Patents

Literature

1048results about "Gas analyser calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

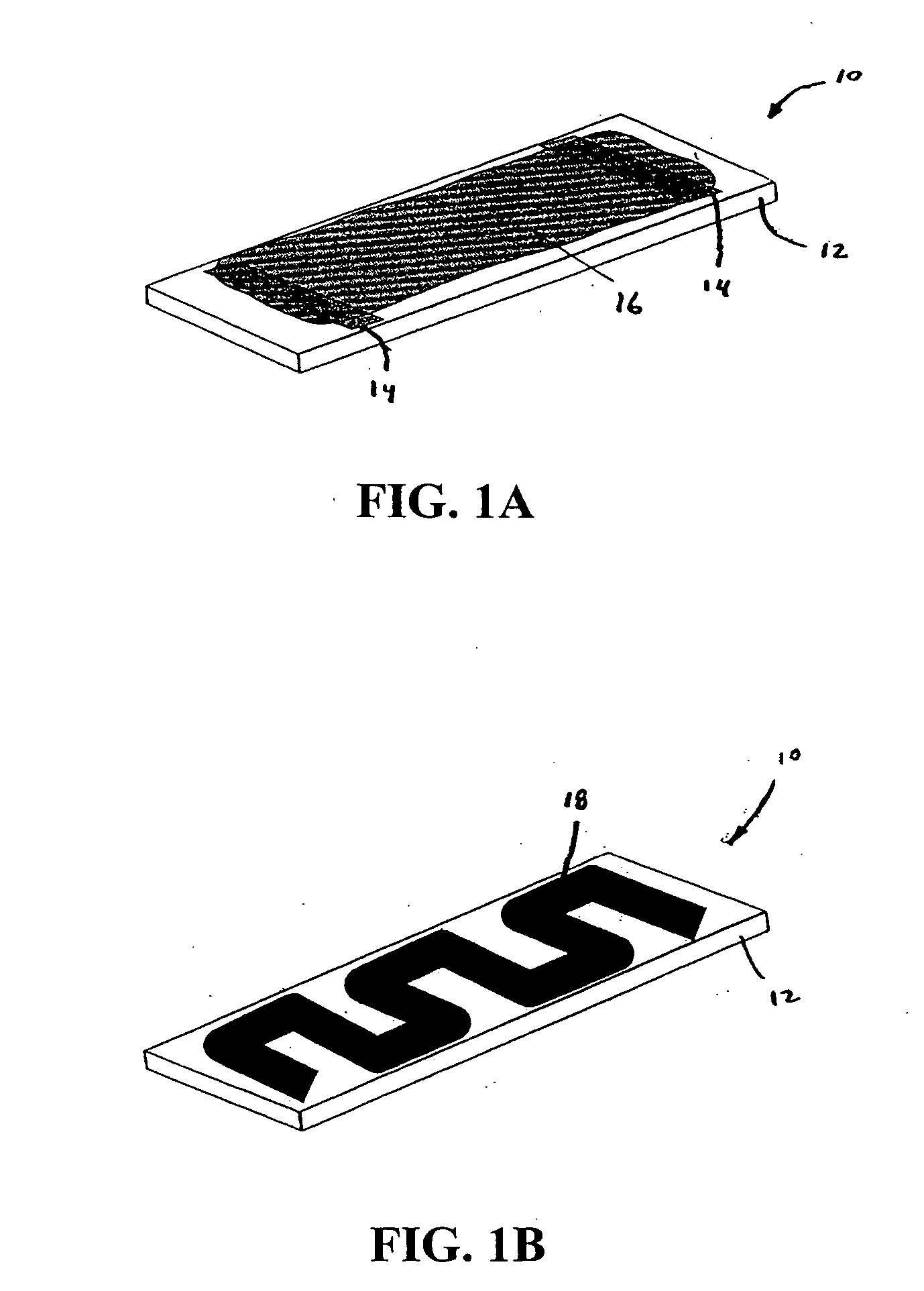

Methods and systems for calibration of RFID sensors

ActiveUS20090278685A1Testing sensing arrangementsGas analyser calibrationMemory chipComplex impedance spectra

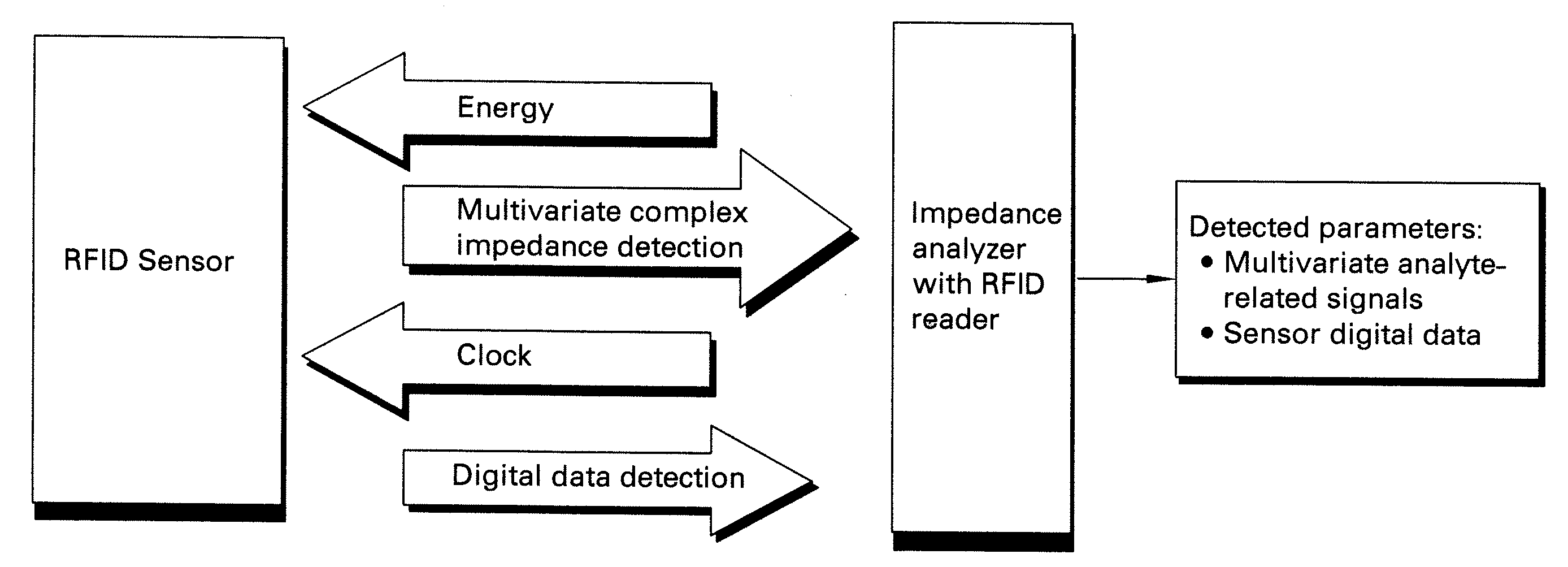

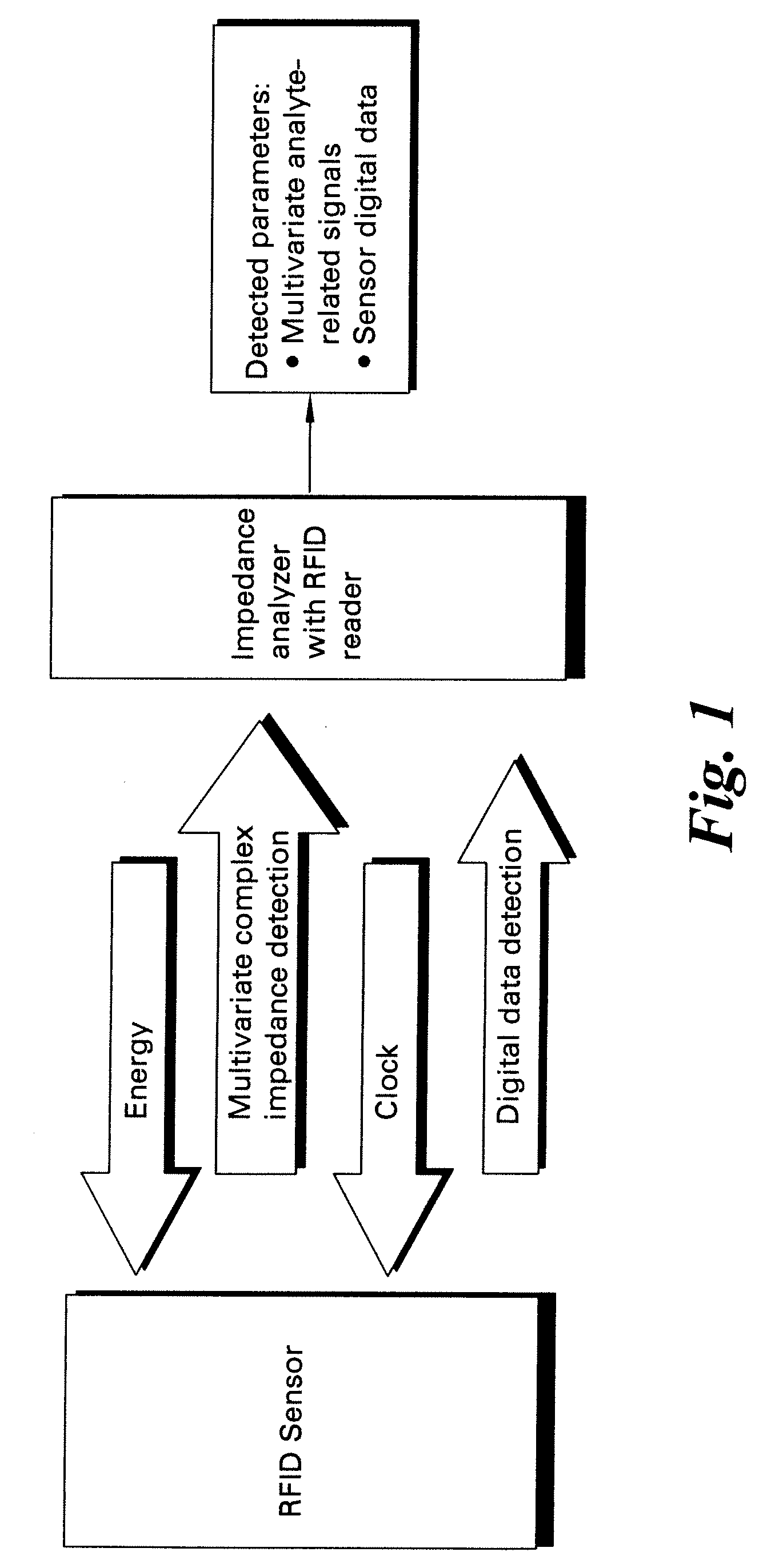

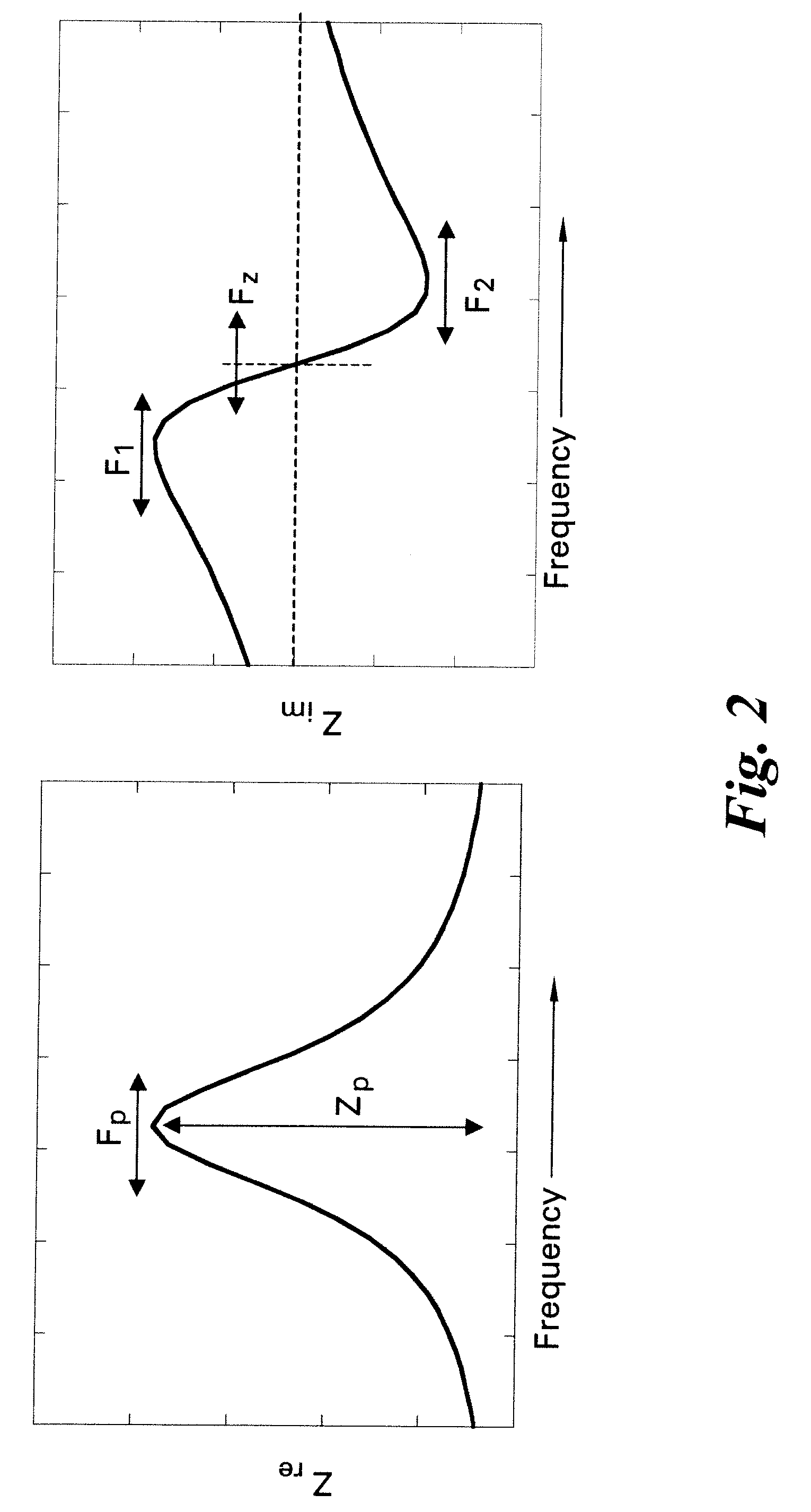

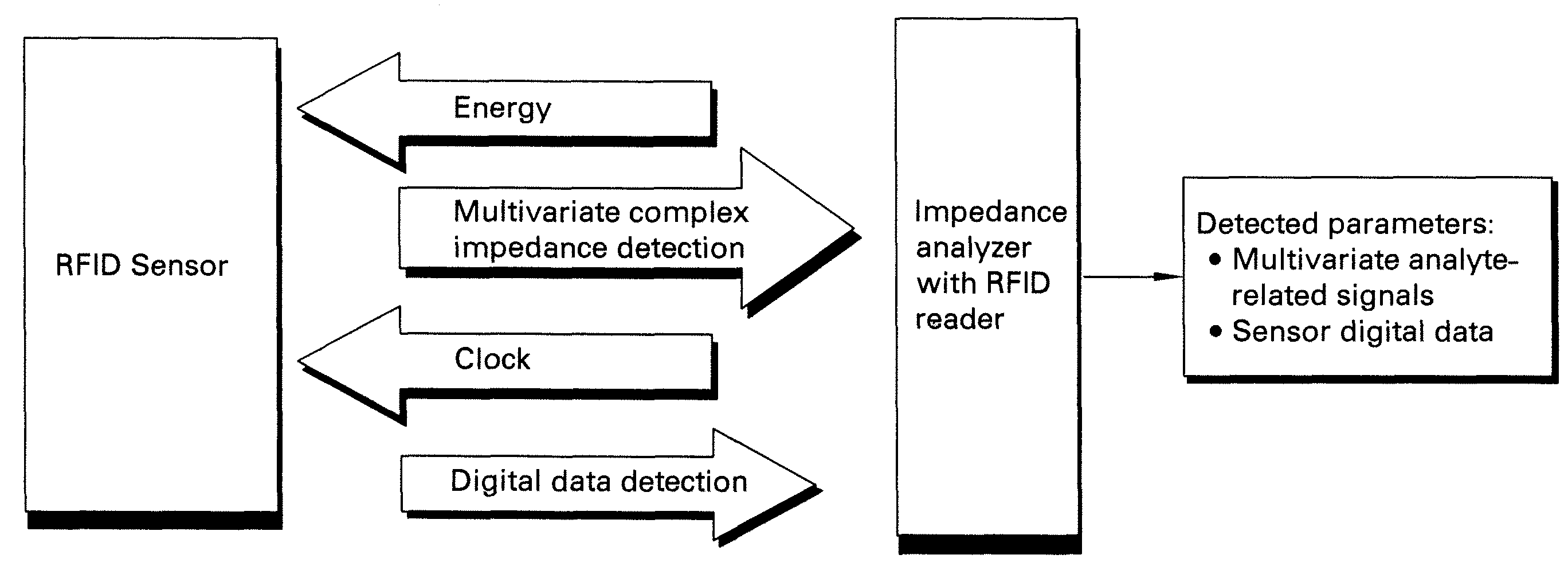

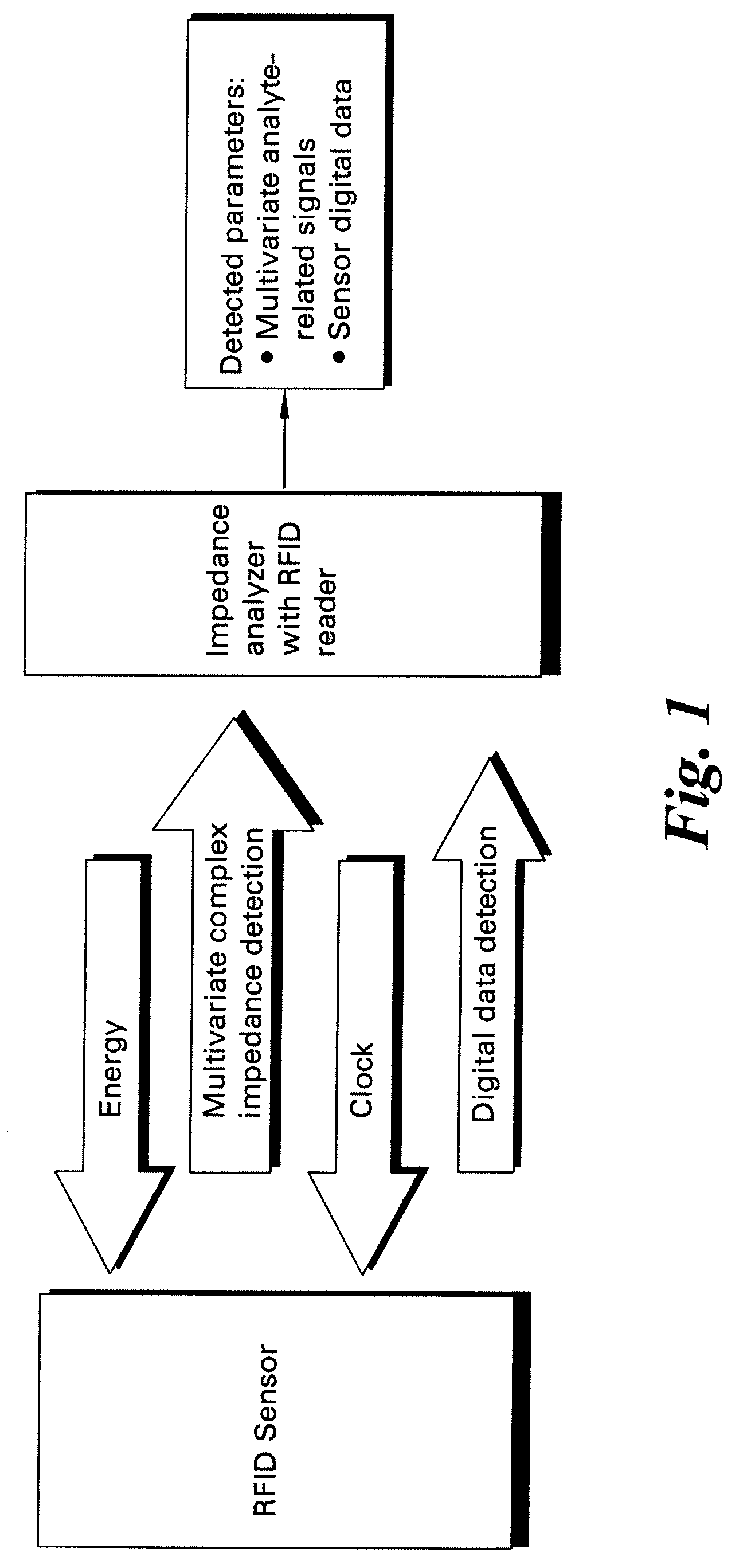

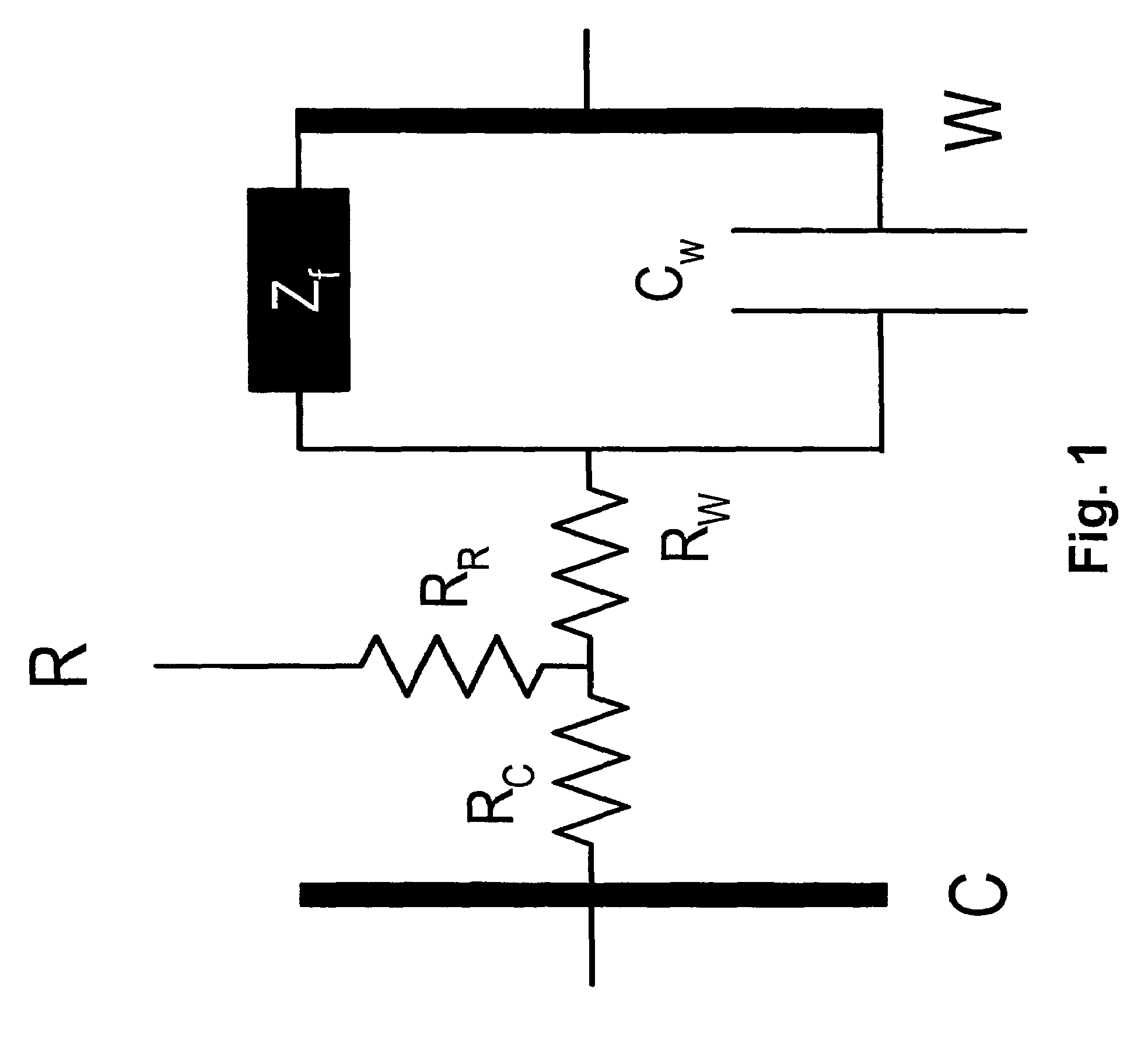

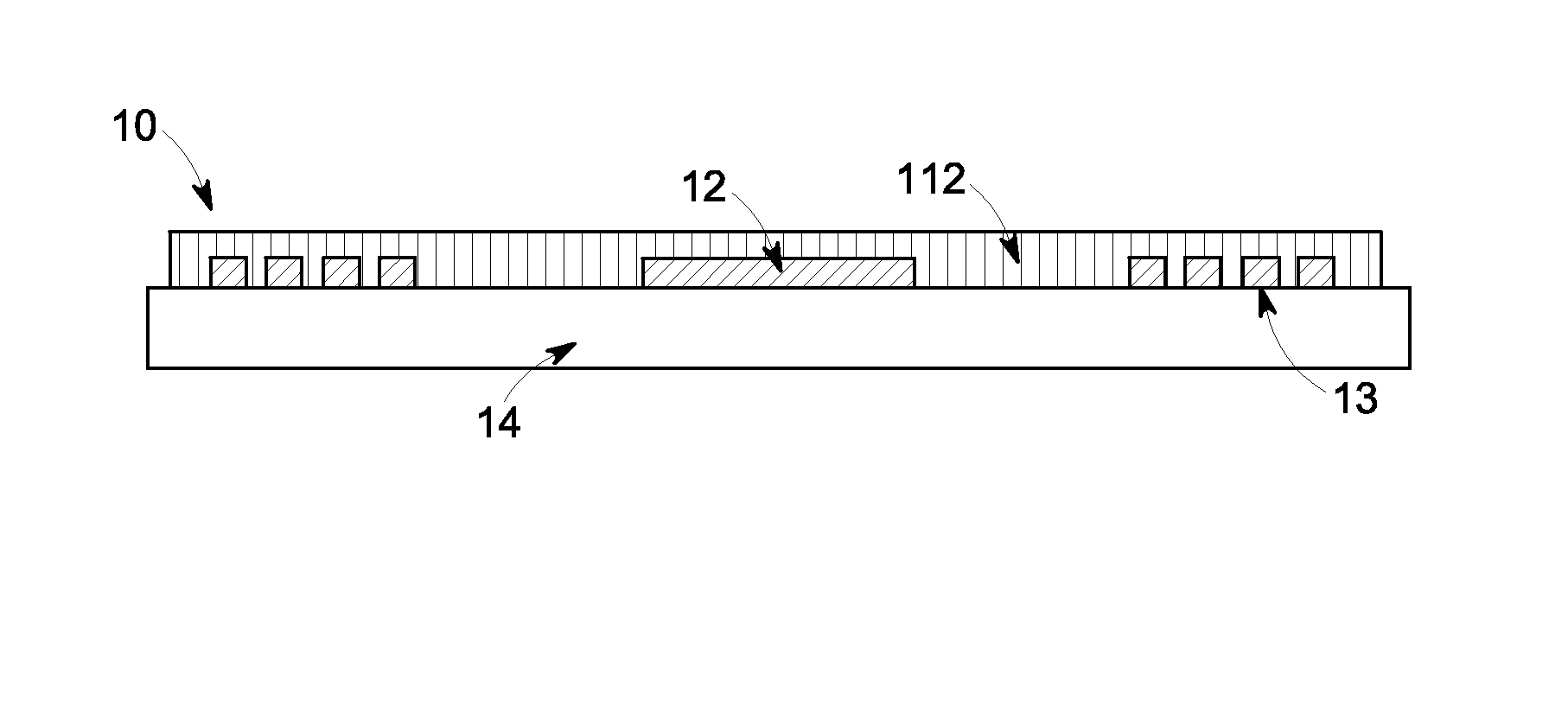

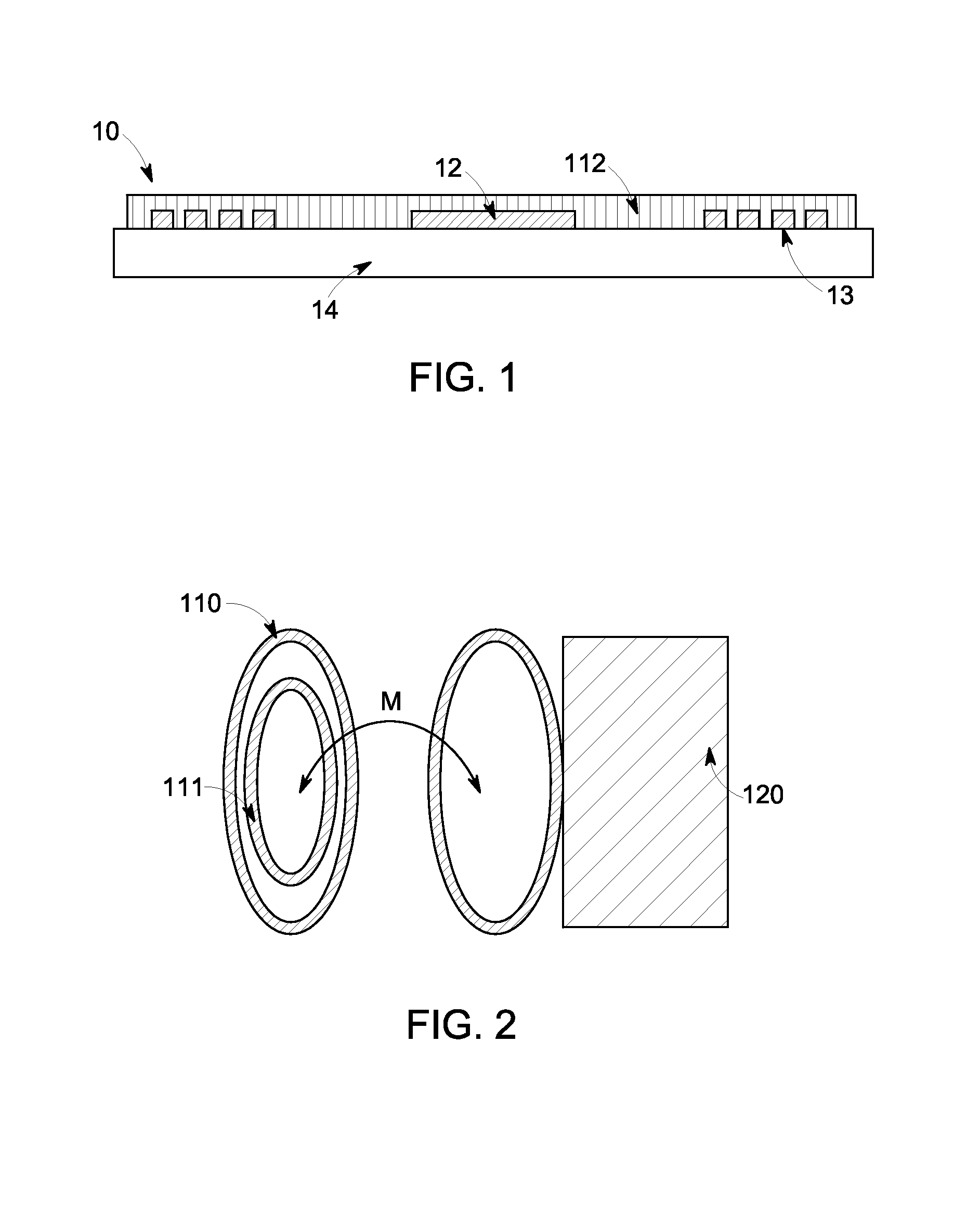

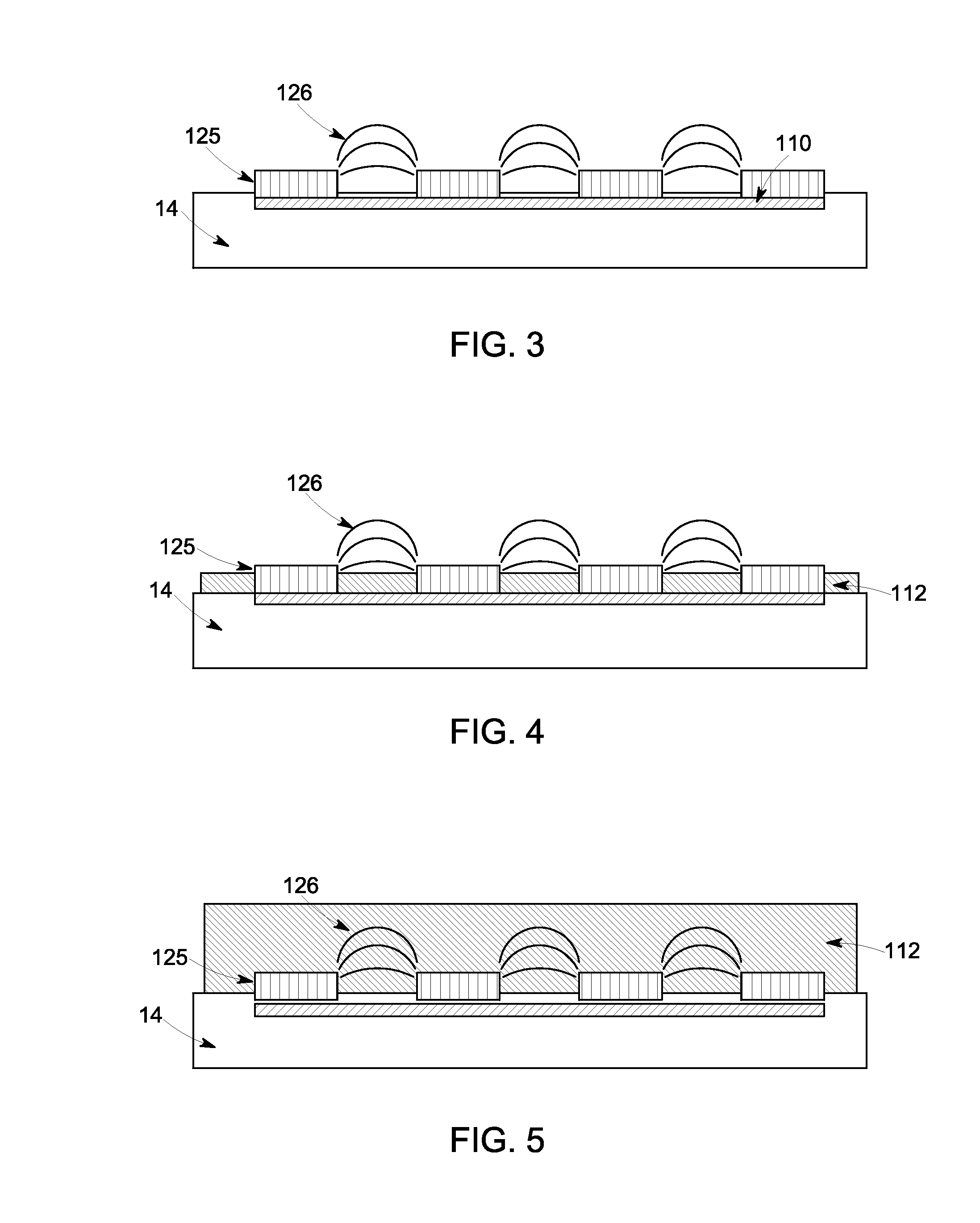

Methods and systems for calibration of RFID sensors used in manufacturing and monitoring systems are provided. The methods include measuring impedance of an RFID sensor antenna, relating the measurement of impedance to one or more parameters (such as physical, chemical and biological properties), computing one or more analytical fit coefficients, and storing the one or more analytical fit coefficients on a memory chip of the RFID sensor. Measuring impedance of the RFID sensor may comprise measuring complex impedance which involves measuring complex impedance spectrum, phase angle and magnitude of the impedance, at least one of frequency of the maximum of the real part of the complex impedance, magnitude of the real part of the complex impedance, zero-reactance frequency, resonant frequency of the imaginary part of the complex impedance, and antiresonant frequency of the imaginary part of the complex impedance. Also provided are manufacturing or monitoring systems comprised of an RFID sensor wherein the RFID sensor comprises, a memory chip, an antenna, and a sensing film wherein analytical fit coefficients are stored on the memory chip to allow calibration of the RFID sensor. Also provided are manufacturing or monitoring systems comprised of an RFID sensor wherein the RFID sensor comprises, a memory chip, an antenna, and a complementary sensor attached to the antenna where the complementary sensor in a pre-calibrated fashion predictably affects the impedance of the antenna.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

