Method for preparing multifunctional titanium dioxide pigment with chlorination method

A titanium dioxide, multi-functional technology, applied in the direction of chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of unsatisfactory weather resistance, achieve prevention of pulverization and loss of gloss, high weather resistance, and improve weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

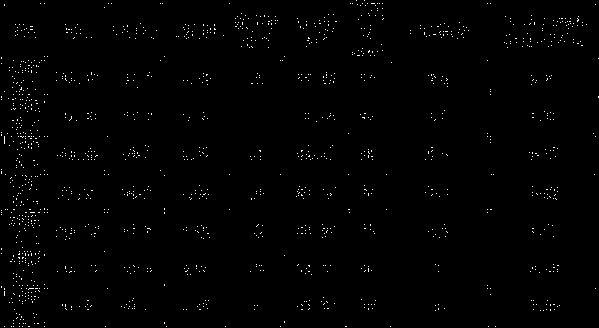

Image

Examples

Embodiment 1

[0021] 1. Weigh 500g of the primary product of titanium dioxide by chloride method, and the content of alumina in the primary product is 1.2%.

[0022] 2. Add deionized water to prepare a 500g / l slurry, adjust the pH value of the slurry to 10.0 with sodium hydroxide solution, add sodium hexametaphosphate solution, the amount of sodium hexametaphosphate solution is based on five Phosphorus oxide accounted for 0.5% by weight of the primary product of titanium dioxide, and dispersed for 30 minutes.

[0023] 3. Add sand into the sand mill, and sand-mill the above-mentioned slurry. After sand-milling, the average particle size of the slurry is 300nm, and the particle size distribution is calculated by quantity. The proportion exceeding 1000nm is 0.24%.

[0024] 4. Remove the grinding media from the slurry.

[0025] 5. Raise the temperature of the above slurry to 80°C.

[0026] 6. Add sodium silicate solution at one time, the amount of sodium silicate solution added is 1.0% based ...

Embodiment 2

[0033] 1. Weigh 400g of the primary product of titanium dioxide by chloride method, and the content of alumina in the primary product is about 0.6%.

[0034] 2. Add deionized water to prepare a 400g / l slurry, adjust the pH value of the slurry to 9.0 with sodium hydroxide solution, add sodium hexametaphosphate solution, the amount of sodium hexametaphosphate solution is five Phosphorus oxide accounted for 0.1% by weight of the primary product of titanium dioxide, and dispersed for 20 minutes.

[0035] 3. Add sand into the sand mill, and sand-mill the above-mentioned slurry. The average particle size of the slurry is 365nm, and the particle size distribution is calculated by quantity, and the proportion exceeding 1000nm is 0.55%.

[0036] 4. Remove the grinding media from the slurry.

[0037] 5. Raise the temperature of the sand-milled slurry to 60°C.

[0038] 6. Add sodium silicate solution at one time, the amount of sodium silicate solution added is 0.5% based on the weight ...

Embodiment 3

[0045] 1. Weigh 600g of the primary product of titanium dioxide by the chloride method, and the content of alumina in the primary product is 1.5%.

[0046] 2. Add deionized water to prepare a 500g / l slurry, adjust the pH value of the slurry to 11.0 with sodium hydroxide solution, add sodium hexametaphosphate solution, the amount of sodium hexametaphosphate solution is based on five Phosphorus oxide accounts for 1.0% by weight of the primary titanium dioxide product, and is dispersed for 30 minutes.

[0047] 3. Add sand into the sand mill, and sand-mill the above-mentioned slurry. The average particle size of the slurry is 500nm, and the particle size distribution is calculated by quantity, and the proportion exceeding 1000nm is 1.0%.

[0048] 4. Remove abrasive impurities from the slurry.

[0049] 5. Raise the temperature of the sand-milled slurry to 90°C.

[0050] 6. Add 2.0% sodium silicate solution at one time, based on the weight of silicon dioxide in sodium silicate as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com