PLC-control-based virtual simulation experiment method and system for fireworks sorting assembly line

A virtual simulation and control system technology, applied in the field of virtual simulation experiments, can solve the problems of lack of real equipment connection and control experience, inconvenience, etc., to avoid the risk of high-risk explosions, meet the needs of training, and verify reliability and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

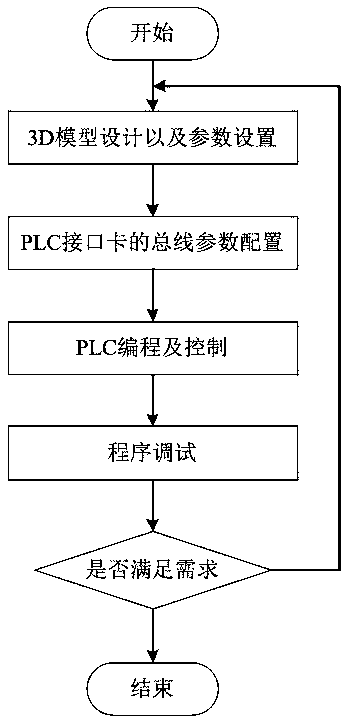

[0036] Such as figure 1 Shown, the present invention is based on the firework sorting assembly line virtual simulation experiment method of PLC control comprising the following steps:

[0037]Step A. Establish a virtual simulation environment for the fireworks sorting line: first use 3D Max to model the working units of the fireworks sorting line, including the line with fireworks products, motors, position detection sensors, and robotic arm modules; then use 3D Unity performs animation simulation for each process involved in the working process of the fireworks sorting line, the process includes: the motor drives the assembly line to move, the position detection sensor detects the position of the fireworks product, and the robotic arm module grabs the fireworks that enter the working space of the robotic arm and releases them. Fireworks products to the designated location;

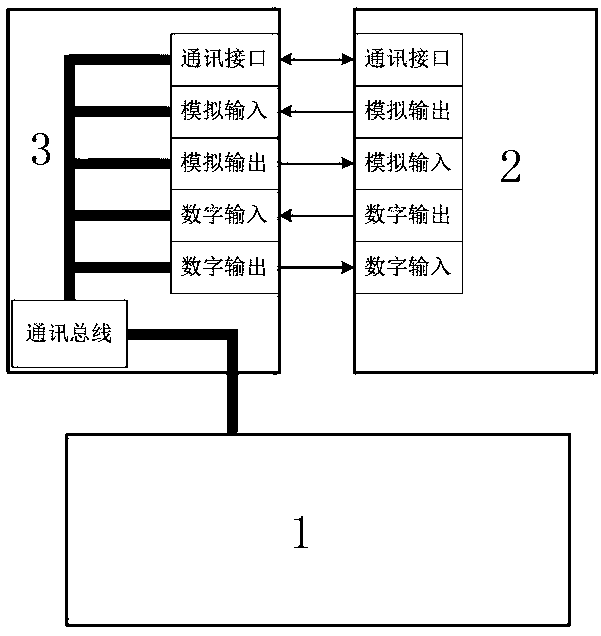

[0038] Step B. Establish the PLC control system 2: compile the PLC control program, the PLC control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com