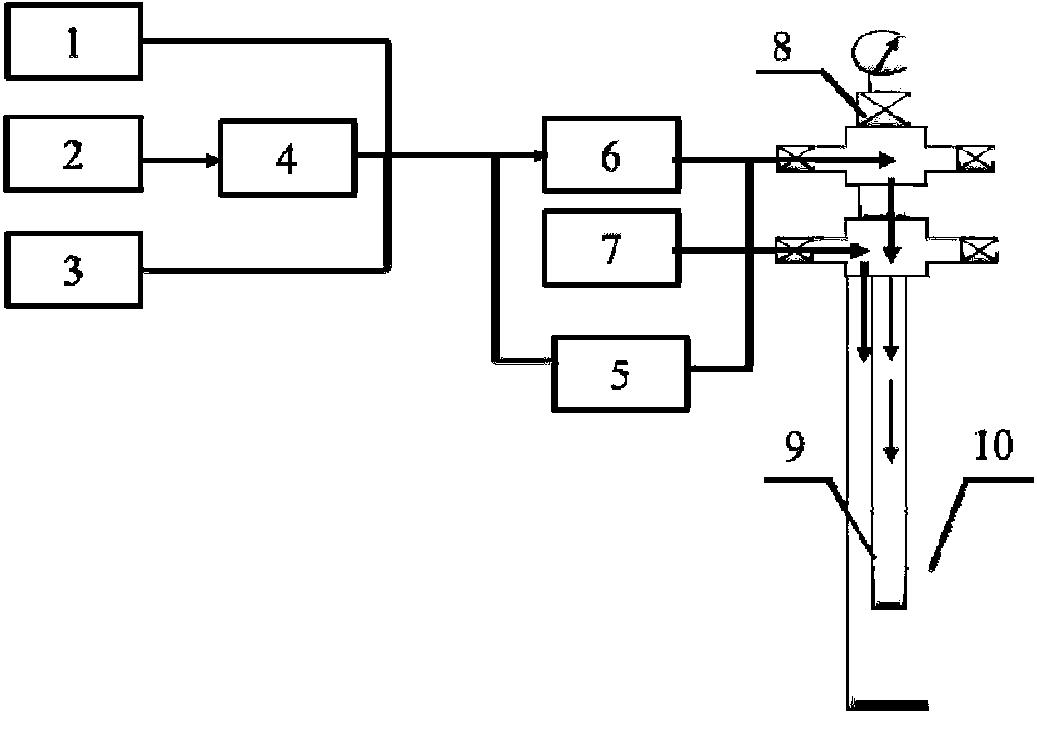

The invention relates to the field of oil and natural gas prospecting and exploitation, and provides a method of low-temperature gas-assisted coalbed methane fracturing technology. According to the method, by the aid of ultralow temperature characteristics of liquid nitrogen, cold shock transformation and ice formation are performed on a coalbed, ice blockage is caused to high-permeability channels (such as fractures), and effect of inorganic harmless dissoluble flowback fluid loss additives, even fracturing diverters and the like is achieved, so that the purpose of improving conventional coalbed methane fracturing technology is achieved. The method of the fracturing technology is suitable for primary fracturing of coalbed methane wells non-fractured or with natural fractures existing at the well bottoms, as well as refracturing of coalbed methane wells already fractured but low in productivity.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

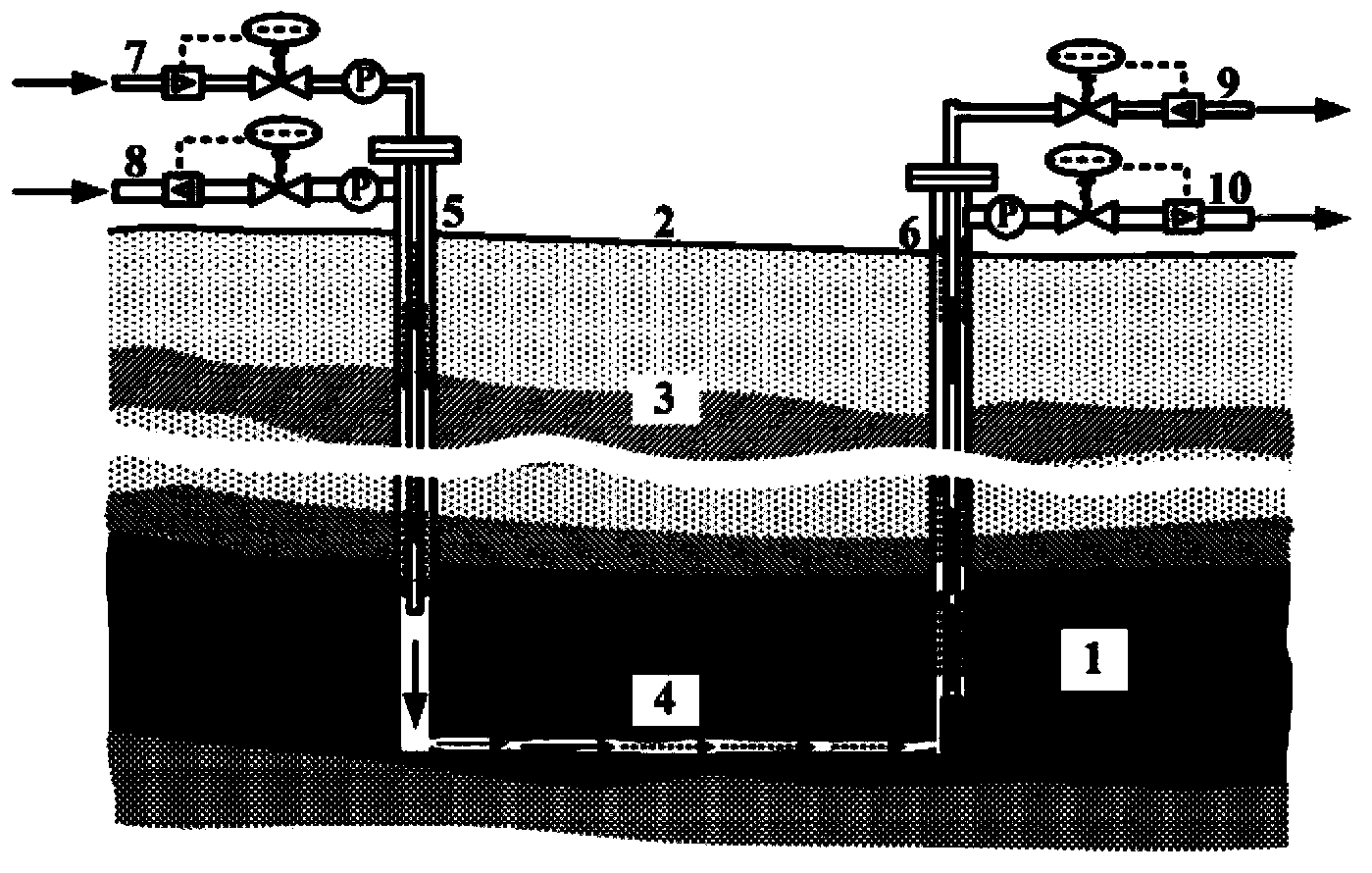

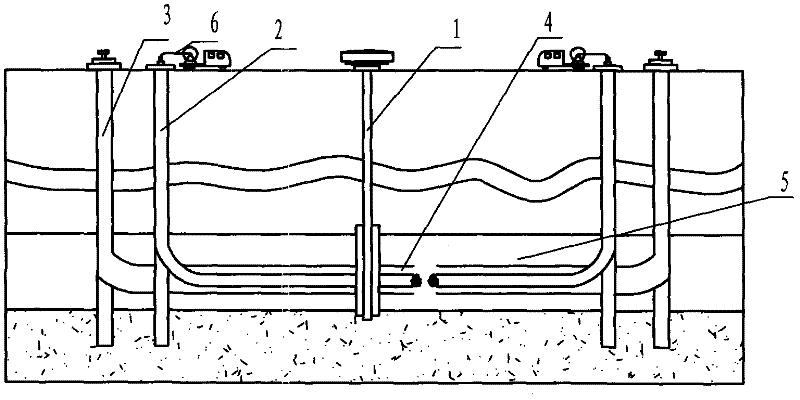

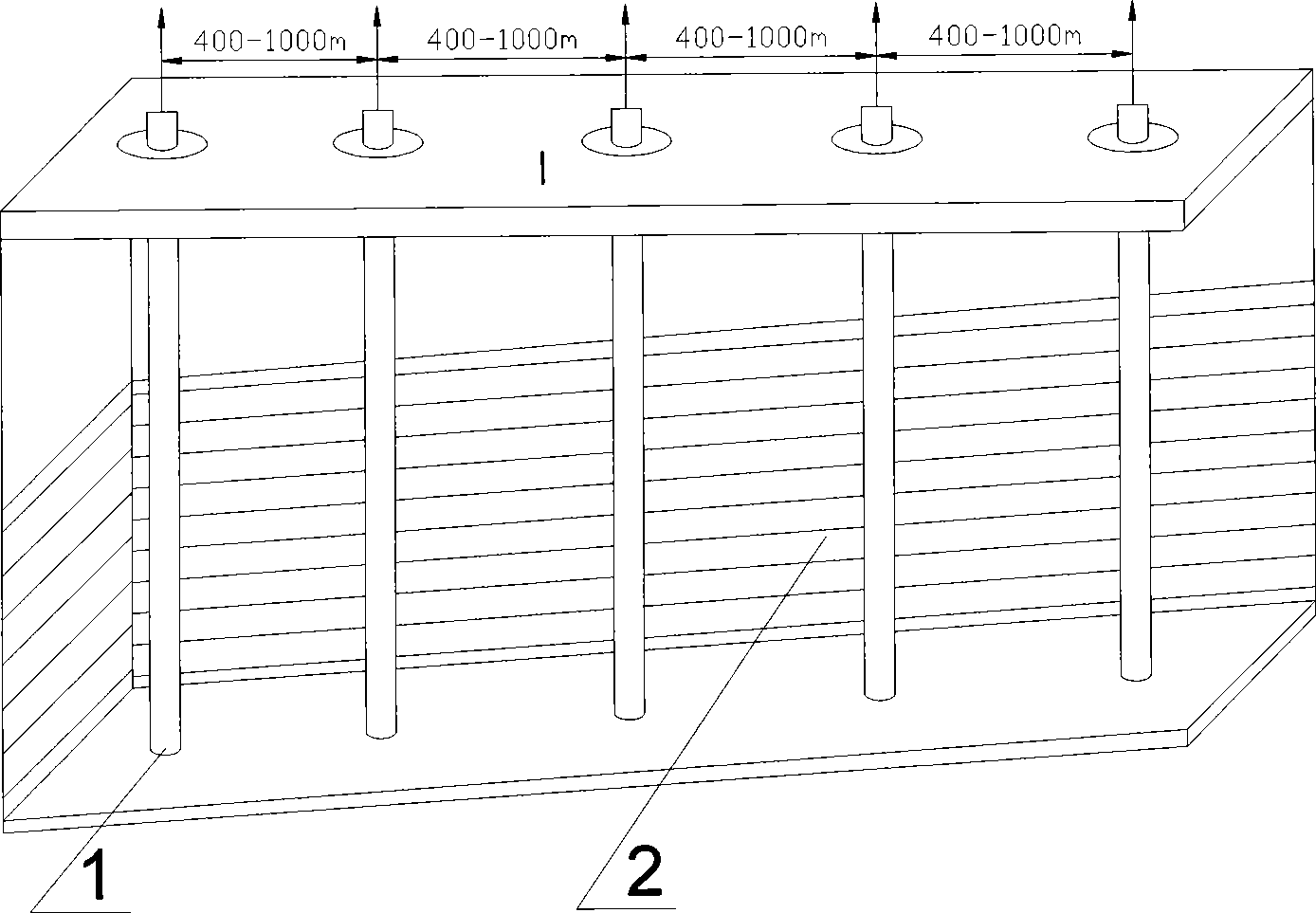

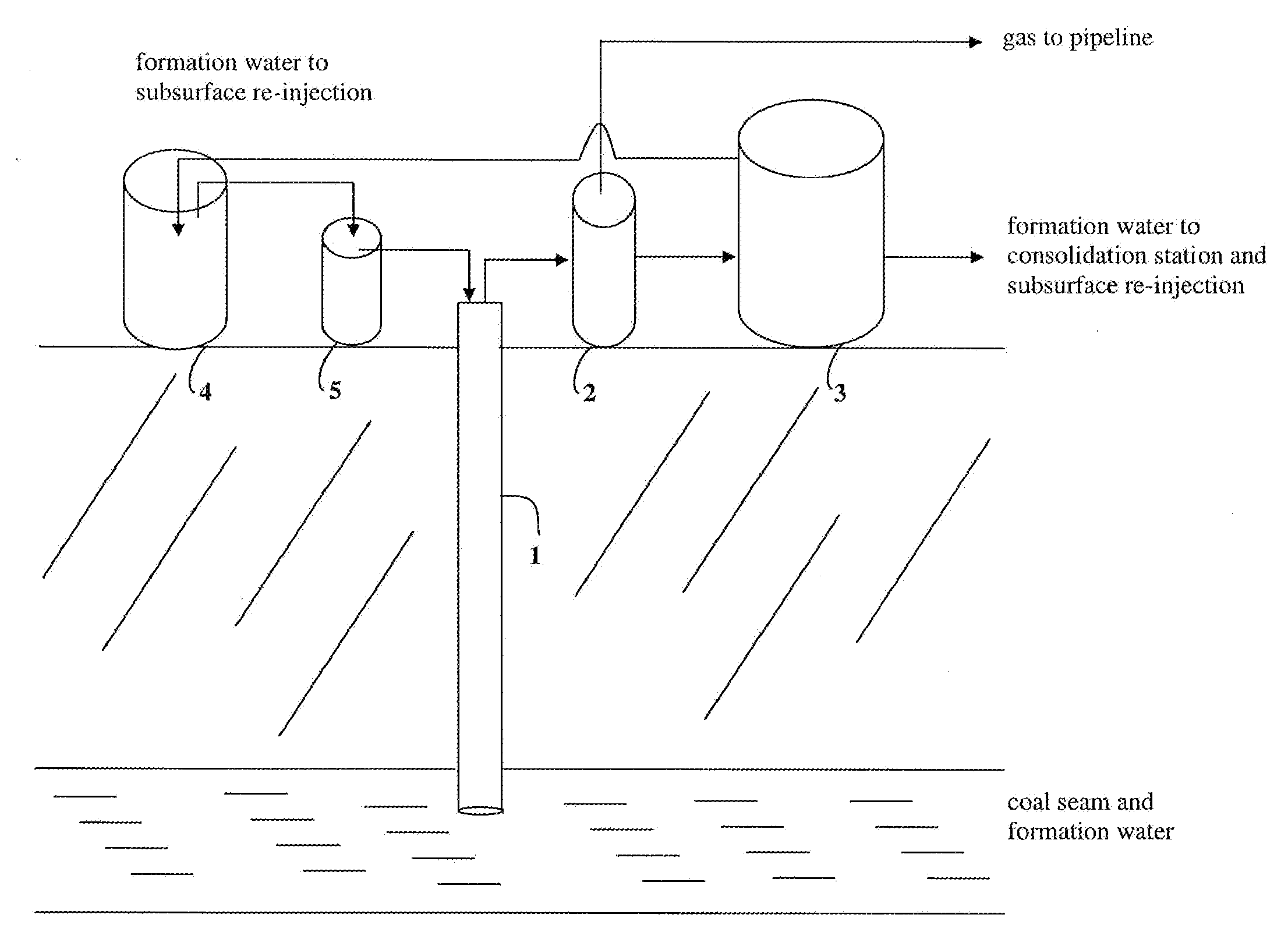

Method for pumping coalbed gas by heating coal bed

ActiveCN101418679AAchieve separationEfficient extractionFluid removalGas removalWater vaporDistilled water

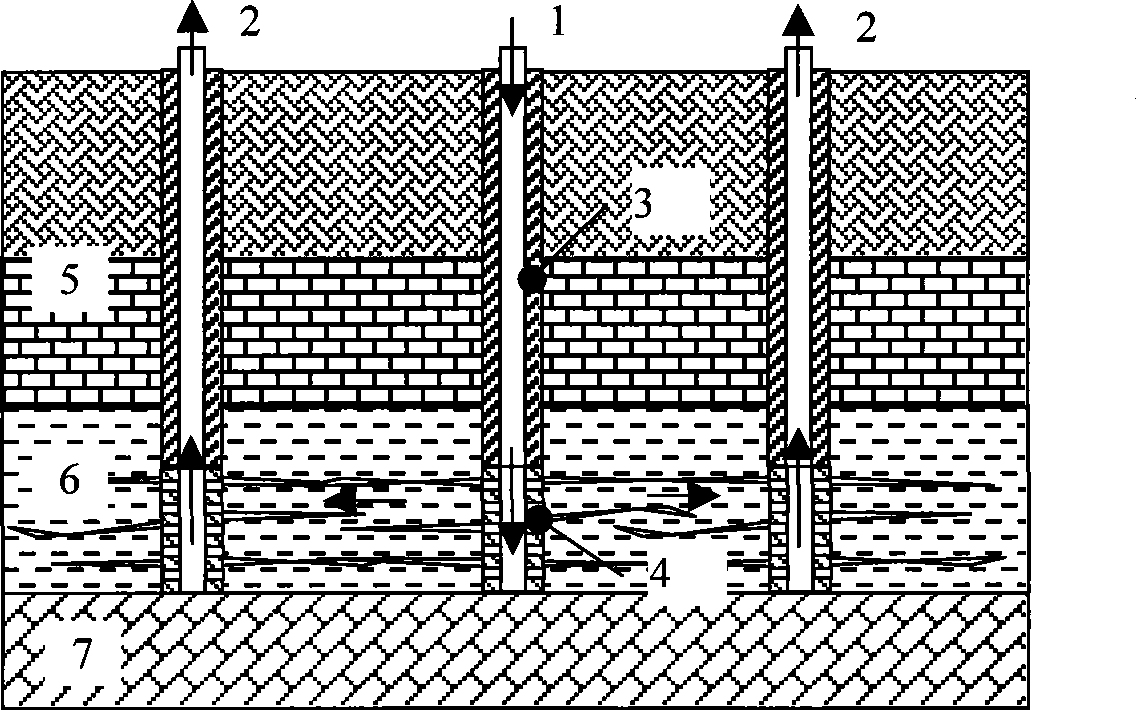

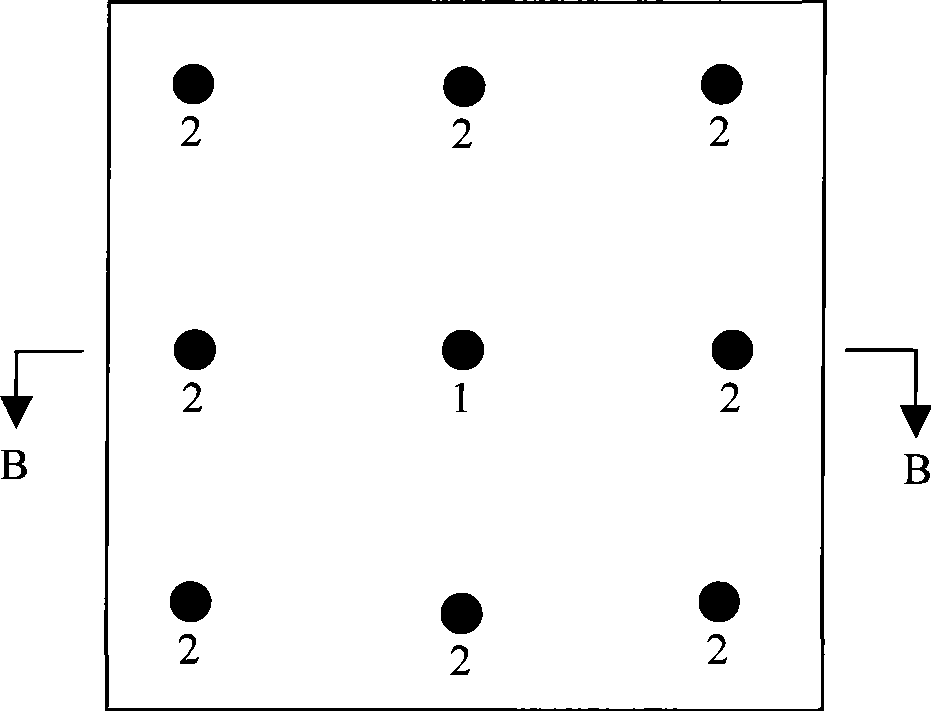

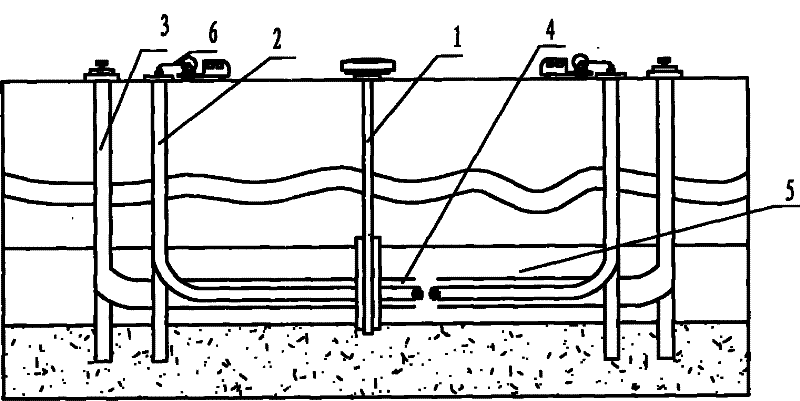

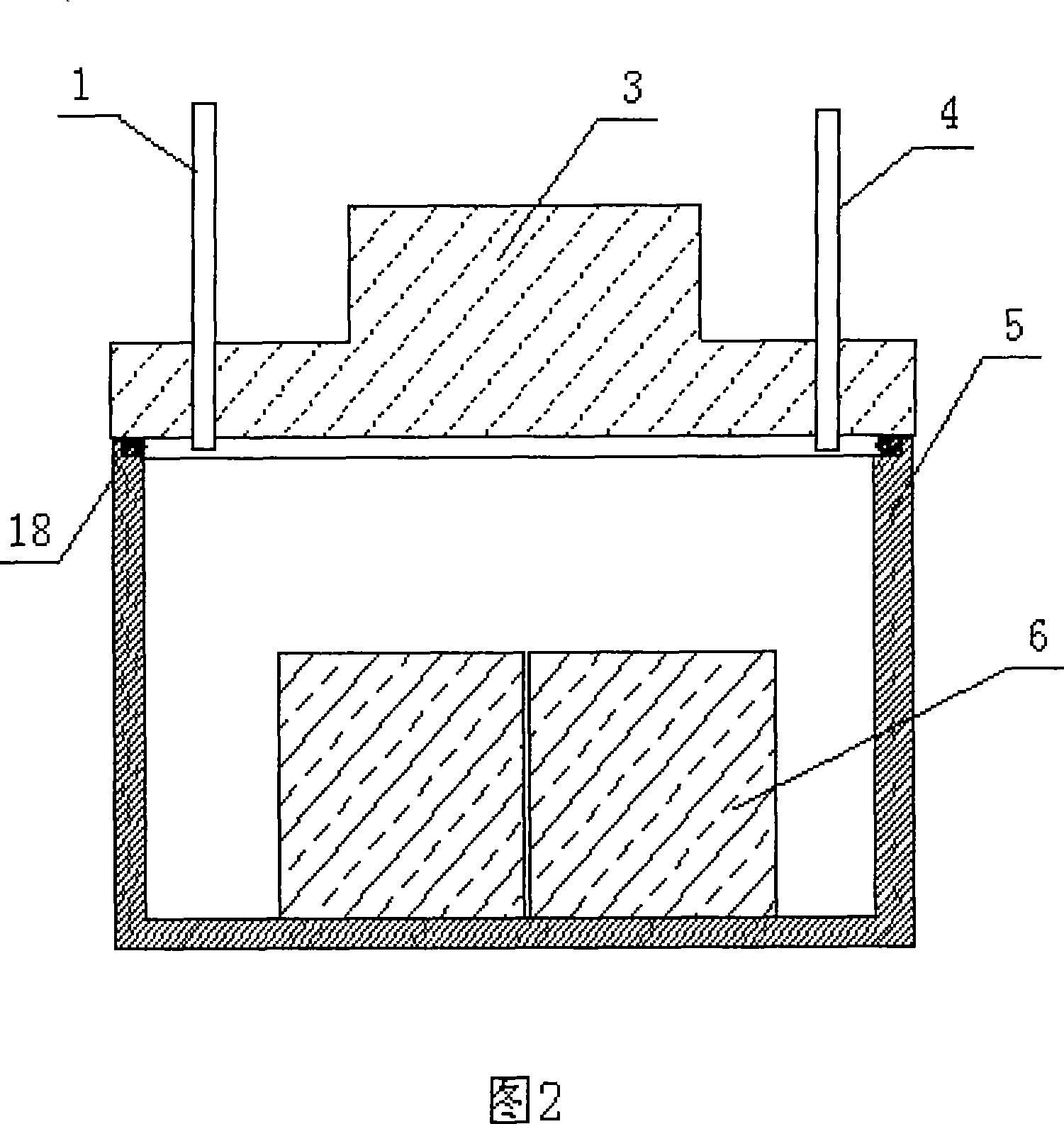

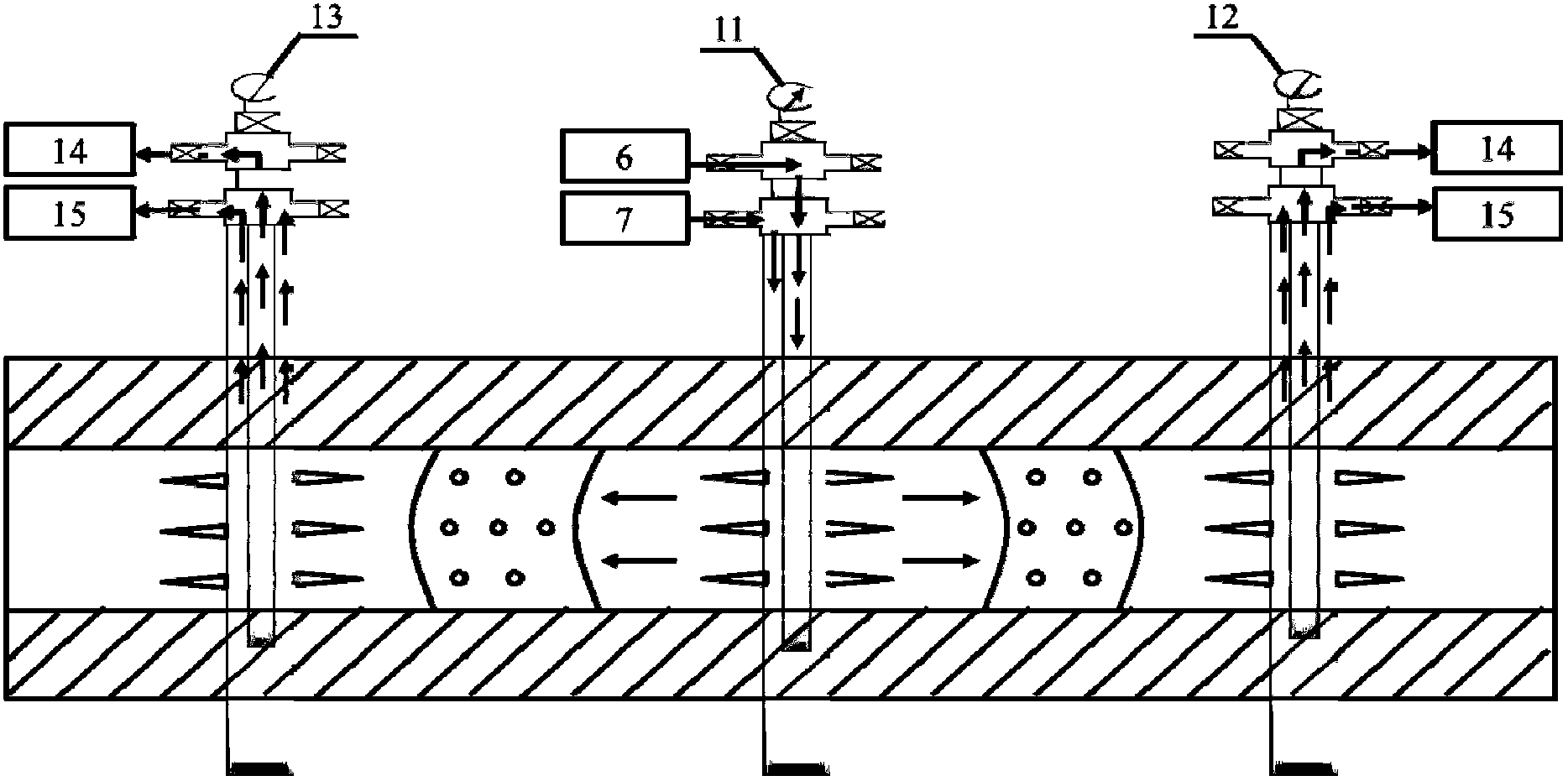

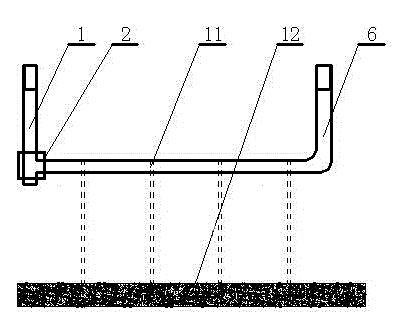

Provided is a method for heating coal seam and extracting coal seam gas. Firstly, a plurality of vertical wells are drilled from the ground to the coal seam, after the drilled well reached to the coal seam, the coal seam is inserted with a screen tube casing (4), the section above the coal seam is inserted with a heat insulation casing (31) and the well is correspondingly fixed. At least one well of the wells is selected to be a heat source injection well (1) and other wells are gas production wells (2), steam with high temperature and high pressure is injected into the heat source injection well (1) to perform fracturing to communicate all the wells in the network. Drainage and pressure reduction are performed to the gas production wells (2) to extract the mixed gas of the coal seam gas and steam. The mixed gas of the coal seam gas and steam is cooled by known cooling method so as to obtain gaseous coal seam gas and liquid distilled water to realize the separation of the mixed gas. According to the change of the coal seam temperature, the heat source injection well (1) and the gas production wells (2) are allocated to control the heated coal seam and extract coal seam gas. The method of he invention can effectively perform the extraction of the coal seam gas, accelerate the coal seam extraction speed, and improve the extraction rate.