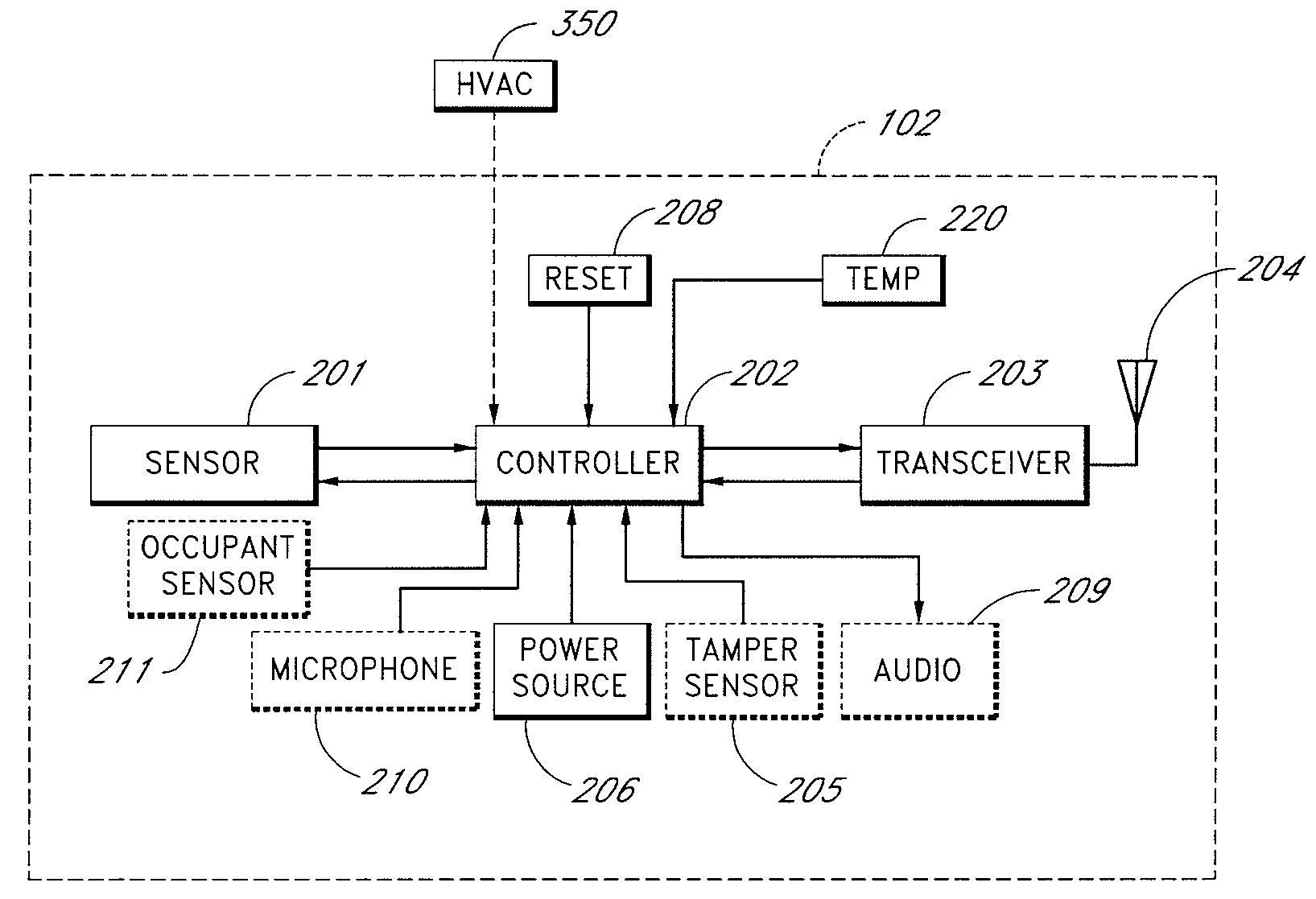

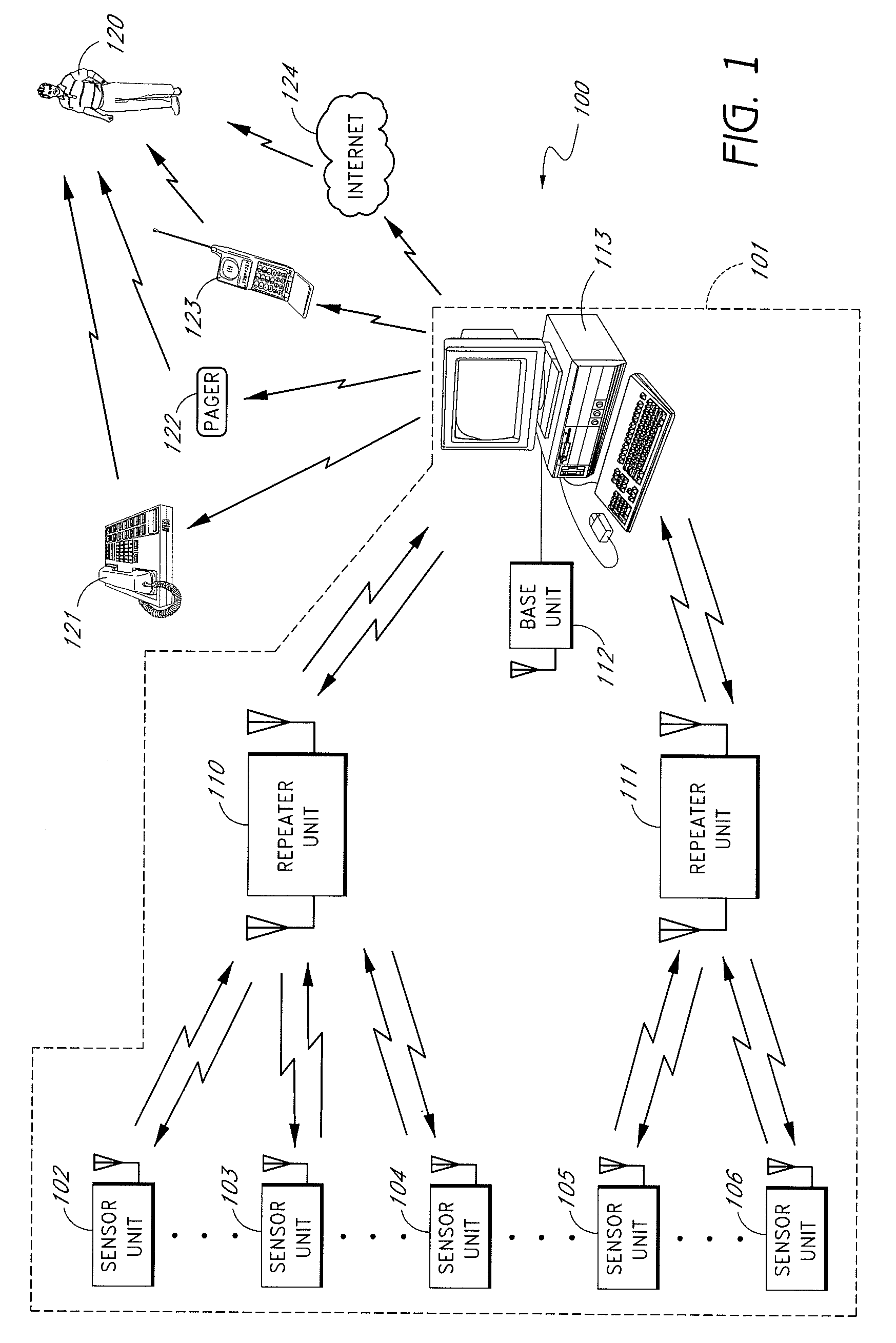

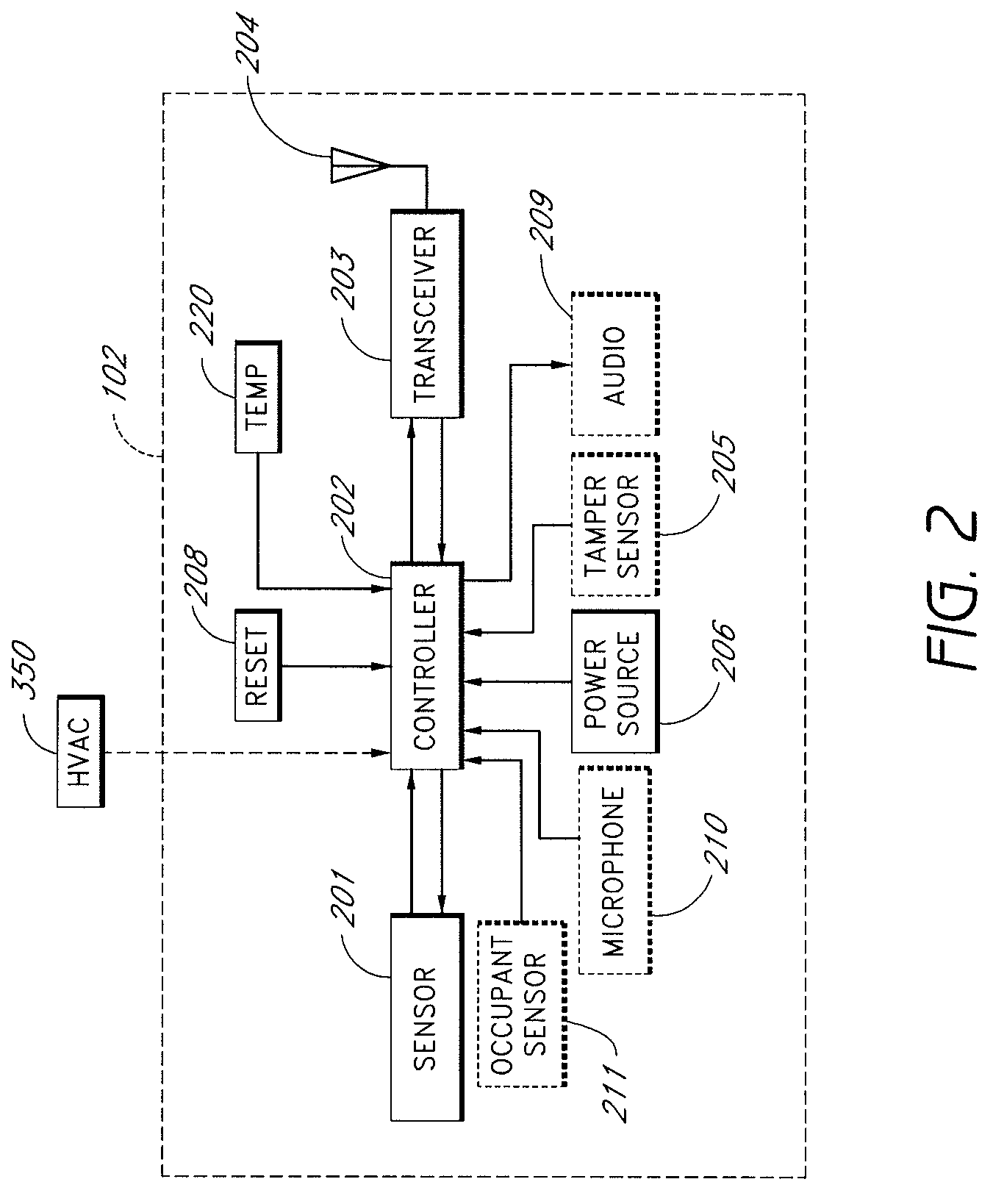

System and method for high-sensitivity sensor

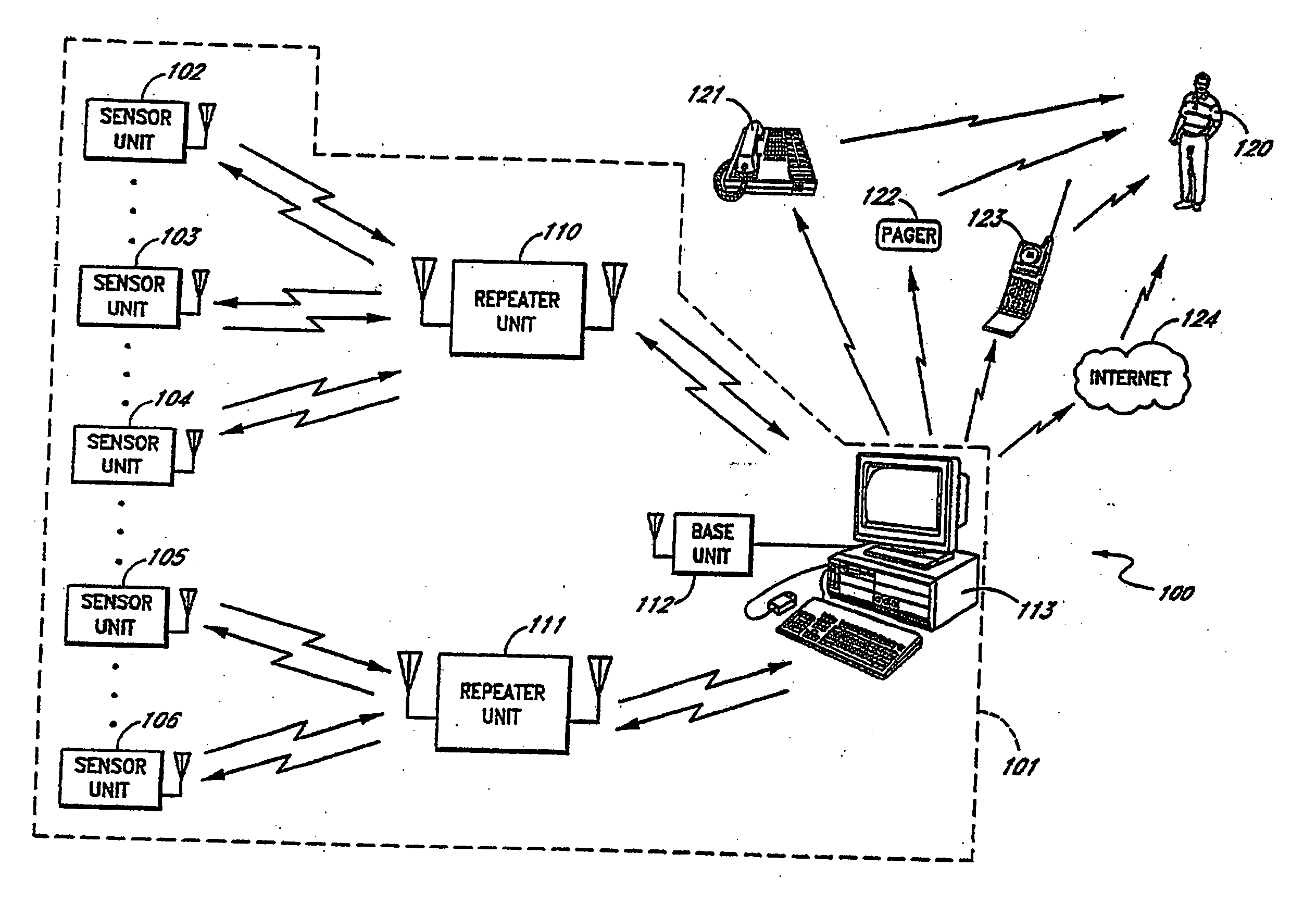

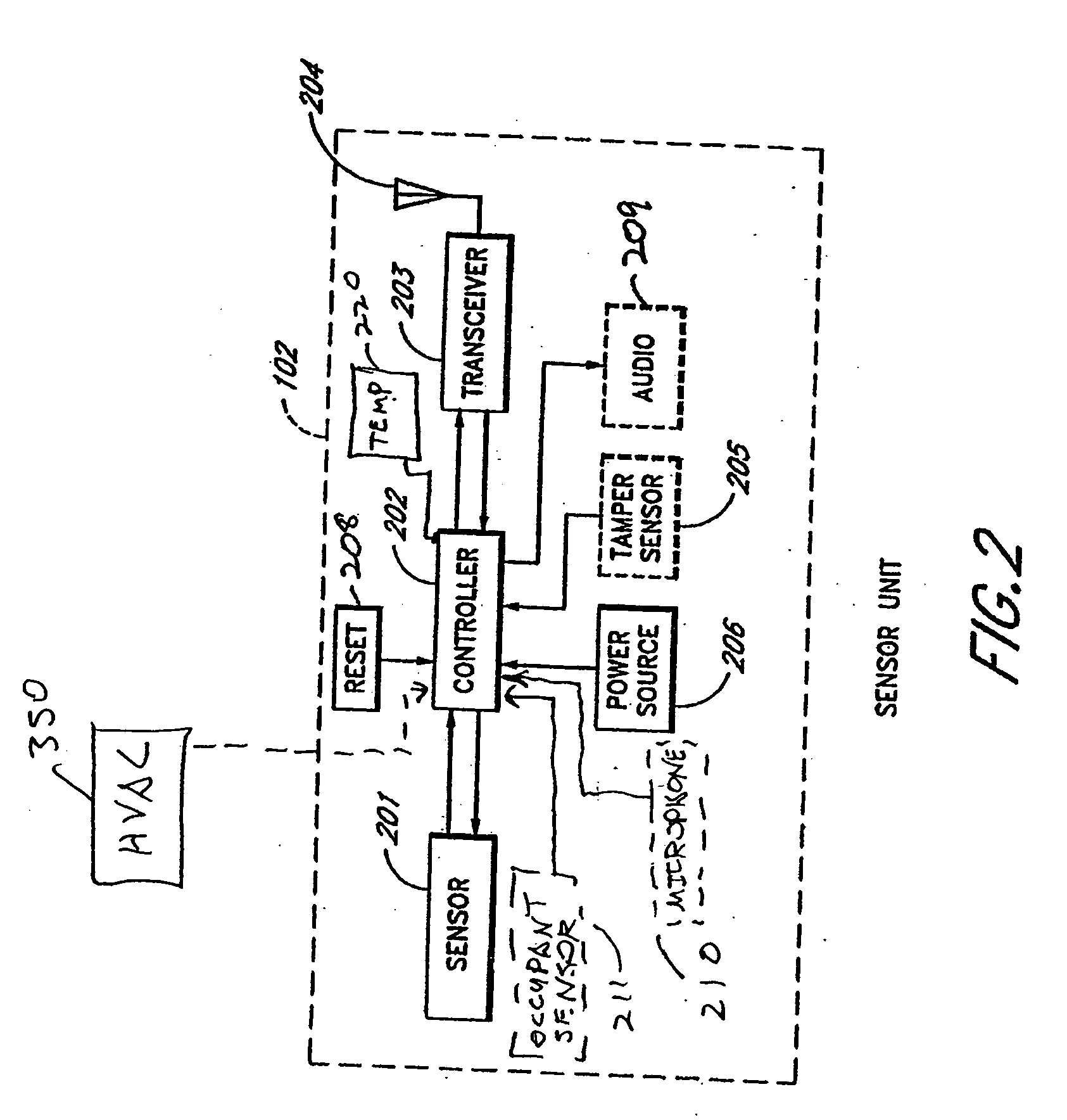

ActiveUS20060267756A1Increase rangeSensitive detection effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringThreshold test

A sensor unit that includes at least one sensor configured to measure an ambient condition is described. The controller can be configured to receive instructions, to report a notice level when the controller determines that data measured by the at least one sensor fails a report threshold test corresponding to a report threshold value. The controller can also be configured to obtain a plurality of calibration measurements from the at least one sensor during a calibration period and to adjust the threshold based on the calibration measurements. The controller can be configured to compute a first threshold level corresponding to background noise and a second threshold level corresponding to sensor noise, and to compute the report threshold value from the second threshold. In one embodiment, the sensor unit adjusts one or more of the thresholds based on ambient temperature.

Owner:GOOGLE LLC

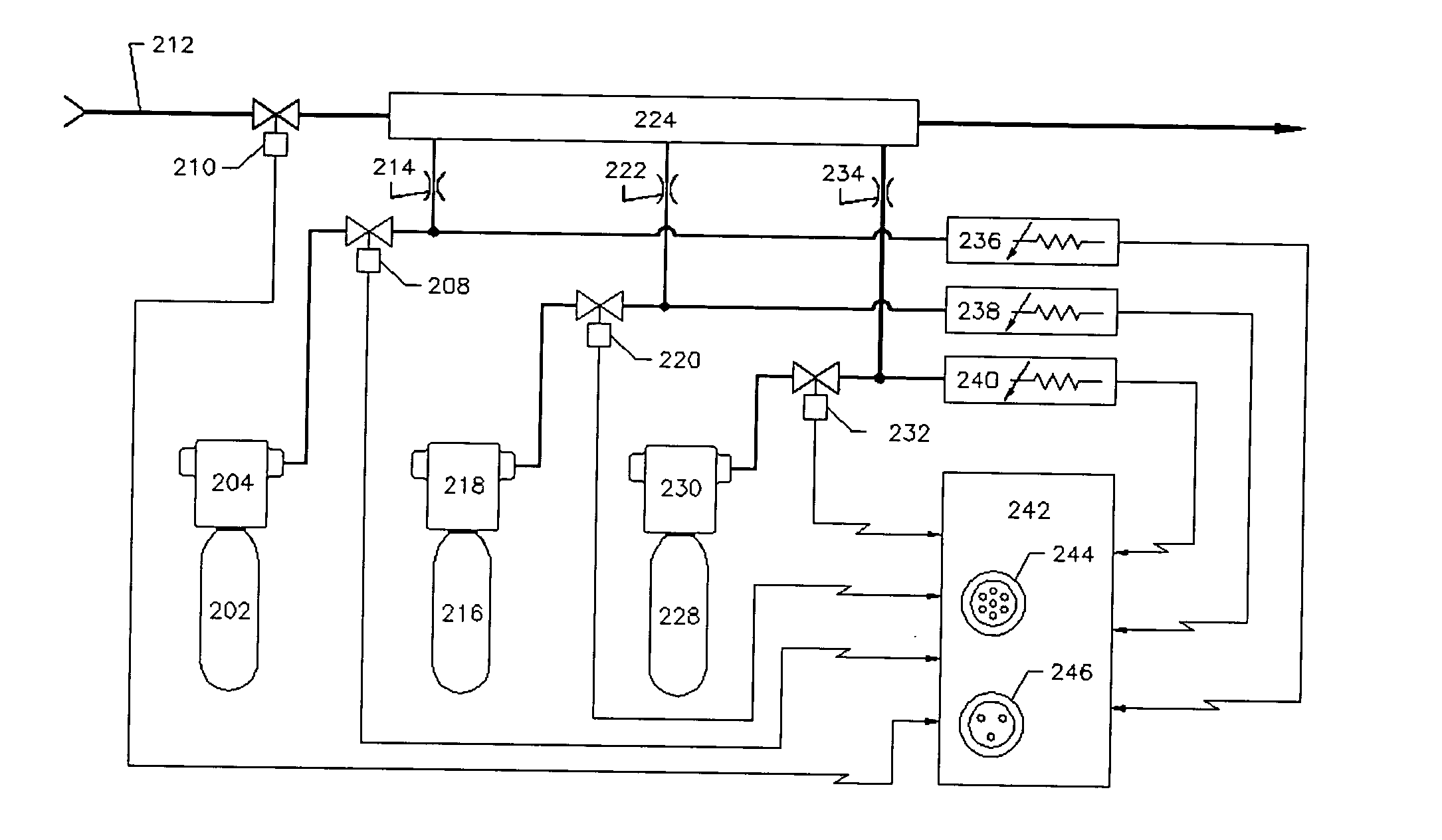

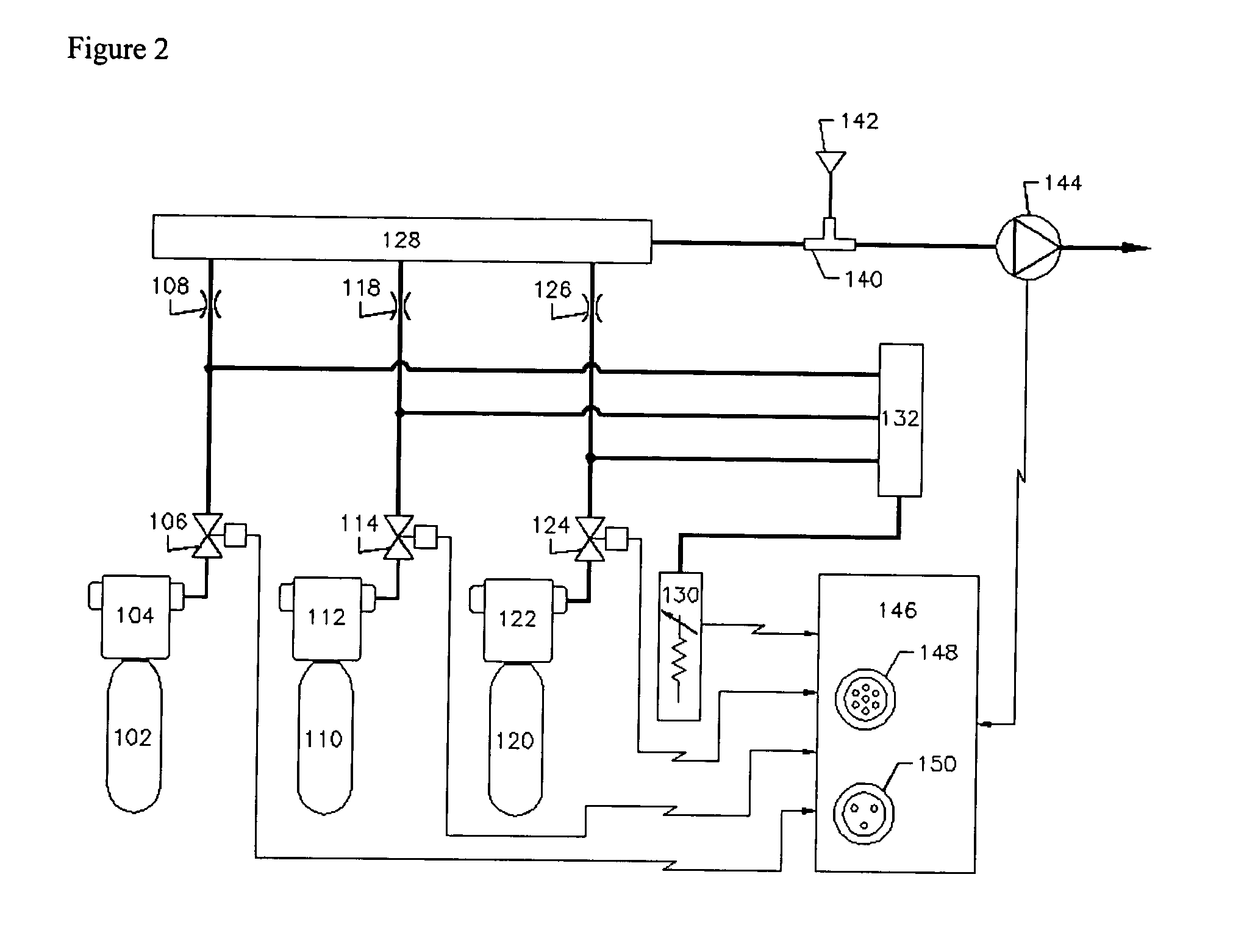

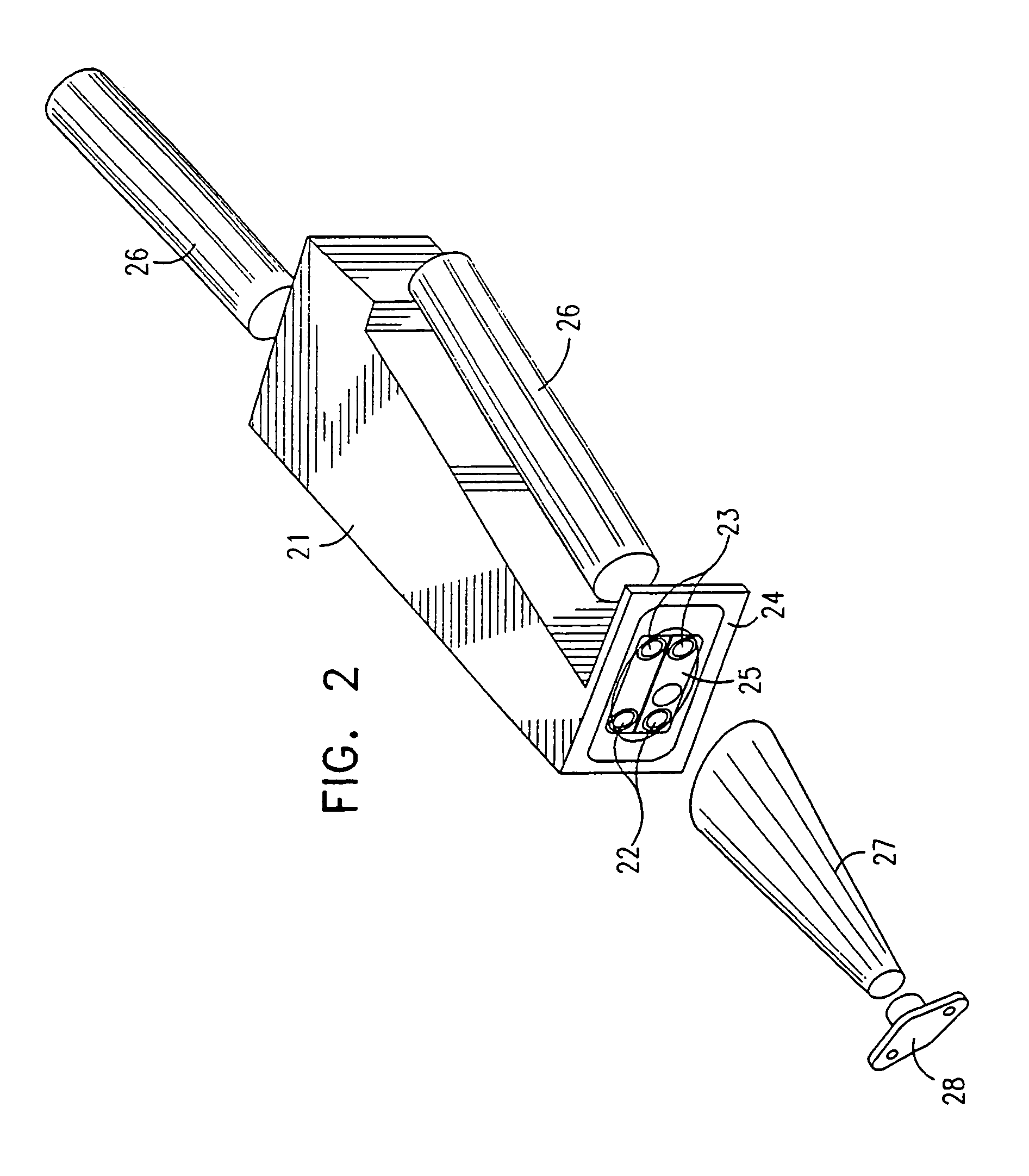

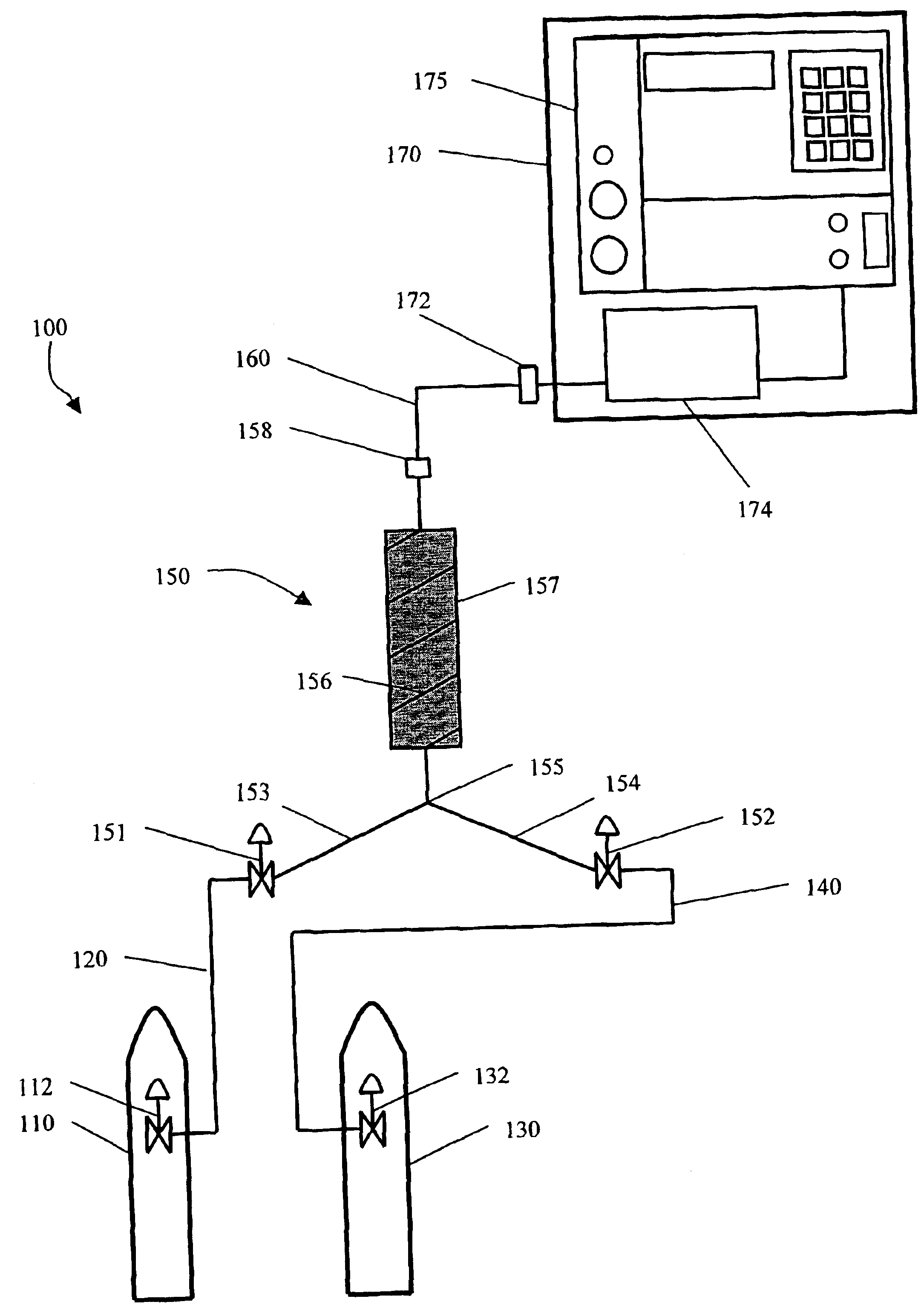

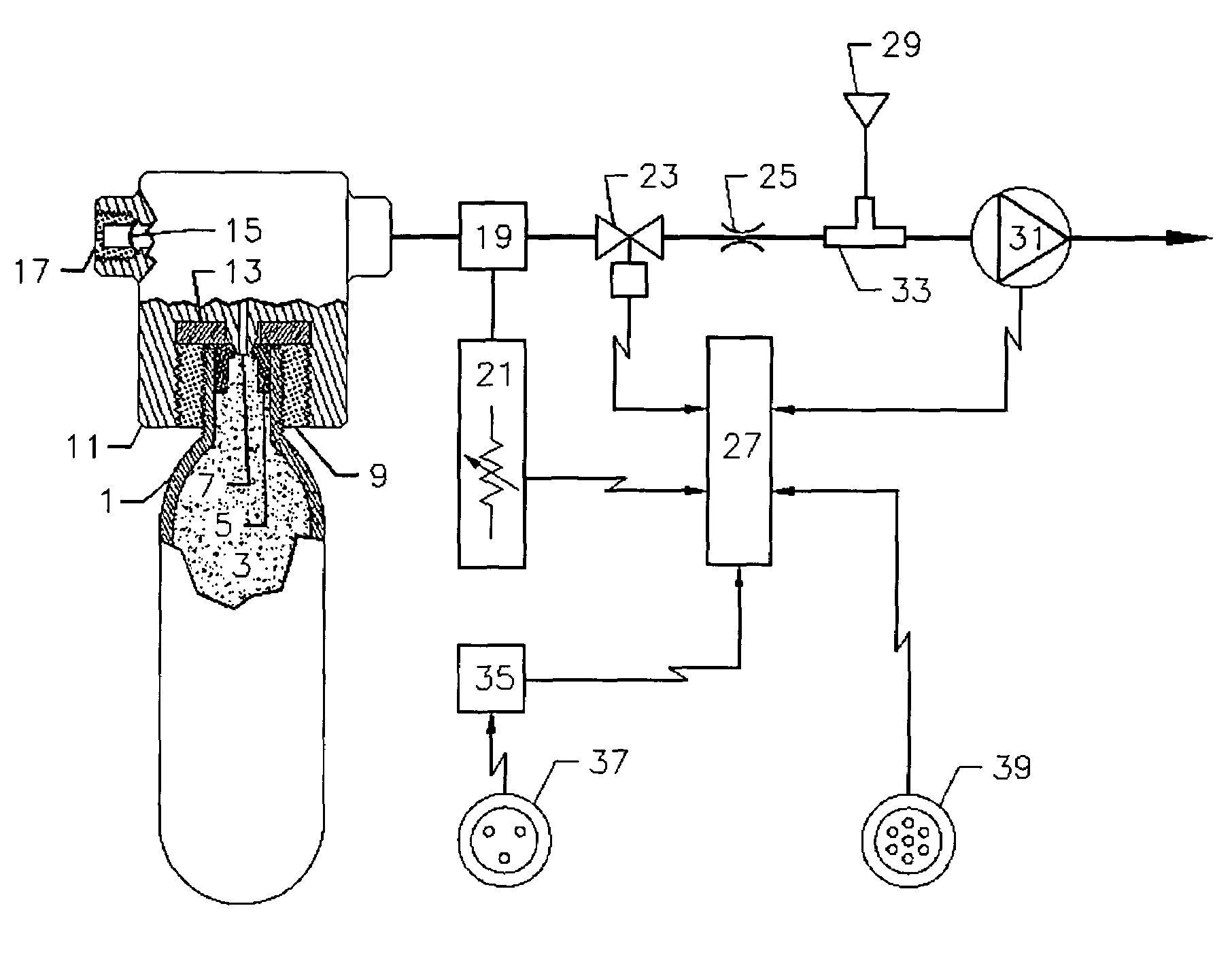

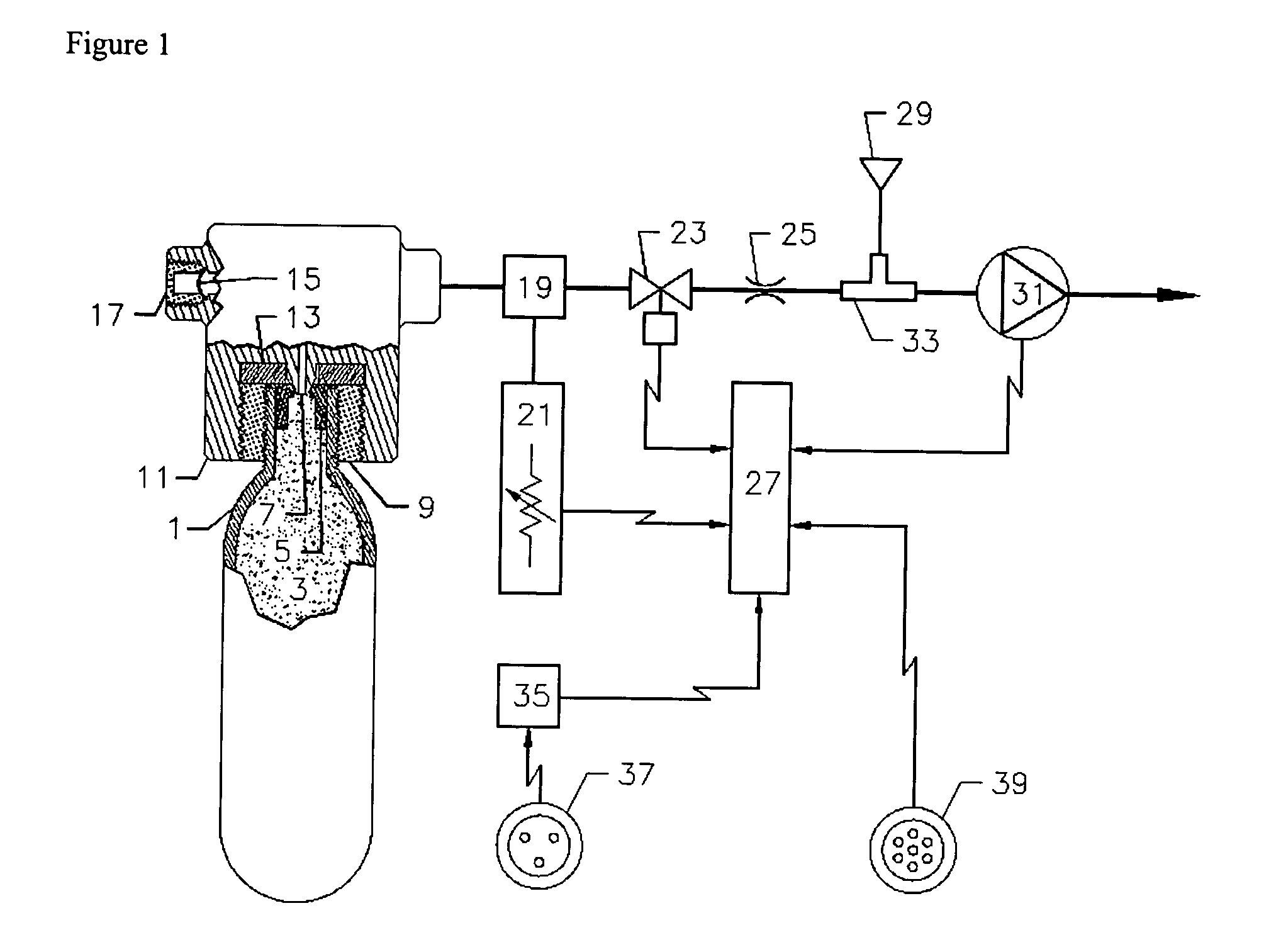

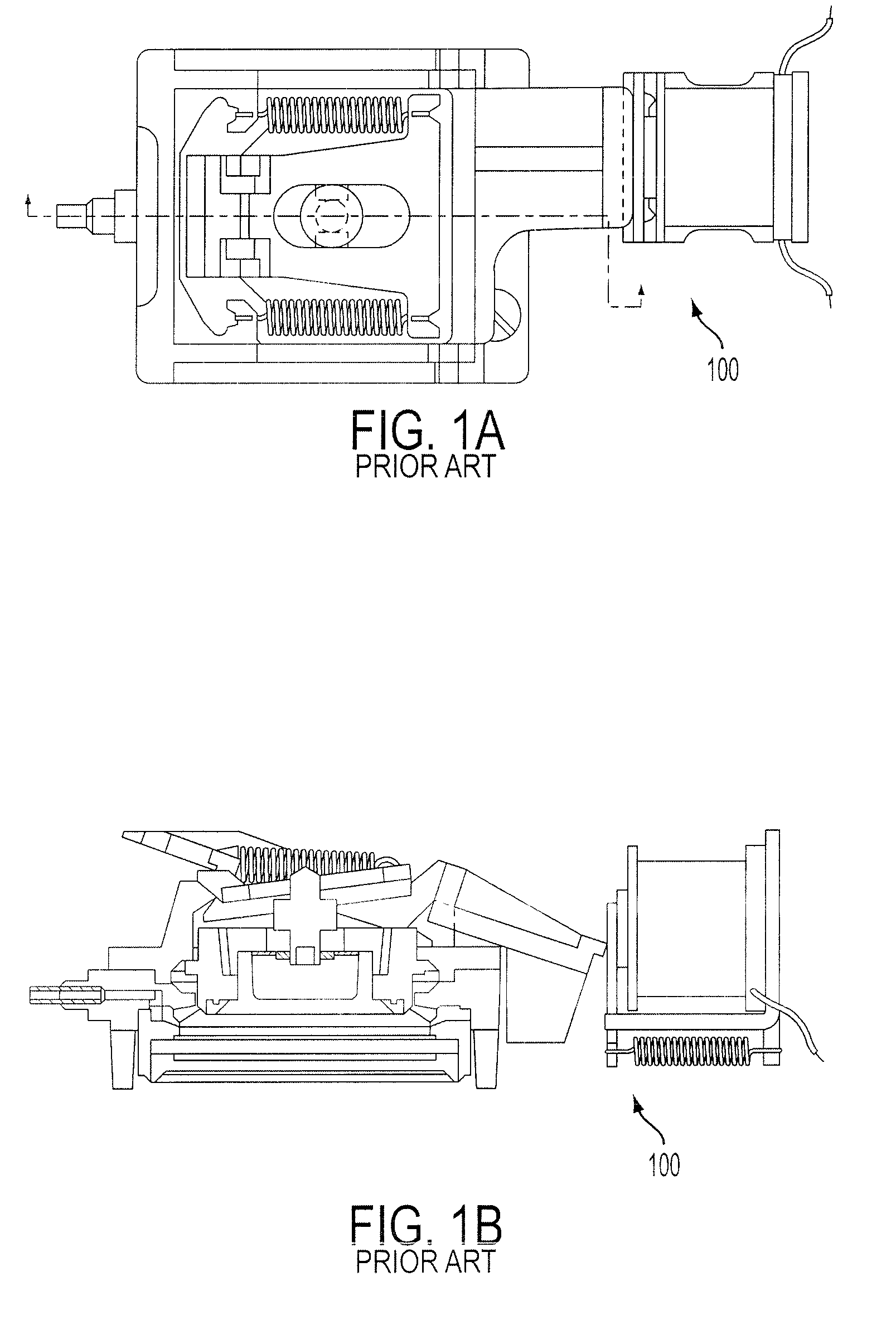

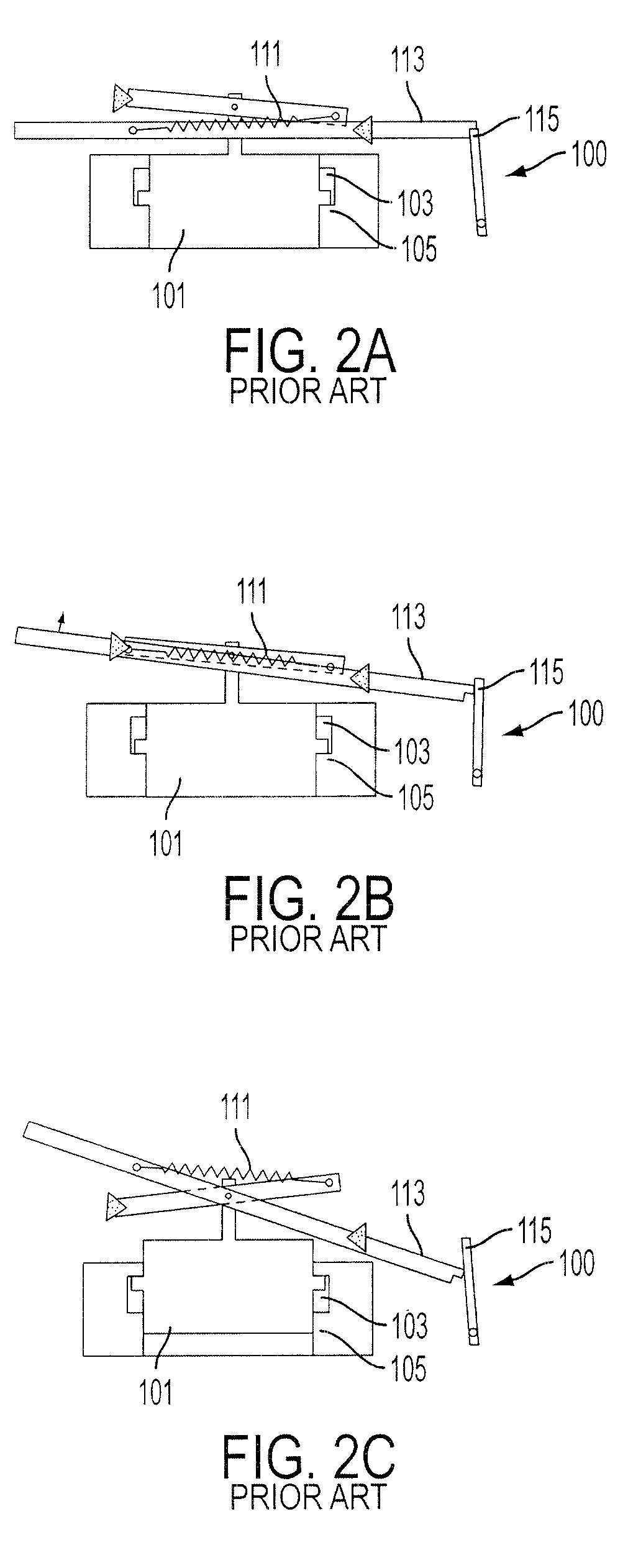

Apparatus and method for generating calibration gas

ActiveUS20050000981A1Low costAccurate concentrationOpening closed containersBottle/container closureDocking stationCalibration gas

