Patents

Literature

3981results about How to "Reduce stress concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

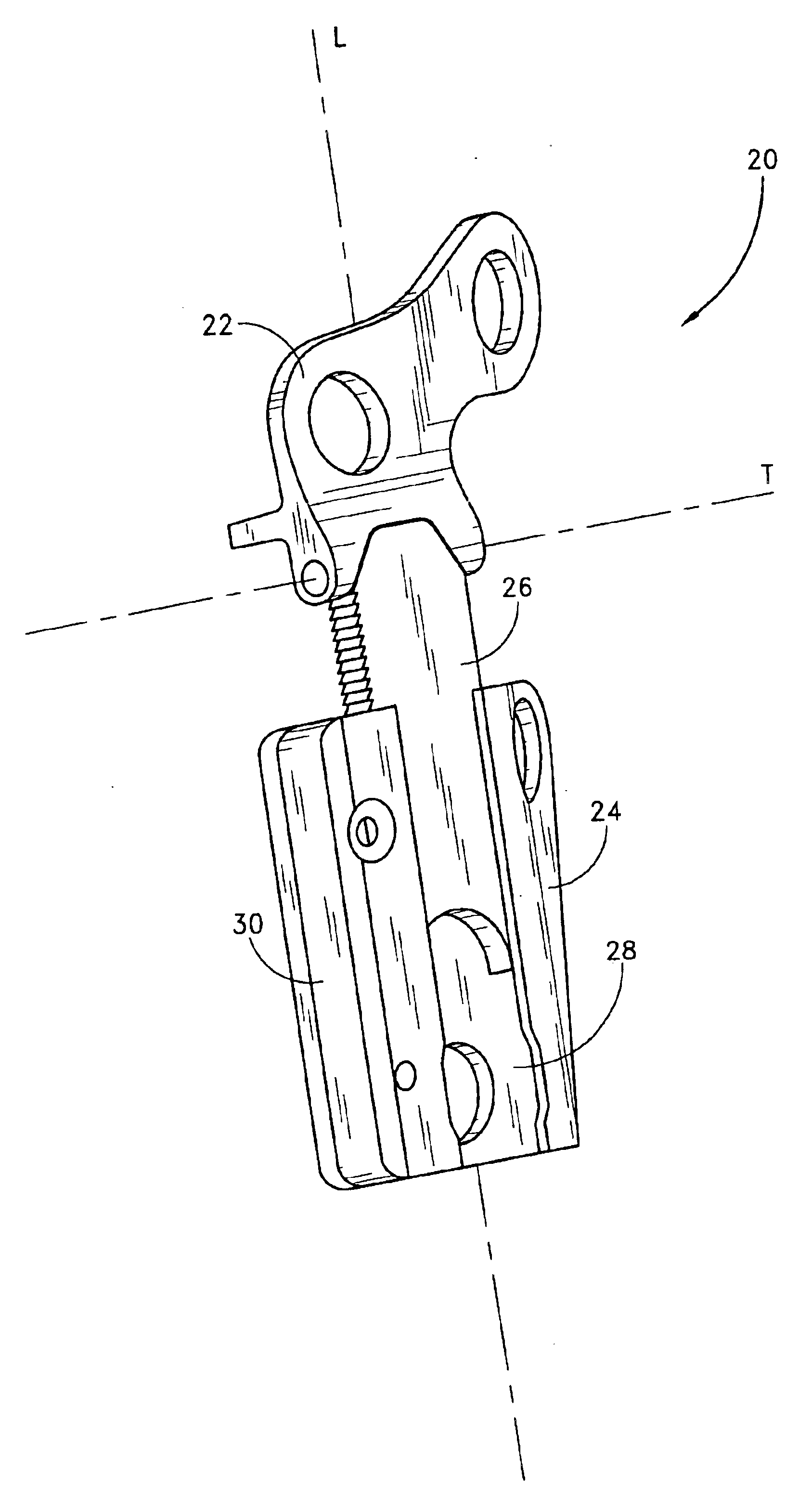

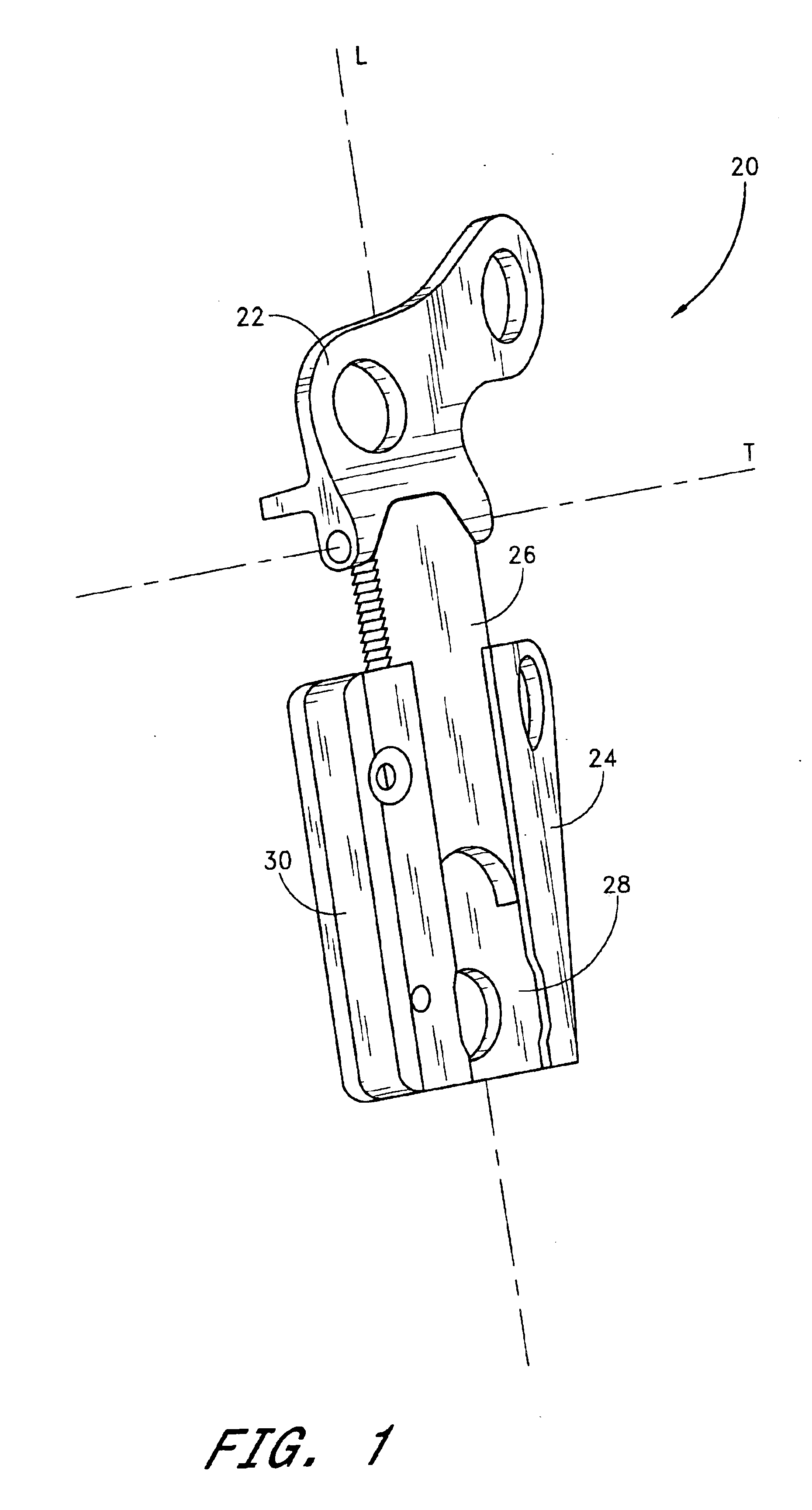

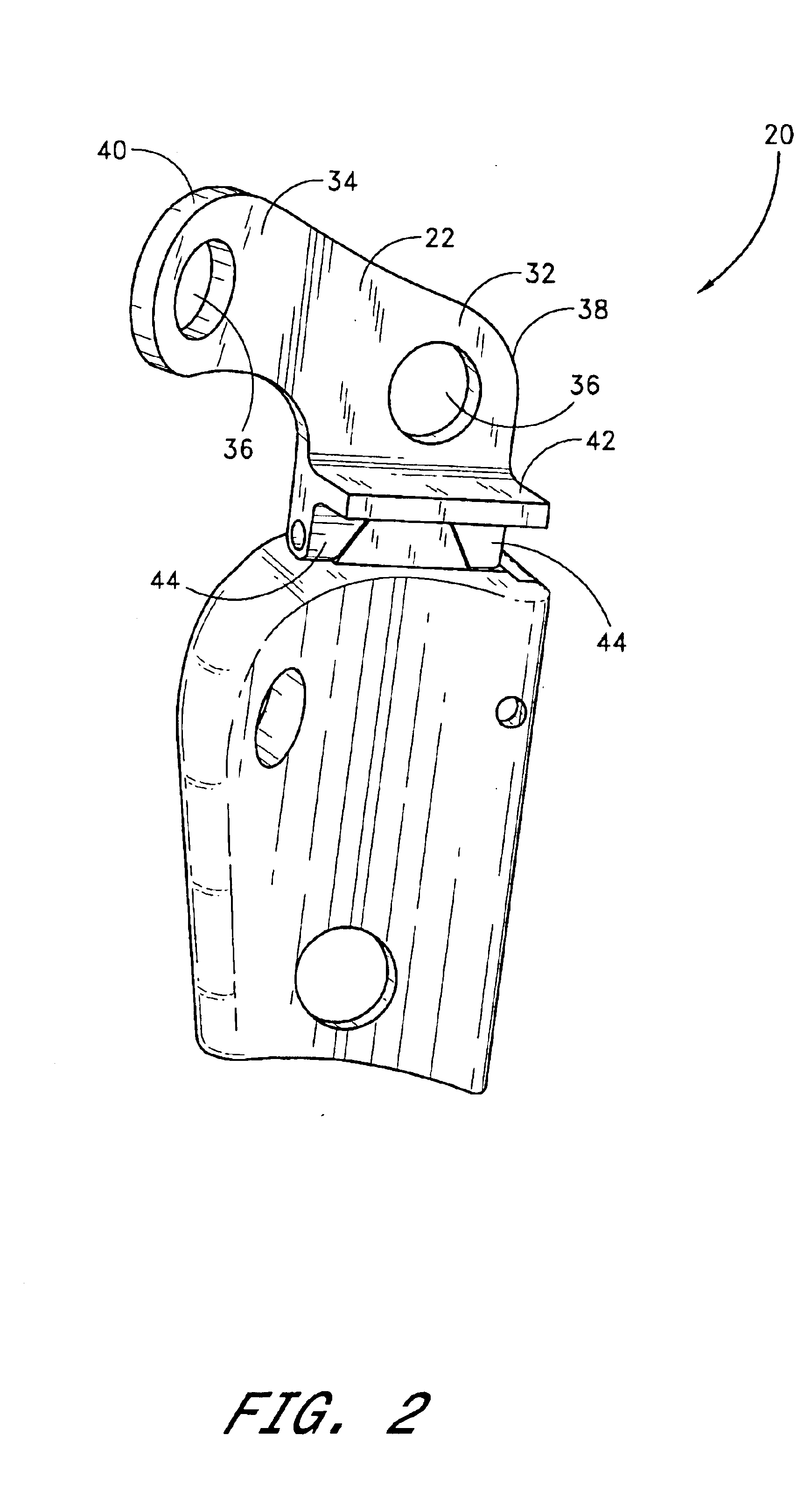

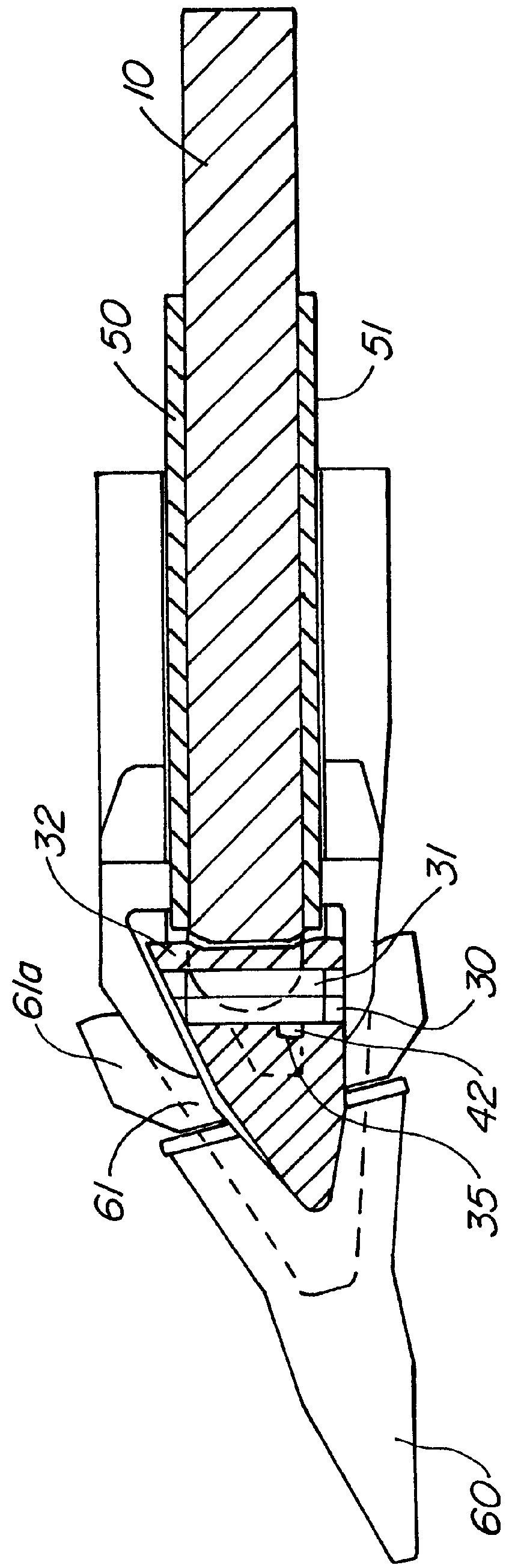

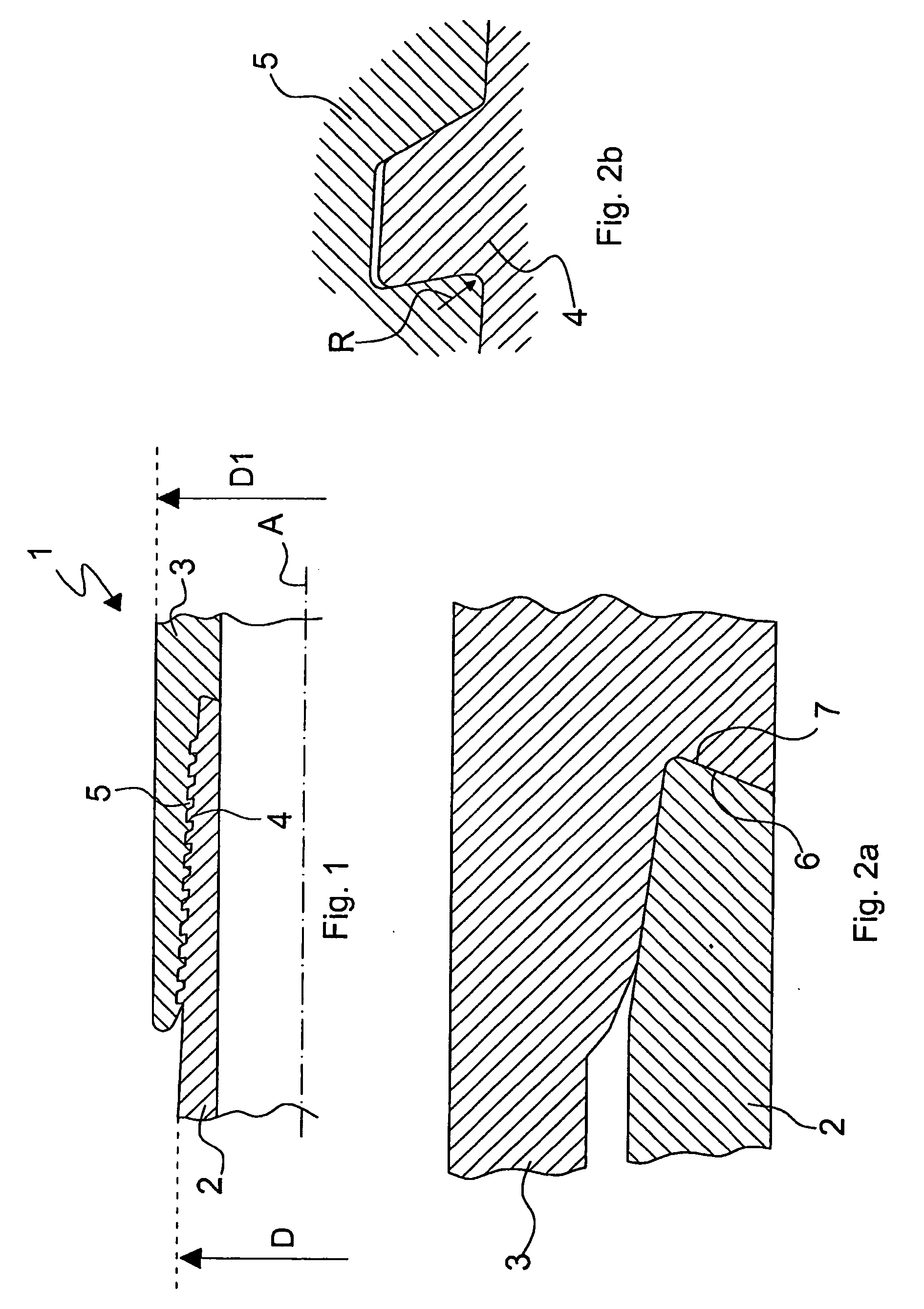

Internal osteotomy fixation device

InactiveUS6852113B2Flexibility in initially fittingLow profileInternal osteosythesisJoint implantsImplanted deviceConstant stress

An internal osteotomy fixation apparatus is provided. The device comprises a distal plate including a channel. A slide is slidably received within the channel such that the slide is translatable with respect to the distal plate along a first axis. A proximal plate is hingedly connected to the slide, such that the proximal plate has two degrees of freedom relative to the distal plate. A ledge protruding from a first portion of the proximal plate is configured to support a proximal bone segment when the device is implanted. The slide includes ratchet teeth. A ratchet arm including teeth is attached to the distal plate, and configured to engage the slide ratchet teeth. A cross-section of the ratchet arm is configured to maintain a constant stress level along a flexed portion of the arm. The distal plate includes a shelf upon which the ratchet arm rests. Compressive loads borne by the device are translated through the shelf to the distal plate. A minimum length of the device is related to the longer of the ratchet arm or the segment of teeth on the slide. The distal plate includes a hole through which a release mechanism is accessible.

