Patents

Literature

2662 results about "Water chlorination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water chlorination is the process of adding chlorine or chlorine compounds such as sodium hypochlorite to water. This method is used to kill certain bacteria and other microbes in tap water as chlorine is highly toxic. In particular, chlorination is used to prevent the spread of waterborne diseases such as cholera, dysentery, and typhoid.

Biocidal applications of concentrated aqueous bromine chloride solutions

Methods for disinfecting surfaces and for sanitizing bodies of water using a single-feed, bromine-based biocide are described. These methods use concentrated liquid biocide compositions comprising biocidally active bromine as the biocide. Also described is a process of producing the concentrated liquid biocide composition: mixed together are (a) bromine chloride and (b) an aqueous solution of alkali metal salt of sulfamic acid having a pH of at least about 7, in amounts such that (i) the active bromine content of the composition is at least about 100,000 ppm (wt / wt), and (ii) the atom ratio of nitrogen to active bromine in the composition is greater than 0.93. Use of bromine chloride as the source of the active bromine in the process is advantageous because in the resulting aqueous compositions, all of the bromine of the bromine chloride is made available as active bromine in solution. In other words, the chlorine of the bromine chloride is converted in the process to dissolved alkali metal chloride salt, thereby liberating all of the bromine as the active bromine content of the biocidal composition.

Owner:ALBEMARLE CORP

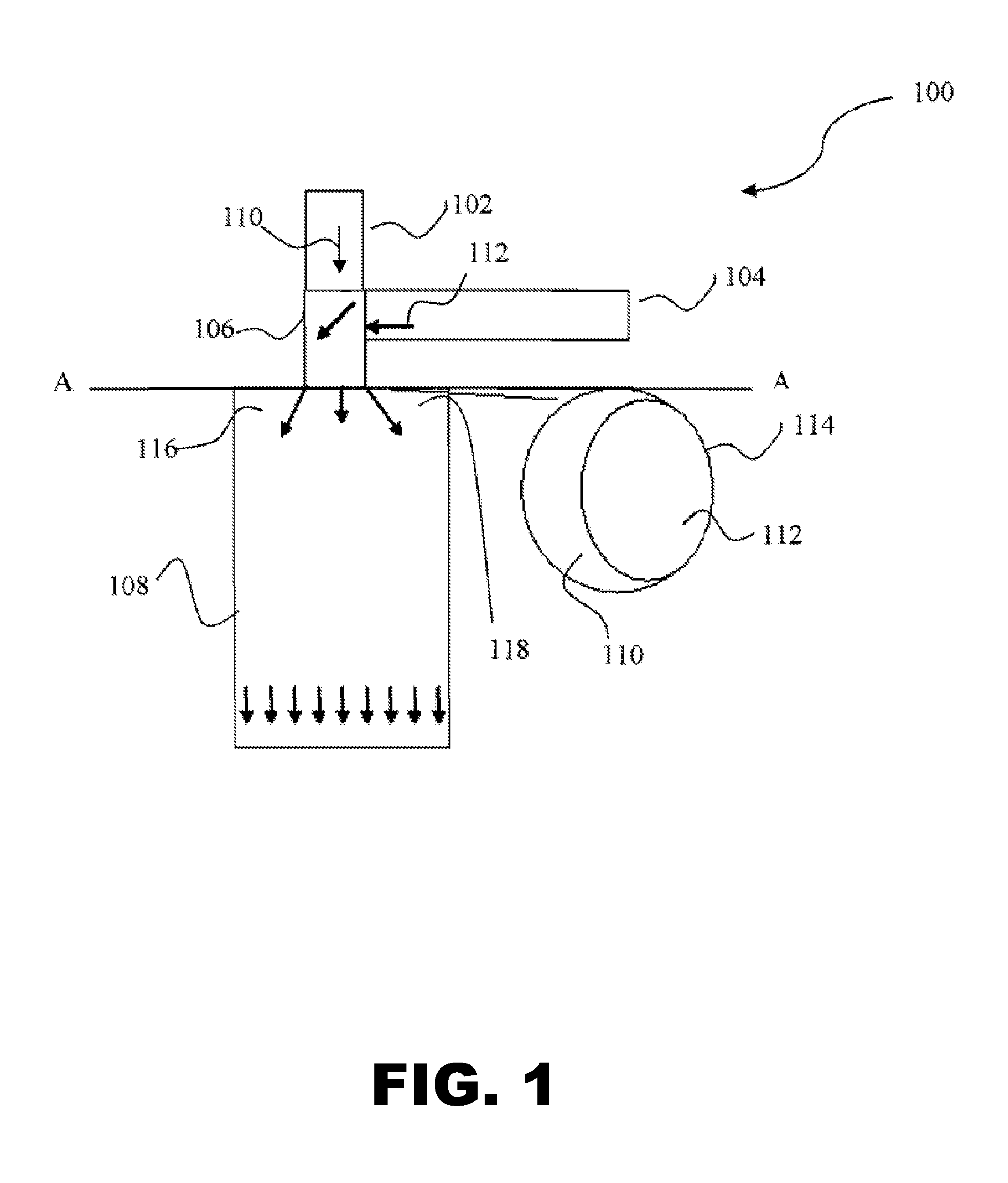

Gravity feed water treatment system

ActiveUS20110303589A1Increase flow rateHigh flow rateTreatment using aerobic processesTreatment involving filtrationFlocculationSiphon

