Patents

Literature

586results about How to "Quick contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method, Apparatus and Computer Program Product for Providing a Link to Contacts on the Idle Screen

InactiveUS20080161045A1Good user interfaceAvoid difficult choicesDigital data information retrievalSubstation equipmentService provisionProcessing element

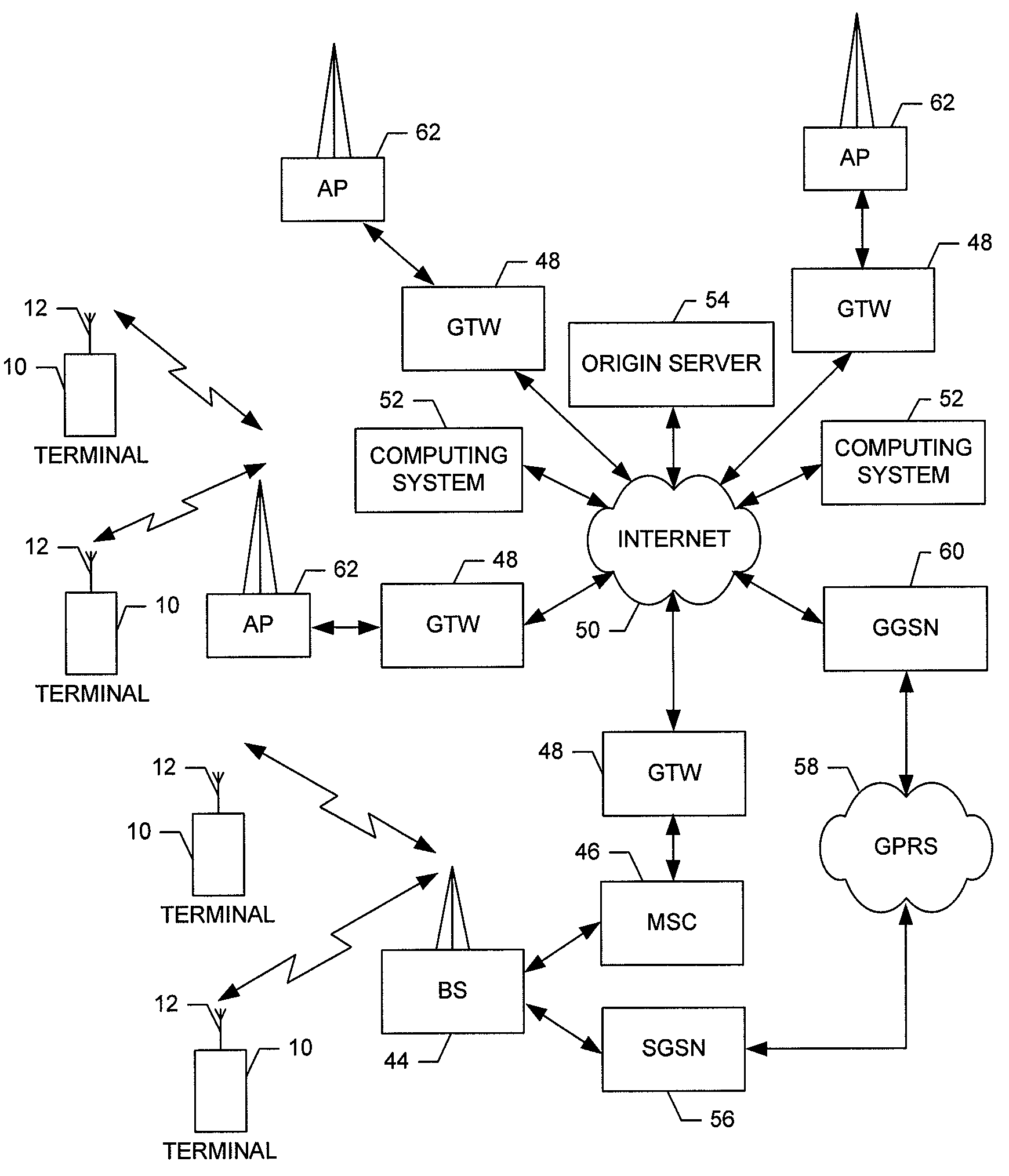

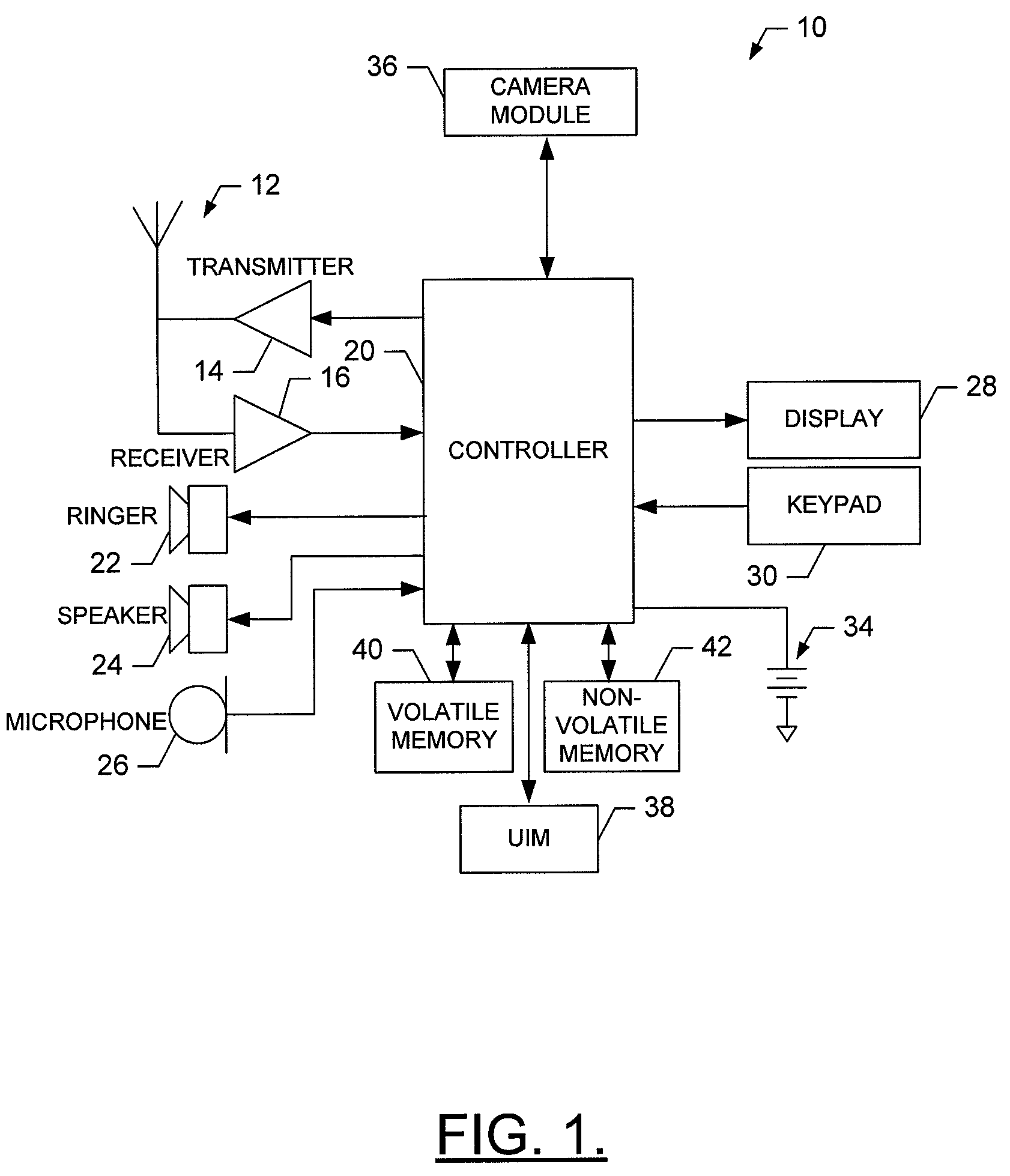

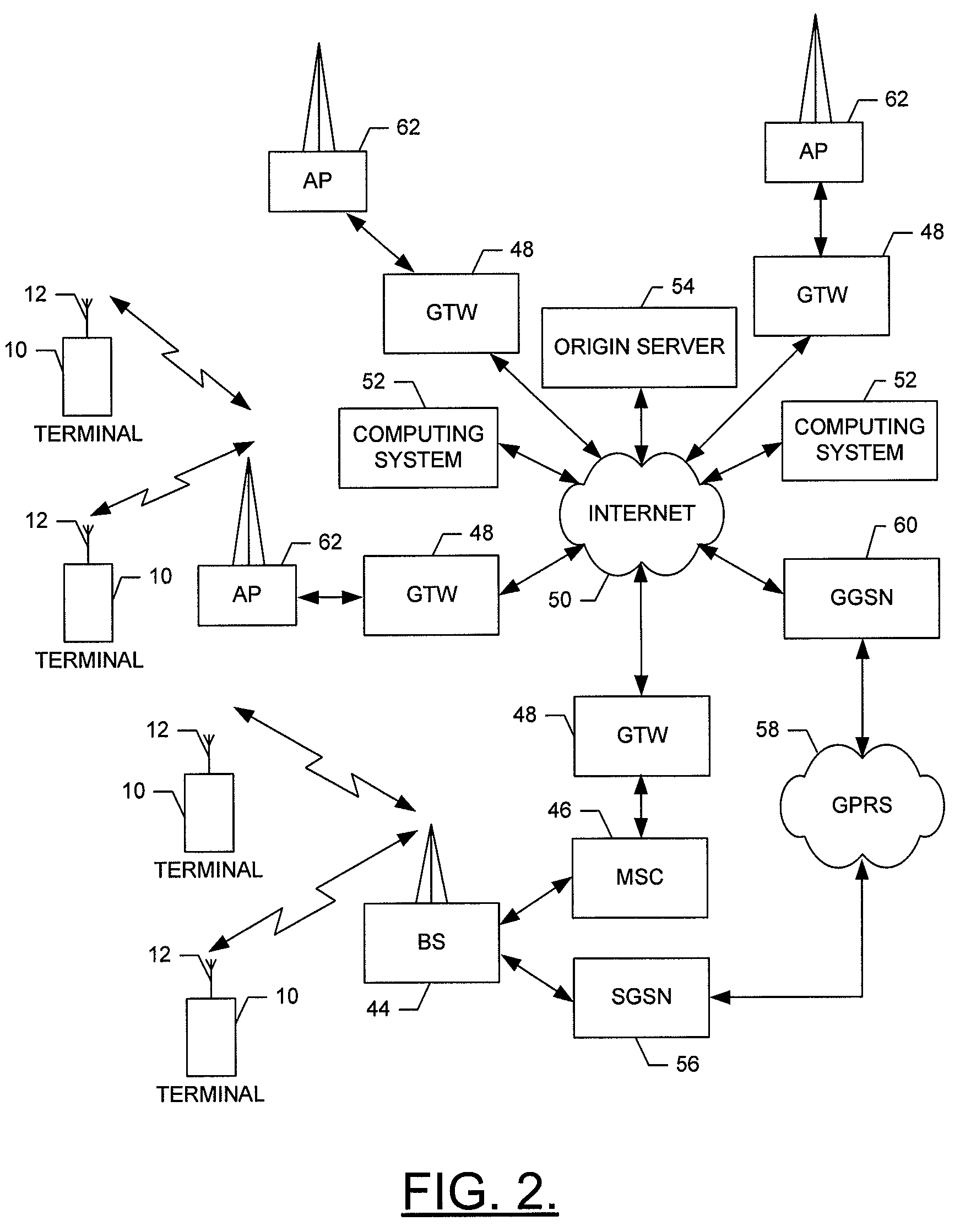

An apparatus for providing a link to contacts on an idle screen may include a processing element. The processing element may be configured to provide an identifier associated with a particular contact for display on an idle screen. In response to receipt of a selection of the identifier, the processing element may be further configured to provide at least one option for a communication related service associated with the identifier. In response to receipt of a selection of an option, the processing element may be further configured to launch an application corresponding to the selected option for executing the communication related service utilizing predefined information associated with the identifier.

Owner:NOKIA CORP

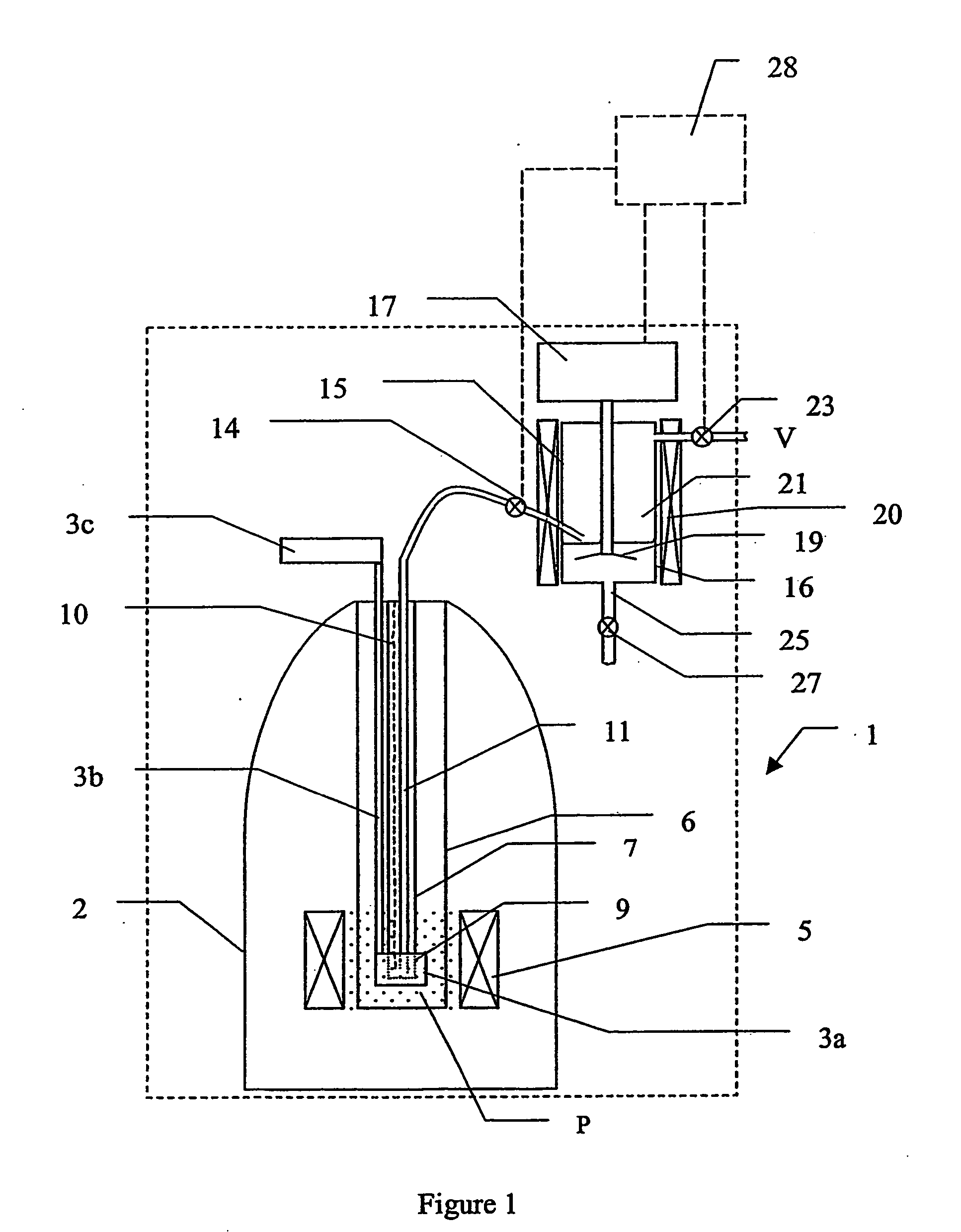

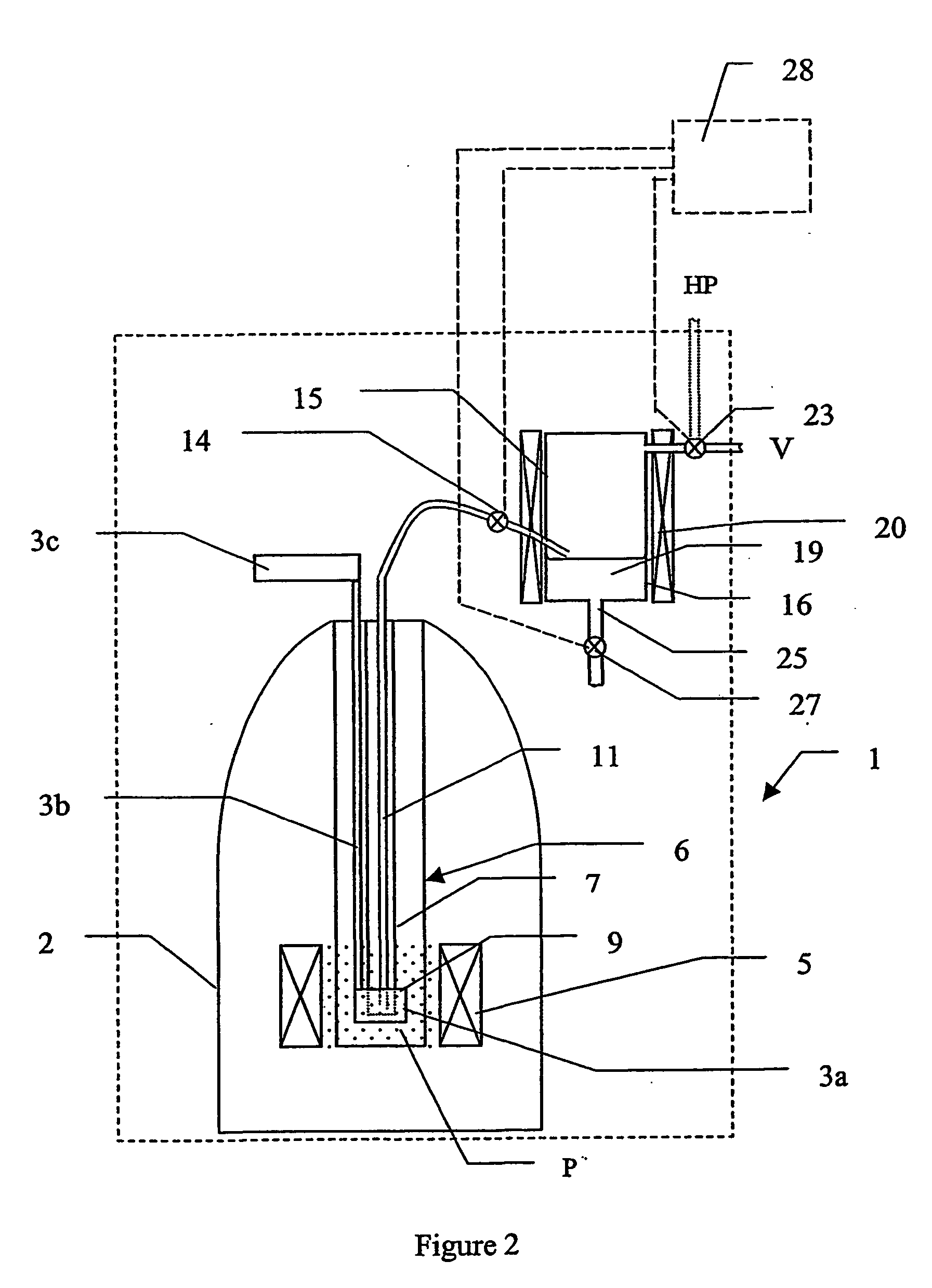

Methods and devices for dissolving hyperpolarised solid material for nmr analyses

ActiveUS20040066193A1Raise the ratioImprove resolutionElectrical measurement instrument detailsPreparing sample for investigationSolid massEngineering

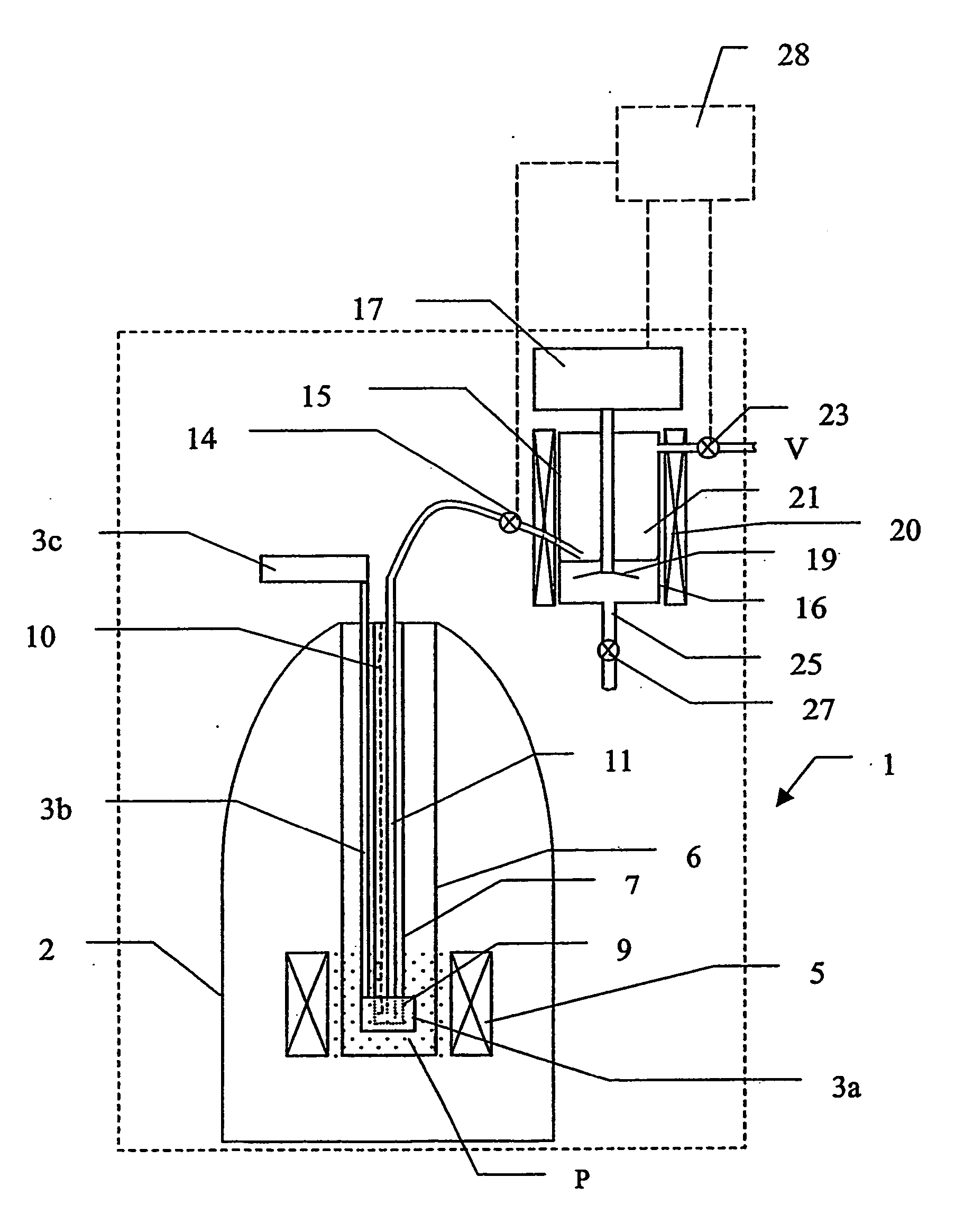

The present invention relates to devices and method for dissolving solid polarised material while retaining a high level of polarisation. In an embodiment of the present invention a material is polarised in a strong magnetic field in a cryostat 2 and then brought into solution while still inside the cryostat 2.

