Patents

Literature

3175 results about "Relative density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

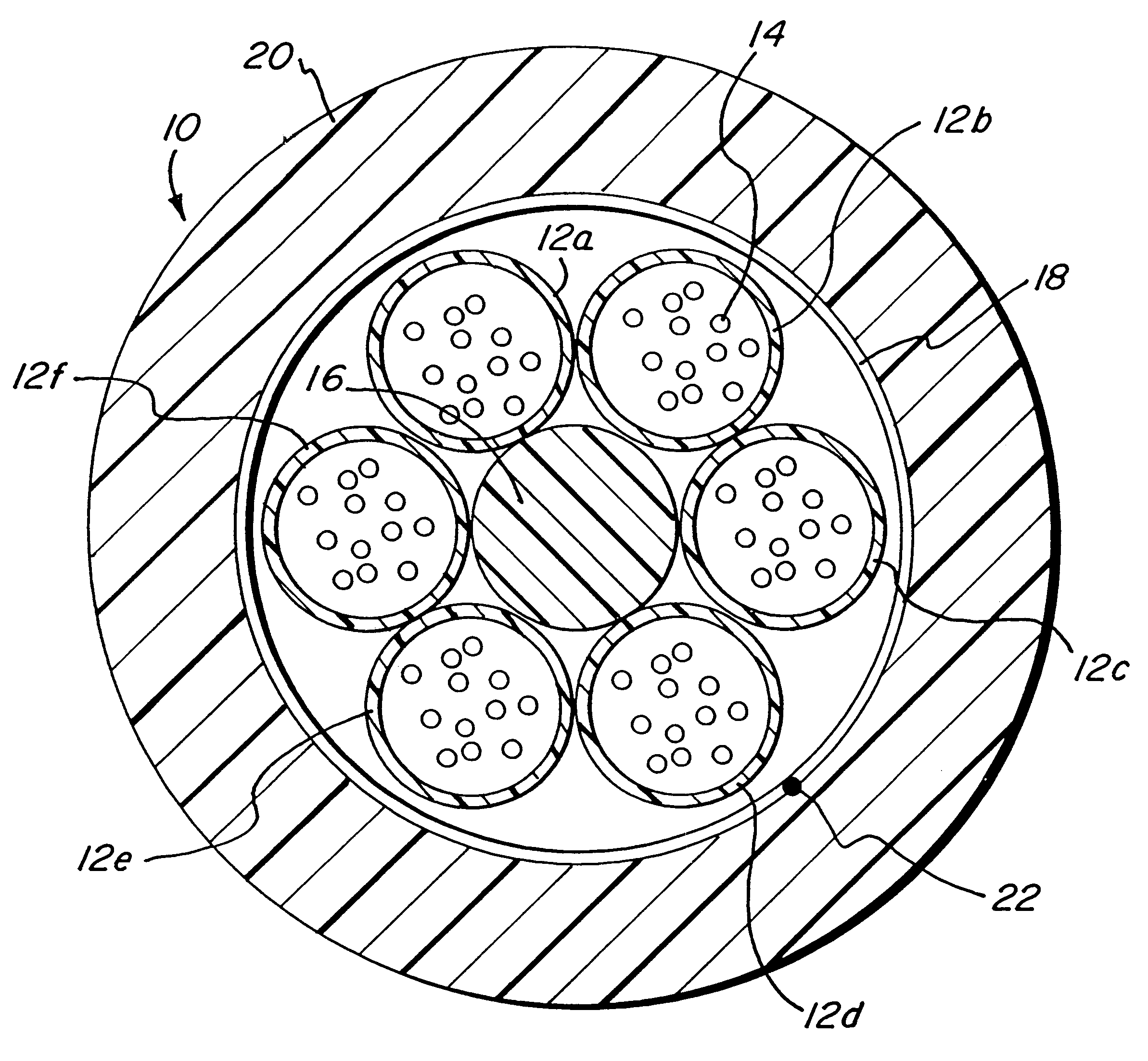

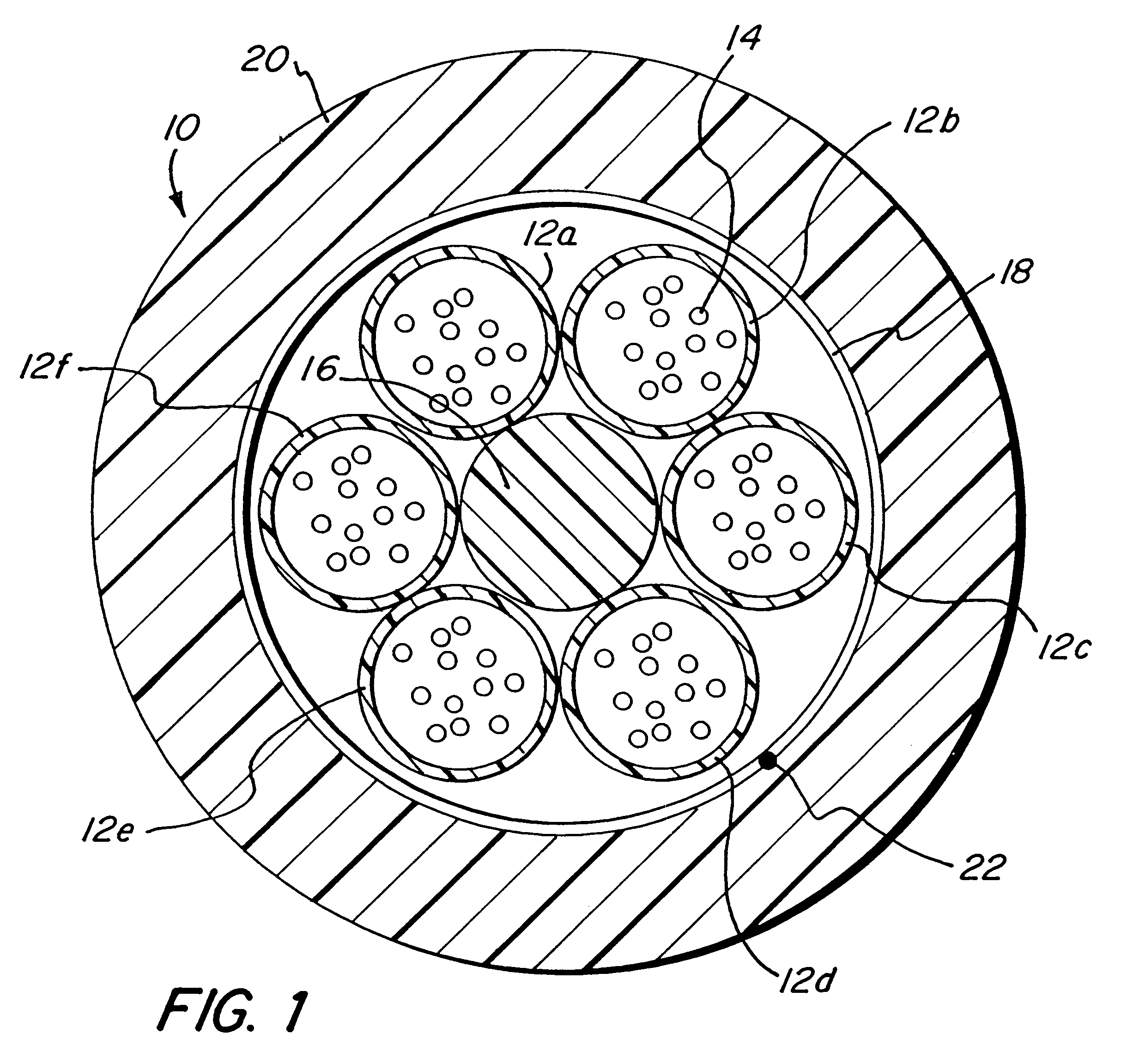

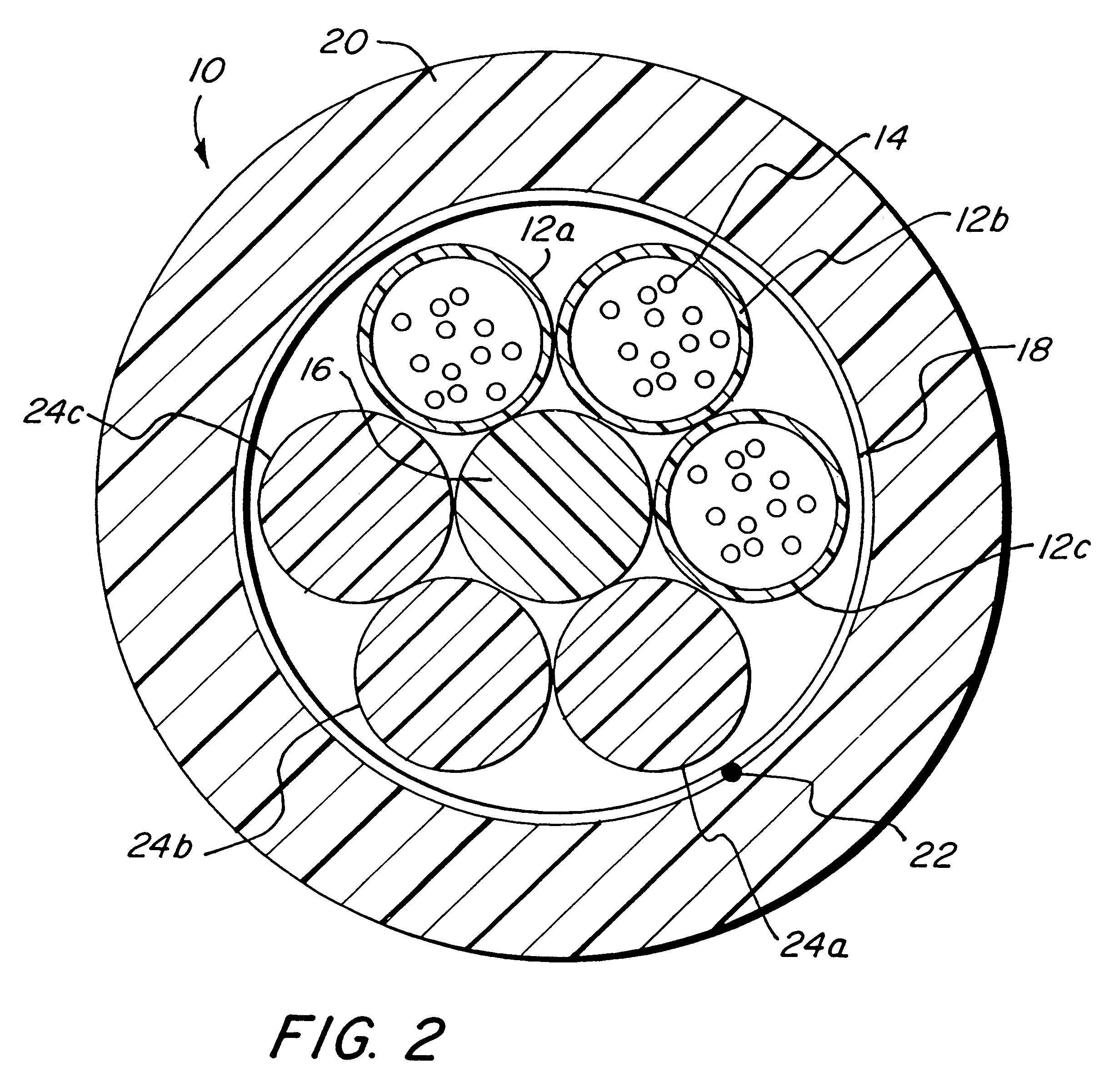

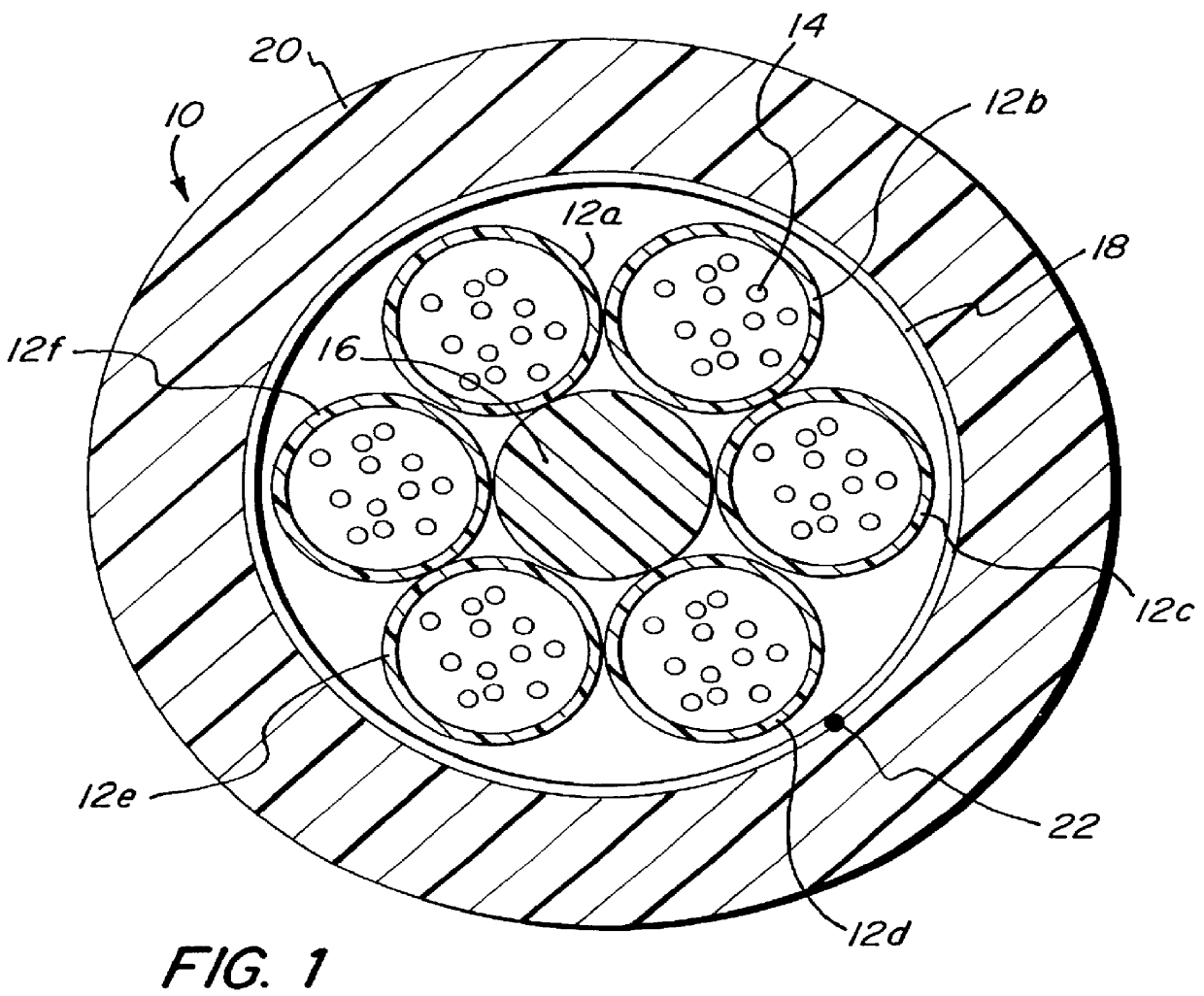

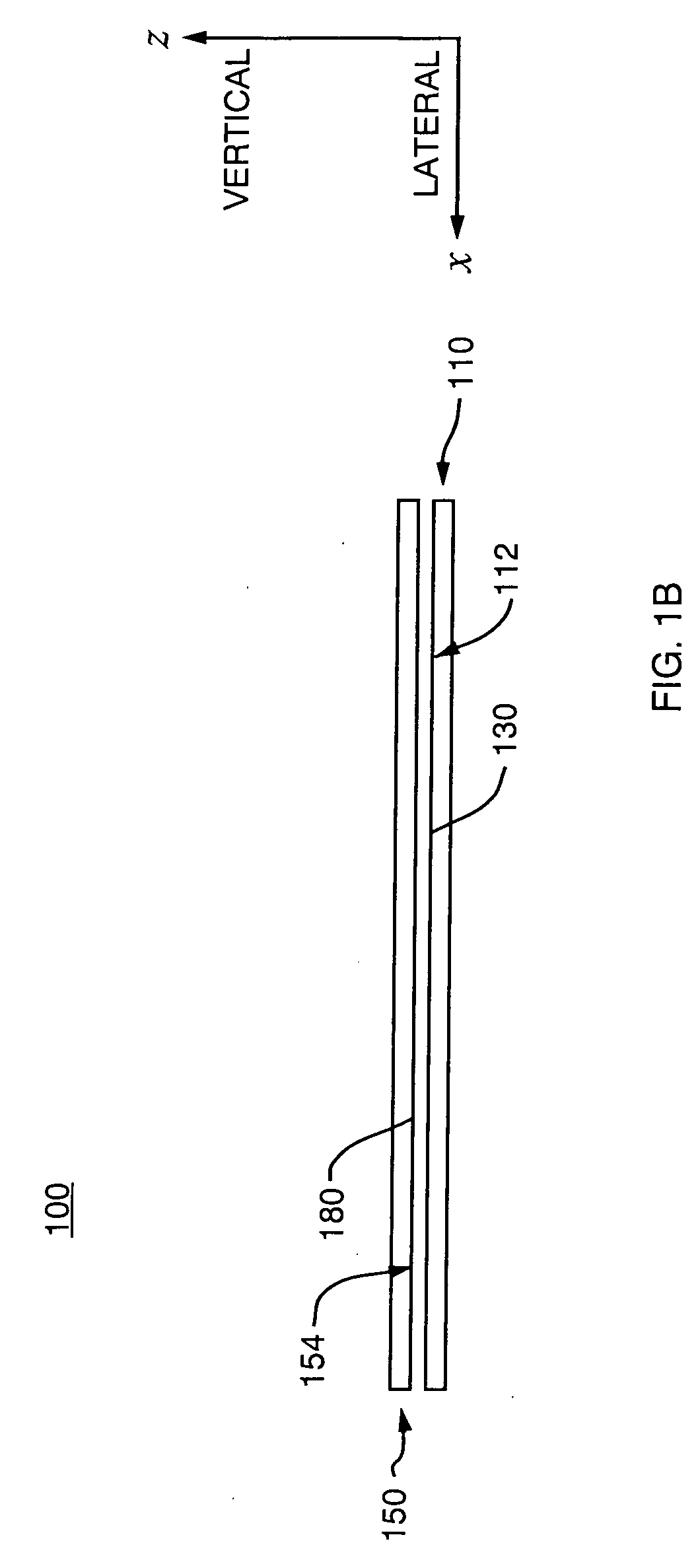

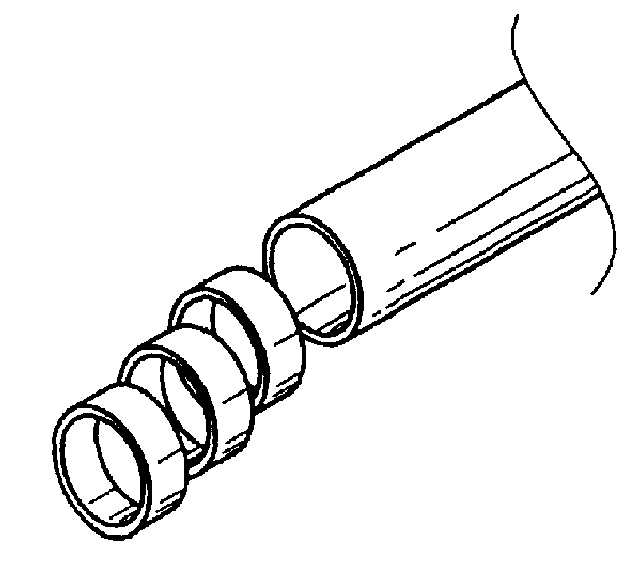

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

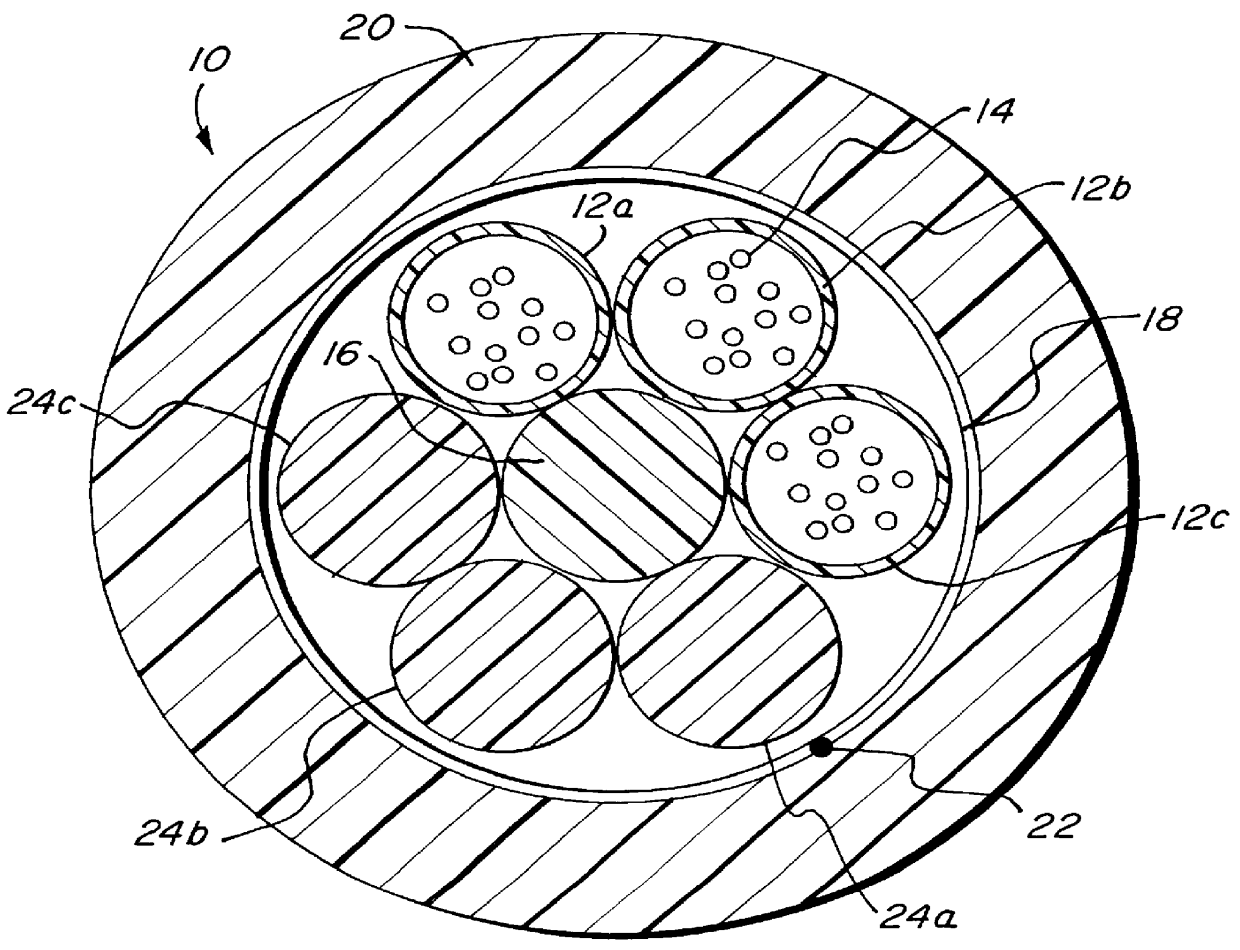

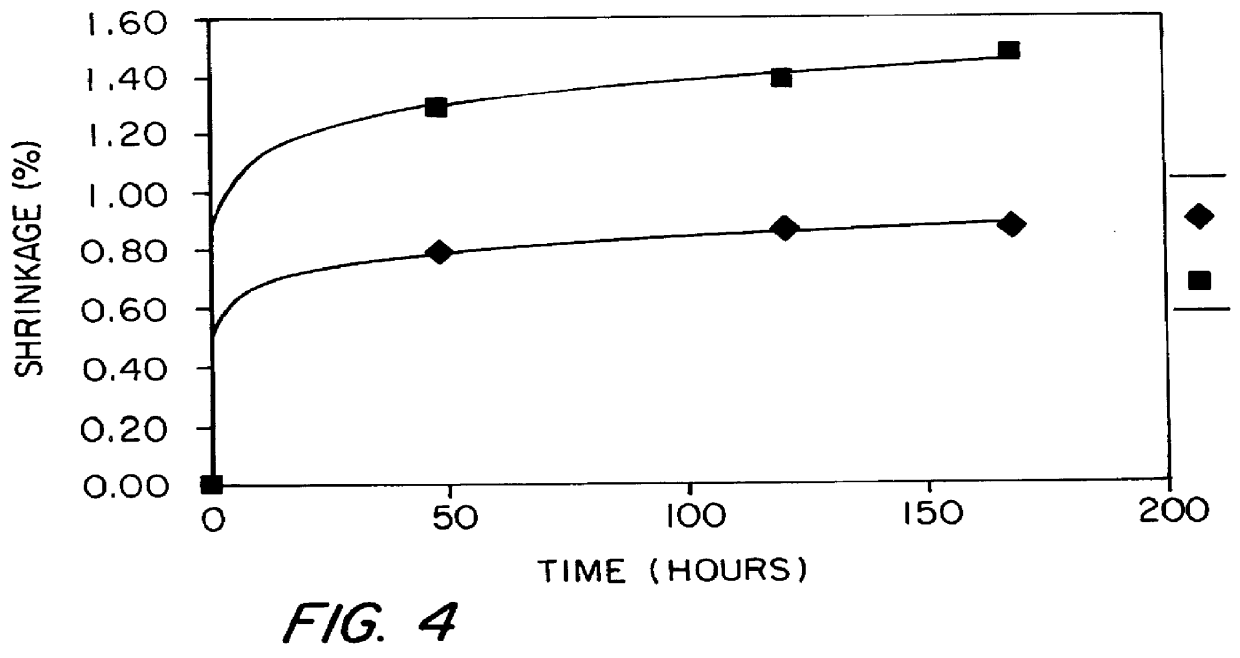

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

Polypropylene filler rods for optical fiber communications cables

InactiveUS6066397ACladded optical fibreFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

