Patents

Literature

5334 results about "Ruthenium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ruthenium is a chemical element with the symbol Ru and atomic number 44. It is a rare transition metal belonging to the platinum group of the periodic table. Like the other metals of the platinum group, ruthenium is inert to most other chemicals. Russian-born scientist of Baltic-German ancestry Karl Ernst Claus discovered the element in 1844 at Kazan State University and named it after the Latin name of his homeland, Ruthenia. Ruthenium is usually found as a minor component of platinum ores; the annual production has risen from about 19 tonnes in 2009 to some 35.5 tonnes in 2017. Most ruthenium produced is used in wear-resistant electrical contacts and thick-film resistors. A minor application for ruthenium is in platinum alloys and as a chemistry catalyst. A new application of ruthenium is as the capping layer for extreme ultraviolet photomasks. Ruthenium is generally found in ores with the other platinum group metals in the Ural Mountains and in North and South America. Small but commercially important quantities are also found in pentlandite extracted from Sudbury, Ontario and in pyroxenite deposits in South Africa.

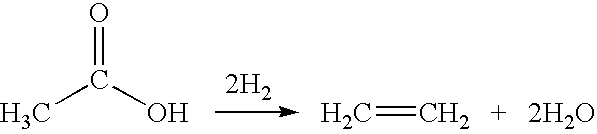

Process for catalytically producing ethylene directly from acetic acid in a single reaction zone

InactiveUS20100030001A1High selectivityHigh yieldHydrocarbonsBulk chemical productionAcetic acidHydrogen

A process for the selective production of ethylene by vapor phase reaction of acetic acid over a hydrogenating catalyst composition to form ethylene in a single reaction zone is disclosed and claimed. In an embodiment of this invention reaction of acetic acid and hydrogen over either a copper supported on iron oxide, copper-aluminum catalyst, cobalt supported on H-ZSM-5, ruthenium-cobalt supported on silica or cobalt supported on carbon selectively produces ethylene in a vapor phase at a temperature in the range of about 250° C. to 350° C.

Owner:CELANESE INT CORP

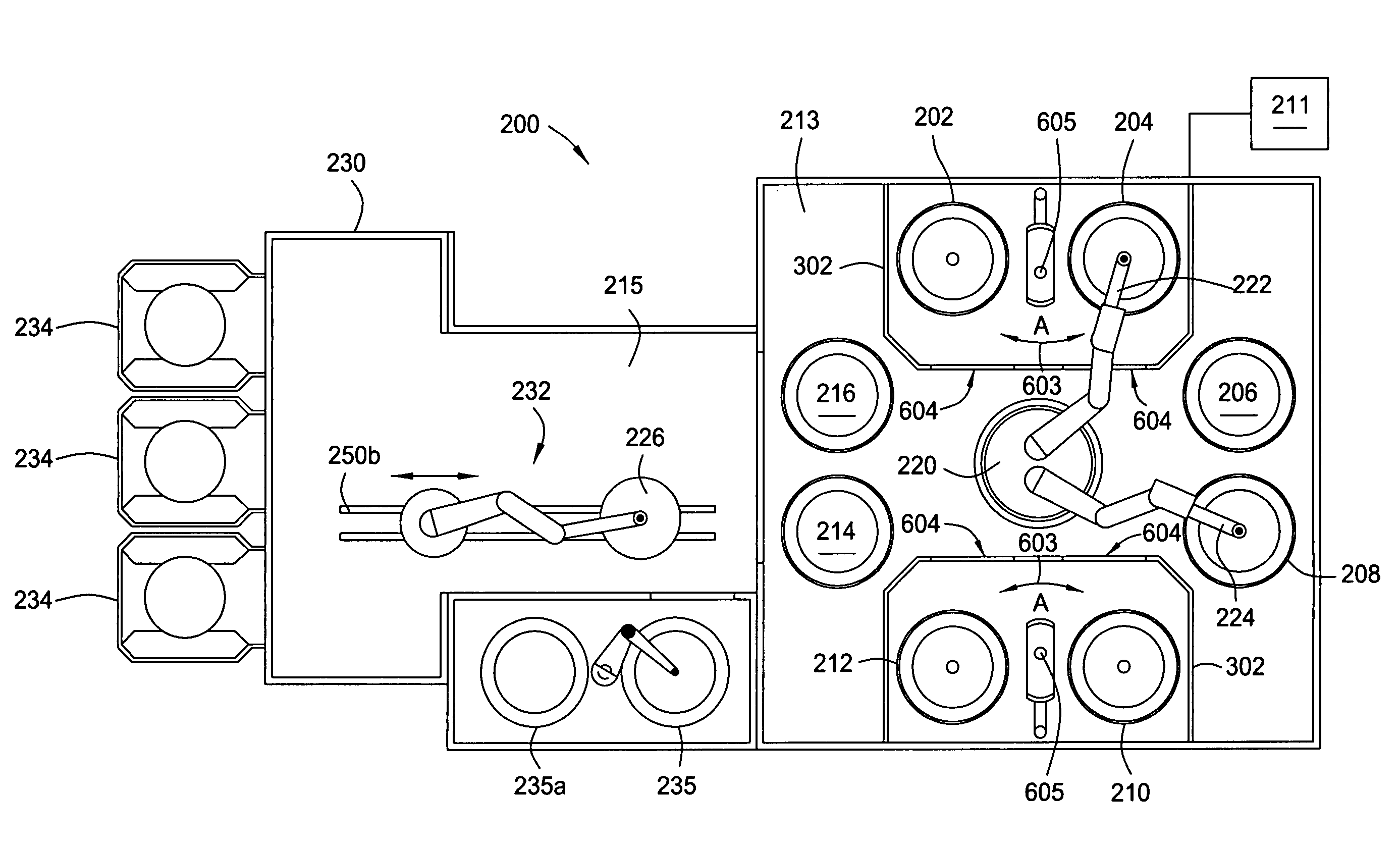

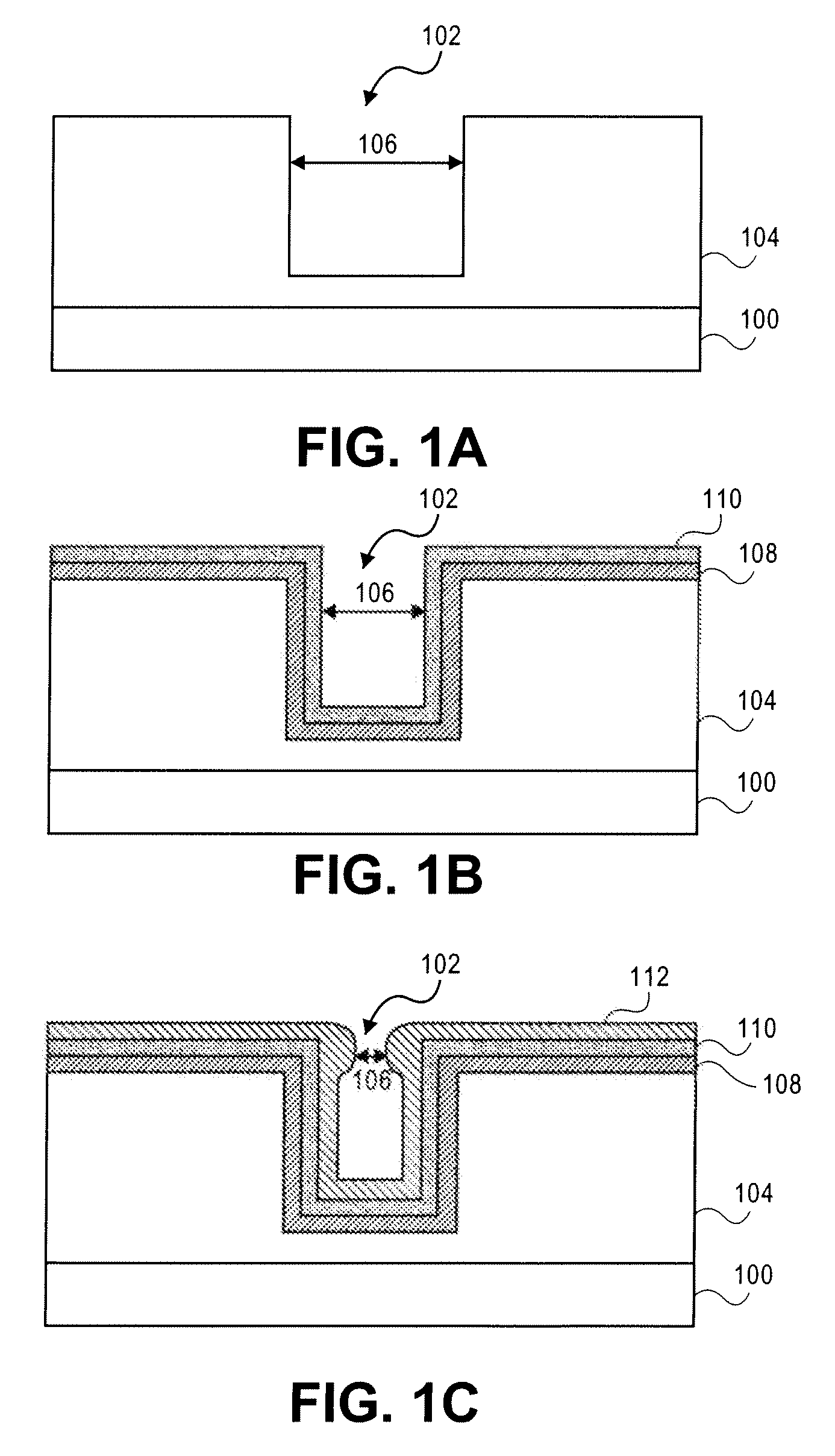

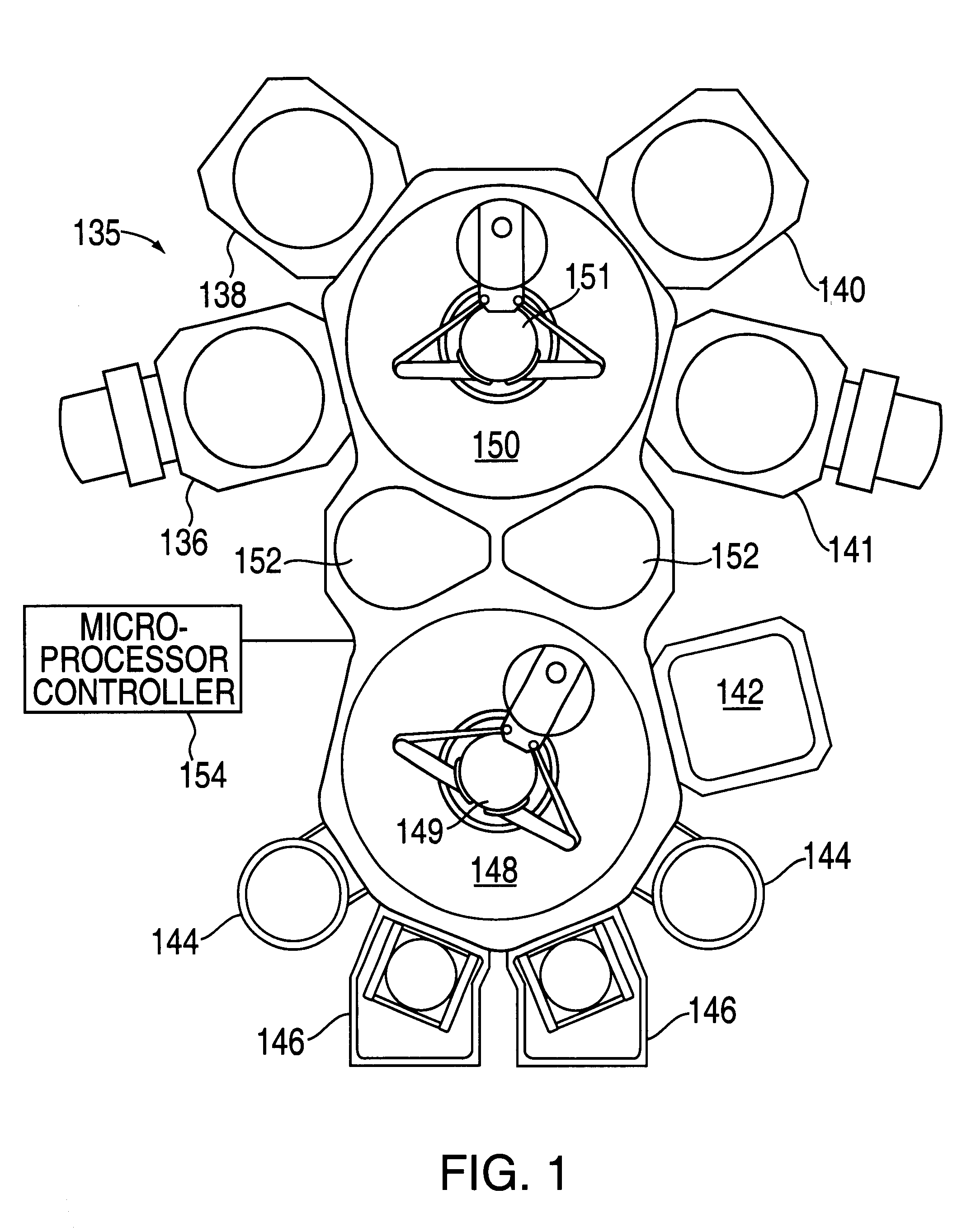

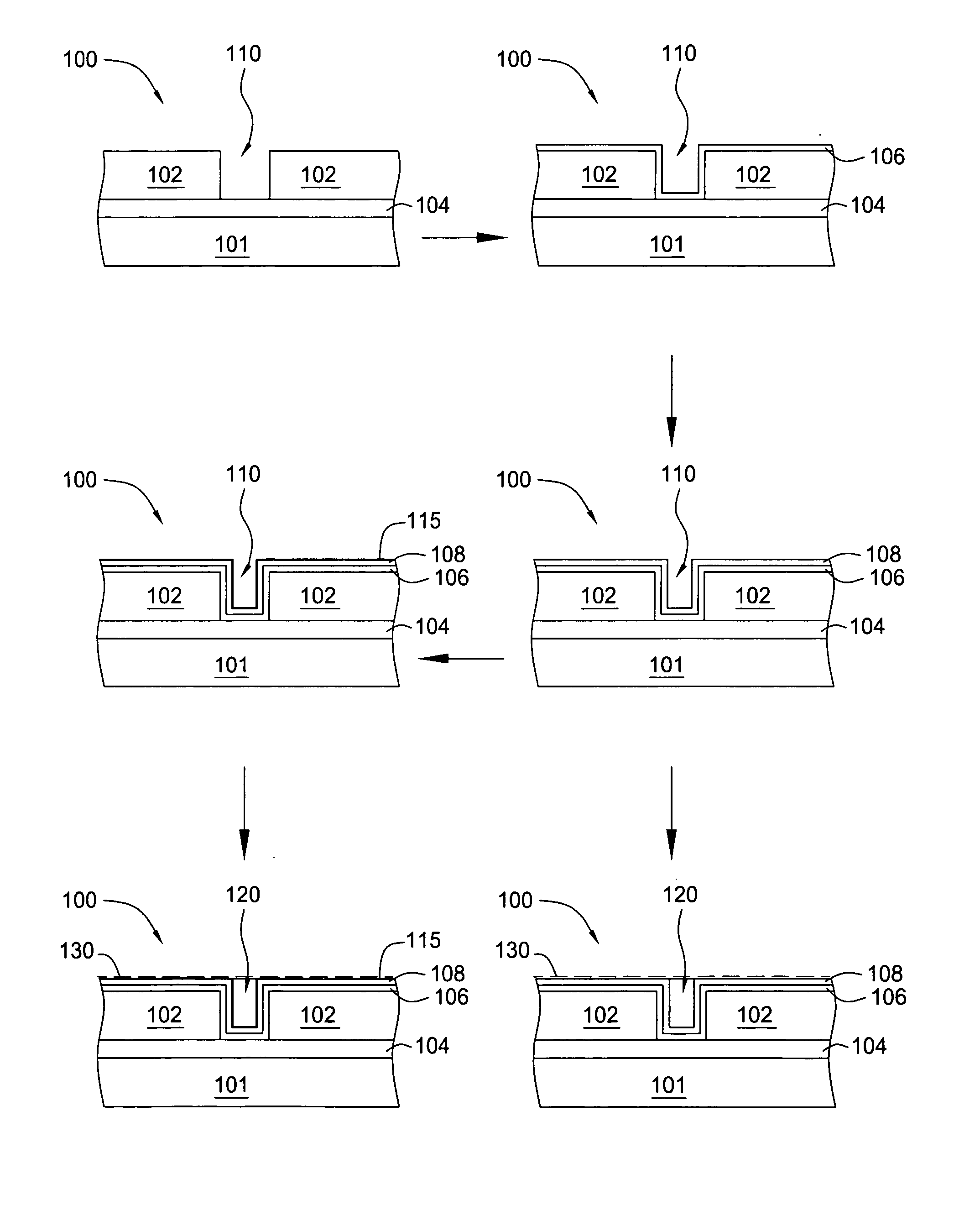

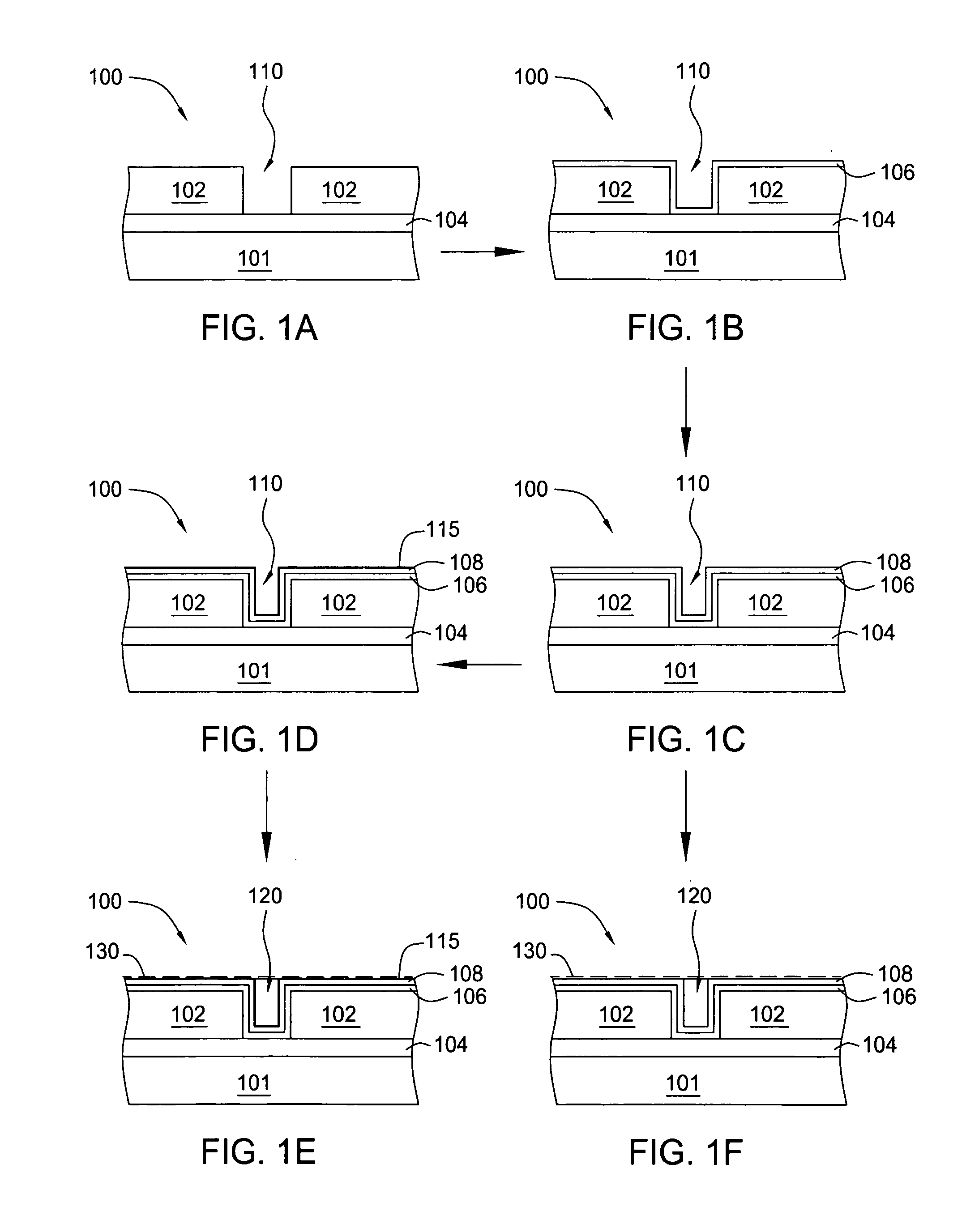

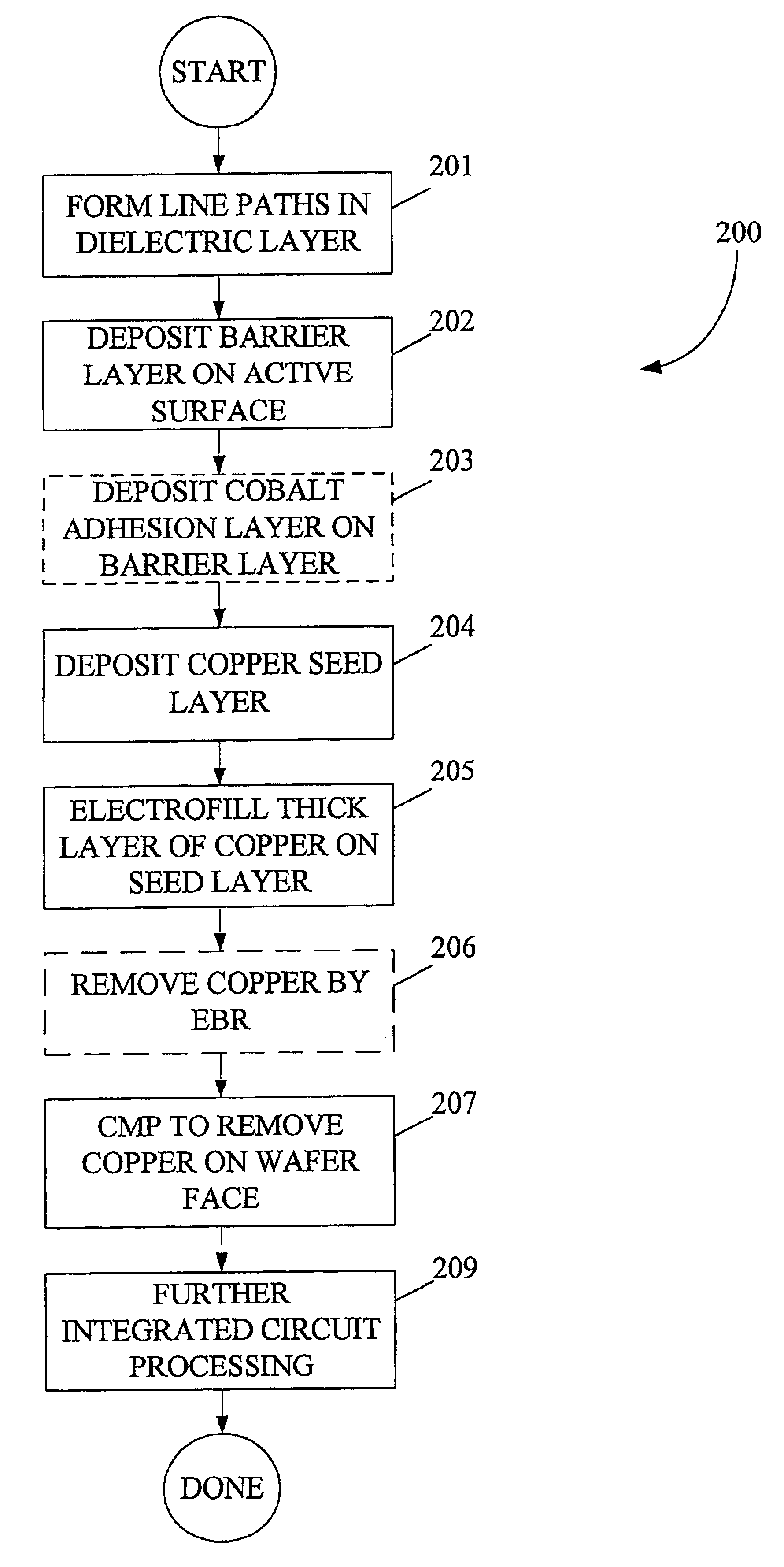

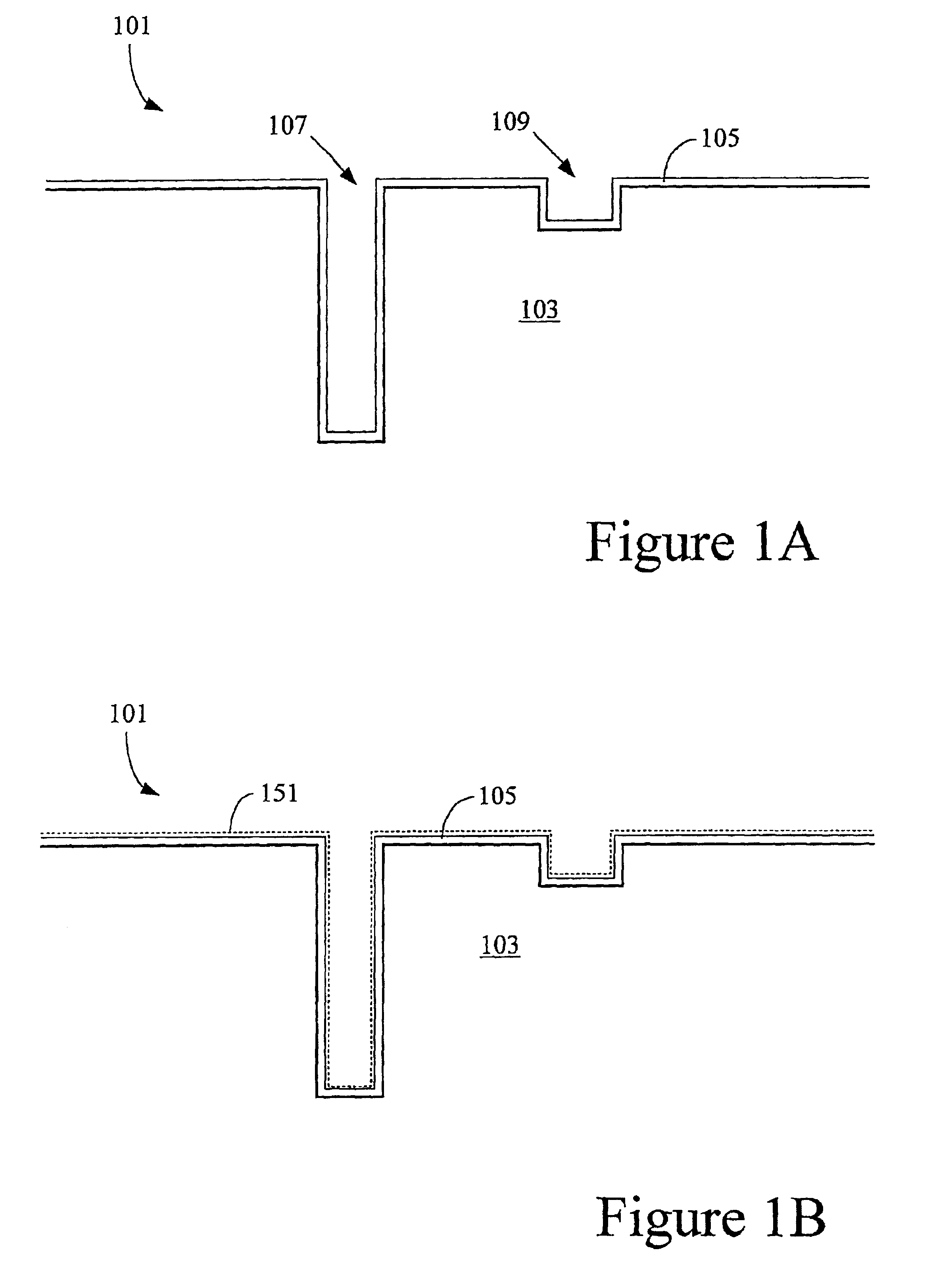

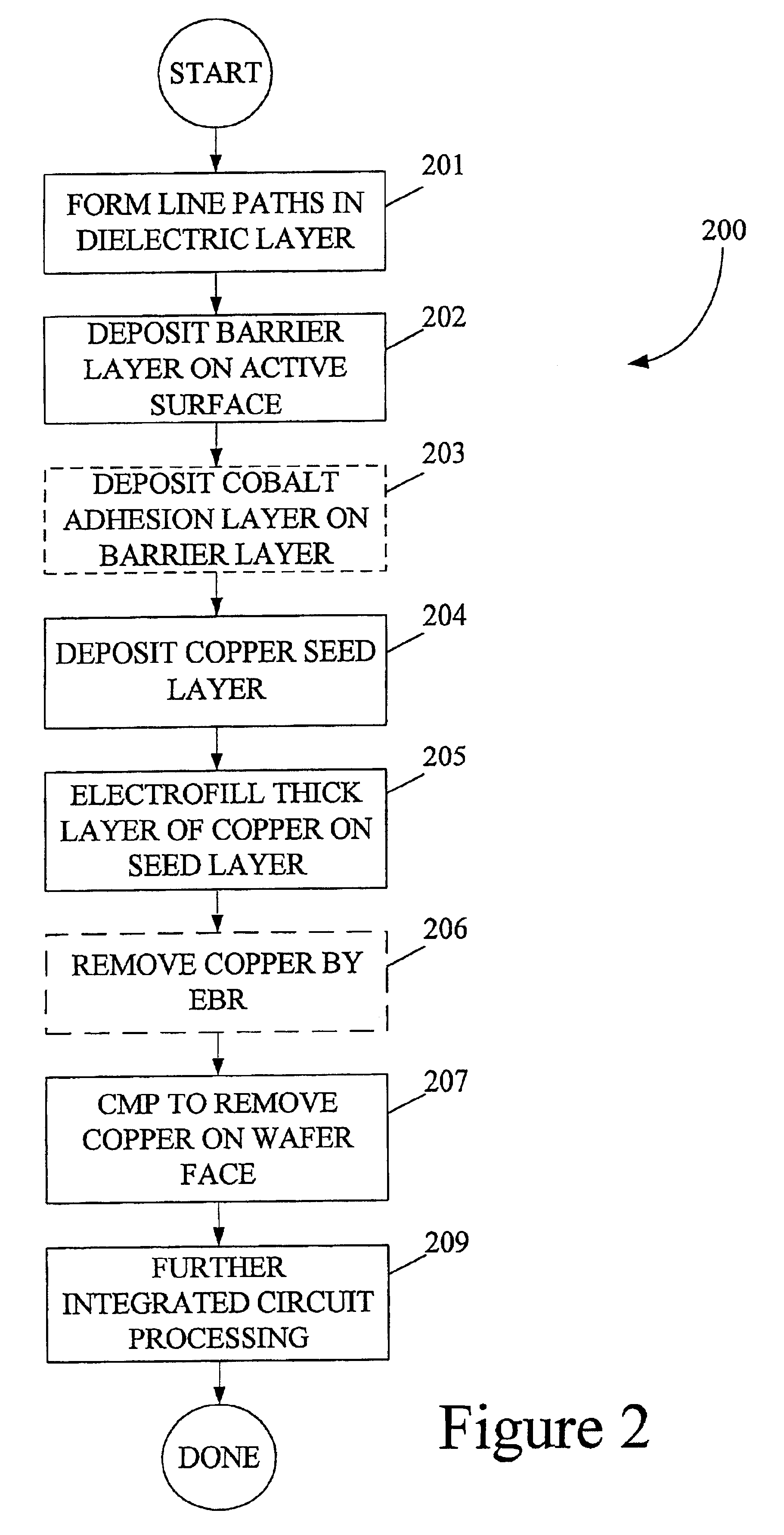

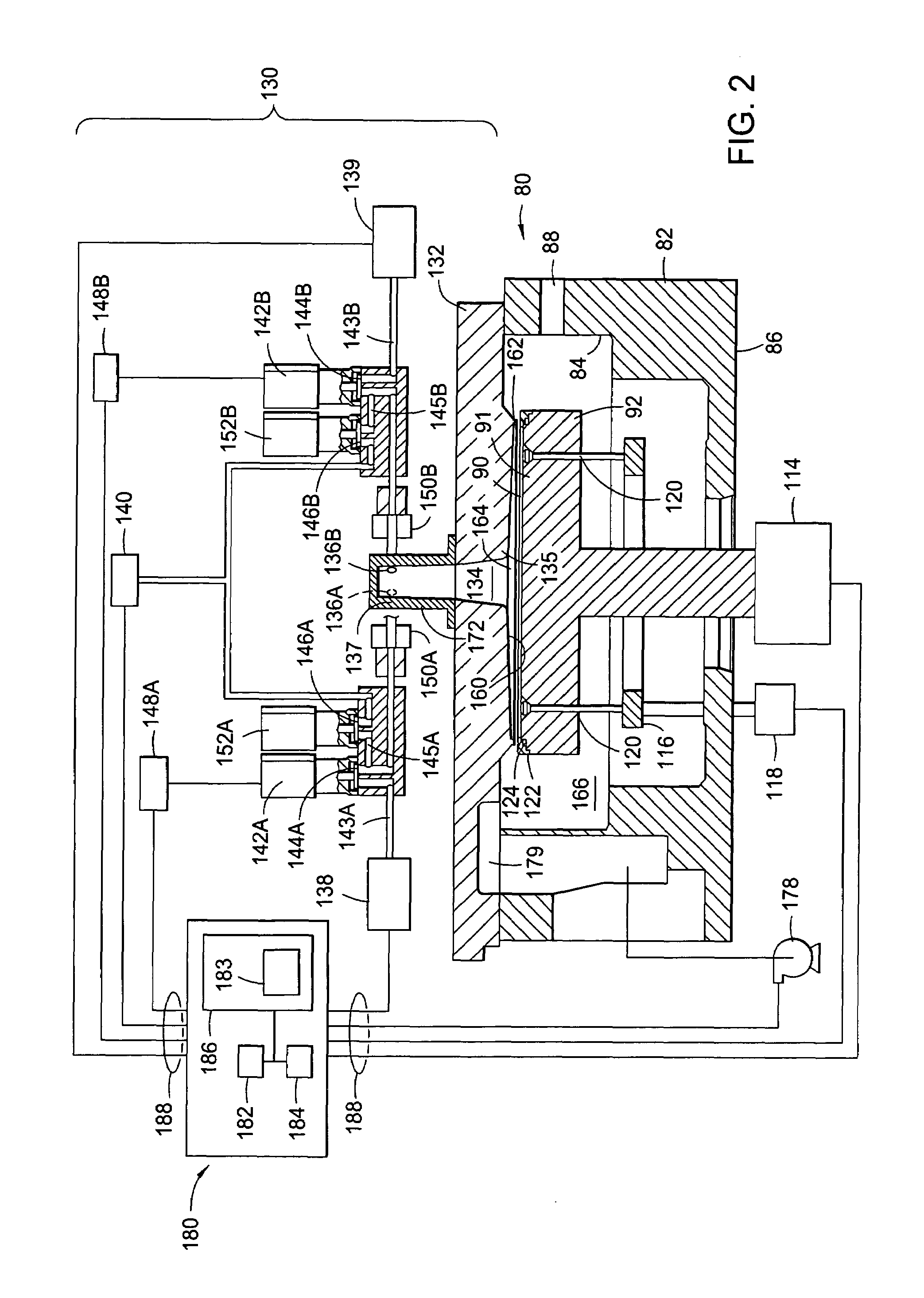

Integrated electroless deposition system

InactiveUS20060033678A1Static indicating devicesSemiconductor/solid-state device manufacturingRutheniumEngineering

Embodiments of the invention provide a cluster tool configured to deposit a material onto a substrate surface by using one or more electroless, electrochemical plating, CVD and / or ALD processing chambers. In one aspect, a ruthenium-containing catalytic layer is formed. Embodiments of the invention provide a hybrid deposition system configured to deposit a seed layer on a substrate with an electroless process and to subsequently fill interconnect features on the substrate with an ECP cell. Other aspects provide an electroless deposition system configured to deposit a seed layer on a substrate, fill interconnect features on a substrate, or sequentially deposit both a seed layer and fill interconnect features on the substrate. One embodiment provides an electroless deposition system configured to form a capping layer over substrate interconnects. The system includes a vapor dryer for pre- and post-deposition cleaning of substrates as well as a brush box chamber for post-deposition cleaning.

