Patents

Literature

5717 results about "Nitrile rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrile rubber, also known as NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene.

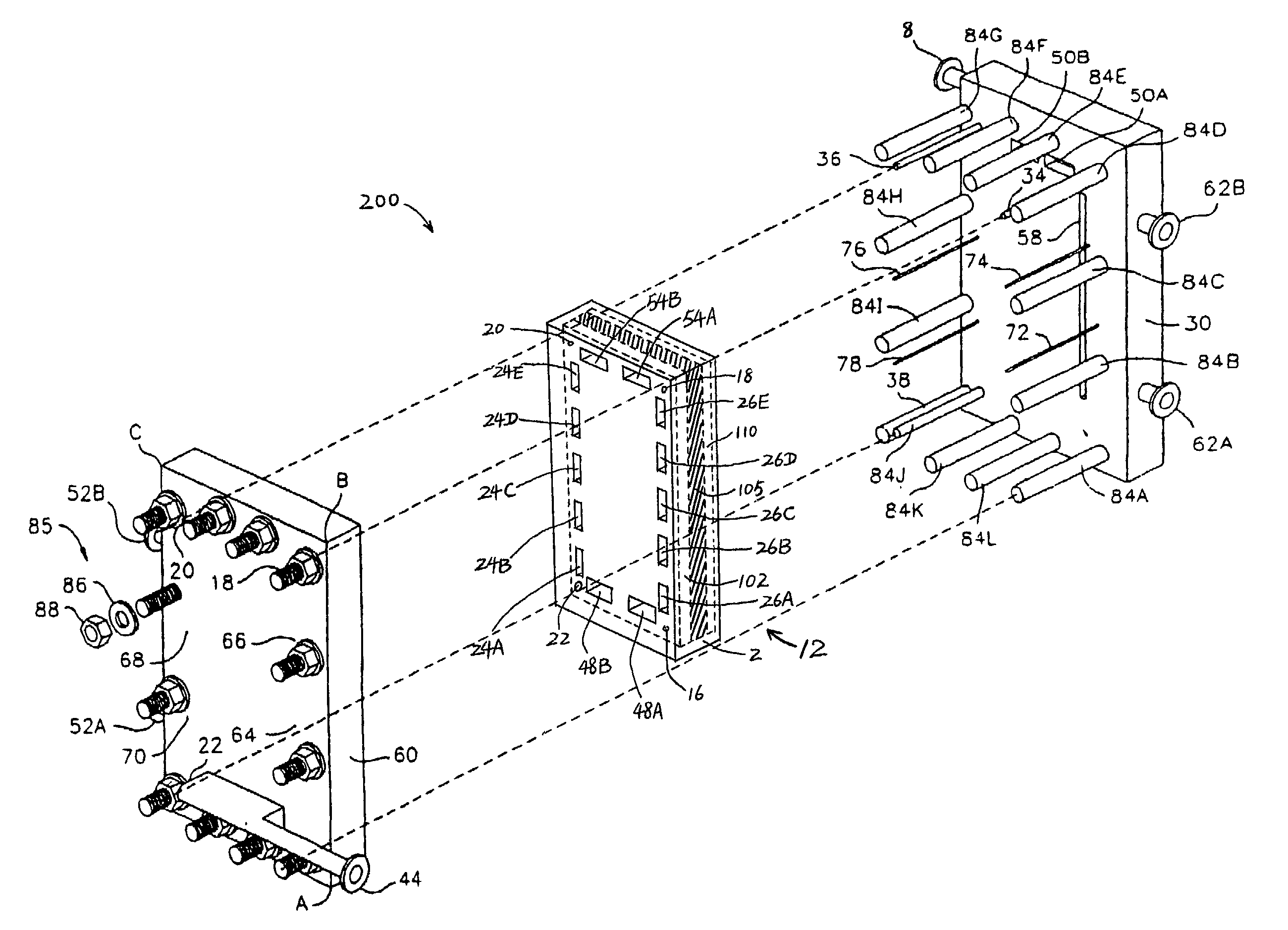

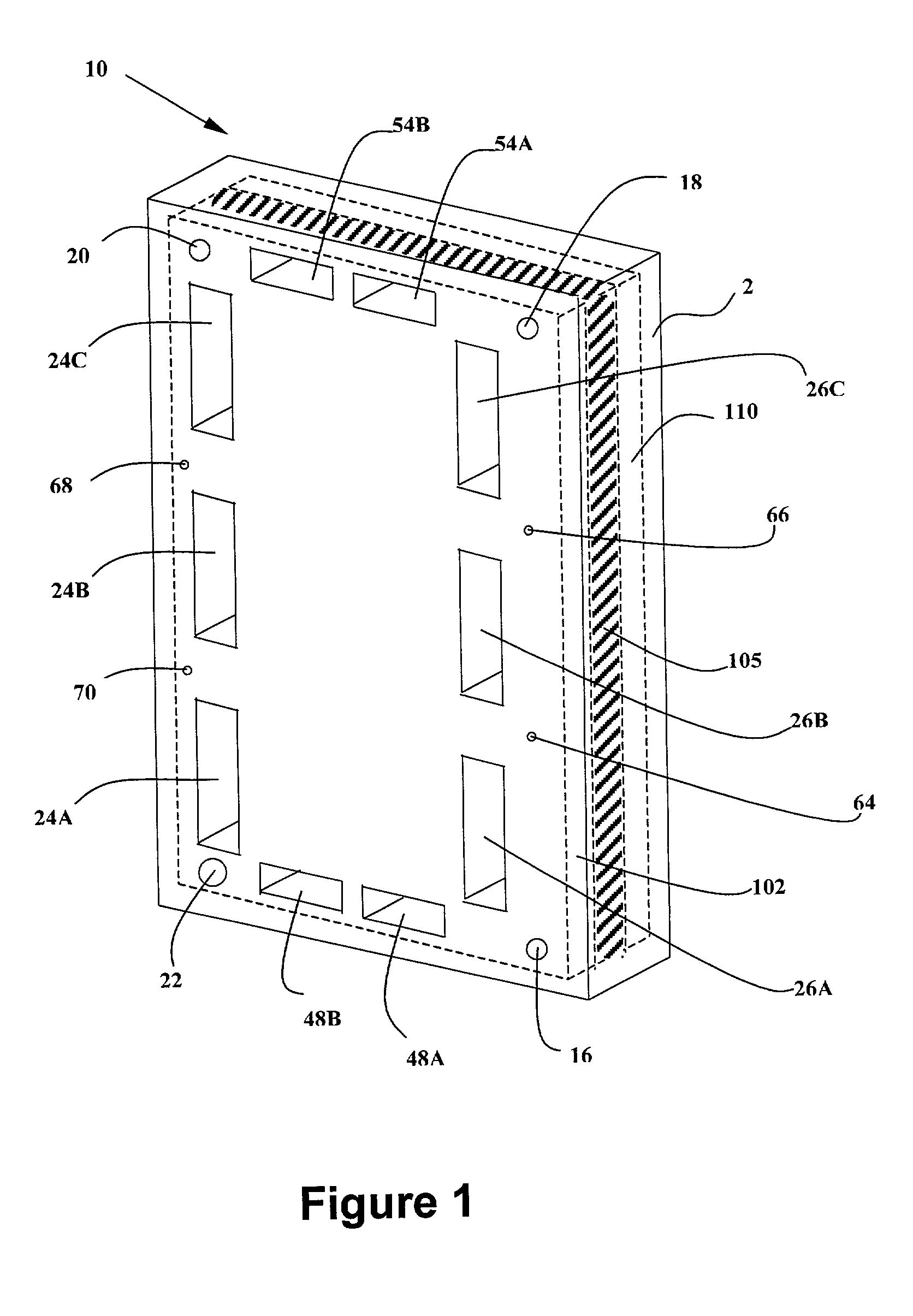

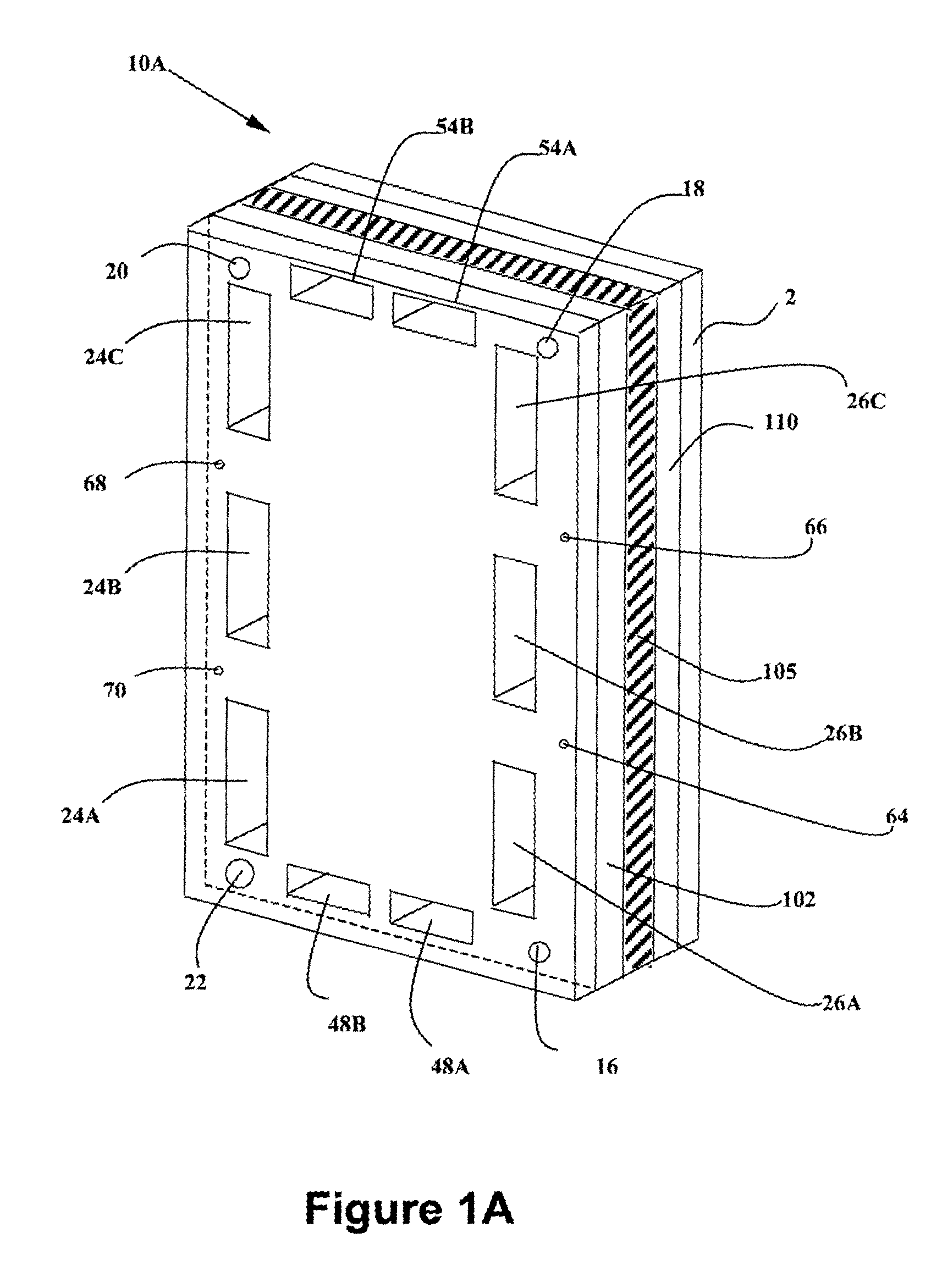

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Epoxy adhesive having improved impact resistance

InactiveUS20030196753A1Polyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyphenolExpandable microsphere

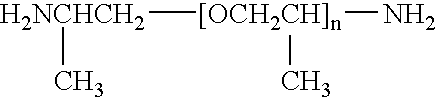

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

Irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material

ActiveCN102070821AGood oil resistanceGood flexibilityPlastic/resin/waxes insulatorsCross-linkSilanes

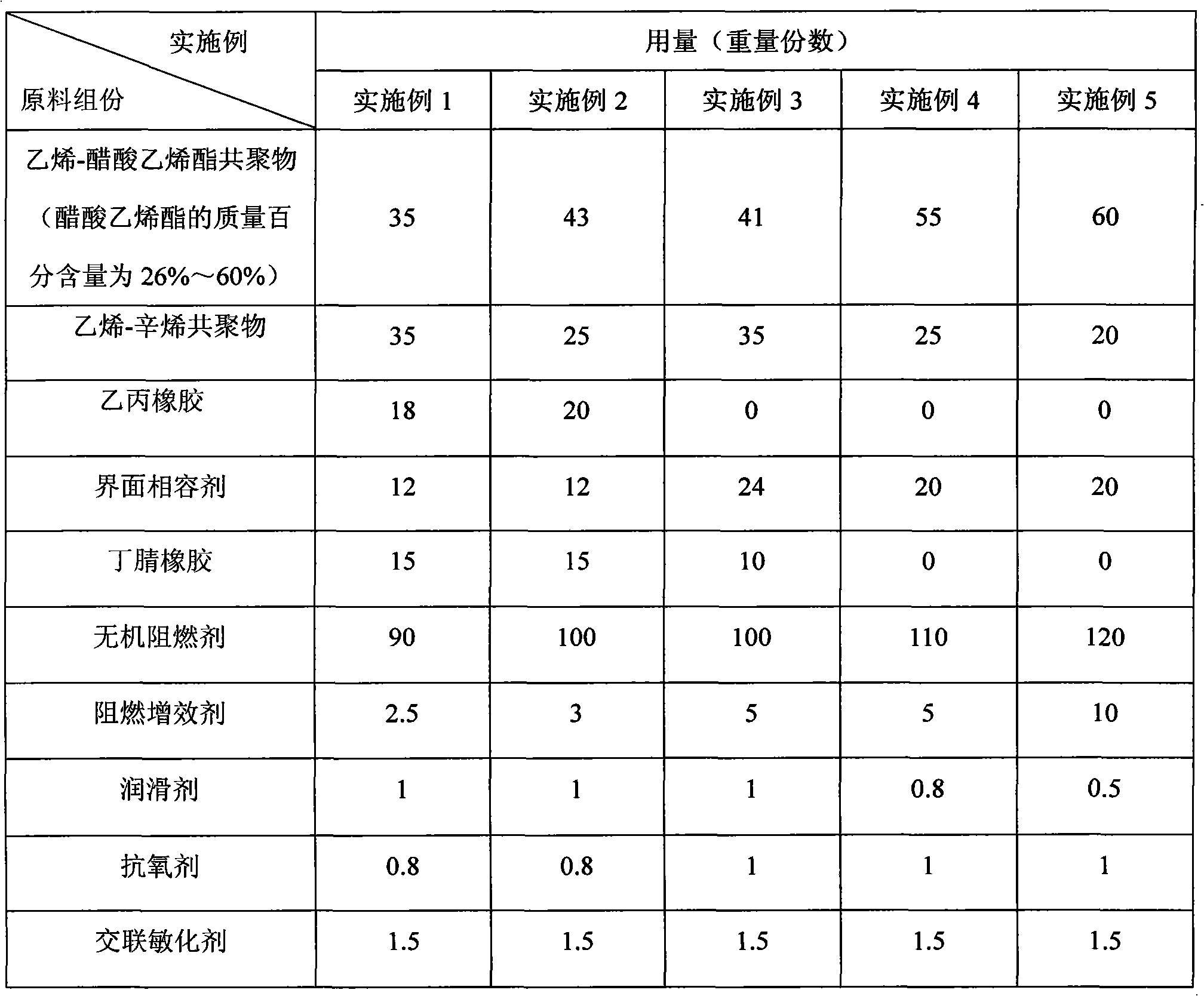

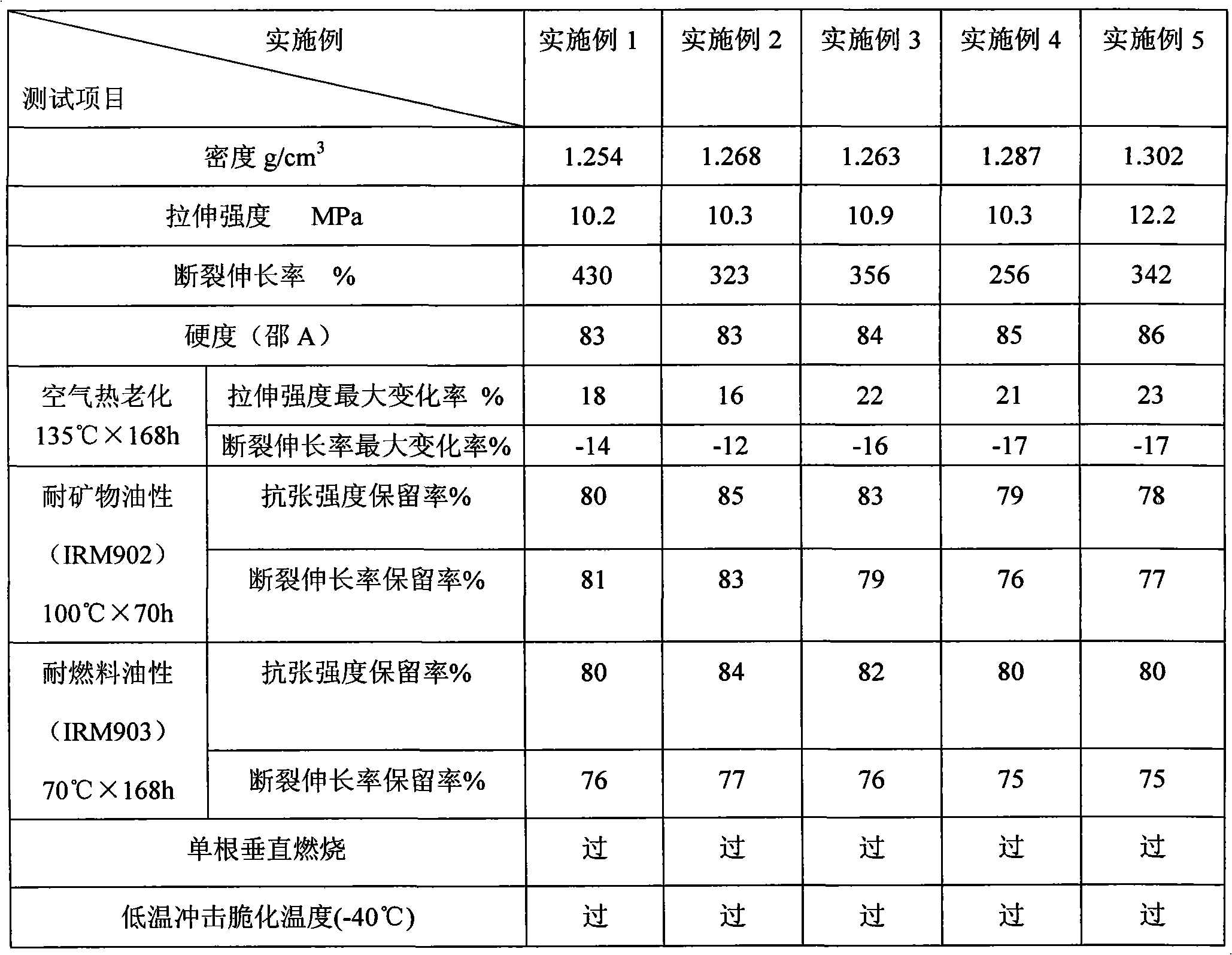

The invention provides an irradiation cross-linking oil resistance type soft low smoke zero halogen flame-retardant cable material which comprises the following components in parts by weight: 60-90 parts of ethylene-vinylacetate copolymer, ethylene-propylene-diene rubber and ethylene-octylene copolymer, 0-20 parts of nitrile rubber, 10-30 parts of interface compatilizer, 80-130 parts of flame retardant, 2-15 parts of flame-retardant synergist, 0.5-1.0 part of antioxidant, 1-2 parts of cross-linking sensitizing agent and 0.5-1.0 part of lubricant. The preparation method of the cable material in the invention mainly comprises the steps of silane surface modification treatment of the flame retardant, mixing and extruding of a double screw mixer-extruder unit or an internal mixer unit, brace water cooling or water ring particle cutting and the like. The cable material provided by the invention has the advantages of superior flame resistance (single cable can vertically burn), good mechanical properties, especially high softness, oil resistance, high-temperature resistance (the cable material can be used in a range of minus 40 DEG C-125 DEG C), low smoke, low toxicity and excellent processability.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