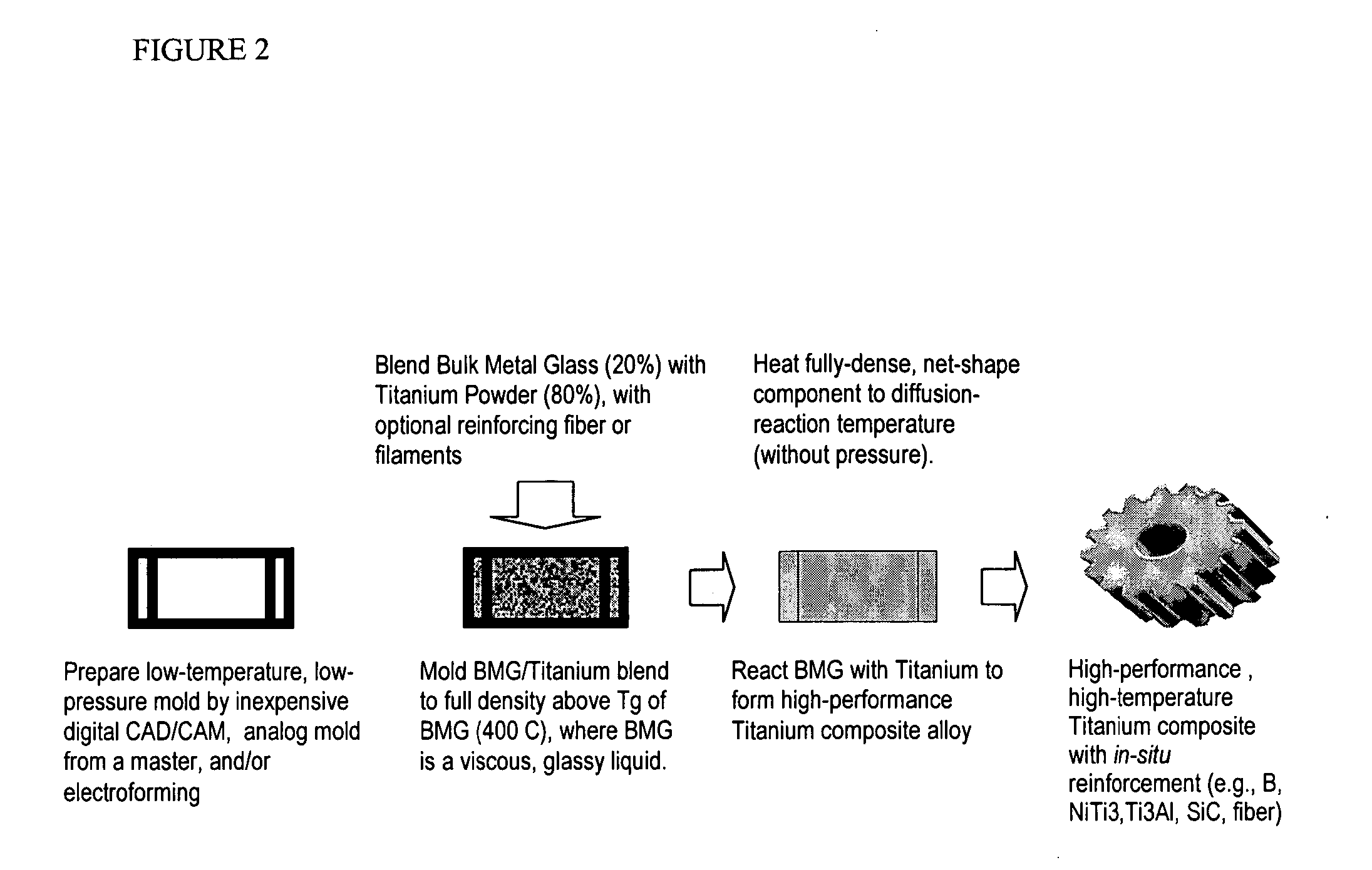

Titanium group powder metallurgy

InactiveUS20050084407A1Excellent cold formabilityImprove hardenabilityVitrificationVolumetric Mass Density

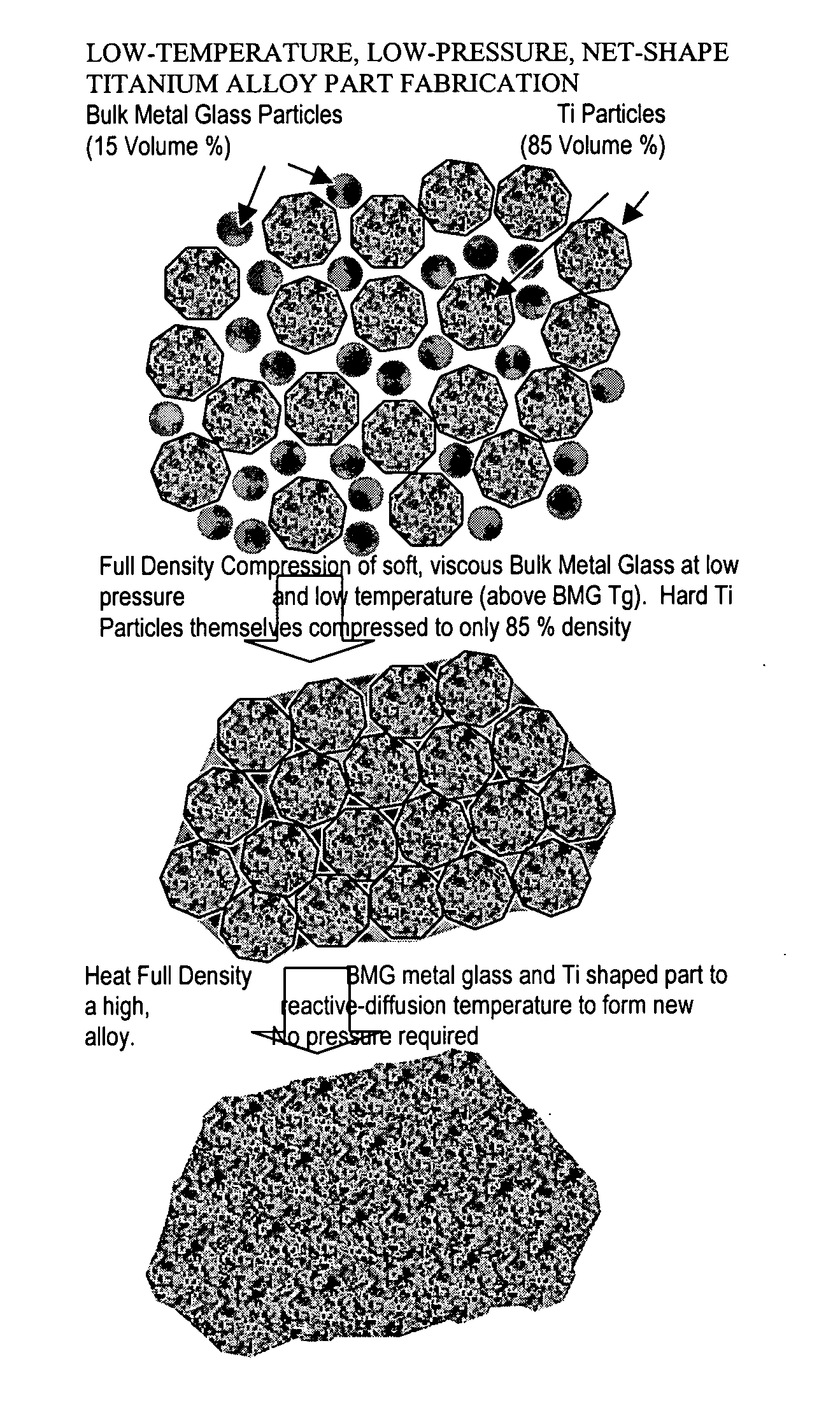

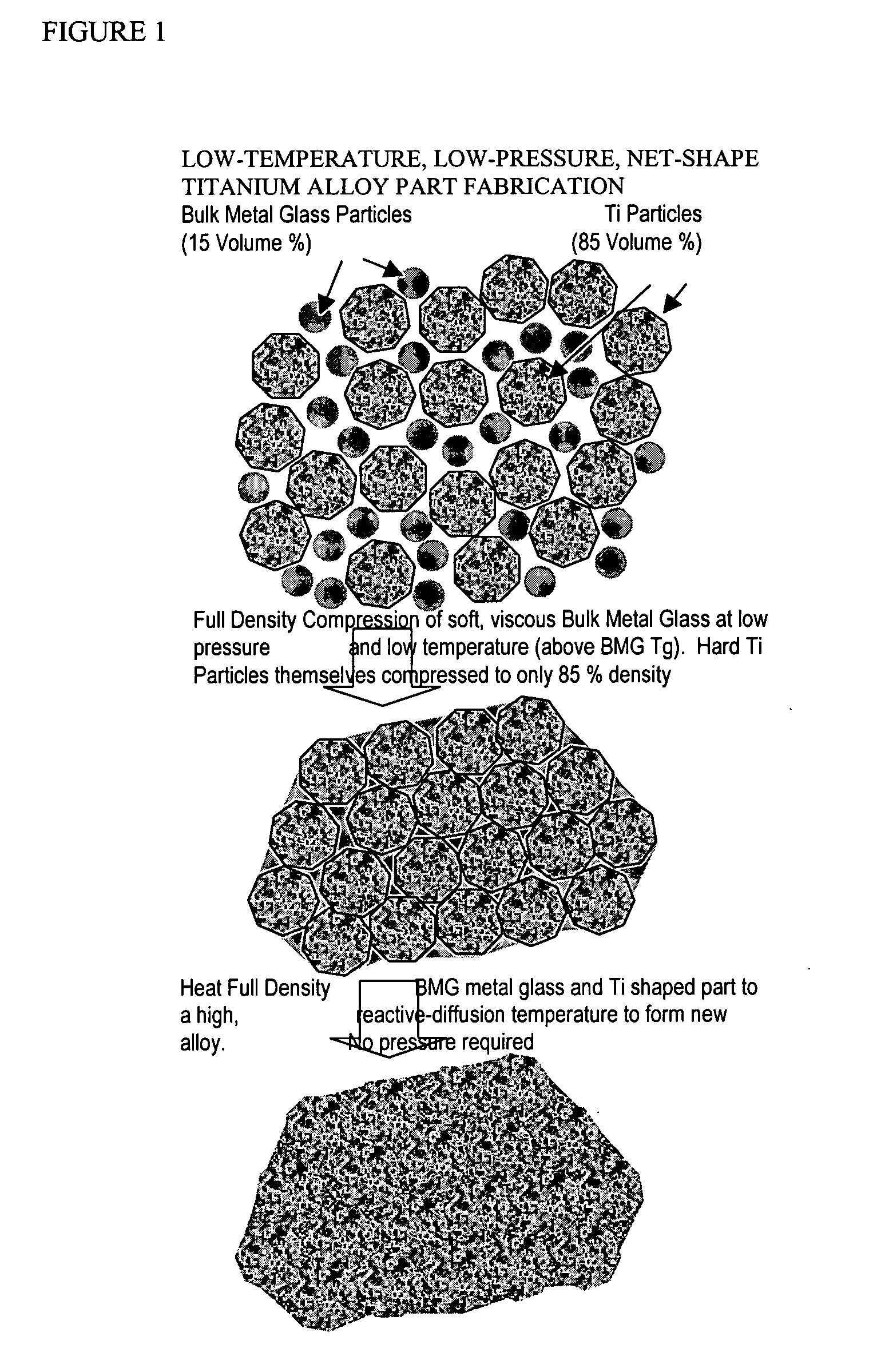

Methods and compositions relating to powder metallurgy in which an amorphous-titanium-based metal glass alloy is compressed above its glass transition temperature Tg with a titanium alloy powder which is a solid at the compression temperature, to produce a compact with a relative density of at least 98%.

Owner:MYRICK JAMES J

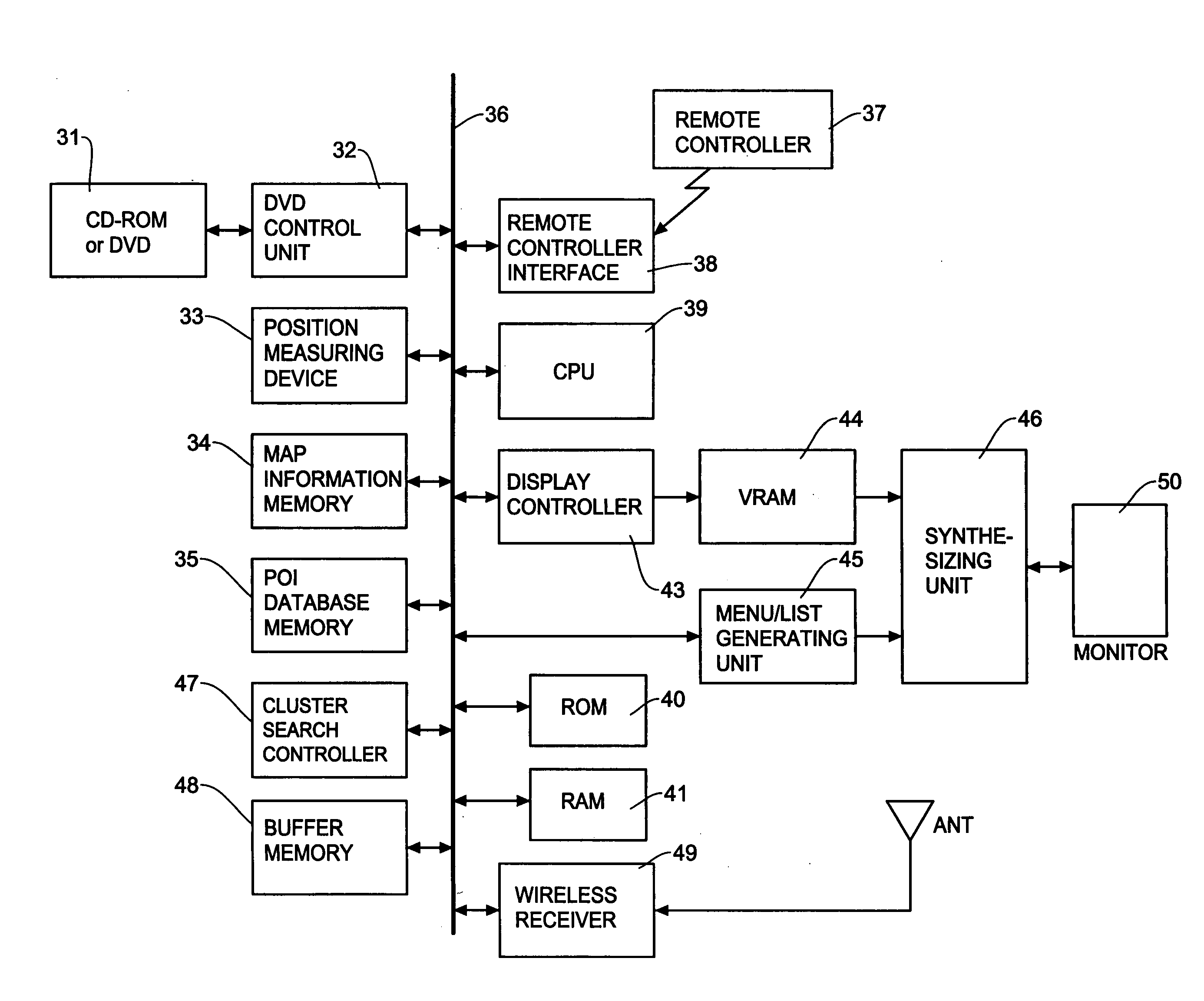

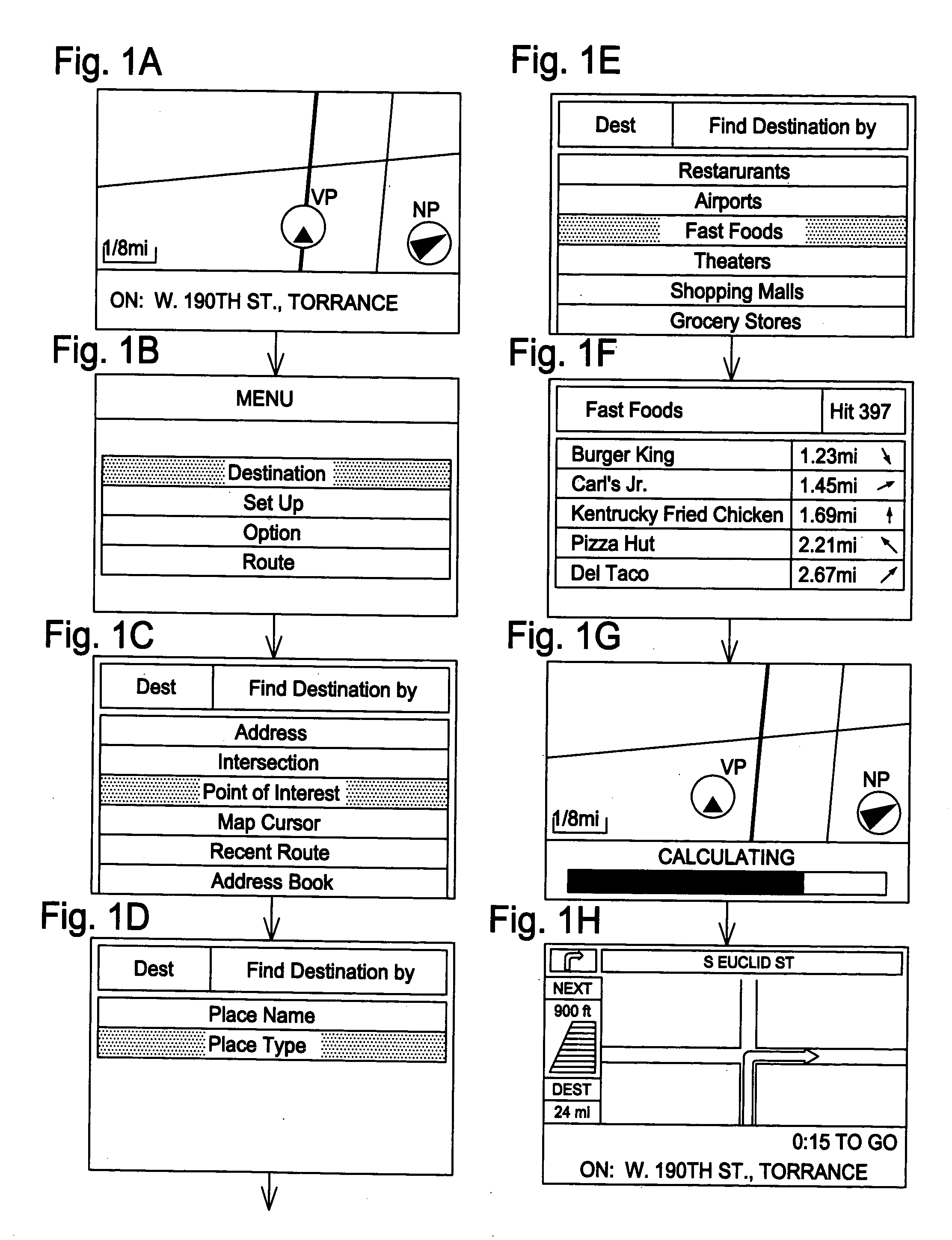

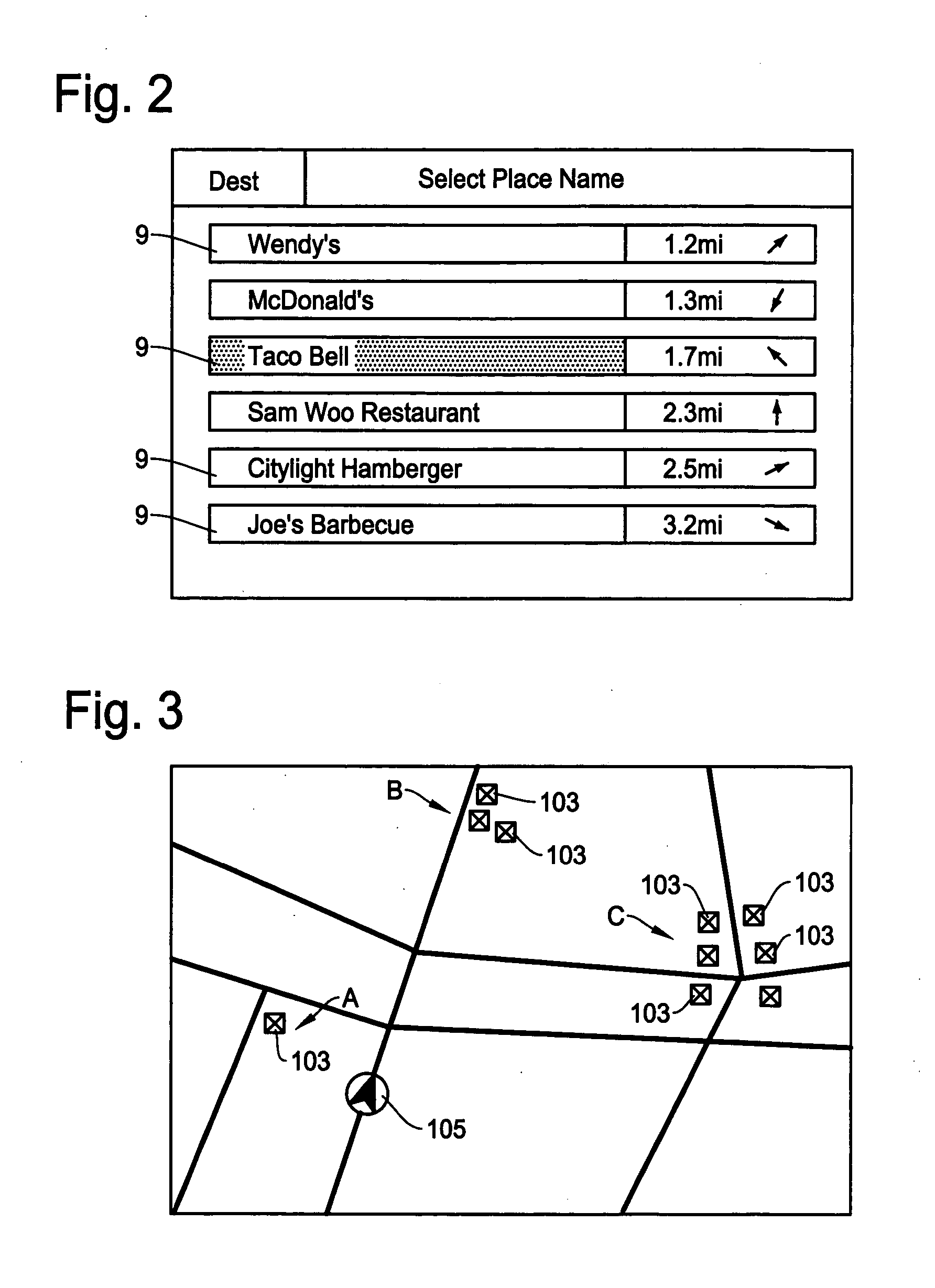

Display method and apparatus for navigation system for performing cluster search of objects

ActiveUS20050177303A1Wide choiceInstruments for road network navigationRoad vehicles traffic controlDistribution matrixNavigation system

A method and apparatus for a navigation system conducts a data search for finding relative density of objects such as points of interest in a specified area and displays the result of the search in various manners. The display method includes the steps of: defining a size and shape of a search template; scanning the search template on the search area by displacing its position by a predetermined increment; counting and recording a number of objects on the search area within the search template at every increment of the displacement position, thereby creating an object distribution matrix; applying a cluster search algorithm to the object distribution matrix, thereby detecting distribution of clusters of the objects; and displaying the clusters of the objects in the search area.

