Process for the metathetic degradation of nitrile rubbers

a technology of nitrile rubber and metathesis catalyst, which is applied in the field of metathetic degradation of nitrile rubber, can solve the problems of inability to reduce the molar mass of the nbr feedstock to be used for hydrogenation, the processingability of hnbr is greatly restricted, and the molar mass of the nbr feedstock can not be reduced, so as to achieve the effect of increasing the activity of metathesis catalyst in the degradation of nitril

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

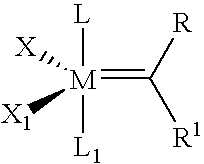

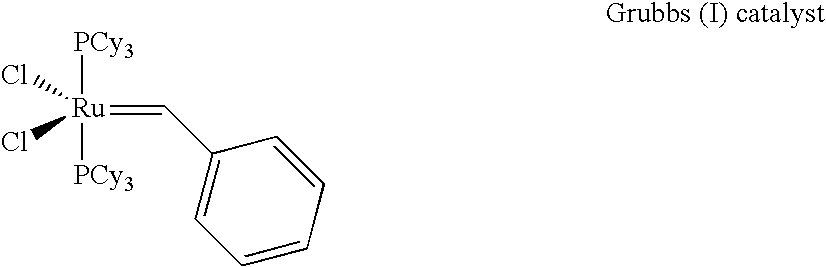

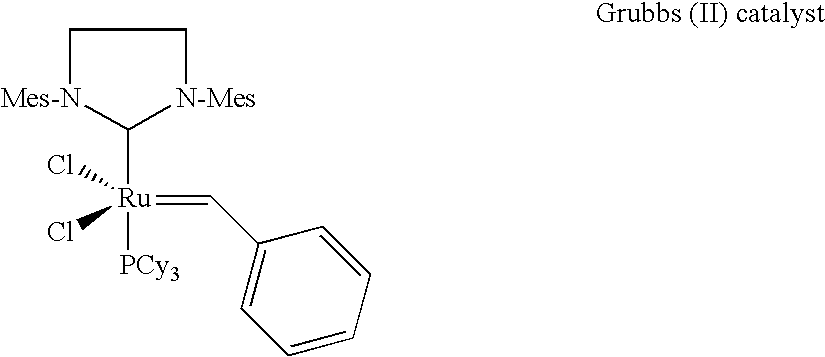

[0234] The following examples were carried out using the following catalysts:

“Grubbs II Catalyst”:

[0235] The Grubbs II catalyst was procured from Materia (Pasadena / Calif.).

“Buchmeiser Nuyken Catalyst”:

[0236] The Buchmeiser-Nuyken catalyst (molecular weight: 781.75 g / mol) was prepared by the synthesis published in Adv. Synth. Catal. 2003, 345, 996.

[0237] As phosphane additives, use was made of tricyclohexylphosphane (molecular weight=280.23 g / mol, referred to as PCy3 for short) and triphenylphosphane (molecular weight: 262.09; PPh3 for short); tricyclohexylphosphane and triphenylphosphane were procured from Aldrich.

[0238] The metathesis reactions were carried out using the nitrile rubber Perbunane NT 3435 from Lanxess Deutschland GmbH as substrate.

[0239] This nitrile rubber had the following characteristic properties:

Acrylonitrile content:35%by weightMooney value (ML 1 + 4 at 100° C.):34Mooney unitsResidual moisture content:1.8%by weightMw:240 000g / molMn:100 000g / molPDI (M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent mass | aaaaa | aaaaa |

| Equivalent mass | aaaaa | aaaaa |

| Equivalent mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com