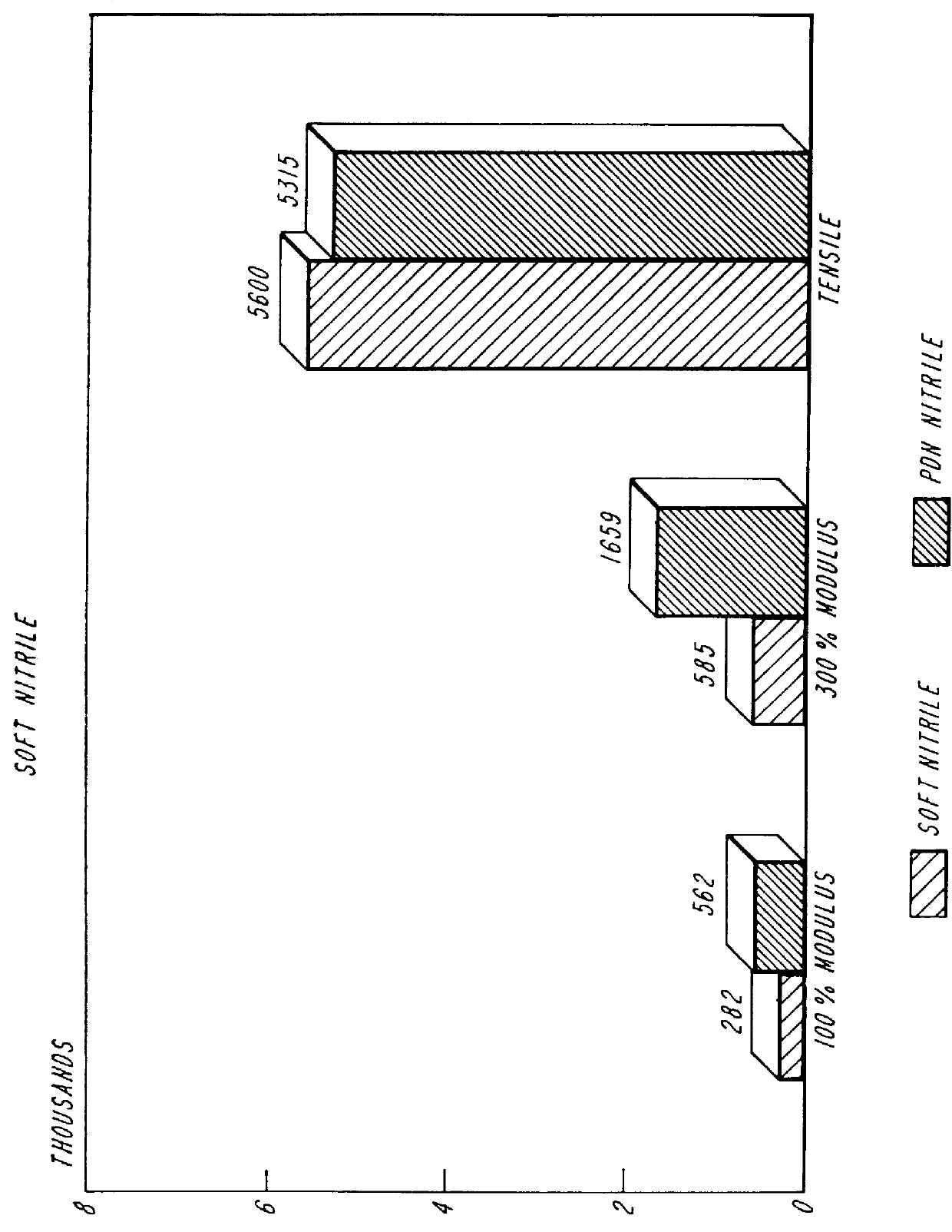

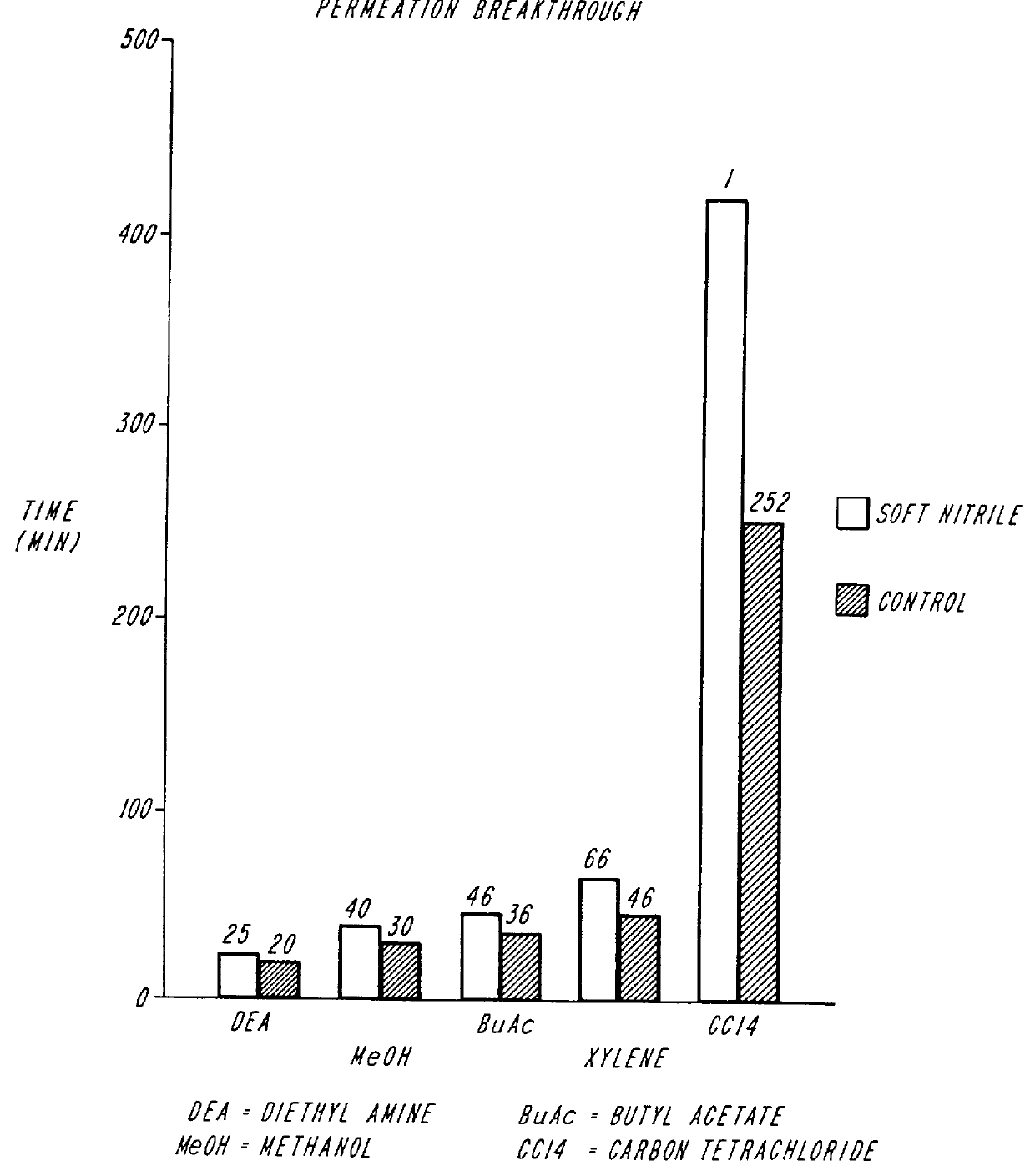

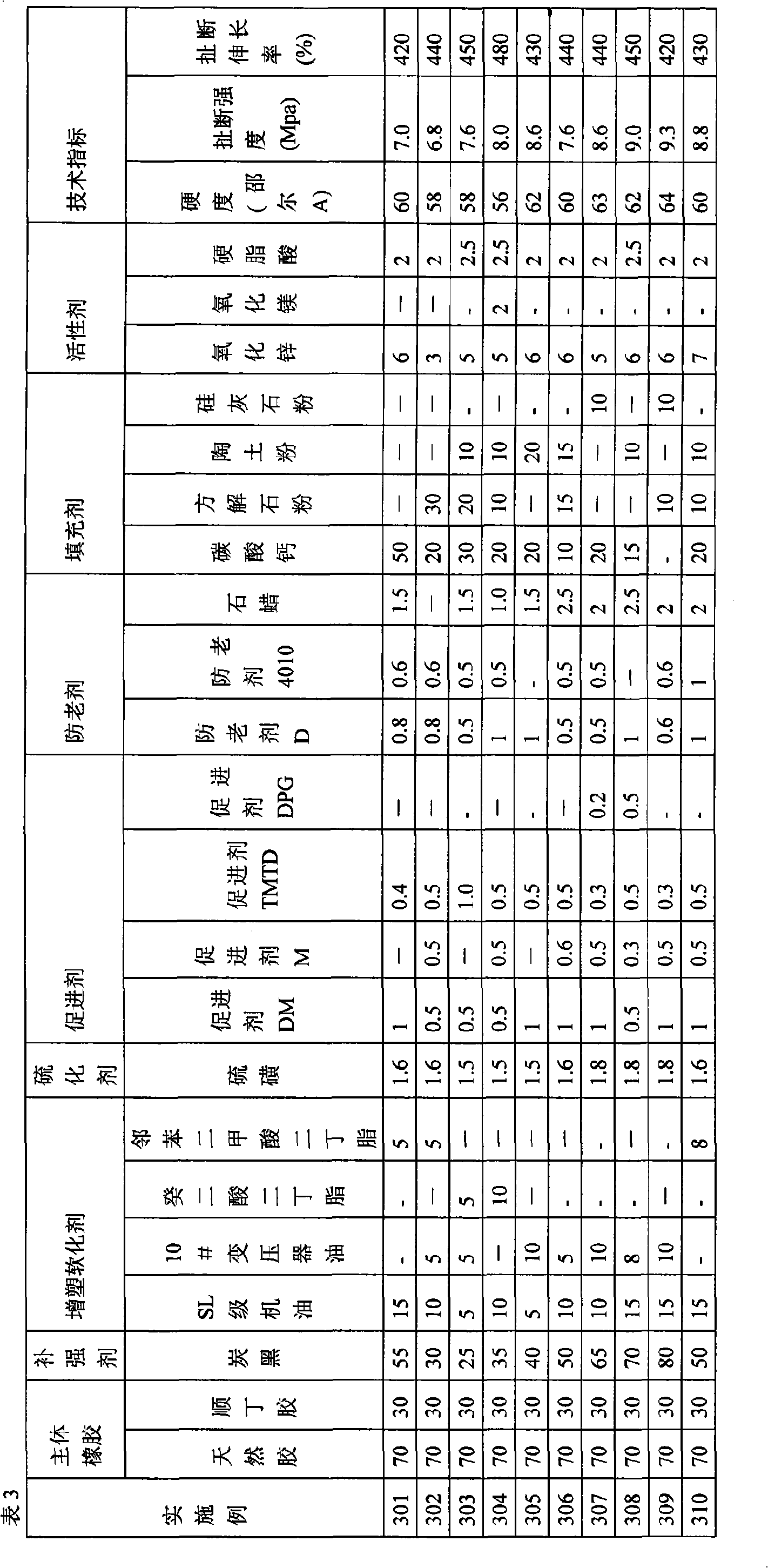

Soft nitrile rubber formulation

Nitrile rubber compositions, articles of manufacture made therefrom, and methods of making them, are disclosed. The nitrile rubber compositions of the invention are substantially free of zinc oxide, and have good strength and chemical resistance while being softer than many conventional nitrile rubbers. The invention provides articles of manufacture, including gloves, which are soft, yet strong, and can be economically manufactured.

Owner:NORTH SAFETY PROD INC

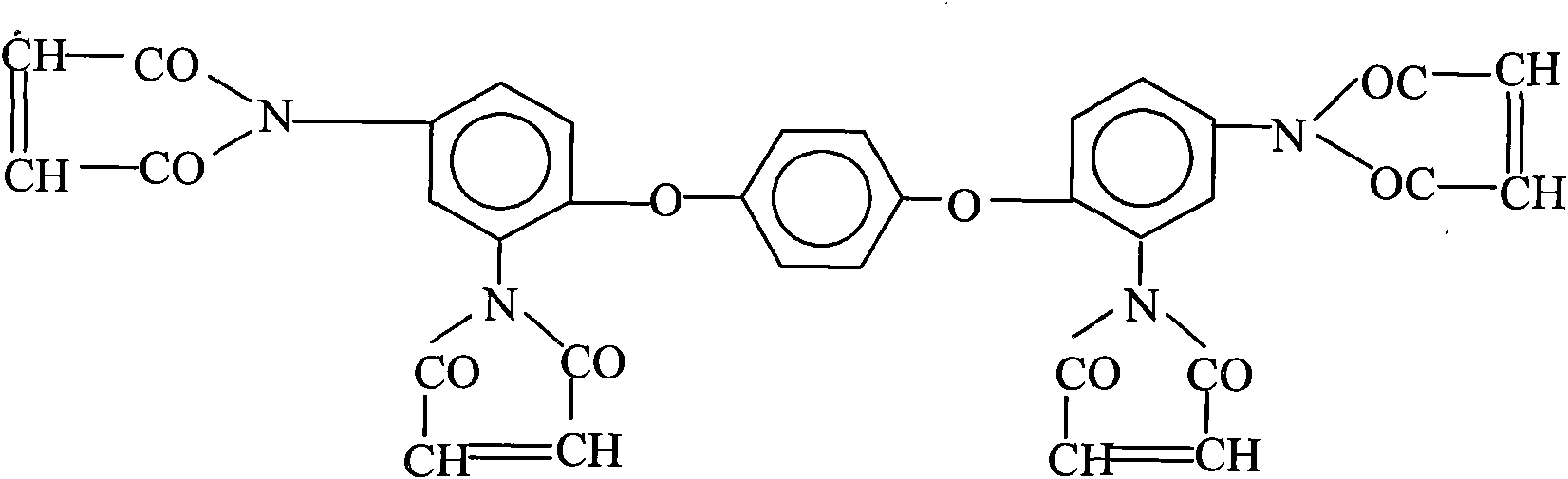

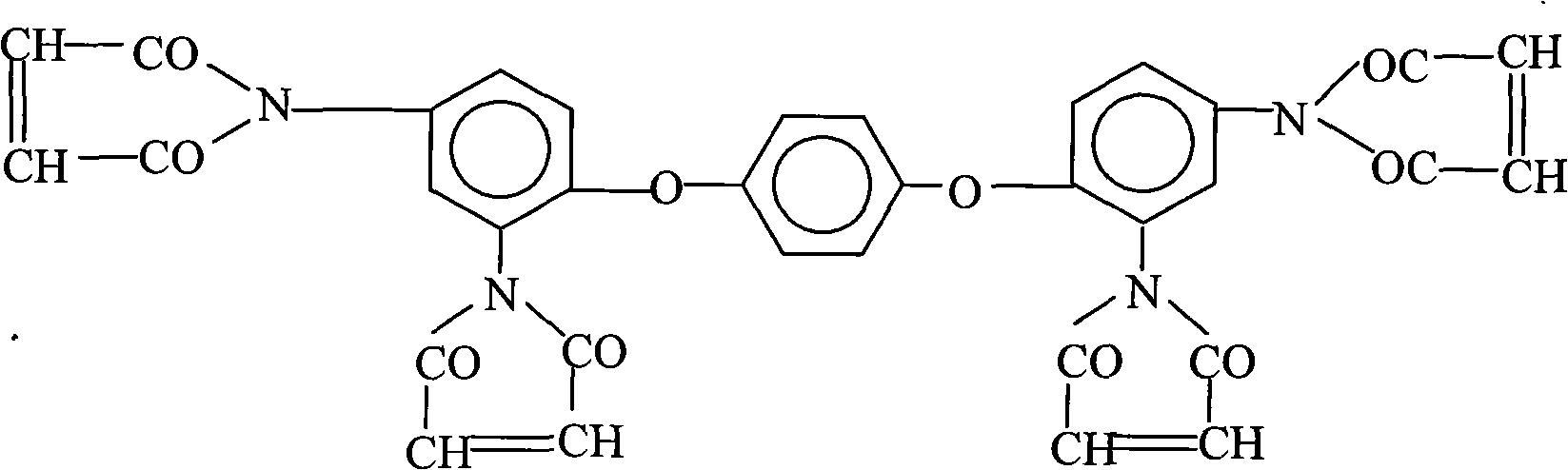

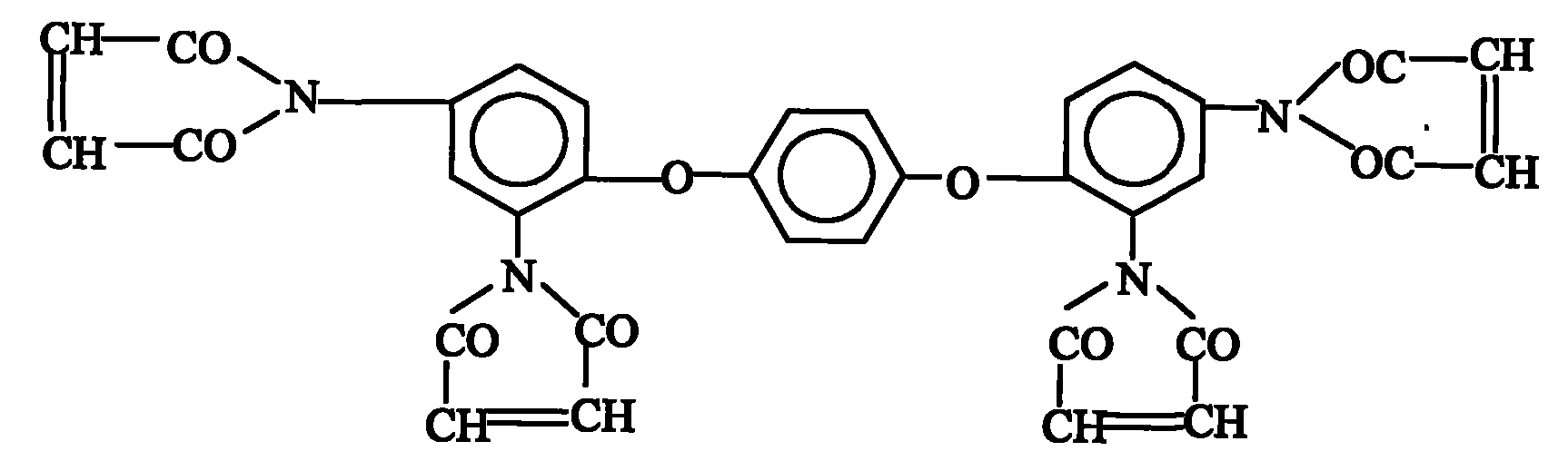

High-temperature-resistant modified polyfunctional epoxy matrix resin for advanced composite material and preparation thereof

The invention relates to high-temperature-resistant modified polyfunctional epoxy matrix resin for an advanced composite material. The resin comprises tetramaleimide resin, carboxy terminated nitrile rubber, polyfunctional epoxy resin, a curing agent and an organic solvent. A preparation method comprises the following steps of: adding the tetramaleimide resin, the carboxy terminated nitrile rubber and the polyfunctional epoxy resin into a reaction kettle and reacting at the temperature of 110 DEG C for one hour; adding the organic solvent and dissolving under stirring to obtain a component A;mixing the curing agent and the organic solvent and dissolving under stirring to obtain a component B; and mixing the component A and the component B and uniformly stirring during use. The high-temperature-resistant modified polyfunctional epoxy matrix resin provided by the invention has the advantages of high room temperature tensile shear strength, high heat resistance, wide application prospect in the fields such as electronics, micro-electronics, printed circuit boards (PCB), motors, aerospace and the like, simple preparation process, low cost and contribution to realizing industrial production.

