Fine-crystal transparent alumina ceramic of high straight-line luminous transmittance and method for preparing same

A technology of alumina ceramics and light transmittance, applied in the field of preparation of transparent ceramic materials, can solve the problems of difficult repeatability, long sample prefabrication stage, high cost, and achieve the effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

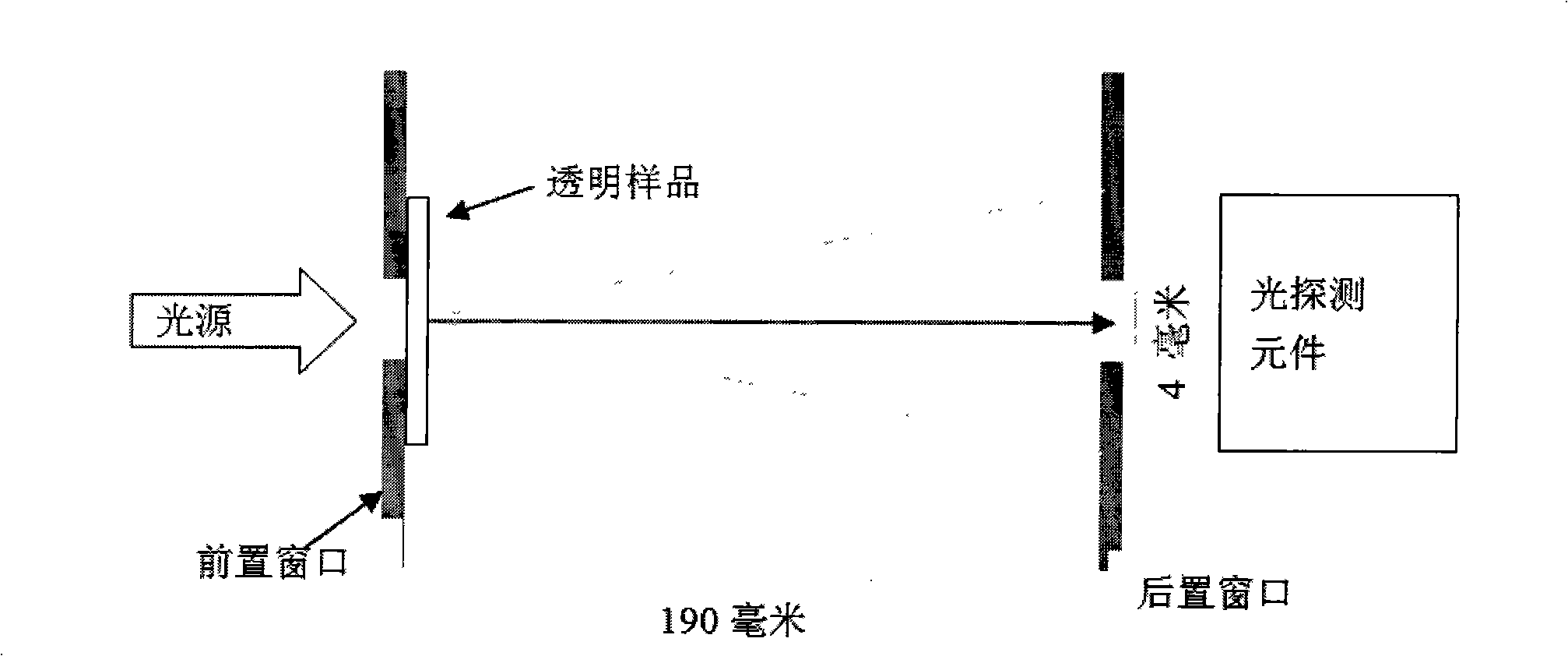

Method used

Image

Examples

Embodiment 1

[0027] Al with a purity of 99.99% and an average particle size of 300nm 2 o 3 The powder is loaded directly into graphite moulds. Control the furnace temperature to rise to 600°C within 3 minutes, then heat to 1150°C for 5 minutes and keep at this temperature for 5 minutes. During the sintering process, keep the pressure at 80MPa, then cut off the power supply and cool down. When the furnace temperature drops to 200°C, take out the graphite mold as a sample . Then, without high-temperature oxidation treatment, the ceramic sheet was directly polished on both sides to a thickness of 0.8 mm to test the optical properties.