Owner:ALPINE ELECTRONICS INC

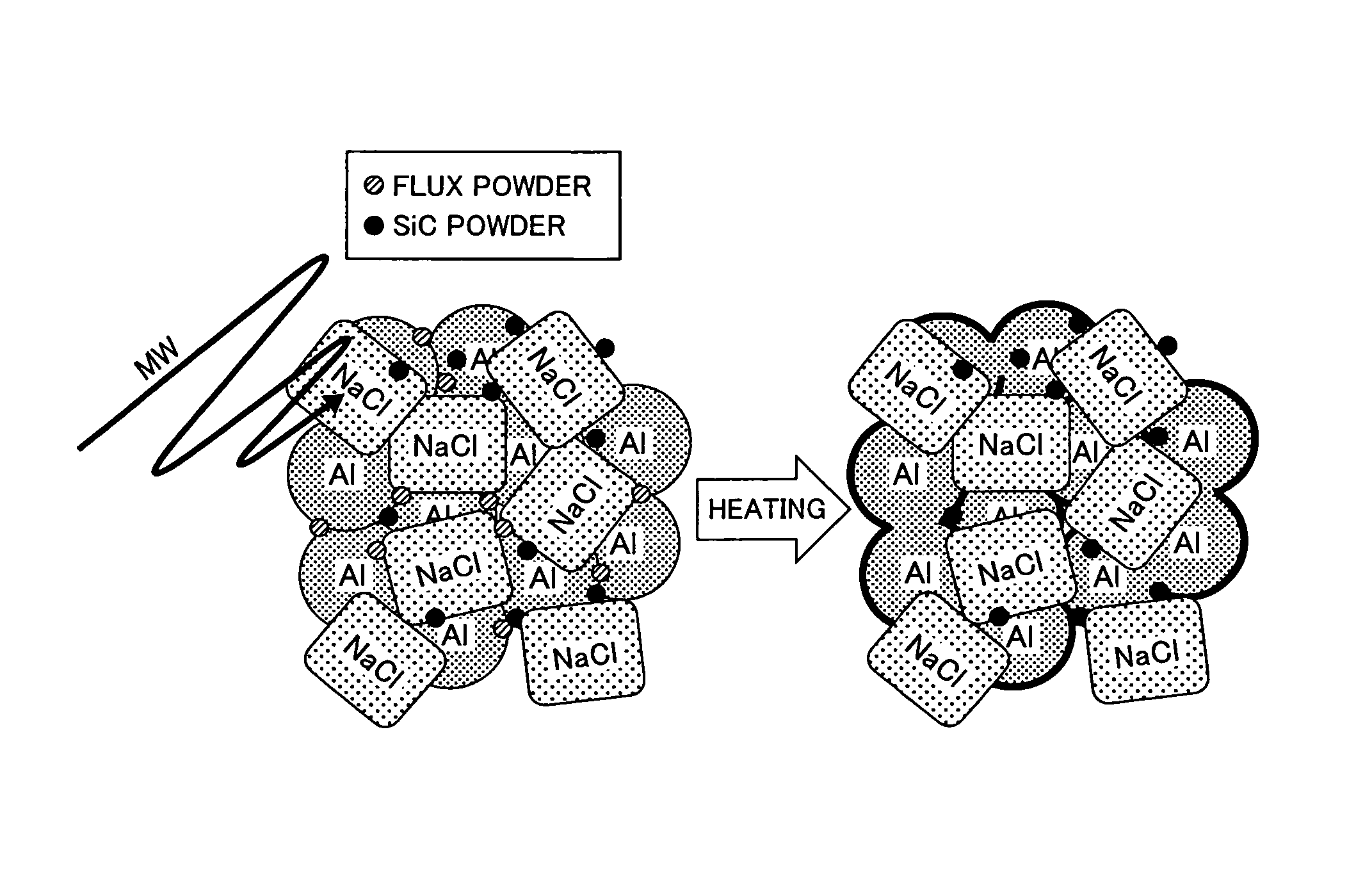

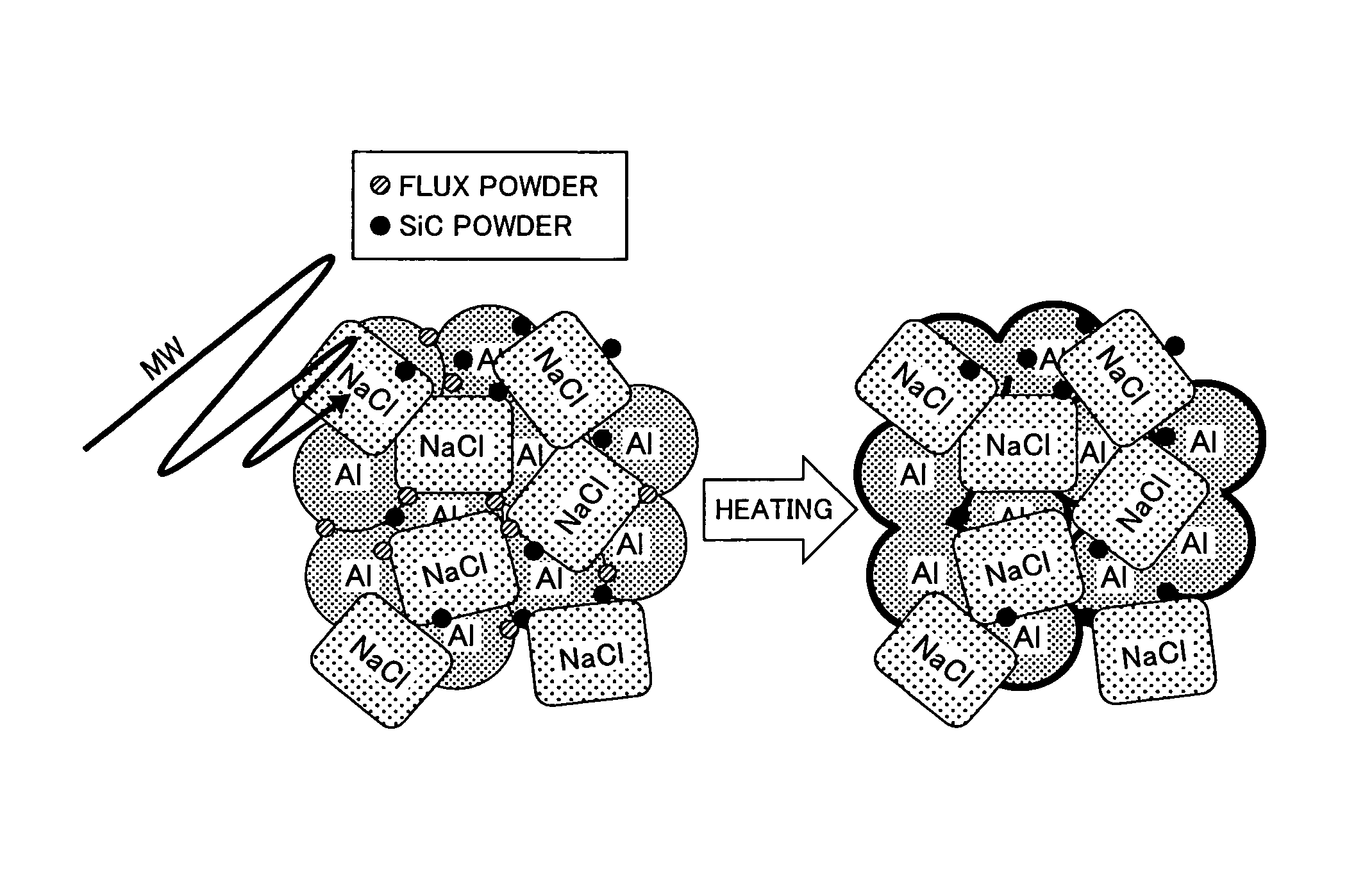

Aluminum porous body and fabrication method of same

It is an objective of the present invention to provide an aluminum porous body which is formed of a pure aluminum and / or aluminum alloy base material and has excellent sinterability and high dimensional accuracy without employing metal stamping. There is provided an aluminum porous body having a relative density of from 5 to 80% with respect to the theoretical density of pure aluminum, in which the aluminum porous body contains 50 mass % or more of aluminum (Al) and from 0.001 to 5 mass % of at least one selected from chlorine (Cl), sodium (Na), potassium (K), fluorine (F), and barium (Ba). It is preferred that the aluminum porous body further contains from 0.1 to 20 mass % of at least one selected from carbon (C), silicon carbide (SiC), iron (II) oxide (FeO), iron (III) oxide (Fe2O3), and iron (II,III) oxide (Fe3O4).

Owner:HITACHI LTD

Raw material carbon composition for carbon material for electrode in electric double layer capacitor

ActiveUS7582902B2Improve the level ofGood reproducibilityTransistorCarbon compoundsMetallurgyHydrogen content

Owner:NIPPON OIL CORP

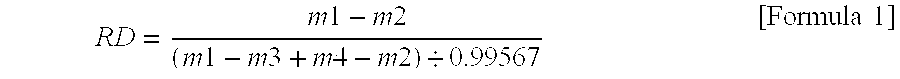

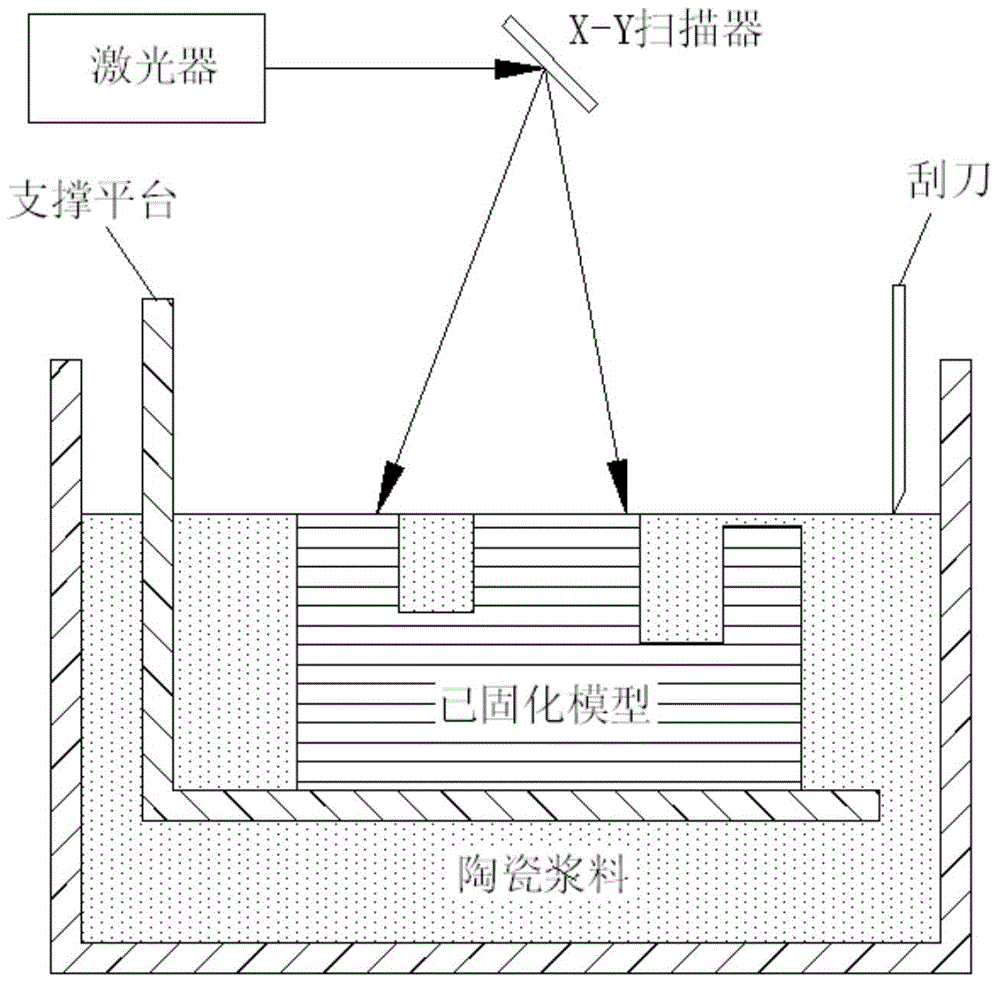

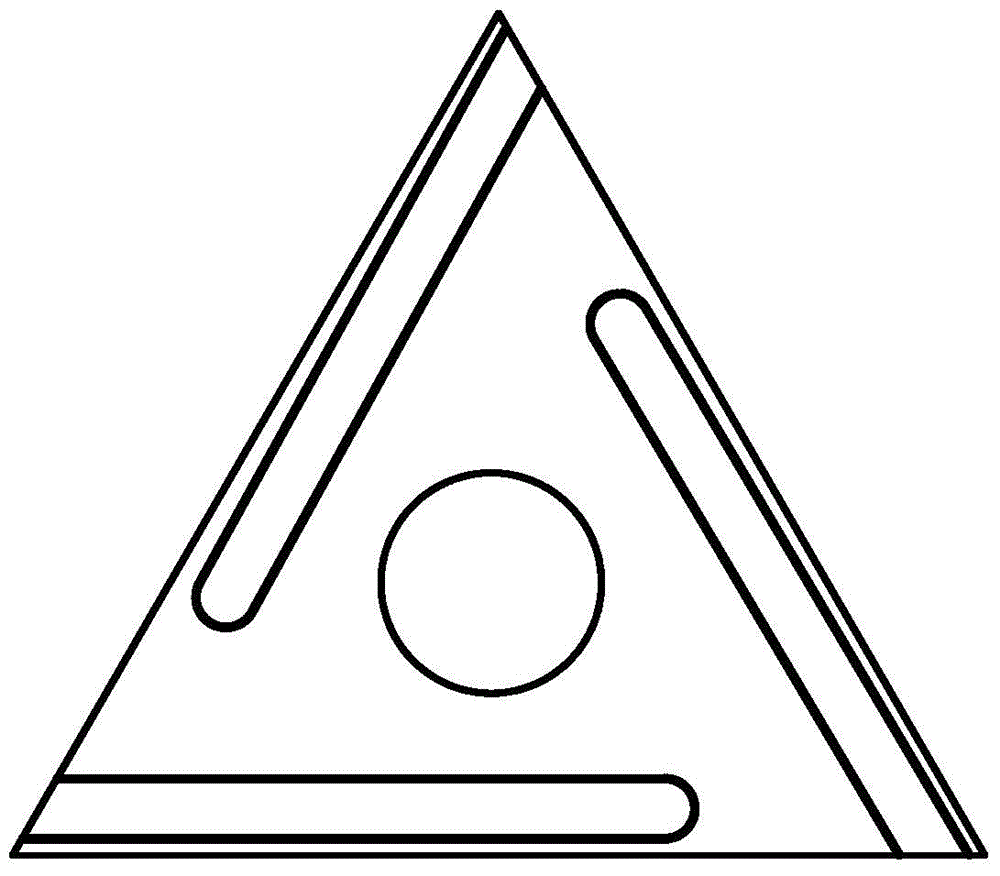

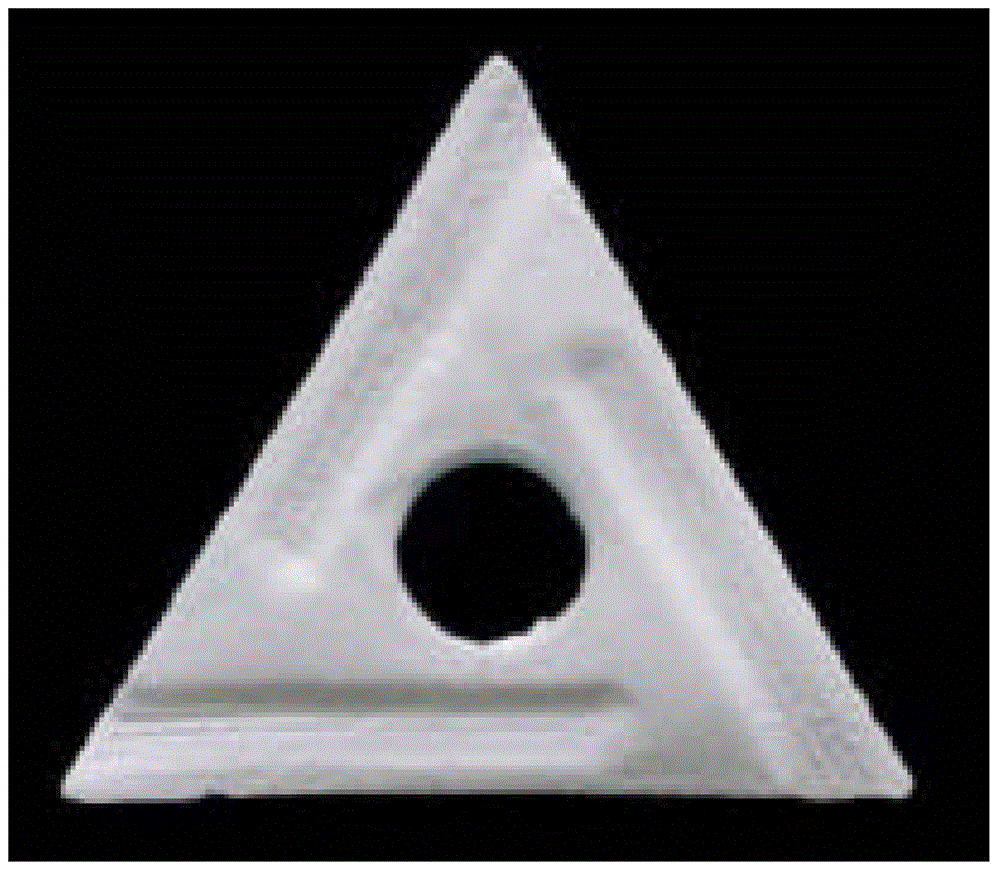

Method for preparing photocuring-formed high-density ceramic

The invention relates to the technical field of ceramic preparation, in particular to a method for preparing photocuring-formed high-density ceramic. According to the method, by optimizing the components and matching of slurry, the slurry is suitable for 3D printing preparation of a high-density ceramic special-shaped piece green body which is complex in structure, and no corresponding mold needs to be especially manufactured. Moreover, when the solid content of the slurry is lower than 40 vol%, the slurry can still be used for manufacturing the high-density ceramic green body, and the relative density of high-density ceramic which is manufactured ultimately can reach up to 99%. The green body is dried in a liquid state drying mode, and thus the method is suitable for manufacturing the high-density ceramic green body which is complex and precise in structure. The two-step degreasing method of vacuum / atmosphere protection latex flow and air latex flow is adopted in the method for conducting latex flow, and therefore the defects of deformation, cracking, blistering and the like of the green body can be reduced. The relative density of the high-density ceramic which is prepared through the method is above 90%, the Vickers hardness is above 12 GPa, and the content of residual carbon is smaller than 0.5 wt%.

Owner:GUANGDONG UNIV OF TECH

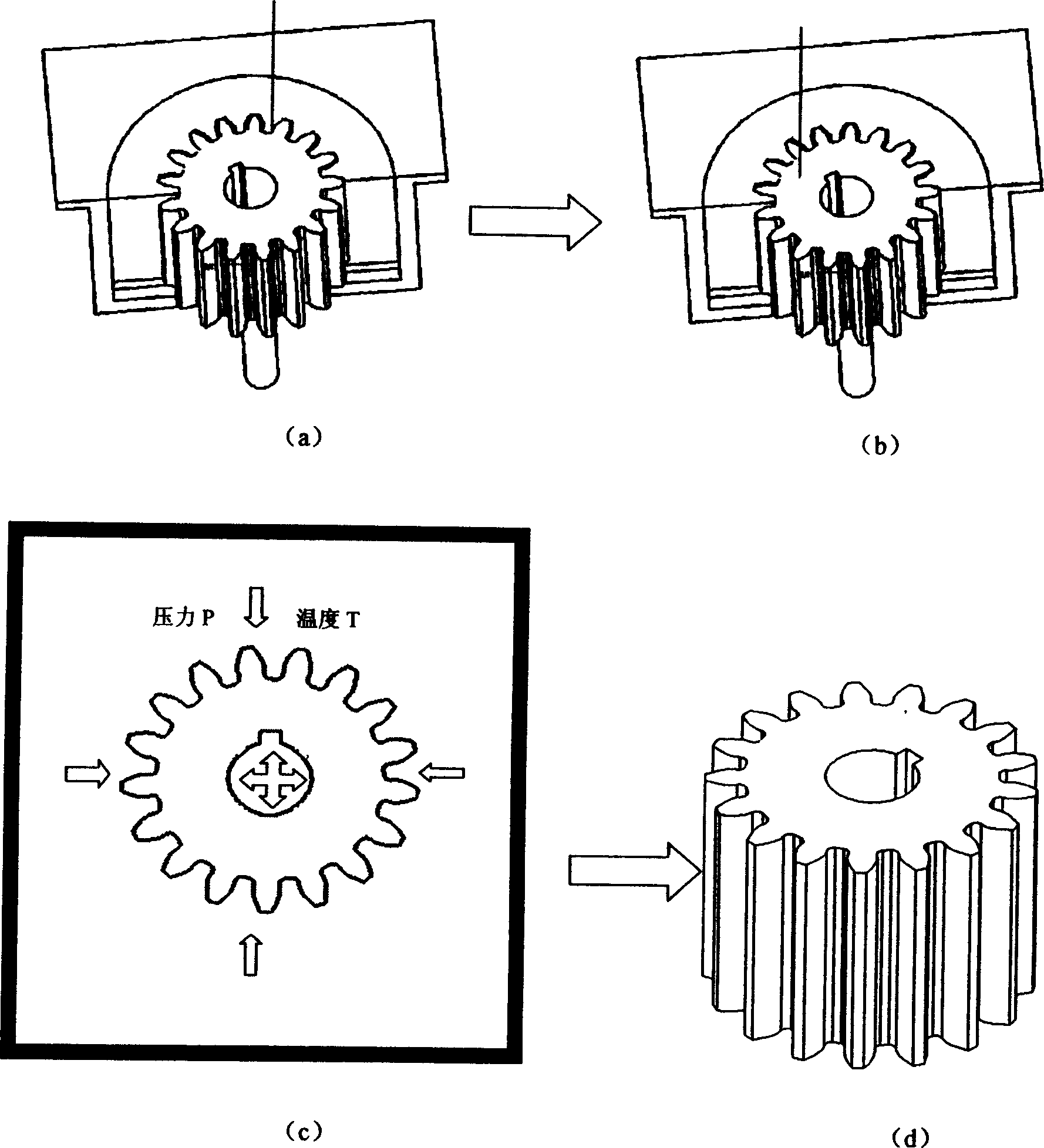

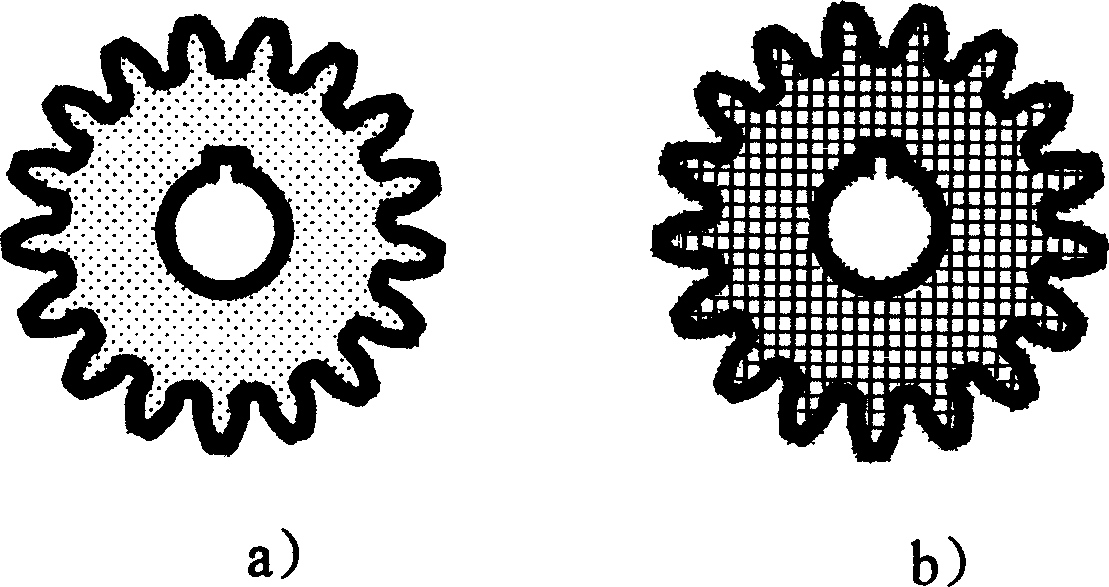

Method for near-purification formation of parts

InactiveCN1861296AEnsure existenceAvoid pollutionIncreasing energy efficiencySelective laser meltingSelective laser sintering

A technology for manufacturing a part by proximal forming method includes such steps as inputting the 3D model of a part to a fast SLM or SLS machine, vacuumizing the shaping chamber of SLM or SLS machine, using laser to scan the metal powder outside the boundary for smelting it, scan the metal powder inside the boundary to form mesh structure, forming a compact shell sealed part, and HIP processing.

