Patents

Literature

226results about How to "Verify stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

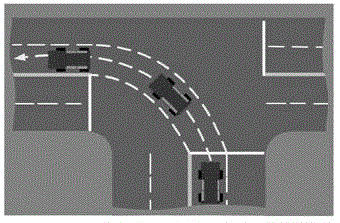

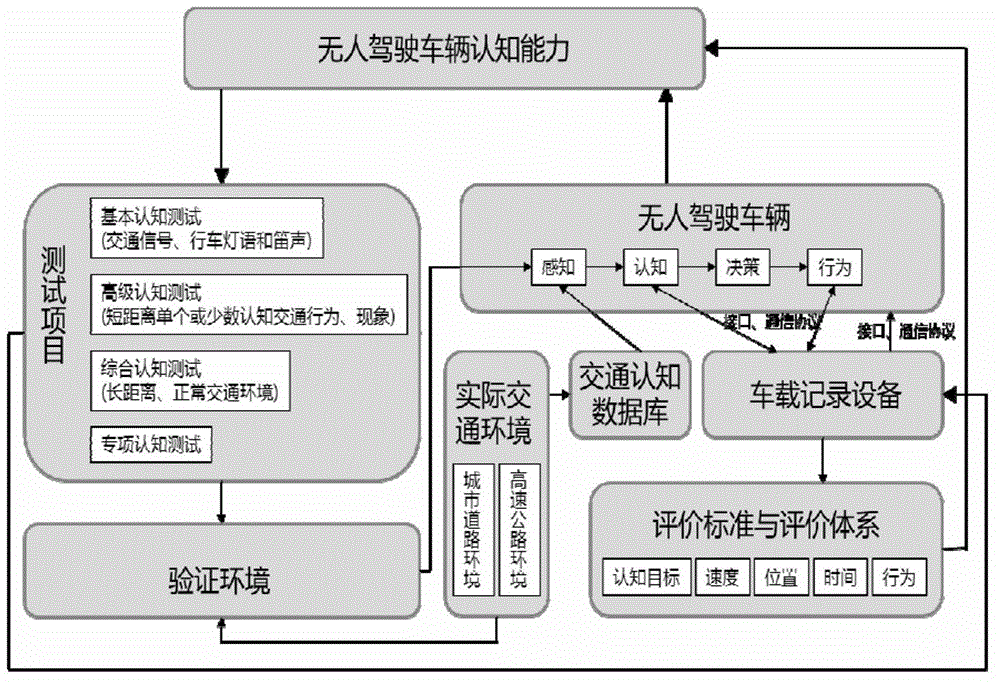

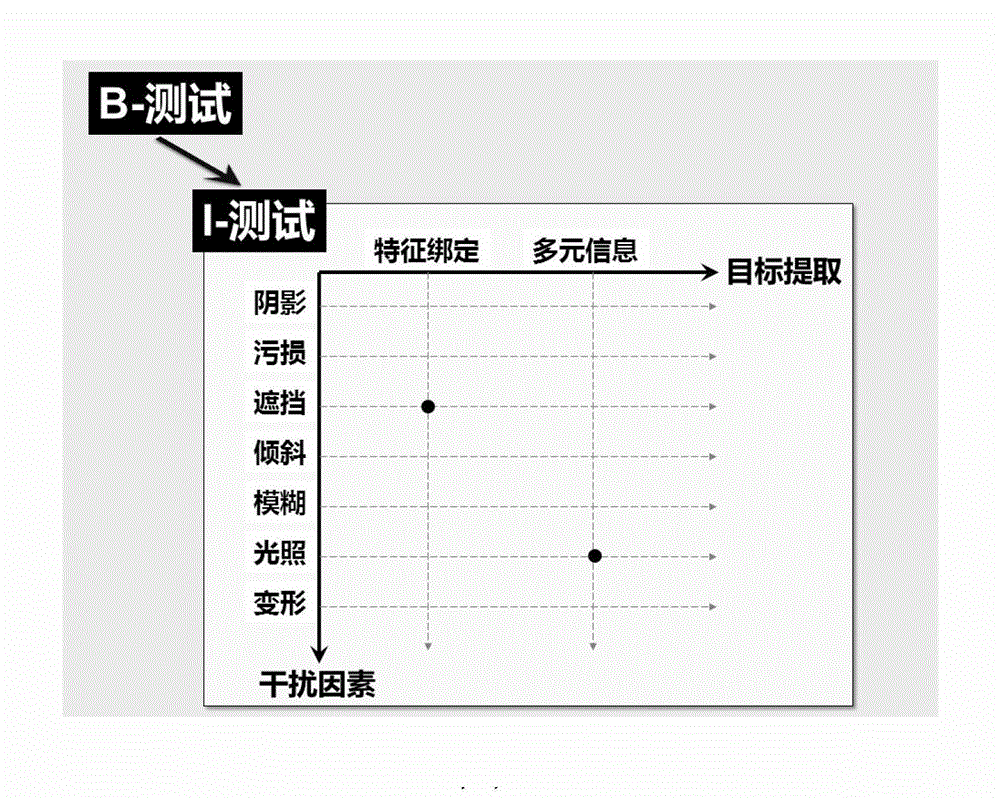

Unmanned driving vehicle cognitive competence testing system and method

ActiveCN103335853AVerify securityVerify reliabilityVehicle testingTesting/monitoring control systemsData transmissionData content

The invention discloses an unmanned driving vehicle cognitive competence testing system which comprises an unmanned driving vehicle and a vehicle-mounted recording unit, wherein the unmanned driving vehicle and the vehicle-mounted recording unit are in wired connection through a communication interface, the vehicle-mounted recording unit is used for inputting cognitive competence testing task to an unmanned driving vehicle, and receiving and storing data output by unmanned driving vehicle cognitive competence test; after receiving testing task through a testing task input program, the unmanned driving vehicle rebuilds serial port connection and starts corresponding program output test data to the vehicle-mounted record unit, the testing task input and the testing data output both of the unmanned driving vehicle cognitive competence test adopt the uniform interface, parameter and data transmission form, while the specific forms of the data contents are different; the communication interface adopts an RS-232 interface.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

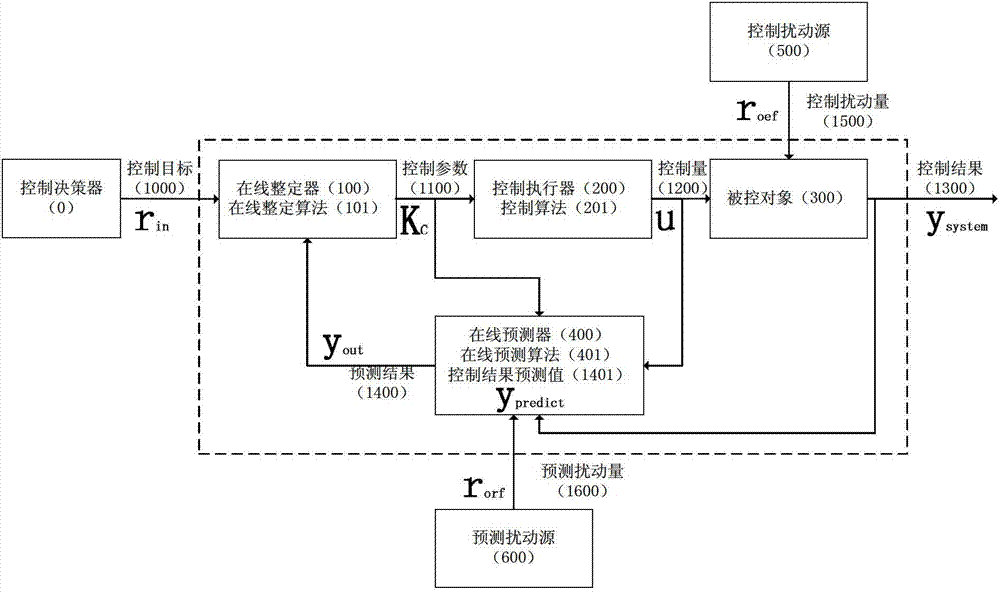

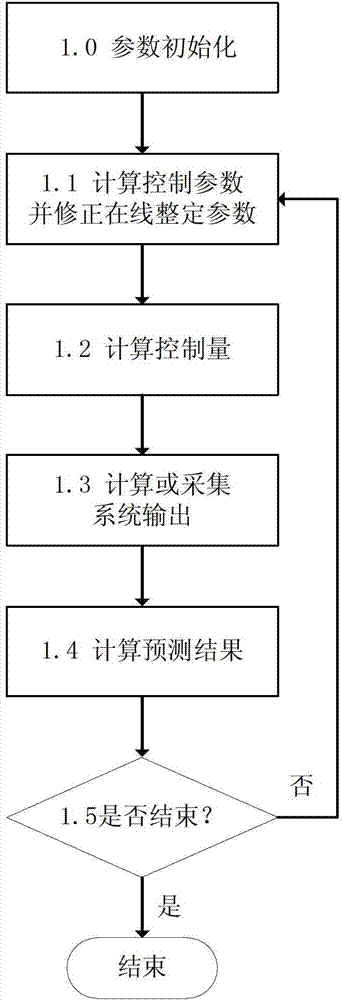

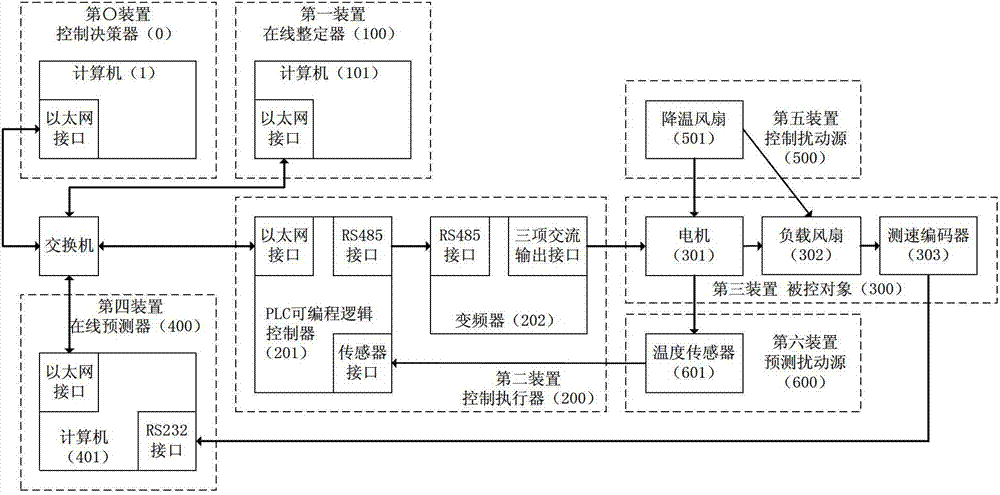

Time series prediction and intelligent control combined online parameter adjustment method and system

The invention discloses a time series prediction-based wavelet neural network online PID adjustment method and a system using the same. The method specifically comprises the steps of initiating the parameters, computing the control parameters and rectifying the online adjustment parameters, computing the control amount, computing or acquiring the system output and computing the prediction result; the system specifically comprises a control decision device, an online adjuster, a control executer, a controlled object, an online predictor, a control perturbation source and a prediction perturbation source; the control decision device is used for realizing the parameter initiation; the online adjuster is used for computing the control parameters and rectifying the online adjustment algorithm parameters; the control executer is used for computing the control amount; the online predictor is used for computing the prediction result; and the control decision device is also used for judging whether the algorithm is finished. According to the method, the wavelet neural network and the classic control method are combined to solve the problem of dependence on the parameter configuration work before the system operates in the control field, so that the control system has the effects of prediction, learning, online parameter optimization and self-adaptation.

Owner:BEIJING UNIV OF TECH

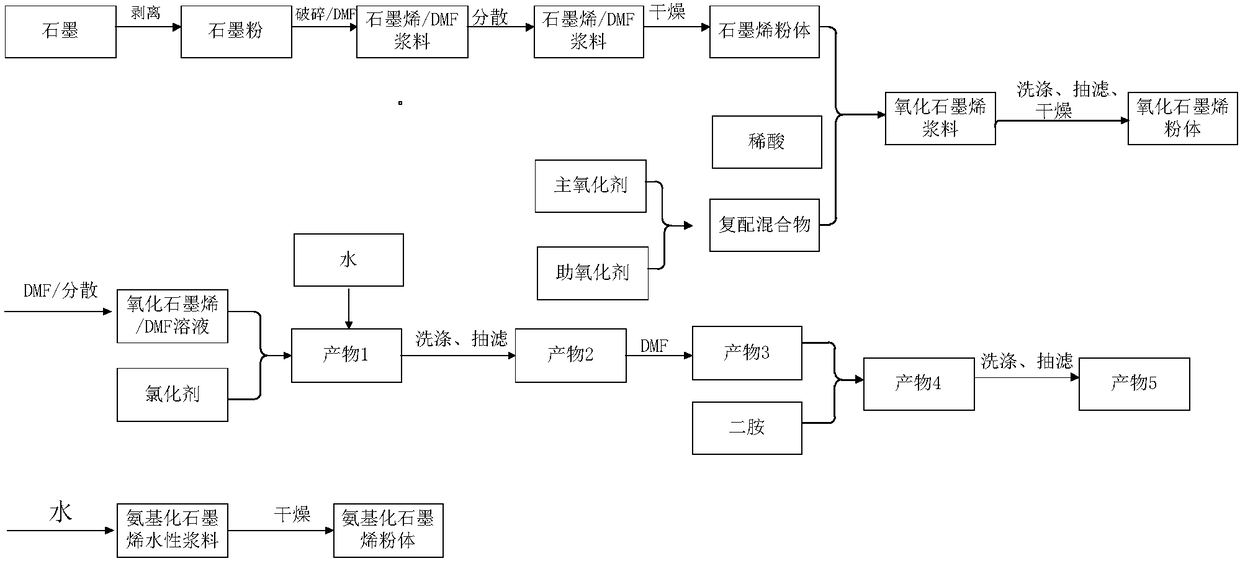

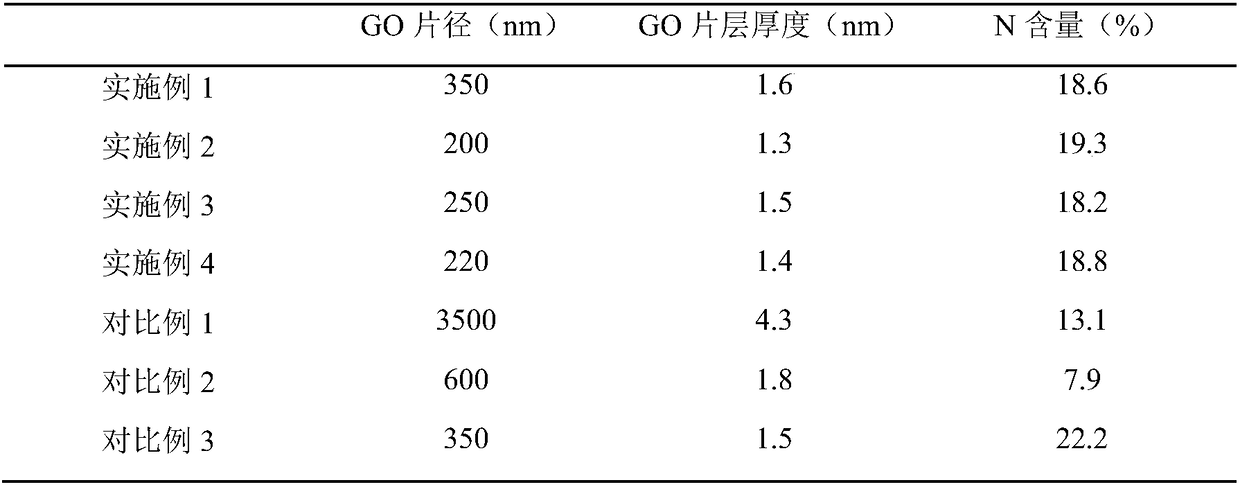

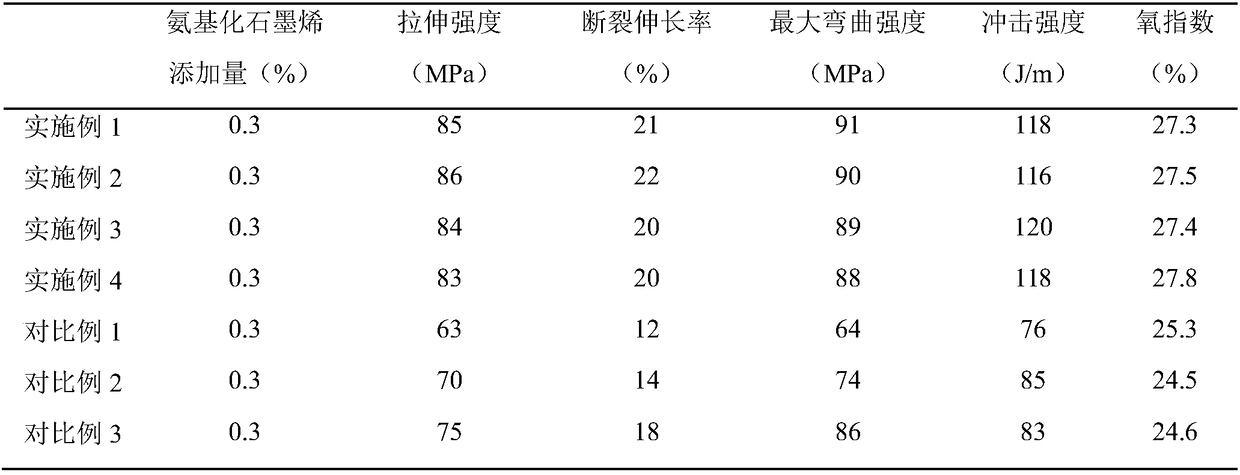

Preparation method of industrial aminated graphene

ActiveCN108373149AReduce dosageLittle damage to the lamellar structureGrapheneBulk chemical productionCvd grapheneDiamine

The invention discloses a preparation method of industrial aminated graphene. The preparation method of the industrial aminated graphene belongs to the technical field of graphene preparation, and comprises the steps of firstly stripping graphite through a mechanical stripping method, oxidizing through adjusting the matching ratio of a main oxidizing agent and an auxiliary oxidizing agent, then activating hydroxyl and carboxyl on the surface of graphene oxide through a chlorinating agent, and finally selecting appropriate diamine for carrying out amination reaction. According to the preparation method of the industrial aminated graphene provided by the invention, through adopting a stripping manner at first, the dosage of the oxidizing agents can be reduced, an ideal effect is achieved atthe same time, and the problem of poor modification effect caused by high oxygen content and severe destructiveness on a graphene slice layer due to large dosage of the oxidizing agents is solved.

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

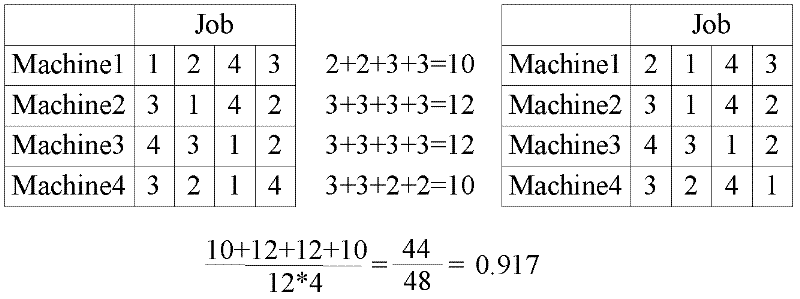

Control method for solving scheduling of operating workshops under complex production environment based on improved genetic algorithm

InactiveCN102609805AVerify validityVerify stabilityGenetic modelsResourcesPopulationFitness function

The invention relates to a control method for solving scheduling of operating workshops under a complex production environment based on an improved genetic algorithm. The control method comprises the following steps: 1) setting an operating workshop scheduling model with a fuzzification parameter and taking the maximized satisfaction for all products and the maximized minimum satisfaction as a target function; 2) solving the target function by adopting the improved genetic algorithm, (2.1) adopting encoding based on working sequence; (2.2) running a G&T algorithm for several times so as to generate an initial group; (2.3) taking the target function as a fitness function for evaluating an individual; (2.4) performing selecting and interlacing operations; (2.5) performing reversal variation; (2.6) combining all groups and continuing to evolve till converging when the individuals of each group are all converged to a certain degree; and (2.7) taking a preset maximum evolving algebra Nmax as a stopping condition, and taking the present best solution as an optimal solution, thereby obtaining a scheme for solving the scheduling of operating workshops under the complex production environment. The control method provided by the invention has the advantages of excellent accuracy, better reliability and strong practicability.

Owner:盐城新咏投资发展有限公司

Early fault determining method for bearing

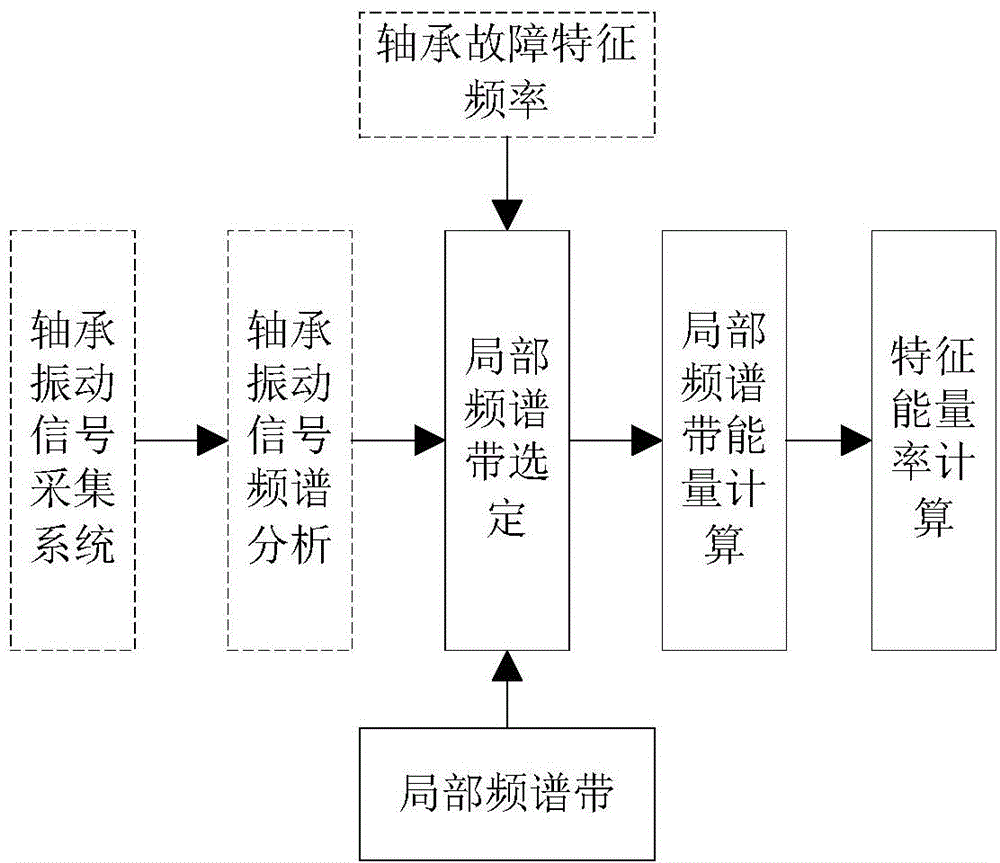

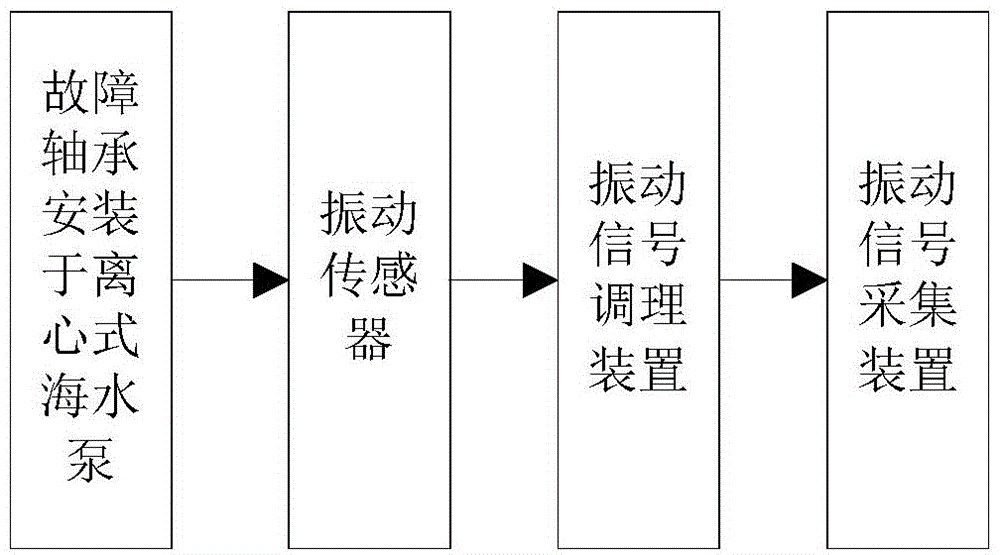

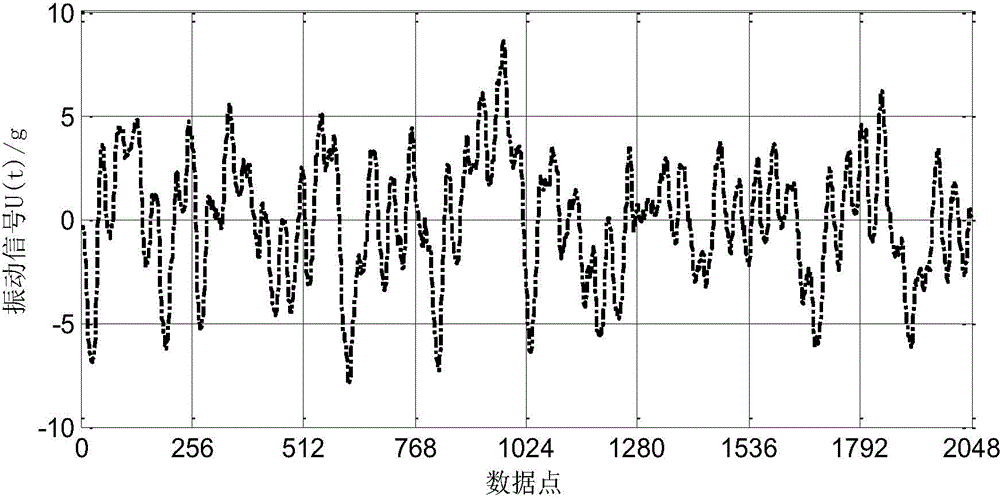

ActiveCN104596766AConfirm authenticityVerify repeatabilitySubsonic/sonic/ultrasonic wave measurementMachine bearings testingTime domainSpectral bands

The invention relates to an early fault determining method for a bearing. The method comprises the steps of cutting an acquired bearing vibration time domain signal into N groups of secondary vibration signals according to the same length; 2, calculating local spectral band energy Mg of each secondary vibration signal, namely, 1) performing frequency domain conversion for each secondary vibration signal; 2) selecting a local spectral band from the whole Hilbert marginal spectrum based on the formula shown in specification as the interval, wherein fp is the bearing fault characteristic frequency calculated based on the bearing structural dimension, and delta f is 2Hz; 3) calculating the local spectral band energy through the formula shown in the specification, wherein h(f) is frequency amplitude in the local spectral band; 3, creating a local spectral band energy sequence through N Mg, wherein the local spectral band energy value of each vibration signal is Mf when the bearing is free of a fault; Mg is not less than the product of K and Mf at M times in the sequence, wherein K is a constant; the characteristic power rate (CPR) is determined according the formula shown in the specification; 4, determining the early fault when the CPR is more than or equal to some constant A.

