Patents

Literature

5551 results about "Blow molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blow molding (BrE moulding) is a specific manufacturing process by which hollow plastic parts are formed and can be joined together. It is also used for forming glass bottles or other hollow shapes.

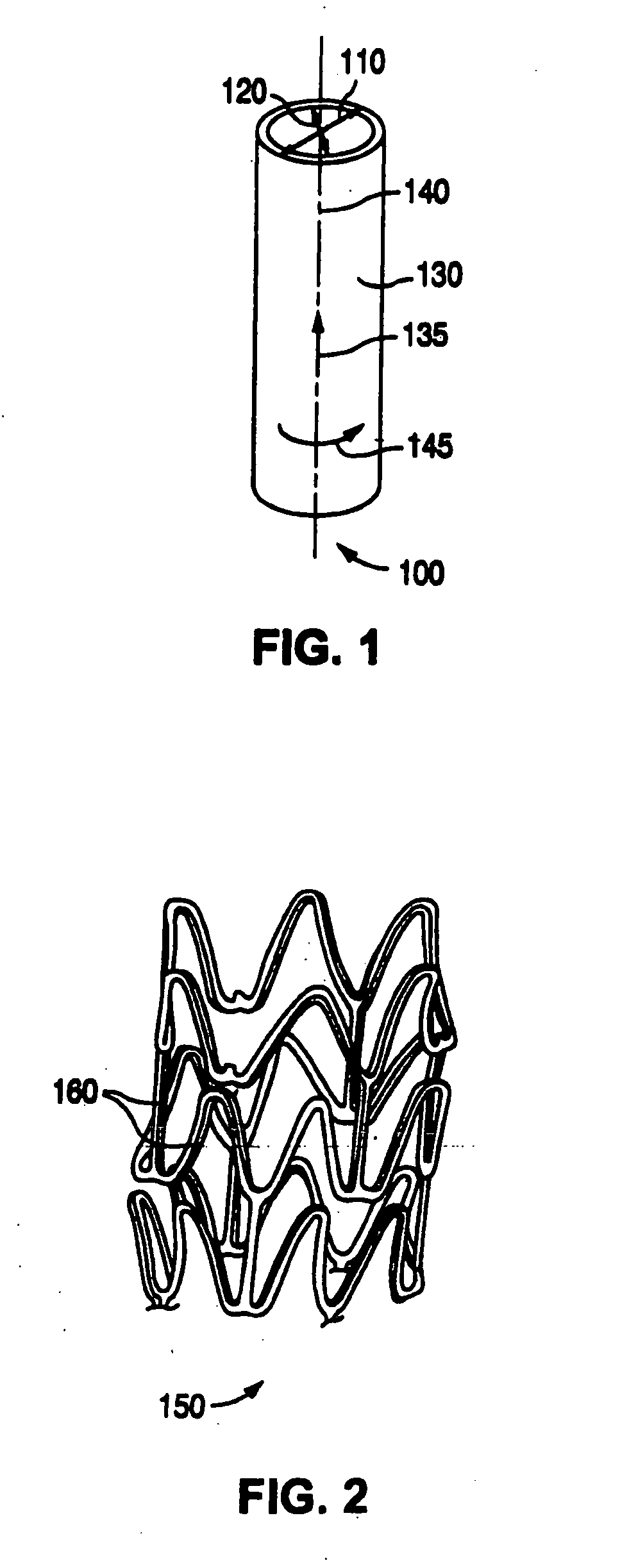

Polymeric Stent

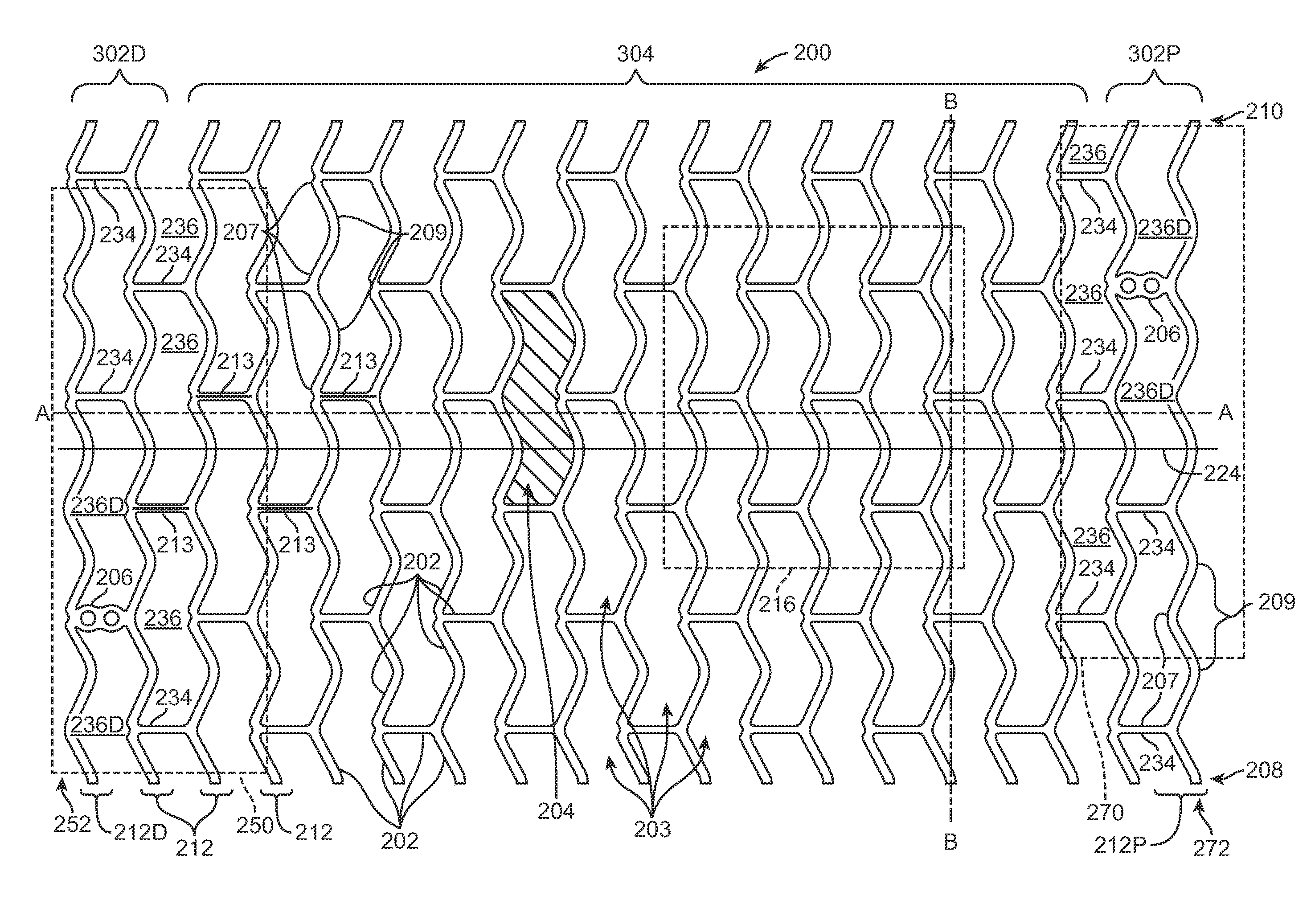

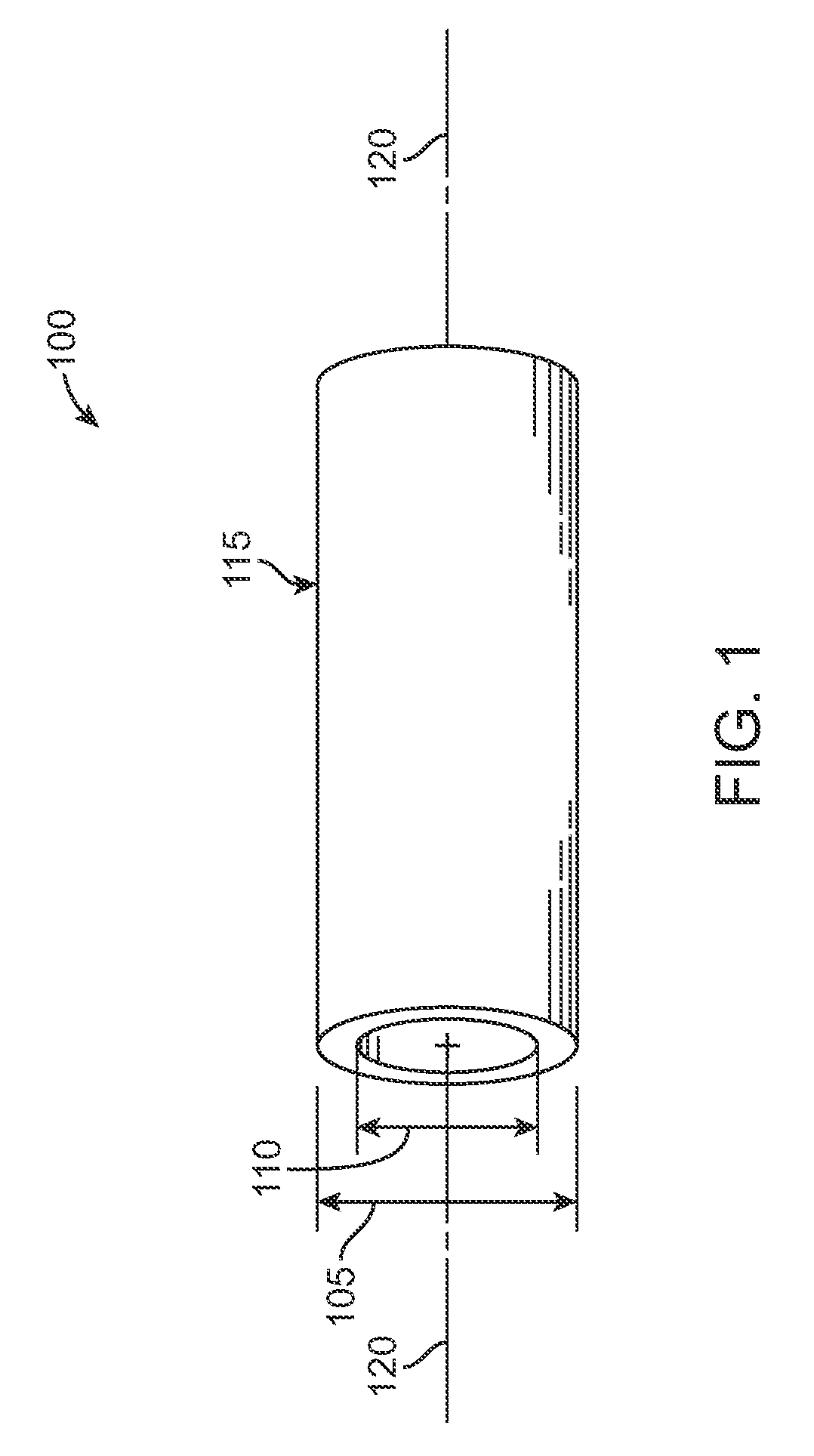

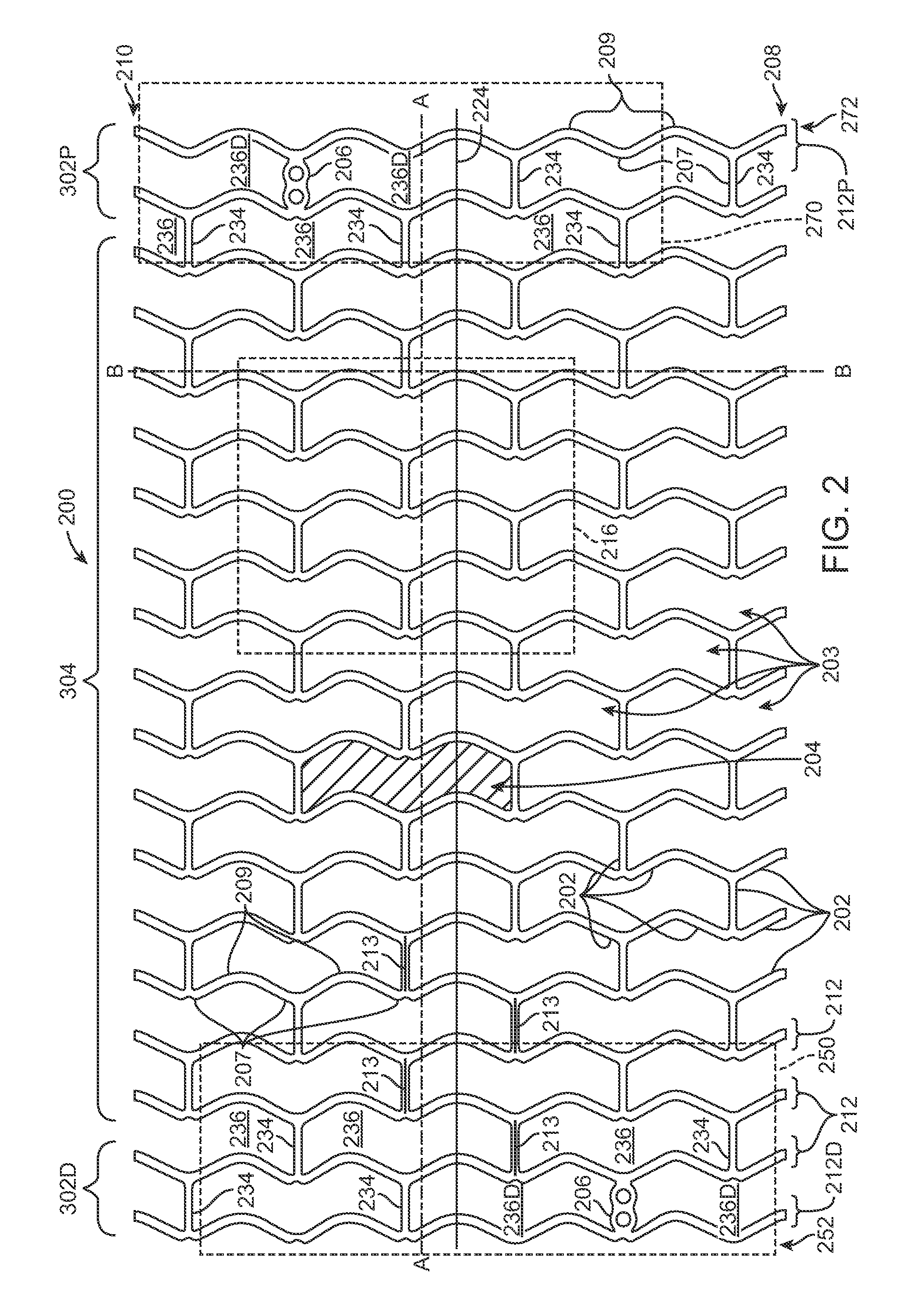

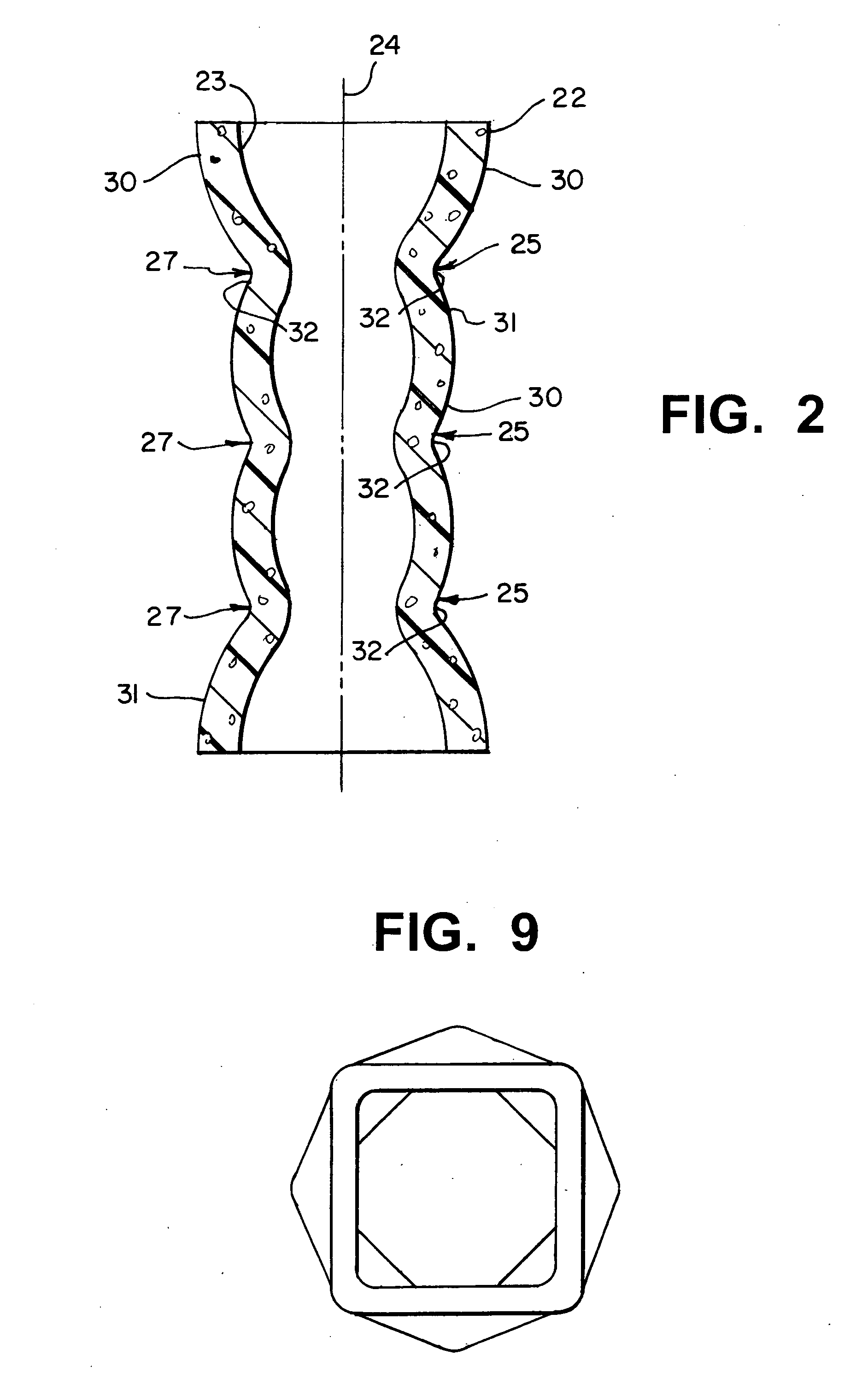

A strut pattern of an endoprosthesis includes a plurality of W-shape cells that define a tubular body, the W-shaped cells at the opposite ends of the tubular body have a modified configuration that is different than the W-shaped cells at the middle portion of the tubular body. At the distal end of the tubular body, the W-shaped cells have crests with axial positions that are axially spaced apart, and have troughs with circumferential positions that are spaced apart. At the intermediate and distal end of the tubular body, the W-shaped cells crests with axial positions that coincide and have troughs with circumferential positions that coincide. The strut pattern is cut from a tubular precursor construct made of PLLA that has been radially expanded and axially extended by blow molding.

