Patents

Literature

1878results about How to "Implement test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

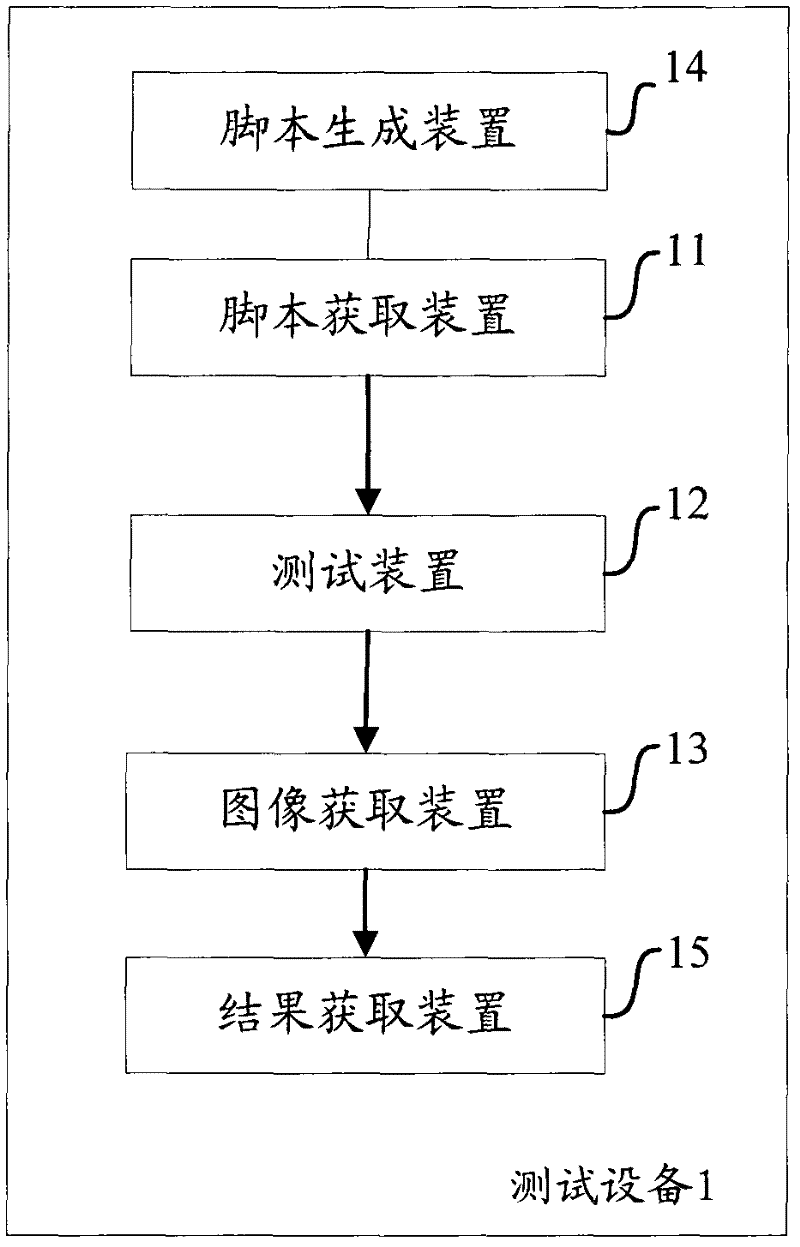

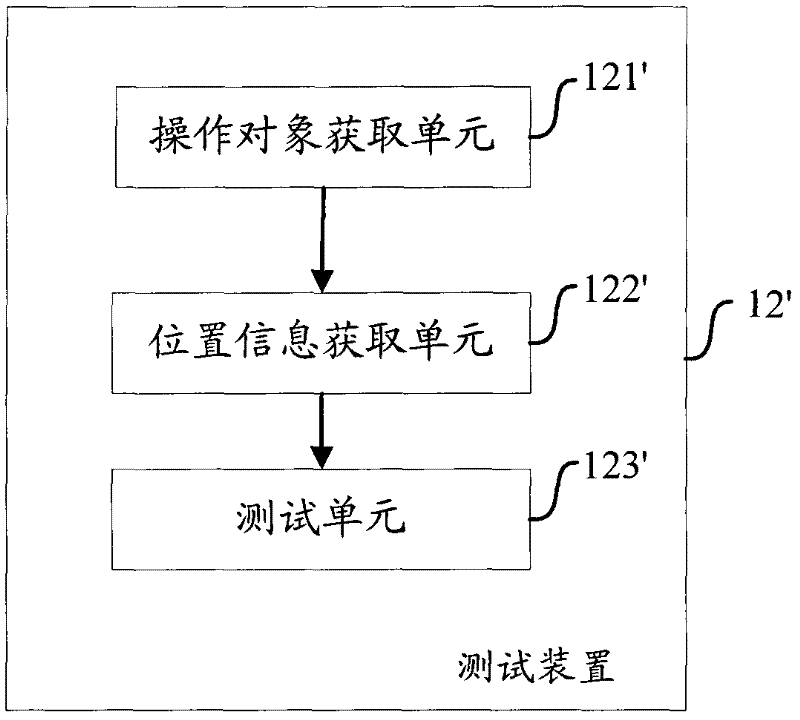

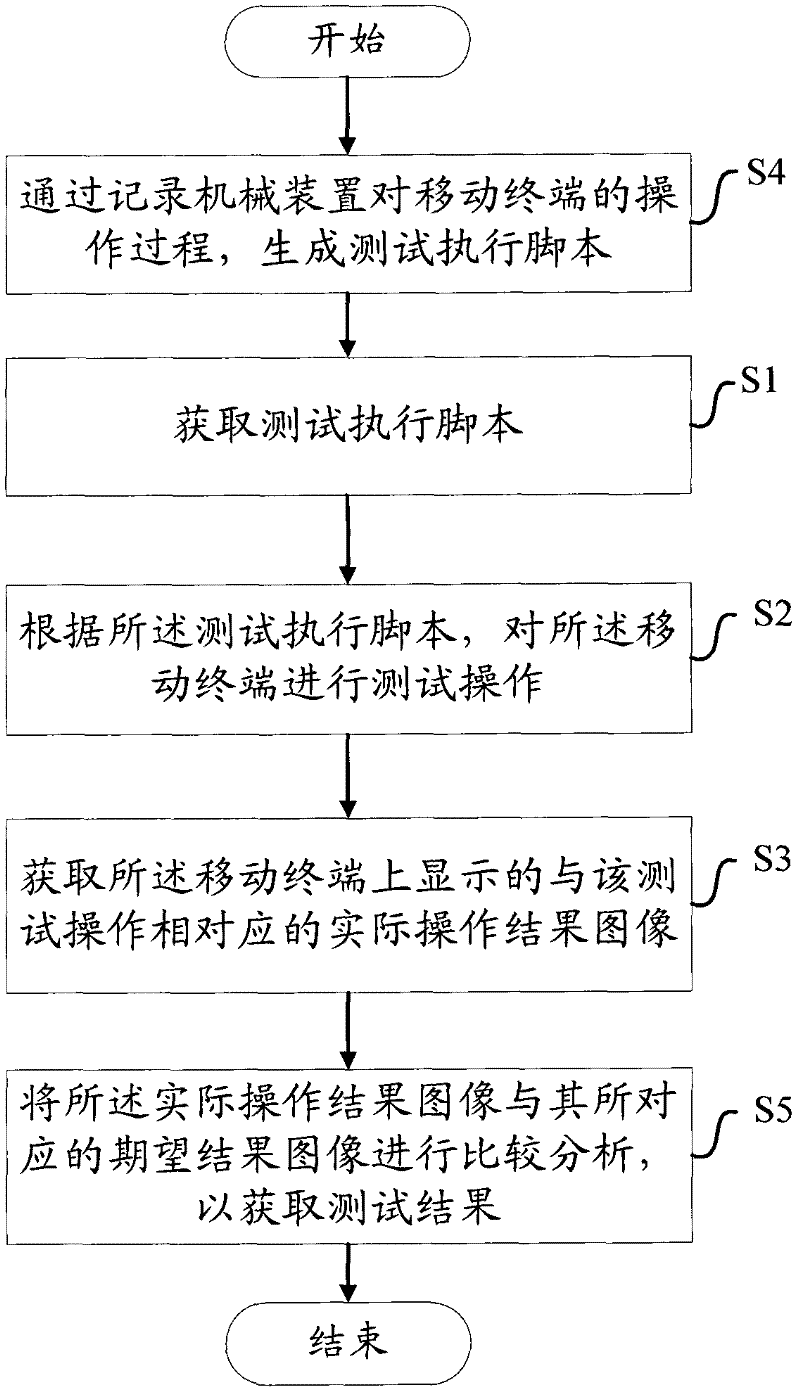

Method and equipment for testing mobile terminal

ActiveCN102314386AImplement automated testingImplement testDetecting faulty computer hardwareComputer hardwareTest efficiency

The invention aims to provide a method and equipment for testing a mobile terminal. The test equipment is used for testing the mobile terminal by generating a test executing script and acquiring a test executing script to obtain a practical operating result image which is displayed on the mobile terminal and corresponds to test operation, and is further used for comparing the practical operating result image with a corresponding desired result image to obtain a test result. Compared with the prior art, the invention has the advantages that: test operation is directly performed on the mobile terminal in a way of recording the operating process of a mechanical device on the mobile terminal for generating and obtaining the test executing script and the like to realize automatic test of a mobile phone, so that the same effect of manual test is achieved without artificial participation, comprehensive test of multiple models is realized through an image recognition technology, the test quality is improved greatly, the test efficiency is increased greatly, and the test cost is further lowered.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

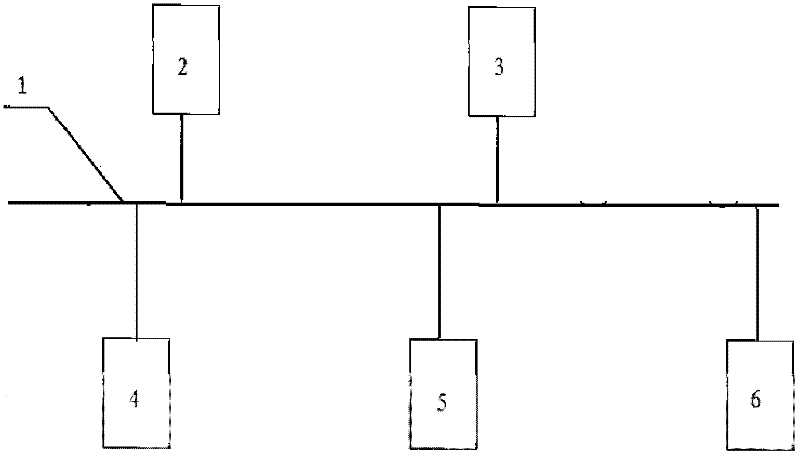

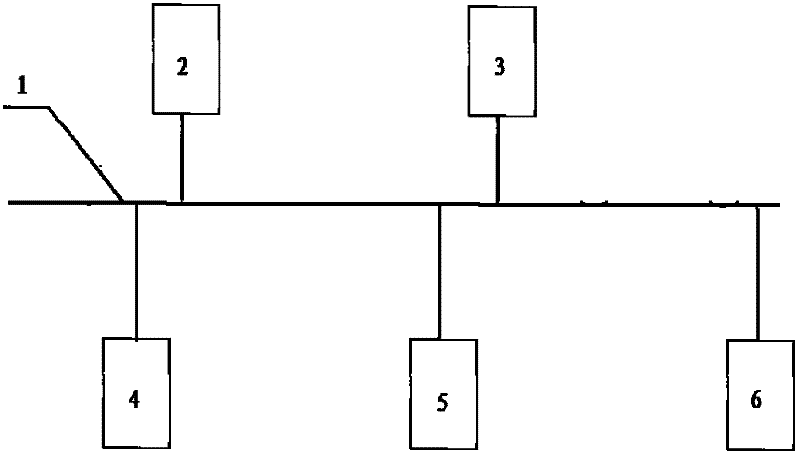

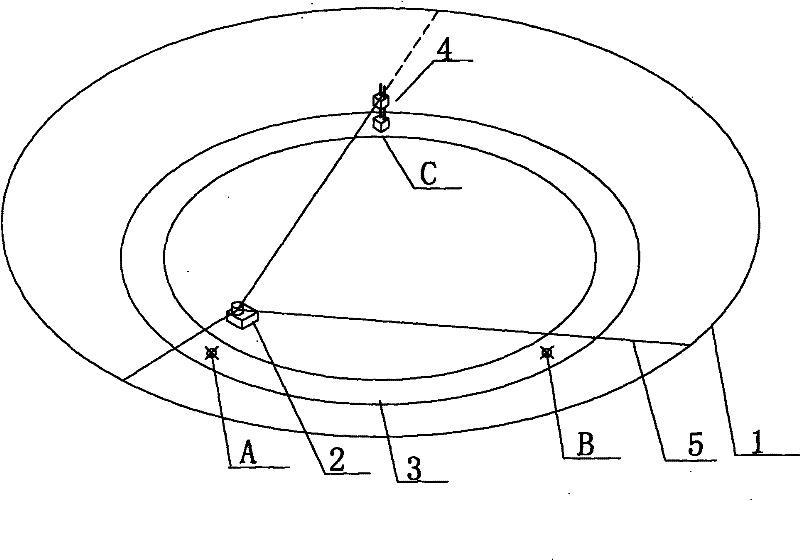

CBTC (Communications Based Train Control) signal system simulation testing platform

The invention provides a CBTC (Communications Based Train Control) signal system simulation testing platform, which comprises a signal bus, a simulation vehicle-mounted and simulation vehicle system, a simulation station, a simulation rail side system, a three-dimensional vision system and a testing platform management system, wherein the simulation vehicle-mounted and simulation vehicle system, the simulation station, the simulation rail side system, the three-dimensional vision system and the testing platform management system are mutually connected through the signal bus. By applying the invention, an integral solution including vehicle, scheduling and signal systems can be checked and demonstrated; a signal system can be subjected to function and performance tests indoors, and failure injection conditions which can not be simulated in various sites can be carried out indoors, thus testing means are enriched and safety of the system is improved; and simulation checking under the condition of multiple vehicles can be passed, a method for analyzing the railway operation capability is deeply researched, and the reference is provided for the layout of signal devices.

Owner:TRAFFIC CONTROL TECH CO LTD

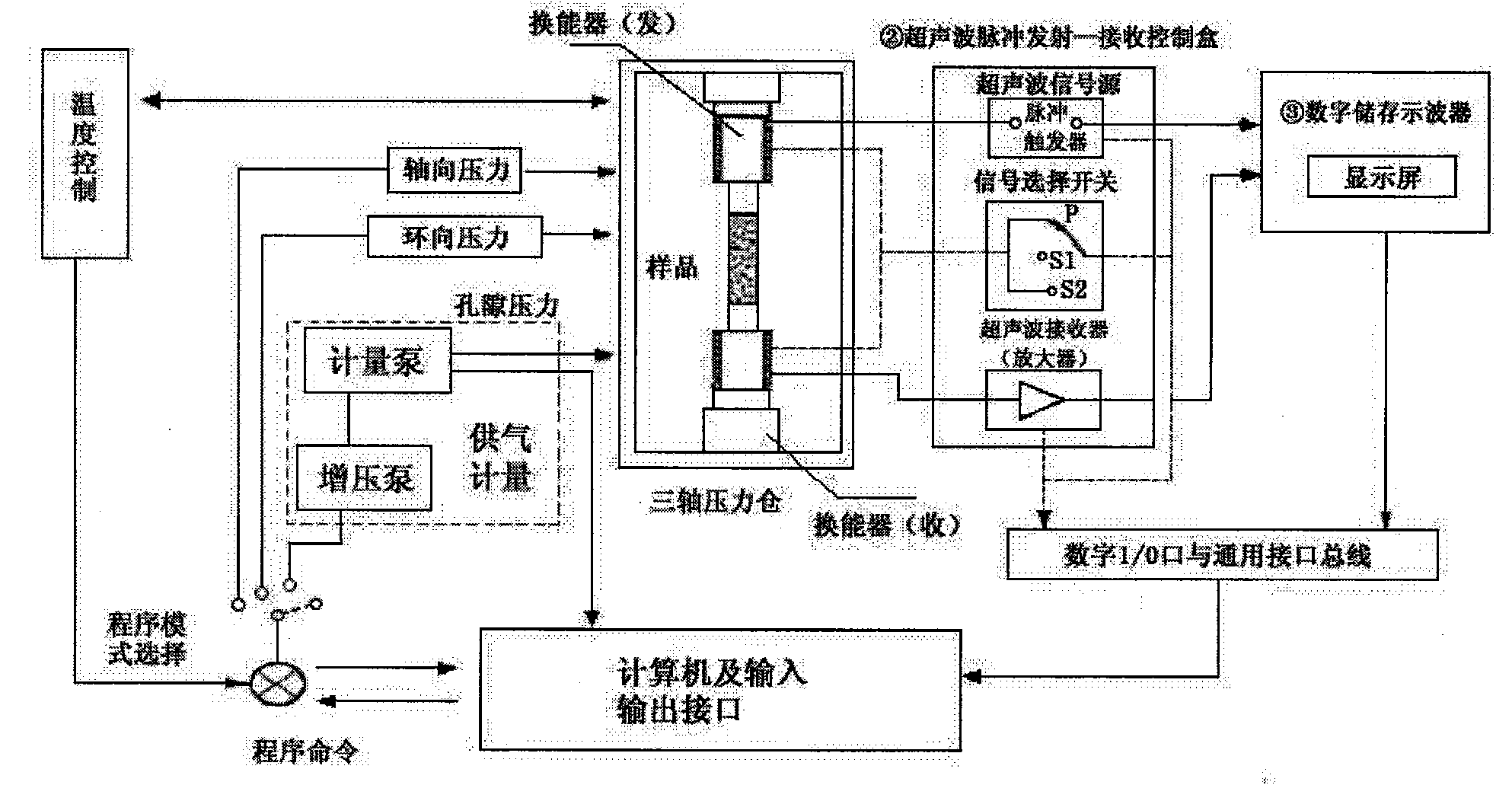

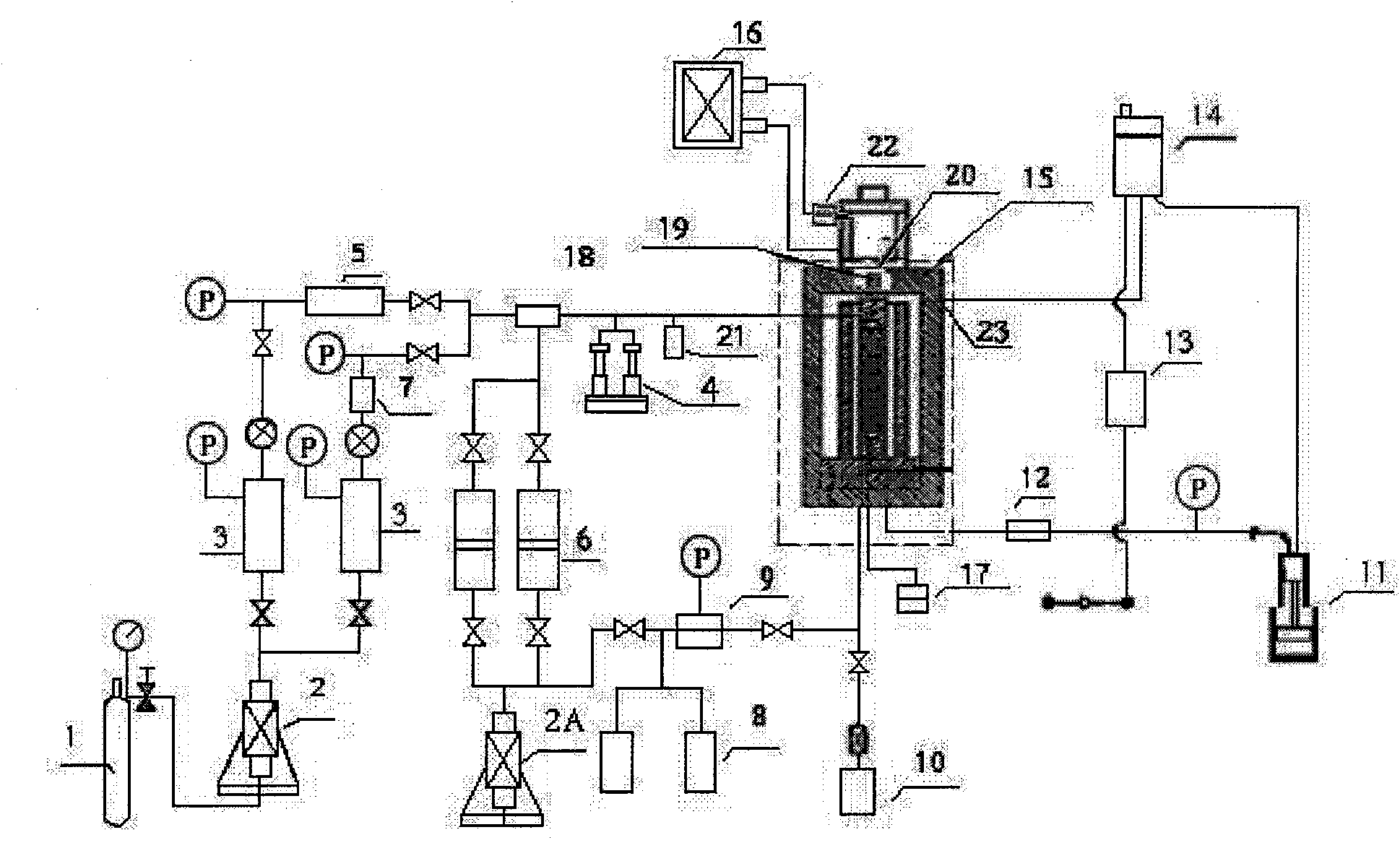

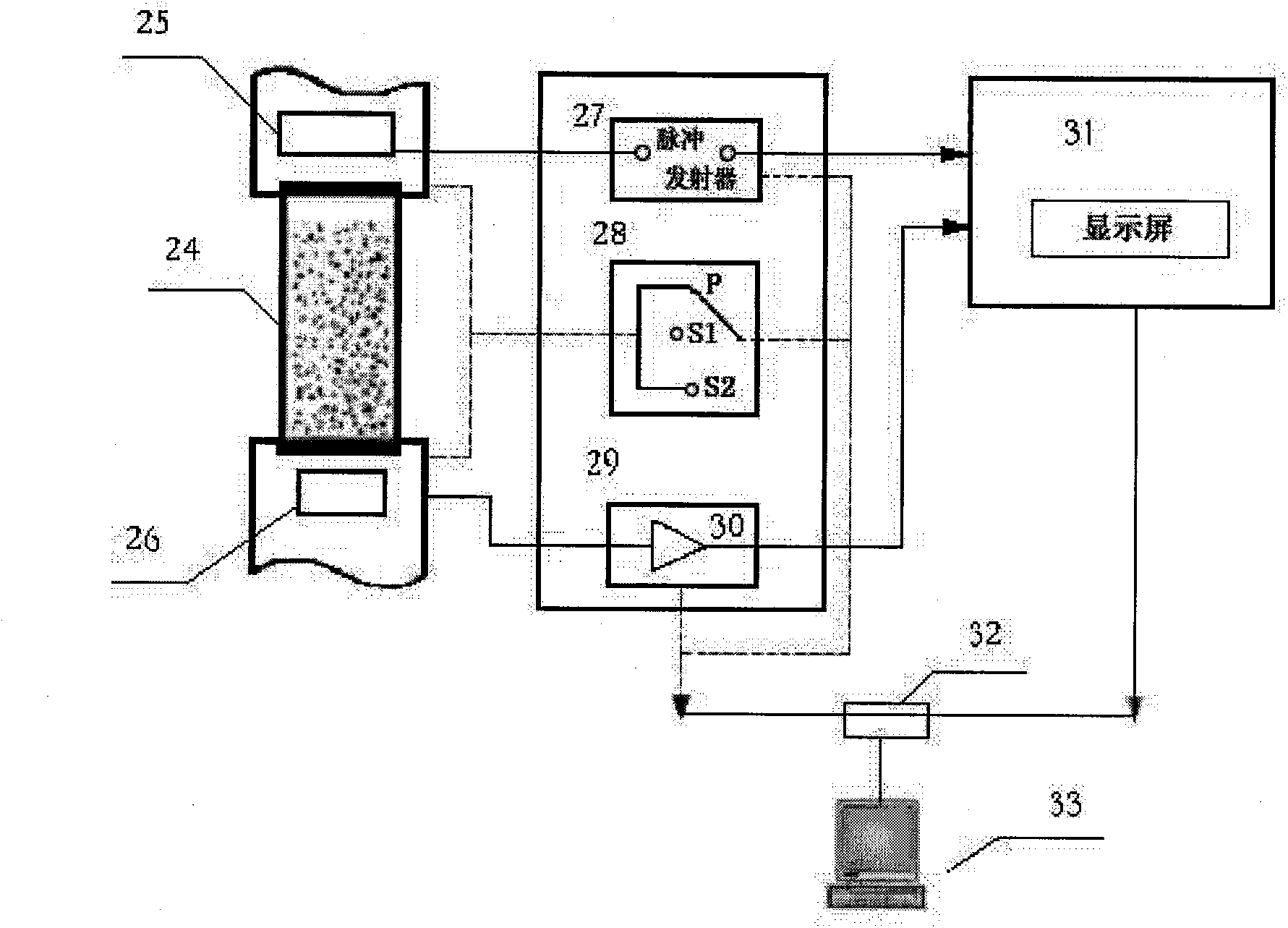

Rock sample detection and data acquisition system and method and application thereof

InactiveCN102053253ATo overcome the insufficiency of the experiment of the physical parameters of coal and rock after the adsorption of gas is difficultImplement testMaterial strength using tensile/compressive forcesSeismic signal receiversUltrasonic sensorData acquisition

The invention relates to a rock sample detection and data acquisition system. The system can realize elastic parameter test of a rock sample in the state of gas adsorption; in the system, a three-shaft pressure cabin is connected with a gas supply and metering control device for absorbing samples in the cabin and accurately metering absorption quantity, moreover, an ultrasonic transducer is installed on a cap of the (high) pressure cabin and integrated with an ultrasonic wave transmitting / receiving device so that the test of elastic parameters of methane absorption on coal can be realized truly. The system can automatically and continuously test in the processes of gas absorption and gas enrichment, thereby ensuring a consistent test environment, acquiring an absorption quantity and elastic parameter relation curve, improving test accuracy and efficiency and saving test time and cost. The rock sample detection and data acquisition system integrates methane enrichment mechanism simulation and rock physical property test, can be applied to seismic prospecting method research on coalbed methane and shale gas, mine advanced detection, coal mine safety research and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

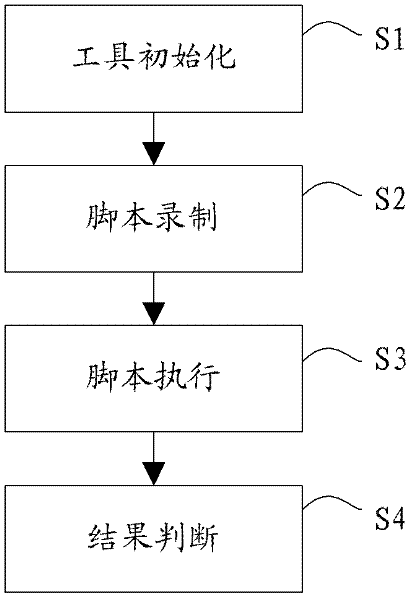

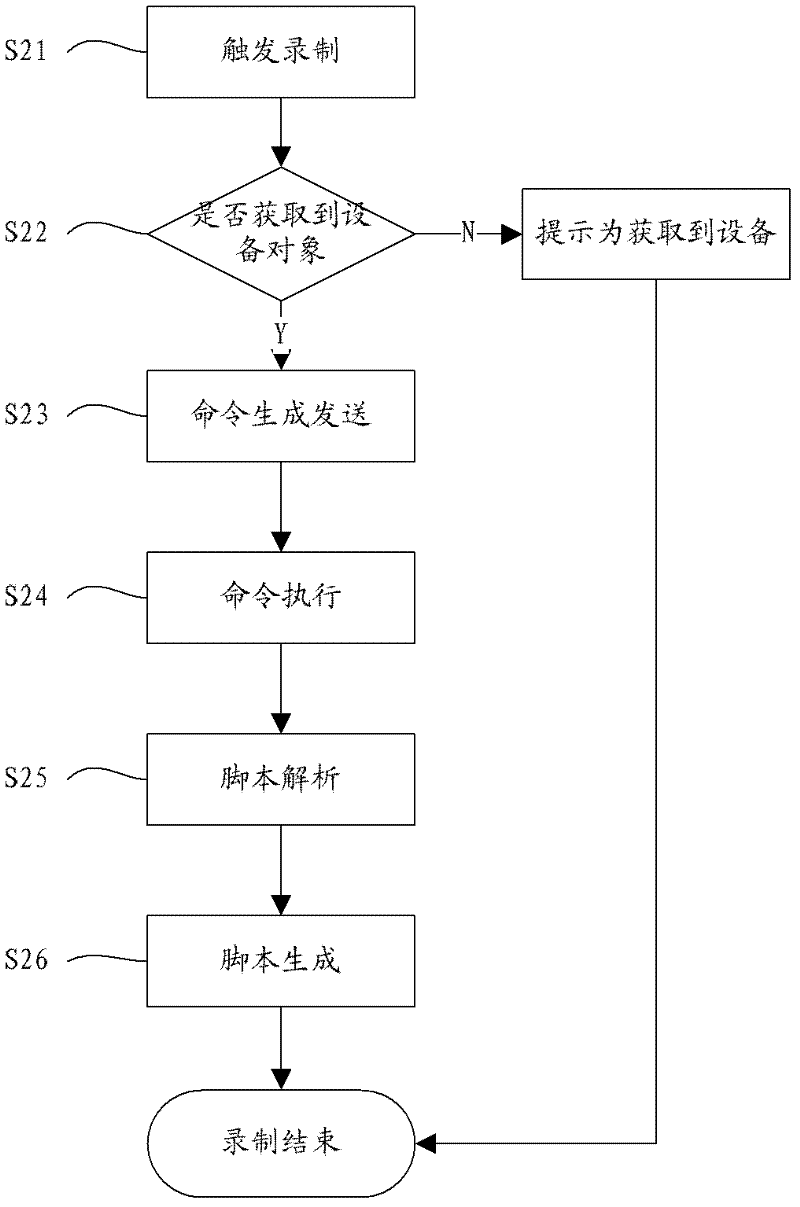

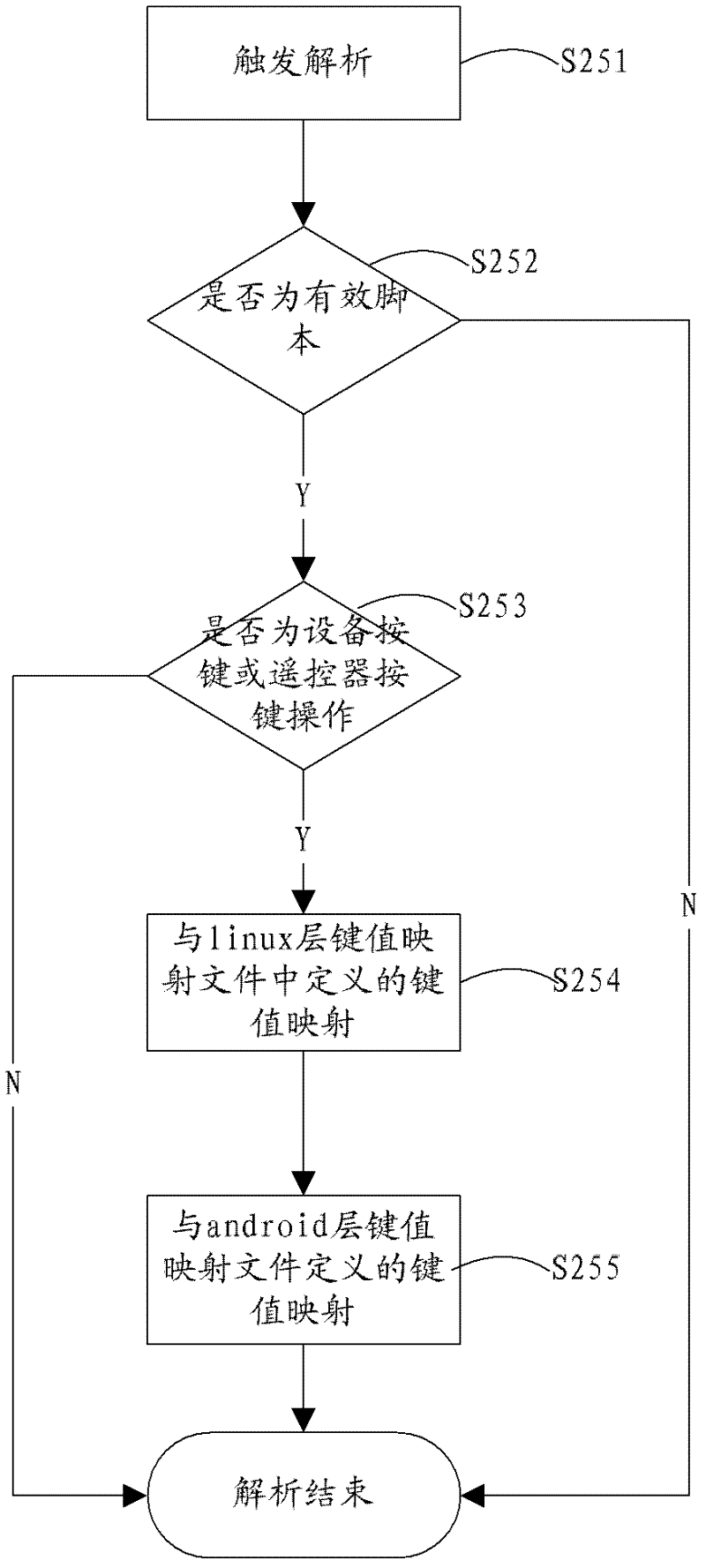

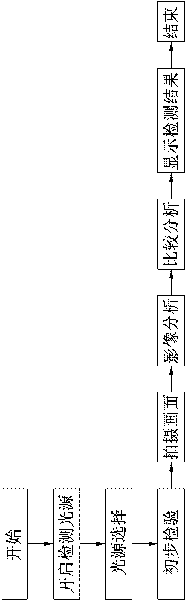

Android-platform-based automated testing method and testing tool

ActiveCN102419732ASave human and material resourcesFull automationSoftware testing/debuggingMaterial resourcesComputer hardware

The invention provides an android-platform-based automated testing method and an android-platform-based testing tool. The testing method comprises the following steps of: script recording: recording operation events and generating an executable script of an android platform; script execution: executing the executable script after an equipment object receives a command for executing the script; and result judgment: judging whether an automated example is adopted according to a script execution result. By adoption of the testing method, the event script is recorded and played back and interface elements are automatically compared to obtain a test result and realize automated testing, and the whole testing process only needs a tester to read the test result, so the method is accurate and fast to implement, and a lot of manpower and material resources are saved. The android-platform-based automated testing method and the android-platform-based testing tool can be used as fast automated testing method and tool which are widely used in the android program test industry.