Owner:ORTHOPAEDIC DESIGNS

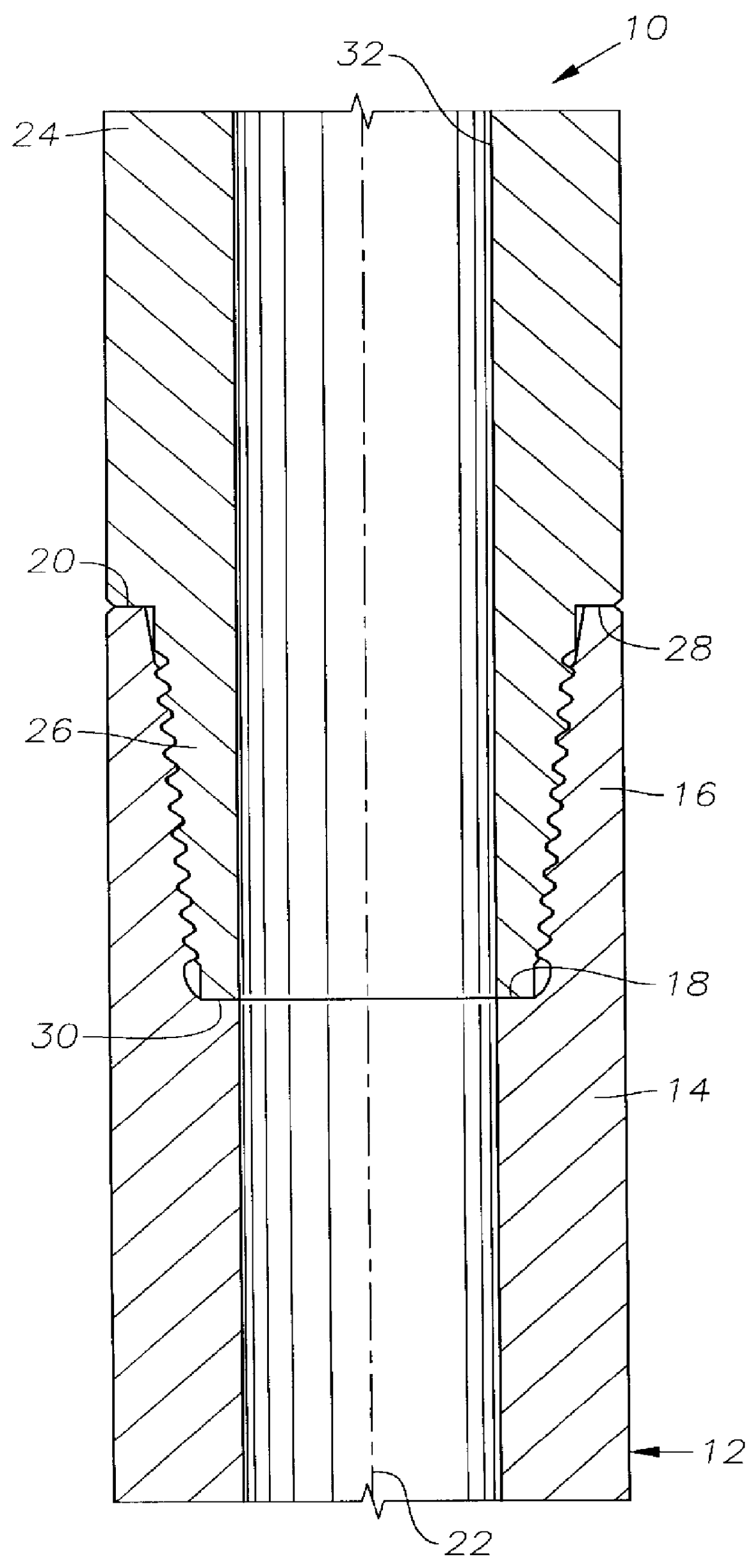

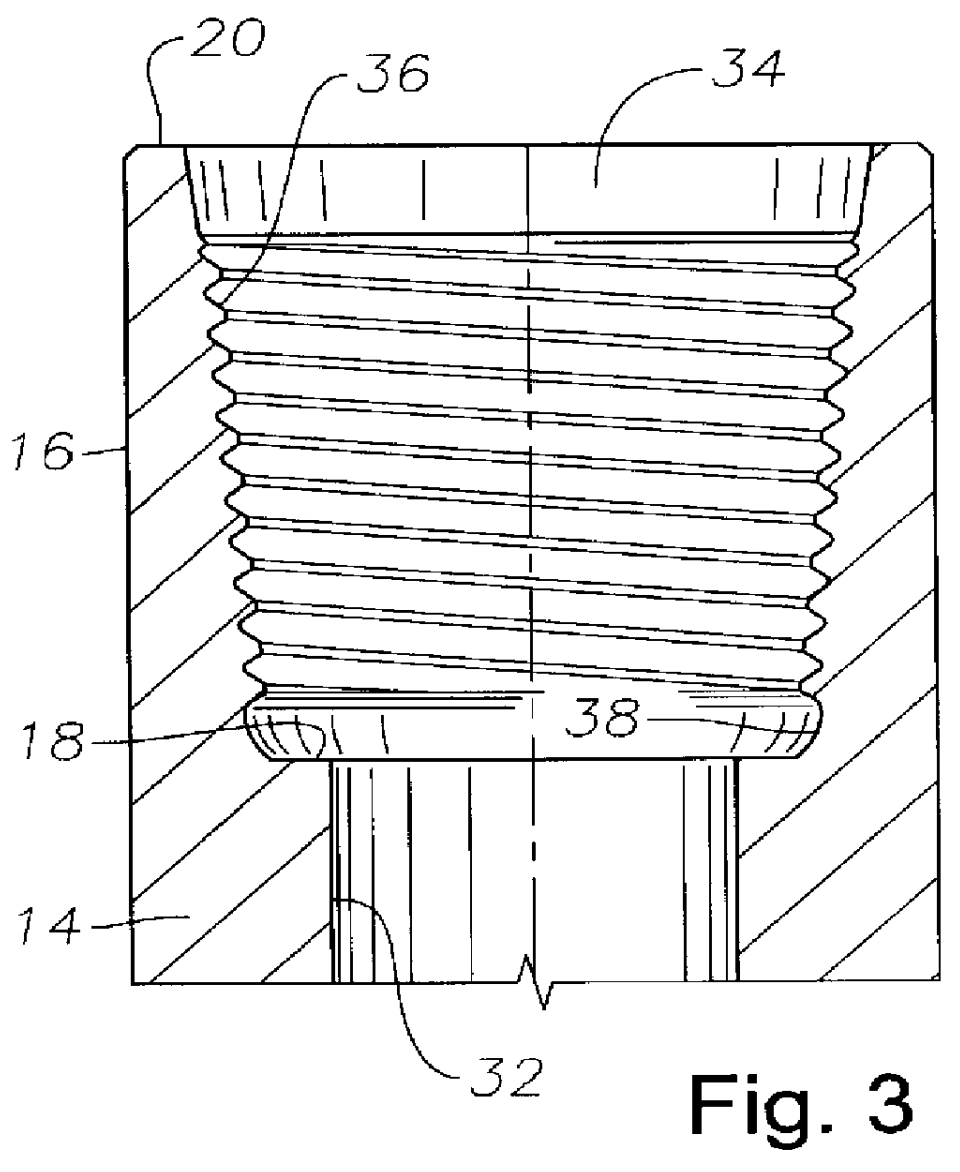

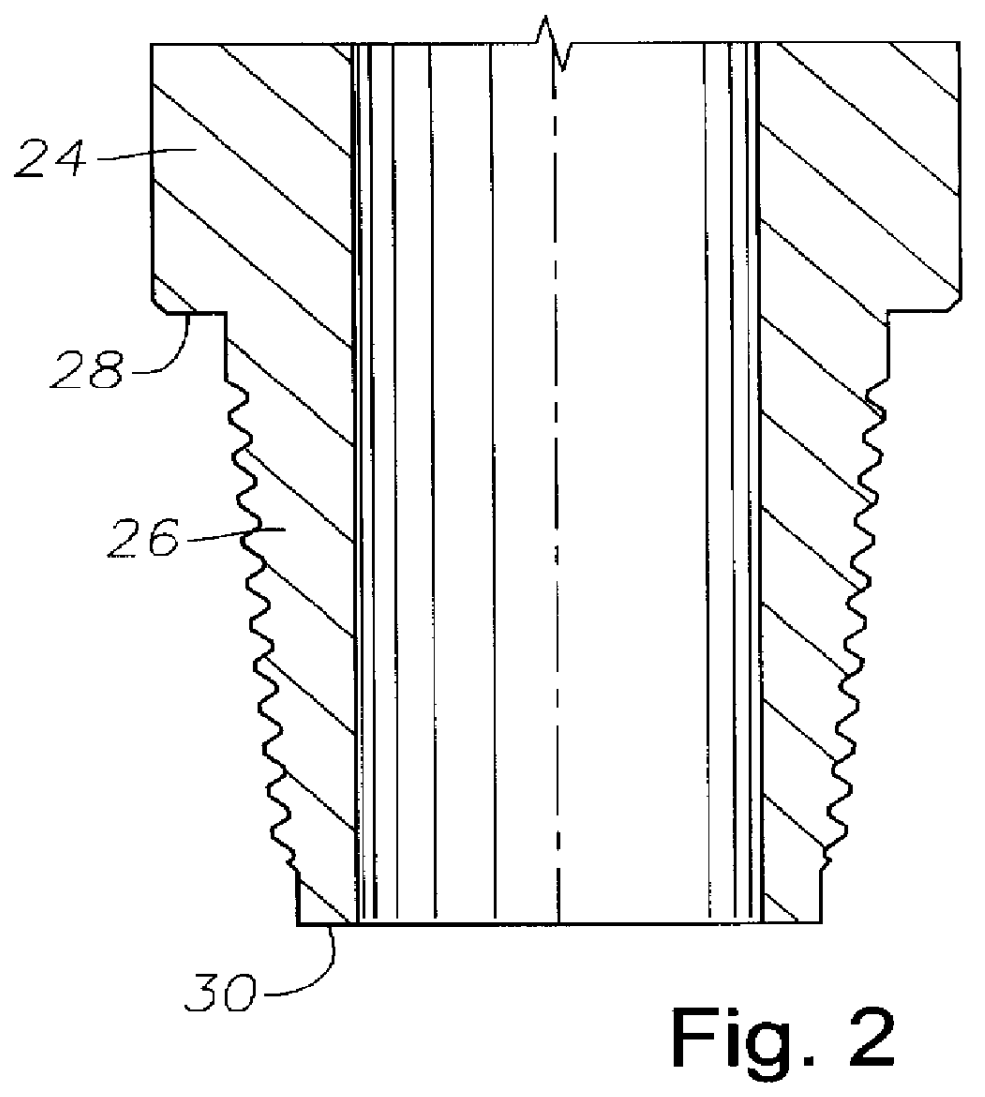

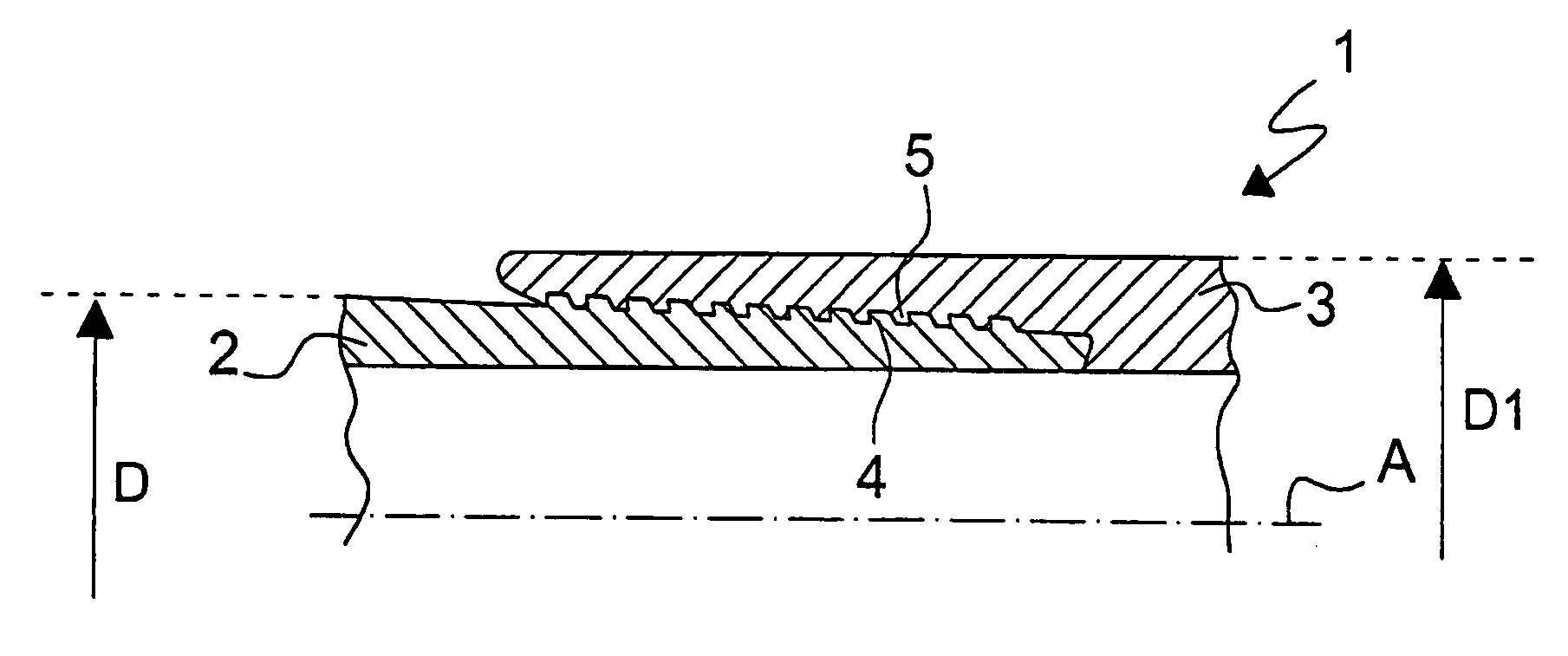

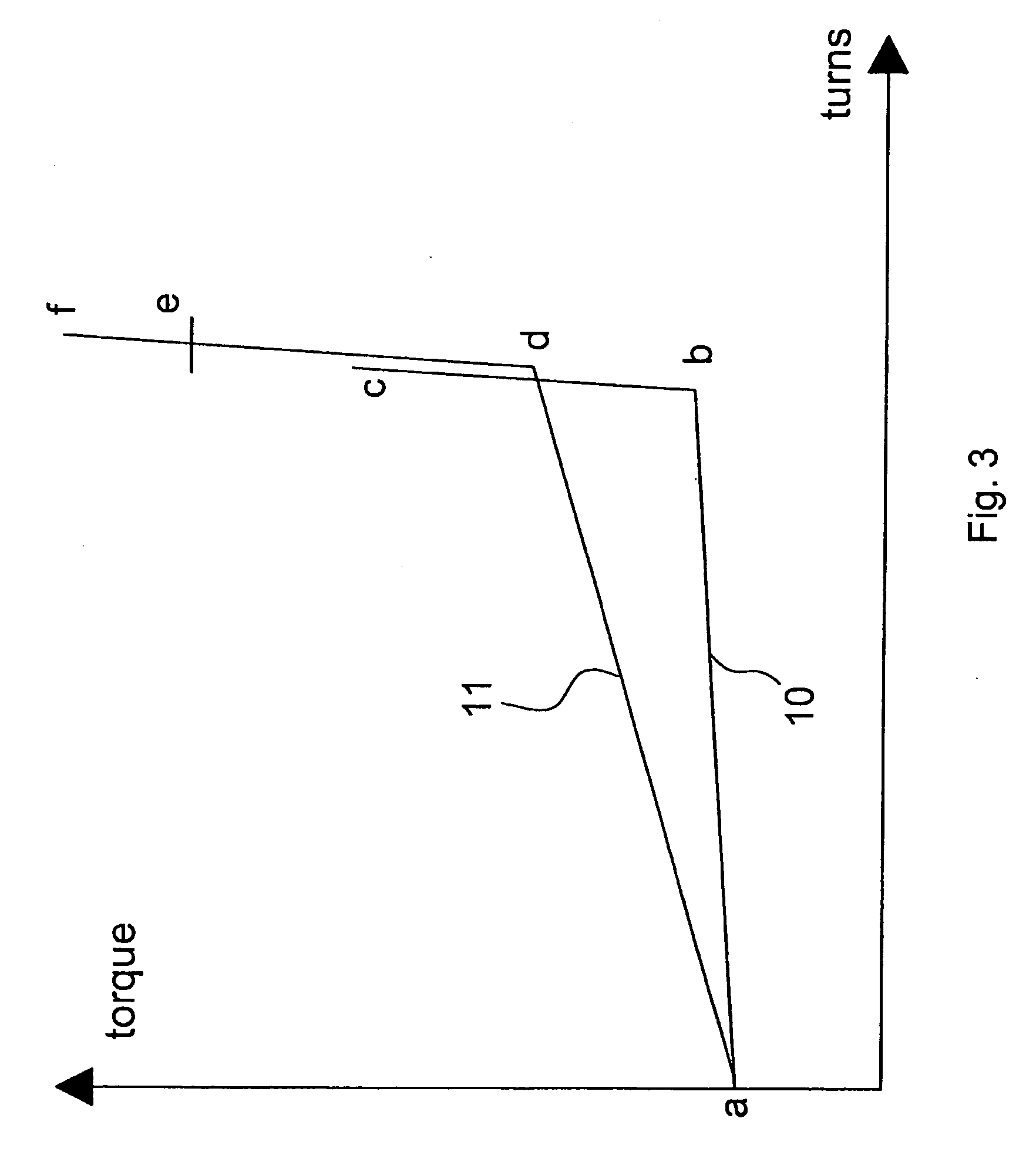

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

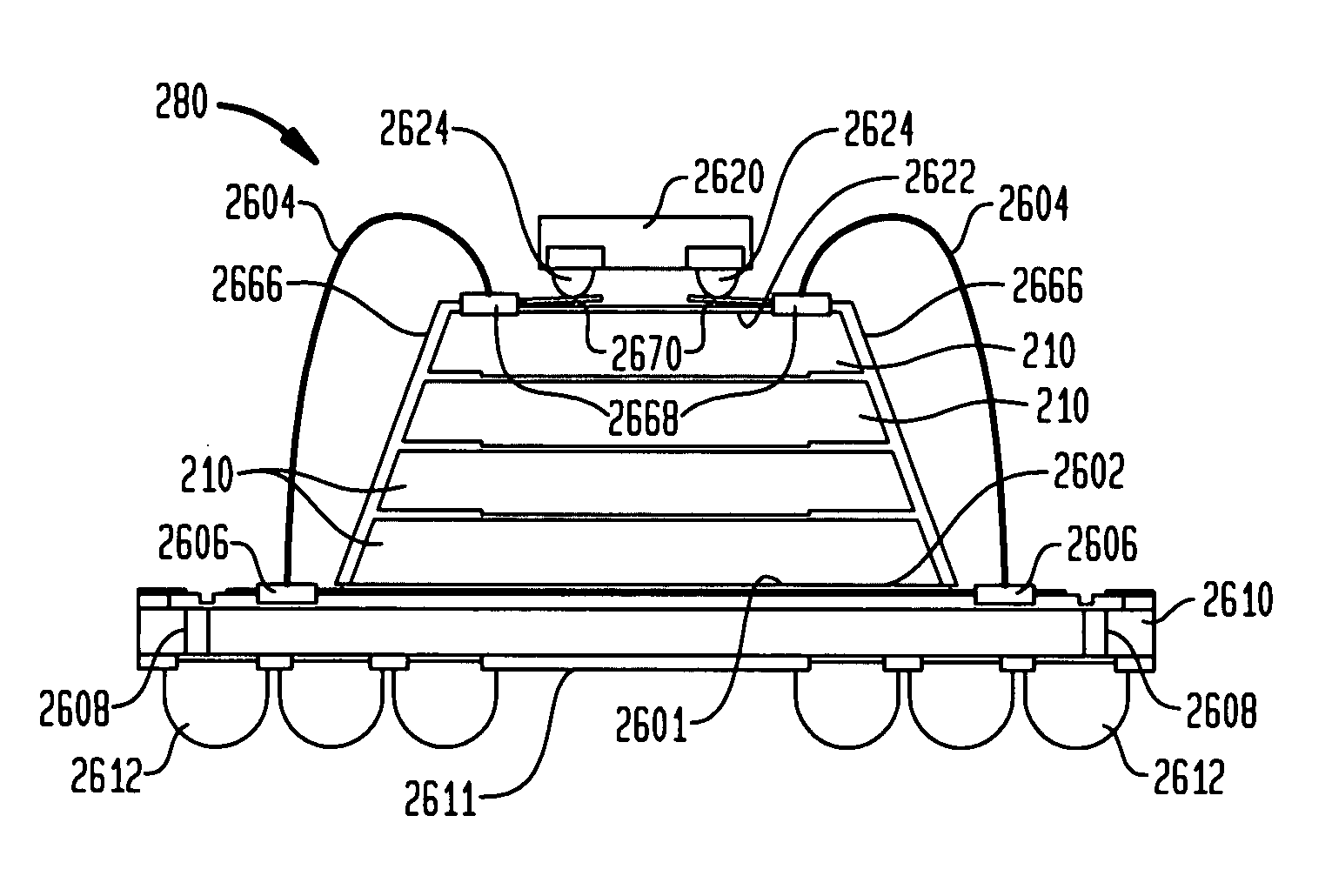

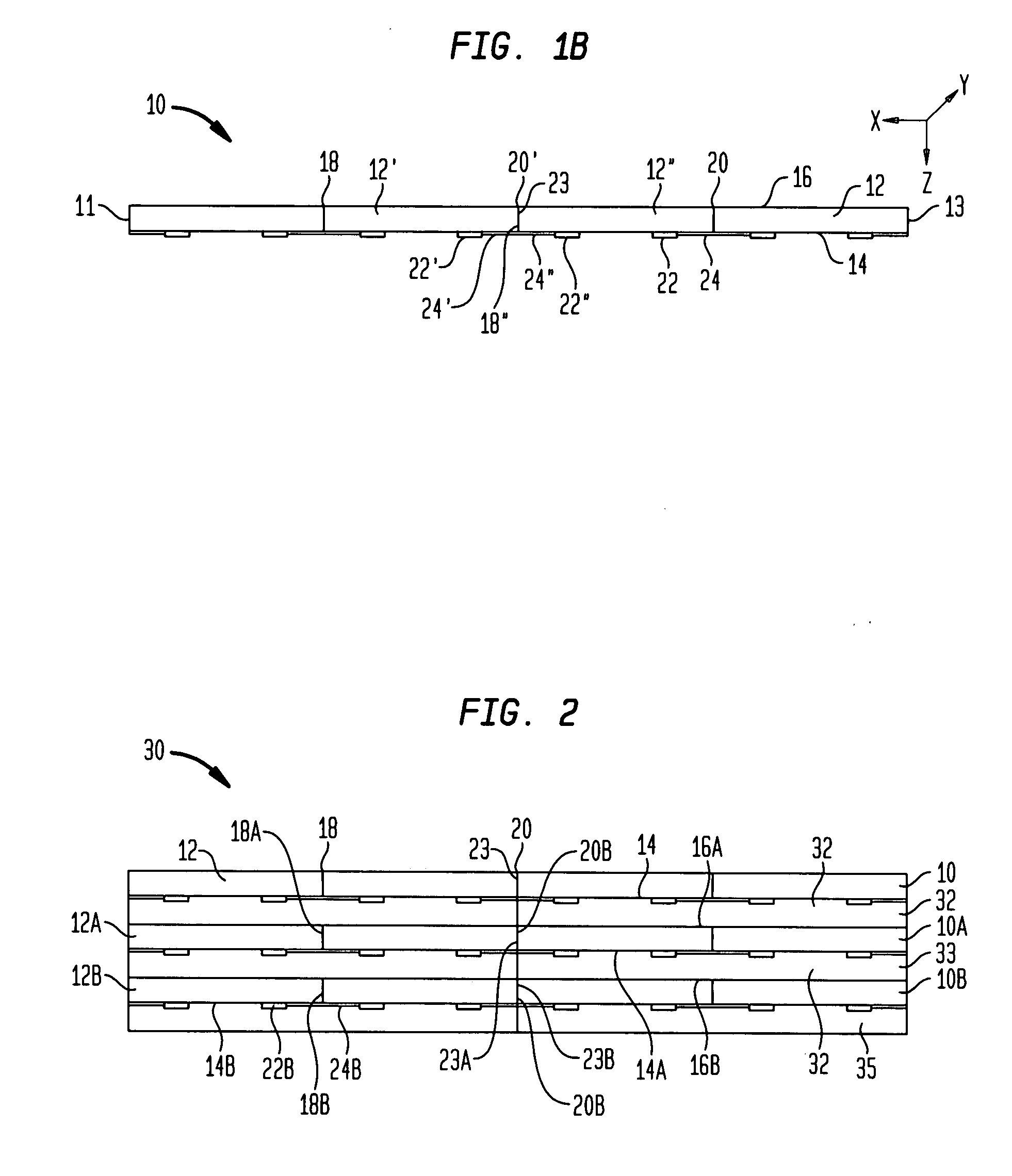

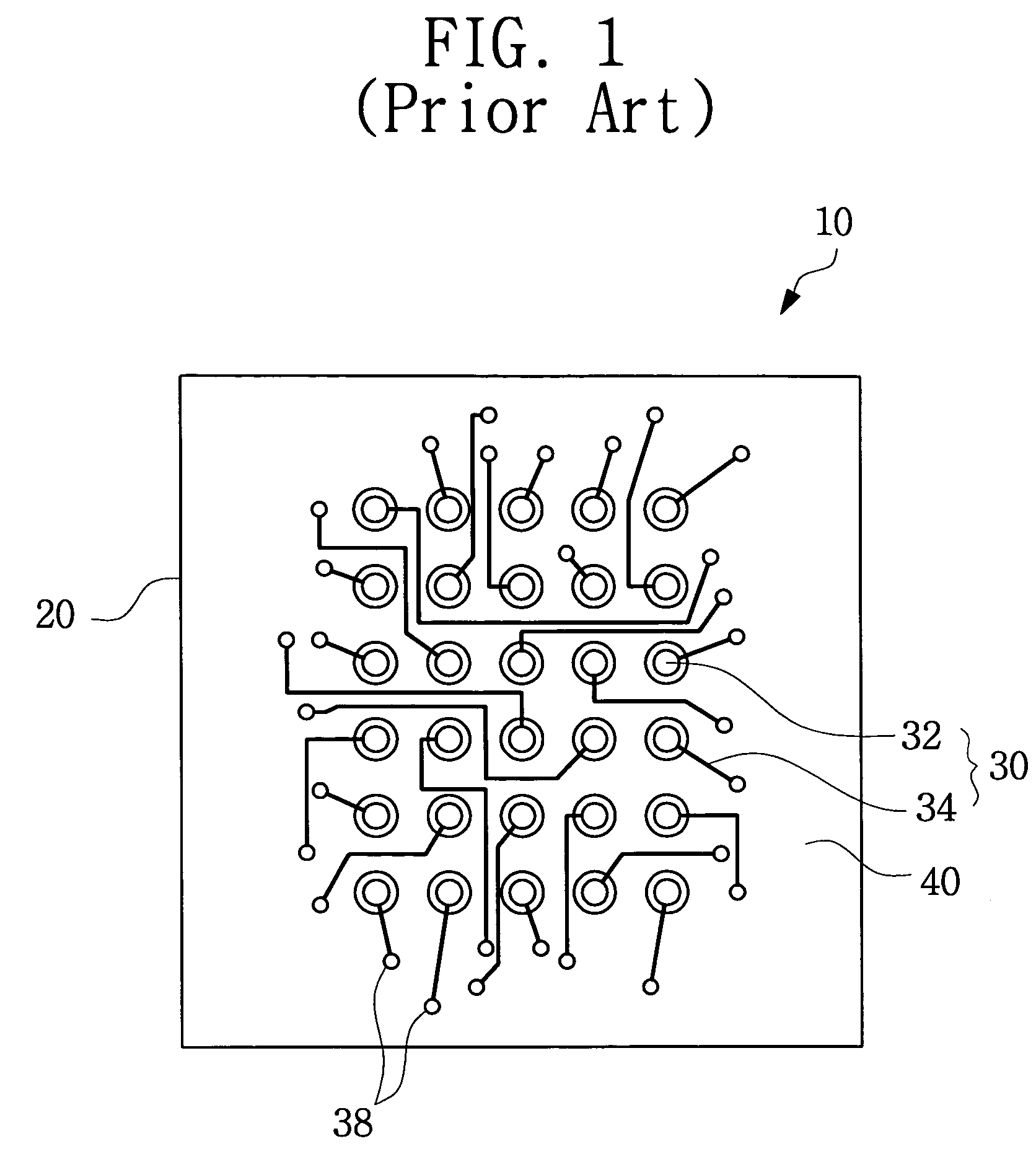

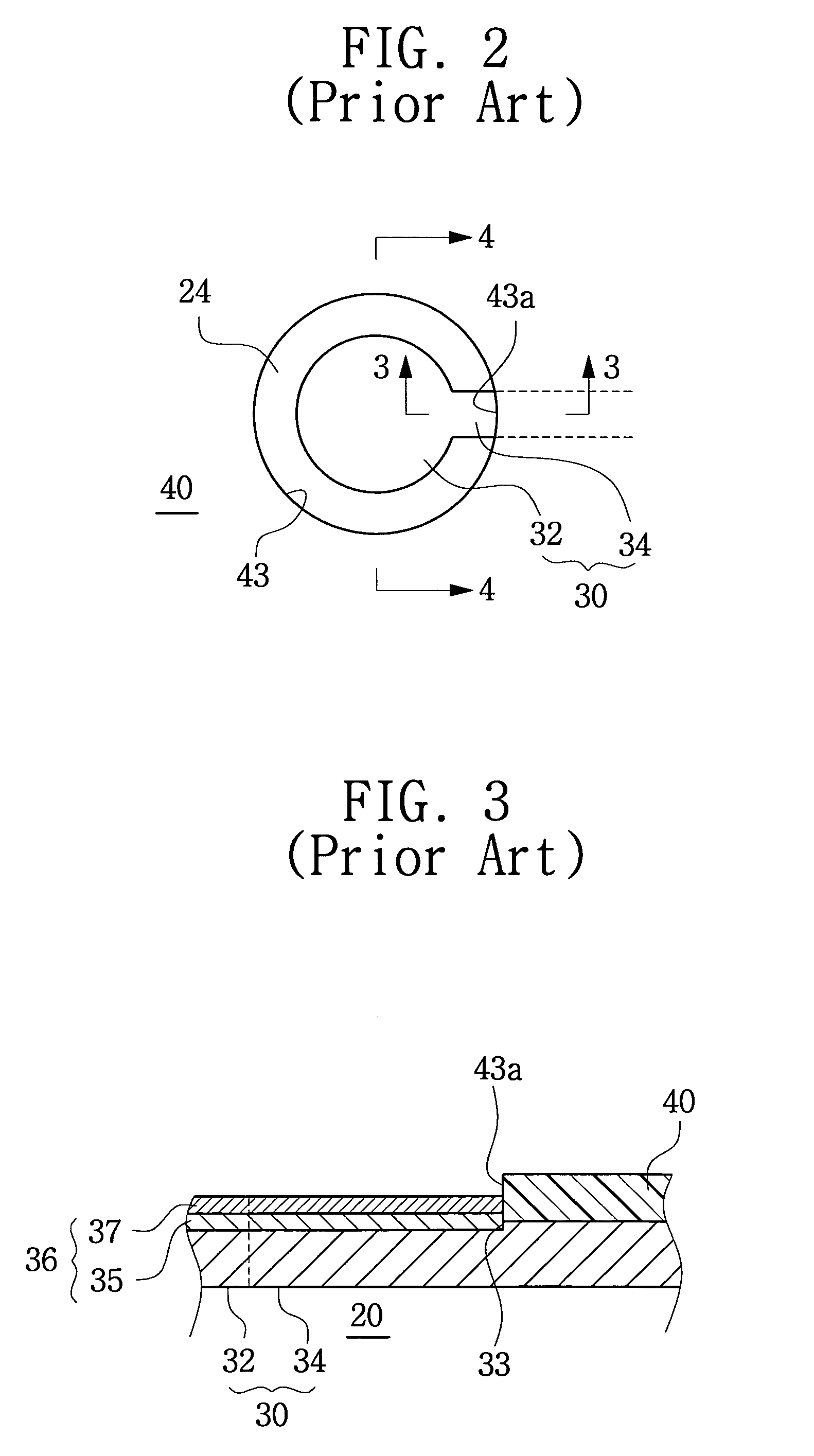

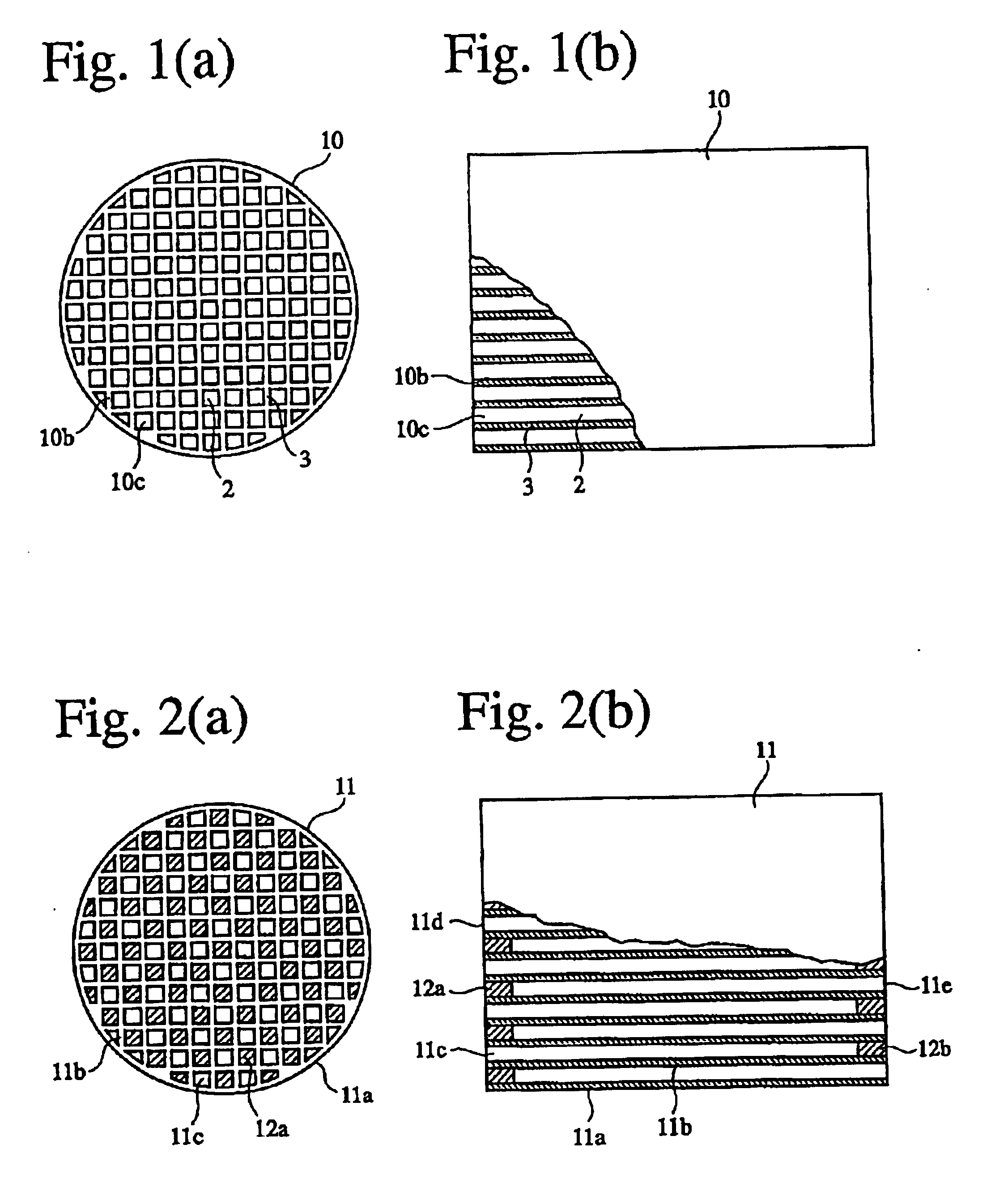

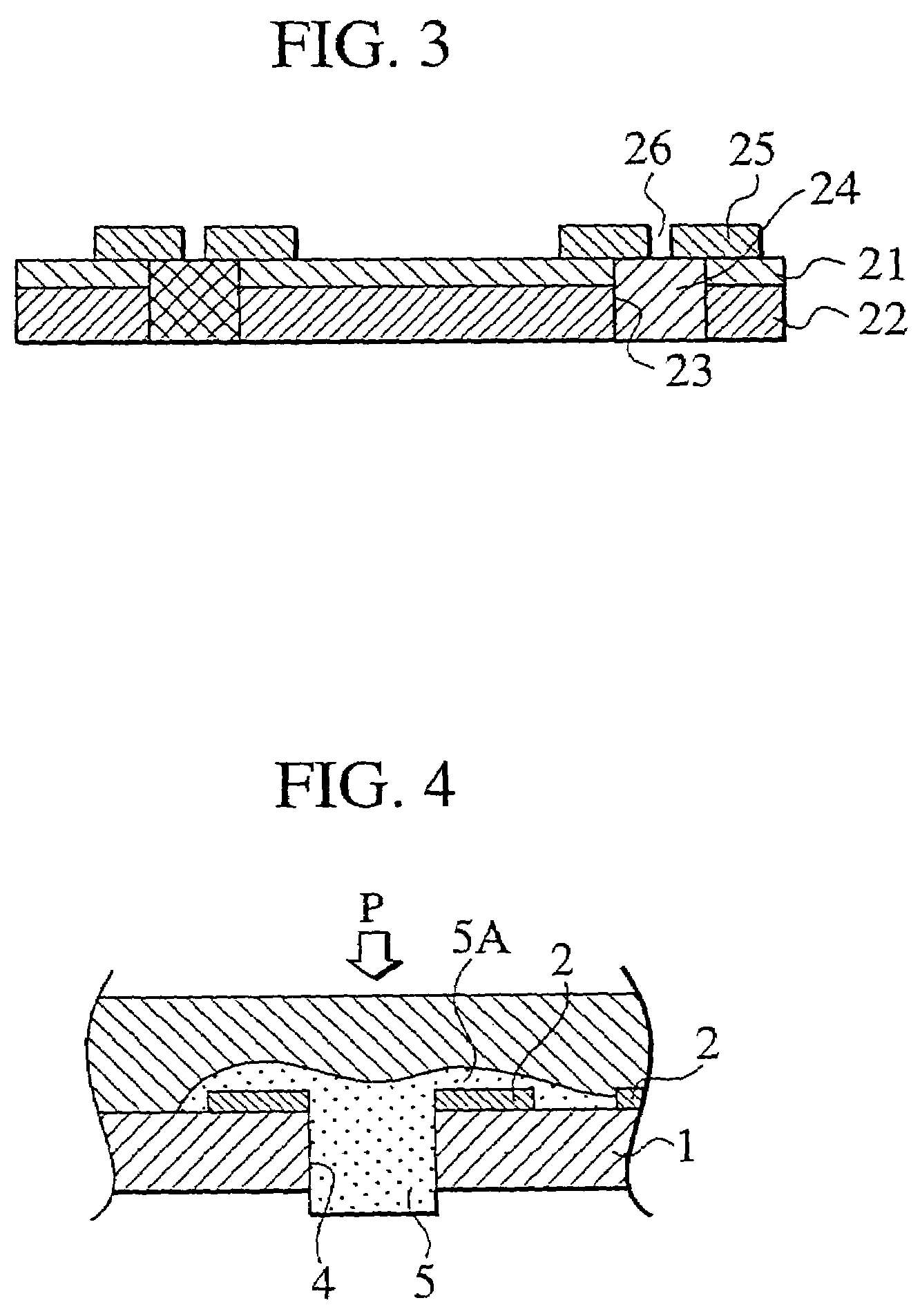

Edge connect wafer level stacking

ActiveUS20080083977A1Low costSmall sizeSemiconductor/solid-state device detailsSolid-state devicesMechanical engineering

In accordance with an aspect of the invention, a stacked microelectronic package is provided which may include a plurality of subassemblies, e.g., a first subassembly and a second subassembly underlying the first subassembly. A front face of the second subassembly may confront the rear face of the first subassembly. Each of the first and second subassemblies may include a plurality of front contacts exposed at the front face, at least one edge and a plurality of front traces extending about the respective at least one edge. The second subassembly may have a plurality of rear contacts exposed at the rear face. The second subassembly may also have a plurality of rear traces extending from the rear contacts about the at least one edge. The rear traces may extend to at least some of the plurality of front contacts of at least one of the first or second subassemblies.