Owner:ABBOTT CARDIOVASCULAR

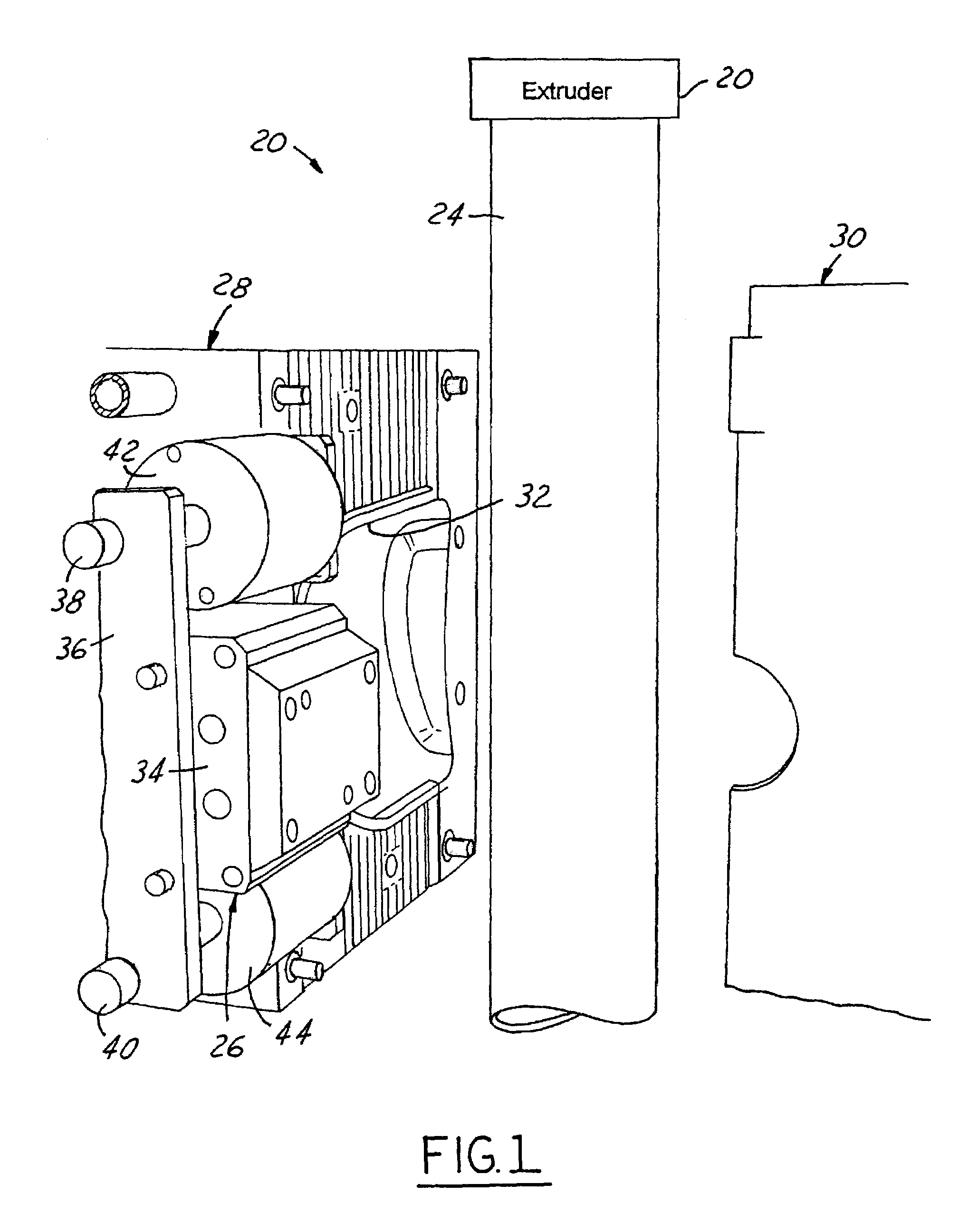

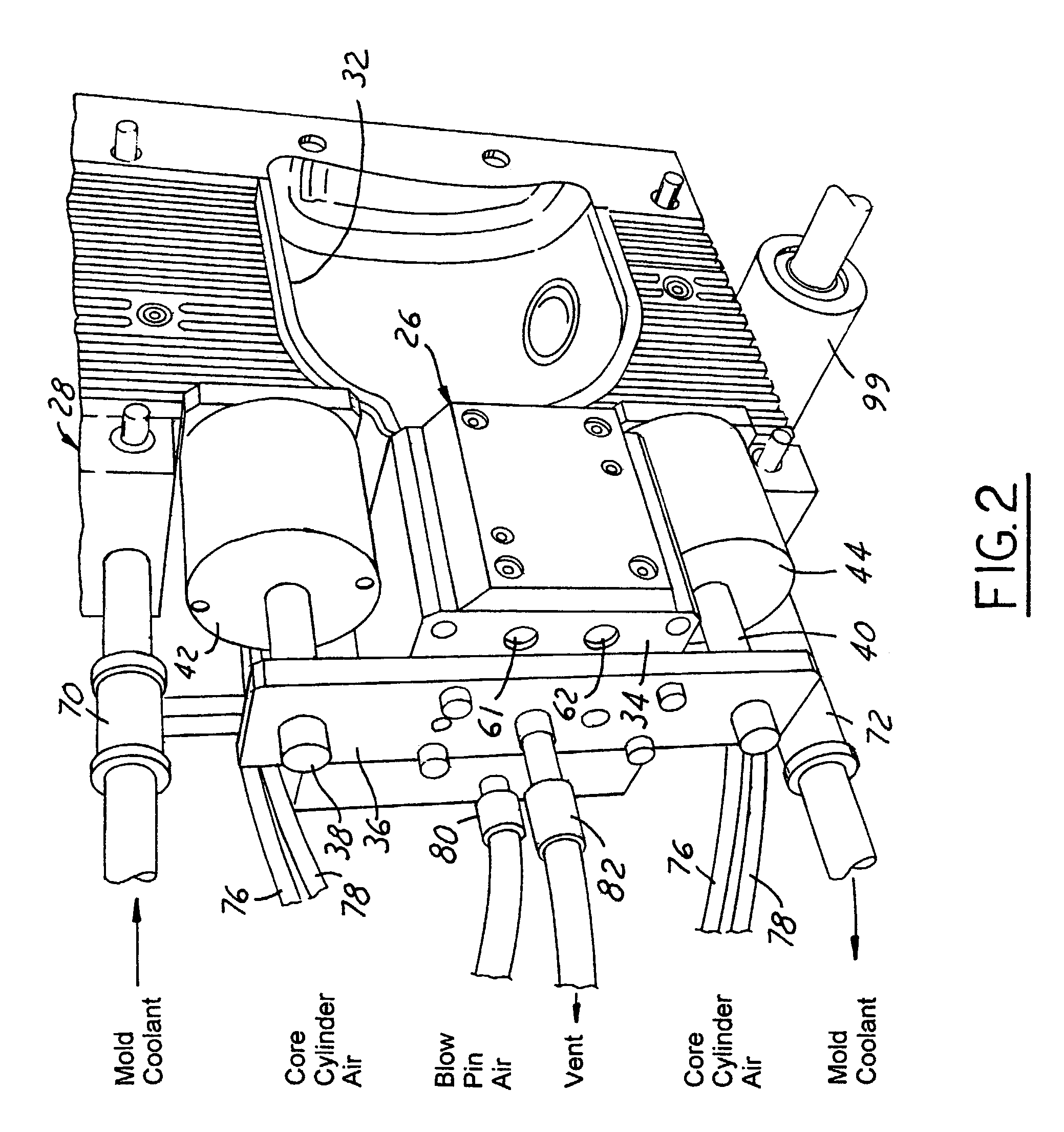

Method and apparatus for blow molding hollow plastic containers

Owner:GRAHAM PACKAGING PLASTIC PRODS

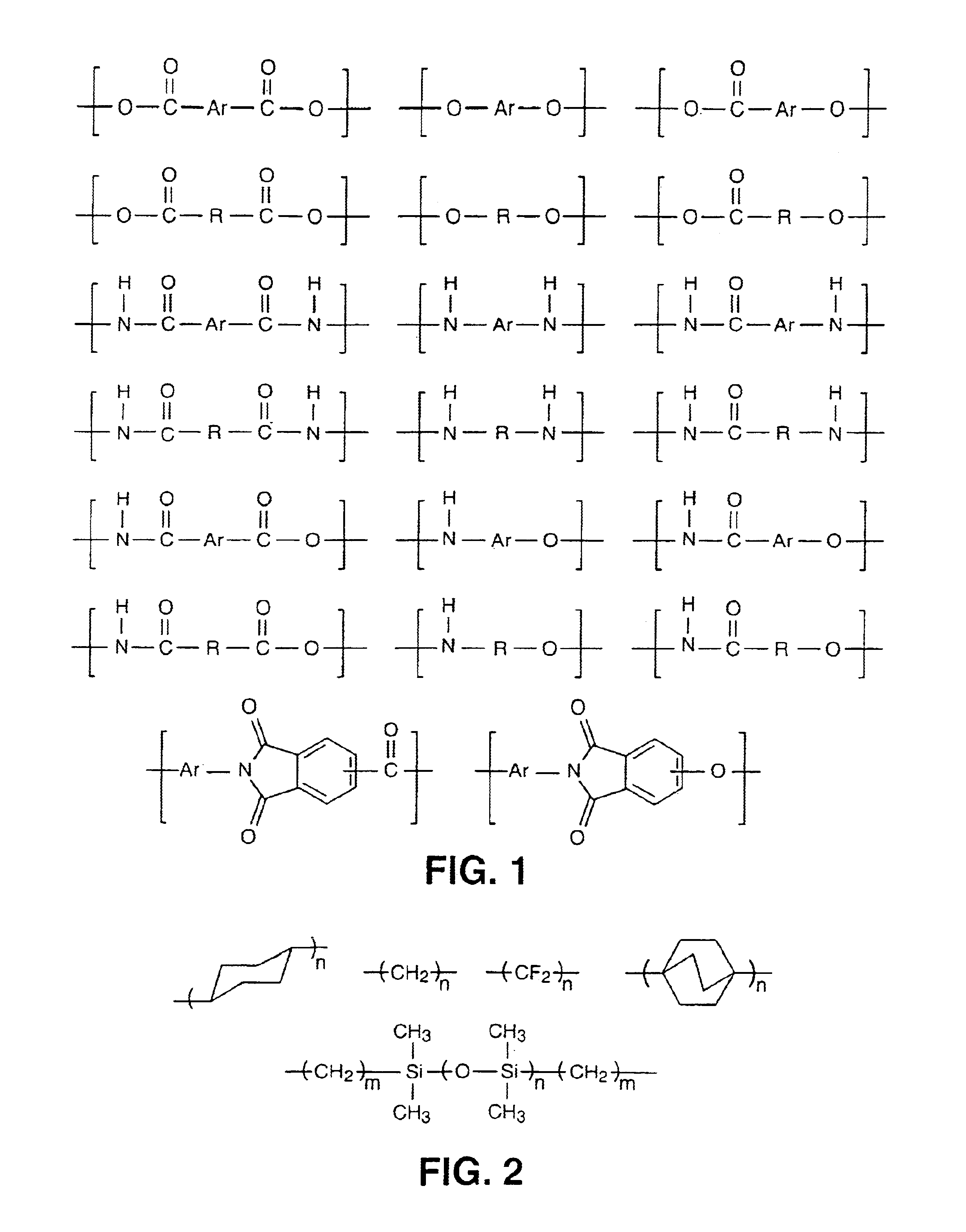

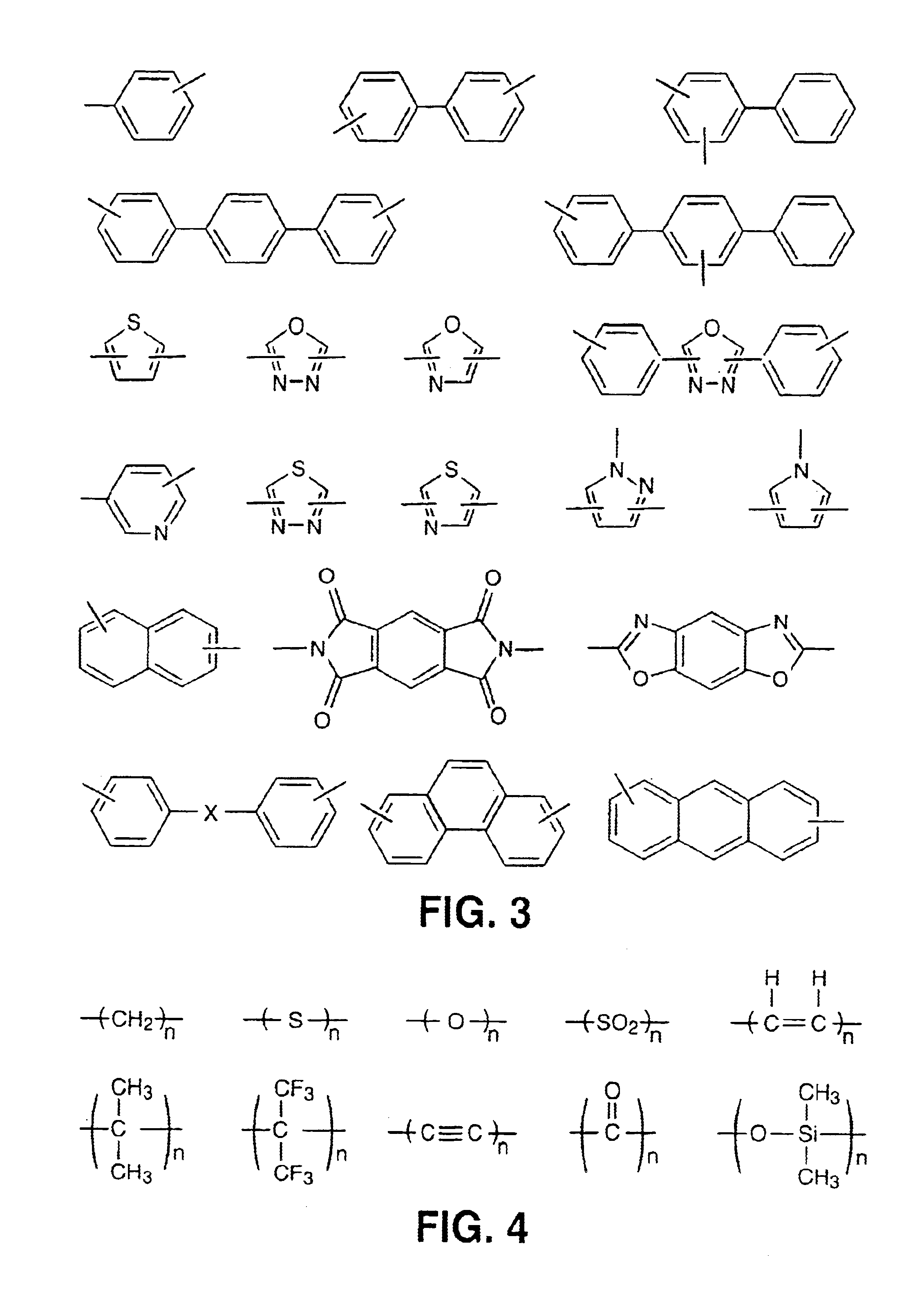

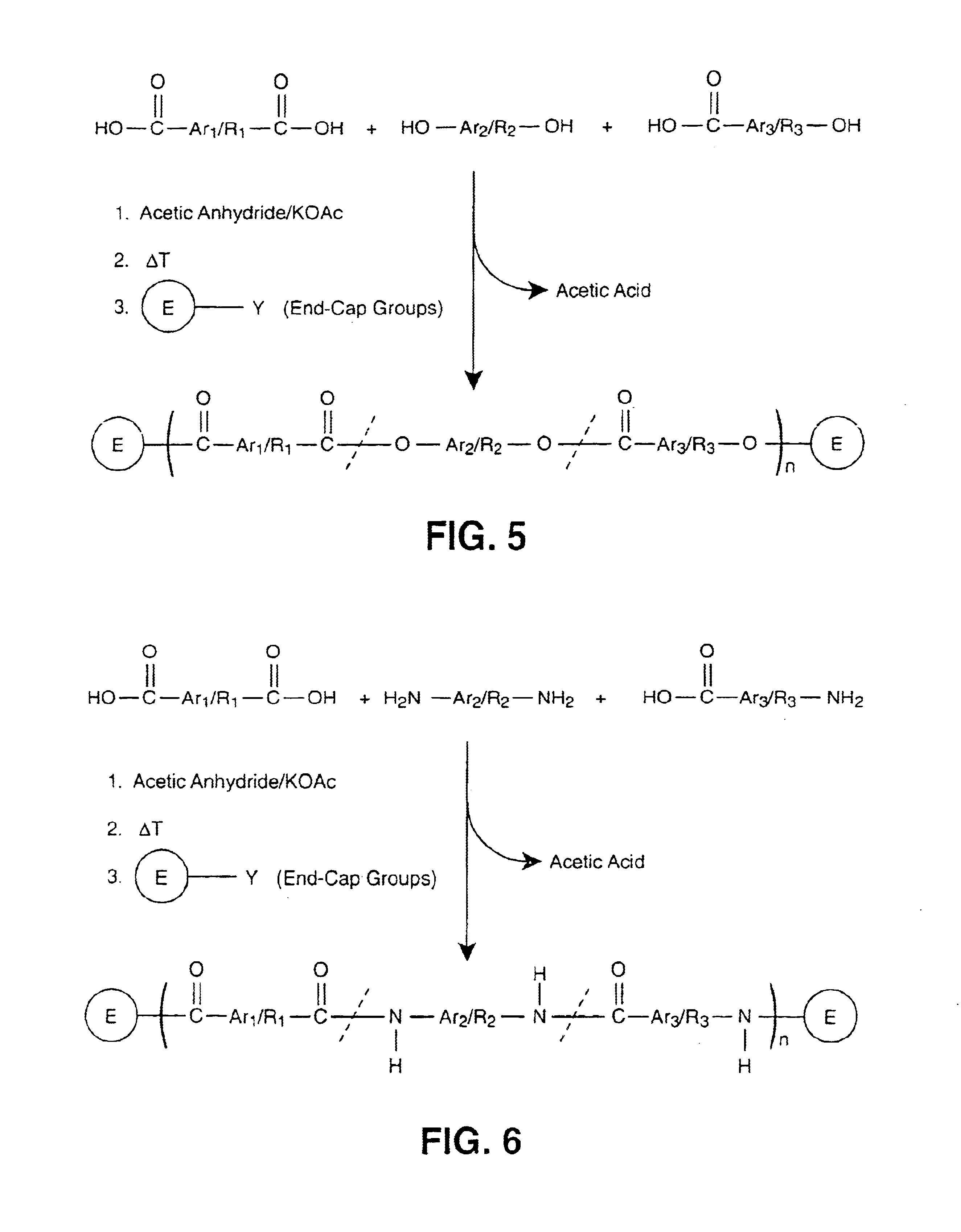

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

InactiveUS6939940B2Low viscosityLow dielectric constantLiquid crystal compositionsLiquid crystallineEnd-group

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

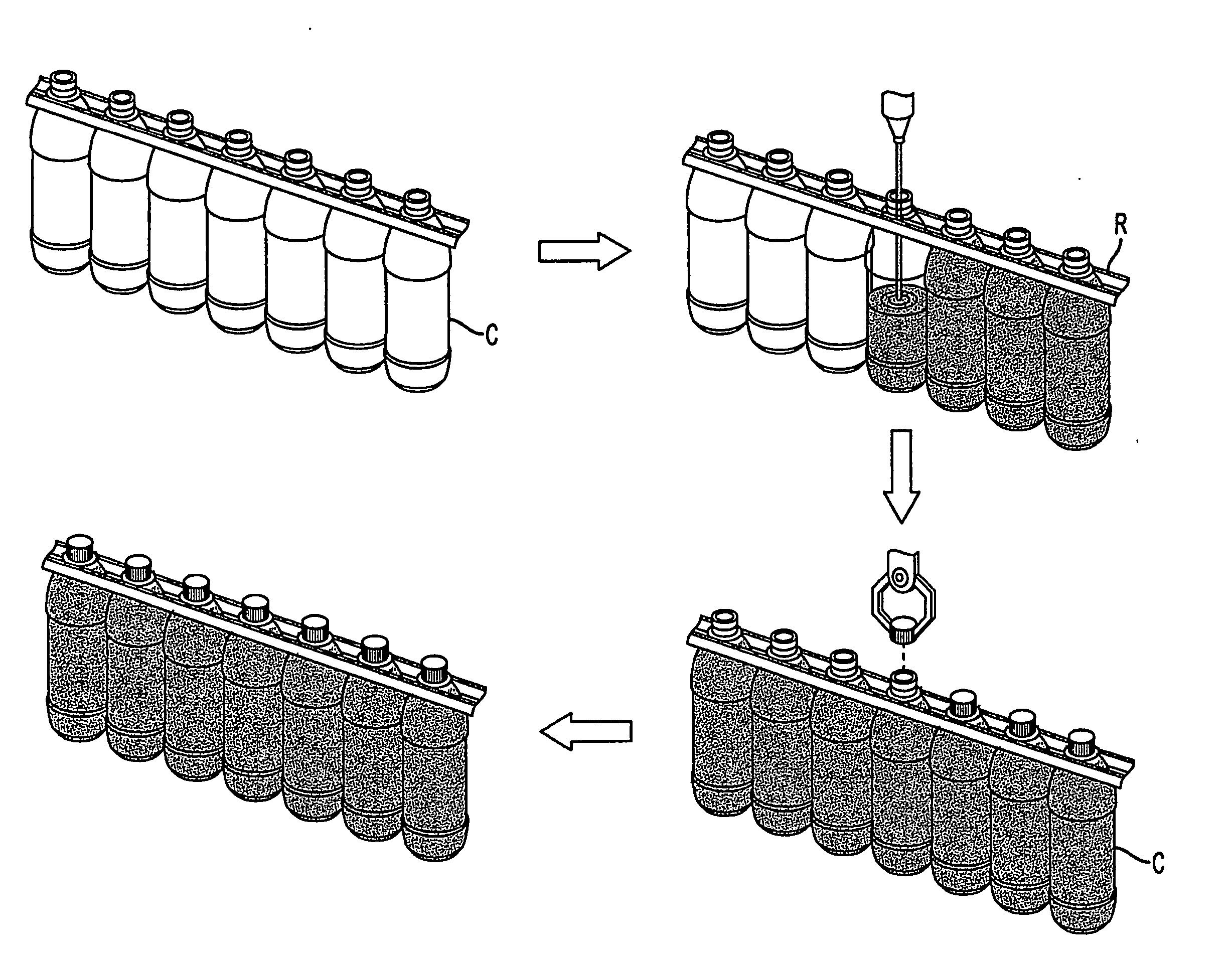

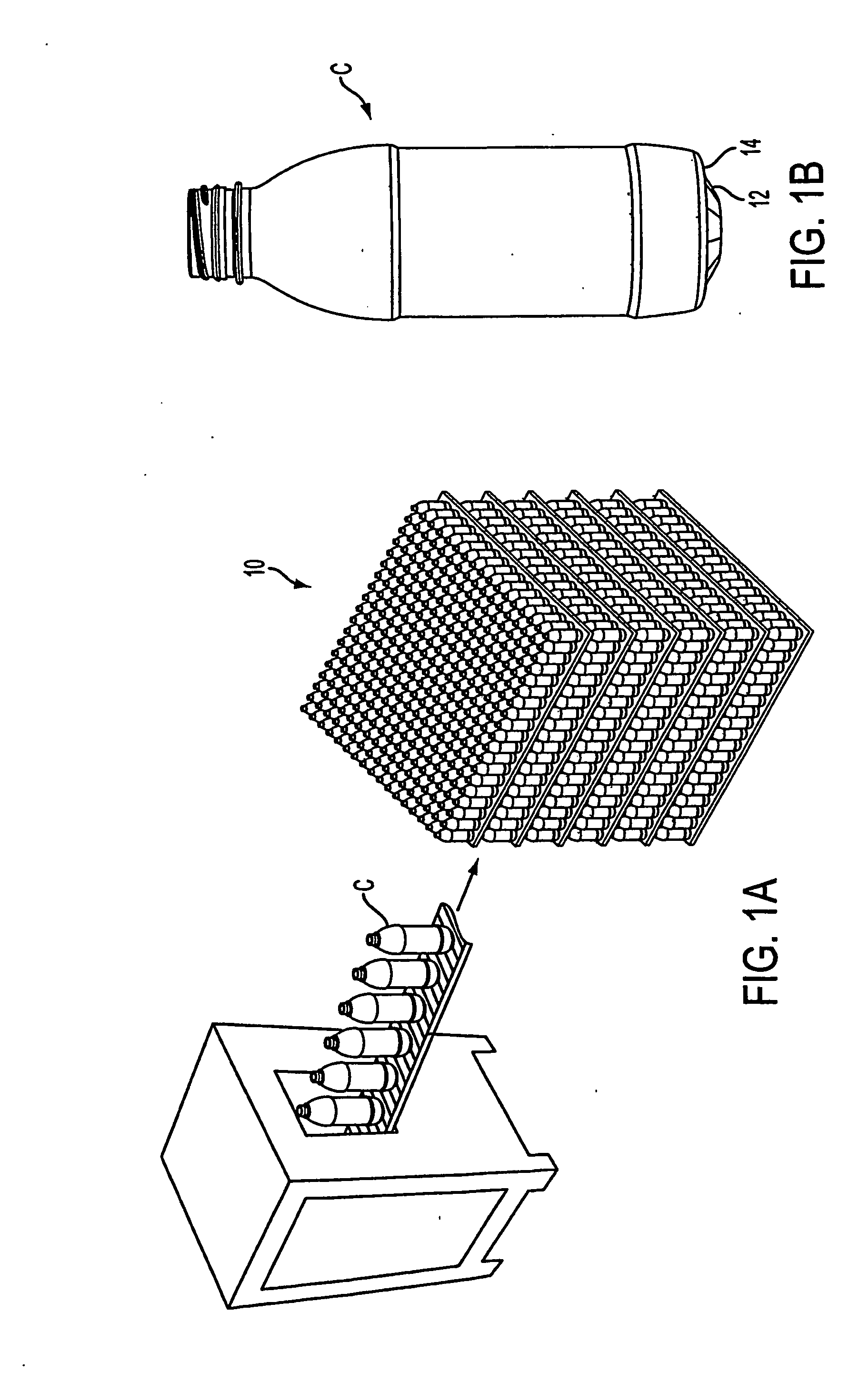

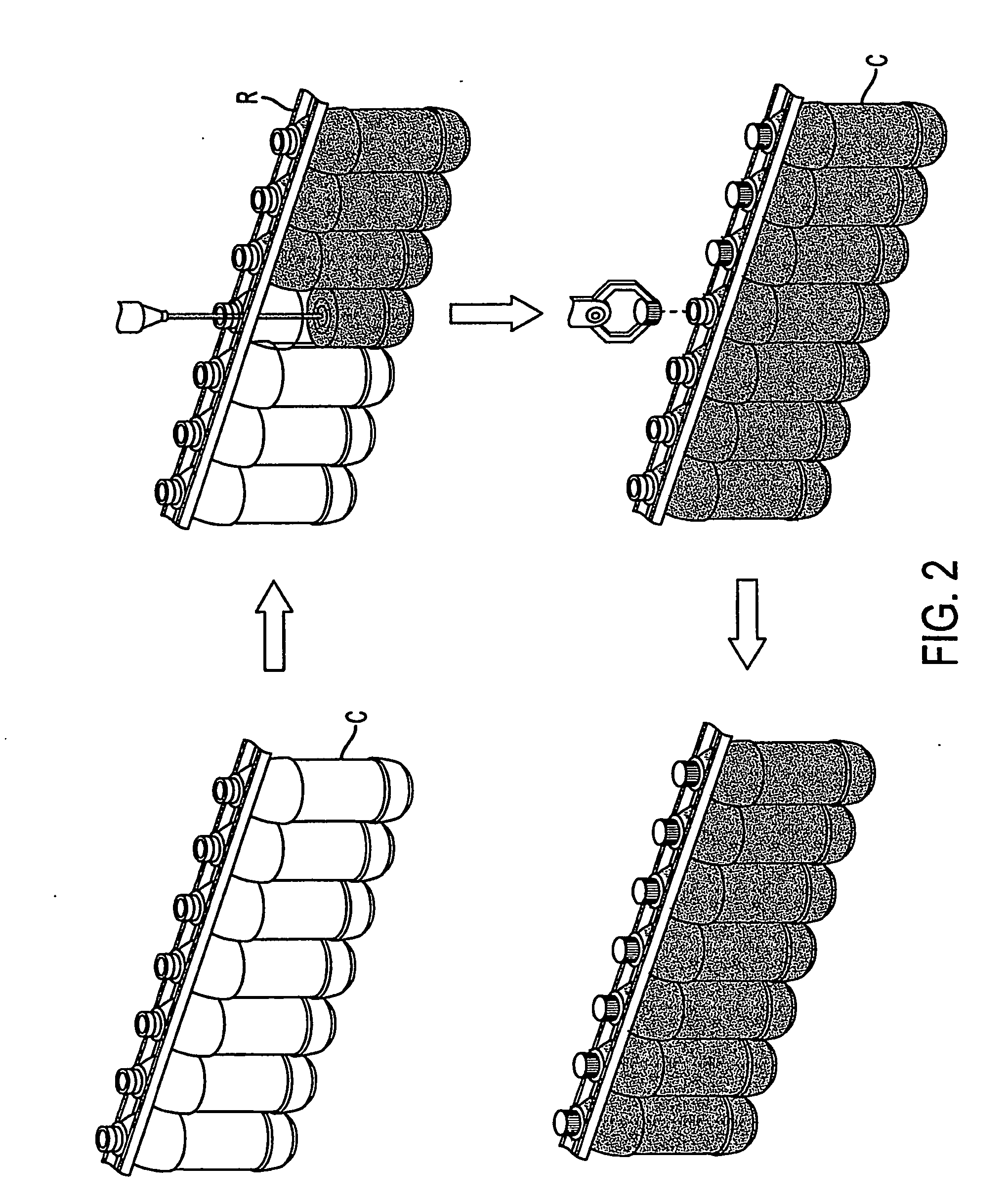

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

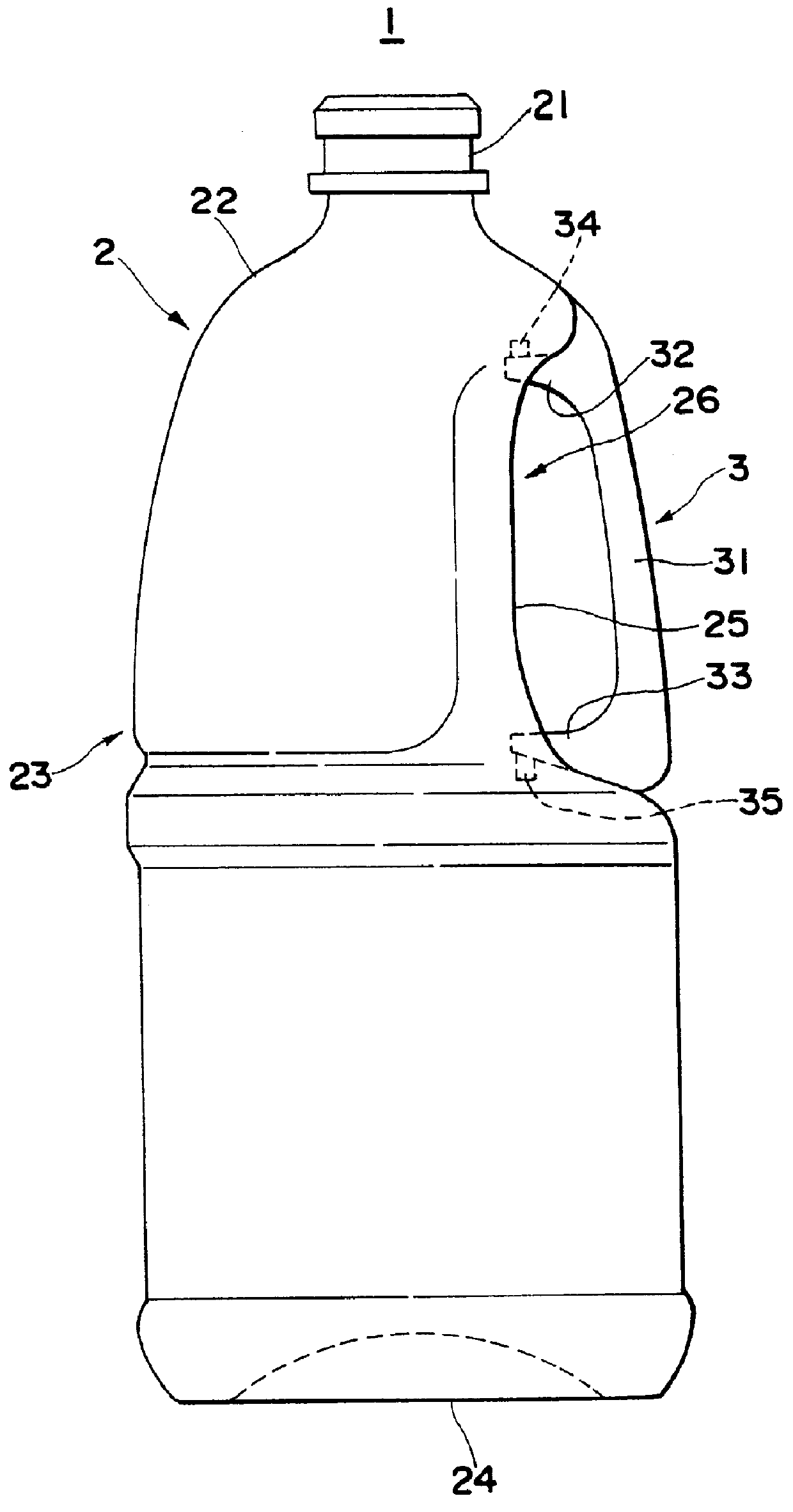

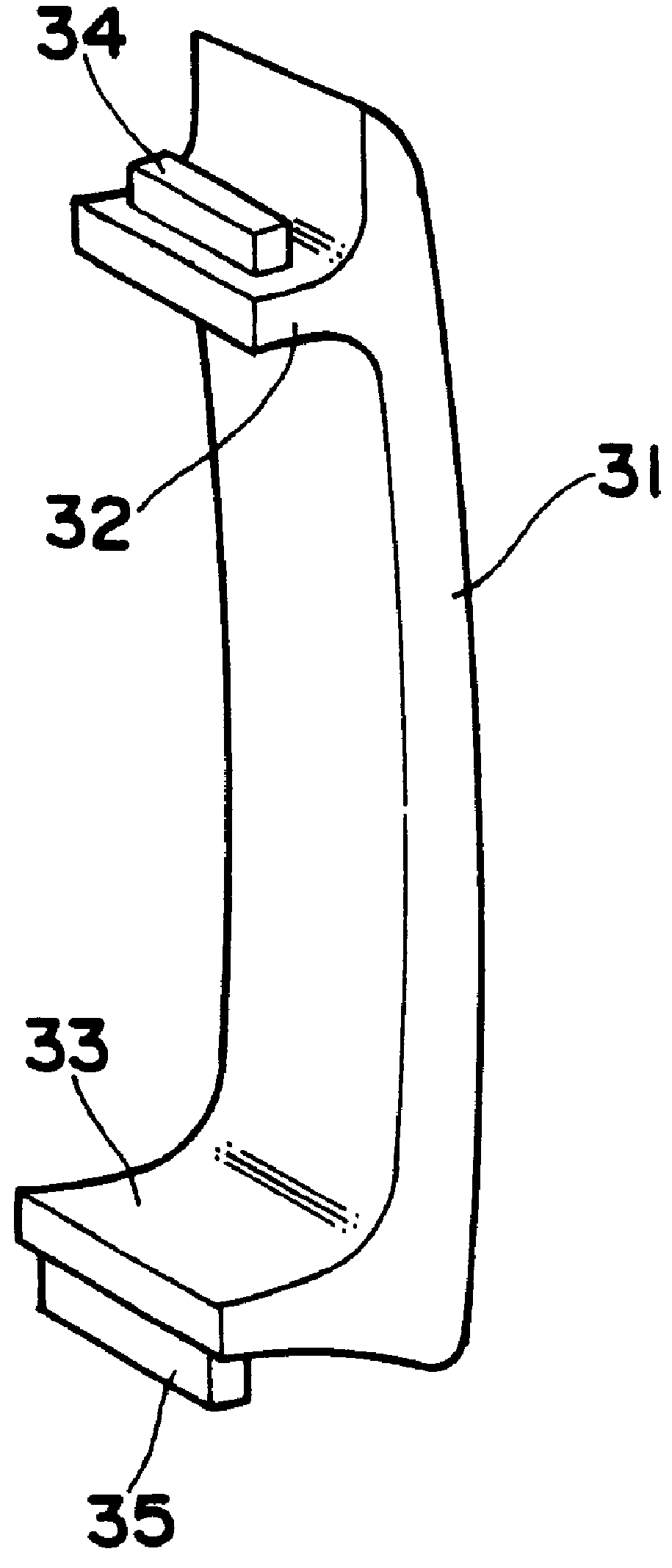

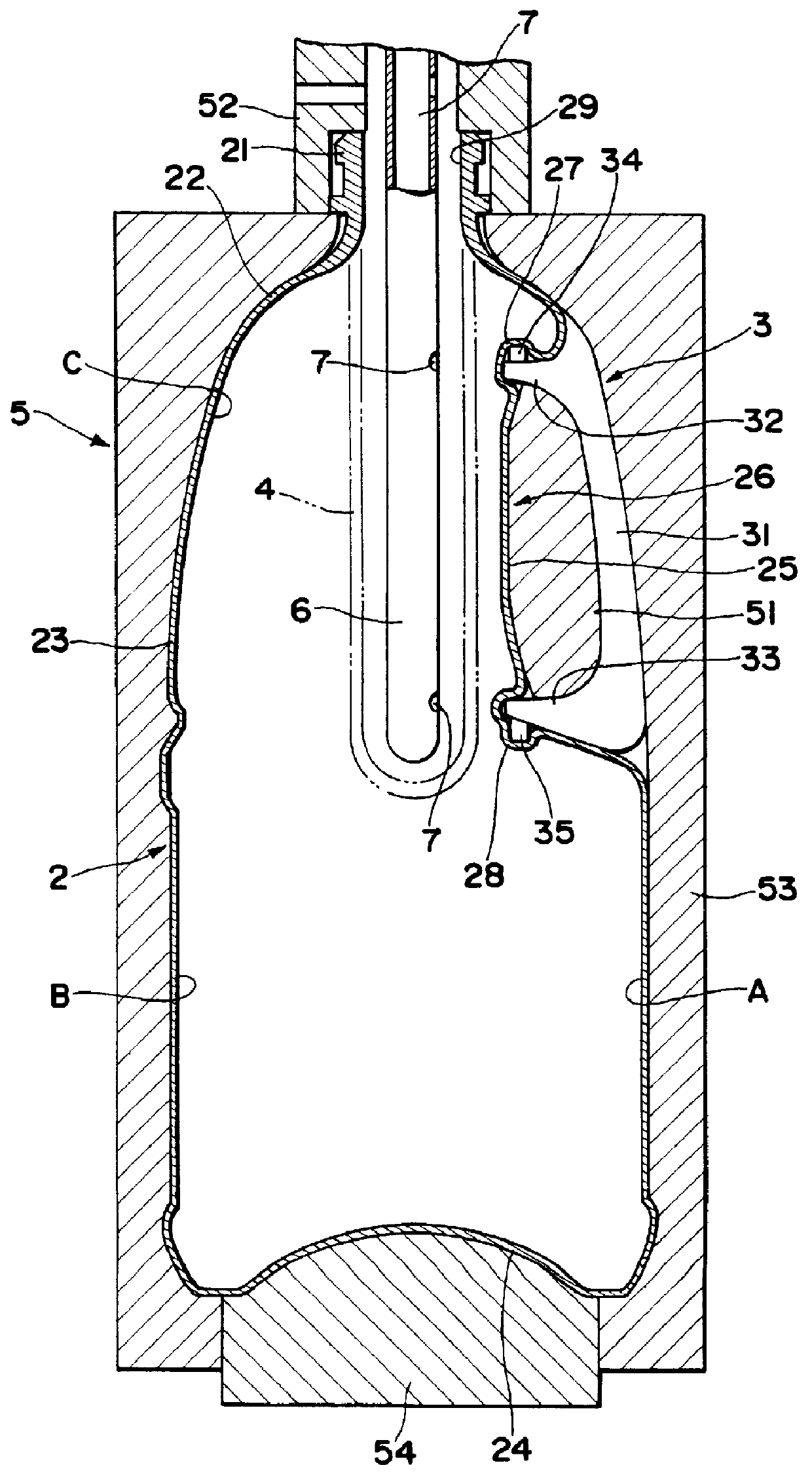

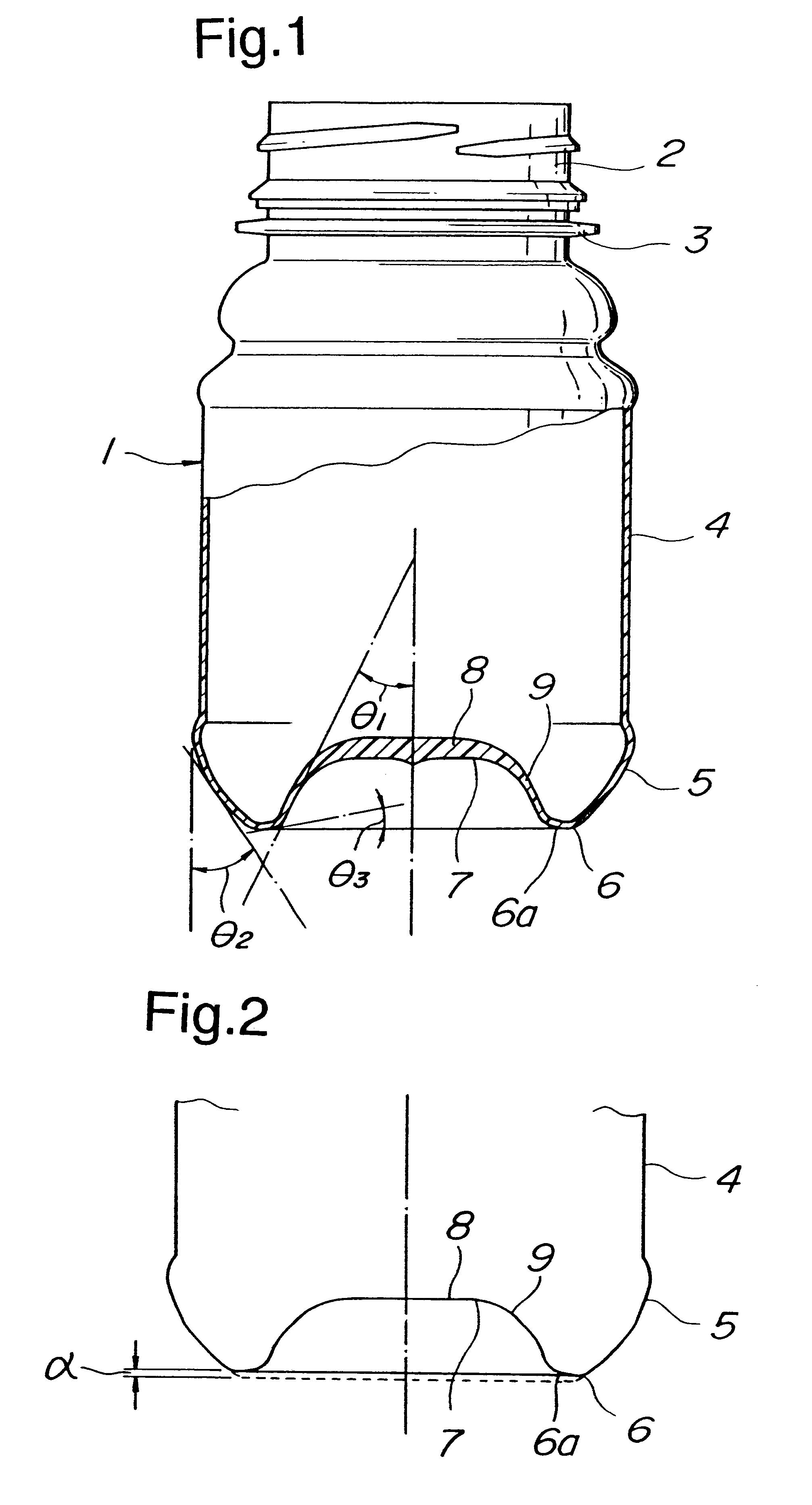

Polyester bottle with a handle and method of manufacturing the same

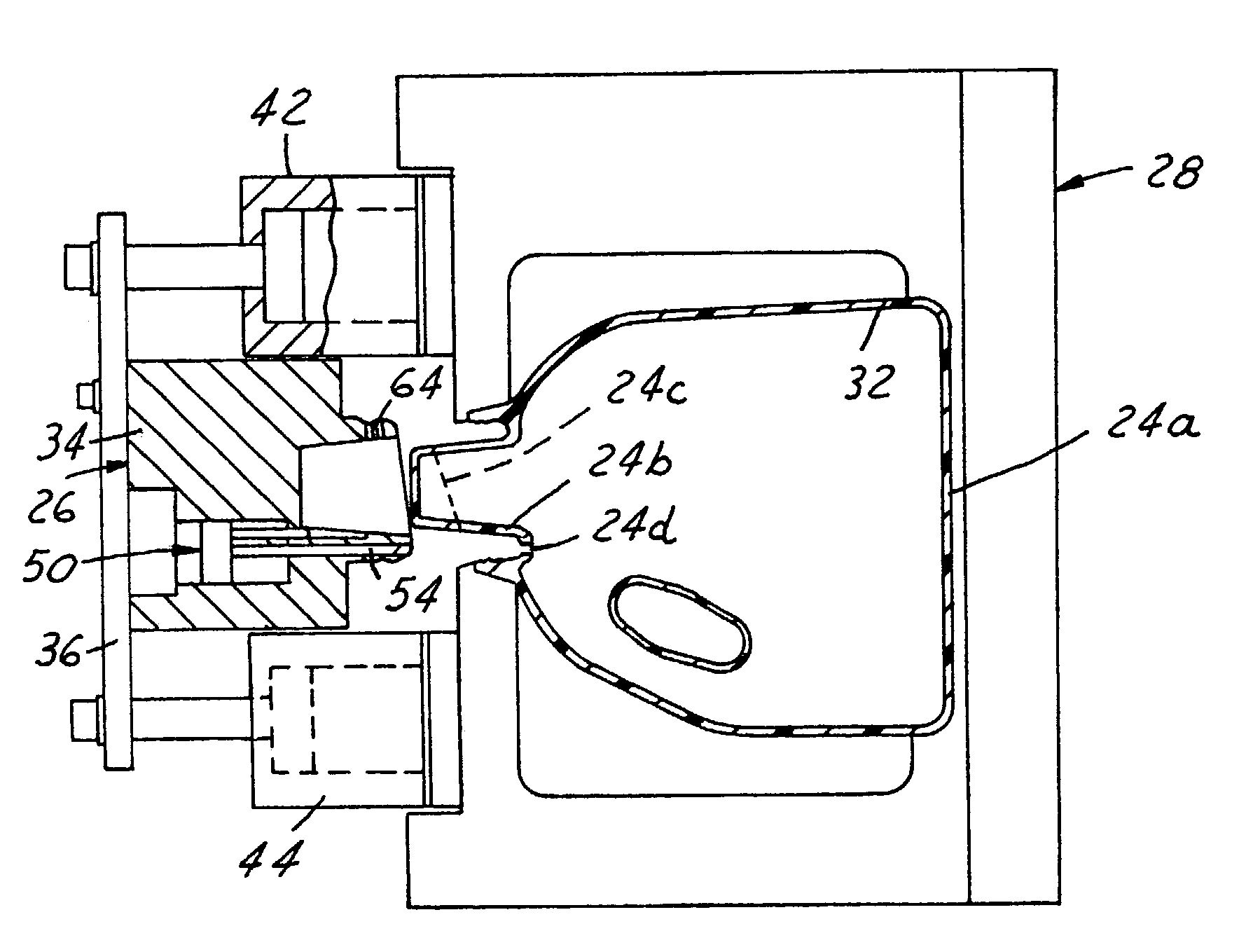

The present invention relates to polyester bottle with a handle comprising a polyester bottle body and a synthetic resin handle body mounted to said bottle body, and the method of manufacturing the same. Said bottle body comprises a neck portion, a shoulder portion continuous from said neck portion, a body portion continuous from said shoulder portion, a bottom portion continuous from said body portion and a handle mounting portion on the wall surface of said body portion formed by blowing air into a preform which is set to a cavity of a mold for biaxial stretch blow molding. Said handle body comprises a grip portion and a fixing portion continuous from said grip portion. Said fixing portion is connected to said handle mounting portion for mounting said handle body to said bottle body. Heat treatment is performed to at least said handle connecting portion of said handle mounting portion by heated air being blown into said bottle body. Said handle body could either be molded separately in advance, or molded after the blow molding of said bottle body by injection molding. Said heat treatment will be performed either after or simultaneously with the blow molding of said bottle body.

