Patents

Literature

2412 results about "Alumina ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance but relatively low strength and fracture toughness. Alumina Ceramics are generally white but may also be pink (88% alumina), or brown (96% Alumina).

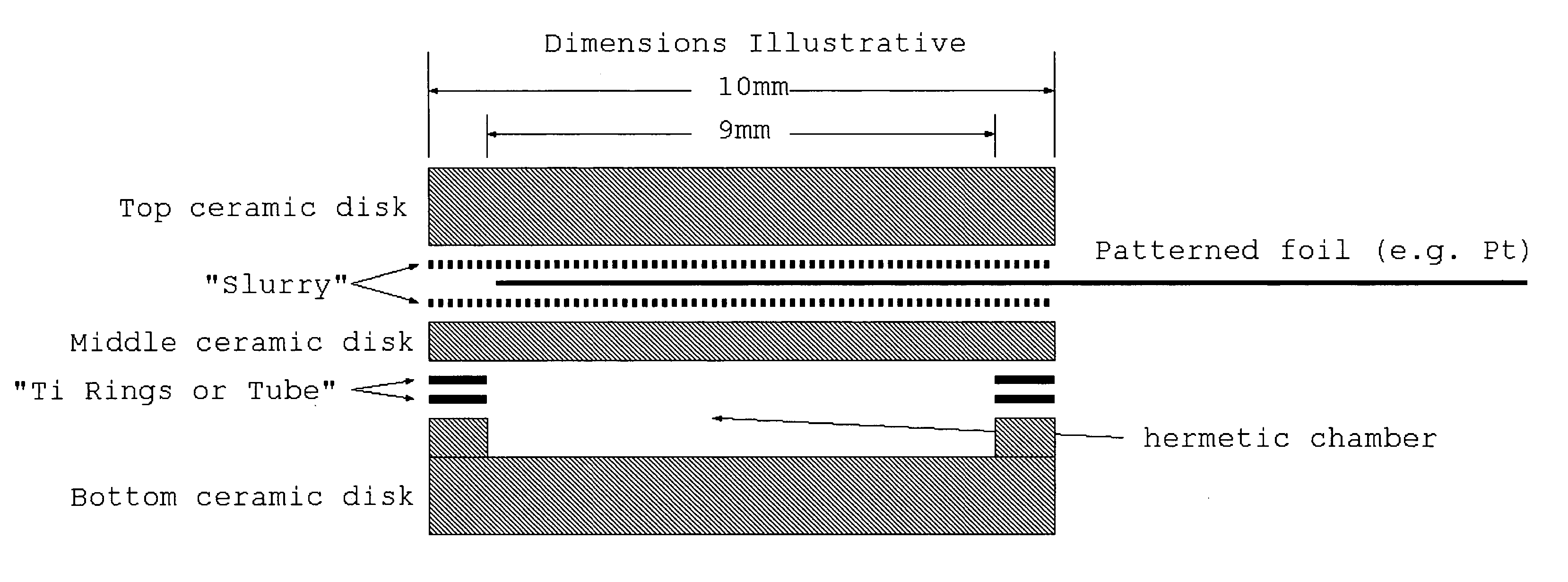

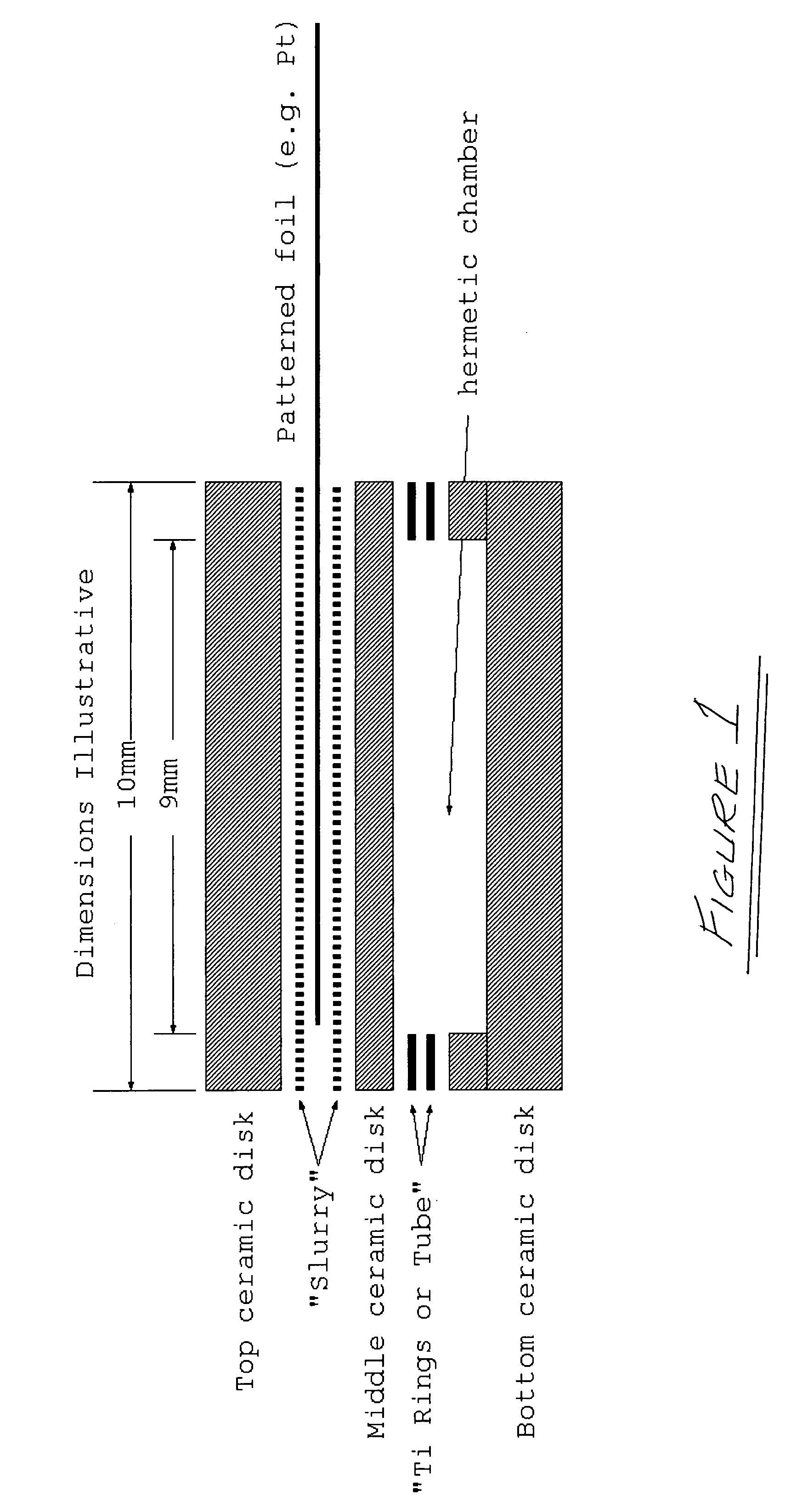

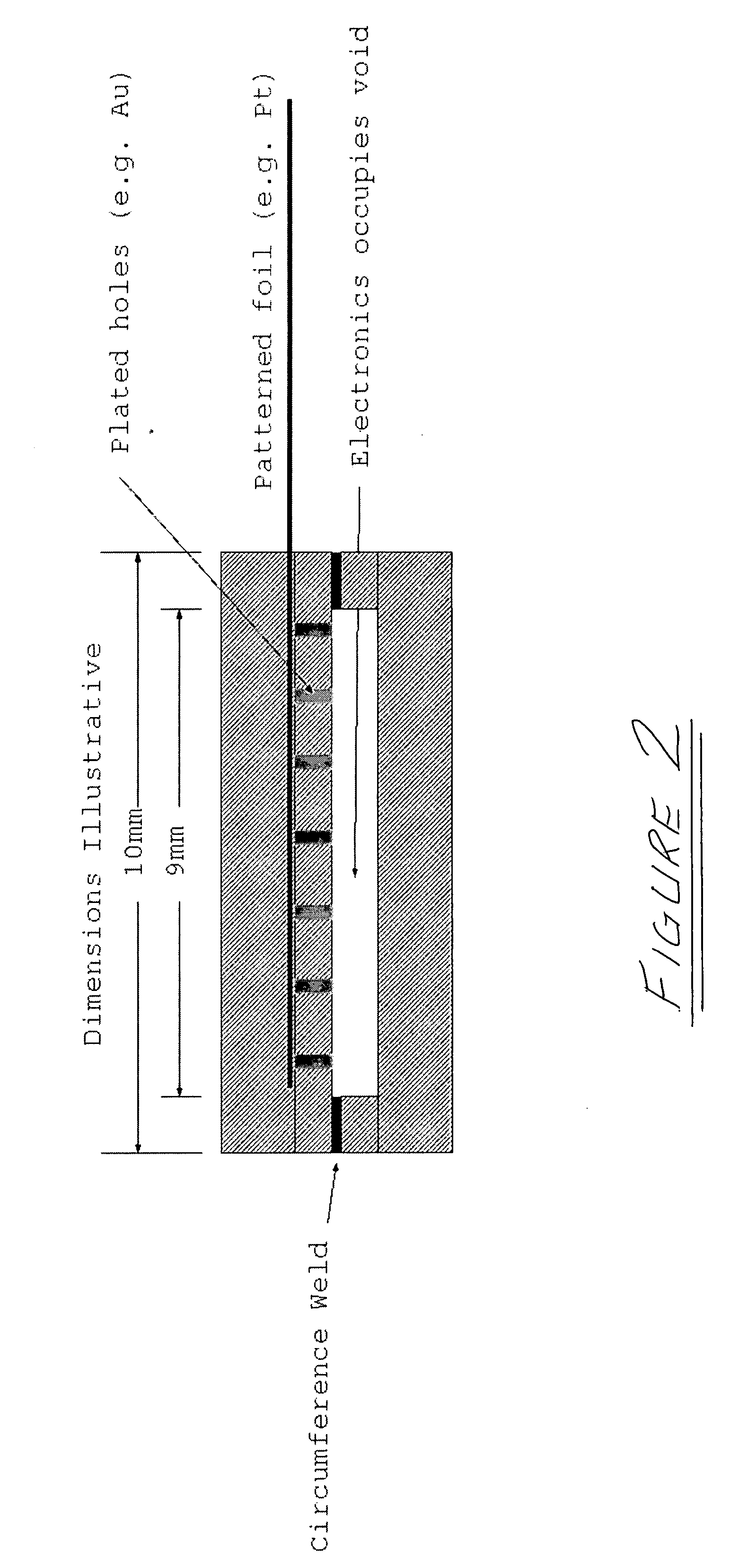

Method for fabrication of hermetic electrical conductor feedthroughs

InactiveUS20070277374A1High bonding strengthComplicated in fabrication procedurePrinted circuit assemblingLine/current collector detailsOxide ceramicPlatinum

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

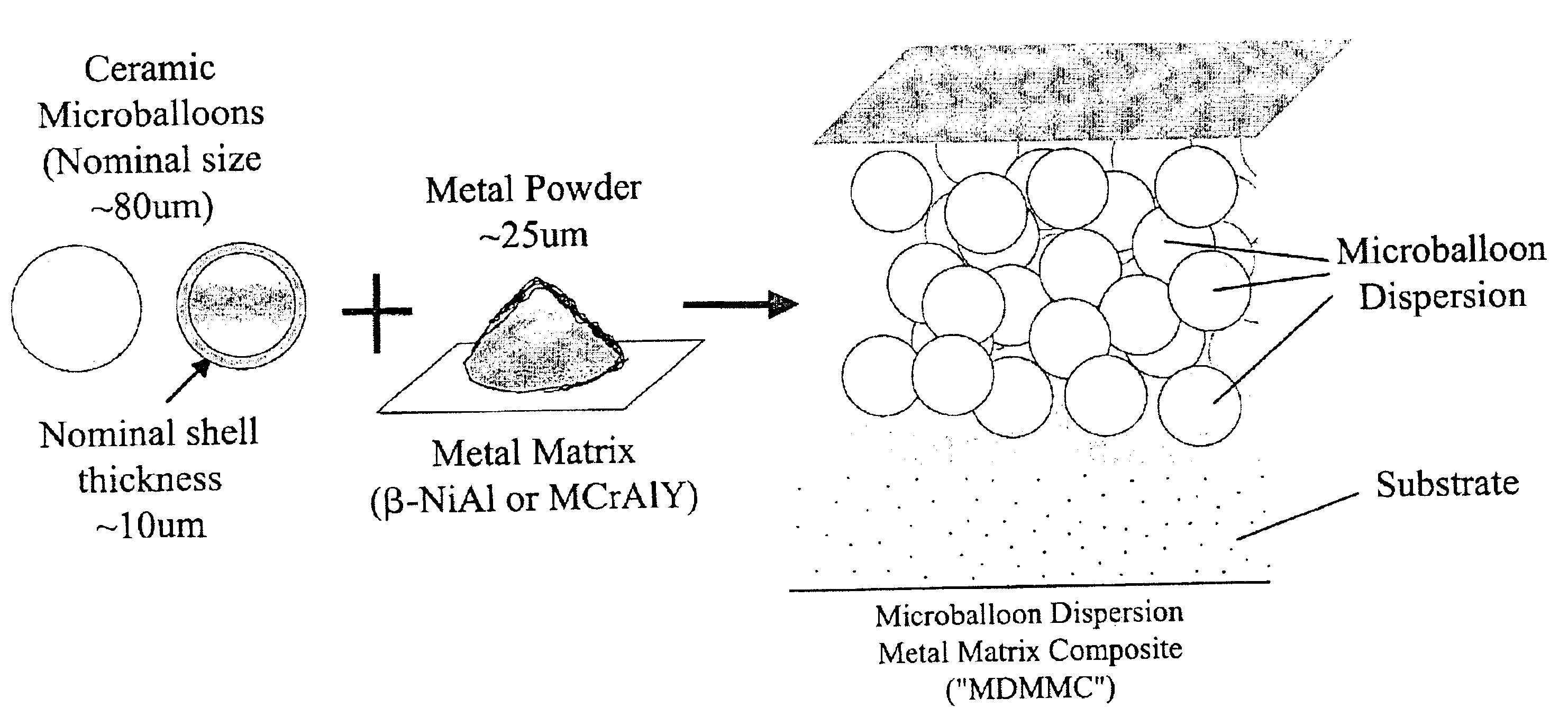

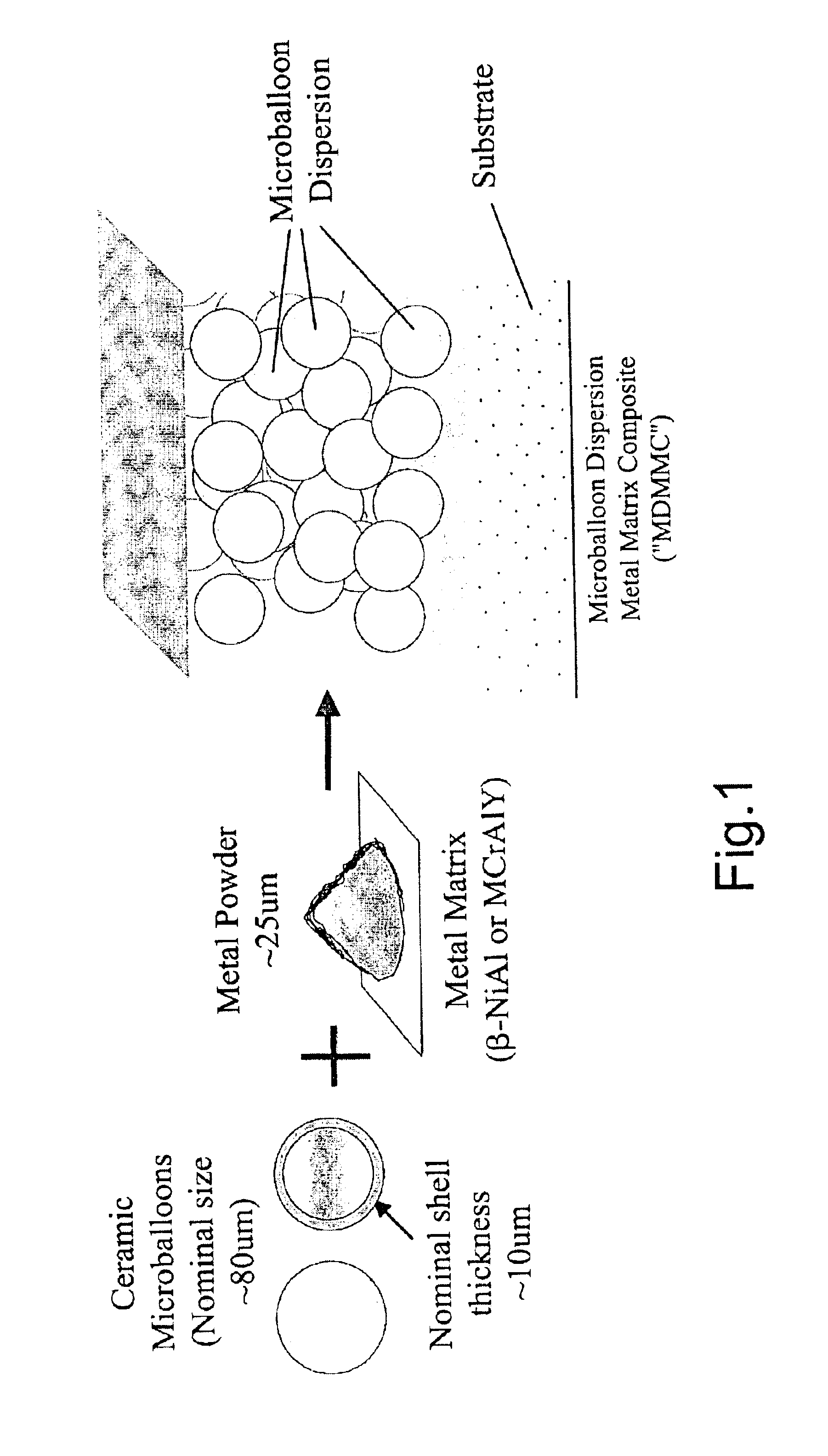

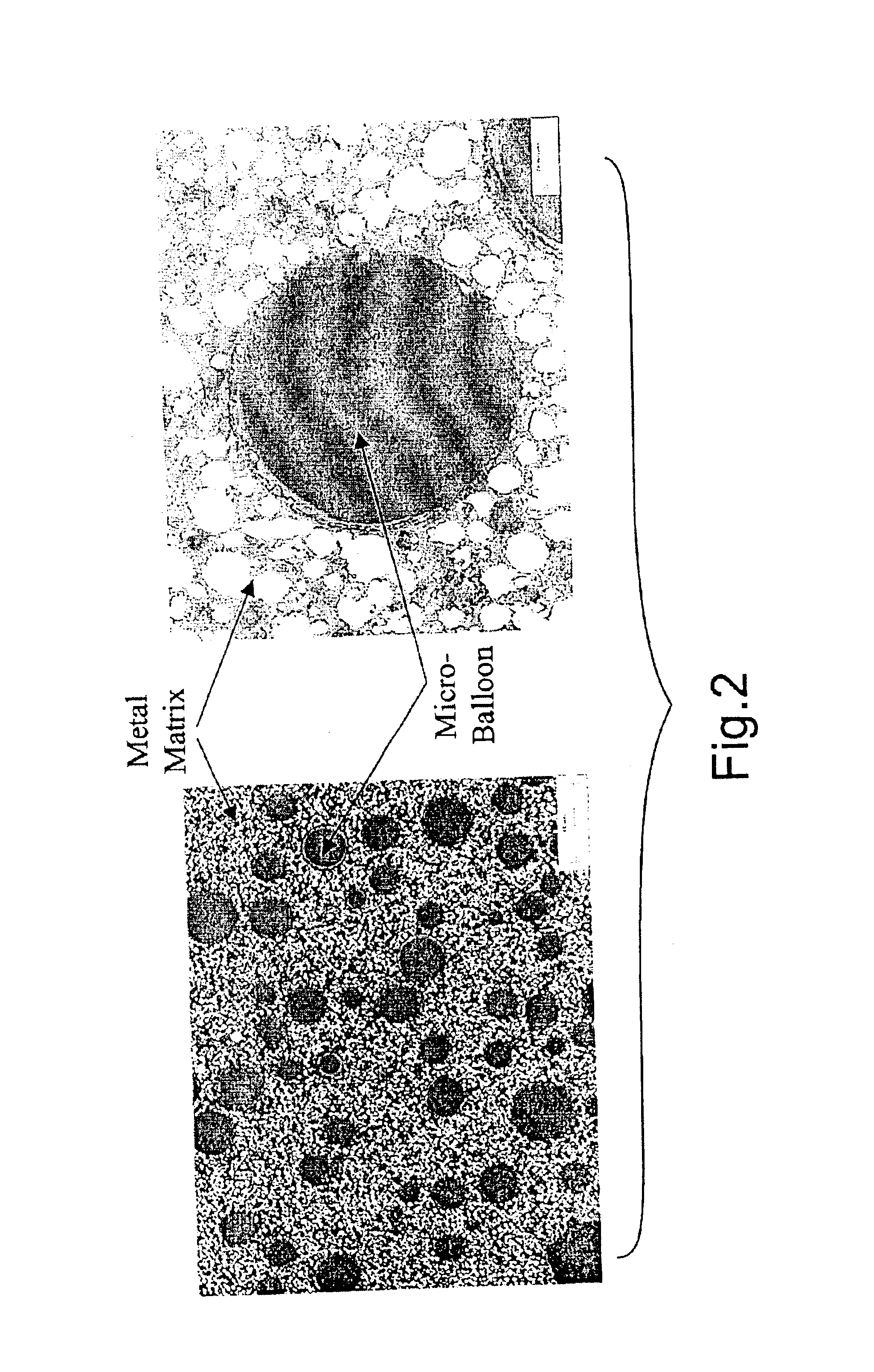

High temperature, oxidation-resistant abradable coatings containing microballoons and method for applying same