An apparatus and method for generating a low concentration of gas within a carrier gas flow employing one or more miniature one-piece cylinders filled under pressure with a pure gas, or a concentrated gas balanced with an inert gas or gas mixture. Released from the cylinder through a pierced or other controlled opening, the flow of the gas is regulated by a pressure regulator and a micro orifice to be blended into a steady stream of diluent gas, typically ambient air, to form a desired gas concentration. No gas is generated if the pressure of the gas in the cylinder, which is monitored constantly by a pressure transducer, is below a predetermined level. The apparatus can be built into a portable device, or an automated docking station (or calibration station) for testing and calibrating gas detection and monitoring instruments, or into a fixed gas detection system for performing such functions.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

System and method for high-sensitivity sensor

ActiveUS7623028B2Increase rangeSensitive detection effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringThreshold test

A sensor unit includes at least one sensor configured to measure an ambient condition. The controller can be configured to receive instructions, to report a notice level when the controller determines that data measured by the at least one sensor fails a report threshold test corresponding to a report threshold value. The controller can also be configured to obtain a plurality of calibration measurements from the at least one sensor during a calibration period and to adjust the threshold based on the calibration measurements. The controller can be configured to compute a first threshold level corresponding to background noise and a second threshold level corresponding to sensor noise, and to compute the report threshold value from the second threshold. In one embodiment, the sensor unit adjusts one or more of the thresholds based on ambient temperature.

Owner:GOOGLE LLC

Methods and systems for calibration of RFID sensors

ActiveUS7911345B2Testing sensing arrangementsMaterial analysis by electric/magnetic meansMemory chipComplex impedance spectra

Methods and systems for calibration of RFID sensors used in manufacturing and monitoring systems are provided. The methods include measuring impedance of an RFID sensor antenna, relating the measurement of impedance to one or more parameters (such as physical, chemical and biological properties), computing one or more analytical fit coefficients, and storing the one or more analytical fit coefficients on a memory chip of the RFID sensor. Measuring impedance of the RFID sensor may comprise measuring complex impedance which involves measuring complex impedance spectrum, phase angle and magnitude of the impedance, at least one of frequency of the maximum of the real part of the complex impedance, magnitude of the real part of the complex impedance, zero-reactance frequency, resonant frequency of the imaginary part of the complex impedance, and antiresonant frequency of the imaginary part of the complex impedance. Also provided are manufacturing or monitoring systems comprised of an RFID sensor wherein the RFID sensor comprises, a memory chip, an antenna, and a sensing film wherein analytical fit coefficients are stored on the memory chip to allow calibration of the RFID sensor. Also provided are manufacturing or monitoring systems comprised of an RFID sensor wherein the RFID sensor comprises, a memory chip, an antenna, and a complementary sensor attached to the antenna where the complementary sensor in a pre-calibrated fashion predictably affects the impedance of the antenna.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP

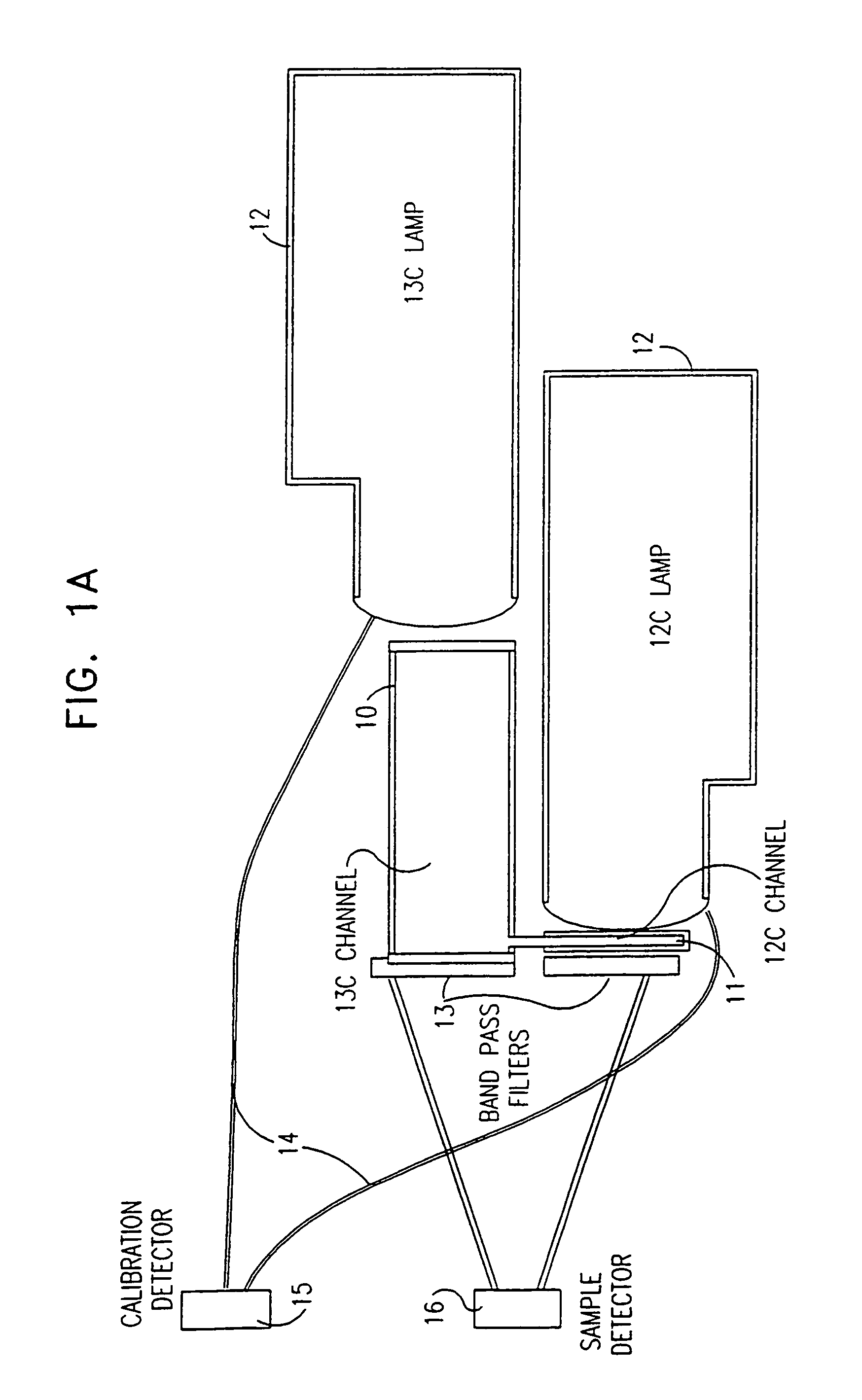

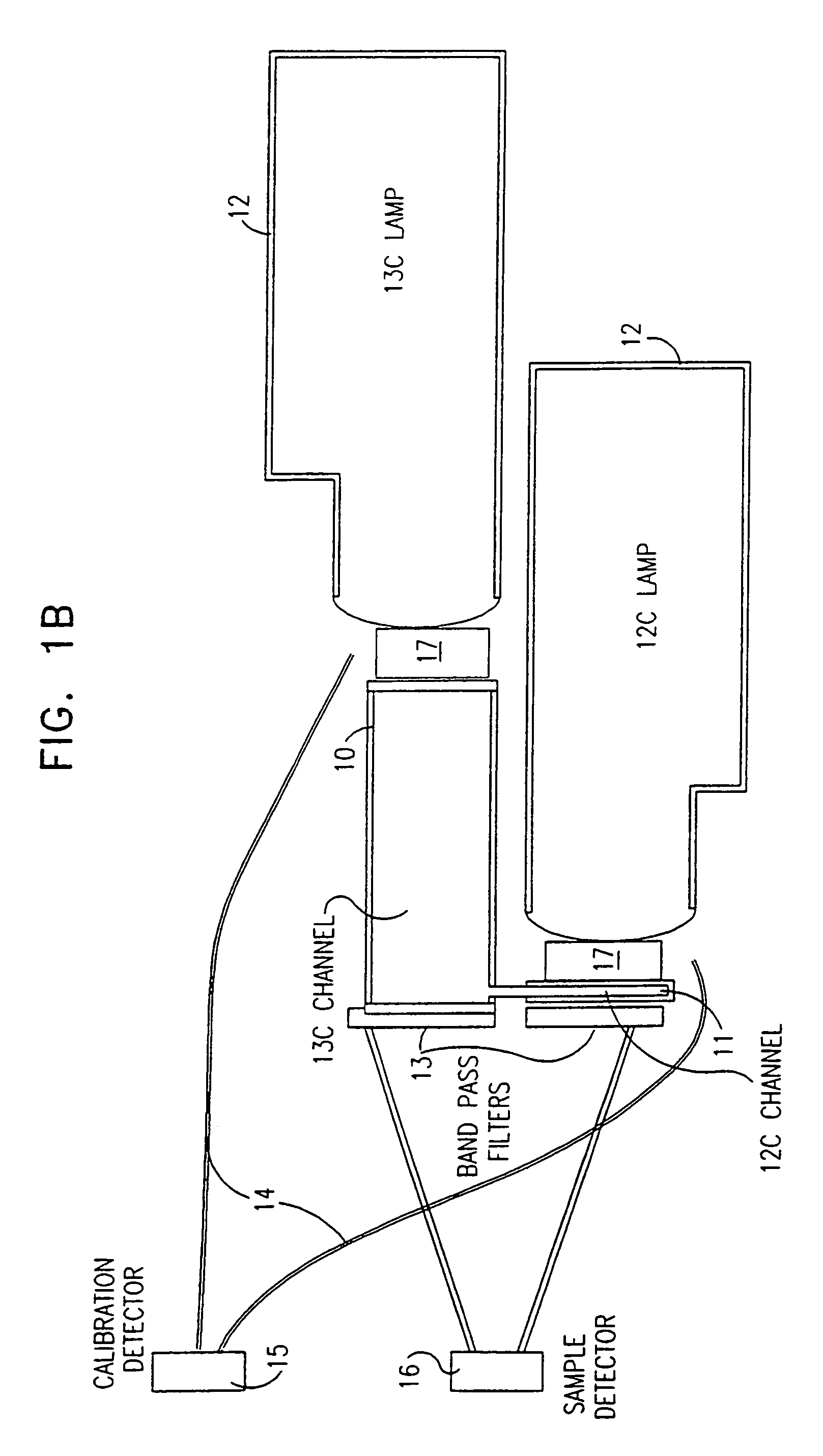

Isotopic gas analyzer

InactiveUS7063667B1Low costShort path lengthWithdrawing sample devicesRespiratory organ evaluationCross sensitivityAbsorption cell

An NDIR spectrometer based on the use of wavelength specific lamp sources, whose emission spectrum consists of discrete, narrow lines characteristic of the isotope present in the lamp, and which it is desired to measure with the spectrometer. This allows very high intrinsic sensitivity, enabling the use of an extremely compact absorption cell with a very short path length. In addition, the source can be self-modulated, such that problems associated with external choppers are avoided. Furthermore, there is insignificant cross sensitivity between the isotopes themselves and between the isotopes and other ambient gases in the operating environment.

Owner:BREATHID 2006

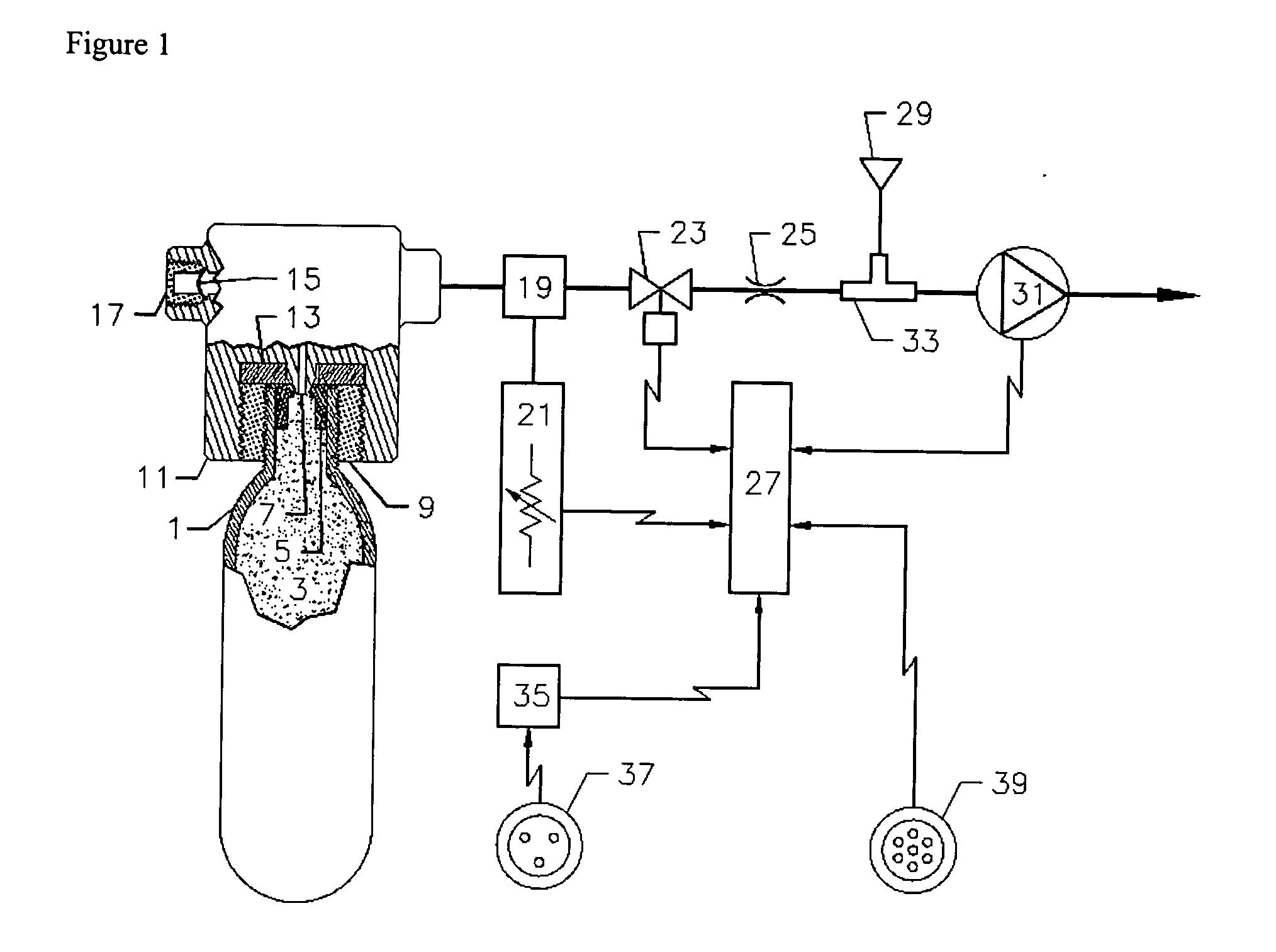

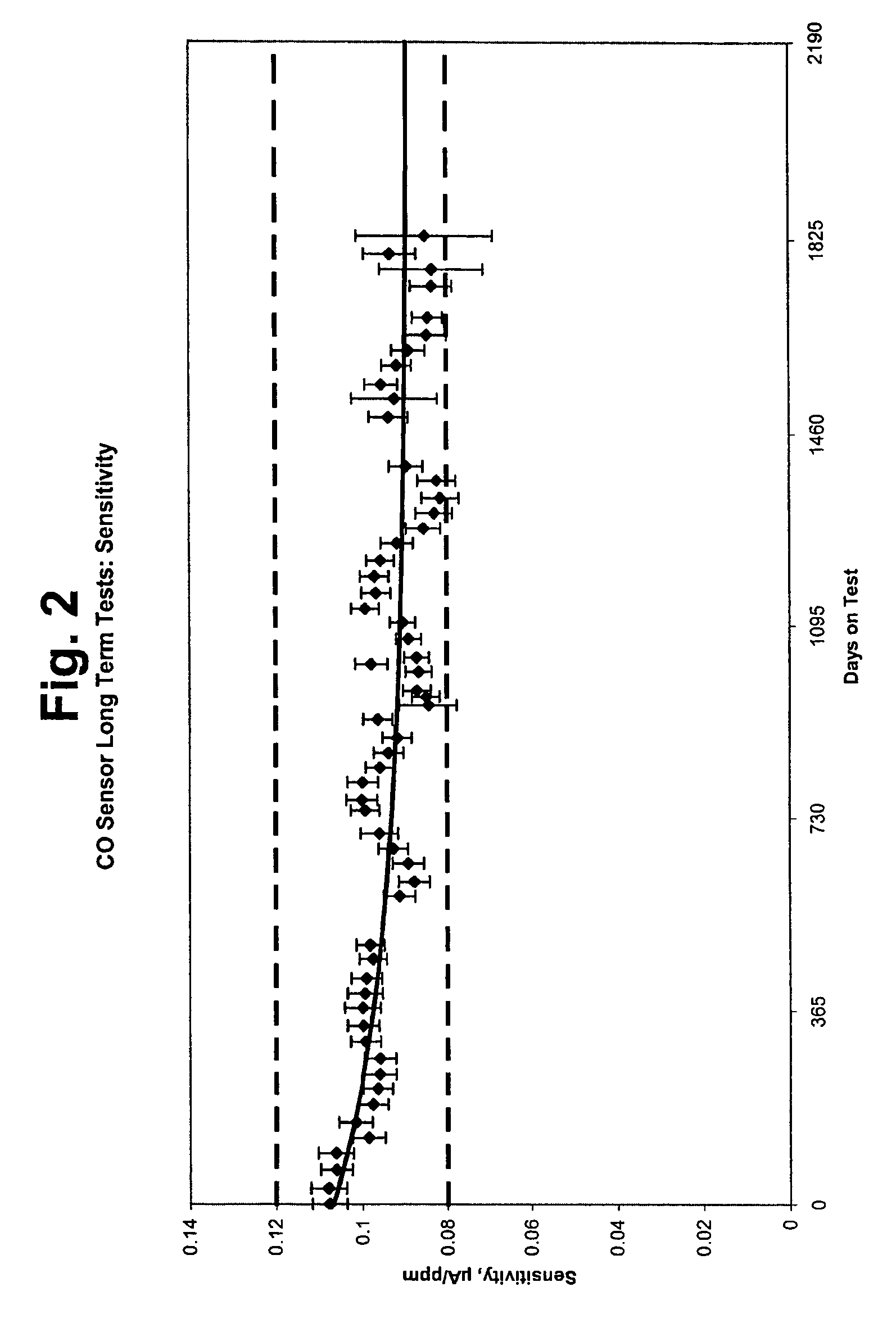

Self-calibrating carbon monoxide detector and method

InactiveUS6948352B2Analysing fluids using sonic/ultrasonic/infrasonic wavesSamplingHydrogenCalibration gas

The self-calibrating carbon monoxide detector and method of the present invention utilize the gas for which the detector was designed to detect as the calibration gas. Specifically, a carbon monoxide gas generator is included in the detector assembly, and is controller to produce a known amount of CO. The sensor response to the quantity of CO generated is monitored, and the calibration thereof adjusted as necessary. The operation of the gas generator is also monitored, and any failures are flagged for user attention. The gas generator specifically suppresses the generation of hydrogen through the materials used in its construction. Temperature effects may also be compensated either through control of gas generation control parameters or compensation of the sensor output in view of the generator temperature effects.

Owner:WALTER KIDDE PORTABLE EQUIP

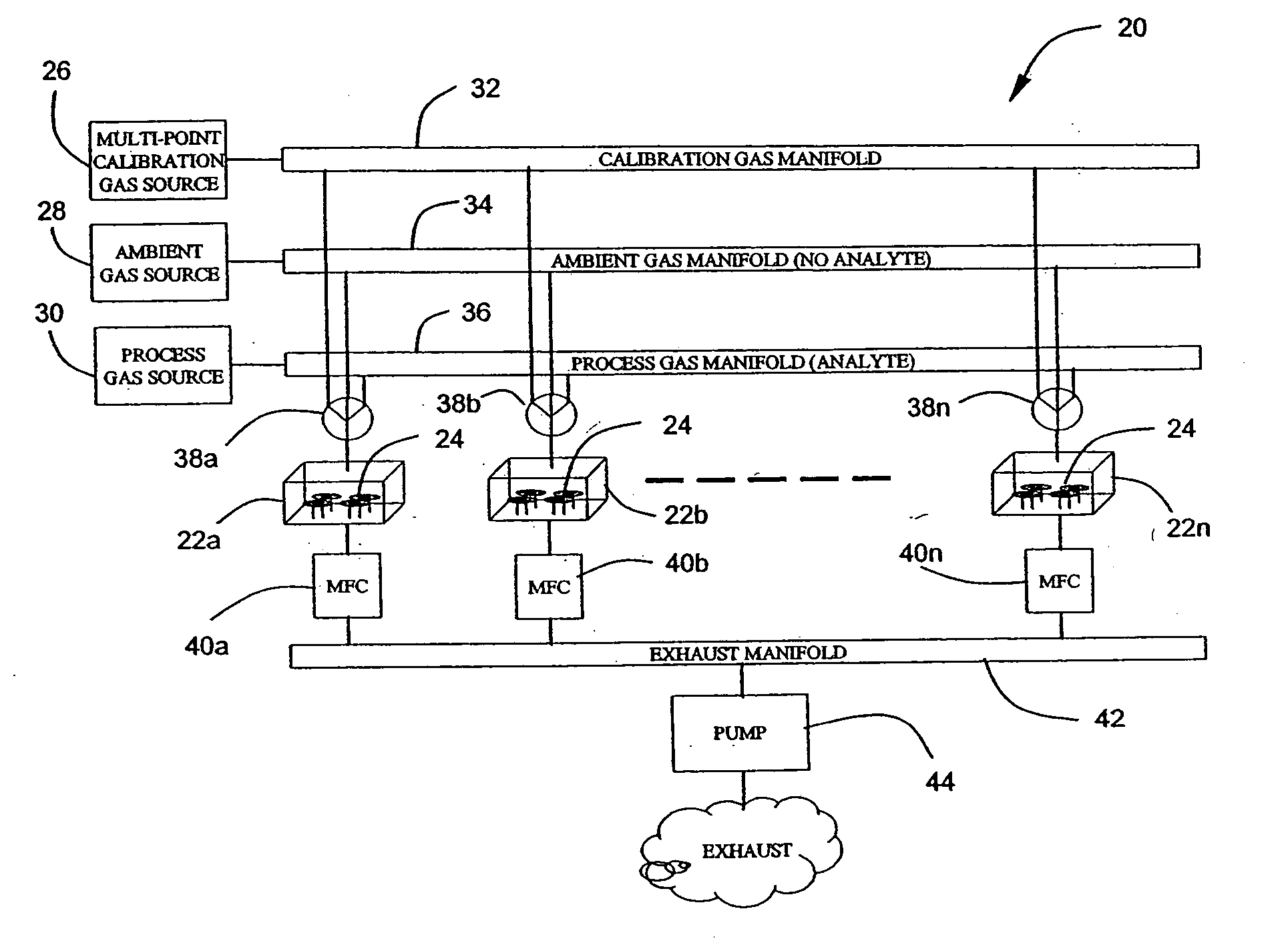

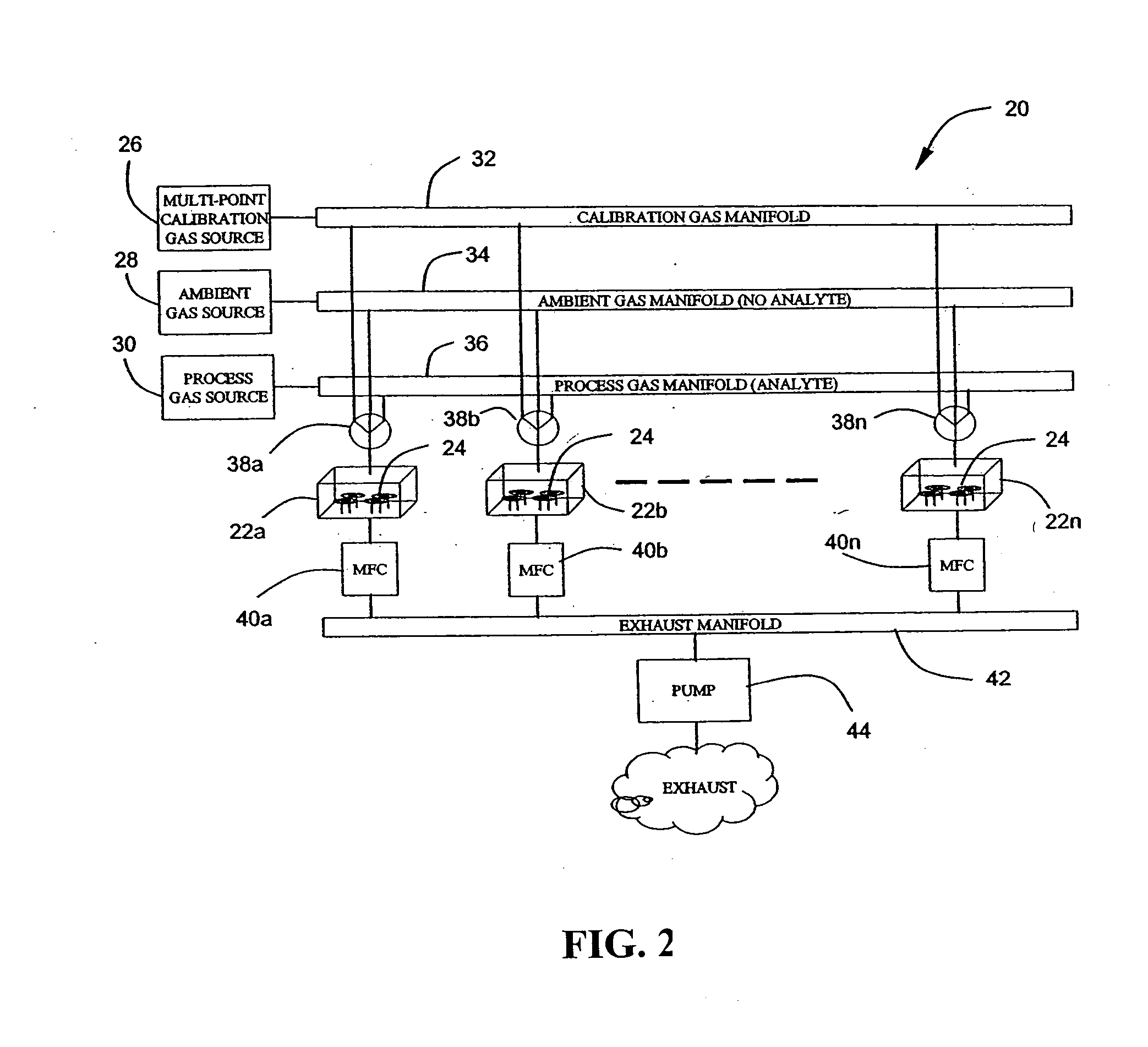

Analyte quantitation using semiconducting metal oxide gas sensors

InactiveUS20060042353A1Analysing fluids using sonic/ultrasonic/infrasonic wavesMaterial analysis by electric/magnetic meansAnalyteElectrical battery

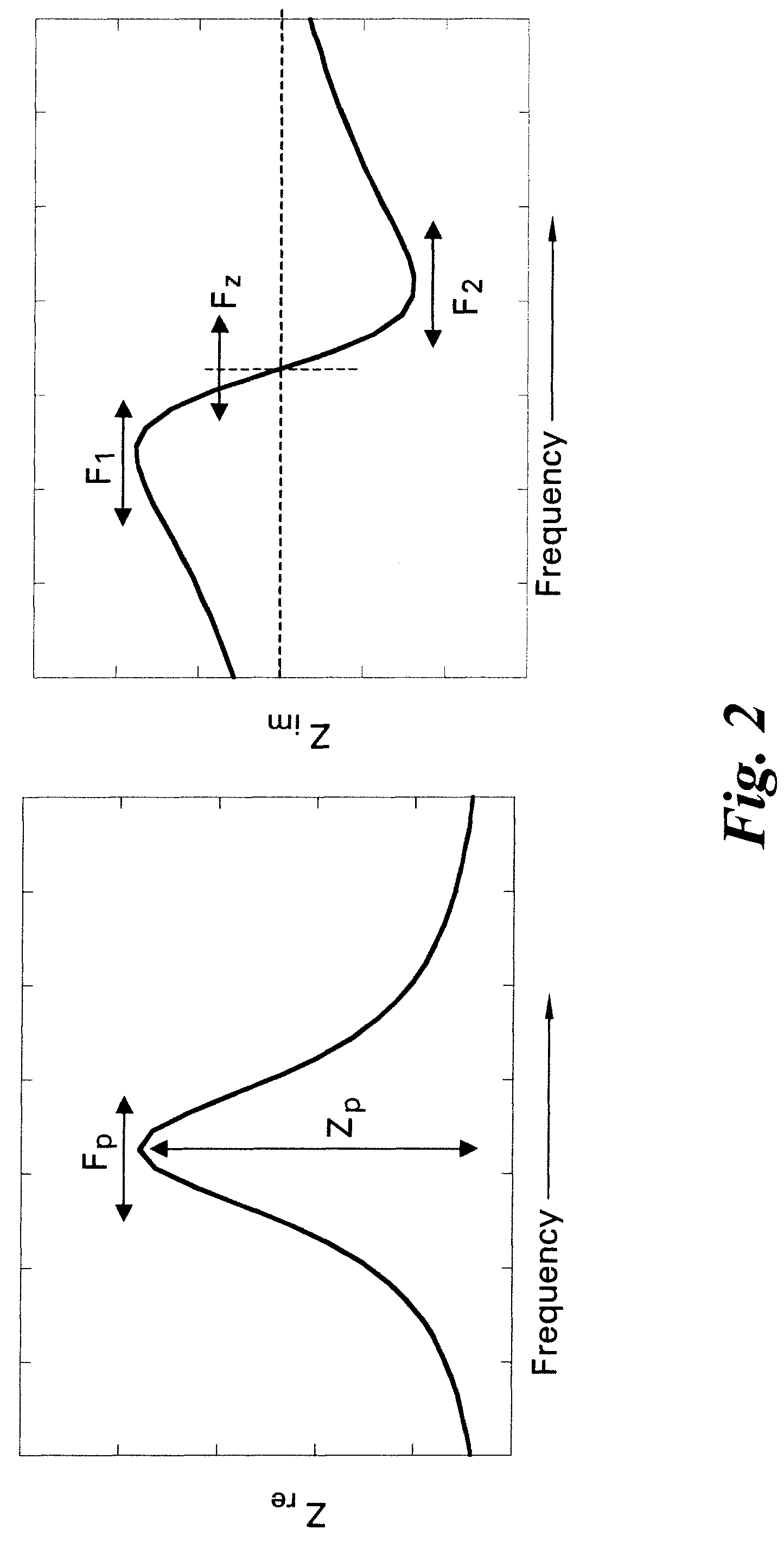

A method for quantitating analyte in a process gas stream using a gas sensor system having a plurality of sensor cells containing multiple semiconducting metal oxide gas sensors. The method includes calibrating and baselining each cell, and flowing a process gas through each cell for a respective time interval. Sensor outputs for each cell are processed to determine the amount of analyte in the process gas for each time interval. Then, the analyte amounts determined for each time interval are added to determine a total analyte quantity. In a first embodiment, all of the cells are calibrated simultaneously prior to any exposure to process gas. In a second embodiment, the cells can be repeatedly and sequentially exposed to process gas over additional time intervals. In this case, each cell is calibrated prior to each of its time intervals.