Owner:CSSC SYST ENG RES INST

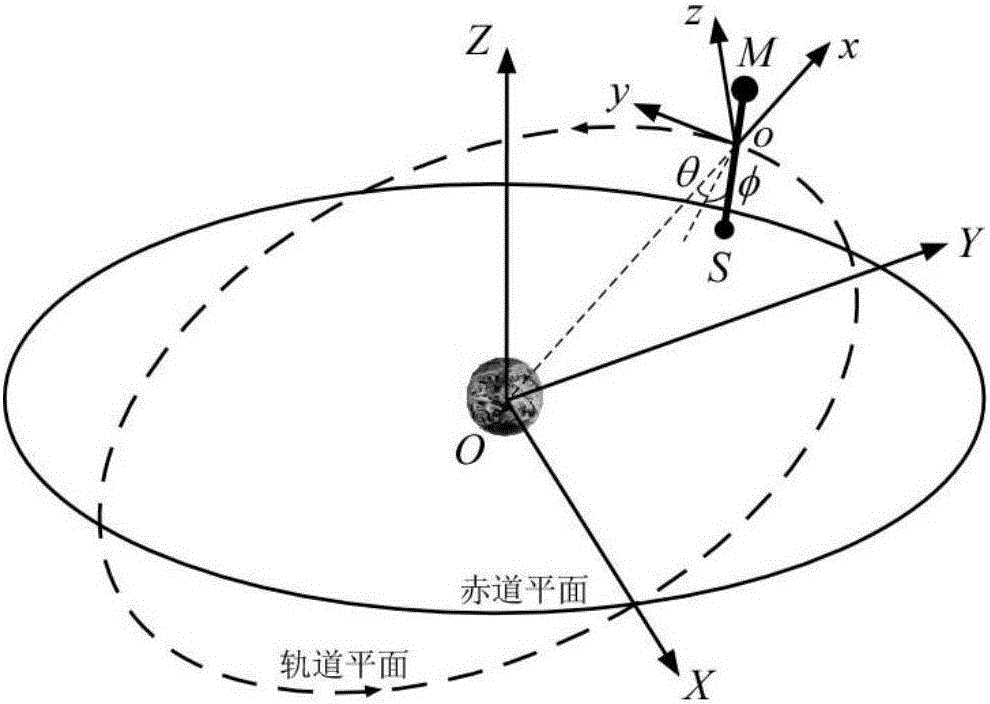

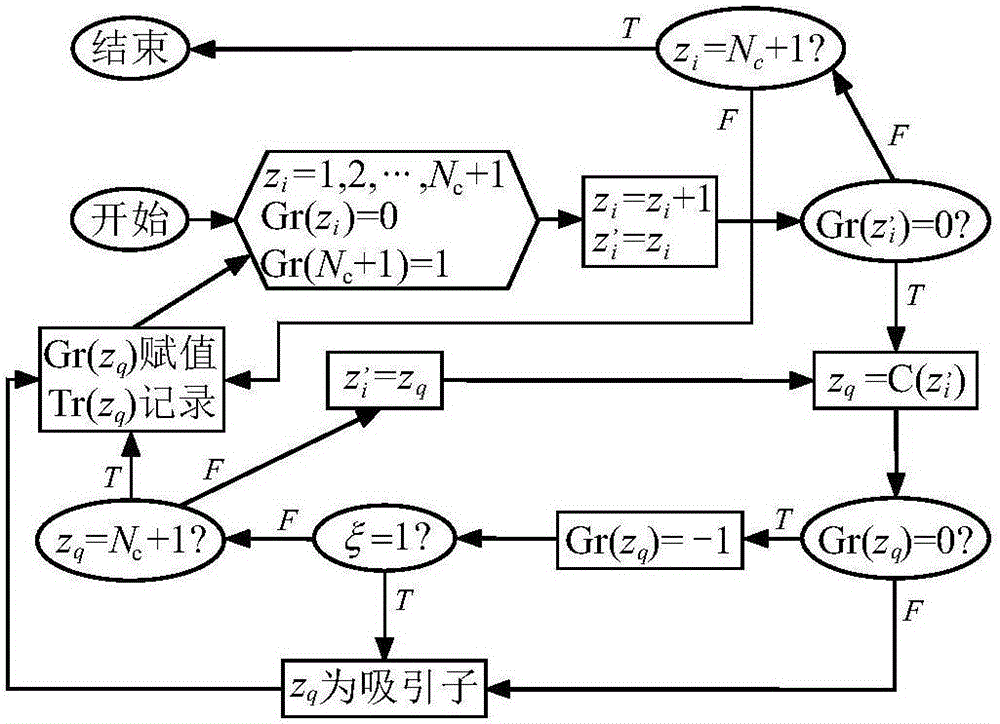

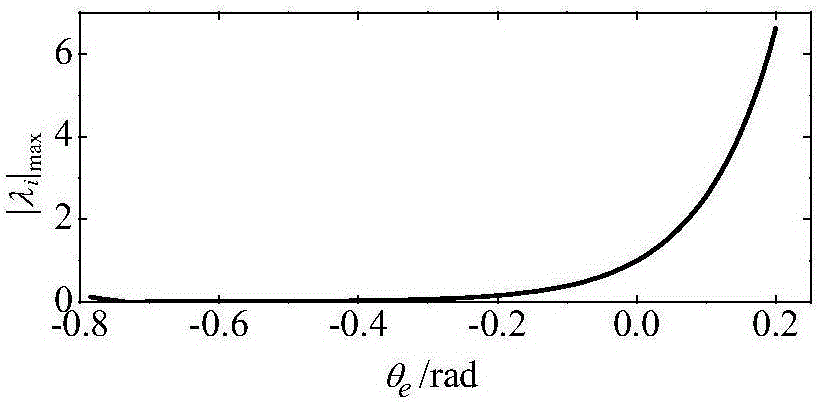

Under-actuated release control method based on nonlinear space tether system

ActiveCN106054906AHas non-linear propertiesVerify stabilityAttitude controlIn planePartial differential equation

The invention provides an under-actuated release control method based on a nonlinear space tether system. The method comprises the following steps: 1, a dumbbell model is adopted, system dynamics differential equations are built according to a second kind Lagrange equation, and a dimensionless form is introduced in the differential equations; 2, based on a normal form expression for the above dynamics differential equations, expected values for a system in-plane pitching angle and an out-plane rolling angle are set, and the balance position of the system in the release process is obtained; 3, starting from the balance position of the system, a tether length change control law for realizing tether release is deduced and obtained; and 4, the range for the expected in-plane pitching angle is determined to ensure the tether release process to be asymptotically stable under effects of the control law. Numerical simulations show that the space tether can be released asymptotically stably under effects of the release control method provided by the invention, and an attractor capable of covering the balance point and an attraction domain with enough thickness can be found out.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

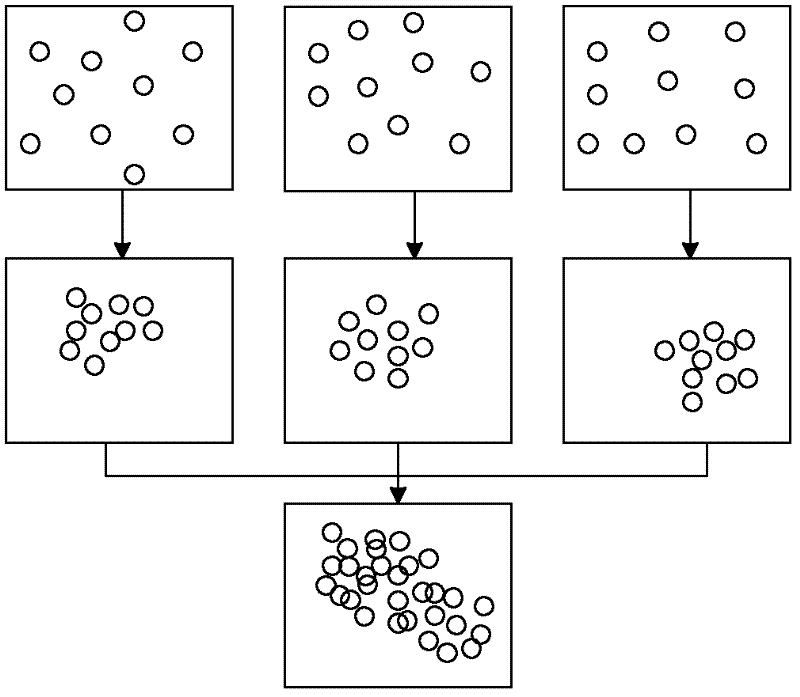

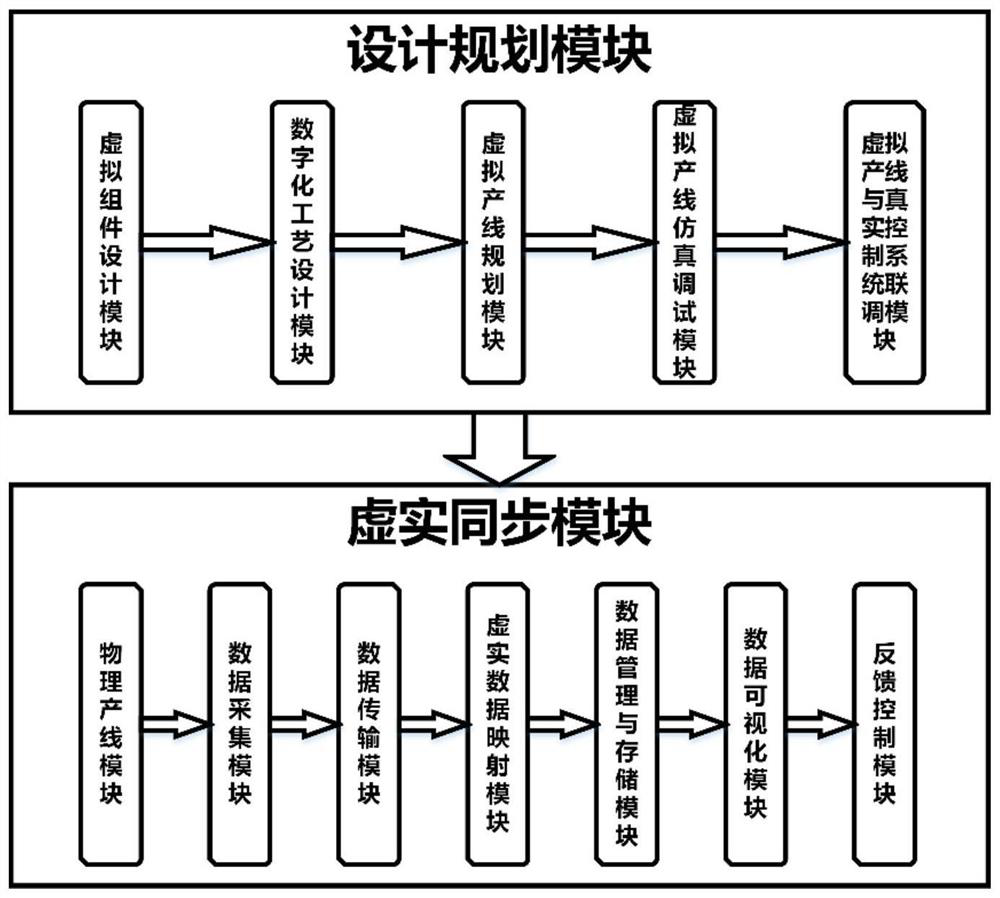

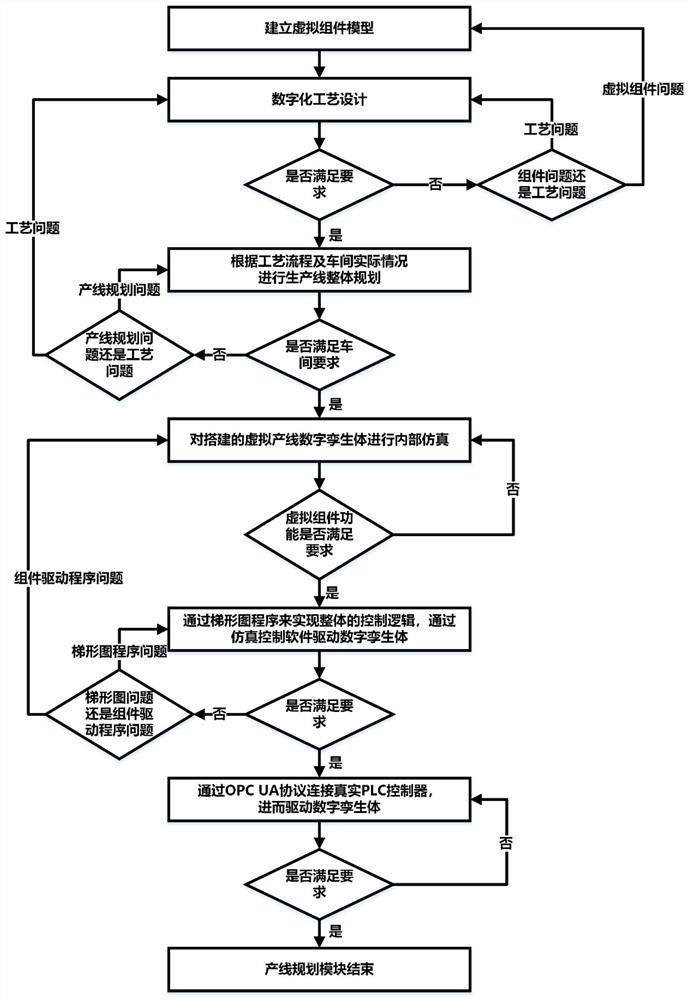

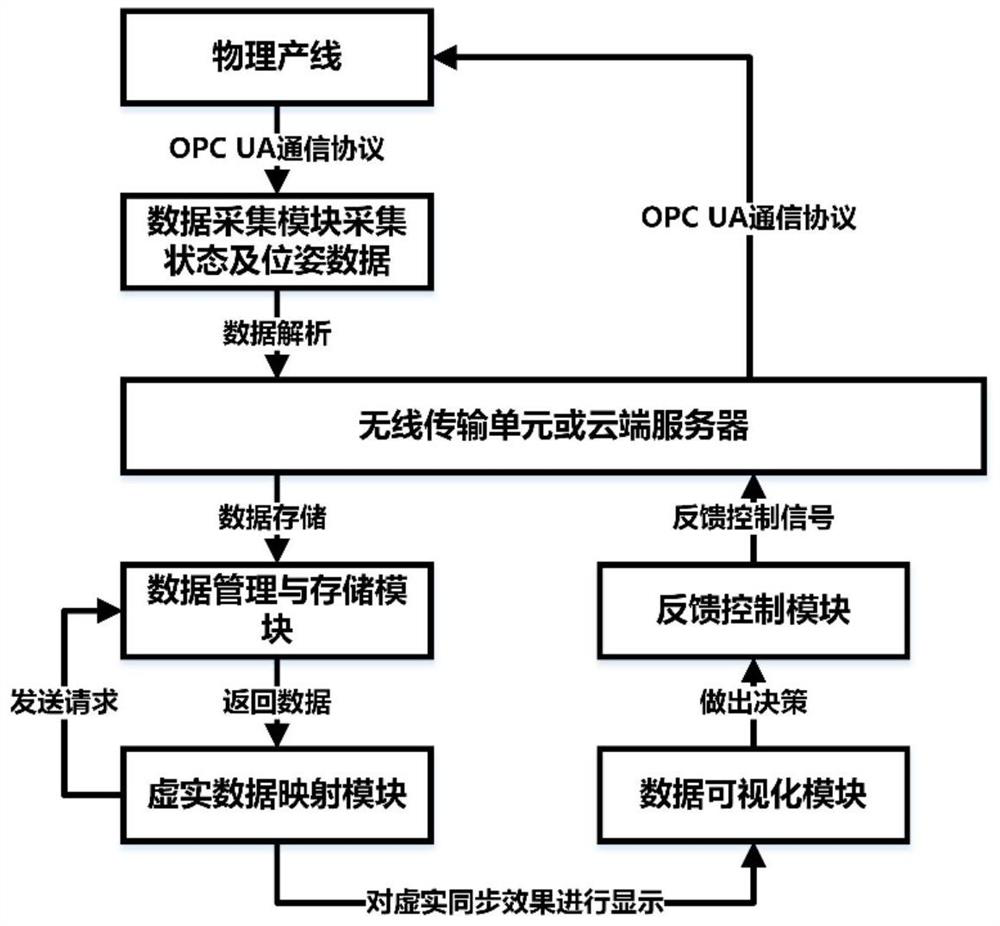

Production process full-period intelligent workshop system based on digital twinning technology and solving method

ActiveCN113110328AGuaranteed connectivityEasy to optimize and improveTotal factory controlProgramme total factory controlFull life cycleFeedback control

The invention discloses a production process full-period intelligent workshop system based on a digital twinning technology and a solving method. The system comprises a design planning module and a virtual-real synchronization module. The design planning module is used for building virtual components required by the digital twin of the automatic workshop in the virtual component design module, carrying out process design according to actual production requirements, arranging an automatic production line, and verifying a production line planning effect and a control program. The virtual-real synchronization module builds a real production line after verification, collects the operation data of the real production line, transmits the operation data to the data management and storage module, completes the synchronization between the real production line data and the digital twin data, and displays the virtual-real synchronization condition and the operation data, and finally guides the actual production by using the data processing result of the digital twin. The system and method run through the full life cycle of the production line, and production accidents and economic losses caused by design defects can be avoided; the simulation credibility is improved; and feedback control is performed on a real production line, so that major safety accidents and property loss can be effectively avoided.

Owner:DALIAN YAMING AUTOMOTIVE PARTS +1

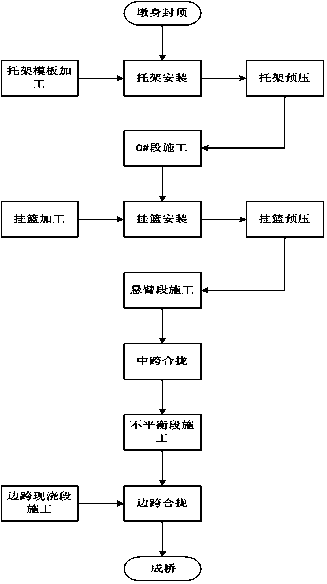

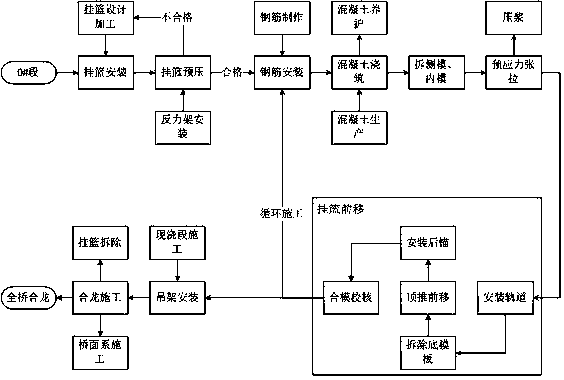

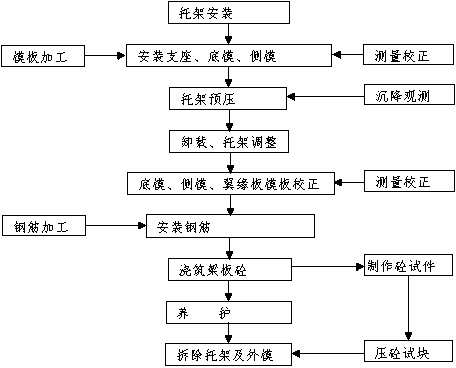

Special construction method for dragging main beam of extra-large bridge

InactiveCN111287095AStrong enoughRigid enoughBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention discloses a special construction method for a main beam of a lower dragging extra-large bridge, which comprises the following steps of: S02: 0 # section construction: pouring twice, andforming a support by once pouring; s03, hanging basket construction is conducted, specifically, a hanging basket is moved forwards to the front end of the zero beam section, and the formwork erectingelevation is determined; and erecting a formwork to bind the No.1 beam section steel bars and finish the arrangement of the prestressed pipeline. Aiming at the conditions that the span of a main beamis 200 m, the length of double cantilevers is large, the width-to-span ratio of a box girder is small, and the construction technical difficulty is large when the construction period goes through strong wind seasons and winter, smooth construction is guaranteed, and good practicability is achieved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP +3

Distribution network system simulation method considering access of doubly-fed type wind motor

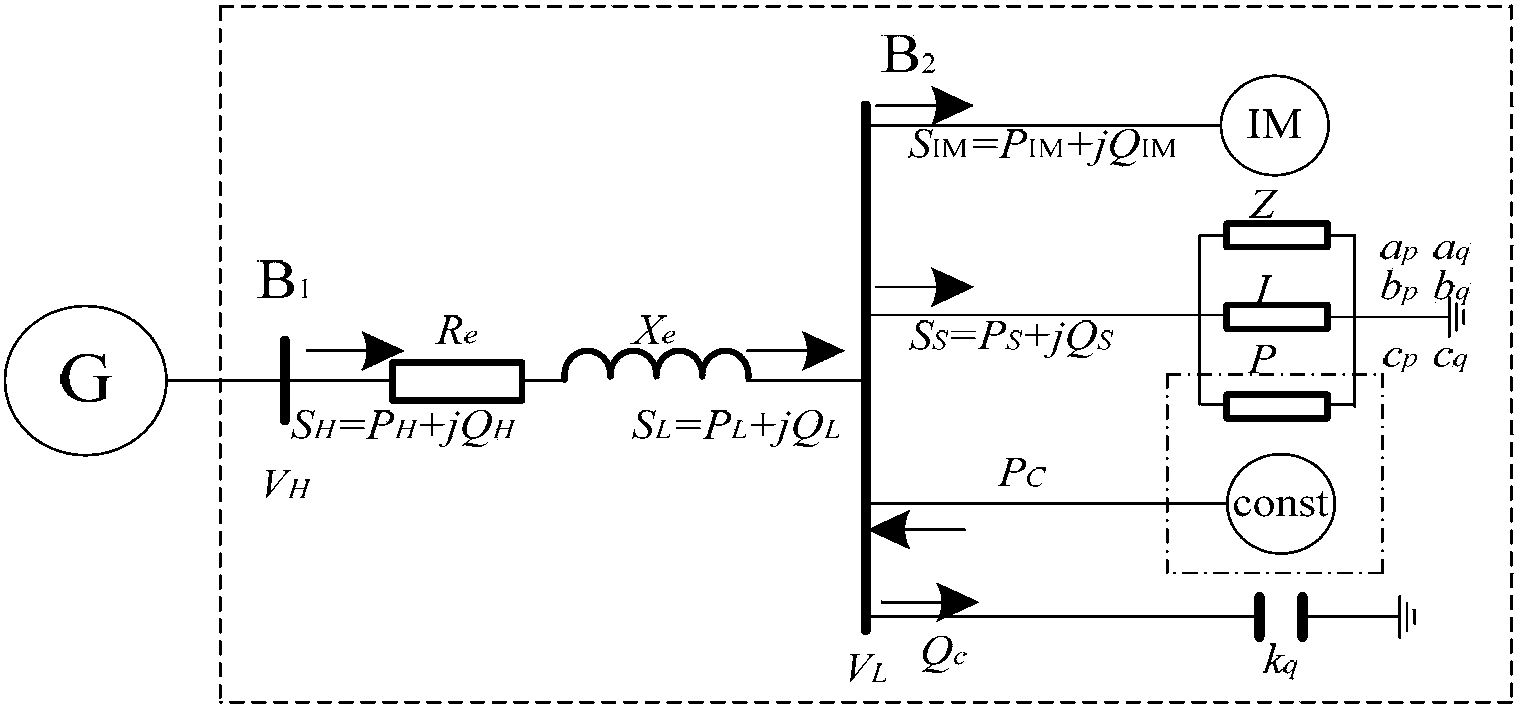

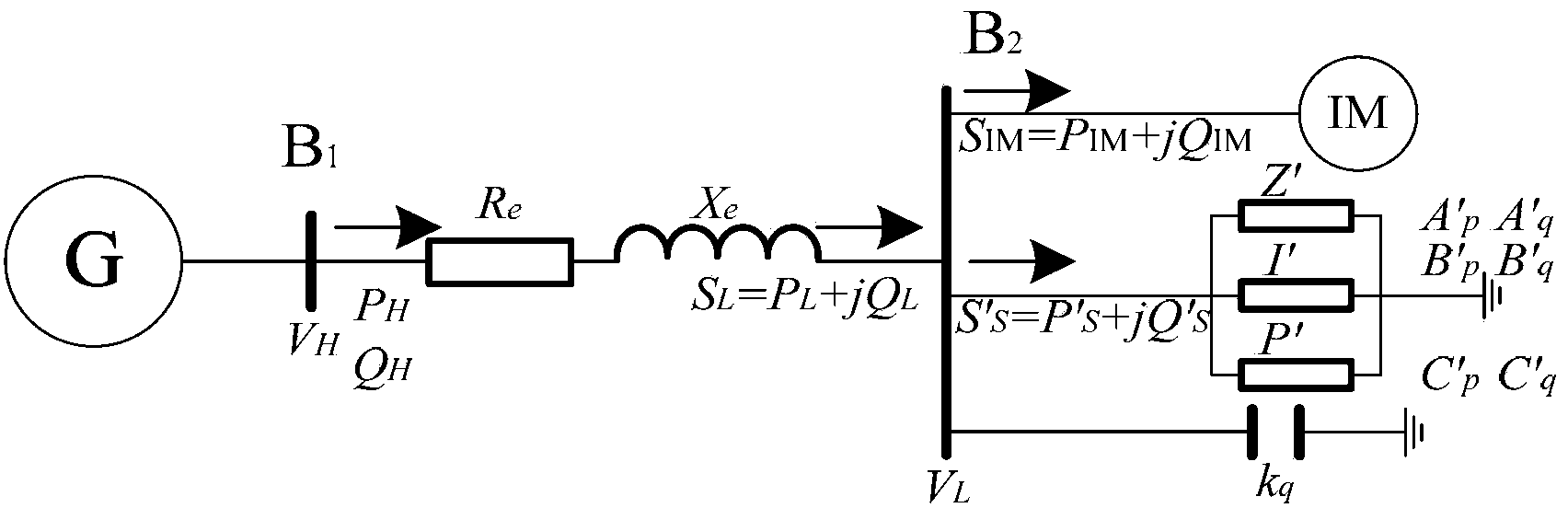

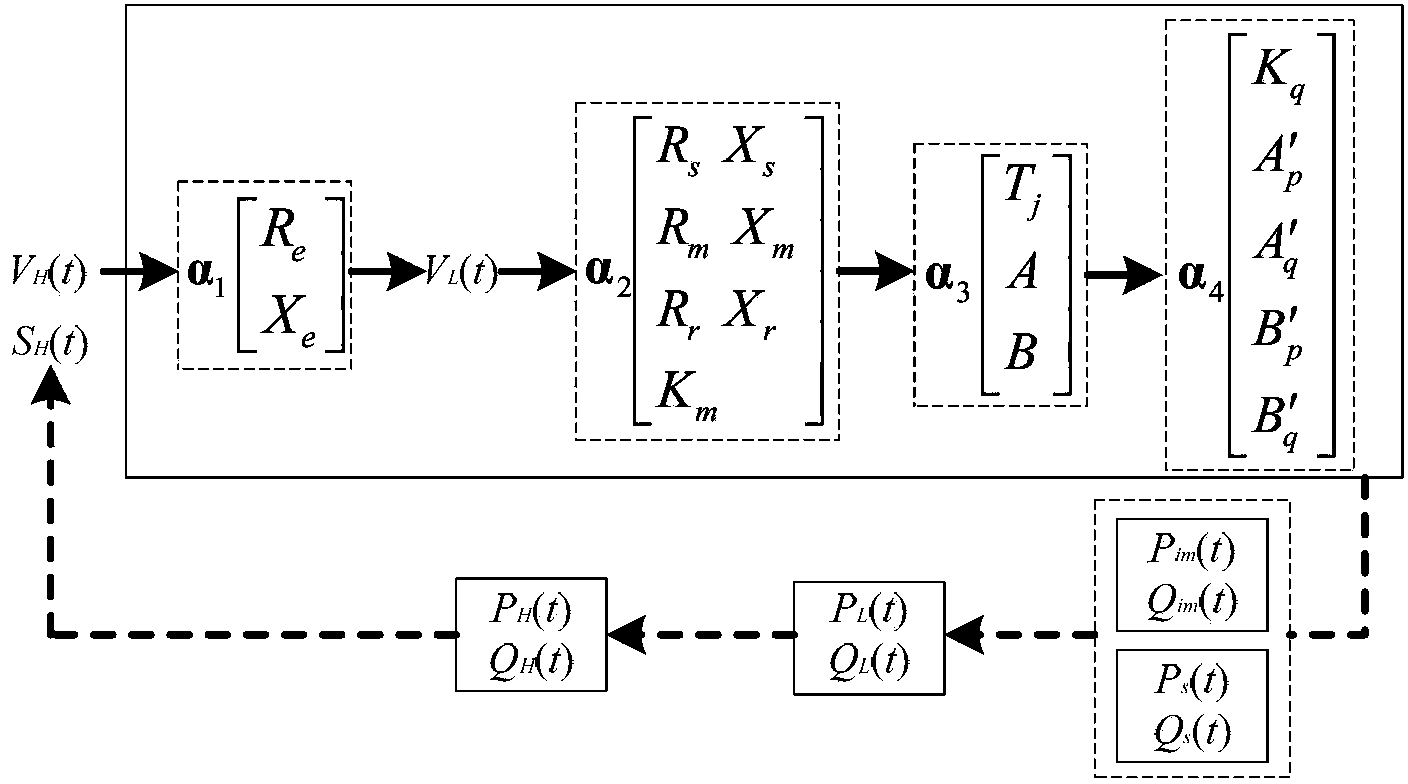

ActiveCN103414212AVerify validityVerify generalization abilitySingle network parallel feeding arrangementsAerodynamics improvementTransient stateSystems simulation

The invention discloses a distribution network system simulation method considering the access of a doubly-fed type wind motor. The load (generalized composite load) of a power distribution network is composed of an induction motor load part, a static load Z'I'P' part and a reactive compensation part. The response of the static load Z'I'P' part is preset. According to the distribution network system simulation method considering the access of the doubly-fed type wind motor, the load of the power distribution network is made to be equal to equivalence ZIP conformation, the distribution side structure is simple, and the temporary state simulation research of the distribution network system considering the access of the doubly-fed type wind motor is made to be more convenient and quick.