InactiveUS6916529B2Effective timeReducing hot gas leakageMolten spray coatingPropellersThermal sprayingMicrosphere

An abradable coating composition for use on shrouds in gas turbine engines or other hot gas path metal components exposed to high temperatures containing an initial porous coating phase created by adding an amount of inorganic microspheres, preferably alumina-ceramic microballoons, to a base metal alloy containing high Al, Cr or Ti such as β-NiAl or, alternatively, MCrAlY that serves to increase the brittle nature of the metal matrix, thereby increasing the abradability and oxidation resistance of the coating at elevated temperatures. Coatings having a total open and closed porosity of between 20% and 55% by volume due to the presence of ceramic microballoons ranging in size from about 10 microns to about 200 microns have been found to exhibit excellent abradability for applications involving turbine shroud coatings. An abradable coating thickness in the range of between 40 and 60 ml provides improved performance for turbine shrouds exposed to gas temperatures between 1380° F. and 1800° F. Abradable coatings in accordance with the invention can be used for new metal components or to repair existing equipment. The coatings can be applied to the metal shroud using thermal spray, processes that integrate sintering and brazing, or direct write techniques.

Owner:GENERAL ELECTRIC CO

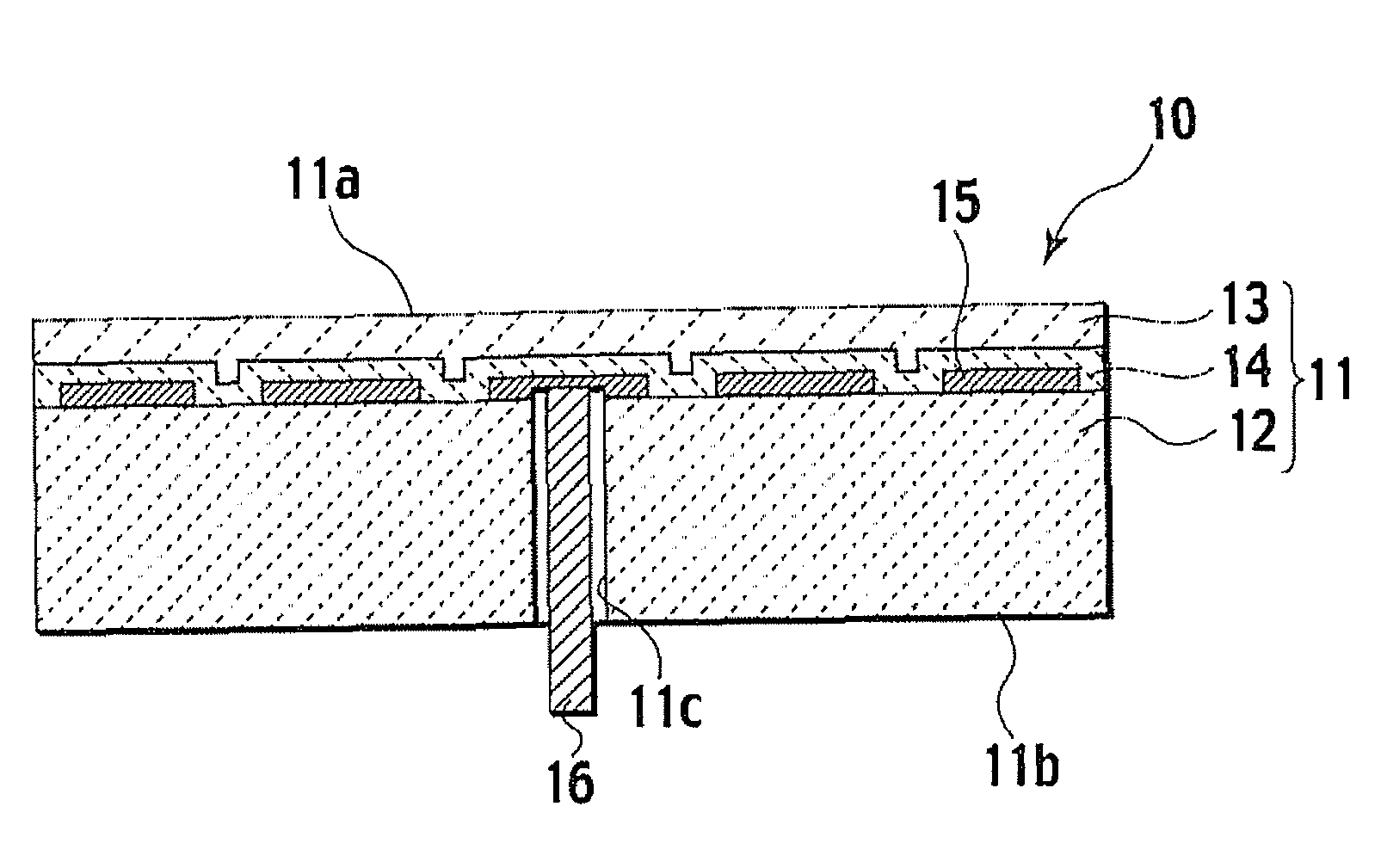

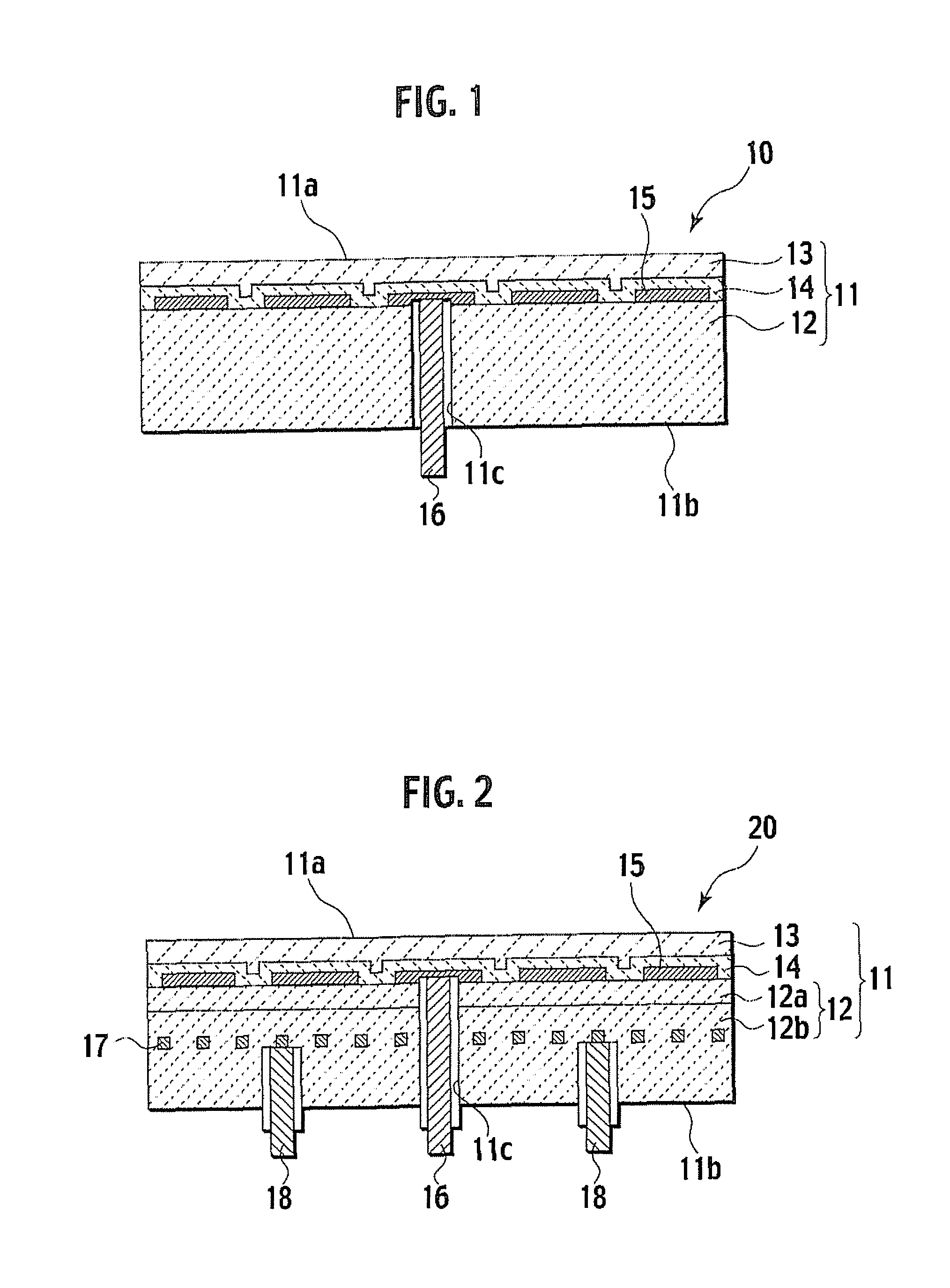

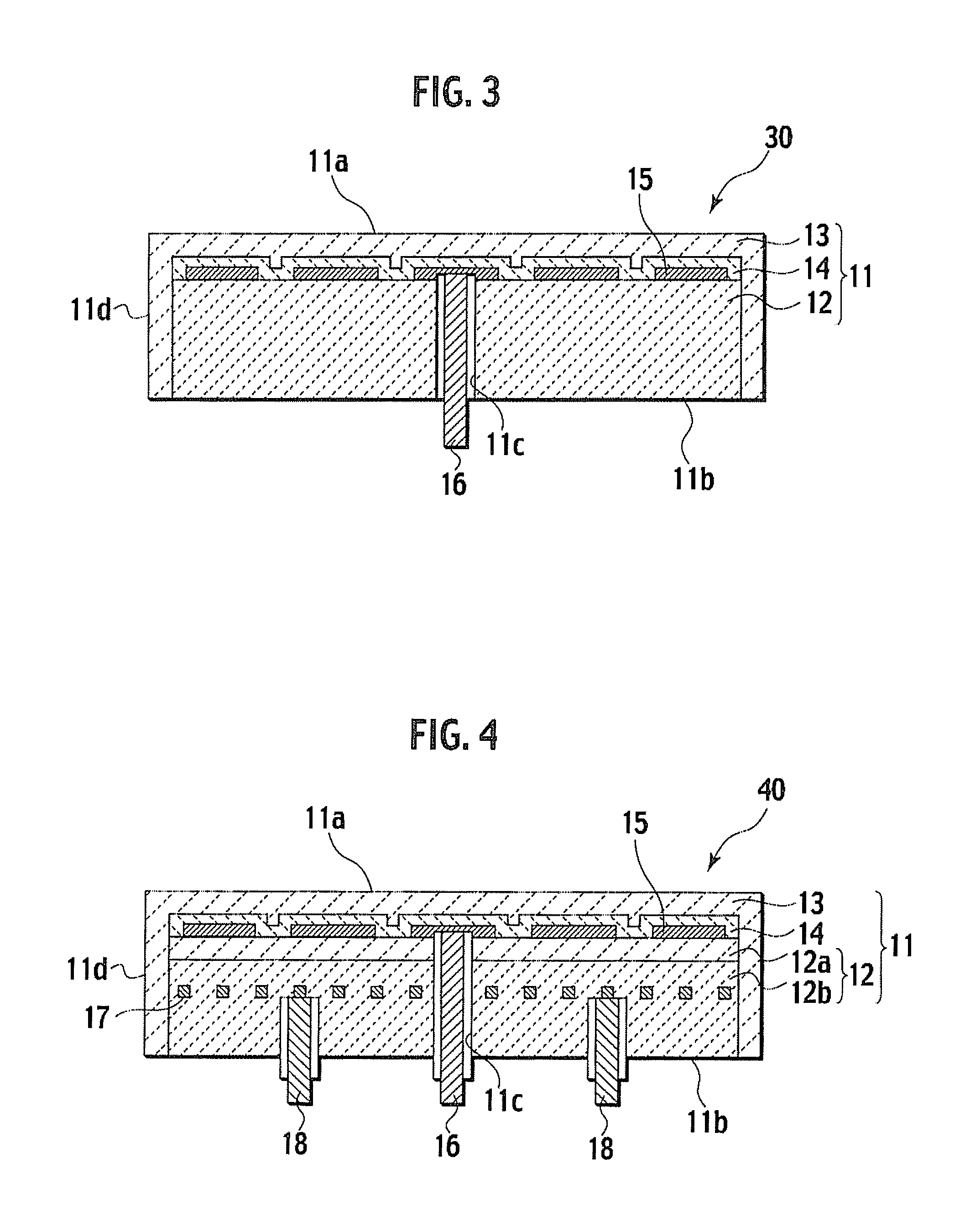

Electrostatic chuck with heater and manufacturing method thereof

ActiveUS20080174930A1Great suctionImprove corrosion resistanceSemiconductor/solid-state device manufacturingCeramic shaping apparatusMaterials scienceAlumina ceramic

An electrostatic chuck includes a base. The base has a support portion made of alumina ceramics, and a surface portion made of yttria ceramics. The surface portion forms at least a substrate mounting surface and side surface of the base on a surface of the support portion. Carbon contents in alumina ceramics of the support portion and yttria ceramics of the surface portion are 0.05 wt % or less.