Owner:TAIYUAN UNIV OF TECH

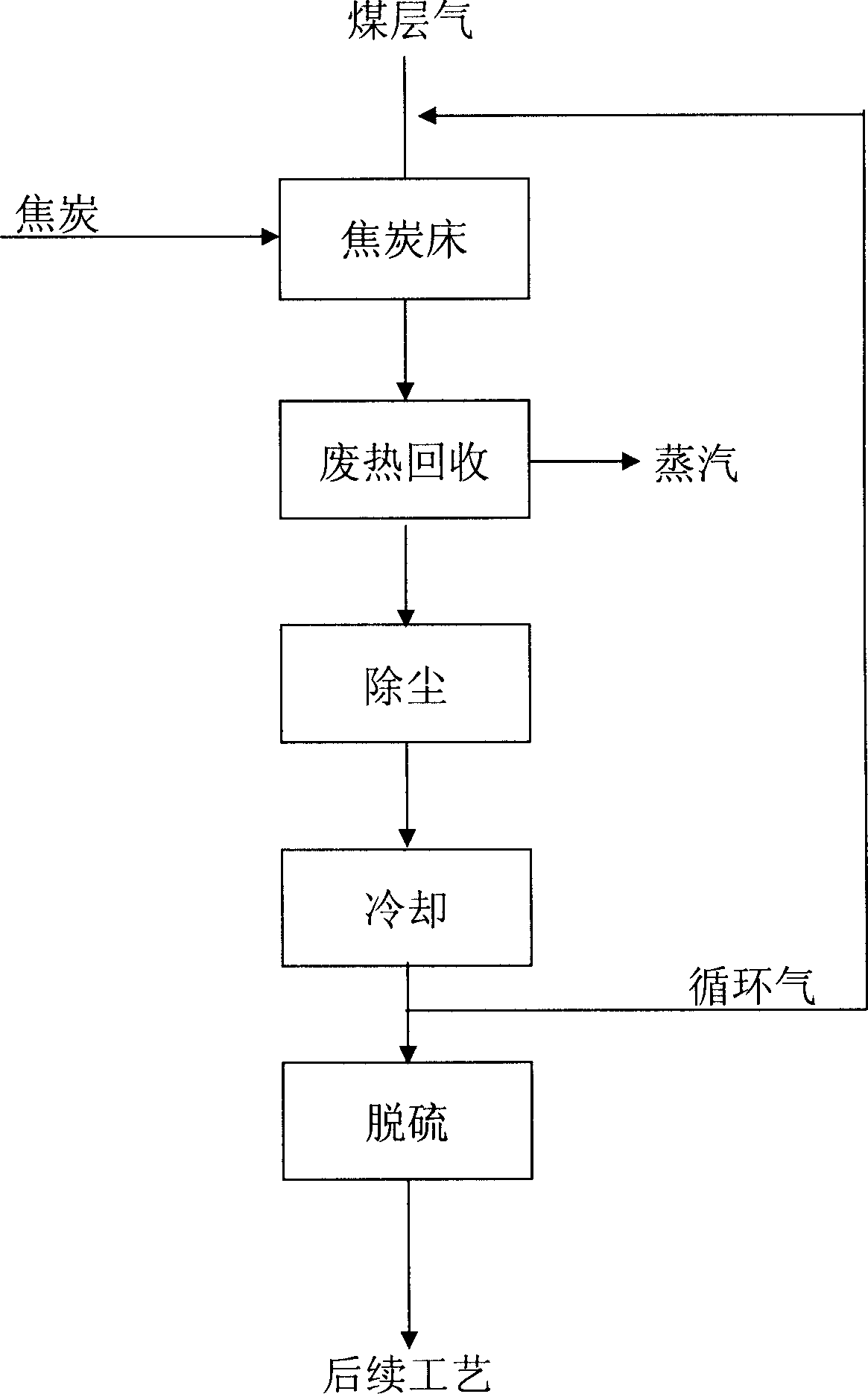

Coal bed gas coke deoxidization technique

The invention discloses the coal bed gas coke deoxidization technology, comprising the following steps: deoxidizing coal bed gas with coke and anthracite coal, keeping the temperature between 600-1000Deg.C, then dedusting, and cooling; adjusting the oxygen content in deoxidation reactor to 5-9%. The technology can keep reaction temperature, remove oxygen of coal bed gas, reduce methane cracking, and improve safety.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

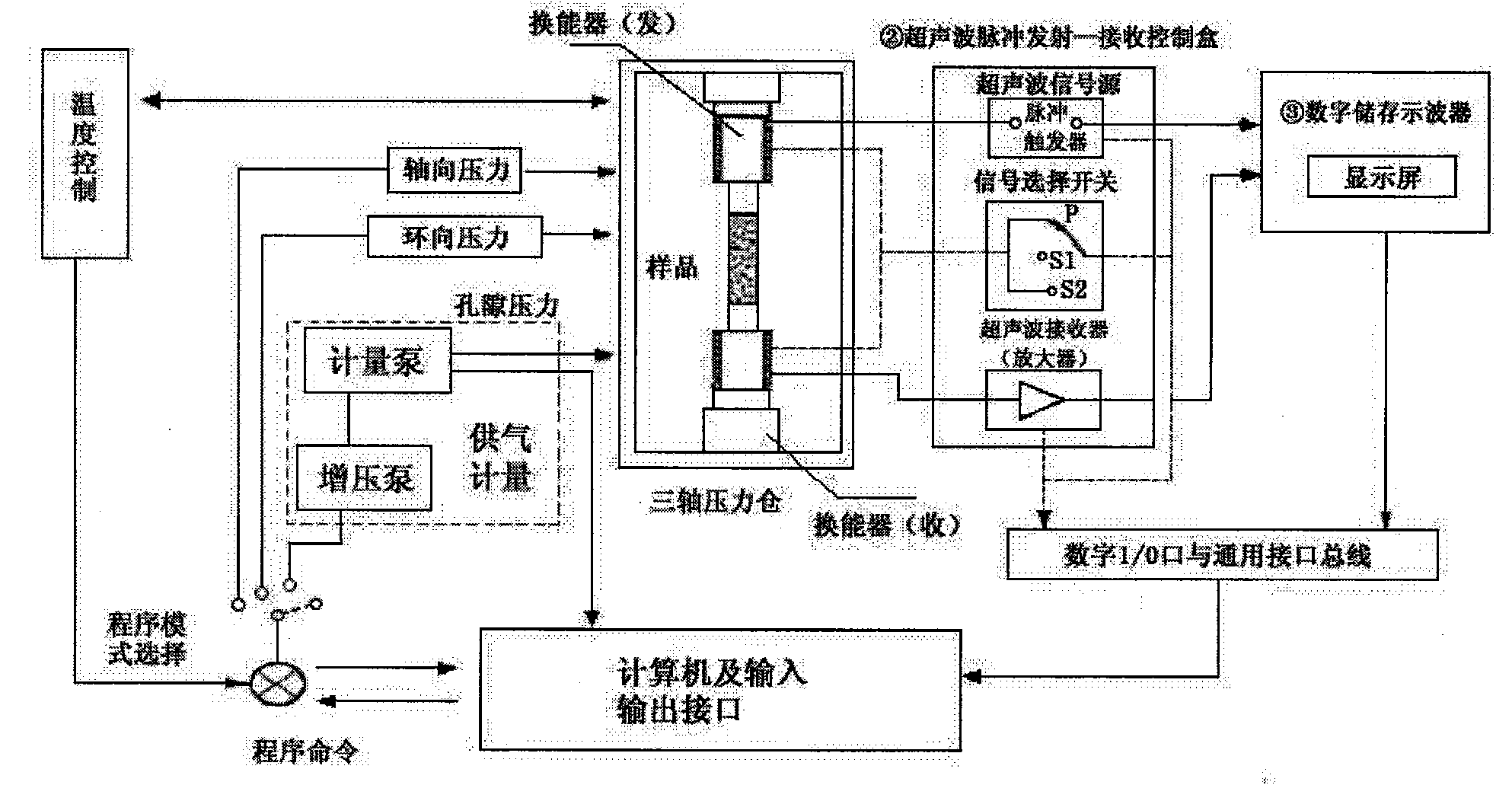

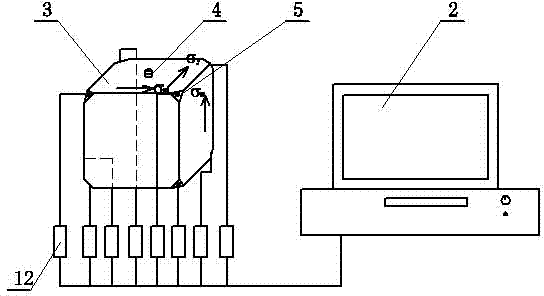

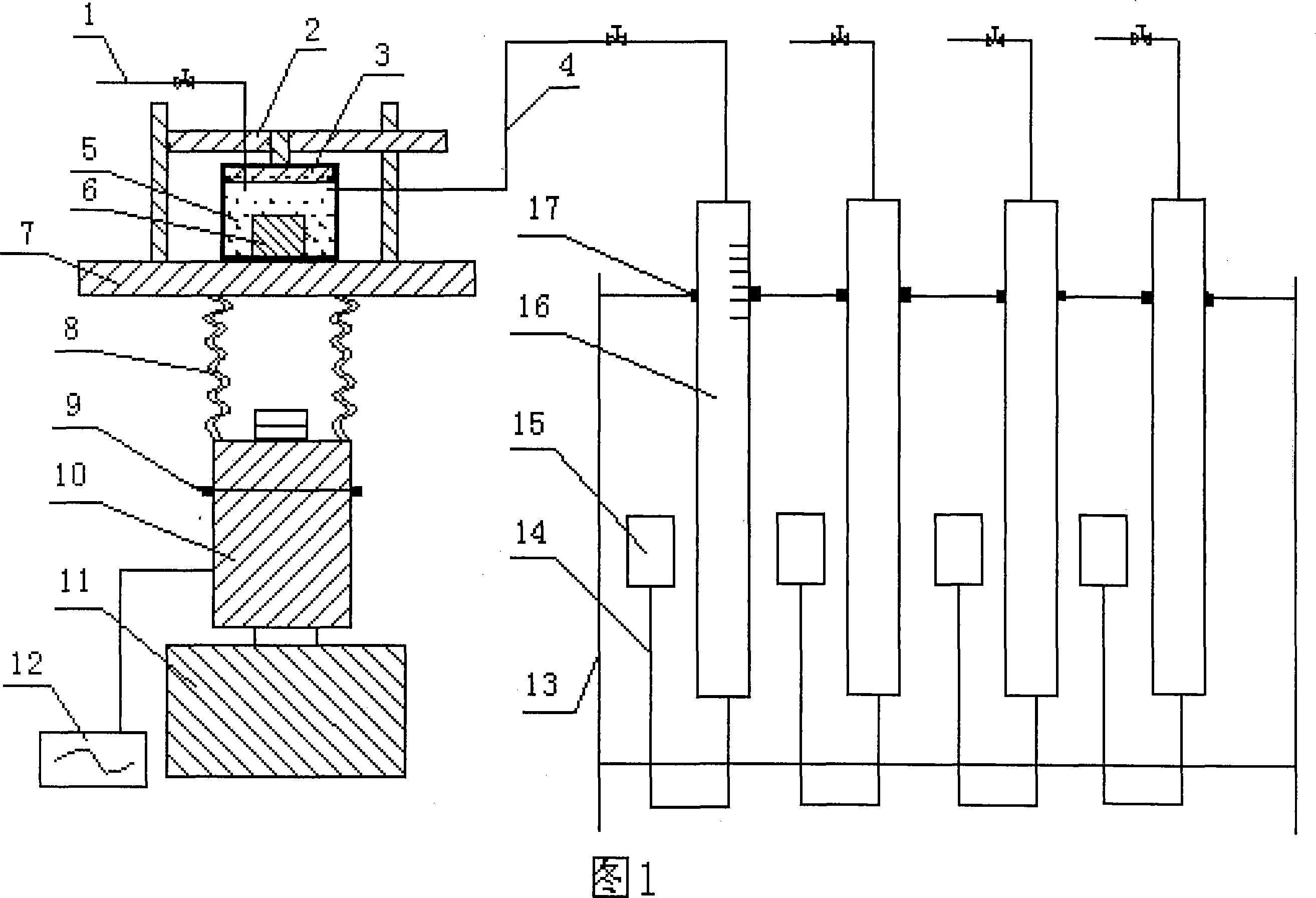

Rock sample detection and data acquisition system and method and application thereof

InactiveCN102053253ATo overcome the insufficiency of the experiment of the physical parameters of coal and rock after the adsorption of gas is difficultImplement testMaterial strength using tensile/compressive forcesSeismic signal receiversUltrasonic sensorData acquisition