Owner:HUAZHONG UNIV OF SCI & TECH

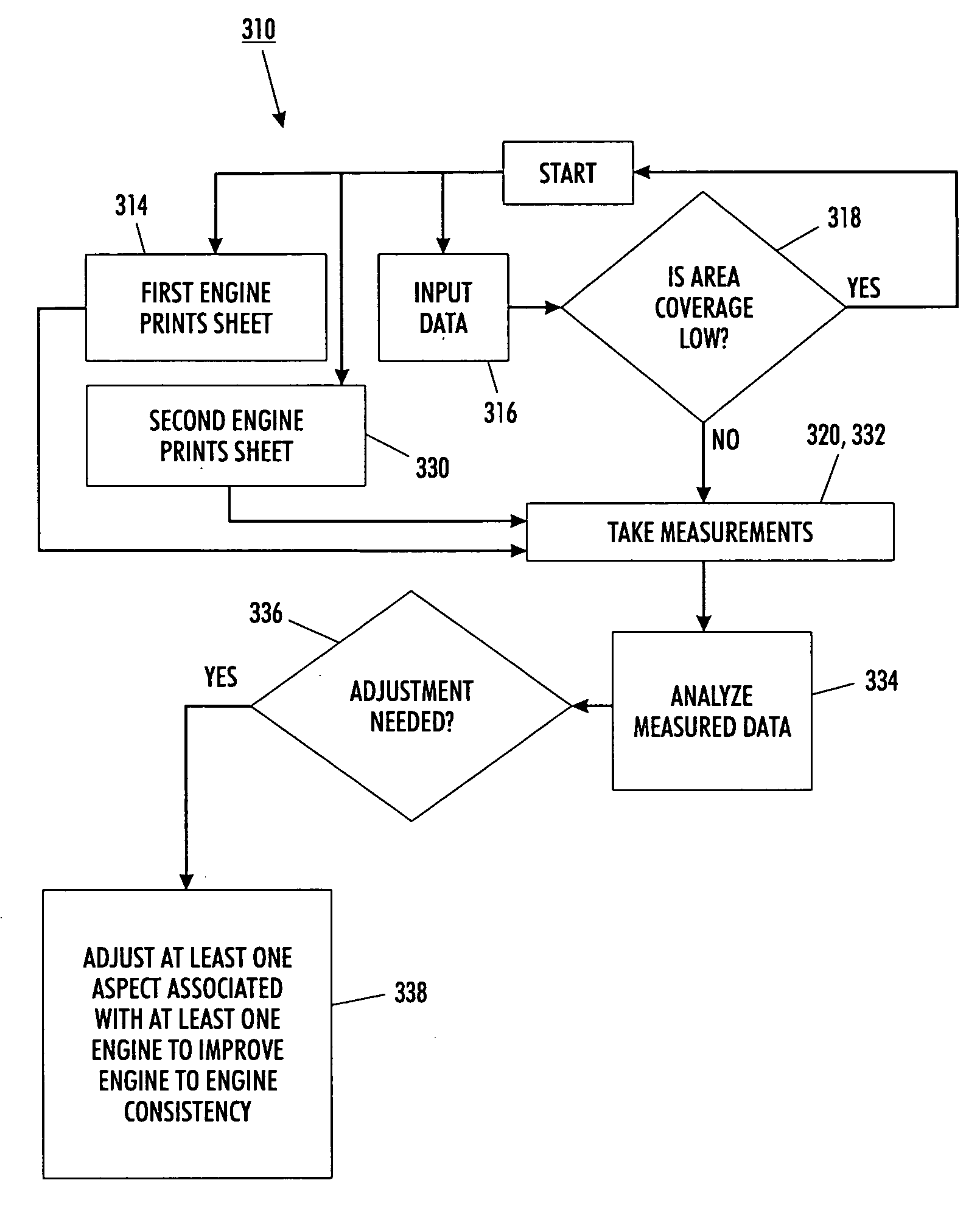

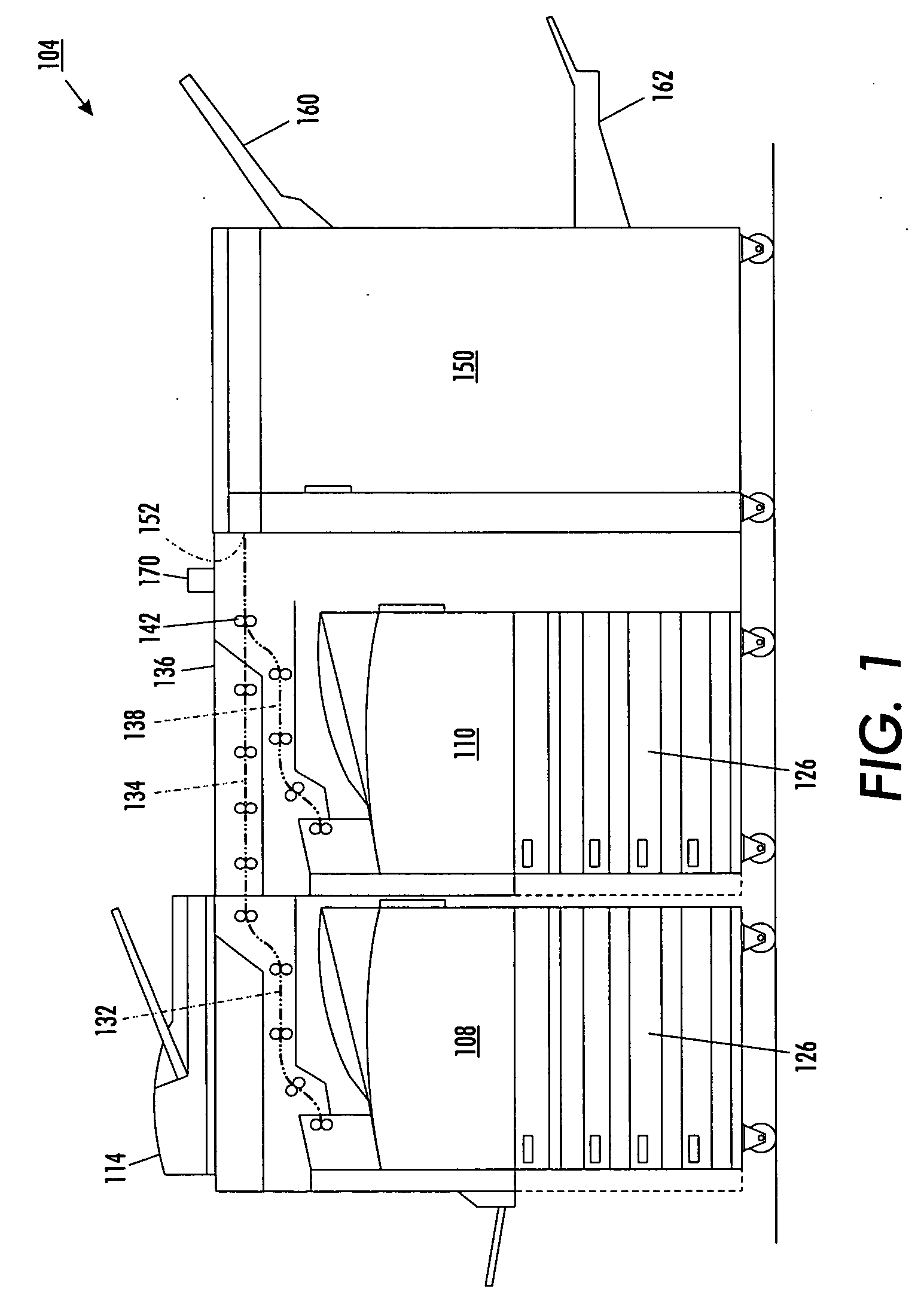

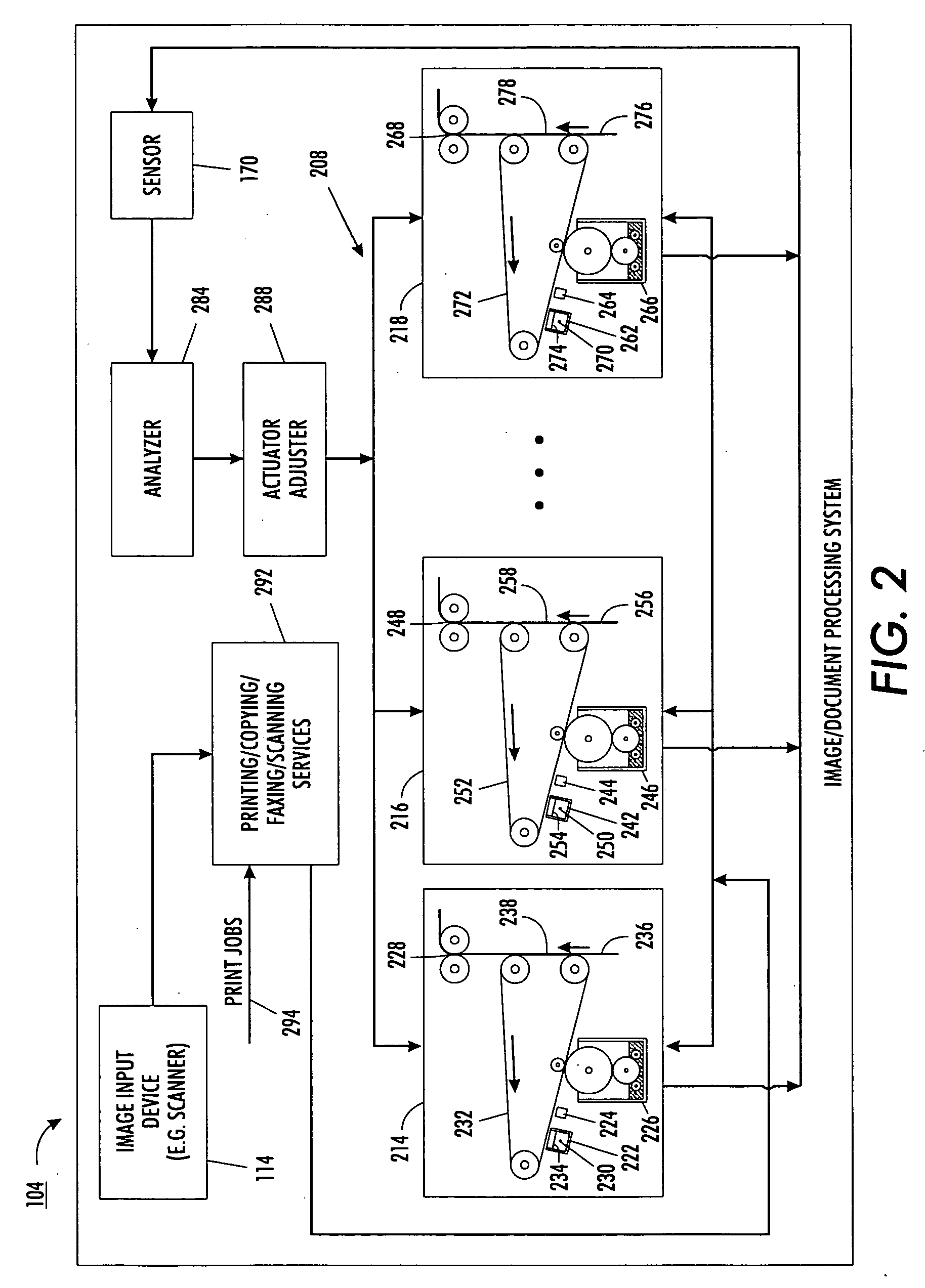

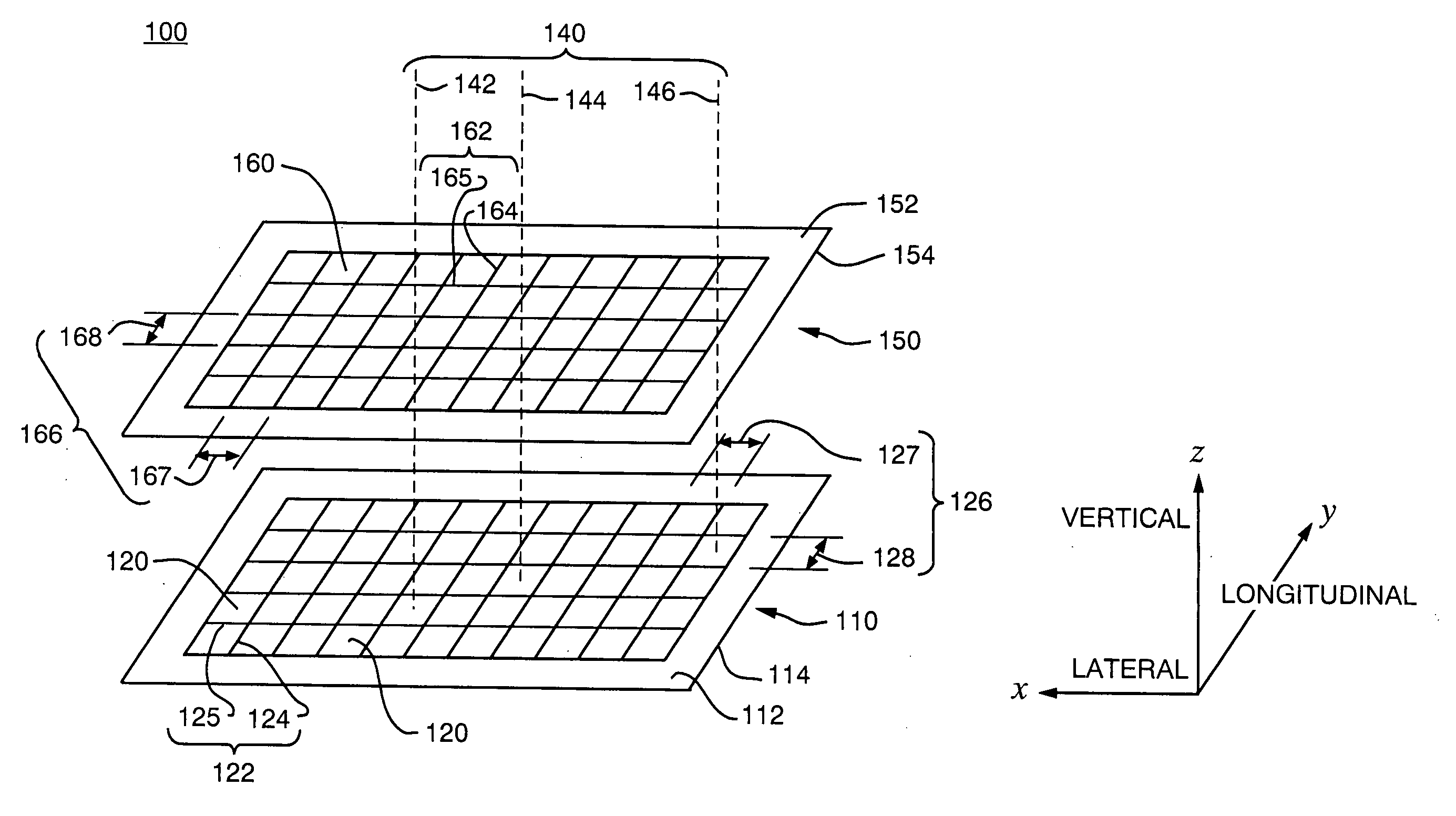

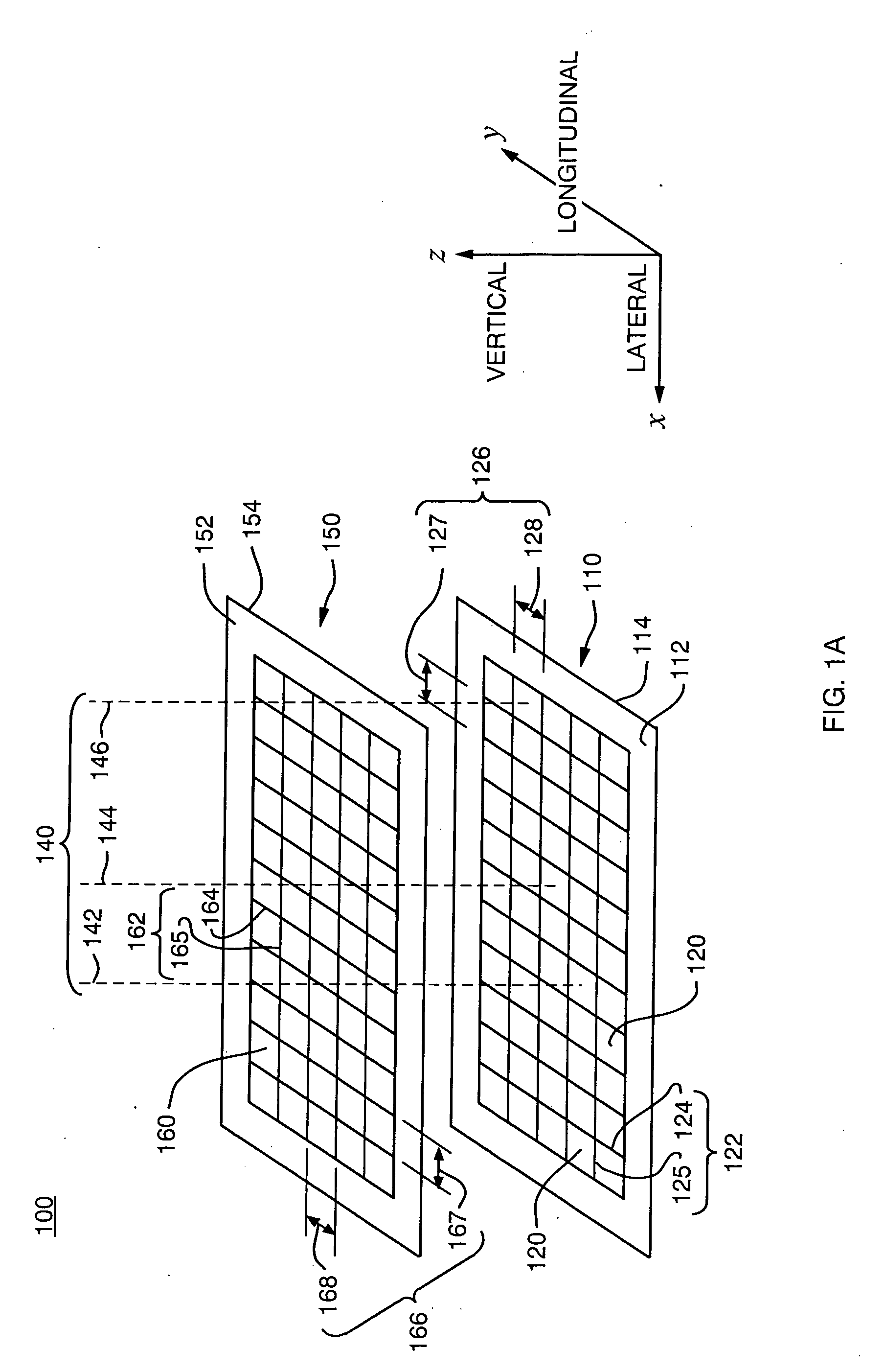

Image quality control method and apparatus for multiple marking engine systems

A full width array CCD sensor is incorporated in the media path to monitor fused pages by calculating area coverage from multiple engines in a Tightly Integrated Parallel Process (TIPP) architecture. With knowledge of the area coverage differences between print engines for a given pixel count to the ROS, a relative density difference of each engine is determined. Based on the determined relative density difference, an adjustment is calculated and applied to the engine with the largest error to match the area coverage(s) of the other engine(s).

Owner:XEROX CORP

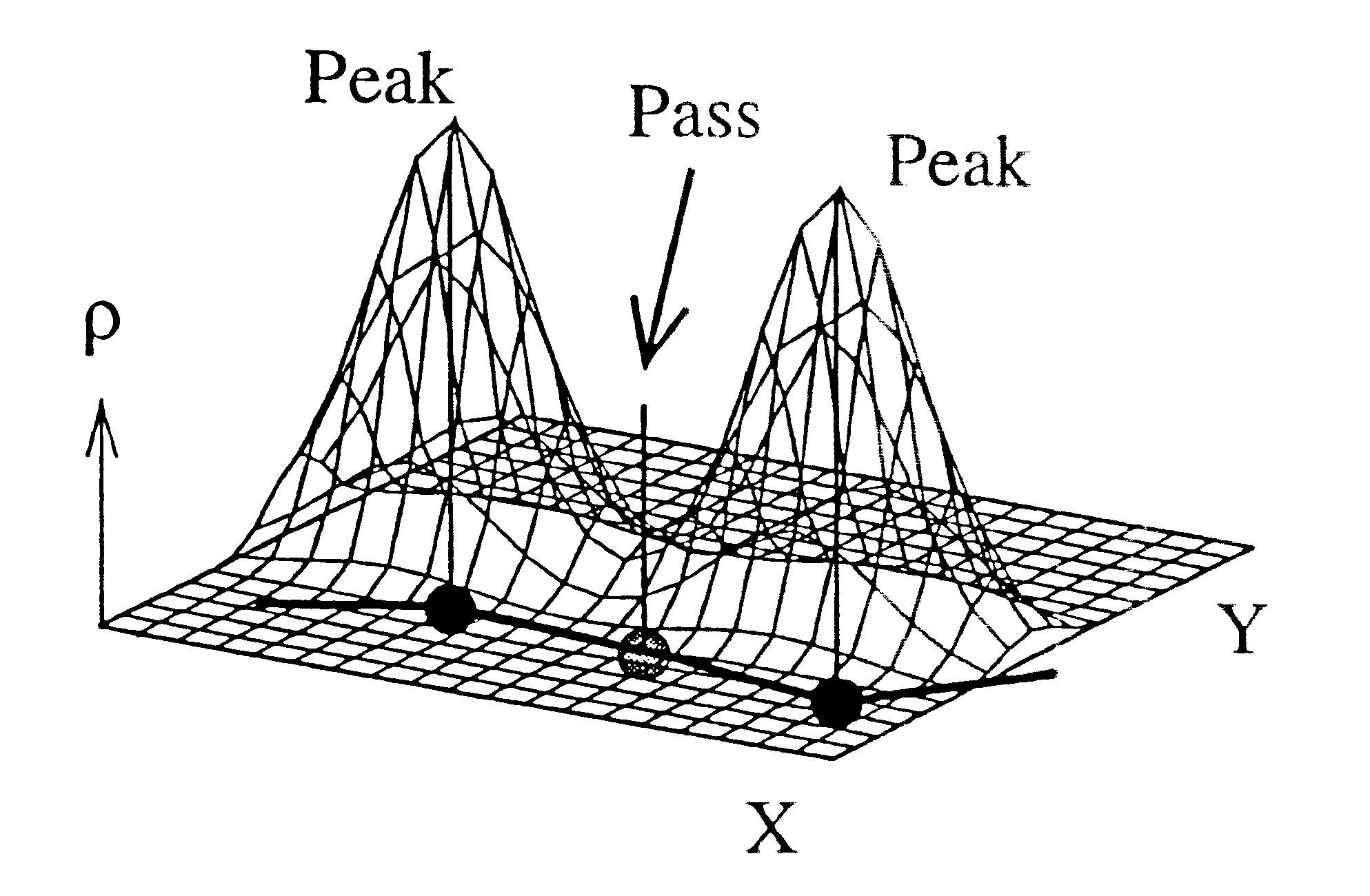

Method and apparatus for determining multi-dimensional structure

InactiveUS6345235B1Chemical property predictionDigital computer detailsFeature vectorMulti dimensional

This invention relates to methods and apparatus for determining the multi-dimensional topology of a substance (system) within a volume (space). A method according to a preferred embodiment of the invention comprises the steps of: acquiring a set of relative values for the density (scalar properties) of the volume, each value for a given location (point) within the volume; interpolating a set of functions to generate a continuous relative density for the volume; identifying critical points of the continuous relative density by using an eigenvector following method; and associating critical points with one another by following a gradient path of the continuous relative density between the critical points, The method is applicable to a wide range of data relating to fields such as crystallography, fluid dynamics, edge detection, and financial markets, to determine the topology of structures contained therein.

Owner:EDGECOMBE KENNETH E

Multifunctional periodic cellular solids and the method of making thereof

ActiveUS20080226870A1Efficient load supportExcellent mechanical impact energy absorptionWeft knittingLaminationPorosityEnergy absorption

A cellular material that can provide a unique combination of properties and characteristics for a variety of applications requiring a cellular solid that possesses one or more of the following characteristics: (1) efficient load support in one or more directions, (2) excellent mechanical impact energy absorption and vibration suppression potential, (3) high convection heat transfer throughout, (4) low pumping requirements for fluid throughput, for example in a second direction orthogonal to one or more load-bearing directions, (5) a substantially linear dependence of the Young's and shear moduli along with the tensile, compressive and shear yield strengths upon relative density (6) a potentially inexpensive textile-based synthetic approach, (7) excellent filtration potential, (8) a high surface area to volume ratio for enhanced activity as a catalyst or catalyst support (9) interconnected, open porosity for device storage, biological tissue in-growth or other functionalities requiring open space, and (10) extendibility to a wide variety of materials.

Owner:UNIV OF VIRGINIA +1

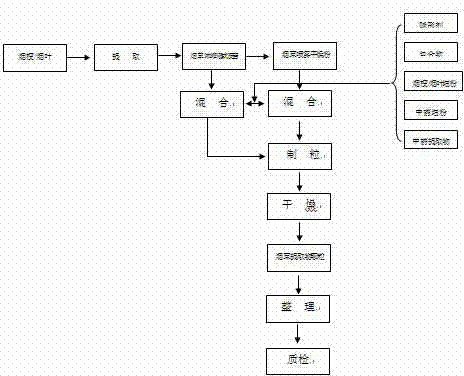

Preparation method of tobacco extract granules

The invention relates to a preparation method of tobacco extract granules, which comprises the following steps: firstly taking and cutting up tobacco leaves and / or tobacco stalks, taking water or ethanol or ethyl ether as a solvent for extraction, settling and filtering to obtain tobacco extract, then concentrating to the relative density of 1.00-1.30, and controlling the temperature to 20-40 DEGC to obtain tobacco extract concentrate or tobacco extractum; and including beta-cyclodextrin and flavouring essence for tobacco according to the mass ratio of 1-3:1 with the inclusion time of 1 / 5-3 hours to obtain a flavouring essence and beta-cyclodextrin inclusion compound, and then spray drying the flavouring essence for tobacco and beta-cyclodextrin inclusion compound and the tobacco extractconcentrate together to obtain tobacco spray dried powder; or directly spray drying the tobacco extractum to obtain the tobacco spray dried powder; and then adding excipient material to the tobacco spray dried powder for dry method or wet method granulation to obtain the tobacco extract granules. The tobacco extract granules obtained in the method disclosed by the invention are applied to cigarettes to improve the tar and harm reduction effect of the cigarettes, and can be used for aroma compensation, the utilization rate of waste tobacco leaf raw material is improved, and the cost of the cigarettes is reduced.

