Stabilizer bushing

A technology of stabilizer bar and bushing, which is applied to springs, suspensions, interconnection systems, etc. made of plastic materials, can solve problems such as stuck noise and abnormal noise, reduce axial flow, and prevent sticking. Separation, strong adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

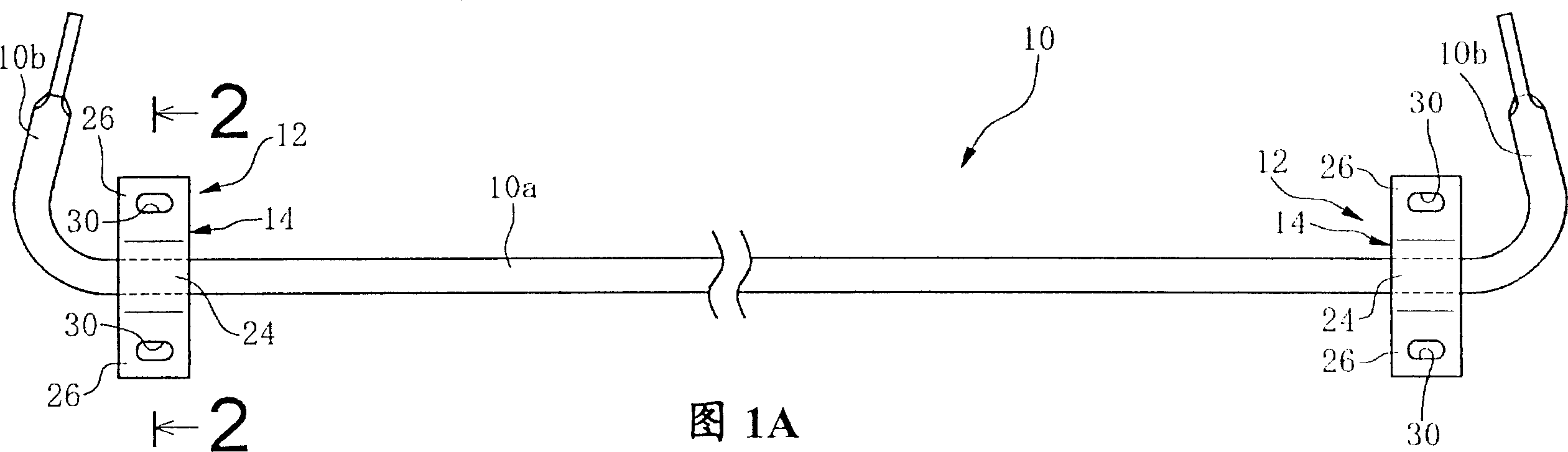

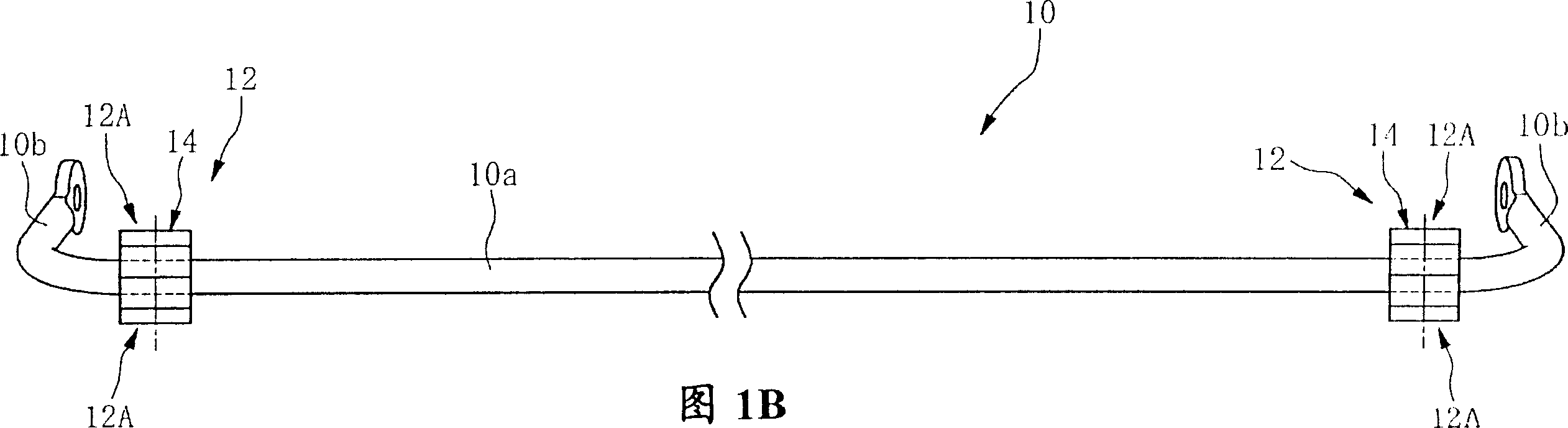

[0042] Referring first to FIGS. 1A and 1B , there is shown a stabilizer bar 10 consisting of a metal rod having a generally portal-shaped planar configuration and a central portion 10a thereof. That is, the stabilizer bar 10 is substantially straight in the vehicle width direction (vehicle lateral direction) and is fixed to the vehicle body via the stabilizer bushing 12 with the arms 10b at both ends thereof fixed at their ends for on the suspension arm that supports the wheel.