Owner:SHENZHEN FALCON NETWORK MEDIA CO LTD

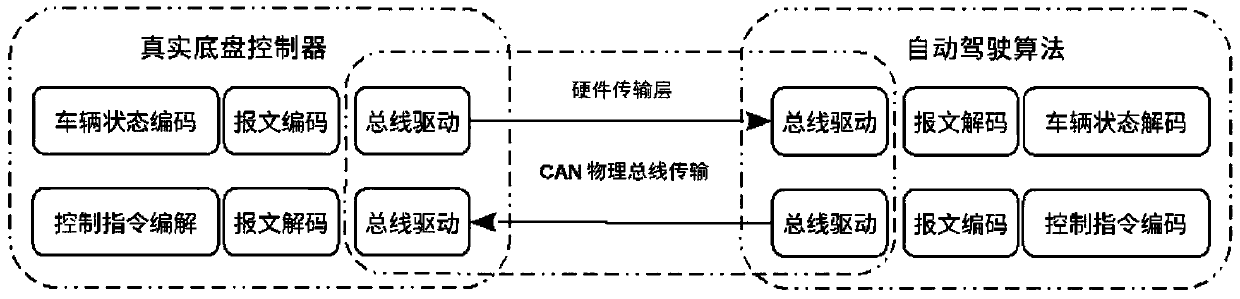

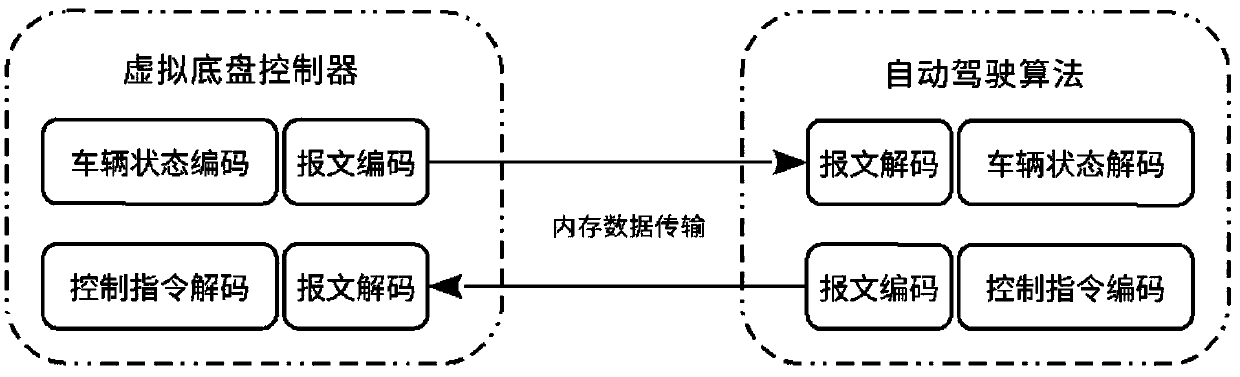

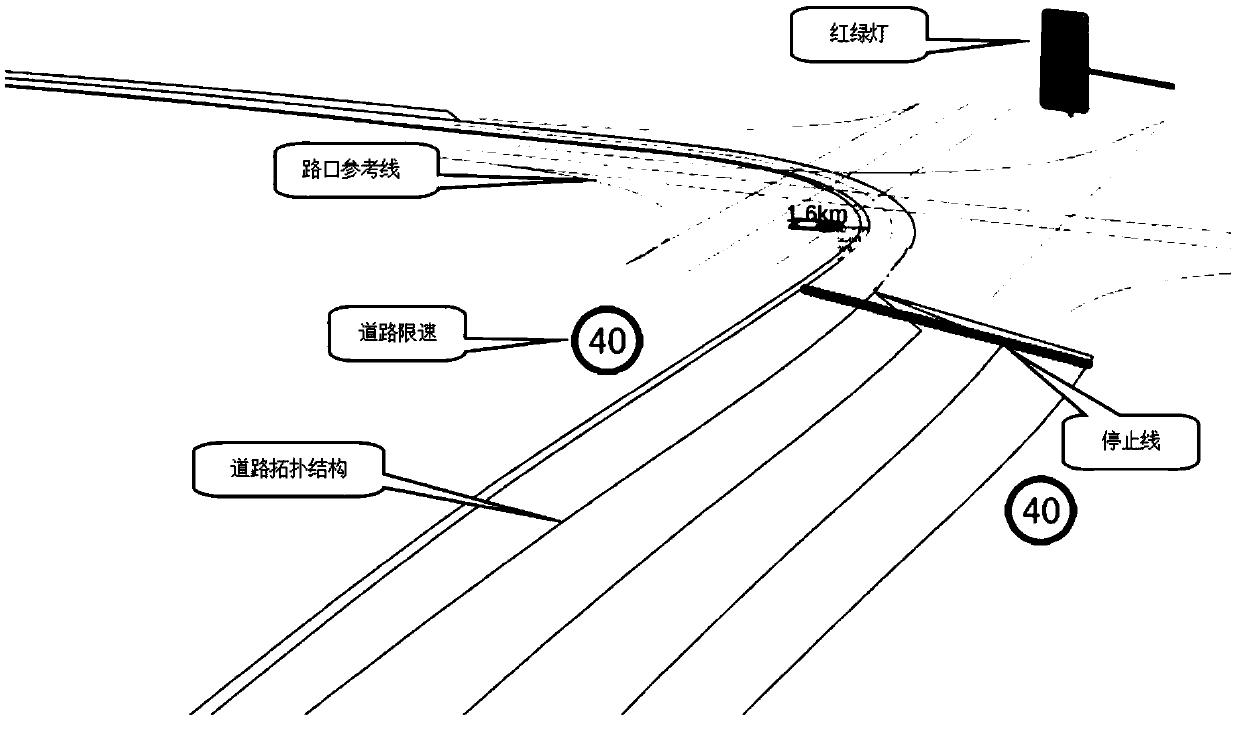

Multifunctional simulation system for automatic driving

ActiveCN108803607AImprove portabilityEfficient verificationPosition/course control in two dimensionsVehiclesVirtual vehicleData interface

The invention provides a multifunctional simulation system for automatic driving. The multifunctional simulation system comprises a virtual vehicle module, a virtual chassis control module, a virtualroad module, a virtual traffic module, a time control unit module and a visualized interactive interface module, the virtual road module provides cartographic information for an automatic driving algorithm and the virtual traffic module, the virtual traffic module provides road conditions including vehicles, pedestrian, traffic lights and the like for the automatic driving algorithm, the automaticdriving algorithm communicates with the virtual vehicle module through a virtual chassis so as to obtain vehicle information and send vehicle control instructions, a visualized interactive interfacesends human-computer interaction information to the simulation system and displays system information in a visualized three-dimensional effect, and finally, the time control unit module controls intervals of simulation time of the simulation system comprising the automatic driving algorithm. Data interfaces of the virtual modules are kept consistent with those of a real system, so that multifunctional modes, including hardware-in-loop simulation, of the simulation system can be realized.

Owner:北京领骏科技有限公司

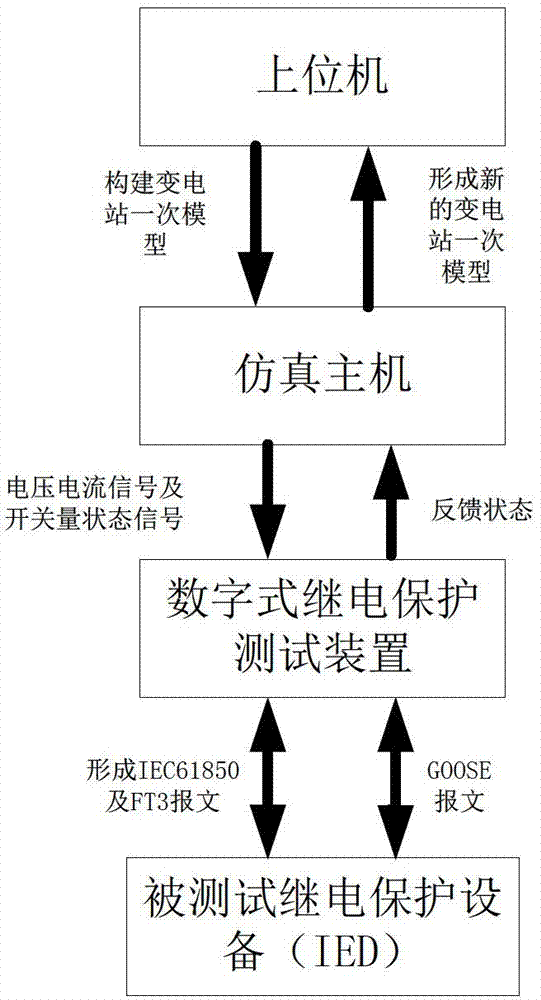

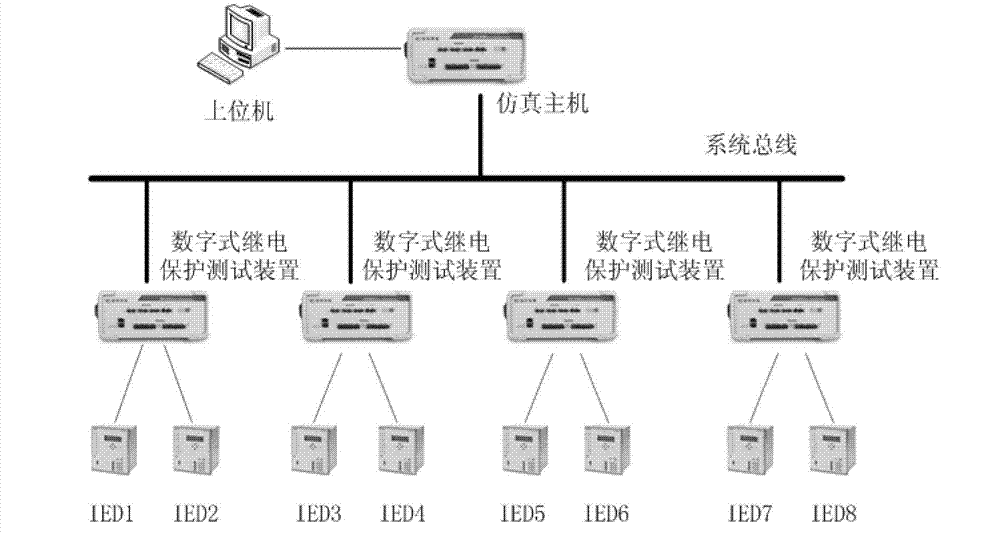

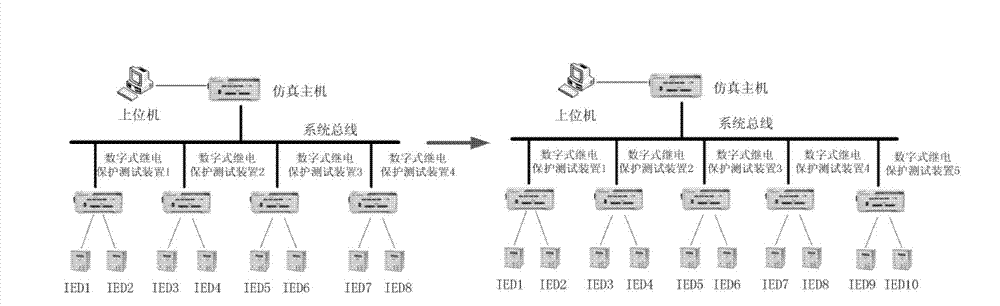

Digital simulation based method and system for testing relay protection function of intelligent substation

The invention discloses a method and a system for automatically testing the relay protection function of an intelligent substation. The simulation system of the entire substation is realized in the mode that a simulation host machine is used for controlling digital relay protection and testing devices, a testing environment is provided, closed-loop testing on intelligent equipment is performed, the intelligent equipment with any scale of the substation can be tested in the mode that the simulation host machine is connected with the digital relay protection and testing devices, when tested equipment is added and the existing simulation system cannot meet the testing scale, the relay protection and testing devices in cascade connection are added to meet the testing requirement for intelligent equipment with larger scale, and besides, testing for a plurality of intelligent equipment can be realized, and the application prospect is better.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

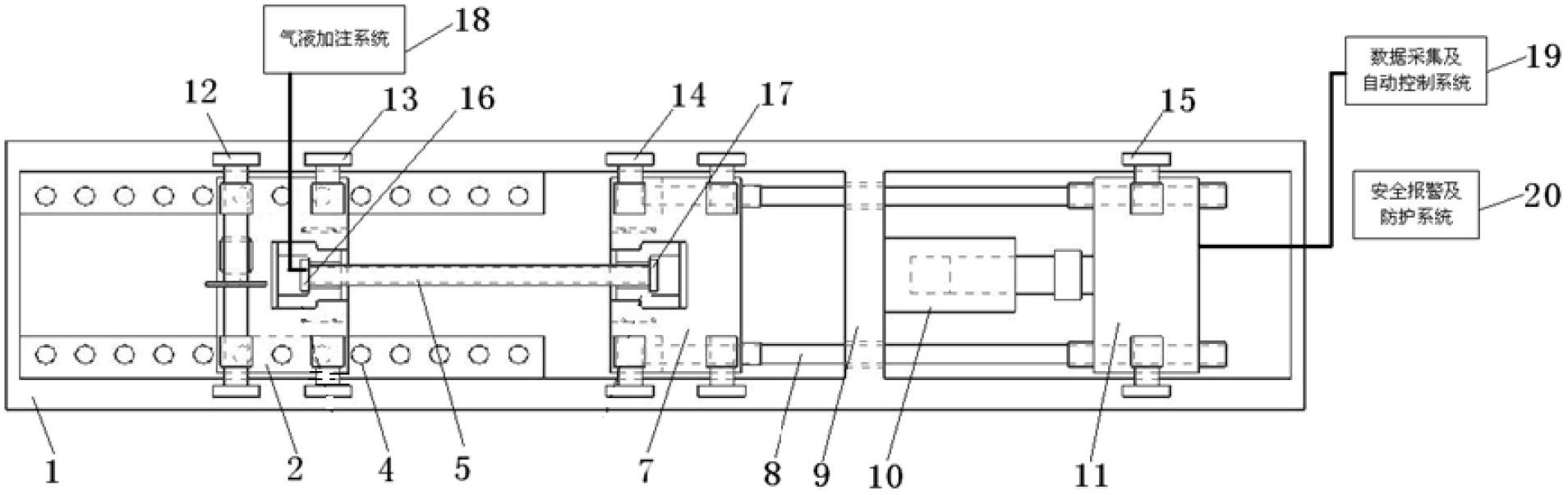

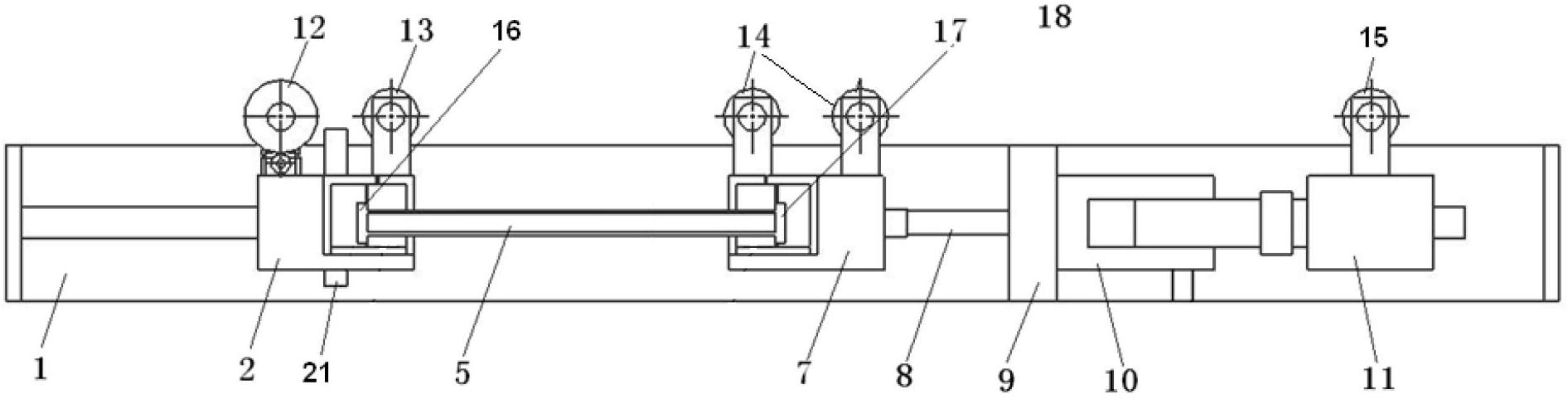

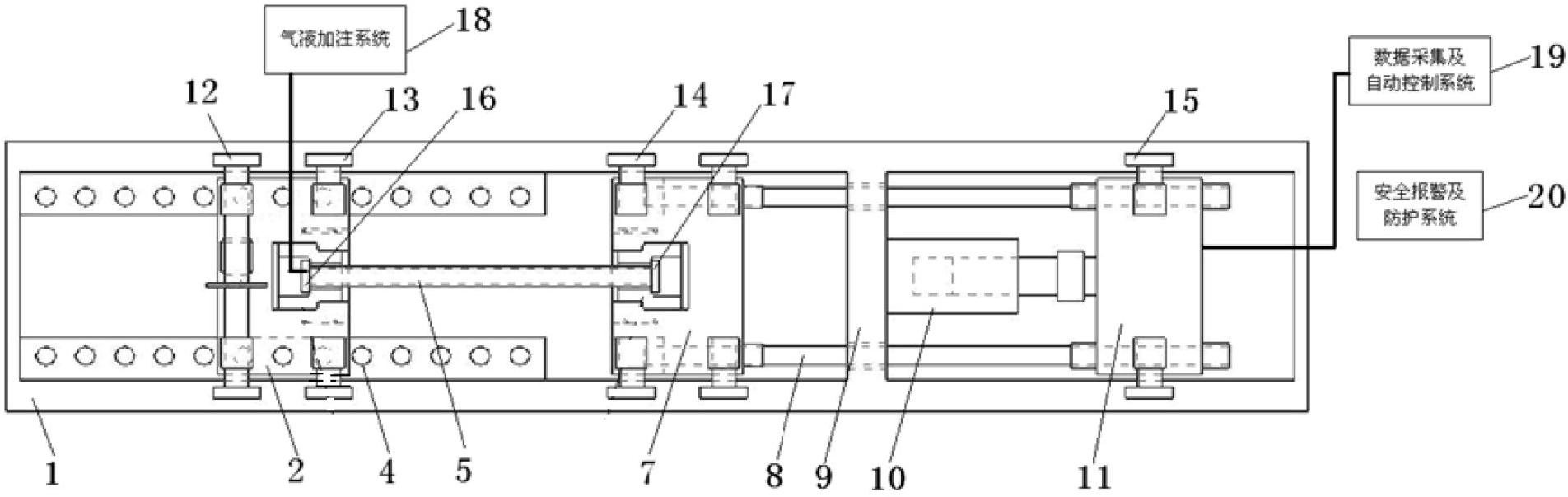

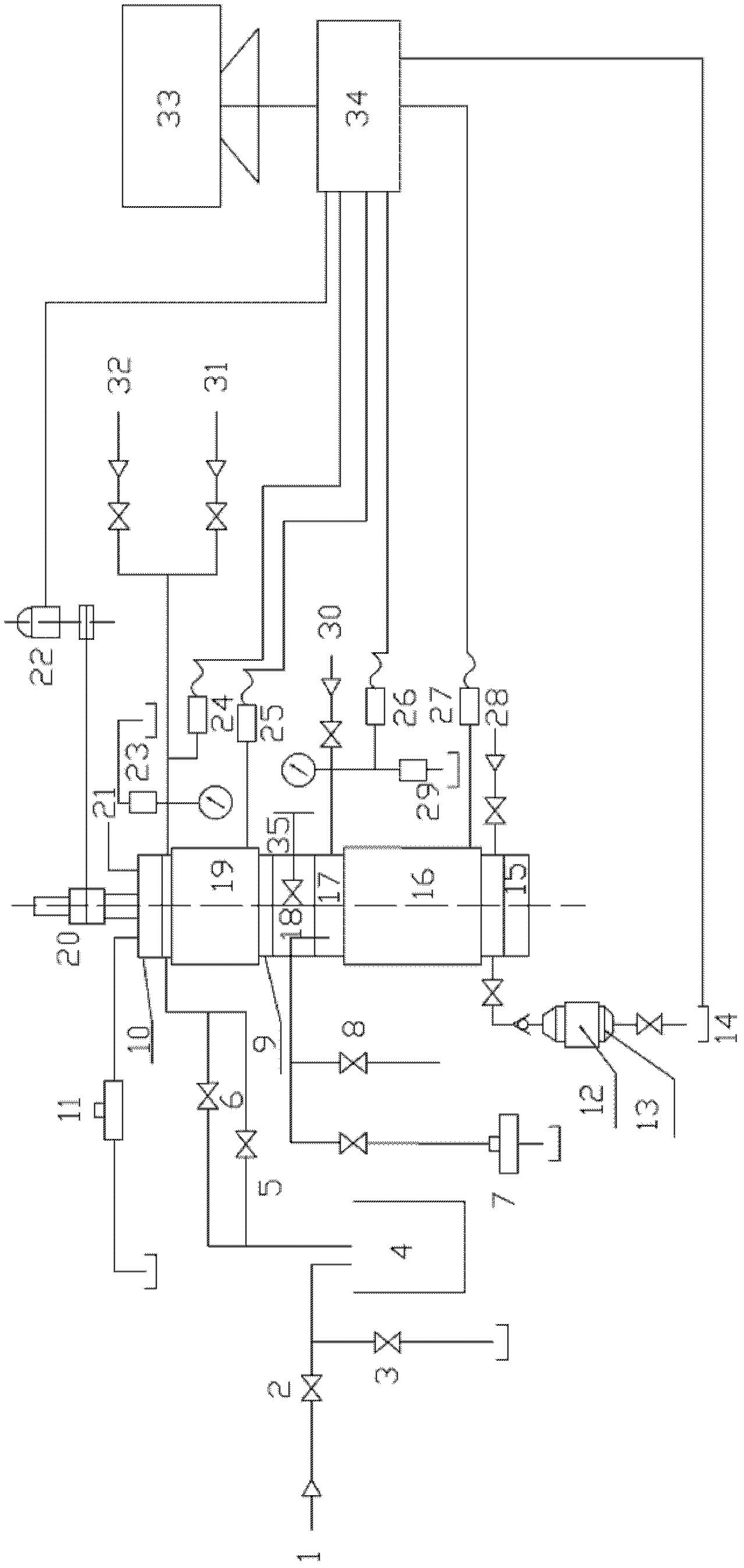

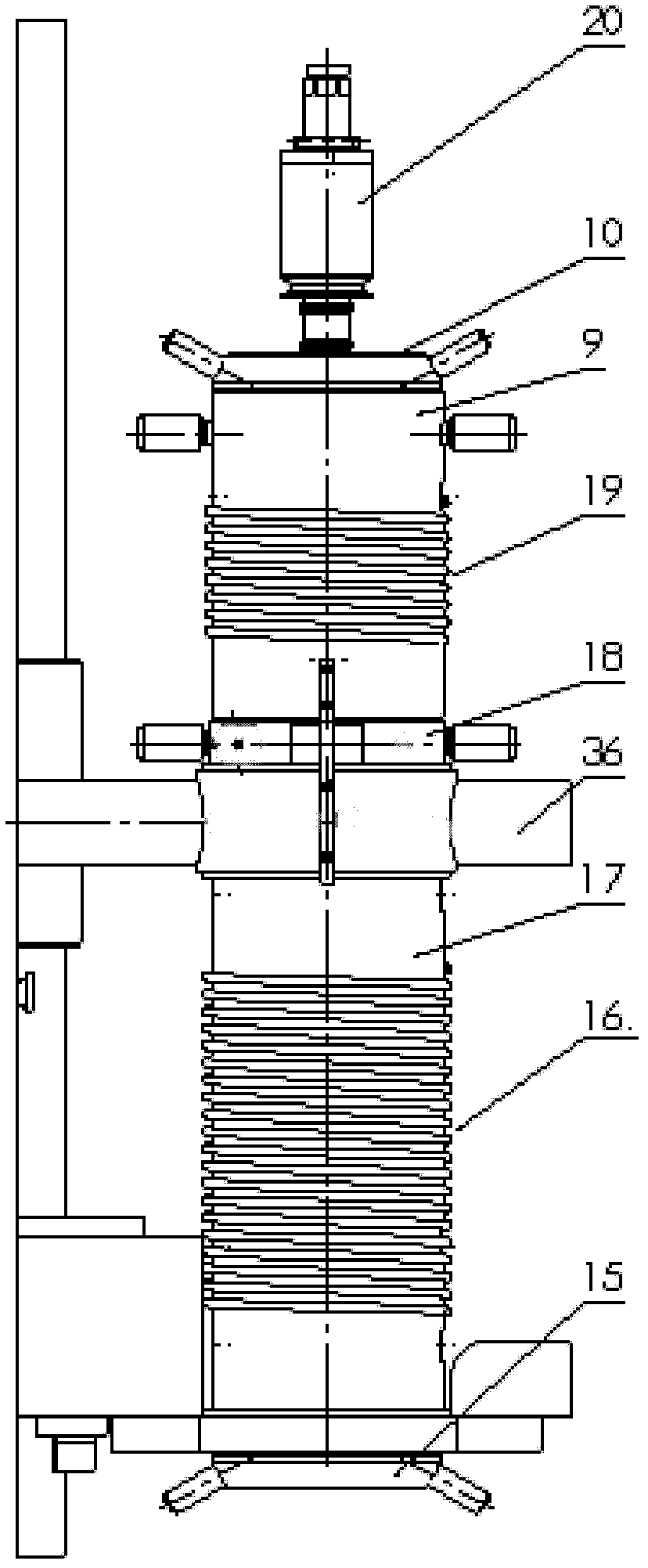

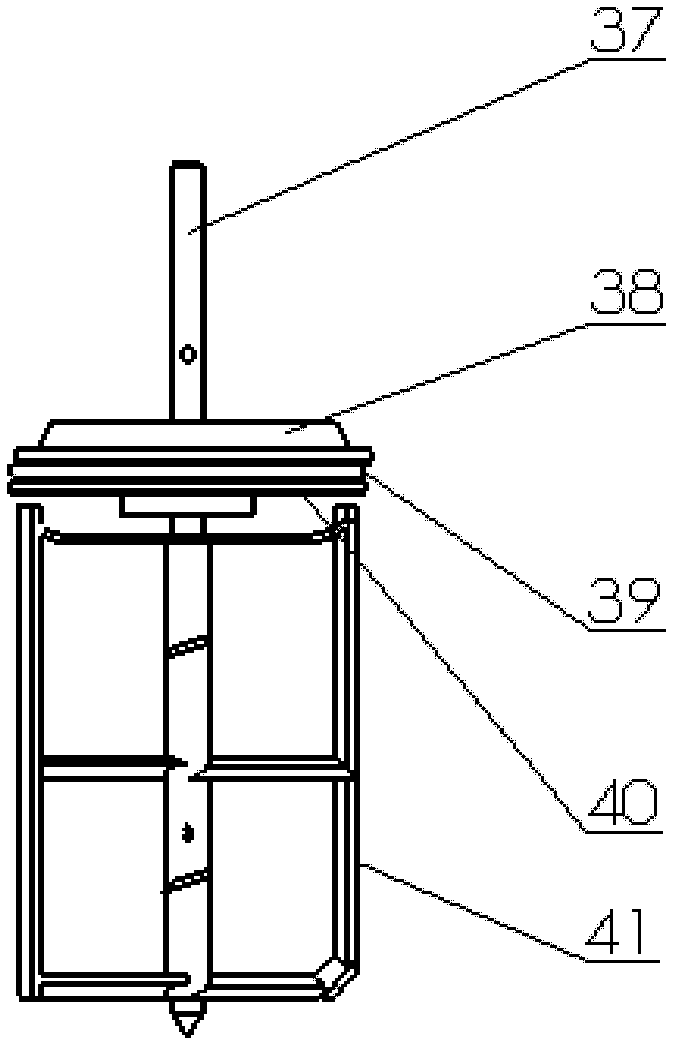

Real stress corrosion testing machine for tubes

ActiveCN102680176AImplement testHigh simulationWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTension stressHigh pressure