Owner:云南拓宝科技有限公司

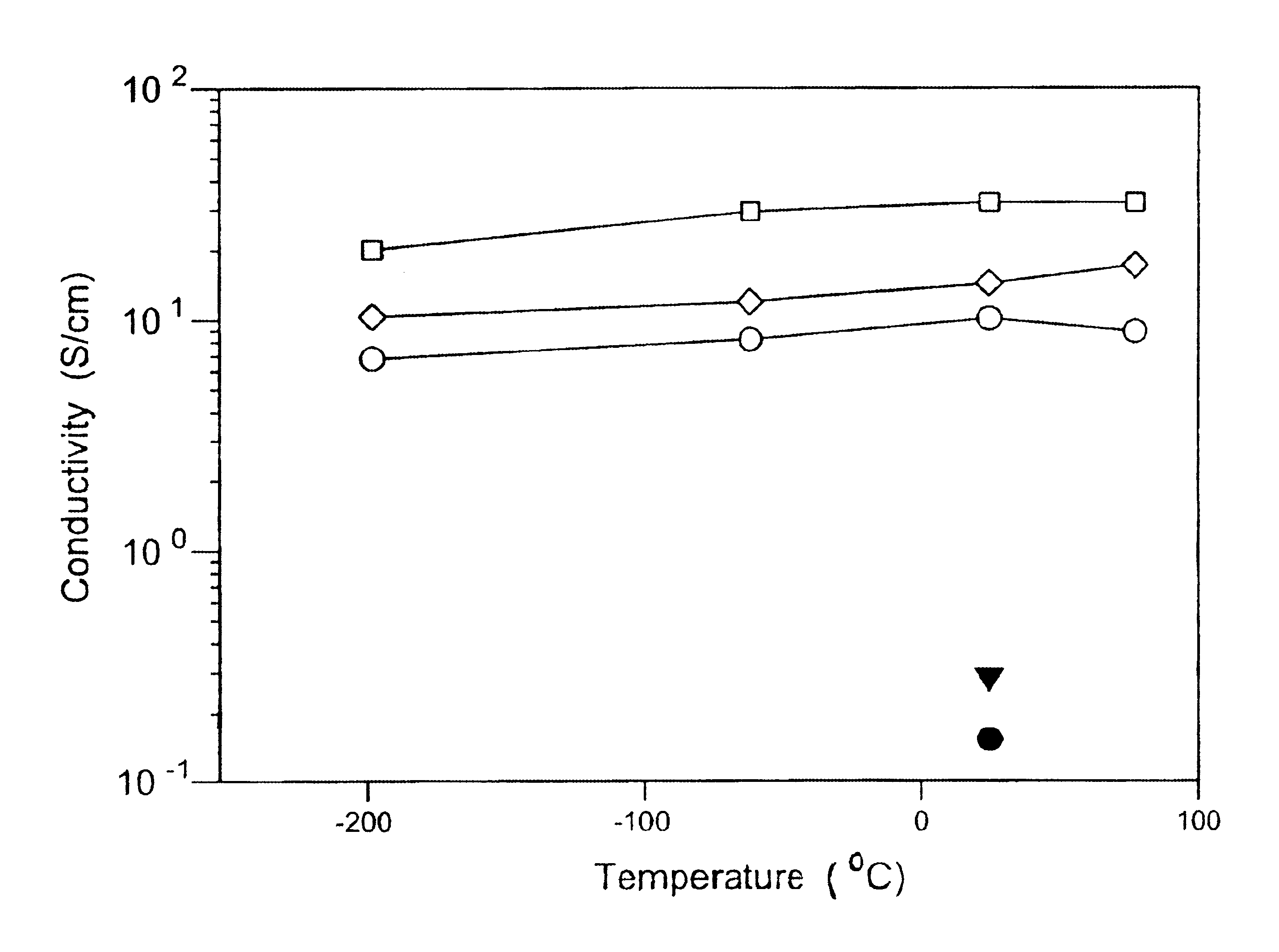

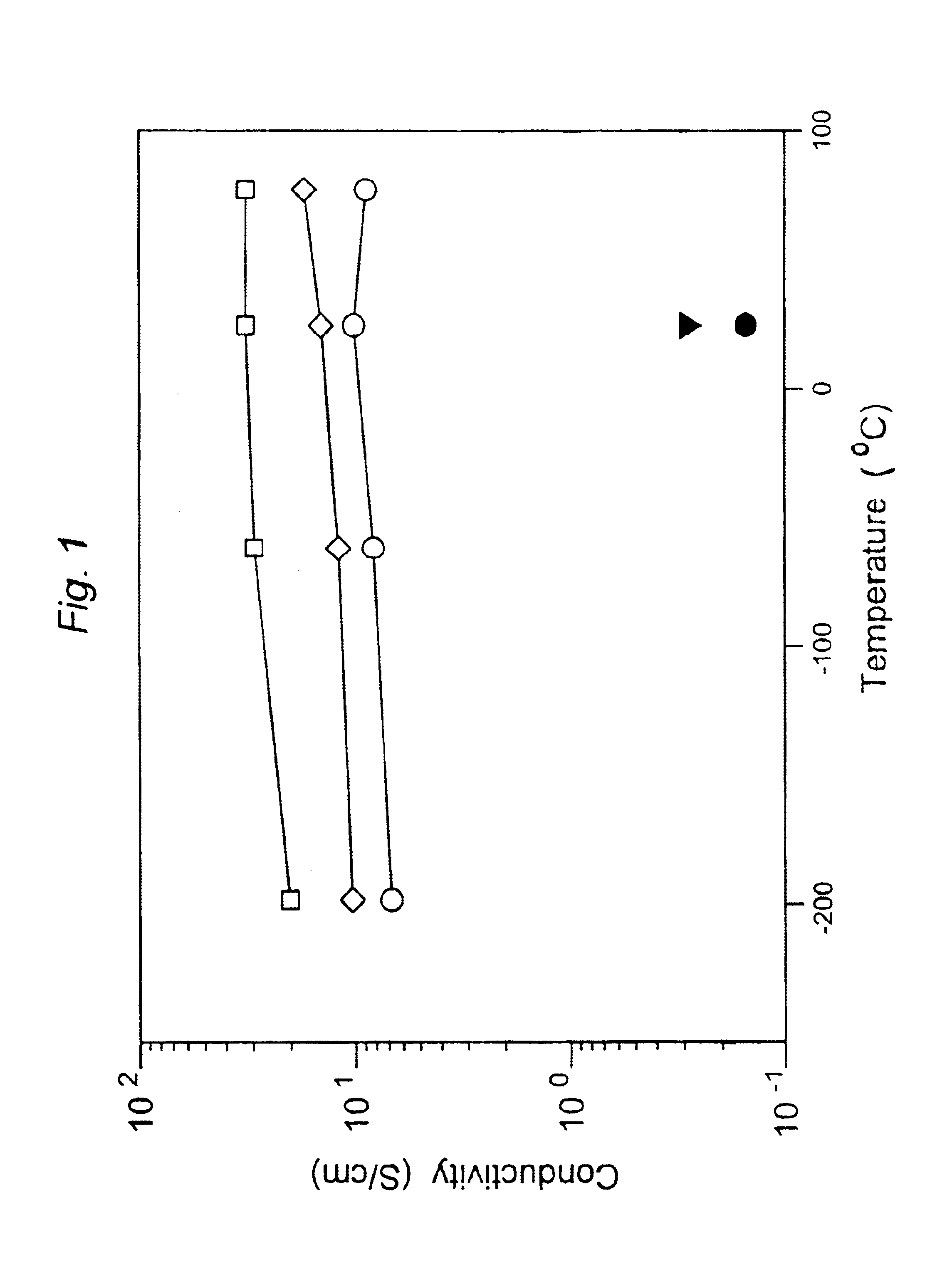

Ceramic materials reinforced with single-wall carbon nanotubes as electrical conductors

InactiveUS6875374B1Reduce processing timeMaterial nanotechnologyOxide/hydroxide preparationHigh fractureElectrical conductor

Composite materials formed of a matrix of fused ceramic grains with single-wall carbon nanotubes dispersed throughout the matrix and a high relative density, notably that achieved by electric field-assisted sintering, demonstrate unusually high electrical conductivity in combination with high-performance mechanical properties including high fracture toughness. This combination of electrical and mechanical properties makes these composites useful as electrical conductors in applications where high-performance materials are needed due to exposure to extreme conditions such as high temperatures and mechanical stresses.

Owner:RGT UNIV OF CALIFORNIA

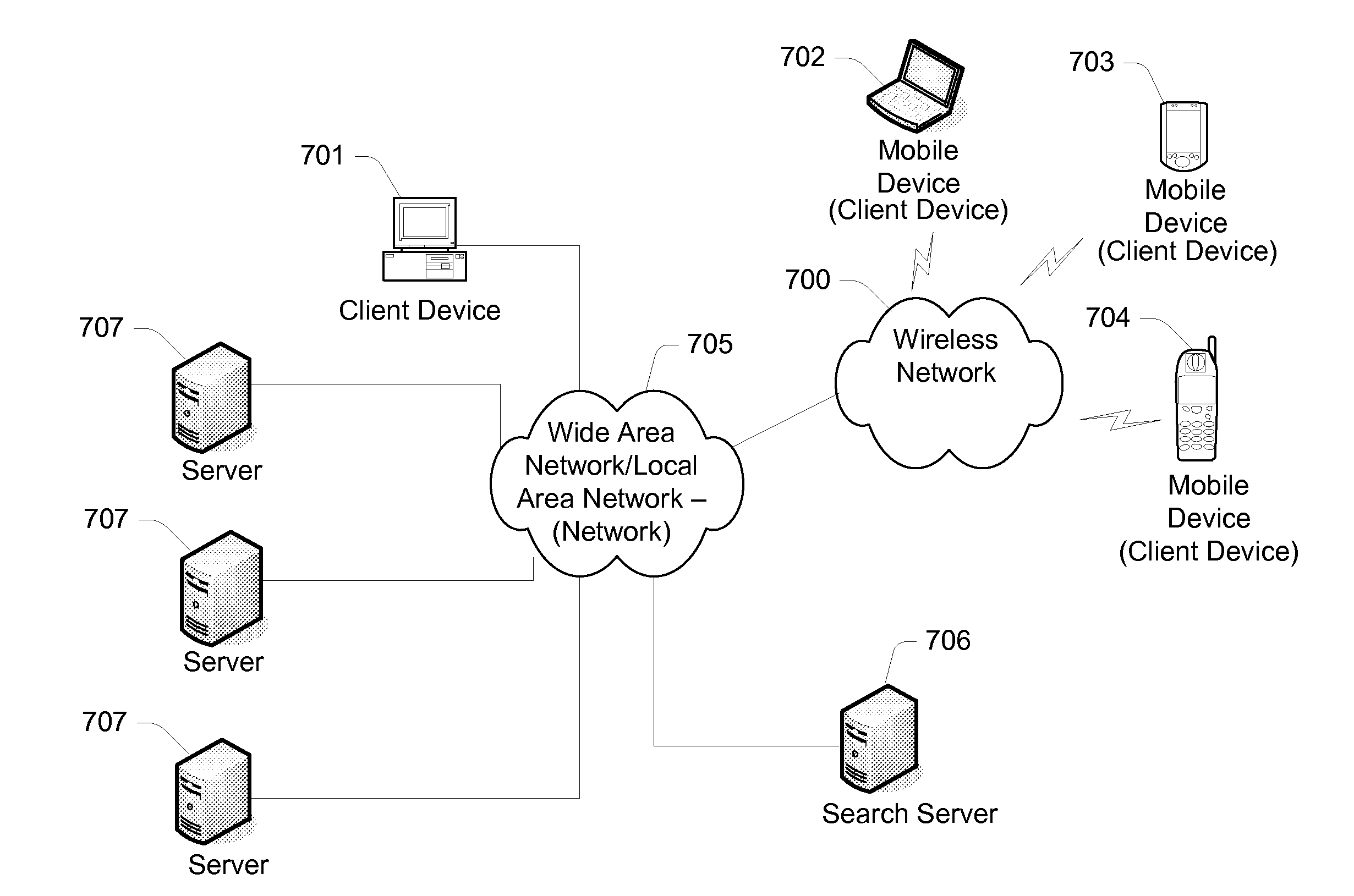

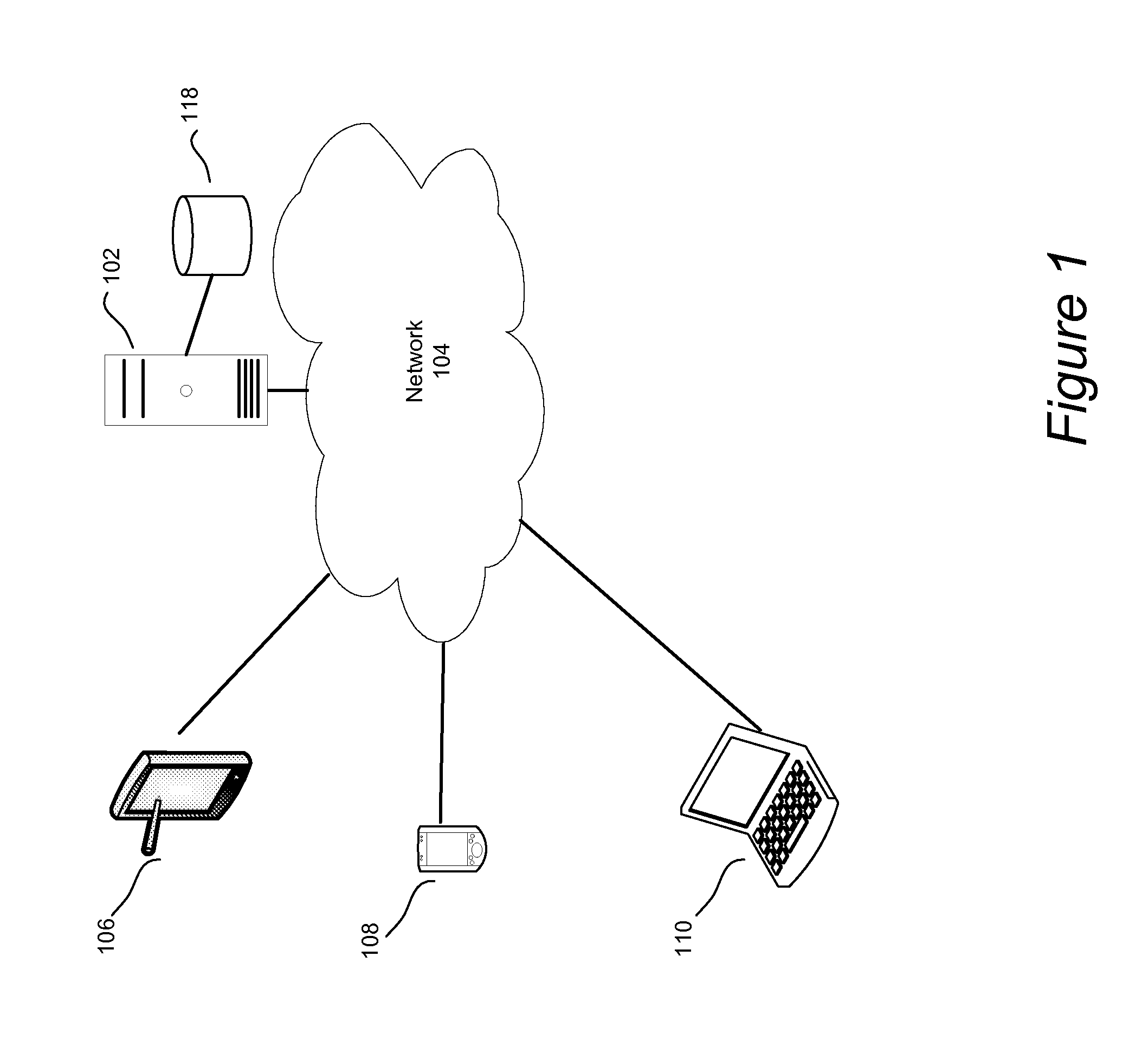

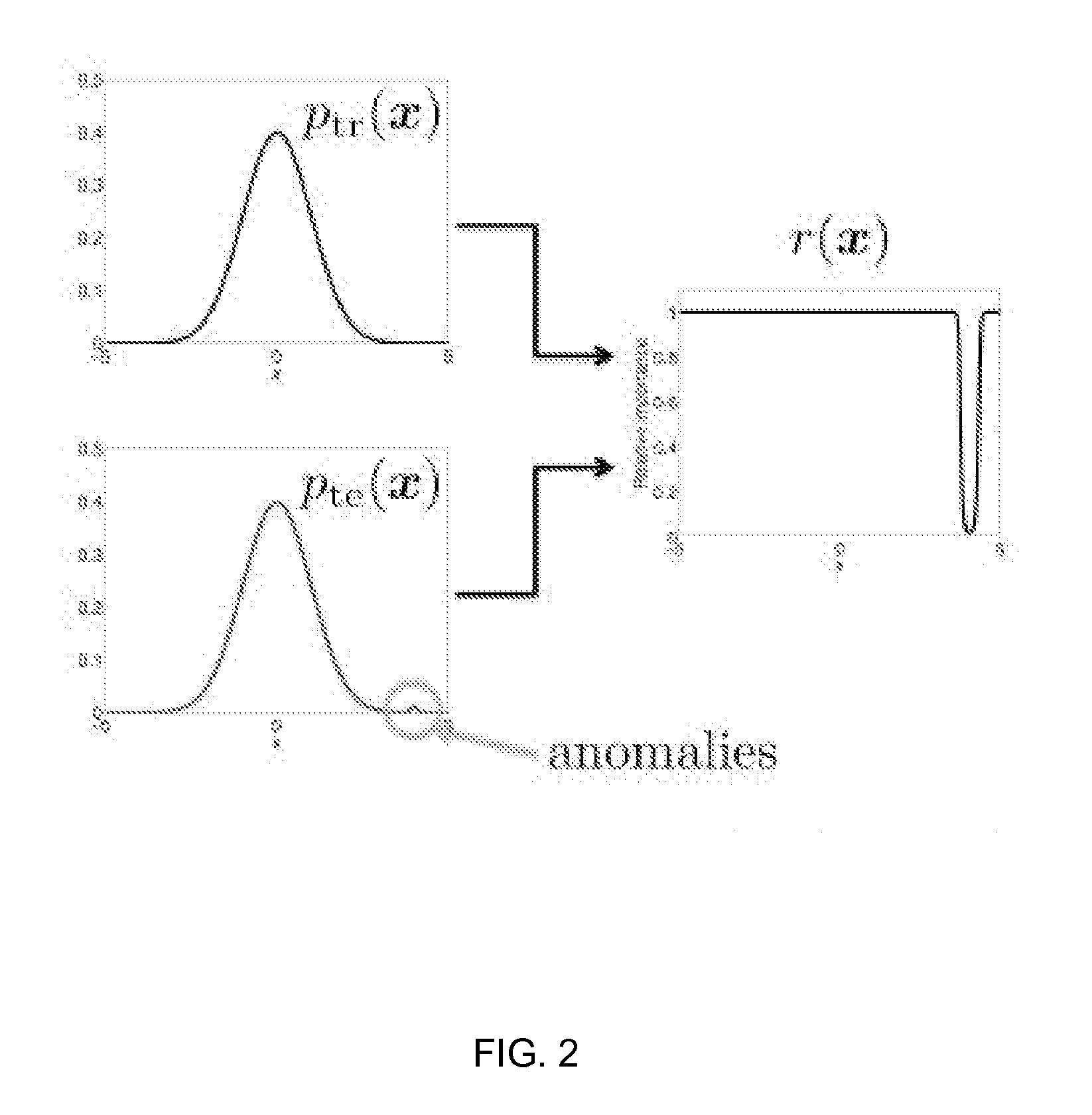

Large-scale anomaly detection with relative density-ratio estimation

In one embodiment, a set of training data consisting of inliers may be obtained. A supervised classification model may be trained using the set of training data to identify outliers. The supervised classification model may be applied to generate an anomaly score for a data point. It may be determined whether the data point is an outlier based, at least in part, upon the anomaly score.

Owner:YAHOO ASSETS LLC

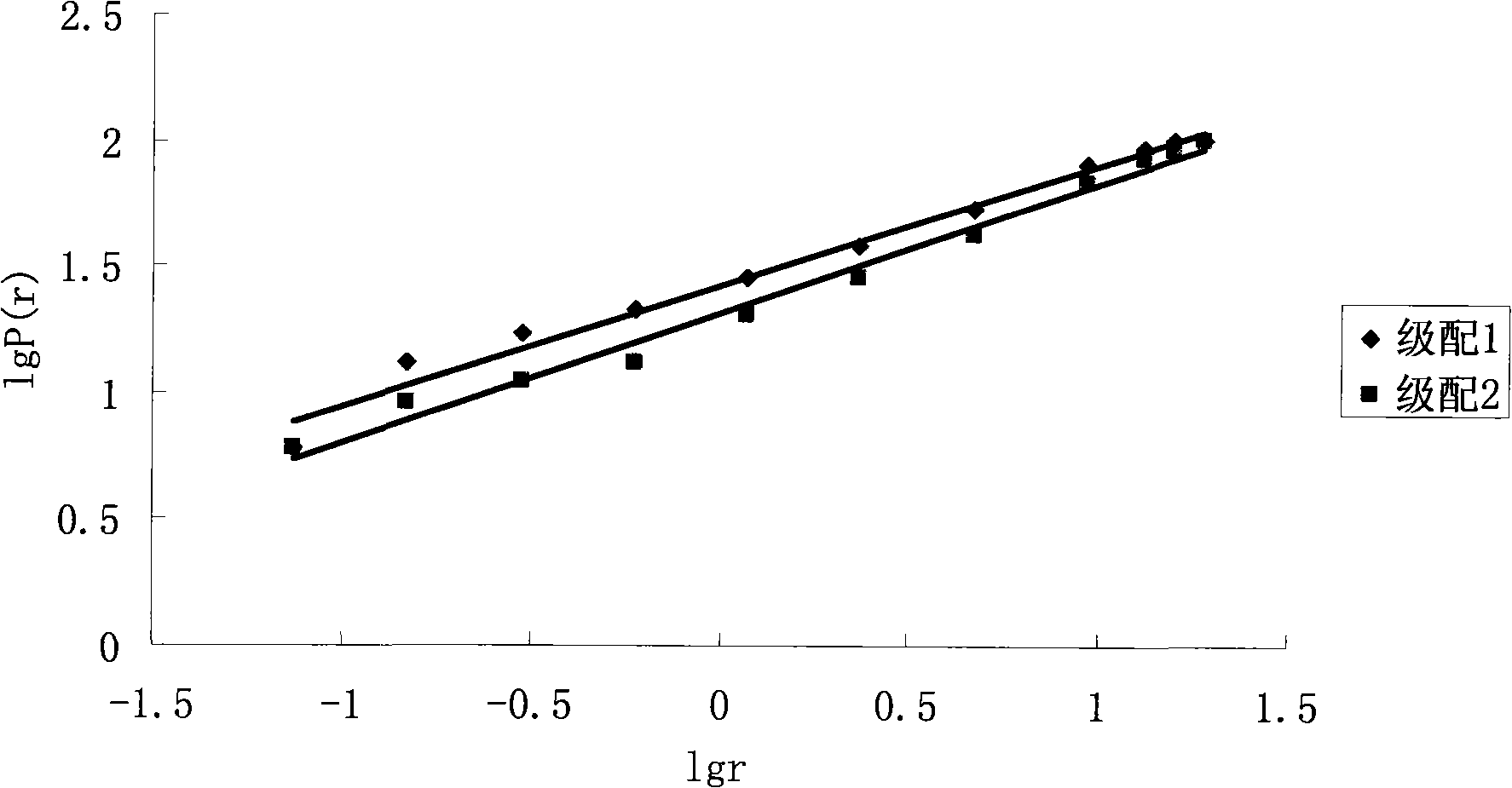

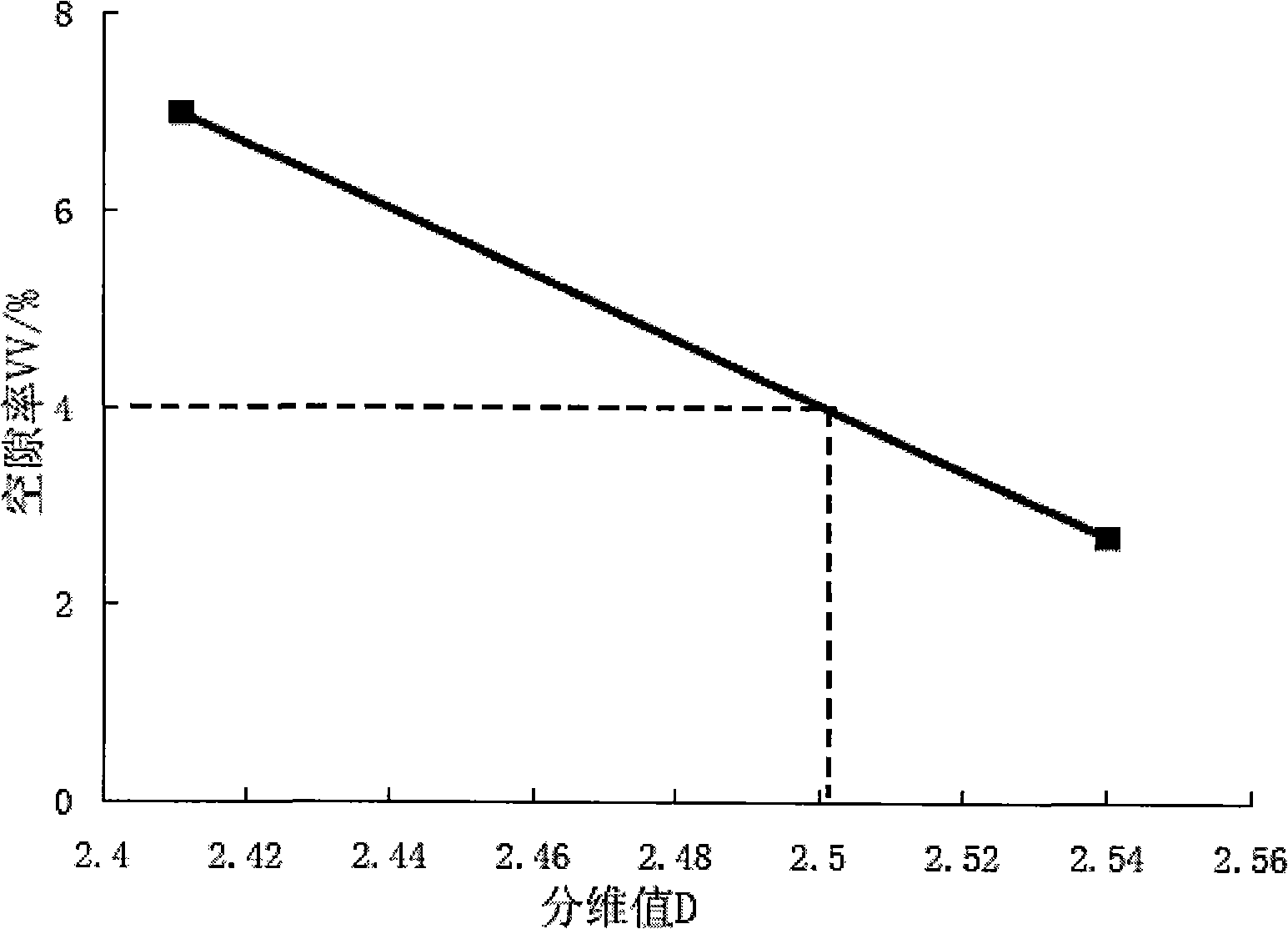

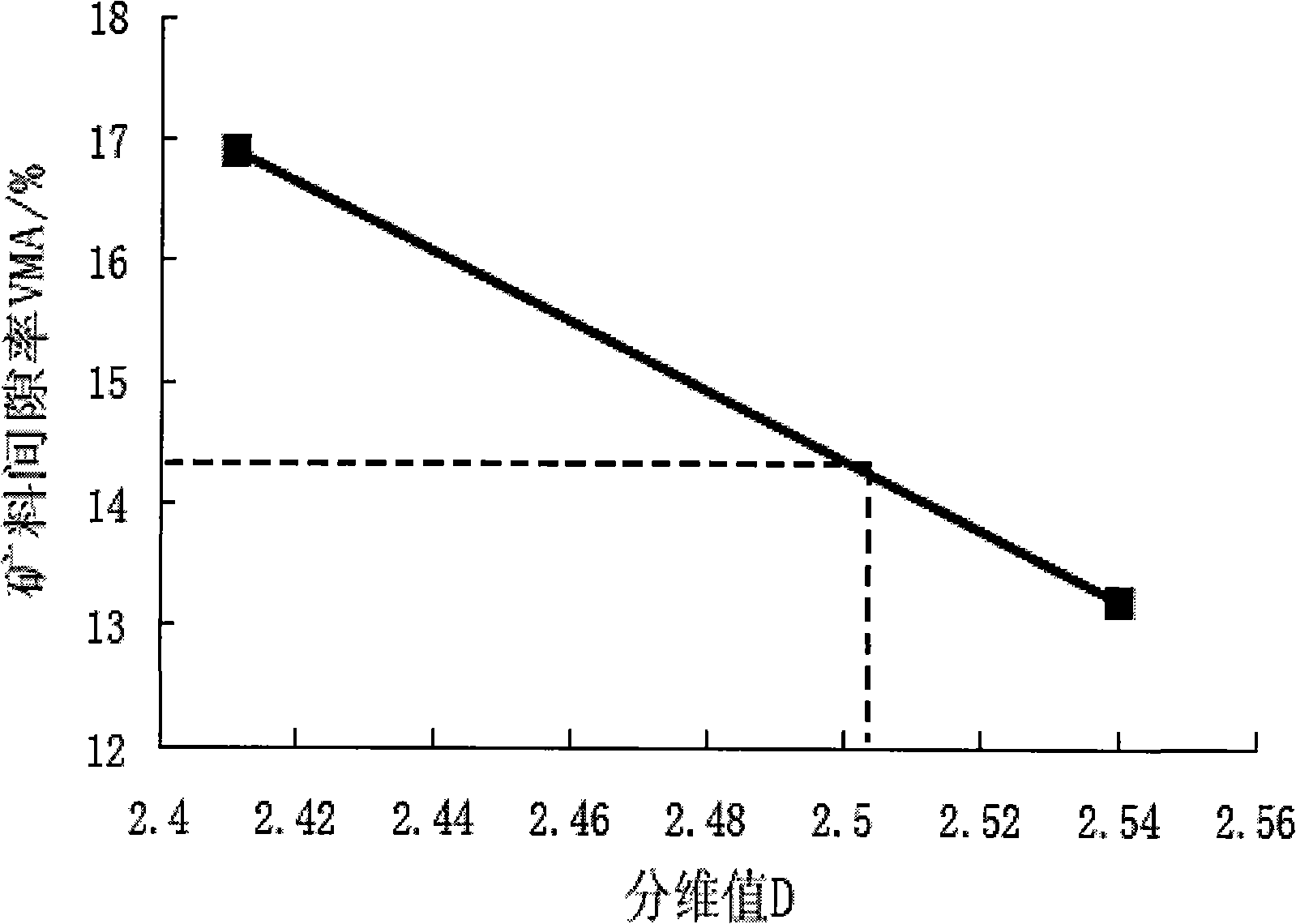

Asphalt mixture mixing proportion design method based on inert solid fractal distribution characteristic