Owner:SENSOR RES & DEV

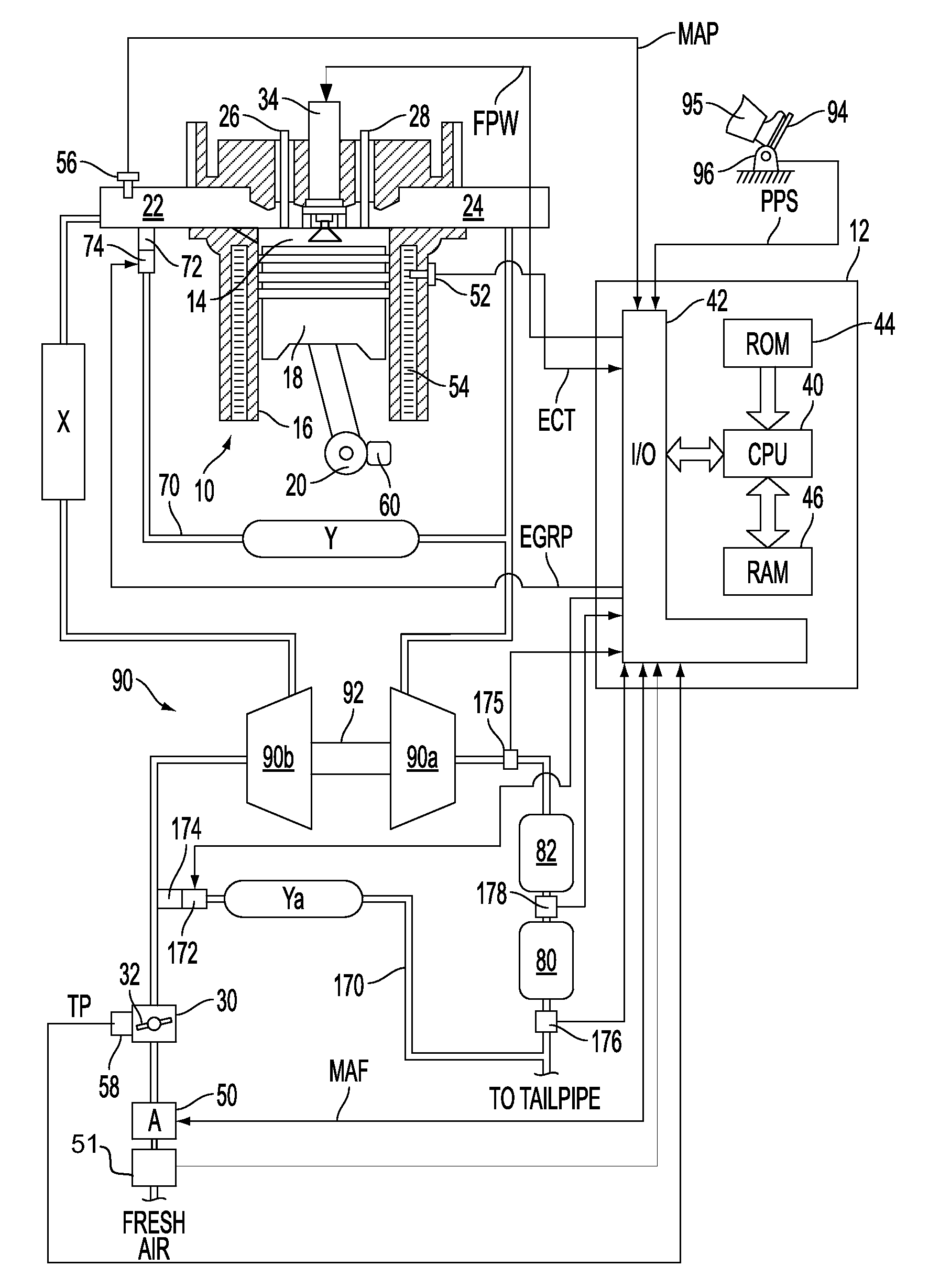

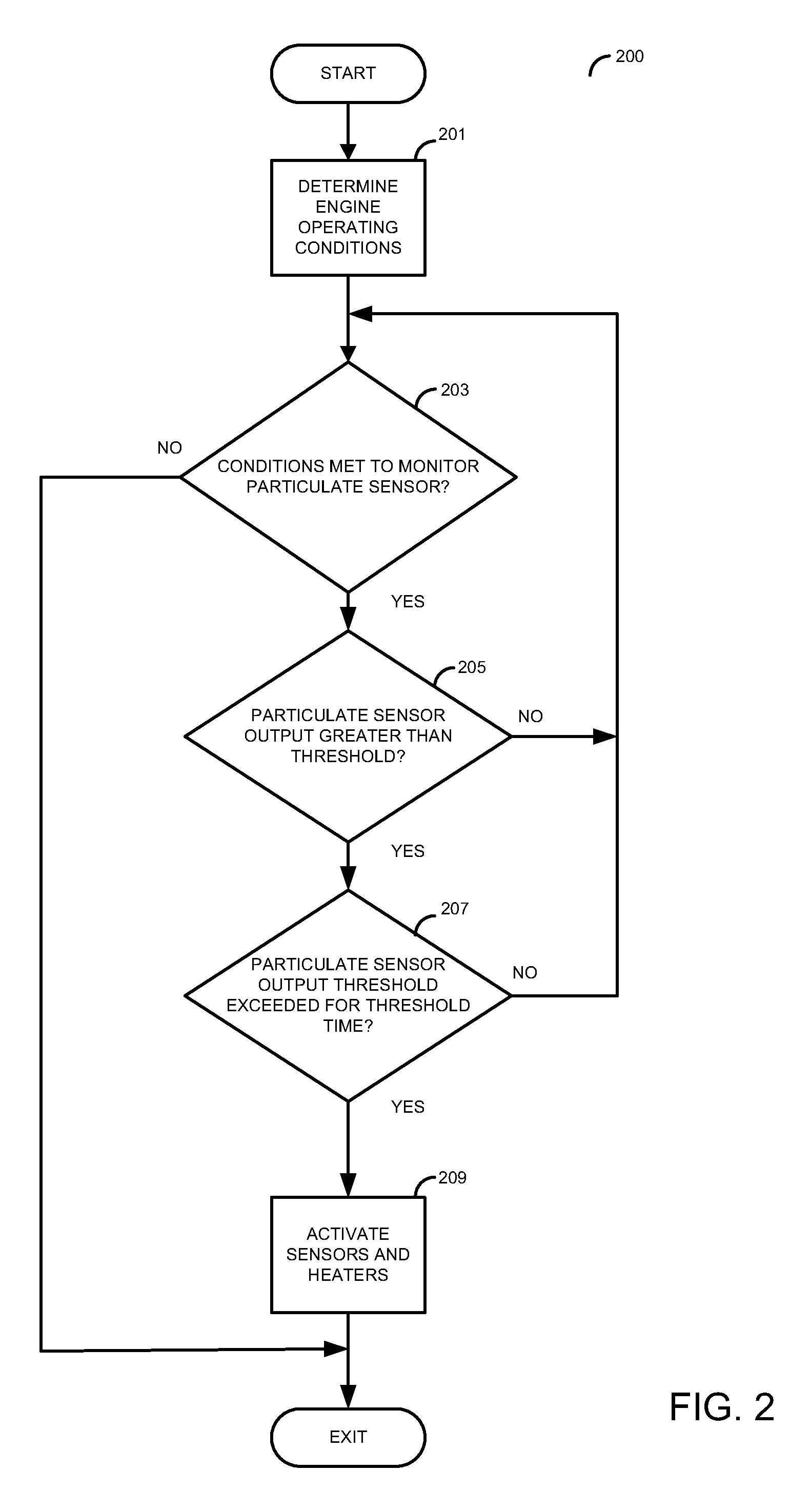

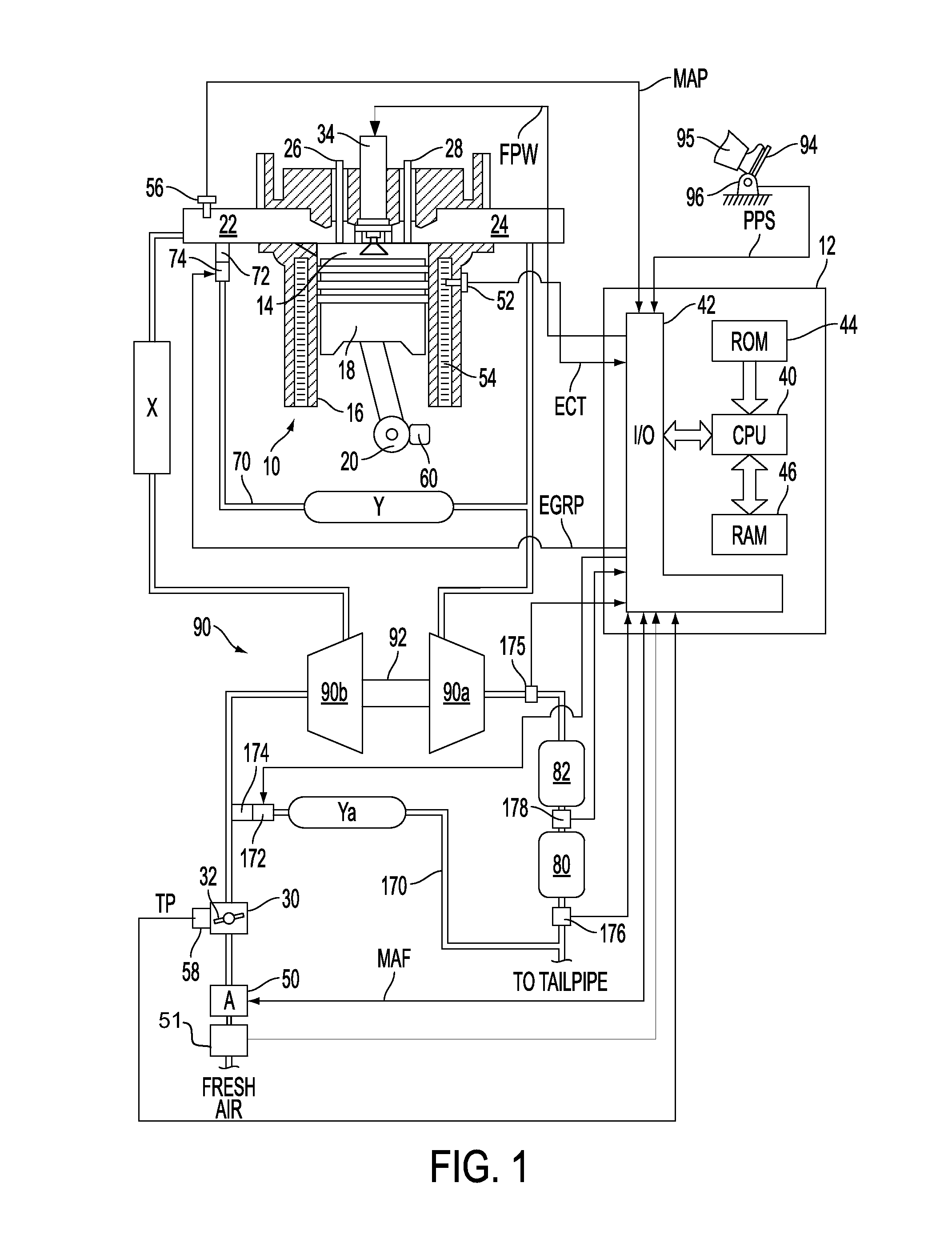

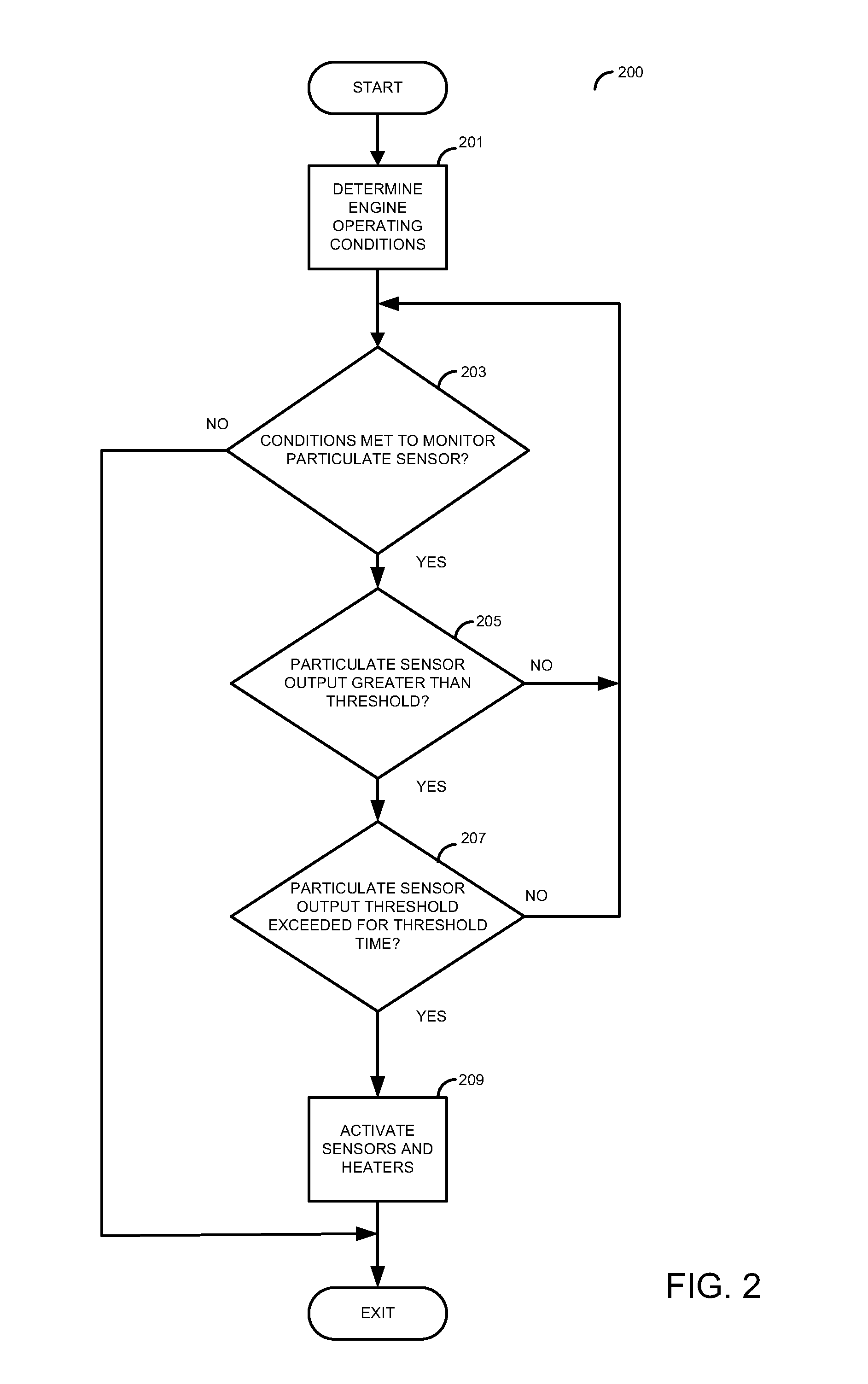

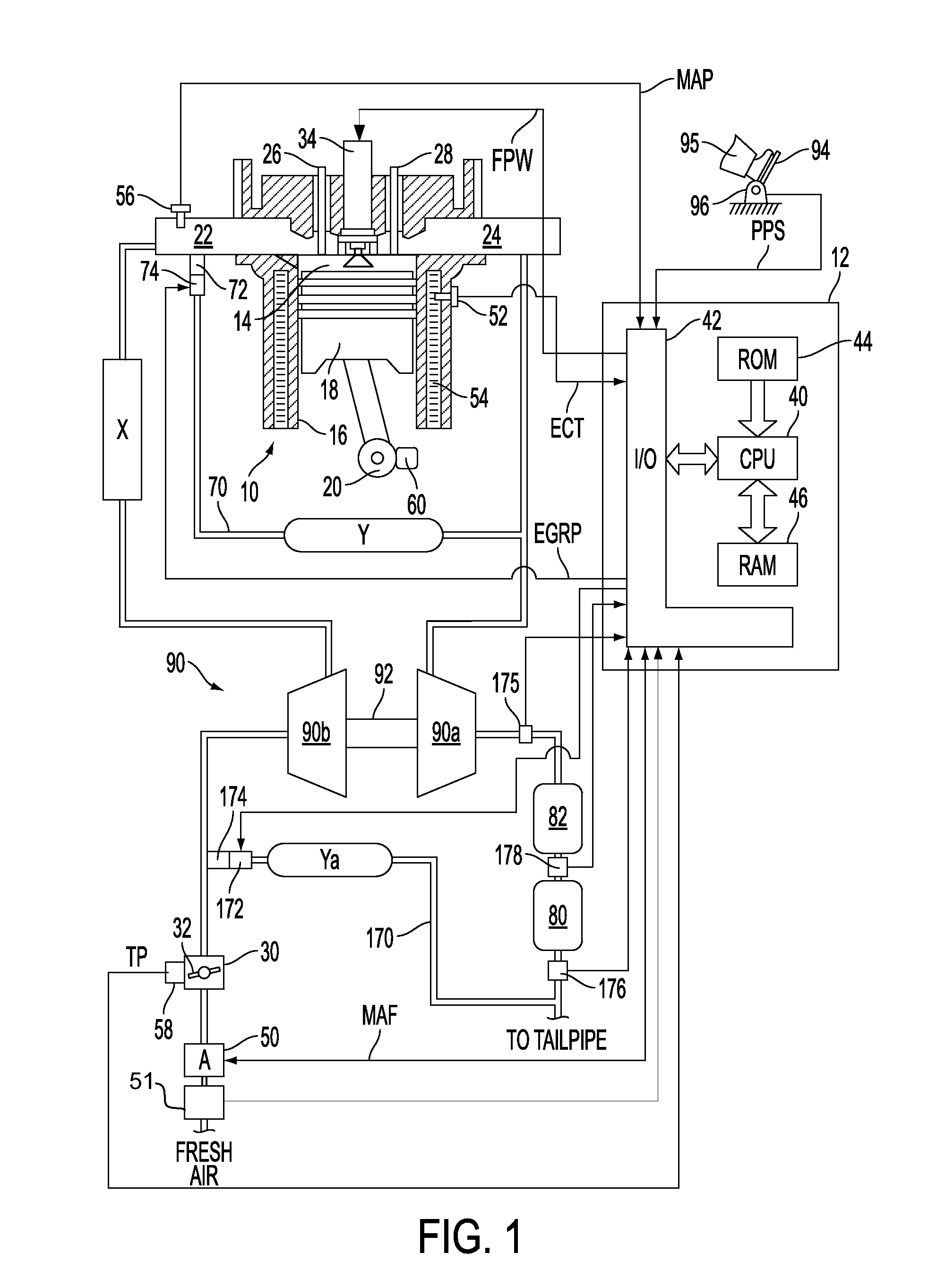

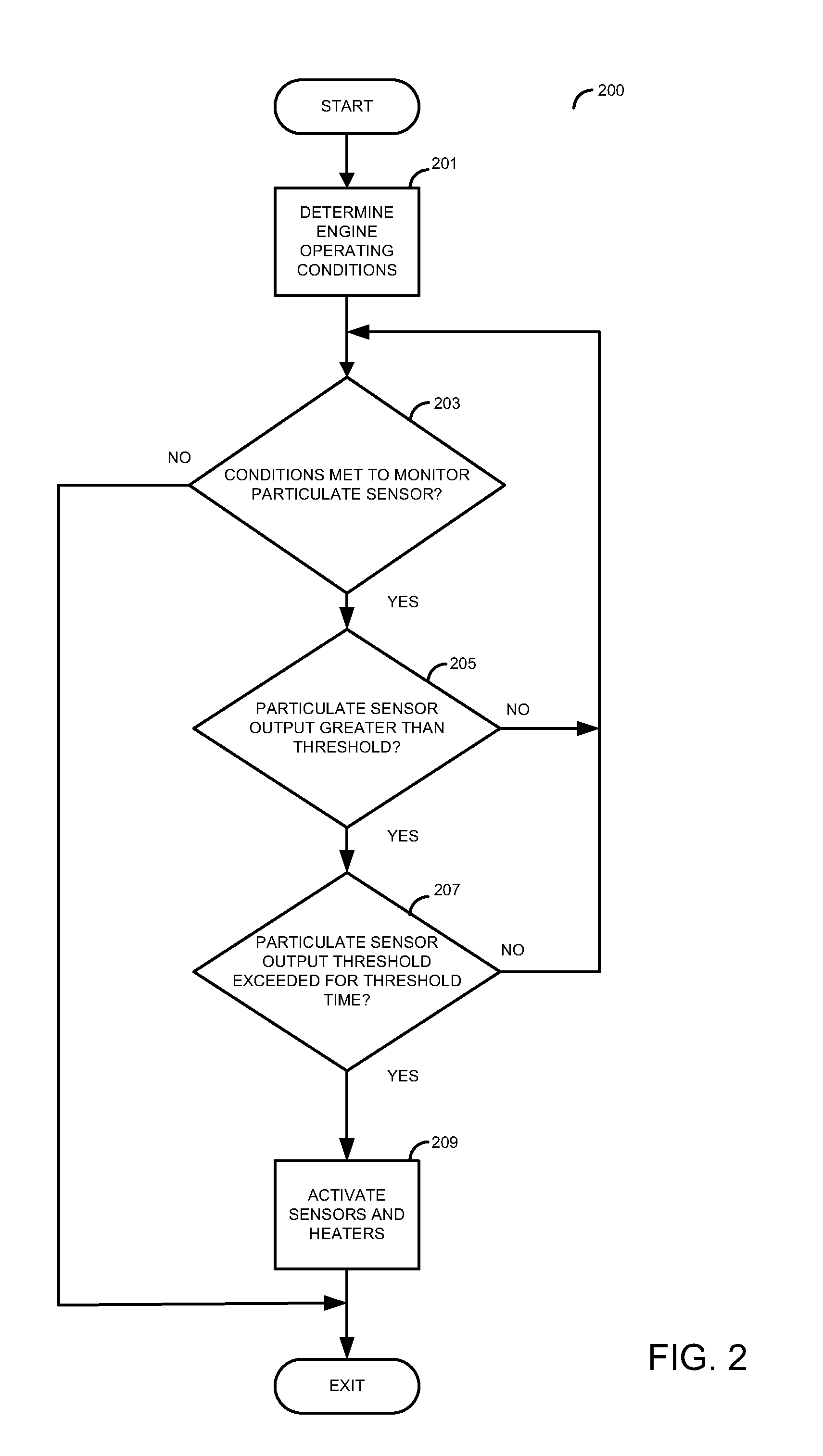

Method for evaluating degradation of a particulate matter sensor

ActiveUS20110047978A1Emission reductionAccelerate emissionsVehicle testingElectrical controlParticulatesIn vehicle

A system for improving operation of an engine having a particulate matter sensor is presented. The system may be used to improve engine operation during cold starts especially under conditions where water vapor or entrained water droplets are present in vehicle exhaust gases. In one embodiment, degradation of a particulate matter sensor is indicated after a temperature of a substrate of the particulate matter sensor exceeds a threshold temperature and an output of the particulate matter sensor is below a threshold value.

Owner:FORD GLOBAL TECH LLC

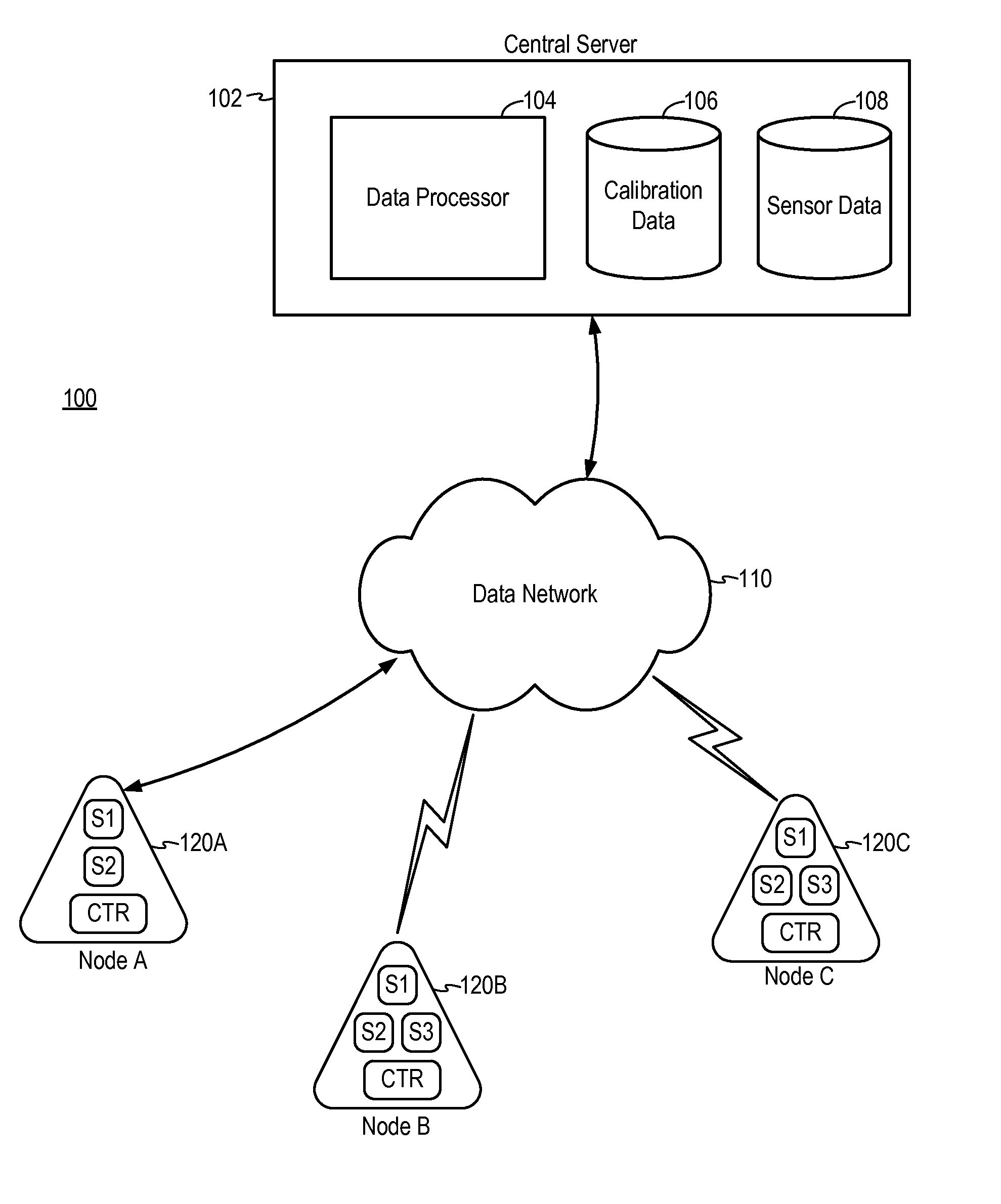

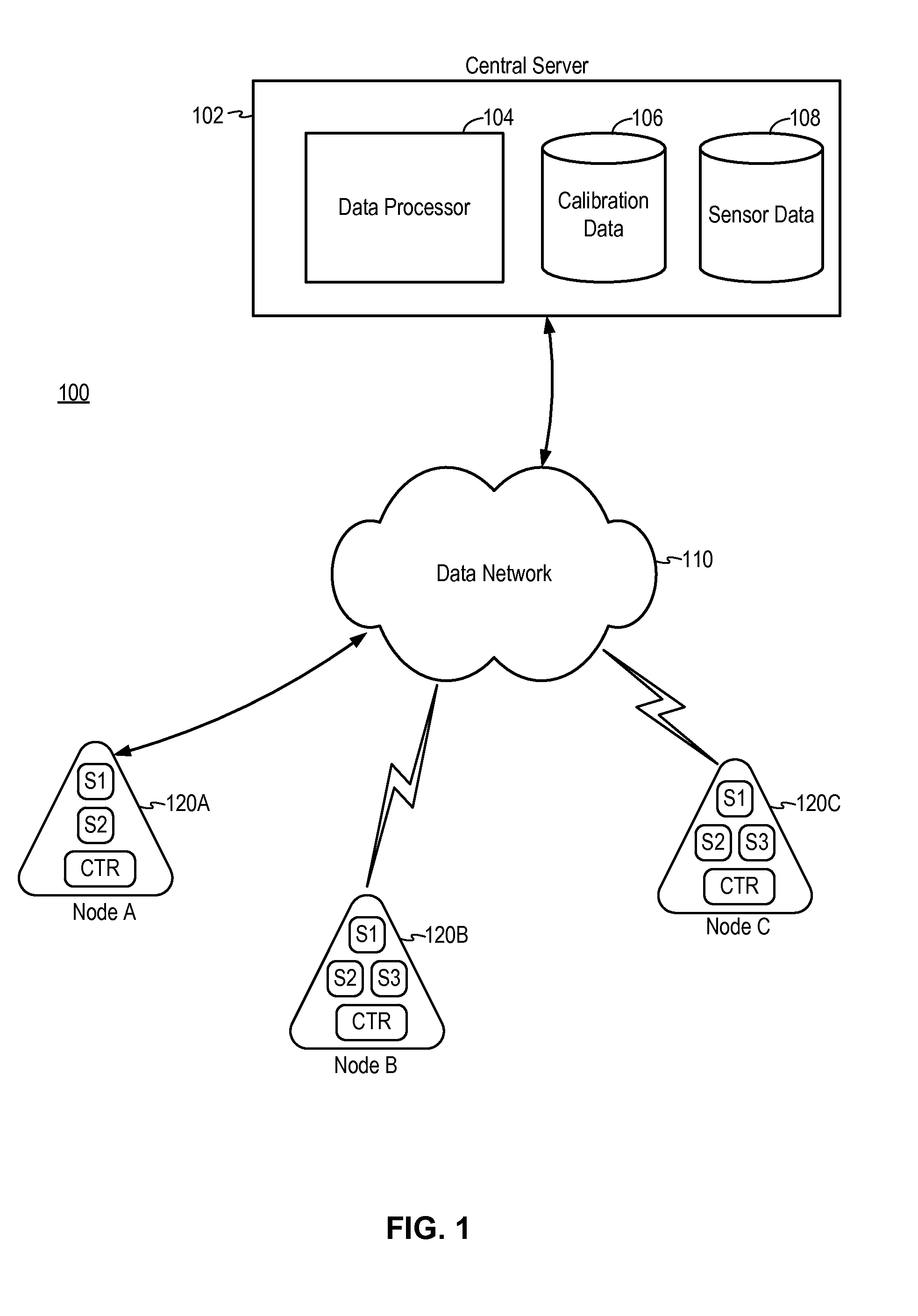

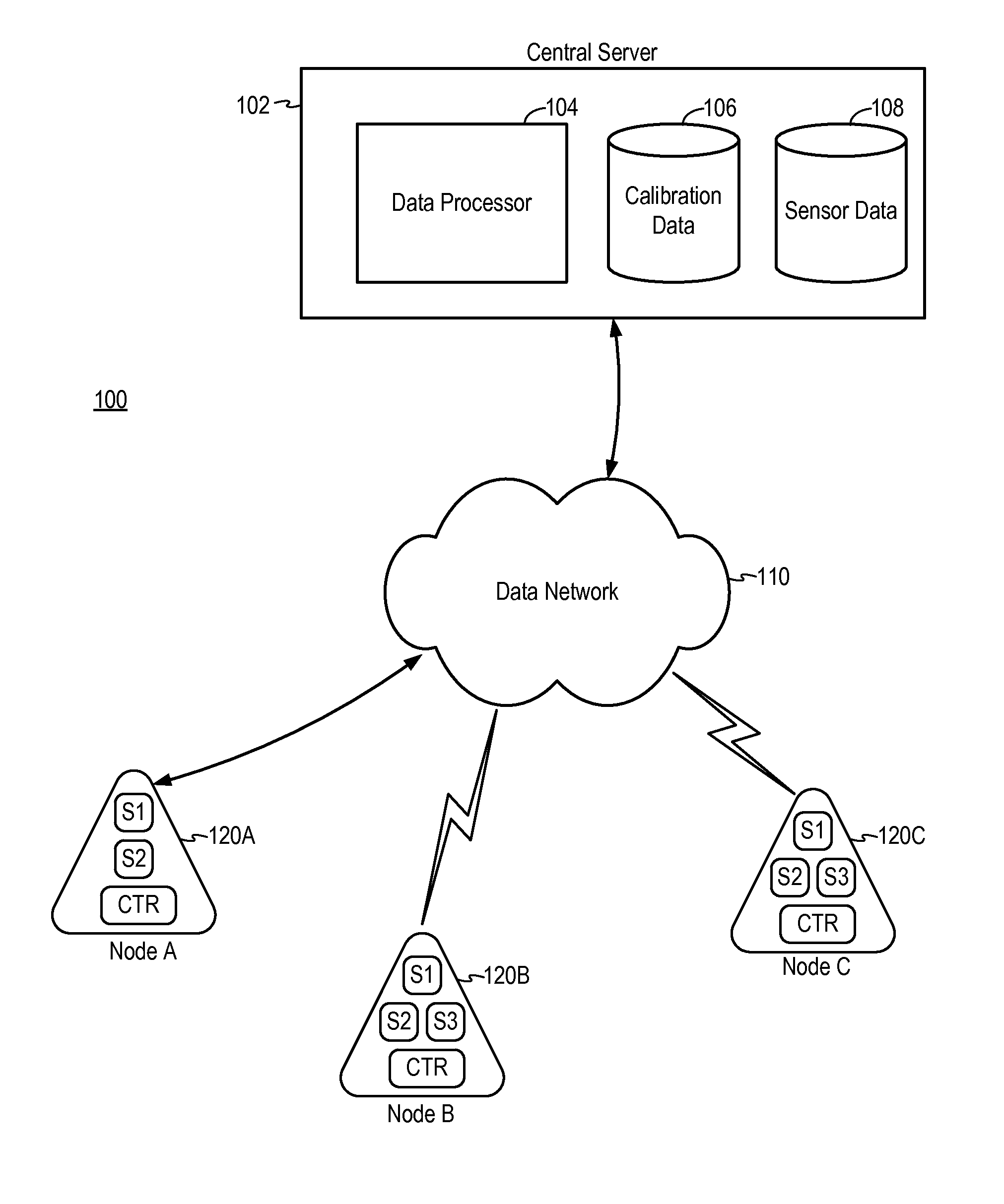

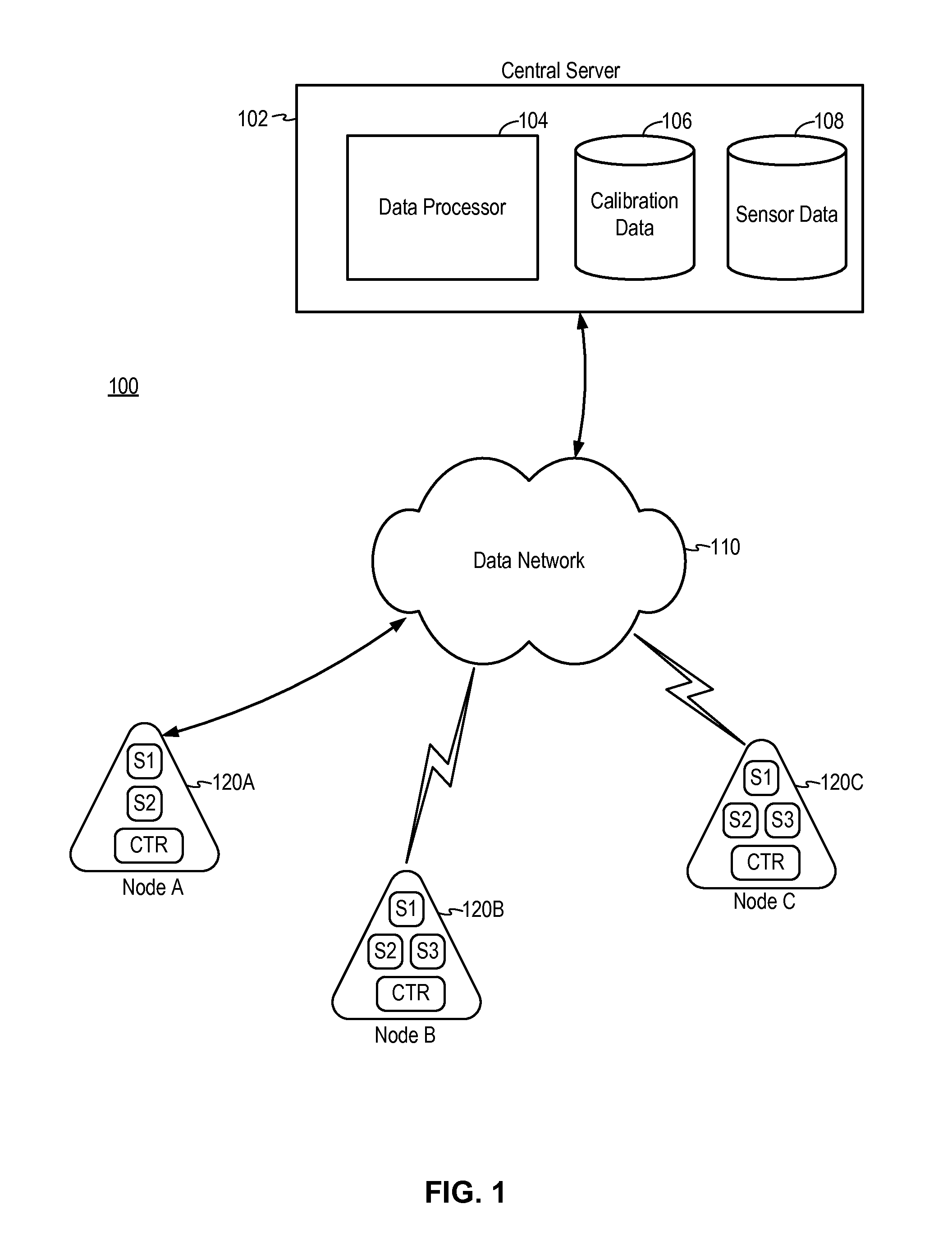

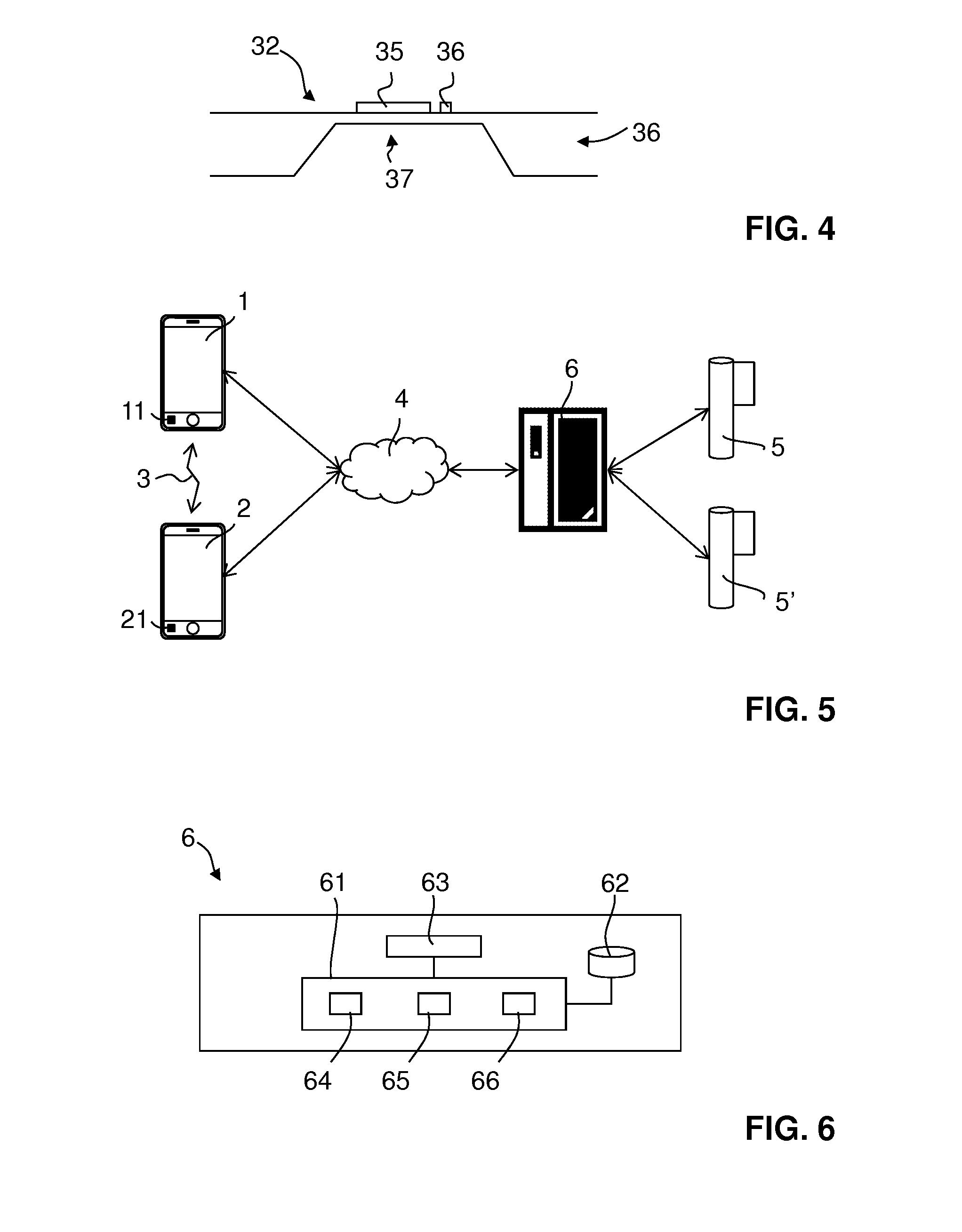

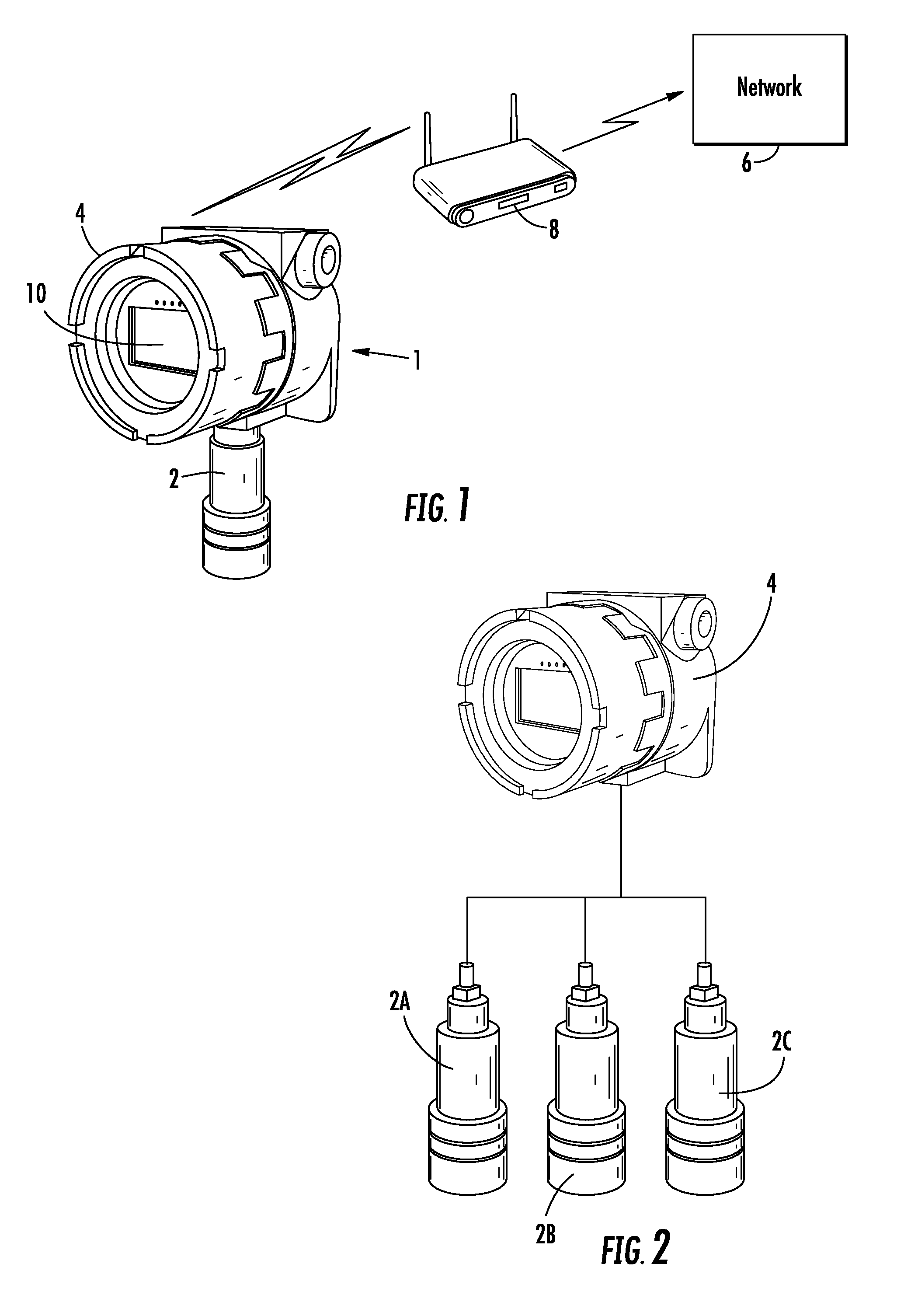

Calibration method for distributed sensor system

ActiveUS20140278186A1Testing/calibration apparatusSpeed measurement using gyroscopic effectsCross sensitivityCrowd sourcing

Methods of calibrating sensors in a distributed sensor system including a set of spatially distributed base units in communication with a central server over a data network include using a reference sensor, using a reference base unit, using crowd-sourced calibration, using sensor data collected in the same base unit, using sensor cross-sensitivity, or using sensor data from known environmental conditions.