Owner:HUNAN UNIV

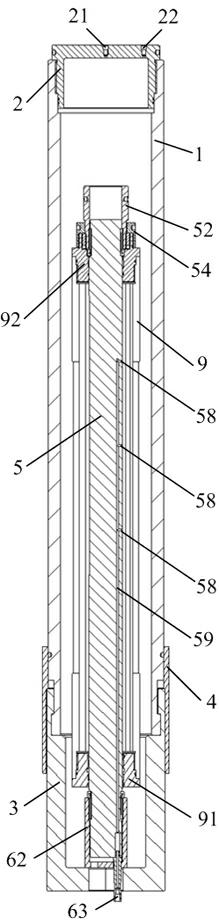

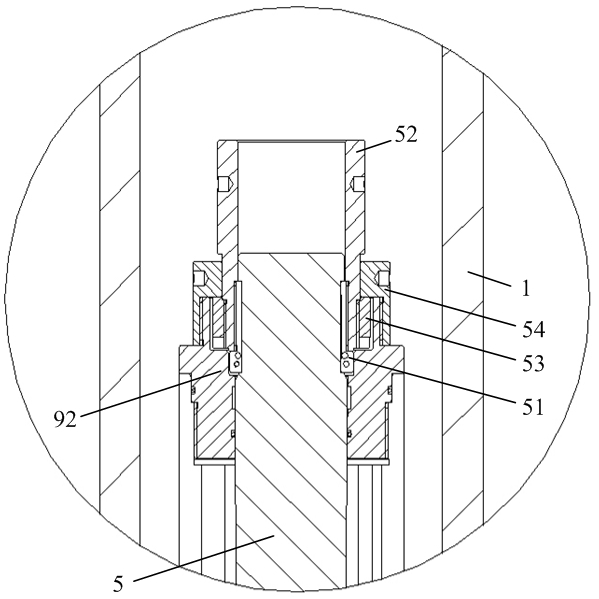

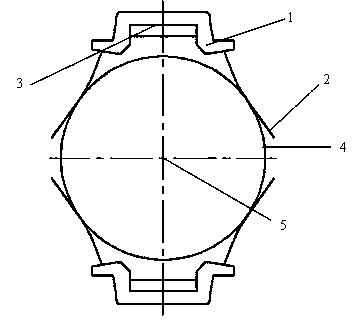

Device and system for testing packer in formation tester

ActiveCN102564702AVerify reliabilityVerify stabilityMachine part testingFluid-tightness measurement using fluid/vacuumEngineeringProtection ring

The invention discloses a device and a system for testing a packer in a formation tester, and aims to test a newly-developed packer in a formation tester. In the test device, a first end of a simulation borehole sleeve is connected with a sleeve end cap, and a second end of the simulation borehole sleeve is sleeved inside a first end of an axial limiting sleeve and contacts the axial limiting sleeve; a protection ring is sleeved outside a contact part of the simulation borehole sleeve and the axial limiting sleeve; a test matrix is positioned in the simulation borehole sleeve and the axial limiting sleeve, and can be in circumferential seal with a sliding end cap of the packer; a first end of the test matrix can be in circumferential seal and fixedly connected with a fixed end cap of the packer, and a second end of the test matrix is connected with a second fixed head; and an expansion pressurizing pipe penetrates through an end face of the axial limiting sleeve and an end face of the second fixed head, and is communicated with a pipeline in the test matrix. The device and the system are used for performing simulation test on the charging pressure resistance and the setting sealability of the packer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

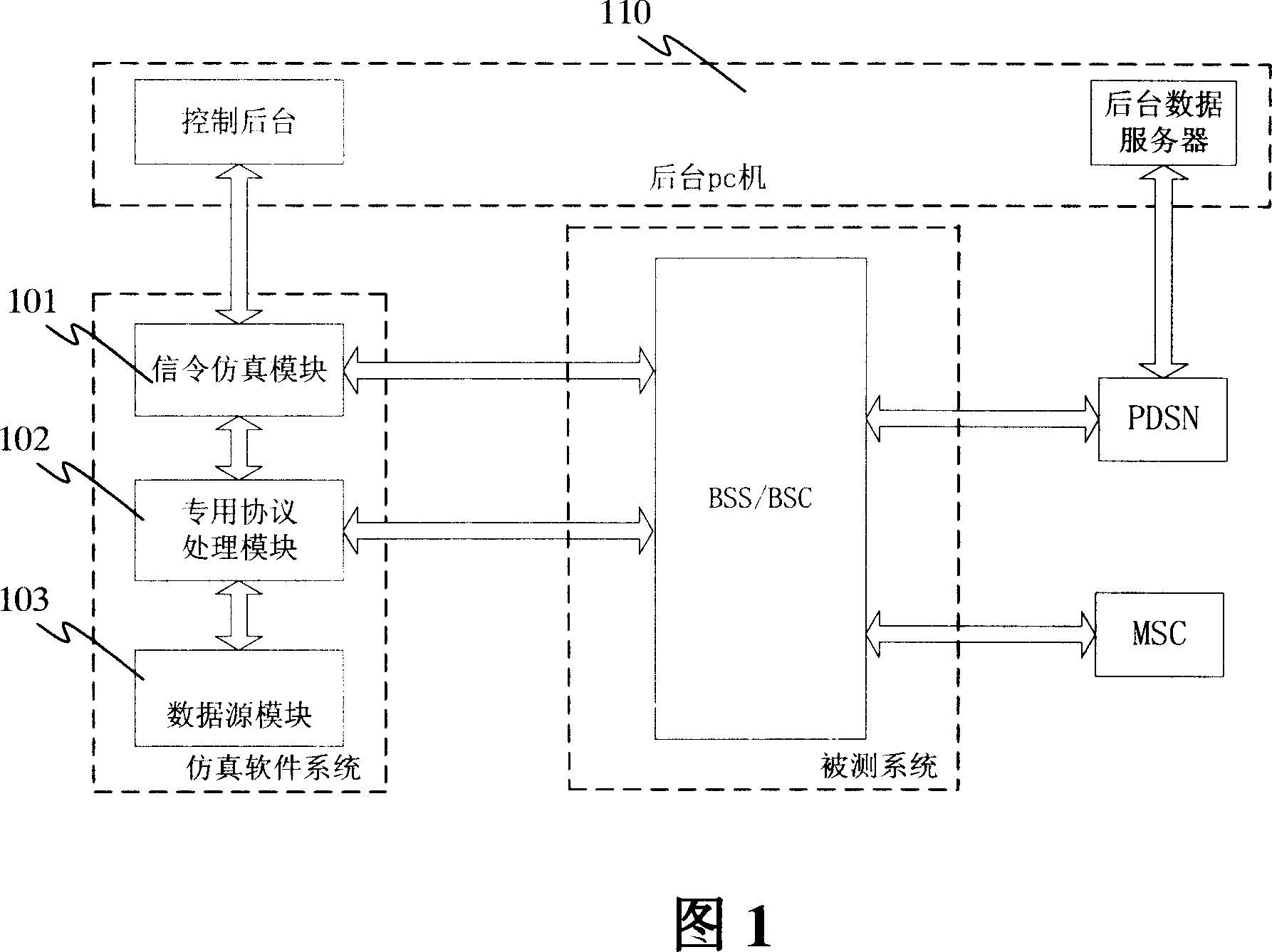

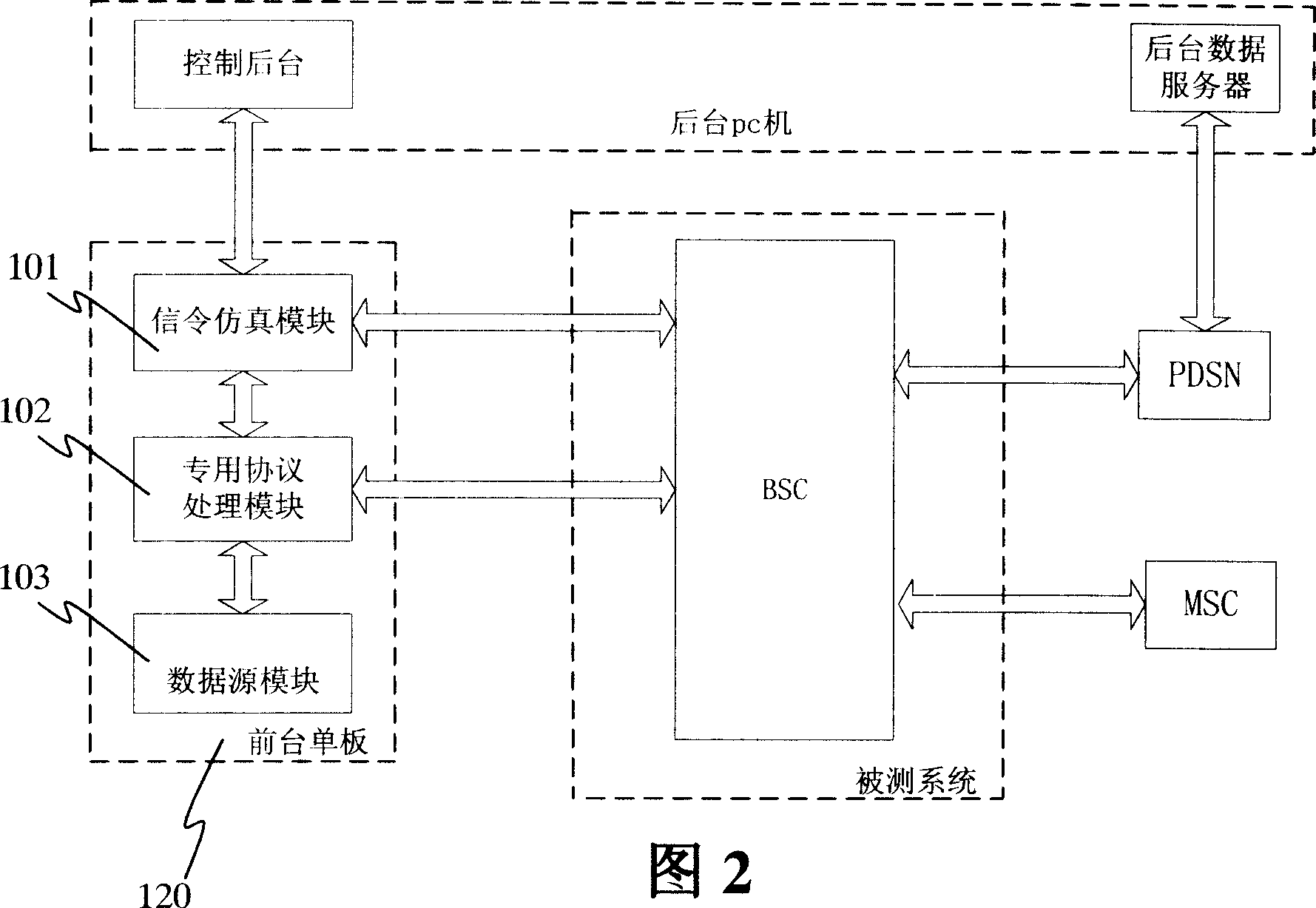

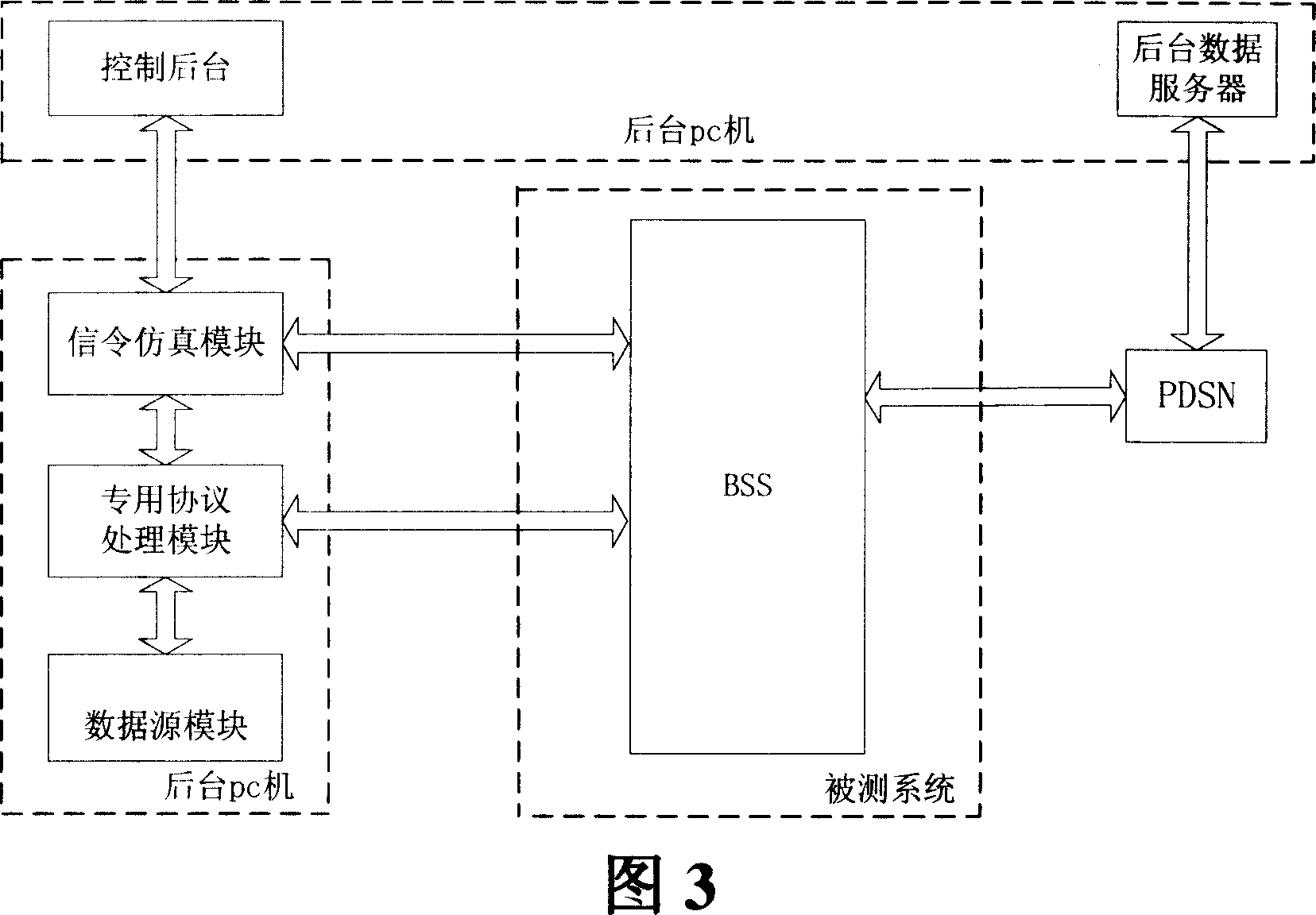

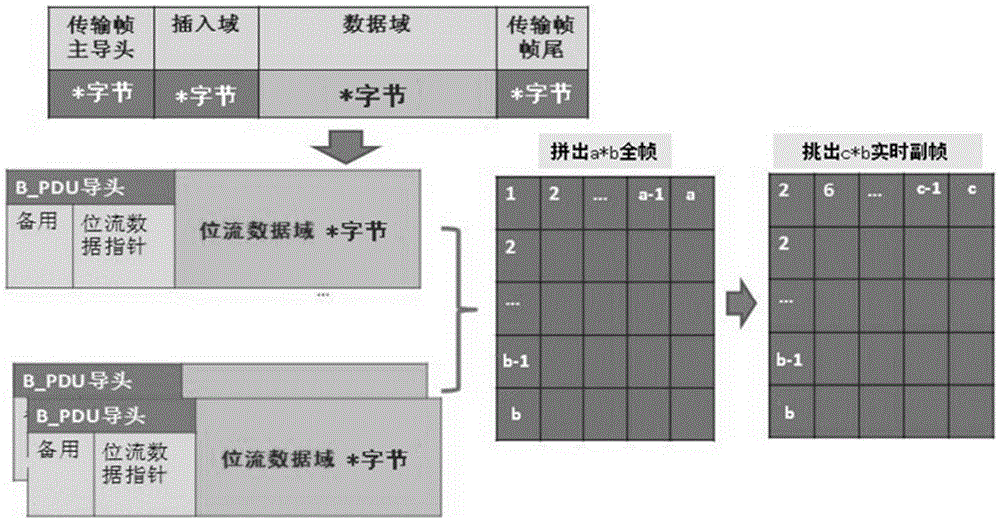

Method and device for large traffic simulation test of packet data service

InactiveCN101035346AVerify reliabilityVerify stabilitySupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsTraffic capacityStatistical analysis

The invention discloses a method and device for grouping data service bulk call simulation test. The characteristic is that, according the test configuration parameters of background control, it can establish ppp connect through grouping data service node and data resources modules which comprise general protocol stack and simulation terminal, bearing ICMP TCP datagram on ppp link. Using sending / response and flow made by data resources modules, the capability of managing grouping data service on base station system is validated through analyzing the related data. The present invention can be applied on different flat roof and system, and it can test fully the fundamental channel and add channel. At the same time, it can simulate grouping data service of base station system.

Owner:ZTE CORP

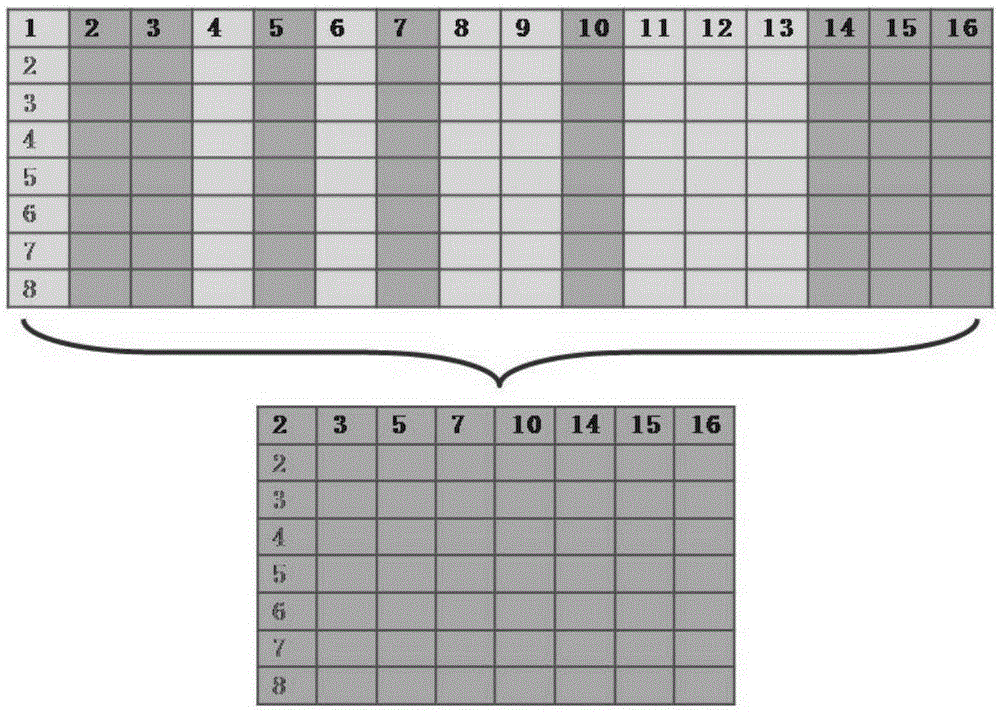

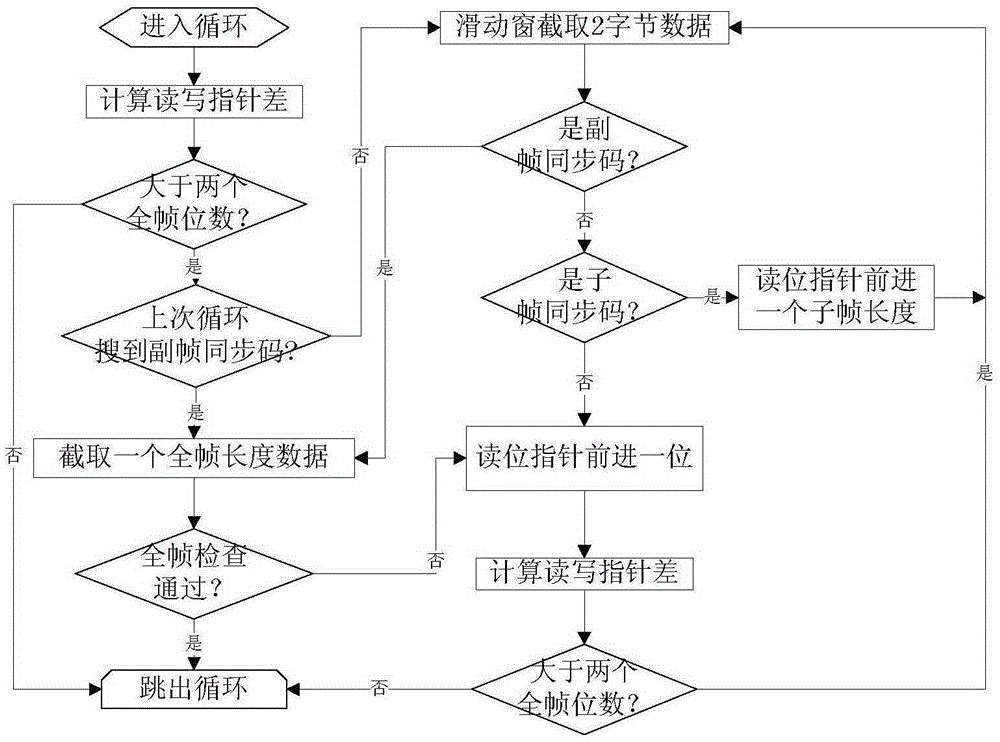

High thrust rocket high flow telemetry data processing method

InactiveCN105306526AReduce complexityEase Network Performance TestsData switching networksRocketComputer science

The invention discloses a high thrust rocket high flow telemetry data processing method, aiming to solve high flow telemetry data rapidly and accurately and having a good effect in practical use. The method comprises steps of building a telemetry data preprocessing model, and selecting and classifying the telemetry data in real time; and building a bus data real-time processing model, and solving the bus data of high flow in the telemetry data in real time. The effectiveness is also verified. The model established by the method is also applicable to processing telemetry data of the rocket in active duty, and is verified accurate and efficient in actual combats of the rocket in active duty and in joint training missions of the new generation high thrust carrier rocket.