Owner:DONGHUA UNIV +1

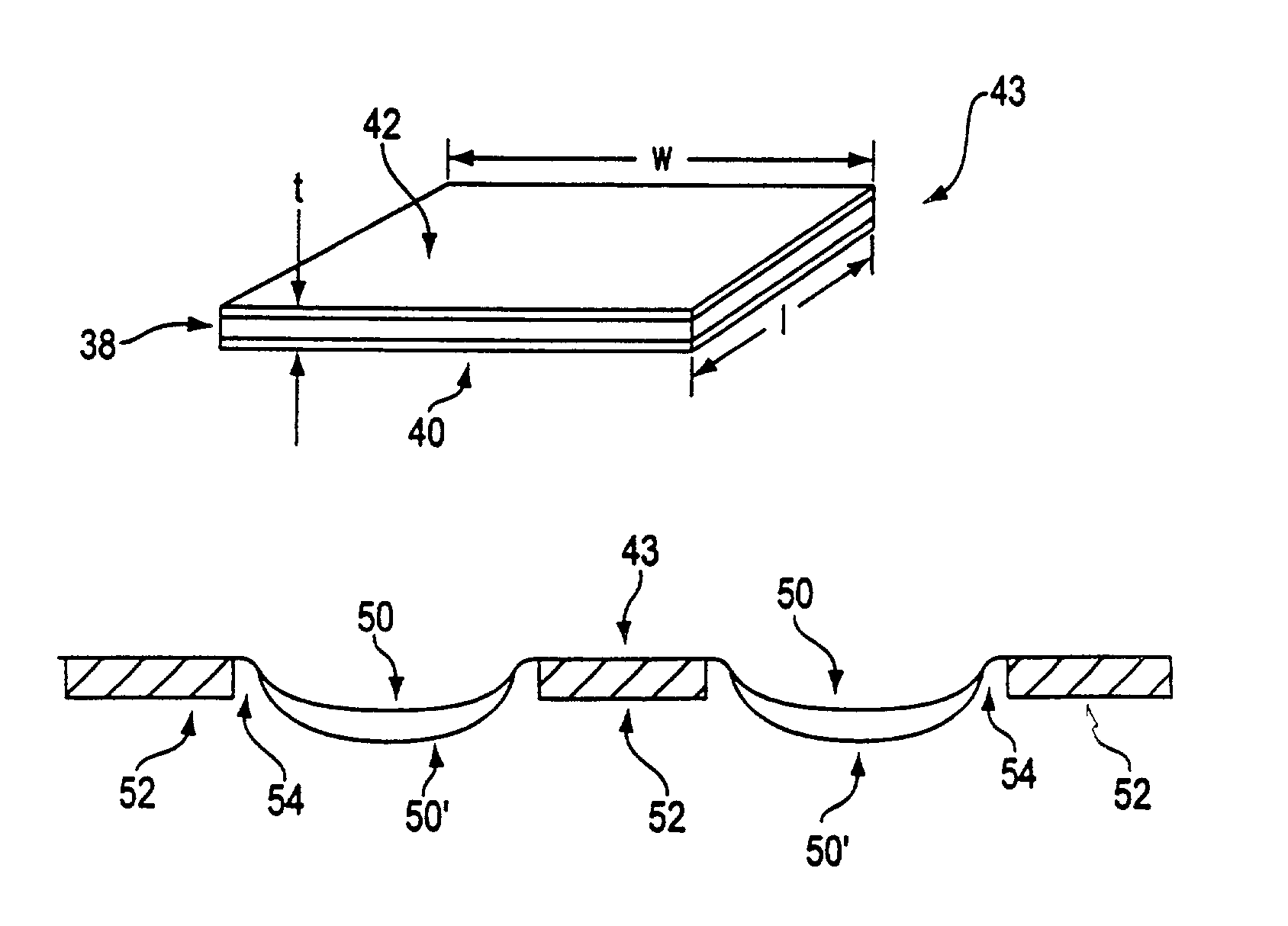

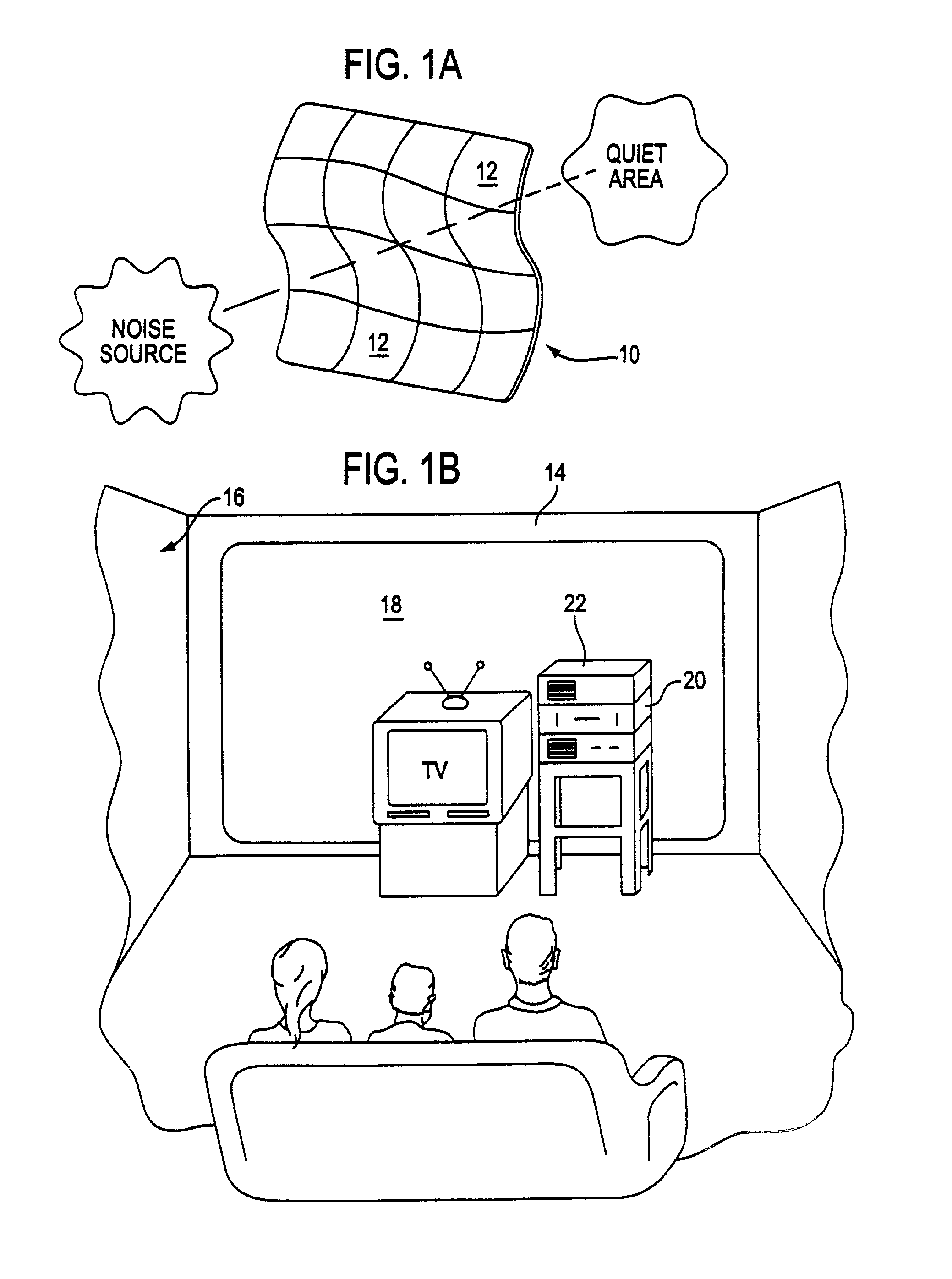

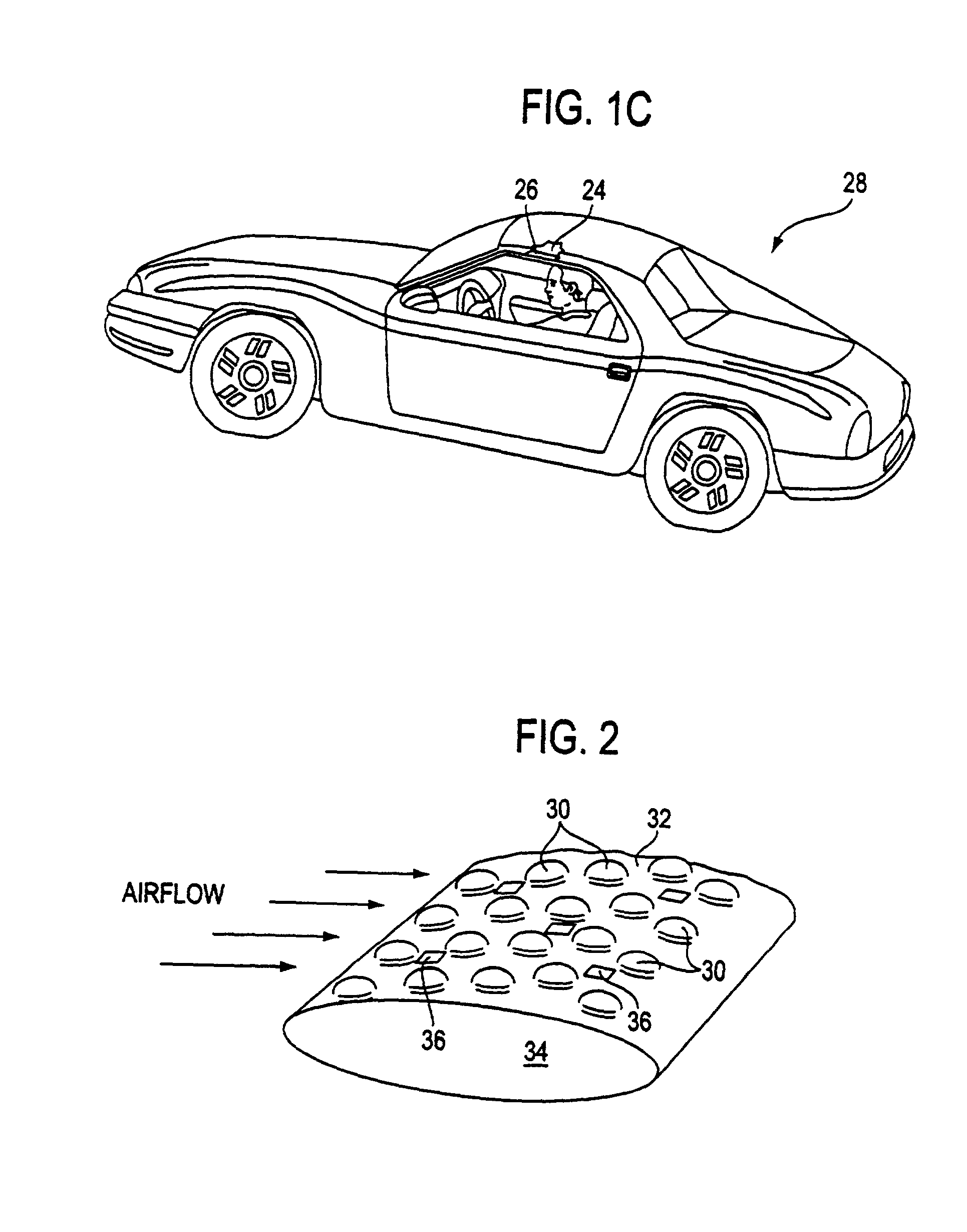

Elastomeric dielectric polymer film sonic actuator

InactiveUS7062055B2Optimize power outputLow working voltagePiezoelectric/electrostrictive gramophone pickupsStirling type enginesDielectricConductive polymer

A sonic actuator including a multi-layer membrane having a non-metallic elastomeric dielectric polymer layer with a first surface and a second surface, a first compliant electrode layer contacting the first surface of the polymer layer, and a second compliant electrode layer contacting the second surface of the polymer layer. The actuator further includes a support structure in contact with the sonic actuator film. Preferably, the non-metallic dielectric polymer is selected from the group consisting essentially of silicone, fluorosilicone, fluoroelastomer, natural rubber, polybutadiene, nitrile rubber, isoprene, and ethylene propylene diene. Also preferably, the compliant electrode layer is made from the group consisting essentially of graphite, carbon, and conductive polymers. The support structure can take the form of grid having a number of circular apertures. When a voltage is applied to the electrodes, portions of the film held at the aperture of the support structure can bulge due to the electrostriction phenomenon. The resultant “bubbles” can be modulated to generate sonic vibrations, or can be used to create a variable surface for airflow control.

Owner:SRI INTERNATIONAL

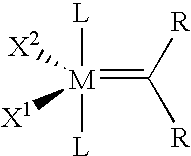

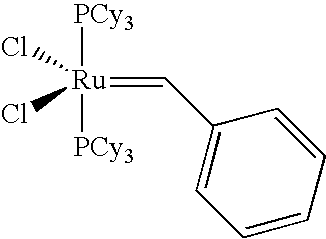

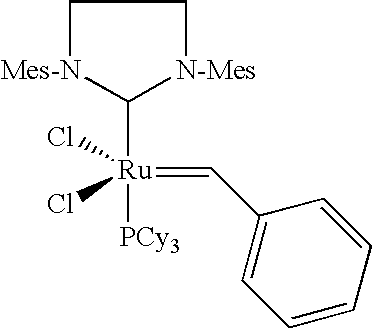

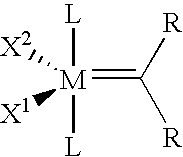

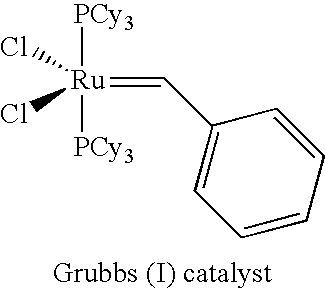

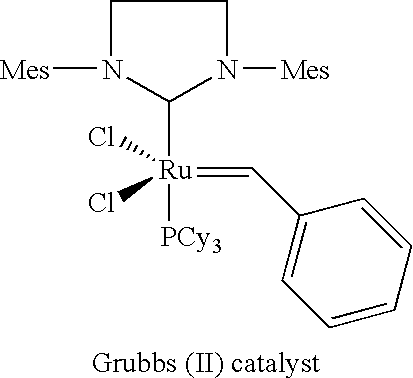

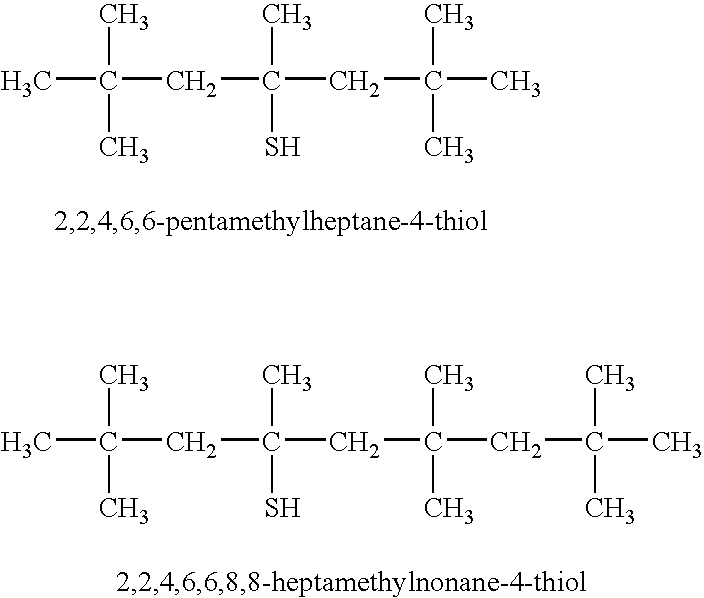

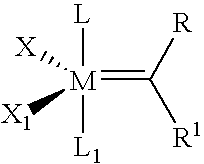

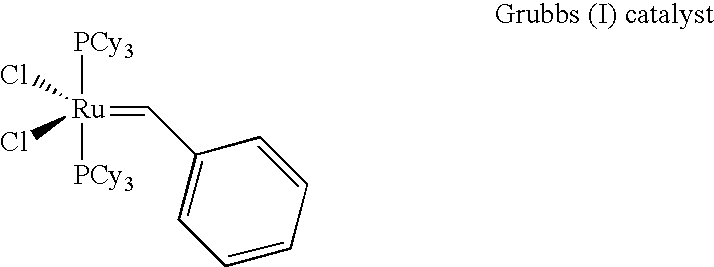

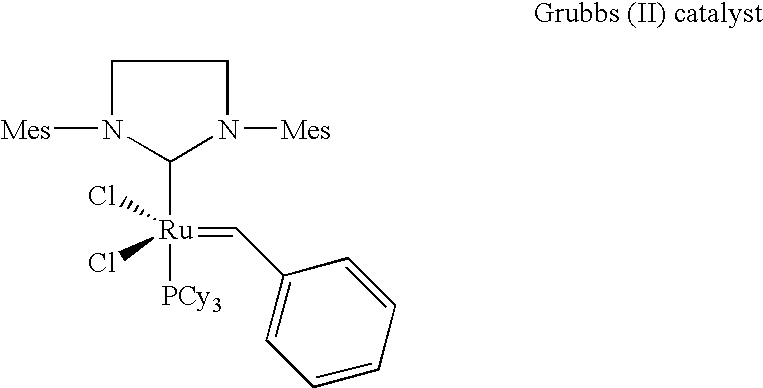

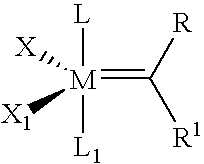

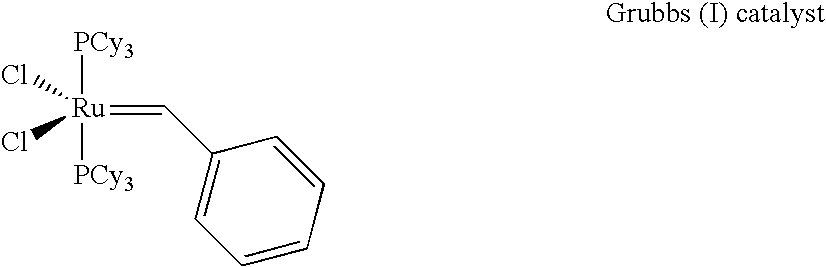

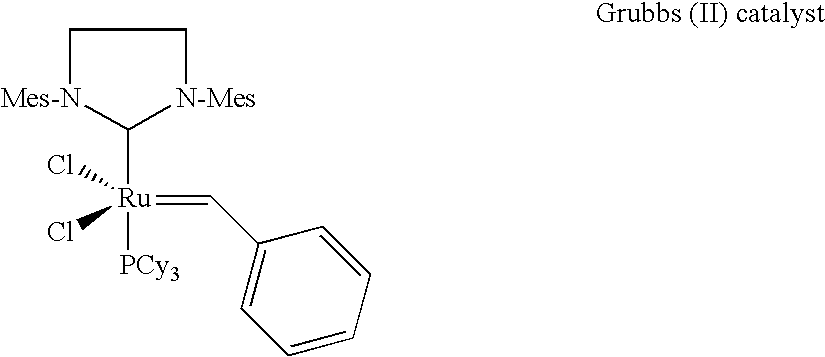

Catalyst systems and their use for metathesis reactions

ActiveUS20090069516A1Narrow molecular weight distributionReduce molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsAdhesive processes with surface pretreatmentNitrile rubberInorganic chemistry

Novel catalyst systems for metathesis reactions, in particular for the metathesis of nitrile rubber, which contain a specific salt additive in addition to the metathesis catalyst are provided.

Owner:ARLANXEO DEUT GMBH

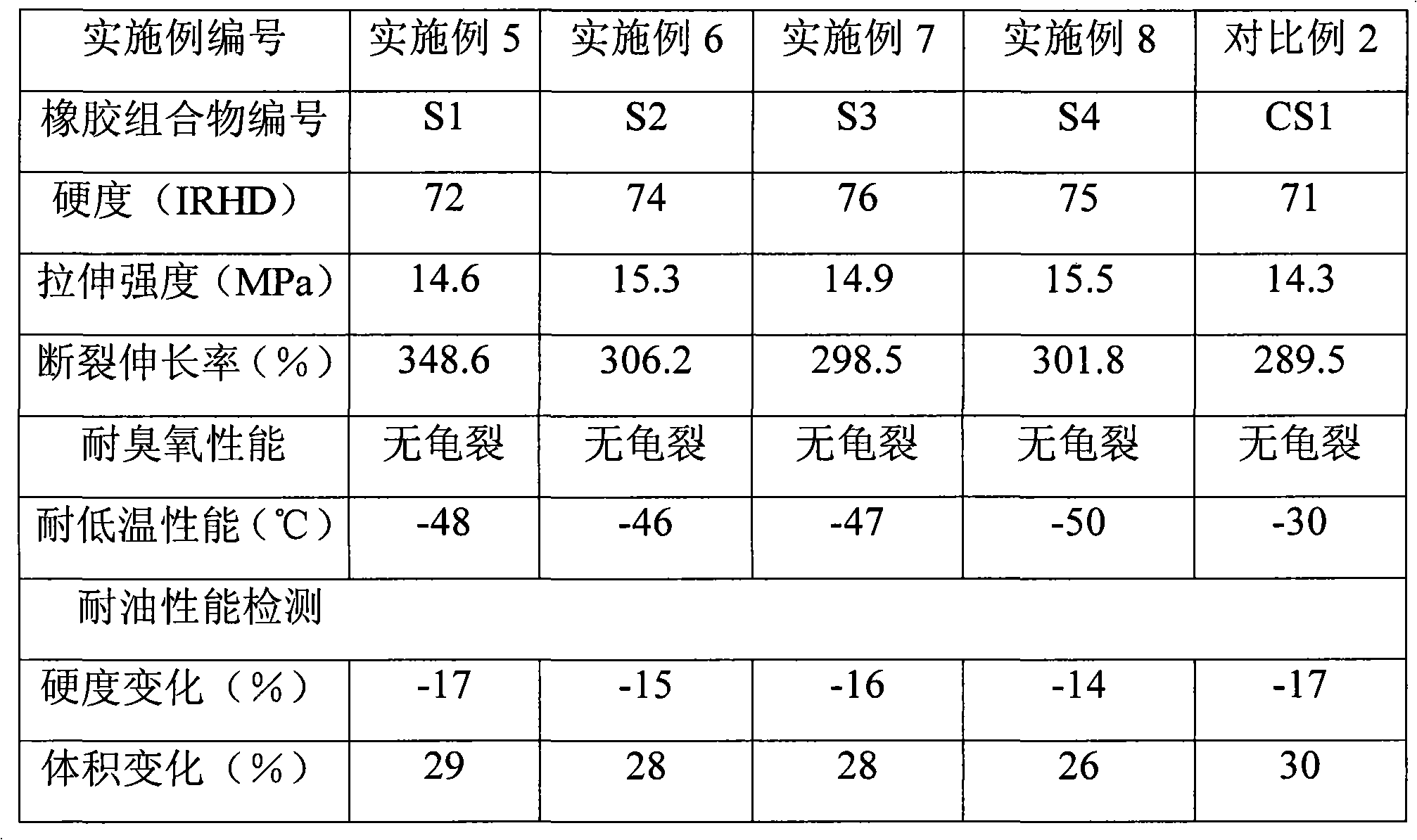

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

Rubber composition and cross-linked rubber

InactiveUS20130280459A1Improve machinabilityImprove cold resistanceClosuresLayered productsCross-linkHalogen

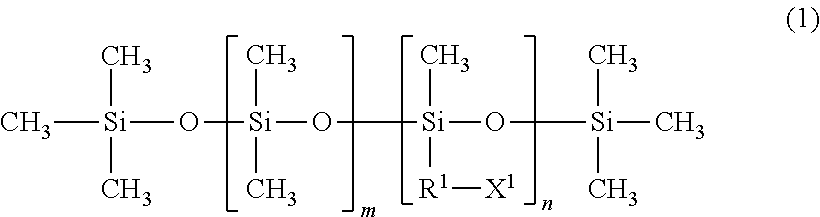

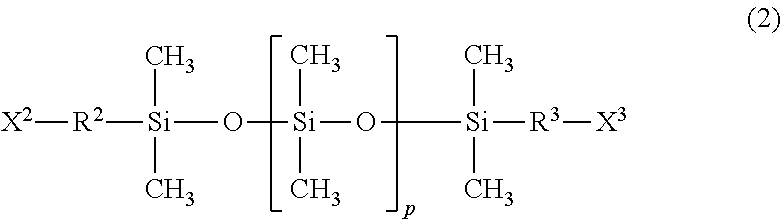

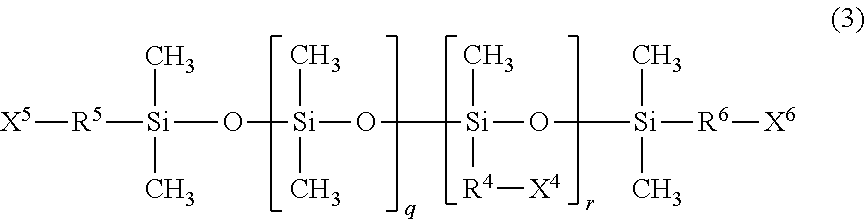

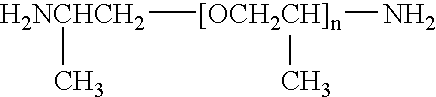

A nitrile rubber composition containing a carboxyl group-containing nitrile rubber and a reactive silicone oil and cross-linked rubber obtained by using that nitrile rubber composition are provided. Further, a rubber composition for sliding member use containing a carboxyl group-containing rubber which contains carboxyl group-containing monomer units in a ratio of 0.1 to 20 wt %, a content ratio of monomer units which have unsaturated carbon-carbon double bonds of 20 wt % or less, and a content ratio of monomer units which have halogen atoms of 5 wt % or less and a reactive silicone oil is provided.

