Patents

Literature

7384 results about "High-density polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a thermoplastic polymer produced from the monomer ethylene. It is sometimes called "alkathene" or "polythene" when used for HDPE pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes and plastic lumber. HDPE is commonly recycled, and has the number "2" as its resin identification code.

Polymer blends from interpolymers of ethylene/alpha-olefins and flexible molded articles made therefrom

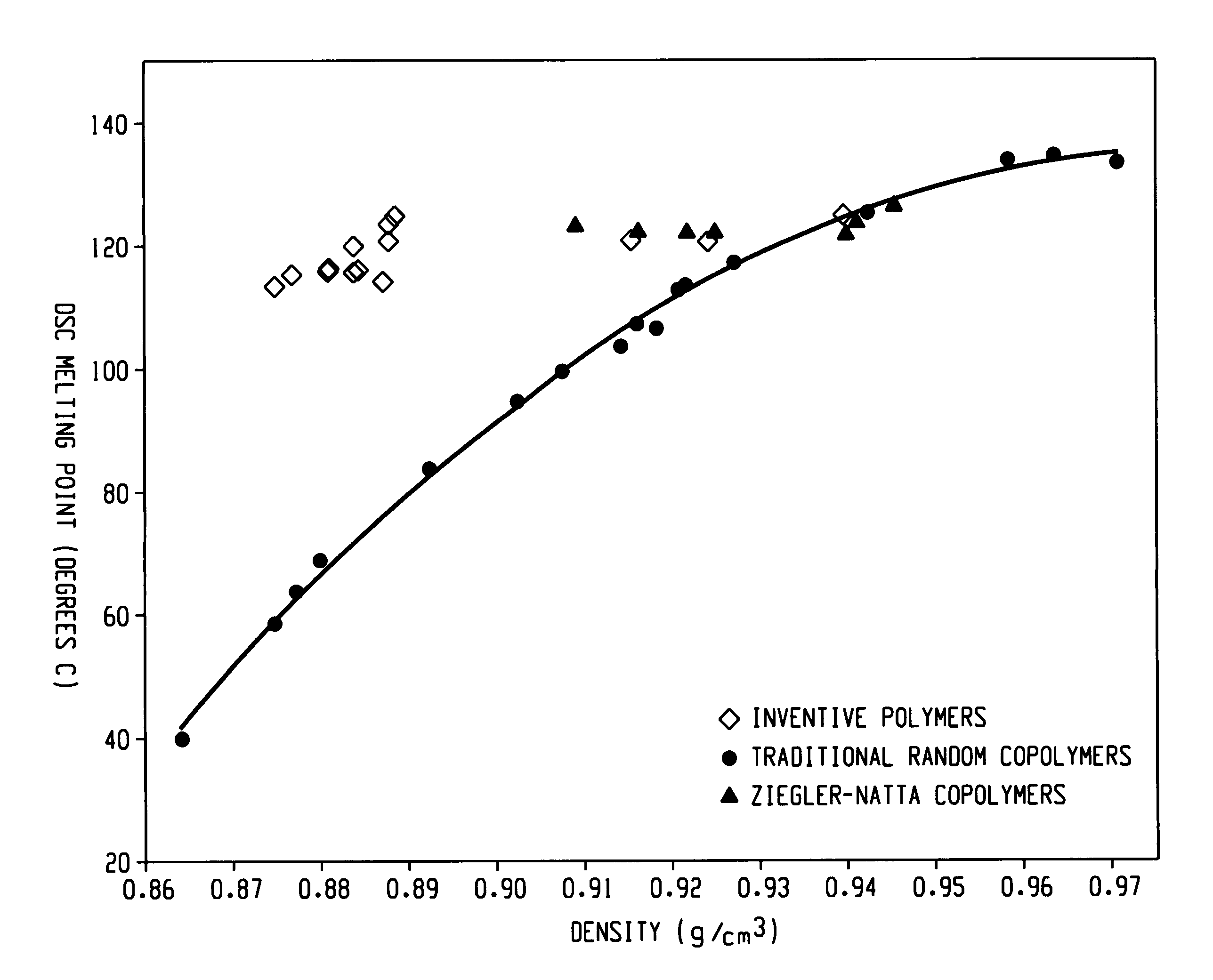

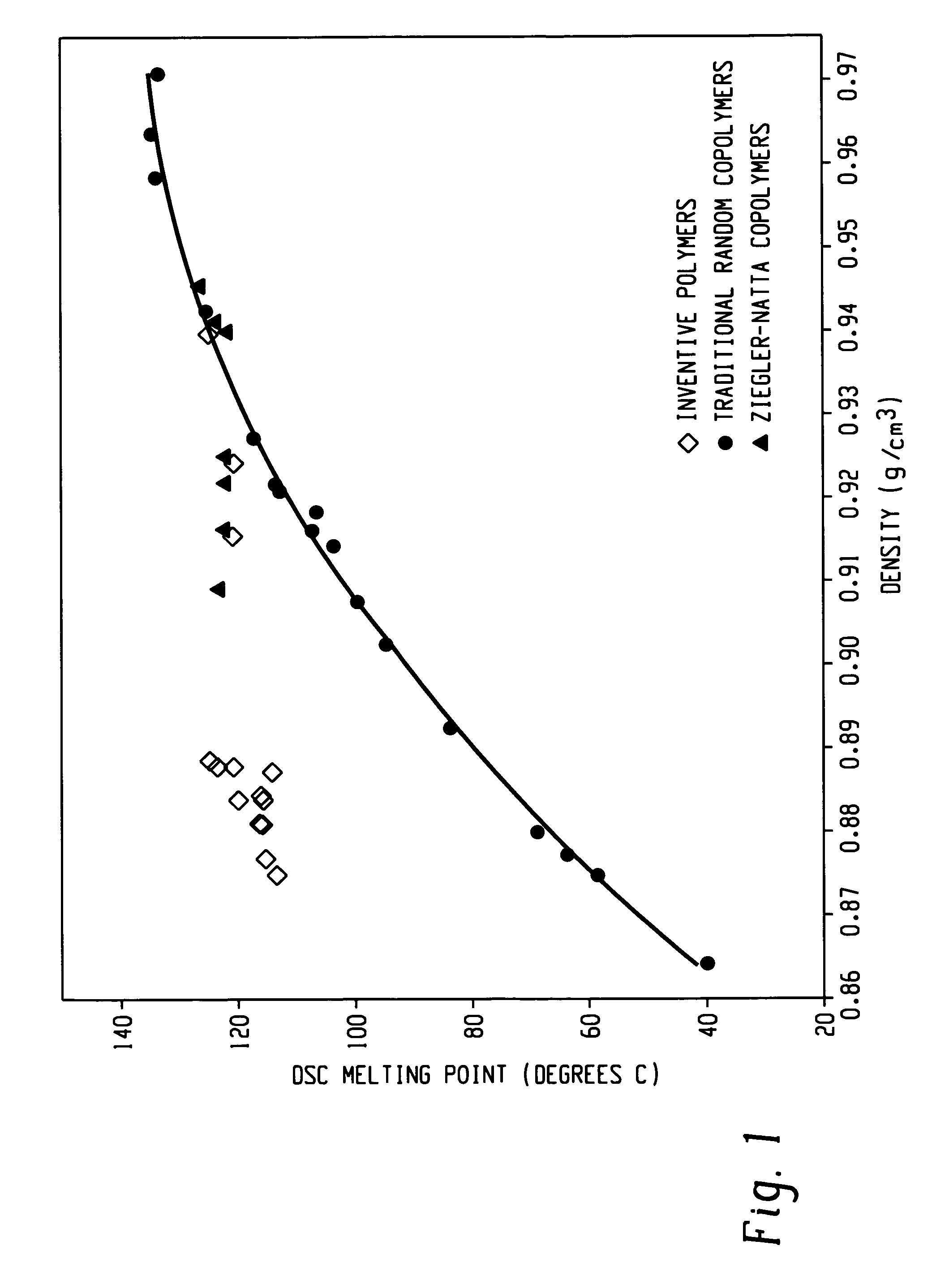

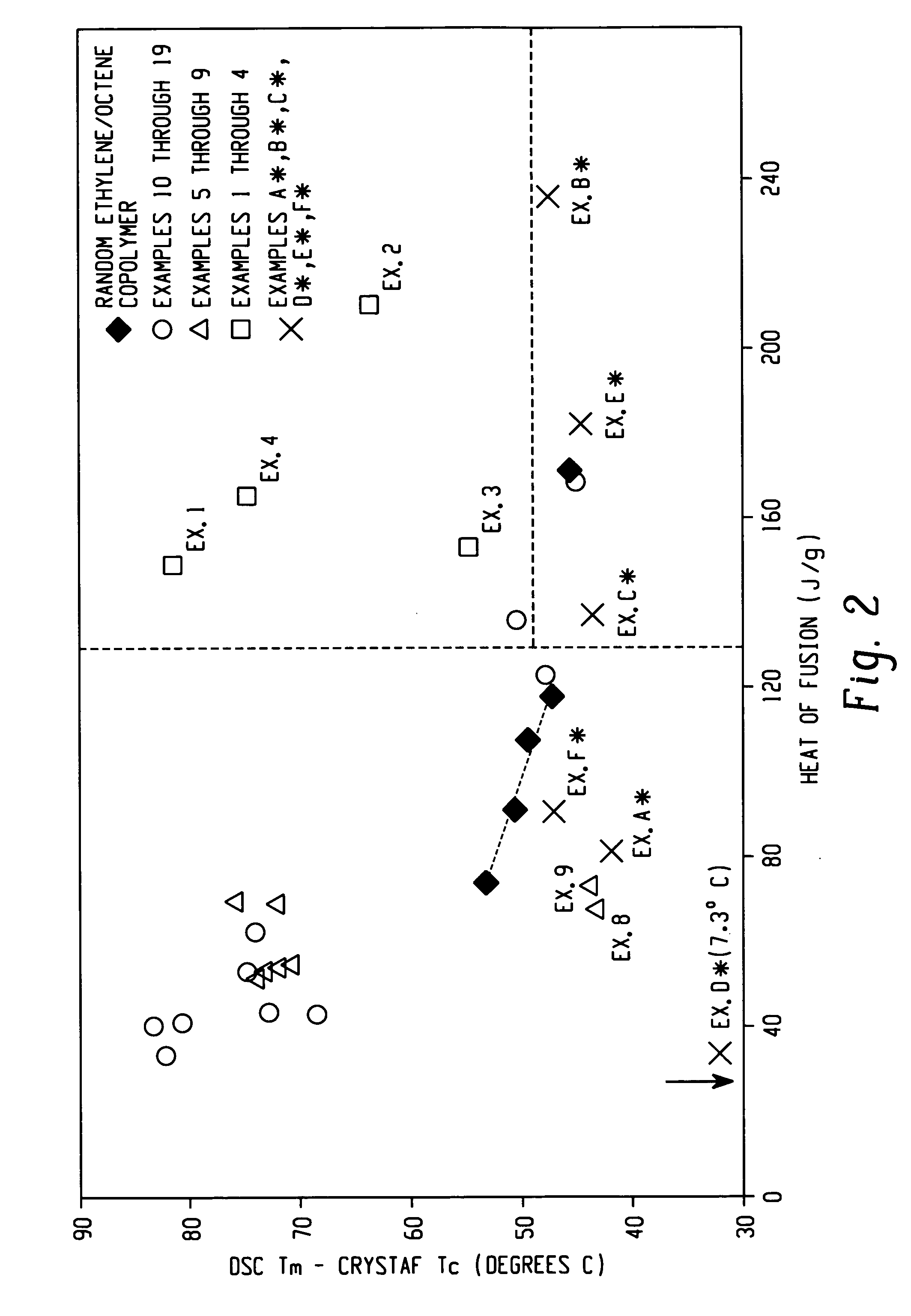

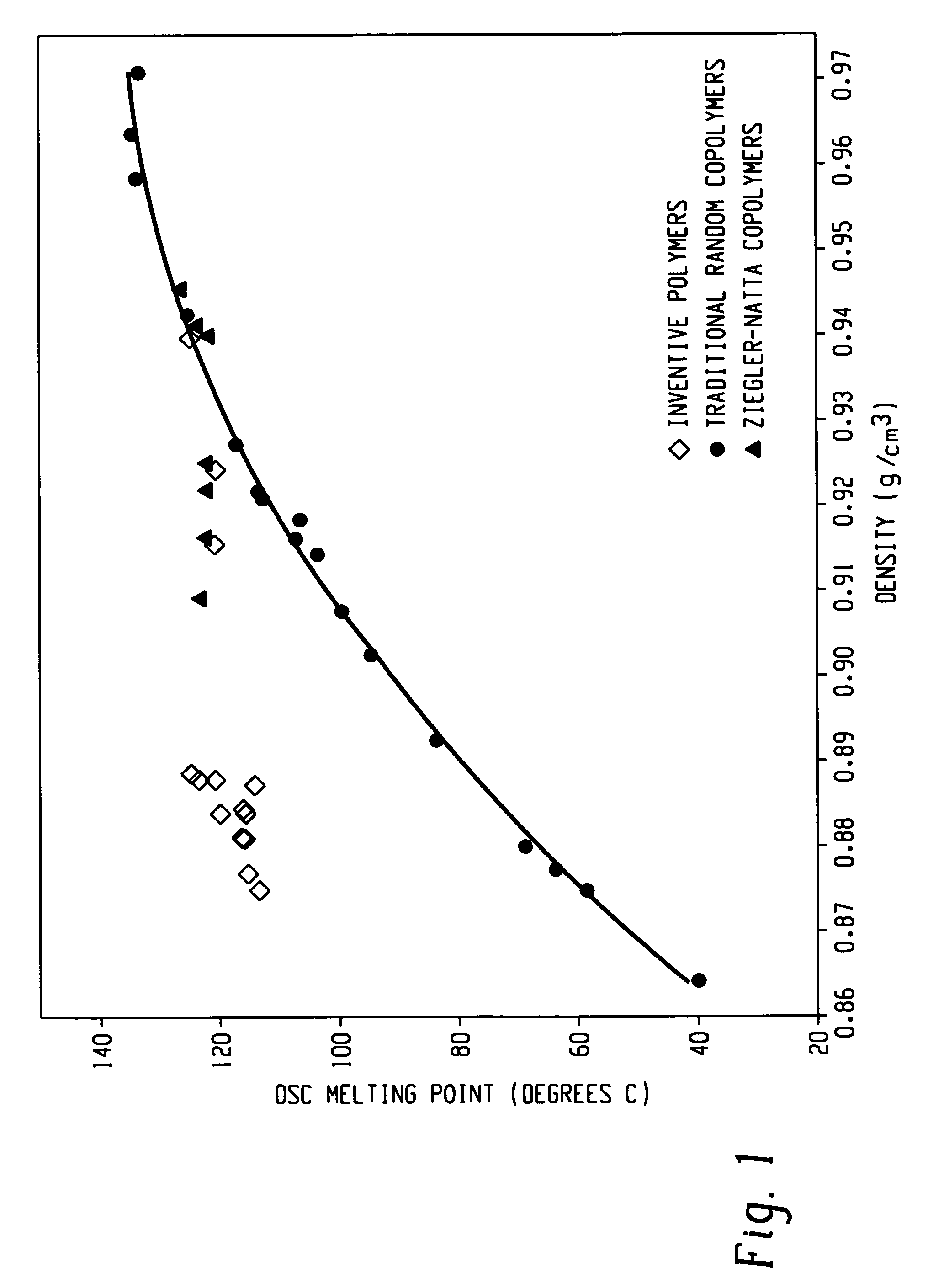

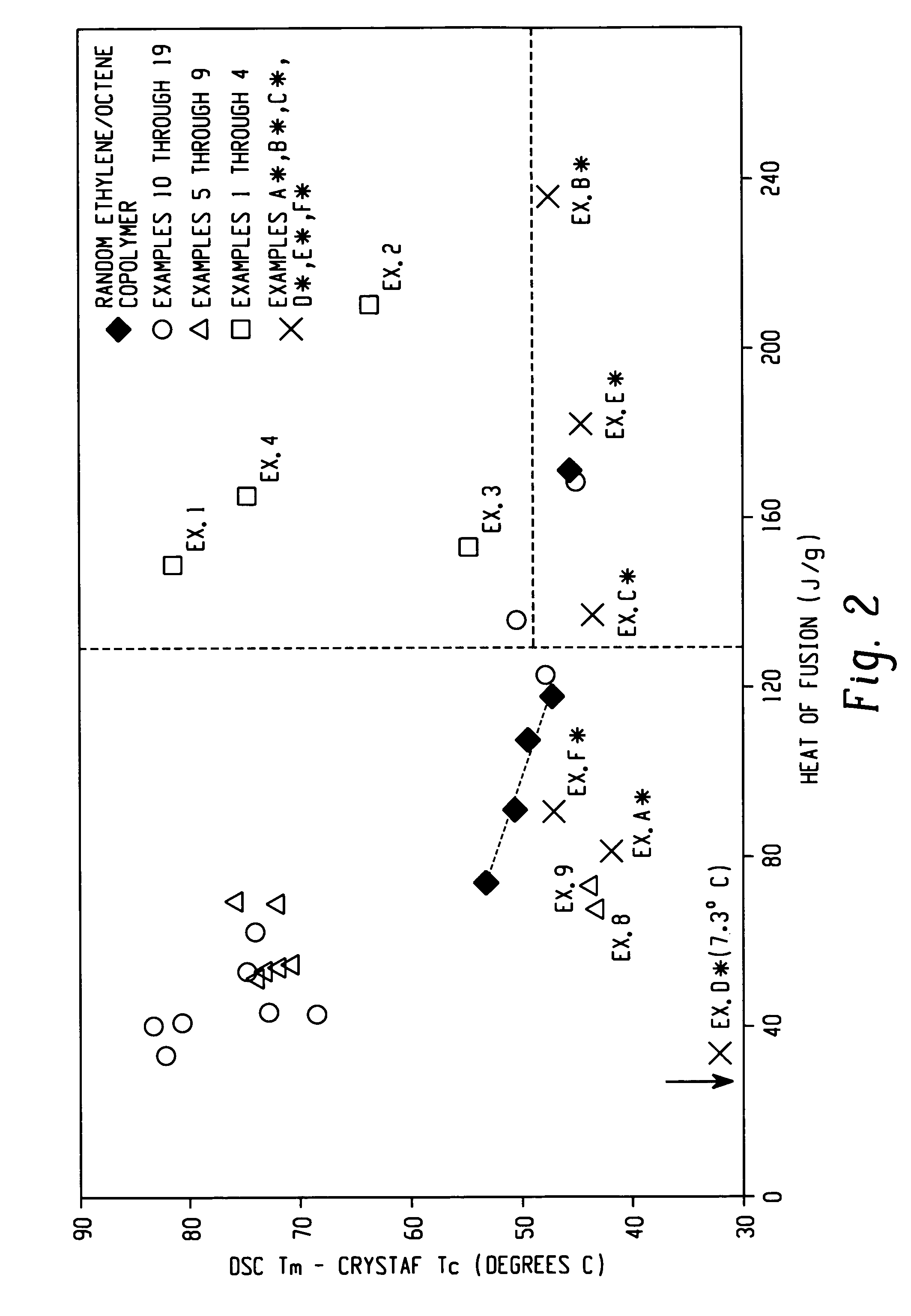

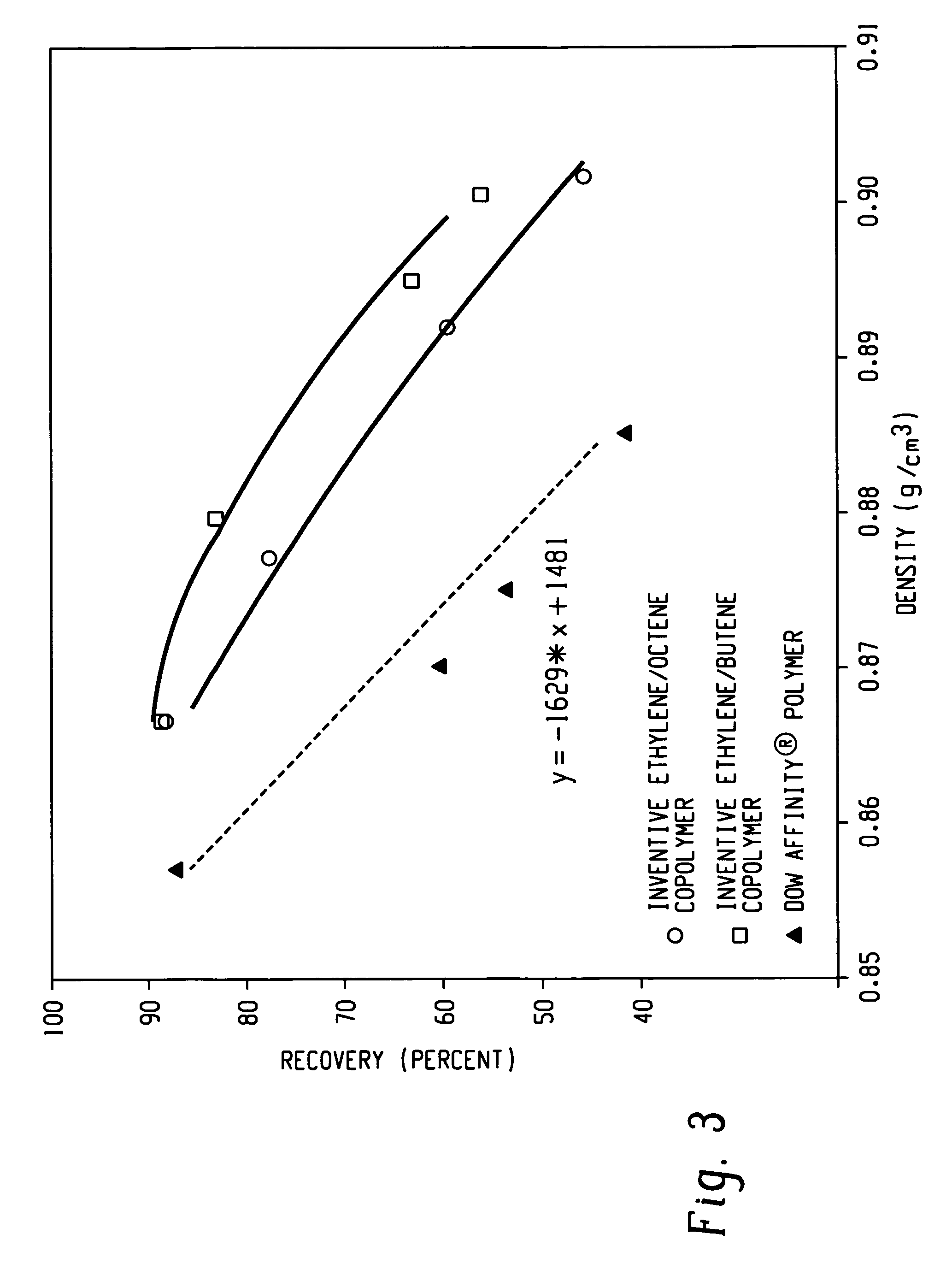

Polymer blends comprises 1) at least one ethylene / α-olefin interpolymer and 2) at least one polyolefin, or at least one styrenic block copolymer, or a combination thereof. Such polyolefins include, but are not limited to, high melt strength high density polyethylene and high melt strength polypropylene. The ethylene / α-olefin interpolymers are random block copolymers comprising at least a hard block and at least a soft block. The polyolefins can be homopolymers or interpolymers. The resulting polymer blends can be used to make flexible molded articles.