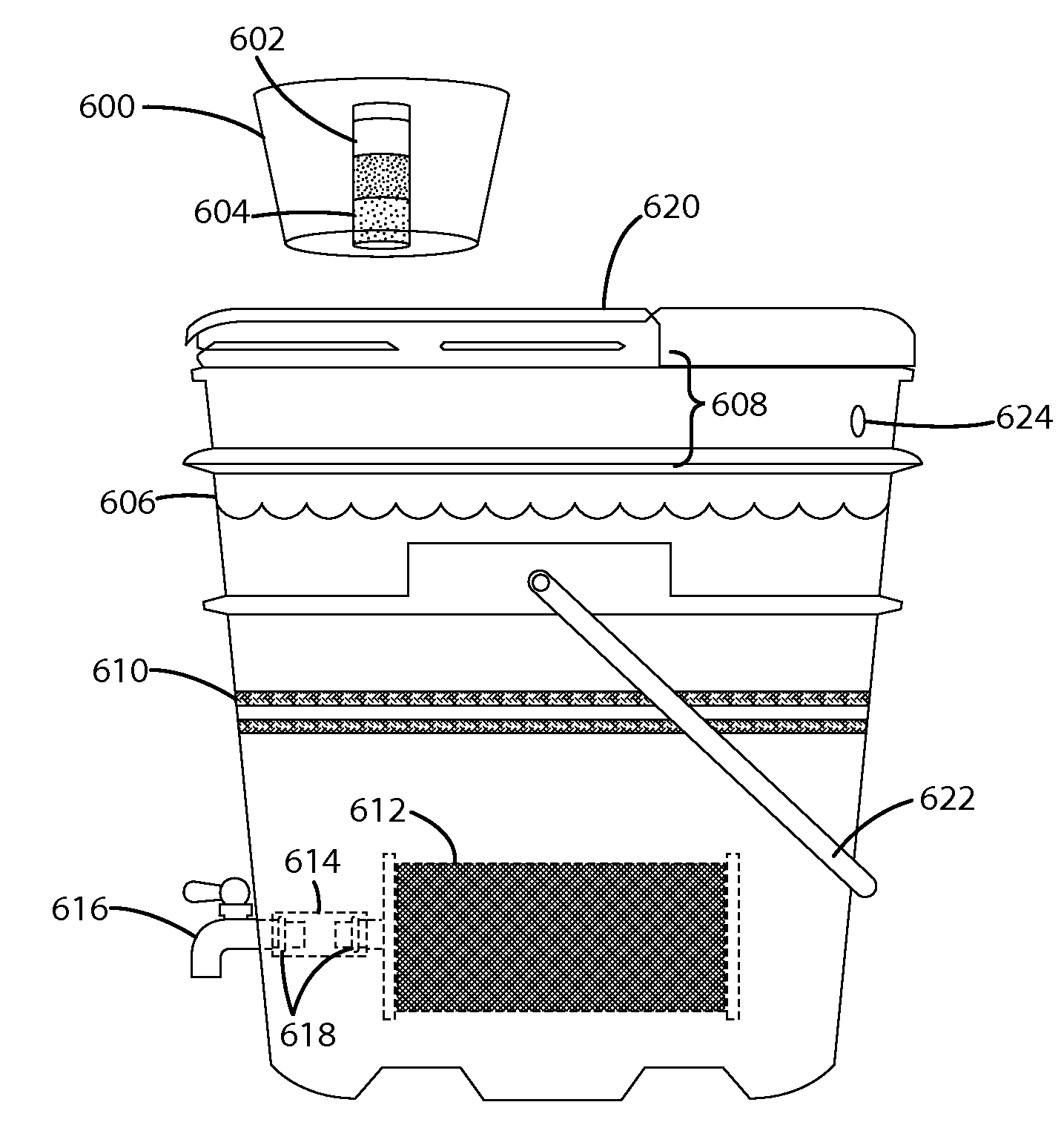

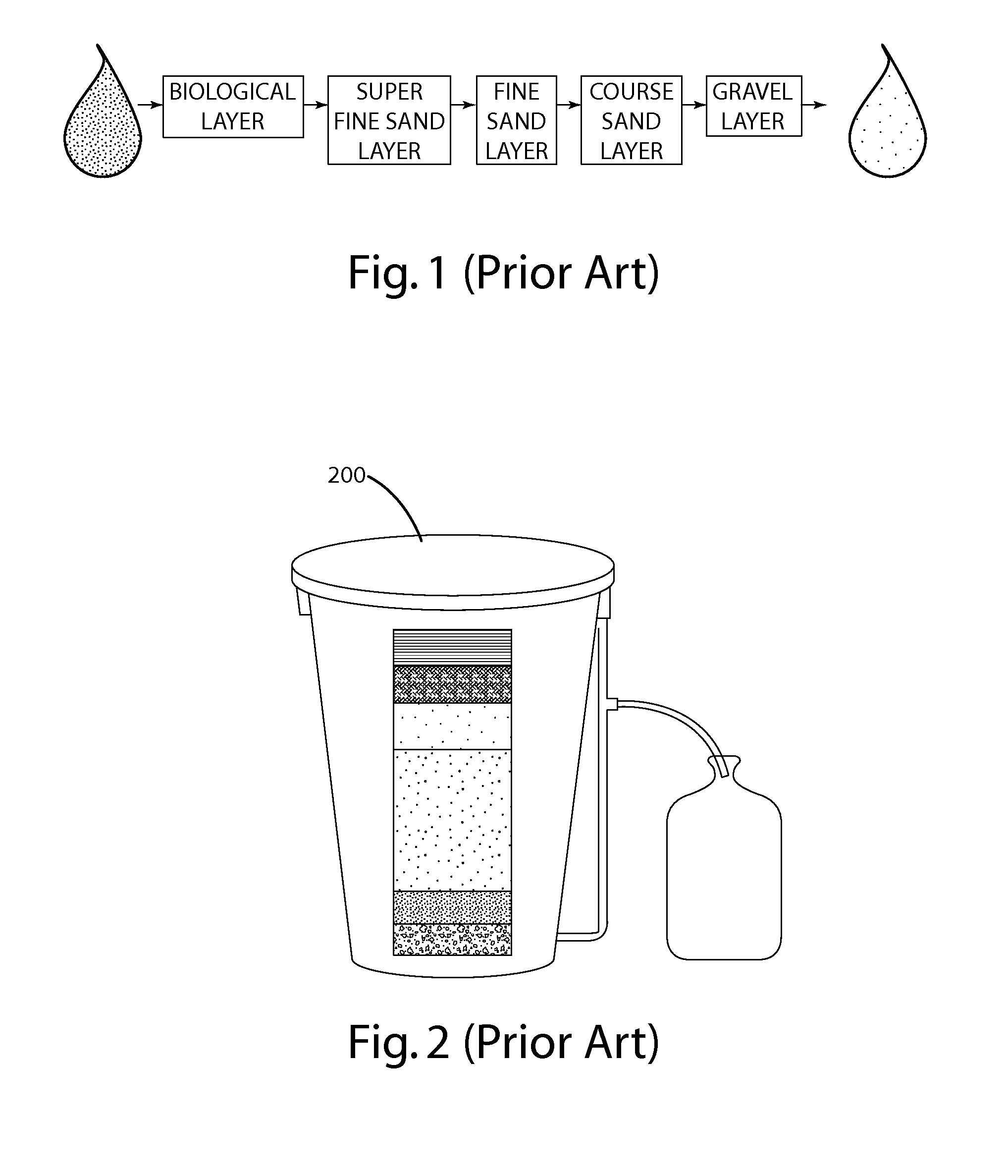

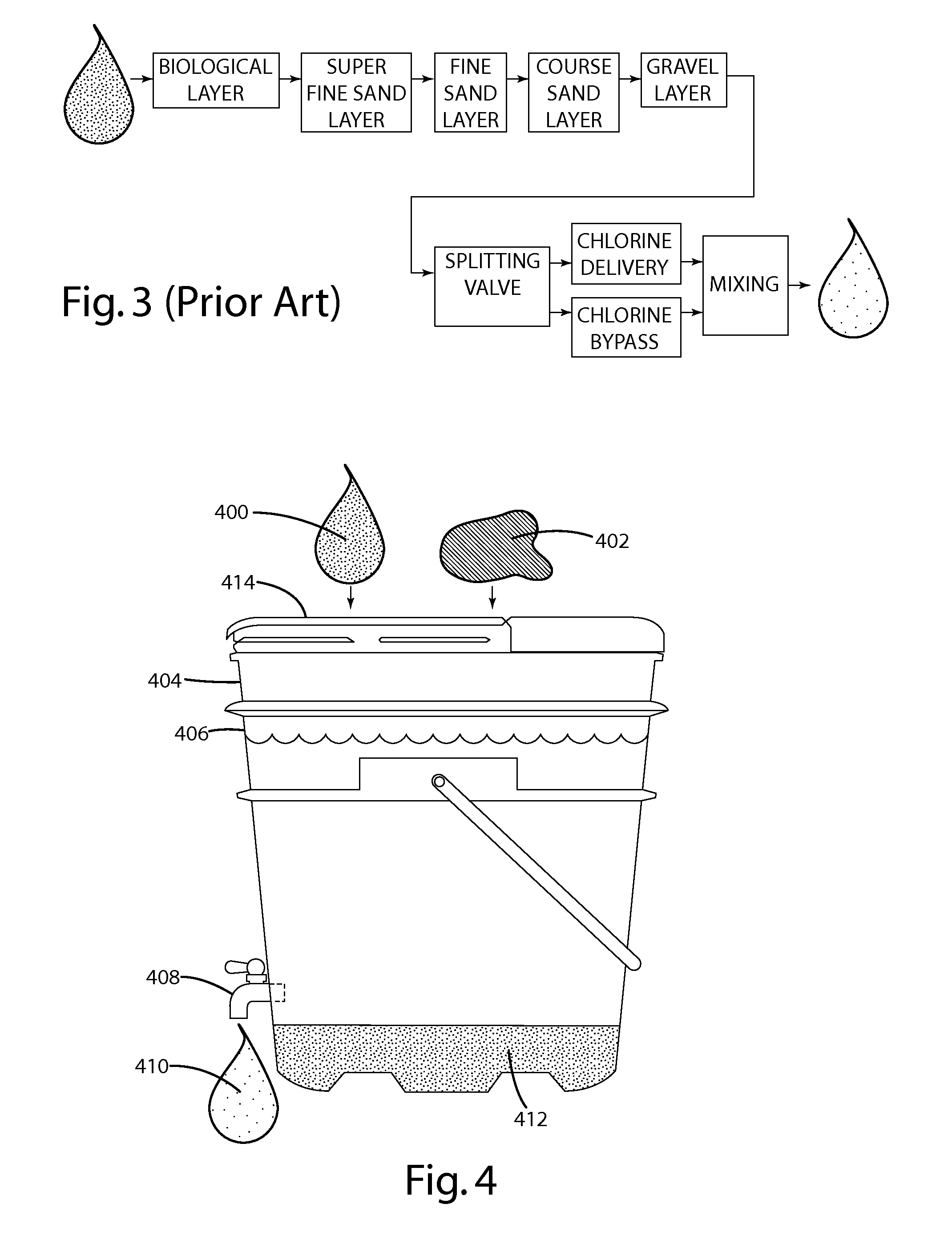

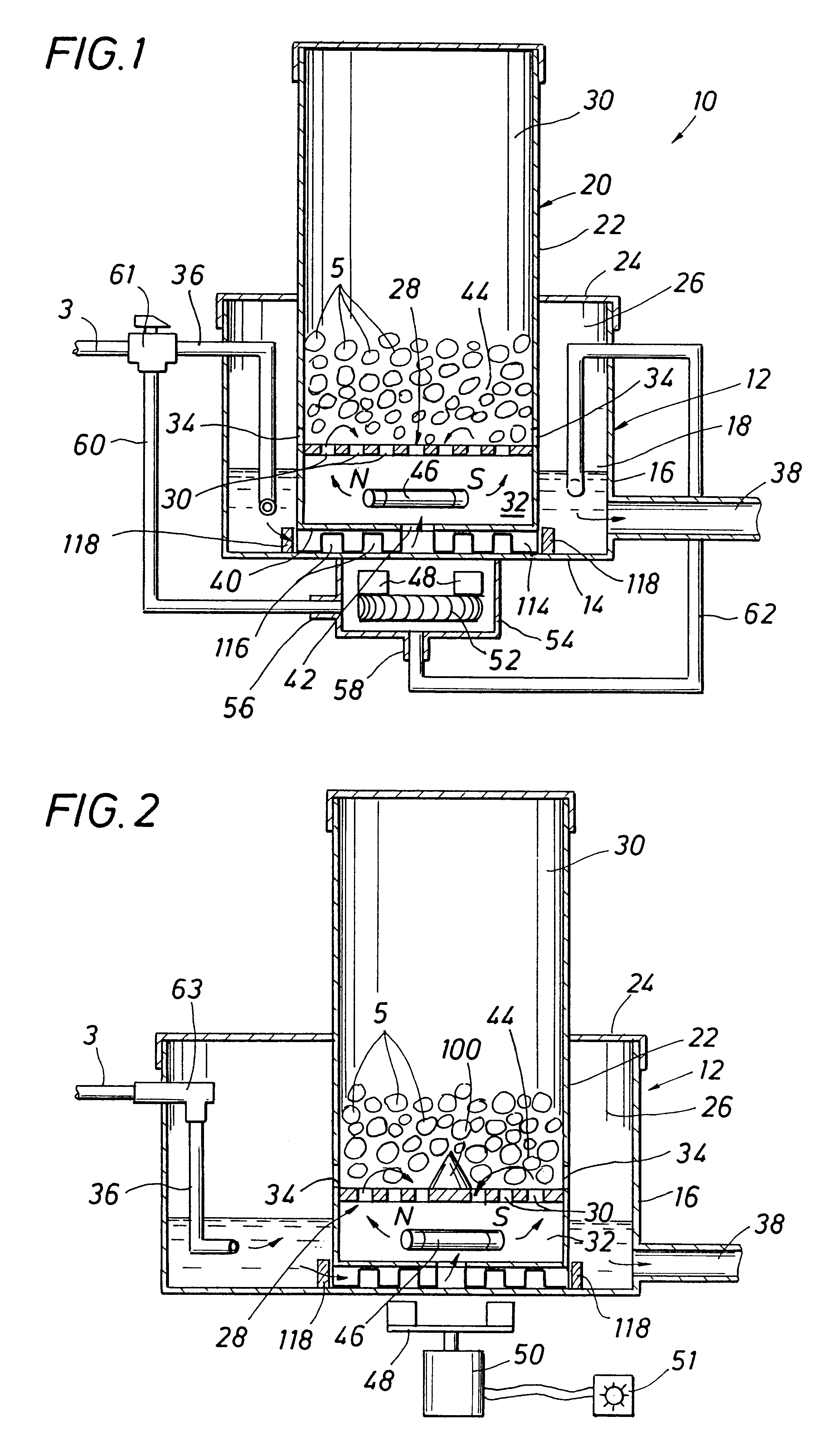

A portable water treatment system includes at least one sub-system to treat water including a flocculation system, a chlorination system, and a bio-sand filter system. The water treatment system may include multiple sub-systems for treating water that feed into one another. The sand filter system may include a mini bio-sand filter, a foam filter, or a pressed block filter. The flocculation system may include a tank bottom that urges settling particles toward a sump and a ladle that removes settled particles. A manual pump or siphon may be included in the water treatment system.

Owner:ACCESS BUSINESS GRP INT LLC

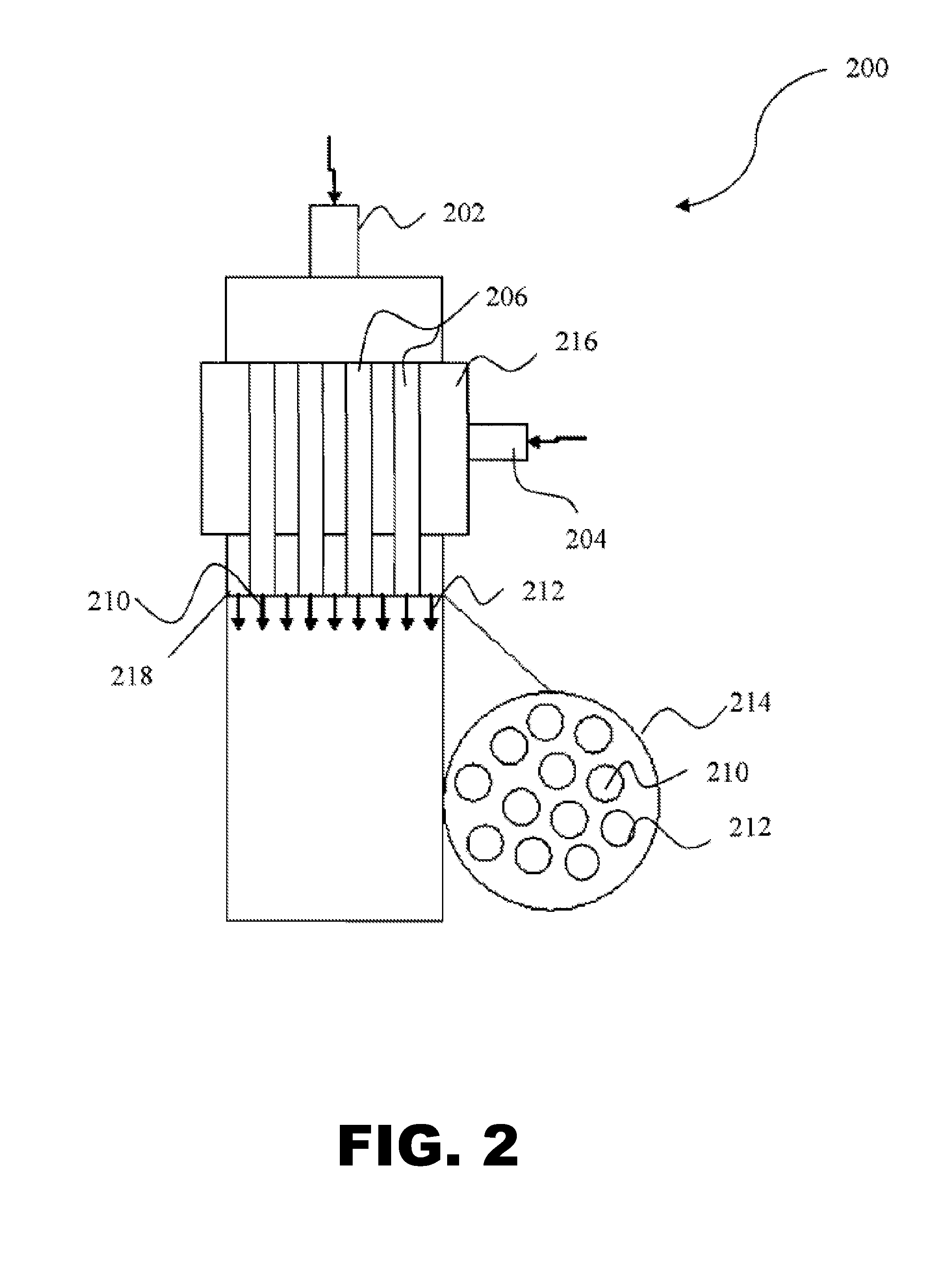

Chlorination apparatus and method

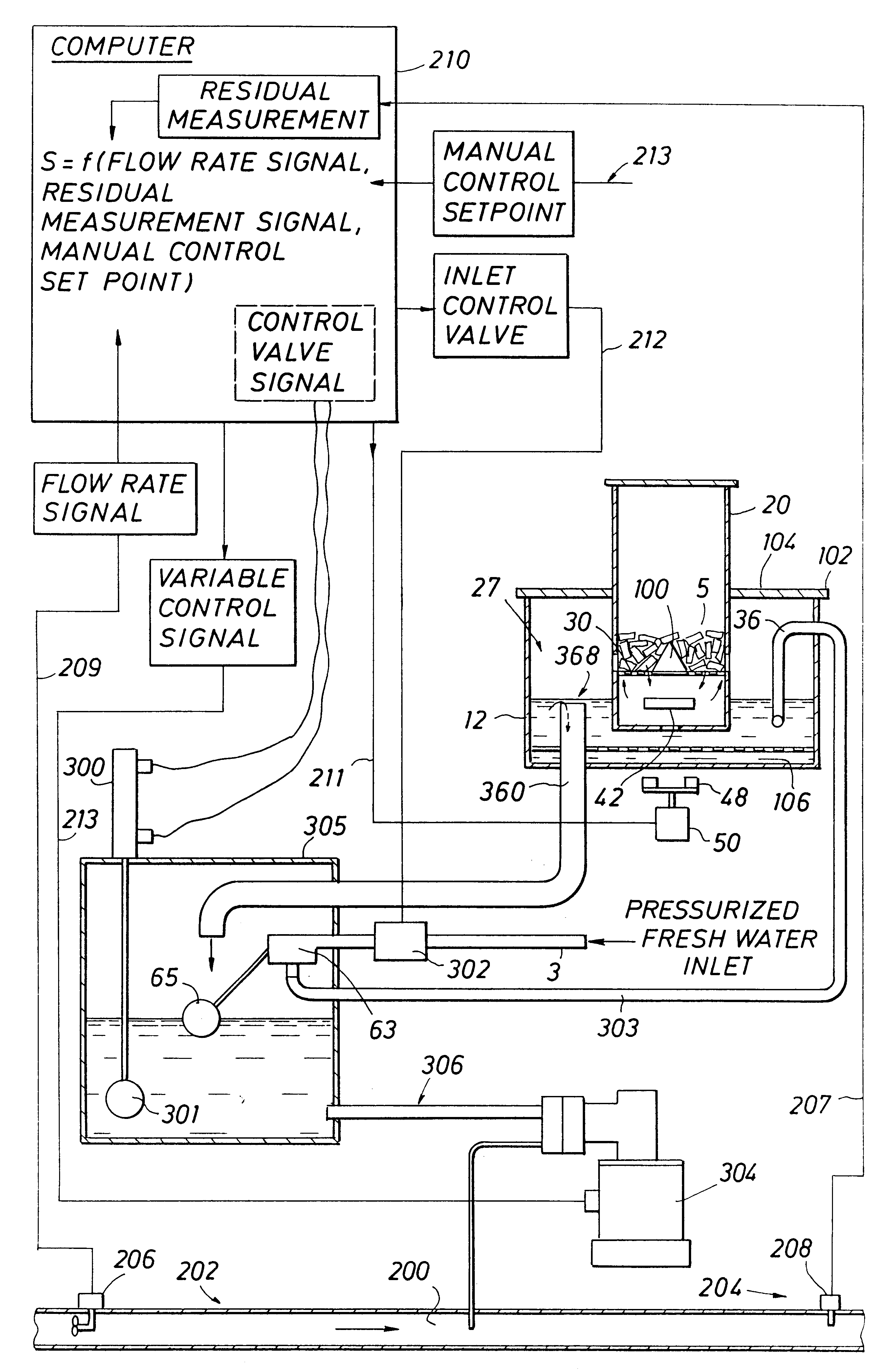

Apparatus and method for dissolving chemical tablets for creating a variable rate of chemical dissolution in a stream of constant flow rate of untreated liquid, especially water. The apparatus includes a housing in which a container is placed. The container includes a sieve plate or perforated grid which separates the container into an upper chamber in which chemical tablets are stored and a lower mixing chamber. A collection reservoir is defined in an annular outside the container wall and inside of the housing. Several arrangements are illustrated by which a vortex of liquid is generated of controllable variable intensity in the lower or mixing chamber thereby creating uneven liquid pressure beneath the perforated grid as a function of radial distance. As a result, fluid passes aggressively through outer radial perforations or holes in the grid and which impinge on the chemical tablets stacked on the grid. The liquid circulates in the upper chamber from the outward radial position toward the center of the grid plate, while eroding the tablets, and returns to the mixing chamber. A portion of the liquid exits into the collection reservoir. Liquid communication also exits from a hole in the bottom of the lower mixing chamber, which is open to the collection reservoir. Varying the intensity of the vortex varies the rate of chemical dissolution, yet the flow rate of liquid through the apparatus is constant.

Owner:HAMMONDS TECHN SERVICES

Method for harmless disposal and recycling of aluminum ash

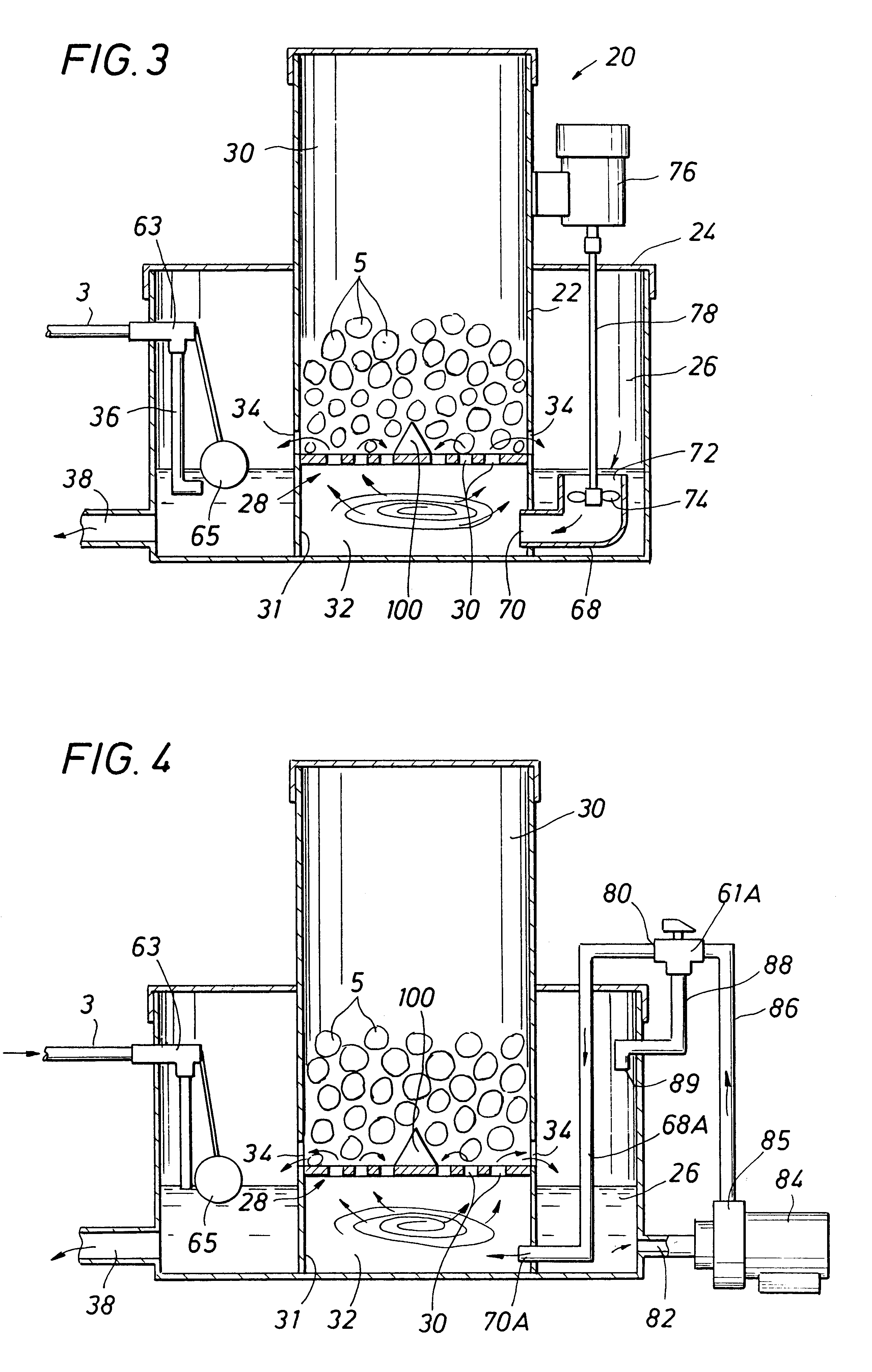

ActiveCN105271327ATo achieve the purpose of comprehensive recycling of resourcesGreat social valueAmmonia preparation/separationAluminium oxides/hydroxidesMetallic aluminumSodium aluminate

The invention discloses a method for harmless disposal and recycling of aluminum ash. The method comprises steps of raw material water immersion nitrogen and chlorine removal, calcination fluorine removal, alkali fusion sintering, sintering material dissolving-out and purifying impurity removal. Aluminum ash generated in metal aluminum smelting process is employed as a raw material, after metal aluminum is recycled through secondary processing, nitrides are removed through water immersion, fluorides are removed through calcinations, alkali fusion sintering is carried out, the sintering materials are dissolved out, impurities are removed through a sodium aluminate solution, the processed aluminum ash is employed as a raw material for producing sand-shaped aluminum oxide. Ammonia gas generated in the aluminum ash harmless disposal process can be employed as an ammonium production raw material, a chlorination liquid generated can be employed as a chlorate production raw material, and silicon fluoride gas generated in the calcination process is absorbed by an aqueous solution. The method is simple and practical, environmental protection benefits are high, the production efficiency is high, the device investment is low, and energy consumption is low. Harmless and recycling disposal of hazardous wastes can be achieved. The obtained product can be applied in practical production.

Owner:YUNNAN WENSHAN ALUMINUM

Stripping floor finishes using composition that thickens following dilution with water

ActiveUS20060234890A1Decrease effectivenessReduced effectivenessOther chemical processesChemical paints/ink removersEngineeringViscosity

Floor finishes can be stripped using a substantially nonchlorinated concentrate comprising a floor finish dissolver and an at least partially water-unactivated water thickener. The concentrate is diluted with water at an intended use location to activate the water thickener and noticeably increase within sixty minutes or less the viscosity of the resulting mixture, then applied to a hardened floor finish atop a floor and allowed to soften or dissolve the floor finish so that the finish may be removed from the floor.