The invention discloses a real stress corrosion testing machine for tubes. The real stress corrosion testing machine comprises a main unit frame, a first stretching seat, a gas and liquid filling system, a stress loading component and a stress transmitting component; the main unit frame comprises two parallel side plates; the first stretching seat, the stress loading component and the stress transmitting component are respectively connected with the two side plates of the main unit frame via supporting rolling shafts, and the two side plates simultaneously support the supporting rolling shafts; the first stretching seat and the gas and liquid filling system are simultaneously connected with one end of a tube to be tested, and the stress transmitting component is connected with the other end of the tube to be tested; and the stress loading component is connected with the stress transmitting component via a force transducer, and the other end of the stress loading component is connected with the frame. The real stress corrosion testing machine for tubes can simulate high-temperature and high-pressure corrosion and stress environments of underground oil casings of oilfields, and tests the oil casings and oil tube joints under underground complex work conditions and in axial tensile stress states.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

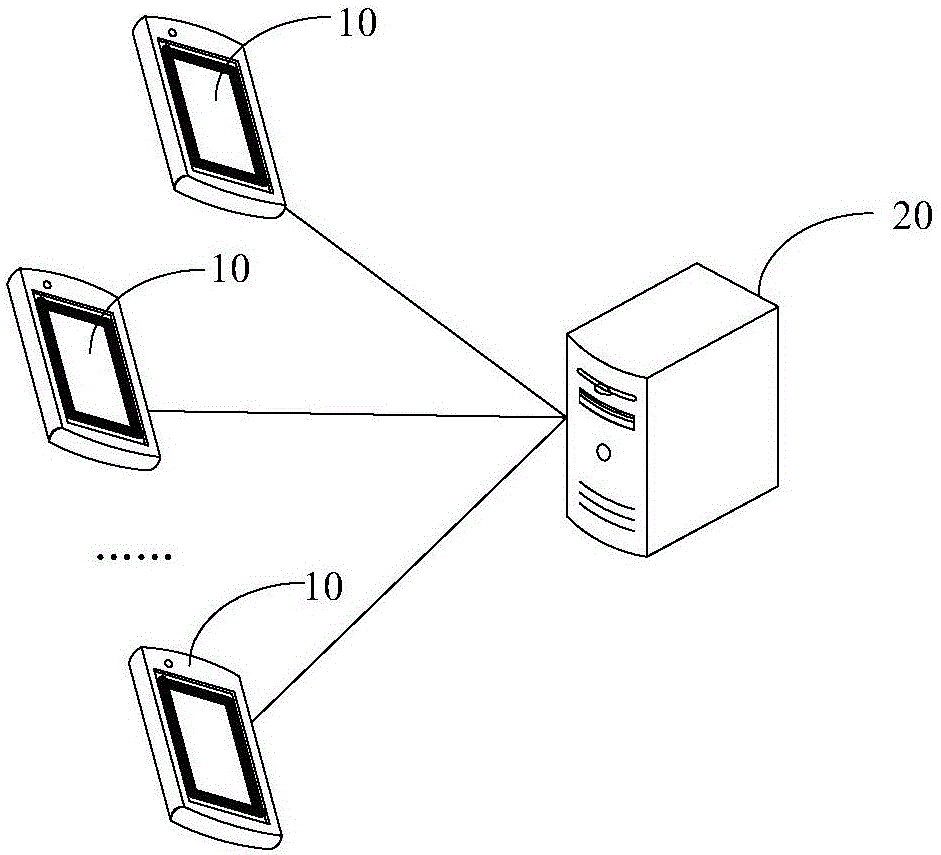

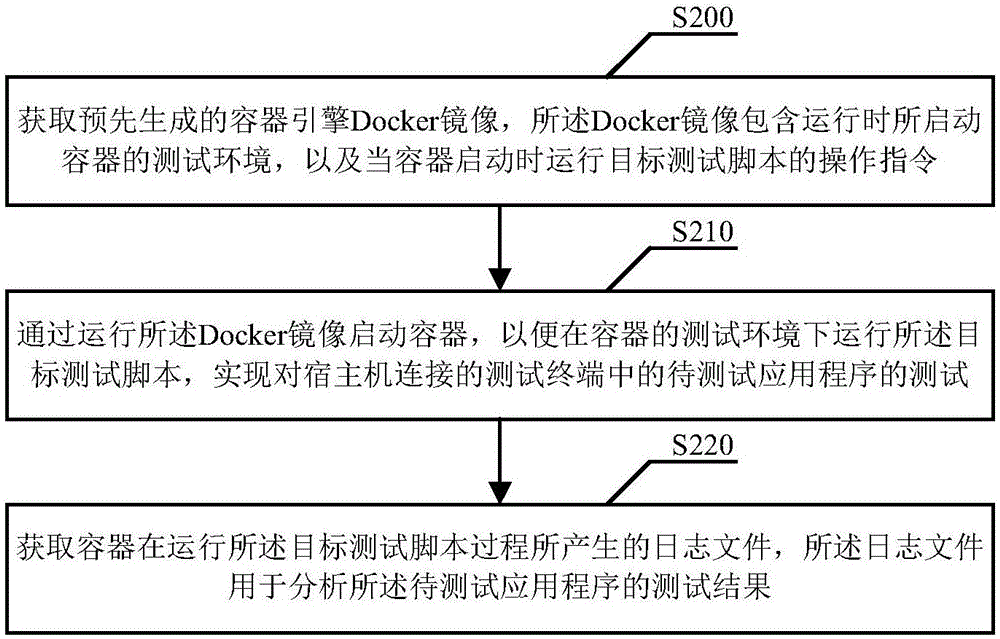

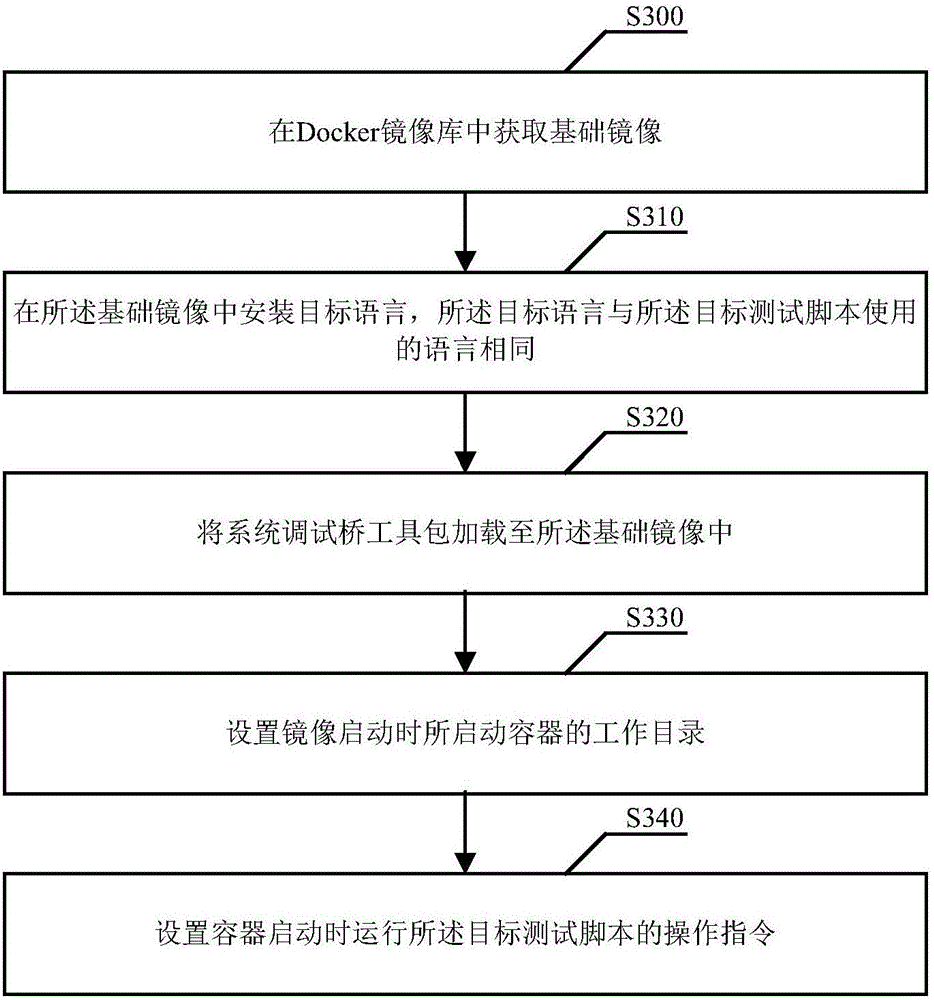

Application program testing method, device and system

InactiveCN106502905AImplement testIndestructibleSoftware testing/debuggingFile systemProgram testing

The invention discloses an application program testing method, device and system. The method comprises the steps of obtaining a container engine Docker mirror image, and executing an operation instruction of a target testing script when a container is started, wherein the Docker mirror image includes testing environment of a container started during operation; executing a target testing script under the testing environment of the container due to the fact that the container is started by operating the Docker mirror image, and achieving testing an application program to be tested in a testing terminal connected with a host machine; obtaining journal files produced when the container executes the target testing script. According to the application program testing method, device and system, the Docker container engine is used for constructing the closed container for the testing script compiled by a developer, by means of the characteristic that the Docker operation environment is completely isolated from the external world, the testing script is executed in the container, testing of the application program to be tested in the testing terminal is achieved, and it is ensured that the testing script cannot damage a file system of the host machine.

Owner:TENCENT TECH (SHENZHEN) CO LTD

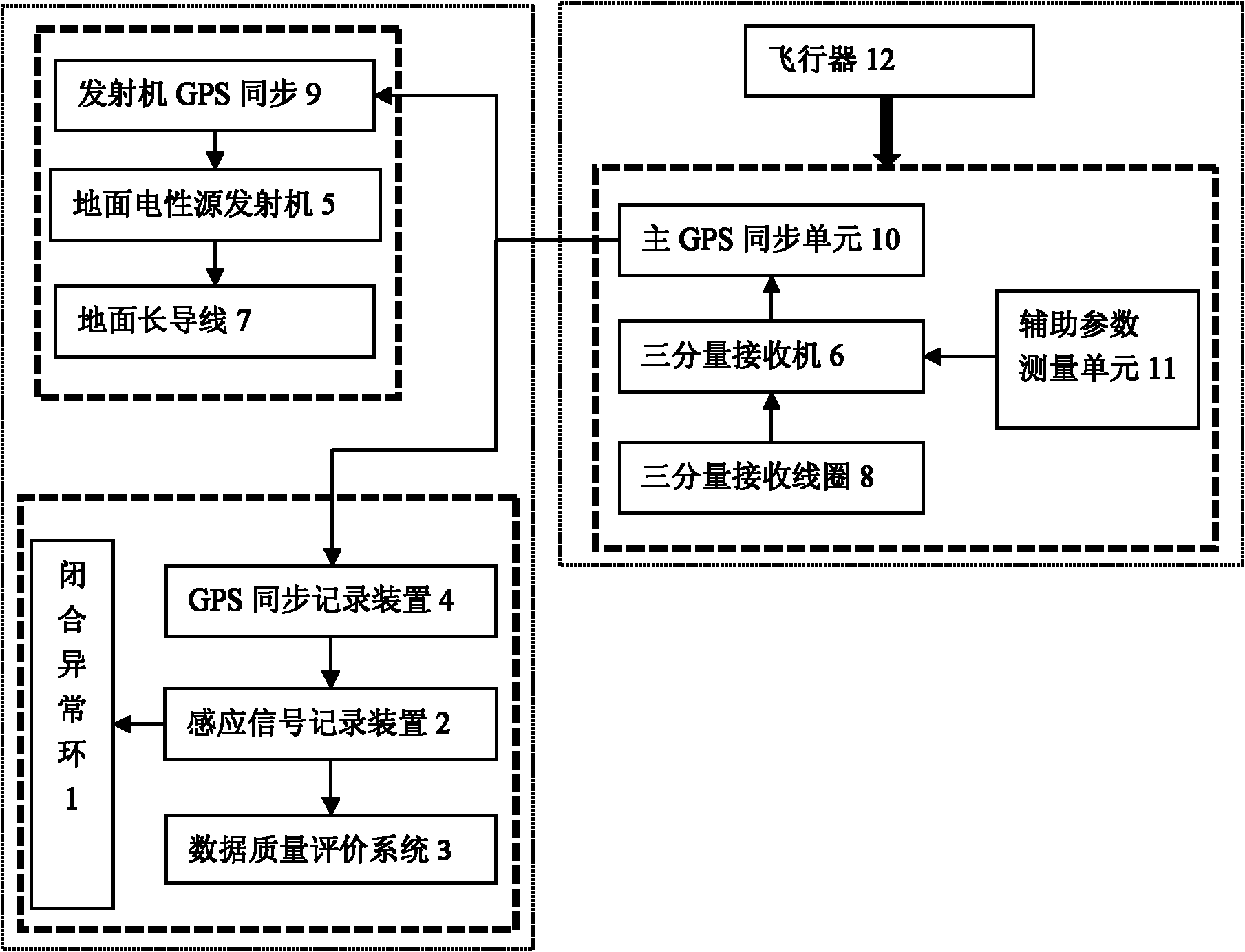

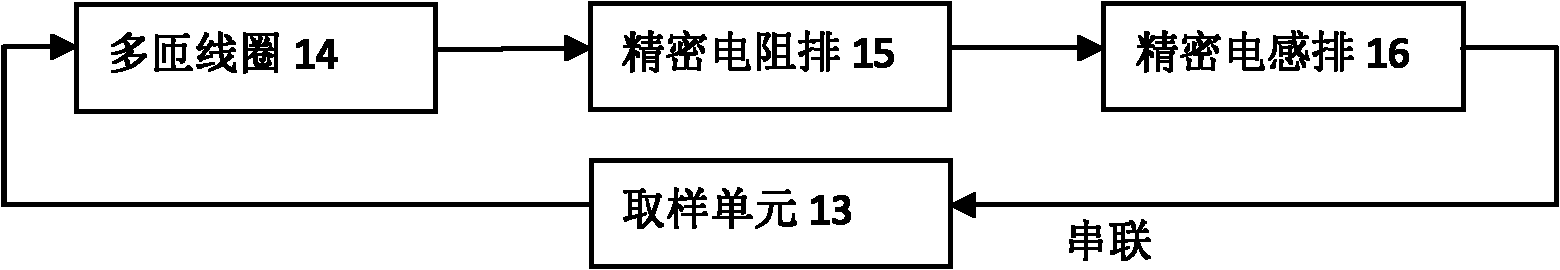

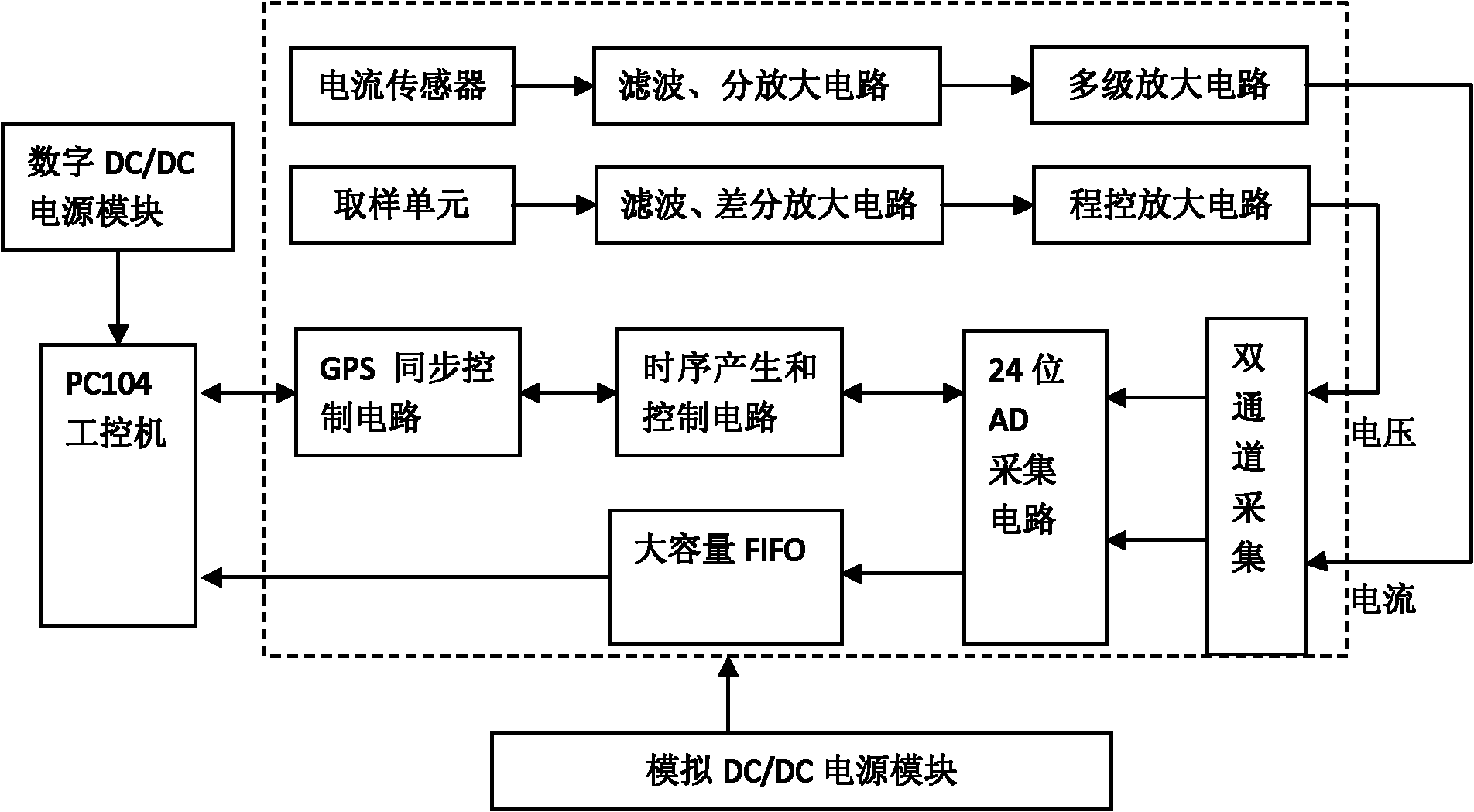

Time-domain ground-air electromagnetic detection system and calibration method

InactiveCN102096113AImplement testRealize CalibrationElectric/magnetic detection for transportGeometric error24-bit

The invention relates to a time-domain ground-air electromagnetic detection system and a calibration method, in particular to a system consisting of an induction signal recording device connected with a ground recording device global position system (GPS) synchronization unit, a closed abnormal ring and a data quality evaluation system, and a calibration method for the time-domain ground-air electromagnetic detection system. The closed abnormal ring and the induction signal recording device are adopted, the induction current and induction voltage are simultaneously recorded, and the 24-bit 200Hz sampling rate, a bandwidth of 0-13KHz and a dynamic range of an amplifier of 160dB are achieved. Moreover, the system is synchronous with a ground transmitter and an air receiver GPS, and during measurement, by removing earth background field data, a pure closed abnormal ring electromagnetic signal containing a geometric error is extracted, is input into the data quality evaluation system, andis compared and fitted with the computed closed abnormal ring theoretical value, the system error, the geometric parameter error and the detection resolution of the time-domain ground-air electromagnetic detection system are determined, and the performance of the electromagnetic detection system is tested and calibrated.

Owner:JILIN UNIV

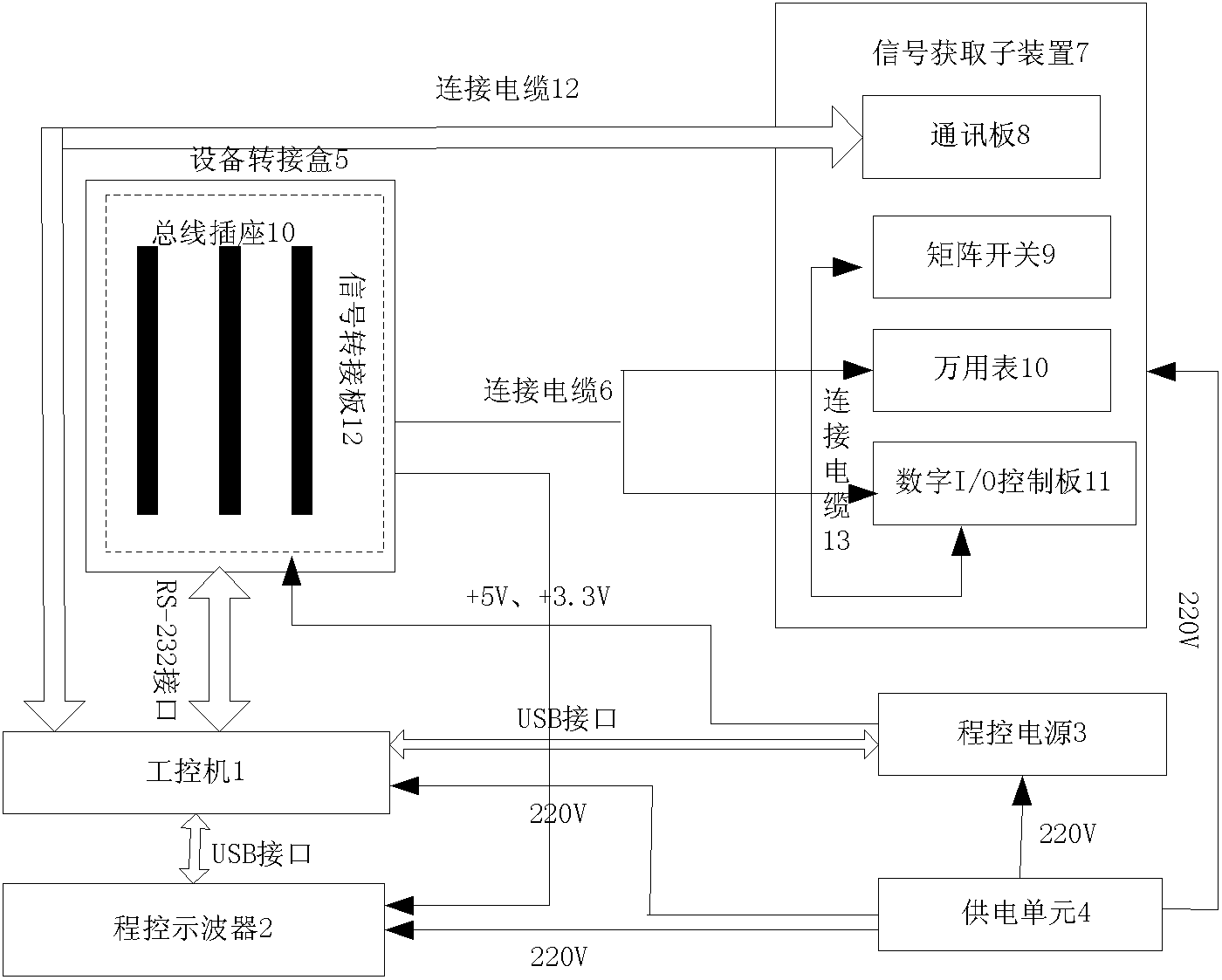

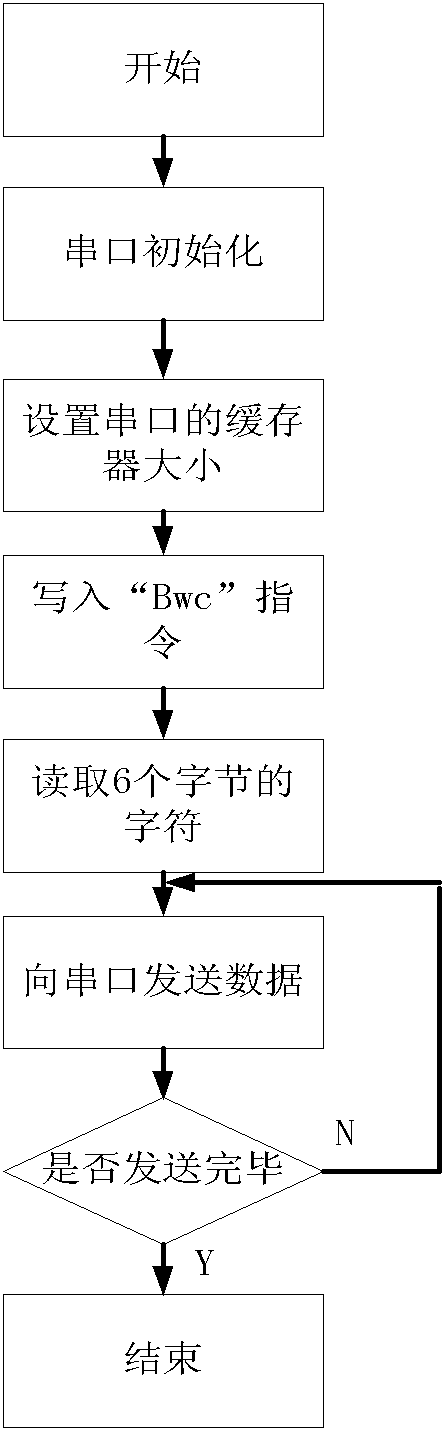

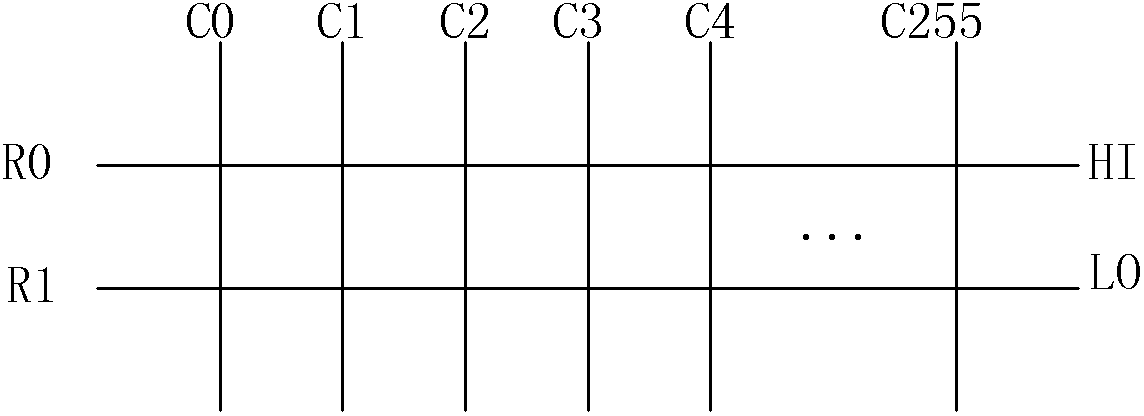

Automatic testing device and method universally used for multiple bus processor modules

The invention discloses an automatic testing device and method universally used for multiple bus processor modules. The automatic testing device comprises a power supply unit, wherein the power supply unit is connected with an industrial personal computer, a programmable oscilloscope, a programmable power supply and a signal acquisition subdevice; the industrial personal computer is connected with an equipment access box, an equipment adapter box is respectively connected with a multimeter and a digital I / O (Input / Output) control panel, the power supply input end of the equipment adapter box is connected with the power supply output end of the programmable power supply; the industrial personal computer is connected with the programmable oscilloscope, the programmable power supply and a communication board; and the programmable oscilloscope and the programmable power supply are connected with the equipment adapter box. The invention mainly realizes portable mechanical loading of different types of different bus processor modules, automatic loading of closed test programs, automatic testing of performances and breakage and short circuit property tests of all pins of the module. By using test hardware of the automatic testing device and matching developed test software, automatic recognition of the processor modules, automatic loading of the closed test programs, real-time display of performance test results, report output and other functions can be realized.

Owner:XI'AN PETROLEUM UNIVERSITY

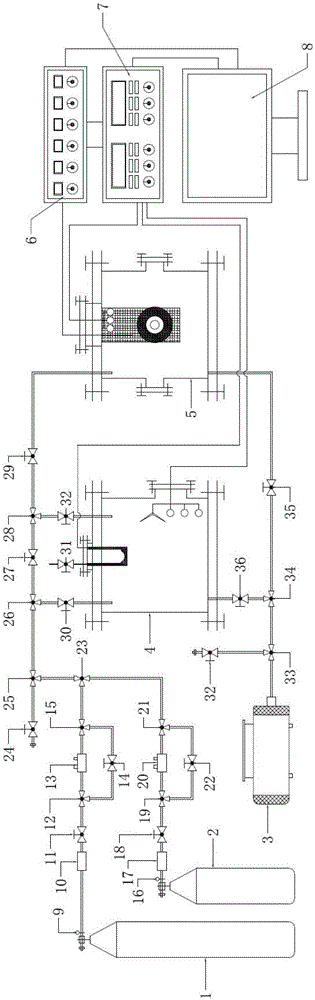

Multifunctional gas sensor testing system

ActiveCN105021777AQuick contactAccurately Test Response TimesGas analyser calibrationSimultaneous control of multiple variablesControl systemSolenoid valve

The invention discloses a multifunctional gas sensor testing system. The multifunctional gas sensor testing system comprises a gas distribution mechanism and a gas distribution chamber, a testing chamber, a control system, a testing mechanism and a vacuum pump, wherein the gas distribution mechanism is used for preparing standard-concentration gas and background gas for the gas distribution chamber; prepared standard-concentration testing gas is stored in the testing chamber and the testing chamber is used for testing a sensor sensitive property under standard concentration of gas to be tested; and the control system is used for controlling gas preparation in the gas distribution chamber and the testing chamber, and comprises temperature and humidity control, gas pressure or vacuum degree control, gas mass and flow control, on-off control of each gas-path solenoid valve, starting / stopping control of the vacuum pump, starting / stopping control of a stirring fan, and testing process control of a detected sensor. According to the multifunctional gas sensor testing system disclosed by the invention, rapid contact of the sensor and standard gas is realized by automatically preparing the standard-concentration gas, and the temperature and humidity of a sensor testing environment also can be controlled; and synchronous testing of electric gas responding of the plurality of sensors and optical gas responding of the single sensor also can be realized.

