Patents

Literature

50 results about "Weak binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Typically, weak binding is due to poor affinities (usually with values of K D between 1 µM and 1 mM). On and off rates are typically high, yielding curves that rise and fall rapidly, with flat or nearly flat plateaus, which reflect steady-state binding. This makes curve fitting difficult.

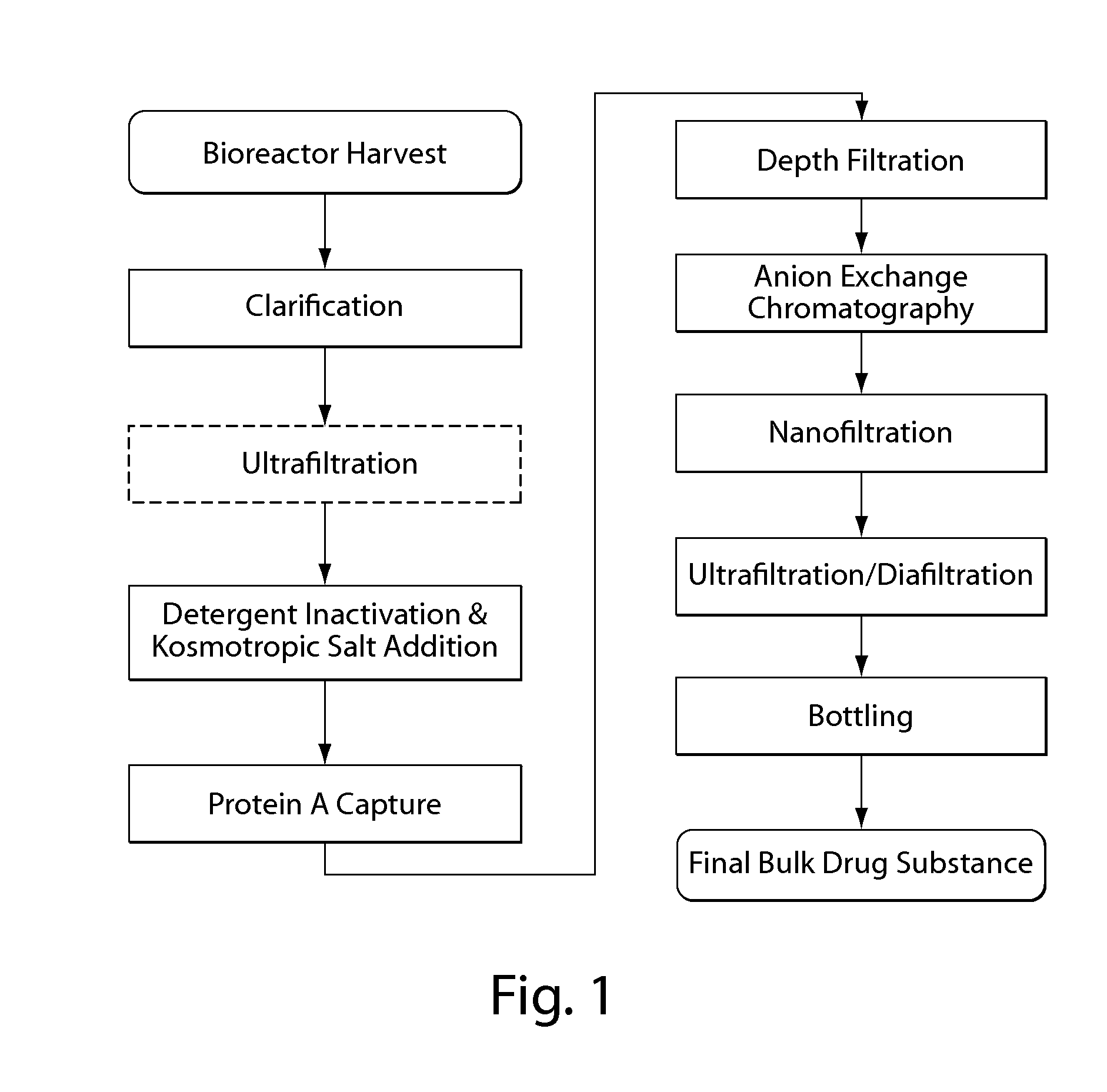

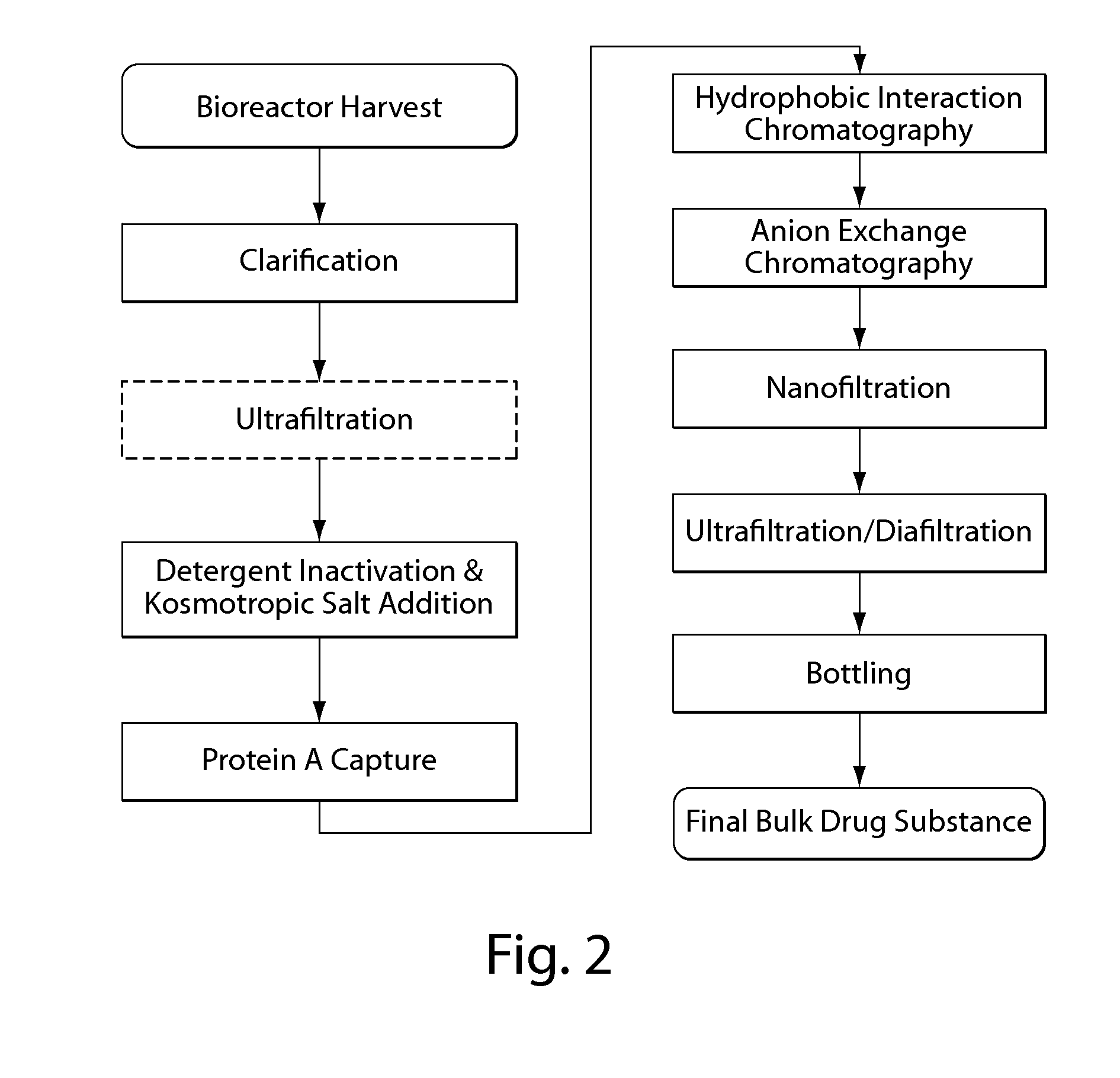

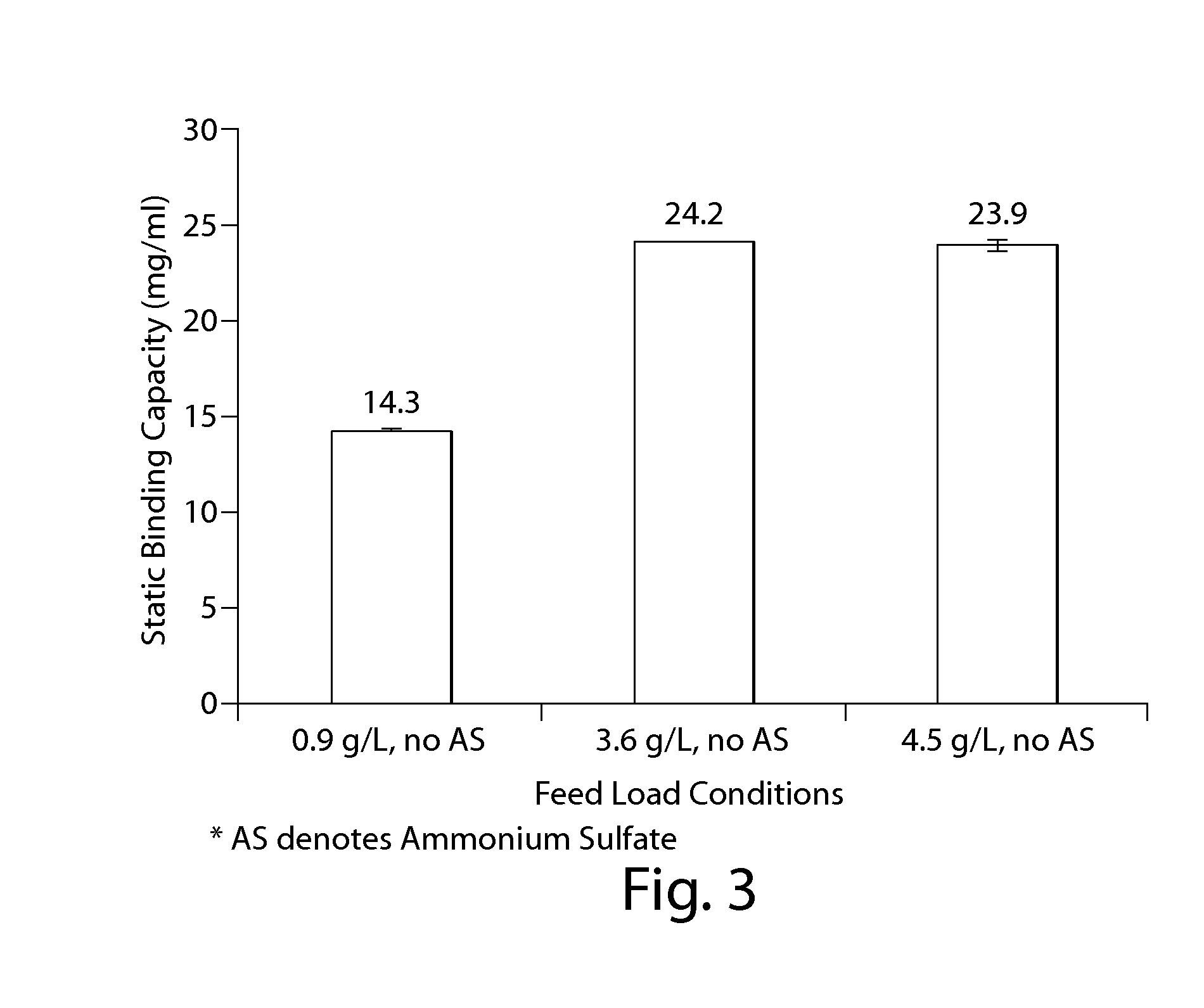

Purification of non-human antibodies using kosmotropic salt enhanced protein a affinity chromatography

InactiveUS20140154270A1Solid sorbent liquid separationPeptide preparation methodsKosmotropicWeak binding

The present invention is directed to methods for purifying a non-human antibody, or antigen binding portion thereof, exhibiting weak binding strength and low binding capacity for Protein A chromatography media. In one aspect, a kosmotropic salt solution is employed to promote the hydrophobic interaction between the non-human antibody, or antigen binding portion thereof, and the Protein A ligand, thereby enhancing the binding of the non-human antibody, or antigen binding portion thereof, to the Protein A chromatography media. In another aspect, the concentration of the non-human antibody, or antigen binding portion thereof, in a sample comprising the antibody, or antigen binding portion thereof, exposed to a Protein A chromatography media is increased to enhance the binding of the non-human antibody, or antigen binding portion thereof, on the Protein A chromatography media.