Owner:NGK INSULATORS LTD

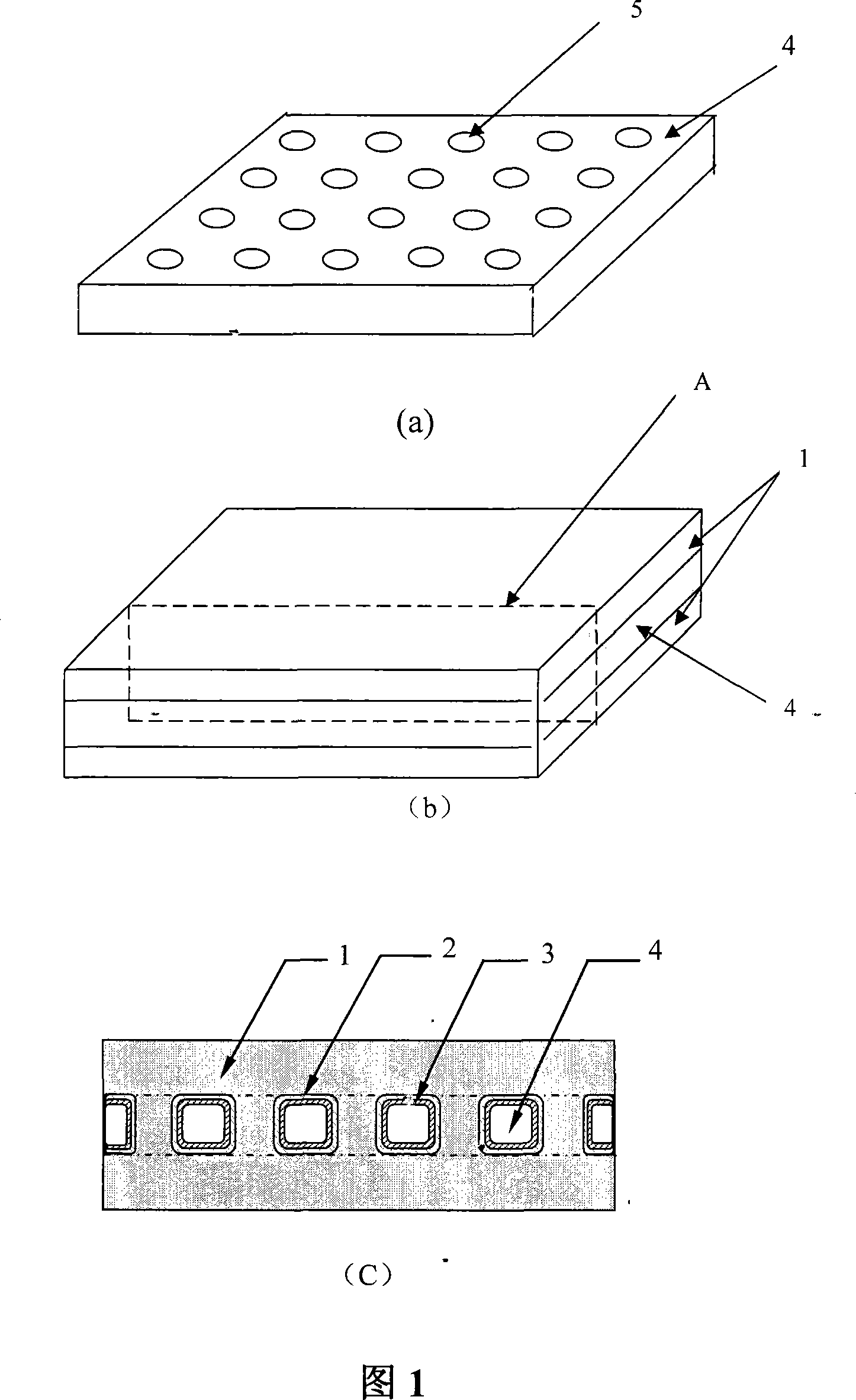

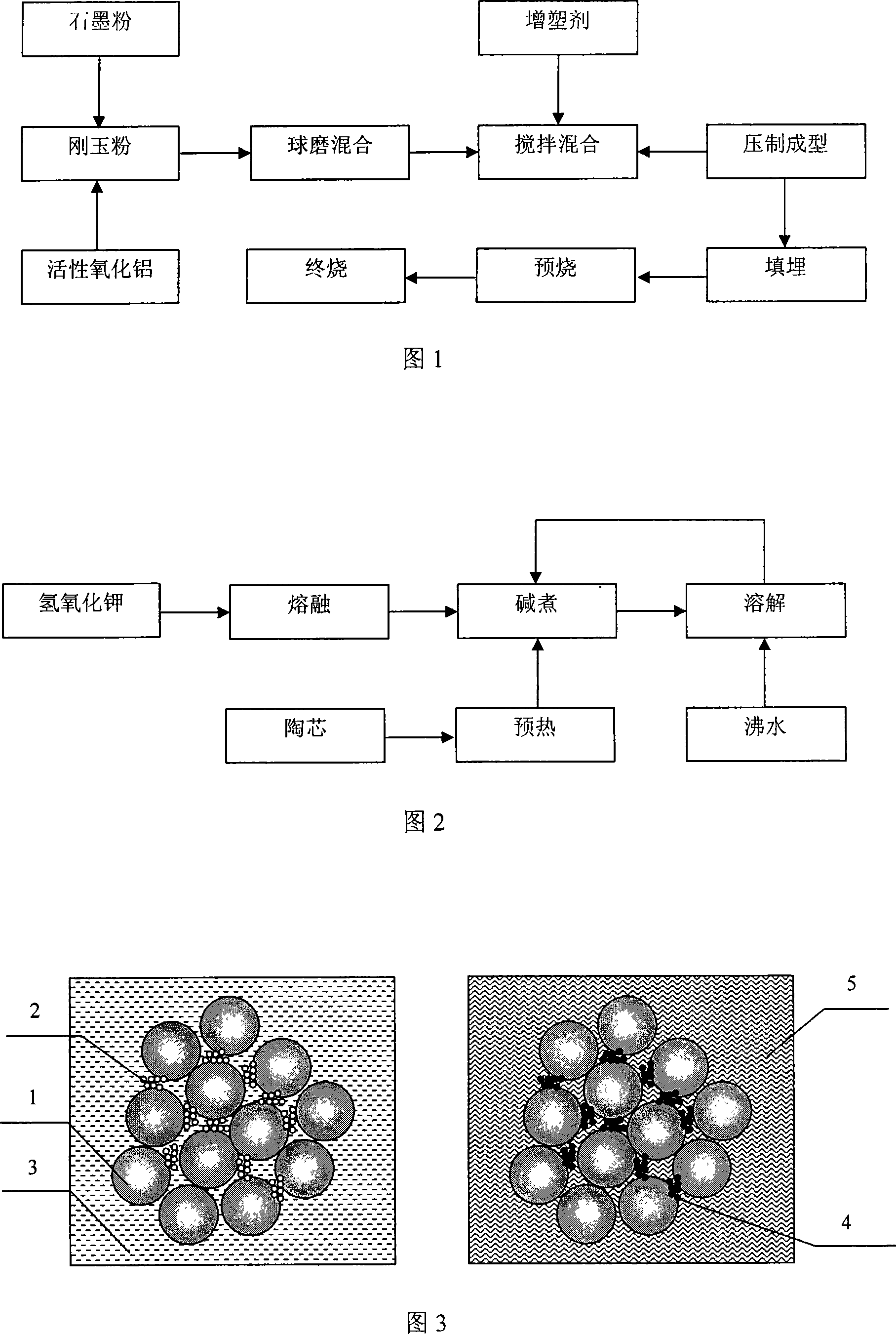

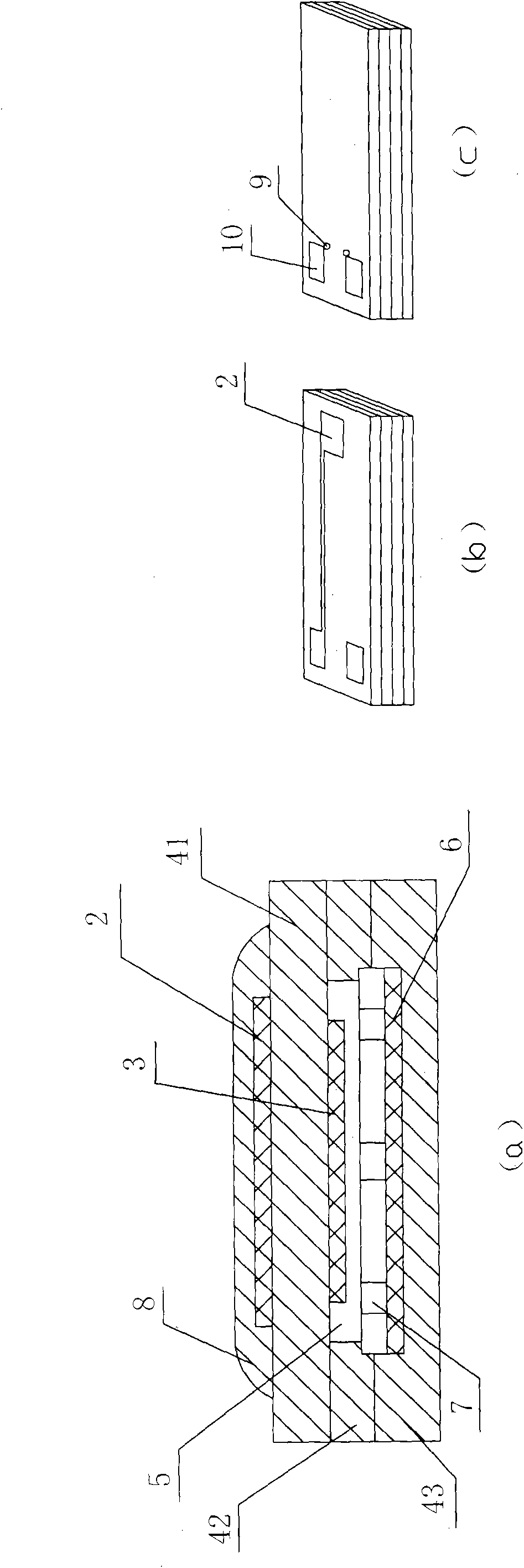

Armor of ceramic-metal composite and preparation method thereof

InactiveCN101158564AHigh hardnessStrong penetration resistanceArmour platesMolten stateCeramic composite

The invention discloses a metallic / ceramic composite armor and preparation method with ordered supporting structure of metallic materials as a framework and alumina ceramic materials as a core, and comprises the following steps: (1) a ceramic core plate with well-ordered pore canals is prepared and comprises working procedures such as forming, first sintering, hole machining and final sintering; (2) the ceramic core plate is sintered and metallized, all the surfaces of the finally sintered ceramic core plate is coated with Mo-Mn metal pastes, after being dried, the finally sintered ceramic core plate is metallized and sintered by being put under a protective atmosphere; (3) the metal is poured or vacuum heating treatment is made, the metal material is heated into a molten state, then poured into a die in which the ceramic core plate is arranged to have a thermostatic treatment, and finally cooled slowly to knock out. The invention can overcome weak binding of articulated connection and plane connection between the metal and the ceramic, etc., and realize high-strength binding between metallic / ceramic interfaces, moreover, the prepared metallic / ceramic composite armor with the sandwiches which can pass mutually is provided with the performance of light weight, high strength and impact resistance, thereby being suitable for a bulletproof composite armor plate and an armored panel on tanks and armored vehicles, etc.

Owner:XI AN JIAOTONG UNIV

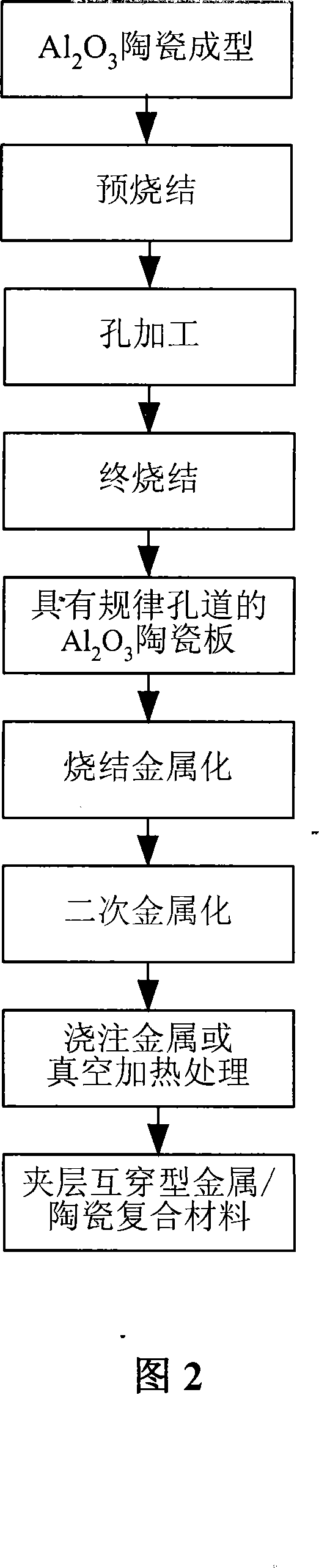

Method for making alumina ceramic core and core leach method

The invention discloses a method for manufacturing alumina ceramic cores, which adopts sintering of solid phase reaction, comprising two sintering methods of pre-sintering and final sintering; sintering temperature decreases to 1,350 to 1,500 DEG C from more than 1,500 DEG C in the prior art and creep resistance of high temperature is favorable. The invention also discloses a method for leaching the alumina ceramic cores. As in the process of the manufacture of the alumina ceramic cores, a volatile pore forming agent is adopted so that the forming alumina ceramic cores have relatively high porosity; in core leaching, melting alkali can reach the internal part of the alumina ceramic cores so as to integrally disperse the alumina ceramic cores. In the invention, a boiling water process and a repeated alkali cooking-dissolving- alkali cooking method are adopted, thus accelerating permeation, reaction and dissolving of the melting alkali to the internal part of the ceramic cores; the core leaching speed decreases to 10 to 16 hours from 25 to 30 hours in the prior art and the core leaching speed is accelerated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low temperature sintered 99 aluminium oxide ceramic and its production method and use

InactiveCN1533999AImprove product qualityAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesSiliconAlumina ceramic

A low-temp sintered alumina ceramics having 99% or 99.6% of alumina is prepared from alumina particles (2.0-2.5 microns), and sintering aid chosen from Y2O5, ZrO2 and MgO throgh shaping by doctor blading process or die pressing, degumming, and sintering in tunnel kiln at temp C04B 35 / 10 C04B 35 / 119 C04B 35 / 622 C04B 35 / 64 C04B 35 / 63 H01L 23 / 15 0 5 3 2003 / 4 / 2 1533999 2004 / 10 / 6 000000000 Yueke Qinghua Electronic Ceramic Co., Ltd., Zhuhai Guangdong 519015 Zhou Heping Wu Chongjuan Dang Guibin

Owner:珠海粤科京华电子陶瓷有限公司

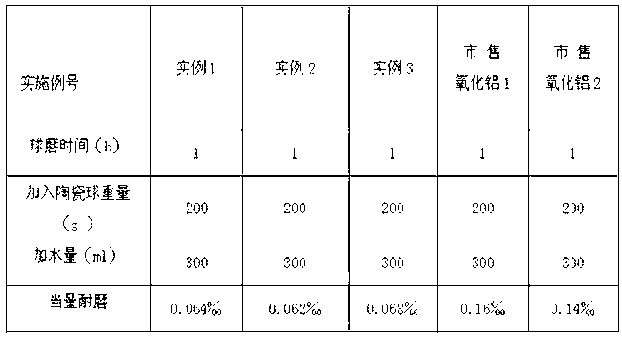

Ultra-wear-resistant alumina ceramic ball and preparation method thereof

The invention provides an ultra-wear-resistant alumina ceramic ball. The ultra-wear-resistant alumina ceramic ball comprises the following chemical components: 90-95% by weight of Al2O3, 5-8% by weight of SiO2, 0.3-0.5% by weight of CaO, 0.5-0.9% by weight of MgO, 1-2% by weight of ZrO and 0.1-0.5% by weight of La2O3 / Y2O3, wherein the equivalent wear loss is less than 72 per mil. A provided preparation method comprises the following process steps of: adopting alumina powder and other mineral raw materials for burdening, refining mud, drying, calcining, synthesizing, ball-milling, granulating, forming and firing to obtain a product. According to the invention, the wear resistance of the product can achieve the standard of the alumina ceramic ball; and furthermore, the ultra-wear-resistant alumina ceramic ball has the advantages of lower cost of the raw materials, better grinding performance and high performance-price ratio of the product, is more suitable for being applied in production, and can reduce the production cost of an enterprise and improve the production efficiency of the enterprise.

Owner:JINGDEZHEN BETTERWEAR NEW MATERIALS

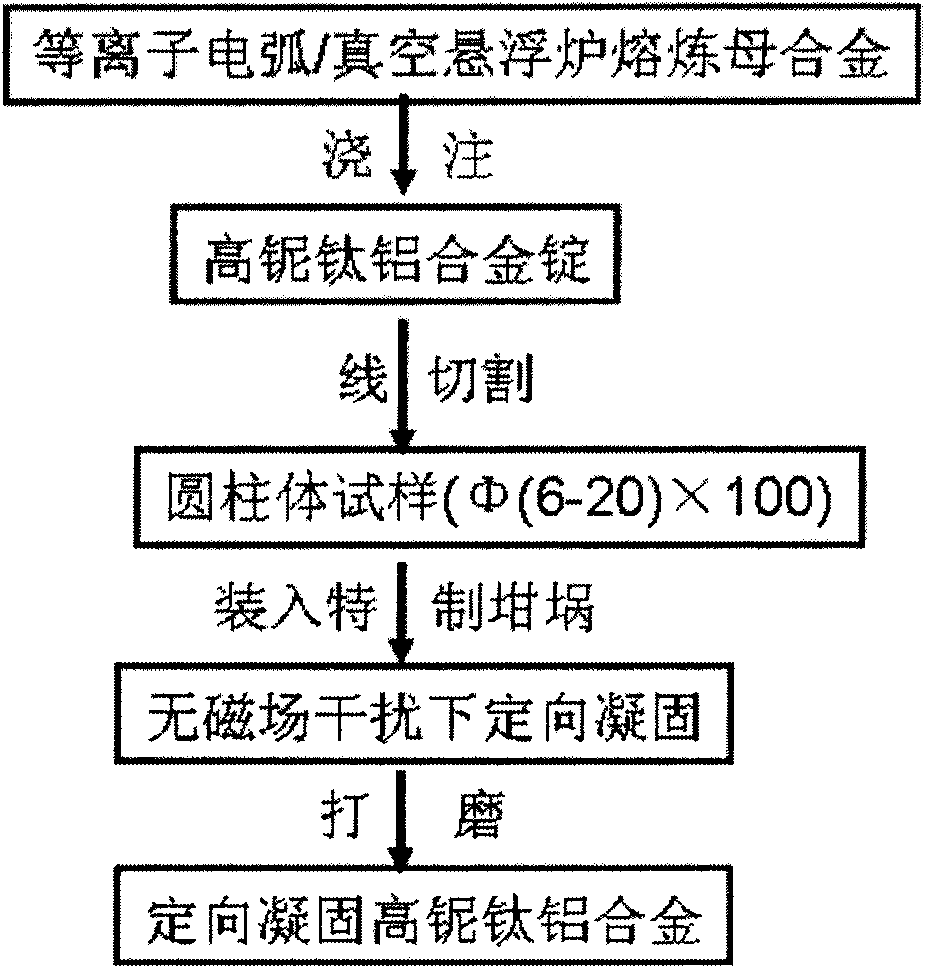

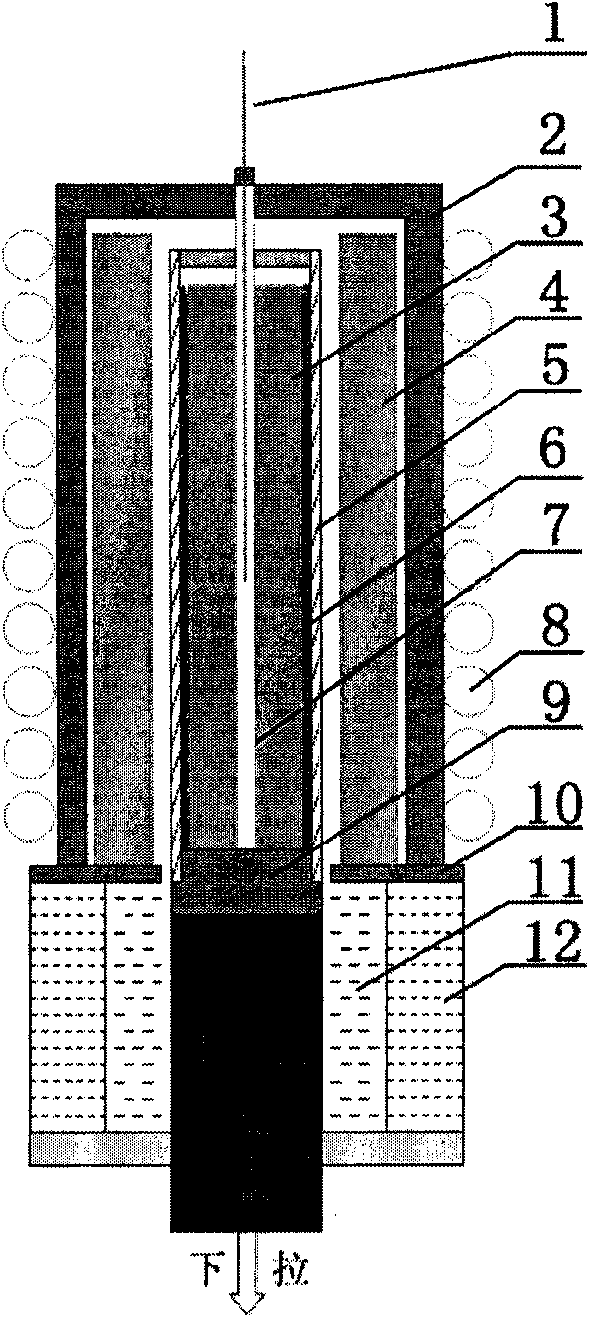

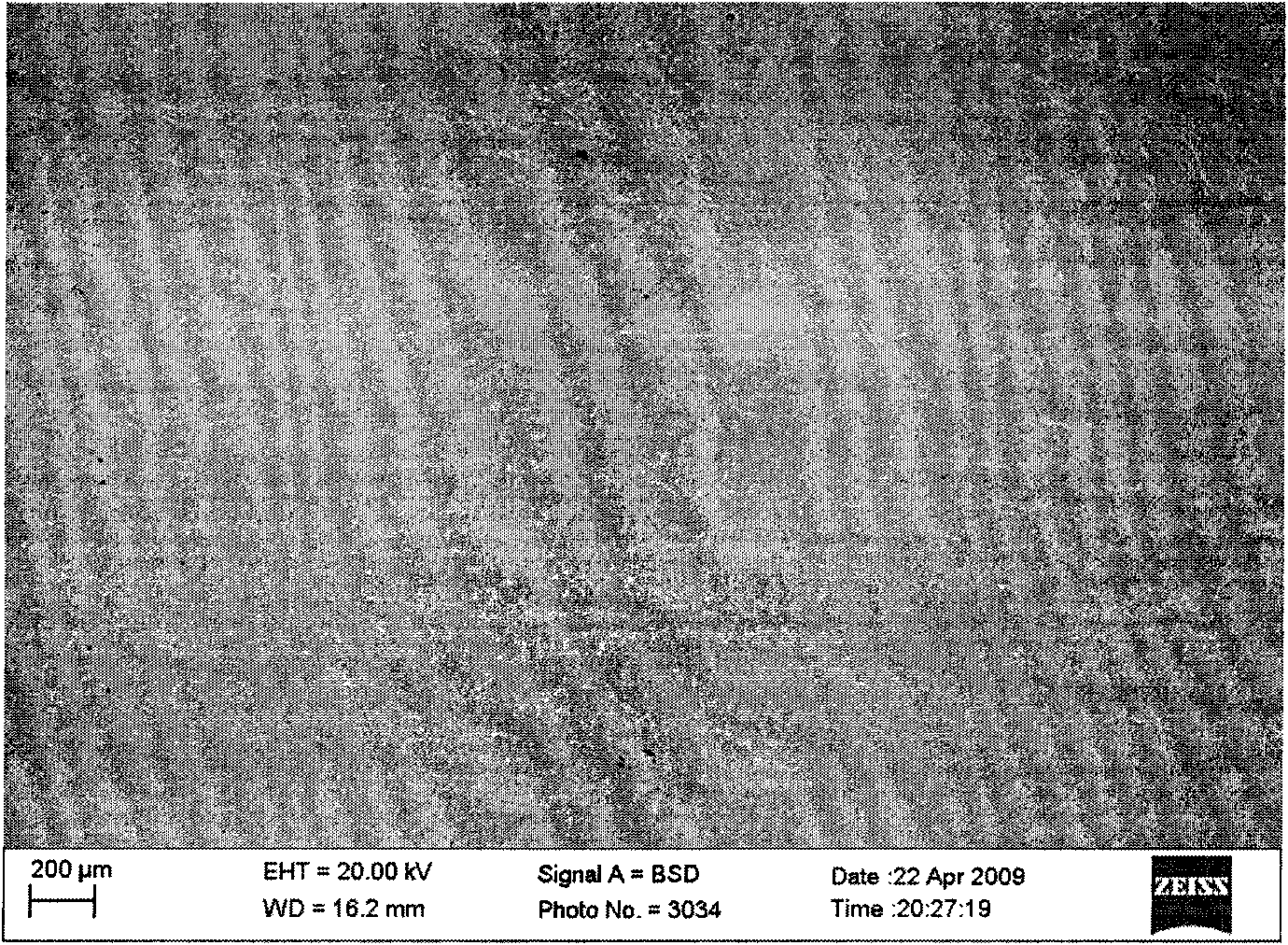

Preparation method of directional solidification high-niobium TiAl-base alloy

ActiveCN101875106AHigh melting pointImprove room temperature performanceMetallic materialsZone melting

The invention discloses a preparation method of a directional solidification high-niobium TiAl-base alloy, which belongs to the field of metal material preparation. The high-niobium TiAl-base alloy contains Ti, Al, Nb, W, Mn, C, B and Y, and the atomic percentage is: (43-49) Ti-(45-46) Al-(6-9) Nb-(0-0.5) (W and Mn)-(0-0.5) (C and B)-(0-0.5) Y, an as-cast master alloy rod which is smelted by plasma arc or vacuum suspension is taken as a raw material, a high-purity alumina ceramic tube with a coating layer of which the main component is yttrium oxide is used as a crucible, Ga-In-Sn alloy liquid is cooling liquid, and the directional solidification high-niobium TiAl-base alloy is successfully prepared by using an improved zone-melting and directional solidification system. The processing technology is simple and reliable, the directional solidification effect is obvious, and the method has universal applicability. The directional solidification high-niobium TiAl-base alloy which is prepared by the directional solidification method has comprehensive and good high temperature performance and room temperature ductility and has wide application prospect in terms of high temperature structural materials.