Owner:MITSUBISHI PLASTICS INC

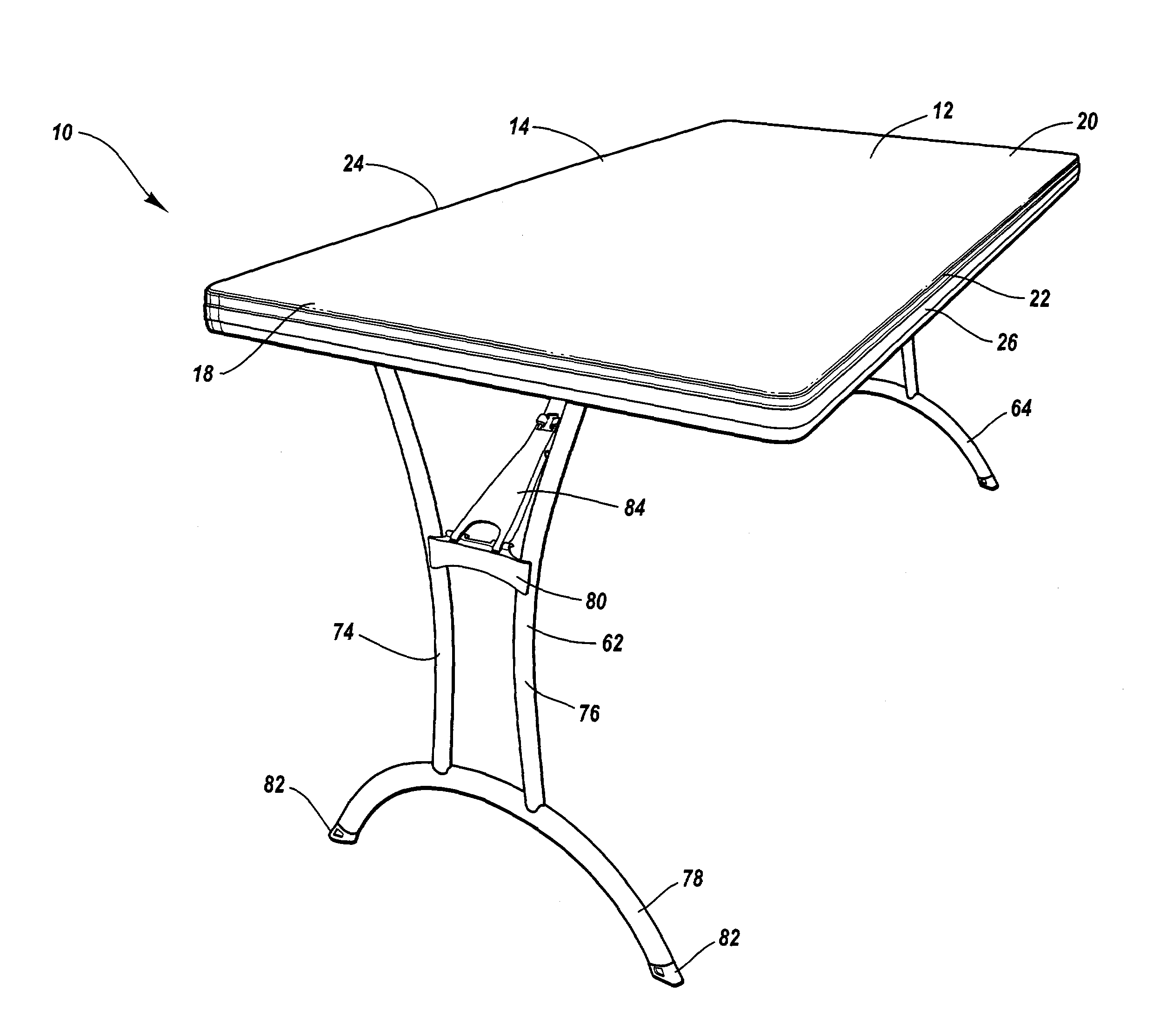

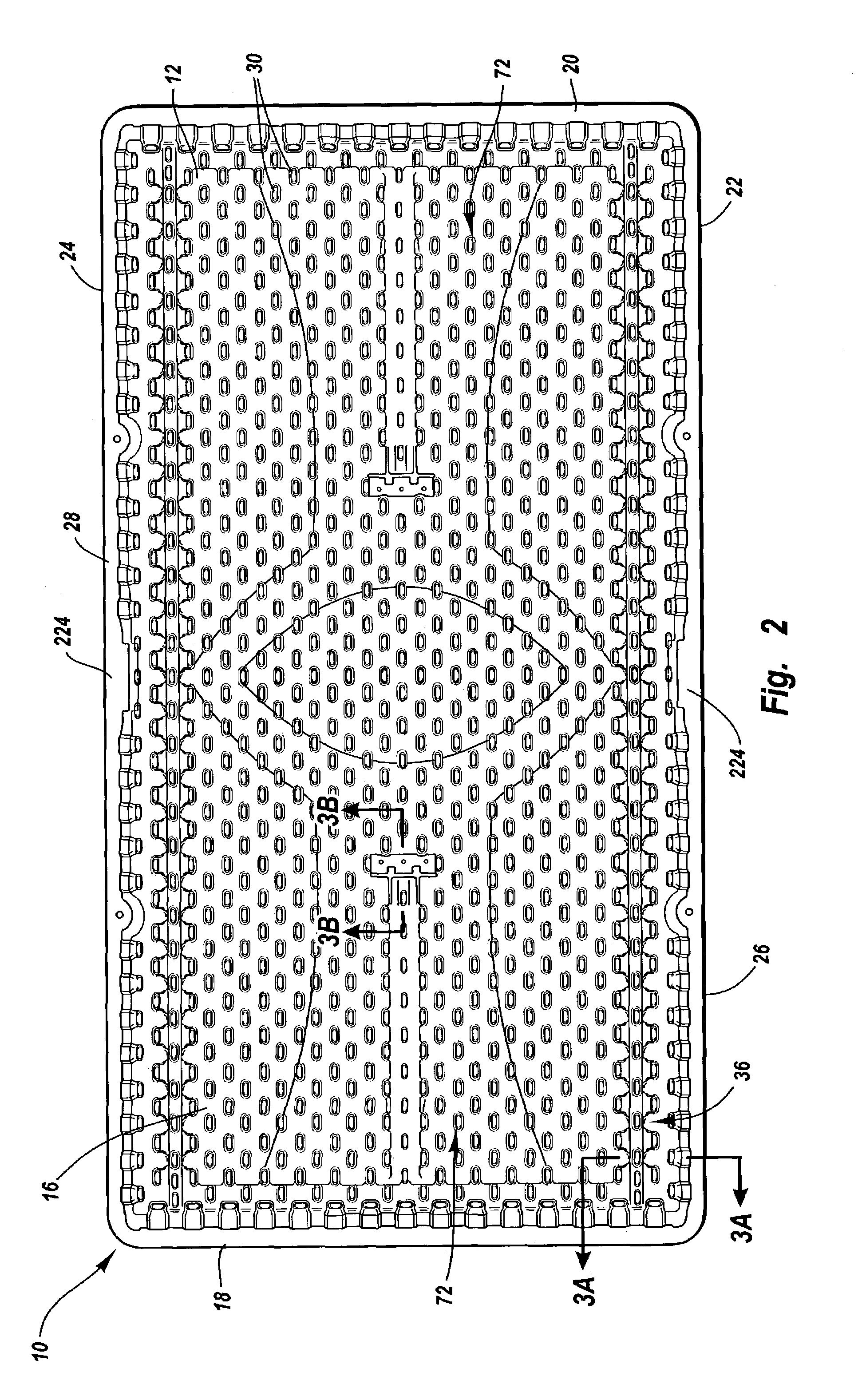

Edge and corner for a table top

Owner:LIFETIME PRODUCTS

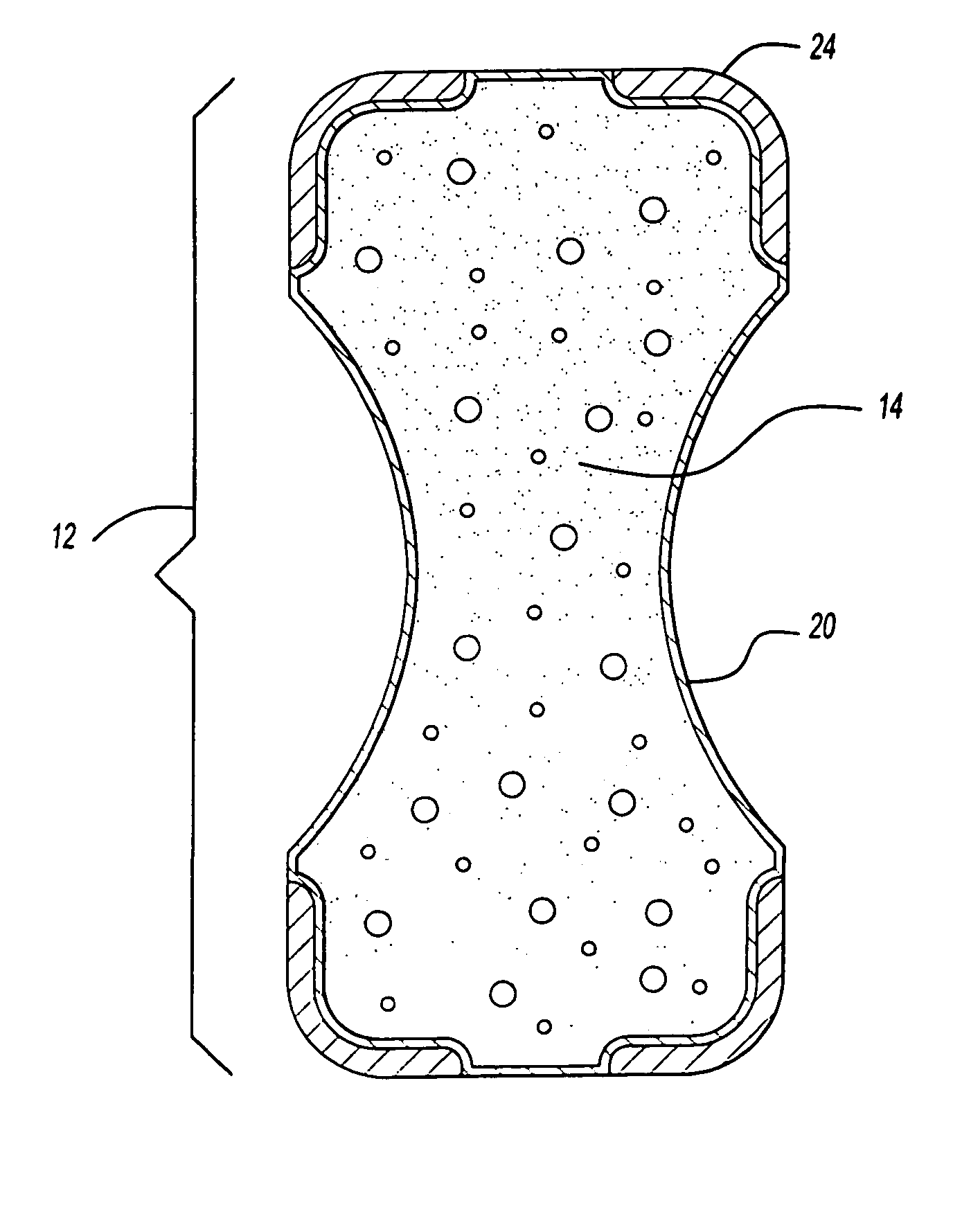

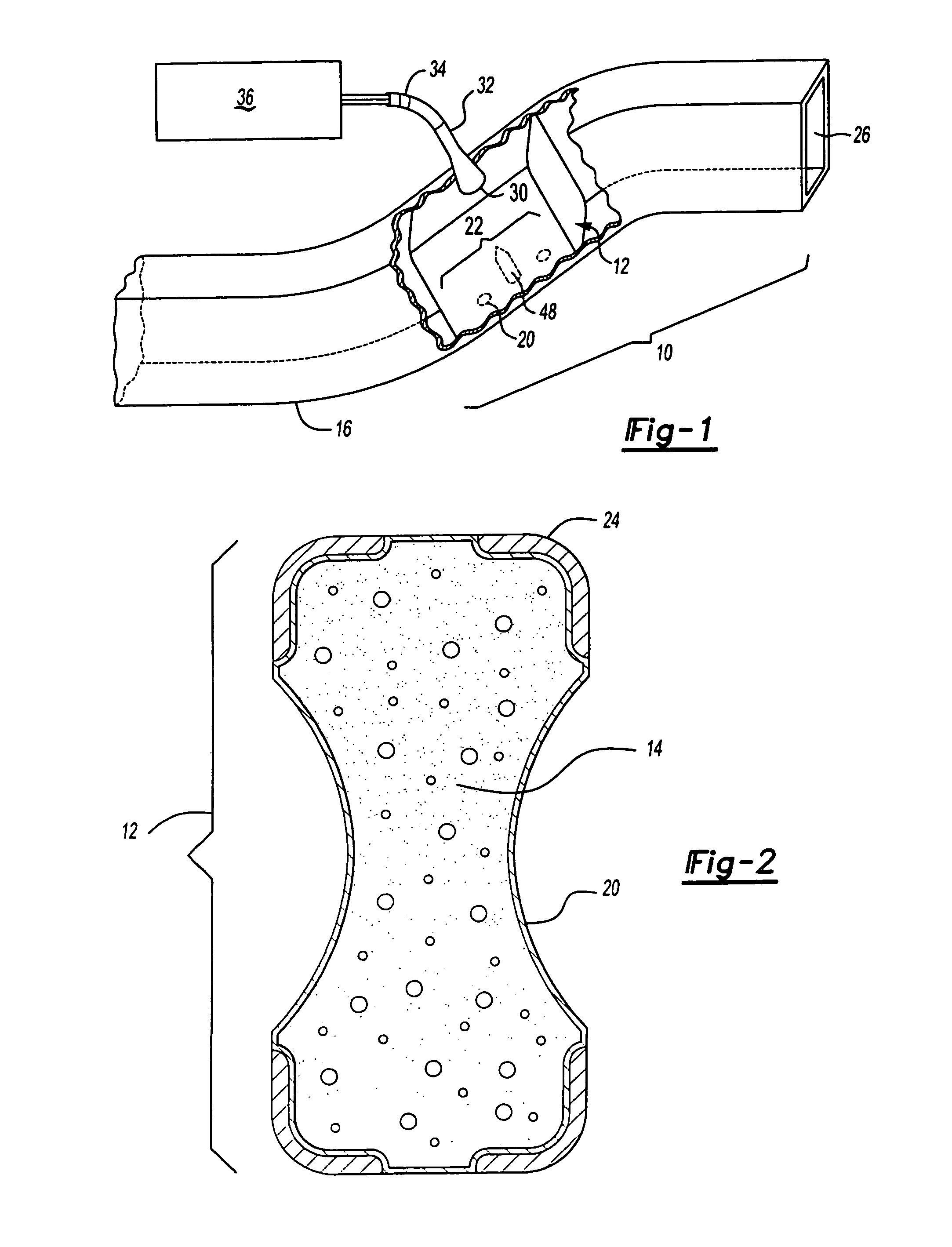

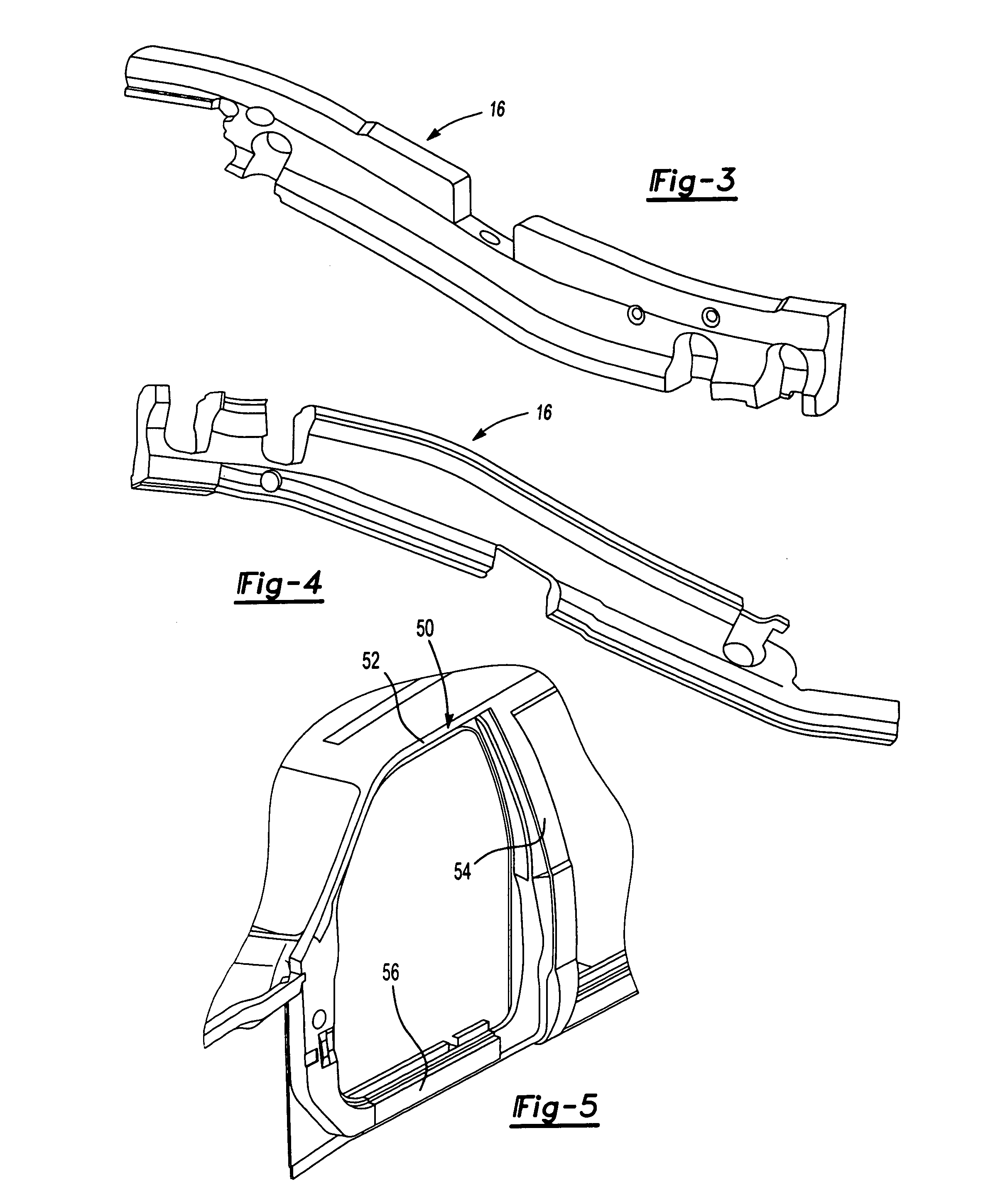

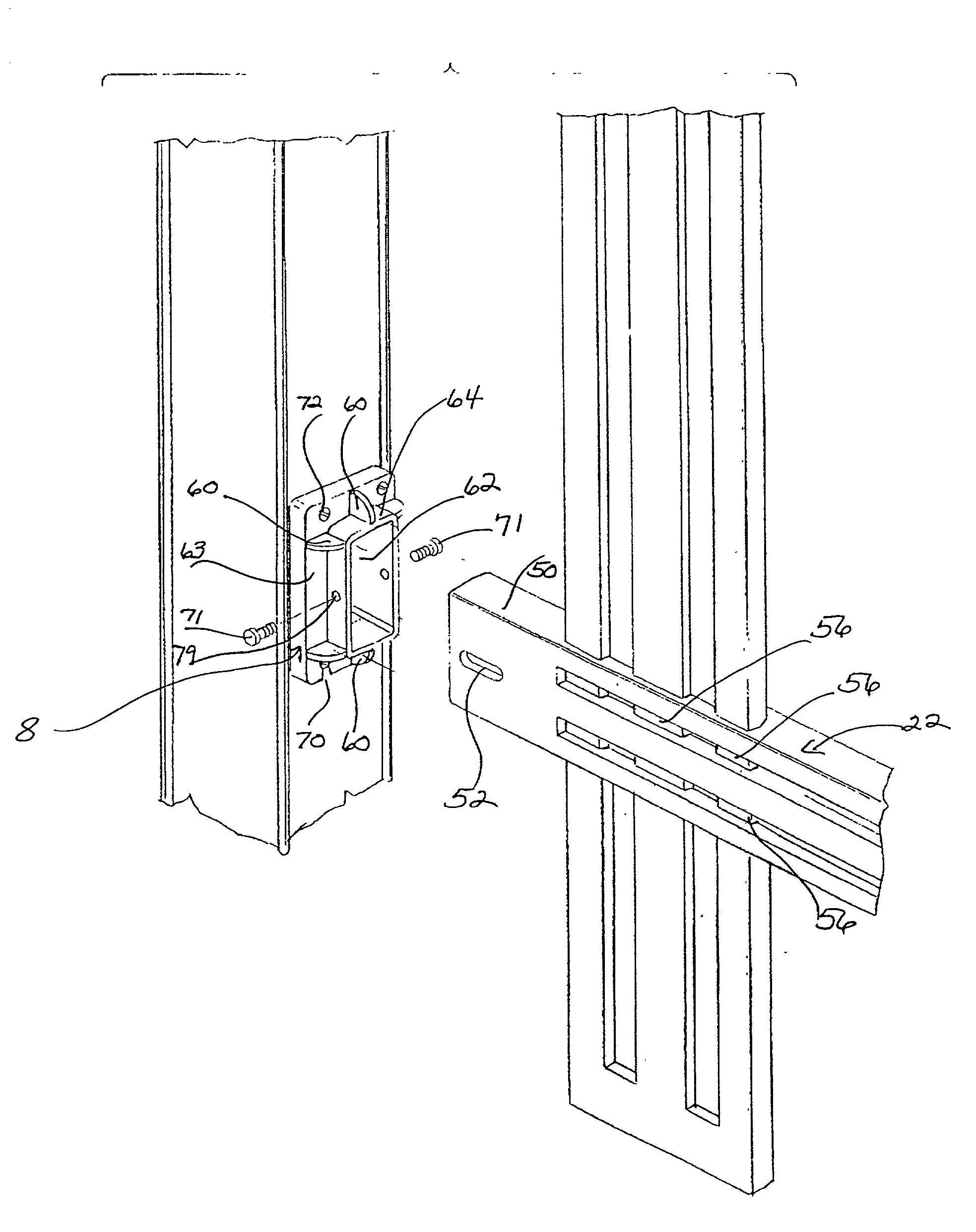

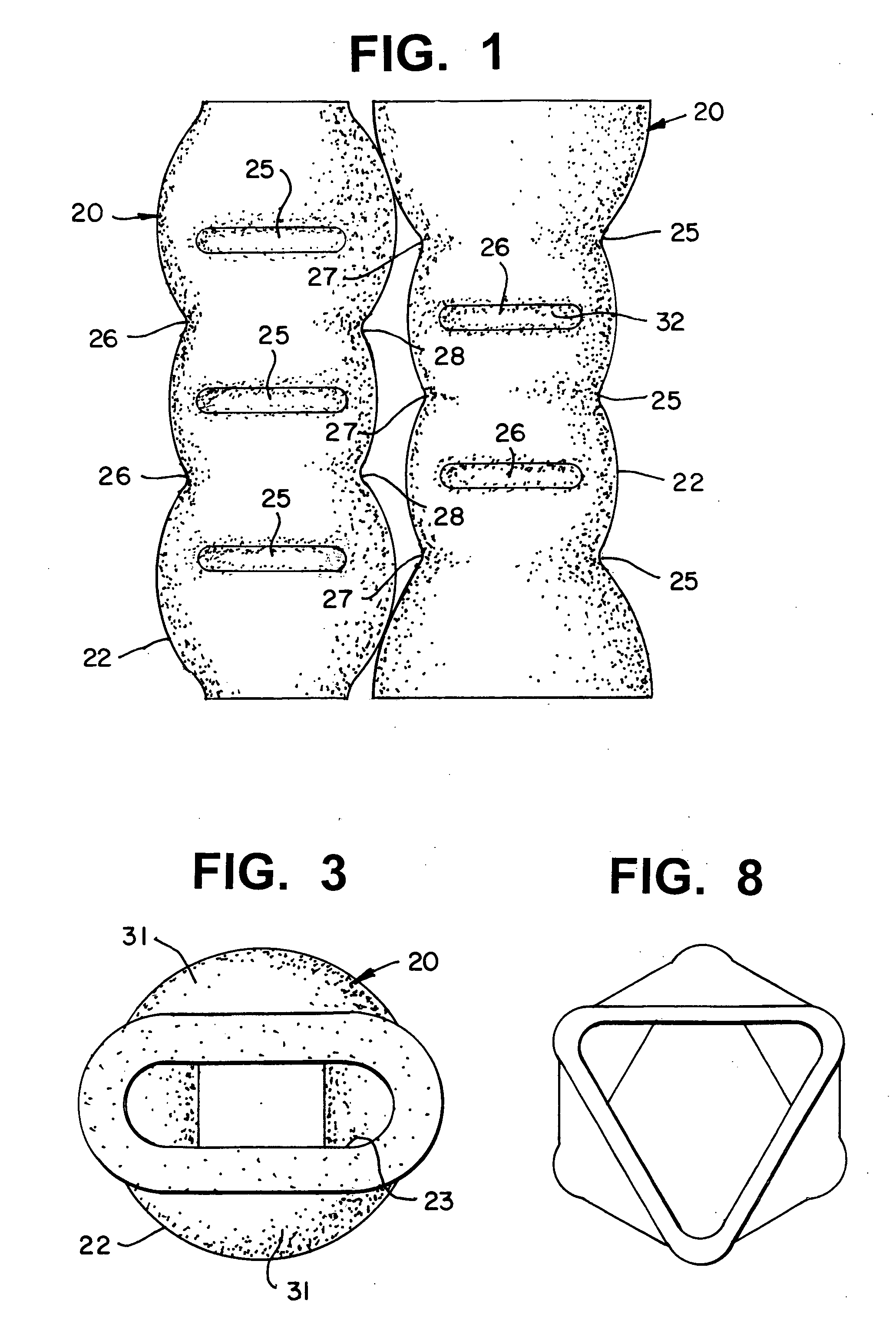

Reinforcement system utilizing a hollow carrier

ActiveUS7077460B2Reduce healthReduce cleanlinessVehicle seatsSynthetic resin layered productsBlow moldingShell molding

A system and method for reinforcing at least a portion of a structural member, including at least one hollow carrier, having an exterior shell and an interior portion, which substantially conforms to the dimensions and geometry of the structural member being reinforced; and a lightweight, low density material for filling the interior portion of one or more of the carriers. The material filling one or more of the carriers of the present invention can be a reinforcement material, self-curing material, or a heat activated expandable material. The carrier can be produced by blow molding or rotational molding and has an adhesive material disposed along at least a portion of the exterior shell used to place, adhere, and affix the carrier to a targeted portion of the structural member selected to be structurally reinforced.