Owner:ABBVIE INC

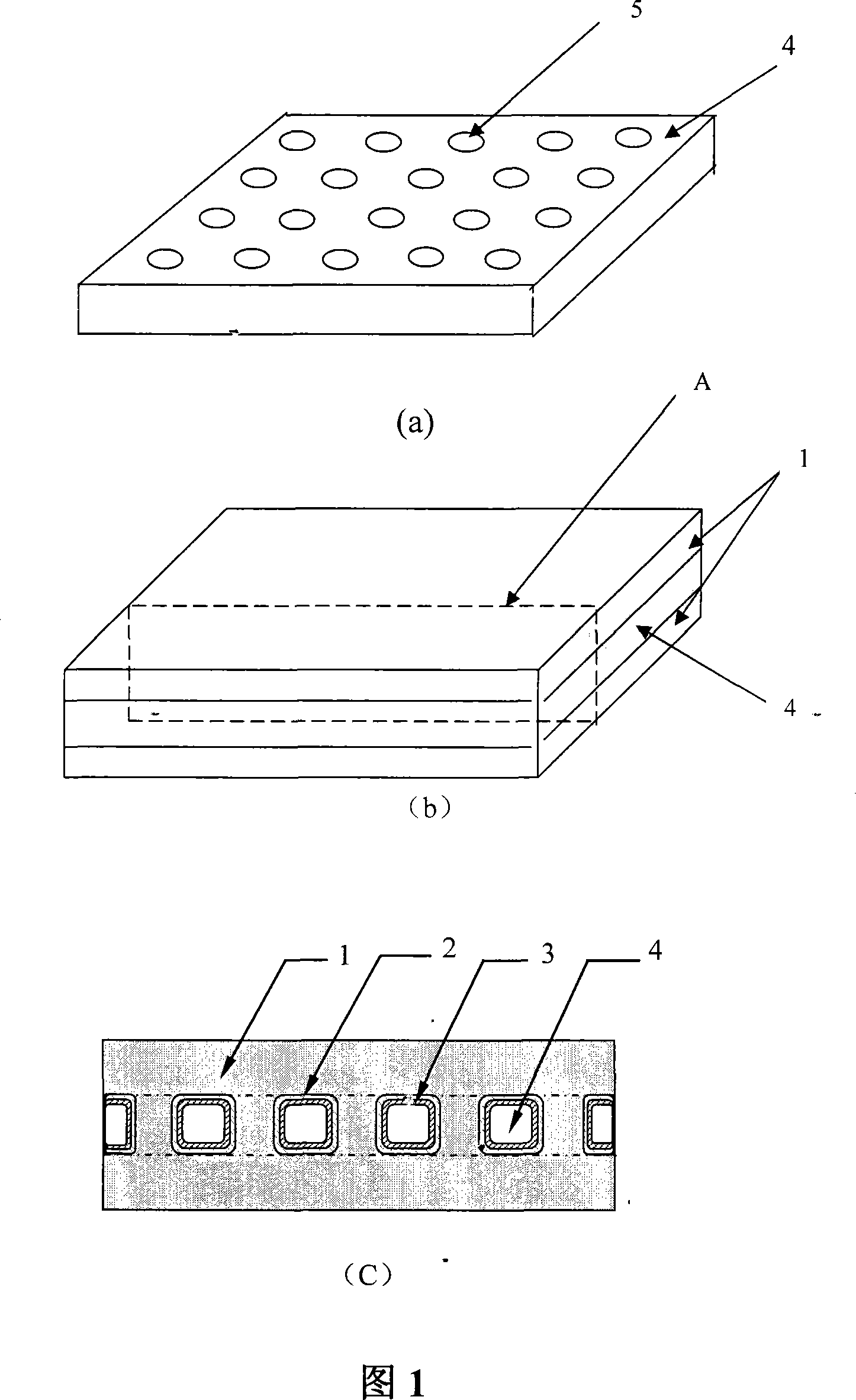

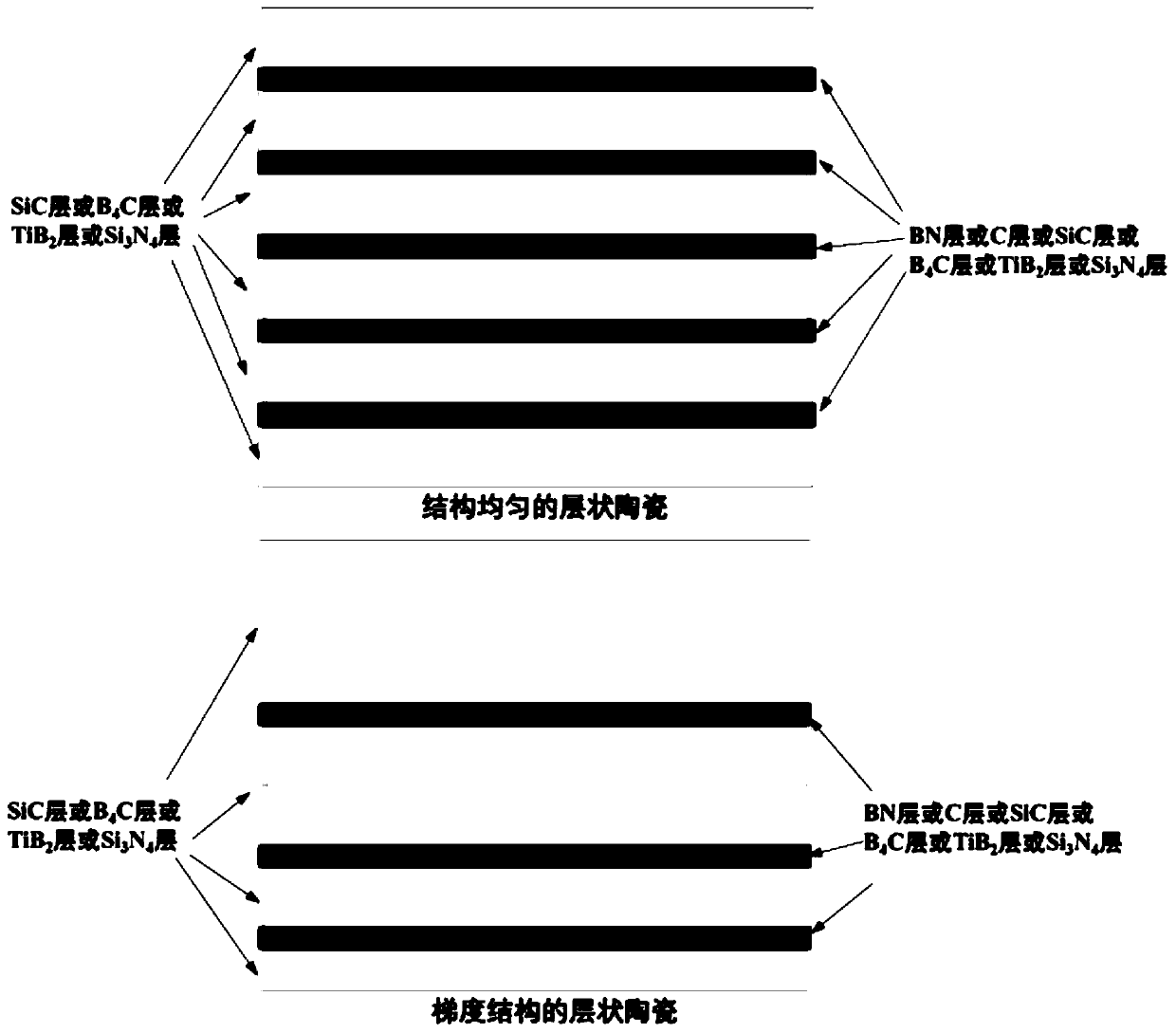

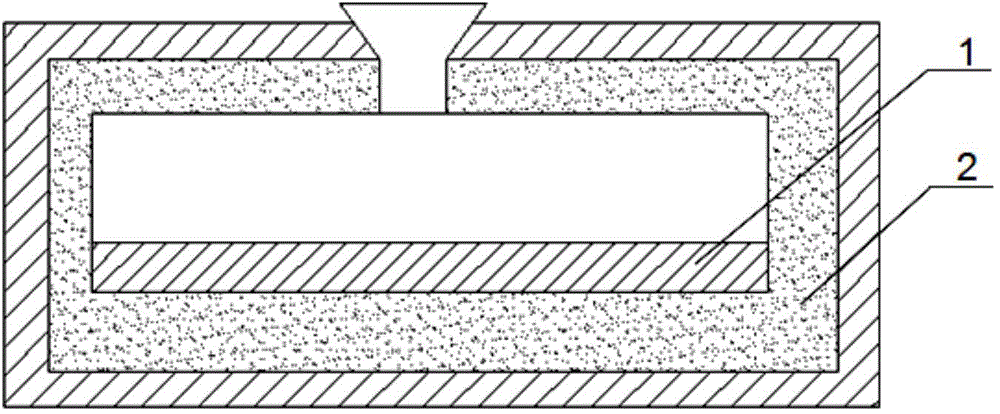

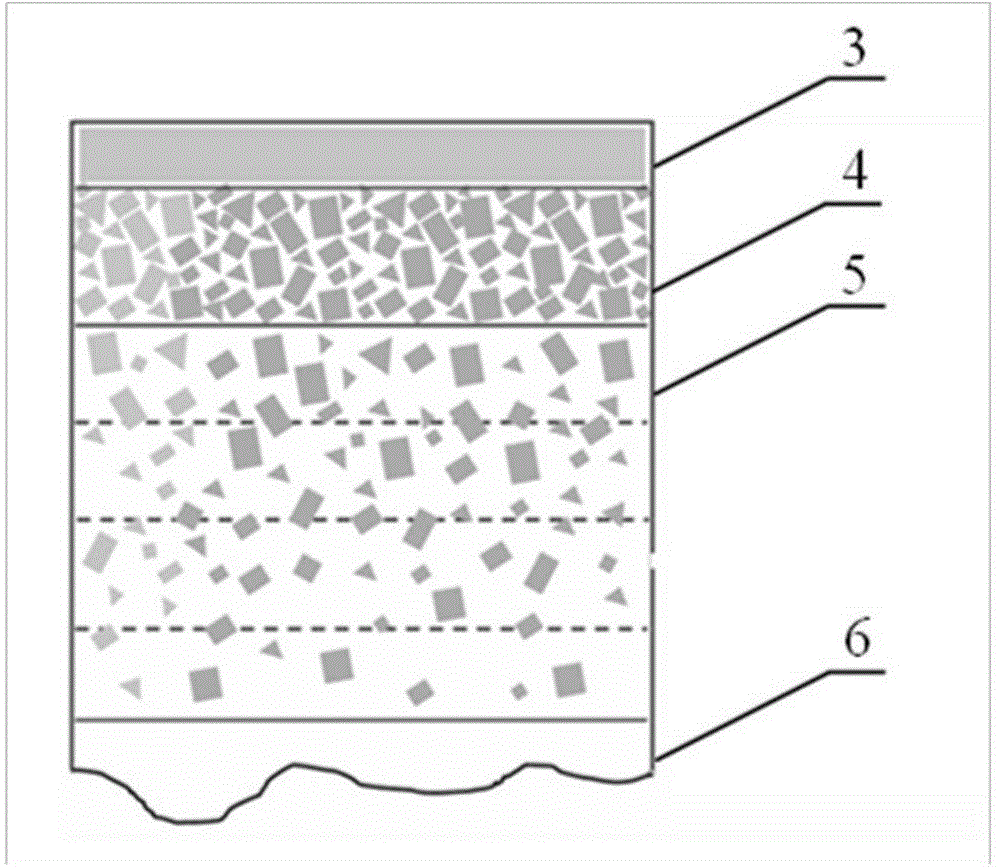

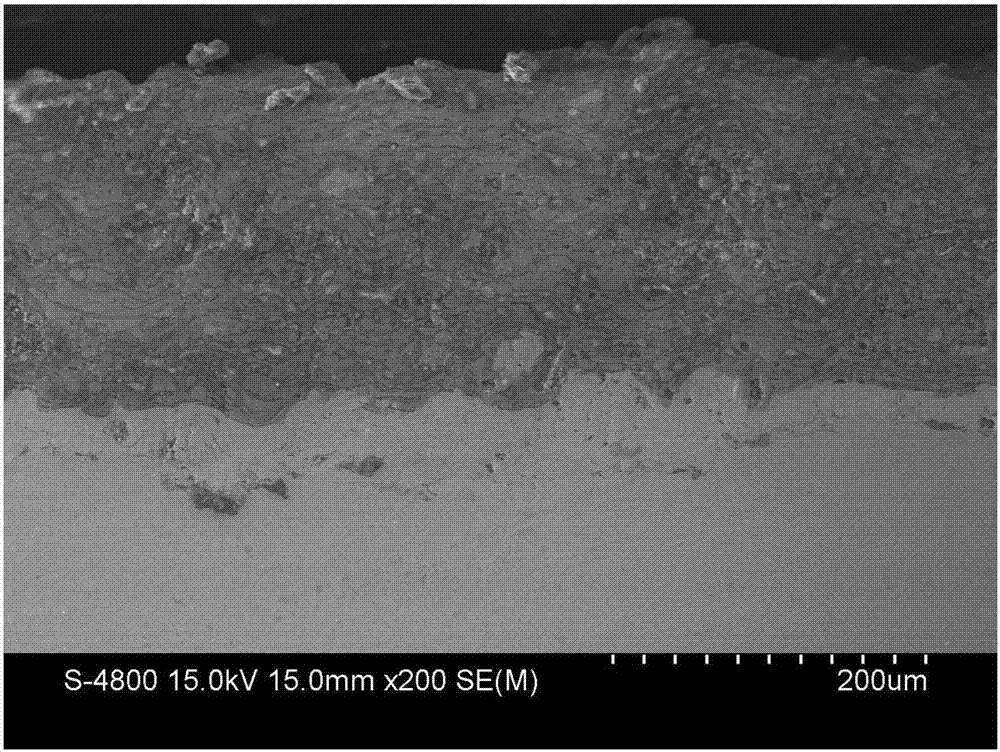

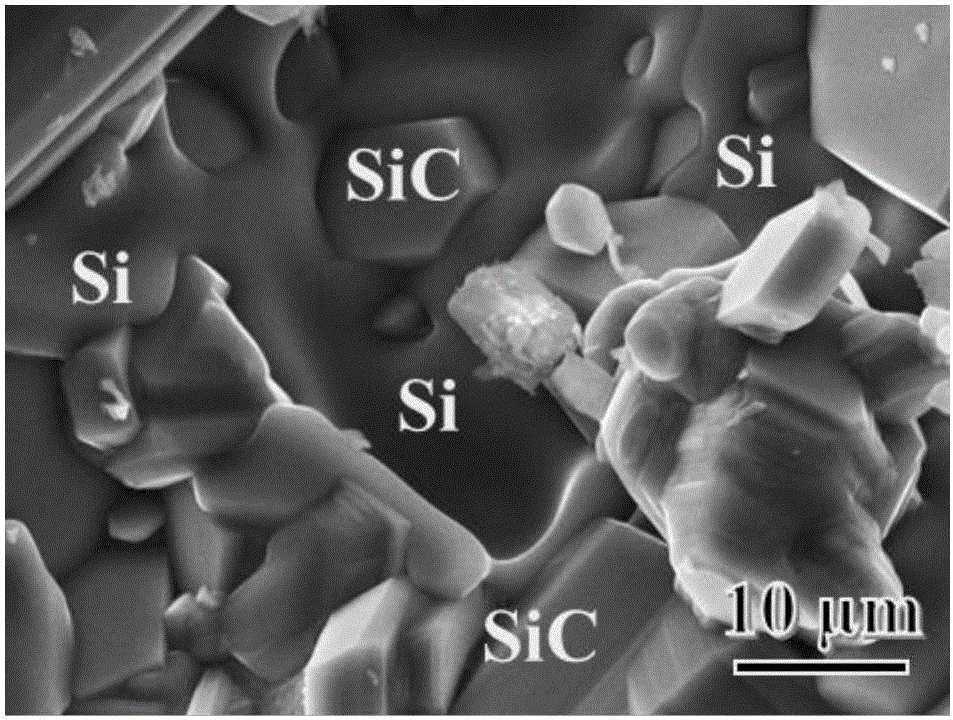

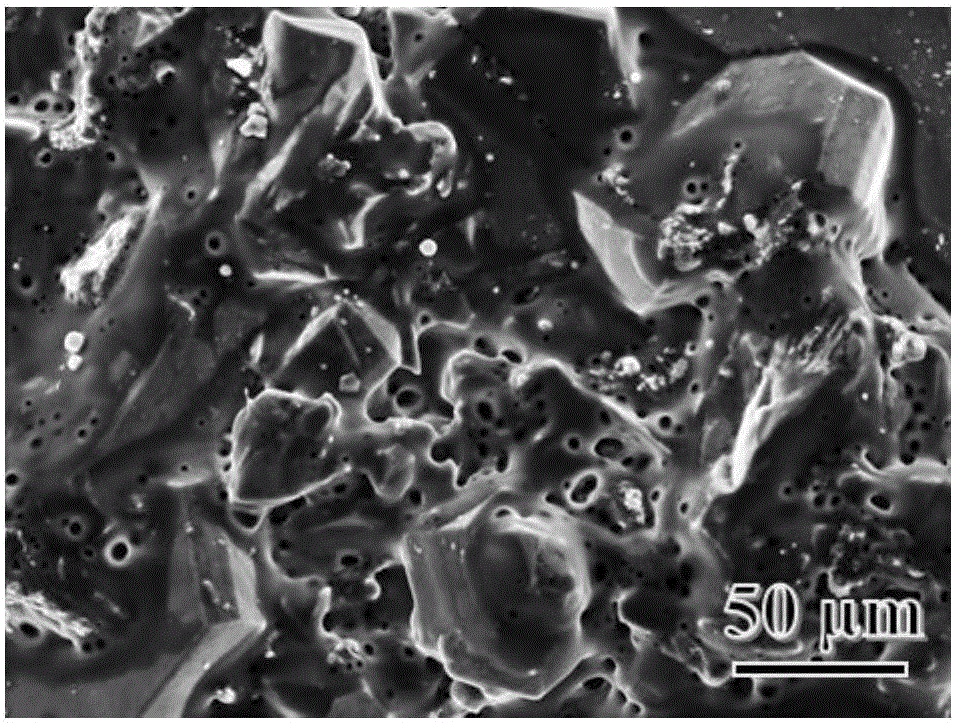

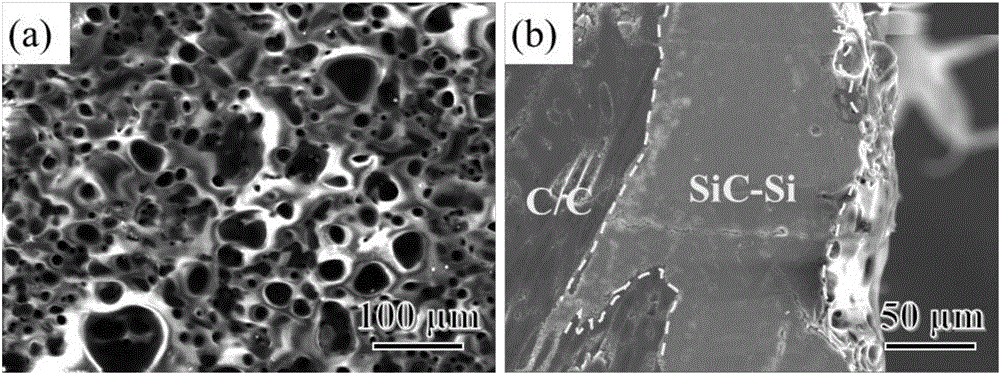

Armor of ceramic-metal composite and preparation method thereof

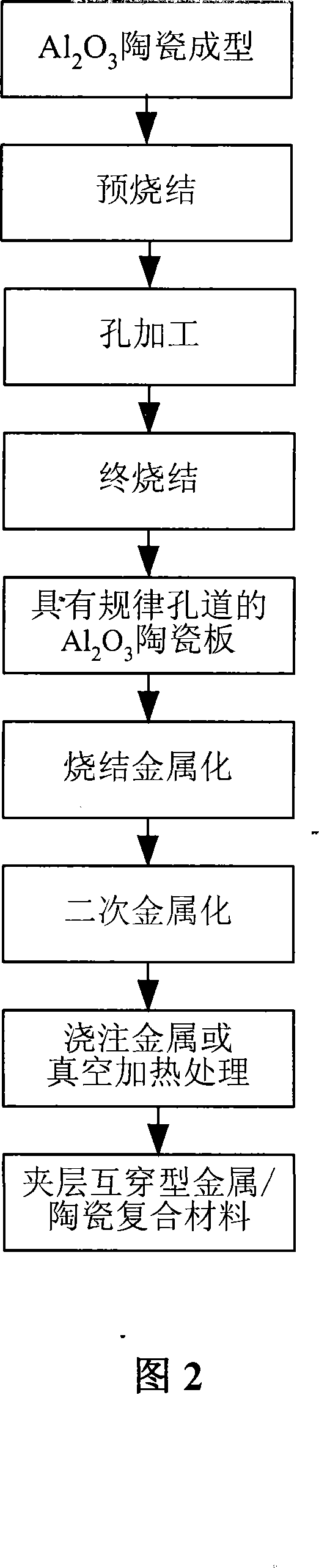

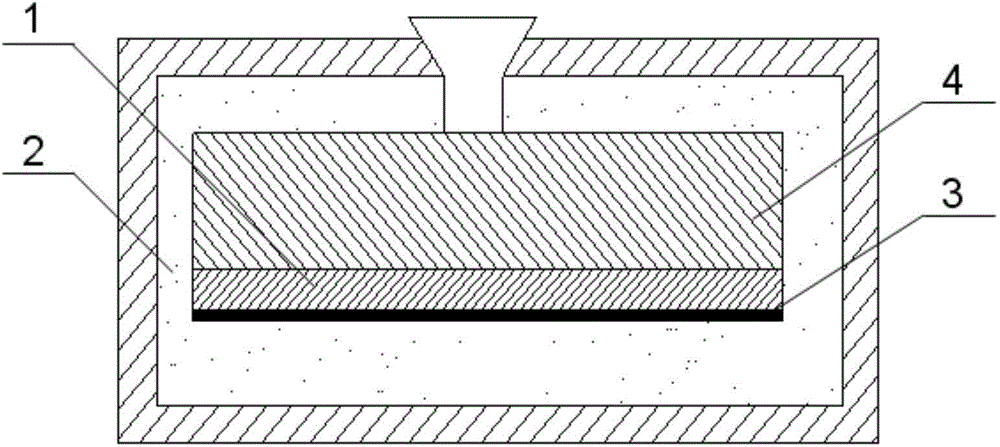

InactiveCN101158564AHigh hardnessStrong penetration resistanceArmour platesMolten stateCeramic composite

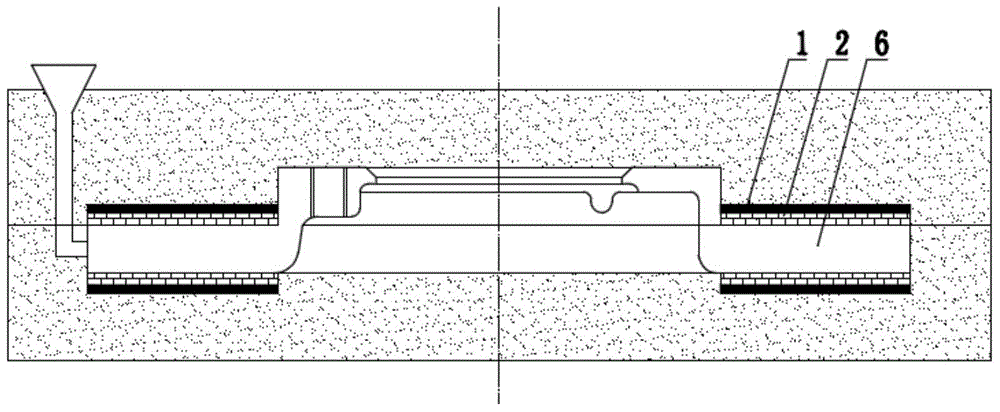

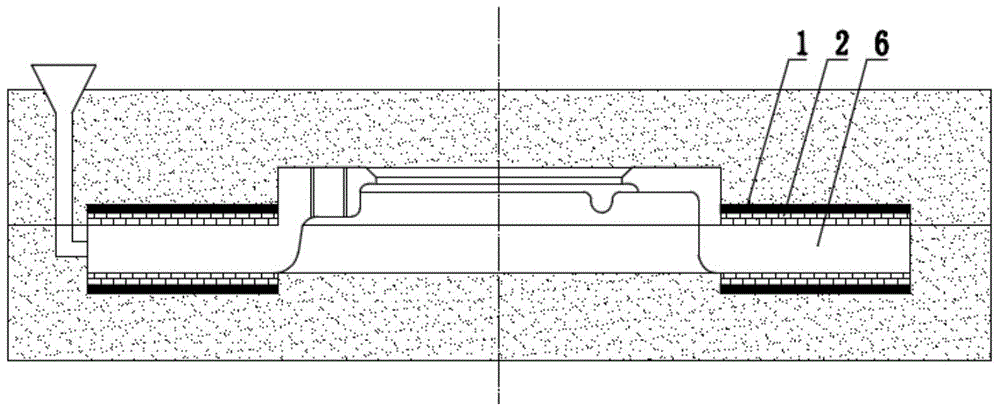

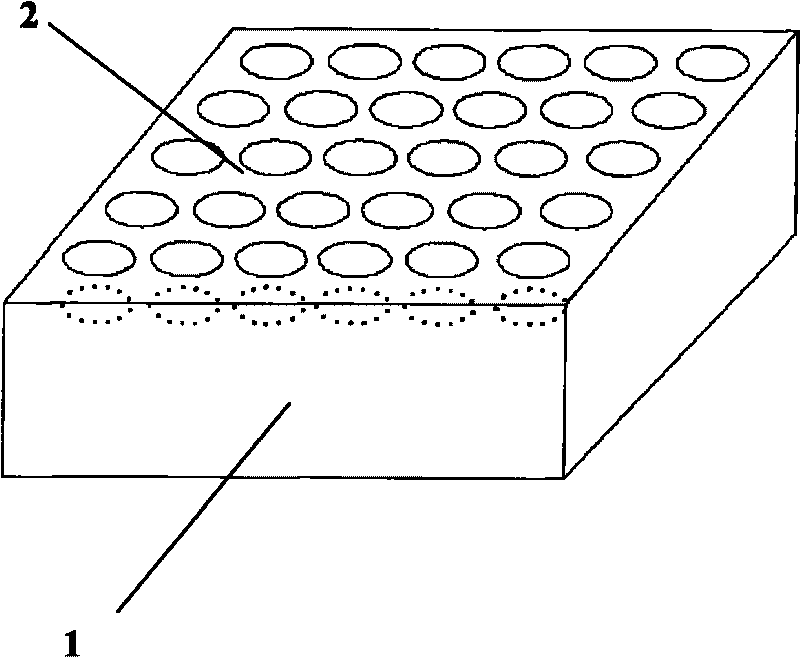

The invention discloses a metallic / ceramic composite armor and preparation method with ordered supporting structure of metallic materials as a framework and alumina ceramic materials as a core, and comprises the following steps: (1) a ceramic core plate with well-ordered pore canals is prepared and comprises working procedures such as forming, first sintering, hole machining and final sintering; (2) the ceramic core plate is sintered and metallized, all the surfaces of the finally sintered ceramic core plate is coated with Mo-Mn metal pastes, after being dried, the finally sintered ceramic core plate is metallized and sintered by being put under a protective atmosphere; (3) the metal is poured or vacuum heating treatment is made, the metal material is heated into a molten state, then poured into a die in which the ceramic core plate is arranged to have a thermostatic treatment, and finally cooled slowly to knock out. The invention can overcome weak binding of articulated connection and plane connection between the metal and the ceramic, etc., and realize high-strength binding between metallic / ceramic interfaces, moreover, the prepared metallic / ceramic composite armor with the sandwiches which can pass mutually is provided with the performance of light weight, high strength and impact resistance, thereby being suitable for a bulletproof composite armor plate and an armored panel on tanks and armored vehicles, etc.

Owner:XI AN JIAOTONG UNIV

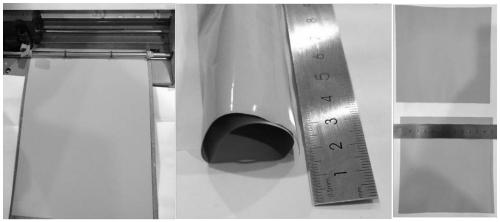

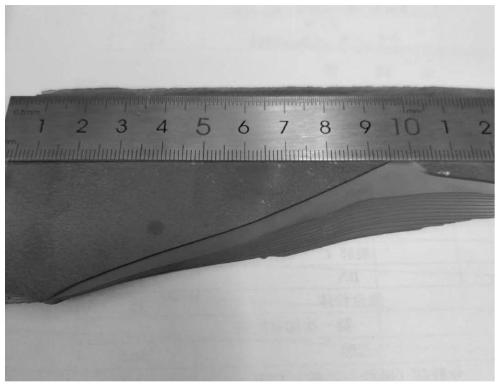

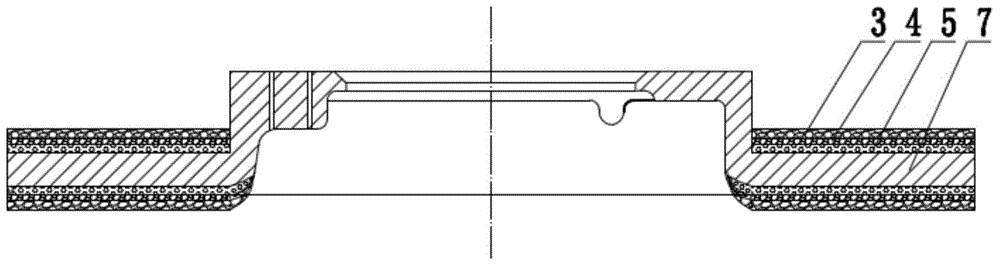

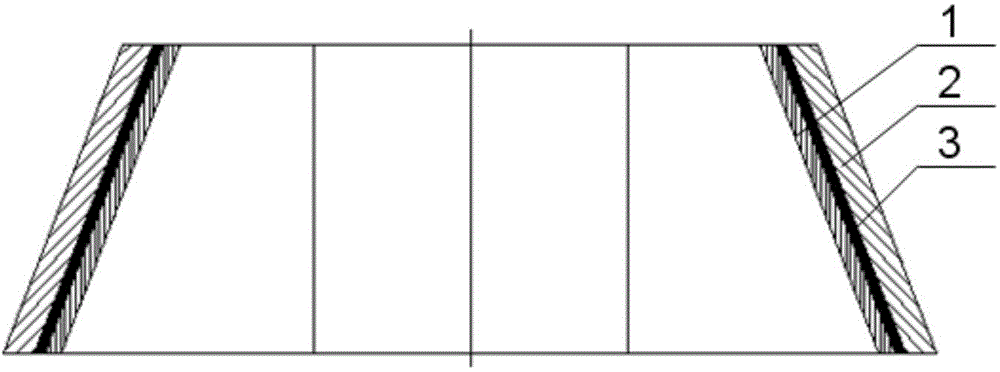

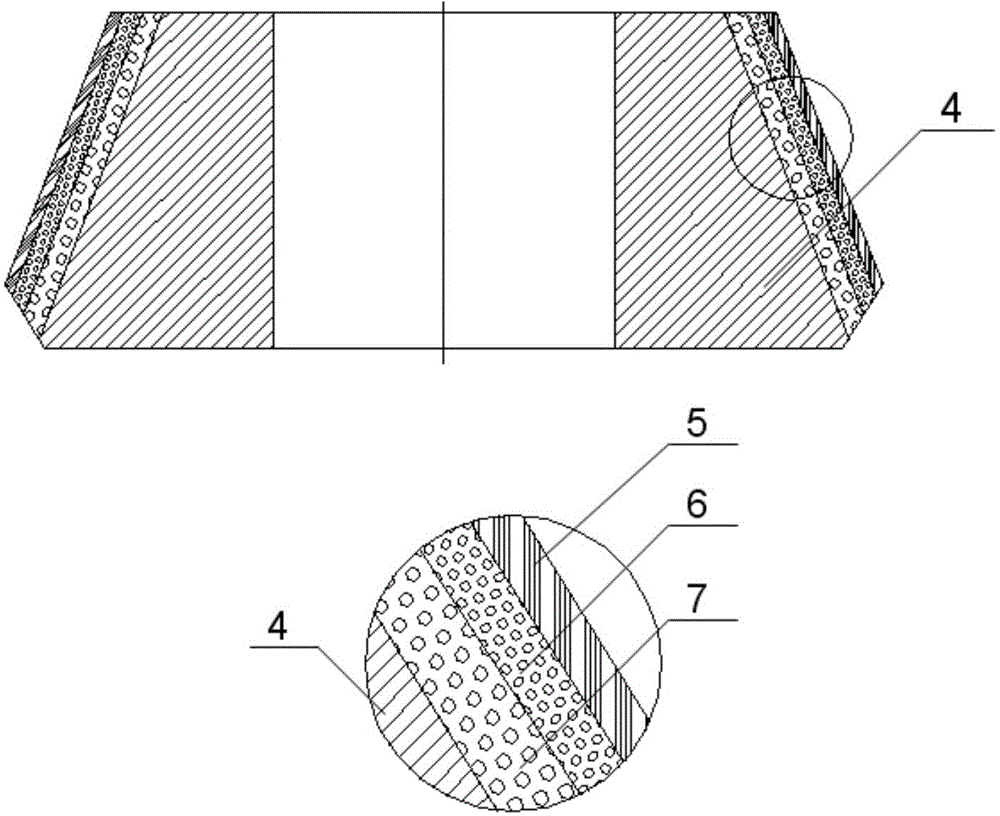

Fiber-metal laminated plate and preparation method thereof

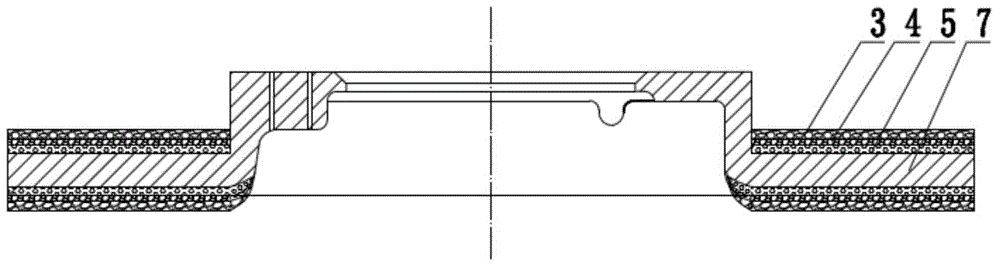

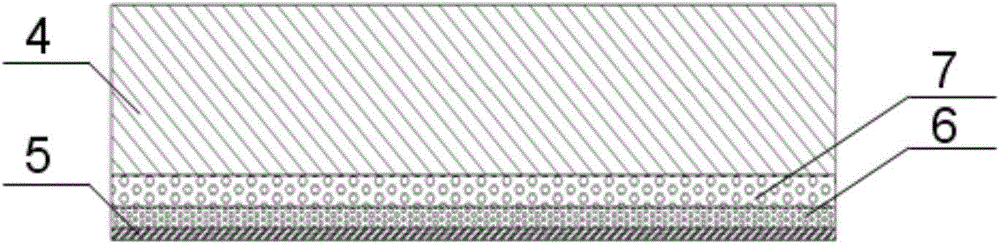

ActiveCN105522788AImprove bindingLayered product treatmentProtective equipmentFiber metal laminateWeak binding

The invention provides a fiber-metal laminated plate. The fiber-metal laminated plate solves the problem of a weak binding force between a metal layer and a fiber cloth in the existing fiber-metal laminated plate. The fiber-metal laminated plate comprises a metal layer, a resin binder layer and a fiber cloth and the metal layer, the resin binder layer and the fiber cloth are orderly stacked, chopped fibers are arranged between the resin binder layer and the fiber cloth and each one of the chopped fibers has a first part inserted in the fiber cloth and a second part fixed in the resin binder layer. The invention also discloses a preparation method of the fiber-metal laminated plate. The fiber-metal laminated plate has a strong binding force between the metal layer and the fiber cloth.