Owner:UNIV OF SCI & TECH BEIJING

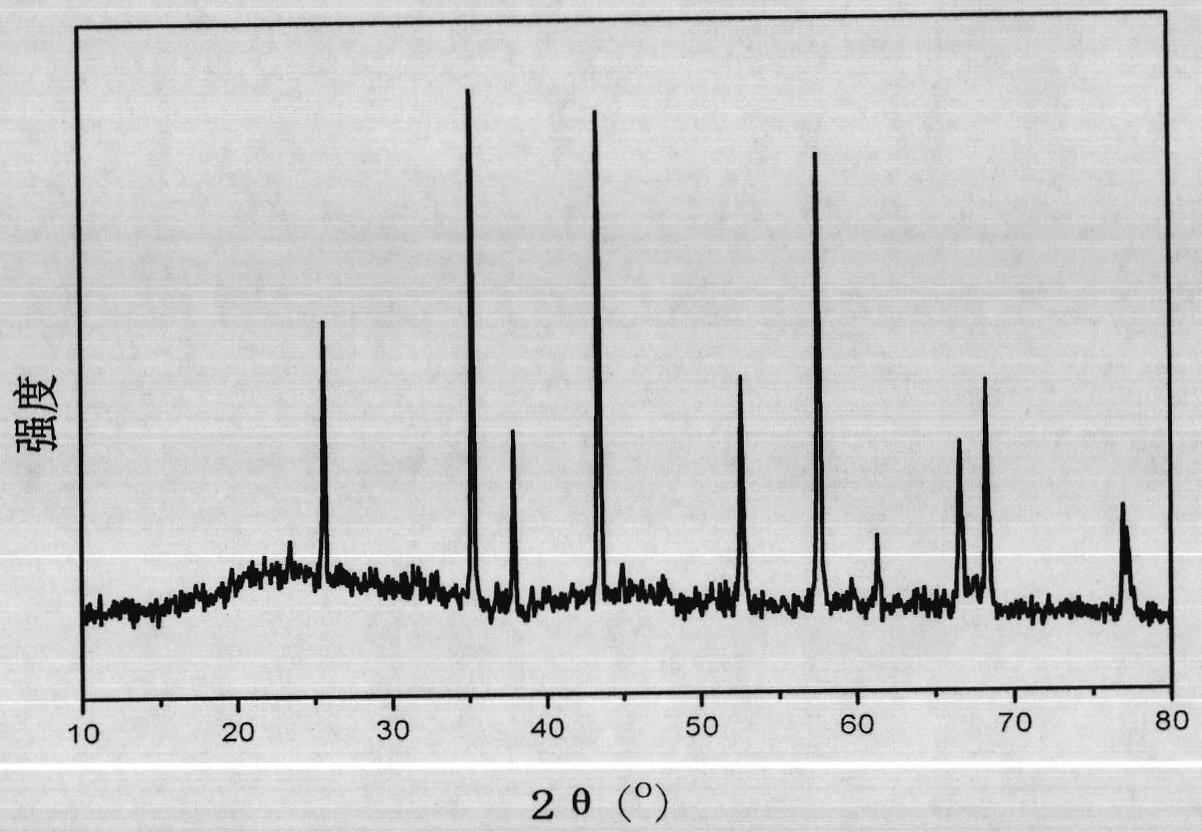

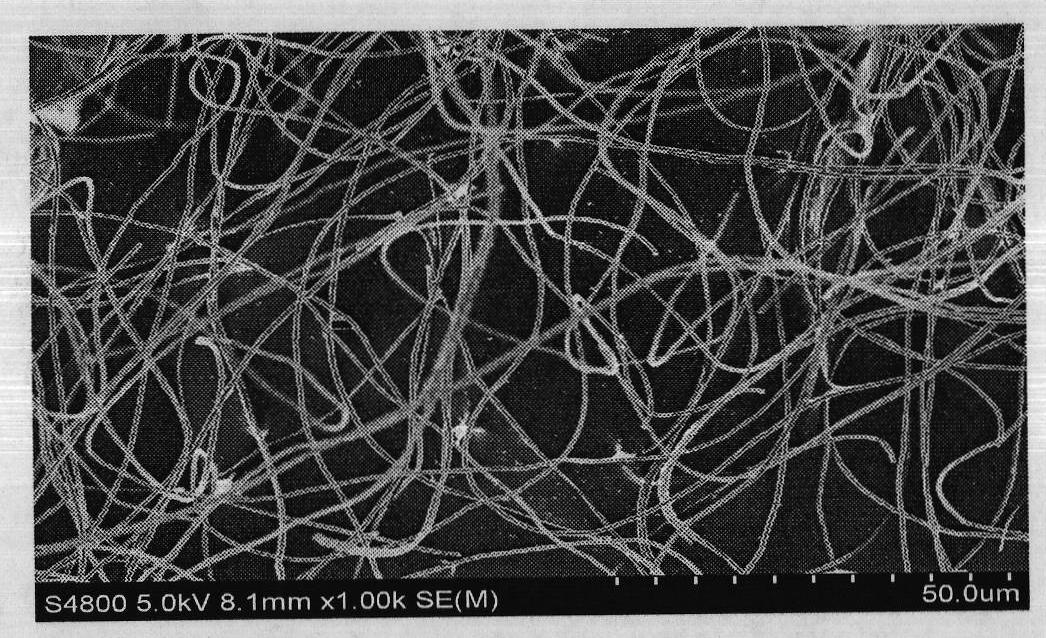

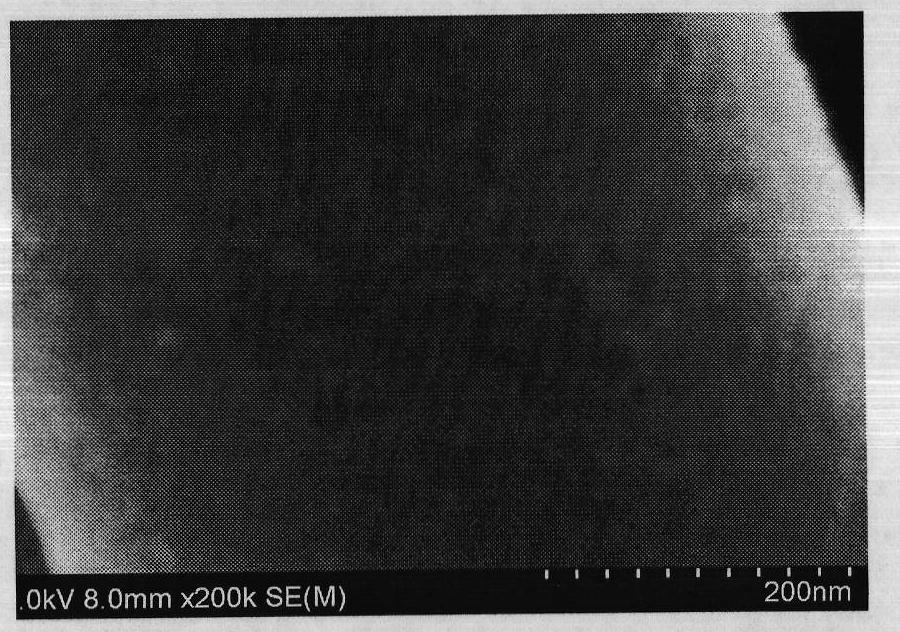

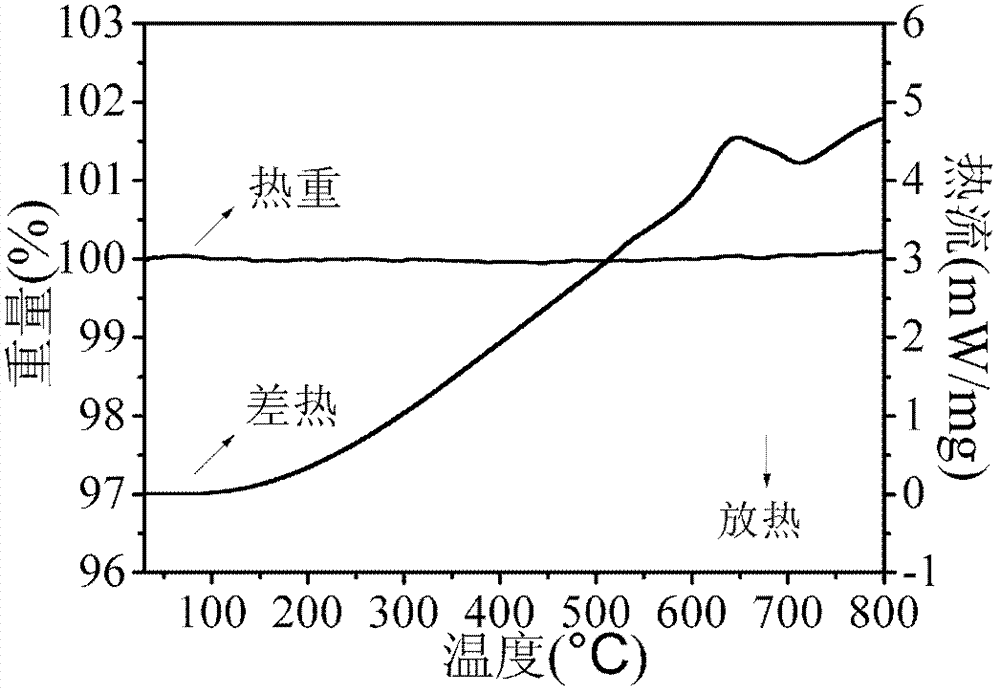

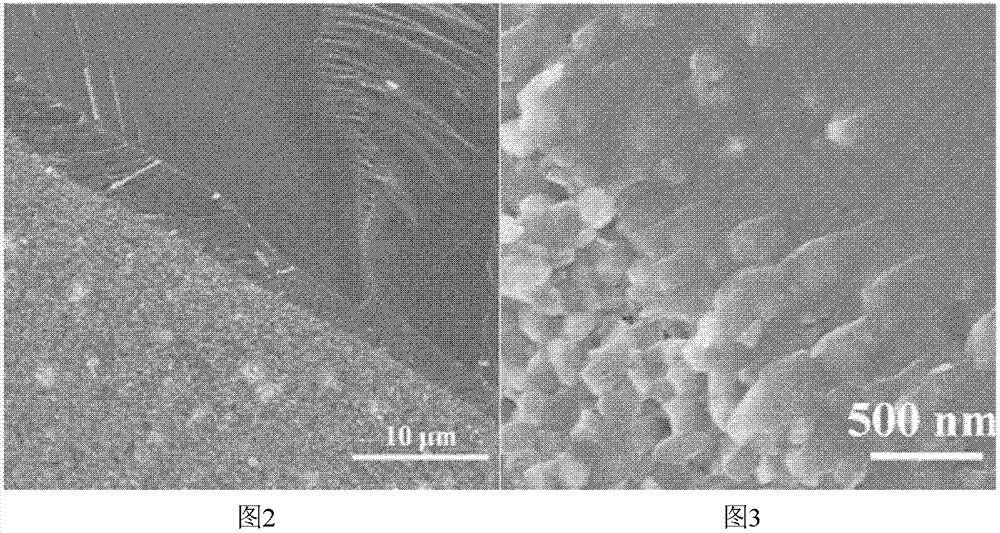

Flexible alumina ceramic fiber and preparation method thereof

The invention relates to a flexible alumina ceramic fiber and a preparation method thereof. Basic structural units of the alumina ceramic fiber are alpha-Al2O3 nano particles of which the particle diameter is 10-40nm and alpha-Al2O3 nano plates which are 20-30nm thick, and the diameter of the fiber is 350-800nm. The preparation method comprises the following steps: preparing a spinning fluid by asol-gel method; preparing a gel fiber by an electrostatic spinning technology; and carrying out two-stage calcination to obtain the alpha-Al2O3 ceramic fiber. The fiber is uniform and continuous, is difficult to break, has favorable flexibility, good thermal stability and excellent mechanical property, can be used as a high-temperature catalyst carrier and high-temperature insulating material, and can also be used as an infrared radiation material and sealing material. Besides, the process provided by the invention has the advantages of simple equipment and high operability, thereby being applicable to large-scale production.

Owner:SHANDONG UNIV

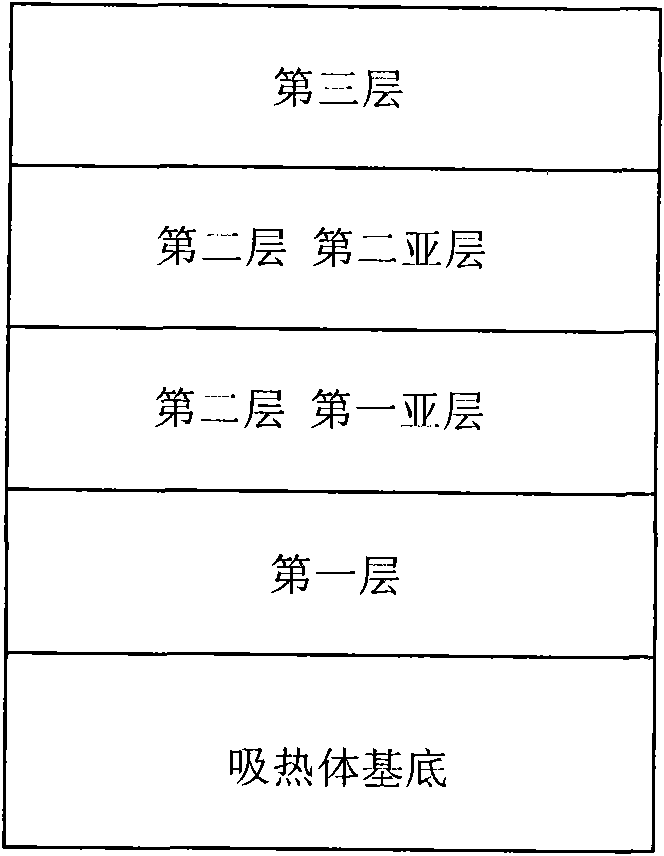

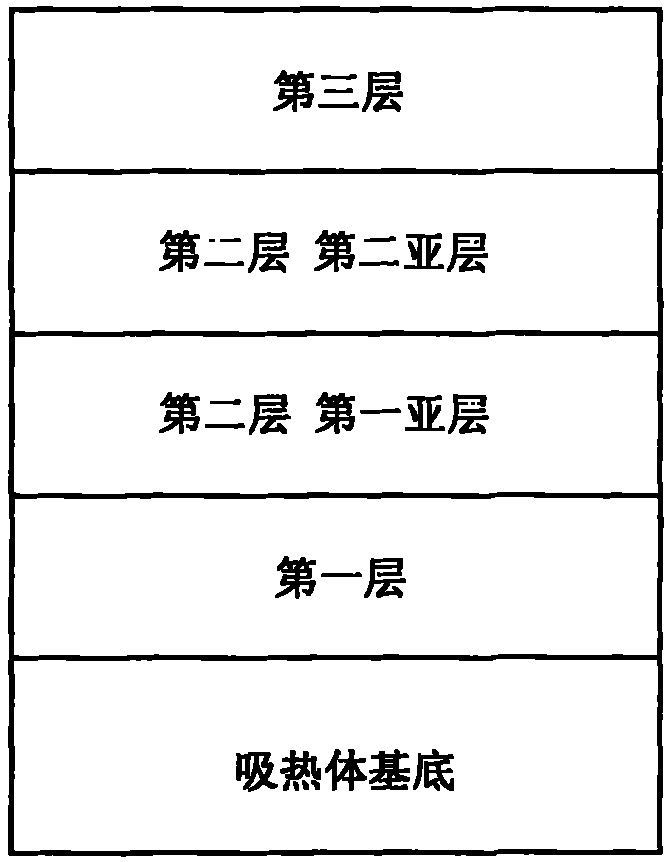

Solar selective absorbing coating and preparation method thereof

ActiveCN101922816ASimple preparation processEasy to operateSolar heat devicesVacuum evaporation coatingAbsorption layerCermet

The invention discloses a solar selective absorbing coating and a preparation method thereof. The coating comprises three layers of films from bottom to top on the surface of a heat absorber substrate; the first layer is an infrared reflective layer and consists of a metal molybdenum film; the second layer is an absorption layer, consists of a composite metal ceramic layer made from Ni-Al alloy particles and an insulating medium and is formed by two sublayers with different thicknesses and different Ni-Al alloy volume percentages in structure, wherein the thickness of the first sublayer is 35-70nm, the Ni-Al alloy volume percentage of the first sublayer is 40-60 percent, the thickness of the second sublayer is 30-60nm, and the Ni-Al alloy volume percentage of the second sublayer is 20-40 percent; the third layer is an anti-reflection layer formed by an aluminum oxide ceramic film. The preparation method thereof comprises three steps. Under the condition that an air quality factor AM is 1.5, the absorptivity of the coating is no less than 0.93, and the emissivity of the coating is no more than 0.09. The coating has good heat stability and can be used in the vacuum environment at the temperature of 600 DEG C for a long term. The invention has the practical value and wide application prospect in the technical field of solar heat utilization and thermal generation.