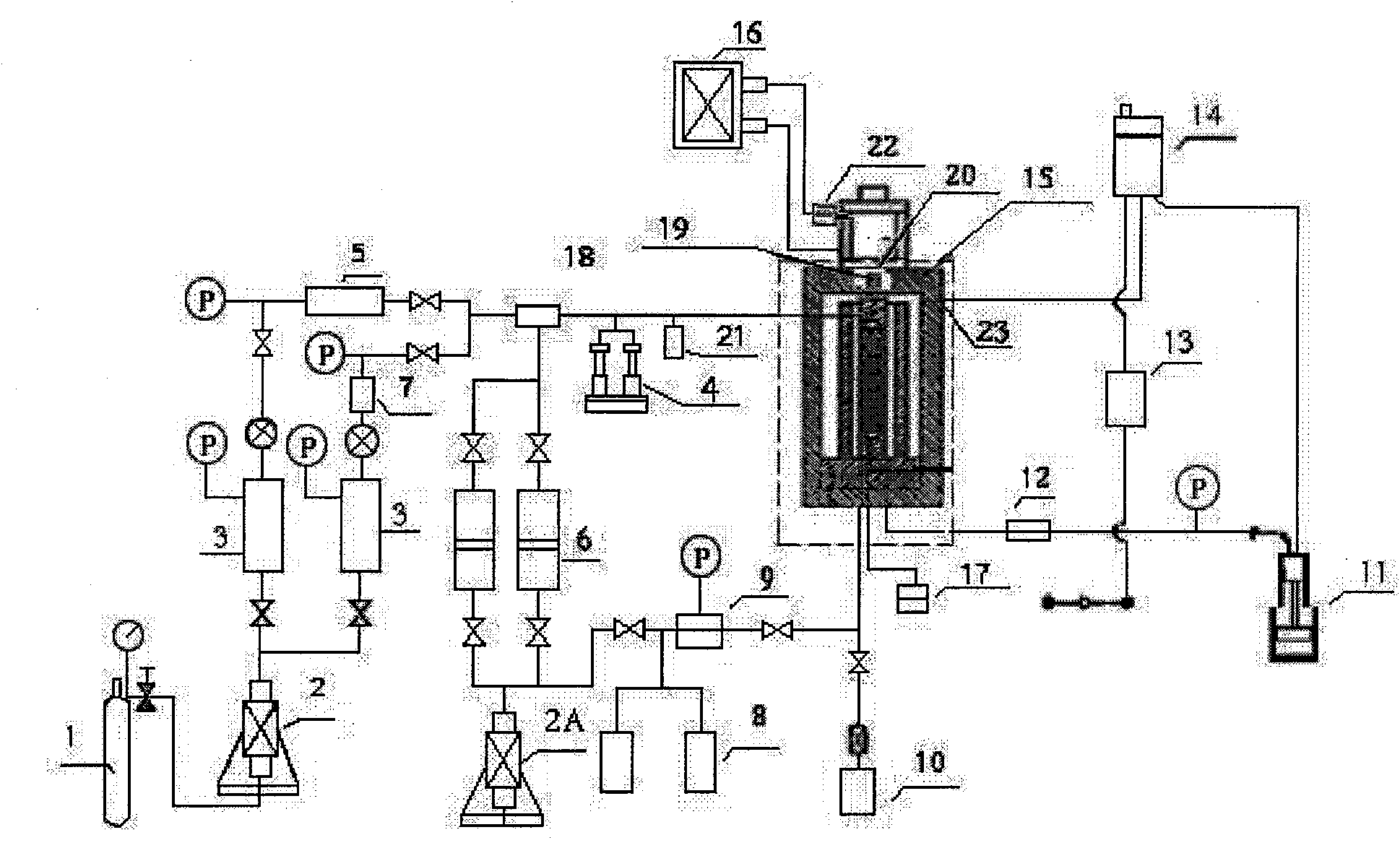

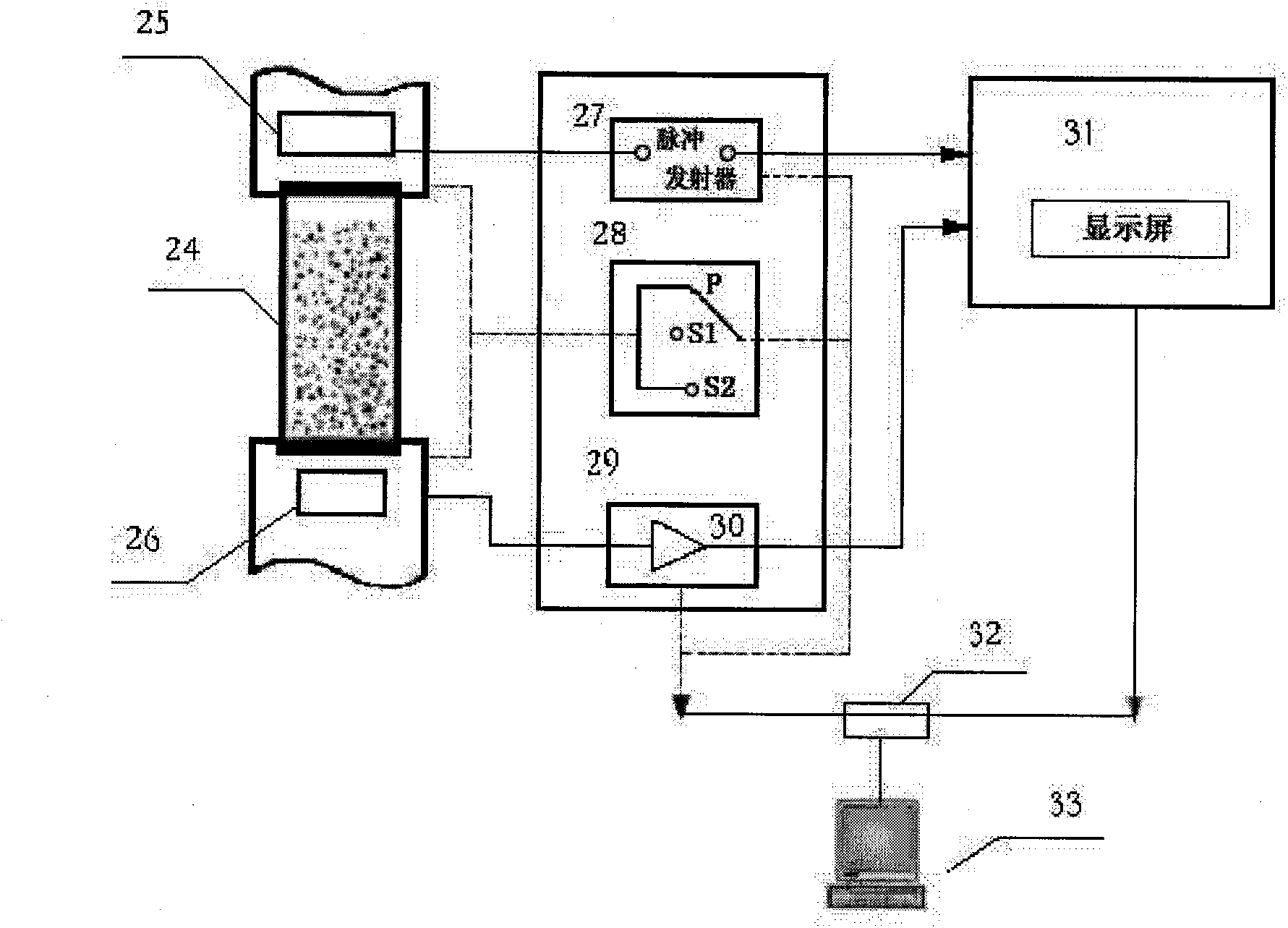

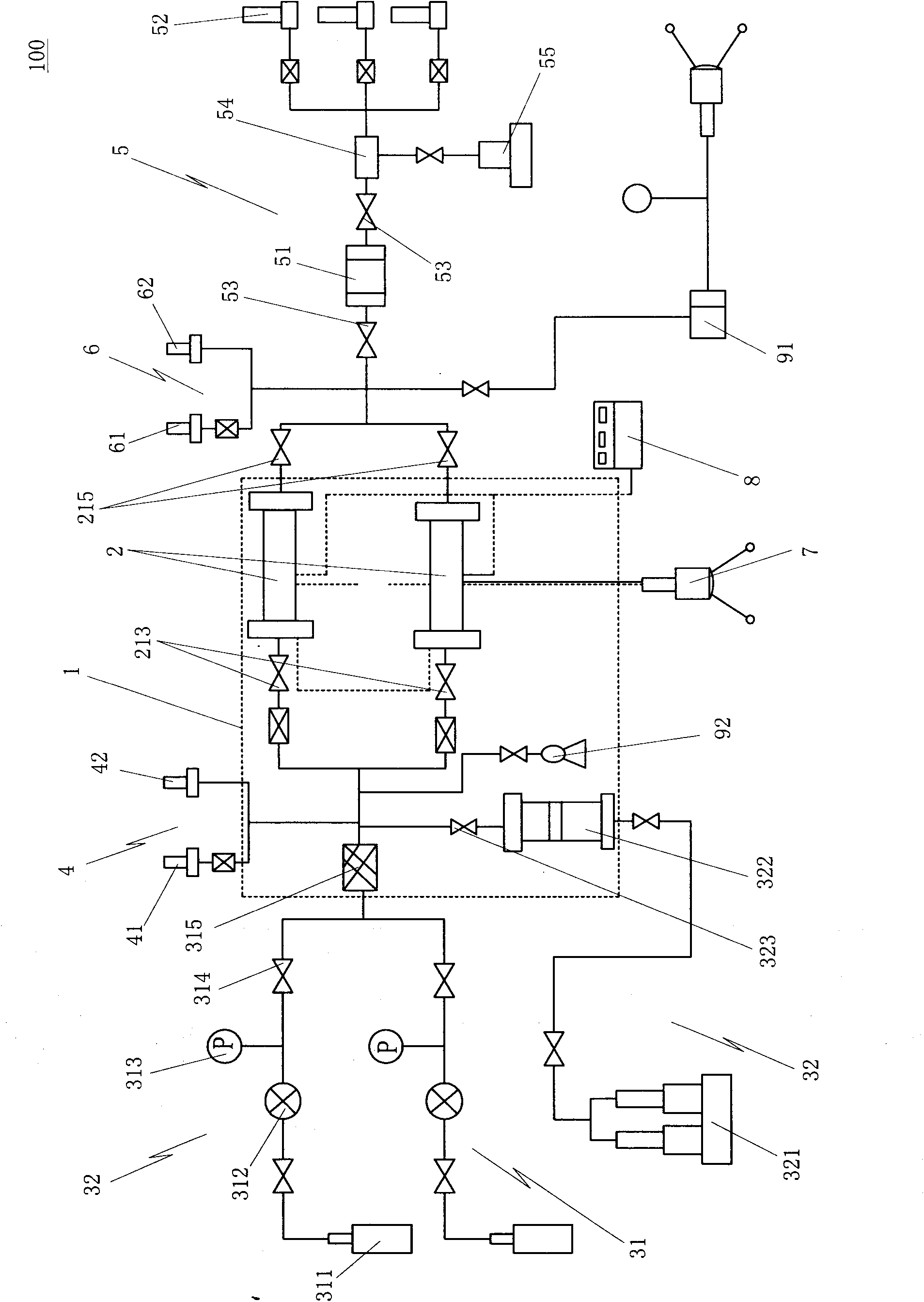

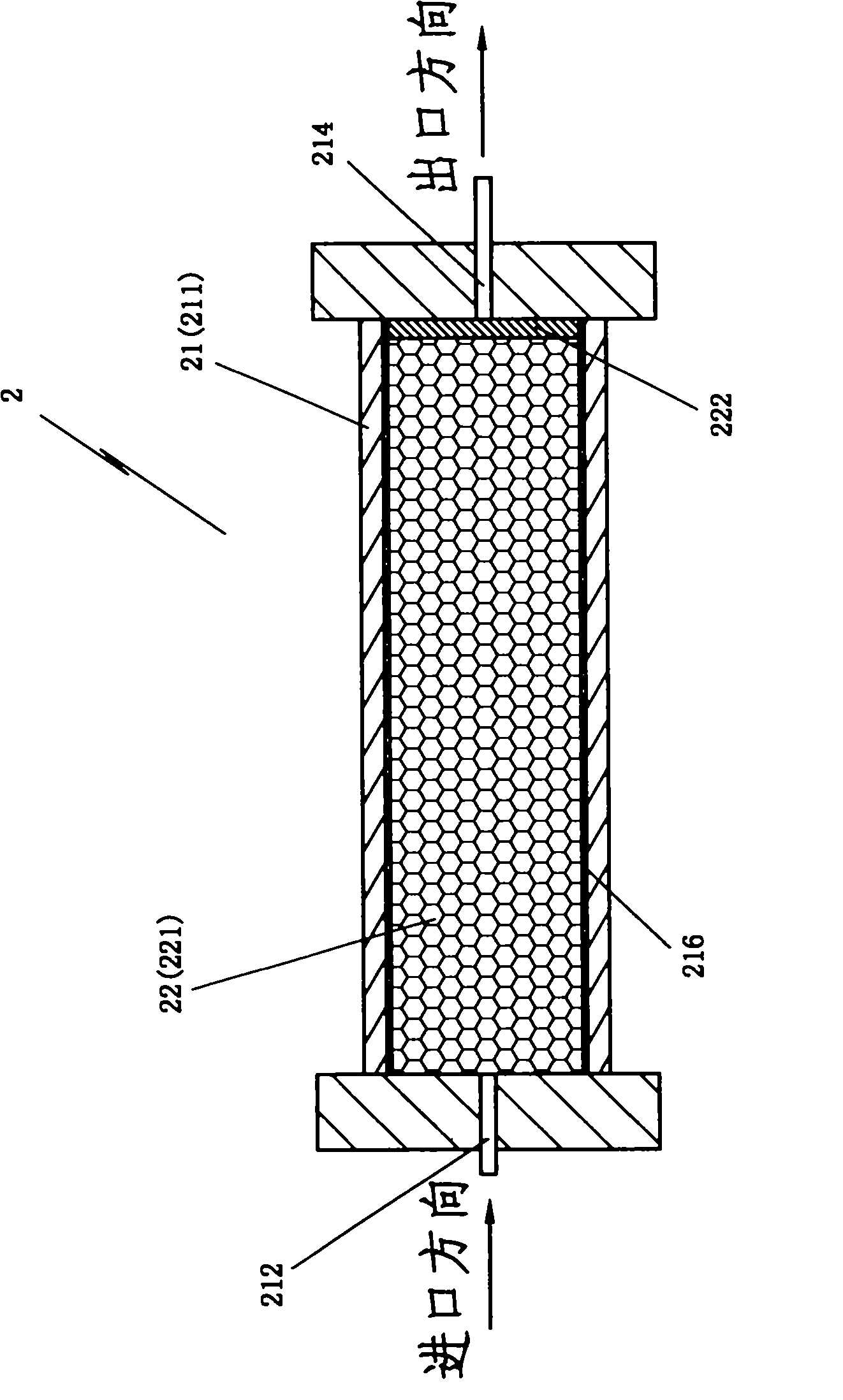

The invention relates to a rock sample detection and data acquisition system. The system can realize elastic parameter test of a rock sample in the state of gas adsorption; in the system, a three-shaft pressure cabin is connected with a gas supply and metering control device for absorbing samples in the cabin and accurately metering absorption quantity, moreover, an ultrasonic transducer is installed on a cap of the (high) pressure cabin and integrated with an ultrasonic wave transmitting / receiving device so that the test of elastic parameters of methane absorption on coal can be realized truly. The system can automatically and continuously test in the processes of gas absorption and gas enrichment, thereby ensuring a consistent test environment, acquiring an absorption quantity and elastic parameter relation curve, improving test accuracy and efficiency and saving test time and cost. The rock sample detection and data acquisition system integrates methane enrichment mechanism simulation and rock physical property test, can be applied to seismic prospecting method research on coalbed methane and shale gas, mine advanced detection, coal mine safety research and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Directional fracturing permeability improvement outburst elimination method in coal mine and device thereof.

InactiveCN101575983AImprove breathabilityRapid and relatively long-lasting releaseFluid removalGas removalUltrasound attenuationFracturing fluid

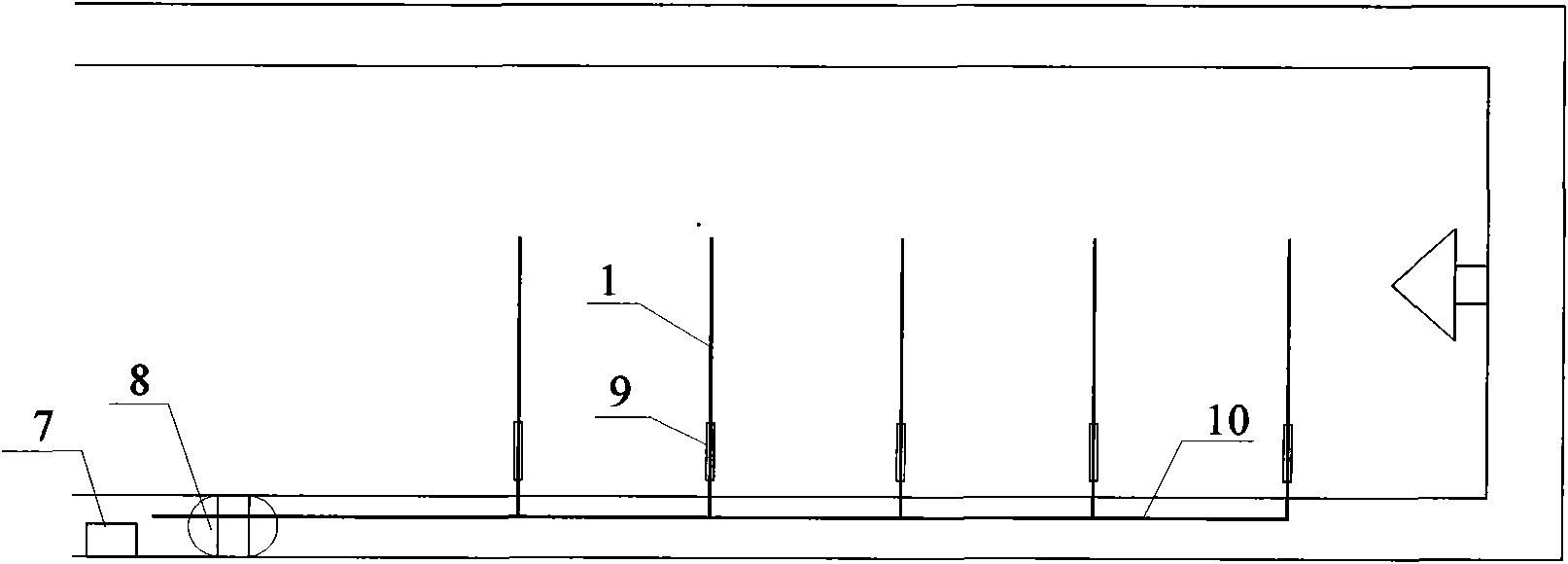

The invention relates to a directional fracturing method in the coal mine and a fracturing permeability improvement outburst elimination device to ensure the coal-bed gas to release rapidly and continually in the coal mine. The method comprises the following steps: fracturing and drilling a bore on a preparing working face along the dip direction and strike direction of a coal bed, fixing a fracturing hole packer with an outer diameter matching with the pore diameter of a fracturing drilling bore into the fracturing drilling bore; connecting a fluid reservoir with a sand mixing machine, connecting the sand mixing machine with a fracturing pump package, and then connecting the fracturing pump package with the fracturing drilling bore; pumping formation fracturing fluid and proppant into the fracturing drilling bore to fracture the formation and sealing the fracturing drilling at above formation fracturing pressure, and completing directional fracturing permeability improvement outburst elimination in the coal mine, thus ensuring that the coal-bed gas discharges rapidly and continually relatively and solving the problems that drainage in low air permeability coal bed can only influence a limited range and the drainage attenuation period is short, improving the drainage rate by over 50% on primary base, decreasing the coal body dynamic phenomenon after fracturing and reginal stress influenced by fracturing, and having a significant effect for eliminating outburst.

Owner:河南省煤层气开发利用有限公司

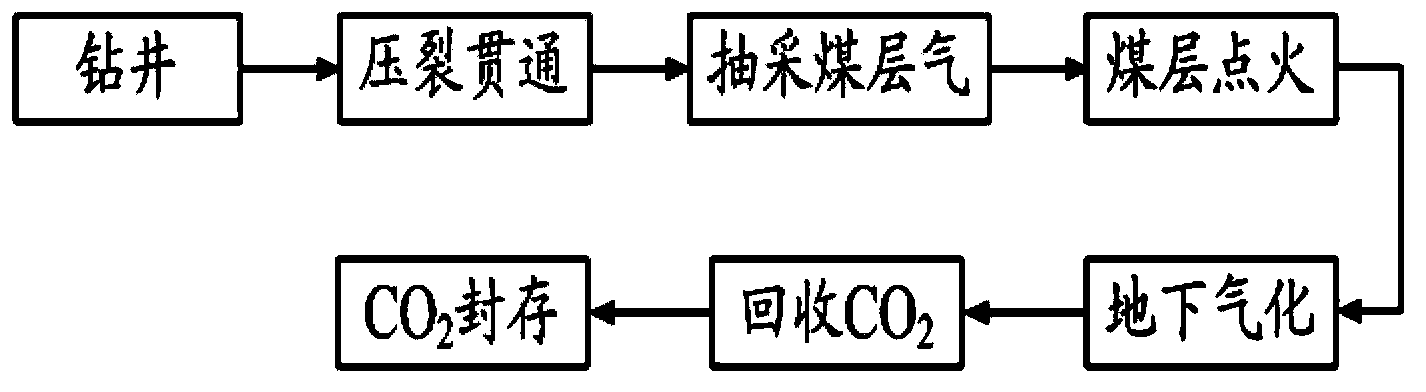

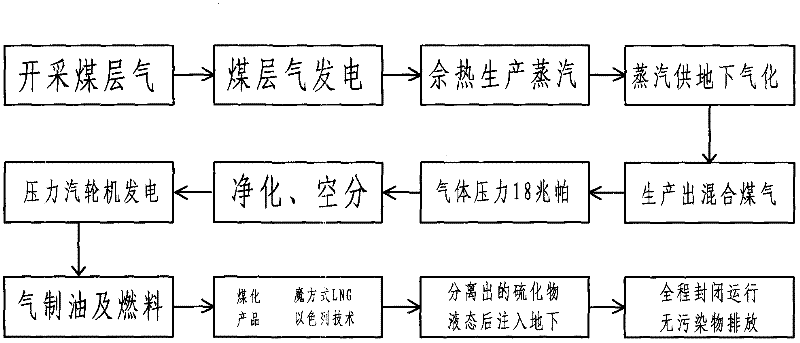

Method for extracting coalbed methane and coal together

ActiveCN103670338AImprove breathabilityEnhanced overall recoveryConstructionsFluid removalWell drillingCoal

The invention relates to a method for extracting coalbed methane and coal together. The method includes a well drilling step, a pressing crack cut-through step, a coalbed methane extracting step an ignition step and an underground gasification step. According to the method, an underground coal gasification technology and a coalbed methane extracting technology are combined, a coal bed can be heated by high temperature of underground gasification to improve breathability of the coal bed and increase extracting ratio of the coalbed methane, well drilling and pressing crack cut-through processes can be performed by the aid of the coalbed methane, and the underground gasification coal extraction efficiency is increased.

Owner:ENN SCI & TECH DEV

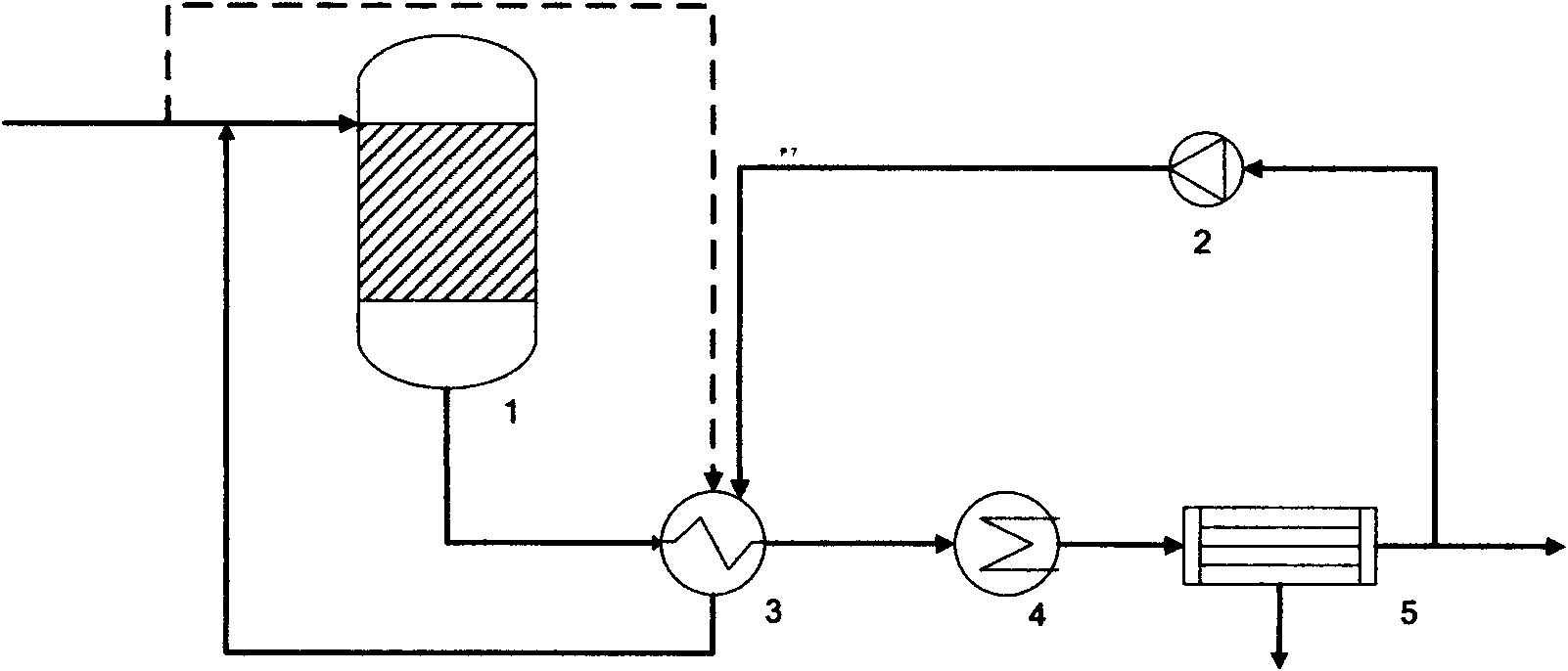

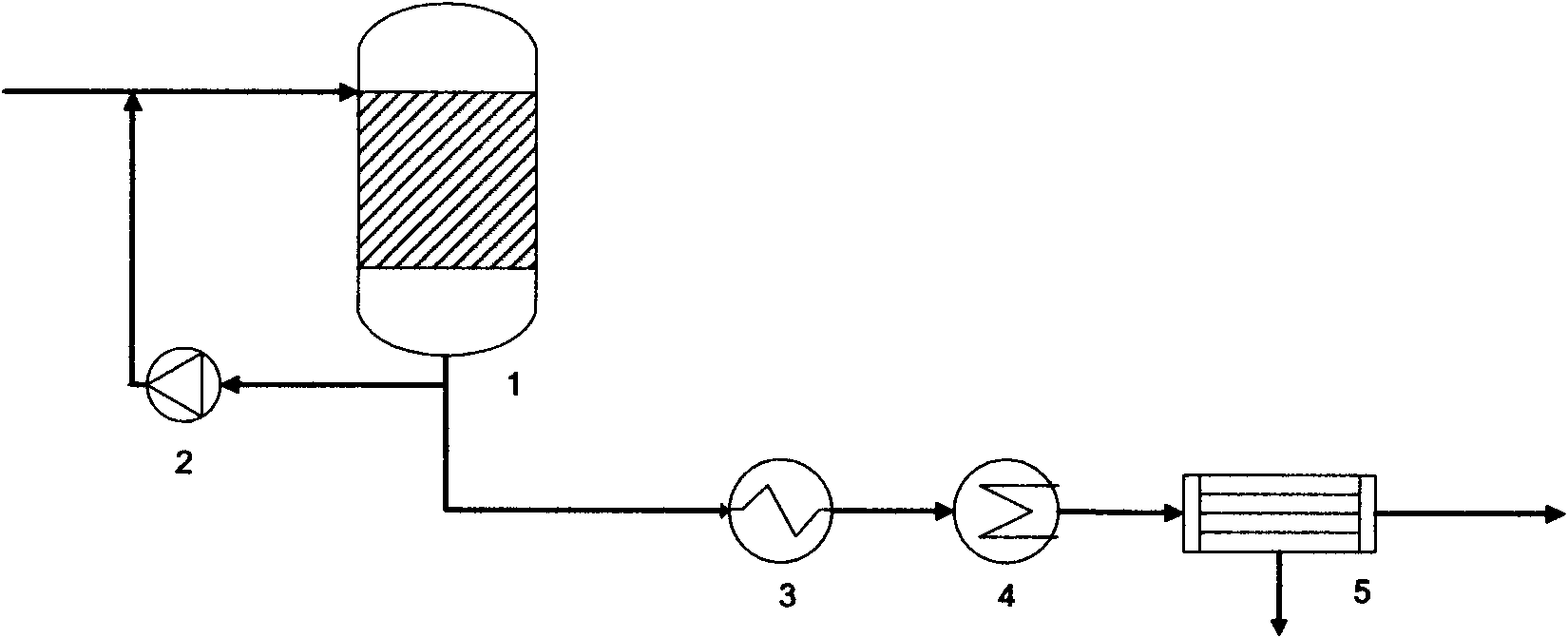

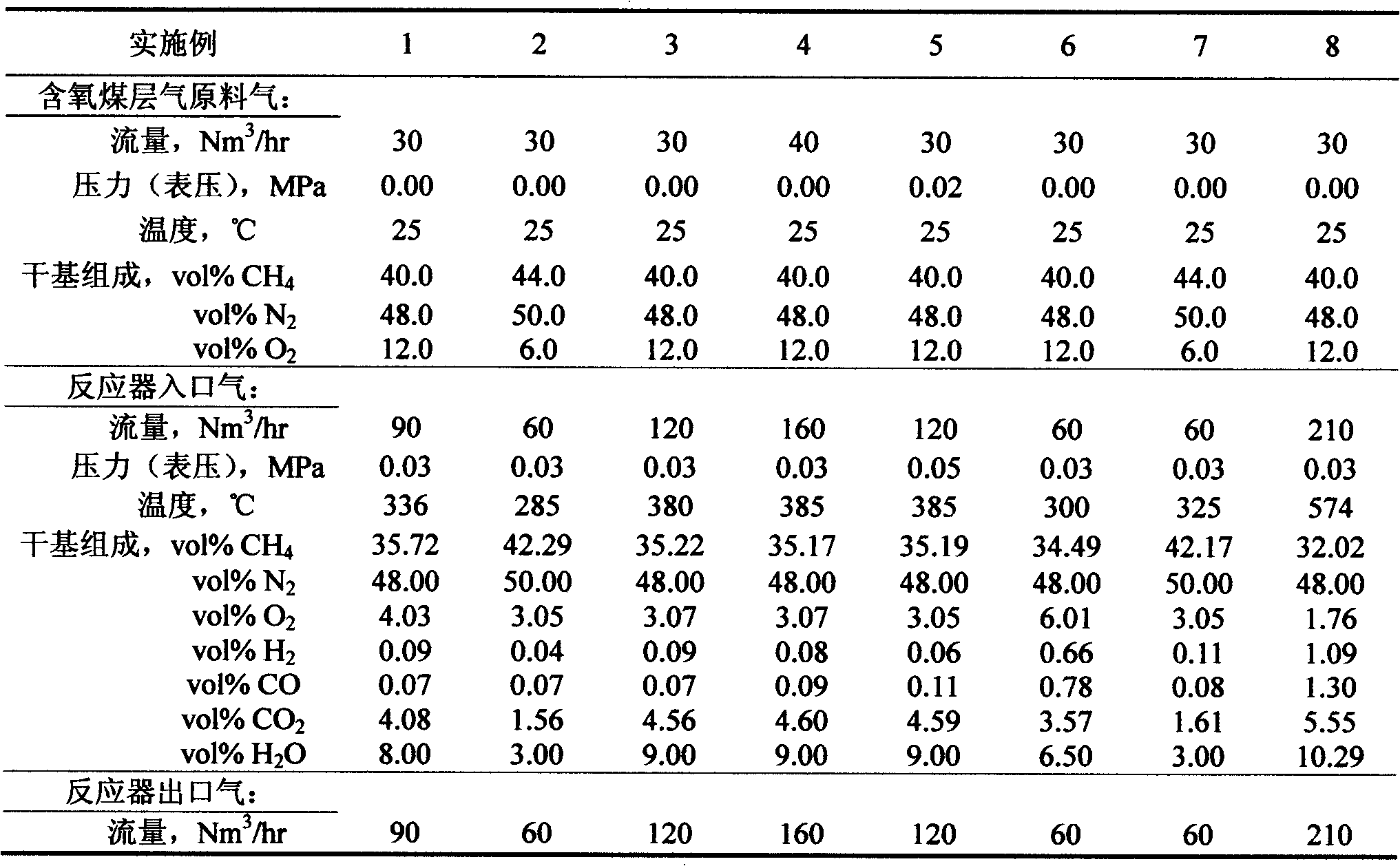

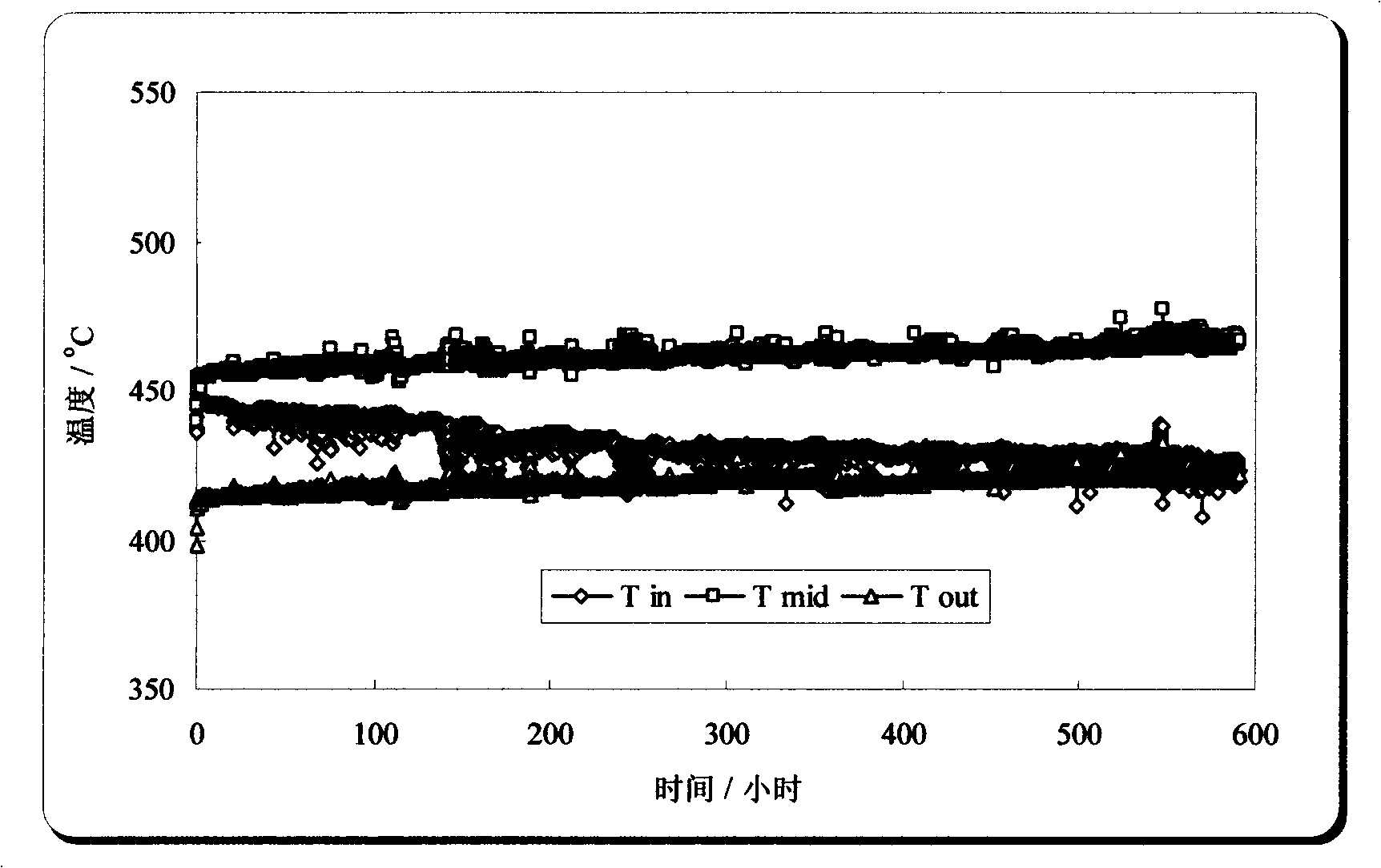

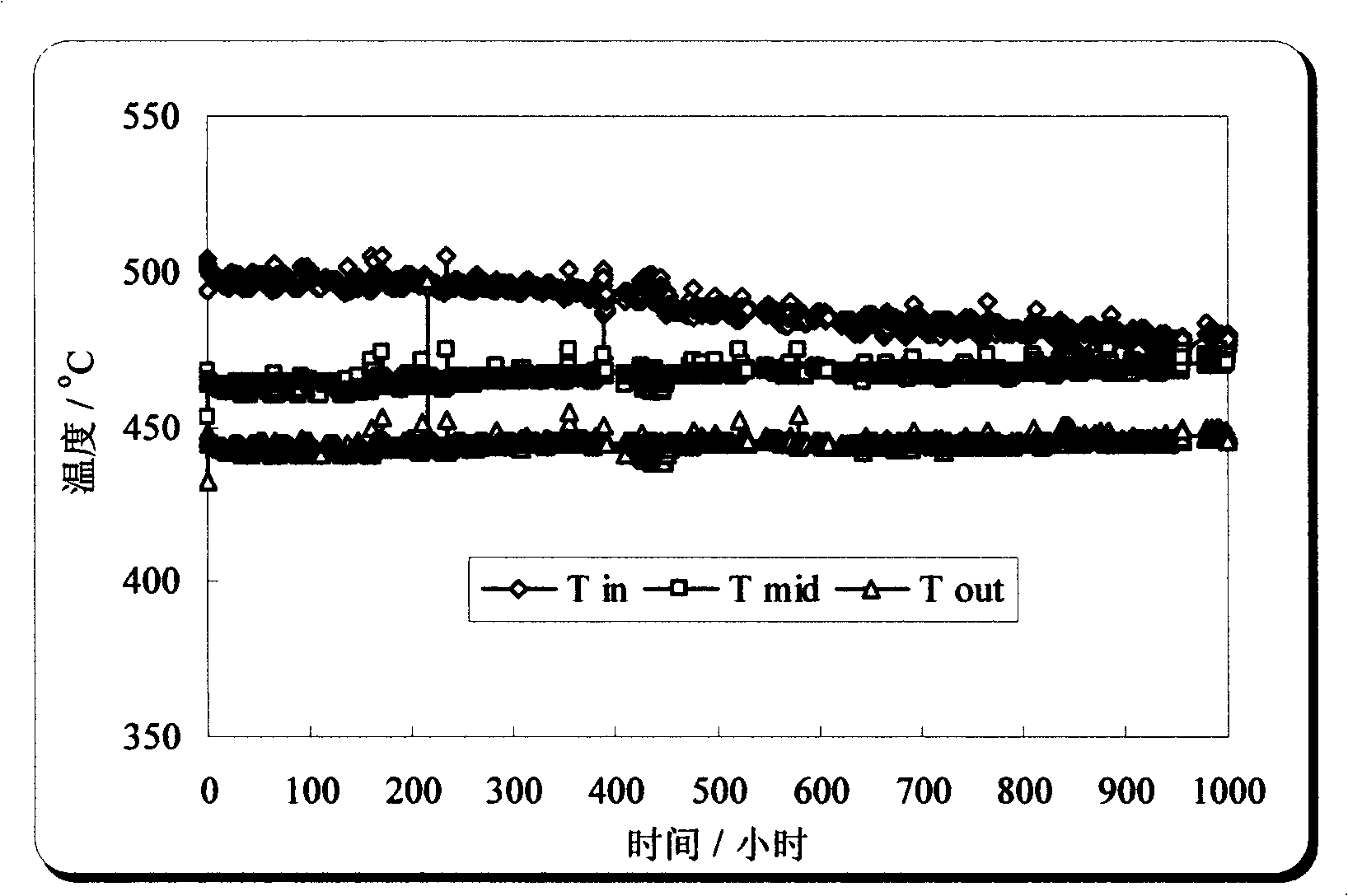

Catalytic deoxidation process of oxygen-contained coal bed gas

InactiveCN101613627AReduced activityHigh activityGas purification by catalytic conversionMetal/metal-oxides/metal-hydroxide catalystsFixed bedProduct gas