Owner:BYD CO LTD

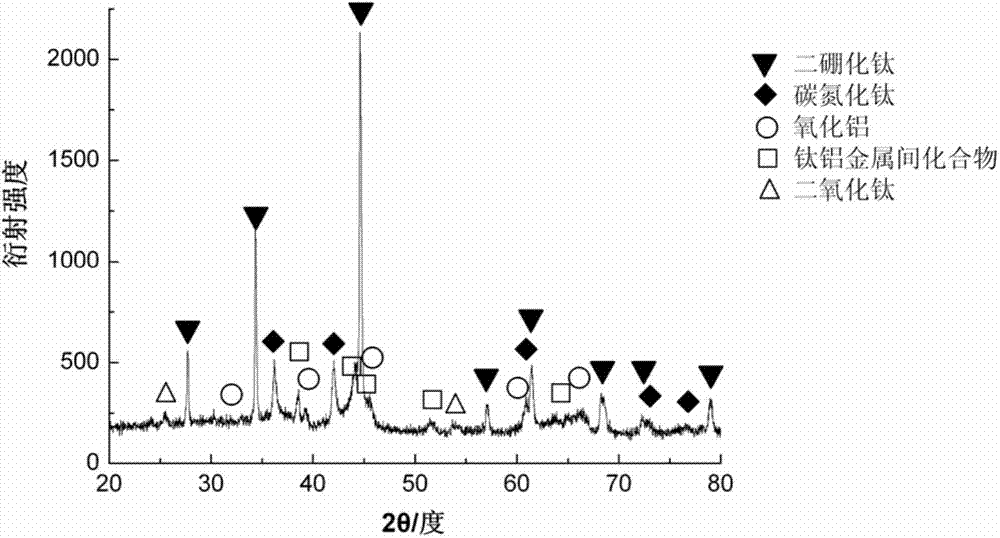

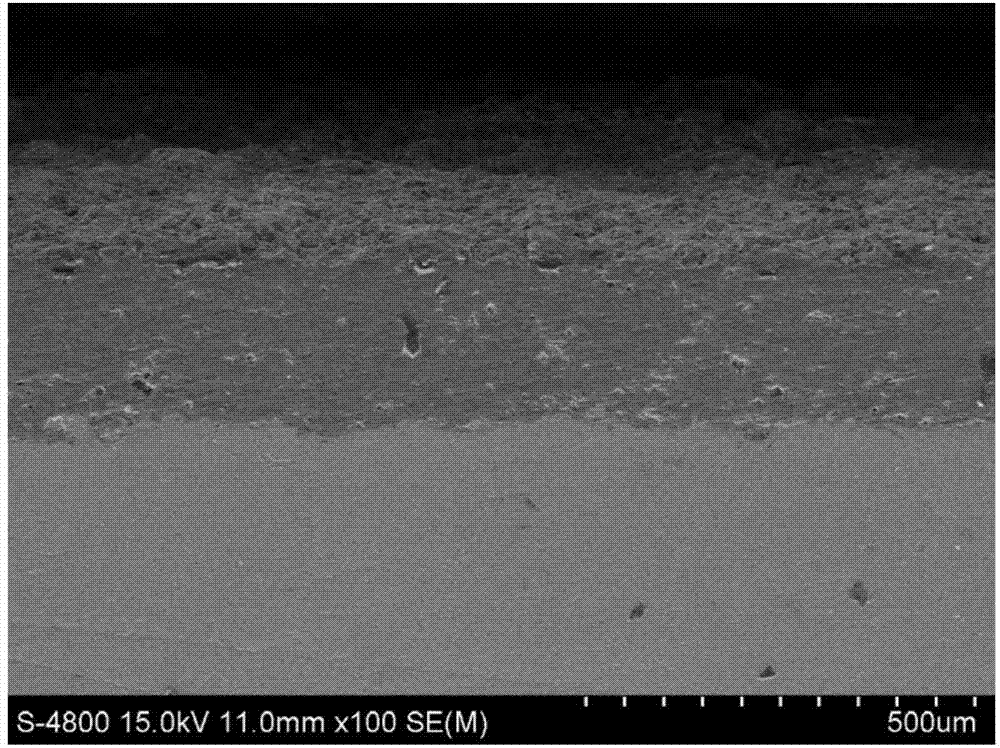

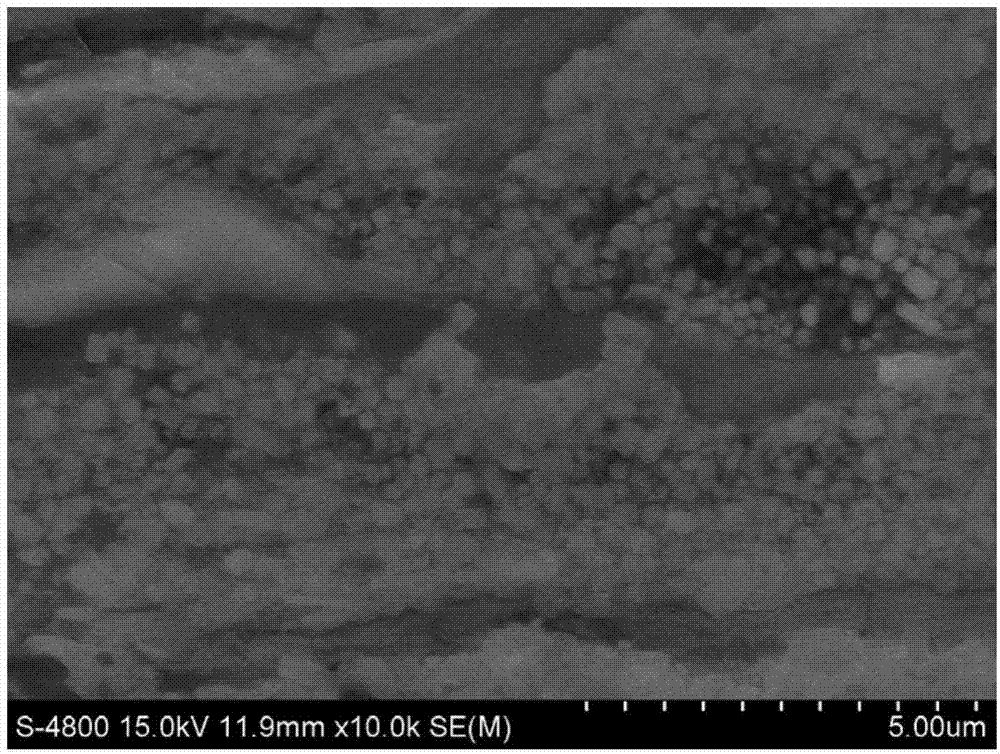

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

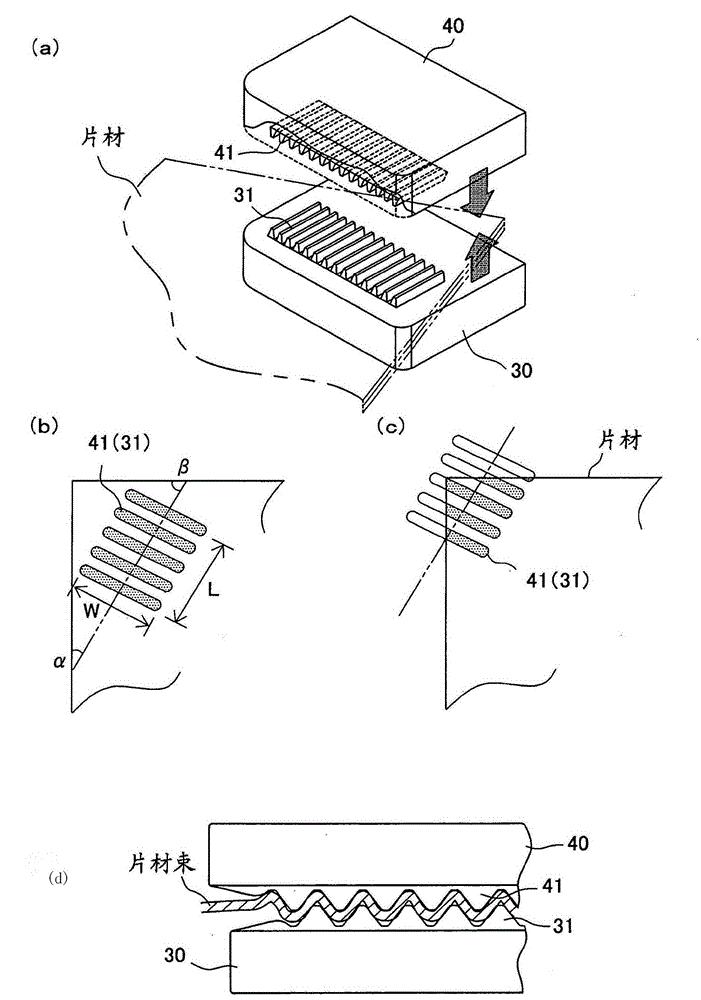

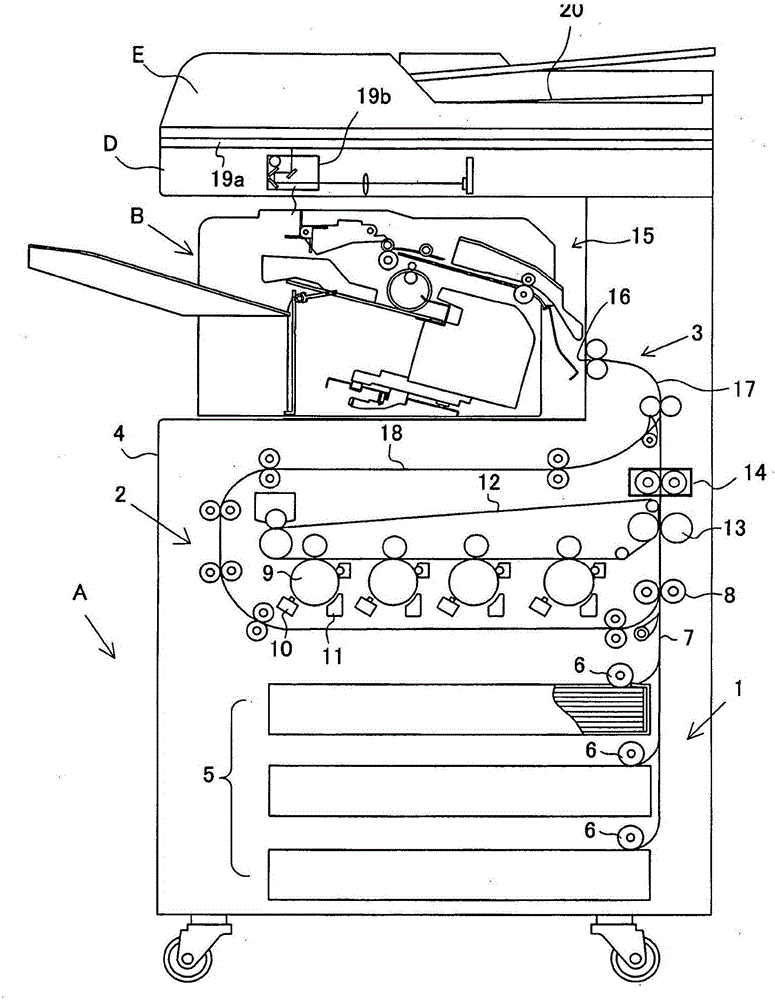

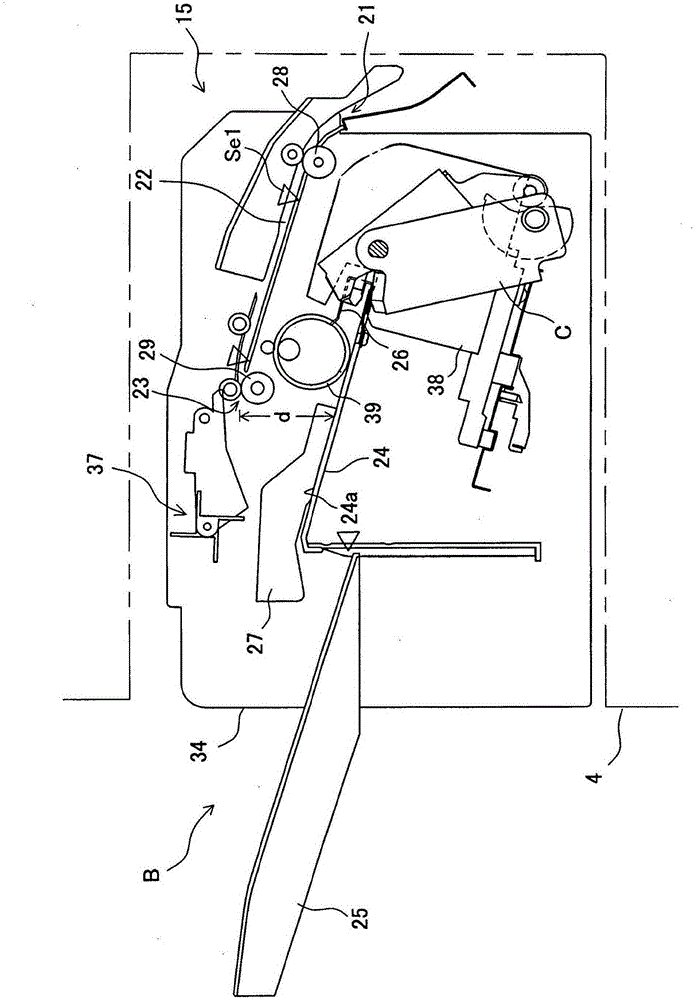

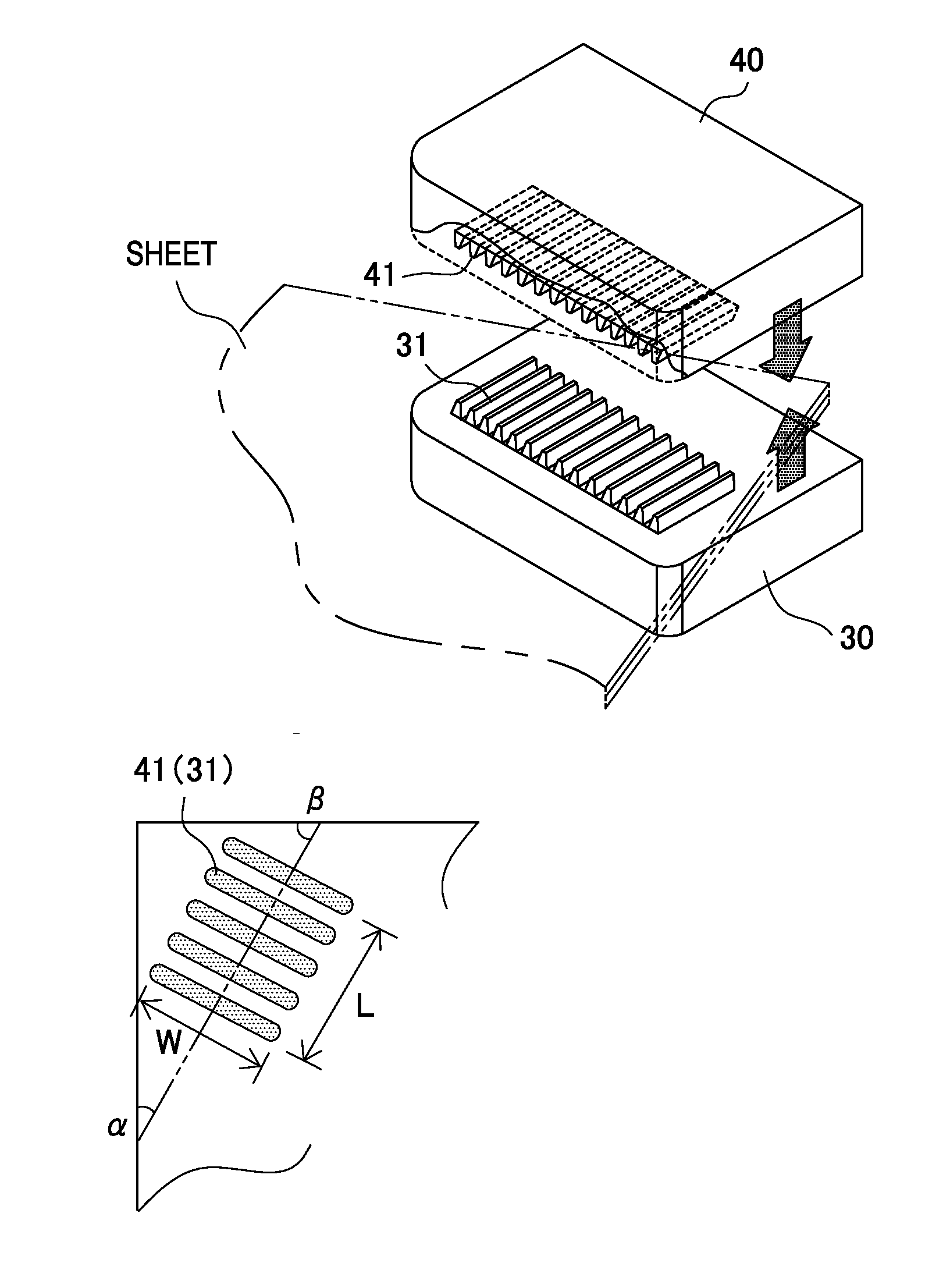

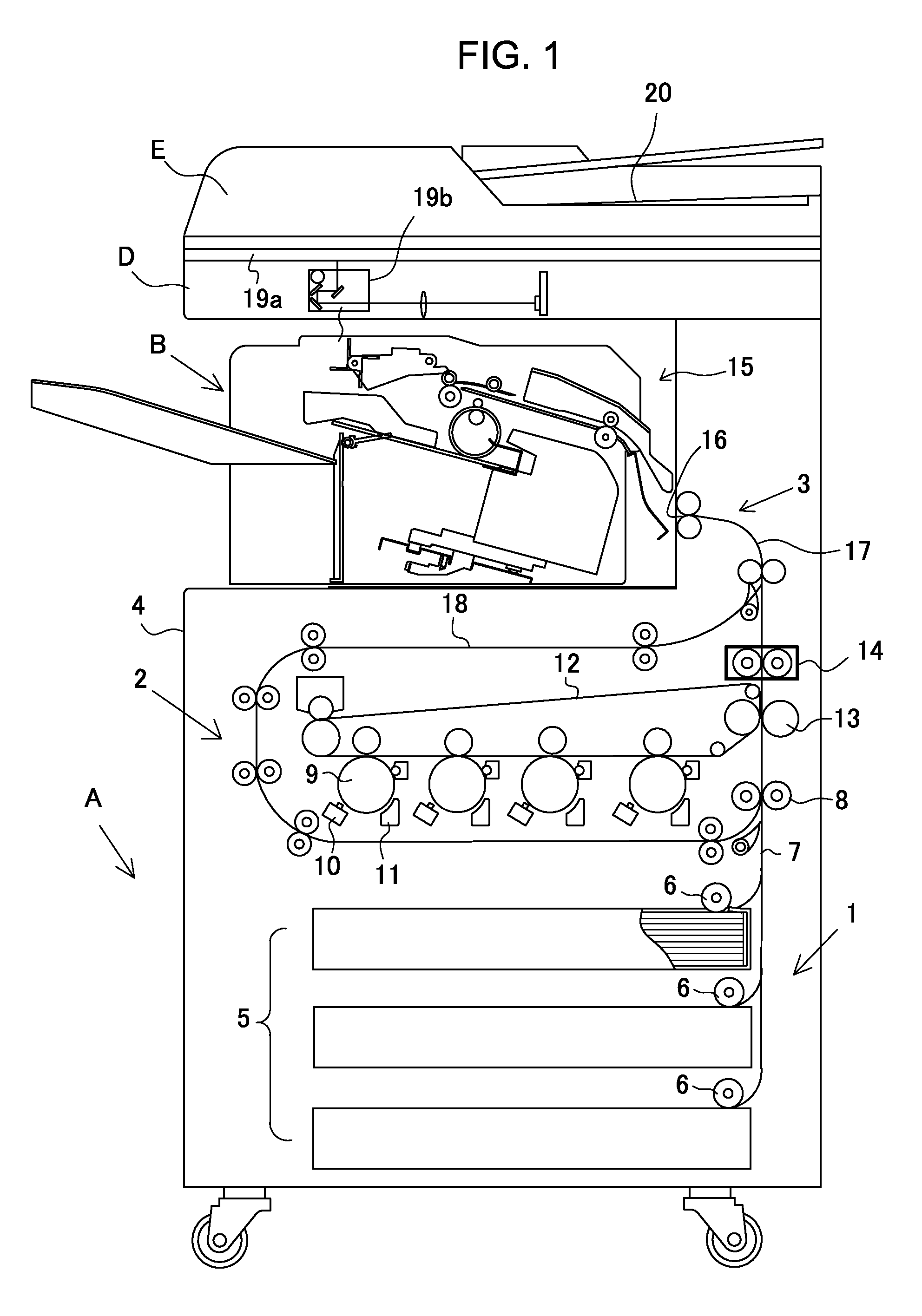

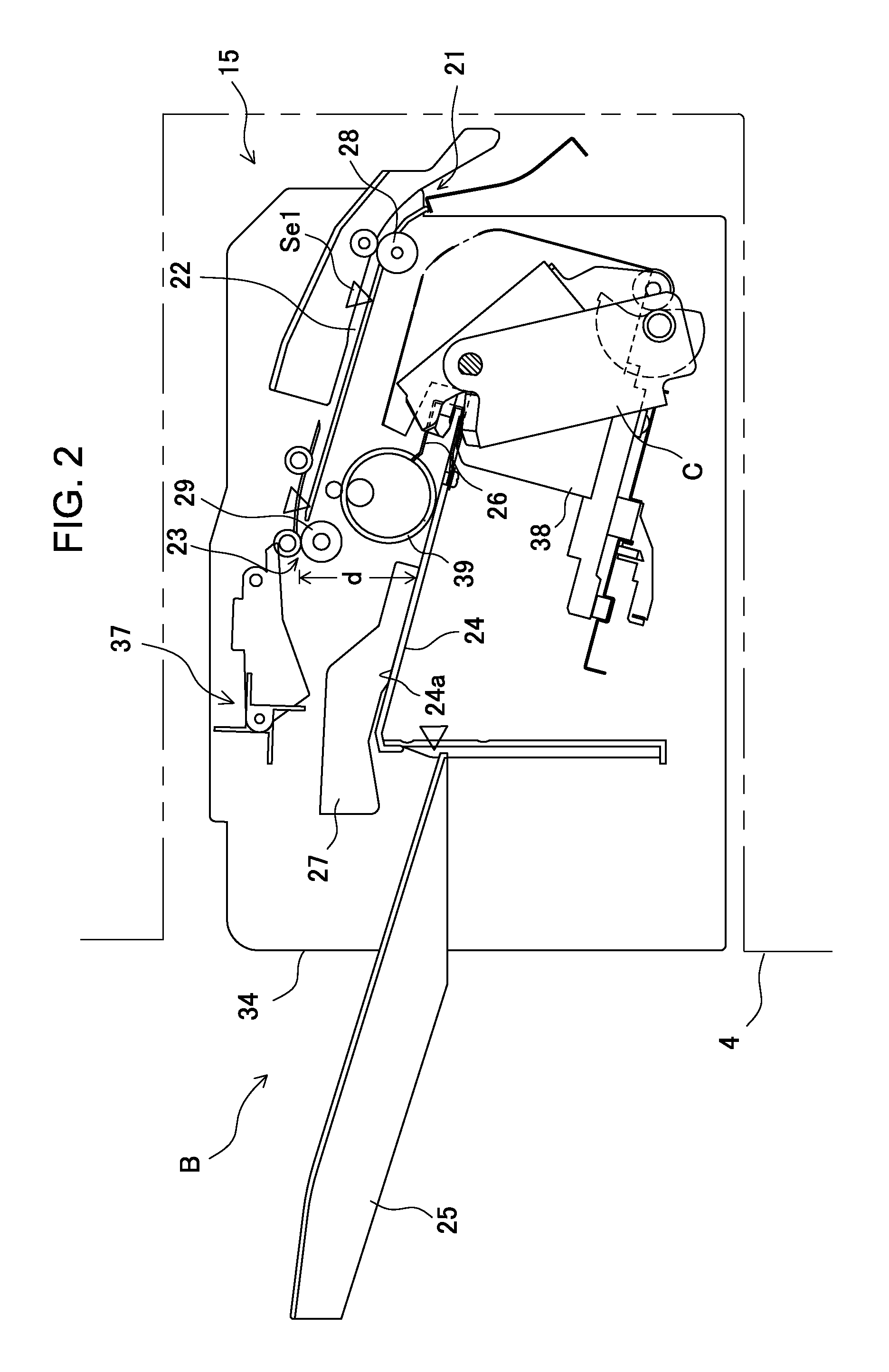

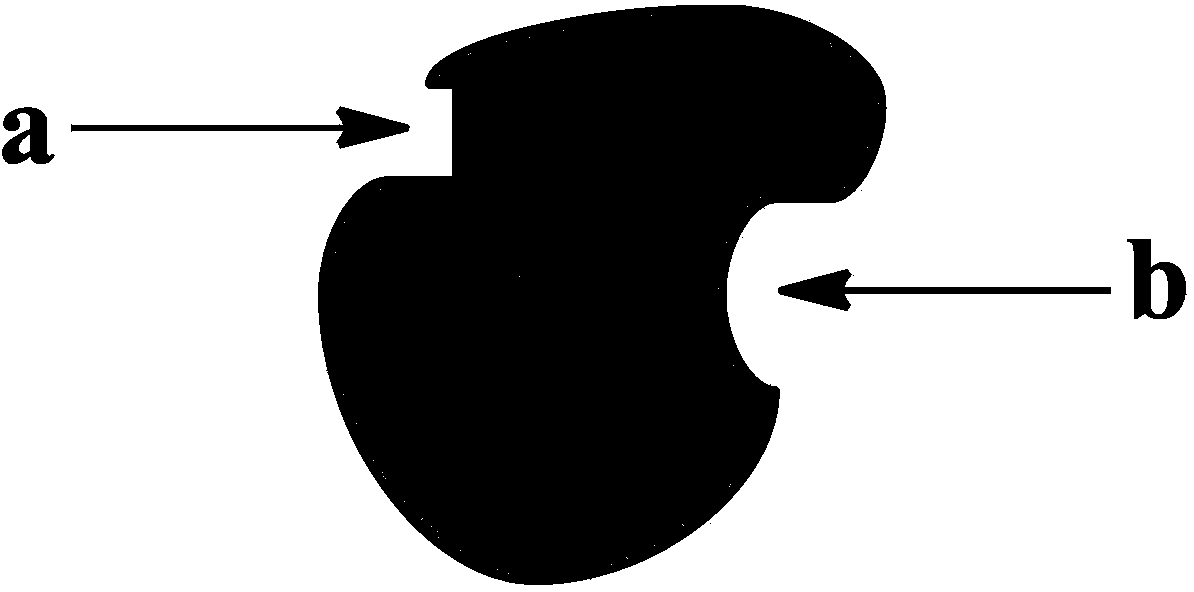

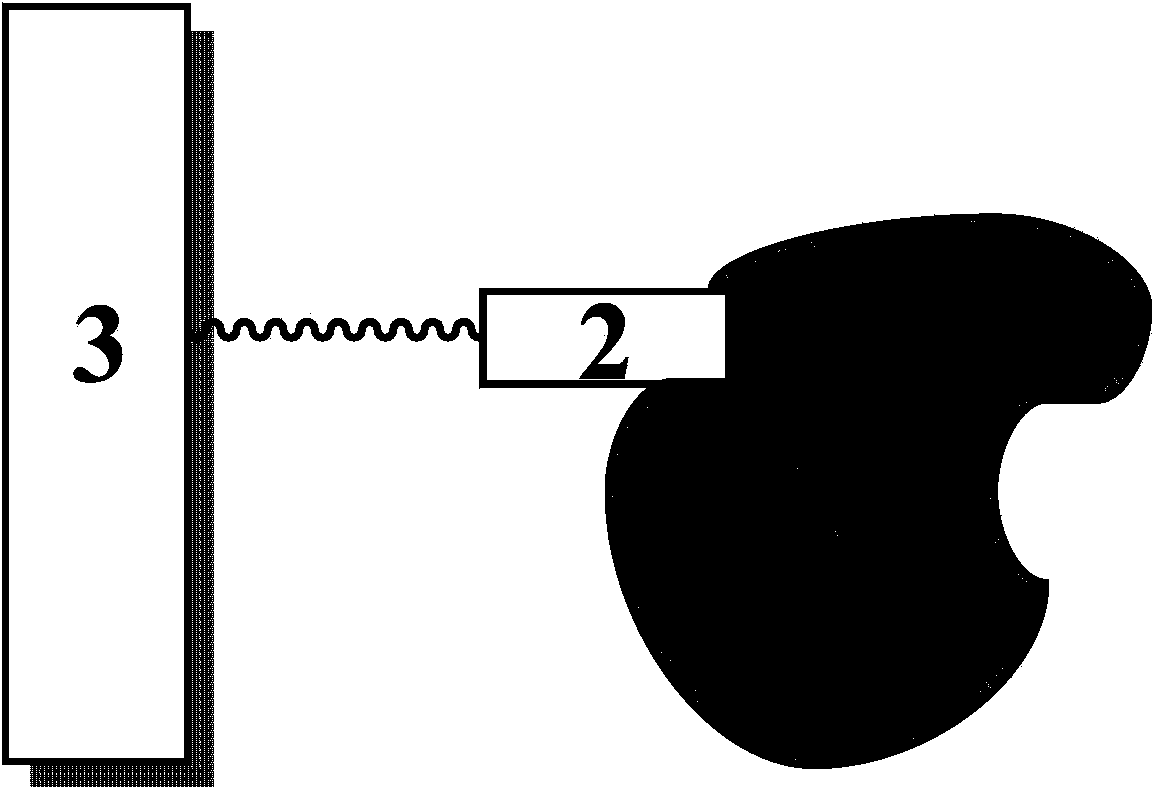

Apparatus for performing binding processing on sheets and post-processing apparatus provided with the same

InactiveCN105197660AAvoid distortionLong binding lengthMechanical working/deformationRegistering devicesWeak bindingEngineering

To provide a sheet binding processing apparatus for enabling strong binding strength or weak binding strength to be selected in a neat sheet posture to perform binding processing in applying narrow pressure to a plurality of sheets with concavo-convex-shaped pressurizing surfaces to perform the binding processing, in positioning sheets in a binding position for press-binding the sheets with the concavo-convex-shaped pressurizing surfaces that mutually mesh to perform the binding processing, it is possible to set an engagement area of the sheets and the pressurizing surfaces in two or more different steps with positioning references or by shifting a position of a binding processing section in the direction for passing over an edge side of the sheets to perform the binding processing.

Owner:COPYER

High-toughness laminar bulletproof ceramic material and preparation method combining tape casting method with hot-pressing sintering method

Owner:NORTHWESTERN POLYTECHNICAL UNIV

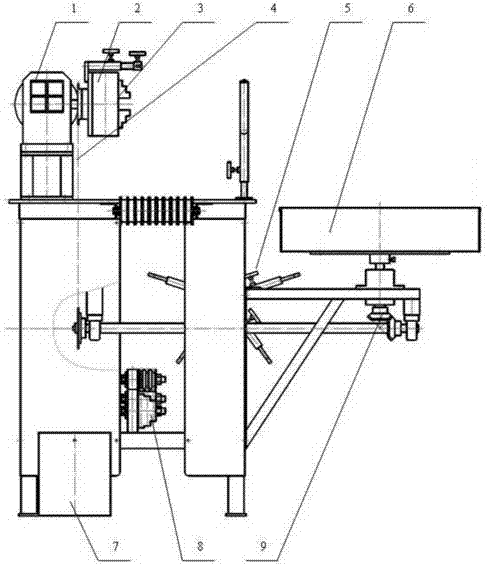

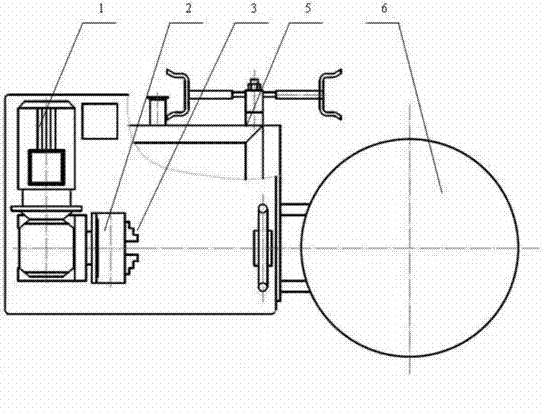

Fire hose binding device

The invention belongs to the technical field of fire equipment and particularly relates to a binding device. A fire hose binding device is structured as follows: above a workbench, a motor (2) is drivingly connected with a binding runner (2), and a hose interface fixing apparatus (3) is arranged at the other side of the binding runner (2); an output shaft of the motor (1) is in transmission connection with a long rotation shaft via a chain (4) or a belt; a reversing gear (9) is engaged with a rotational hose plate (6); a binding wire reel (5) is arranged at the side part of the workbench; a plurality of binding wire traveling wheels (8) used for guiding and pre-tightening binding wires are arranged at the lower part of the binding runner (2); and a control switch (7) is also arranged on the workbench. The fire hose binding device related by the invention is rational and compact in structure, easy to operate and suitable for site emergency use for fire brigades. The fire hose binding device is used for completely removing worries about delay of fire water supply and wounding accidents caused by weak binding and separation of a hose and an interface at any time and has a great application prospect and an actual use value.

Owner:SHANGHAI FIRE RES INST OF MEM

Brake disc and preparation method thereof

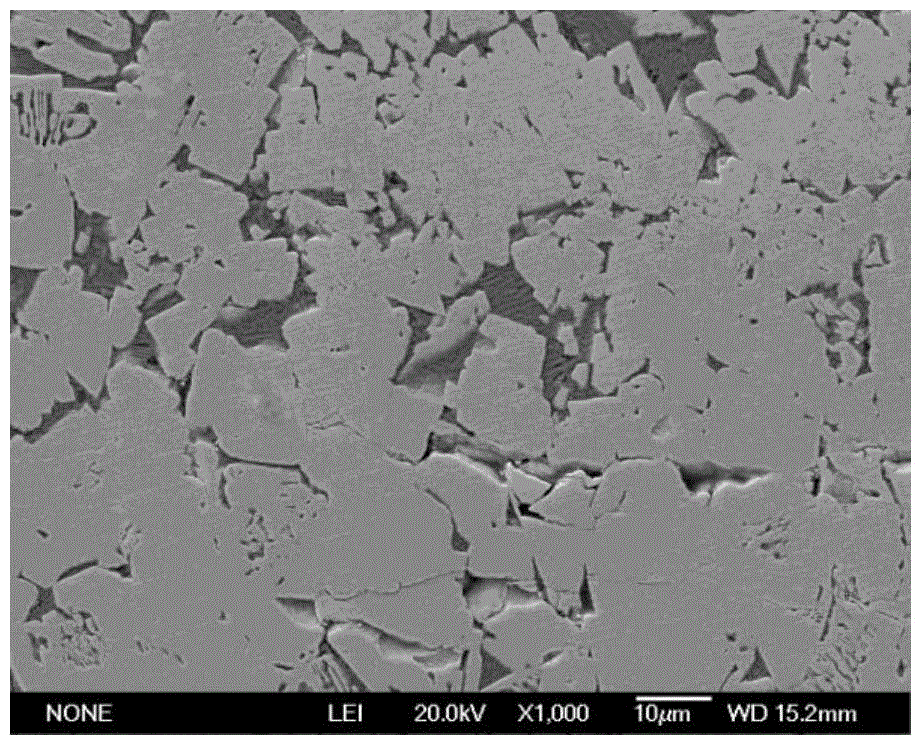

ActiveCN104533993AGood chemical stabilityImprove wear resistanceBraking discsFoundry mouldsCarbide coatingWeak binding

The invention aims to provide a brake disc; carbide coating layers are arranged on surfaces of a working part of the brake disc; and the invention provides a preparation method for obtaining the brake disc. The brake disc is provided with the carbide coating layers on the upper and lower surfaces of the working part. A pseudo-single crystal WC compact ceramic layer, a micron WC ceramic layer and a compound layer of WC and a matrix are gradiently distributed in sequence from outside to inside, and are applied to the surface of carbon steel. The brake disc can be applied to the surface of the carbon steel. A matrix and tungsten compound body obtained through casting is externally leaded in an external carbon source, and is heated and insulated to form the carbide coating layers on the surfaces of the matrix; and the coating layers and the matrix are metallurgically bonded, so that the binding force is strong, the problems of weak binding force and easy dropping of particles caused by traditional non-metallurgical bonding between hard particles and metal matrix, and the wear resistance of the working surface of the brake disc is largely improved.