Owner:安徽科鑫光热技术有限公司

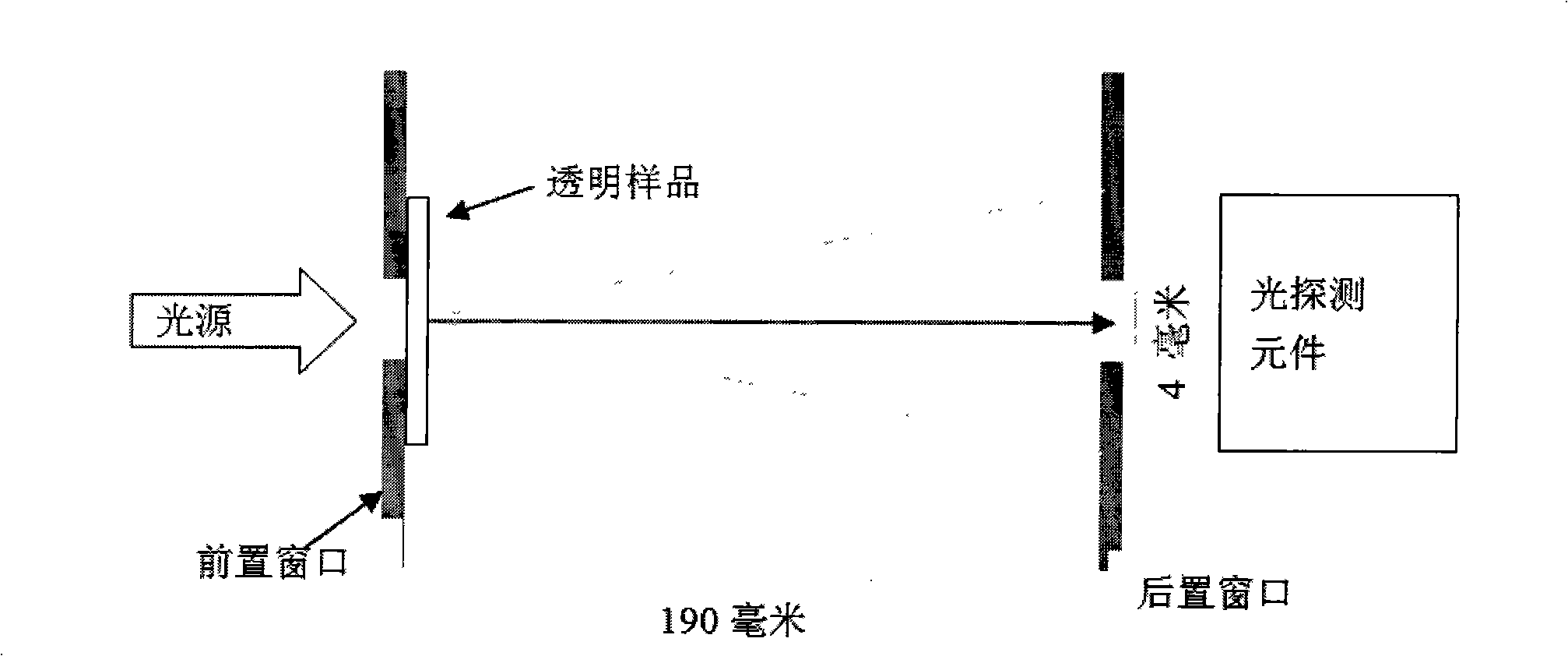

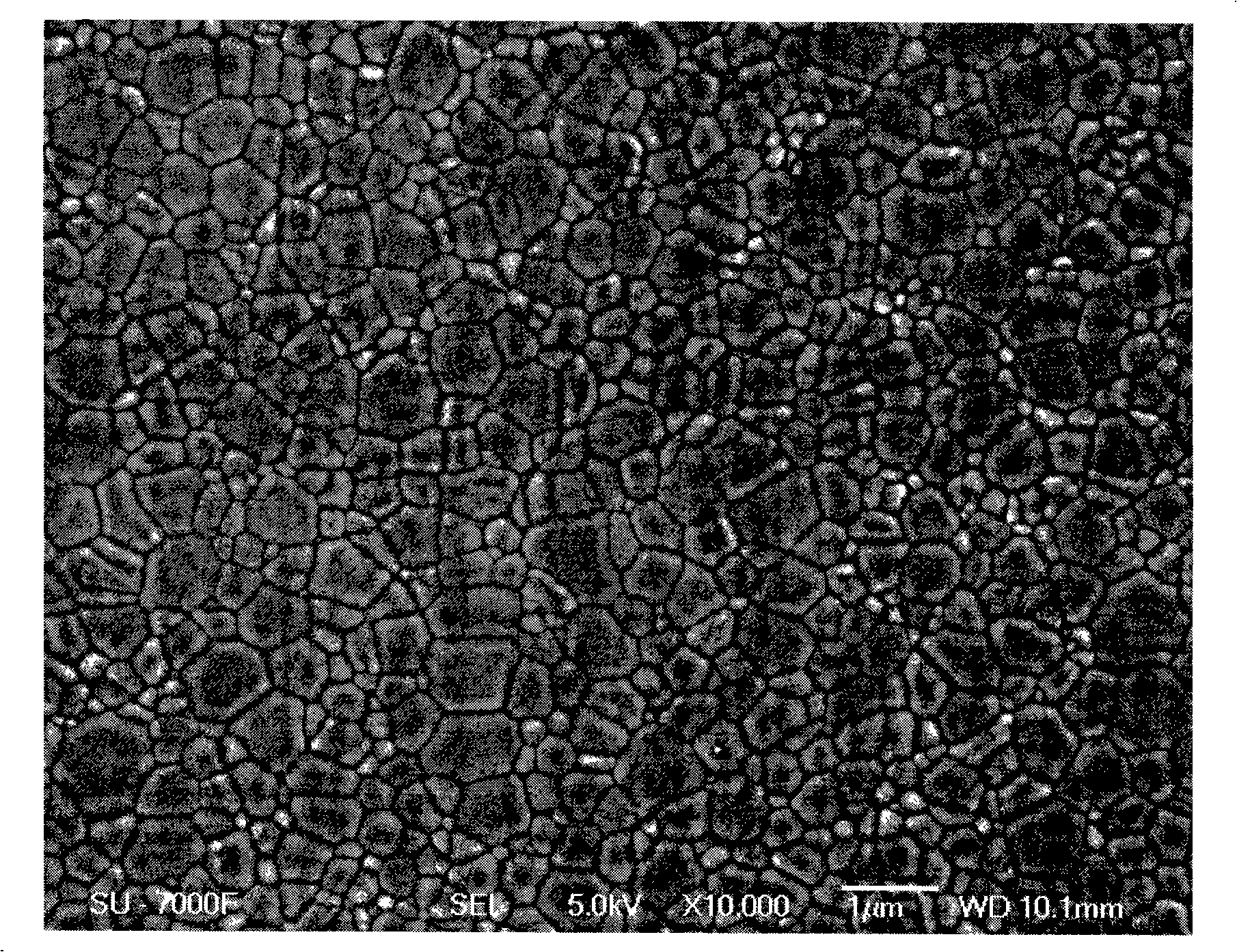

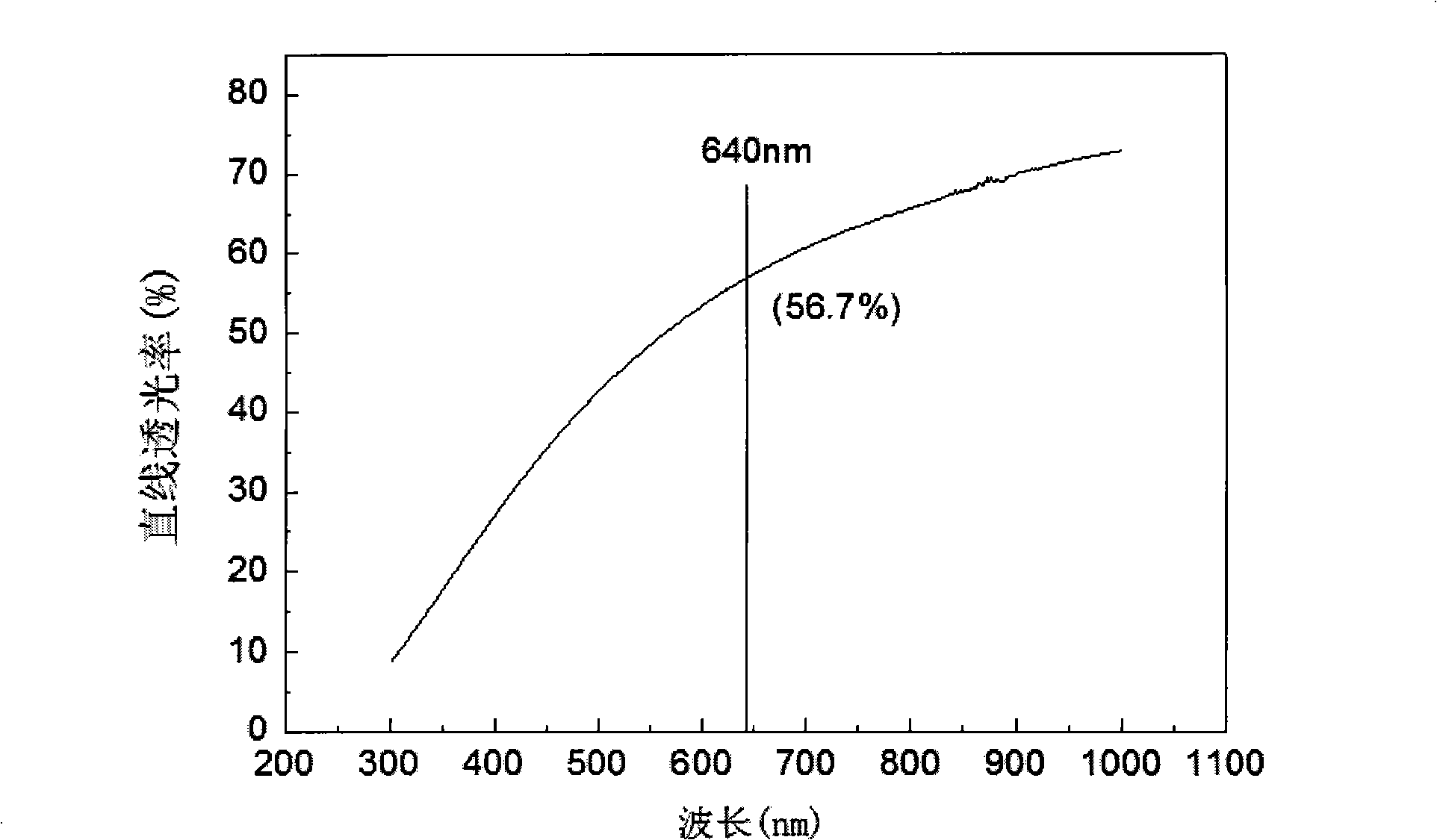

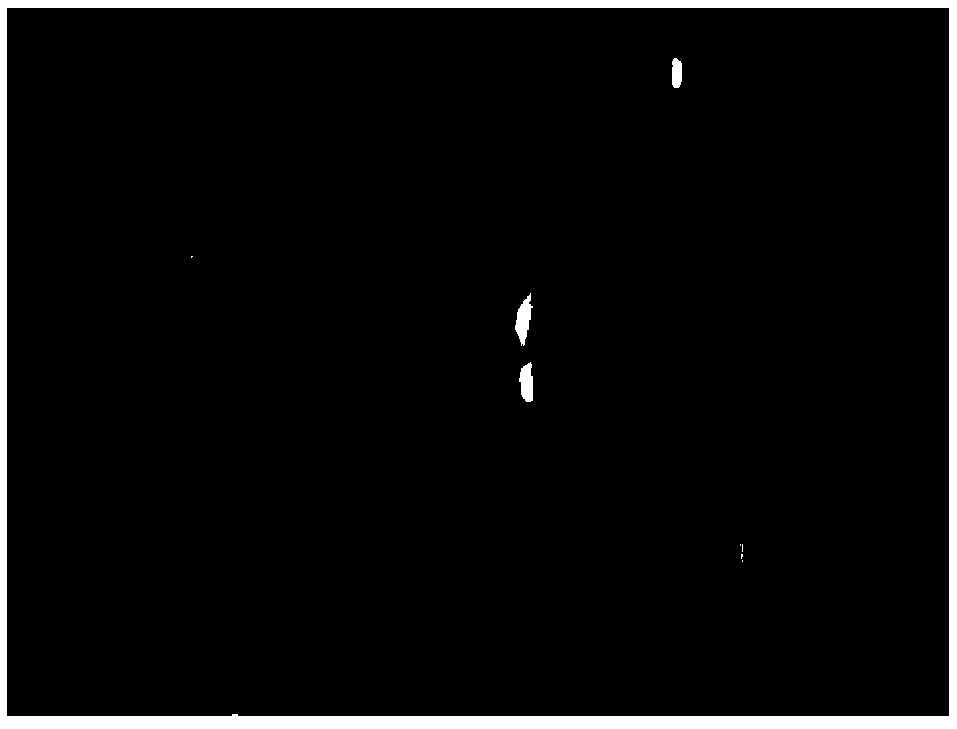

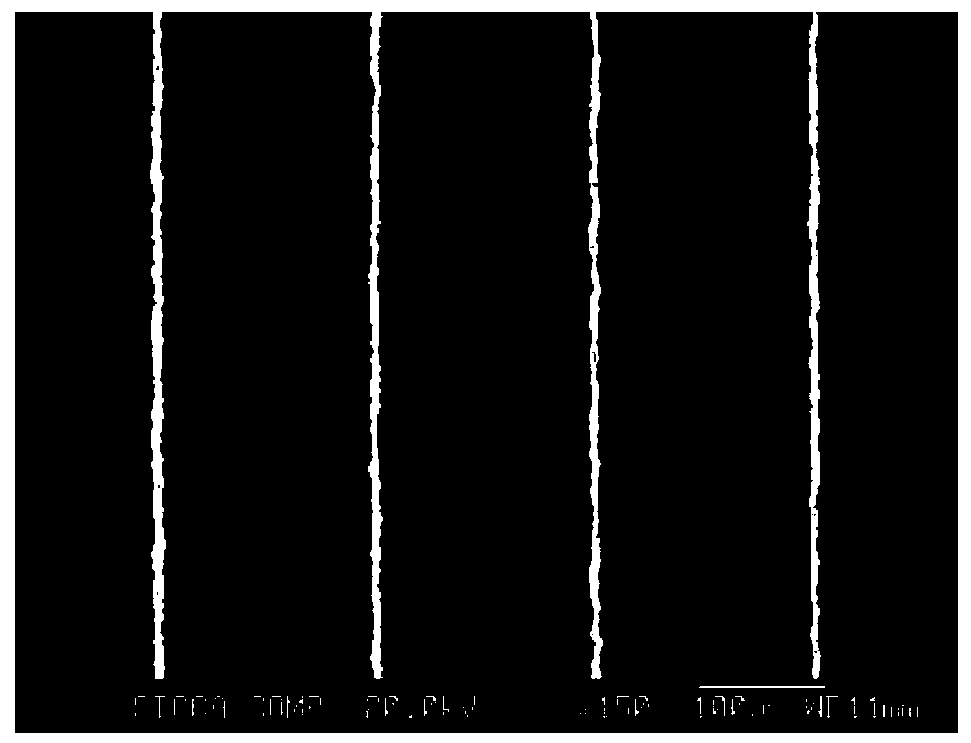

Fine-crystal transparent alumina ceramic of high straight-line luminous transmittance and method for preparing same

The invention discloses high-linear light transmittance fine crystalline transparent alumina ceramics and a method for making the same under the condition of a pulse electric field. The transparent alumina ceramics is sintered within a temperature range of between 1,050 and 1,400 DEG C with the time of the entire sintering process less than 30 minutes; moreover, the material has a relative density higher than 99.5 percent, average grain size of between 0.3 and 1 micron, Vickers hardness more than 20GPa, bending strength of between 700 and 900 MPa, fracture toughness of between 3 and 4 MPam<1 / 2> and linear light transmittance more than 50 percent; and the linear light transmittance of a better material can reach to more than 62 percent. The transparent alumina ceramics can be pure alumina with the purity more than 99.99 percent, or can be alumina ceramics in which one sort, or any two sorts, or any three sorts of addition agents including 0.01 to 0.5 percent of MgO, 0.01 to 0.5 percent of Y2O3, 0.01 to 0.5 percent of La2O3 and 0.01 to 0.5 percent of ZrO2 are added. The method for making the transparent alumina ceramics has the characteristics of low temperature and quickness; moreover, the technology has high reliability, and the deviation between the mechanical property and the optical performance of transparent alumina made in different batches is not more than 2 percent.

Owner:王昕

Preparation method for self-complement sub-micron crystal alumina ceramic

The invention relates to a preparation method of a low-cost self-reinforced submicron grain alumina ceramic, which belongs to the fine ceramic field. The method comprises the steps of: adopting industrial aluminum hydroxide or boehmite as a raw material, adding fine grain Alpha-alumina and water for ball milling so as to obtain an even slurry; adding water for mixing at a temperature between 70 and 90 DEG C, and adding acid to control the pH value at 2 to 5, so as to form an emulsion; and adding an additive which is a mixture selected from one or more than two of zinc oxide, magnesium oxide, calcium oxide, yttrium oxide, lanthanum oxide, zirconium oxide, boric oxide, ferric oxide, vanadium oxide, silicon oxide or titanium oxide for forming a gel after water is evaporated, and drying the gel and then sintering the gel under high temperature for preparing the self-reinforced submicron grain alumina ceramic containing alumina elongated grains. The ceramic is characterized in that crystal grains have diameters of less than 0.5mu m, and a microstructure contains elongated alumina grains have length-diameter ratios of larger than 5, and has the advantages of high hardness, high toughness and good wear resistance, and can be widely used in ceramic grinding media and the abrasives industry.

Owner:SUZHOU CHUANGYUAN INVESTMENT DEV

Construction and Manufacturing of Long Tubes with Embedded Corrosion- and Wear-Resistant Coatings Applied Directly to the Interior Surfaces

InactiveUS20120160361A1Cost-effective and highly-productive manufactureEnvelopes/bags making machinerySoldering apparatusSolid structureWear resistant

Owner:FISCHER GEORG +1

Self-dispersion type nanometer gamma A100H and its preparation method and use

A gamma-AlOOH nanocrystal powder able to be automatically dispersed in aqueous and some organic solvents for preparing self-dispersing superfine non-toxic aluminum hydroxide flame-retarding agent, or the high-molecular polymer / inorganic nano-material composition, or the microcrystalline alumina ceramics or high-performance alumina ceramics as grinding medium is prepared through reaction of sodium aluminate or Al salt solution in alkaline medium, extracting the generated deposit, adding peptizing agent and disperser, peptizing and dispersing to obtain aluminum hydroxide colloid, reacting on additive and surfactant for surface modifying, and spray drying.

Owner:GUANGXI UNIV FOR NATITIES

Preparation method of continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material

The invention belongs to a continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material preparation technology and relates to a preparation method of a continuous alumina fiber-reinforced aluminum oxide ceramic matrix composite material. Firstly, an oxide organic polymer precursor is adopted as a raw material, a porous oxide ceramic coating is prepared through PIP process to serve as a fiber and matrix interface in the composite material, then a freeze drying process of aluminum oxide ceramic slurry is utilized to obtain a porous aluminum oxide matrix green body framework provided with three-dimensional network through holes, the oxide organic polymer precursor is utilized to repeatedly dip the porous aluminum oxide matrix green body framework to obtain a dense matrix green body, and finally the composite material green body is sintered to obtain the high-performance composite material. The freeze drying process is adopted in the matrix compactness process so that the high compactness matrix can be obtained, it can be also ensured that the interlayer layer does not crack before high-temperature heat treatment, obtaining of the porous oxide coating is ensured, so that a weak interface is formed between the fiber and the matrix of the composite material, and a toughness improving effect of the composite material is achieved.