Owner:TESSERA INC

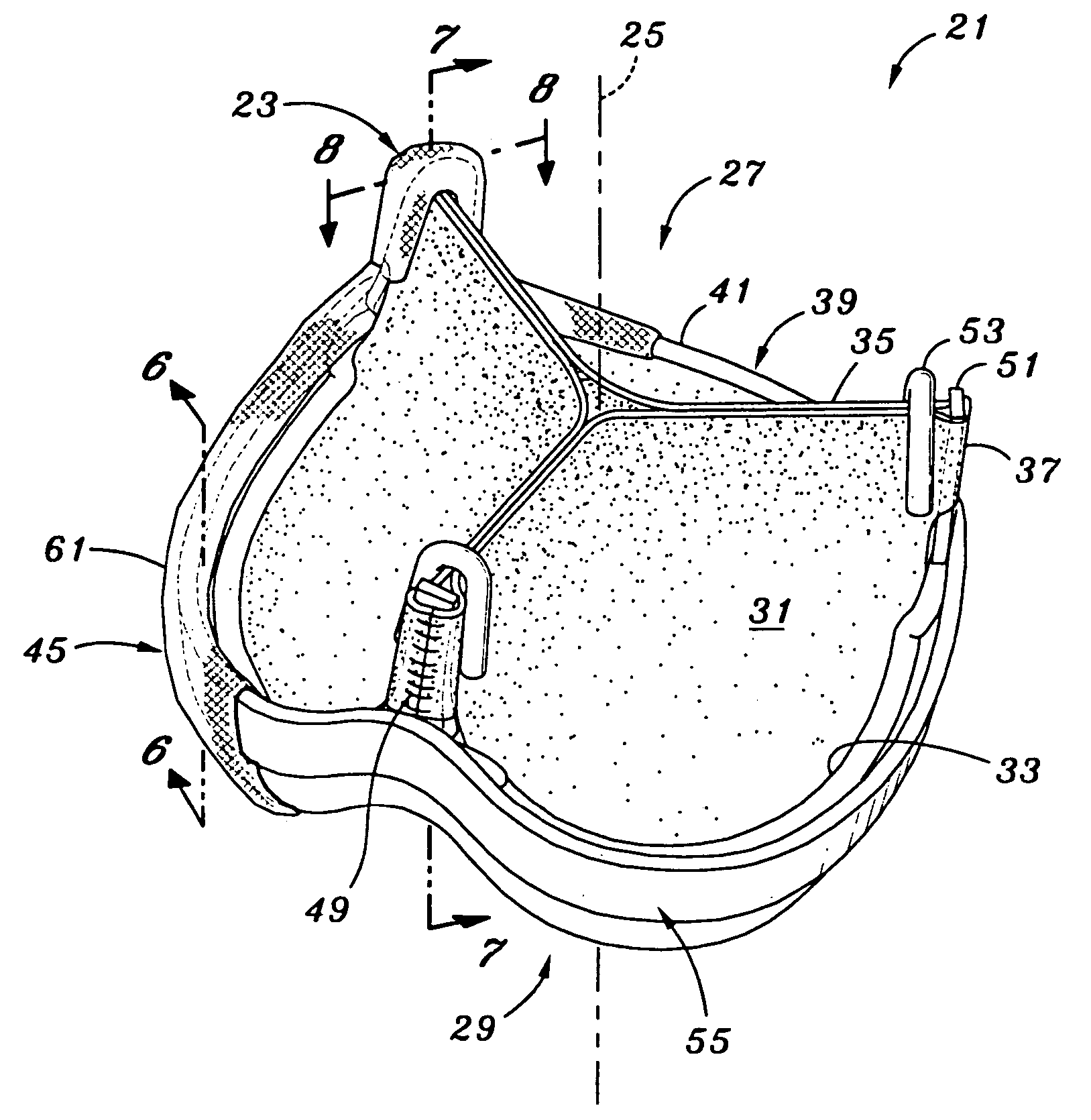

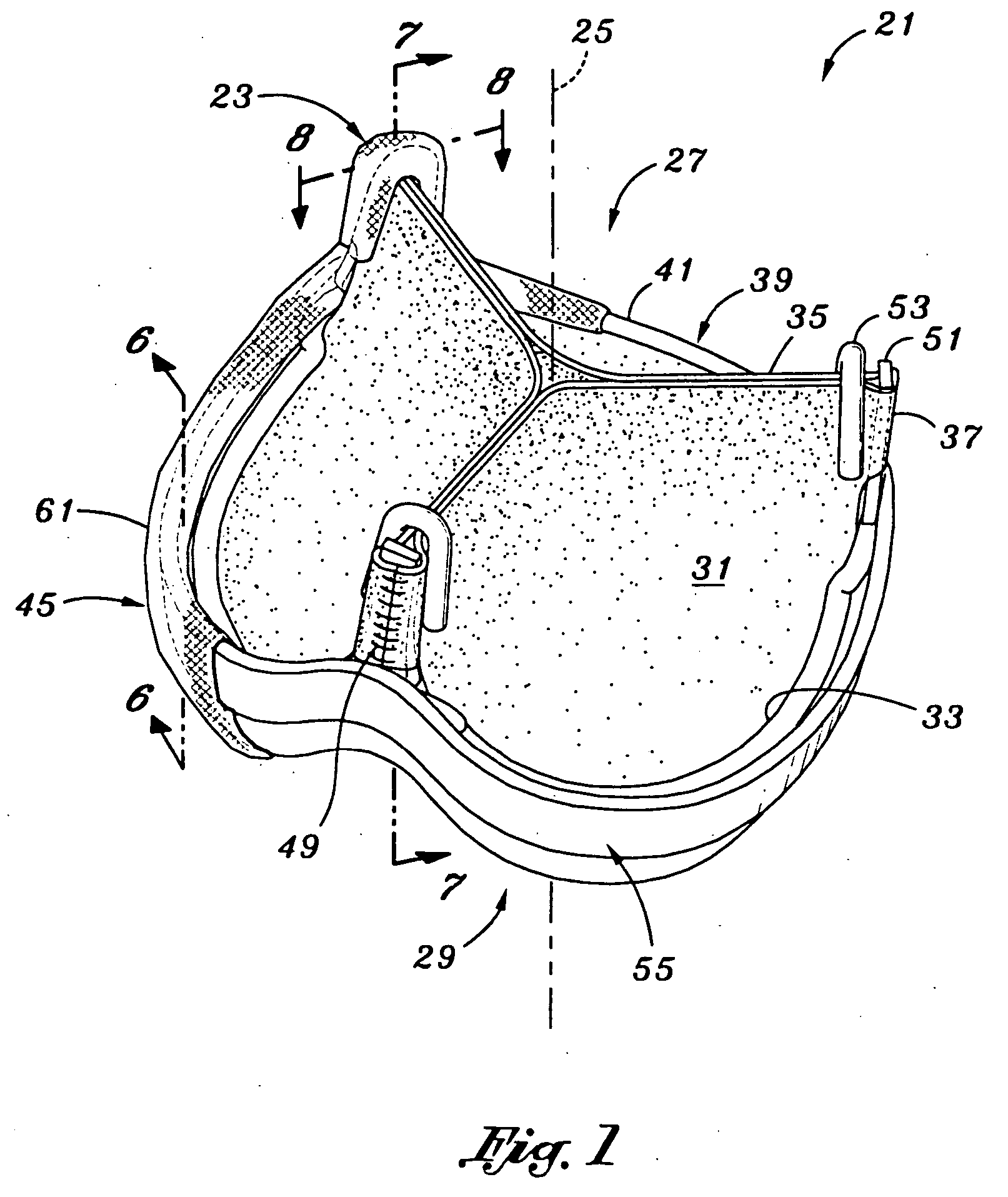

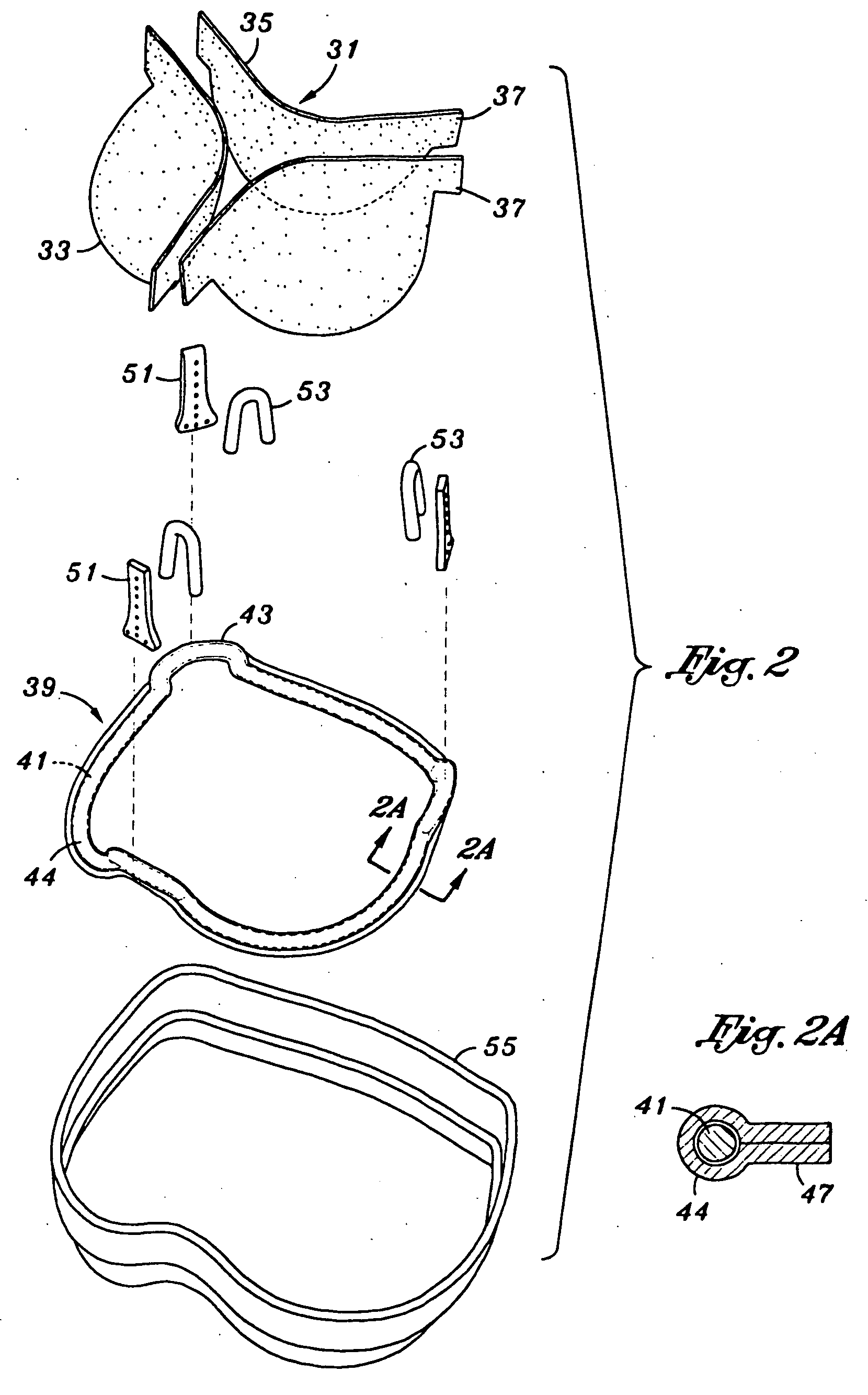

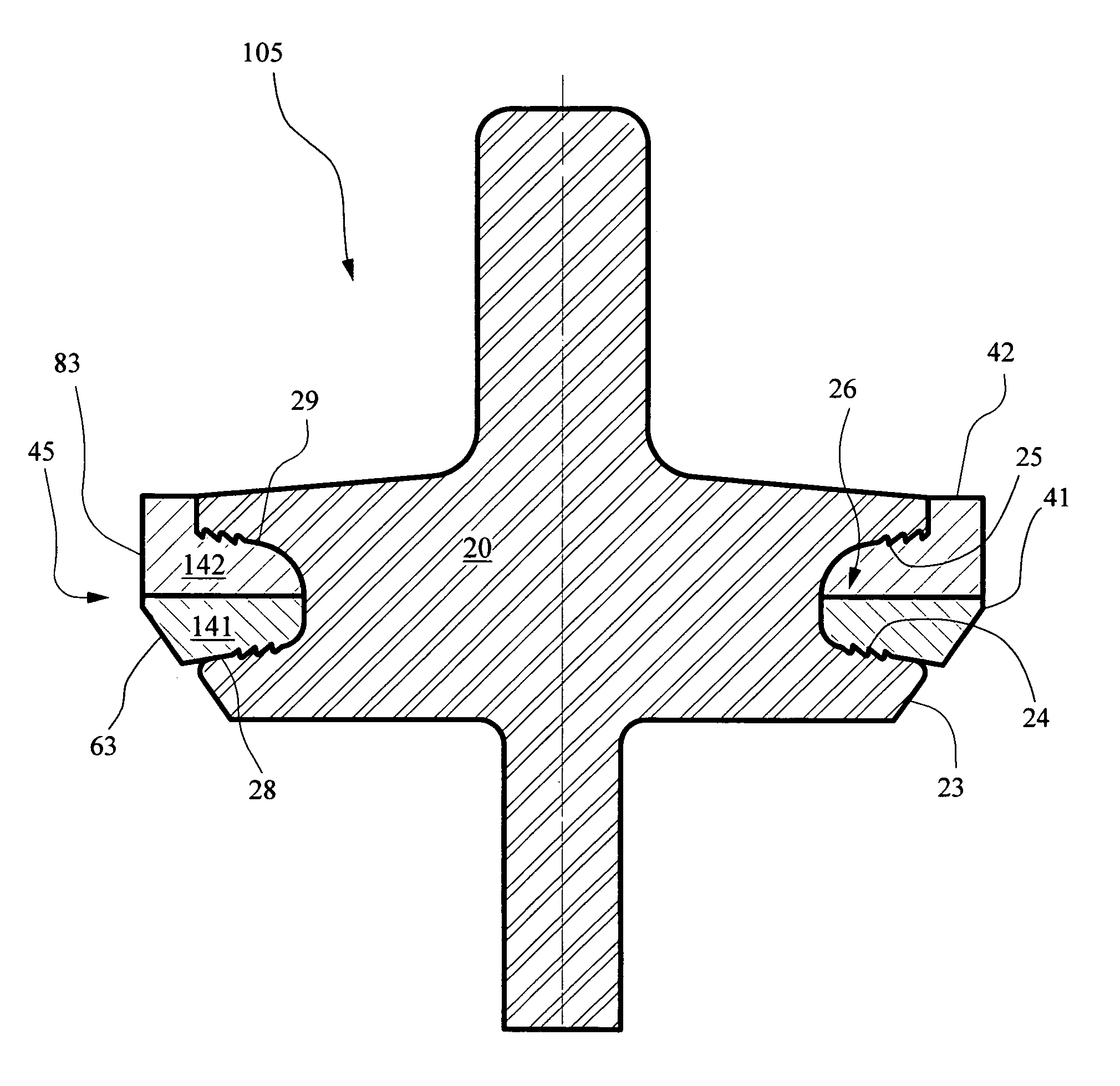

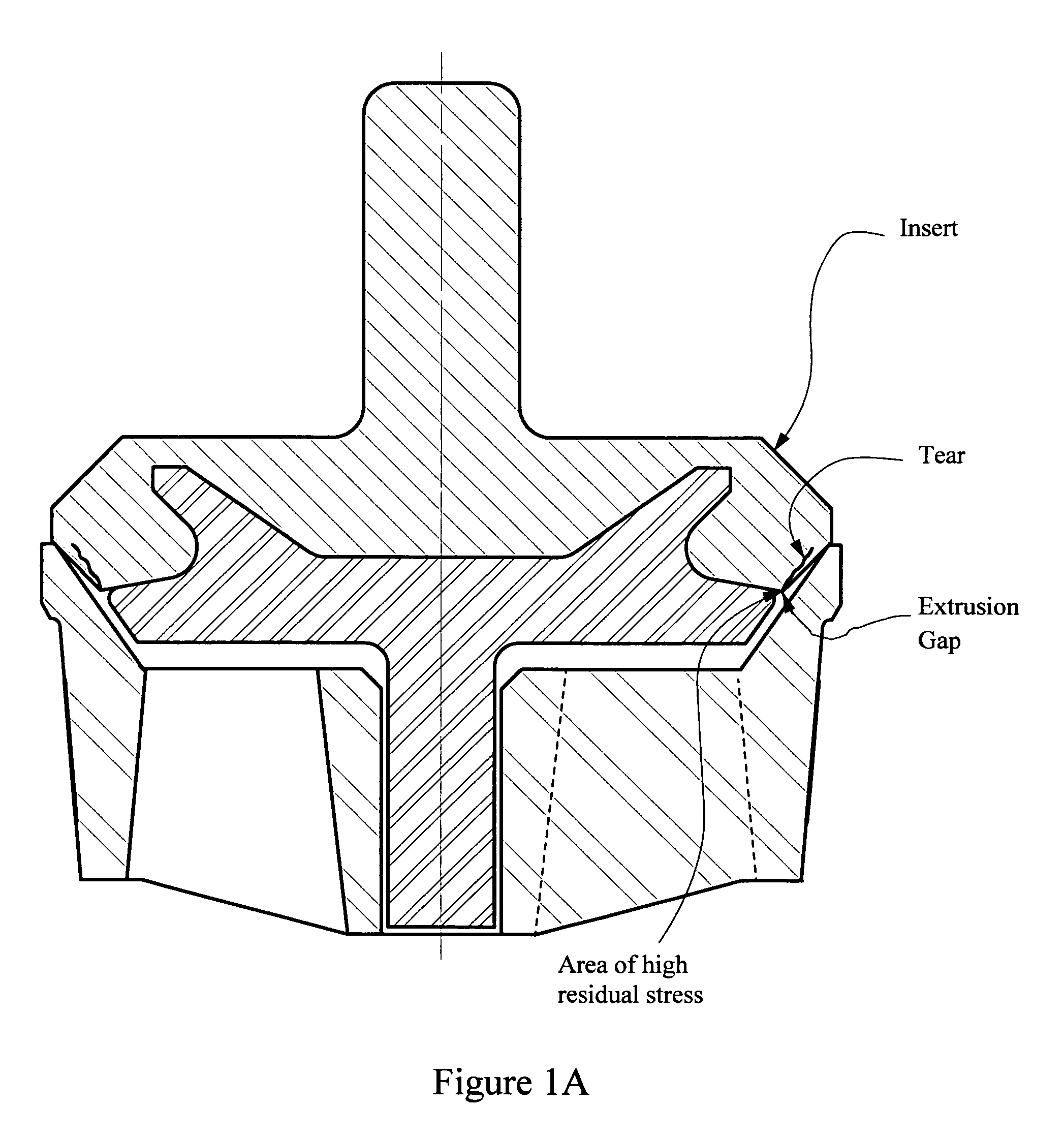

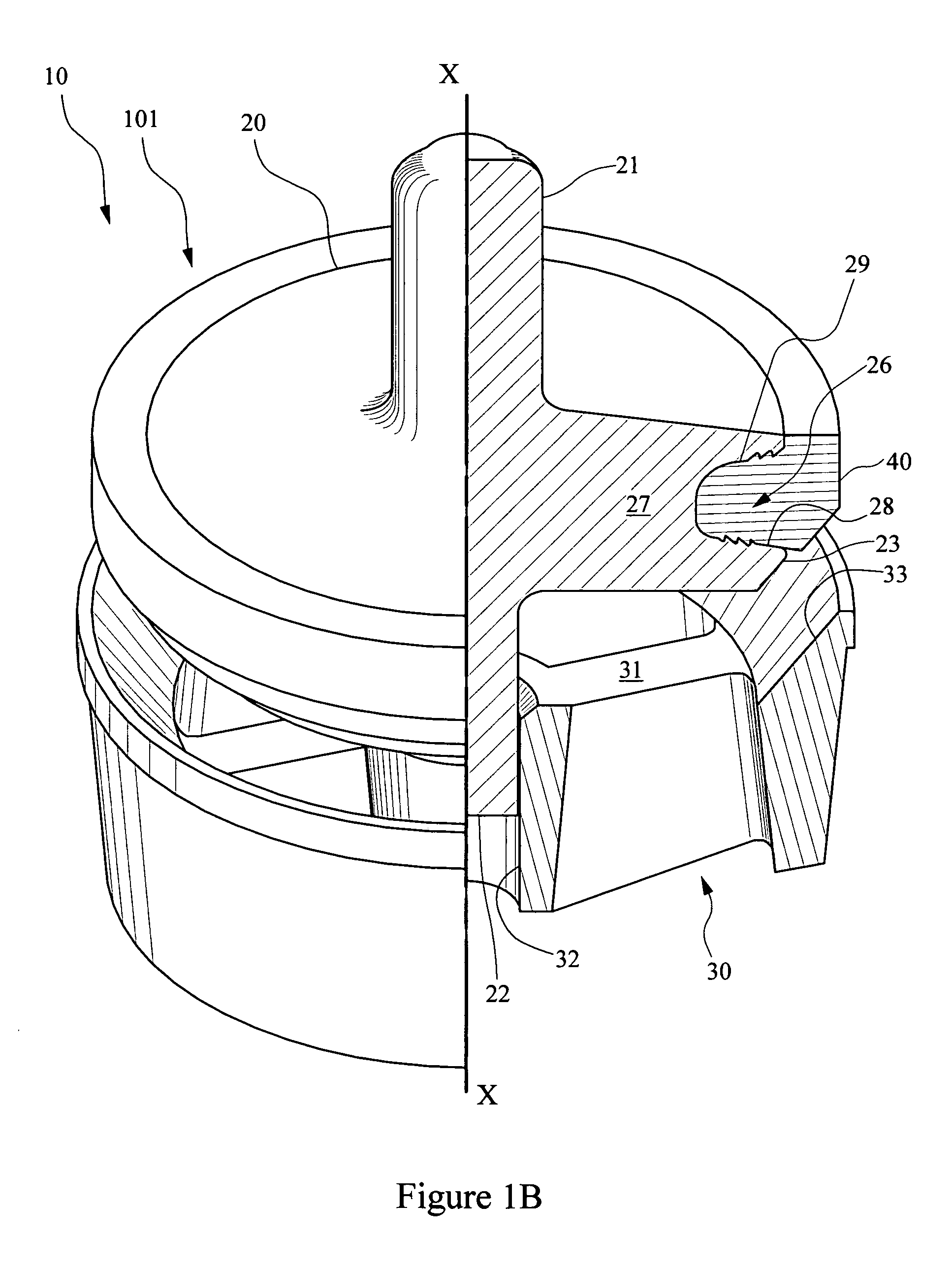

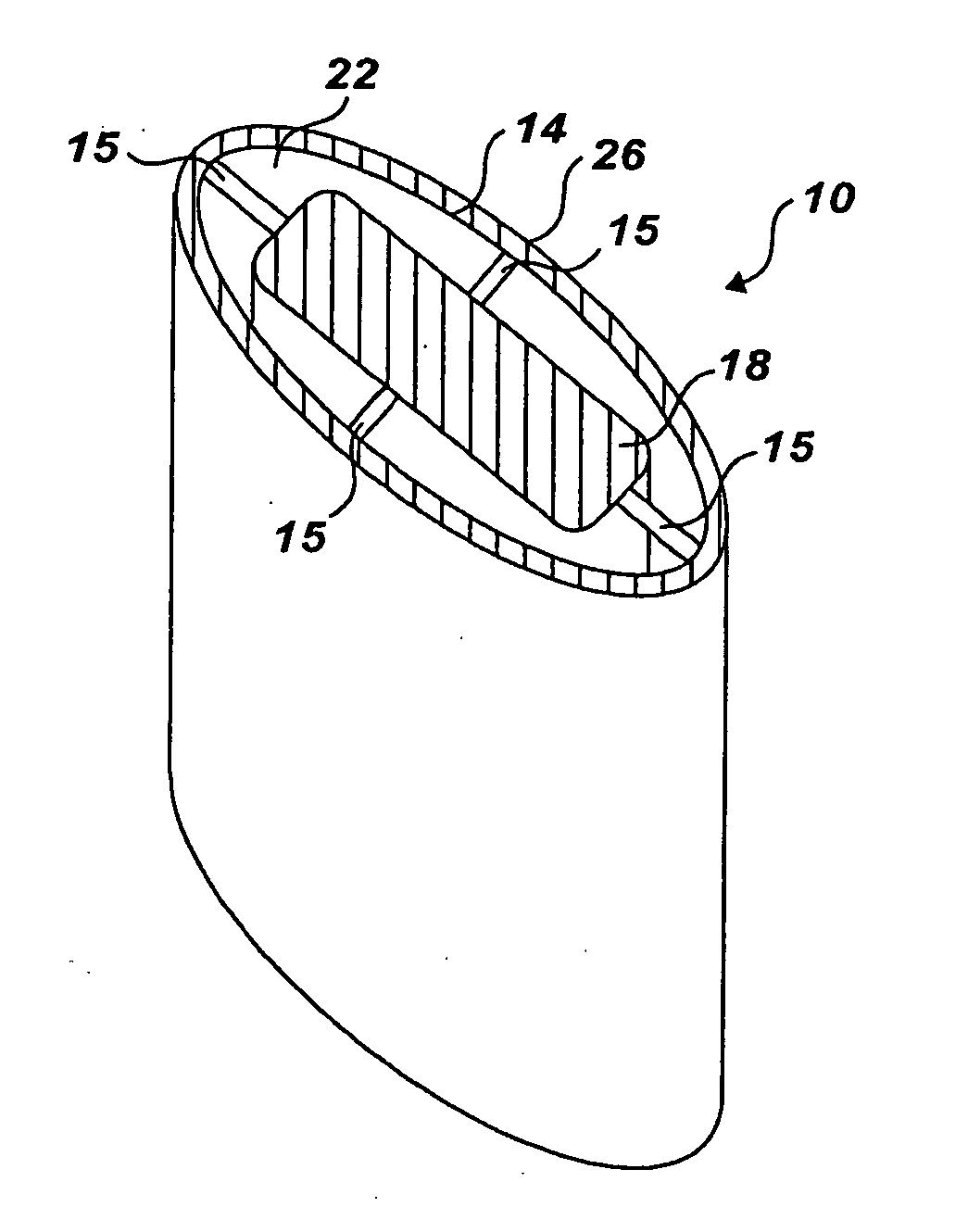

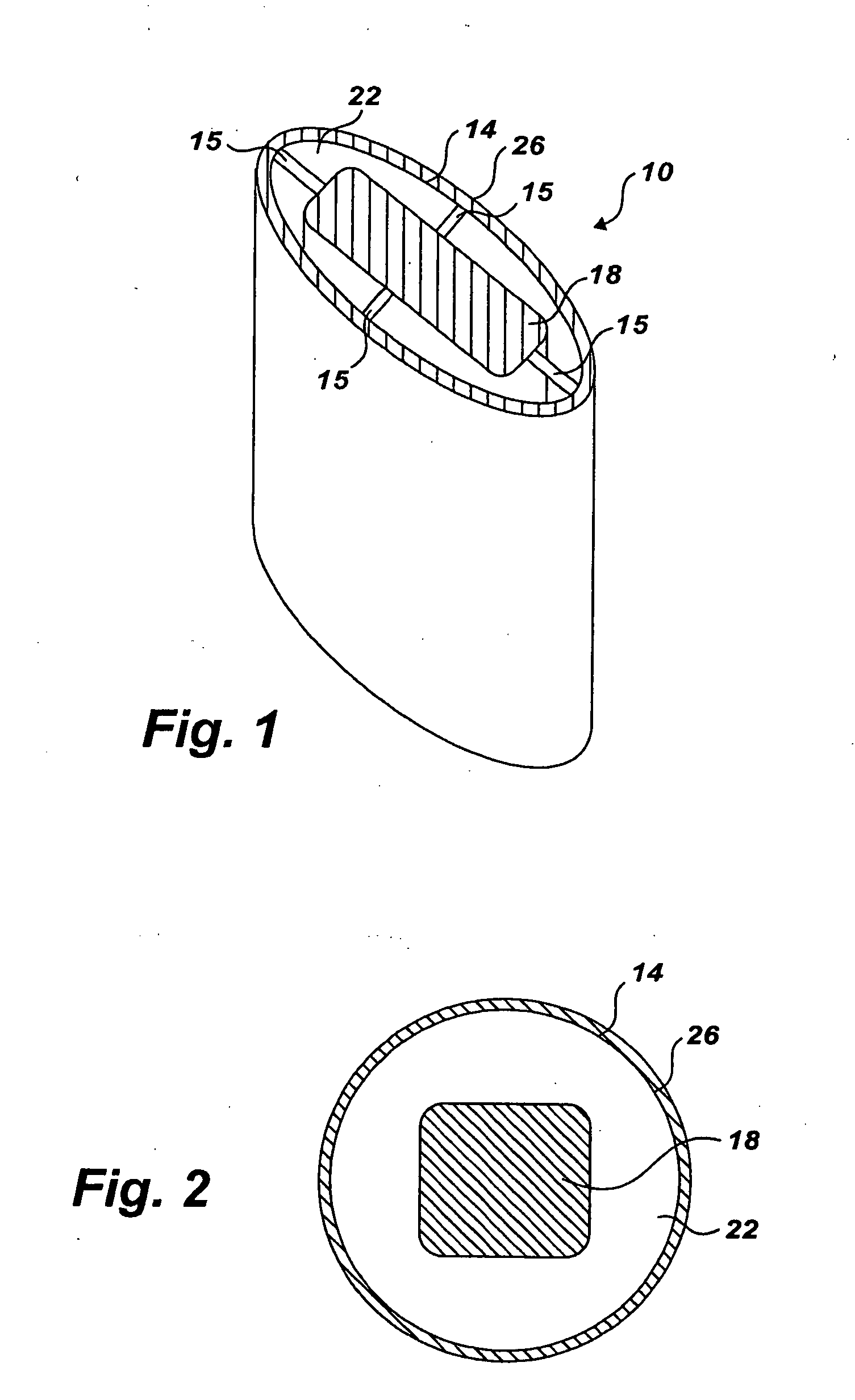

Flexible heart valve

A flexible prosthetic tissue-type heart valve having commissures that are substantially decoupled from a cusp support structure. The valve includes three leaflets having arcuate cusp edges and opposed concave shaped free edges, with outwardly-directed attachment tabs therebetween. A cusp support structure in either one or more pieces attaches to the leaflet cusp edges. Three commissures are each formed partly with an axially-extending insert member to which two adjacent leaflet tabs attach. An inverted V-shaped clip maintains close contact between the adjacent leaflet tabs and provides a stress-relieving clamping action in conjunction with the insert member. The insert member attaches about its lower end to base sections of the cusp support structure, or to an intermediate sewing ring, so that the commissures may pivot about the cusp support structure.

Owner:EDWARDS LIFESCIENCES CORP

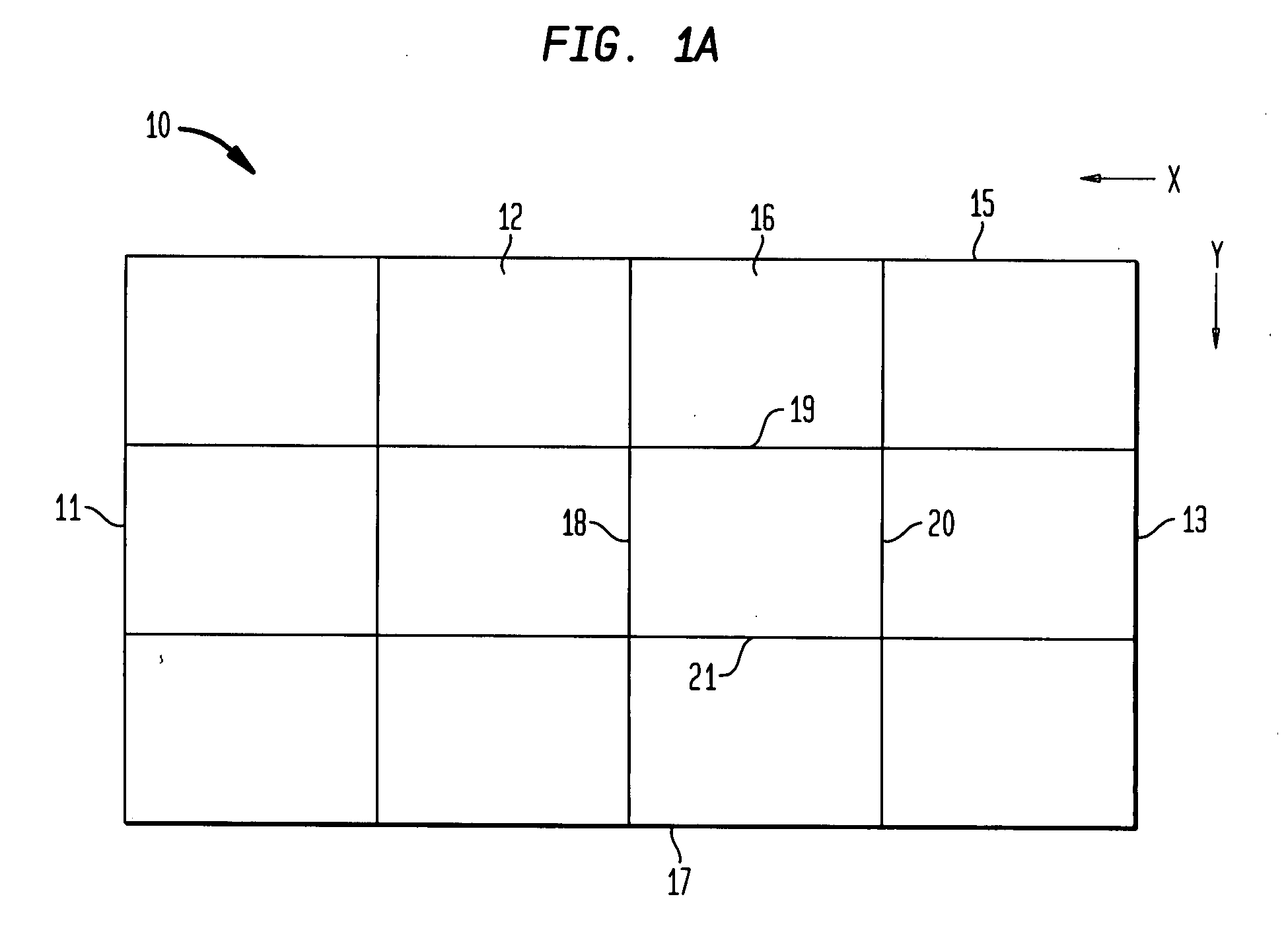

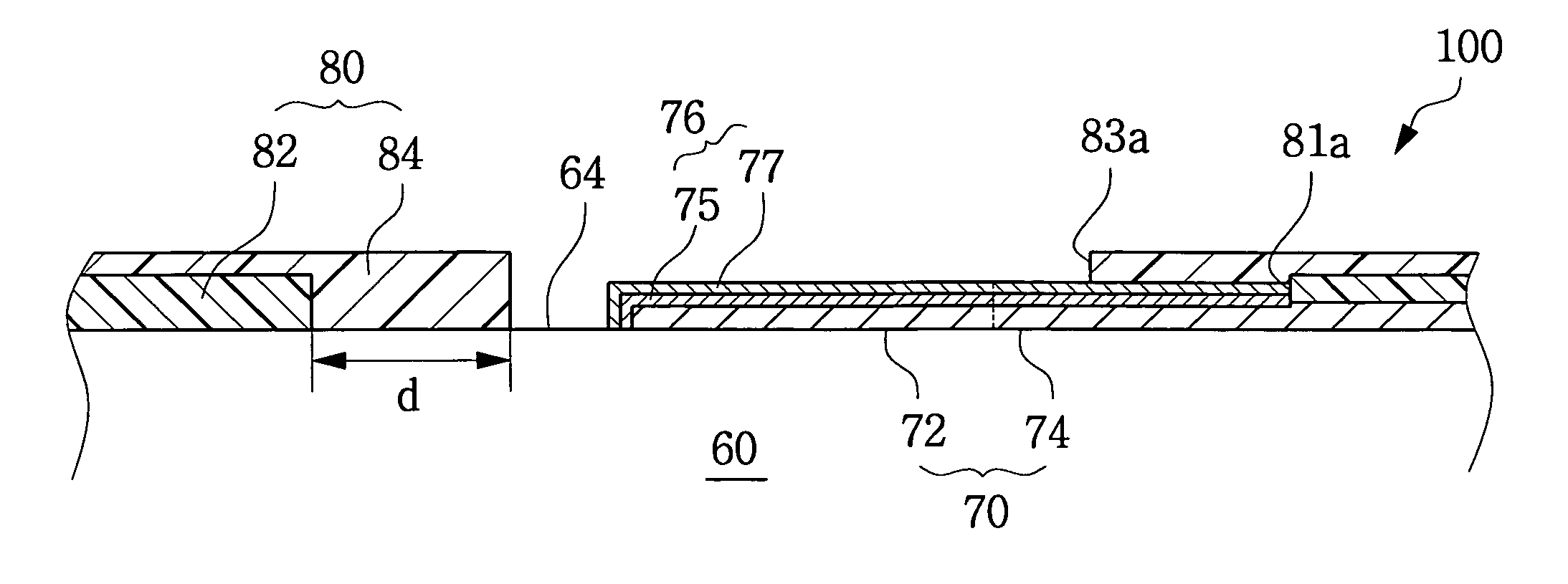

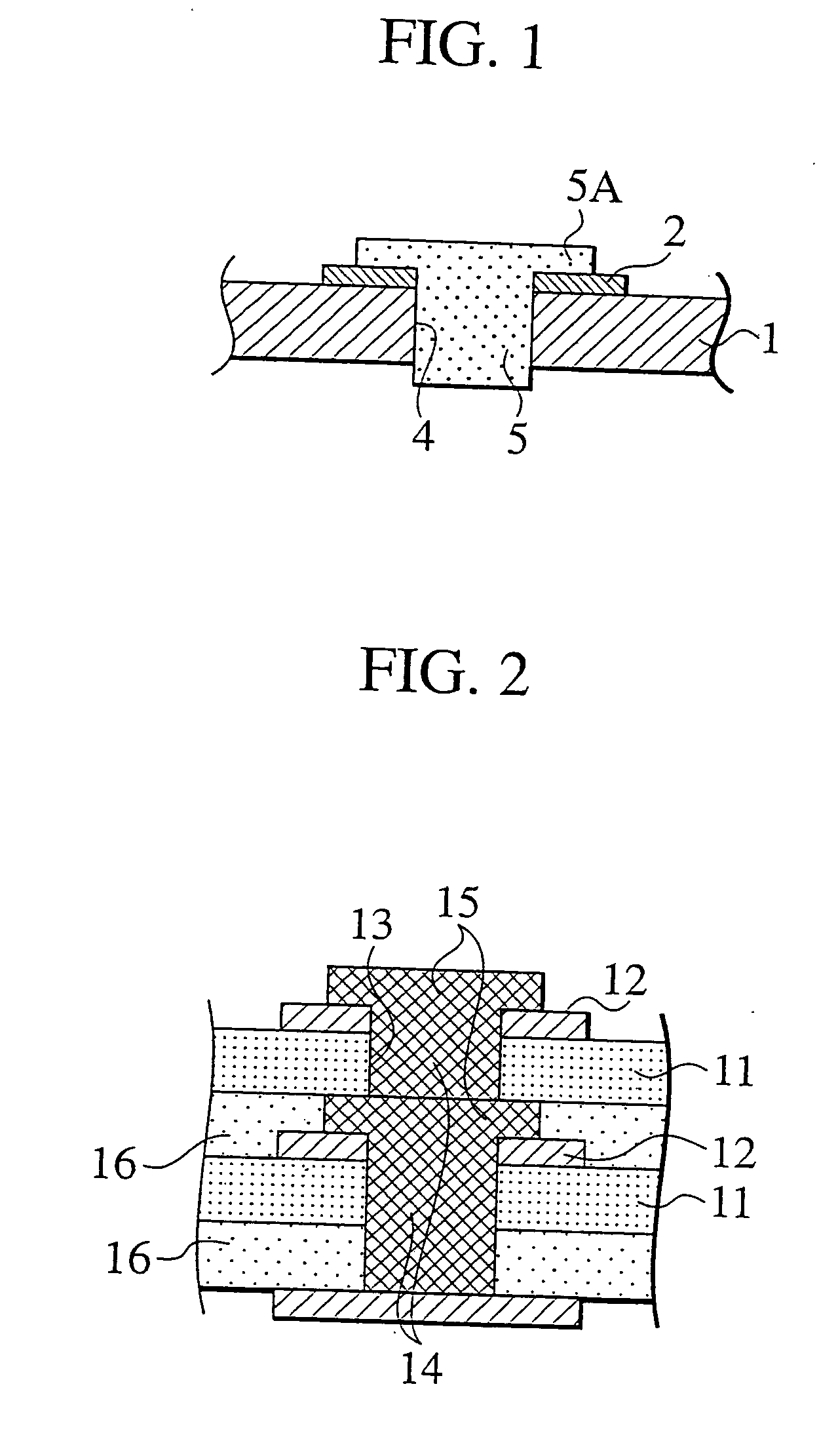

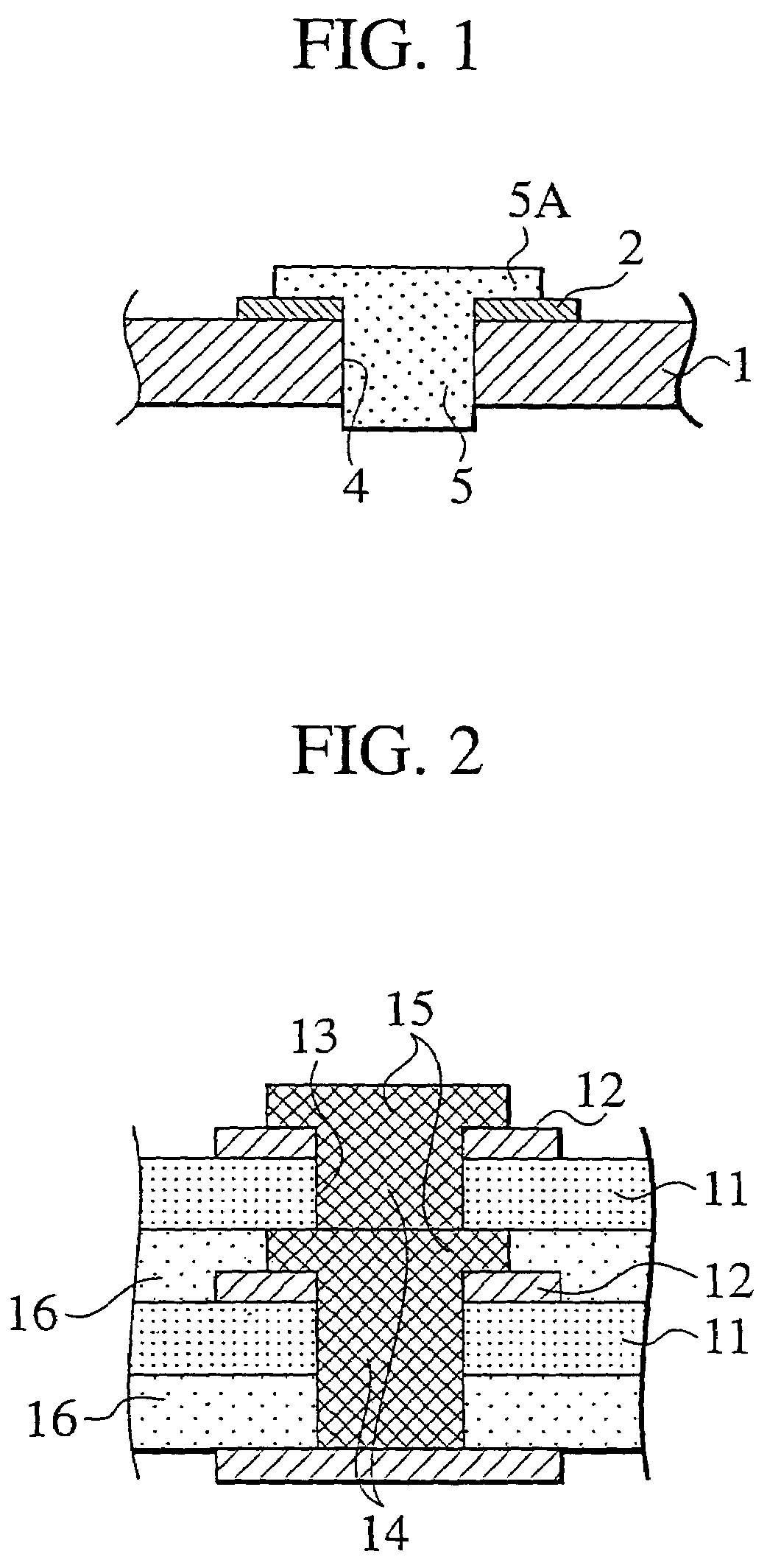

Non-solder mask defined (NSMD) type wiring substrate for ball grid array (BGA) package and method for manufacturing such a wiring substrate

ActiveUS7098407B2Reduce crackingReduce stress concentrationPrinted circuit assemblingSemiconductor/solid-state device detailsStress concentrationSolder mask

In one embodiment, a pad is formed on a substrate surface. The pad is connected with a connecting pattern. A first mask is formed on the substrate. The first mask has a first opening exposing at least a portion of the pad and a portion of the connecting pattern. A second mask is formed on the first mask. The second mask has a second opening exposing at least a portion of the pad and a portion of the connecting pattern. A boundary surface or sidewall of the first opening is not coplanar with a boundary surface or sidewall of the second opening. Therefore, stresses may be prevented from concentrating on the boundary surface of the first opening, thereby allowing dispersion of the stresses and restraining pattern cracks.

Owner:SAMSUNG ELECTRONICS CO LTD

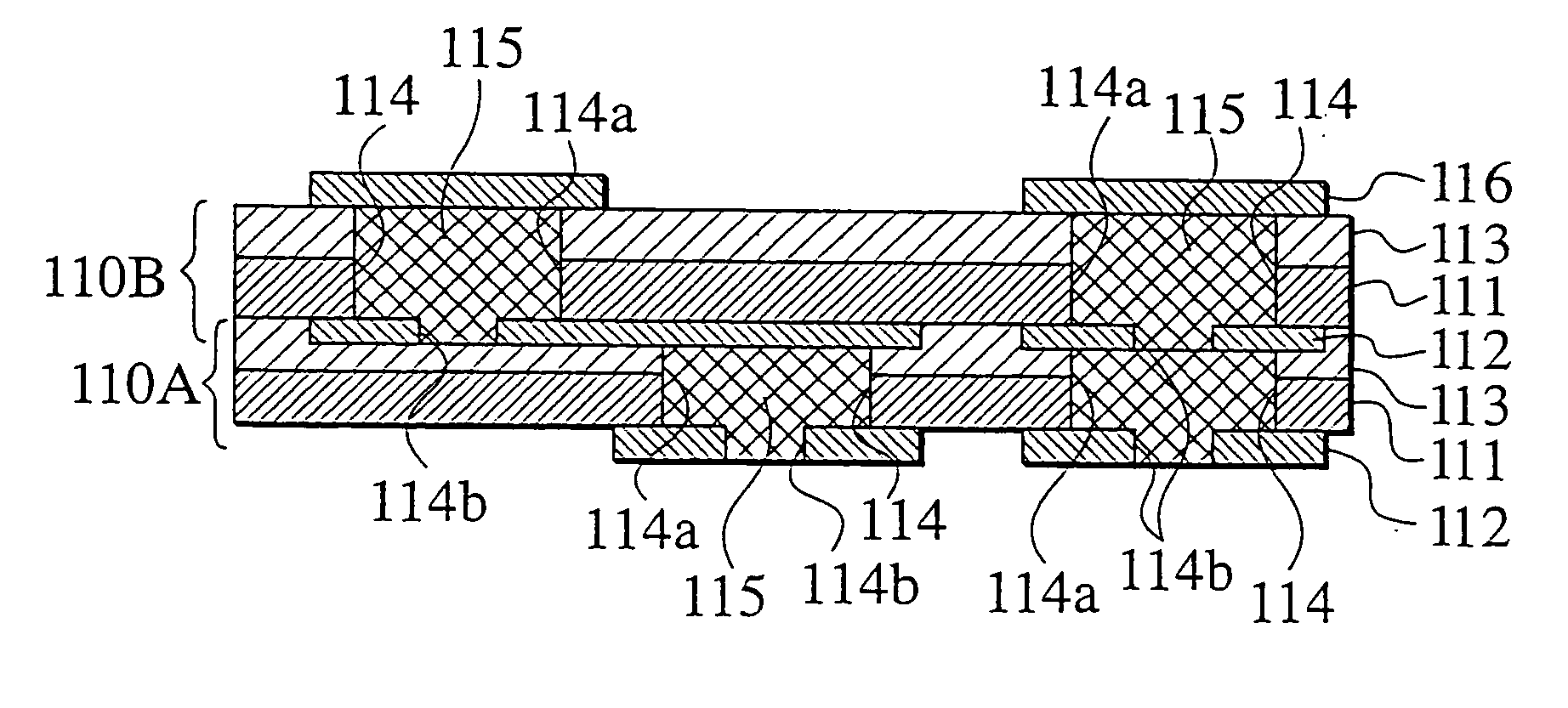

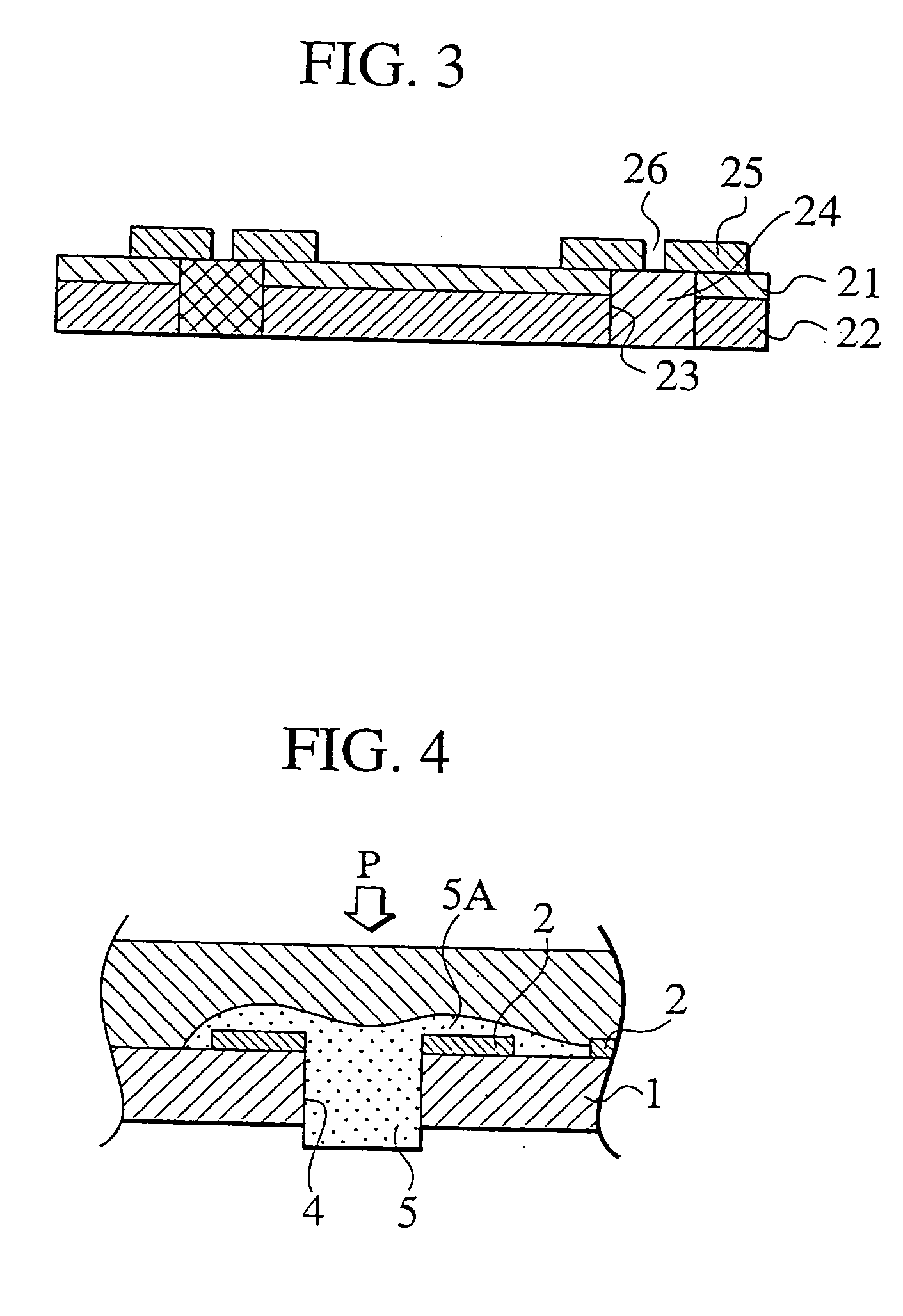

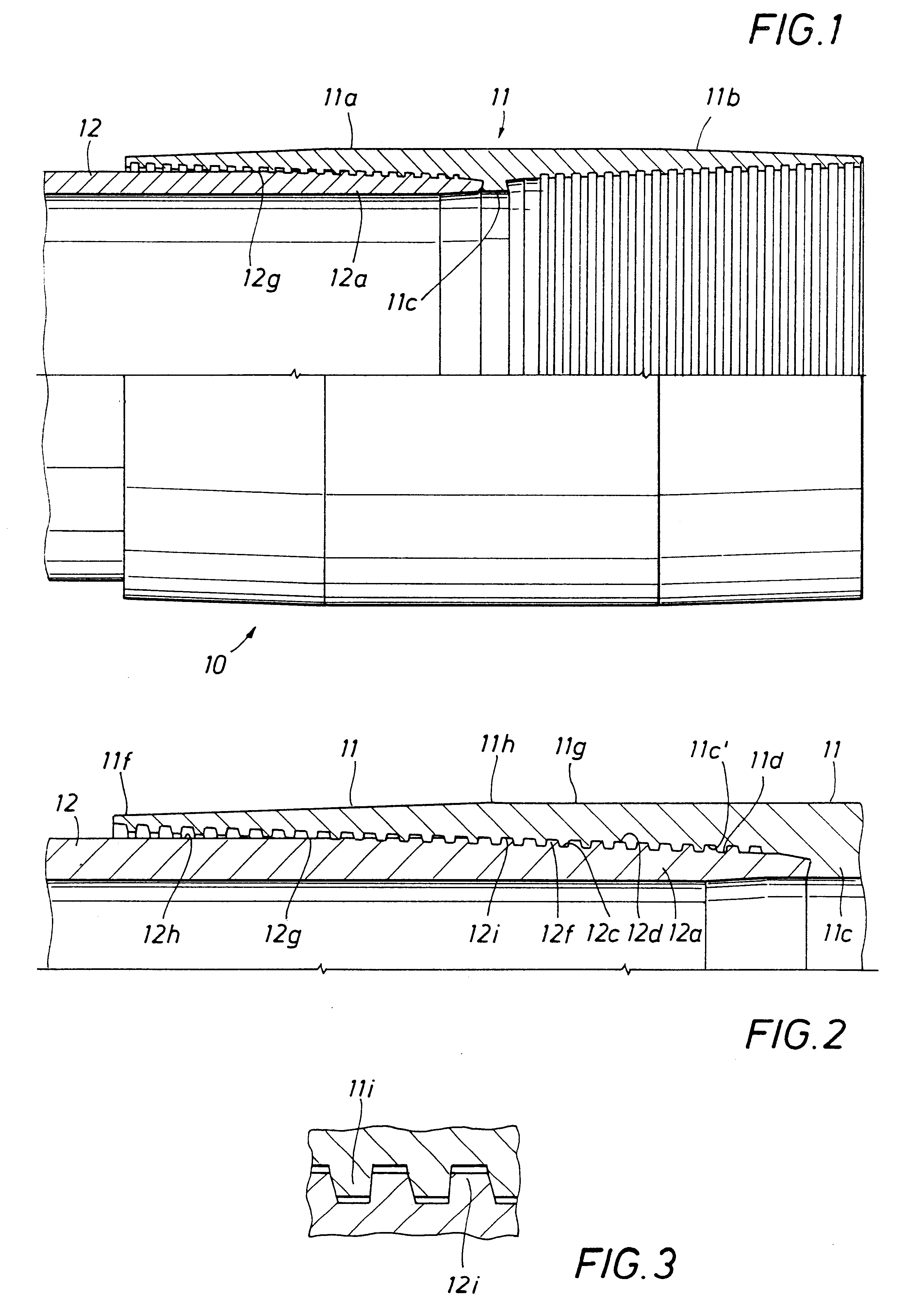

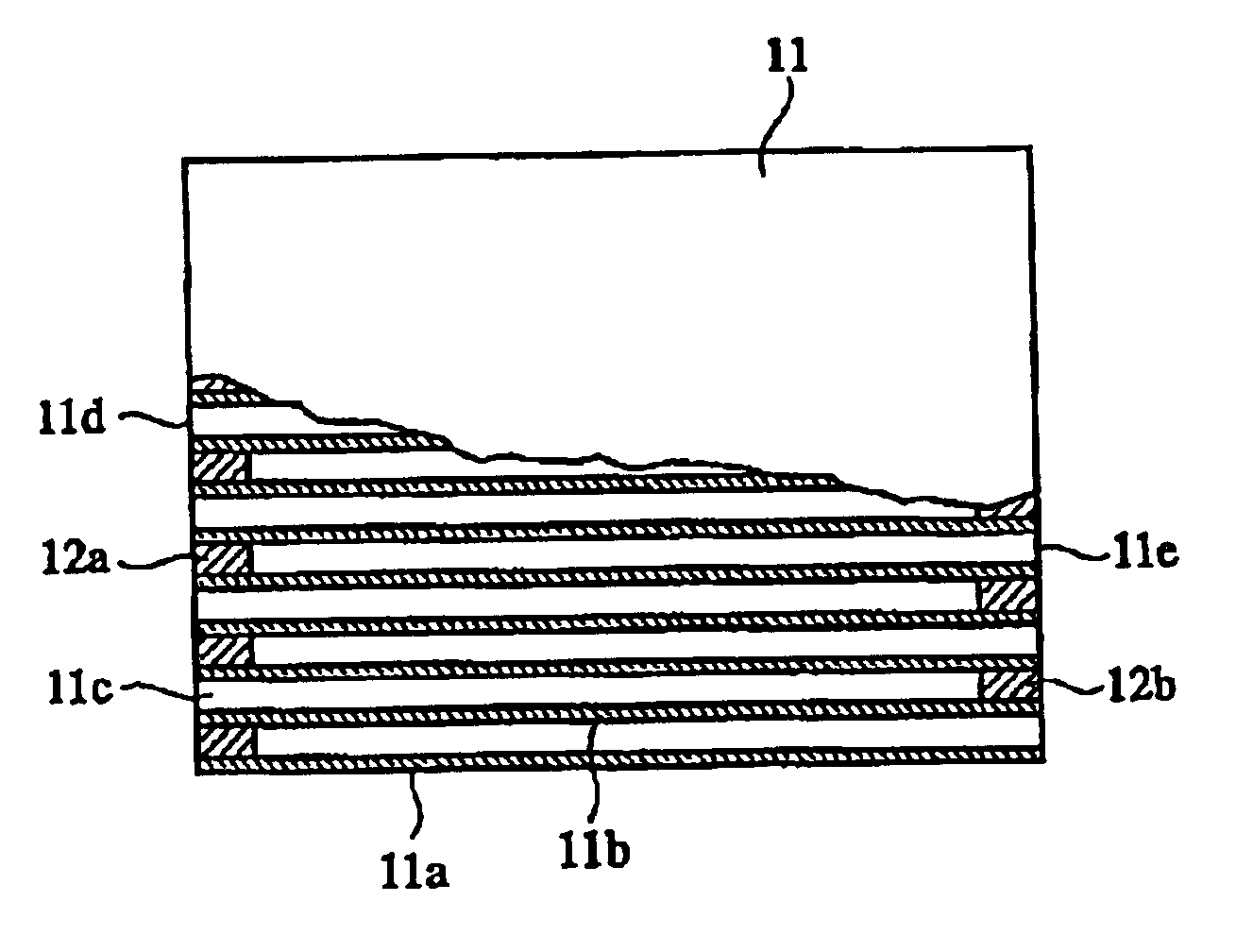

Multilayer wiring board, base for multilayer wiring board, printed wiring board and its manufacturing method

InactiveUS20050155792A1Solve the real problemIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionInterconnection

A multilayer wiring board assembly component comprises: an insulating substrate component (the insulating resin layer 111); a conductive layer 112 formed on one surface of said insulating substrate component 111 in the form of an electrode pattern; an adhesive layer 113 formed on the other surface of said insulating substrate component 111; and a conductive resin composition 115 with which is filled a through hole passing through said insulating substrate component 111, said adhesive layer and said conductive layer in order to make interlayer interconnection. The bore diameter of the conductive layer portion 114b of the through hole 114 is smaller than the bore diameter of the insulating resin layer portion and the adhesive layer portion 114a to establish electrical connection between the conductive resin composition 115 and the conductive layer 112 by the rare surface 112a of the conductive layer 112.