Owner:APPLIED MATERIALS INC

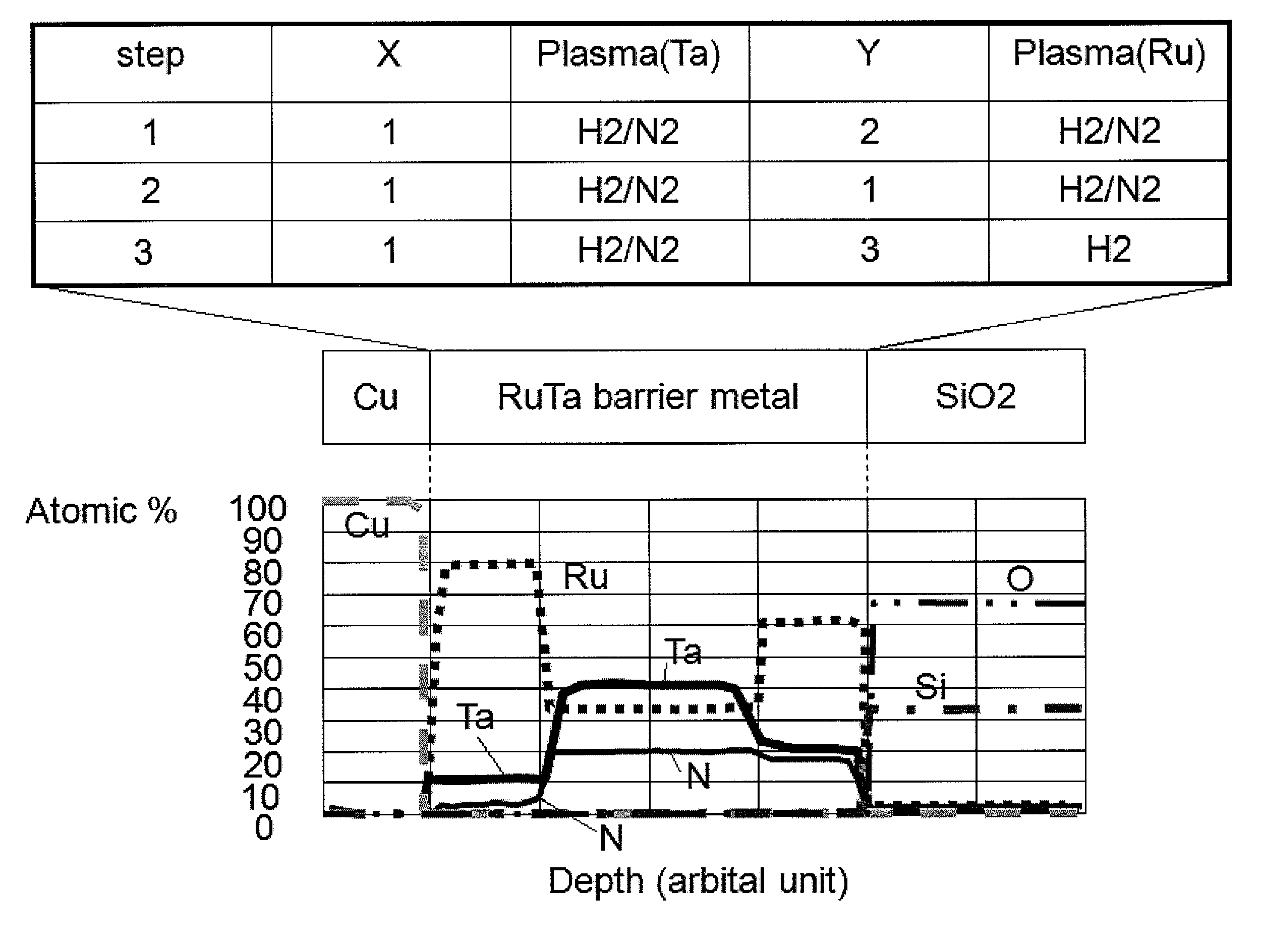

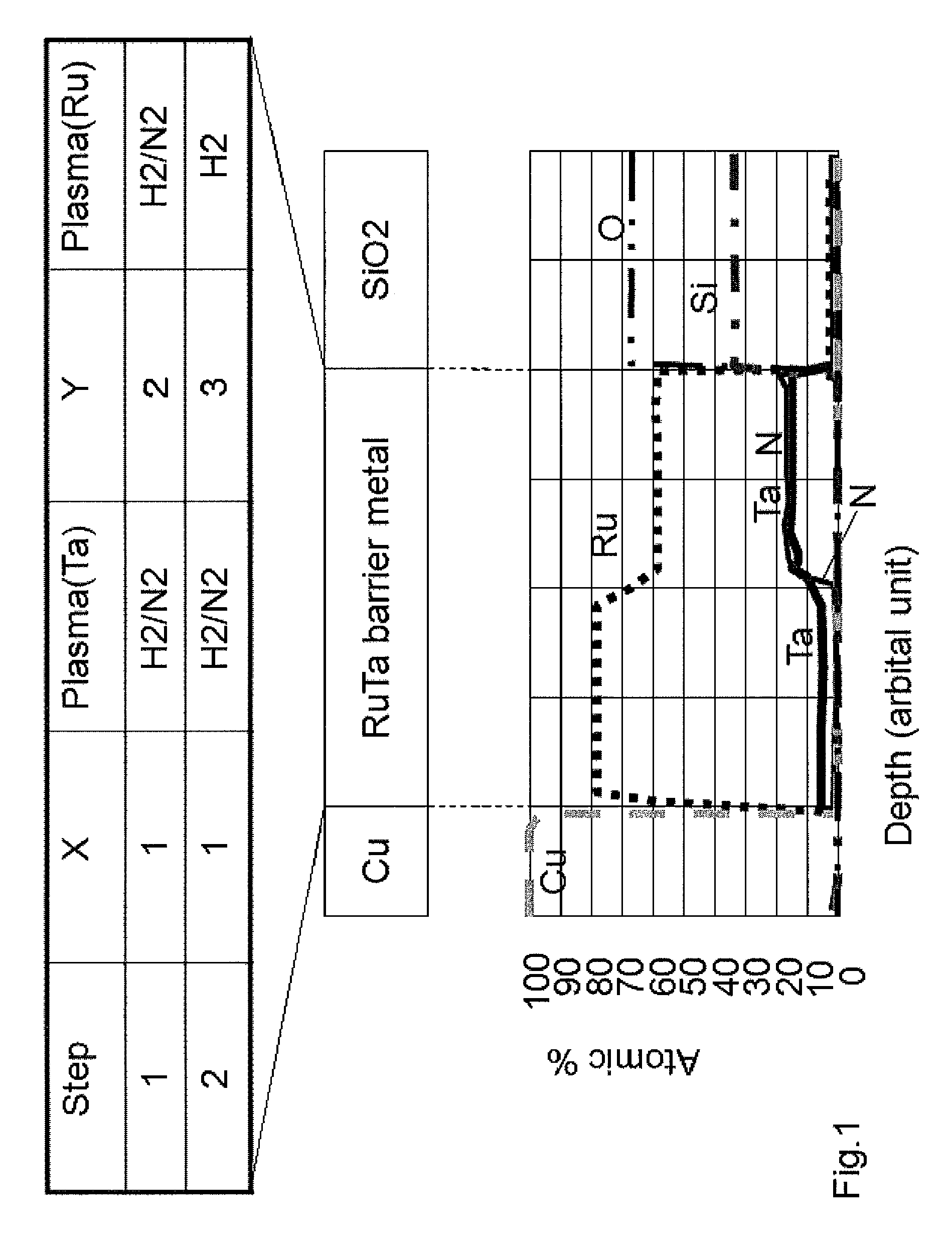

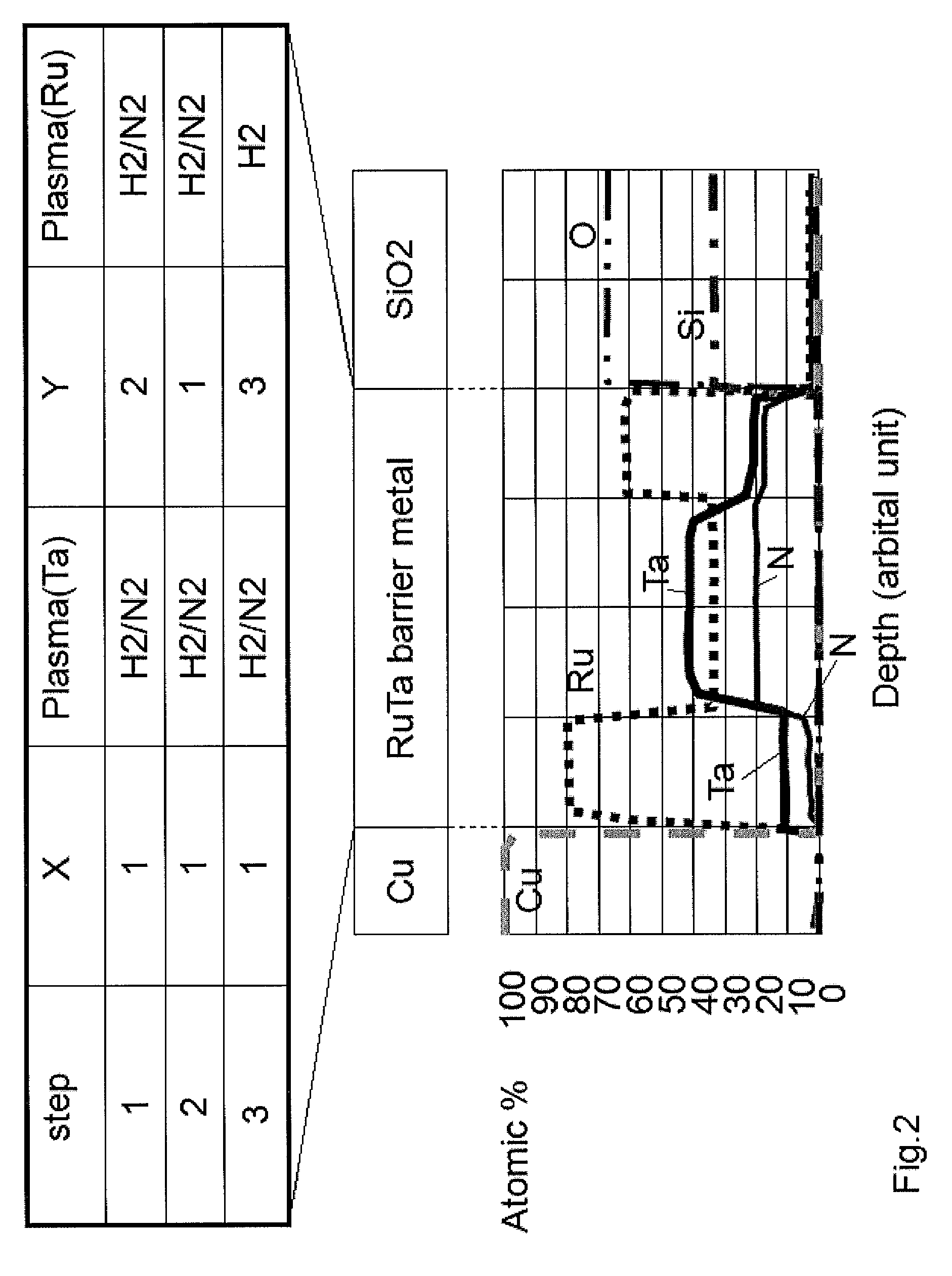

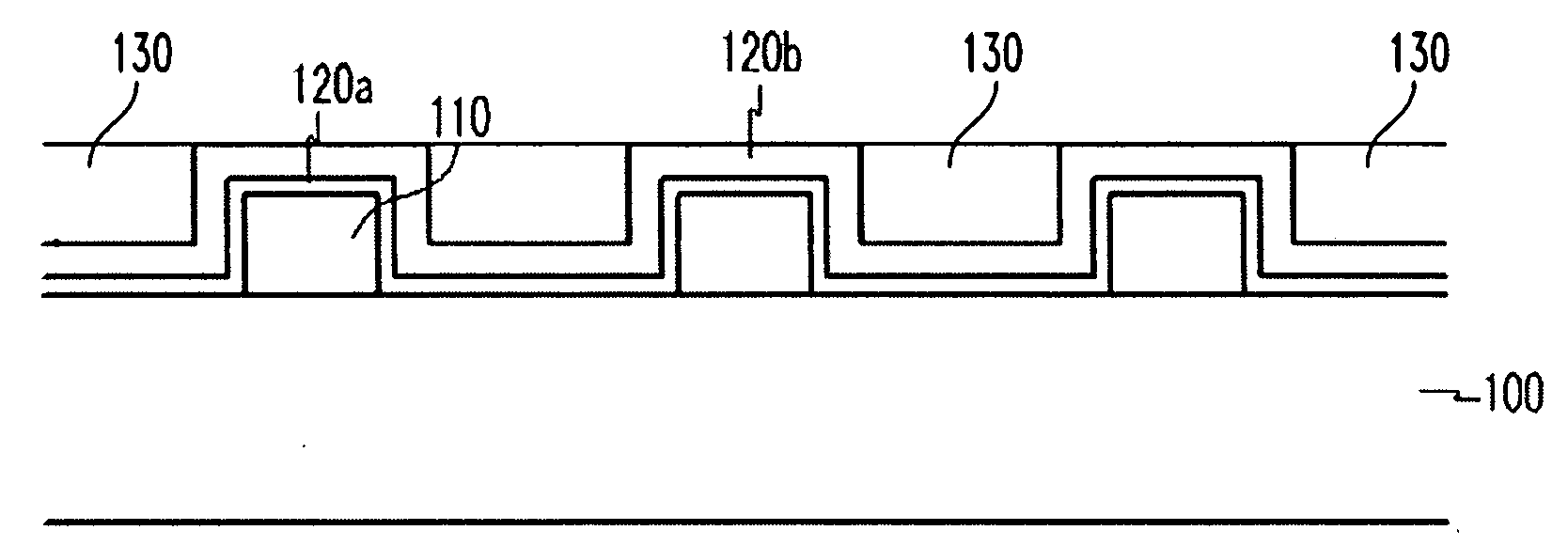

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

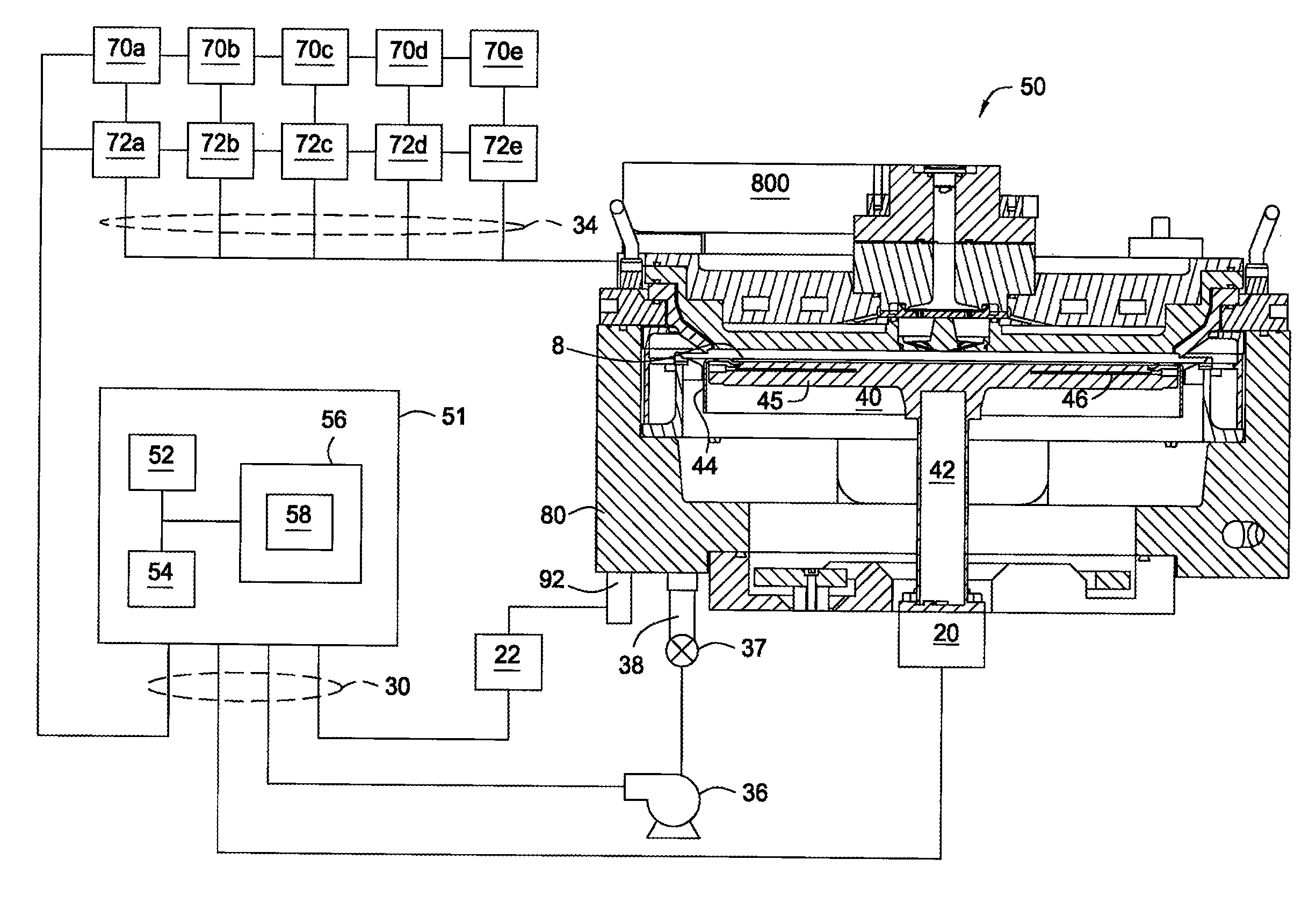

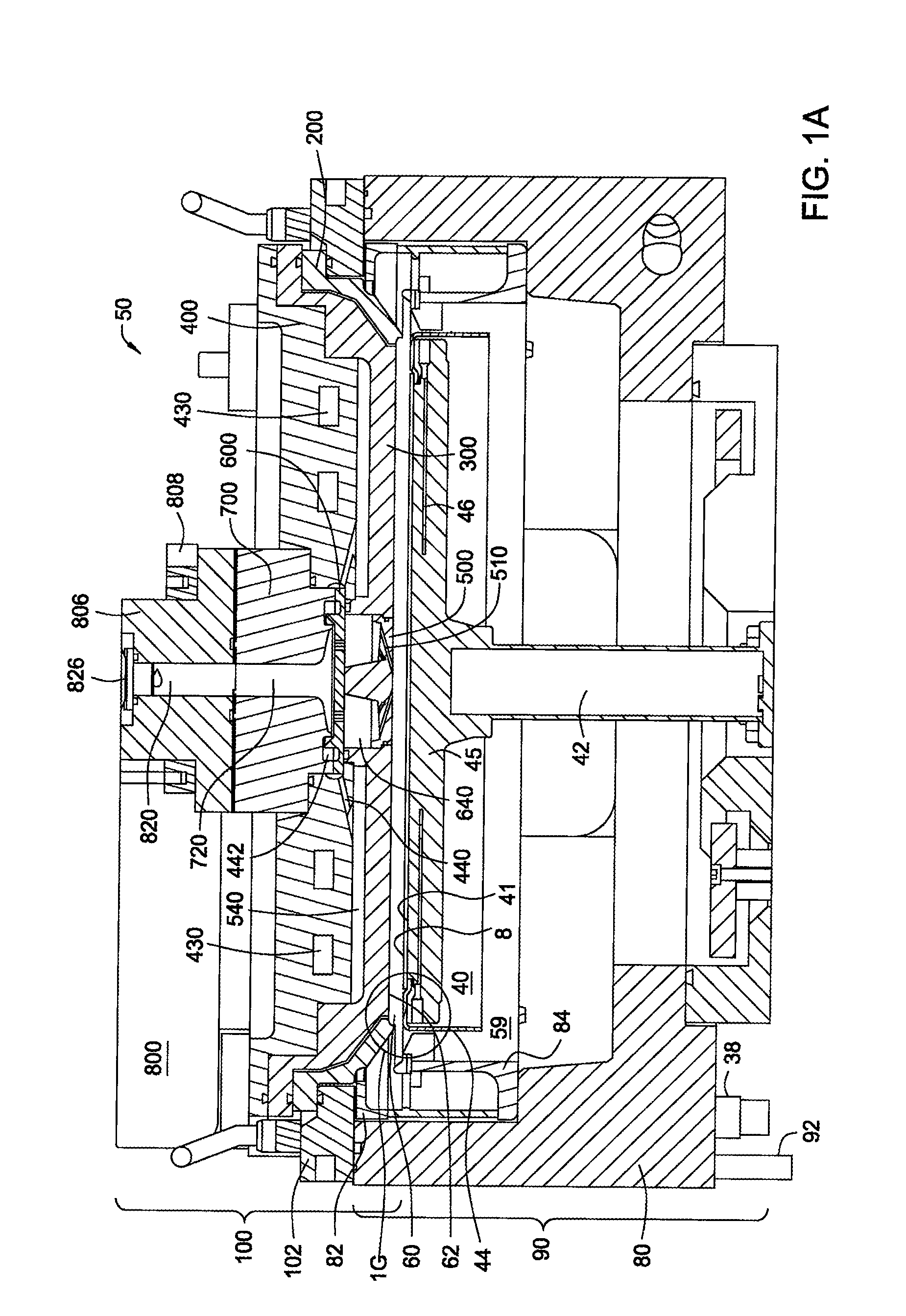

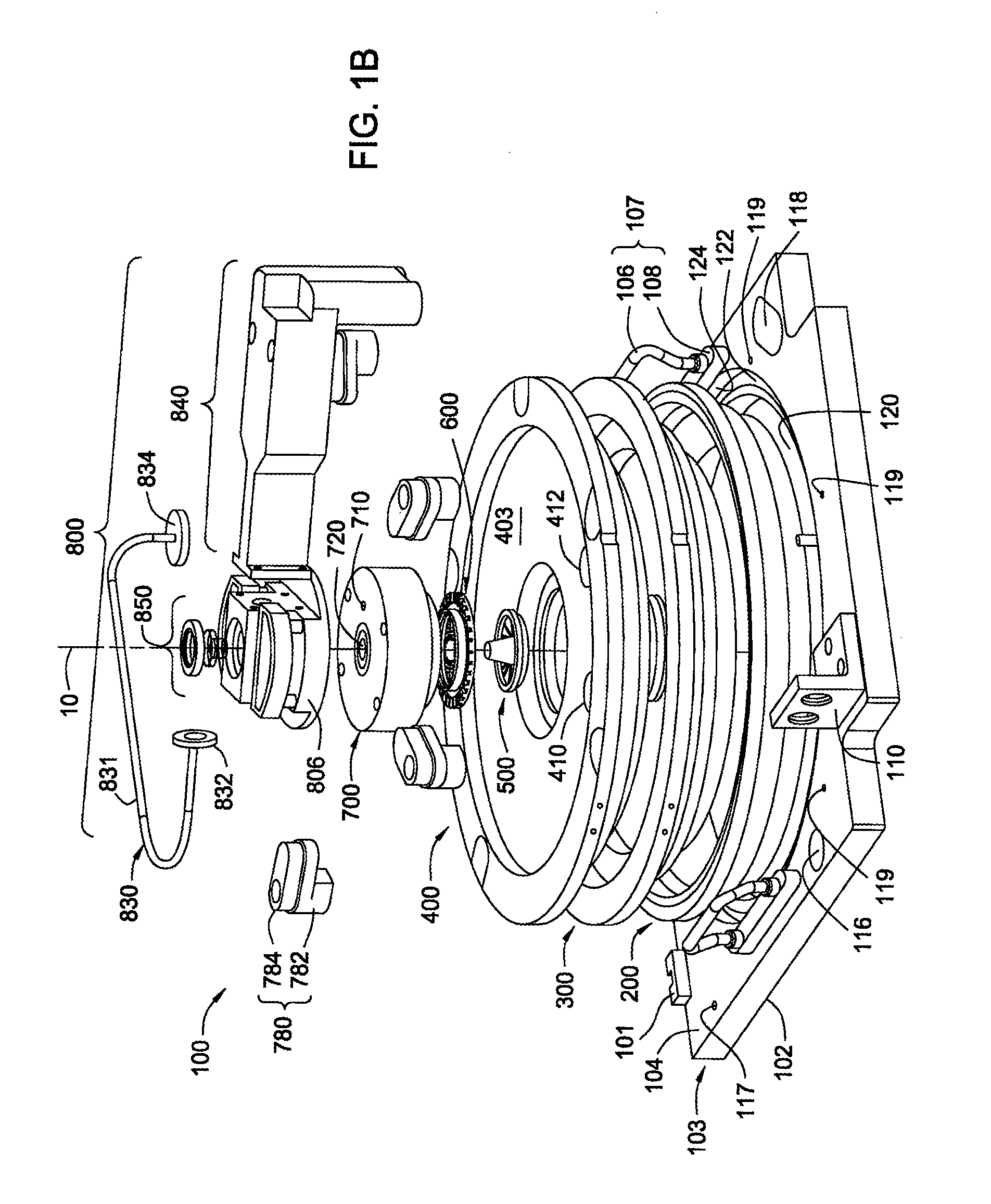

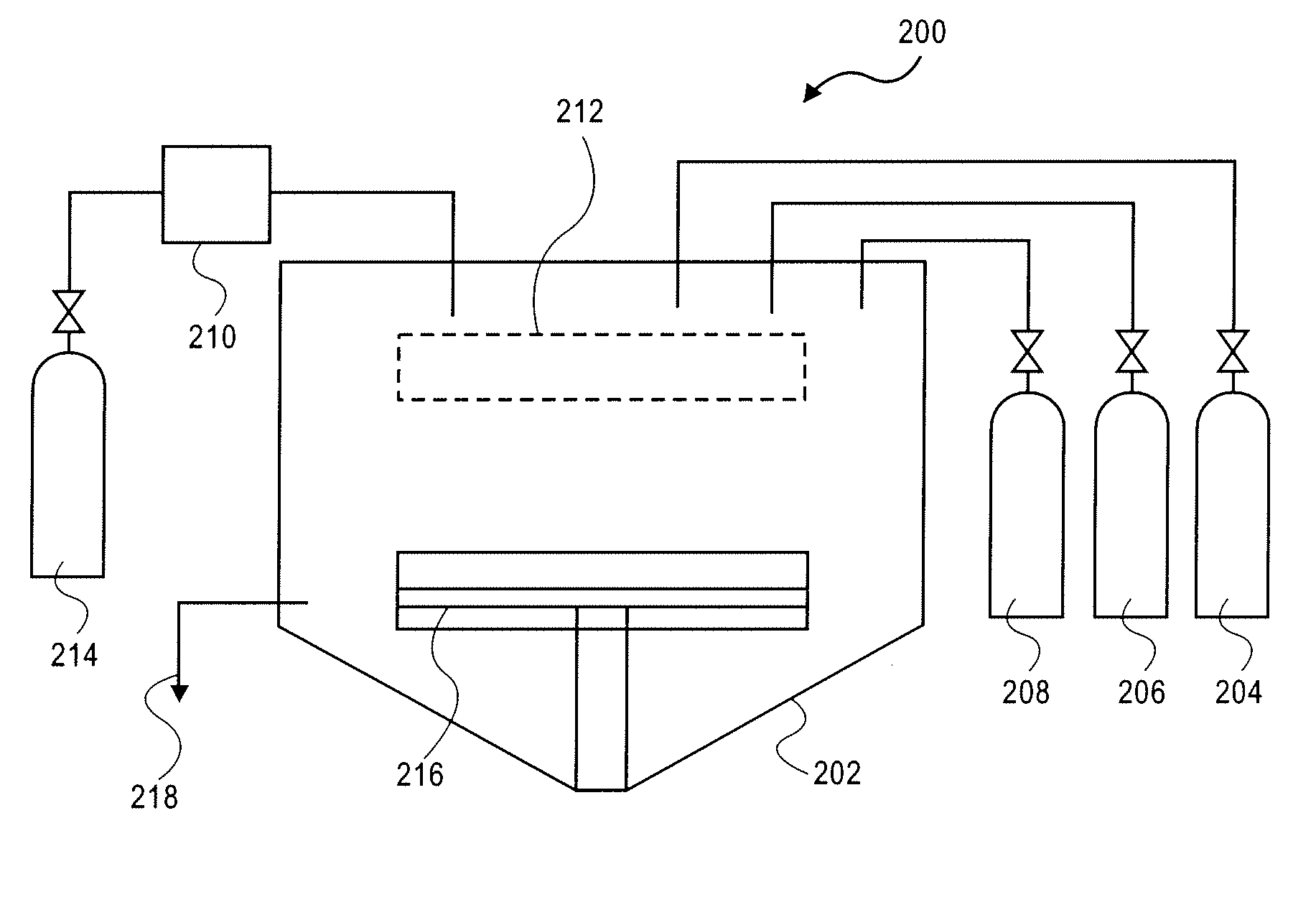

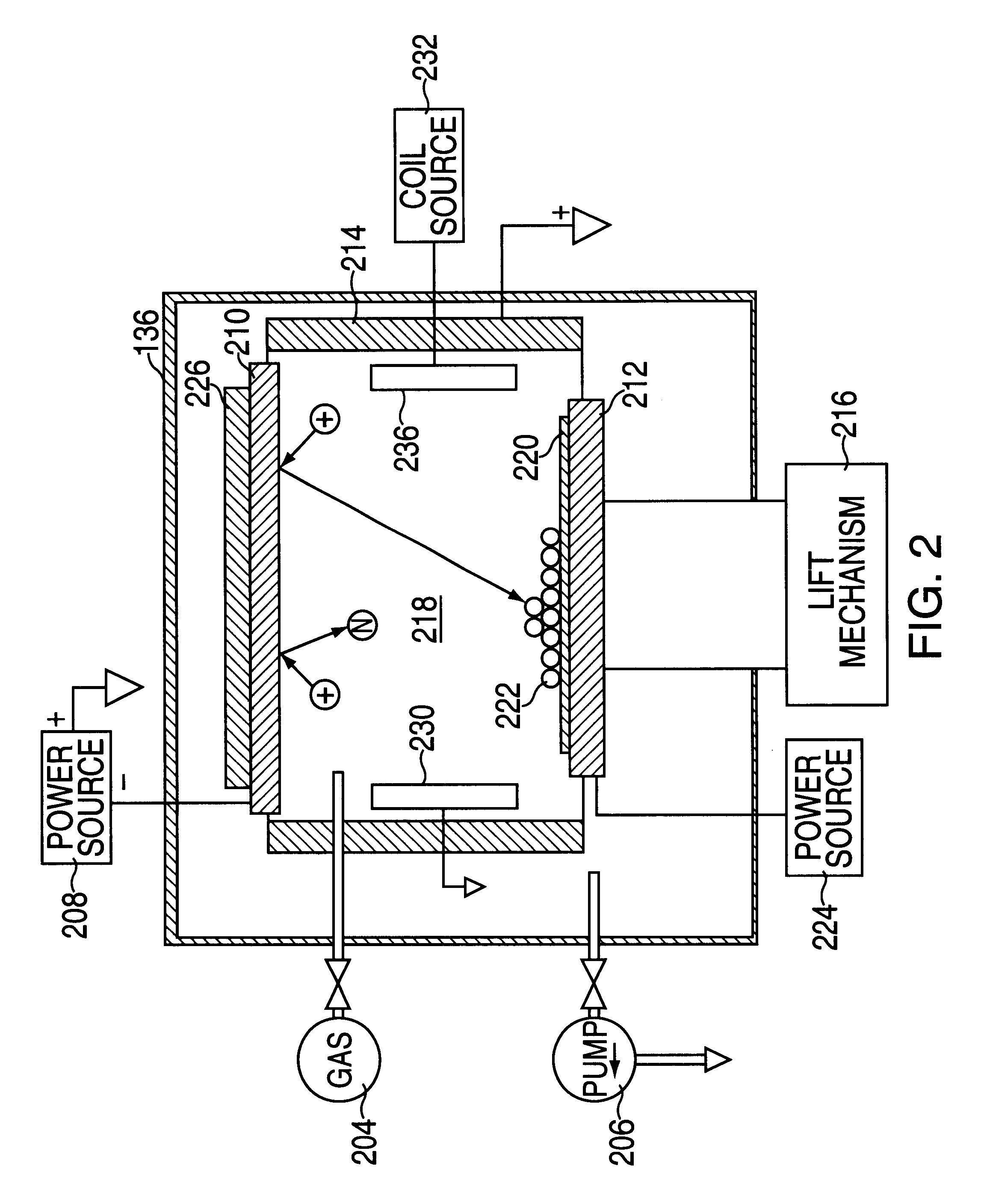

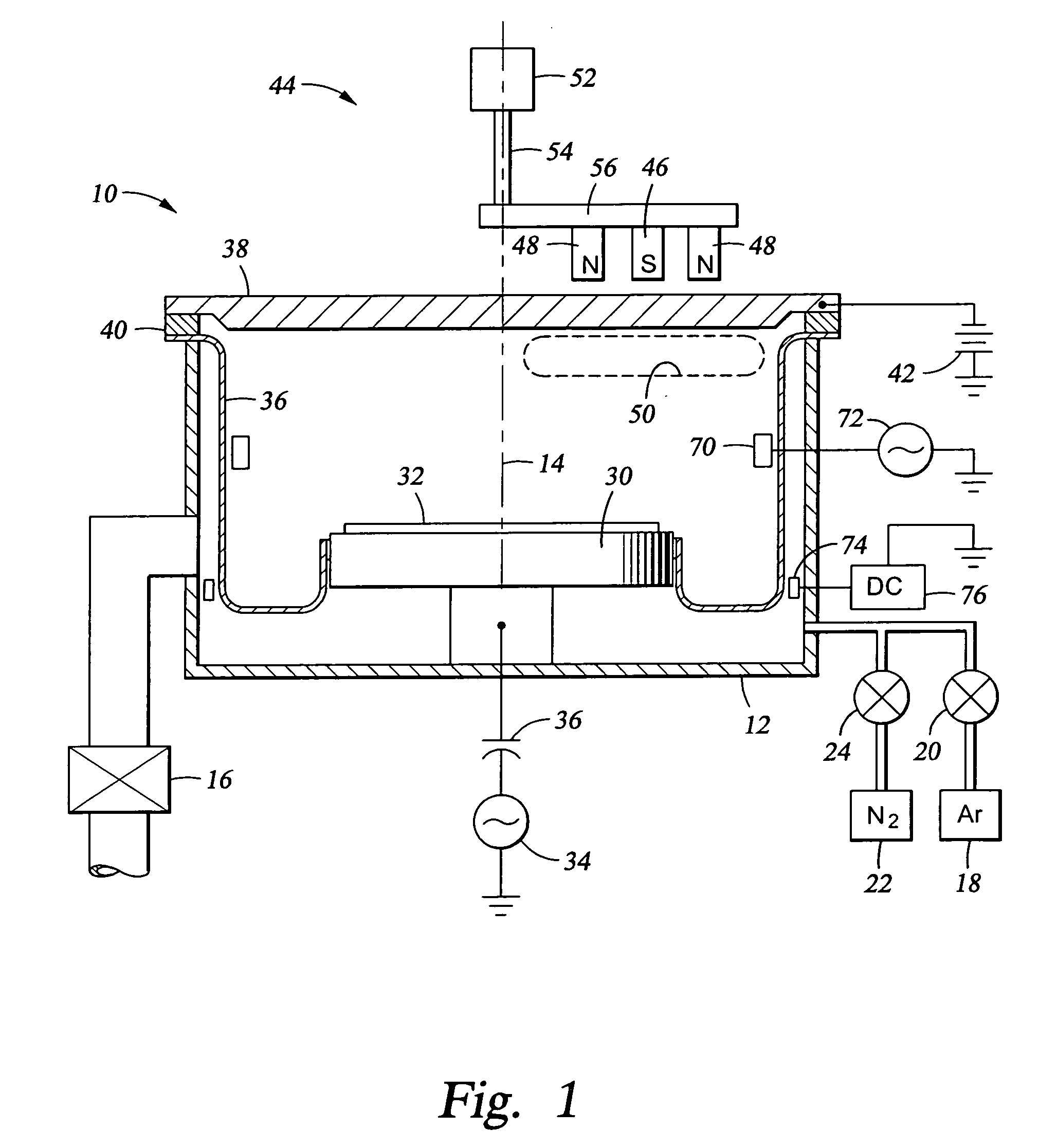

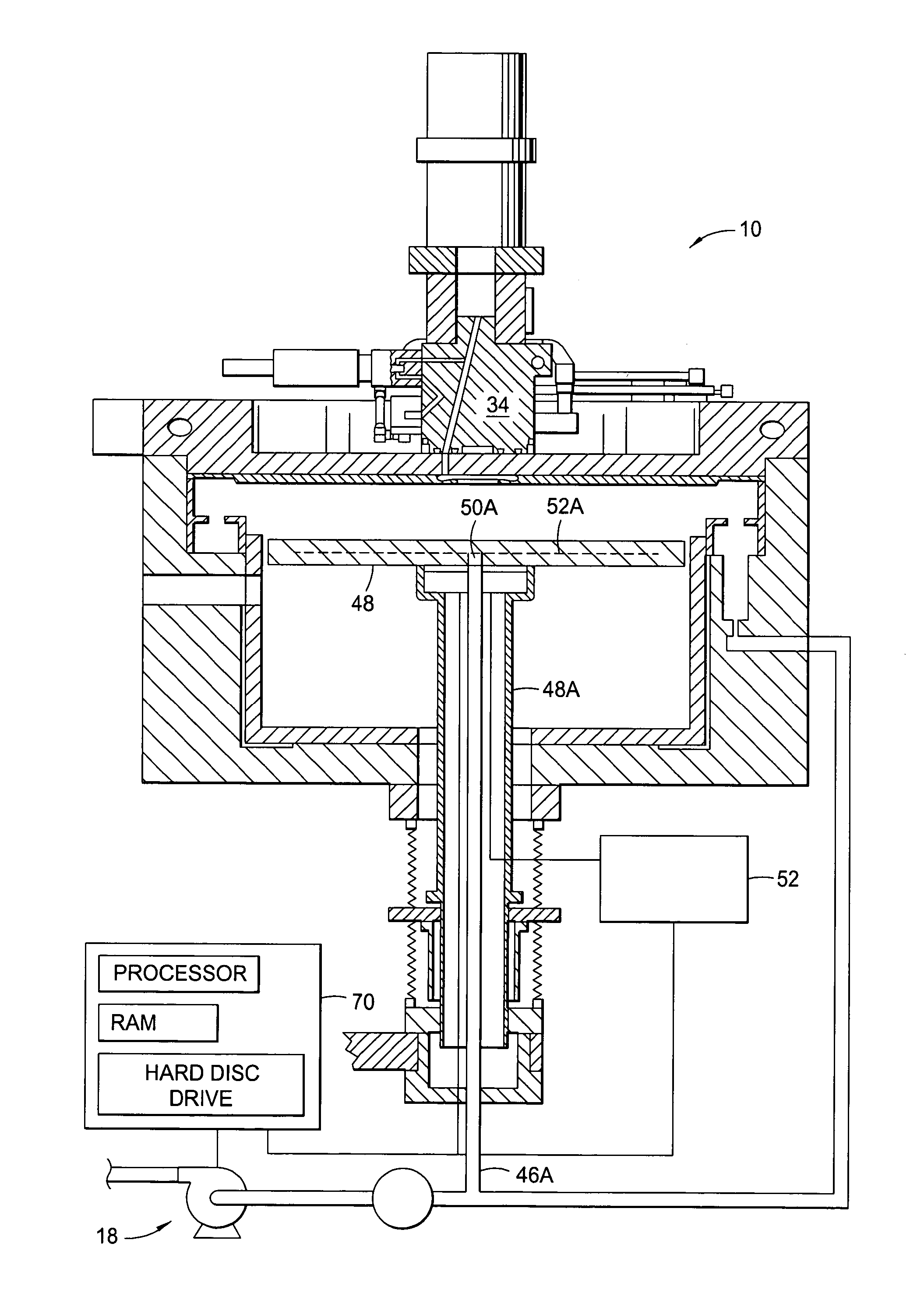

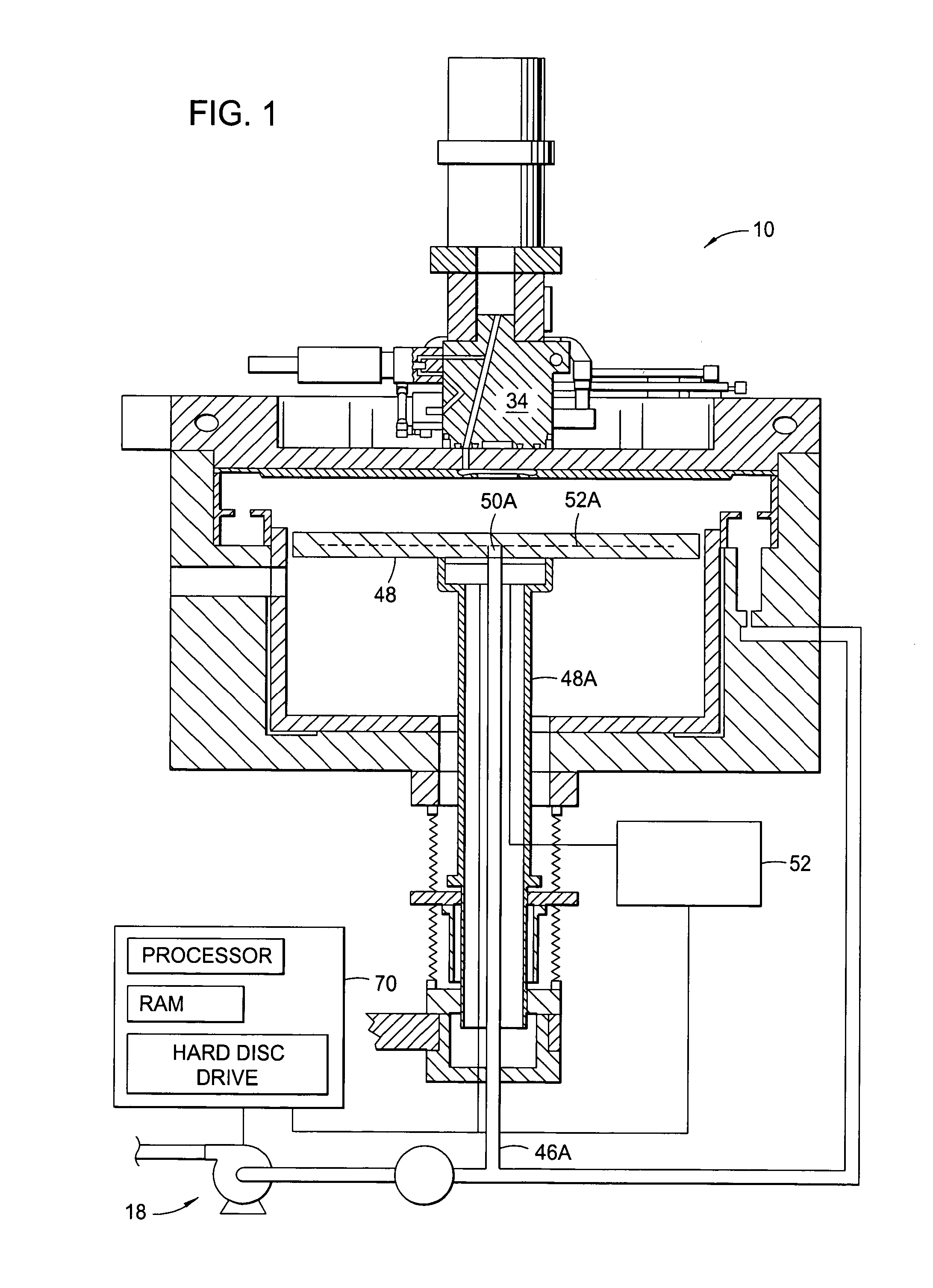

Apparatus and process for plasma-enhanced atomic layer deposition

Embodiments of the invention provide a method for forming a material on a substrate during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a method is provided which includes flowing at least one process gas through at least one conduit to form a circular gas flow pattern, exposing a substrate to the circular gas flow pattern, sequentially pulsing at least one chemical precursor into the process gas and igniting a plasma from the process gas to deposit a material on the substrate. In one example, the circular gas flow pattern has circular geometry of a vortex, a helix, a spiral, or a derivative thereof. Materials that may be deposited by the method include ruthenium, tantalum, tantalum nitride, tungsten or tungsten nitride. Other embodiments of the invention provide an apparatus configured to form the material during the PE-ALD process.

Owner:APPLIED MATERIALS INC

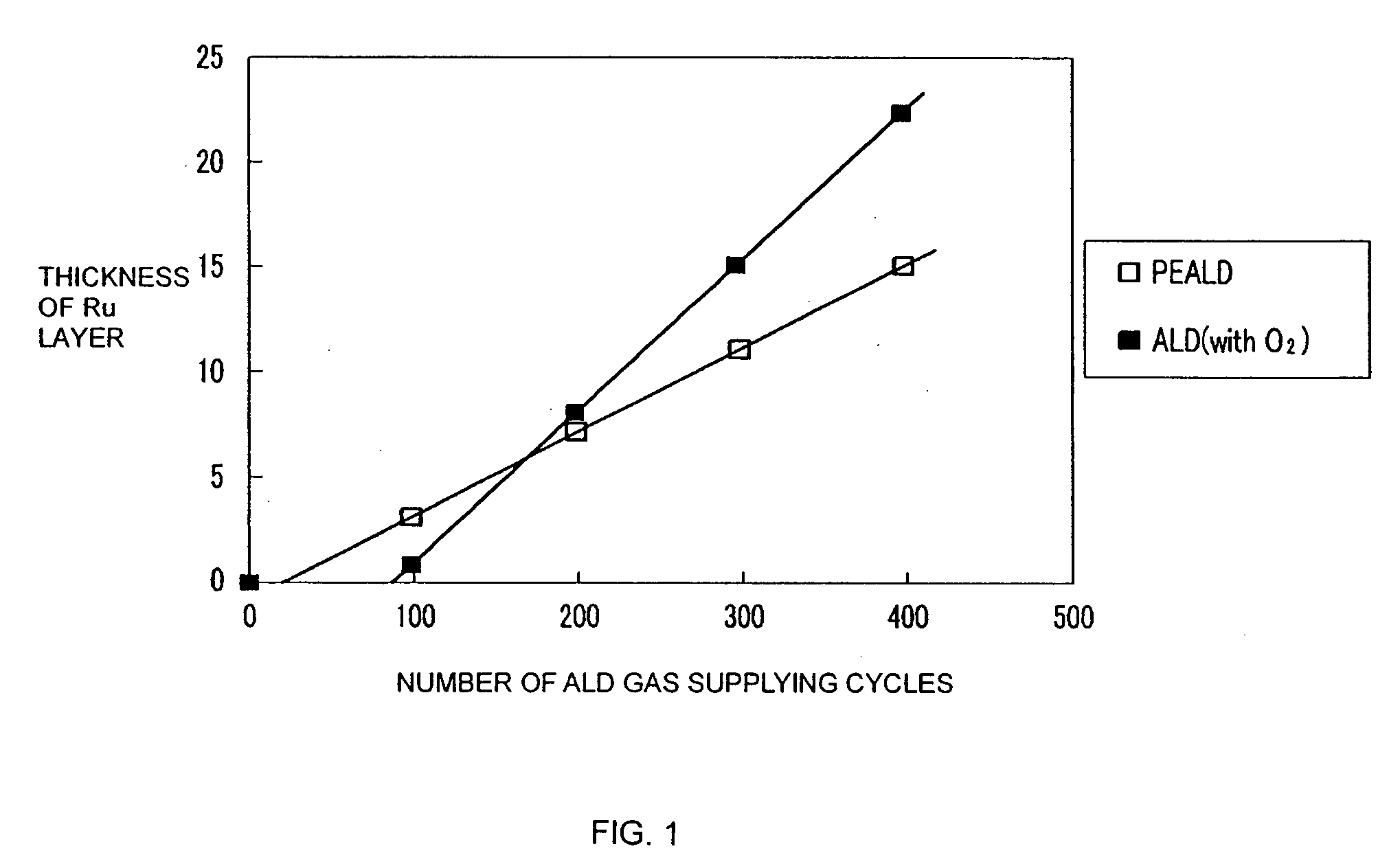

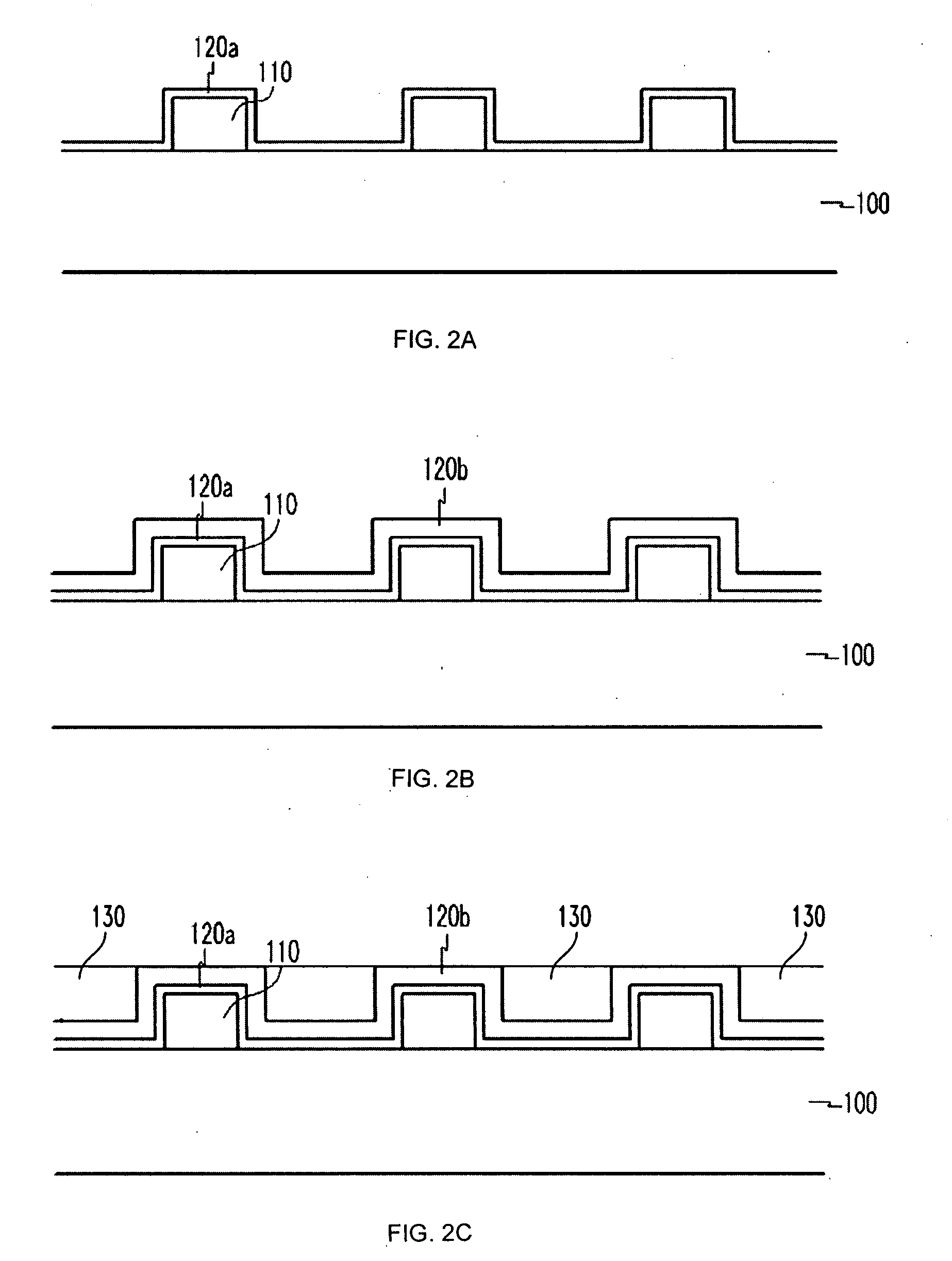

Method of depositing Ru films having high density

ActiveUS20070190782A1Good step coverageHigh densityData processing applicationsSemiconductor/solid-state device detailsHigh densityRuthenium

A ruthenium film deposition method is disclosed. In one embodiment of the method, a first ruthenium film is deposited by using a PEALD process until a substrate is substantially entirely covered with the first ruthenium film. Then, a second ruthenium film is deposited on the first ruthenium film by using a thermal ALD process having a higher deposition speed than that of the PEALD process. In the method, a ruthenium metal film having a high density is formed in a short time by combining a PEALD process of depositing a ruthenium film at a low deposition speed and a deposition process of depositing a ruthenium film at a higher deposition speed. Accordingly, it is possible to form a ruthenium film having high density, a smooth surface, good adhesiveness, and a short incubation period. Therefore, according to the embodiment, in comparison to cases of using only a PEALD process or an ALD process that has a long incubation period, it is possible to obtain a ruthenium film having a large thickness and a high density in the same time interval. As a result, the ruthenium film formed by the ruthenium film deposition method according to the embodiment is more suitable for electrode structures of semiconductor devices than the ruthenium films formed by using conventional methods.