Owner:AVIC COMPOSITES

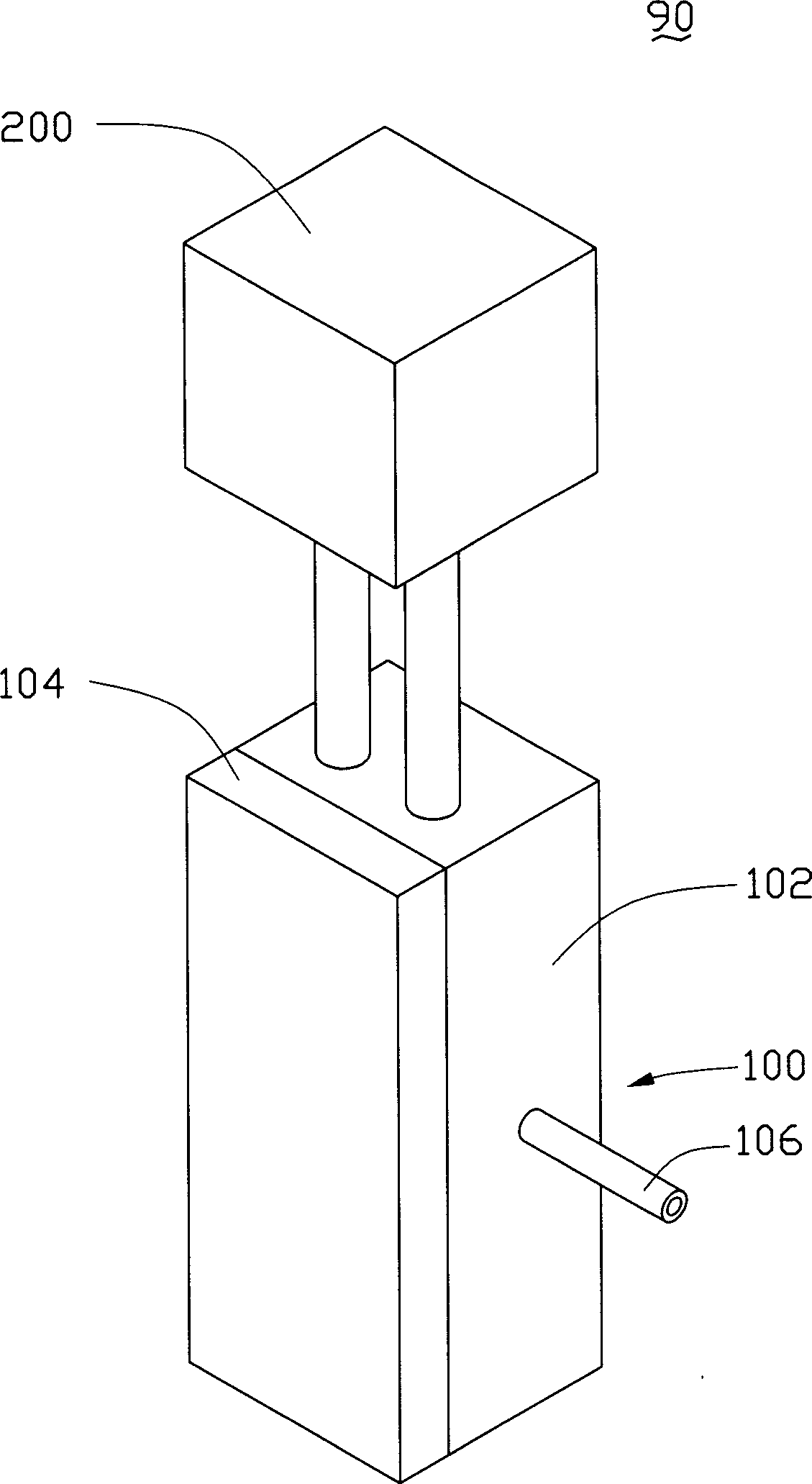

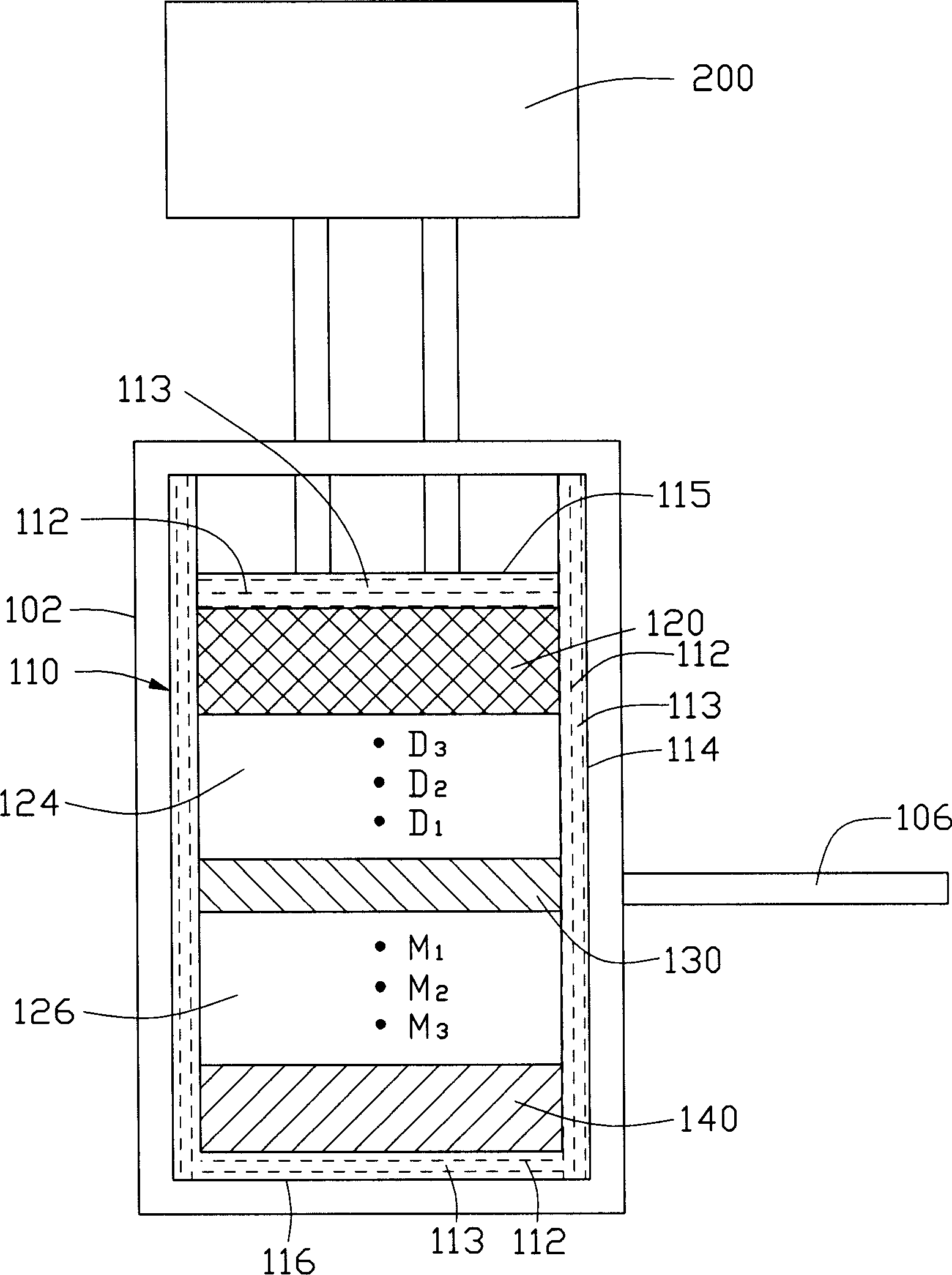

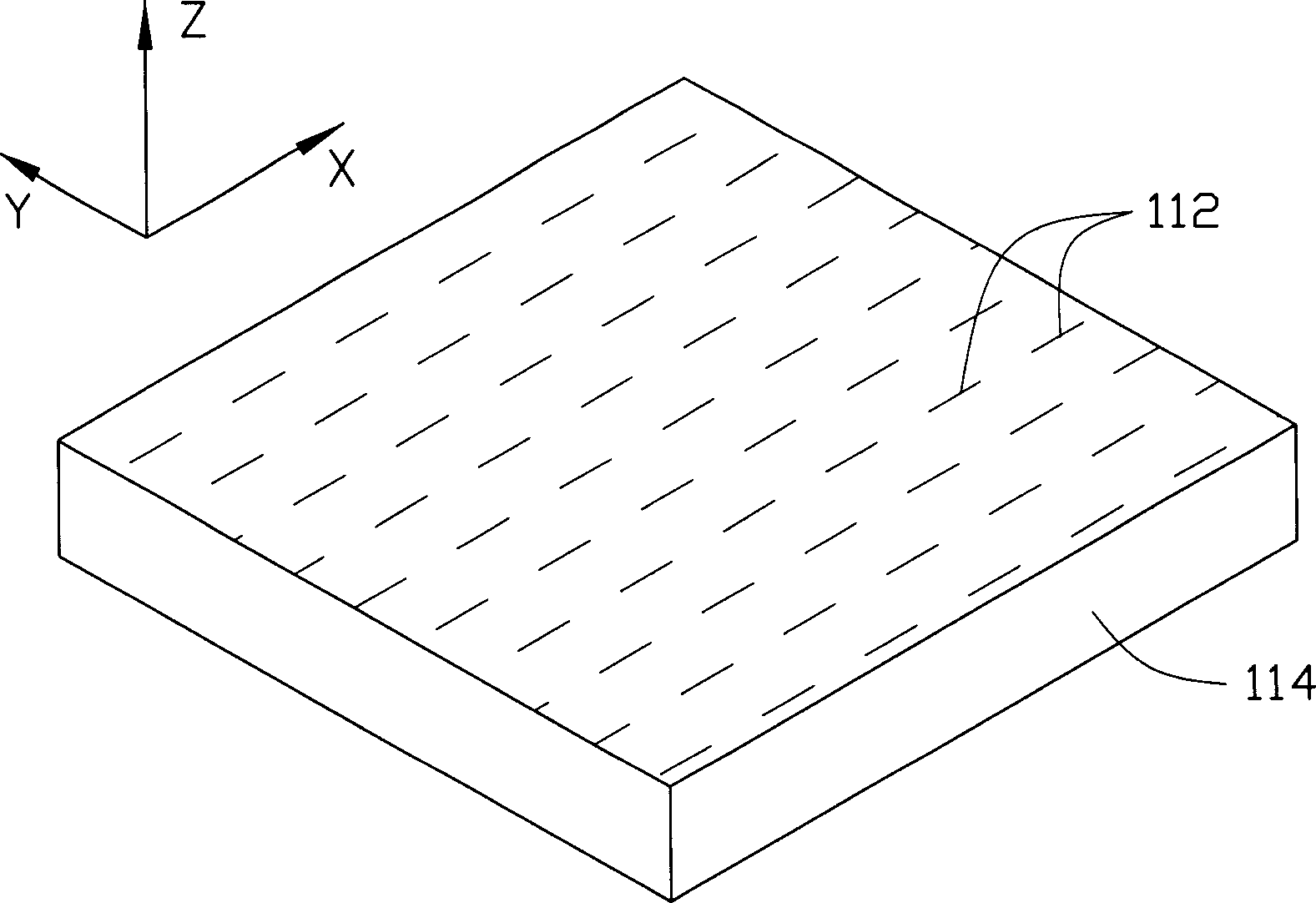

Device for measuring thermal coefficient

InactiveCN1657923AGuaranteed measurementGood insulation performanceMaterial heat developmentMeasurement deviceHeat conducting

The invention discloses a heat conducting coefficient measuring device which consists of a sealed heat insulation device and a vacuum system. The heat insulation device consists of heat source, two metal blocks, samples, a cooling device. The heat insulation device is made by spark-plasma sintering the aluminum oxide ceramic basal material with carbon nanometer tube uniformly arranged in with a intensity of 5 to 10 percent. The carbon nanometer tube distributes along the direction perpendicular to the direction which the heat travels. By pumping out the inner gas with the vacuum system, the adverse effect of the gas is eliminated which the carbon nanometer tube reflect the heat back in consequence that the carbon nanometer tube is radial heat insulation.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

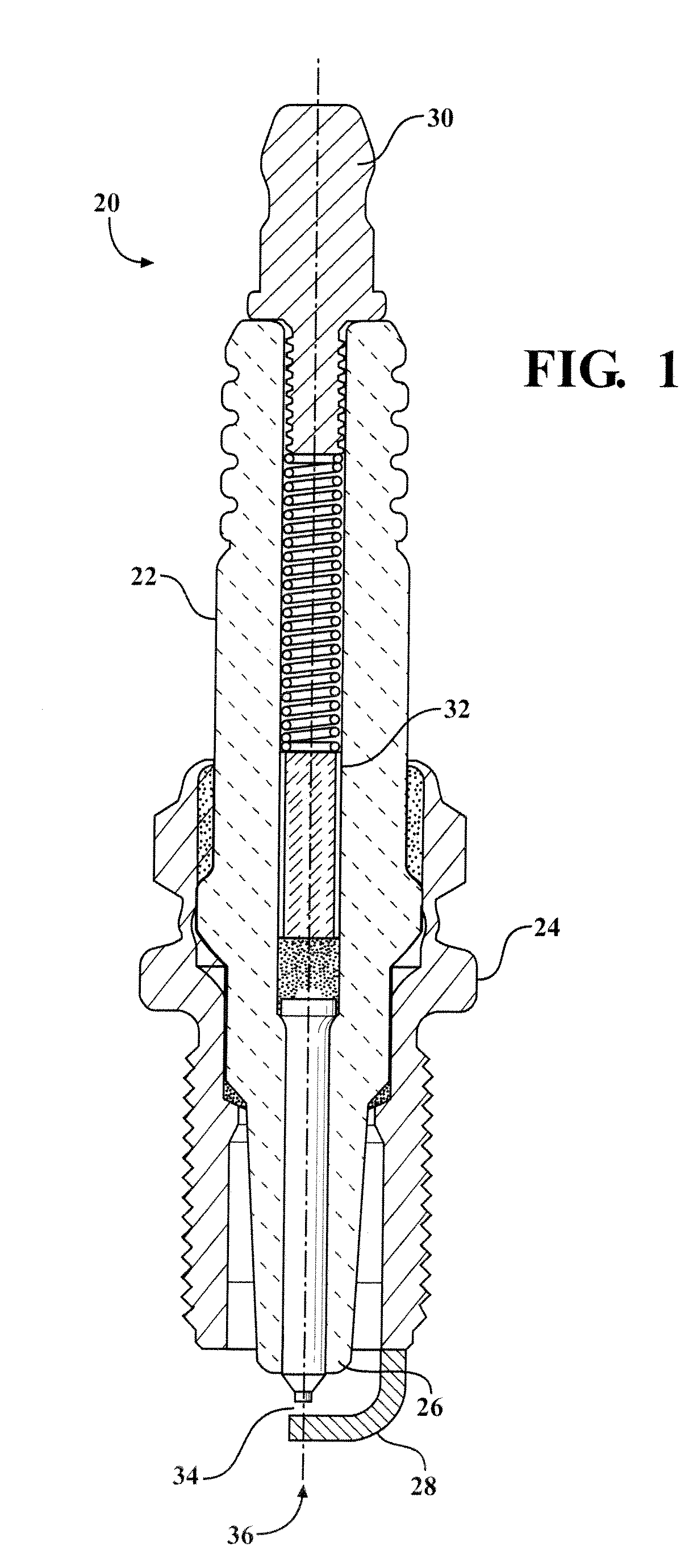

Alumina ceramic for spark plug insulator

ActiveUS20110077141A1Improve conductivityHigh strengthElectric discharge tubesDischarge tube main electrodesAluminateMullite

A spark plug includes an insulator formed of a ceramic material. The ceramic material comprises Al2O3 in an amount of 98.00 wt % to 99.50 wt %; Group 2 oxides in an amount of 0.16 wt % to 0.70 wt %; SiO2 in an amount of 0.25 wt % to 0.75 wt %, Group 4 oxides in an amount of 0.01 wt % to 0.16 wt %, Group 1 oxides in an amount less than 0.0060 wt %, and P2O5 in an amount of less than 0.0040 wt %. The Al2O3 is formed of particles having a D50 median particle size by volume of 1.2 μm to 1.8 μm. The ceramic material is pressed, sintered, and formed to a predetermined shape. The sintered ceramic material includes a glass phase comprising the Al2O3, Group 2 oxides, and SiO2. The sintered ceramic material also includes secondary crystals of calcium hexa-aluminate (CaAl12O19) spinel (MgAl2O4), anorthite (CaAl2Si2O8), and mullite (Al6Si2O13).

Owner:FEDERAL MOGUL IGNITION

Method for preparing ligh high strength aluminium oxide hollow ball ceramic

InactiveCN1554616AWith shrinkageWith thermal shock resistanceCeramicwarePhosphoric acidShock resistance

The light high-strength alumina ceramic ball has phosphoric acid solution as binding agent, alpha-alumina powder as basic material and hollow alumina ball as aggregate. Compared with dense refractory material, it has low density, high heat shock resistance, good heat insulating performance, low heat capacity and other features; and compared with common heat insulating material, it has high compression strength, high loaded softening temperature, low re-burning linear shrinkage and other features. It may be used as heat insulating material directly and may be also used in direct contact with flame, such as being used as lining material in high temperature furnace and kiln. In addition, its strength may be further raised in secondary sintering.

Owner:ZHEJIANG UNIV

Embedded igniter system for internal combustion engines

InactiveUS7299785B1Eliminate homogeneityEliminate auto advanceSparking plugsElectric ignition installationFiberElectricity