Owner:HUBEI UNIV

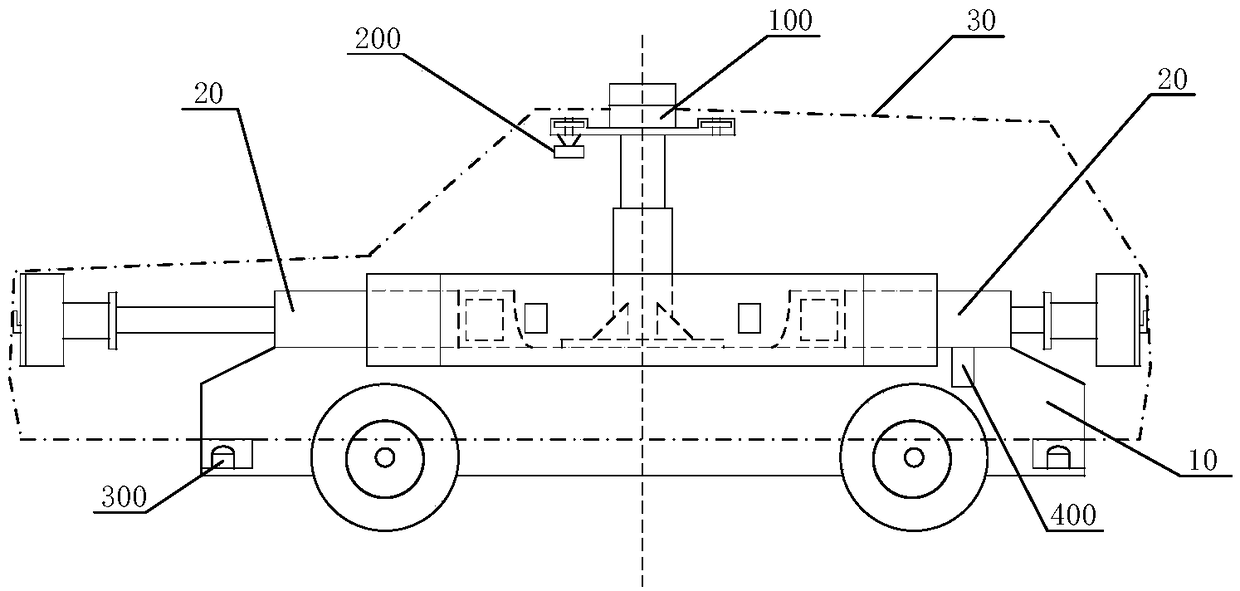

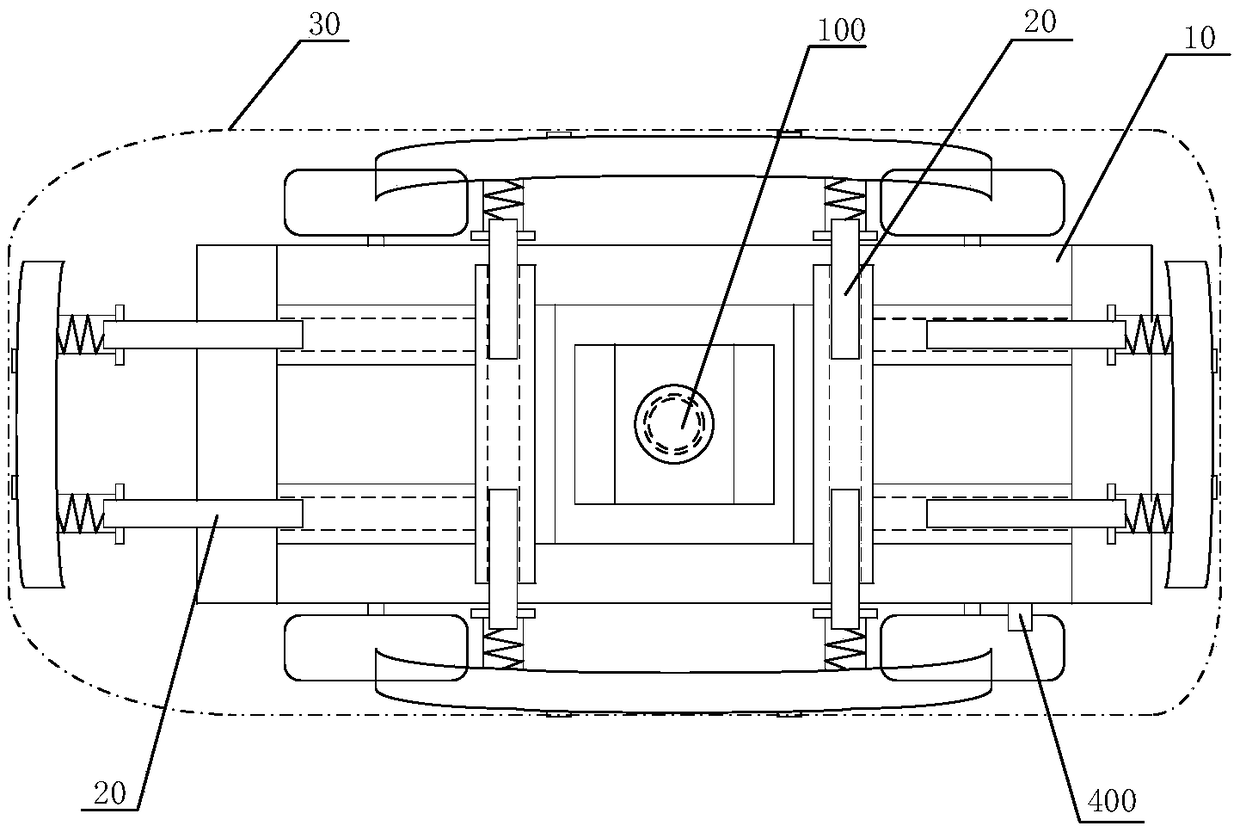

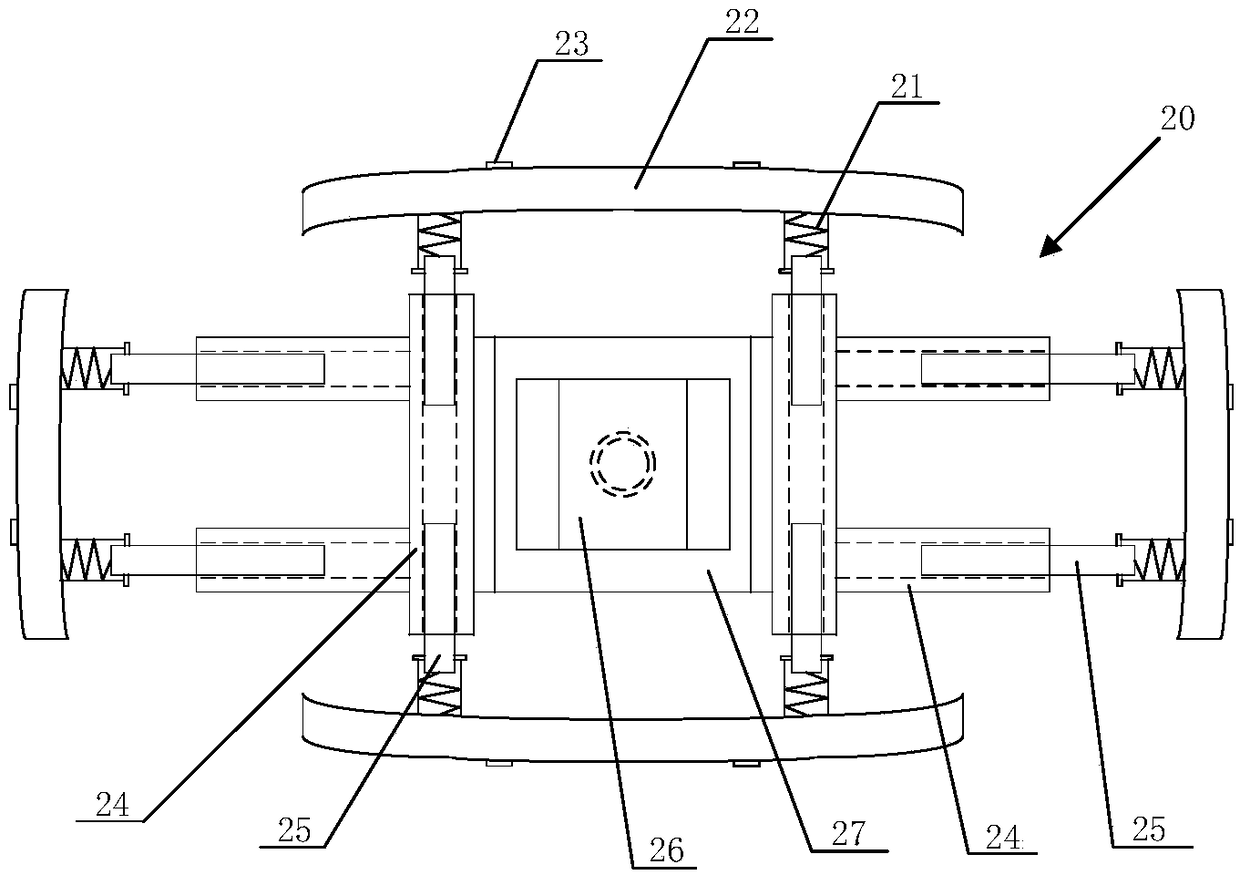

Unmanned testing vehicle platform for automatic driving testing site, and method

ActiveCN109187041AAchieve changeChanges to achieve conversion between different modelsVehicle testingControl systemFeedback control

The invention discloses an unmanned vehicle general platform for automatic driving testing, and a method. The unmanned vehicle general platform comprises a vehicle body shape transformation system which comprises a chassis; a telescopic device is mounted on the chassis, the telescopic device changes the size of a vehicle body through telescopic deformation, and different quick assembly simulationshells are matched to simulate different vehicle models and vehicles; a feedback control system is further mounted on the chassis; the feedback control system comprises a central control device whichis connected to a motor, a braking device and a steering device; and the central control device is further connected to a vehicle sensor measuring unit, and the motion state of a vehicle is obtained through the vehicle sensor measuring unit to decide and control various operation behaviors of the testing vehicle. One testing vehicle can simulate the various vehicles (such as cars, off-road vehicles and trucks), the perceive difficulty of the tested vehicles is increased, and the testing cost is lowered.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION +1

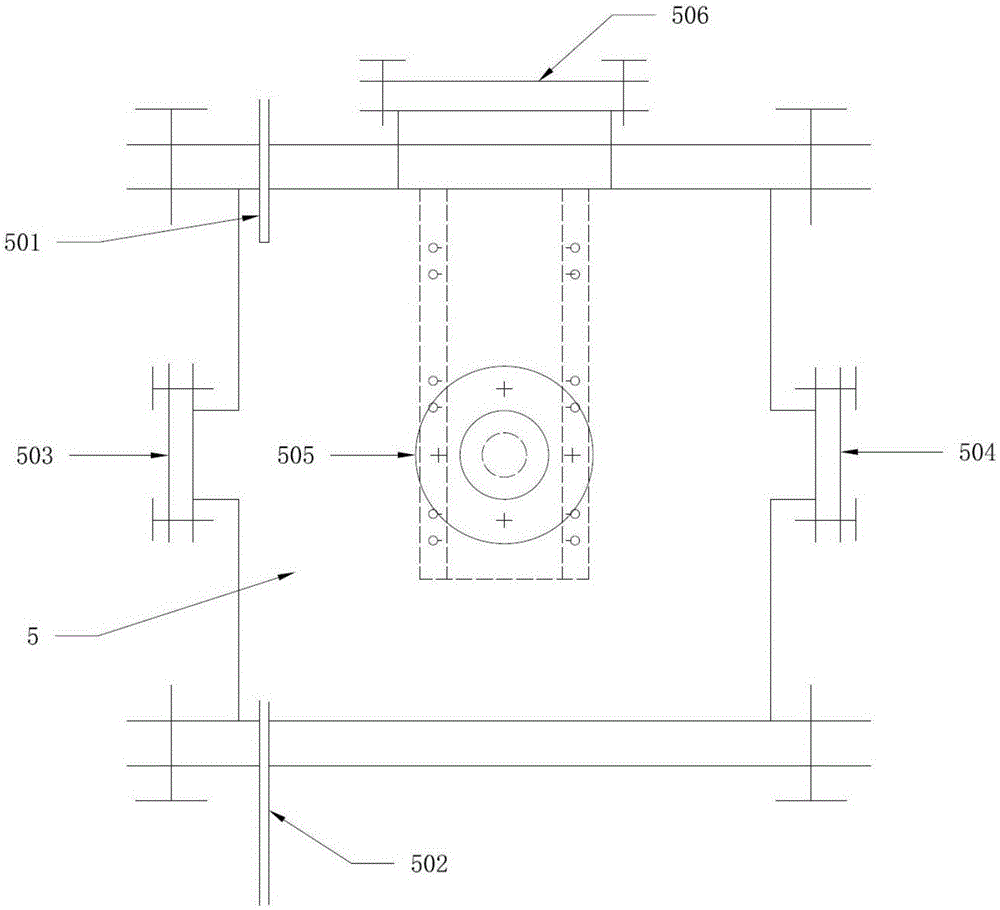

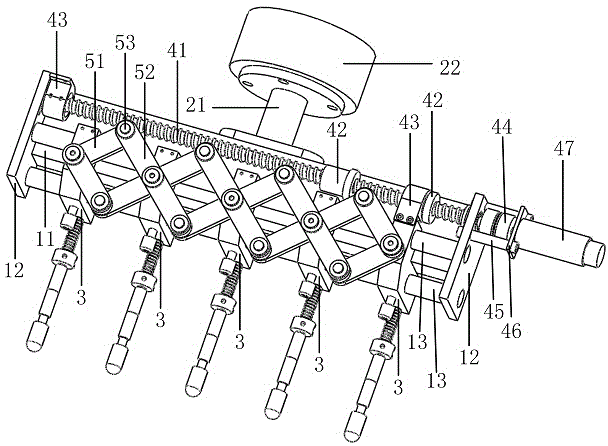

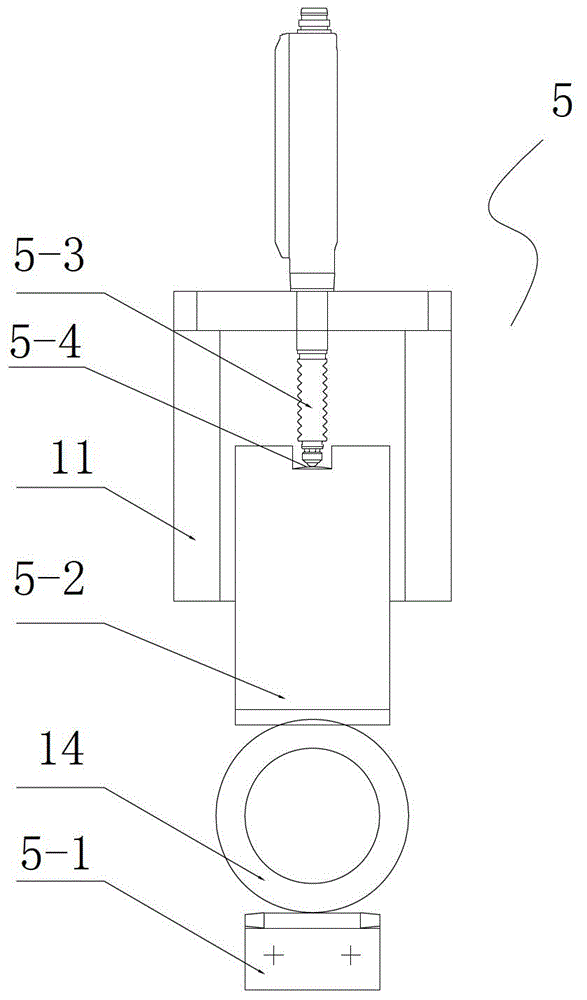

Tool used for testing function and performance of touch control equipment

ActiveCN103954860ADynamically adjustable spacingImprove basic test actionsElectrical testingTest efficiencySimulation

The invention provides a tool used for testing the function and performance of touch control equipment. The tool has the characteristic that multiple fingers simulate a human hand and move in a combined mode. The tool structurally comprises a plurality of finger modules, movement relations are transmitted through a connection rod telescopic mechanism among the finger modules, the aim of dynamically controlling the distances between the fingers during a touch test can be achieved, and the test function of a traditional touch screen test instrument is perfected. Moreover, on the basis that the tool has the characteristic that the multiple fingers can flexibly move, the tool is installed on a movement platform to carry out test movements, test difficulties of multi-shape touch screen devices are eliminated, various single-item touch screen tests can be completed in an integrated mode so that test efficiency can be improved, meanwhile, real touch operations, such as touch force changes and finger moving track deviation, of the hand of a person can be simulated by means of the device, user experience of the touch control equipment can be accessed when touch operations are carried out by the hand of the person, and accordingly product design can be improved, and the tool can assist in development of multi-finger application programs.