InactiveCN101318794AImprove road performanceSimple internal structureSolid waste managementCeramic shaping apparatusMathematical modelTest sample

The invention relates to a method of designing a mixed ratio for a bitumen mixture based on fractal and distributional features of ore materials. The method comprises the following steps: (1) mathematical models for particle diameter distribution and mass distribution of the ore materials are set up respectively; (2) the type and the grading limit of the bitumen mixture are determined; (3) raw materials are selected and checked; (4) graduations of two arbitrary groups of the ore materials are determined and corresponding fractal dimension values(D) are worked out; (5) the use level of the bitumen is worked out; (6) the bitumen mixture is prepared by stirring; (7) a Marshall test sample is made, the relative density of the bulk volume of the test sample is determined, the theoretical maximum relative density is determined, and the volume index is worked out; (8) relationship curves between the fractal dimension values(D) and the volume indexes are drawn; (9) the graduation of the ore materials and the optimum use level of the bitumen are determined; (10) the road performance of the bitumen mixture is tested; and (11) the construction mixed ratio of the bitumen mixture is determined. The invention utilizes the fractal theory to set up the mathematical models, and in the process of designing the mixed ratio of the bitumen mixture, the optimum bitumen use level and the optimum graduation of the ore materials meeting and regulating all design rules of the bitumen mixture can be quickly determined.

Owner:LANZHOU JIAOTONG UNIV

Seamless, ring-shaped brazing material and method for producing same

InactiveUS6164517AReduce necessityWelding/cutting auxillary devicesAuxillary welding devicesNonferrous metalMetal powder

The seamless, ring-shaped brazing material comprises a brazing metal and a flux uniformly dispersed in the brazing metal for brazing nonferrous metal members and has a relative density of 0.90 or more. The seamless, ring-shaped brazing material is produced by (a) mixing brazing metal powder and flux powder uniformly; (b) pressing the resultant mixture to a powder compact billet; (c) forming the billet into a pipe by hot extrusion; and (d) slicing the pipe into rings.

Owner:SUN KWANG BRAZING FILLER METAL +2

Cu-In-Ga-Se or Cu-In-Al-Se solar cell absorption layer target material and preparation method thereof

InactiveCN101397647AAvoid lostReduce adverse effectsVacuum evaporation coatingSputtering coatingIndiumElectrical battery

The invention discloses a Cu-In-Ga-Se or Cu-In-Al-Se solar battery absorbing layer target pertaining to the field of photoelectric functional materials, and a preparation method thereof. High-purity cuprous selenide powder, indium selenide powder, gallium selenide powder or aluminum selenide powder are fully mixed evenly according to the stoichiometric ratio of a CuIn1-xGaxSe2 or CuIn1-xAlxSe2 solar battery absorbing layer, and then sintered and molded by hot-pressing under protective atmosphere or made into a biscuit after cold press molding or cold isostatic pressing, and the biscuit is sintered under protective atmosphere and certain pressure or does not go through pressure sintering. The technique of the invention is simple and convenient, has high efficiency and low cost, and the produced sputtering target is provided with uniform composition and homogeneous CuIn1-xGaxSe2 or CuIn1-xAlxSe2 phase, with the relative density more than 90 percent and stable performance. The invention is mainly applied to the preparation of a Cu-In-Ga-Se and Cu-In-Al-Se solar thin film battery absorbing layer.

Owner:TSINGHUA UNIV +1

High strength and high toughness foamed SiC/Al material and its preparing method

The present invention relates to heterogeneous foamed ceramic / metal material, and is especially one kind of high strength and high toughness foamed SiC / Al material and its preparation process. The foamed SiC / Al material has basic units of closed polygonal ring to form connected 3D network structure, and each of the closed polygonal ring units is heterogeneous foamed ribs comprising SiC in 50-95 vol% and metal Al in 5-50 vol% and with the relative density not lower than 99 %. The foamed SiC / Al material is prepared through organic foam soaking, hot pressing to densify, pressure injection filling, thermal decomposition and reaction sintering. The preparation process is simple and low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermoelectric material and method for producing same

InactiveUS20060053969A1Improve performanceLow thermal conductivityThermoelectric device manufacture/treatmentGenerators/motorsThermoelectric materialsFine powder

A thermoelectric material has an average crystal particle size of at most 50 nm and has a relative density of at least 85%. A method of manufacturing a thermoelectric material includes the steps of preparing a fine powder and sintering or compacting the fine powder under a pressure of at least 1.0 GPa and at most 10 GPa.

Owner:SUMITOMO ELECTRIC IND LTD

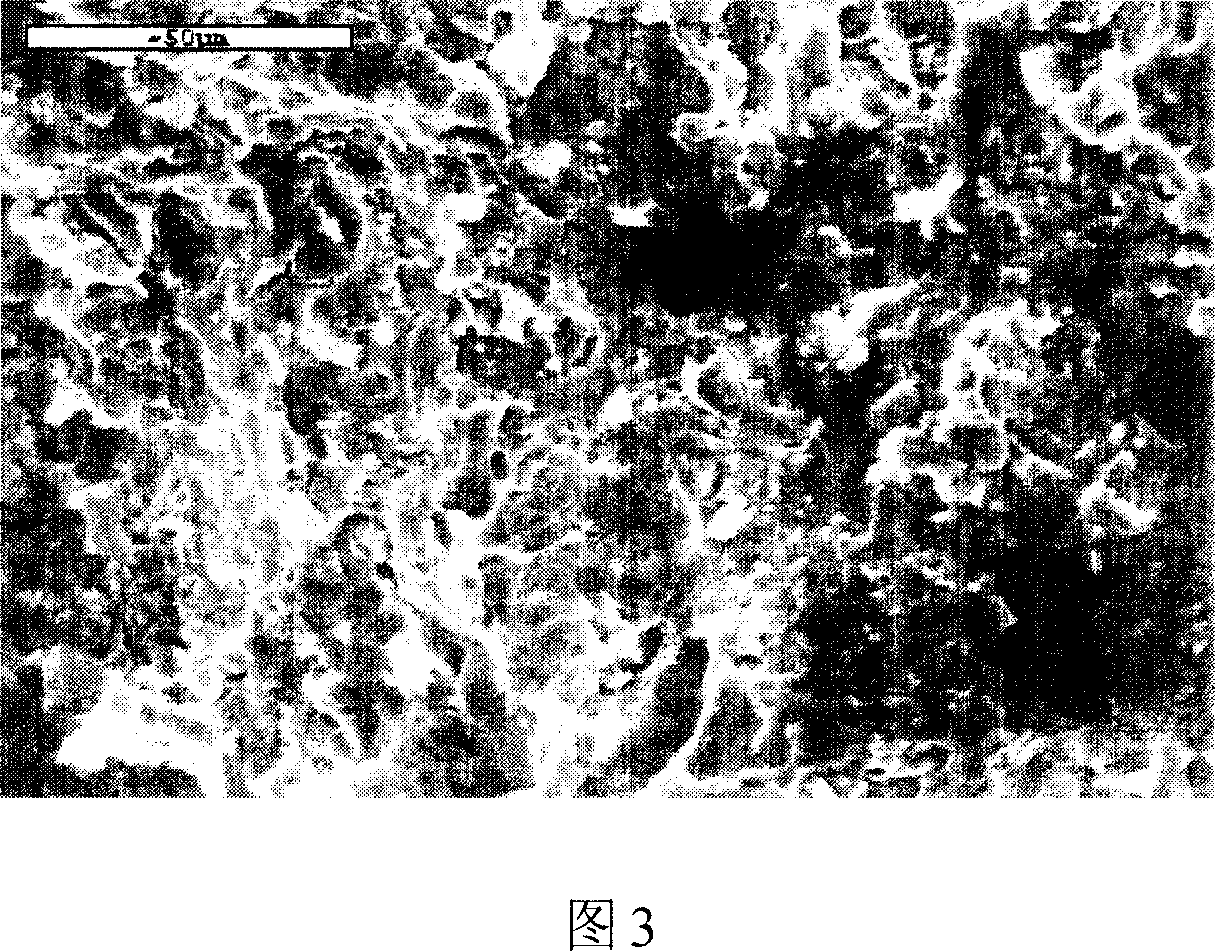

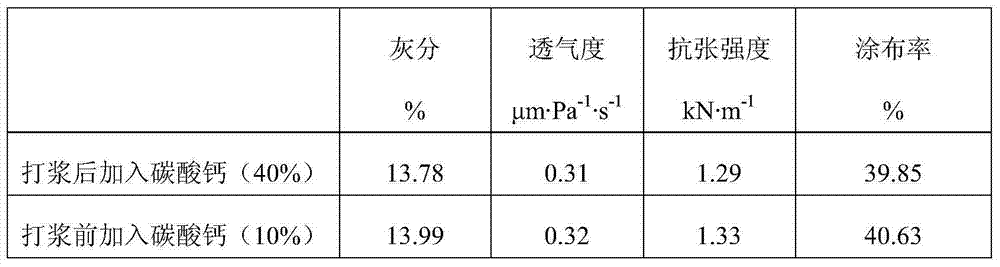

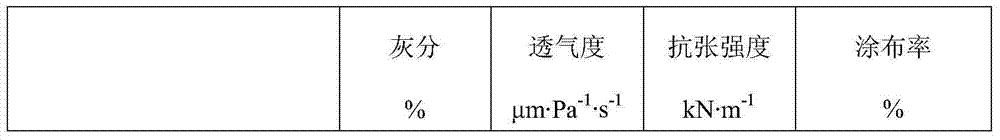

Method for improving calcium carbonate retention rate through adding calcium carbonate before pulp beating

The invention discloses a method for improving the calcium carbonate retention rate through adding calcium carbonate before pulp beating. The method includes the steps that tobacco powder, tobacco stem and fragmentary tobacco pieces are immersed in water to obtain mixed slurry, and the mixed slurry is extracted and separated to obtain soluble tobacco fiber and non soluble tobacco fiber; mixed beating is conducted to the non soluble tobacco fiber and calcium carbonate to obtain slurry material, outer fiber and chitosan are added to the obtained slurry material to obtain slurry material before pulping after being evenly mixed, and the slurry material before pulping is manufactured into a substrate in a pulped mode; evaporation and concentration, and fragrance adding and tinting are conducted on the obtained soluble tobacco fiber to obtain coating liquid with relative density ranging from 1.102 to 1.325; the coating liquid is sprayed on the substrate, and finally after drying and slicing up are conducted, the reconstituted tobacco is obtained. The method for improving the calcium carbonate retention rate through adding the calcium carbonate before pulp beating is simple and practical, the prepared reconstituted tobacco is better in coating rate and calcium carbonate retention rate than the reconstituted tobacco prepared through an existing technology, the quality of the reconstituted tobacco is not influenced, and popularization and application in actual production are facilitated.

Owner:HUBEI CHINA TOBACCO IND +1

Dynamic reserve calculation method and system for fracture and cave type carbonatite oil reservoir fracture and cave unit

InactiveCN105464652ADynamic Reserve OptimizationImprove accuracyBorehole/well accessoriesPorosityGas oil ratio

The invention relates to a dynamic reserve calculation method and system for a fracture and cave type carbonatite oil reservoir fracture and cave unit. The method comprises a fracture and cave unit type division step, a material balance equation simplification step and a dynamic reserve calculation step. According to the method, firstly, the driving types of the fracture and cave unit are divided according to the communication relationship between the fracture and cave unit and a water body; then, a simplified material balance equation is obtained according to different driving types; then, the dynamic reserve calculation parameters in the material balance equation are optimized by combining production dynamic data through the combined relationship of the ground crude oil density, the natural gas relative density and the gas-oil ratio and the relationship between the elasticity modulus and the porosity; and the dynamic reserve in the dynamic reserve calculation parameters is calculated. The method and the system have the advantages that the precision and the accuracy of the dynamic reserve calculation result are improved; and the basis is provided for the oil reservoir development and exploration and the engineering layout.

Owner:恒泰艾普集团股份有限公司 +1

Translucent zirconia sintered body, process for producing the same, and use of the same

InactiveUS20110027742A1High densityGood light transmissionMaterial nanotechnologyDental implantsTransmittanceBody density

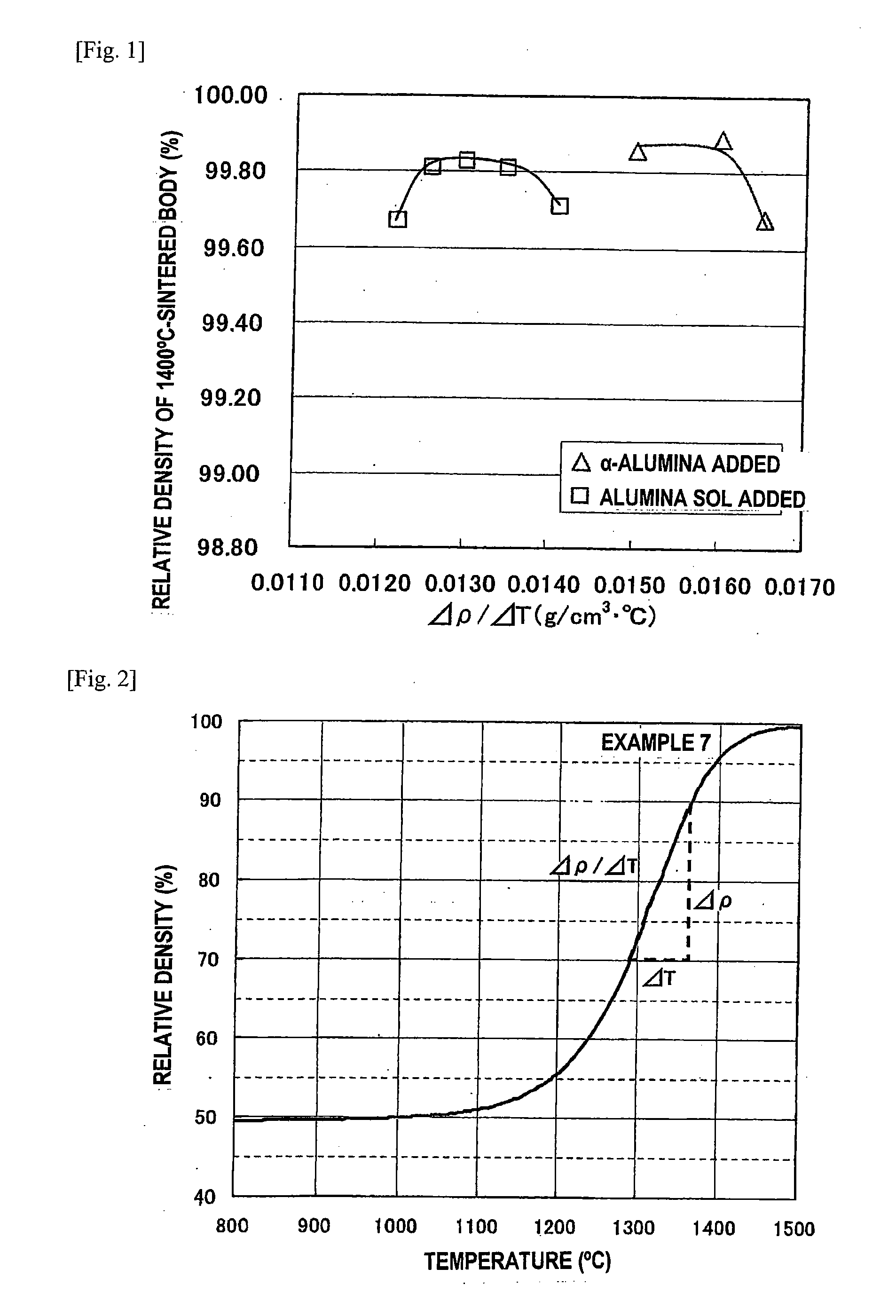

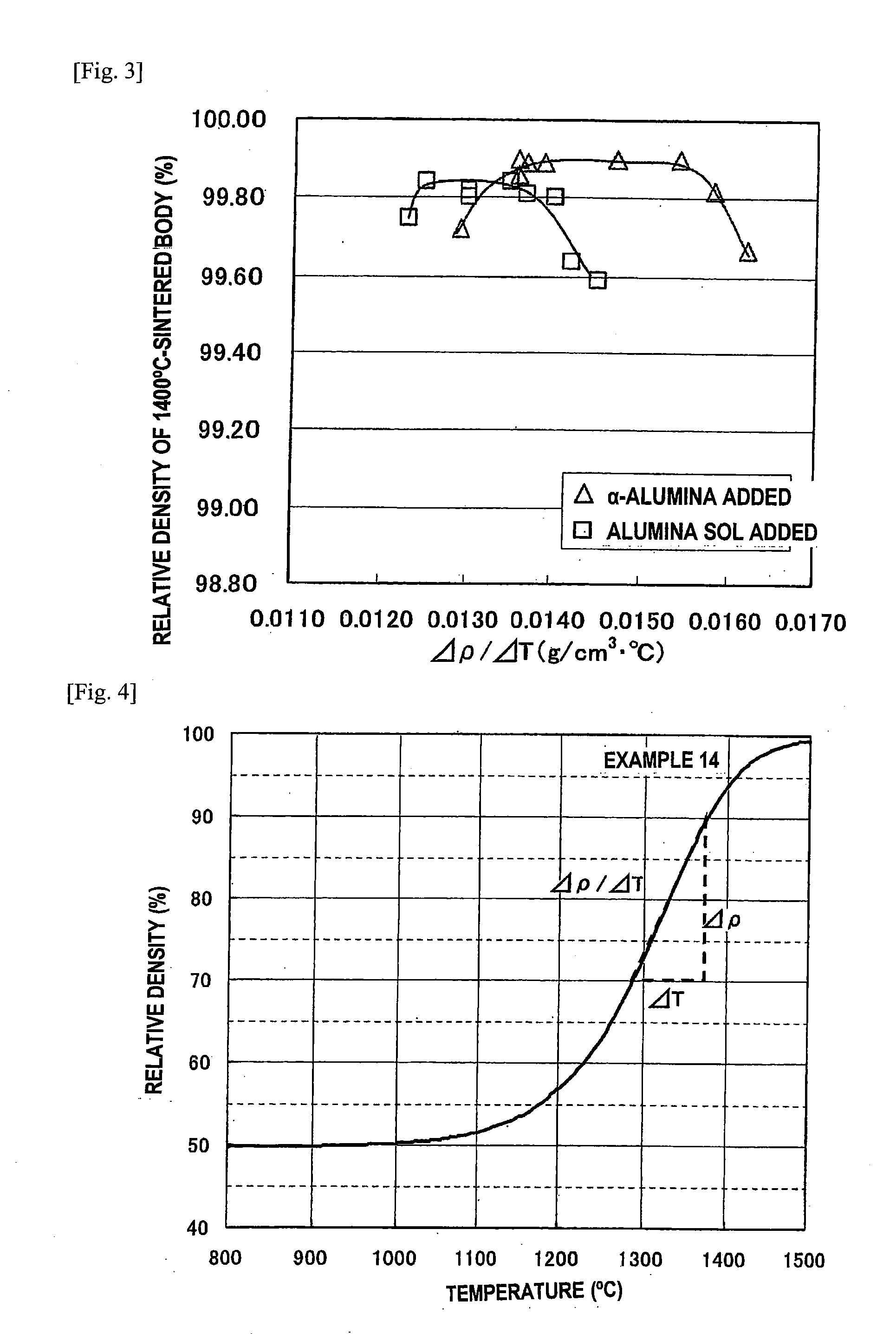

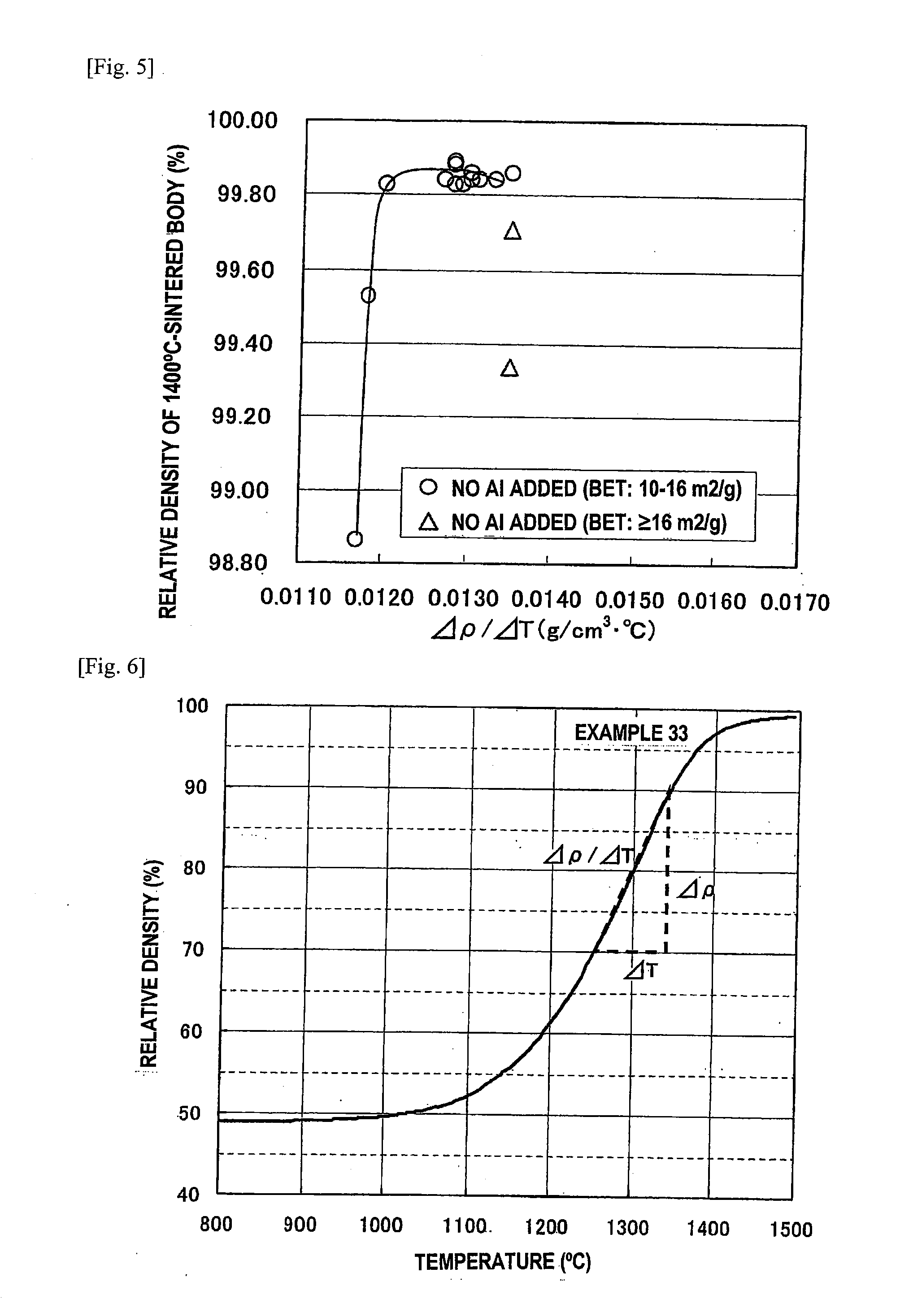

A subject of the invention relates to providing a powder for a translucent zirconia sintered body which is necessary for the production of a zirconia sintered body having a high sintered-body density and high strength and giving an excellent sense of translucency, without conducting any special sintering, such as HIP sintering. The invention relates to a technique for obtaining, through normal-pressure sintering, a translucent zirconia sintered body characterized by comprising zirconia which contains 2-4 mol % yttria as a stabilizer and has an alumina content of 0.2 wt % or lower, and by having a relative density of 99.8% or higher and a total light transmittance, as measured at a thickness of 1.0 mm, of 35% or higher. It is preferred that a powder containing 0-0.2 wt % alumina with a particle diameter of 0.01-0.5 μm, having a BET specific surface area of 5-16 m2 / g and an average particle diameter of 0.3-0.7 μm, and having a rate of sintering shrinkage in normal-pressure sintering (Δρ / ΔT; g / cm3·° C.) of 0.0125 or higher but 0.0160 or lower should be subjected to normal-pressure sintering in the atmosphere.