Owner:ROHM & HAAS CO +1

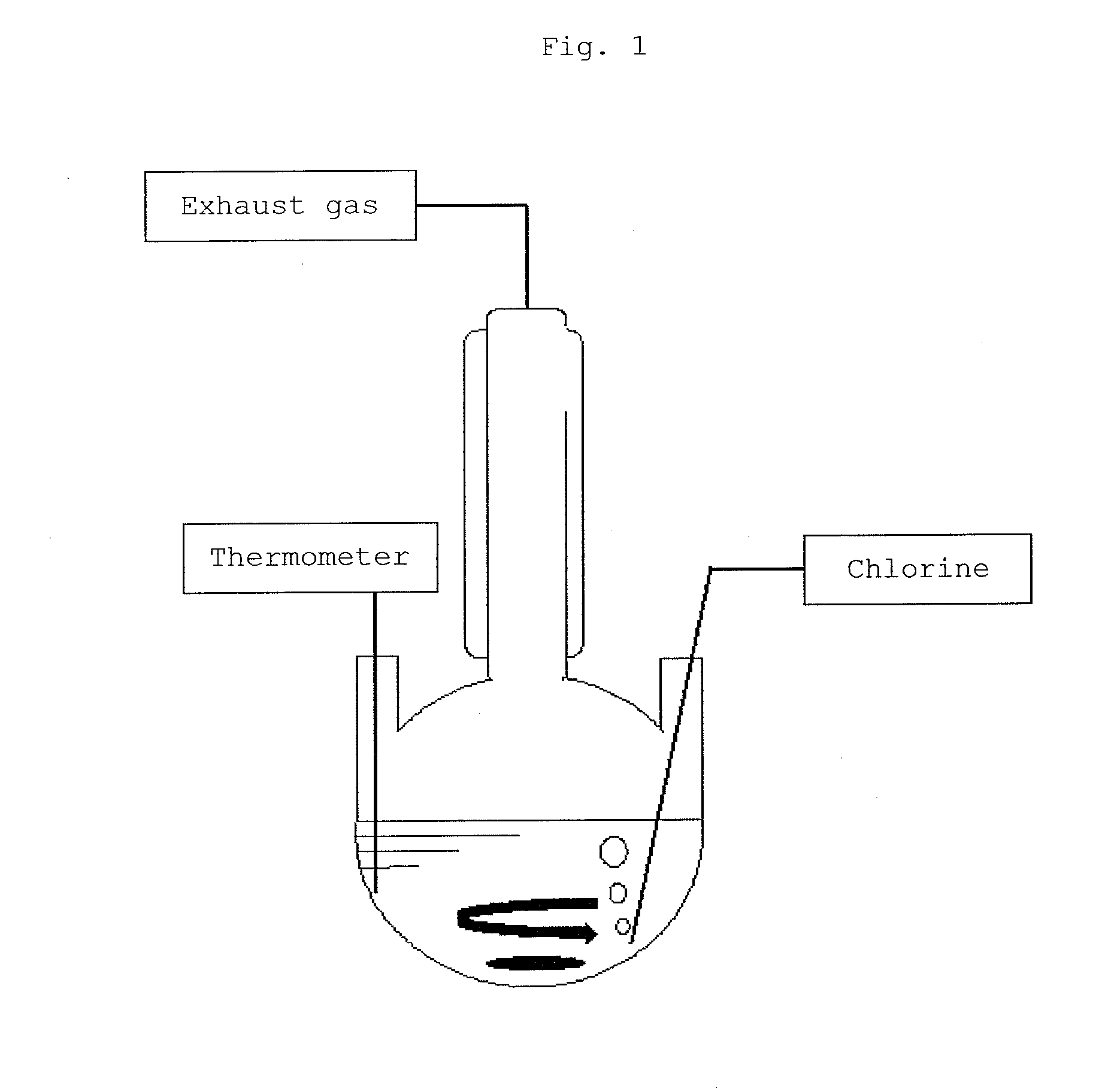

Preparation method of paraphthaloyl chloride with high purity

ActiveCN101560146AAdvantages of preparation methodSimple production processOrganic compound preparationDispersed particle separationExhaust gasPhotochemistry

The invention discloses a preparation method of paraphthaloyl chloride with high purity, which takes terephthalic acid and a chlorinating agent as materials to prepare the paraphthaloyl chloride with high purity by reflux reaction and distillating separation for one time under the condition of catalysts, and then the method conducts treatment on byproducts to obtain additional products which can be utilized. The method has the advantages of being capable of improving the yield of the product to over 90-95 percent, realizing closed cycle for tail gas absorption and utilization, having no pollution to environment and being capable of achieving over 99.95 percent of product purity.

Owner:SHANDONG KAISHENG NEW MATERIALS

Method for preparing multifunctional titanium dioxide pigment with chlorination method

ActiveCN102079885AGood weather resistanceGood light fastnessPigment physical treatmentPhosphatePapermaking

The invention relates to a method for preparing multifunctional titanium dioxide pigment with a chlorination method, which comprises the following steps of: blending a titanium dioxide primary product into titanium dioxide slurry by adopting a chlorination method and adjusting a pH value between 9.0 and 11.0; adding a phosphate dispersing agent and carrying out grinding treatment; removing a grinding medium from the slurry and heating; adding a water-soluble silicate solution for curing; adjusting the pH value of the slurry for forming amorphous silica and curing for forming a first coating layer; cooling the slurry to 50-70 DEG C; adding a sodium metaaluminate solution and curing; adjusting the pH value of the slurry between 8.0 and 9.0, curing and forming an amorphous alumina coating layer on the first coating layer; adding an aluminum salt solution, maintaining the pH of the slurry between 7.0 and 9.0 and curing; adjusting the pH value of the slurry between 6.0 and 7.0 and curing; and washing the slurry with deionized water till the conductivity of a filter cake is larger than 15,000 ohm.cm, and carrying out drying and steaming pulverizing treatment to obtain a finished product. The multifunctional titanium dioxide pigment prepared with the method has higher weather resistance, whiteness, covering capability, opacity and dispersibility and excellent processing performance in the fields of coating, plastics, papermaking, and the like.

Owner:中信钛业股份有限公司

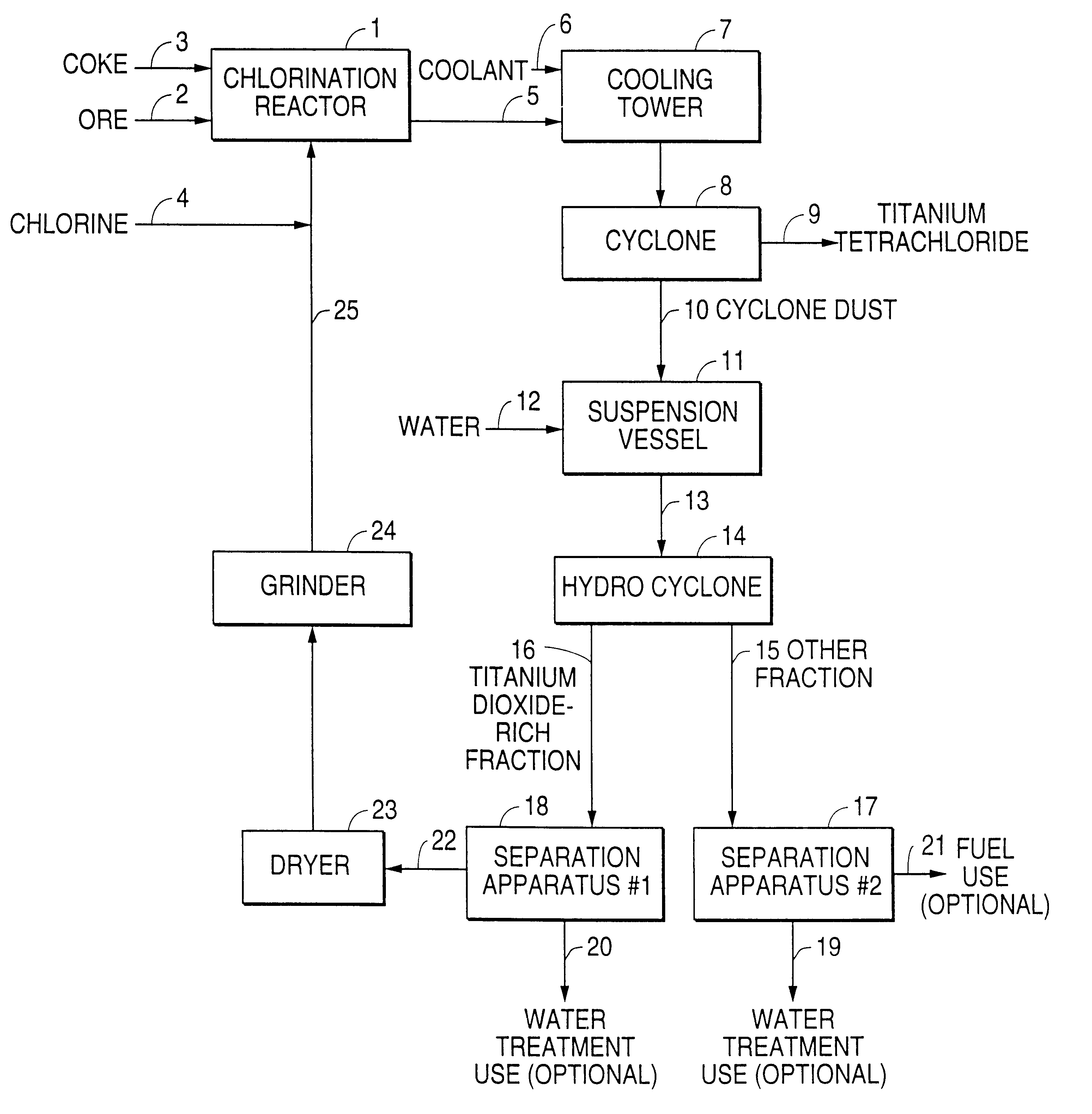

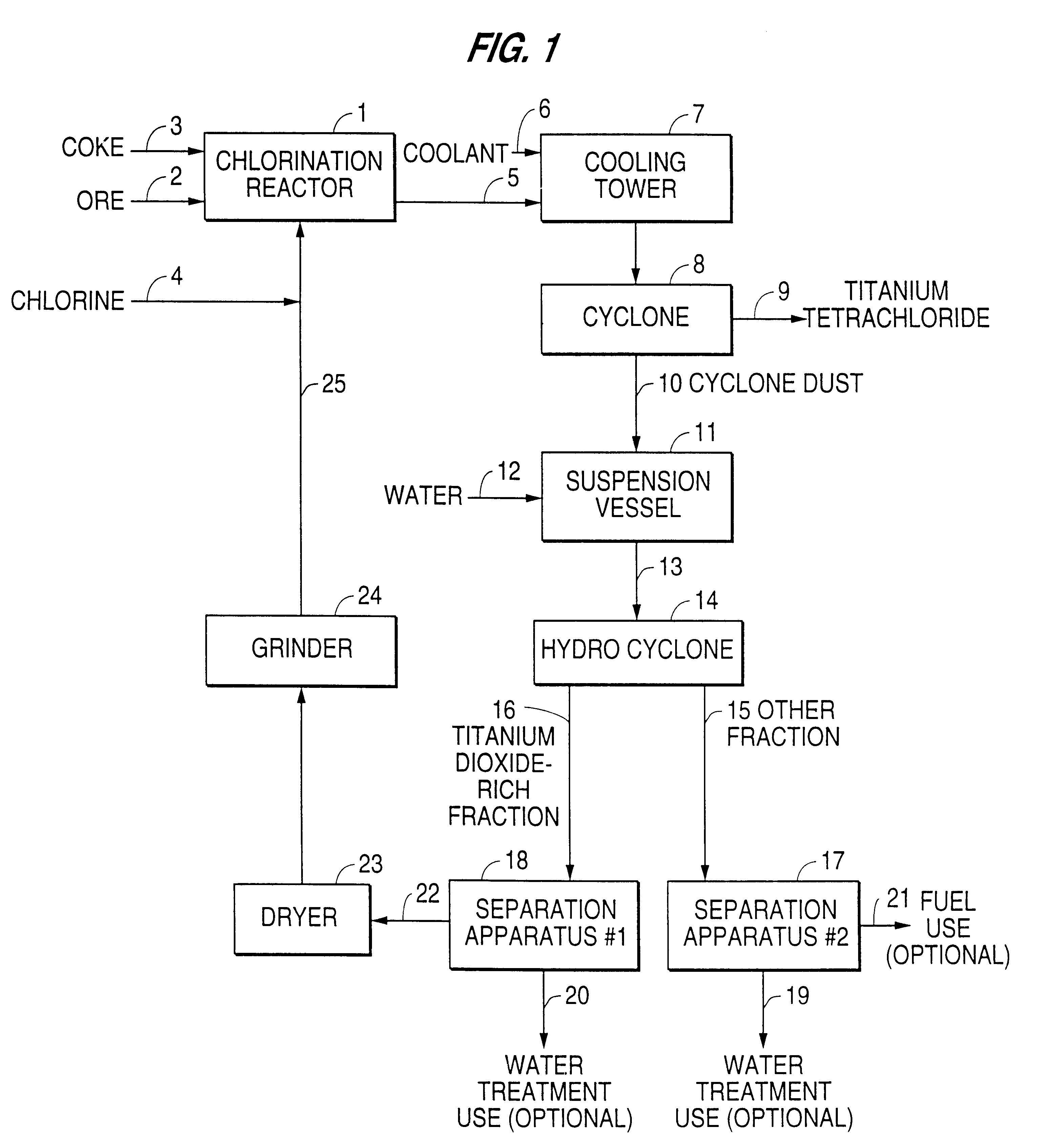

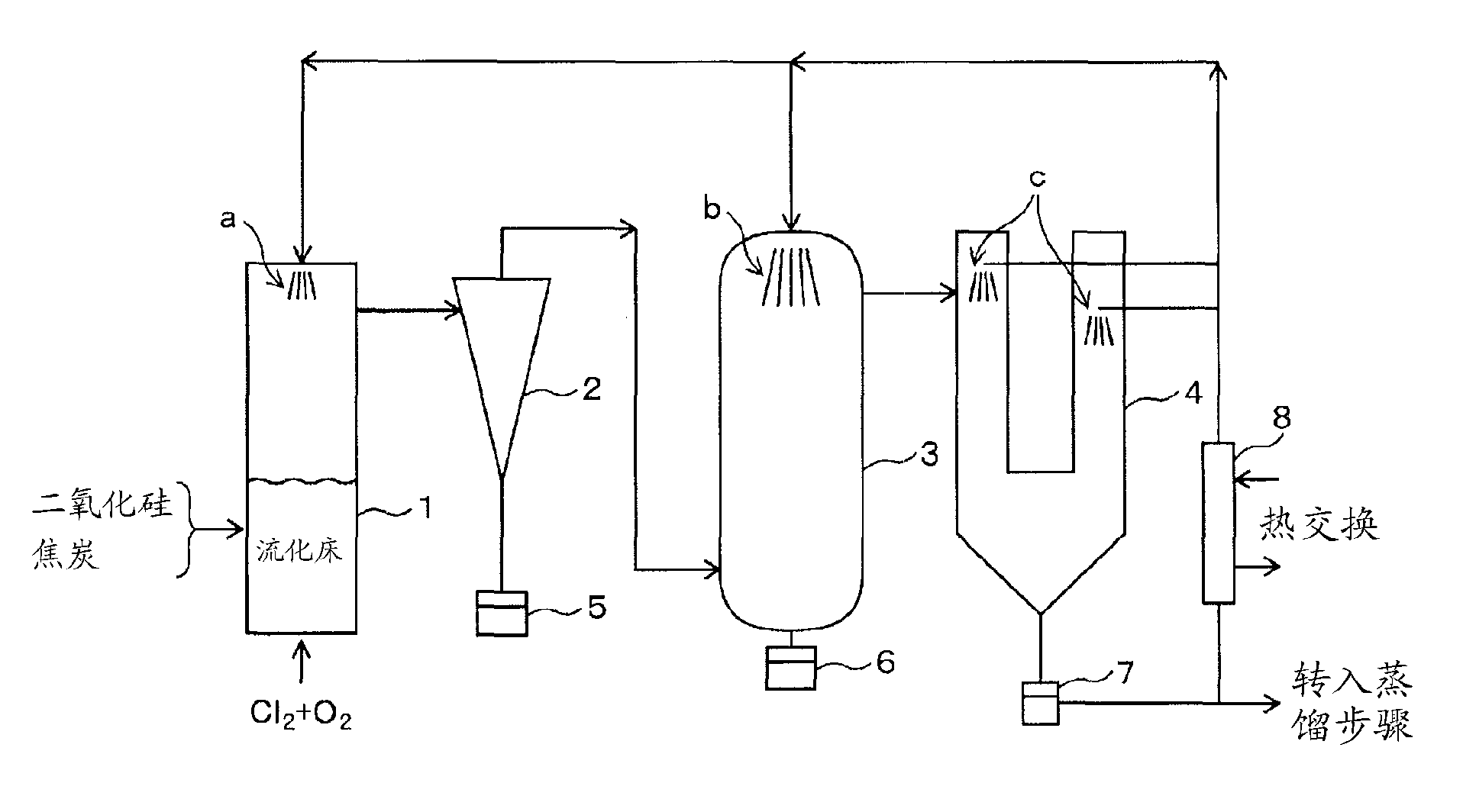

Process for increasing the yield in the manufacture of titanium dioxide by the chloride process

InactiveUS6399033B1Reduce coke contentReduced silica contentZirconium compoundsTitanium dioxideSingle stageFluidized bed

An improvement to the chloride process of making titanium dioxide. By recycling some of the cyclone dust, the yield in the chlorination of titanium-containing raw materials can be increased. In order to prevent silica accumulation in the fluidized bed, the cyclone dust is divided into two fractions. An economic solution is described of a single-stage separation of the cyclone dust in a hydrocyclone, the majority of the titanium dioxide occurring in the hydrocyclone underflow, although the separation is not sharp. By grinding and drying the solids from the hydrocyclone underflow, the titanium dioxide particles returned to the lower region of the fluidized-bed reactor are rapidly chlorinated, while the quartz and coke particles are rapidly discharged again from the fluid bed, so that no silica contamination occurs.