Owner:江苏古田自动化股份有限公司

Brake disc and preparation method thereof

ActiveCN104533992AGood chemical stabilityImprove wear resistanceBraking discsSolid state diffusion coatingWeak bindingCarbide

The invention discloses a brake disc; carbide coating layers are arranged on the surfaces of a working part of the brake disc; and the invention further provides a preparation method for obtaining the brake disc. The brake disc is provided with the carbide coating layers on the upper and lower surfaces of the working part. A pseudo-single crystal TiC compact ceramic layer, a micron TiC ceramic layer and a compound layer of TiC and a matrix are gradiently distributed in sequence from outside to inside, and are applied on the surface of carbon steel. The brake disc can be applied to the surface of the carbon steel. A matrix and titanium compound body obtained through casting is externally leaded into an external carbon source, and is heated and insulated to form the carbide coating layers on the surfaces of the matrix; the coating layers and the matrix are combined metallurgically, so that the binding force is strong, the problems of weak binding force and easy particle dropping caused by traditional non-metallurgical combination between hard particles and metal matrix are overcome, and the weak resistance of the working surface of the brake disc is largely improved.

Owner:XIAN UNIV OF TECH

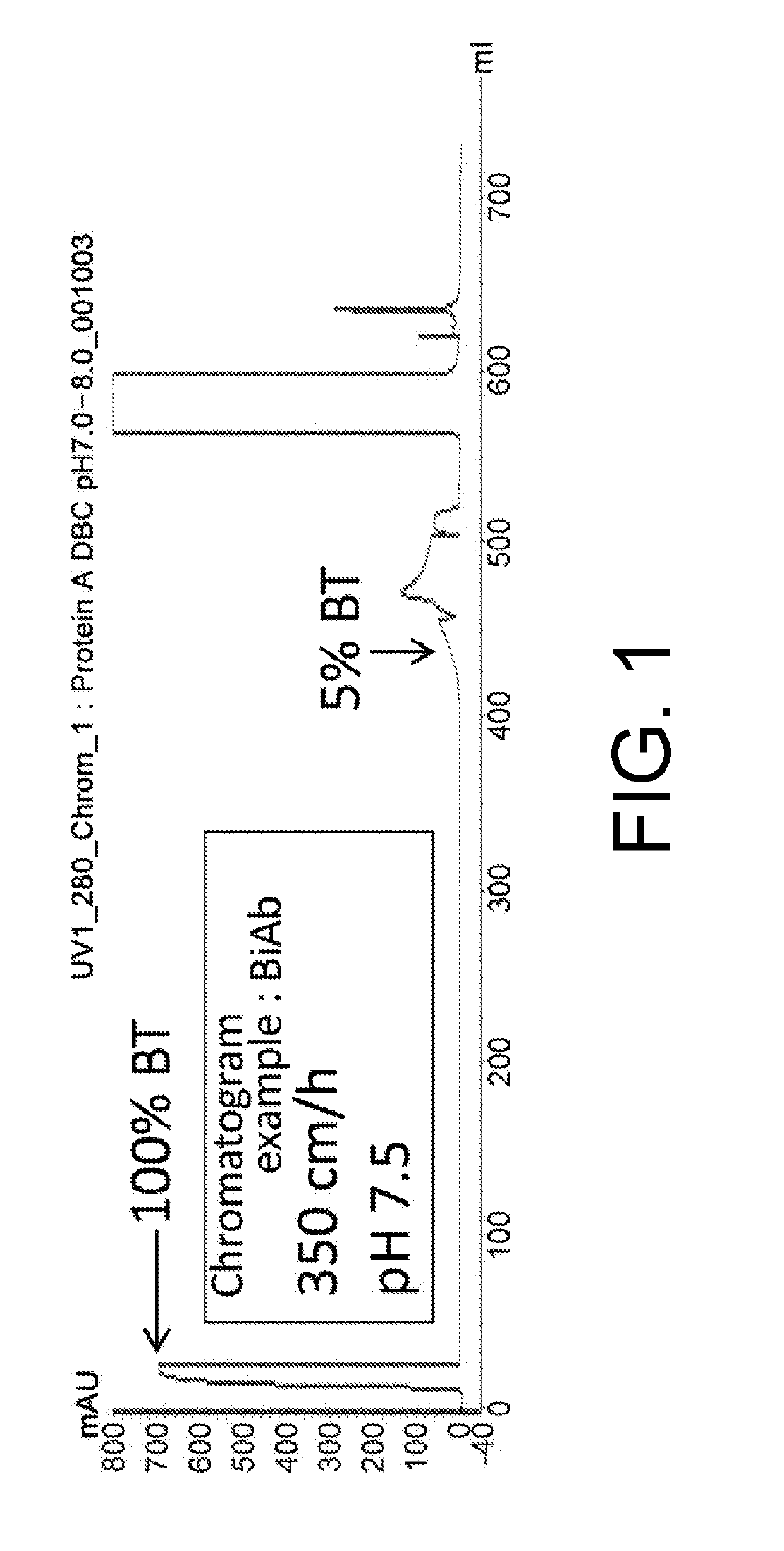

Method for promoting efficiency of purification of fc region-containing polypeptide

ActiveUS20190330268A1Efficient purificationIncrease capacityImmunoglobulins against blood coagulation factorsPeptide preparation methodsWeak bindingChemistry

It was discovered that, by preparing an Fc region of an Fc region-containing polypeptide in which the first polypeptide chain of the Fc region binds to a Protein A resin, but the second polypeptide chain of the Fc region does not bind to the resin or shows weak binding to it, the amount of the Fc region-containing polypeptide bound per volume of the resin is increased, and more efficient purification of the above-mentioned Fc region-containing polypeptide is possible.

Owner:CHUGAI PHARMA CO LTD

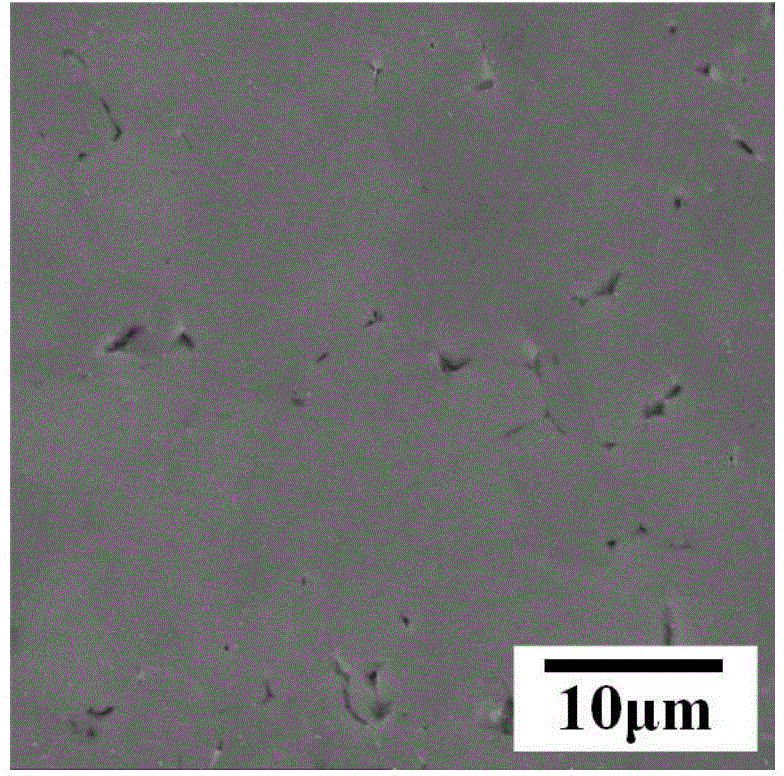

Wear resistant carbide coating layer and preparation method thereof

ActiveCN104525900AImprove mechanical propertiesOvercome the problem of easy sheddingSolid state diffusion coatingCarbide coatingWear resistant

The invention discloses a wear resistant carbide coating layer. The wear resistant carbide coating layer comprises a pseudo-single crystal phase TiC compact ceramic layer, and can further comprise a micron TiC ceramic layer and a fused layer of TiC and a matrix. The pseudo-single crystal phase TiC compact ceramic layer, the micron TiC ceramic layer and the fused layer of TiC and the matrix are gradiently distributed in sequence. The wear resistant carbide coating layer can be applied to the surface of a metal matrix. A metal matrix and titanium compound body obtained through casting is externally leaded in an external carbon source, and is heated and insulated to form the carbide coating layer on the surface of the metal matrix; and the coating layer and the matrix are metallurgically bonded, so that the binding force is strong, the problems of weak binding force and easy particle dropping due to traditional non-metallurgical bonding between hard particles and the metal matrix are overcome, and the surface wear resistance of the metal matrix is largely improved.