Owner:ACLIMA

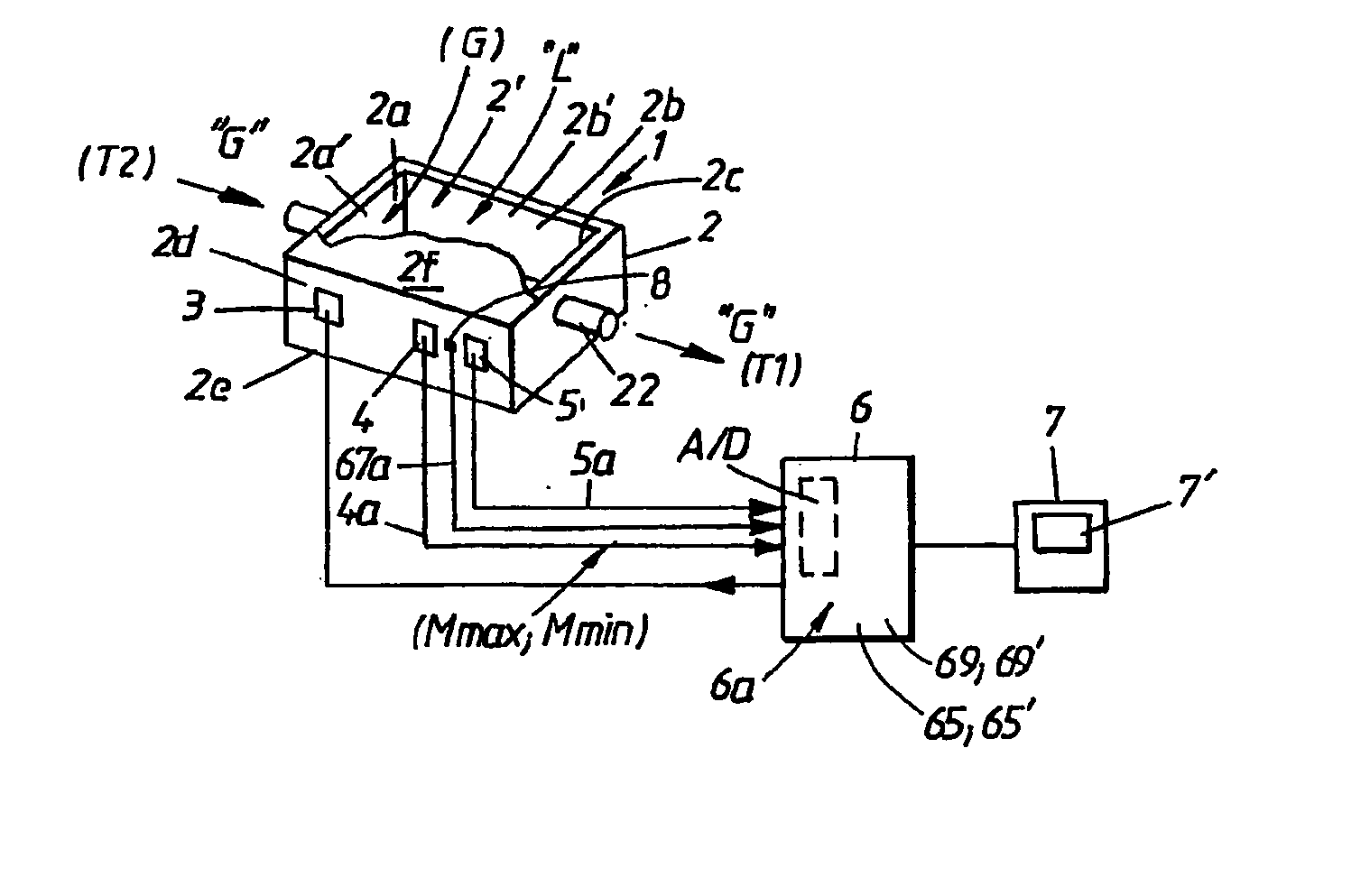

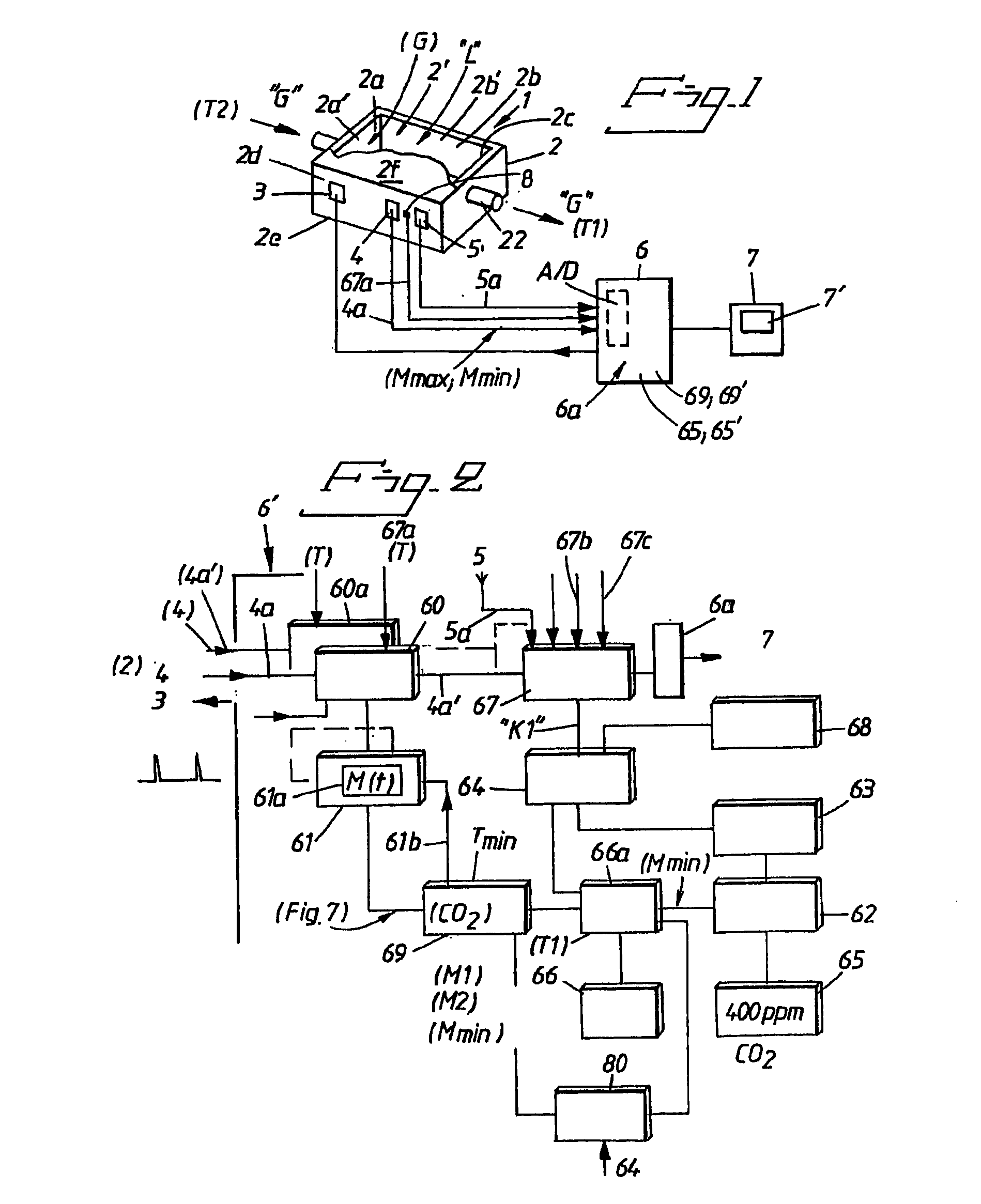

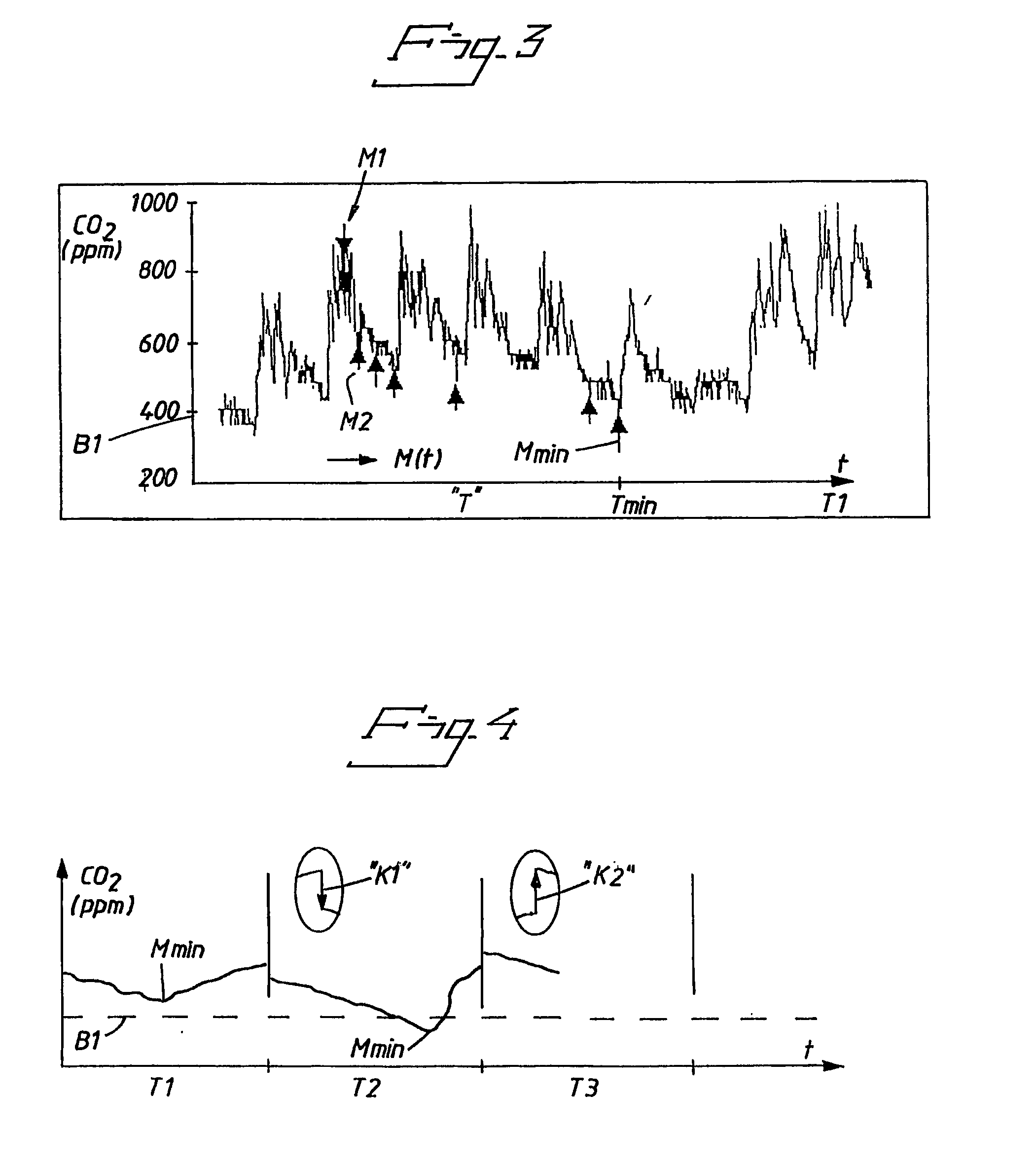

Method of compensating for a measuring error and an electronic arrangement to this end

InactiveUS20060173637A1Sure easyConveniently obtainModulated-carrier systemsColor/spectral properties measurementsComputational physicsControl theory

A method and electronic arrangement for measuring errors with the aid of a gas sensor wherein a plurality of measurement valves occurring instantly during mutual sequential measuring cycles are detected. The electronic circuit arrangement has a plurality of circuit arrangements for compensating measurement errors wherein the measurements are affect with a gas sensor.

Owner:MARTIN HANS EVALD GORAN

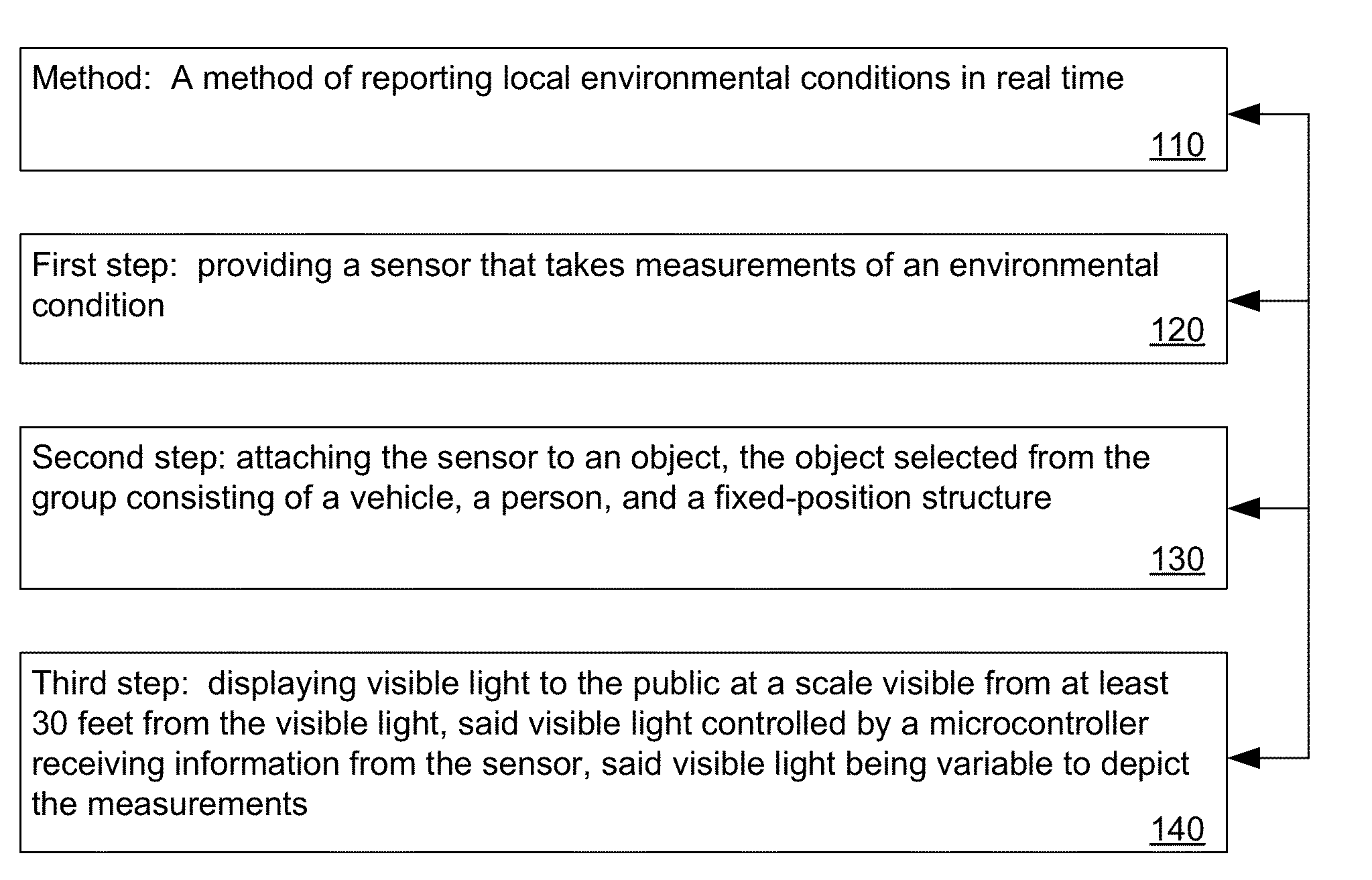

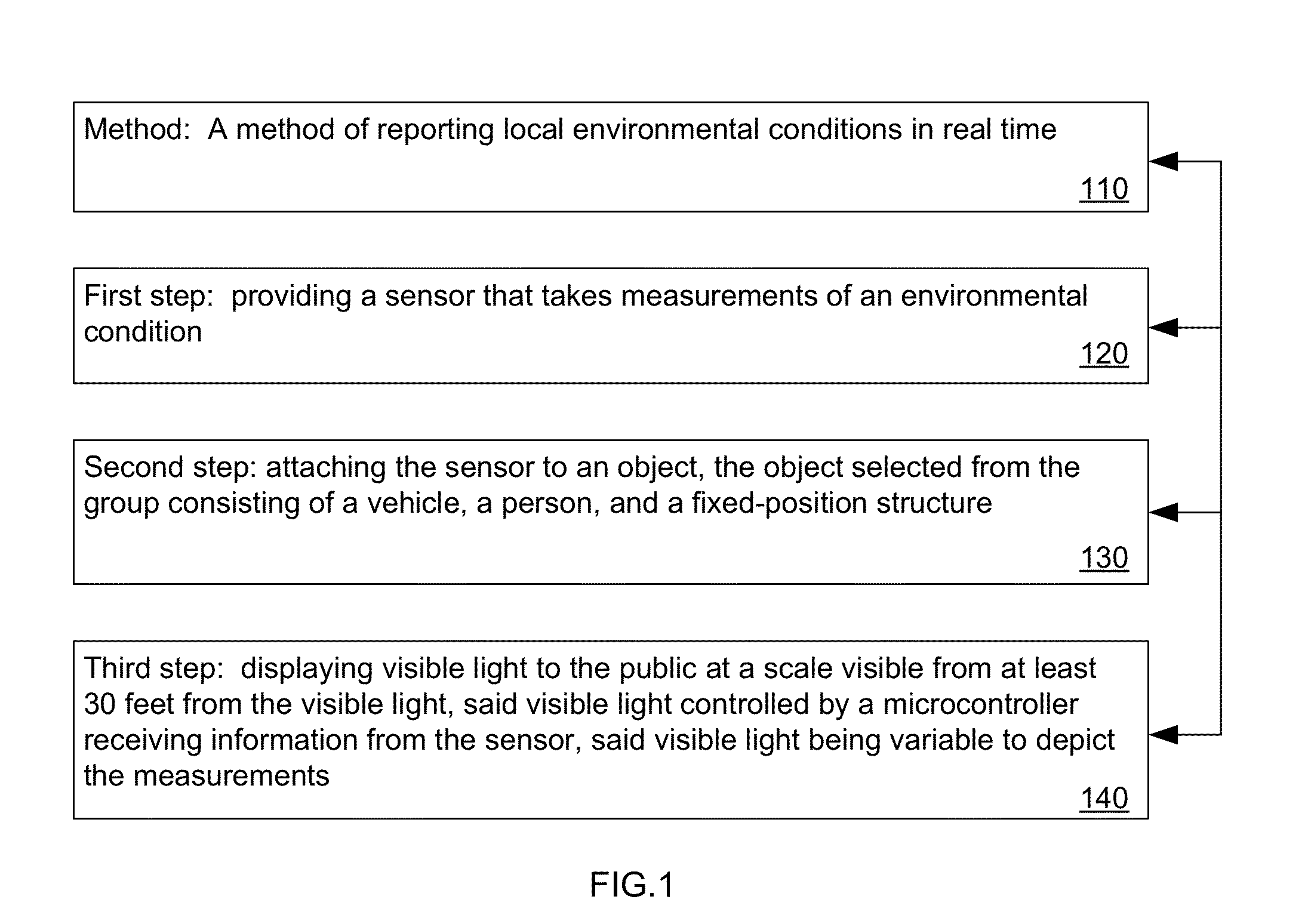

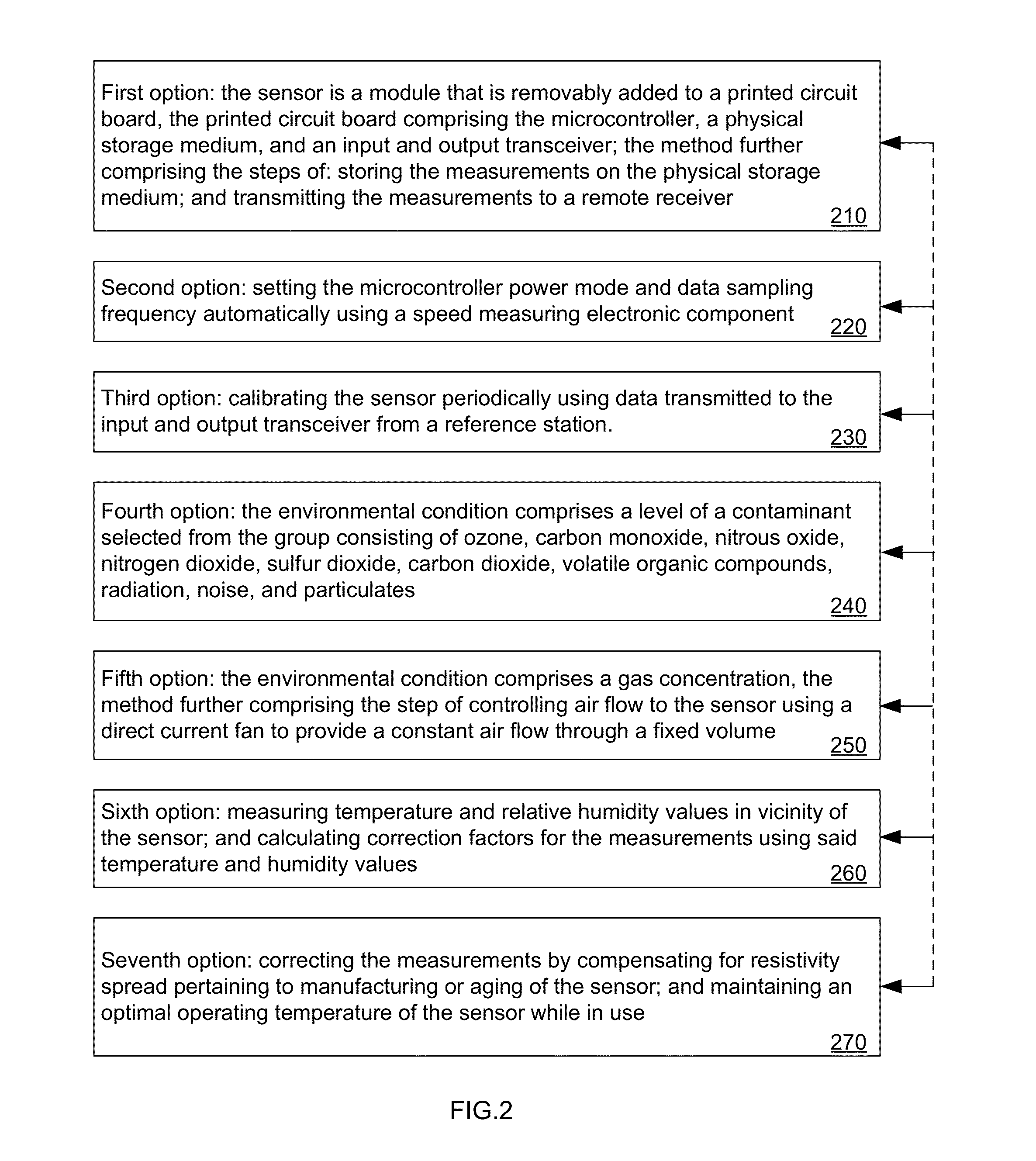

Method and system for visually reporting a local environmental condition

InactiveUS20130278427A1Low costEnhance layeringGas analyser calibrationFire alarm smoke/gas actuationMicrocontrollerEngineering

A method of reporting local environmental conditions in real time is implemented by providing a sensor that takes measurements of an environmental condition; attaching the sensor to a vehicle, a person, an object such as a street lamp or other structure; and displaying visible light to the public at a scale visible from at least 30 feet from the visible light. The visible light is controlled by a microcontroller receiving information from the sensor. The visible light is either variable to depict the measurements, such as in color, frequency of illumination, or is variable in a plurality of lamps lighted in accordance with the magnitude of the measurements or in accordance with a composite index. The sensor is preferably modular so that it can be swapped in and out of a printed circuit board.

Owner:SETTON MICHAEL

Method and system for creating a mercury halide standard for use in testing a mercury analyzer system

InactiveUS6852542B2Withdrawing sample devicesMaterial analysis by electric/magnetic meansGas cylinderElemental mercury

A method and system are provided for creating a mercury halide standard, and for using that standard to test a mercury analyzer system. Gaseous elemental mercury of a known concentration from a gas cylinder and a halogen donor are fed to a reaction chamber where they react to form mercury halide. The mercury halide is fed to a mercury analyzer system where it is converted to reform gaseous elemental mercury which is then measured by a mercury analyzer. By comparing either the amount of elemental mercury supplied to the reaction chamber or the amount of mercury halide formed in the reaction chamber with the amount of elemental mercury converted from the mercury halide, the ability of the mercury analyzer system to convert mercury halide to gaseous elemental mercury can be evaluated.

Owner:SPECTRA GASES

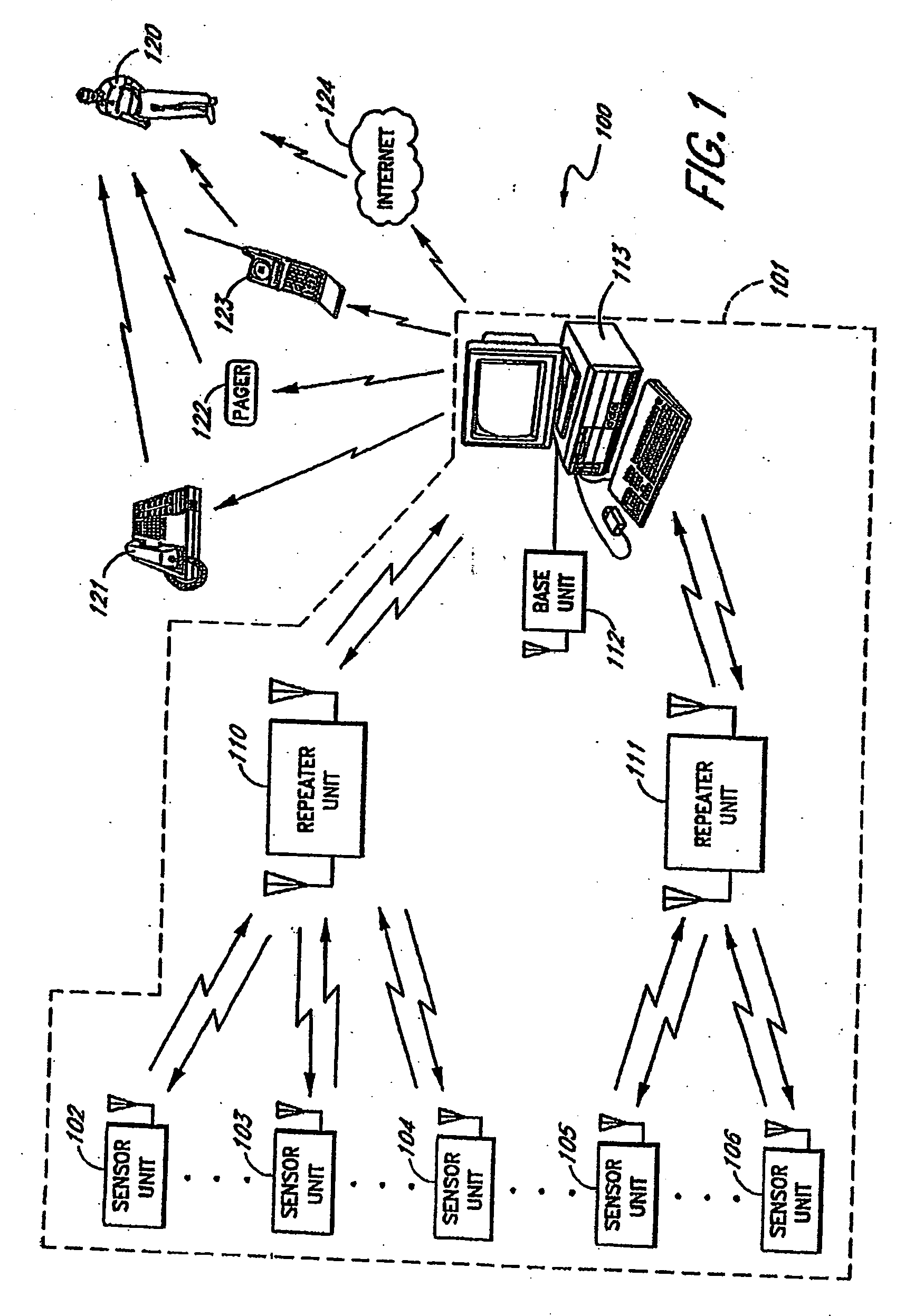

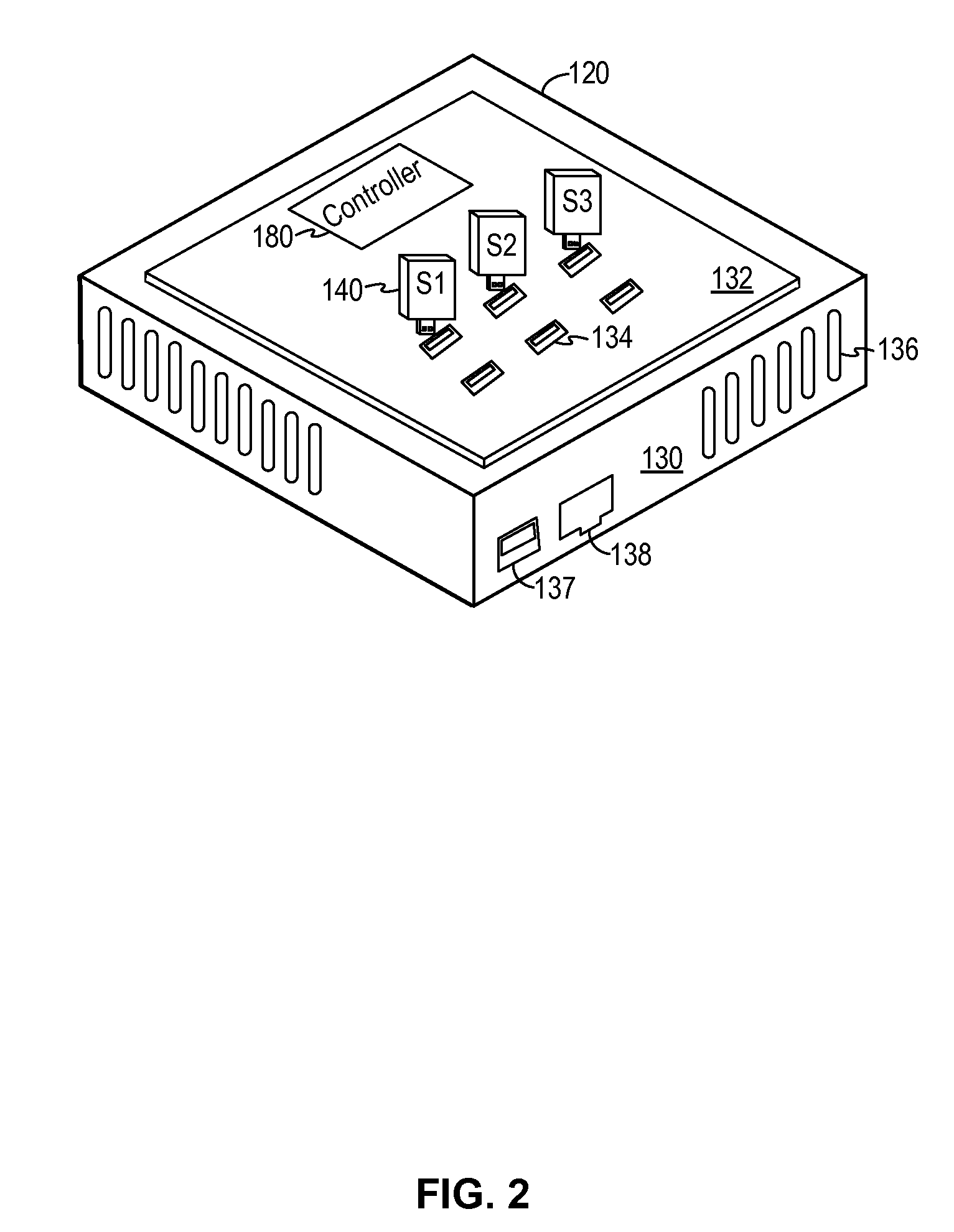

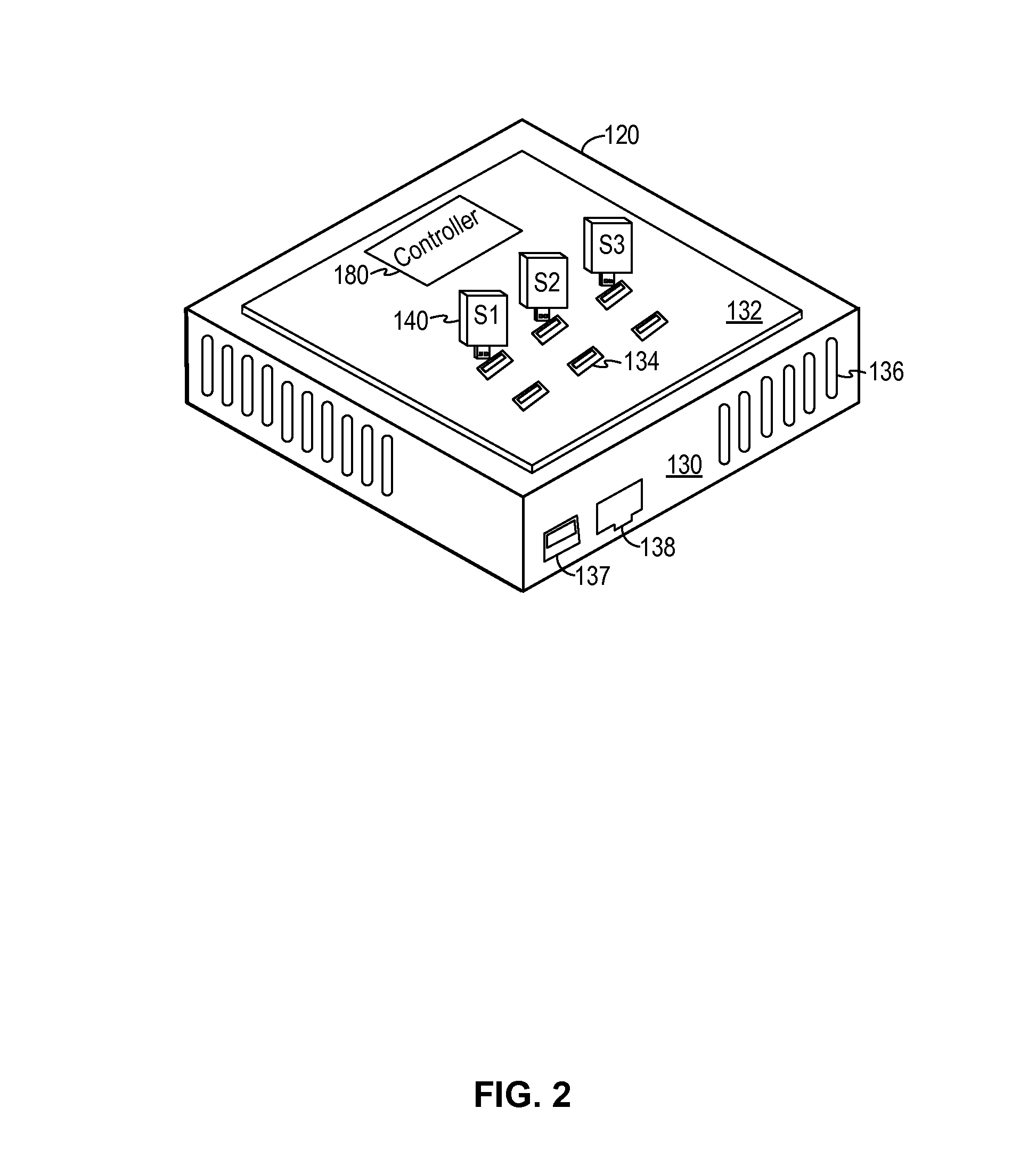

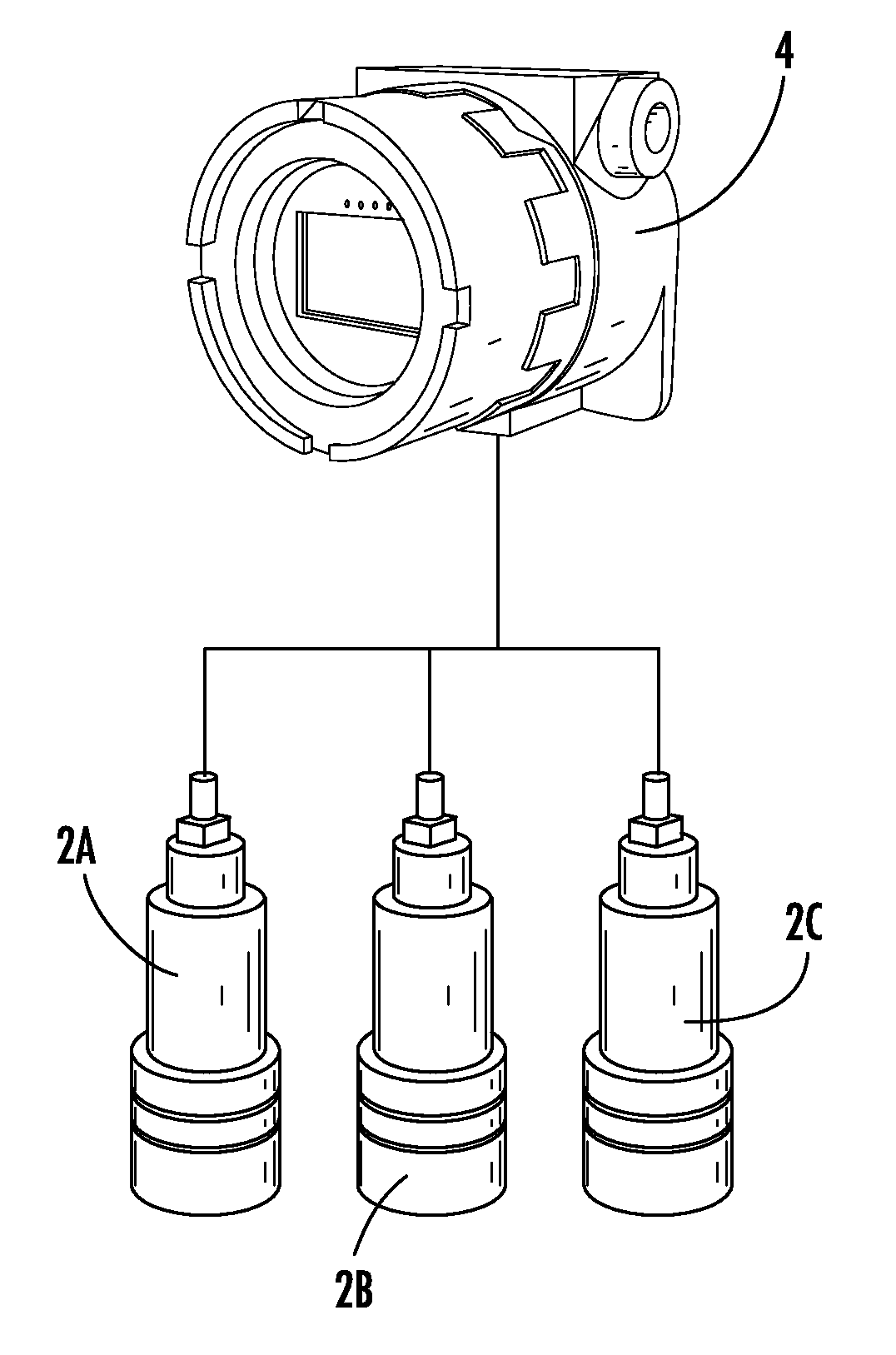

Distributed sensor system with remote sensor nodes and centralized data processing

ActiveUS20140278144A1Speed measurement using gyroscopic effectsApparatus with stored calibration coefficientsComputer scienceData store

A distributed sensor system includes a set of spatially distributed base units and a central server both in communication with a data network. Each base unit includes a controller and one or more sensor modules where each sensor module includes a sensor configured to measure an air quality parameter. Each base unit transmits raw sensor data associated with each of the sensor modules over the data network and the central server receives the raw sensor data from the base units and stores the raw sensor data in a database.

