Patents

Literature

1002 results about "Cyclic Olefins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyclic olefin copolymer (COC) is an amorphous polymer made by several polymer manufacturers. COC is a relatively new class of polymers as compared to commodities such as polypropylene and polyethylene.

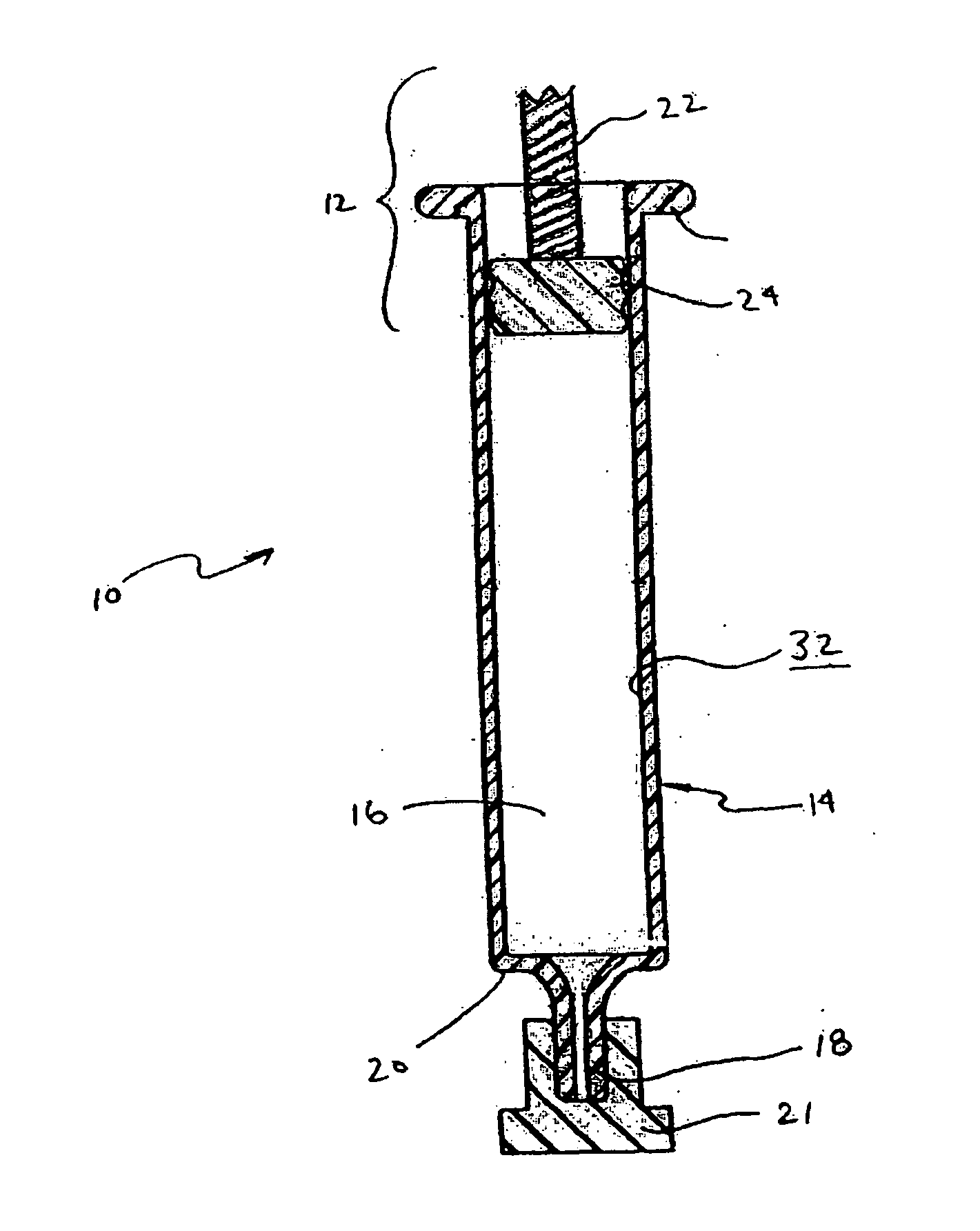

Low extractable, thermoplastic syringe and tip cap

InactiveUS20050075611A1Low extractable levelWithout loss of flexible and resilient propertyAmpoule syringesLavatory sanitoryThermoplastic elastomerPrefilled Syringe

A prefilled syringe and syringe assembly having a syringe and a tip cap are produced from materials that do not interfere with the substance contained in the syringe and enable long term storage. The tip cap is made from a blend of a cyclic olefin polymer or copolymer and a thermoplastic elastomer. The thermoplastic elastomer is blended with the cyclic olefin copolymer in an amount so that the normally stiff and hard cyclic olefin copolymer is flexible and resilient to effectively seal and couple to the tip of a prefilled syringe.