Owner:OXFORD INSTR MOLECULAR BIOTOOLS

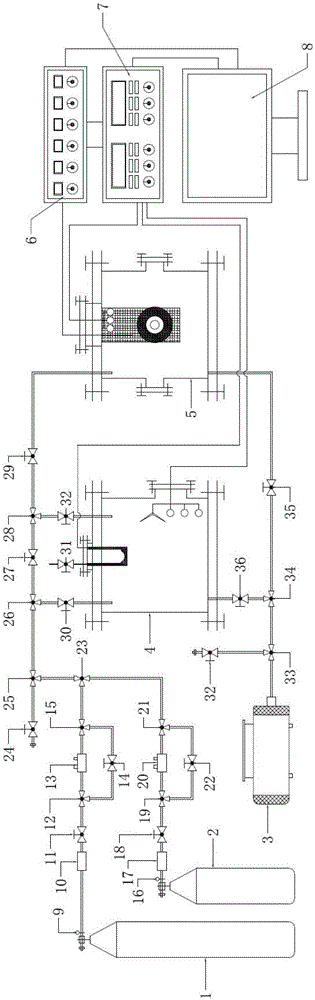

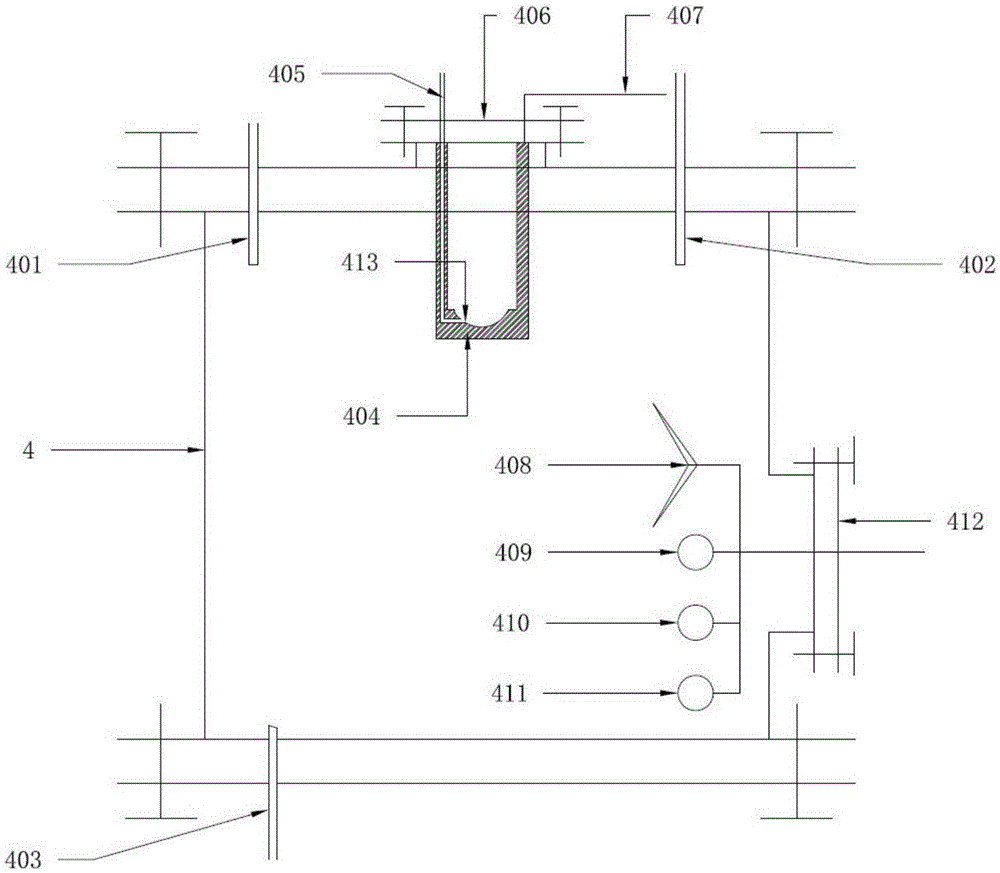

Multifunctional gas sensor testing system

ActiveCN105021777AQuick contactAccurately Test Response TimesGas analyser calibrationSimultaneous control of multiple variablesControl systemSolenoid valve

The invention discloses a multifunctional gas sensor testing system. The multifunctional gas sensor testing system comprises a gas distribution mechanism and a gas distribution chamber, a testing chamber, a control system, a testing mechanism and a vacuum pump, wherein the gas distribution mechanism is used for preparing standard-concentration gas and background gas for the gas distribution chamber; prepared standard-concentration testing gas is stored in the testing chamber and the testing chamber is used for testing a sensor sensitive property under standard concentration of gas to be tested; and the control system is used for controlling gas preparation in the gas distribution chamber and the testing chamber, and comprises temperature and humidity control, gas pressure or vacuum degree control, gas mass and flow control, on-off control of each gas-path solenoid valve, starting / stopping control of the vacuum pump, starting / stopping control of a stirring fan, and testing process control of a detected sensor. According to the multifunctional gas sensor testing system disclosed by the invention, rapid contact of the sensor and standard gas is realized by automatically preparing the standard-concentration gas, and the temperature and humidity of a sensor testing environment also can be controlled; and synchronous testing of electric gas responding of the plurality of sensors and optical gas responding of the single sensor also can be realized.

Owner:HUBEI UNIV

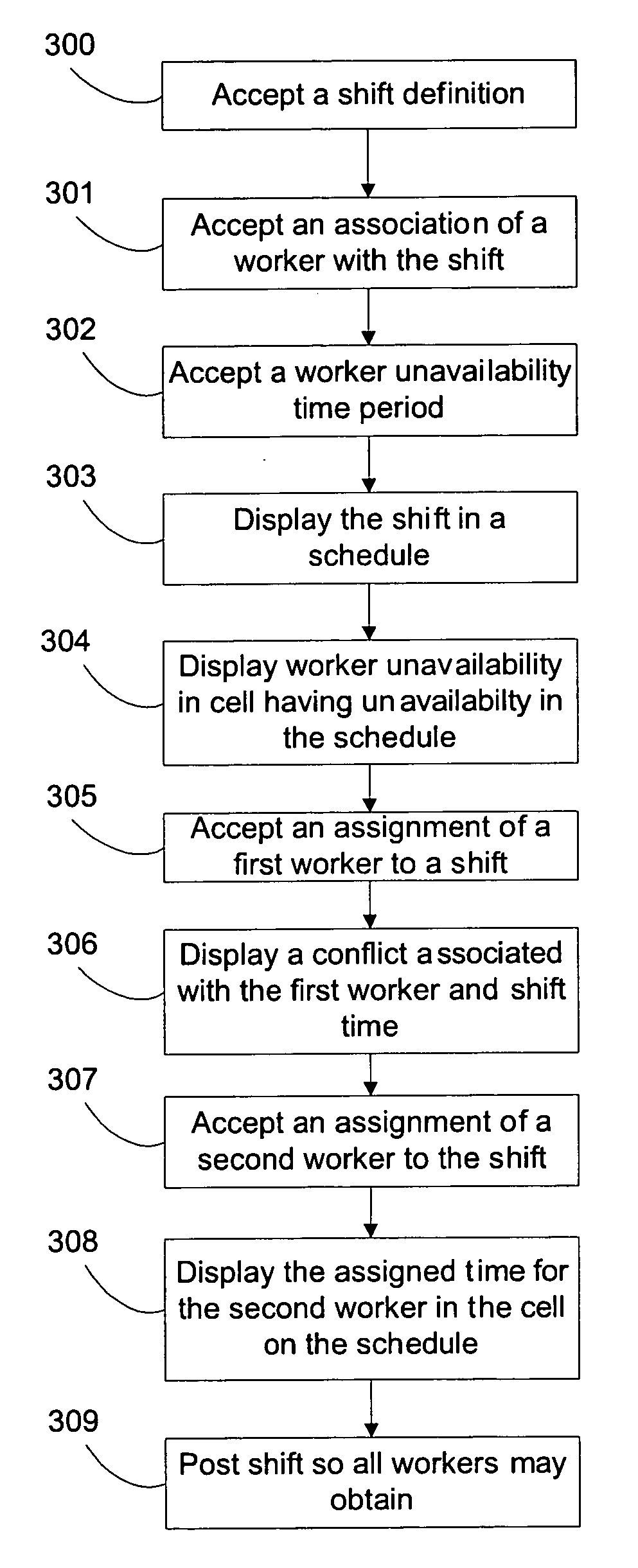

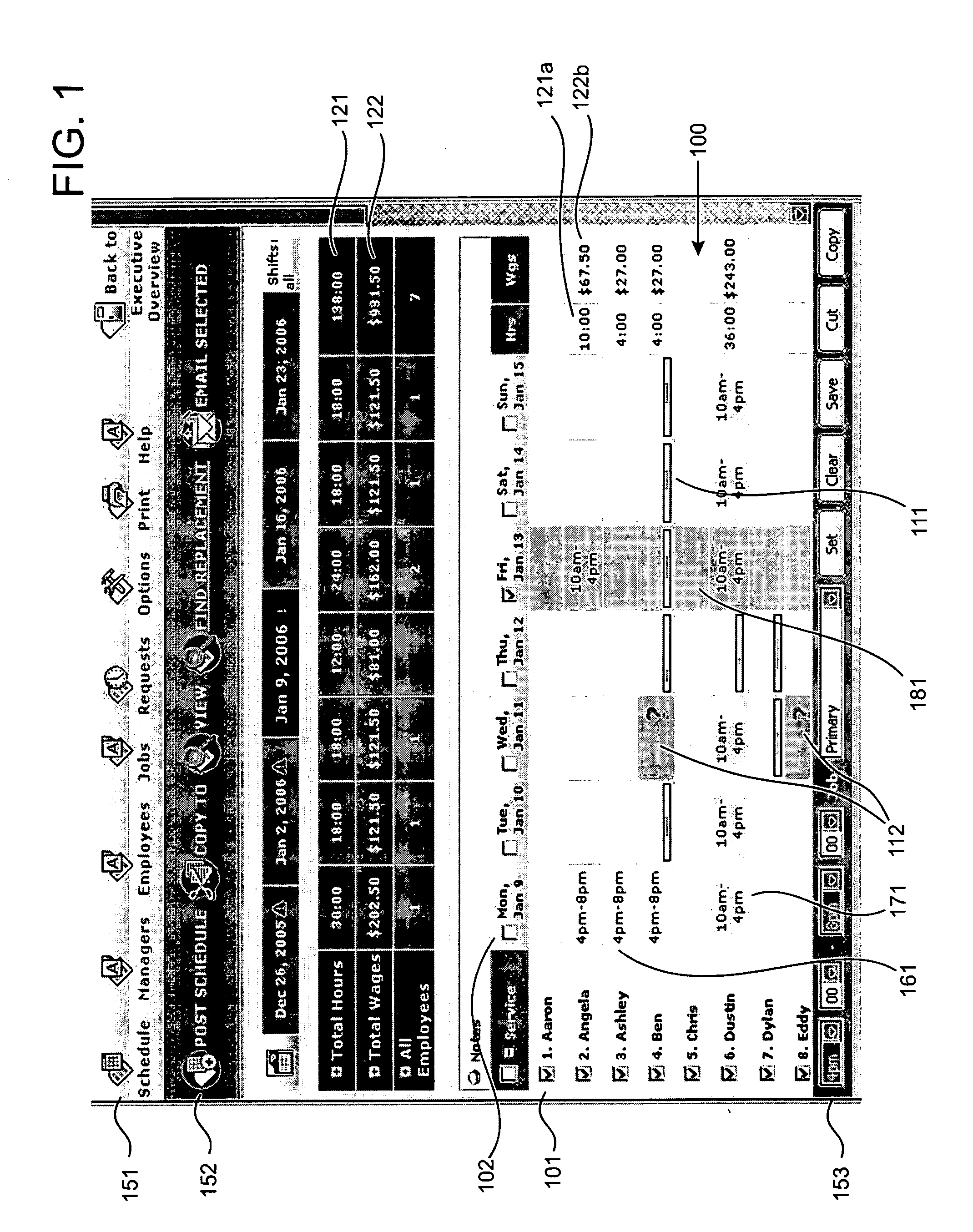

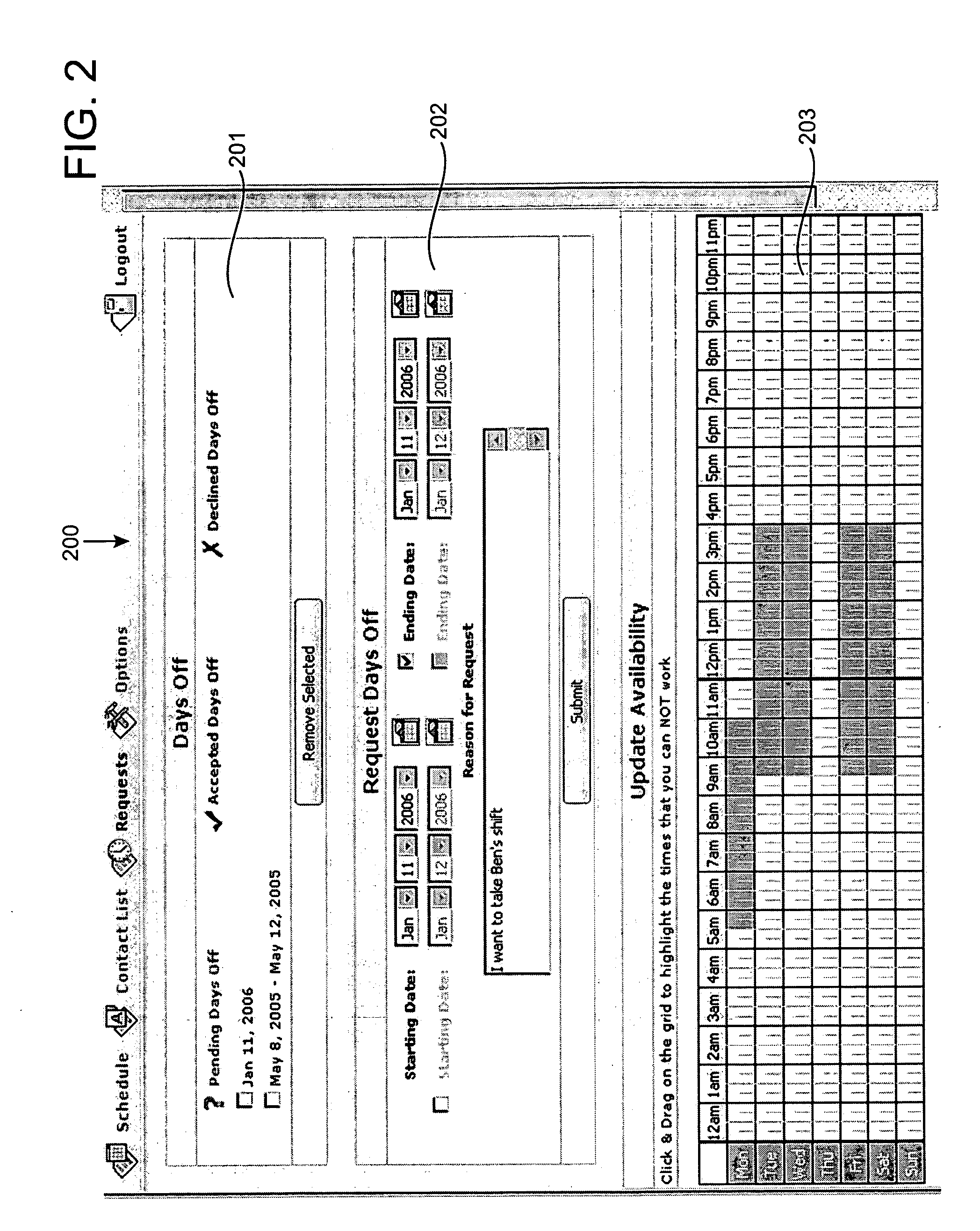

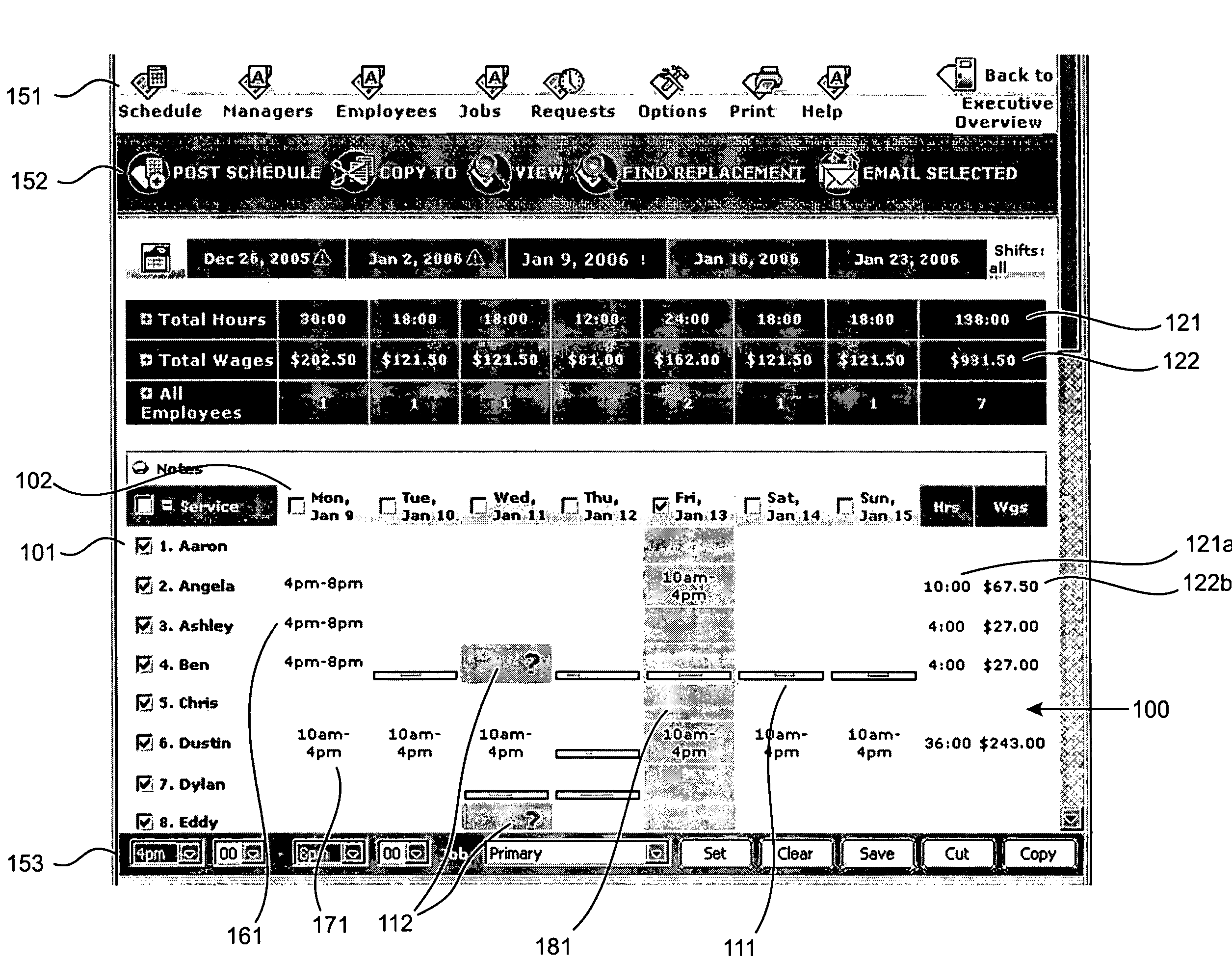

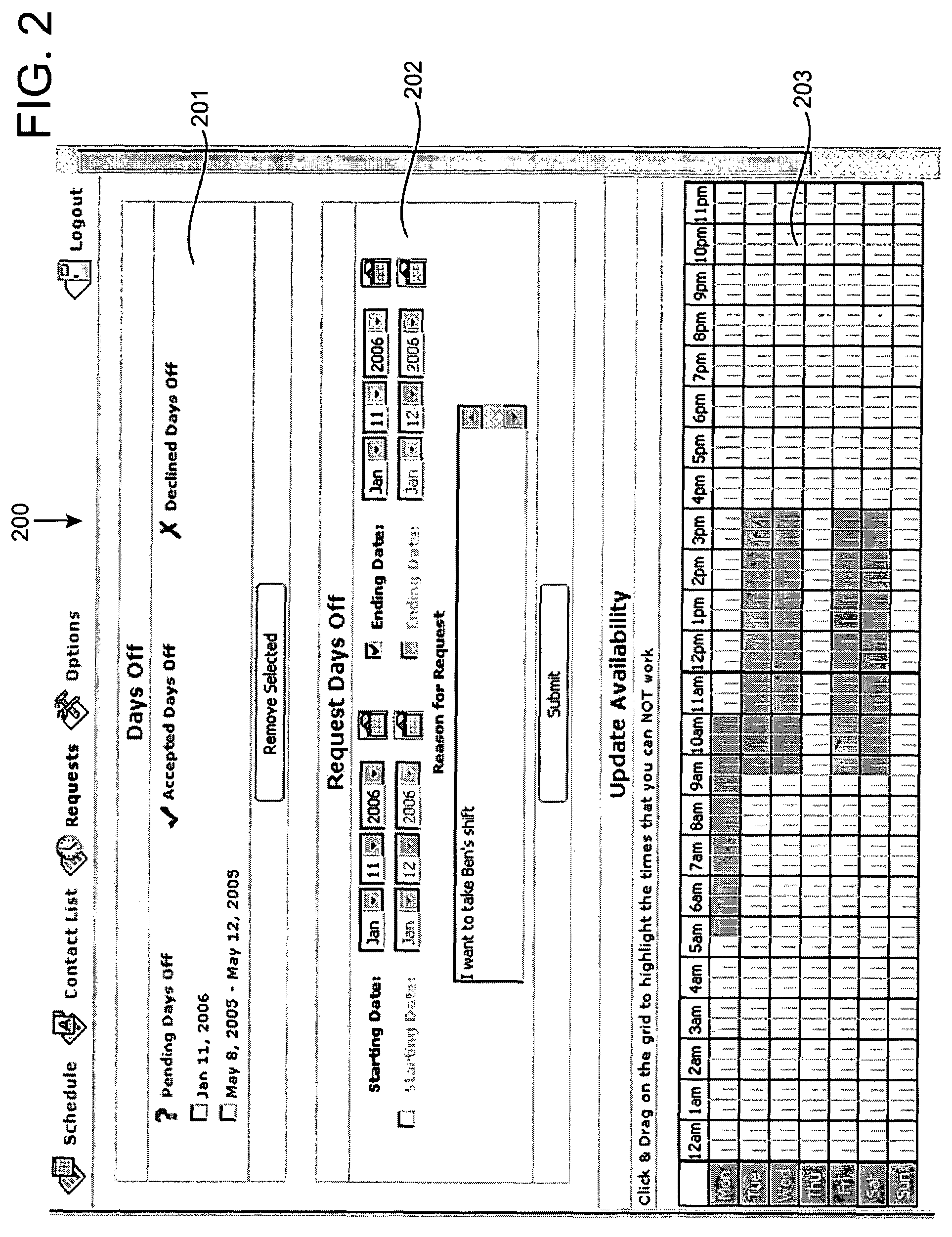

System and method for scheduling employee shifts

ActiveUS20070179830A1Readily observe conflictEasy schedulingDigital computer detailsResourcesTime scheduleProgram planning

A system and method for scheduling employee shifts. Two types of users generally utilize the system to post and view schedules, managers and workers. A manager may define shifts for work areas and post the shifts so workers may obtain their schedule and know when to work. Workers may retrieve the schedule from any network enabled device located anywhere. Worker unavailability times and requests for schedule changes may be made remotely by the worker at any network enabled computing device. Managers may accept or reject requests and utilize employee unavailability times to schedule workers to a shift and readily observe conflicts and schedule around these conflicts using a schedule screen that shows the workers, their unavailability times and scheduled times. Time and wage summaries may be updated directly on the screen when changes to the shifts are made to allow a manager to minimize wages for a shift or work area.

Owner:IKNOIAN MATTHEW

Telemedicine service system and realizing method thereof based on cloud technology

InactiveCN103150469ALow input costAvoid restrictionsDiagnosticsSurgeryThe InternetCustomer-premises equipment

The invention discloses a telemedicine service system based on a cloud technology, which comprises CPE (customer premise equipment) controlled by a patient, a remote cloud server communicated with the CPE through a remote communication network, and medical end equipment which is controlled by medical staff and communicated with the remote cloud server through the remote communication network or the internet, wherein each of the CPE and the medical end equipment comprises personal portable medical equipment or family medical equipment. The invention further discloses a realizing method for the telemedicine service system. Through the system and the method, excellent medical staff around the world can be gathered for reasonable distribution and application of the human resources, and teletherapy can be realized truly. Therefore, the system and the method have high utility value and popularization value.