Owner:ZEPHYROS INC

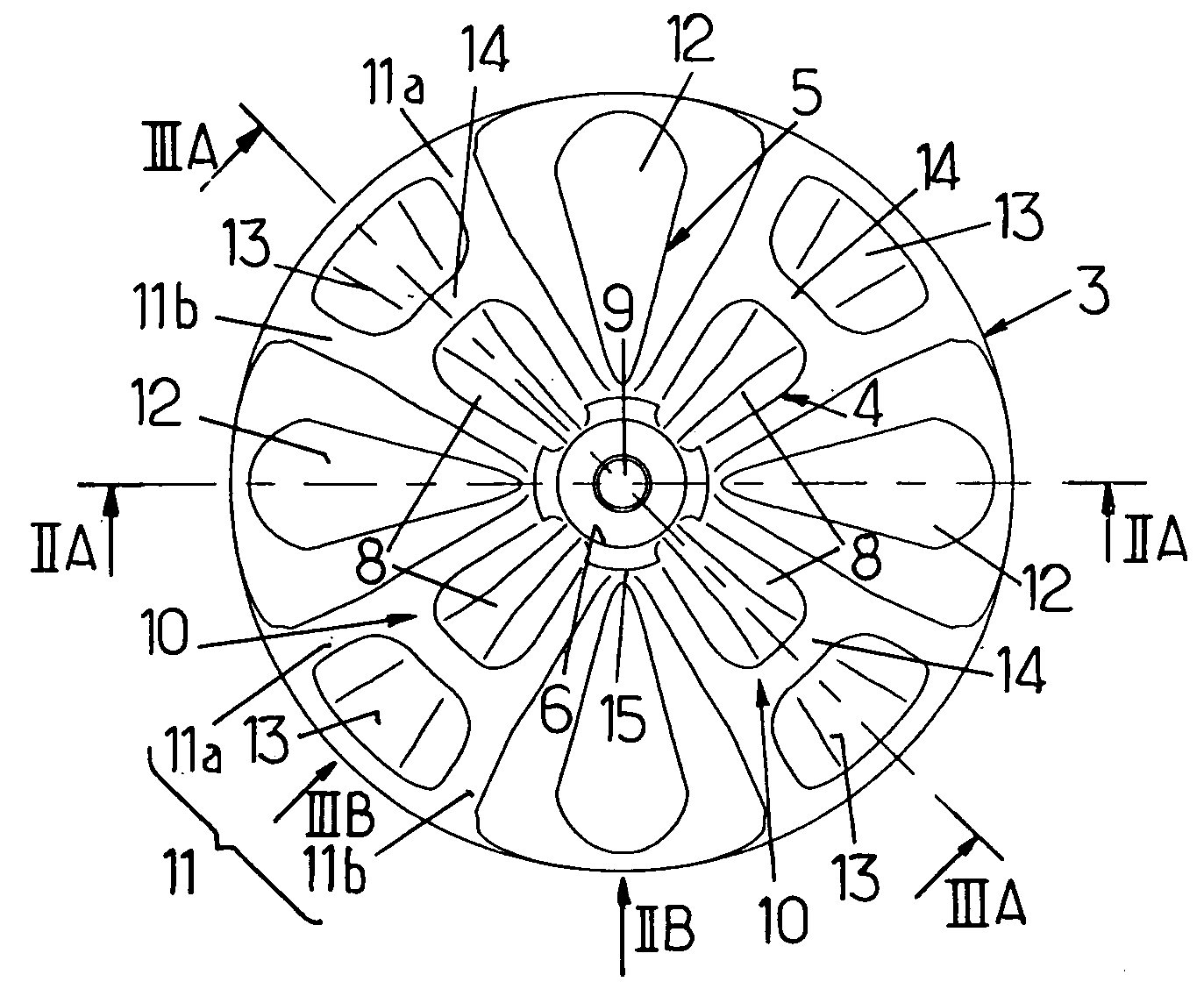

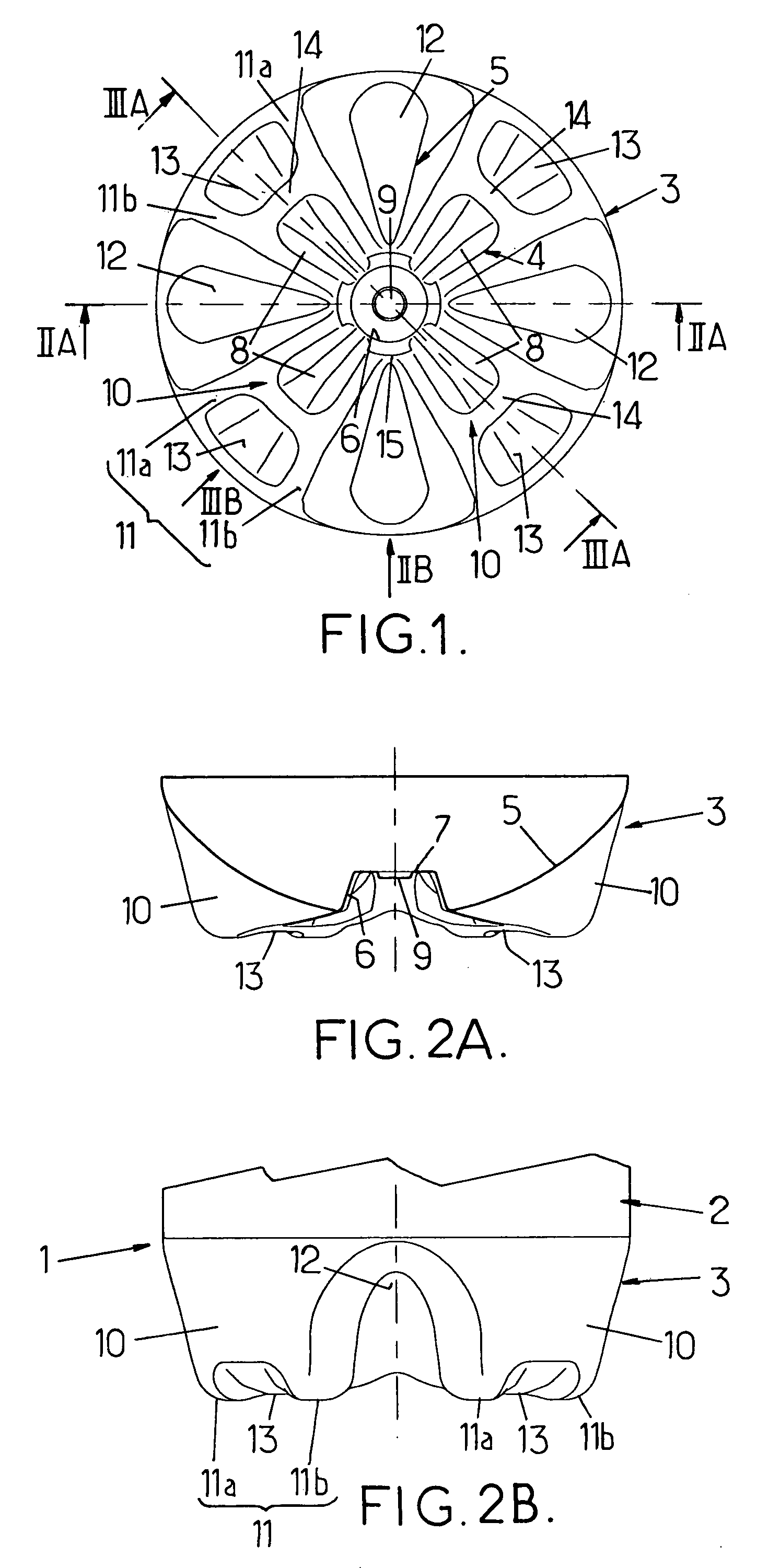

Thermoplastic container whereof the base comprises a cross-shaped impression

A thermoplastic container obtained by blow-molding of a preform, with a base including in its central part a multiple-branch cross-shaped impression provided with a central recess from which radial branches radiate; the base is of the petal-shaped type with at least three legs formed by protuberances located near the periphery; there are as many legs as branches mutually aligned radially; each leg includes a notch for absorbing stresses radially separated from the end of the respective branch.

Owner:SIDEL PARTICIPATIONS SAS

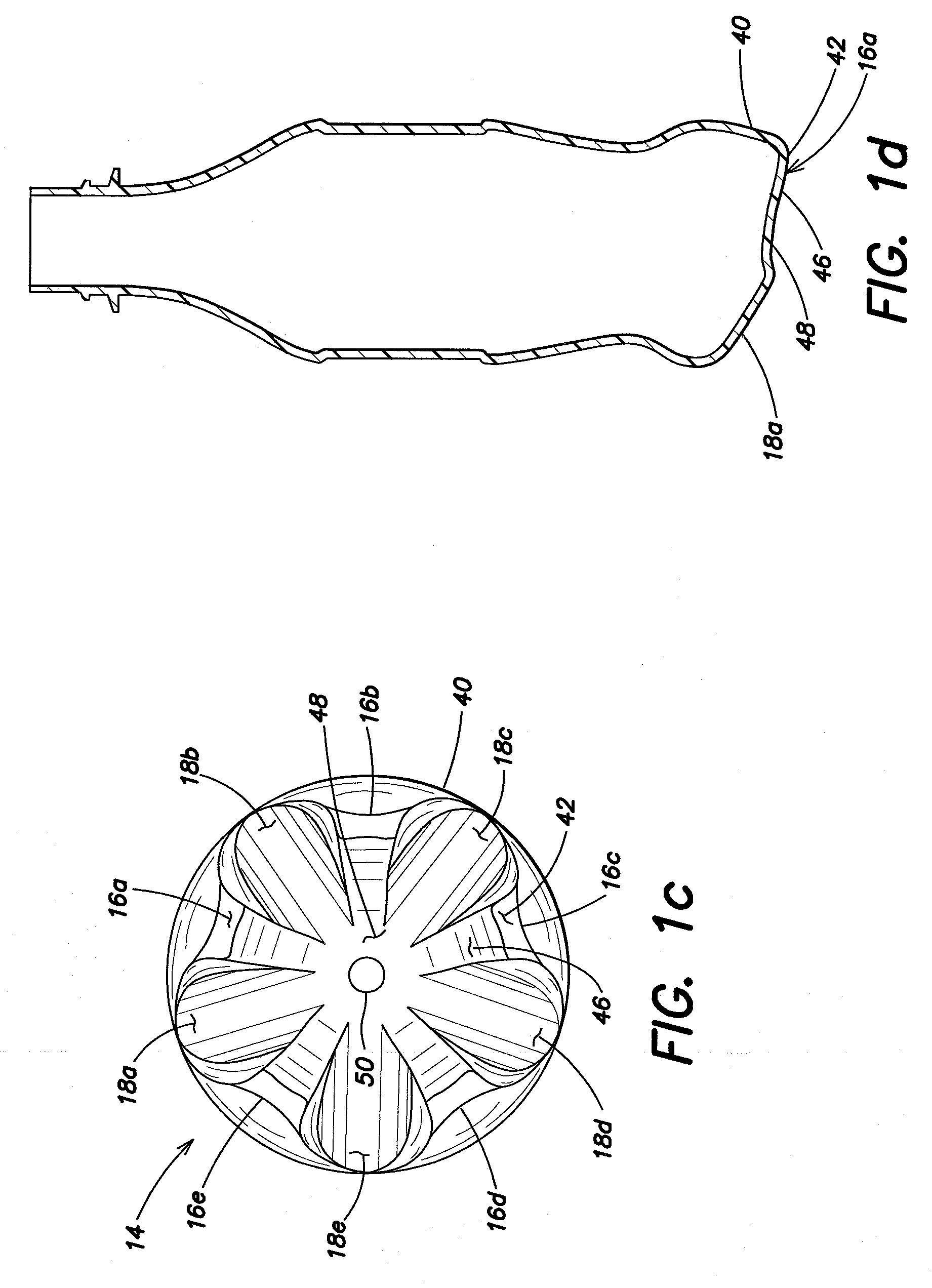

Method of fabricating a stent with features by blow molding

The invention provides a method of manufacturing a stent, the method comprising: disposing a polymeric tube into a cylindrical mold, the cylindrical mold having a variable diameter along a portion of the inside surface of the mold; radially expanding the tube by blowing a gas or liquid into the cylindrical mold, the outside surface of the tube conforming to the variable diameter portion of the outside surface of the mold, causing the radially expanded tube to have a variable diameter along the conformed length of the tube; and fabricating a stent from the expanded tube.

Owner:ABBOTT CARDIOVASCULAR

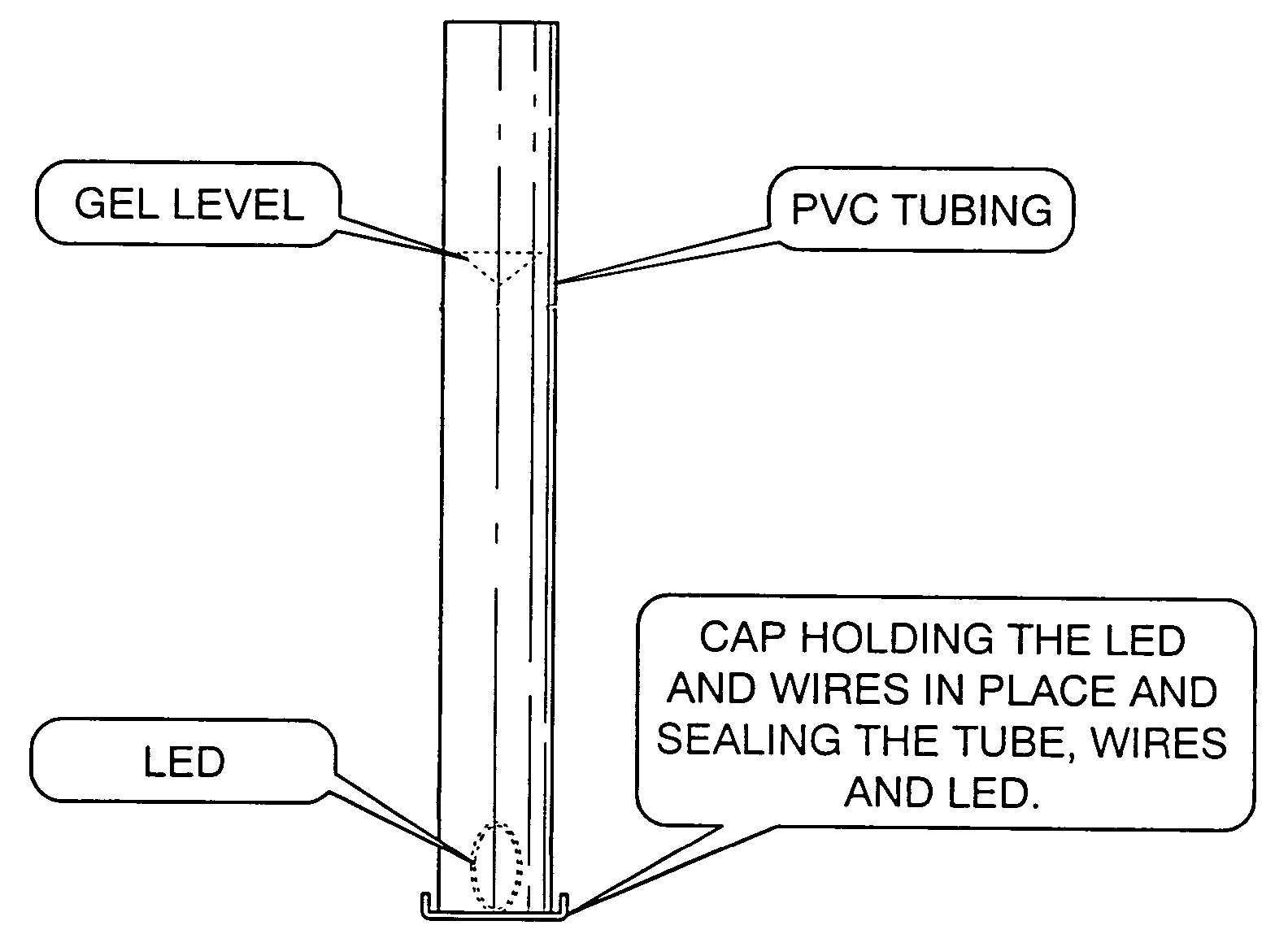

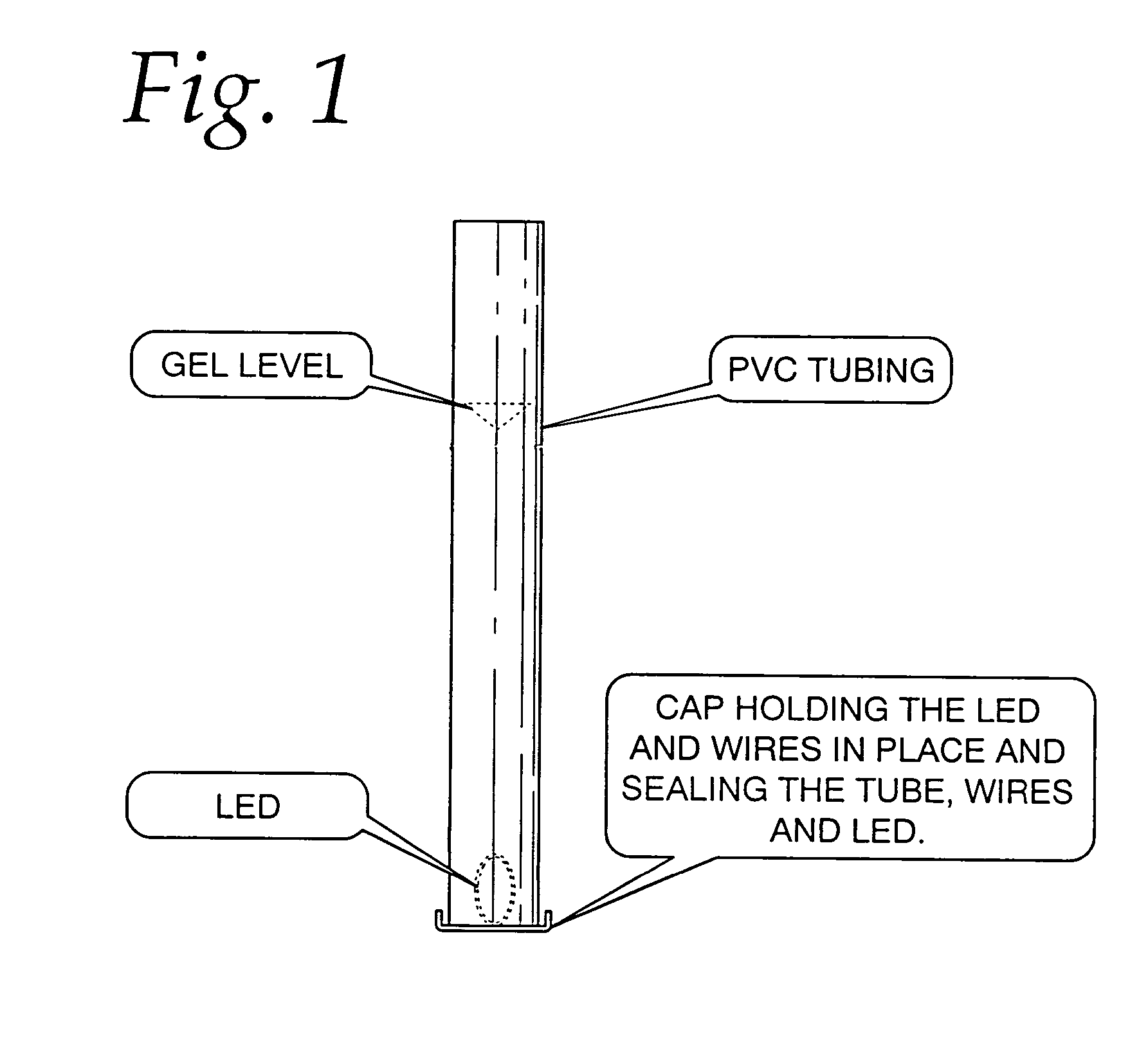

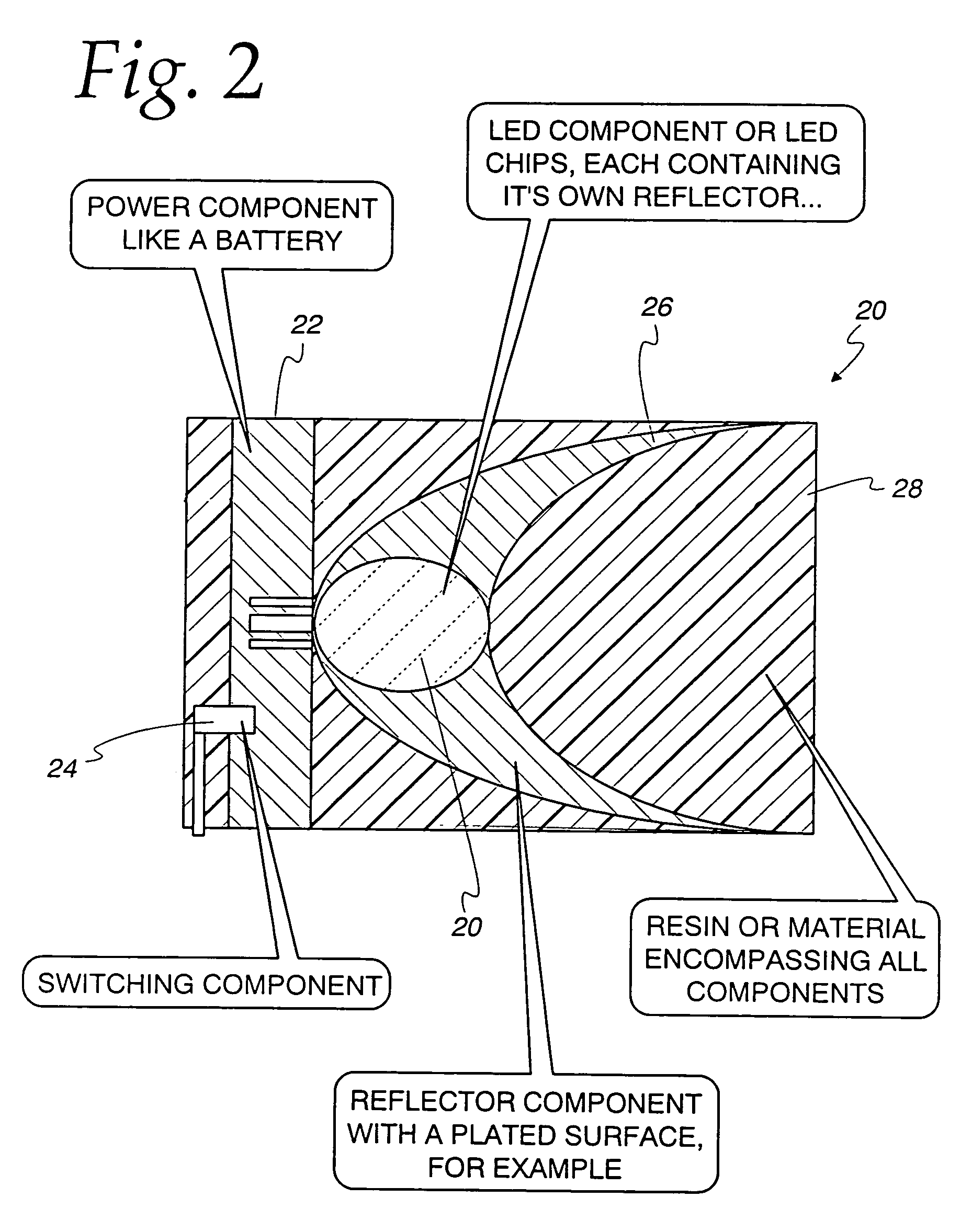

Light emitting medium and illumination system

Owner:ZARIAN JAMES ROUBEN +1

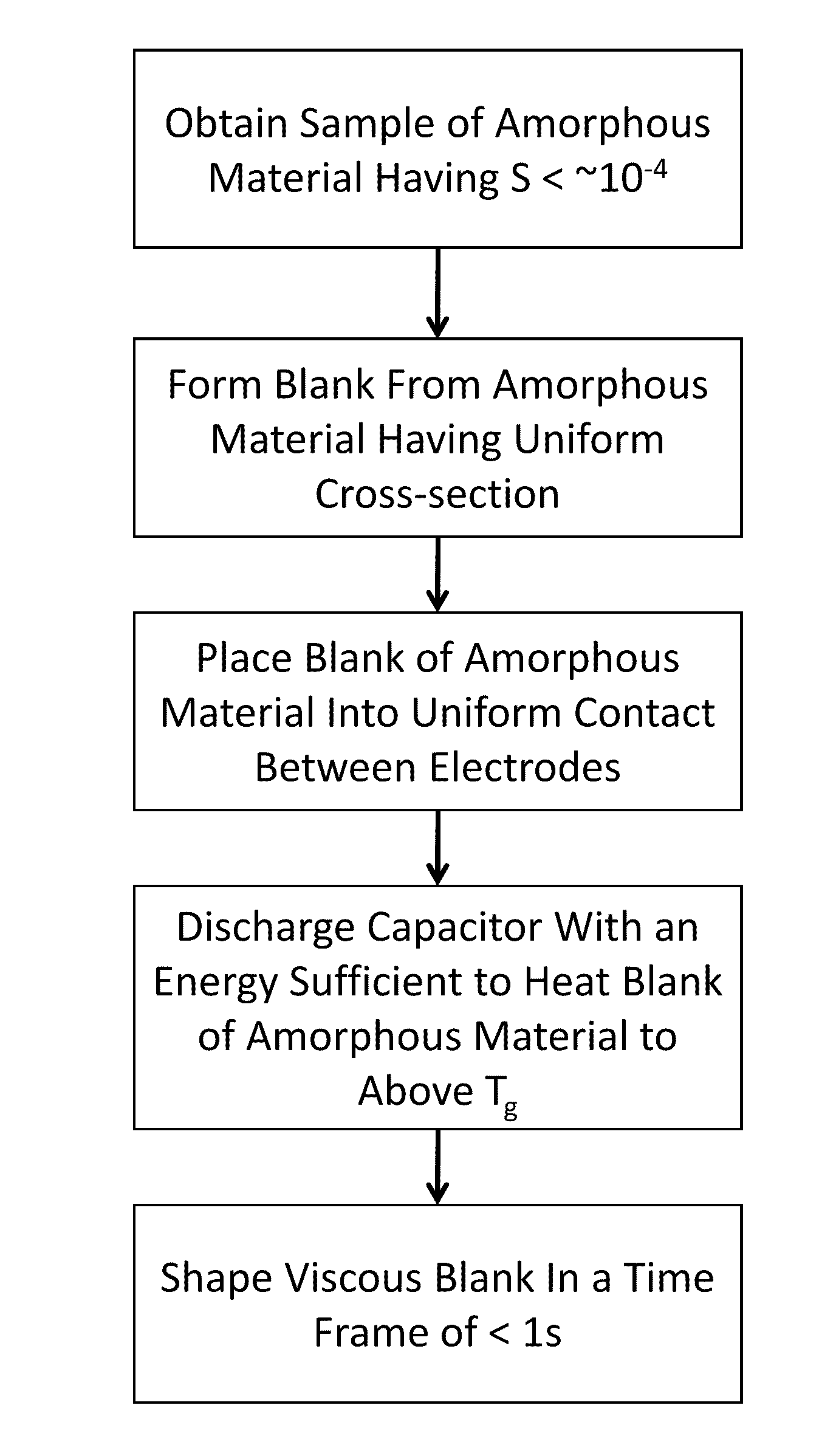

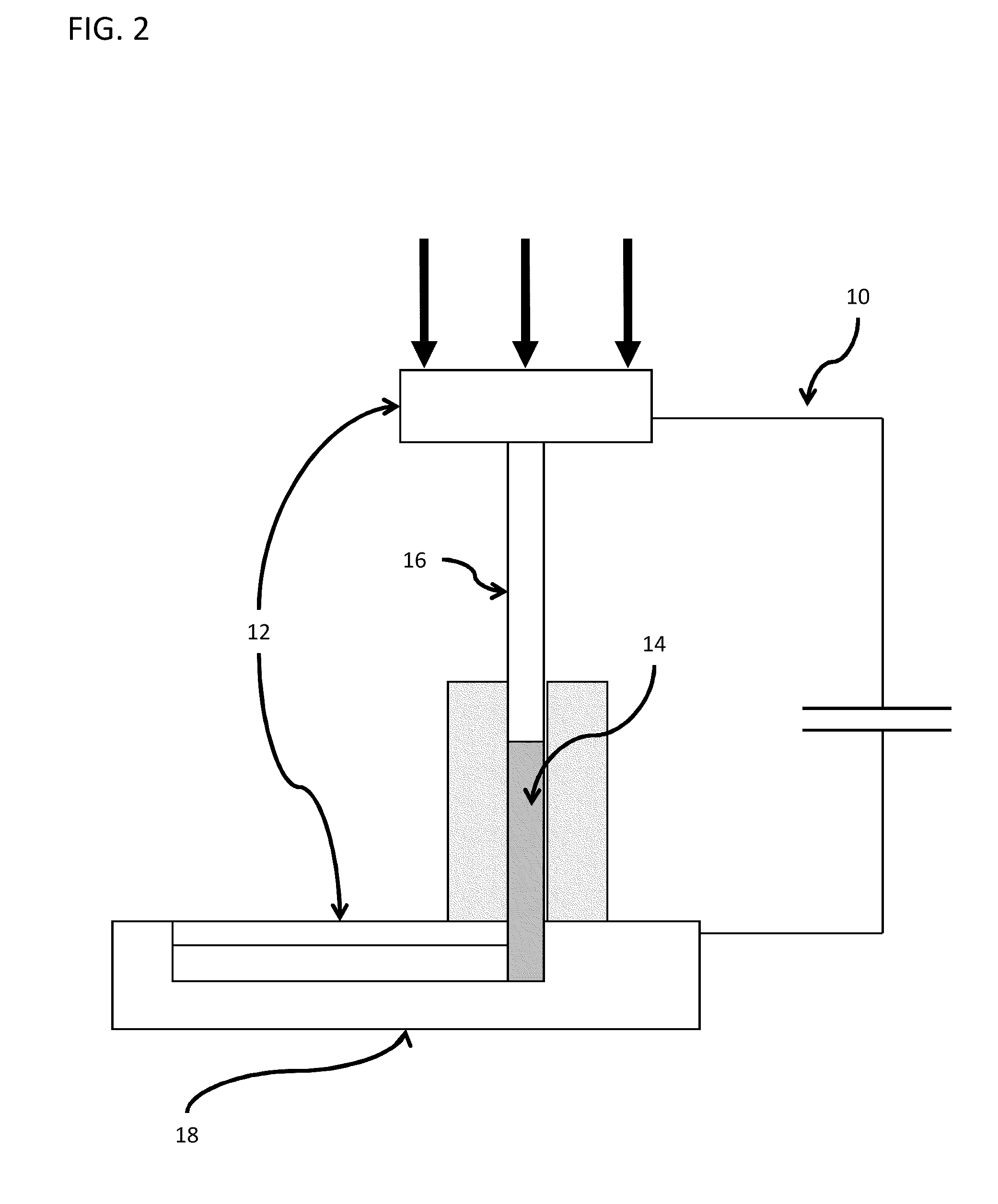

Forming of metallic glass by rapid capacitor discharge

ActiveUS20090236017A1Avoid failureAvoid thermal transport and development of thermalDielectric heatingShaping toolsAlloyGlass transition

An apparatus and method of uniformly heating, rheologically softening, and thermoplastically forming metallic glasses rapidly into a net shape using a rapid capacitor discharge forming (RCDF) tool are provided. The RCDF method utilizes the discharge of electrical energy stored in a capacitor to uniformly and rapidly heat a sample or charge of metallic glass alloy to a predetermined “process temperature” between the glass transition temperature of the amorphous material and the equilibrium melting point of the alloy in a time scale of several milliseconds or less. Once the sample is uniformly heated such that the entire sample block has a sufficiently low process viscosity it may be shaped into high quality amorphous bulk articles via any number of techniques including, for example, injection molding, dynamic forging, stamp forging, and blow molding in a time frame of less than 1 second.