Owner:BECTON DICKINSON & CO

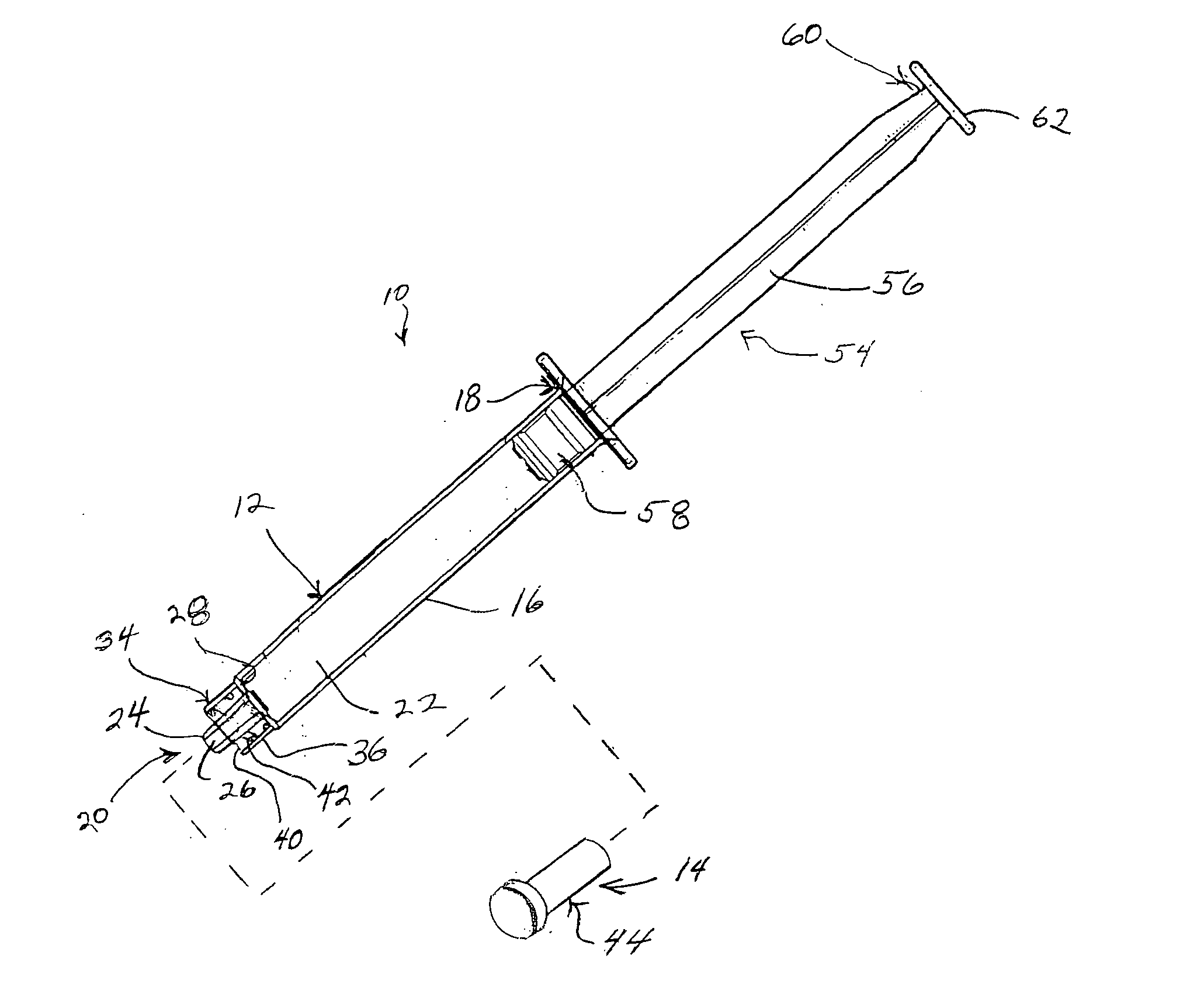

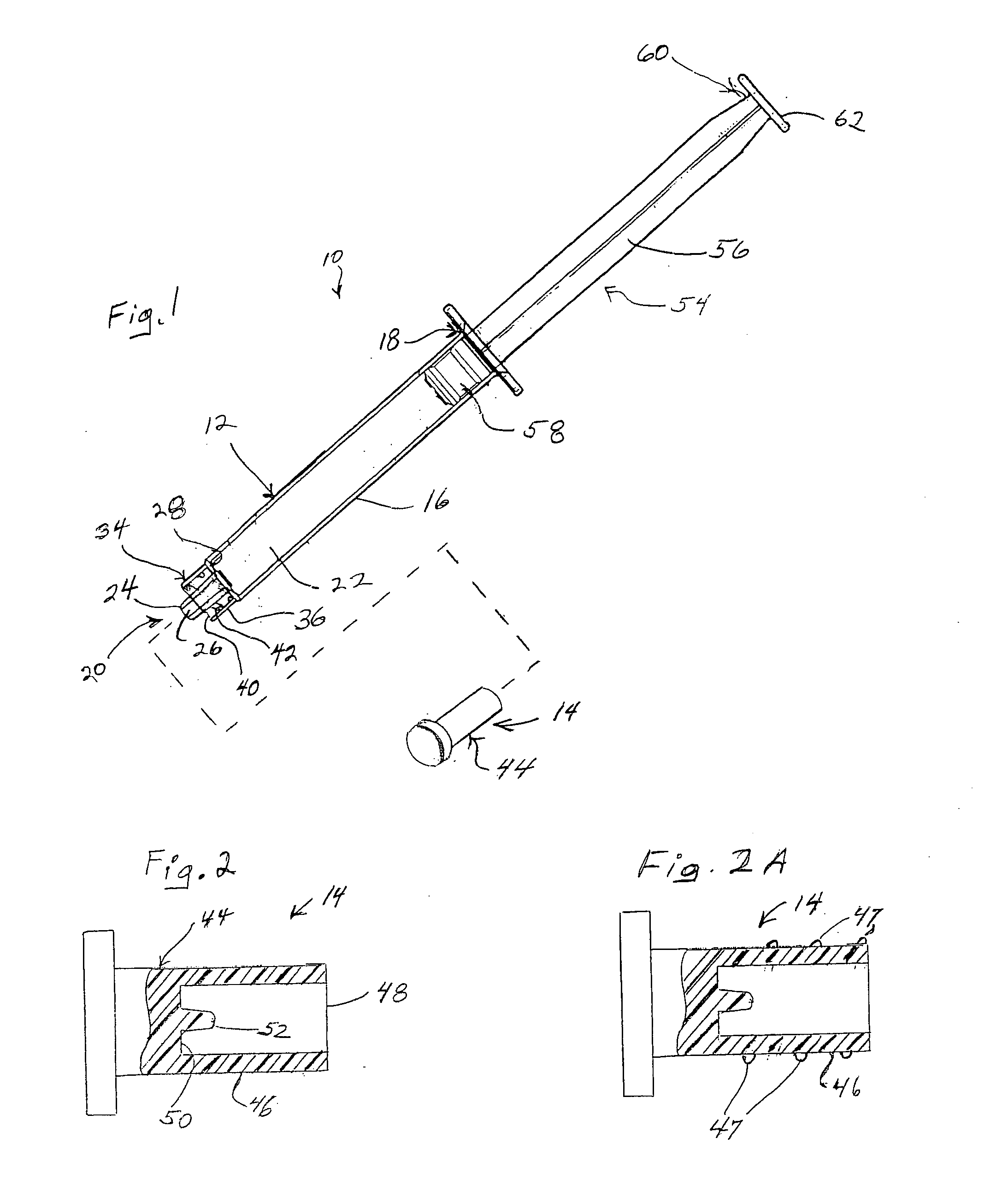

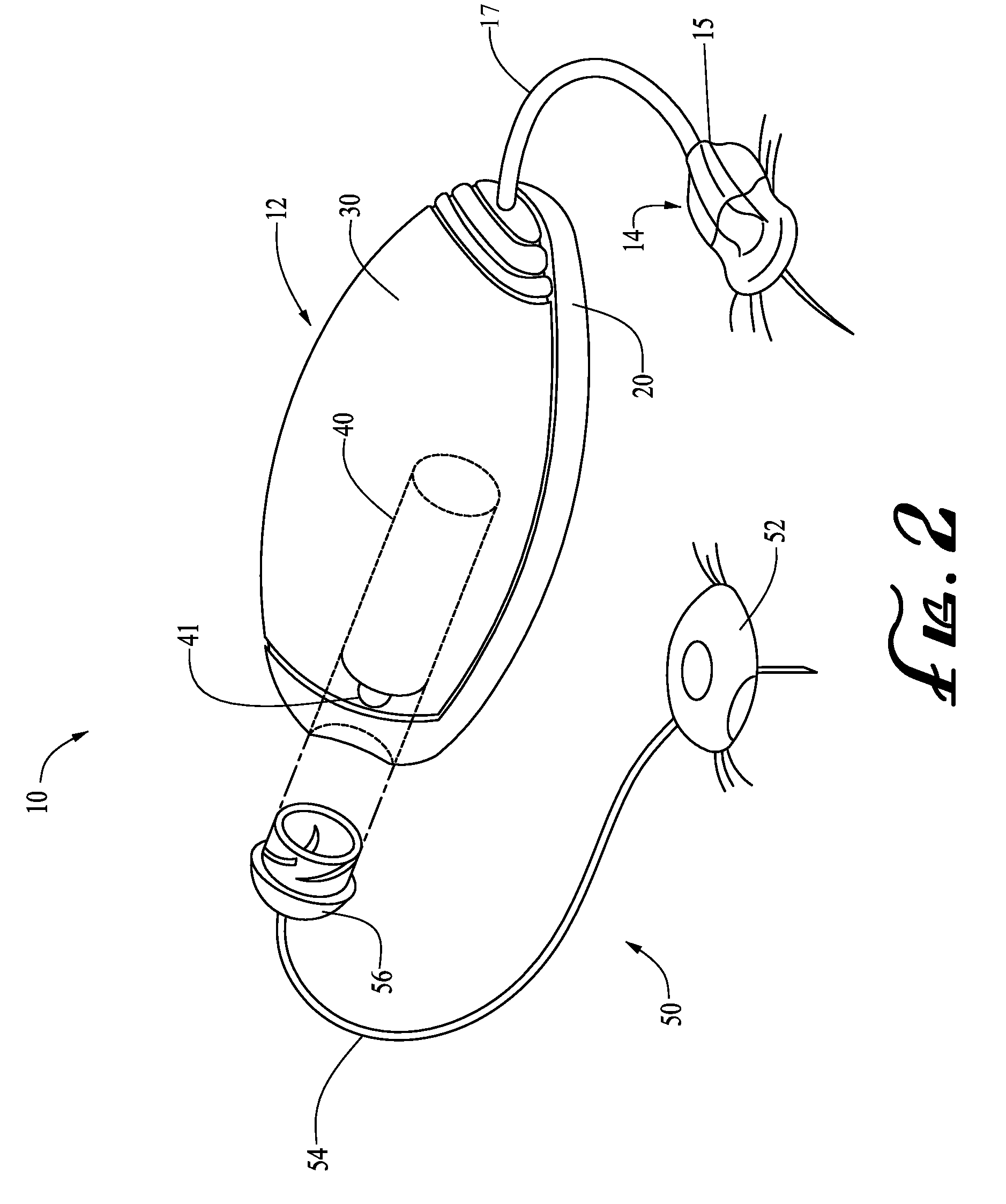

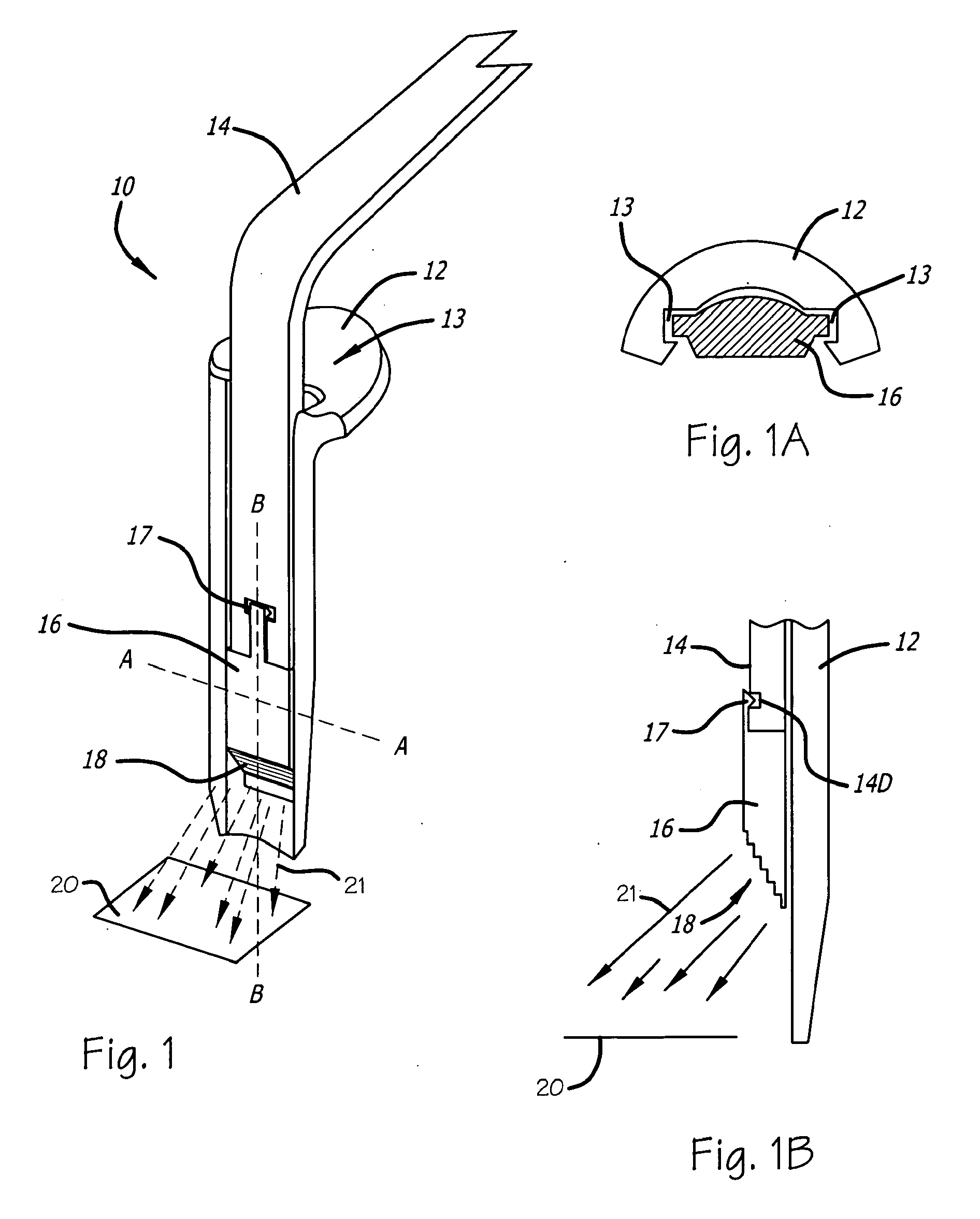

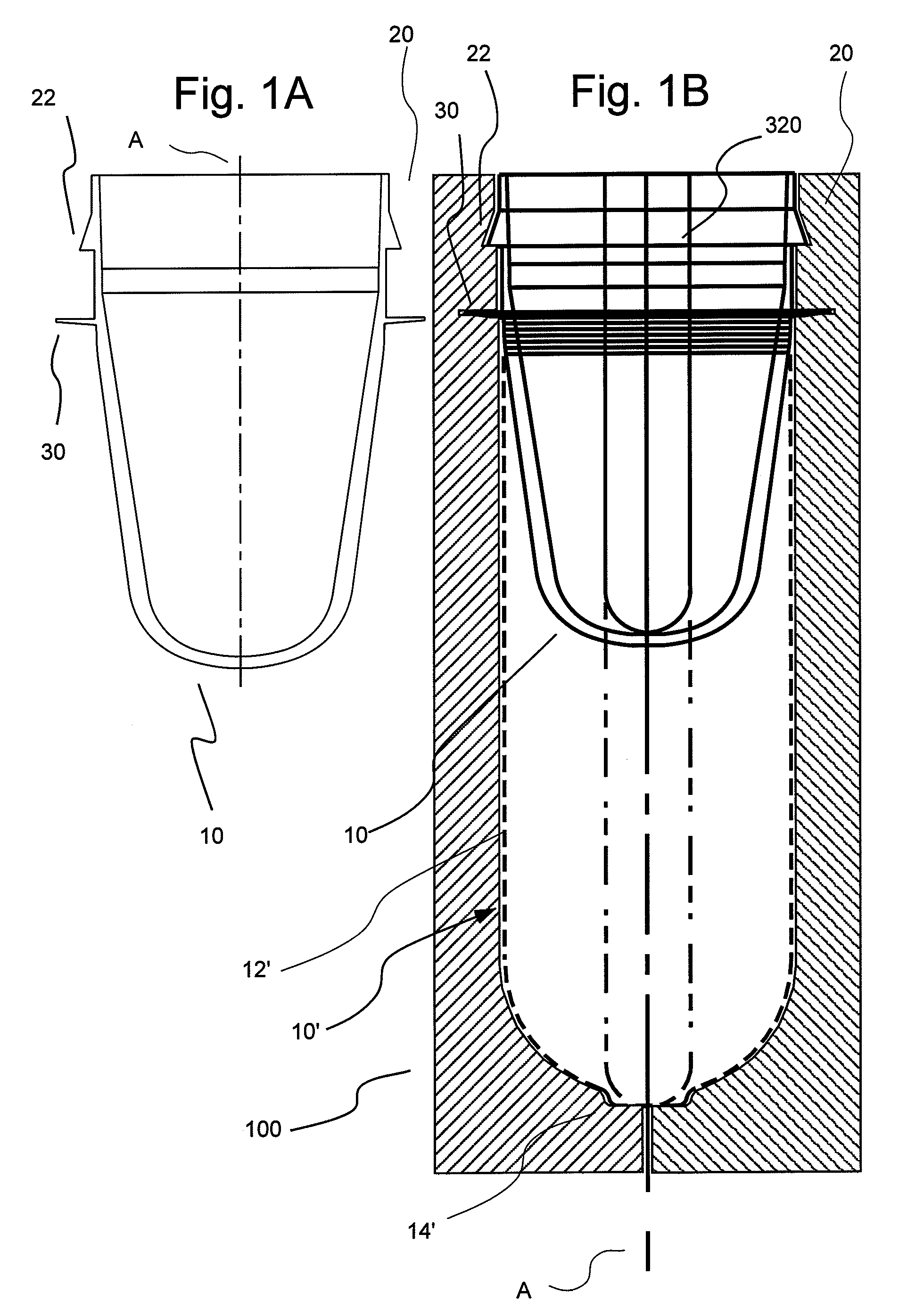

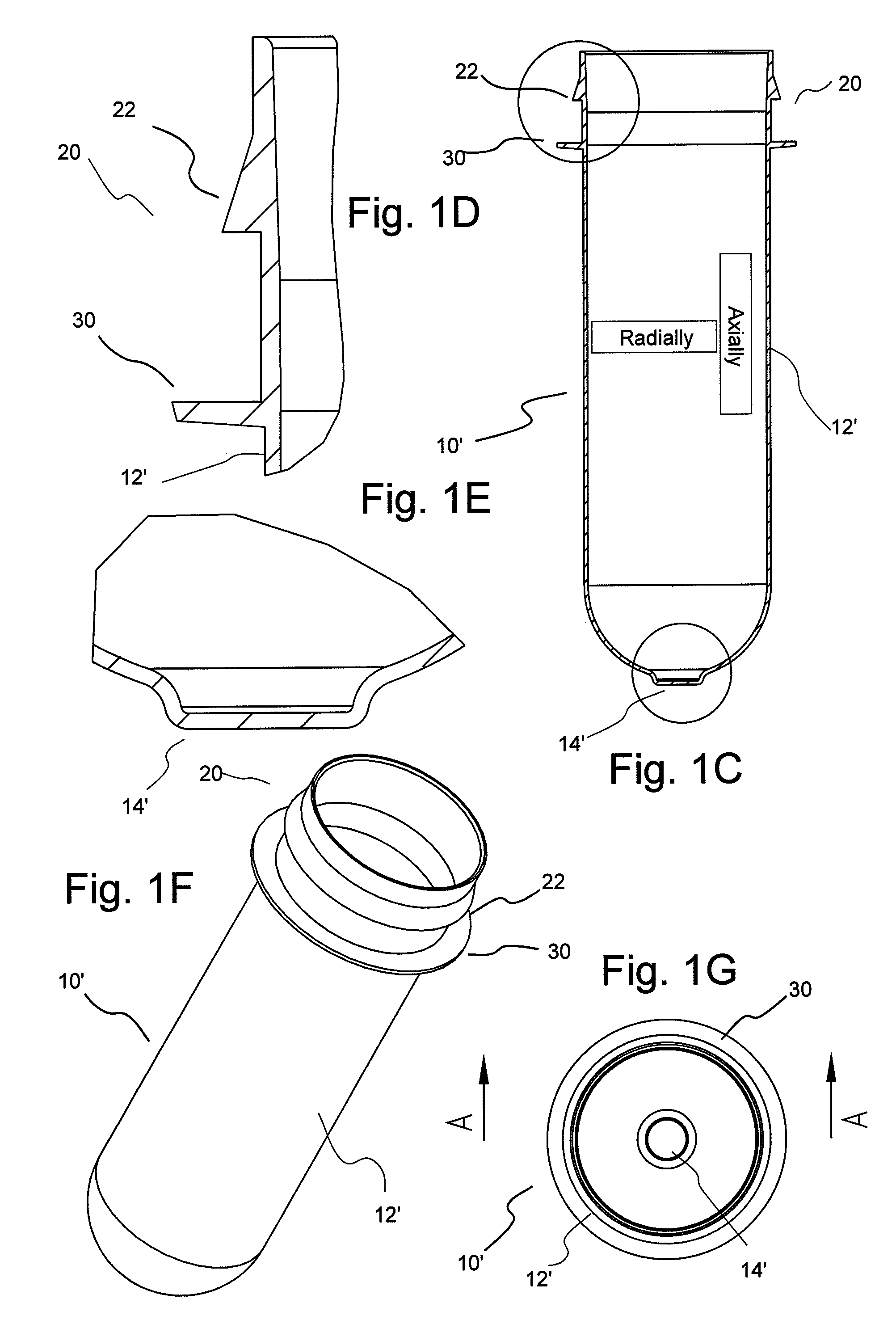

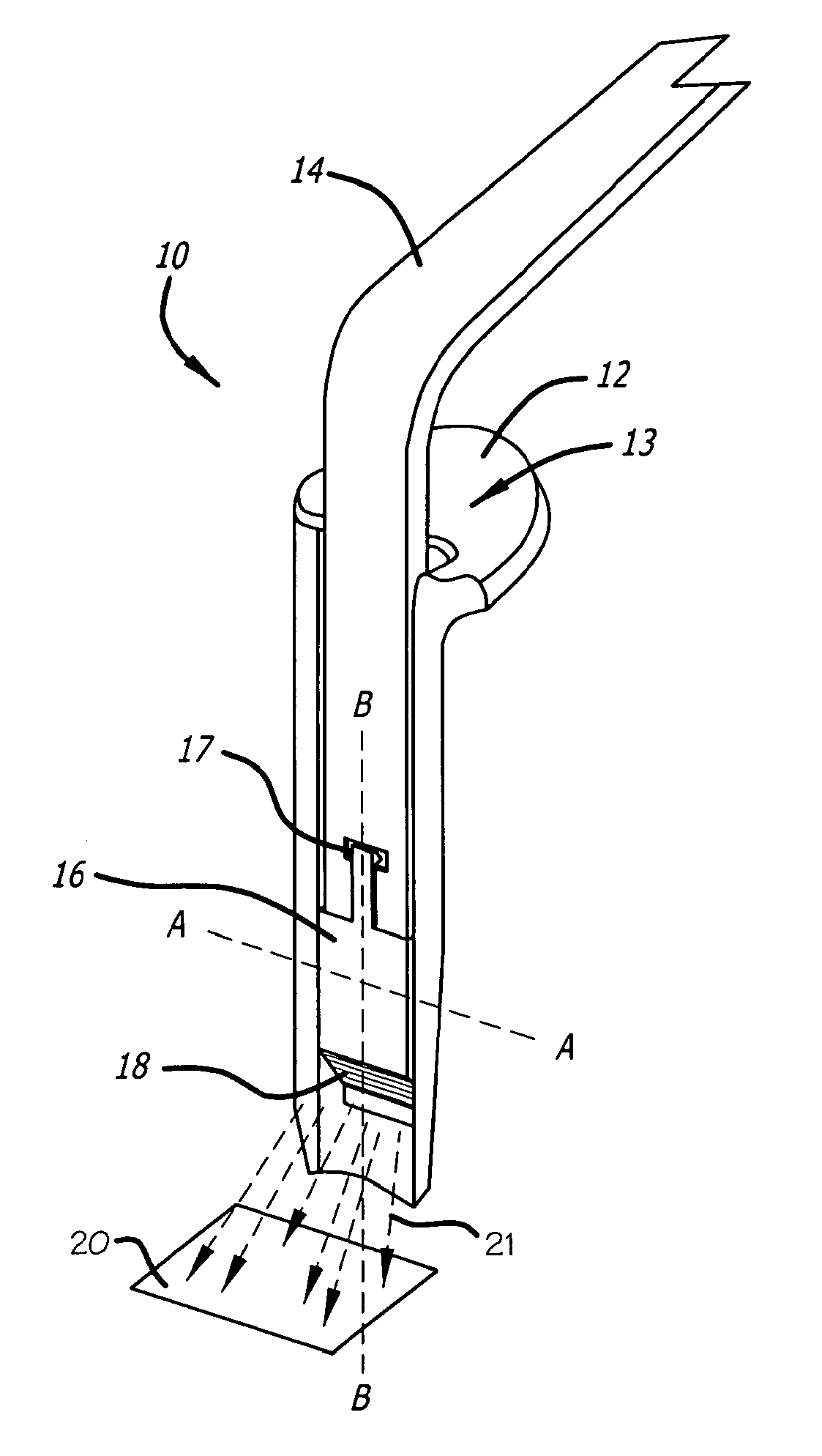

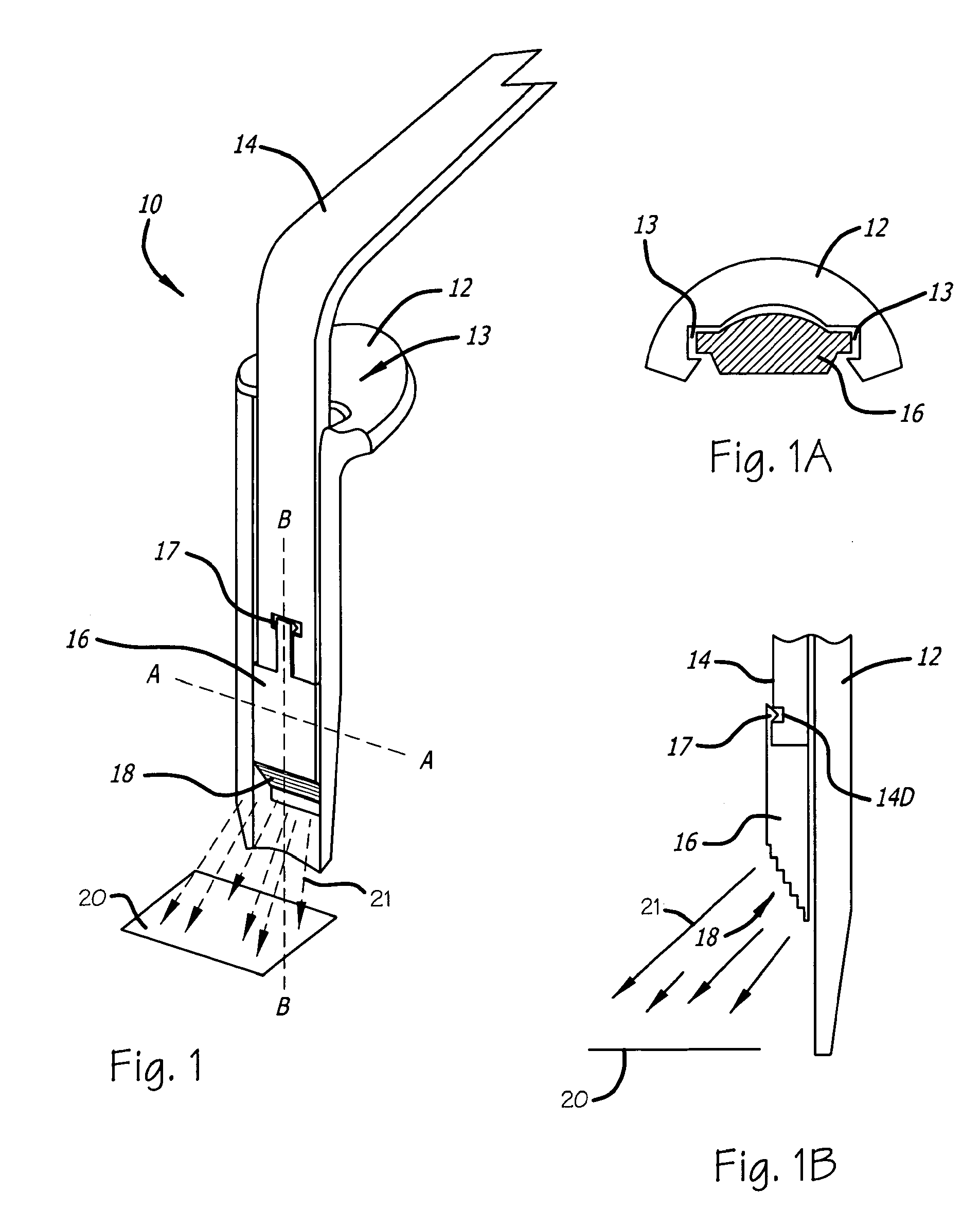

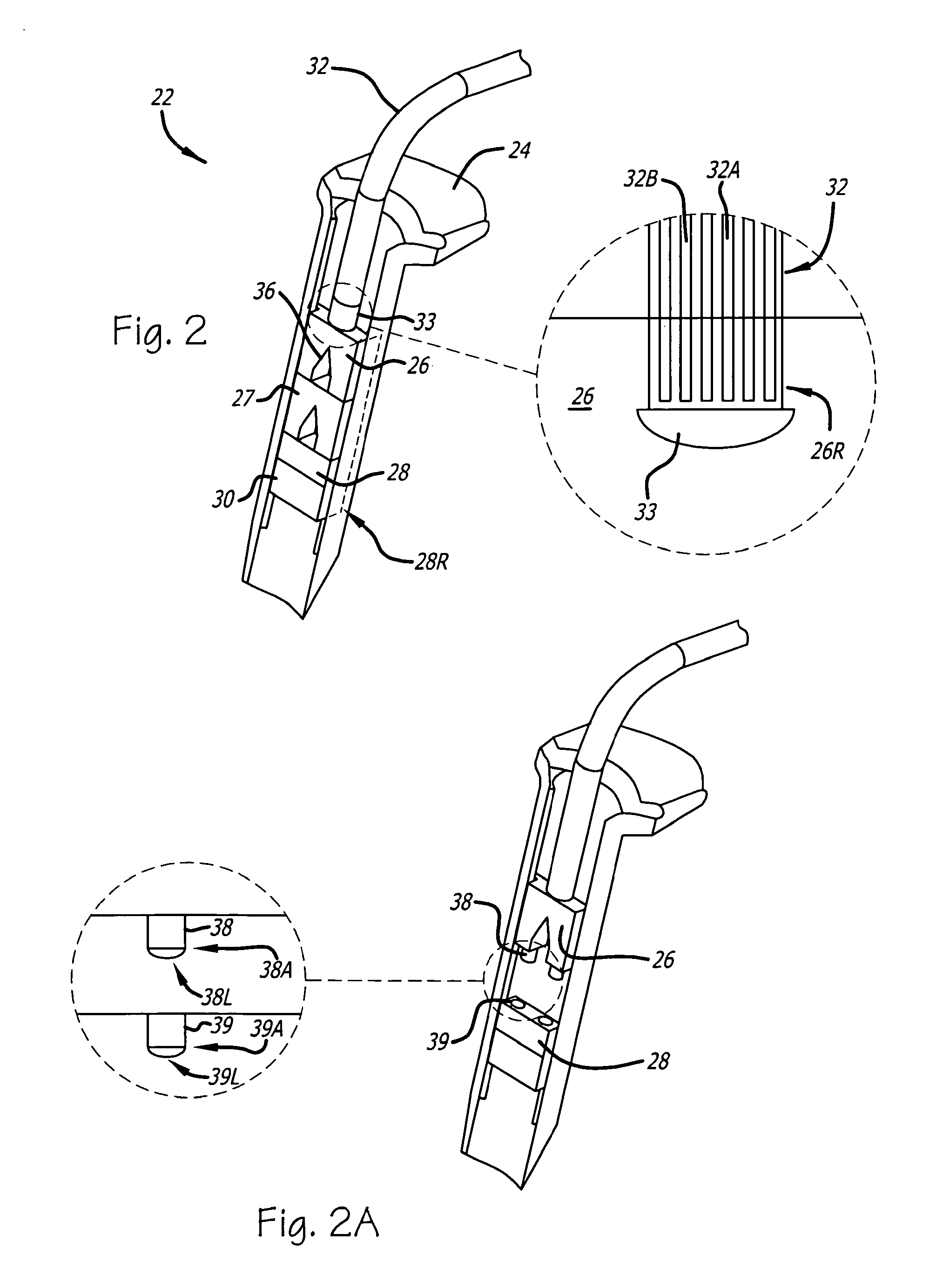

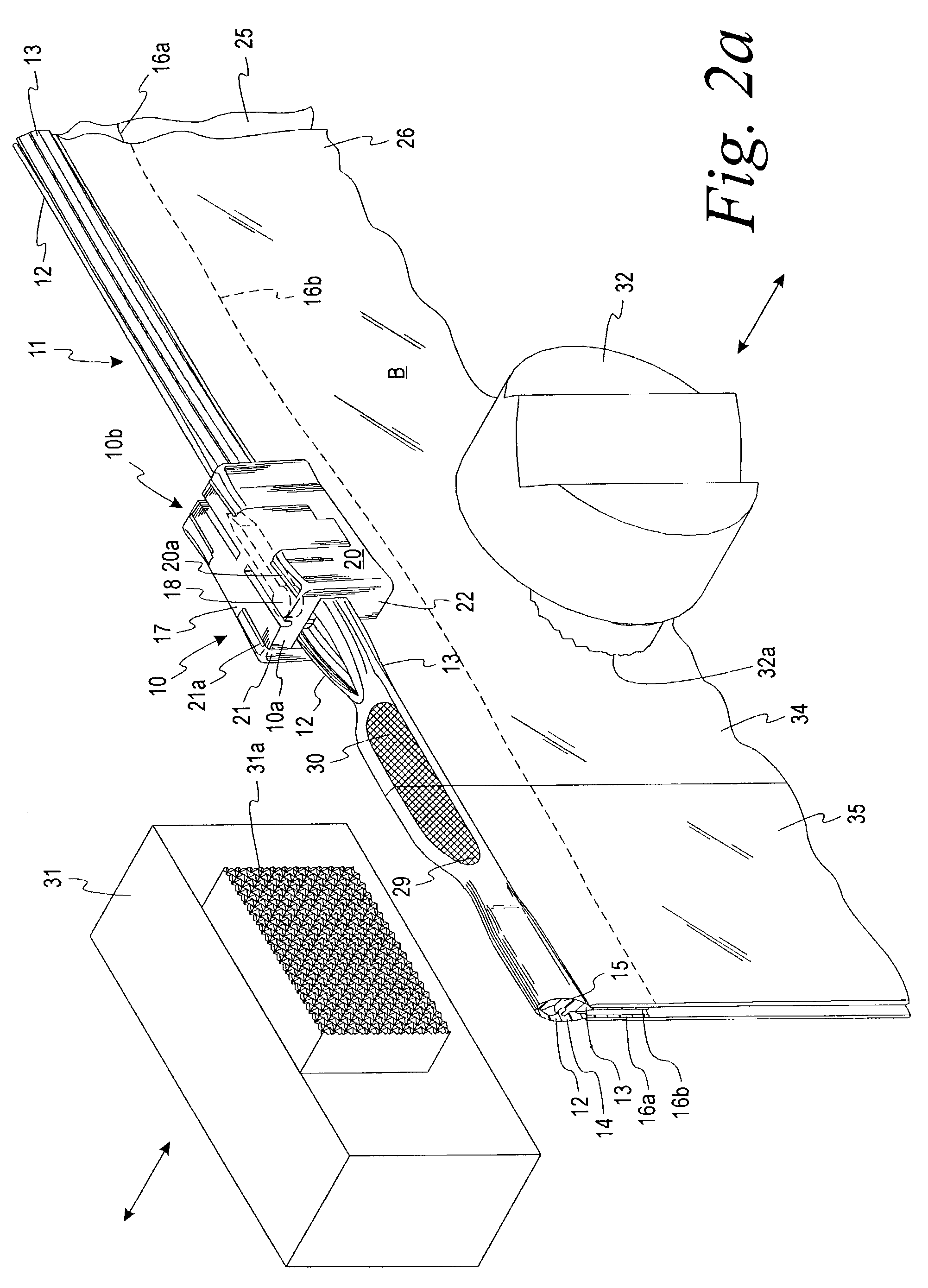

Piston assembly for syringe

InactiveUS20050010175A1Reduce connectionsReduce chanceIntravenous devicesEngineeringParylene coating

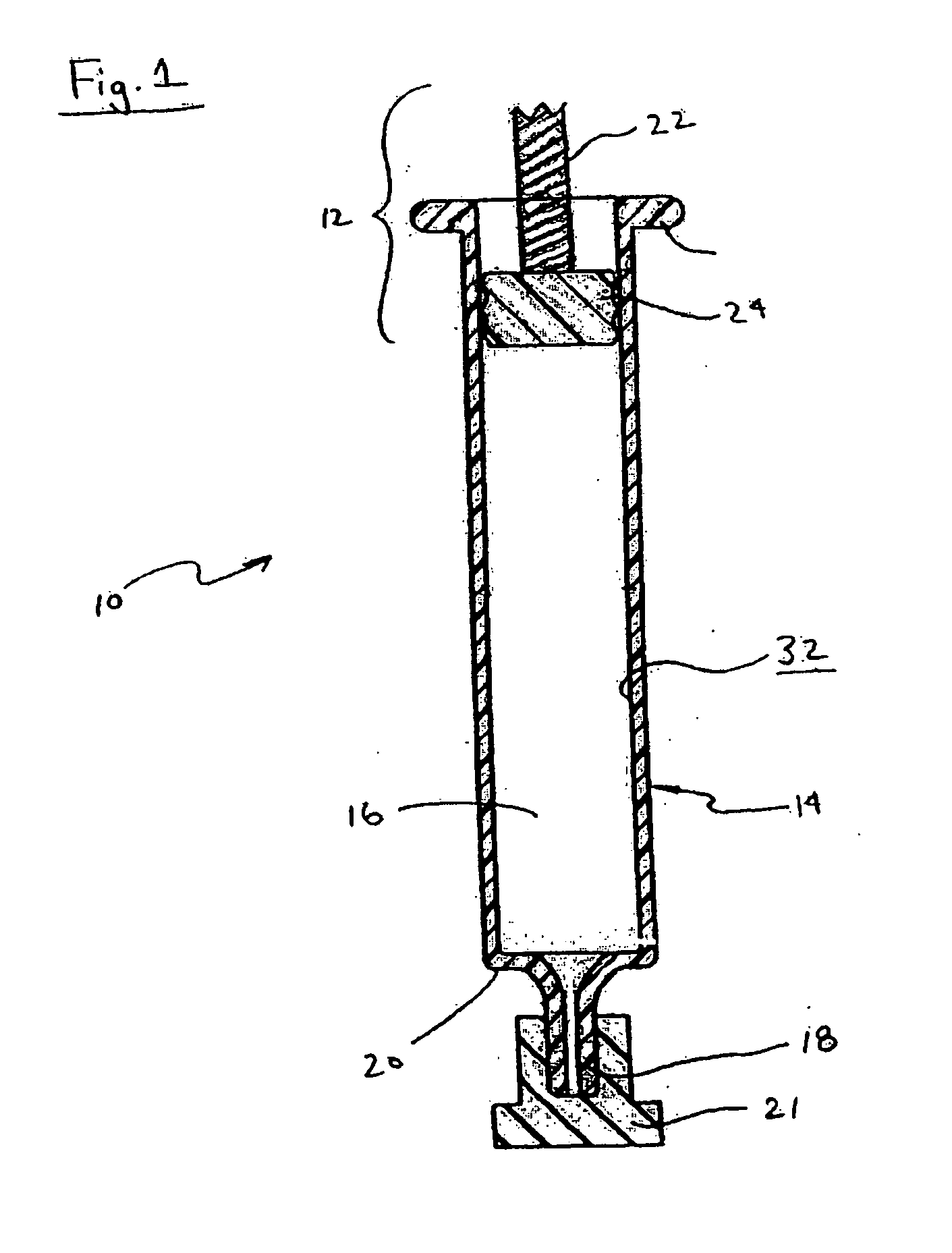

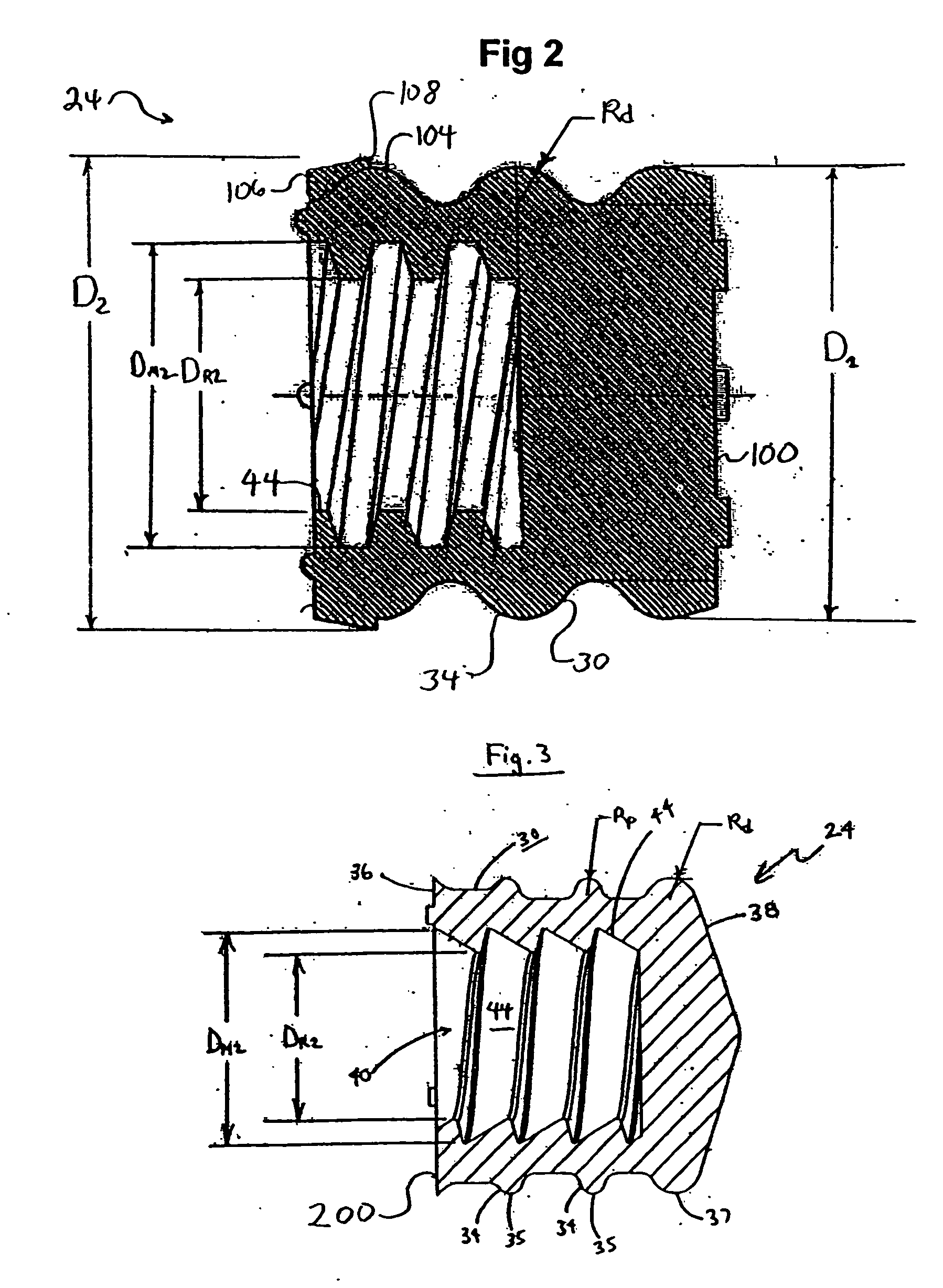

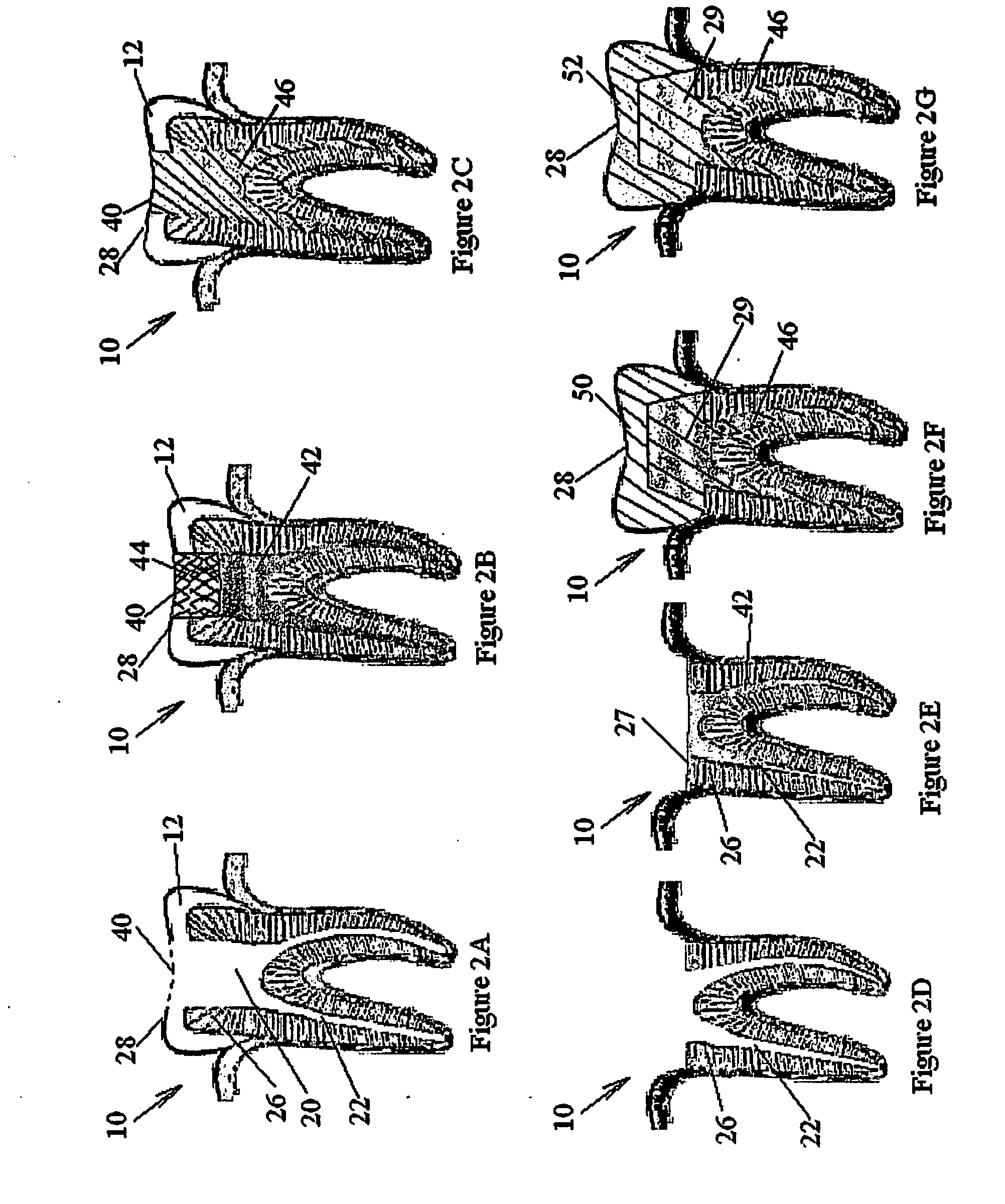

A piston assembly (10) for a flowable materials container having a barrel (14) defining a fluid containing chamber (16). The barrel (14) is made of a body of a cyclic olefin containing polymer or a bridged polycyclic olefin containing polymer. An elastomeric piston (24) is slidably attached to the barrel (14) and provides a seal of the chamber. The piston (24) has a parylene coating on an outer surface thereof to reduce the necessary break away force. A plunger (22) is also provided and has a second mating member (42) removably connecting the plunger to a first mating member (44) of the piston. The first mating member (44) has a series of threads having a major diameter and a minor diameter, and the second mating member (42) has a series of threads having a major diameter and a minor diameter. The major and minor diameters of the second mating members (42) is appreciably smaller than the major and minor diameters of the other of the first mating member (44) to provide ease of connection.

Owner:BAXTER INT INC

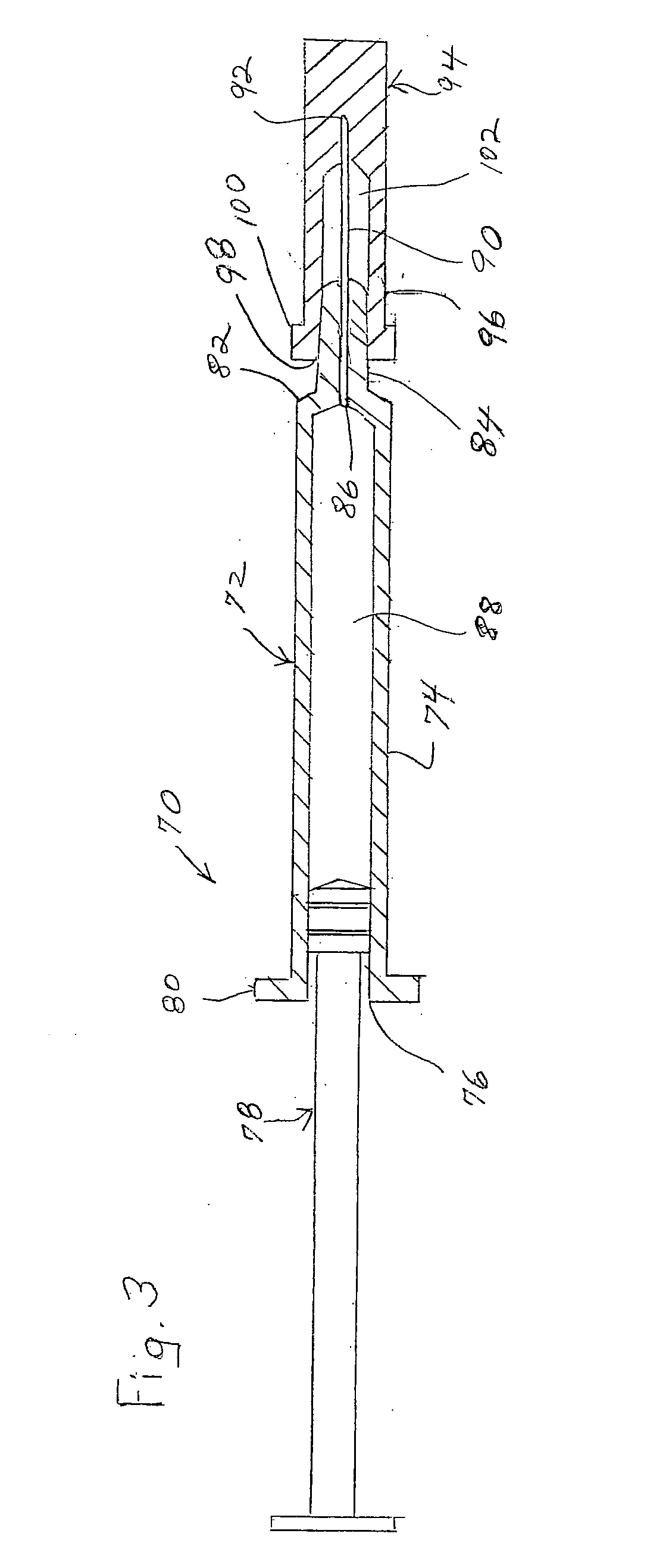

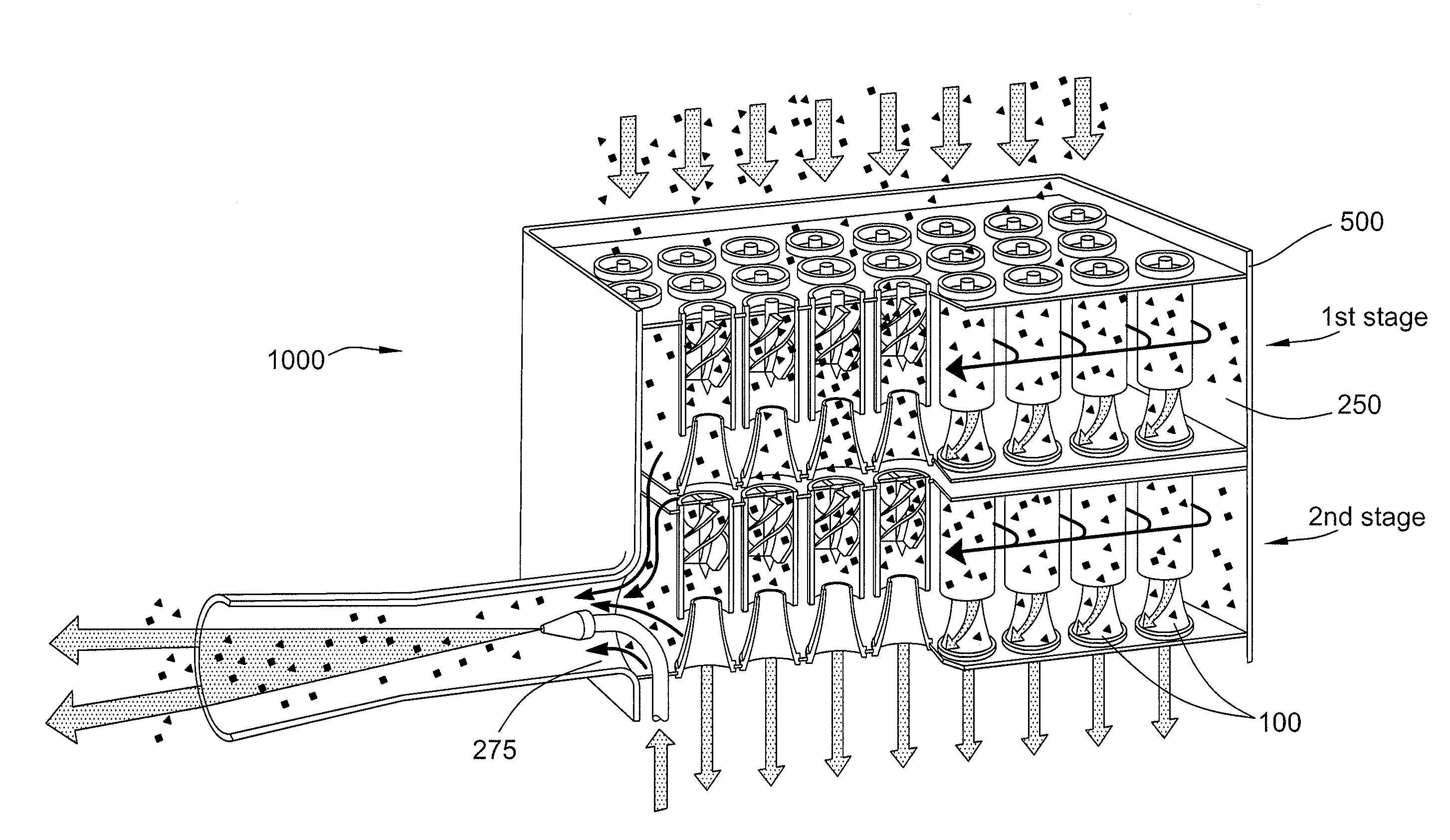

Reservoir barrier layer systems and methods

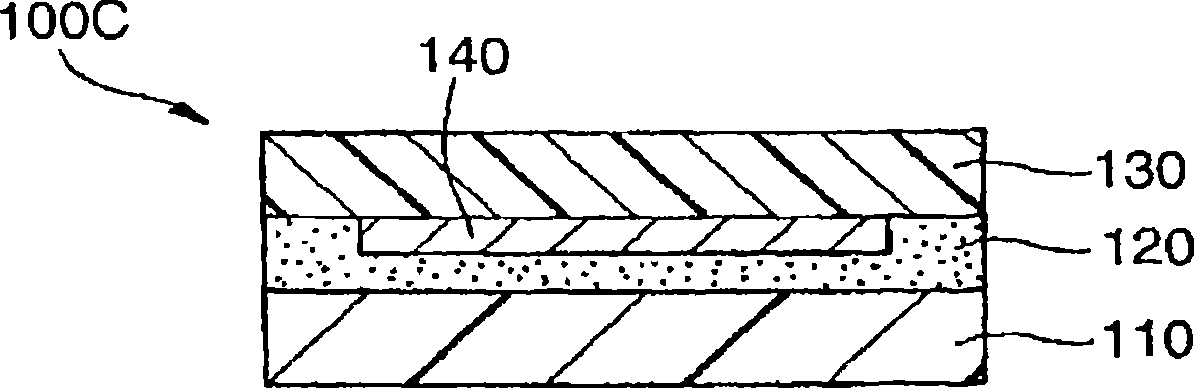

ActiveUS20090259183A1Reduce retentionAmpoule syringesSynthetic resin layered productsCyclic olefin copolymerBiomedical engineering