Owner:SICHUAN XUKANG MEDICAL ELECTRICAL EQUIPCO

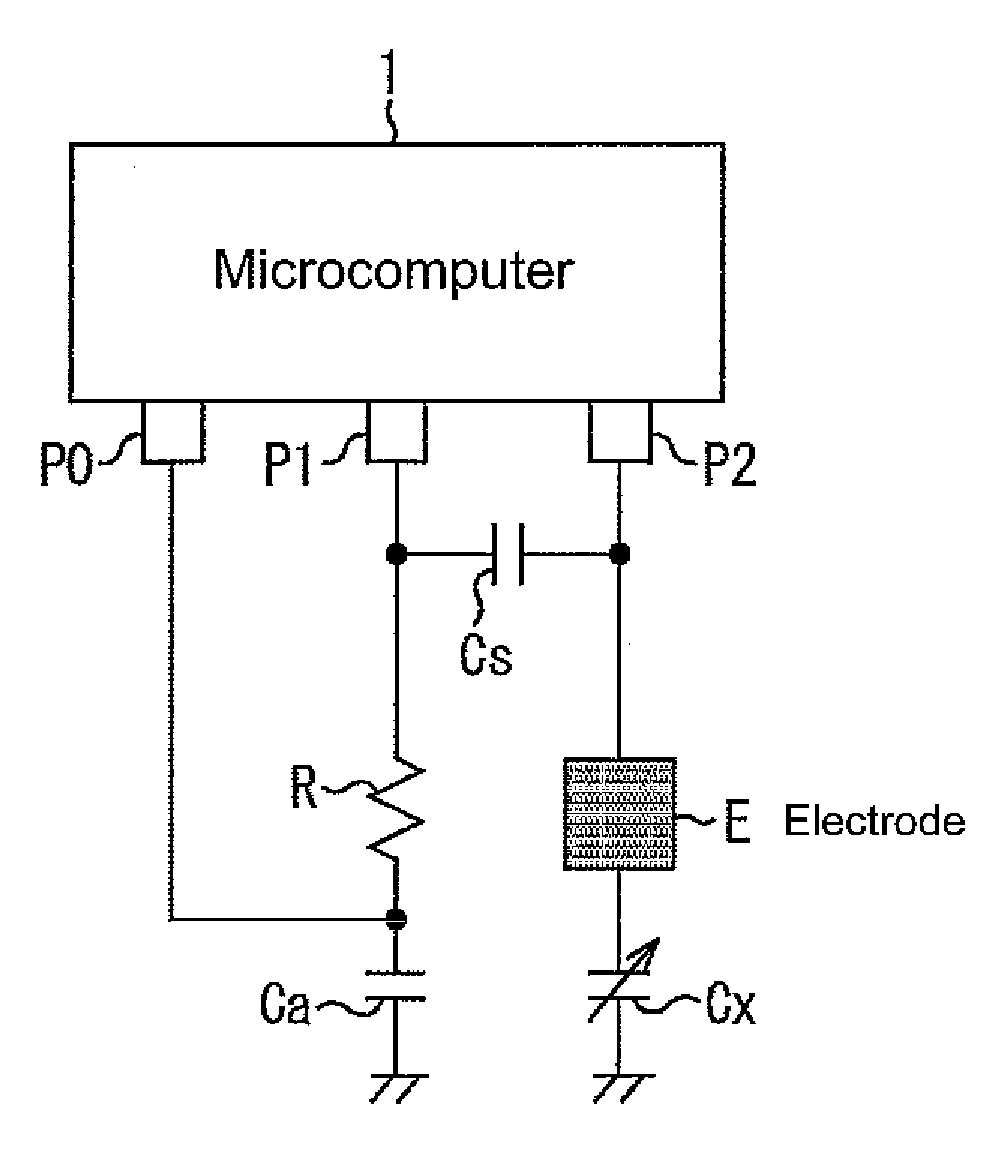

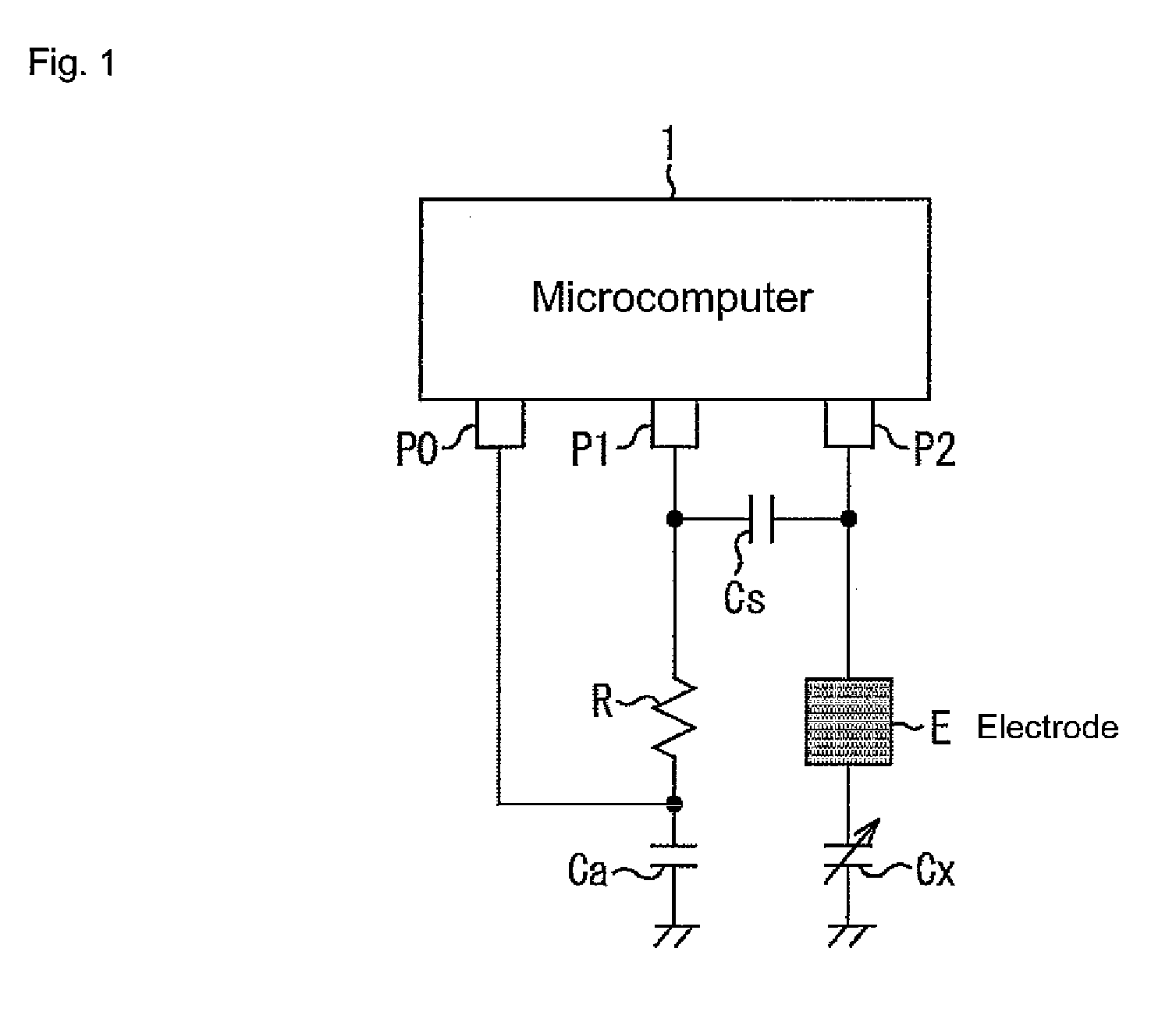

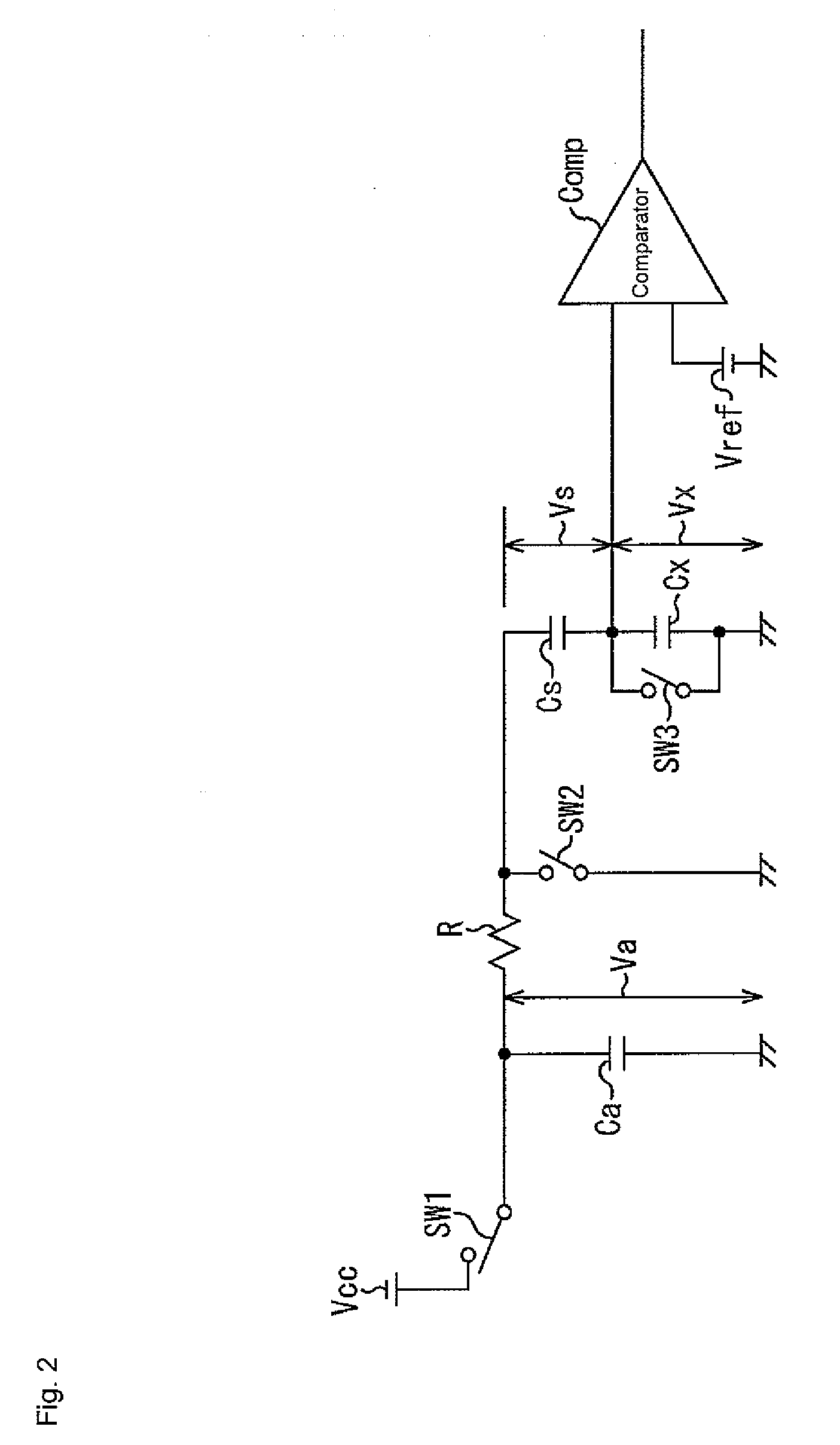

Sensing apparatus and method, and program therefor

ActiveUS20090073140A1Reduce false detectionChange in electrostatic capacitanceResistance/reactance/impedenceElectronic switchingCapacitanceAbsolute difference

Human contact / non-contact is detected speedily and accurately. A measurement section measures capacitance of each of sites to which a plurality of electrodes are connected where a human body touches, a comparison section compares the capacitance with a threshold value for each contacting electrode, and a control section determines whether a human body has come in contact based on the comparison result. A reference value calculation section calculates a reference value serving as electrode-specific reference capacitance based on the measurement results corresponding to the plurality of electrodes cumulatively stored in a storage section, a difference calculation section calculates an absolute difference value between the electrode-specific reference capacitance and a plurality of measurement results, and a threshold value adjustment section adjusts the threshold value by subtracting from the electrode-specific threshold value a value of the sum of the calculated absolute difference value for each of the electrodes other than the absolute difference value of each of the electrodes. The present invention can be applied to a touch sensor.

Owner:ORMON CORP

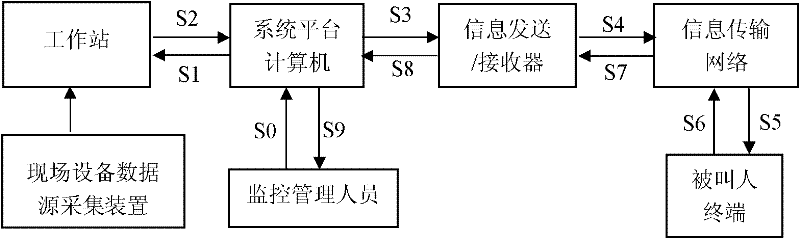

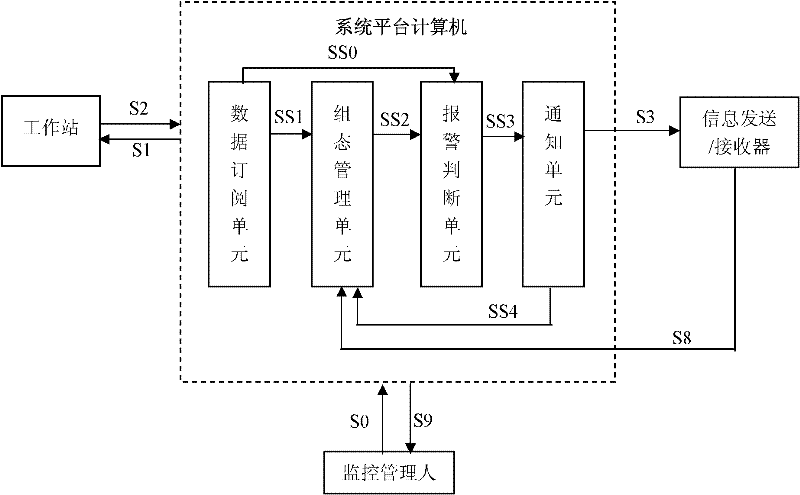

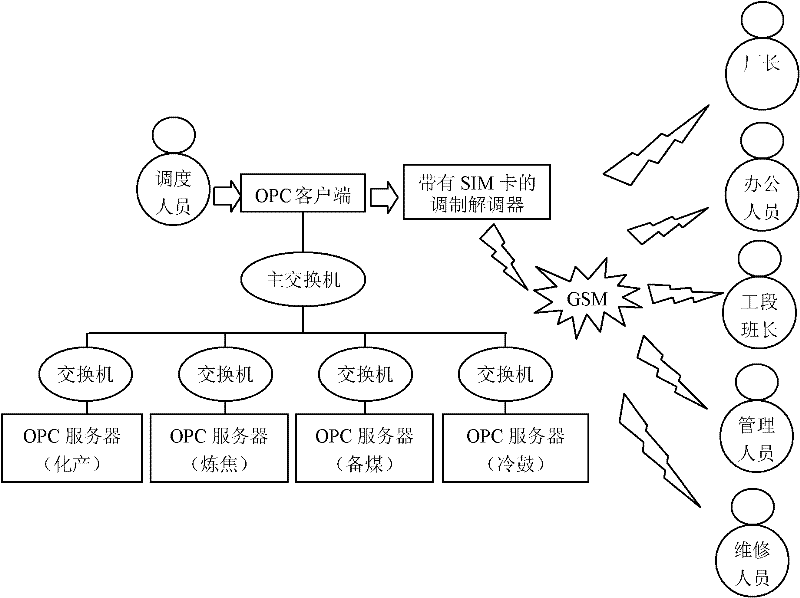

Real-time alarm system for industrial enterprise and method thereof

ActiveCN102200769AImprove understandingKeep abreast ofTotal factory controlProgramme total factory controlInformation transmissionEnterprise process

The invention provides a real-time alarm system for industrial enterprise and a method thereof. The system comprises work stations, a system platform computer, an information transmitter-receiver, an information transmission network, and a called terminal. According to the invention, technical methods such as industrial data communication and mobile phone short message sending are used to carry out real-time monitoring of industrial enterprise process data, send alarm information in real time and realize the real-time alarm function for industrial enterprise.

Owner:中广核智能科技(深圳)有限责任公司

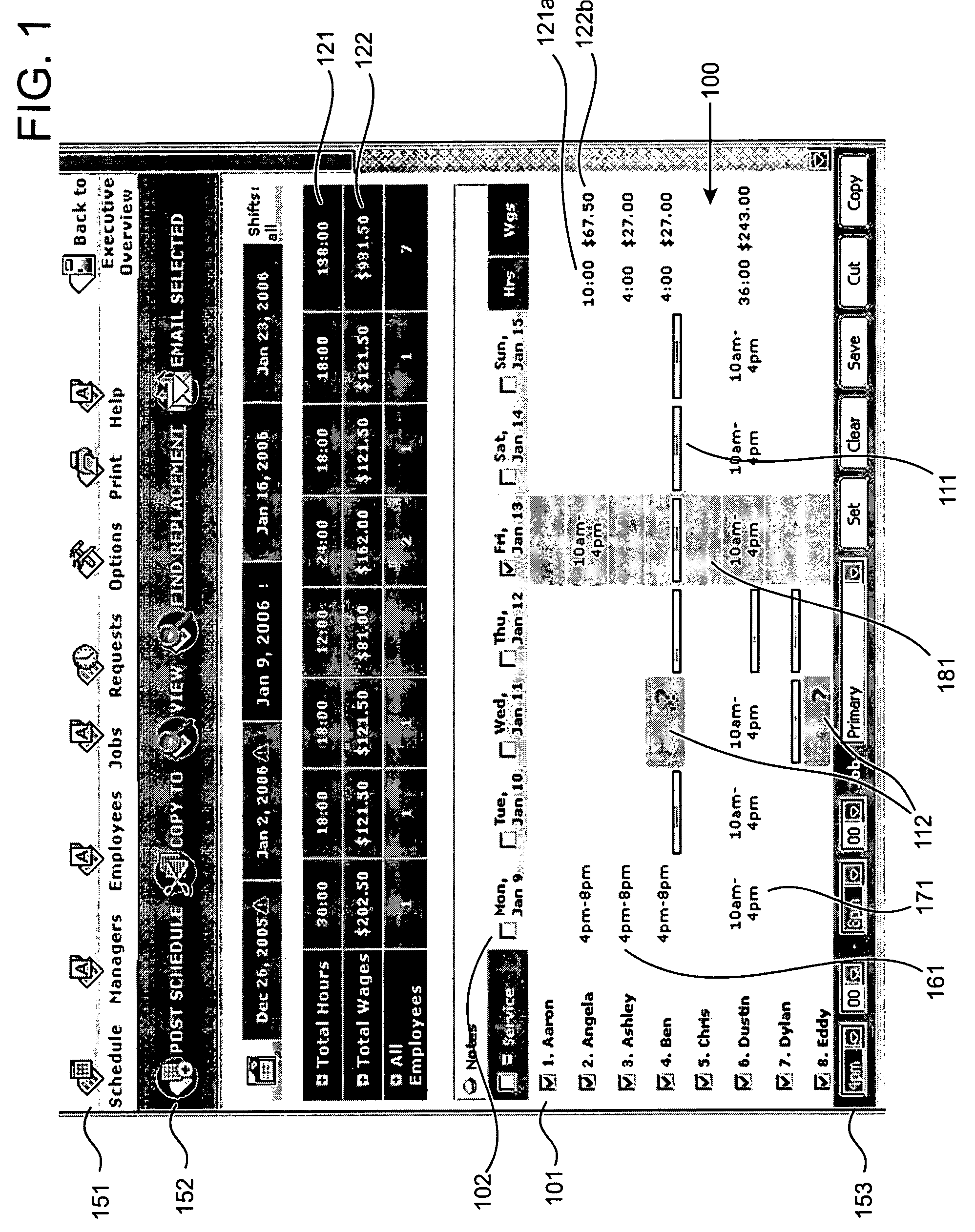

System and method for scheduling employee shifts

A system and method for scheduling employee shifts. Two types of users generally utilize the system to post and view schedules, managers and workers. A manager may define shifts for work areas and post the shifts so workers may obtain their schedule and know when to work. Workers may retrieve the schedule from any network enabled device located anywhere. Worker unavailability times and requests for schedule changes may be made remotely by the worker at any network enabled computing device. Managers may accept or reject requests and utilize employee unavailability times to schedule workers to a shift and readily observe conflicts and schedule around these conflicts using a schedule screen that shows the workers, their unavailability times and scheduled times. Time and wage summaries may be updated directly on the screen when changes to the shifts are made to allow a manager to minimize wages for a shift or work area.