Owner:CALIFORNIA INST OF TECH

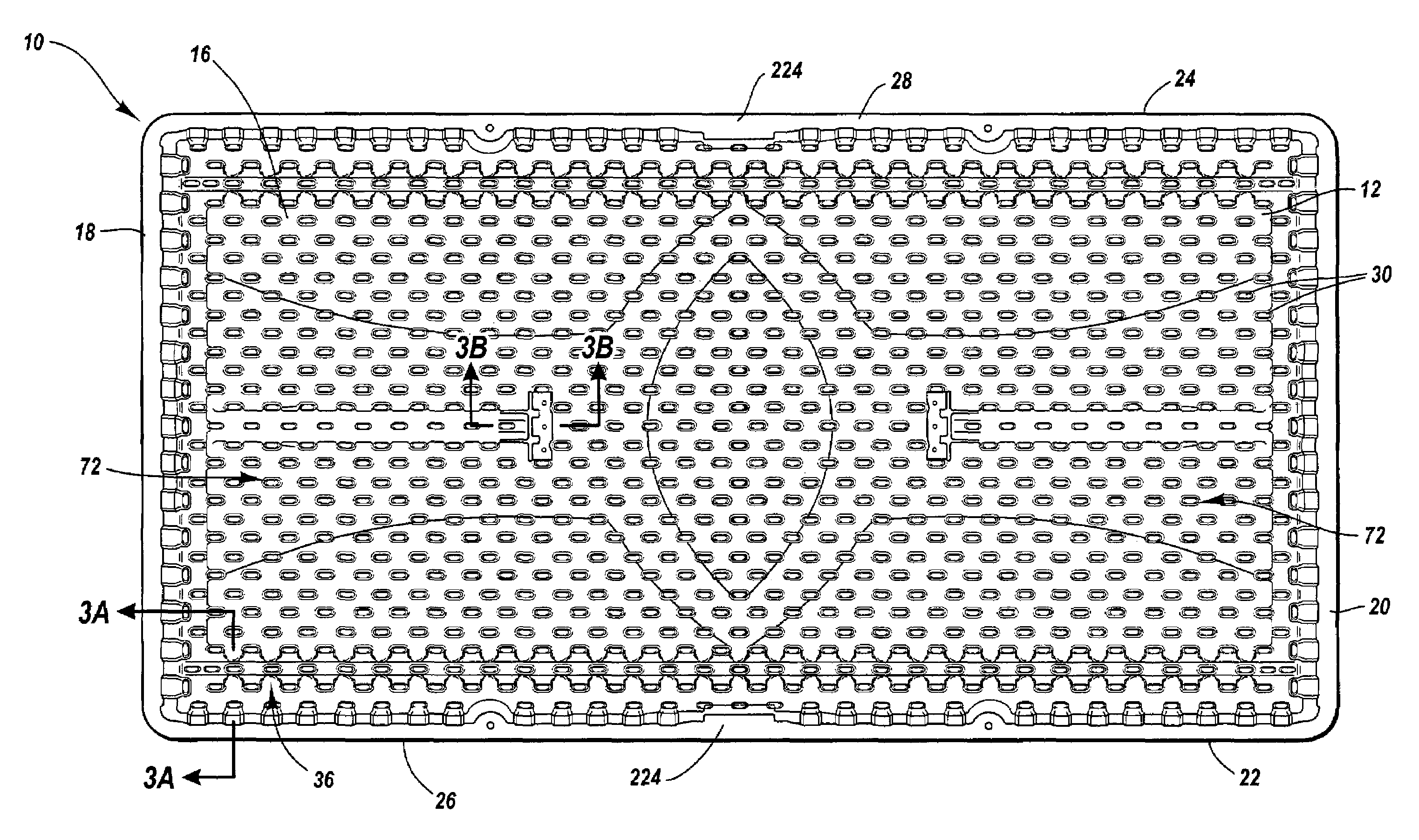

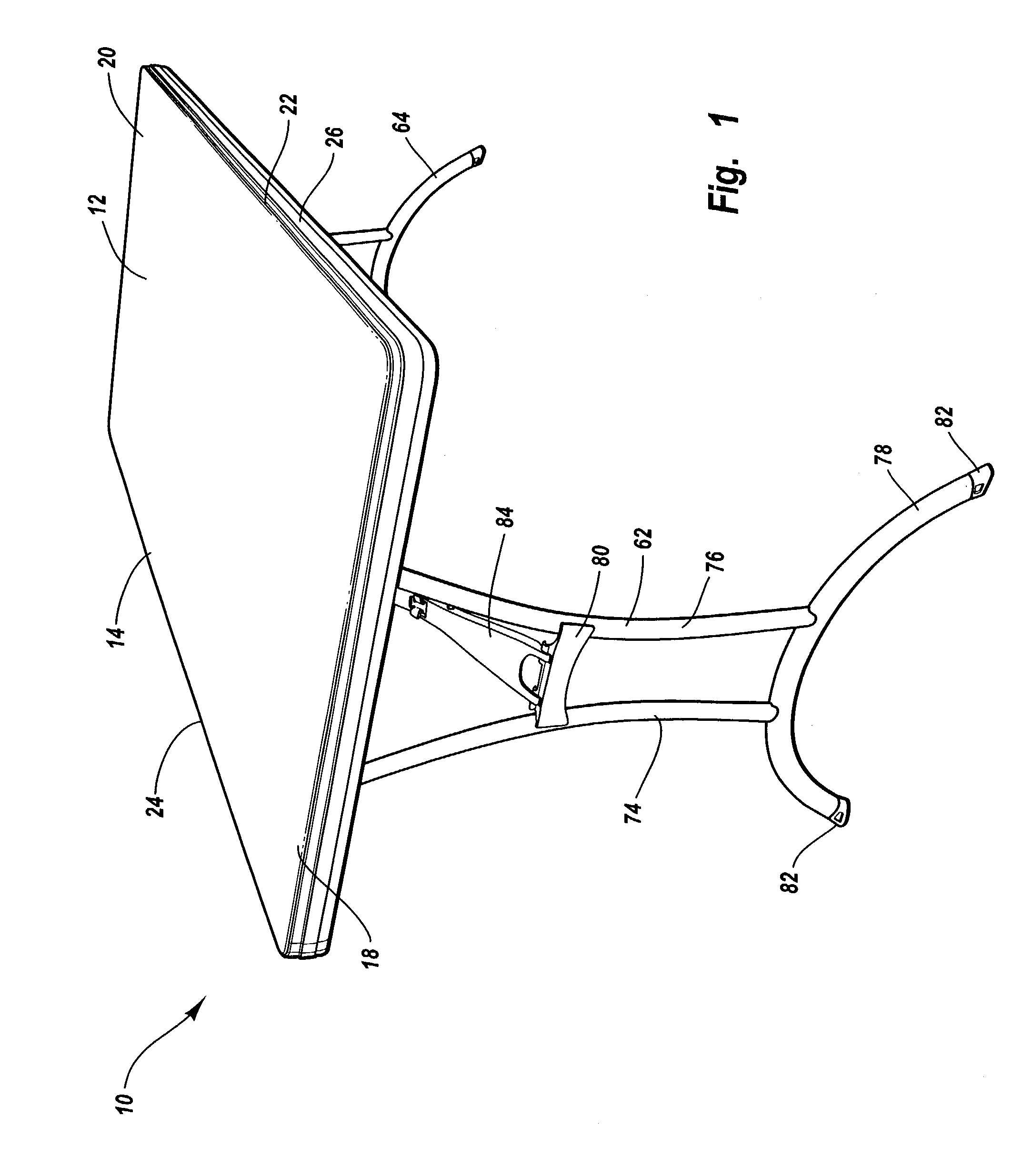

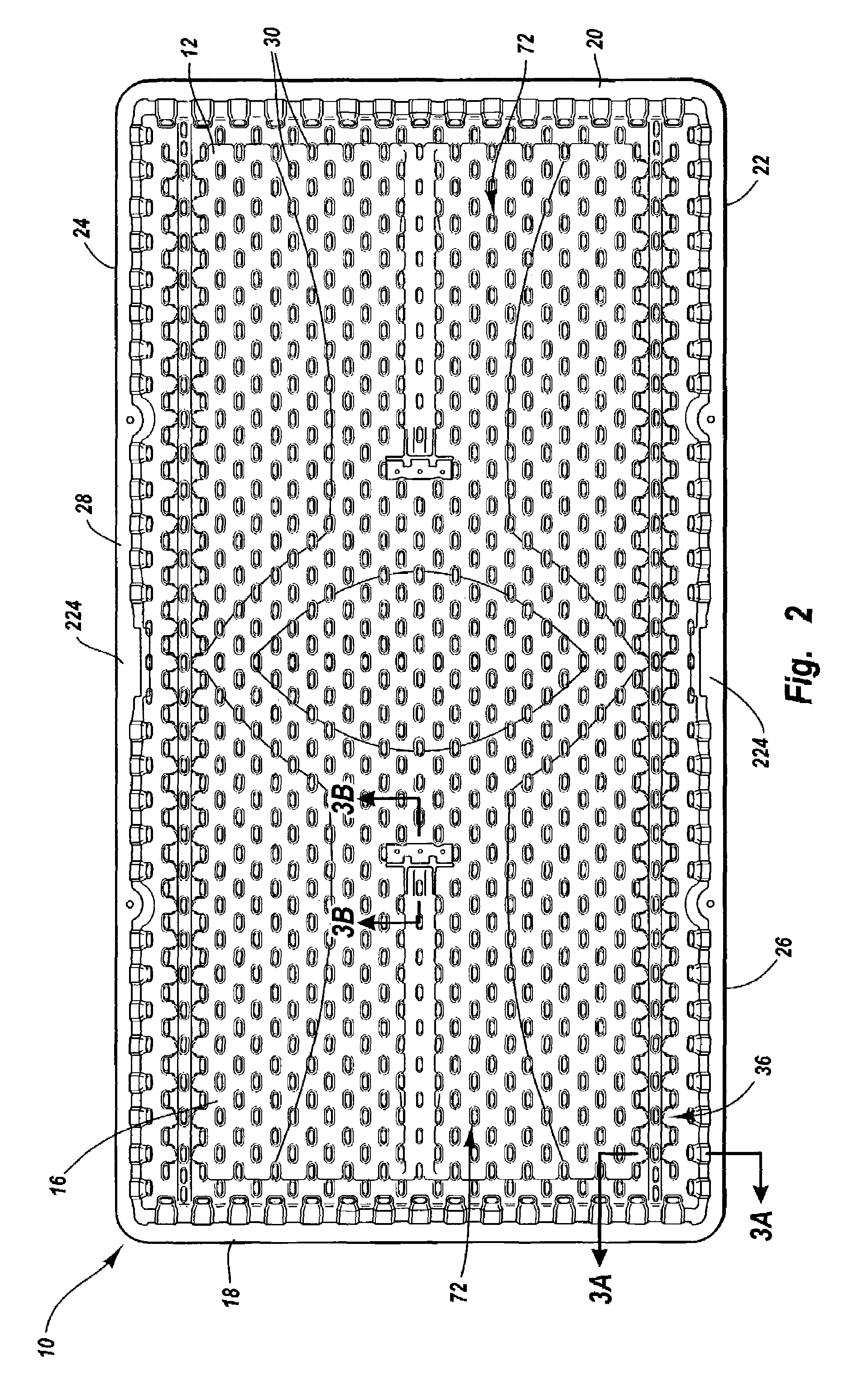

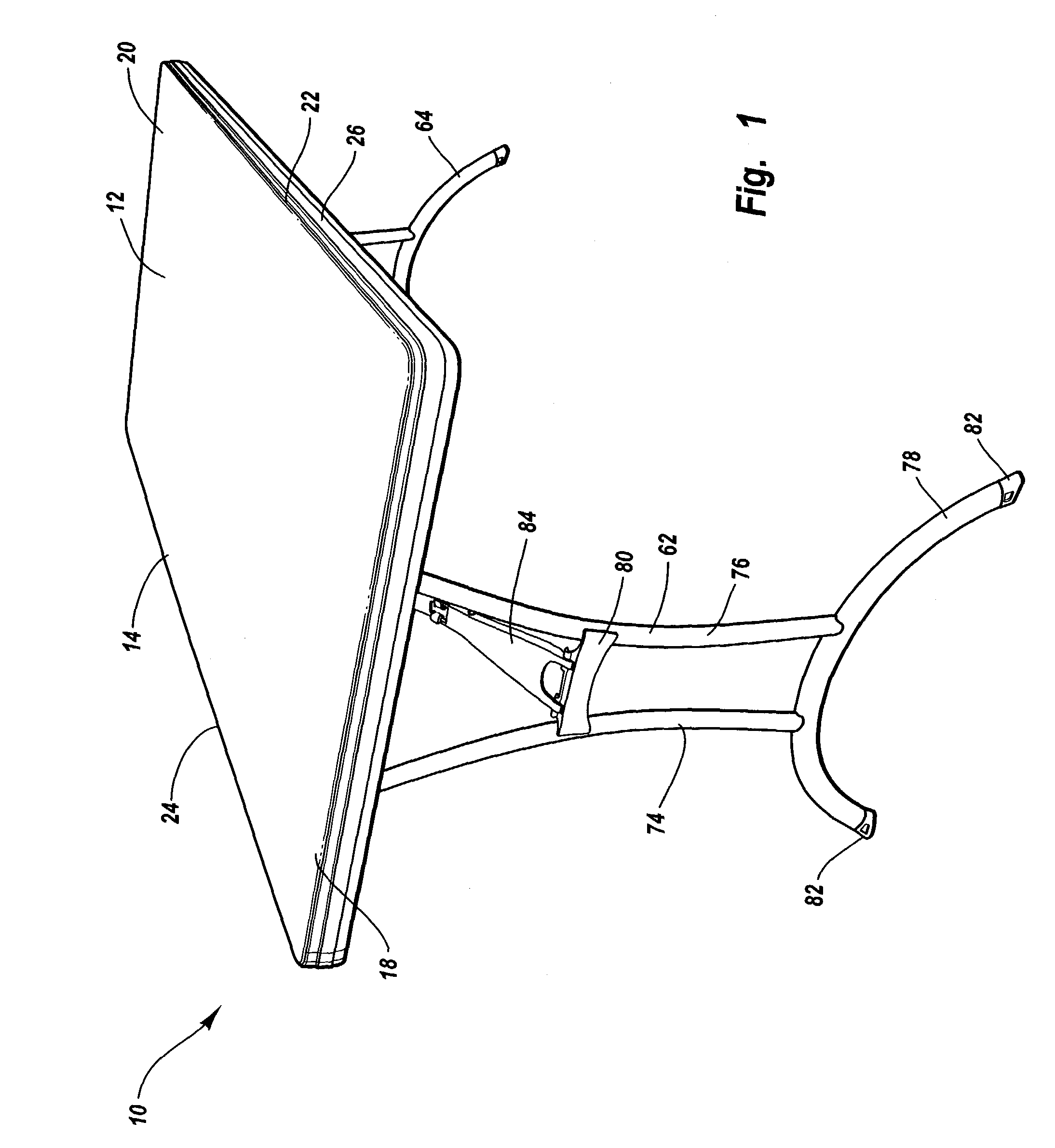

Portable folding table

A table that includes a table top with a first half which is pivotally connected to a second half. The first and second halves of the table top are movable between a first position in which the halves are generally aligned and a second position in which the halves are generally placed adjacent to each other. The first and second halves of the table top are preferably constructed from blow-molded plastic and each of the halves desirably have a generally hollow interior. The first and second halves of the table top may include interlocking portions that are interconnected when the halves are in the aligned position. Desirably, the interlocking portions have generally hollow interiors that are integrally formed with the generally hollow interiors of the halves of the table top during the blow-molding process. The table top may also include one or more overlapping portions that are interconnected when the halves of the table top are in the aligned position. The overlapping portions may also have generally hollow interiors that are integrally formed with the generally hollow interiors of the halves of the table top during the blow-molding process.

Owner:LIFETIME PRODUCTS

Molding composition with good capability for blow molding

InactiveUS6677015B2Reduce concentrationIncrease stiffnessSynthetic resin layered productsThin material handlingBlow moldingPolymer science

A molding composition of at least 50% by weight of a polyamine-polyamide copolymer obtained from 0.05 to 2.5% by weight of a polyamine having at least 4 nitrogen atoms and having a viscosity of at least 5 000 Pa.s at 250° C. and at a shear rate of 0.1 l / s, and having a viscosity ratio of at least 7 at 250° C., when the melt viscosities at shear rates of 0.1 l / s and 100 l / s are compared with one another, has high melt stiffness and is easy to cut, and performs well in blow molding.

Owner:EVONIK DEGUSSA GMBH

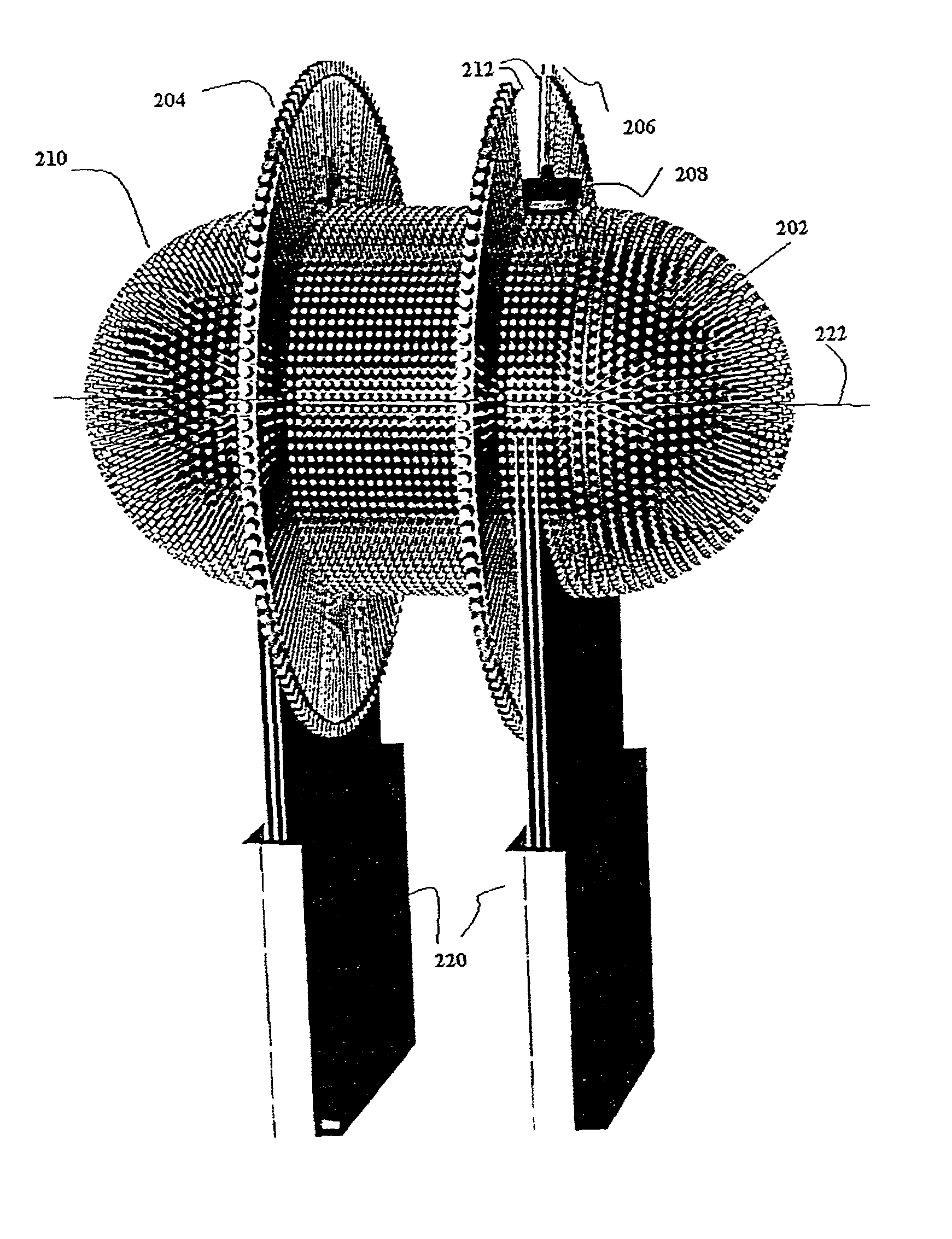

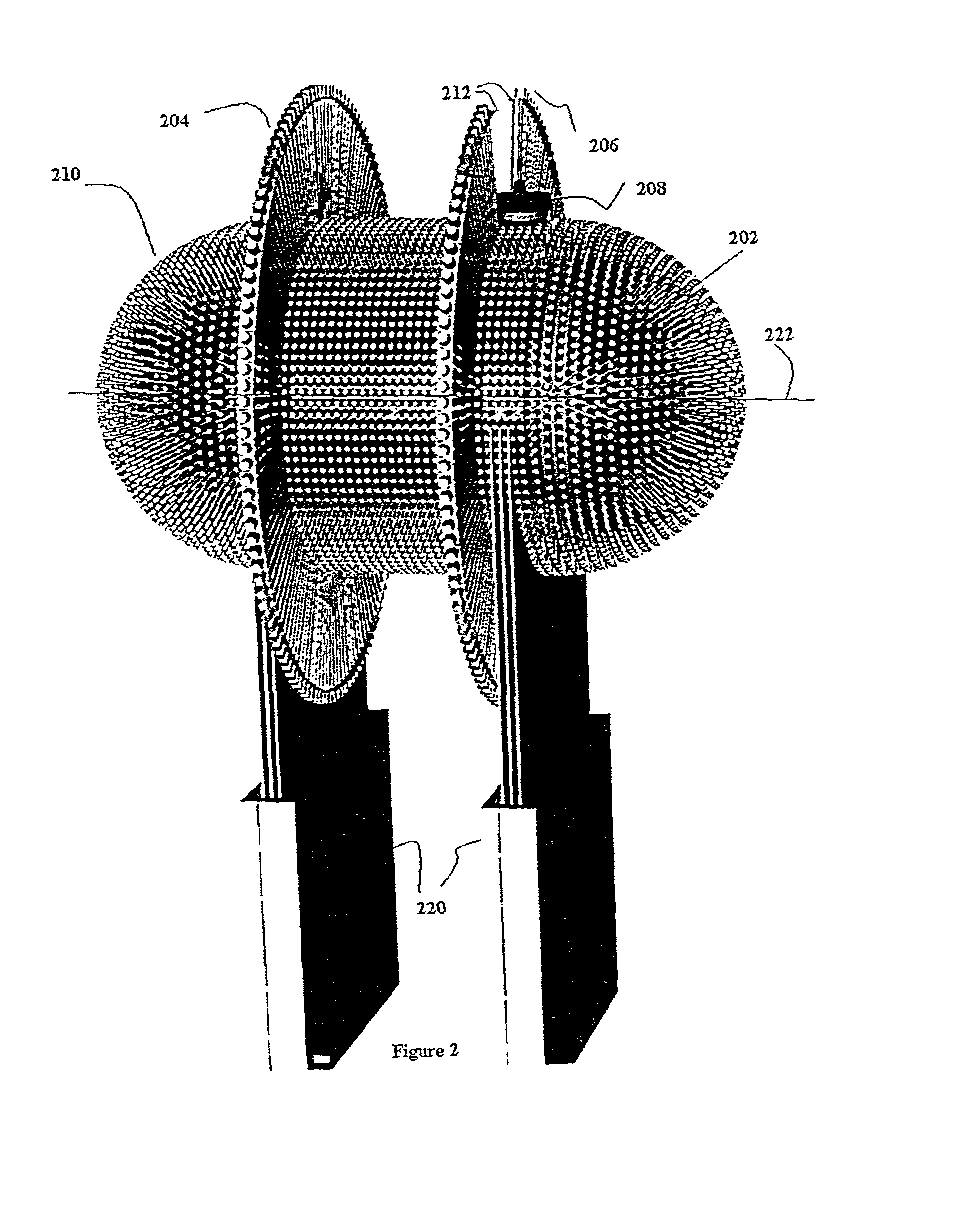

System, method and computer program product for forming a reconfigurable cavity and an expandable shoe last and for constructing a shoe

The present invention is an exemplary embodiment of the present invention is directed to a system, method and computer program product for creating a three-dimensionally reconfigurable cavity. The system can include a container that is configurable to create a three dimensional cavity. The system can be operative to form a footwear last in the cavity. The last can be formed from a plastic-like material. The system can include a blow molding apparatus having at least one directional deflector. The container can be capsule, hemispherical, cylindrical, or spherical-shaped. The system can include a container having holes to receive rods. The system can include an array of rods. The rods can be movable through the container. The system can further include rods that are threaded; gear-driven; coupled to a belt; coupled to a partial belt; or belt-driven. The cavity can be formed by an inner end of the rods. If more than one rod occupies a single point of the cavity, then only one rod participates in forming the cavity and other rods will not participate. Participating rods can be selected according to an optimizing module. The software module can determine an intersection of a rod with a digitized cluster of points representing a 3 dimensional surface. A method of forming a footwear last from a collapsible and expandable last is described.

Owner:SAJEDI MOHAMMAD H

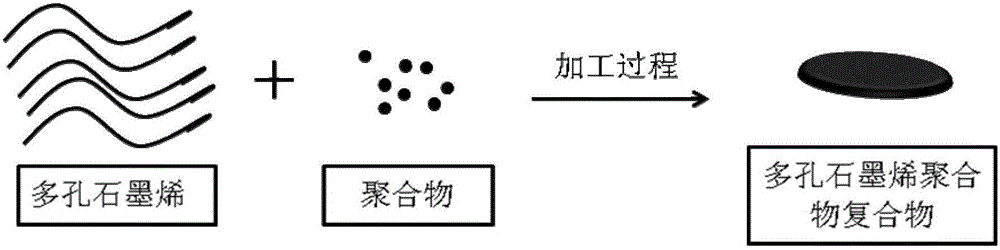

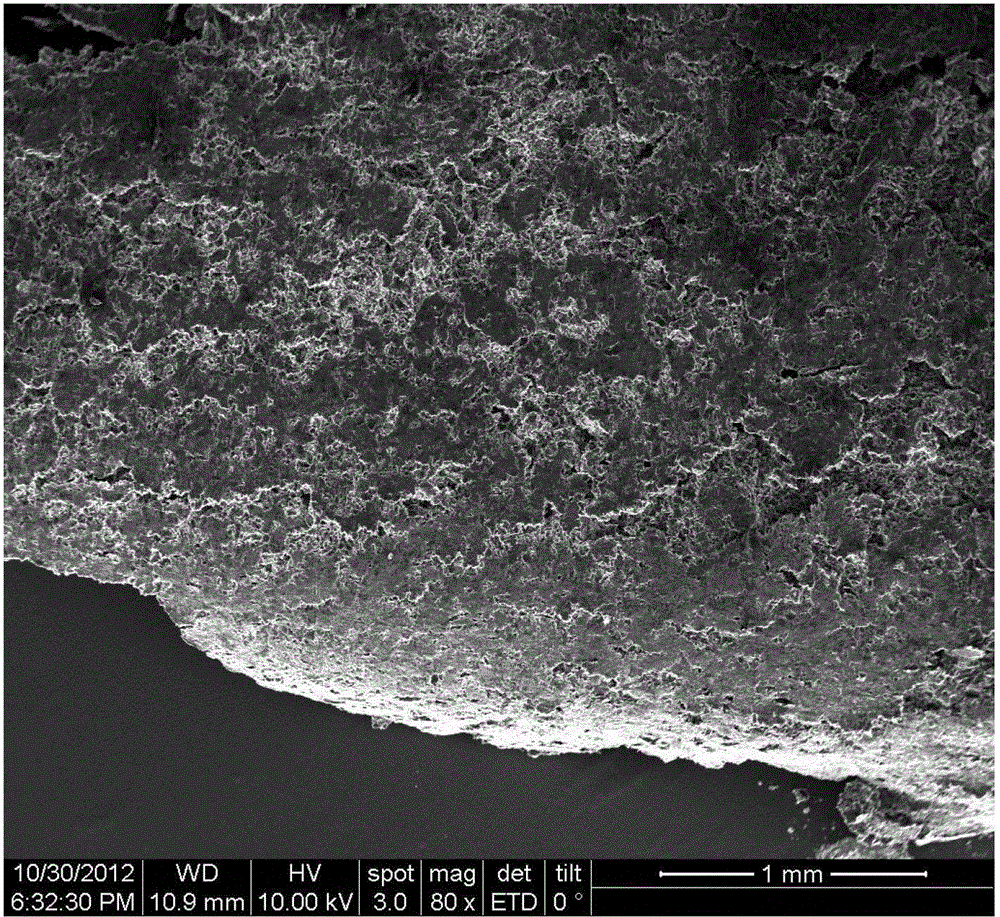

Porous graphene/polymer composite structure and preparation method and application thereof

The invention discloses a porous graphene / polymer composite structure, and a preparation method and application thereof. The composite structure mainly comprises a compound formed by porous graphene and more than one polymer and / or polymer monomer. The preparation method comprises the following steps of: compounding polymers and / or polymer monomers with porous graphene to form a target product, wherein the compounding manner comprises single-screw / double-screw fusing processing, injection molding, blow molding, melt spinning, solution spinning, electrostatic spinning, electrostatic spraying, powder metallurgy, liquid mixing or high speed mechanical stirring dispersion. The invention is simple in process, wide in source of raw materials, easy to implement in large scale, low in cost, safe, environment-friendly and free from toxic and harmful wastes, and the product obtained is excellent in thermal and electric properties, and has wide application prospect in the fields of heat conduction, radiation, electric conduction, anti-static electricity, electromagnetic shielding and the like.