Owner:THE FUJIKURA CABLE WORKS LTD

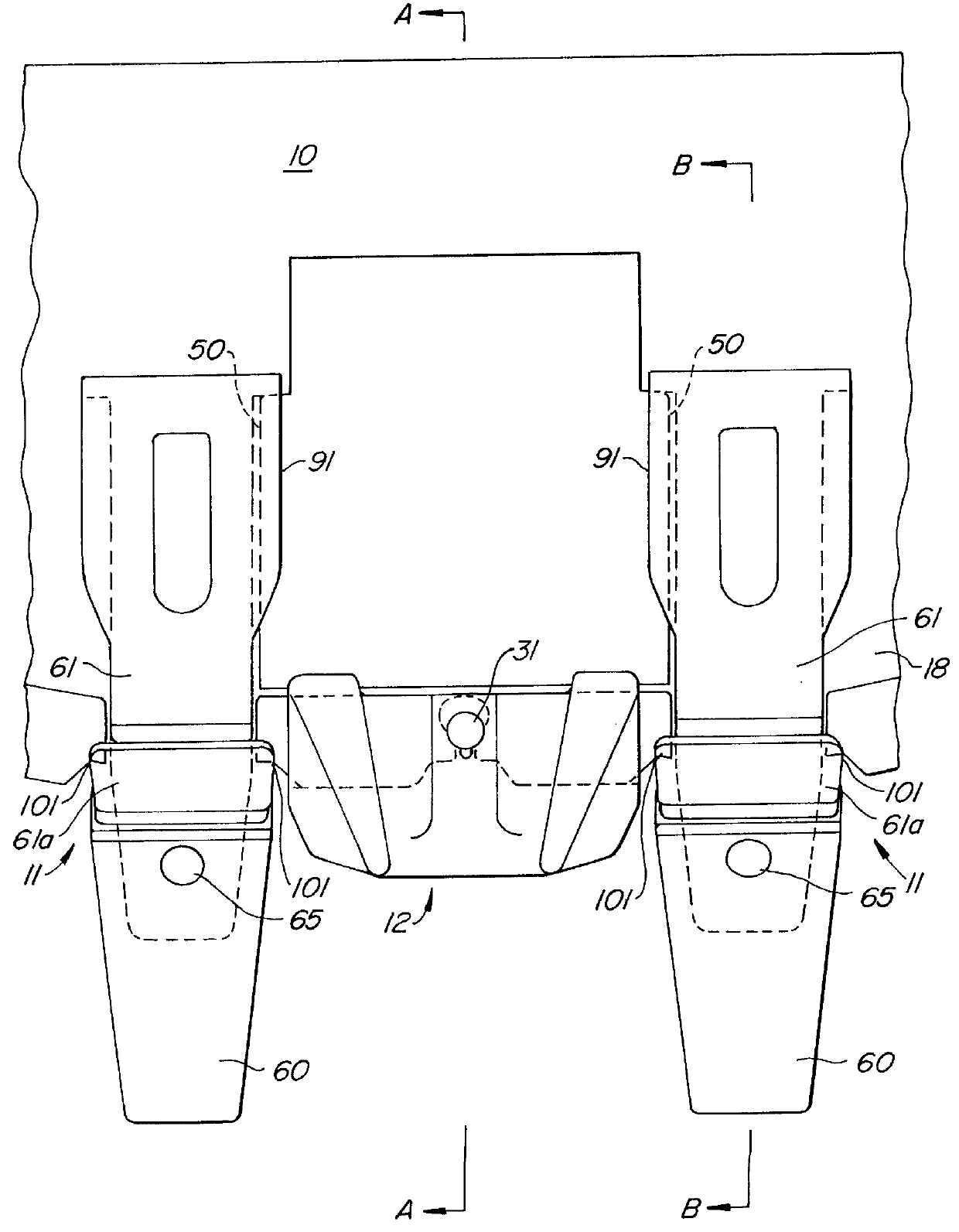

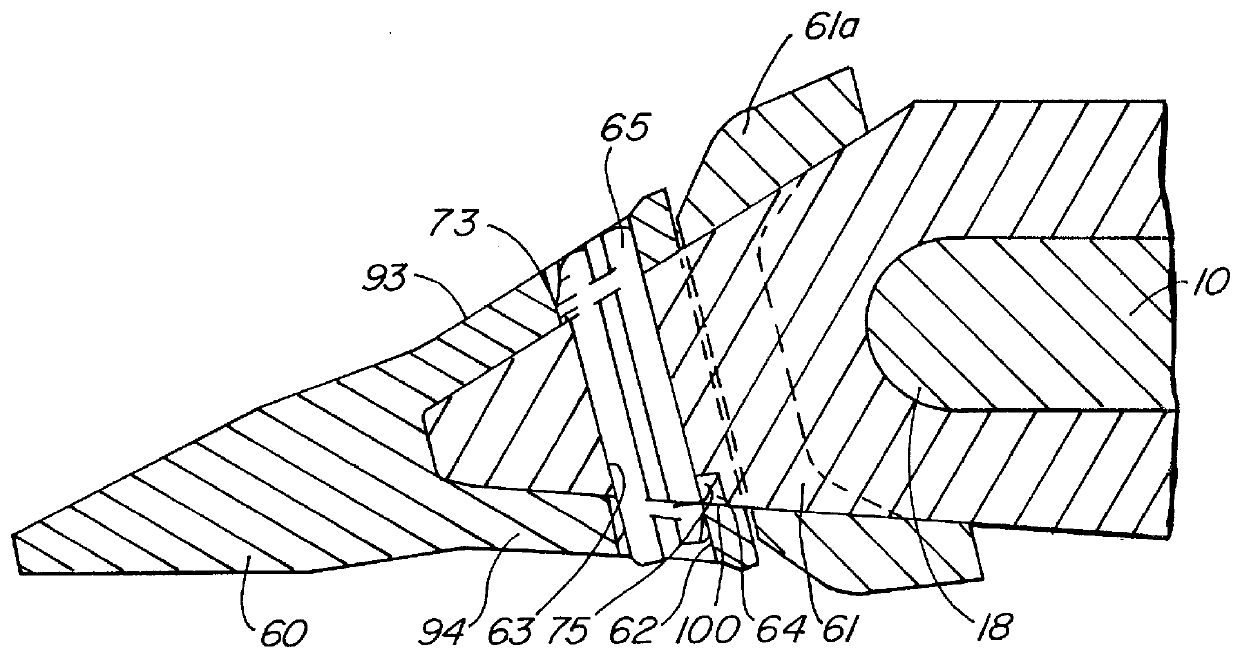

Bucket assembly with an improved lip

An excavation bucket assembly for an excavation apparatus such as a front-end loader includes a plurality of shrouds and tooth assemblies mounted along a lip of the bucket body. The shrouds are connected via reusable connection pins that are biased within aligned connection-holes with a plunger assembly mounted within the connection pin. The connection-holes are defined by two overlapping ovals, with the proximal oval having a larger radius as compared to the distal oval. Additionally, an improved attachment pin is utilized to connect a tooth portion to a tooth body portion of the tooth assemblies that provides for a secure and reliable attachment and easy exchange of worn tooth portions.

Owner:BIERWITH ROBERT S

Valve body and seal assembly

InactiveUS7513483B1Minimize impactReduce stress concentrationCheck valvesEqualizing valvesStress concentrationElastomer

A valve body and seal assembly comprising a valve body having one or more peripheral integral seal retention grooves and one or more peripheral single-durometer and / or dual-durometer elastomeric seals, each seal being cast-in-place in an integral seal retention groove having adhesion-inhibiting surfaces and offset circular serrations of predetermined height on opposing groove walls. Adhesion-inhibiting surfaces reduce or eliminate internal elastomer stress due to curing of cast-in-place elastomeric seals. Serrations on each of the opposing groove walls are offset to accommodate differing stress concentrations in the walls. Opposing groove walls diverge peripherally. Offset serrations result in decreased metal fatigue from impact and bending stress. Offset serrations also improve valve sealing and increase valve service life by maintaining correct seal position on the valve body while minimizing background stress in the seal elastomer(s). Valve service life is also increased by appropriate choice of differing elastomer compositions for dual-durometer seals.

Owner:NOVATECH HLDG CORP

Threaded and coupled connection for improved fatigue resistance

InactiveUS6609735B1Reduce horizontal sizeReduce stress concentrationDrilling rodsFluid pressure sealed jointsCouplingEngineering

Threaded and coupled pipe connections are provided with a number of design features that increase resistance of the connection to fatigue failure from cyclical side loading. The features acting alone or in combination include the provision of a pin thread that is formed along a single taper and that vanishes at the surface of the pipe. The coupling engages the pin such that the threaded area of the coupling engages all of the pin threads and extends beyond the vanish point of the pin threads at the optimum coupling makeup position. The threads of the coupling and pipe may engage along both the stab and load flanks to distribute the side loading. The external surface of the coupling may be tapered from the center toward each coupling end to reduce the stiffness ratio of the connection, and the ends or faces of the coupling may be reduced in radial thickness to prevent coupling splitting. The coupling length may be extended to exceed standard coupling lengths to provide the additional threaded area and / or taper areas and / or reduced stiffness ratios.

Owner:DEUT BANK TRUST COMPANY AMERICAS

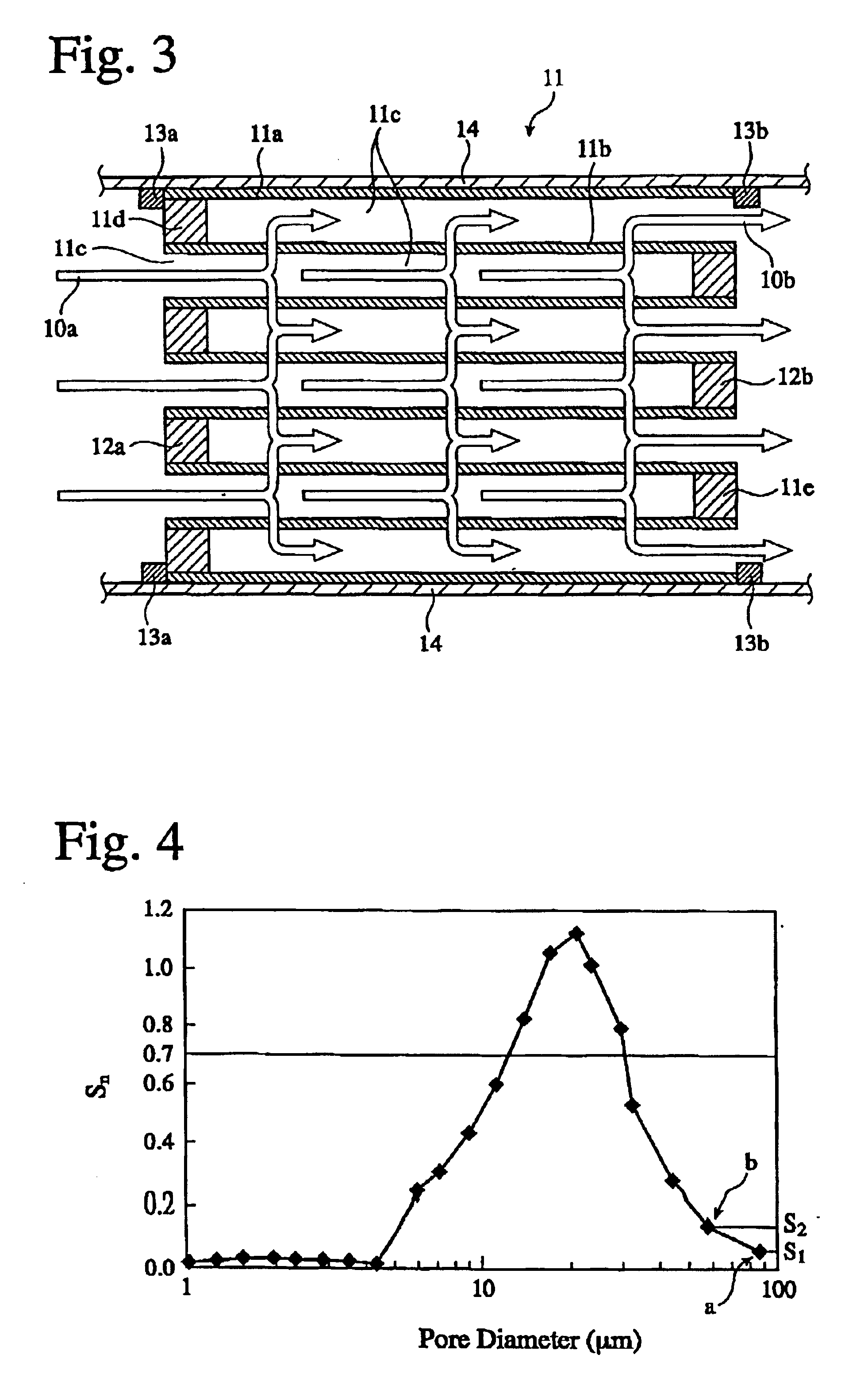

Ceramic honeycomb filter

InactiveUS6827754B2Increased durabilityHigh strengthCombination devicesAuxillary pretreatmentParticulatesMeasurement point

A ceramic honeycomb filter comprising a ceramic honeycomb structure having porous partition walls defining a plurality of flow paths for flowing an exhaust gas through the porous partition walls to remove particulates from the exhaust gas, the predetermined flow paths among the flow paths being sealed at their ends, a catalyst being carried by the porous partition walls, the porous partition walls having a porosity of 60-75% and an average pore diameter of 15-25 mum when measured according to a mercury penetration method, and the maximum of a slope Sn of a cumulative pore volume curve of the porous partition walls relative to a pore diameter obtained at an n-th measurement point being 0.7 or more, the Sn being represented by the following formula (1):wherein Dn is a pore diameter (mum) at an n-th measurement point, Dn-1 is a pore diameter (mum) at an (n-1)-th measurement point, Vn is a cumulative pore volume (cm<3> / g) at an n-th measurement point, and Vn-1 is a cumulative pore volume (cm<3> / g) at an (n-1)-th measurement point.

Owner:HITACHI METALS LTD +1

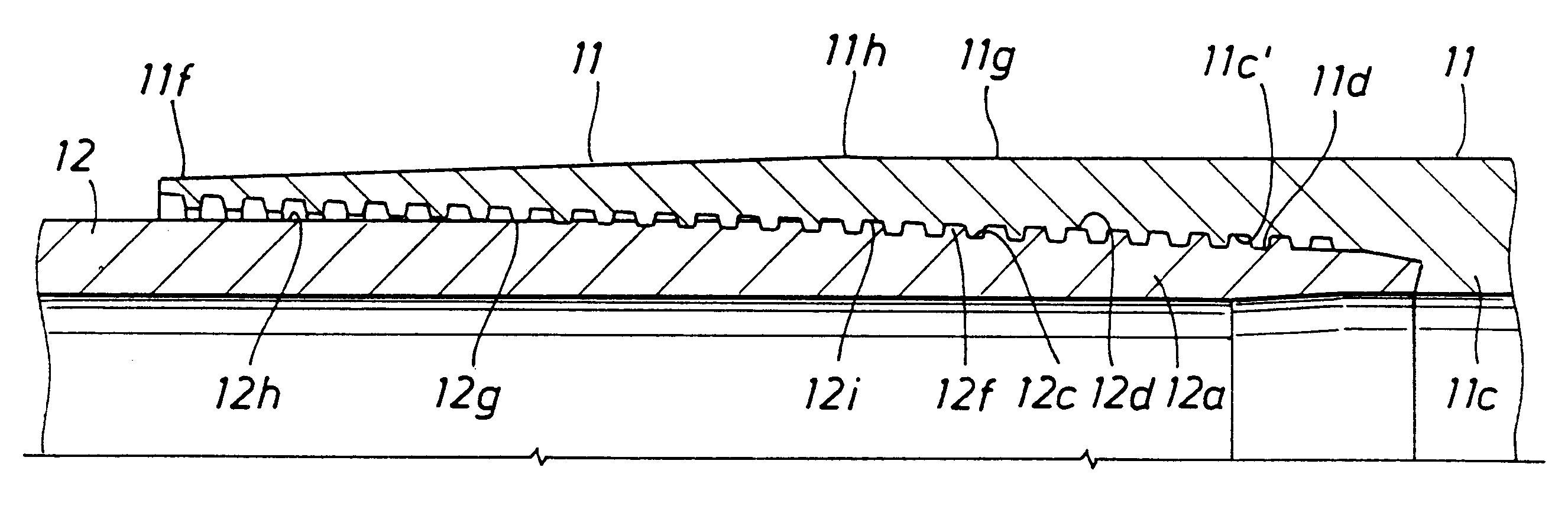

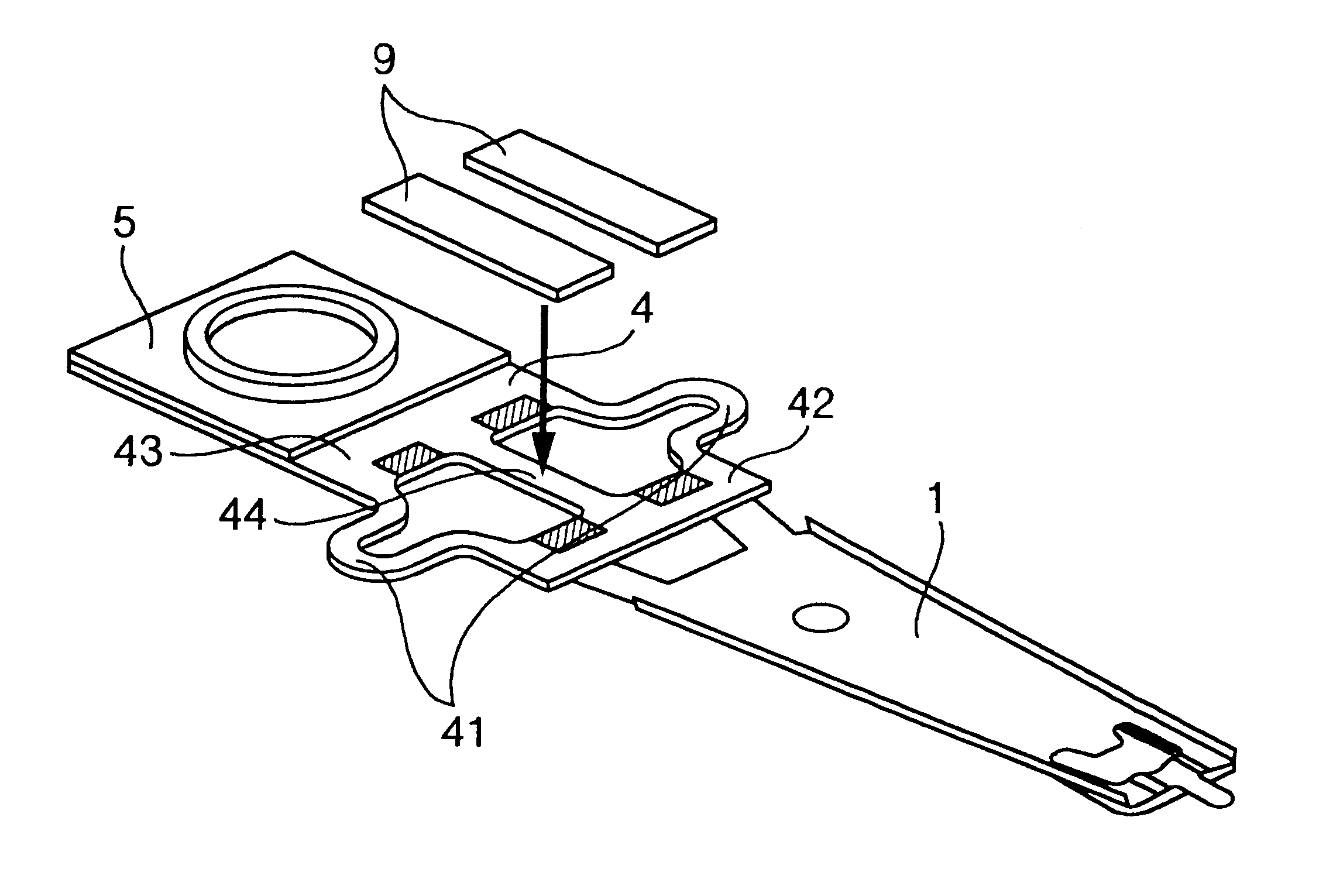

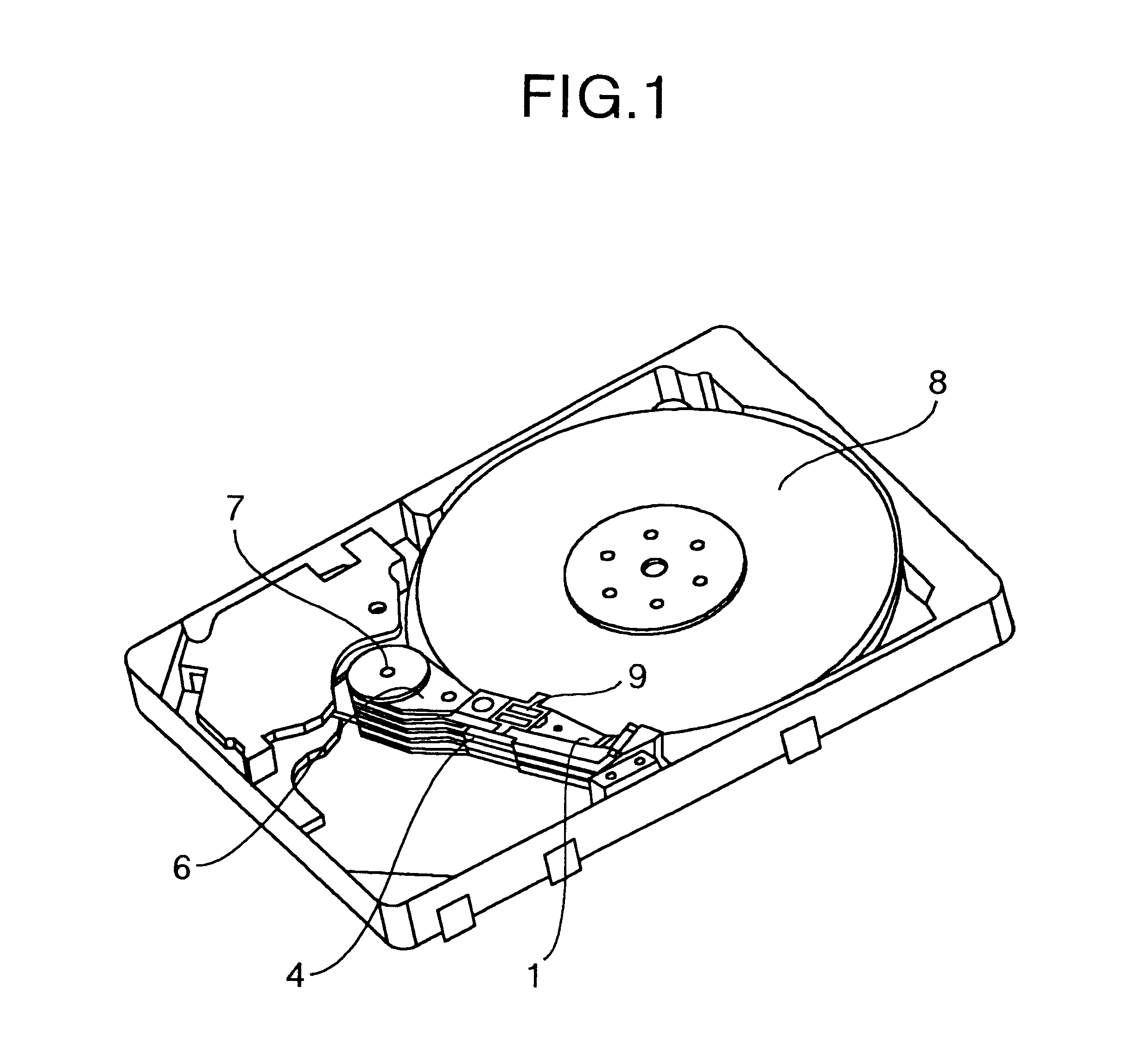

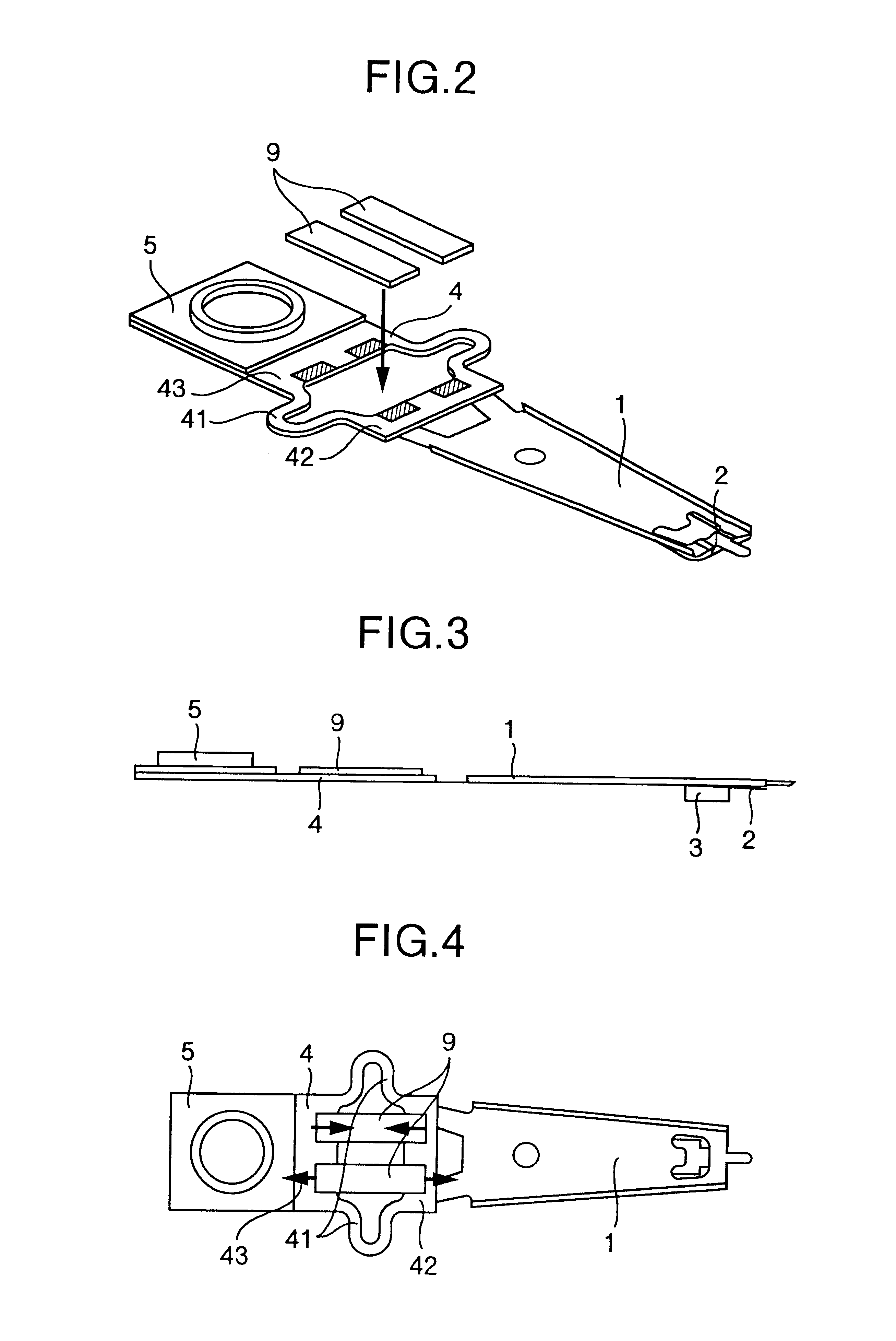

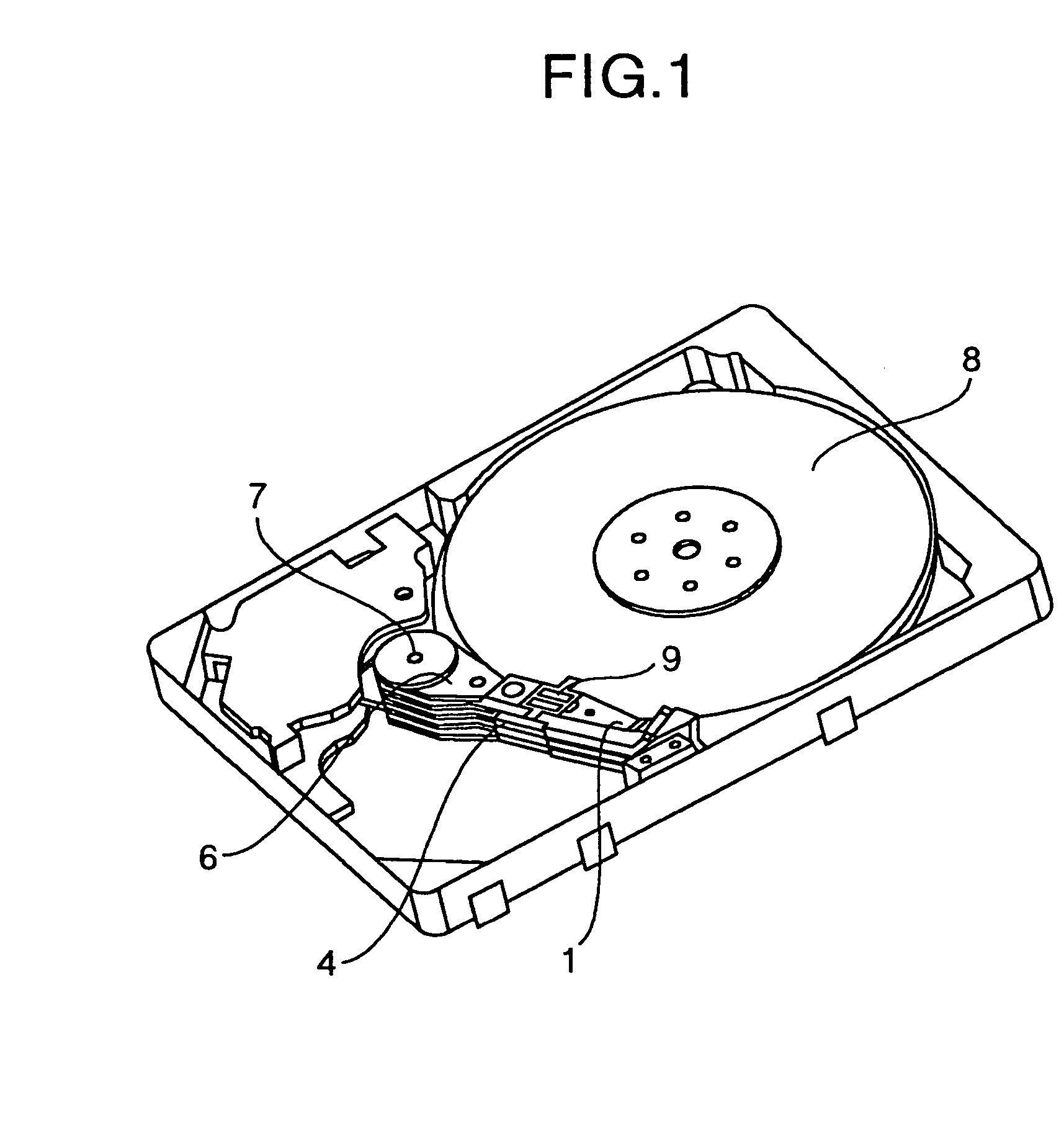

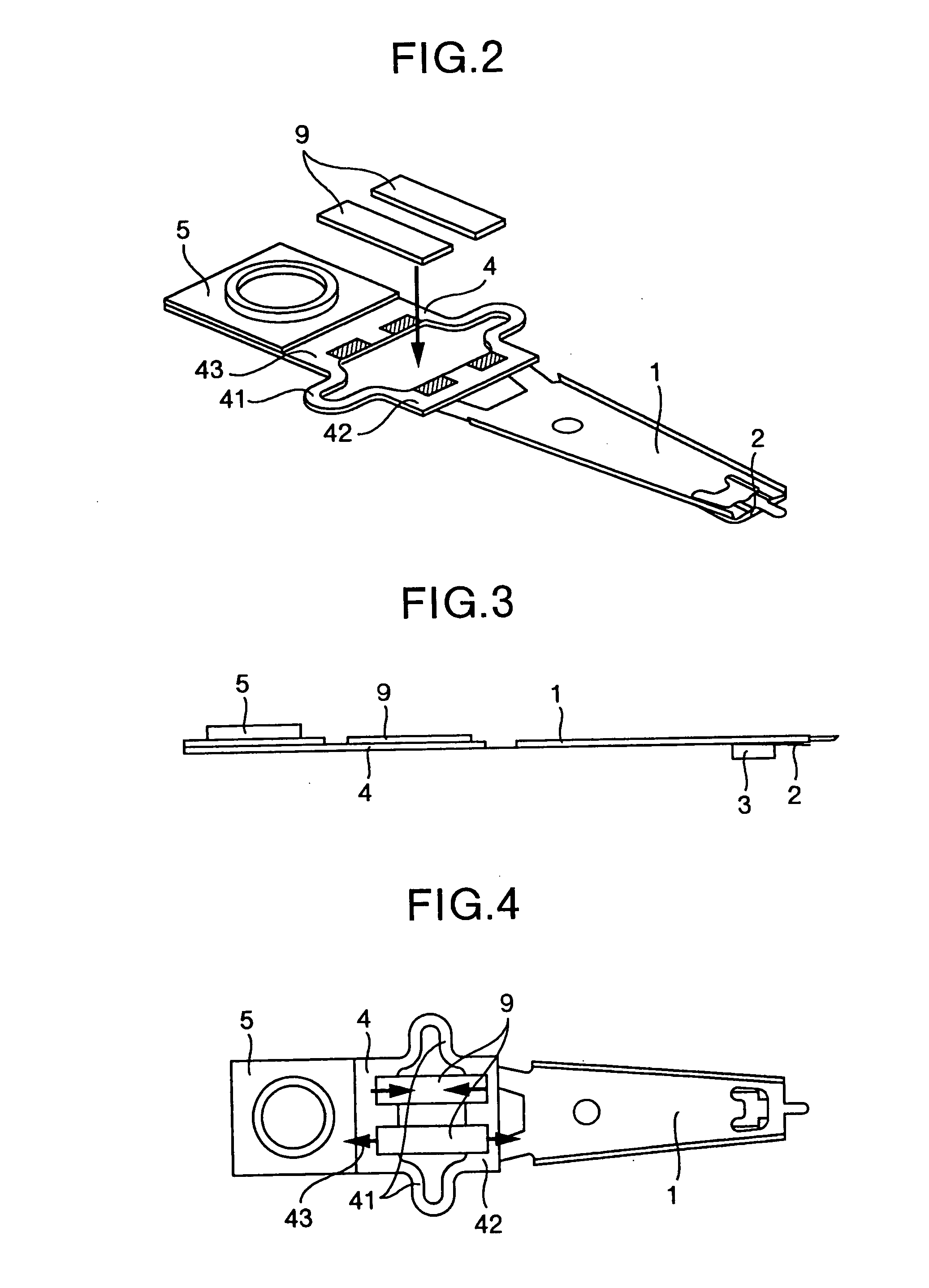

Magnetic disk apparatus

InactiveUS6614627B1Precise positioningSimple structureArm with actuatorsRecord information storageCouplingEngineering

A magnetic disk apparatus of the present invention is equipped with a microactuator for micro motion using piezoelectric elements in addition to a coarse adjustment actuator such as a voice coil motor or the like, eliminates parts that slide between the microactuator and surrounding members, and alleviates stress on the piezoelectric elements even if an impact is given to the magnetic disk apparatus. Thus, a first actuator fixing portion on a carriage side and a second actuator fixing portion on a magnetic head side of a microactuator mounting portion are coupled with a plurality of flexible coupling portions and coupling portions are placed outside the microactuator in substantially symmetric with respect to a centerline in a longitudinal direction of a suspension.

