Physical simulation method of coal-bed gas well hydraulic fractures

A hydraulic fracturing and physical simulation technology, applied in the field of physical simulation, can solve problems such as inability to fully detect cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

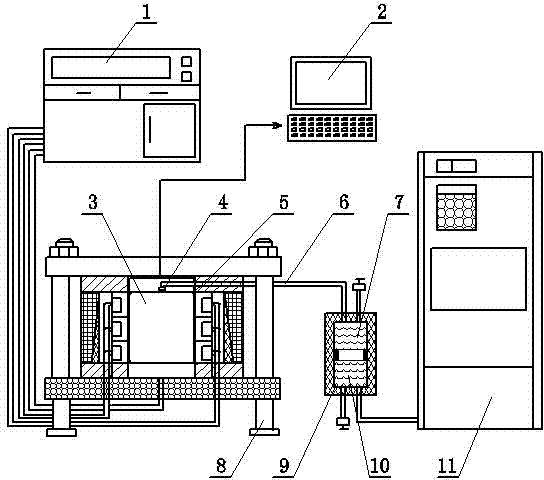

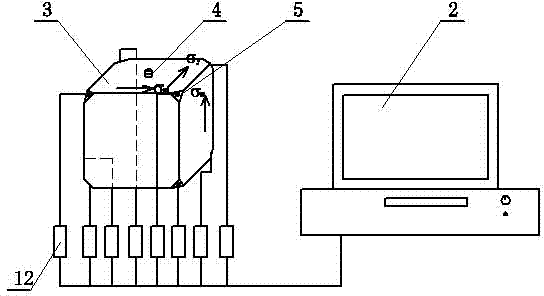

[0020] In the figure, a physical simulation method for hydraulic fracturing of a coalbed methane well, including a hydraulic pressure stabilizer 1, an acoustic emission receiver 2, a fracturing test piece 3, a simulated wellbore 4, an acoustic emission probe 5, a fracturing fluid pipeline 6, and a guanidine Glue fracturing fluid 7, true triaxial simulated fracturing test stand 8, oil-water isolator 9, oil 10, console 11, acoustic emission signal amplifier 12; the simulation method is provided with a true triaxial simulated fracturing test stand 8, so A fracturing test piece 3 with a simulated wellbore 4 is placed inside the real three-axis simulated fracturing test frame 8, and the eight corners of the fracturing test piece 3 are tightly bonded with plastic, respectively, with acoustic emission probes 5 and acoustic emission probes 5 An acoustic emission receiver 2 is connected through an acoustic emission signal amplifier 12; a hydraulic pressure stabilizer 1 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com