Owner:ZEON CORP

Epoxy adhesive having improved impact resistance

InactiveUS6998011B2Increase resistanceImprove toughnessPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesivePolyolNitrile rubber

In the preparation of an improved adhesive composition, an epoxy-based prepolymer is obtained by the reaction of one or more epoxy resins with amino-terminated polyethers and / or carboxyl-terminated butadiene-nitrile rubbers. In one embodiment of the invention, both a solid epoxy resin and a liquid epoxy resin, each of which is a diglycidyl ether of a polyphenol such as bisphenol A, are used. The epoxy-based prepolymer is mixed with an acrylate-terminated urethane resin (preferably, one based on a polyol having a number average molecular weight of at least about 400) and a heat-activated latent curing agent to make an adhesive composition which can be pumpable at room temperature. Curable adhesives capable of expansion to about 100% with high impact resistance after curing may be obtained by inclusion of expanding agents such as expandable microspheres.

Owner:HENKEL KGAA

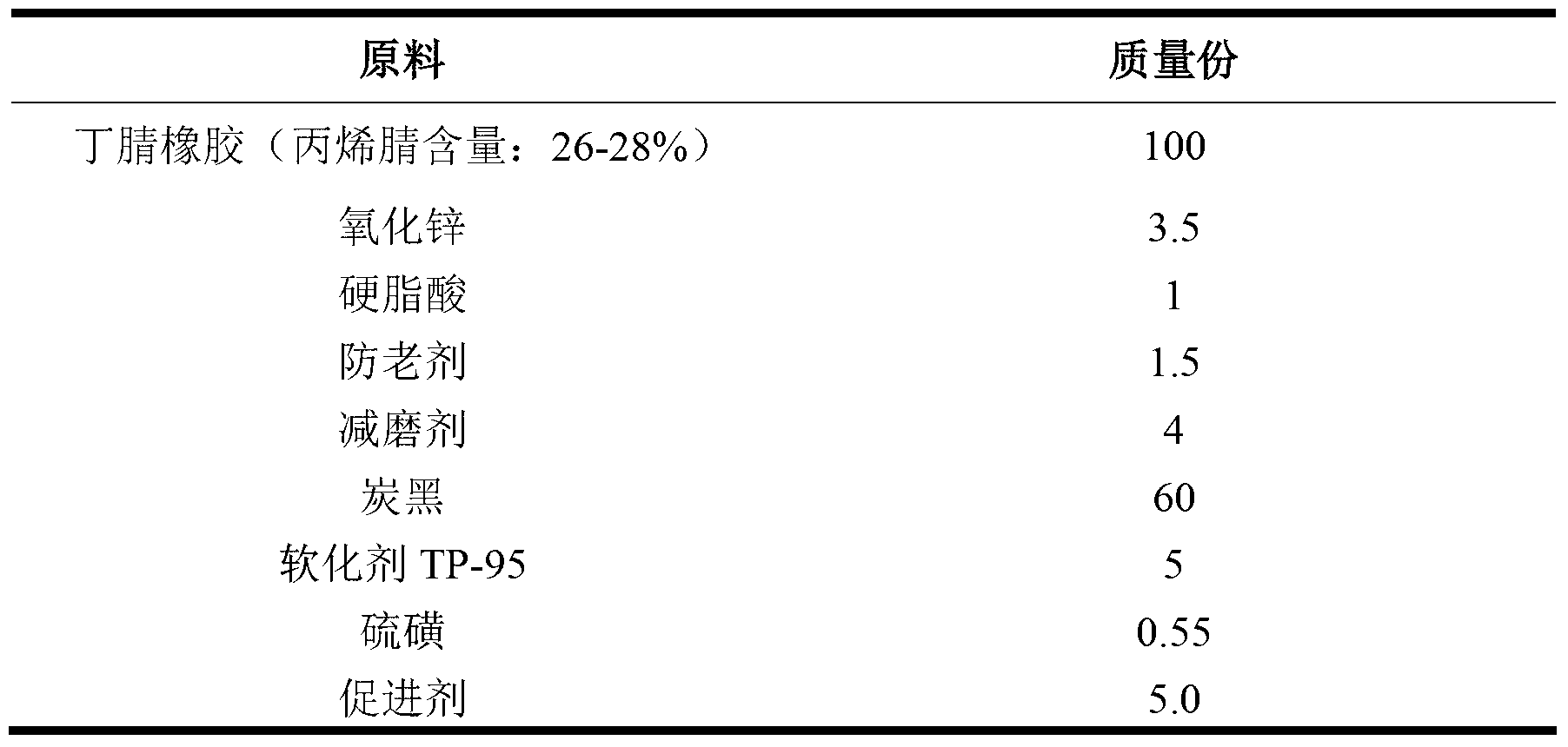

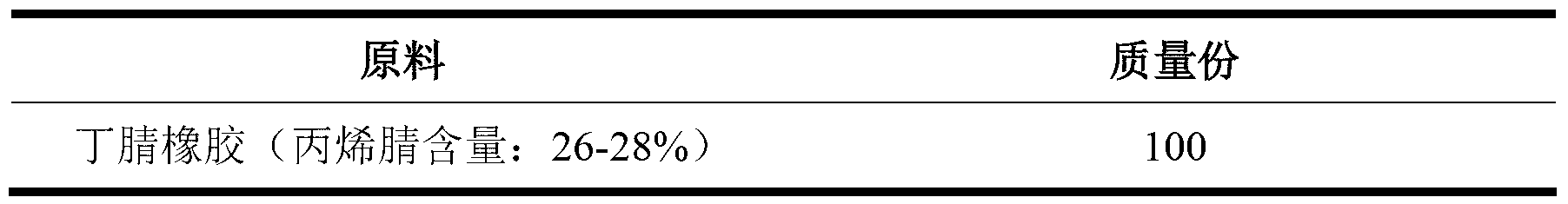

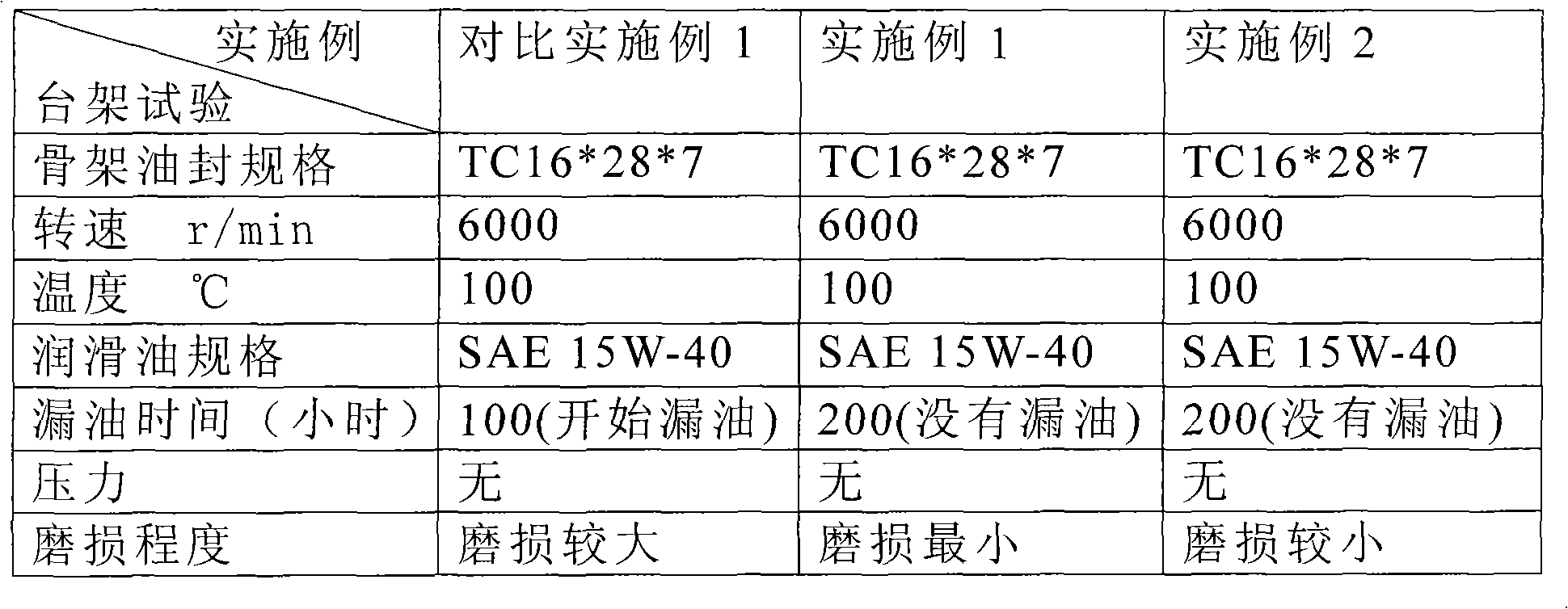

Cold-resistant wear-resistant nitrile rubber sealing material and preparation method thereof

ActiveCN103289150ACompatibility is reasonableImprove wear resistanceOther chemical processesPolymer scienceNitrile rubber

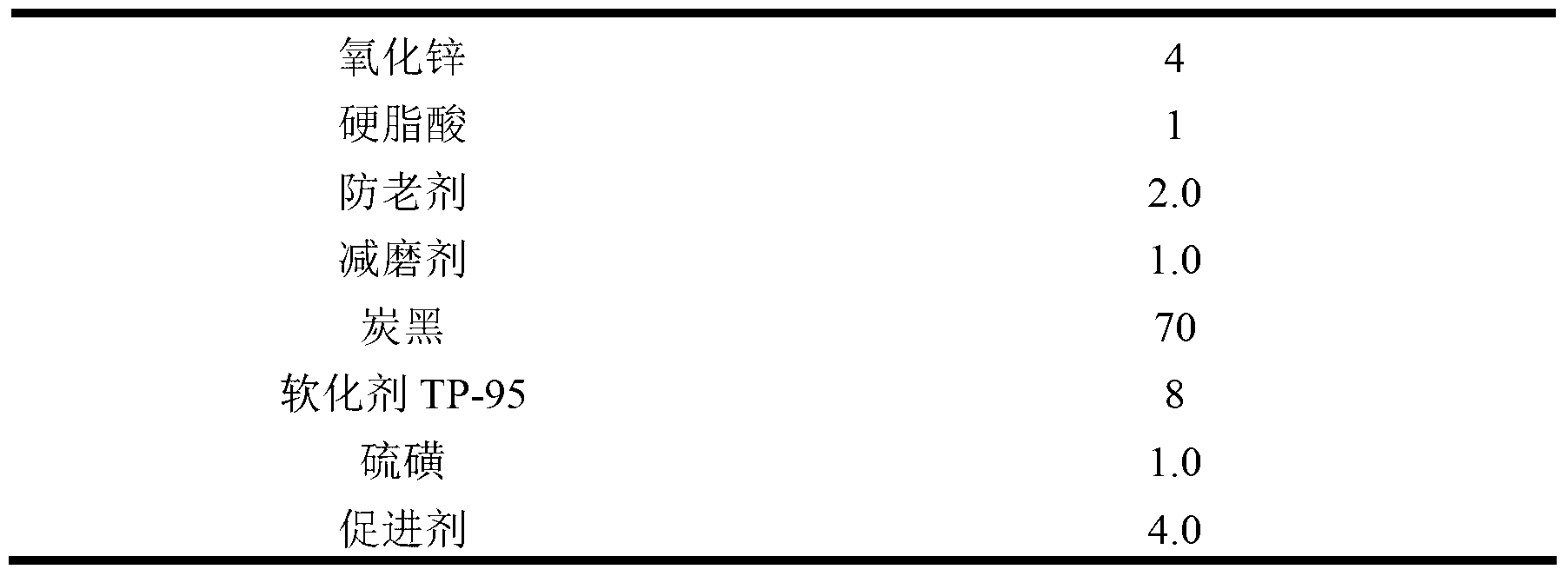

The invention discloses a cold-resistant wear-resistant nitrile rubber sealing material which comprises the following raw materials of: by weight, 100 parts of nitrile rubber, 3.5-8 parts of zinc oxide, 1 part of stearic acid, 1.5-3.5 parts of an antioxidant, 0.5-4.0 parts of an antifriction agent, 60-115 parts of carbon black, 2-10 parts of TP-95, 0.3-1.0 parts of a vulcanizing agent and 3.0-5.5 parts of an accelerant. A preparation method of the nitrile rubber sealing material comprises the steps of plasticating the nitrile rubber, adding the zinc oxide, the stearic acid, the antioxidant and the antifriction agent to carry out mixing, adding 1 / 2 of the carbon black to continue mixing after last mixing, then adding the residual carbon black and TP-95 to continue mixing, discharging glue stock and refining the glue stock with turning, obtaining a segment of rubber compound and placing the segment of the rubber compound, adding the rubber compound to a rubber covered roll of an open mill, adding the accelerant to carry out mixing, milling and packaging in a triangular bag, adjusting thickness and discharging material sheets. The nitrile rubber sealing material provided by the invention has better cold resistance and wear resistance.

Owner:GUANGZHOU JST SEALS TECH

Microgel-containing vulcanizable composition based on hydrogenated nitrile rubber

A novel vulcanizable composition is provided, based on at least one hydrogenated nitrile rubber, on at least one peroxide, on at least one unsaturated carboxylic acid and / or salts thereof, and also on specific microgels. These vulcanizable compositions can be used to obtain vulcanized products which can in particular be used for drive belts, roll coverings, hoses and cables.

Owner:ARLANXEO DEUT GMBH

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

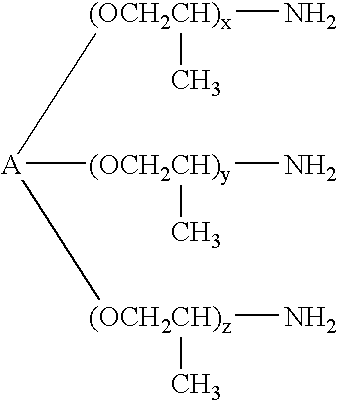

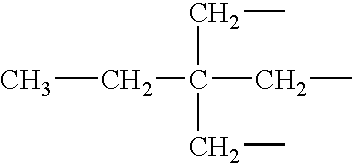

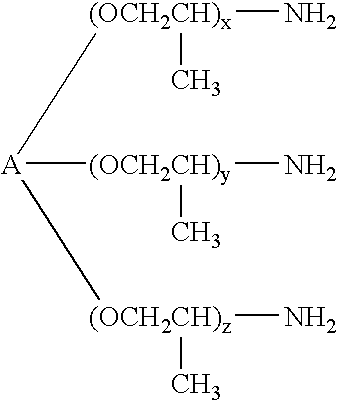

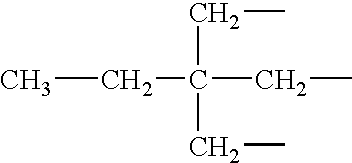

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

Novel catalyst systems and a process for reacting chemical compounds in the presence of said catalyst systems

InactiveUS20070208206A1Activity of metathesis can be increasedHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationNitrile rubberChemical compound

New catalyst systems for metathesis reactions, in particular for the metathesis of nitrile rubber, are provided.