Owner:ASM KOREA LTD

Organometallic precursors for seed/barrier processes and methods thereof

InactiveUS20080194105A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseRuthenium

Organometallic precursors and methods for deposition on a substrate in seed / barrier applications are herein disclosed. In some embodiments, the organometallic precursor is a ruthenium-containing, tantalum-containing precursor or combination thereof and may be deposited by atomic layer deposition, chemical vapor deposition and / or physical vapor deposition.

Owner:INTEL CORP

Graphitic nanotubes in luminescence assays

Graphitic nanotubes, which include tubular fullerenes (commonly called "buckytubes") and fibrils, which are functionalized by chemical substitution, are used as solid supports in electrogenerated chemiluminescence assays. The graphitic nanotubes are chemically modified with functional group biomolecules prior to use in an assay. Association of electrochemiluminescent ruthenium complexes with the functional group biomolecule-modified nanotubes permits detection of molecules including nucleic acids, antigens, enzymes, and enzyme substrates by multiple formats.

Owner:MESO SCALE TECH LLC

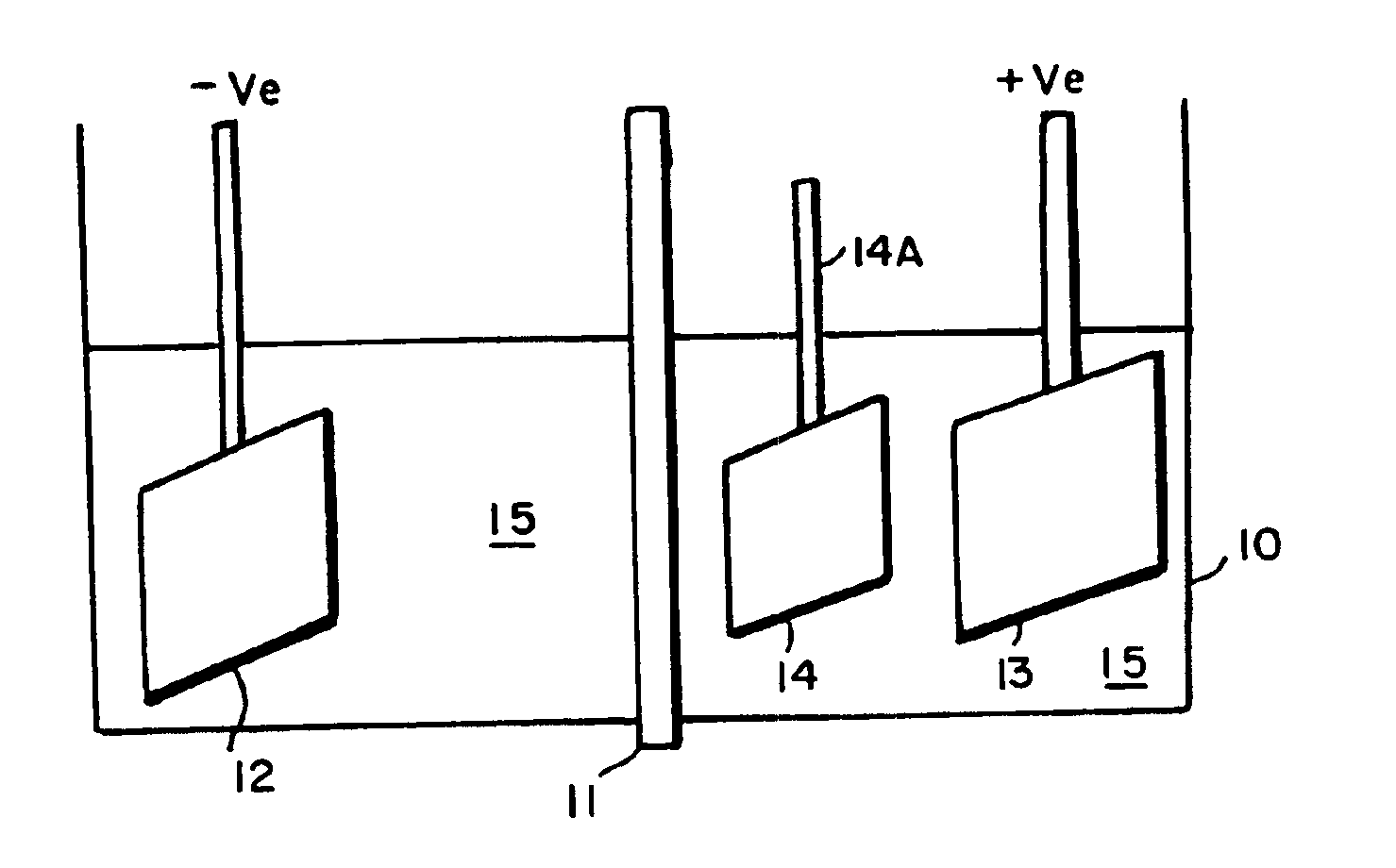

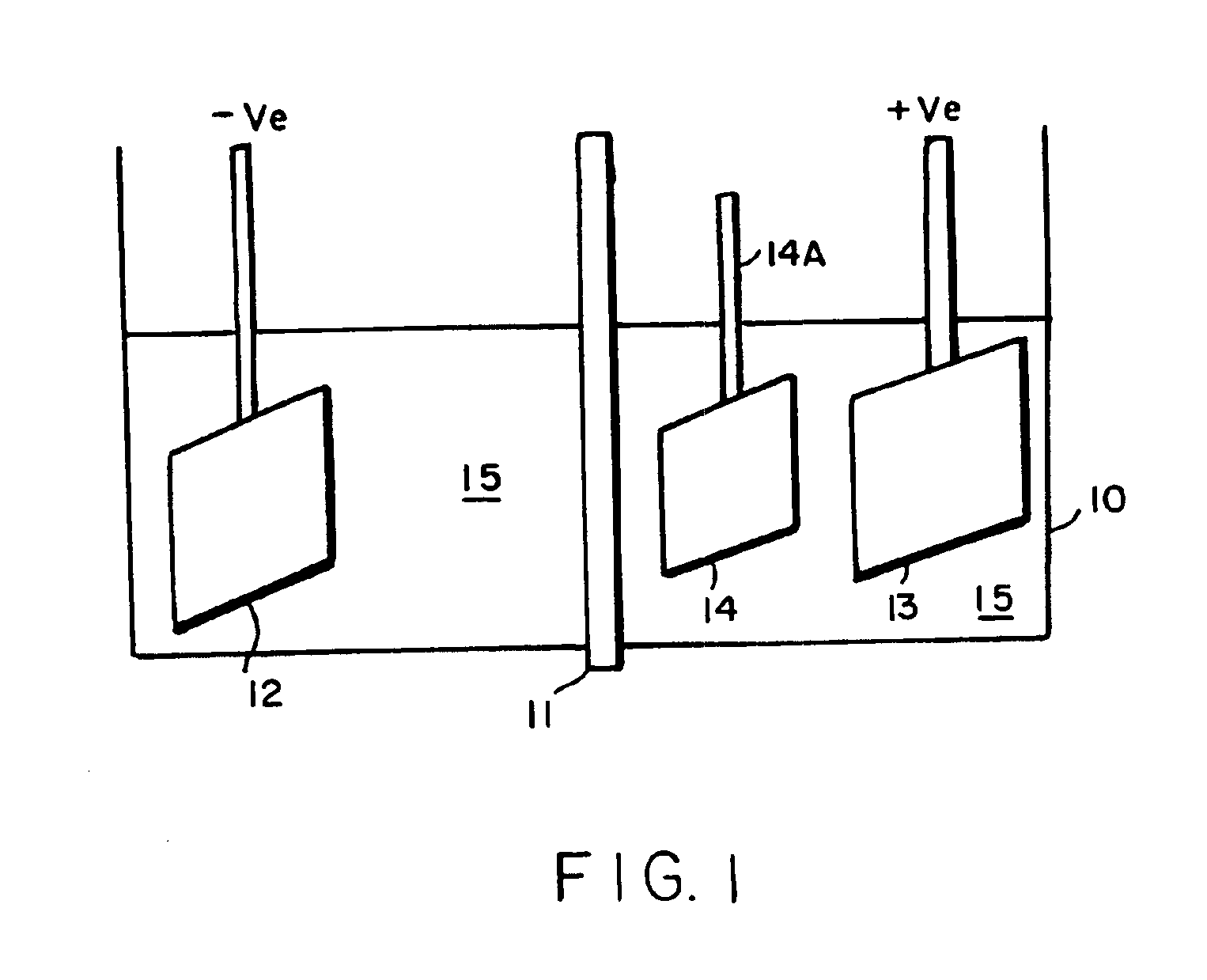

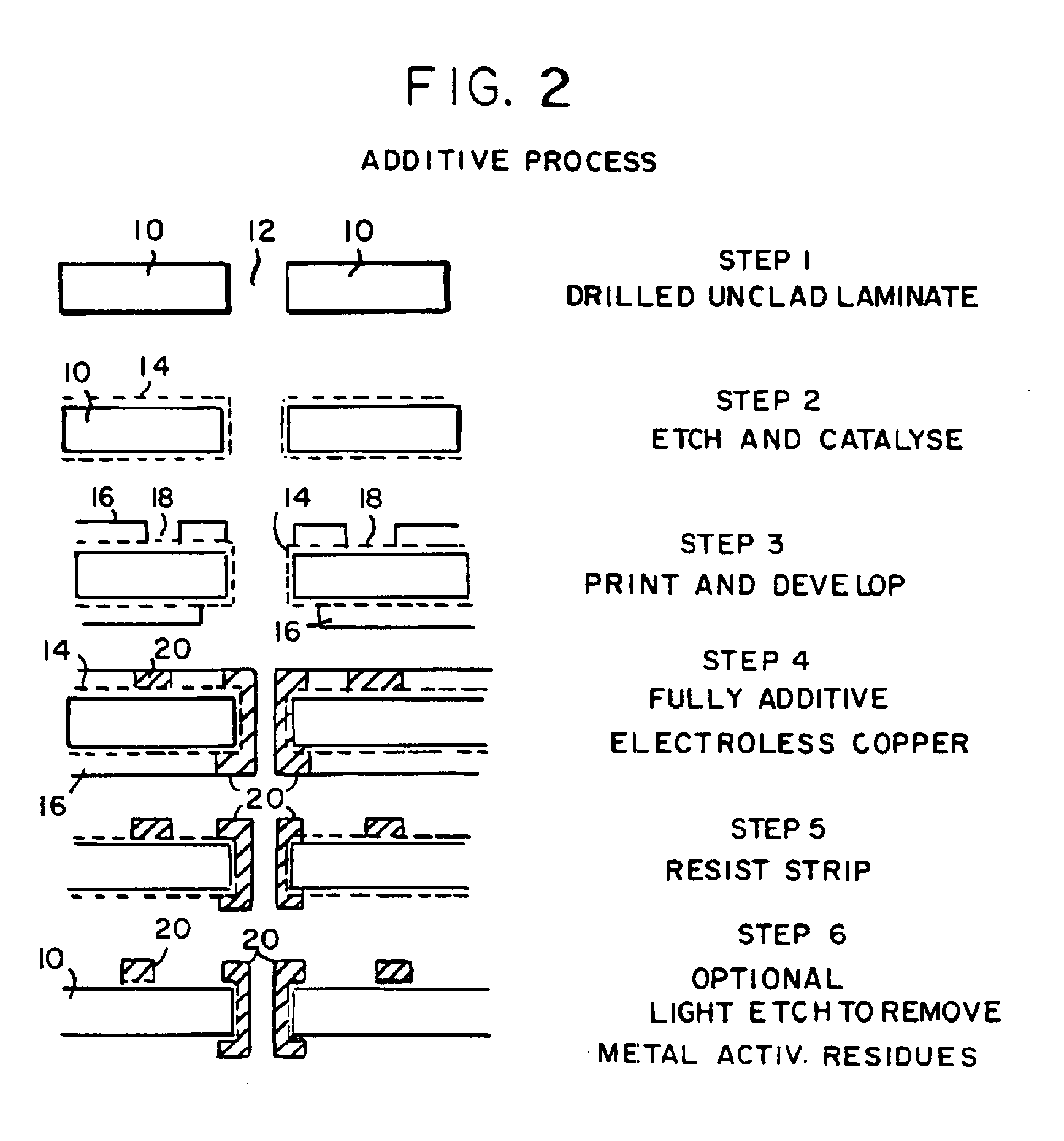

Electroless plating processes

InactiveUS6861097B1Reducing problem encounteredSimple methodPaper/cardboard articlesDecorative surface effectsPolymeric surfaceOxidation state

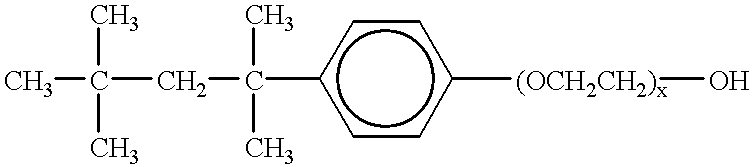

The invention includes processes for combined polymer surface treatment and metal deposition. Processes of the invention include forming an aqueous solution containing a metal activator, such as an oxidized species of silver, cobalt, ruthenium, cerium, iron, manganese, nickel, rhodium, or vanadium. The activator can be suitably oxidized to a higher oxidation state electrochemically. Exposing a part to be plated (such as an organic resin, e.g. a printed circuit board substrate) to the solution enables reactive hydroxyl species (e.g. hydroxyl radicals) to be generated and to texture the polymer surface. Such texturing facilitates good plated metal adhesion. As part of this contacting process sufficient time is allowed for both surface texturing to take place and for the oxidized metal activator to adsorb onto said part. The part is then contacted with a reducing agent capable of reducing the metal activator to a lower ionic form, or a lower oxidation state. That reduction can result in the formation of metallic catalytic material over the surface of the part. The reduced metal activator can then function to catalyze the electroless deposition of metal such as copper from solution by contacting the part with the plating solution.

