Molded picket fence section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

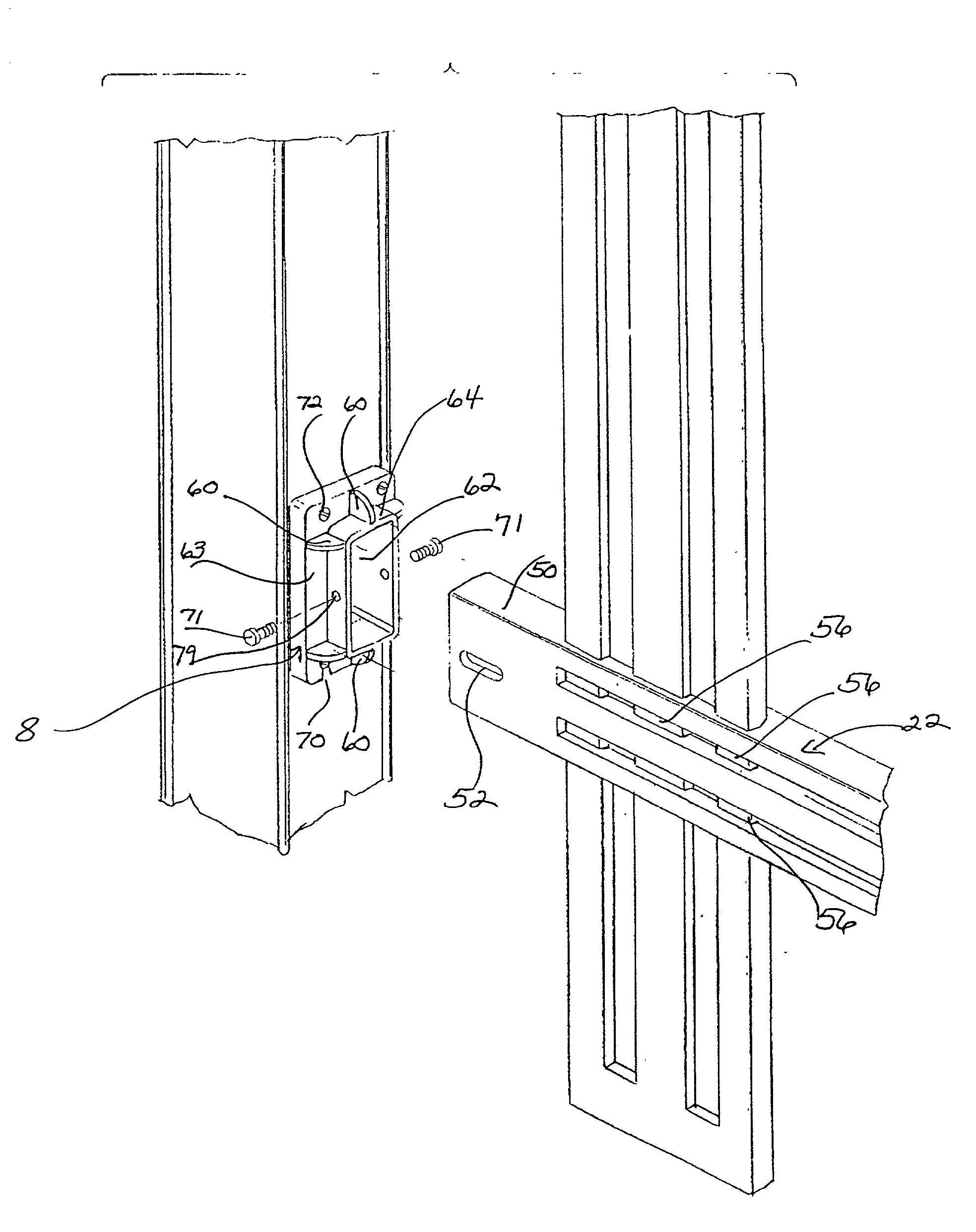

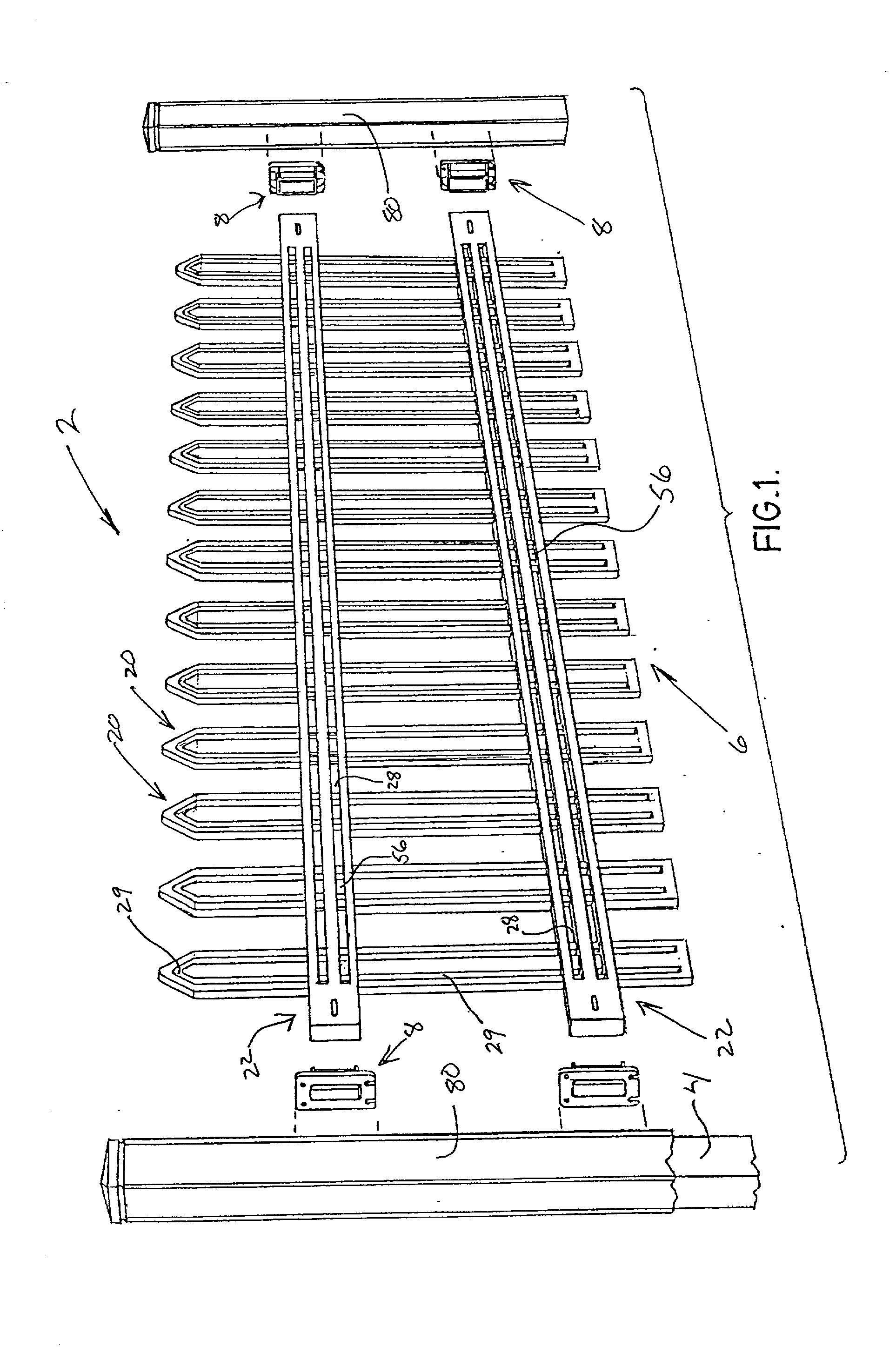

[0030] The picket fence 2 shown in FIGS. 1 and 2 includes a picket fence section 6 which is manufactured by blow molding and is a single piece. The picket fence section is supported at either ends by posts 4 and connectors 8. The connectors 8 engage the horizontal members 22 of the picket fence section and these connectors are mechanically fastened to the post 4.

[0031] The posts 4 are preferrably made of wood and include an outer cover 80 which encloses the wood post. This outer cover is also preferrably manufactured by blow molding and is a single integral piece including the top cap of the post.