Owner:中国人民解放军63796部队

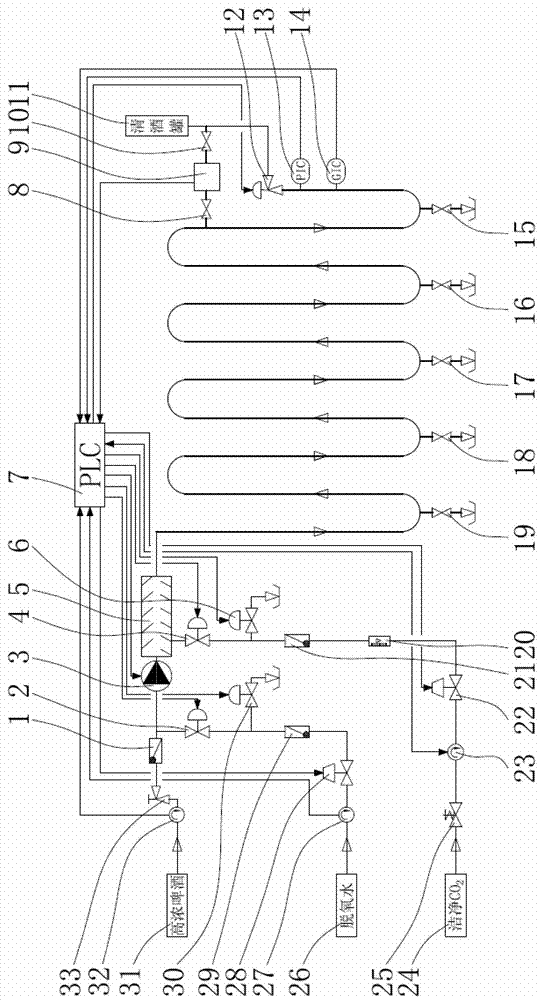

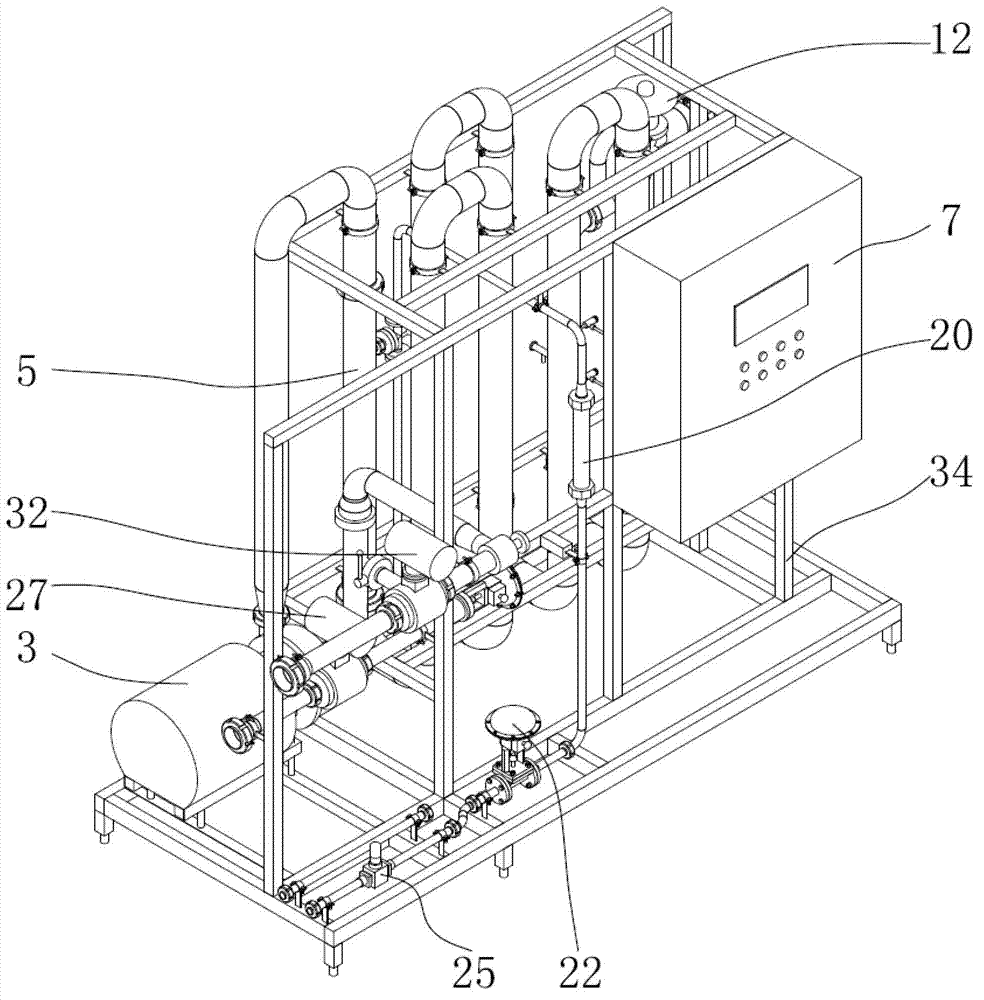

Full-automatic high-concentration beer dilution ratio mixing machine and mixing method thereof

InactiveCN102827717AReduce the impactAvoiding problems with feedback regulation hysteresisBeer brewingHysteresisHigh concentration

The invention discloses a full-automatic high-concentration beer dilution ratio mixing machine and a mixing method thereof, relating to the technical field of multi-material mixing processes such as biology and wine fermentation engineering, food beverage engineering, bio-pharmaceuticals, fine chemistry industry and chemical engineering. The full-automatic high-concentration beer dilution ratio mixing machine comprises a frame, a PLC (Programmable Logic Controller) control cabinet, a static mixer and a diluting pump, wherein the PLC control cabinet is arranged on the outer side of the frame; the static mixer is arranged above the frame; the diluting pump is arranged at the lower end of the static mixer; and the full-automatic high-concentration beer dilution ratio mixing machine is externally connected with high-concentration beer, deoxygenated water, clean CO2 and a finished beer tank. The mixing method comprises the following steps of: mixing high-concentration beer with deoxygenated water in the diluting pump; and mixing with clean CO2 in the static mixer, and feeding into the finished wine tank. The method is practicable; a mass flow meter is applied, so that a reliable precondition is provided for accurate adding of CO2 into diluted beer; a mathematical model is established, so that reliable basis is provided for accurate adding of deoxygenated water and CO2 into high-concentration beer; an open-ring control principle is applied, so that the phenomenon of incorrect mixture ratio caused by hysteresis of feedback adjustment and detection data distortion in closed-ring control is avoided; and automation control in an entire process is realized, so that the labor strength is greatly lowered, the possibility of human errors is lowered, and the product quality and uniformity are improved.

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

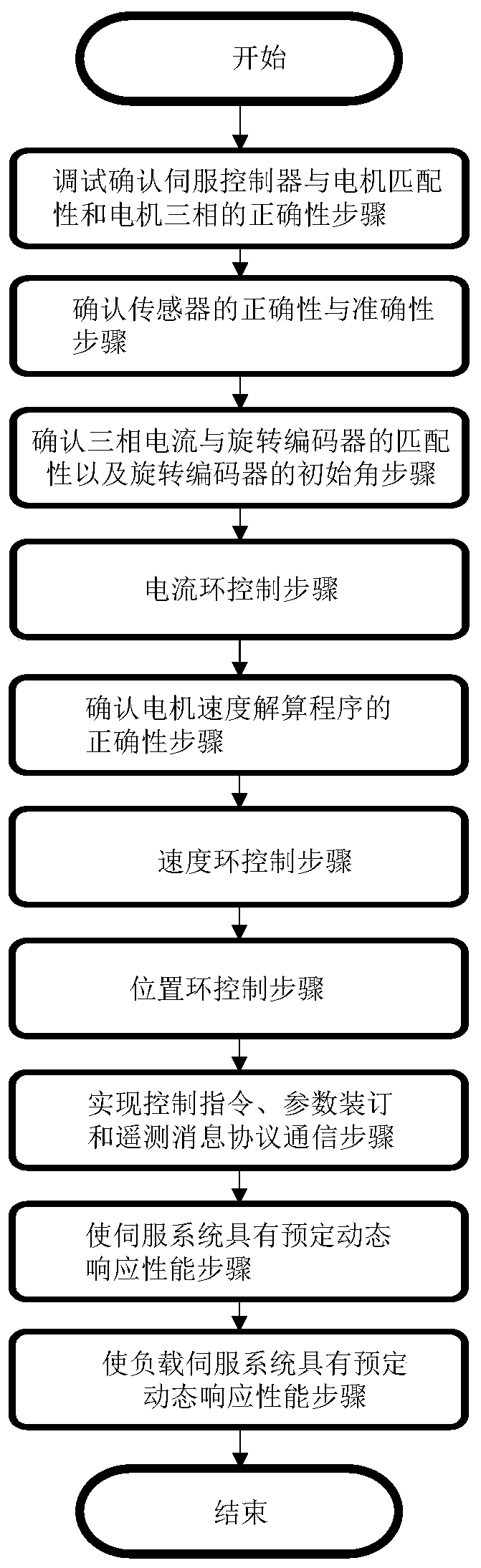

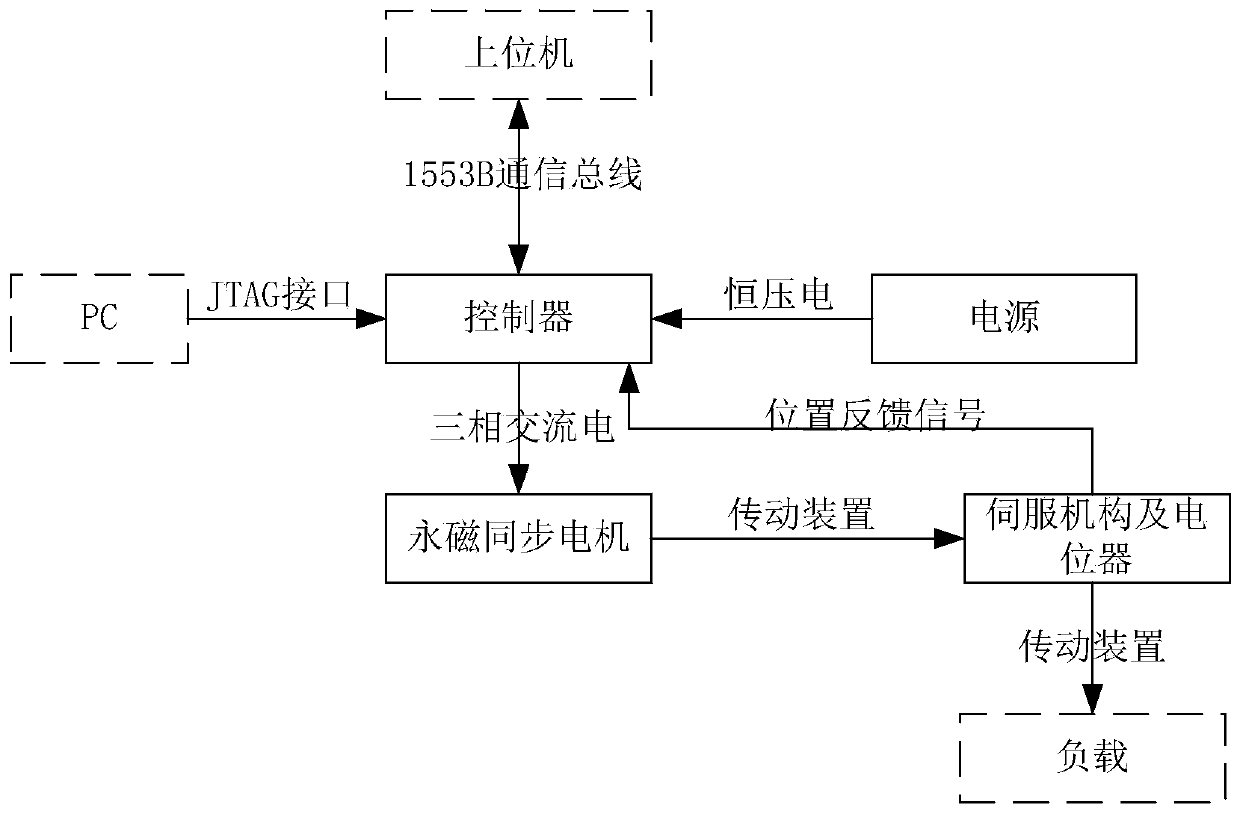

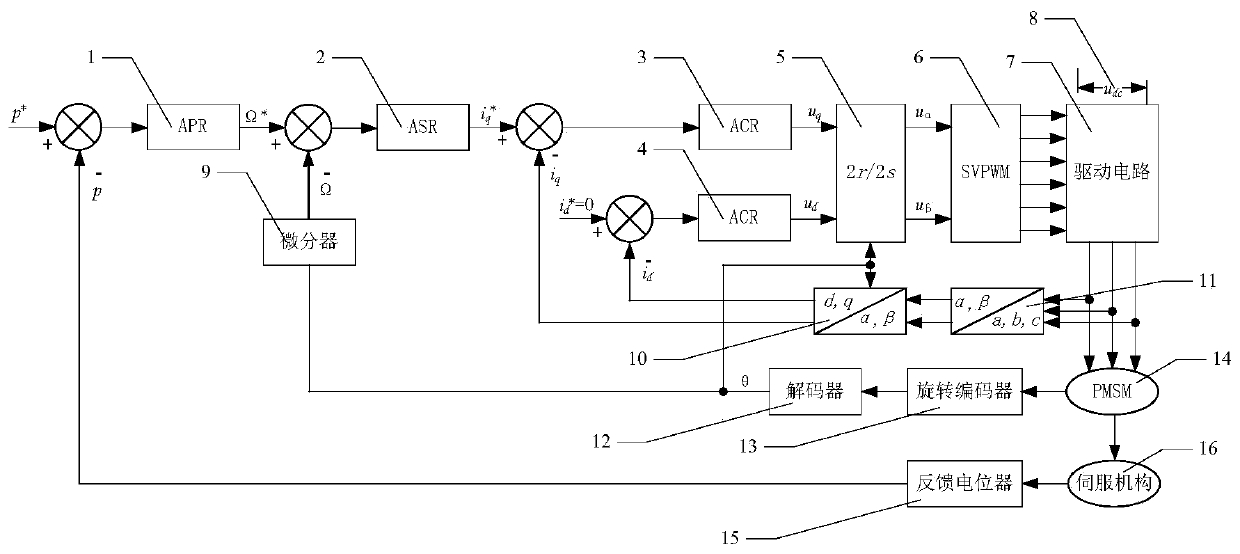

Dynamic performance debugging method and system suitable for servo system

ActiveCN110568836AVerify correctnessVerify matchProgramme controlElectric testing/monitoringMotor speedThree-phase

The invention provides a dynamic performance debugging method and system suitable for a servo system. The method comprises a step of debugging and confirming the property of matching between a servo controller and a motor and the correctness of three phases of the motor, a step of confirming the correctness and accuracy of a sensor, a step of confirming the property of matching between a three-phase current and a rotary encoder and an initial angle of the rotary encoder, a step of controlling a current loop, a step of confirming the correctness of a motor speed solver, a step of controlling aspeed loop, a step of controlling a position loop, a step of realizing control instruction, parameter binding and telemetry message protocol communication, a step of enabling the servo system to havethe predetermined dynamic response performance, and a step of enabling the load servo system to have the predetermined dynamic response performance. Debugging under a load condition can be carried outin a realest environment, so that a simulation link is reduced; a high-power electromagnetic environment can be included; various parameters of the system are most accurate; and at the moment, the optimal dynamic performance of the servo system can be obtained.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

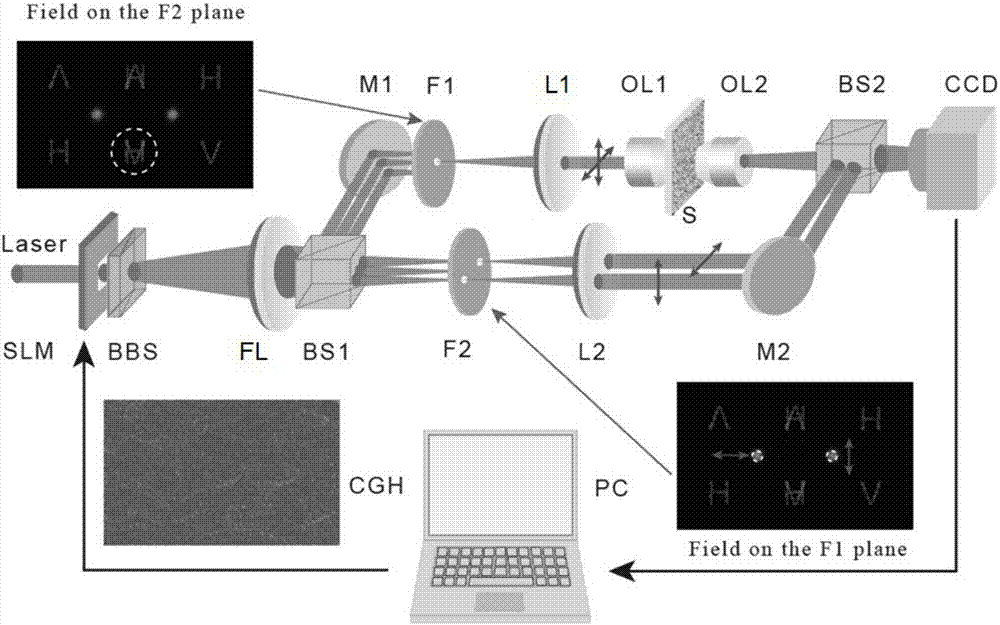

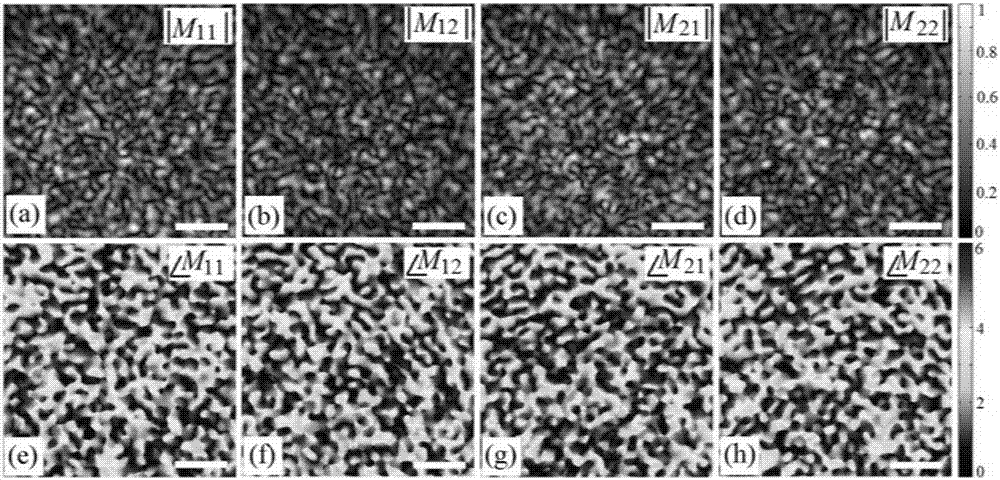

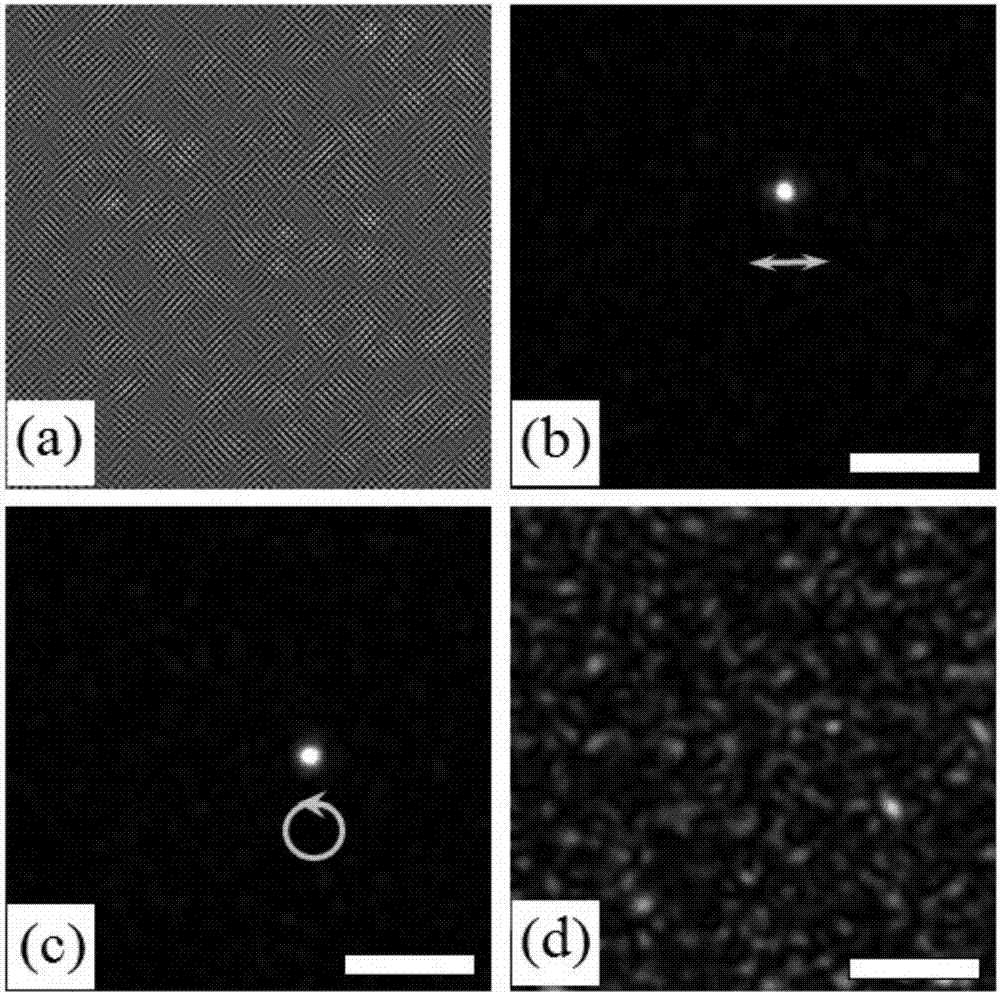

Measurement device and method of vector transmission matrix of scattering medium

ActiveCN107014784ARealize point-by-point controlGuaranteed accuracyTransmissivity measurementsMeasurement devicePrism

The invention discloses a measurement device of a vector transmission matrix of a scattering medium. The measurement device comprises a vector space light modulation unit, a fourier lens, Mach-Zehnder interference system, an image sensor and computing equipment, wherein the vector space light modulation unit comprises a transmission space light modulator and a small-angle birefringence polarization light splitter; light transmitting through the vector space light modulation unit and the fourier lens is divided into two beams of by a first light splitter prism to enter the Mach-Zehnder interference system and further reaches a recording surface of the image sensor; the beams reaching the recording surface generate interference to form a dual-channel angular multiplexing polarization hologram; and the computing equipment obtains complex amplitude and polarization information of a scattering light field of a sample to be measured and furthers calculates the vector transmission matrix by using the dual-channel angular multiplexing polarization hologram. The vector transmission matrix can be measured quickly and accurately based on the device.

Owner:SHANDONG NORMAL UNIV

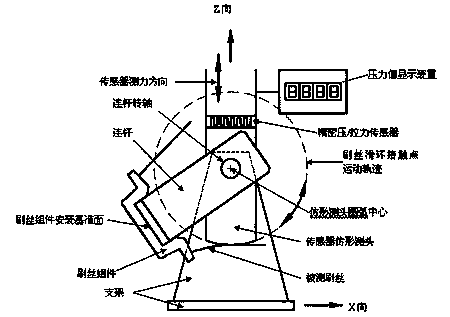

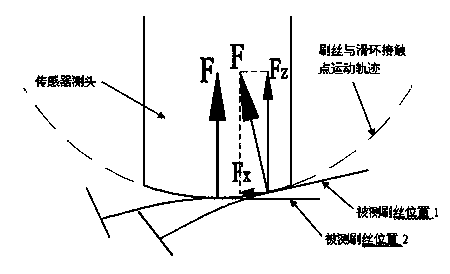

Method for detecting contact pressure between conductive slip ring and conductive brush wire

InactiveCN103674377AAccurate detection of contact pressureVerify stabilityApparatus for force/torque/work measurementContact pressureEngineering

The invention provides a method for accurately detecting the contact pressure between a conductive slip ring and a conductive brush wire. The method comprises the following steps: a cross-shaped sliding table is adjusted; a brush wire component to be detected is mounted on a measuring device, and the cross-shaped sliding table is adjusted in the Y direction to enable the brush wire to be detected to be in correct contact with a circular arc of a measuring head according to the working conditions of a product; a connecting rod of the measuring device is slowly swung to enable the brush wire to be in sliding contact with the circular arc of the measuring head, a measuring head system measures and displays the component force, in the force-measuring direction of a sensor, of the contact pressure between the brush wire and the measuring head in real time, the normal direction of a common tangent at the contact point of the brush wire and the circular arc of the measuring head is consistent with the force-measuring direction of the sensor in the swinging measurement process, and the displayed pressure is the contact pressure between the brush wire and the slip ring. The method can accurately detect the practical contact pressure comprehensively formed by factors including the shape error and mounting position error of the brush wire, the elastic coefficient of a brush wire-slip ring contact pair and the like, so that a scientific method is provided for control and adjustment of the contact pressure between the brush wire and the slip ring, the design requirement for reliability of the contact pressure between the slip ring and the brush wire is effectively guranteed.