Owner:SHIPLEY CO LLC

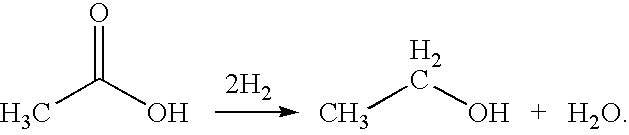

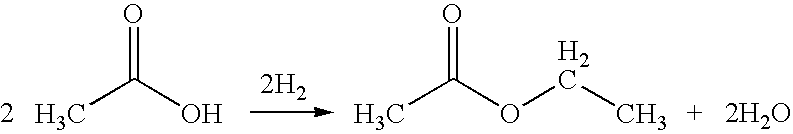

Method for producing alcohols by hydrogenation of carbonyl compounds

InactiveUS6486366B1Less amountHigh strengthSugar derivativesOrganic compound preparationCobaltPt element

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

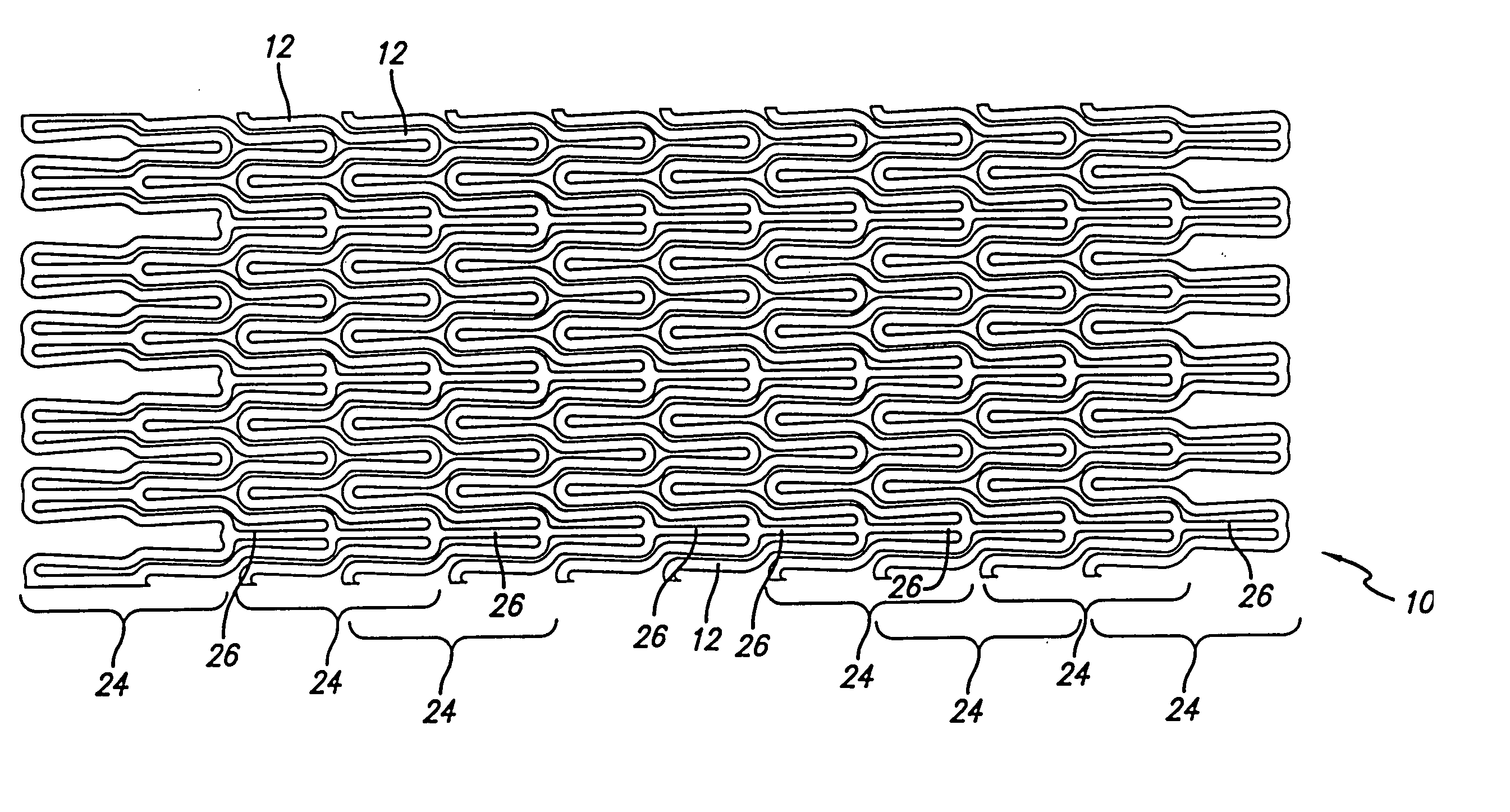

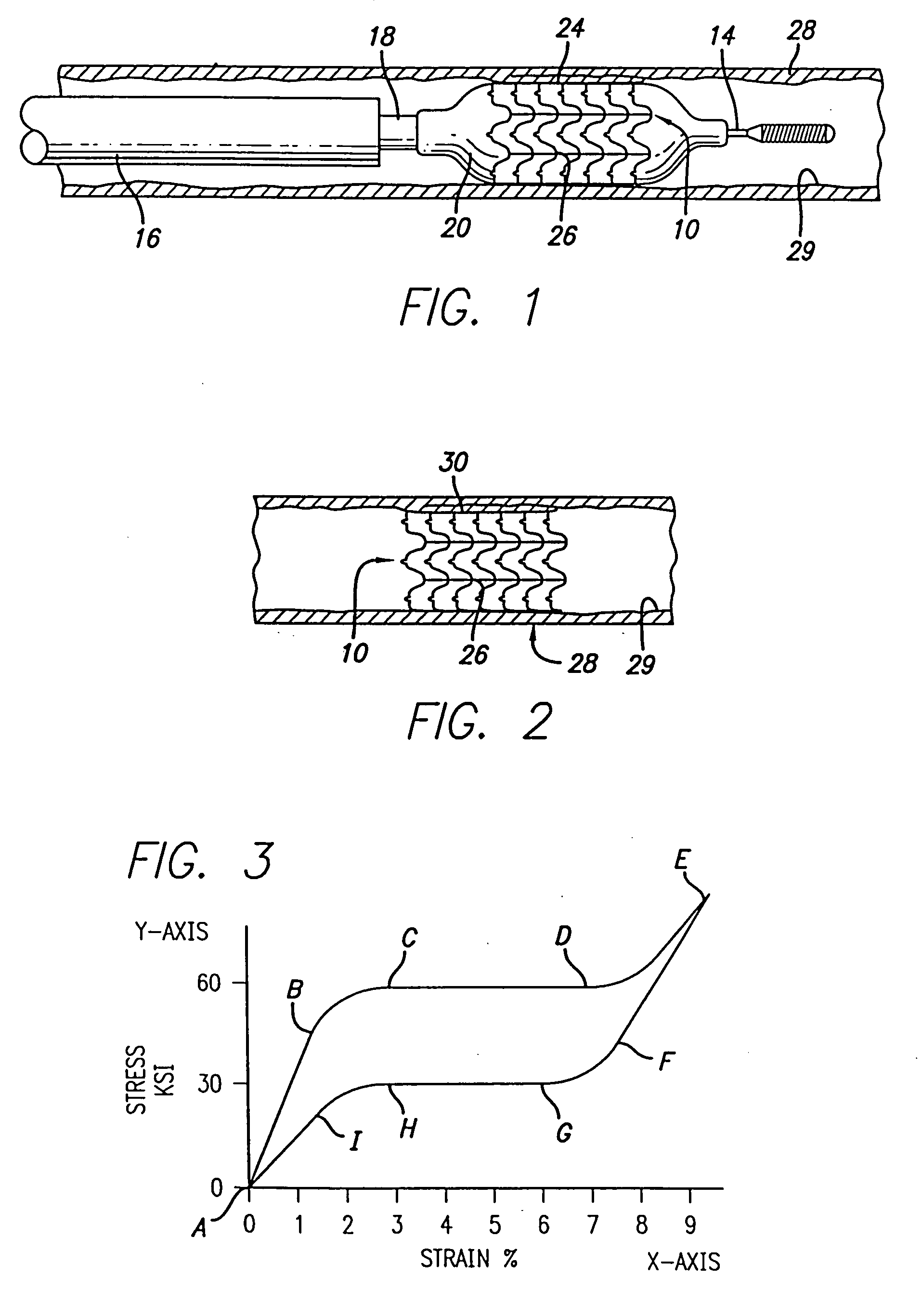

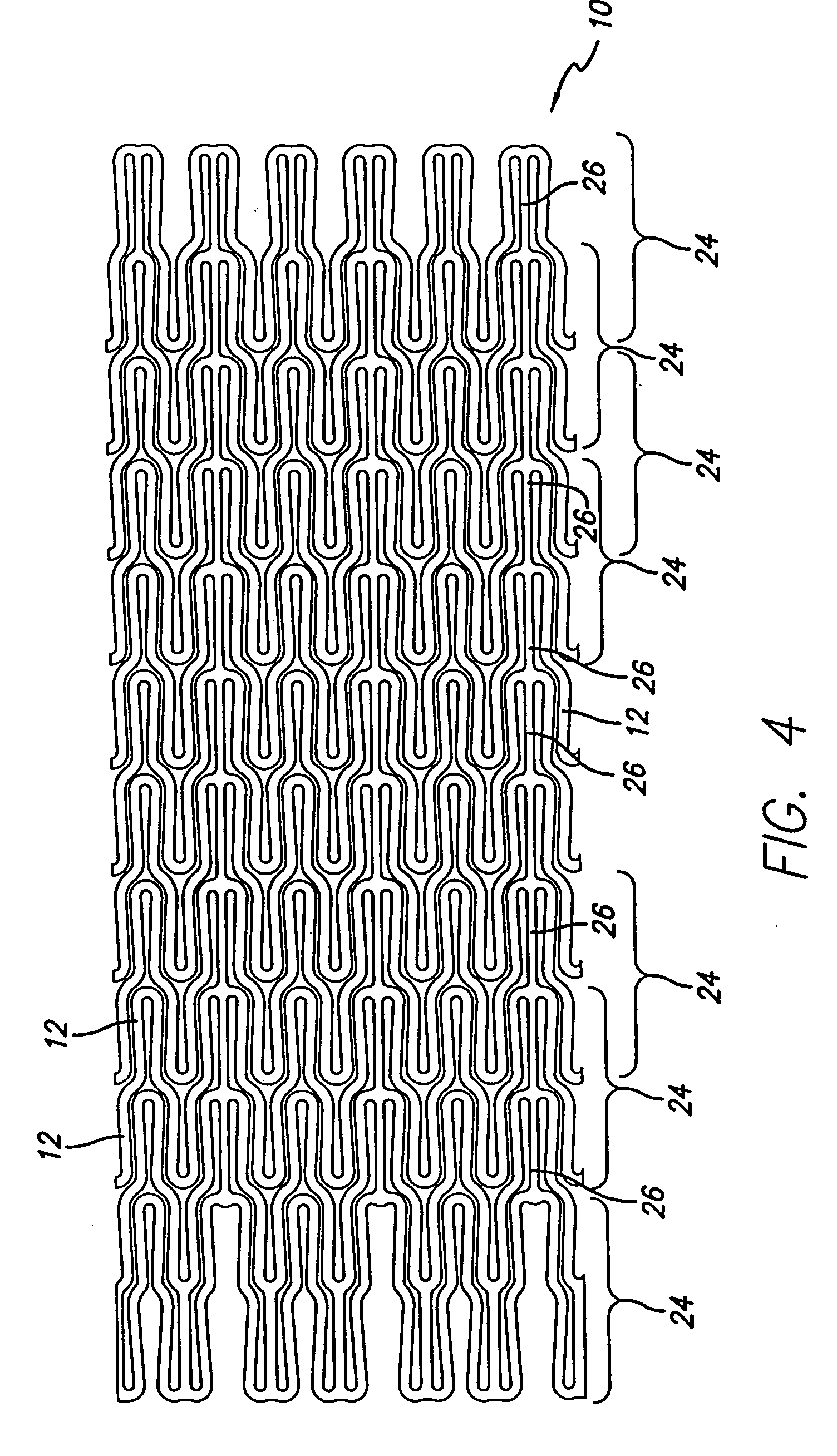

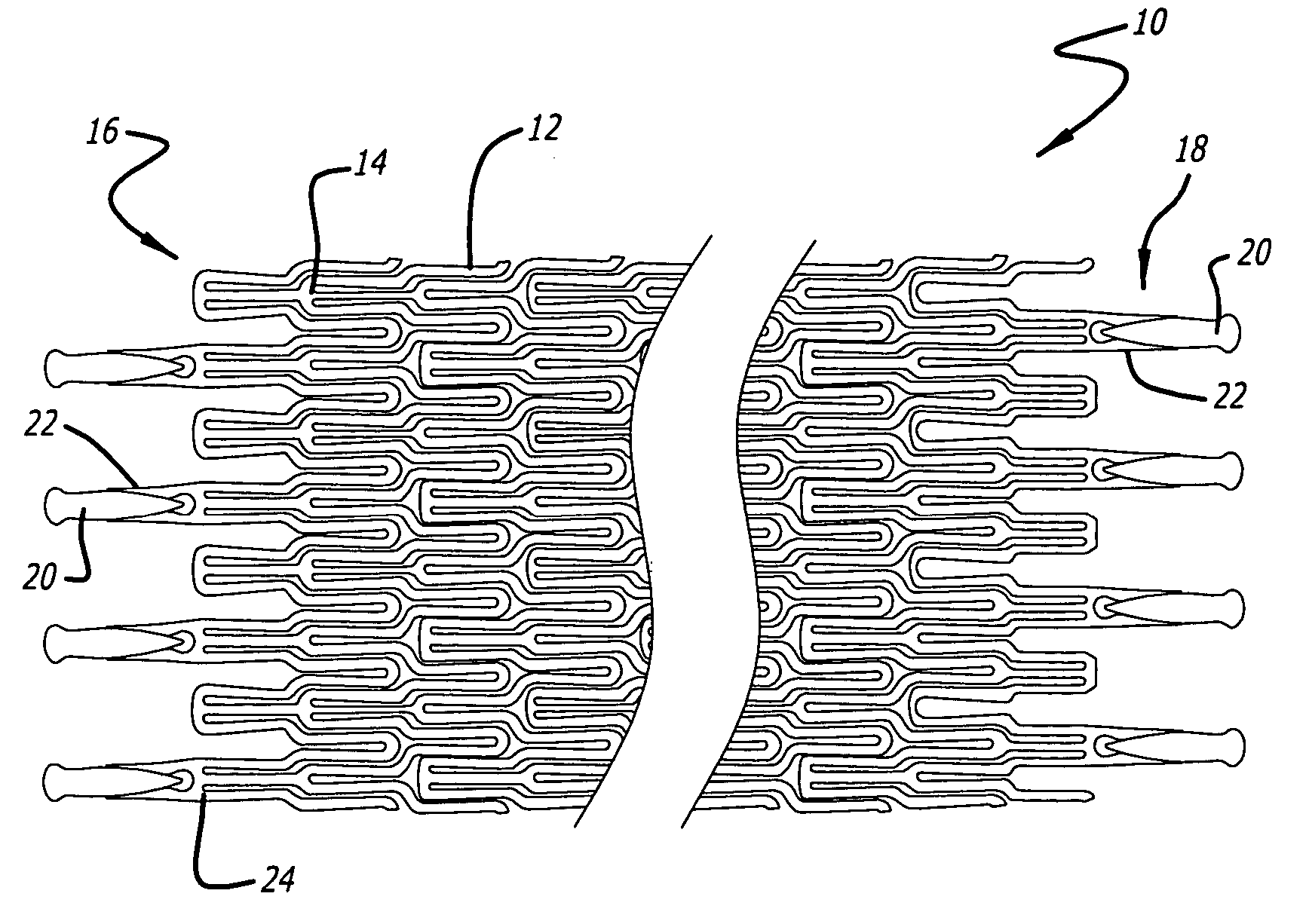

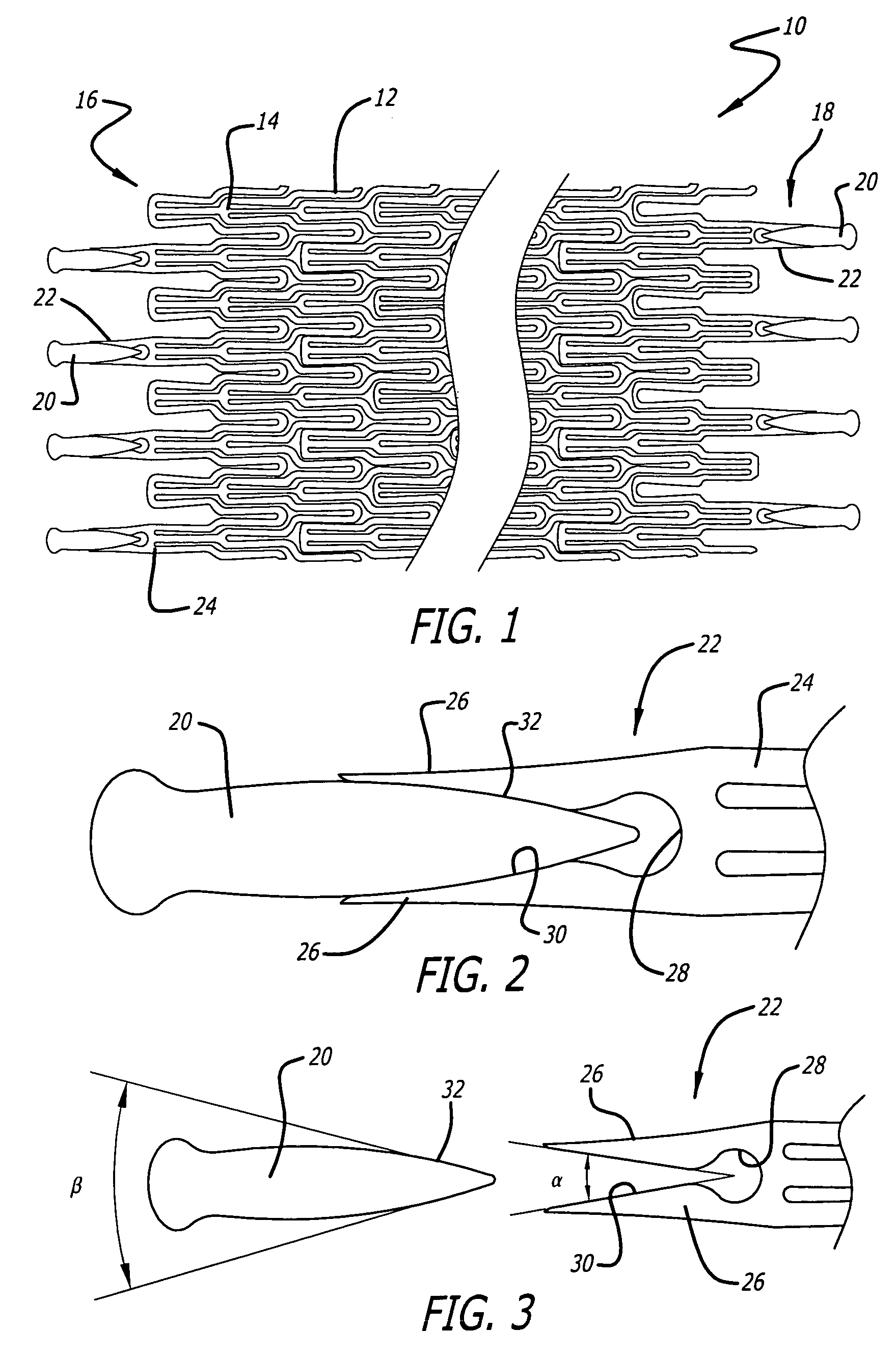

Radiopaque nitinol alloys for medical devices

Owner:ABBOTT CARDIOVASCULAR

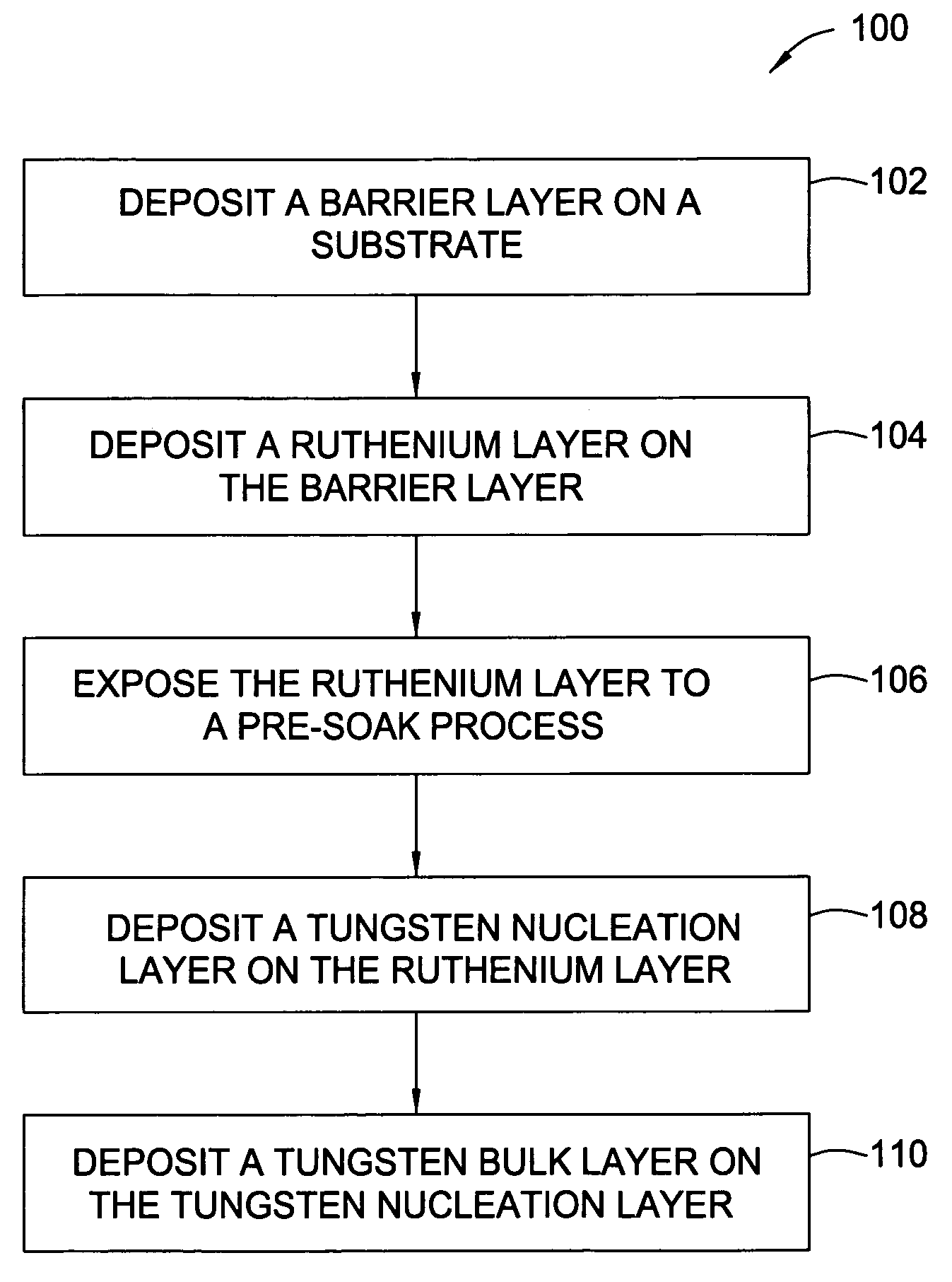

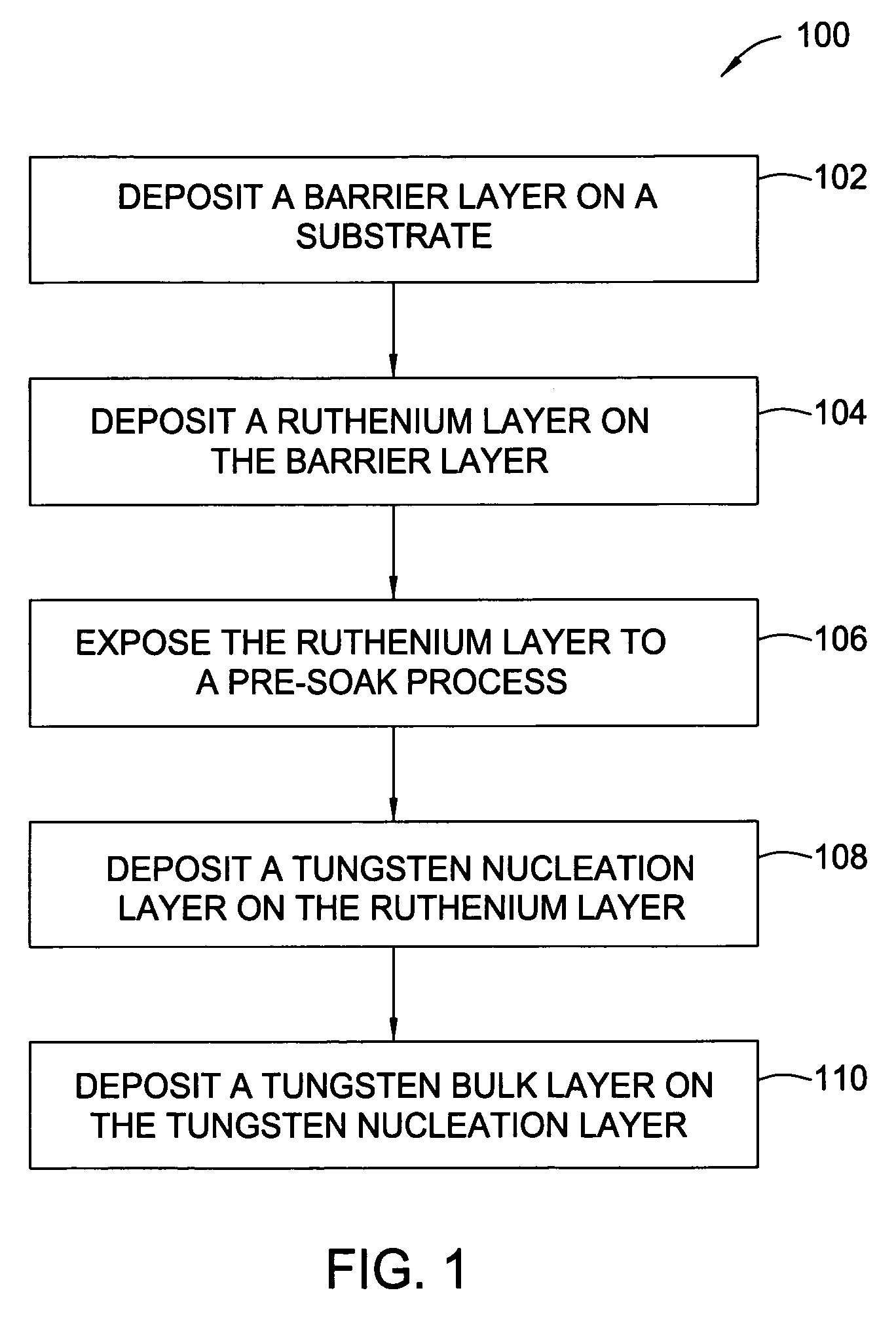

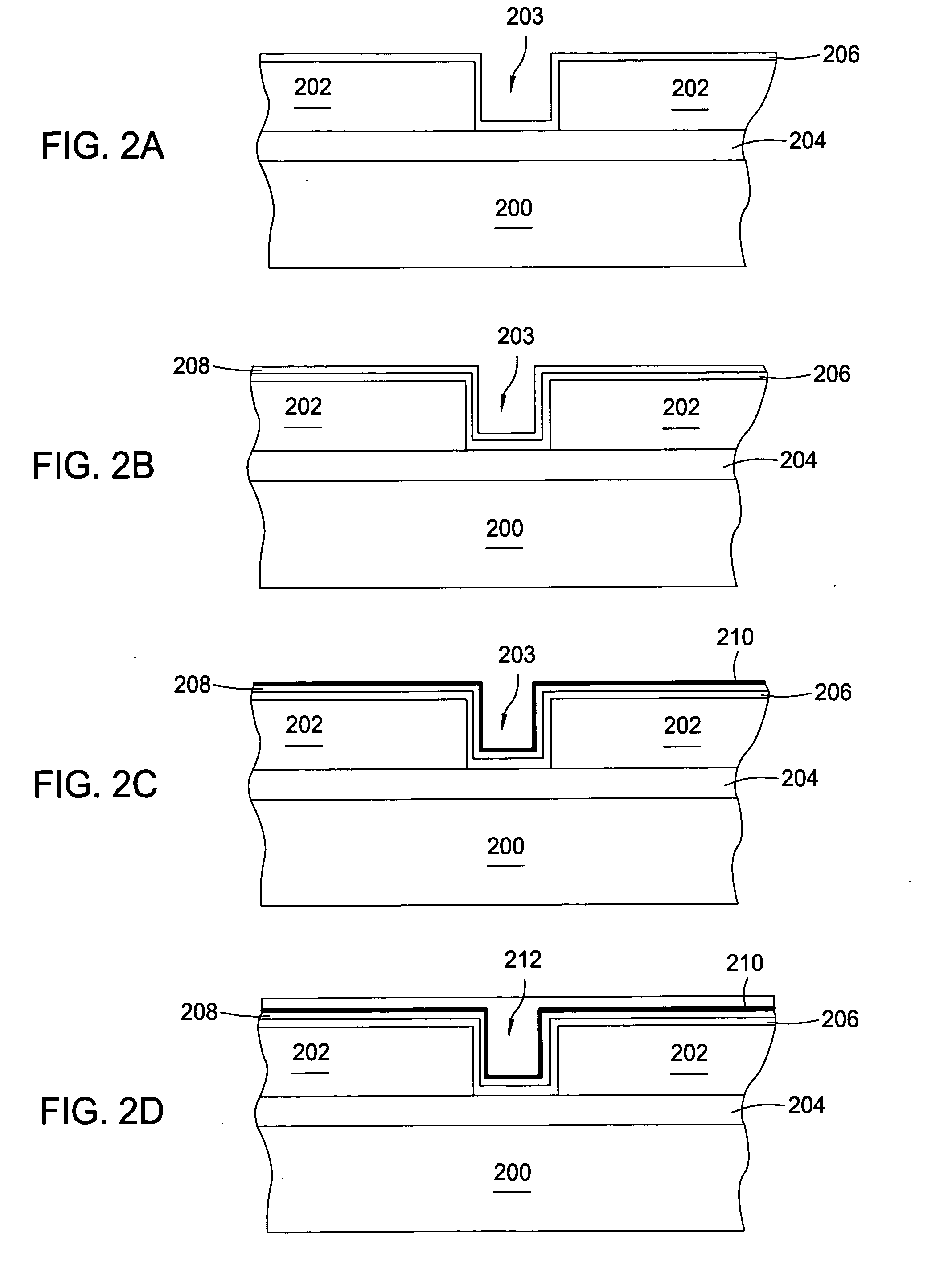

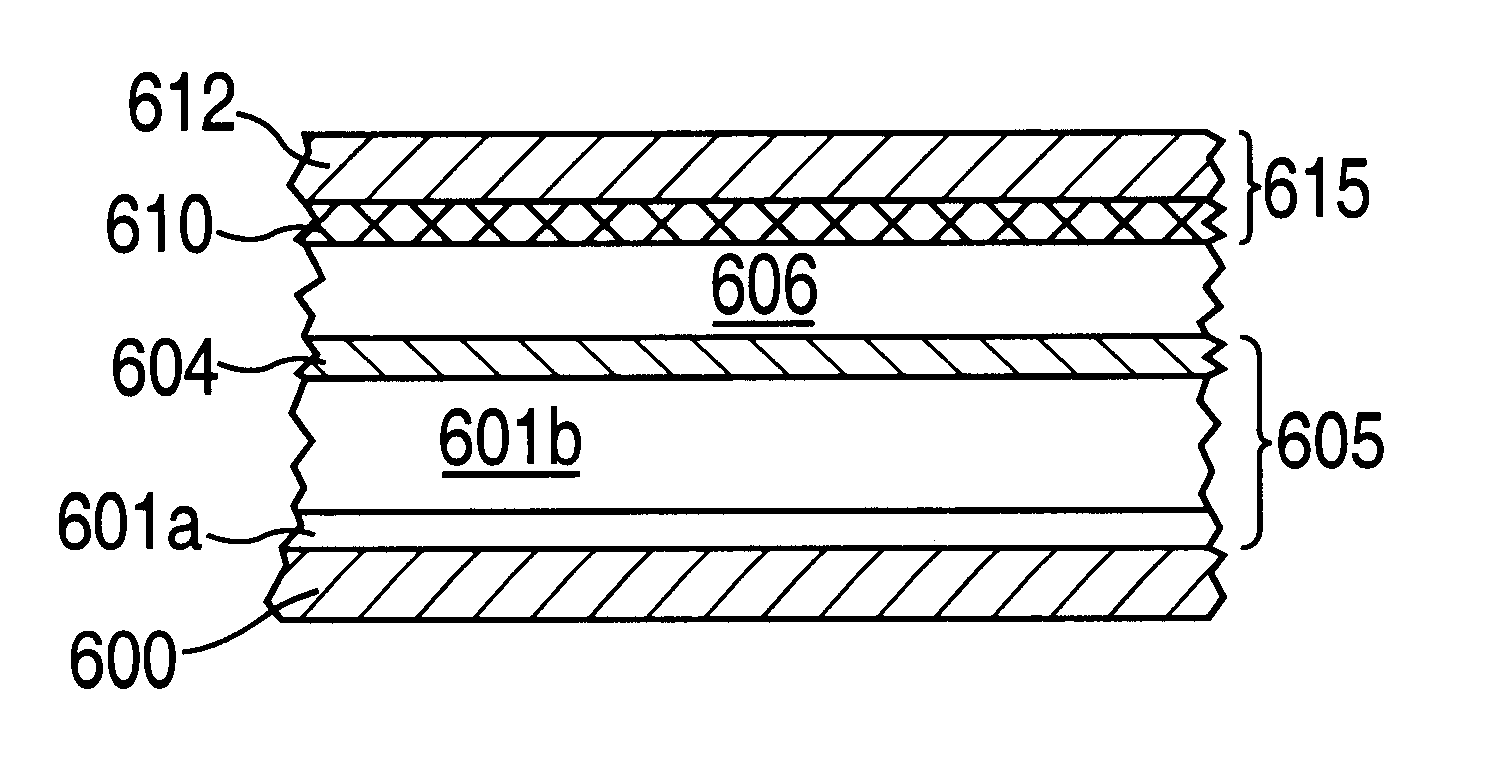

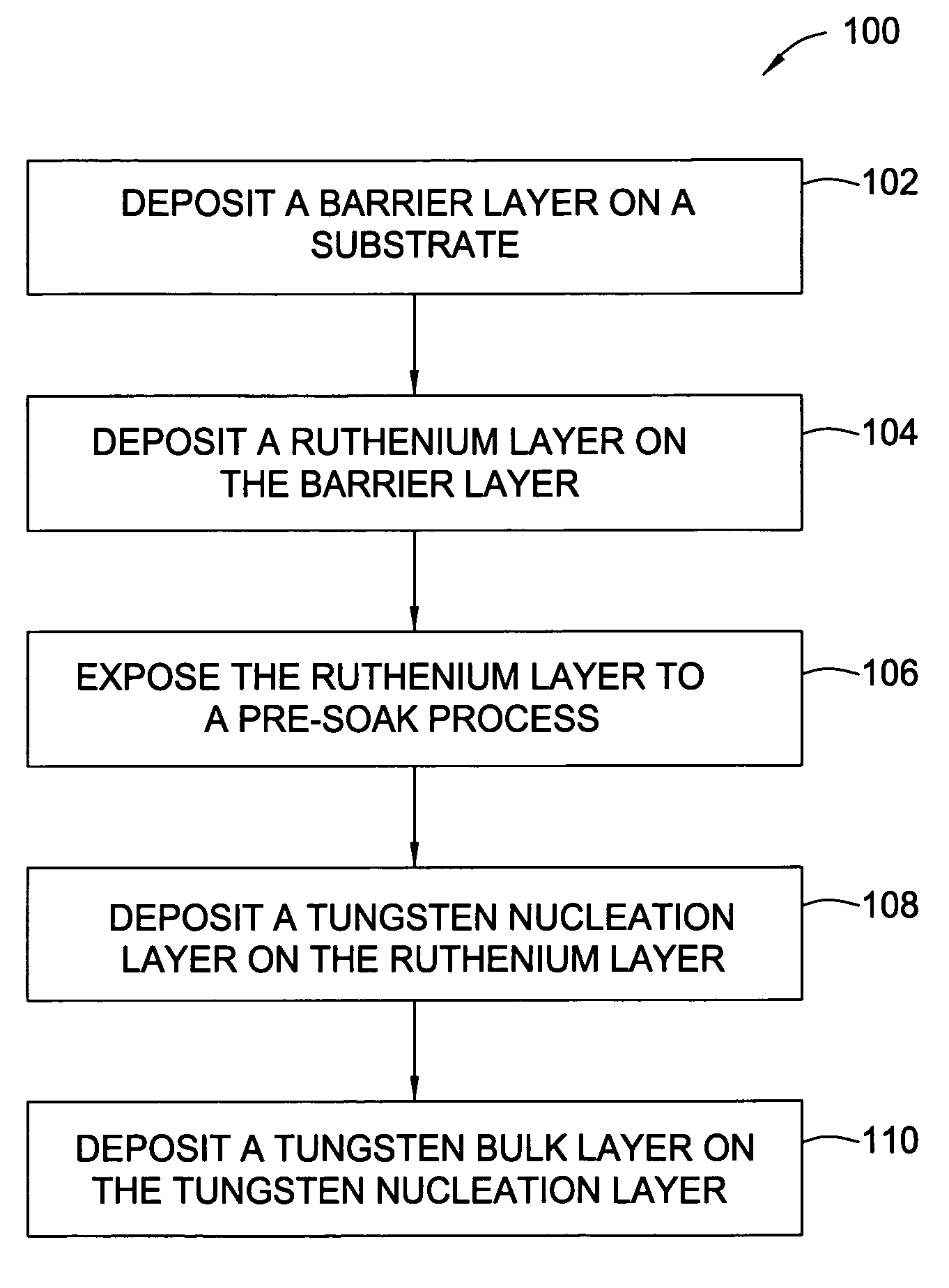

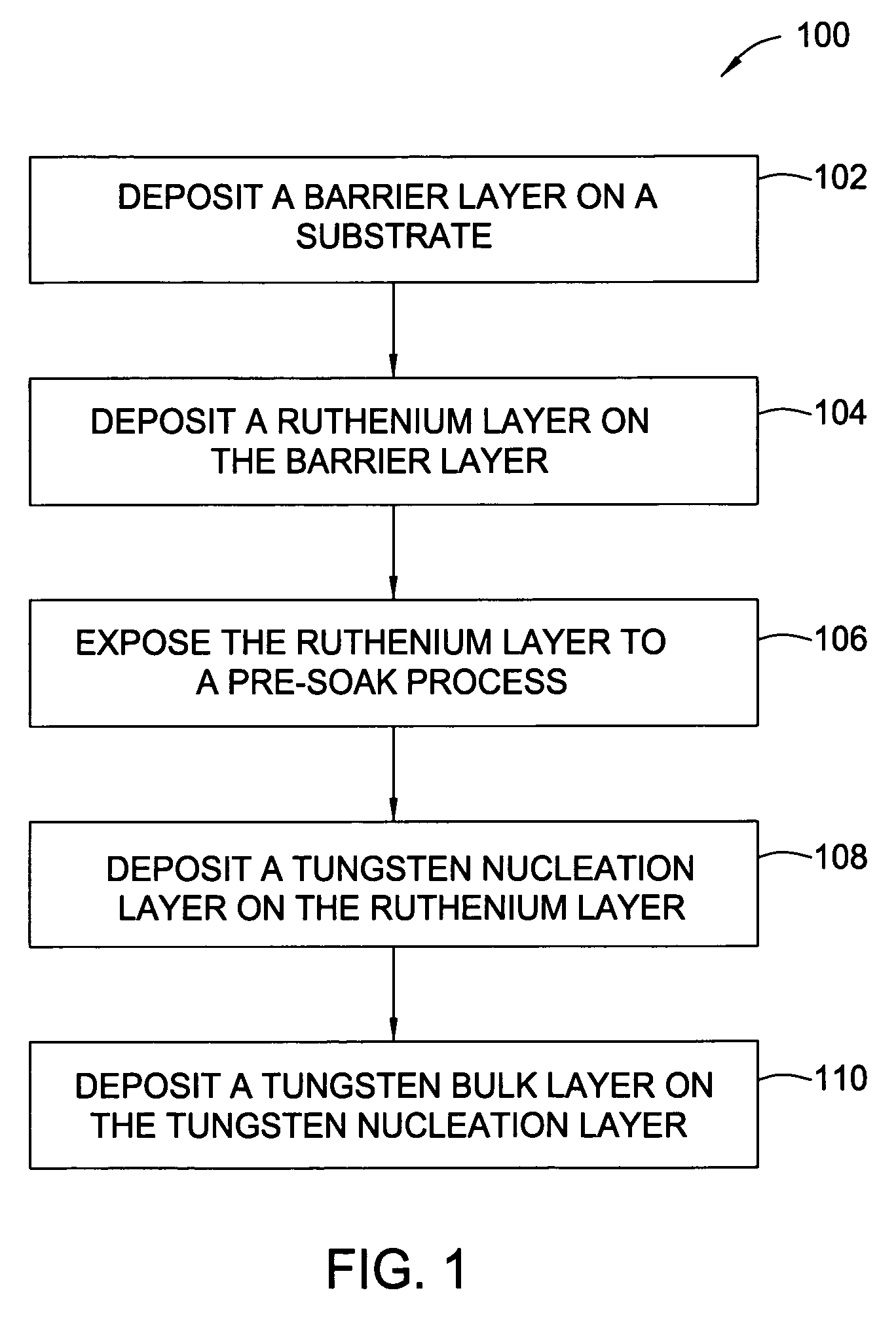

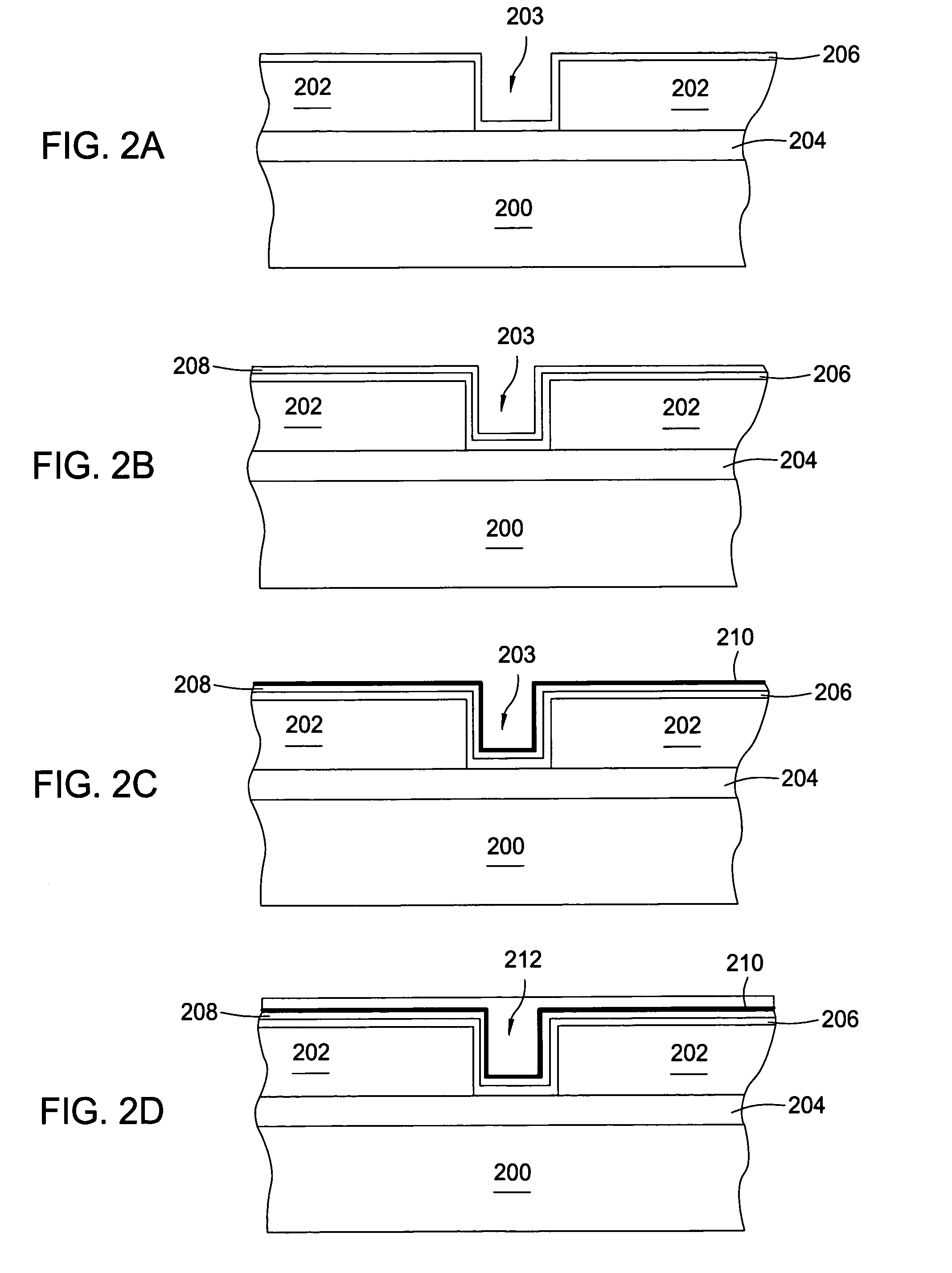

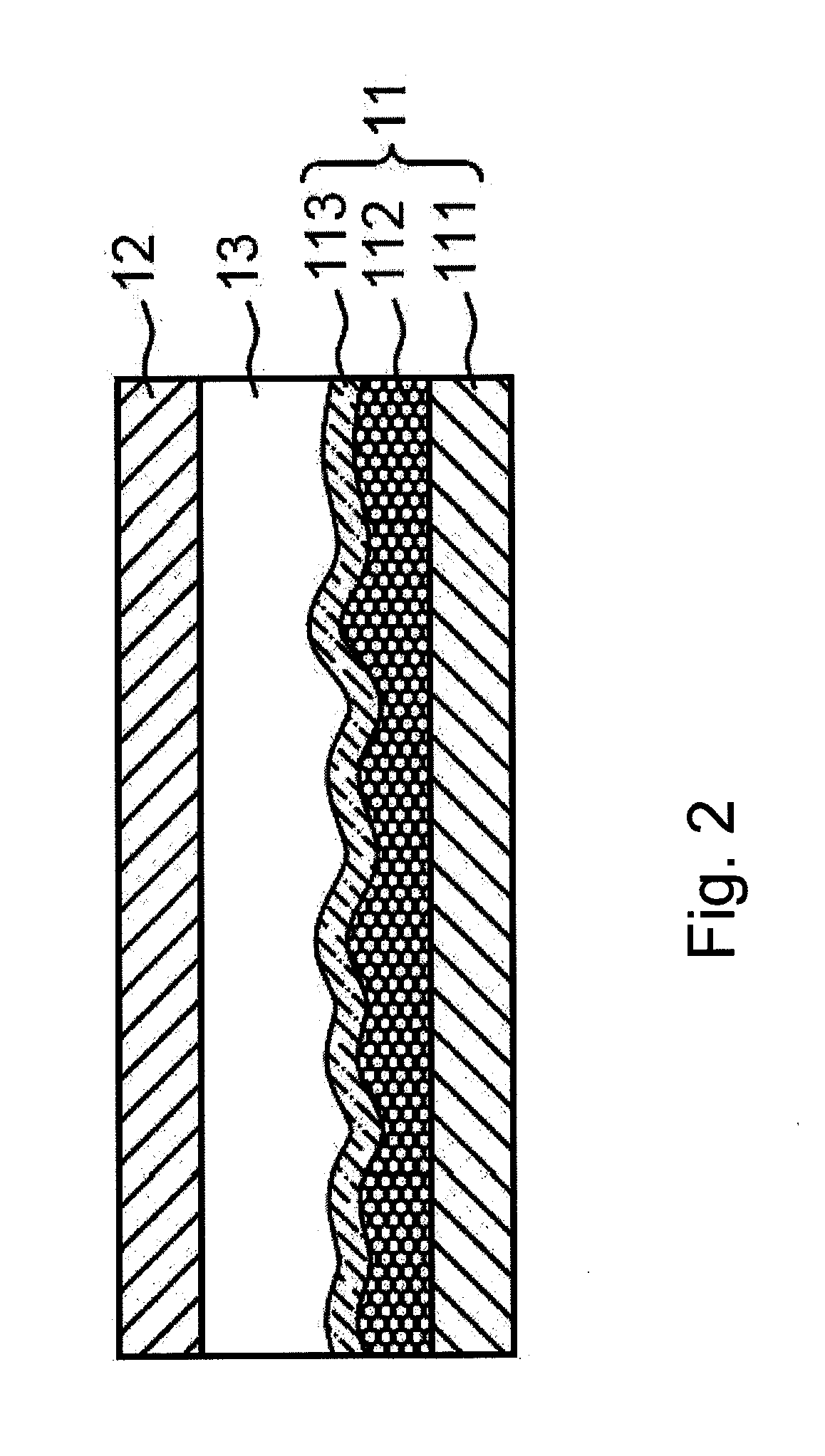

Ruthenium as an underlayer for tungsten film deposition

InactiveUS20060128150A1Semiconductor/solid-state device manufacturingSpecial surfacesRutheniumTitanium

In one embodiment, a method for depositing a tungsten-containing film on a substrate is provided which includes depositing a barrier layer on the substrate, such as a titanium or tantalum containing barrier layer and depositing a ruthenium layer on the barrier layer. The method further includes depositing a tungsten nucleation layer on the ruthenium layer and depositing a tungsten bulk layer on the tungsten nucleation layer. The barrier layer, the ruthenium layer, the tungsten nucleation layer and the tungsten bulk layer are independently deposited by an ALD process, a CVD process or a PVD process, preferably by an ALD process. In some examples, the substrate is exposed to a soak process prior to depositing a subsequent layer, such as between the deposition of the barrier layer and the ruthenium layer, the ruthenium layer and the tungsten nucleation layer or the tungsten nucleation layer and the tungsten bulk layer.

Owner:APPLIED MATERIALS INC