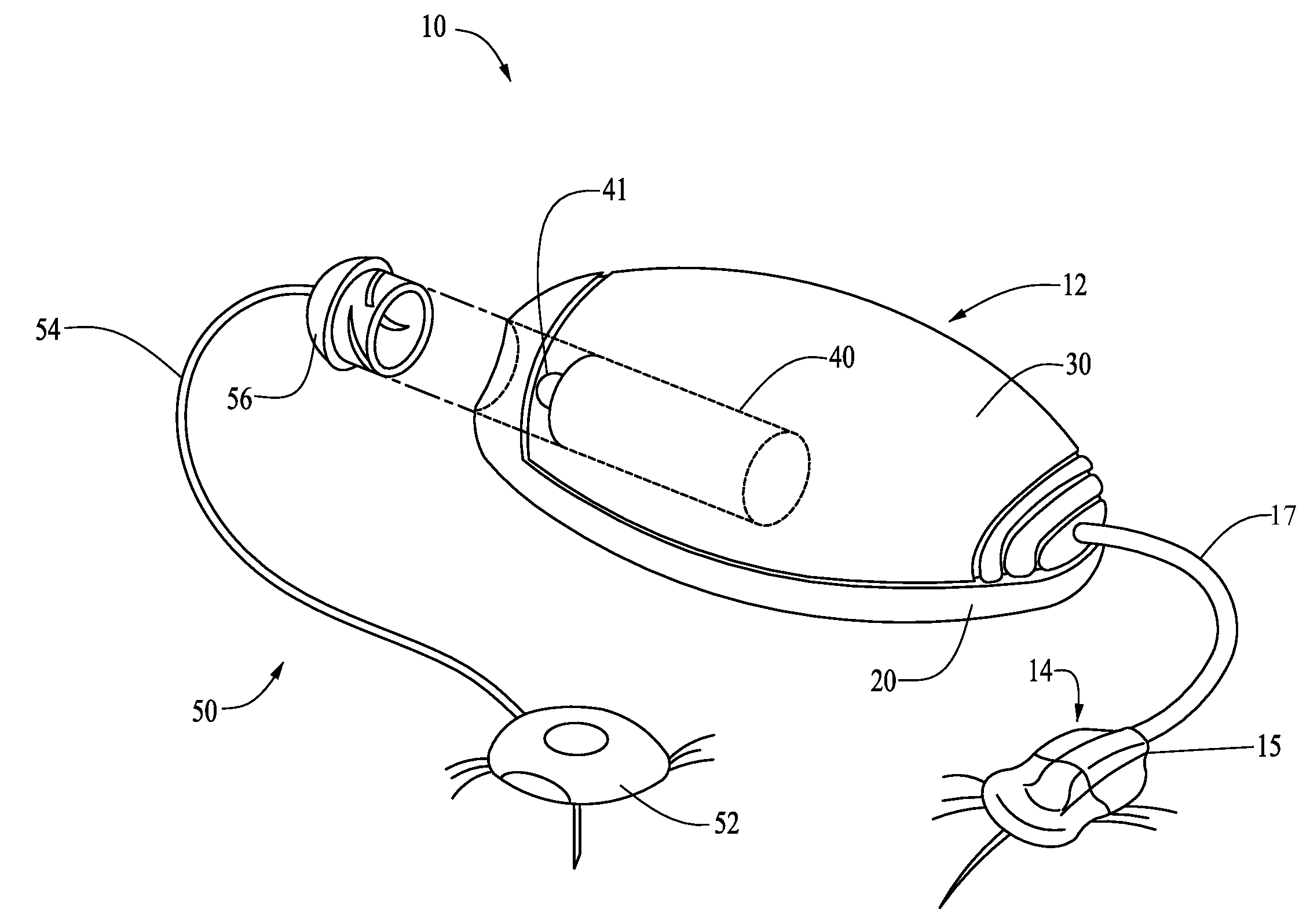

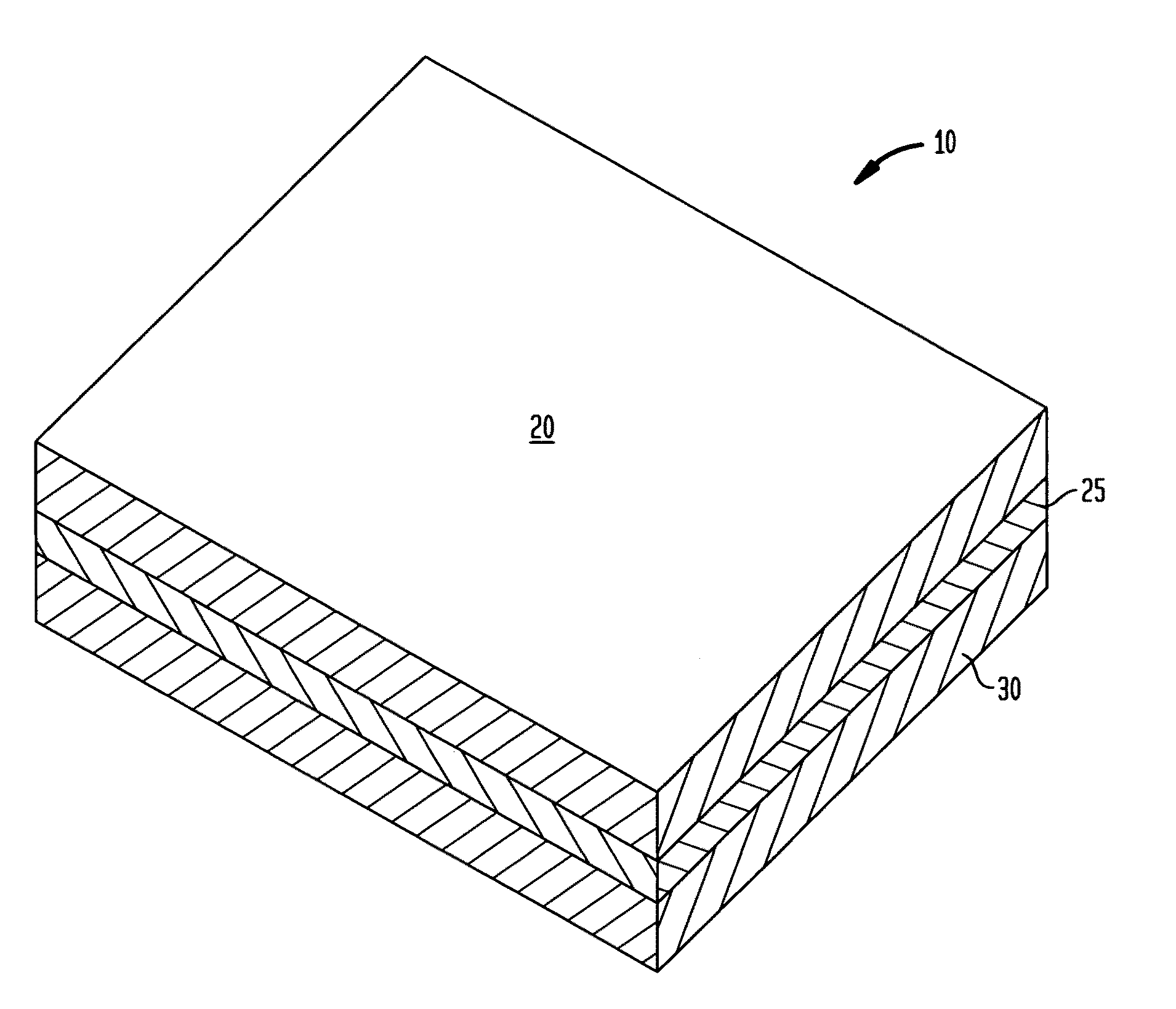

A reservoir and a plunger head contained within may be configured to move relative to each other in response to at least one of the reservoir being detached from a base, the base and / or the reservoir being removed from a packaging, and the base and / or the reservoir being moved relative to each other. A first layer may be configured to define a reservoir, the first layer, which may be made of a material compatible with fluidic media in the reservoir, may be adjacent a second layer for inhibiting a diffusion through the second layer. A first layer that may be less than 0.3 mm and made of a cyclic olefin copolymer may be configured to define a reservoir. A reservoir may be defined by a wall made of a cyclic olefin copolymer and the wall may be for substantially preventing light from passing through the reservoir.

Owner:MEDTRONIC MIMIMED INC

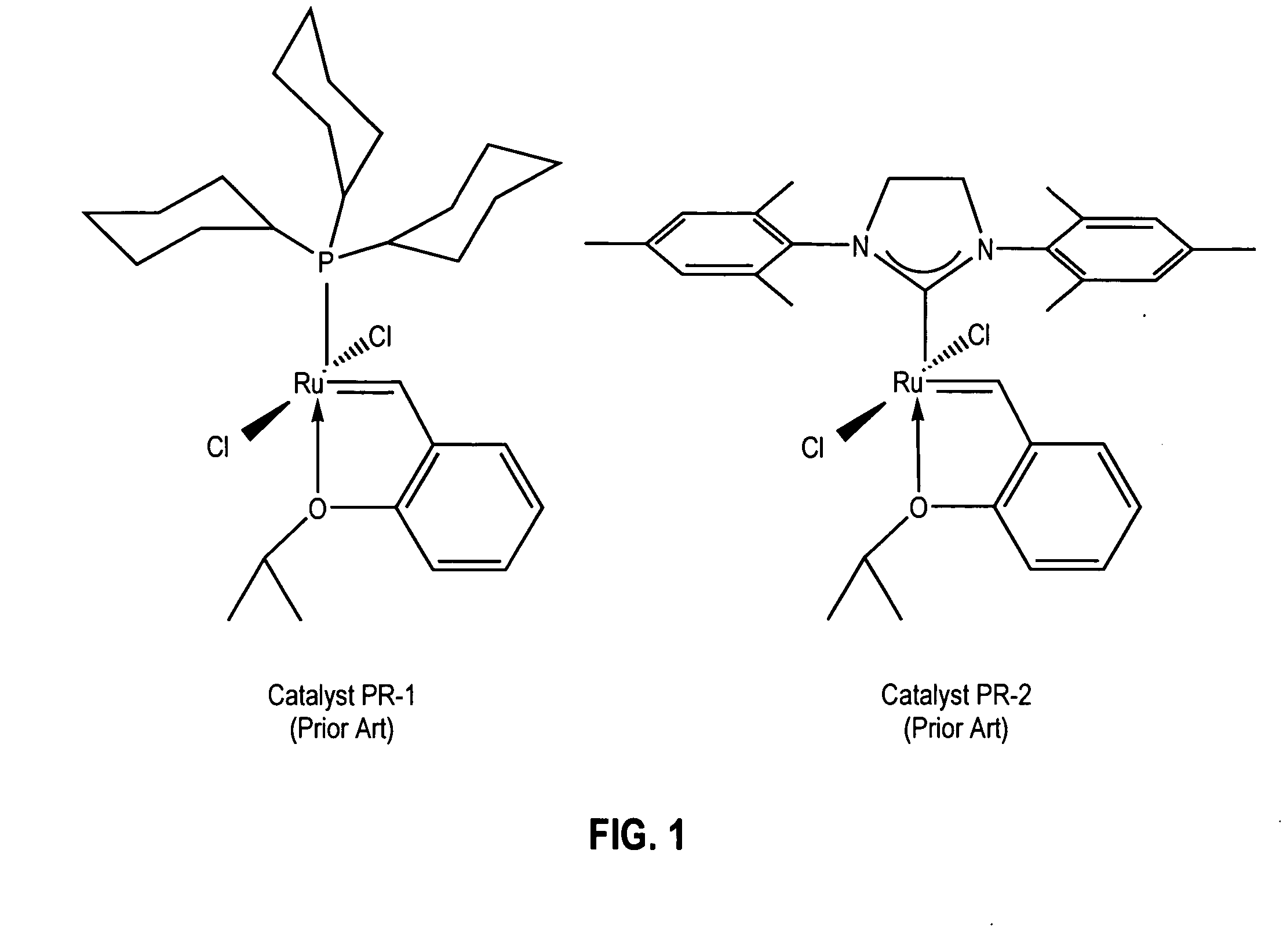

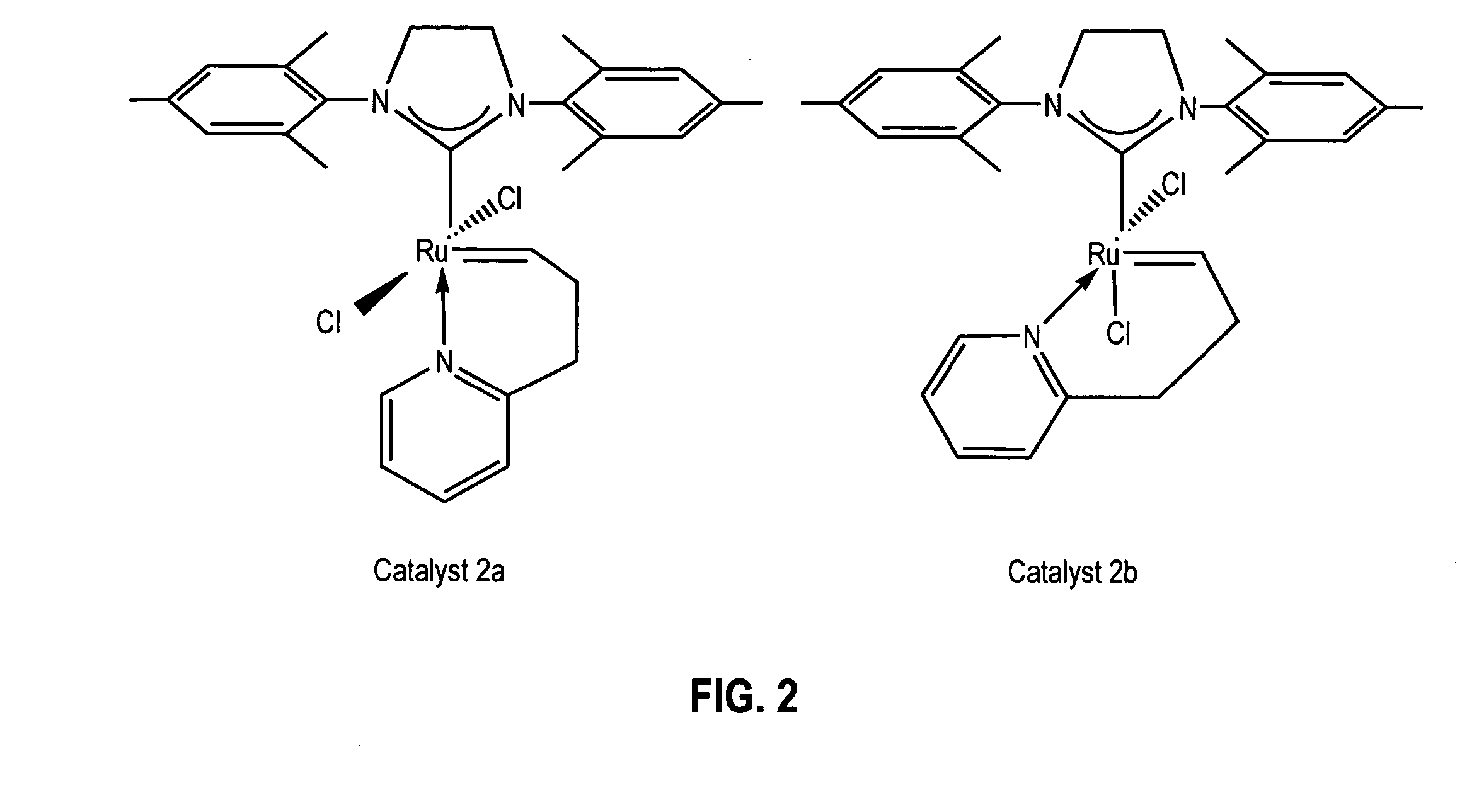

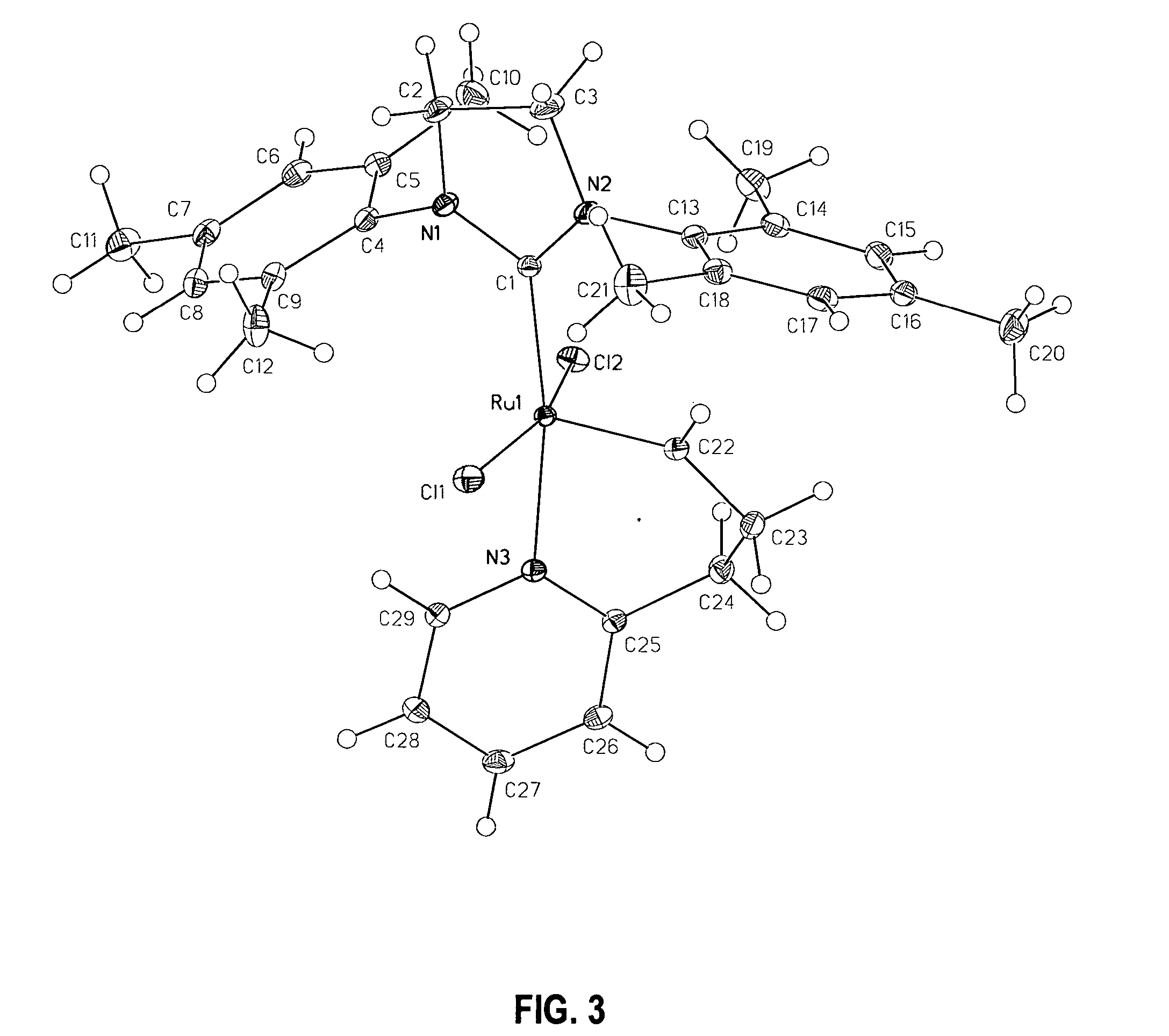

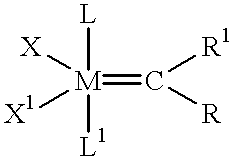

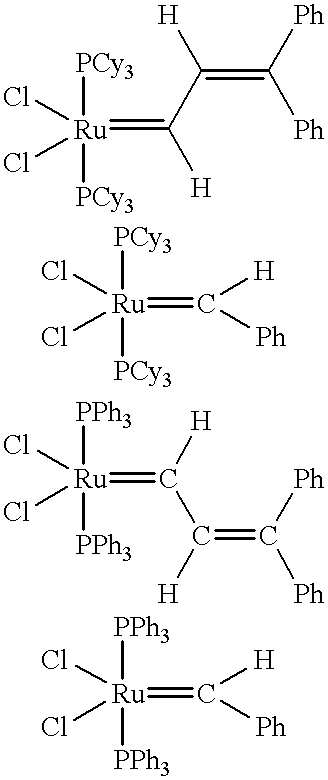

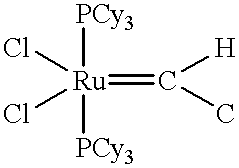

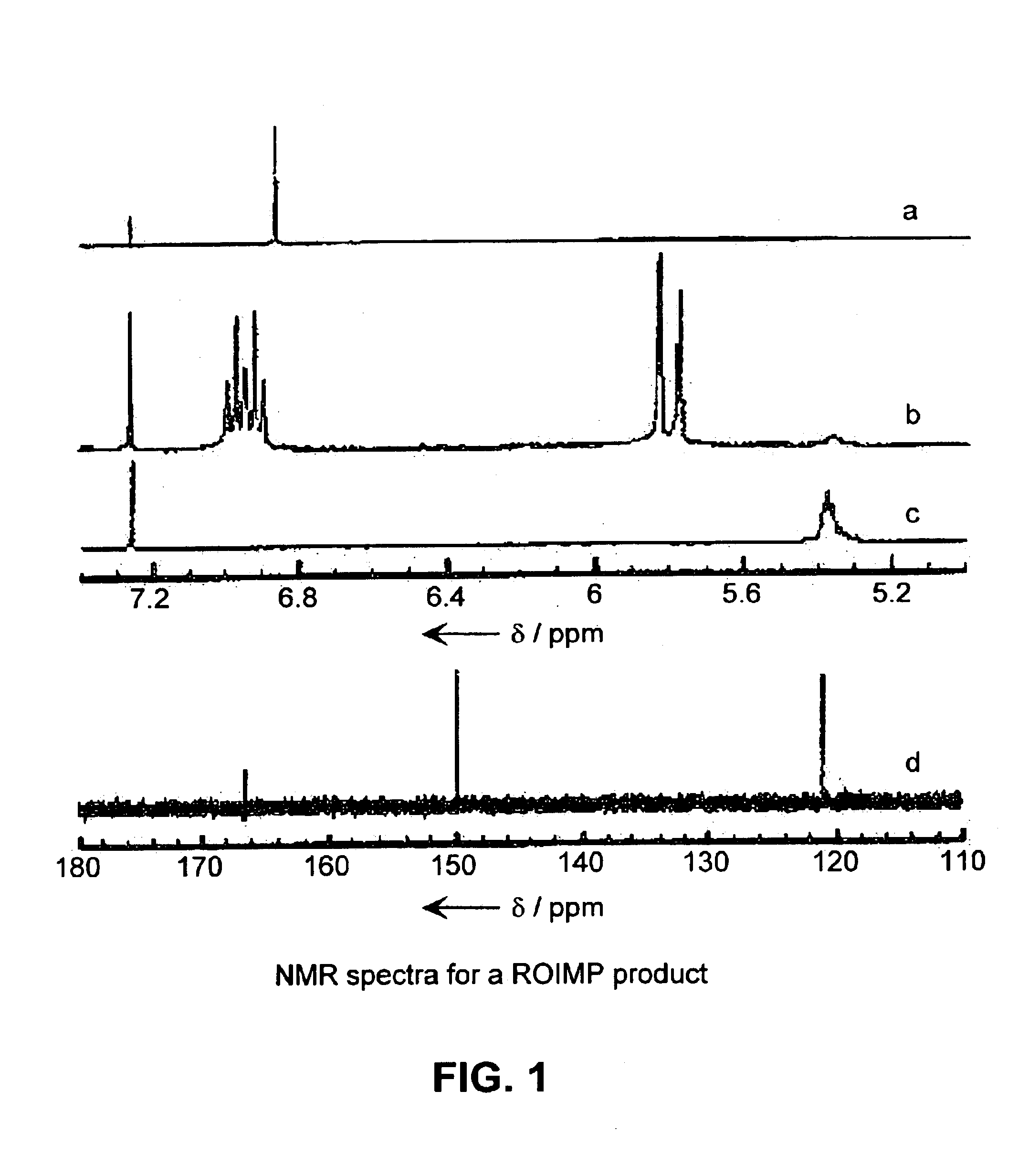

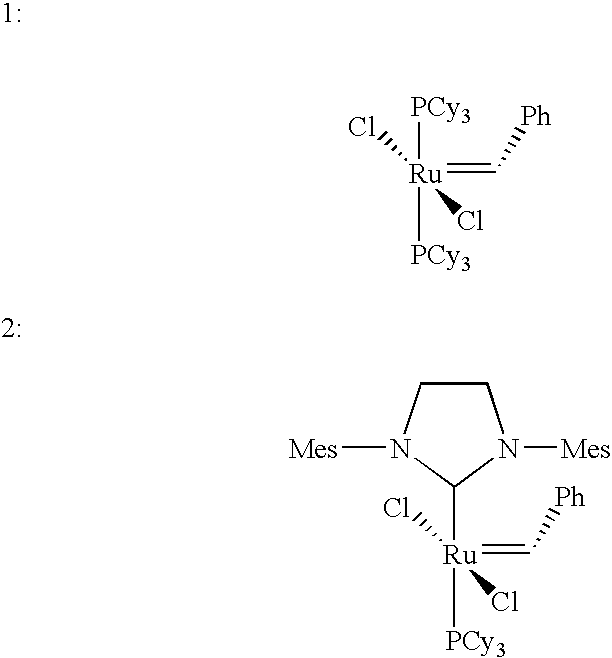

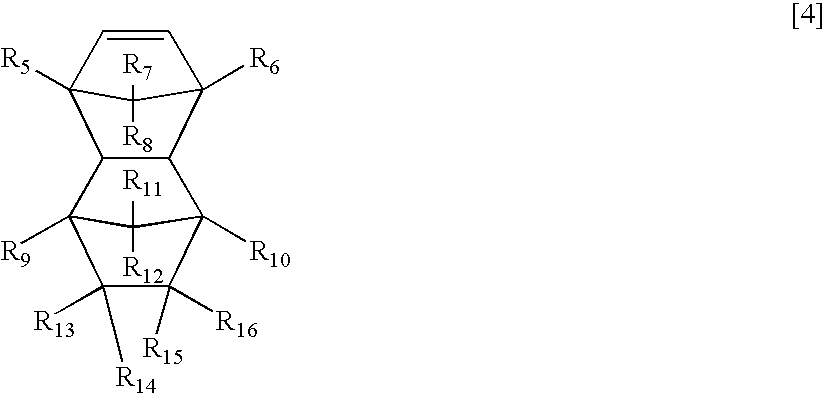

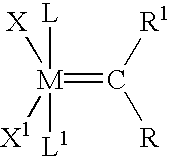

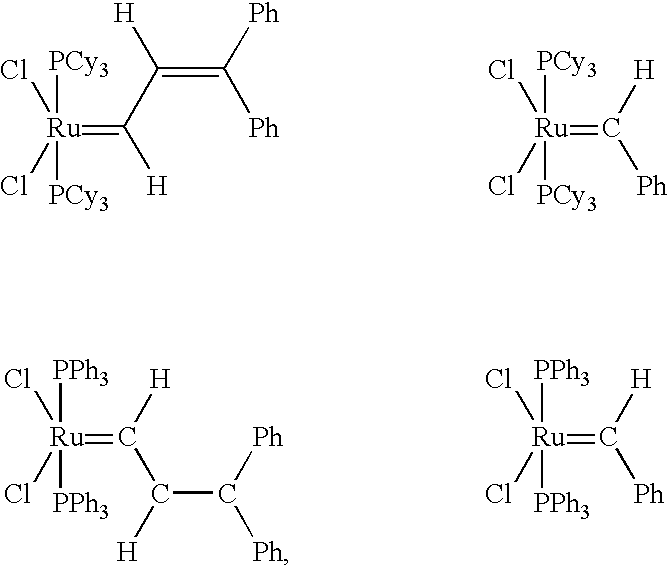

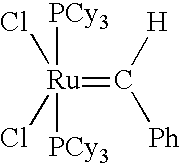

Latent, high-activity olefin metathesis catalysts containing an N-heterocyclic carbene ligand

InactiveUS20050261451A1Ruthenium organic compoundsOrganic compound preparationRing-closing metathesisAlkene

The invention provides novel organometallic complexes useful as olefin metathesis catalysts. The complexes have an N-heterocyclic carbene ligand and a chelating carbene ligand associated with a Group 8 transition metal center. The molecular structure of the complexes can be altered so as to provide a substantial latency period. The complexes are particularly useful in catalyzing ring closing metathesis of acyclic olefins and ring opening metathesis polymerization of cyclic olefins.

Owner:CALIFORNIA INST OF TECH +1

Metathesis polymerizered olefin composites including sized reinforcement material

A reinforced polyolefin article is provided which includes a sized reinforcement material incorporated in the article. The article may be prepared by polymerizing a cyclic olefin monomer in the presence of the sizing agent and a metathesis polymerization catalyst which includes ruthenium or osmium.

Owner:ABELL III NELSON D +1

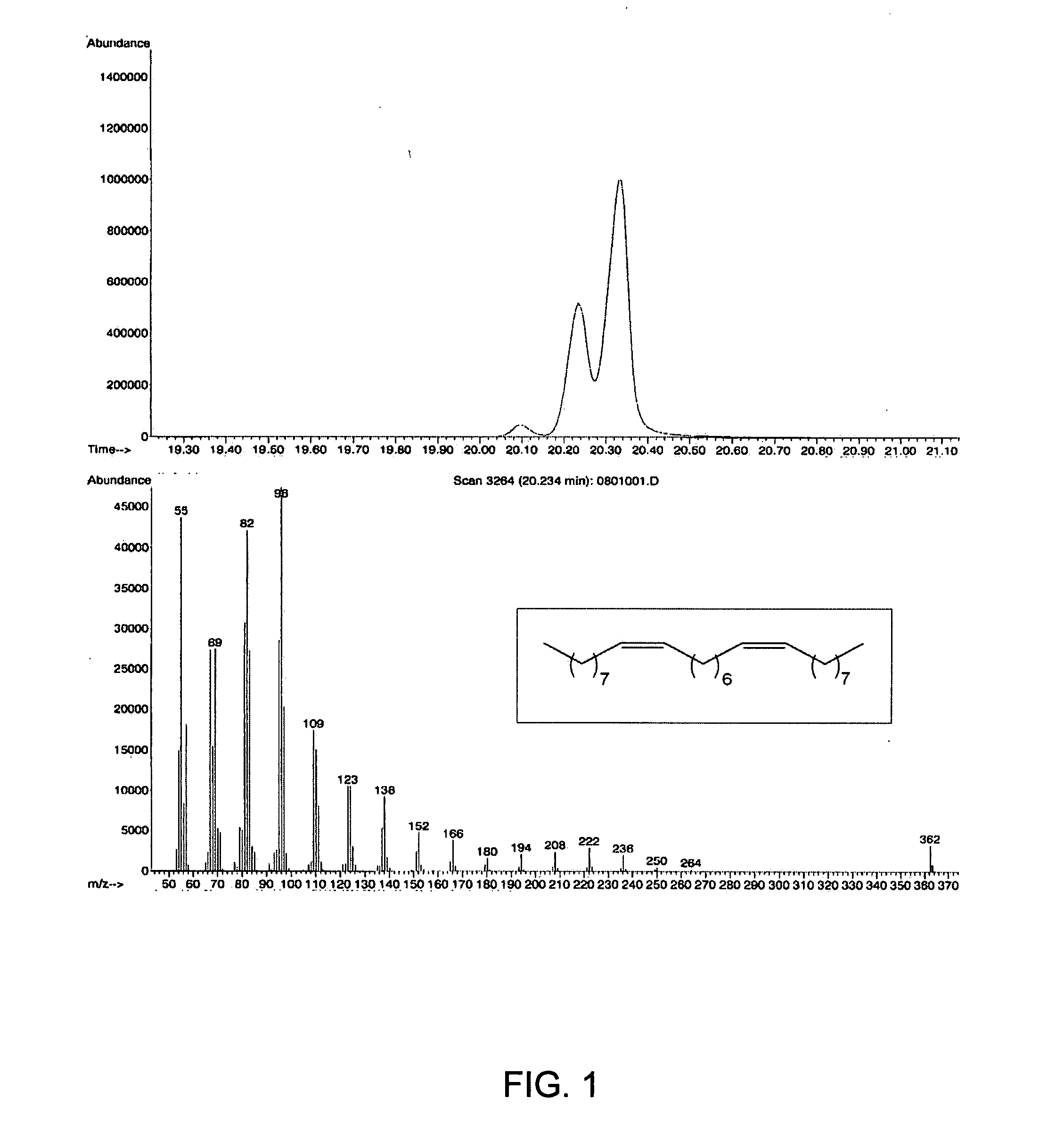

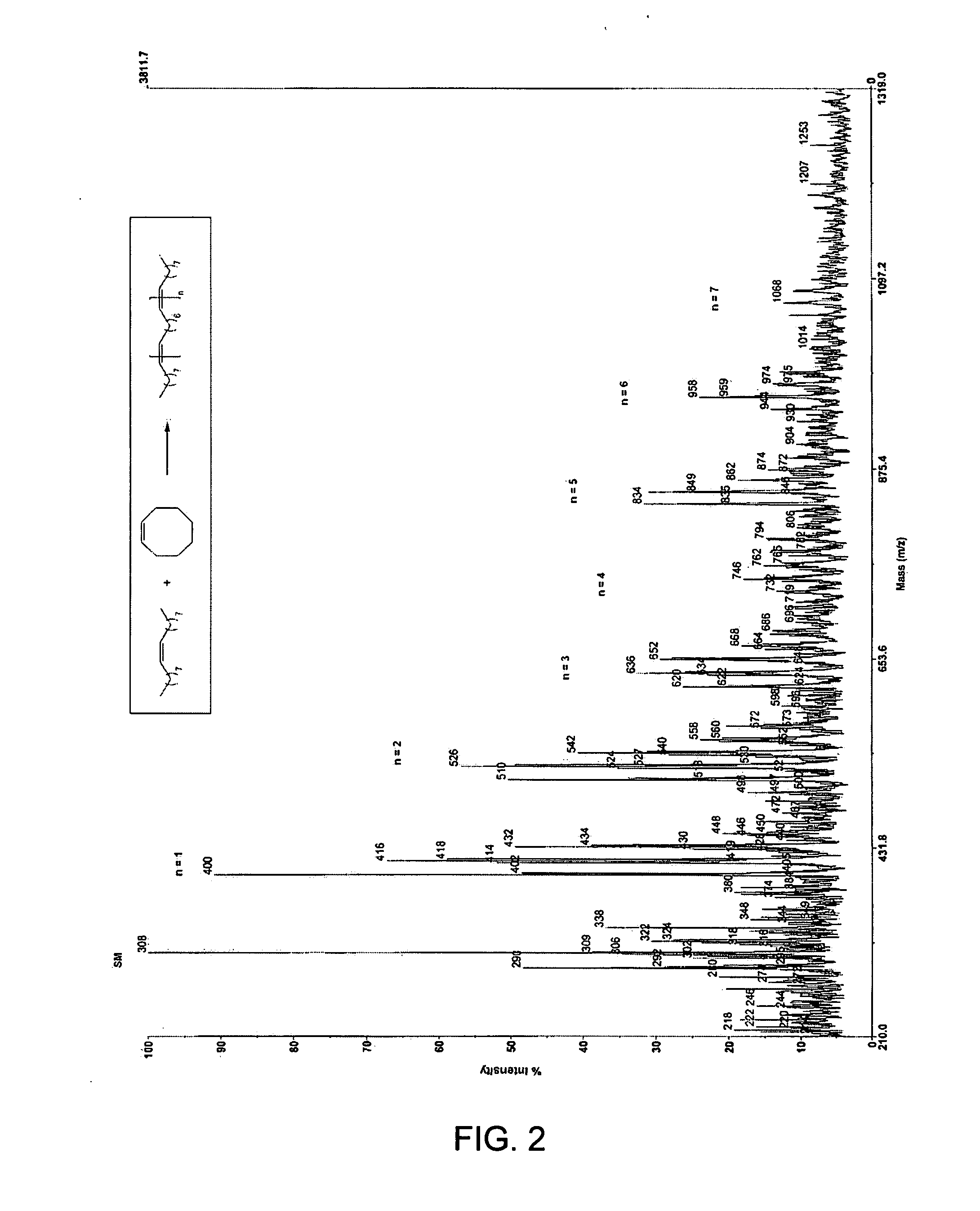

Ring opening cross-metathesis reaction of cyclic olefins with seed oils and the like

ActiveUS20080064891A1Fatty acid esterificationOrganic compound preparationOrganic synthesisRuthenium

This invention relates generally to olefin metathesis, and more particularly relates to the ring-opening, ring insertion cross-metathesis of cyclic olefins with internal olefins such as seed oils and the like. In one embodiment, a method is provided for carrying out a catalytic ring-opening cross-metathesis reaction, comprising contacting at least one olefinic substrate with at least one cyclic olefin as a cross metathesis partner, in the presence of a ruthenium alkylidene olefin metathesis catalyst under conditions effective to allow ring insertion cross metathesis whereby the cyclic olefin is simultaneously opened and inserted into the olefinic substrate. The invention has utility in the fields of catalysis, organic synthesis, and industrial chemistry.

