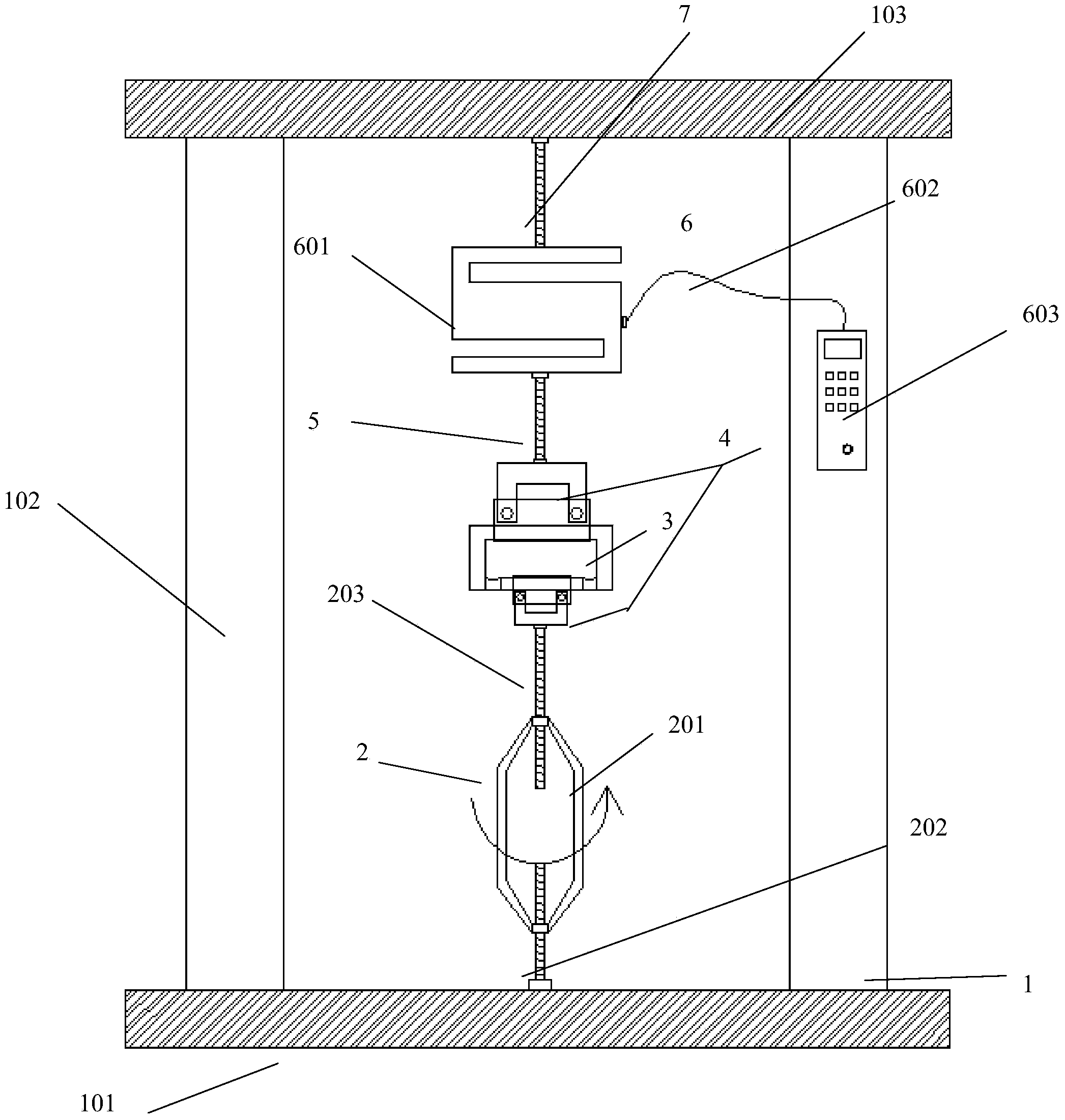

Test device and test method for building structural adhesive bonding tensile stress relaxation

A technology of building structural glue and tensile stress, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems of data discontinuity and other issues, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1: test the stress relaxation coefficient of glass and fluorocarbon sprayed aluminum alloy bonding substrate

