Ceramic thermal-insulating composite material as well as preparation method and application thereof

A technology of composite materials and ceramics, which is applied in the field of ceramic heat-insulating composite materials and its preparation, can solve problems such as lower boiler thermal efficiency, high boiler surface temperature, and loss of moisture heat energy, and achieve improved boiler thermal efficiency, lower furnace surface temperature, and reduced heat loss. Dissipated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 A ceramic thermal insulation composite material

[0028] A ceramic thermal insulation composite material is composed of the following raw materials in parts by weight: 15 parts of aluminum dihydrogen phosphate, 5 parts of zirconia powder with a particle size of 800 mesh, 5 parts of magnesium oxide powder with a particle size of 800 mesh, and alumina with a particle size of 800 mesh 5 parts of fine powder, 10 parts of ceramic porous beads with a particle size of 400 mesh, 10 parts of ceramic fiber powder with a particle size of 200 mesh, 5 parts of rare earth driers, 10 parts of far-infrared ceramic mud, 5 parts of bentonite with a particle size of 200 mesh, The particle size is 10 parts of 200 mesh alumina, 5 parts of titanium oxide, and 15 parts of deionized water.

[0029] The preparation method includes the following steps:

[0030] 1) Add 15 parts of aluminum dihydrogen phosphate, 5 parts of zirconia powder, 5 parts of magnesium oxide powder, 5 parts of aluminum...

Embodiment 2

[0032] Example 2 A ceramic thermal insulation composite material

[0033] A ceramic thermal insulation composite material is composed of the following raw materials in parts by weight: 20 parts of aluminum dihydrogen phosphate, 5 parts of zirconia powder with a particle size of 800 mesh, 5 parts of magnesium oxide powder with a particle size of 800 mesh, and alumina with a particle size of 800 mesh. 5 parts of fine powder, 15 parts of ceramic porous beads with a particle size of 400 mesh, 5 parts of ceramic fiber powder with a particle size of 200 mesh, 5 parts of rare earth driers, 10 parts of far-infrared ceramic mud, 5 parts of bentonite with a particle size of 200 mesh, The particle size is 10 parts of 200 mesh alumina, 5 parts of titanium oxide, and 15 parts of deionized water.

[0034] The preparation method includes the following steps:

[0035] 1) Add 20 parts of aluminum dihydrogen phosphate, 5 parts of zirconia powder, 5 parts of magnesium oxide powder, 5 parts of aluminum...

Embodiment 3

[0037] Example 3 Application of Ceramic Insulation Composite Material

[0038] 1) Clean the ash on the boiler lining, and spray the surface with clean water;

[0039] 2) Stir the ceramic thermal insulation composite materials prepared in Example 1 and Example 2 and spray them on the surface of the lining of a high-temperature boiler respectively, with a spray thickness of 3-5mm;

[0040] 3) Use a brush to trim the sprayed surfaces of the three boilers to a smooth and even surface;

[0041] 4) Sinter the sprayed boiler lining at 600℃ for 2h.

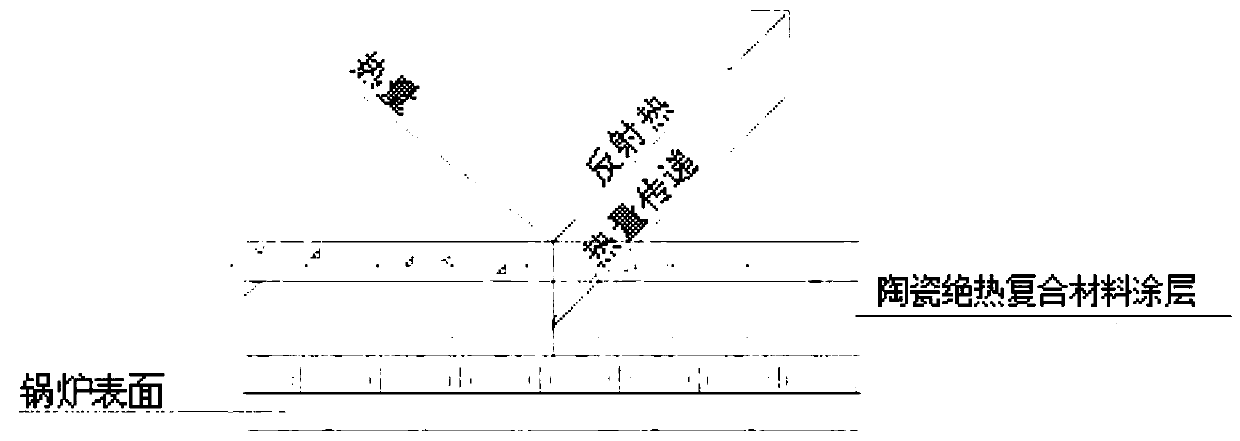

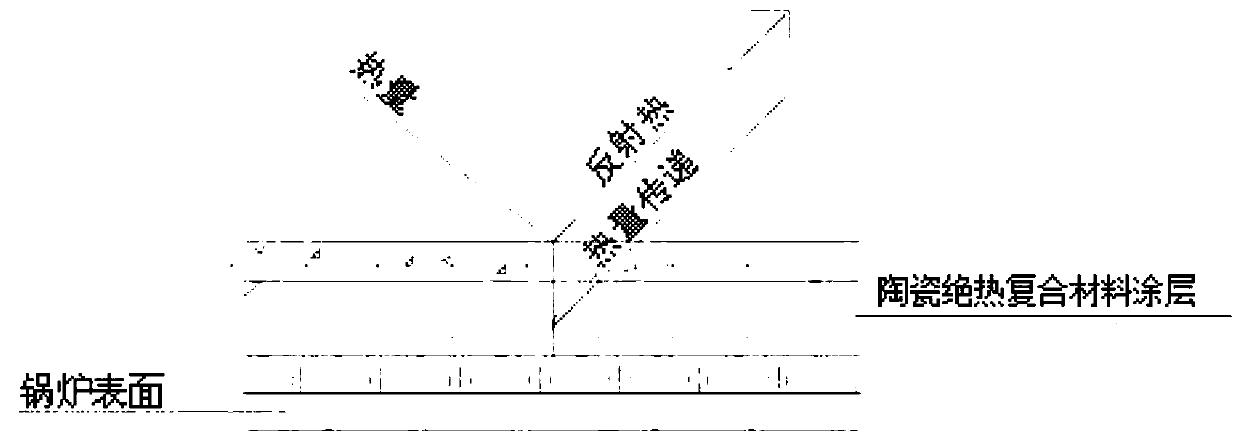

[0042] Such as figure 1 As shown, the boiler lining sprayed ceramic thermal insulation composite material is sintered at a high temperature to form a ceramic shell. In use, it can reflect most of the internal heat of the boiler and reduce the heat transfer to the outside of the boiler. Reduce the temperature of the external surface of the boiler and improve the thermal efficiency of the boiler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com