Owner:WILMAR TRADING PTE LTD

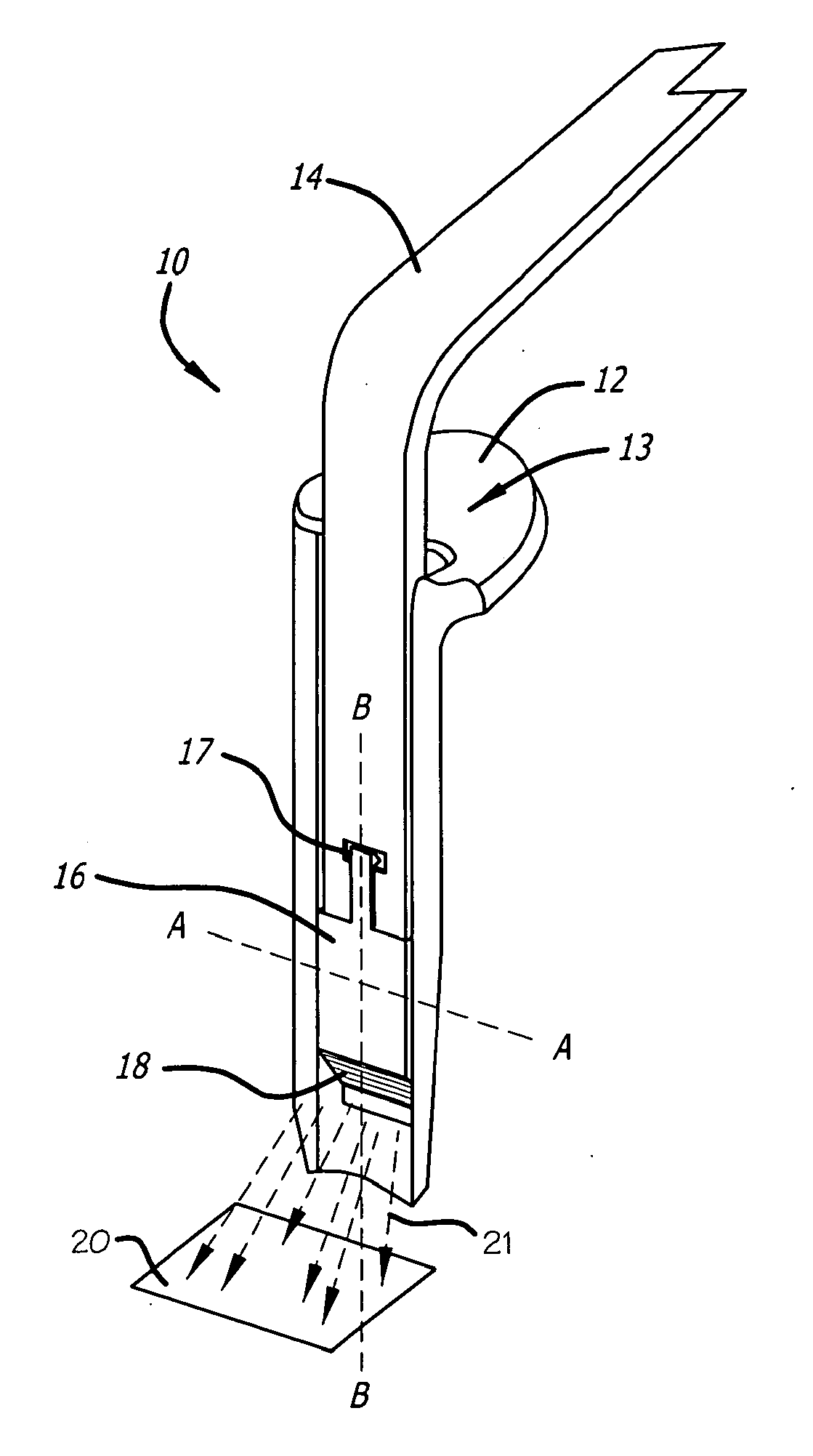

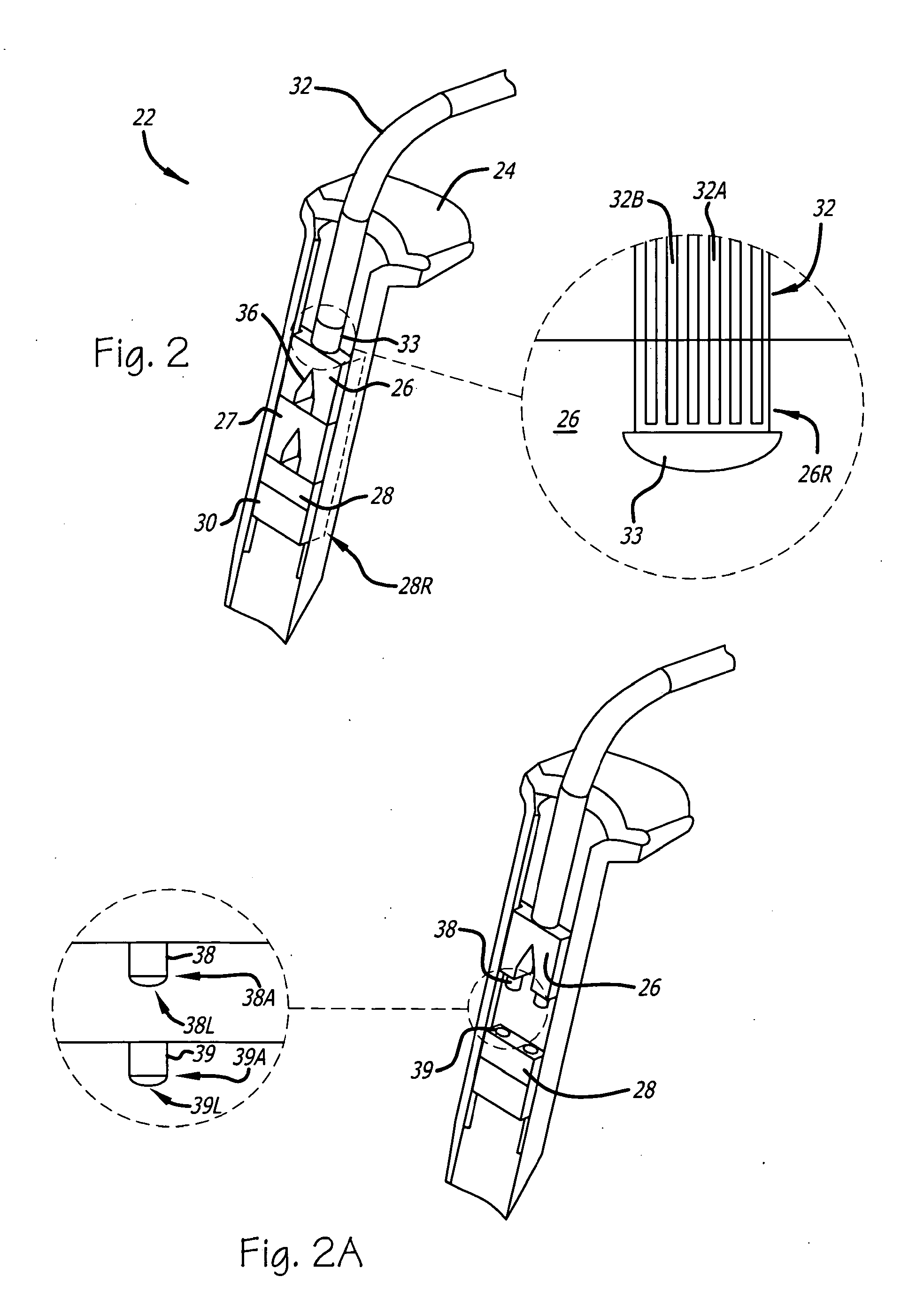

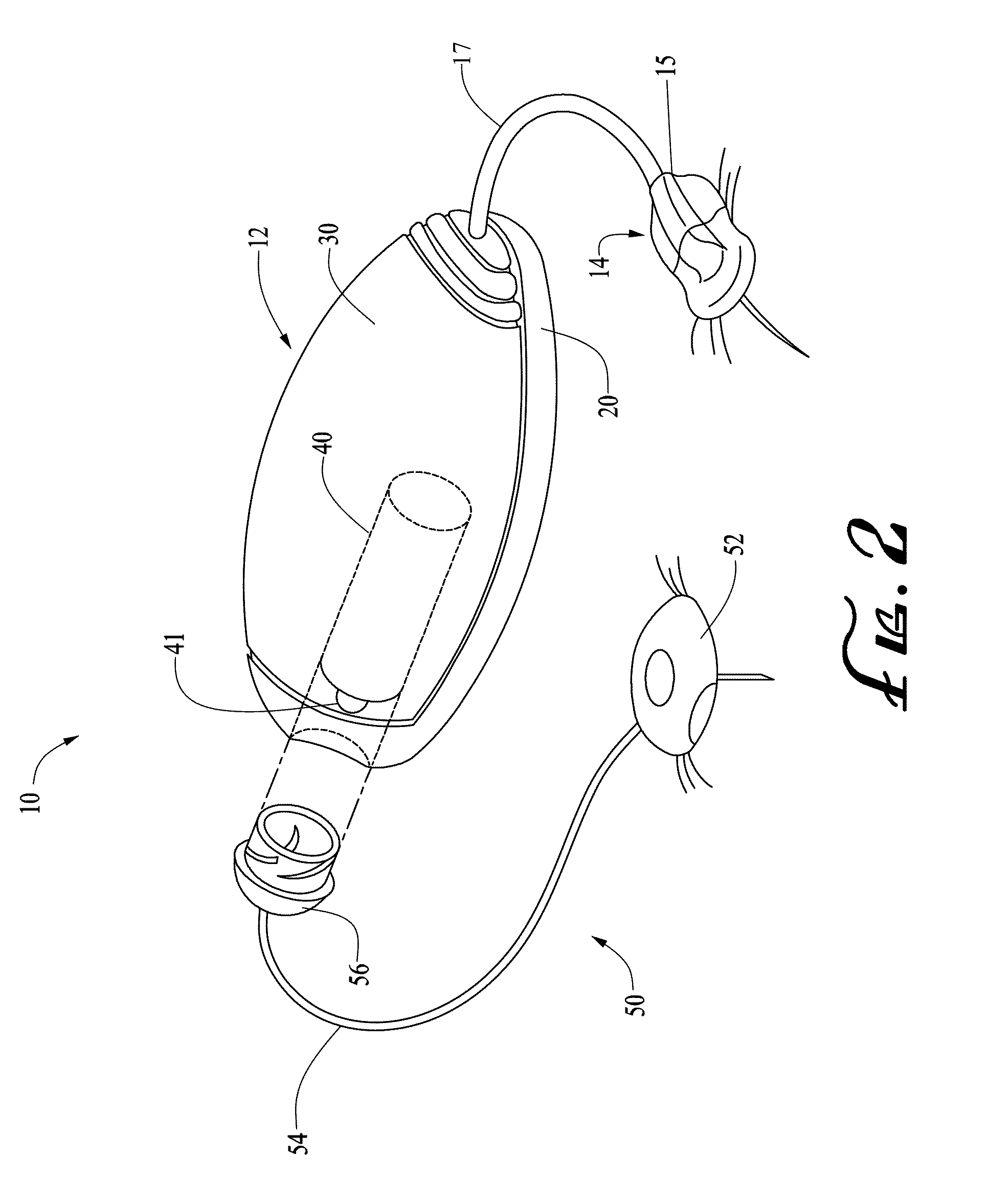

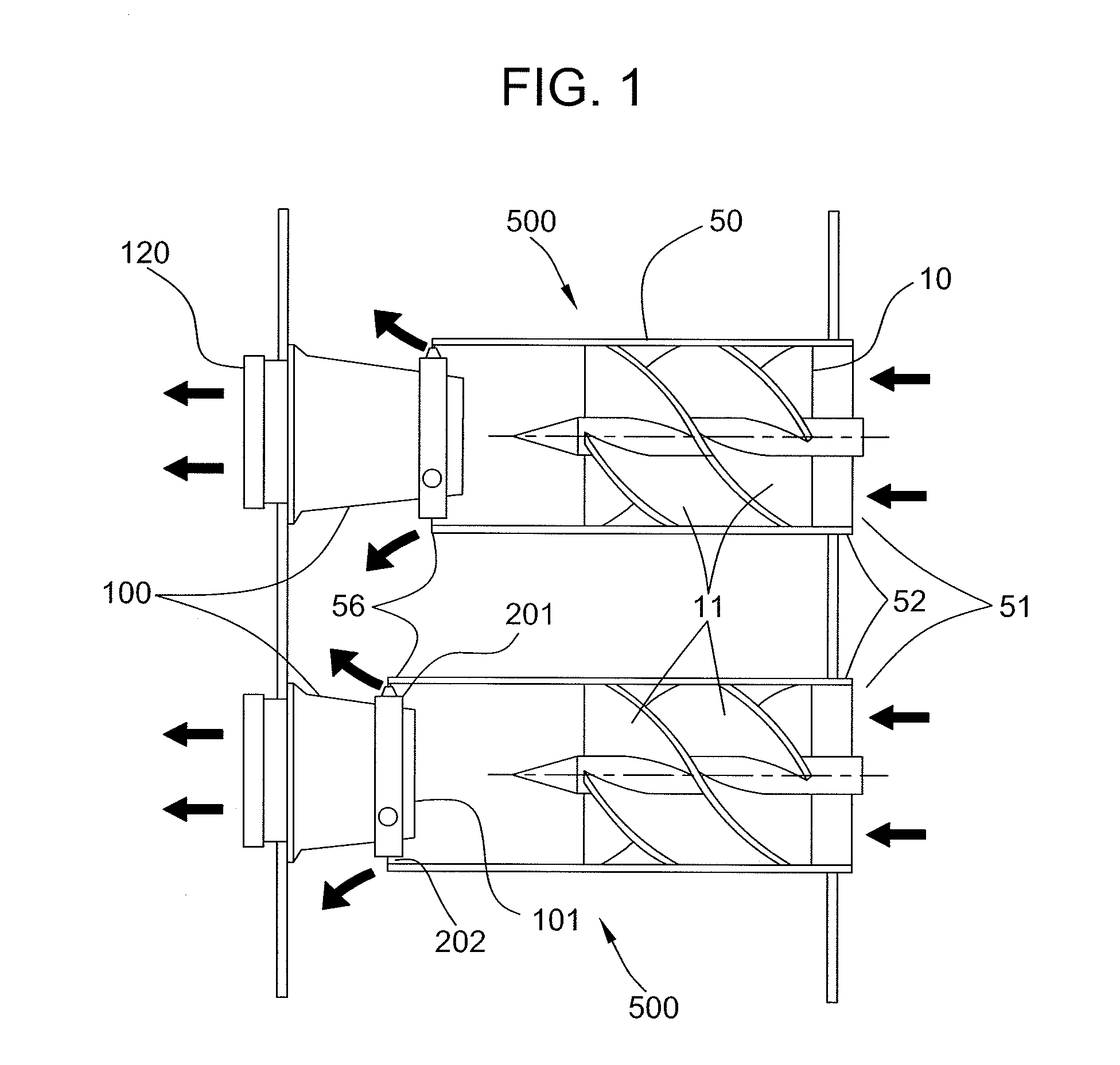

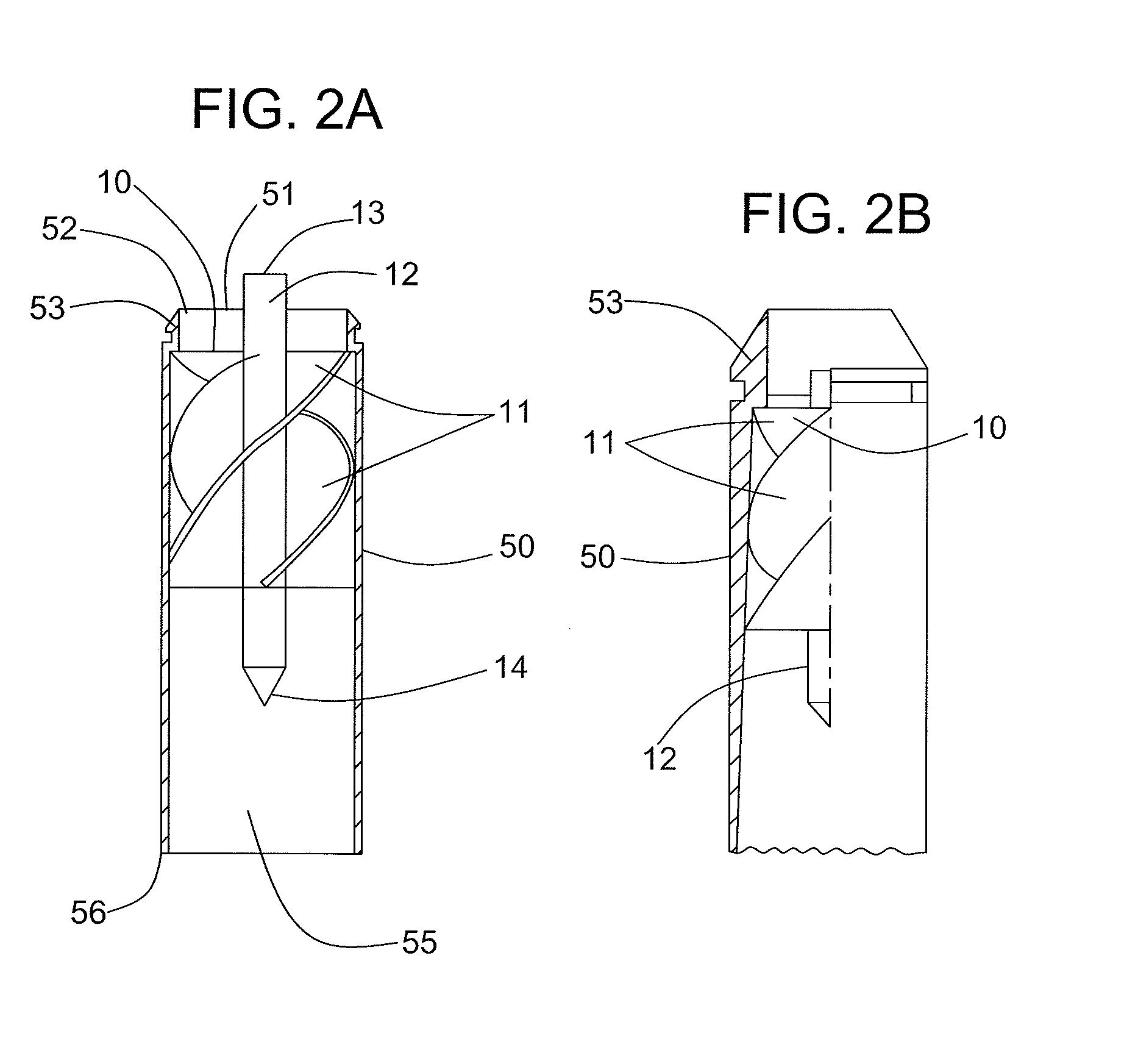

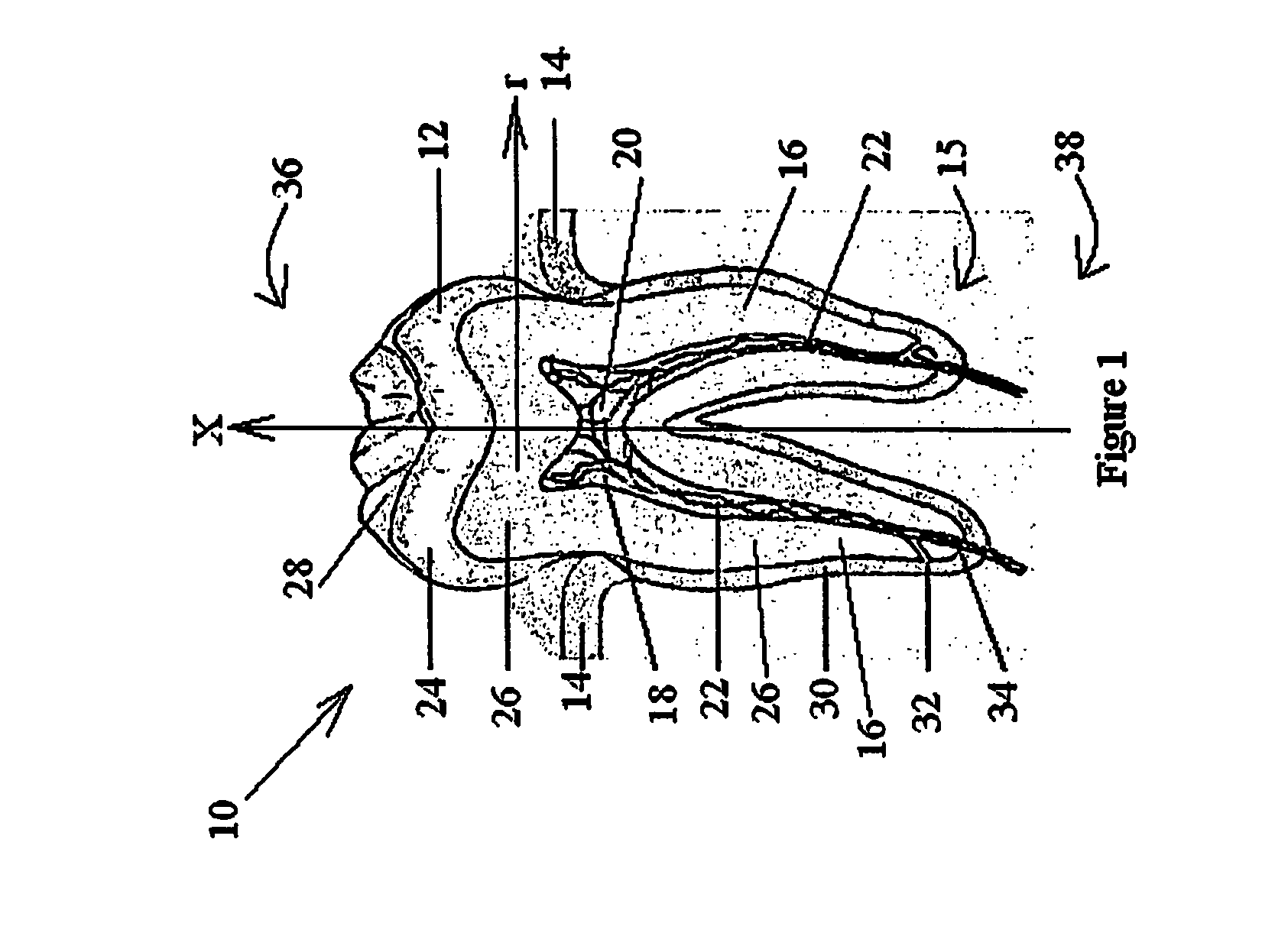

Cyclo olefin polymer and copolymer medical devices

ActiveUS20120041268A1Different performanceBronchoscopesLaryngoscopesDistal portionCyclo olefin polymer

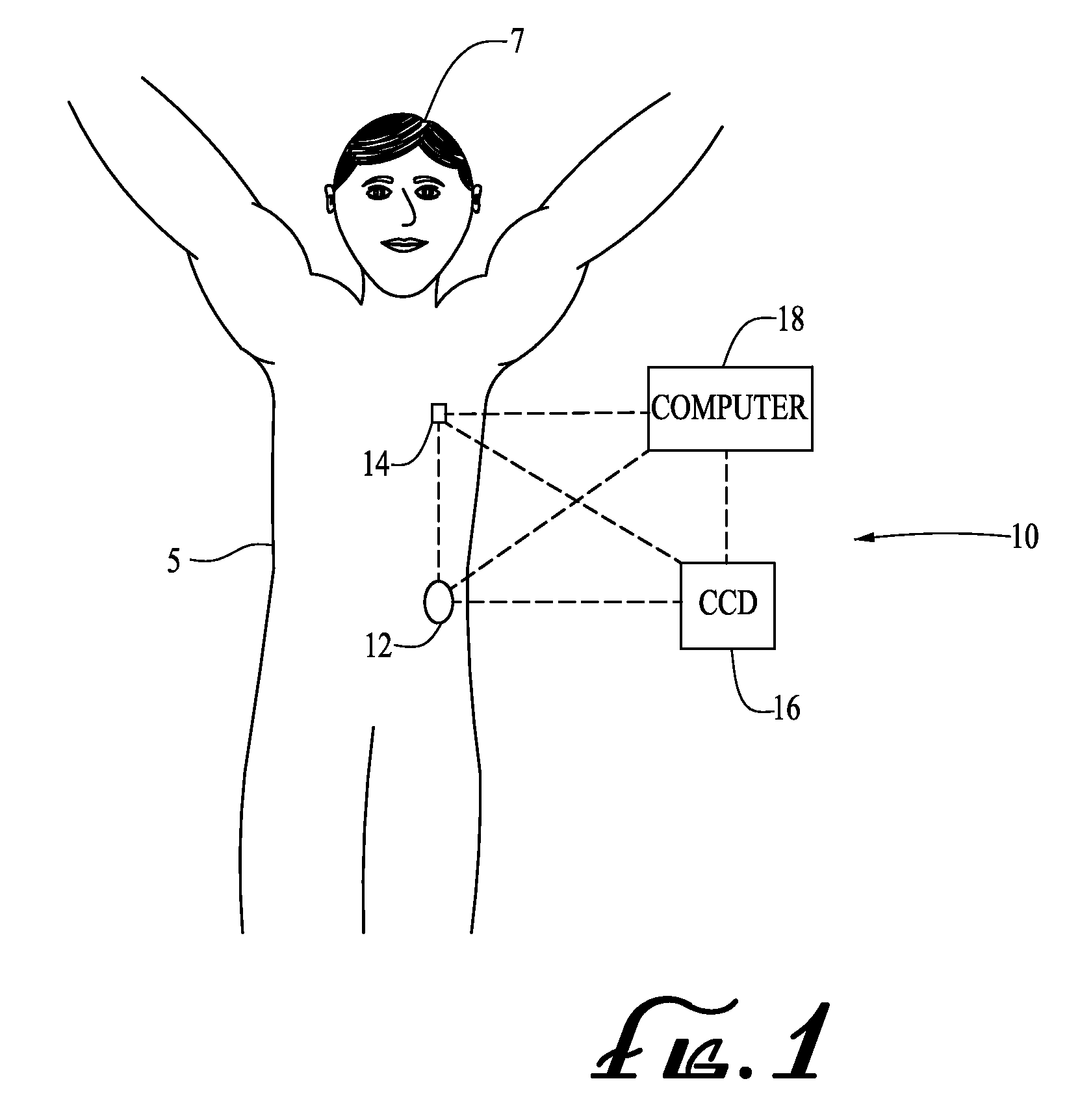

An illuminated medical system comprises a medical instrument and a light transmitting waveguide. The waveguide projects lights from a distal portion of the waveguide toward a target area. The waveguide is formed primarily of a cyclic olefin copolymer or a cyclic olefin polymer.

Owner:INVUITY

Metathesis polymerized olefin composites including sized reinforcement material

A reinforced polyolefin article is provided which includes a sized reinforcement material incorporated in the article. The article may be prepared by polymerizing a cyclic olefin monomer in the presence of the sizing agent and a metathesis polymerization catalyst which includes ruthenium or osmium.

Owner:WARNER MARK +2

Reservoir plunger head systems and methods

A plunger head moveable in an axial direction within a reservoir having an interior volume for containing fluidic media may have a first portion in contact with fluidic media when fluidic media is in the interior volume of the reservoir, the first portion comprising a first material compatible with fluidic media in the interior volume of the reservoir, a second portion located on an opposite side of the plunger head from the interior volume of the reservoir, the second portion connectable to a plunger arm, and a third portion located between the first portion and the second portion of the plunger head, at least one of the first portion, second portion, and the third portion is made of a material that comprises one of a cyclic olefin copolymer and a cyclic olefin polymer.