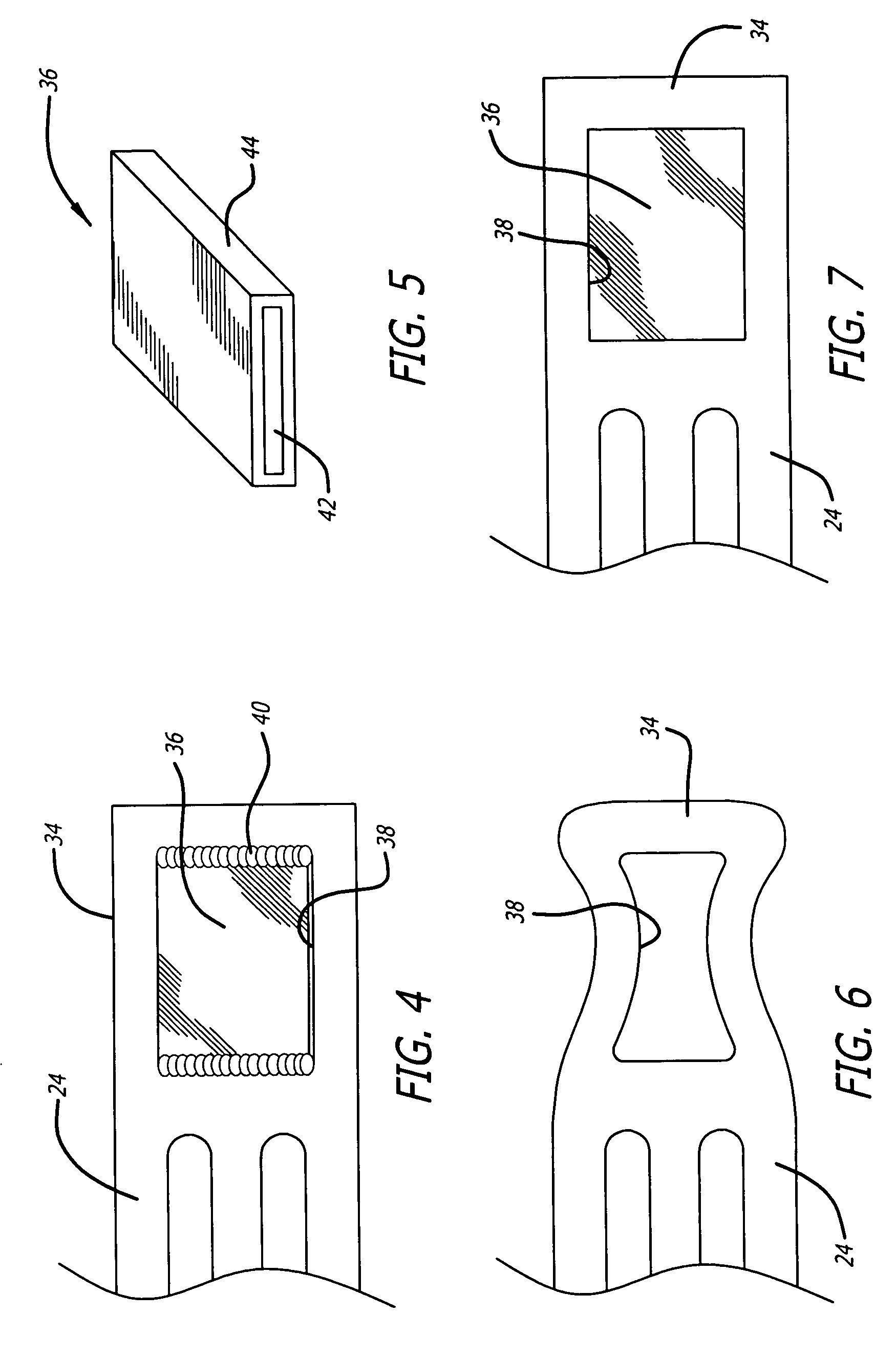

Radiopaque markers for medical devices

InactiveUS20050060025A1High level of radiopacitySufficient radiopacityStentsBlood vesselsIridiumRhenium

An implantable medical device includes a structural body made from a superelastic material and includes one or more marker holders integrally formed on the structural body. Each marker holder is designed to hold a radiopaque marker which has a level of radiopacity greater than the superelastic material. The radiopaque marker can be made from a nickel-titanium alloy which includes a ternary element. The ternary element can be selected from the group of elements consisting of iridium, platinum, gold, rhenium, tungsten, palladium, rhodium, tantalum, silver, ruthenium, and hafnium. In one form, the marker holder includes a pair of projecting fingers connected together at a notched region to cooperatively create a particular-shaped opening. This opening, in turn, is adapted to receive a similarly shaped portion formed on the radiopaque marker. In one form, the radiopaque marker includes an inner core which is partially, or completely, encased by an outer layer. This inner core can be made from a highly radiopaque material while the outer layer is formed from a material that is easier to weld to the marker.

Owner:ABBOTT VASCULAR SOLUTIONS

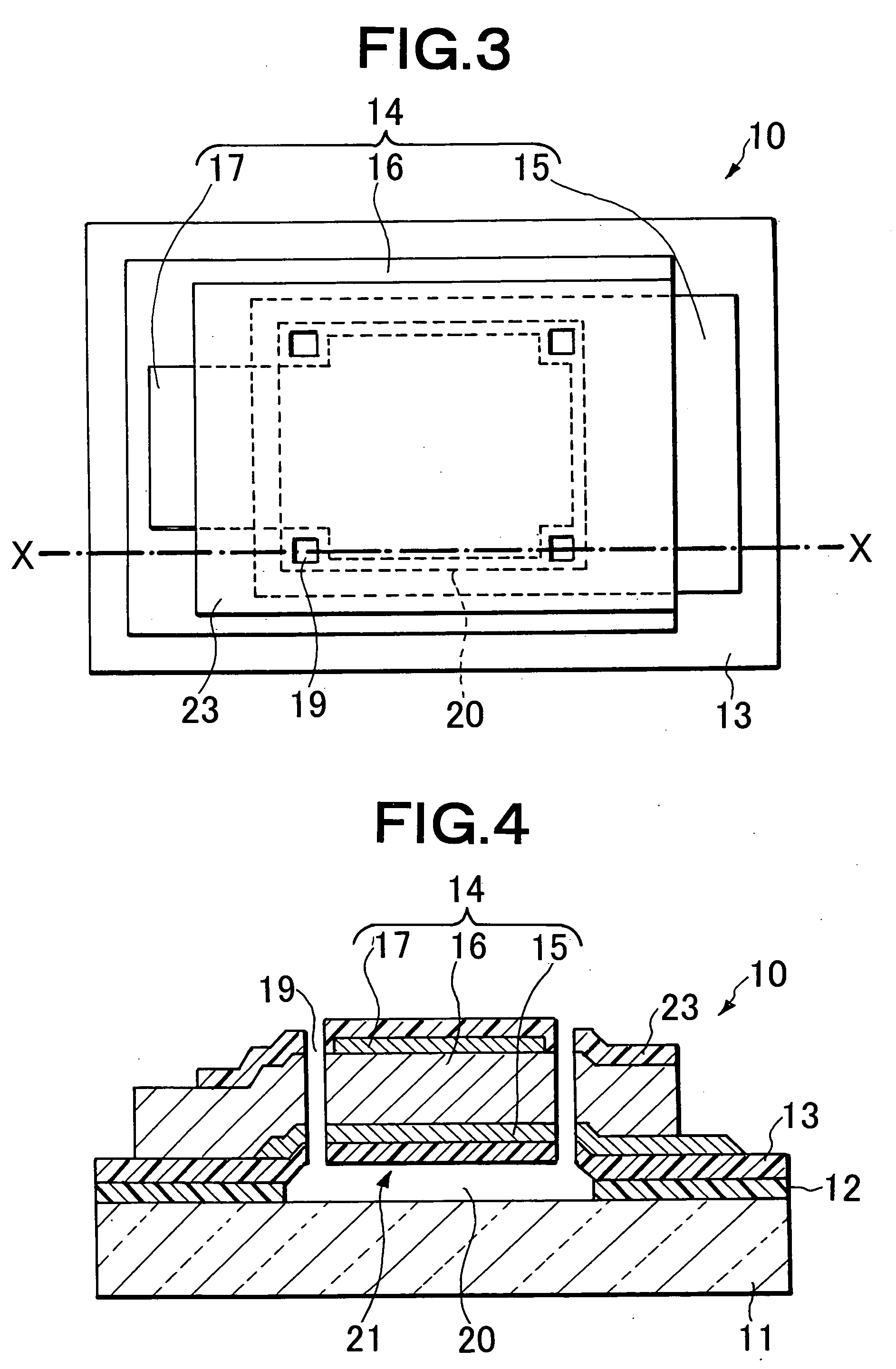

Method of forming metal electrodes

A capacitor structure comprising a bottom electrode, an insulator and a top electrode, and method for manufacturing the same. The bottom and top electrodes preferably include a metal portion and a conducting oxygen-containing metal portion. In one embodiment, a layer of ruthenium is deposited to form a portion of the bottom electrode. Prior to deposition of the insulator, the ruthenium is annealed in an oxygen-containing environment. The insulator is then deposited on the oxygen-containing ruthenium layer. Formation of the top electrode includes depositing a first metal on the insulator, annealing the first metal and then depositing a second metal. The first and second metals may be ruthenium.