Owner:SHANGHAI SPACEFLIGHT INST OF TT&C & TELECOMM

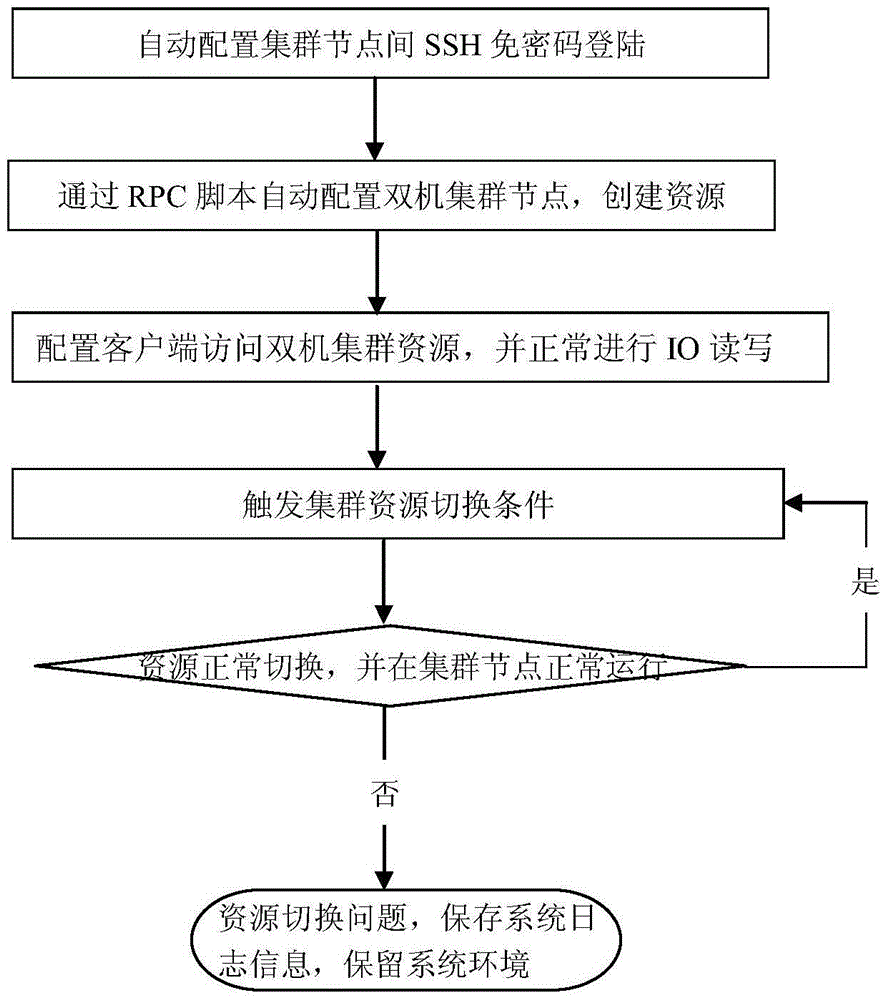

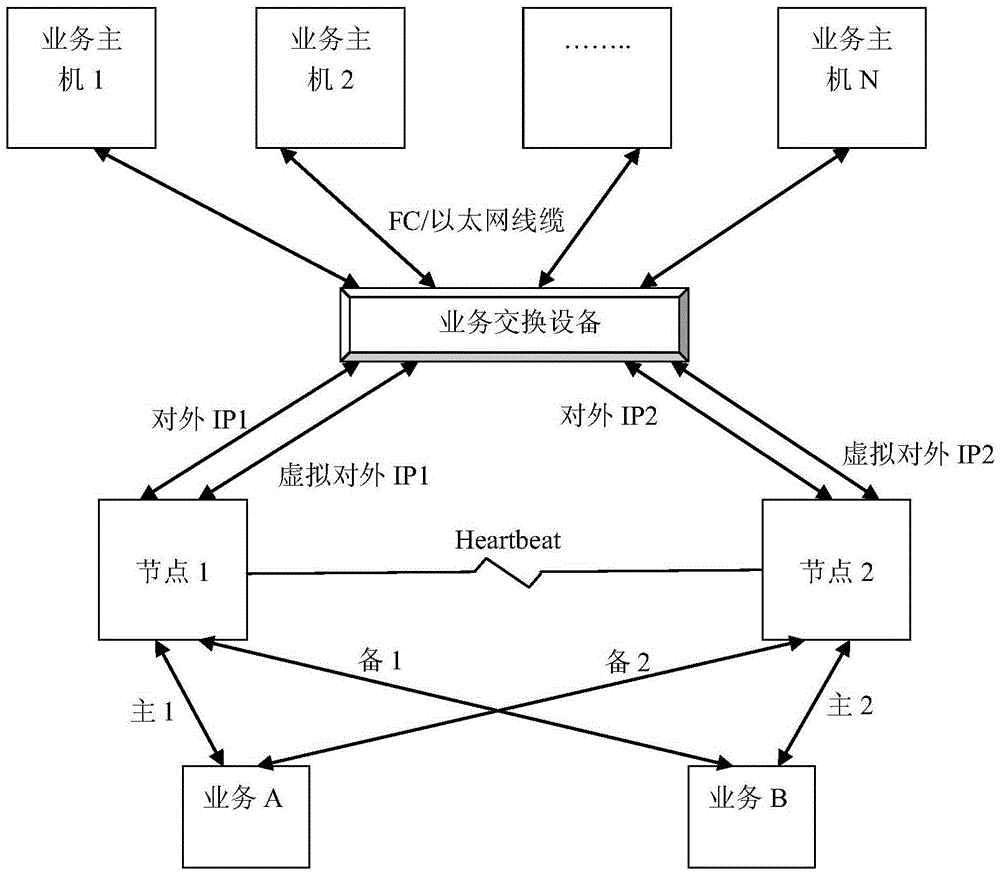

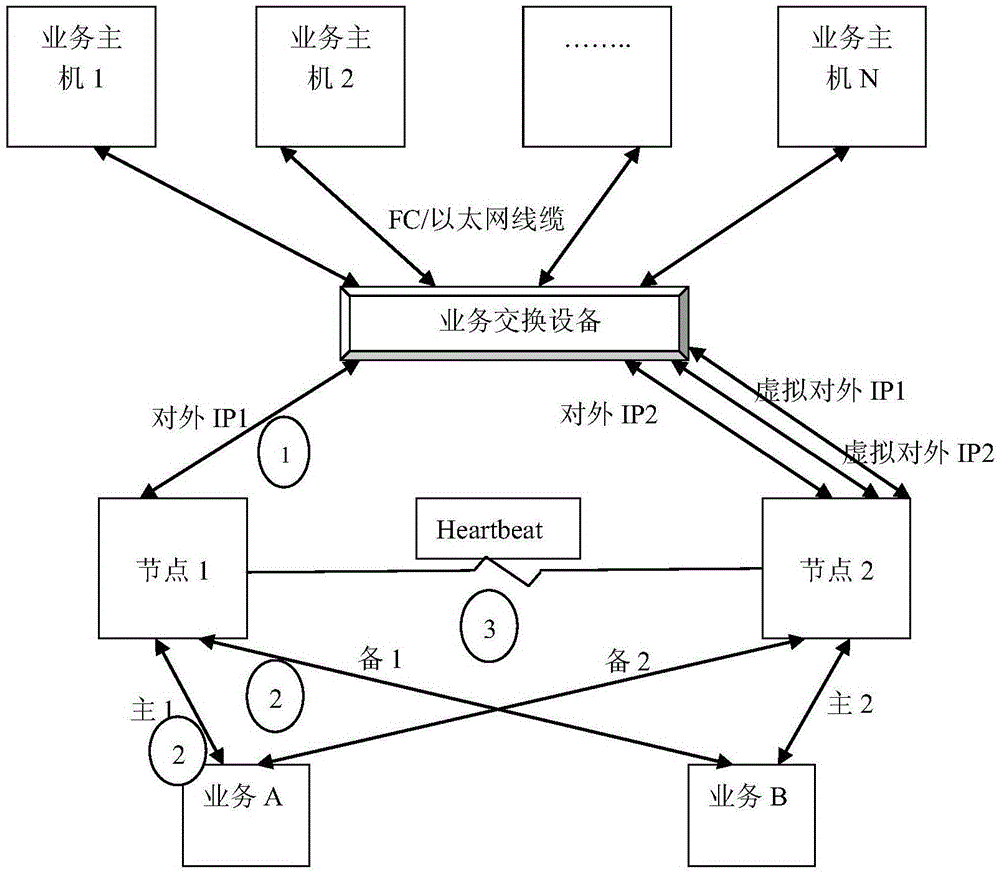

Automated testing method for switching of configuration two-computer resources

InactiveCN105553783AShorten the test cycleVerify stabilityConcurrent instruction executionData switching networksComputer resourcesAuto-configuration

The invention relates to an automated testing method for switching of configuration two-computer resources, which is suitable for a dual-computer cluster of any business and belongs to the field of computer storage technologies. An implementation process of the method comprises the following steps of automatically configuring pass-free login of an SSH (Secure Shell) between cluster nodes; automatically configuring dual-computer cluster nodes and creating dual-computer cluster resources; configuring a client to access the dual-computer cluster resources and normally carrying out IO read-write; traversing conditions for triggering switching of the dual-computer cluster resources; and testing switching of the resources due to any one fault for more than thousands of times. If the client IO has no interruption and the status of the resources on the current node can be queried, the test is carried out again, otherwise the test is stopped, the system log information is stored and the system environment is retained. Through the method, the switching test of the two-computer resources can be effectively and accurately executed, and when a problem occurs, the reliable information can be provided for analyzing the problem.

Owner:TOYOU FEIJI ELECTRONICS

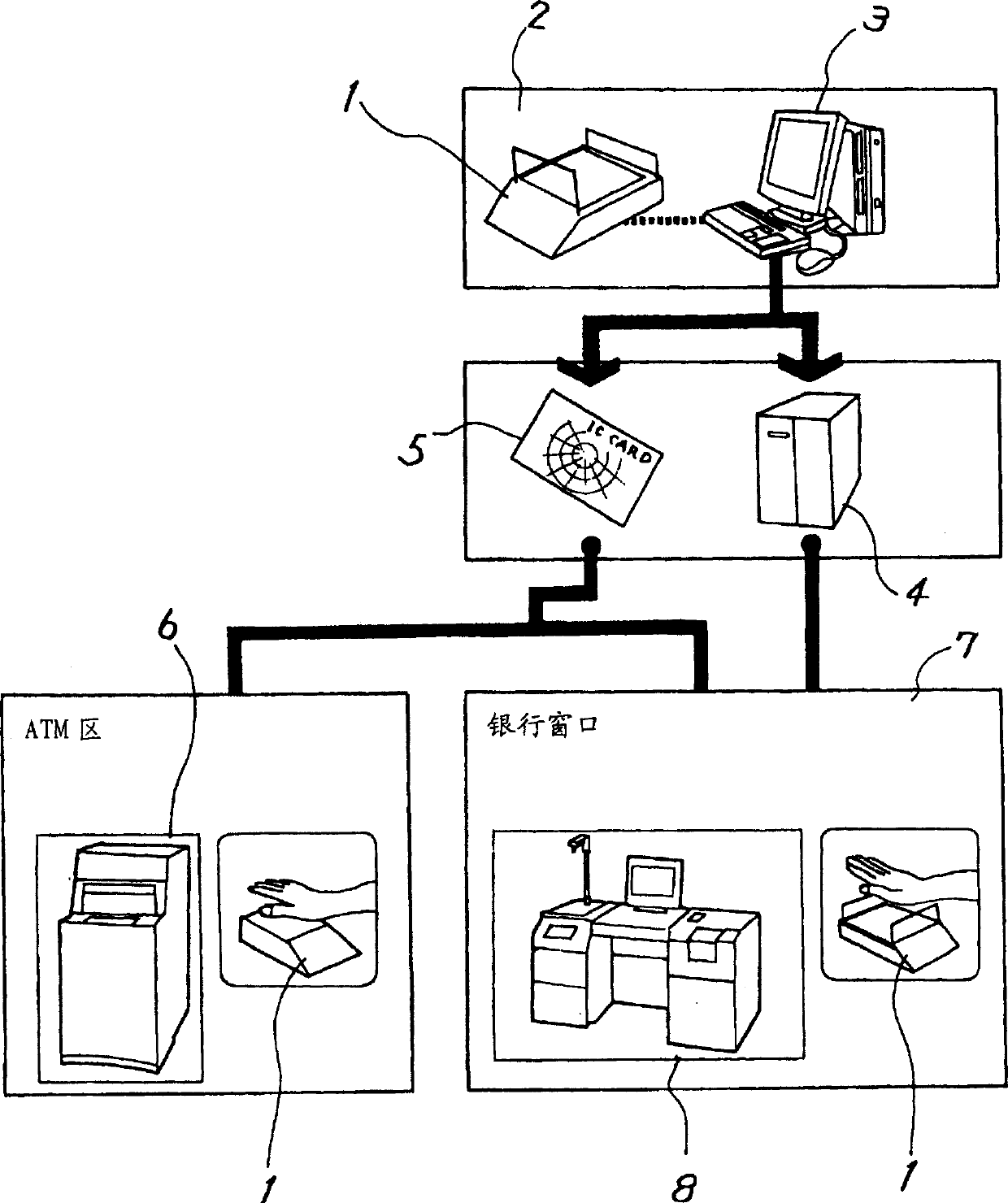

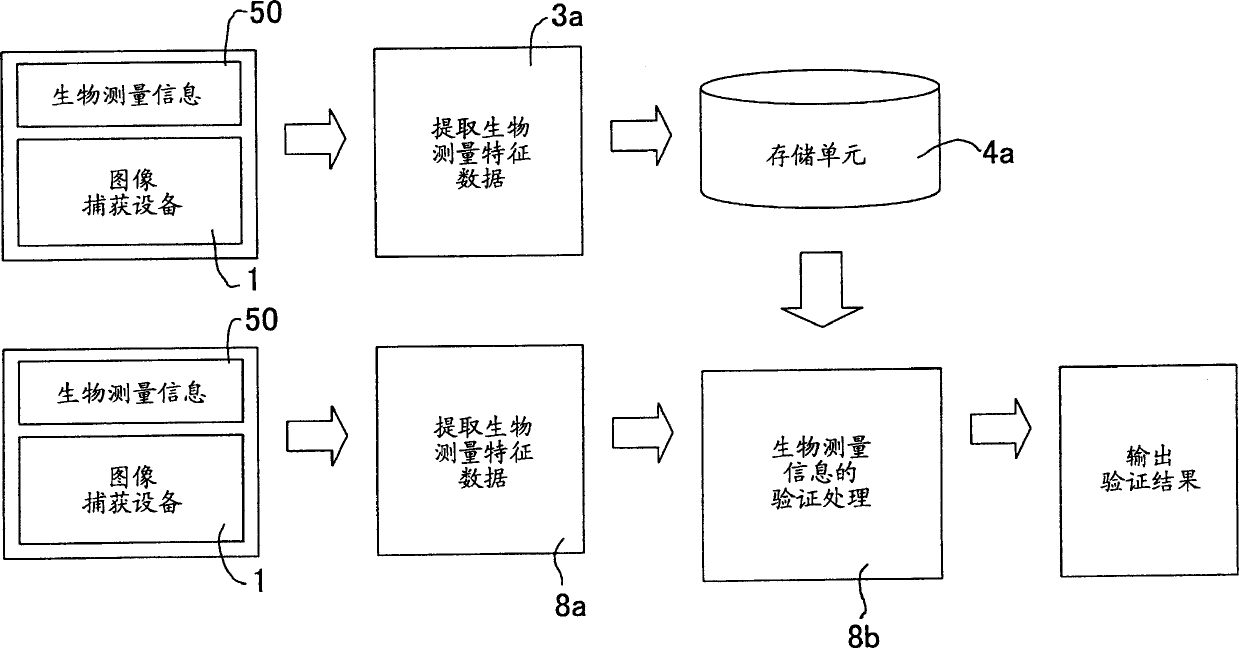

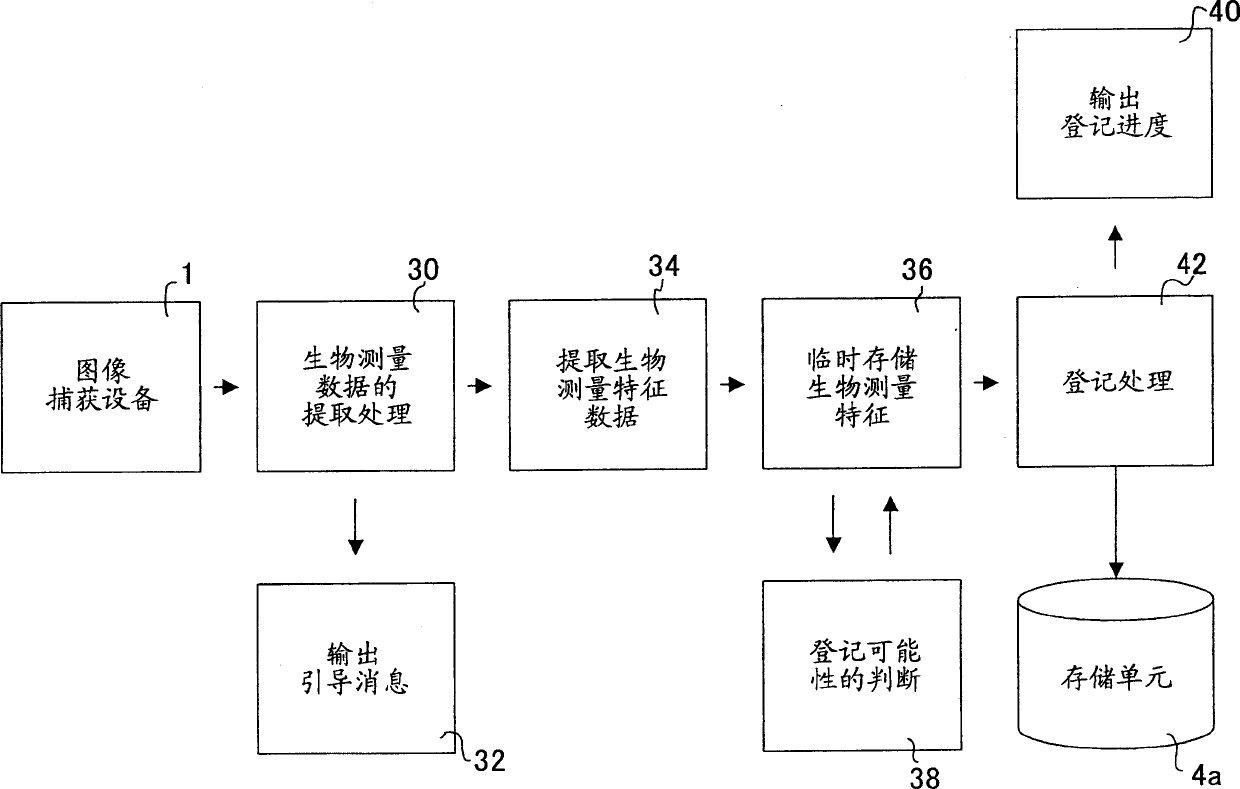

Registration method for biometrics authentication system, biometrics authentication system, and program for same

InactiveCN1716278APrevent other problemsVerify stabilityOperating means/releasing devices for valvesSubcutaneous biometric featuresAuthentication systemLiving body

The present invention provides a registering method of a biological measure certification system, the biological measure certification system and a procedure thereof. The biological measure certification system certificates an individual by biological measure information. A processing unit obtains the biological measure information of one living body for a plurality of times by a detection unit to judge mutual similarity among biological measure characteristic data groups picked up from the biological measure information obtained for a plurality of times and register a plurality of biological measure characteristic data groups with high similarity in a memorizing unit. Therefore, the present invention can implement validation fit for the change of the living body state.

Owner:FUJITSU LTD +1

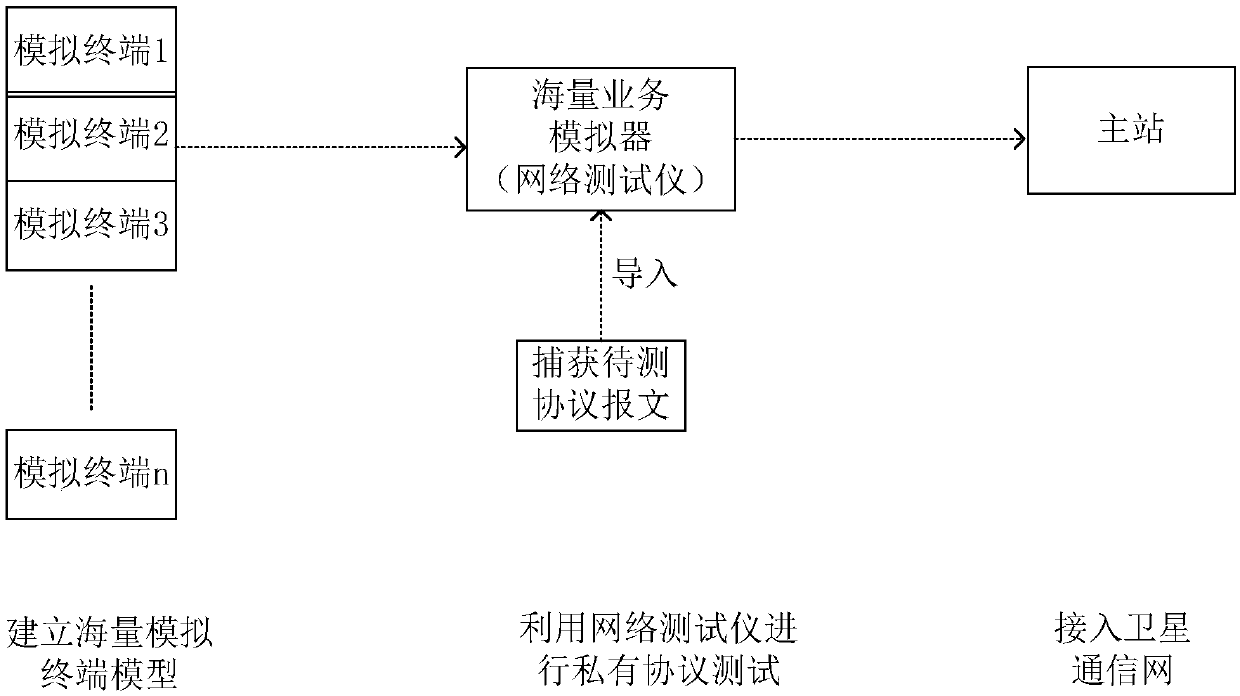

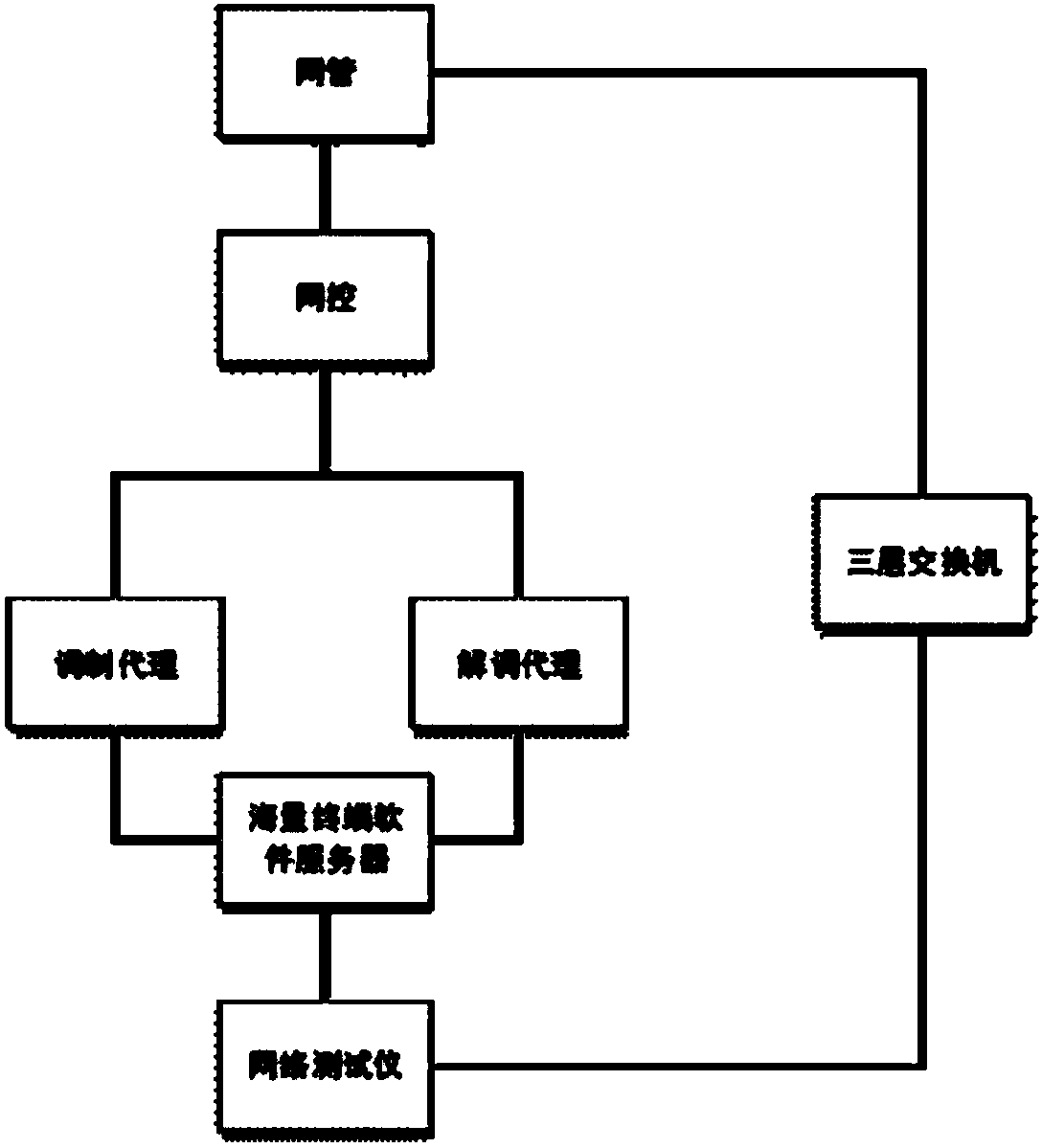

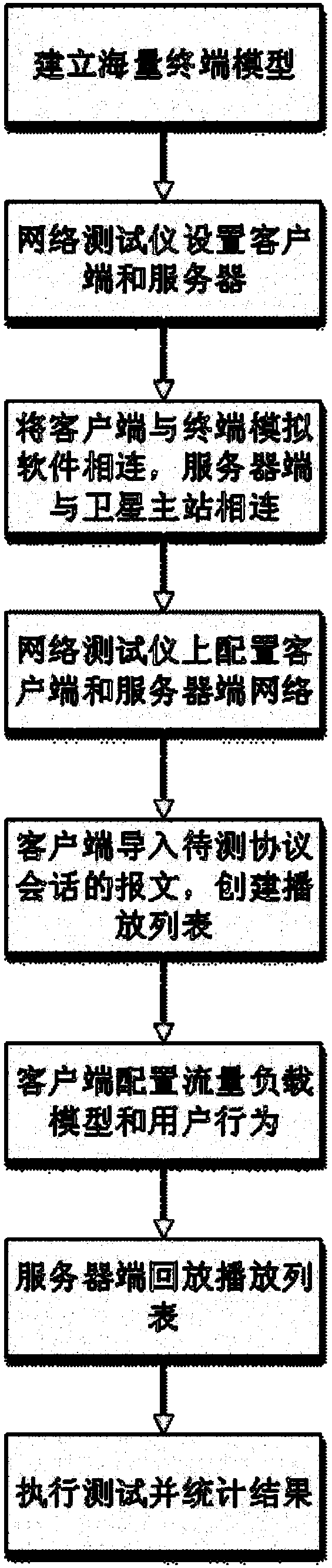

Massive terminals-based satellite communication network private protocol test method

ActiveCN107819649AReduce hardware costsImprove system test coverageRadio transmissionData switching networksSatelliteServer-side

The invention provides a massive terminals-based satellite communication network private protocol test method that is applied to test whether the satellite communication network supports massive terminals to access a certain TCP / UDP-based private protocol. The method comprises the steps of developing massive terminal simulation software and establishing a tens of thousands of magnitude simulationterminal model; setting a client and a server on a network tester, wherein the client and the server are respectively connected with massive terminal simulation software and a satellite main station;configuring networks of the client and the server on the network tester; importing, by the client, a captured session packet of a to-be-tested protocol, creating a playback list, and configuring a load model and user behaviors; playing, by the server, a flow file in the playback list imported by the client and executing a test; and collecting statistic information of test results by the network tester, and forming a test report. The method has the beneficial effects of developing simulation model software, exploiting characteristics of existing test tools, and jointly using the tools for testing.