Owner:DOW GLOBAL TECH LLC

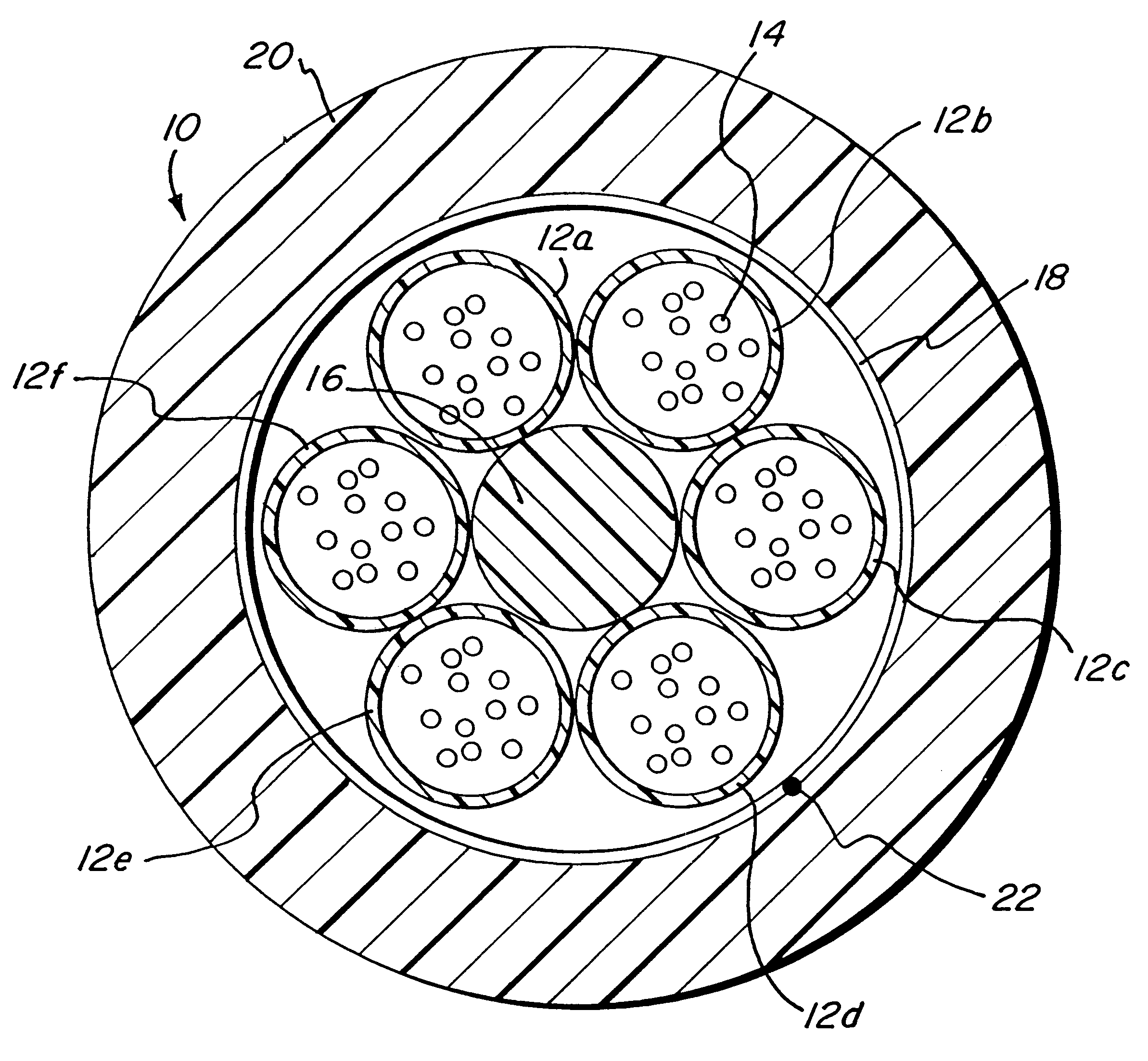

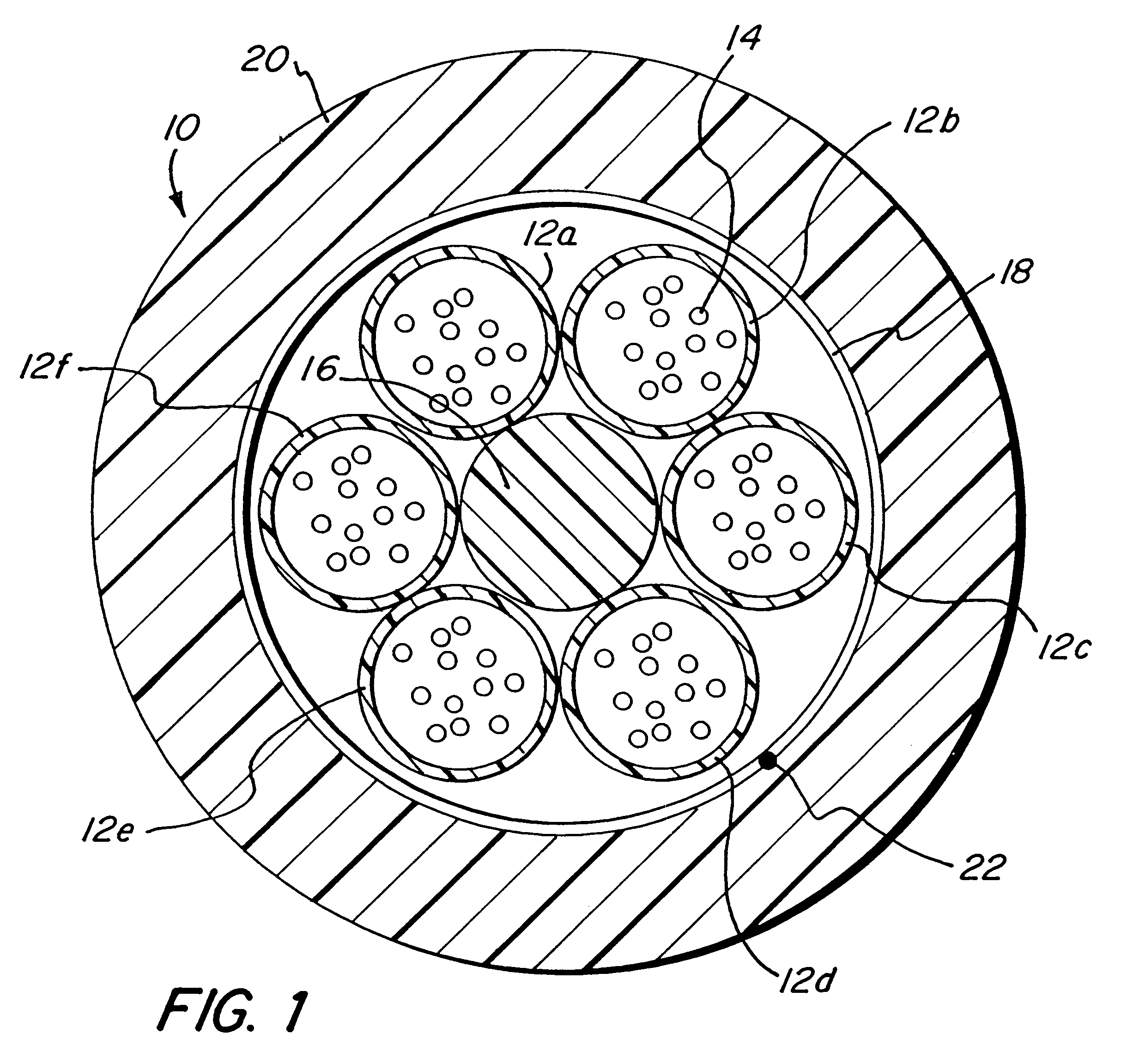

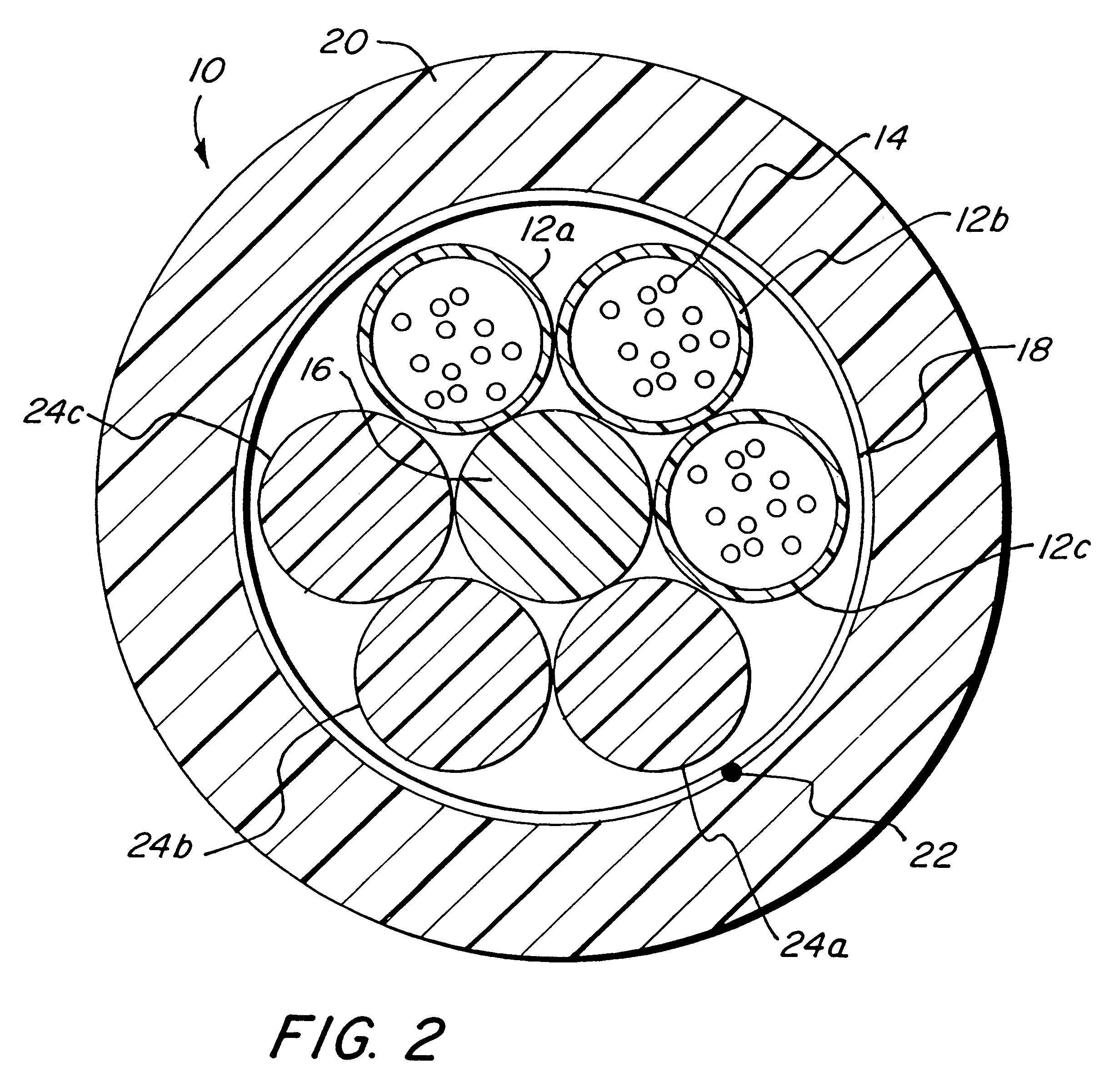

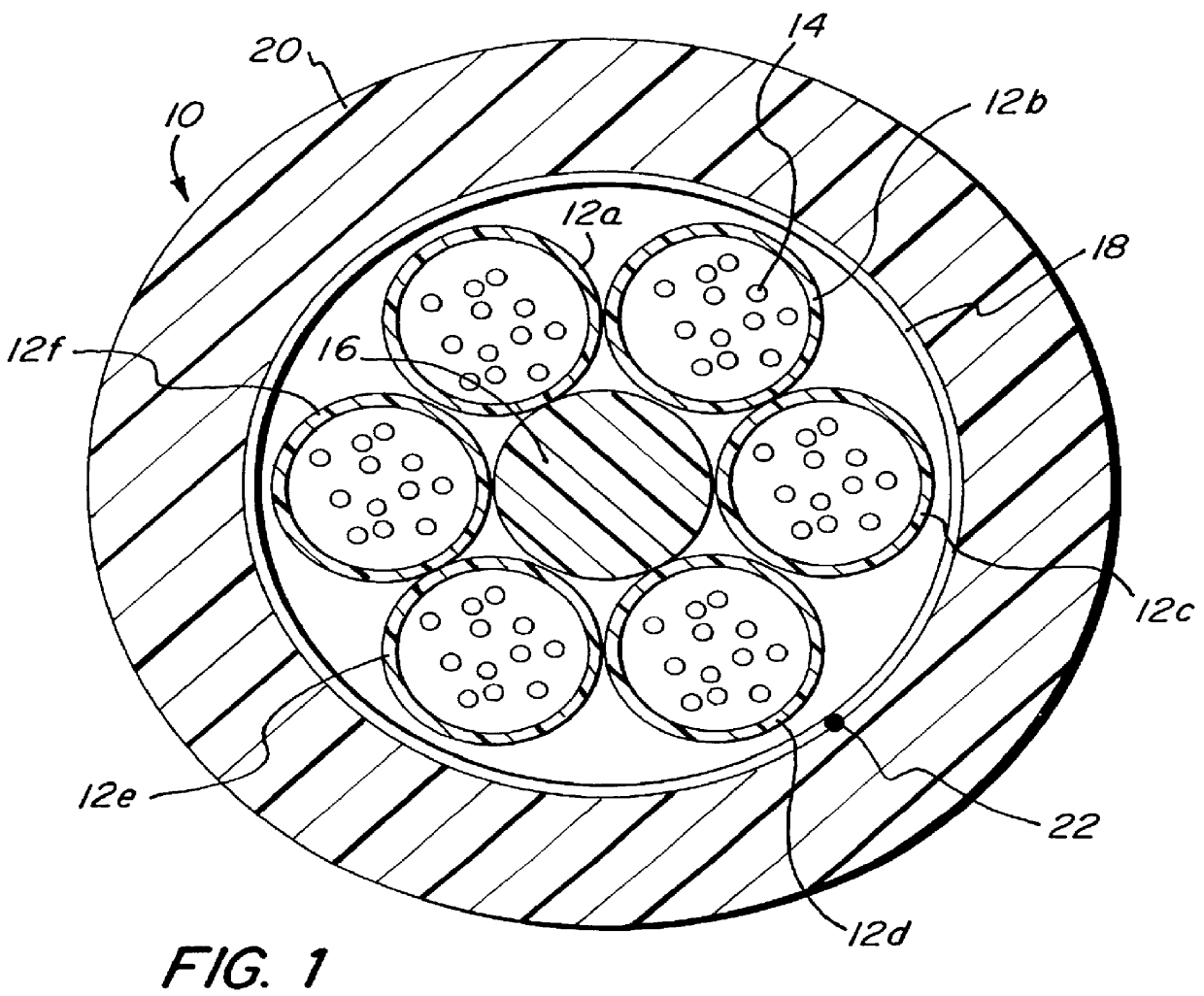

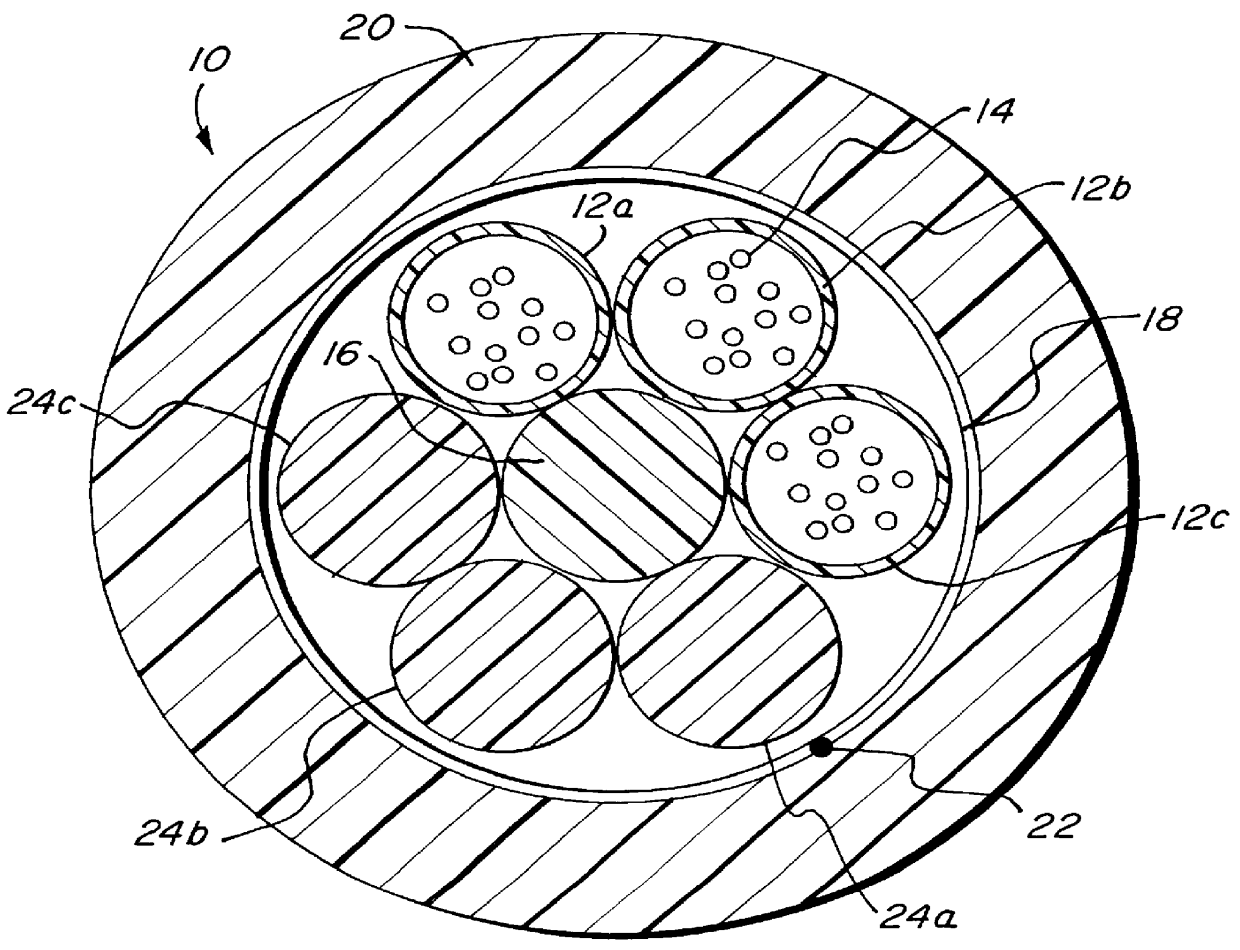

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

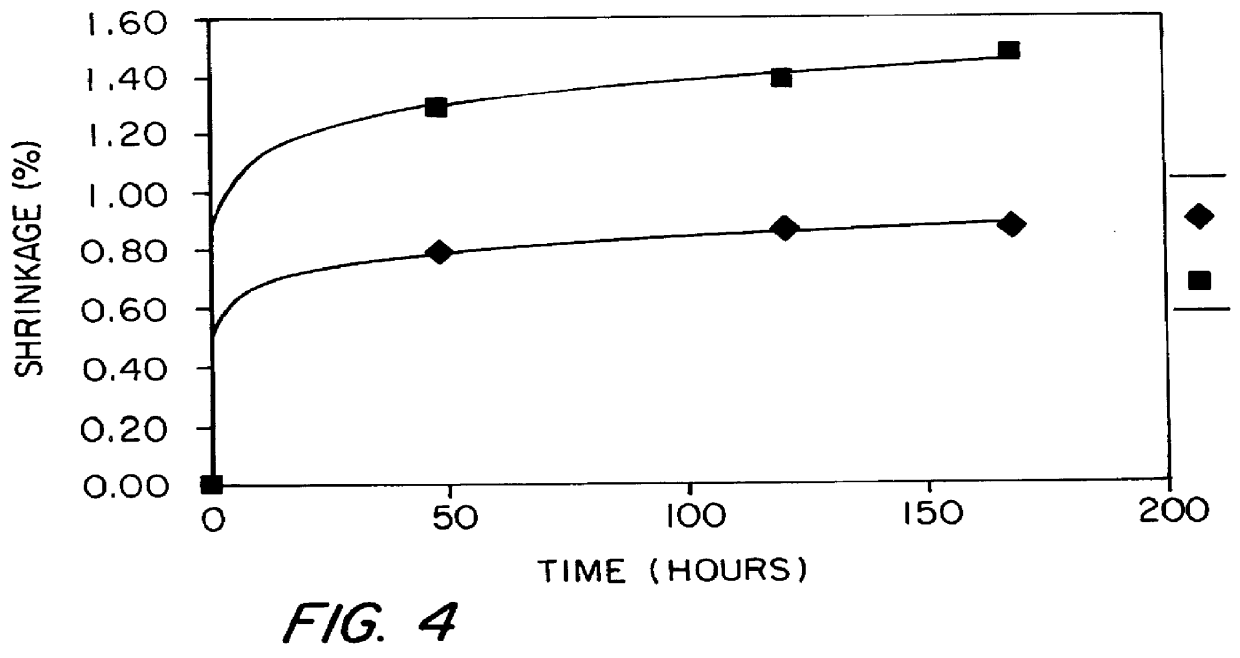

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

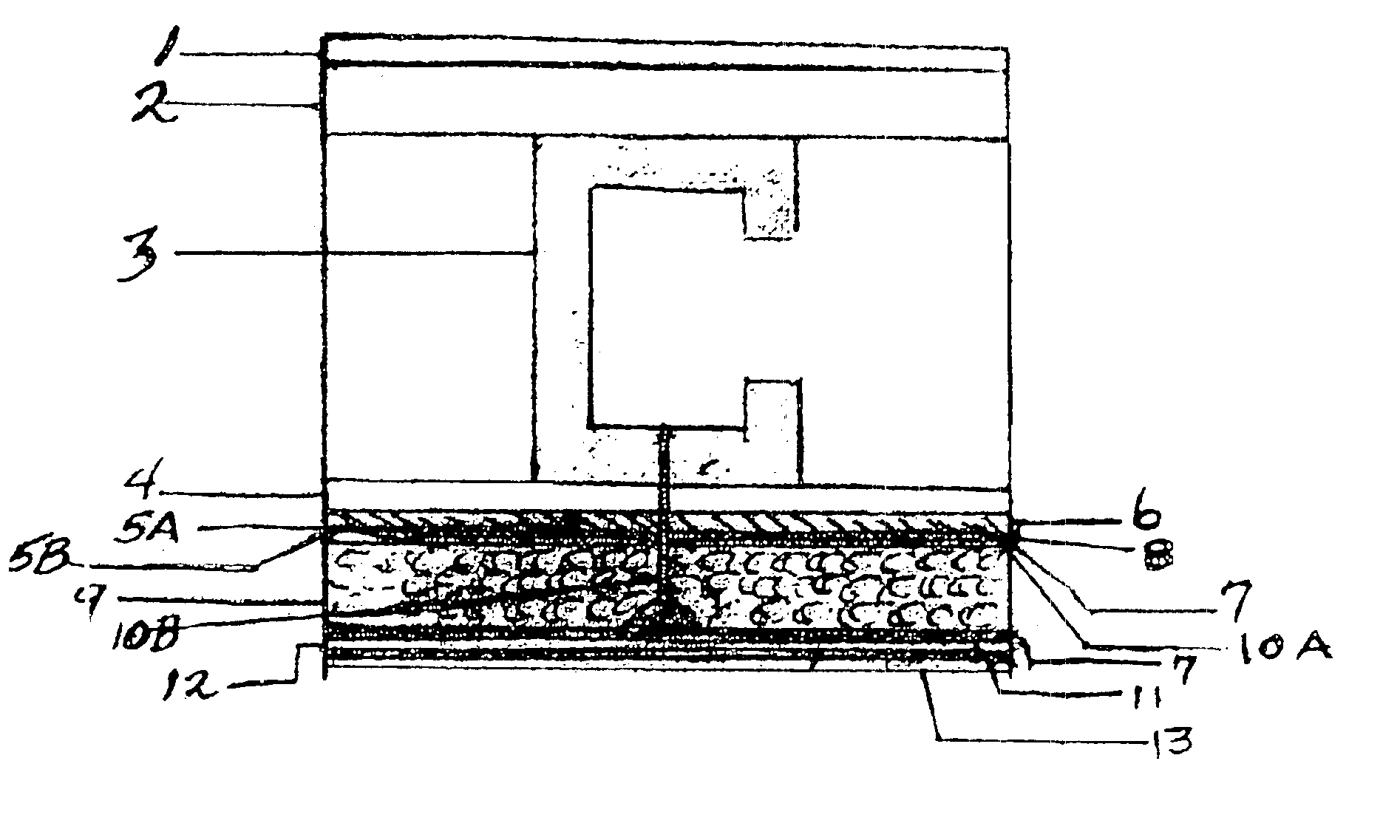

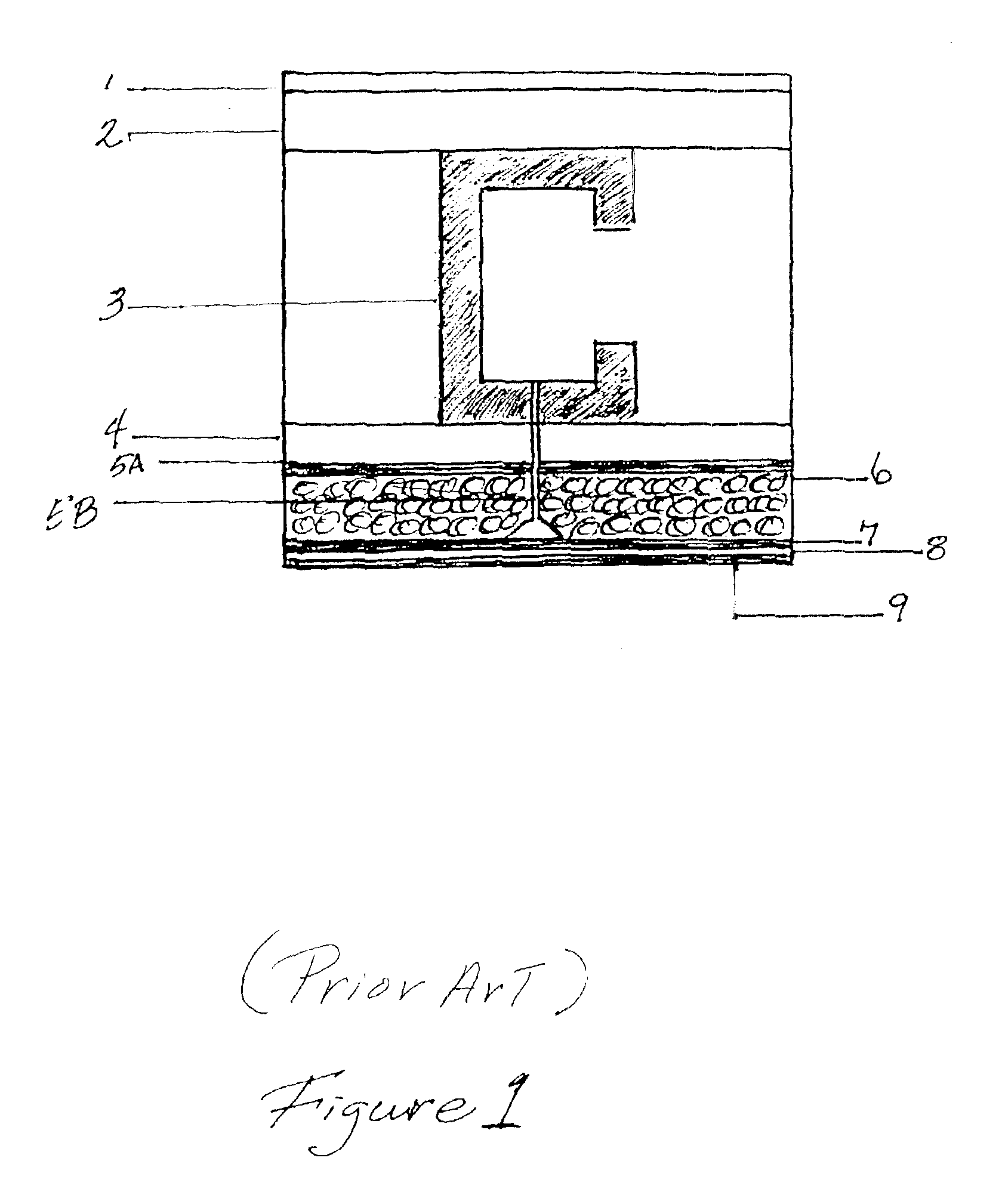

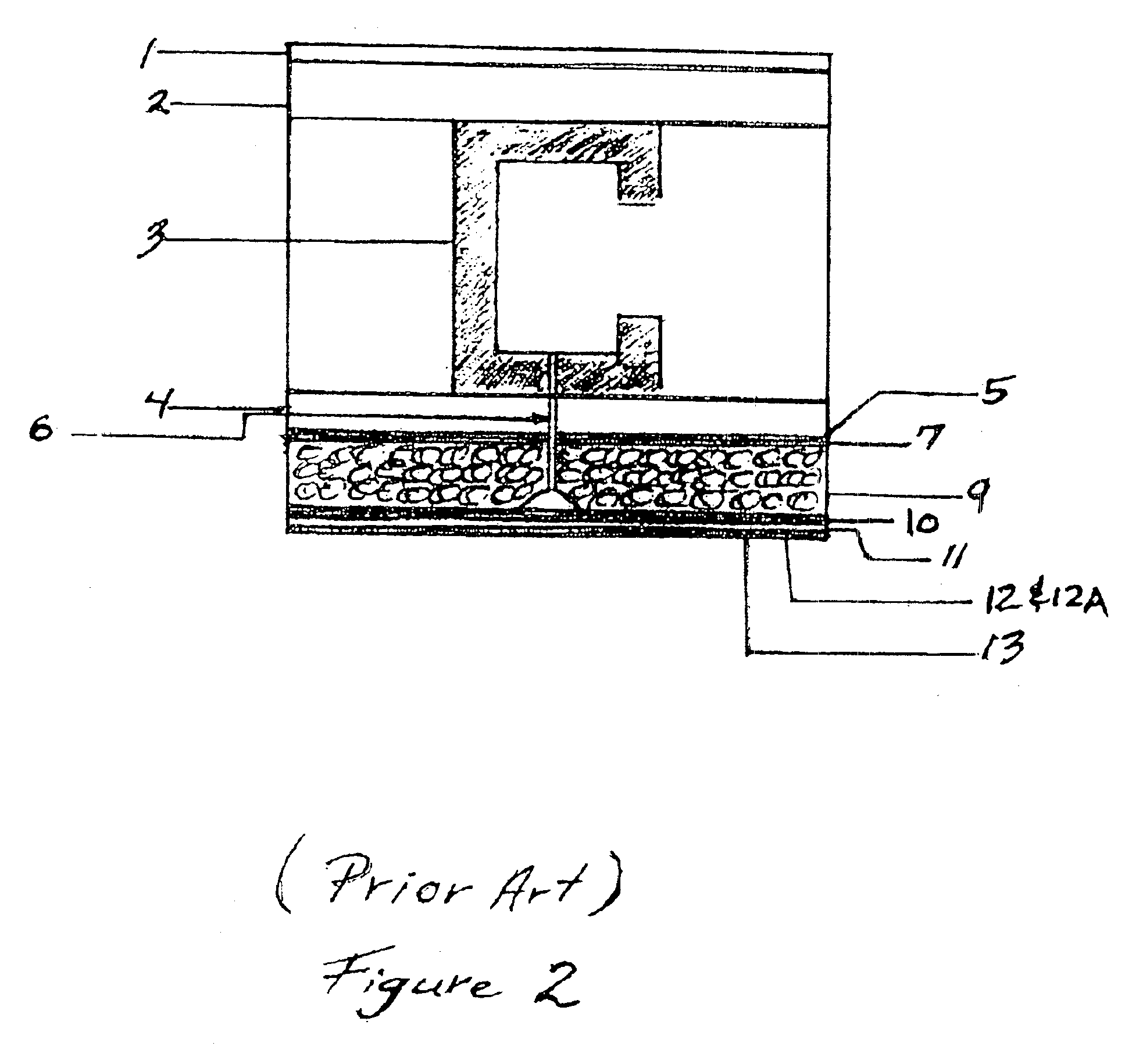

Polypropylene filler rods for optical fiber communications cables

InactiveUS6066397ACladded optical fibreFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