Owner:SUZHOU FURUTA AUTOMATION TECH

Apparatus for performing binding processing on sheets and post-processing apparatus provided with the same

InactiveUS20150368062A1Easy to separateDesired binding strengthMechanical working/deformationRegistering devicesWeak bindingEngineering

To provide a sheet binding processing apparatus for enabling strong binding strength or weak binding strength to be selected in a neat sheet posture to perform binding processing in applying narrow pressure to a plurality of sheets with concavo-convex-shaped pressurizing surfaces to perform the binding processing, in positioning sheets in a binding position for press-binding the sheets with the concavo-convex-shaped pressurizing surfaces that mutually mesh to perform the binding processing, it is possible to set an engagement area of the sheets and the pressurizing surfaces in two or more different steps with positioning references or by shifting a position of a binding processing section in the direction for passing over an edge side of the sheets to perform the binding processing.

Owner:COPYER

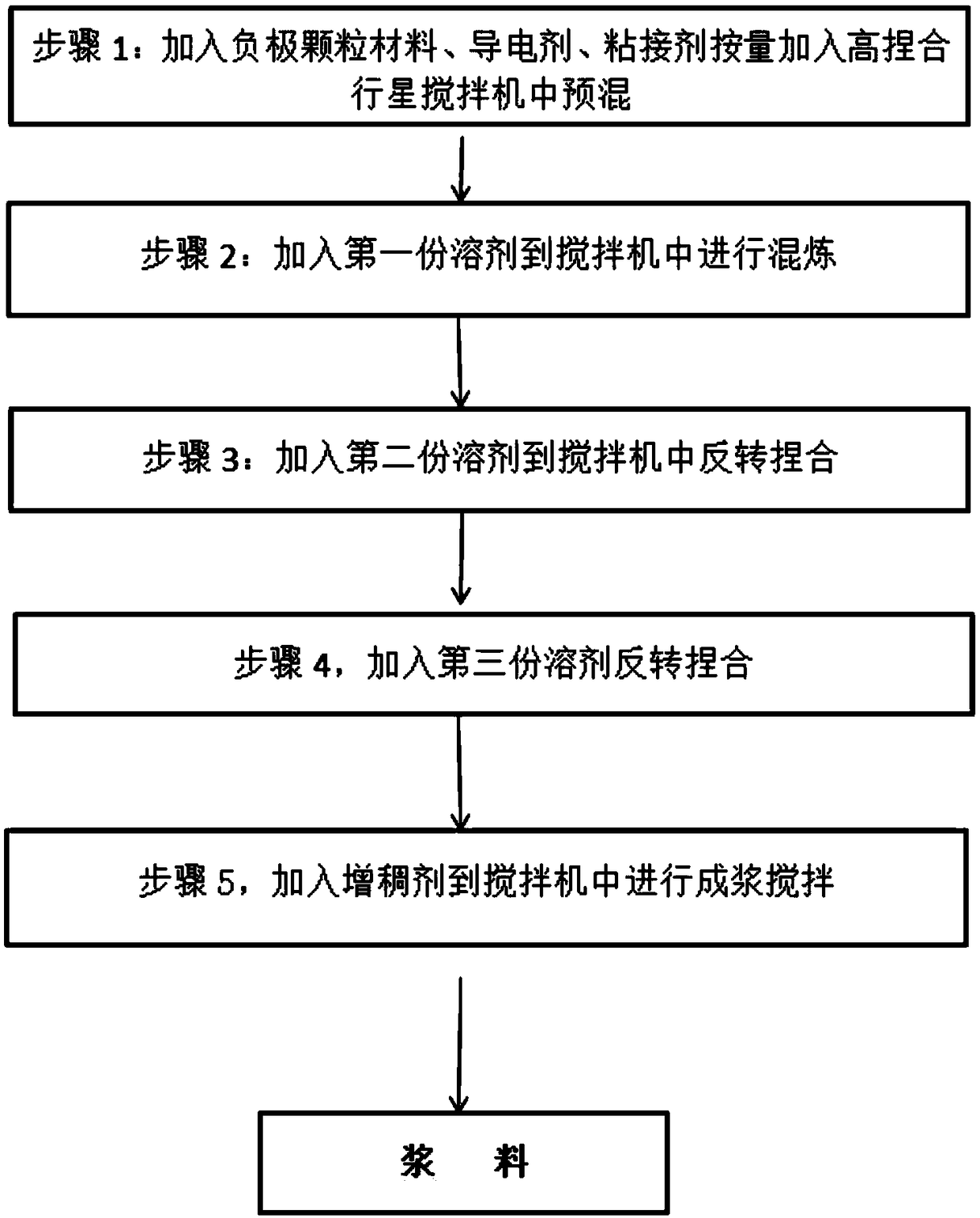

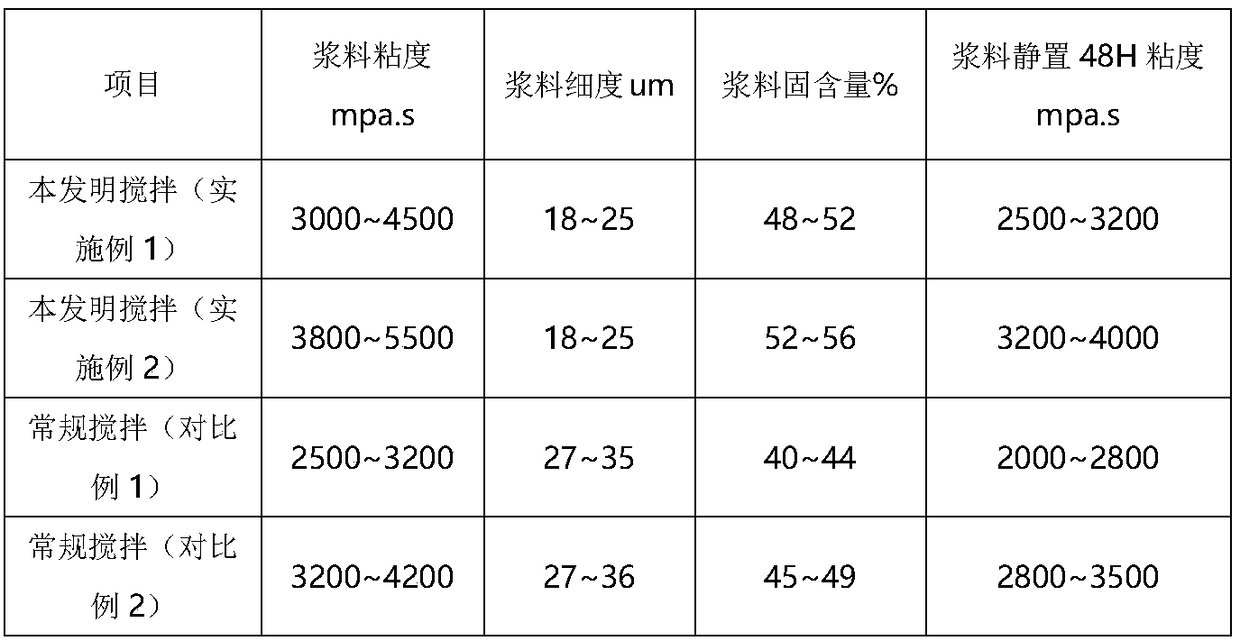

Lithium ion battery cathode material pulp and preparation method thereof

InactiveCN108899469AImprove the phenomenon of secondary reunionImprove adhesionElectrode manufacturing processesSecondary cellsWeak bindingPole piece

The invention provides a preparation method for a lithium ion battery cathode material pulp. According to the invention, a high kneading stirring technology is adopted for quickly stirring and mixingactive materials and a conductive agent, and the small-grain powder is attached to large particles, so that the surface energy is reduced, the probability of the small-grain powder of agglomerating and forming large particles in solvents is reduced, the adhesive force of energy-repulsive reinforced glue chains between particles is increased, the time for preparing the pulp is reduced, the use rateof device is increased, the capacity is increased, the forming of cathode pulp particles is overcome and the problem of weak binding force of the pole piece is solved.

Owner:桑顿新能源科技(长沙)有限公司

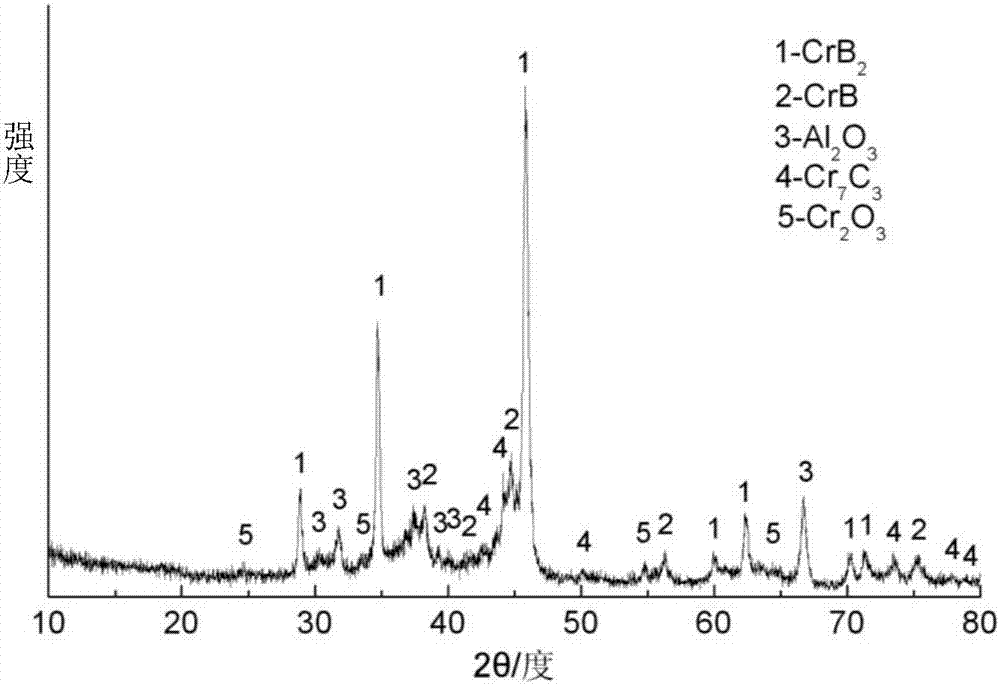

Preparation method of chrome boride-based coating

The invention provides a preparation method of a chrome boride-based coating, and relates to plating of metal materials with chrome boride. Chrome boride-based compound ceramic coatings are synthesized through thermal spraying in-situ reaction. The method comprises the steps of preparing chrome oxide / boron carbide / aluminum composite powder for thermal spraying; pretreating metal matrix materials; preparing the chrome boride-based coating. According to the preparation method provided by the invention, the shortcomings of complicated preparation technology of the chrome boride coating, high energy consumption, severe pollution, low efficiency, small coating thickness, high coating porosity, weak binding force between the coating and the matrix, and difficult powder preparation in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

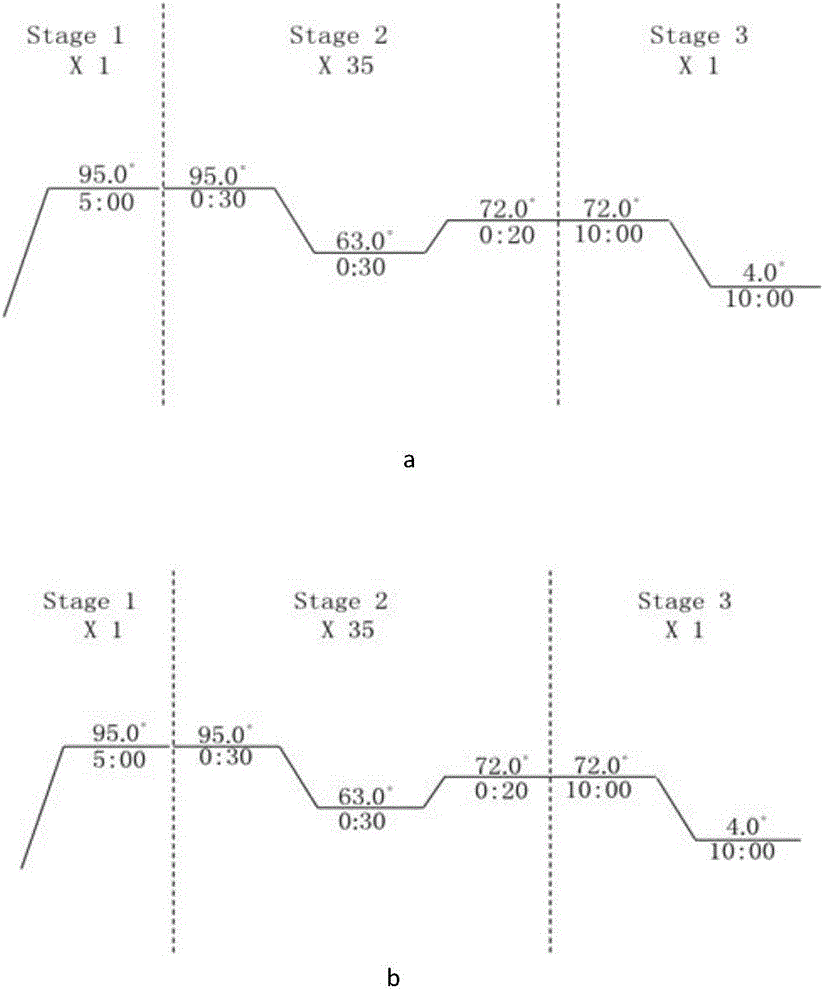

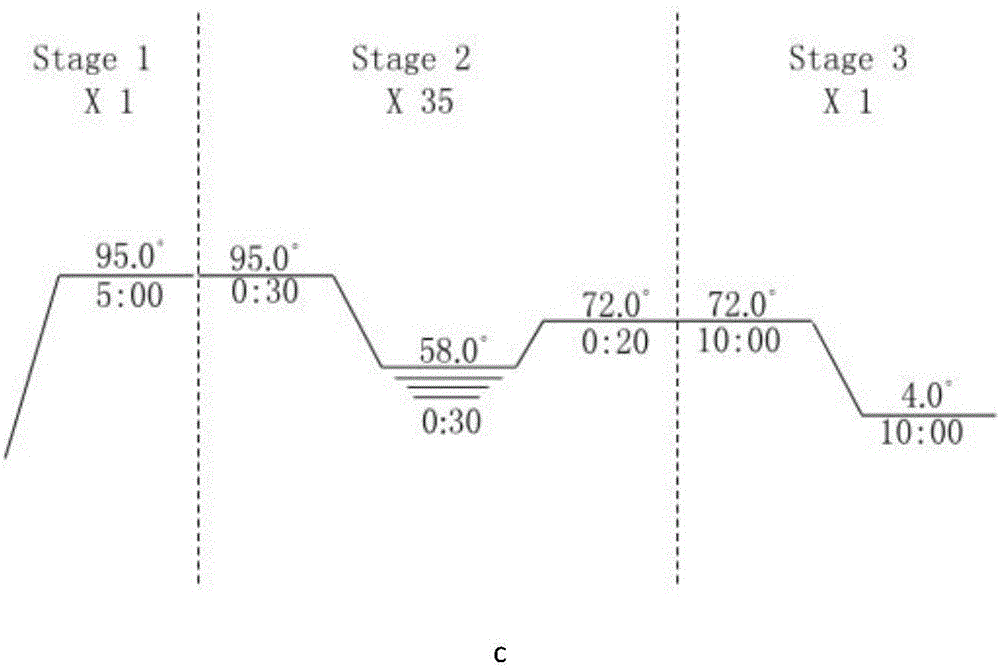

Preparation method for hydrocolloid dressing for promoting wound repairing

ActiveCN106310361AReduce the number of replacementsPromote healingAbsorbent padsBandagesCross-linkFiber

The invention discloses a preparation method for hydrocolloid dressing for promoting wound repairing, belonging to the technical field of medical dressing preparation. The method comprises the following steps: adding AFGF freeze-dried powder into a mixed solution of gelatin and carboxymethyl chitosan, thereby acquiring an AFGF-loaded transparent fluid; mixing with dissolving fluid of the matters including sodium carboxymethylcellulose, apple pectin, and the like; ultrasonically oscillating and then adding a cross-linking agent; performing cross-linking reaction under a certain temperature, acquiring reaction fluid and then mixing with resin viscous fluid, thereby acquiring a spinning solution; spinning by adopting a wet method, thereby acquiring an AFGF-loaded fiber; mixing with a pure cotton fiber and spinning to form cloth. According to the preparation method, the apple pectin is added, so that the water absorption lasting time of the dressing is increased and the gelling is quickened; styrene-isoprene segmented copolymer is added, so that the dressing viscidity and the peeling strength are effectively improved; hydrocolloid is prepared into weaved cloth and no film substrate is required, so that the problem of weak binding force between hydrocolloid and polymer film is solved and the wound repairing can be effectively promoted; the preparation method has wide application prospect.

Owner:青岛华元精细生物制品有限公司

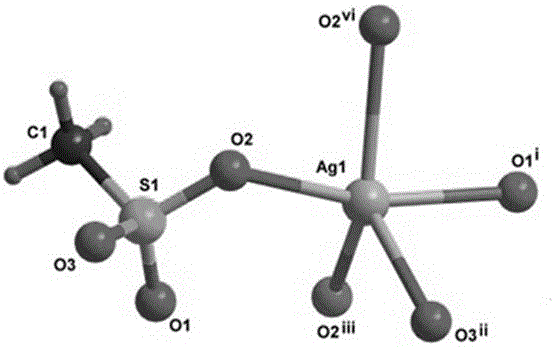

Electroplating liquid of cyanide-free silver plated tin alloy and electroplating method thereof

The invention provides electroplating liquid of a cyanide-free silver plated tin alloy and an electroplating method. Silver methane sulfonate and tin methane sulfonate are used as main salt of a silver plated tin alloy; carving sulfonic acid is used as a complexing agent; other additive components are compounded for improving the effect; cyanide-free electroplating silver tin alloy solution contains no cyanide, is free of poison and harm to environments and human bodies, is reasonable in formula, and is excellent in stability; pulse electroplating is used during electroplating, so that such problems as high plating layer strain and brittleness and weak binding force are effectively solved, and a plating layer with good binding performance with a basal body, low strain and good compactness and brightness is obtained; the obtained silver plated tin alloy layer is suitable for application of reflecting layers, high electric conducting layers and brazing plating layers in the fields of photoelectricity and microelectronics; and the formed plating layer can improve the microelectronic packing electric conductivity and reliability, and largely reduces the signal distortion caused by circuit resistance.