Owner:APPLIED MATERIALS INC

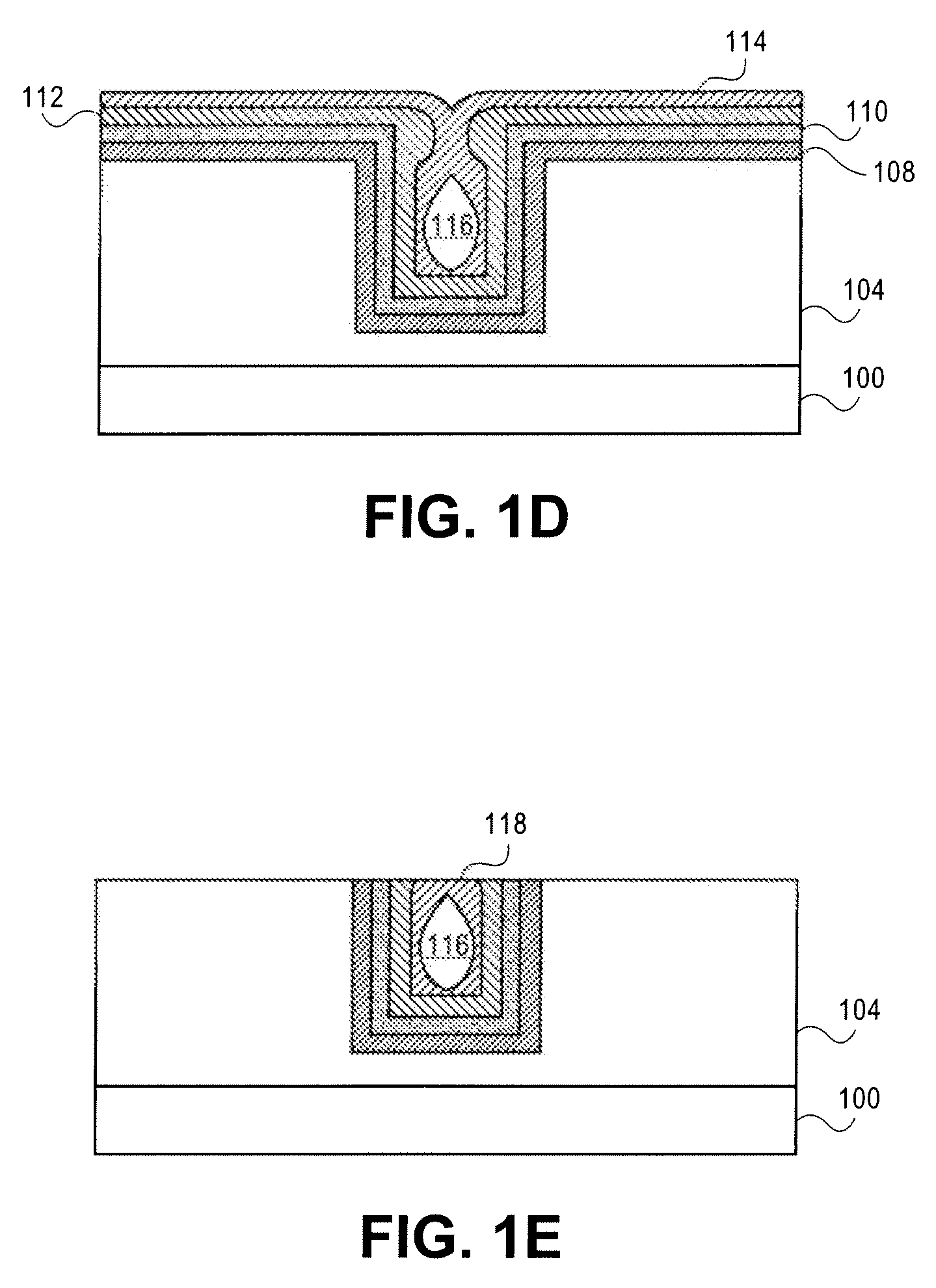

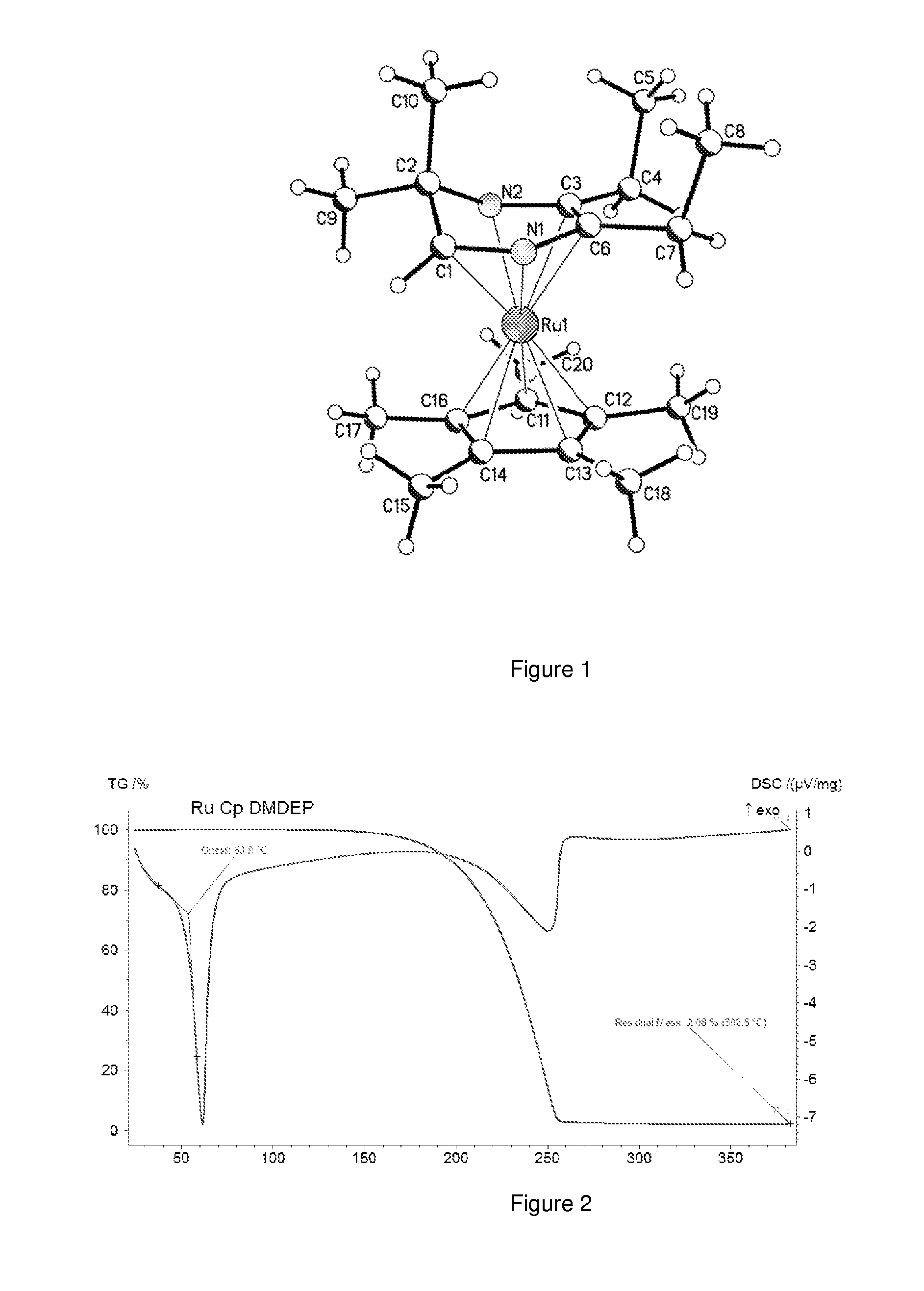

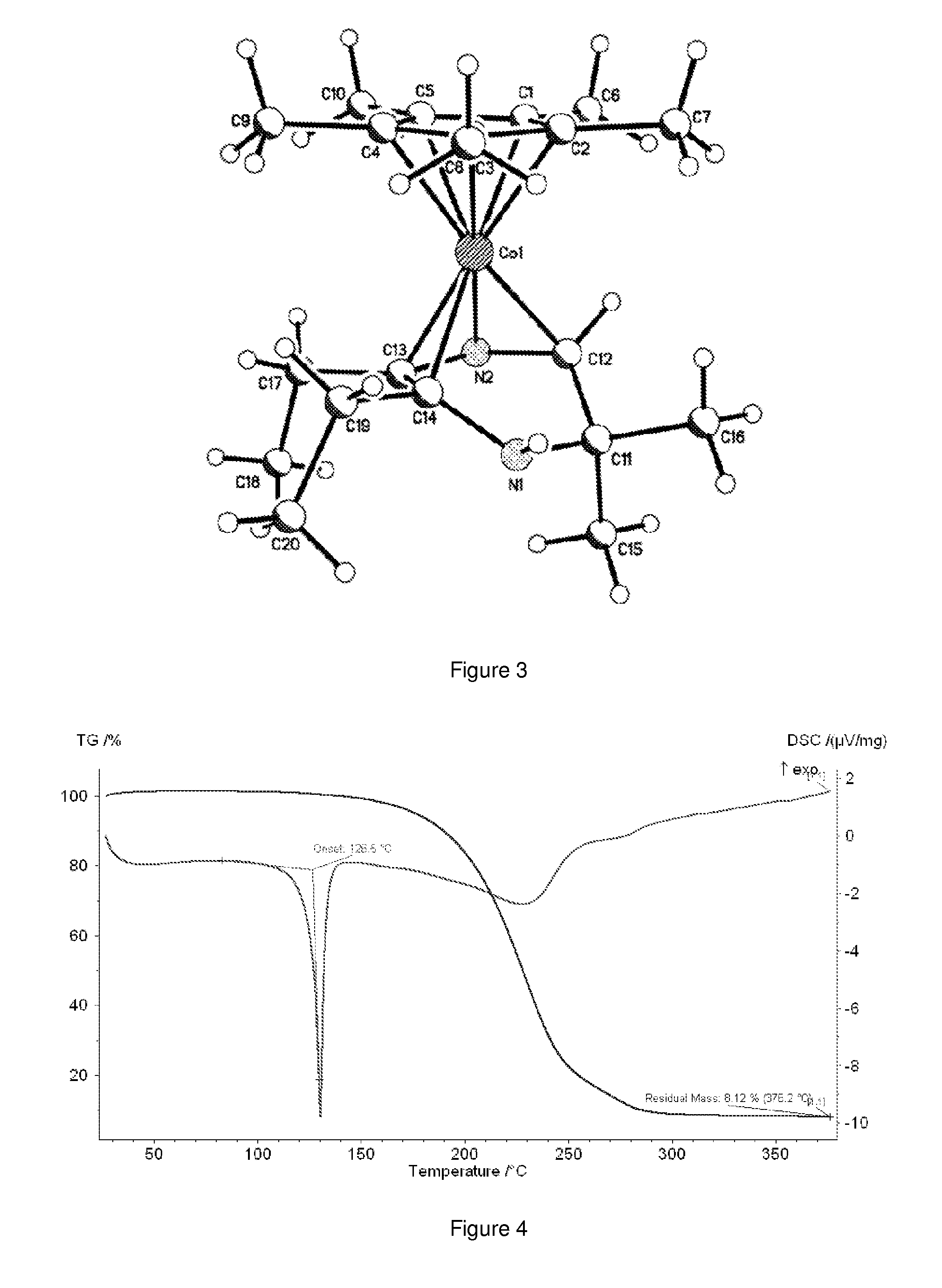

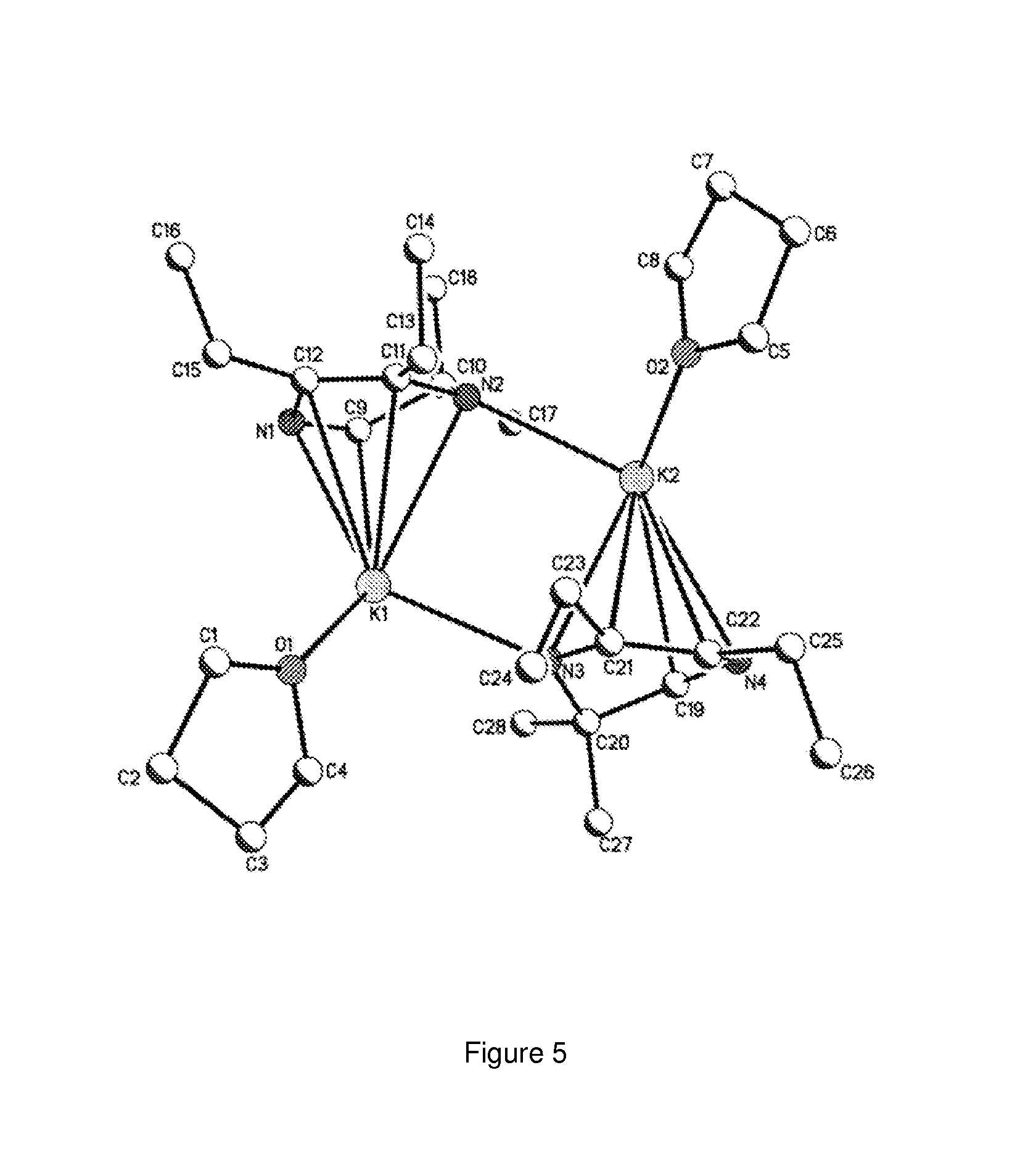

Volatile dihydropyrazinly and dihydropyrazine metal complexes

ActiveUS20150030782A1Improve responseHighly effectiveGroup 5/15 element organic compoundsVacuum evaporation coatingProtonationRuthenium

A composition comprising dihydropyrazinyl anions that can be coordinated as 6 electron ligands to a broad range of different metals to yield volatile metal complexes for ALD and CVD depositions are described herein. Also described herein are undeprotonated dihydropyrazines that can coordinate to metals as stabilizing neutral ligands. In one embodiment, the composition is used for the direct liquid injection delivery of the metal dihydropyrazinyl complex precursor to the chamber of an ALD or CVD chamber for the deposition of metal-containing thin films such as, for example, ruthenium or cobalt metal films.

Owner:VERSUM MATERIALS US LLC

Process for electroless copper deposition

InactiveUS20070099422A1Solid-state devicesSemiconductor/solid-state device manufacturingCopper platingRuthenium

Embodiments of the invention provide a method for depositing a copper material on a substrate by an electroless deposition process and also provide a composition of an electroless deposition solution. In one embodiment, the copper material is deposited from an electroless copper solution that contains an additive, such as an inhibitor, to promote a bottom-up fill process. In one aspect, the field of the substrate may be maintained free of copper material or substantially free of copper material during the electroless deposition process. Prior to the electroless deposition process for forming the copper material, a barrier layer may be deposited on the substrate, and thereafter, a ruthenium layer may be deposited thereon. In one example, the copper material is formed during a bottom-up, electroless deposition process directly on the ruthenium layer. Alternatively, a seed layer may be formed on the ruthenium layer prior to depositing the copper material.

Owner:APPLIED MATERIALS INC

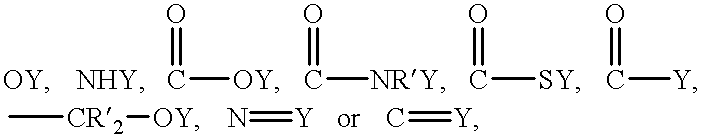

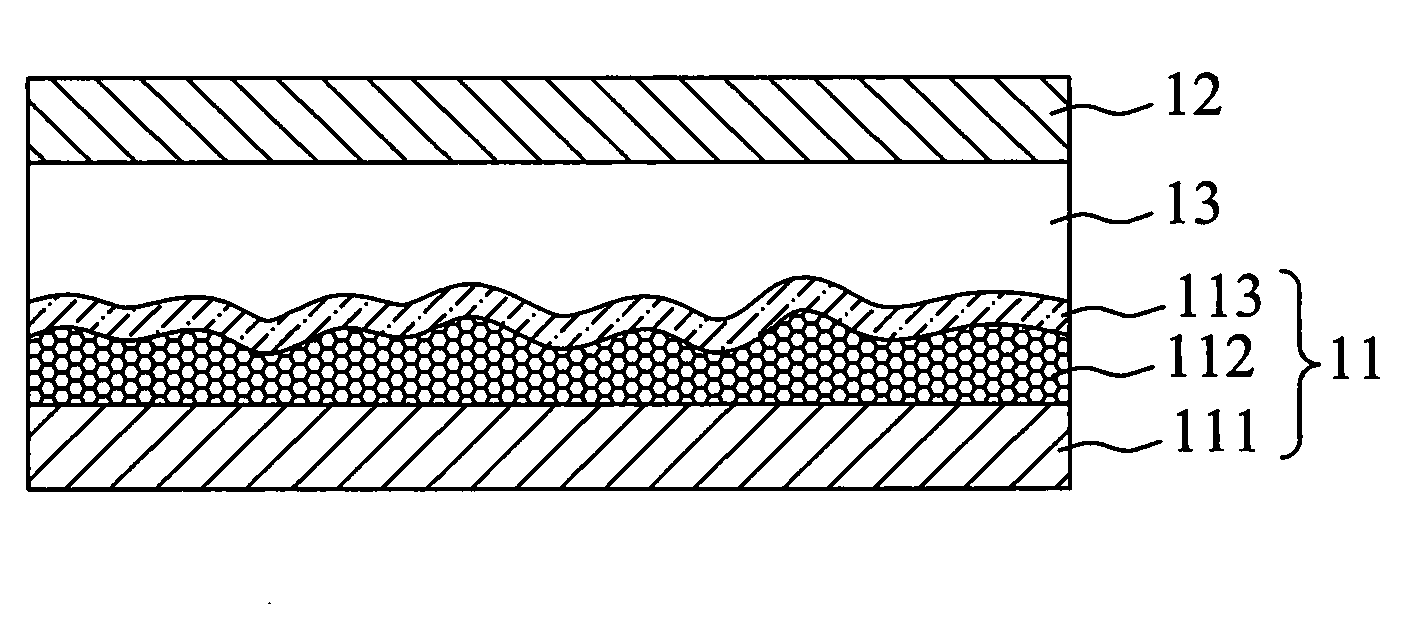

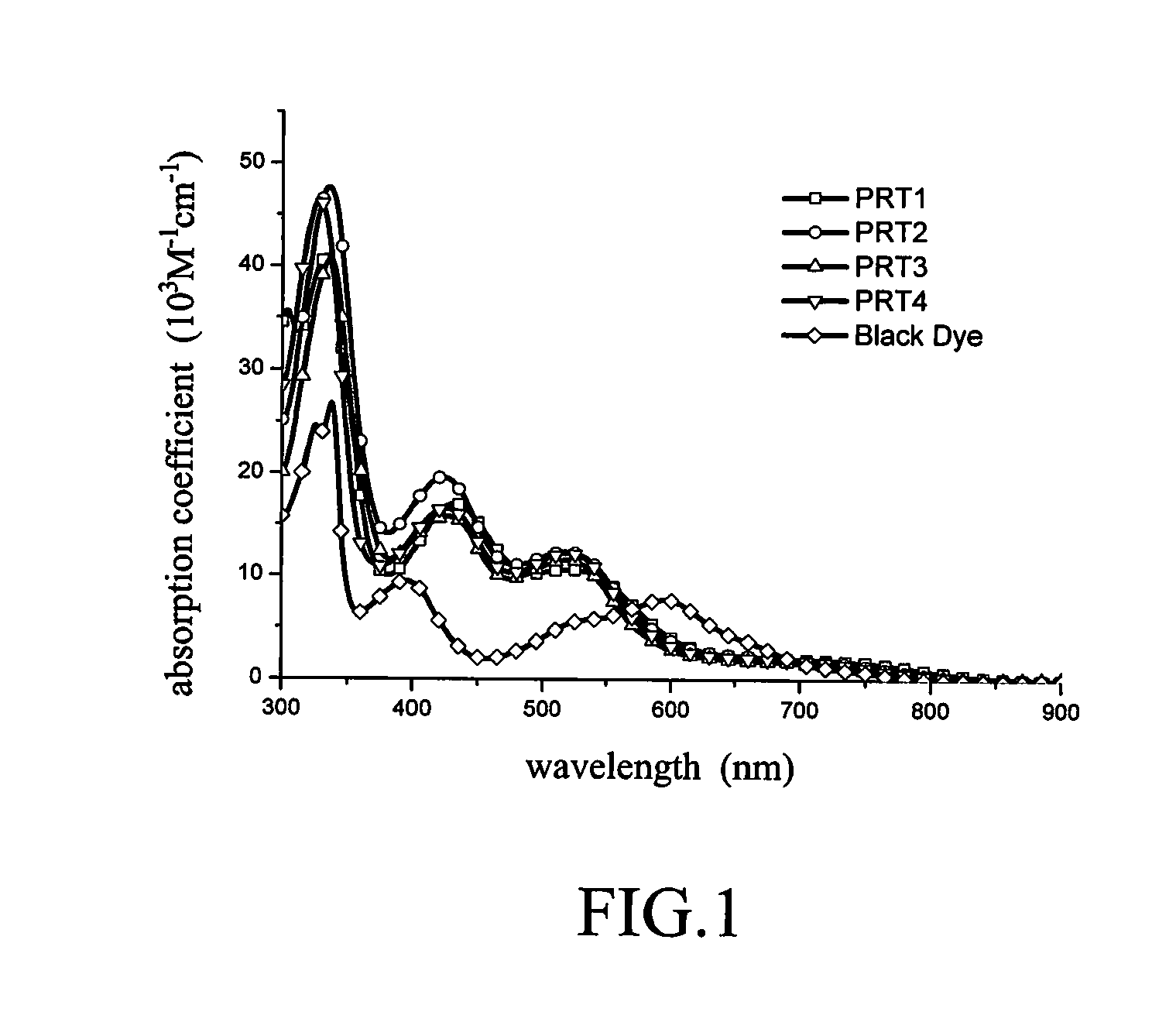

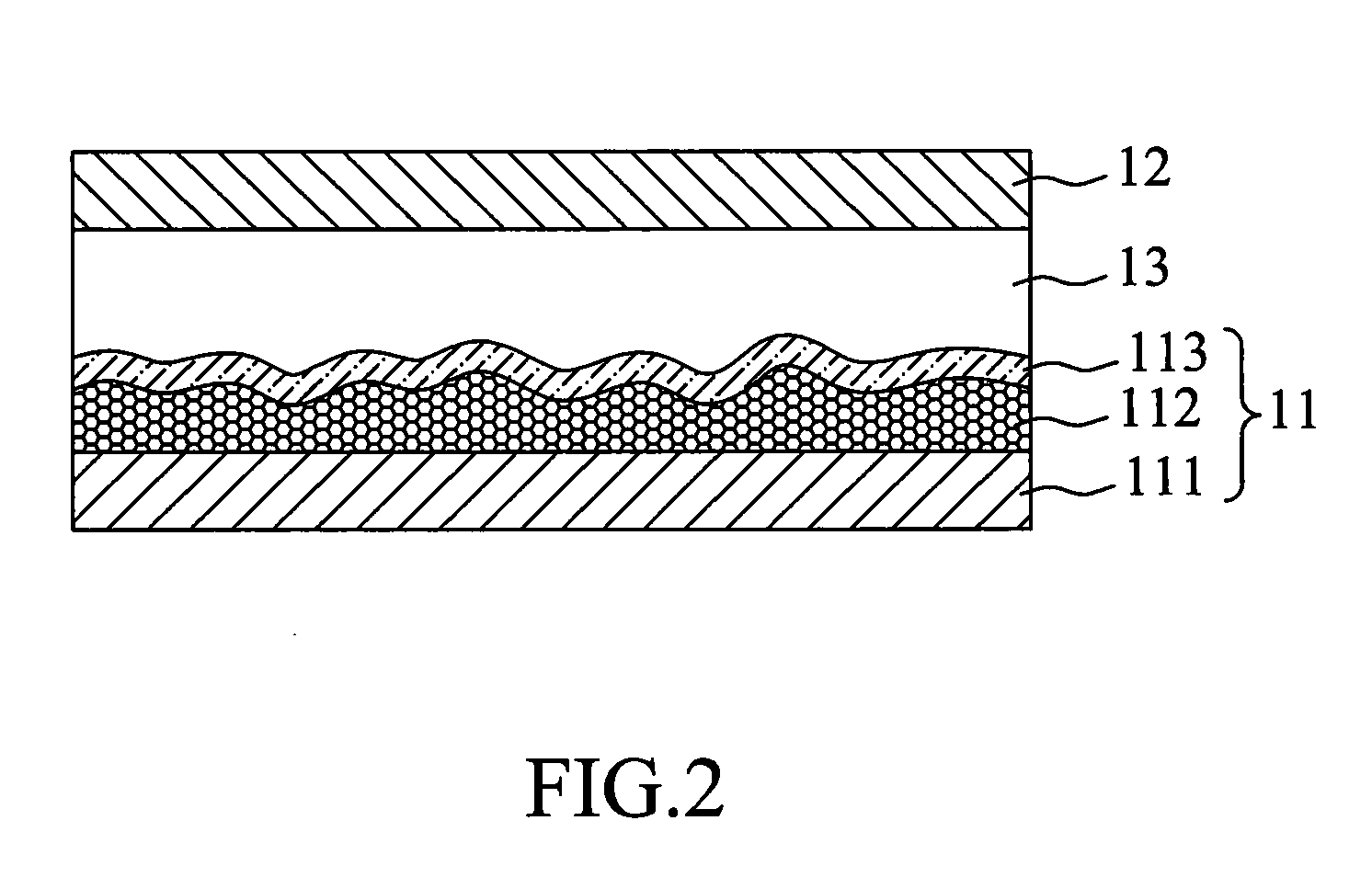

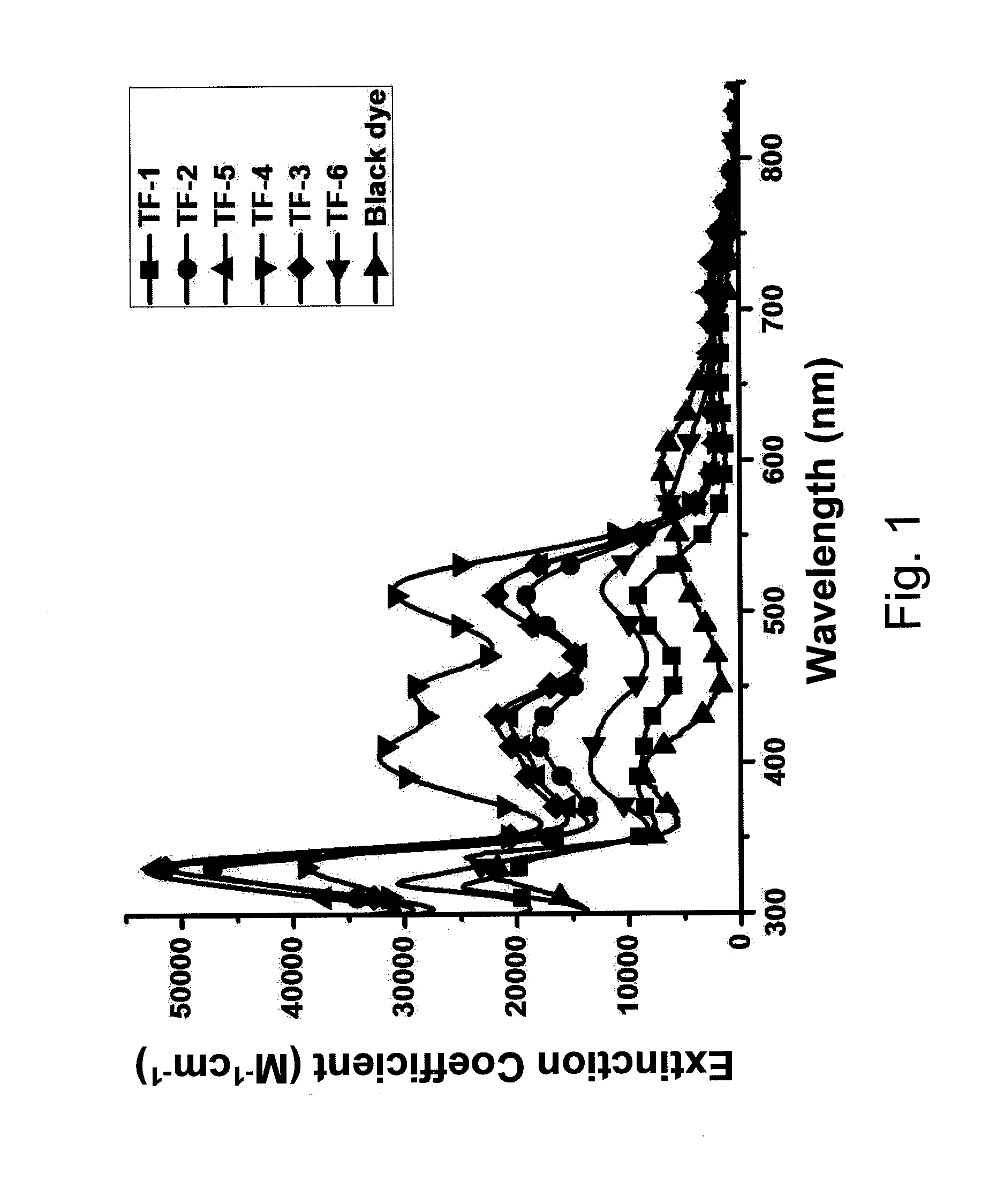

Panchromatic photosensitizers and dye-sensitized solar cell using the same

InactiveUS20100258175A1Improve photoelectric conversion efficiencyImprove response efficiencyRuthenium organic compoundsElectrolytic capacitorsPhosphoric acidCarboxylic acid

Panchromatic photosensitizers having a Formula of ML1L2X were synthesized, wherein M comprises ruthenium atom; X is a monodentate anion; L1 is heterocyclic bidentate ligand having one of formulae listed below:wherein G2 has one of formulae listed below:and L2 is a tridentate ligand having a formula listed below:The substituents R1, R2, R3, R4, R5, R6, R7 of L1 and L2 are the same or different, and represent alkyl, alkoxy, alkylthio, alkylamino, halogenated alkyl, phenyl or substituted phenyl group, carboxylic acid or counter anion thereof, sulfonic acid or counter anion thereof, phosphoric acid or counter anion thereof, amino-group, halogens, or hydrogen. The above-mentioned photosensitizers are suitable to use as sensitizers for fabrication of high efficiency dye-sensitized solar cell.