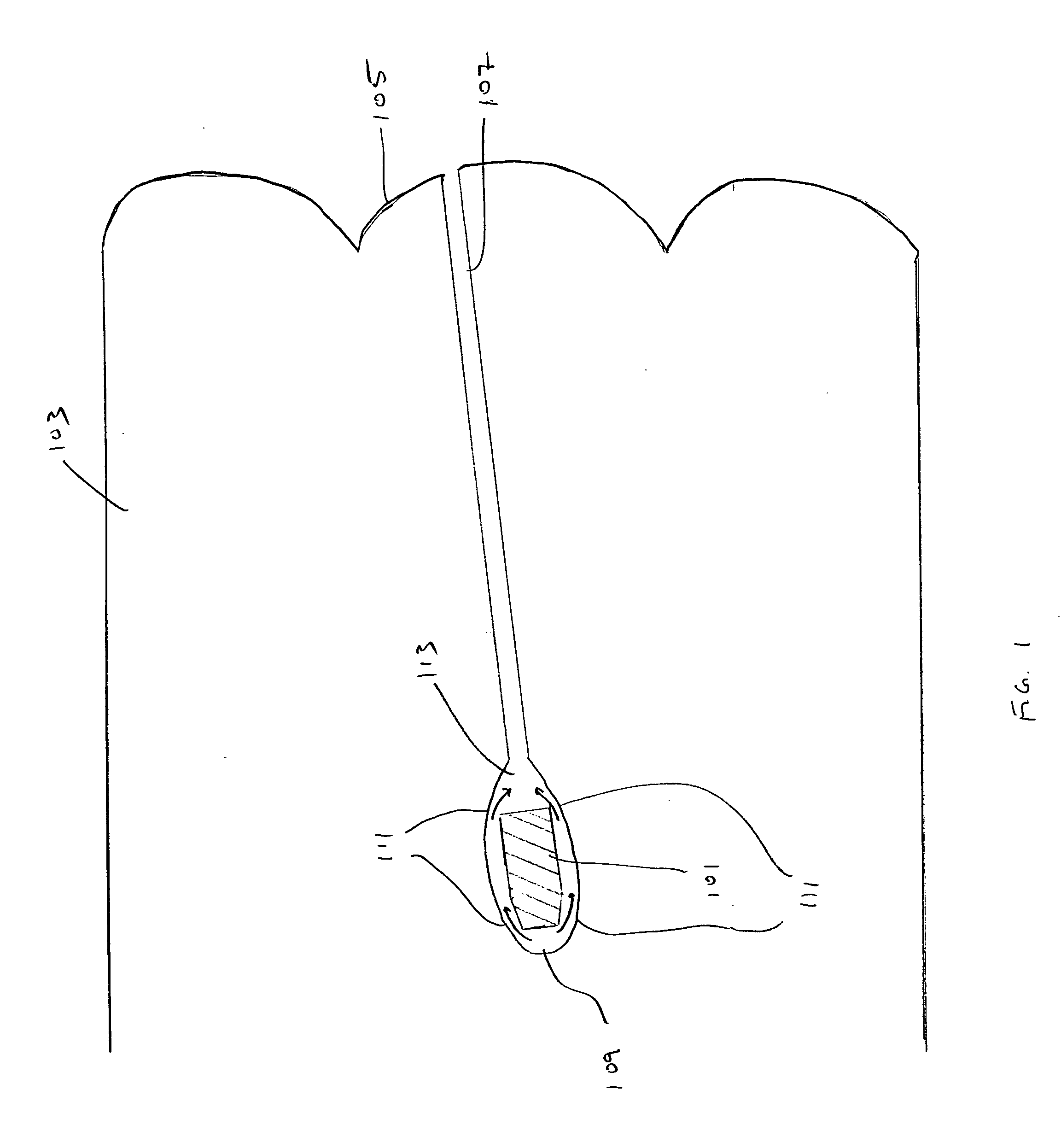

Storm drain liner

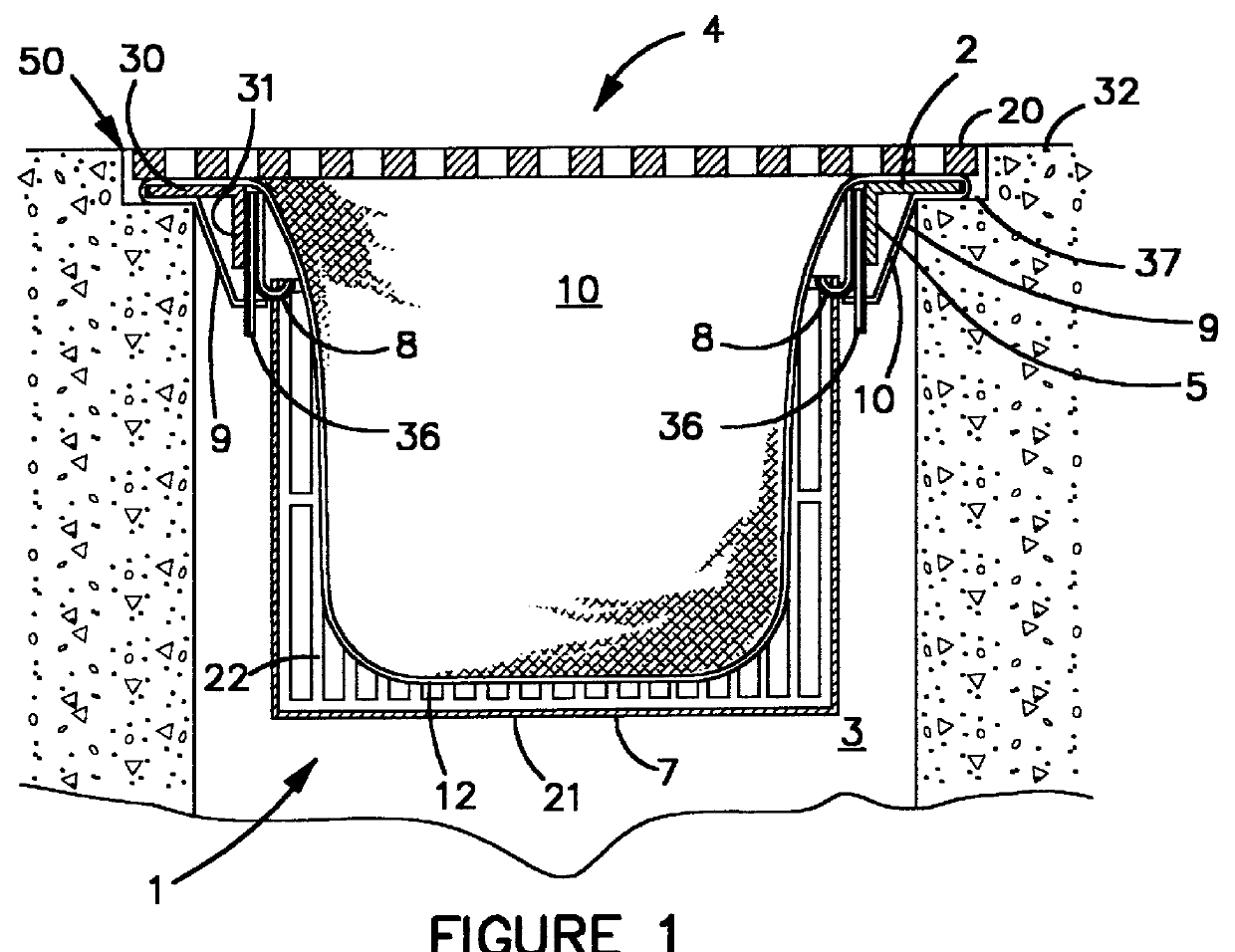

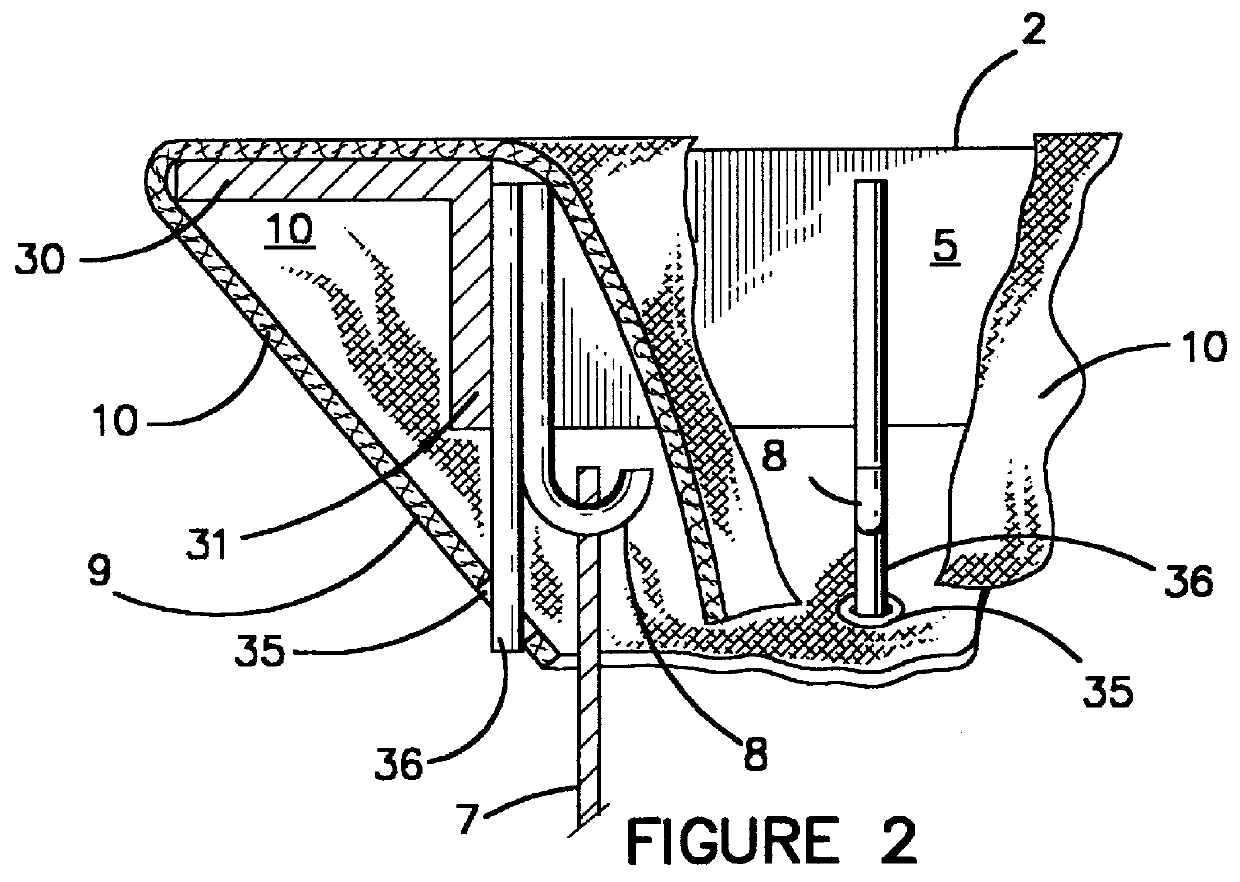

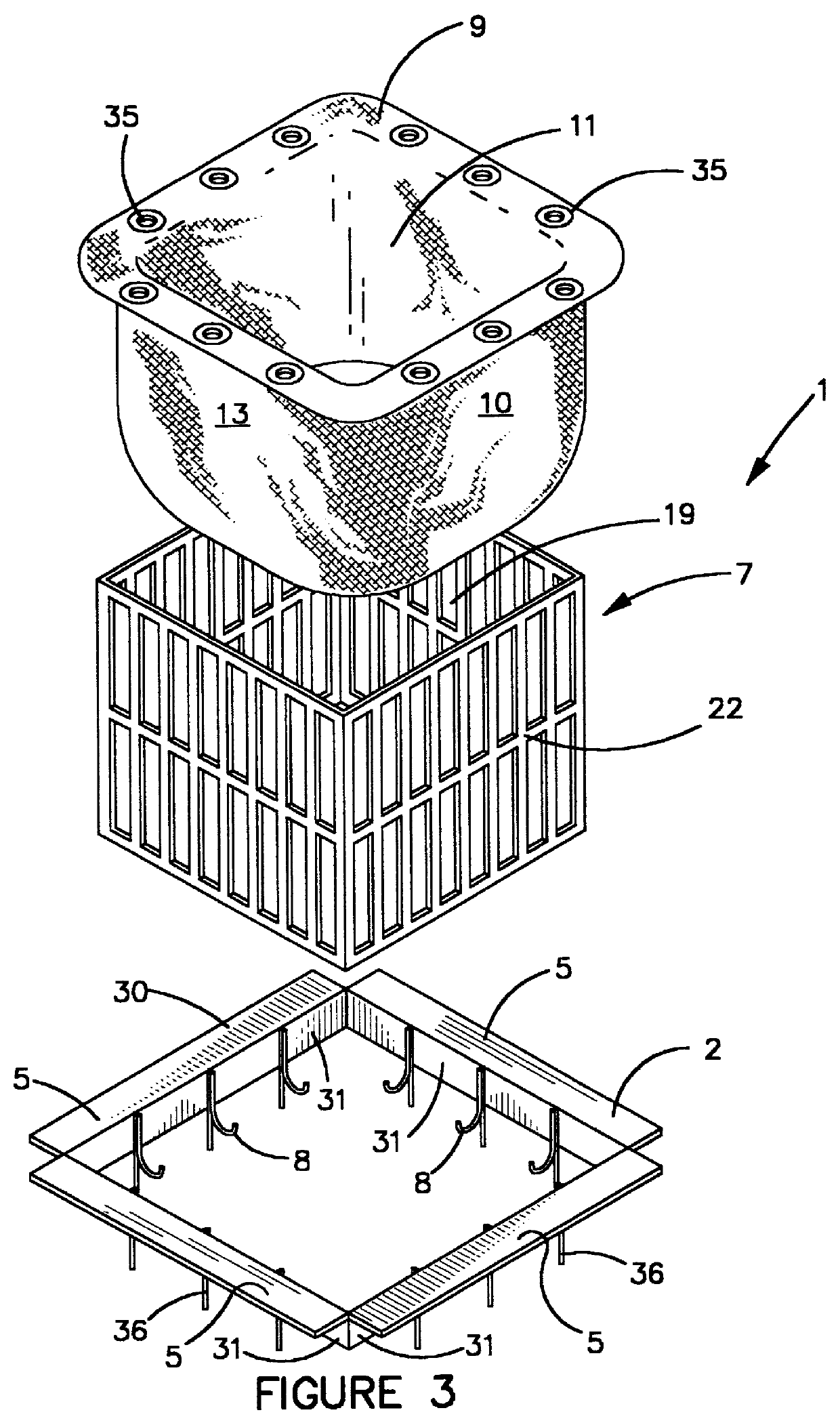

InactiveUS6086758AIncrease flow rateFatty/oily/floating substances removal devicesGround-workFilter systemEnvironmental engineering

A drain filtering system is disclosed, comprising a filter placed within a basket which is suspended from frame positioned underneath a drain grate atop the inlet to a storm drain. The filter is constructed from materials which filter out heavy metals and hydrocarbons from the water passing through. The filter also has overflow outlets to prevent back-up of storm water during periods of heavy rain. The basket is constructed from a corrosion resistant material, preferably high density polyethylene which can withstand the extreme pressures exerted by waste and water collected within the filter.

Owner:PACTEC

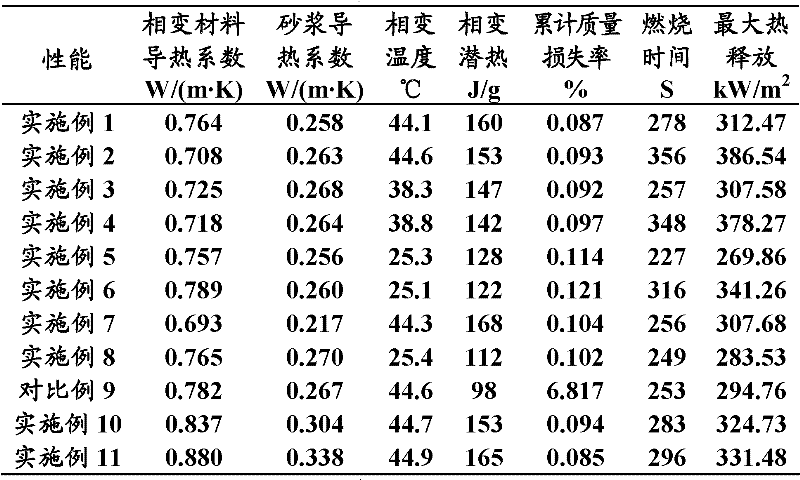

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

Closures for bottles

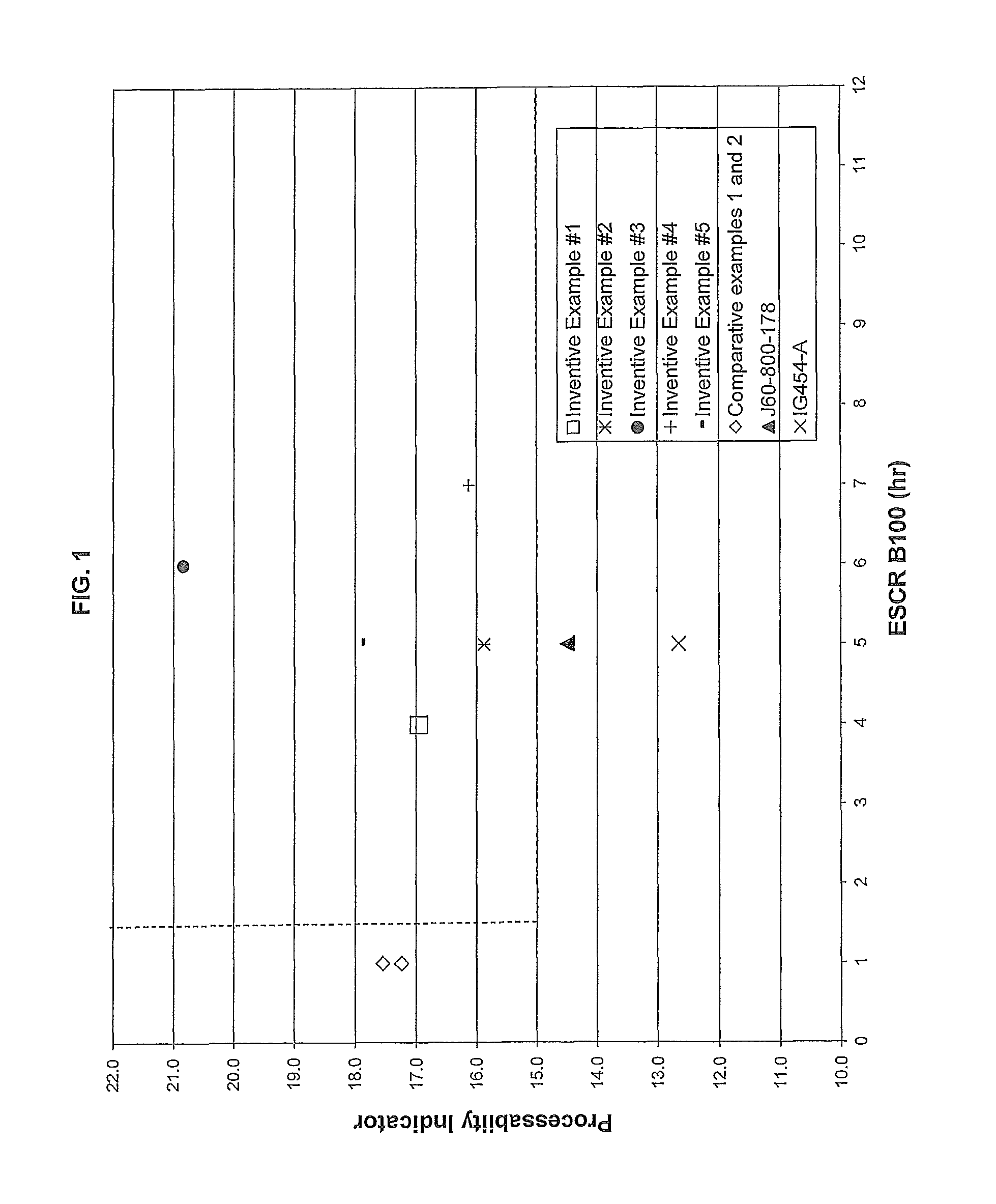

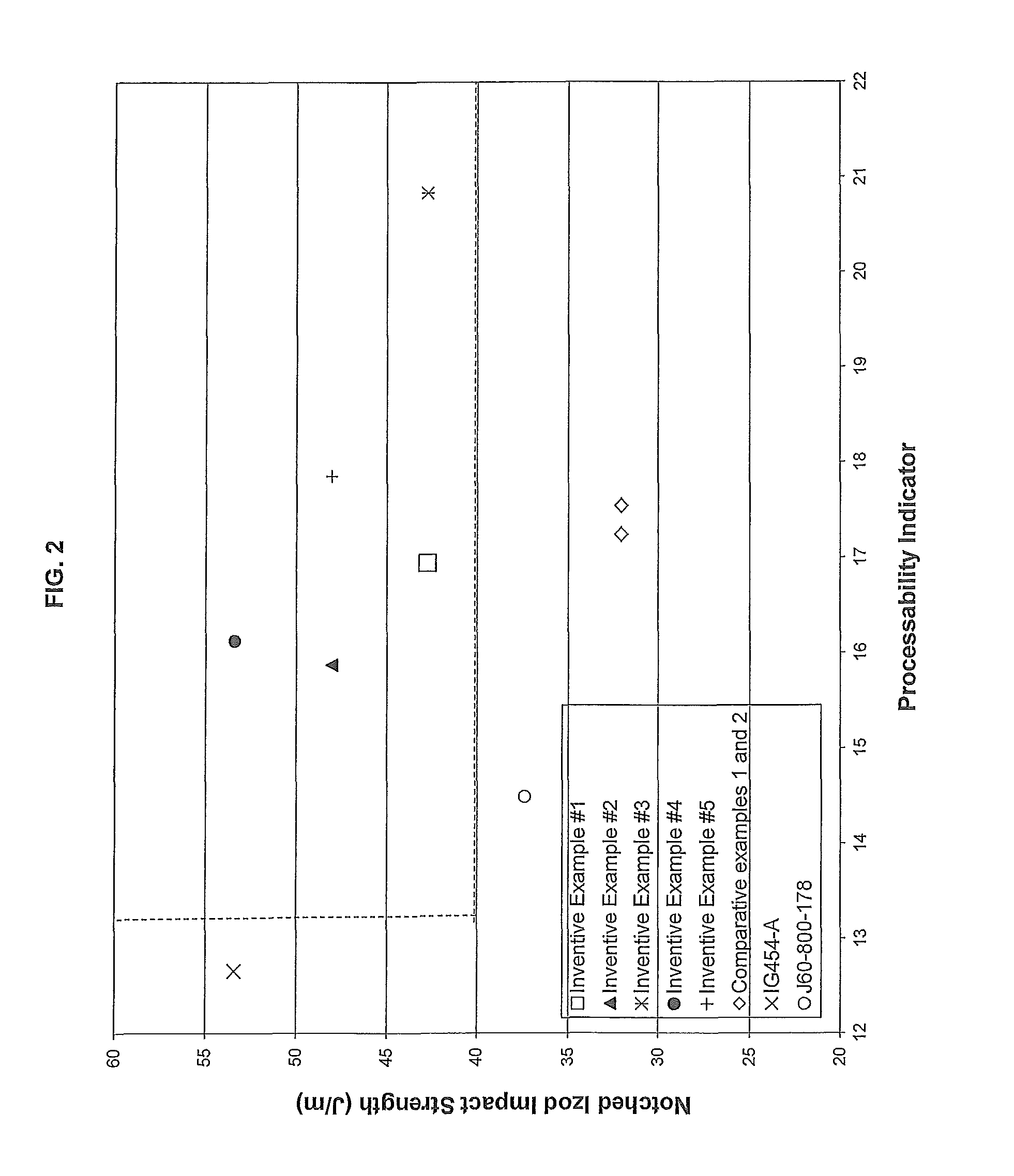

ActiveUS8022143B2Improved balance of Theological and processing and organoleptic propertyCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

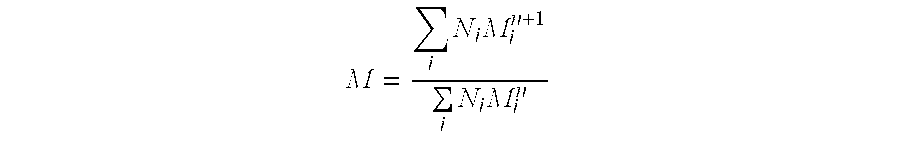

Production of polyethylene having a broad molecular weight distribution

InactiveUS6221982B1High densityImprove mechanical propertiesOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceZiegler–Natta catalyst

A process for producing high density polyethylene in the presence of a Ziegler-Natta catalyst system in two liquid full loop reactors in series, wherein in a first reactor a first polyethylene product is polymerized substantially by homopolymerization of ethylene and hydrogen, optionally with a minor degree of copolymerization of ethylene with an alpha-olefinic comonomer comprising from 3 to 8 carbon atoms, and in a second reactor serially connected to the first reactor downstream thereof a second polyethylene product is copolymerized from ethylene and an alpha-olefinic comonomer comprising from 3 to 8 carbon atoms, and a hydrogenation catalyst is introduced into the reactants downstream of the first reactor.

Owner:FINA RES SA

Polymeric ballistic material and method of making

PendingUS20060013977A1Dissipating projectile energySlow its forward motionLayered productsArmour platesBallistic impactPolymer

This invention relates to a polymeric ballistic material comprising a high molecular weight, high density polyethylene (HMW-HDPE) and / or composite, and to articles made from this ballistic material suitable for stopping projectiles. The articles may include backstops for firing ranges and home use, armor for vehicles, personnel, and aircraft, training targets, protection for temporary or mobile military and / or police installations, buildings, bunkers, pipelines or any “critical” need equipment that might require protection from ballistic impact, and the like.