Owner:苏州格瑞丰纳米科技有限公司

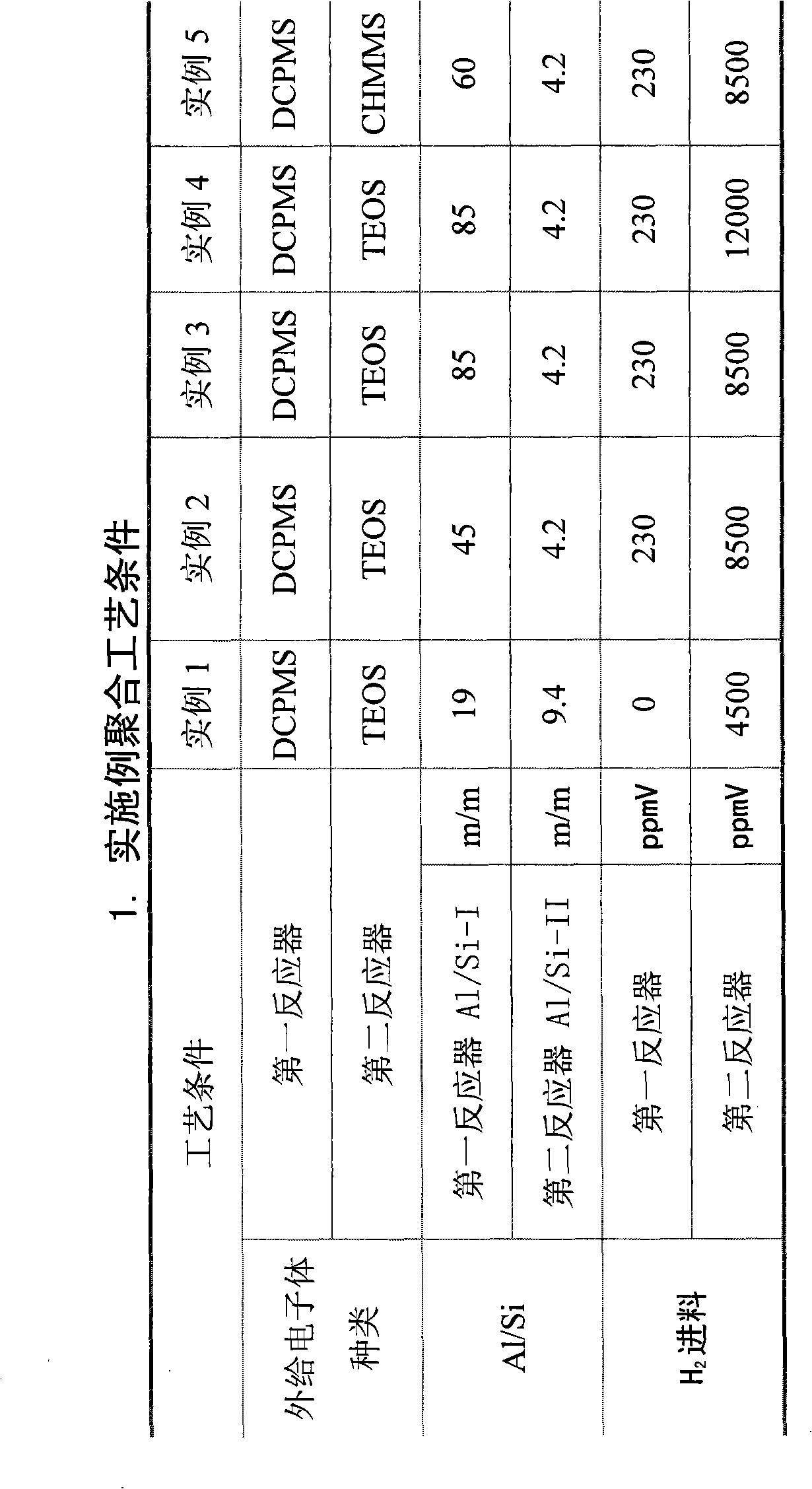

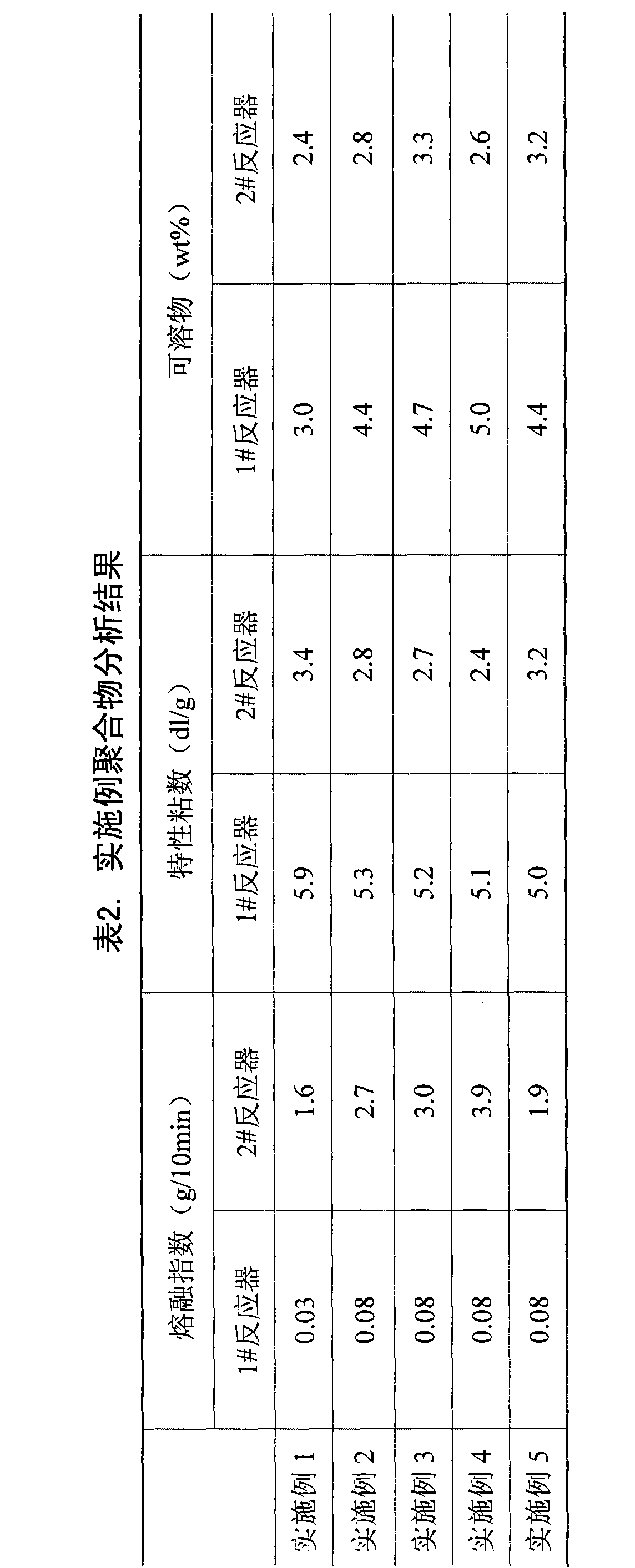

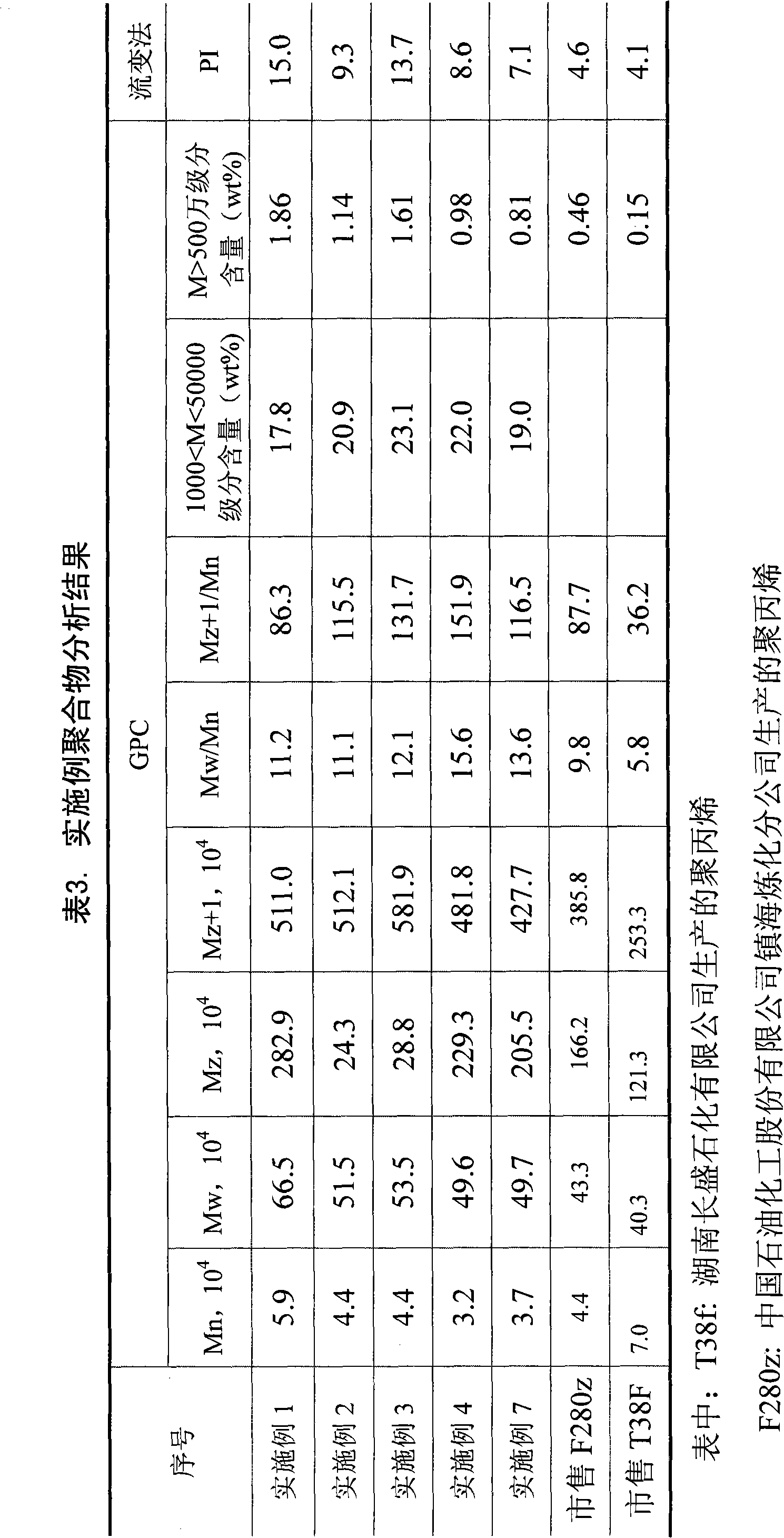

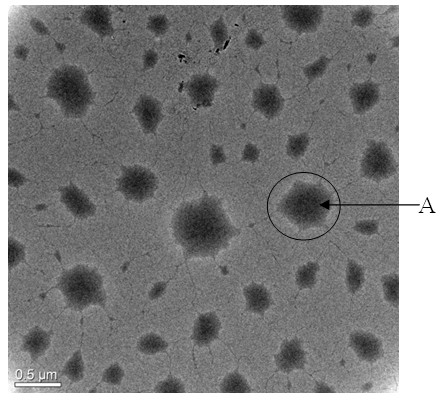

Polypropylene with high melt strength and product thereof

The invention provides homo-polypropylene with high isotacticity and high melt strength, which is characterized in that: (1) the melt index is (190 DEG C / 2.16kg)1.0-10g / min; (2) the molecular weight distribution Mw / Mn=6-20; (3) the content of molecules with the molecular weight of greater than 5 million fractions is greater than or equal to 0.8wt%; and (4) Mz+1 / Mn is greater than or equal to 70. The polymer can be used for producing foamed products, hot forming products, biaxially oriented films, blown films and blow molding products.

Owner:CHINA PETROLEUM & CHEM CORP +1

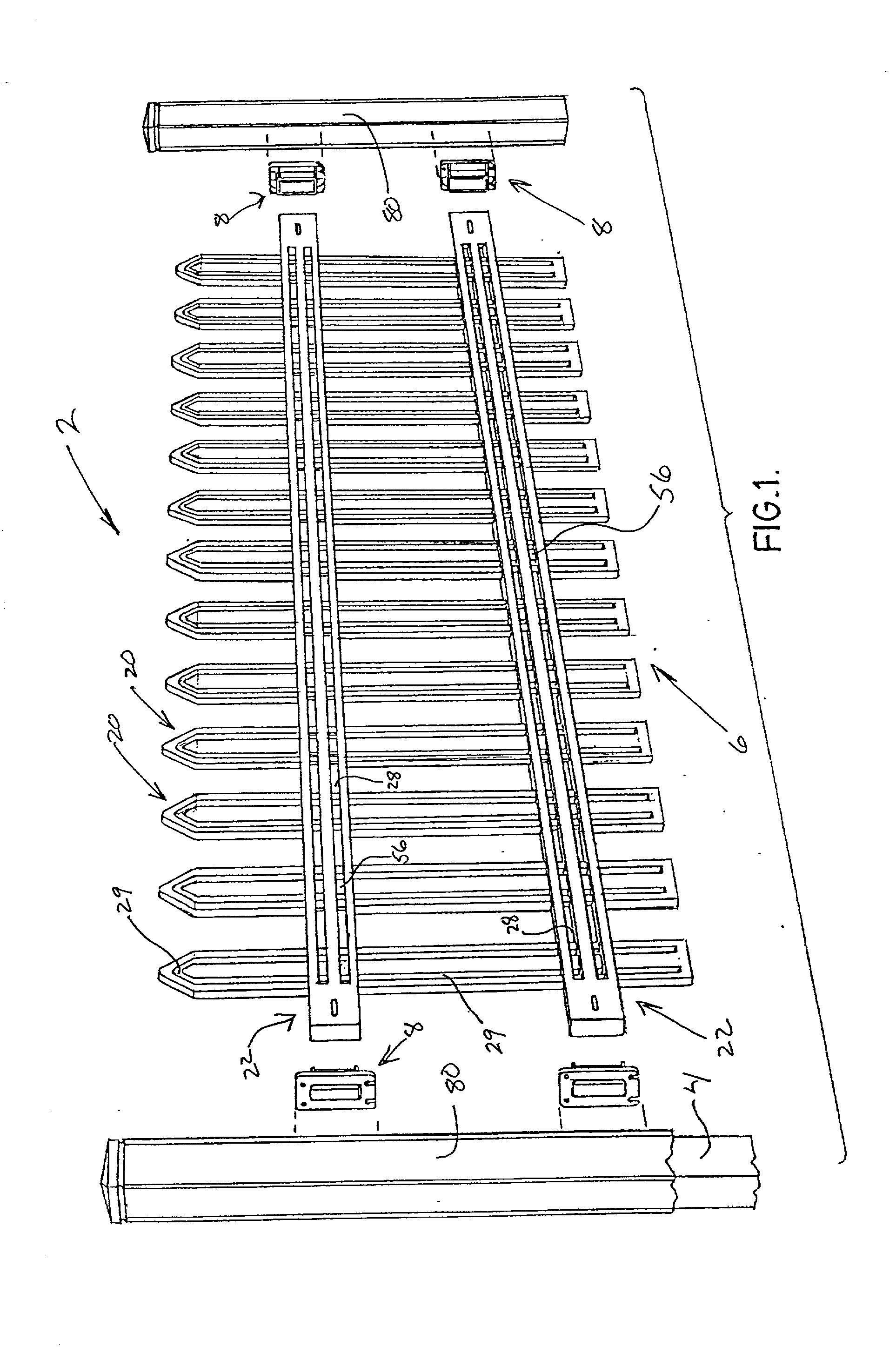

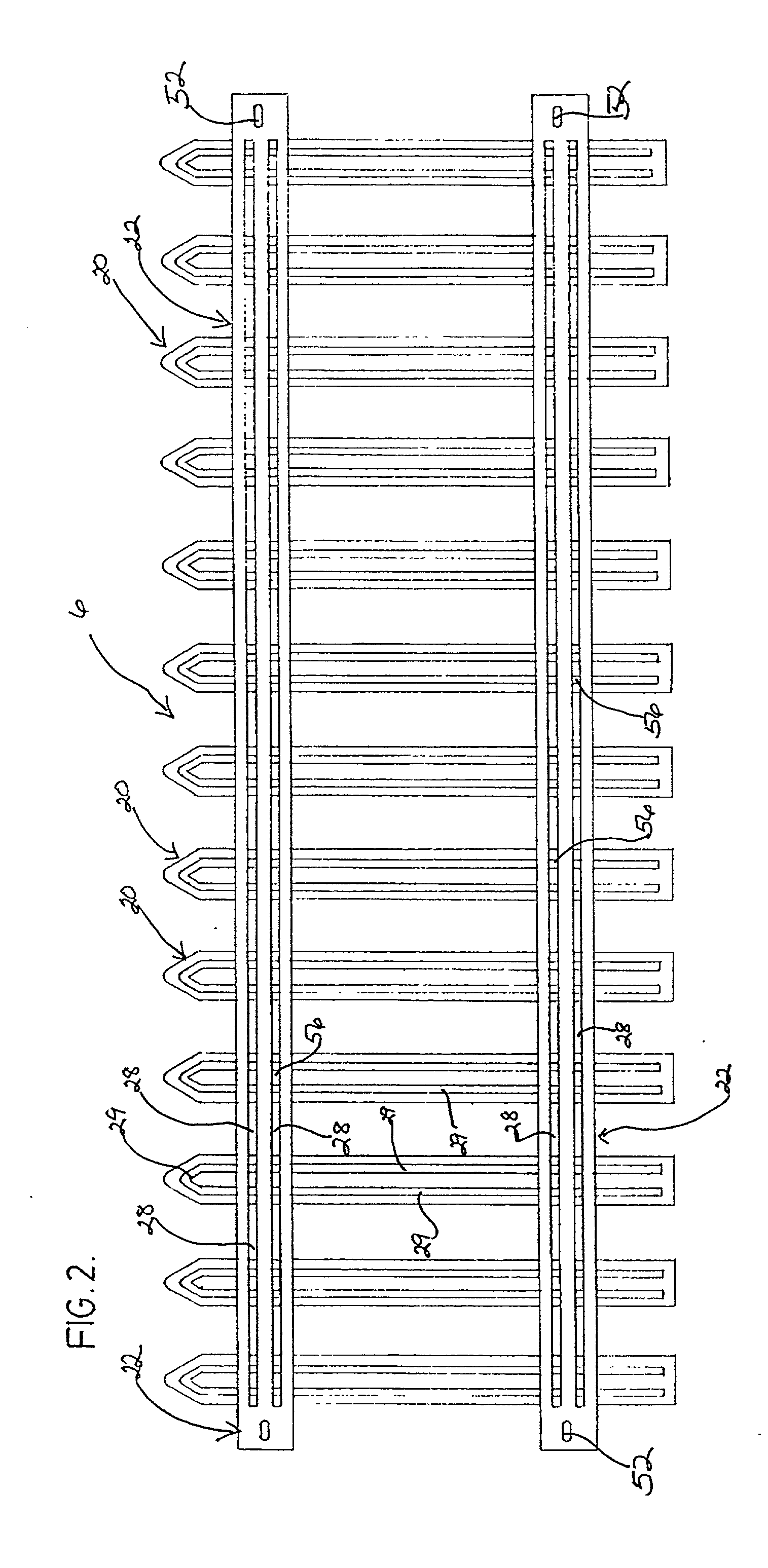

Molded picket fence section

A picket fence section is made as a single integral plastic component. The fence section can be made in various length including a length appropriate for securement between posts spaced at eight foot centers. The picket fence section is preferrably of a high density polyethylene material and made by blow molding.

Owner:GSW

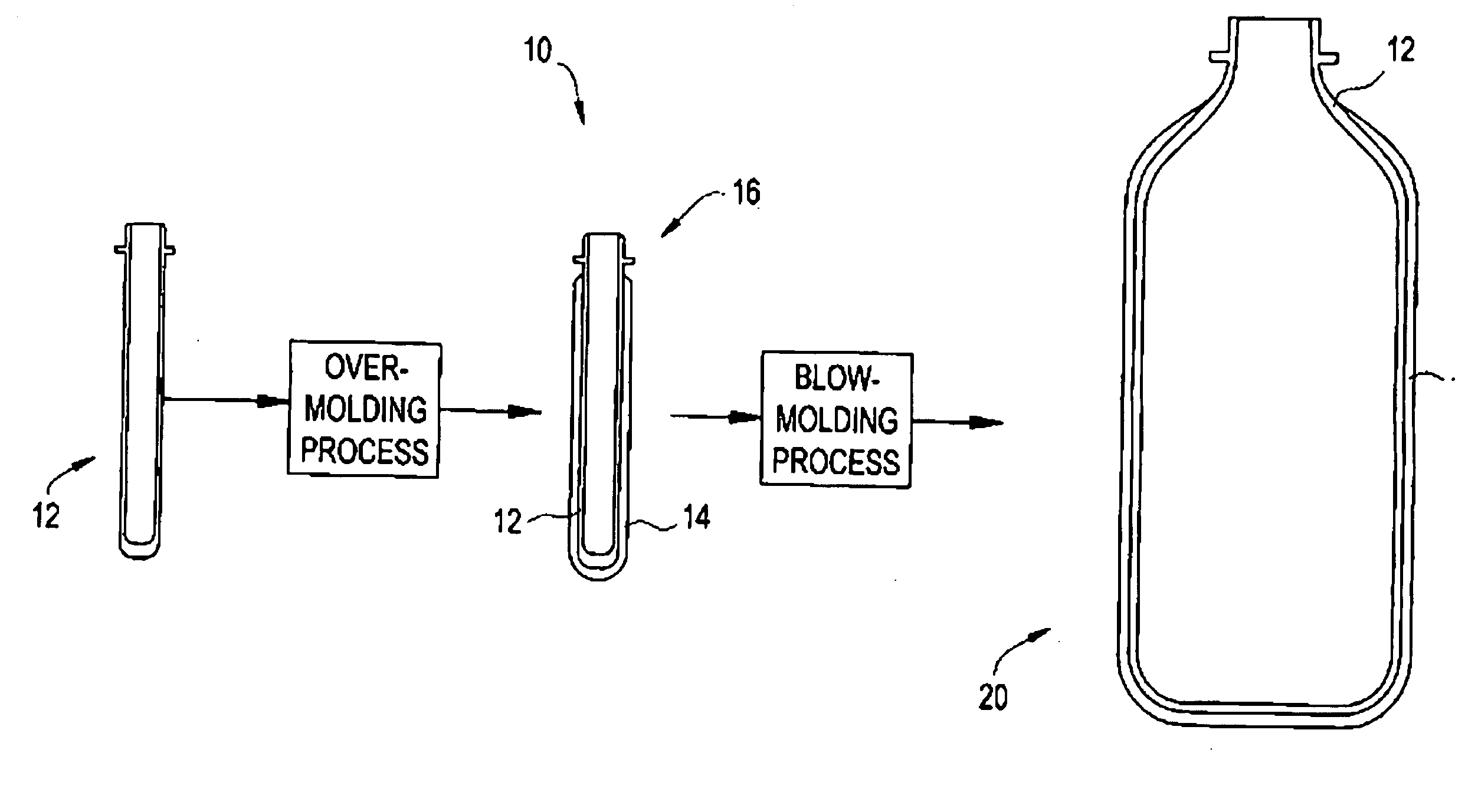

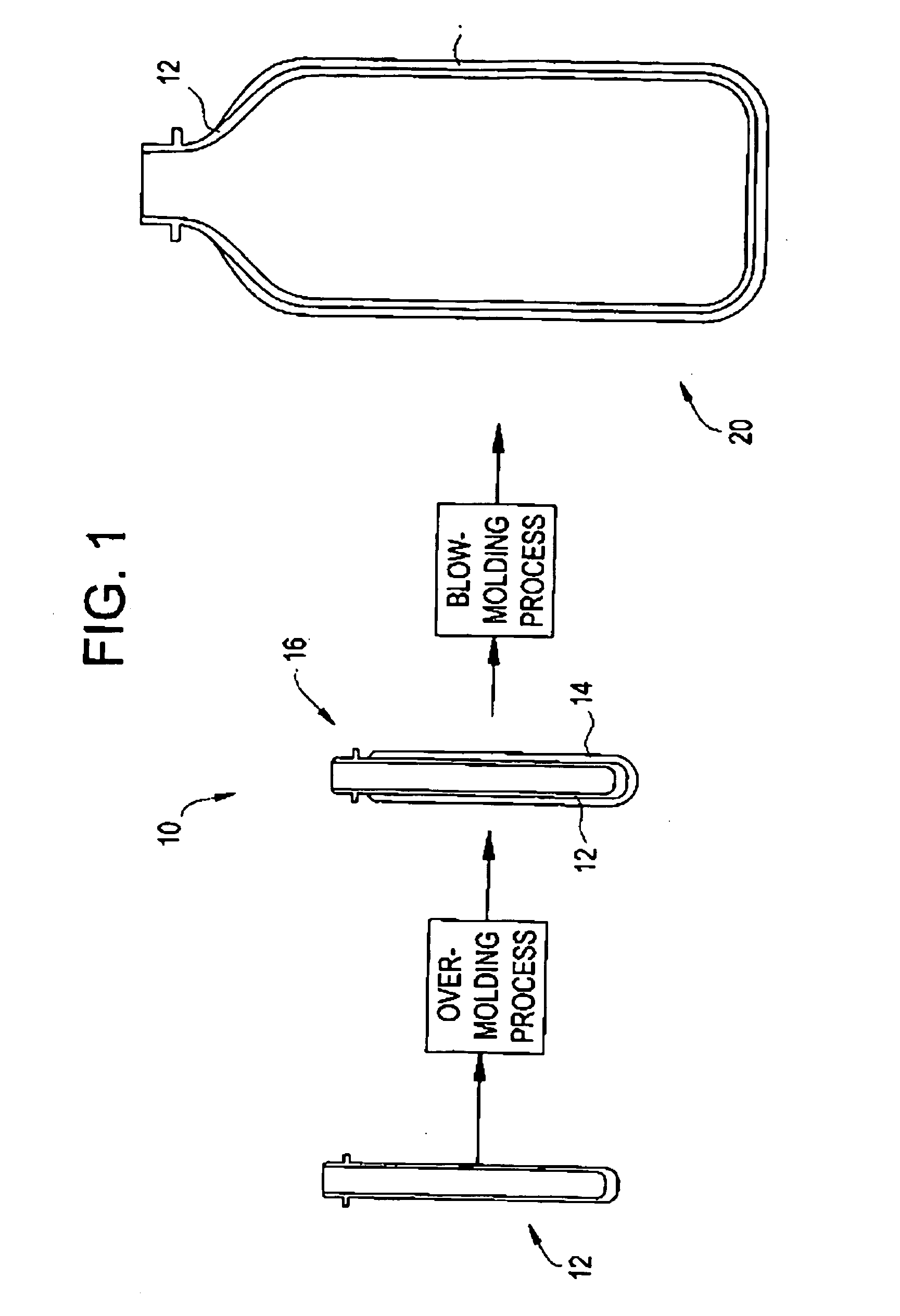

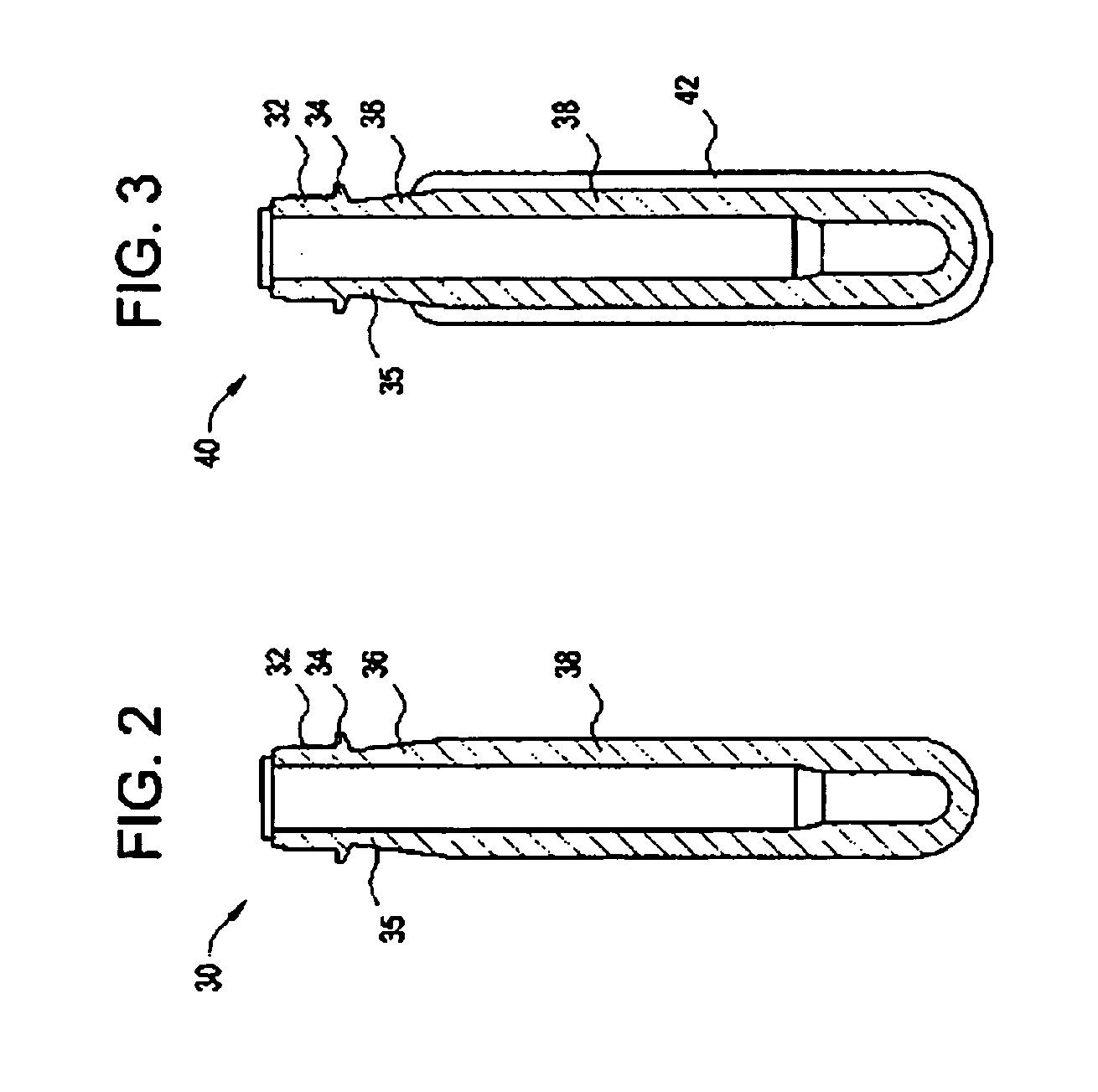

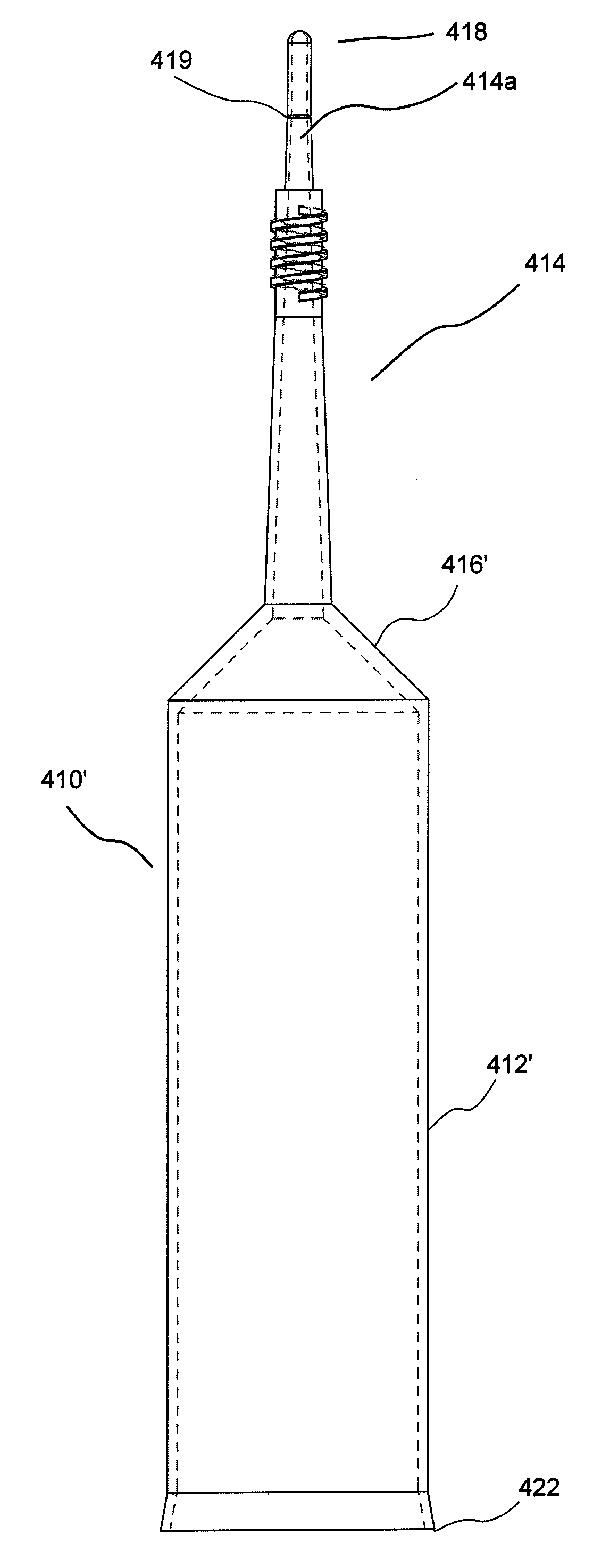

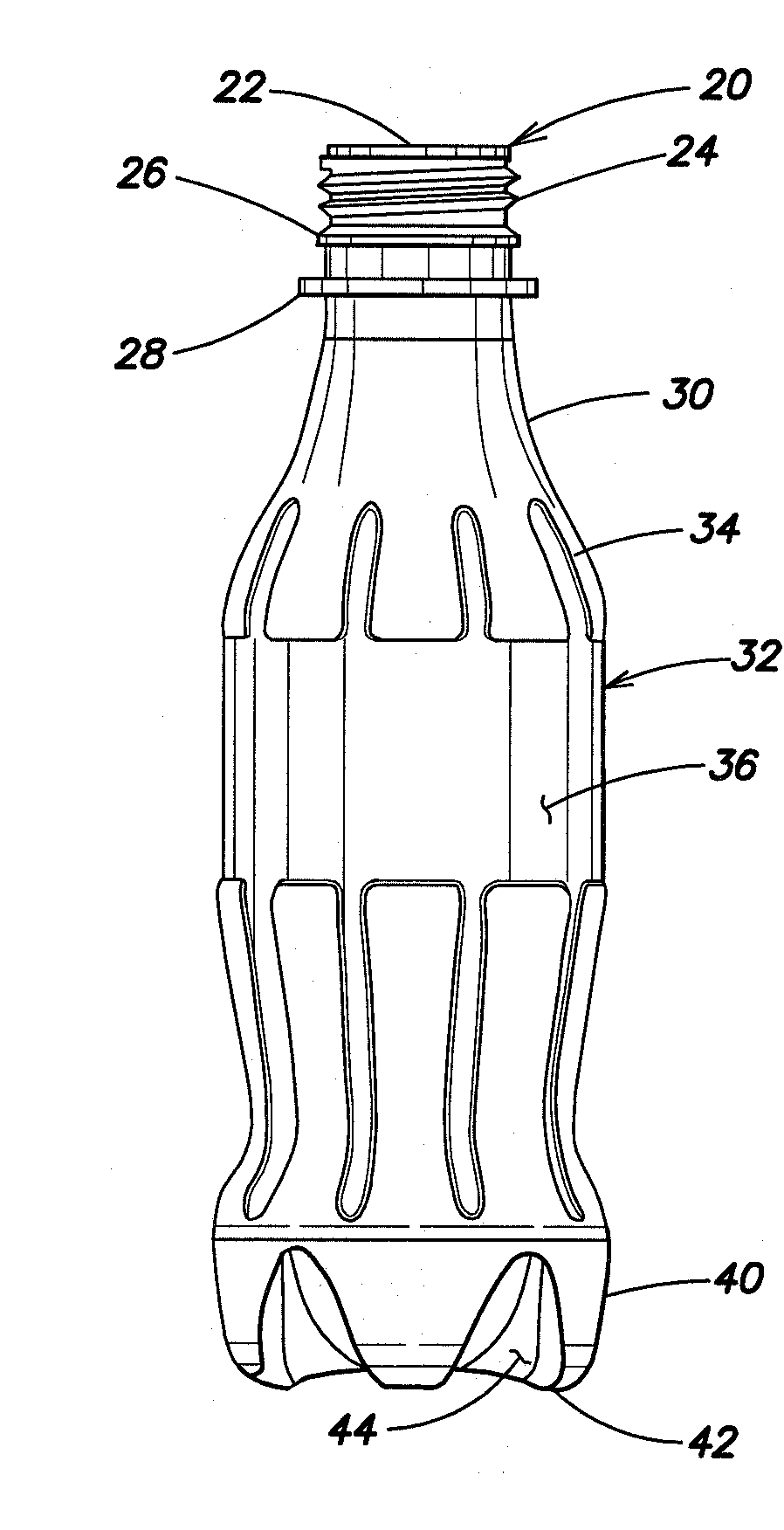

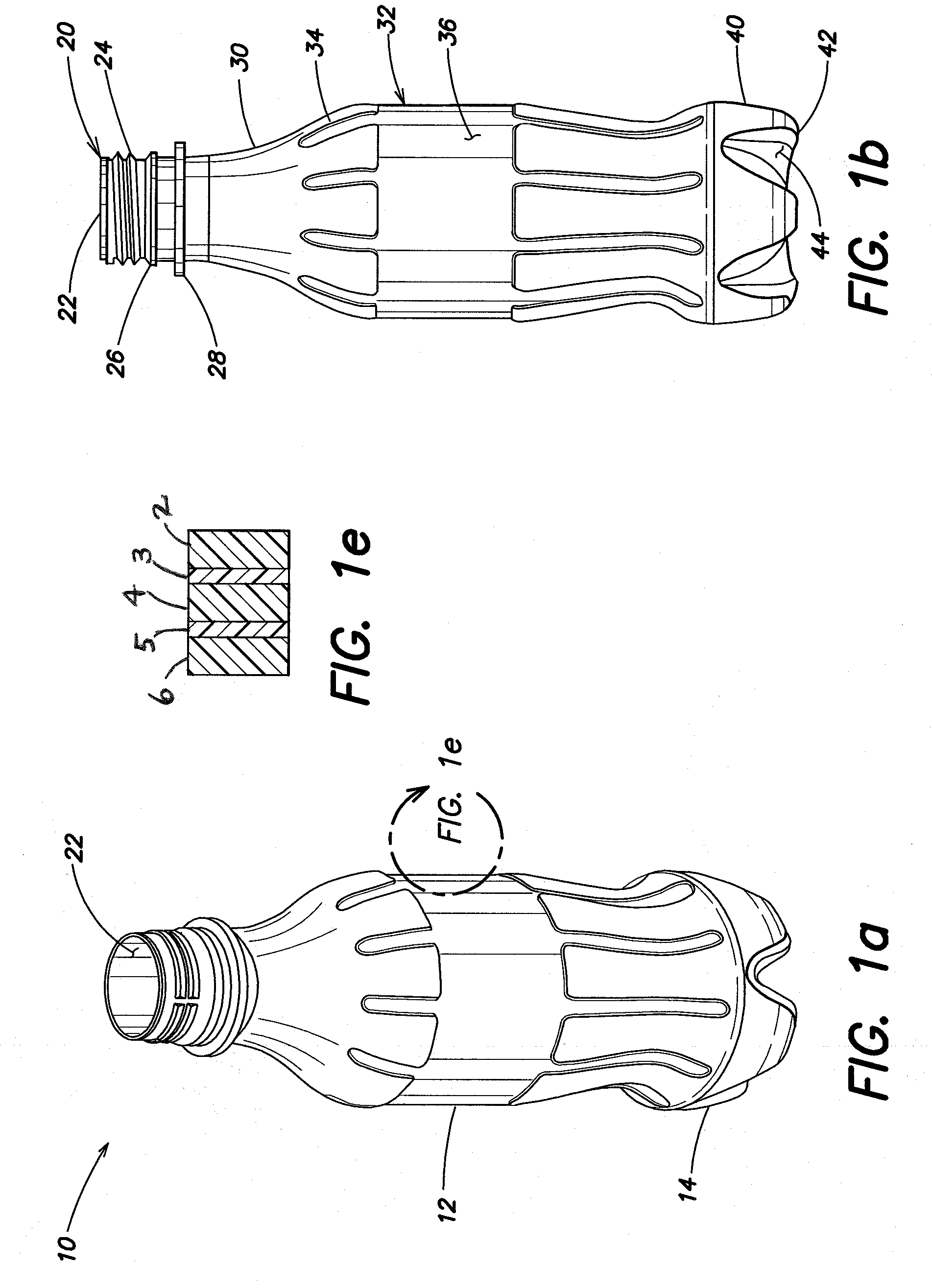

Overmolded containers and methods of manufacture and use thereof

ActiveUS20060210746A1Enhanced visualEnhanced tactile characteristicBottlesPlastic recyclingBlow moldingThermal insulation

Overmolded containers and methods of manufacture thereof are disclosed, which may provide enhanced visual and tactile characteristics, enabling innovative packaging designs, improved grippability and thermal insulation. The containers can be made cost effectively manner, with minimal impact on polymer recycling streams. The methods of making the container include the steps of providing a container preform which comprises a thermoplastic polymer, such as a PET copolymer; overmolding an elastomeric material over at least a portion of the preform to form an overmolded preform; and blow-molding the overmolded preform to form an overmolded container. In one embodiment, the overmolded container is a beverage container.