Owner:WESTERN DIGITAL TECH INC +1

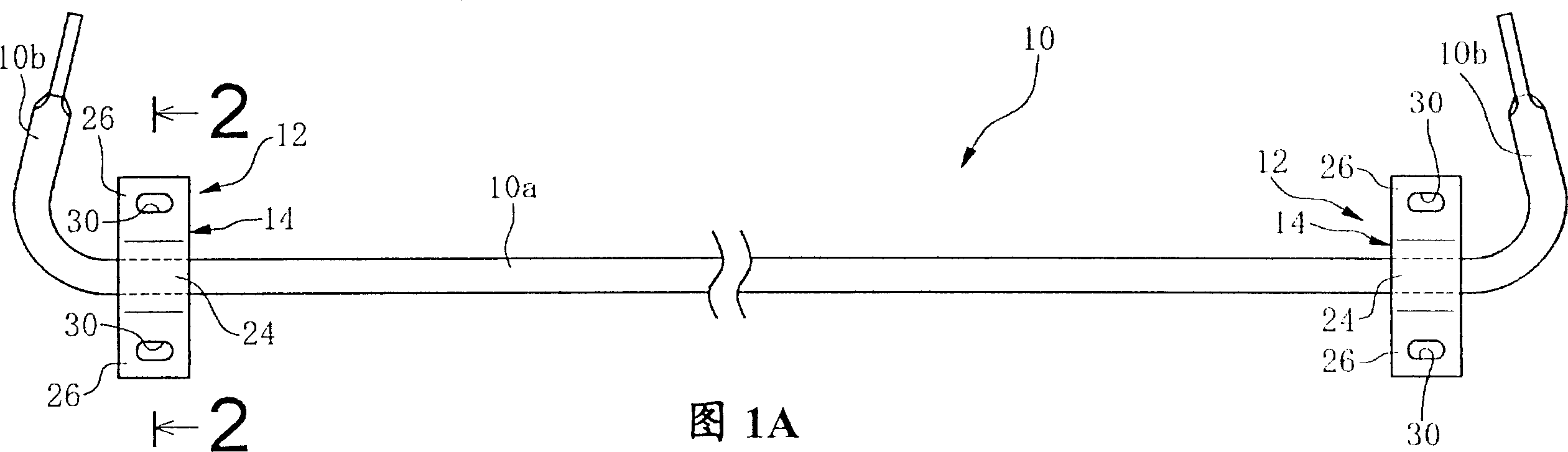

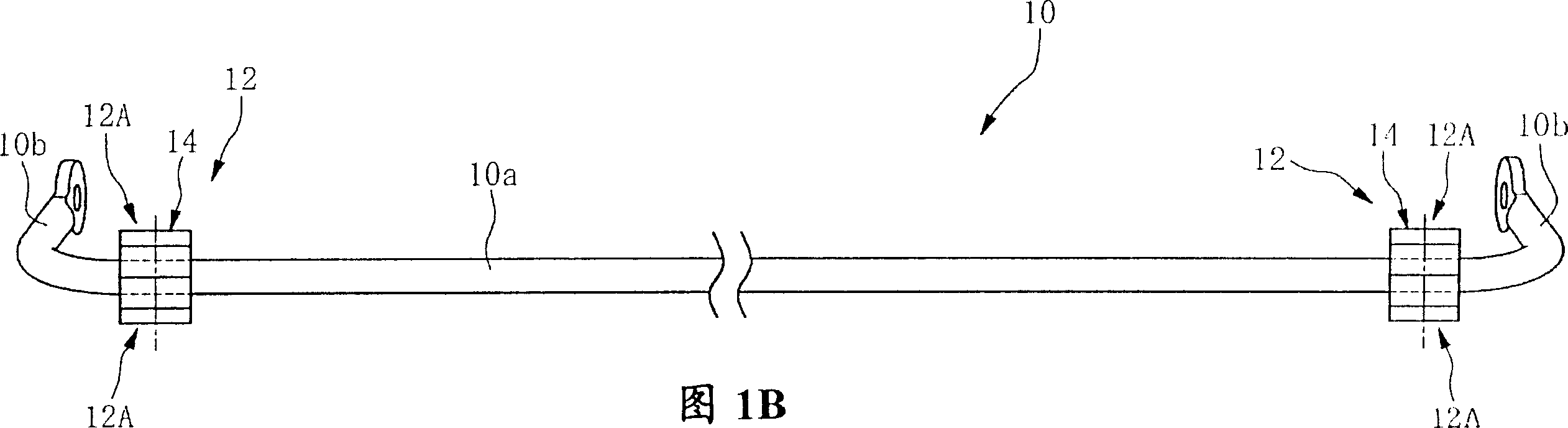

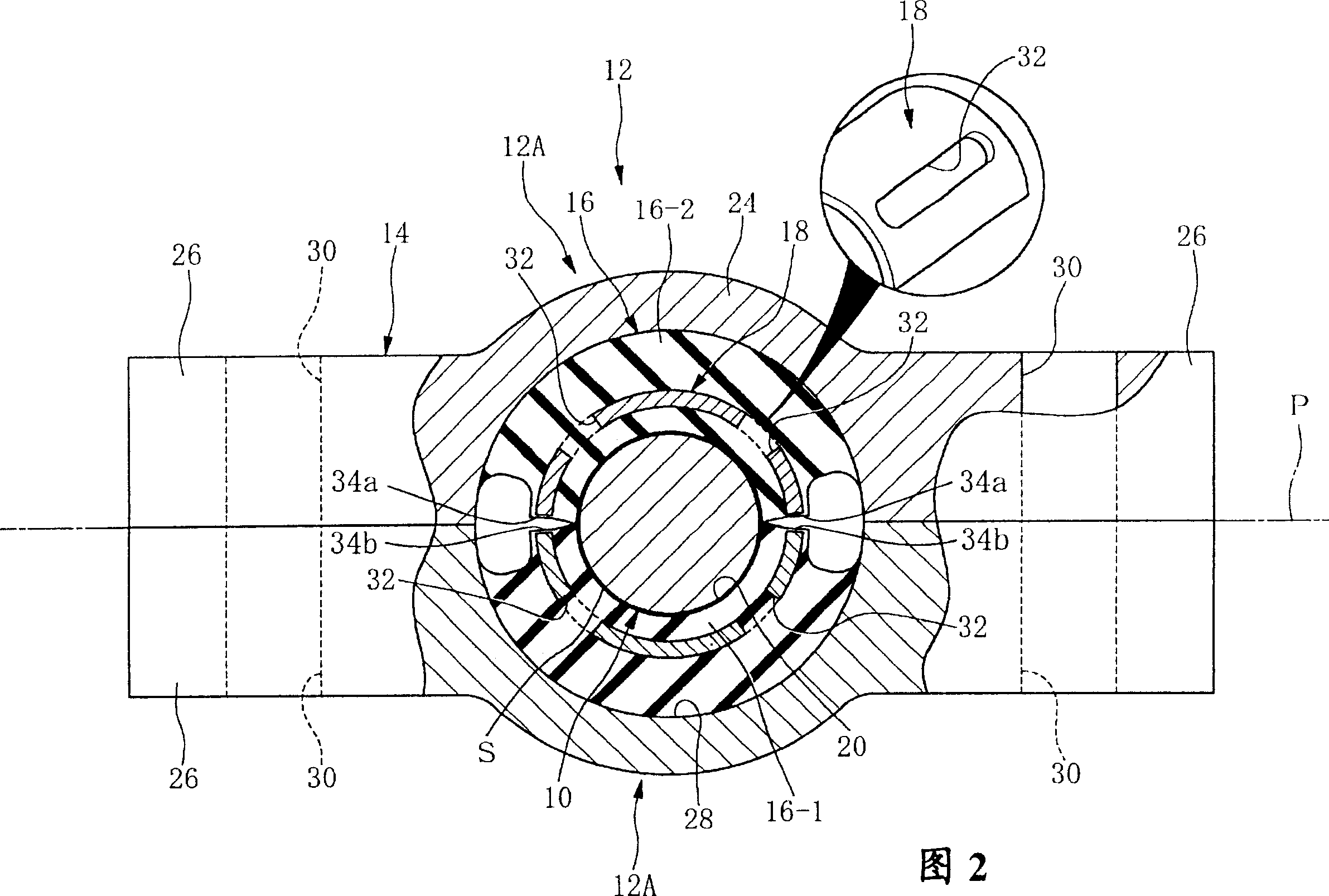

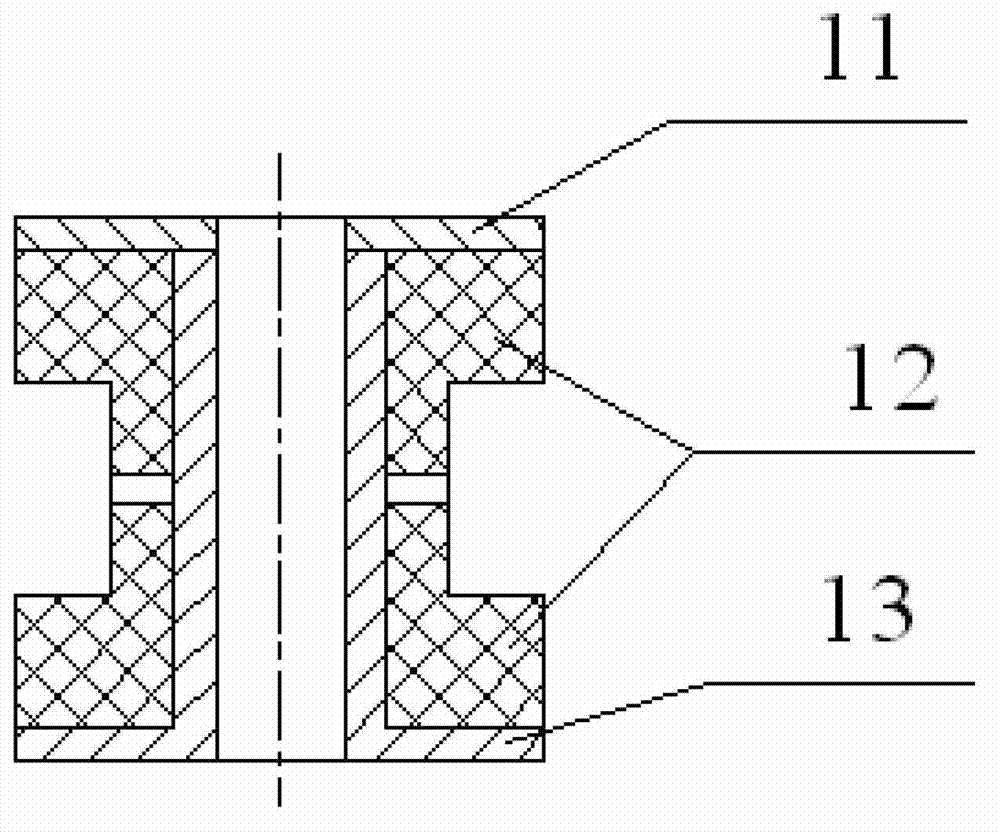

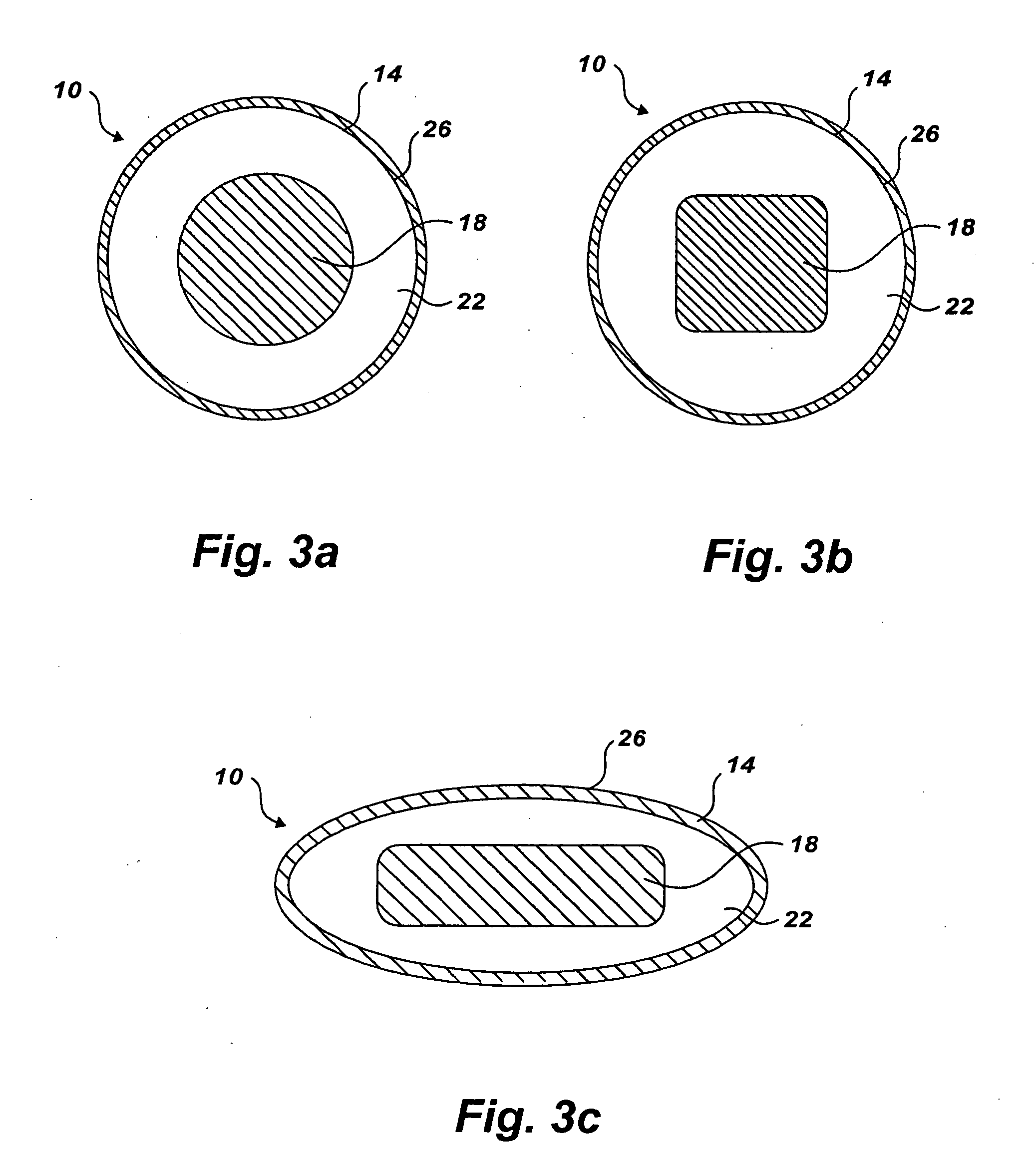

Stabilizer bushing

InactiveCN1766362AReduce axial flowReduce stress concentrationInterconnection systemsRubber-like material springsElastomerAdhesive

The invention relates to a stabilizer bar bushing (12), comprising a rubber elastic body (16); a bracket (14) and a middle part embedded in the rubber elastic body along the axis vertical direction so as to extend substantially the entire axial direction of the rubber elastic body An intermediate plate (18) extending in length, whereby the rubber elastic body is divided by the intermediate plate into an inner rubber layer (16-1) and an outer rubber layer (16-2) with a spring constant smaller than the inner rubber layer. The stabilizer bar bushing is composed of two circumferential divisions (12A, 12A), wherein the bracket and the middle plate are integrally vulcanized with the divisions, and the divisions are assembled together to clamp the stabilizer bar along the vertical direction of the axis ( 10) and withstand the compression along the vertical direction of the axis, so that the inner surface of the through hole (20) is bonded to the outer peripheral surface of the stabilizer bar through the adhesive (S).

Owner:TOYOTA JIDOSHA KK +1

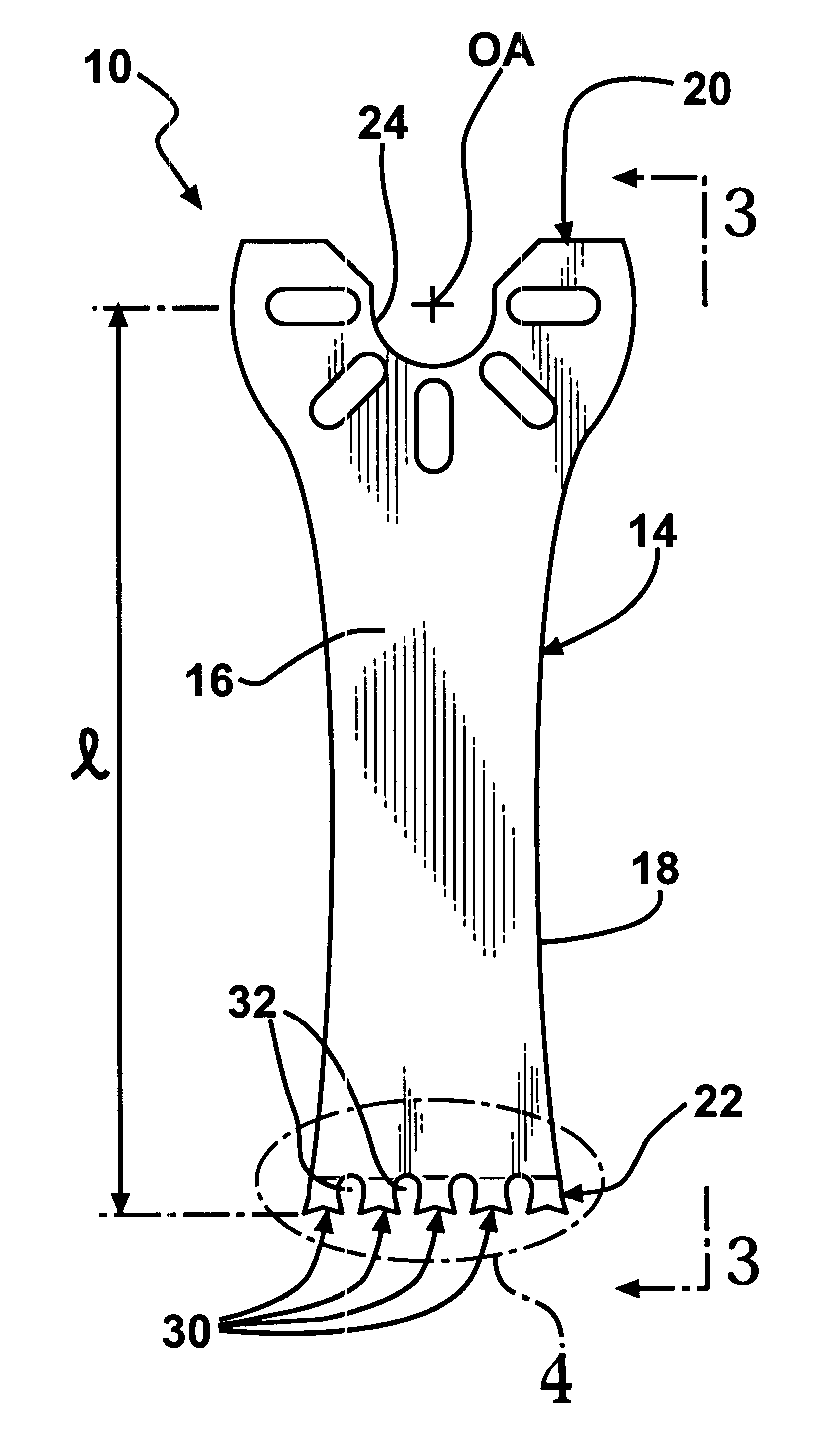

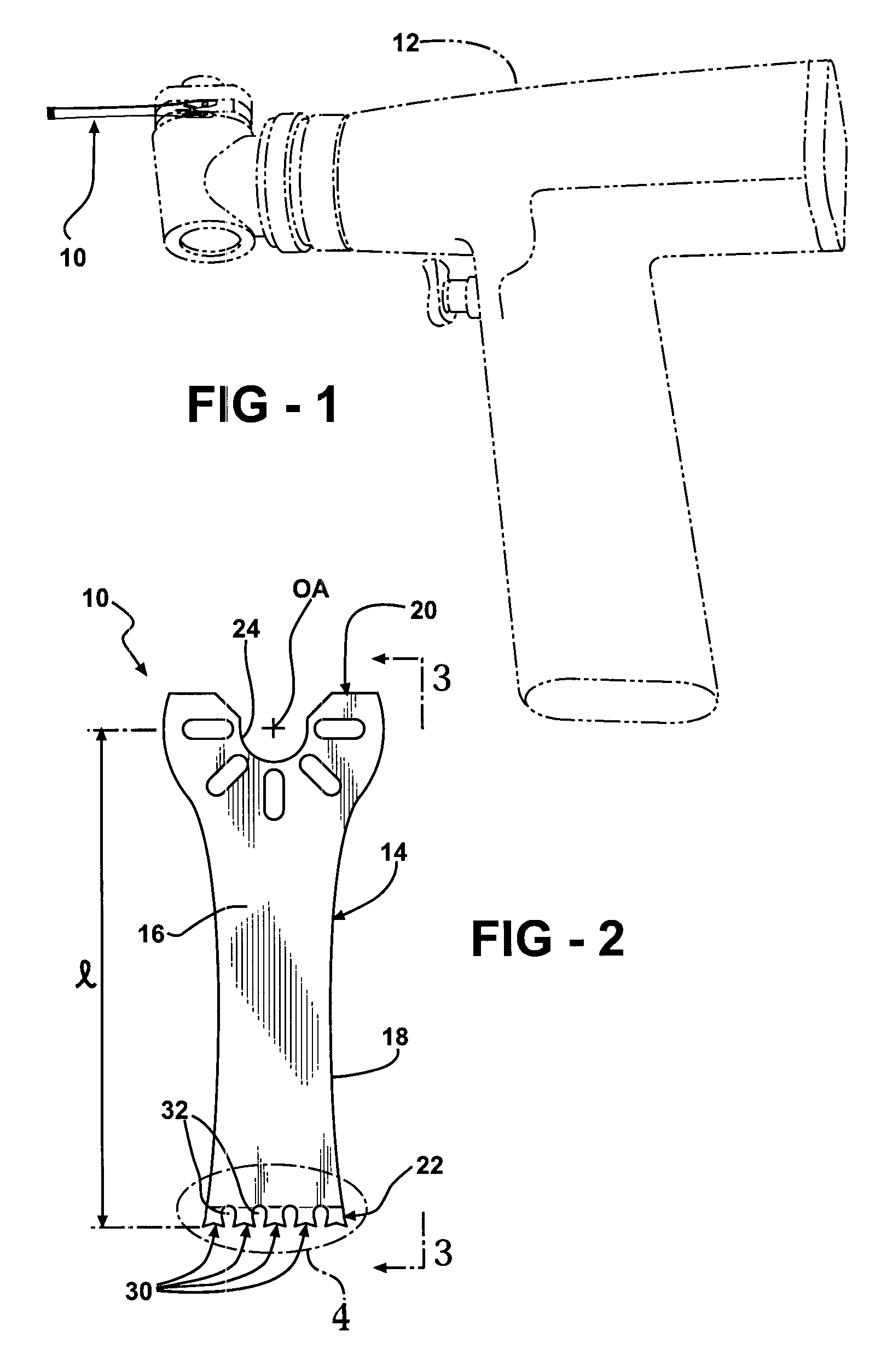

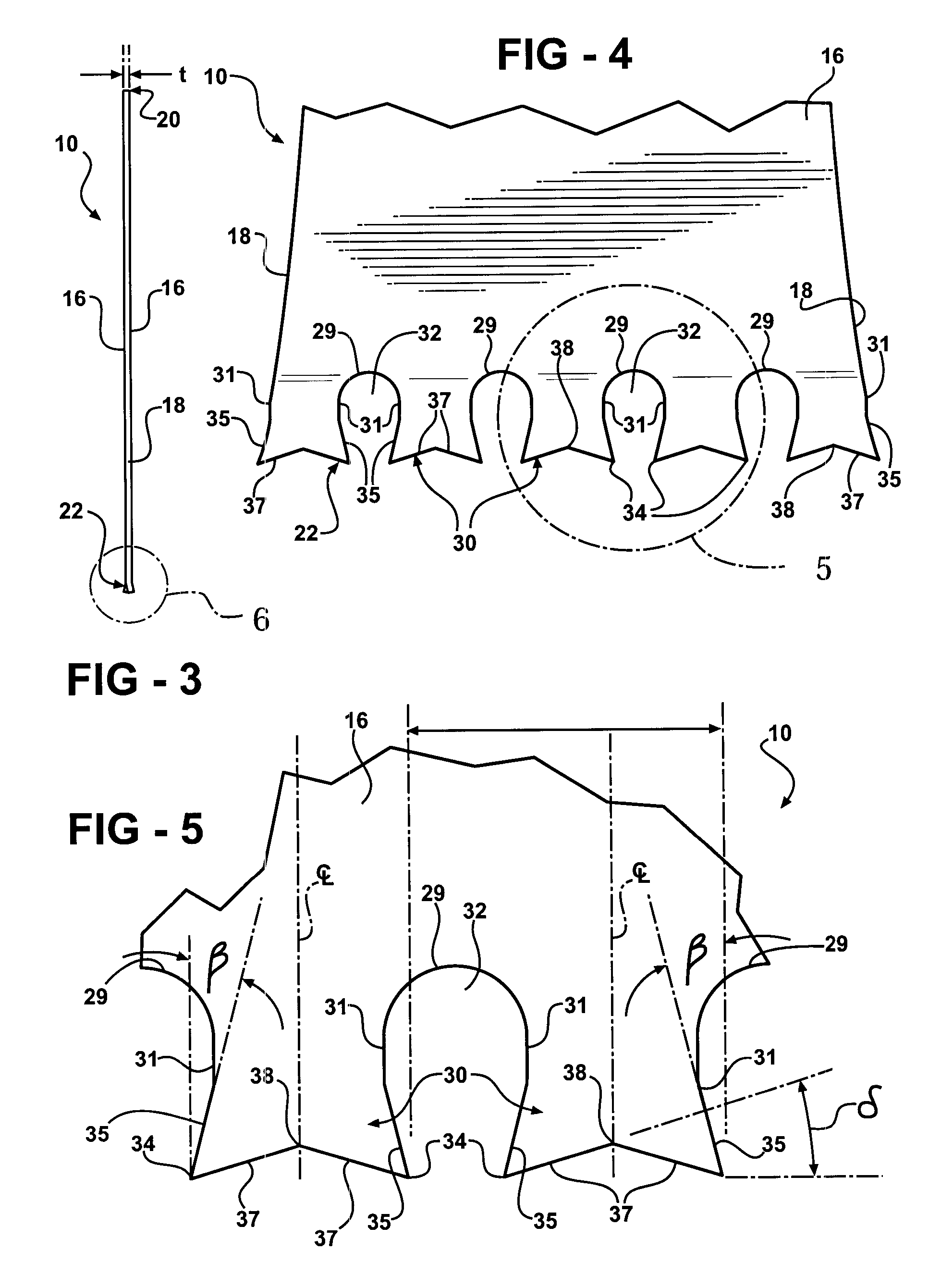

Dual cut surgical saw blade

InactiveUS20060272468A1Less stressEasy to controlMetal sawing devicesMetal sawing toolsEngineeringSurgical saw

A surgical saw blade operatively couples to an oscillatory power tool for oscillation about an oscillation axis (OA). The saw blade includes a plurality of cutting teeth separated from one another by a clean out opening along a distal end. The clean out opening comprises an arcuate closed end and straight side walls extending from the closed end. Each tooth comprises first and second rake surfaces and first and second relief surfaces intersecting to define first and second cutting edges, respectively. The first and second cutting edges are oppositely disposed from one another. One cutting tooth protrudes a distance (de) from one side face of the blade and the next adjacent cutting tooth protrudes the same distance (de) from the other side face of the blade to cut a groove having a width (dg) wider than the thickness (t) of the blade.

Owner:STRYKER CORP

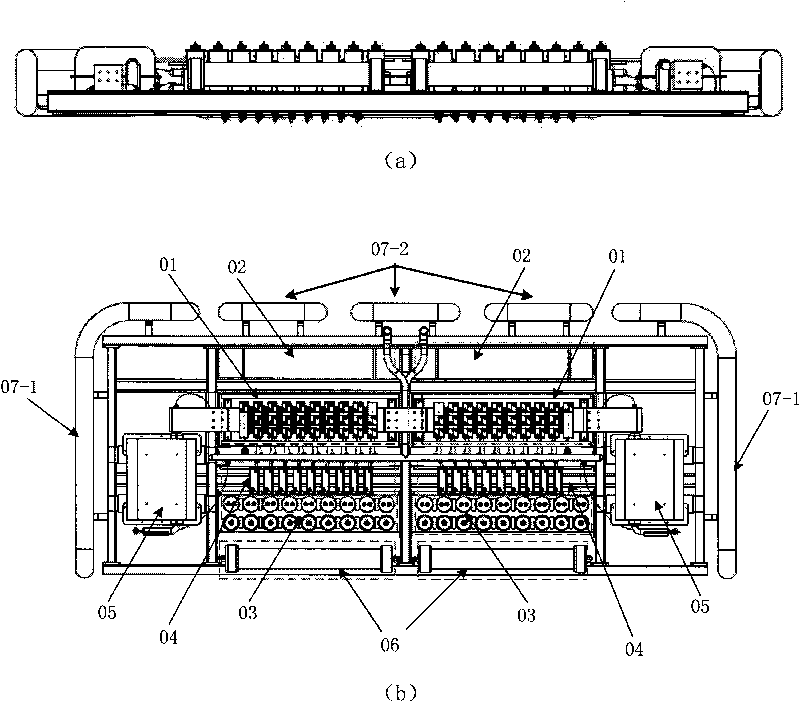

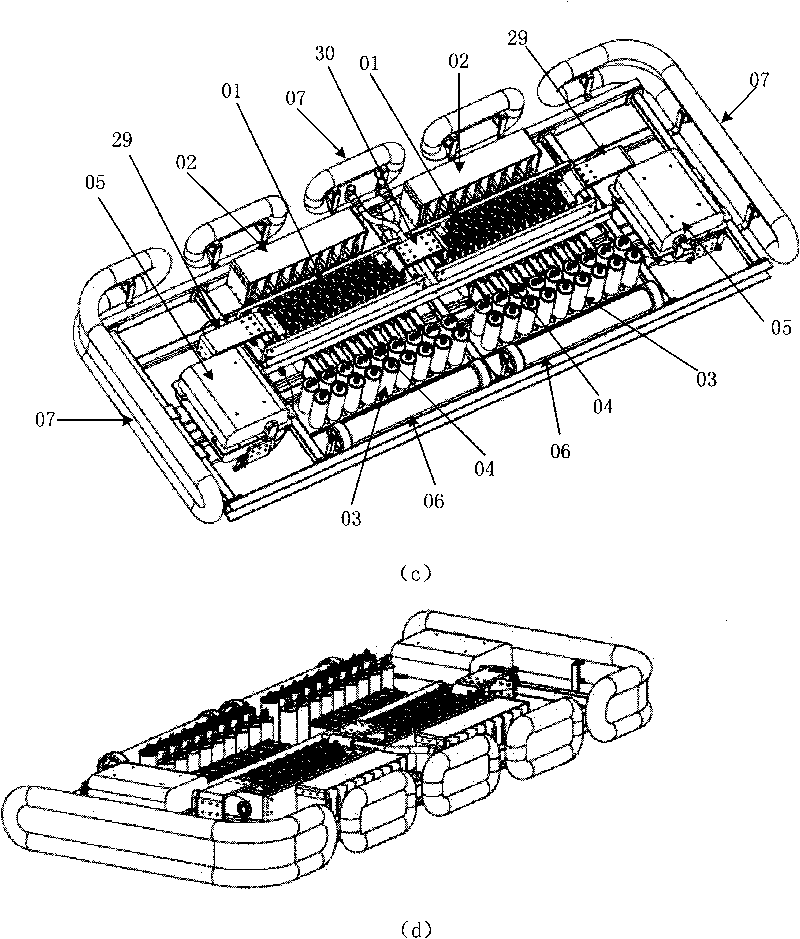

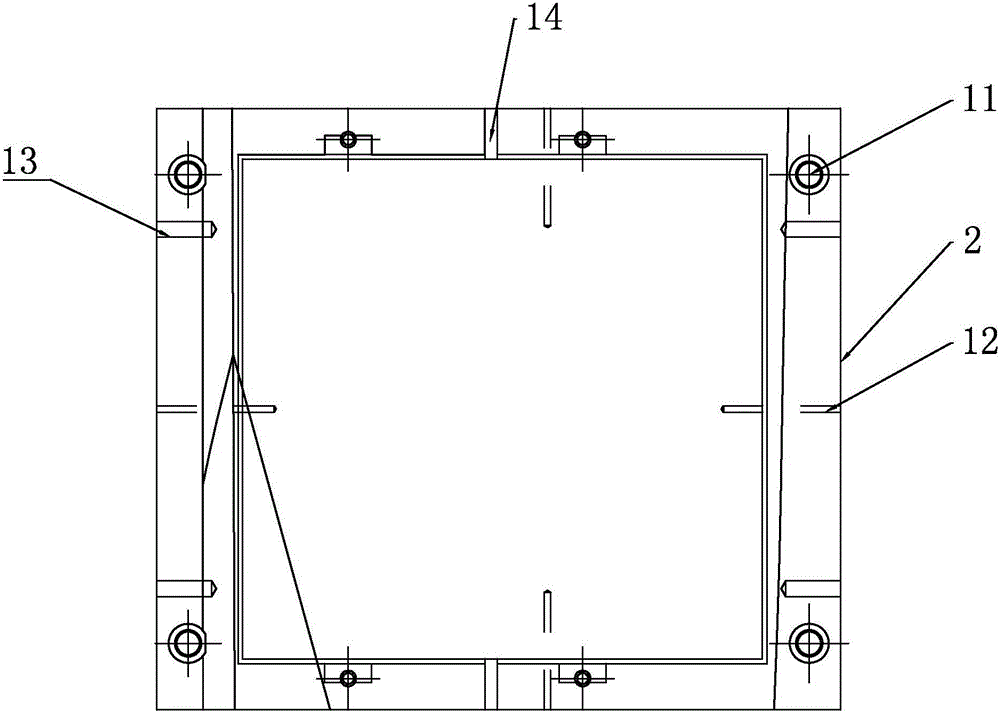

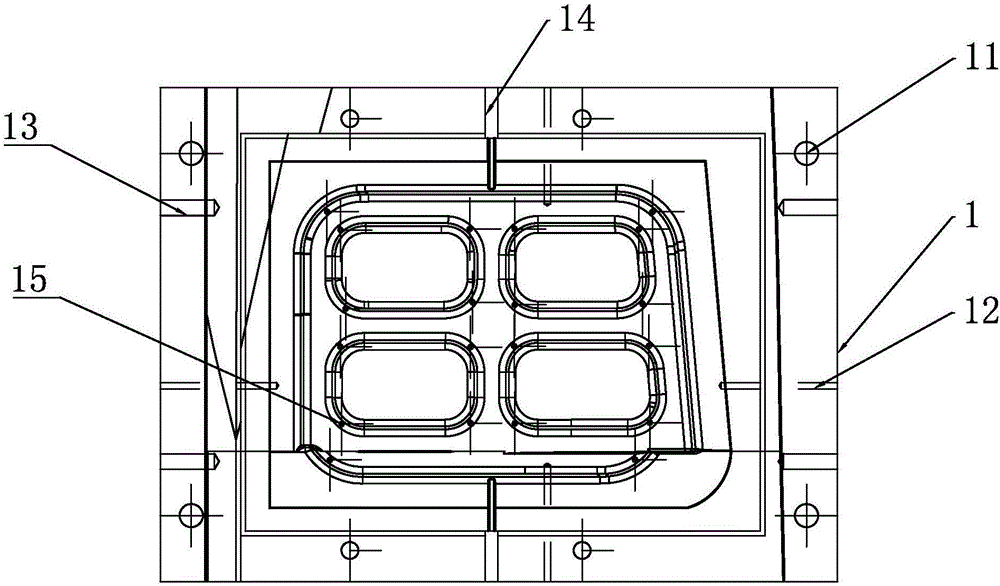

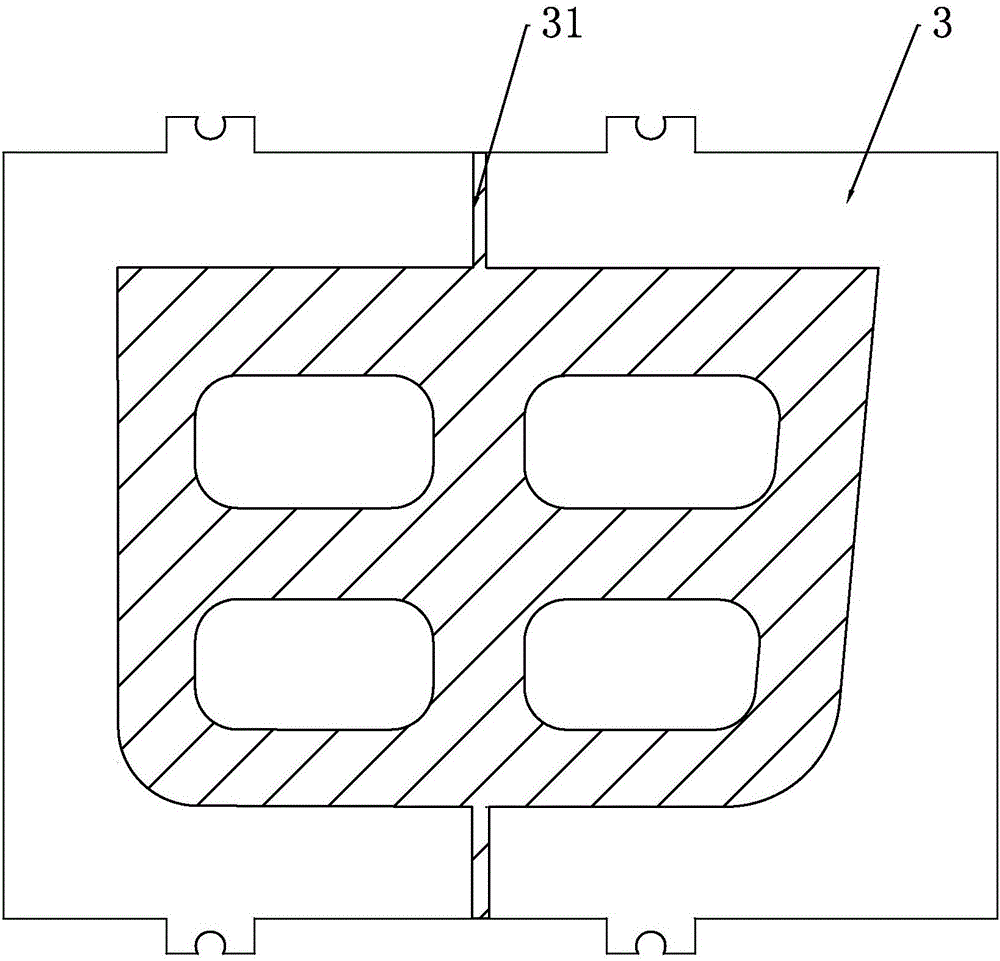

Novel thyristor converter valve module

ActiveCN101719719AReduce weightSmall geometryConversion constructional detailsElectric power transfer ac networkCapacitanceMechanical engineering

The invention provides electronic equipment with high voltage and high power, which is used for converting alternating current (AC) voltage into direct current (DC) voltage or converting DC voltage into AC voltage, in particular a thyristor converter valve module. A whole valve module is divided into two same segments, and each segment comprises a saturable reactor, a thyristor, a DC equalizing resistor unit, an energy-extracting resistor unit, a damping resistor unit, a damping capacitor unit, a gate electrode unit and a water cooling system, wherein the reactors of the electronic equipment are connected in series to meet the requirements on different transmission powers and different power voltage grades. The equipment is core equipment for high-voltage DC power transmission and can be applied to a DC-AC converting system, meet the requirements of different voltage grades and for the DC converting system with different voltage grades, including the super high voltage of 800 kV or above.

Owner:CHINA ELECTRIC POWER RES INST

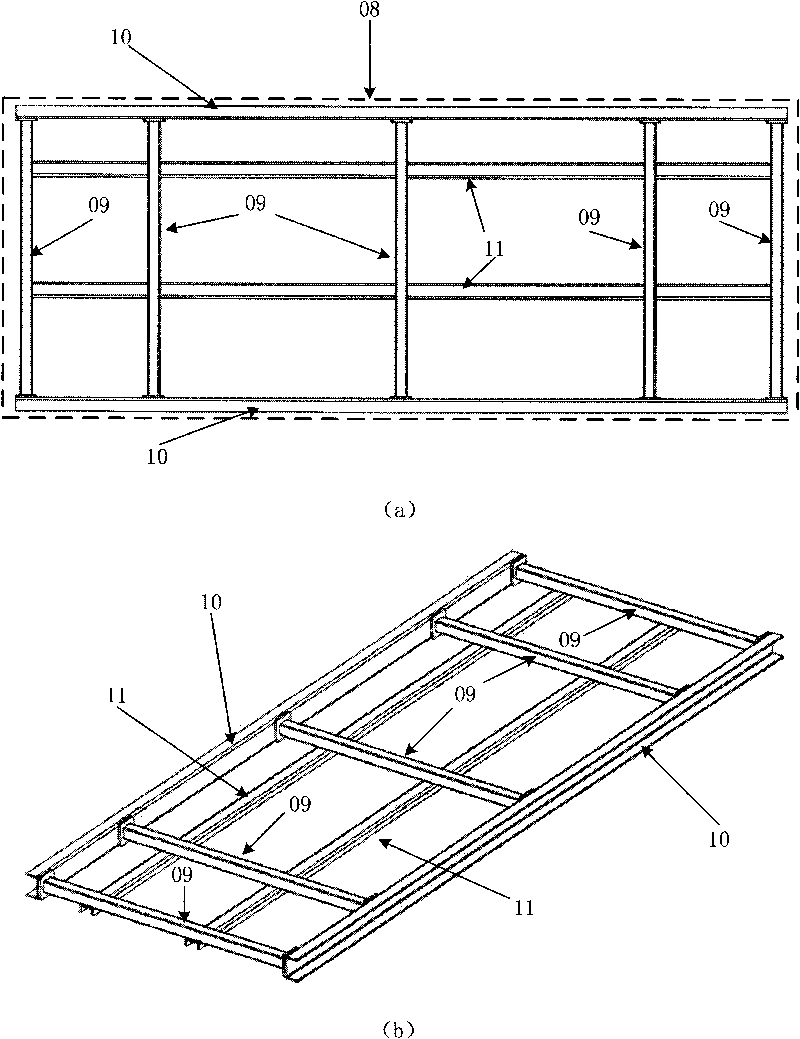

Flexible Truss Frame and Method of Making the Same

ActiveUS20130020438A1Low costReduce the numberMetal-working apparatusLaminationEngineeringMechanical engineering

Owner:THE BOEING CO

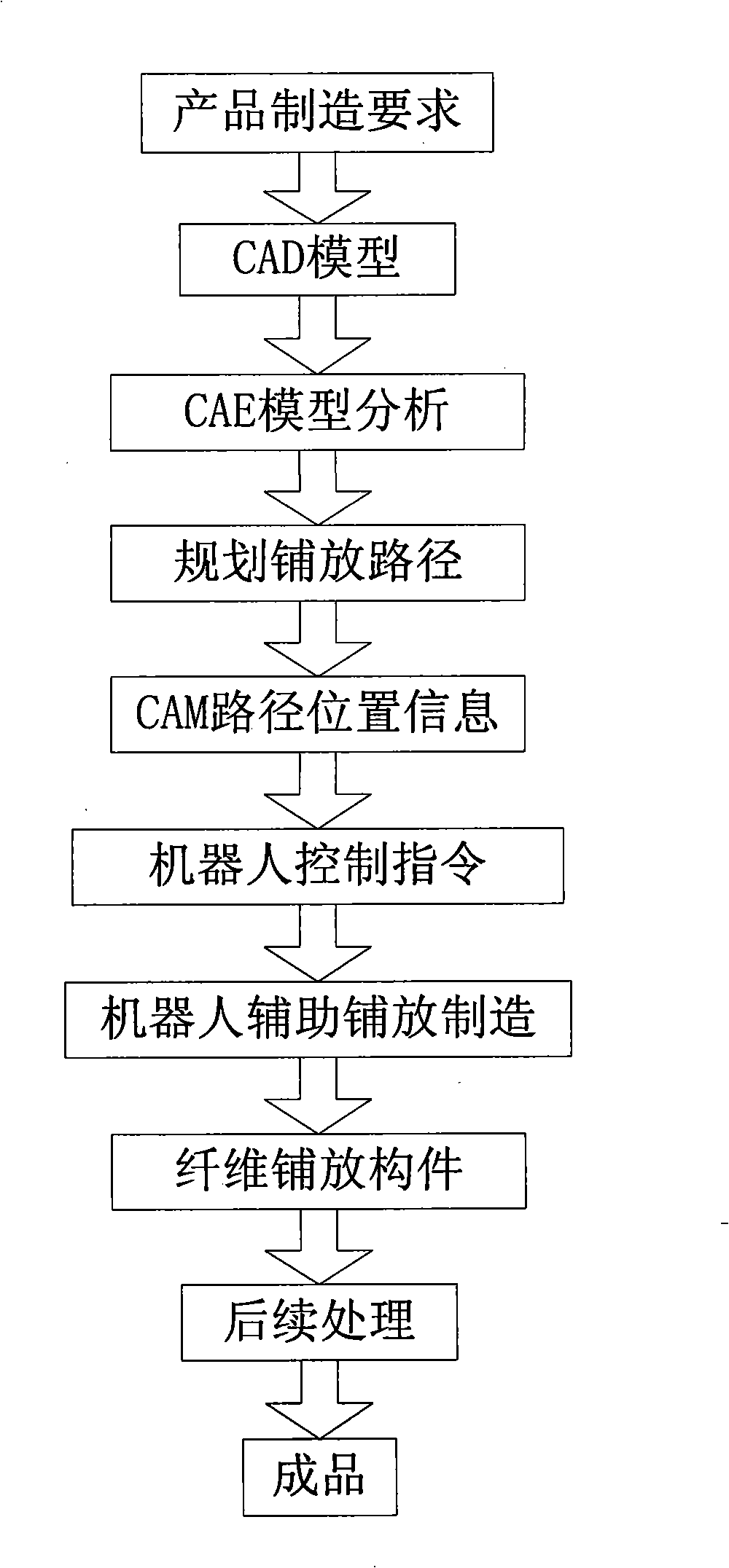

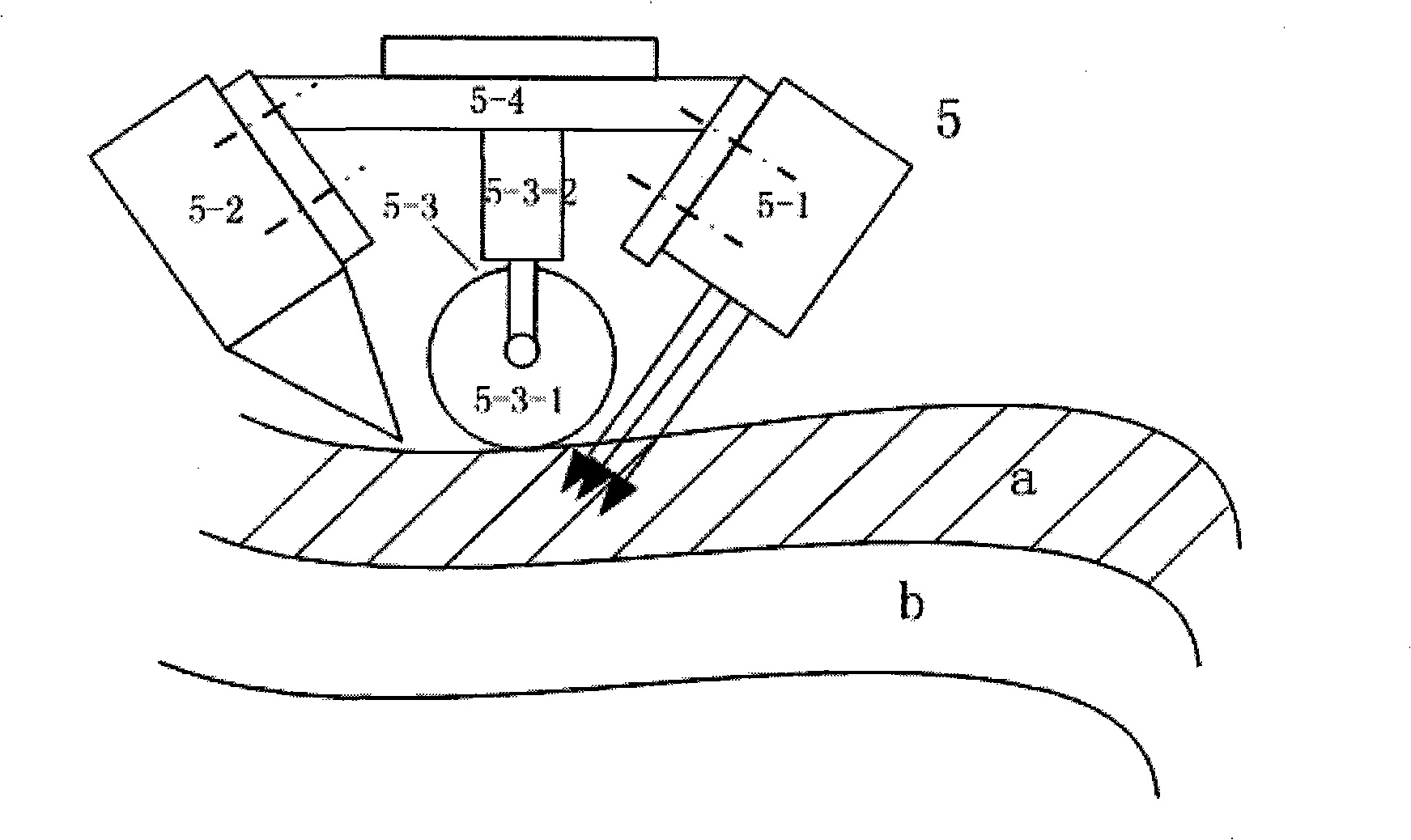

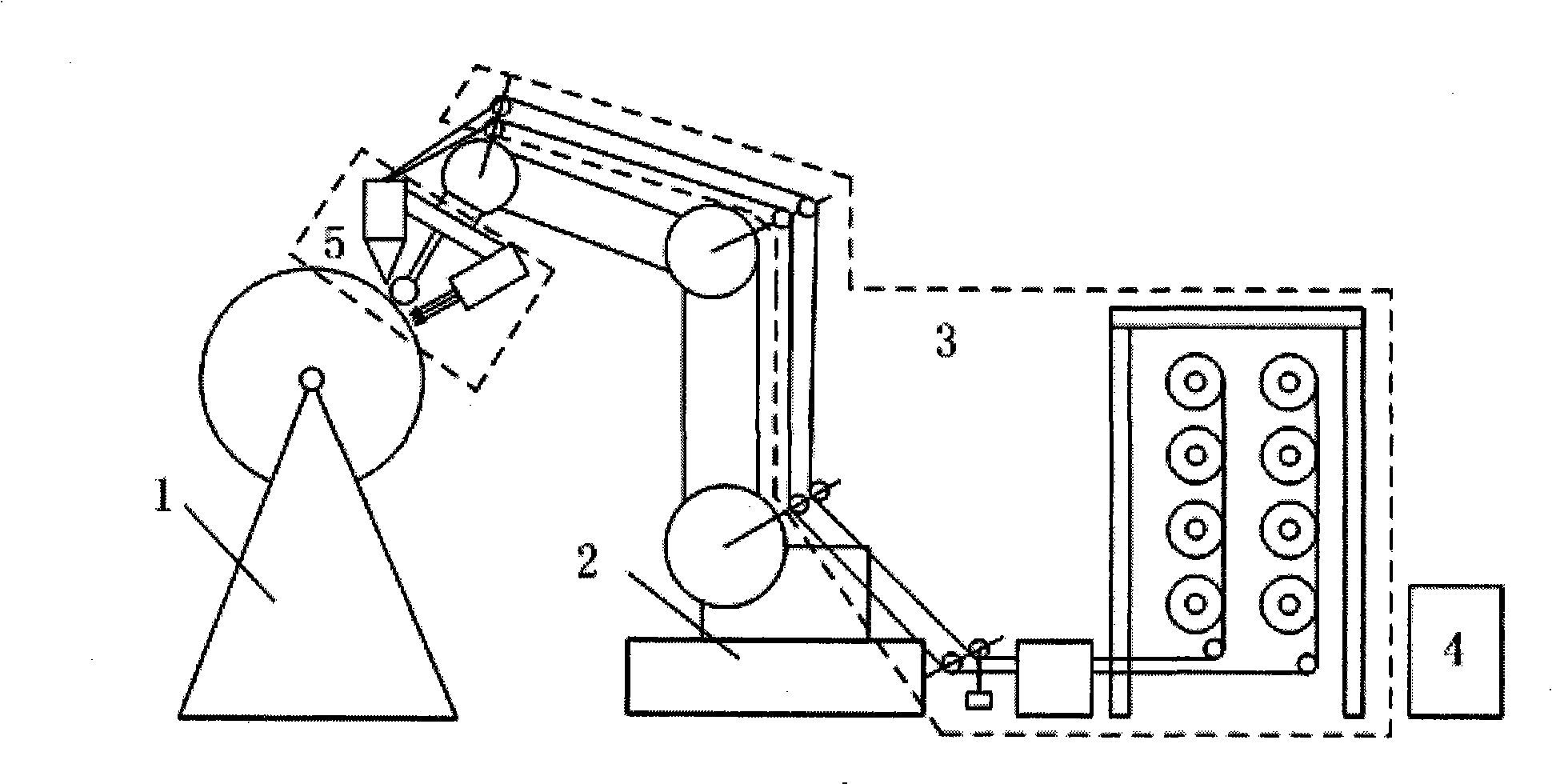

In-situ consolidation fibre laying method and device for producing resin-based compound material component