Owner:KRONOS INCORPORATED

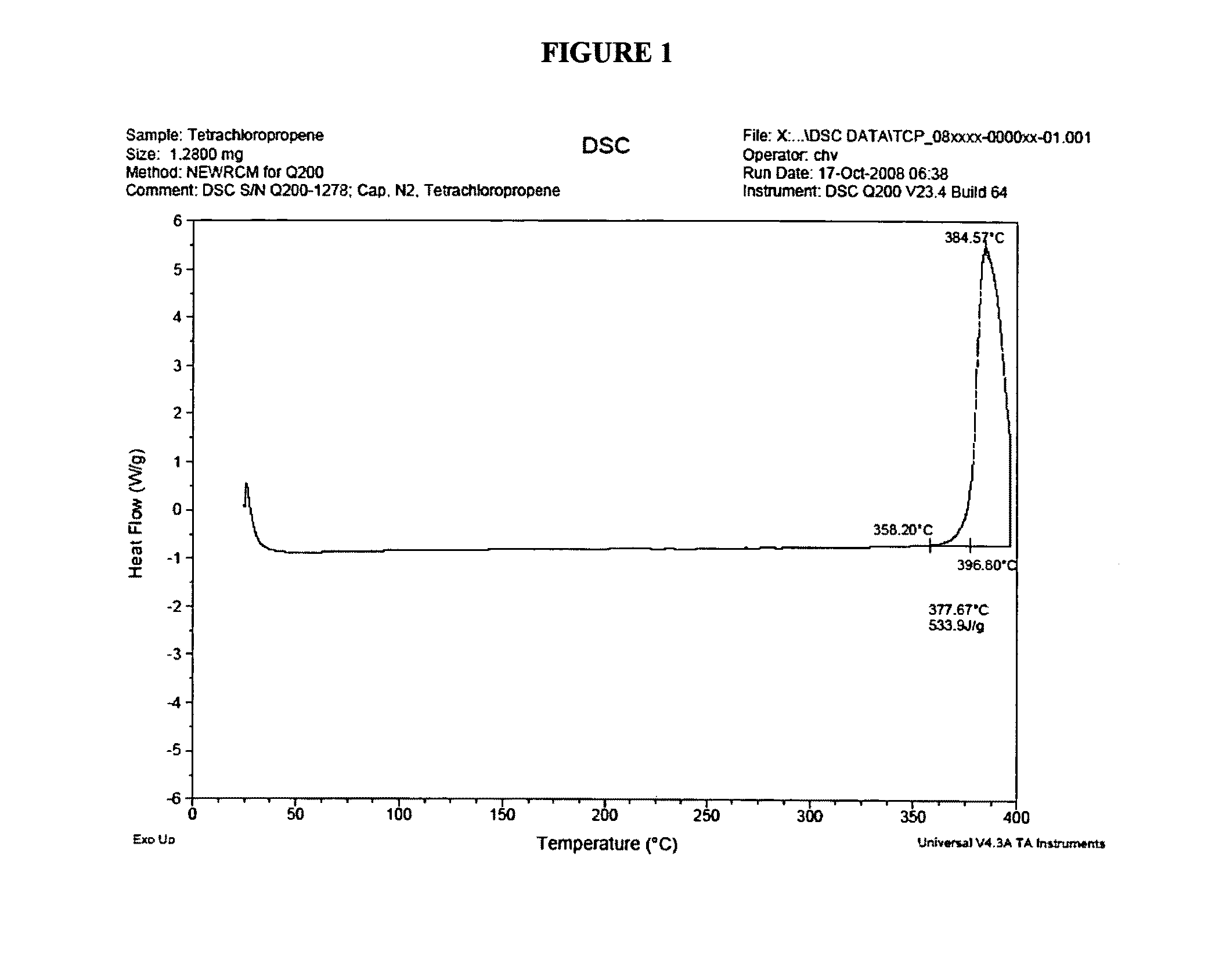

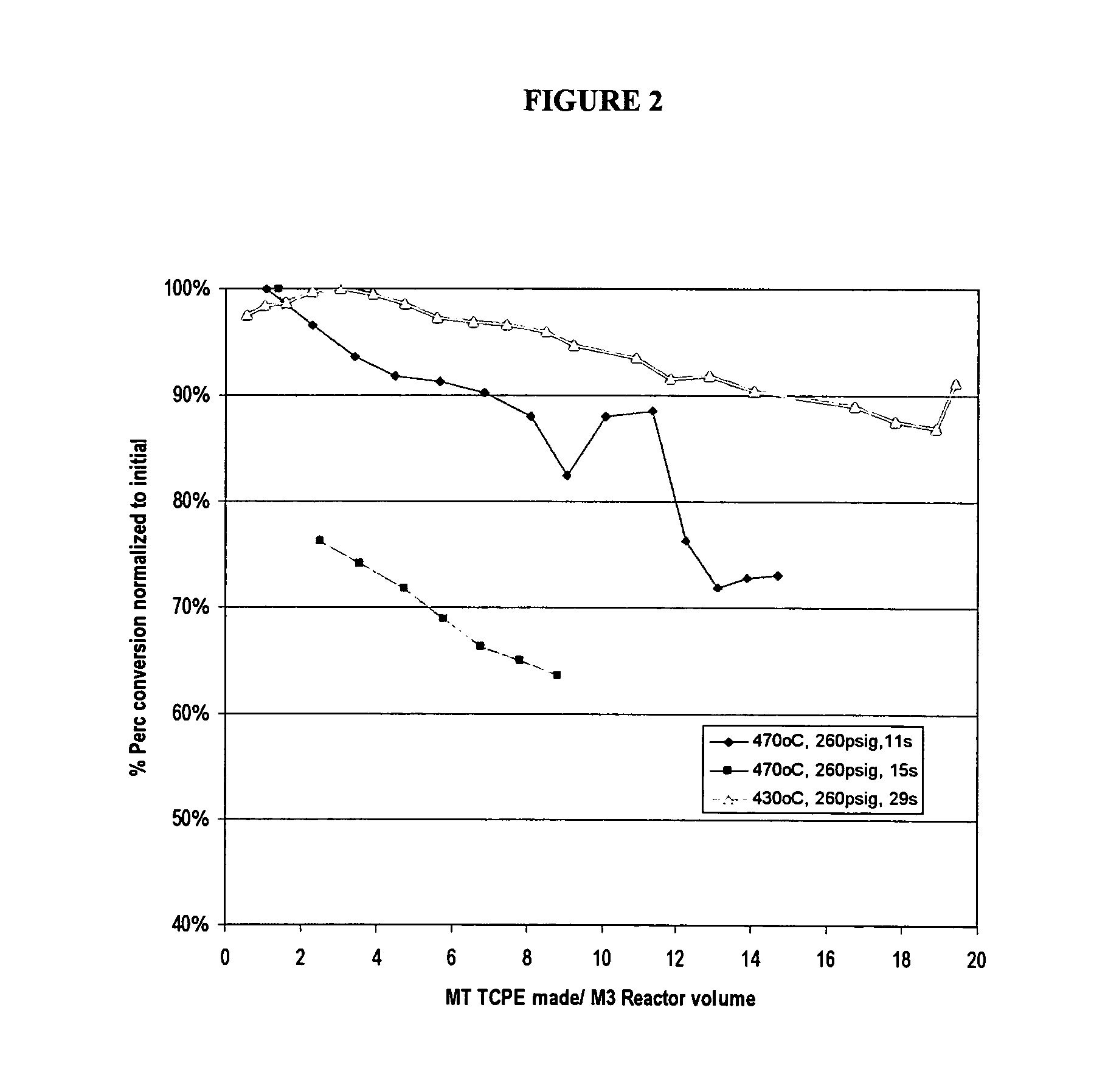

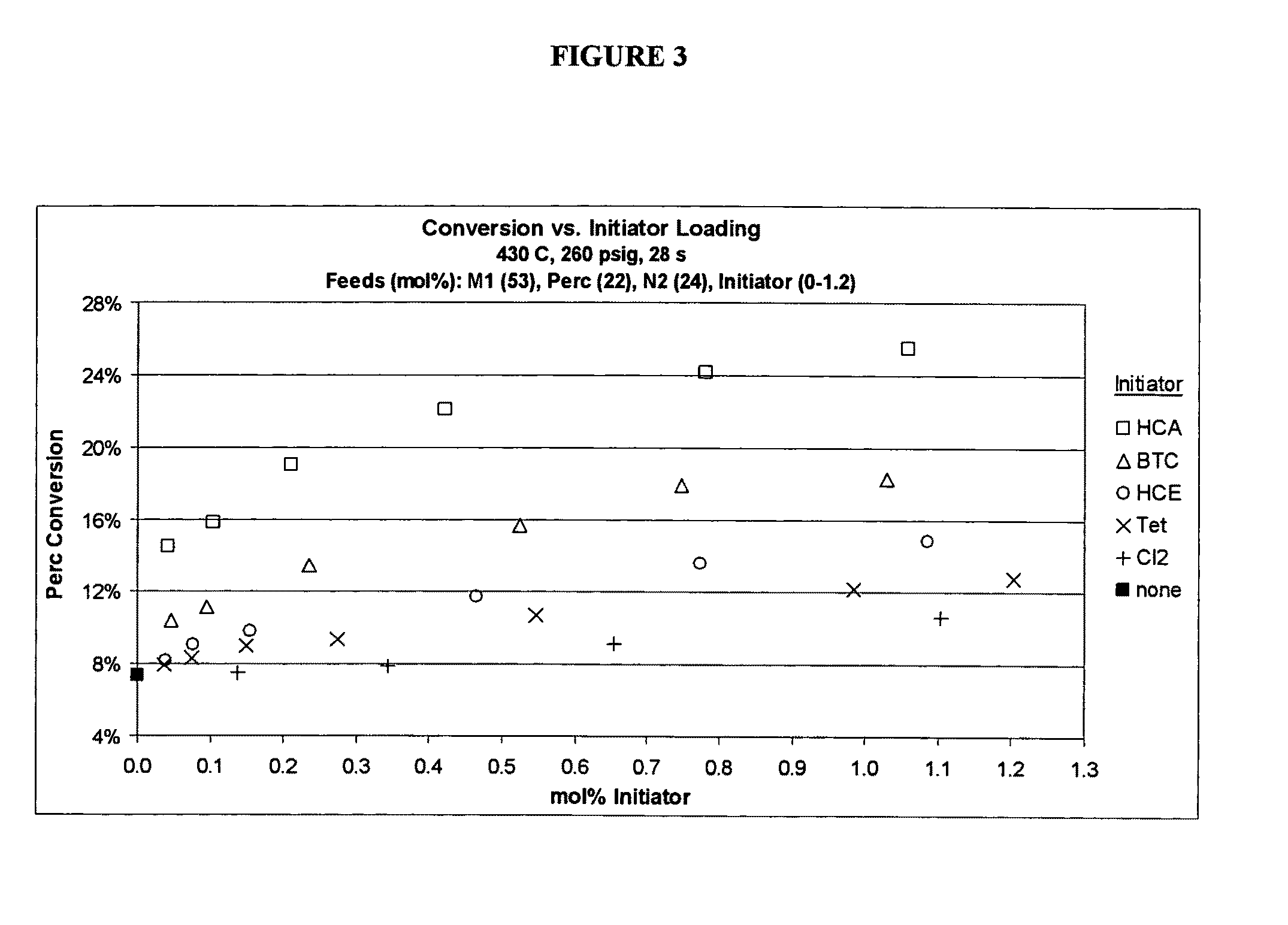

Process for the production of chlorinated and/or fluorinated propenes

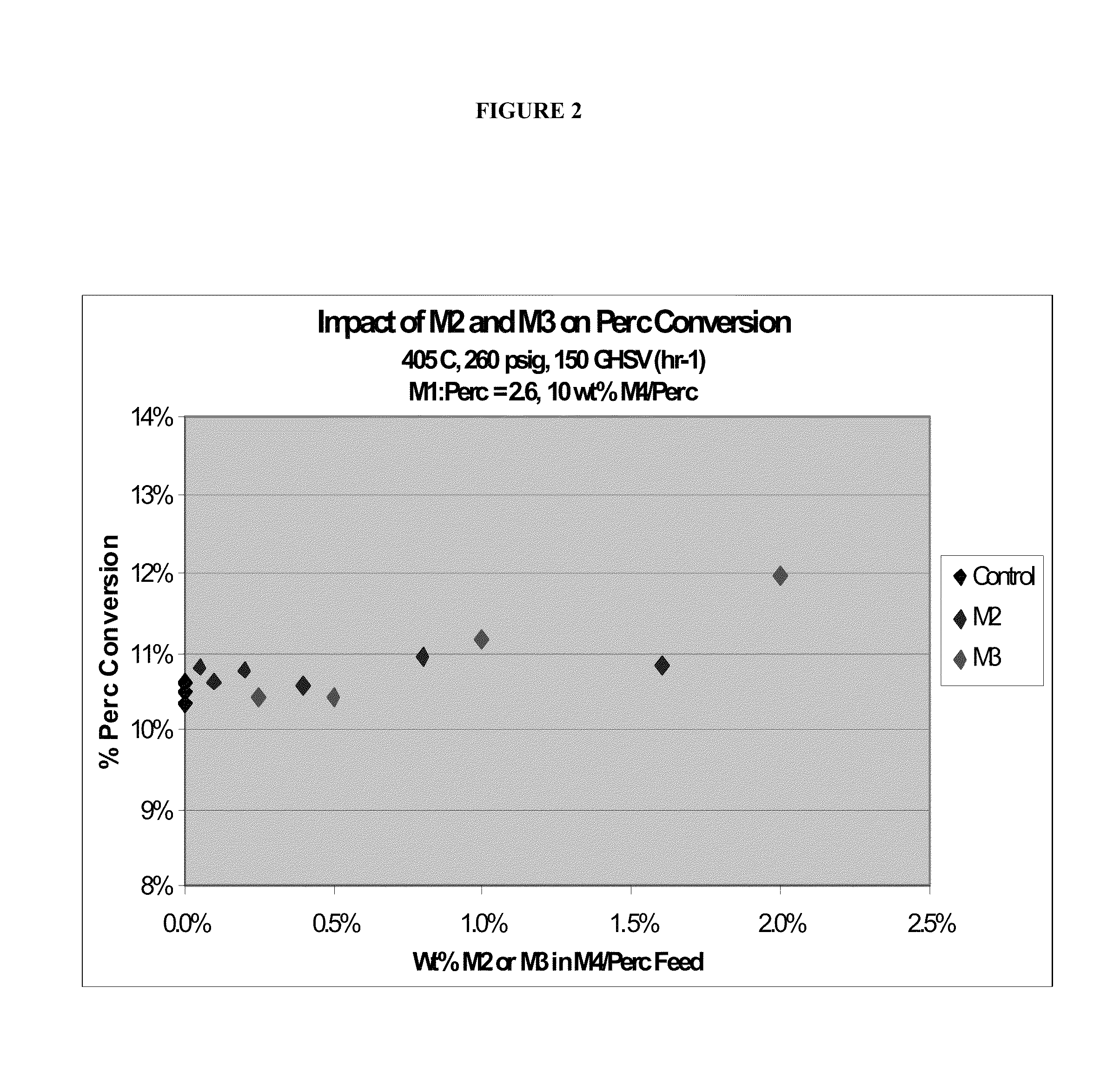

InactiveUS20110083955A1Preparation by halogen replacementHalogenated hydrocarbon separation/purificationPtru catalystWater chlorination

The present invention provides one-step processes for the production of chlorinated and / or fluorinated propenes. The processes provide good product yield with low, e.g., less than about 20%, or even less than 10%, concentrations of residues / by-products. Advantageously, the processes may be conducted at low temperatures than 500° C. so that energy savings are provided, and / or at higher pressures so that high throughputs may also be realized. The use of catalysts or initiators may provide additional enhancements to conversion rates and selectivity, as may adjustments to the molar ratio of the reactants.