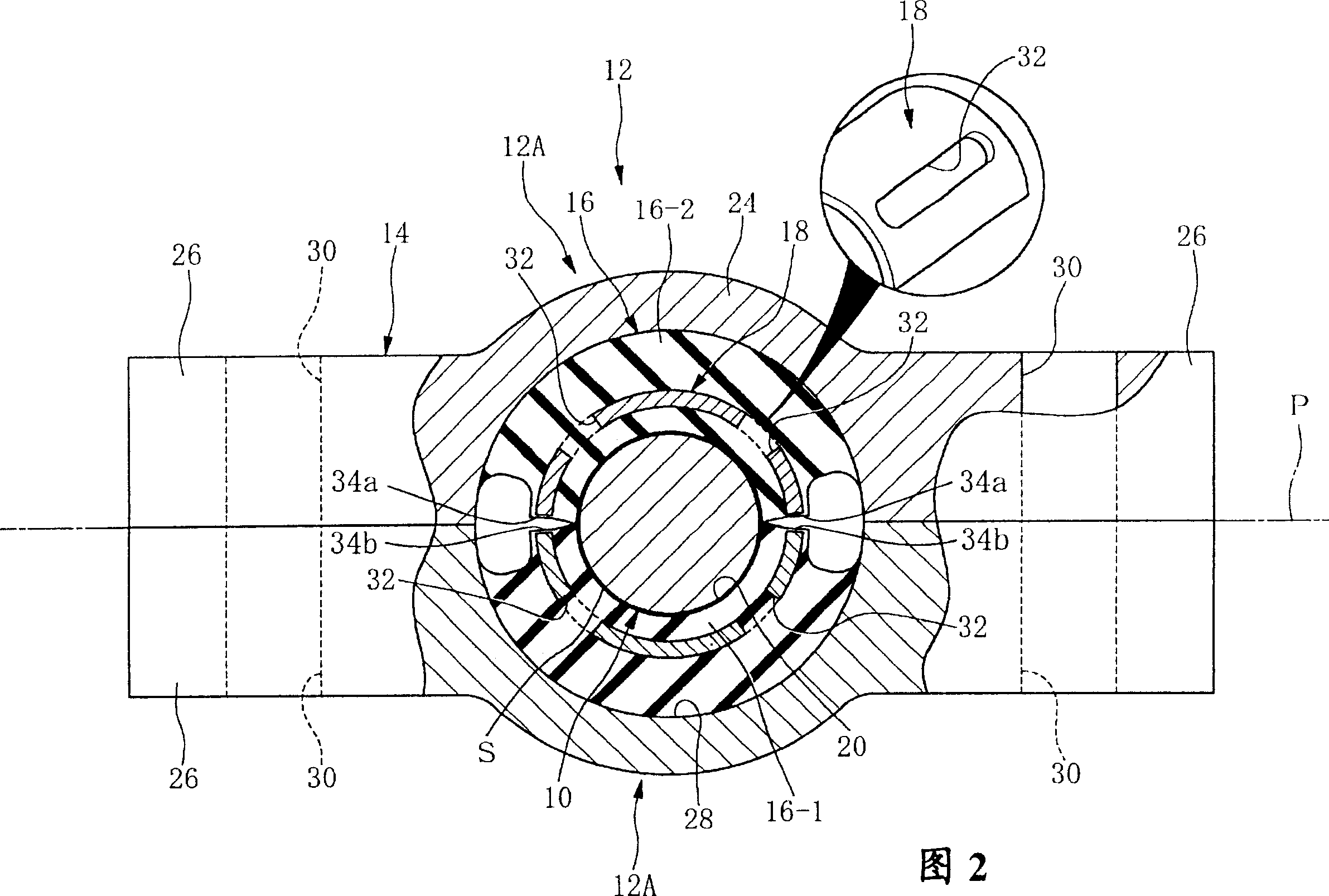

[0043] In FIGS. 2 and 3 , the specific configuration of the stabilizer bushing 12 mounted to the stabilizer bar 10 and the stabilizer bar 10 itself are shown in detail. As apparent from the drawings, the stabilizer bush 12 of the present embodiment has a rigid bracket 14 made of metal, a rubber elastic body 16 , and a rigid intermediate plate 18 made of metal embedded in the rubber elastic body 16 .

[0044] The rubber elastic body 16 is cylindrical in cross section, and has an annular through hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com