The invention relates to a catalytic deoxidation process of oxygen-contained coal bed gas. The oxygen-contained coal bed gas and coal bed gas product gas returned with a certain recycle ratio are mixed to go to a fixed bed adiabatic catalytic reactor, methane in the coal bed gas is reacted with oxygen to generate carbon dioxide and water, thereby the concentration of the oxygen in the coal bed gas product gas is reduced to be lower than 0.2 percent. The invention can effectively remove the oxygen in the oxygen-contained coal bed gas with the concentration of the oxygen of 1-15 percent, the recovery ratio of the methane is similar to theoretical recovery ratio obtained by calculation according to complete conversion of the methane and the oxygen, and security risk which exists in subsequent coal bed gas separation (liquification, pressure varying adsorption, barrier separation, and the like) technical process can be completely eliminated due to the low-concentration oxygen in the product gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

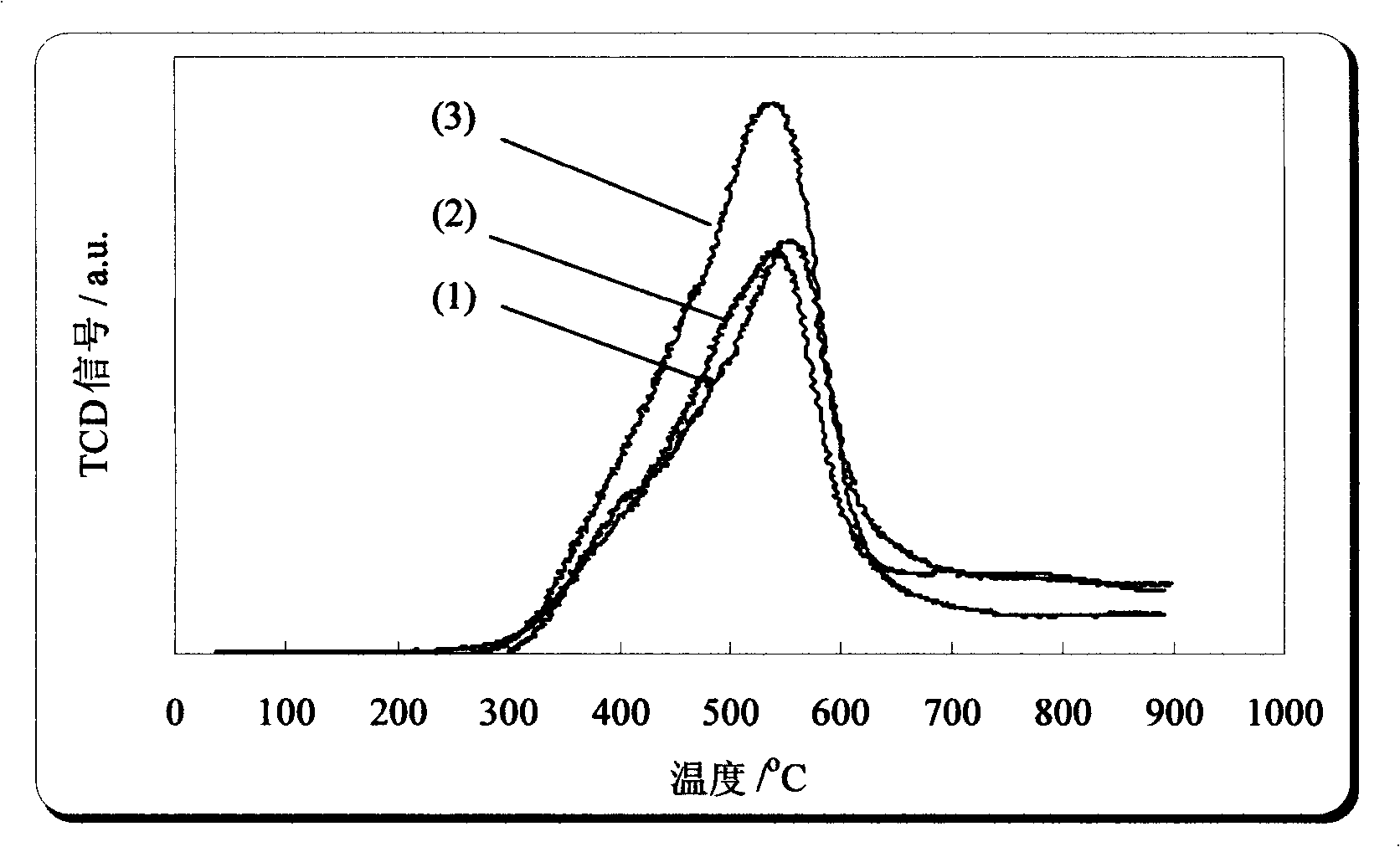

Coal bed gas deoxidation catalyst as well as preparation method and application thereof

InactiveCN101664679AExtend your lifeElimination of active oscillationsGas purification by catalytic conversionCatalyst activation/preparationRare-earth elementAlkaline earth metal

The invention relates to a coal bed gas deoxidation catalyst as well as a preparation method and the application thereof. The coal bed gas deoxidation catalyst takes one or the combination of severalplatinum group noble metals, i.e. Pd, Pt, Ru, Rh and Ir, as main catalyzing active components and takes one or the combination of several alkali metal / alkaline-earth metal oxides, i.e. Na2O, K2O, MgO,CaO, SrO and BaO, and multi-element compound oxides of CeO2, lanthanide series rare earth elements, i.e. Pr, Nd, Sm, Eu, Gd, and the like, or / and transition elements, i.e. Y, Zr, La, and the like, or / and gamma-Al2O3 as auxiliary catalysts, and the catalyzing components are loaded on an inert carrier in a coating way so as to prepare an integral catalyst. The coal bed gas deoxidation catalyst hasthe advantages of low igniting temperature, stable combustion process, high activity, long service life, and the like, is suitable for the methane catalyzing and combustion process taking coal bed gasdeoxidation purification as a purpose and can also be extensively applied to the catalyzing and combustion process of CO and low-carbon hydrocarbon under fuel-rich and oxygen-poor reducing atmosphere.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method and use of carbon molecular sieve

InactiveCN101935032ASolve the problem of difficult and efficient separation of methane-nitrogenNitrogen purification/separationOther chemical processesHigh concentrationLoss rate

The invention relates to a preparation method and use of a carbon molecular sieve. The preparation method comprises the following steps: preparing a conventional carbon molecular sieve; and expanding the pores in the conventional carbon molecular sieve by using a secondary activation technique and modifying the conventional carbon molecular sieve by adjusting the pores. The new carbon molecular sieve is prepared by using coal, coconut shell or phenolic resin, and the like as raw materials, by the conventional production steps of crushing, forming, carbonizing, steam activating, hydrocarbon settling and shrinking and the like and by secondary activation with KOH or CO2 as an activator. The activation temperature is between 550 and 850 DEG C; and the ignition loss rate of the product is kept be between 0.1 and 30 percent. In aspect of use, the carbon molecular sieve can be used for absorbing nitrogen molecules and can also be used for absorbing and separating methane and nitrogen in seam gas under a variable pressure while achieving an adsorption dynamic separation effect and allowing high-concentration methane gas to be collected at the exit of an adsorption tower directly; and thus, the methane in the seam gas can be used efficiently.

Owner:TONGJI UNIV

Deep coal and coal bed gas combined mining method

The invention relates to a deep coal resource mining method. When the buried depth of a coal bed is 800 to 3,000 meters, the thickness is more than 3 meters, an inclination angle is less than 10 degrees, and pressure is more than 10 Mpa, the most advanced well drilling and cementing, high-temperature resistant and high-pressure well completion technologies in oil industry, vertical shafts and vertical shafts and gas injection and gas production combined methods are adopted; the method is characterized by comprising the following steps of: drilling three vertical shafts first, wherein the distance between the wells is 500 meters; drilling a horizontal well which is more than 500 meters deep from a secondary well to a central well, combusting a long tunnel which is 1,000 meters long and 10 meters wide by a special combustion method, wherein the tunnel is a gasification tunnel special for gas production, observation, monitoring and the like, and drilling a plurality of overlong horizontal wells in the reverse direction according to the inclination gradient of the coal bed. The deep coal bed gas and the deep coal are gasified underground, and exploited in a combined way, so the problem of shortage in energy resources in China can be greatly improved, the method is a new environment-friendly, low-carbon, innovative new-energy development technology, and low in cost and has great economic value, and investment is reduced.

Owner:GUODING DALIAN INVESTMENT

Sedimentary formation unit-based seismic facies analysis method

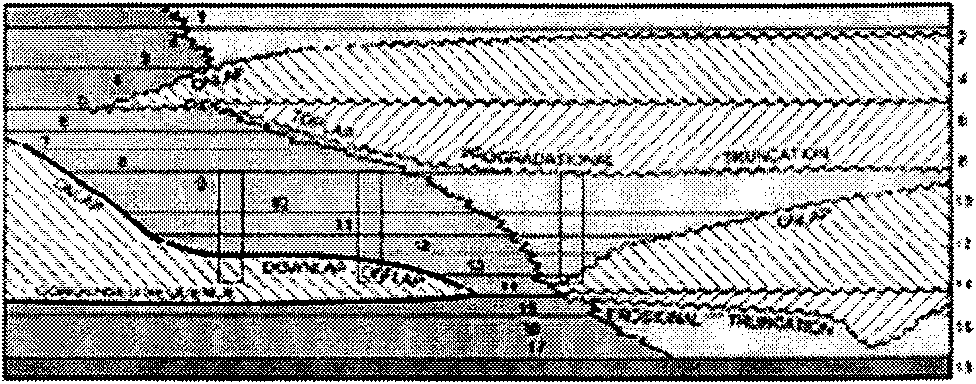

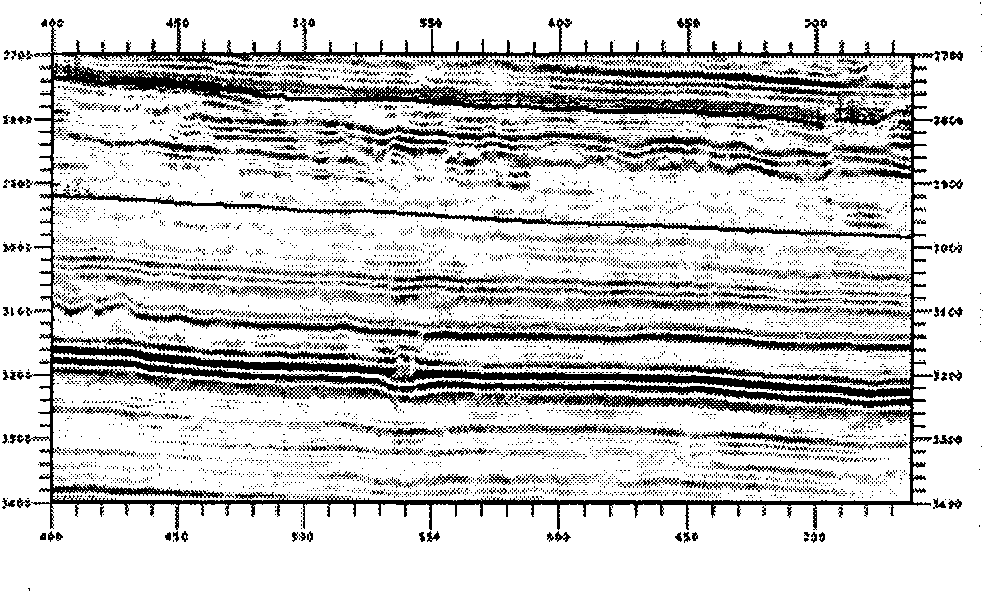

ActiveCN102053270AImprove analysis accuracyClear geological significanceSeismic signal processingLithologySeismic attribute

The invention belongs to the technical field of oil gas and coal-bed gas seismic exploration and development, and in particular relates to a reservoir sedimentary evolution analysis method in the exploration and development process. The method is used for providing reliable basic data for optimizing favorable target bed series and zone for oil gas and coal-bed gas exploration and development. In the method, sedimentary characteristics of reservoirs are analyzed by a three-dimensional seismic attribute data body, and high-resolution sequence stratigraphic principle and method, a seismic attribute analysis method and a pattern recognition method are applied; and a K-mean clustering algorithm is adopted, and the analysis process of sedimentary characteristics and sedimentary evolution of a sedimentary formation unit is performed under the control of a sedimentary isochronous interface. The method is used for assisting in reservoir sedimentary evolution research work in the exploration and development process of oil gas including unconventional oil gas, guiding the description of sedimentary characteristics of fine reservoirs of lithologic and stratigraphic trapped oil gas reservoirs, and providing the reliable basic data for optimizing the favorable target bed series and zone for the oil gas and coal-bed gas exploration and development.

Owner:CHINA PETROLEUM & CHEM CORP +1

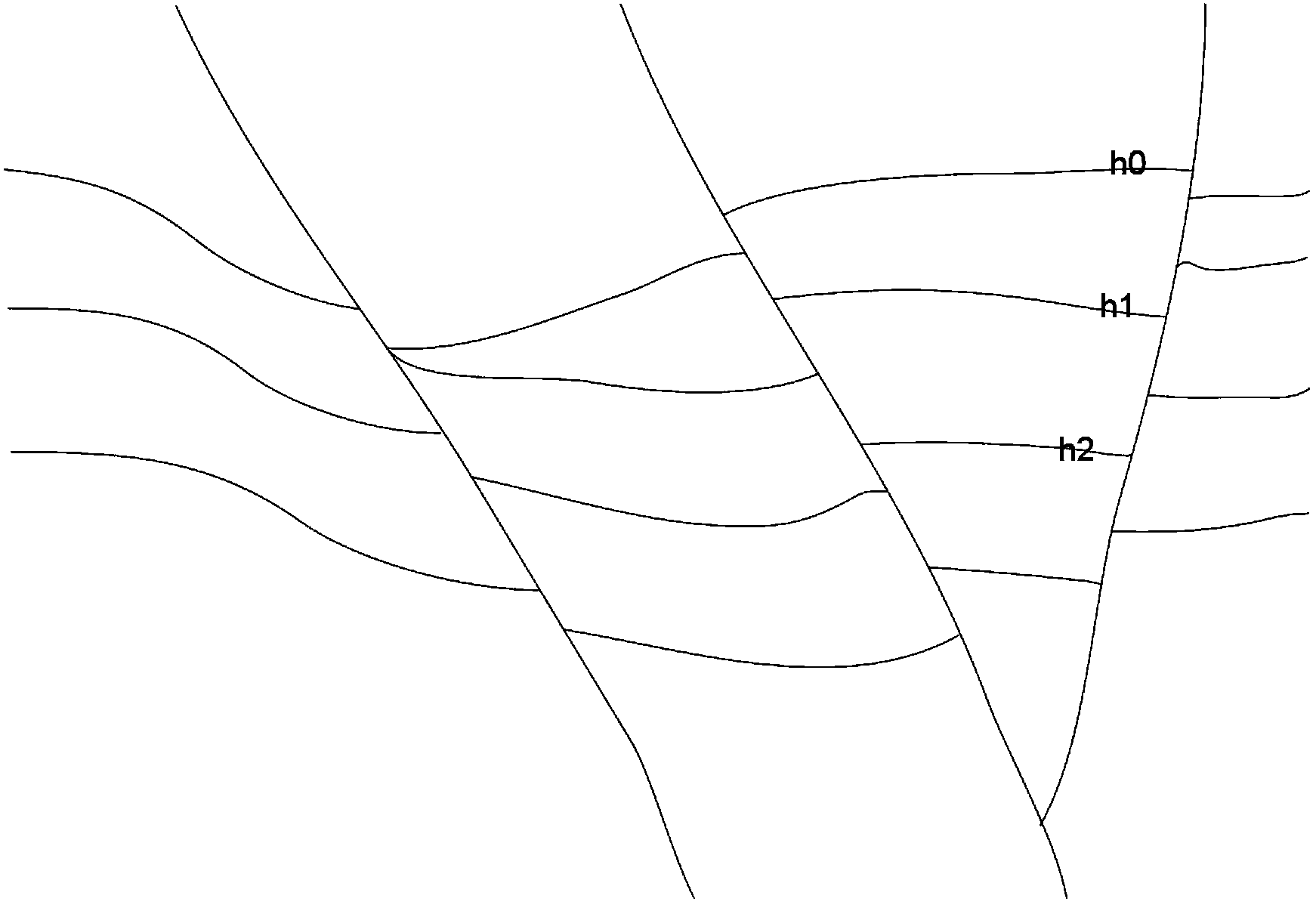

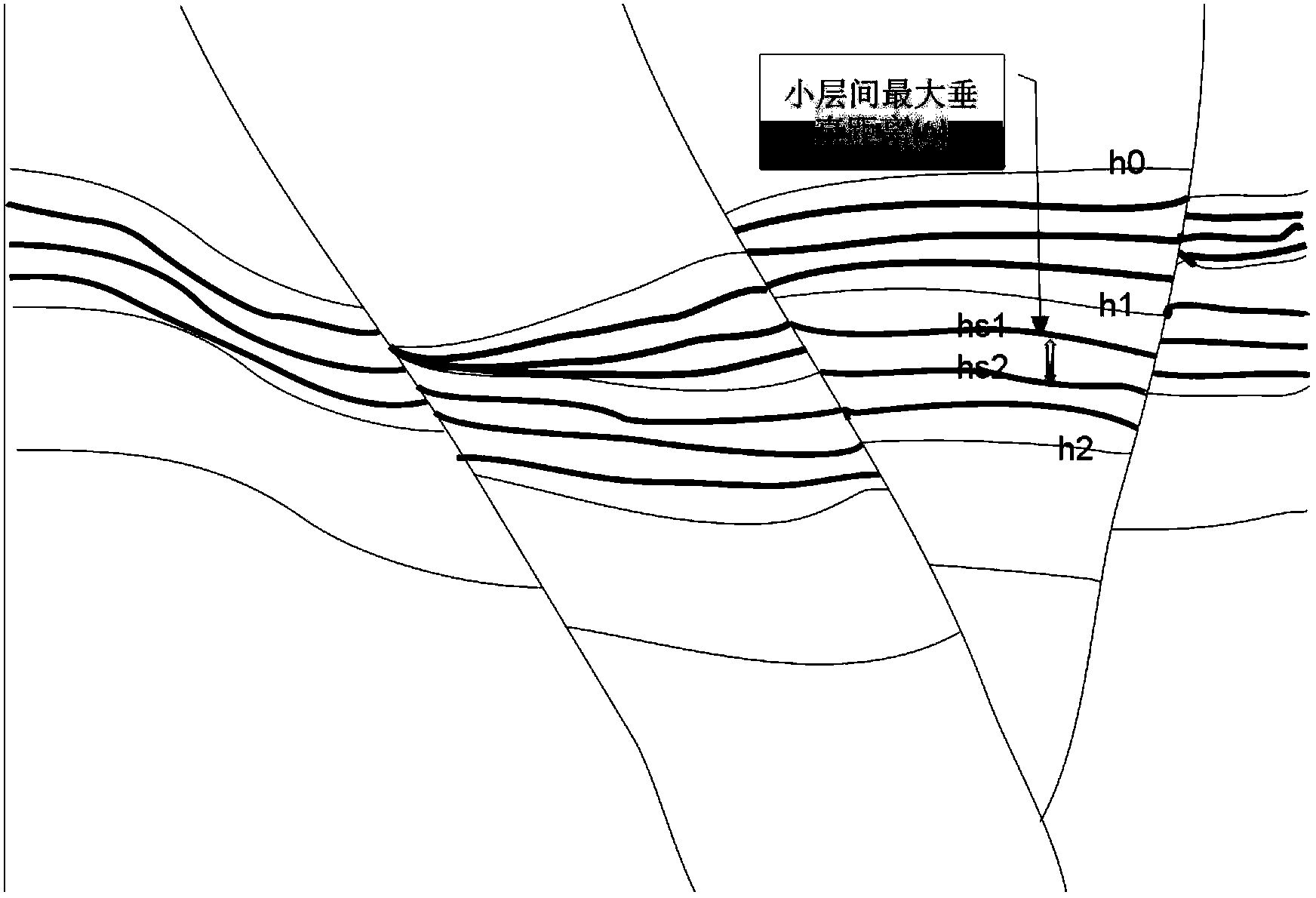

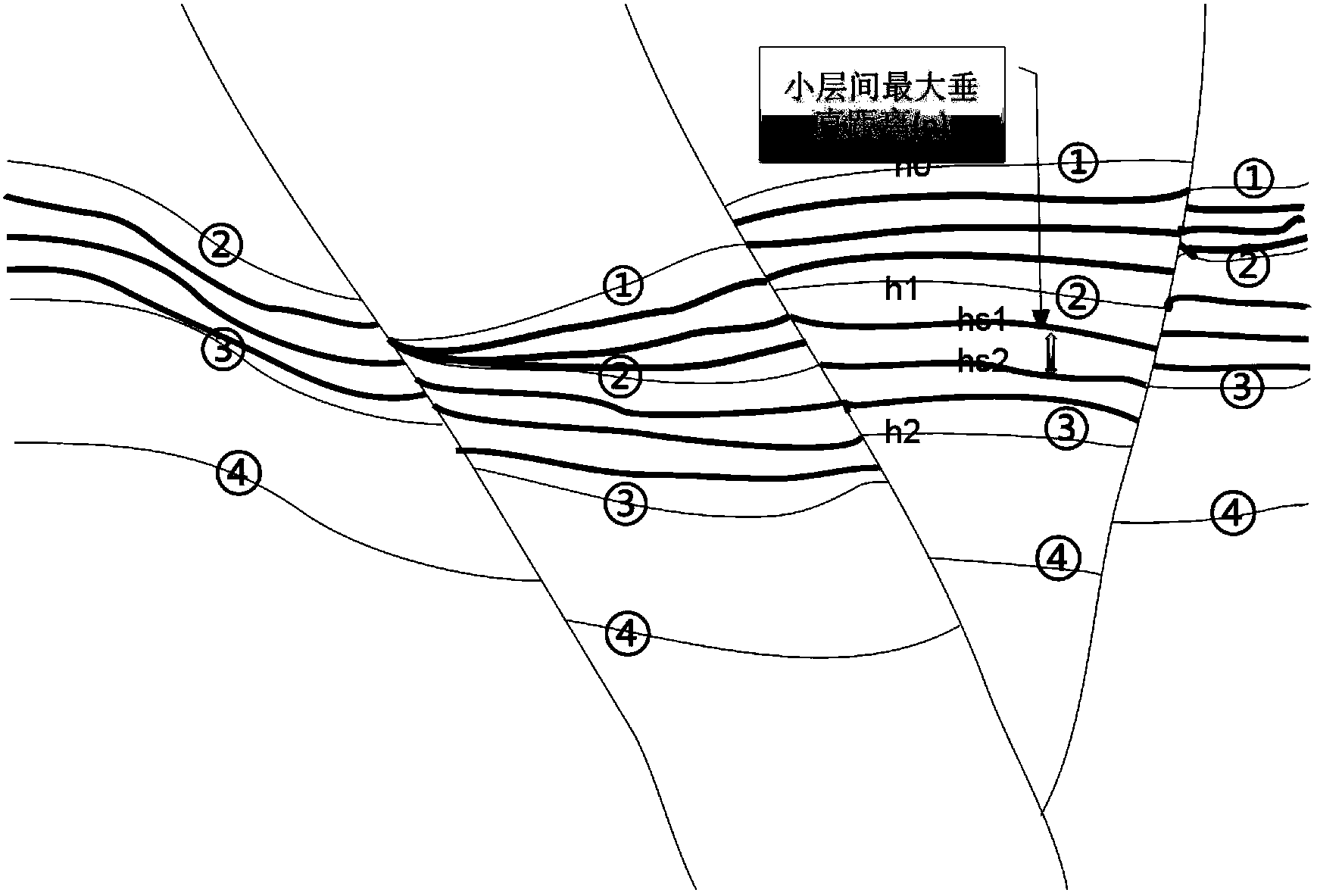

S Stratification position flattening method-based ancient landform restoration method

ActiveCN103424773AEasy to implementGuaranteed effectSeismic signal processingChannel dataRestoration method

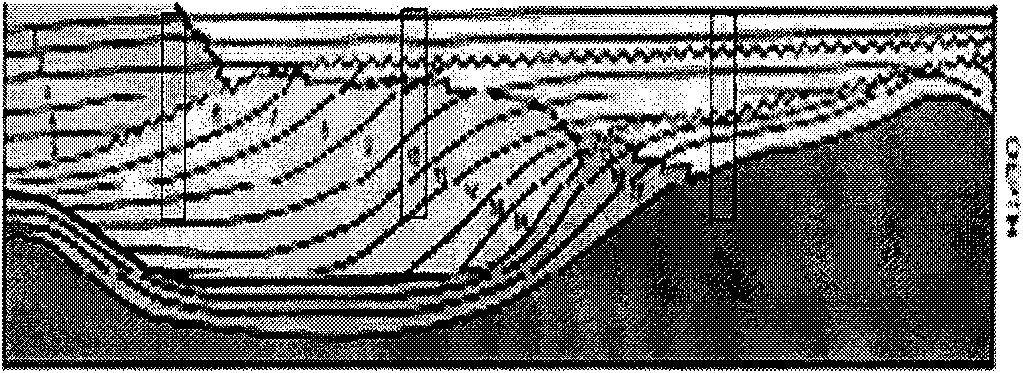

The invention, which belongs to the oil gas and coalbed methane seismic exploration and development field, provides a stratification position flattening method-based ancient landform restoration method. The provided method comprises the following steps that: firstly, geologic stratification position defining is carried out; secondly, a geologic stratification position sequence is defined; thirdly, a small stratification is divided between two adjacent geologic stratification positions; fourthly, a maximum distance between two adjacent small stratifications between two adjacent geologic stratification positions at vertical direction is defined; fifthly, interpolation is carried out on channel data between the two adjacent small stratifications according to the maximum distance at the vertical direction and after the interpolation is completed, the distances at the vertical direction between the two small stratifications are equal, thereby completing stratification position flattening of the two small stratifications; sixthly, the step three and the step five are repeatedly carried out on all the two adjacent stratification positions so as to complete all the stratification position flattening; and seventhly, zero value filling is carried out on the truncation portion. The method can be implemented easily by a computer; and the actual effect required by the ancient landform restoration theory can be ensued.

