Exterior wall coating and preparation method thereof

A technology for exterior wall coatings and pigments and fillers, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of affecting the decorative appearance of buildings, low gloss, easy back-sticking, etc., and achieve easy large-scale promotion and application, low equipment requirements, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

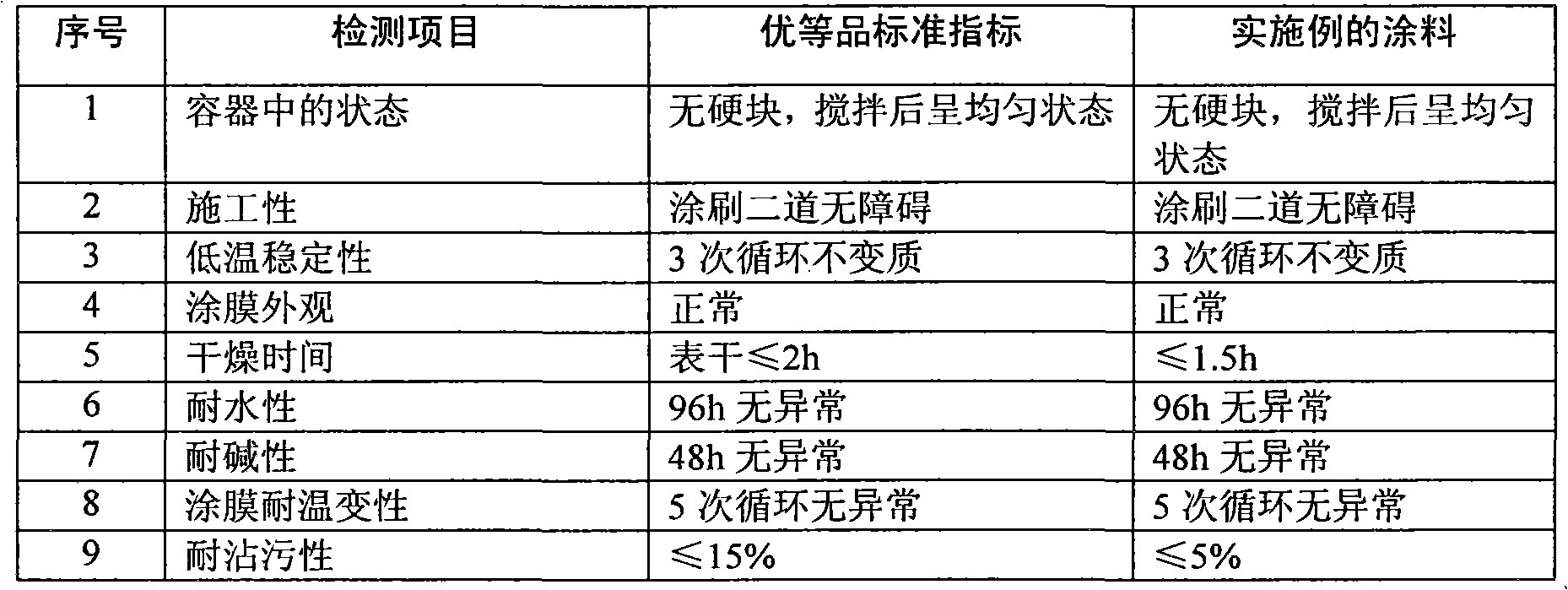

Examples

Embodiment 1

[0055] Formulation composition of exterior wall paint:

[0056] raw material

Dosage(kg)

Manufacturer / Supplier

water

24.2

[0057] Interpenetrating network structure silicone acrylic emulsion

20

self made

Styrene acrylic emulsion

20

National starch

Modified Nano Silica

5

self made

10

Shanghai Yantai

Ultrafine Calcium Carbonate Powder

10

Shenzhen peak

Kaolin

9

Shenzhen peak

Dispersant 5040

0.3

Rufa Chemical

Defoamer TP-39

0.1

Japan Nopco

Preservative KSG201

0.1

Guangdong Dimei

Leveling agent RM2020

0.3

Rohm and Haas

Thickener 3800

1

Haichuan Chemical

total

100

[0058] The preparation process of the silicone acrylic emulsion with network interpenetrating structure is as follows:

[0059] (1) First, 20 parts by weight...

Embodiment 2

[0074] Formulation composition of exterior wall paint:

[0075] raw material

Dosage(kg)

Manufacturer / Supplier

water

11.8

Interpenetrating network structure silicone acrylic emulsion

30

self made

Silicone acrylic emulsion

20

National starch

Modified Nano Titanium Dioxide

5

self made

10

Shanghai Yantai

Ultrafine Calcium Carbonate Powder

10

Shenzhen peak

Kaolin

10

Shenzhen peak

Dispersant 5040

1

Rufa Chemical

Defoamer TP-39

0.2

Japan Nopco

[0076] Preservative KSG201

0.1

Guangdong Dimei

Leveling agent RM2020

0.4

Rohm and Haas

Thickener 3800

1.5

Haichuan Chemical

total

100

[0077] The preparation process of the silicone acrylic emulsion with network interpenetrating structure is as follows:

[0078] (1) First, 22 parts...

Embodiment 3

[0092] Formulation composition of exterior wall paint:

[0093] raw material

Dosage(kg)

Manufacturer / Supplier

water

21.9

Interpenetrating network structure silicone acrylic emulsion

10

self made

Pure acrylic emulsion

40

National starch

Modified Nano Titanium Dioxide

5

self made

20

Shanghai Yantai

Dispersant 5040

0.3

Rufa Chemical

Defoamer TP-39

0.1

Japan Nopco

Preservative KSG201

0.1

Guangdong Dimei

Leveling agent RM2020

0.6

Rohm and Haas

Thickener 3800

2

Haichuan Chemical

total

100

[0094] The preparation process of the silicone acrylic emulsion with network interpenetrating structure is as follows:

[0095] (1) First, 23 parts by weight of vinyltriethoxysilane, 6 parts by weight of isobutyl methacrylate, 0.25 parts by weight of N-methylolacrylamide, 0.3 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com