Owner:BEIJING SATELLITE INFORMATION ENG RES INST

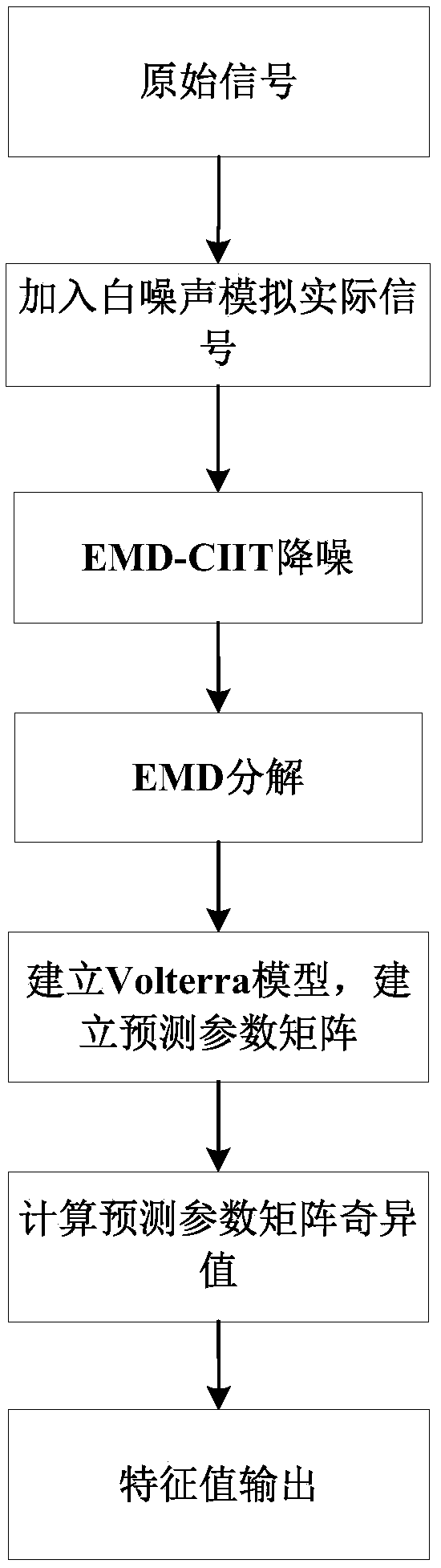

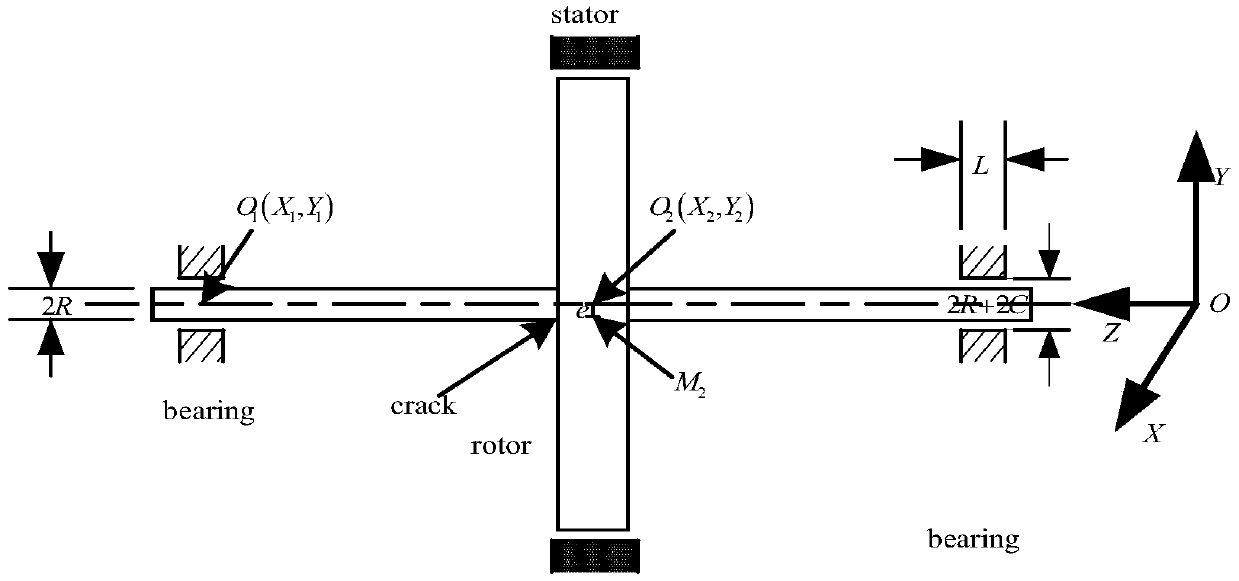

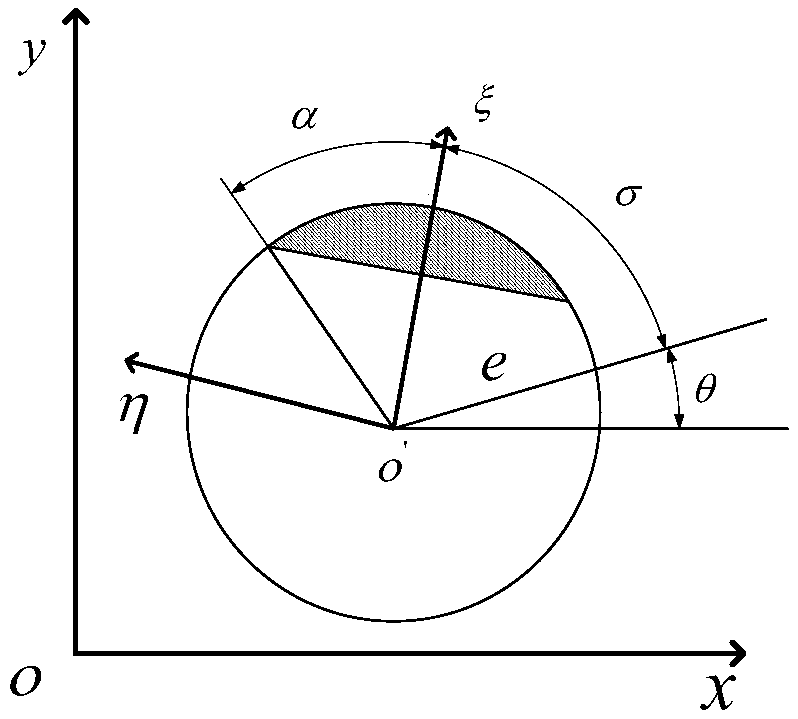

Transverse crack fault characteristic quantity extraction method of rotor-bearing system

The present invention discloses a transverse crack fault characteristic quantity extraction method of a rotor-bearing system. The method comprises the steps of: establishing a crack rotor-bearing system dynamics model to obtain a system dynamics equation and calculate system response signals in different crack angles; adding white noise simulation actual signals for system response in different crack angle, and performing EMD-CIIT noise reduction processing of the signals adding the white noise to obtain denoised signals; performing EMD decomposition of the denoised signals to extract IMF components; constructing a Volterra series model for each IMF component, and taking the Volterra model parameter of each IMF component as the horizontal vector of the matrix to construct a prediction parameter matrix; and taking the singular value of the obtained matrix as a system fault characteristic quantity. The transverse crack fault characteristic quantity extraction method can analyze the influence of different crack angles on the system response at the bearing position in different non-linear oil-film force.

Owner:XIAN UNIV OF TECH

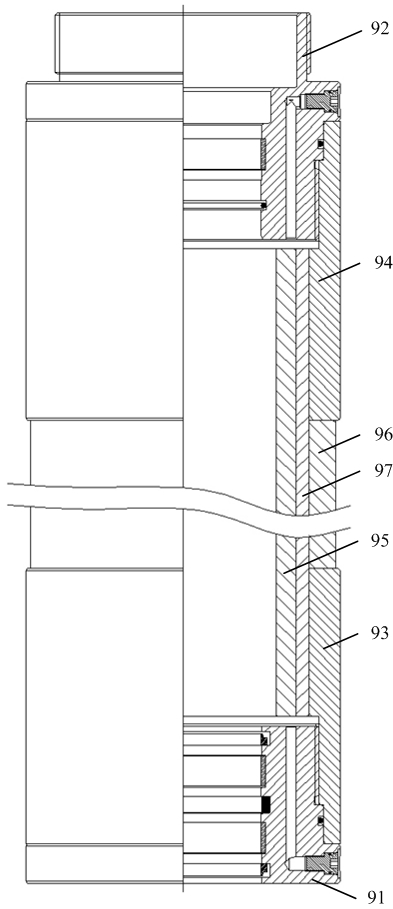

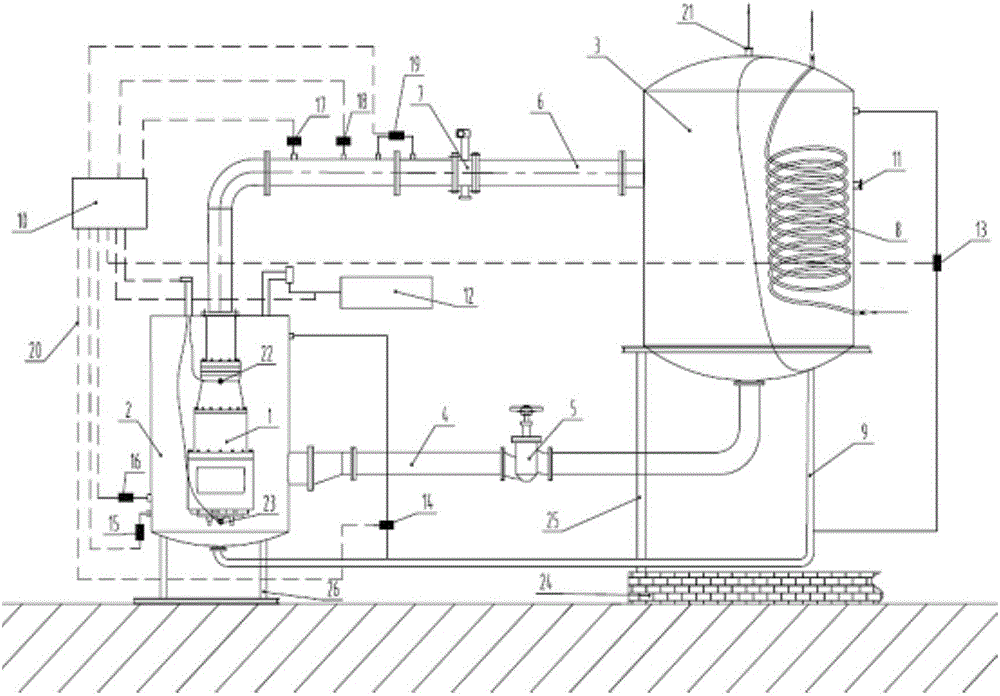

Ultralow-temperature test device suitable for LNG immersed pump

ActiveCN105864018AEasy to judgeVerify stabilityPump testingPositive-displacement liquid enginesAxial displacementWork performance

The invention discloses an ultralow-temperature test device suitable for an LNG immersed pump. The ultralow-temperature test device comprises a test storage tank, a circulation storage tank, a suction pipe and a discharge pipe. An inlet of the discharge pipe is inserted in an outlet of the test storage tank in a sealed mode. An inlet of the test storage tank is connected with an outlet of the suction pipe. An inlet of the suction pipe is connected with an outlet of the circulation storage tank. An inlet of the circulation storage tank is connected with an outlet of the discharge pipe. The test storage tank is internally provided with a vibration sensor and an axial displacement sensor. A pump suction port thermometer, a pump suction port pressure meter and an electrical connection sealing piece are arranged on the test storage tank. The discharge pipe is provided with a pump outlet thermometer, a pump outlet pressure meter and a pump outlet flowmeter. A cooling mechanism for cooling test media is arranged in the circulation storage tank. According to the ultralow-temperature test device suitable for the LNG immersed pump, the working condition of the LNG immersed pump during practical application is simulated to conduct performance testing, the performance presentation of the LNG immersed pump in the practical operation process can be evaluated maximally, and the working performance, the safety performance and the stability of the LNG immersed pump are verified.

Owner:WUHAN MARINE MACHINERY PLANT

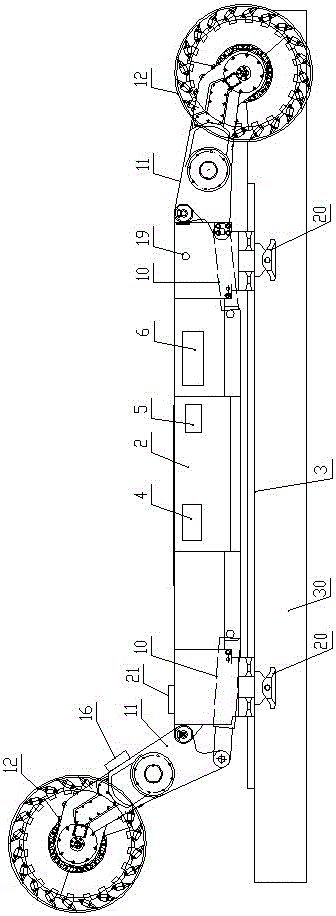

Experimental facility for research on coal mining machine intelligent control strategy based on multi-information fusion

InactiveCN105781544AReal-time controlEasy to controlMeasurement devicesCutting machinesEngineeringTest platform

The invention discloses an experimental facility for research on coal mining machine intelligent control strategy based on multi-information fusion. The experimental facility comprises a computer, a frequency converter, a coal mining machine model and a field controller. The coal mining machine model comprises a body arranged from left to right horizontally, a test platform, a drag chain, a guide rail and two guide shoes. The two guide shoes are fixed to the front bottom of the body; the guide rail and the drag chain are fixed to the test platform in a front-to-back correspondence manner; and the front side of the body is in slide connection with the guide rail through the guide shoes. The experimental facility can simulate actual work states of a coal mining machine in a laboratory and prove stability and reliability of a multi-information fusion method under interference of various information inputs. As compared with actual field working conditions, the experimental facility which is applied in the laboratory is convenient and rapid, needs low cost for experiment, and has a certain guiding significance in intelligent research and development of coal mining machines in our country.

Owner:HENAN POLYTECHNIC UNIV

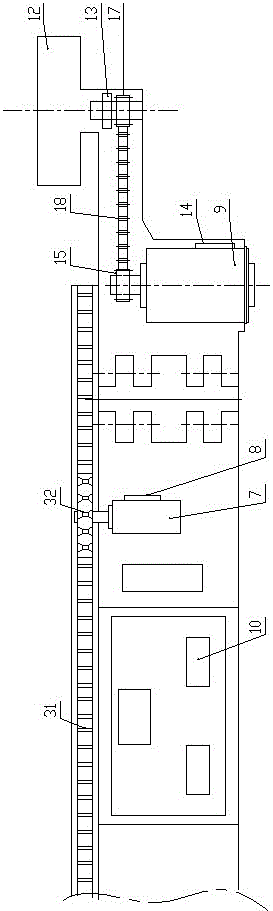

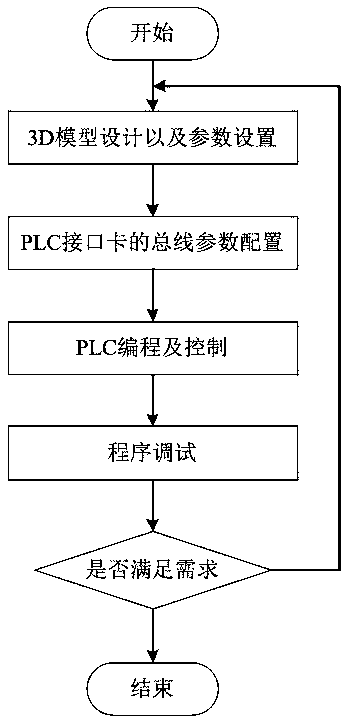

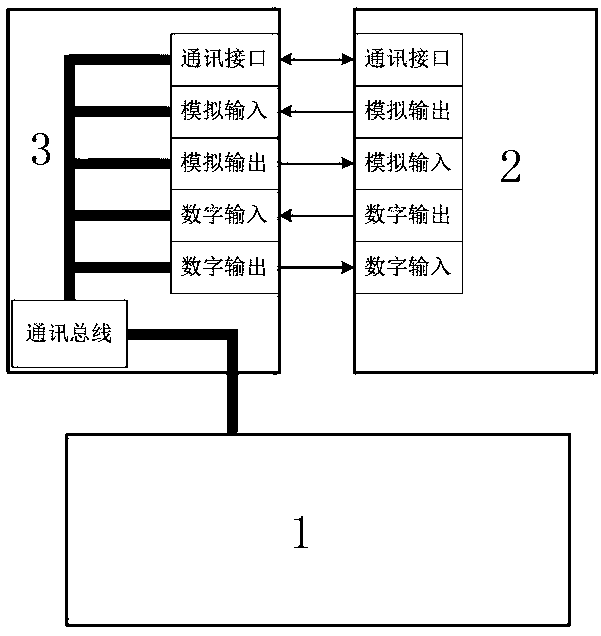

PLC-control-based virtual simulation experiment method and system for fireworks sorting assembly line

InactiveCN108762188AMeet the needs of practical engineering trainingVerify reliabilityProgramme control in sequence/logic controllersAnimationControl system

The invention discloses a PLC-control-based virtual simulation experiment method and system for fireworks sorting assembly line. The virtual simulation experiment method comprises: step A, establishing a virtual simulation environment for a fireworks sorting assembly line; to be specific, carrying out modeling on a working unit of the fireworks sorting assembly line and carrying out animation simulation on all procedures involved in the working process of the fireworks sorting assembly line; step B, establishing a PLC control system; step C, establishing communication between eh virtual simulation environment of the fireworks sorting assembly line and the PLC control system; and step D, carrying out debugging. According to the invention, the risk of dangerous explosion of the actual fireworks sorting assembly line is eliminated and the needs of actual PLC engineering training by students can be satisfied; the optimal control strategy and plan of the fireworks sorting assembly line canbe determined quickly during the fireworks sorting assembly line modification process; the dependence on the OPC service program of the manufacturer is eliminated; the PLC device from any manufacturercan be selected; and a phenomenon of carrying out designing and debugging again because of changing of a PLC mode or a manufacture factory is avoided.

Owner:湖南商学院

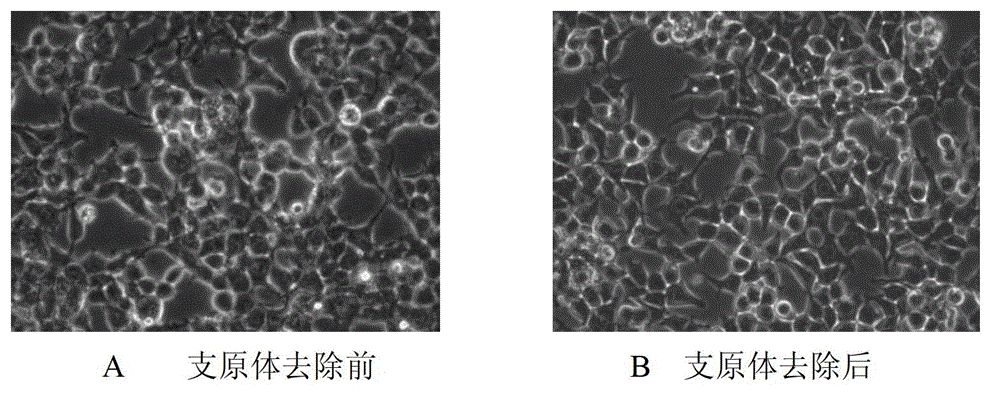

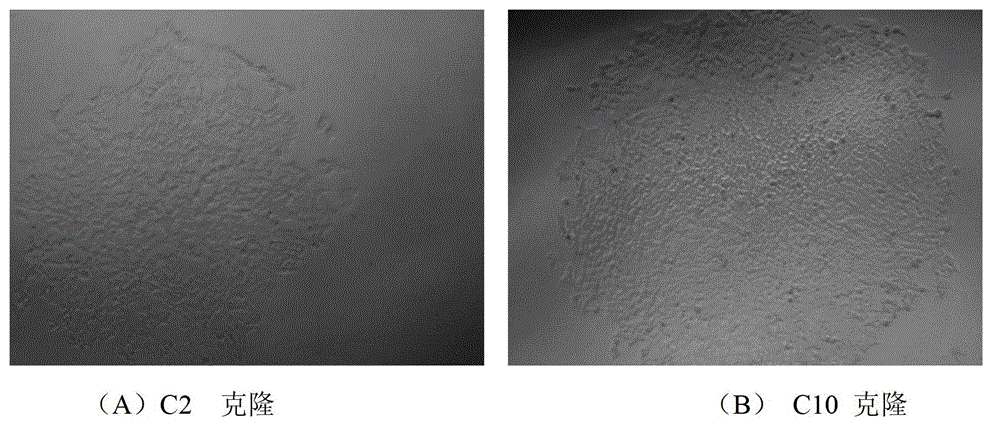

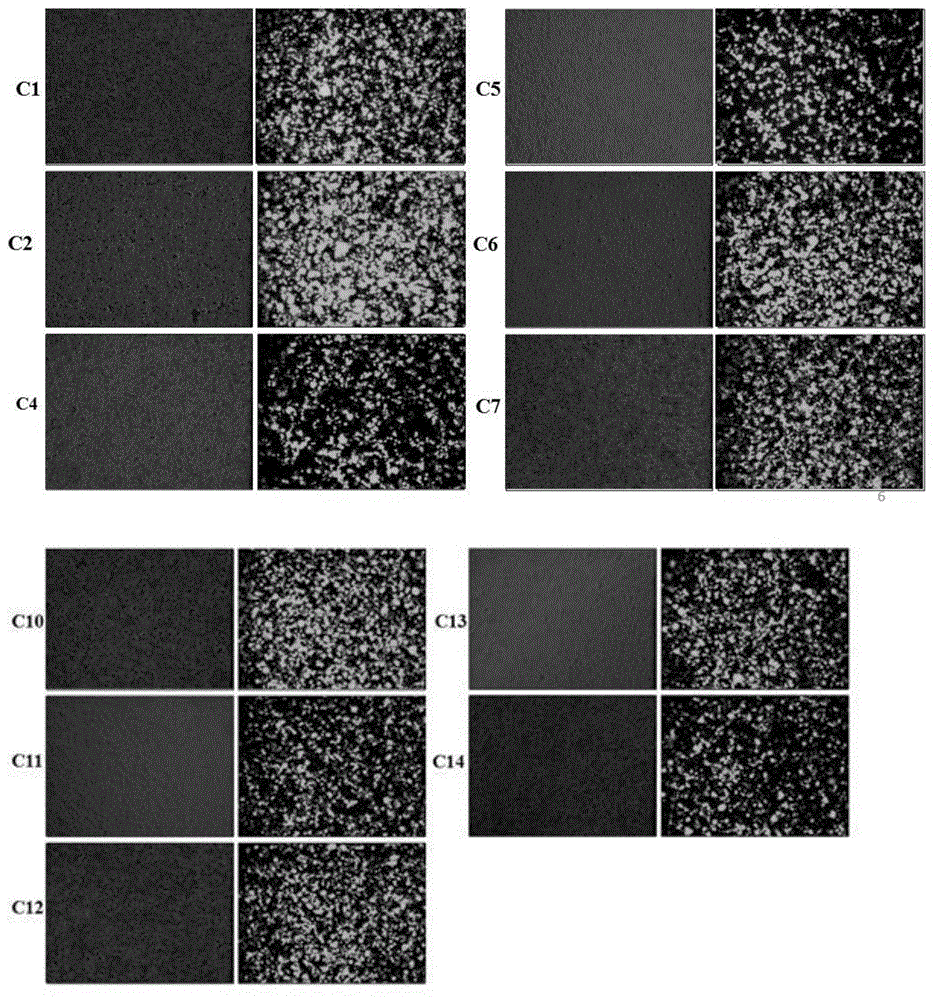

Monoclonal cell strain of human embryo kidney cell 293T-C10 as well as preparation and application of monoclonal cell strain

InactiveCN102911911ALow toxicityToxic titer is stableMicroorganism based processesViruses/bacteriophagesScreening methodEmbryo

The invention relates to the field of biotechnology, in particular to a monoclonal cell strain of a human embryo kidney cell 293T-C10 for packaging viruses as well as a screening method of the monoclonal cell strain. 293T cell mycoplasmas are removed, monoclonal screening is carried out during logarithmic growth period to obtain uniform monoclonal cells, different transfection and virus removal efficiencies are compared, and screening is carried out to obtain the monoclonal cell strain. Such cell strain has a collection number of CCTCC C201281, is very high in transfection efficiency and virus packaging stability, is remarkably improved in virus removal efficiency of 293T cells than that before screening, and can infect a majority of tumors and other cells to be infected without ultracentrifugation, so as to meet most of experimental demands.

Owner:上海溥生生物科技有限公司

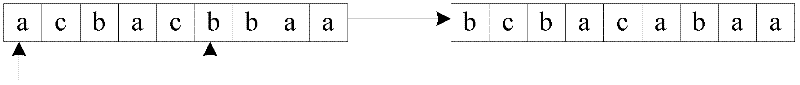

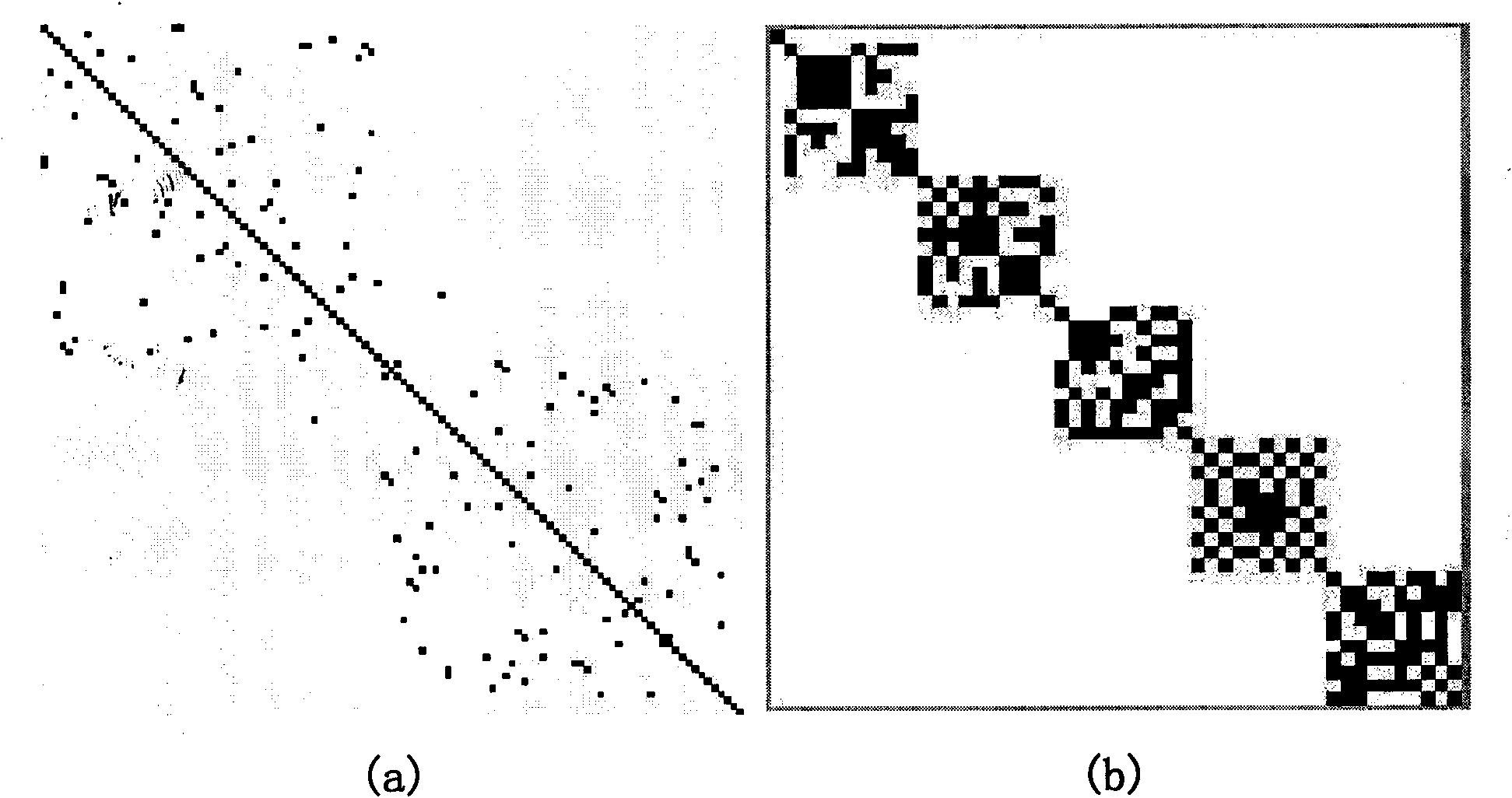

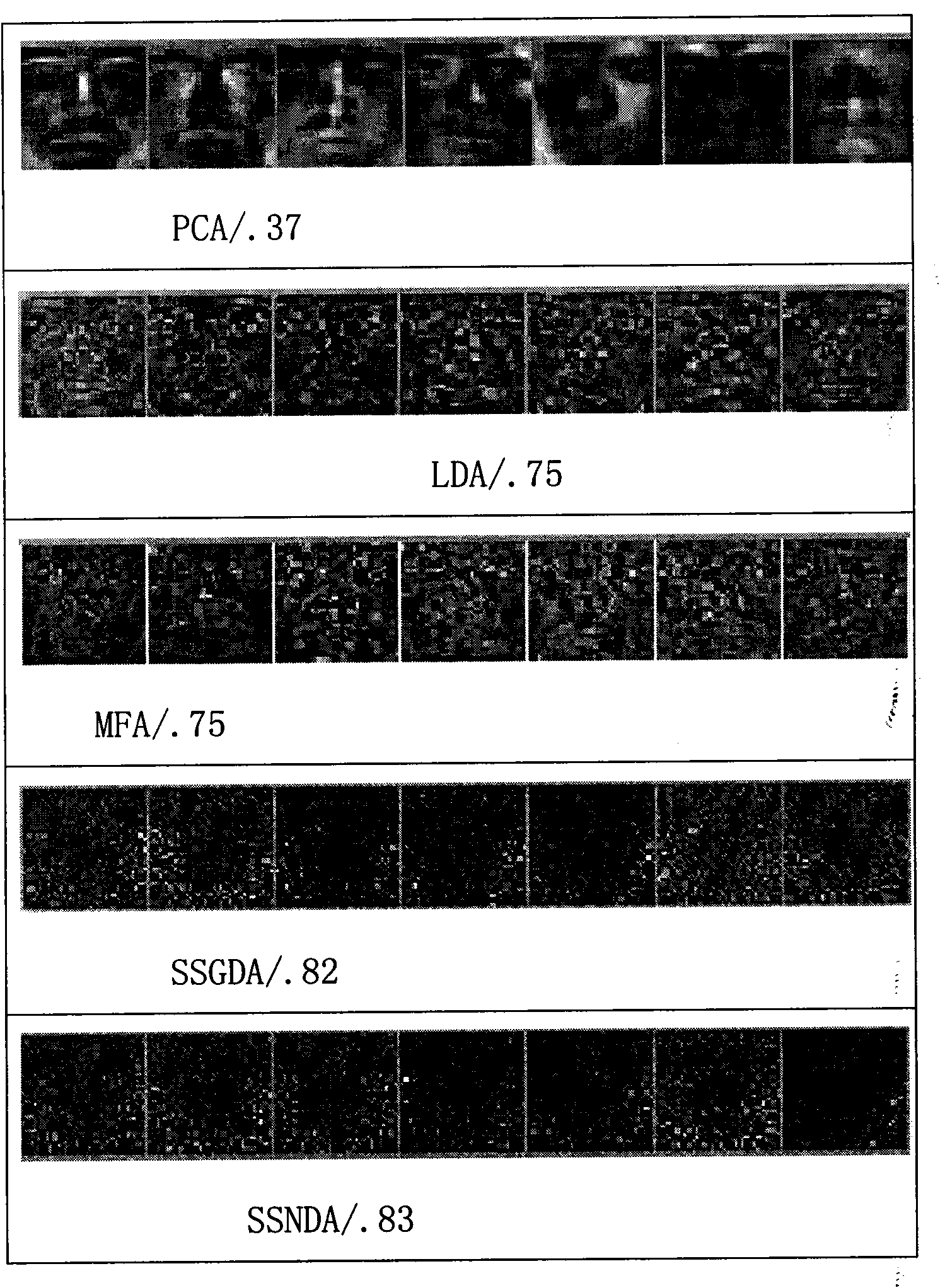

Semi-supervised neighborhood discrimination analysis method for face recognition

InactiveCN101877053AVerify stabilityImprove performanceCharacter and pattern recognitionLabeled dataLocal structure

The invention discloses a semi-supervised neighborhood discrimination analysis method for face recognition, belonging to the technical range of image treatment. The method can retain a local structure of data and have the discrimination capacity. The semi-supervised neighborhood discrimination analysis (SSNDA) method is designed against facial image data and comprises the steps of utilizing the spectral graph theory as a tool, fully utilizing information provided by a marked data type label and similarity information between the marked data and the unmarked data for constructing an adjacent matrix ASSNDA, and fully utilizing the information provided by the marked data type label and the similarity information between the marked data and the unmarked data. Therefore, the method constructs the adjacent matrix A-SSNDA: the low-dimensional feature of the SSNDA represents that the SSNDA contains discrimination information of the marked data and the information of the local structure of the marked and the unmarked data. Actual face recognition experiments verify the high efficiency and the stability of the SSNDA, and the performances of the method are better than those of the LDA method.