InactiveCN101254652ASimple manufacturing processShorten the manufacturing cycleCrazingThermal deformation

The invention discloses a method and a device for manufacturing resin-based composite material component by using fiber placement technology. By adopting fiber placement technology, the method and the device can place a fiber placement layer on the surface of a core die by a compaction mechanism to solve the problem of conventional winding equipment that is incapable of manufacturing surface component with negative curvature and non-gyrorotor component. Meanwhile, in-situ instantaneous stratified radiation curing is adopted to eliminate the influence of a tensile force in the fiber placement layer on the shape of the product and to solve the problems and disadvantages of large thermal deformation and easy generation of cracks due to autoclave curing treatment, the restriction of the autoclave volume on the component size, high production cost, and long production period. Based on industrial robot as the manufacture body, the device can improve the problems of prior placement equipment such as the deficiency of the flexibility in manufacturing more complex surface and complex structure.

Owner:XI AN JIAOTONG UNIV

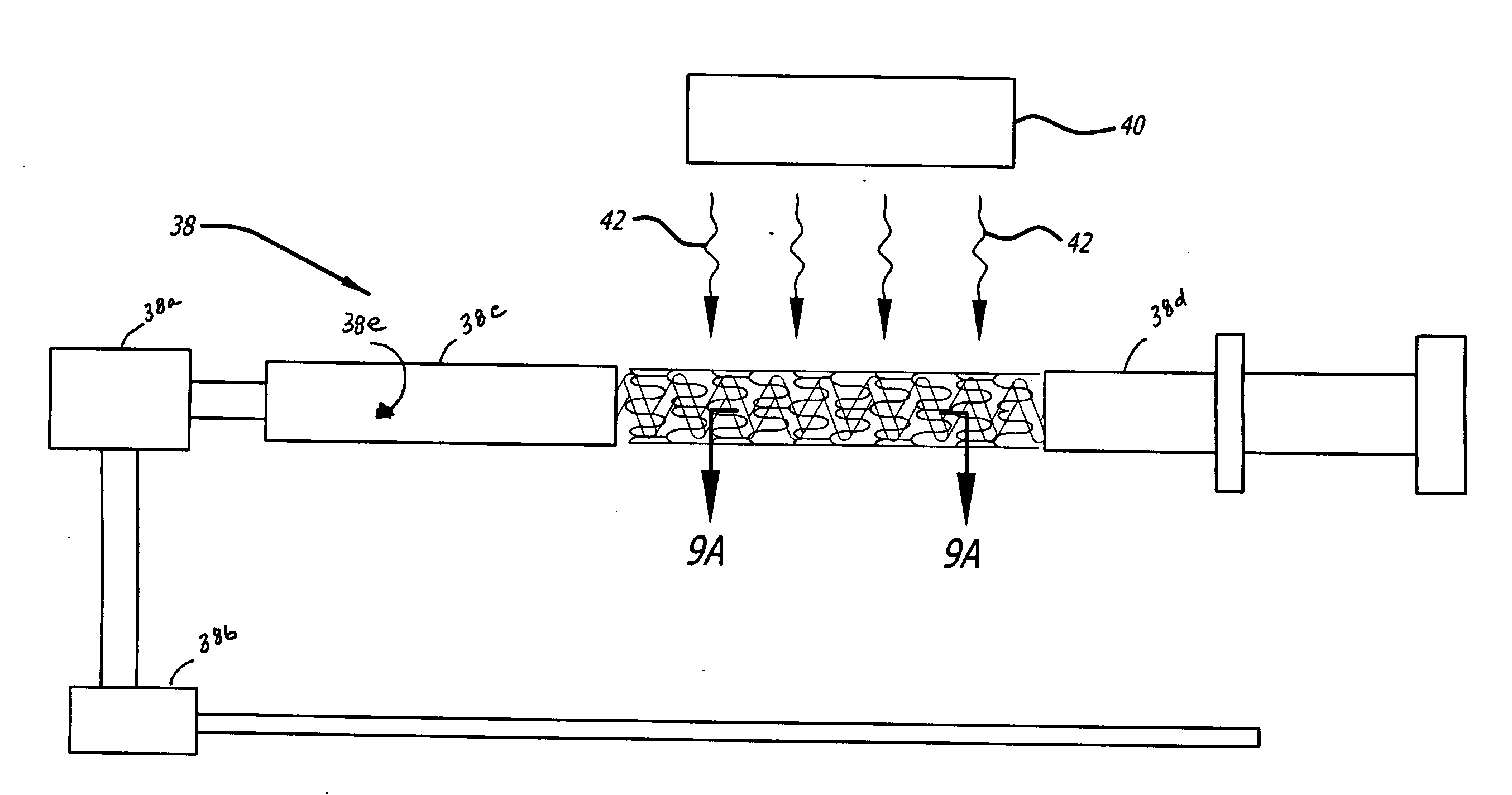

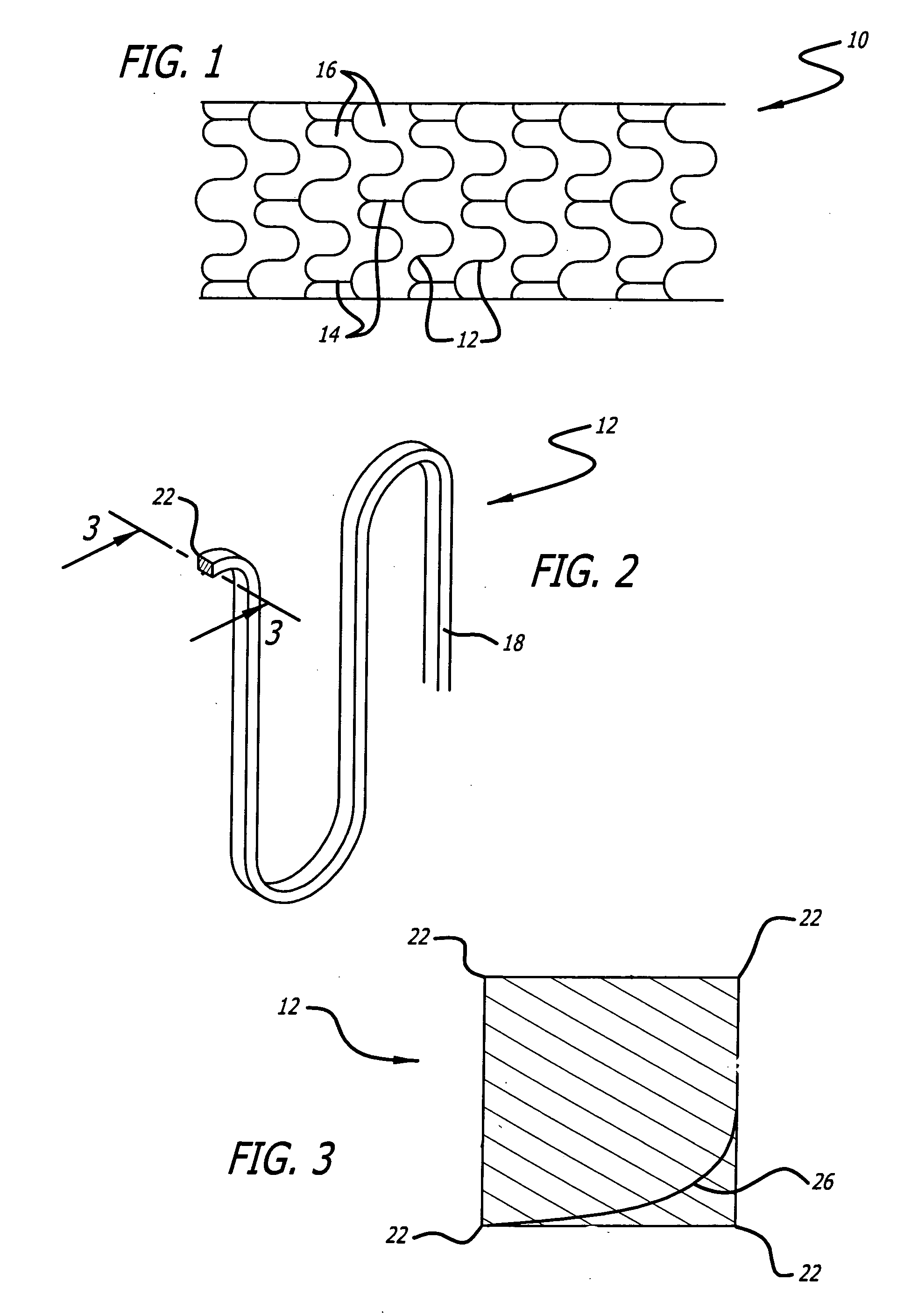

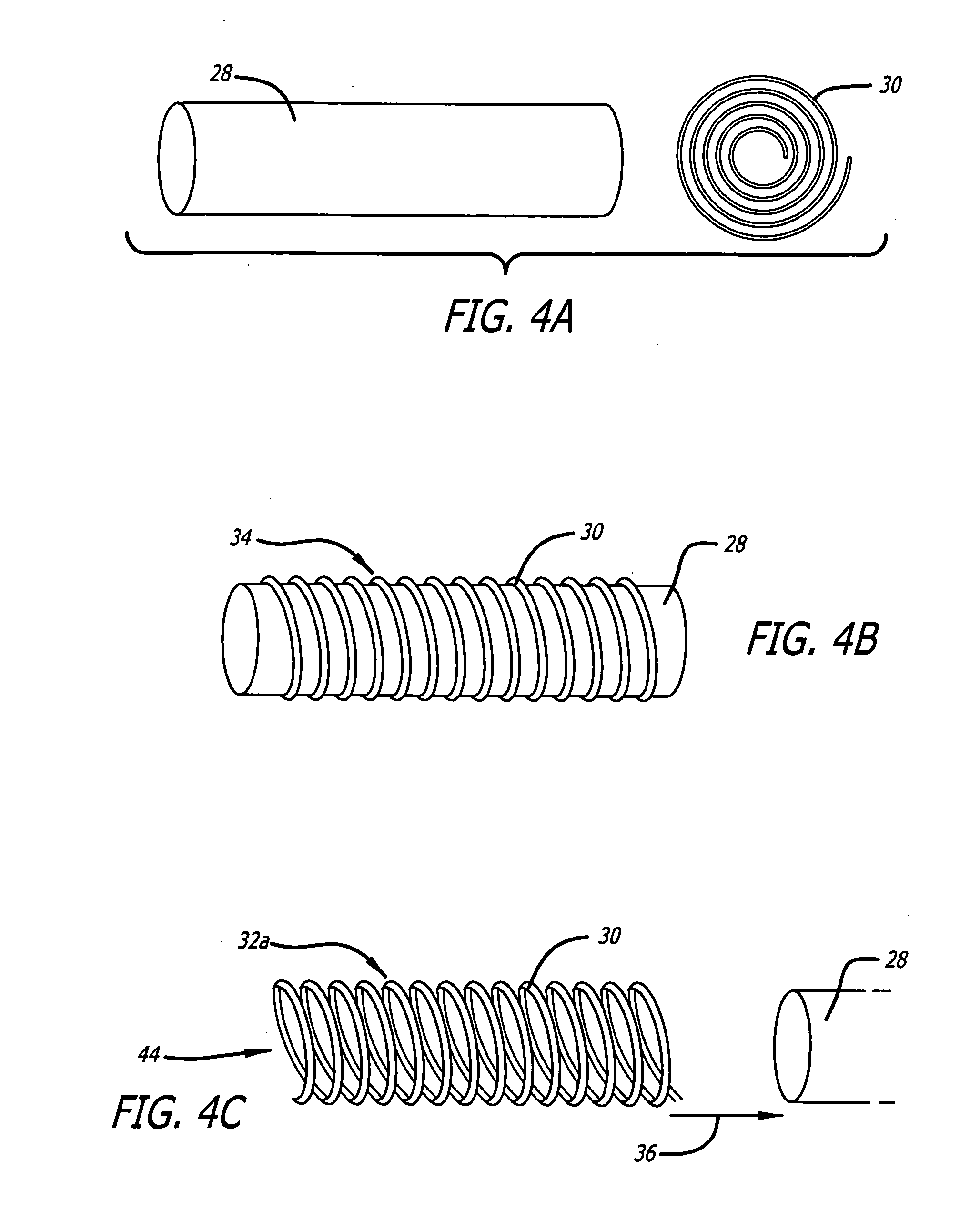

Polymeric stent polishing method and apparatus

InactiveUS20070023974A1Reduce stress concentrationEqually distributedStentsAuxillary shaping apparatusInsertion stentGlass transition

A method and apparatus for simultaneously polishing the inner and outer surfaces of an unpolished polymeric stent using a heat process. The unpolished stent can be mounted, for example, on a “spiral-mandrel,” a tubular helical structure with gaps in between a series of coils of the structure. Heat from a heat source can then applied to the spiral-mandrel at a range between the glass transition temperature and melting temperature of the polymer of the stent.

Owner:ABBOTT CARDIOVASCULAR

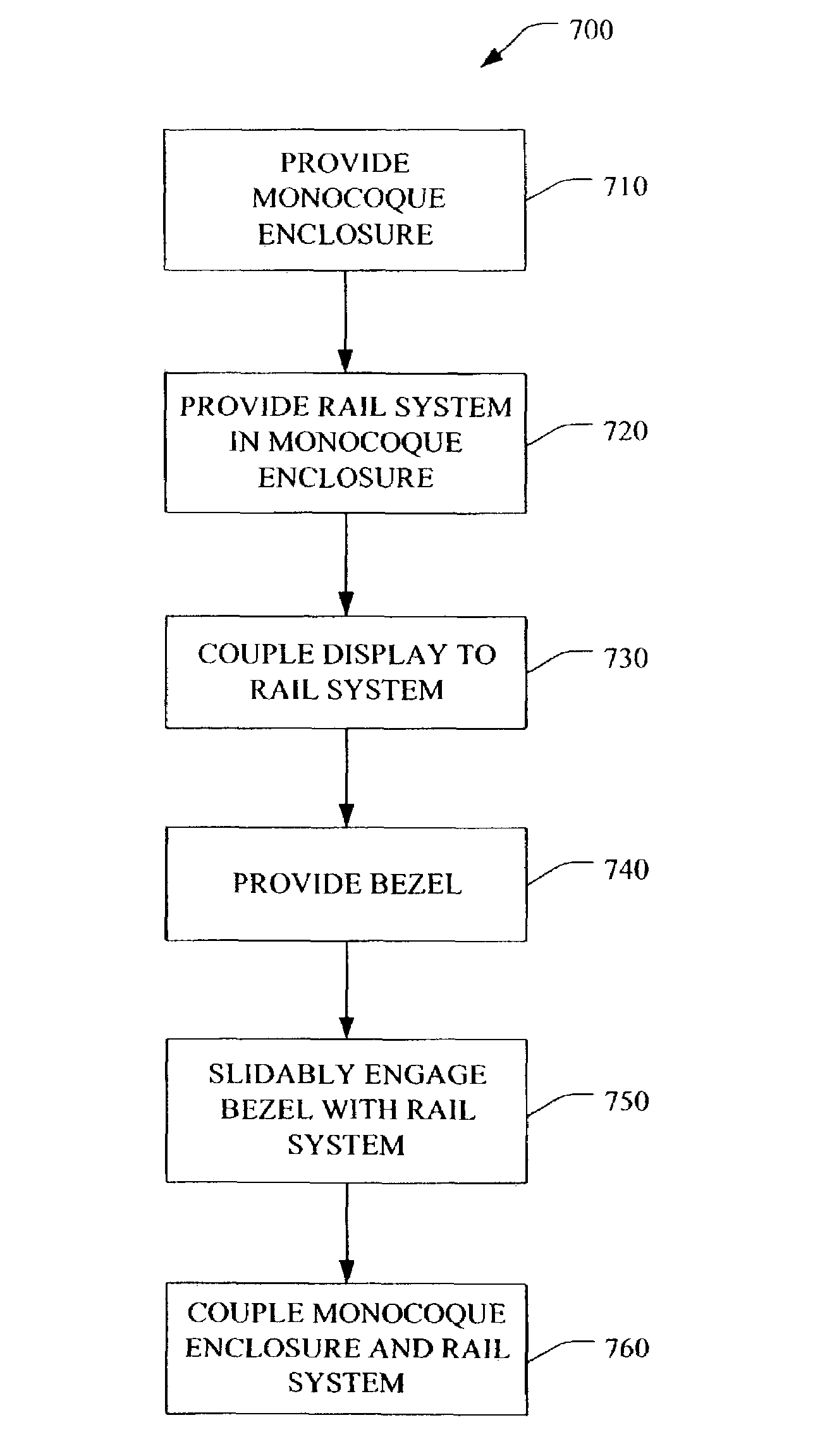

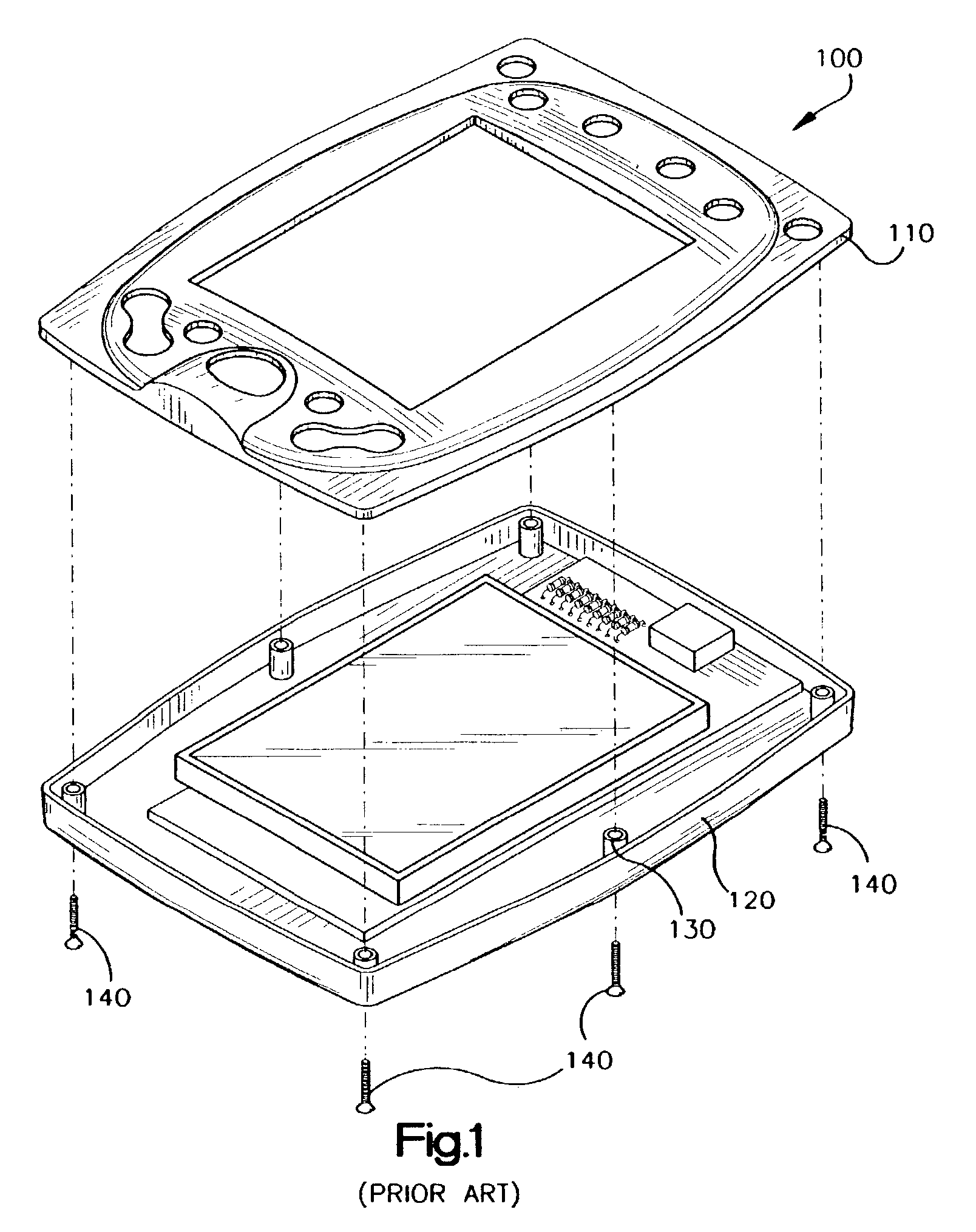

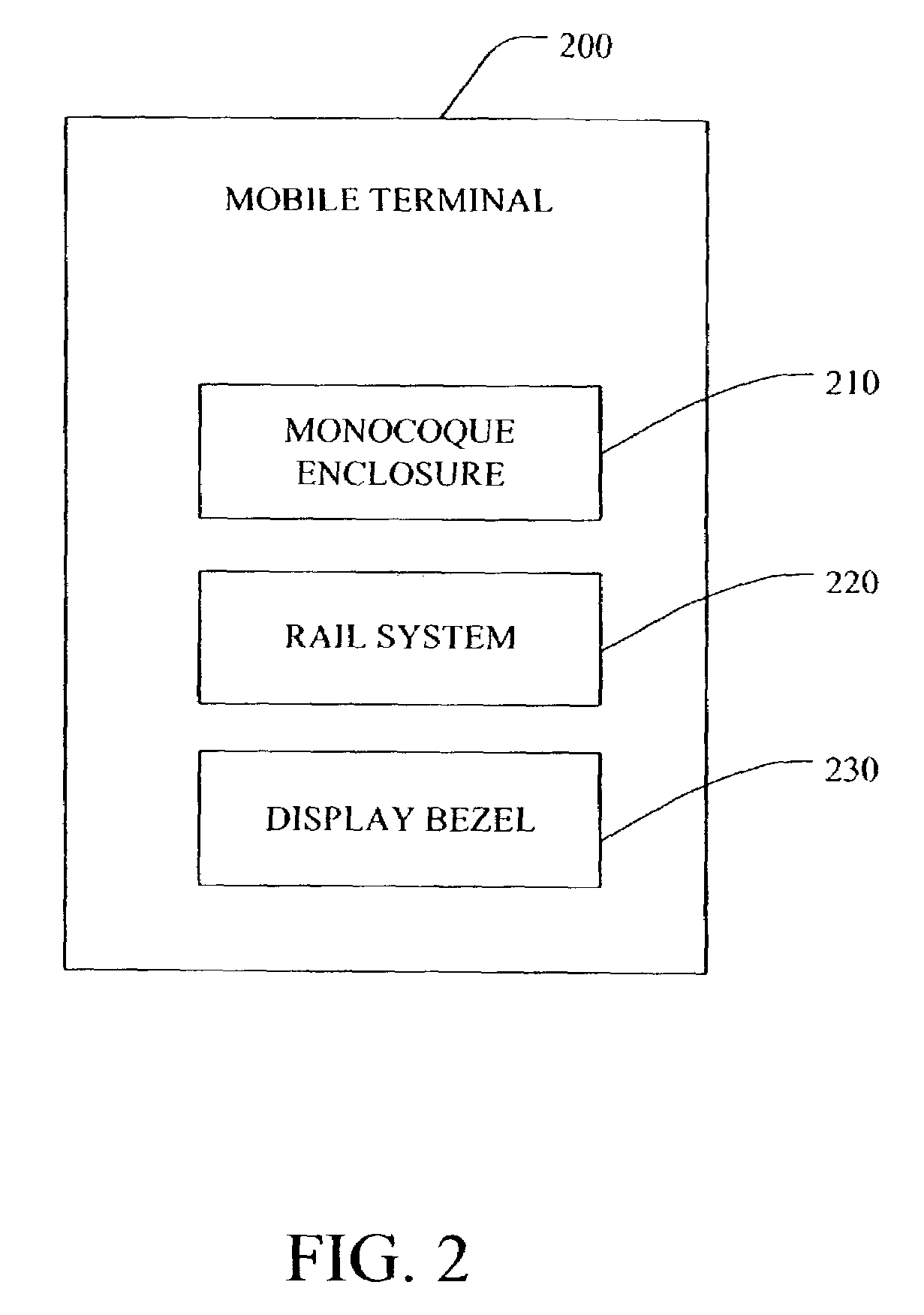

Rugged design for hand held mobile terminals

ActiveUS7522889B2Increased torsional stiffnessEasy to assembleInterconnection arrangementsMounting boards securingDisplay deviceHand held

Systems and methods for a rugged hand held mobile terminal design are provided. The mobile terminal design includes a monocoque enclosure for housing electronic components. The electronic components are mounted on a rail system, which is positioned within an interior portion of the enclosure through an open end of the enclosure. The mobile terminal design also includes a display bezel. The display bezel and the rail system have mating parts for securing the assembly together.