Owner:ACLIMA

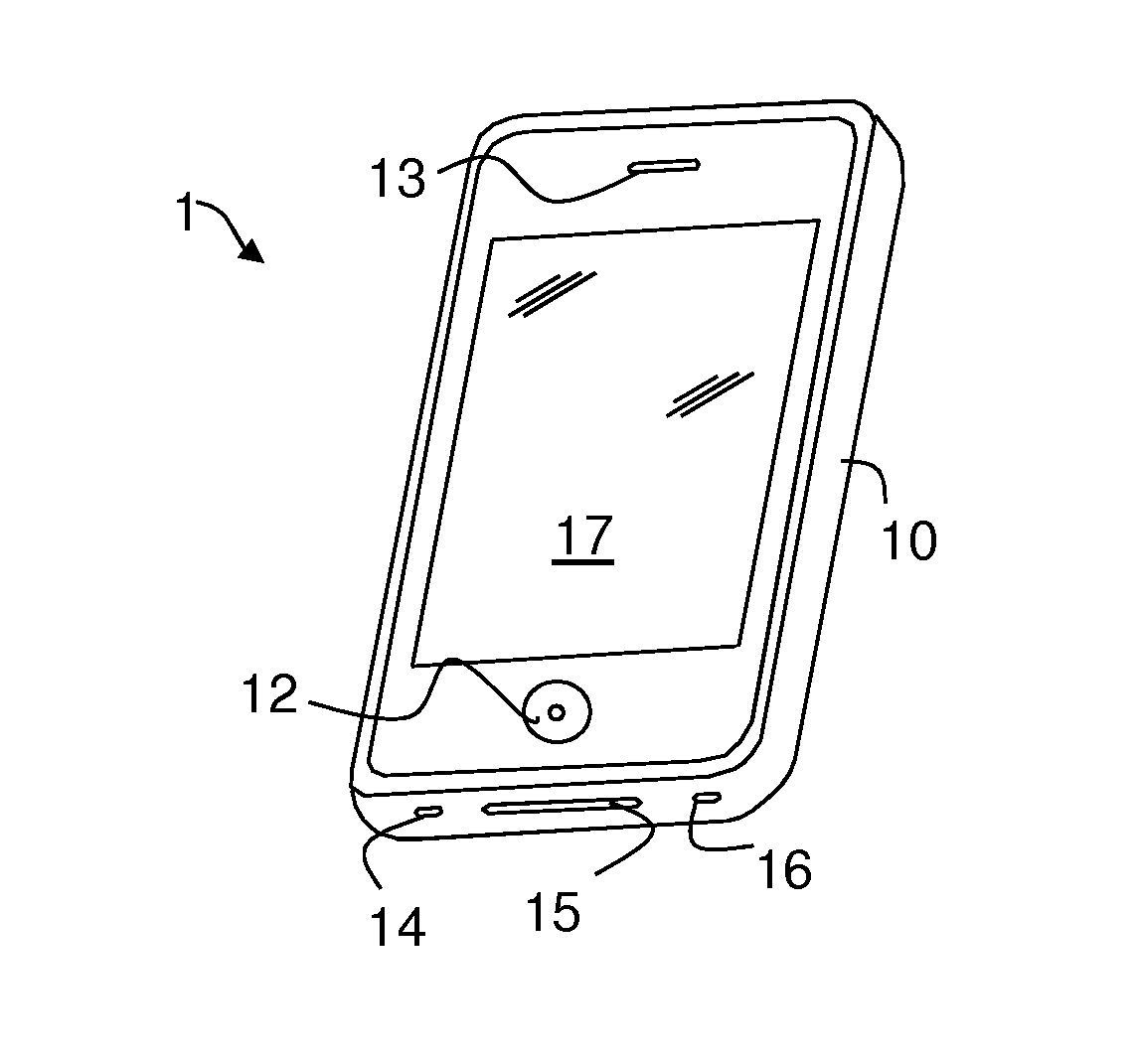

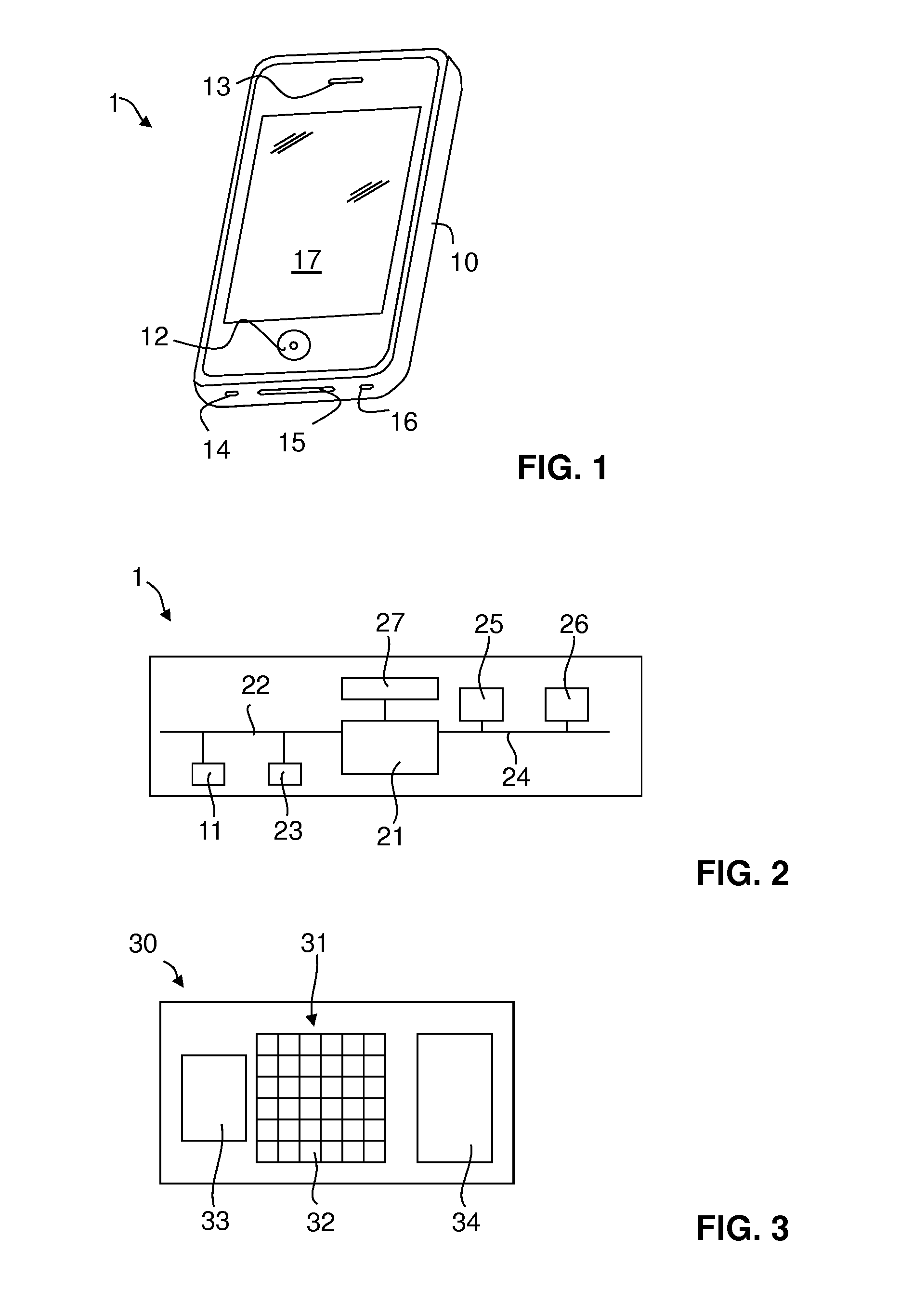

Calibration of a chemical sensor in a portable electronic device

InactiveUS20140244198A1Reduce the impactReduce impactTesting/calibration apparatusSpeed measurement using gyroscopic effectsEngineeringElectric equipment

In a method for calibrating a portable first electronic device (1) comprising a first chemical sensor, a determination is carried out whether the first electronic device is located near a second electronic device comprising a second chemical sensor. If this is the case and if optionally other criteria are fulfilled, readings of the first and second chemical sensor are compared. Subject to the comparison, calibration values for the first chemical sensor are derived.

Owner:SENSIRION AG

Apparatus and method for generating calibration gas

ActiveUS6997347B2Low costAccurate concentrationOpening closed containersBottle/container closureDocking stationCalibration gas

An apparatus and method for generating a low concentration of gas within a carrier gas flow employing one or more miniature one-piece cylinders filled under pressure with a pure gas, or a concentrated gas balanced with an inert gas or gas mixture. Released from the cylinder through a pierced or other controlled opening, the flow of the gas is regulated by a pressure regulator and a micro orifice to be blended into a steady stream of diluent gas, typically ambient air, to form a desired gas concentration. No gas is generated if the pressure of the gas in the cylinder, which is monitored constantly by a pressure transducer, is below a predetermined level. The apparatus can be built into a portable device, or an automated docking station (or calibration station) for testing and calibrating gas detection and monitoring instruments, or into a fixed gas detection system for performing such functions.

Owner:INDUSTRIAL SCIENTIFIC CORPORATION

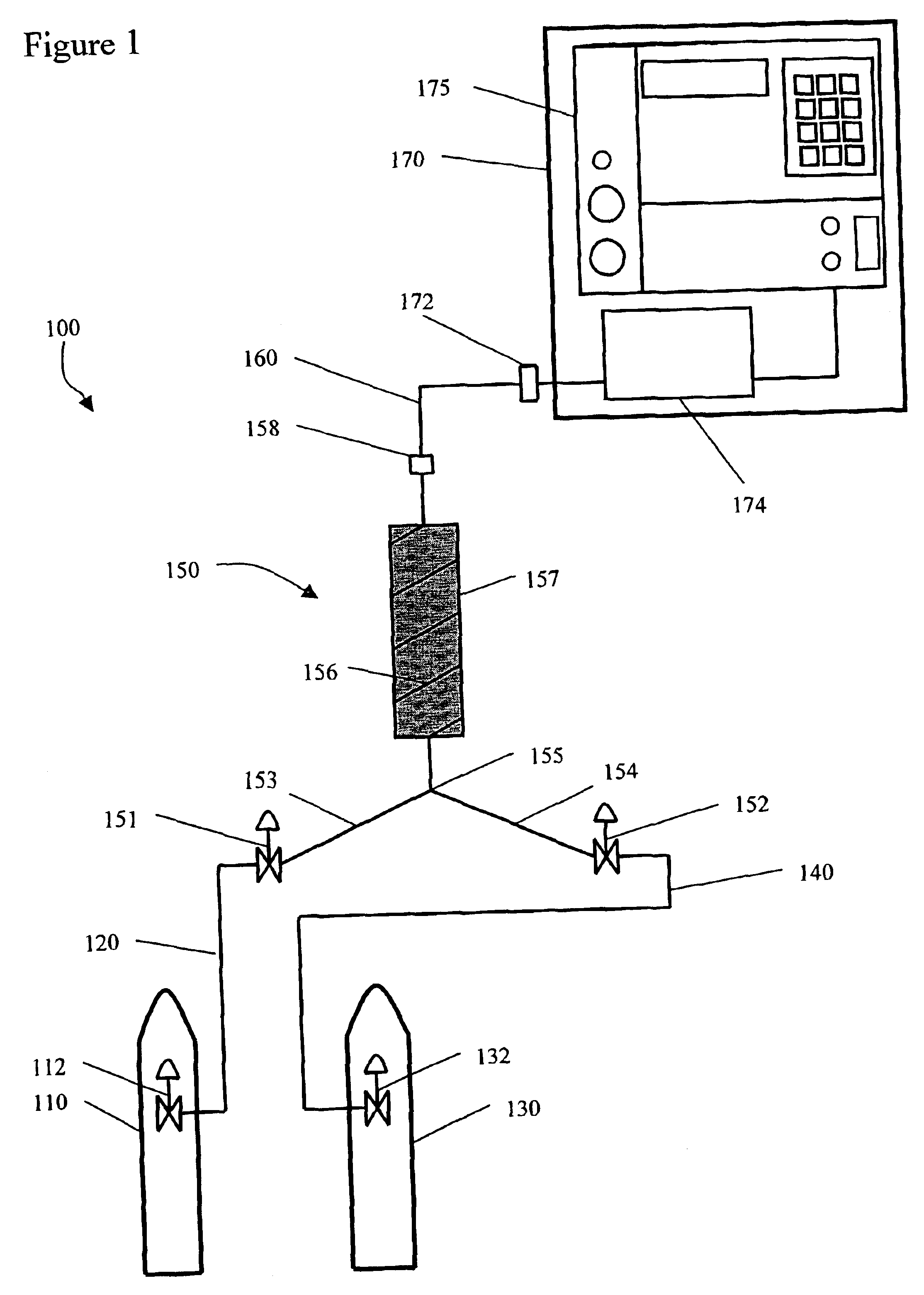

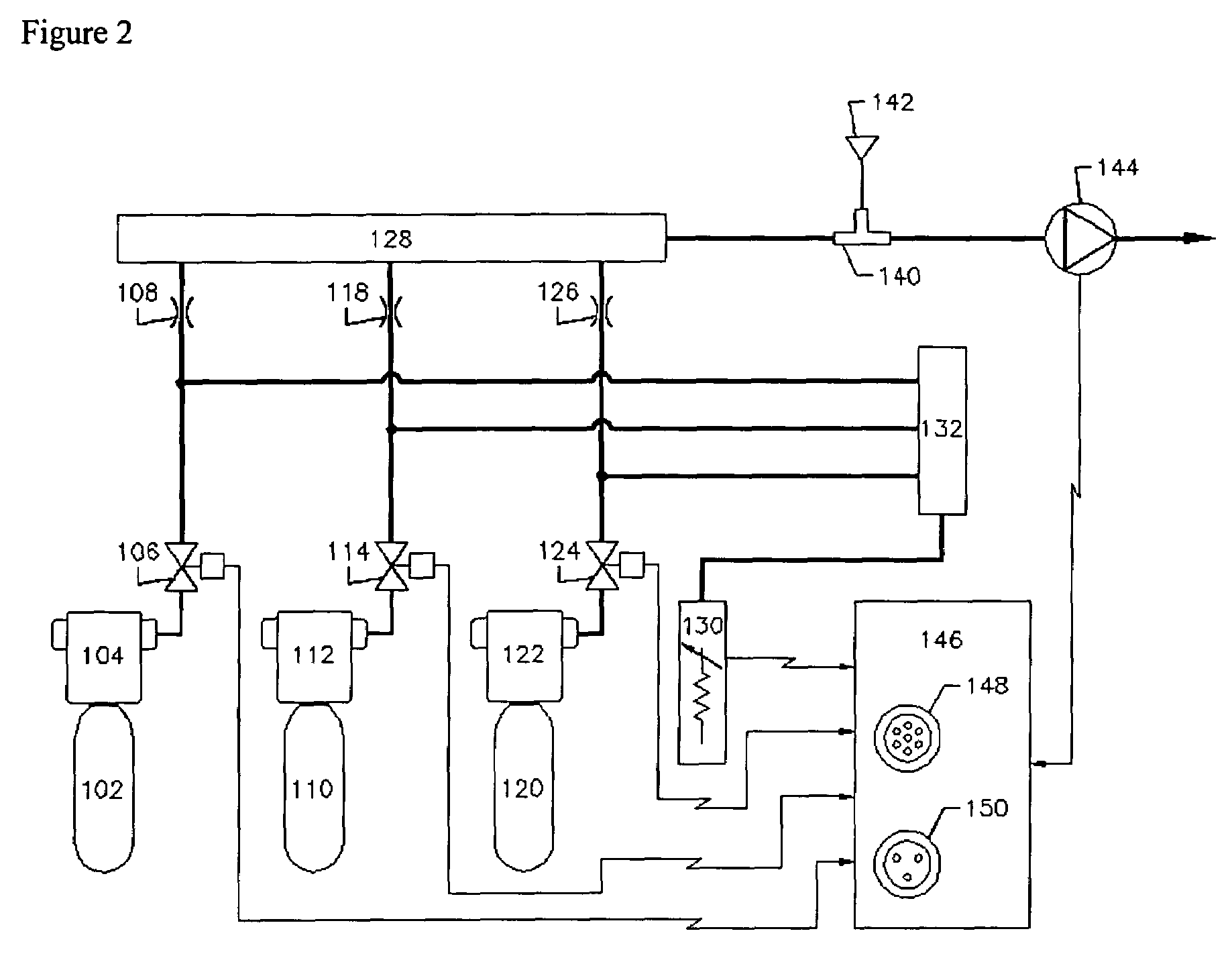

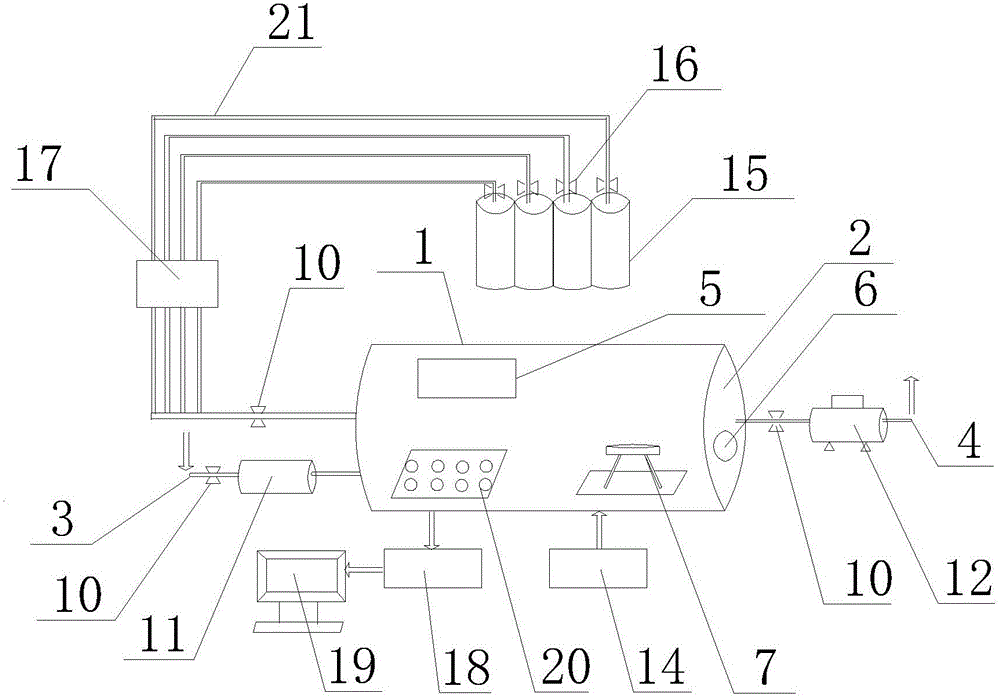

Multifunctional gas sensor testing system

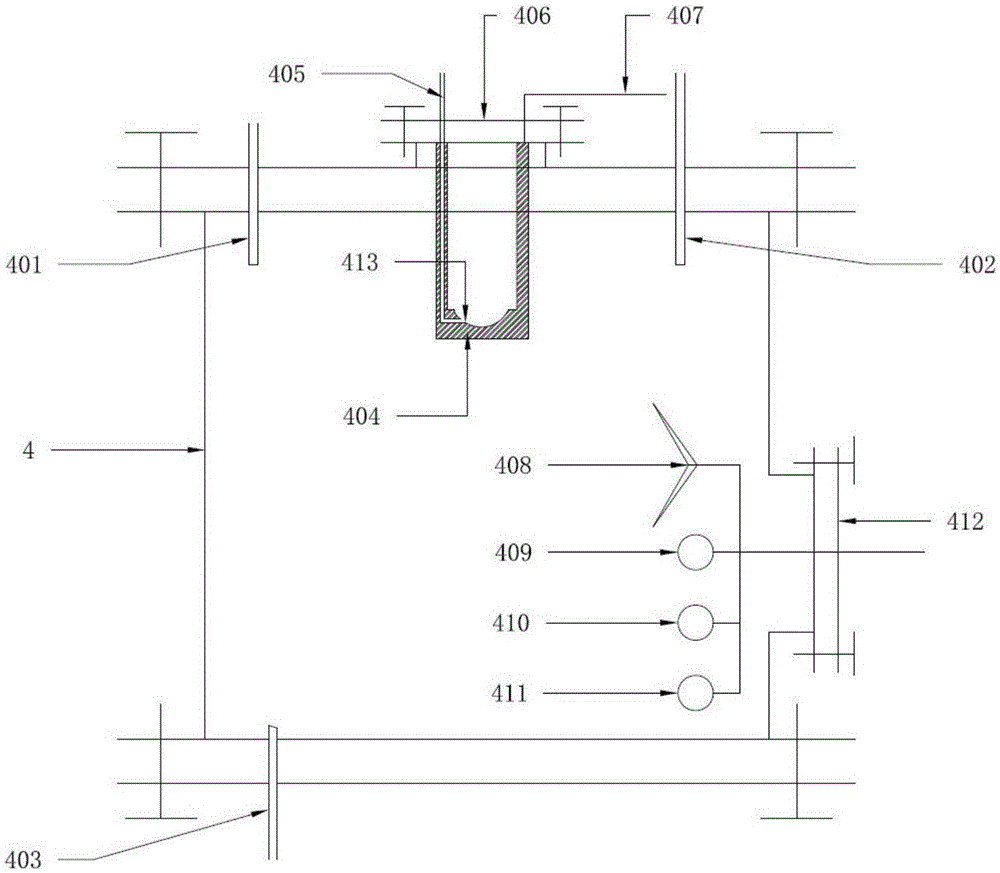

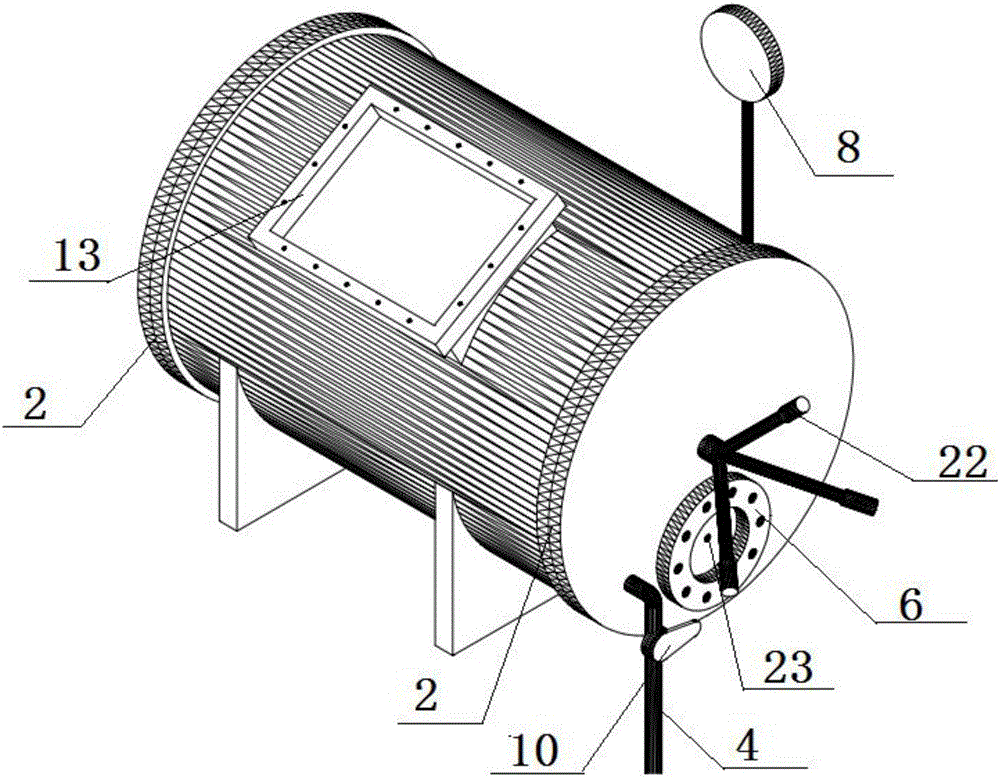

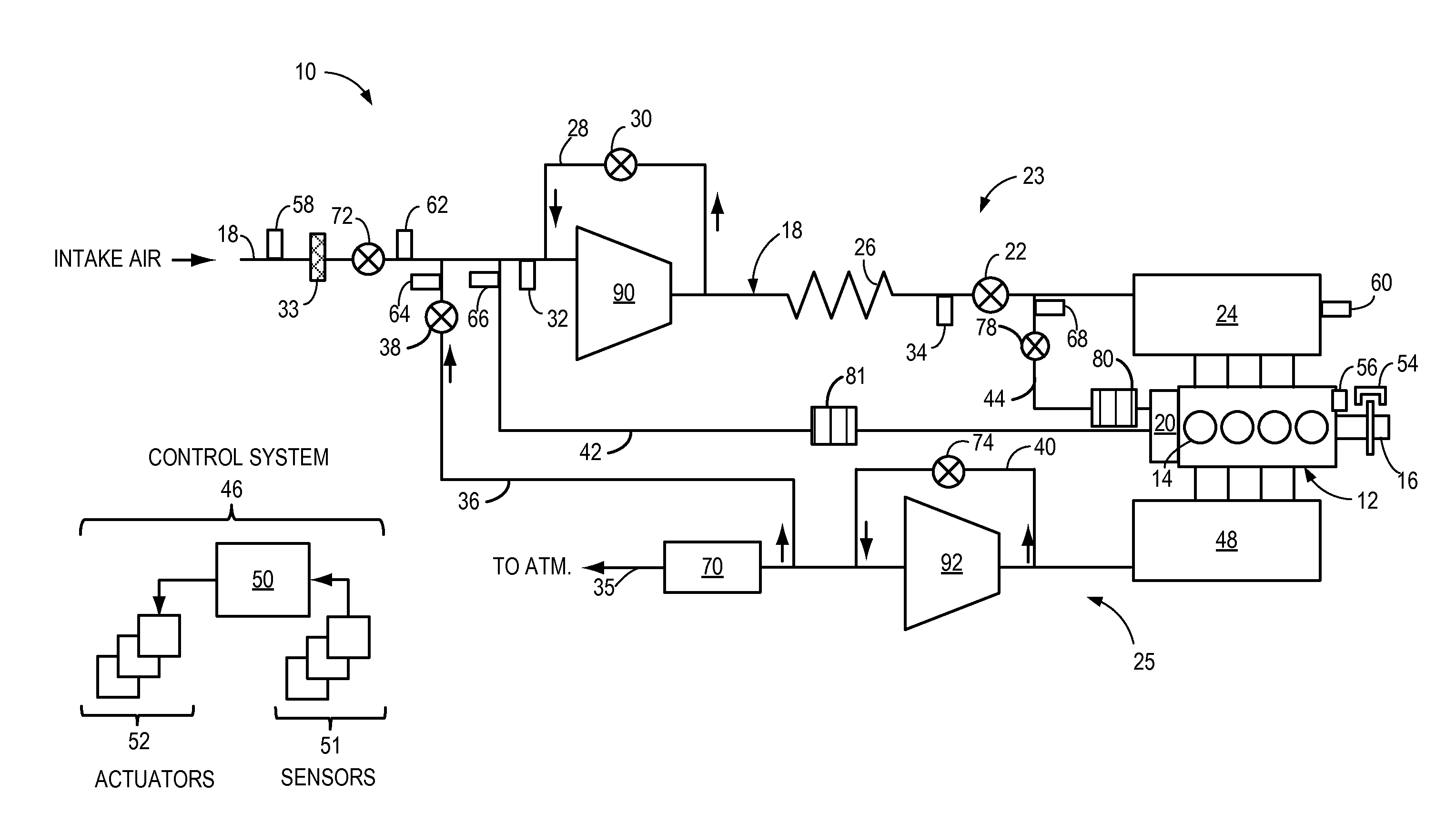

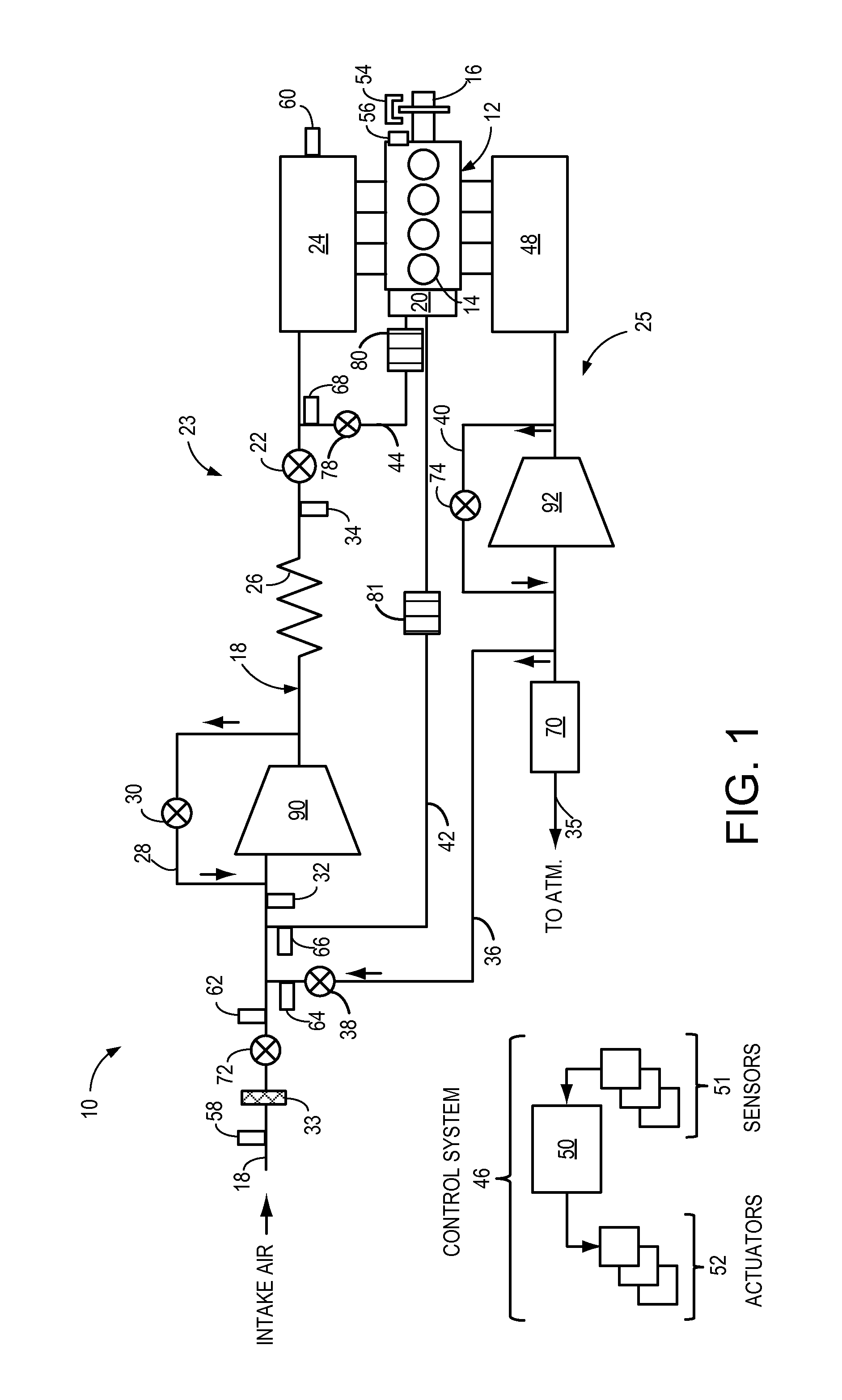

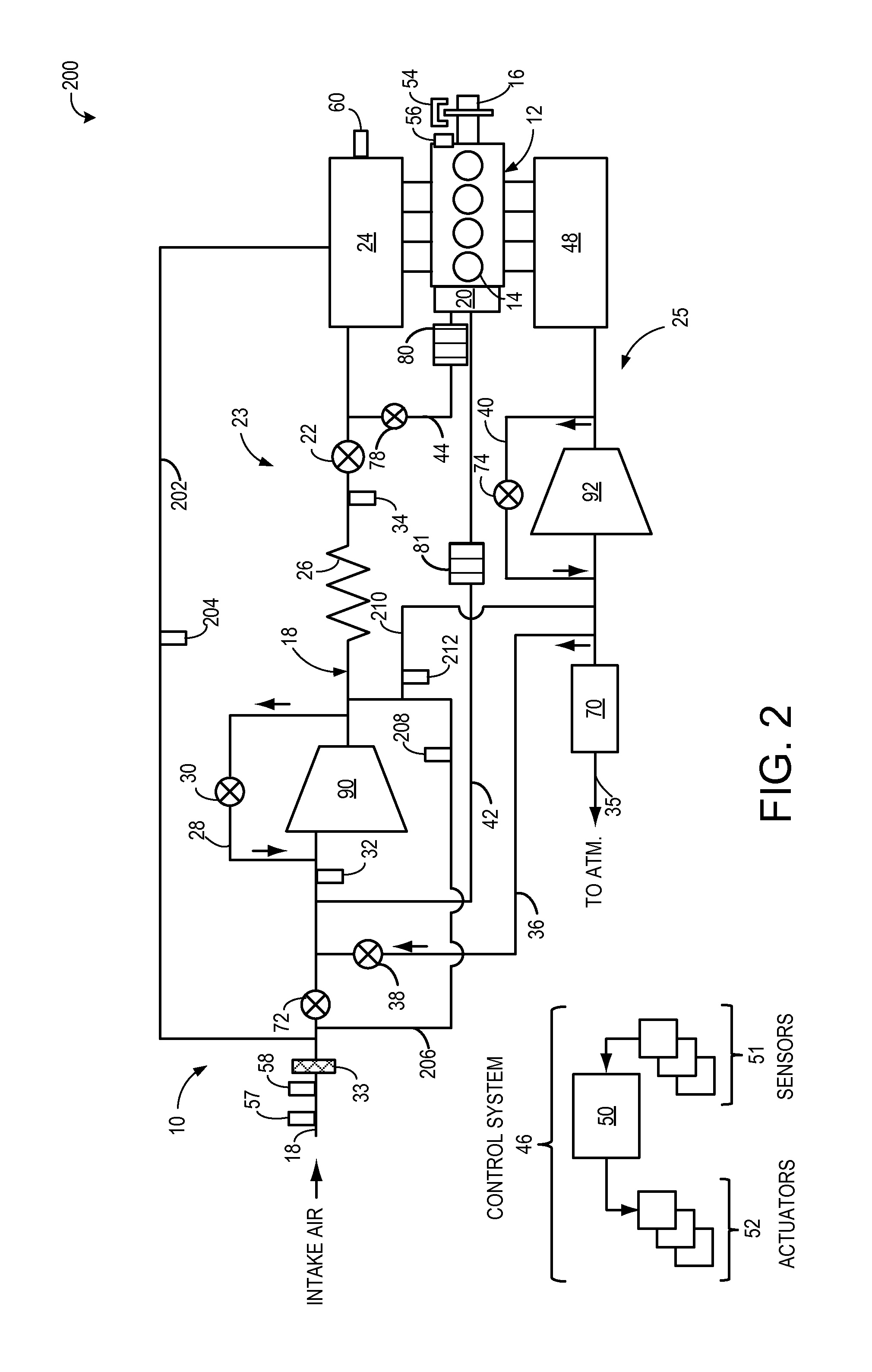

ActiveCN105021777AQuick contactAccurately Test Response TimesGas analyser calibrationSimultaneous control of multiple variablesControl systemSolenoid valve

The invention discloses a multifunctional gas sensor testing system. The multifunctional gas sensor testing system comprises a gas distribution mechanism and a gas distribution chamber, a testing chamber, a control system, a testing mechanism and a vacuum pump, wherein the gas distribution mechanism is used for preparing standard-concentration gas and background gas for the gas distribution chamber; prepared standard-concentration testing gas is stored in the testing chamber and the testing chamber is used for testing a sensor sensitive property under standard concentration of gas to be tested; and the control system is used for controlling gas preparation in the gas distribution chamber and the testing chamber, and comprises temperature and humidity control, gas pressure or vacuum degree control, gas mass and flow control, on-off control of each gas-path solenoid valve, starting / stopping control of the vacuum pump, starting / stopping control of a stirring fan, and testing process control of a detected sensor. According to the multifunctional gas sensor testing system disclosed by the invention, rapid contact of the sensor and standard gas is realized by automatically preparing the standard-concentration gas, and the temperature and humidity of a sensor testing environment also can be controlled; and synchronous testing of electric gas responding of the plurality of sensors and optical gas responding of the single sensor also can be realized.