Owner:SHANGHAI UNIV

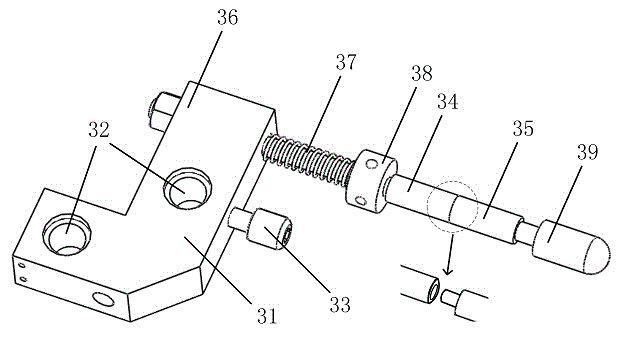

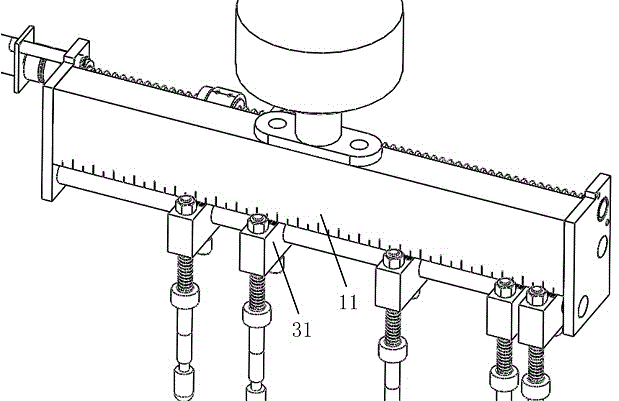

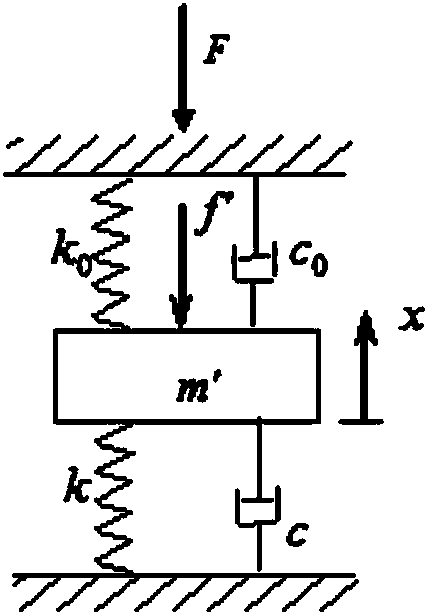

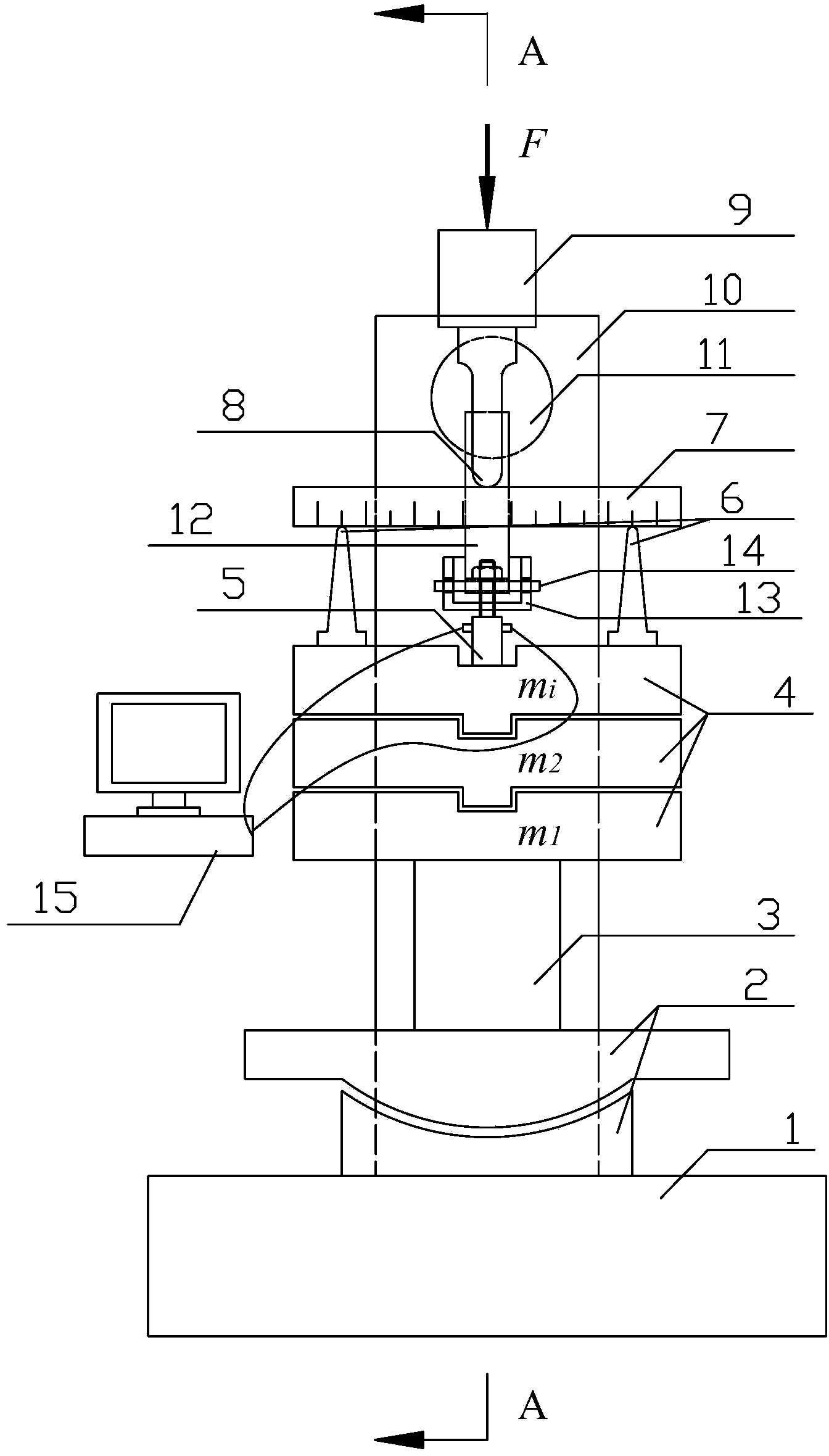

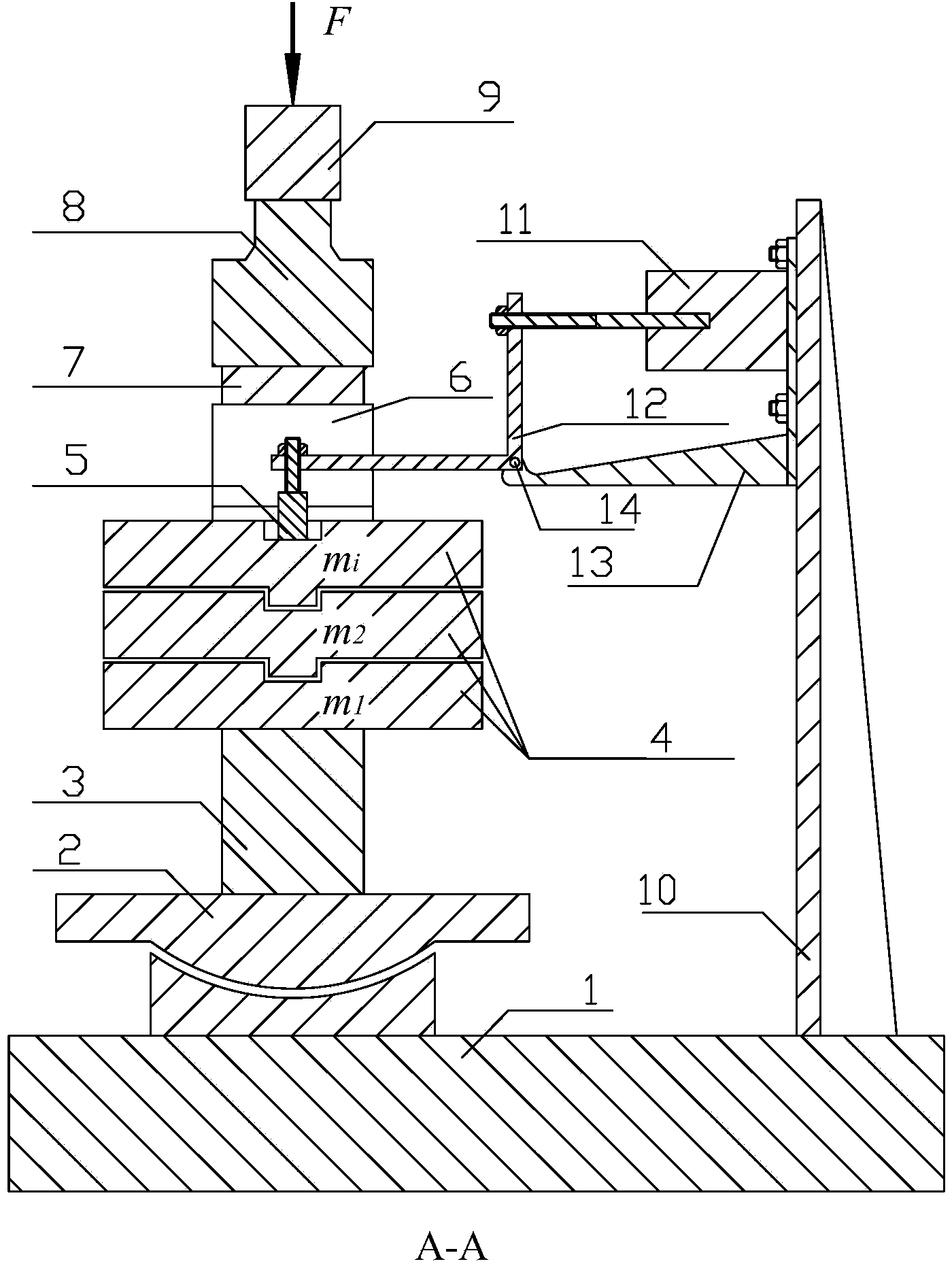

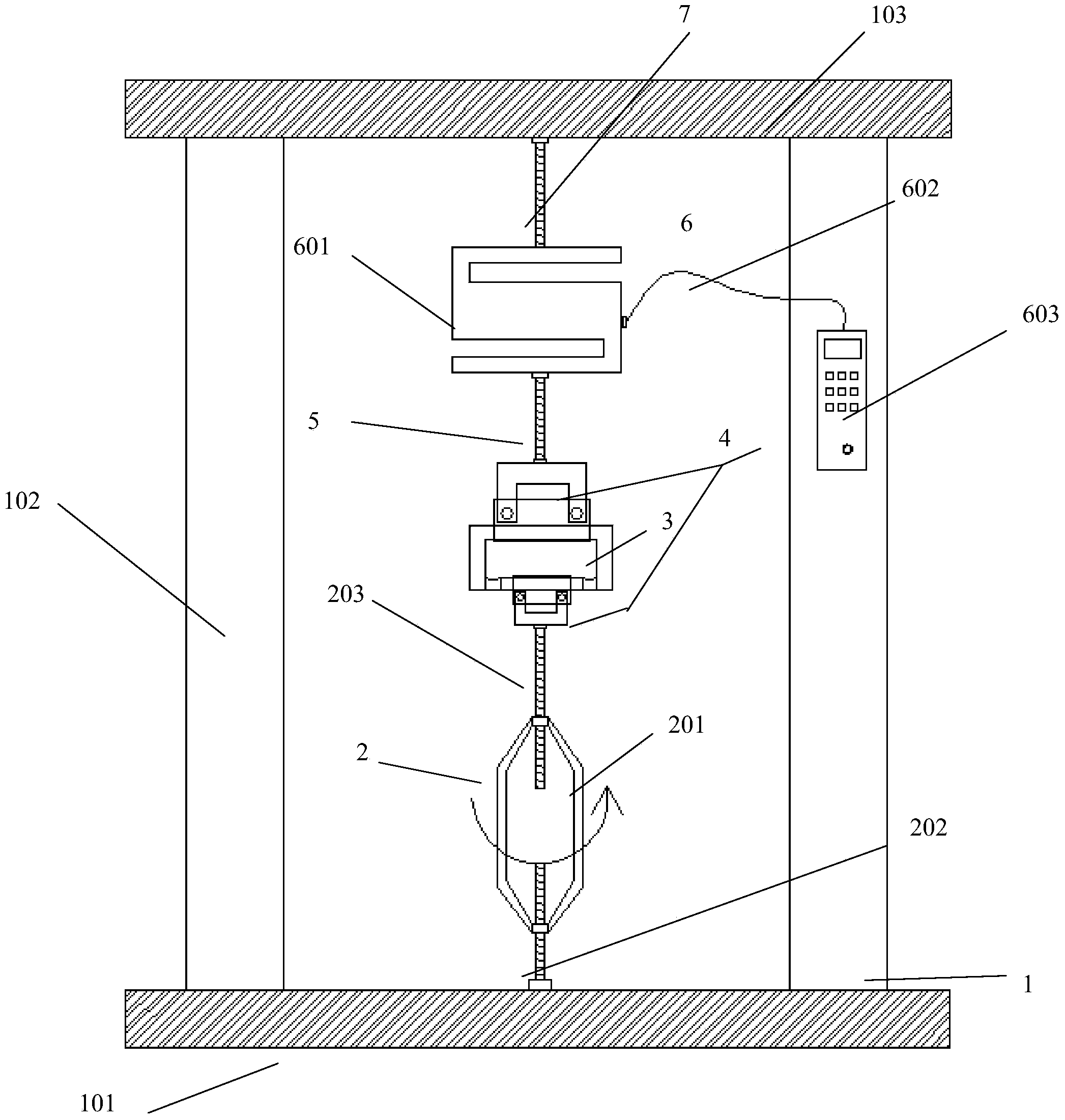

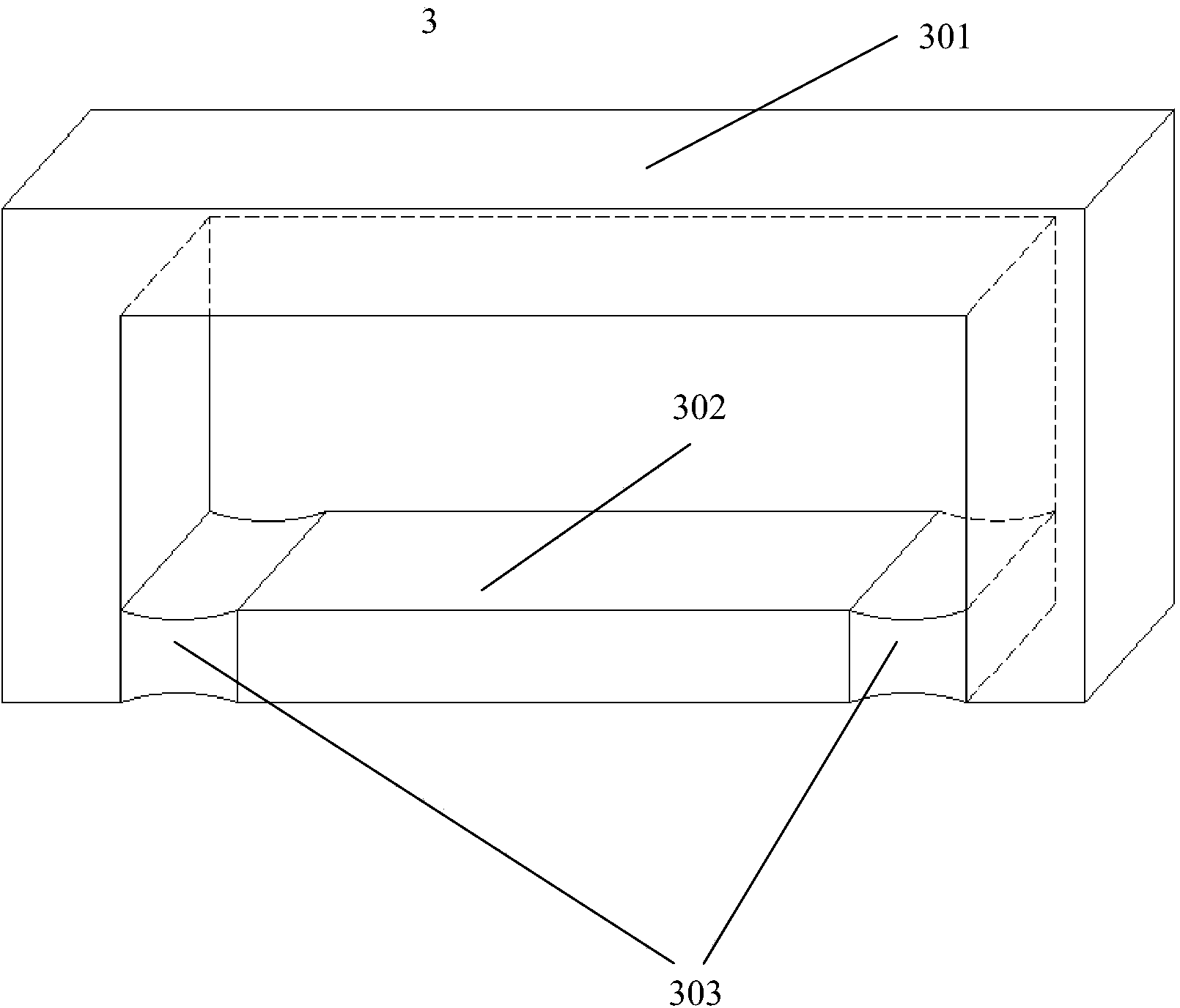

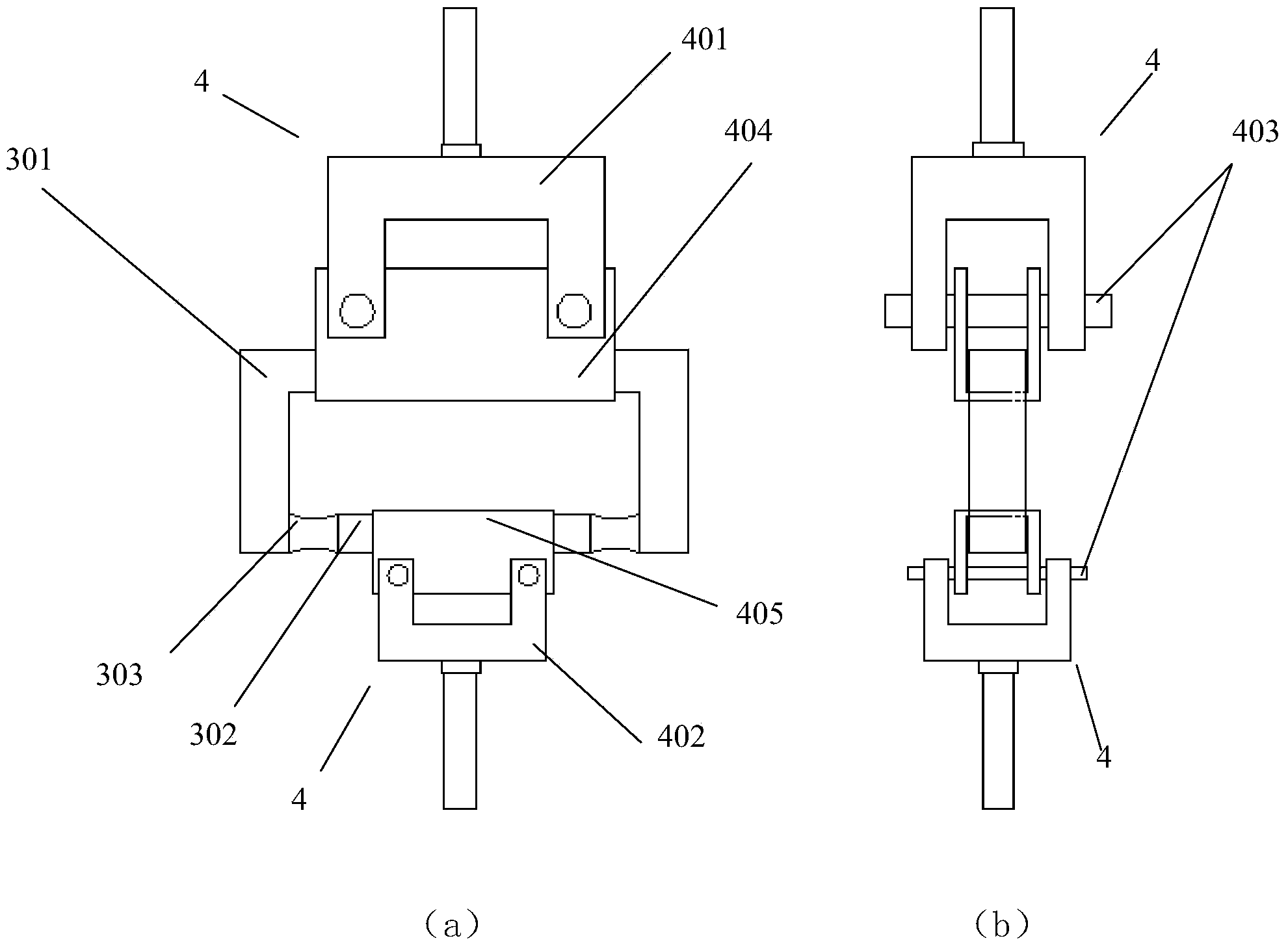

Method and device for testing dynamic stiffness of vibration isolator

InactiveCN103808499ASolve clumsySolve the test costMachine part testingVibration testingDynamic stiffnessHigh rate

The invention discloses a method and a device for testing dynamic stiffness of a vibration isolator. The method comprises the steps of establishing an equivalent test model of a single-degree-of-freedom vibration system in a vibration isolation direction by using a static loading device, a combined vibration mass block and an elastic simply supported beam, measuring a frequency response function of the equivalent test model by an exciting method, and then indirectly obtaining the dynamic stiffness of the vibration isolator by virtue of a vibration equation, the similarity of the vibration system and the characteristics of the single-degree-of-freedom system. The method avoids the problem that the existing methods all need to simulate a rated load or a working load with an equivalent mass block in an ingenious way, and solves the problem that the test system is clumsy, high in test cost and test difficulty and even unachievable if the mass block is used for simulating high rated load or working load; the testing device is light and simple in structure, convenient to operate, and economical and practical; the method and the device are applicable to the dynamic stiffness tests of all single-axis vibration isolators, high in applicability, and especially capable of realizing testing of the dynamic stiffness of a large-rated load vibration isolator and ensuring high precision.

Owner:JIANGSU UNIV OF SCI & TECH

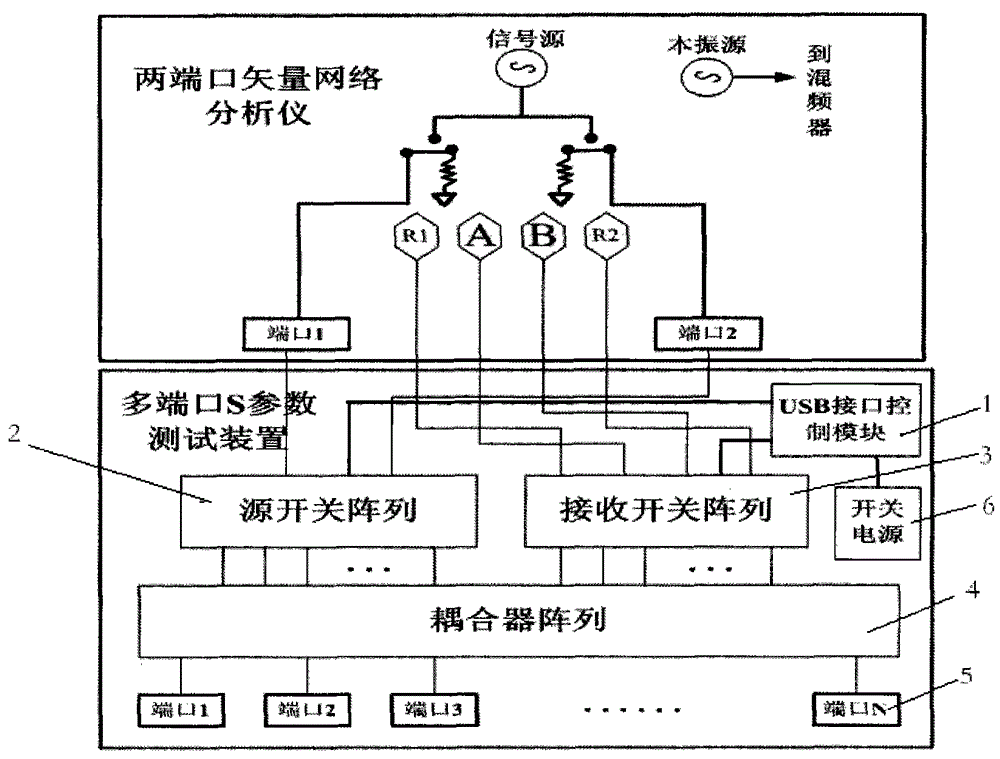

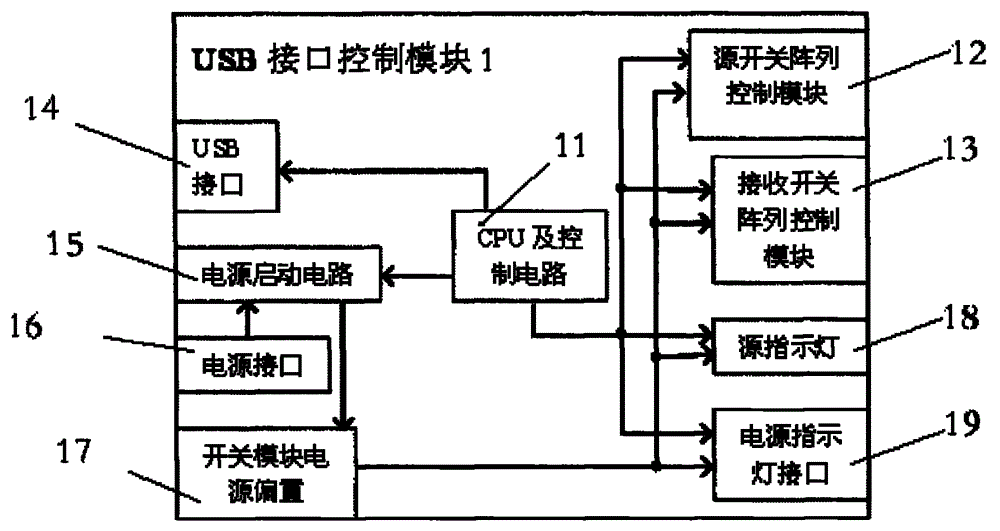

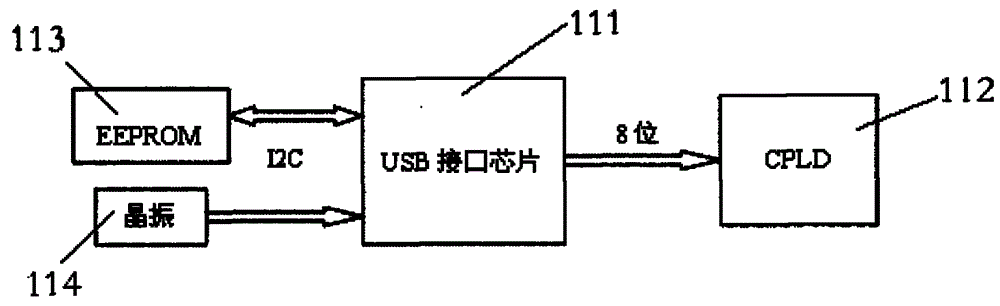

Multi-port S parameter test device based on USB interface

The invention belongs to the signal test technology field and related to a multi-port S parameter test device based on a USB interface. The multi-port S parameter test device comprises a USB interface module, a source switch array, a reception switch array and a coupler array, wherein the USB interface module is respectively connected with the source switch array and the reception switch array, and the source switch array and the reception switch array are respectively connected with the coupler array. According to the multi-port S parameter test device, a two-port network analyzer which is taken as a host can be expanded into a multi-port network analyzer while cost is quite low, the multi-port S parameter test device can be used for measuring various multi-port, multi-function assemblies and modules and has advantages of simple structure and high stability.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

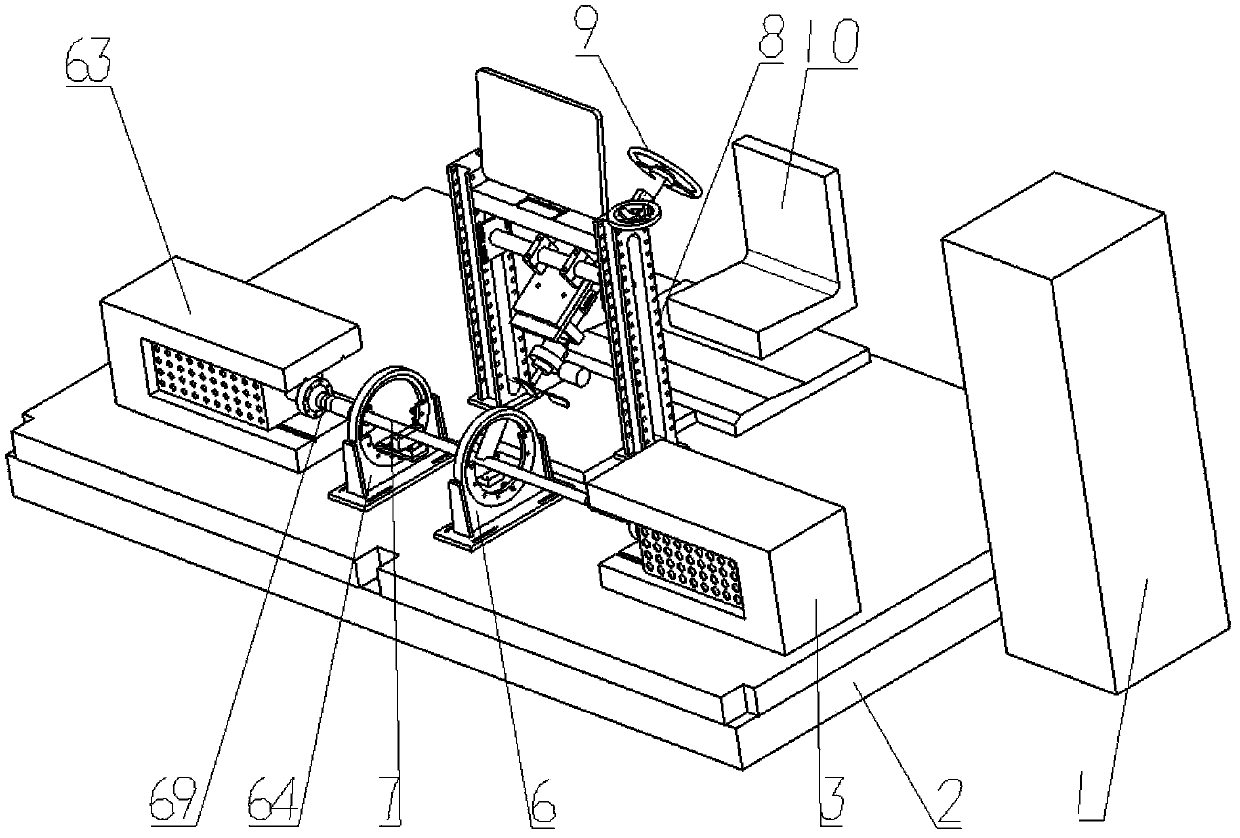

Testing device of electric power steering system

InactiveCN103364209ARealize developmentImplement testVehicle steering/rolling behaviourElectric machineryDriving simulator

The invention discloses a testing device of an electric power steering system, in order to overcome the problems of low control accuracy of a resistance device, complicated drive system, simple vehicle model, and oil leakage of a hydraulic system. The testing device of the electric power steering system comprises a T-shaped groove platform, two linear motor assembly mechanisms, two steering gear stationary fixture assemblies, a steering pipe column stationary fixture assembly, a steering wheel simulation driving mechanism and a driving simulator assembly; a voltage stabilizing power supply, a power supply cabinet and a measurement and control cabinet are fixed on the foundation around the T-shaped groove platform; the steering gear stationary fixture assemblies are fixed on the left side of the T-shaped groove platform; linear motors are installed on the T-shaped groove platform at the outer side of the stationary steering gear stationary fixture assemblies; output ends of the linear motors are connected with two ends of steering gears fixed on the steering gear stationary fixture assemblies; the driving simulator assembly is fixed on the right side of the T-shaped groove platform; the steering pipe column stationary fixture assembly is fixed on the T-shaped groove platform between the steering gears and the driving simulator assembly; the steering wheel simulation driving mechanism is inserted on a steering pipe column.

Owner:JILIN UNIV

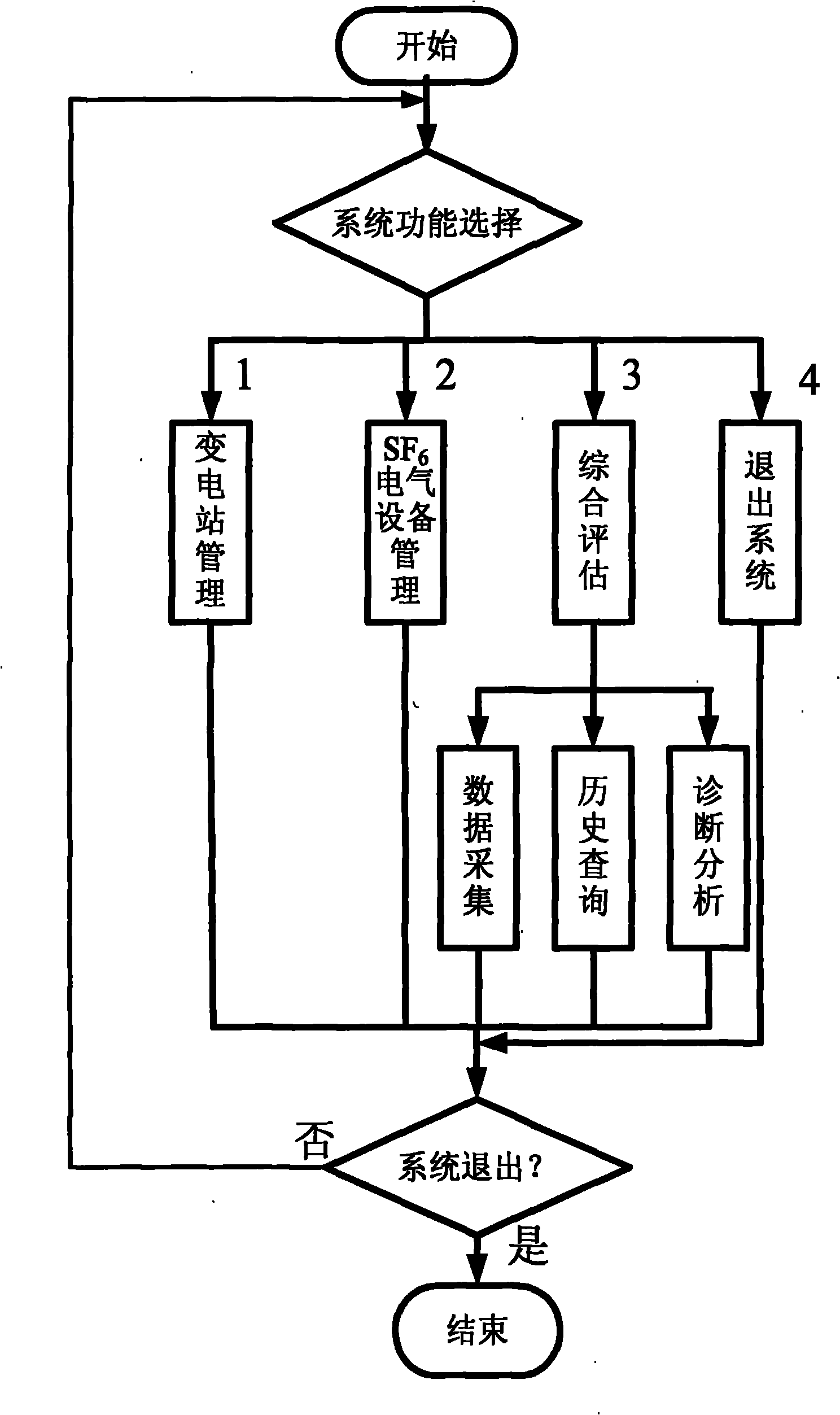

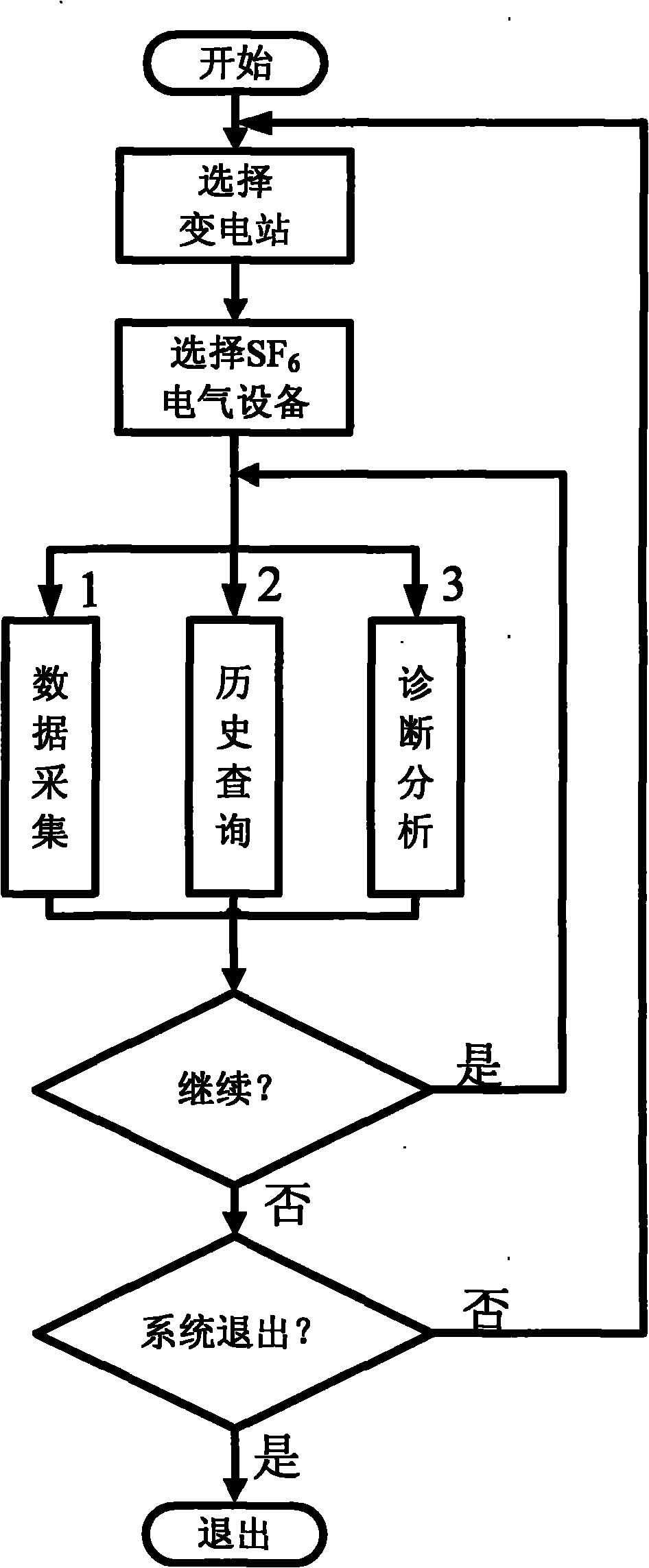

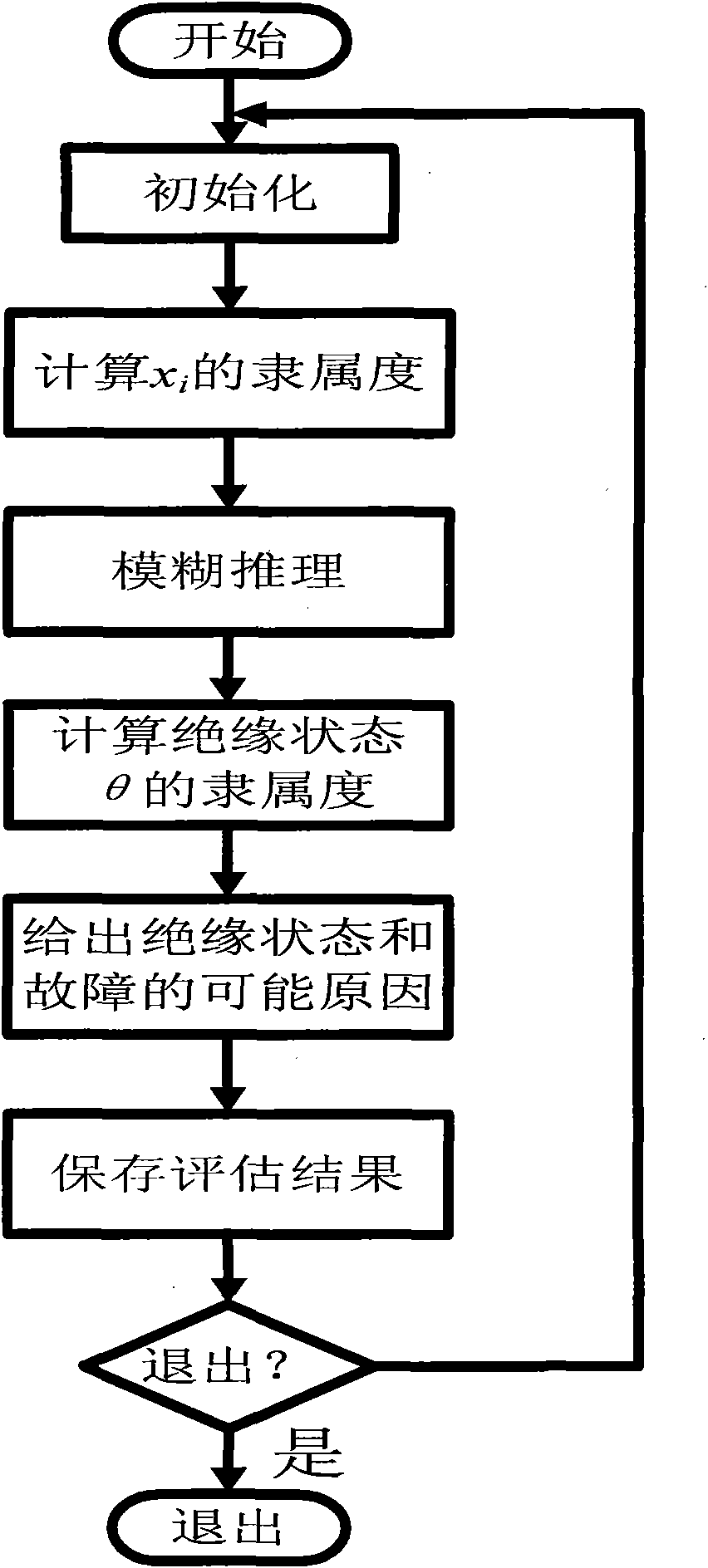

Method for comprehensively estimating insulation state of sulfur hexafluoride electrical equipment

InactiveCN102034019AAccurate running statusAccurate assessmentSpecial data processing applicationsPower stationDecomposition

The invention relates to a method for comprehensively estimating the insulation state of sulfur hexafluoride electrical equipment and belongs to the technical field of monitoring and estimation on the insulation state of the sulfur hexafluoride electrical equipment. In the method, a computer and a comprehensively estimating device of the sulfur hexafluoride electrical equipment with the application number of 201020240900.0 are utilized, a fuzzy theory and a neural network method are applied by utilizing a program, and then the method carries out comprehensive estimation to the insulation state of the SF6 electrical equipment by adopting the working mode of an Windows interface. The method can be used for carrying out monitoring, intelligent analysis and comprehensive estimation to the running indexes comprising brackish water, mainly discharged decomposition products (HF, CO, SO2 and H2S) and the concentrations thereof and the like in SF6 gas of the SF6 electrical equipment, and has the characteristics of simple operation, high efficiency, flexible and convenient use, convenient on-site rapid diction and estimation and the like. The method can be widely applied to rapidly detecting and estimating the insulation state of the SF6 electrical equipment in power stations and transformer substations.