Owner:TOSOH CORP

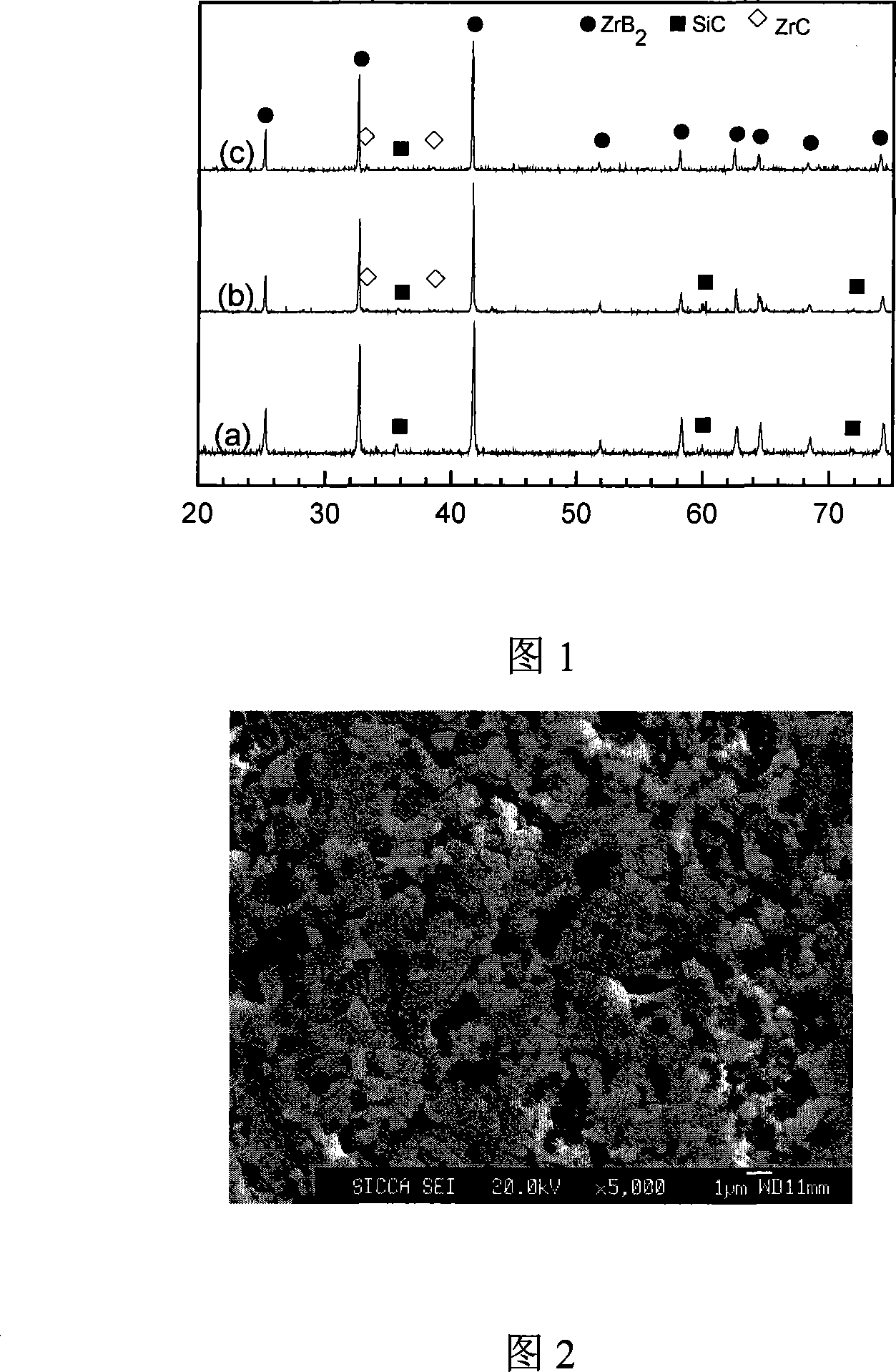

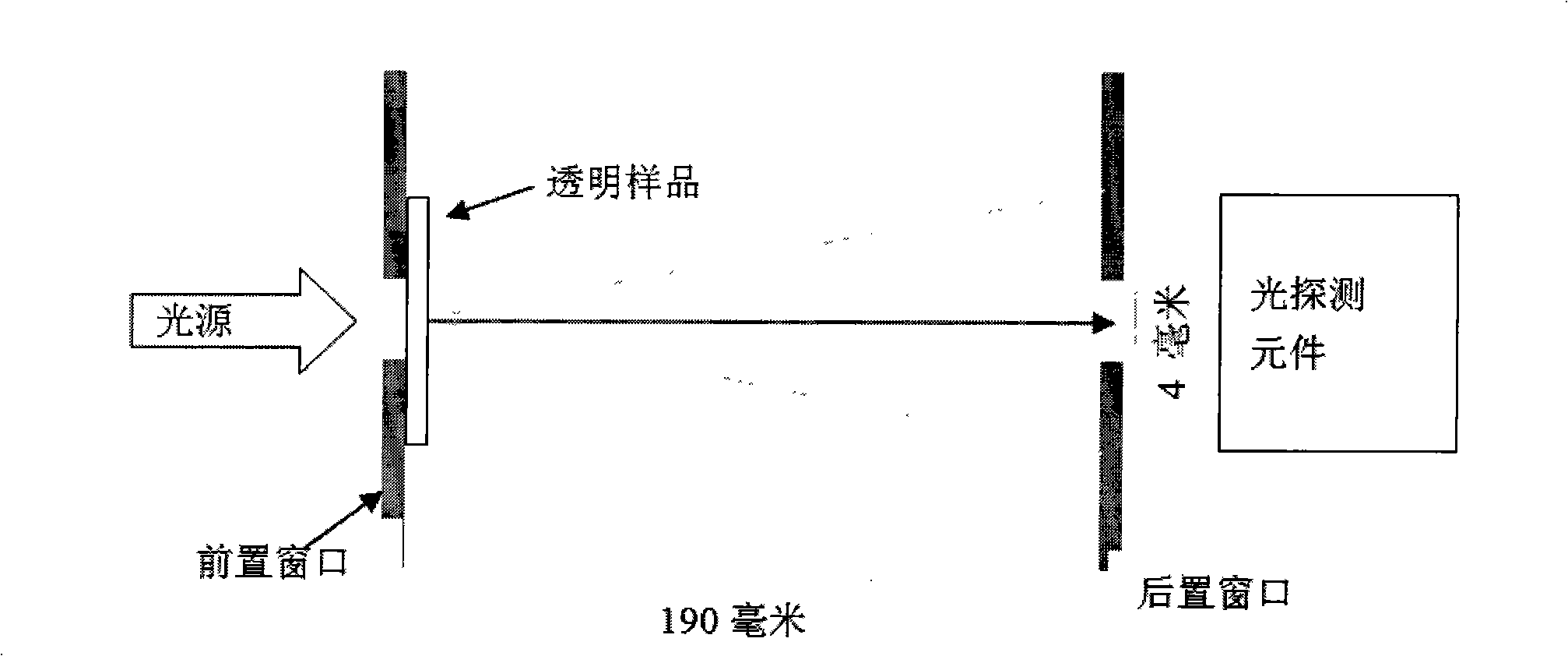

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

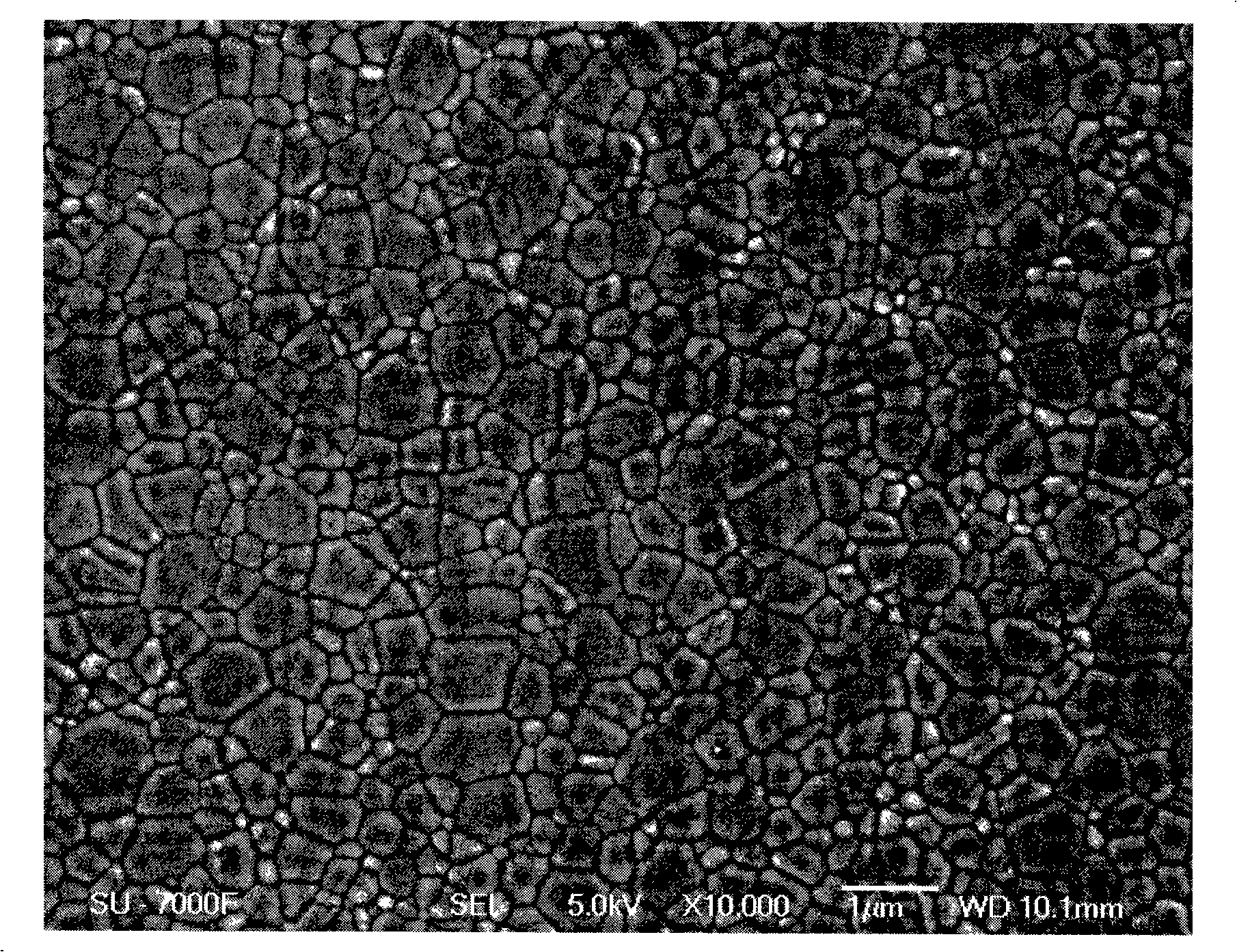

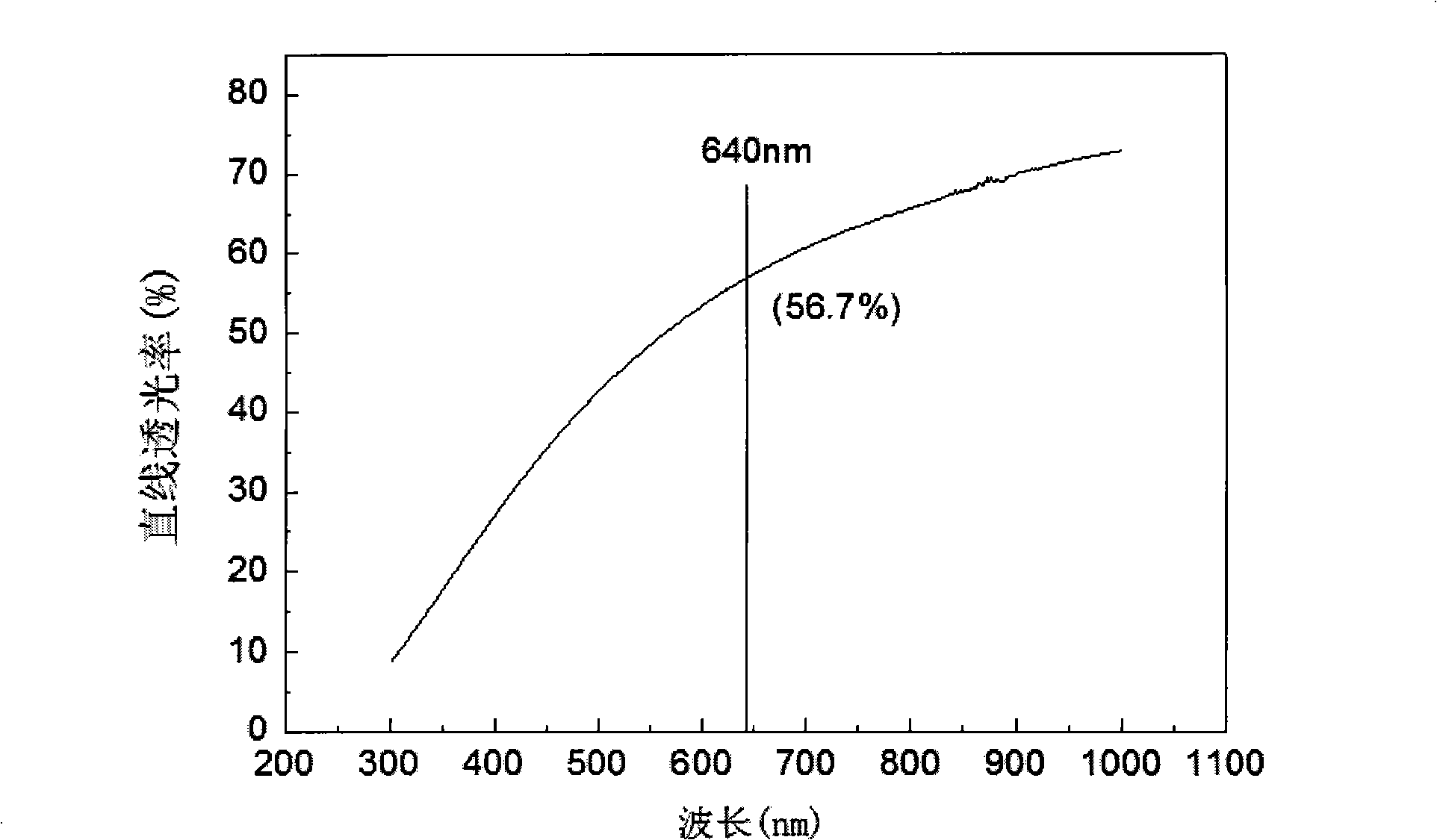

Fine-crystal transparent alumina ceramic of high straight-line luminous transmittance and method for preparing same

The invention discloses high-linear light transmittance fine crystalline transparent alumina ceramics and a method for making the same under the condition of a pulse electric field. The transparent alumina ceramics is sintered within a temperature range of between 1,050 and 1,400 DEG C with the time of the entire sintering process less than 30 minutes; moreover, the material has a relative density higher than 99.5 percent, average grain size of between 0.3 and 1 micron, Vickers hardness more than 20GPa, bending strength of between 700 and 900 MPa, fracture toughness of between 3 and 4 MPam<1 / 2> and linear light transmittance more than 50 percent; and the linear light transmittance of a better material can reach to more than 62 percent. The transparent alumina ceramics can be pure alumina with the purity more than 99.99 percent, or can be alumina ceramics in which one sort, or any two sorts, or any three sorts of addition agents including 0.01 to 0.5 percent of MgO, 0.01 to 0.5 percent of Y2O3, 0.01 to 0.5 percent of La2O3 and 0.01 to 0.5 percent of ZrO2 are added. The method for making the transparent alumina ceramics has the characteristics of low temperature and quickness; moreover, the technology has high reliability, and the deviation between the mechanical property and the optical performance of transparent alumina made in different batches is not more than 2 percent.

Owner:王昕

Application of micro injection molding technique for preparing tungsten-base alloy product and micro injection molding method of tungsten-base alloy powder

The invention discloses an application of micro injection molding technique for preparing a tungsten-base alloy product, which can prepare a micro tungsten-base alloy part with a mass less than 0.5g and a relative density greater than 96 percent. The invention also discloses a micro injection molding method of tungsten-base alloy powder, comprising steps of mixing, milling mixing, pelletizing, injection molding, green-ware degreasing, sintering and the like. The adhesive consists of wax, polyethylene, surface modifier and the like, wherein the modifier consists of stearic acid and organic naphthaline by a certain proportion, and the viscosity of the adhesive is dramatically reduced at a high shearing rate, thereby being favorable for filling. The invention adopts two degreasing steps of solvent degreasing and heat degreasing, wherein the first step of solvent degreasing can degrease wax of low melting point and partial surface modifier, and the second step of heat degreasing mainly degreases polymer of high melting point. The high-temperature insulation can remove the adhesive, sinter the degreased green body, improve the intensity of the green body and ensure conformality of the green bodies.

Owner:厦门博兴纳新材料科技有限公司

Composite oxide sintered body and sputtering target comprising same

InactiveUS20110260121A1Reduce rateLower bulk resistanceConductive materialVacuum evaporation coatingBulk resistanceComposite oxide

A composite oxide sintered body includes In, Zn, and Sn, and has a relative density of 90% or more, an average crystal grain size of 10 μm or less, and a bulk resistance of 30 mΩcm or less, the number of tin oxide aggregate particles having a diameter of 10 μm or more being 2.5 or less per mm2 of the composite oxide sintered body.

