Armor of ceramic-metal composite and preparation method thereof

A technology of ceramic composite materials and metals, applied in the field of composite armor and its preparation, can solve the problems of fragmentation, missile impact damage, poor impact resistance, etc., and achieve strong penetration resistance, low manufacturing cost, and impact resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

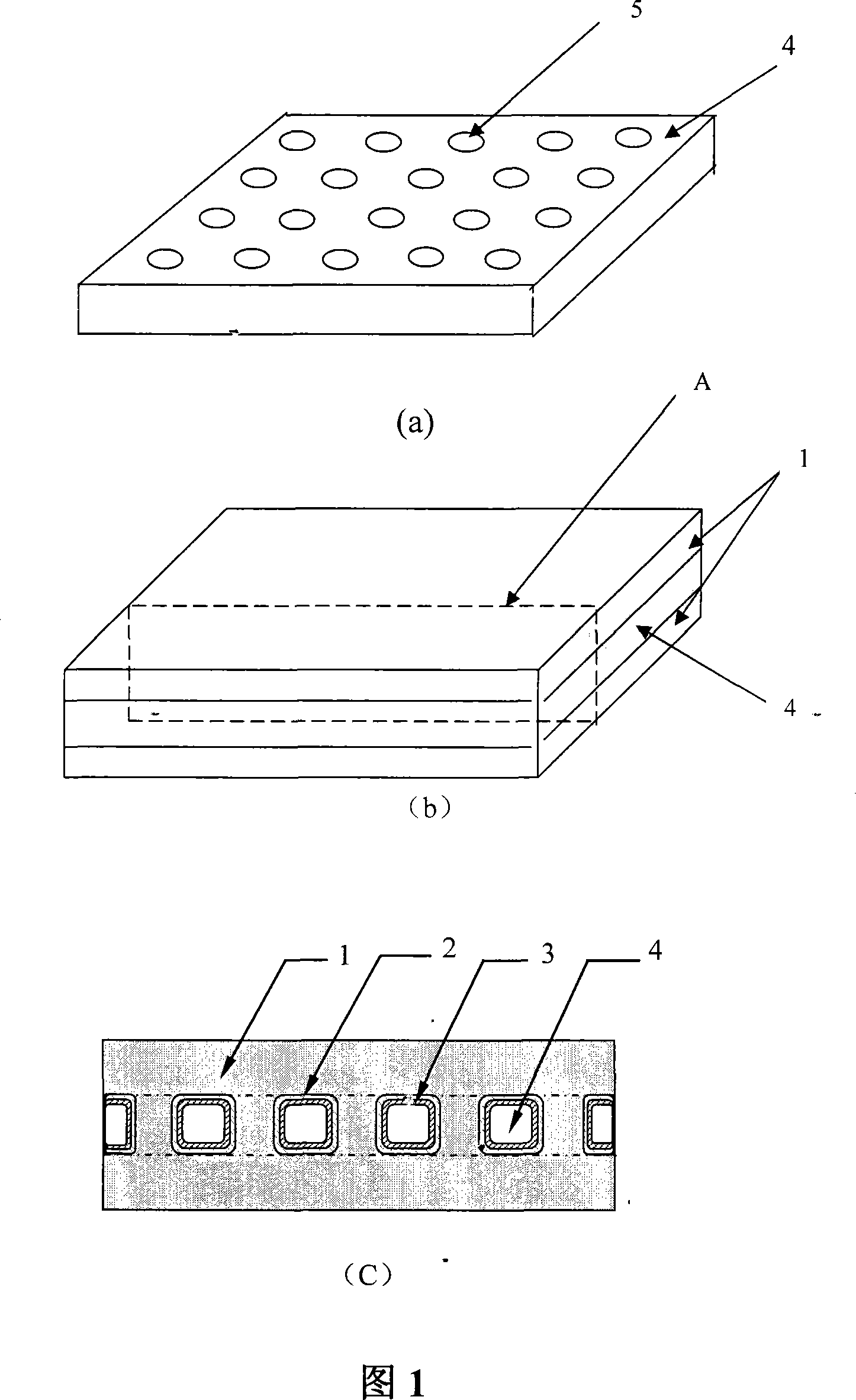

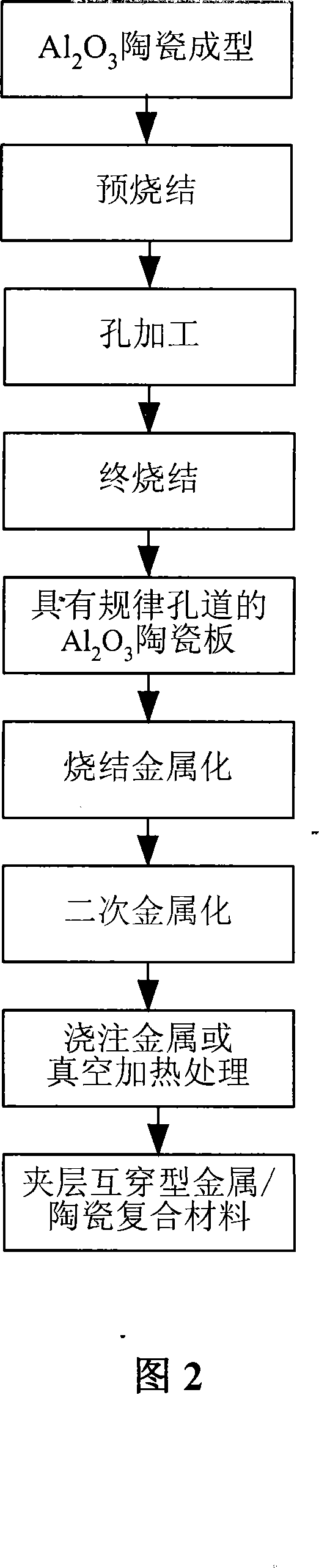

[0027] 1. Preparation of ceramic core plate 4 with orderly arranged channels:

[0028] (1) Ceramic forming: the molding process is adopted. Roll and mix ball mill (add absolute ethanol, ball mill for 36h), granulate (granulation glue contains 10% polyvinyl alcohol solution) and sieve (200 mesh) containing 95wt% Al 2 o 3 , 2.5wt% SiO 2 Alumina ceramic powder with 2.5wt% MgO is placed in a 60*60mm metal mold, the loading pressure is 5-10MPa, the pressure is kept for 15-30 seconds, and the thickness of the formed ceramic body is 7-8mm. The debinding process of the formed ceramic body adopts the process of slowly raising the temperature to 450°C, keeping the temperature for 2 hours, and cooling slowly. The molding process of the present invention is not limited to compression molding, and hot die casting, grouting, cold isostatic pressing, etc. can also be used.

[0029] (2) Pre-sintering: Pre-sinter the alumina ceramic body after debinding at 1000-1200° C. for 0.5-2 hours in ...

Embodiment 2

[0036] The process steps 1, 2, and 3 of this embodiment are the same as those in Example 1, and the process step 4 adopts vacuum heat treatment: put the cast aluminum alloy powder or block into the mold of the ceramic core plate 4 with a built-in pad, and then combine Put it in a vacuum furnace and heat it to 800°C, keep it warm for 40 minutes, and finally cool it slowly, take it out, and demould. At this time, the upper and lower thicknesses of the poured metal of the ceramic core board 4 are 10 mm and 20 mm, respectively, and then the metals on both sides are machined to have an upper and lower thickness of 8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com