Owner:CHONGQING UNIV

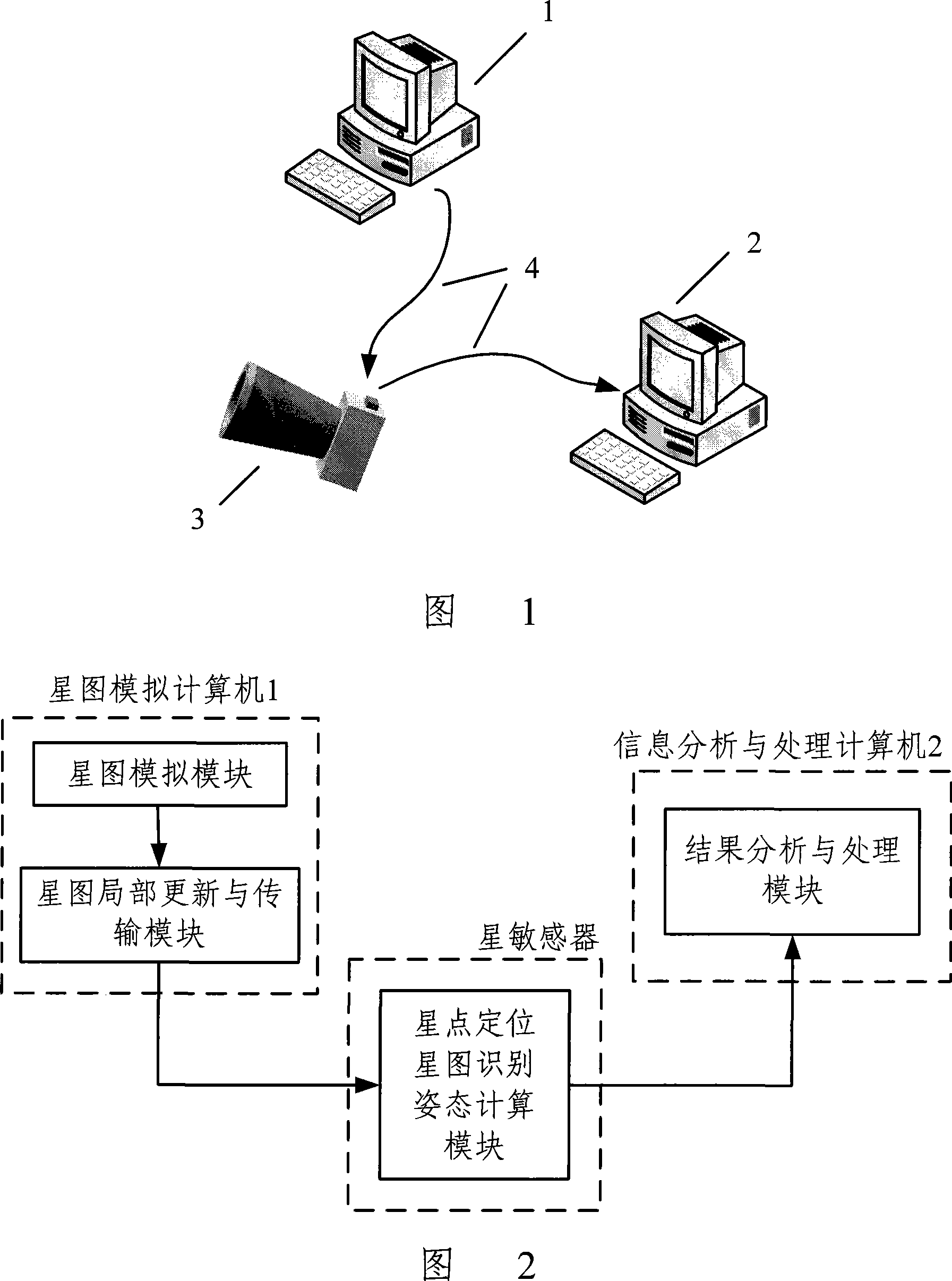

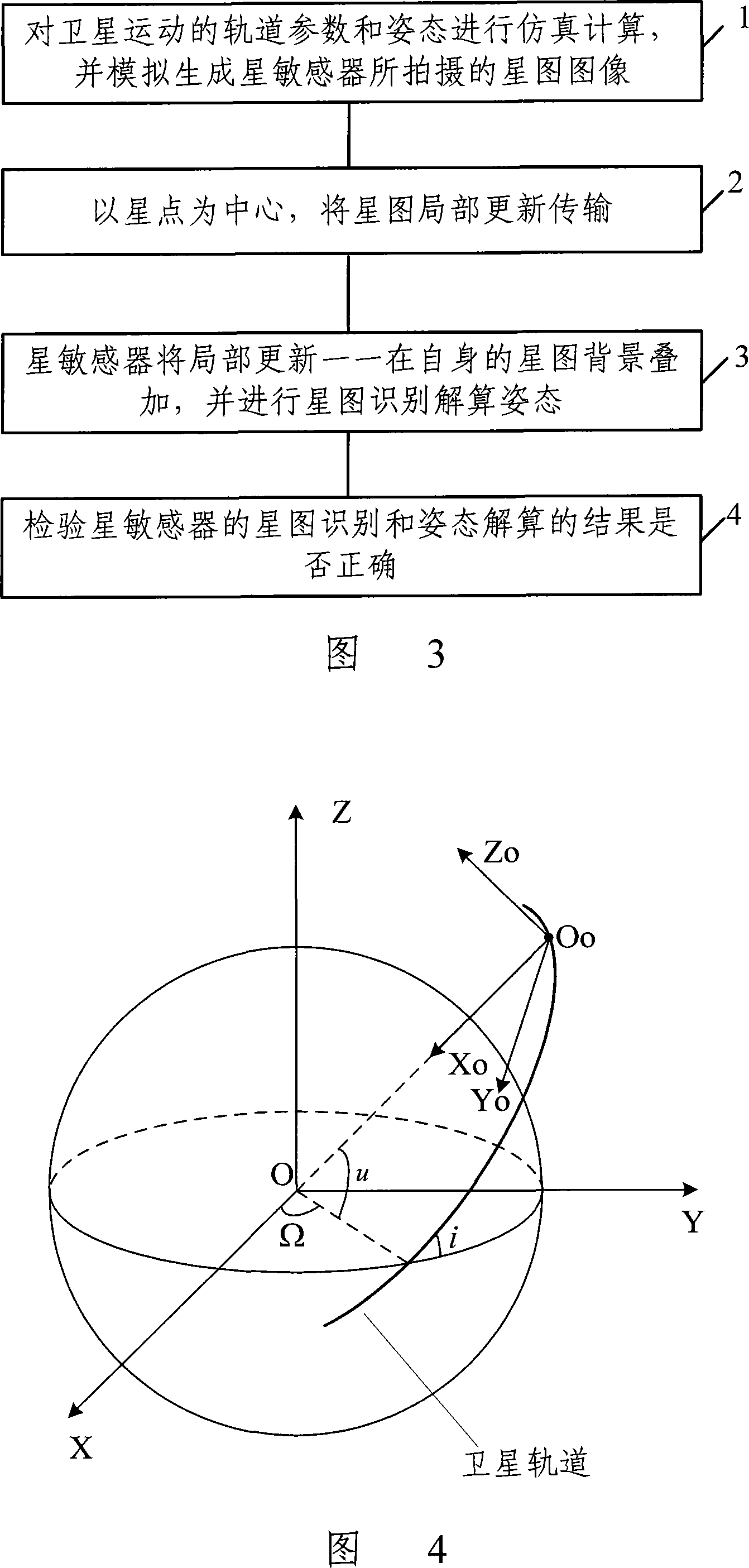

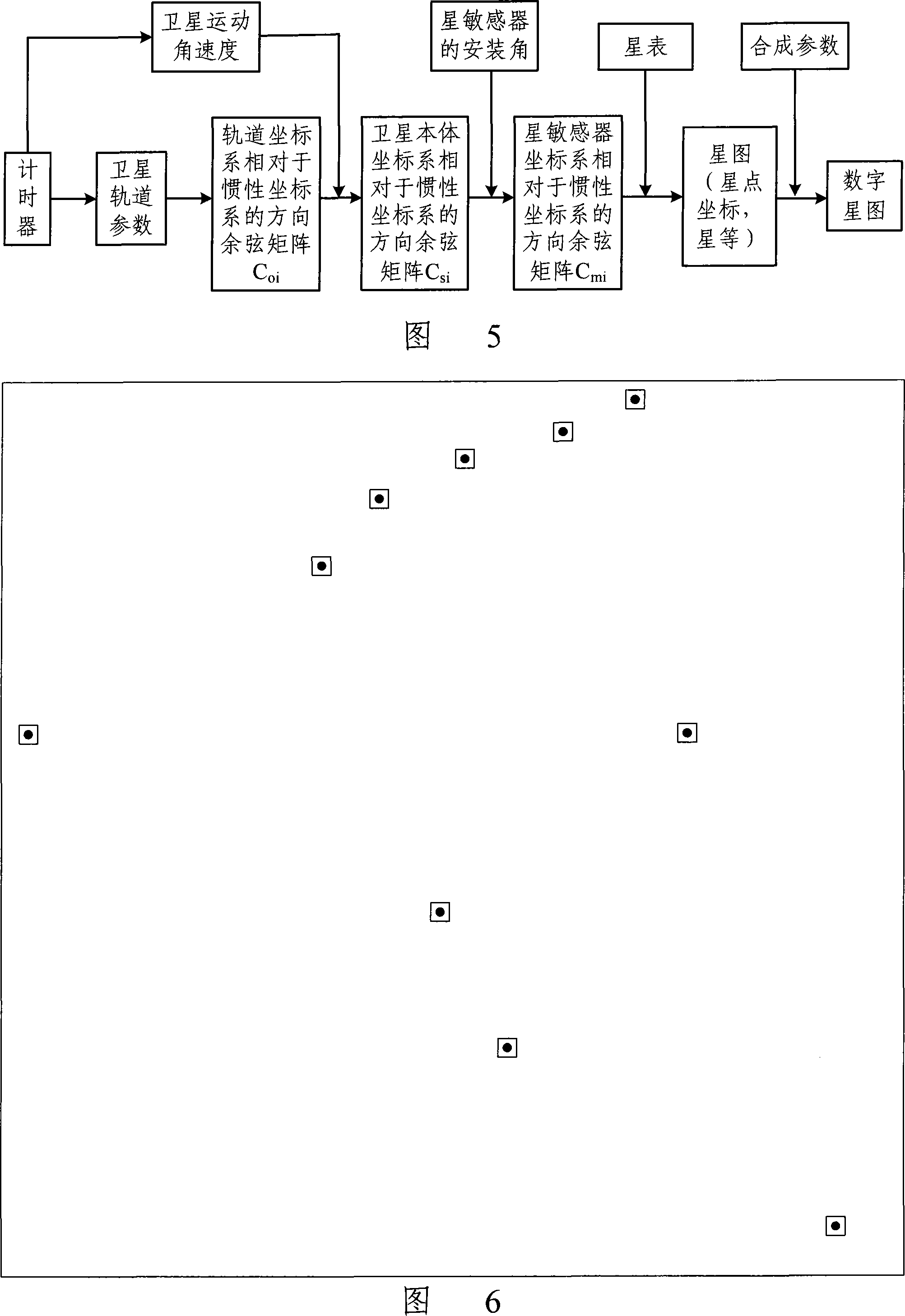

Method and apparatus for testing star sensor function based on electric injection star map

InactiveCN101226113AComprehensive testImplement testStructural/machines measurementNavigation by astronomical meansElectricityFunctional testing

The invention discloses a star sensor function test method based on electric injection star map, which comprises simulating the track parameter and attitude of satellite motion and simulating a star map shot by a star sensor, using the star point center to refresh and transmit part of the star map, laminating the part refreshes in the star map background of the star sensor, positioning star point, recognizing star map and calculating altitude, checking the results of the star map recognition and altitude calculation of the star sensor. The invention discloses a relative device. The invention has high refresh rate of star map, which can simulate the track altitude of star sensor and can process ground simulation test with whole star system, without additional external devices and special application condition demand, but with strong versatility.

Owner:BEIHANG UNIV

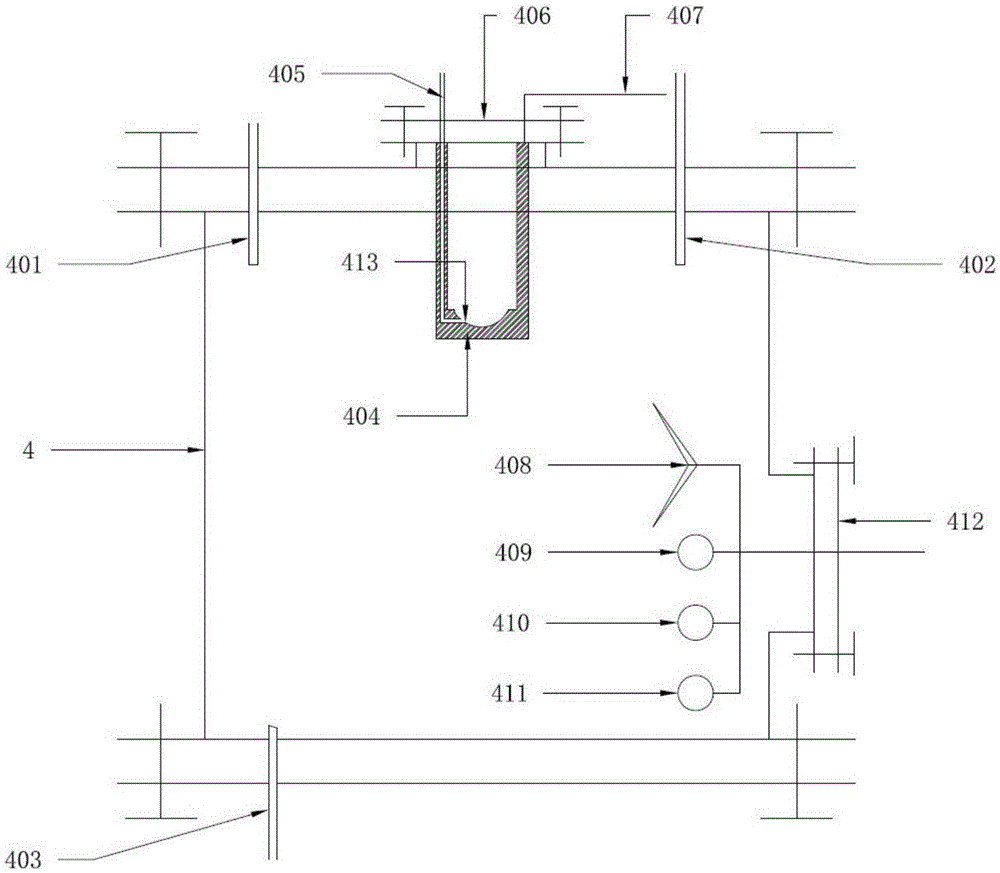

Test device capable of simulating plugging of high temperature and high pressure dropping strata

ActiveCN102518432ATest realization of blocking effectImplement testSealing/packingMagnetic tension forceWater source

The invention relates to a test device capable of simulating plugging of high temperature and high pressure dropping strata, which is mainly composed of a gas source, an oil tank, an upper kettle body, a lower kettle body, a water source, a magnetic force driver, a central processing system and a liquid collecting tank. The upper kettle body is connected with the oil tank and the gas source, the lower kettle body is connected with the water source, the upper kettle body and the lower kettle body are not only respectively connected with a pressure pump and a pressure-release pump, but also respectively connected with a pressure sensor and a thermalcouple, and the pressure sensor and the thermalcouple are connected with the central processing system. A blade is arranged in the upper kettle body, a blade rotary shaft is driven by a frequency converting motor to rotate through the magnetic force driver, and a simulation rock core is arranged in the lower kettle body and connected with theliquid collecting tank. The test device capable of simulating plugging of high temperature and high pressure dropping strata can simulate complex working conditions of drilling working liquid under stratum conditions with different well depth, temperature, pressure and dropping types, slurry body flow states, differential pressure under high temperature and high pressure between a shaft and the stratum and the like, can test relevant parameters of plugging to determine dropping plugging effects so as to preferably select a drilling working liquid system.

Owner:SOUTHWEST PETROLEUM UNIV

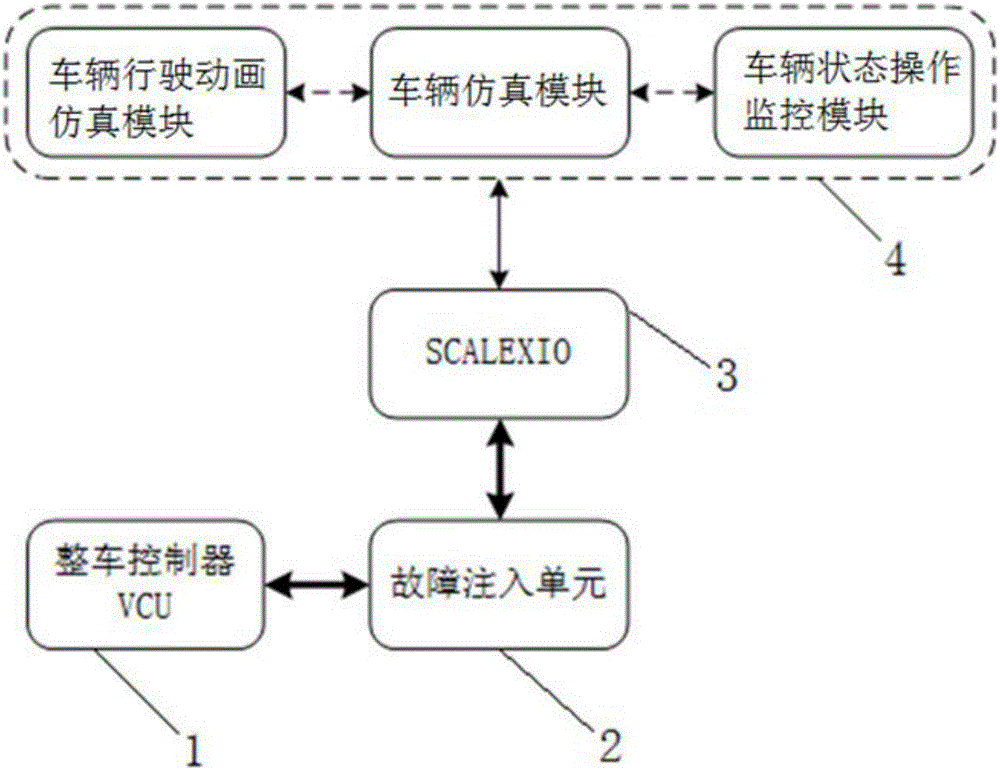

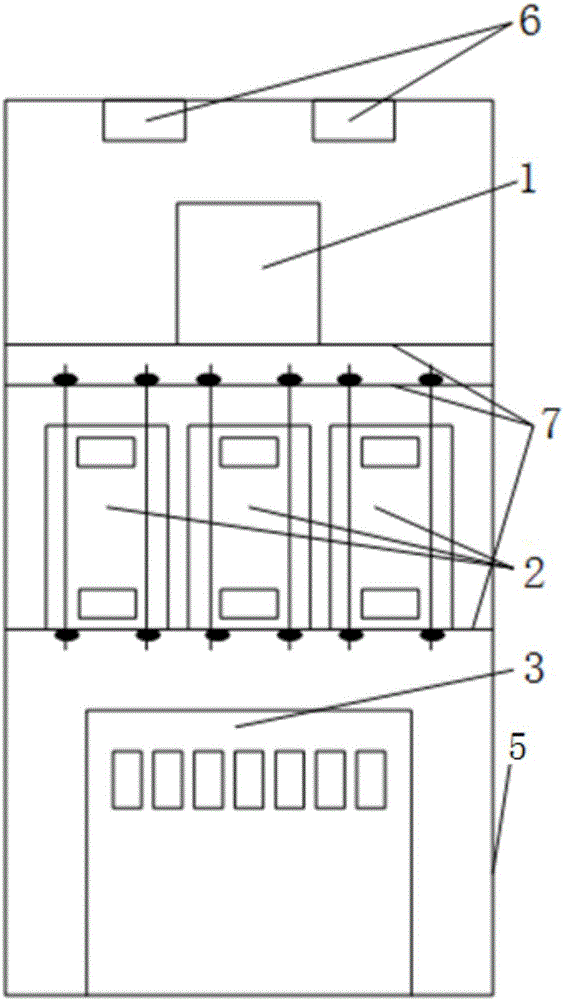

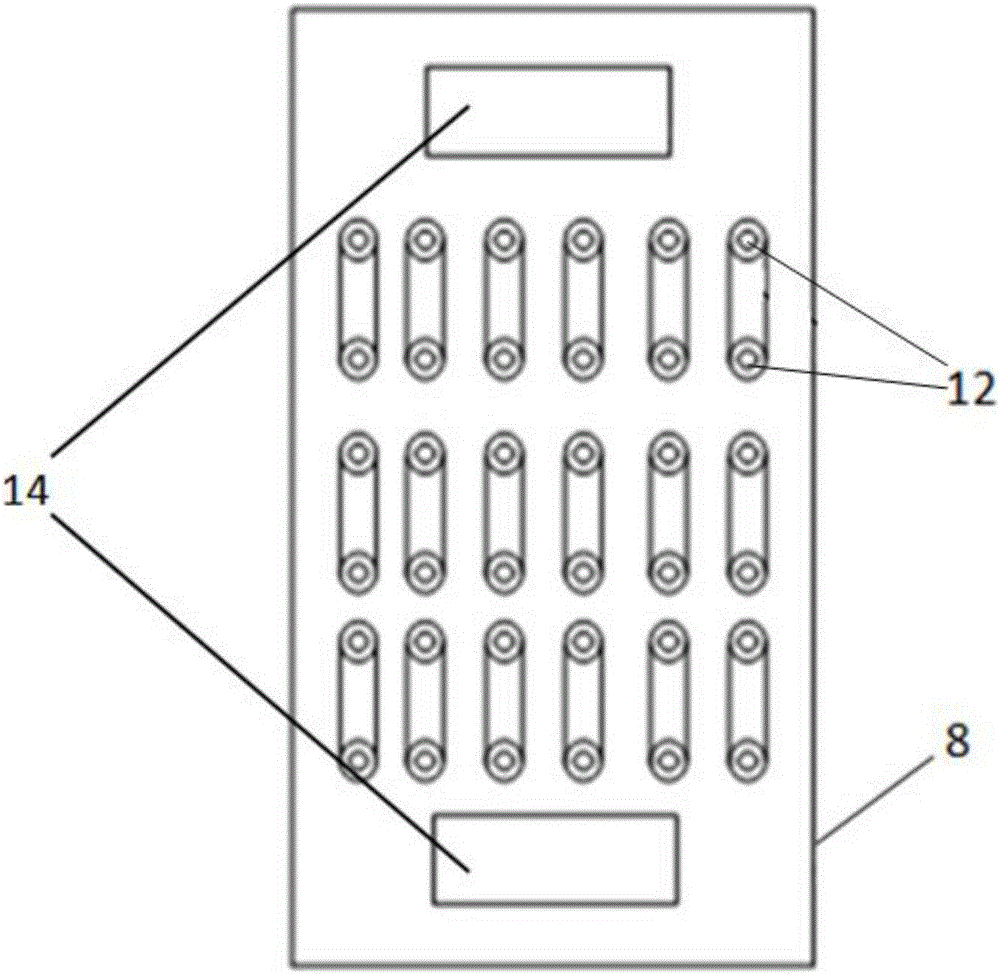

Hardware-in-the-loop test system for whole vehicle controller for electric vehicle and test method

PendingCN106444721AGood value for moneyDoes not occupy a large areaElectric testing/monitoringTest efficiencyAnimation

The invention discloses a hardware-in-the-loop test system for a whole vehicle controller for an electric vehicle and a test method. The hardware-in-the-loop test system comprises a whole electric vehicle controller, a fault injection hardware unit, an SCALEXIO, and a vehicle simulating module, a vehicle driving animation simulating module and a vehicle state operating and monitoring module in a computer. Connection and communication among the SCALEXIO, the fault injection hardware unit and the whole electric vehicle controller is achieved through a wire harness, and connection and communication between the SCALEXIO and the computer is achieved through a network line; through the corresponding SCALEXIO software in the computer, SCALEXIO channel selection is achieved, and communications of a vehicle simulating model, vehicle driving animation and vehicle state operation and monitoring interact in the computer. The hardware-in-the-loop test system can effectively save the development time and reduce the development cost of the whole vehicle controller, can achieve performance testing on the whole vehicle controller under the limit driving condition of the vehicle, can achieve systematic, integrated and automatic testing on the whole vehicle controller and generate a test report, effectively reduces the testing cost and improves the testing efficiency.

Owner:NANJING YUEBOO POWER SYST CO LTD

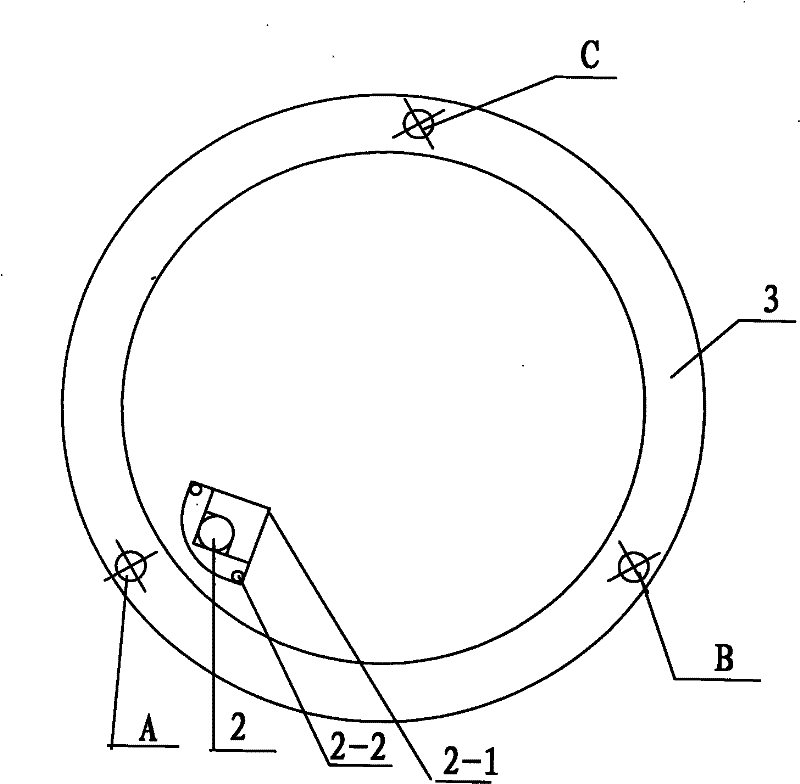

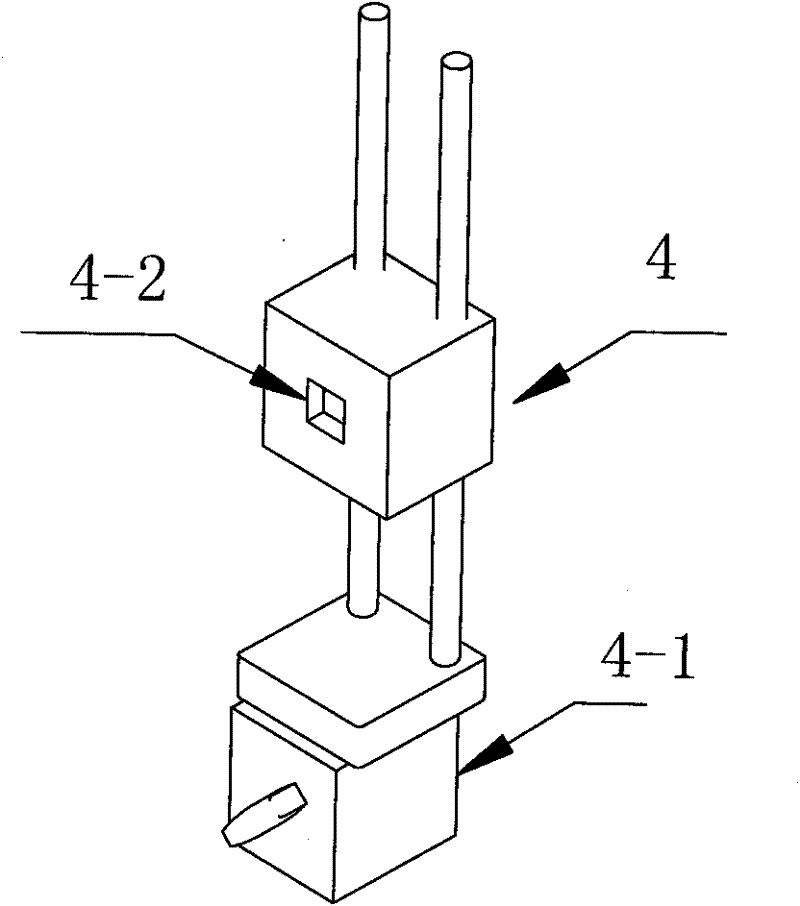

Method for detecting flatness of large-scale flange

InactiveCN102252637AHigh precisionImprove acquisition efficiencyUsing optical meansLaser transmitterMeasurement point

The invention discloses a method for detecting flatness of a large-scale flange. The method comprises the following steps of: selecting three measurement datum points on a flange plane; erecting a laser transmitter, and determining a laser beam sweeping surface which is parallel to the flange plane to be detected as a measurement referent surface by matching three datum points serving as basis and a laser detector; determining a measurement point, sequentially measuring recorded data point by point; and calculating the flatness of the flange according to the measured data. By the measurement method, the flatness of the processing surface of the large-scale flange at any gesture can be quickly and accurately measured at any time. Laser equipment has a display result which is high in accuracy, and can guarantee the measurement accuracy of the large-scale flange; a detection method is not related to the gesture of the flange plane and the field detection result can be obtained efficiently; and detection does not depend on machining equipment serving as base, the method has independence, and the detection accuracy is not influenced by the machining equipment.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Test device and test method for building structural adhesive bonding tensile stress relaxation

ActiveCN104237012AGood or bad anti-agingThe performance of resistance to stress relaxation is good or badMaterial strength using tensile/compressive forcesDynamometerEngineering

The invention provides a test device and a test method for testing building structural adhesive bonding tensile stress relaxation. The test device comprises a fixed support, a tensioning device, a test piece, a fixture and a digital dynamometer, wherein the test piece is detachably mounted on the fixture and receives the tensile force from tensioning device through the fixture. The test method comprises the steps as follows: the cured test piece is assembled on the test device; a turnbuckle of the tensioning device is rotated to adjust the force applied to the test piece; the test device is entirely placed on an outdoor natural exposure field or selectively placed in a manual ageing chamber, so that the tensile stress under the corresponding ageing condition can be measured; the tensile stress after ageing is compared with the tensile stress before ageing, so that the tensile stress relaxation coefficient can be obtained. By the aid of the test device and the test method, building structural adhesive bonding tensile stress relaxation after various ageing tests can be tested, changes of the tensile stress can be monitored in real time, and a means is provided for evaluation of the bonding ageing durability and prediction of the service life of a building structural adhesive.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

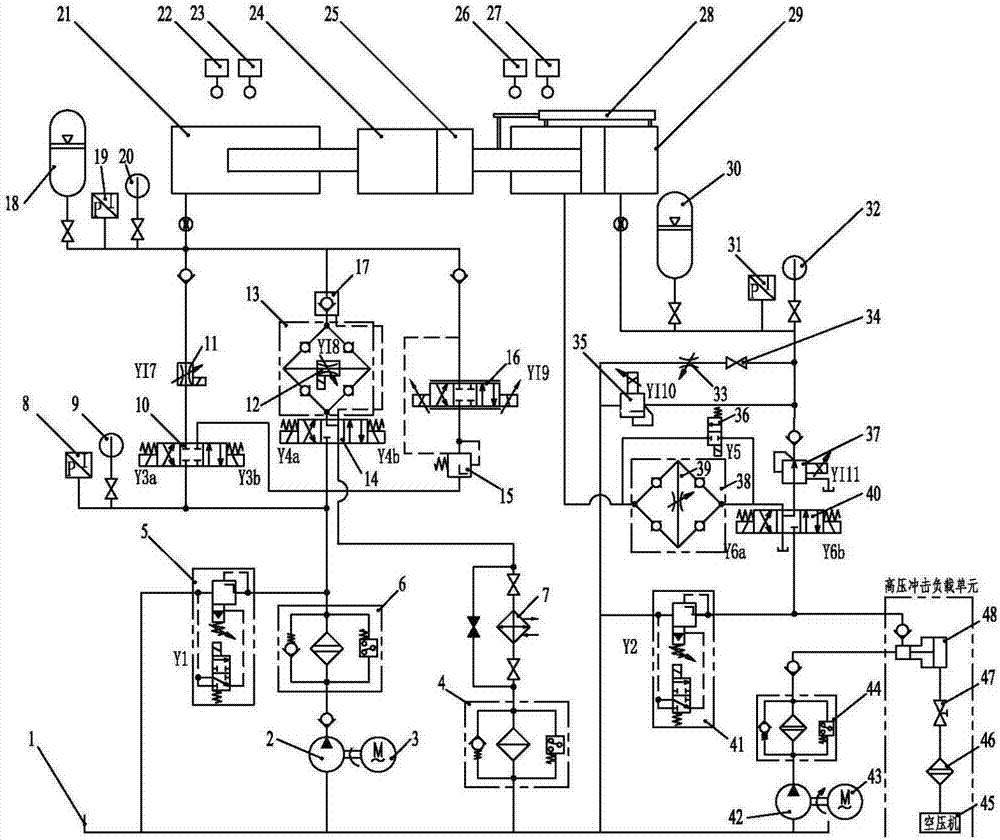

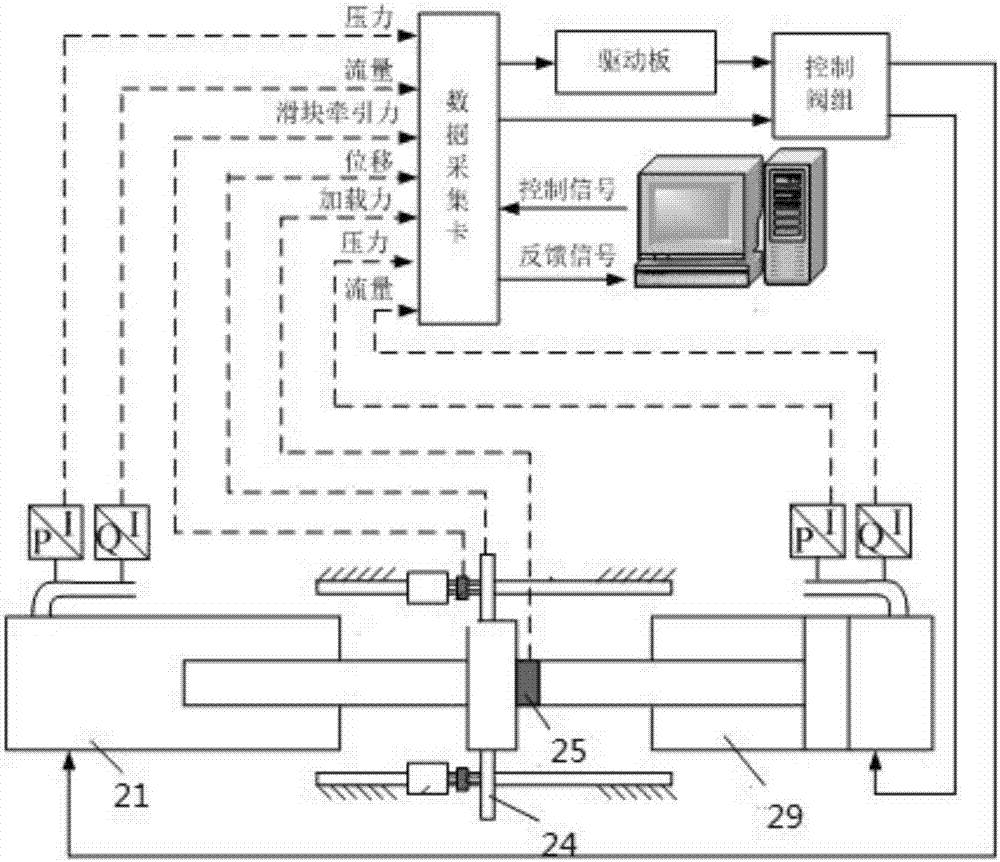

Comprehensive test platform for dynamic performance of hydraulic cylinder of engineering machine

ActiveCN107023536AImplement testWide speed rangeFluid-pressure actuator testingServomotor componentsHydraulic cylinderCombined test

The invention discloses a comprehensive test platform for the dynamic performance of a hydraulic cylinder of an engineering machine. The comprehensive test platform for the dynamic performance of the hydraulic cylinder of the engineering machine comprises a test platform body, a hydraulic system and an electrical test control system. The hydraulic system comprises a drive system unit and a loading system unit. The drive system unit comprises a first hydraulic pump, a first filter and three liquid inlet valve banks. Oil outlets of the three liquid inlet valve banks are connected with an oil inlet of the tested hydraulic cylinder. The loading system unit supplies oil to a loading hydraulic cylinder. The electrical test control system controls all the valve banks of the hydraulic system according to feedback signals. According to the comprehensive test platform for the dynamic performance of the hydraulic cylinder of the engineering machine, a drive system, a loading system and a gas-liquid supercharging system which are independently arranged are used for meeting test and control needs under different loads and different working conditions; and the comprehensive test platform also utilizes the feedback signals to control the test process, when the oil pressure, the flow, the filter precision, the system temperature and other indexes are not at the normal level, the system gives out an alarm to remind people and stops, and therefore system operation reliability is guaranteed.