Owner:HUBEI UNIV

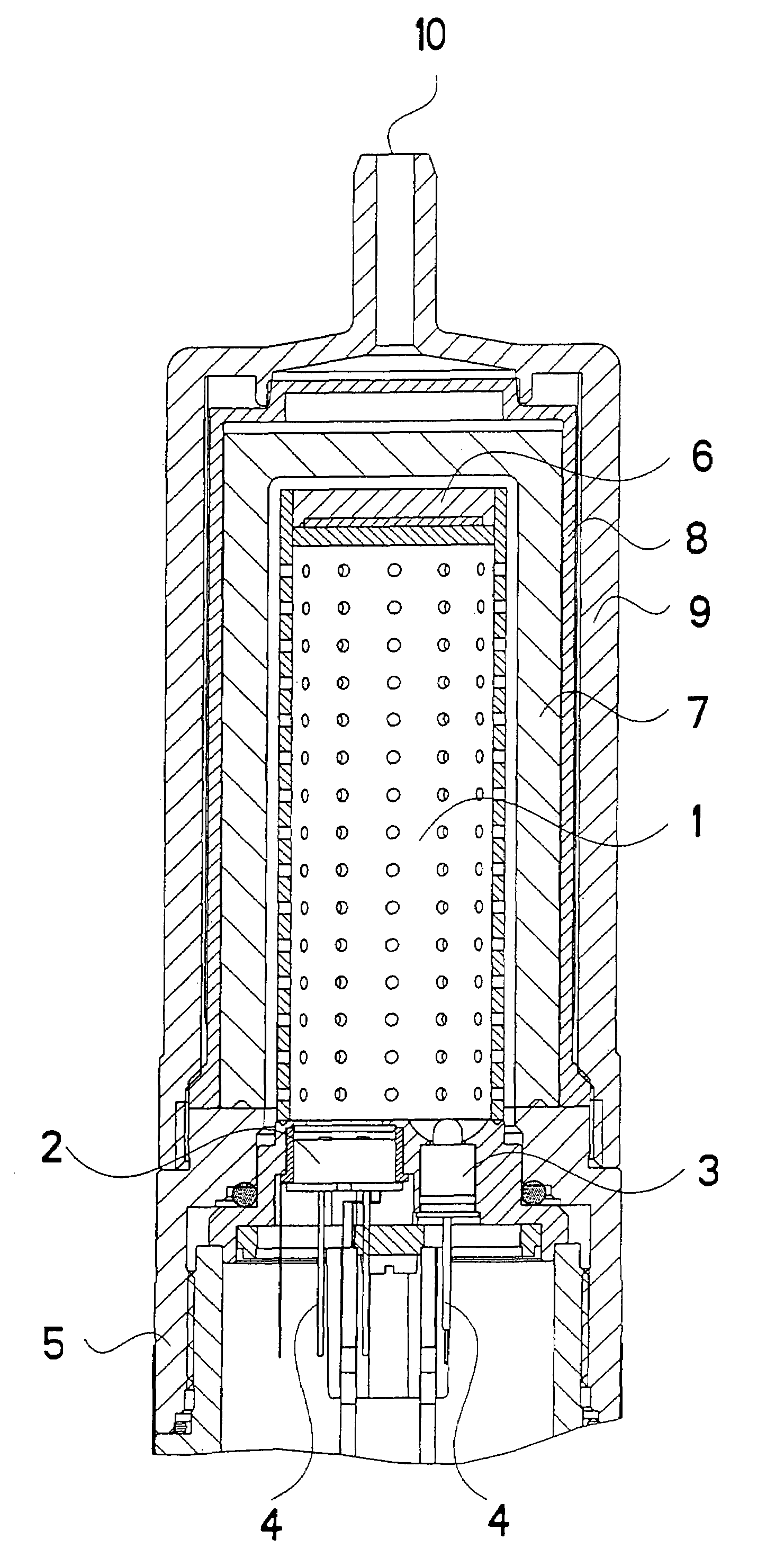

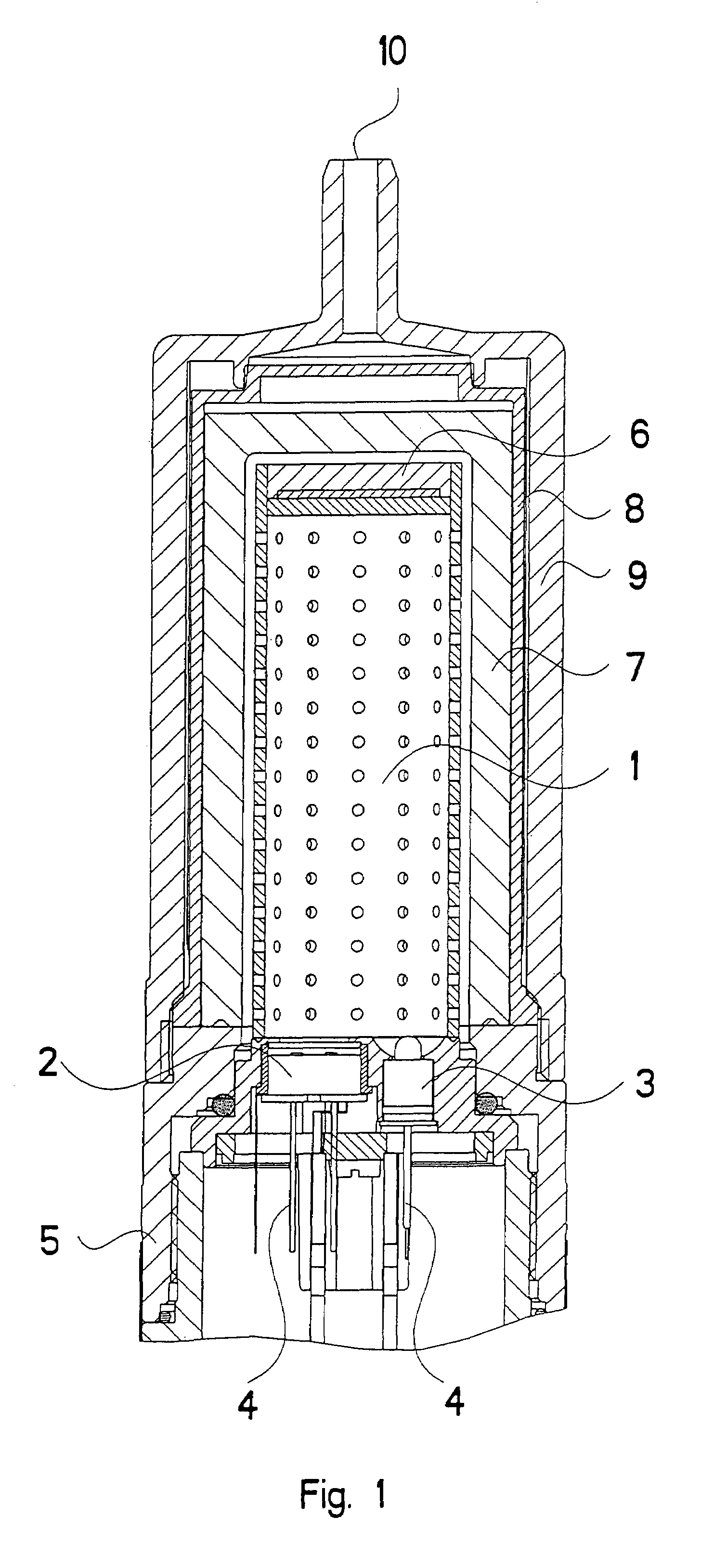

Gas sensor

ActiveUS7406854B2Reduce effortCalibration reducedFuel testingTransmissivity measurementsSpecial designEnvironmental engineering

Owner:DRAGER SAFETY

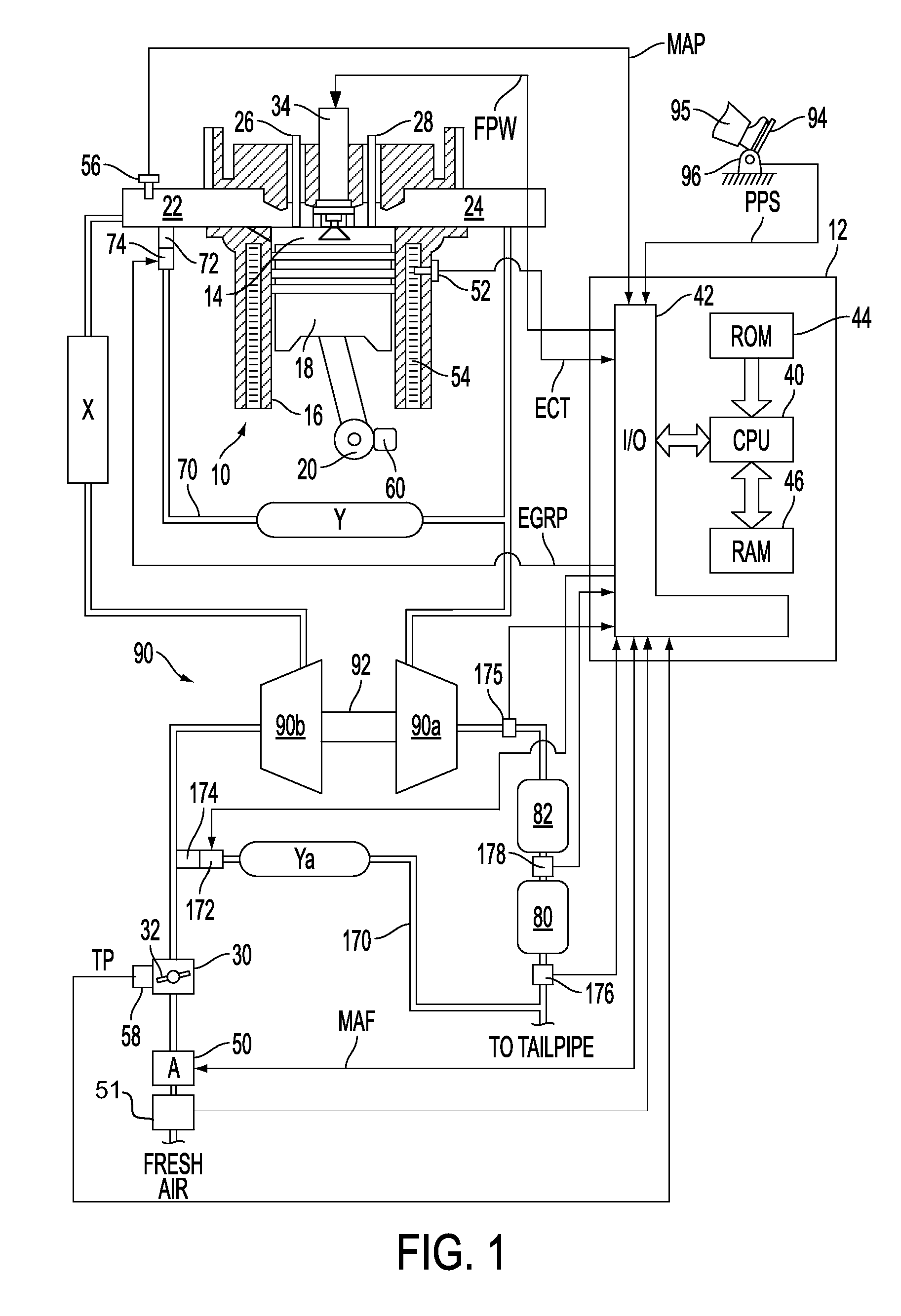

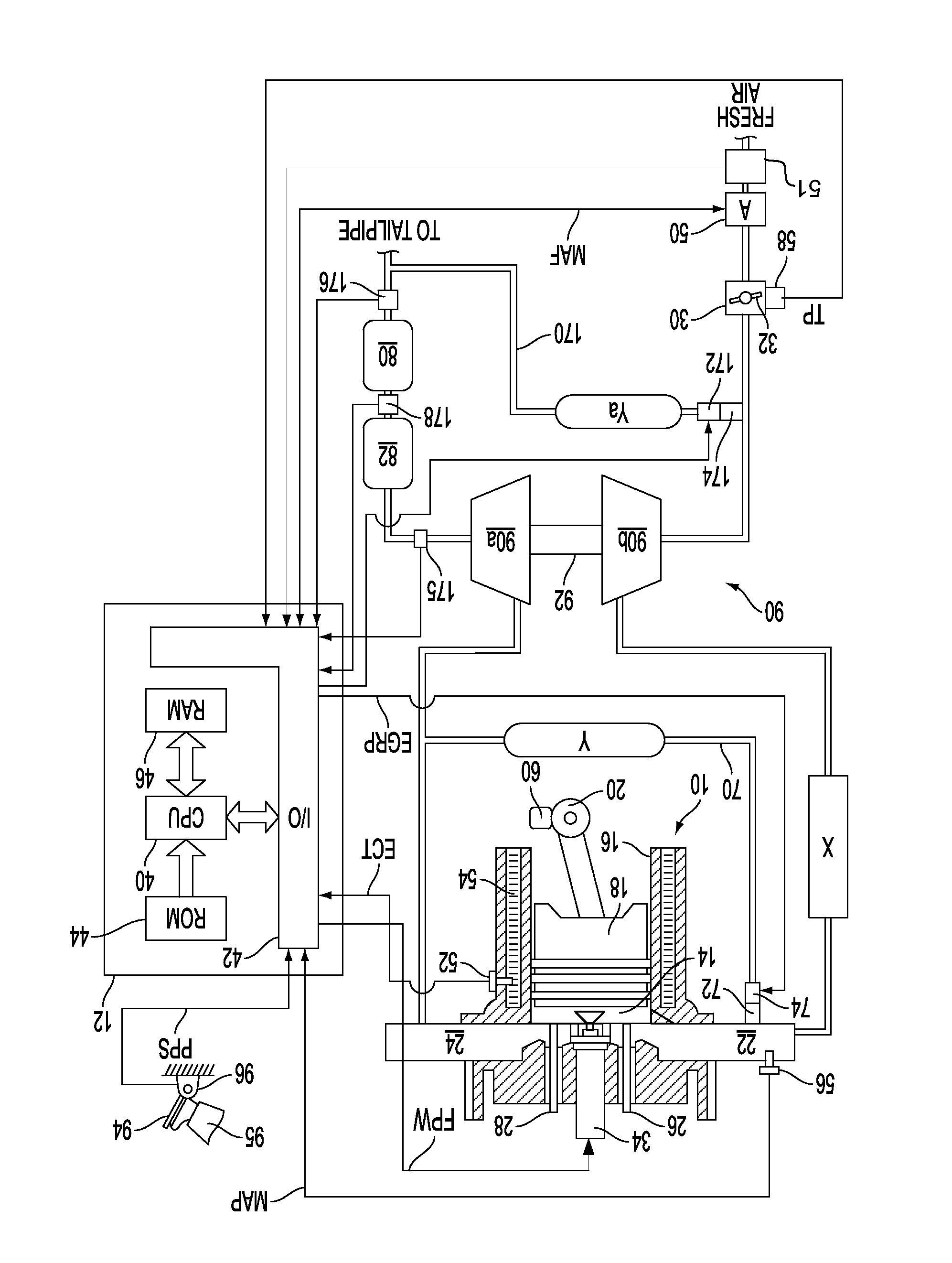

System for an engine having a particulate matter sensor

ActiveUS20110047985A1Easy to controlPerformance of oxygen degradeElectrical controlInternal combustion piston enginesParticulatesWater vapor

A system for improving operation of an engine having a particulate matter sensor is presented. The system may be used to improve engine operation during cold starts especially under conditions where water vapor or entrained water droplets are present in vehicle exhaust gases. In one embodiment, an engine controller that activates a heater of an exhaust gas sensor after an output of a particulate matter sensor exceeds a threshold value after an engine is started.

Owner:FORD GLOBAL TECH LLC

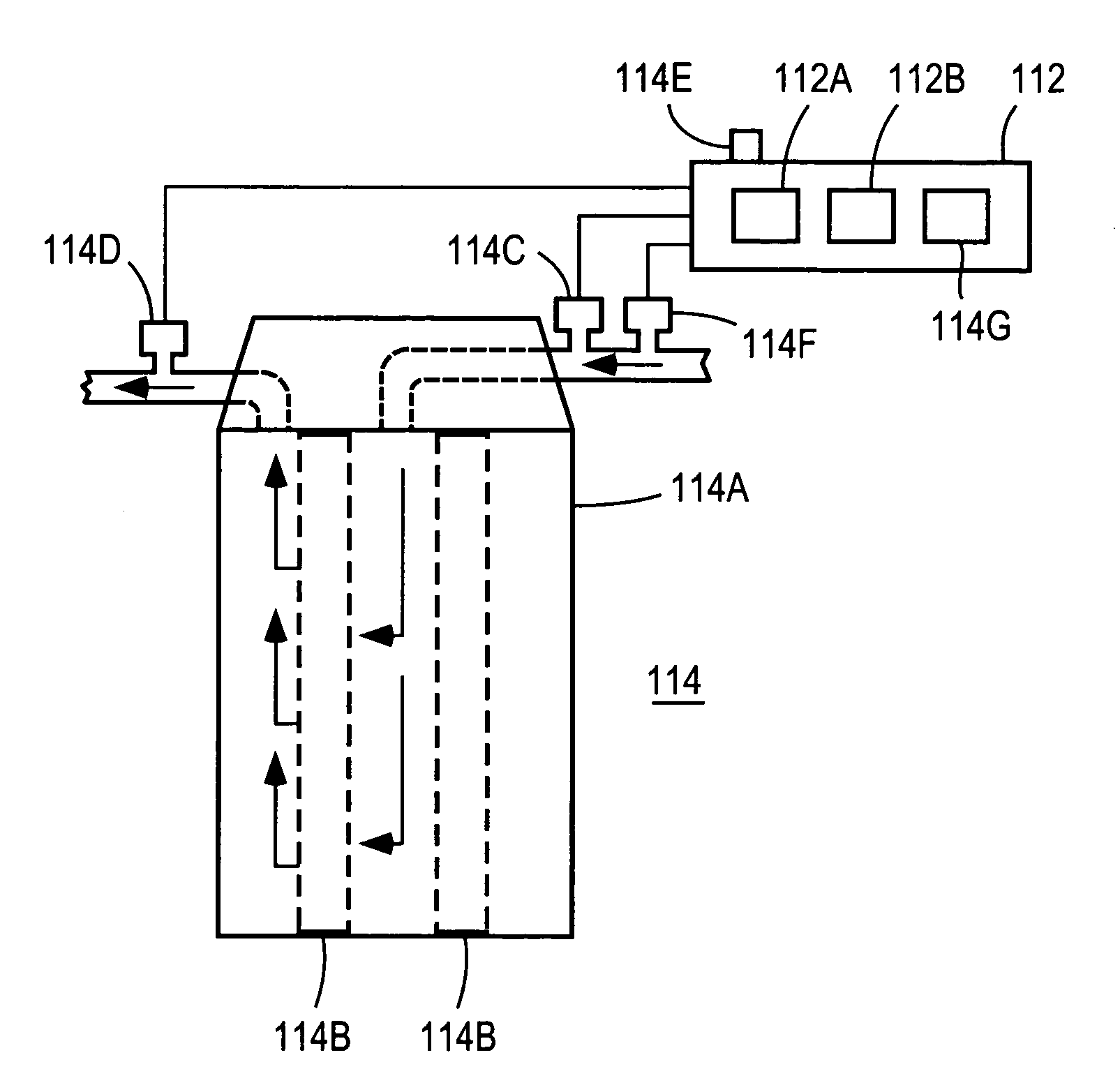

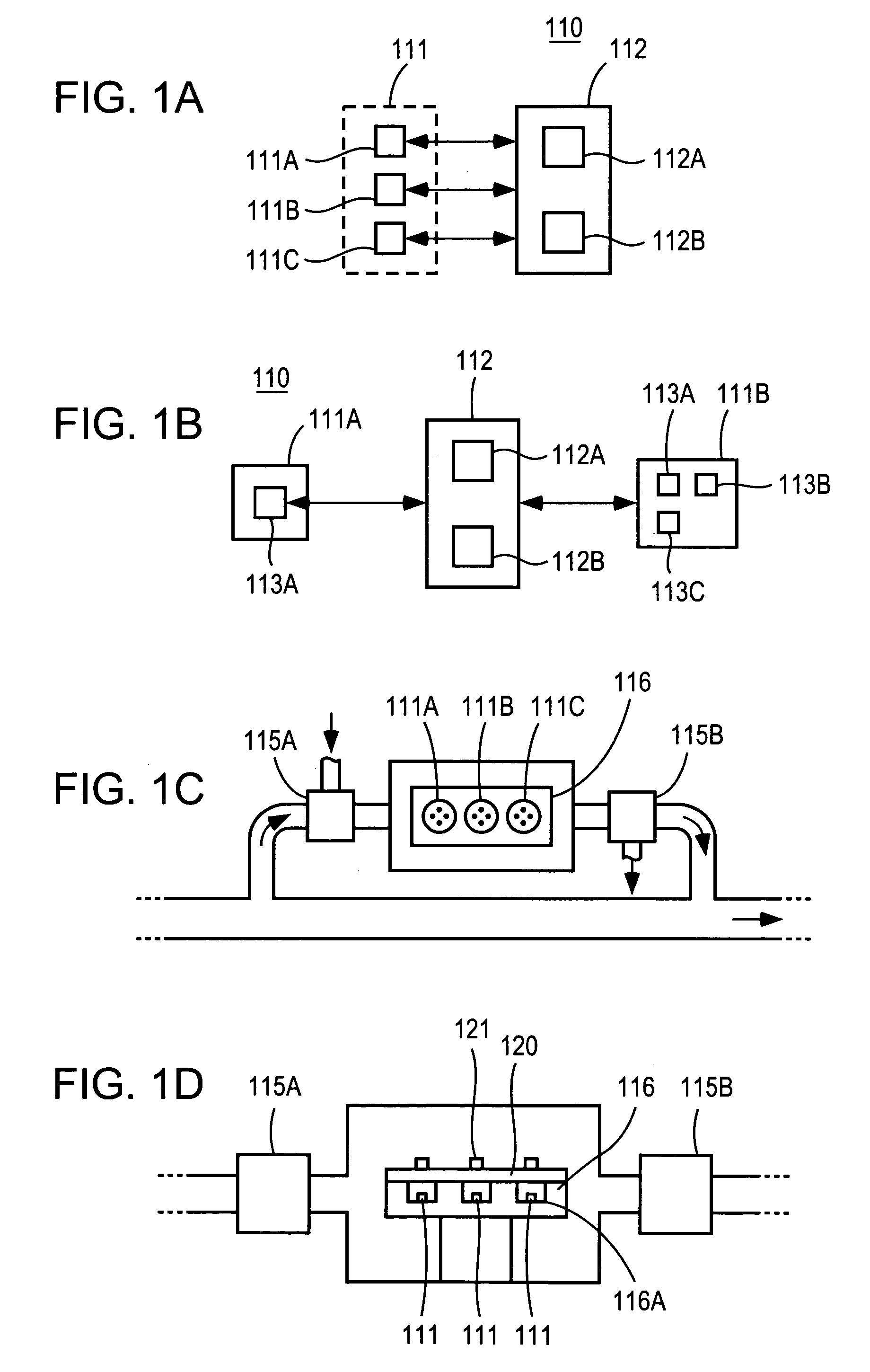

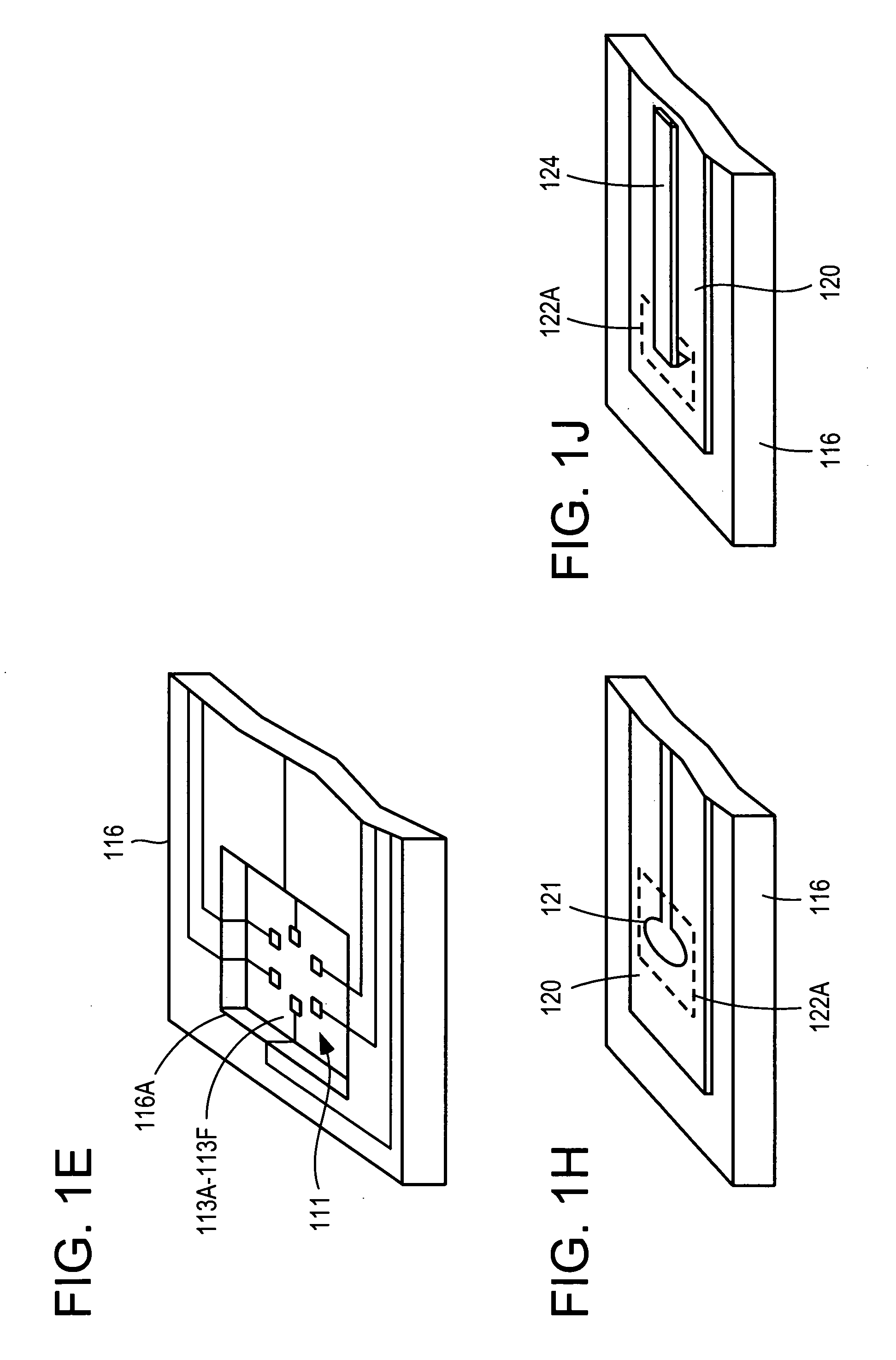

Fluid treatment apparatus with input and output fluid sensing

Various sensor unit configurations are disclosed within the context of a fluid quality monitoring system. The distribution of sensor units can be accomplished using existing product distribution channels to sell, distribute and install sensor units so that a fluid distribution monitoring system can be established at relatively low cost, on a wider basis, and by locating sensor units at the most desirable location from problem detection standpoint, the location of the end user.

Owner:GE ANALYTICAL INSTR +1

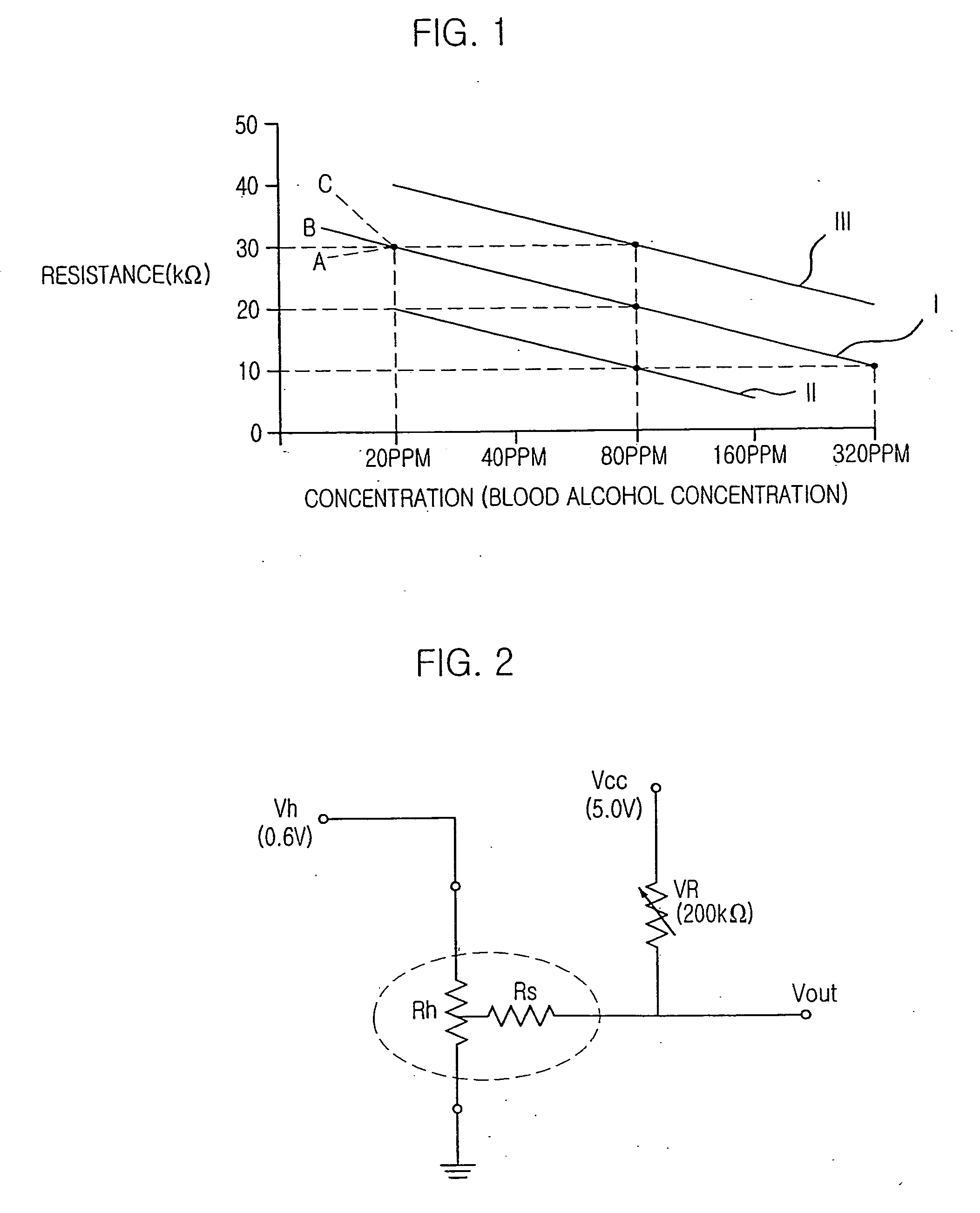

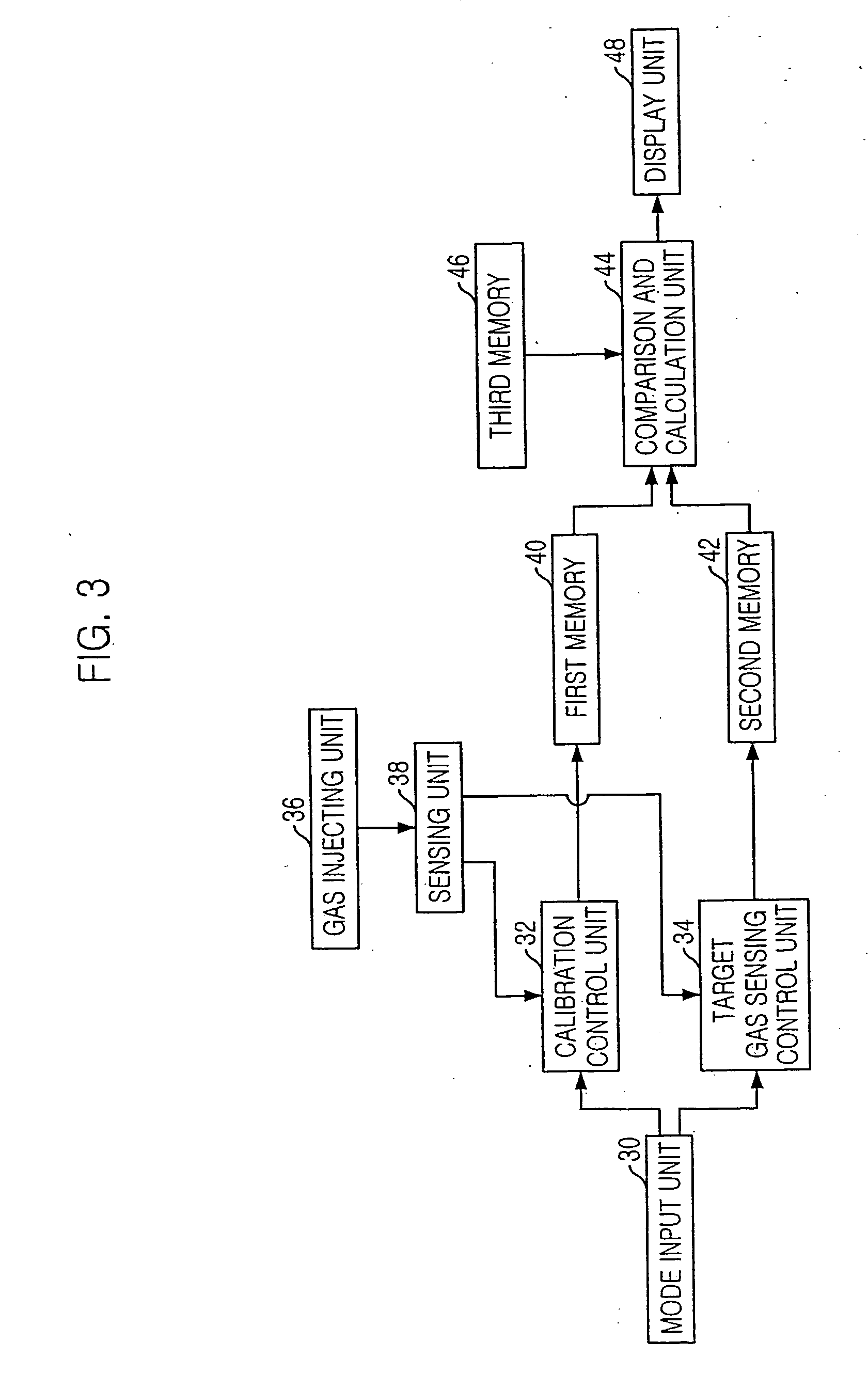

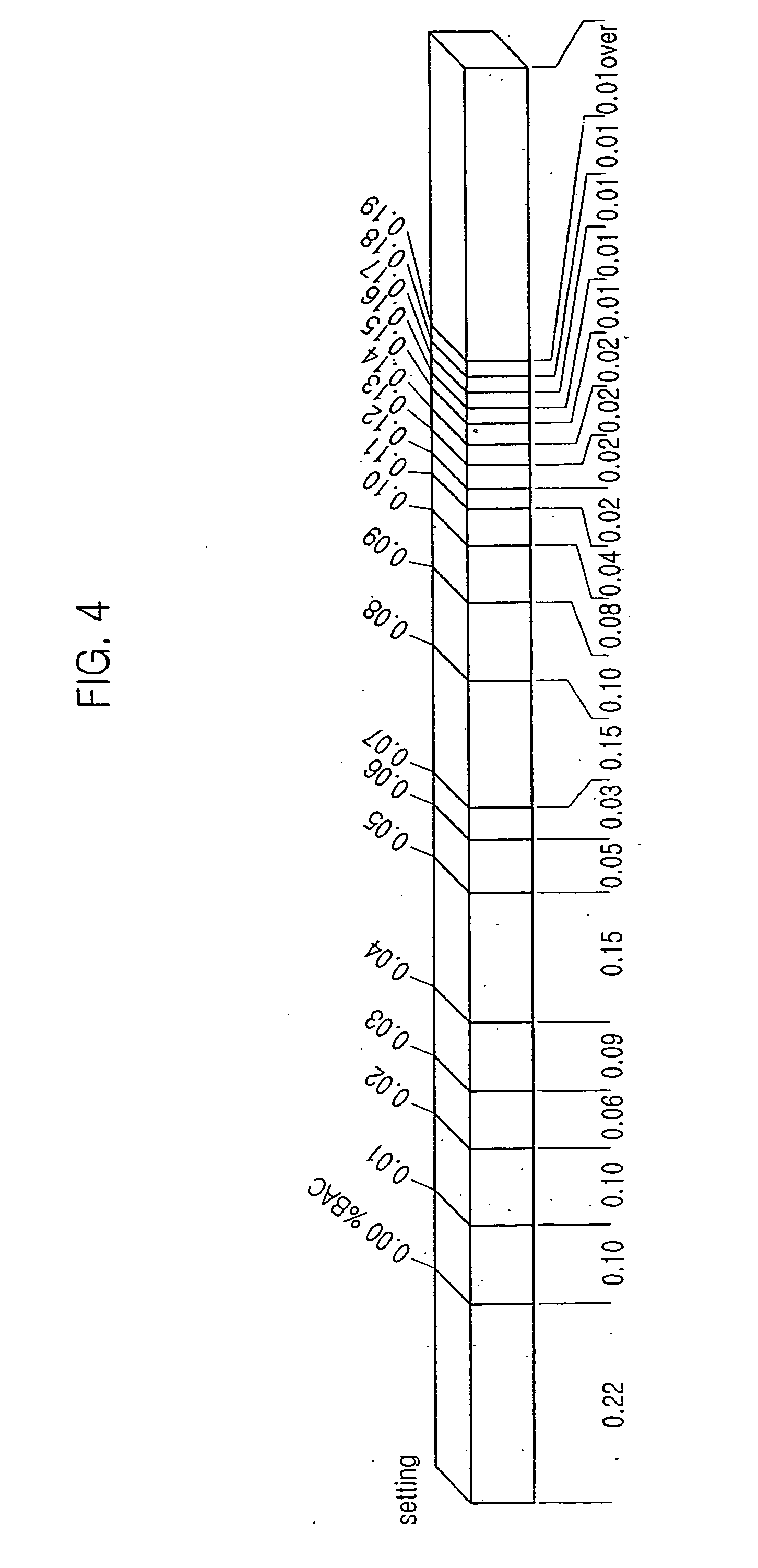

Portable gas sensor and method for calibrating the same

InactiveUS20060263254A1Convenient calibrationMaterial analysis by electric/magnetic meansMaterial analysis by optical meansElectrical resistance and conductanceVoltage reference

The present invention provides a portable gas sensor having a sensing material reacted with a target gas. The portable gas sensor includes a mode input unit for selecting an operation mode; a gas inhaling unit for accepting an external gas; a sensing unit for outputting a voltage value corresponding a varied resistance value of the sensing material reacted with the external gas; a first memory for storing a reference voltage value corresponding a resistance value of the sensing material reacted with a reference gas; a calibration control unit for storing a first voltage value corresponding to a resistance value of the sensing material reacted with a substitute reference gas in the first memory by substituting the reference voltage value; a target gas sensing control unit for storing a second voltage correspond to a resistance value of the sensing material reacted with the target gas into the second memory; a comparison and calculation unit for comparing and calculating the first voltage value and the second voltage value; and a display unit for displaying a concentration of the target gas calculated in the comparison and calculation unit.