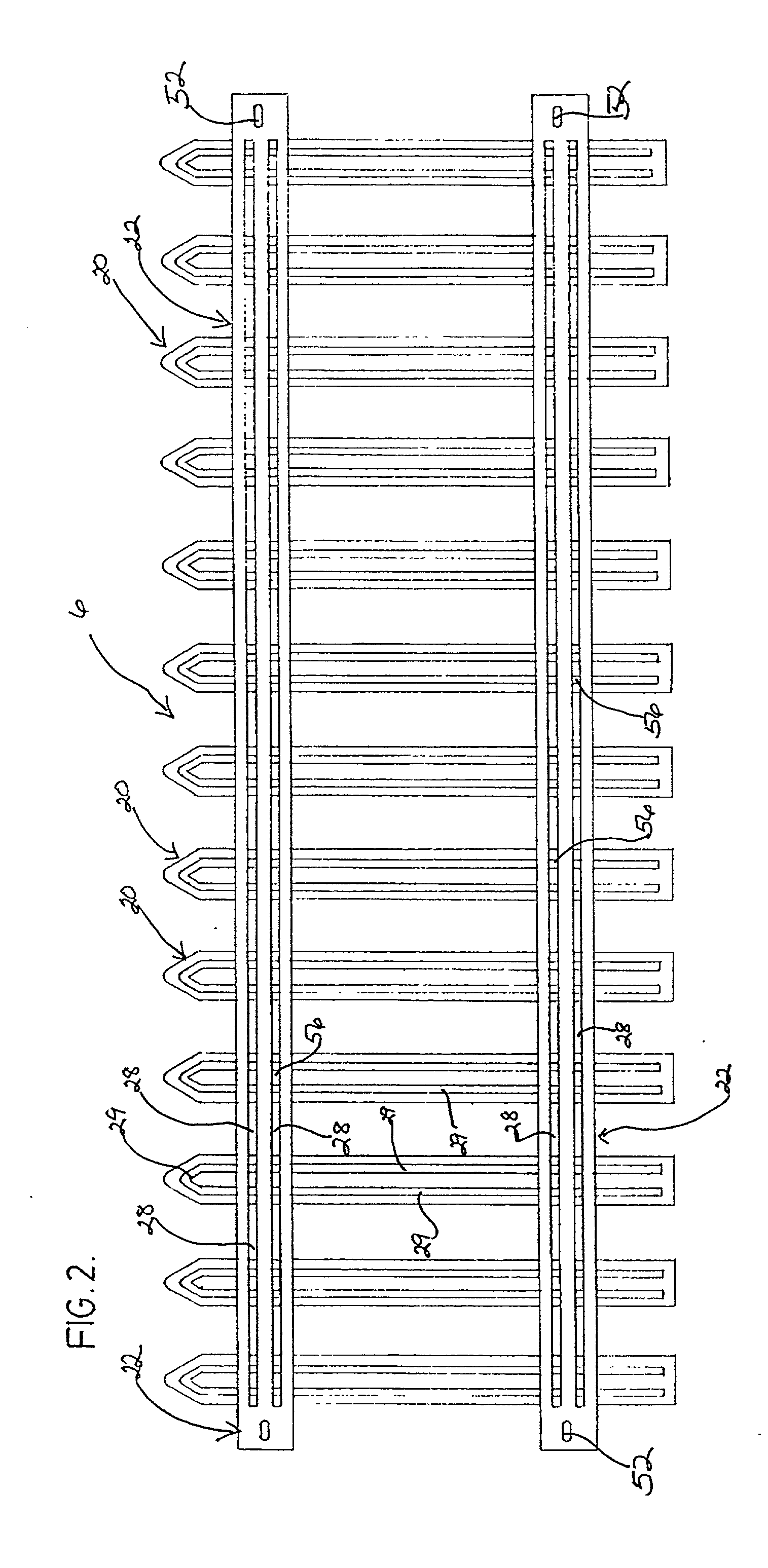

[0032] The picket fence section 6 as shown in FIG. 2 includes horizontal members 22 and a series of pickets 20. The pickets in this case are all of the same height, however, it is possible to have pickets of different heights. The component shown in FIG. 2 is a single integral piece manufactured by blow molding. Preferrably, the picket fence section 6 is approximately eight feet long and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com