Owner:CENT SOUTH UNIV

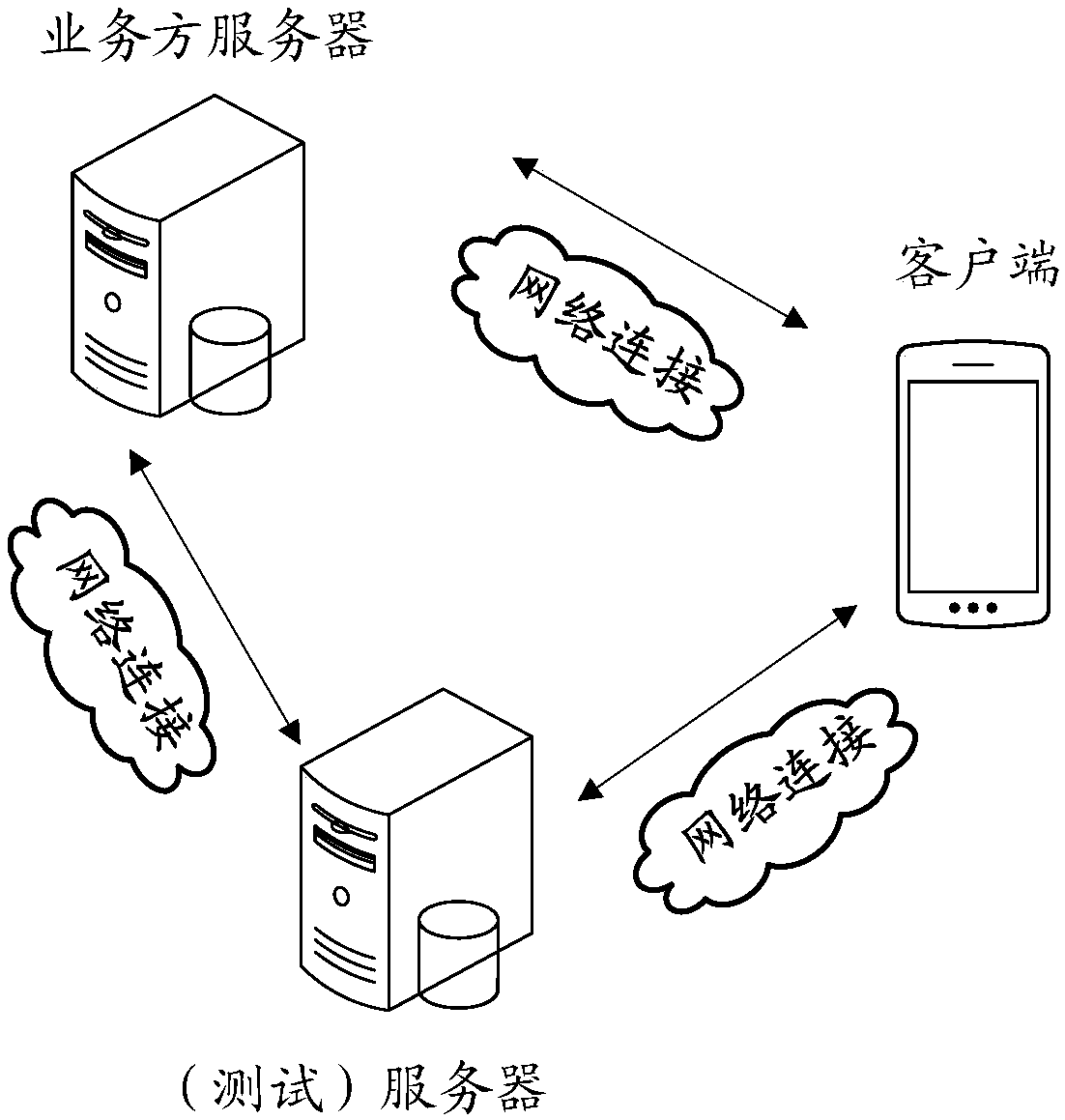

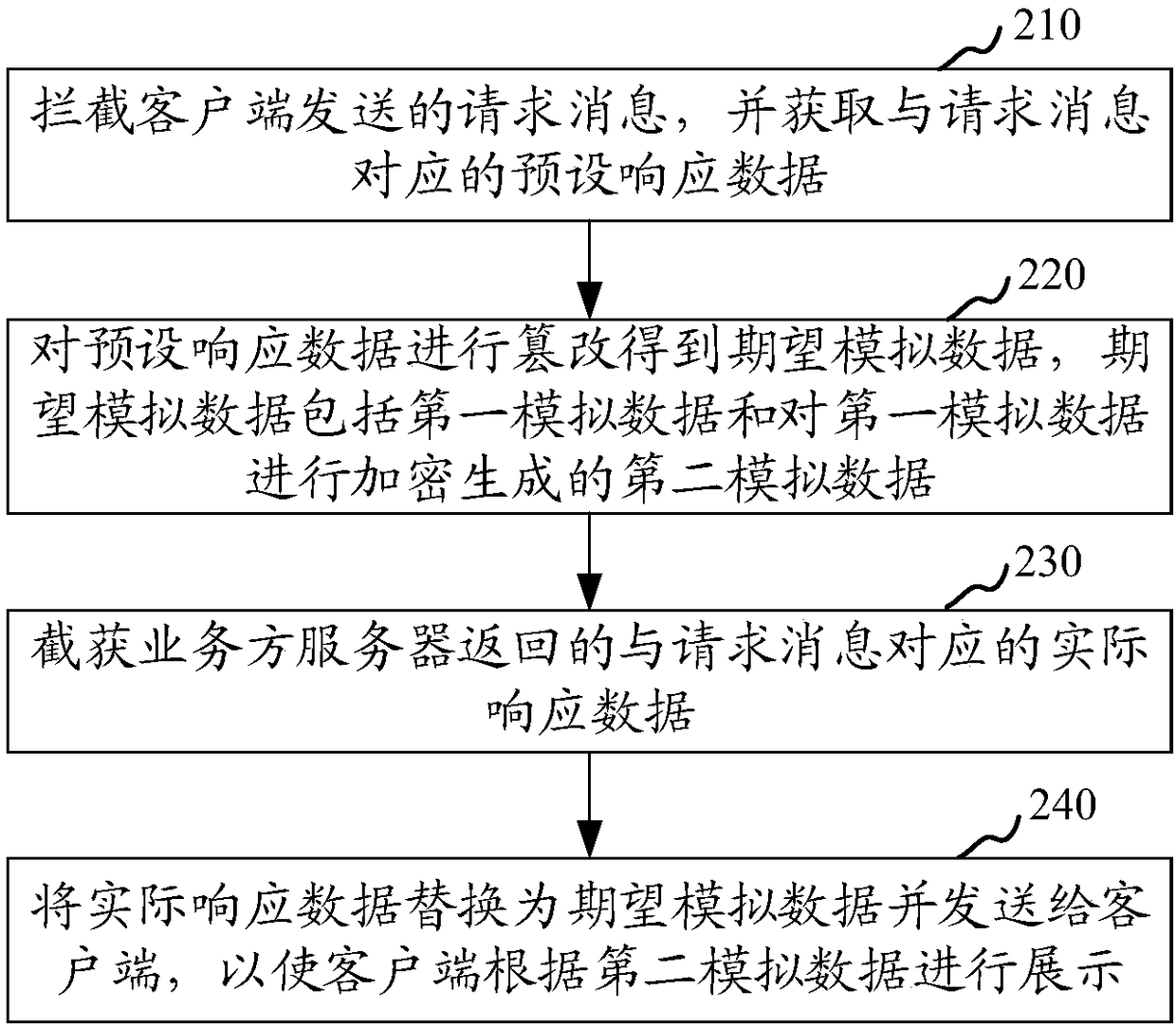

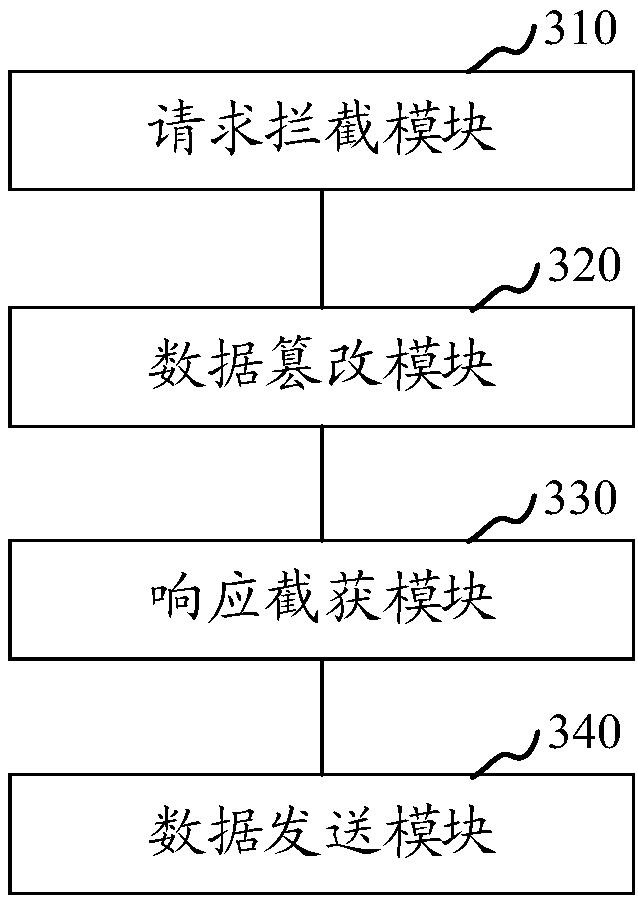

Application program testing method, device, computer device and storage medium

ActiveCN108268375AEasy to testImplement testSoftware testing/debuggingProgram testingApplication software

The application relates to an application program testing method, system, a computer device and a storage medium. The method comprises following steps: intercepting a request message sent by a client,and obtaining preset response data corresponding to the request message; tampering the preset response data to obtain expected simulation data, wherein the expected simulation data comprises first simulation data and second simulation data generated by encrypting the first simulation data; intercepting actual response data corresponding to the request message returned by a service provider server; replacing the actual response data with the expected simulation data and send it to the client so that the client can display according to the second simulation data. The method can be used to improve application testing efficiency.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

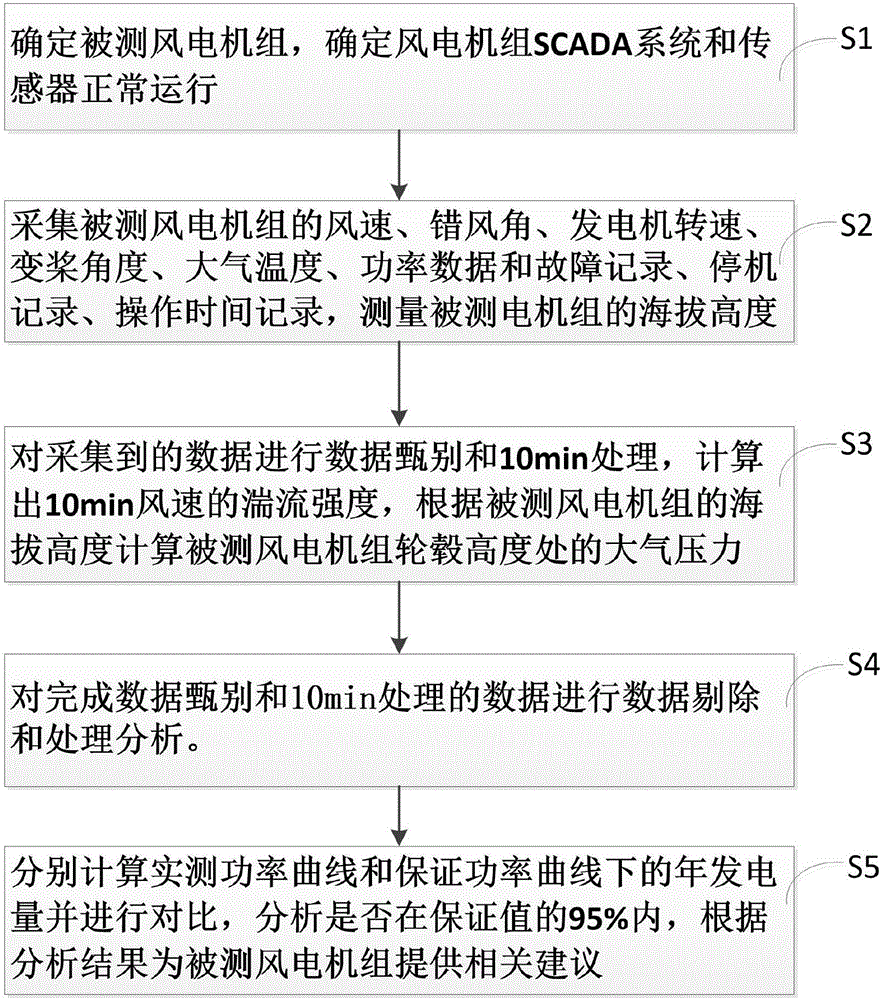

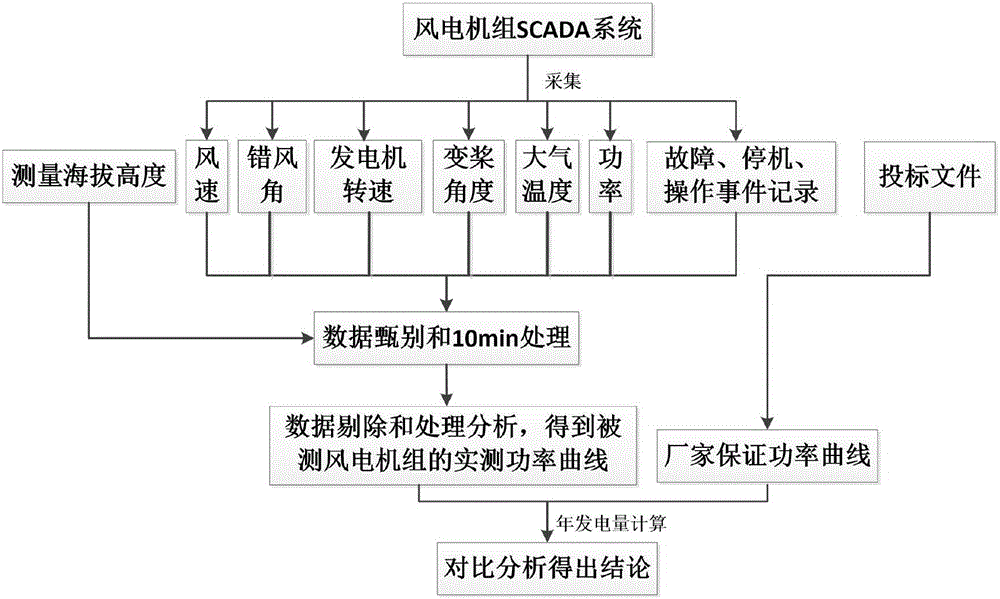

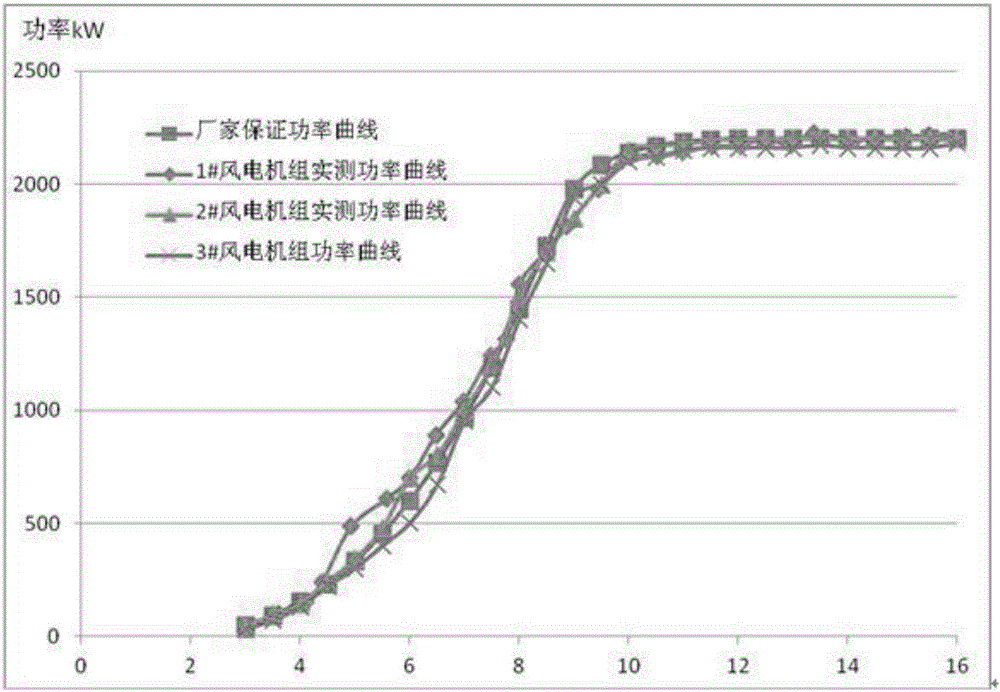

Wind turbine generator set power curve testing method based on SCADA (supervisory control and data acquisition) system

InactiveCN106368908AImprove convenienceEasy to operateEngine fuctionsMachines/enginesElectricitySCADA

The invention relates to a wind turbine generator set power curve testing method based on a SCADA (supervisory control and data acquisition) system. The method is based on related data such as wind speeds and generator rotating speeds acquired by the SCADA system of a wind power plant and records such as faults and machine halt and comprises the following steps of: carrying out data reduction and analytical calculation by using SCADA big data of a wind turbine generator set to obtain actual measured power curves of the wind turbine generator sets in the whole plant; and comparing the actual measured power curves of the wind turbine generator sets in the whole plant with guaranteed power curves during set bidding, thereby guiding operation, overhauling and out-of-warranty management of the wind power plant and improving the electric energy production of the wind turbine generator set in the whole plant.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

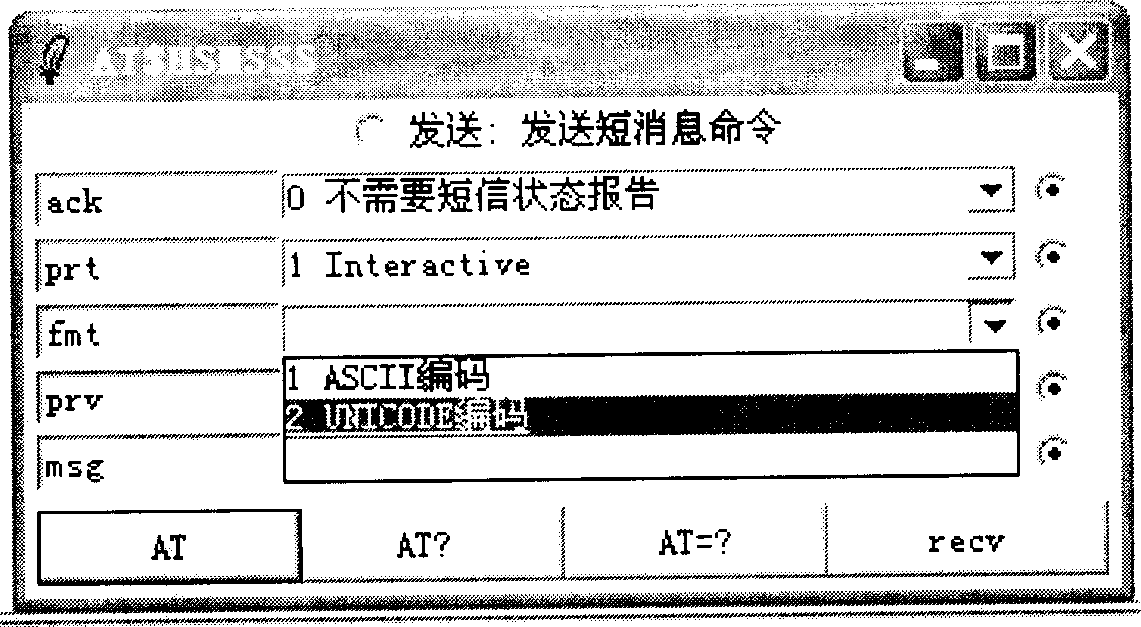

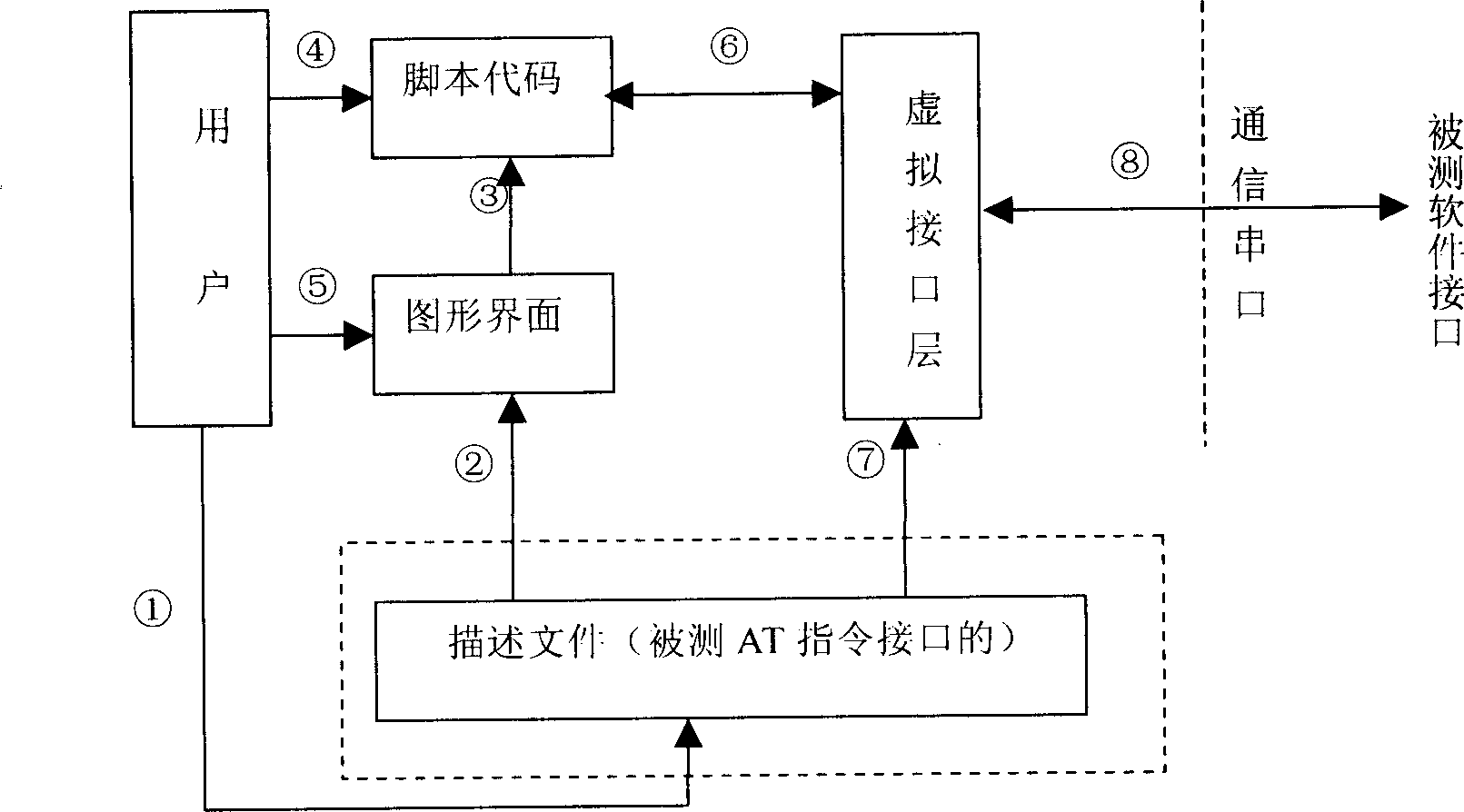

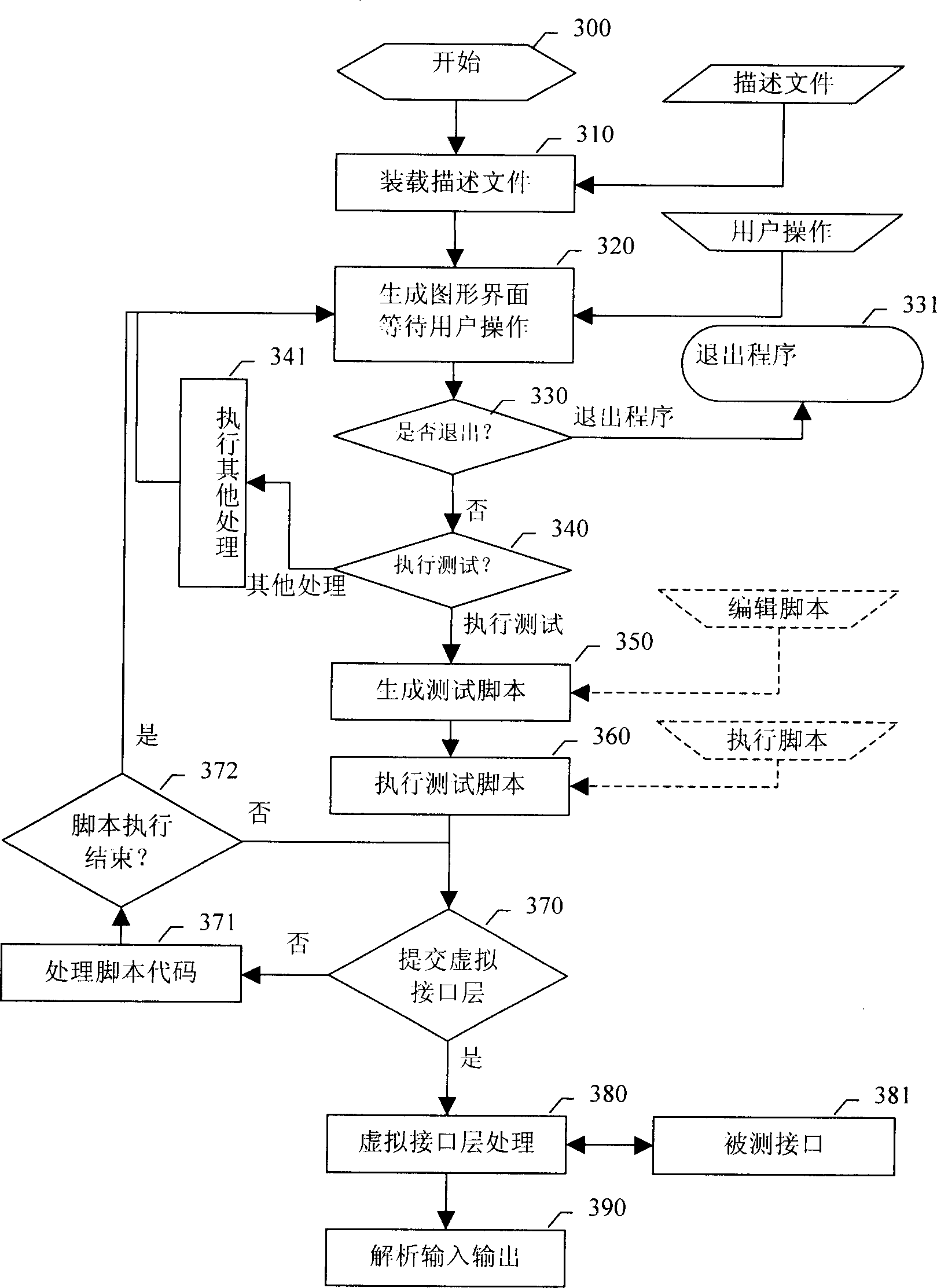

Software interface testing method and apparatus

InactiveCN1866221AImprove portabilityImprove reusabilitySoftware testing/debuggingExtensibilityGraphics

The disclosed software interface testing method comprises: according to pre-set grammar format, describing the software interface to be tested, and dynamic generating the GUI for testing. Wherein, it just needs to modify description information and dynamic generate a GUI for testing when the target interface changes. This invention implements seamless transplantation, and improves testing tool expandability and portability fit to different testing request.