Owner:HUIZHOU LEADAO ELECTRONICS MATERIAL

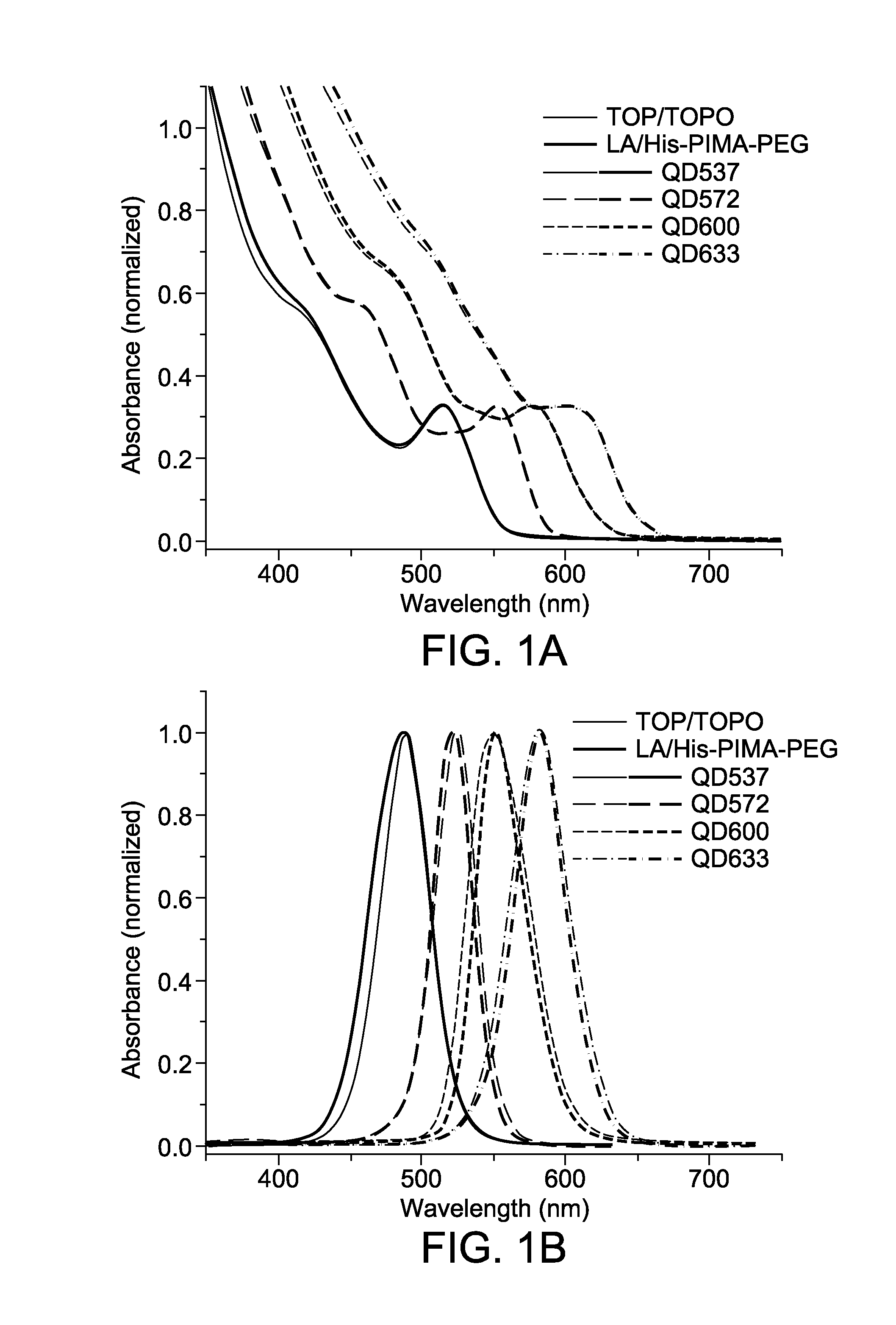

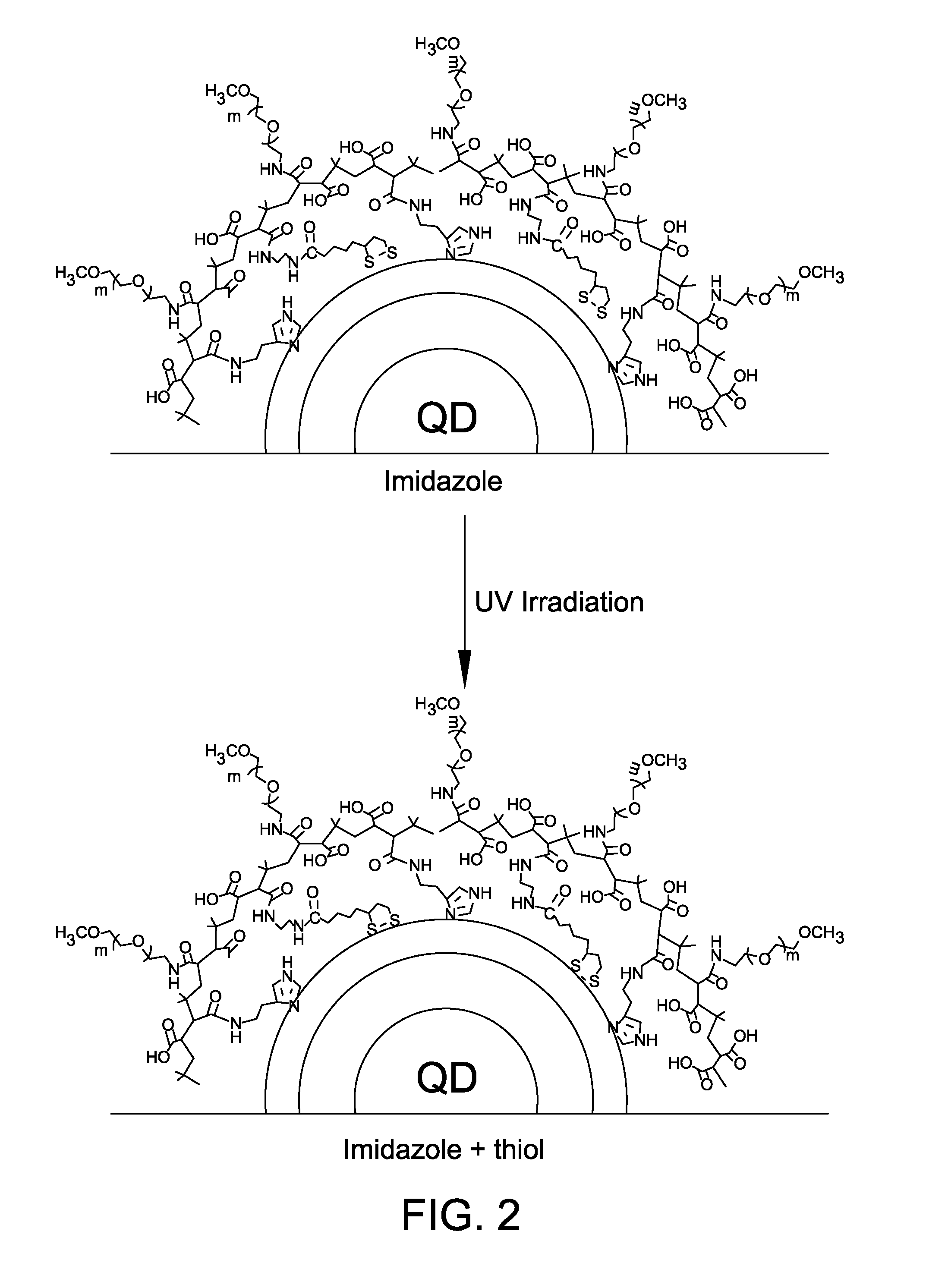

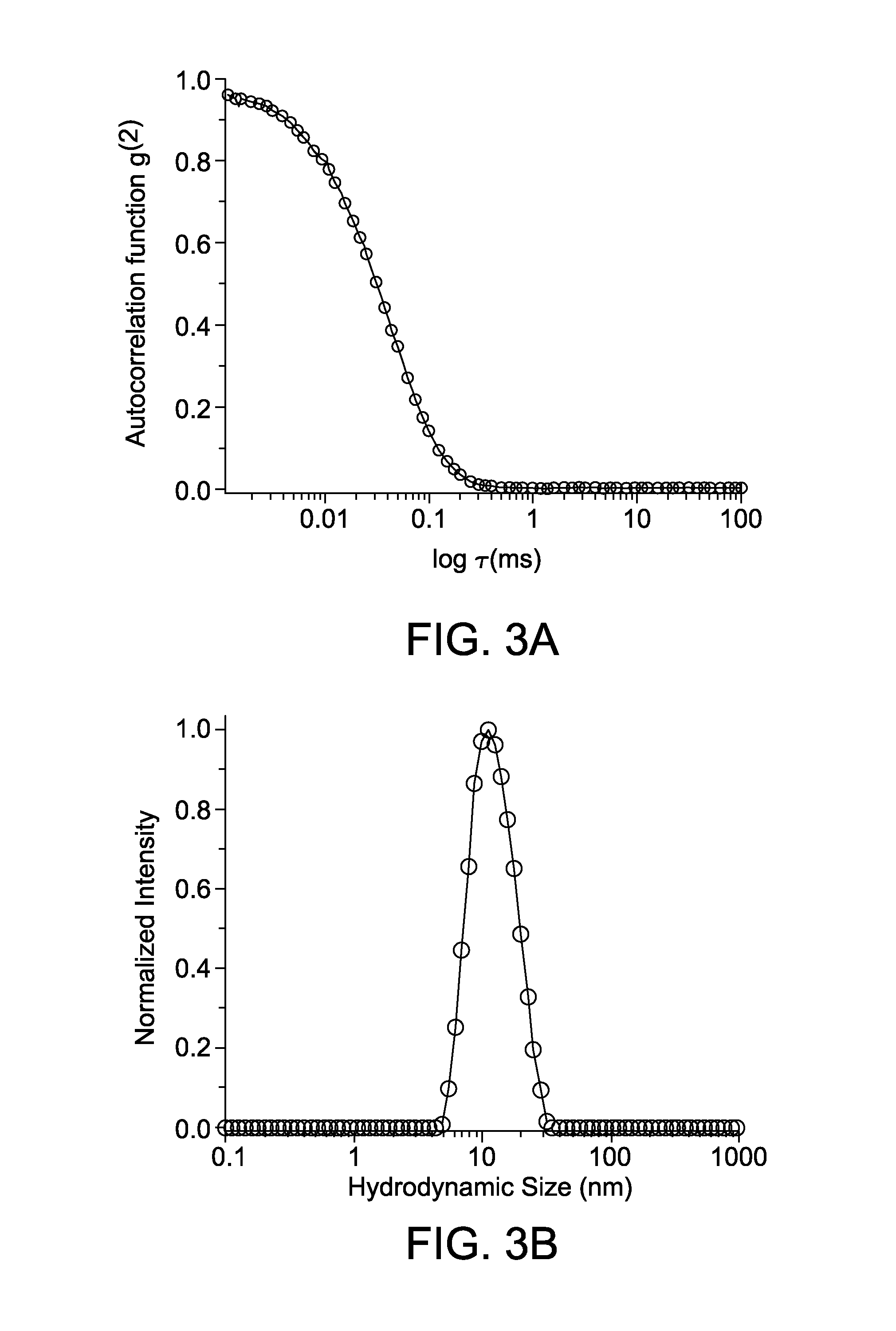

Photoligation of an amphiphilic polymer with mixed coordination provides compact and reactive quantum dots

ActiveUS20150284493A1Enhancing overall ligand-to-QD affinityHigh quantum yieldInorganic material magnetismOrganic dyesFluorescenceWeak binding

The disclosure is directed to multi-coordinating polymers as ligands that combine two distinct metal-chelating groups, lipoic acid and imidazole, for the surface functionalization of QDs. These ligands combine the benefits of thiol and imidazole coordination to reduce issues of thiol oxidation and weak binding affinity of imidazole. The ligand design relies on the introduction of controllable numbers of lipoic acid and histamine anchors, along with hydrophilic moieties and reactive functionalities, onto a poly(isobutylene-alt-maleic anhydride) chain via a one-step nucleophilic addition reaction. We further demonstrate that this design is fully compatible with a novel and mild photoligation strategy to promote the in-situ ligand exchange and phase transfer of hydrophobic QDs to aqueous media under borohydride-free conditions. Ligation with these polymers provides highly fluorescent QDs that exhibit great long-term colloidal stability over a wide range of conditions.

Owner:FLORIDA STATE UNIV RES FOUND INC

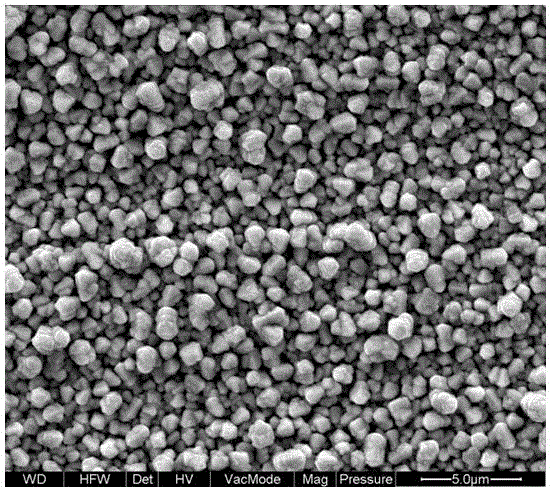

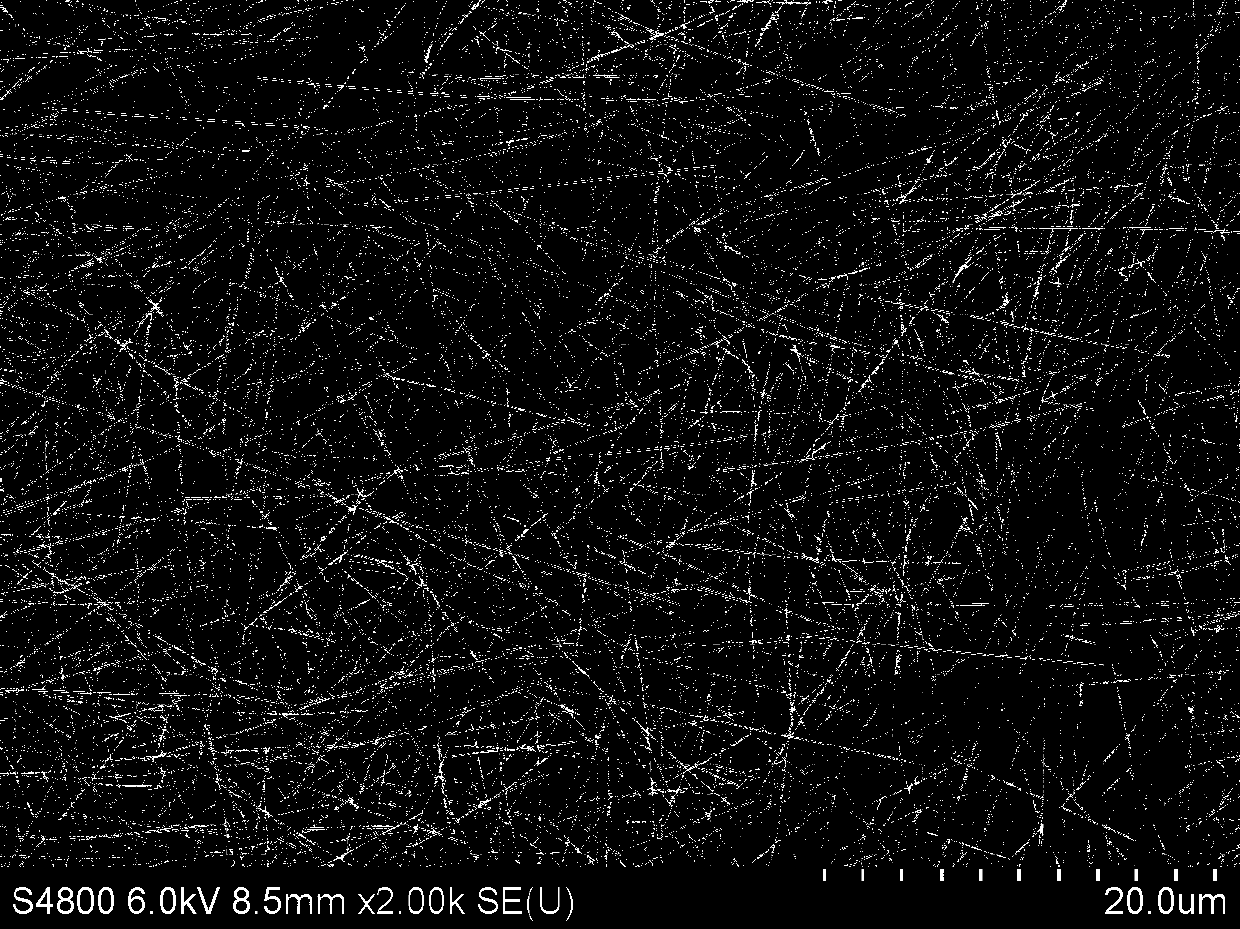

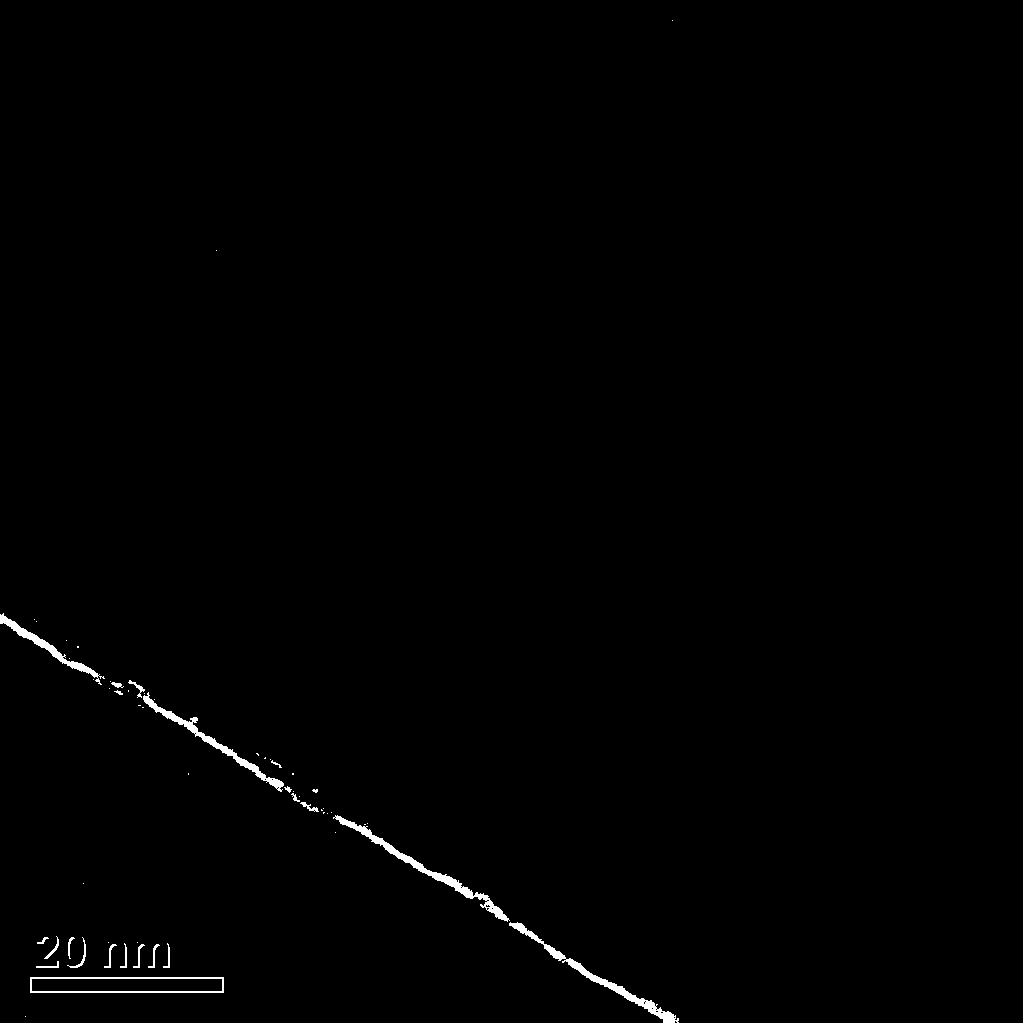

Silver nanowire modified polyacrylate conductive composite coating and preparation method thereof

InactiveCN107556849AGood compatibilityImprove bindingMaterial nanotechnologyElectrically-conductive paintsWeak bindingMechanical property

The invention relates to the technical field of nanocomposite materials, in order to solve the problem of the poor compatibility between the silver nanowires prepared in the prior art and the polymer matrix, which makes it difficult for the silver nanowires to disperse uniformly in the matrix, and the The weak binding force of the substrate affects the comprehensive performance of the composite coating. The present invention proposes a silver nanowire modified polyacrylate conductive composite coating and its preparation method, using polyacrylamide as the protective agent for the silver nanowire to synthesize silver nanowires, and then disperse the prepared silver nanowires into a heat-curable polyacrylate matrix by a conventional blending method, so that a silver nanowire-modified polyacrylate conductive composite coating with excellent comprehensive properties can be prepared . The composite coating has good electrical conductivity and mechanical properties.

Owner:深圳赢特科技有限公司

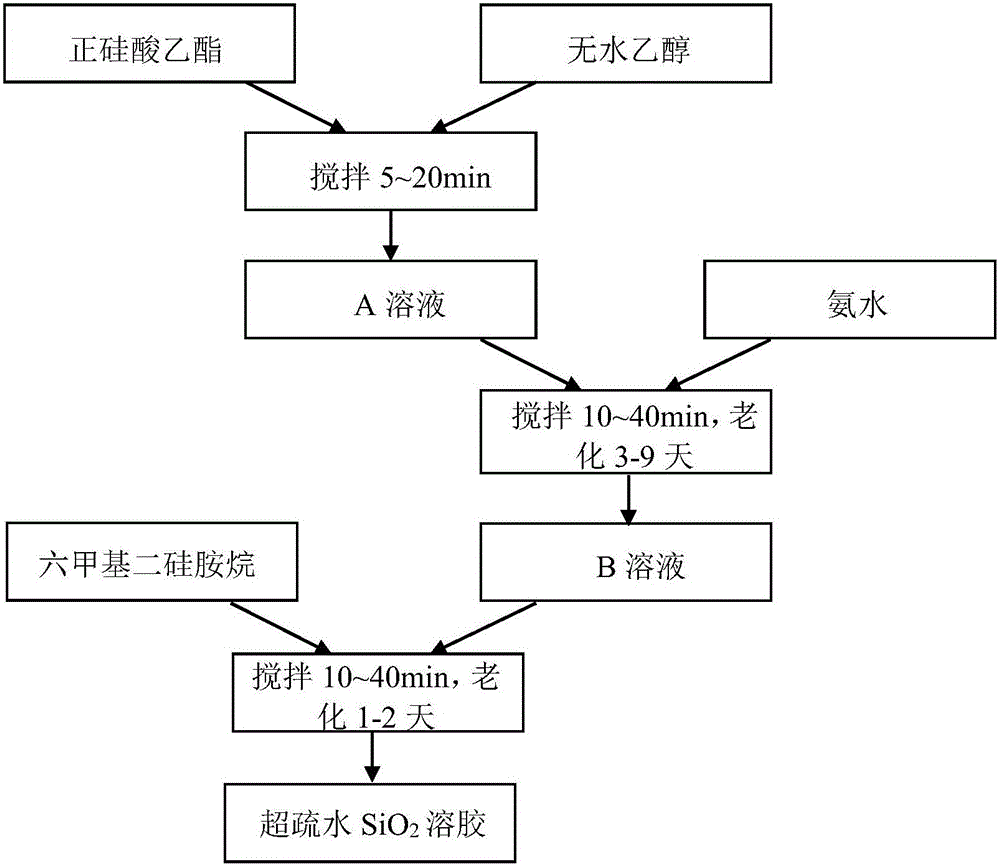

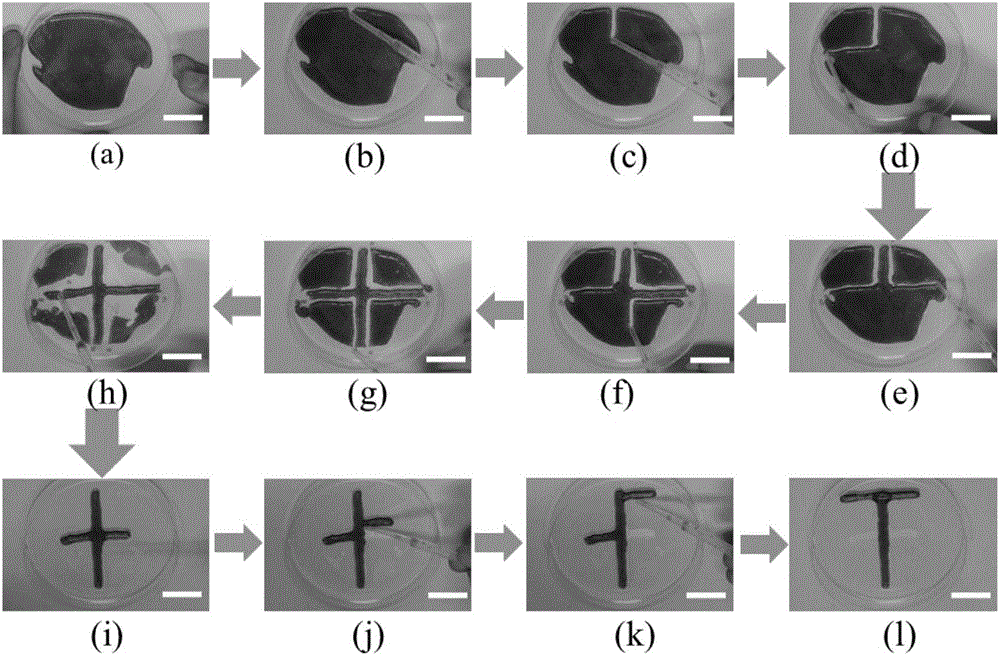

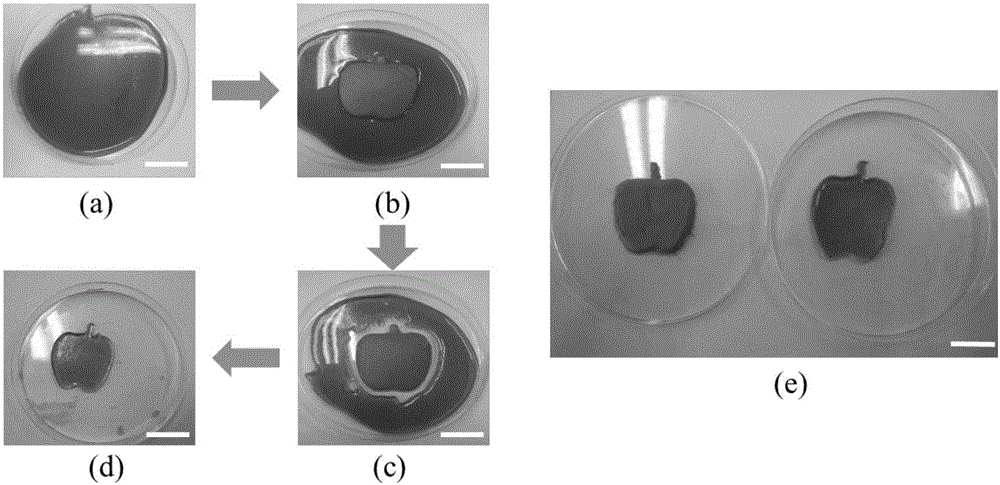

Method for preparing liquid plasticine and plasticine molding method

The present invention relates to a method for preparing liquid plasticine and a plasticine forming method. 2 Sol, depositing multiple layers of weakly binding hydrophobic SiO on the bottom and wall of containers such as petri dishes by dipping and pulling coating method 2 Nanoparticles, and then put an appropriate amount of water in the container, and use the method of tilting or shaking the container to make the water collide with the wall of the container according to the volume of the water, which can cause the outermost layer of SiO on the wall of the container. 2 The nanoparticles are transferred to the surface of the water and form a close-packed state on the surface of the water that cannot move freely, so that the water droplets cannot return to their normal curvature and become complex droplets with plastic shapes - liquid plasticine. On this basis, the liquid plasticine is operated by a combination of cutting, extraction and water injection, so as to realize the regulation of its shape. The method for preparing and regulating the shape of liquid plasticine involved in the present invention is suitable for constructing liquid plasticine of complex shape.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

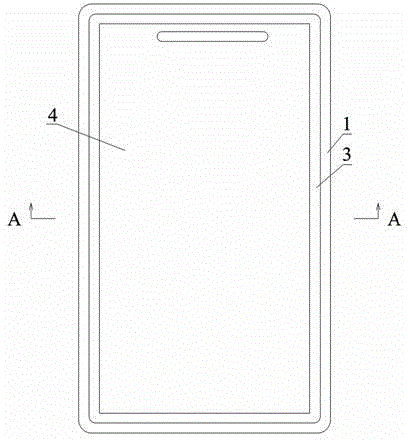

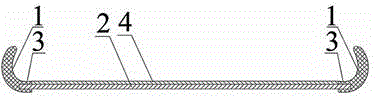

Digital electronic equipment protective film and machining process thereof

InactiveCN104960763AImprove wear resistanceImprove buffering effectFlexible coversWrappersTectorial membraneDie casting

The invention discloses a digital electronic equipment protective film. The digital electronic equipment protective film comprises a plastic frame (1) integrally molded through injection molding, and a rectangular basal plate (2), wherein the bottom of the plastic frame (1) has an annular connecting edge (3) for mounting the basal plate (2); the annular connecting edge (3) tightly coats the edge of the basal plate (2); and the edge of the basal plate (2) is embedded in the annular connecting edge (3). The invention further discloses a machining process of the digital electronic equipment protective film. The digital electronic equipment protective film and the machining process thereof have the following beneficial effects: the digital electronic equipment protective film synthesizes the advantages of glass materials and silica gel materials (including silica gel and such plastics as pet, abs, pp and pc), so that excellent protection effect can be achieved, the thickness of the protective film can be decreased, and the transparency is excellent; and the machining method adopting the high-precision mold injection molding or the die casting of the frame at the periphery of the glass basal plate guarantees excellent connecting structure between the glass basal plate and the plastic frame, and overcomes the defect of weak binding force between the glass materials and the silica gel materials.