Owner:BALLISTICS RES +1

Processes for producing polymer blends and polymer blend pellets

InactiveUS7803876B2Beneficial performance characteristicBeneficial storage and handling characteristicCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsLow-density polyethylenePolyester

Owner:EXXONMOBIL CHEM PAT INC

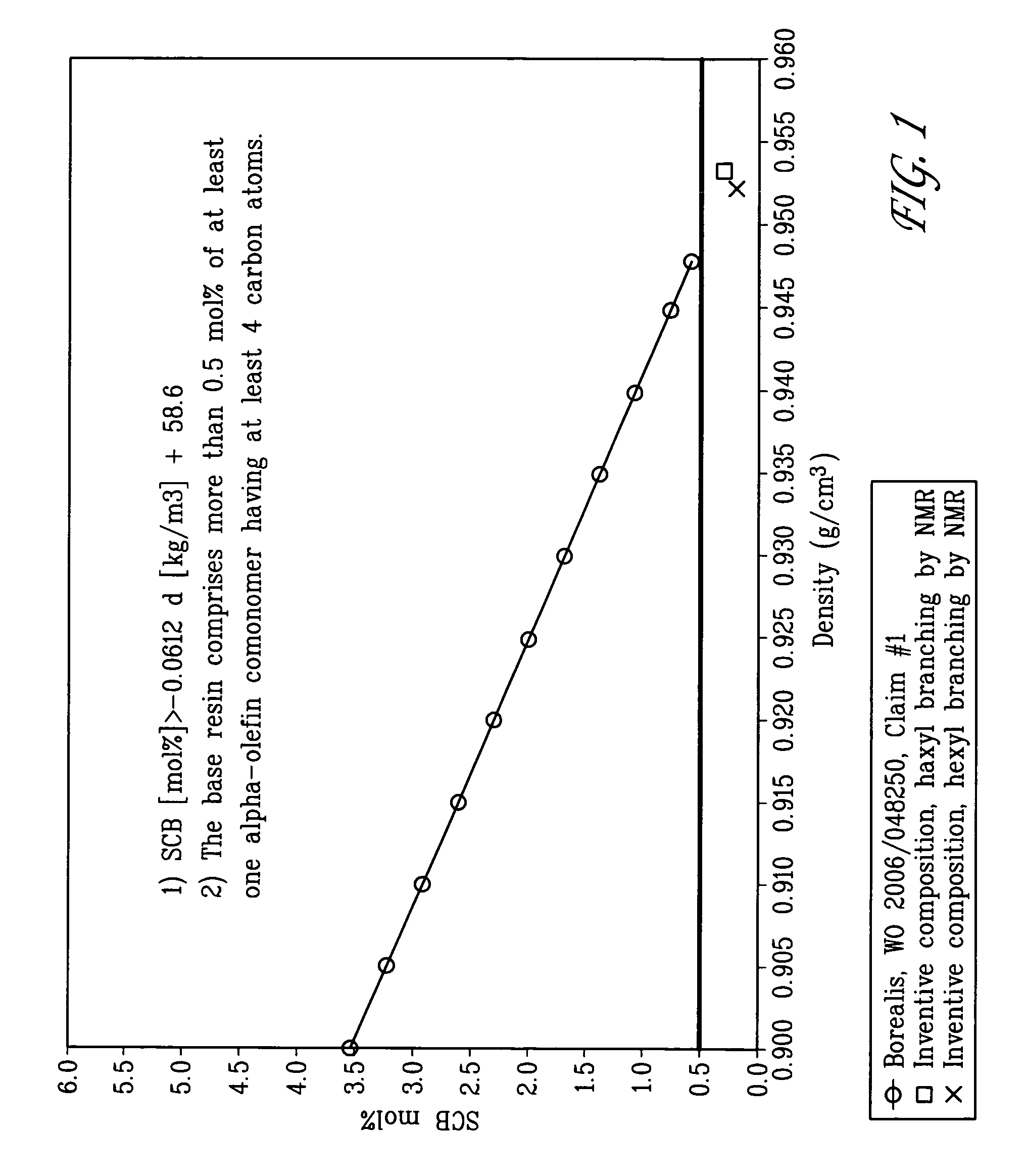

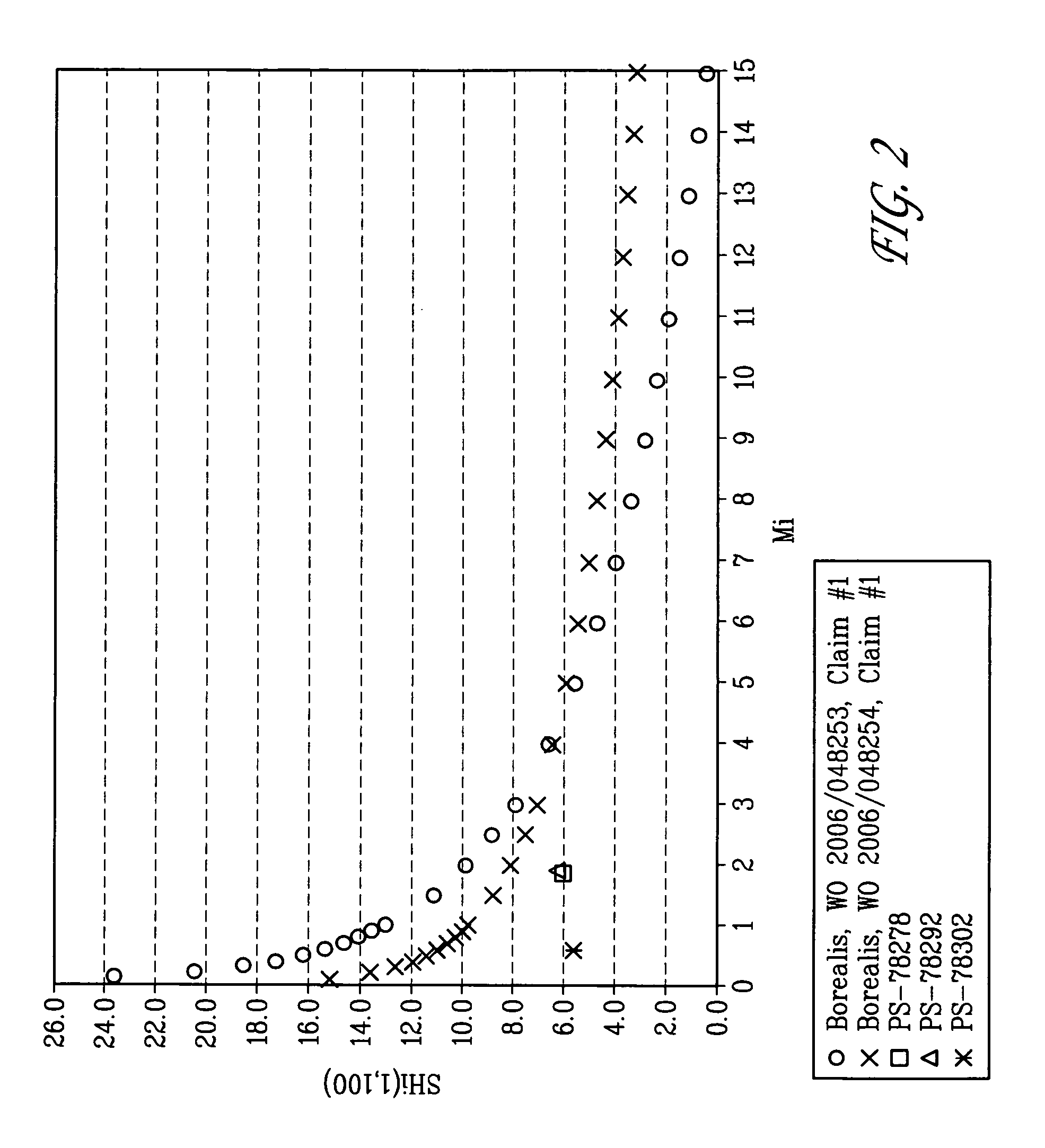

High density multimodal polyethylene

Provided is a high density multimodal polyethylene, having a shear ratio (SR) of 18 or more and a HLMI of 15 g / 10 mins or less comprising at least 20% by weight of a high molecular weight fraction, which high molecular weight fraction has:(a) a density (rho) of 0.930 g / cm3 or less; and(b) a high load melt index (HLMI) of 0.30 g / 10 mins or less.

Owner:FINA RES SA

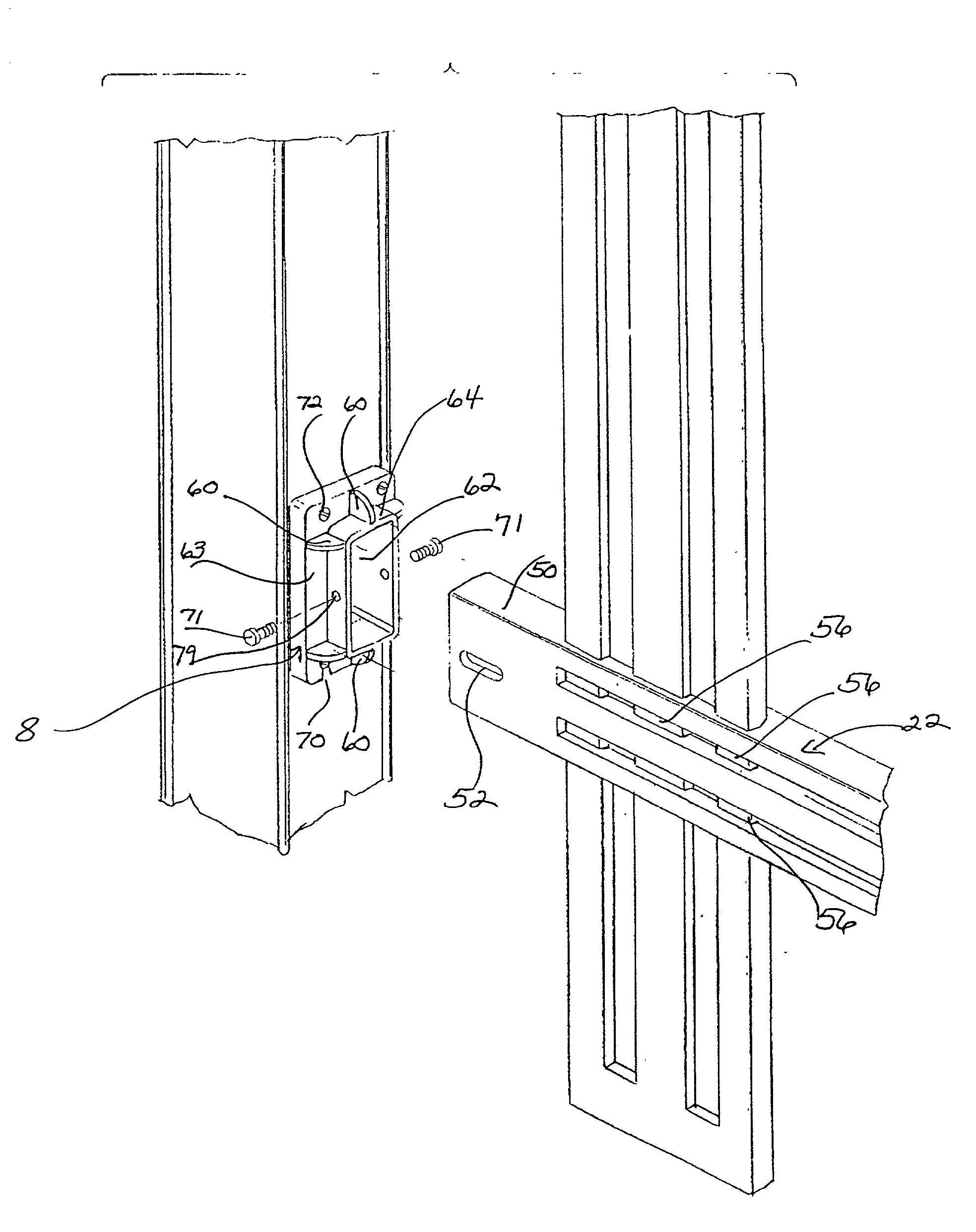

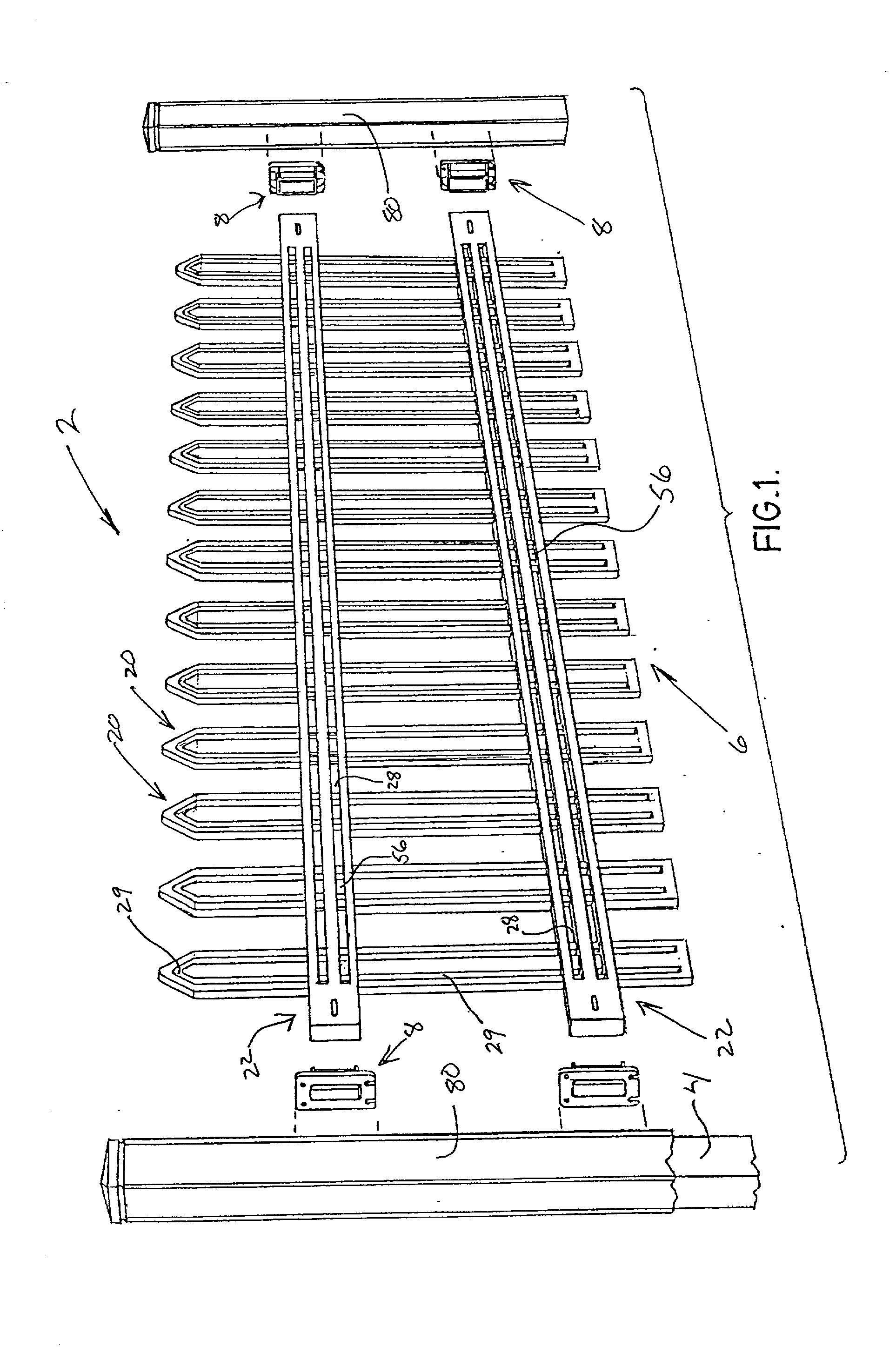

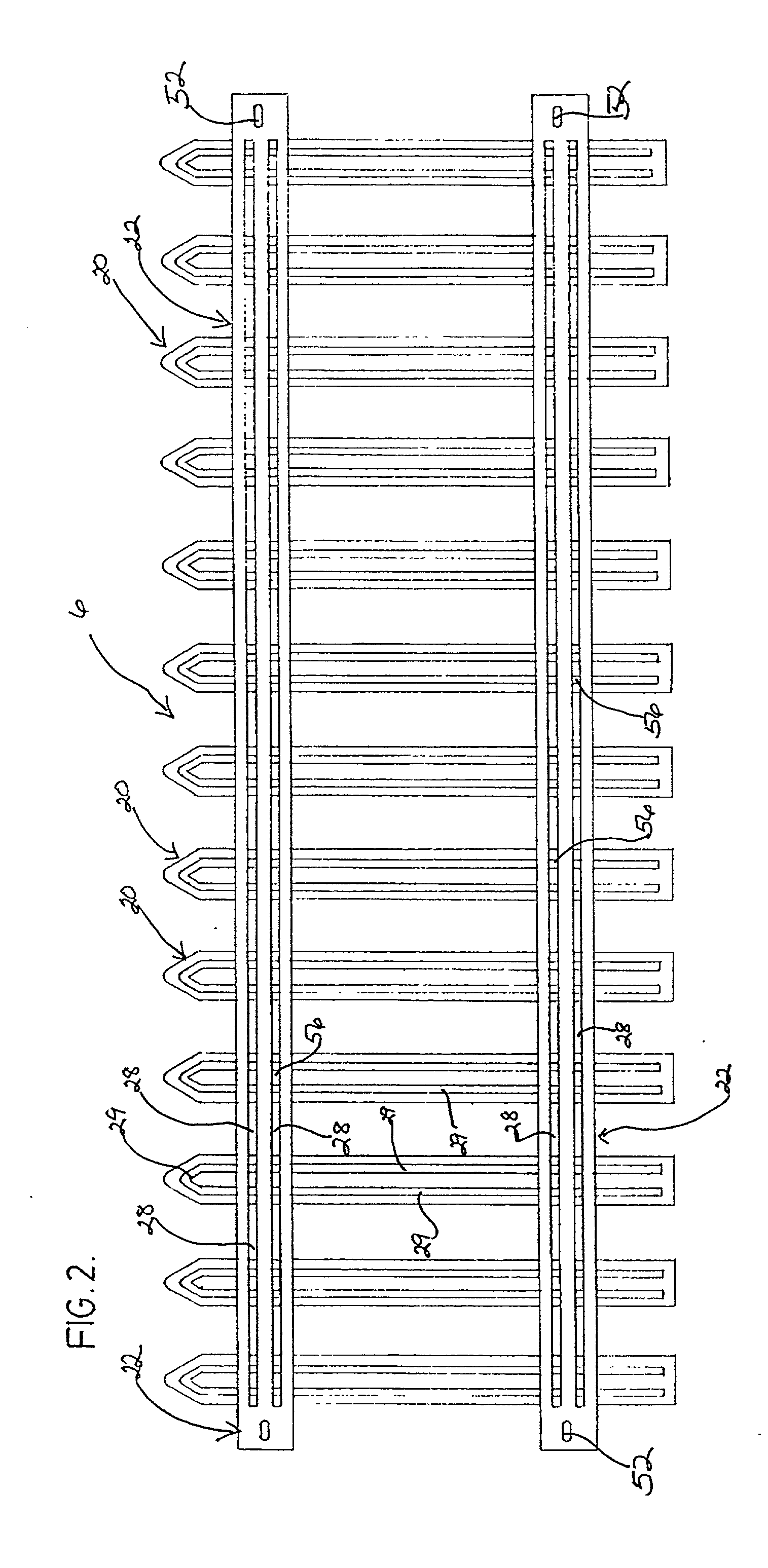

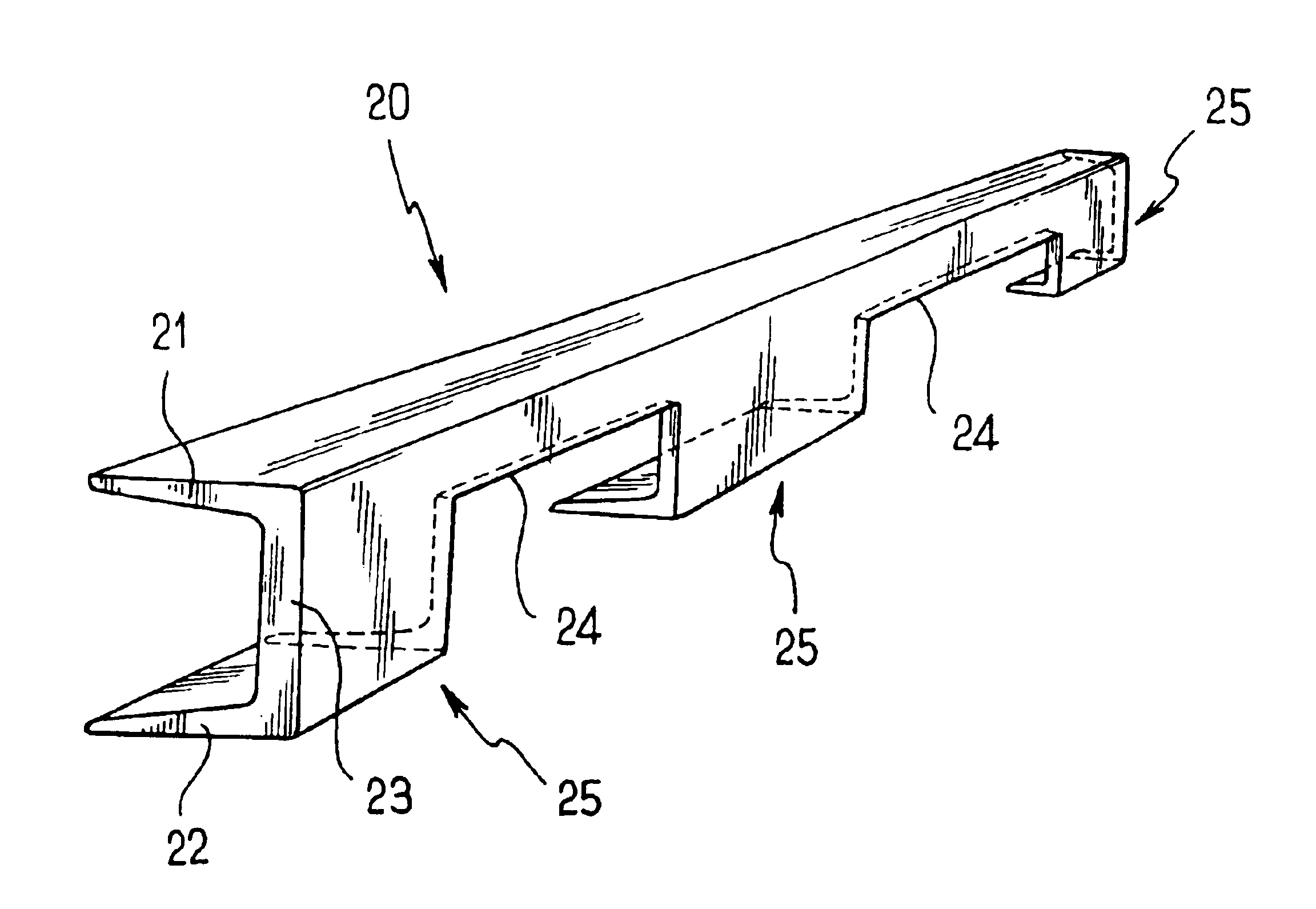

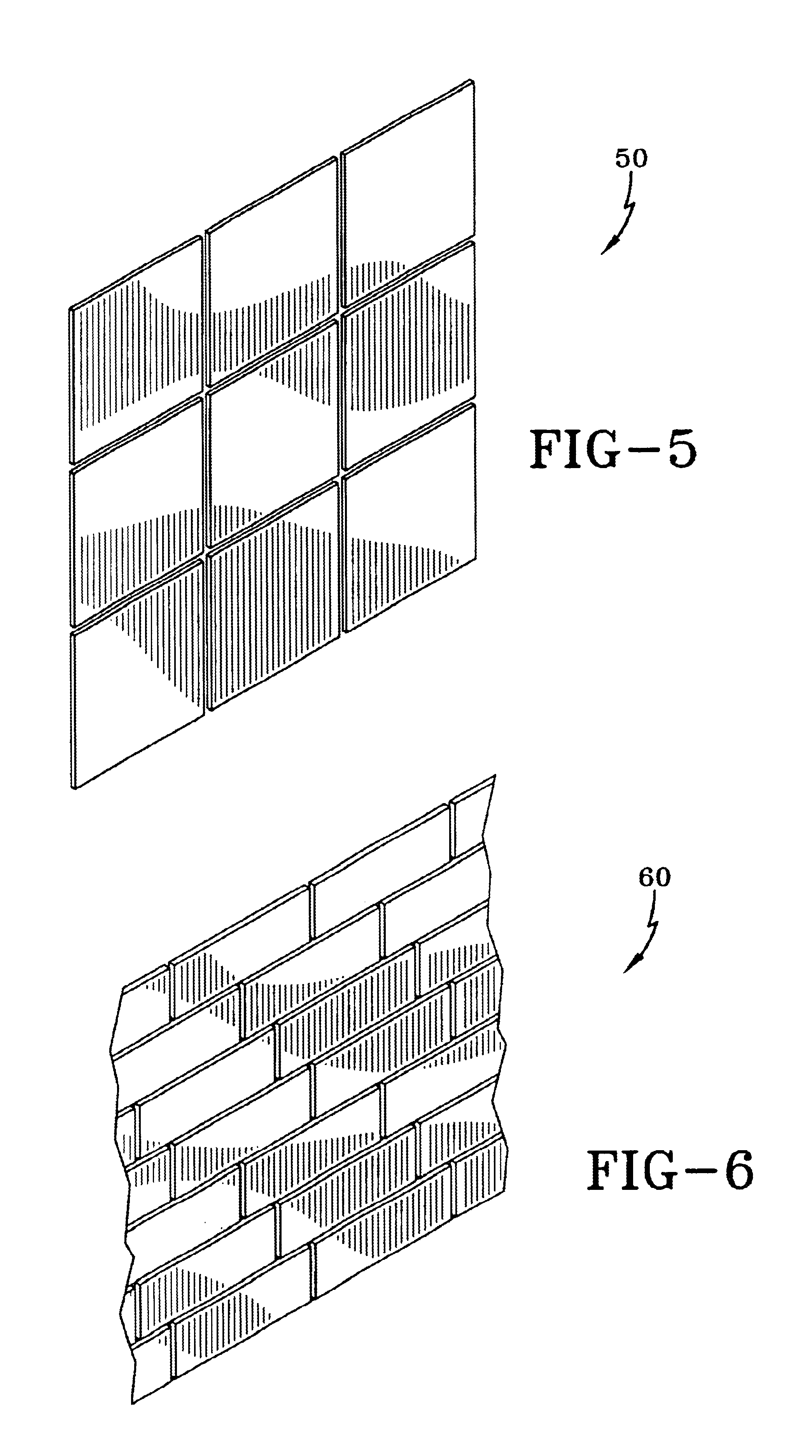

Molded picket fence section

A picket fence section is made as a single integral plastic component. The fence section can be made in various length including a length appropriate for securement between posts spaced at eight foot centers. The picket fence section is preferrably of a high density polyethylene material and made by blow molding.