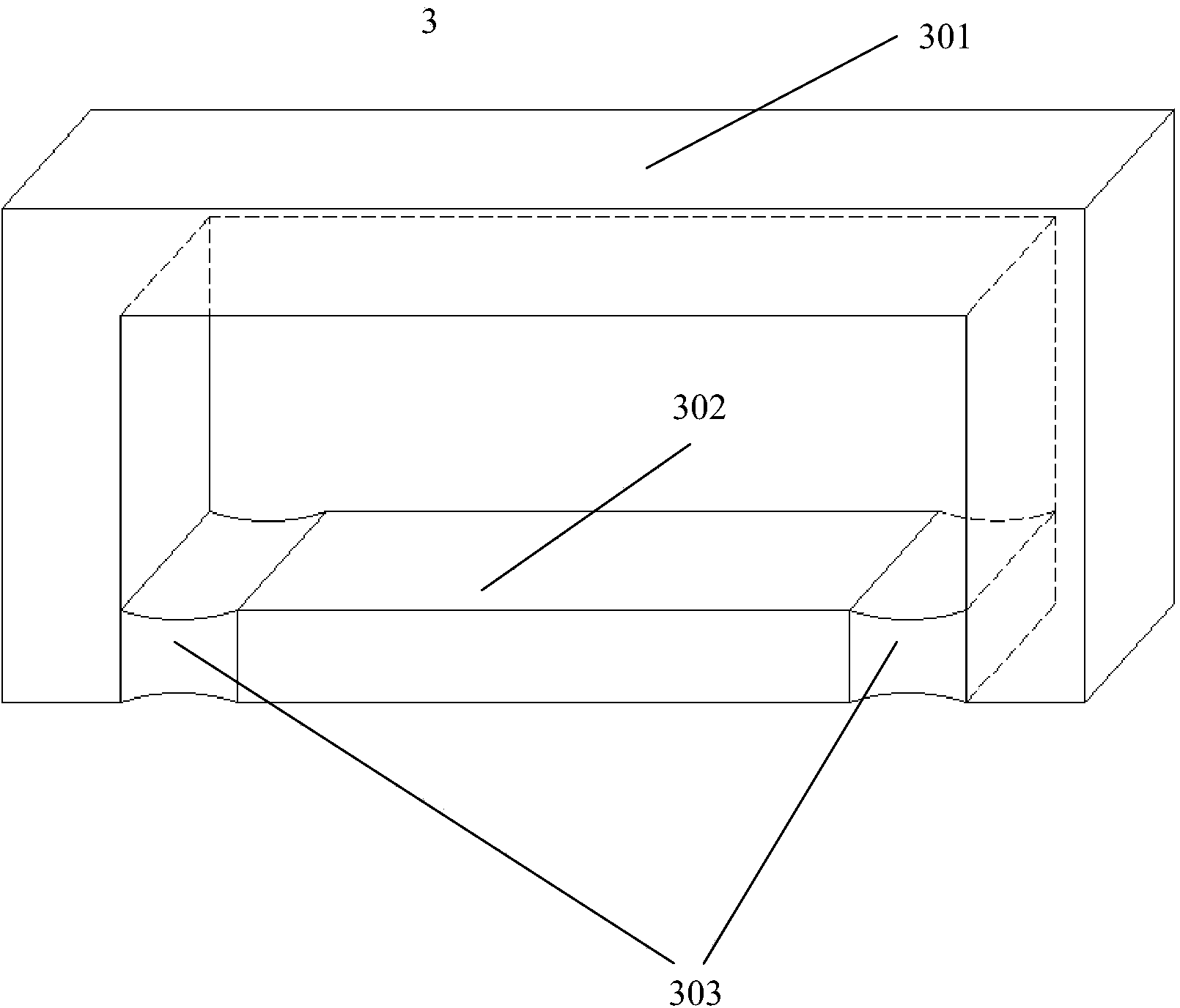

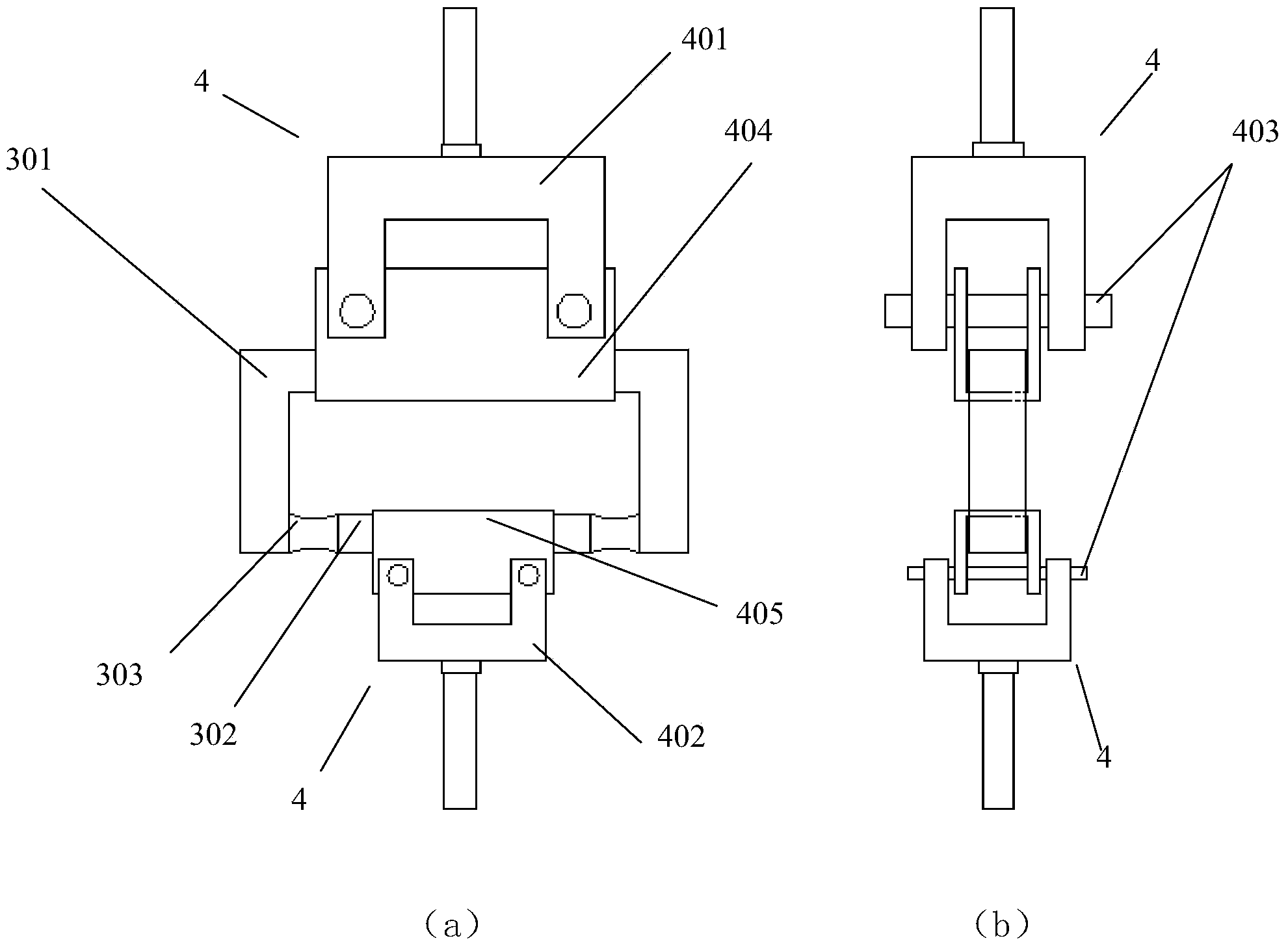

[0070] Specimen: Use glass and bonded base material fluorocarbon sprayed aluminum alloy, prepare and maintain the specimen according to step 1 (S1), and connect the specimen to the fixture through the upper and lower clamps.

[0071] Among them, the substrate specimen is bonded with fluorocarbon sprayed aluminum alloy, with a cross-section of 12mm×10mm; the bonded specimen is glass, with a size of 100mm×12mm×5mm;

[0072] The structural adhesive is: two-component silicone structural adhesive, the size of the bonding surface is: 12mm×5mm,

[0073] Initial tensile force F 0 For: 200N; Aging conditions: Natural placement in the laboratory at room temperature, the temperature is (23±2) ℃, relative humidity is (50±5)%; Aging time: 7 days,

[0074] The result of the test: the tensile force value F measured after 7 days t 120N, the result of evaluating t...

Embodiment 2

[0075] Embodiment 2: the stress relaxation coefficient of test glass and fluorocarbon sprayed aluminum alloy bonding substrate

[0076] Adopt aging box, other conditions are the same as embodiment 1.

[0077] Put the same specimen in an aging box at 40°C for 7 days, and measure the tensile force value F t is 30N, then the tensile stress relaxation coefficient at this time is reduced, which is R t =F t / F 0 =30N / 200N=0.15. It can be seen that the internal cohesion of the structural adhesive decreases under the condition of high temperature aging-stress coupling.

[0078] The testing device and testing method of the present invention can also be used for tensile stress relaxation testing of other adhesive sealing materials, such as building sealants and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com