Owner:李灵敏

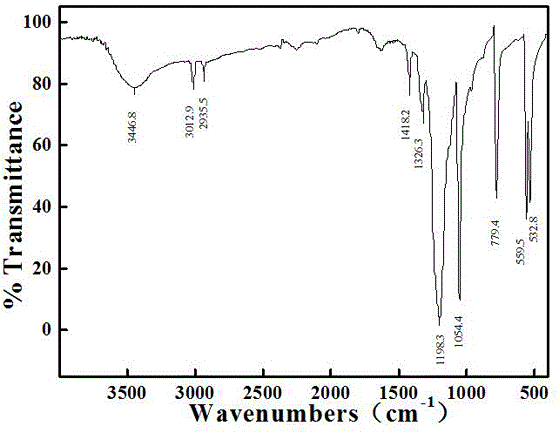

Preparation method of bentonite-based durable slow-release antibacterial agent

InactiveCN106280639ARaw materials are easy to getEasy to prepareAntifouling/underwater paintsPaints with biocidesCalcium bicarbonateWeak binding

The invention relates to a preparation method of a bentonite-based durable slow-release antibacterial agent and belongs to the technical field of preparation of antibacterial agents. According to the method, natural bentonite is soaked in deionized water and quickly frozen with liquid nitrogen such that water permeating in the bentonite is iced, the water has increased volume upon icing, interlayer spacing of the bentonite is enlarged, the bentonite with the enlarged interlayer spacing is then mixed with natto, thick amino acid material on the surface of the natto is used to modify the interlayer of the bentonite under action of microorganisms, interlayer active groups are added to the bentonite, an active adsorption site is provided for silver ions, binding degree between the silver ions and the bentonite is increased, the heated bentonite is finally poured into calcium bicarbonate solution, the calcium bicarbonate is heated to decompose and produce calcium carbonate that covers the surface of the bentonite, freeing of the silver ions is further avoided, and the problem is solved that as the interlayer silver ions in the natural bentonite having weak binding are easily freed and reduced and the natural bentonite has low loading capacity, poor antibacterial property and low durability are caused.

Owner:吴迪

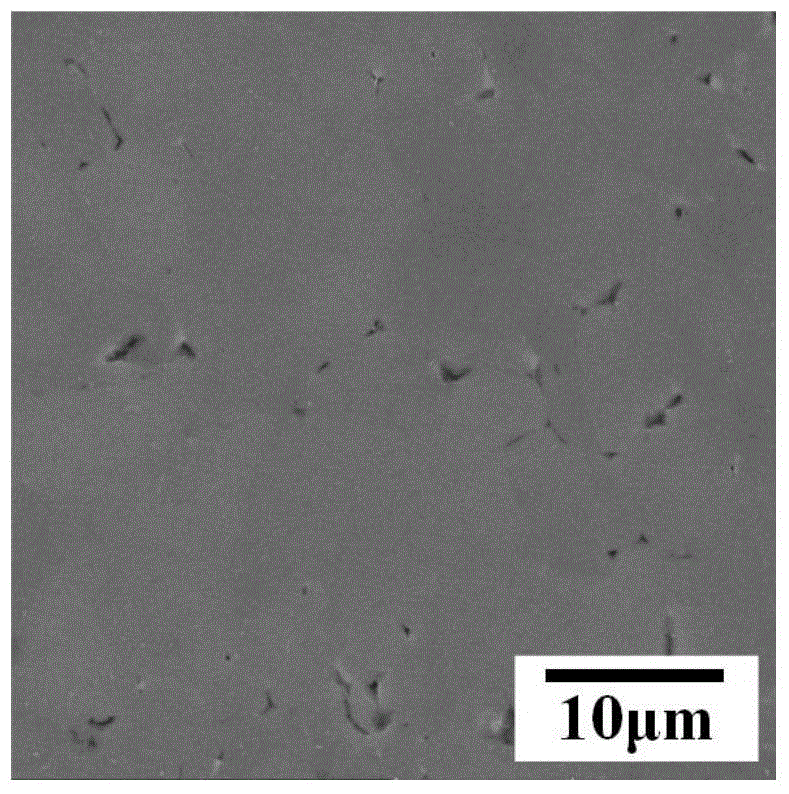

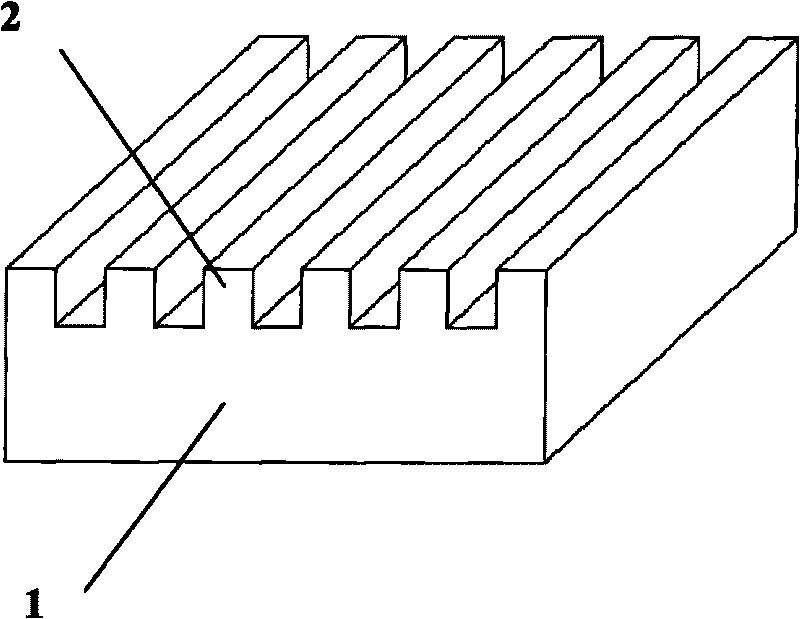

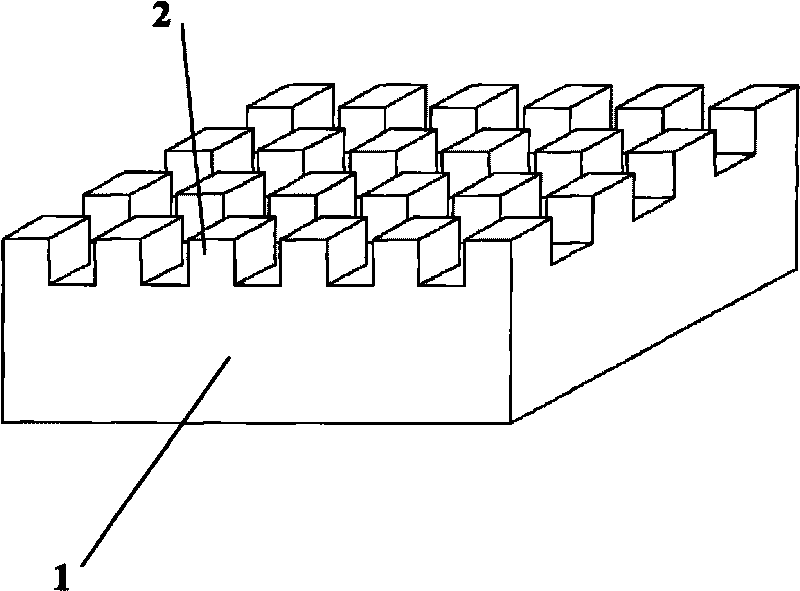

Titanium alloy piece with anti-cavitation property on surface and preparation method thereof

InactiveCN101701663AImproved cavitation wear resistanceImprove coherenceConstructions elementsLaser beam welding apparatusCavitationShape change

The invention discloses a titanium alloy piece with anti-cavitation property on surface and a preparation method thereof. The titanium alloy piece comprises a matrix and surface texture layers which are in texture structures processed by laser. The texture structure is grid or linear or spotted texture. The processing method comprises the following steps: preprocessing the matrix of the titanium alloy piece, and utilizing laser processor to carry out surface texture structure process on the surface of the titanium alloy piece so as to prepare surface texture layers of titanium alloy with gaps of 50 mu m and 100 mu m. In the invention, as the surface of titanium alloy is processed into a grid or linear or spotted texture structure with different gaps by laser, the anti-cavitation property of the titanium alloy is significantly improved. The laser beam used by the invention has good coherence and directivity, thereby ensuring no shape change of the working piece, and not causing the problems of loose organization structure and weak binding force of workpiece and the like.

Owner:DALIAN MARITIME UNIVERSITY

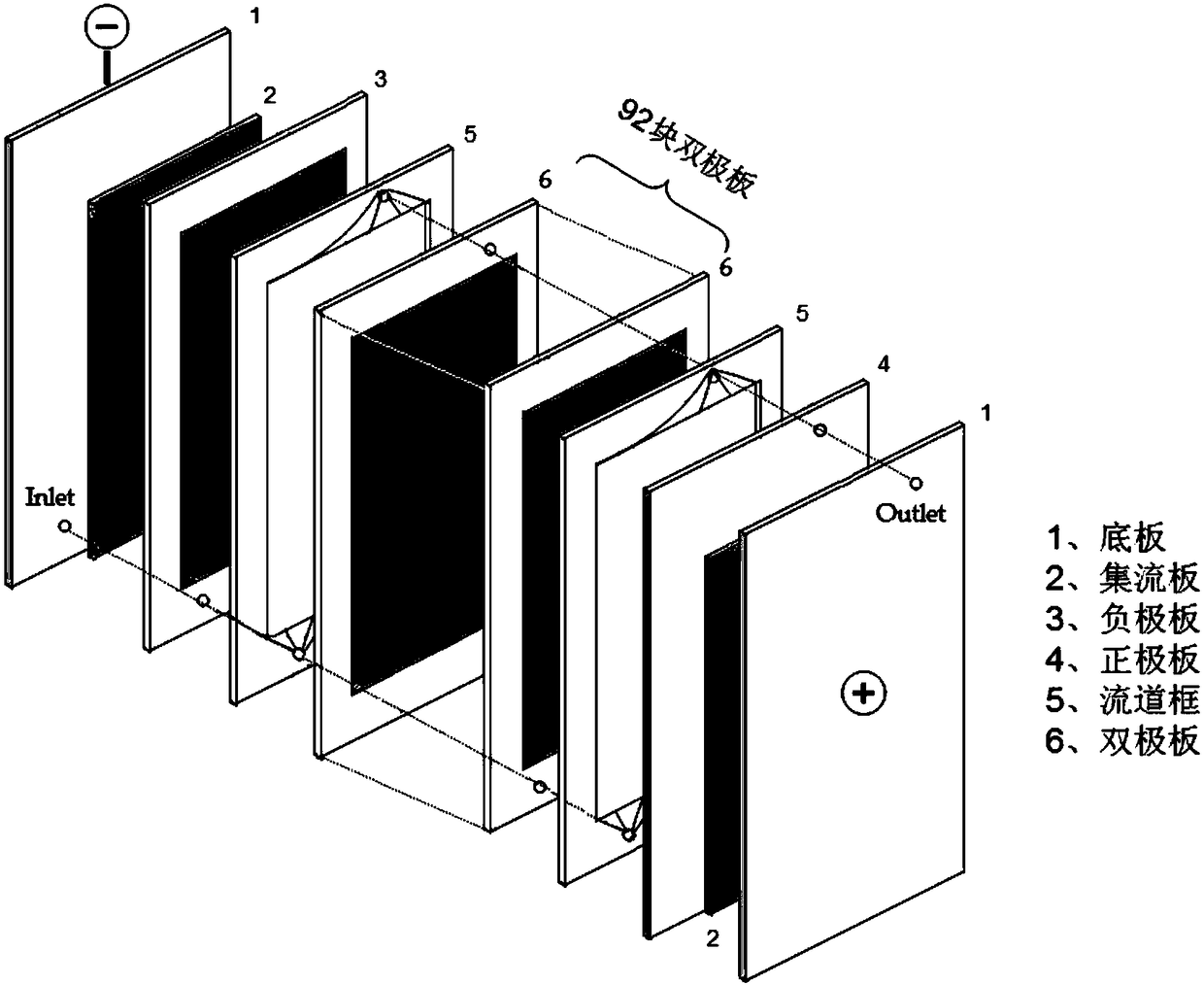

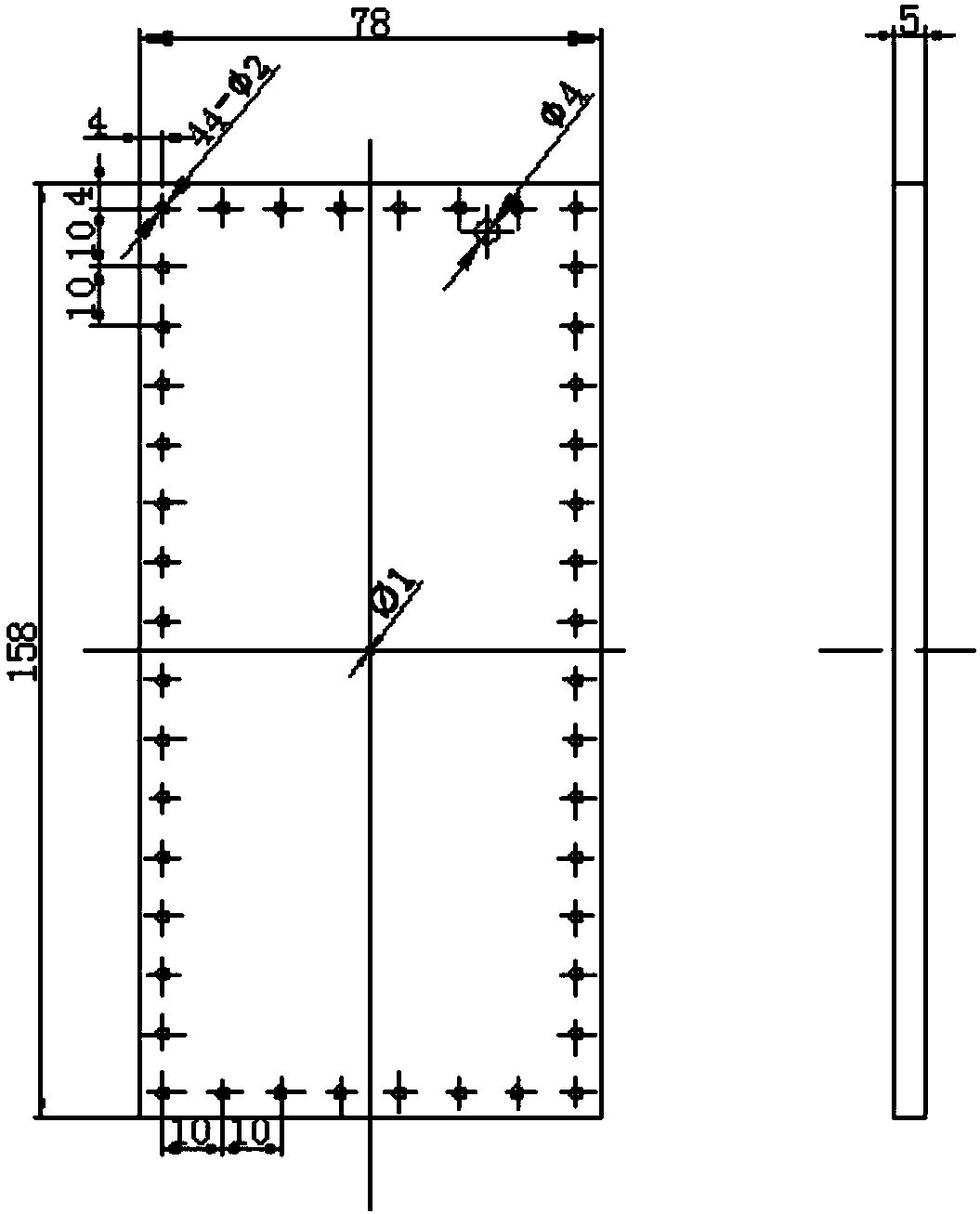

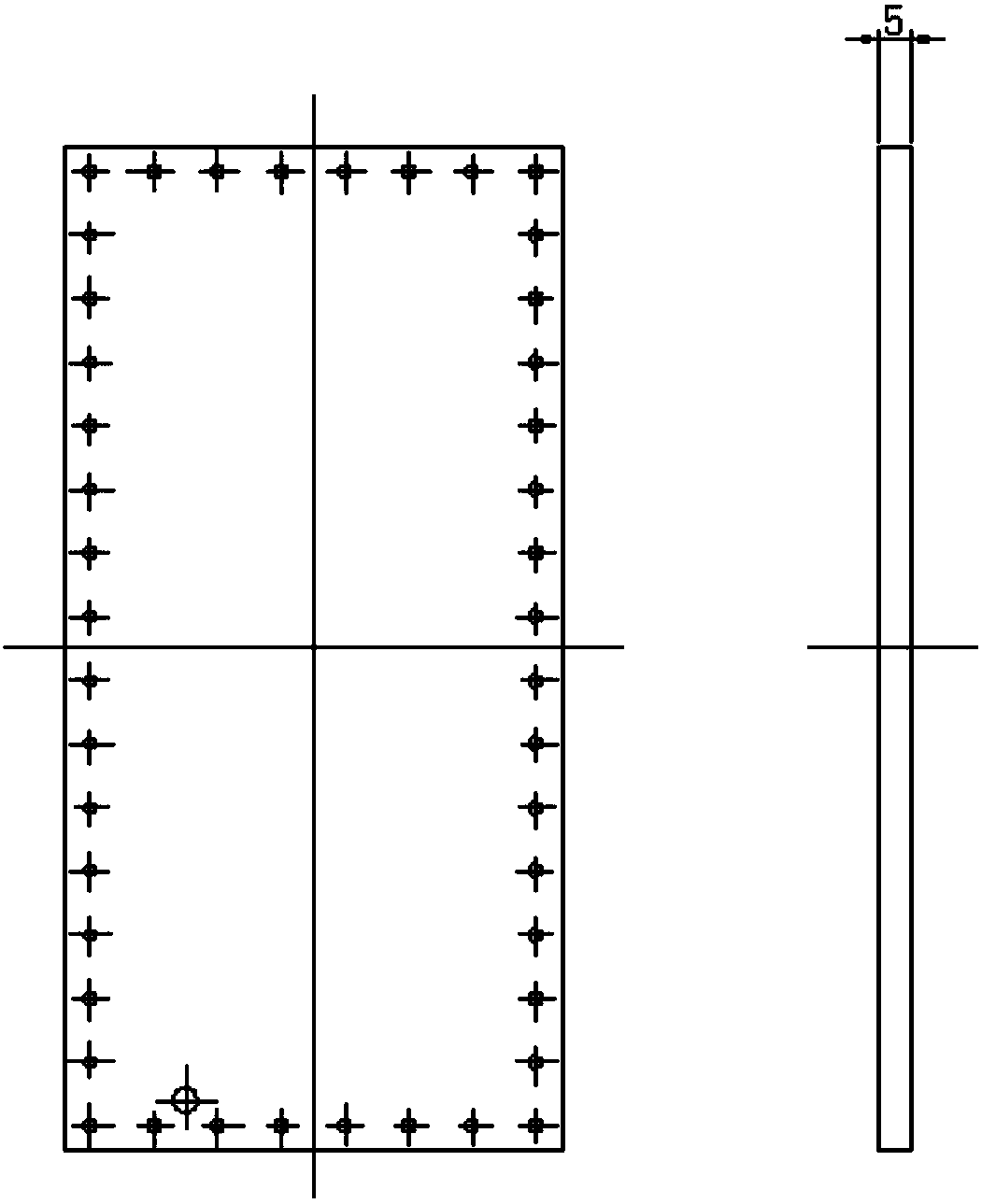

Lead flow battery

InactiveCN108390076AImprove bindingHigh voltageRegenerative fuel cellsElectrochemical responseElectrical battery

The invention discloses a lead flow battery. The lead flow battery comprises a positive electrode plate, a negative electrode plate and a Pb<2+>-containing electrolyte; the positive electrode plate comprises a conductive plate and a positive electrode active layer compounded to one side of the conductive plate; the negative electrode plate comprises a conductive plate and a negative electrode active layer compounded to one side of the conductive plate; the Pb<2+>-containing electrolyte flows through the positive electrode active layer and the negative electrode active layer to be subjected toan electrochemical reaction to form potential difference; the positive electrode active layer comprises a titanium mesh and a tin antimony oxide coating layer arranged on the surface of the titanium mesh; and the tin antimony oxide is a mixture of SnO<2> and Sb<2>O<3>. By virtue of the lead flow battery, the problem of battery short circuit caused by negative electrode Pb dendritic crystal growthand weak binding force and severe fall off of PbO<2> and the positive electrode material can be solved; and the flow battery disclosed in the invention has the advantages of simple assembling, convenient operation, high voltage, space saving and the like, and can be widely applied to the fields of electric power energy storage, a power supply of a carrying tool and the like.

Owner:HAOFA ENVIRONMENTAL PROTECTION TECH SHENZHEN CO LTD

Lining plate and preparation method thereof

ActiveCN104525912AGood chemical stabilityImprove wear resistanceLayered productsVanadium CompoundsCarbide coating

The invention discloses a lining plate; a carbide coating layer is arranged on the upper surface of a working surface of the lining plate; a matrix of the lining plate is alloy steel; and the invention further provides a preparation method for obtaining the lining plate. The lining plate has the carbide coating layer on the working surface; the carbide coating layer comprises a V2C compact ceramic layer, and can further comprise a micron V8C7 compact ceramic layer and a fusion layer of V8C7 and the matrix. The V2C compact ceramic layer, the micron V8C7 compact ceramic layer and the fusion layer of V8C7 and the matrix are gradiently distributed in sequence. The lining plate can be applied to the surface of the alloy steel. A matrix and vanadium compound body obtained through casting is externally leaded in an external carbon source, and is heated and insulated to form the carbide coating layer on the surface of the matrix; and the coating layer and the matrix are metallurgically bonded, so that the binding force is strong, the problems of weak binding force and easy particle dropping due to traditional non-metallurgical bonding between hard particles and a metal matrix are overcome, and the wear resistance of the working surface of the lining plate is largely improved.