Owner:IKNOIAN MATTHEW

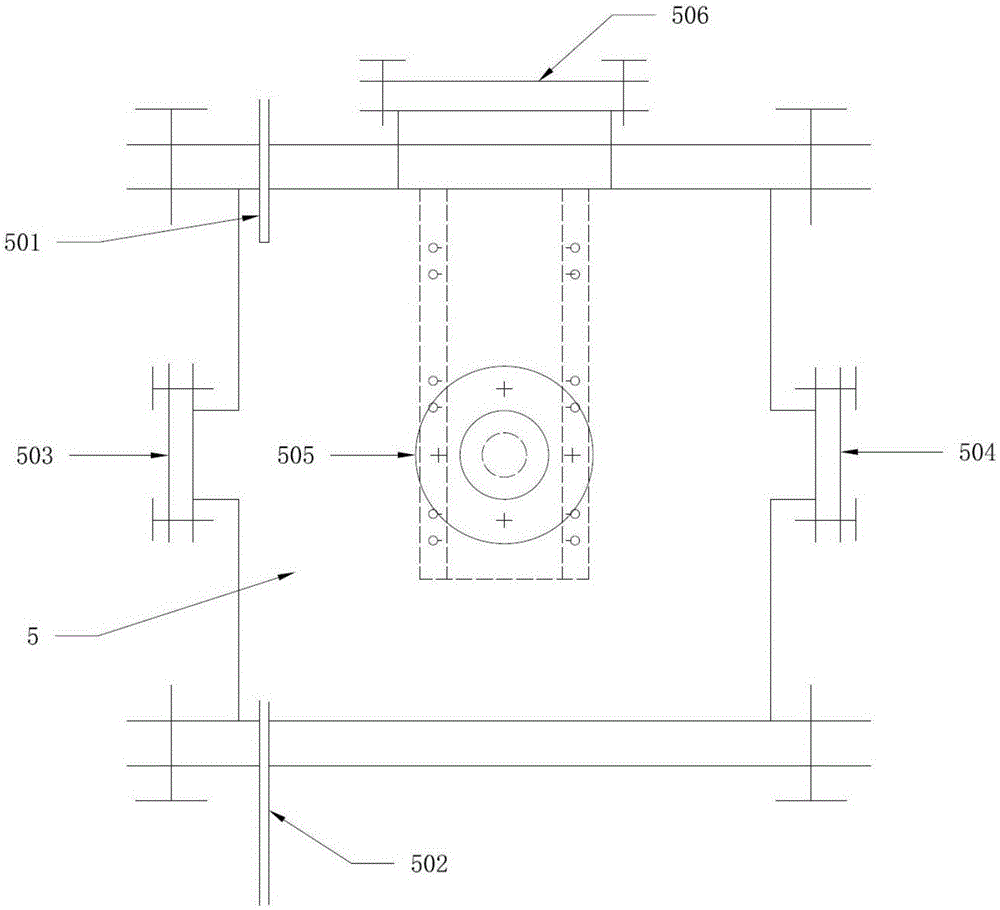

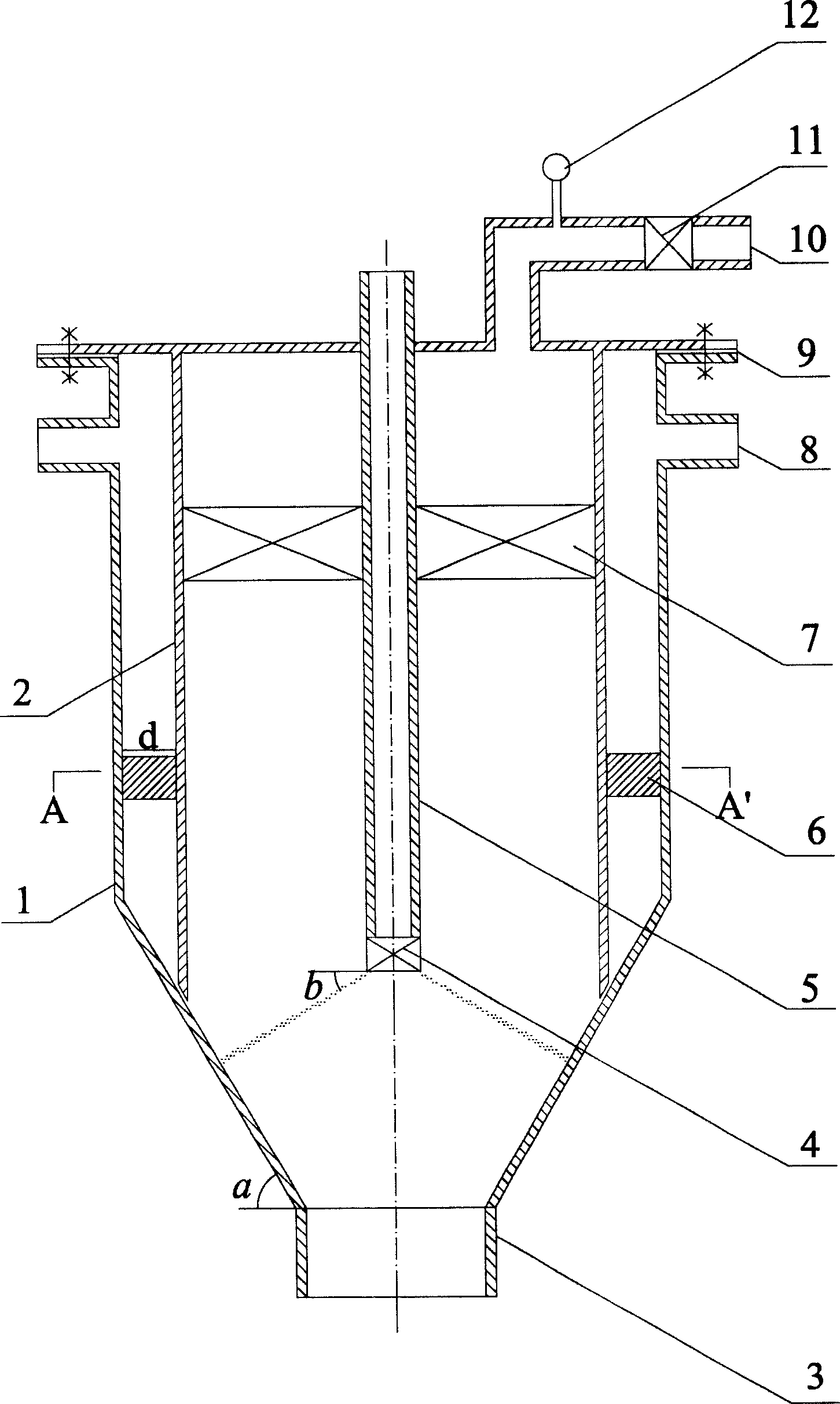

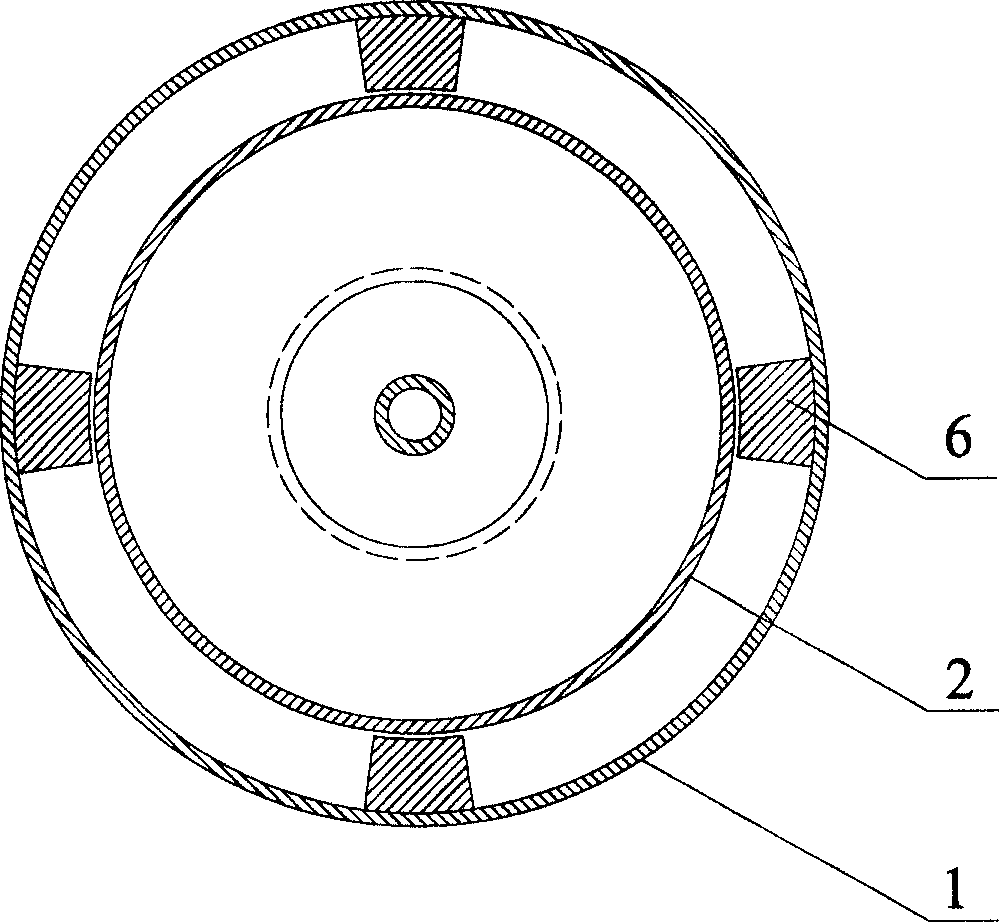

Liquid-liquid fast-mixing reactor

InactiveCN1669631AGuaranteed to proceed normallyEfficient mixingChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesCycloneSpray nozzle

The invention relates to a liquid-liquid fast-mixing reactor, which comprises a housing, an inner casing, a liquid conducting tube, an injector, a demister, a backing sheet, a pad, an adjusting valve, a manometer, wherein the housing (1) has a liquid feed inlet (8), the necked-in parts, and a liquid outlet (3); the inner casing (2) has the liquid conducting tube (5), the injector (4), the air outlet (10), the adjusting valve (11) and the manometer (12) inside. The space between the inwall of the housing (1) and the inner casing (2) forms a channel cyclone or non-cyclone through which a fold of liquid inlets, and another liquid passes the liquid conducting tube and the injector and forms the droplet distributed circlewise, the droplet connects with the film formed when the first fold of liquid passing the chine, and the two folds of liquid mix in the meeting point rapidly, then the product will be discharged from the liquid outlet (3).

Owner:TSINGHUA UNIV

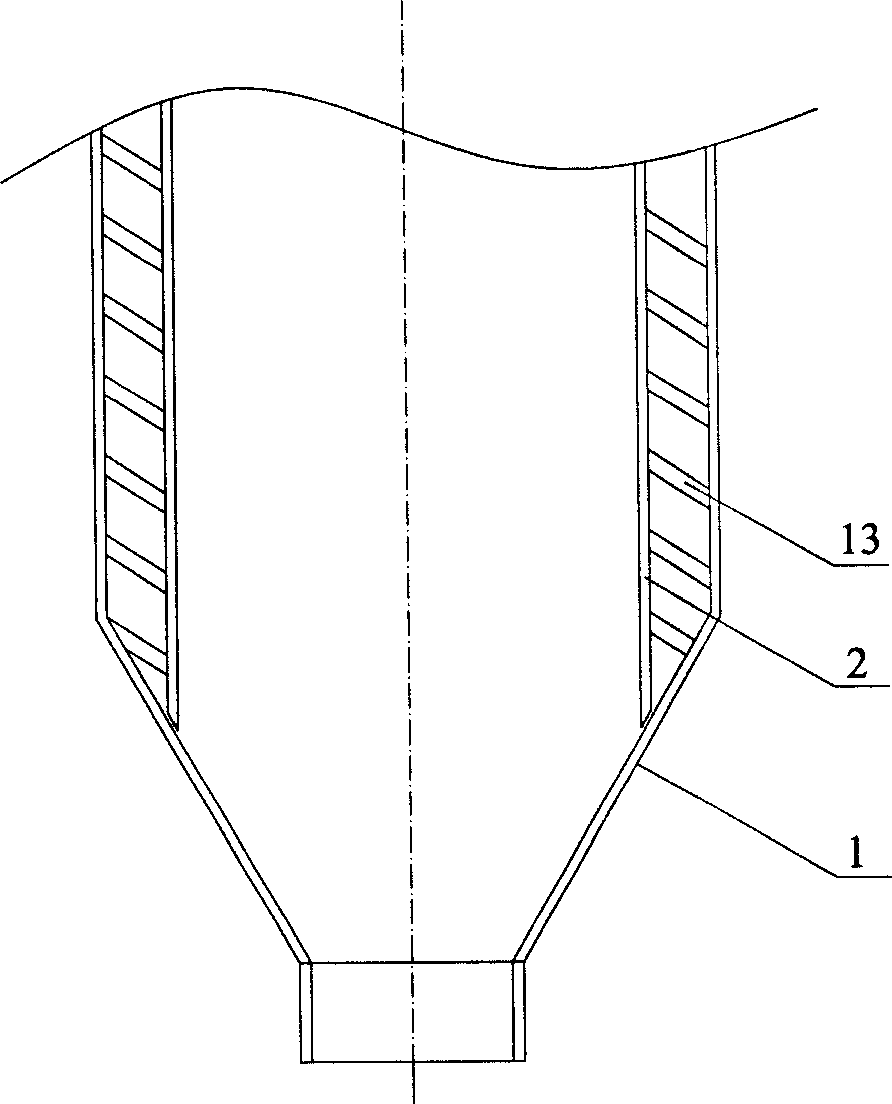

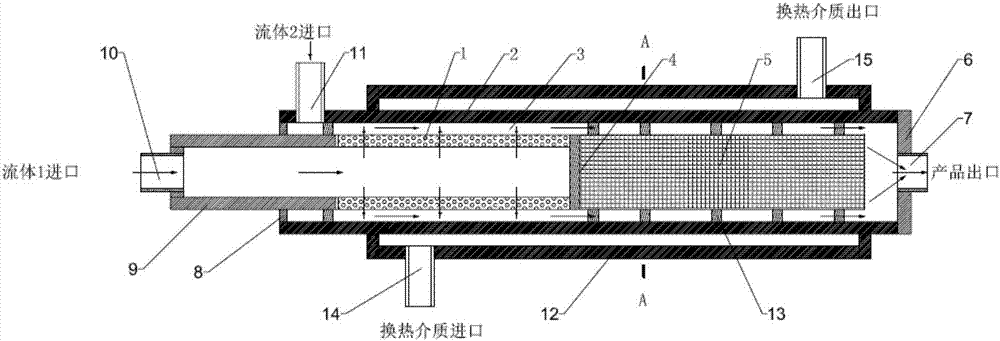

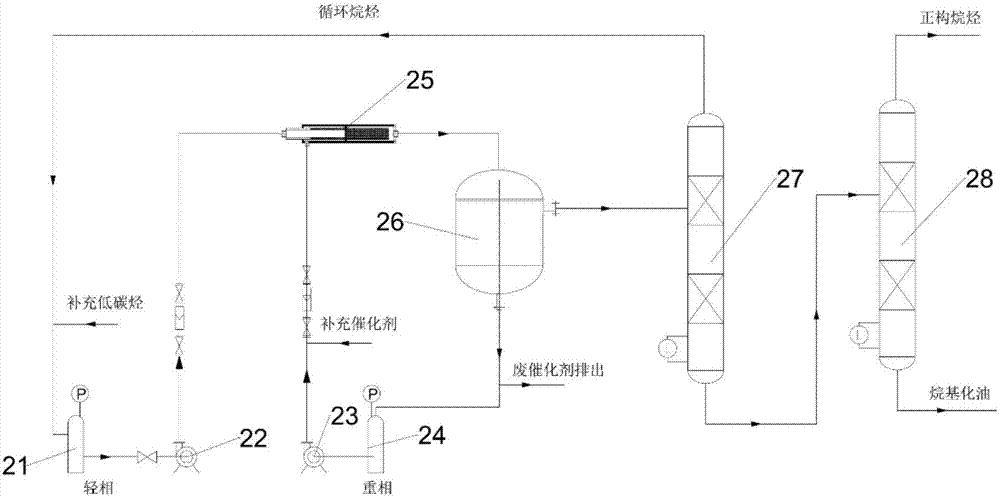

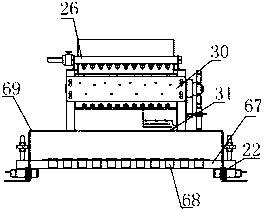

Microreactor and system for liquid-liquid multi-phase reaction and liquid acid alkylation method

ActiveCN107261997AGuaranteed uptimeAchieve microChemical/physical/physico-chemical microreactorsLiquid hydrocarbon mixtures productionMicroreactorAlkyl transfer

The invention relates to the technical field of organic synthesis chemistry and particularly relates to a microreactor and system for a liquid-liquid multi-phase reaction and a liquid acid alkylation method. The microreactor comprises an inner pipe and an outer casing pipe, the inner pipe and the outer casing pipe are coaxial, the inner tube and the outer casing pipe form an annular microchannel, a first diversion pipe, an inner film pipe and a second diversion pipe having the same external diameters are orderly connected to form the inner pipe, the upper side of the outer casing pipe is provided with a heavy phase inlet, an end cap is arranged between one end of the outer casing pipe and the wall of the first diversion pipe, the other end of the outer casing pipe is provided with a product outlet, the heavy phase inlet and the inner pipe are arranged so that a heavy phase flow and a light phase flow contact in a parallel flow way and a distance-determination structure is arranged in the annular microchannel. The system comprises the microreactor, a light phase storage device, a heavy phase storage device and a separation device. The liquid-liquid phase interfaces of the microreactor are increased by 10 times or more than that of the general reactor so that the small size, high efficiency, high selectivity, large treatment amount, small energy consumption and high universality are realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

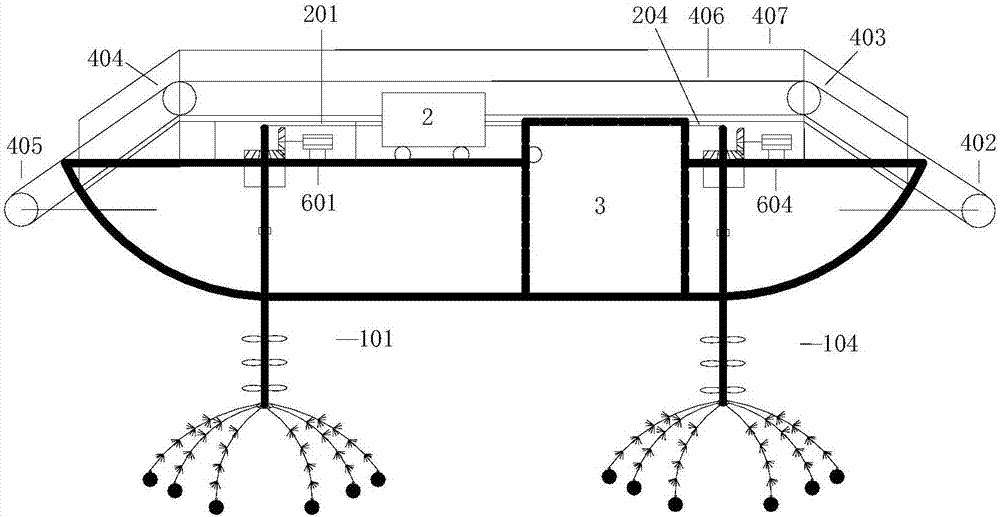

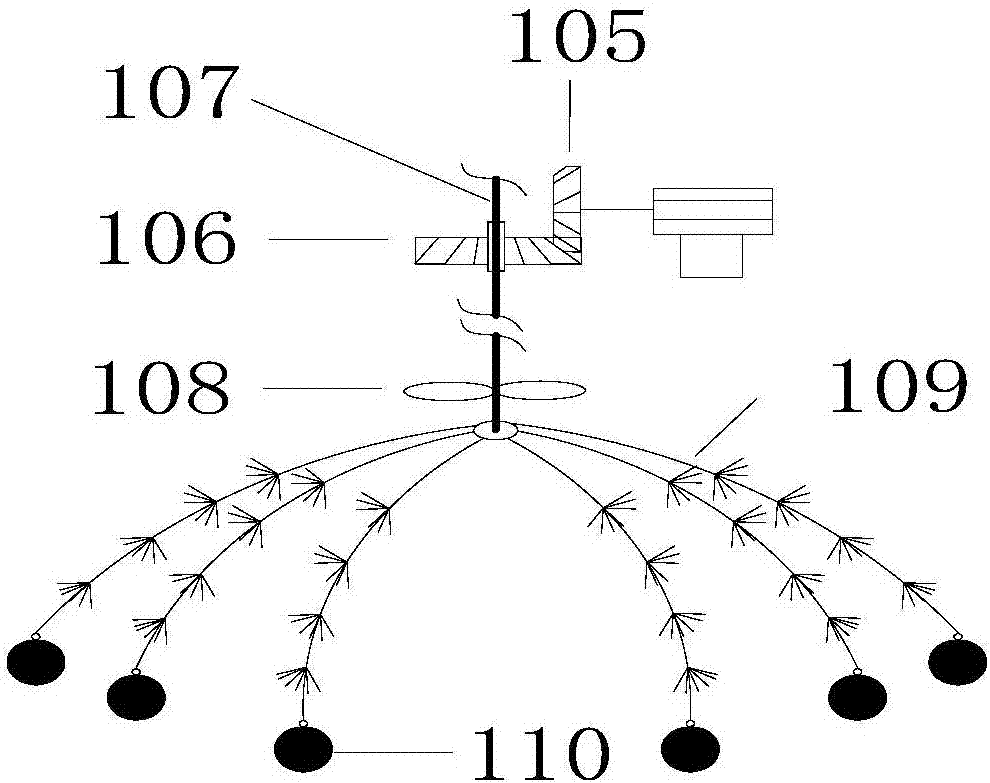

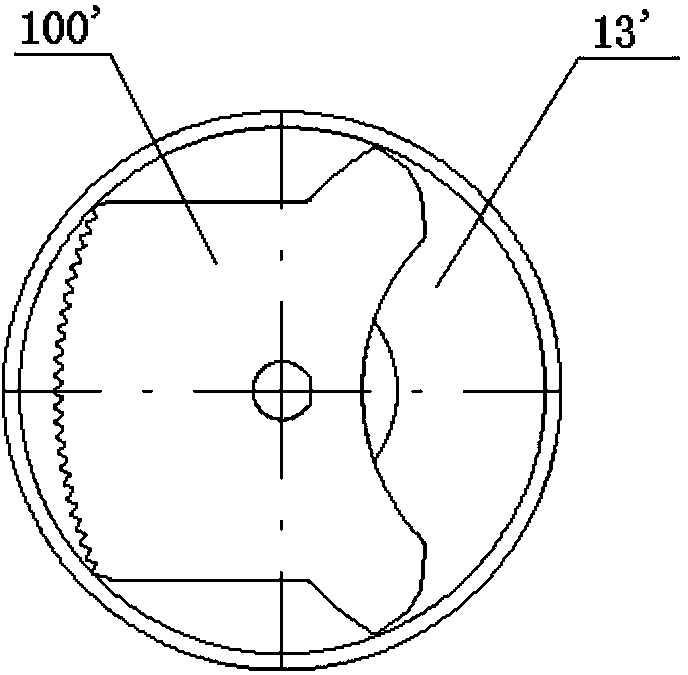

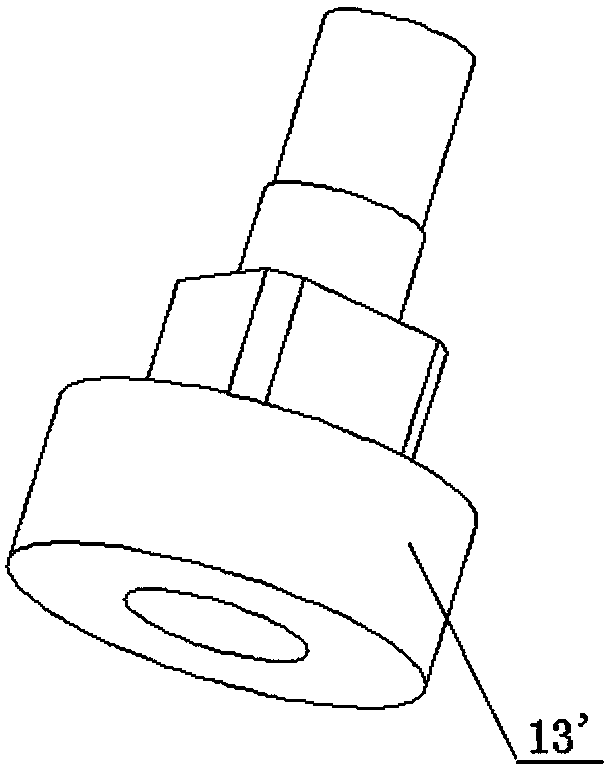

Sowing machine capable of realizing intelligent precision dibbling

InactiveCN102696317AImprove seeding accuracyPrecise sowingCultivating equipmentsSeed depositing seeder partsControl systemEngineering

The invention relates to a sowing machine capable of realizing intelligent precision dibbling. The method comprises a master controller (13), a rack (1), a transmission assembly (8) arranged on the rack, a substrate filling assembly (3), an indenting assembly (7), a seed dibbling assembly (6) and an earthing assembly (4), wherein the seed dibbling assembly is realized by adopting the following manner: a seedling raising plate moves to a position sensor and triggers a master control system to control a stepping motor to drive a sowing roller to rotate, seeds enter a corresponding sowing hole when the sowing roller rotates, unnecessary seeds on the sowing hole are cleaned by virtue of a gas seed cleaning device, seeds reserved in the sowing hole are dropped at a fixed position by virtue of a seed protective device, the seeds enter the corresponding holes along a guide pipe, and thus the accurate sowing is realized. The sowing machine disclosed by the invention solves the technical problems that the conventional sowing is inaccurate, the time and the effort are wasted and the working efficiency is low; and the sowing machine disclosed by the invention has the advantages of high sowing accuracy, accurate and passive indenting, simplicity, energy conservation and high efficiency.