Owner:GSW

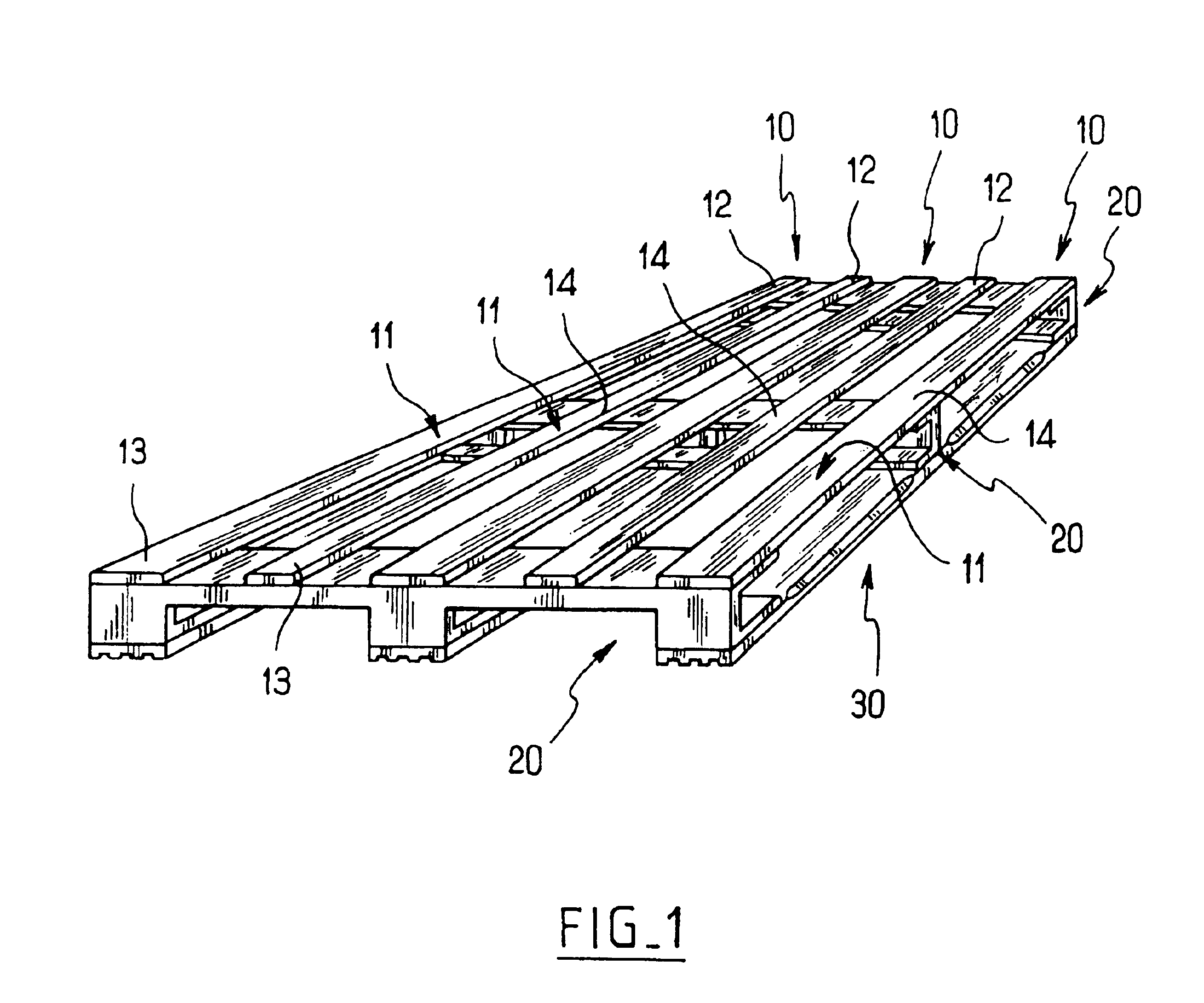

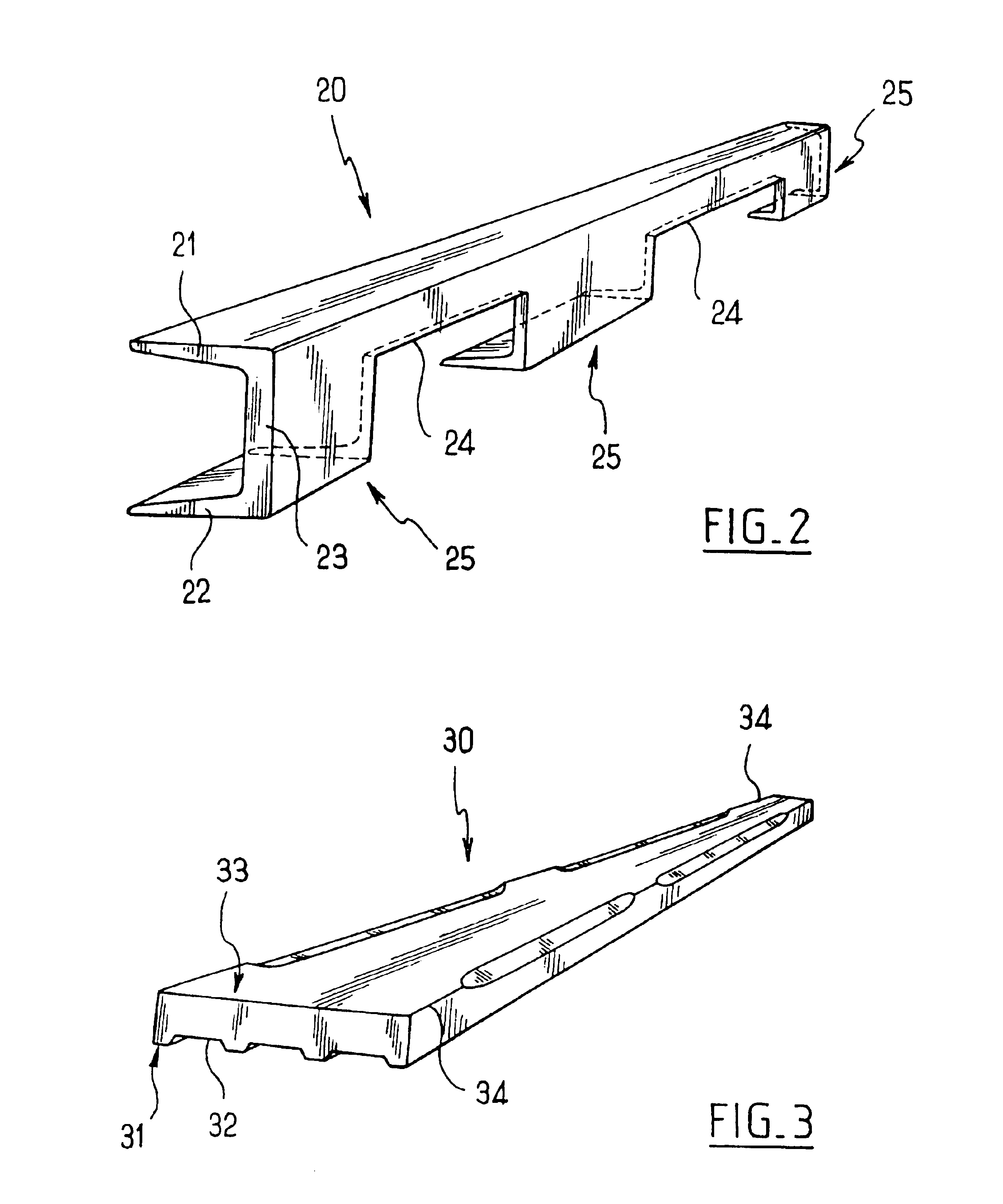

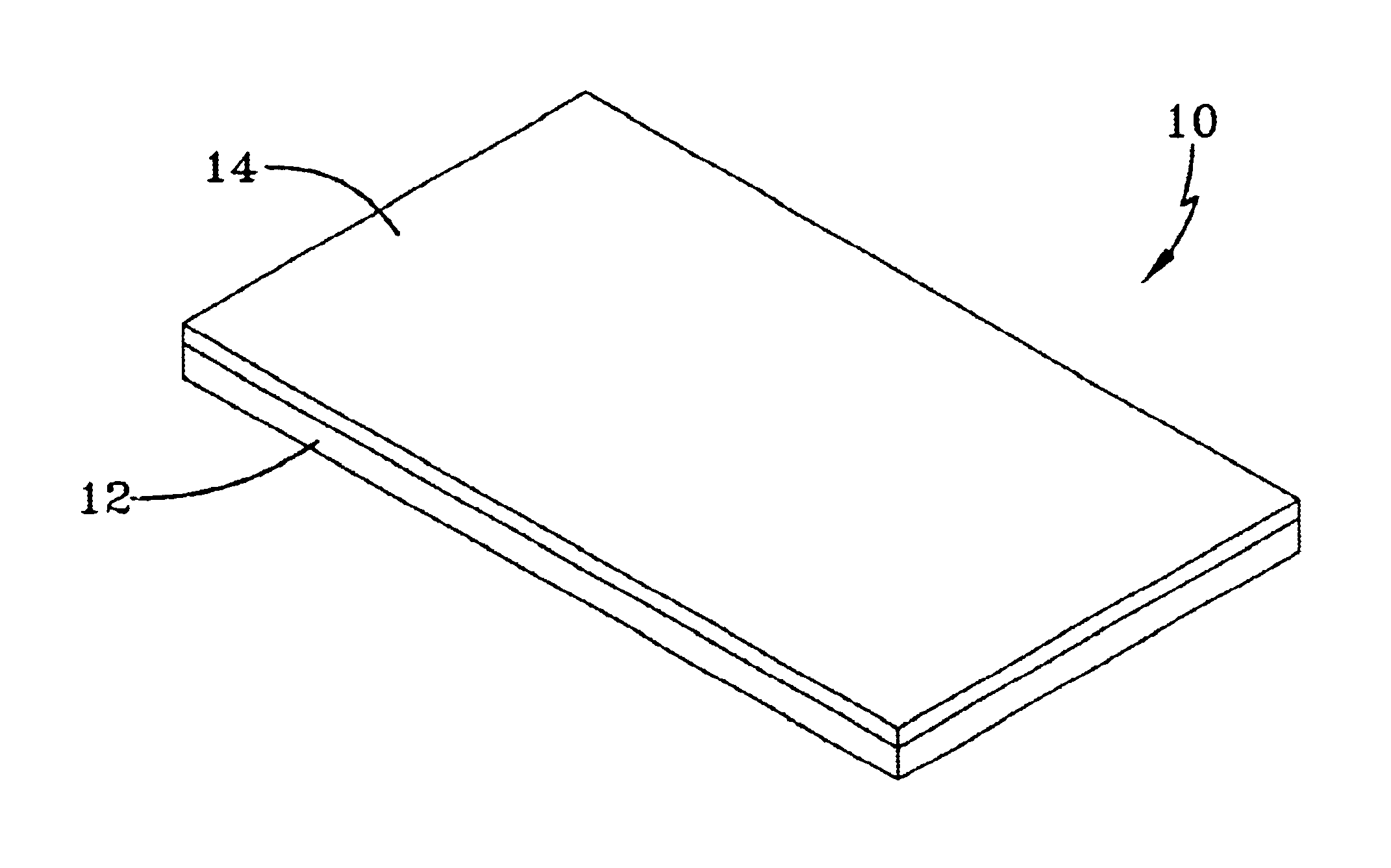

Part made of recycled thermoplastic material, a corresponding method of manufacture, and a pallet comprising at least one bar of this type

InactiveUS6780500B2Improve featuresSatisfactory characteristicSynthetic resin layered productsPlastic recyclingPolyethylene terephthalateEngineering

Owner:DUMOUCHEL CATHERINE +1

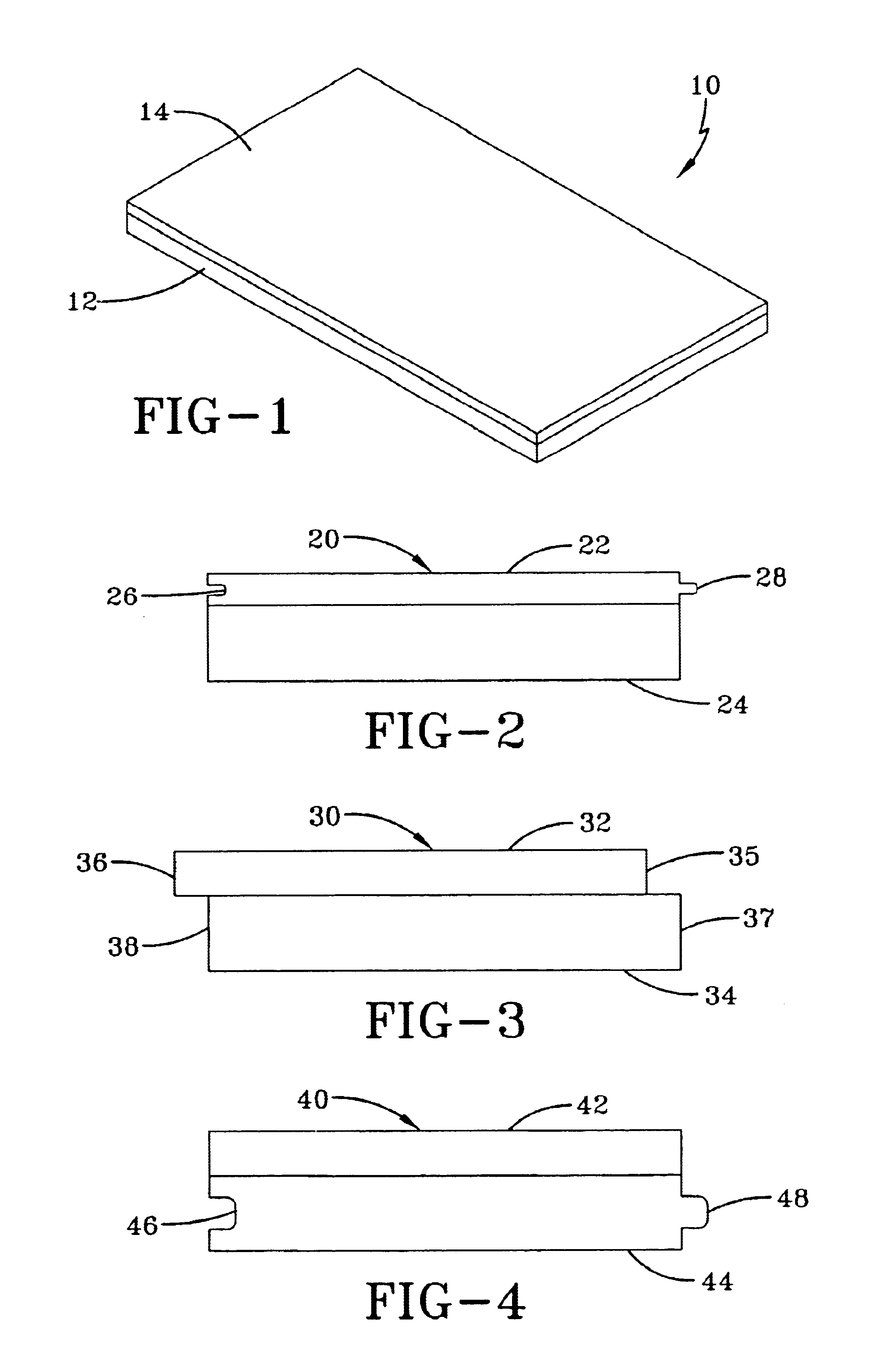

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

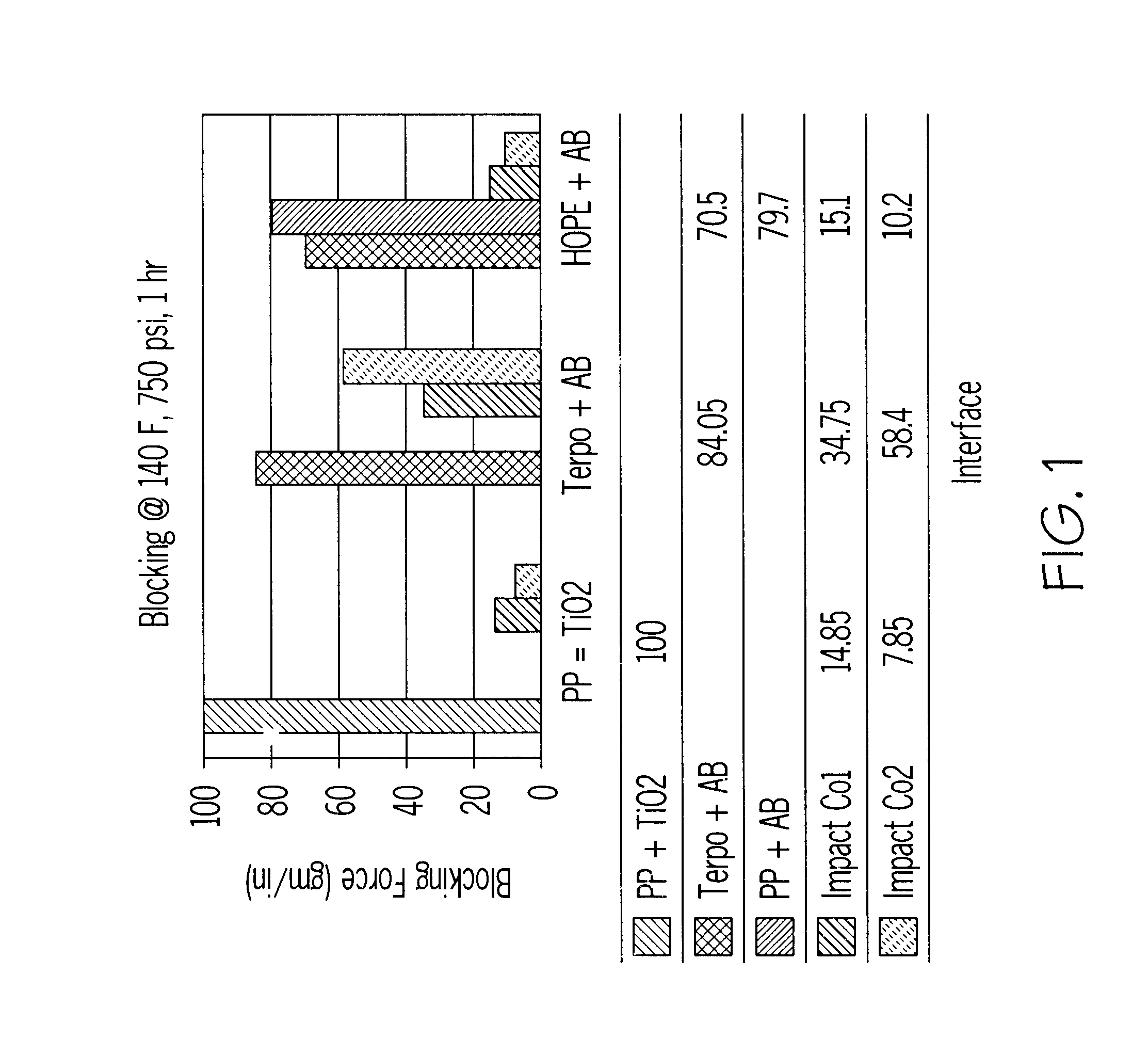

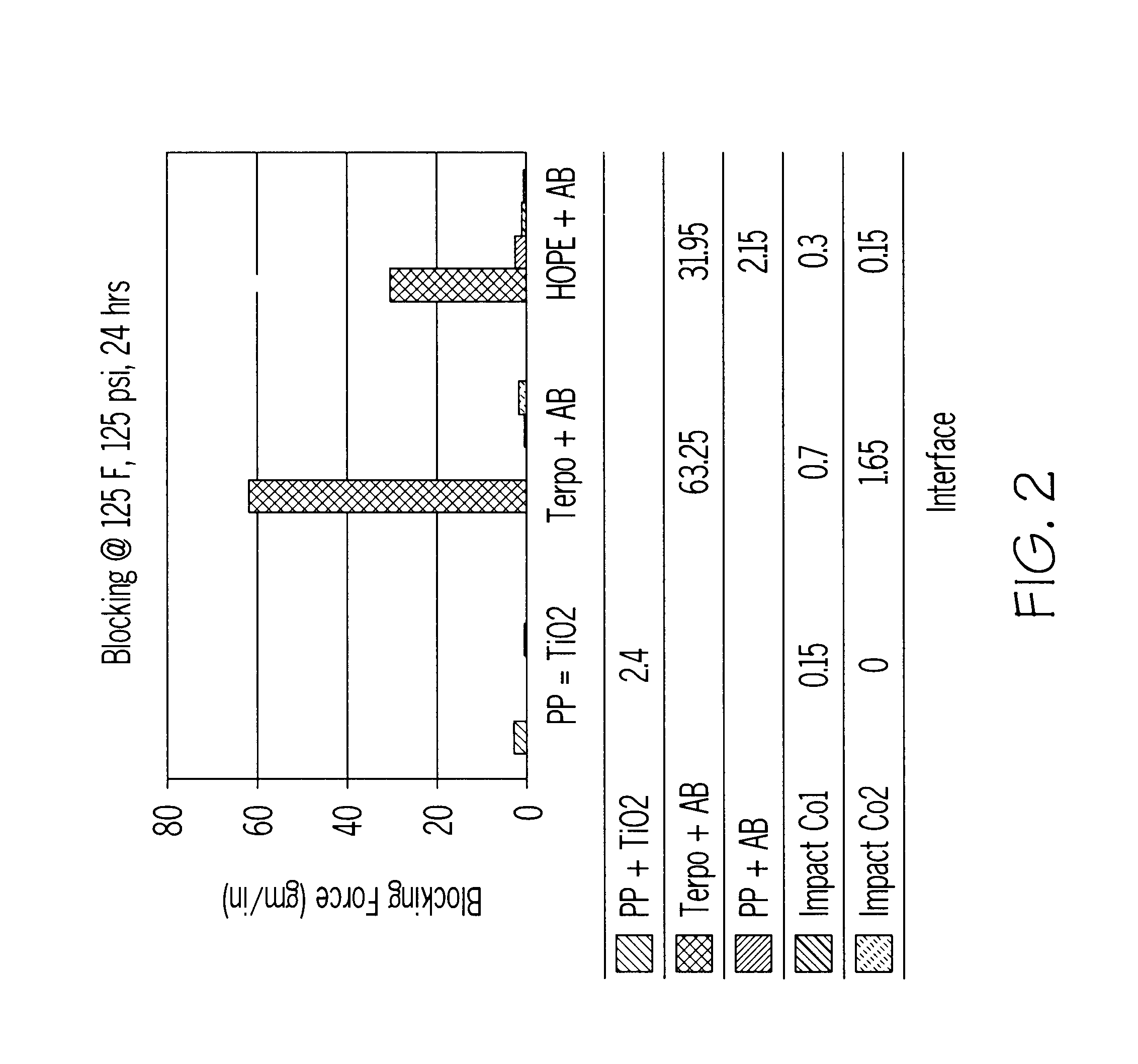

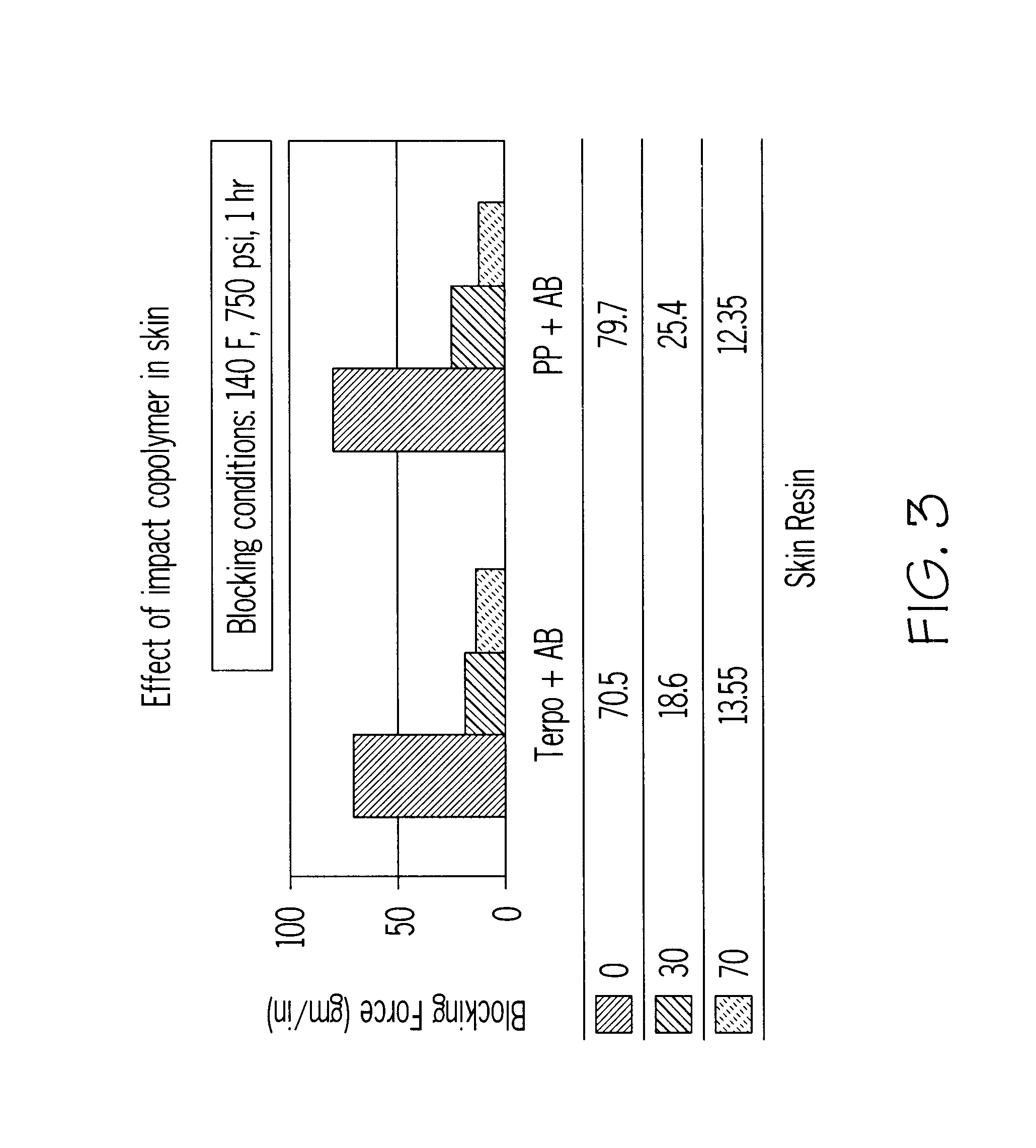

Films with improved blocking resistance and surface properties

InactiveUS6495266B1Lamination ancillary operationsSynthetic resin layered productsLinear low-density polyethylenePolypropylene

The invention discloses methods of improving blocking resistant properties and reducing the coefficient of friction of a multilayer film comprising providing at least one layer of an ethylene-propylene impact copolymer having from about 3% to about 30% by weight ethylene, wherein said copolymer has no more than two peaks in the melting curve within the range from about 110° C. to about 165° C., and wherein said layer is non-heat sealable, to a multilayer film having a core layer comprising polypropylene, high density polyethylene (HDPE) or linear low density polyethylene (LLDPE), whereby anti-blocking and coefficient of friction characteristics of said film is improved without necessity of adding an antiblock or slip agent.

Owner:JINDAL FILMS AMERICAS LLC

Preparation method of recycled polyester chip microfilaments and usage thereof

InactiveCN101747596ASimple compositionNo smellFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterLinear low-density polyethylene

The invention relates to a preparation method of recycled polyester chip microfilaments and a usage thereof, belonging to the field of plastic modification and category of composite material / alloy promoter. The polyester chip microfilament is an ideal promoter which has excellent performance, environment-friendliness, high added value, wide application range and broad market prospect and can change the mechanical property of the composite material / alloy. Recycled blow molding polyester (RPET / RPBT) is taken as main raw material, and the following formula and process are adopted for preparing the microfilament according to parts by weight: 100 parts of recycled polyester (RPET / RPBT), 5-30 parts of wire-drawing high-density polyethylene (HDPE) / polypropylene (PP) / linear low-density polyethylene (LLDPE), 0.1-4 parts of crosslinking agent / chain extender / anchoring agent, 0.1-0.8 part of antioxidant, 0.5-6 parts of nucleating agent, and 1-5 parts of nucleate accelerant, and other processing aids (such as lubricant and plasticizer) / functional aids (such as fire retardant and ultraviolet absorber) can be additionally and appropriately added. The microfilament is prepared through extrusion, cooling, drawing and granulating by the reaction under 90-260 DEG C under the action of mechanical shear. The recycled polyester (RPET / RPBT) microfilament prepared in the invention can endow the composite material / alloy with excellent mechanical property.