Owner:SYMBOL TECH LLC

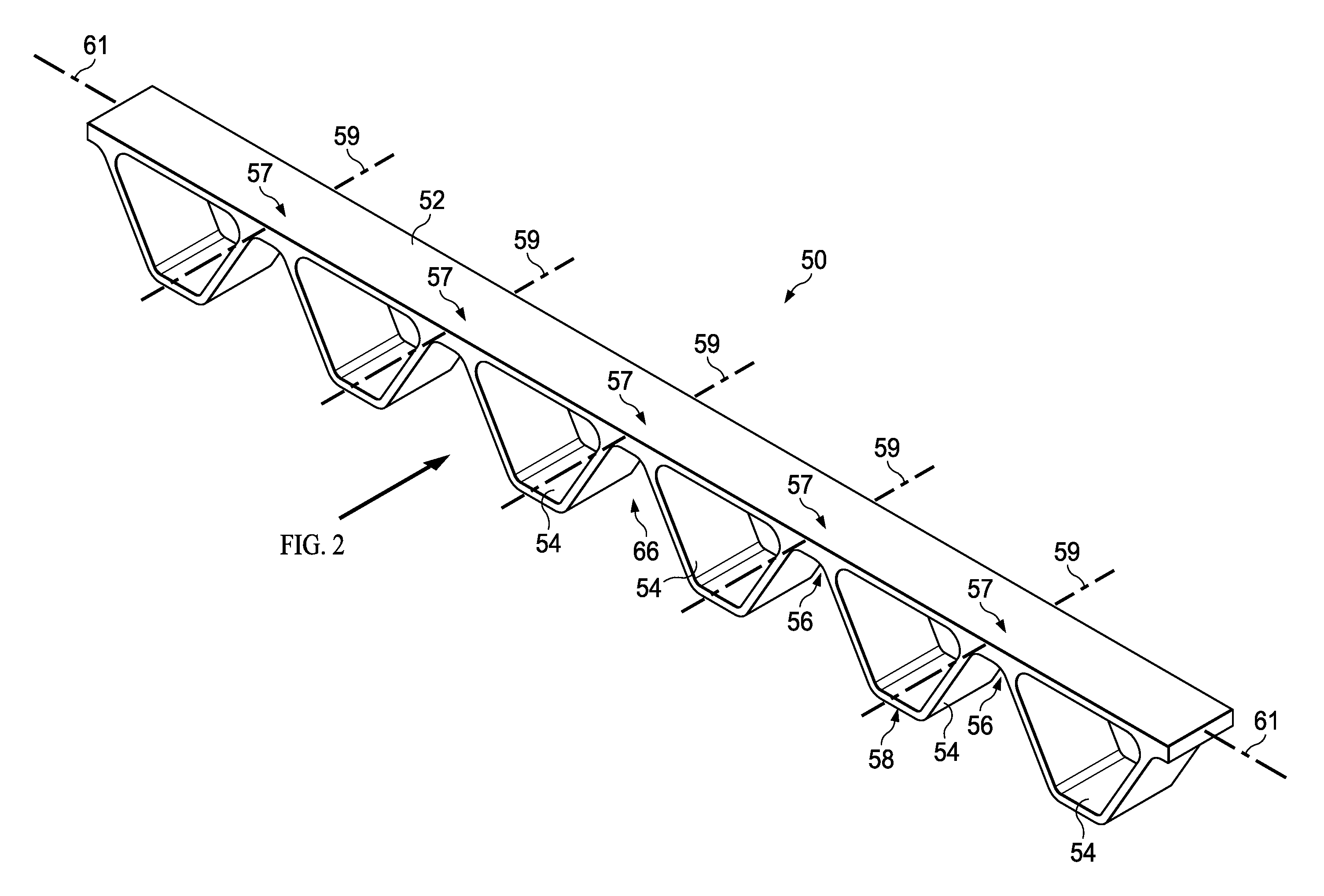

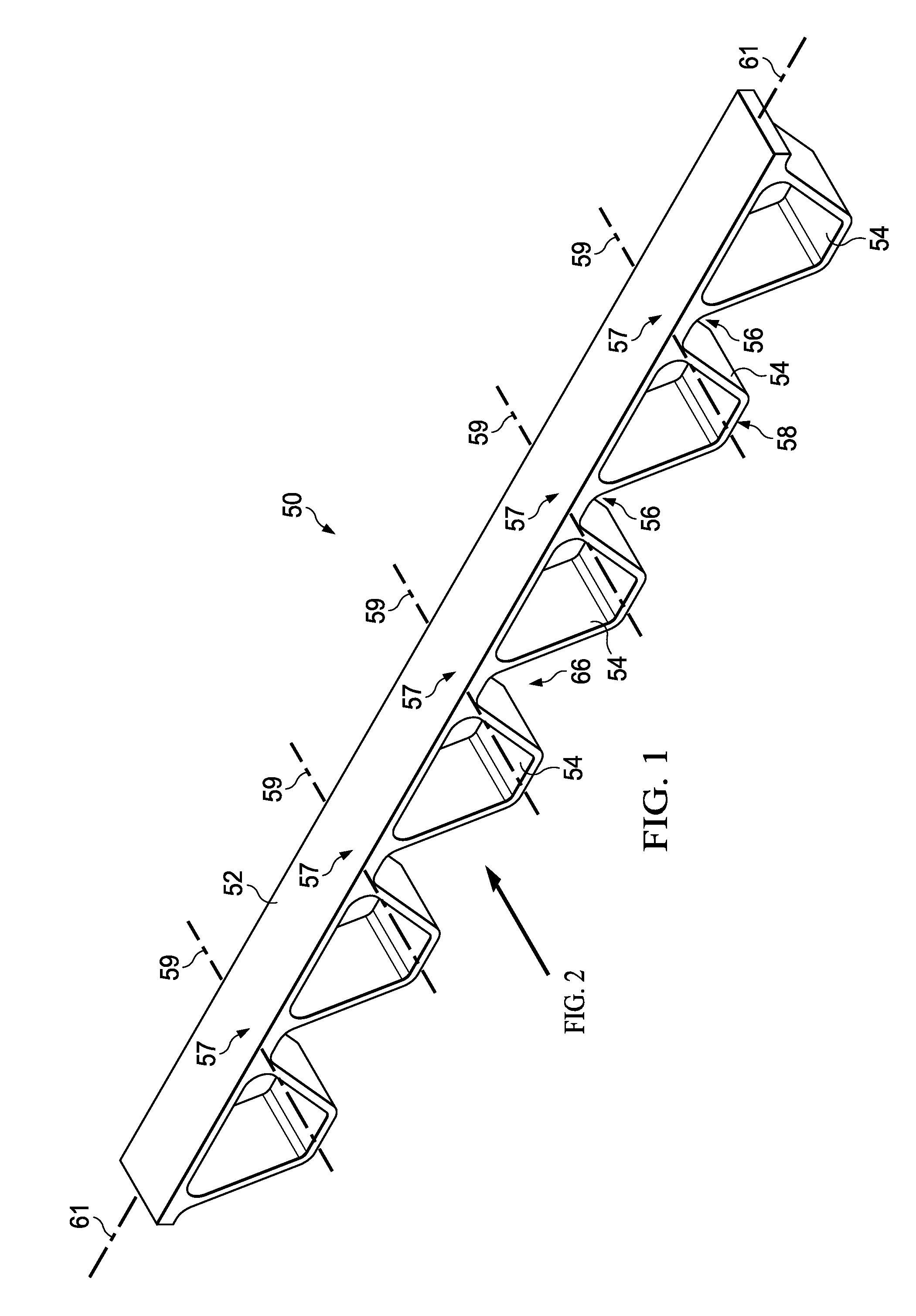

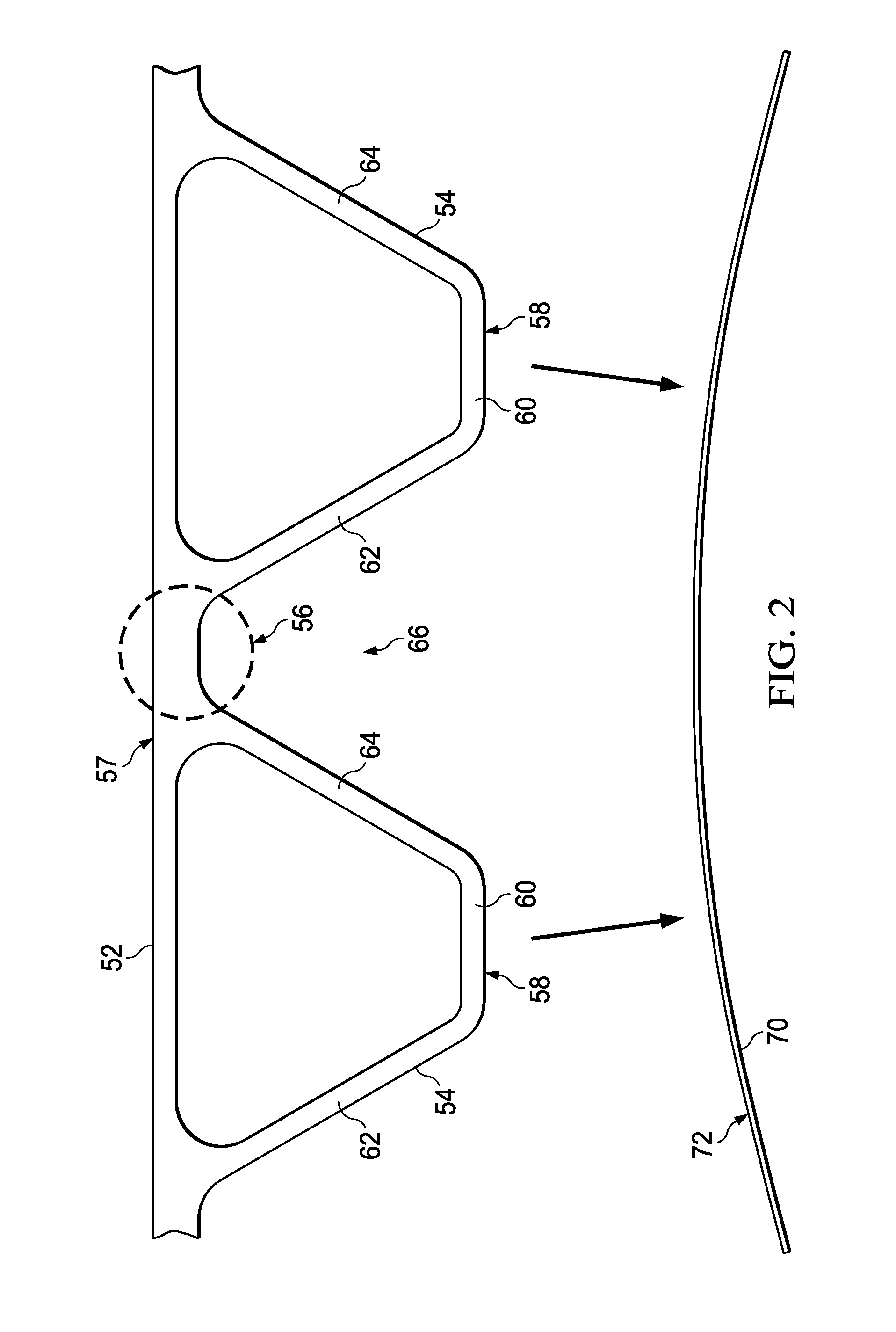

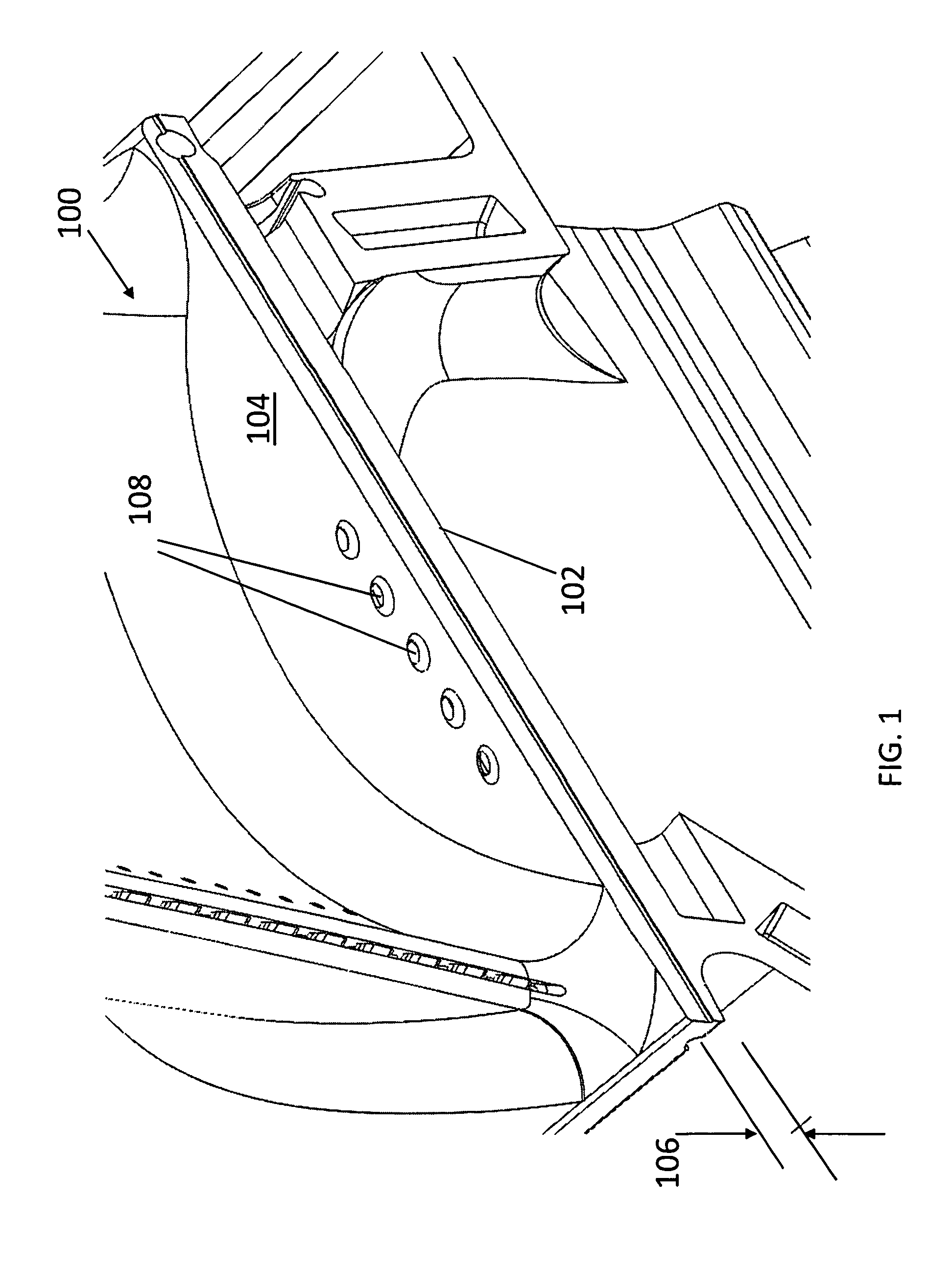

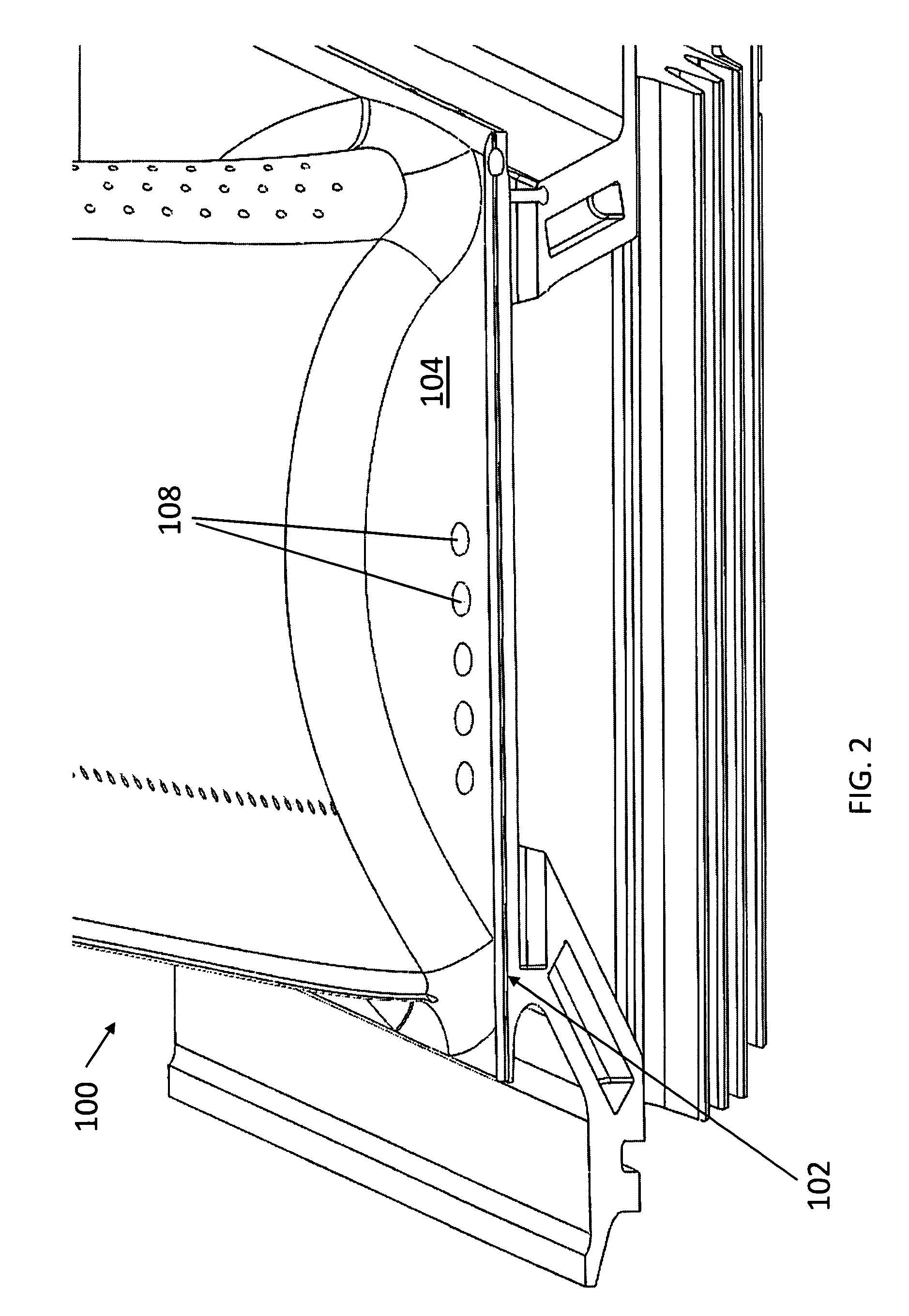

Shaped cooling holes for reduced stress

ActiveUS8066482B2Enhances the cooling of a turbine bladeLow stress levelPropellersEngine manufactureStress concentrationStress level

Owner:H2 IP UK LTD

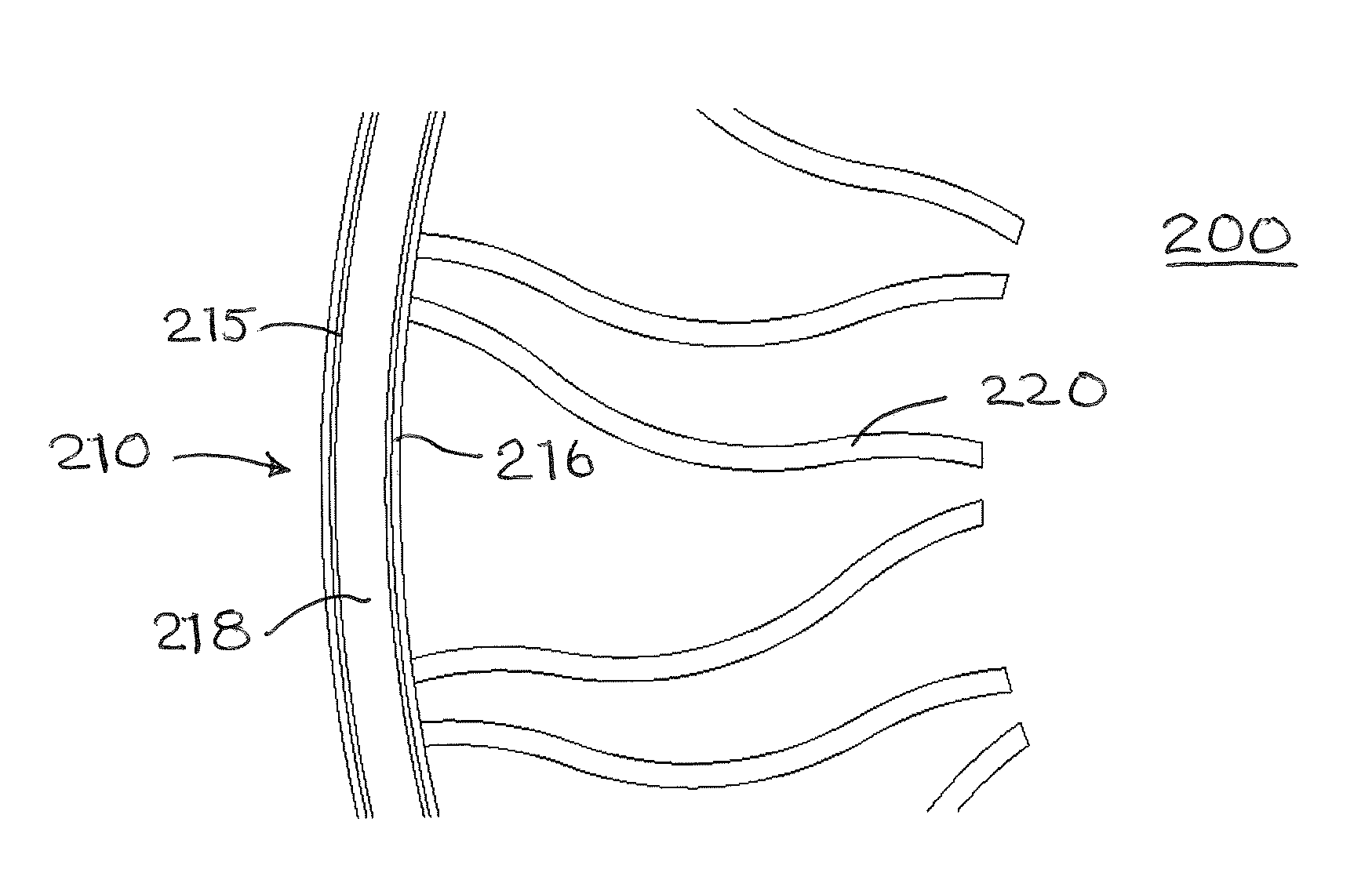

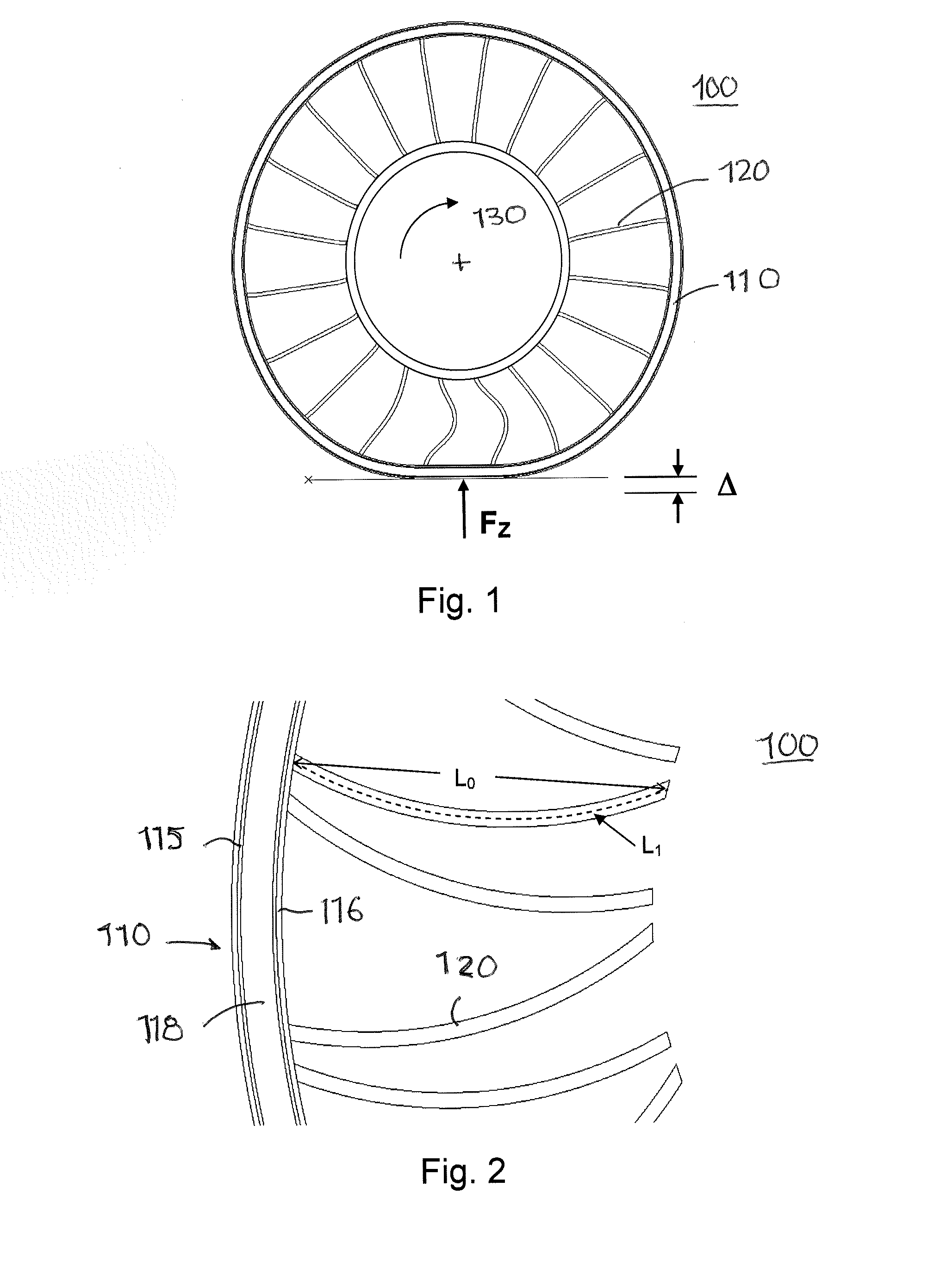

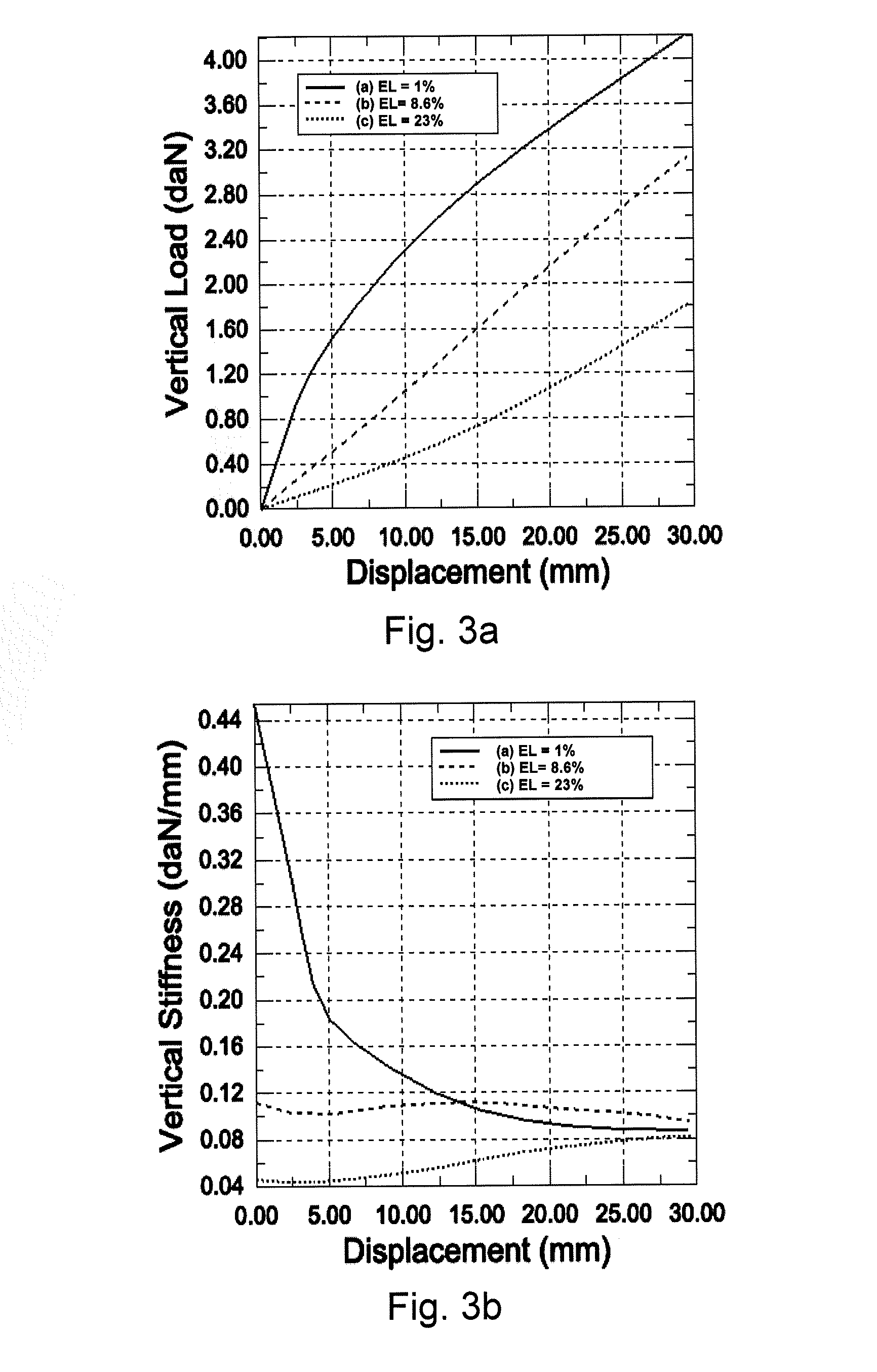

Variable Stiffness Spoke For a Non-Pneumatic Assembly

InactiveUS20090294000A1Reduce stress concentrationNon-inflatable tyresHigh resiliency wheelsVariable stiffnessEngineering

The invention described herein provides a non-pneumatic deformable structure having a variable stiffness spoke assembly that provides a method of adjusting the vertical stiffness. The structure comprises an outer annular band having a predetermined stiffness, a set of spoke elements having an outer end and an inner end, where the outer end is connected to the outer band, with the spoke element extending inward and having its inner end connected to a hub, the hub being configured to attach the structure to a vehicle axle or other apparatus capable of rotation about an axis. Each of the spoke elements has a curvilinear length greater than the length of a straight line segment extending from a point of connection of the outer end of the spoke element with the outer annular band to a point of connection of the inner end of the spoke element to the hub. The outer end of said spoke element is tangent to the straight line segment, and the inner end of said spoke element is tangent to the straight line segment.

Owner:MICHELIN RECH & TECH SA +1

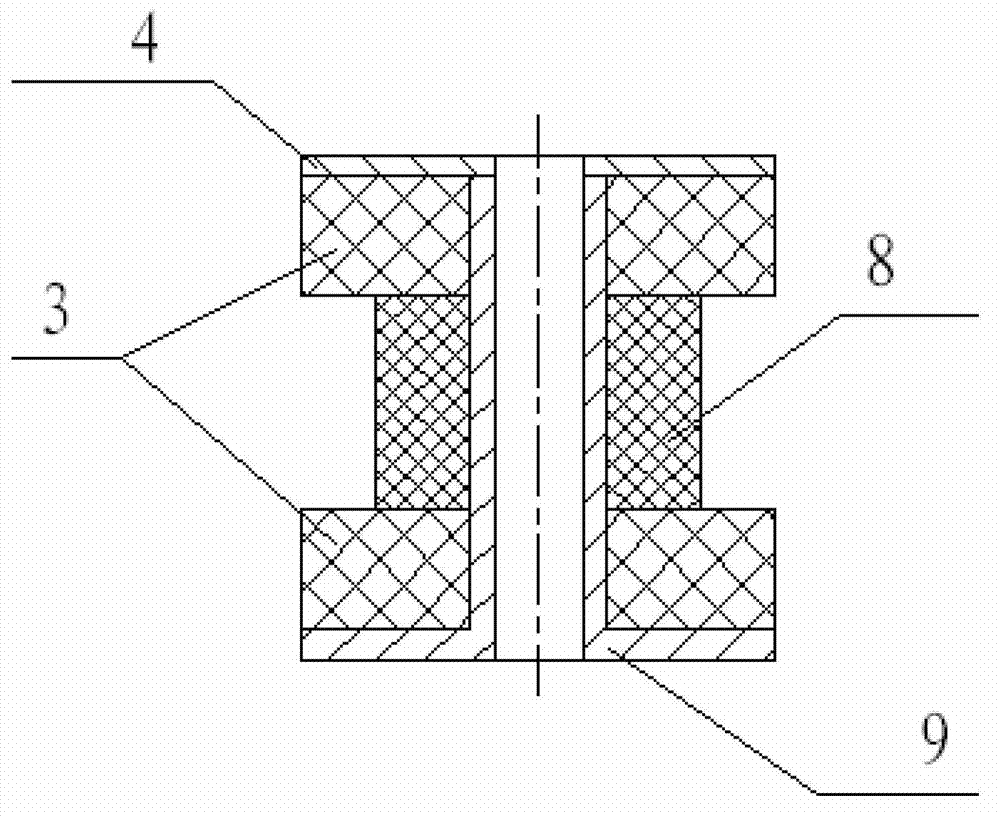

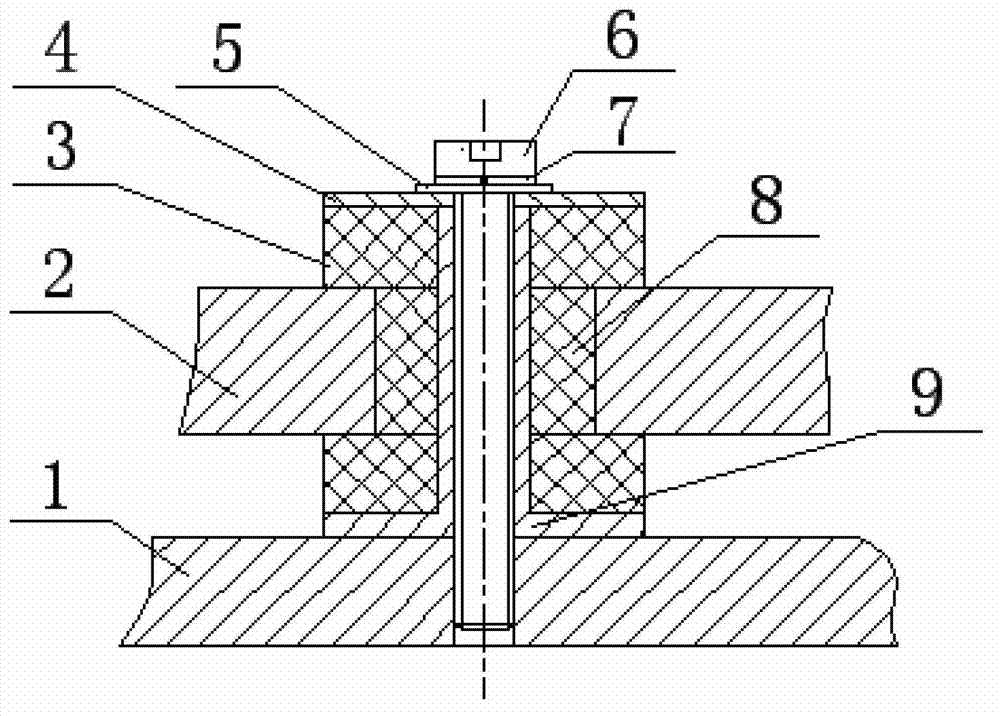

Combined type rubber shock absorber

ActiveCN103115100AImprove reliabilityStrong designabilityMultiple spring combinationsRubber materialEngineering

The invention relates to a combined type rubber shock absorber and belongs to the technical field of rubber vibration isolators. The combined type rubber shock absorber is mainly used for vibration and buffering processing of electronic equipment or instruments. The combined type rubber shock absorber comprises a rubber anti-vibration pad, a rubber anti-vibration column, a metal limiting lining and a metal limiting gasket. According to the combined type rubber shock absorber, vibration and impact energy is translated into heat energy and deformation energy of rubber materials through the deformation of rubber parts by means of a combined shock absorber structure, the rubber anti-vibration pad is capable of reducing dynamic energy of an instrument with vibration to be isolated in the axial direction, the rubber anti-vibration column is capable of reducing dynamic energy of the instrument with the vibration to be isolated in the radial direction, the metal limiting lining and the metal limiting gasket are used in a matching mode, dynamic displacement of the shock absorber is limited due to the fact that the shock absorber is installed on a base plate of the instrument through bolts, and then an installation function and a limiting function are achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

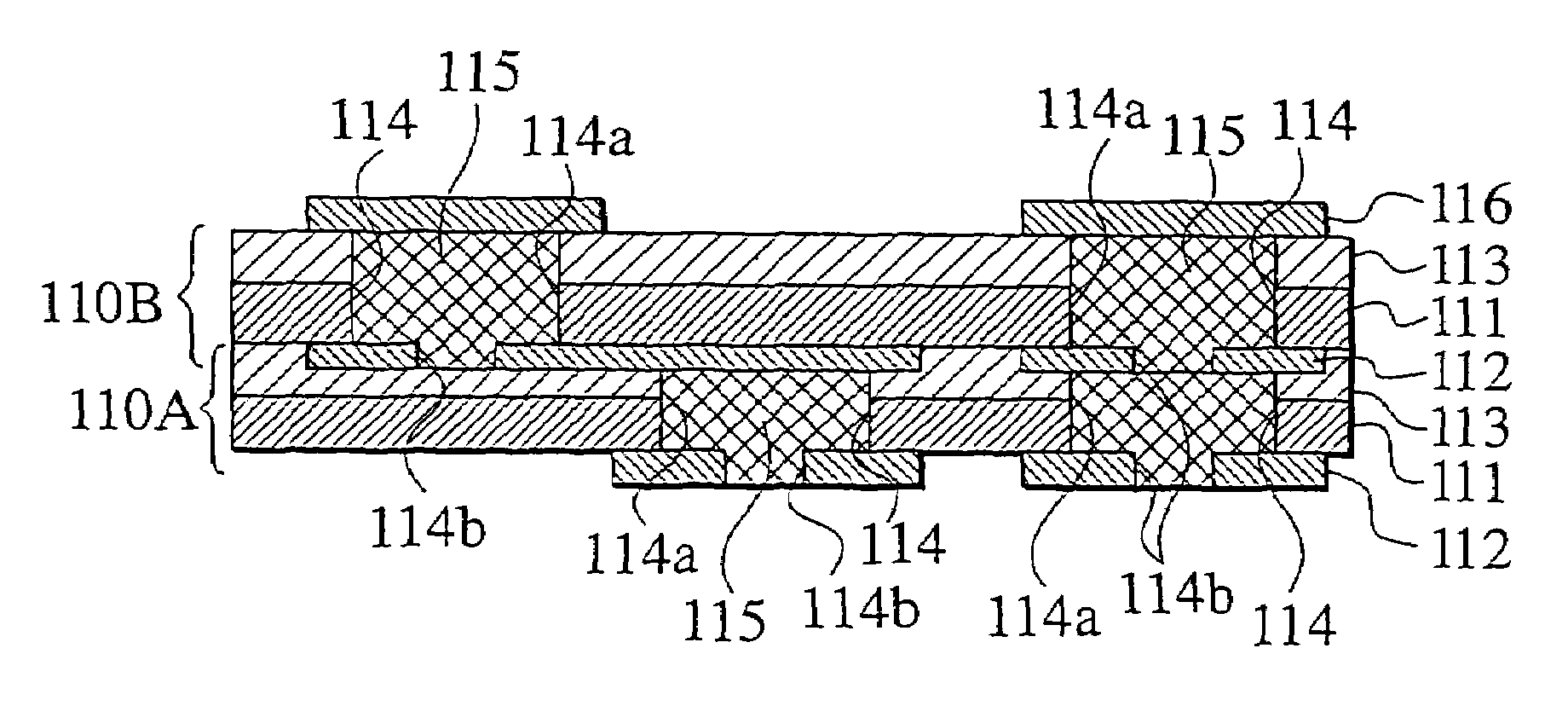

Multilayer wiring board, base for multilayer wiring board, printed wiring board and its manufacturing method

InactiveUS7312400B2Improve connection reliabilityReduce distortionSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionInterconnection

A multilayer wiring board assembly component comprises: an insulating substrate component (the insulating resin layer 111); a conductive layer 112 formed on one surface of said insulating substrate component 111 in the form of an electrode pattern; an adhesive layer 113 formed on the other surface of said insulating substrate component 111; and a conductive resin composition 115 with which is filled a through hole passing through said insulating substrate component 111, said adhesive layer and said conductive layer in order to make interlayer interconnection. The bore diameter of the conductive layer portion 114b of the through hole 114 is smaller than the bore diameter of the insulating resin layer portion and the adhesive layer portion 114a to establish electrical connection between the conductive resin composition 115 and the conductive layer 112 by the rare surface 112a of the conductive layer 112.

Owner:FUJIKURA LTD

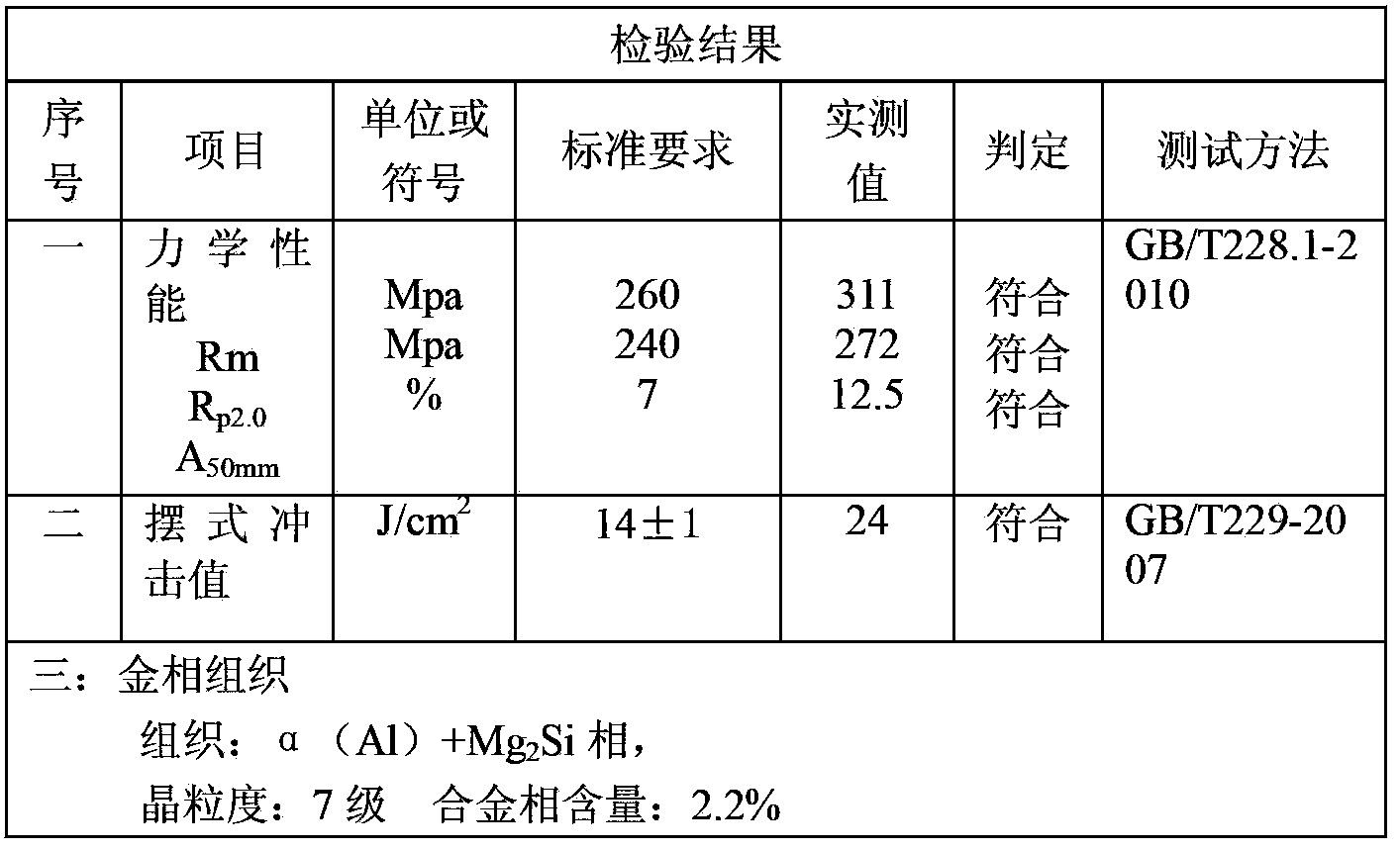

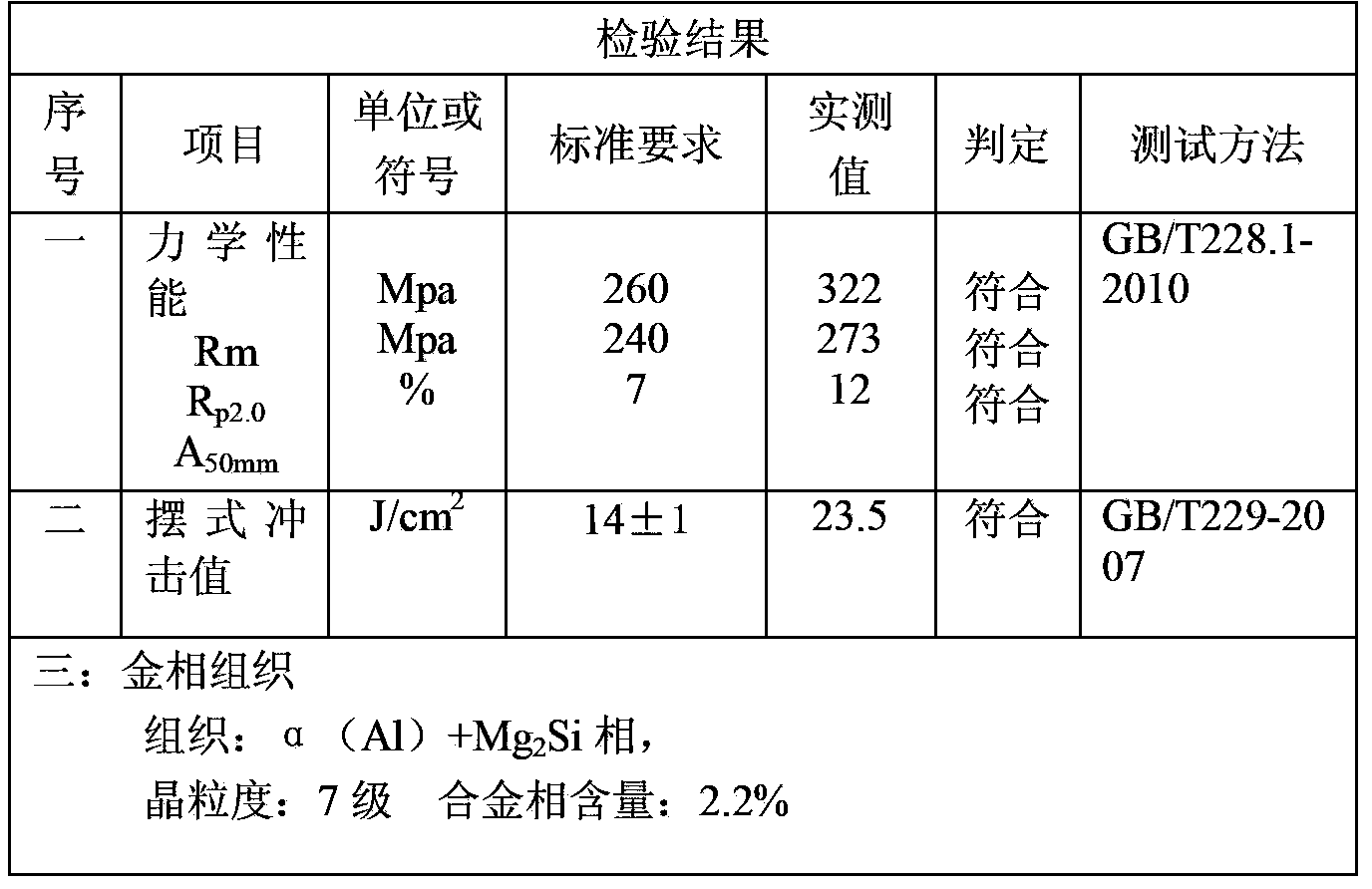

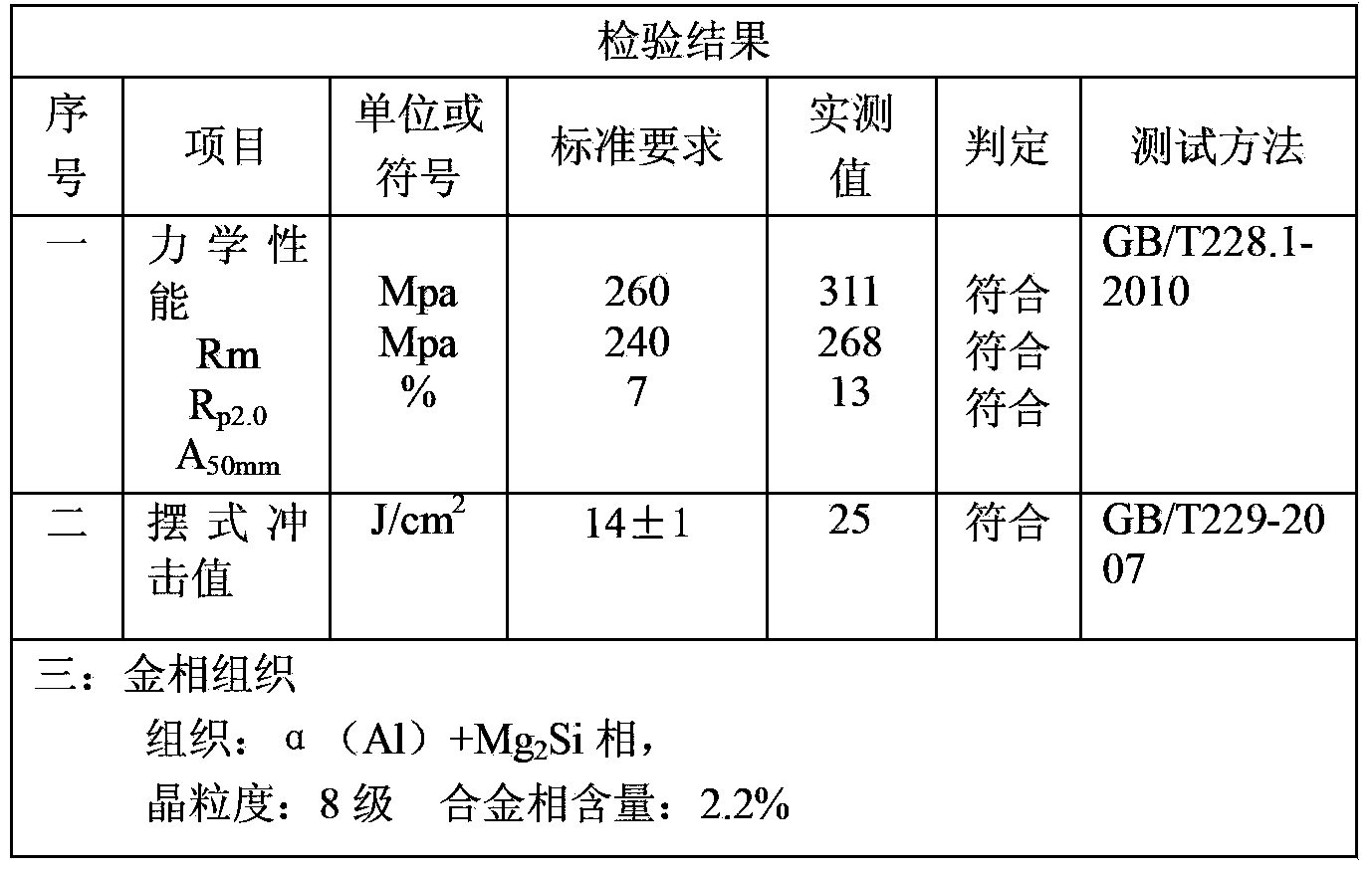

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

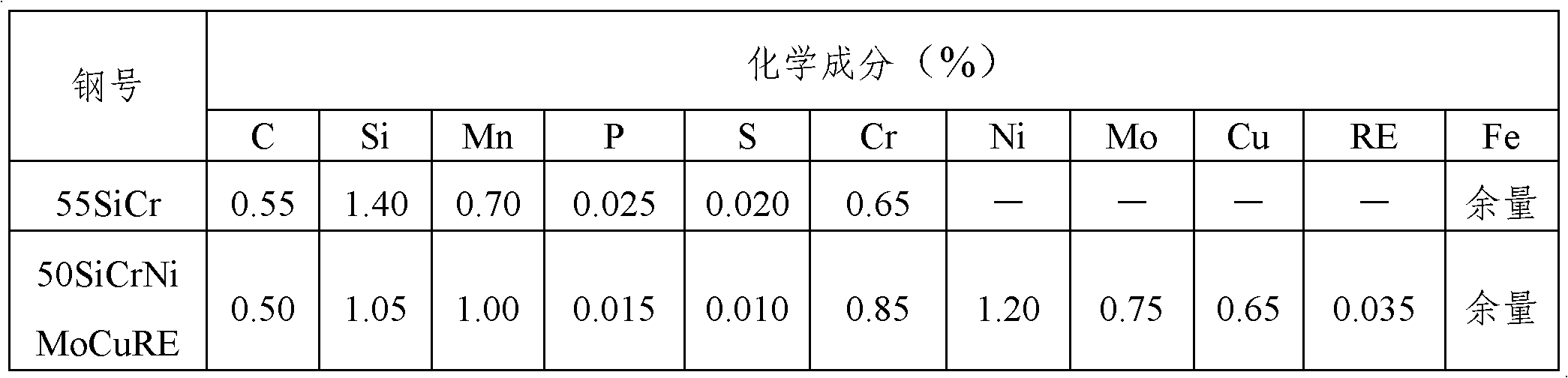

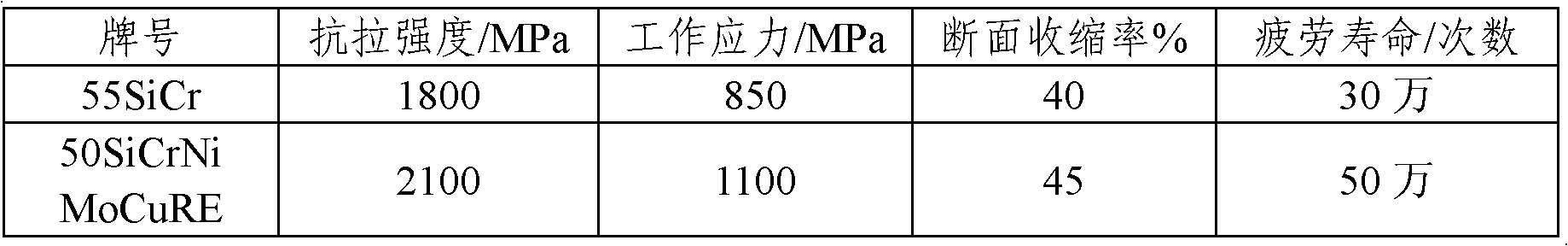

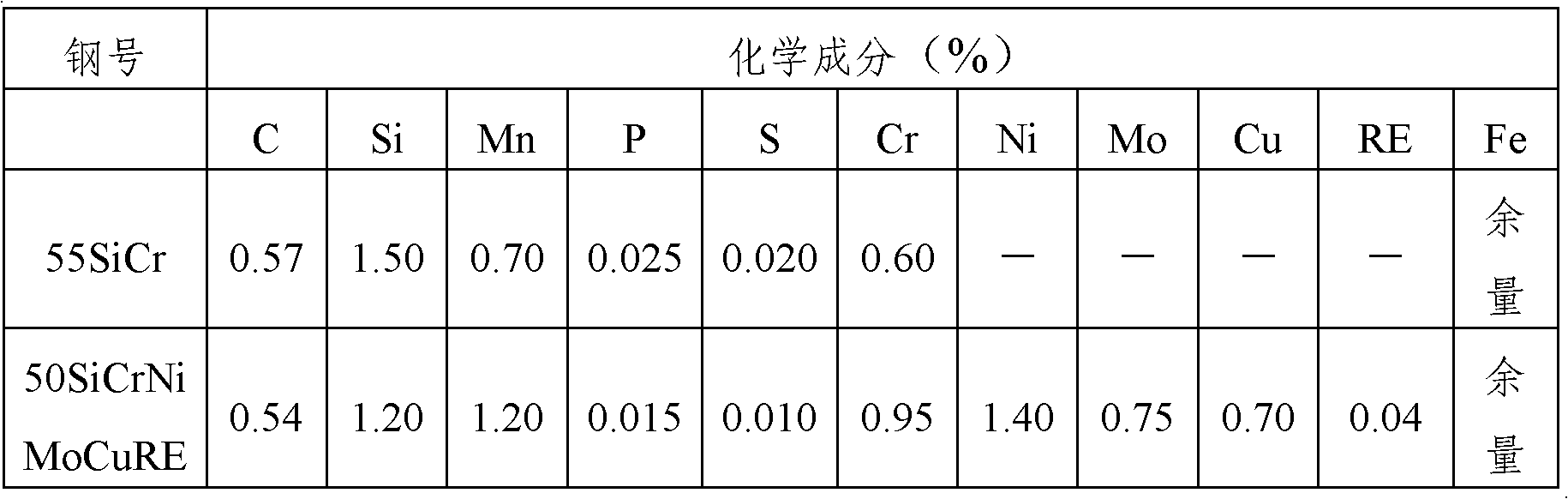

Spring steel used for automobile suspension as well as preparation method and application thereof