Owner:LANXESS DEUTDCHLAND GMBH

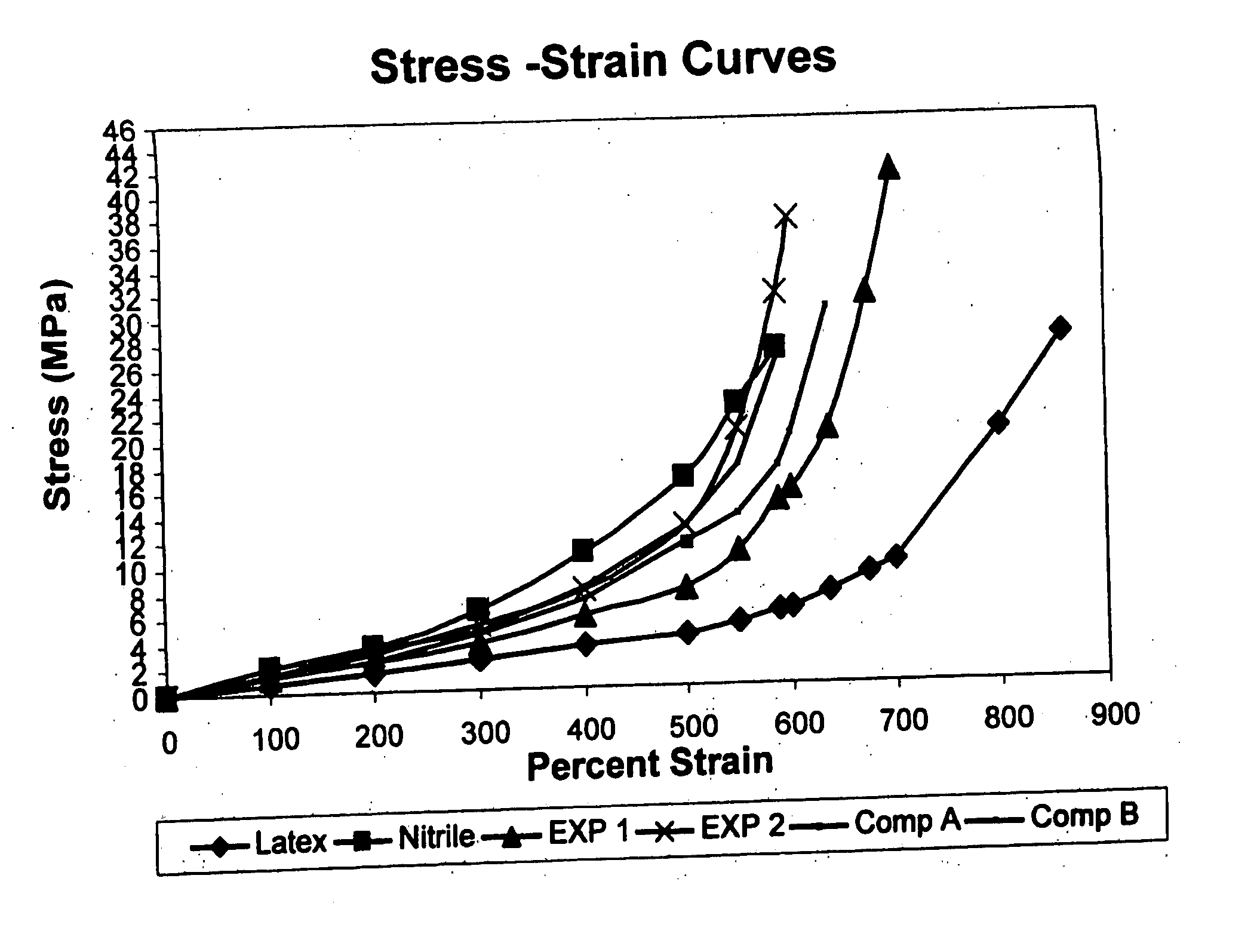

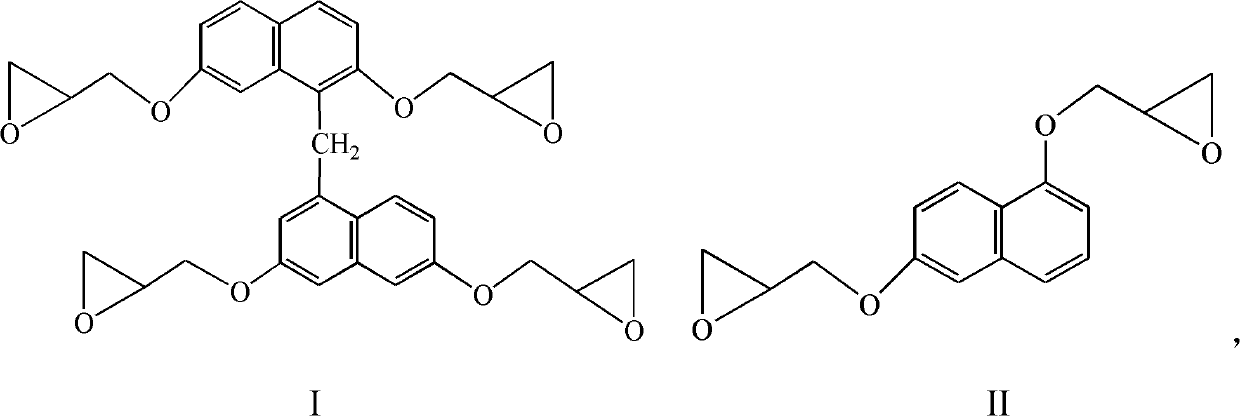

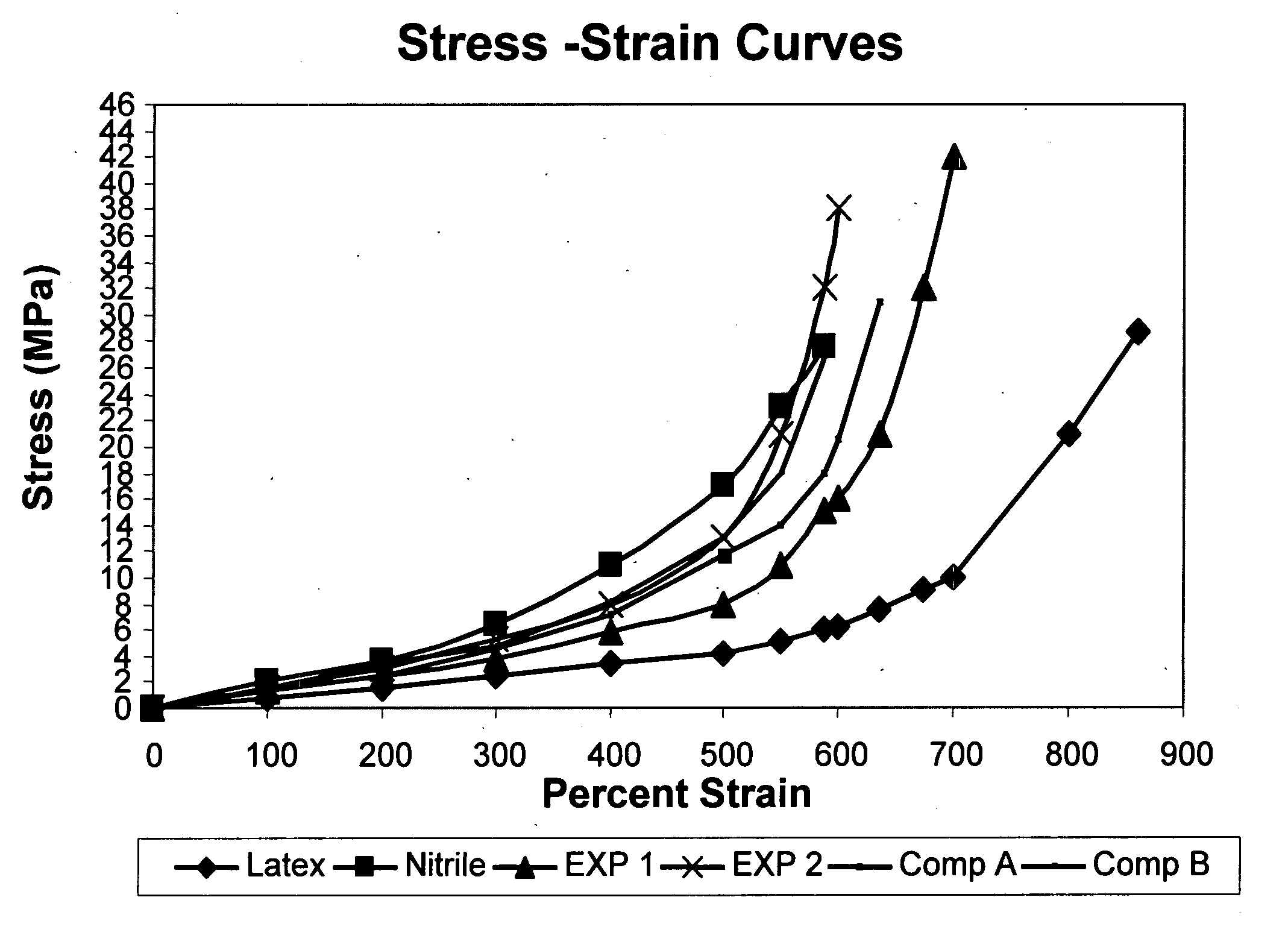

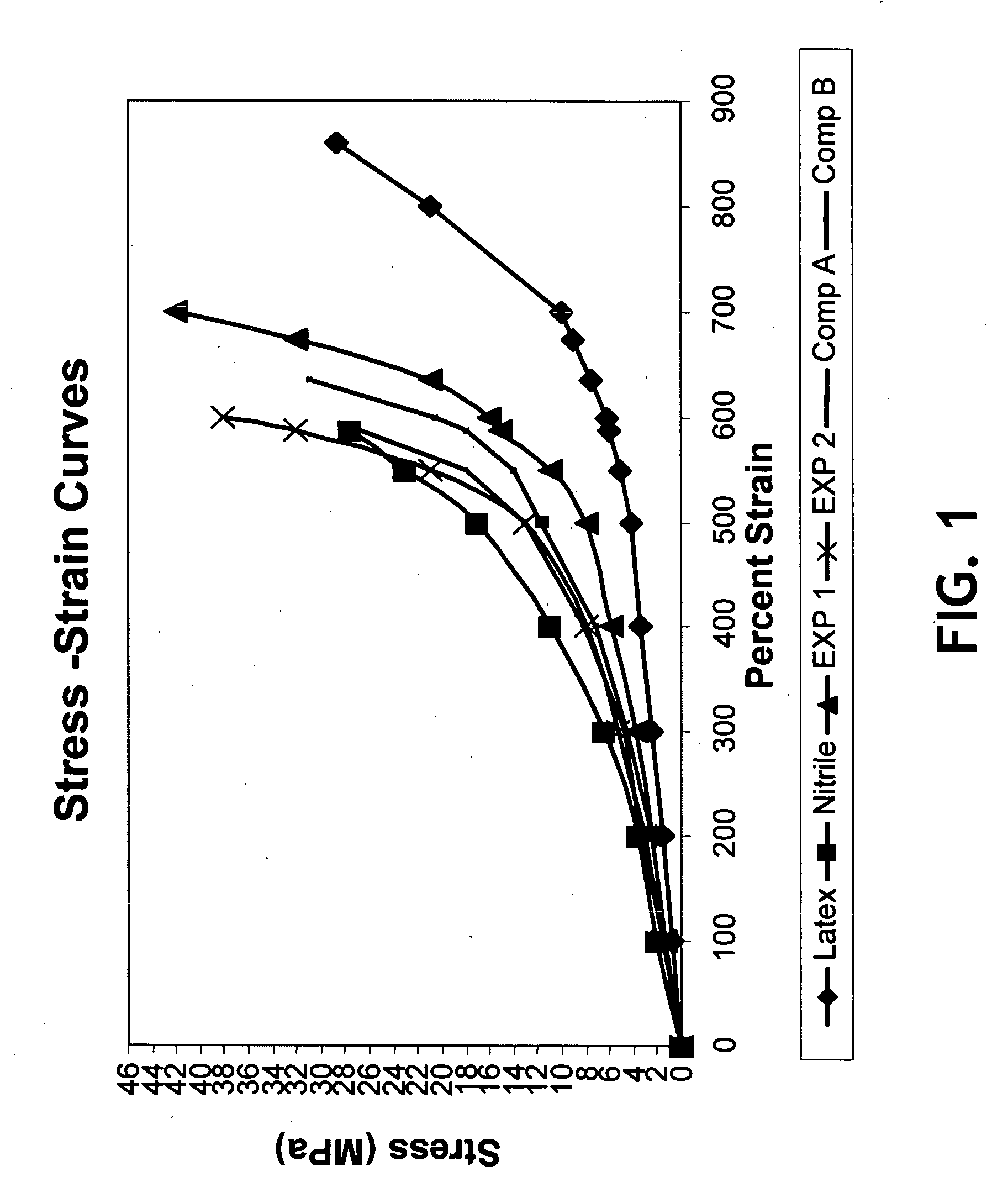

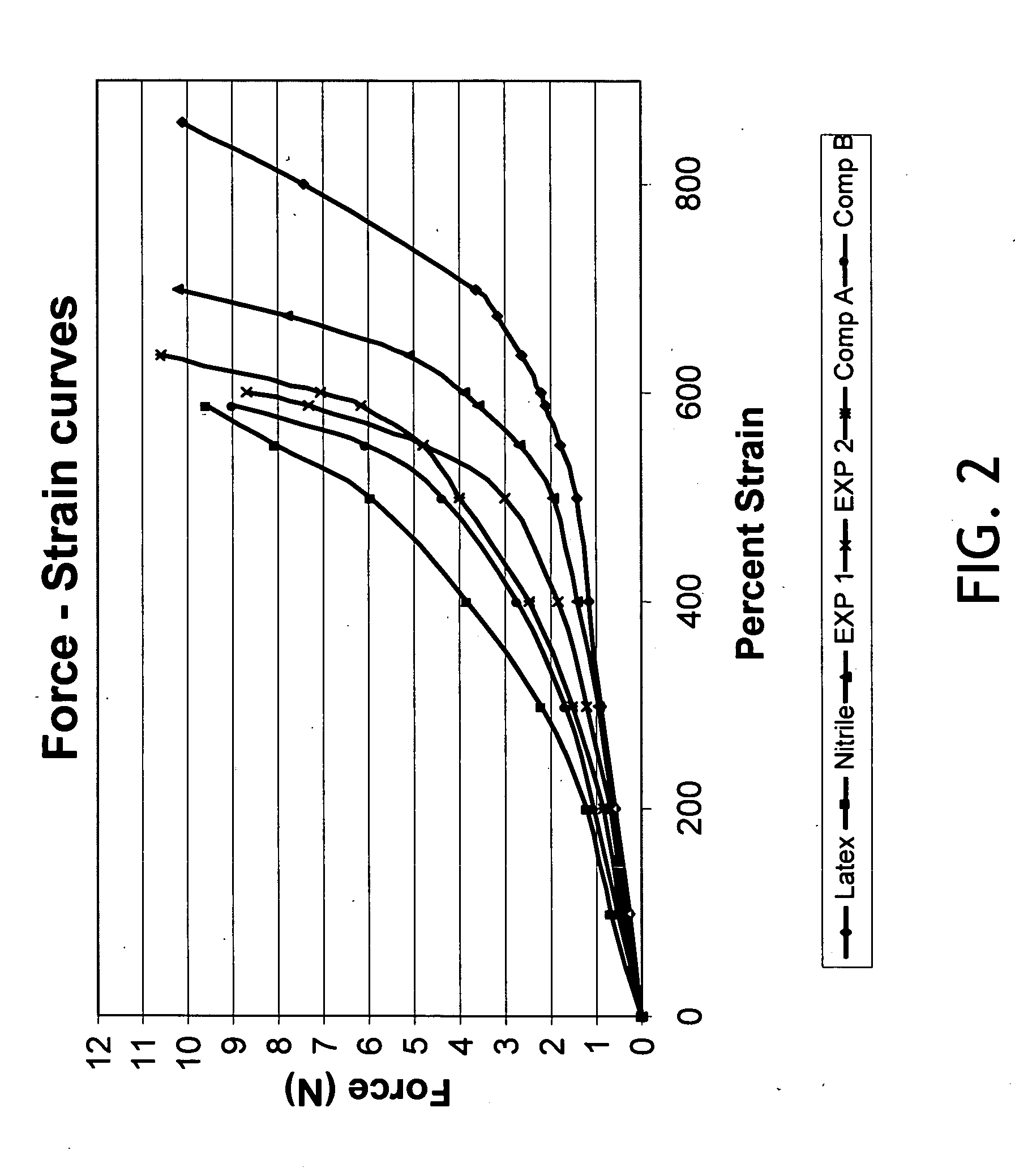

Exterior-coated nitrile rubber article having natural rubber characteristics

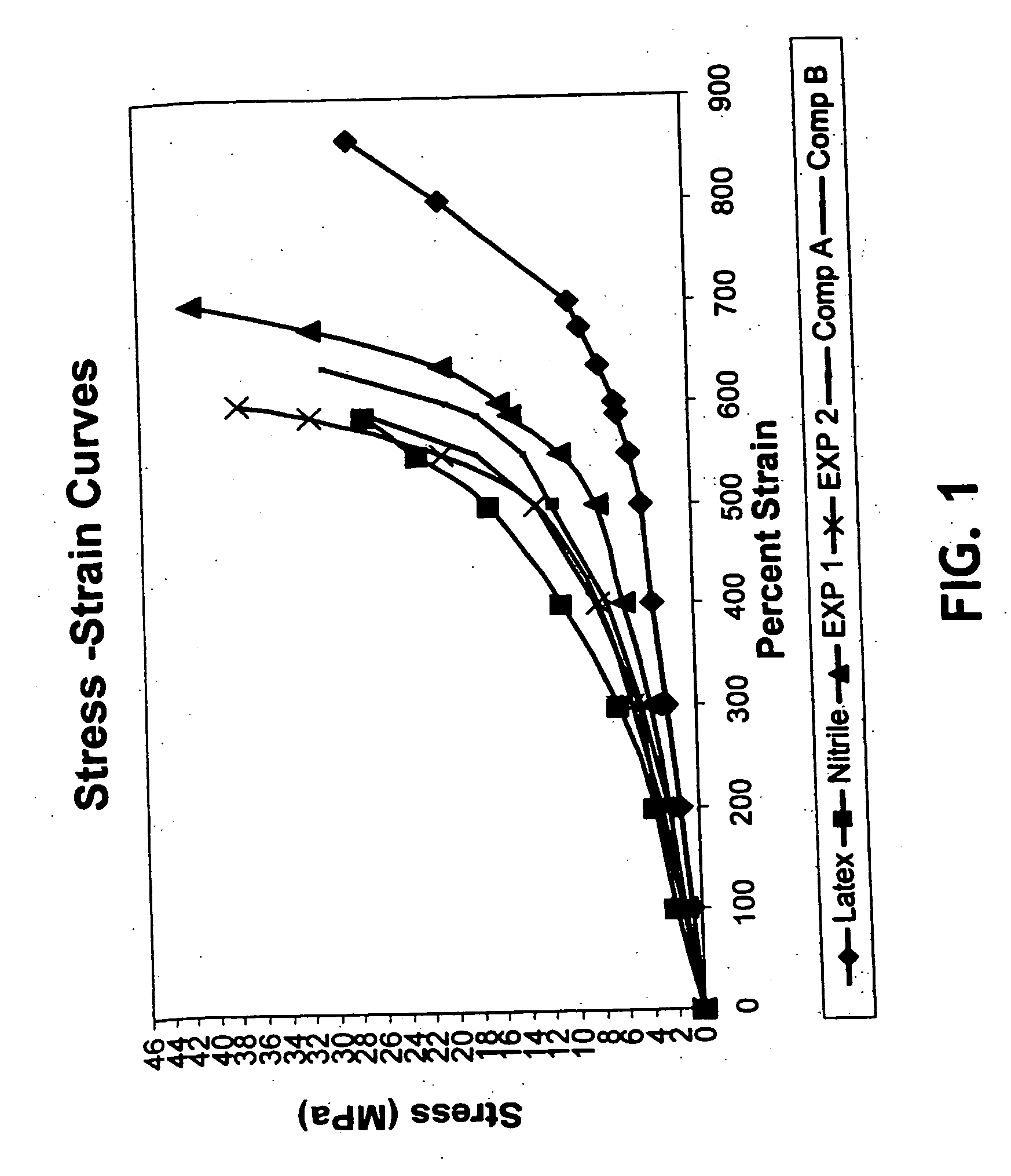

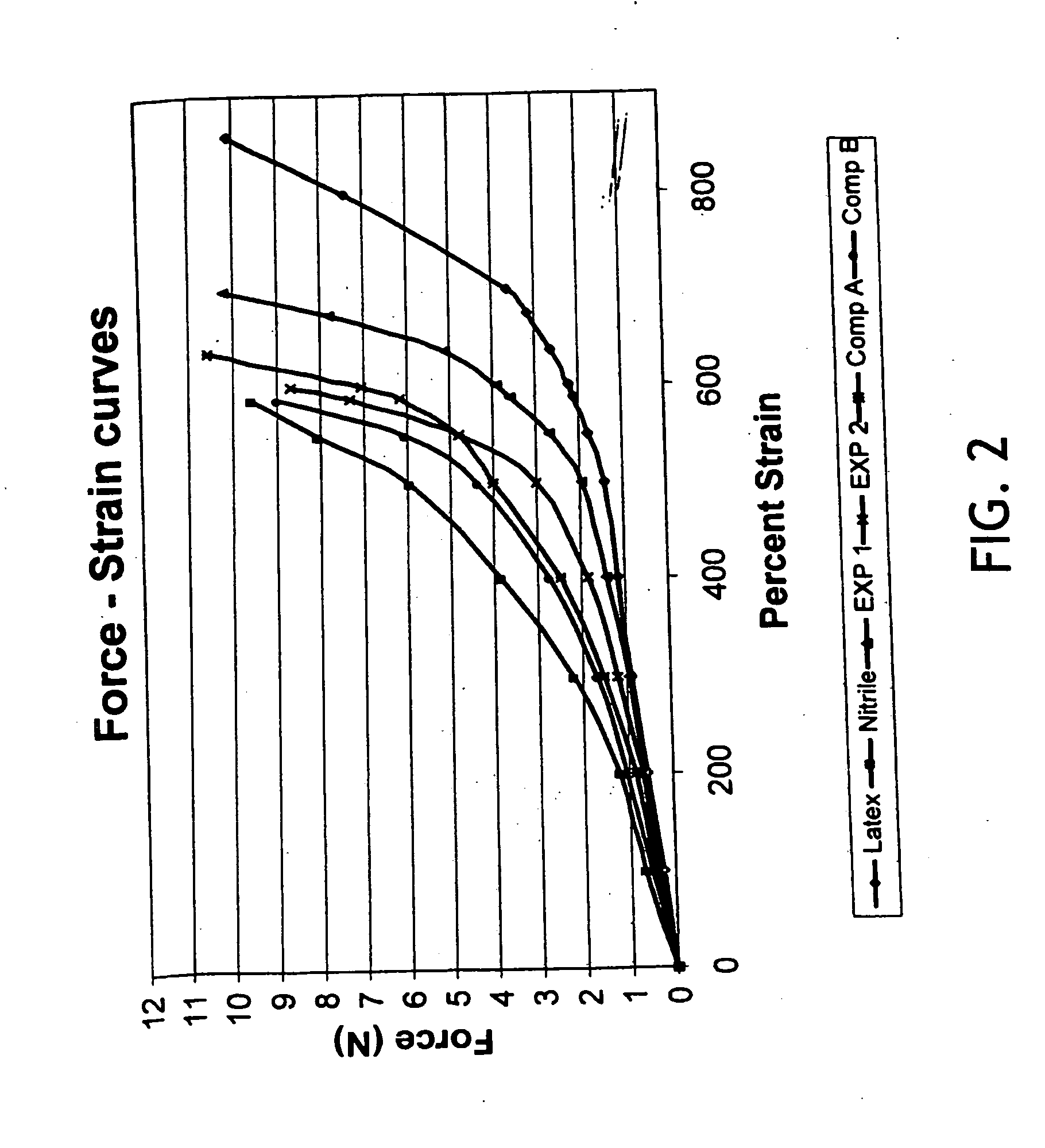

ActiveUS20060257674A1Maximize material strengthMinimize forceCosmetic preparationsBiocideRubber materialPolymer science