Owner:BEIJING JIAOTONG UNIV

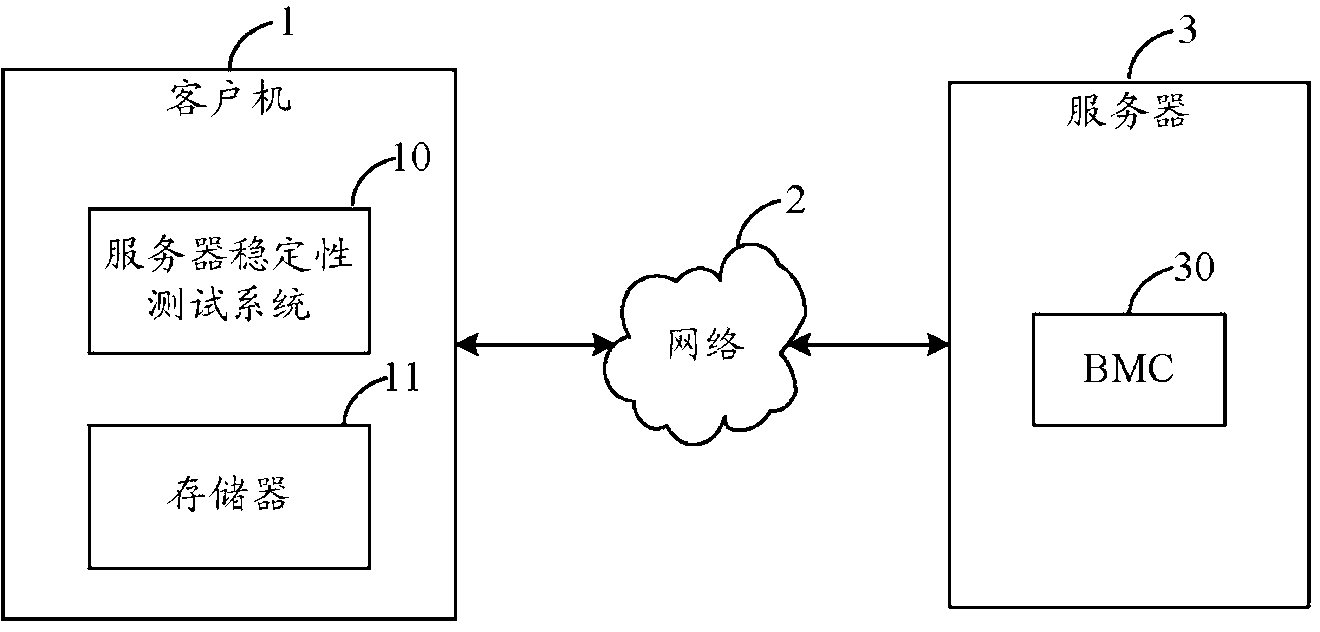

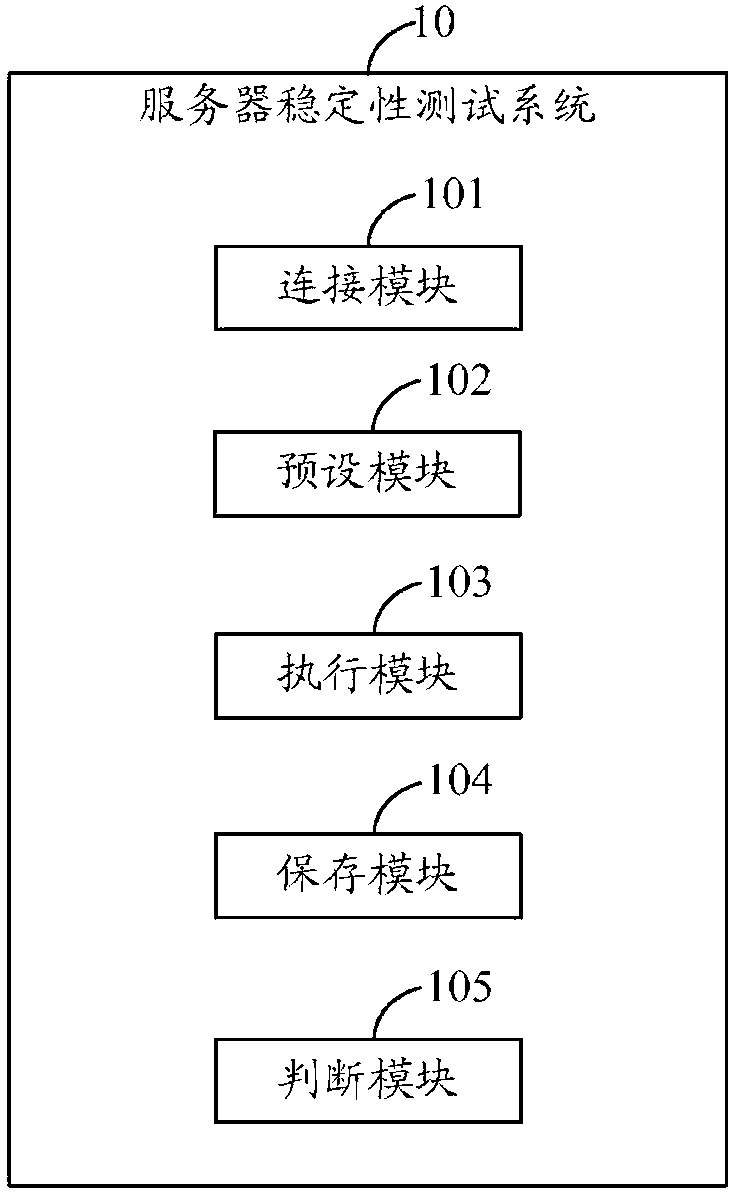

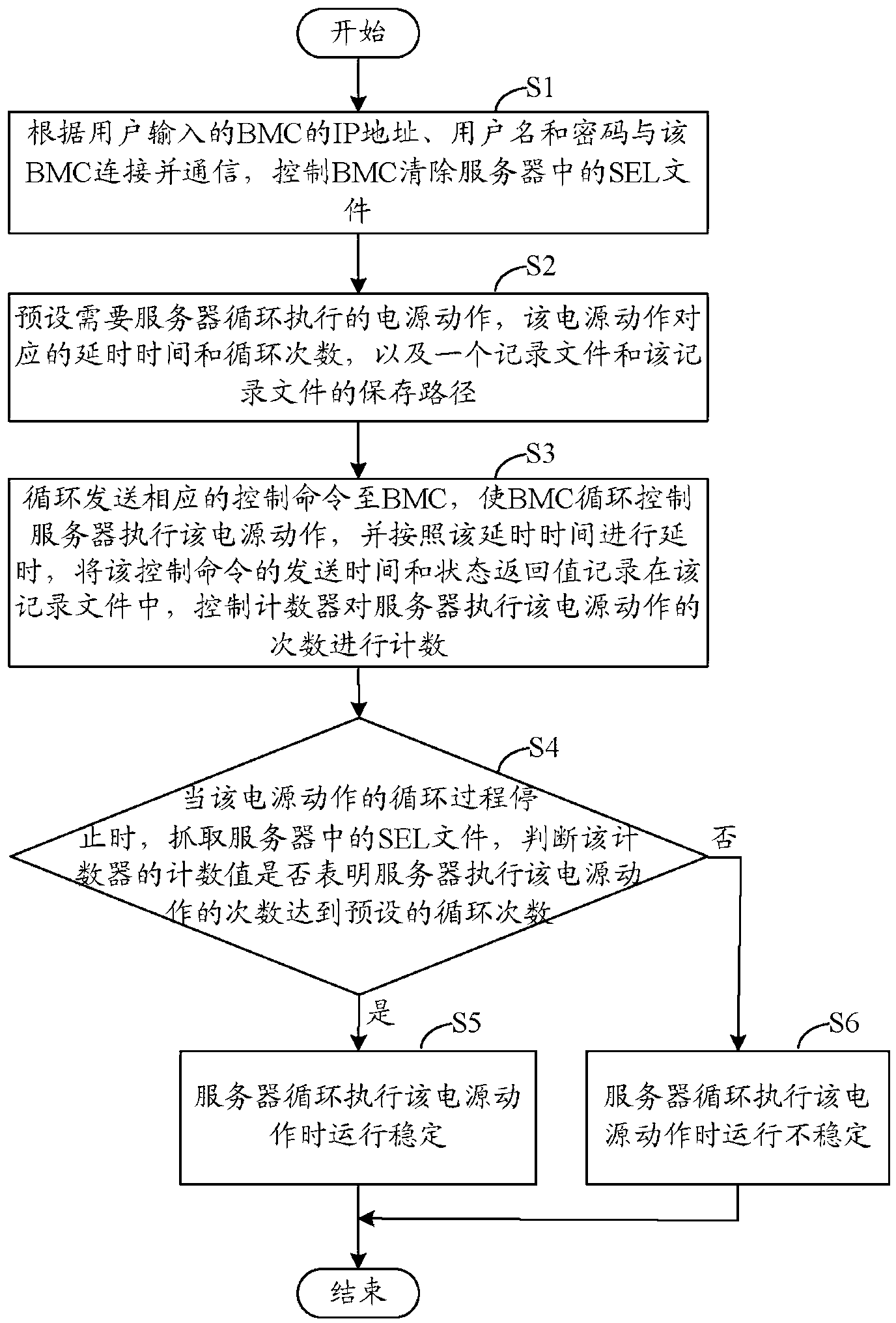

Method and system for testing stability of server

InactiveCN102937927AVerify stabilityLarge coverageDigital data processing detailsDetecting faulty computer hardwareCyclic processMultiplexer

The invention discloses a method for testing the stability of a server. The method includes that power source actions needed to be circulated by the server and circulating times are preset; corresponding control commands are sent to a block multiplexer channel (BMC) of the server so that the BMC controls the server to circulate the power source actions, and a counter is controlled to count times of the power source actions circulated by the server; and when the circulating process of the power source actions stop, if count values of the counter show that the times of the power source actions circulated by the server reach preset circulation times, the server is judged to operate stably while circulating the power source actions, and if the multiple count values show that times of the power source actions circulated by the server does not reach preset circulation times, the server is judged to operate unstably while circulating the power source actions. The invention further provides a system for testing the stability of the server. By the aid of the method and the system for testing the stability of the server, the stability of the server can be verified when the server performs various power source actions.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

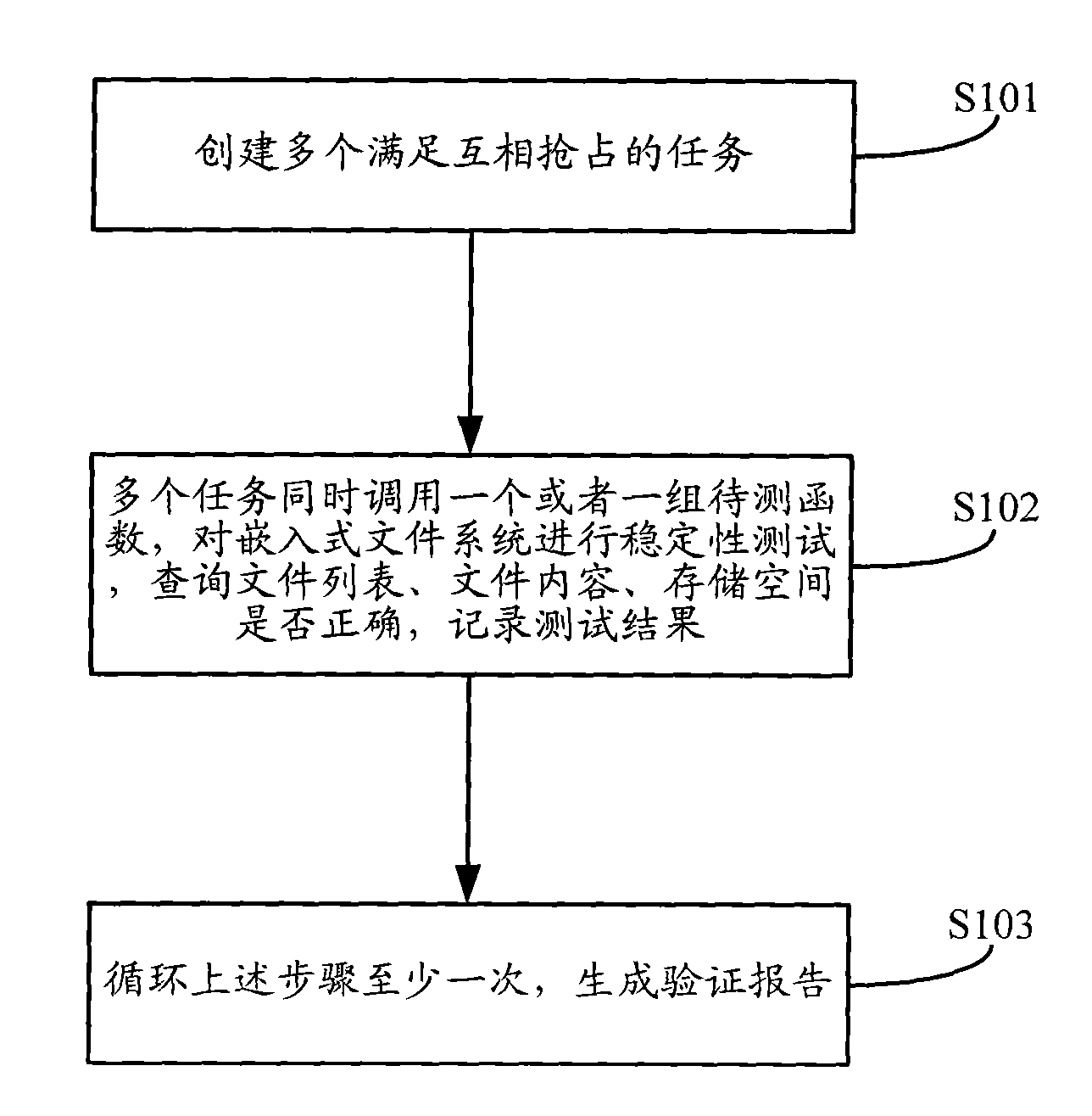

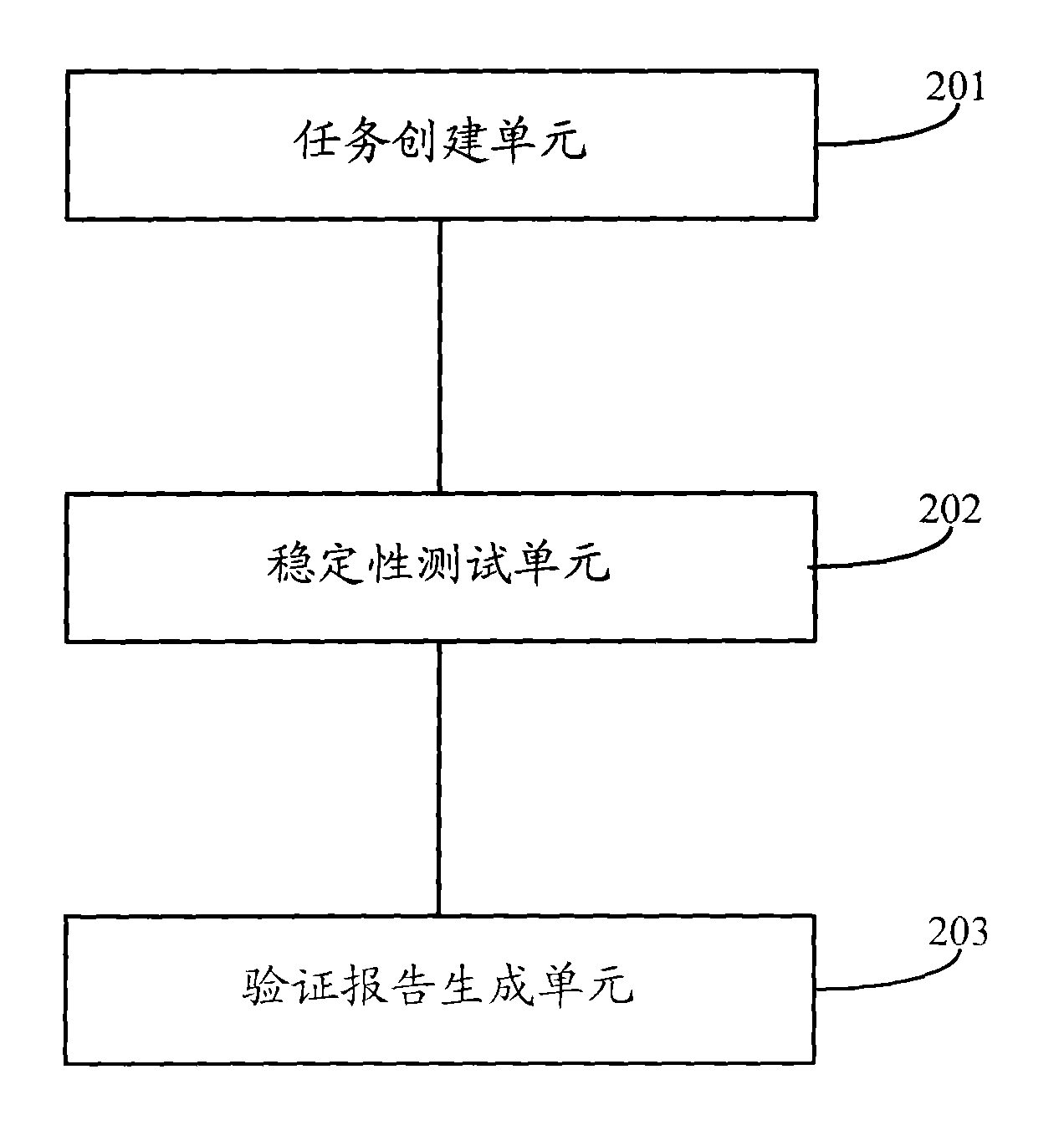

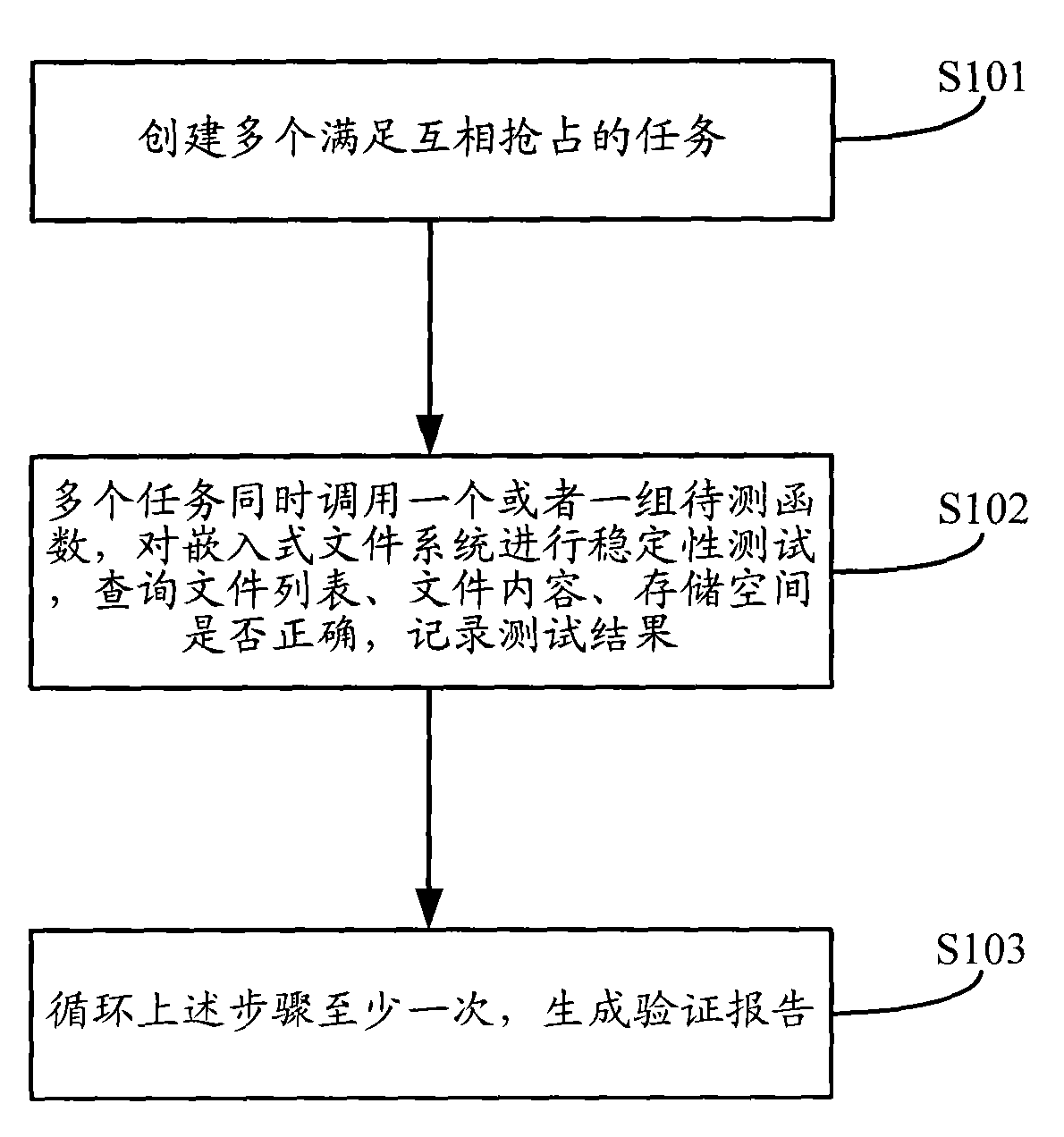

Verification method and device on embedded file system stability

InactiveCN102117272AVerify stabilityAccurate judgment of stabilitySpecial data processing applicationsFile systemValidation methods

The invention discloses a verification method and a device on embedded file system stability. The verification method comprises the following steps of creating a plurality of tasks meeting the mutual occupying requirement; calling one or one group of functions to be tested at the same time by the plurality of tasks, conducting stability test on an embedded file system, querying for ensuring whether the listed files, the file content and the storage space are correct or not, and recording the test result; and generating a verification report after at least one-time step cycle. The method and device conduct stability test on the embedded file system through different angles in and outside the embedded file system, and can verify the stability of the embedded file system in the round, help a developer to locate the problem fast, improve the technical scheme of the embedded file system and judge the work stability of the embedded file system accurately.