Owner:THE COCA-COLA CO +1

Enhanced ESCR bimodal HDPE for blow molding applications

Bimodal polyethylene compositions and blow molded bottles made therefrom are provided. In at least one specific embodiment, the composition includes at least one high molecular weight polyethylene component having a molecular weight distribution (MWD) of about 6 to about 9, a short chain branch content of less than about 2 branches per 1,000 main chain carbons, and a Mz of about 1,100,000 or more. The composition also includes at least one low molecular weight polyethylene component where a ratio of weight average molecular weight of the high molecular weight polyethylene component to weight average molecular weight of the low molecular weight polyethylene component is about 20 or less. The polyethylene composition has a density of about 0.94 g / cc or more, an ESCR of about 600 hours or more, a percent die swell of about 70% or more, and may comprise at least 70% ethylene-derived units.

Owner:UNIVATION TECH LLC

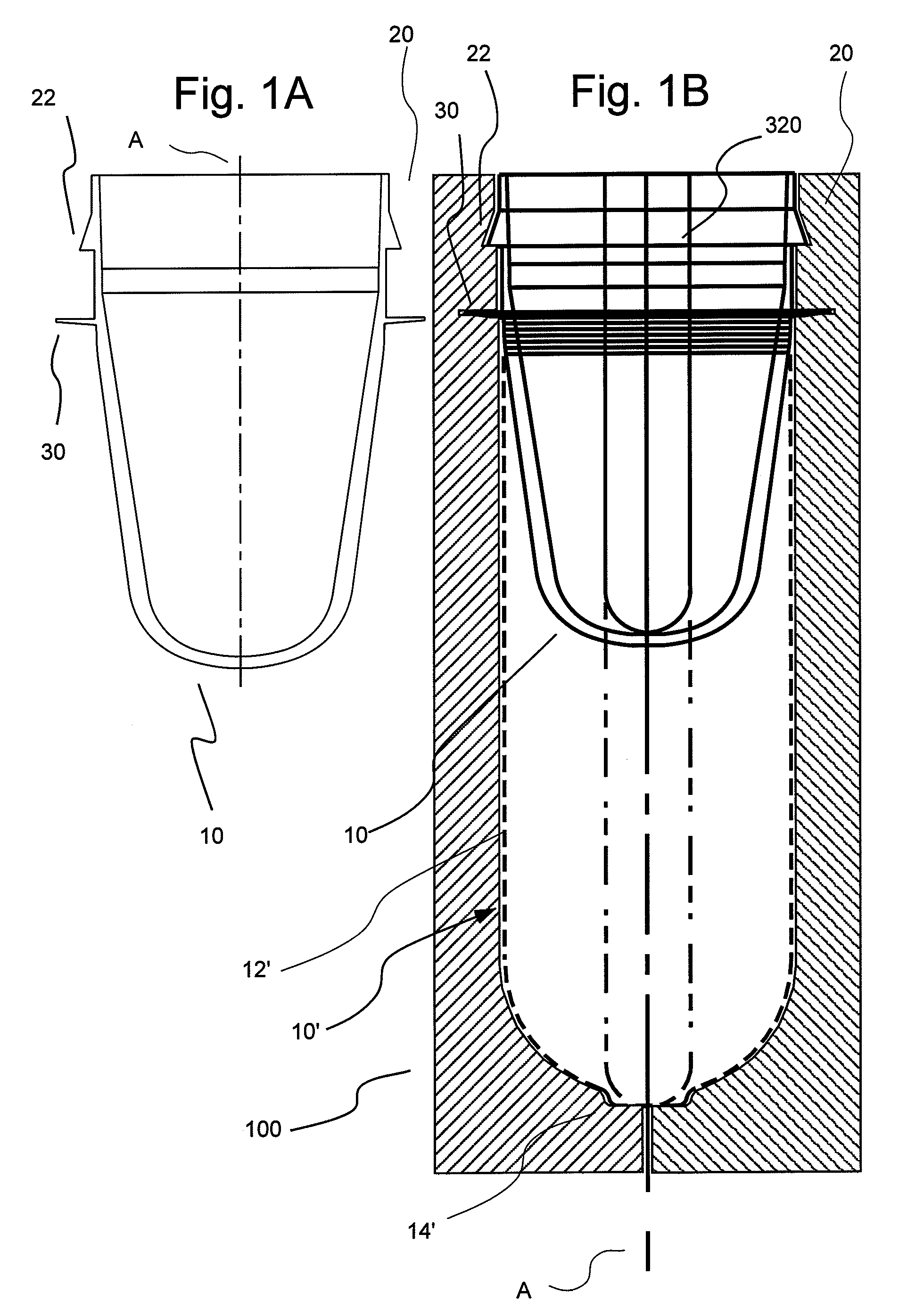

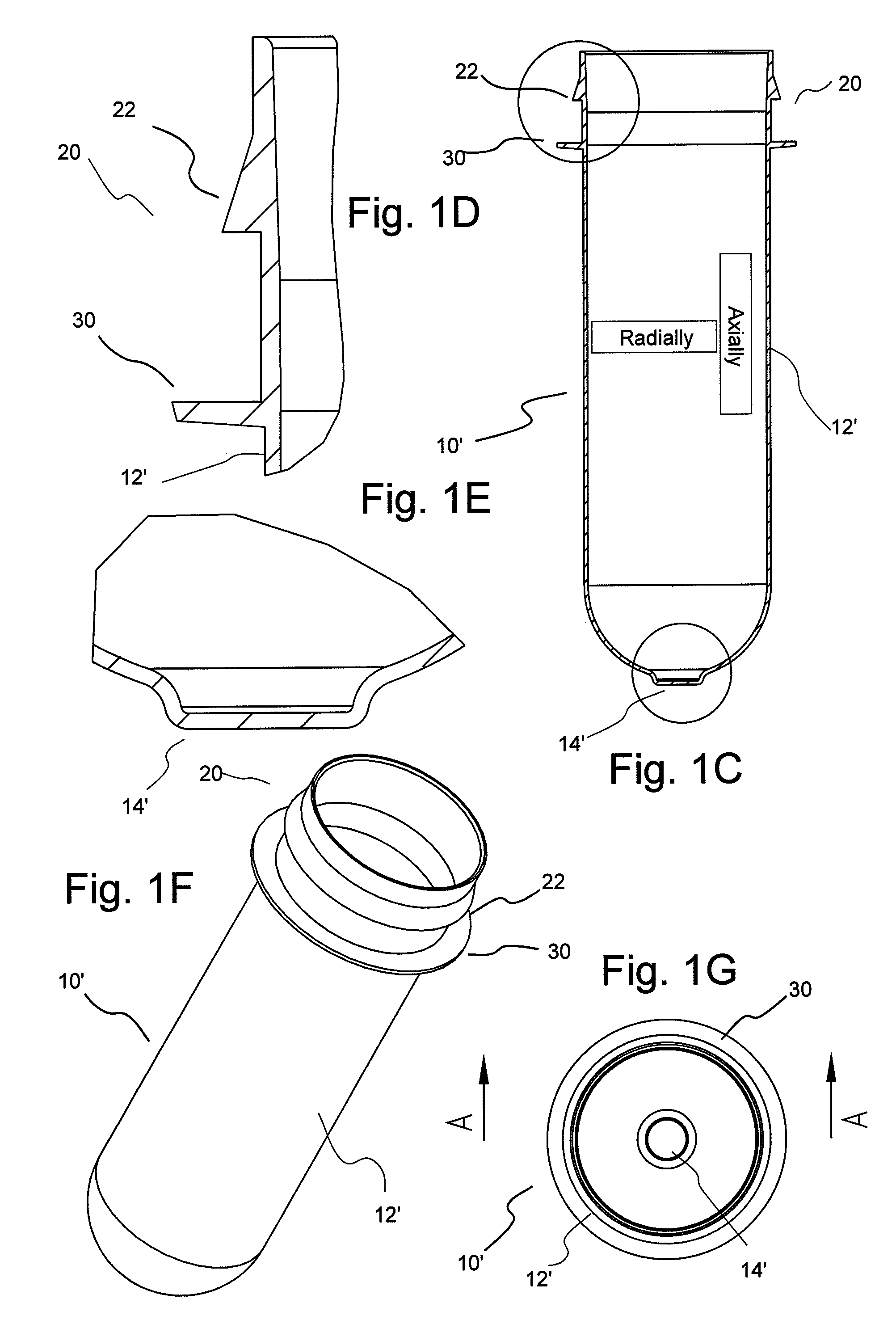

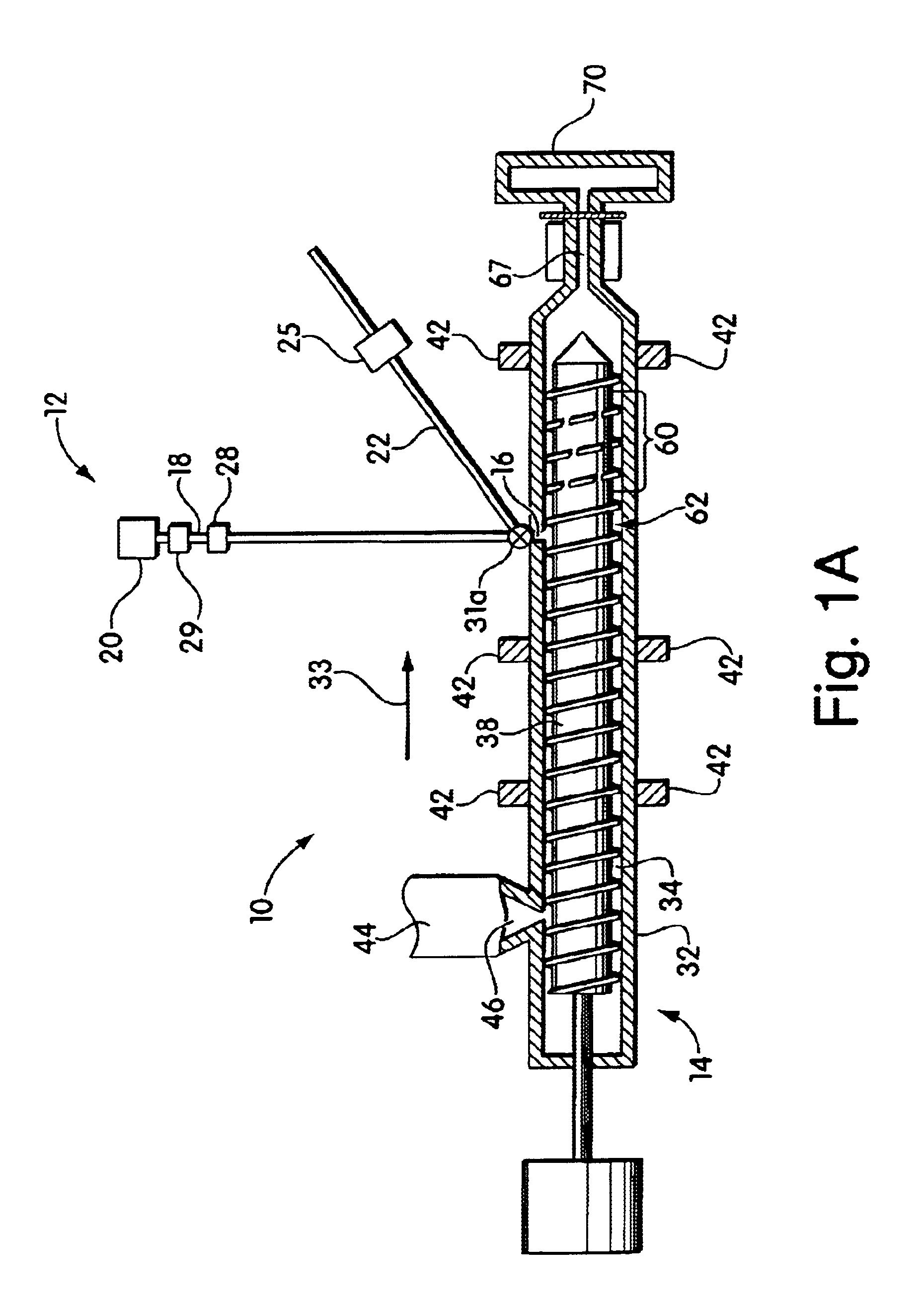

Syringe for use with injectors and methods of manufacturing syringes and other devices

ActiveUS20080033367A1Reduce thicknessInfusion syringesMedical devicesPolystyreneCyclo olefin polymer

A syringe for use in a pressurized injection of a fluid includes a syringe barrel including a polymeric material having undergone expansion via blow molding. An inner diameter of the syringe barrel can, for example, be sufficiently constant (over at least a portion of the axial length of the syringe) that a plunger slidably positioned within the syringe barrel and in generally sealing contact with an inner wall of the syringe barrel can be used within the syringe barrel to generate a pressure of at least 1 psi within the syringe barrel. In several embodiment, the inner diameter of the syringe barrel is sufficiently constant to generate a pressure of at least 100 psi, at least 300 psi, or even at least 500 psi within the syringe barrel. A method of forming a syringe includes the steps of: injection molding at least one polymeric material to form a preform; placing the preform into an blow mold die; and expanding at least a portion of the preform while heating the preform within the die to form a barrel of the syringe. The syringes can be formed to withstand relatively high pressures as described above. The at least one polymeric material can, for example, be polyethyleneterephthalate, cyclic olefin polymer, polypropylene, polystyrene, polyvinylidene chloride, polyethylene napthalate and / or nylon.

Owner:BAYER HEALTHCARE LLC

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

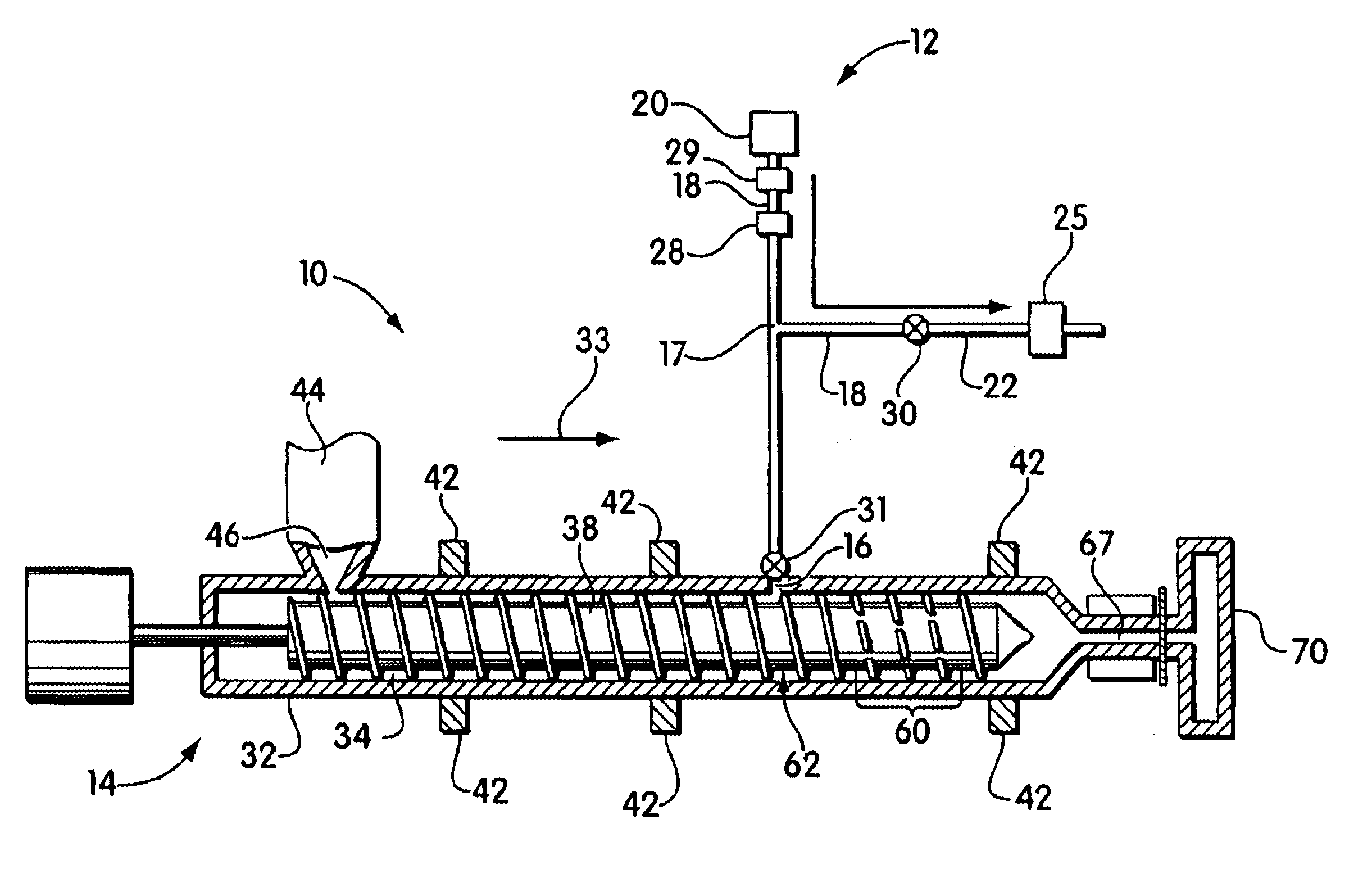

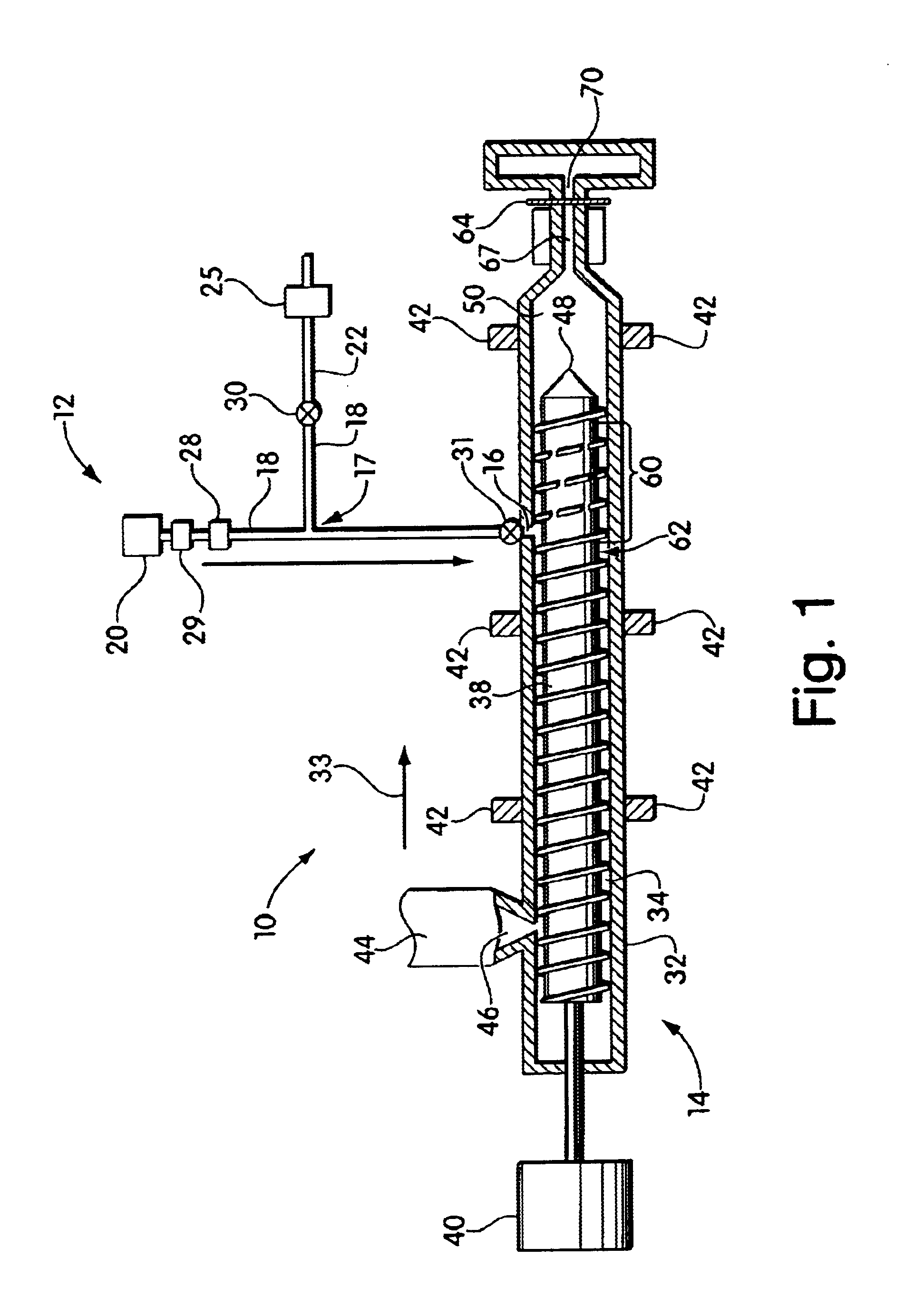

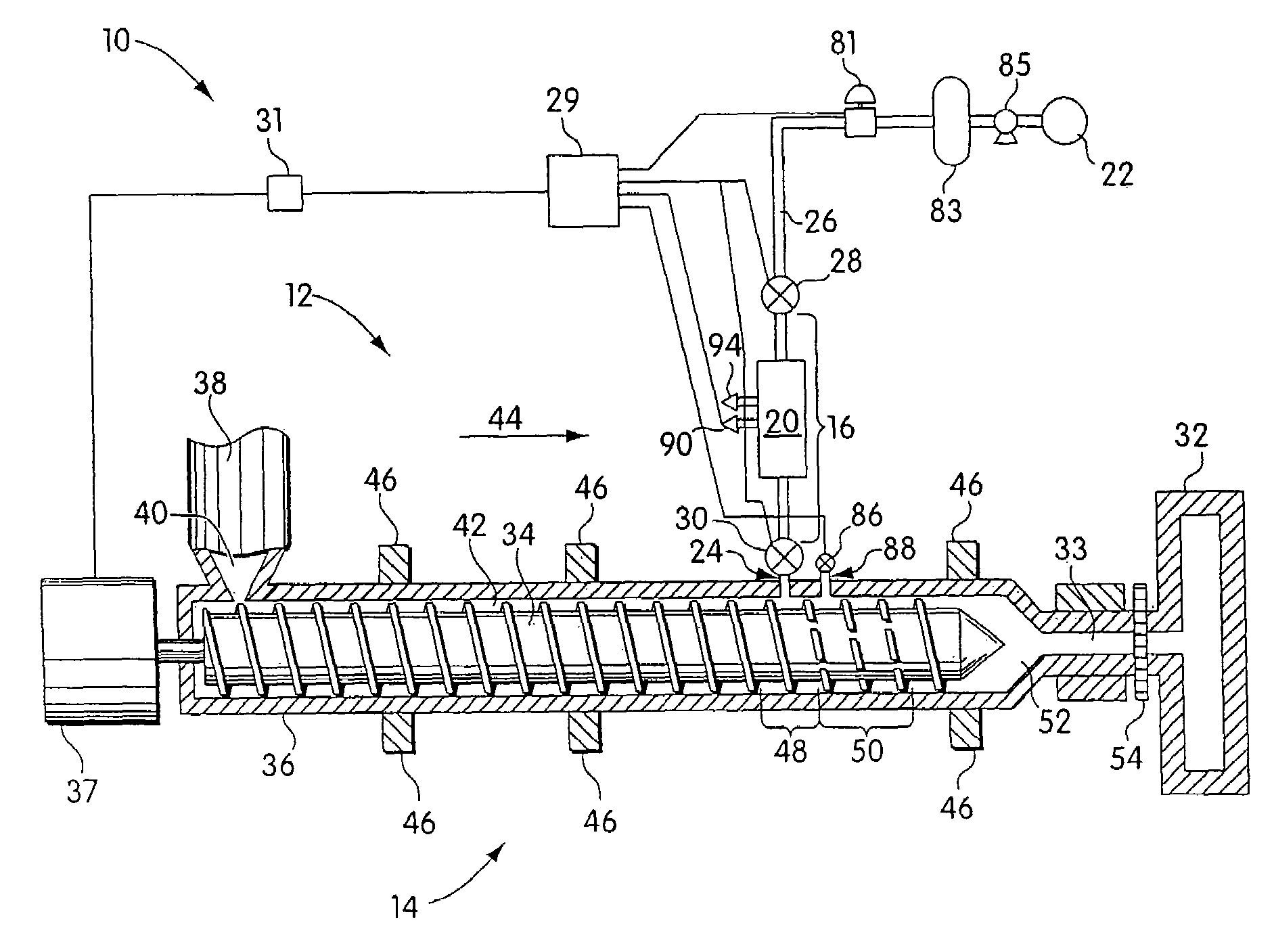

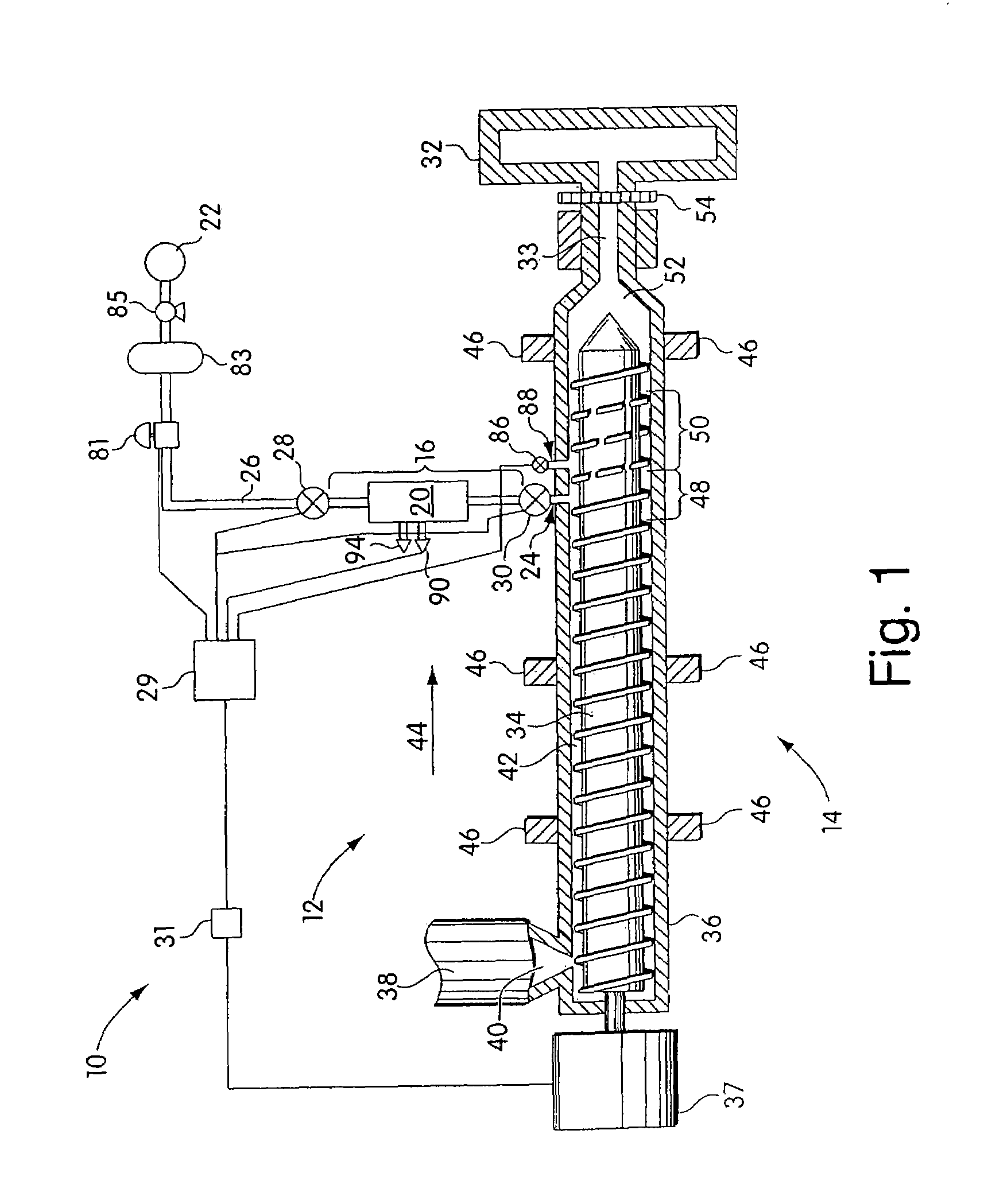

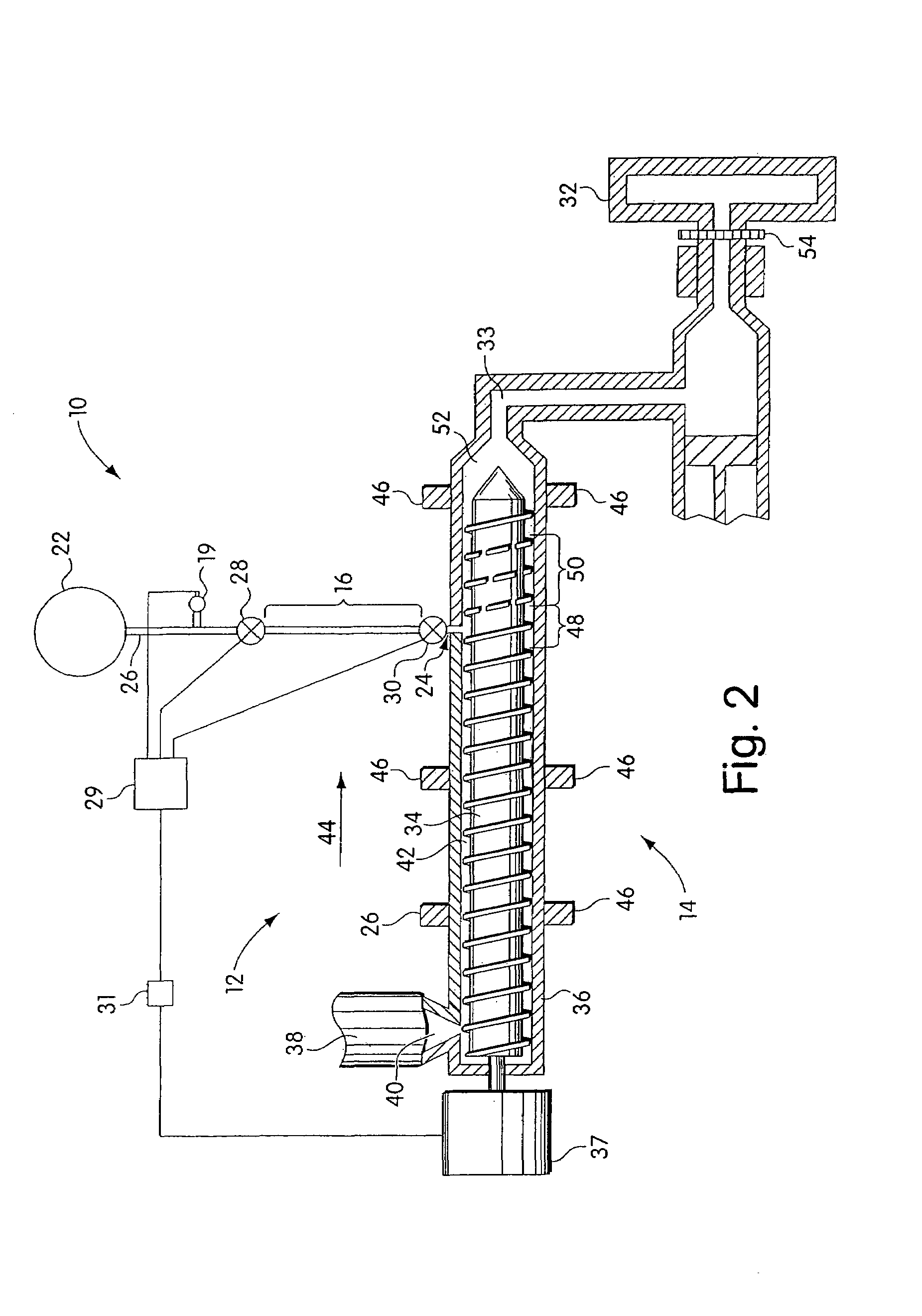

Blowing agent delivery system

InactiveUS6926507B2Easy to controlPrevents output inconsistencyAuxillary shaping apparatusFood shapingBlow moldingInjection molding machine

The invention provides a blowing agent delivery system for introducing a blowing agent into a polymeric foam processing system. The delivery system is designed to discontinuously introduce blowing agent from a continuous source into polymeric material within an extruder. The system, thus, may improve control over blowing agent delivery in discontinuous polymer processing systems such as injection molding or blow molding. In some embodiments, the blowing agent delivery system selectively directs blowing agent flow from the source to the extruder barrel, or through a bypassing passageway. In this manner, blowing agent may be continuously supplied by the source but discontinuously injected into the extruder barrel. During use, the delivery system may cause blowing agent to flow through the bypassing passageway, for example, when the screw stops plasticating polymeric material.