Owner:BLUE CUBE IP

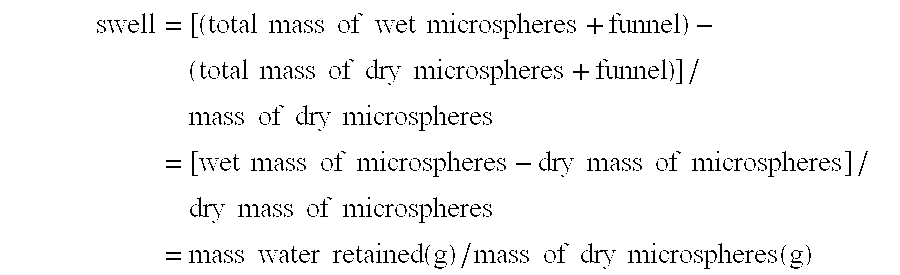

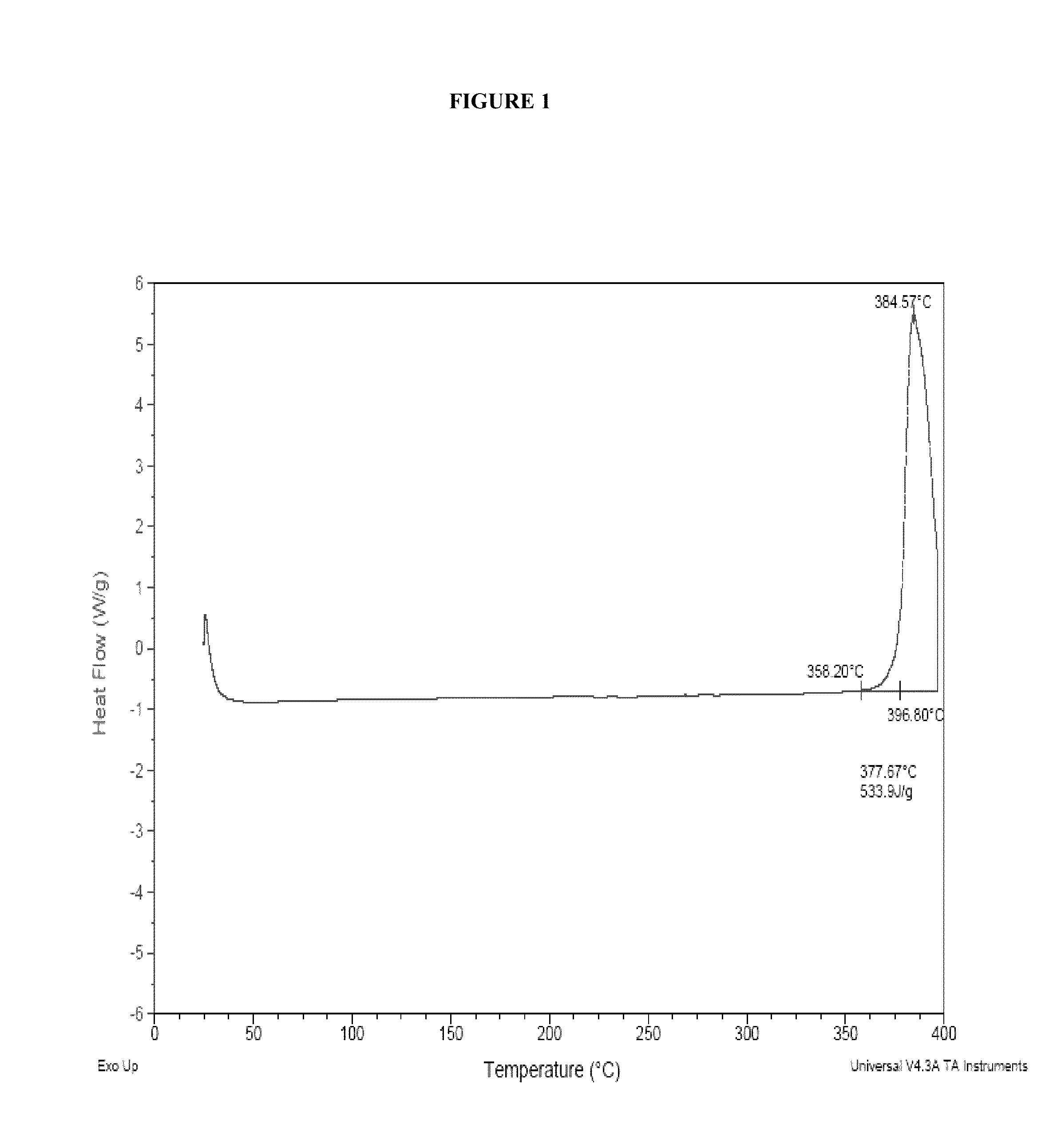

Process for preparation of swellable and degradable microspheres

InactiveUS20090041850A1Satisfies needPowder deliveryIn-vivo radioactive preparationsMicrosphereSolvent

A process for producing microspheres was developed that provides microspheres that are swellable and degradable. The process is reliable and high yielding, and makes use of a low temperature azo initiator, a small molecule chlorinated solvent as the organic phase, and a heat treatment step, and is carried out in absence of a crosslinking agent. The microsphere preparation made using the process is particularly useful as a degradable embolic material.

Owner:EI DU PONT DE NEMOURS & CO

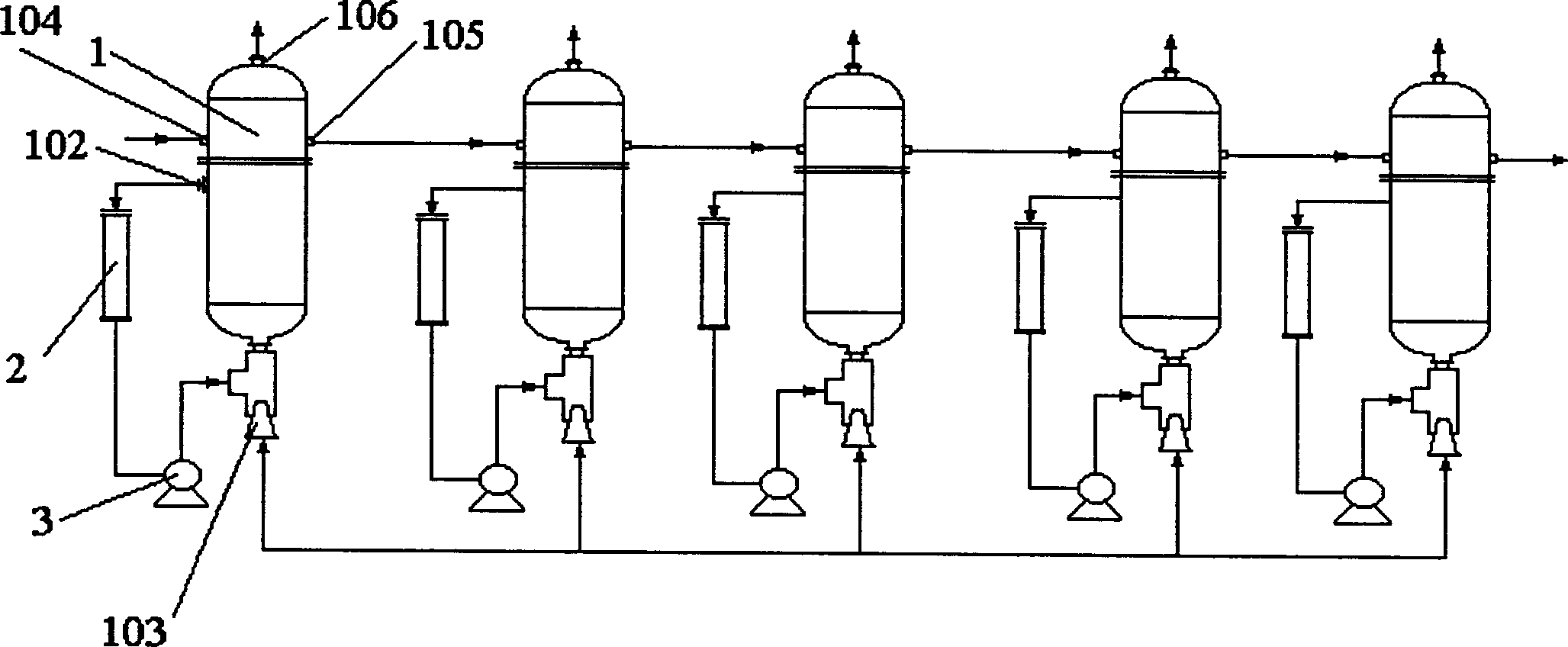

Continuous production method of chlorinated paraffin

InactiveCN1824737APrevent burning phenomenonAvoid production accidentsPetroleum chemical modificationParaffin oilsChlorinated paraffins

The present invention discloses a method for continuously producing chloroparaffine. Said method includes the following steps: making paraffin oil be passed through paraffin oil inlet and continuously fed into reactor; making chlorine gas be passed through circulation material and chlorine gas feeding device and fed into reactor from bottom portion of said reactor; under the catalysis of UV light making them implement chlorination reaction; making reaction product of the prior-stage be fed into reactor of next-stage to make continuous reaction, making the reaction product of the last reactor be fed into subsequent work-shop section to make refinement; making the reaction product overflowed from upper portion of reactor be fed into inlet of external cooling device, cooled, then passed through circulating pump, conveyed and premixed with chlorine gas, then fed into reactor.

Owner:SHANGHAI CHLOR ALKALI CHEM

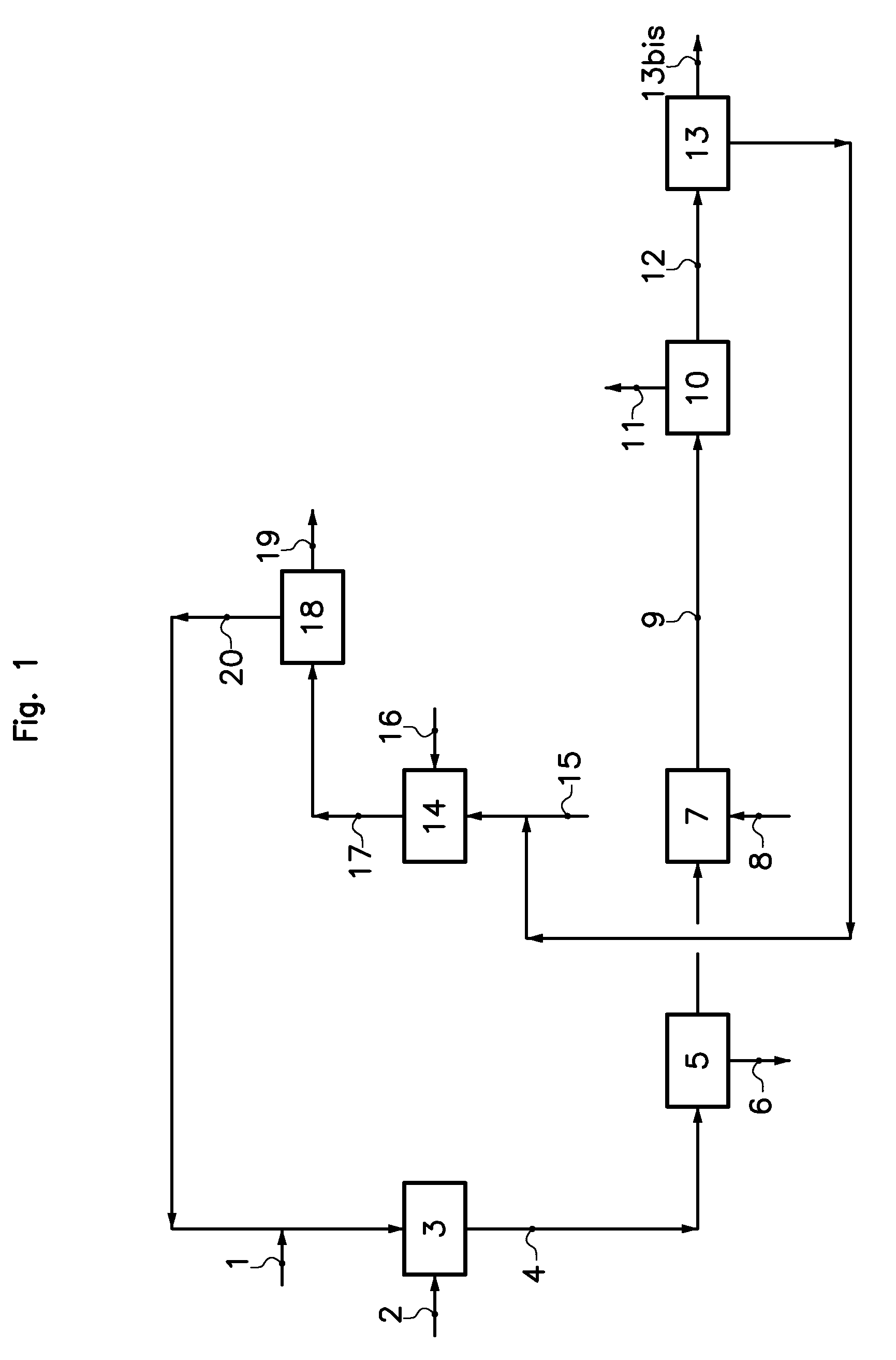

Processes for the production of chlorinated and/or fluorinated propenes and higher alkenes

InactiveUS8581012B2Improve efficiencyLow costPreparation by halogen replacementHalogenated hydrocarbon separation/purificationAlkaneGas phase

The present invention provides continuous, gas phase, free radical processes for the production of chlorinated and / or fluorinated propenes or higher alkenes from the reaction of chlorinated and / or fluorinated alkanes and chlorinated and / or fluorinated alkenes, wherein wherein at least a portion of any intermediate boiler by-products generated by the process are removed from the process.

Owner:BLUE CUBE IP

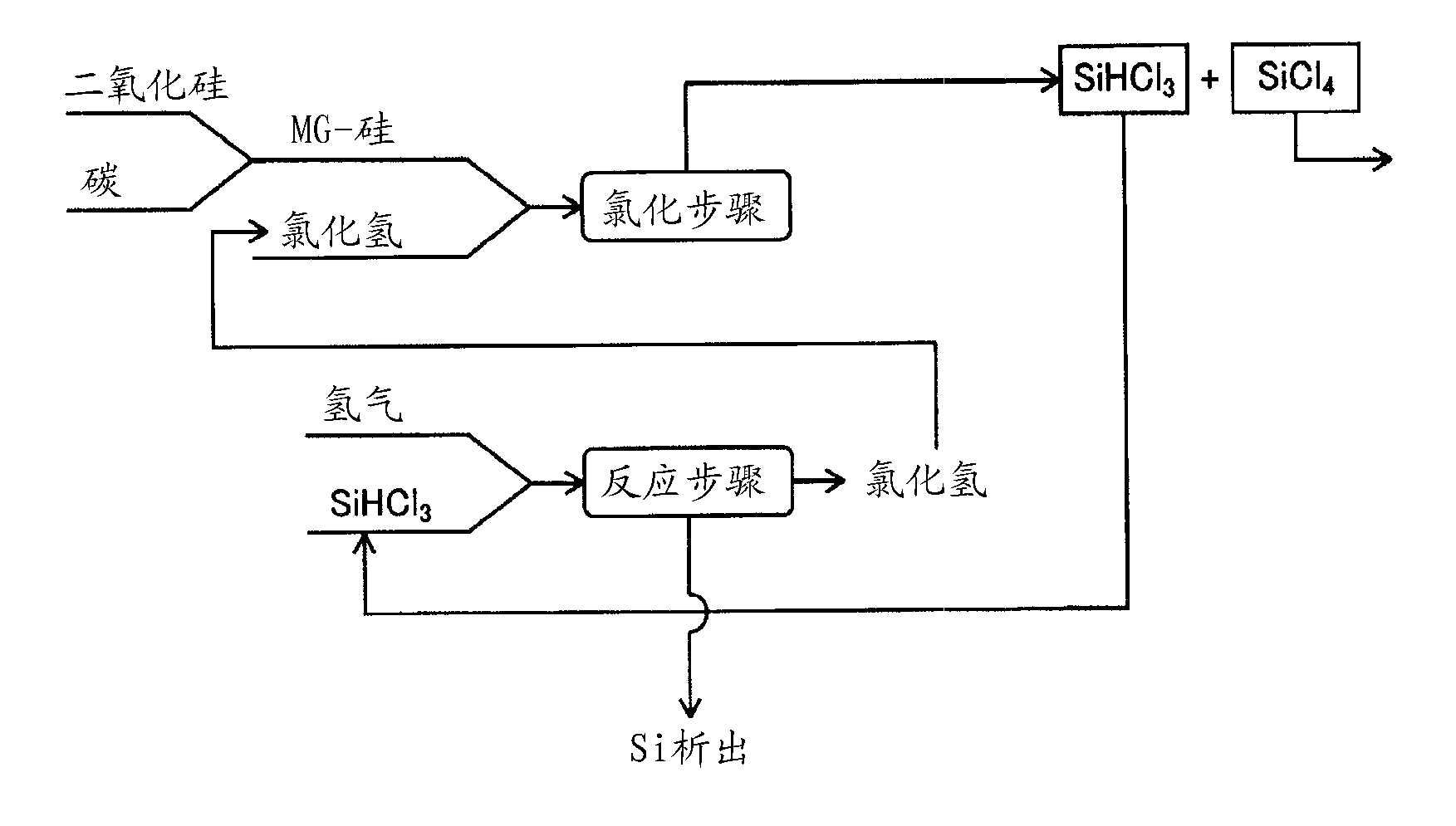

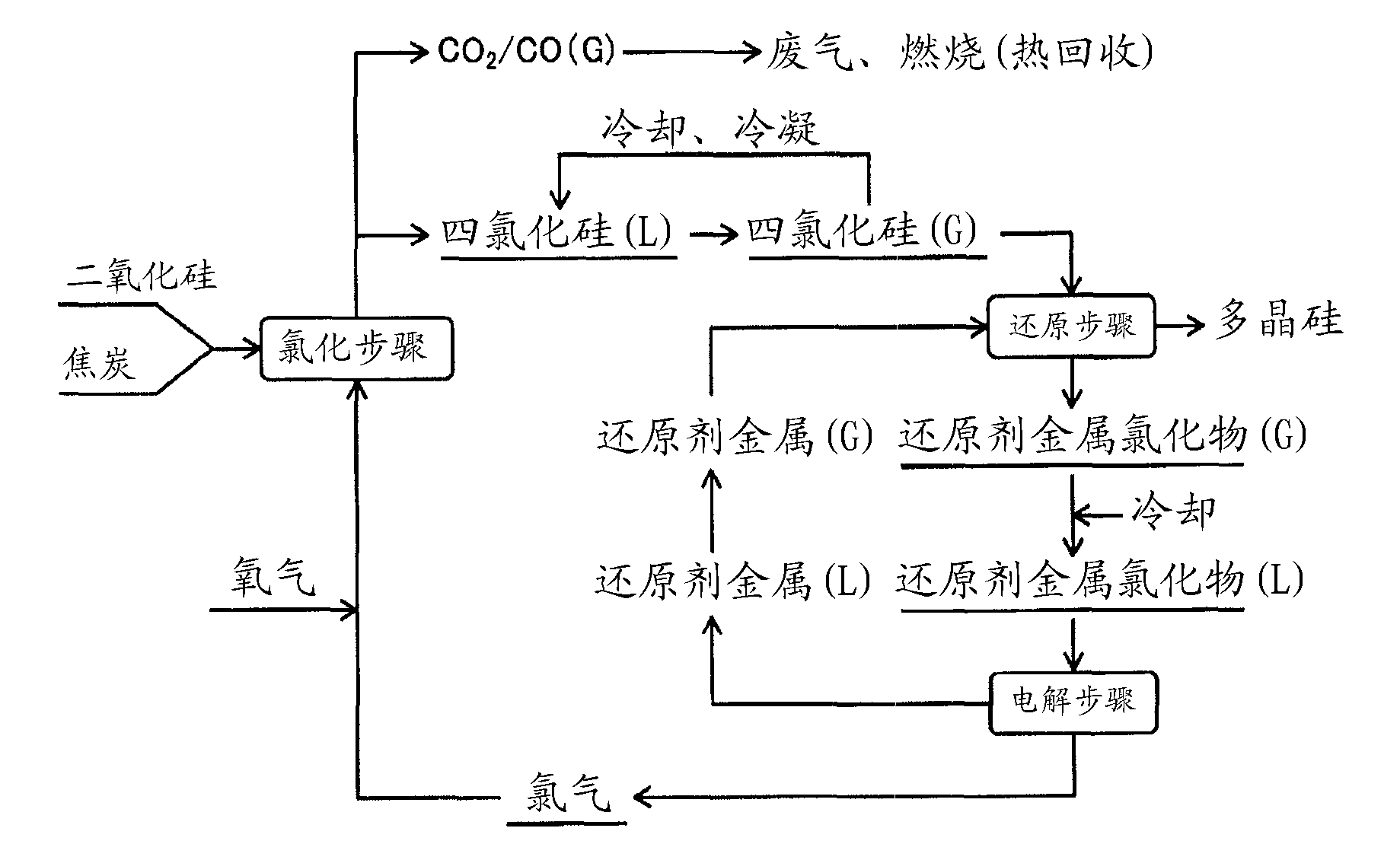

Method for manufacturing polysilicon and method for manufacturing silicon tetrachloride

InactiveCN102686514AEfficient use ofCheap manufacturingSiliconHalogenated silanesElectrolysisSilicon dioxide

Provided is a method for manufacturing polysilicon and silicon tetrachloride. The polysilicon manufacturing process used in said method is energy-efficient and can use an inexpensive raw material, the supply of which is stable. The chlorination reaction in said process proceeds smoothly and post-chlorination impurities are minimized. The provided method comprises: a chlorination step which generates silicon tetrachloride by chlorinating granules comprising silicon dioxide and a carbon-containing substance; a reduction step which generates polysilicon by using a reducing metal to reduce the silicon tetrachloride; and an electrolysis step which generates chlorine gas and a reducing metal by performing molten-salt electrolysis on a reducing metal chloride generated as a by-product from the reduction step. In the chlorination step, chlorine gas is supplied to the silicon dioxide and the carbon-containing substance in the presence of oxygen gas in order to react said substances. The reducing metal generated in the electrolysis step is reused as the reductant for the silicon tetrachloride in the reduction step, and the chlorine gas generated in the electrolysis step is reused in the chlorination step.