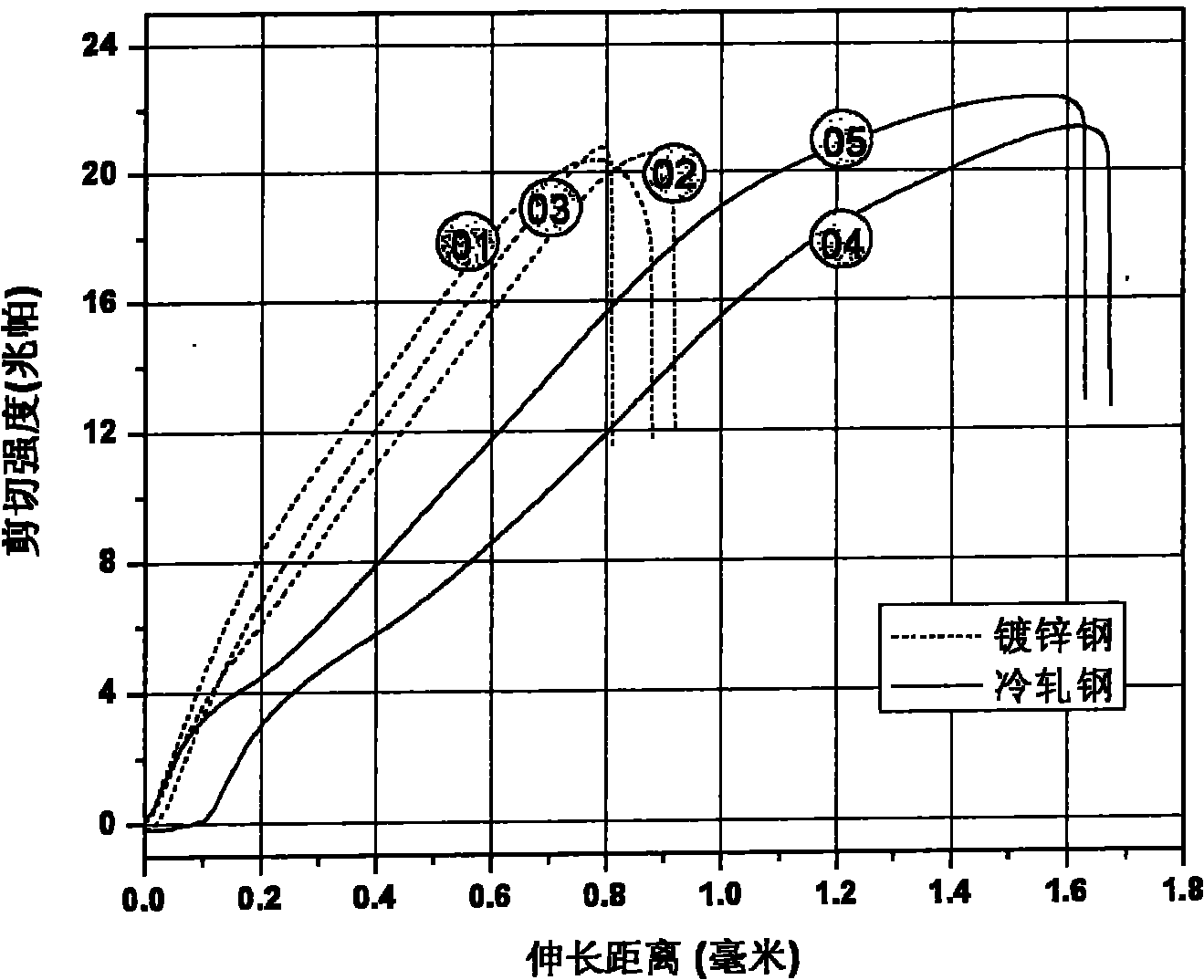

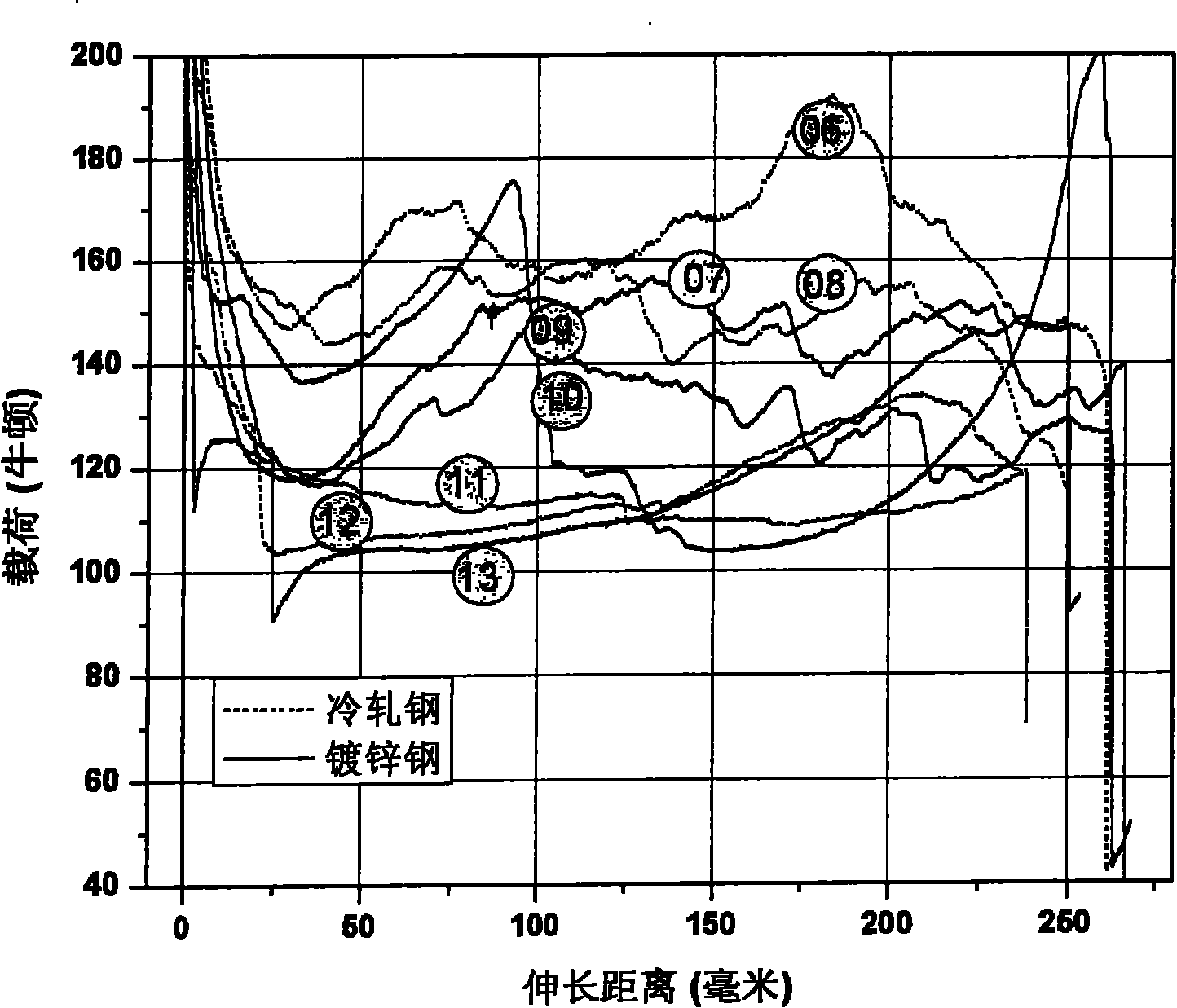

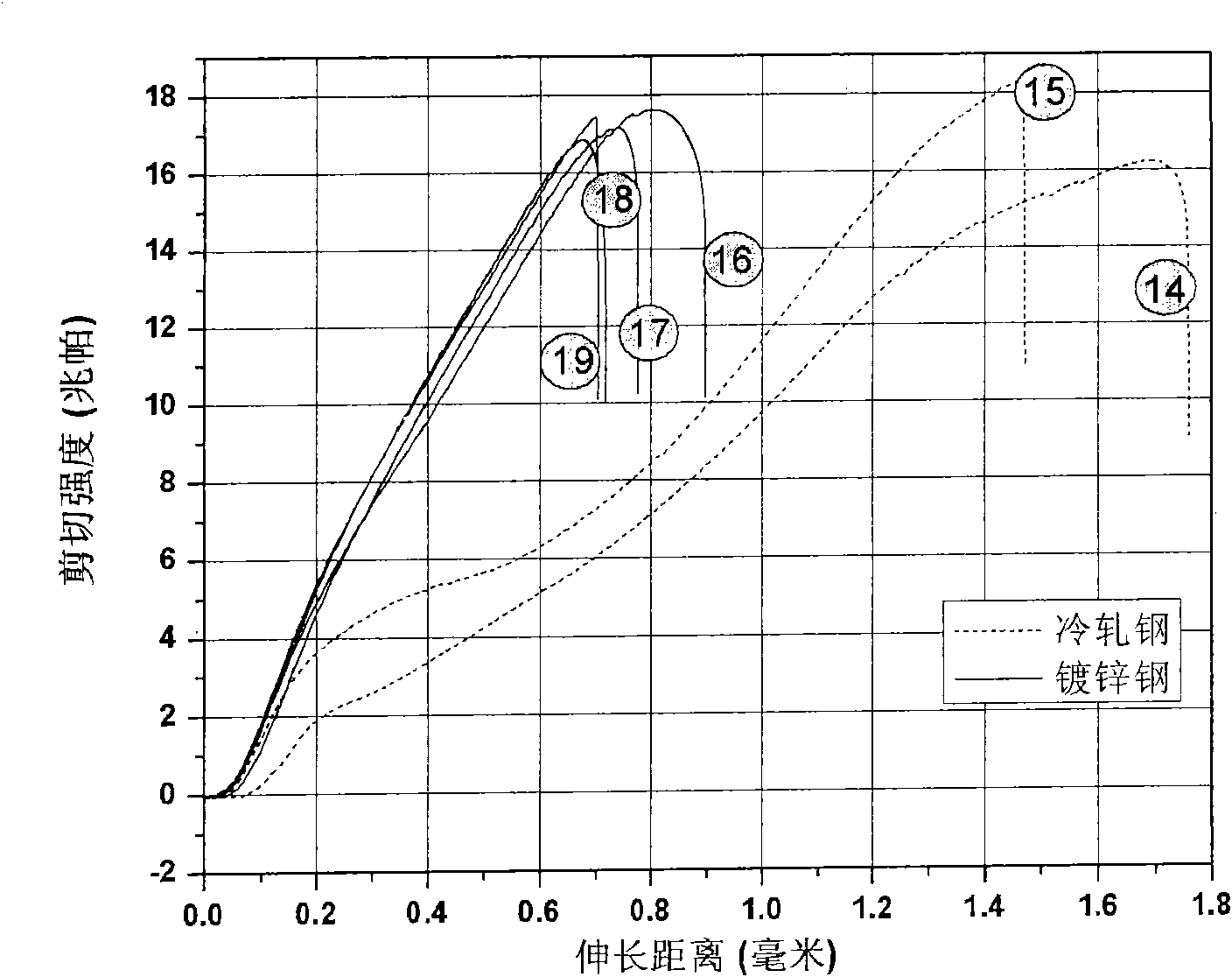

A material for making elastomeric nitrile rubber articles is disclosed. In particular, the process and material formulation can produce nitrile rubber based articles, which exhibit force-strain characteristics that are comparable to those of natural rubber latex articles, while maintaining the tensile strength properties of nitrile rubber. The process includes an accelerator composition at the pre-cure stage having a dithiocarbamate, a thiazole, and a guanidine compound. The invention also includes an elastomeric nitrile rubber product made by the process, such as examination, surgical, or work gloves, which can have an exterior coating over naked rubber selected from either a silicone emulsion or oil, glycerin solution, a combined mixture of silicone and glycerin / glycerol, a fluorocarbon release agent, or a natural or synthetic hydrocarbon-based oil in amounts that do not degrade said substrate rubber material.

Owner:O&M HALYARD INC

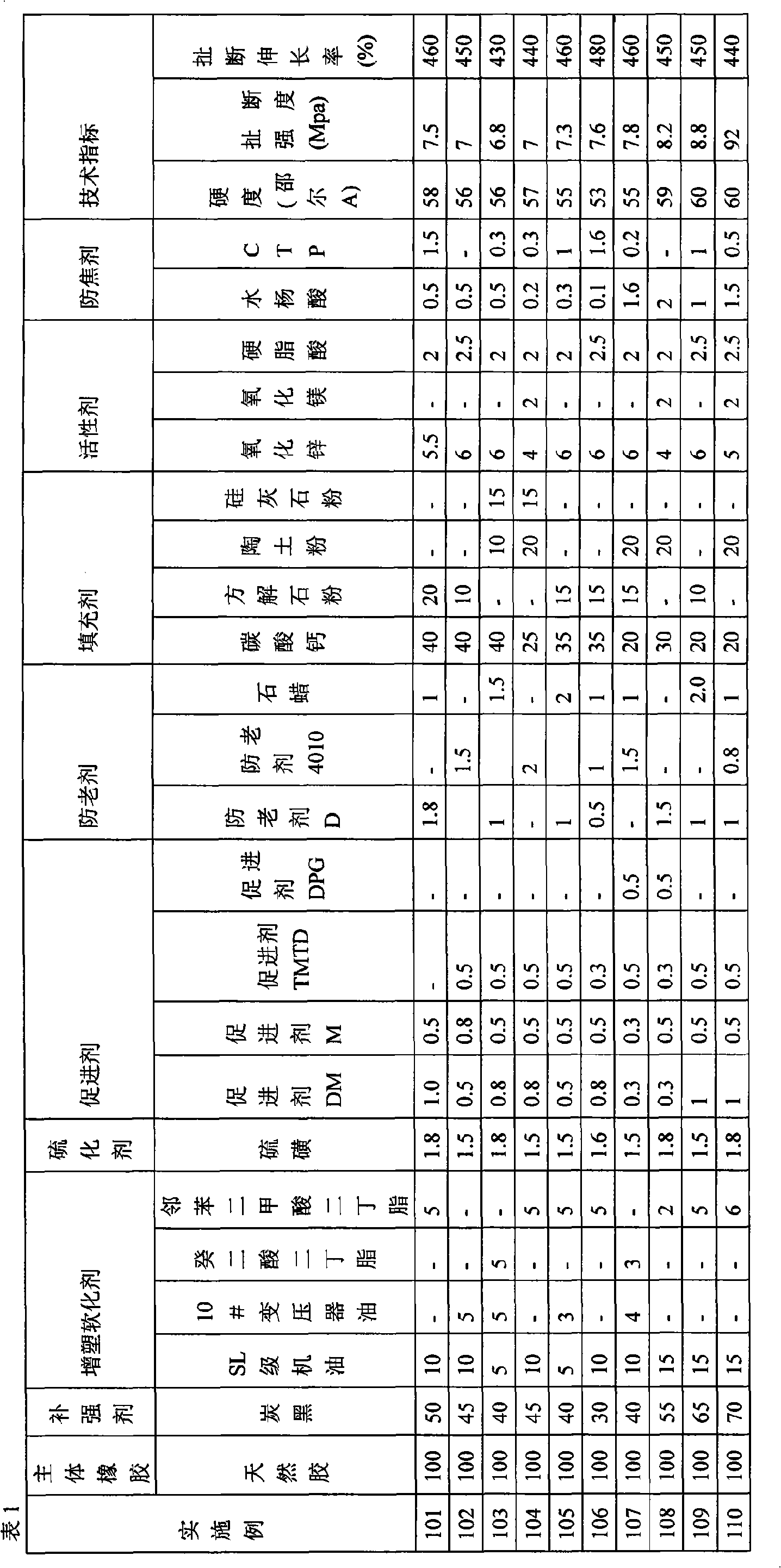

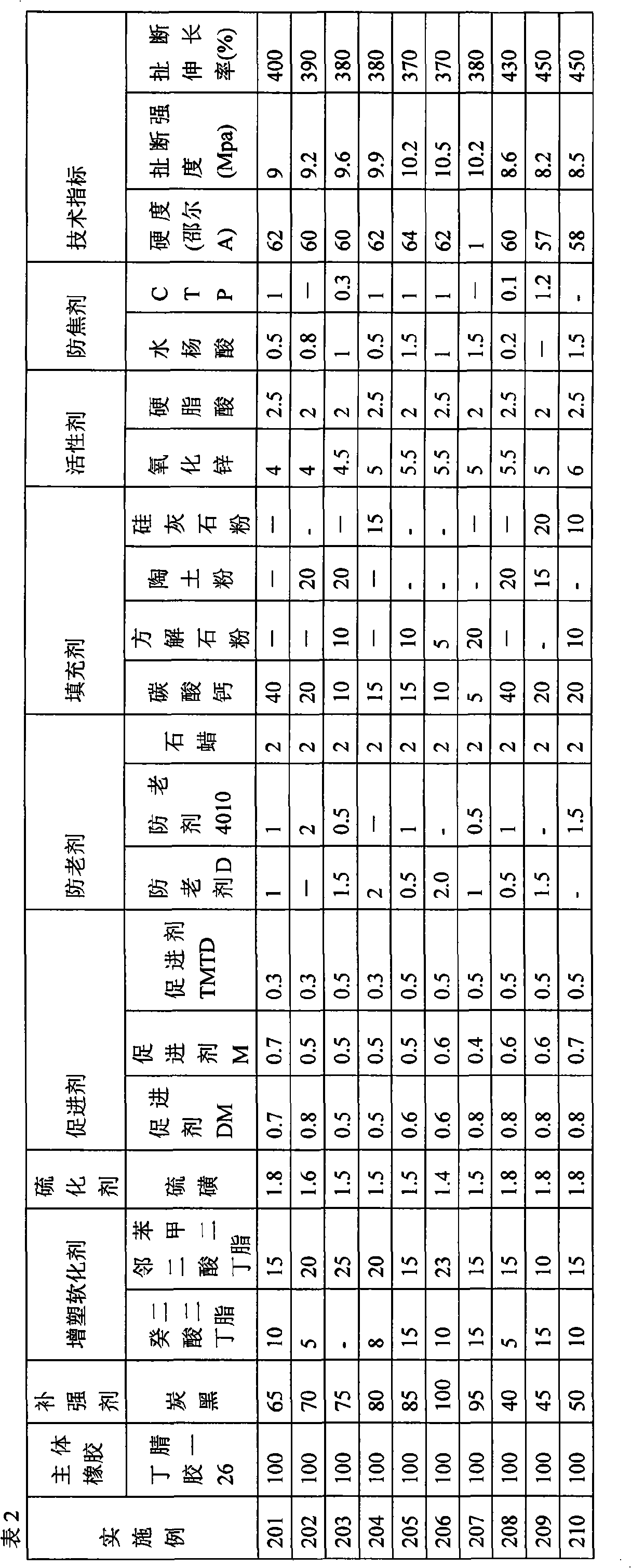

Cold resistant rubber

The invention aims at providing a low-temperature resistant rubber which can be used for a long time in low temperature and has almost the same tensile strength and elongation at break and the same hardness at low temperature as at normal temperature. The low-temperature resistant rubber contains main body rubber, strengthening agent, plasticization softener and curing ingredient, and the weight ratio of main body rubber : strengthening agent : plastifying softener : curing ingredient is 100:10-350:5-75:0.5-3; the main body rubber is natural gum, styrene-butadiene-rubber, cis-butadiene rubber, butyl rubber, ethylene propylene diene rubber, butadiene nitrile rubber or the combination of natural gum and cis-butadiene rubber; the strengthening agent is black carbon or white carbon; the plastifying softener is machine oil, transformer oil, dibutyl sebacate, dibutyl phthalate or silicon oil; the curing ingredient is 2,5-dimethyl curing ingredient or sulphur.