Owner:TREXEL

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

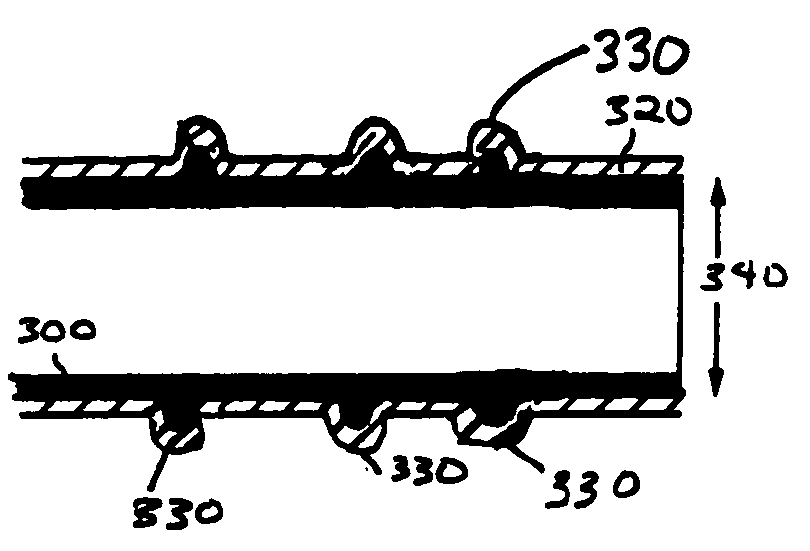

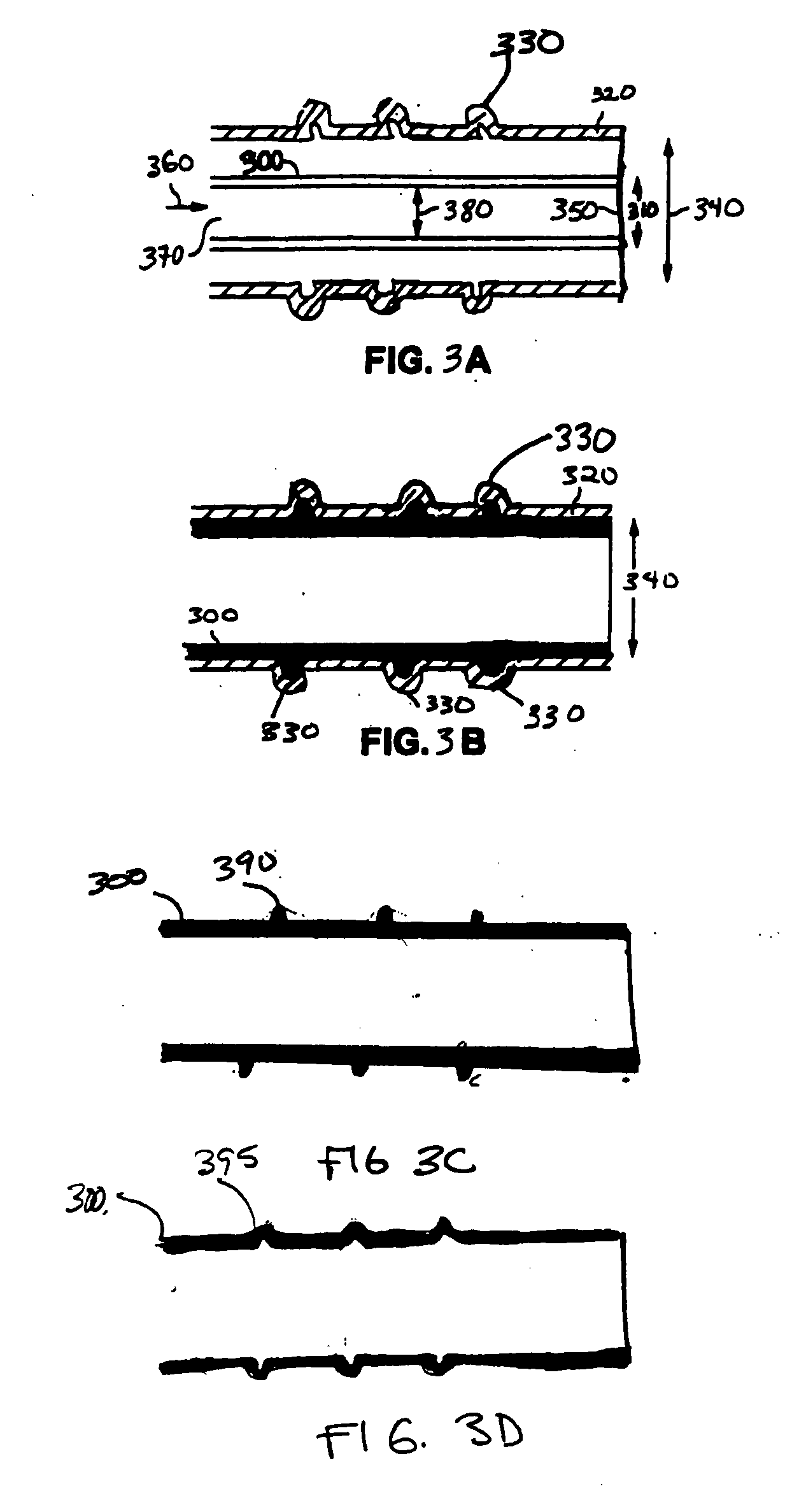

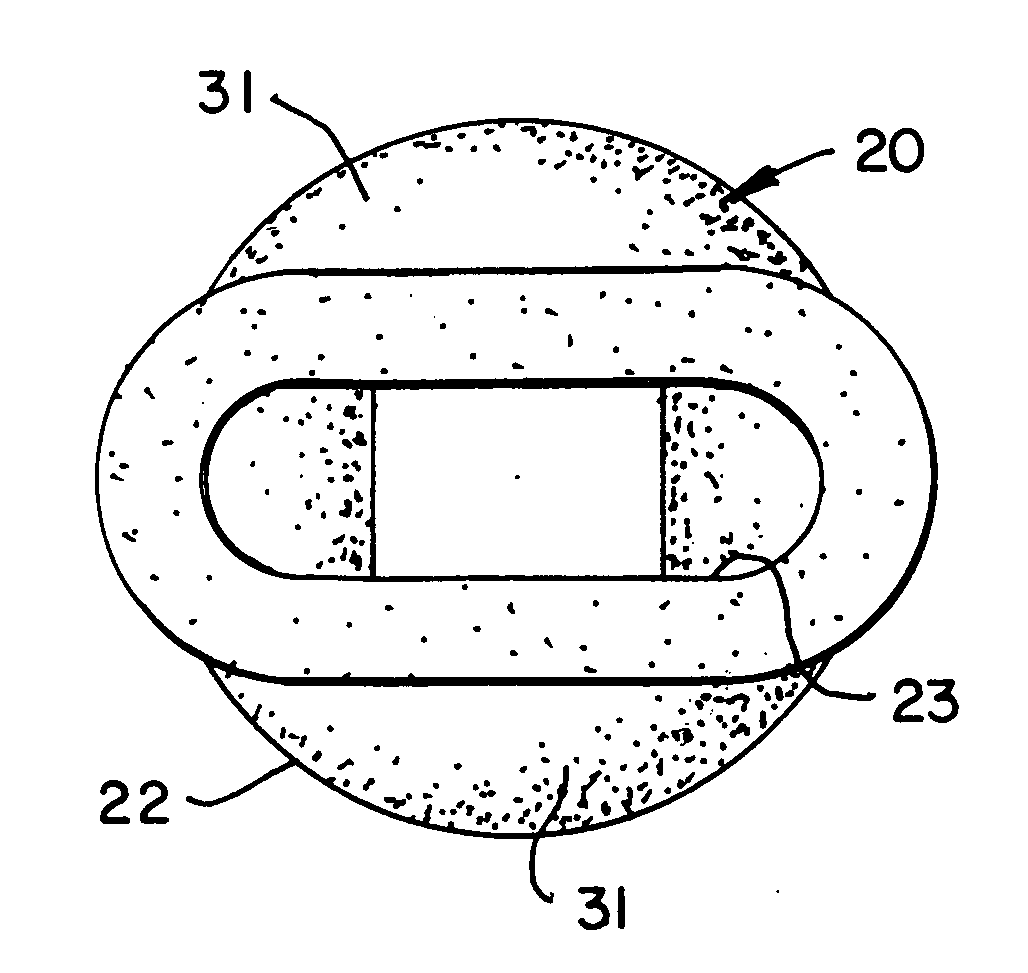

Load bearing or cushioning elements and method of manufacture

InactiveUS20060290039A1Easy to produceInexpensive load bearing, cushioning and/or supportingStuffed mattressesSpring mattressesBlow moldingCushioning

By providing an elongated profile which incorporates a plurality of indentations formed therein, a load bearing / cushioning / supporting element is realized. By employing this construction, the element accommodates large strain under force, and shows good resiliency and repeated recovery. The element can be produced from a continuous extrusion process with immediate manipulation to re-shape the extrusion profile, or secondary thermal forming process which follows the extrusion process, or blow molding process, or injection molding process.

Owner:NOMACO

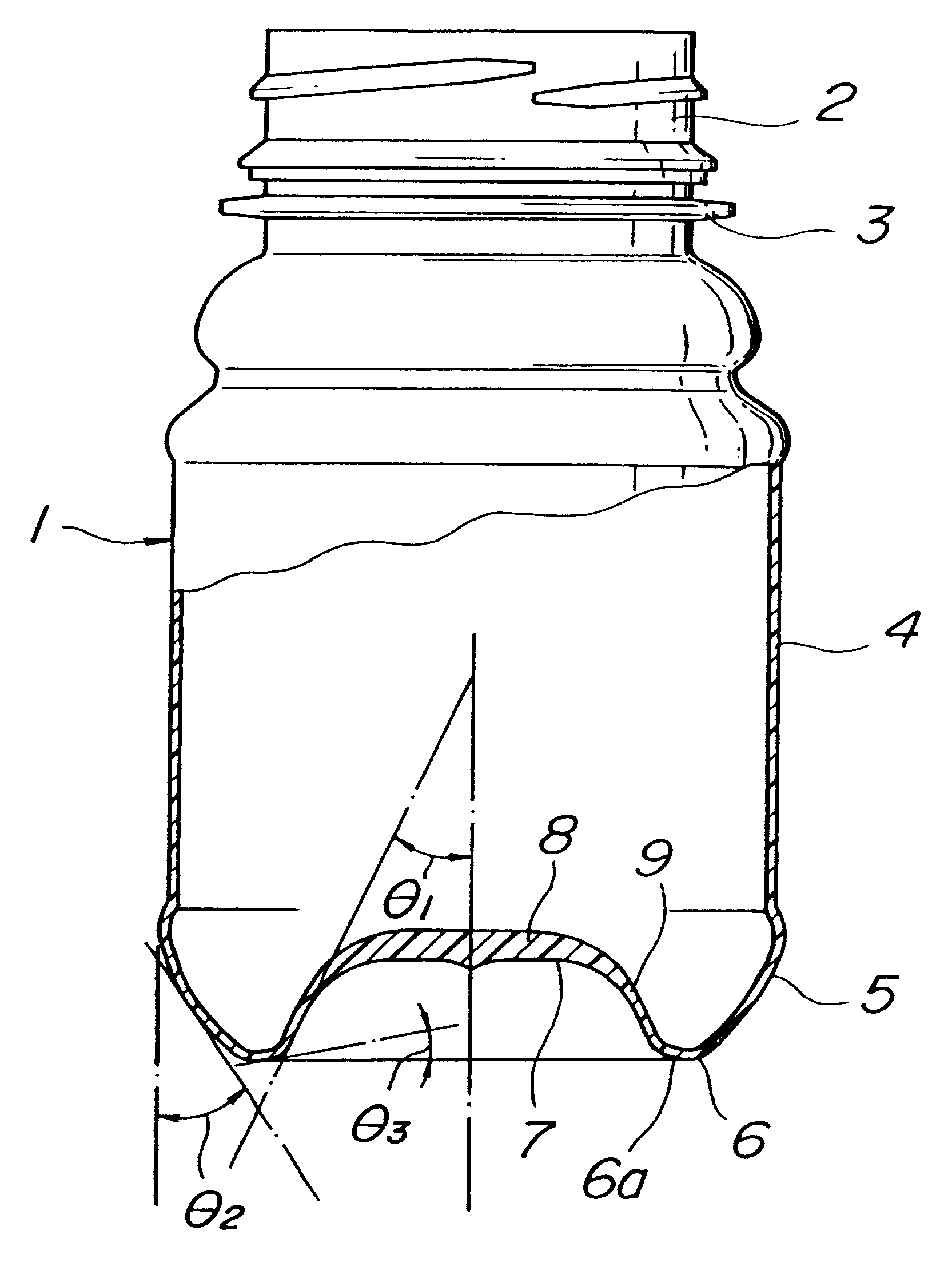

Heat-resistant packaging container made of polyester resin

A heat-resistant packaging container made of a polyester resin, formed by stretch-blow molding is provided. A top portion of a bottom face is formed to have a large wall thickness to impart a resistance to heat deformation. A peripheral wall of the bottom face is formed to have a wall thickness that is gradually reduced from the top portion toward an arc grounding edge around the bottom face. An outer peripheral wall of the bottom portion is stretch molded from inside of the grounding edge so as to have a wall thickness as same as that of the body portion to attain a heat resistance. The inside of the grounding edge connecting to the peripheral wall of the bottom face is formed into a tilt surface which is oriented upwardly in consideration of an amount of expanding deformation alpha of the grounding edge due to heating and loading. By forming the bottom face in consideration of a deformation amount of the grounding edge of the bottom face of the container due to heating and loading of contents, it is possible to keep the levelness of the grounding edge even after the heating.

Owner:A K TECH LAB INC

Blowing agent introduction systems and methods

The present invention provides blowing agent introduction systems and methods for introducing blowing agent into polymeric foam processing systems. The methods may involve introducing one or more doses of blowing agent into polymeric material in an extruder during a plastication period of a molding cycle. Prior to introduction, a dose is confined in an accumulator which, for example, has a volume defined between an inlet valve and an outlet valve. A control system may receive inputs related to system parameters (e.g., pressure of polymeric material in extruder, axial position of screw in barrel, whether screw is rotating, and the like) and based on the inputs coordinates operation of the valves to confine and introduce the blowing agent dose(s). The introduction systems may be used in discontinuous plasticating processes, such as injection molding and blow molding, and can be particularly useful in processes that use precise quantities of blowing agent.

Owner:TREXEL

Preform Base and Method of Making a Delamination and Crack Resistant Multilayer Container Base

InactiveUS20080257855A1Reduce weightLow viscosityLarge containersThin material handlingBlow moldingEngineering

Molded preform for blow molding a plastic container for pressurized applications, the preform having a base with a multilayer wall for forming a delamination and crack resistant multilayer footed container base. The preform base forming region has an end cap portion with a non-spherical inner wall, including a flattened central section joined by arcuate corner sections to a generally cylindrical outer section. The inner wall sections provide a varying end cap thickness profile which enhances orientation in select portions of the footed container base for improved performance and / or lightweighting of the container base.

Owner:GRAHAM PACKAGING CO LP

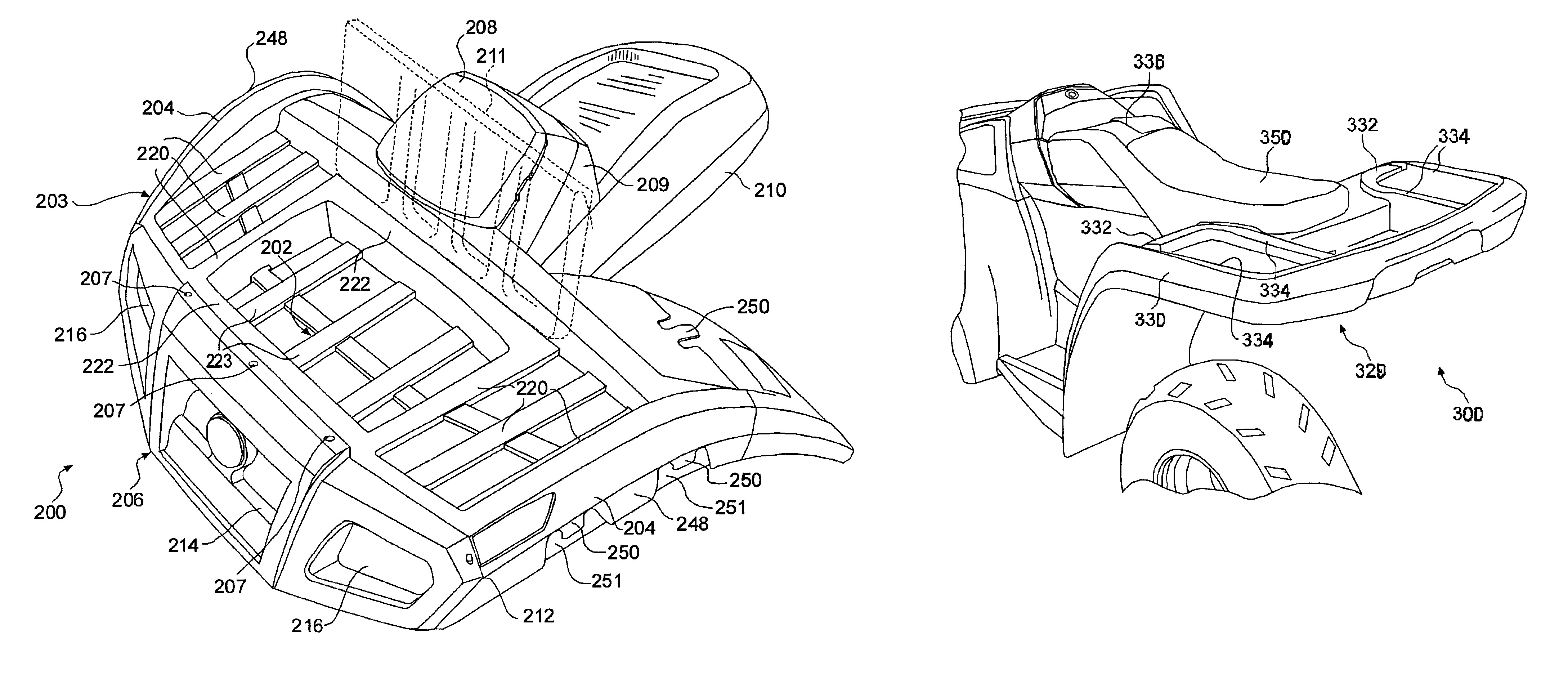

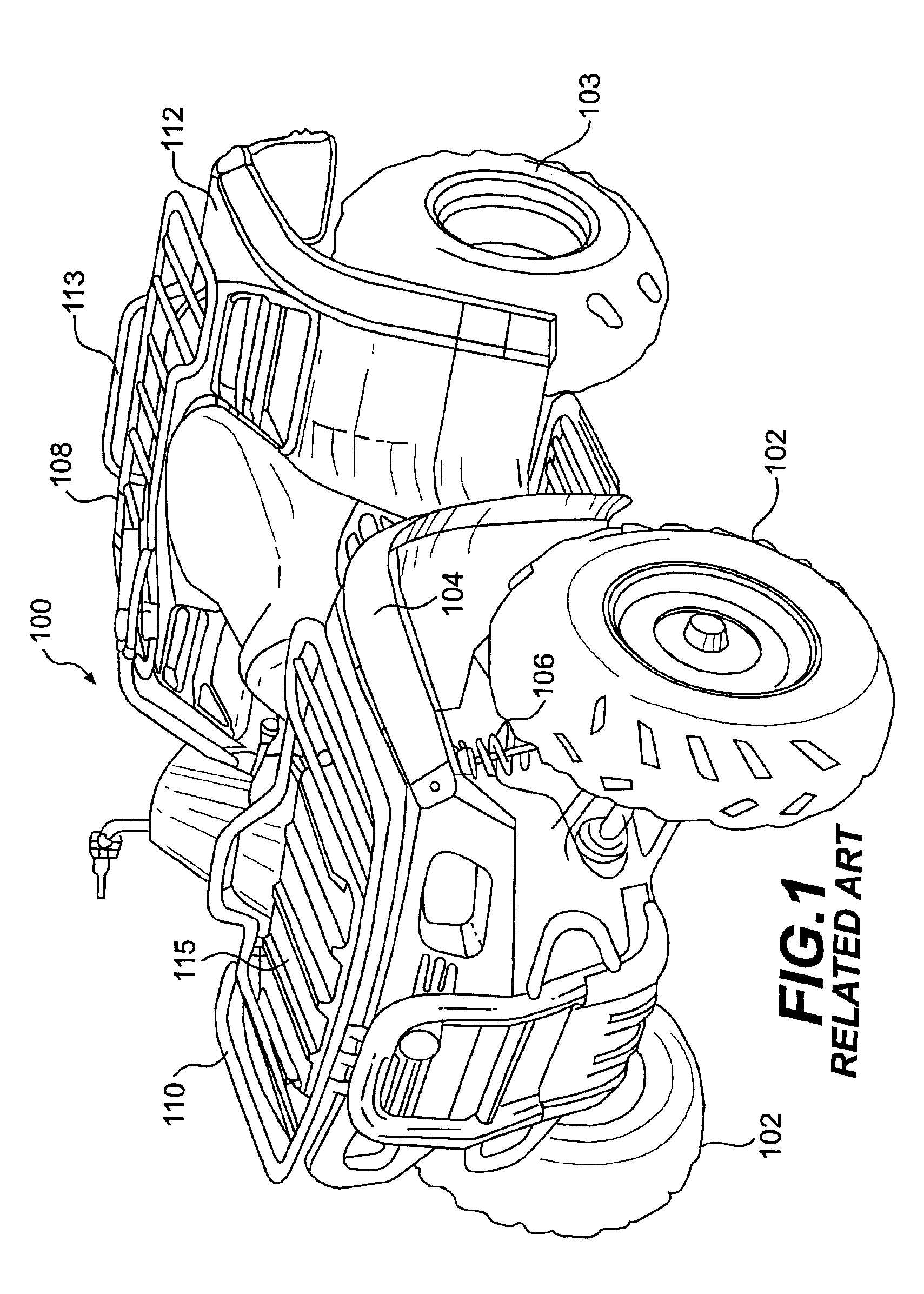

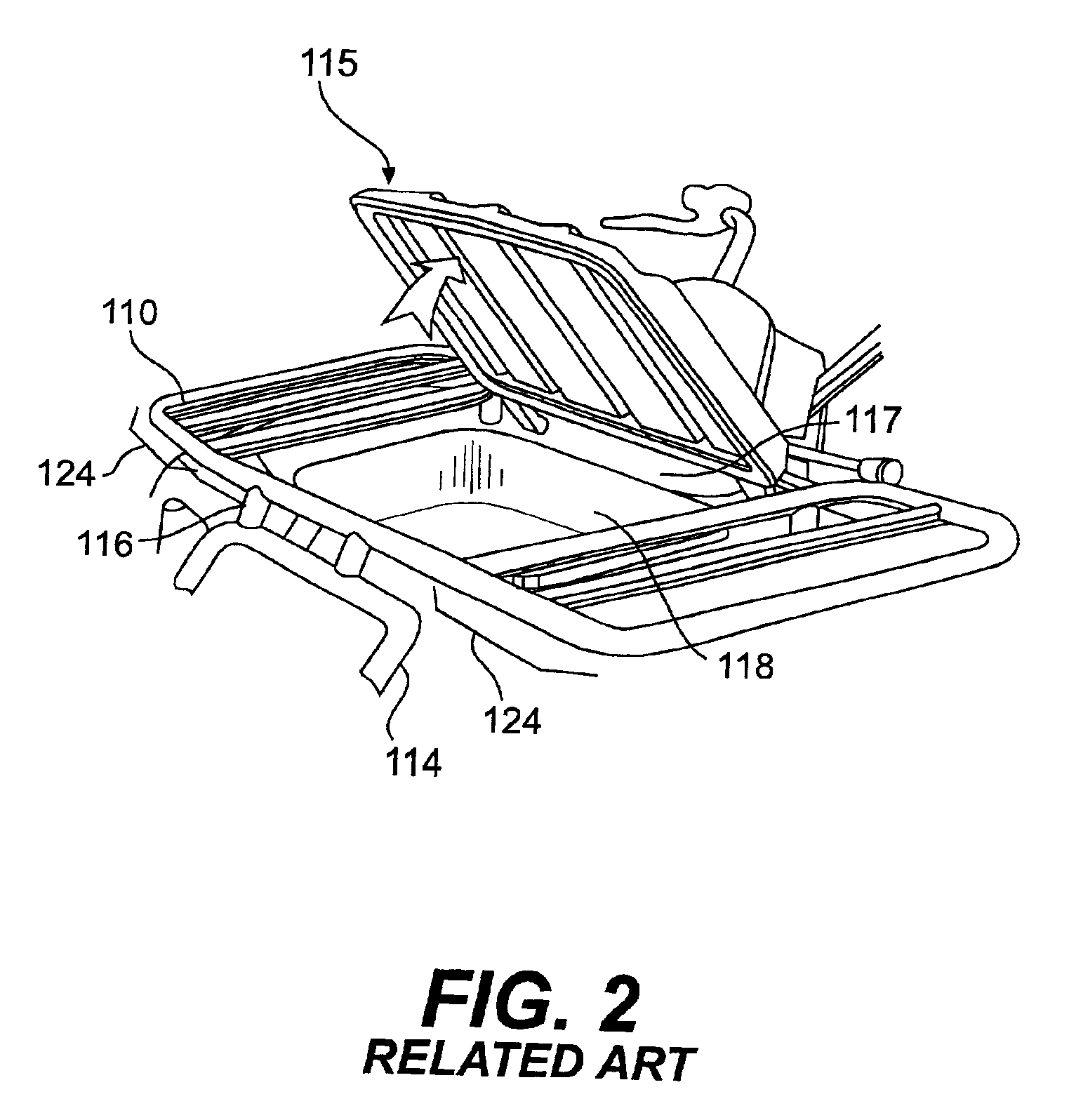

Fender structure for an all terrain vehicle

An all terrain vehicle (ATV) includes a plurality of wheels and a fender structure positioned over the wheels having a support portion designed as and defining a load-bearing surface. The fender structure may include a plurality of raised support portions that increase rigidity and load capacity. Additionally, it is not necessary to support either the fender structure or the support portion using the bumper of the ATV. The fender structure may be formed with plastic material, such as polyethylene, polypropylene or fiberglass-charged polyethylene, and may be manufactured using a blow-molding technique or an injection molding technique. The ATV may also include mud guards and a floor board that extends between the mud guards. The mud guards and the floor board may be formed as an integral or one piece unit with the fender structure. The mud guards can be injection molded or blow-molded while the fender structure can be blow-molded.

Owner:BOMBARDIER RECREATIONAL PROD INC

Full-biodegradable film and preparation method thereof

The invention relates to a composition of a high-tenacity full-biodegradable film and a preparation method thereof. The film is prepared from polylactic acid (PLA), poly propylene carbonate (PPC), polybutylene adipate terephthalate (PBAT) and a heat stabilizer. Blending modification sections are prepared by adopting a twin-screw extruder, blow molding is carried out by adopting a single-screw extruder, the prepared film has excellent tenacity and full biodegradable performance, and meanwhile the cost is low, so that the film is an ideal substitute for a current non-degradable film packing material.

Owner:NANTONG LONGDA BIO TECH NEW MATERIALS CO LTD

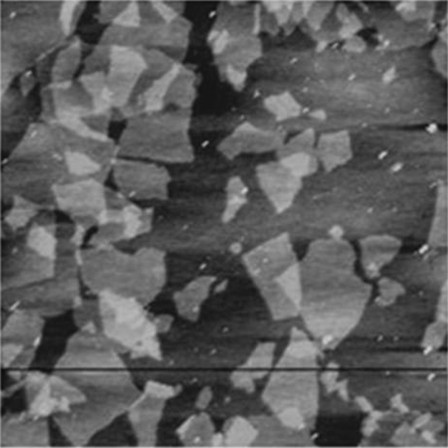

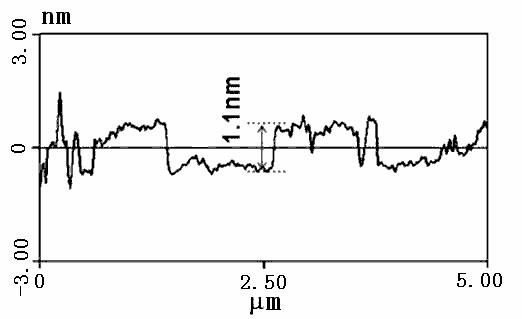

Preparation method for graphene oxide with high barrier property and polymer nanocomposite film

The invention provides a preparation method for graphene oxide with high barrier property and a polymer nanocomposite film. The preparation method comprises the following steps: graphene oxide is added in solvent for stirring to obtain a colloidal suspension of graphene oxide during the ultrasonic processing at the temperature of 20 to 45 DEG C; a polymer is added in the colloidal suspension of graphene oxide for stirring during the ultrasonic processing at the temperature of 20 to 120 DEG C, until the polymer is completely dissolved to obtain a solution of graphene oxide / polymer; and after air bubbles in the solution of graphene oxide / polymer are removed, the graphene oxide / polymer nanocomposite film is obtained by a casting method or blow molding method. The carbon dioxide transmission coefficient of the prepared nanocomposite film containing graphene oxide is reduced by more than 150 times, and the prepared nanocomposite film containing graphene oxide can be used for packaging food and drugs with higher requirements of barrier property.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com