Owner:XIAN SENWAS AGRI SCI & TECH

High-speed washing program of washer

InactiveCN1373248AEffective dissolutionQuick soakControl devices for washing apparatusTextiles and paperWater flowInlet valve

A program for fastly washing clothes in washer includes charging water to level No.1, turning on motor and draining pump, slowly rotating internal drum and pulsator, charging water to half of predefined level, slow streaming water to predefined water level, internal circulating, washing for 3-8 min, smoothing water flow for 10-30 seconds, intermittent extracting water for draining the water in internal drum while stopping internal drum and pulsator for 1-25 min, continuous extracting water for 30-65 seconds, cycling 2-5 times, closing water inlet valve, continuous extracting water for 30-90 seconds, inertial extracting water for 10-40 seconds and braking. It can shorten time by 2 / 3 and save water by 2 / 3.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

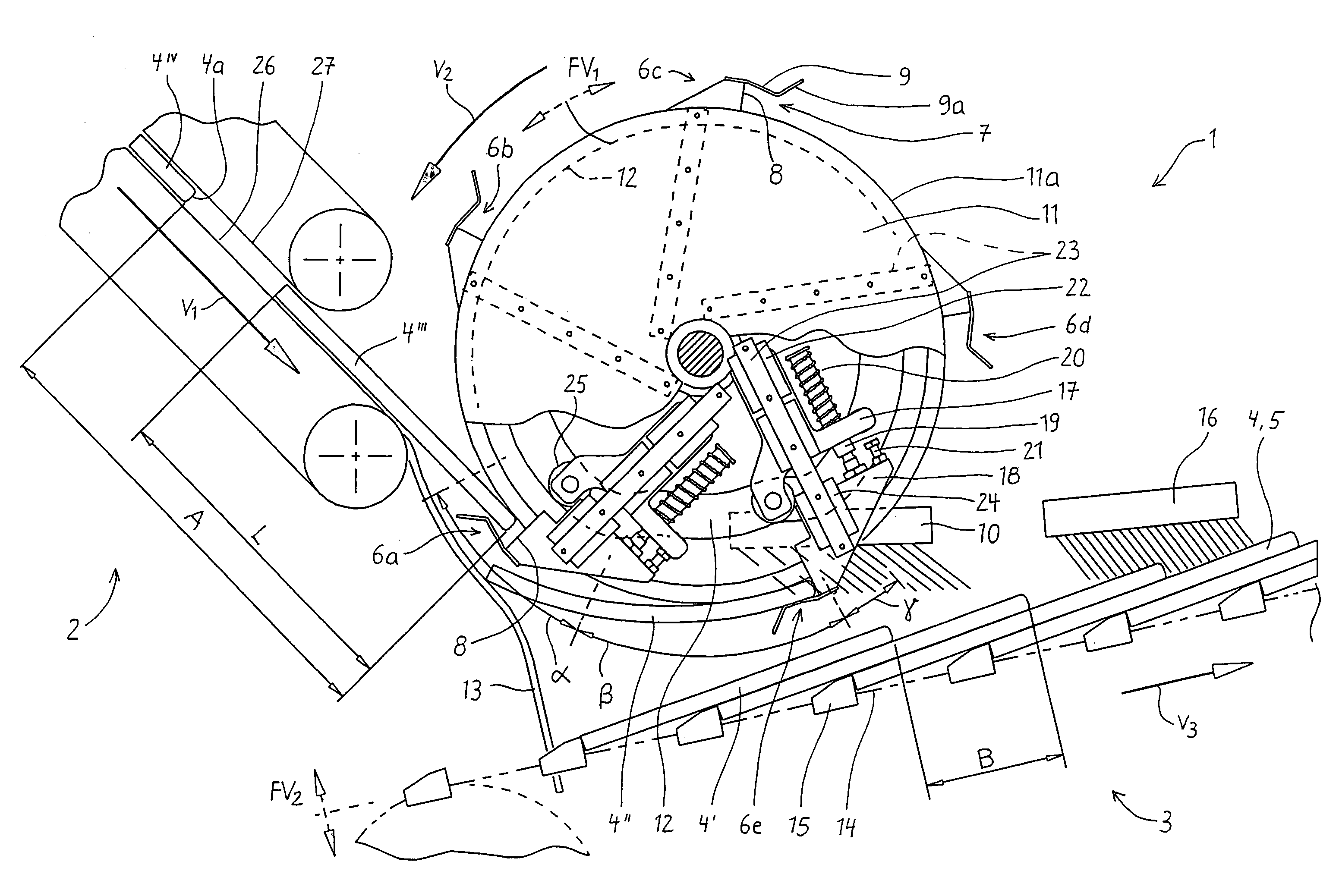

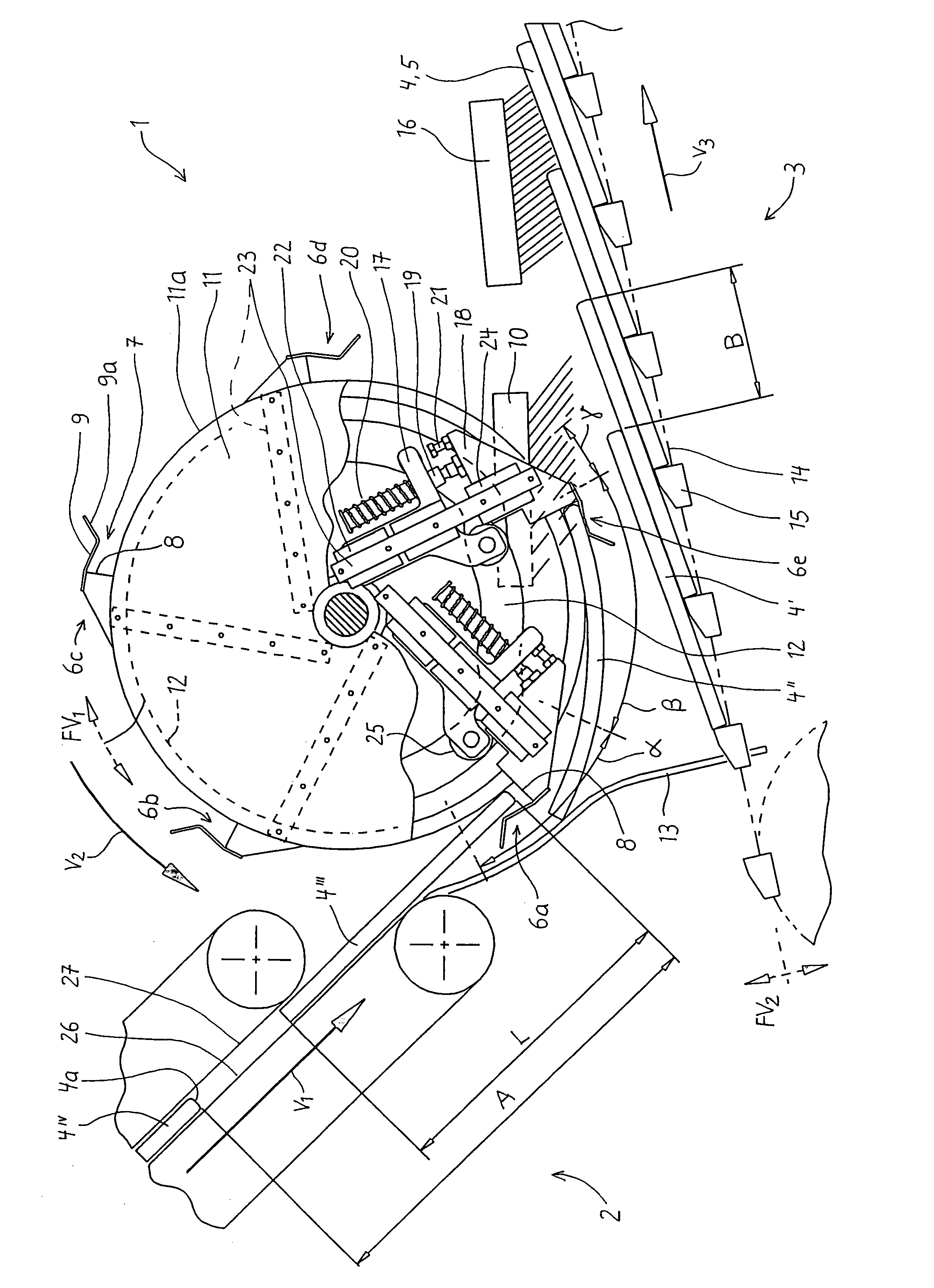

Device for depositing individual printed products, supplied in succession, in shingle formation

InactiveUS20070164501A1Reliably flawlessly deposit less-flexibleFast processingFunction indicatorsArticle deliveryEngineeringMechanical engineering

A device for depositing individual printed products (4), preferably magazines, brochures or book blocks, that are supplied in succession by means of a feed conveyor (2) on a downstream conveyor (3) with slower transport speed (v3) in shingle formation (5), wherein said device comprises a stream feeder (1) that receives the printed products (4) from the feed conveyor (2) by means of rotating grippers (6a to e) that are opened and closed in the appropriate cycle with the aid of a stationary cam (12) and deposits the printed products on the downstream conveyor (3). In order to reliably and flawlessly deposit the printed products, particularly thick and / or less flexible printing products, in shingle formation, the stream feeder includes a plurality of grippers (6a to e) that are rotatively driven with a slower speed (v2) than the feed speed (v1), wherein the grippers (6a to e), opened for receiving the printed products, respectively include a short pocket (7) with a bottom stop (8), with which the respectively supplied printed product (4) comes in contact due to the higher feed speed (v1). The clamped transport takes place within an angular range (β) of the rotational movement of the grippers, namely up to a defined distance upstream of a stripping element (10) for reliably releasing the printed products (4). They drop on the downstream conveyor (3) along a short path.

Owner:KOLBUS

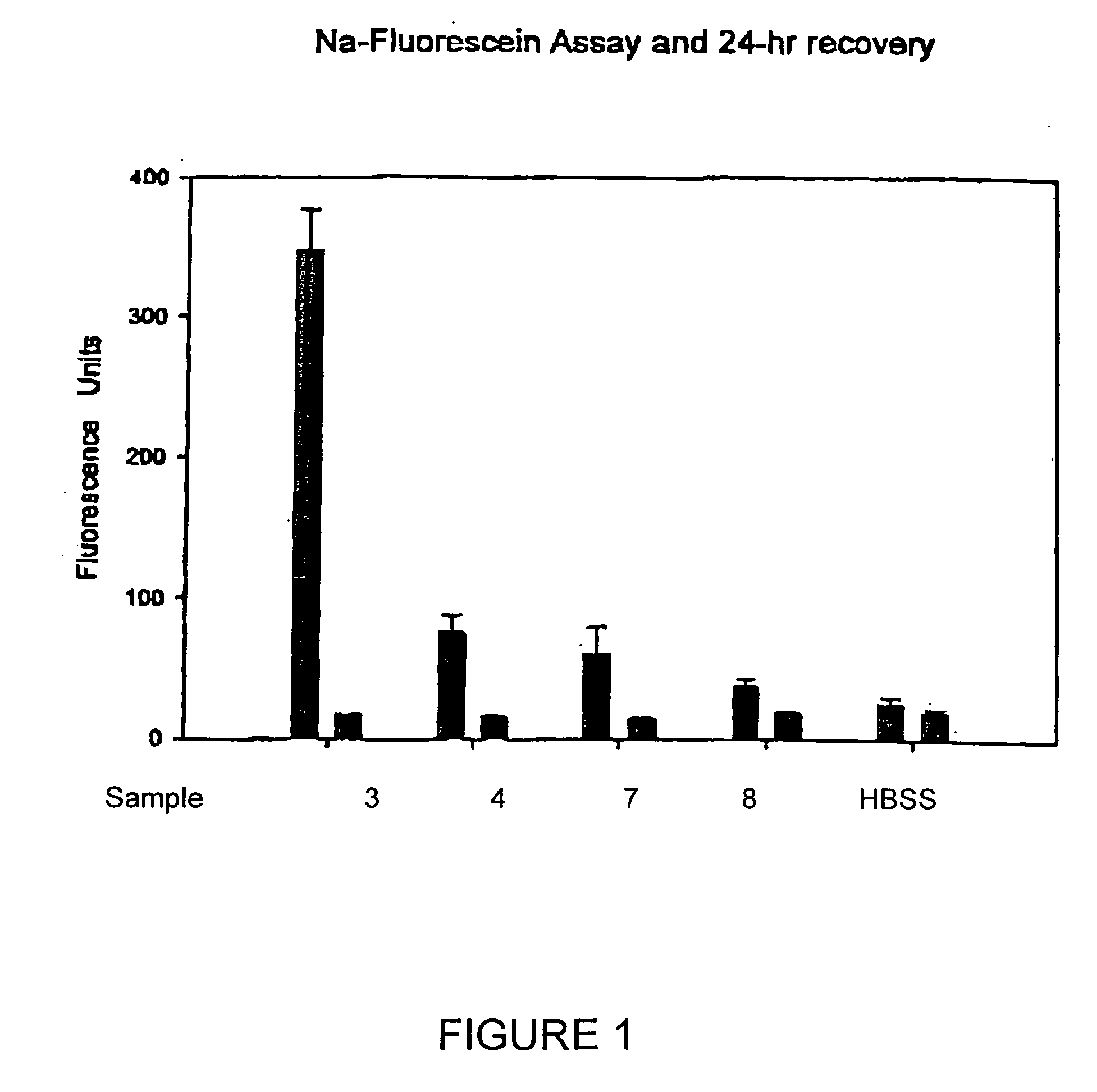

Antimicrobial compositions and uses thereof

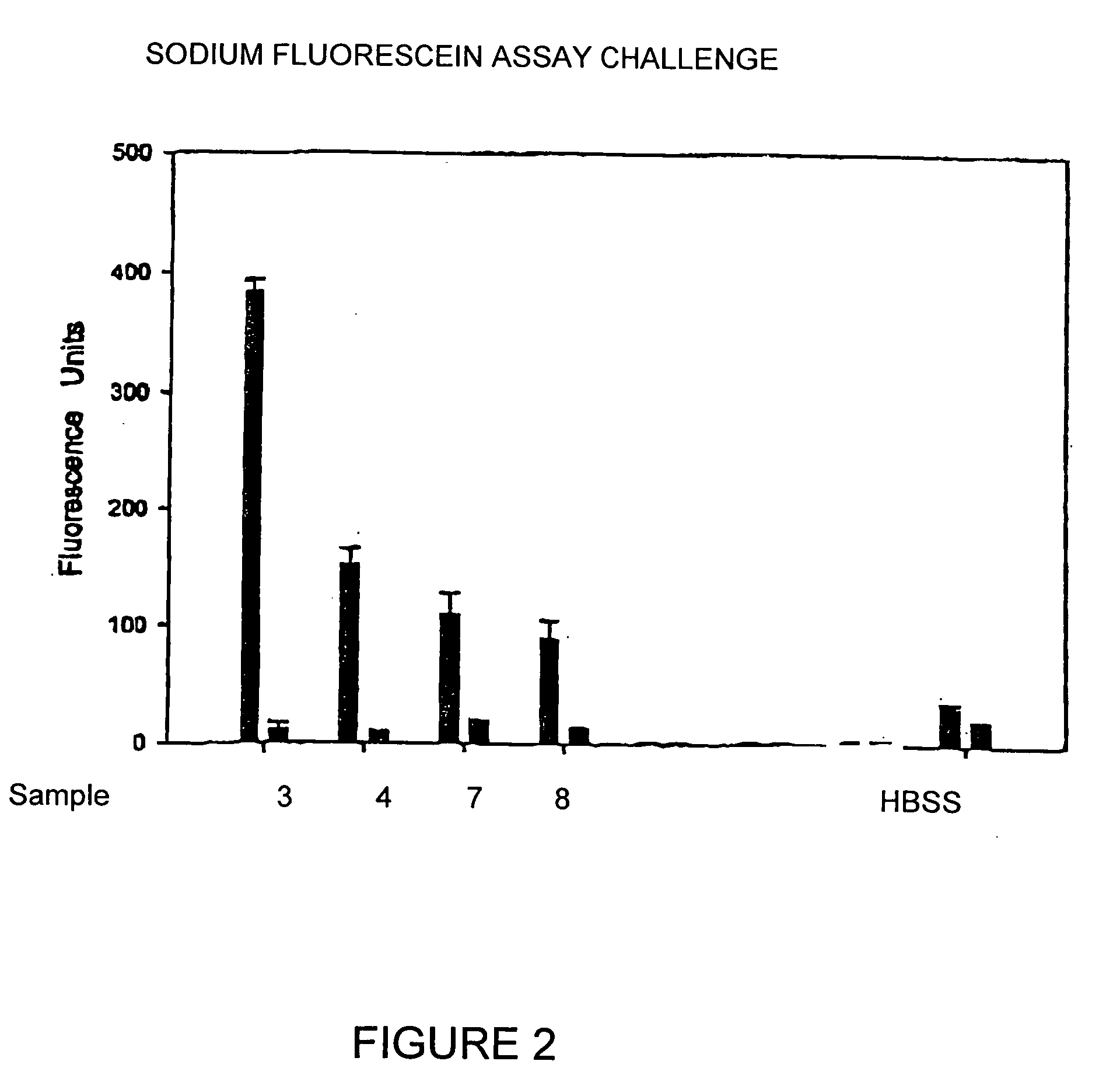

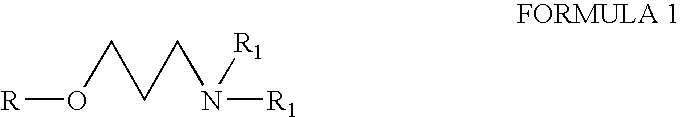

InactiveUS20050260099A1Enhanced and rapid disinfectionQuick contactBiocideLavatory sanitoryMicrobial agentEther

The use of compositions containing one or more ether amine antimicrobial agents and / or ether amine derivative antimicrobial agents in an amount effective to disinfect and / or preserve medical devices is described. Solutions containing one or more ether amine antimicrobial agent- and / or ether amine derivative antimicrobial agent-containing compositions and methods of making and using the same are also described.

Owner:BAUSCH & LOMB INC

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

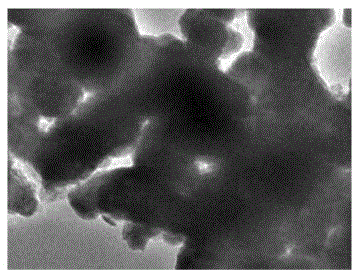

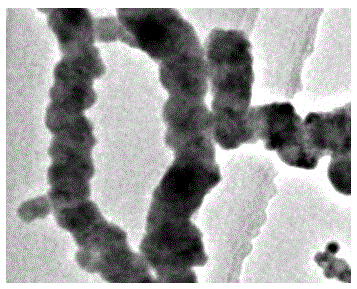

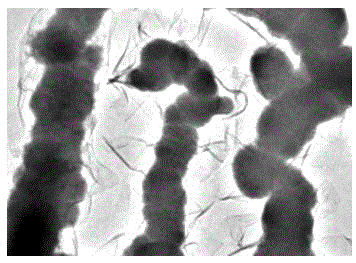

Dispersant modified nano zero-valent iron and preparing method and application thereof

The invention discloses a preparing method for dispersant modified nano zero-valent iron. Through a polymerization inhibitor, MEHQ or PEI serves as a dispersant to modify nano zero-valent iron; through the space steric hindrance effect and the electrostatic steric hindrance effect, the agglomeration phenomenon of the nano zero-valent iron is reduced; in the preparing process of the nano zero-valent iron, the surface of the nano zero-valent iron is modified, agglomeration of the nano zero-valent iron is reduced, dispersibility of the nano zero-valent iron is improved, and the nano zero-valent iron with the higher dispersibility is prepared; nano zero-valent iron particles prepared through the method have the good dispersion stability, inoxidizability and higher reducibility; in the synthetic process of the nano zero-valent iron particles, protection by nitrogen or other inert gases is not needed; and the method is low in cost, easy to operate and environment-friendly. Chlorinated organic compounds, heavy metal, antibiotics, coloring matter and the like in water can be effectively degraded, and the method has a wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

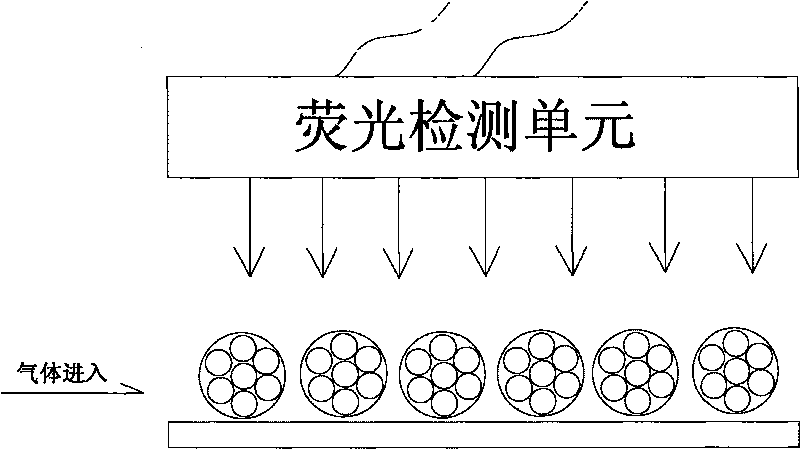

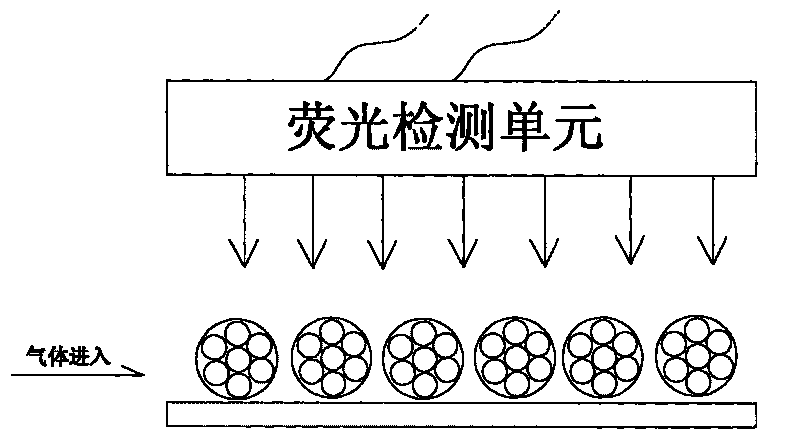

Flow-type gas sensor array and preparation method thereof

InactiveCN101762571ADetection speedHigh sensitivityMaterial analysis by observing effect on chemical indicatorFluorescence/phosphorescenceEngineeringPorphyrin structure

The invention discloses a flow-type gas sensor array and a preparation method thereof. The array comprises a plurality of gas-sensitive units, wherein each gas-sensitive unit comprises a flow carrier of three-dimensional colloid crystal microspheres; and porphyrin, phthalocyanine molecules or a hydrophobic PH indicator is fixed on the flow carrier. The array effectively solves the problems of low detection speed, large size of the required sample, and the like in the prior fixed-type sensor array, has the characteristics of stable performance, convenient detection, low detection limit and the like, and is free from the effect of ambient humidity.

Owner:SOUTHEAST UNIV

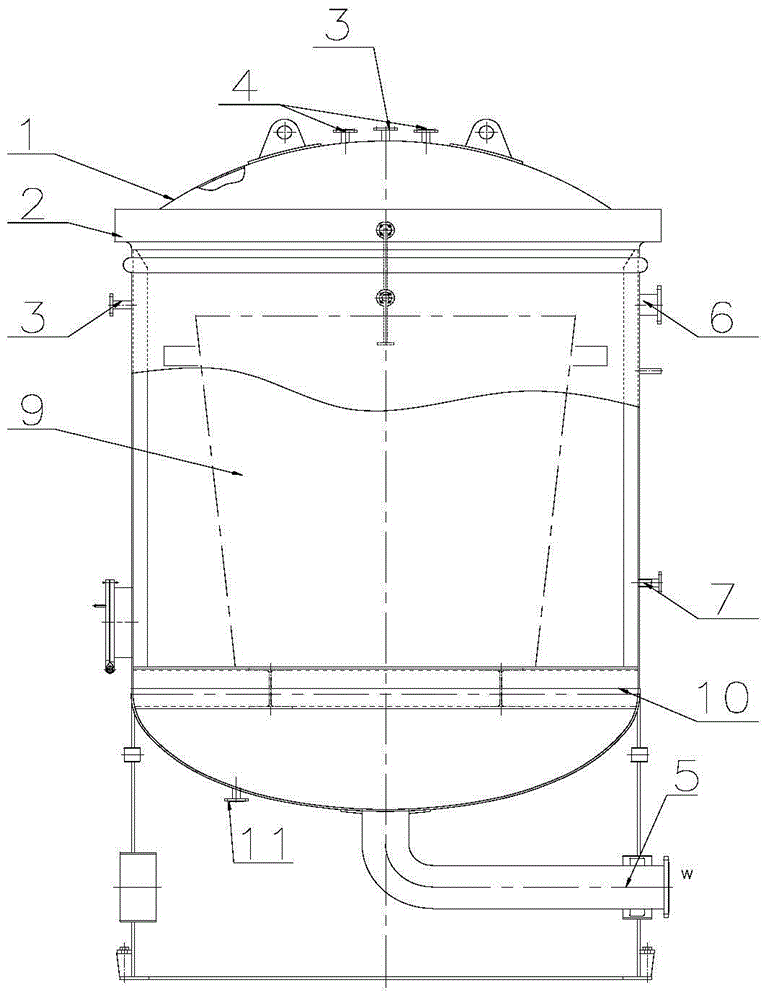

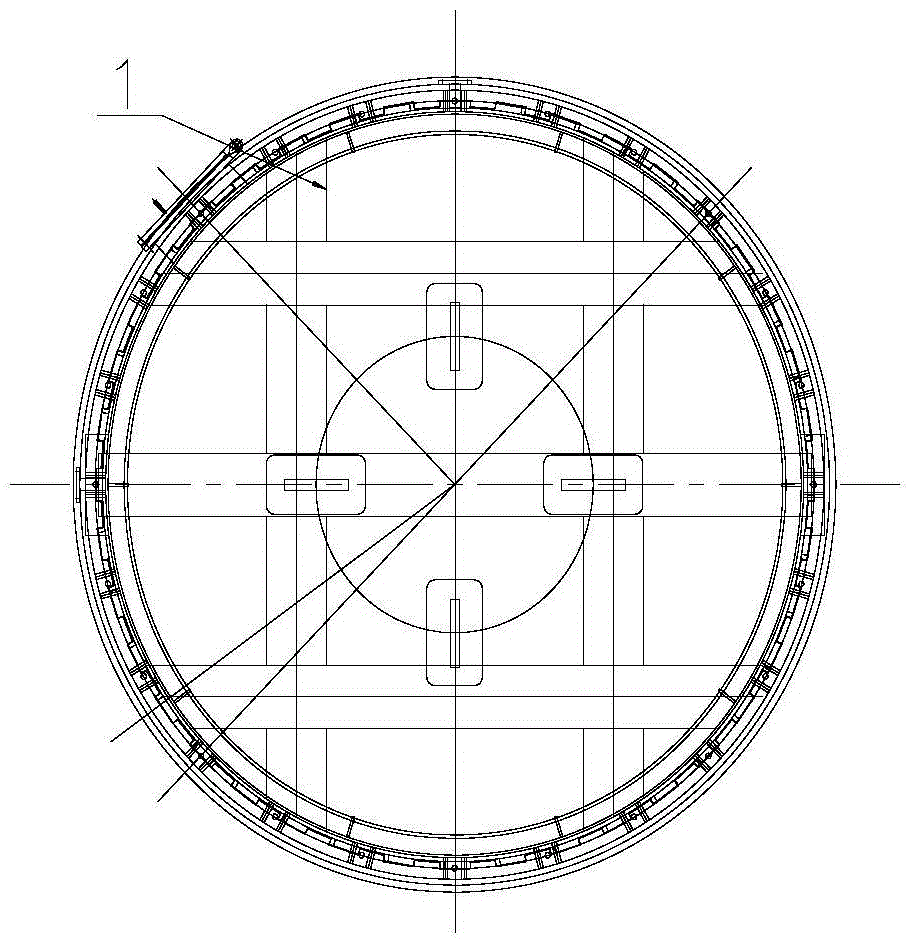

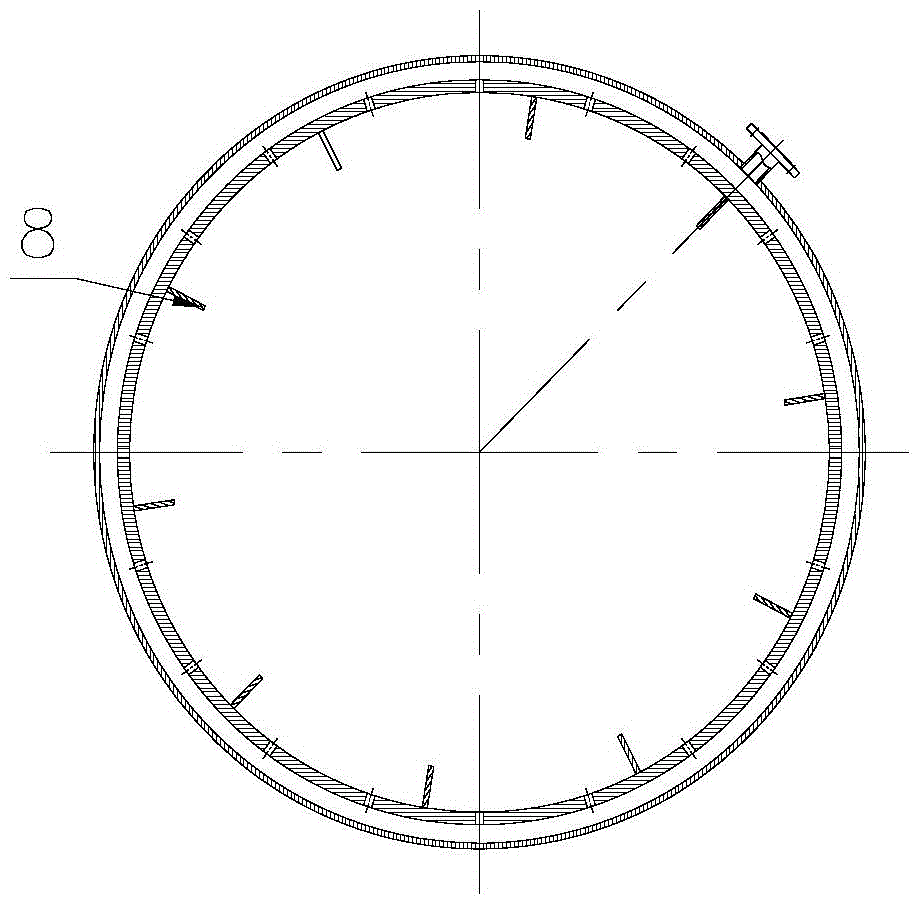

Vertical steel slag pressure hot-disintegration still kettle and slag processing method