Owner:CHINA PETROLEUM & CHEM CORP +1

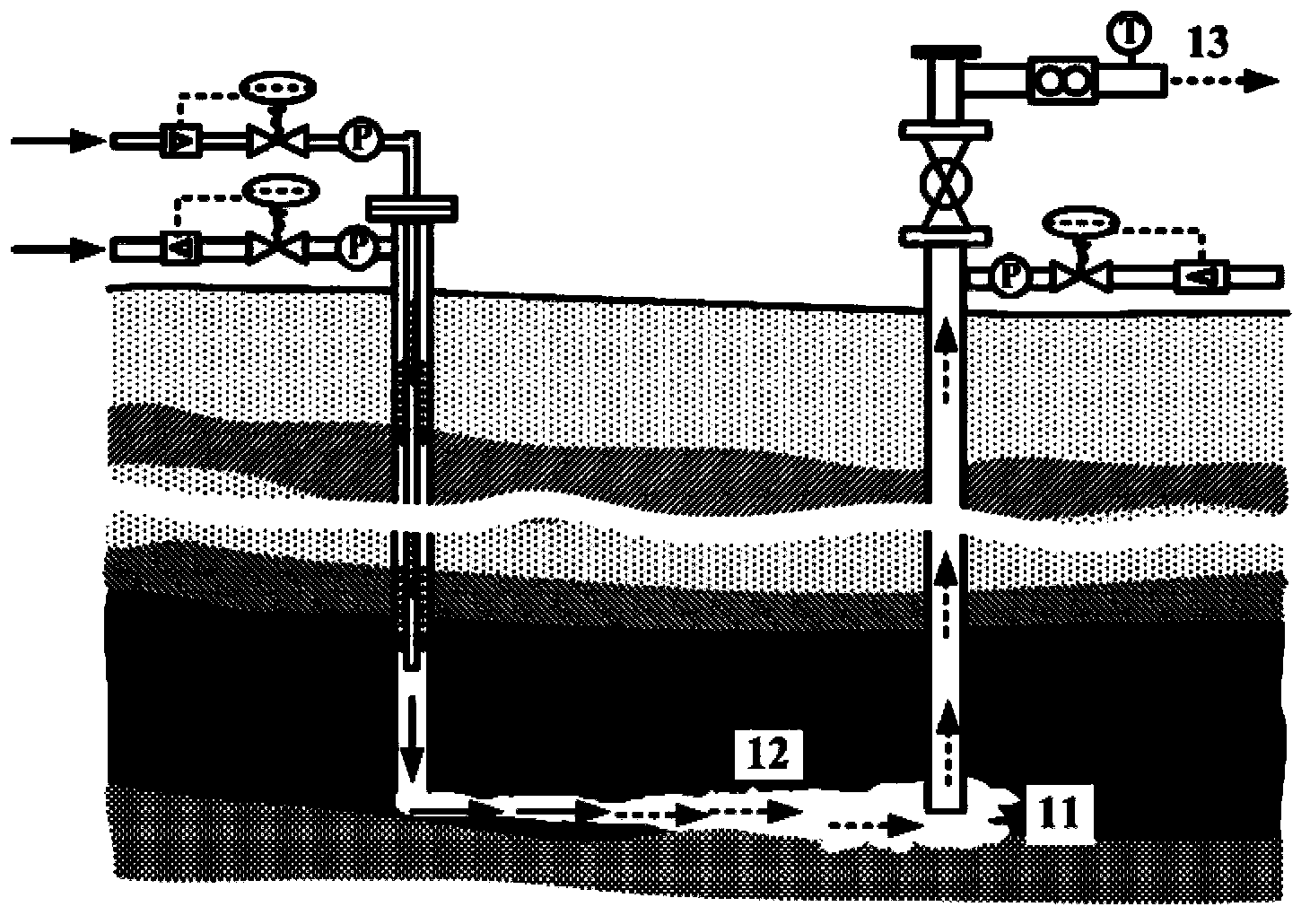

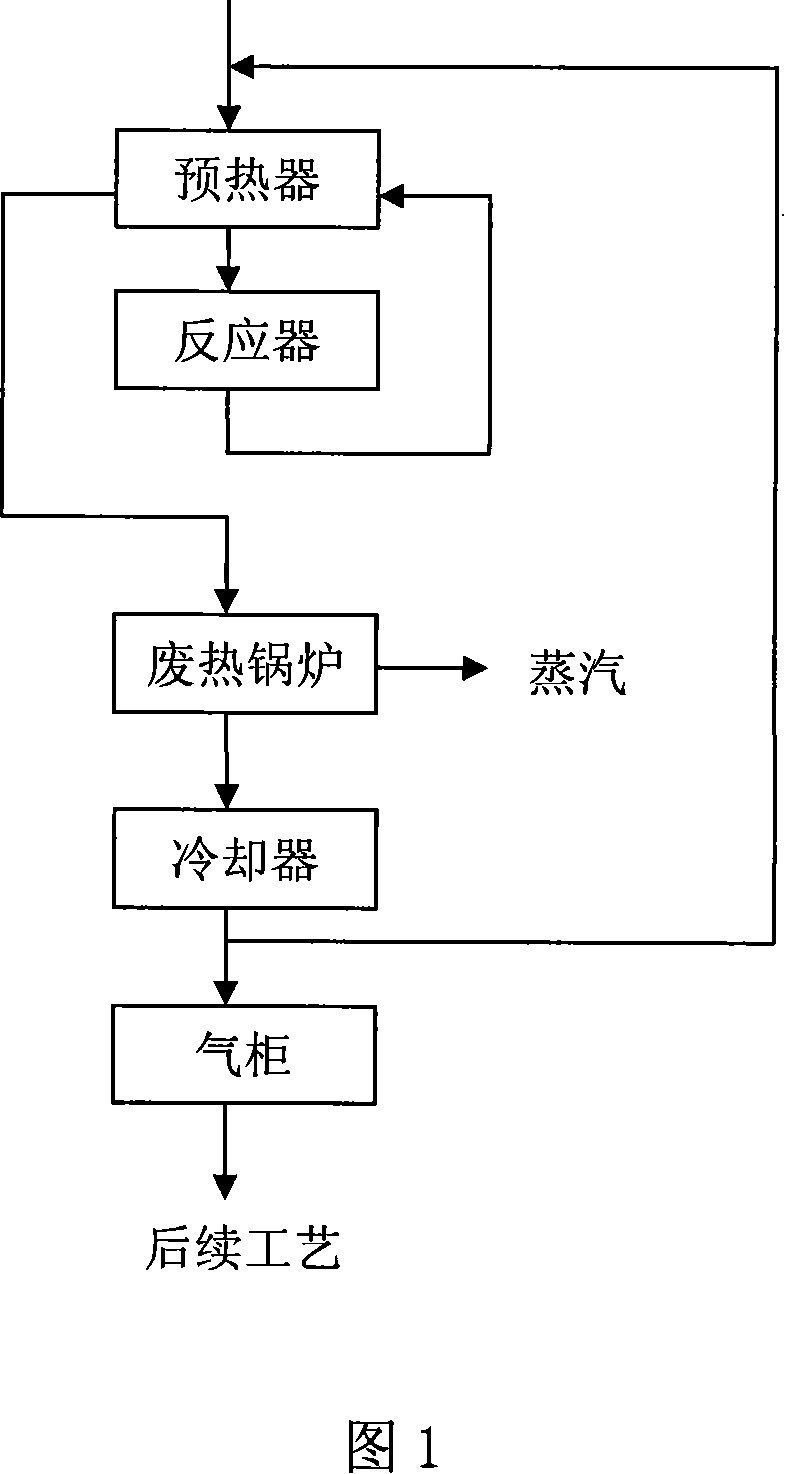

Novel coalbed gas thermal recovery process

The invention relates to a new coalbed gas thermal production process which is characterized in that full hot coke is arranged on the lower part of a coalbed gas production well or a gasification well, a gasification agent is pressed in so as to ignite a hole bottom coalbed; and the heat released from the combustion of part of the coalbed can heat up the adjacent coalbed, and improve the analysis capability, permeability coefficient and osmotic pressure of the coalbed, thereby improving the gas yield of the coalbed.

Owner:ENN SCI & TECH DEV

High-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology

InactiveCN105332684AAccurately determine the scope of influenceWide variety of sourcesFluid removalGas removalHigh pressure waterHigh pressure

The invention discloses a high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology comprises the following steps: ground stress state determination, hole sealing section drilling and sealing, hole drilling and slitting, charging, water injection hole sealing, high-pressure water burst crack starting, supercritical or liquid CO2 fracturing and gas extraction. A ceramsite proppant is mixed in the supercritical or liquid CO2, in a continuous fracturing process of the liquid CO2, extension conditions of burst cracks can be monitored in real time by a microseism monitoring instrument, and fracturing is stopped after an expected effect of extension in a set range is achieved. During guided slitting, slitting can be carried out step by step after holes are drilled according to the number of slits and a set distance between each two adjacent slits, and a mode of drilling holes and slitting alternately can also be adopted. The high-pressure water burst and CO2 fracturing combined coal bed gas displacement extraction technology has the advantages that the permeability of a low-permeability coal bed gas reservoir can be increased effectively, construction amount is reduced, and coal bed gas extraction efficiency is high.

Owner:CHONGQING UNIV

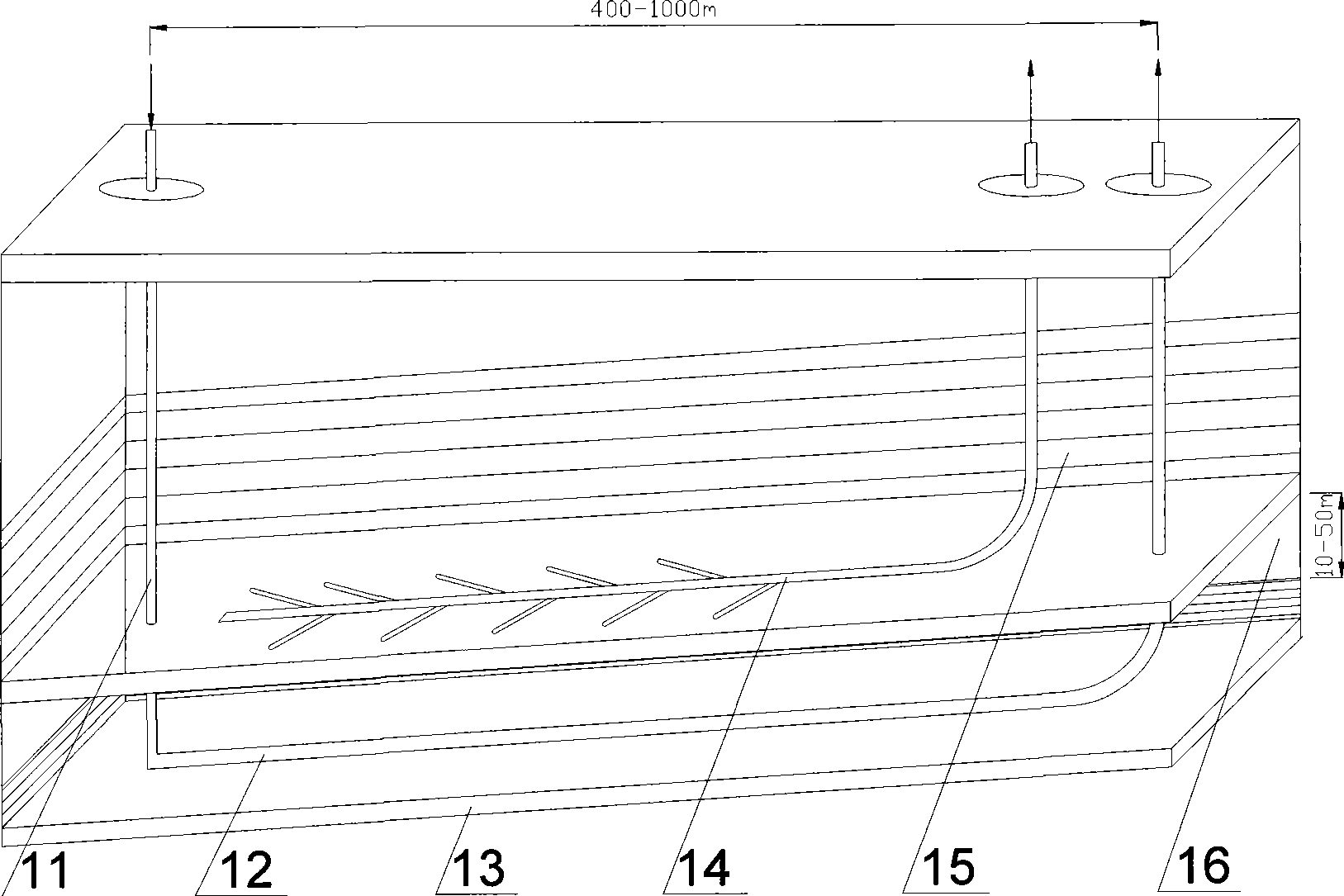

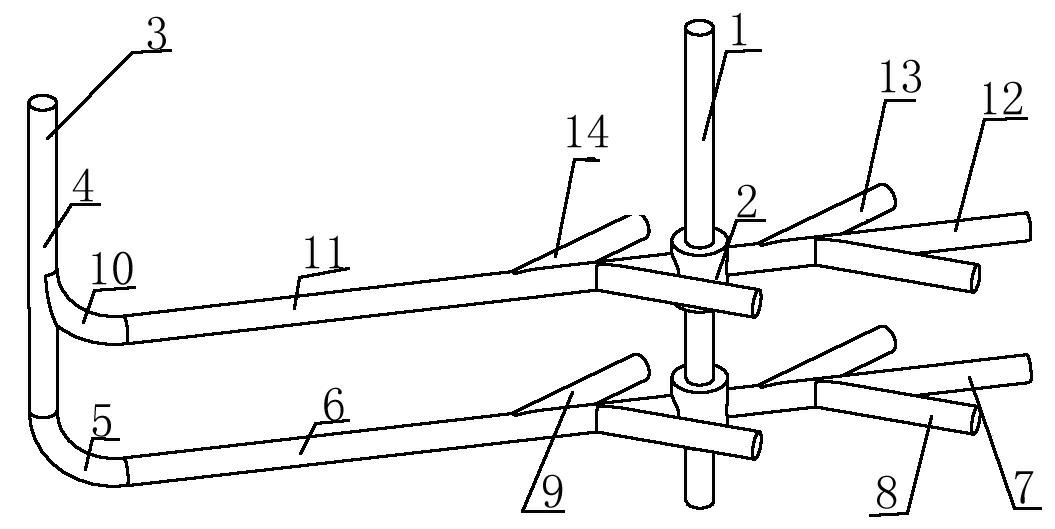

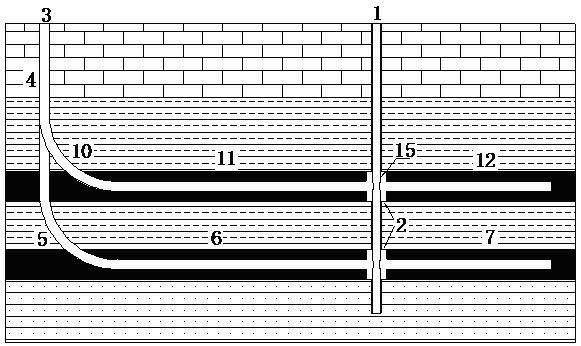

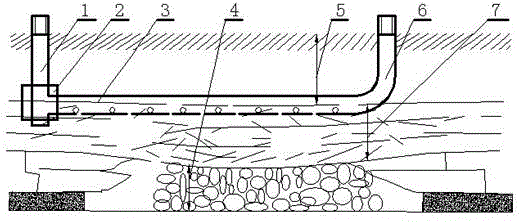

Construction method for enhancing extraction effect of ground coal bed gas

ActiveCN102116140AImprove the extraction effectShorten the construction periodFluid removalDirectional drillingLand useCoal

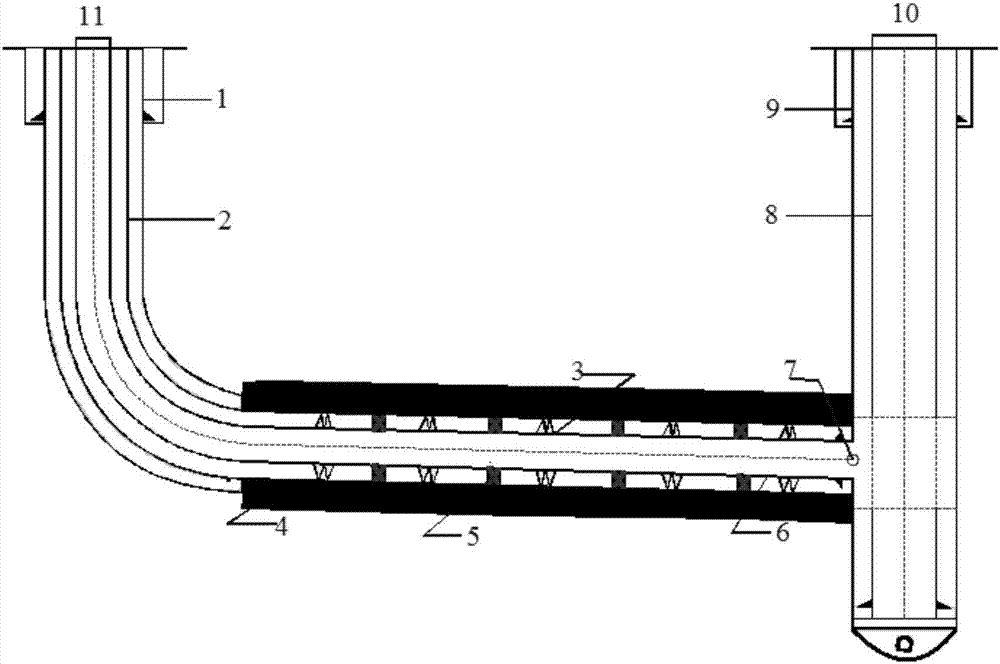

The invention relates to a construction method for enhancing the extraction effect of a ground coal bed gas, comprising the following steps of: (1) constructing a vertical cave well, forging caves on coal beds with coal bed gases needed to extract, and placing fiberglass casings into the caves; (2) constructing a vertical well section and a lower branched main horizontal well hole of a horizontal well, respectively forwards constructing the lower branched main horizontal well hole and a horizontal branched well hole positioned in front of a lower branched cave after butting with the vertical cave well, returning to a position nearby the rear end of the vertical cave well and then constructing a horizontal branched well hole positioned at the rear of the lower branched cave; (3) after a lower branched well hole is constructed, carrying out side drilling to construct an upper branched well hole; (4) after an uppermost branched well hole is constructed, plugging inclined well sections of main horizontal well holes inside the horizontal well from a side drilling windowing point to a coal seeing point by using cementing cement; (5) drilling and flushing the vertical cave well, installing discharge and extraction equipment, and extracting the coal bed gas by discharging water and reducing pressure on the ground. The invention can shorten the construction period, reduce the construction and production cost, decrease the lands used for construction and extraction and enhance the extraction effect of the ground coal bed gas.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Permeability improvement technology for coal bed gas reservoir cap by using three-dimensional fracture network modification

InactiveCN102392677AImprove permeabilityIncrease contact areaFluid removalGas removalMining engineeringHorizontal wells

The invention relates to a permeability improvement technology for a coal bed gas reservoir cap by using three-dimensional fracture network modification. The technology is as follows: building a bedding horizontal well from ground to top and bottom plates of the coal bed of an area not mined; building bedding, three-dimensional cross-type or multi-branch long boreholes on the top and bottom plates of the coal bed of the area not mined through perforation and segmented fracturing or existing sinking and driving engineering, and then carrying out hydraulic fracturing; modifying the coal bed gas reservoir cap into a crisscross fracture network system to form a modified volume; building various types of drainage boreholes in the modified volume; and carrying out negative pressure extraction together with a fractured well, so that coal bed gas can be continuously desorbed and dispersed and then extracted out in large scale through the modified volume. According to the invention, the crisscross fracture network system is formed in the coal bed gas reservoir cap, so that the coal bed gas can be continuously desorbed and dispersed at negative pressure and then extracted out in large scale through the modified volume, thus the content of coal bed gas in the modified bed can be quickly reduced to be below the safety standard in the outburst prevention formulation, and safe and high-efficiency production of mines can be realized on the basis of forming scale coal bed gas development.