Owner:JNC CORP +2

Process for the production of chlorinated and/or fluorinated propenes

InactiveUS8258353B2Low costShorten the timePreparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystWater chlorination

The present invention provides one-step processes for the production of chlorinated and / or fluorinated propenes. The processes provide good product yield with low, e.g., less than about 20%, or even less than 10%, concentrations of residues / by-products. Advantageously, the processes may be conducted at low temperatures relative to conventional processes, so that energy savings are provided, and / or at higher pressures so that high throughputs may also be realized. The use of catalysts may provide enhancements to conversion rates and selectivity over those seen in conventional processes, as may adjustments to the molar ratio of the reactants.

Owner:BLUE CUBE IP

Process for the manufacture of 1,2-dichloroethane

InactiveUS8058490B2Low costHigh purityPreparation by hydrogen halide split-offChemical recyclingCatalytic oxidationEthane Dichloride

Process for the manufacture of 1,2-dichloroethane (DCE) starting from a stream of ethane which is subjected to a catalytic oxydehydrogenation (ODH) thus producing a gas mixture containing ethylene which is then dried and conveyed to a chlorination reactor supplied with a flow of chlorine so that at least 10% of the ethylene is converted to DCE. The stream of products derived from the chlorination reactor is then conveyed to an oxychlorination reactor in which the majority of the balance of ethylene is converted to DCE.

Owner:SOLVAY SA

Method for recycling iron and zinc containing waste hydrochloric acid solution

ActiveCN105696010ATake advantage ofSolve the problem of no separation and recyclingProcess efficiency improvementZinc hydroxideChloride

The invention discloses a method for recycling an iron and zinc containing waste hydrochloric acid solution. The method specifically comprises the following steps that 1, acid consuming and reducing are carried out, acidity is made to meet the requirement, and ferric iron in waste acid is reduced into ferrous iron; 2, zinc and iron are extracted and separated, and a ferrous chloride solution is obtained; 3, an organic phase transfers zinc into a strip liquor through reverse extraction, and the organic phase is extracted for reuse; and 4, the strip liquor is subjected to subsection kalizing treatment, zinc hydroxide is obtained, and the strip liquor is reused. According to the method, iron and zinc are separated through different extracting capacities of N235 to the ferrous iron and zinc, and therefore pure ferrous chloride liquid and zinc hydroxide solids are obtained. Ferrous chloride can be oxidized into ferric trichloride, and ferrous chloride and ferric trichloride both can be used as a water treatment agent; and zinc hydroxide can be used as a raw material for preparing zinc oxide or zinc chloride.

Owner:3R ENVIRONMENTAL TECH CO LTD

Microbiological control in animal processing

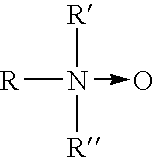

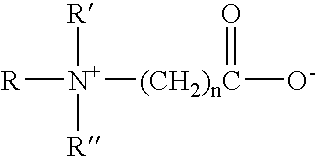

InactiveUS6919364B2Reduce Microbial ContaminationProduced economicallyOrganic active ingredientsBiocideWater chlorinationZoology

Fecal bacterial contamination in an animal is reduced by providing it with drinking water containing a microbiocidally-effective amount of halogen-based microbiocide resulting from mixing with water (A) a product formed in water from (i) bromine, chlorine, or bromine chloride, or any two or more thereof, (ii) a water-soluble source of sulfamate anion, and (iii) a water-soluble base; (B) at least one 1,3-dihalo-5,5-dialkylhydantoin in which one of the halogen atoms is a chlorine atom and the other is a chlorine or bromine atom, and in which each alkyl group, independently, contains in the range of 1 to about 4 carbon atoms; (C) at least one 1,3-dibromo-5,5-dialkylhydantoin in which one of the alkyl groups is a methyl group and the other alkyl group contains in the range of 1 to about 4 carbon atoms; or (D) any two or more of (A), (B), and (C).

Owner:ALBEMARLE CORP

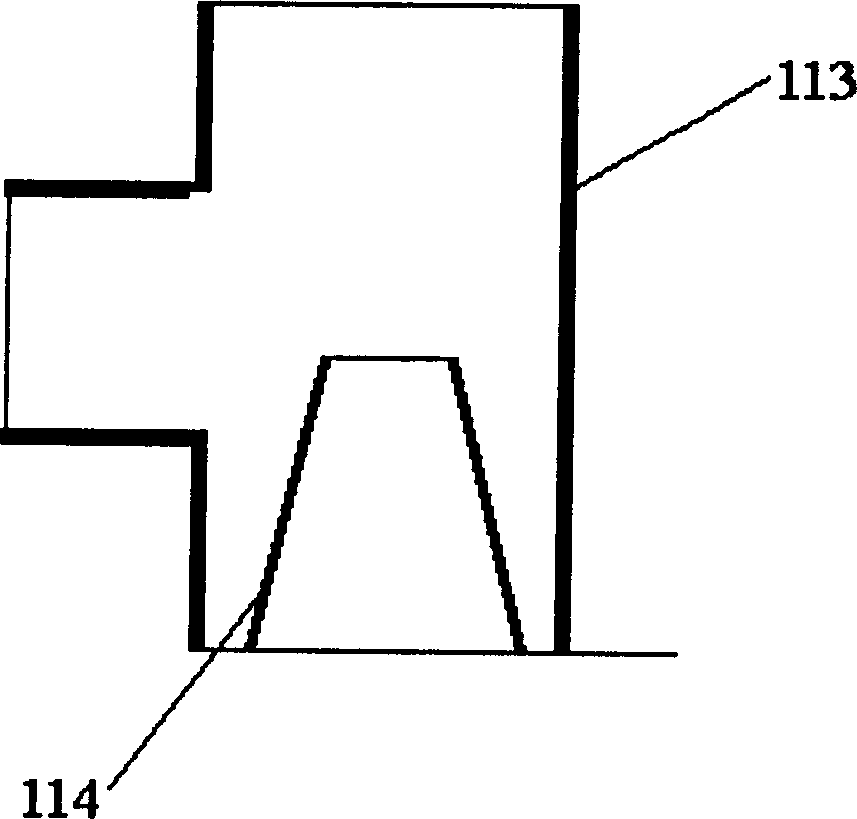

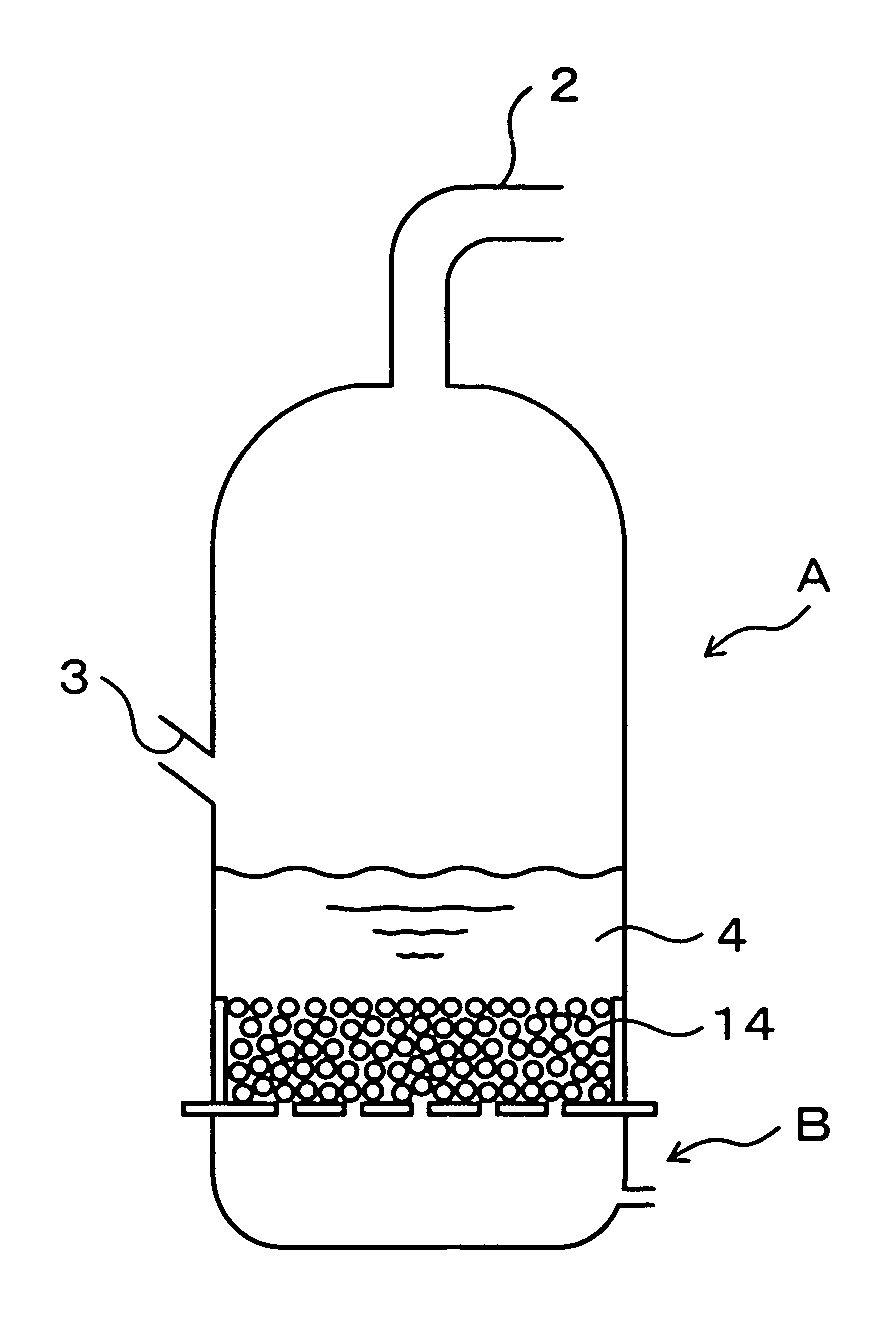

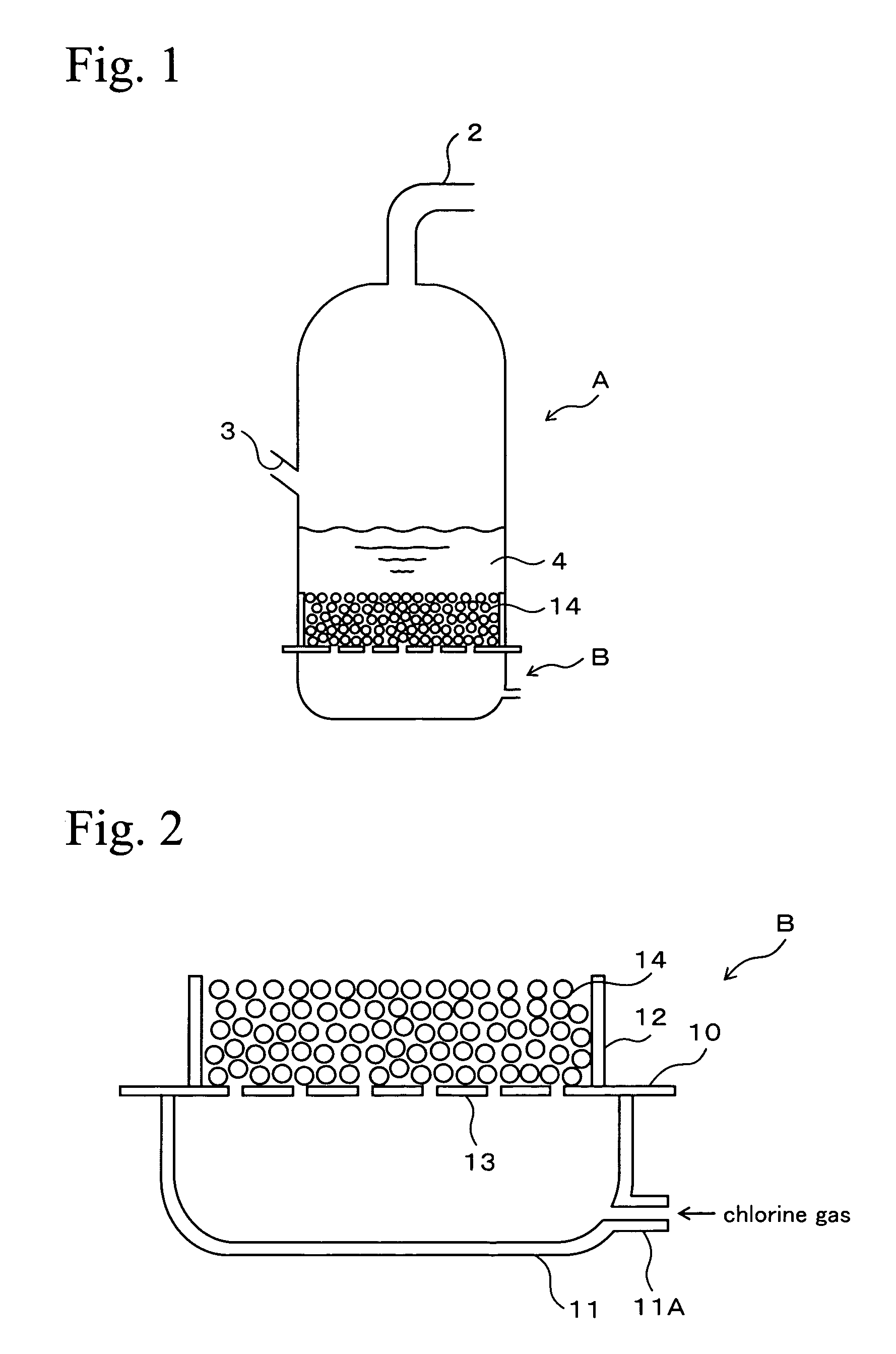

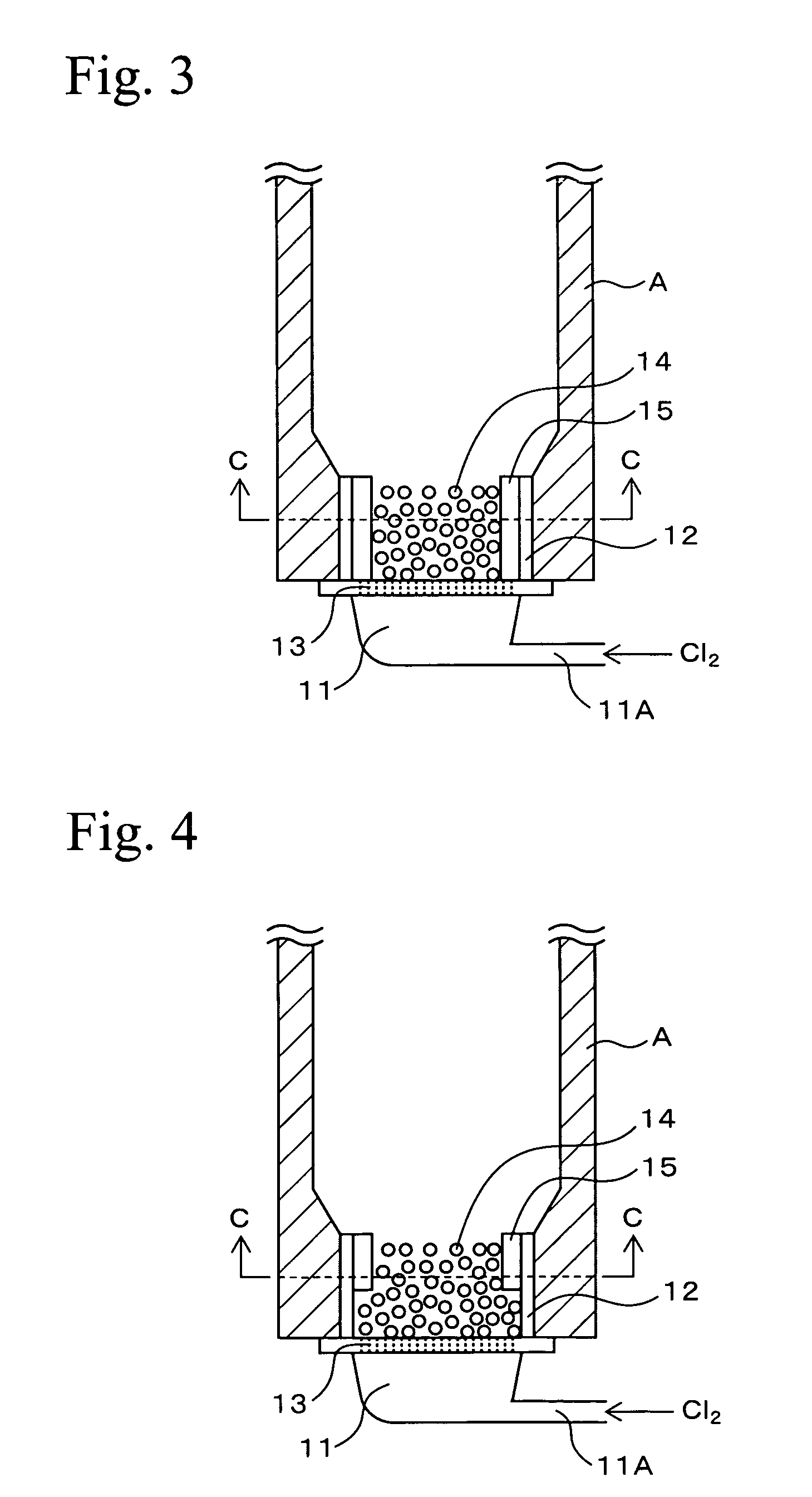

Apparatus for production of metal chloride

InactiveUS20070178028A1Increased durabilityEfficient productionPhysical/chemical process catalystsChloride preparationMetal chlorideFluidized bed