Owner:南京固柏橡塑制品有限公司

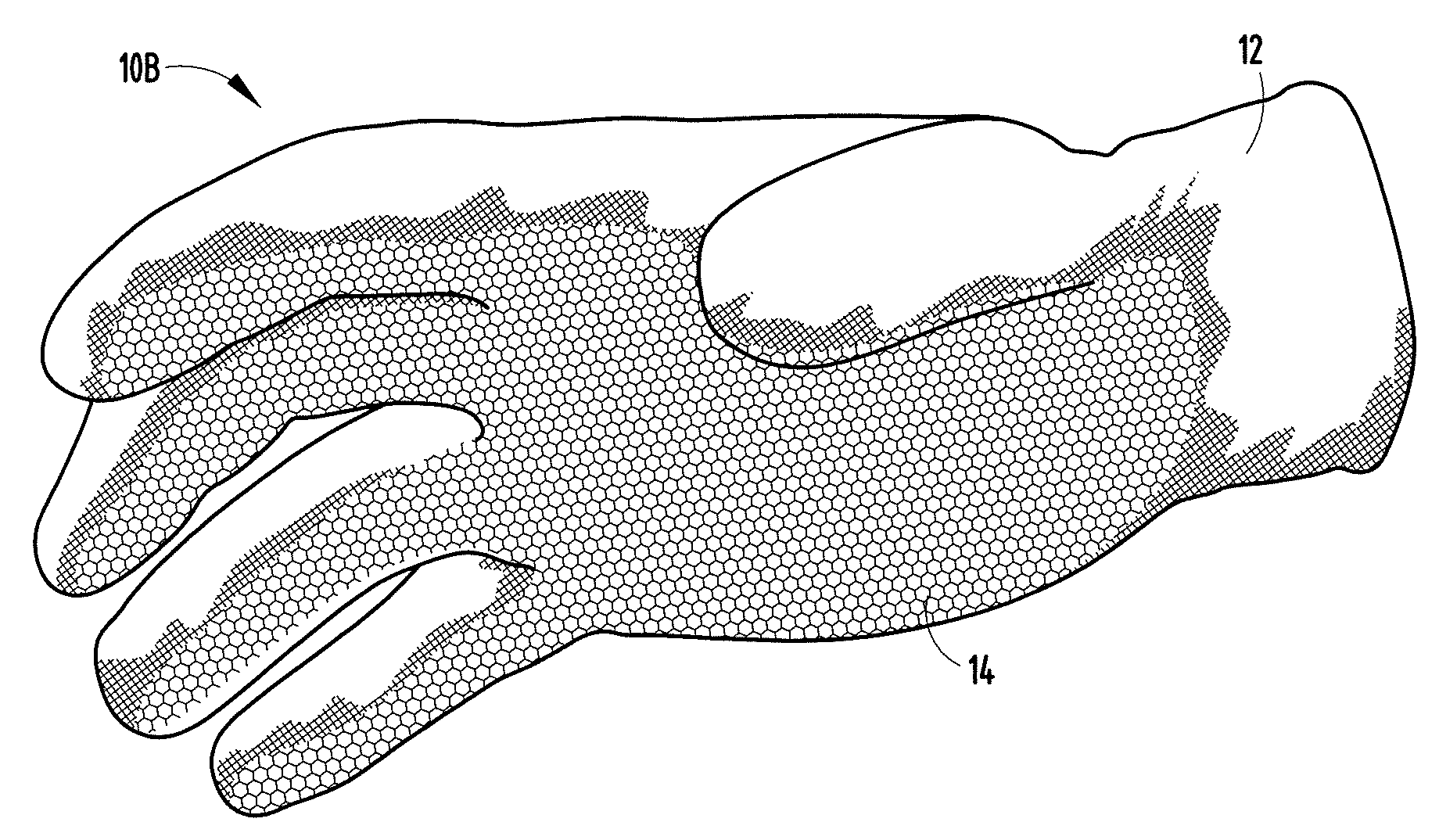

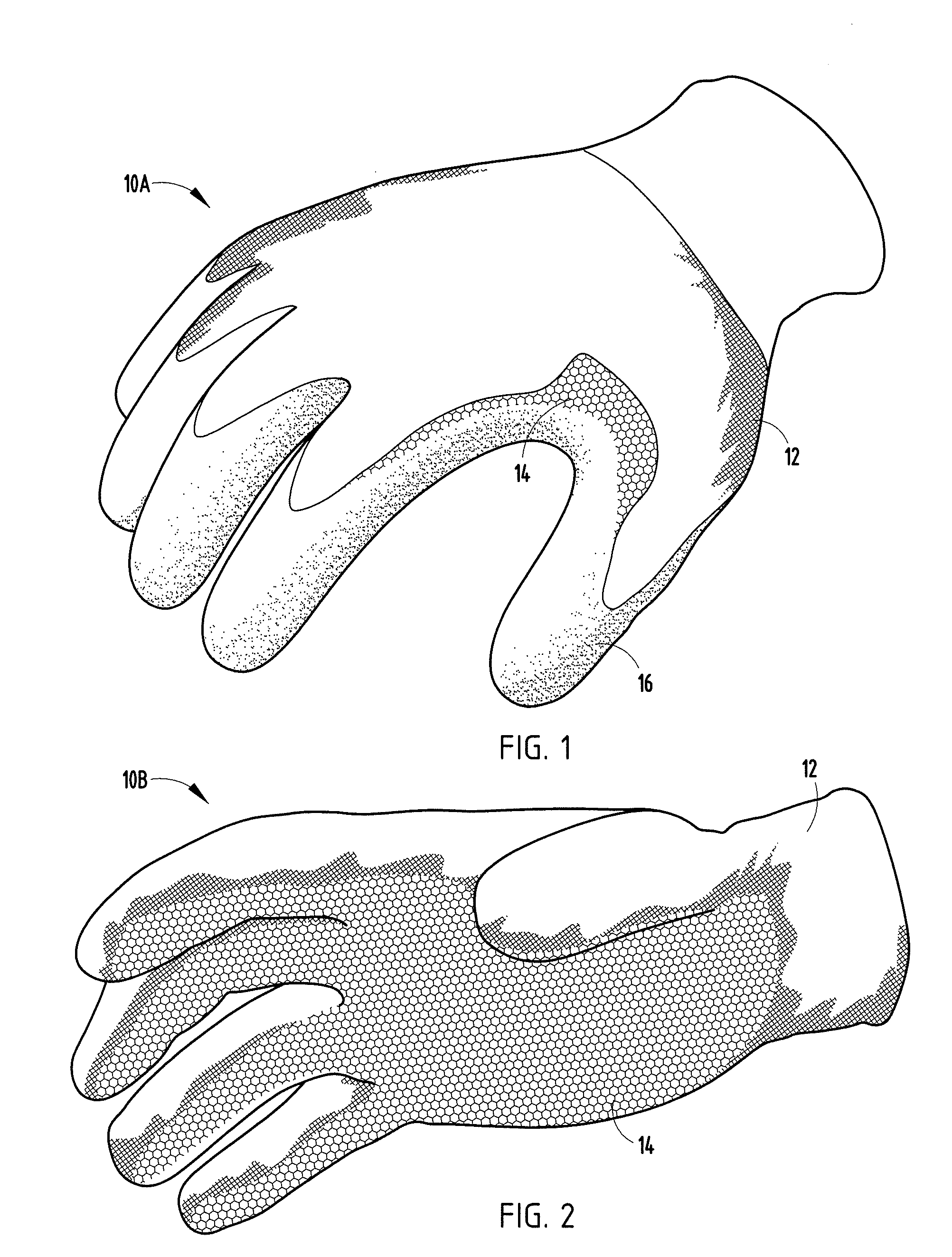

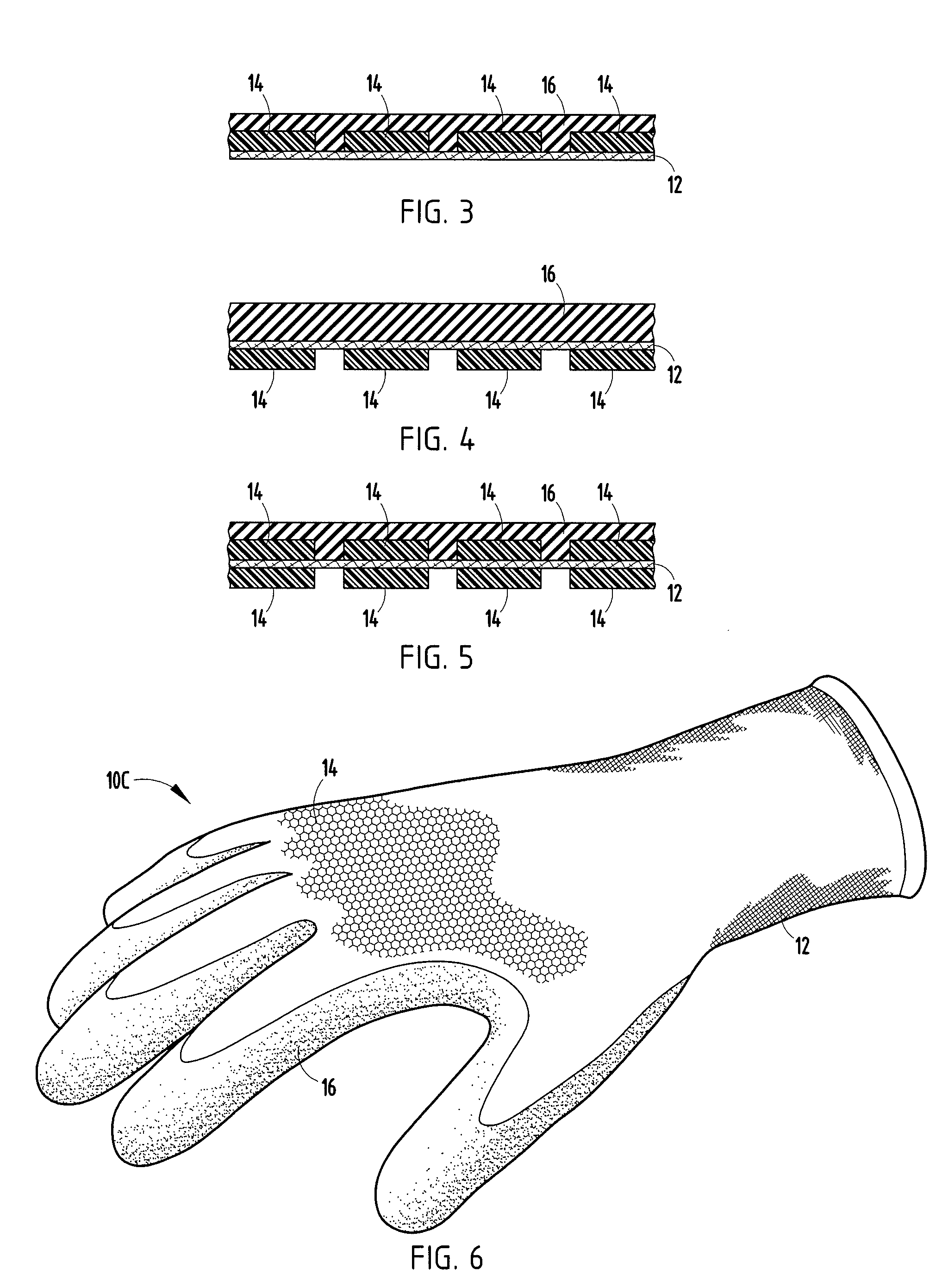

Protective knit gloves

InactiveUS20090139011A1Exceptional physical/mechanical propertyIncrease resistanceGlovesGlass fiberEpoxy

The invention relates to a protective knit glove and methods of manufacturing thereof. The protective knit glove includes a knit glove shell having inner and outer surfaces; and a plurality of discrete rigid plates separated from each other by gaps of approximately 5 to 40 mils and directly adhered to the inner and / or outer surfaces. One or more rubbery layers may be directly adhered to one or more of the rigid plates. Preferably, the knit glove shell may be constructed from polyamide, cotton and polyurethane, polyaramid, ultra high molecular weight polyethylene, or glass fiber. Preferably, the discrete rigid plates may be made from epoxy and the rubbery layer may be made from nitrile rubber, polyurethane rubber, PVC rubber, or natural rubber. The protective knit glove provides a higher level of cut protection, added puncture protection and enhanced abrasion resistance compared to a glove without the discrete rigid plates.

Owner:PERFORMANCE FABRICS

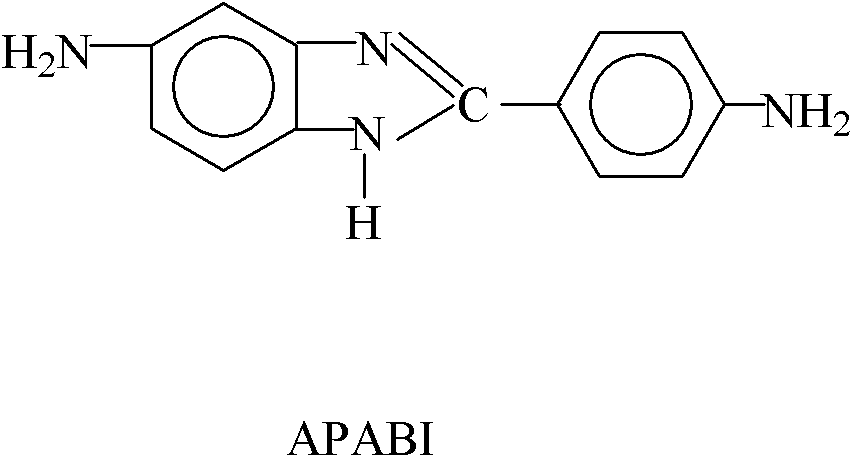

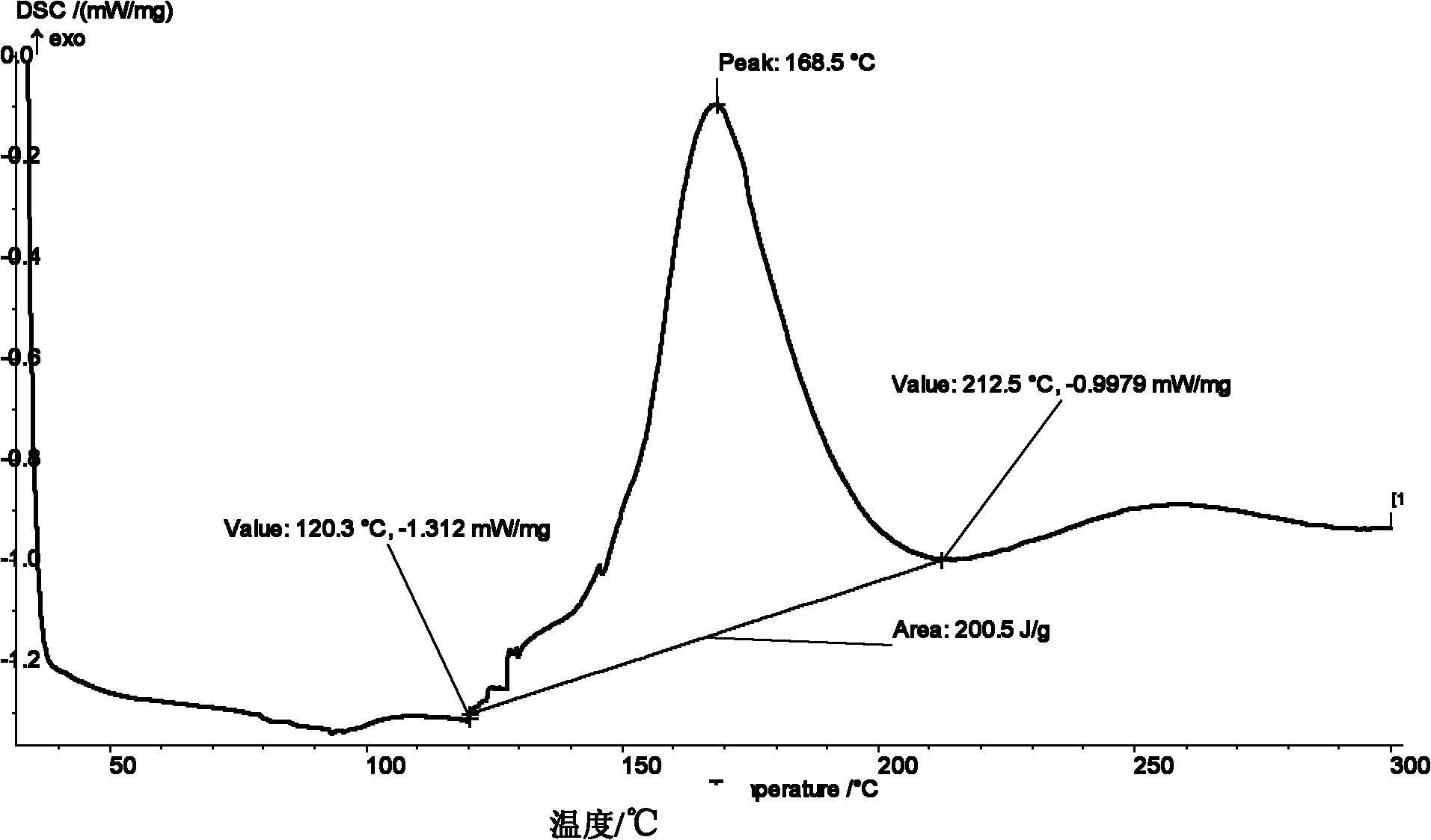

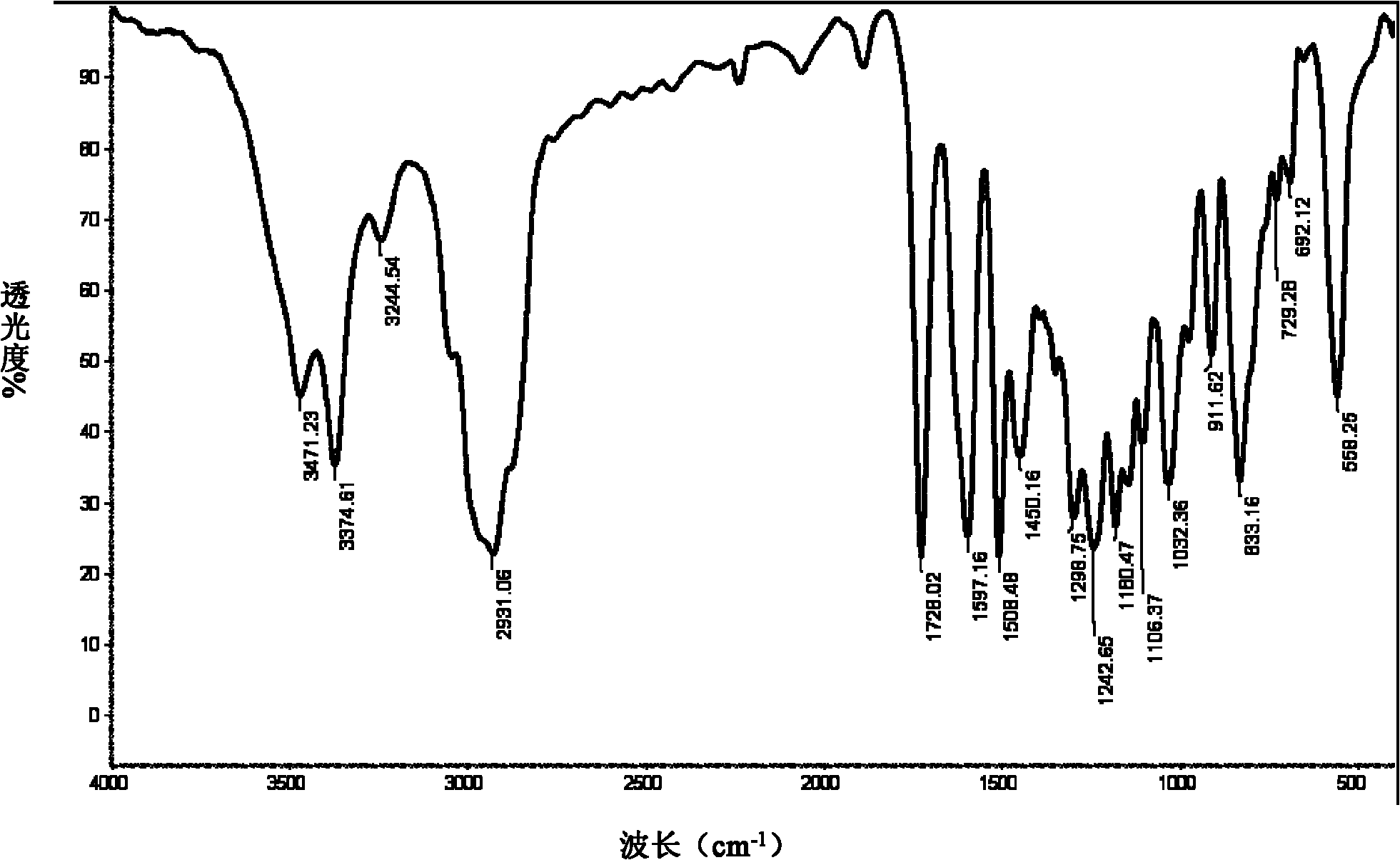

Benzimidazole diamine curing type epoxy adhesive and preparation method thereof

InactiveCN102031082AHigh tensile and shear strength at room temperatureConvenient sourceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesViscous liquidElectronics

The invention relates to a benzimidazole diamine curing type epoxy adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials: a component A, namely a benzimidazole diamine curing agent and a component B, wherein the component B is prepared from terminal carboxyl group butadiene-nitrile rubber, epoxy resin and a reactive diluent. The preparation method comprises the following steps of: (1) adding the terminal carboxyl group butadiene-nitrile rubber and the epoxy resin into a reaction kettle, reacting at the temperature of 90 DEG C with stirring, cooling to the temperature of 50 DEG C, adding the reactive diluent, and stirring at the temperature of 80 DEG C to obtain homogeneous and transparent viscous liquid, namely the component B; and (2) mixingthe components A and B, and stirring uniformly to obtain the adhesive. The tensile shear strength of the adhesive is 33.5MPa at the room temperature, and the adhesive has wide application prospect infields of electronics and microelectronics, rigid copper-clad laminates, motors, aerospace and the like; and the preparation process is simple, is low in cost and is convenient to operate, the resources of reaction raw materials are wide, and the adhesive can be conveniently industrially produced.

Owner:DONGHUA UNIV +1

Modified hydrogenated nitrile-butadiene rubber and its preparing method

The present invention relates to the preparing technology of composite rubber material. Carbon nanotube via surface treatment and liquid rubber are ultrasonically mixed and added into partial hydrogenated nitrile-butadiene rubber to prepare mother rubber; the mother rubber is mixed with the rest hydrogenated nitrile-butadiene rubber, carbon black, zinc oxide and sulfurizing agent, and the mixture is mixed in a rolling mixer or a Banbury mixer and sulfurized to obtain the carbon nanotube modified hydrogenated nitrile-butadiene rubber. The present invention has the beneficial effects of raised heat performance, antiwear performance, mechanical strength, antiageing performance, etc. raised use performance and expanded application range.