Owner:MEDTRONIC MIMIMED INC

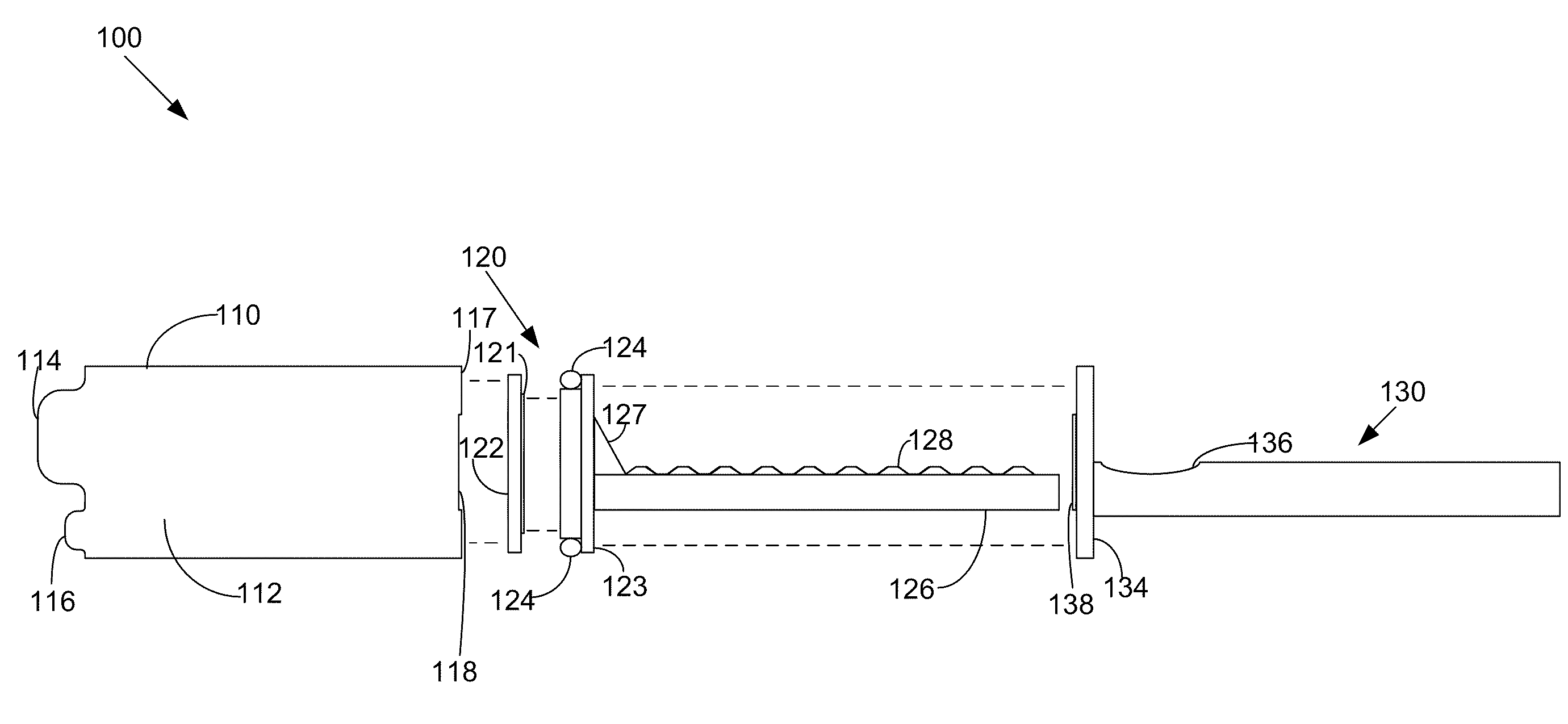

Syringe for use with injectors and methods of manufacturing syringes and other devices

ActiveUS20080033367A1Reduce thicknessInfusion syringesMedical devicesPolystyreneCyclo olefin polymer

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

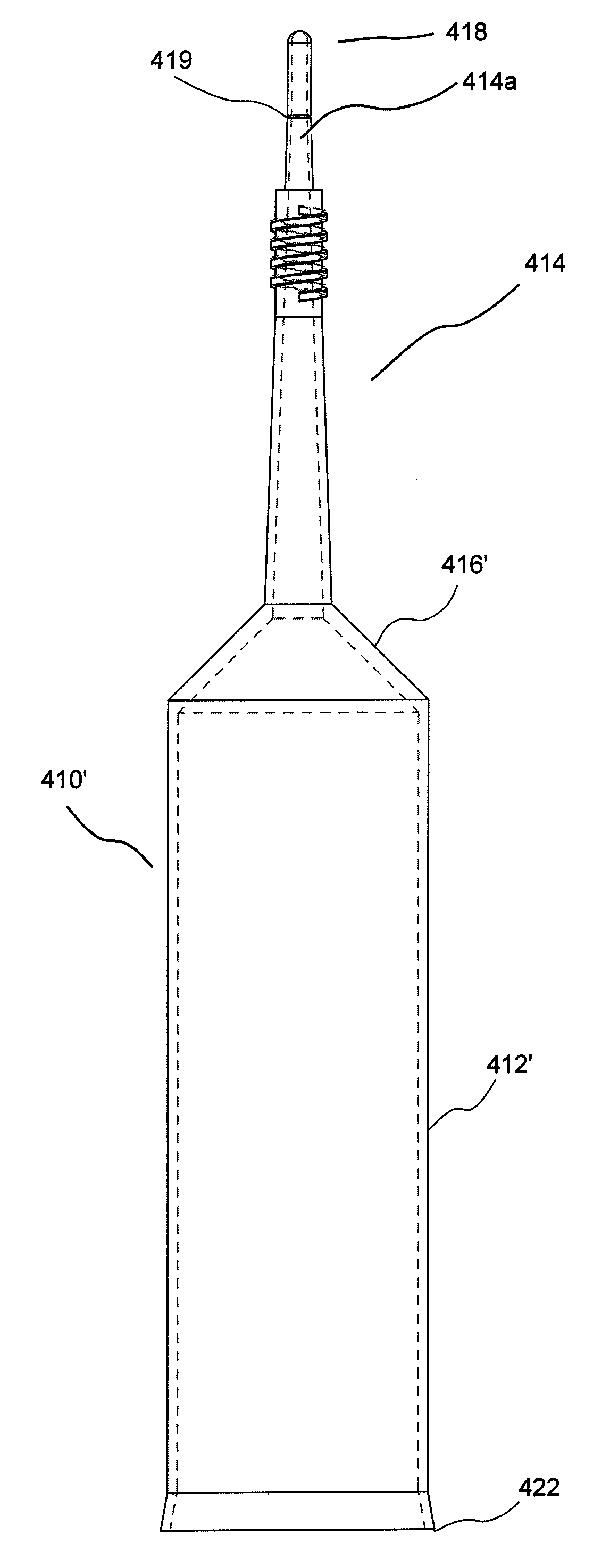

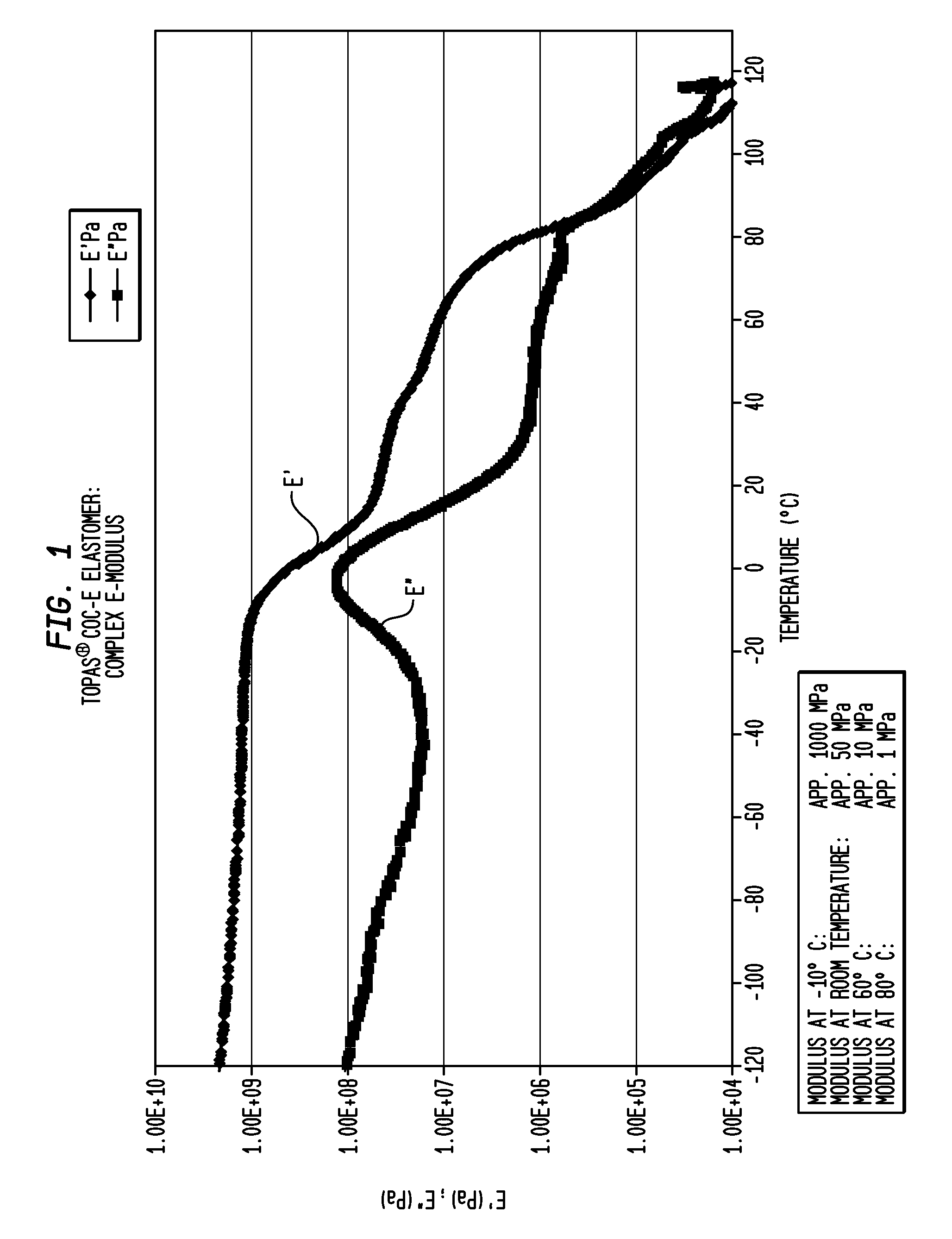

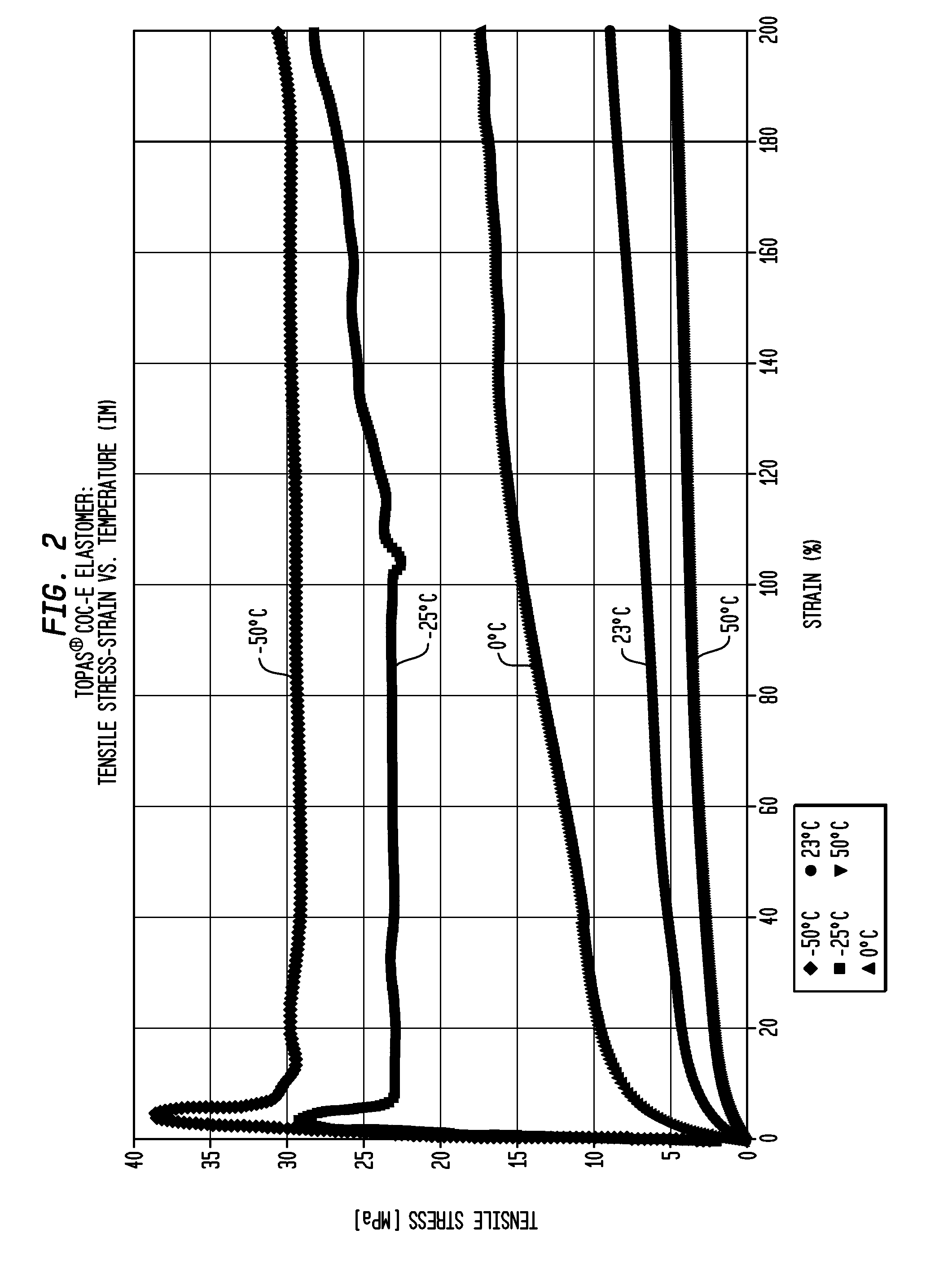

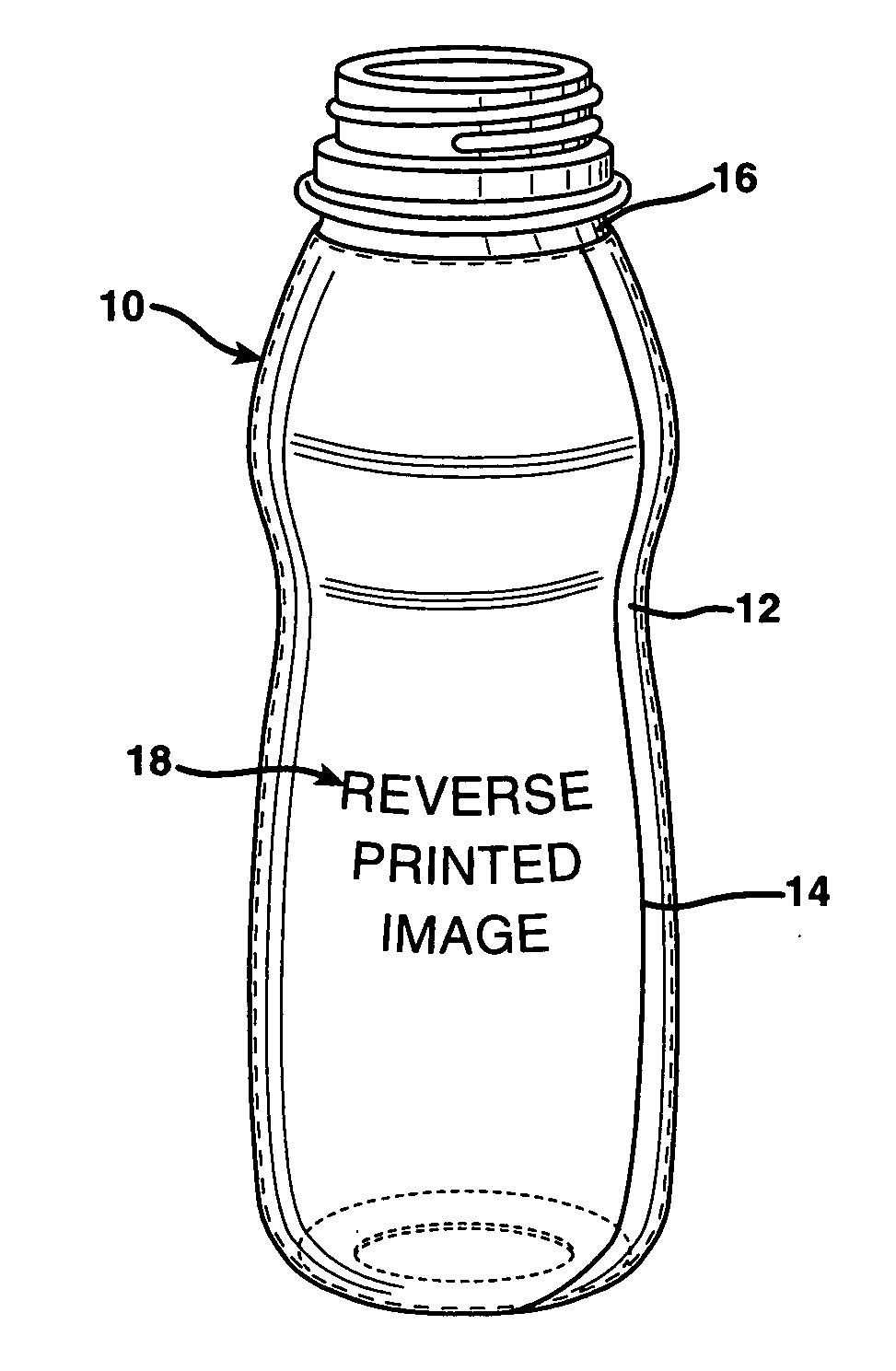

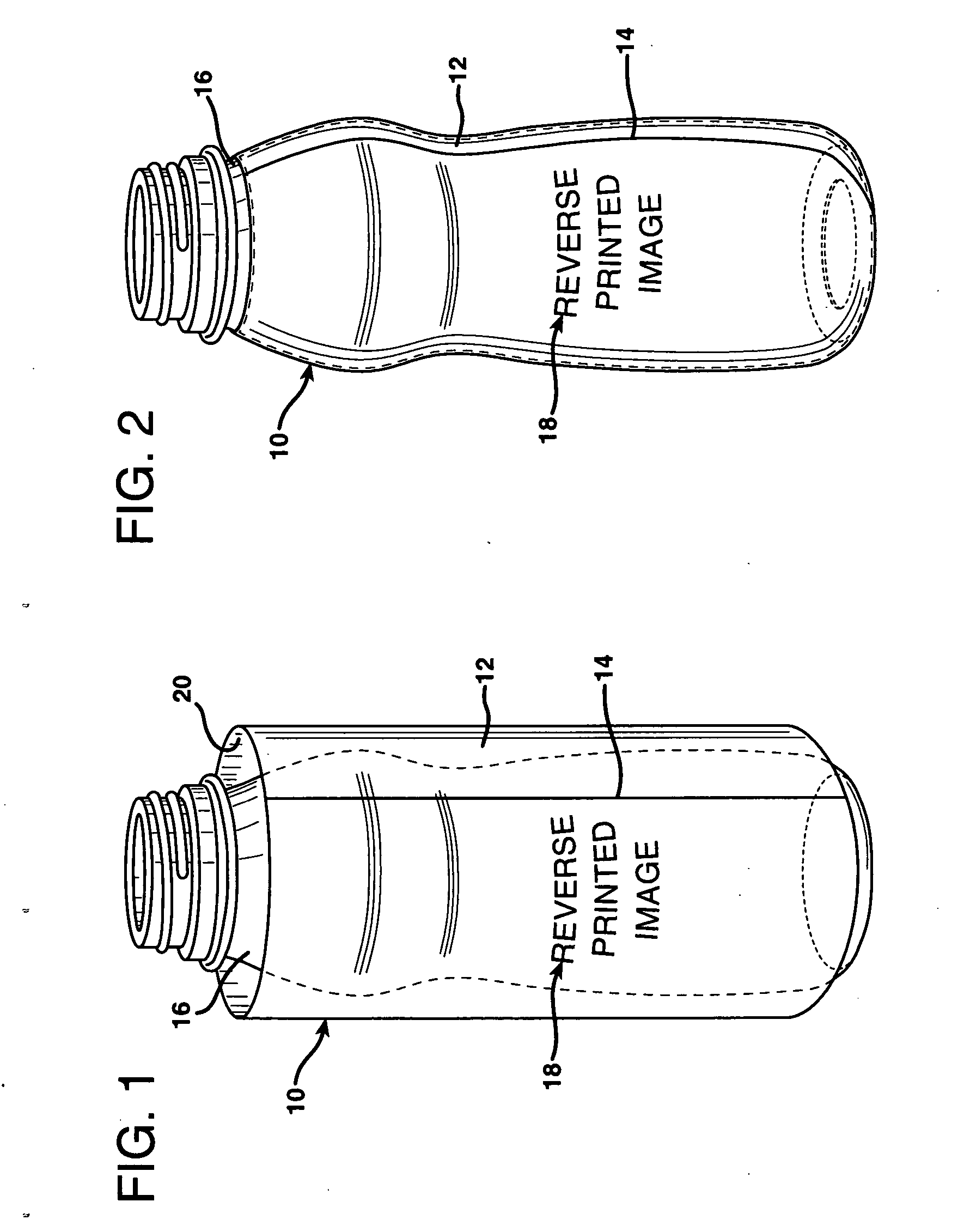

Transparent, Flexible Products Made With Partially Crystalline Cycloolefin Elastomer

InactiveUS20120021151A1Allocation is accurateImprove mechanical propertiesWrappers shrinkageClosuresElastomerNorbornene

Shaped articles made with a partially crystalline, cycloolefin elastomer of norbornene and ethylene typically having at least one glass transition temperature (Tg) in the range of from −10° C. to 15° C. and a crystalline melting temperature in the range of from 60° C. to 125° C. and a % crystallinity by weight in the range of from 5% to 40%. The shaped articles may be in the form of medical tubing; a contact lens mold or component thereof; a container such as a bottle, a squeeze bottle or a squeeze tube; an eyedropper or eyedropper component; an elastomeric closure, optionally a pierceable elastomeric closure or the shaped article is selected from shrink film and / or shrink tubing.

Owner:TOPAS ADVANCED POLYMERS

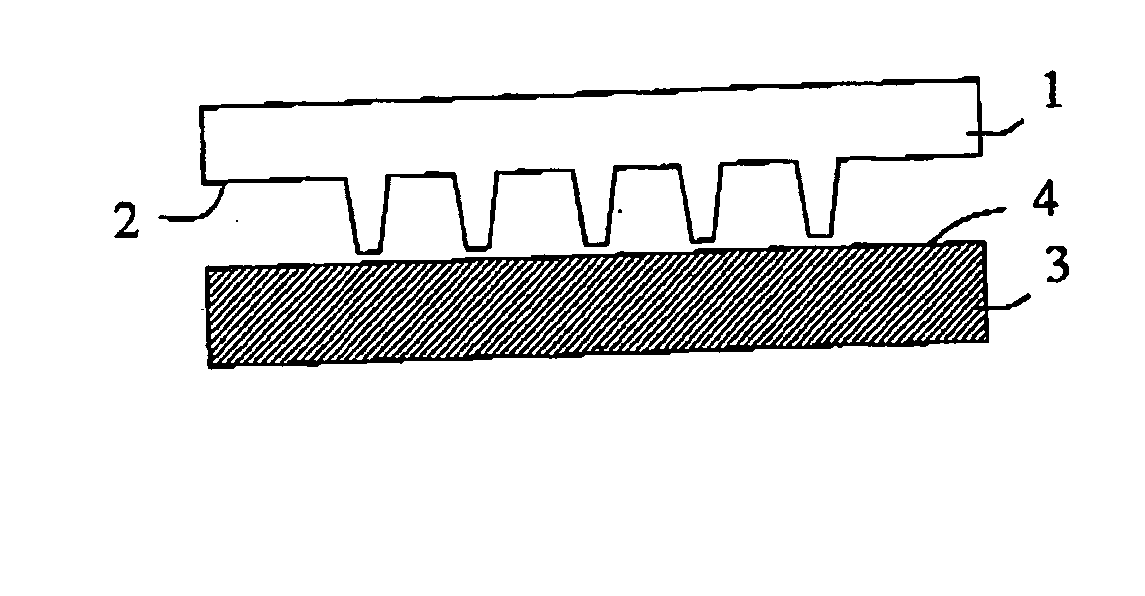

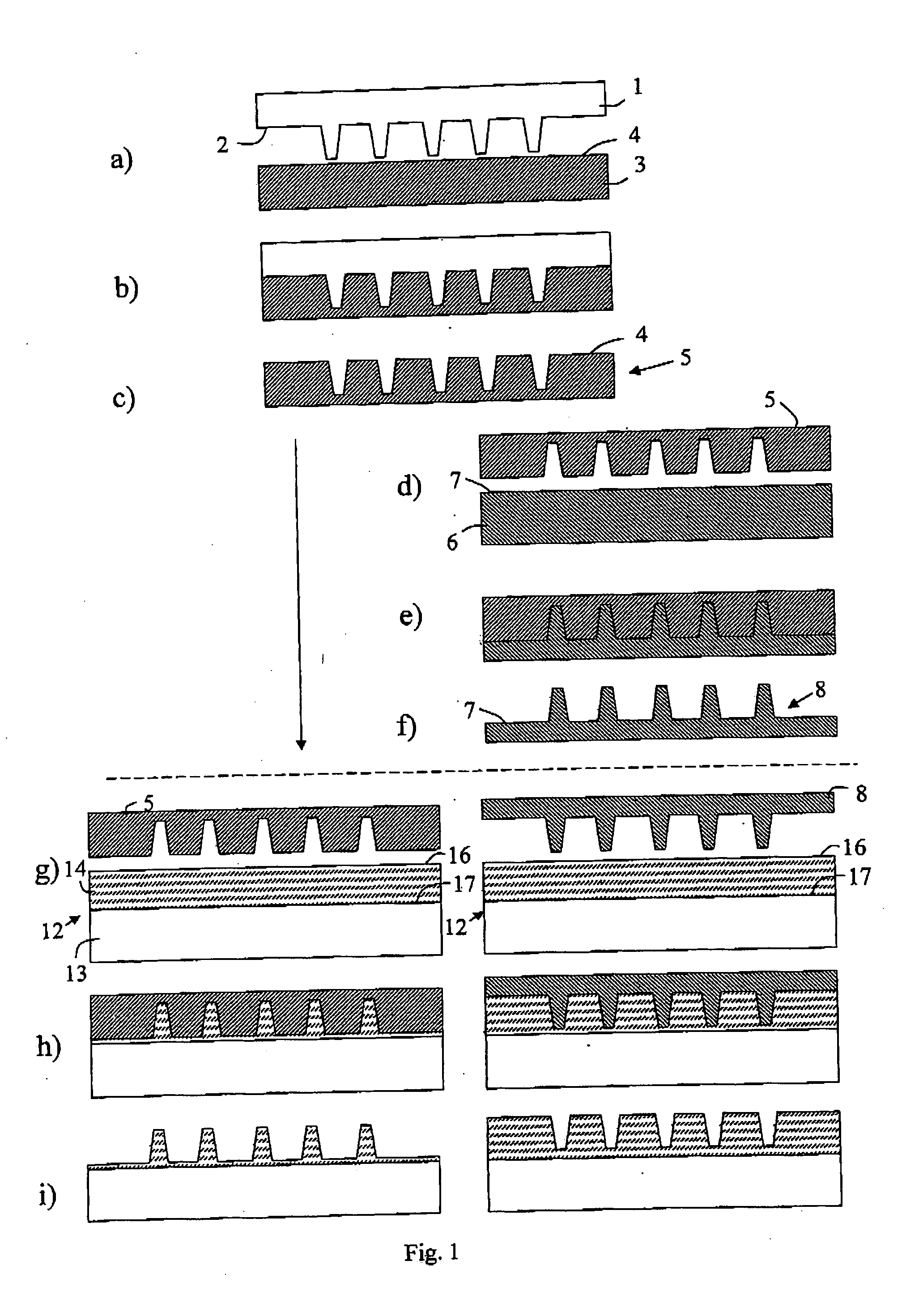

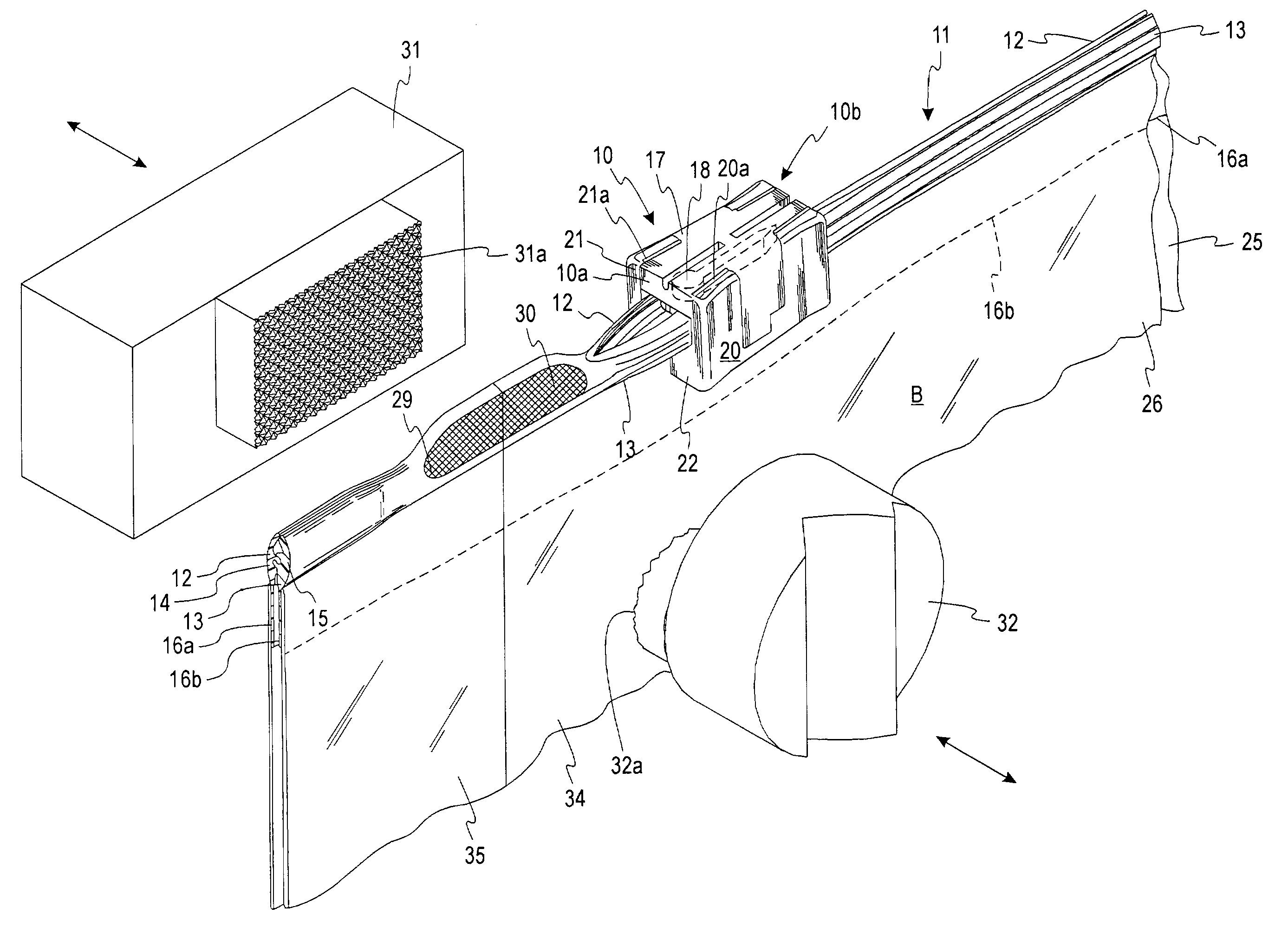

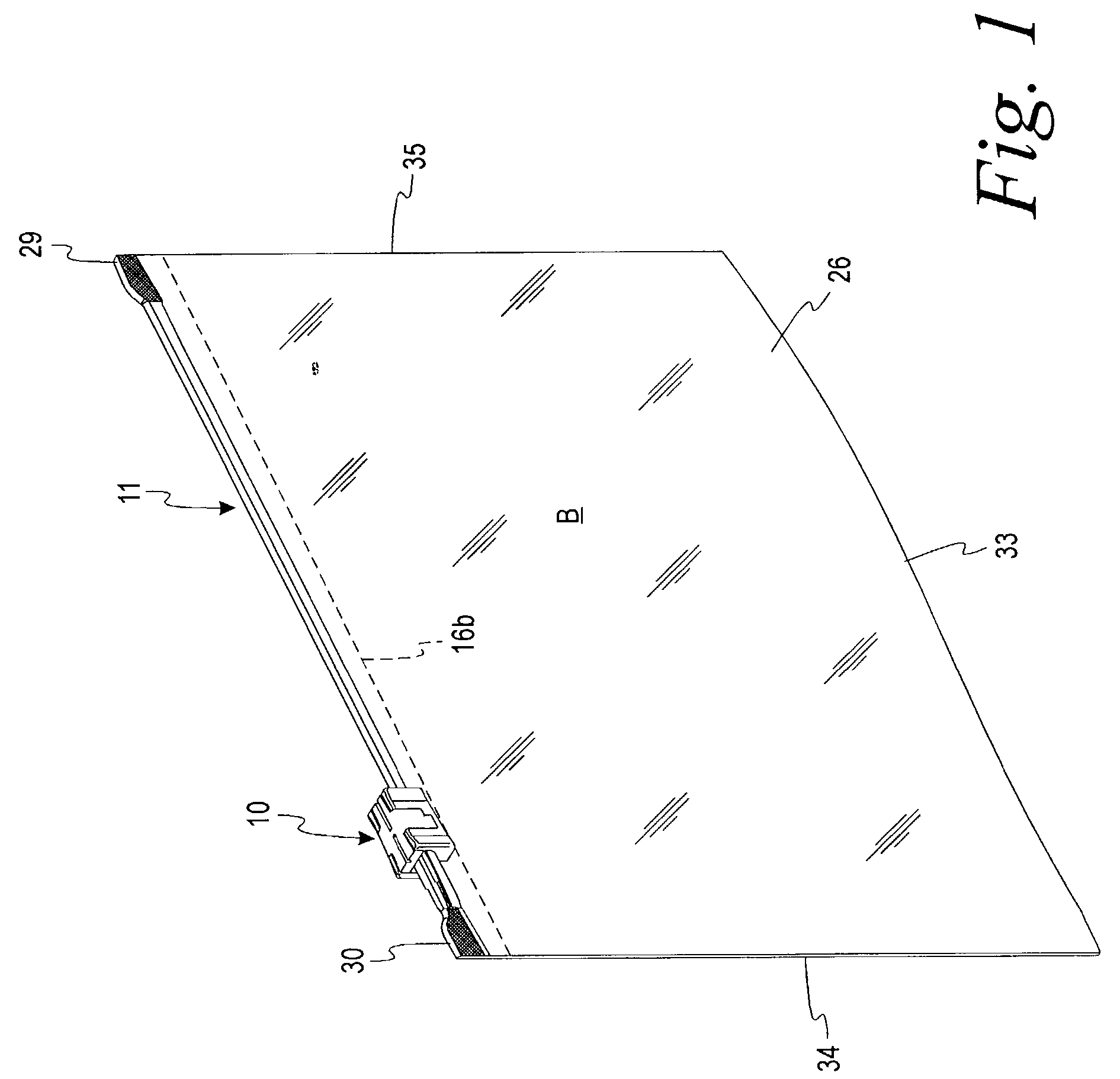

Imprint stamp comprising Cyclic Olefin copolymer

ActiveUS20070212522A1Easy and suitable to employ industriallyImprove fidelityLayered productsNanoinformaticsResistCyclic olefin copolymer

A method is provided for transferring a pattern from a template (1) to an object (12) in an imprint process, using a two-step process. The first step includes contacting a pattern of the template surface with a polymer material comprising one or more Cyclic Olefin Copolymers (COCs), to produce a flexible polymer replica having a structured surface with an inverse of the pattern of the template surface. In a second step, after releasing the flexible polymer replica from the template, the inverse pattern of the flexible polymer replica is pressed into a resist layer on a substrate, to imprint a replica of the pattern of the template surface in therein.