ActiveCN105063255AFully digest free CaOImprove stabilityRecycling and recovery technologiesExternal energySlag

The invention relates to a vertical steel slag pressure hot-disintegration still kettle and a slag processing method. The still kettle and the slag processing method with the still kettle adopted are included. The still kettle comprises a top cover (1), a cylinder body (2), water spraying devices (3), safety devices (4), a water drainage device (5), an exhaust voltage stabilizing device (6), a safety monitoring device (7), a guide device (8), a slag tank (9), a slag tank support (10) and a gas replacement device (11). According to the vertical steel slag pressure hot-disintegration still kettle, steel slag is processed in an airtight pressure container through waste heat of the steel slag, no external energy source is consumed, no dust is generated, and the still kettle is efficient and environment-friendly, and saves energy; and in the processing process, water does not make contact with the melted steel slag, the pressure container is equipped with the safety devices, and the vertical steel slag pressure hot-disintegration still kettle and the slag processing method are safe and reliable.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +1

Short-flow processing method for beamed plush fabric

ActiveCN103757812AQuick contactEmission reductionSolvent-treatmentSucessive textile treatmentsPolyesterProcess engineering

The invention discloses a short-flow processing method for s beamed plush fabric. The processing method comprises the steps of weaving of a polyester drawn textured yarn raw material, air current dyeing, decolorizing and soft shaping. By adopting the short-flow processing method, the process flow is shortened by 60 percent, the processing cost is saved by 65 percent, energy is saved by 70 percent, water is saved by 50 percent, and sewage disposal is reduced by 50 percent.

Owner:JIANGSU WEIMIAO TEXTILE TECH CO LTD

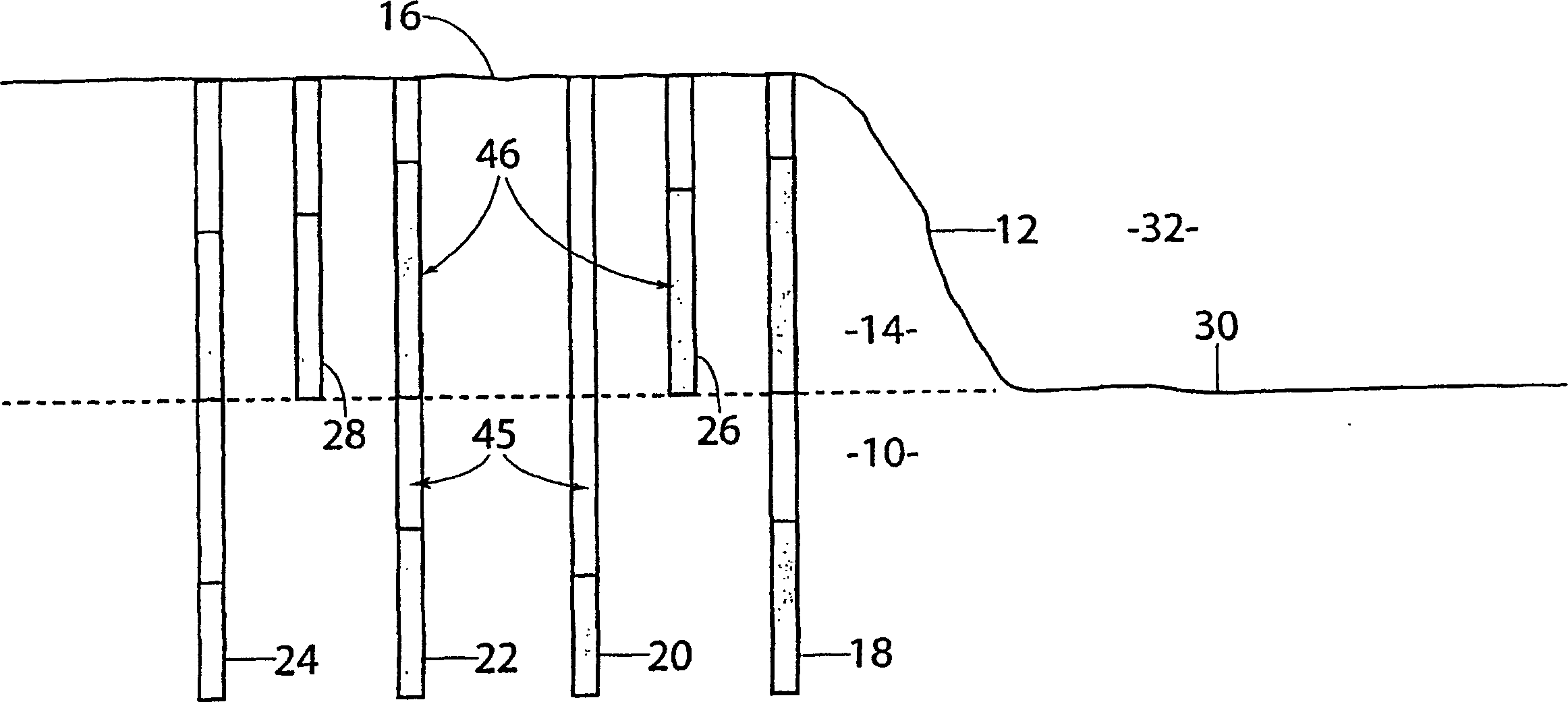

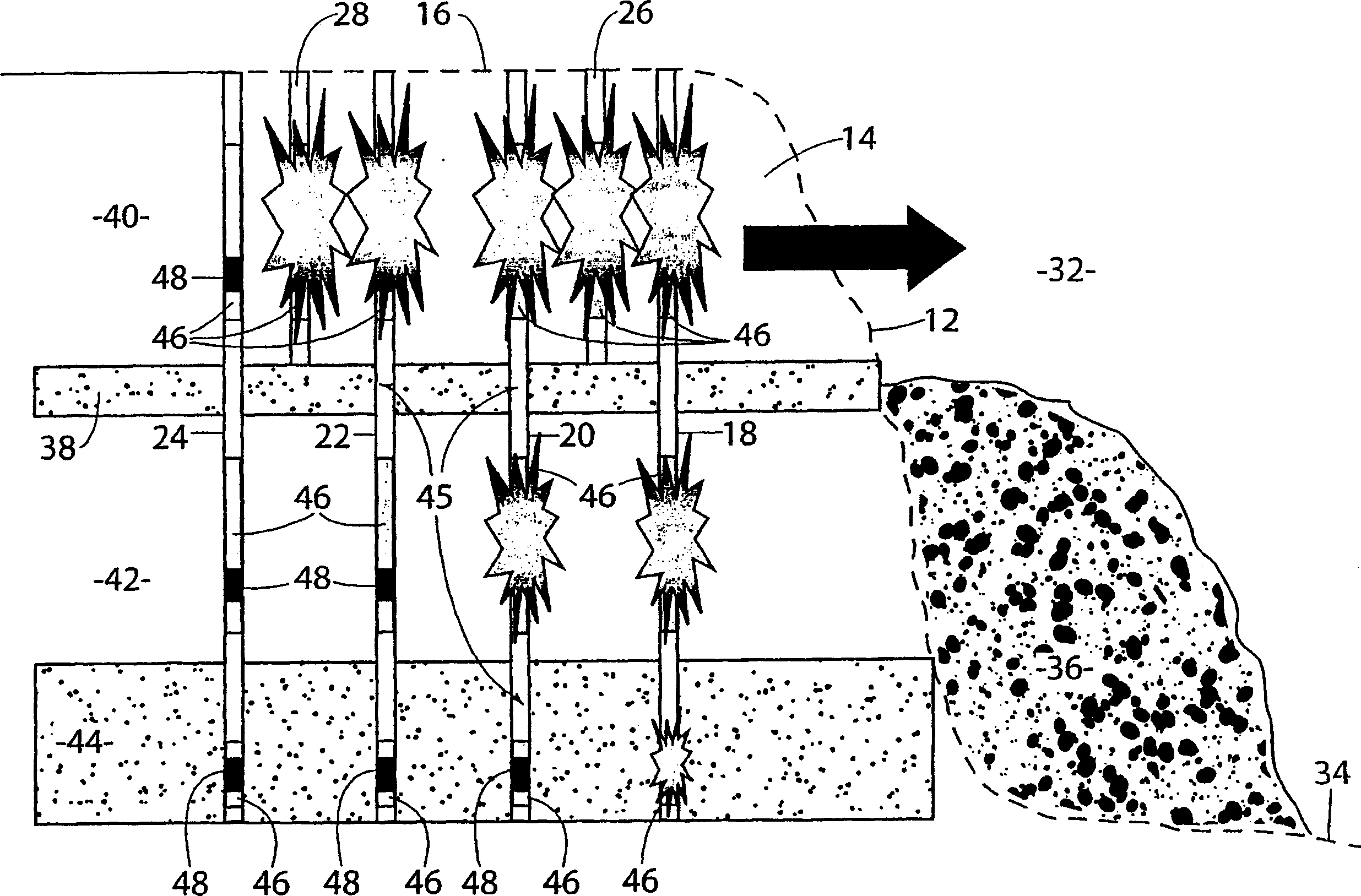

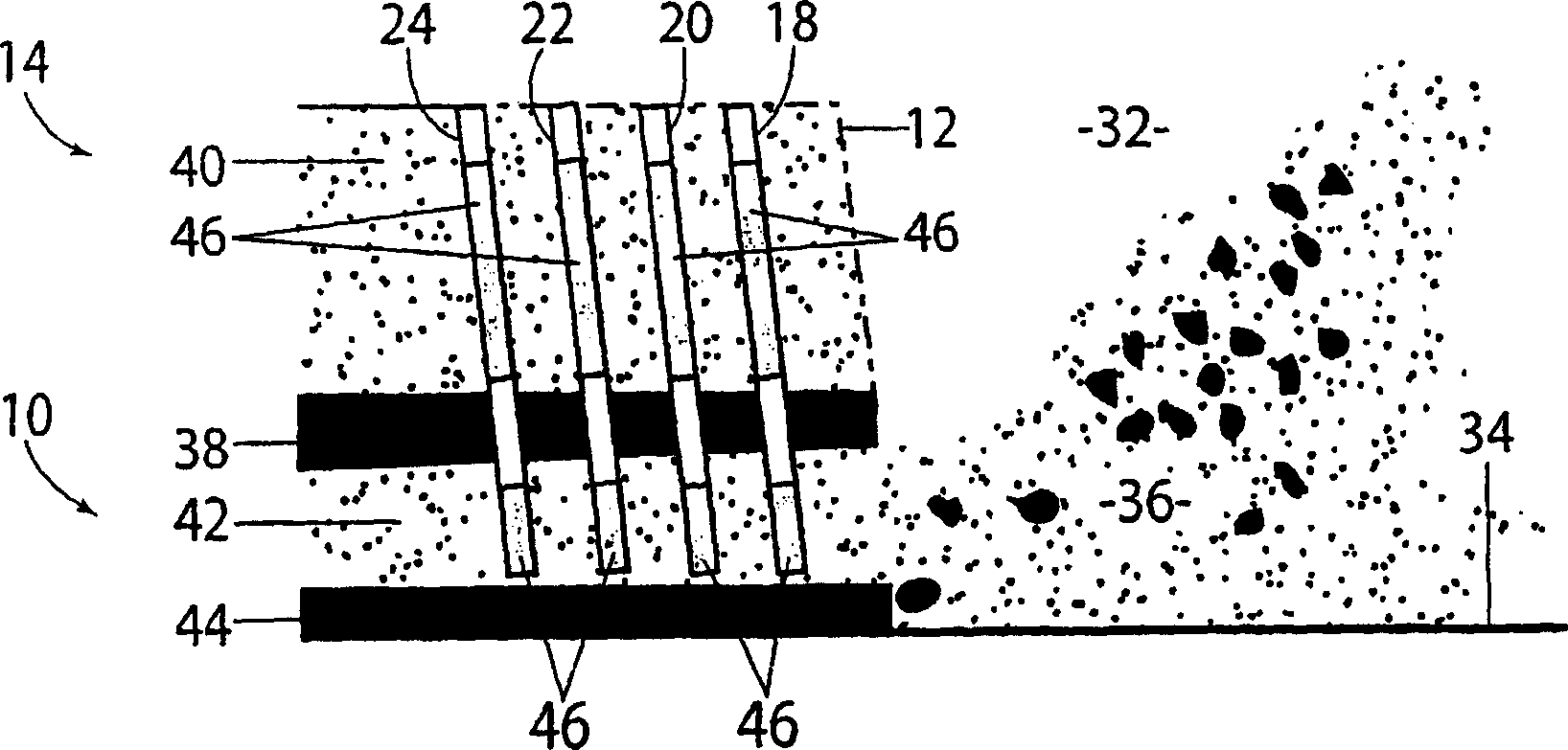

Method of blasting multiple layers or levels of rock

A method of blasting plural layers of material (38, 40, 42, 44) in a blastfield (16) that reduces the amount of mechanical excavation required to expose a lower layer of material. The method includes using rows of equally spaced blastholes (18, 20, 22, 24) that pass through all of the layers and additional intermediate rows of blastholes (26, 28) that pass down only through top layer (40). Each blasthole is capped with stemming material and includes one or more decks of explosives material (46) and detonators (48), with air decks or inert stemming (45) separating adjacent explosives decks (46). The detonators in layer (40) are detonated first in order from row (18) rearwards to throw a substantial amount of the blast material from layer (40) forwardly of free face (12) onto floor (34). In the same blasting cycle and within seconds of the throw blast, explosives material in layers (42, 44) is detonated in a stand-up blast in which material in layers (38, 42, 44) is broken up but otherwise minimally displaced or thrown forwardly. Layers (38, 44) may be coal seams which are separated by interburden layer (42) and covered by overburden layer (40).

Owner:ORICA EXPLOSIVES TECH PTY LTD

Enhanced disinfecting compositions for medical device treatments

InactiveUS20050261148A1High user complianceGreat universal appealBiocideOrganic active ingredientsMedical deviceContact lens