Owner:SNAPTRACK

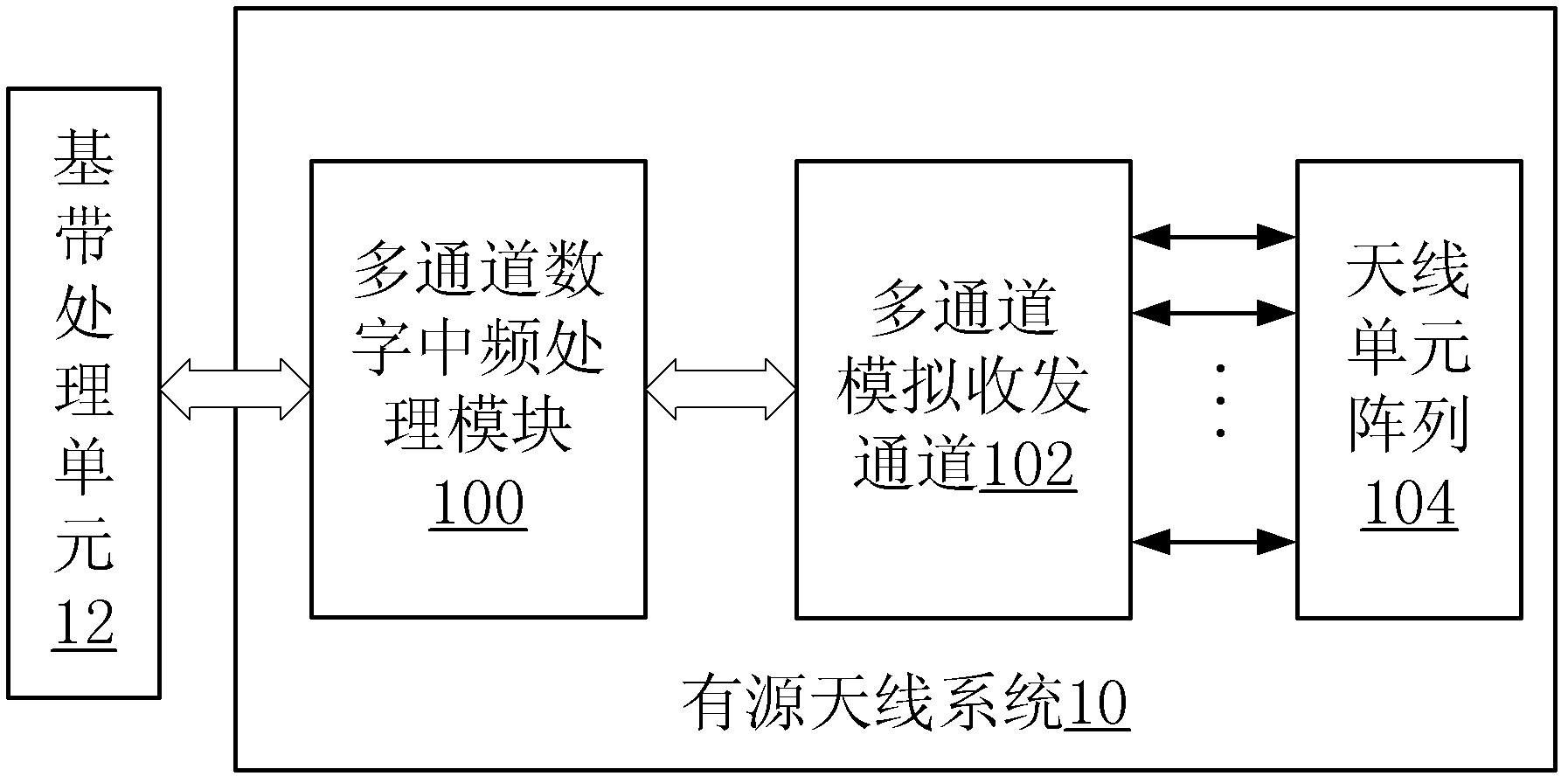

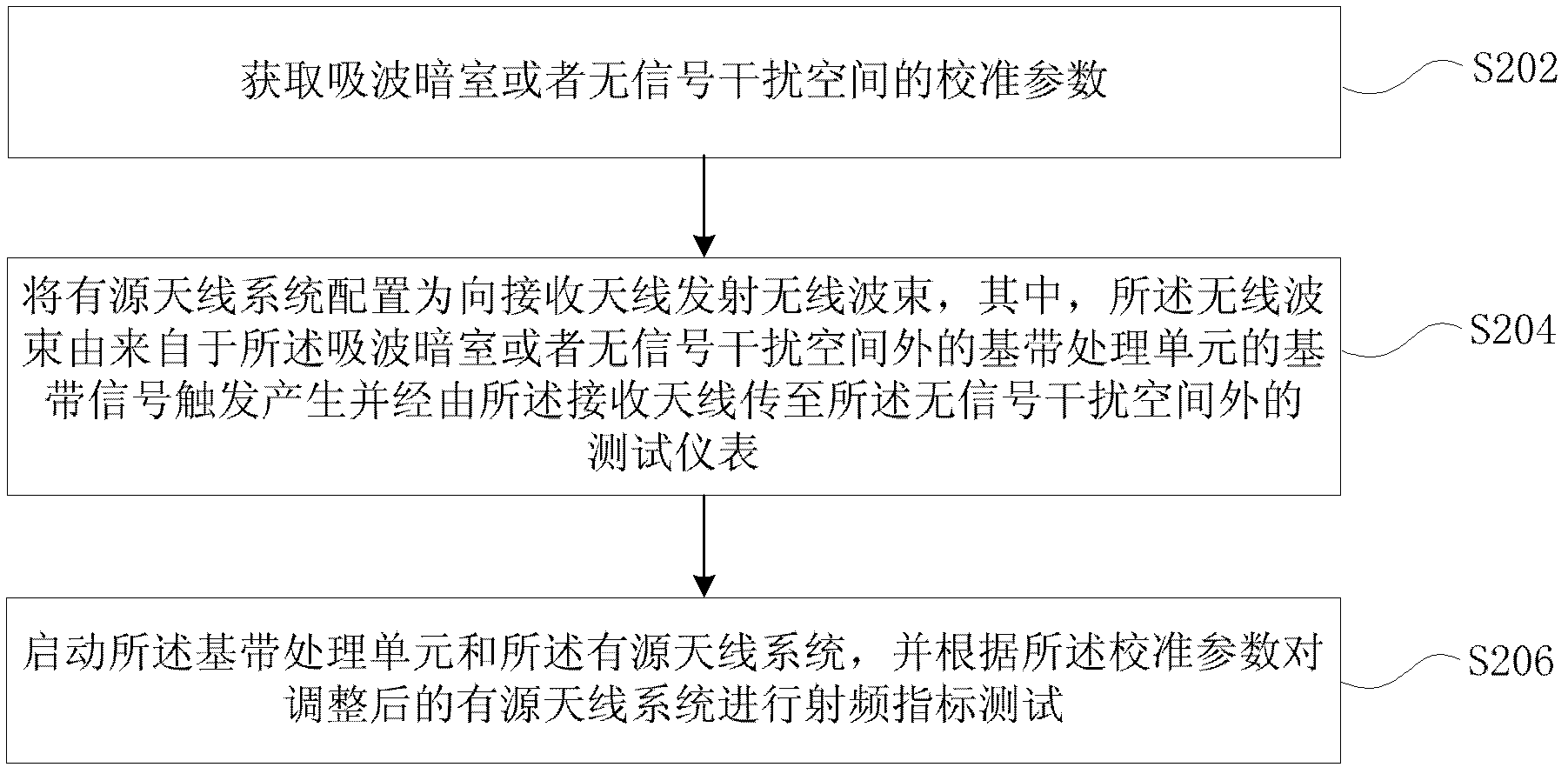

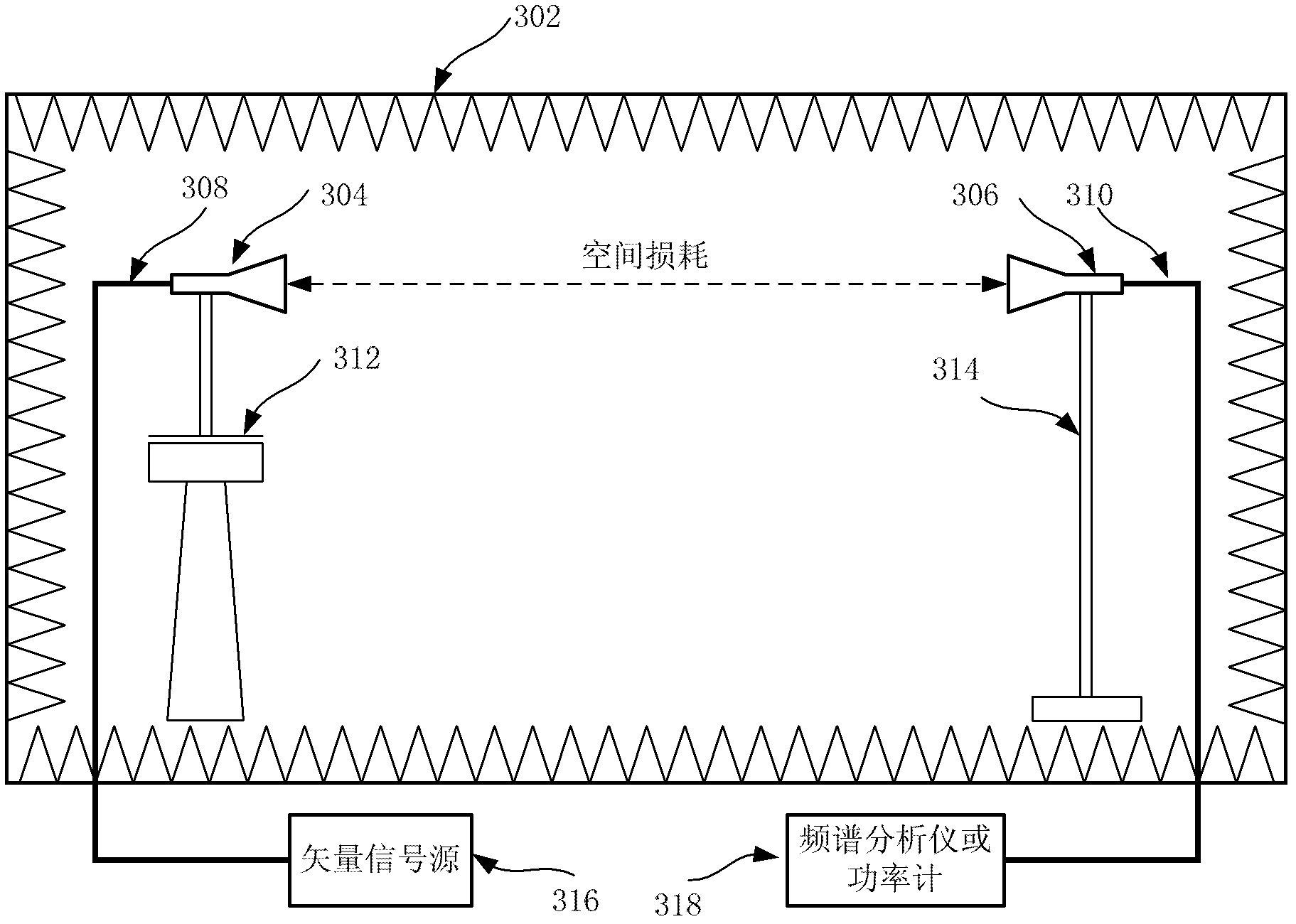

Methods and devices for testing downlink and uplink wireless indexes of active antenna system

The invention provides methods and devices for testing downlink and uplink wireless indexes of an active antenna system. The method for testing the downlink wireless index is carried out in a wave-absorbing dark room or a signal non-interference space and comprises the following steps of: acquiring calibration parameters of the wave-absorbing dark room or the signal non-interference space; configuring the active antenna system to transmit a wireless wave beam to a receiving antenna, wherein the wireless wave beam is triggered and generated by a base-band signal from a base-band processing unit outside the wave-absorbing dark room or the signal non-interference space, and then transmitted to a test instrument outside the wave-absorbing dark room or the signal non-interference space through the receiving antenna; and starting the base-band processing unit and the active antenna system, and testing the wireless indexes of the adjusted active antenna system according to the calibration parameters. By adoption of the technical scheme provided by the invention, testing of various wireless indexes of the active antenna system is realized.

Owner:NANJING ZHONGXING SOFTWARE

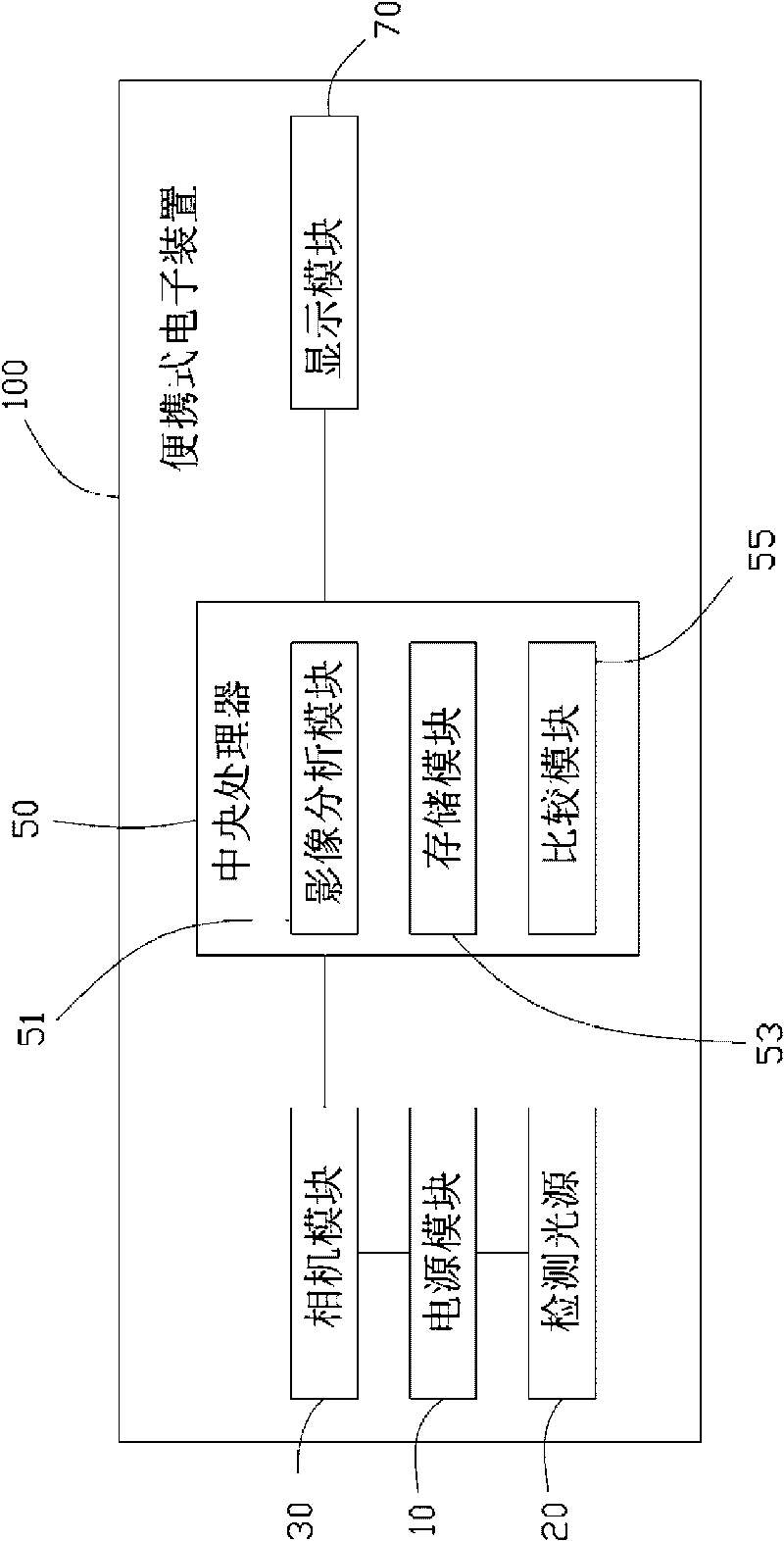

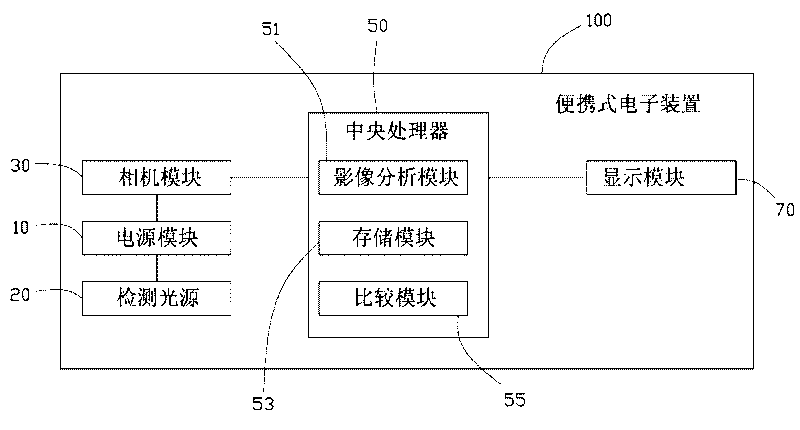

Multifunctional portable electronic device

InactiveCN101751714AEasy to useImplement testPrintersPaper-money testing devicesOptical propertyImaging analysis

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

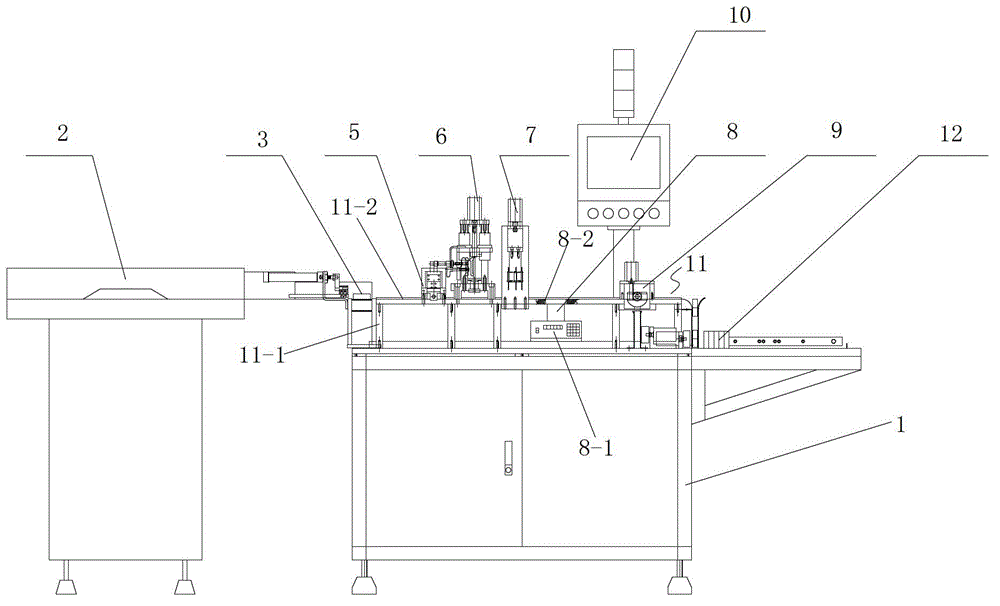

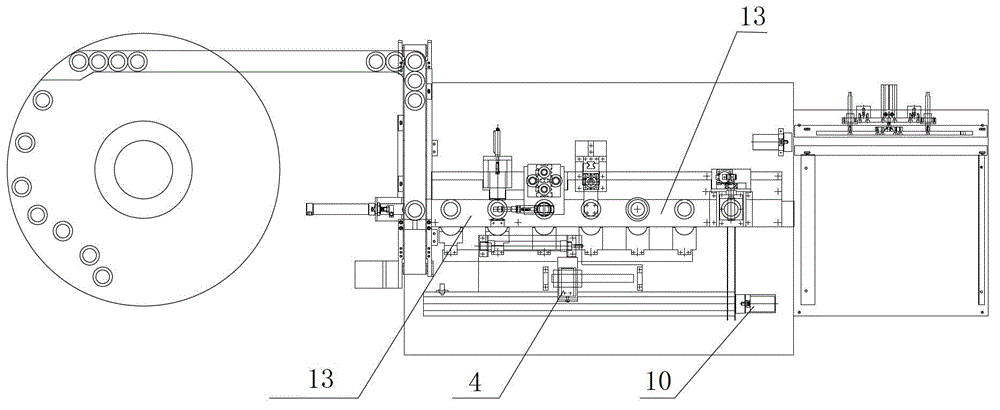

Full-automatic inspection production line for circular parts

ActiveCN102721387ARealize automatic movementAchieve permutationSpecial purpose weighing apparatusProduction lineProximity sensor

The invention belongs to detection equipment and particularly relates to a full-automatic inspection production line for circular parts. The full-automatic inspection production line is characterized in that the full-automatic inspection production line comprises a machine tool body, a disk type electromagnetic oscillation feeding device, a feeding conveyor belt device, a workpiece moving mechanism, and an external diameter detection mechanism, an internal diameter detection mechanism, a thickness detection mechanism, a weight detection mechanism and a screening mechanism which are sequentially arranged as well as a touch display screen which is fixedly connected with the machine tool body. The full-automatic inspection production line has the benefits of realization of automatic moving and arrangement as well as gradual-item detection of external diameter, internal diameter, thickness and weight. Core parts of the detection mechanism comprise an inlet high-precision contact type sensor, a linear potentiometer, a high-precision electronic scale and the like; automatic moving and inspection are realized by using a pneumatic element for driving, and thus high automatic degree and high detection precision are realized; and automatic screening and arranging can be realized and automatic control is realized by being matched with a proximity sensor.

Owner:天津市中马骏腾精密机械制造有限公司

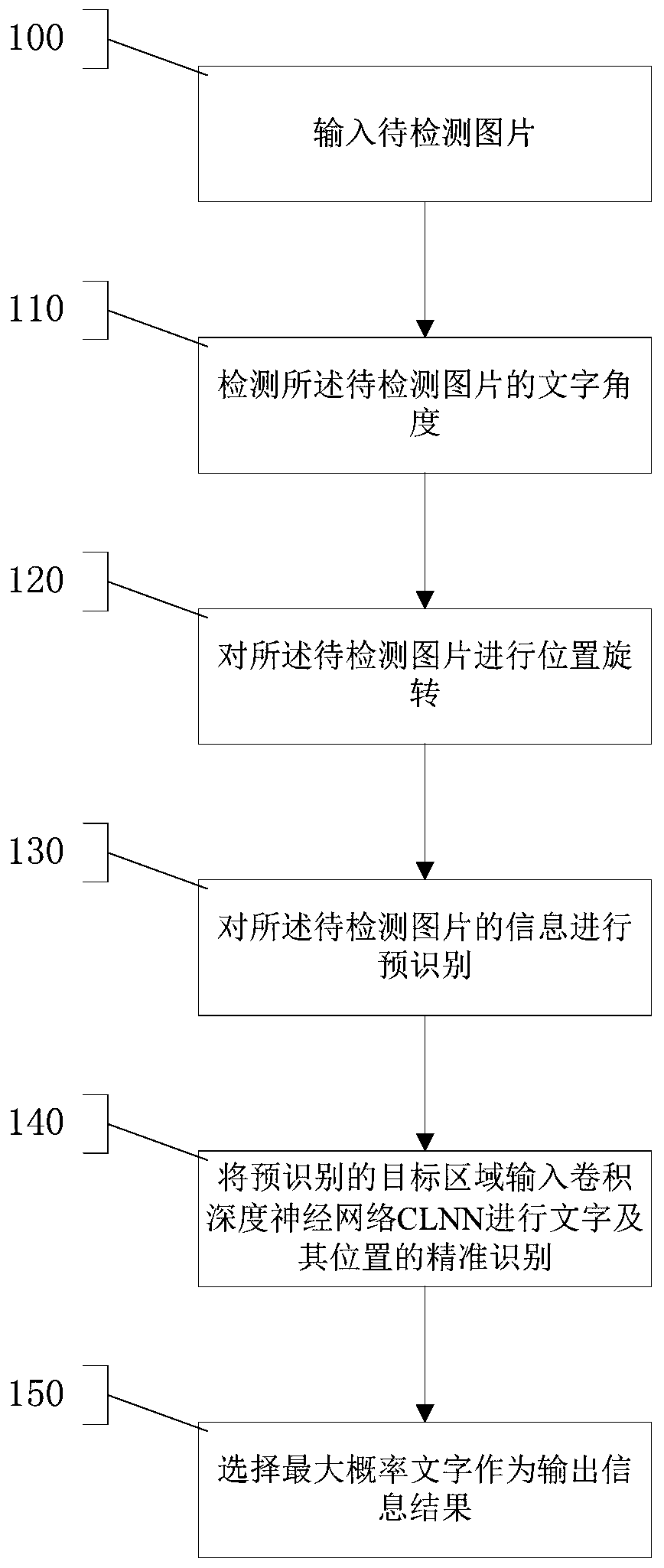

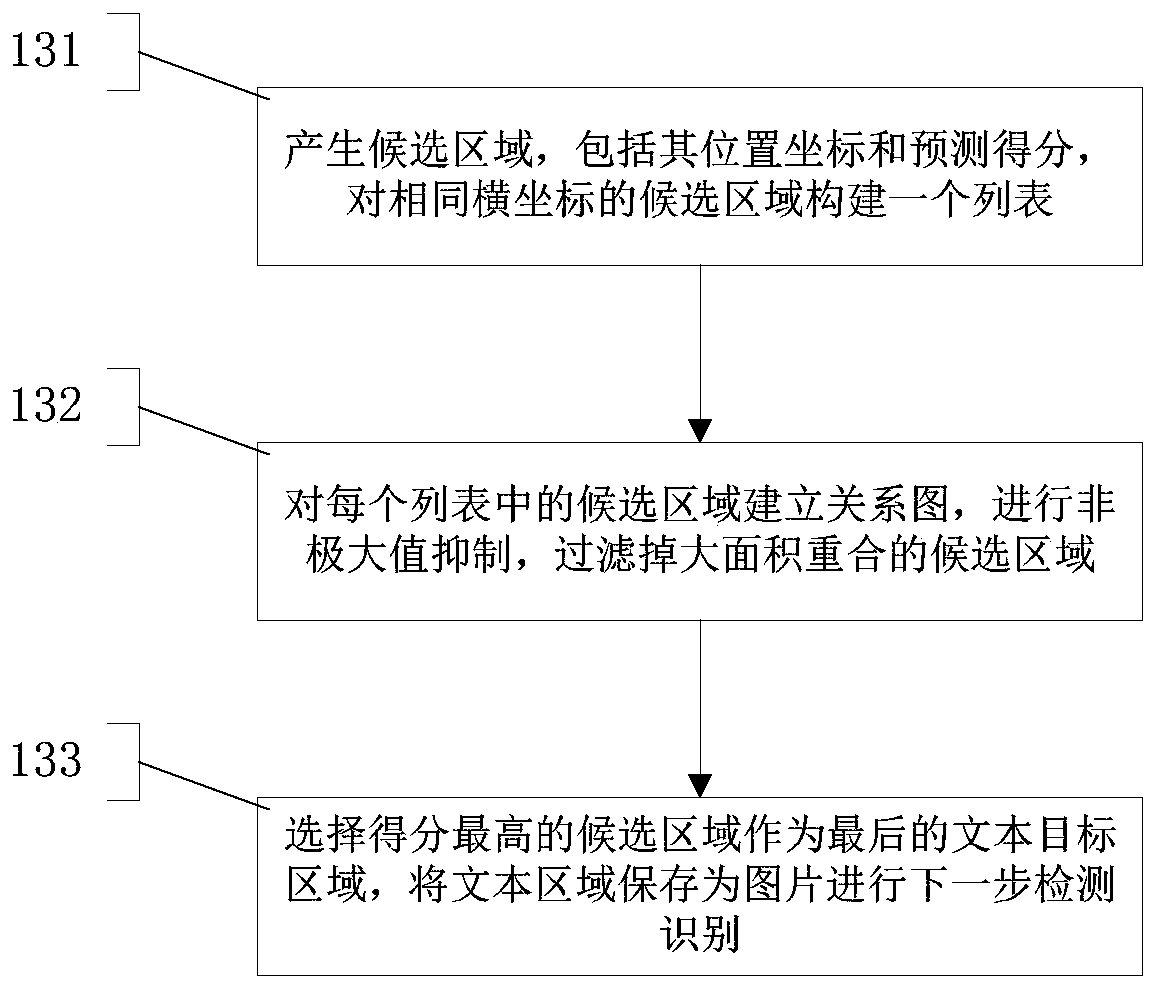

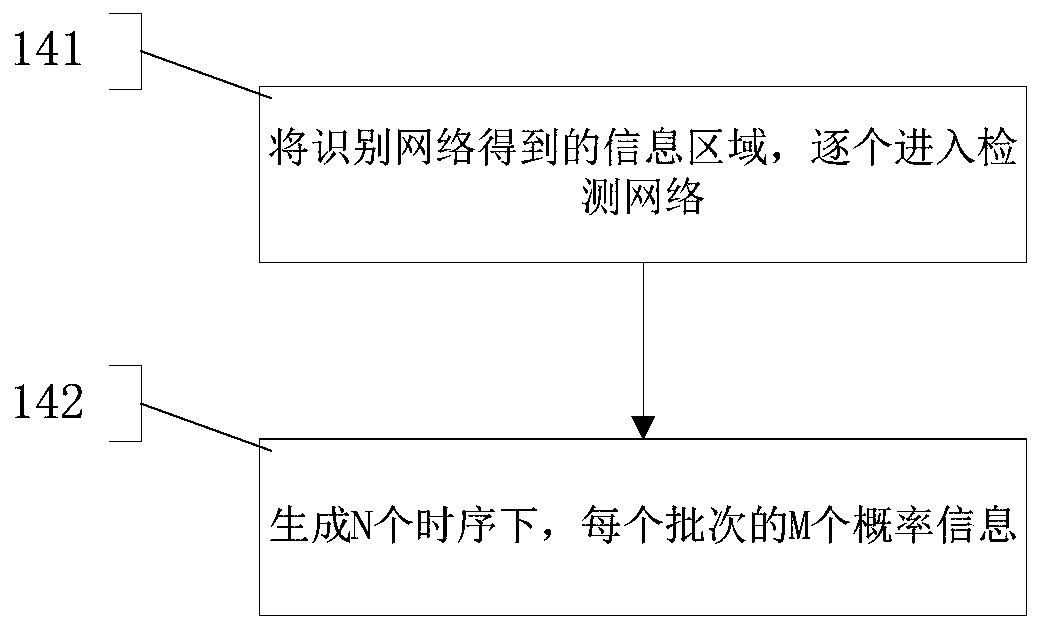

Image correction and text and position identification method and system

ActiveCN109993160AImplement testCharacter and pattern recognitionNeural architecturesPattern recognitionBusiness card

The invention provides an image correction and text and position recognition method and system, and the method comprises the steps: inputting a to-be-detected picture and also comprises the followingsteps of detecting character angles of the to-be-detected picture, fitting a straight line, counting the slope of the straight line, and taking mode direction Theta as the correction direction of thepicture; utilizing affine transformation matrix to rotate the position of a to-be-detected picture; pre-identifying information of the to-be-detected picture by using fast-rcnn positioning technology;inputting a pre-identified target area into convolutional deep neural network CLNN for accurate identification of characters and positions thereof; and outputting a recognition result. The inventionprovides the image correction and text and position identification method and system. According to the image correction and text and position identification model based on a neural network, the problems of identification of texts such as an identity card, a business card and a table picture and position identification of the texts are solved so as to meet the application requirements of various industries and bring better experience to a user.

Owner:BEIJING UNION UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com