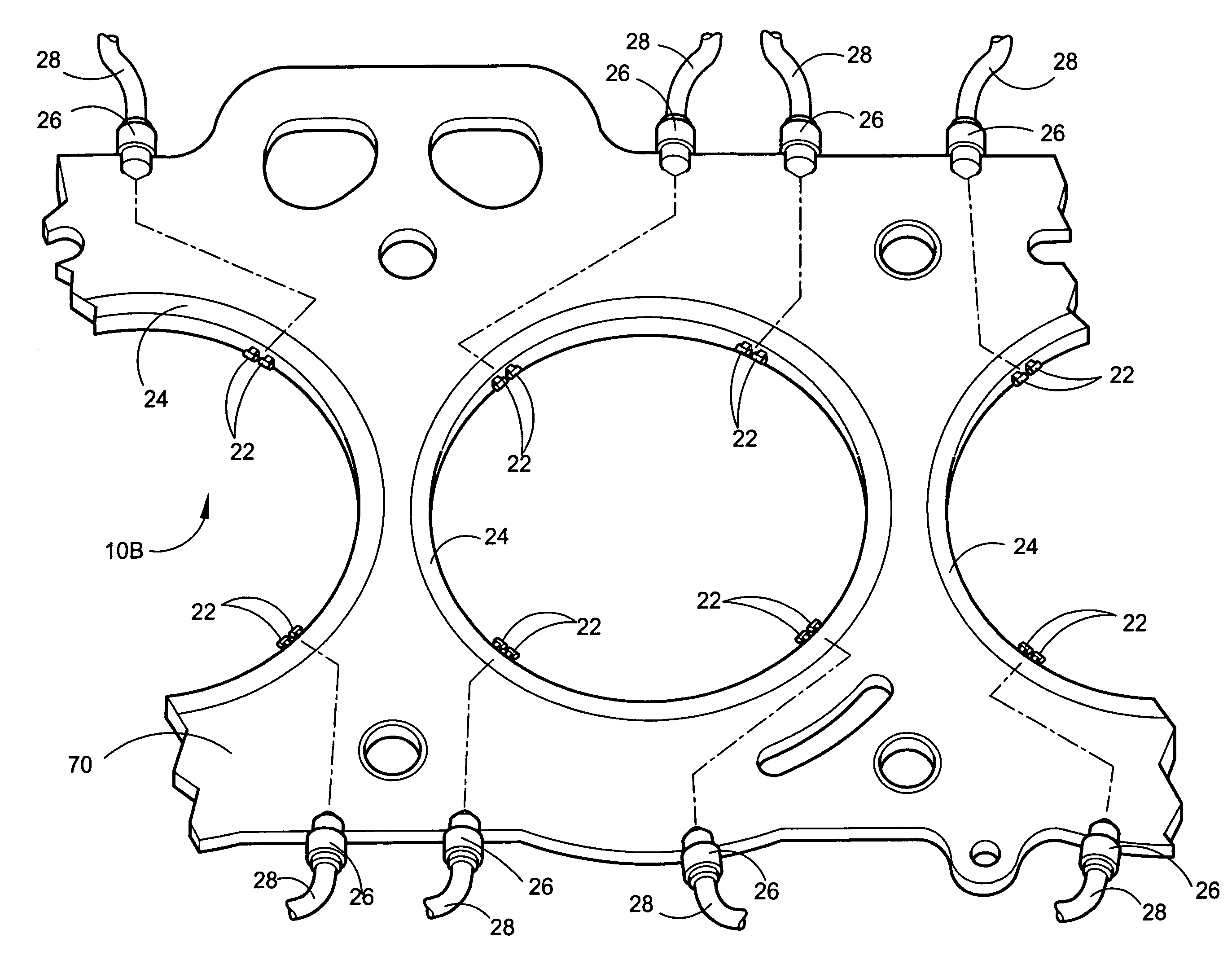

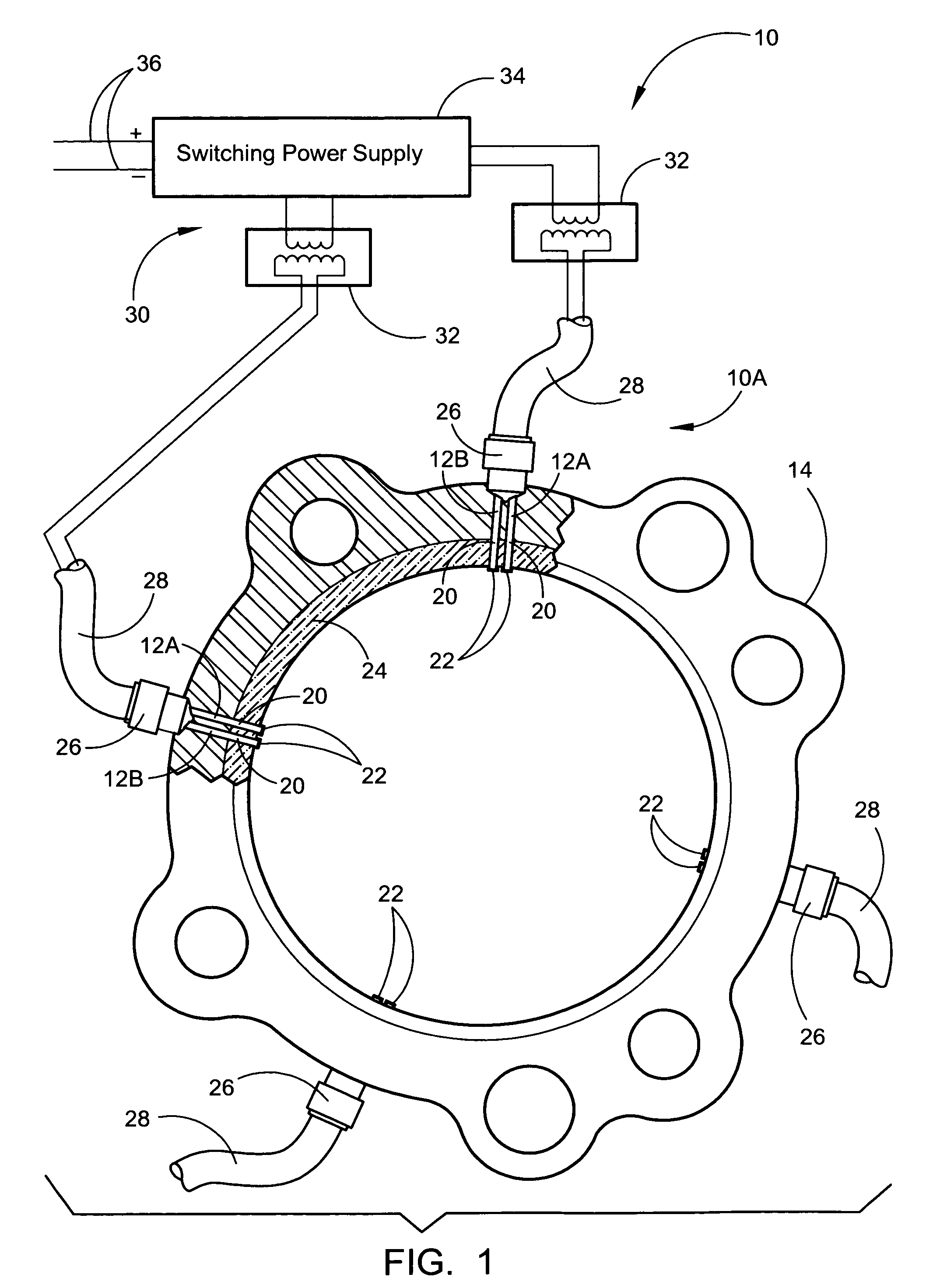

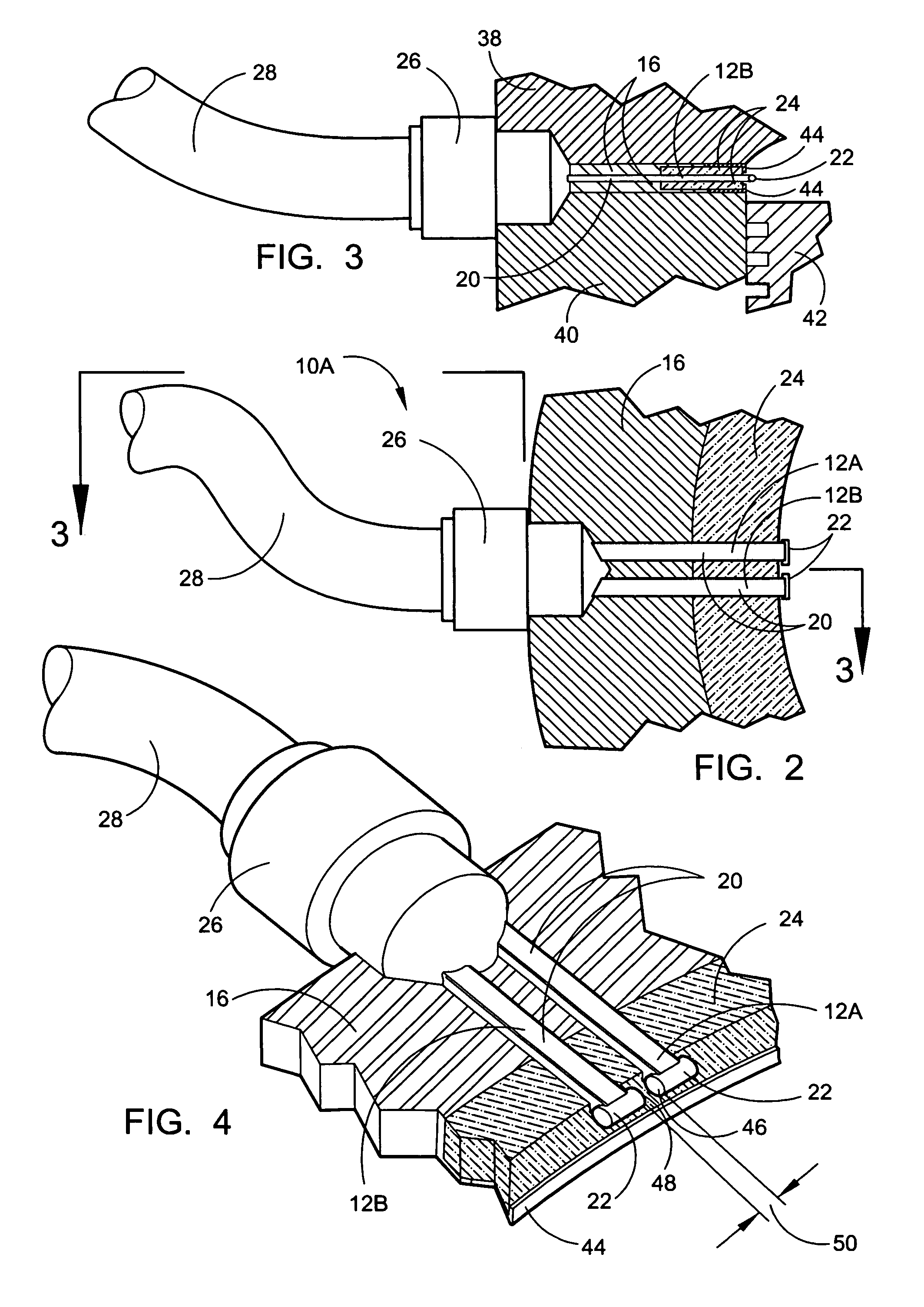

An embedded igniter for internal combustion engines consisting of a multiple ignition system with separate control for individual pairs of igniters that has been designed to replaces the spark plugs of internal combustion engines. This device allows for a more complete burn of the fuel / air mixture within the combustion chamber. The embedded igniter system will consist of one or more igniter units consisting of a pair of rectangular tantalum bars with iridium electrode pins at the ends. The paired igniter pins are encased in alumina ceramic, a high dielectric / high temperature housing positioned around the combustion chamber holding and insulating the electrodes relative to their position in reference to the combustion chamber. One or more igniter units may be incorporated around each cylinder opening of a head gasket made from a composite of polyamide, carbon fiber and copper or equivalent material or may be incorporated into an internal combustion engine that does not require a head gasket.

Owner:BROWNE BRUCE D +1

Silicon carbide ceramic support body and preparation method thereof

InactiveCN102389719AHigh strengthExtended service lifeSemi-permeable membranesHydrogen atmospherePlasticizer

The invention relates to a silicon carbide ceramic support body and a preparation method thereof. The raw material powder of the support body is mixed powder consisting of silicon carbide powder 1 and silicon carbide powder 2, wherein the silicon carbide powder 1 has a median particle diameter D50 of 25-45mu m, the silicon carbide powder 2 has a median particle diameter D50 of less than 5mu m, the ratio of the D50 of the silicon carbide powder 1 to the D50 of the silicon carbide powder 2 is not less than 6, and the consumption of the silicon carbide powder 2 is 0.5-13 percent of the weight of the used silicon carbide powder 1. The raw material powder is mixed with a solvent, an adhering agent, a plasticizer and a pore-forming agent to form pug, the pug is subjected to stamping to form a raw blank, the raw blank is dewatered and degreased to form a calcined product, and the calcined product is sintered in argon or hydrogen atmosphere or vacuum to form the support body of a recrystallized silicon carbide ceramic membrane. The support body of the recrystallized silicon carbide ceramic membrane has filtering flux and strength which are higher than those of the traditional commercial support body of an aluminum oxide ceramic membrane.

Owner:SANDA FILM SCI & TECH XIAMEN

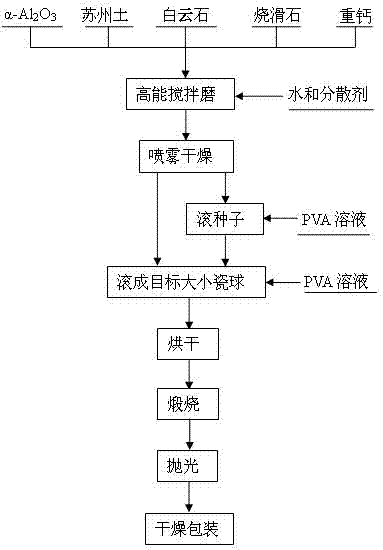

Method for producing aluminium oxide ceramic ball

The invention relates to a method for producing a high wear resisting aluminium oxide ceramic ball, comprising the following steps: (1) weighing ceramic powder according to the following weight ratio; (2) adding water and 0.1-1 wt% of polyacrylamide as a dispersant in the ceramic powder to prepare a slurry, and carrying out ball milling; (3) carrying out spray drying; (4) preparing an aluminium oxide ceramic ball seed; (5) putting the ceramic ball seed in a bowl machine to produce a ceramic ball body; (6) drying the ceramic ball body; (7) putting the dried ceramic ball body in a high temperature kiln to calcine, and sintering; and (8) polishing the ceramic ball until the surface of the ceramic ball has a shining luster, discharging, drying and then packaging. According to the invention, the produced wear resisting aluminium oxide ceramic ball with a diameter of 10 mm only has an abrasion of 0.02-0.04 g / (kg.h). The method has the advantages of low sintering temperature, low cost of the raw materials, and easy popularization, and can realize industrialization.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

Preparation method of alumina foam ceramic

The invention discloses a preparation method of alumina foam ceramic, and relates to the technical field of production of high-tech ceramic product foam ceramic. The preparation method comprises the steps of stirring polyether or polyester polyol with a catalyst, a surfactant and a foaming agent, adding nano magnesium oxide and alumina ceramic powder, uniformly stirring, adding a curing agent, completely and uniformly mixing, reacting and curing in a shaping container, implementing perforation treatment on a cured foam ceramic sponge, and sintering at high temperature to obtain the alumina foam ceramic. The preparation method disclosed by the invention, which directly forms a three-dimensional reticulated foam ceramic green body, can greatly reduce production process, guarantee uniform and consistent alumina foam ceramic structure prepared, greatly reduce manpower demand and manual labor, shorten production cycle, and can also improve stability of product performance.

Owner:JIANGSU WEISHI STRUCTURAL CERAMICS

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

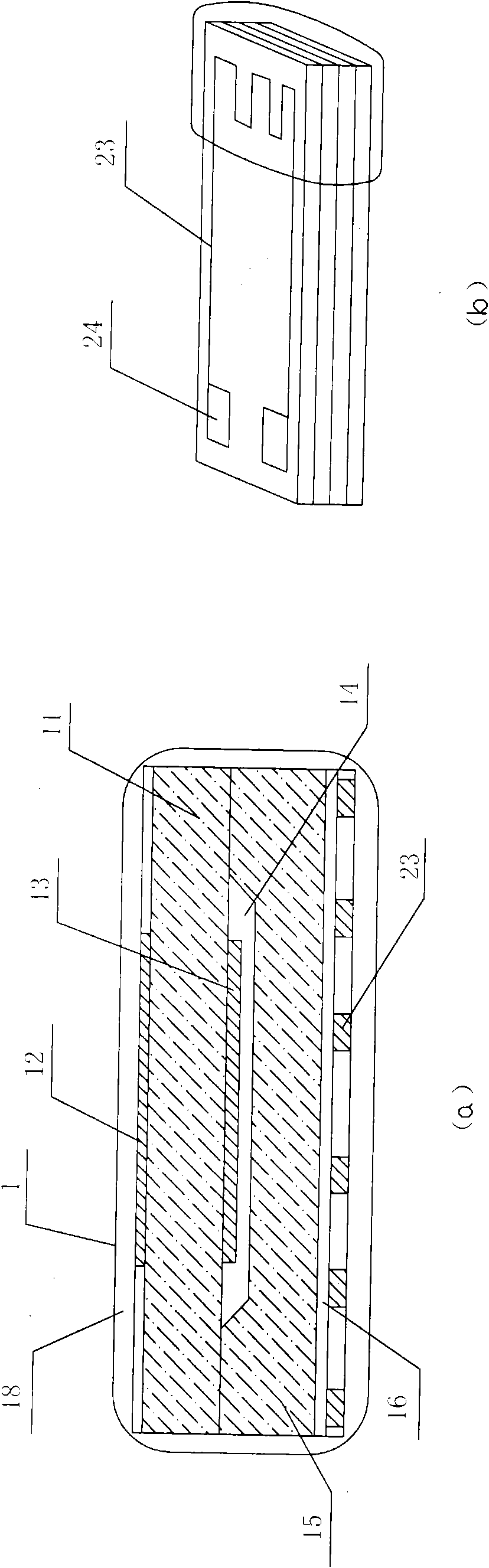

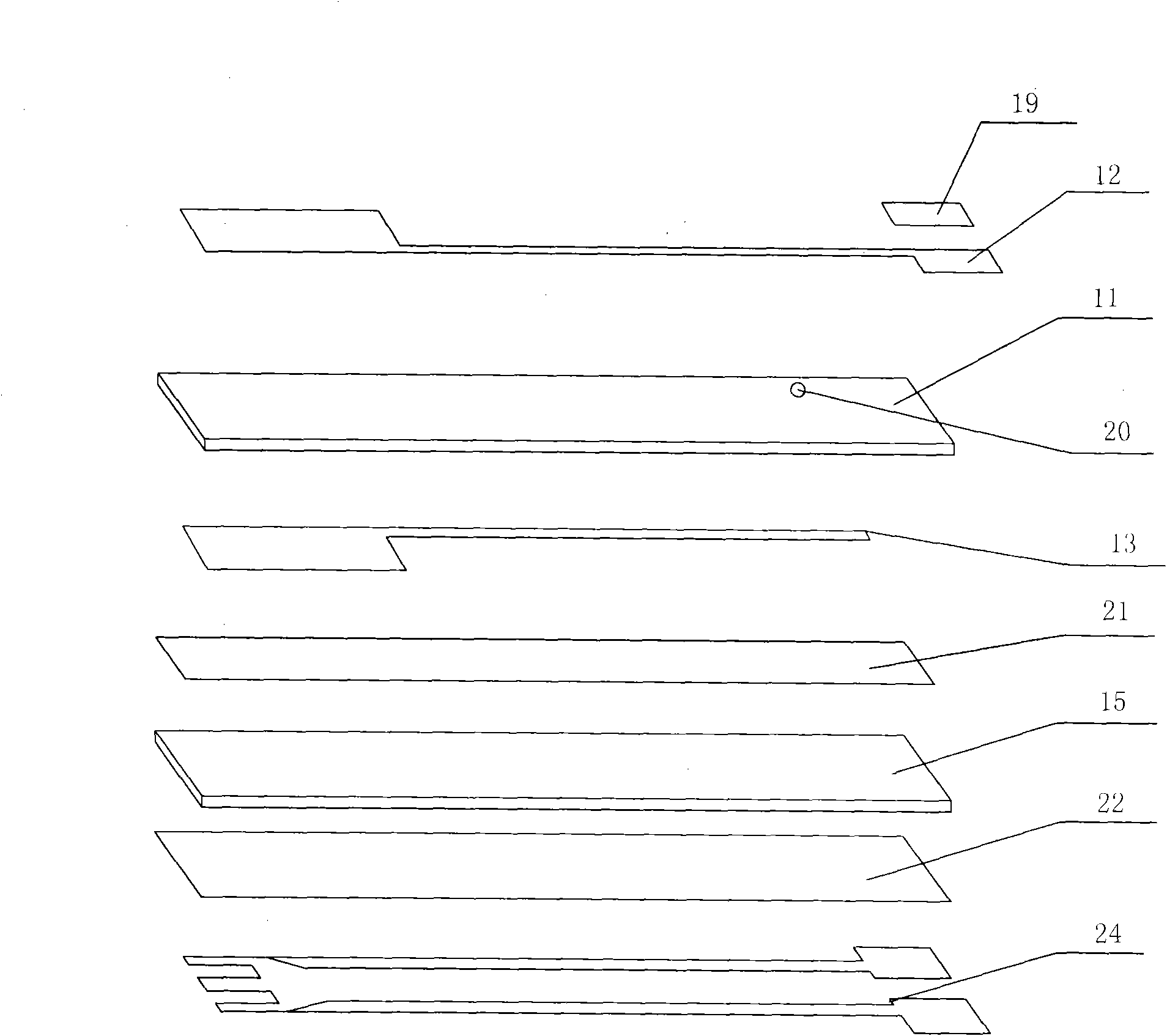

Integrated chip type oxygen sensor and manufacturing method thereof

ActiveCN101806768AThe overall thickness is thinReduce volumeMaterial analysis by electric/magnetic meansPlatinumOxygen sensor

The invention relates to the technical field of integrated chips used for zirconium oxide sensors, in particular to an integrated chip type oxygen sensor and a manufacturing method thereof. The integrated chip type oxygen sensor comprises a zirconium oxide substrate, wherein the zirconium oxide substrate consists of an upper layer of zirconium oxide substrate and a lower layer of zirconium oxide substrate; an external surface of the upper layer of zirconium oxide substrate is provided with a measuring electrode, and an internal surface of the upper layer of zirconium oxide substrate is provided with a reference electrode and a long and narrow gap; an internal surface of the lower layer of zirconium oxide substrate directly contacts the long and narrow gap, and an alumina ceramic insulating layer is coated on an external surface of the lower layer of zirconium oxide substrate; the alumina ceramic insulating layer is directly integrated with a platinum heating element; a heating electrode plate and the platinum heating element are directly connected together on the external surface of the zirconium oxide substrate; and the outermost layer of the zirconium oxide substrate is provided with a porous ceramic protective layer. The integrated chip type oxygen sensor provided by the invention is only provided with two layers of zirconium oxide substrates and integrated with the heating elements, and has the advantages of thin thickness, and simple preparation method, high production efficiency and high stability.