Owner:BAUSCH & LOMB INC

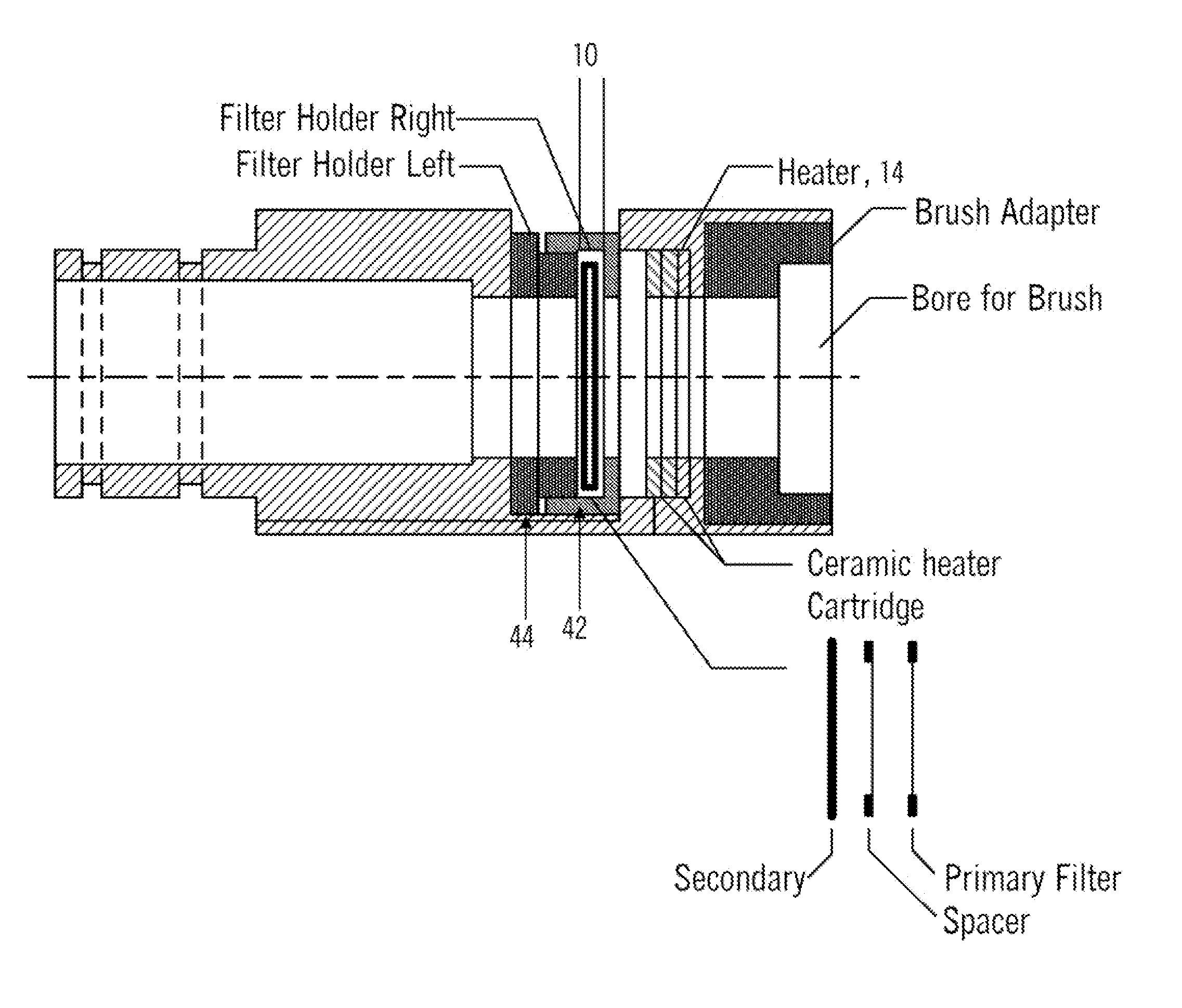

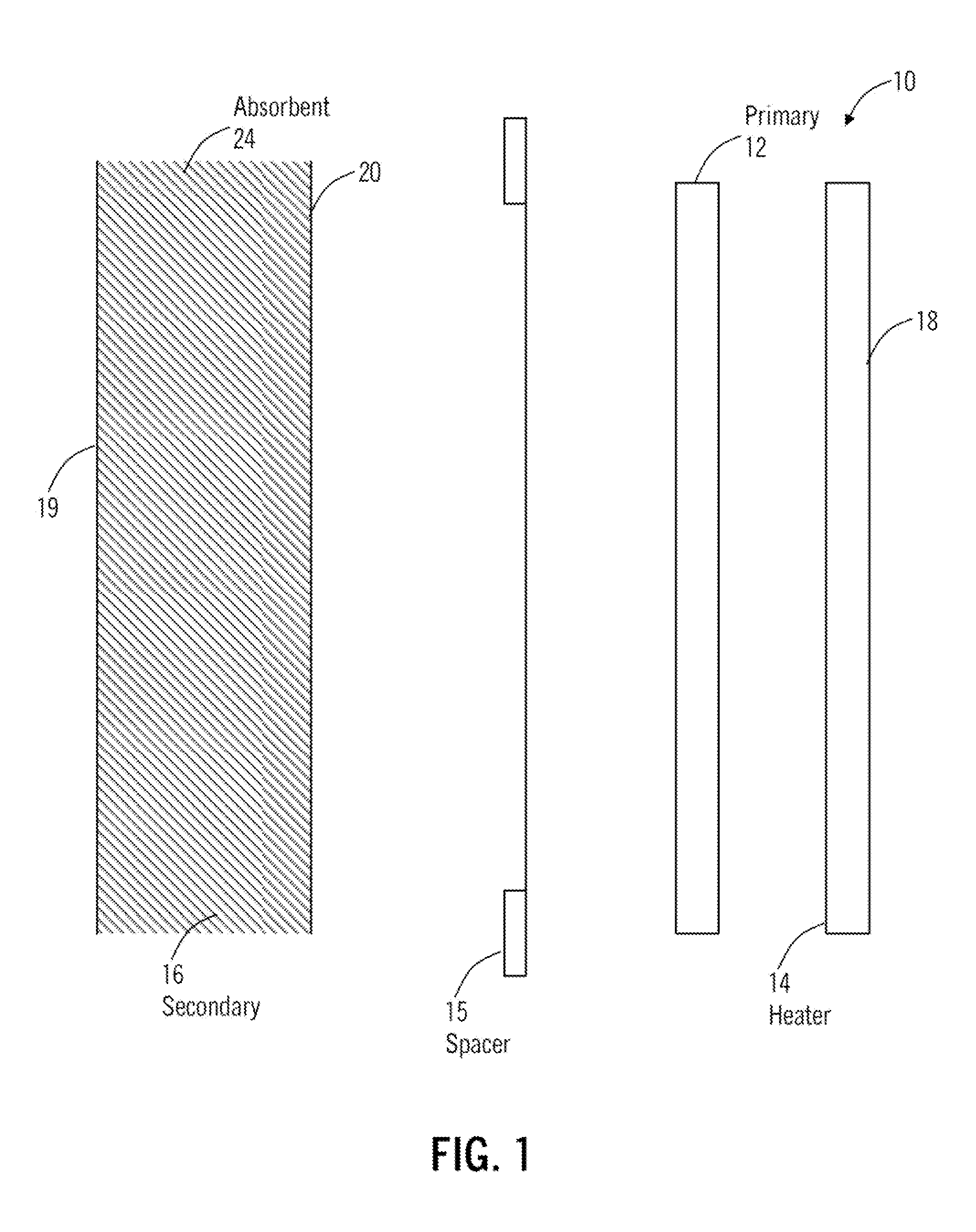

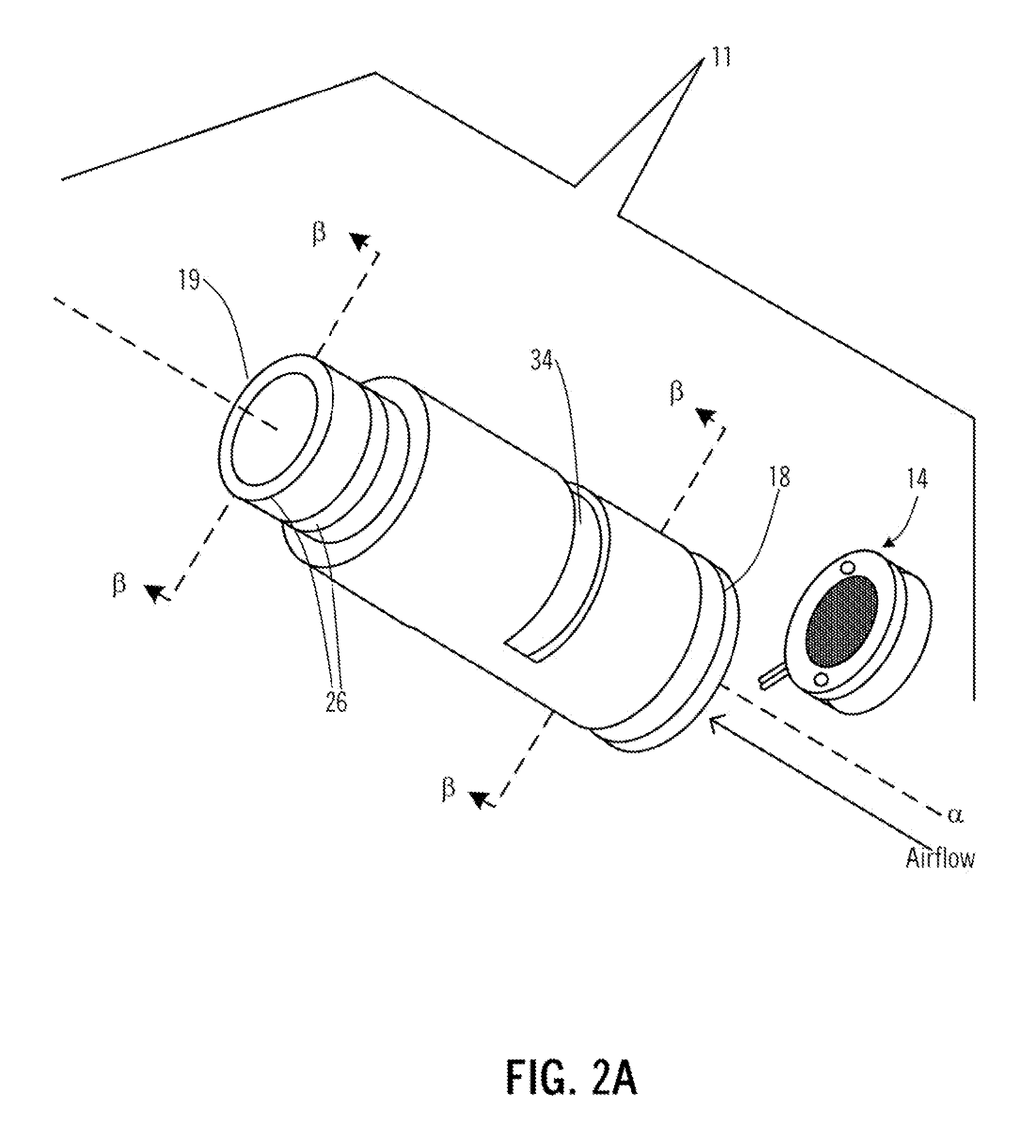

High volume sampling front end collection device

ActiveUS8578796B2Efficient and rapid collectionLow costWithdrawing sample devicesPreparing sample for investigationEngineeringHeating element

A device for sampling surfaces for the presence of compounds is provided, including a housing having a proximal end adapted to receive it negative pressure gradient and a distal end adapted to contact the surfaces; a heating element spaced from the distal end; a primary filter spaced from the heating element; and a secondary filter spaced from the primary filter, the secondary filter removably received by the housing. Also provided is as method for sampling a surface for the presence of compounds, the method including contacting the surface to dislodge the compounds from the surface; capturing first fractions of the compounds with a primary filter while allowing second fractions of the compounds to pass through the primary filter; heating the primary filter to volatilize the first fractions; capturing the volatized first fractions and the second fractions with a secondary filter; and analyzing the secondary filter to identify the compounds.

Owner:US DEPT OF HOMELAND SECURITY

Process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves

ActiveCN102727538AQuick contactAccelerated leaching extractionNervous disorderGinkgophyta medical ingredientsAfter treatmentBULK ACTIVE INGREDIENT

The present invention discloses a process for extracting ginkgo biloba flavone, ginkgo biloba lactone and ginkgo biloba phenolic acid from ginkgo biloba leaves. The process comprises the following steps: (1) carrying out a pretreatment on ginkgo biloba leaves; (2) carrying out extraction by an ultrasonic device; (3) carrying out reduced pressure concentration; (4) loading the resulting solution on a macroporous resin to carry out a treatment; (5) collecting the resulting eluate; (6) carrying out reduced pressure concentration; (7) detecting the resulting extract; and (8) carrying out drying and storing on the extract. With the process of the present invention, the ginkgo biloba flavone content and the ginkgo biloba lactone content in the extract prepared by the process of the present invention are high, the loss of active ingredients are avoided, the production process is simplified, the production cycle is shortened, and the ginkgo biloba phenolic acid content after treatment is substantially reduced.

Owner:JIANGSU EHAI PHARMA CORP

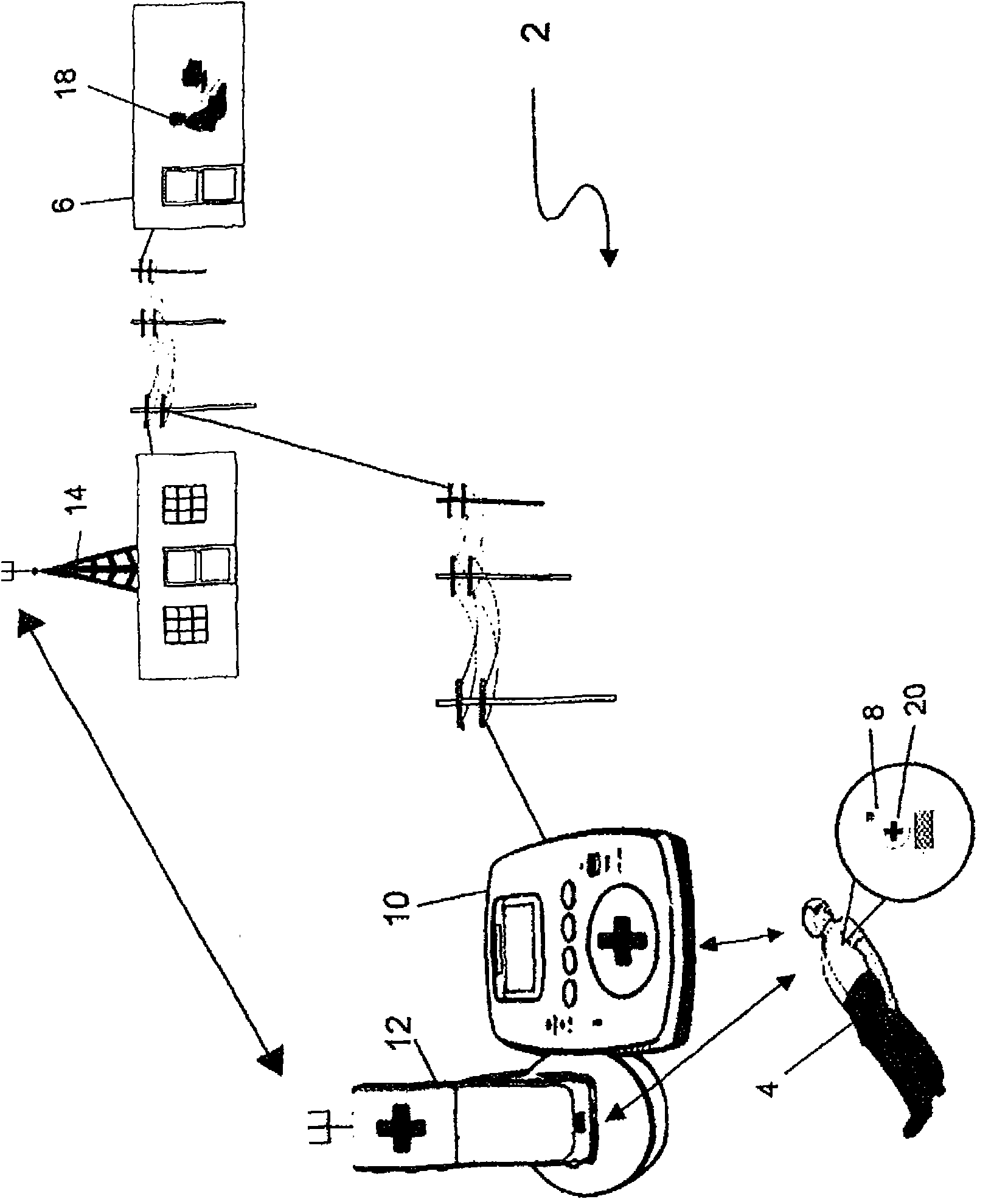

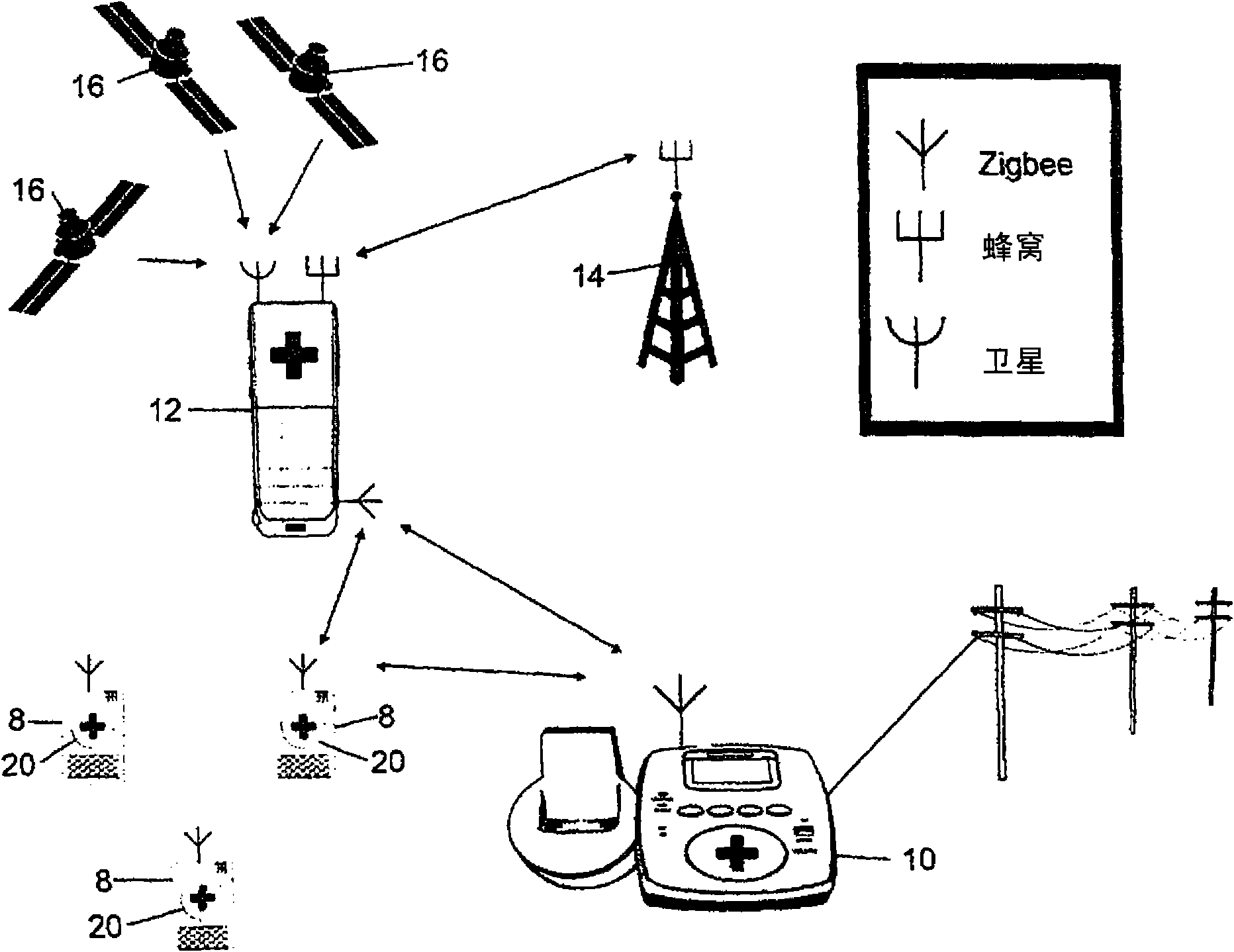

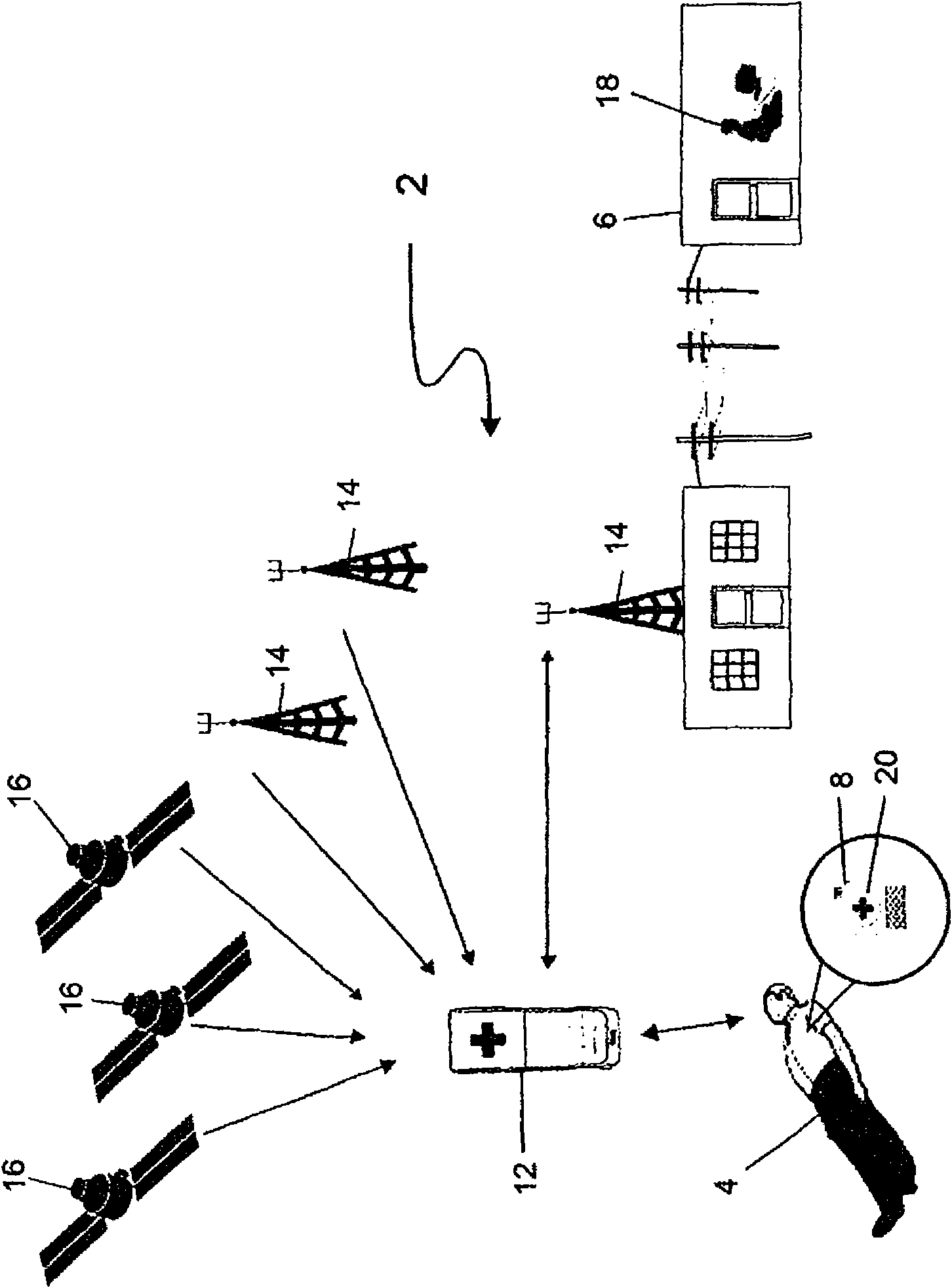

Pasition-based individual emergency responding system

Provided is a safety system inclduing a plurality of wearbale transceivers. The wearbale transceivers can be indepent from a plurality of telephones and cell phones based on land lines for operation, so that connection is established between the wearbale transceivers and a central monitoring station. The wearbale transceivers are used for sensing bumping or falling, informing the monitoring station the accidents via the telephones or cell phones based on land lines, and determining the position of the accidents with the help of a GPS. Unless the wearbale transceivers stay in an inactivated state by pressing a commubication button, the infomation is about to be provided to a monitor within a short preset time after activation. If the wearbale transceivers are activatated not by bumping or falling, a user can press the communication button to establish communication with the monitoring state, such that services with various types are obtained. The invention also discloses a cell phone with functions of a spare battery, an accelerator and an auxiliary GPS.

Owner:VAUCAIRE

Method and device for treating and maintaining black and odorous water body by inoculating with activated sludge

ActiveCN106865754AStable operation managementMaintain ecological balanceClimate change adaptationEnergy based wastewater treatmentActivated sludgeAmmoniacal nitrogen

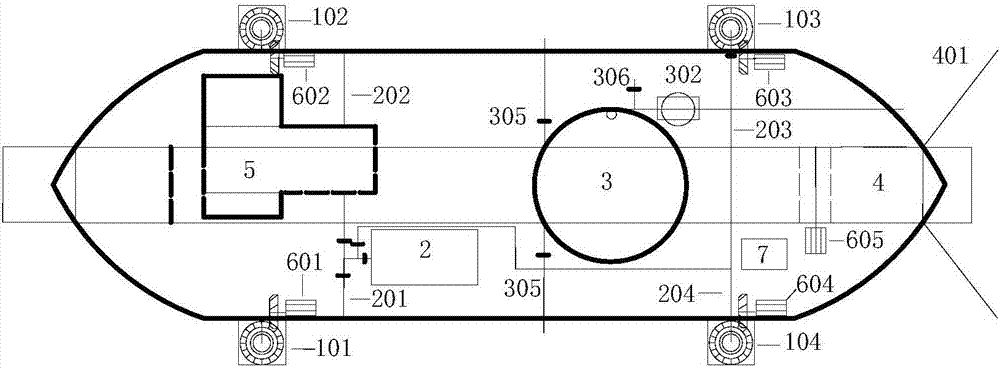

The invention discloses a method and device for treating and maintaining a black and odorous water body by inoculating with activated sludge, and belongs to the technical field of water environment control. According to the method and device for treating and maintaining the black and odorous water body by inoculating with the activated sludge, the black and odorous water body is treated synchronously by ''inoculating with the activated sludge and planting floating plants'', the amount of active microorganisms with degradability in the water body is increased, the removal effect of organic pollutants in the water body is improved and the nutrient pollution ammonia nitrogen concentration is reduced; and the device for treating and maintaining the black and odorous water body is a workboat which integrates the functions of activated sludge addition, sediment collection, ventilation and oxygenation, mixing of sludge and water, floating plant collection and transmission, compression and dehydration and the like, conducts in-situ control and remediation without destructive work on the water ecology, and has broad application prospects in the field of black and odorous water body control.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Continuous processing technology for non-shrink treatment of chlorine-free wool top and wool product

ActiveCN105986484AQuick contactAct quicklySucessive textile treatmentsSolvent-treatmentWater chlorinationPulp and paper industry

Owner:天津市诺奥科技发展股份有限公司

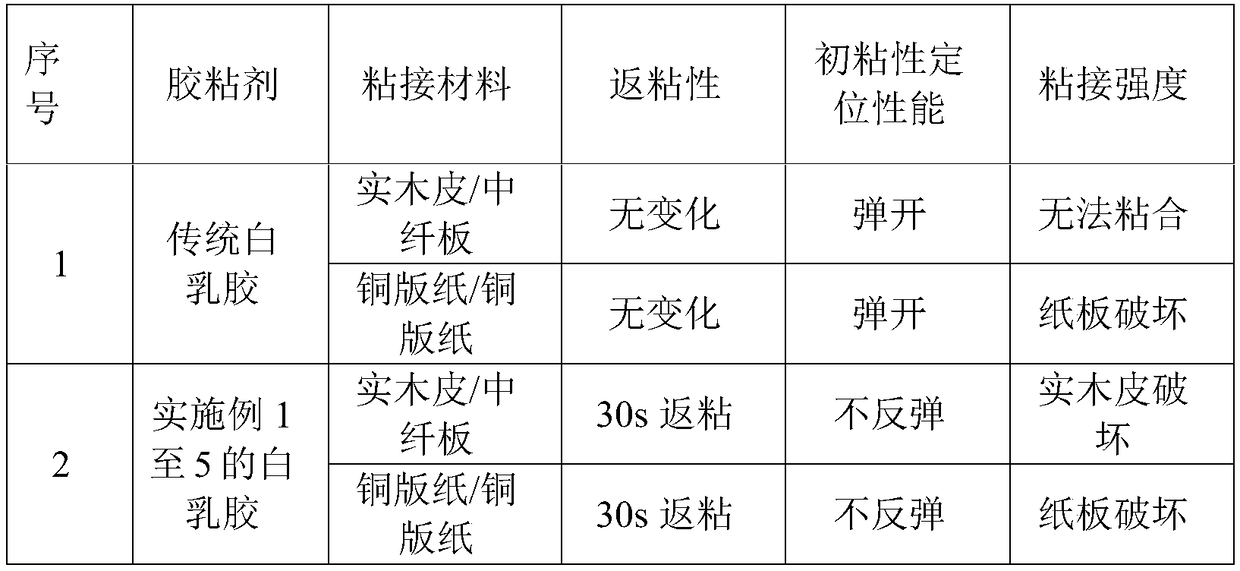

Rewetting repairable modified waterborne white latex and preparation method thereof

ActiveCN109306250ASolve irreparable technical problemsSensitive rehumidity responseMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPersulfateAdhesive

The invention relates to the technical field of waterborne adhesives and in particular relates to rewetting repairable modified waterborne white latex and a preparation method thereof. A formula comprises the following components: 35.0 to 50.0 parts of de-ionized water, 10.0 to 20.0 parts of protective colloid polyvinyl alcohol, 0.5 to 2.5 parts of a non-ionic emulsifier, 0.5 to 2.5 parts of a buffering agent, 0.5 to 1.5 parts of a persulfate initiator, 0.01 to 0.05 part of a chain transfer agent dodecyl mercaptan, 25.0 to 54.0 parts of vinyl acetate, 5.0 to 15.0 parts of butyl acrylate, 5.0 to 15.0 parts of a carboxyl-containing polymerizable monomer, a crosslinking agent and the like. Compared with the prior art, the white latex provided by the invention can be used for realizing secondary adhesion through the effect of water and the technical difficult in the prior art that the white latex cannot be repaired after the white latex is cured into a film is overcome; the wet-state adhesion performance of the white latex is greatly improved; the rewetting repairable modified waterborne white latex has the advantages of rapid rewetting viscosity response, good initial adhesion positioning and high bonding strength.