Owner:神木中科新星复合材料技术有限公司

Fusion protein for screening weak MdmX inhibitor or testing inhibition activity of weak MdmX inhibitor

ActiveCN106632687AVerify stabilityReduce the binding forceAntibody mimetics/scaffoldsP53 proteinHomologous sequenceP53 binding

The invention discloses a fusion protein for screening a weak MdmX inhibitor or testing the inhibition activity of a weak MdmX inhibitor. The testing sequence is an MdmX sequence or a homologous sequence thereof. The combination sequence is the mutant of p53 segment of the MdmX binding domain of p53 sequence. The linker arm sequence is a peptide segment, and the upstream and lower stream of the linker arm sequence are connected to one of the testing sequence and the combination sequence. The emission spectrums of tryptophan in the fusion protein are different when the combination structural domain and the testing structural domain are connected / disconnected; and for the mutant of p53 segment, compared with a wild p53 segment, the interaction between the p53 combination structural domain and the MdmX combination structural domain is weakened, so that the MdmX inhibitor with a weak binding force can compete with the combination sequence to combine the testing sequence, and thus the inhibition degree of the weak MdmX inhibitor on MdmX can be effectively measured.

Owner:HUBEI UNIV OF TECH

Grinding roller and preparation method thereof

ActiveCN104525887AGood chemical stabilityImprove wear resistanceSolid state diffusion coatingFurnace typesCarbide coatingWeak binding

The invention provides a grinding roller; a carbide coating layer is arranged on the surface of a roller body; a roller core adopts a grey cast iron matrix; and the invention further provides a preparation method for obtaining the grinding roller. The carbide coating layer comprises a V2C compact ceramic layer, and can further comprise a micron V8C7 compact ceramic layer and a fusion layer of V8C7 and a matrix. The V2C compact ceramic layer, the micron V8C7 compact ceramic layer and the fusion layer of V8C7 and the matrix are gradiently distributed in sequence. The carbide coating layer and the matrix are metallurgically bonded, so that the binding force is strong, the problems of weak binding force and easy particle dropping due to traditional non-metallurgic bonding between hard particles and metal matrix are overcome, and the surface wear resistance of the roller body of the grinding roller is largely improved.

Owner:XIAN UNIV OF TECH

Enzyme directed immobilization method based on protein surface screening

InactiveCN104046610AHigh activityStrong specificityOn/in organic carrierOn/in inorganic carrierWeak bindingStrong binding

The invention provides a novel enzyme directed immobilization method. The method comprises the following steps: (1) conducting enzyme surface analysis, and selecting a depression away from catalytic center on the enzyme as a fixed cavity; (2) screening docking molecules, and selecting small molecules with strong binding with the fixed cavity and weak binding with the catalytic center; and (3) preparing an oriented immobilized enzyme: connecting the small molecules to carrier surface and incubating with the enzyme molecule, so as to obtain the composite oriented immobilized enzyme. The immobilized enzyme catalyst obtained by the method has the advantages of high efficiency, good stability and superiority to the traditional immobilized enzyme.

Owner:CHINA AGRI UNIV

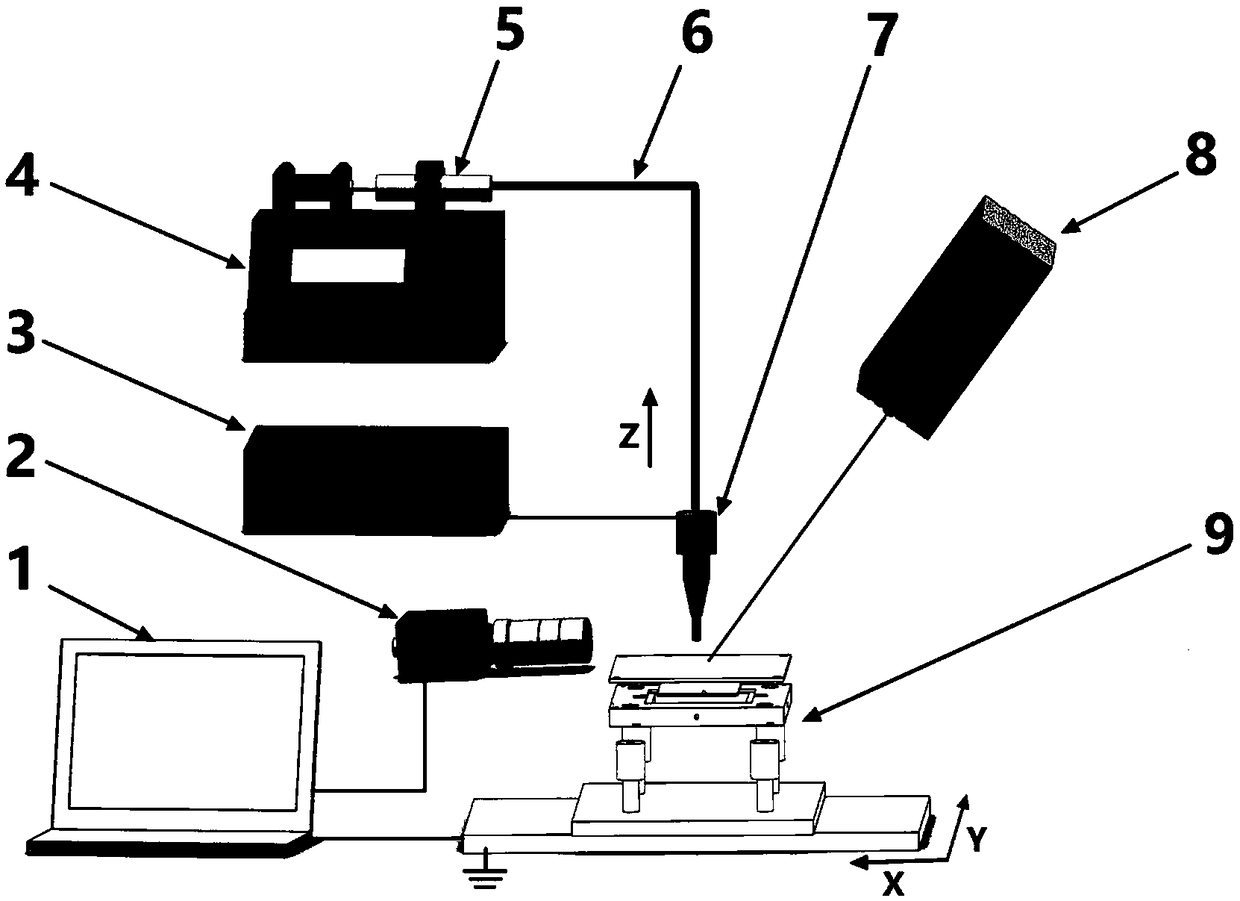

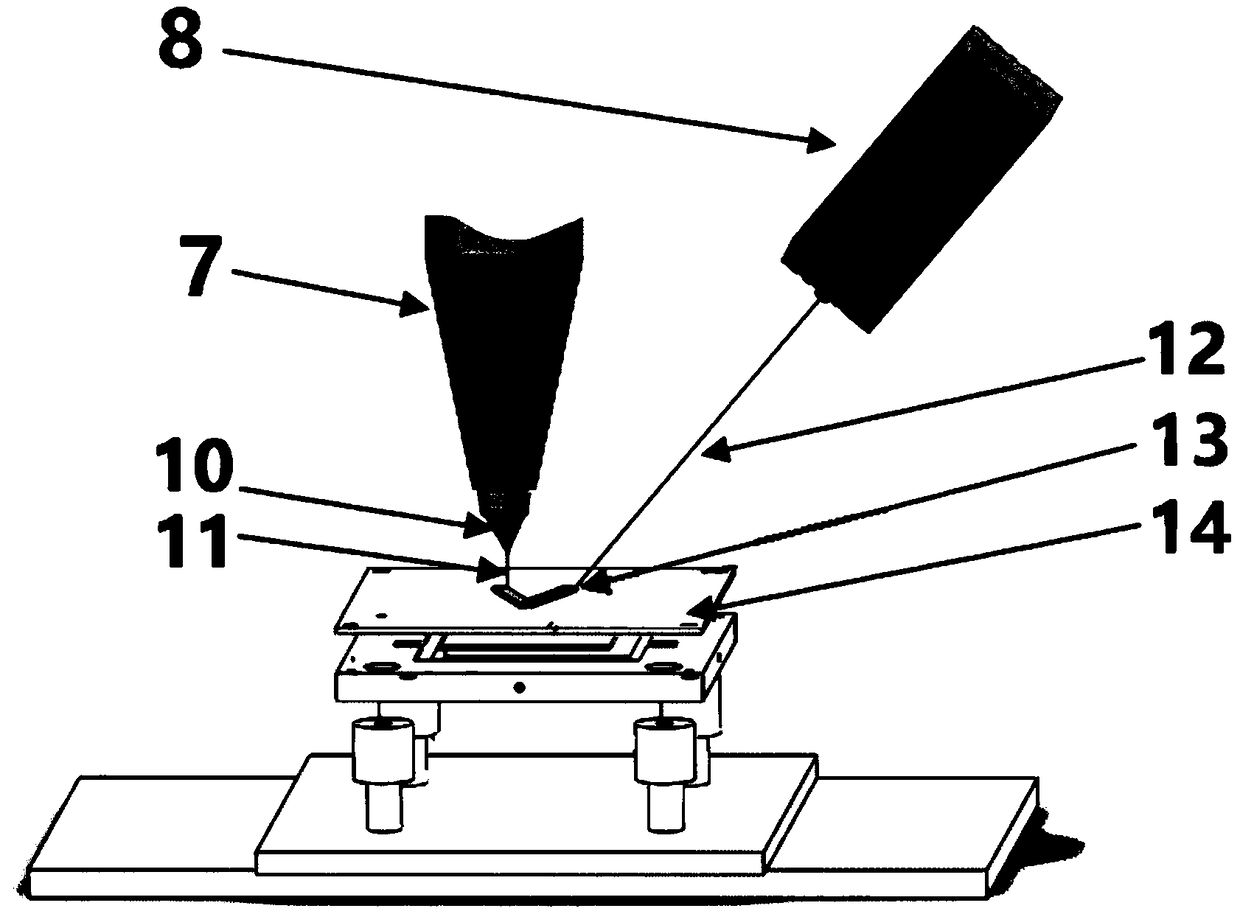

Laser-assisted electrospray in-situ printing device

ActiveCN109159422AHigh dimensional accuracyHigh bonding strengthAdditive manufacturing apparatus3D object support structuresMicro nanoElectricity

The invention belongs to the technical field of advanced manufacture, and provides a laser-assisted electrospray in-situ printing device. The laser-assisted electrospray in-situ printing device comprises an electrospray printing module and a laser functional processing module; functional material ink of the electrospray printing module flows out from a spray needle mouth under the action of pressure, forms stable Taylor cone jet and ejects stable refined jet flow under an electro-hydrodynamic effect, and is ejected on a matrix to form a printing layer. The laser functional processing module isused for carrying out in-situ compounding on the printing layer so as to synchronously realize functional processing such as in-situ high-temperature curing and in-situ crystallization of a printingstructure. According to the device, functional structures and devices are directly realized on required matrixes, so that the secondary positioning error difficulties such as transfer printing, pasting and splicing of traditional methods are eliminated, the problems of weak binding force and low sensitivity caused by gluing process are avoided, the precision and binding strength of the printing structure are improved, the accuracy of printing micro-nano structures is ensured, and the in-situ functionalization of functional materials is realized.

Owner:DALIAN UNIV OF TECH

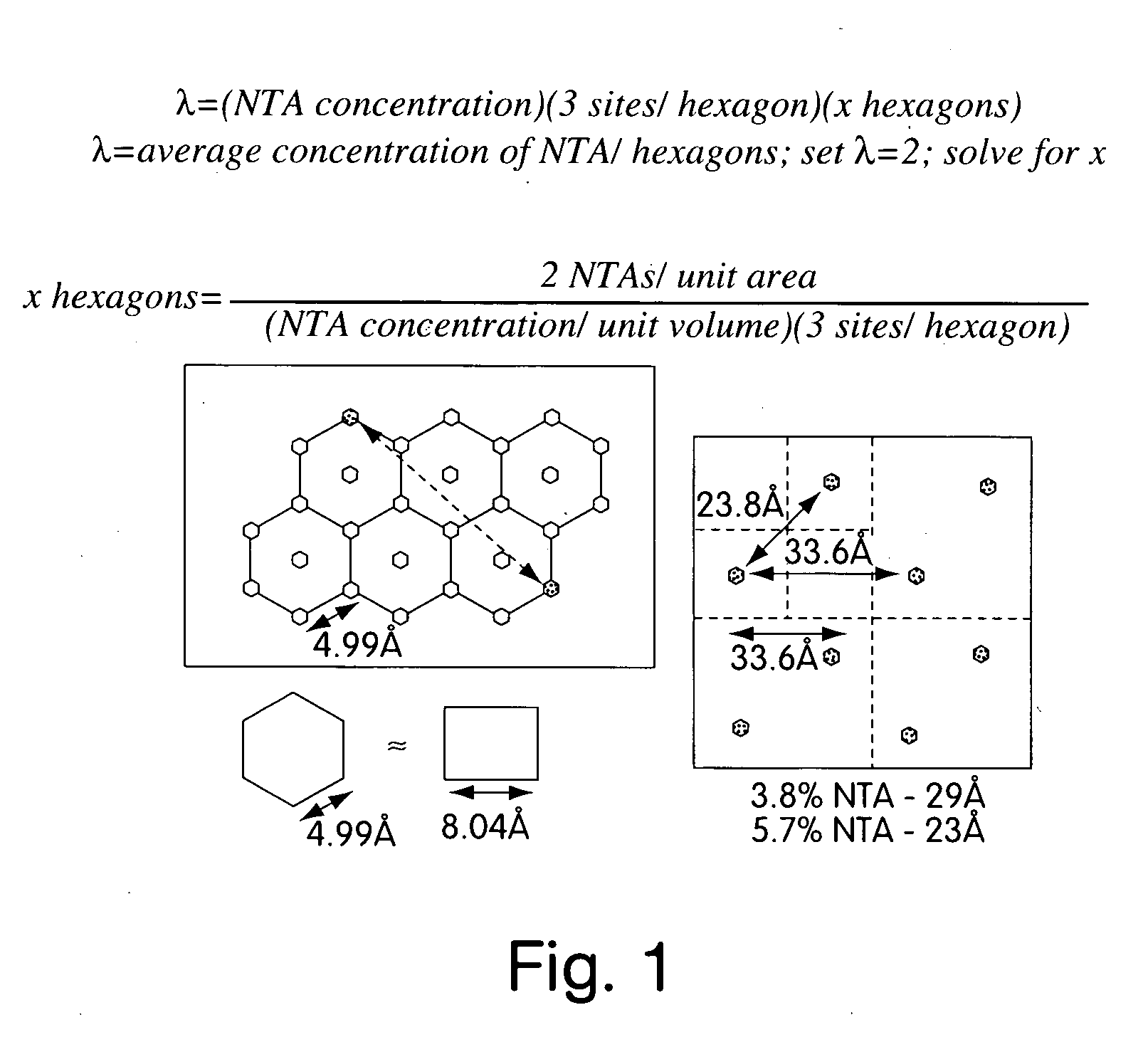

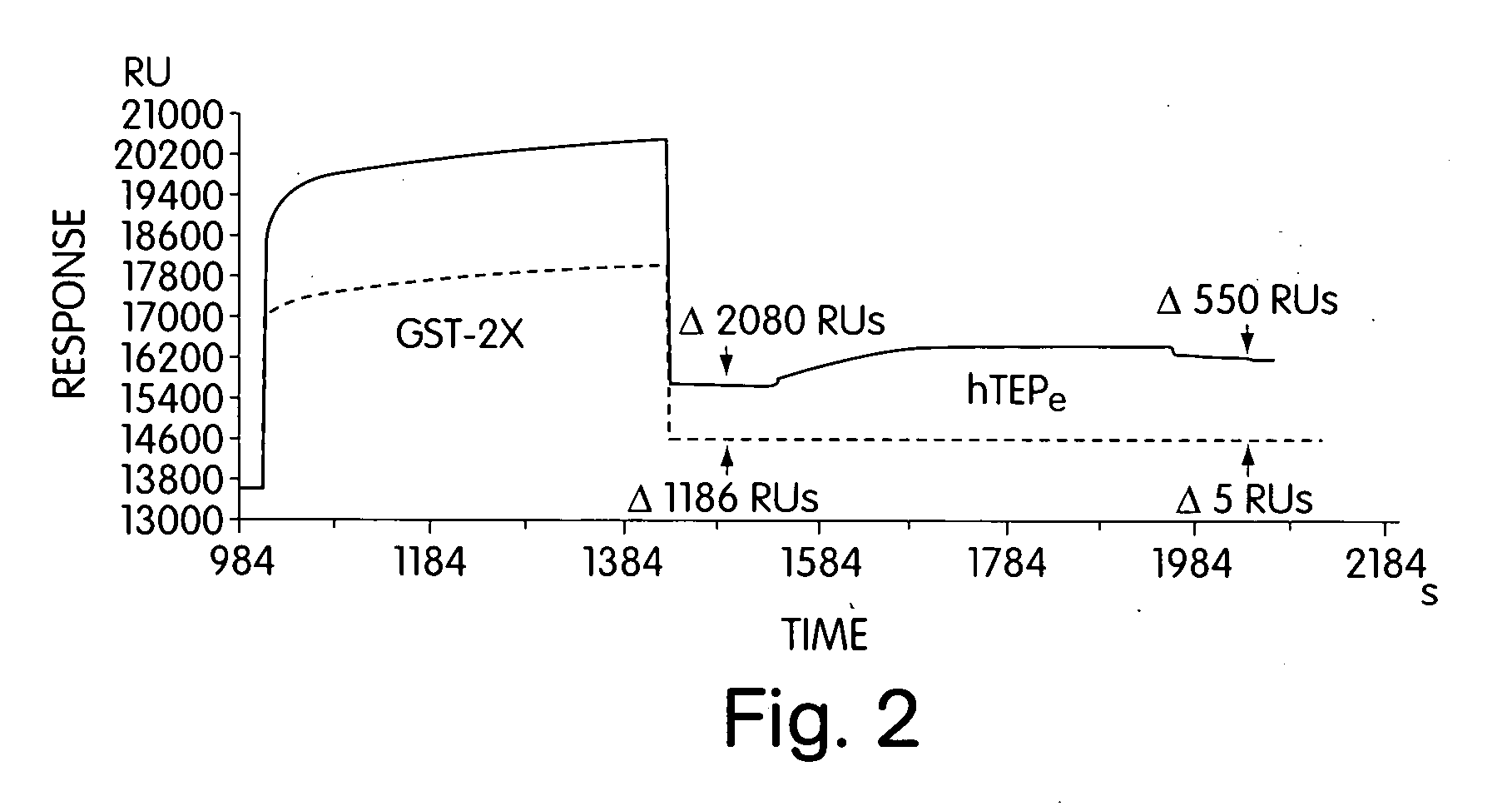

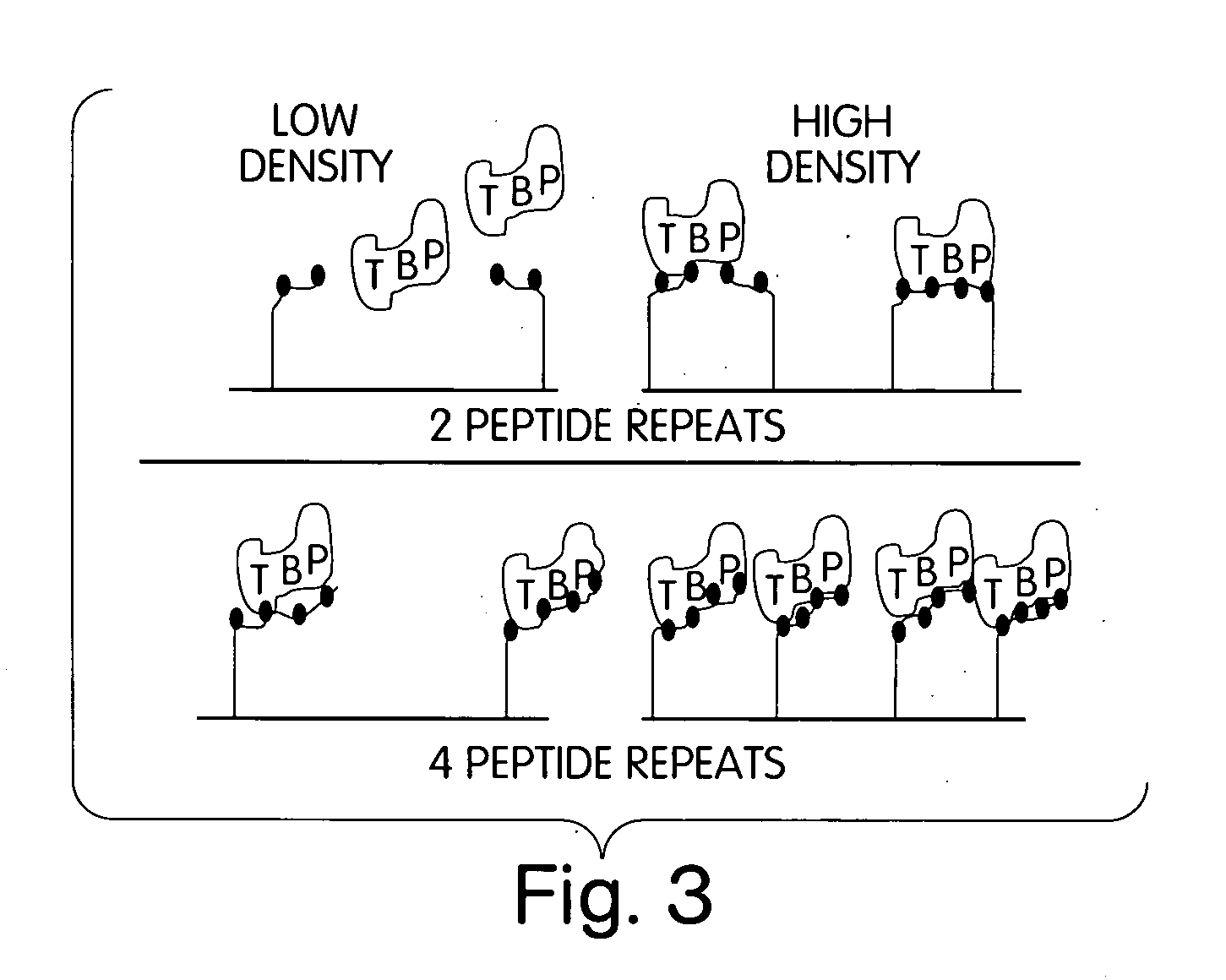

Use of self-assembled monolayers to probe the structure of a target molecule

InactiveUS20050089931A1High binding affinityMaterial nanotechnologyBiological material analysisHeterologousSelf-assembled monolayer

Owner:MINERVA BIOTECH

Method for promoting shearing performance of carbon/carbon-lithium aluminum silicon joint

ActiveCN106518129AIncrease the effective connection areaSolve the problem of weak bindingLithiumHoneycomb

The invention relates to a method for promoting the shearing performance of a carbon / carbon-lithium aluminum silicon joint. The method comprises the following steps: firstly, constructing a honeycomb porous structure on a surface of a modified layer of a silicon base ceramic by utilizing a controllable oxidizing method, and then forming an interlocked embedded interface structure by a glass interlayer and the modified layer in a hot-pressing process. According to the invention, through the design of the embedded interface structure, the effective connecting area of the modified layer and the glass interlayer is obviously increased, and the problem of weak binding of the interface is solved to a certain extent. The average shearing strength of a C / C-LAS joint prepared according to the method can reach up to 32.46+ / -1.35MPa and is 35% higher than that of a gradient joint of the patent 1. Through the construction of the embedded interface structure, the effective connecting area of the modified layer and the interlayer is increased, the problem of weak binding of the interface is solved to a certain extent, and the shearing strength of the C / C-LAS joint is obviously increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com