Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

A technology of titanium dioxide and plastic profiles, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems that the weather resistance can not be truly satisfied, and the covering power of dense silicon is not effectively improved, so as to improve the opacity, improve the Compatibility and the effect of improving optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

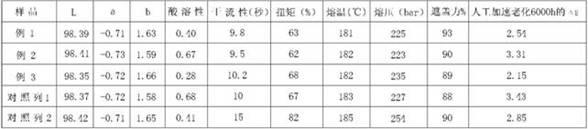

Examples

Embodiment 1

[0021] Weigh 500g of the primary product powder of titanium dioxide by chlorination method, wherein alumina accounts for 0.6% of the weight of the primary product of titanium dioxide, add deionized water to prepare a 500g / l slurry, and use a concentration of 20% sodium hydroxide solution to adjust the pH of the slurry value to 4.5; add sodium hexametaphosphate solution, phosphorus pentoxide in the phosphate dispersant accounts for 0.3% of the weight of the initial titanium dioxide product, and disperse for 30 minutes. Sand was added into a sand mill, and the above-mentioned slurry was sand-milled to obtain a slurry with an average particle size of 318nm, and the particle size distribution was calculated by quantity, and the proportion exceeding 800nm was 0.5%. Remove the grinding medium from the water slurry, raise the temperature of the sand-milled slurry to 80°C, and maintain this temperature throughout the silicon coating process, add 3.0% sodium silicate solution in 2 hou...

Embodiment 2

[0023] Weigh 400g of the primary product powder of titanium dioxide obtained by the chlorination method, wherein alumina accounts for 1.5% of the weight of the primary product of titanium dioxide, add deionized water to prepare a 400g / l slurry, and use a concentration of 20% sodium hydroxide solution to adjust the pH of the slurry value to 4.0, add sodium hexametaphosphate solution, phosphorus pentoxide in the phosphate dispersant accounts for 0.1% of the weight of the initial titanium dioxide product, and disperse for 20 minutes. The average particle diameter of the obtained slurry is 400nm, and the particle size distribution is calculated by number, and the proportion exceeding 800nm is 1.0%. Remove the grinding medium from the water slurry, raise the temperature of the sand-milled slurry to 60°C, and maintain this temperature throughout the silicon coating process, add 2.0% sodium silicate solution within 1 hour, and use 10% hydrochloric acid at the same time The solution...

Embodiment 3

[0025] Weigh 600g of the primary product powder of titanium dioxide obtained by the chlorination process, wherein alumina accounts for 1.0% of the weight of the primary product of titanium dioxide, add deionized water to prepare a 600g / l slurry, and use a concentration of 20% sodium hydroxide solution to adjust the pH of the slurry value to 5.0, add sodium hexametaphosphate solution, phosphorus pentoxide in the phosphate dispersant accounts for 1.0% of the weight of the initial titanium dioxide product, and disperse for 30 minutes. Sand was added into a sand mill, and the above-mentioned slurry was sand-milled to obtain a slurry with an average particle size of 327nm, and the particle size distribution was calculated by number, and the proportion exceeding 800nm was 0.5%.

[0026]Remove the grinding medium from the water slurry; raise the temperature of the sand-milled slurry to 90°C, and maintain this temperature throughout the silicon coating process, add 4.0% sodium silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com