Porous plate 13 is disposed between wind box 11 of dispersion board B and cylindrical vessel wall 12. Filling layer 14 of a structure packed with ceramic particles such as those of fused silica is disposed on the porous plate 13 so as to fill the inside of the cylindrical vessel wall. The filling layer 14 is composed of ceramic particles, so that the corrosion wear by chlorine gas can be inhibited and the durability thereof enhanced. Furthermore, a chlorine resistant member is disposed in a form so as to adhere to the internal surface of the cylindrical vessel wall 12, so that the corrosion wear by chlorine gas of the cylindrical vessel wall 12 can also be effectively inhibited. As a result, damage to the internal wall of the chlorination furnace can be minimized, and the state of allowing chlorine gas to be uniformly dispersed and supplied to fluidized bed 4 containing titanium ore and coke can be maintained for prolonged periods.

Owner:TOHO TITANIUM CO LTD

Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

ActiveCN102070921APrevent chalkingGood weather resistancePigment treatment with organosilicon compoundsPigment physical treatmentPhosphateSlurry

The invention provides a method for preparing special titanium dioxide pigment for plastic sectional materials by a chlorination method, which comprises the following steps that: the chlorination method is adopted for preparing titanium dioxide primary products into slurry, and the pH value of the slurry is regulated to 4.0 to 5.0; phosphate dispersing agents are added; grinding treatment is carried out, then, grinding media is removed, and the temperature is raised; water-soluble silicate solution is added, the pH value of the slurry is maintained between 3.5 and 4.5, amorphous silicon oxide is formed, curing is carried out, and a first covering layer is formed; the pH value of the slurry is regulated to 6.0 to 7.0, curing is carried out, and a second covering layer is formed; aluminum salt solution is added, the pH value is controlled between 7.0 and 9.0, curing is carried out, a third covering layer is formed, the pH value of the slurry is regulated to 6.0 to 7.0, and curing is carried out; the slurry is washed by de-ionized water until the conductivity of filter cake is higher than 15000 ohm*cm, and then, drying and air powder treatment are carried out; modified polysiloxane is added in the air powder process, and a fourth organic covering layer is formed; and materials are recovered through a bag filter. The titanium dioxide pigment prepared by the method provided by the invention has the advantages of high weatherability, high shielding capability, high non-transparency and excellent processing performance in the field of plastic sectional materials.

Owner:中信钛业股份有限公司

Method of cleaning dairy pipelines using enzyme pretreatment

InactiveUS20020177220A1Inorganic/elemental detergent compounding agentsHydrolasesProteinase activityPolyol

Owner:WEST AGRO

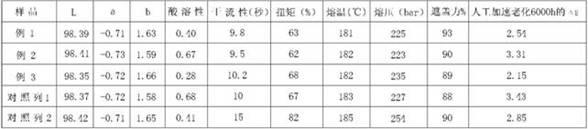

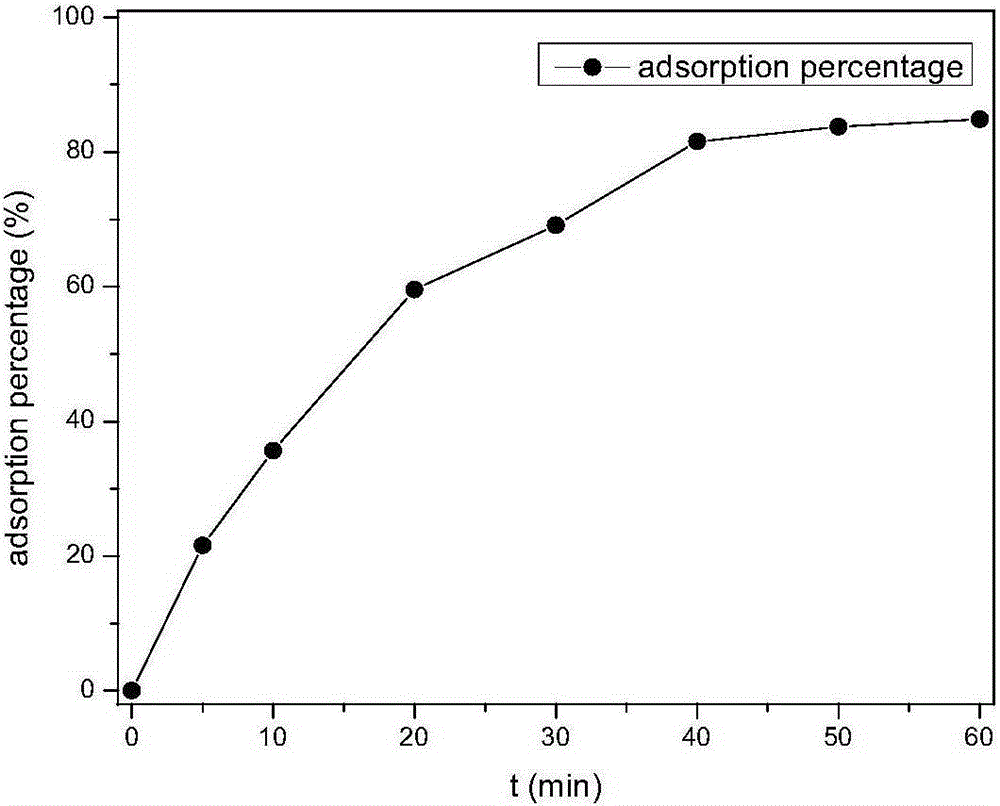

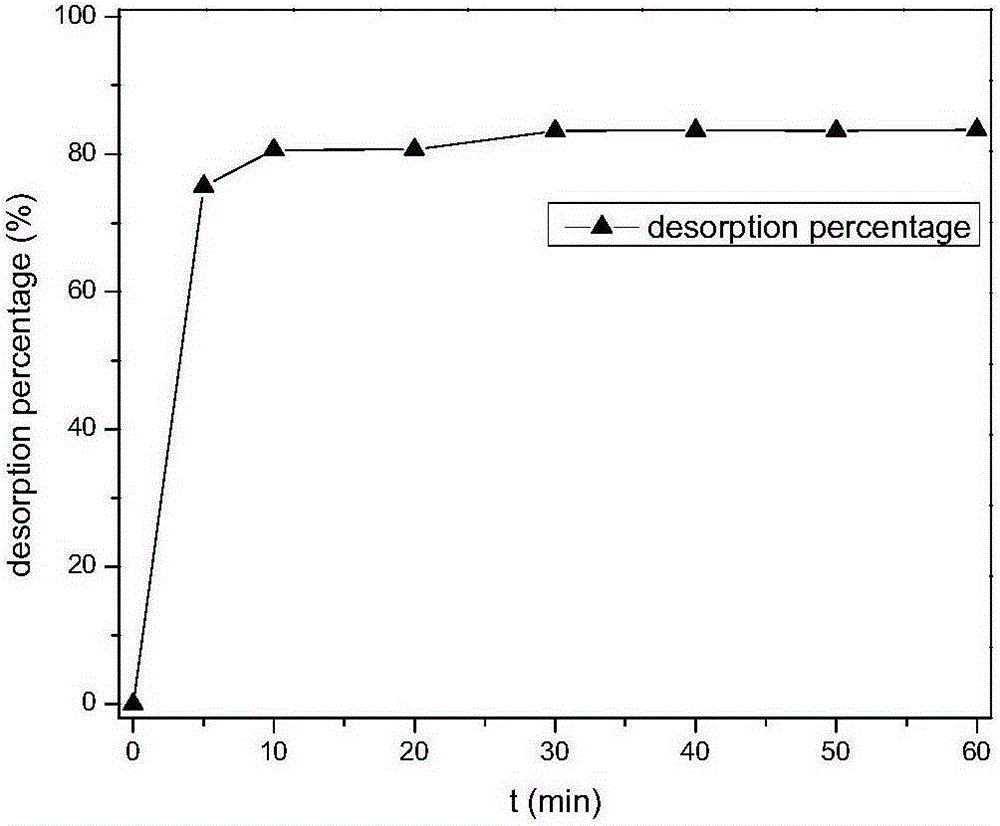

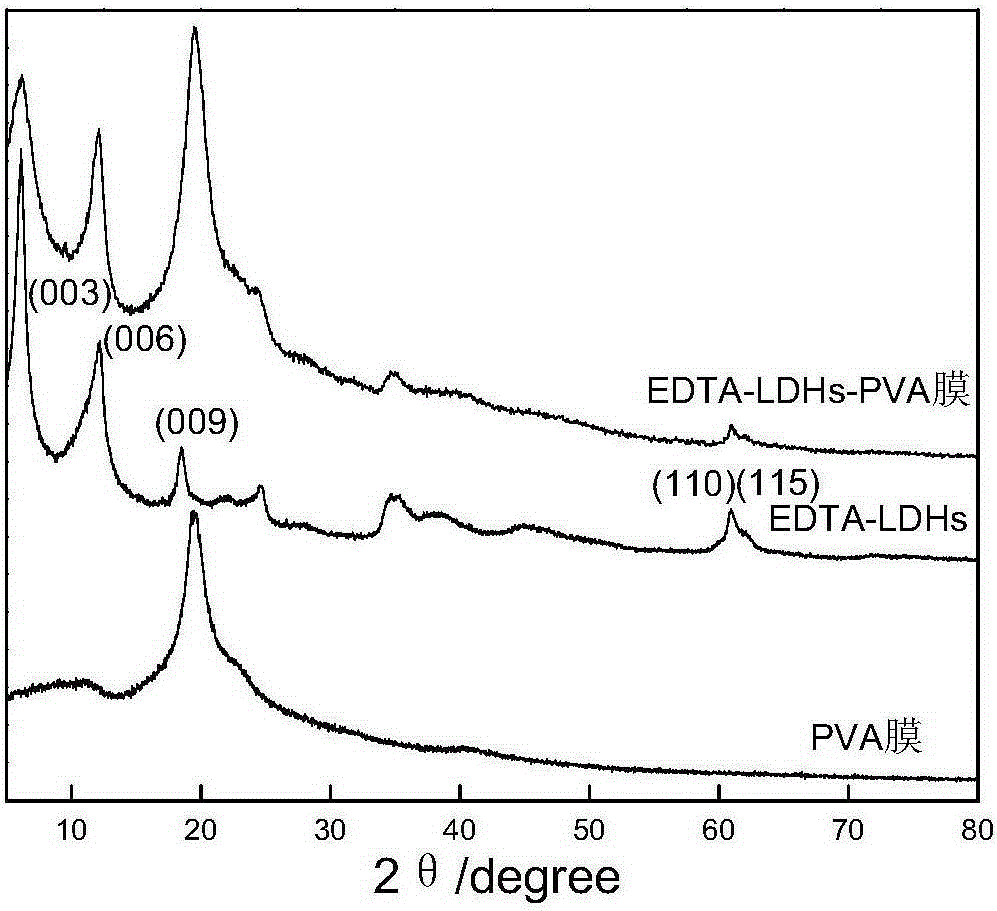

Preparation method for LDHs/PVA composite membrane and application of LDHs/PVA composite membrane in heavy metal wastewater

ActiveCN105344335AMild preparation conditionsLow costOther chemical processesWater contaminantsDivalent metalNitrate salts

The invention belongs to the technical field of composite membrane materials, and particularly relates to a preparation method for a layered double hydroxides composite material and an application of the layered double hydroxides composite material in heavy metal wastewater. The preparation method comprises the steps of: by adopting a coprecipitation method, firstly preparing a nitrate or chlorate aqueous solution A of divalent metal cations M<2+> and a nitrate or chlorate aqueous solution of trivalent metal cations M<3+>, and adding an aqueous solution C wherein organic salt of a heavy metal ion chelating agent is fully dispersed; obtaining layered double hydroxides of the heavy metal ion chelating agent through aging, vacuum drying, crushing and sieving; and mixing the layered double hydroxides with PVA to prepare a membrane and then preparing an LDHs / PVA composite membrane. As a composite membrane adsorbing material is soaked into heavy metal wastewater containing Cu<2+>, Cd<2+> or Pb<2+>, the adsorption rate can reach 92%. The method provided by the invention is mild in preparation condition and low in cost and has a good application prospect.

Owner:FUJIAN NORMAL UNIV

Electrolytic plating assisting method for hot dip galvanizing of steel wire and electrolytic plating assistant

InactiveCN101948990AEasy to dryImprove protectionHot-dipping/immersion processesElectrolysisEthylic acid

The invention relates to electrolytic plating assistant for hot dip galvanizing of a steel wire. Electrolytic plating assistant comprises the following components: 30-220 g / L of zinc chloride, 0-150 g / L of potassium chloride, 0-150 g / L of sodium chloride, 2-90 g / L of ammonium chloride, 0-100 g / L of boric acid, 0-70 g / L of acetic acid, 1-25 g / L of sodium fluoride, 2-50 g / L of cerium chloride, 0-50 g / L of potassium fluozirconate, 0-50 g / L of methanol, 0.5-20 g / L of hydrogen peroxide and the balance of water. The electrolytic plating assisting method comprises the following steps: washing with alkali, removing oil, washing with water, washing with acid to remove rust, washing with water, activating with weak acid, electrolyzing to assist plating, drying, and purifying the electrolytic plating assistant. The method can reduce the generation of AlCl3, prevent skip plating and reduce the generation of smoke dust. The electrolytic plating assistant has the characteristic of relatively high melting point, and thus, can increase the drying temperature and shorten the drying time. The dried plating assistant has the characteristics of low brittleness, high compatibility with electrogalvanizing, and low tendency to shedding.

Owner:NORTHEASTERN UNIV

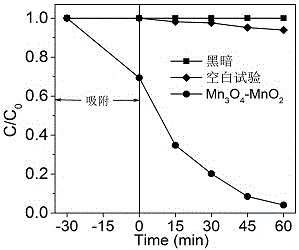

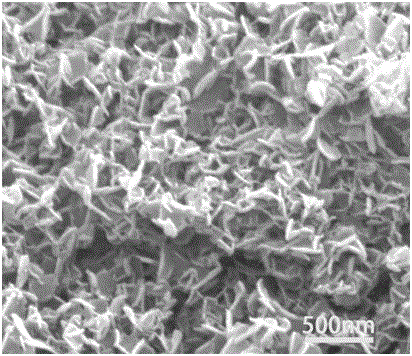

Preparation method of Mn3O4-MnO2 nano composite material and application thereof

InactiveCN106475090ASimple processEasy to operateMaterial nanotechnologyWater/sewage treatment by irradiationAlcoholRoom temperature

The invention relates to a preparation method of Mn3O4-MnO2 nano composite material and an application thereof; the preparation method includes steps of adding tetrahydrate manganese chloride and polyvinylpyrrolidone in de-ionized water, and adding the prepared mixing solution to the de-ionized water; adding sodium hydroxide and reacting; adding potassium permanganate in the reacted solution; keeping the stirring for 3-6 hours, and then cooling to room temperature; performing the centrifugal separation and obtaining precipitate; after alternatively washing the precipitate by de-ionized water and absolute ethyl alcohol, drying and obtaining the Mn3O4-MnO2 nano composite material, wherein the material thickness is 10-30 nm; the prepared nano composite material can be importantly applied to advanced oxidization technology. The process is simple in flow and free from pollution; the production and manufacturing costs of Mn3O4-MnO2 nano composite material can be reduced; meanwhile, the Mn3O4-MnO2 nano composite material prepared by the method can fundamentally degrade the organic pollutant in the water.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Scrubbed waste water treating and resource recovering process during the production of chlorobenzene

InactiveCN1347849AReach emissionsZero emissionMultistage water/sewage treatmentHigh concentrationChlorobenzene

The scrubbed waste water treating and resource recovering process includes introducing HCl to waste water while distilling off benzene and chlorobenzene; eliminating iron through passing through strong alkali anionic exchange resin to obtain hydrochloric acid effluent; eluting iron complex anion in the strong alkali anionic exchange resin with distilled water as regenerant to obtain eluting liquid, which is high concentration iron trichloride solution capable of being used as water purifier, while regenerating the resin. When the process is used in treating waste water containing Fe ion 2000-8000 mg / L, hydrochloric acid 2.5-4.0 mol / L, benzene 500-1000 mg / L and chlorobenzene 100-200 mg / L, Fe ion over 99 % and benzene and chlorobenzene over 95% may be eliminated while the resource being recovered.