Owner:HENAN COAL CHEM IND GROUP INST

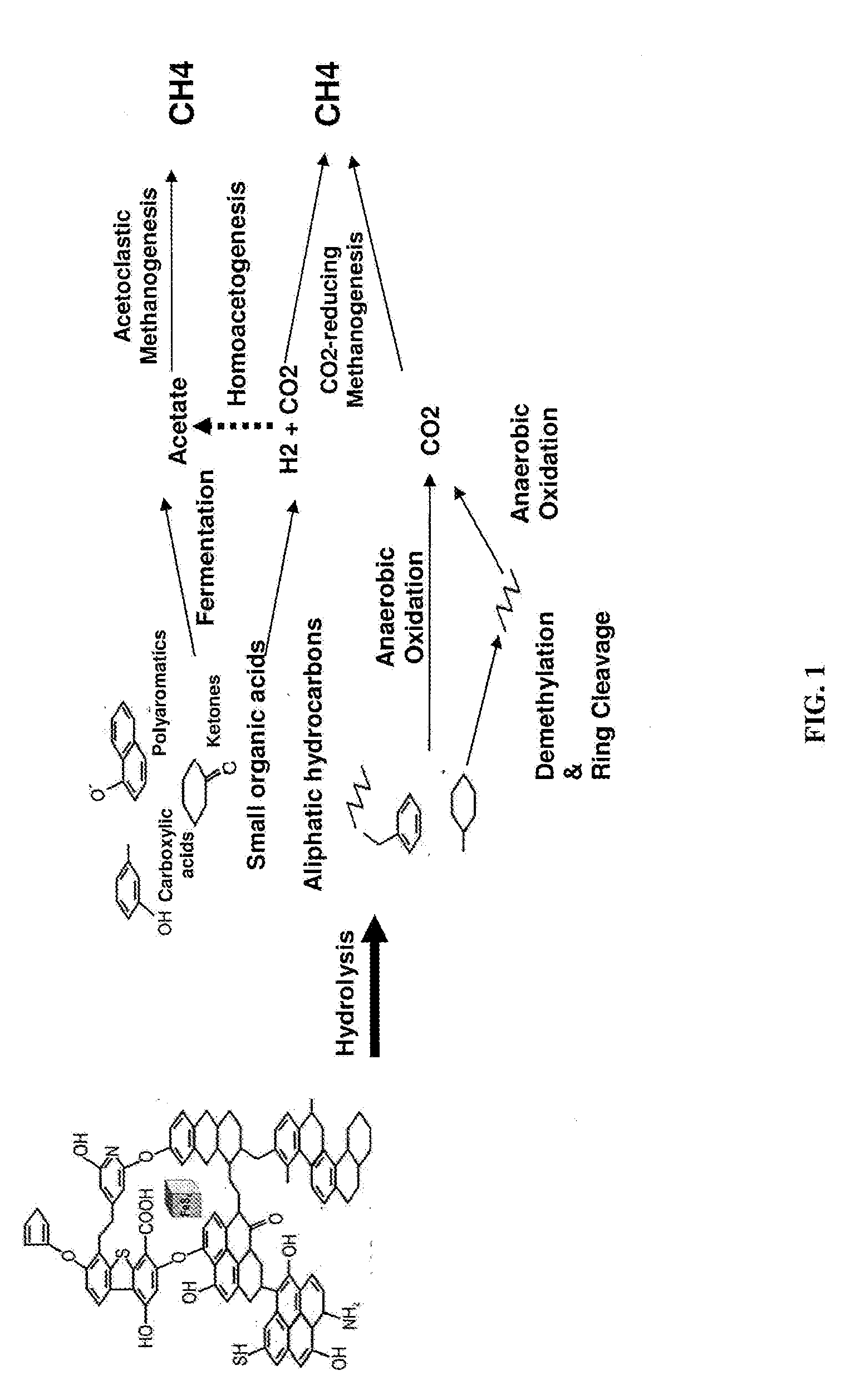

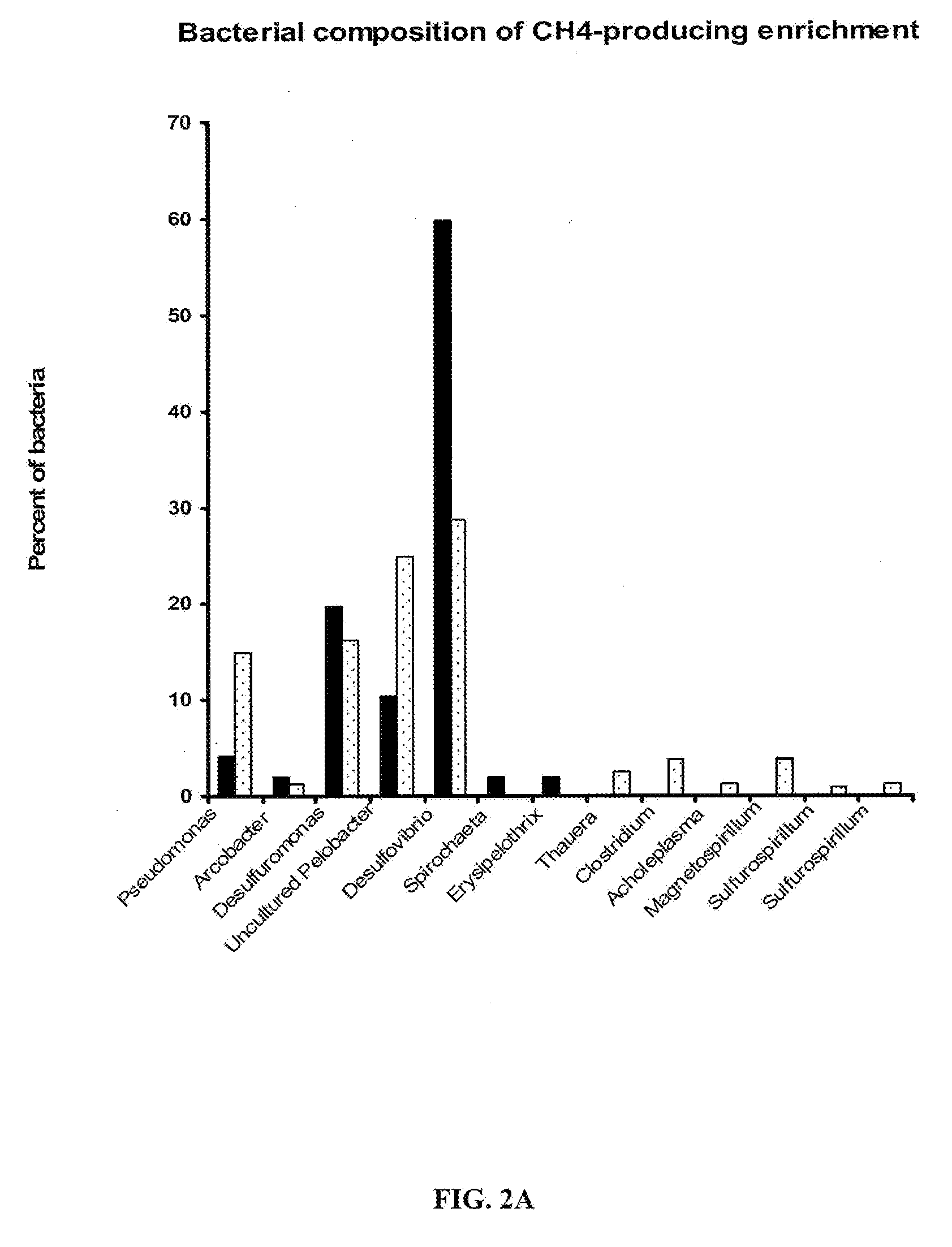

Methods to stimulate biogenic methane production from hydrocarbon-bearing formations

The present invention describes methods of identifying stimulants for the biogenic production of methane in hydrocarbon-bearing formations. Methods involve the use of microbial nucleic acid sequence information for the determination of gene products that are enzymes in a variety of pathways involved in the conversion of hydrocarbons to methane. Enzymes and stimulants identified by invention methods can be used in processes for enhancing biogenic methane production, for example, by addition to coal seams and coalbed methane wells.

Owner:SYNTHETIC GENOMICS INC

Sulfur-resistant catalytic deoxidization process for methane-rich gas

InactiveCN101139239ALow priceSulfur resistanceMetal/metal-oxides/metal-hydroxide catalystsChemical modification purification/separationReaction temperatureManganese

The present invention discloses a sulfur wearable and catalyzing and oxidizing method for gas abundant of firedamp; the raw material gas abundant of firedamp such as coal bed gas firstly passes through a preheater for preheating, and then enters a oxidizing reaction device; under the condition of 0-0.5MPa of pressure, 500-750 DEG C of reaction temperature, 1000-3000h-1of reaction air speed, the firedamp in the air is reacted with oxygen to produce carbon dioxide and water in manganese base sulfur wearable and catalyzing and oxidizing bed; at the same time, a small quantity of firedamp is decomposed to produce carbon and hydrogen gas; the carbon and the hydrogen after being decomposed are also reacted with oxygen so as to reach the purpose of getting rid of oxygen in the airs abundant of firedamp effectively. The present invention adopts much newer and more economical new catalyzer, which does not need to desulfurize firstly for the air; the air can directly enter the oxidization reaction device for oxidization. So the present invention can decrease the cost and simplify the technics process.

Owner:HAO HUA CHENGDU TECH

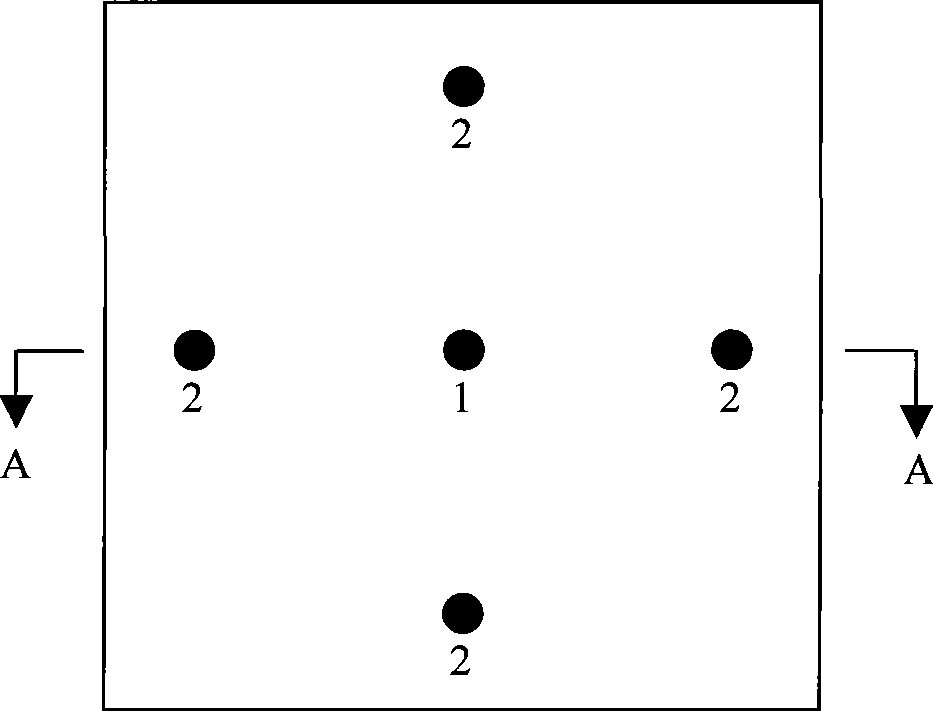

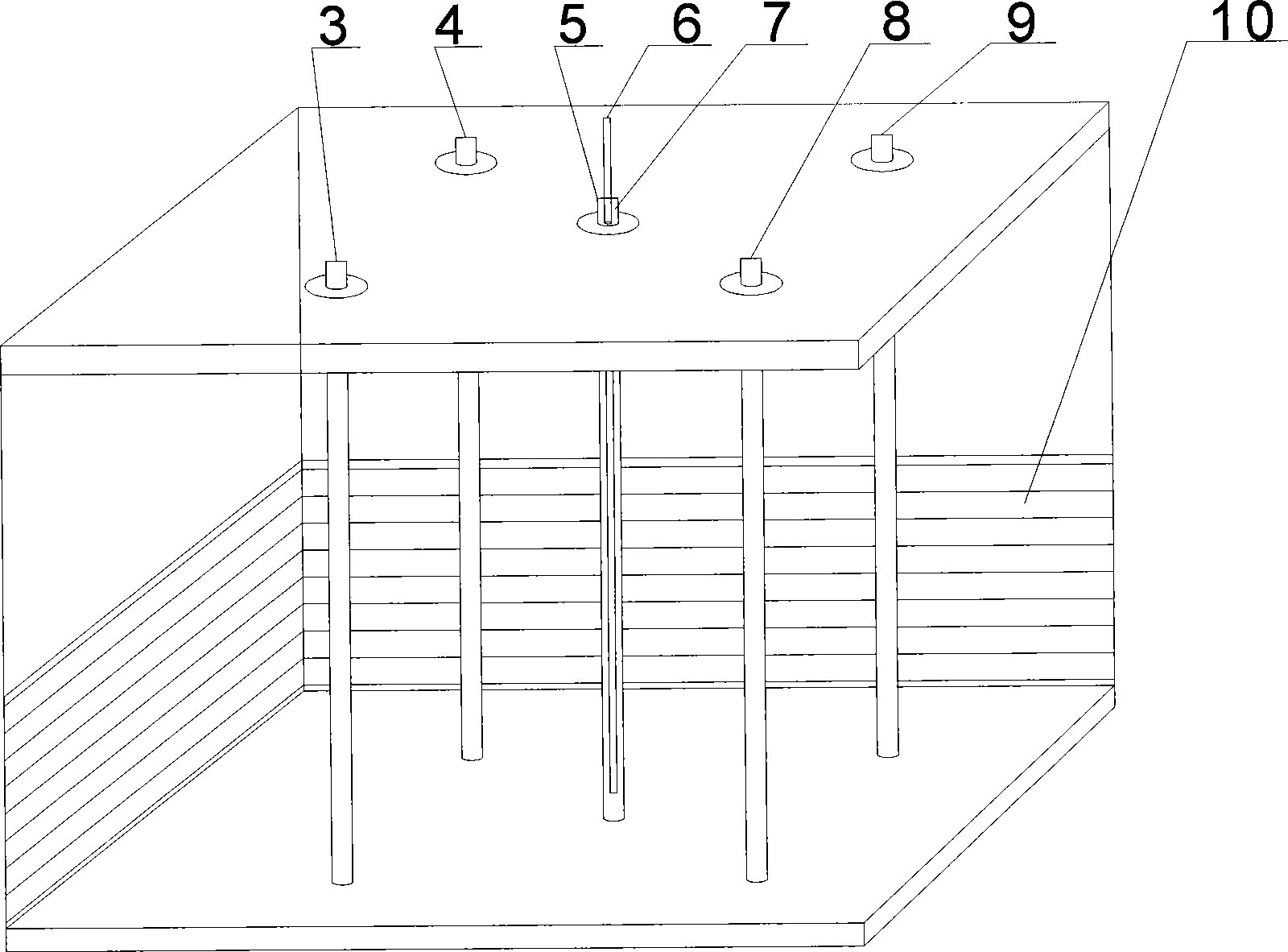

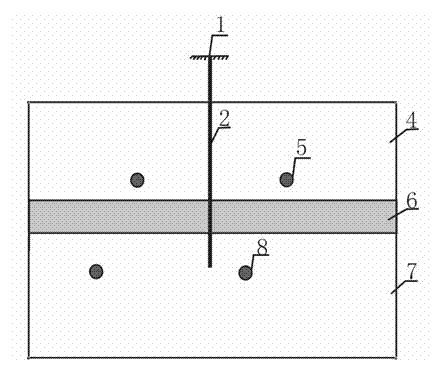

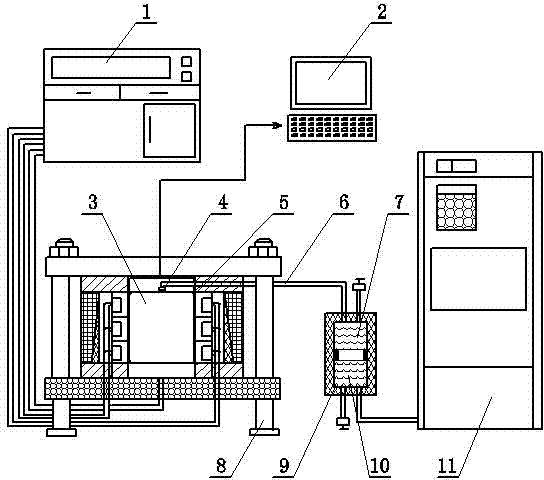

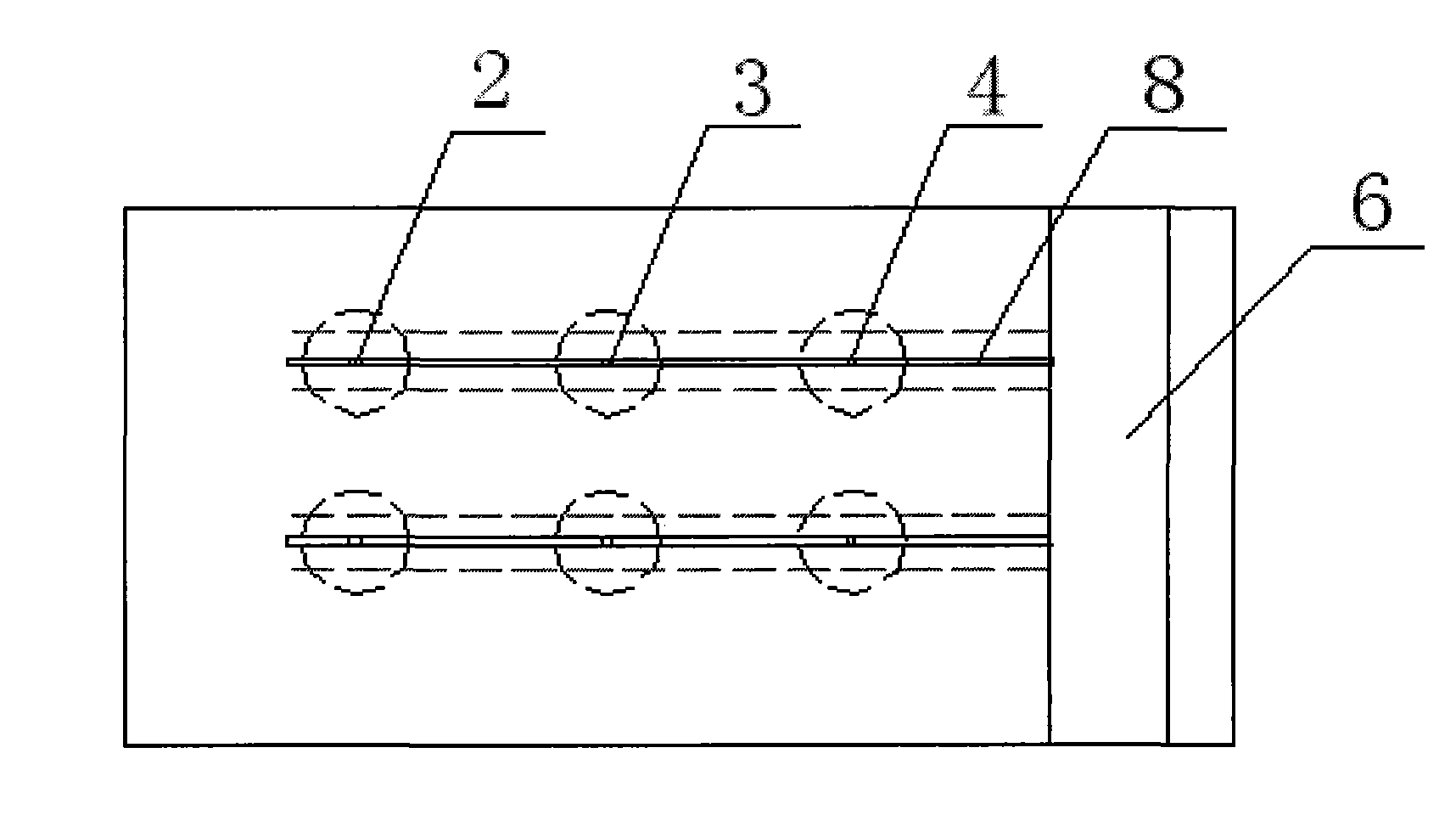

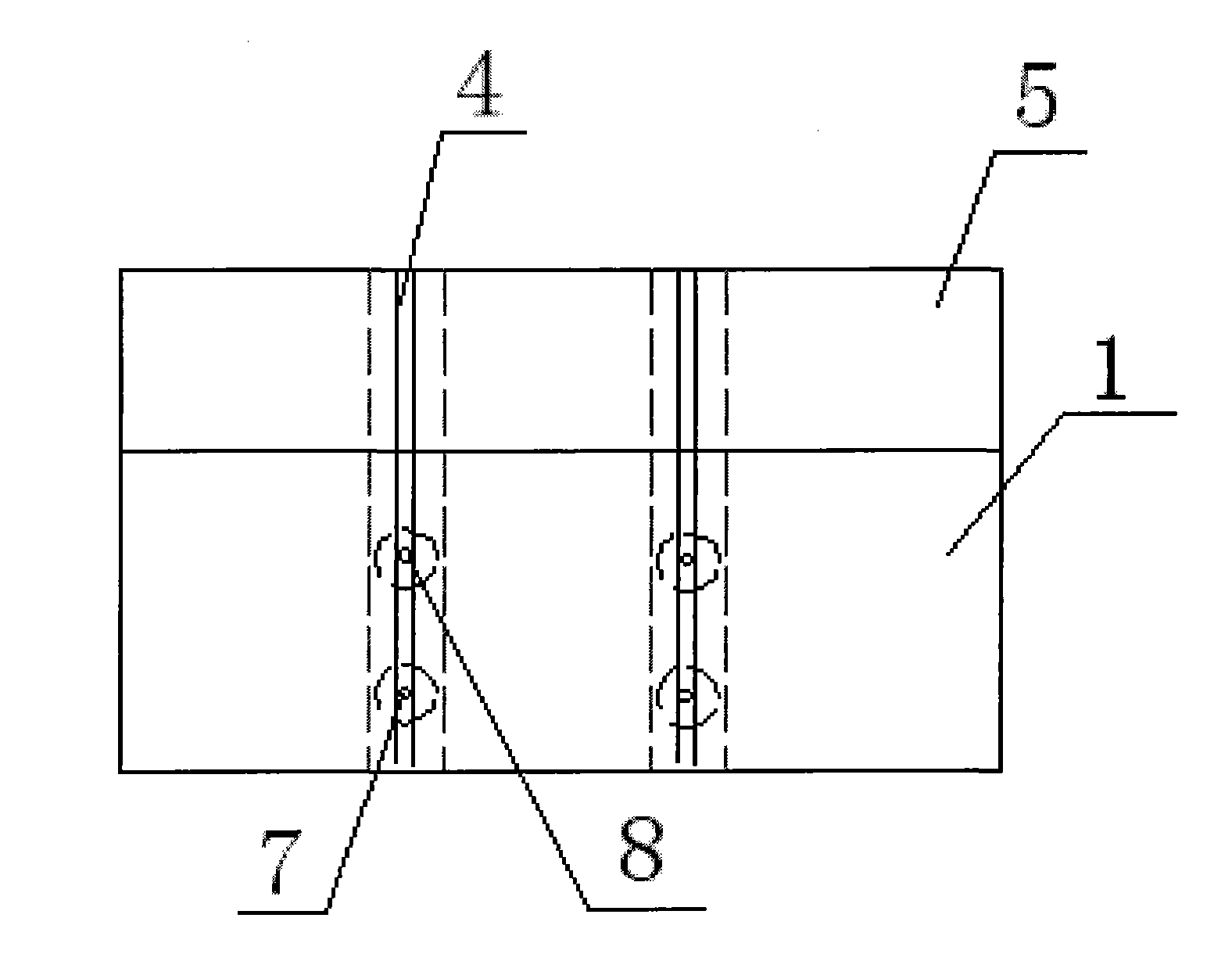

Physical simulation method of coal-bed gas well hydraulic fractures

The invention discloses a physical simulation method of coal-bed gas well hydraulic fractures. According to the method, a real three-shaft fracture simulating test frame is arranged, a fracture test piece with a wellbore hole simulator is placed in the real three-shaft fracture simulating test frame, and sound transmitting probes tightly adhere to the eight corners of the fracture test piece respectively through plastic cement and are connected with sound transmitting receivers through acoustic emission signal amplifiers; a hydraulic pressure stabilizer is connected to the exterior of the real three-shaft fracture simulating test frame; the top of the wellbore hole simulator is connected with an oil and water separator through a fracturing liquid pipeline, guar glue hydraulic fracturing liquid is added to the upper portion of the oil and water separator, and oil is added to the lower portion of the oil and water separator; a control panel is connected to the bottom of the oil and water separator. With the physical simulation method of coal-bed gas well hydraulic fractures, generation and development of fractures in the test piece can be detected in real time in the hydraulic fracturing physical simulation process in a laboratory, the three-dimensional characteristic analysis of the fractures is paid attention to, the method is not confined to observation on the extension of the fractures on the surface of the fracture test piece, and the extension process of the fractures can be better reflected.

Owner:CHINA UNIV OF MINING & TECH

Oxygen-containing coal bed gas deoxidation catalyst and preparation thereof as well as applications

InactiveCN101322942ALow priceSulfur resistanceMolecular sieve catalystsGaseous fuelsMordeniteAluminum silicate

The invention discloses a deoxidizing catalyst for a coal-seam gas containing oxygen and a preparation method as well as an application thereof. The deoxidizing catalyst of the invention consists of an active component, an active auxiliary and a porous carrier. The active component is the compound of Co; the active auxiliary is one or more compounds of Mn, Fe, Zn and Cu; the porous carrier is one or more of aluminum oxide, titanium oxide, zirconium oxide, magnesium oxide, calcium oxide, silicon oxide, a phosphor-aluminium molecular sieve, an A-typed molecular sieve, an X-typed molecular sieve, a Y-typed molecular sieve, a mordenite, a ZSM-5 zeolite, diatomaceous earth, kaolinite, natural clay, aluminum silicate and magnesium silicate; calculated by oxide, the weight percentage of the active component is 1 to 60 percent; the weight percentage of the active auxiliary is 1 to 50 percent; the rest is the carrier. The catalyst of the invention has certain sulfur-resistance performance, is applicable to the deoxidization treatment of coal-seam gas with an oxygen content of 3 to 6 percent (V / V) and is capable of causing the oxygen content in the coal-seam gas to be lower than 0.5 percent by deoxidization.

Owner:HAO HUA CHENGDU TECH

Fast desorption meter for gas content of goal seam

ActiveCN101034050ASimple structural designAccurate coal seam gas content dataPreparing sample for investigationContent distributionGraduated cylinder

This invention relates to a coal seam gas content quick desorption instrument design to test coal core, quickly and accurately determine coal seam gas content. The invention include computer processing, quick desorption and measuring system. The feature is; Quick desorption system include sample sealable tank and chip sample platform. Sealable tank top has sealing cover, and inter has whip piece. Sealable tank connect with intake pipe and vent-pipe, vent-pipe connect measuring system. Sealable tank fix on platform. Quick desorption system include measuring cylinder and water bottle, measuring cylinder's top link vent-pipe, measuring cylinder's bottom through gas tube connect with water bottle. The effect: this invention can test shattered coal core sample, pick coal seam air content data, quickly appraise this region's coal-seam gas potential stocks and exploration prospects, research differently region gas content characteristic, gas content distribution and coal reservoir bed.