Owner:CHANGZHOU LAMBDA ELECTRONICS

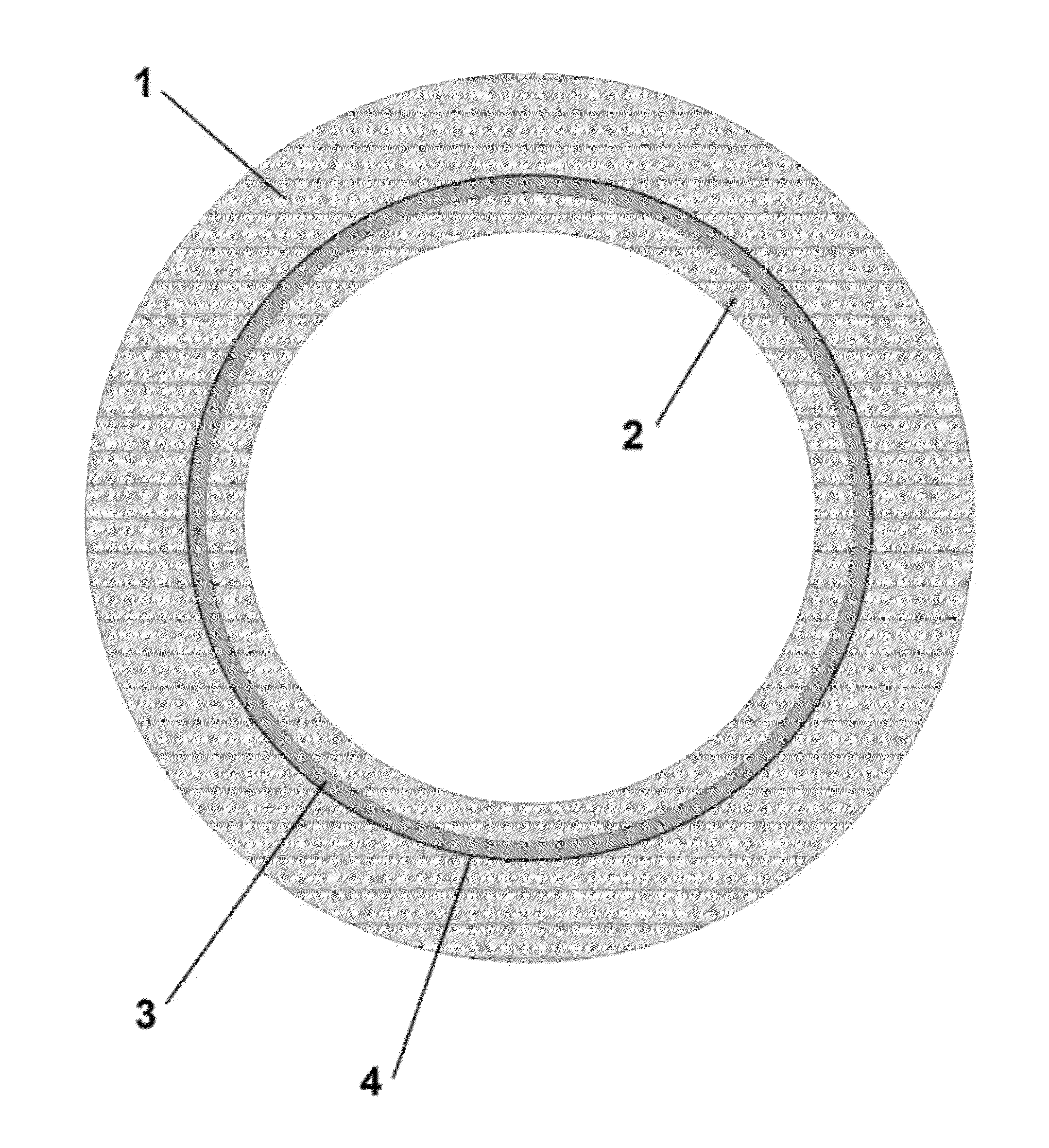

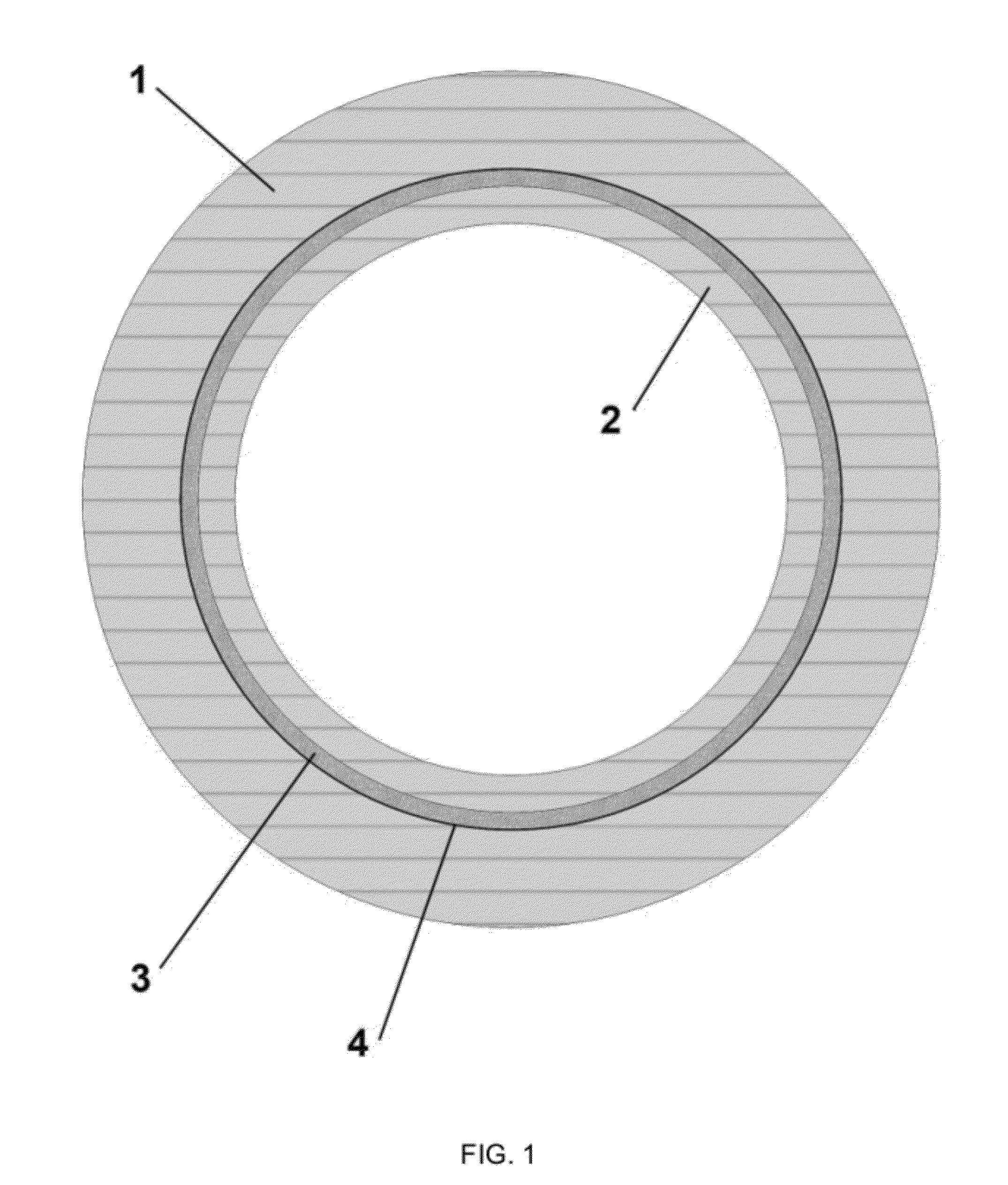

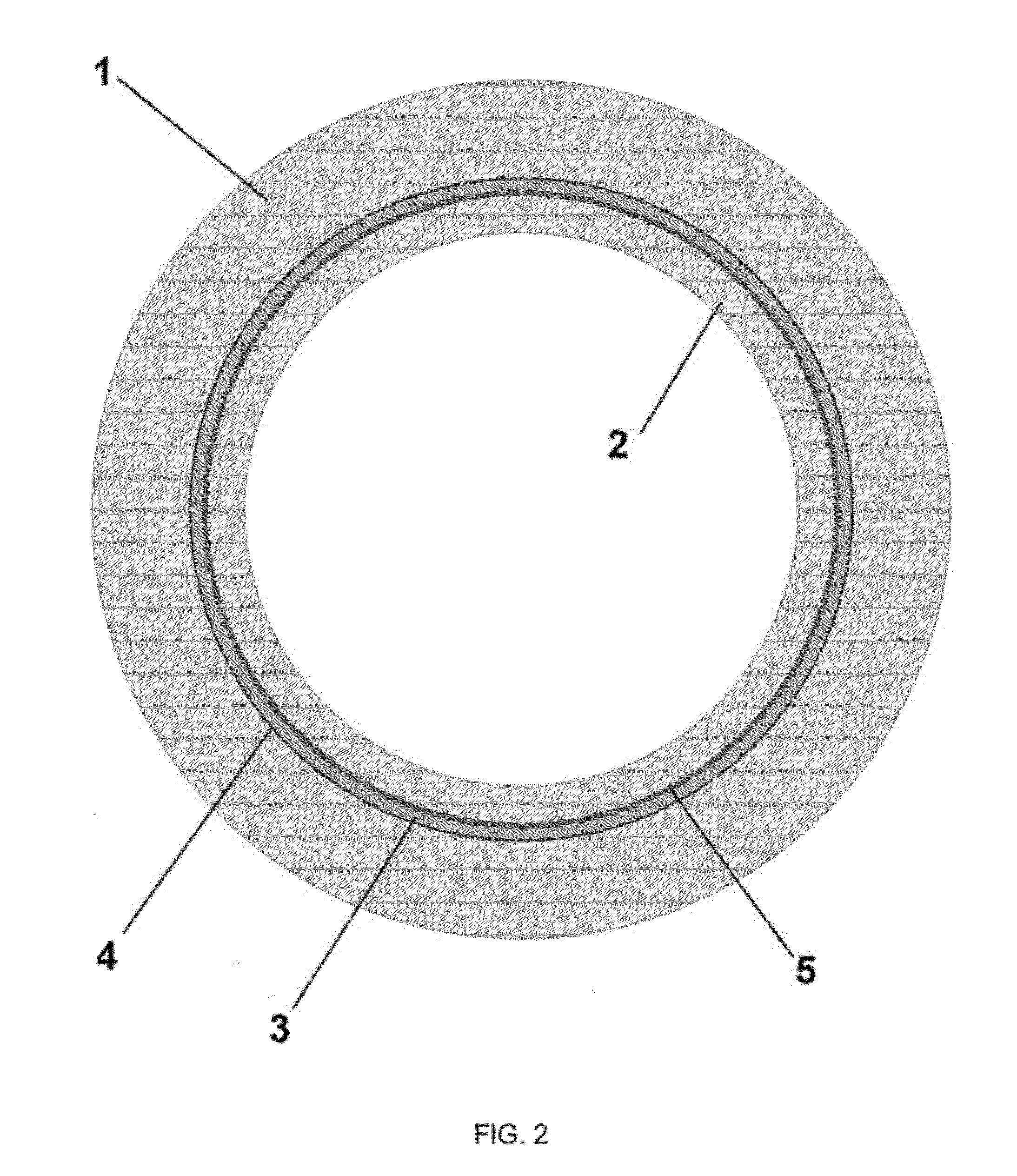

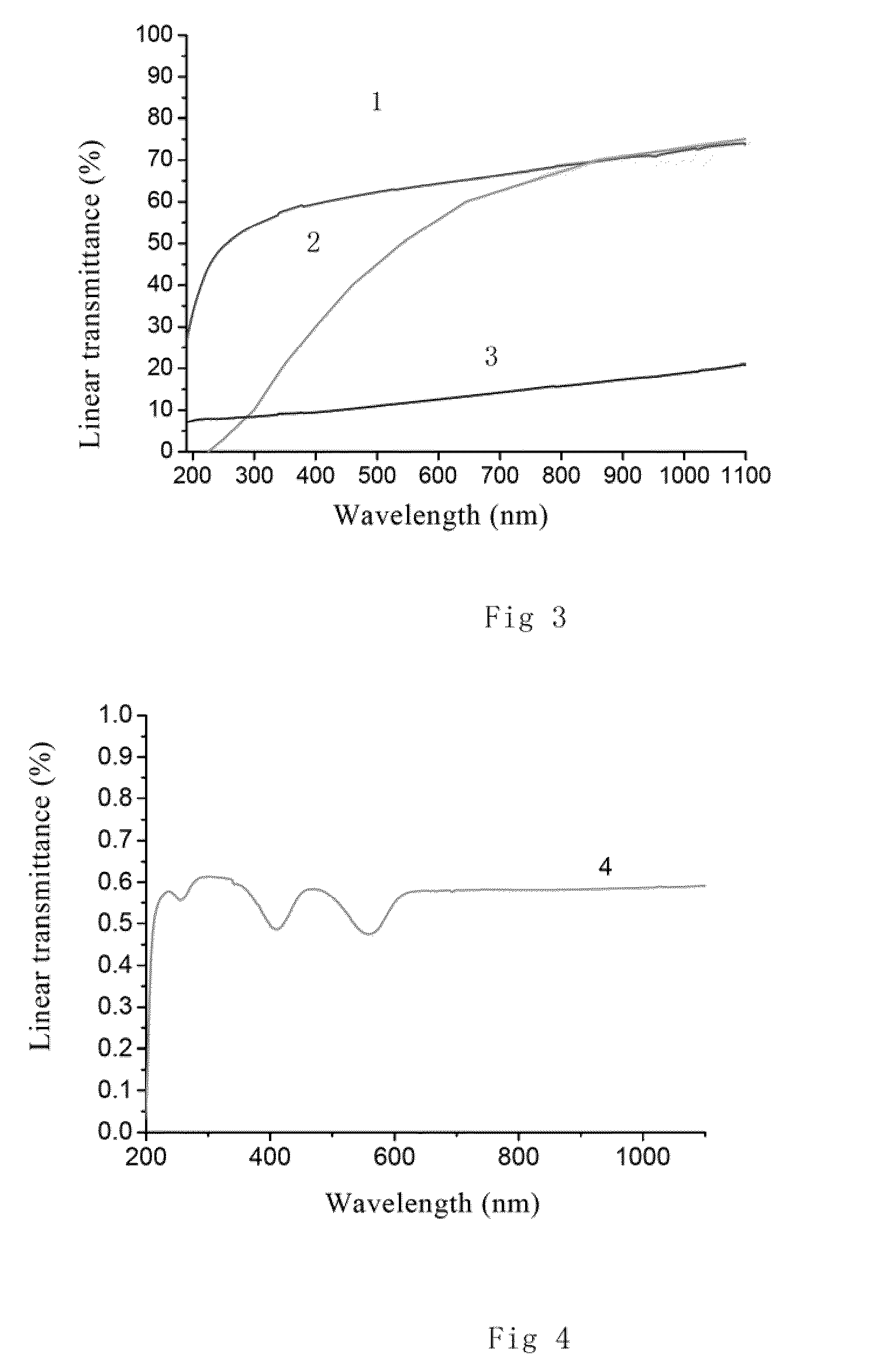

Transparent alumina ceramics with oriented grains and preparation method thereof

InactiveUS20110039685A1High in-line transparencyCeramic shaping apparatusElectric/magnetic/electromagnetic heatingOptical axisOptoelectronics

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Alumina ceramic and preparation method thereof

The invention provides alumina ceramics and a manufacturing method of the alumina ceramics. The main materials of the alumina ceramics are as follows: alumina micro mist or a superfine alumina micro mist which is formed by Gamma alumina and an Alpha alumina with an particle diameter of between zero point one to three point five micron and a purity of ninety-nine point nine percent or more than ninety-nine point nine percent according to certain proportion. One or a mixture of a small quantity of magnesia, yttria, lanthana, thulia and yttria stabilized zirconia is added into the micro mist as sinter accessory ingredient and is subject to dry pressing, grouting and isostatic cool pressing after being even mixed evenly, thus ceram green pressing is obtained. Only a little organic addition agent is needed to be added. After drying, the green pressing body does not need to be roasted and can be directly introduced to an ordinary high temperature si-mo rod resistance furnace or a continuous type si-mo rod electrothermal tunnel kiln to be sintered for one to three hours at a temperature below one thousand six hundred and seventy Celsius system. Therefore, the alumina ceramics can be obtained with high tightness, mechanical property and good dielectric property and with a nonconventional structure and a placode the size of which is zero point two to two hundred millimeter and a purity of ninety nine to ninety-nine point nine percent.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

Low-temperature co-fired ceramic tape casting material and preparing method and application thereof

The invention relates to a low-temperature co-fired ceramic tape casting material and a preparing method and application of the low-temperature co-fired ceramic tape casting material. The low-temperature co-fired ceramic tape casting material comprises, by weight, 35-50% of inorganic-phase components and 50-65% of organic-phase components. The inorganic-phase components include borosilicate glass powder and aluminum oxide ceramic powder, wherein the weight ratio of the borosilicate glass powder to the aluminum oxide ceramic powder is 2:3-3:2, and the borosilicate glass powder includes CuO which accounts for less than 3% of the power in weight. The organic-phase components include a solvent, an adhesion agent, a plasticizing agent and a dispersing agent, wherein the solvent is an alcohol-ester mixed solvent, and alcohol accounts for 20-70% in the mixed solvent in weight.

Owner:ZHEJIANG SIRAMIC TECH CO LTD

Submicron transparent crystal alumina ceramic possessing high linear transmittance

The present invention belongs to the field of transparent ceramic material technology, and is especially preparation process of submicron transparent crystal alumina ceramic possessing high linear transmittance. The transparent alumina ceramic is prepared with high purity alumina and nanometer zirconia additive, and through drying pressing and cold isostatic pressing or gel injecting to form, low temperature pre-sintering and hot isostatic pressing sintering. It has ceramic body relative density greater than 99.95 %, average crystal size not greater than 0.5 micron, Vickers hardness of 2200, bending strength of 650-800 MPa and linear transmittance at 600 nm greater than 60 %. It is suitable for use in making transparent bulletproof armoring, high temperature observation window, false teeth, etc.

Owner:韩敏芳 +1

Bonding agent for low-melting high-strength microcrystalline alumina ceramic grinding tool and preparation method thereof

The invention relates to a bonding agent for a microcrystalline alumina ceramic grinding tool and a preparation method thereof. The bonding agent comprises the following components according to molar percentage: 45-65% of SiO2, 5-20% of Al2O3, 10-30% of B2O3, 8-20% of (M1) 2O, 0-8% of (M2) 2O, 1.5-2.5% of ZnO, and 1.5-2.5% of XF, wherein one or more raw materials adopt nanoscale particles, ZnO and XF are added to increase the liquidity of the bonding agent, and the bonding agent is prepared by calcination, water quenching, drying and ball milling. The bonding agent is stable in performance, good in wettability for microcrystalline alumina abrasive, high in reaction capability, low in initial melting temperature, and can be used for firing a high-strength ceramic grinding tool at the low temperature of 700-800 DEG C. The prepared microcrystalline alumina ceramic grinding tool is good in grinding performance, and can be widely used in the fields of iron and steel, machinery, buildings, aviation, military industry and the like.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com