Owner:NANJING UNIV

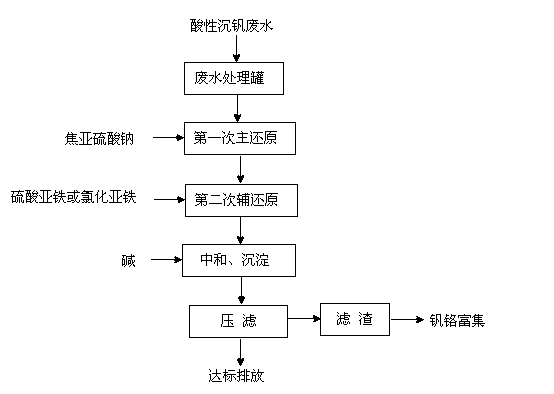

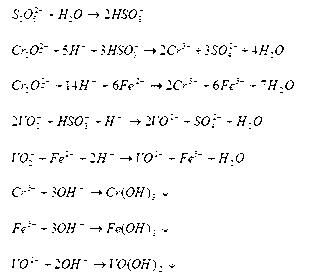

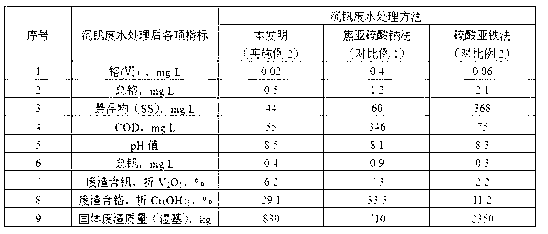

Treatment method for wastewater after vanadium precipitation

InactiveCN102795721AAchieve emission standardsReduce CODWater contaminantsMultistage water/sewage treatmentChemical oxygen demandSulfite salt

A treatment method for wastewater after vanadium precipitation comprises: detecting the concentrations of chromium (VI) and vanadium (V) in the wastewater after vanadium precipitation, and adding solid sodium pyrosulfite according to the total mass of the chromium (VI) and the vanadium (V) for a first reduction reaction; detecting the concentrations of the chromium (VI) and the vanadium (V) in the wastewater after vanadium precipitation and after the first reduction reaction, and adding ferrous sulphate or ferrous chloride according to the total mass of the chromium (VI) and the vanadium (V) for a second auxiliary reduction reaction; and adjusting pH value by using alkali, neutralizing, precipitating, press filtering, and the wastewater reaching the discharge standard for discharging. The indexes of chemical oxygen demand (COD), the suspension solids (SS), the total chromium (TCr) and the chromium (VI) are easy to control after the wastewater after vanadium precipitation being treated by using the method, and all the indexes meet the wastewater discharge standard of the nation. By using the method, a small quantity of waste residue is produced, the chromium and the vanadium are fully enriched in waste residue, and the waste residue can be used as the raw material for producing the vanadium and chromium, realizing the recycle of resource, eliminating environmental pollution and reducing wastewater treatment cost.

Owner:CITIC JINZHOU METAL

Method for producing a chlorinated hydrocarbon having 3 carbon atoms

InactiveUS20130165705A1High selectivityExcellent in reaction conversionPreparation by hydrogen halide split-offPreparation by halogen additionChlorideCarbon tetrachloride

A method of producing a chlorinated hydrocarbon having 3 carbon atoms, comprising a conversion step for converting a chloropropane represented by the following formula (1) into a chloropropane represented by the following formula (2) by reacting it with chlorine in the presence of anhydrous aluminum chloride.CCl3—CCl(2-m)Hm—CCl(3-n)Hn (1)(In the above formula (1), m is 1 or 2, and n is an integer of 0 to 3.)CCl3—CCl(3-m)H(m-1)—CCl(3-n)Hn (2)(In the above formula (2), m and n are the same integers as in the formula (1), respectively.)

Owner:TOKUYAMA CORP

Methods and compositions for wastewater treatment

Methods and compositions for wastewater treatment. The compositions comprise CaCO3, MgCO3, lanthanum chloride, or chitosan, and can be applied easily with conventional wastewater treatment processes and equipments. The methods and compositions of the present invention significantly improve treatment efficiency and reduce amount of required chemical additives.

Owner:BRUMMETT KEN

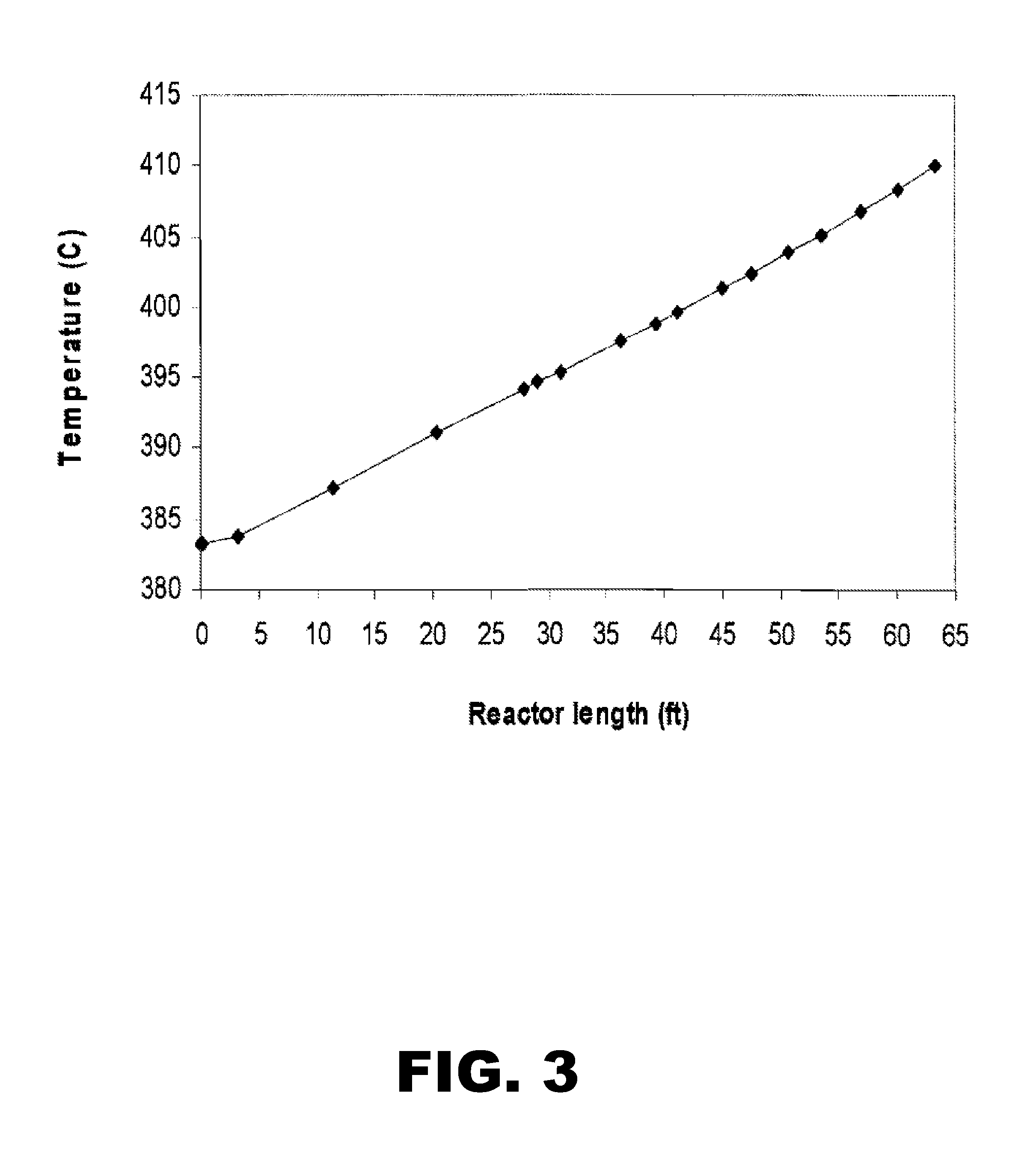

Adiabatic plug flow reactors and processes incorporating the same

InactiveUS20160347692A1Precise temperature controlWell mixedPreparation by halogen replacementChemical/physical/physico-chemical reactor detailsAlkeneChemistry

The present invention provides adiabatic plug flow reactors suitable for the production of chlorinated and / or fluorinated propene and higher alkenes from the reaction of chlorinated and / or fluorinated alkanes and chlorinated and / or fluorinated alkenes. The reactors comprise one or more designs that minimize the production of by-products at a desired conversion.

Owner:BLUE CUBE IP

Algaecide compositions and methods of removing algae

InactiveUS6291397B1TimeKeep for a long timeBiocideDead animal preservationLithium hydroxidePotassium hydroxide

An algaecide formulated in a concentrated, solid composition form for subsequent dissolution in water is disclosed. The algaecide is designed to remove algae from a variety of interior and exterior surfaces. The preferred algaecide compositions chlorinated isocyanurates, such as sodium dichloro-s-triazinetrione, alkali hydroxides selected from the group consisting of sodium hydroxide, potassium hydroxide, calcium hydroxide, and lithium hydroxide; metal sulfates selected from the group consisting of copper sulfate, zinc sulfate, and aluminum sulfate; and a buffer.

Owner:WILKINS JR JOE S

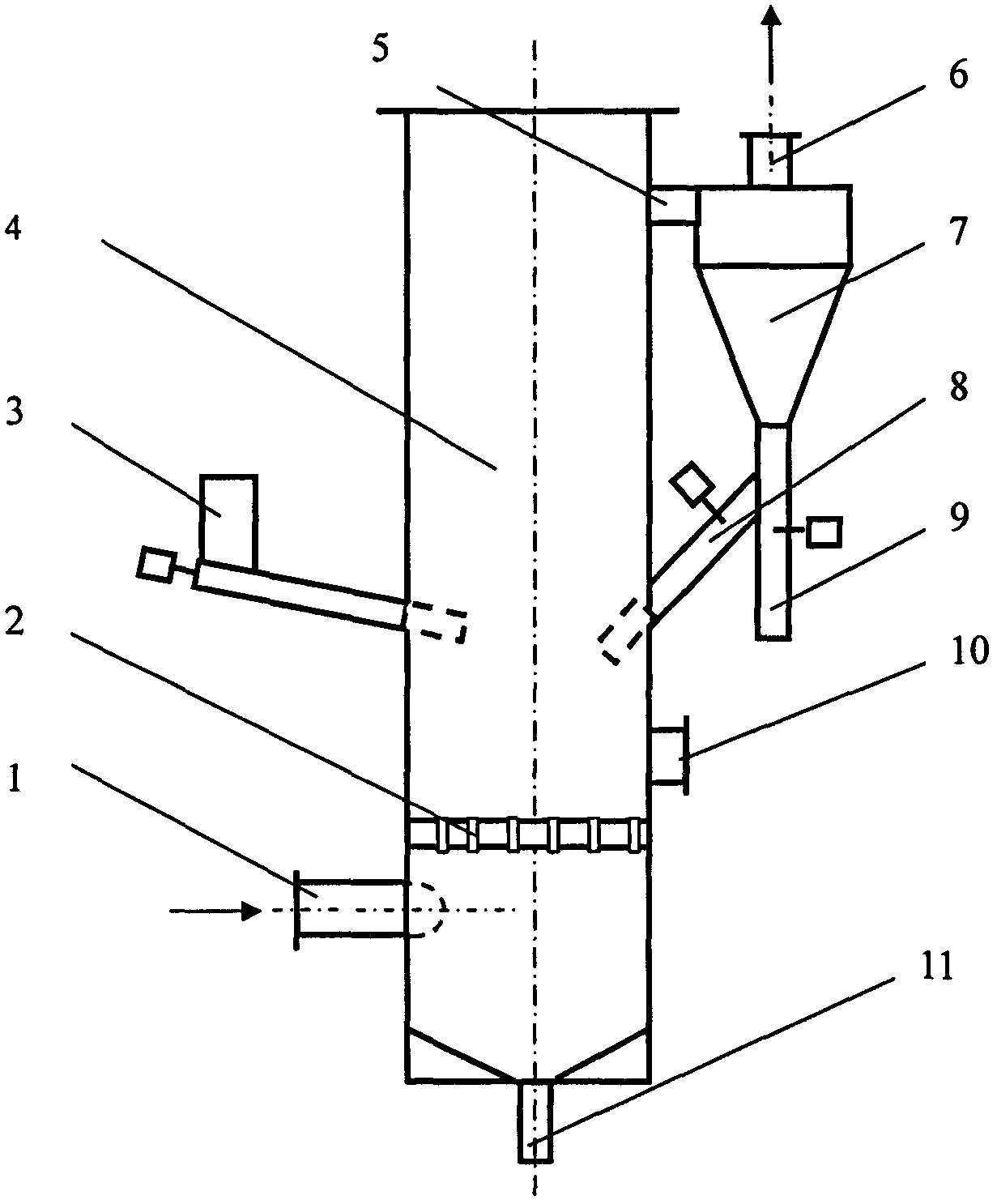

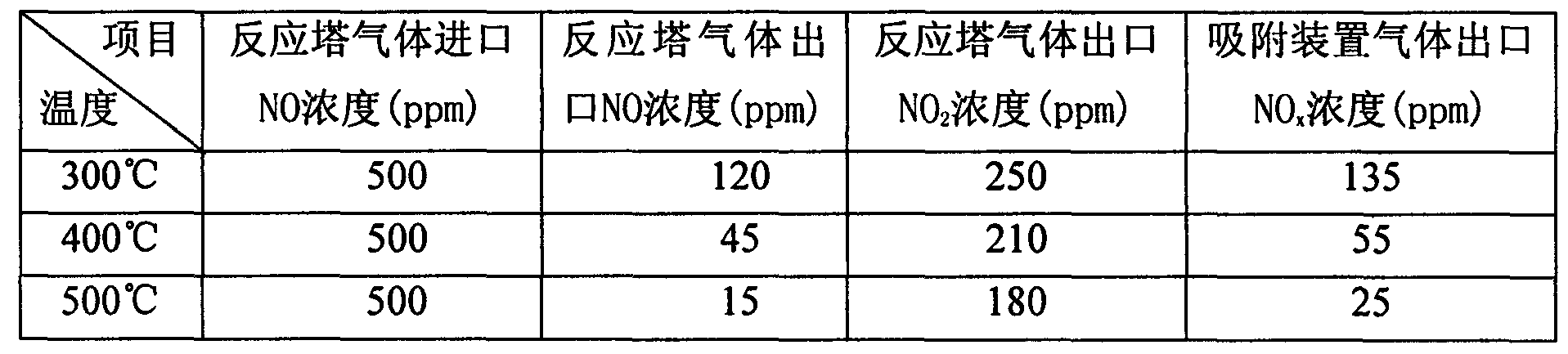

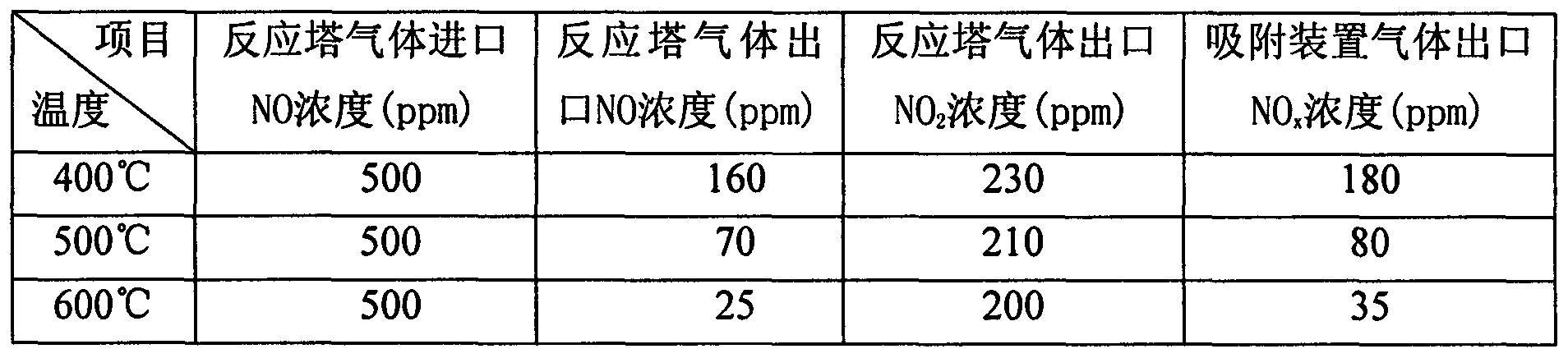

Method and device for simultaneous reduction and oxidation of nitrogen oxides from airflow

InactiveCN104353347ATo achieve the purpose of purificationImprove processing efficiencyDispersed particle separationAir quality improvementMetal chlorideNitrogen dioxide

The invention discloses a method and a device for simultaneous reduction and oxidation of nitrogen oxides from airflow. According to a treating process, the treated airflow is guided into a gas-solid reaction tower, solid ferrous chloride, ferric chloride, manganese chloride or magnesium chloride metal chloride particles are guided into the gas-solid reaction tower simultaneously, and the metal chloride is decomposed at the high temperature and reacts with nitric oxide in the airflow, so that part of nitric oxide contained in the airflow is reduced to nitrogen, the rest nitric oxide is oxidized into nitrogen dioxide, generated nitrogen dioxide reacts with an alkaline absorbent easily to be removed, and the purpose of gas purification is achieved. The invention further discloses the special device. The method and the device have the characteristics of low investment cost as well as operation and application cost, simplicity in operation, high treatment efficiency and high treatment capacity.

Owner:黄立维

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com