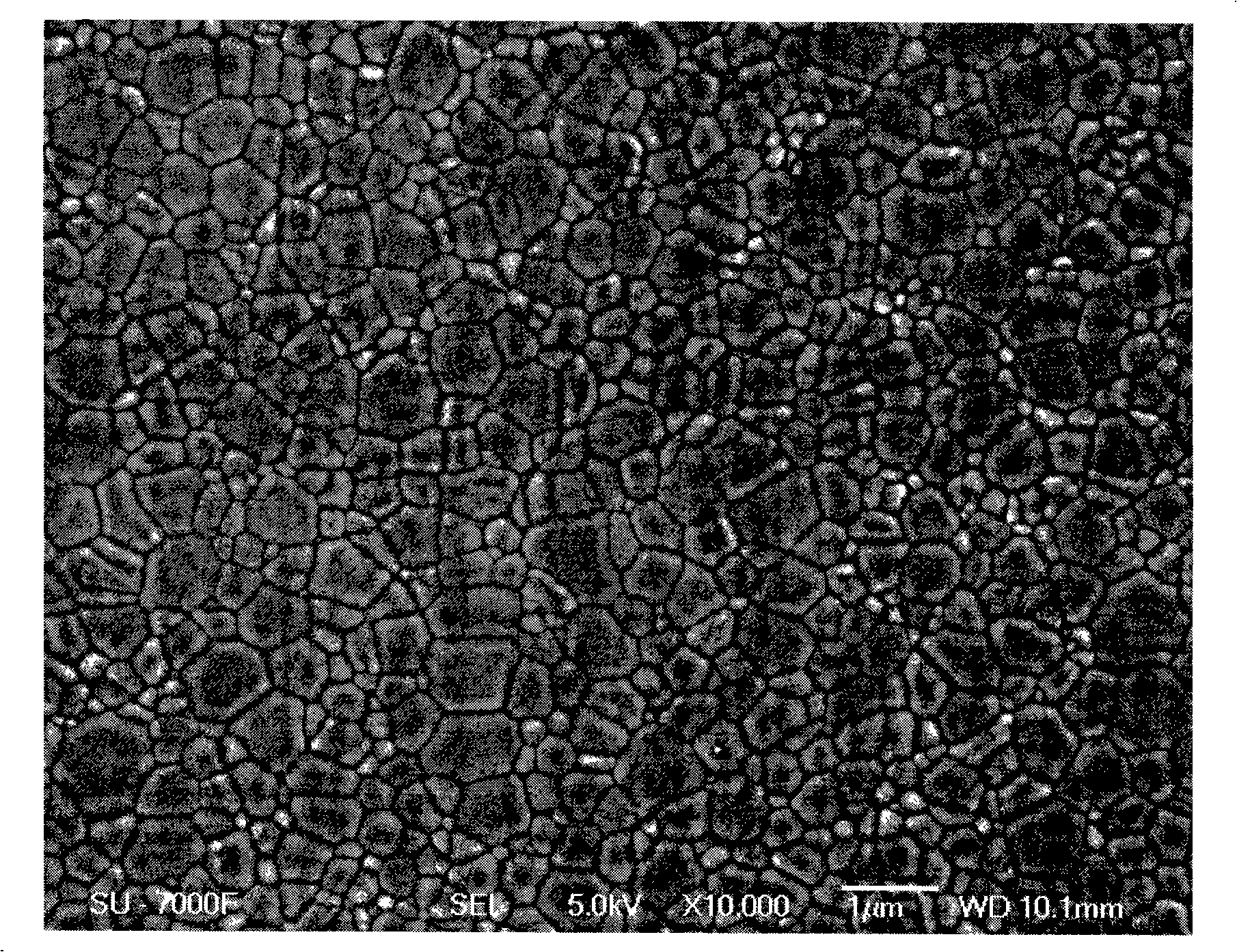

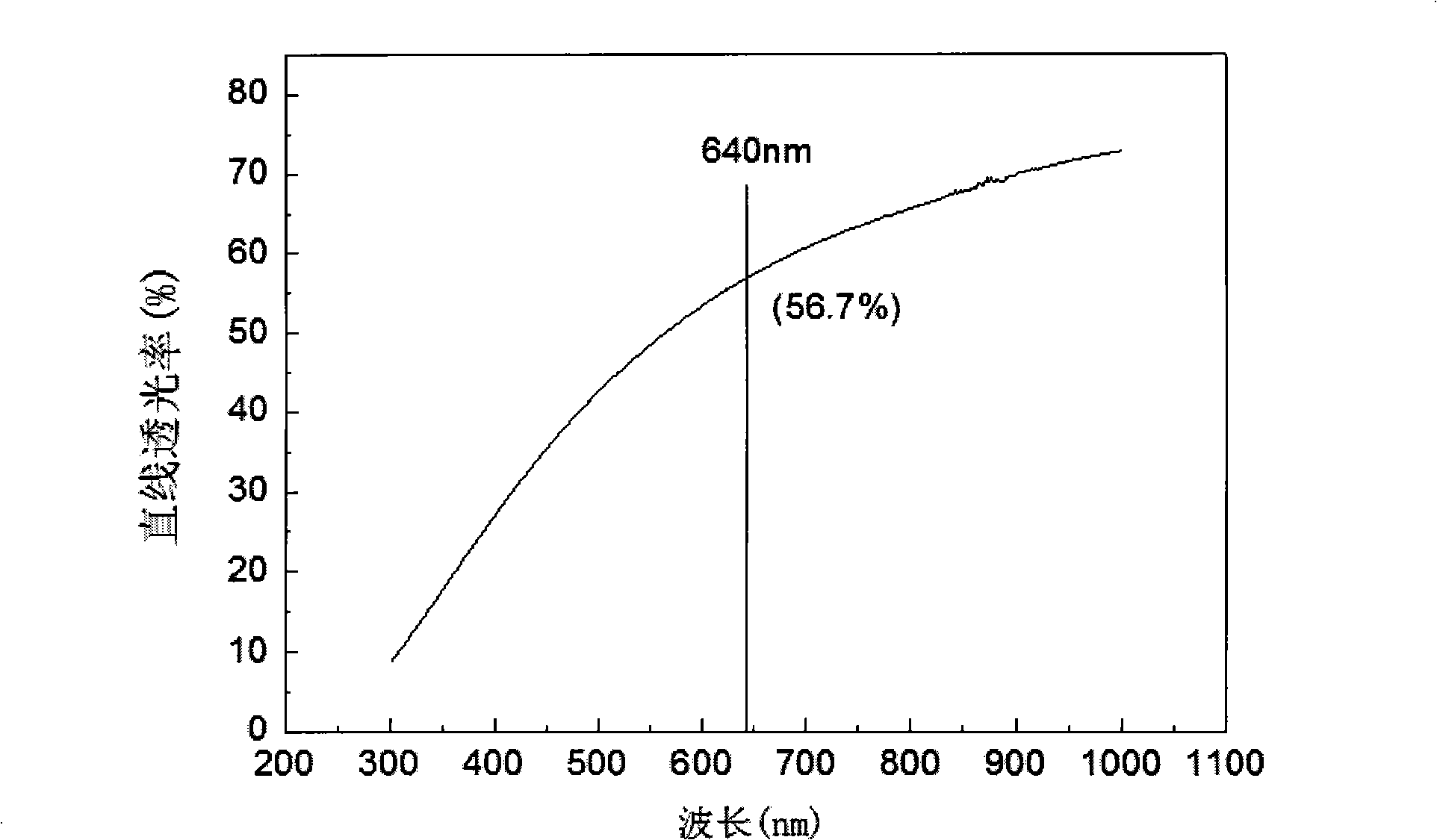

[0028] The relative density of the sintered ceramic sample is 99.7%, the average grain size is 0.5 micron, and the linear light transmittance of the material is 56.7% when the wavelength is 640nm. The Vickers hardness of the material is 21.3GPa, the bending strength is 770MPa, and the fracture toughness is 3.2MPam 1 / 2 . The transparent ceramic sheet is as...

Embodiment 2

[0030] Taking alumina as 100%, weigh MgO with a mass percentage of 0.02%, and then Al with a purity of 99.99% and an average particle size of 400nm 2 o 3 The powder was put into a ball mill jar and milled with water and high-purity alumina balls as the medium for 1 hour, and the pH value was adjusted to 3 with 0.1M nitric acid solution before ball milling. After ball milling, vacuum-dry at 80°C for 4 hours and pass through a 60-mesh sieve. Dry press the sieved powder with a steel mold at 50 MPa, and then press at 200 MPa to obtain a green body. Then put the biscuit into the graphite mold, control the furnace temperature to rise to 600°C within 3 minutes, then heat it to 1280°C for 6 minutes and keep it at this temperature for 7 minutes. During the sintering process, keep the pressure at 50 MPa, then cut off the power supply to cool, and the furnace temperature drops When the temperature reaches 200°C, take out the graphite mold as a sample. Afterwards, it was treated under ...

Embodiment 3

[0033] Taking alumina as 100%, weigh 0.3% of Y by mass 2 o 3 , and then with the quotient Al with a purity of 99.99% and an average particle size of 300nm 2 o 3 The powder was put into a ball mill jar and milled with water and high-purity alumina balls as the medium for 1 hour, and the pH value was adjusted to 3 with 0.1M nitric acid solution before ball milling. After ball milling, vacuum-dry at 80°C for 4 hours and pass through a 60-mesh sieve. Dry press the sieved powder with a steel mold at 50 MPa, and then press at 200 MPa to obtain a green body. Then put the biscuit into the graphite mold, control the furnace temperature to rise to 600°C within 3 minutes, then heat it to 1200°C for 6 minutes and keep it at this temperature for 10 minutes, keep the pressure at 50MPa during the sintering process, then cut off the power supply to cool, and the furnace temperature drops When the temperature reaches 200°C, take out the graphite mold as a sample. Afterwards, it was treate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com