Owner:DONGGUAN STAR COSM POLYMER

Deburring machine

ActiveCN104339236AQuick contactImprove deburring efficiencyEdge grinding machinesGrinding drivesSpeed reductionElectric machine

The invention discloses a deburring machine. The deburring machine comprises a loading station, a plane abrasion station and a teeth sweeping station, wherein the three stations are respectively and correspondingly provided with a loading mechanism, a plane abrasion mechanism and a teeth sweeping mechanism. The deburring machine also comprises a station shifting mechanism for transferring workpieces from the previous station to the next station; the plane abrasion mechanism comprises a first motor, a speed reduction transmission mechanism connected with the first motor, a grinding wheel, a revolution adapting piece and a rotation driving piece, wherein the revolution adapting piece is connected with an output shaft of the speed reduction transmission mechanism; the rotation driving piece and the revolution adapting piece rotate relative to each other; the rotation driving piece is eccentric to the output shaft of the speed reduction transmission mechanism; the grinding wheel is concentrically connected with an output shaft of the rotation driving piece. By adopting the structure, the grinding wheel simultaneously does revolution motion and rotation motion in the operating process, and the motion track forms an envelope line track, thus, the workpieces are conveyed to the lower part of the grinding wheel by virtue of the clamping mechanism, and the operating surface of the grinding wheel can be quickly in contact with the end surfaces of the workpieces, therefore the deburring efficiency is greatly improved.

Owner:HUBEI AVIATION PRECISION MASCH TECH CO LTD

High-power direct current engine comprising a collector and carbon brushes for a racing car serving as prototype

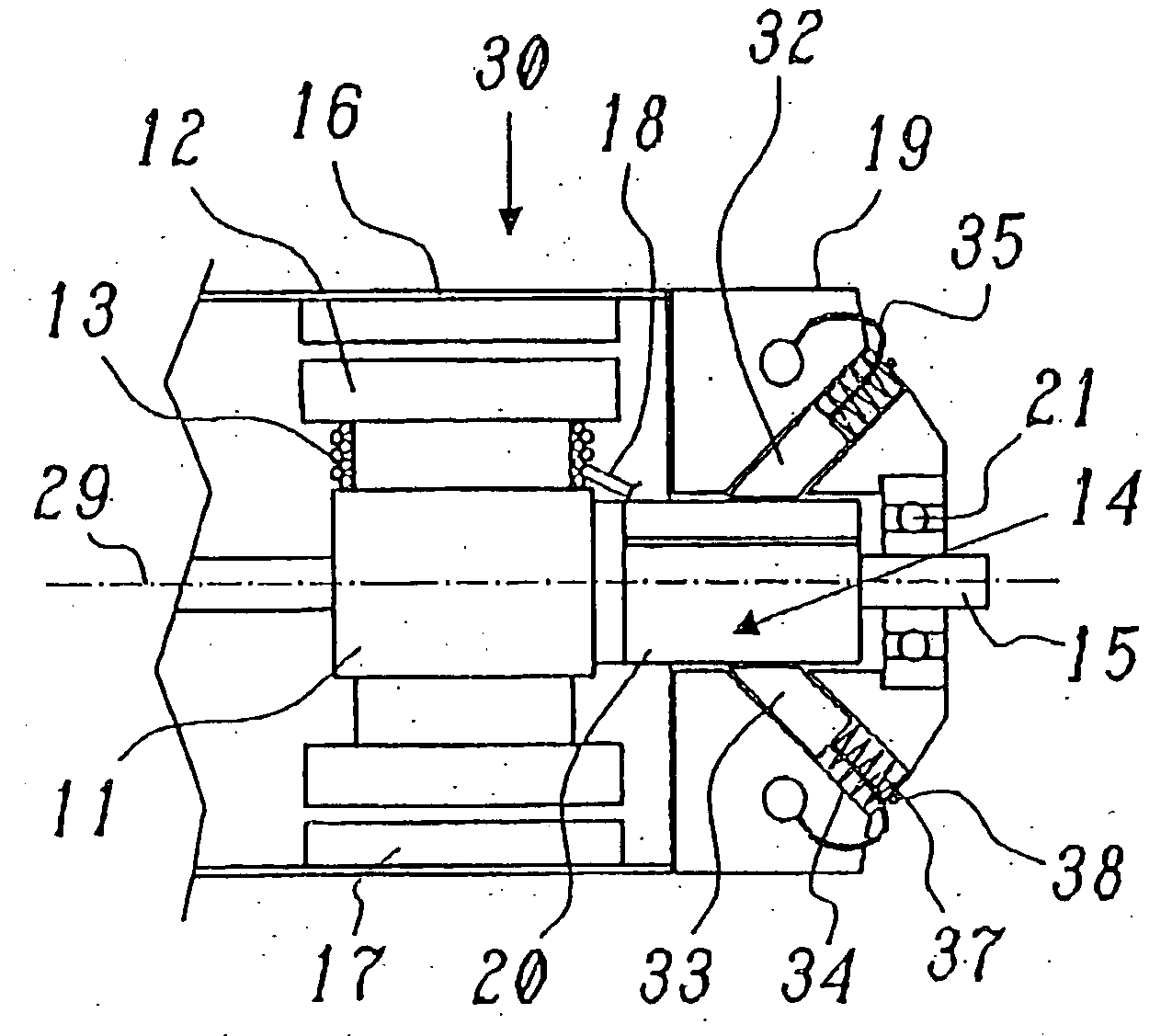

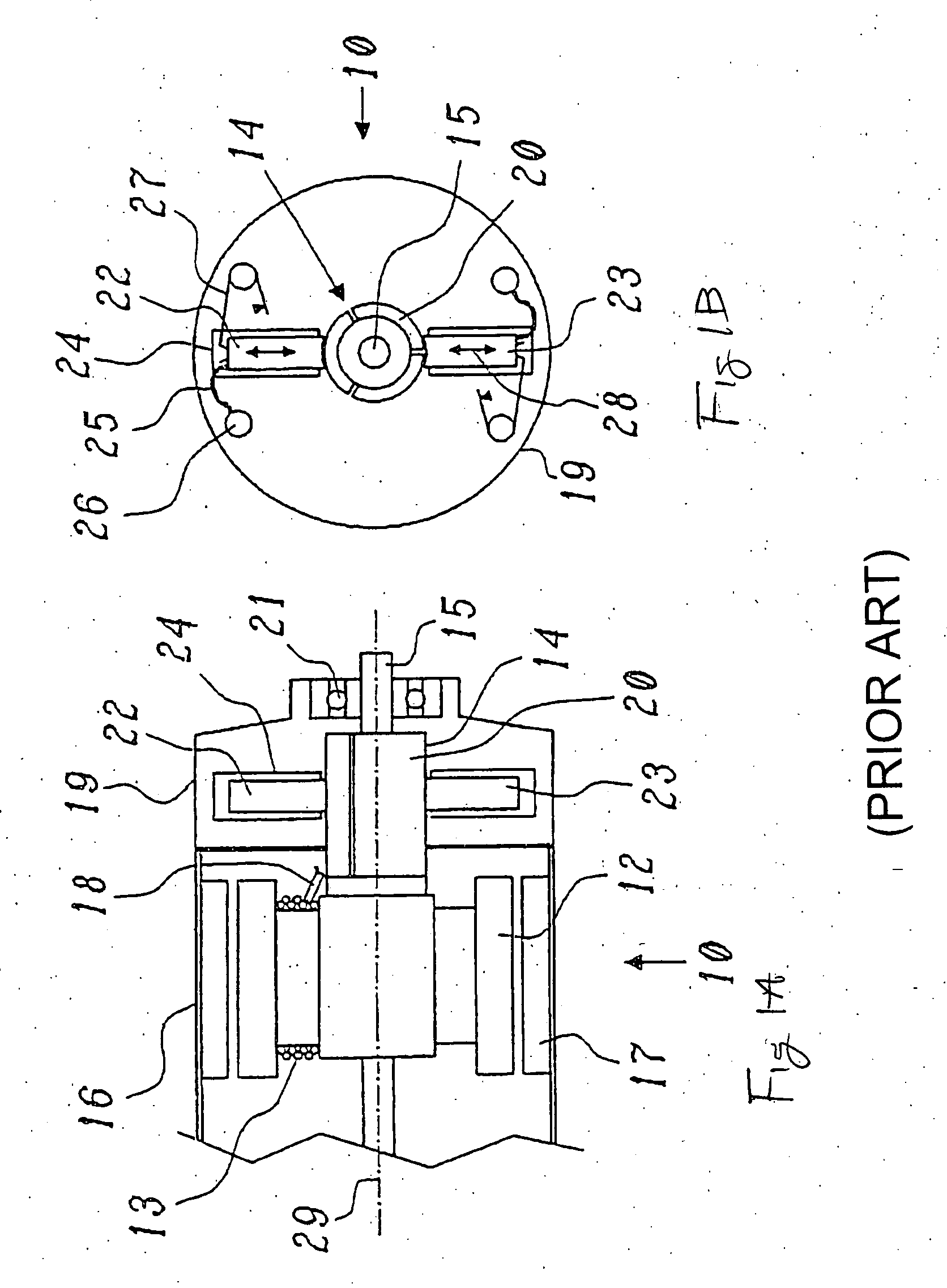

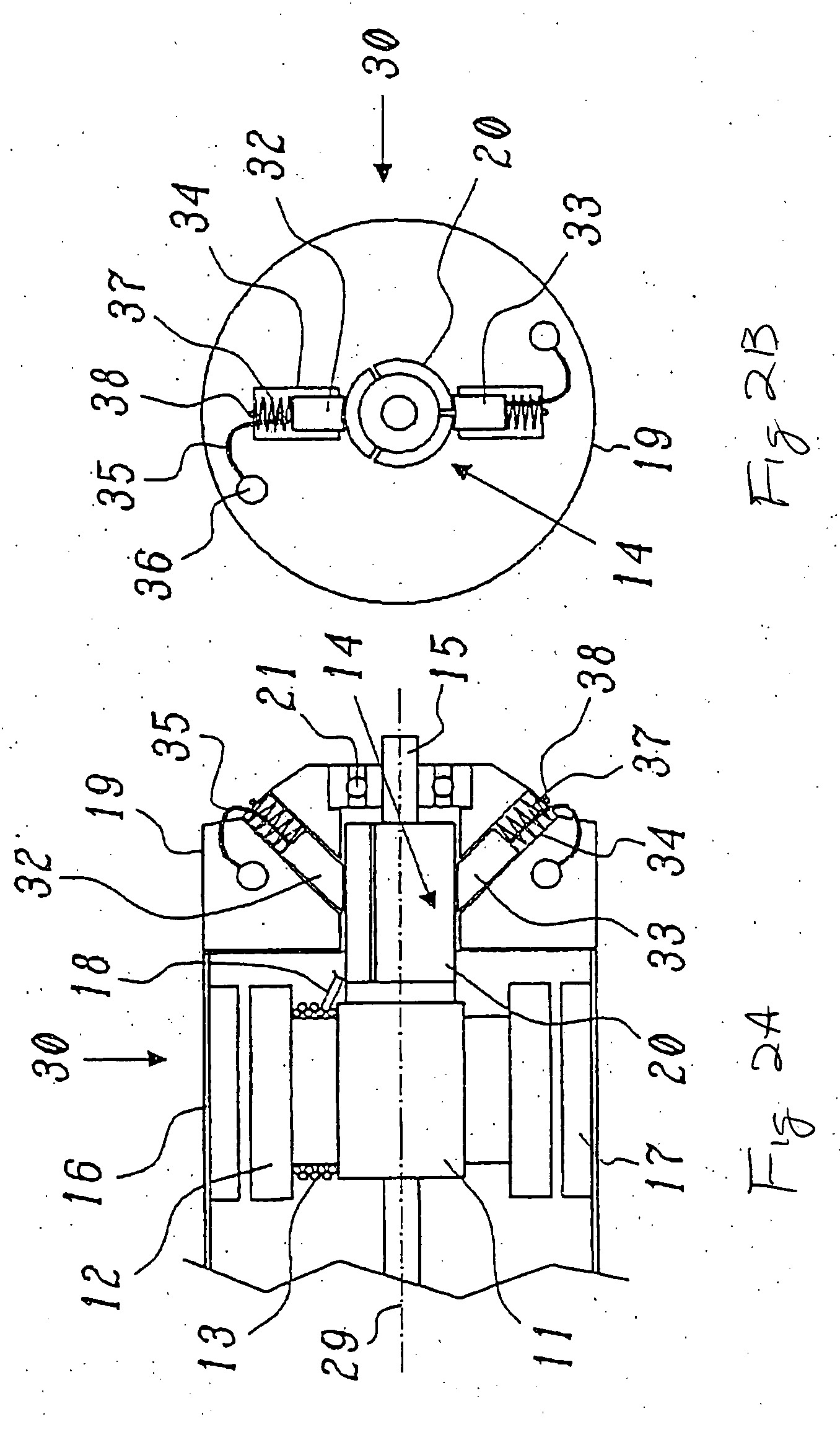

InactiveUS20050029895A1Reduce electric resistanceReduce total motor powerRotary current collectorToysMechanical engineeringDirect current

A DC motor includes a rotor which is mounted in a housing so that it can rotate about an axis. The rotor includes at least one winding to which direct current is applied from the outside in alternating directions via a commutator, which is arranged on the rotor. Brushes are seated on the commutator and are mounted whereupon they can move relative to the commutator while being pushed by spring pressure onto the commutator.

Owner:TEAM ORION EURO

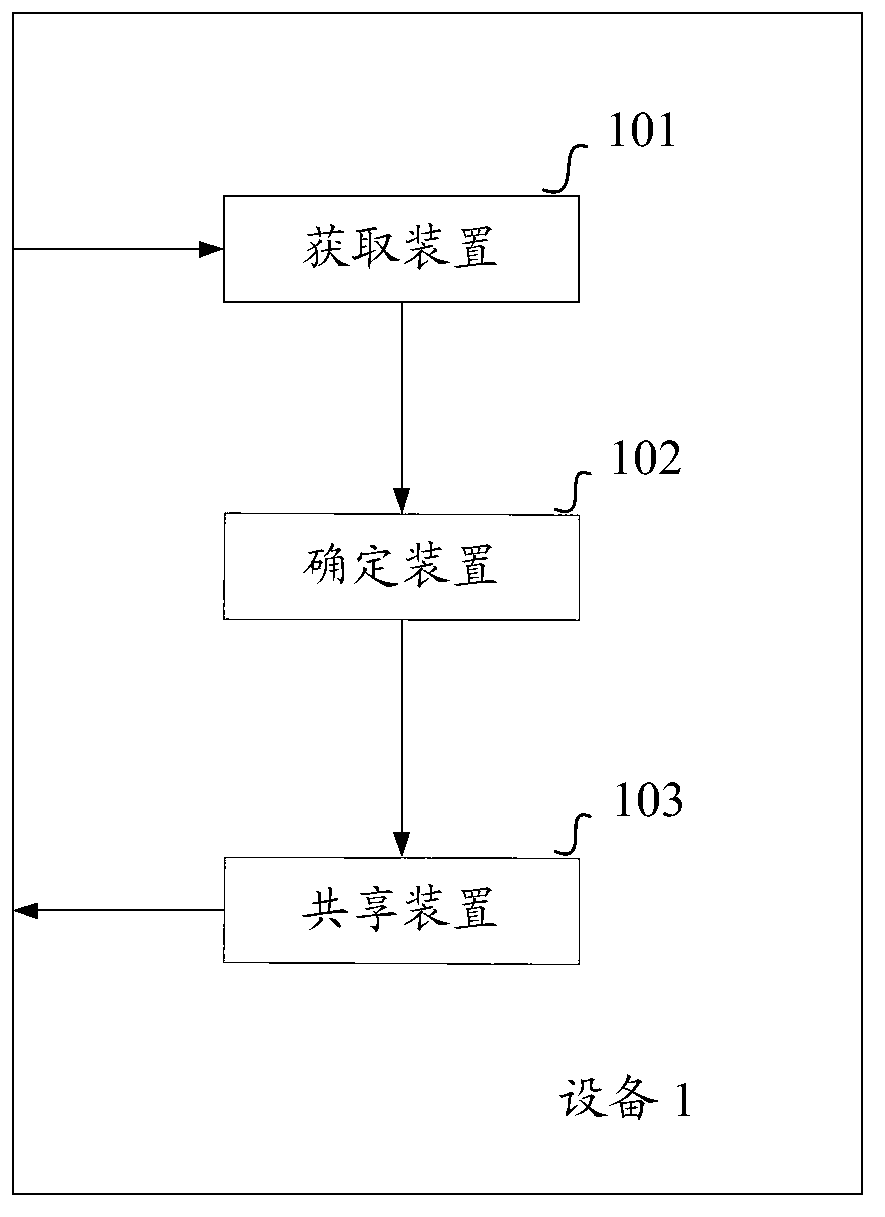

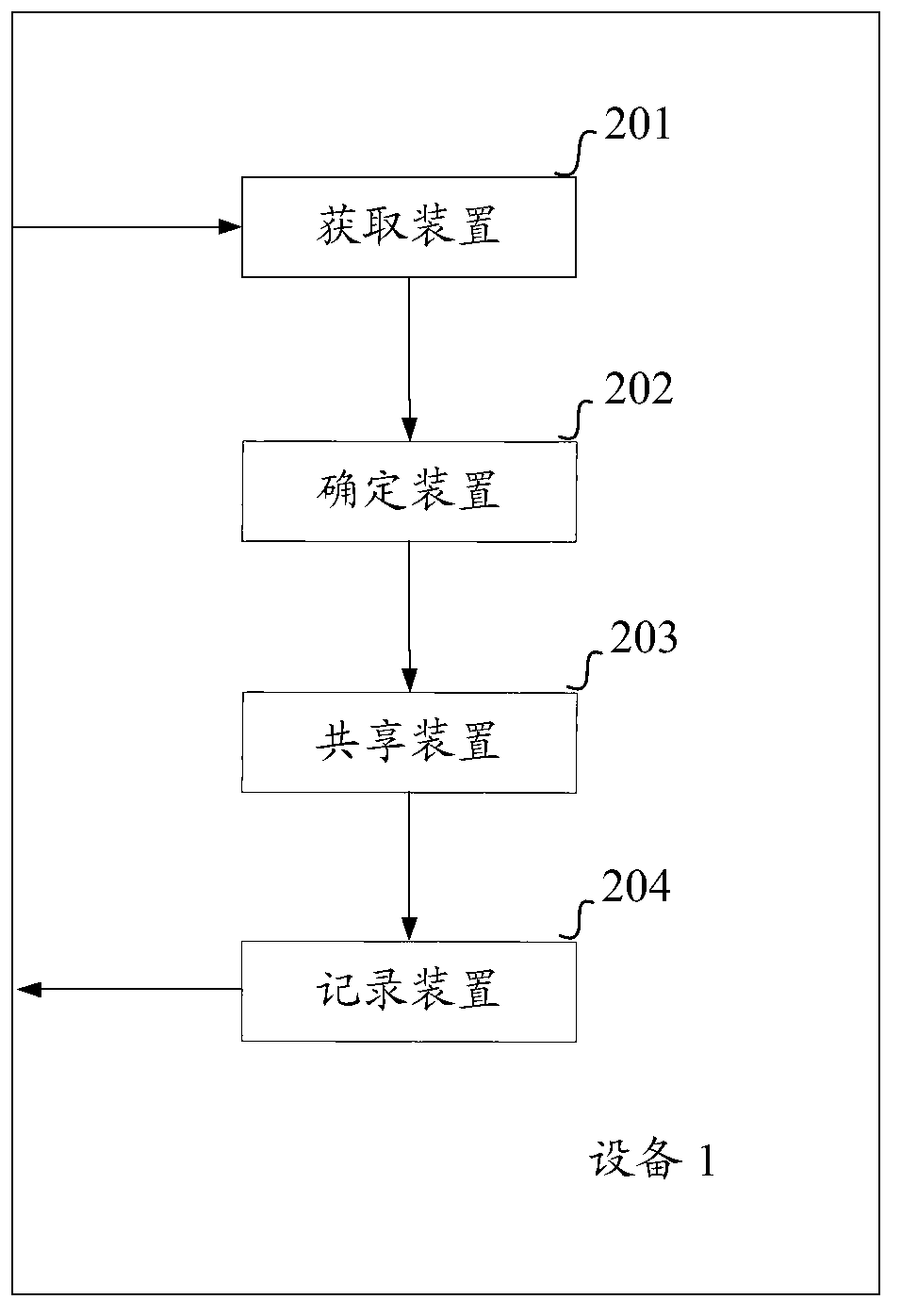

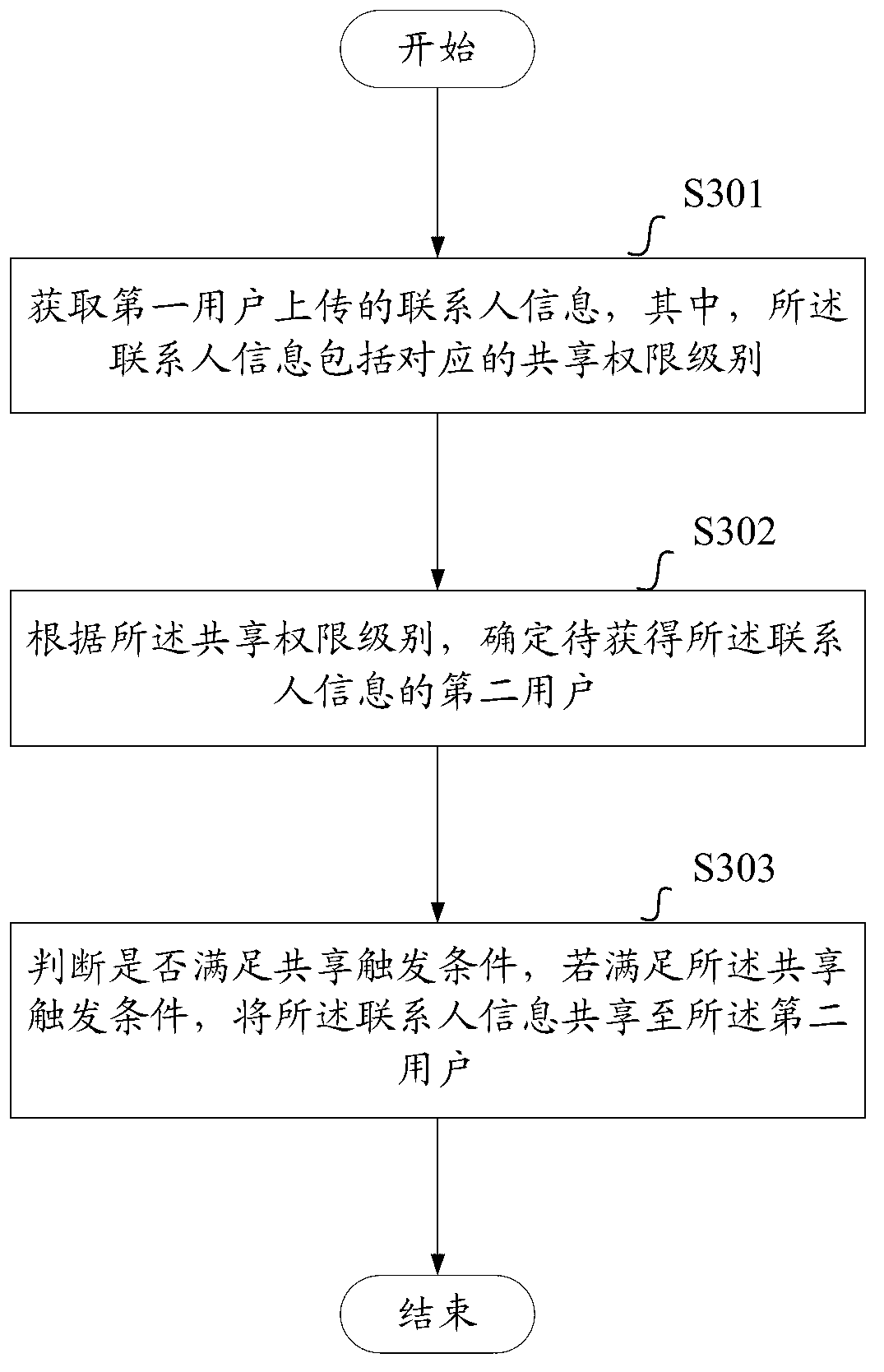

Contact person information sharing method and equipment based on sharing permission level

ActiveCN103327013AIncrease stickinessLow costData switching networksInformation sharingCommunications software

The invention provides a contact person information sharing method and equipment based on a sharing permission level. The method includes obtaining contact person information uploaded by a first user, wherein the contact person information includes the corresponding sharing permission level; confirming a second user to obtain the contact person information according to the sharing permission level; judging whether sharing triggering conditions are met, and if the answer is positive, sending the contact person information to the second user. Compared with the prior art, the contact person information sharing method and equipment confirms the second user to obtain the contact person information on the basis of the sharing permission level of the contact person information uploaded by the first user, sends the contact person information to the second user when the sharing triggering conditions are met, achieves safe interaction of the contact person information, improves information sharing efficiency and improves use experience of users, and the users of communication software can mutually share contact information safely.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com