Owner:SINOPEC OILFIELD EQUIP CORP

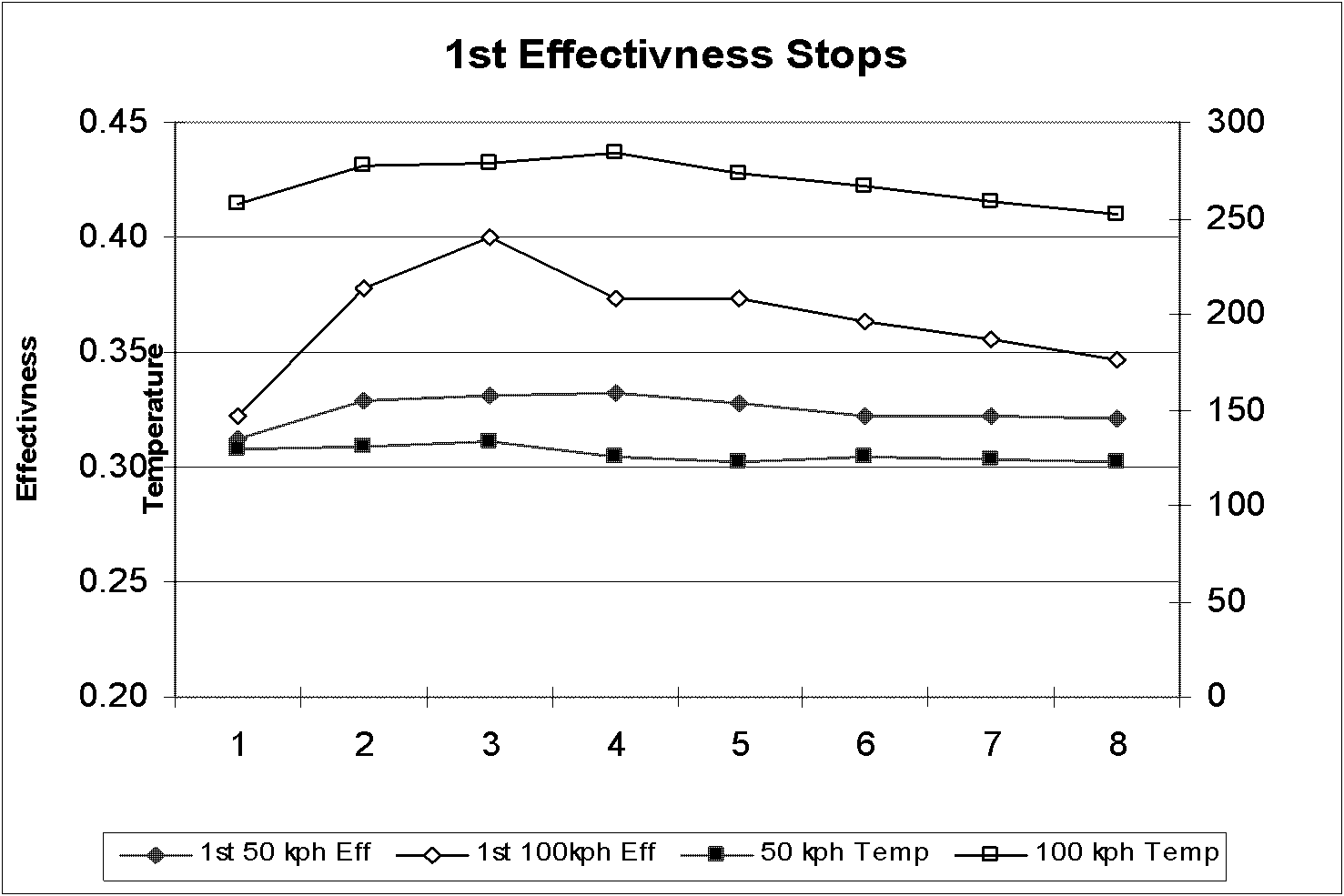

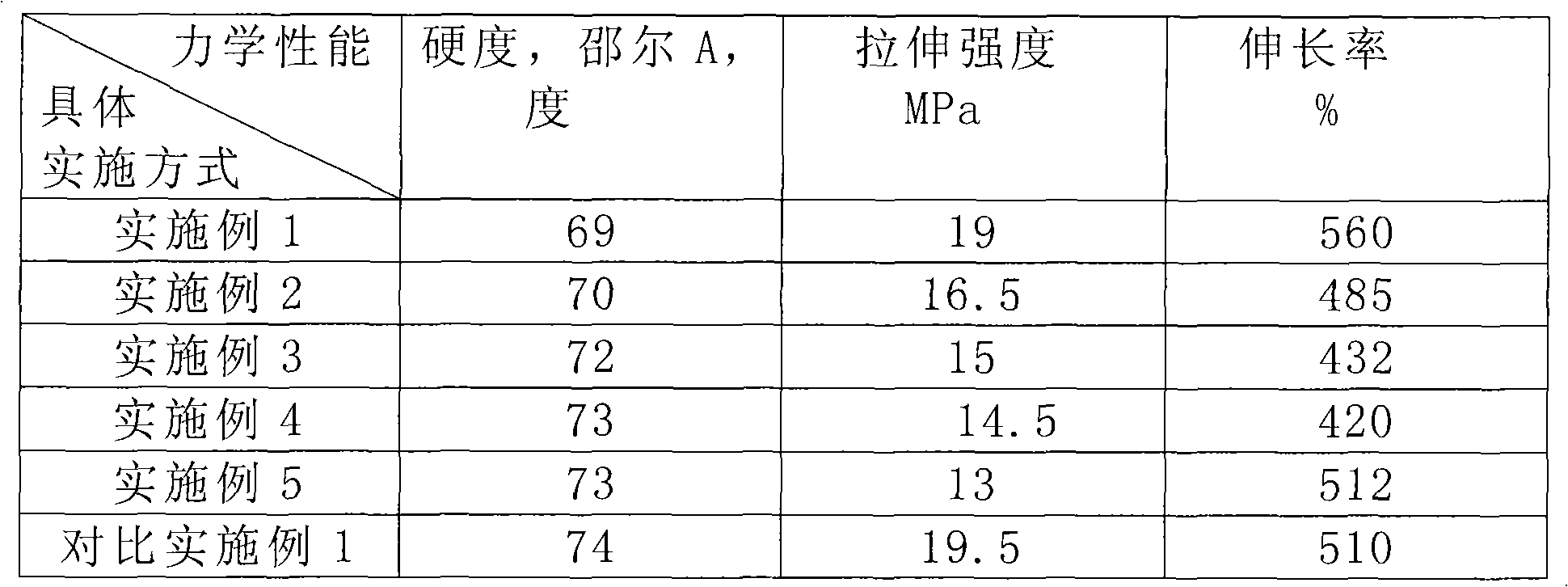

Copper-free ceramic friction material with little falling ash and preparation method thereof

InactiveCN101823856AAvoid secondary pollutionMeet the requirements of environmental protectionBraking membersFriction liningAdhesiveAramid

The invention discloses a copper-free ceramic friction material with little falling ash and a preparation method thereof. The copper-free ceramic friction material with little falling ash is prepared by mixing, shaping and thermally processing the following raw materials in percentage by weight: 5 to 14 percent of adhesive, 20 to 45 percent of reinforcing material, 10 to 40 percent of ceramic material, 10 to 18 percent of lubricant and the balance of filler, wherein nitrile rubber modified phenolic resin and nitrile rubber powder are used as the adhesive; the reinforcing material is one or a mixture of more of aramid fiber, carbon fiber, steel fiber, foam iron powder and aluminum oxide fiber; the ceramic material is one or a combination of more of molybdenum disulfide, magnesium oxide andferrous disulphide; the lubricant is the mixture of graphite and mica; and the filler is the mixture of composite filler, barite, friction powder and aluminum powder. The material has high friction performance, low brake noise and high heat fading resistance, and particularly shows high performance in aspects of wear resistance, long life and great reduction in the falling ash of a wheel hub; therefore, the material can meet both the requirement of a modern automobile braking system on operating conditions and the requirement on economy and environment friendliness when an automobile is used.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

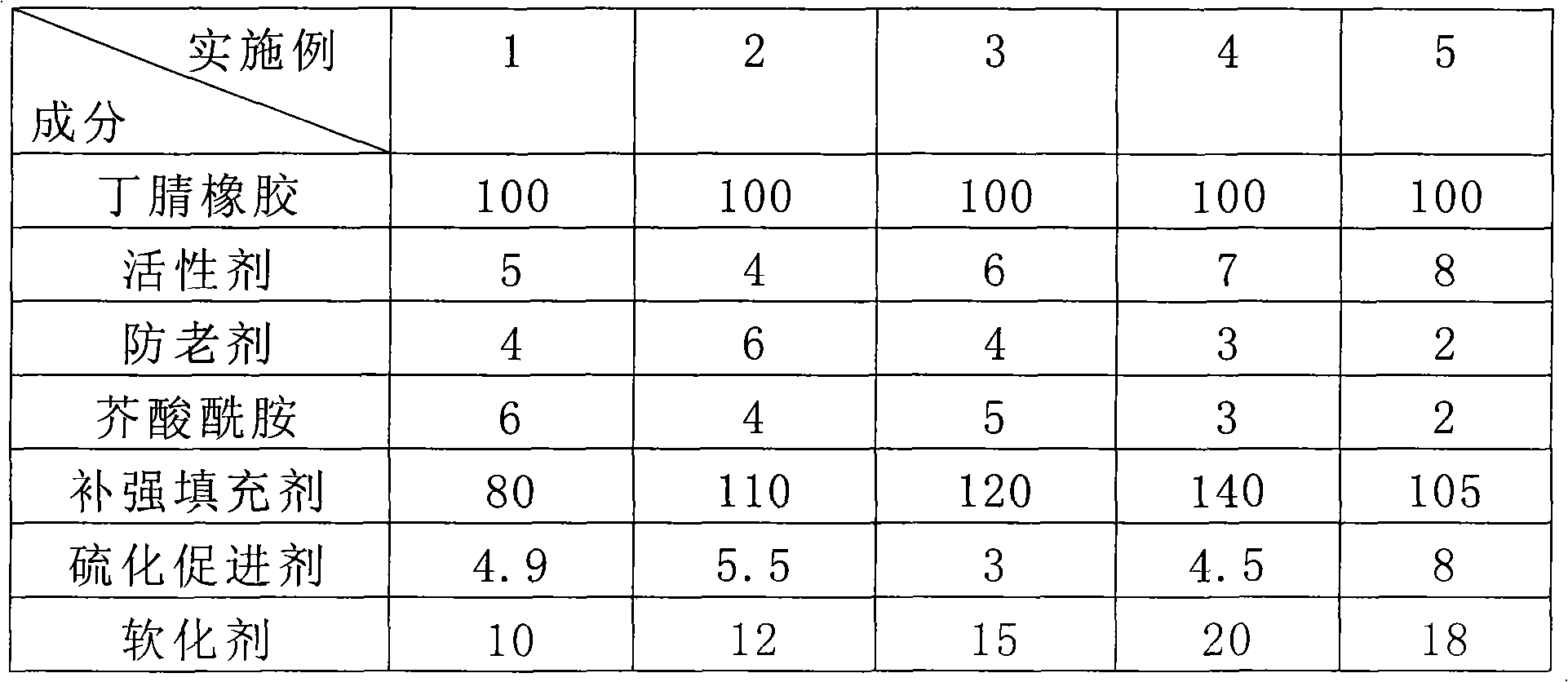

Highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and preparation method thereof

InactiveCN101597391AThe ingredients are well matchedReduce coefficient of frictionNitrile rubberVulcanization

The invention provides a highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber and a preparation method thereof. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber comprises the following components according to parts by weight: 100 parts of butadiene-acrylonitrile rubber, 3-8 parts of active agent, 1-6 parts of antiager, 2-6 parts of erucamide, 50-150 parts of reinforcing filler and 3-8 parts of vulcanizing accelerator, wherein acrylonitrile content in the butadiene-acrylonitrile rubber is 34-41 percent by weight, and Mooney viscosity (ML[1+4] of the butadiene-acrylonitrile rubber is 45-70. The preparation method of the butadiene-acrylonitrile-rubber vulcanized rubber comprises the steps of A. mixing and processing and B. recycled processing and vulcanization. The butadiene-acrylonitrile-rubber vulcanized rubber has reasonable component mixing and higher abrasion resistance. The highly-abrasion-resistant butadiene-acrylonitrile-rubber vulcanized rubber prepared according to the method has high elongation and long service life.

Owner:ANHUI RUNKANG RUBBER & PLASTIC TECH CO LTD

Friction material and method for manufacturing friction plate by using friction material

InactiveCN103012876AImprove wear resistanceReduce hardnessOther chemical processesFriction liningNitrile rubberVulcanization

The invention provides a friction material comprising an adhesive, a reinforcing material, a friction-enhancing material, a lubricant, and a filling material. The adhesive is a mixture of liquid nitrile rubber and phenolic resin. The invention also provides a method for manufacturing a friction plate by using the friction material. According to the invention, liquid nitrile rubber is adopted as a substrate of the friction material, and the friction plate with a required shape is manufactured through extrusion granulation and vulcanization molding. The friction plate has the advantages of high abrasion resistance and low hardness. When the friction plate is used in mine hoisting machinery and agricultural working machinery, the friction plate can be processed into special shapes, and another special requirement of good weather resistance can be satisfied.

Owner:BYD CO LTD

Preparation method of high temperature and high pressure resistant rubber sealing material

InactiveCN101824172AImprove mechanical propertiesImprove heat resistanceSealing/packingPolymer scienceVulcanization

The invention belongs to the technical field of rubber sealing material, and relates to a preparation method of a high temperature and high pressure resistant rubber sealing material which can be applied to an oilfield deep oil production engineering process; first, 100 parts of hydrogenated nitrile rubber is weighed by parts in weight, put into a mixing mill to be plasticated; and then 2 to 20 parts of metal oxide, 1 to 5 parts of stearic acid, 5 to 100 parts of acrylate, 10 to 70 parts of carbon black, 1 to 6 parts of aging inhibitor, 5 to 30 parts of plasticizer, 2 to 10 parts of antiscorcher, 2 to 10 parts of vulcanizer and 2 to 10 parts of vulcanization aid are sequentially added into the mixing mill to be mixed uniformly; mixing rubber is vulcanized primarily in a plate vulcanizing press, the vulcanizing temperature is controlled to be 150 to 180DEG C, the vulcanizing time is 20 to 40min, and the vulcanizing pressure is 10 to 20MPa; after being taken out from the plate vulcanizing press, the rubber is secondarily vulcanized at 150 to 180DEG C to obtain vulcanized rubber with excellent performance; and the preparation method of the high temperature and high pressure resistant rubber sealing material has the advantages of simple process, convenient operation and use, low preparation cost, excellent mechanical performance, and in particular better high-temperature mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH +1

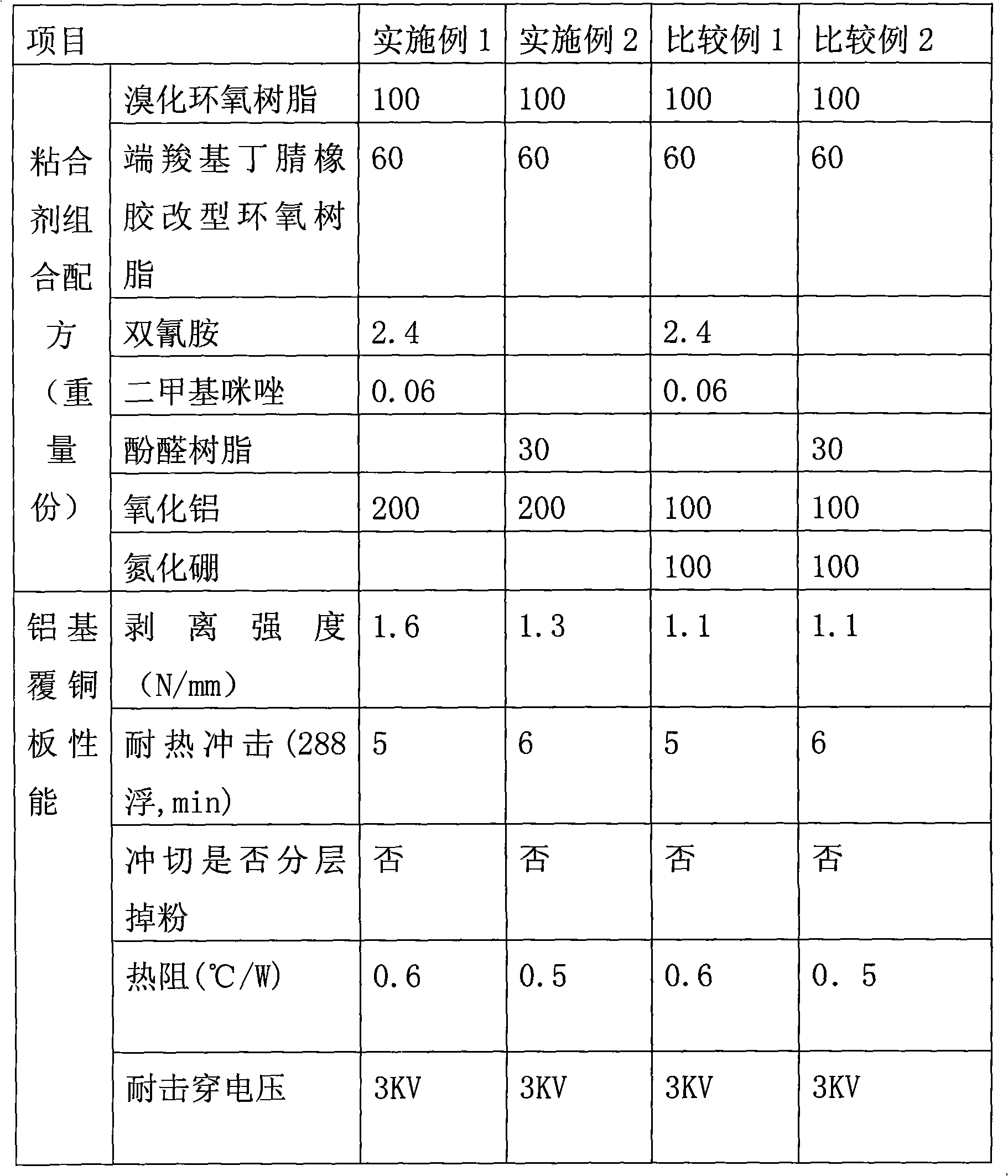

Epoxy resin composition, glue film made of same and preparation method

The invention discloses an epoxy resin composition, a continuous glue film made of the same and a preparation method. The epoxy resin composition comprises solid ingredients and organic solvents, wherein the solid ingredients comprise epoxy resin (A), thermoplastic resin or / and synthetic nitrile rubber (B), solidified agents (C), curing accelerators (D) and inorganic heat-conducting fillers (E). In addition, the invention also relates to the continuous glue film made of the epoxy resin composition and the preparation method. Because the continuous glue film is made by automated equipment, thecontinuous glue film has good consistency on thickness and performance, so that the breakdown voltage of a metal based copper-clad laminate and the stability of thermal resistance are ensured. The product made by the invention has good heat-conducting performance and electric insulation performance.

Owner:广东全宝科技股份有限公司

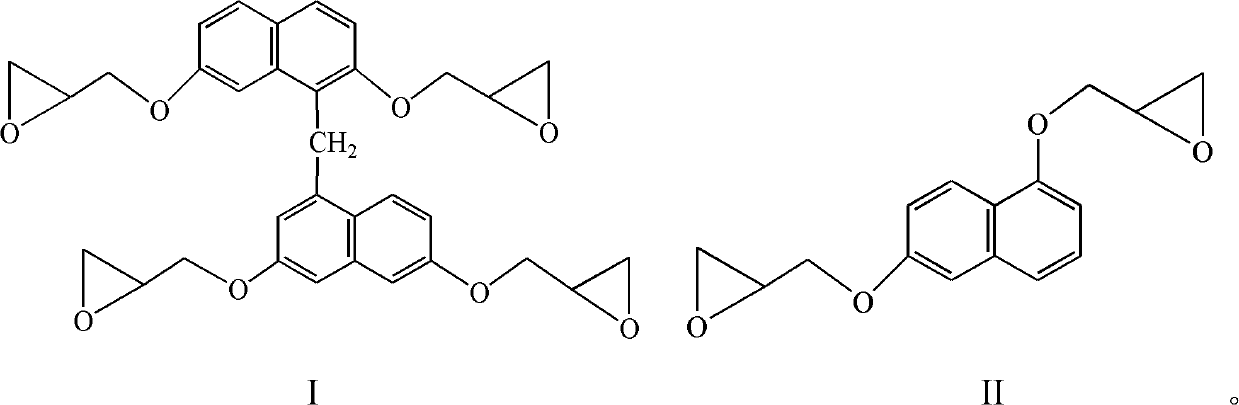

Bi-component adhesive composition and preparation method thereof

ActiveCN103305170AHigh bonding strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNitrile rubberHeat resistance

The invention provides a bi-component adhesive composition composed of an A component and a B component. The A component contains an epoxy resin mixture, a first toughening agent, filler and a thixotropic agent; the B component contains a second toughening agent, a normal temperature curing agent, a high-temperature curing agent and an accelerant; the epoxy resin mixture contains a first epoxy resin, a second epoxy resin and a third epoxy resin, the first epoxy resin is a bisphenol A epoxy resin or a bisphenol A epoxy resin, the second epoxy resin is a chelate modified epoxy resin, and the third epoxy resin is a naphthalene-nucleus modified epoxy resin; the first toughening agent is a core-shell structure rubber nano particle, the second toughening agent is an end-isocyanate polyurethane and / or end-carboxy nitrile rubber. The invention further provides a preparation method of the bi-component adhesive. The adhesive composition provided by the invention is high in adhesion strength, high in heat resistance, low in water adsorption, high in impact resistance, and capable of satisfying the use requirement of structural adhesive for connecting structural members of an automobile.

Owner:BYD CO LTD

Nitrile rubber article having natural rubber characteristics

ActiveUS20060253956A1Maximize material strengthMinimization requirementsCosmetic preparationsBiocidePolymer scienceCarbamate

An improved process and material for making elastomeric nitrile rubber articles is disclosed. In particular, the process and material formulation can produce nitrile rubber based articles, which exhibit force-strain characteristics that are comparable to those of natural rubber latex articles, while maintaining the tensile strength properties of nitrile rubber. The process includes an accelerator composition at the pre-cure stage having a dithiocarbamate, a thiazole, and a guanidine compound. The invention also includes an elastomeric nitrile rubber product made by the process, such as examination, surgical, or work gloves.

Owner:O&M HALYARD INC

Nitrile rubbers

ActiveUS20080293889A1Easy to processEnhance the imageGroup 4/14 element organic compoundsConductive materialNitrile rubberPhotochemistry

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a specific calcium and chloride content and have a particularly high storage stability.

Owner:ARLANXEO DEUT GMBH

Method for the degradation of nitrile rubber by metathesis in the presence of ruthenium- or osmium-based catalysts

A novel process for the degradation of nitrile rubber by metathesis using ruthenium- or osmium-based catalysts which have both a substituted or unsubstituted imidazolidine ligand and a carbene ligand bearing a phosphonium radical is provided.

Owner:LANXESS DEUTDCHLAND GMBH

Special material for automotive seal strip and preparation method thereof

ActiveCN101519578AExcellent tear strengthIncrease elasticityEngine sealsOther chemical processesRubber materialVulcanization

A material for automotive seal strip comprises PVC with a certain amount of powdered nitrile rubber, plasticizer, heat stabilizer, lubricant, inorganic filler, coloring agent, curing agent and vulcanization aid; and squeezing granulation is carried out by a screw extruder. The invention utilizes the PVC thermoplastic elastomer to replace part of the rubber material and has the features possessed by the rubber material, thus significantly reducing the cost of raw materials and having the characteristics of simple processing technology, easy recycling of materials and the like, and improving shortcomings in the prior art that the materials can not be recycled after rubber vulcanization. Compared with other thermoplastic elastomers, the PVC thermoplastic elastomer seal strip provided by the invention has excellent compression set resistance reaching below 40%, low temperature resistance reaching minus 40 DEG C, and excellent chemicals resistance. The material has flexibility, and soundproofing, dustproofing, watertight and shock-absorbing functions, and can meet performance requirement of rubber automotive sealing strips.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com