Owner:王世和

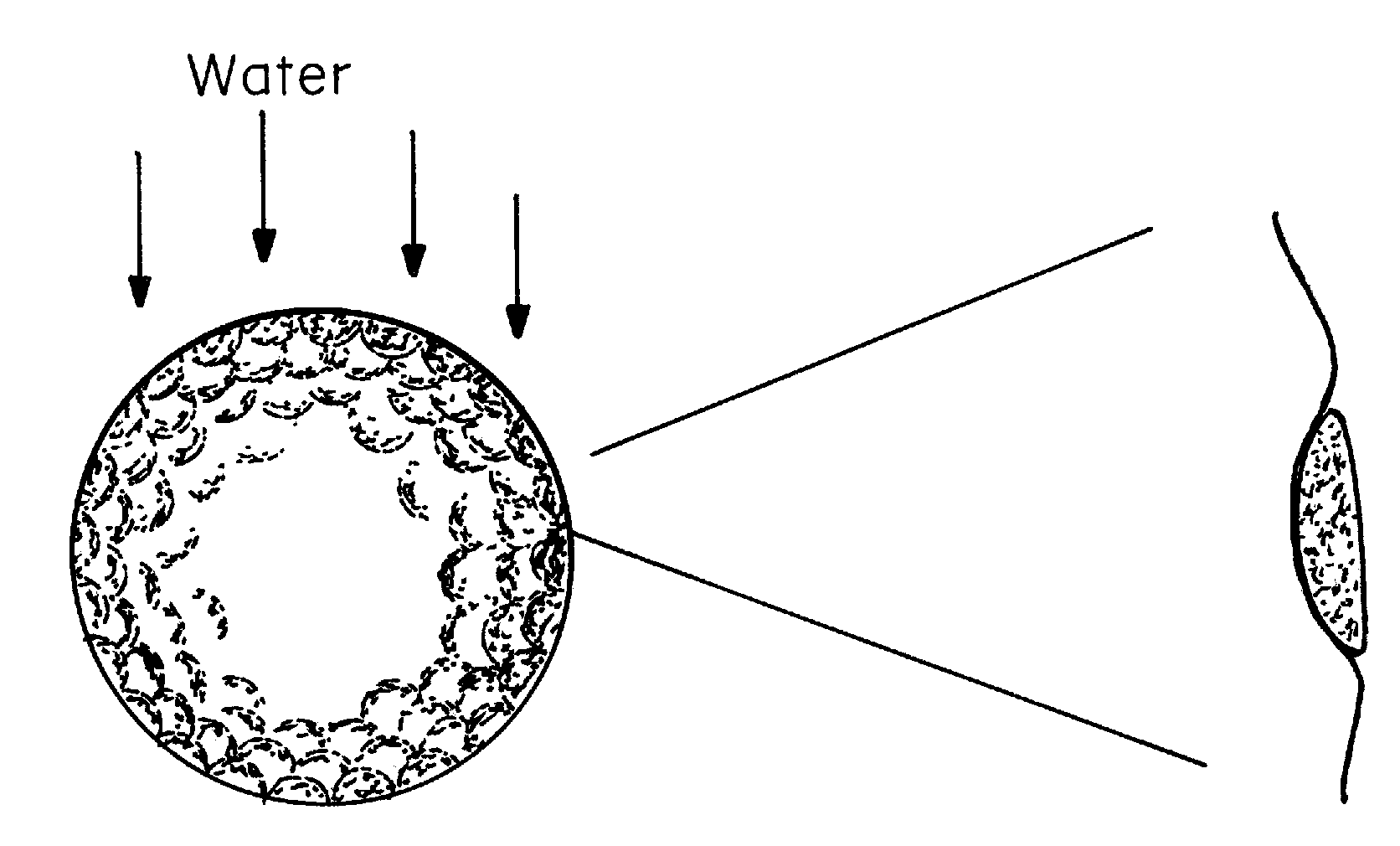

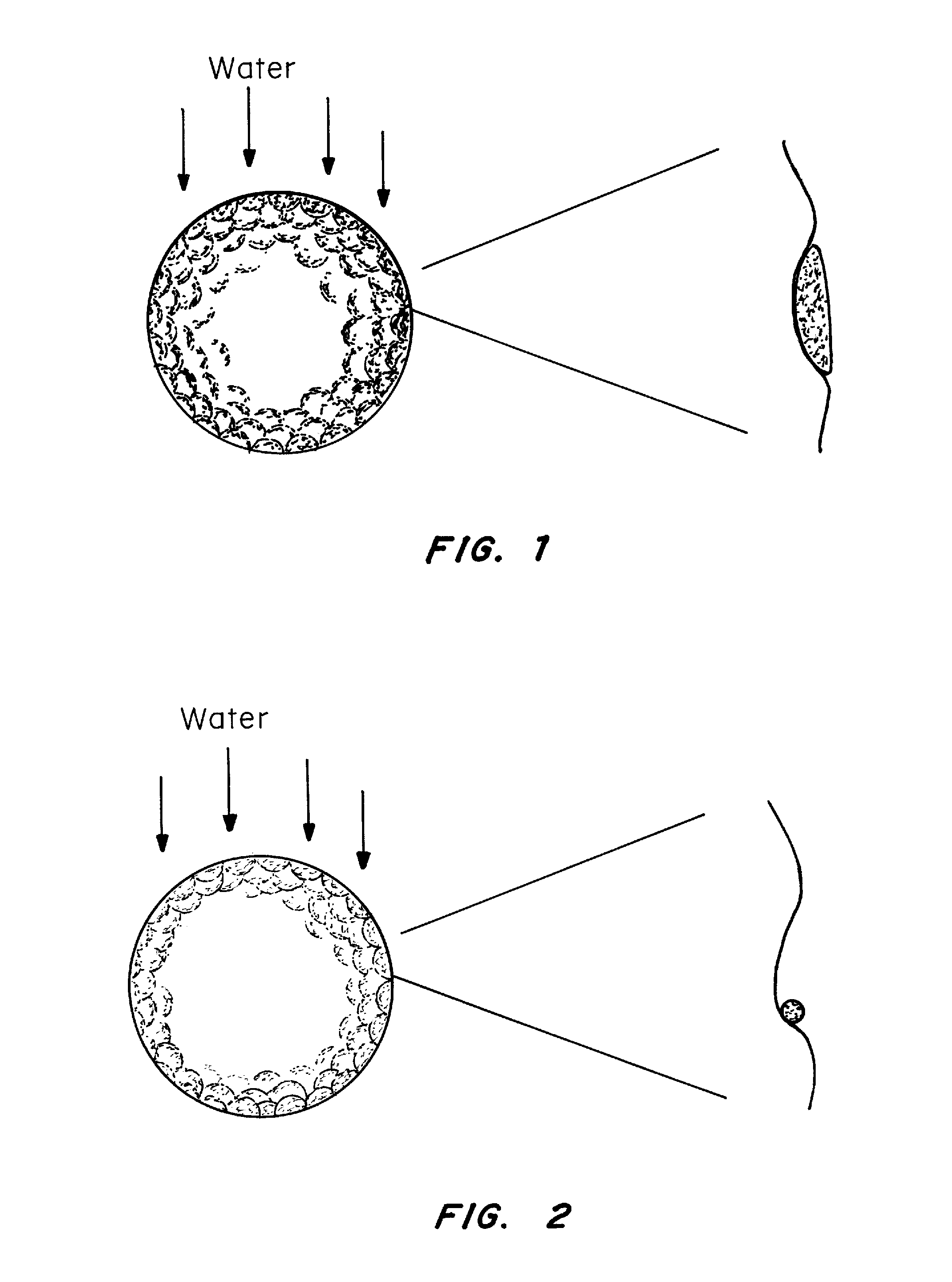

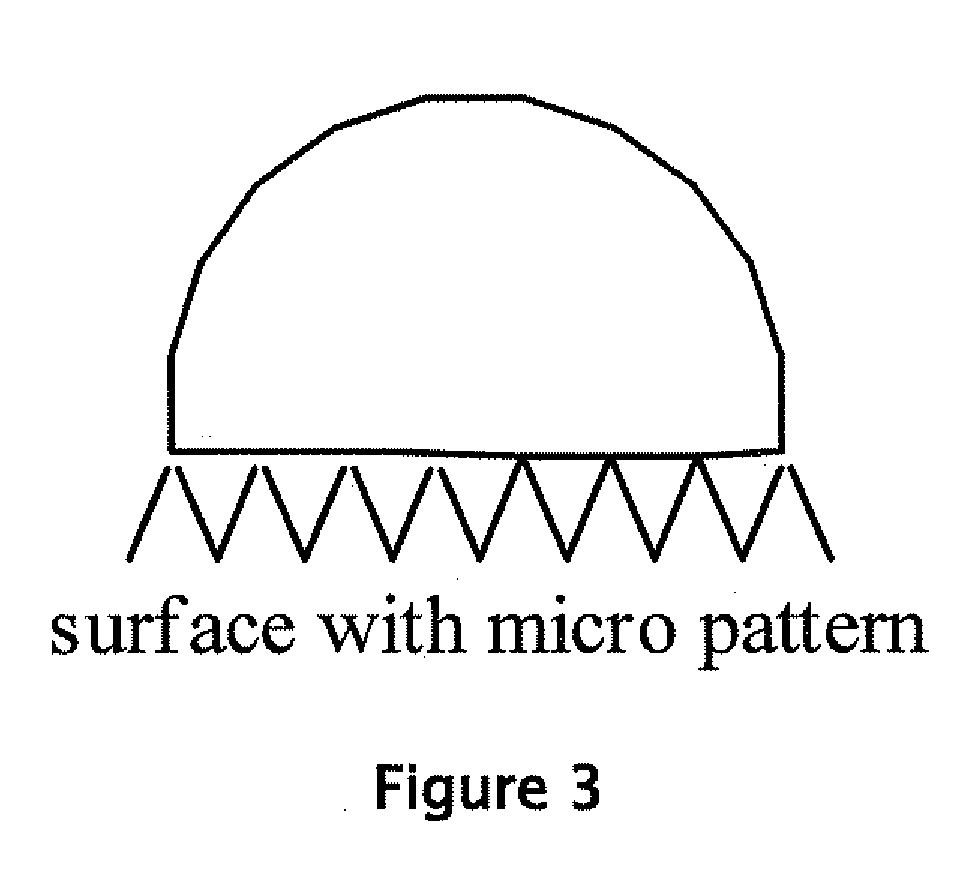

Water Repellant Golf Balls Containing a Hydrophobic or Superhydrophobic Outer Layer or Coating

InactiveUS20080280699A1Improve performanceSynthetic resin layered productsPaper coatingPolymer sciencePolyethylene glycol

Water-repellant, self-cleaning coatings and methods of making and using thereof are described herein. In one embodiment, a hydrophobic or super hydrophobic coating is applied to the surface of a golf ball to make the golf-ball water-repellant and self-cleaning. Suitable coating materials include silicone compounds, silicone compounds, nanoparticles, silanes, fluorocarbon polymers, perfluoroalkyl ethyl methacrylate (PPFEMA) coated polycaprolactone, hydrocarbons, polymer mats made of polystyrene and poly[tetrafluoroethylene-co-(vinylidene fluoride)-co-propylene] (PTVFP); polyethylene glycol with glucose and sucrose in conjunction with a hydrophobic substance; combinations of nanoparticles with polyethylene or polypropylene; high density polyethylene, technical waxes; films of rough particles of metal oxides, polymer binder layers containing a plurality of porous protrusions, and combinations thereof. Suitable coating techniques include, but are not limited to, spraying, dipping, painting, brushing, or wiping (such as applying the coating from a towel or sponge). The coating material or the outer layer of the golf ball may be modified to create nano- or micro roughness or patterns on the surface of the golf ball, which can induce the lotus effect. This roughness or pattern can be created using a variety of techniques known in the art including, but not limited to, etching, top / down methodologies, bottom / up methodologies, or combinations thereof.