Owner:NATIONAL TSING HUA UNIVERSITY

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

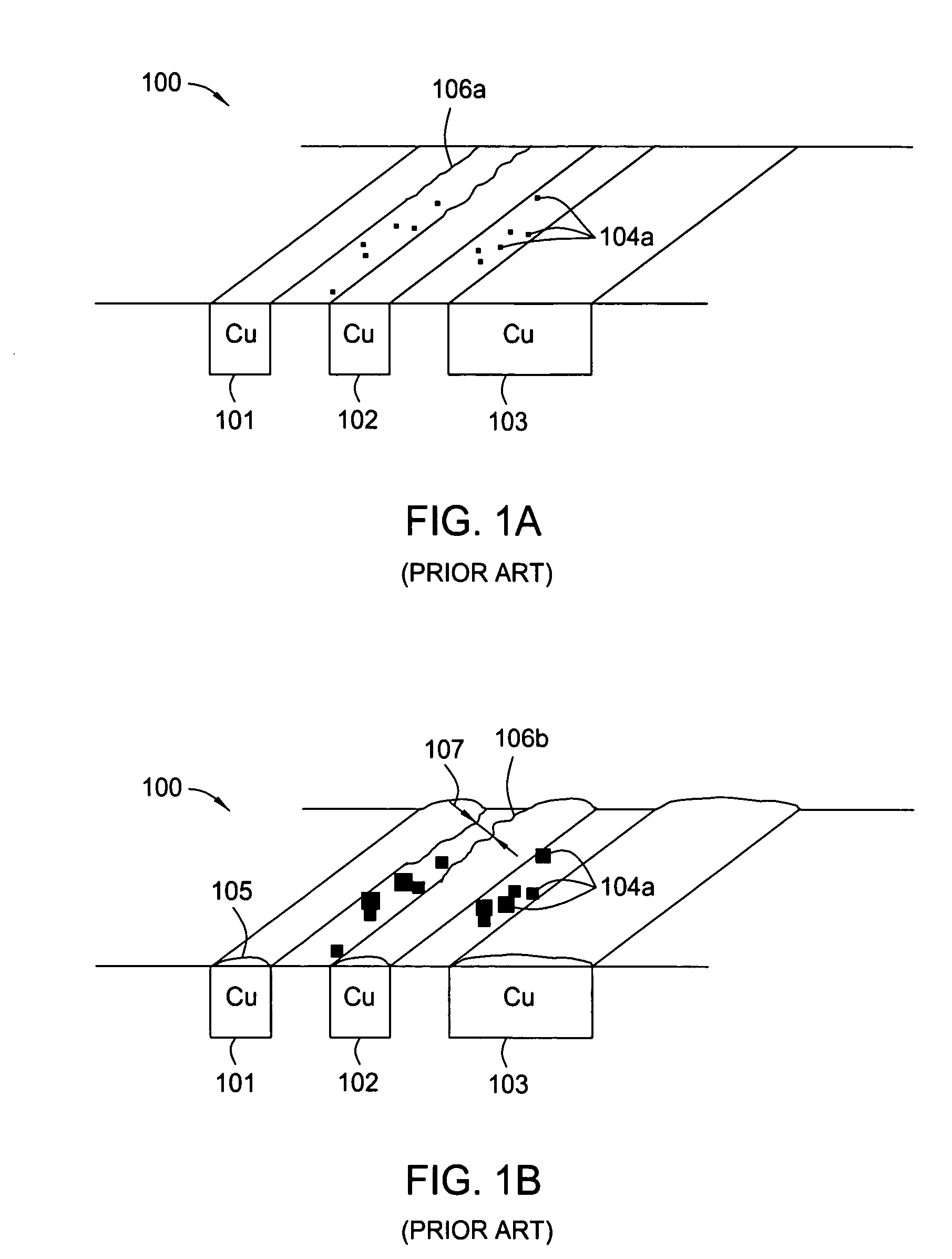

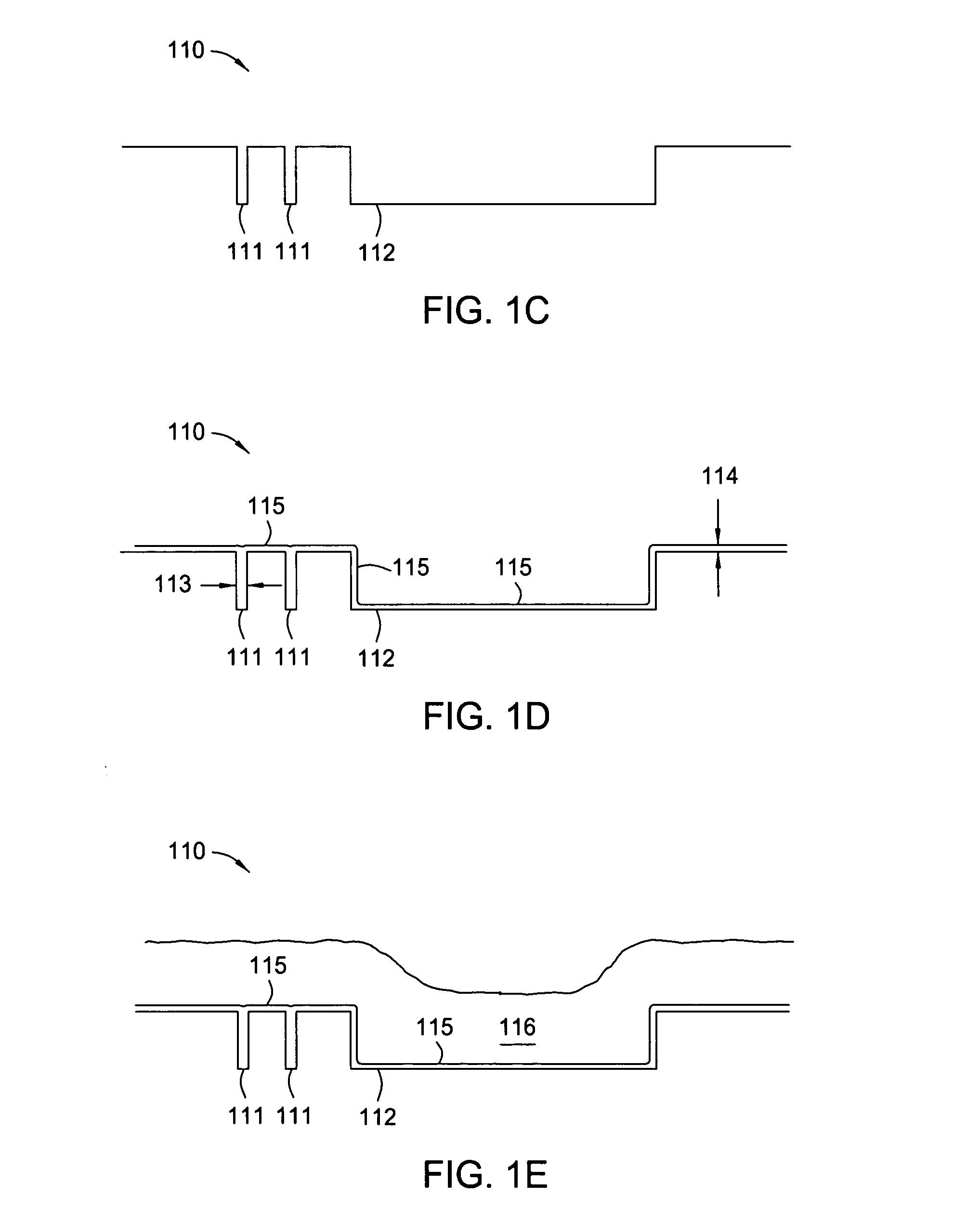

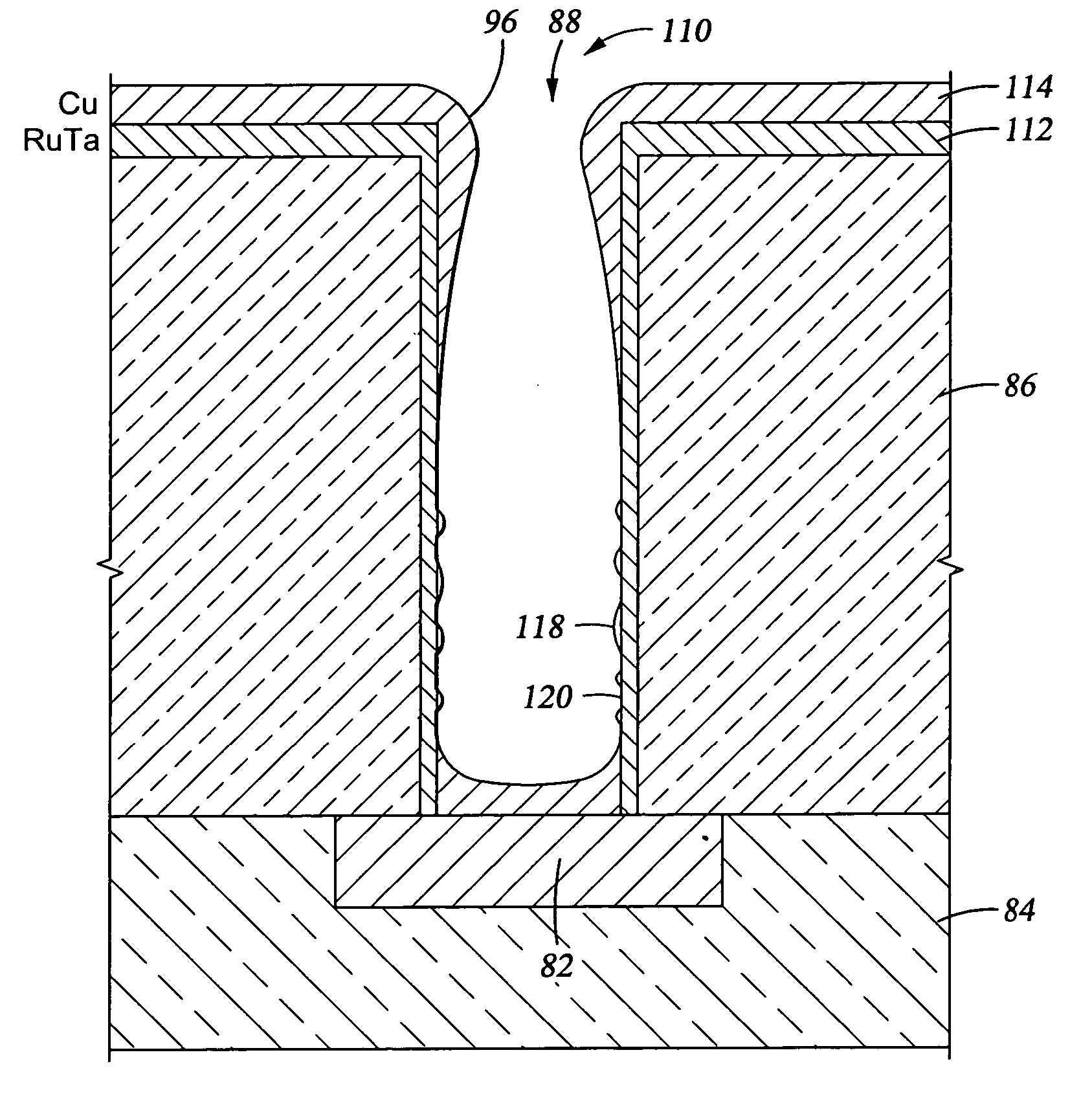

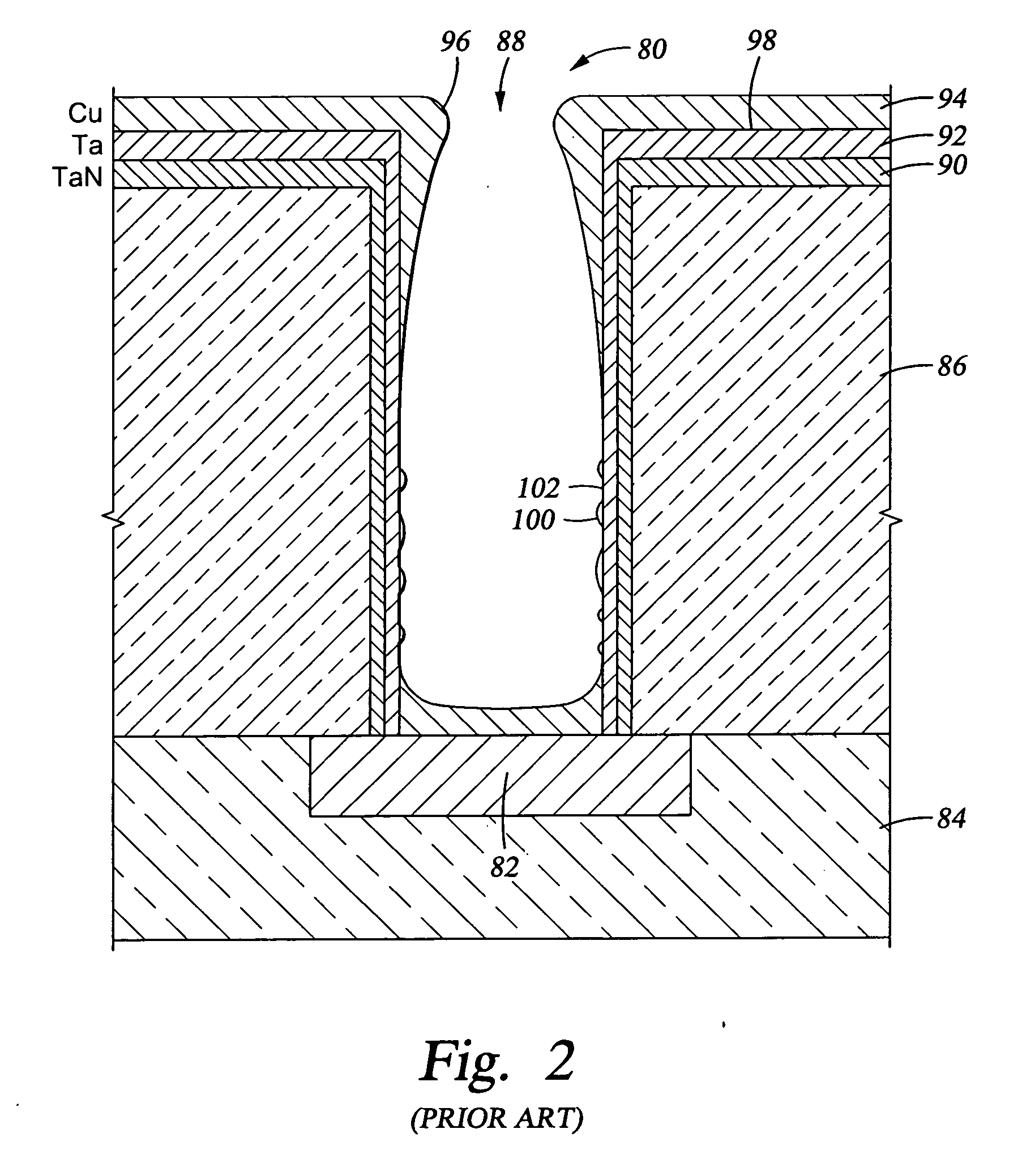

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

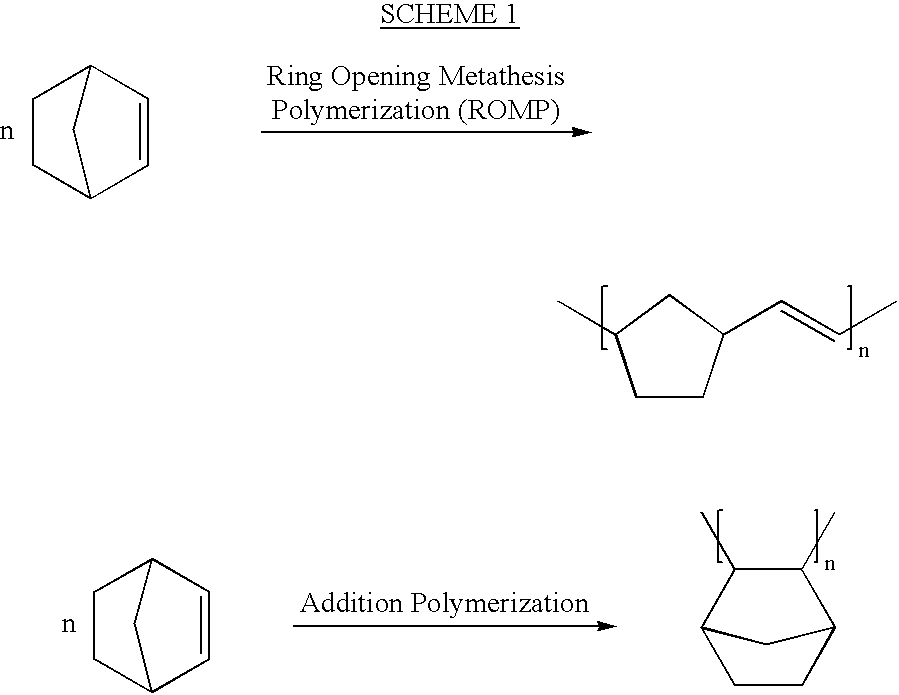

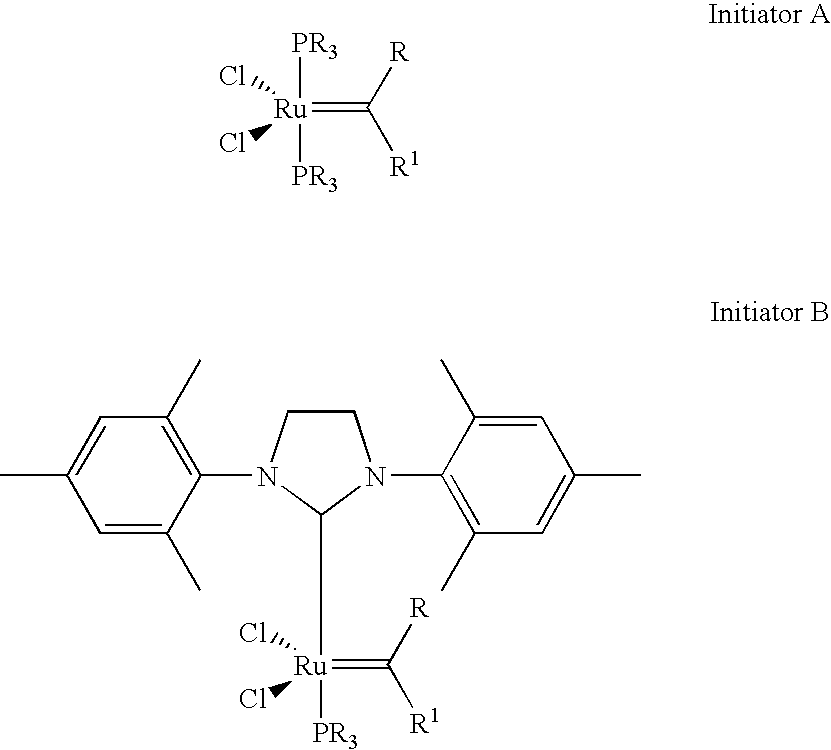

High activity metal carbene metathesis catalysts generated using a thermally activated N-heterocyclic carbene precursor

The invention provides a method for converting a less active or slower to initiate system to a higher activity system so that at the end of a polymerization the most active species is present in the system. The invention generally relates to a process for converting a less active or slower to initiate catalyst system to a higher activity catalyst system wherein the process comprises contacting a protected N-heterocyclic carbene with a metathesis catalyst and an olefin in the presence of energy. One of the benefits of the invention is that the amount of catalyst required is less than or lowered in the presence of the protected N-heterocyclic carbene as compared to the amount of catalyst required in the absence of the protected N-heterocyclic carbene. The protected N-heterocyclic carbene can be unsaturated or saturated. In addition, the invention describes novel ruthenium initiators and methods of making the same.

Owner:CALIFORNIA INST OF TECH +1

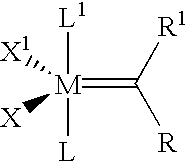

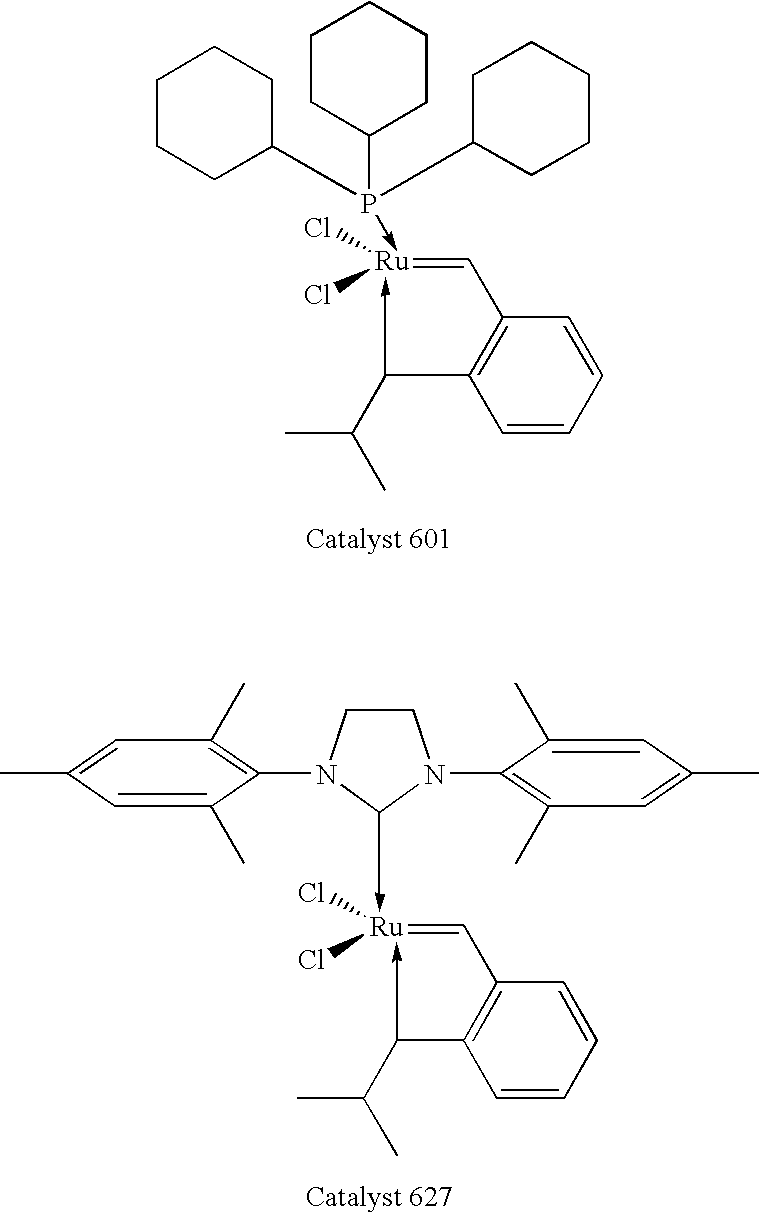

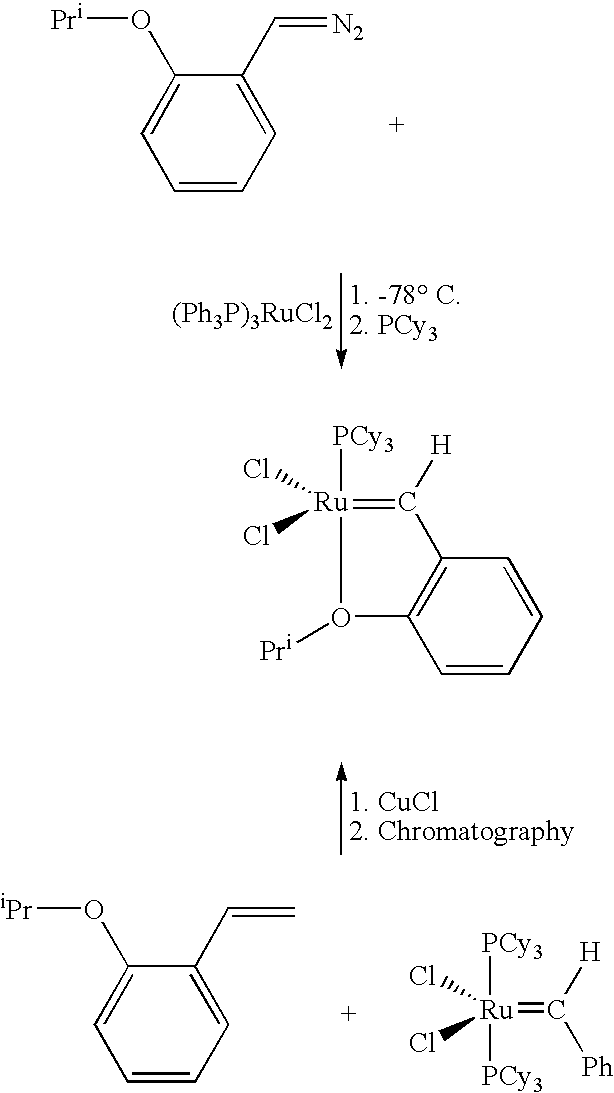

Chelating carbene ligand precursors and their use in the synthesis of metathesis catalysts

InactiveUS7026495B1High yieldImprove isolationRuthenium organic compoundsGroup 5/15 element organic compoundsHigh concentrationCarbene

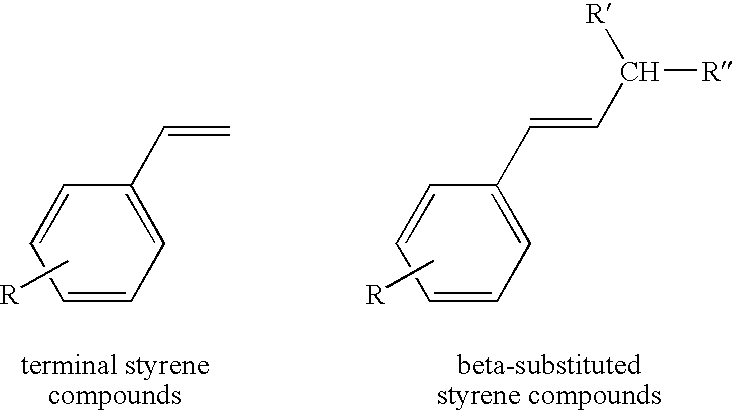

Chelating ligand precursors for the preparation of olefin metathesis catalysts are disclosed. The resulting catalysts are air stable monomeric species capable of promoting various metathesis reactions efficiently, which can be recovered from the reaction mixture and reused. Internal olefin compounds, specifically beta-substituted styrenes, are used as ligand precursors. Compared to terminal olefin compounds such as unsubstituted styrenes, the beta-substituted styrenes are easier and less costly to prepare, and more stable since they are less prone to spontaneous polymerization. Methods of preparing chelating-carbene metathesis catalysts without the use of CuCl are disclosed. This eliminates the need for CuCl by replacing it with organic acids, mineral acids, mild oxidants or even water, resulting in high yields of Hoveyda-type metathesis catalysts. The invention provides an efficient method for preparing chelating-carbene metathesis catalysts by reacting a suitable ruthenium complex in high concentrations of the ligand precursors followed by crystallization from an organic solvent.

Owner:UMICORE AG & CO KG

Anode catalyst for fuel cells with polymer electrolyte membranes

A platinum / ruthenium alloy catalyst that includes finely dispersed alloy particles on a powdery, electrically conductive carrier material. The catalyst is particularly resistant to carbon monoxide poisoning when the alloy particles display mean crystallite sizes of 0.5 to less than 2 nm.

Owner:EVONIK DEGUSSA GMBH

Thin layer metal chemical vapor deposition

InactiveUS6849122B1Efficient fillingPolycrystalline material growthFrom chemically reactive gasesIndiumGas phase

A CVD method deposits conformal metal layers on small features of a substrate surface. The method includes three principal operations: depositing a thin conformal layer of precursor over some or all of the substrate surface; oxidizing the precursor to convert it to a conformal layer of metal oxide; and reducing some or all of the metal oxide to convert it to a conformal layer of the metal itself. The conformal layer of precursor may form a “monolayer” on the substrate surface. Examples of metals for deposition include copper, cobalt, ruthenium, indium, and rhodium.

Owner:NOVELLUS SYSTEMS

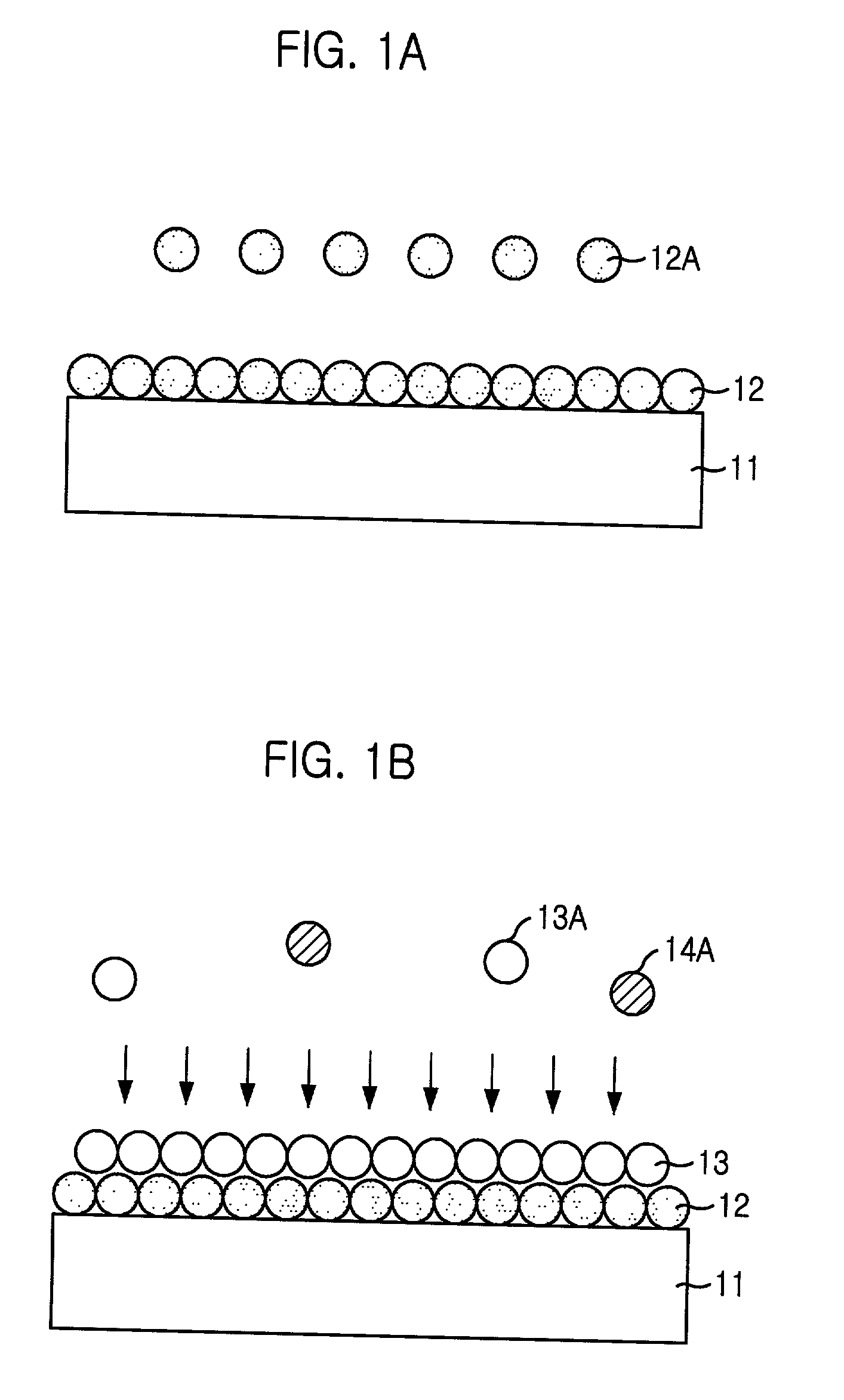

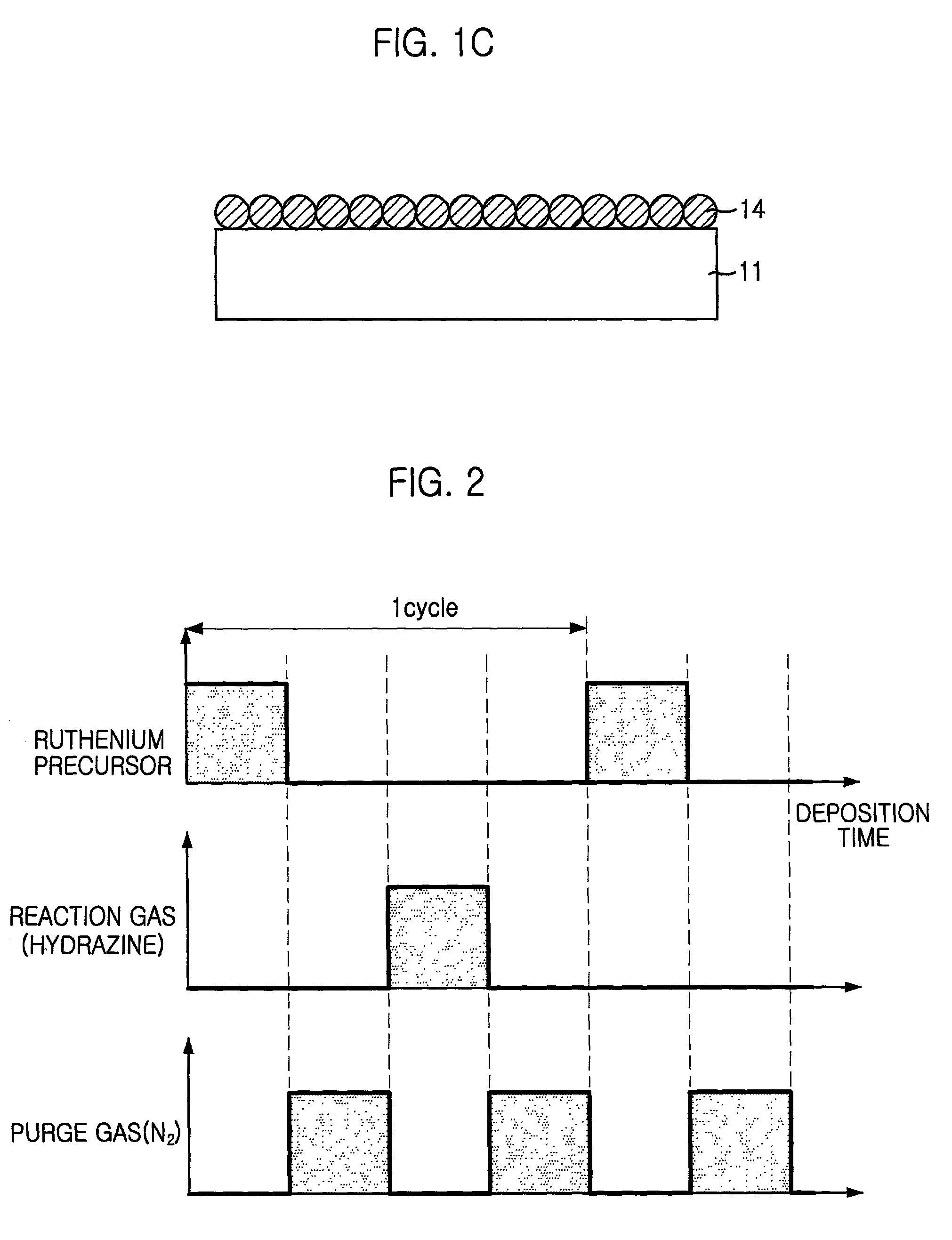

Ruthenium layer formation for copper film deposition

InactiveUS7264846B2Material nanotechnologySemiconductor/solid-state device manufacturingRutheniumDeposition process

A method of ruthenium layer formation for high aspect ratios, interconnect features is described. The ruthenium layer is formed using a cyclical deposition process. The cyclical deposition process comprises alternately adsorbing a ruthenium-containing precursor and a reducing gas on a substrate structure. The adsorbed ruthenium-containing precursor reacts with the adsorbed reducing gas to form the ruthenium layer on the substrate.

Owner:APPLIED MATERIALS INC

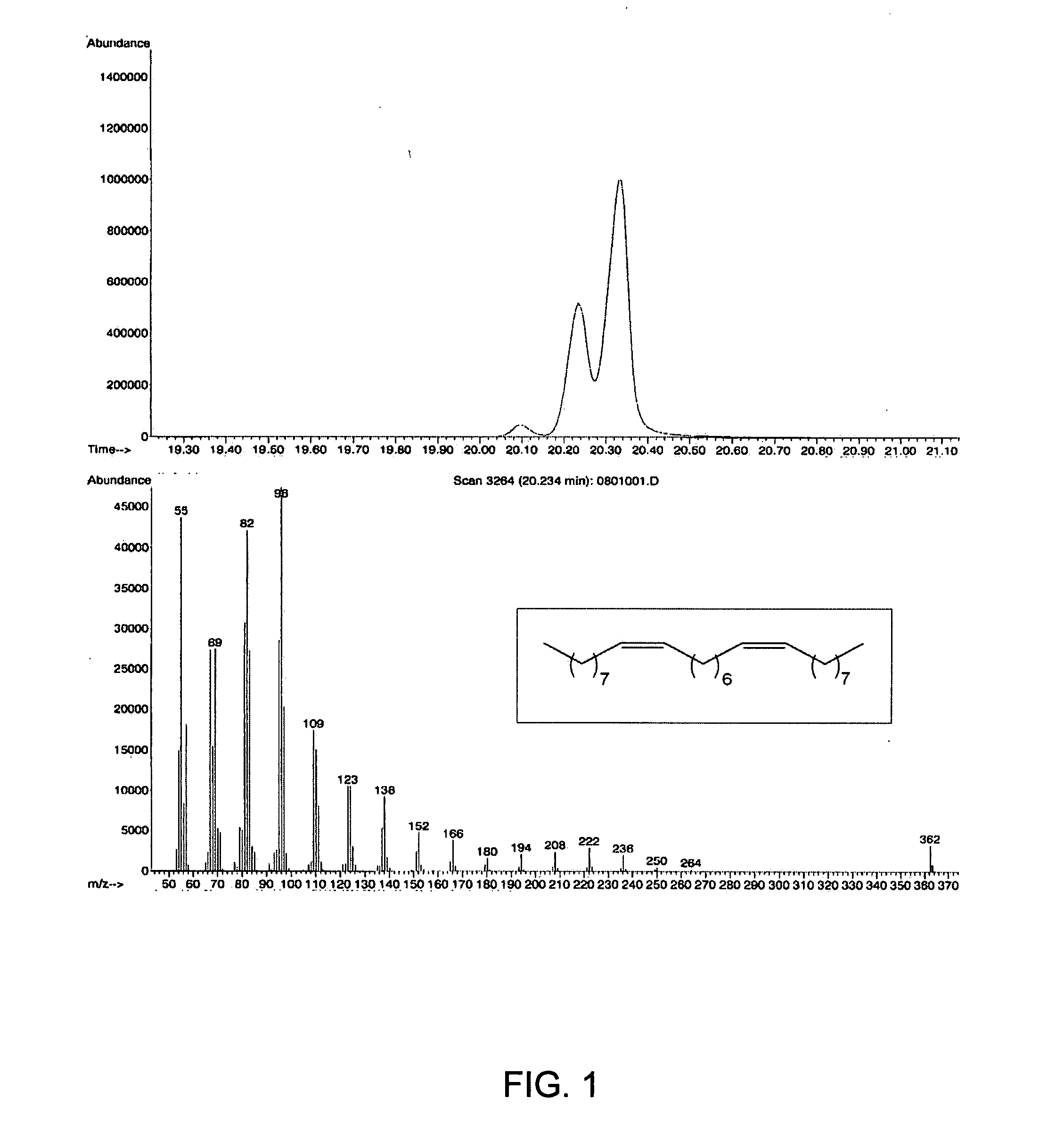

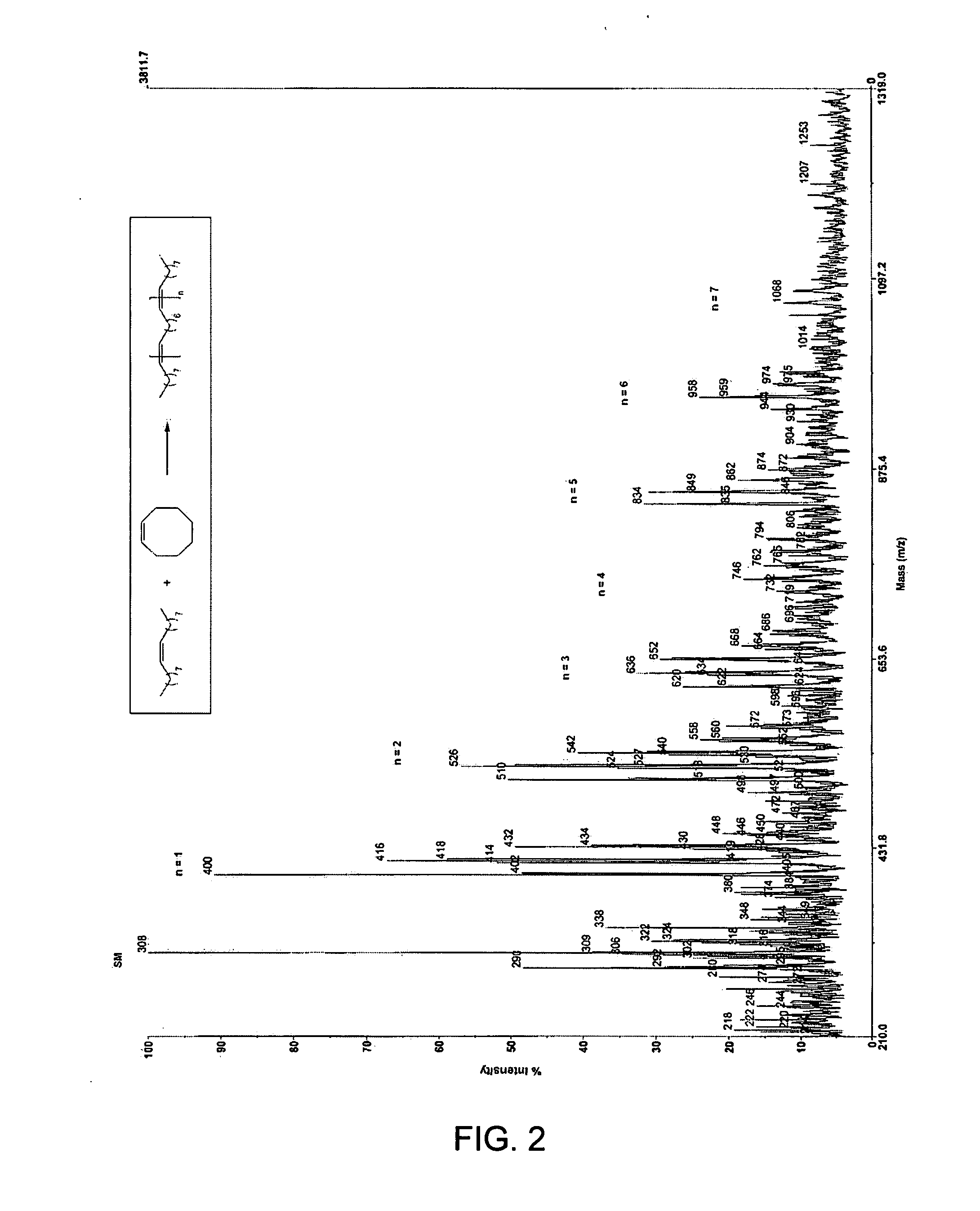

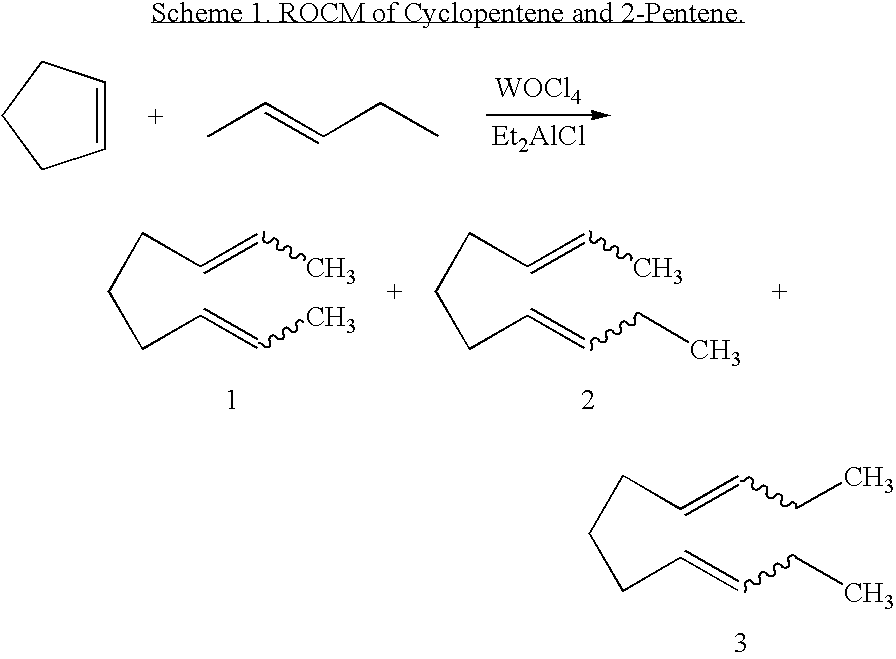

Ring opening cross-metathesis reaction of cyclic olefins with seed oils and the like