Owner:OBDUCAT AB SE

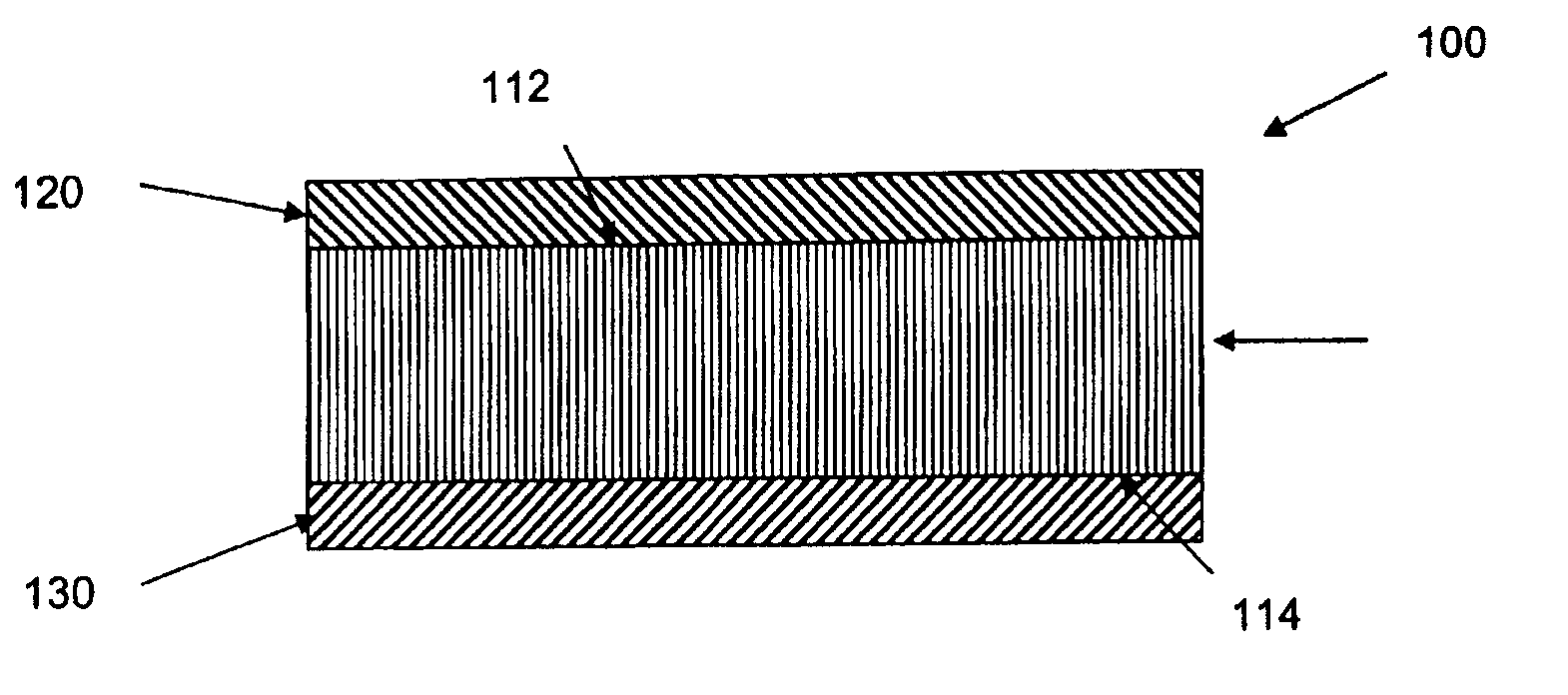

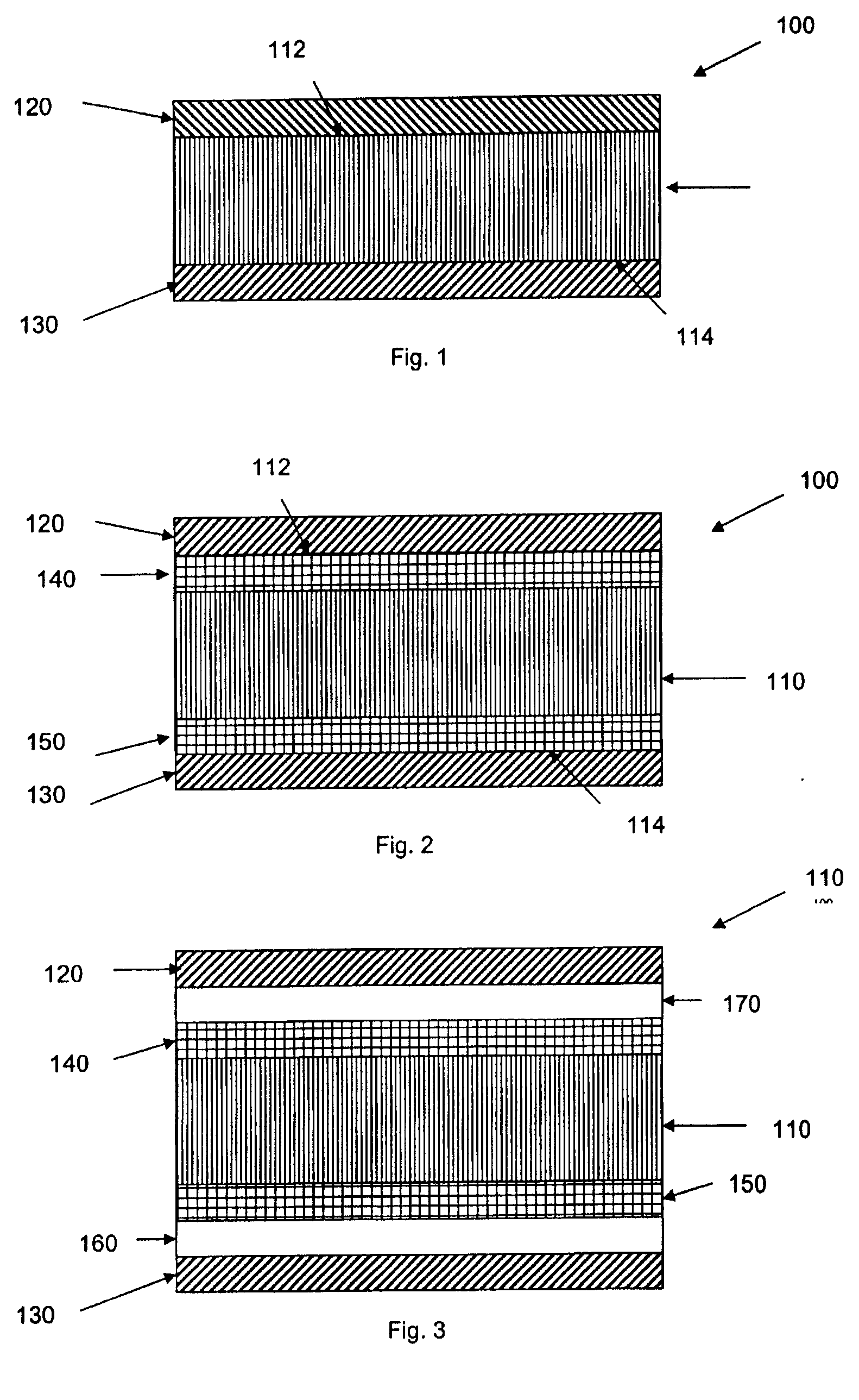

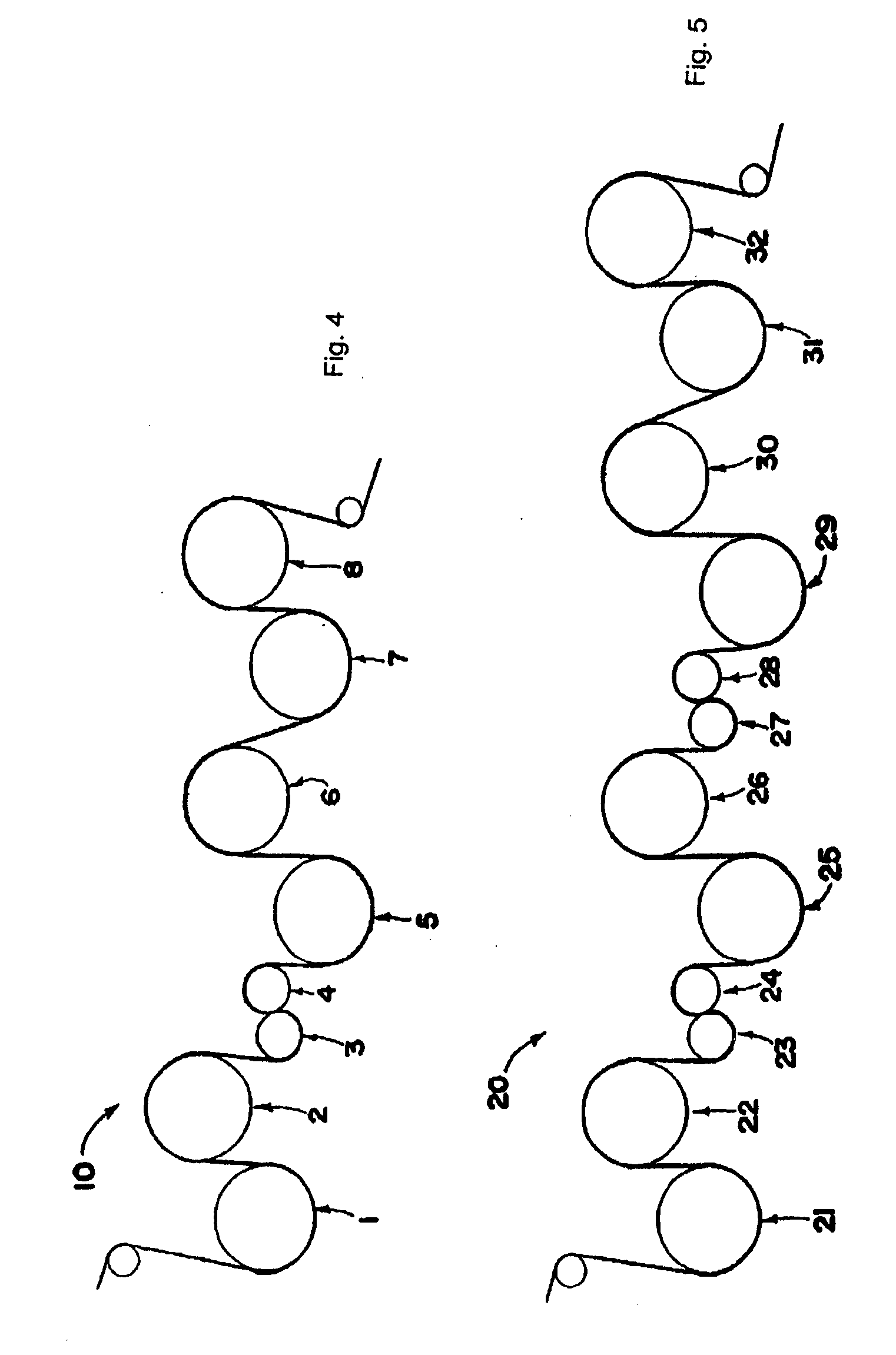

High free shrink, high modulus, low shrink tension film with elastic recovery

A film includes a core layer including a homogeneous random alpha-olefin / cyclic olefin copolymer; and first and second outer layers including an olefinic polymer; the film having Young's modulus between about 50,000 and about 200,000 psi, free shrink between about 10% and about 80% at 240° F., and shrink tension of less than about 400 psi, or a shrink force of between about 20 and about 180 grams, at 240° F. First and second intermediate layers including an ethylene copolymer having a melt index less than about 2 g / 10 minutes can be optionally included. Alternatively, a film includes a core layer including an ethylene copolymer having melt index less than about 2 g / 10 minutes; first and second intermediate layers including a homogeneous random alpha-olefin / cyclic olefin copolymer; and first and second outer layers including an olefinic polymer; the film having properties as disclosed above.

Owner:CRYOVAC ILLC

Shrink sleeve label

A shrink film comprises a skin layer and a base layer. The skin layer may comprise polystyrene or modified polyester. The base layer may comprise alpha-olefin / cyclic-olefin copolymer or alpha-olefin / vinyl aromatic copolymer. The film has a free shrink at 100° C. of at least about 10%. The film is useful for shrink sleeve applications.

Owner:CRYOVAC INC

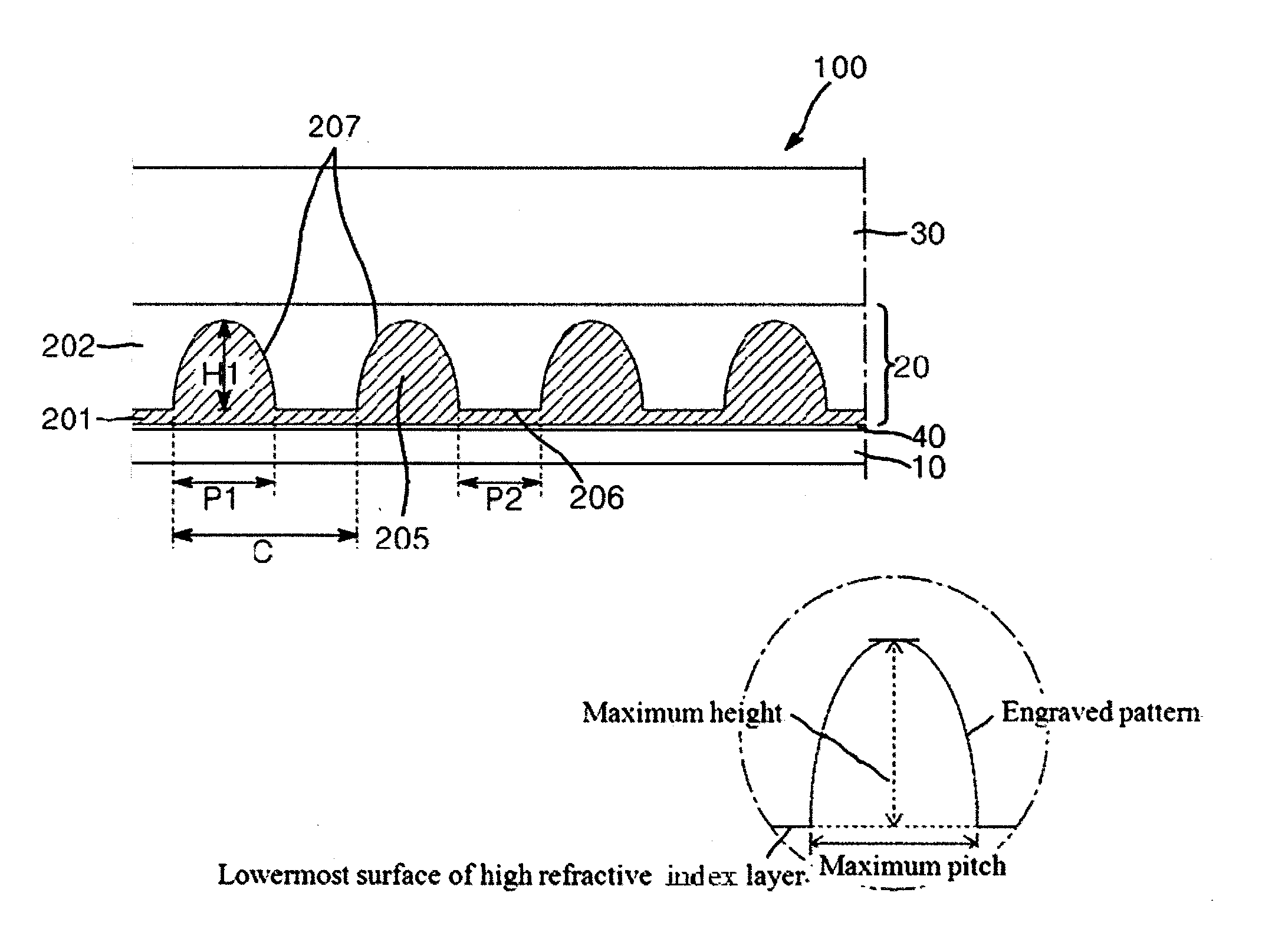

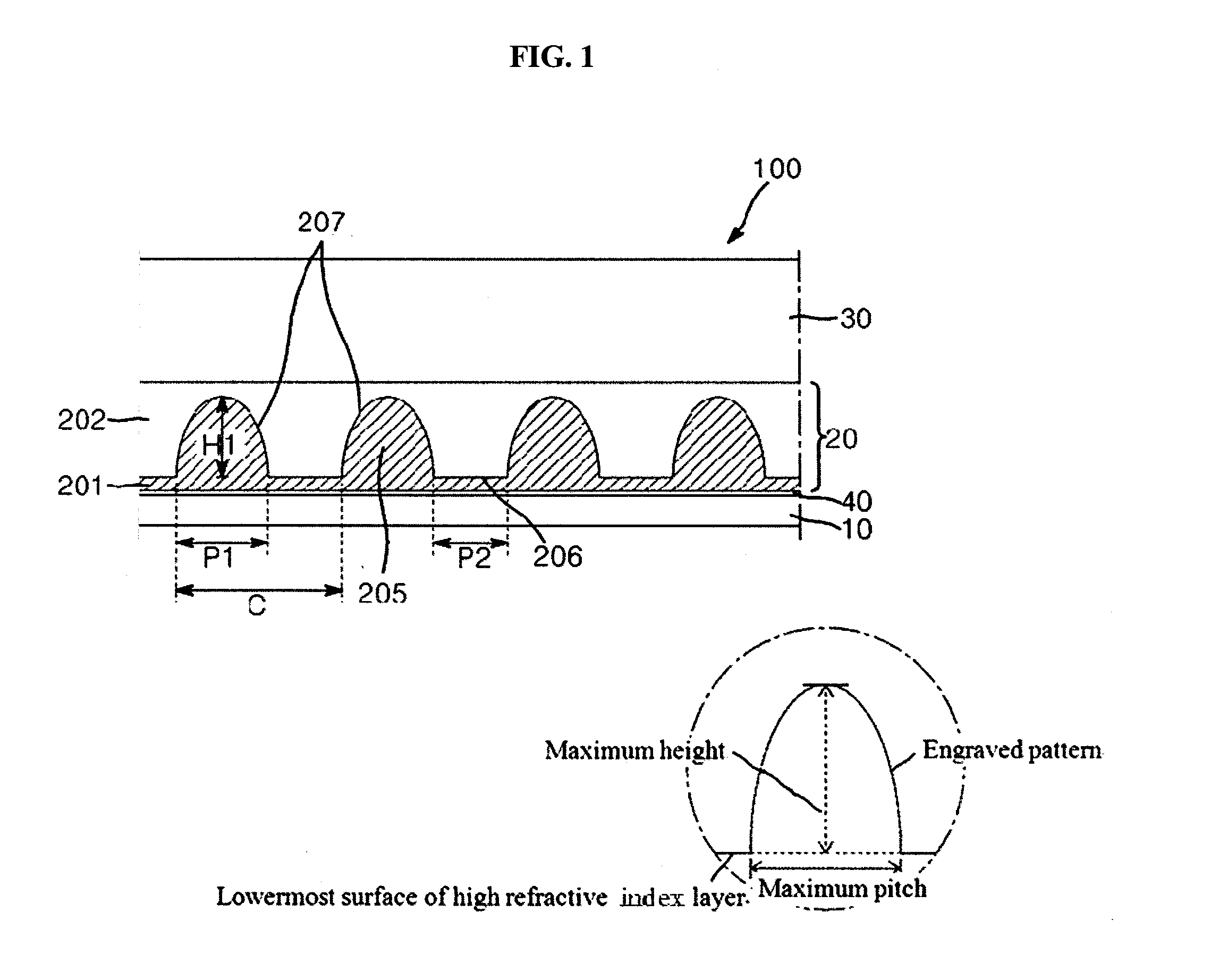

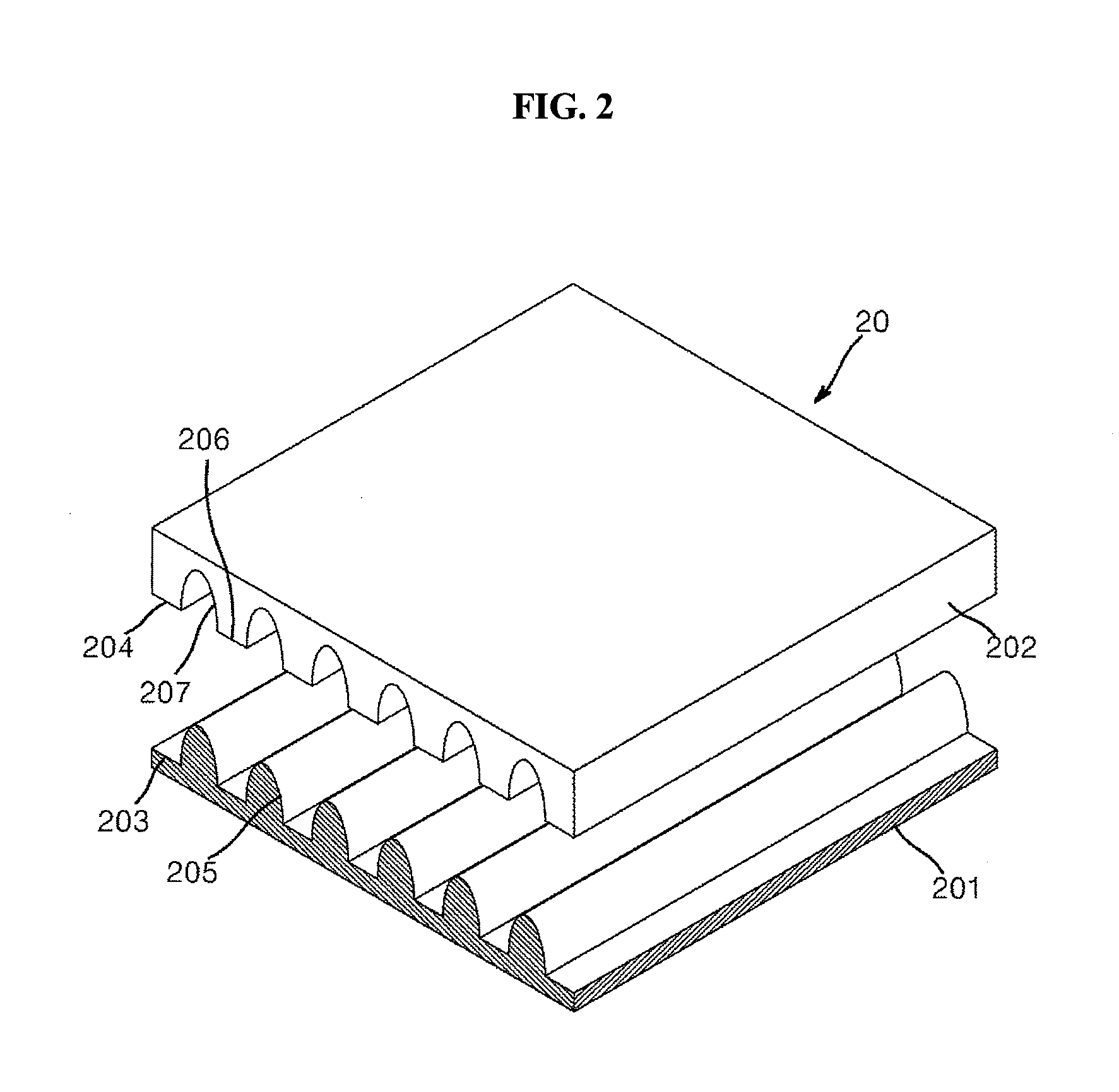

Polarizing plate and liquid crystal display comprising the same

ActiveUS20160252665A1High refractive indexPolarising elementsNon-linear opticsLiquid-crystal displayPolyethylene terephthalate

A polarizing plate includes: a polarizer; a pattern layer on one surface of the polarizer, the pattern layer including a first refractive index layer having at least one engraved pattern and a second refractive index layer having a filling pattern filling at least a portion of the engraved pattern, the first refractive index layer having a higher refractive index than the second refractive index layer; and a first protective layer. The polarizing plate has a structure in which the polarizer, the second refractive index layer, the first refractive index layer and the first protective layer are sequentially stacked in that order, or in which the polarizer, the first protective layer, the second refractive index layer and the first refractive index layer are sequentially stacked in that order. The first protective layer includes a base film including at least one resin of triacetylcellulose, polyethylene terephthalate, cyclic olefin polymer, and acrylic resins.

Owner:SAMSUNG SDI CO LTD

Thermoplastic vulcanizates from a cyclic olefin rubber, a polyolefin, and a compatiblizer

A blend of a semicrystalline polyolefin, a rubbery polymer containing repeat units from norbornene, and a polymeric compatibilizer is disclosed. This composition has reduced oil swell as compared to thermoplastic vulcanizates from a semicrystalline polyolefin and hydrocarbon rubbers.

Owner:ADVANCED ELASTOMER SYST LP

Inertial separator

An inertial separator comprising a tubular body, the tubular body comprises a composition comprising a polymer selected from the group consisting of a cyclic olefin polymer and a cyclic olefin copolymer, and, a polyhedral oligomeric silsesquioxane and / or a flame retardant and / or an anti-static additive, is disclosed.