Owner:JARVHOLM ERIK JONAS

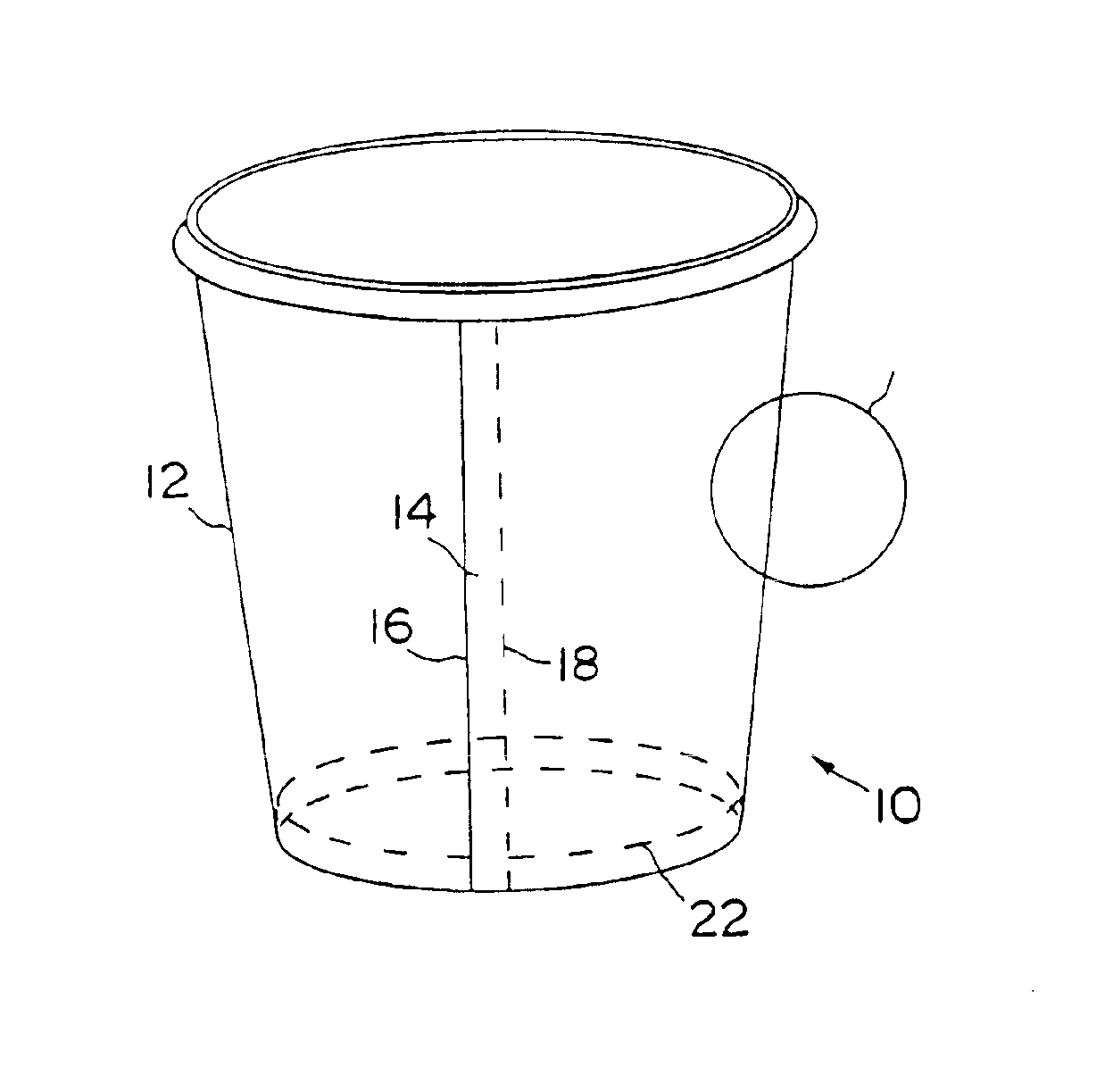

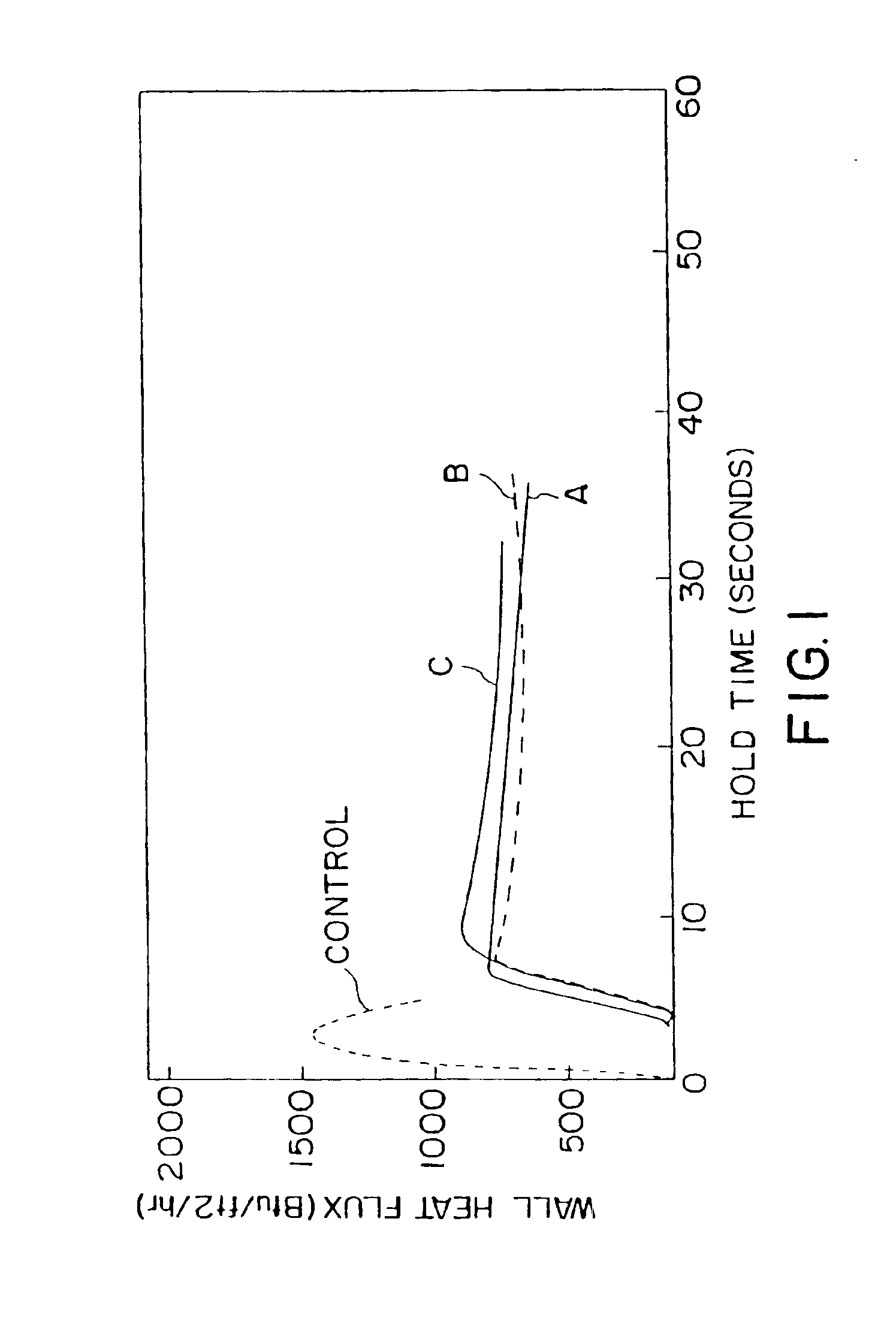

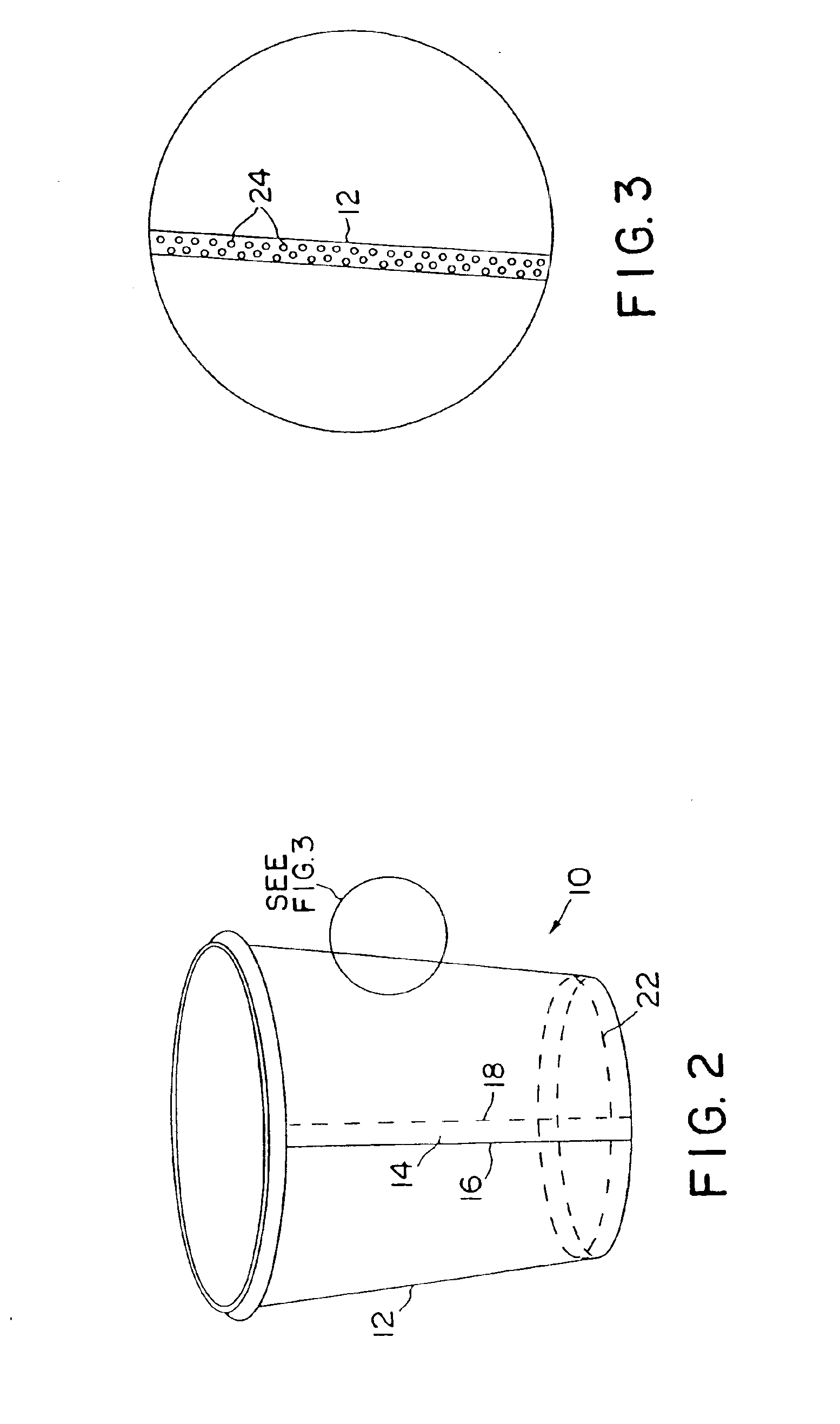

Low density paperboard articles

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

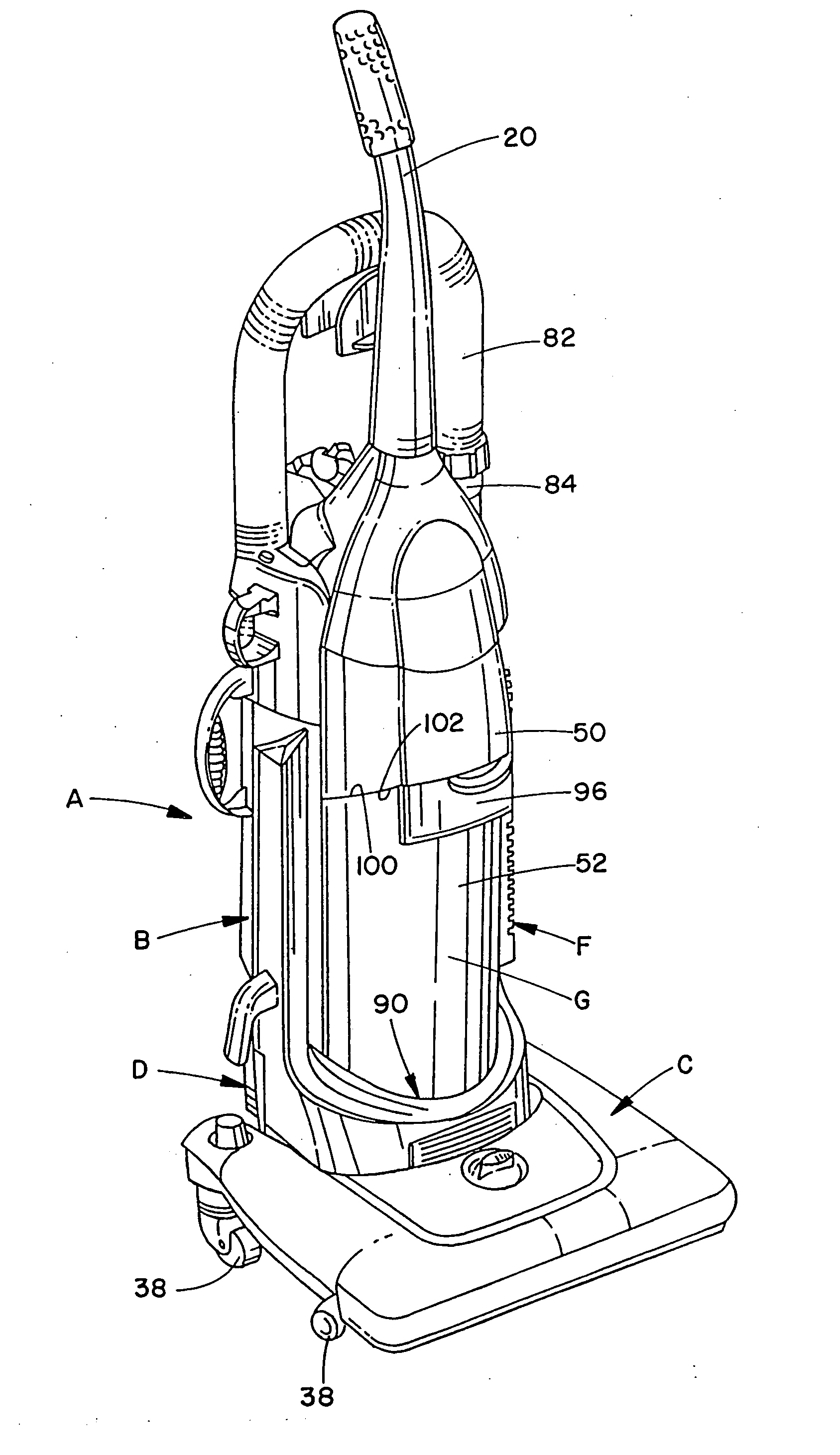

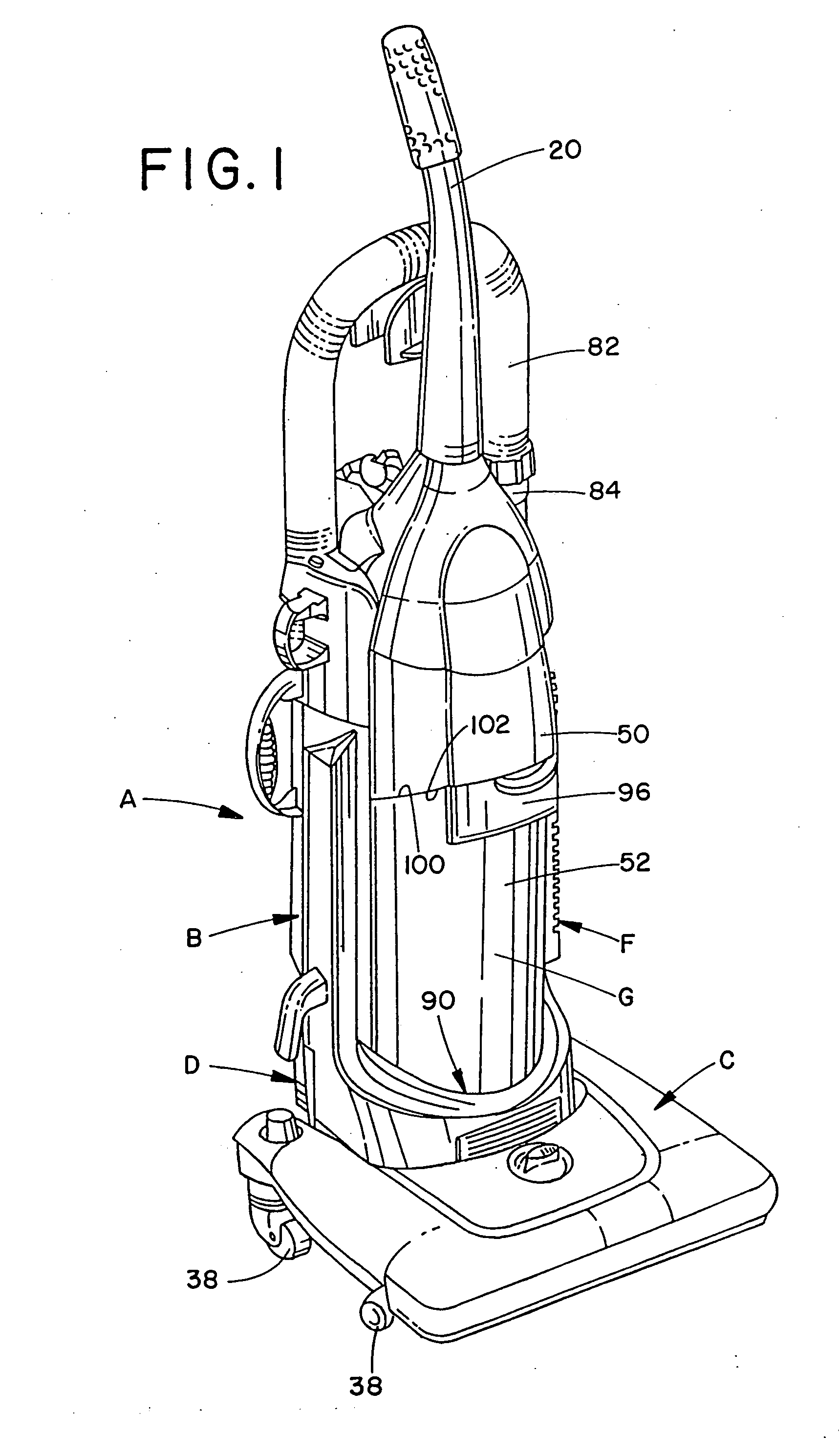

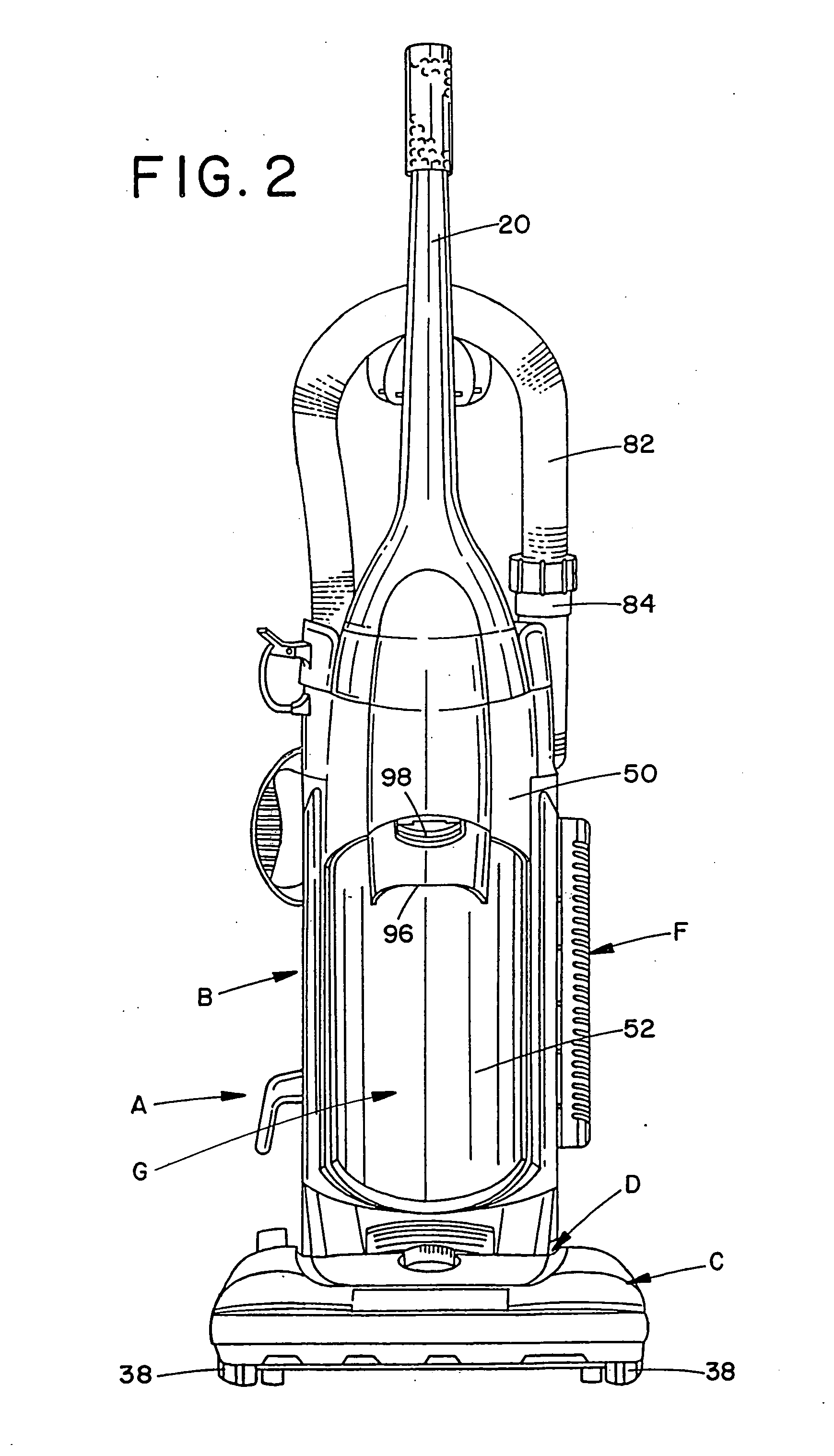

Upright vacuum cleaner with cyclonic airflow

InactiveUS20050091787A1Easily and conveniently emptiedEffectively filters residual contaminantsCleaning filter meansCombination devicesHigh densityFilter media

An upright vacuum cleaner (A) includes an upright housing section (B) and a nozzle section (C). A cyclonic airflow dirt and dust separating chamber (54) is defined in said upright housing section. A suction source (E) pulls air and entrained dirt, dust, and other contaminants through a main suction opening (26) formed in the underside (24) of the nozzle and into the cyclonic airflow chamber (54). The cyclonic airflow chamber causes the suction airstream to travel in a cyclonic path such that the entrained contaminants are separated therefrom and deposited into a dirt container (52) that defines the chamber (54). A main filter element (K) filters residual contaminants from the suction airstream between the chamber and the suction source. The main filter element is preferably made from high-density polyethylene porous filter media. A final filter assembly (F) filters the suction airstream discharged by the suction source to ensure that the air discharged into the atmosphere is contaminant free, including those contaminants introduced into the airstream by the suction source itself.

Owner:TECHTRONIC FLOOR CARE TECH LTD

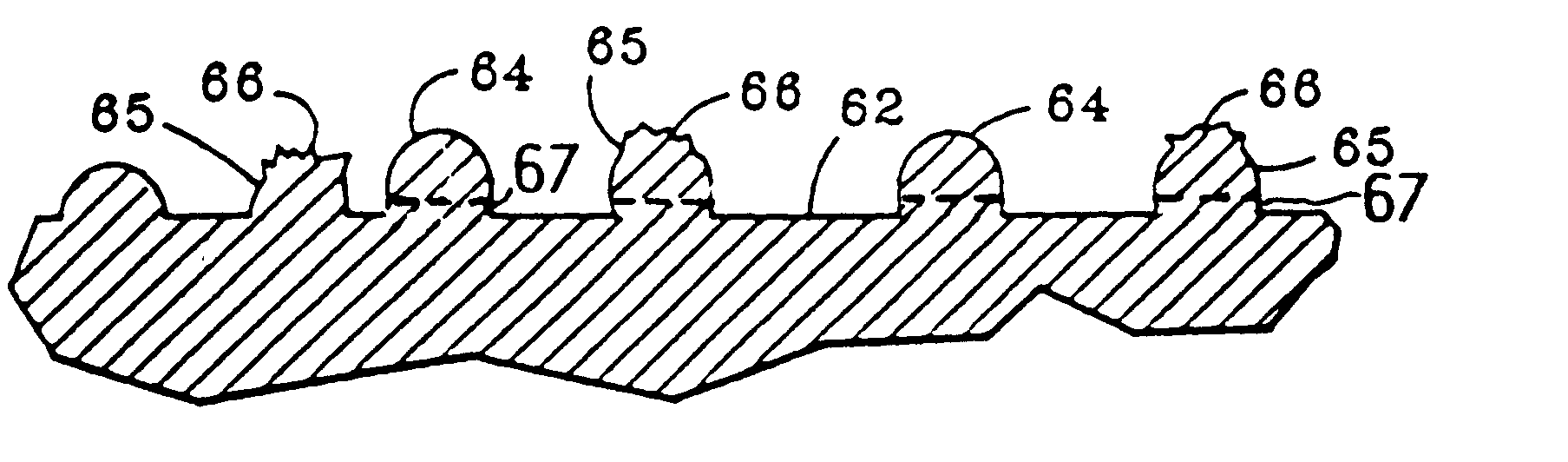

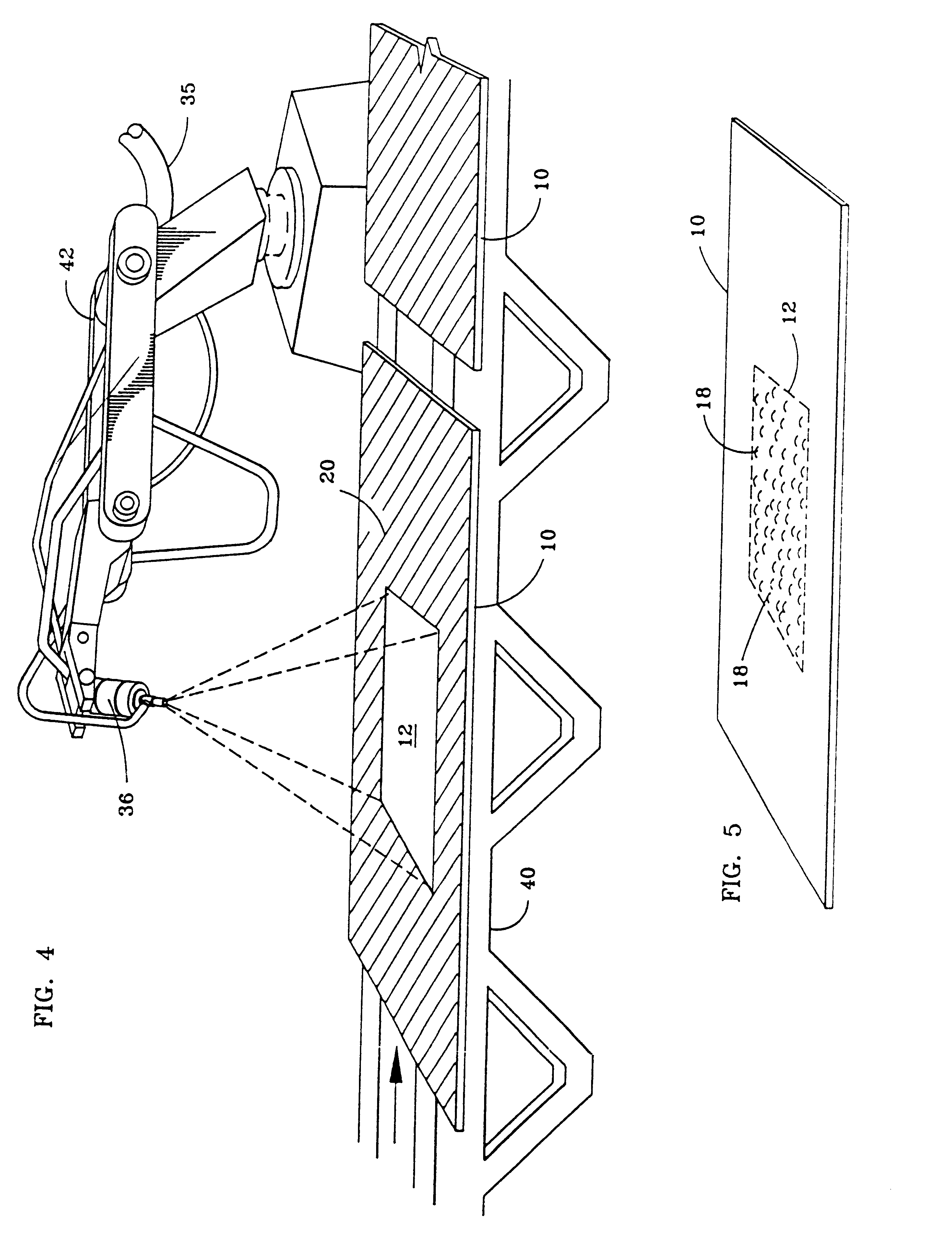

Thermoplastic products having antislip surfaces

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

Production technology of embossing laminating release paper

ActiveCN101597874AWon't happenUnity of depthPaper coatingLaminationLow-density polyethylenePulp and paper industry

The invention discloses a production technology of embossing laminating release paper, the production technology is characterized by comprising the following steps: 1) preparing laminating paint, adding the high-density polyethylene and the low-density polyethylene into a stirring vessel to mix and stir for 5-10 minutes to mix evenly, the weight ratio of the high-density polyethylene and the low-density polyethylene is 1:1.5-2, and then heating, bridging, heating and melting, pressing and extruding the mixture. 2) preparing the embossing laminating release paper, laminating the extruded polyethylene mixture to the surface of the paper by a composite wheel, pressing and compositing the mixture by the composite wheel, and cooling the temperature at 30-40 DGE C after compositing, continually moving the paper after laminating driven by a roller and cooling the paper at the temperature of 12-20 DGE C, and side cutting, rolling, packaging for the paper, finally, coating silicon oil on the surface of the laminating paper to prepare the finished product of the embossing laminating release paper. The invention has convenient production technology; the embossing laminating release paper prepared by the production technology has the advantages of beautiful shape and good use effect, can be widely used in the technology of manufacturing the embossing laminating release paper.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