ActiveUS20080064891A1Fatty acid esterificationOrganic compound preparationOrganic synthesisRuthenium

This invention relates generally to olefin metathesis, and more particularly relates to the ring-opening, ring insertion cross-metathesis of cyclic olefins with internal olefins such as seed oils and the like. In one embodiment, a method is provided for carrying out a catalytic ring-opening cross-metathesis reaction, comprising contacting at least one olefinic substrate with at least one cyclic olefin as a cross metathesis partner, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring insertion cross metathesis whereby the cyclic olefin is simultaneously opened and inserted into the olefinic substrate. The invention has utility in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:WILMAR TRADING PTE LTD

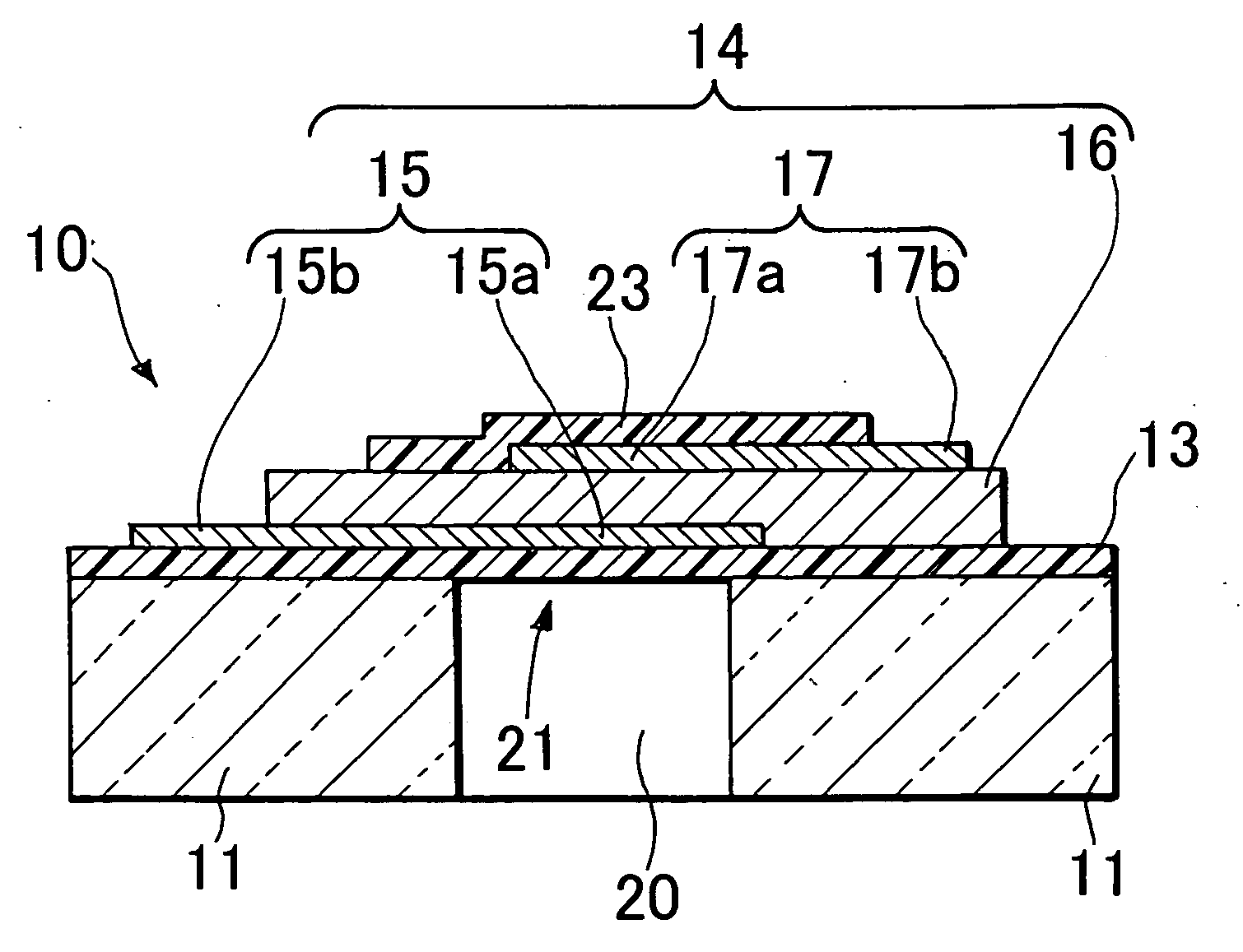

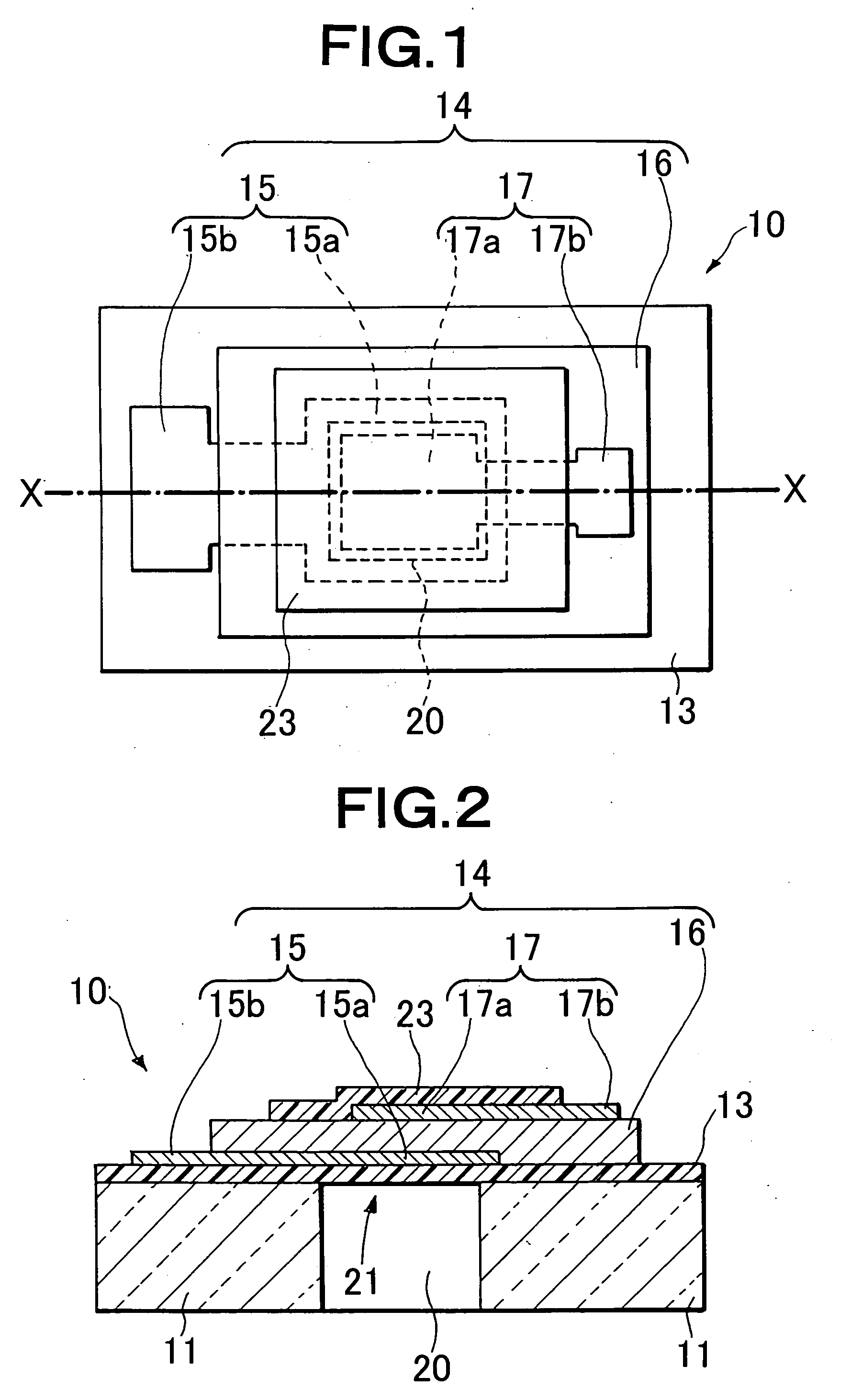

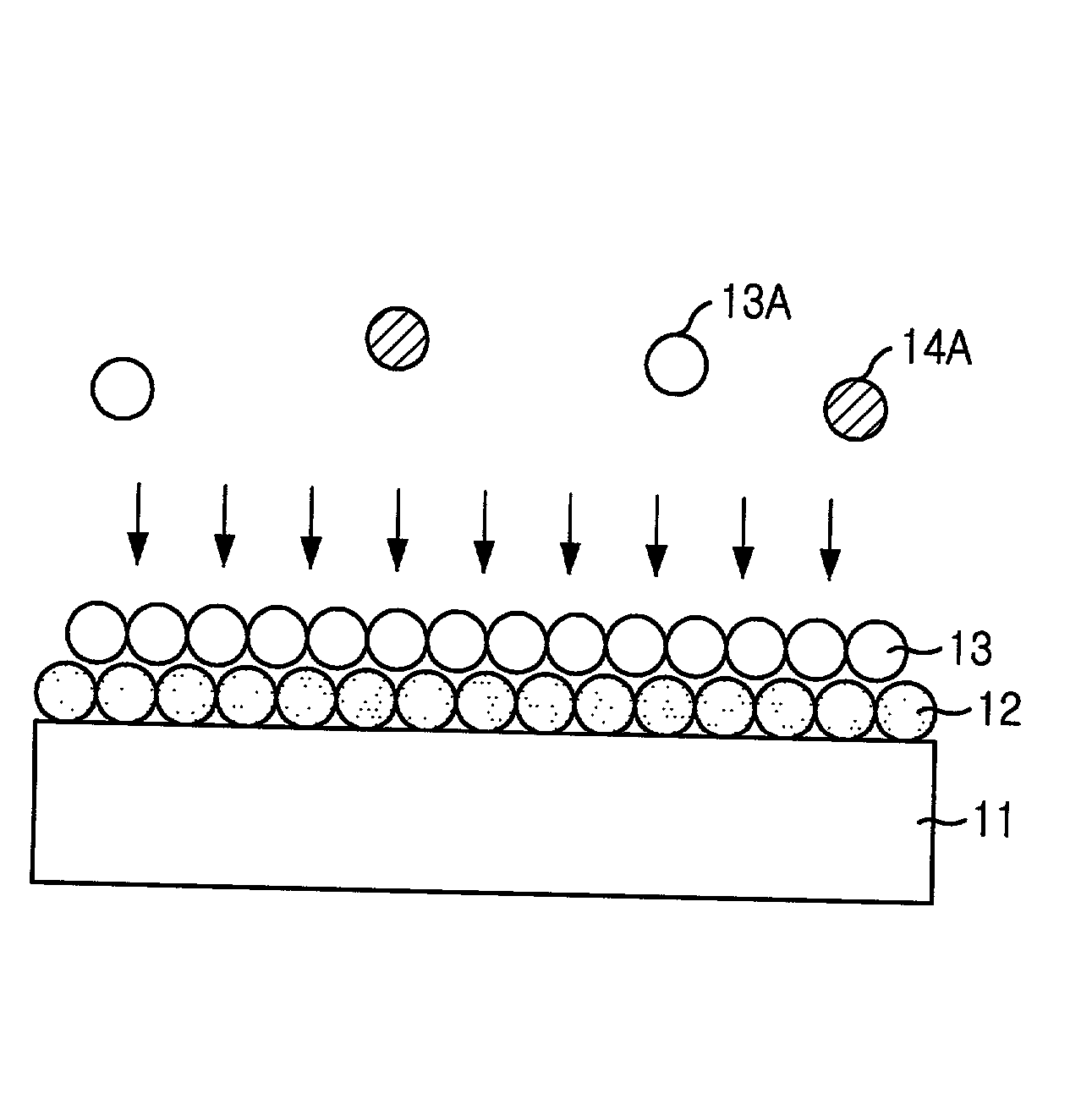

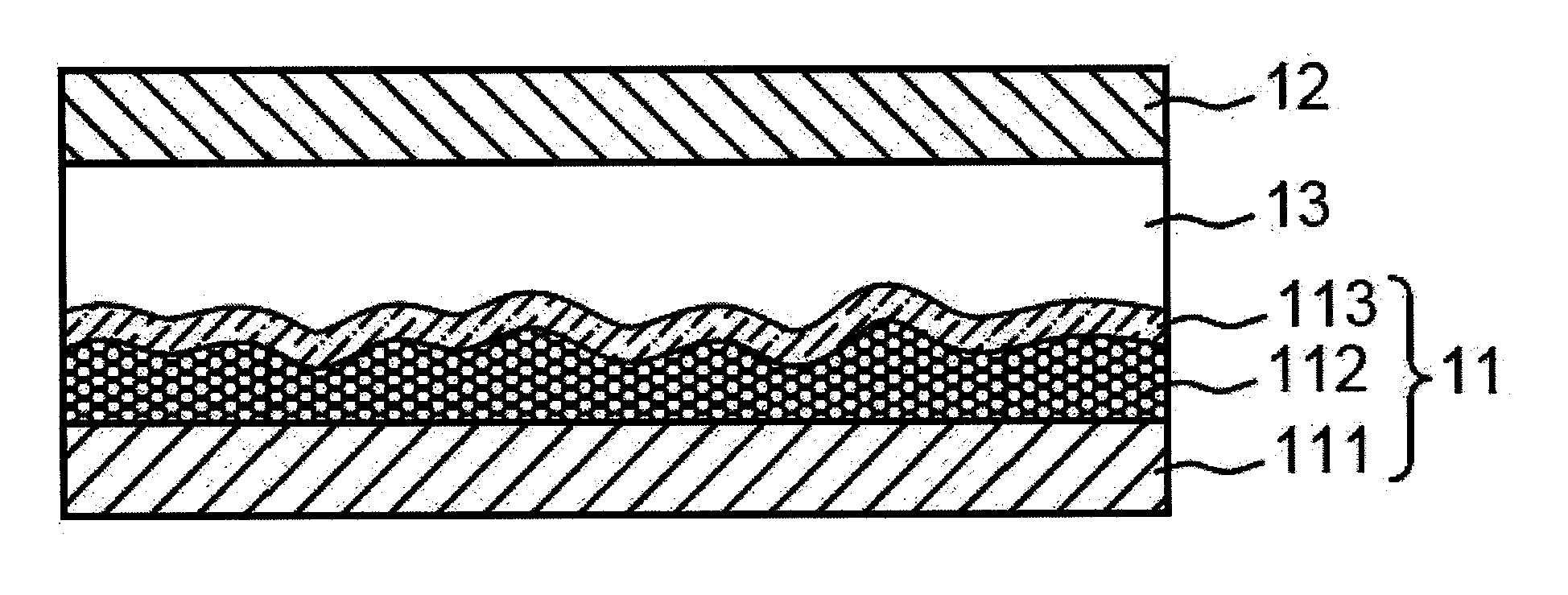

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

Hydrocarbon-Producing Catalyst, Process for Producing the Same, and Process for Producing Hydrocarbons Using the Catalyst

InactiveUS20080064769A1Increase probabilityStably and smoothly promoteHydrocarbon from carbon oxidesOrganic compound preparationRutheniumLiquid hydrocarbons

An object of the present invention is to provide a catalyst which, in the FT process, exhibits a high chain growth probability, and a high catalytic activity, can stably and smoothly promote the reaction, exhibits a high productivity of C5+, and can efficiently produce liquid hydrocarbons, and a process therefor.The invention relates to a hydrocarbon-producing catalyst obtainable by supporting a ruthenium compound on a support composed of a manganese oxide and an aluminum oxide, and which satisfies at least one of characteristics (1) and (2): (1) the catalyst being treated with an aqueous alkaline solution and subsequently subjected to calcination treatment in the air at 150 to 500° C., (2) the aluminum oxide being an aluminum oxide wherein pore volume formed by pores having a pore diameter of 8 nm or more accounts for 50% or more of total pore volume.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

Ruthenium as an underlayer for tungsten film deposition

In one embodiment, a method for depositing a tungsten-containing film on a substrate is provided which includes depositing a barrier layer on the substrate, such as a titanium or tantalum containing barrier layer and depositing a ruthenium layer on the barrier layer. The method further includes depositing a tungsten nucleation layer on the ruthenium layer and depositing a tungsten bulk layer on the tungsten nucleation layer. The barrier layer, the ruthenium layer, the tungsten nucleation layer and the tungsten bulk layer are independently deposited by an ALD process, a CVD process or a PVD process, preferably by an ALD process. In some examples, the substrate is exposed to a soak process prior to depositing a subsequent layer, such as between the deposition of the barrier layer and the ruthenium layer, the ruthenium layer and the tungsten nucleation layer or the tungsten nucleation layer and the tungsten bulk layer.

Owner:APPLIED MATERIALS INC

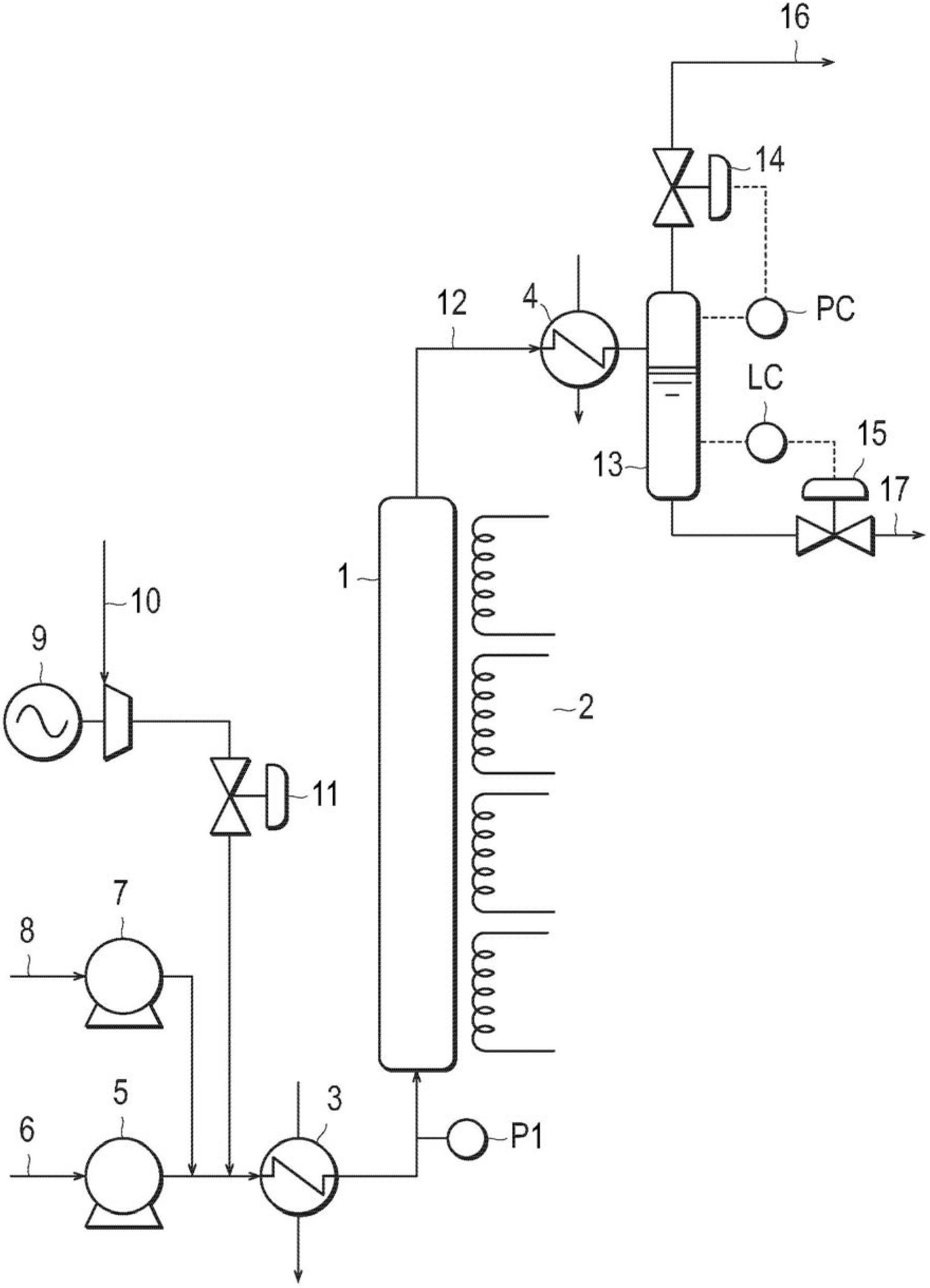

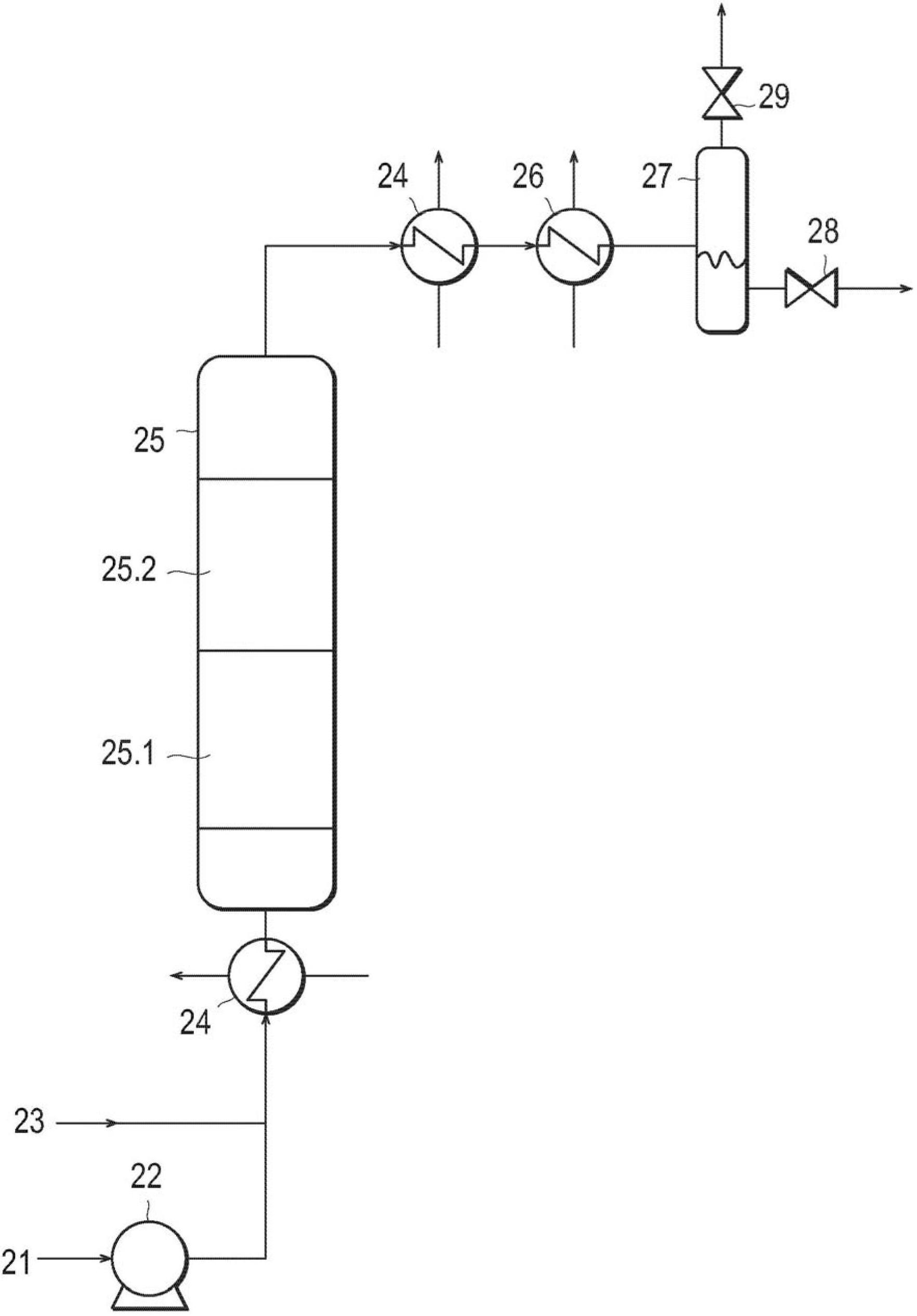

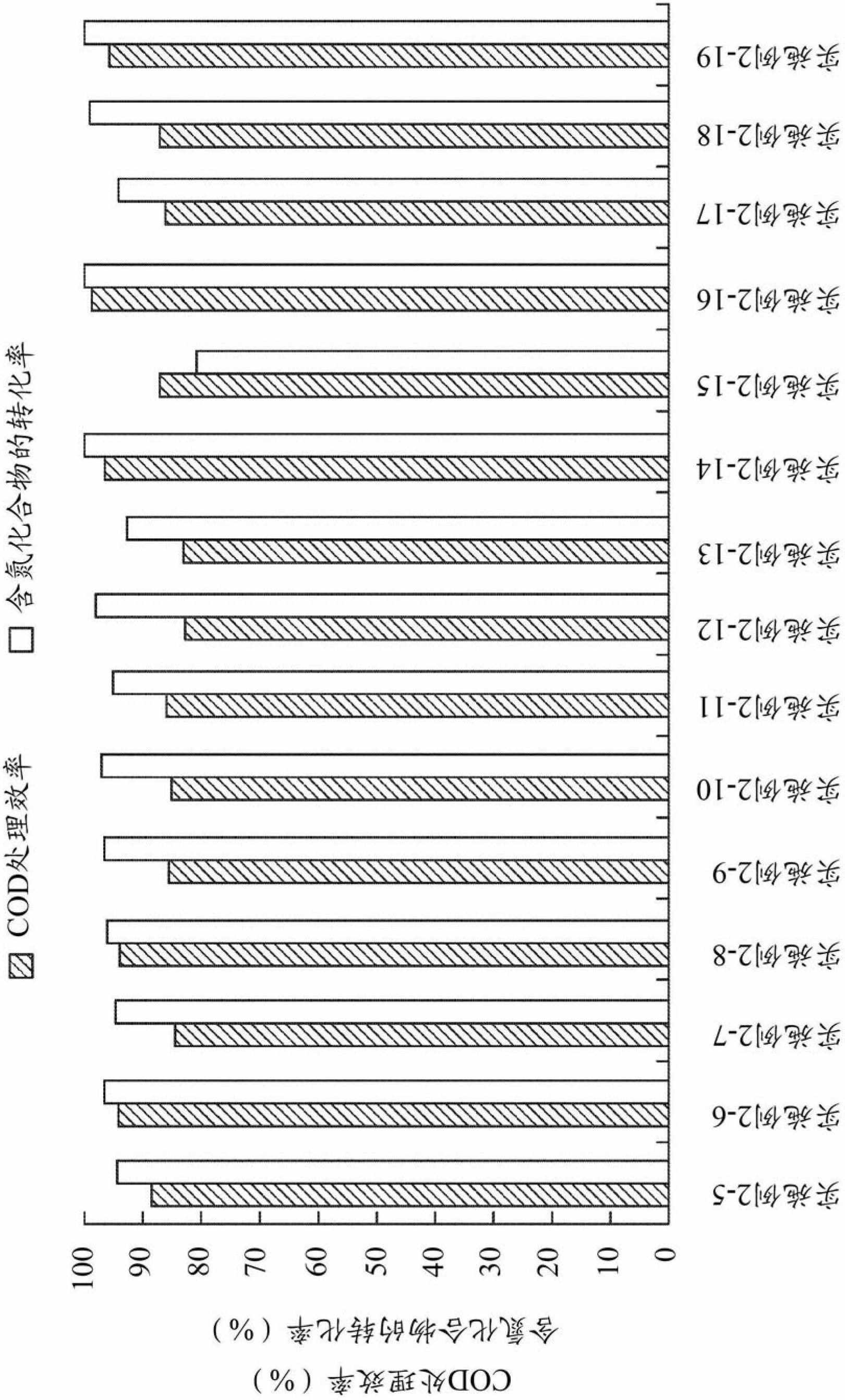

Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

InactiveCN102686521AStabilizationImprove purification effectWater contaminantsCatalyst activation/preparationIridiumWater use

Disclosed are: a catalyst which can exhibit an excellent catalytic activity and excellent durability for a long period in the wet oxidation treatment of waste water; a wet oxidation treatment method for waste water using the catalyst; and a novel method for treating waste water containing a nitrogenated compound, in which a catalyst to be used has a lower catalytic cost, the waste water containing the nitrogenated compound can be treated at high purification performance, and the high purification performance can be maintained. The catalyst for use in the treatment of waste water comprises an oxide of at least one element selected from the group consisting of iron, titanium, silicon, aluminum, zirconium and cerium as a component (A) and at least one element selected from the group consisting of silver, gold, platinum, palladium, rhodium, ruthenium and iridium as a component (B), wherein at least 70 mass% of the component (B) is present in a region positioned within 1000 [mu]m from the outer surface of the component (A) (i.e., the oxide), the component (B) has an average particle diameter of 0.5 to 20 nm, and the solid acid content in the component (A) (i.e., the oxide) is 0.20 mmol / g or more. The waste water treatment method uses a catalyst (a pre-catalyst) which is placed on an upstream side of the direction of the flow of the waste water and can convert the nitrogenated compound contained in the waste water into ammoniacal nitrogen in the presence of an oxidizing agent at a temperature of not lower than 100 DEG C and lower than 370 DEG C under a pressure at which the waste water can remain in a liquid state and a downstream-side catalyst (a post-catalyst) which is placed downstream of the direction of the flow of the waste water and can treat the waste water containing ammoniacal nitrogen.

Owner:NIPPON SHOKUBAI CO LTD

Method for fabricating ruthenium thin layer

InactiveUS20020173054A1Solid-state devicesSemiconductor/solid-state device manufacturingRutheniumThin layer

A method for fabricating a Ru thin layer by using an atomic layer deposition (ALD) technique is disclosed. The method comprises the steps of loading a substrate into a reaction chamber for an atomic layer deposition, adsorbing RuXn (wherein n is 2 or 3), which is a Ru precursor, onto the substrate and injecting a reductive reaction gas into the reaction chamber.

Owner:SK HYNIX INC

Heteroleptic, dual tridentate ru(II) complexes as sensitizers for dye-sensitized solar cells

InactiveUS20120073660A1Improve stabilityImprove photoelectric conversion efficiencyRuthenium organic compoundsElectrolytic capacitorsPhotosensitizerRuthenium

Photosensitizers having a formula of RuL1L2 (1) are provided, wherein Ru is ruthenium; L1 and L2 are heterocyclic tridentate ligands. L1 has a formula of (2), and L2 has a formula of G1G2G3 (3), wherein G1 and G3 are selected from the group consisting of formulae (4) to (7), and G2 is selected from the group consisting of formulae (7) and (8). The above-mentioned photosensitizers are suitable to be used as sensitizers for fabrication of high efficiency dye-sensitized solar cells.

Owner:NATIONAL TSING HUA UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com