Owner:PALL CORP

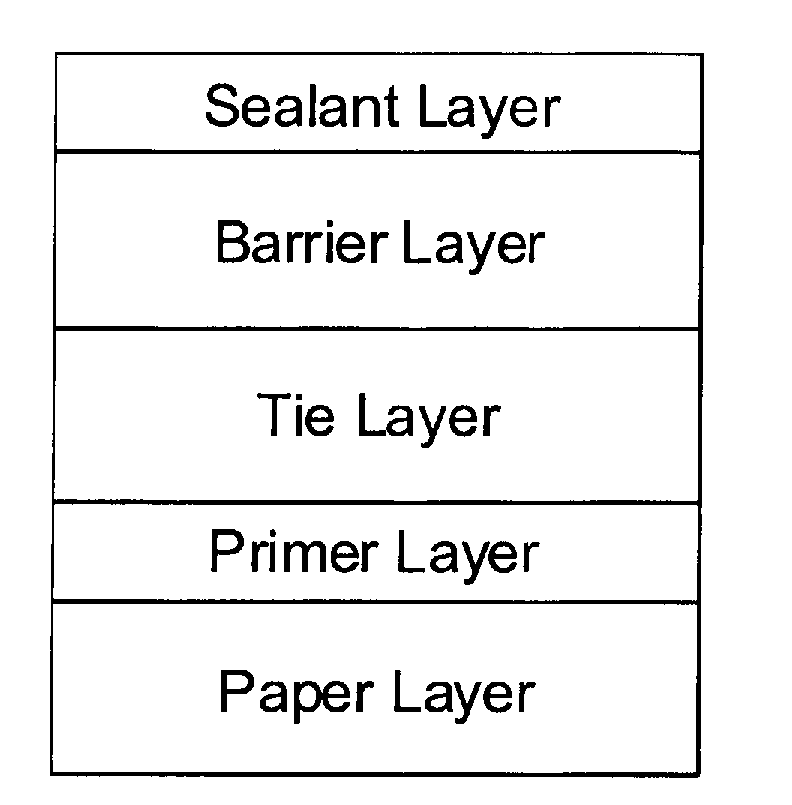

Paper-based lidding for blister packaging

ActiveUS20100170820A1Successfully addressSpecial ornamental structuresPattern printingMedicinePaper based

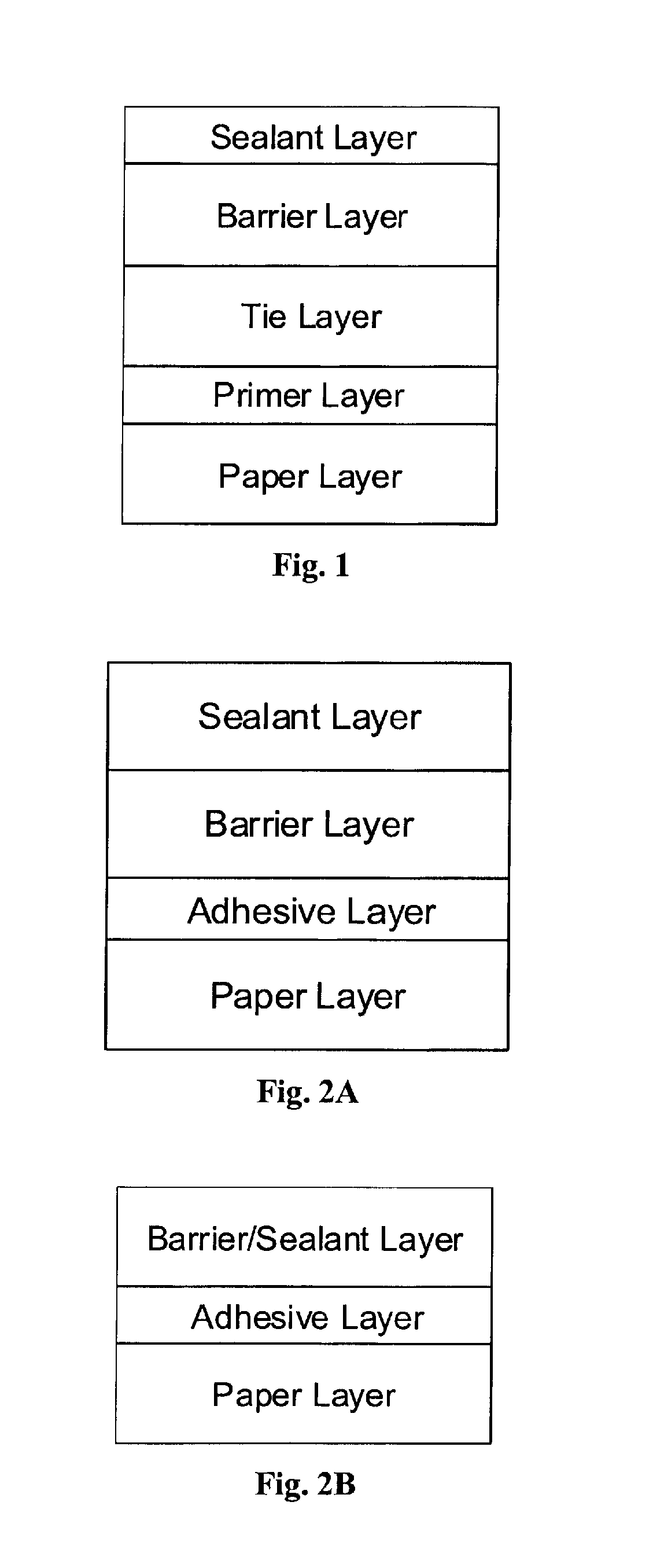

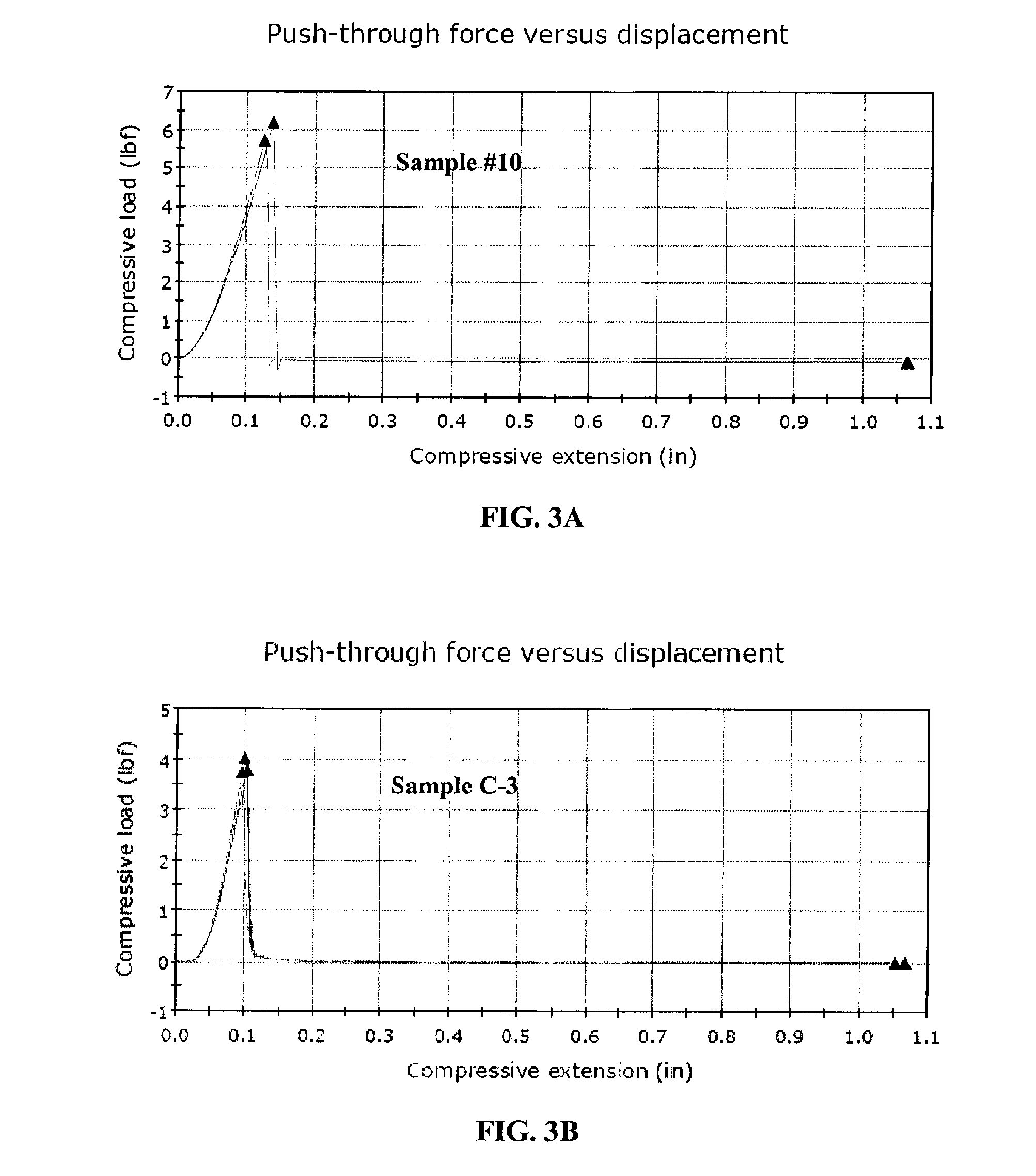

The present invention provides a paper-based lidding material, which includes a paper layer and a layer containing a cyclic olefin copolymer. The material is useful for blister packaging and particularly suitable for push-through pharmaceutical and food blister packaging. In one embodiment, the lidding material is formed by extrusion coating and includes at least one paper layer, at least one primer layer, at least one tie layer, at least one barrier layer containing one or more cyclic olefin copolymers, and at least one sealant layer in that order. In another embodiment, the paper-based lidding material includes a paper layer laminated to one or more barrier layers containing one or more cyclic olefin copolymers adjacent to one or more sealant layers. Embodiments of the invention can be sealed to a variety of blister films, including films that are chloride-free, to provide environmentally benign blister packages having good moisture properties.

Owner:WINPAK HEAT SEAL PACKAGING

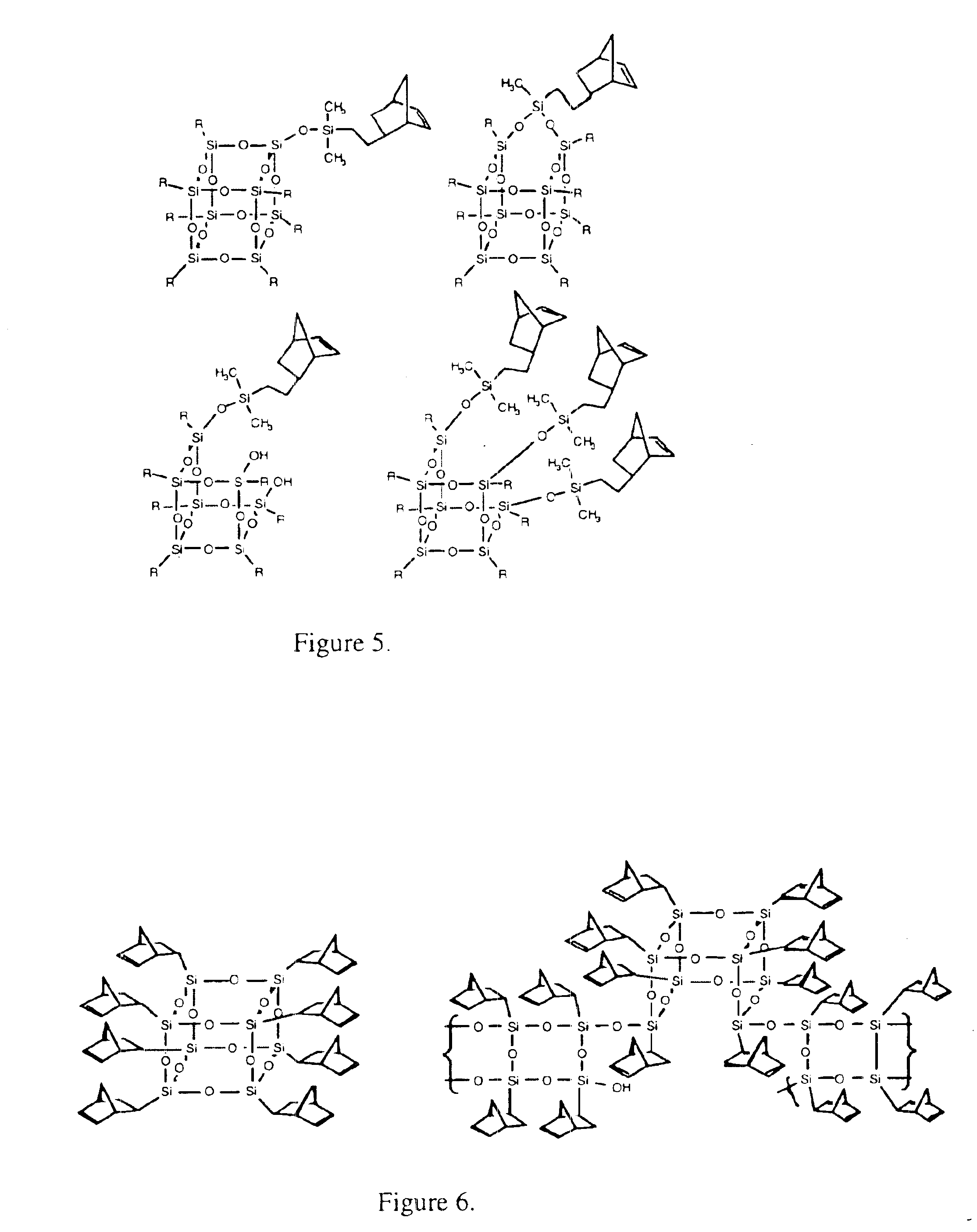

Polyhedral oligomeric -silsesquioxanes, -silicates and -siloxanes bearing ring-strained olefinic functionalities

InactiveUS6911518B2Improving biocompatabilityImprove fire resistanceSilicon organic compoundsGroup 6/16 organic compounds without C-metal linkagesAlkaline earth metalChemical reaction

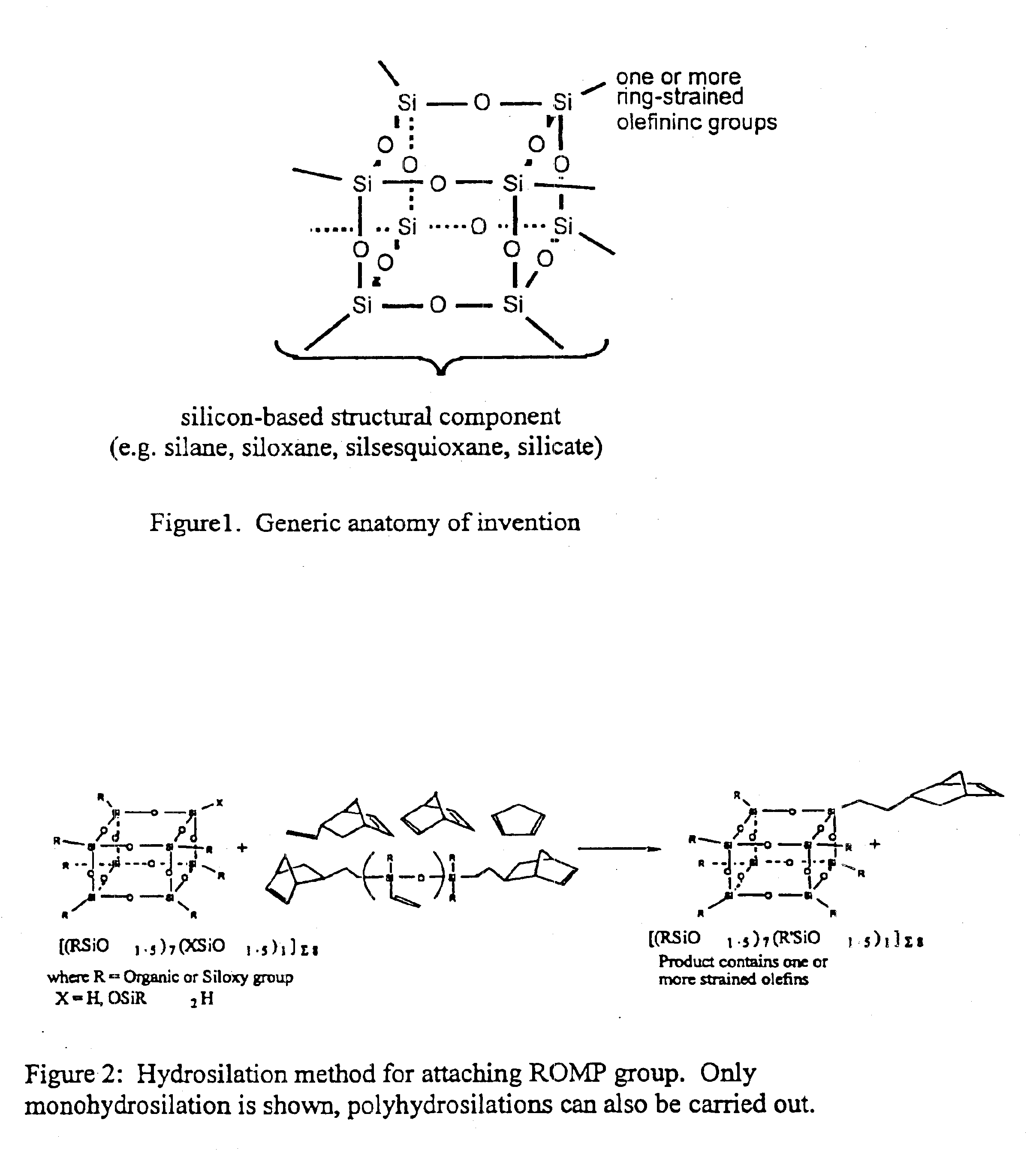

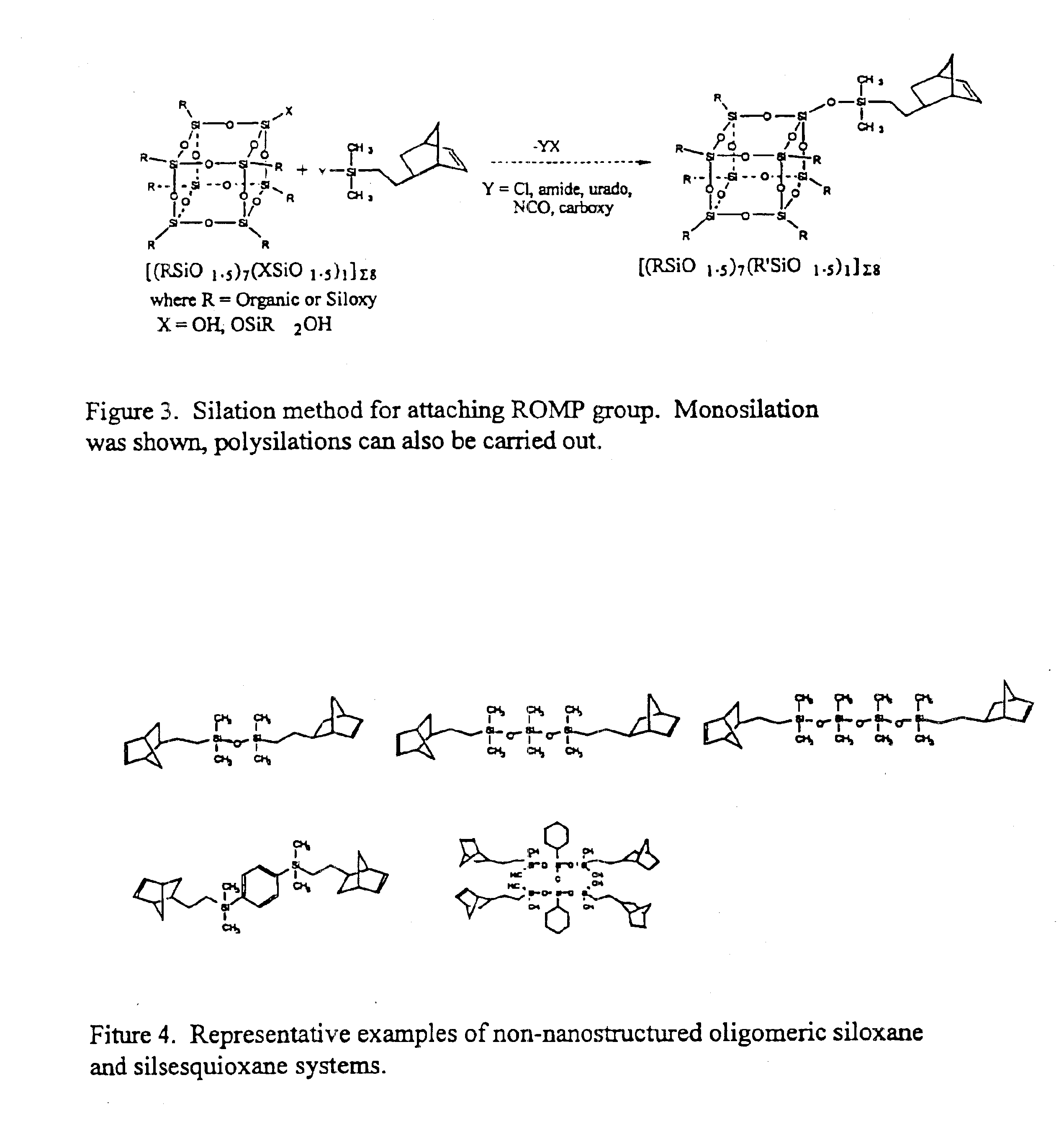

Processes have been developed for the manufacture of polyhedral oligomeric silsesquioxanes (POSS), polysilsesquioxanes, polyhedral oligomeric silicates (POS), and siloxane molecules bearing reactive ring-strained cyclic olefins (e.g. norbornenyl, cyclopentenyl, etc. functionalities). The preferred manufacturing processes employ the silation of siloxides (Si—OA, where A=H, alkaline or alkaline earth metals) with silane reagents that contain at least one reactive ring-strained cyclic olefin functionality [e.g., X3-ySi(CH3)y(CH2)2 where y=1-2 and X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R]. Alternatively, similar products can be prepared through hydrosilation reactions between silanes containing at least one silicon-hydrogen bond (Si—H) with ring-strained cyclic olefin reagents [e.g., 5-vinyl, 2 norbornene CH2═CH, cyclopentadiene]. The two processes can be effectively practiced using polymeric silsesquioxanes [RSiO1.5]∞ where ∞=1-1,000,000 or higher and which contain unreacted silanol or silane groups at chain terminus or branch points, on POSS nanostructures of formulas [(RSiO1.5)n]Σ#, homoleptic, [(RSiO1.5)m(R′SiO1.5)n]Σ#, heteroleptic, and {(RSiO1.5)m(RXSiO1.0)n}Σ#, functionalized heteroleptic nanostructures, on silanes RSiX3, linear, cyclic, oligomeric and polymeric siloxanes (polymeric formula RX2Si—(OSiRX)m—OSiRX2 where m=0-1000, X=OH, Cl, Br, I, alkoxide OR, acetate OOCR, peroxide OOR, amine NR2, isocyanate NCO, and R). Each of the processes result in new chemical species bearing one or more ring strained olefins that can undergo polymerization, grafting, or other desirable chemical reactions to form polymeric products. These polymeric systems are most desirably utilized in polymerizations for the modification of properties of thermoplastic or thermoset resin systems or for the preparation of polymers with utility in electronics, medical devices, sporting goods, and aerospace as coatings and structural components.

Owner:HYBRID PLASTICS INC

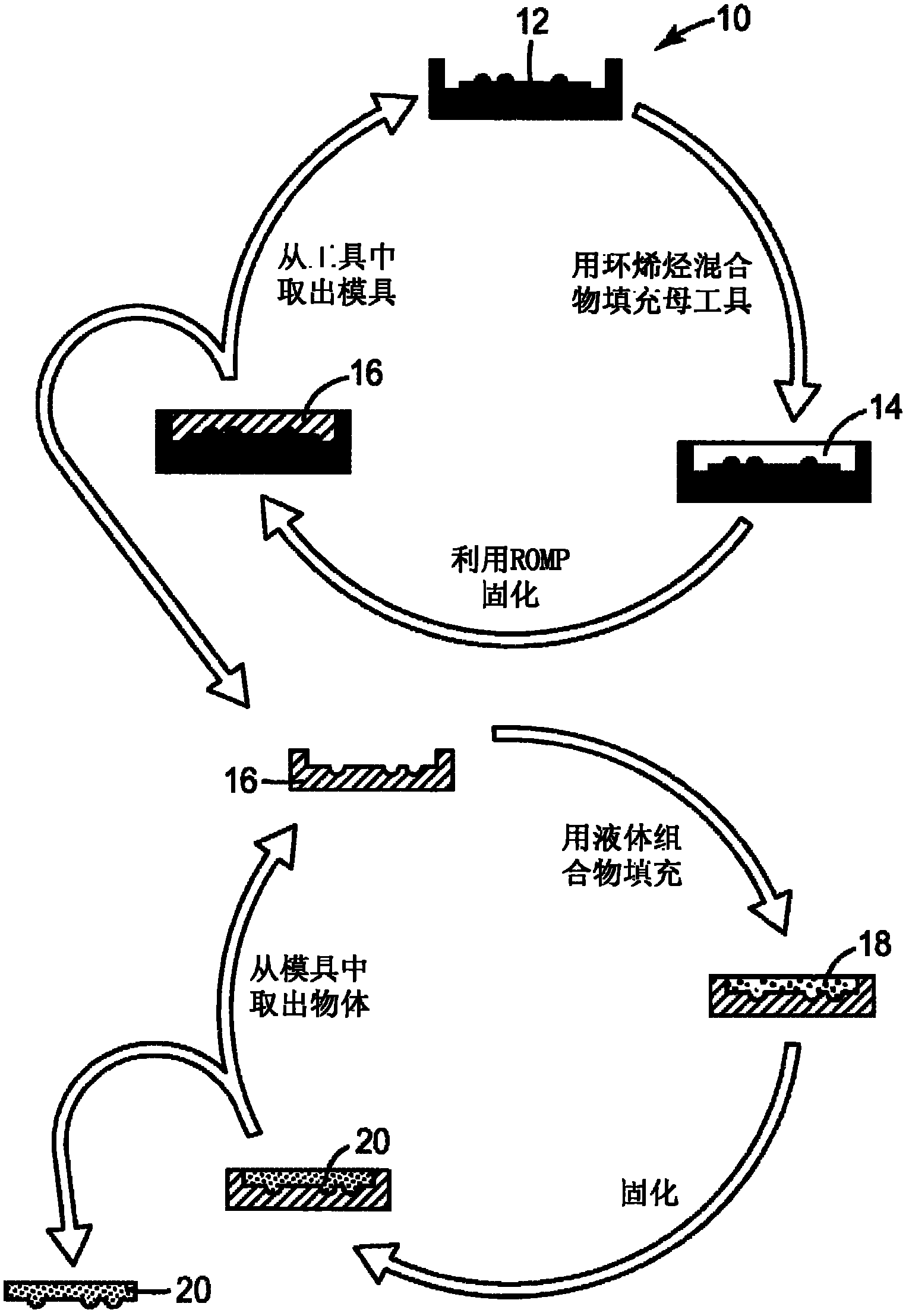

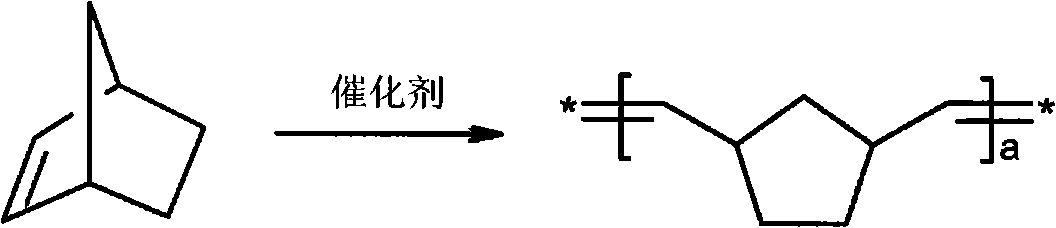

Polymeric molds and articles made therefrom

Disclosed herein are polymeric molds that can be used to make molded articles. The polymeric molds are made from cyclic olefin polymers that may be formed by ring opening metathesis polymerization (ROMP) of a polycyclic monomer having two or more reactive double bonds and a cyclic monomer comprising one reactive double bond. Fluorinated monomers may be used. The polymeric molds may be structured molds in that they have at least one microstructured feature having a dimension of less than about 2 mm, or less than about 500 um. The polymeric molds may also have a plurality of such microstructured features. Also disclosed herein are methods of making the polymeric molds, methods of making molded articles therefrom, and the molded articles.

Owner:3M INNOVATIVE PROPERTIES CO

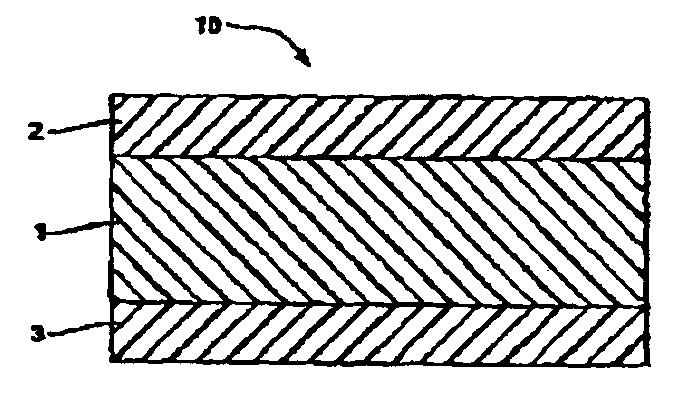

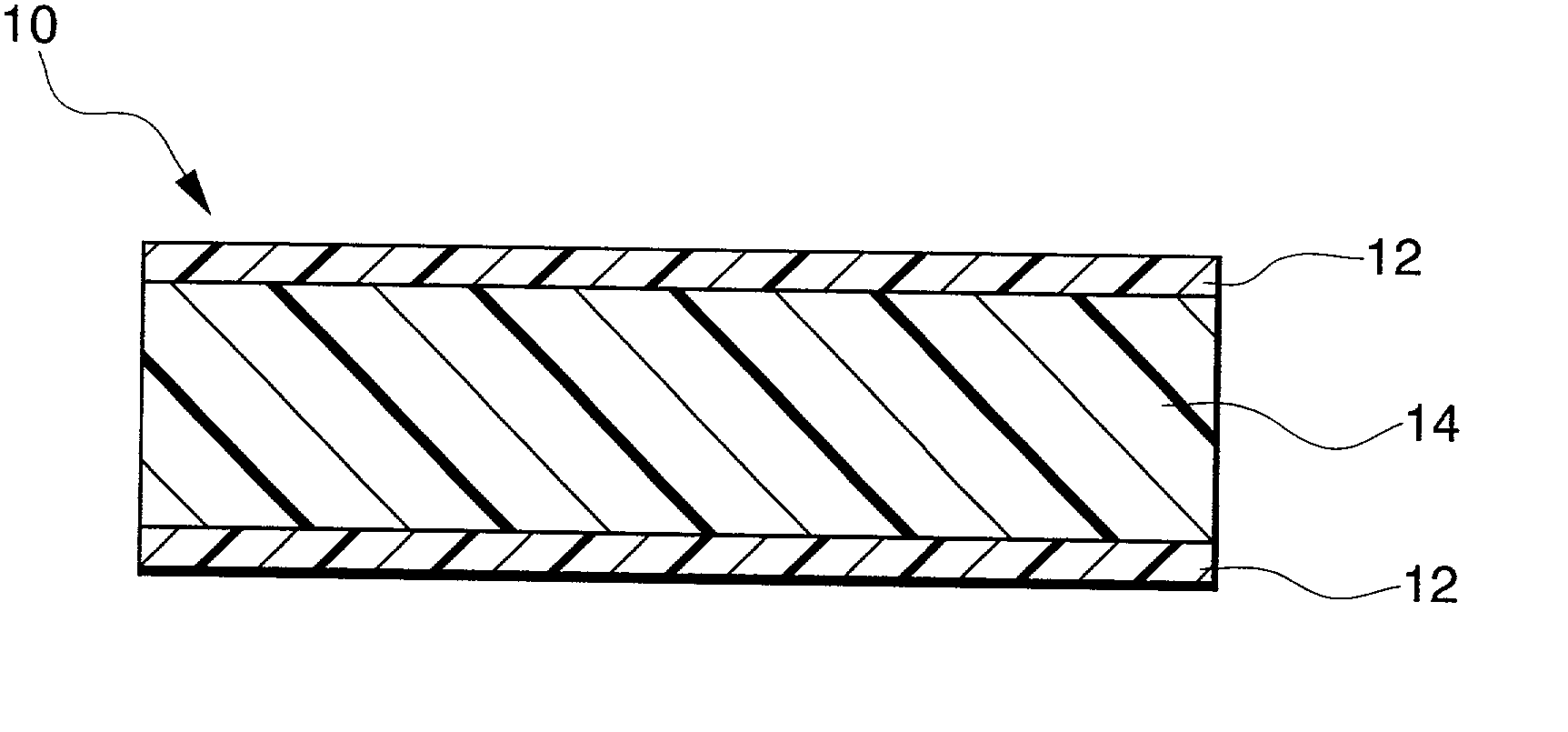

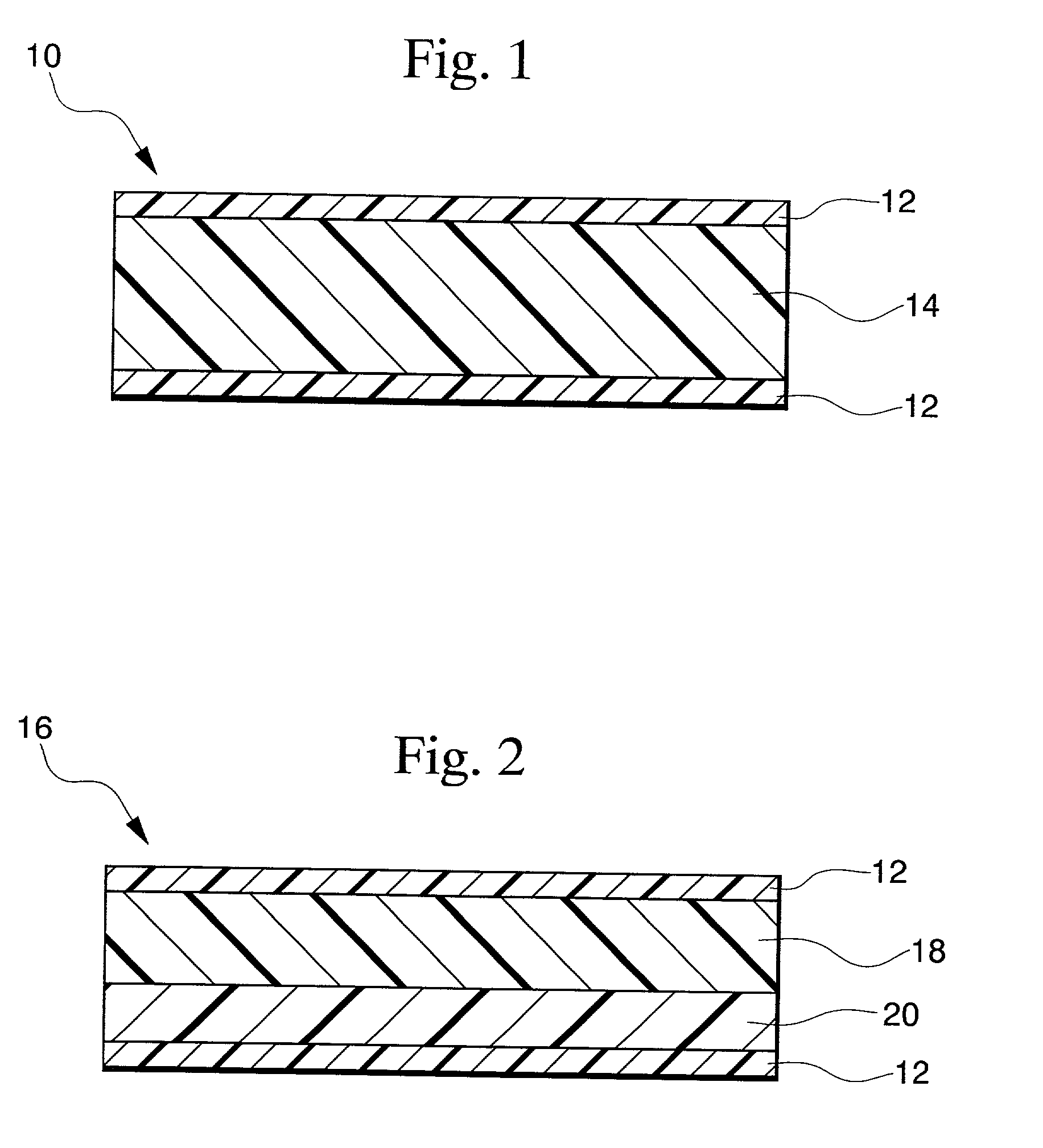

Heat shrinkable polyolefin film

InactiveUS20020192412A1Advantage in productivityAdvantage in recyclingBottlesSynthetic resin layered productsInter layerPolyolefin

The present invention relates to a heat shrinkable polyolefin film preferably for a label to be attached to a PET bottle and the like. Improvement of in the lightness, the solvent sealing property, and transparency is an object. The heat shrinkable polyolefin film according to the present invention is a laminate comprising surface layers composed of a resin material containing a specific cyclic olefin resin as a main component, and an intermediate layer composed of a resin material containing a polyethylene resin as a main component.