ActiveCN102634735AHigh tensile strengthIncrease work stressProcess efficiency improvementChemical compositionSpring steel

The invention provides a spring steel used for an automobile suspension. the spring steel comprises the following ingredients in percentage by weight: 0.46-0.56% of C, 0.90-1.20% of Si, 0.80-1.20% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.70-1.0% of Cr, 0.90-1.50% of Ni, 0.60-0.90% of Mo, 0.50-0.80% of Cu, 0.02-0.07% of RE and the balance of Fe and inevitable impurities. The invention also provides a preparation method for the spring steel and a method for preparing a spring steel wire by using the spring steel. According to the invention, the chemical components of the spring steel are reasonably designed, and the smelting rolling and steel wire preparation method and the auxiliary material adding method and proportion are improved. Compared with the existing 55SiCr steel, the tensile strength of the spring steel disclosed by the invention is improved by 400MPa, the working stress is improved by 200MPa, and the fatigue life is improved by 200 thousand times.

Owner:GUANGZHOU ORSA WIRE SCI & TECH

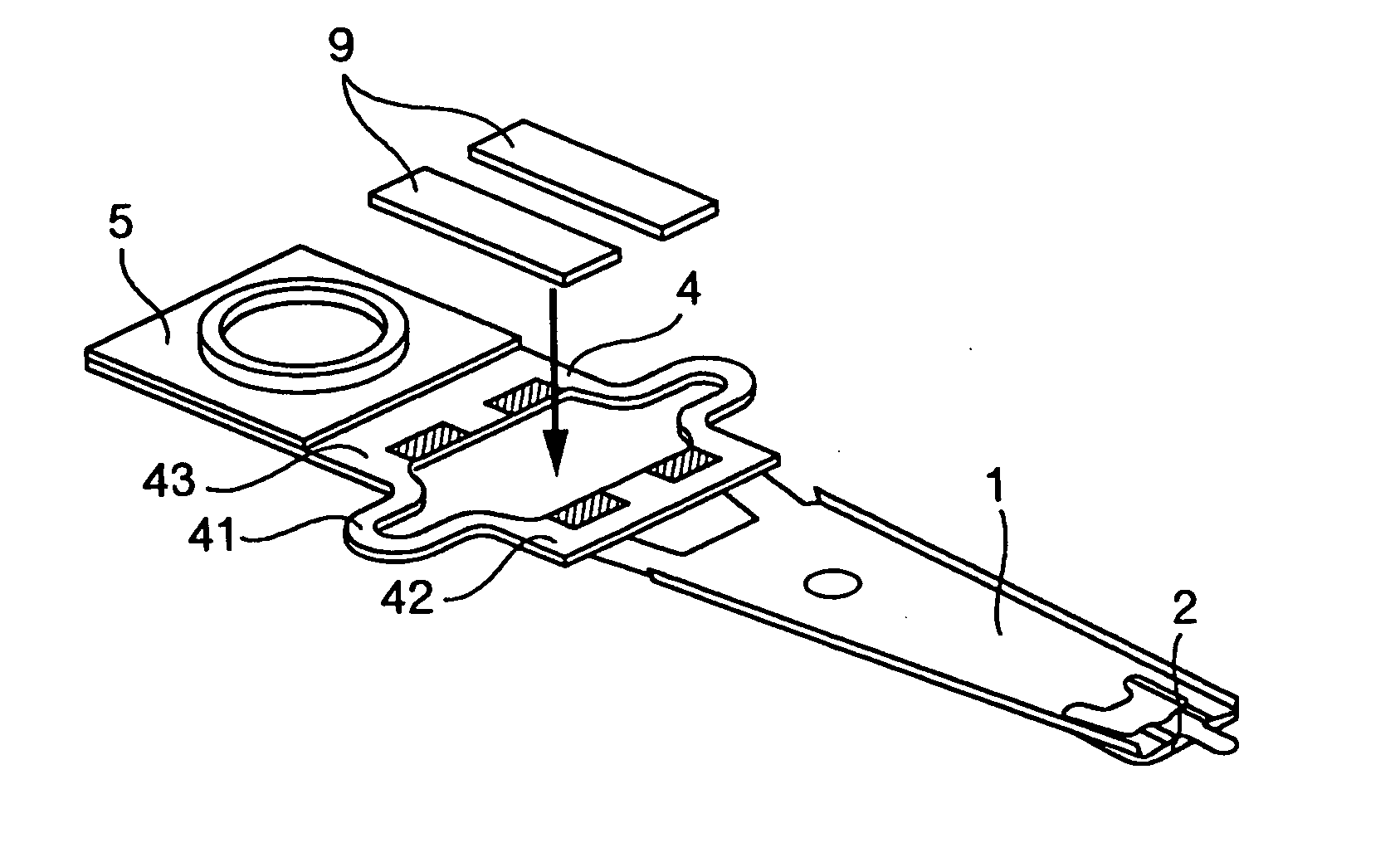

Magnetic disk apparatus

InactiveUS20040027727A1Precise positioningReduce stress concentrationArm with actuatorsRecord information storageControl theoryMicroactuator

A head support mechanism includes a slider equipped with a magnetic head to read / write information from / to a magnetic disk, a load beam to provide the slider with an appropriate load, the load beam being flexible in a direction substantially perpendicular to the disk, and a microactuator mounting portion equipped with a microactuator. A first actuator fixing portion, which connects the microactuator mounting portion to a carriage, and a second actuator fixing portion on the magnetic head side of the microactuator mounting portion, which connects the microactuator mounting portion to the load beam, are coupled by two arm portions of the microactuator mounting portion. The microactuator is mounted on the microactuator mounting portion so that the microactuator does not come into contact with the microactuator mounting portion between the first actuator fixing portion and the second actuator fixing portion.

Owner:WESTERN DIGITAL TECH INC +1

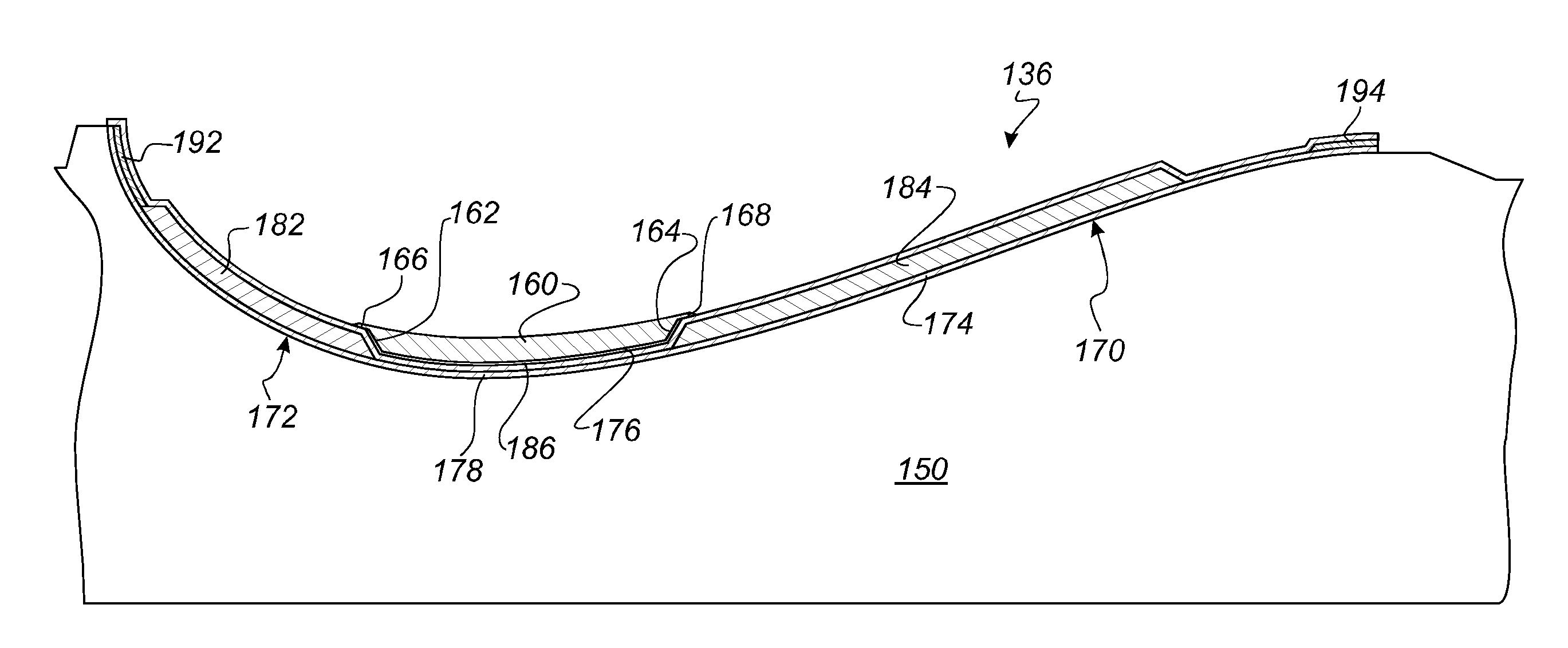

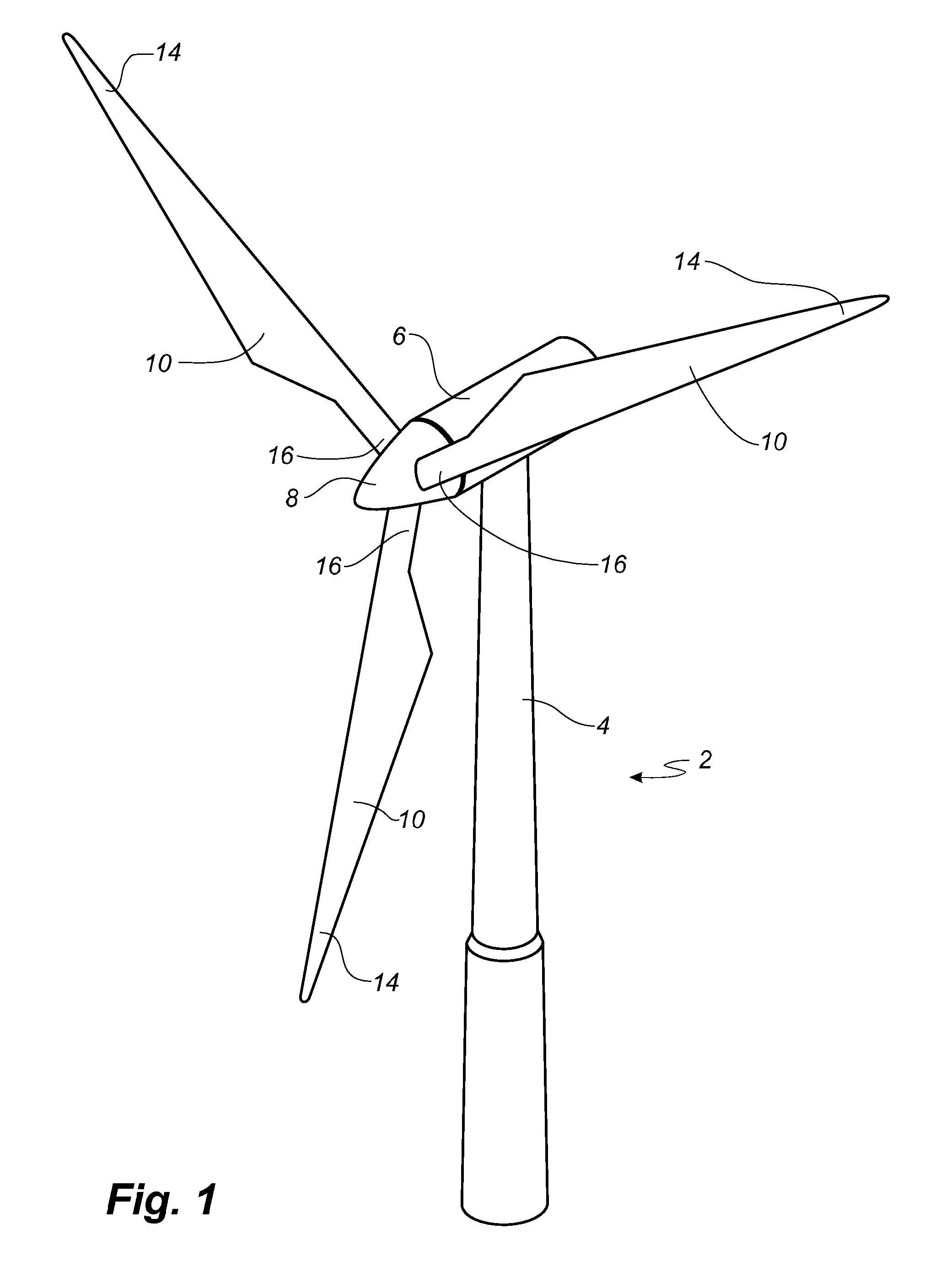

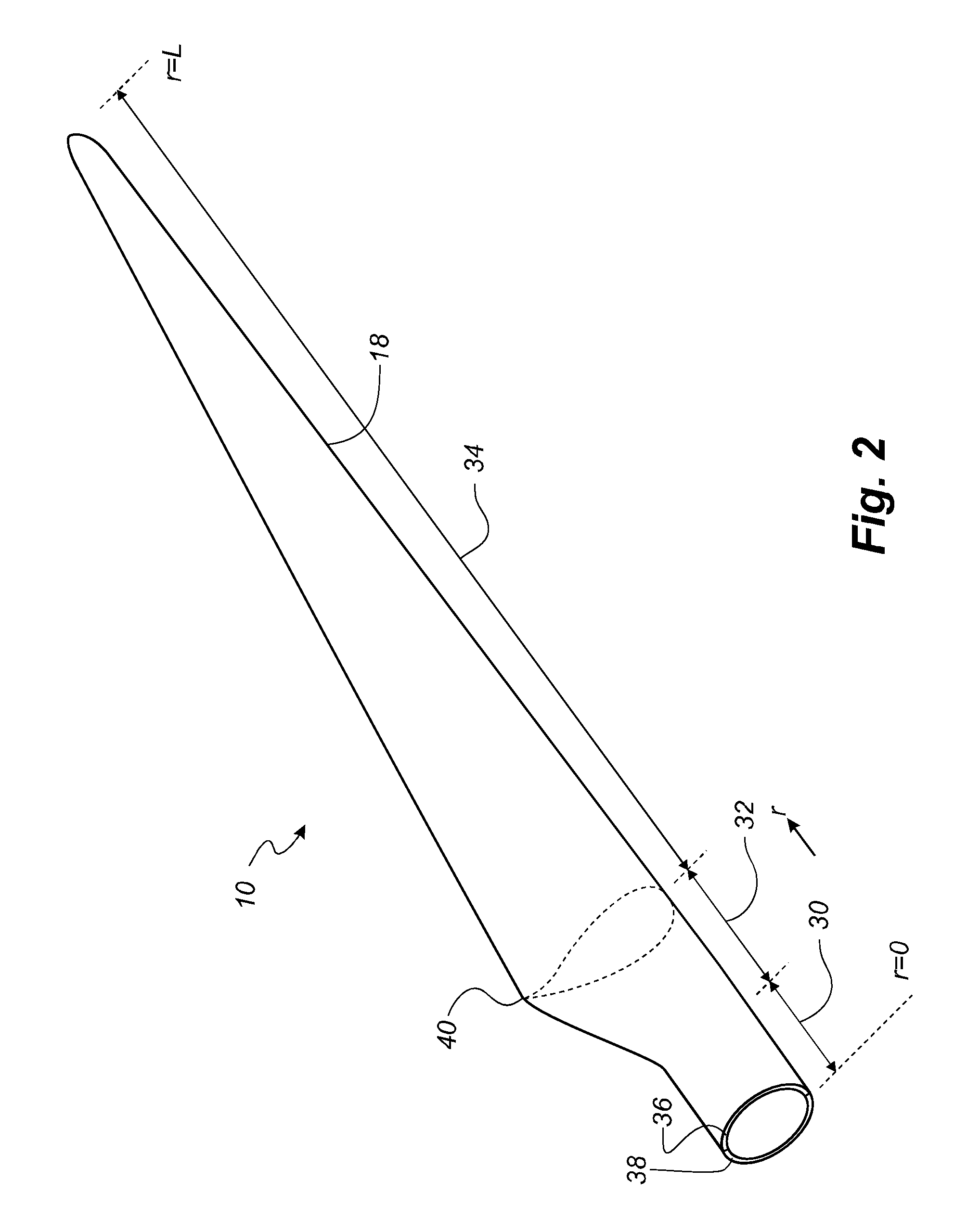

A wind turbine blade comprising an aerodynamic blade shell with recess and pre-manufactured spar cap

InactiveUS20150308404A1Well formedReduce stress concentrationPropellersFinal product manufactureTurbine bladeWind force

A wind turbine blade has a load carrying structure including at least a first spar cap and an aerodynamic shell having an outer surface forming at least part of an exterior surface of the wind turbine blade and an inner surface. The aerodynamic shell includes a first recess at the inner surface of the blade shell with a first thickened part at a first side of the first recess and a second thickened part at a second side of the first recess. The first recess is tapered towards the first side of the recess and tapered towards the second side of the recess, and the first spar cap is arranged in the first recess of the aerodynamic shell. The first spar cap is tapered towards a first side of the spar cap and further is tapered towards a second side of the spar cap.

Owner:LM WP PATENT HLDG

Threaded joint with high radial loads and differentially treated surfaces

ActiveUS20110042946A1Improve fatigue lifeImprove fatigue resistanceDrilling rodsPipe elementsEngineeringScrew thread

A threaded joint has an interference between thread roots of pin and thread crests of the box of value comprised between 1% and 5% of the average thickness of the connection, and a root to load flank radius R comprised in the range of 0.2 mm and 0.4 mm and a surface treatment comprising shot peening applied to the beginning and end of the threaded zone of the pin. In other embodiments the interference can be between thread roots of box and thread crests of the pin.

Owner:TENARIS CONNECTIONS

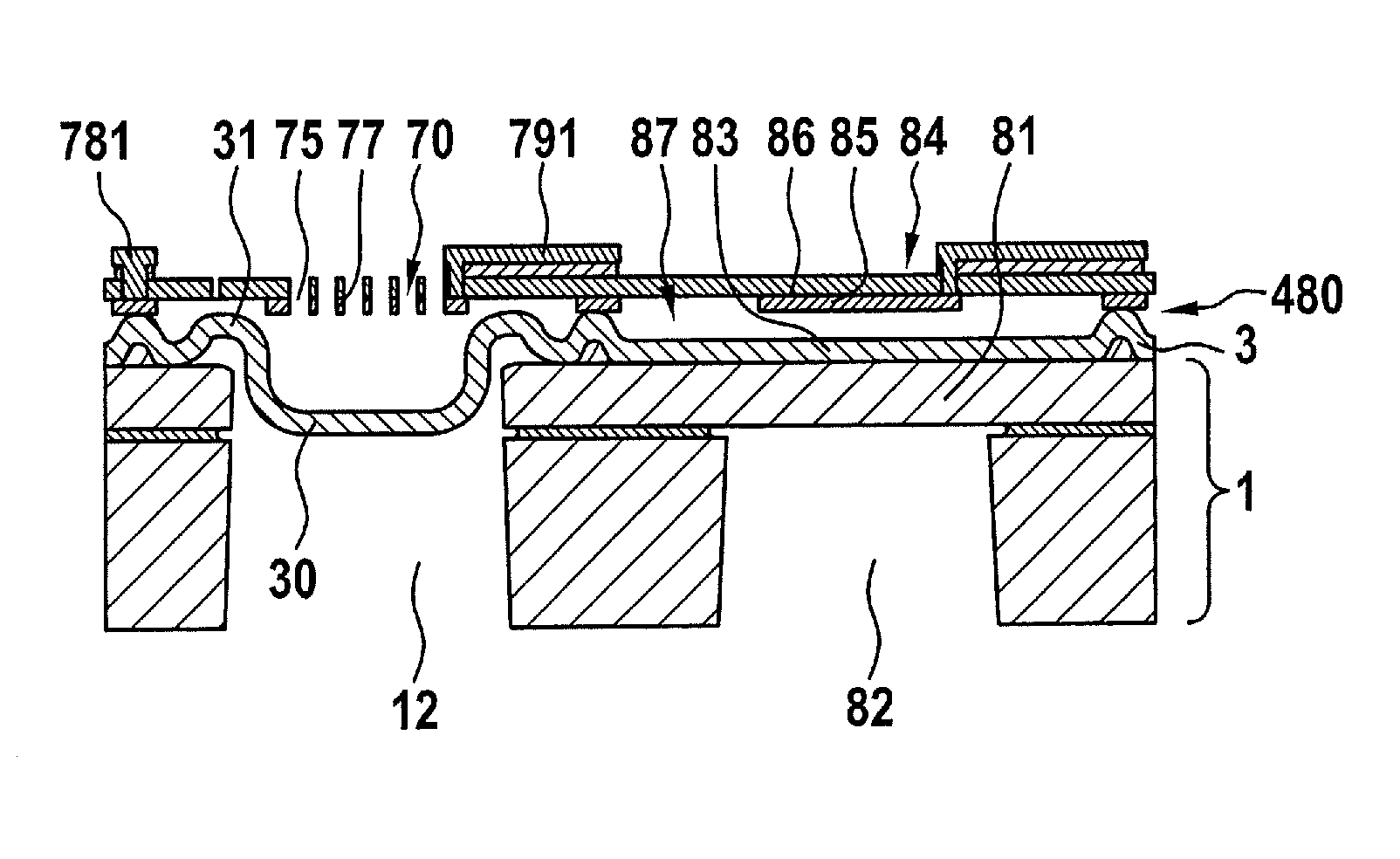

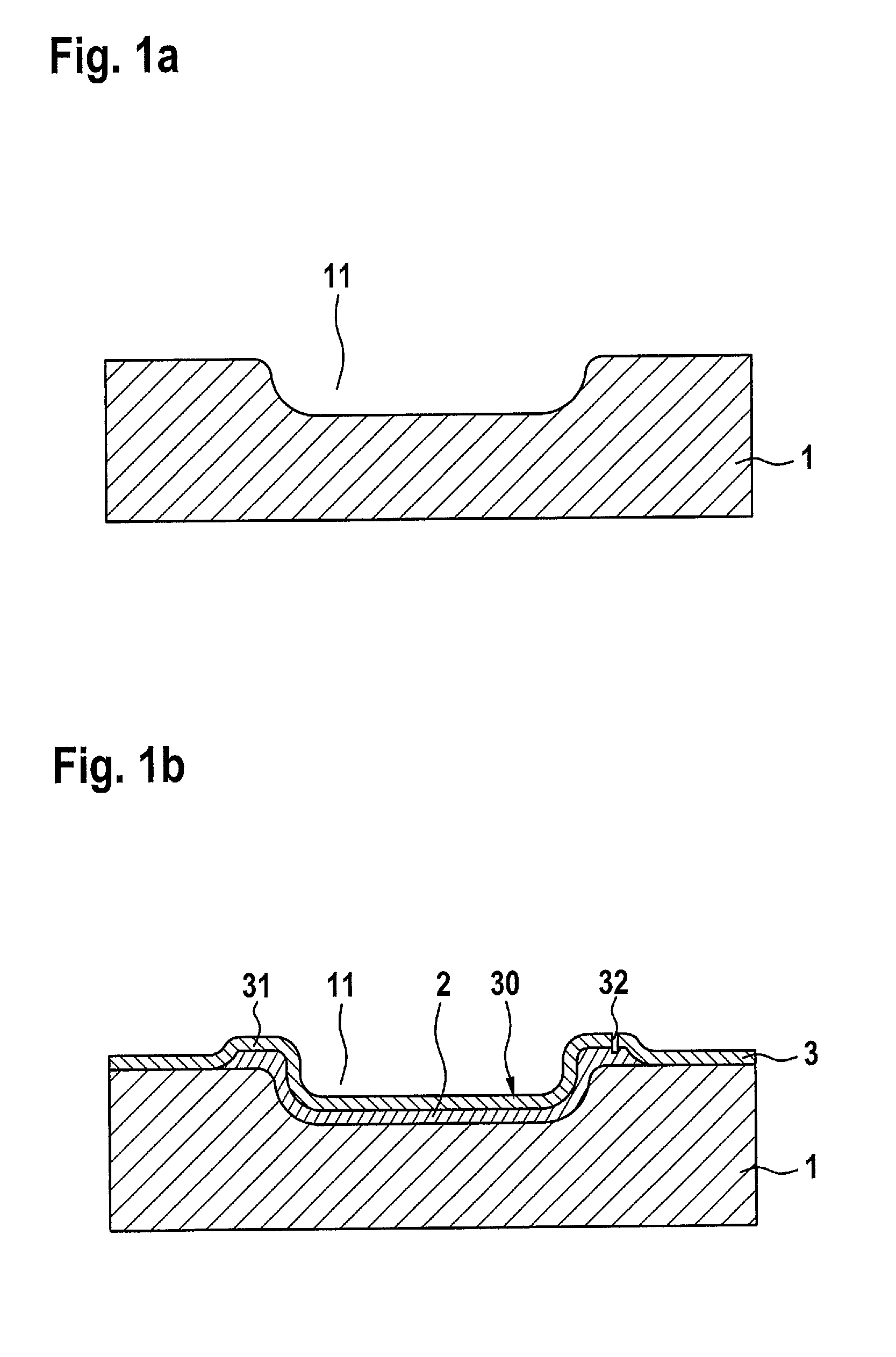

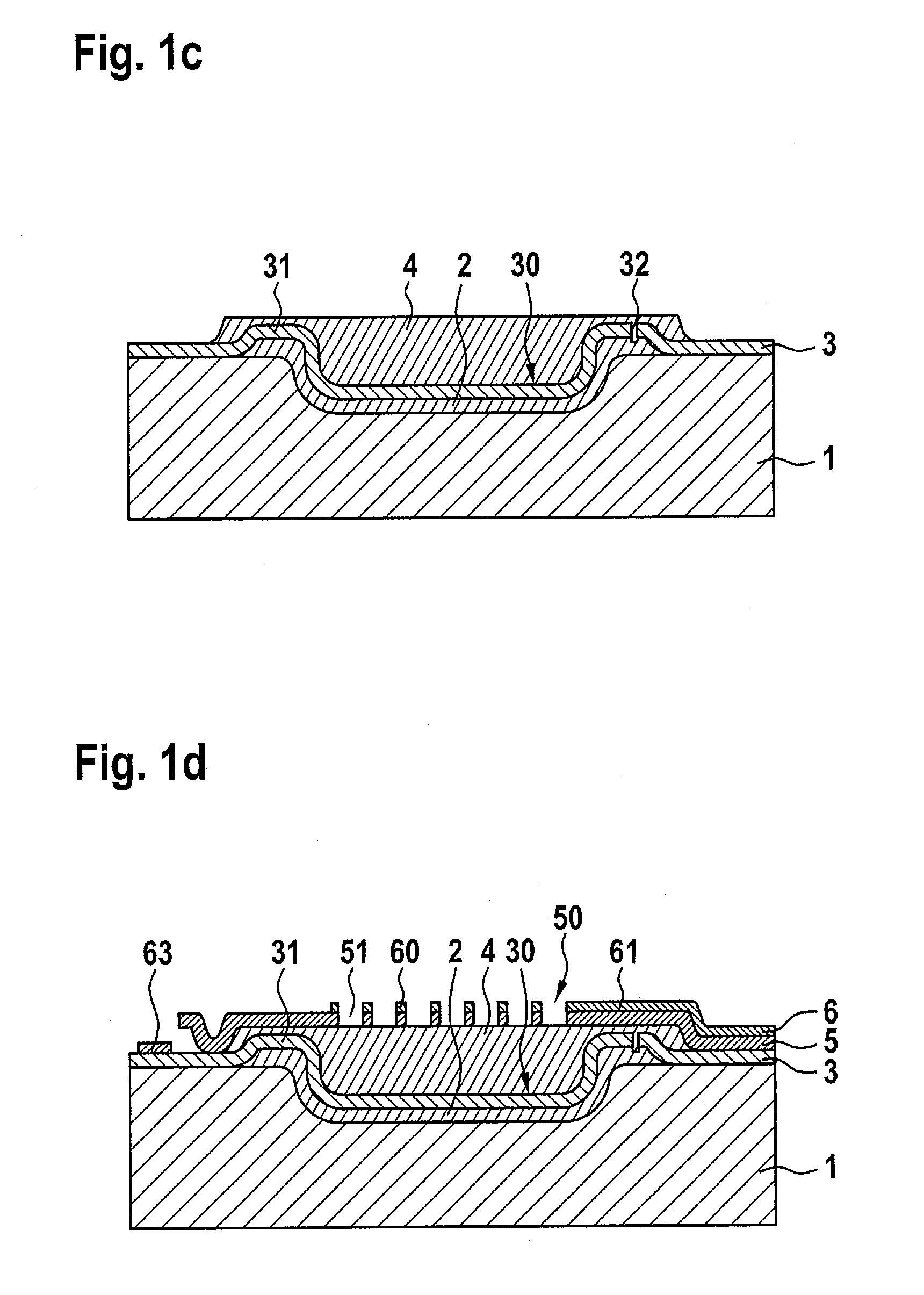

MEMS device having a microphone structure, and method for the production thereof

ActiveUS9403670B2Improve sealingReduce generationMicrophonesDecorative surface effectsCapacitanceEngineering

Owner:ROBERT BOSCH GMBH

Superplastic forming/diffusion bonding forming method for heat-resistant titanium alloy envelope

ActiveCN106271439AHigh strengthIncrease stiffnessWelding apparatusTitanium alloyUltimate tensile strength

The invention belongs to the technical field of metal plastic processing, and aims at providing a superplastic forming / diffusion bonding forming method for a heat-resistant titanium alloy envelope with high material utilization ratio, high dimension control precision and high product performance. As a mould is adopted to control the appearance and dimension of a workpiece, the forming of a titanium alloy workpiece provided with a complex profile is completed, the production process of the heat-resistant envelope workpiece is shortened, and production cost is lowered; as the process of diffusion bonding followed by superplastic forming is adopted, the diffusion bonding is realized at the contact part of an inner envelope and an outer envelope, and the superplastic forming is realized at a separated part, the once-formed heat-resistant envelope with the complex profile and a hollow structure has the advantages of greatly improved structural integrity of a component, enhanced specific strength and specific stiffness of the component and increased welding rate of the diffusion bonding; the processed workpiece has the advantages of high dimension accuracy, high integral performance, light weight and the like; and the method disclosed by the invention has the advantages of shortened processing period, high material utilization ratio and lowered production cost.

Owner:北京普惠三航科技有限公司

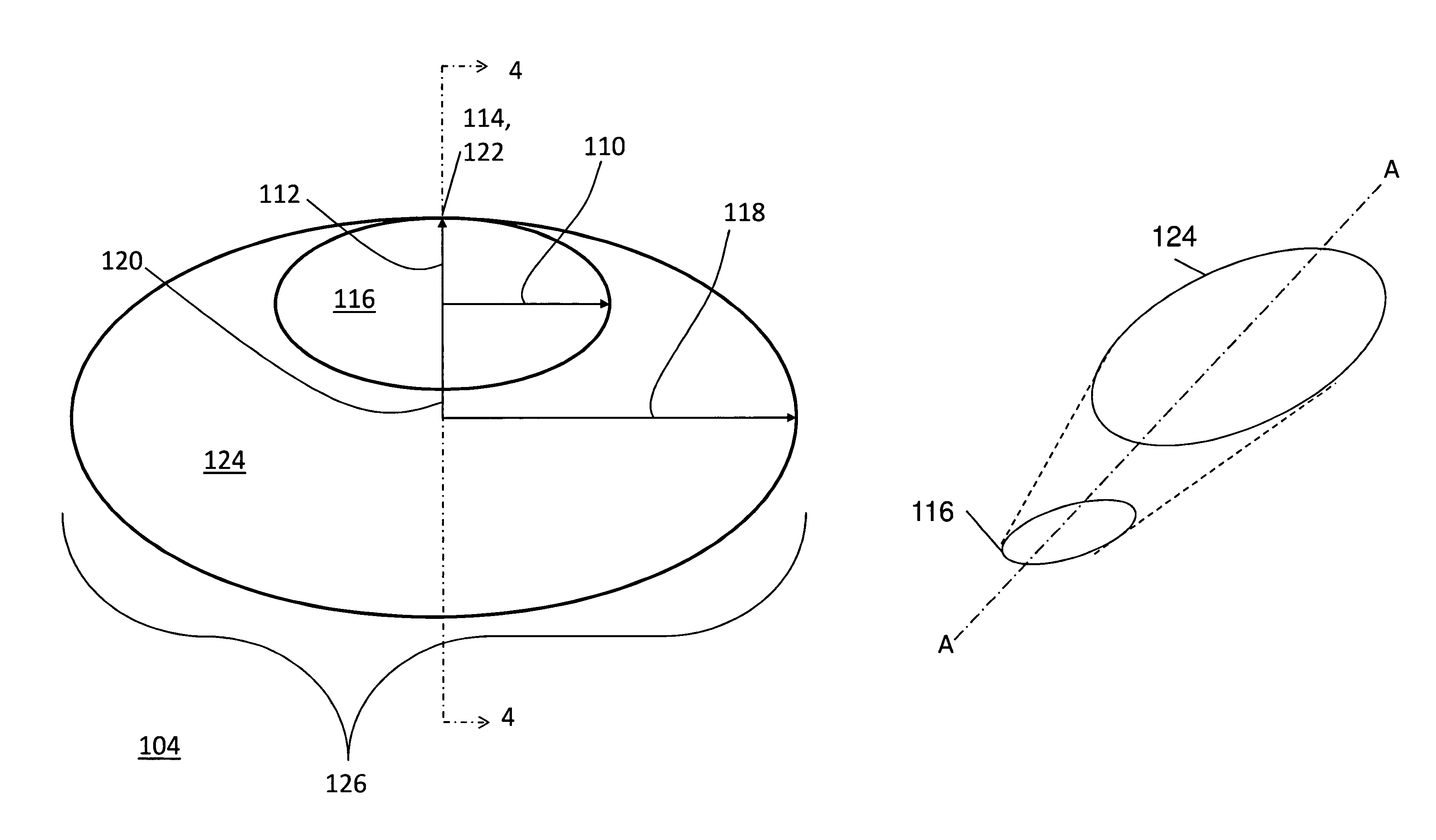

Shape modification and reinforcement of columns confined with FRP composites

InactiveUS20060070338A1Reduce concentrationReduce failureStrutsPillarsReinforced concrete columnHigh intensity

Strengthening reinforced concrete columns by using Fiber Reinforced Polymer (FRP) composites can be an effective method of retrofitting existing columns. FRP composites have a number of advantages over steel, including their high strength-to-weight ratio and excellent durability. The confinement effectiveness of FRP materials for rectangular sections can be improved by performing shape modification such that a rectangular column section is modified into a shape that does not have 90 degree comers such as an elliptical, oval or circular column. An expansive concrete can be advantageously used between the FRP material and the existing concrete in order to post-tension the FRP material circumferentially and improve confinement of the concrete. A finite element analytical model is also disclosed which model describes the stress-strain relationship for the FRP-confined columns after shape modification.

Owner:PANTELIDES CHRIS P +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com