Owner:PETROCHINA CO LTD

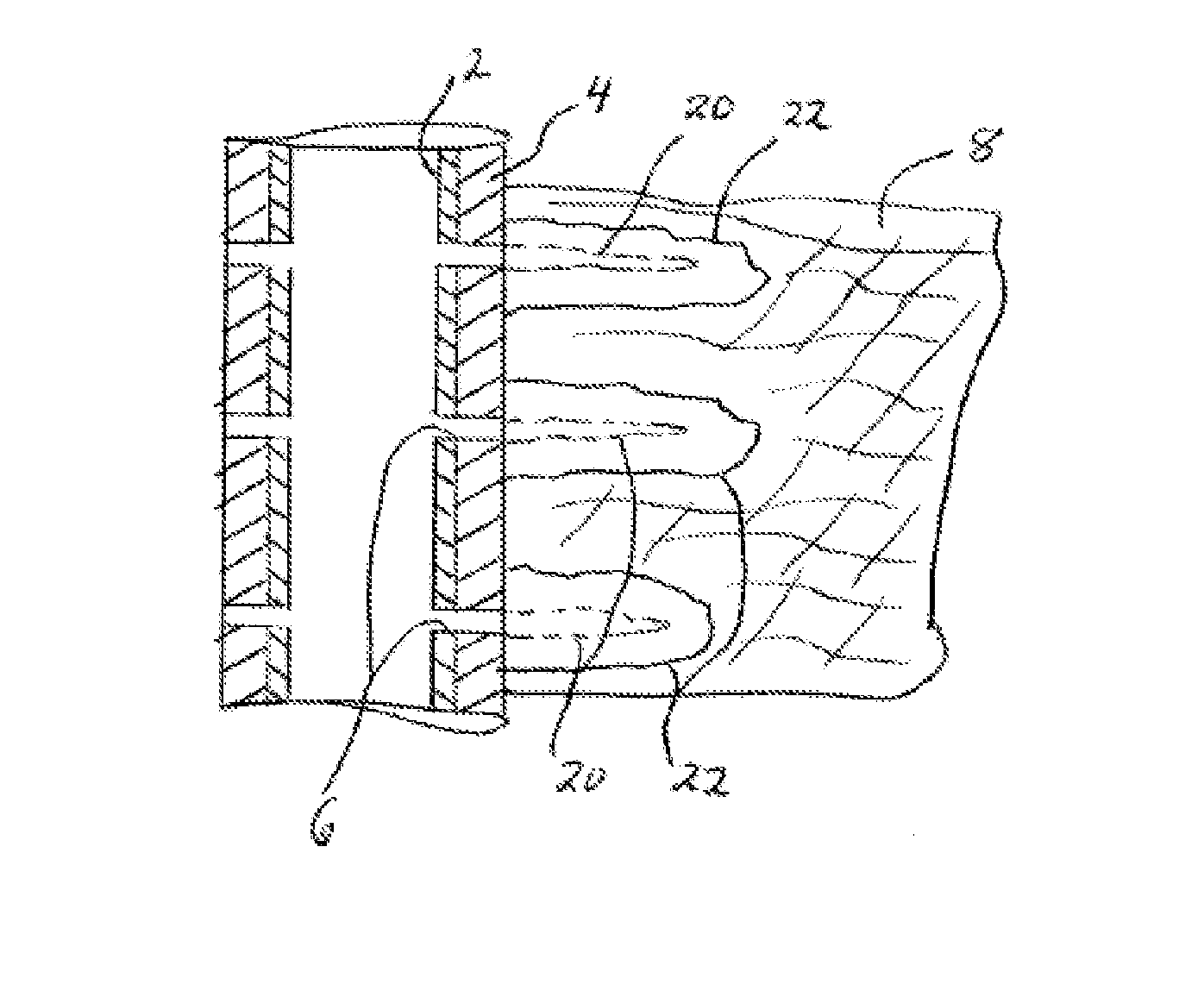

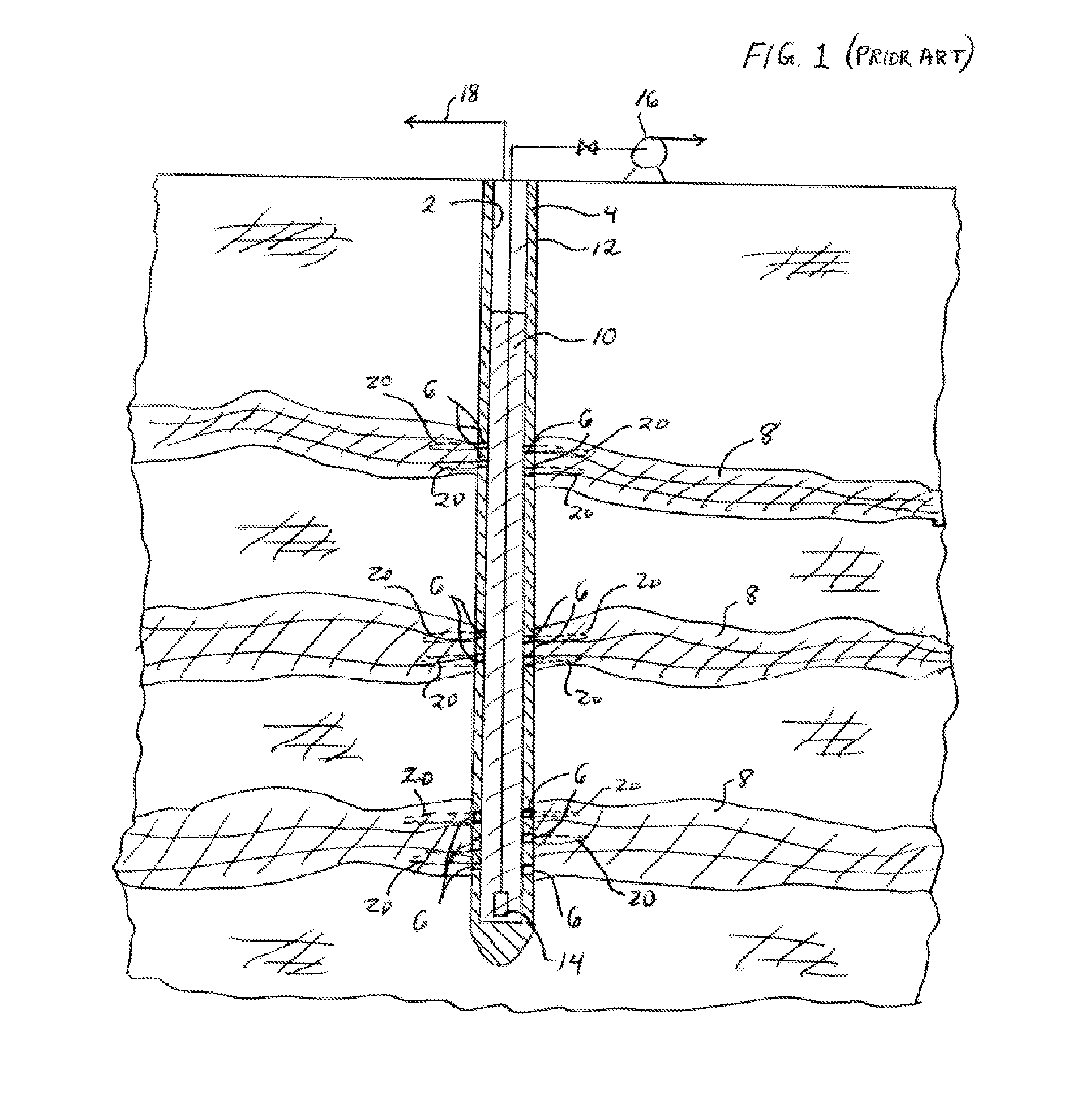

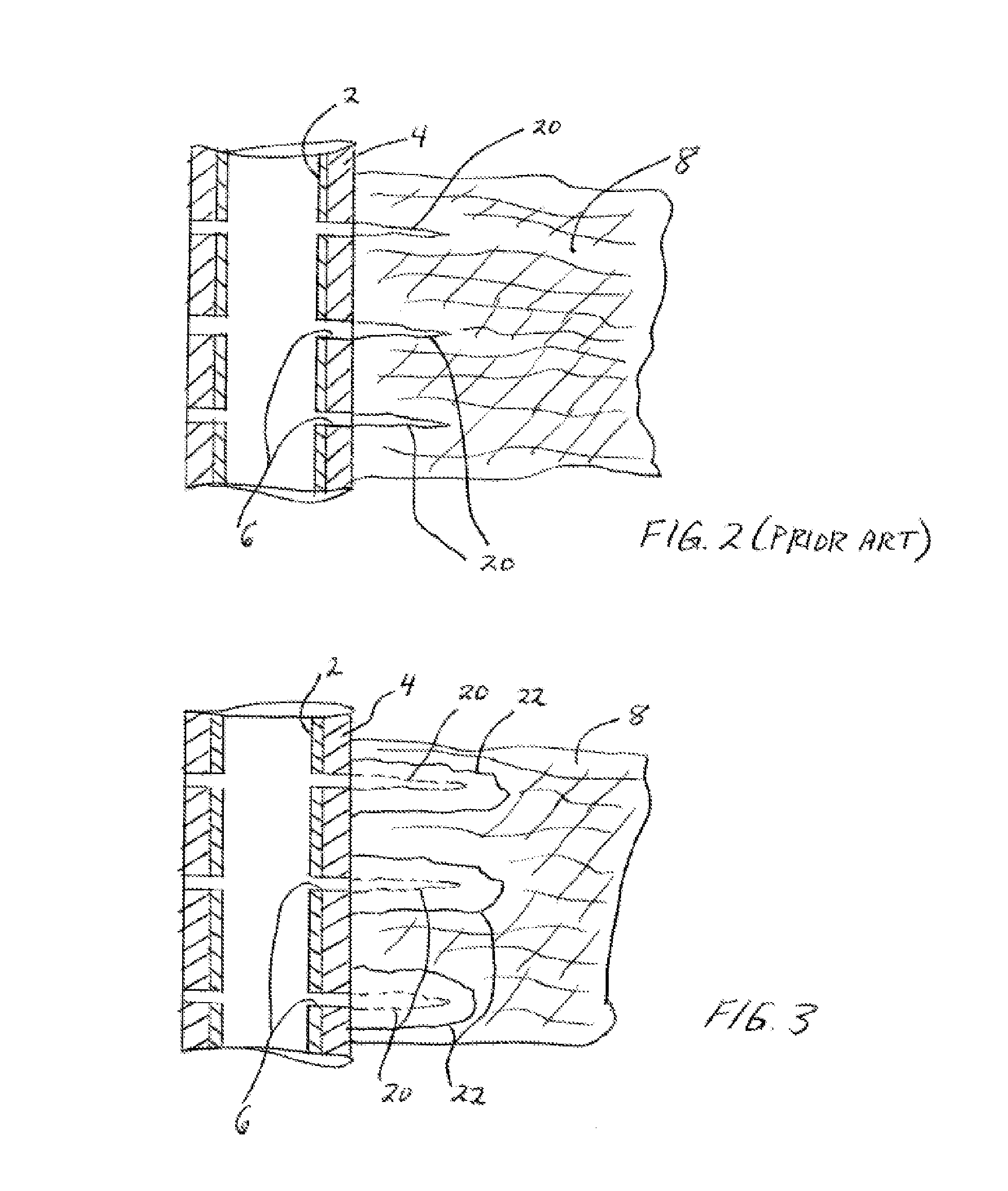

Sub-Surface Coalbed Methane Well Enhancement Through Rapid Oxidation

Methods of stimulating production of coalbed methane from a coal-bearing formation are described, one method involving providing a perforation charge comprising a standard charge portion and a charge additive able to produce localized temporary oxidizing environments in perforations; perforating a coal-bearing formation with the perforation charge to form initial perforations defined by carbonaceous material, the initial perforations having localized temporary oxidizing environments in them, and initiating combustion of the carbonaceous material using the oxidizing environments, thus enlarging the initial perforations. Other methods involve perforating the coal-bearing formation with a standard perforation charge, thereby creating perforations; and treating the perforations with a composition creating temporary local oxidizing environments involving an oxidant in the perforations, and initiating combustion of carbonaceous material using the excess oxidant, thus enlarging the perforations.

Owner:SCHLUMBERGER TECH CORP

Test device for evaluating well completion manner of coal bed methane

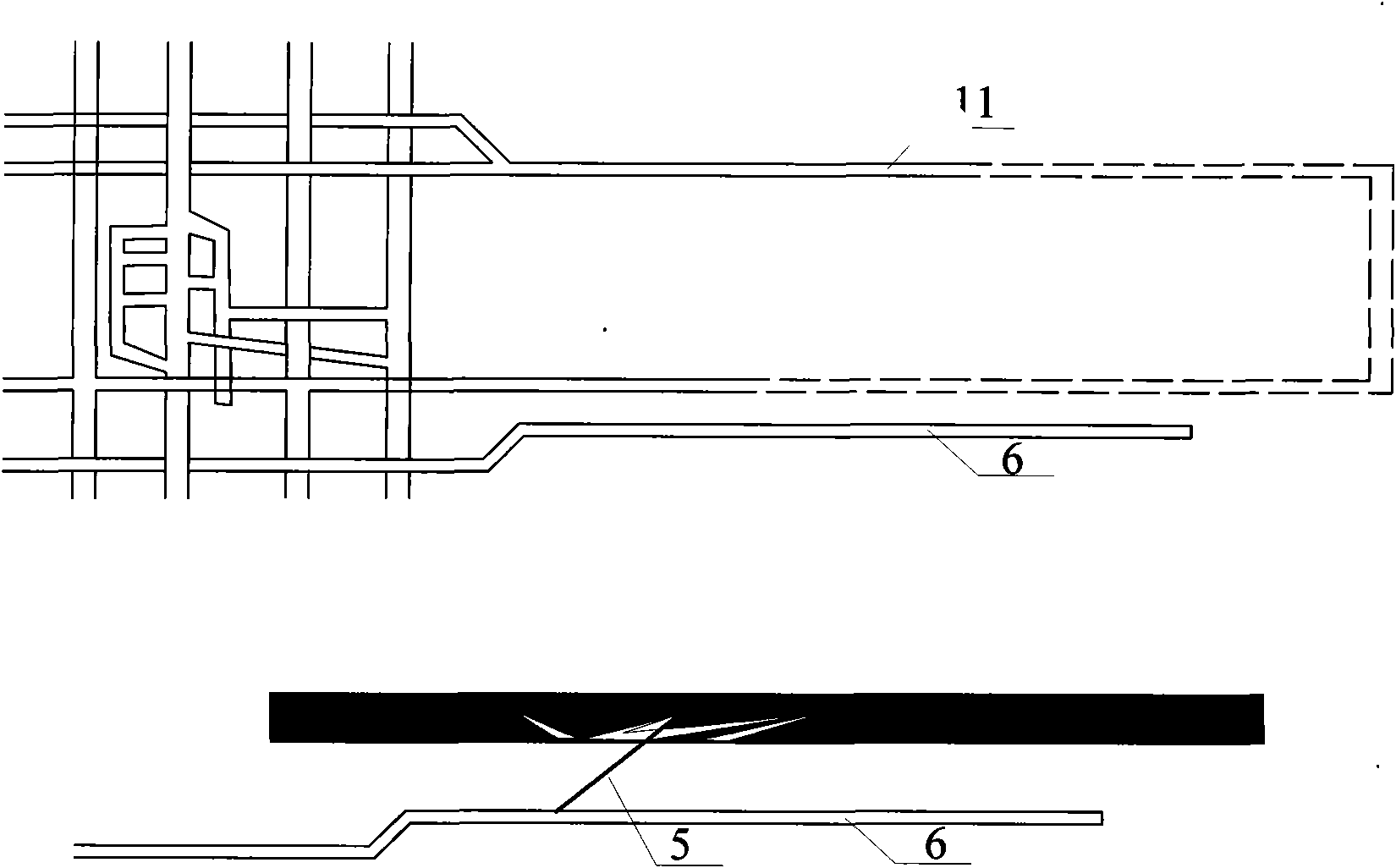

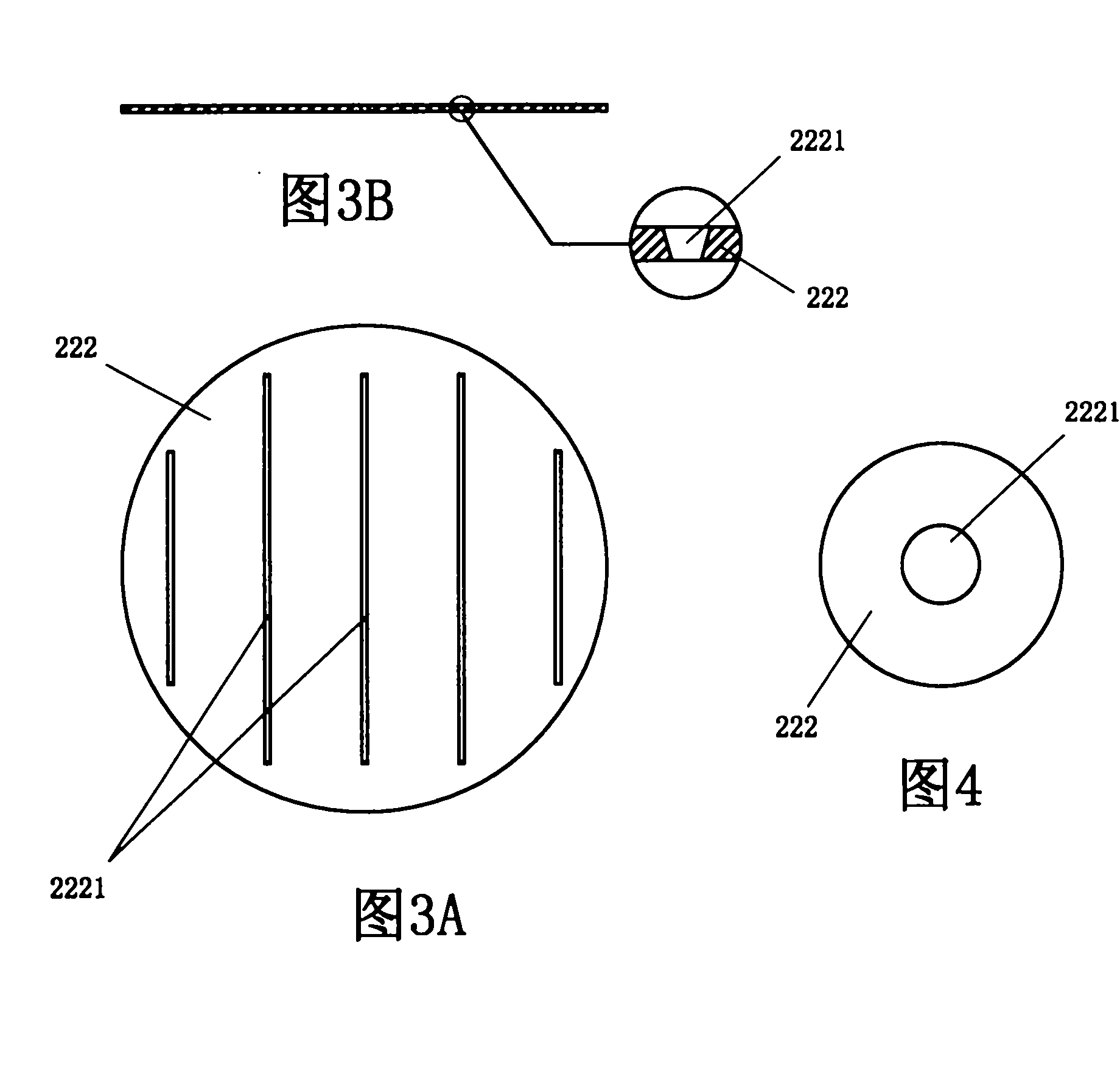

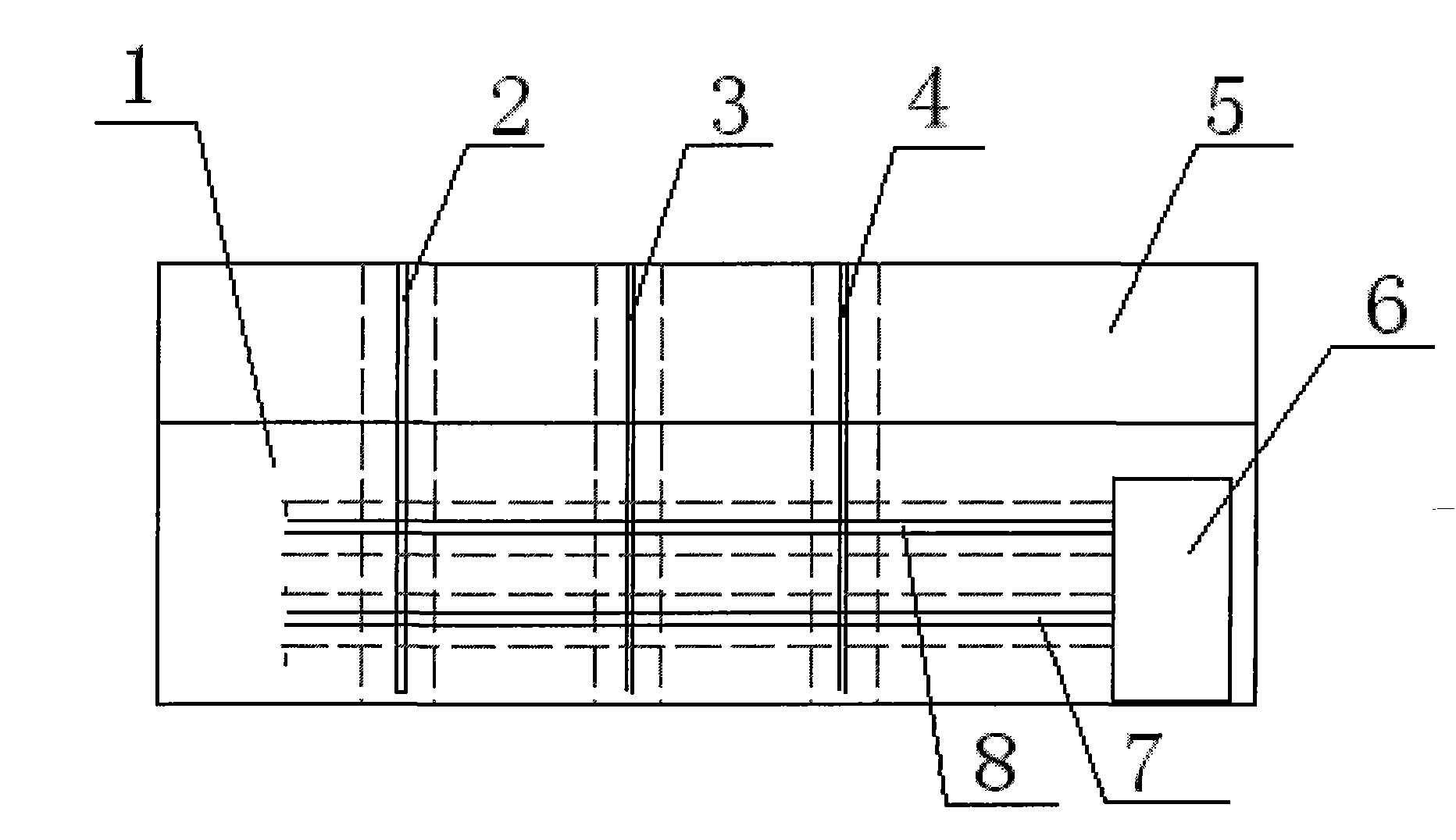

The invention relates to a test device for evaluating a well completion manner of coal bed methane. The test device comprises a well completion manner simulation model system which is arranged in a constant-temperature box; the well completion manner simulation model system consists of a core holder and a well completion model which is arranged in the core holder; the core holder comprises a metal cylinder with both sealed ends; a gas-liquid inlet is arranged at one sealed end of the metal cylinder, and a gas-liquid outlet is arranged at the other sealed end of the metal cylinder; a cylindrical rubber sleeve with both opened ends is sleeved in the metal cylinder; the well completion model comprises a cylindrical raw coal core which is arranged in the cylindrical rubber sleeve; a well completion simulation sheet provided with a through cutting seam or a through hole is adhered to the end face opposite to the gas-liquid outlet of the raw coal core; a gas-liquid pressurized injection system and an inlet pressure sensor are connected with the gas-liquid inlet of the core holder; the gas-liquid outlet is connected with a coal powder collecting and metering system and an outlet pressuresensor; and the core holder is connected with a loading device which is used for loading a confining pressure to the well completion model inside the metal cylinder.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