Owner:CI KASEI COMPANY

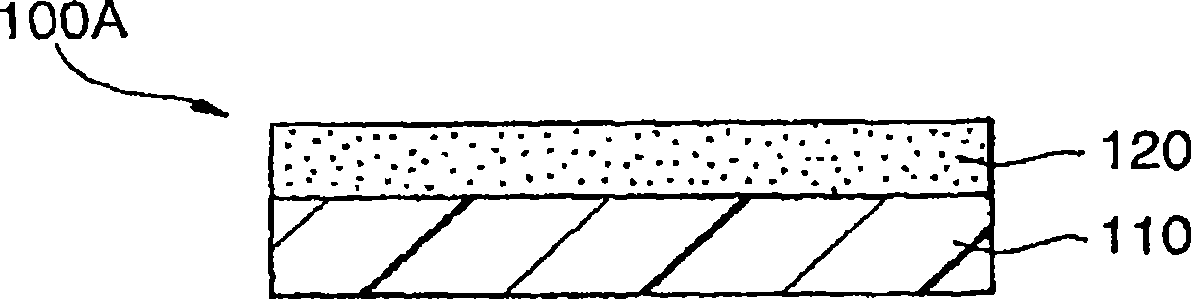

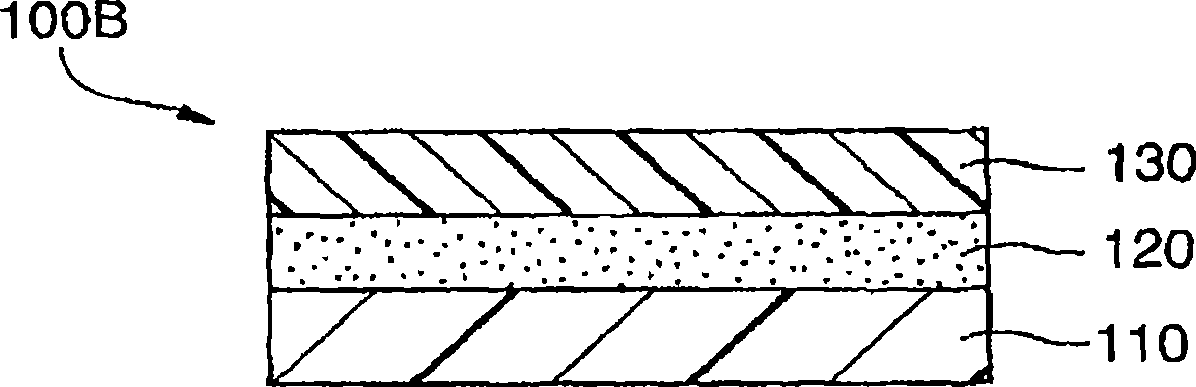

Adhesive encapsulating composition film and organic electroluminescence device

InactiveCN101370889AImprove maneuverabilityImprove featuresThin material handlingLuminescent compositionsOrganic electroluminescenceCyclic Olefins

An adhesive encapsulating composition and an encapsulating film, which are useful as an encapsulant for an organic electroluminescence device or other electronic devices is provided. The adhesive encapsulating composition includes a hydrogenated cyclic olefin-based polymer and a polyisobutylene resin having a weight average molecular weight of 500,000 or more. Some embodiments of the adhesive encapsulating composition include a hydrogenated cyclic olefin-based polymer, a polyisobutylene resin having a weight average molecular weight of 500,000 or more, a photocurable resin, and a photopolymerization initiator.

Owner:3M INNOVATIVE PROPERTIES CO

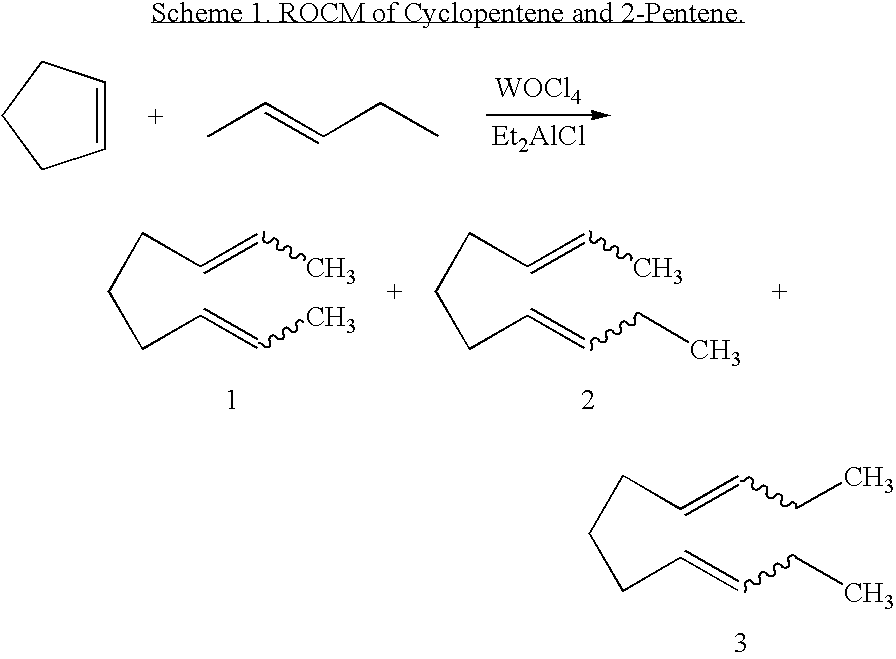

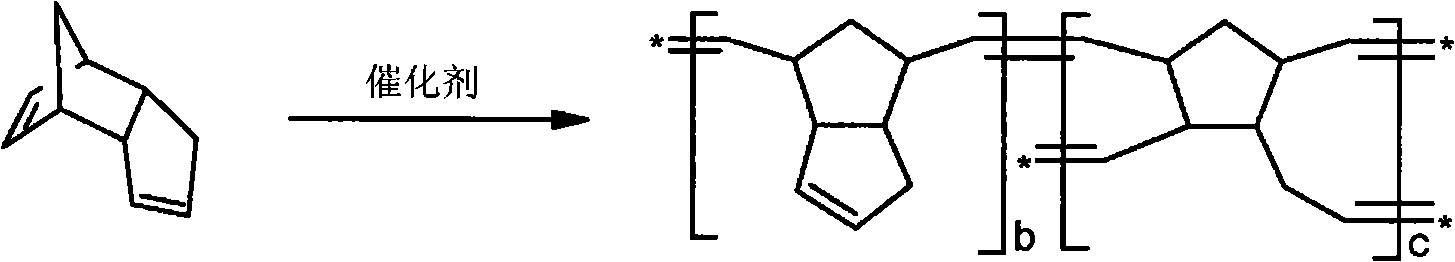

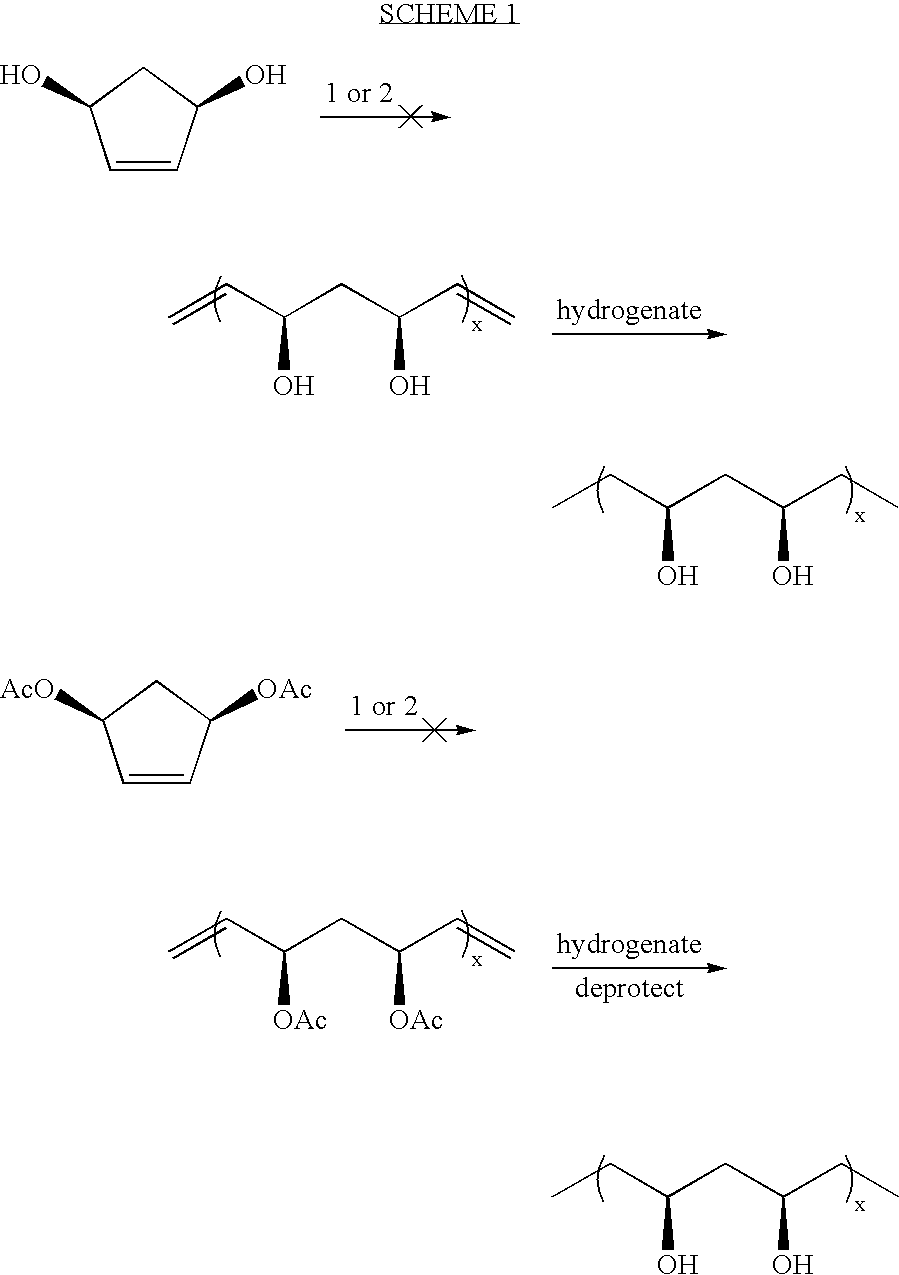

Synthesis of A,B-alternating copolymers by olefin metathesis reactions of cyclic olefins or olefinic polymers with an acyclic diene

InactiveUS6987154B2Limited utilityImproves inventionGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceOlefin polymerization

This invention relates generally to synthetic procedures that include the step of ring-opening metathesis of cyclic olefins and reaction with an acyclic diene co-reactant to produce regularly repeating A,B-alternating olefin polymers. The A,B-alternating polymers are produced by varying reaction conditions and / or reactant proportions and using only two types of olefin metathesis (ring-opening and cross) to provide regularly repeating ABAB . . . etc. polymers via ring-opening metathesis polymerization (ROMP). More particularly, the invention pertains to synthesis of A,B-alternating olefin polymers via olefin metathesis reactions using a Group 8 transition metal complex as the metathesis catalyst. Polymers provided herein have utility in a variety of fields, including not only polymer chemistry per se, but also in the pharmaceutical, biomedical, and packaging industries where the structure and properties of polymers need to be tightly controlled.

Owner:CALIFORNIA INST OF TECH

Cyclo olefin polymer and copolymer medical devices

An illuminated medical system comprises a medical instrument and a light transmitting waveguide. The waveguide projects lights from a distal portion of the waveguide toward a target area. The waveguide is formed primarily of a cyclic olefin copolymer or a cyclic olefin polymer.

Owner:INVUITY

Process for producing hydrogenated product of cyclic olefin polymer prepared through ring-opening polymerization

A process for producing a hydrogenated product of a polymer prepared through ring-opening polymerization which comprises a polymerization step of polymerizing a cyclic olefin through ring-opening polymerization in the presence of a polymerization catalyst comprising an organoruthenium compound or an organoosmium compound to prepare a polymer, and a hydrogenation step of adding a hydrogenation catalyst and hydrogen into a polymerization system resulting from the polymerization step to hydrogenate the carbon-carbon double bonds of the polymer prepared through the ring-opening polymerization. When the organoruthenium compound- or organoosmium compound-containing catalyst further comprises a carbene compound, the catalyst exhibits a higher activity for the ring-opening polymerization.

Owner:ZEON CORP

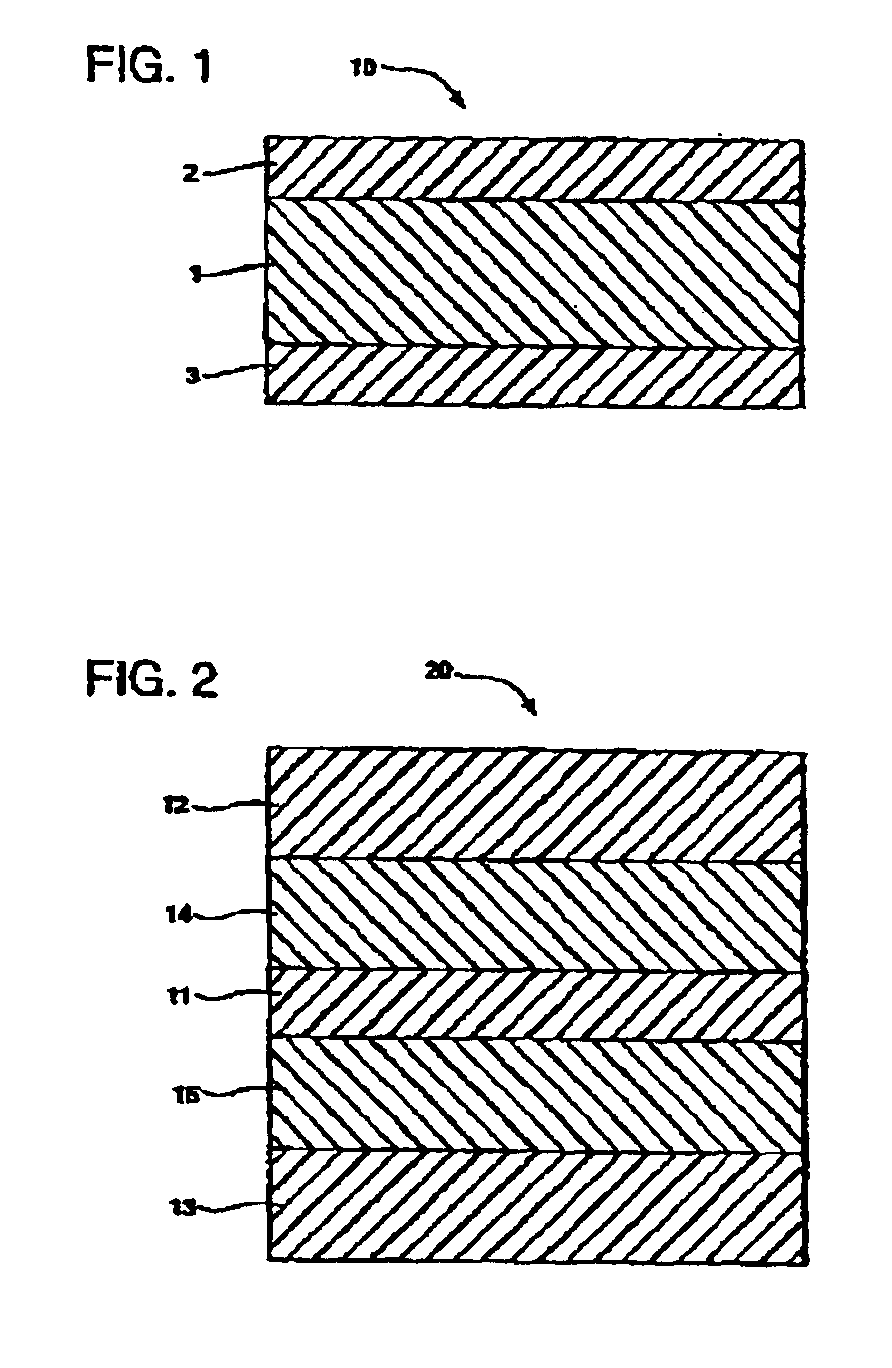

Heat shrink films and articles encapsulated therein

InactiveUS20090068486A1Synthetic resin layered productsDomestic containersPolymer scienceThin membrane

The present invention relates to a heat shrink film for encapsulating articles comprising a core layer having an upper surface and a lower surface, a first skin layer on the upper surface of the core layer, and a second skin layer underlying the lower surface of the core layer, wherein the core layer comprises a blend of (i) at least one polyterpene and (ii) a syndiotactic polypropylene or a cyclic olefin copolymer, wherein the ultimate shrinkage of the film is at least 25% at 135° C.

Owner:AVERY DENNISON CORP

Ultrasonic end stops on zipper closure bags and methods for making same

ActiveUS7267856B2Reduce thicknessEnvelopes/bags making machineryWrappersHigh densityCyclic olefin copolymer

Ultrasonic end stops and methods of making ultrasonic end stops are provided The present invention relates to plastic reclosable fasteners with sliders for opening and closing the reclosable fasteners on plastic bags and the like and particularly to the use of protruding end stop structures on reclosable fasteners to prevent travel of sliders past the fastener ends The end stop structures include at least one of high density polyethylene, medium density polyethylene, polypropylene, a cyclic olefin copolymer, a high density material, or a high modulus material and may optionally include low density polyethylene or linear low density polyethylene

Owner:REYNOLDS CONSUMER PROD INC

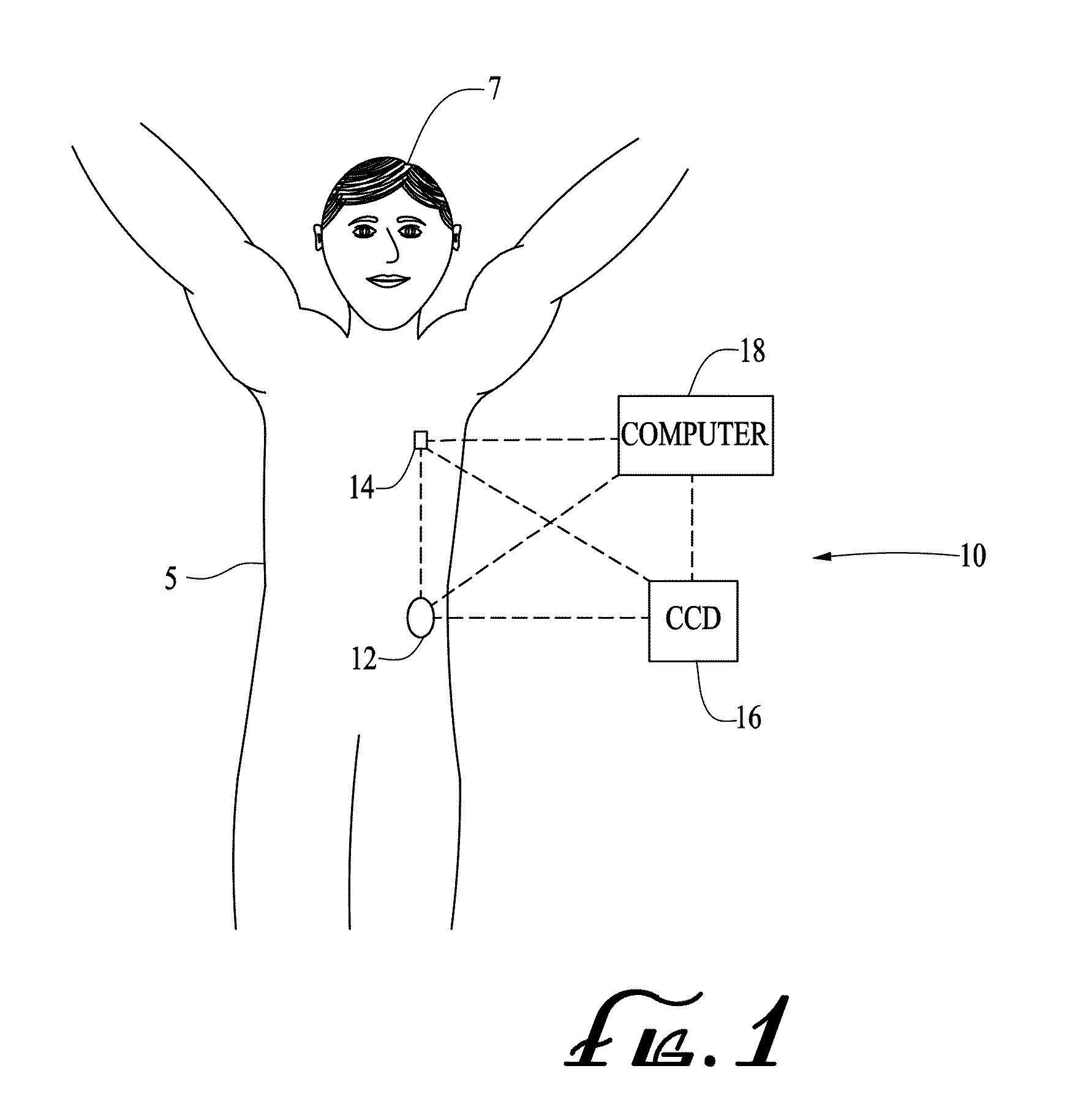

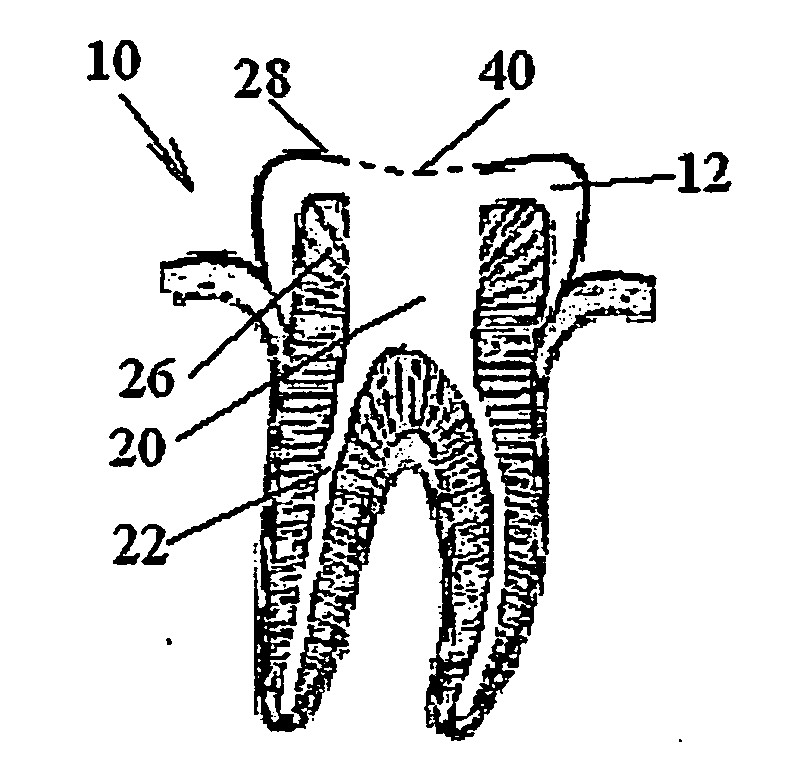

Photo-sterilization

InactiveUS20070072153A1Excellent light diffusionHigh light transmittanceDisinfectionLight therapyEndodontic therapyMedicine

The present invention provides substances, devices, methods, and kits for photo-sterilization of a root canal, prior to and when performing endodontics, as well as periodically as post-endodontic prophylactic measures. The root-canal filling includes a light-transmitting element, operative as a diffuser, and methods are provided for communicating light to the diffuser, for disinfecting the walls of the root canals, by photo sterilization. The diffuser may be formed of silicone polymers, synthetic fused silica, quartz or the like, and may be surrounded by a light-transmitting sealer. The diffuser may be incorporated with an endodontic post, or a specially designed post, which may be transparent and (or) hollow. In a preferred embodiment, the diffuser is formed of a light transmitting conical shell of Cyclic Olefin Copolymers (COC), filled with a fluid such as air, distilled water, or silicone oil.

Owner:INTERLIGHT

Pipe made from metathesis polymerized olefins

InactiveUS6410110B1Extended validity periodImprove responseLayered productsBottlesPolymer sciencePipe fitting

Thermosetting resin pipes and pipe fittings are provided which are prepared by polymerizing a cyclic olefin monomer in the presence of a ruthenium or osmium metathesis polymerization catalyst. These articles may be prepared by various methods, such as centrifugal casting. Reinforced articles may also be prepared by filament winding.

Owner:A O SMITH +1

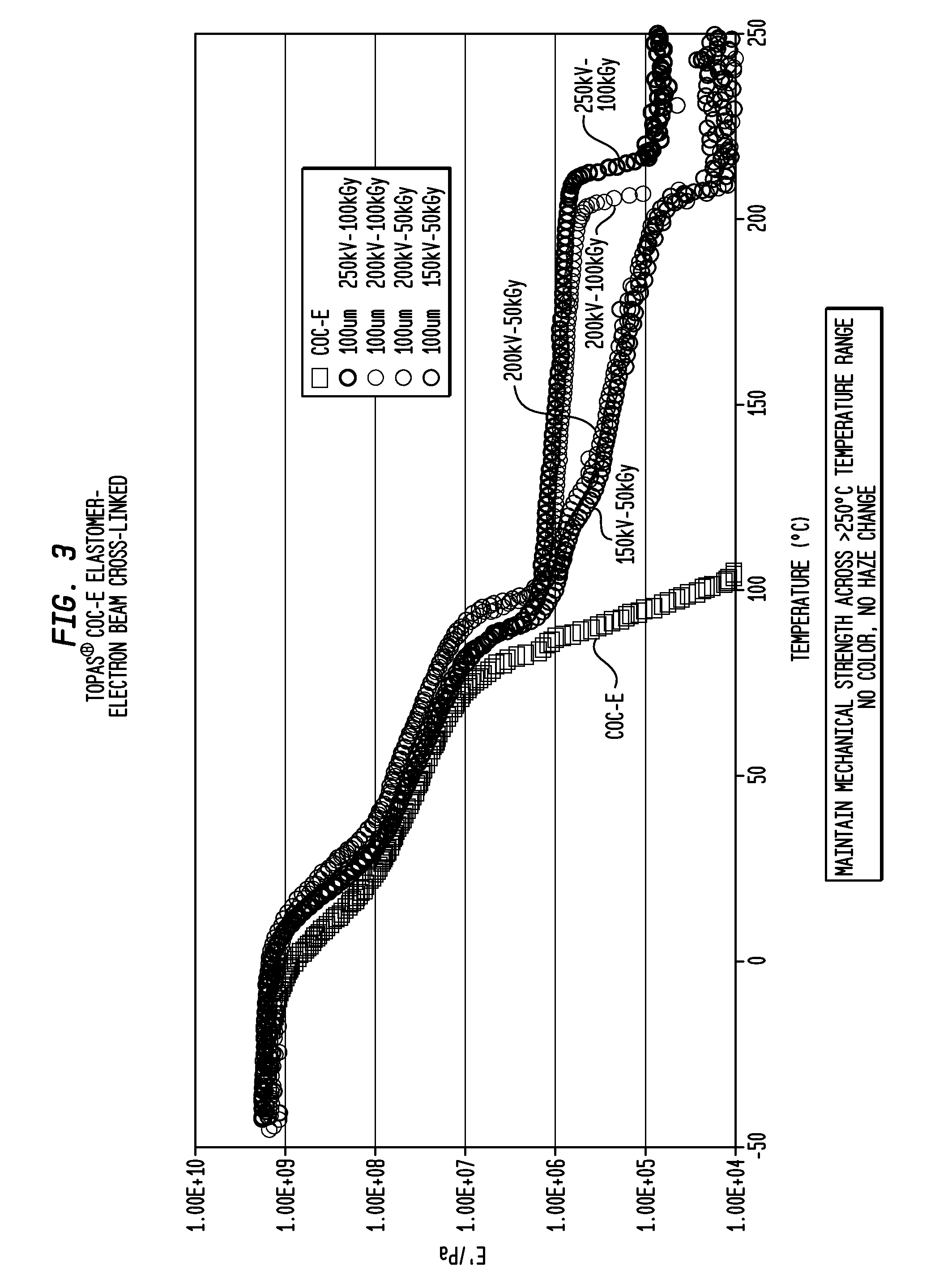

Melt blends of amorphous cycloolefin polymers and partially crystalline cycloolefin elastomers with improved toughness

ActiveUS20110256373A1Simple compositionImprove toughnessSynthetic resin layered productsThin material handlingElastomerCyclo olefin polymer

A melt-blend resin composition prepared by melt-blending includes from 60 parts to 99 parts per hundred weight resin in the blend of an amorphous cycloolefin polymer composition exhibiting a glass transition temperature in the range of from 30° C. to 200° C.; and from 40 parts to 1 part per hundred weight resin in the blend of a partially crystalline, cycloolefin elastomer of norbornene and ethylene preferably having a glass transition temperature in the range of from −10° C. to 15° C. and a crystalline melting temperature in the range of from 60° C. to 125° C. and a % crystallinity by weight in the range of from 5% to 40%. The partially crystalline, cycloolefin elastomer optionally has a second glass transition temperature at less than −90° C.

Owner:TOPAS ADVANCED POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com