Owner:IDEMITSU KOSAN CO LTD

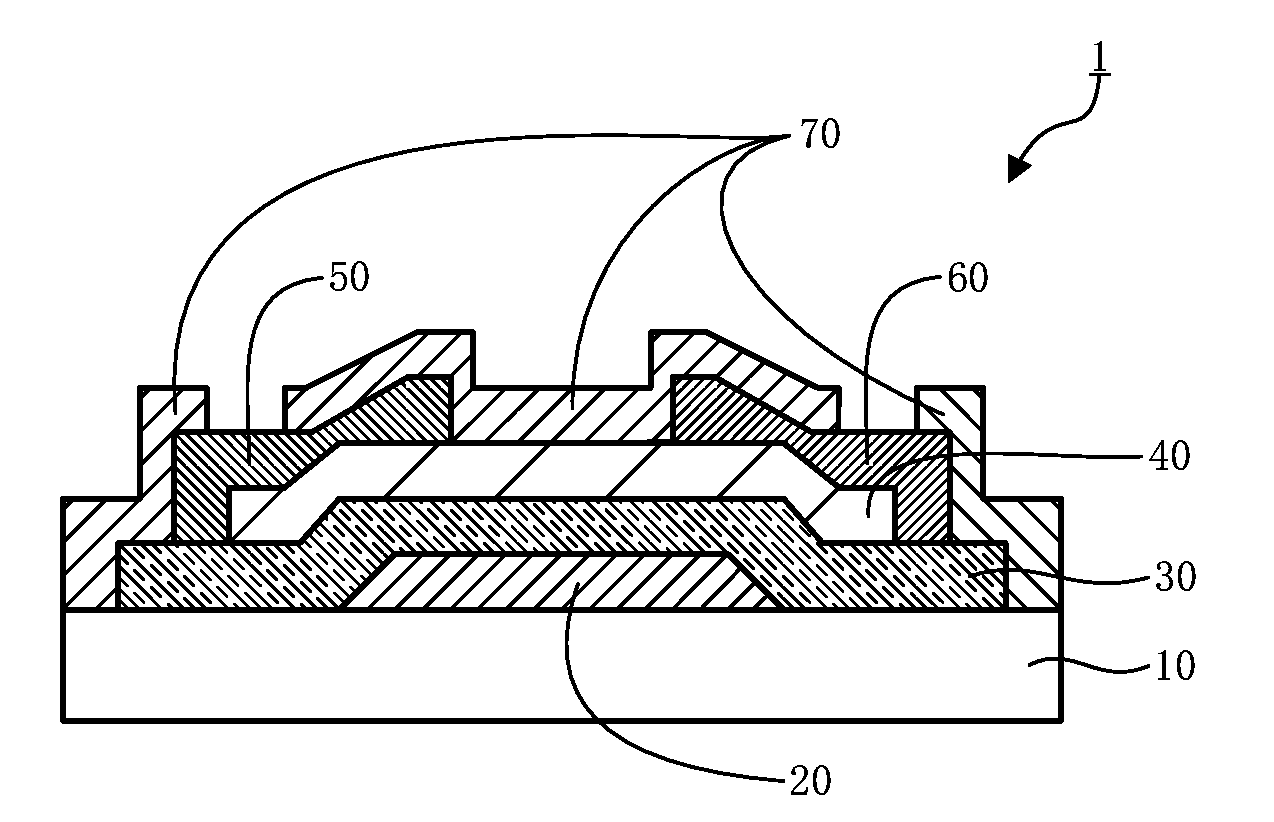

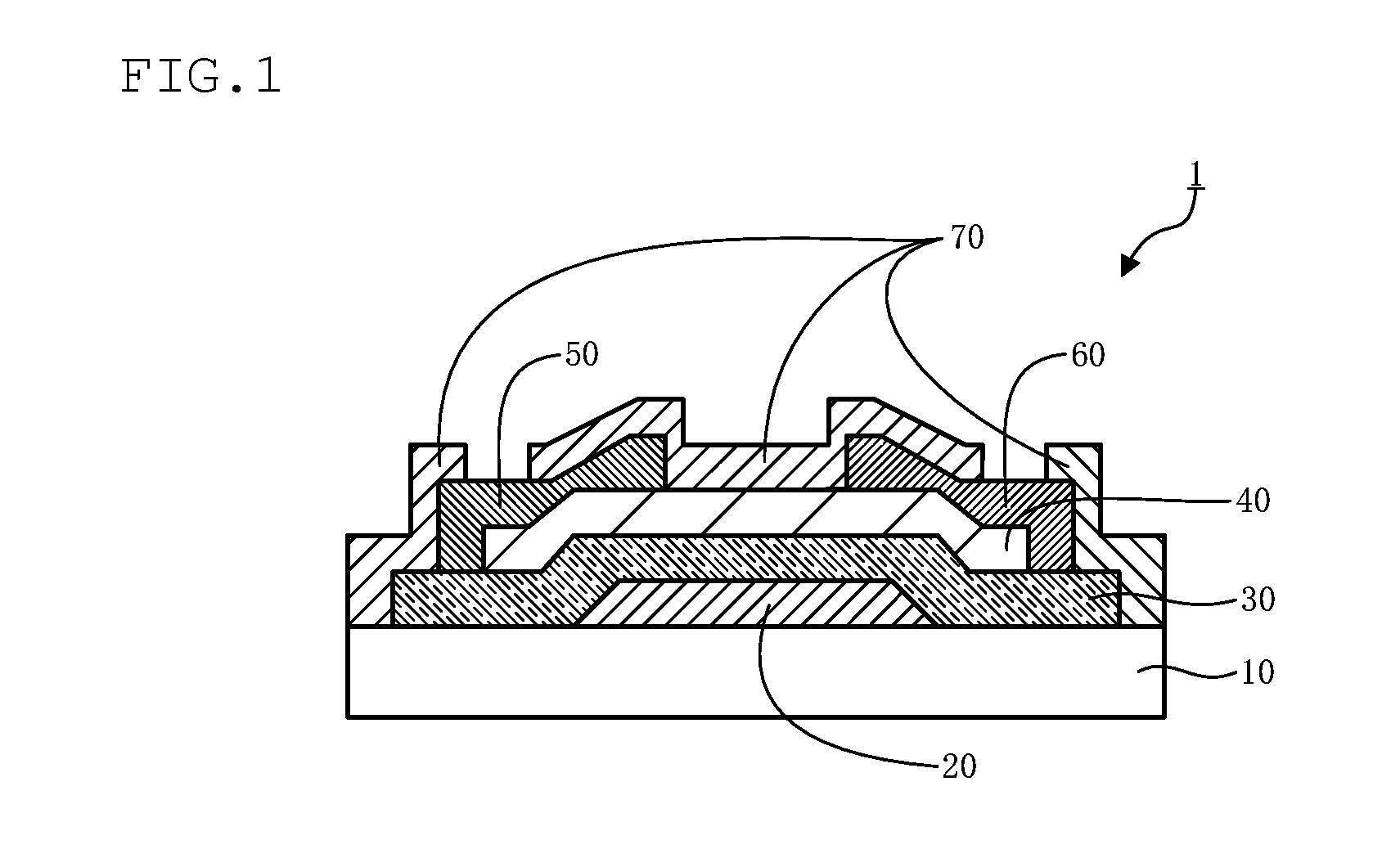

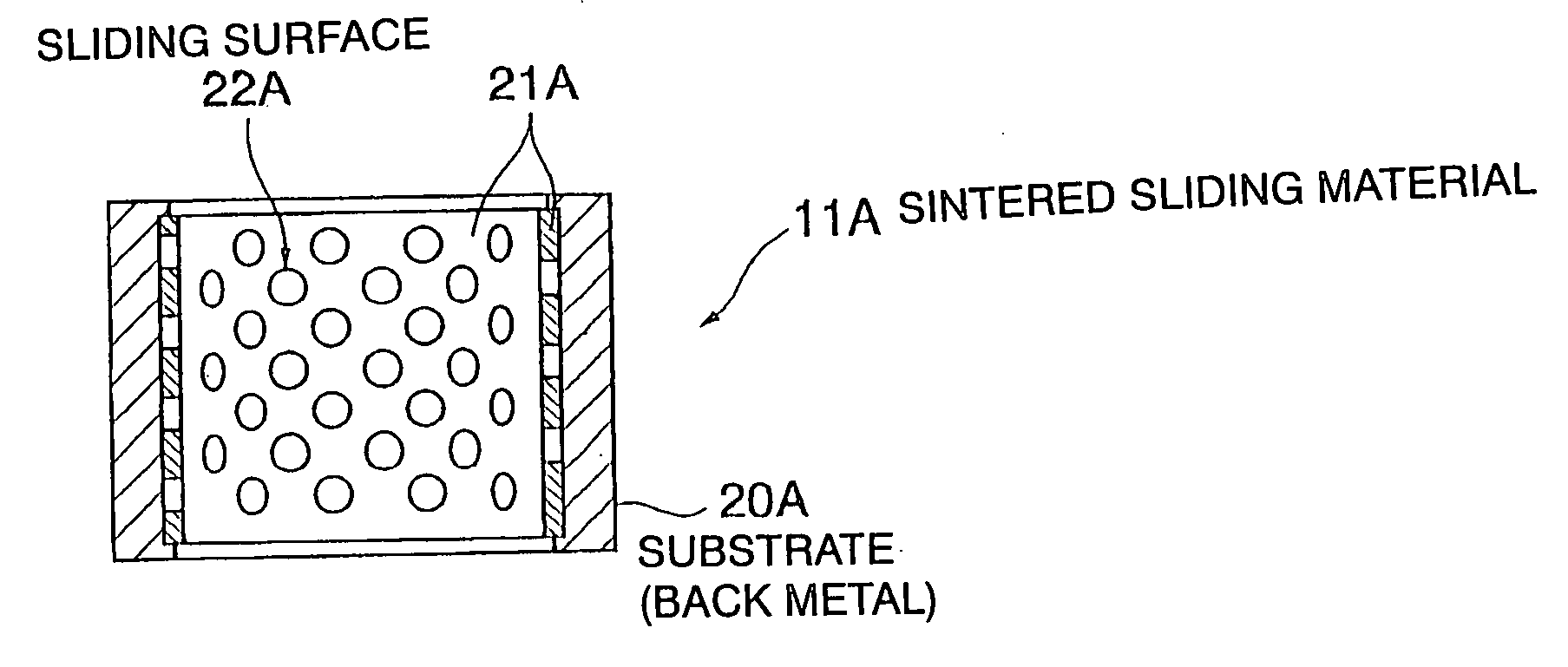

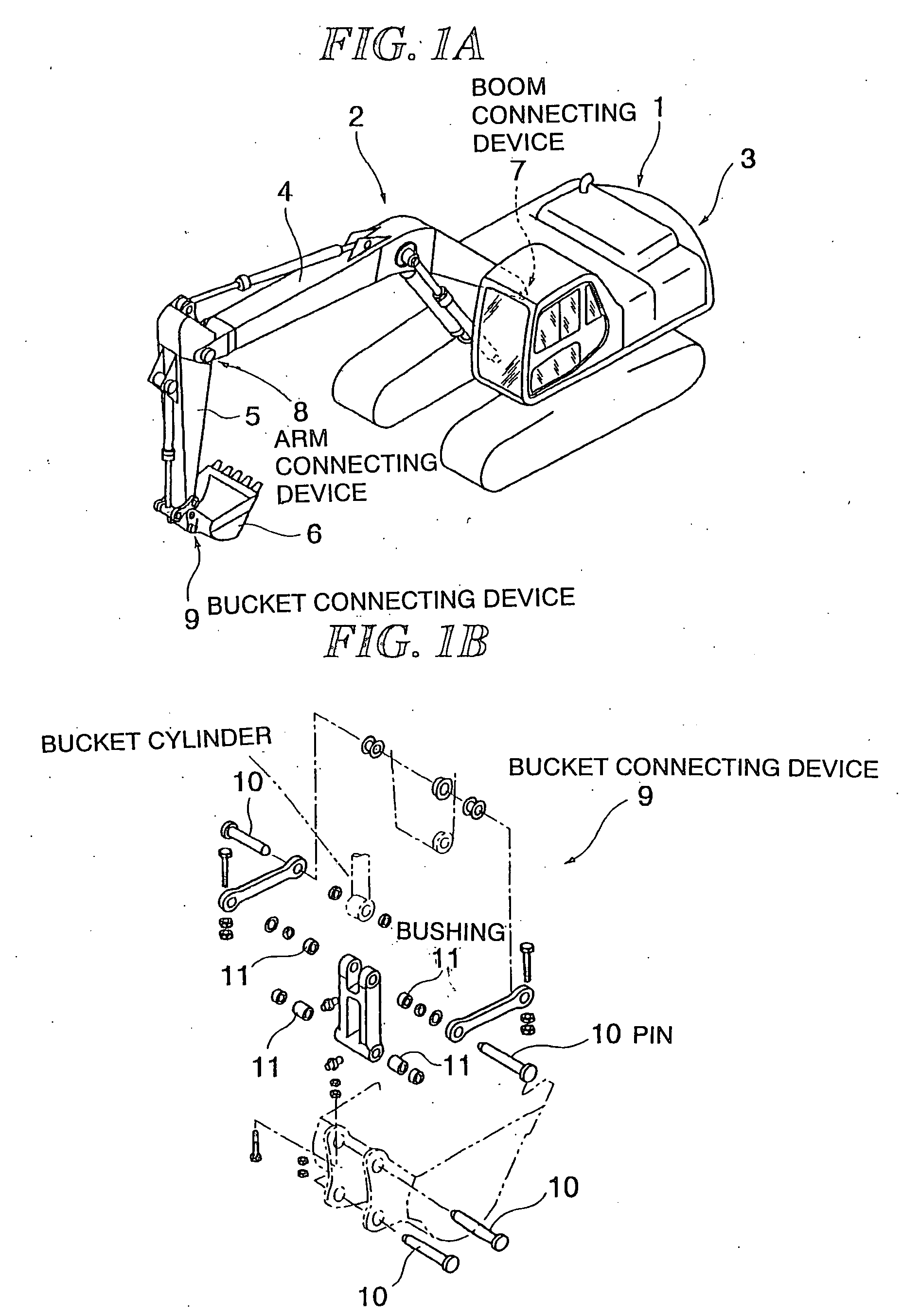

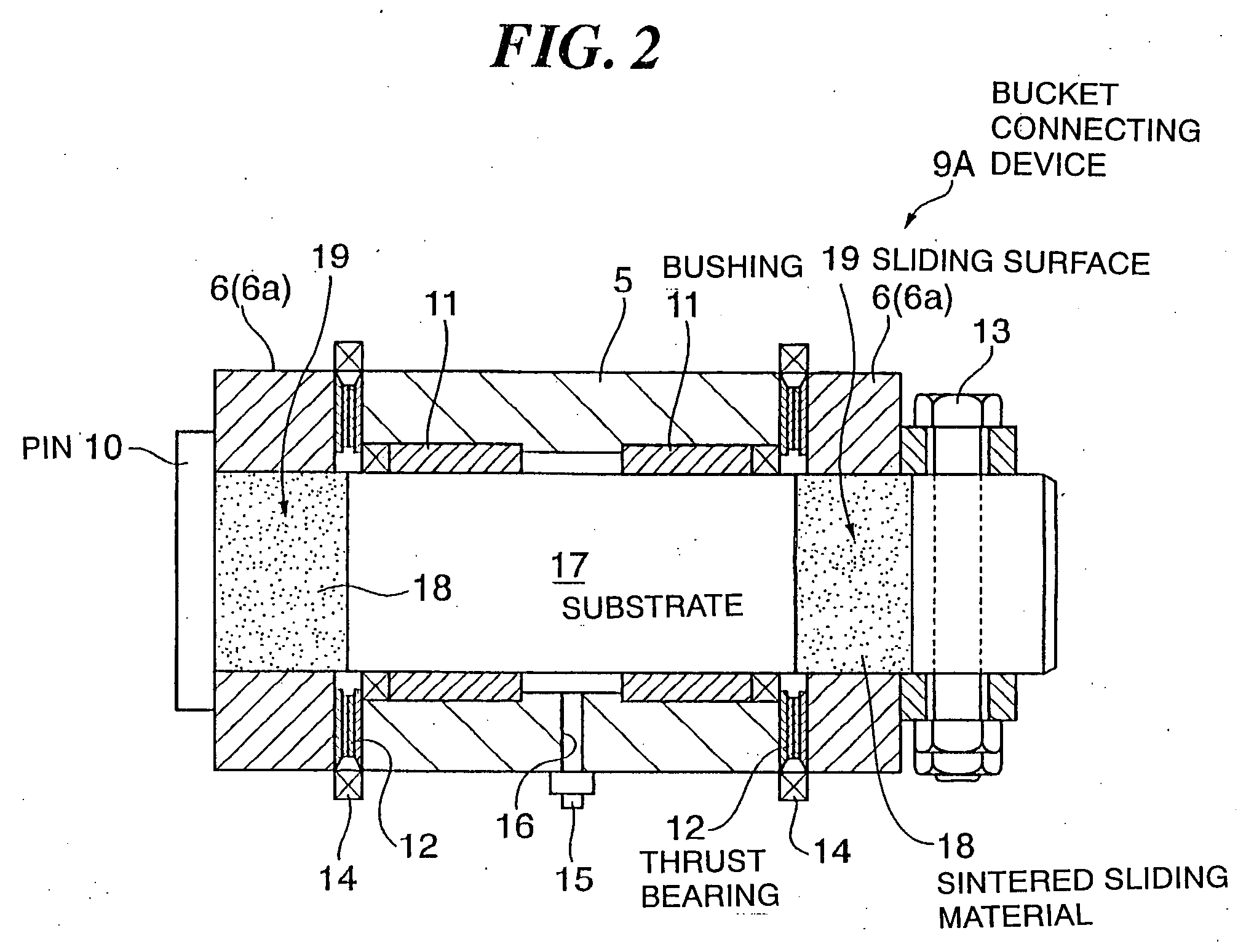

Sintered sliding material, sliding member, connection device and device provided with sliding member

InactiveUS20070009757A1Excellent seizing resistanceExcellent abrasion resistanceThermometers using material expansion/contactionShaftsVolumetric Mass DensityRelative density

A sintered sliding material, a sliding member and a connecting device capable of demonstrating excellent seizing resistance and abrasion resistance under very bad lubricating conditions such as a high-bearing stress and slow-speed sliding condition and an oscillating condition can be provided. The sintered sliding material is composed of a sintered compact containing Cu or Cu alloy in an amount of 10 to 95 wt % and a residue made of Mo principally, in which the sintered compact has a relative density of 80% or more.

Owner:KOMATSU LTD

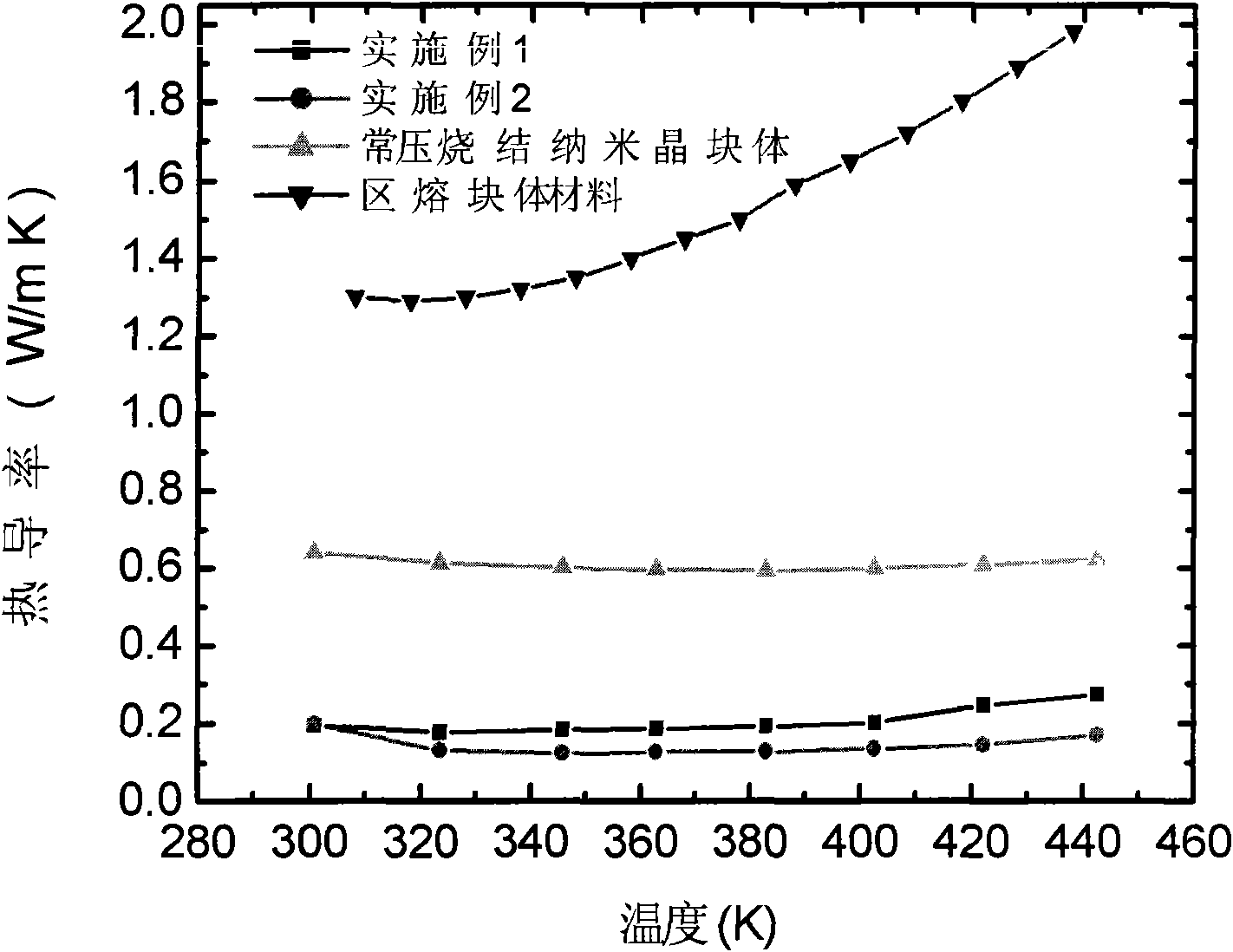

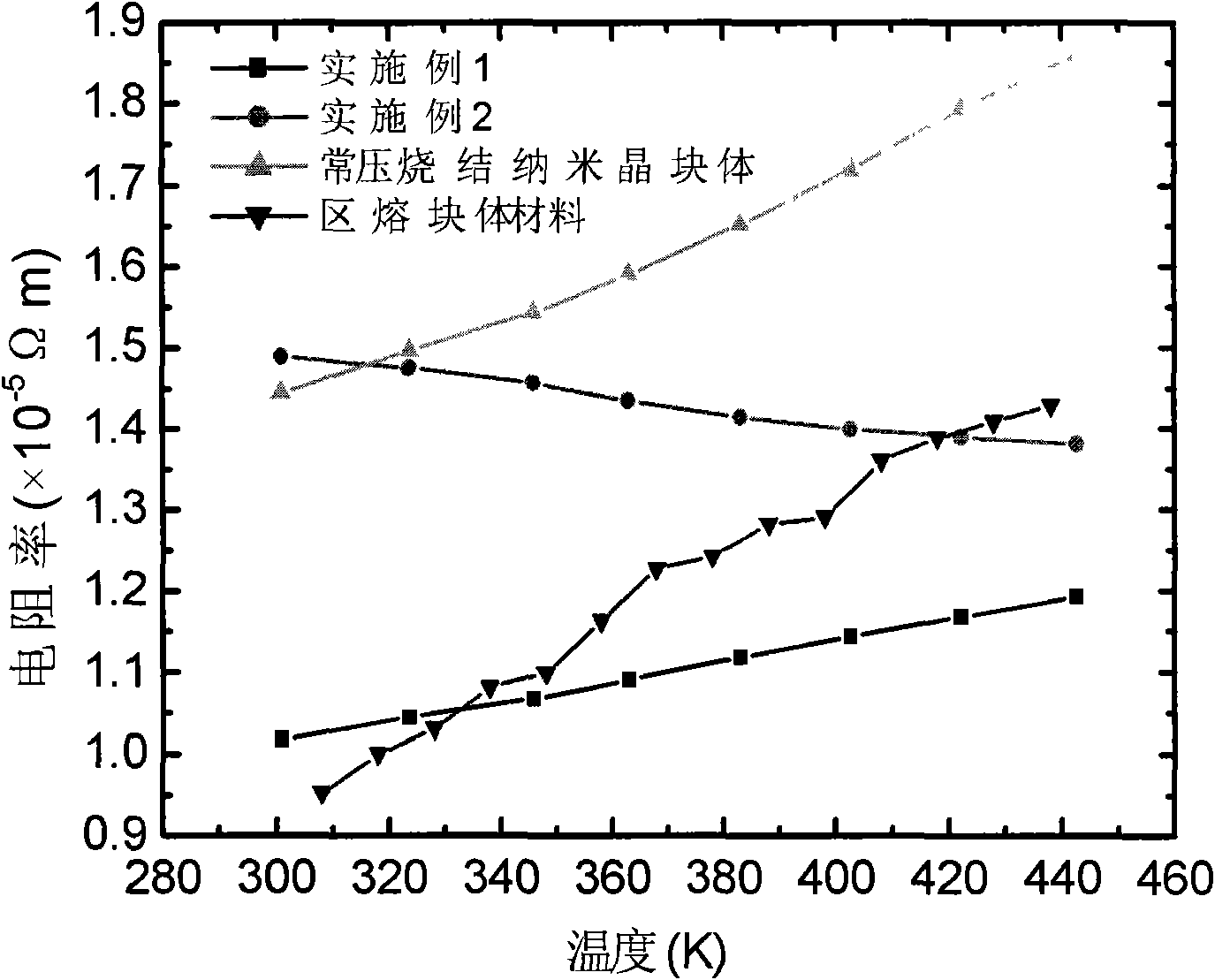

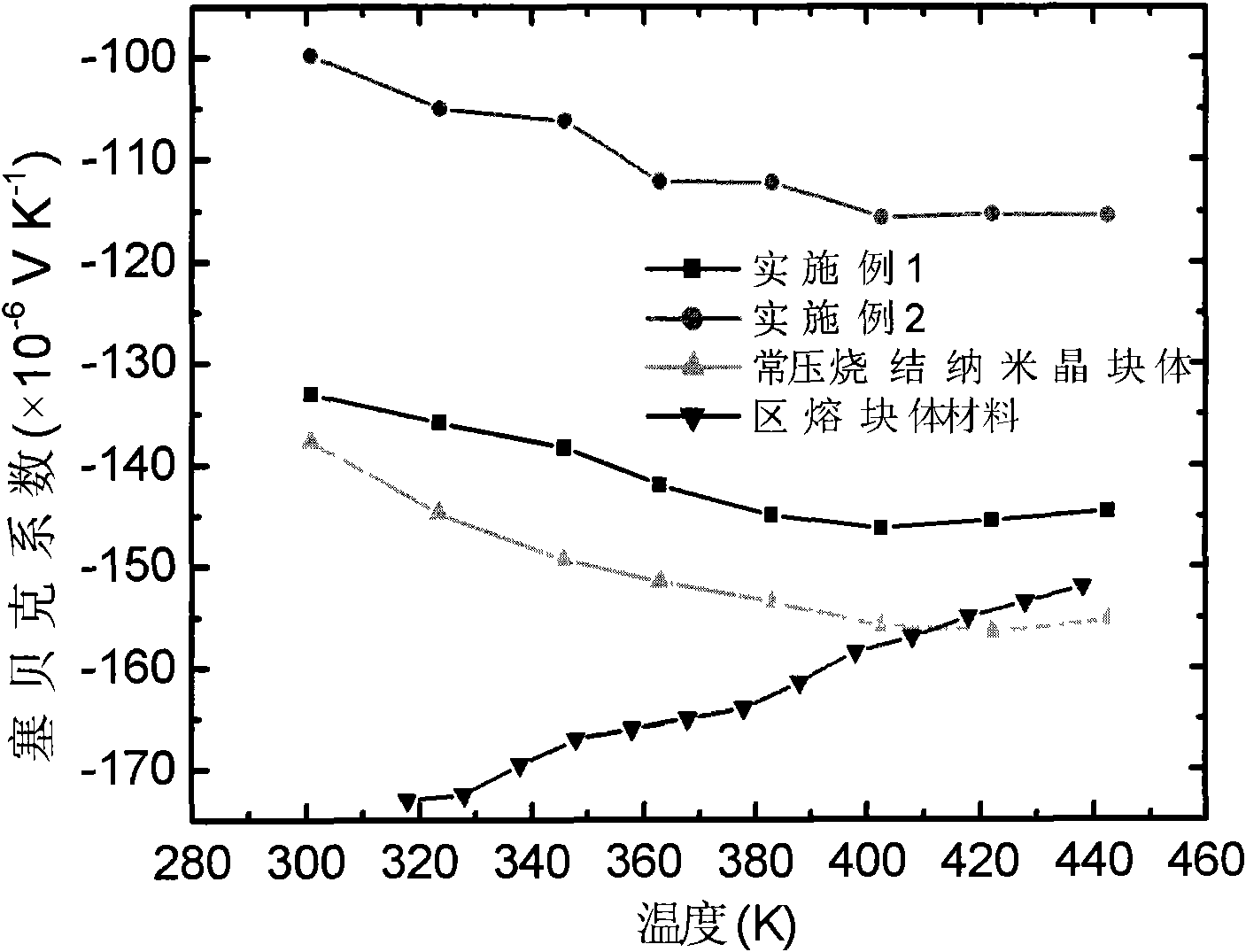

High-pressure sintering preparation method of high-densification high-performance nano crystal block thermoelectric material

InactiveCN101549405ASimple processSimple stepsMaterial nanotechnologyThermoelectric device manufacture/treatmentThermoelectric materialsCondensed matter physics

The invention discloses a high-pressure sintering preparation method of high-densification high-performance nano crystal block thermoelectric material, characterized in that: (1) preparing nano crystal alloy powder using a ball milling method, with crystal grain size of 5nm-30nm; (2) preparing nano crystal block thermoelectric material using the high-pressure sintering technique, at pressure range of 0.8GPa-6GPa and sintering temperature range of 0.25-0.8T[melting point] for sintering time range of 10-120 minutes and the relative density of the obtained nano crystal block thermoelectric material is 90-100% and the average grain size is 10-50 nm. The technique is simple and the zero dimension thermoelectricity Q-value (ZT) is above 2.0. The prearation method increase the density of the nano crystal block thermoelectric material on the basis of ensuring the material with high thermoelectricity with good industrialization foreground.

Owner:YANSHAN UNIV

Method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing complex enzyme

InactiveCN103255190AImprove enzymatic hydrolysis efficiencyReduce manufacturing costFermentationWater bathsNeutral protease

The invention discloses a method and process for extracting animal micro-molecule polypeptides and amino acids by utilizing a complex enzyme. The method comprises the following steps: (1) crushing animal tissues so that the animal tissues can pass through a sieve of 80-200 meshes, and adding water to prepare a suspension with the concentration of 8-30 percent; (2) raising the temperature to be 35-40 DEG C, regulating the pH value to be 8.0-9.0 by using sodium carbonate, adding a complex enzyme I accounting for 0.5-2.0 percent of the animal tissues, performing ultrasonic enzymolysis at 14-16 kHz for 1-2 hours so that the proteins between cells are subjected to full enzymolysis, regulating the pH value to be 6.5-7.5, adding a complex enzyme II accounting for 0.5-3.0 percent of the animal tissues, fully and uniformly stirring, controlling the temperature of the water bath to be 37-45 DEG C, and performing ultrasonic enzymolysis at 15-17 kHz for 1-6 hours; (3) raising the temperature of the enzymolysis solution to be 90-100 DEG C to inactivate the enzyme for 20-30 minutes after the enzymolysis is finished; (4) filtering the solution subjected to enzymolysis through a 0.22mu m microfiltration membrane; and (5) concentrating the filtrate to the relative density of 1:1.0-1:1.2 to prepare the concentrated solution, wherein the complex enzyme II consists of Alcalase, Flavourzyme, Protamex, neutral protease and papain. According to the method, the enzymolysis efficiency can be improved, and the production cost can be reduced.

Owner:WEIHAI KANGBOER BIOLOGICAL PHARMA +1

Low-sintered glass ceramic composite material and its preparing method

InactiveCN1935739AFast transmissionThe flexural strength is not lowCeramic compositeThermal expansion

The ivnetnion discloses a novel low temperature-fired glas ceramic composite and the preparing method thereof. And it comprises aluminum nitride and cordierite-based glass in the weight ratio of 35-57 to 65- 43, where the latter comprises SiO2 50-53wt%, Al2O3 20-26wt%,MgO 15-23wt%,B2O3 1.5-5wt%,P2O5 0-2.5wt%,and RxOy 1-6.5wt%, where R in RxOy is one of Bi, Ce and Zn, x=1-2 and y=1-3. When used in advanced electronic package, it has relative density up to above 97.2%, maximum heat conductivity up to 7.5W / m.K, thermal expansion coefficient 3.2- 3.8*10-6K-1, folding strength not lower than 168MPa, fracture toughness not lower than 2.38MPa.m1 / 2, low dielectric constant, largely improved mechanical properties, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com