Owner:ZTE CORP

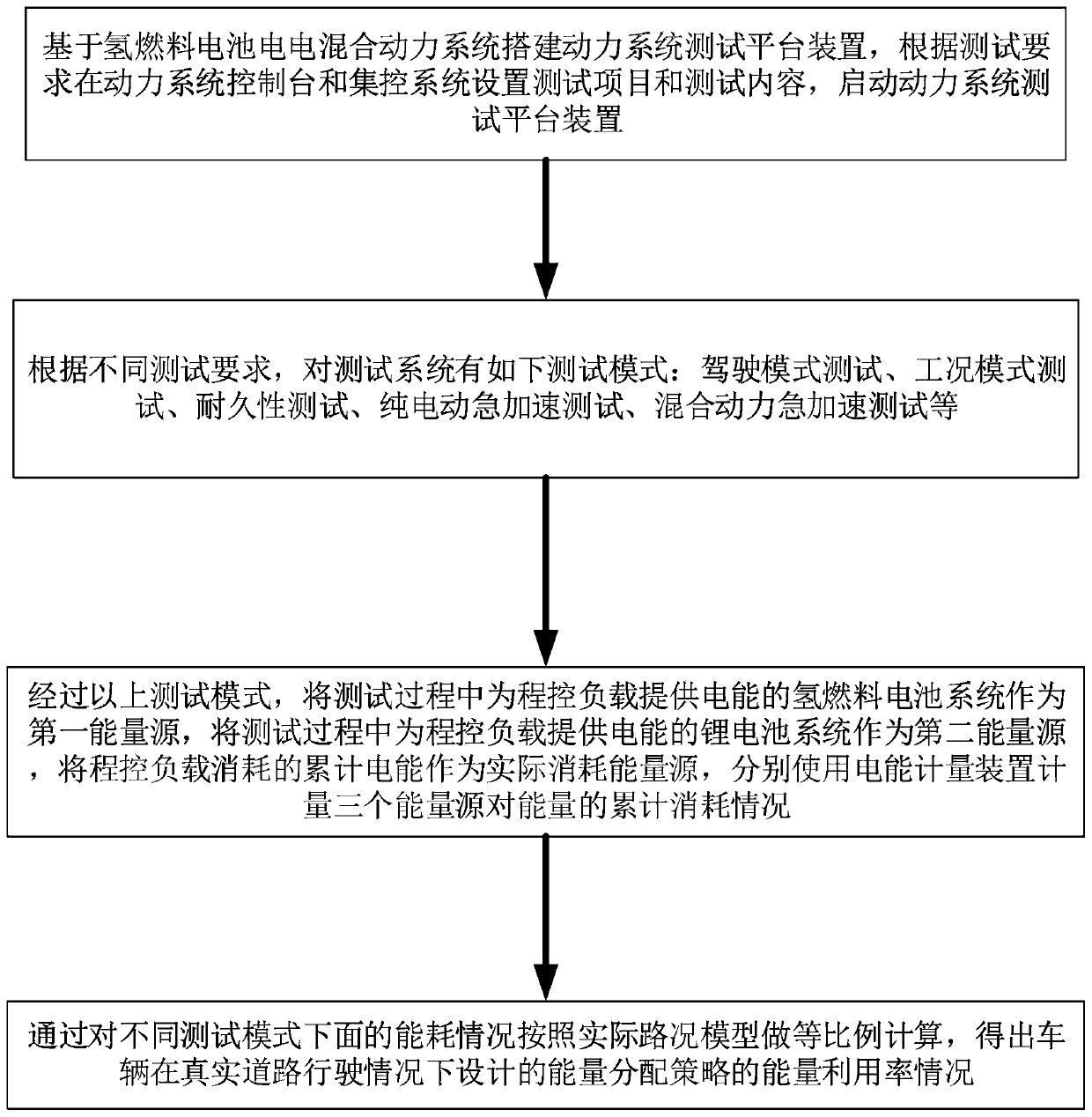

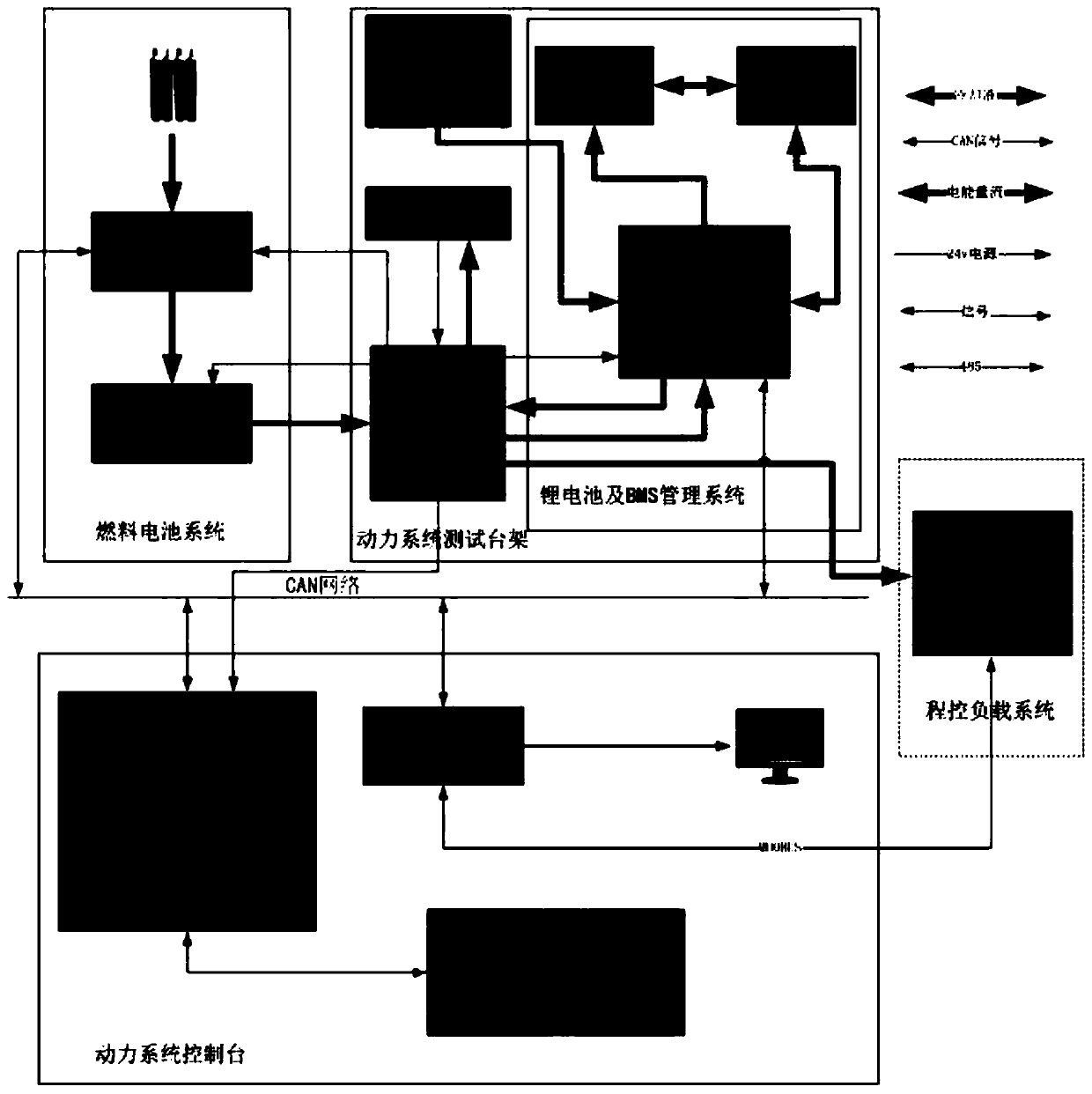

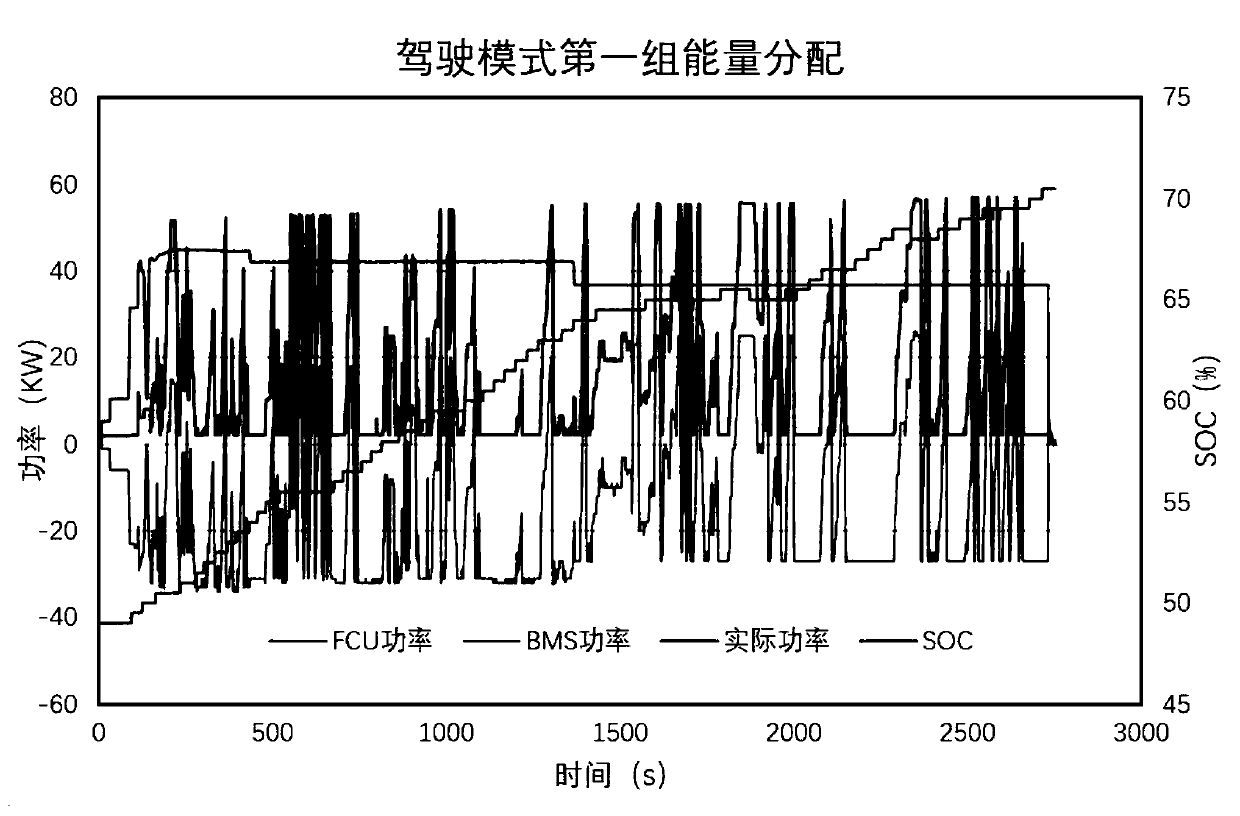

Fuel cell power system test platform test method and device

ActiveCN111366854AOptimal Energy Allocation StrategyOptimal Control StrategyElectrical testingHydrogen fuel cellComputer science

The invention discloses a fuel cell power system test platform test method and device. The method comprises steps of extracting electric energy consumption data of a hydrogen fuel cell vehicle runningfor a long time under an actual road condition, and building an electric energy consumption data model according to an existing test model; carrying out data fitting of the electric energy consumption data and the electric energy consumption data model to obtain equal-proportion test duration required by a hydrogen fuel cell vehicle under each test model; building a power system test platform device and the like based on the hydrogen fuel cell electric-electric hybrid power system. The method is advantaged in that a whole vehicle power system platform is built in a laboratory environment as much as possible to simulate a real vehicle use environment, statistics of system energy consumption conditions under different energy distribution strategies tested under a test model is performed, anequivalent minimum power consumption control scheme is obtained, so an optimal energy distribution strategy and an optimal control strategy are screened in the laboratory environment.

Owner:武汉海亿新能源科技有限公司

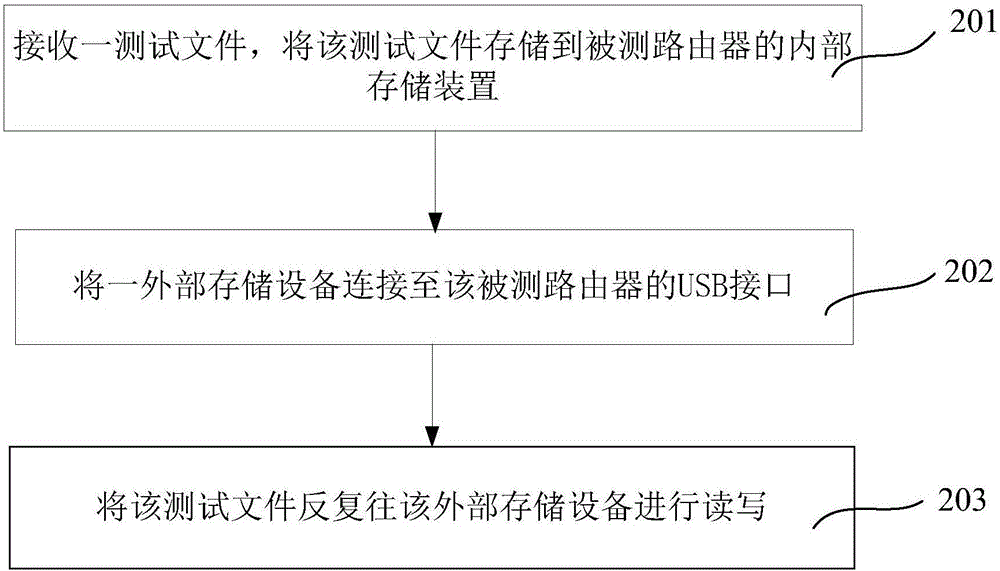

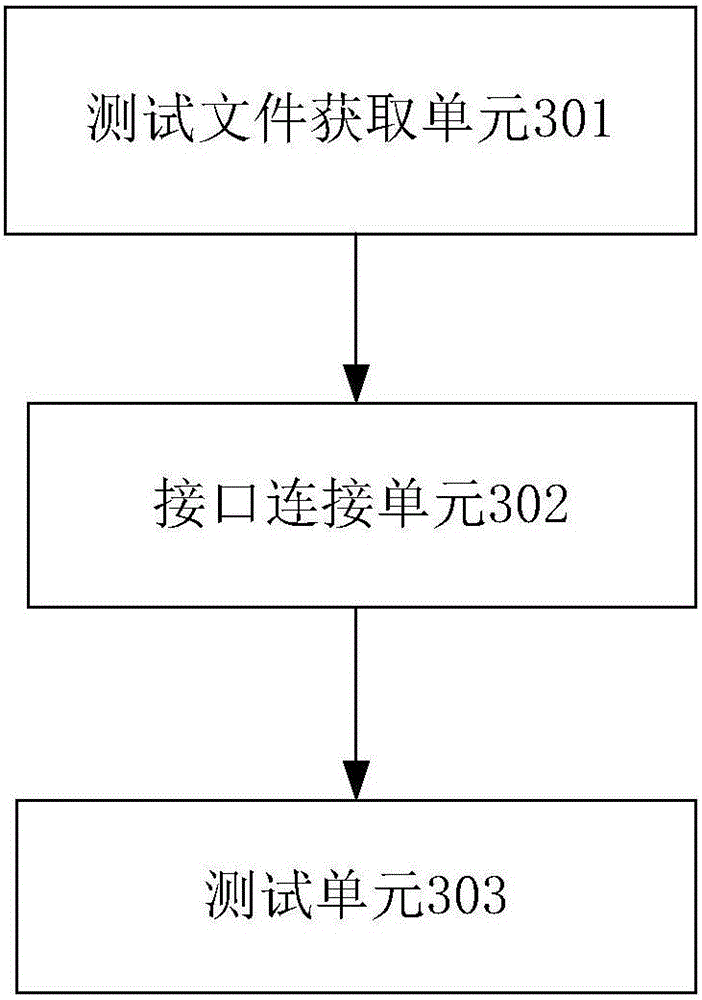

Test method and system for USB (Universal Serial Bus) storage stability of route

InactiveCN106528358AVerify stabilityVerify robustnessDetecting faulty computer hardwareData switching networksExternal storageSystem stability

The invention discloses a test method and system for USB (Universal Serial Bus) storage stability of a route. The method comprises the following steps of receiving a test file, wherein the test file is stored in an external storage device of a tested route; receiving a USB interface, connected to the tested route, of external storage equipment; and repeatedly reading and writing the test file in the external storage equipment. By the method, the purposes of verifying the stability and the robustness of a USB storage system of the route can be achieved.

Owner:PHICOMM (SHANGHAI) CO LTD

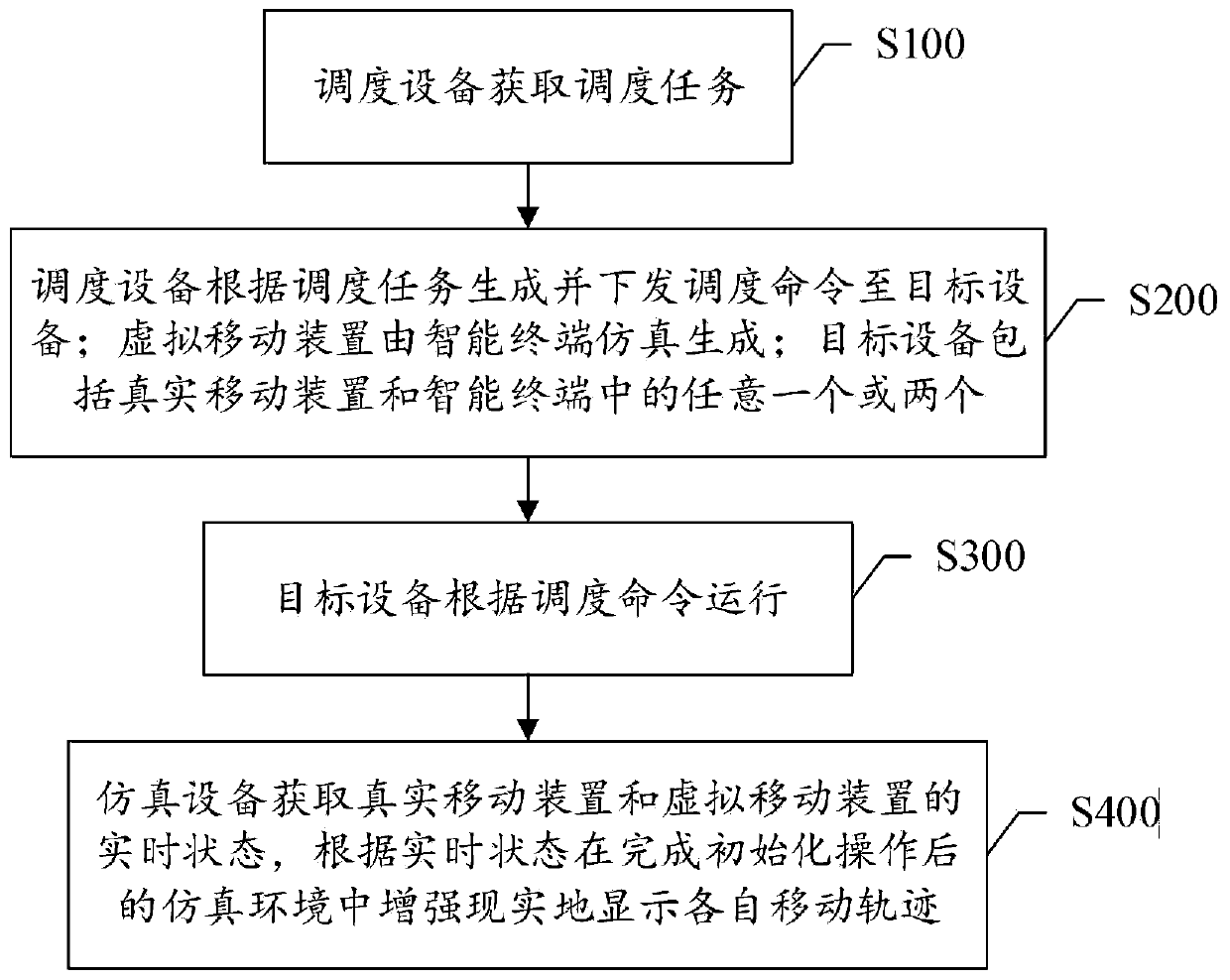

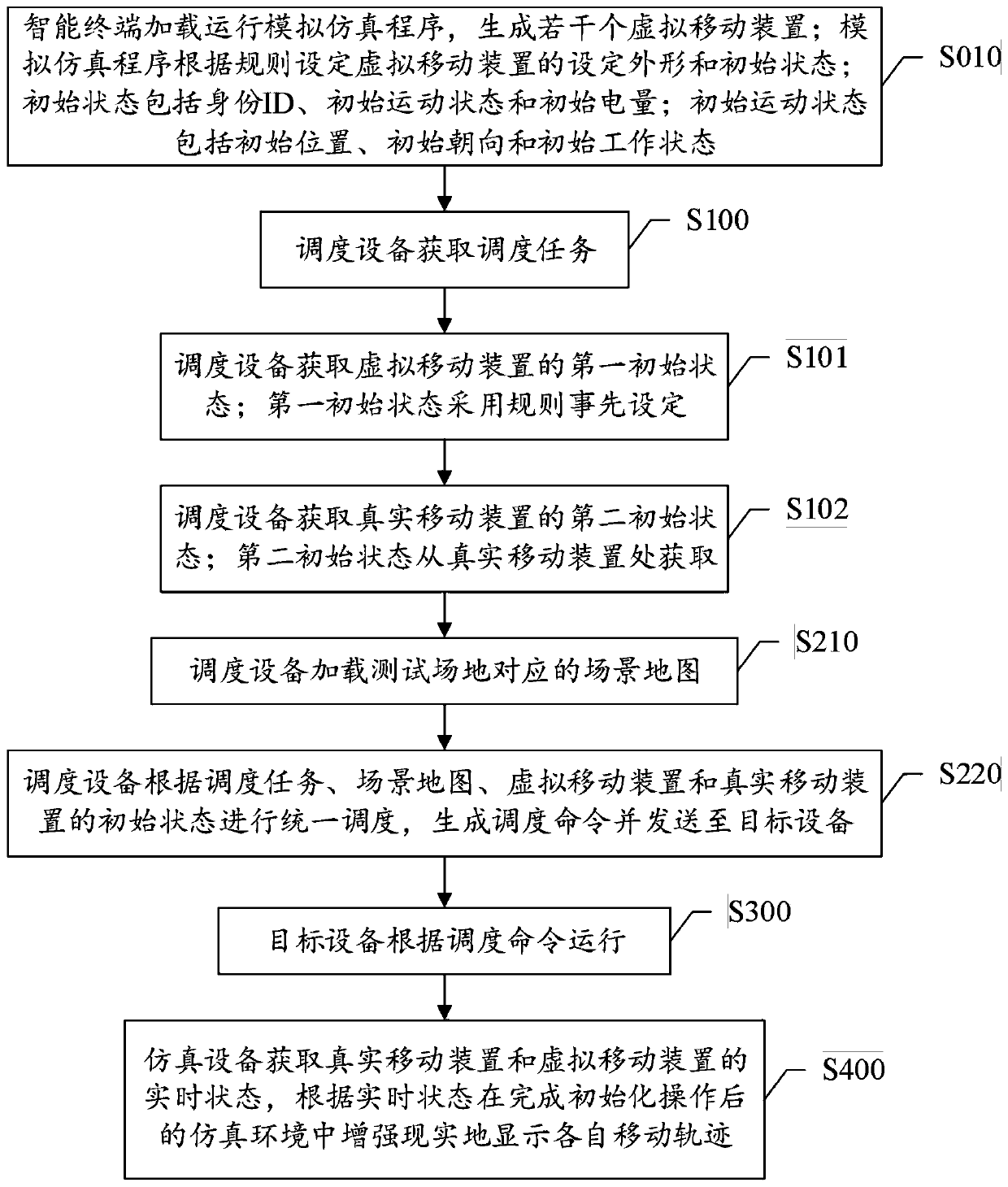

Test method and system

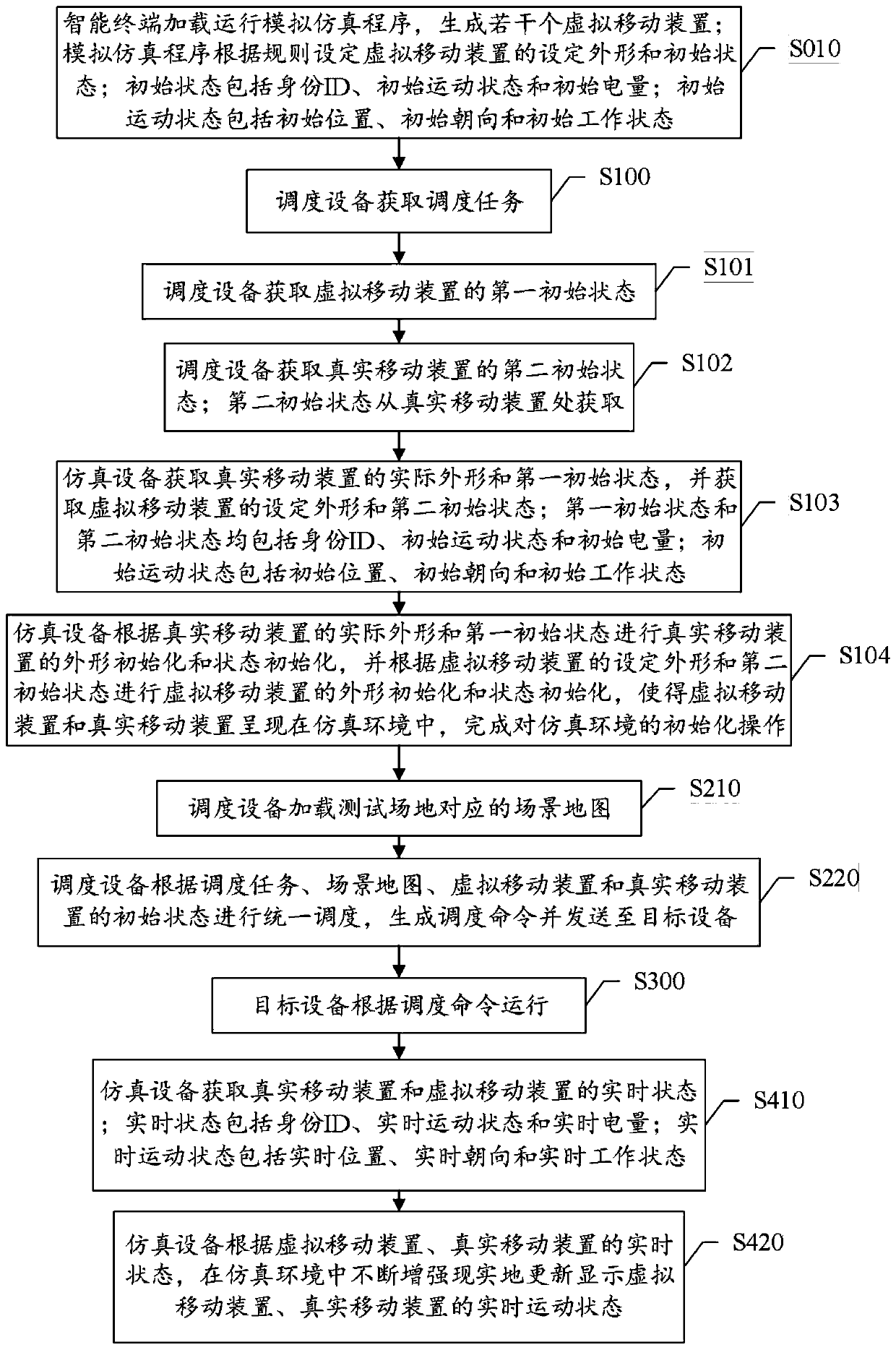

ActiveCN109696915AVerify the running effectVerify feasibilityPosition/course control in two dimensionsVehiclesData visualizationDemand side

The invention provides a test method and system. The method comprises the steps that: scheduling equipment acquires a scheduling task; the scheduling device generates and issues a scheduling command to the target device according to the scheduling task, wherein the target device comprises any one or two of a real mobile device and an intelligent terminal and a virtual mobile device is generated bysimulation of the intelligent terminal; the target device operates according to the scheduling command; and a simulation device acquires real-time states of the real mobile device and the virtual mobile device, and displays respective moving tracks in the simulation environment after the initialization operation is completed in an augmented reality manner according to the real-time states. According to the invention, the function and performance of a mobile device can be displayed to others in a systematic, clustered and data-visual manner, the operation effect of the mobile device under a real condition can be verified, the feasibility and stability of a large number of mobile devices can be visually and conveniently verified at low cost, and a demand side and an implementation side of aproject can carry out clear and effective communication.

Owner:SHANGHAI ATOVO ROBOTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com