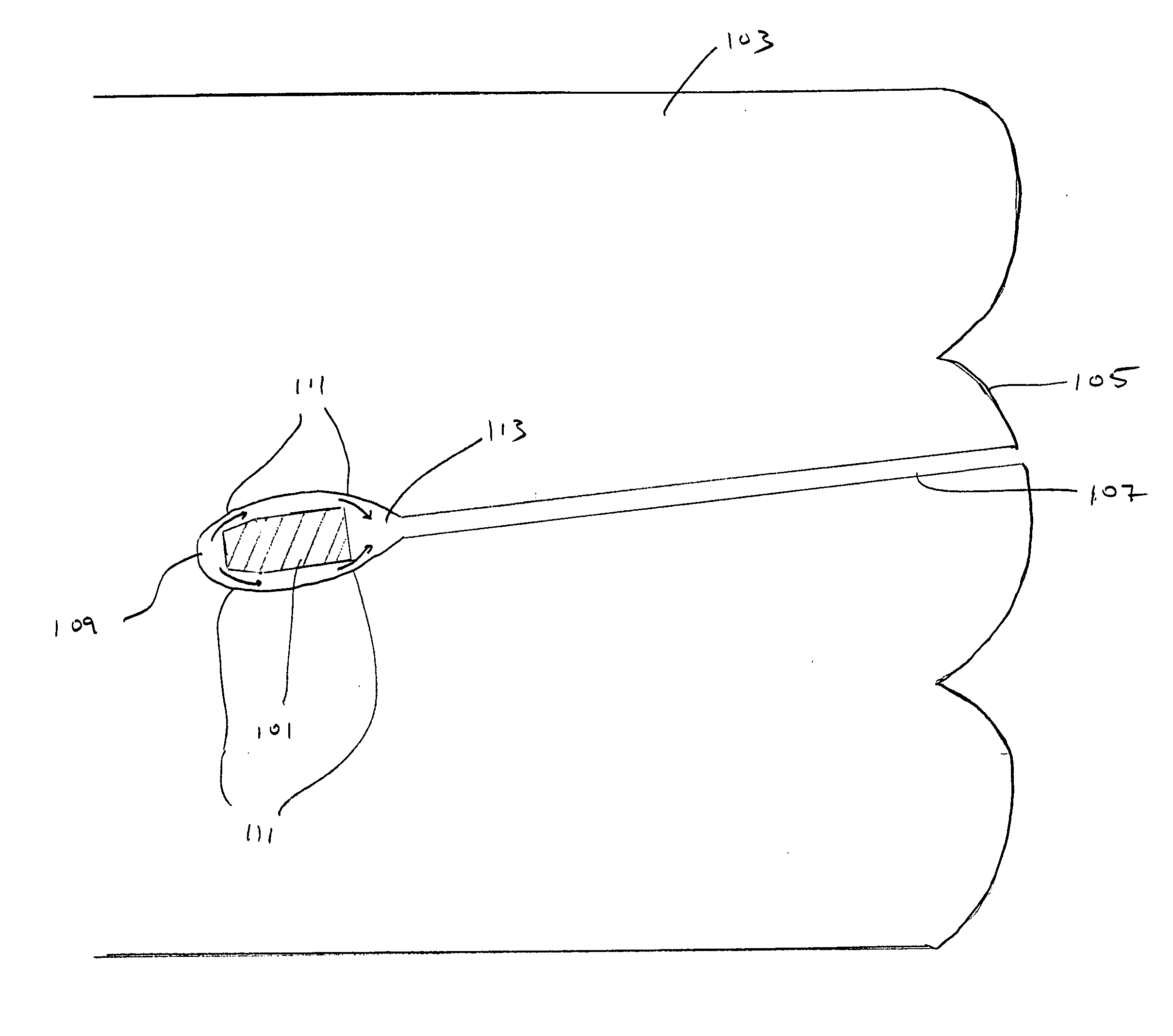

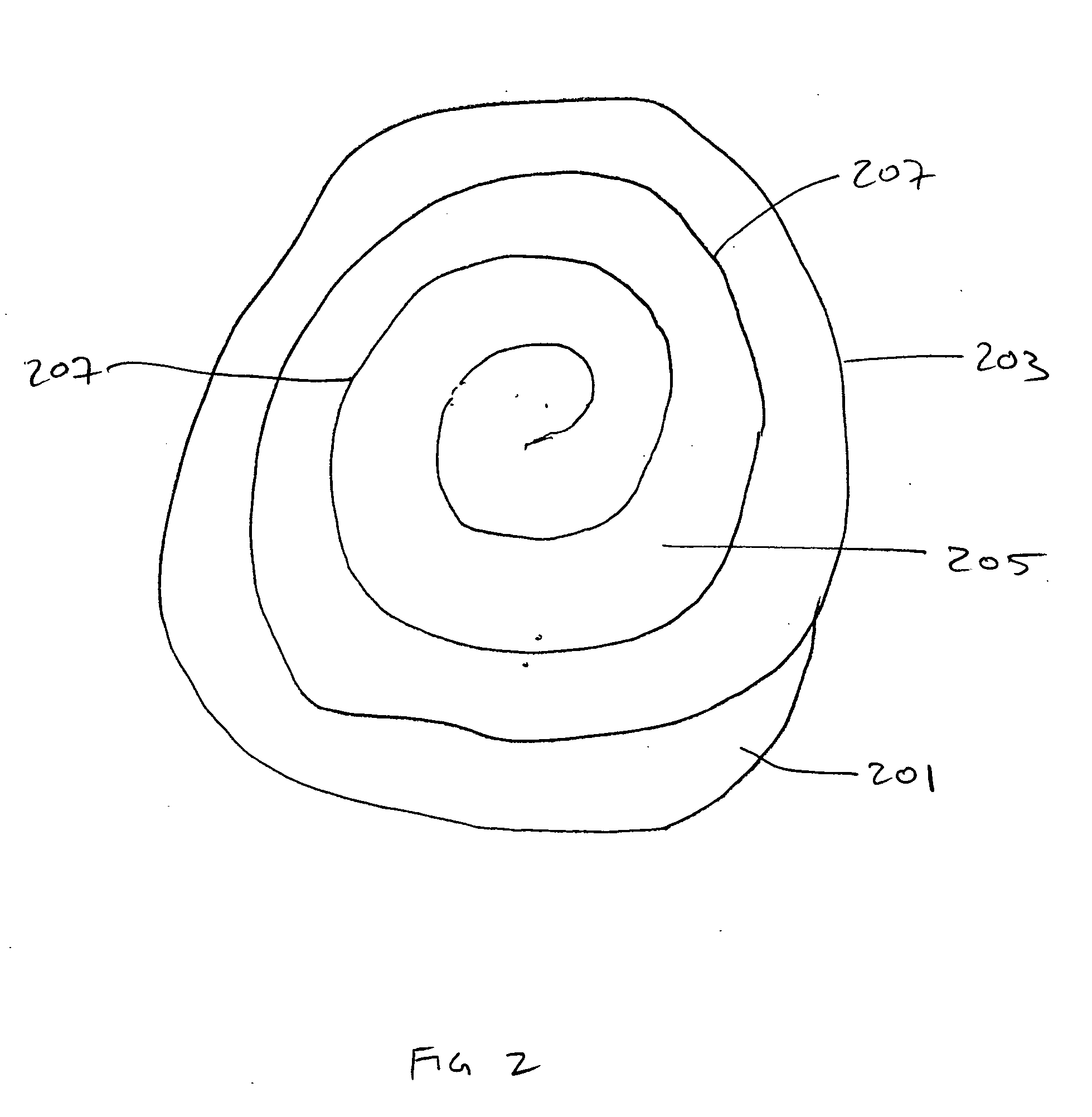

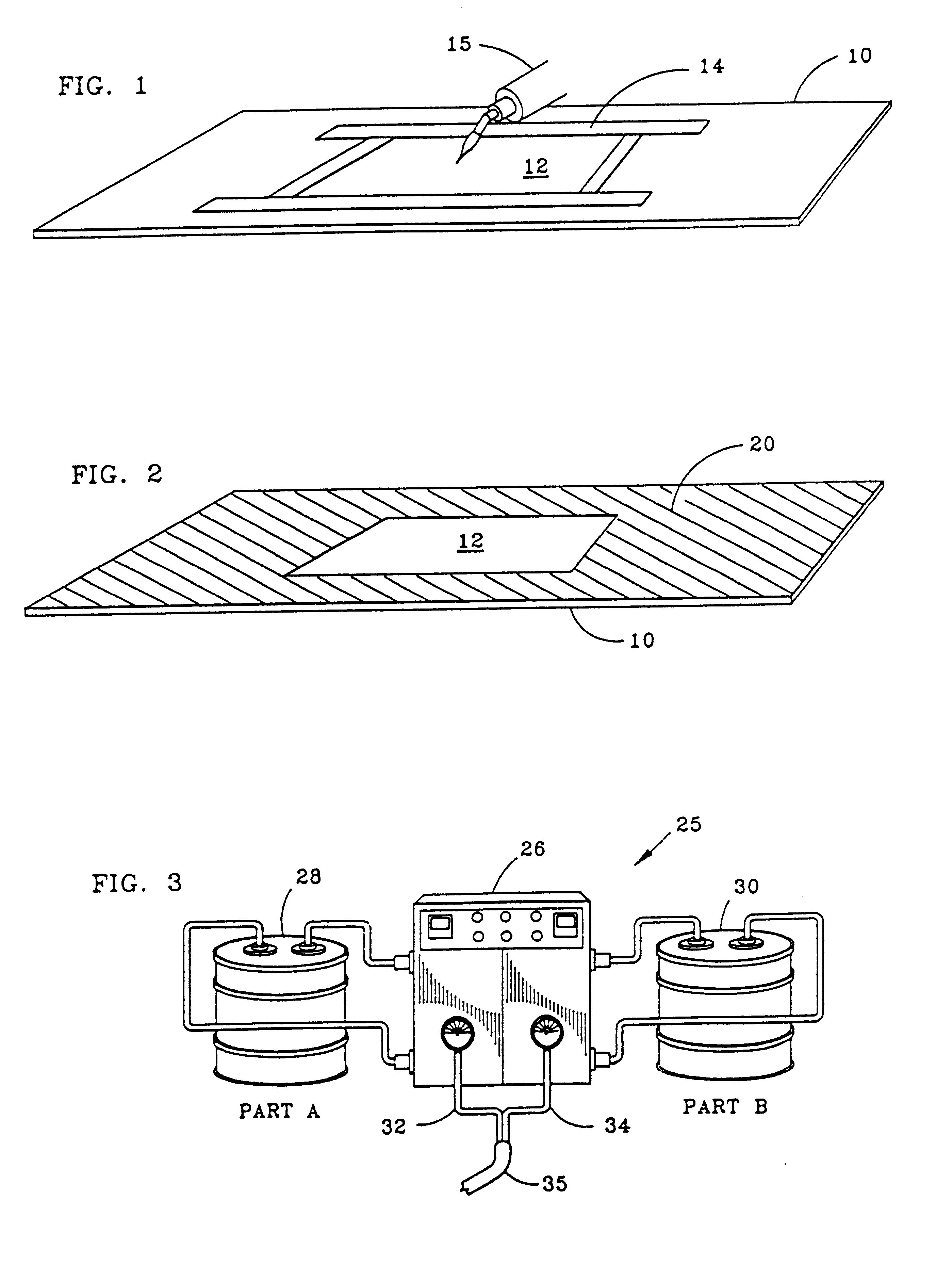

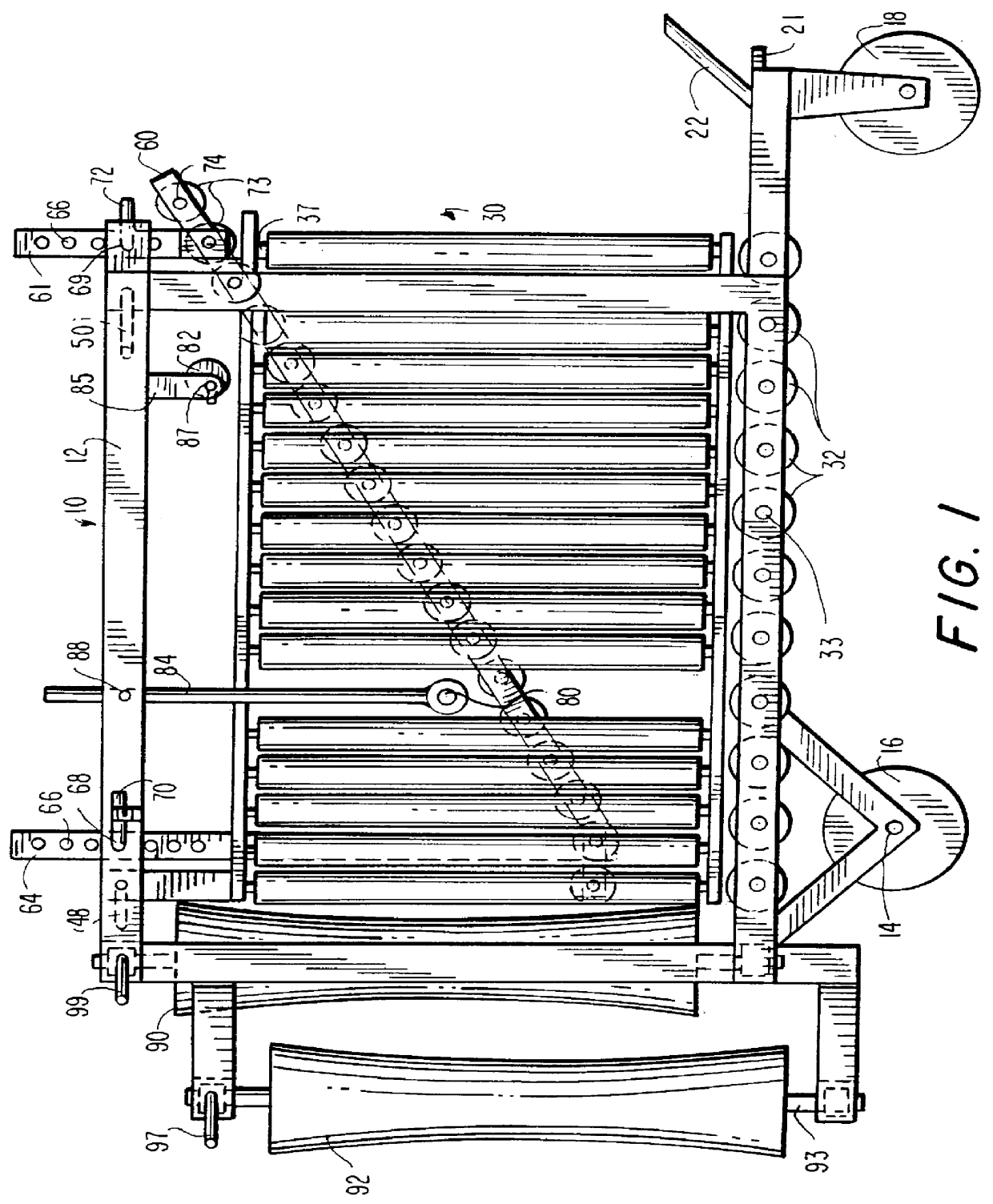

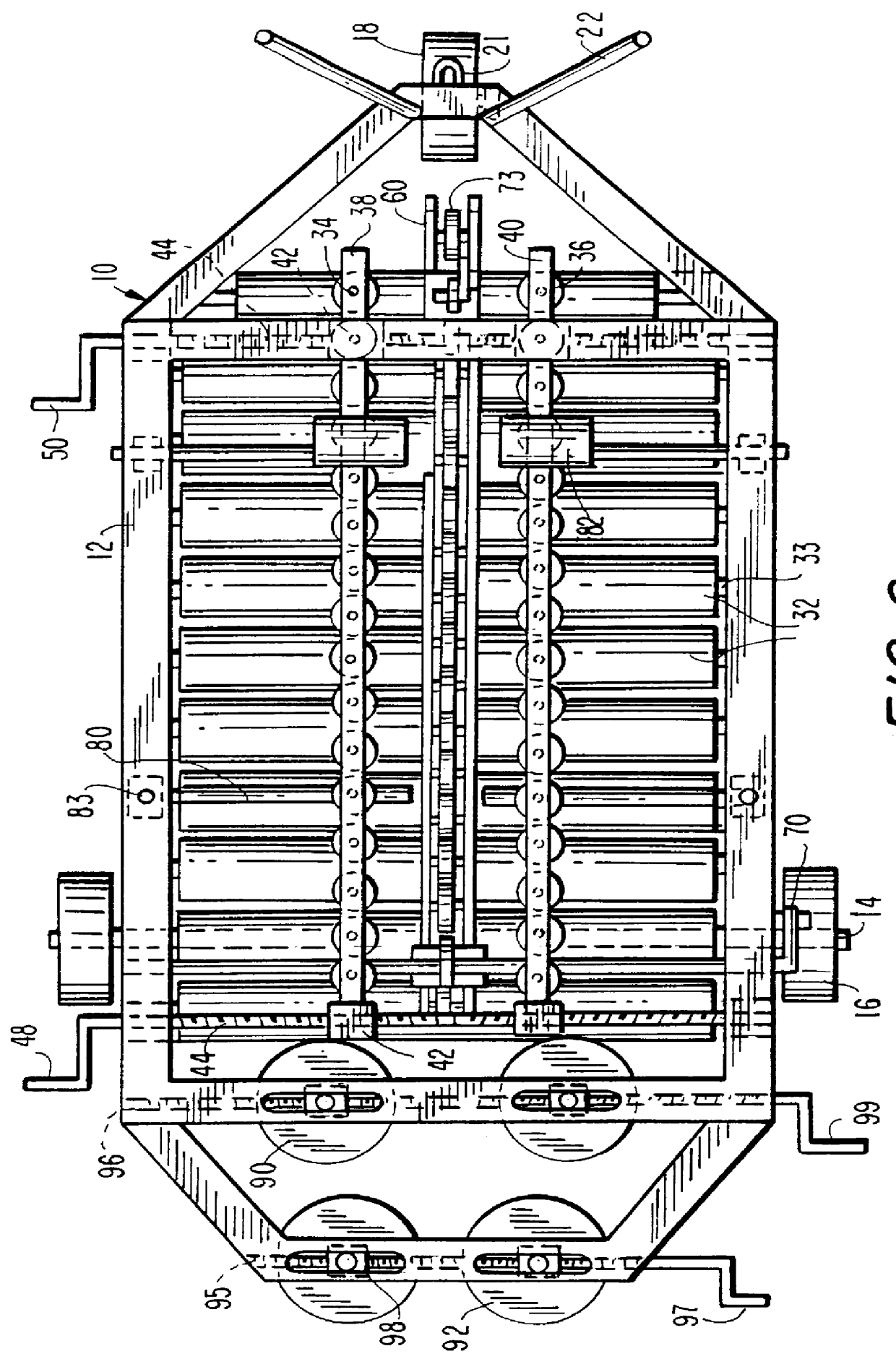

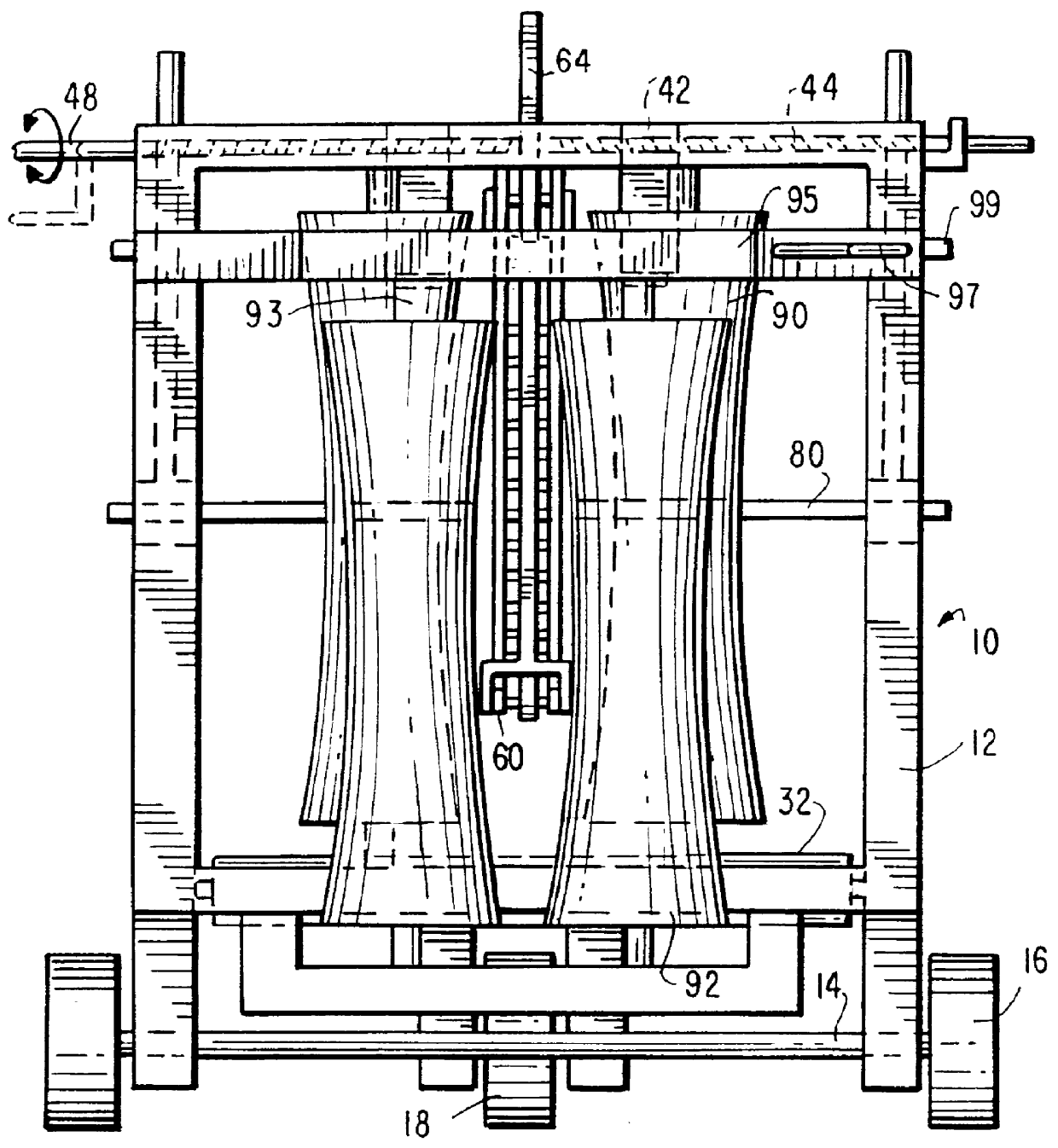

Polymeric pipe deformer and method for relining existing pipelines

InactiveUS6058978AEconomical and efficientReduce the overall diameterHeat exhanger conduitsPipe elementsInternal pressureEngineering

A method and apparatus for relining, repairing or reconstructing existing infrastructure pipeline systems that are new, structurally deficient or experiencing an excessive amount of exfiltration or infiltration, or converting new or damaged pipelines into dual-containment pipelines. A plurality of stock, high density polyethylene lining pipes having a cylindrical cross-section with a diameter up to 36 inches and lengths of 40-50 feet are joined together to a job specific length. The lining pipe is then heated to its flex temperature and gradually deformed to a reduced diameter. At the job site, the deformed lining pipe is inserted into the existing pipe and a controlled, pressurized environment is created therein for a period of time dependent on the pipe's length. Pressurized steam is first inserted to provide heat and internal pressure to expand the pipe. Then, compressed air is inserted to cool the pipe while maintaining the internal pressure to complete the expansion and set the pipe. When converting to dual-containment pipelines, the deformed pipe will have a plurality of spacers attached thereon such that the existing and deformed pipes are axially aligned and have an annular space therebetween.

Owner:CSR PARTIES

Mineral wax composite shape-setting phase-change material and process for preparation

The invention provides a mineral wax composite shape-setting phase-change material and process for preparation, wherein the material comprises 70-80 wt% paraffin wax substance with 44-50 deg. C melting point, 4-15% of cross bond high-density polyethylene, 4-15 wt% of styrene / ethane-butylene / styrene copolymer (SEBS), and 4-6 wt% of expanded graphite.

Owner:BEIJING UNIV OF TECH

Polymer blends from interpolymers of ethylene/.alpha.-olefins and flexible molded articles made therefrom

Owner:DOW GLOBAL TECH LLC

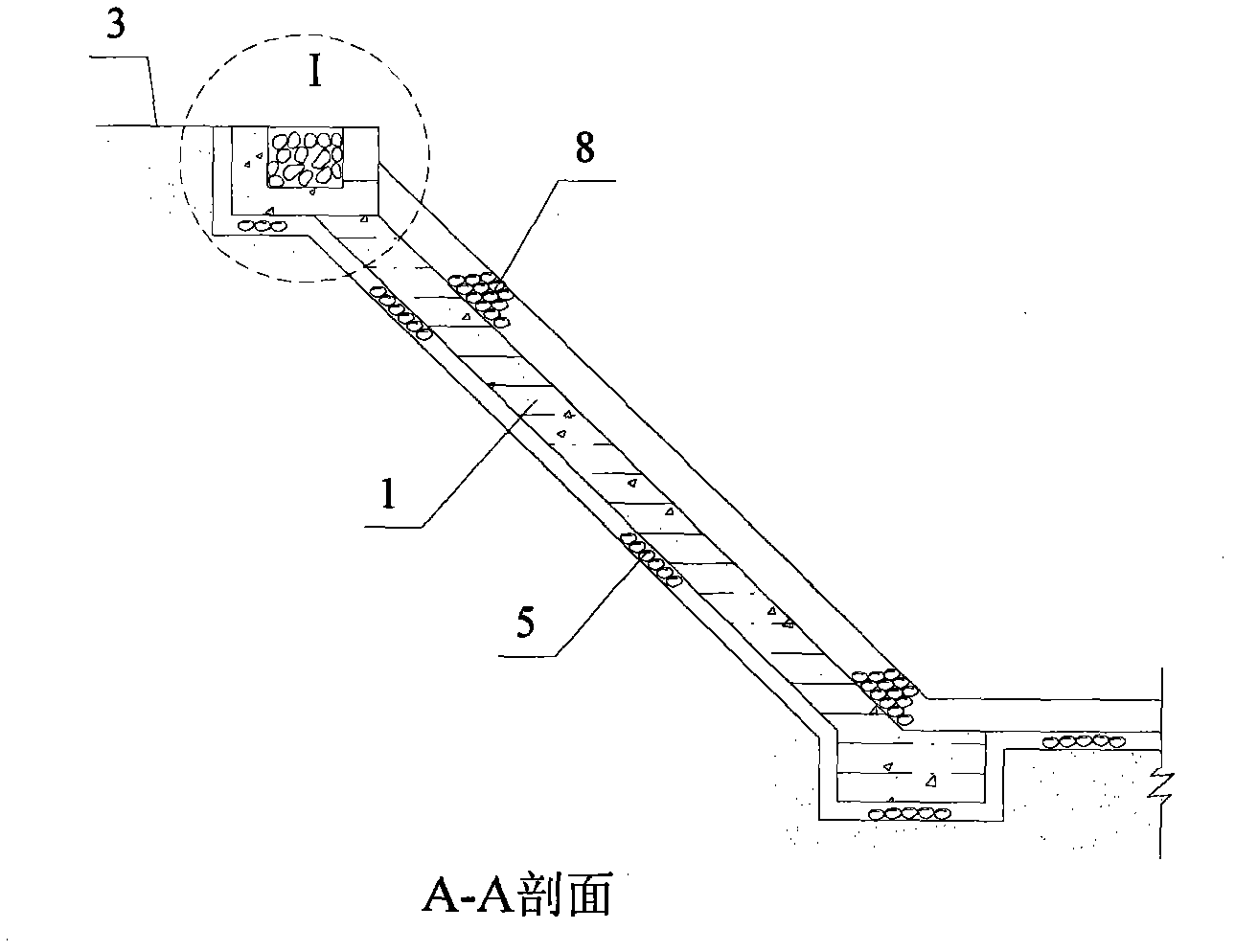

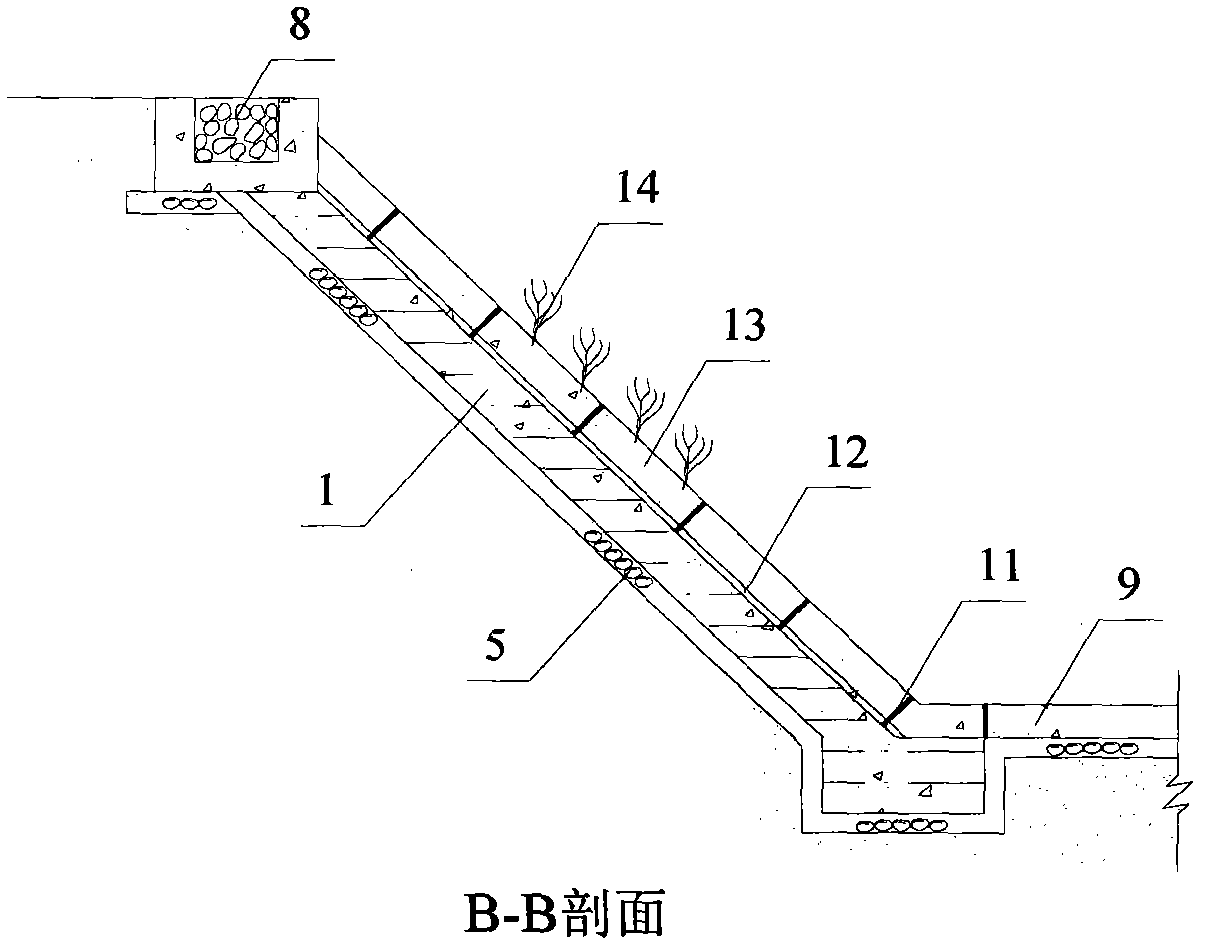

Hard reinforced concrete revetment slope biological repairing method

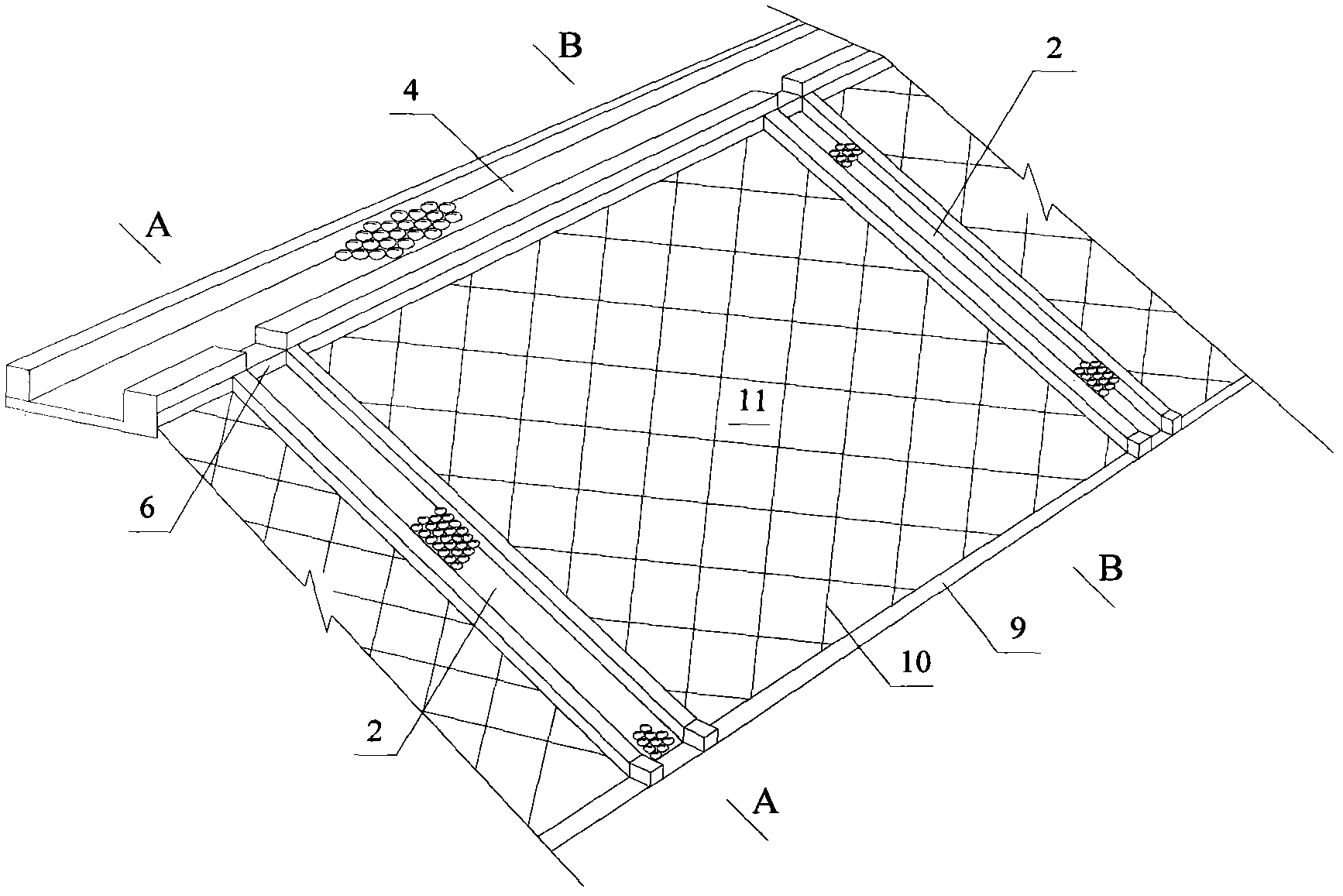

InactiveCN102071697AEffectively fixedPrevent landslidesSoil drainageCoastlines protectionPlant rootsRainfall runoff

The invention discloses a hard reinforced concrete revetment slope biological repairing method, which is characterized by comprising the steps of: roughing a concrete revetment and constructing drainage ditches at set intervals; digging a water collecting tank on one side of the cross of the revetment and a road, reserving an opening at the joint of the drainage ditch and the water collecting tank, and constructing a watertight concrete overflow bank; filling gravels in the water collecting tank and the drainage ditches; and welding earthwork grids by high-density polyethylene stripes on the protection slope, laying gravel cushion coats in the earthwork grids, and finally pouring biological slurry. The method has the advantages that: the whole project is stable and safe; rain flows into the water collecting tank and passes through grave areas, non-watertight sand-free concrete, a slope cushion coat, plant roots and the like to seep into rivers, so water quality is improved to a relatively large extent; when rainfall runoff is overlarge, the rain overflows from the overflow bank and passes through the graves of the drainage ditches, so the water quality is also purified to a certain extent, meanwhile the slope is protected; the biological slurry poured onto the slope is prepared from biological materials, and has certain anti-erosion strength and can be used as a substrate for plant growth, so the cost is low and the operation is simple.

Owner:HOHAI UNIV

Polyethylene pipes

A pipe composition comprising, in one embodiment, from 80 to 99 wt % of a high density polyethylene by weight of the composition and from 1 to 20 wt % of a filler by weight of the composition; the polyethylene having a density of from 0.940 to 0.980 g / cm3, and an 121 of from 2 to 18 dg / min; characterized in that the pipe composition extrudes at an advantageously low melt temperature and at an advantageously high specific throughput. Also provided is a method of forming a pipe comprising in embodiment providing a filler composition comprising from 5 to 50 wt % of a filler and from 95 to 50 wt % of a low density polyethylene and from 0 to 3 wt % of one or more stabilizers; then melt blending the filler composition and a high density polyethylene having a density of from 0.940 to 0.980 g / cm3, and an I21 of from 2 to 18 dg / min to a target drop temperature of from 16° C. to 185° C. to form a pipe composition, melt blending such that the pipe composition comprises from 1 to 20 wt % of the filler by weight of the pipe composition; and extruding the pipe composition to form a pipe.

Owner:UNIVATION TECH LLC

Multilayer barrier film

InactiveUS20090029182A1Increase WVTR performanceExcellent WVTR performanceSynthetic resin layered productsDomestic containersHigh densityWater vapor

Multilayer “barrier” films which have excellent Water Vapor Transmission Rate (WVTR) performance are prepared using a core layer which comprises a blend of two different high density polyethylenes (HDPEs) and a nucleating agent. The films are suitable for the preparation of packages for dry foods such as crackers and breakfast cereals.

Owner:NOVA CHEM (INT) SA

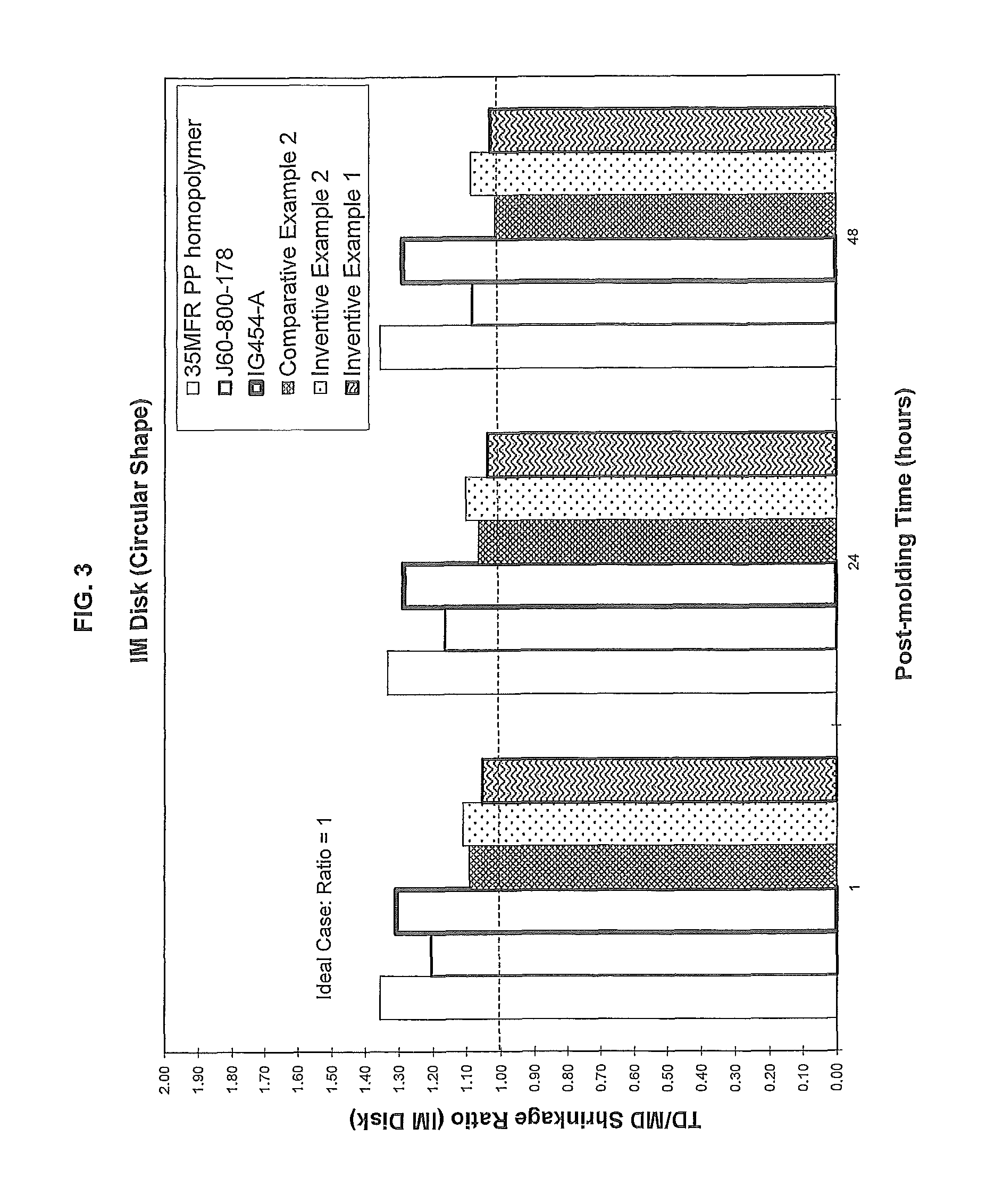

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

External insulated finish system with high density polystyrene layer

An External Insulated And Fixed System (EIFS) and method for making the same. The method provides a cost effective procedure for constructing an EIFS that can meet current hurricane high impact test protocol, especially for non-combustible EIFS “Systems”. A reinforcing high impact layer of fiber glass mesh is eliminated, and a high-density compression molded expandable polystyrene board is provided that yields significantly improved impact resistance.

Owner:FUTURE FOAM TECH A WASHINGTON LIABILITY

Odor control cassette

InactiveUS7073311B2Reduce odorInexpensive and easy to manufactureLayered productsCharge supportsHigh densityMagnetic tape

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:WELLS FARGO BANK NAT ASSOC

Special material for antistatic impact fire resistant polyethylene pipe

InactiveCN1657561AImprove antistatic performanceMeet the use requirementsTubular articlesPolymer scienceAntistatic agent

An antistatic, anti-impact and flame-retarded polyethene used for pipeline is proportionally prepared from high-density polyethene, antistatic agent, flame retarder, flame-retarded synergist, toughening agent, optical stabilizer and antioxidizing agent through mixing part of polyethene with others, extruding out to become particles, mixing with rest of polyethene, dual-screw extruding out, cooling, drying and cutting to become particles.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com