Owner:SEJU ENG CO LTD

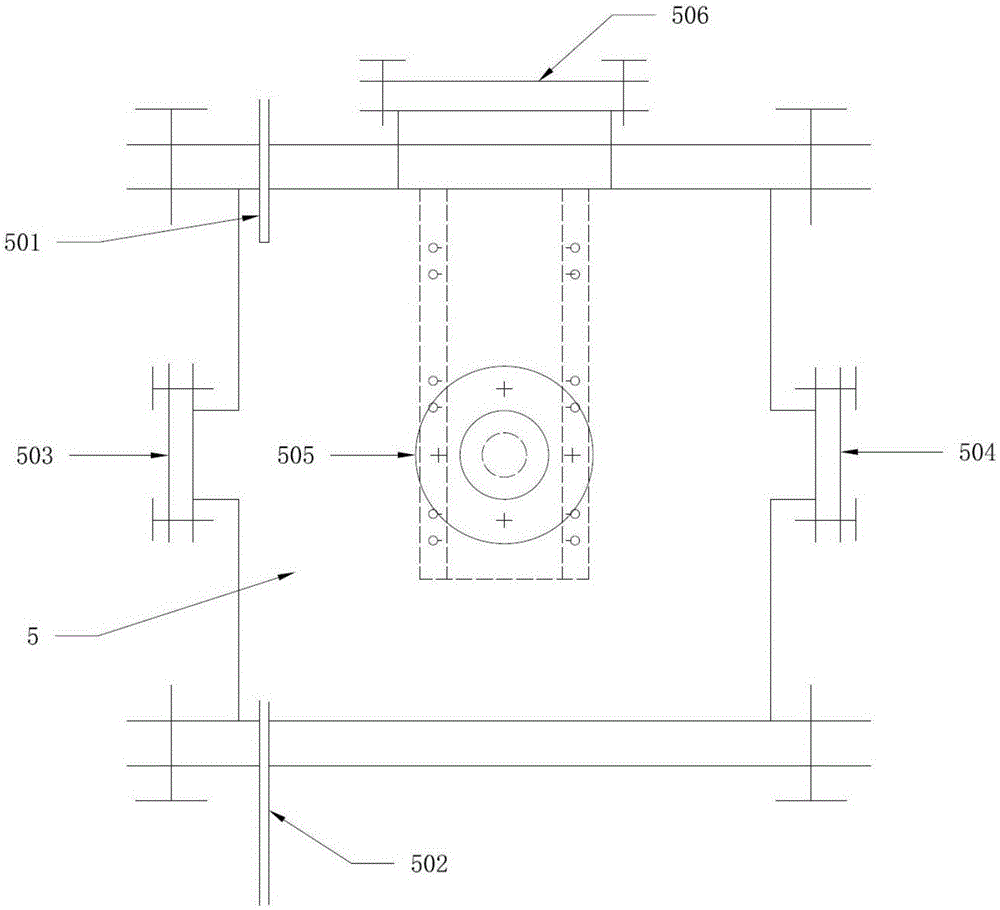

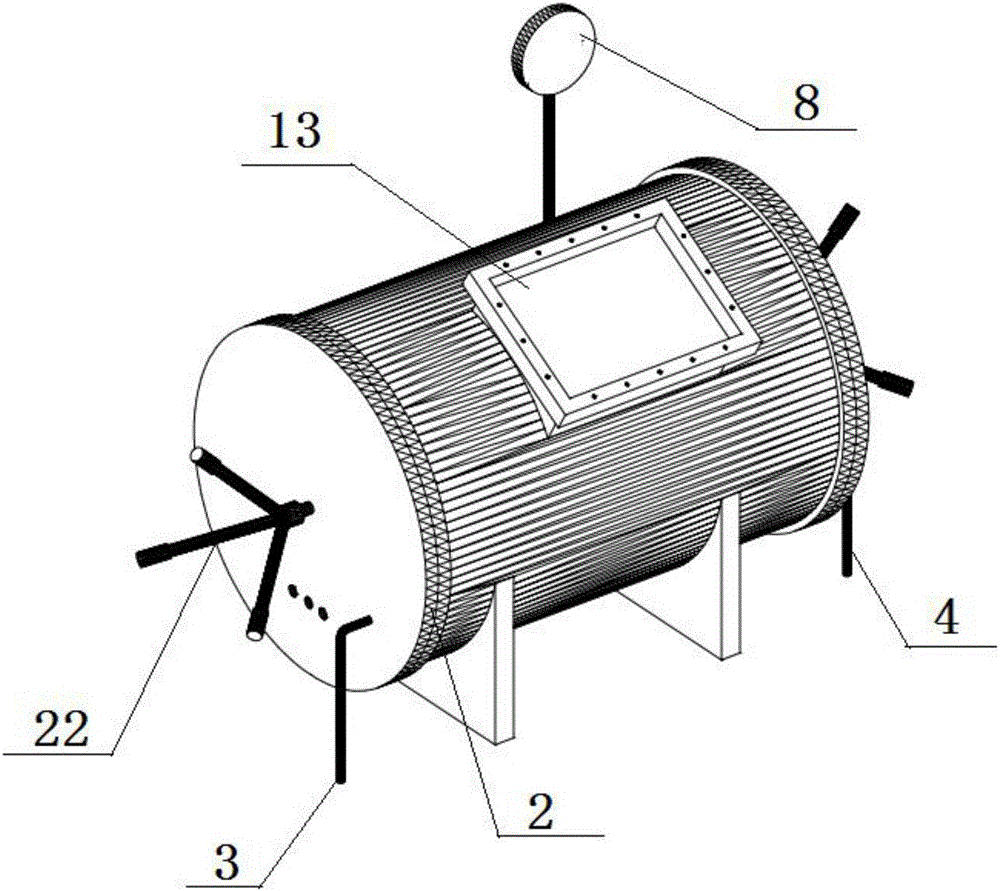

Gas sensor test system for dynamic and static gas distribution dual purposes

InactiveCN105866331AAvoid accumulationReduce adsorptionGas analyser calibrationGas detectorEngineering

The invention relates to a gas sensor test system for dynamic and static gas distribution dual purposes, and belongs to the technical field of gas sensor test. The system comprises: a test cavity, wherein the main body of the test cavity is a stainless steel cavity; sealed cabin ports, wherein the quantity of the sealed cabin ports is 2, the sealed cabin ports are respectively arranged at two ends of the test cavity, and every sealed cabin port is matched with a sealed cabin door; a gas inlet pipeline arranged on one of the sealed cabin ports; a gas outlet pipeline arranged on the other one of the sealed cabin ports; a humiture sensor arranged in the test cavity; a liquid injection window arranged on the sealed cabin door provided with the gas outlet pipeline and used for injecting a liquid to the test cavity; and a heating platform arranged in the test cavity, wherein the liquid injection window cooperates with the heating platform to heat the injected liquid in order to vaporize the liquid. The system can realize simulation of dynamic gas environment and static gas environment, and also can realize performance calibration and test of a gas sensor in different gas environments.

Owner:NINGBO UNIV

Method for sensor reader calibration

ActiveUS20140028327A1Mitigate for environmental parameterReduce the environmentMaterial analysis by electric/magnetic meansDiagnostic recording/measuringLoad circuitResonance

In one embodiment a method for sensor reader calibration comprising: performing a calibration of a sensor reader wherein the calibration comprises open circuit calibration, a short circuit calibration, and a load circuit calibration, or any combination thereof in any succession; enabling connection of a pickup coil to the sensor reader to measure a sensor response; and applying a baseline correction to the sensor response, wherein the baseline correction is obtained utilizing measurements from the calibration step. In a further embodiment, a method for sensor response calibration incorporating environmental correction comprising: measuring a first resonance impedance spectrum of the sensor with a first applied power to the pickup coil; measuring a second resonance impedance spectrum of the sensor with a second applied power to the pickup coil; and applying a correction to the sensor response corresponding to the respective measured first and second resonance impedance spectrum to mitigate for environmental parameters.

Owner:GENERAL ELECTRIC CO

Humidity sensor diagnostics

Embodiments for diagnosing a humidity sensor are provided. One example method comprises adjusting an engine operating parameter based on humidity of a first gas flow measured by a humidity sensor, and indicating degradation of the humidity sensor if a humidity of a second gas flow measured by the humidity sensor is different than an expected humidity. In this way, degradation of the humidity sensor may be indicated if the humidity of the second gas flow measured by the humidity sensor is different than expected.

Owner:FORD GLOBAL TECH LLC

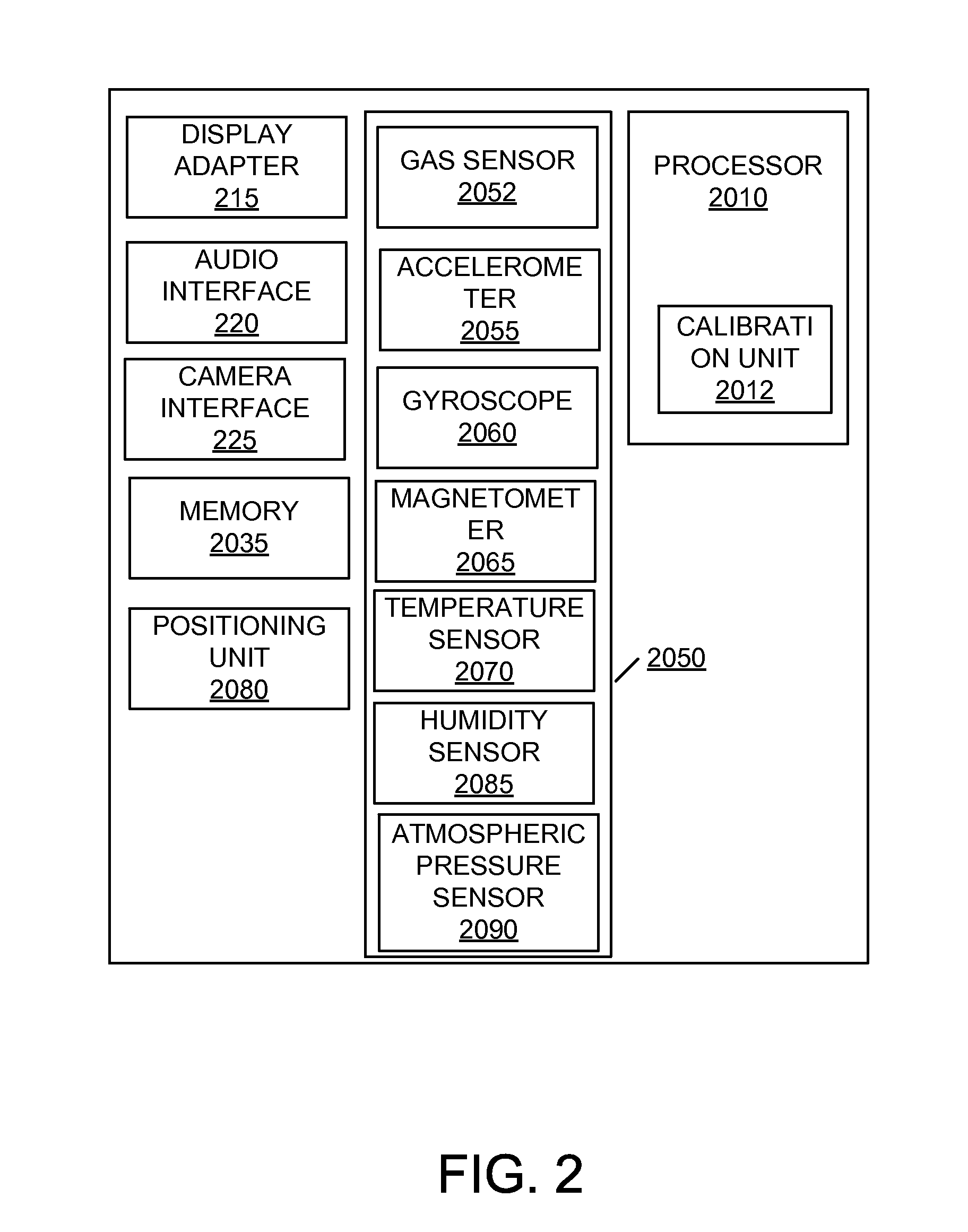

Method for calibration of sensors embedded or wirelessly connected to a mobile device

InactiveUS20140238100A1Reduce pollution levelsImprove accuracyMaterial analysis by electric/magnetic meansDevices with sensorElectrochemical gas sensorEngineering

Methods, systems, computer-readable media, and apparatuses for obtaining accurate gas sensor data are presented. A mobile device may receive gas sensor data from at least one gas sensor. The mobile device can include the at least one gas sensor and at least one environmental component. Additionally, the mobile device may receive environmental data from the at least one environmental component. Subsequently, the mobile device may calibrate the received gas sensor data based on the received environmental data and one or more reference characteristic curves. In one or more arrangements, the gas sensor can be a Metal Oxide Semiconductor (MOS) gas sensor or an electrochemical gas sensor configured to sense carbon monoxide.

Owner:QUALCOMM INC

System and method for automatically adjusting gas sensor settings and parameters

ActiveUS20120192623A1Low costTariff metering apparatusAutomatic recalibrationAuto regulationAudio power amplifier

A system and method are disclosed including an automatic sensor excitation voltage adjustment feature, a multi-range concentration feature, and a single calibration feature. The automatic sensor excitation voltage adjustment feature may include a transmitter having an associated microprocessor that provides an initial voltage to an associated sensor. The sensor may include a microprocessor, and as the voltage changes a correction signal may be relayed from the sensor microprocessor to the transmitter microprocessor. The correction signal may be used by the transmitter microprocessor to adjust the voltage applied to the sensor. The multi-range concentration sensor feature may include an amplifier associated with the sensor / microprocessor to create gain settings used to optimize sensor resolution by changing a gain value associated with the sensor. This, in turn, enables a single sensor to be used for a variety of different concentration ranges, as desired by a user. The single calibration feature enables a sensor to be calibrated at a single gas concentration value, and thereafter be used for a variety of different concentration range applications. Other embodiments are described and claimed.

Owner:TELEDYNE DETCON INC

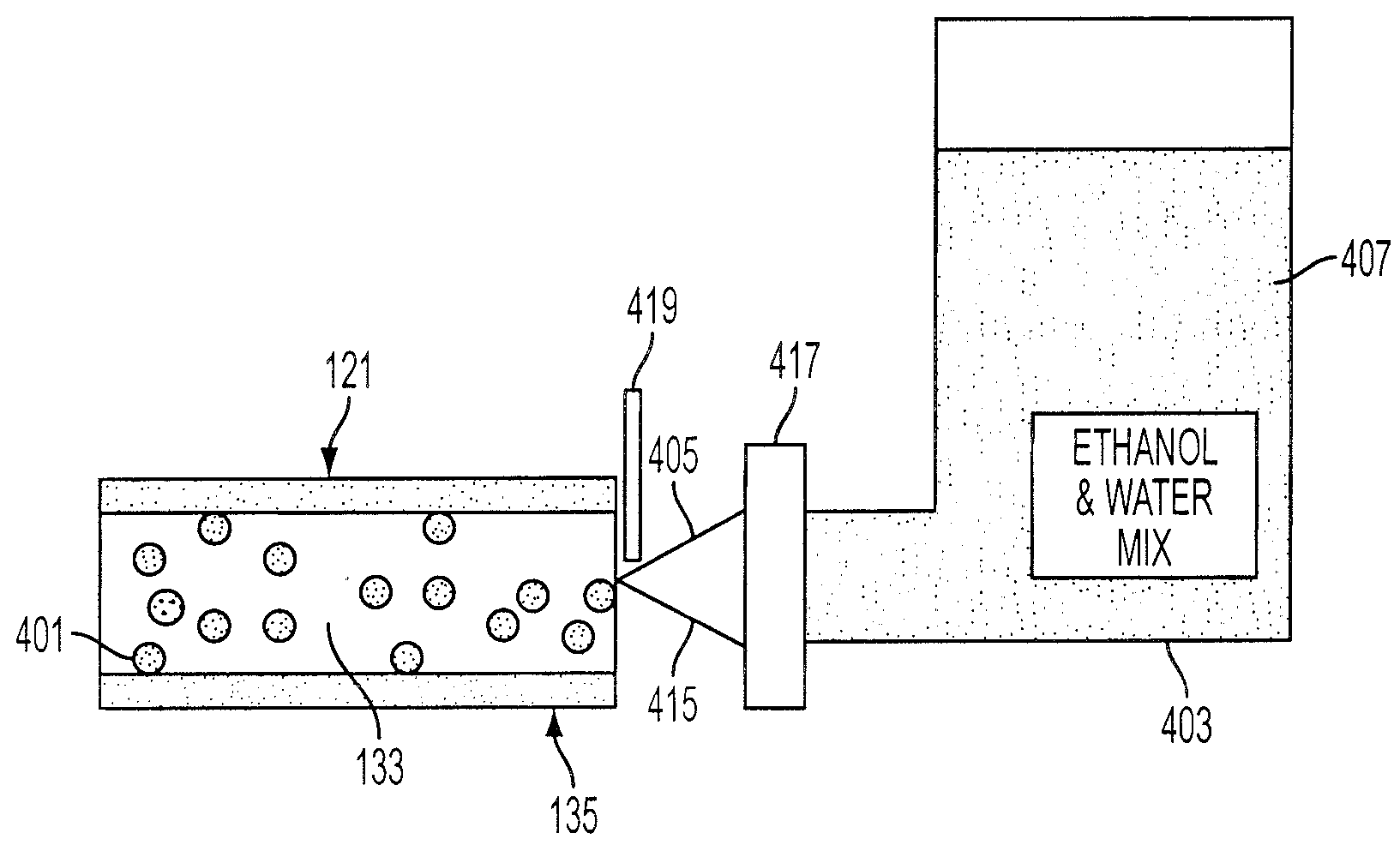

Calibration and Accuracy Check System for a Breath Tester

InactiveUS20100223975A1Withdrawing sample devicesMaterial analysis by electric/magnetic meansAlcoholTester device

Calibration and accuracy check systems for a chemical sniffer, such as a breath alcohol tester, which utilize the dispensing of droplets with determinable concentration of alcohol and / or other liquids in a determinable number either directly to a reaction chamber, or into a carrier gas which can be sampled. The systems generally provide for accurate sample concentration being provided to the breath tester while also providing for a simplified system which can be easier to move, and require less operational complexity, than prior wet or dry calibrating systems.

Owner:ALCOTEK

Method for evaluating degradation of a particulate matter sensor after an engine start

ActiveUS20110048106A1Emission reductionAccelerate emissionsElectrical controlInternal combustion piston enginesParticulatesWater vapor

A system for improving operation of an engine having a particulate matter sensor is presented. The system may be used to improve engine operation during cold starts especially under conditions where water vapor or entrained water droplets are present in vehicle exhaust gases. In one embodiment, particulate sensor degradation is indicated in response to an output of said particulate matter sensor staying below a threshold as engine temperature increases past the dewpoint temperature.

Owner:FORD GLOBAL TECH LLC

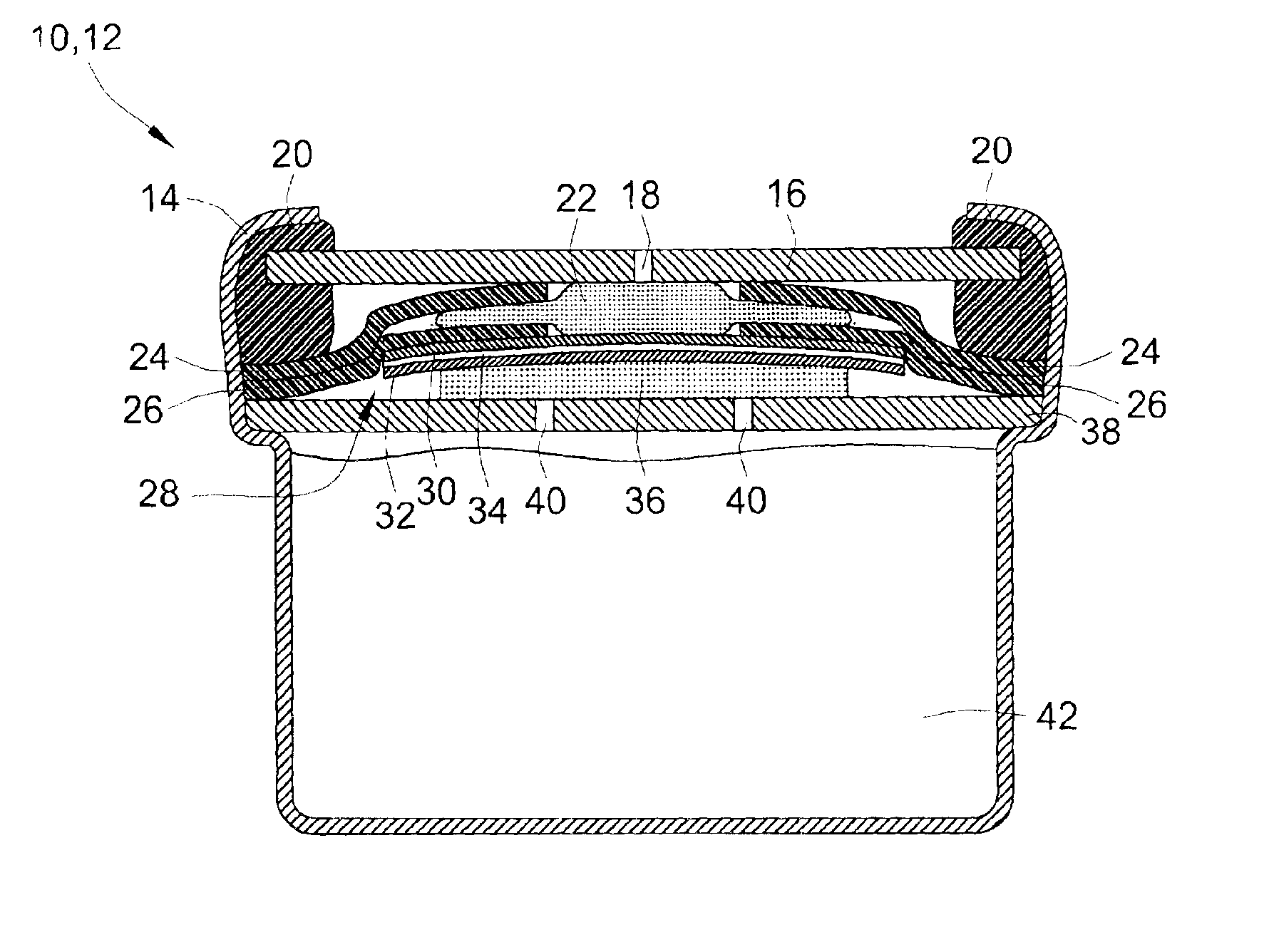

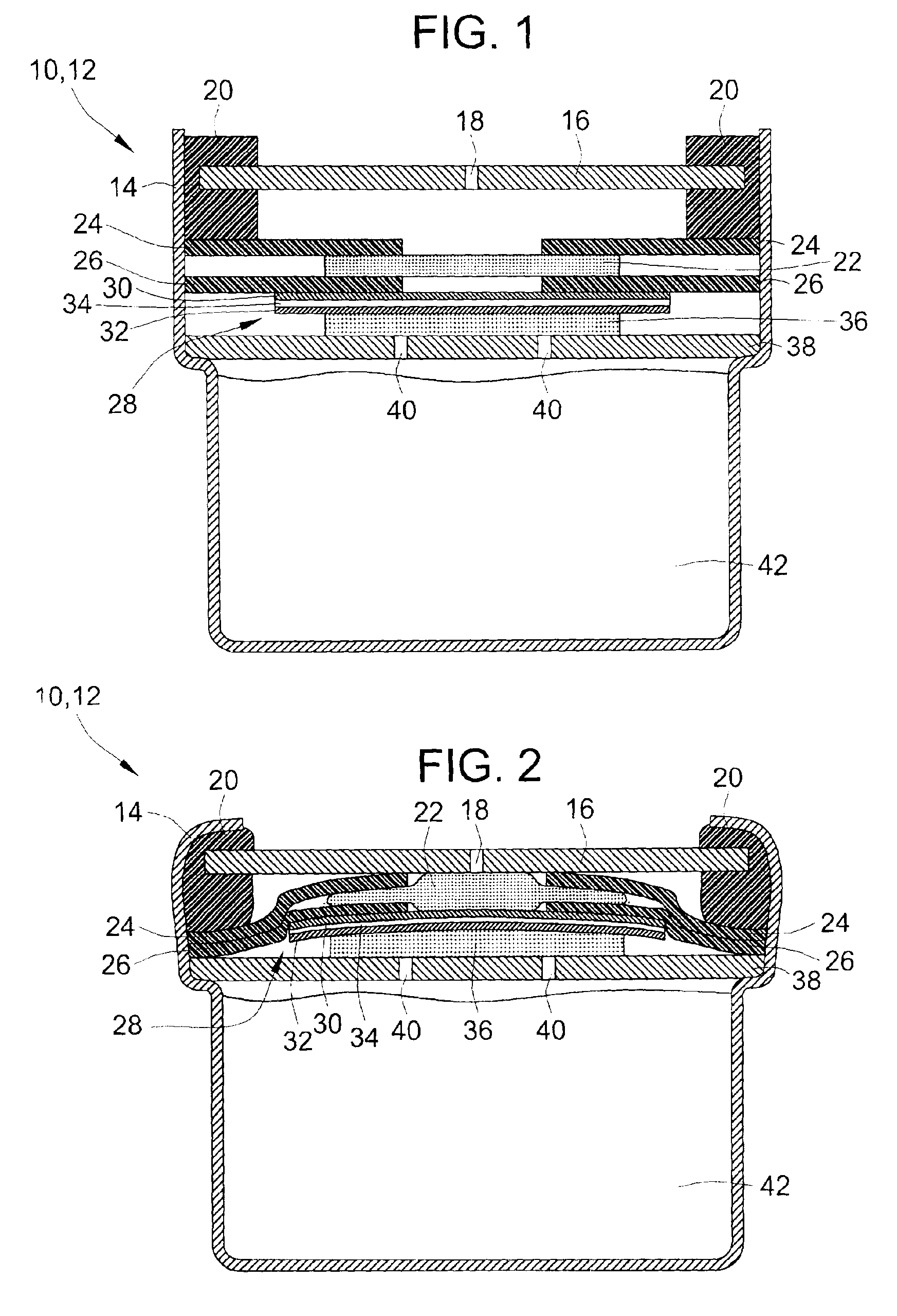

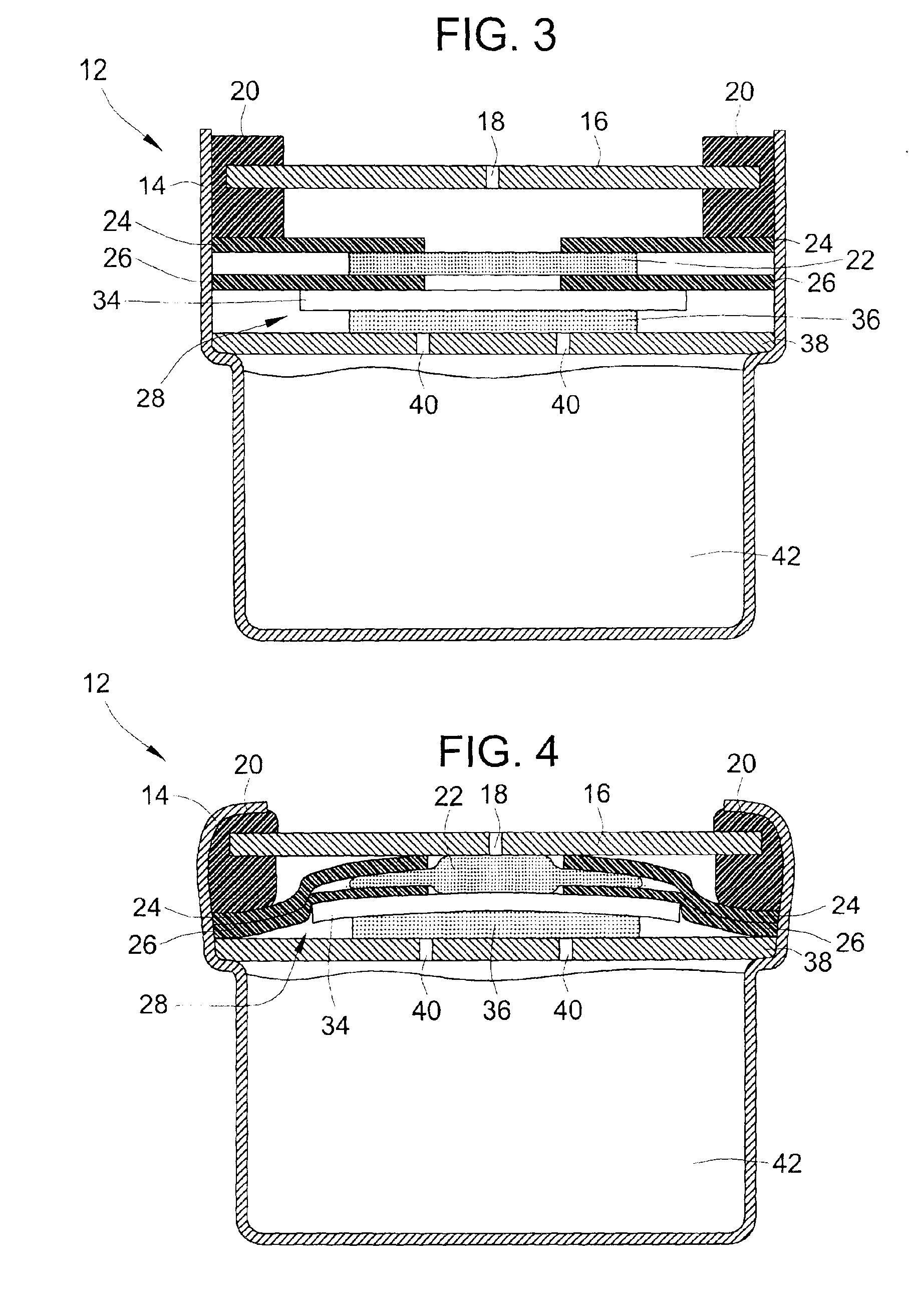

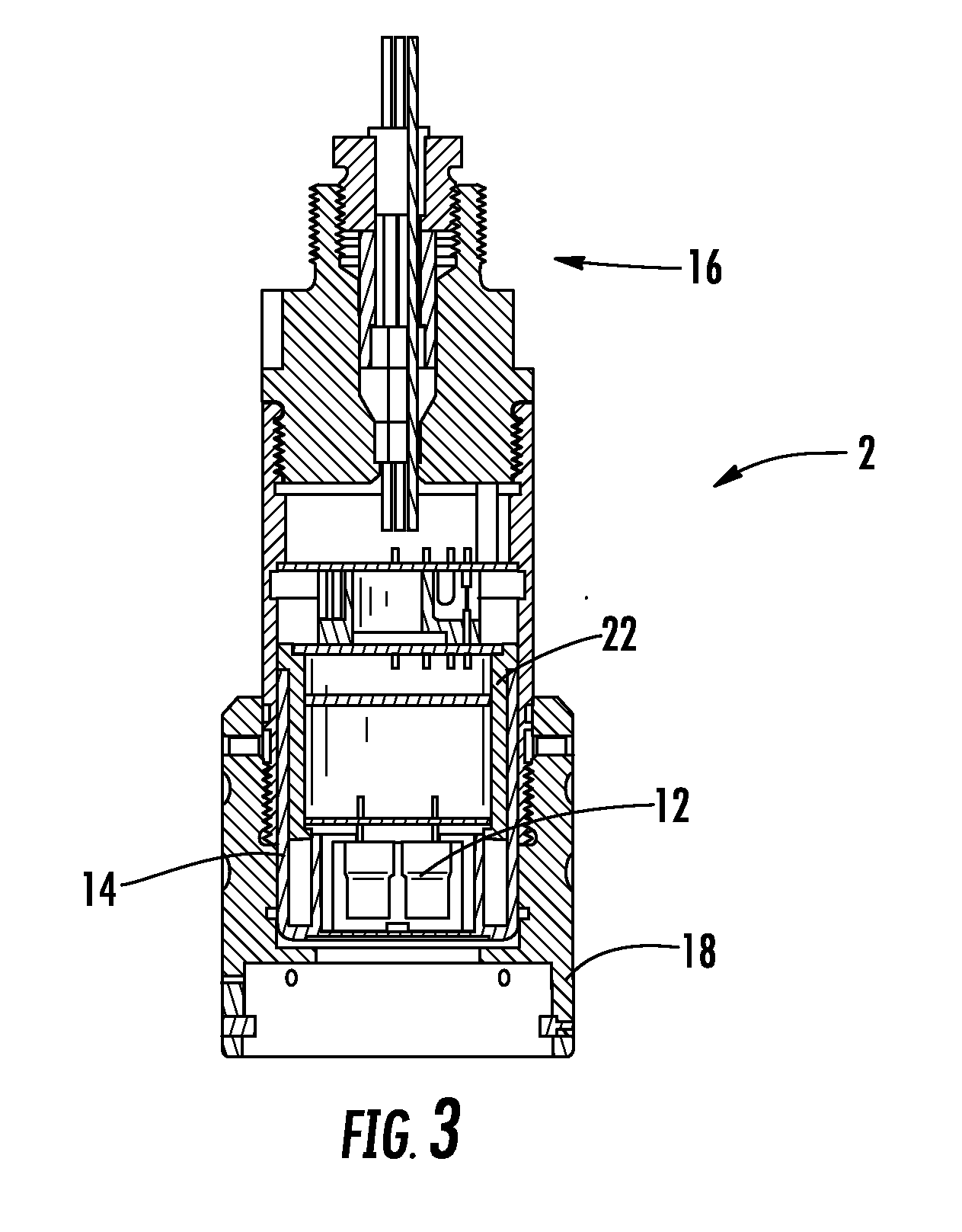

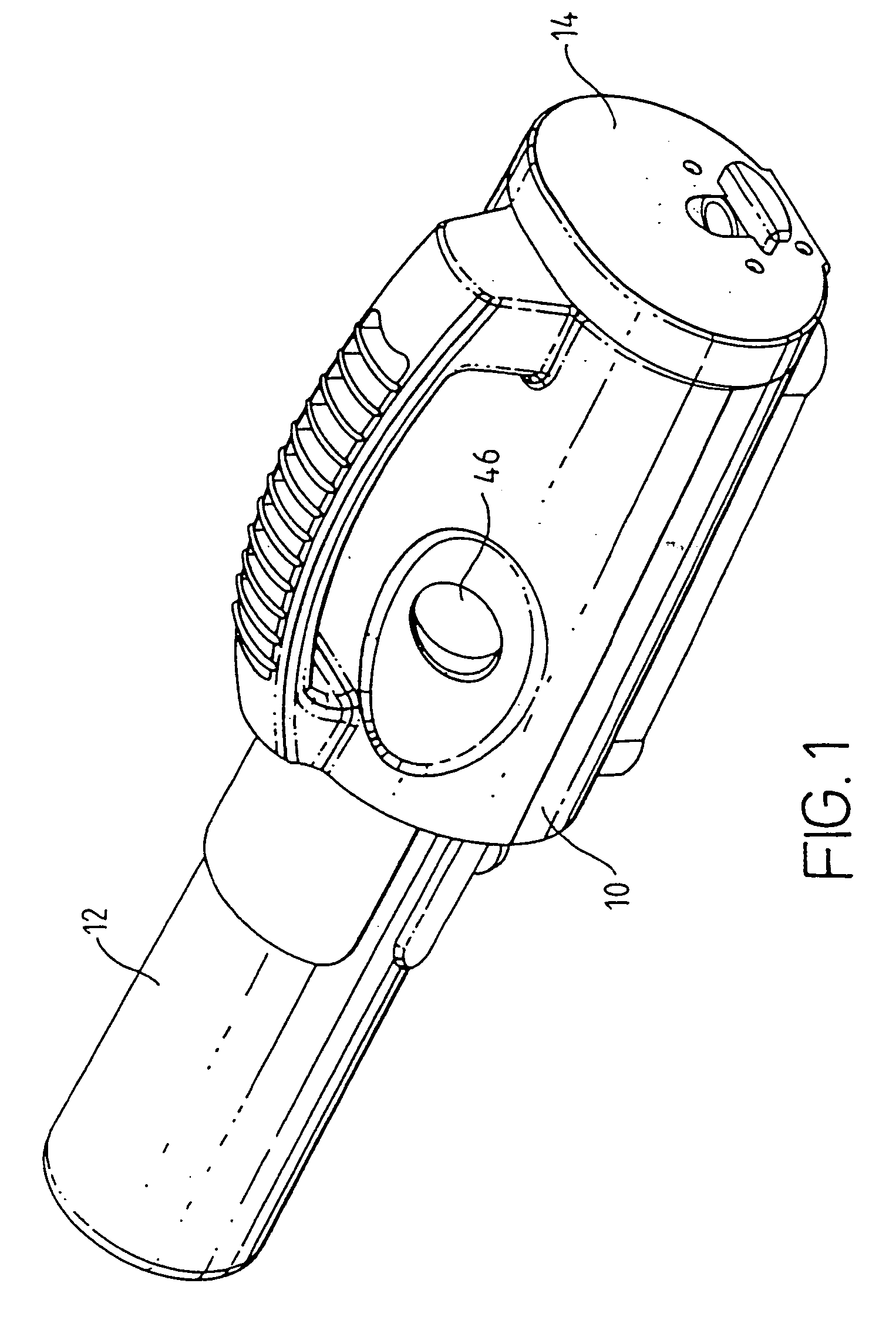

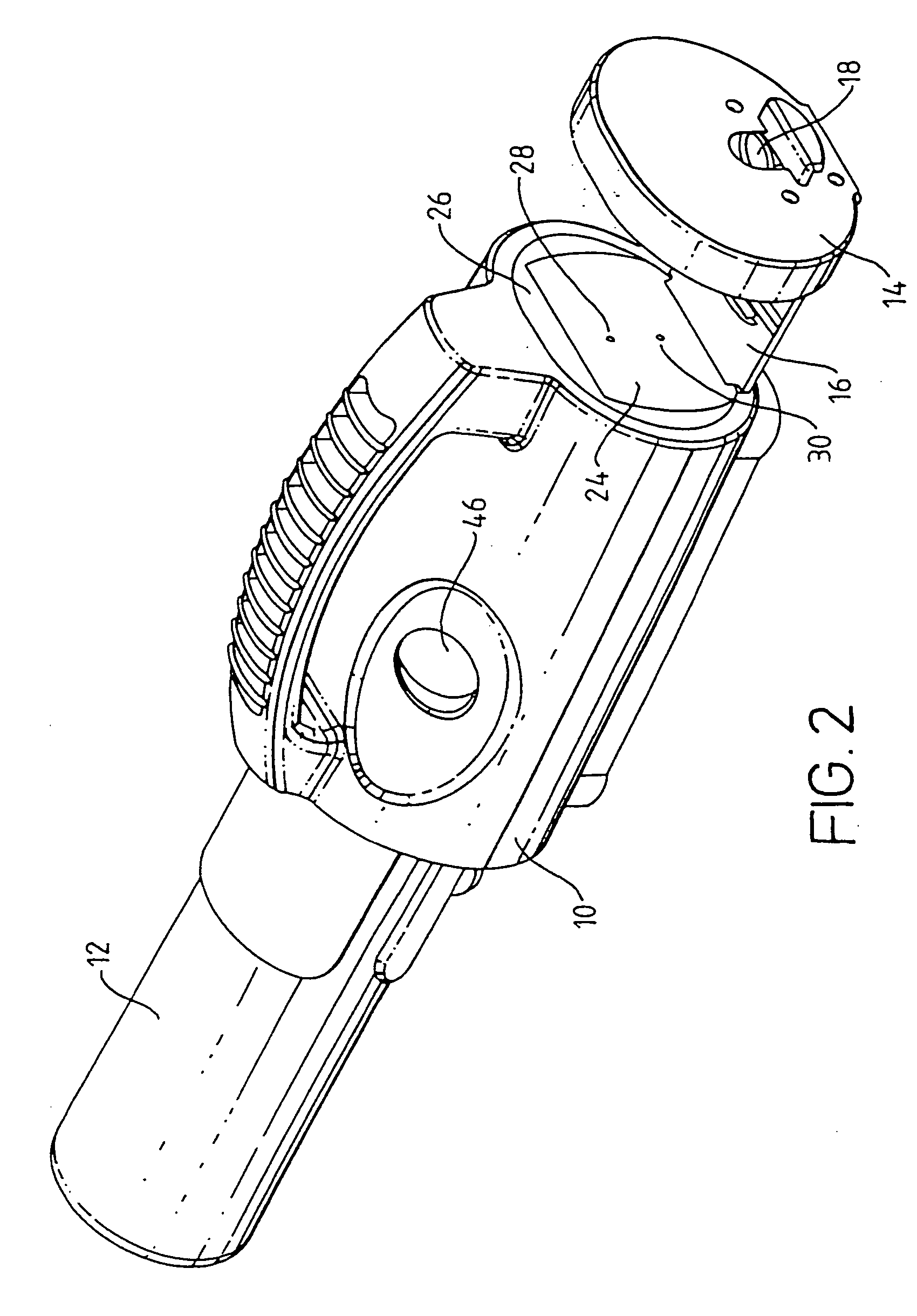

Gas sensor calibration system

InactiveUS20040074279A1Lower the volumeReduce consumptionTesting/calibration apparatusSamplingElectricityPhase detector

An apparatus is described for calibrating at least one sensor within a gas detector (22), which detector has a gas inlet in fluid communication with the or each sensor, the apparatus comprising a housing (10) that contains: a) a surface (24) for abutting against the detector (22); b) a holder (14) for holding the gas detector (22) with respect to the housing (10) in such a manner that a region of the detector containing the gas inlet abuts against the surface (24) of the housing to form a sealed gas interface between the surface (24) and the detector (22); c) a connector for connecting a source of pressurised calibration gas (12) to the apparatus, d) a conduit (32) for delivering a calibration gas from the connector (34) to the interface between the detector and the apparatus housing, e) electrical connections (40) within the holder for forming electrical connections between the apparatus and a detector held within the holder, and e) a flow controller (34, 36) within the conduit for providing calibration gas at a predetermined level to the interface, the flow controller including an electrically-operated valve (36) being controllable for initiating and terminating the flow of calibration gas through the conduit (32) by means of signals received from the detector via the electrical connections (40). The whole calibration is controlled by he detector and not the calibration apparatus.

Owner:HONEYWELL ANALYTICS LTD

Popular searches

Subscribers indirect connection Record carriers used with machines Burglar alarm by hand-portable articles removal Burglar alarm electric actuation Lighting and heating apparatus Space heating and ventilation control systems Transmission Electric signalling details Control inputs involving air properties Ventilation systems

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com