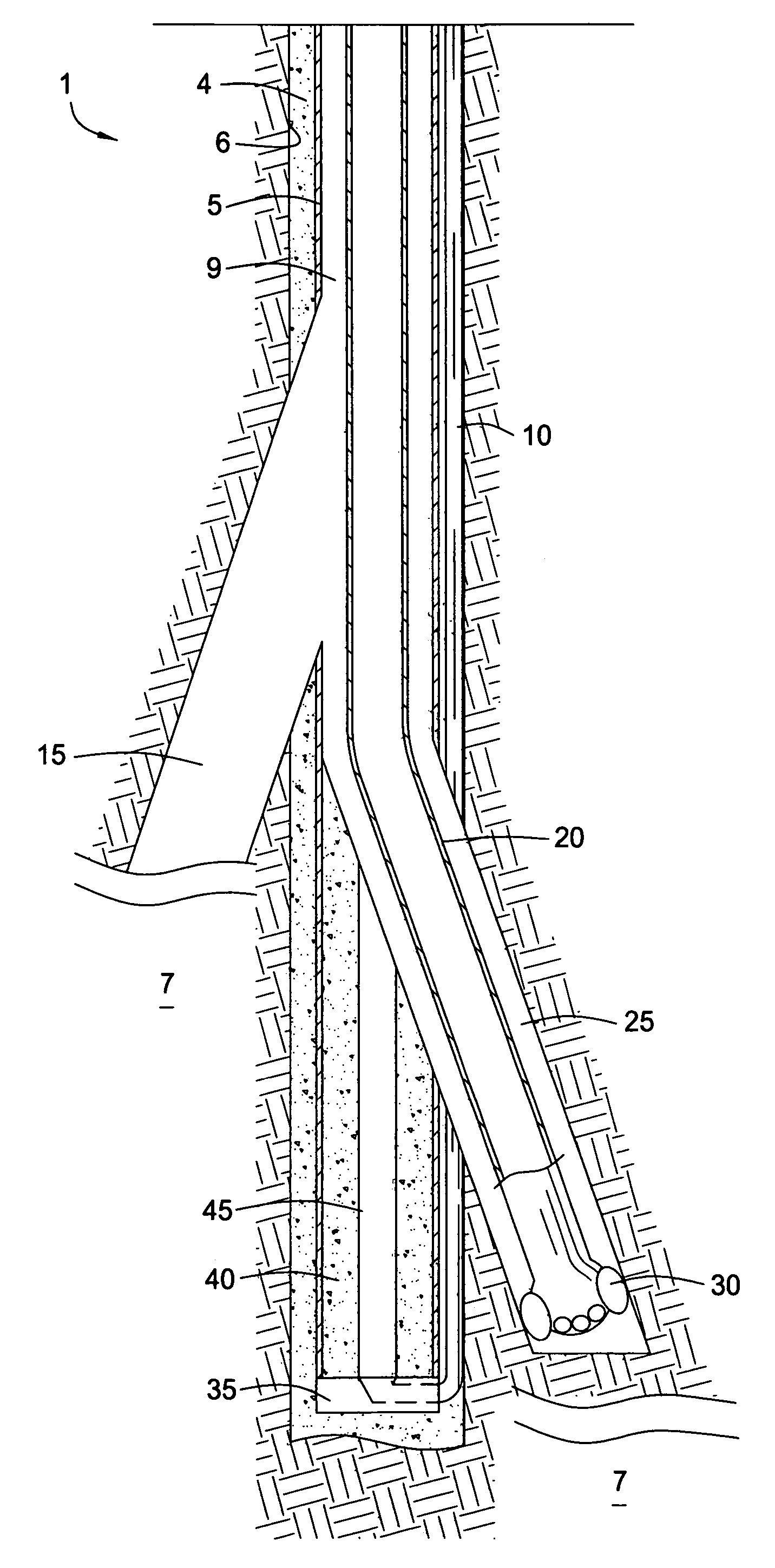

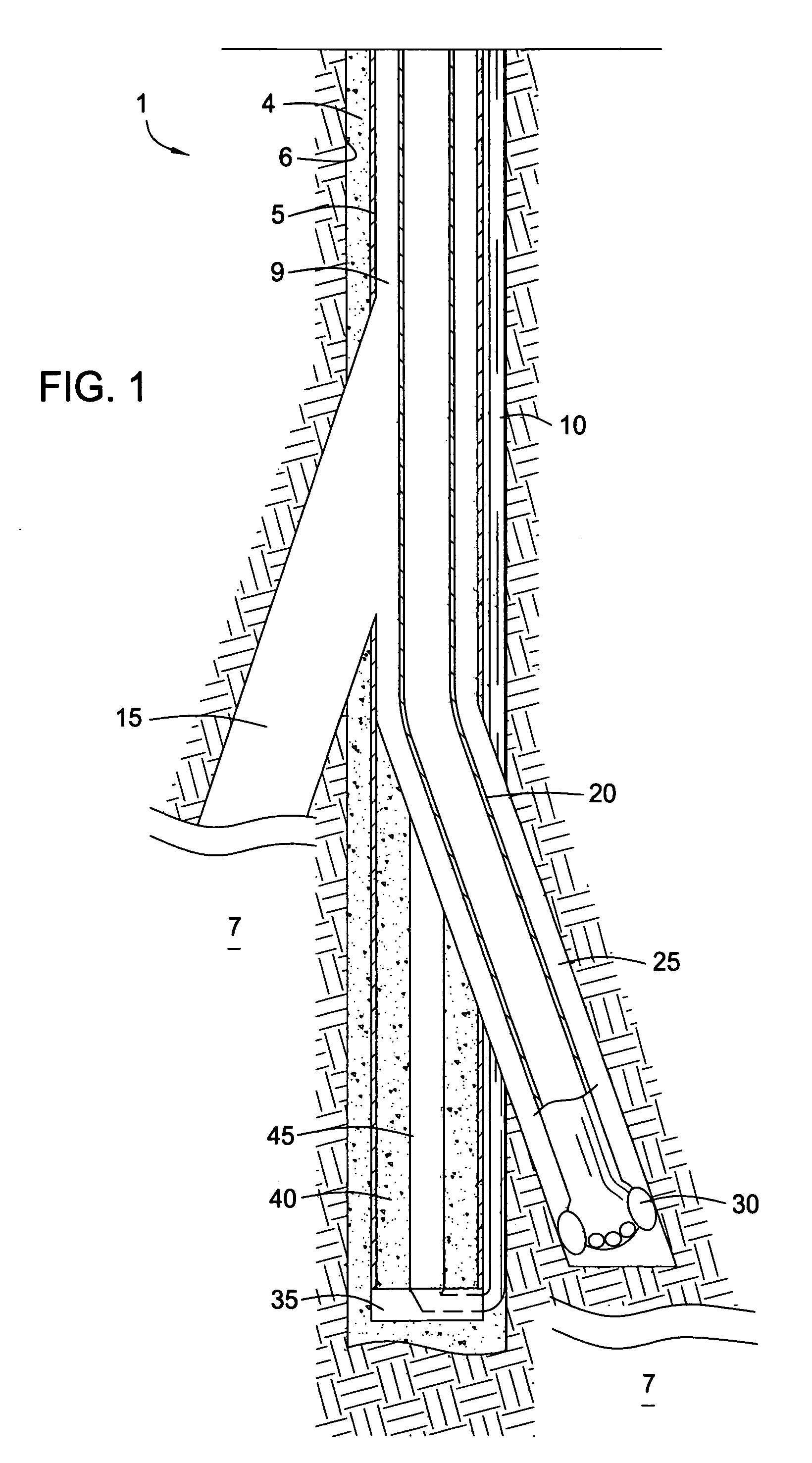

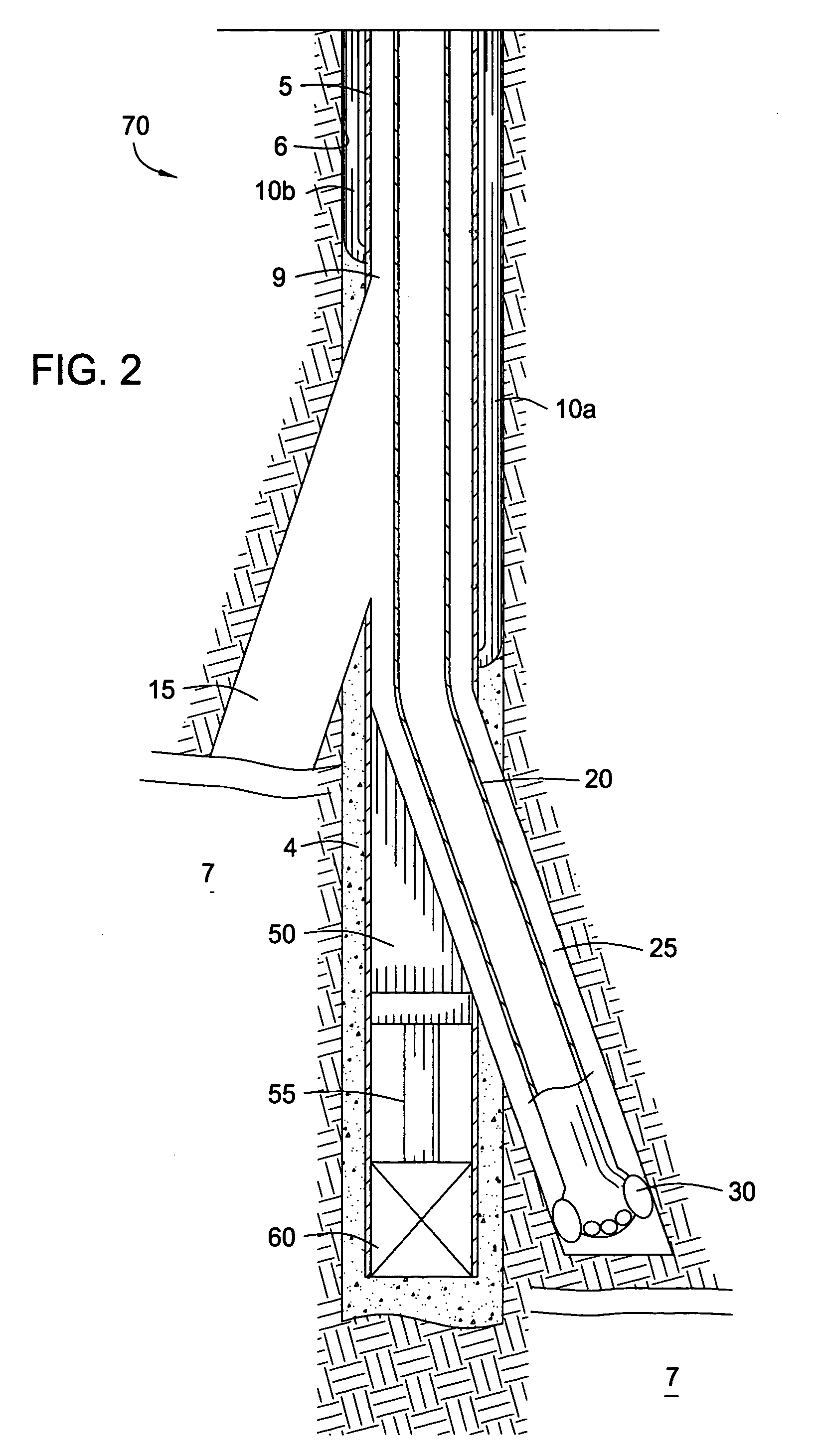

Method for extracting coal bed methane with source fluid injection

The present invention generally provides an inexpensive method for drilling a multilateral wellbore where the pressure exerted on a formation of interest by a column of drilling fluid may be controlled. In one aspect, a method for drilling a lateral wellbore from a main wellbore is provided, including running a string of casing with an injection line connected thereto into the main wellbore, wherein the injection line is disposed along an outer side of the casing and a portion of the casing corresponding to a starting depth of the lateral wellbore is made from a drillable material; running a drillstring through the casing to the starting depth of the lateral wellbore, wherein the drillstring comprises a drill bit; injecting drilling fluid through the drill sting; and injecting a second fluid, having a density less than that of the drilling fluid, through the injection line at a rate corresponding to an injection rate of the drilling fluid to control hydrostatic pressure exerted by a column of the drilling fluid and the second fluid returning through the casing.

Owner:WEATHERFORD TECH HLDG LLC

Method for coagulating coal-bed gas produced water

InactiveCN102060363AEasy to handleResource optimizationWater/sewage treatment by flocculation/precipitationChemical compoundSuspended matter

The invention relates to a method for coagulating coal-bed gas produced water, which is realized in a way that: coal-bed gas produced water is coagulated by combining a chemical compounded from an inorganic coagulant and an organic flocculant with a coagulation assistant, or combining an inorganic coagulant, an organic flocculant and a coagulation assistant; a pretreatment pool is arranged at the outlet of the coal-bed gas produced water, a coagulation assistant dissolving box is arranged at the water inlet of the pretreatment pool, and the amount of the coagulation assistant is controlled by using a measuring pump or flowmeter; and the coal-bed gas produced water is firstly conditioned by the coagulation assistant, and then treated by the chemical compounded from the inorganic coagulant and the organic flocculant, or treated by combining the inorganic coagulant and organic flocculant. The amounts of the compounded or combined inorganic coagulant and organic flocculant are controlled by using the measuring pump or flowmeter, thereby effectively removing suspended matters in the coal-bed gas produced water, being beneficial to removing oil, multiple soluble ions, other organic substances and the like, reducing the consumption of chemicals and relieving the treatment load of the subsequent technique, so that the treated produced water can be discharged under the standard or can be conveniently recycled.

Owner:CHINA UNIV OF MINING & TECH +2

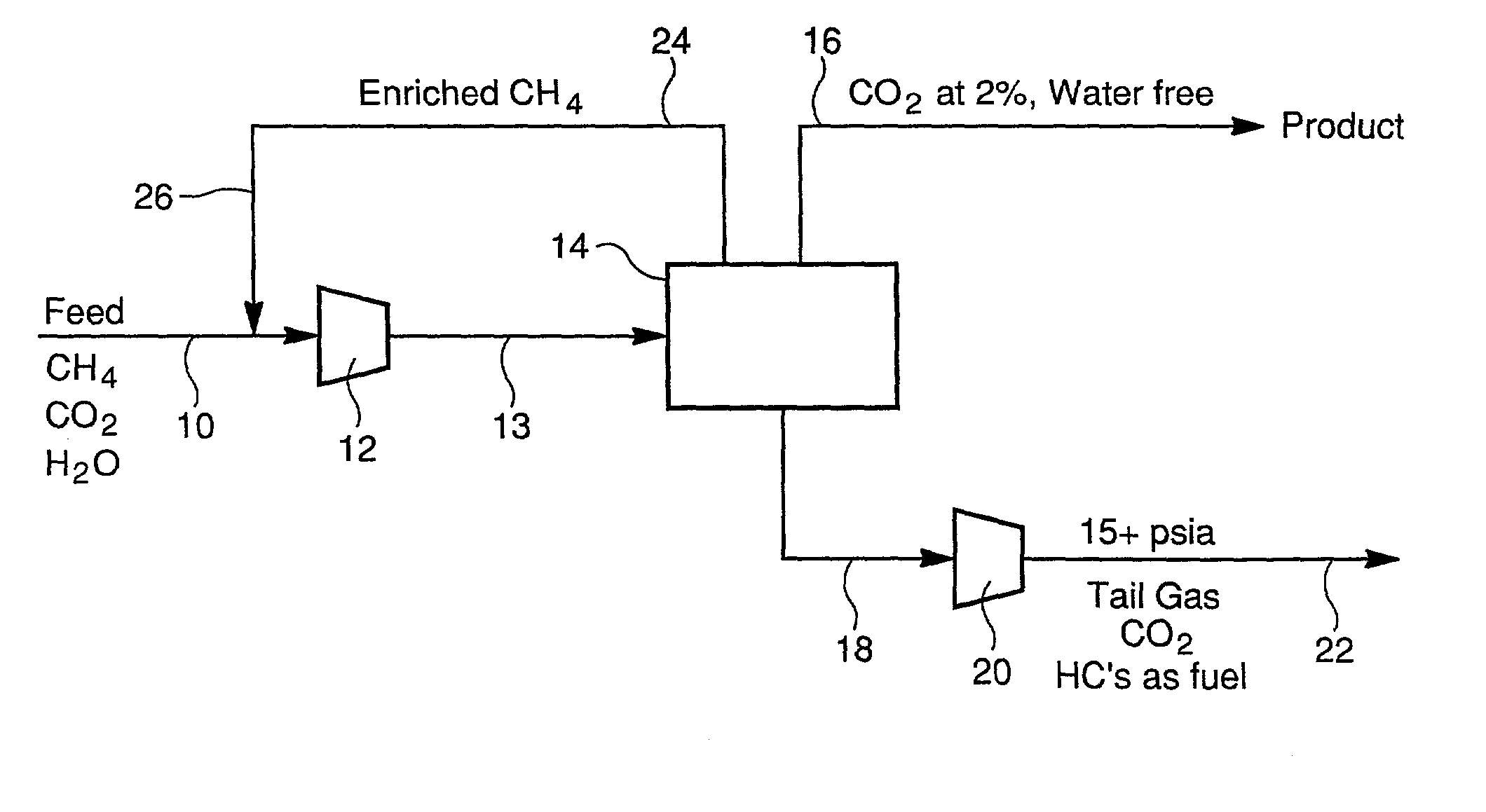

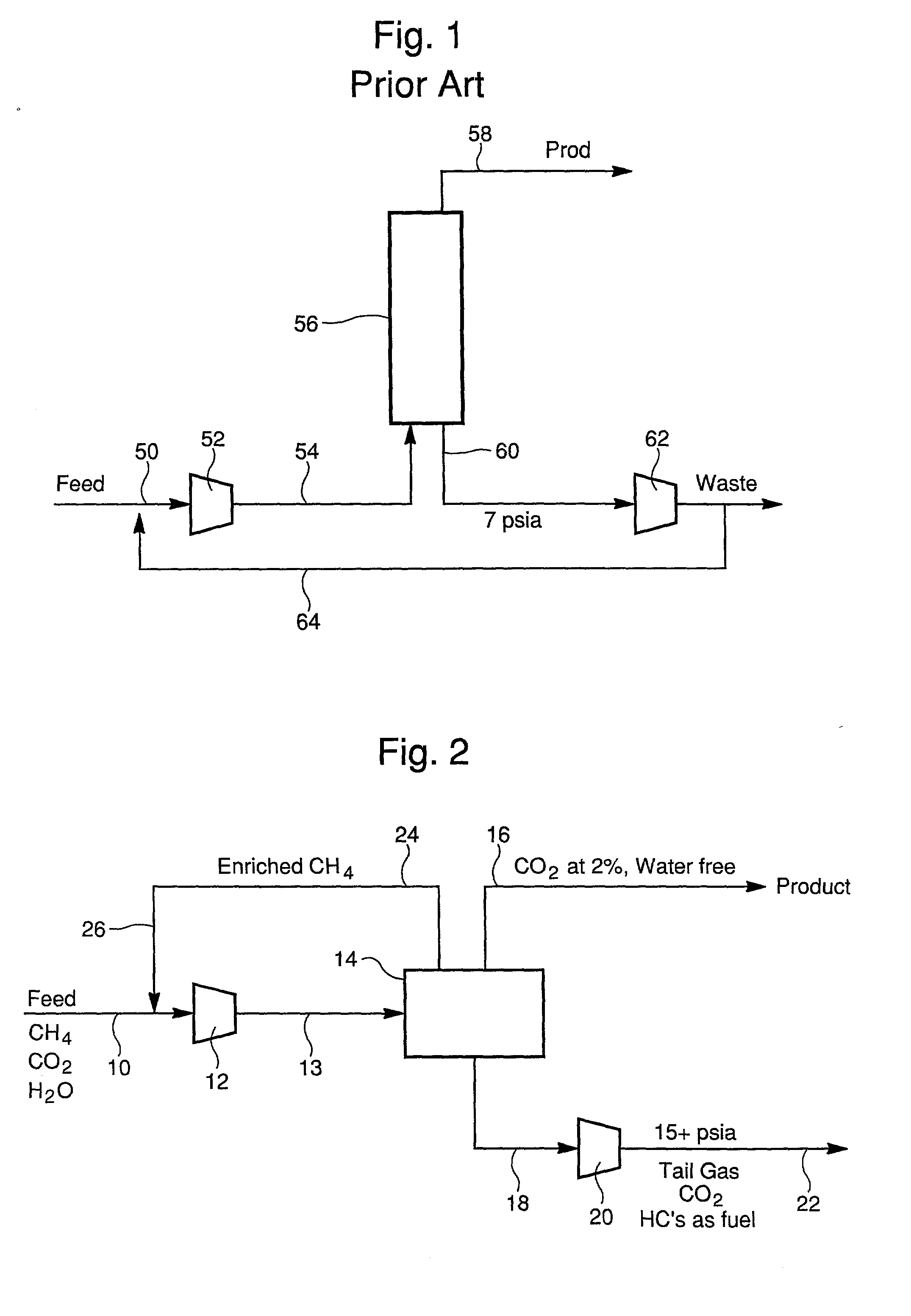

CO2 rejection from natural gas

An improved pressure swing adsorption process is provided for removing or separating a gas from a mixture of gases. The PSA process comprises selectively adsorbing a gas from the mixture to form a product gas having a reduced concentration of the selectively adsorbed gas and a low pressure purge stream containing a higher level of the selectively adsorbed gas than contained in the mixture. During regeneration of the adsorbent a co-current recycle stream is provided which has a pressure less than the product stream, but greater than the purge stream for recycle to feed so as to minimize loss of the product gas to purge. The PSA process is particularly useful for removing carbon dioxide from coal bed methane.

Owner:ENGELHARD CORP

Method for coal bed methane mining by multi-element thermal fluid foam displacement

ActiveCN103061730AImprove permeabilityHard to getOther gas emission reduction technologiesFluid removalHigh pressure waterHigh pressure

The invention discloses a method for coal bed methane mining by multi-element thermal fluid foam displacement. Multi-element thermal fluid is injected into a coal bed of an injection-production well group through an injection well, and foaming agent is injected at intervals. A multi-element thermal fluid foam slug is formed in the coal bed to displace the coal bed methane in order to improve the recovery efficiency of the coal bed methane. The method specifically includes that extracted coal bed methane is compressed and mixed with compressed air, and then the mixture is injected into a multi-element thermal fluid generation device for ignition, extracted processed ground water is mixed to produce the multi-element thermal fluid mainly with high-temperature and high-pressure water vapor and mixed gas of carbon dioxide and nitrogen, the produced multi-element thermal fluid is injected into the underground coal bed through the injection well, a foaming system composed of preferred alkyl ether sulfonate and corrosion inhibitor is injected from an oil jacket annulus at intervals, the multi-element thermal fluid foam slug is formed under the ground to displace the coal bed methane, and water is drained and gas is recovered from a production well. The method has the advantages that fuel is easy to obtain, principles are clear and distinct, and the like, and can provide guidance for implementation of well stimulation of the coal bed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

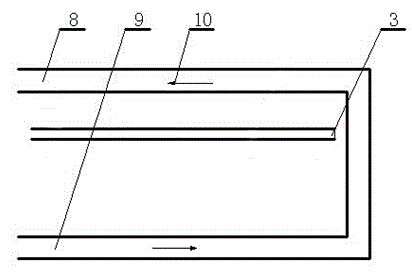

Drainage method of non-cell-cementation cased-hole-completion coal bed gas horizontal well

ActiveCN107387034AAvoid pollutionImprove fracturing effectFluid removalSand blastingProduction effect

The invention discloses a drainage method of a non-cell-cementation cased-hole-completion coal bed gas horizontal well. The method includes: a U-shaped butted well is used, the horizontal section of the horizontal well is deployed along the declination direction of a coal bed and a direction parallel to the minimum main stress of the coal bed, and well completion is performed by using casing running and an external self-expansion casing packer in a non-cell-cementation manner; the setting section, perforation and fracturing section of the external casing packer of the horizontal well are optimized; perforation is performed in a large-displacement and fixed-direction hydraulic abrasive perforation manner, and slug insertion type sand-carrying fracturing is performed on the horizontal well section by section in a large-displacement, large-scale, high-prepad-fluid-ratio and medium-sand-ratio manner; draining is performed at the wellhead of a drainage vertical well, and gas production is performed at the wellhead of the horizontal well. The drainage method has the advantages that pollution of a coal reservoir and production and operation costs can be lowered, the fracturing transformation effect and draining and gas production effect of the non-cell-cementation cased-hole-completion horizontal well are improved, the drainage efficiency and effect of the horizontal well are increased, the coal bed gas content of soft, broken and low-permeability coal beds can be lowered in a large-range and fast manner, and intensified coal bed gas drainage is achieved.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

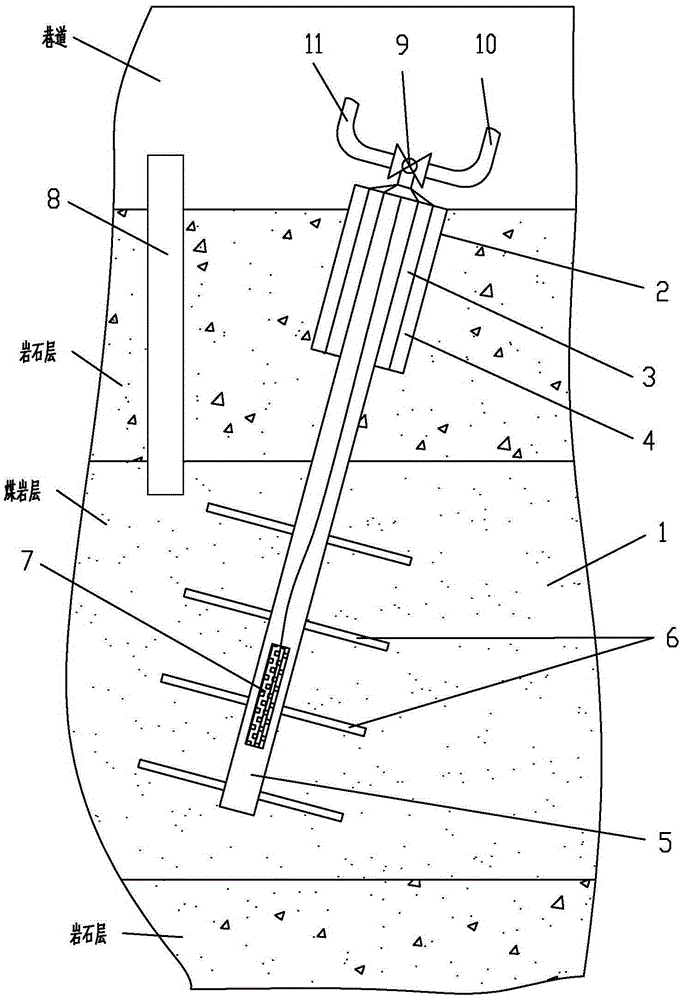

Method for extracting coalbed gases from coal mines by upper and lower combination

The invention relates to coalbed gas mining technology, in particular to a method for extracting coalbed gases from coal mines by upper and lower combination. The method solves the problem of poor gas drainage effects through surface well drilling and hole drilling in the coalbed. The method comprises the following steps: constructing extraction drilled wells on the surface, constructing underground directional long drilled holes in the coalbed, crosslinking the fracture areas of the extraction drilled wells with the drainage areas of the underground directional long drilled holes, then effectively sealing the underground directional long drilled holes in the coalbed, then utilizing fracturing equipment on the surface to fracture the drainage areas drilled on the surface and the drainage areas of the long drilled holes in the coalbed via the extraction drilled wells and finally carrying out extraction. The method has the advantages of improving the extraction rate and efficiency of the coalbed gases and shortening the construction period of the coalbed gas extraction engineering.

Owner:山西蓝焰煤层气集团有限责任公司

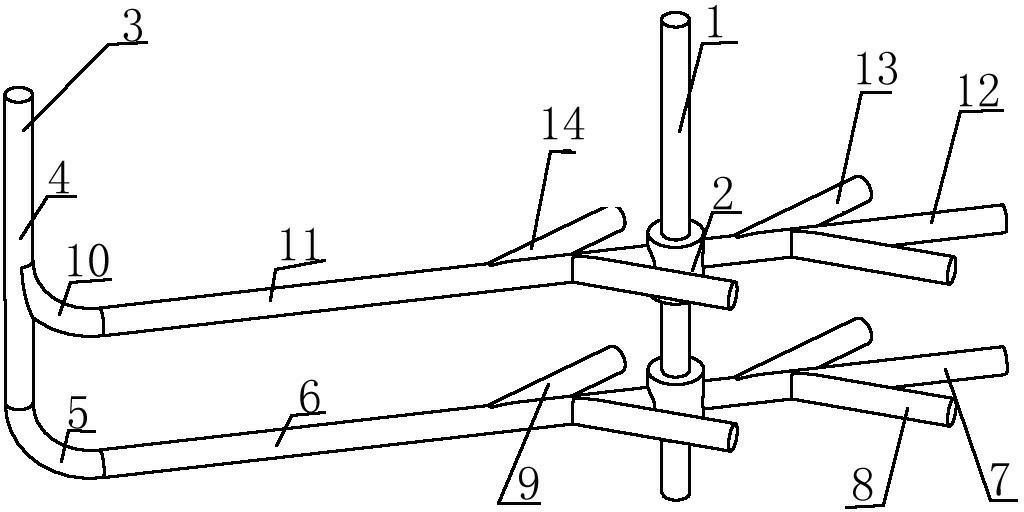

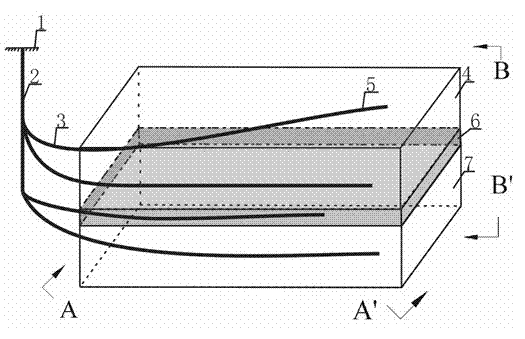

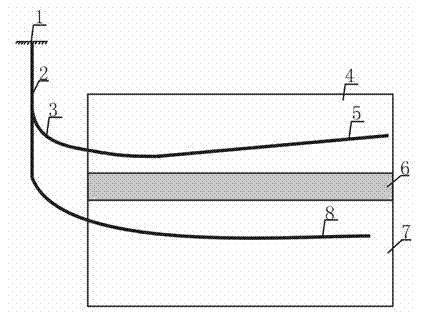

Coal-bed gas well vertical three-dimensional united extraction method

ActiveCN104131831ASolve the extraction problemDoes not affect normal safe miningGas removalButt jointProduct gas

A coal-bed gas well vertical three-dimensional united extraction method comprises the steps that a horizontal well and a vertical well are connected in a butt-joint mode in a transition area between a fractured zone and a curved sinking zone, and the horizontal section of the horizontal well is properly close to the return airway side of a stope working face; a large-diameter extraction pipe with the diameter larger than 200 mm is adopted, segmentation hydraulic fracturing, segmentation sealing and the gradient negative pressure extraction technology are used, and different extraction wells are selected to conduct coal-bed gas extraction in different coal mining stages. According to the method, after coal stoping, synchronous extraction in different zones can be achieved in time, three-dimensional type extraction in different zones can be achieved in space, the coal-bed gas extraction efficiency is improved, meanwhile, surrounding rock gas of top plates of a coal bed can be extracted, and the united extraction of different types of gases and multiple purposes of one well are achieved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com