An experimental device for measuring liquid-liquid mass transfer coefficient

A technology of mass transfer coefficient and experimental equipment, which is applied in the field of teaching, scientific research and experimental technical equipment, can solve problems such as complex structure and unfavorable interface stability, and achieve the effects of reducing interface disturbance, promoting radial flow, and reducing axial flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described below with reference to the accompanying drawings and embodiments.

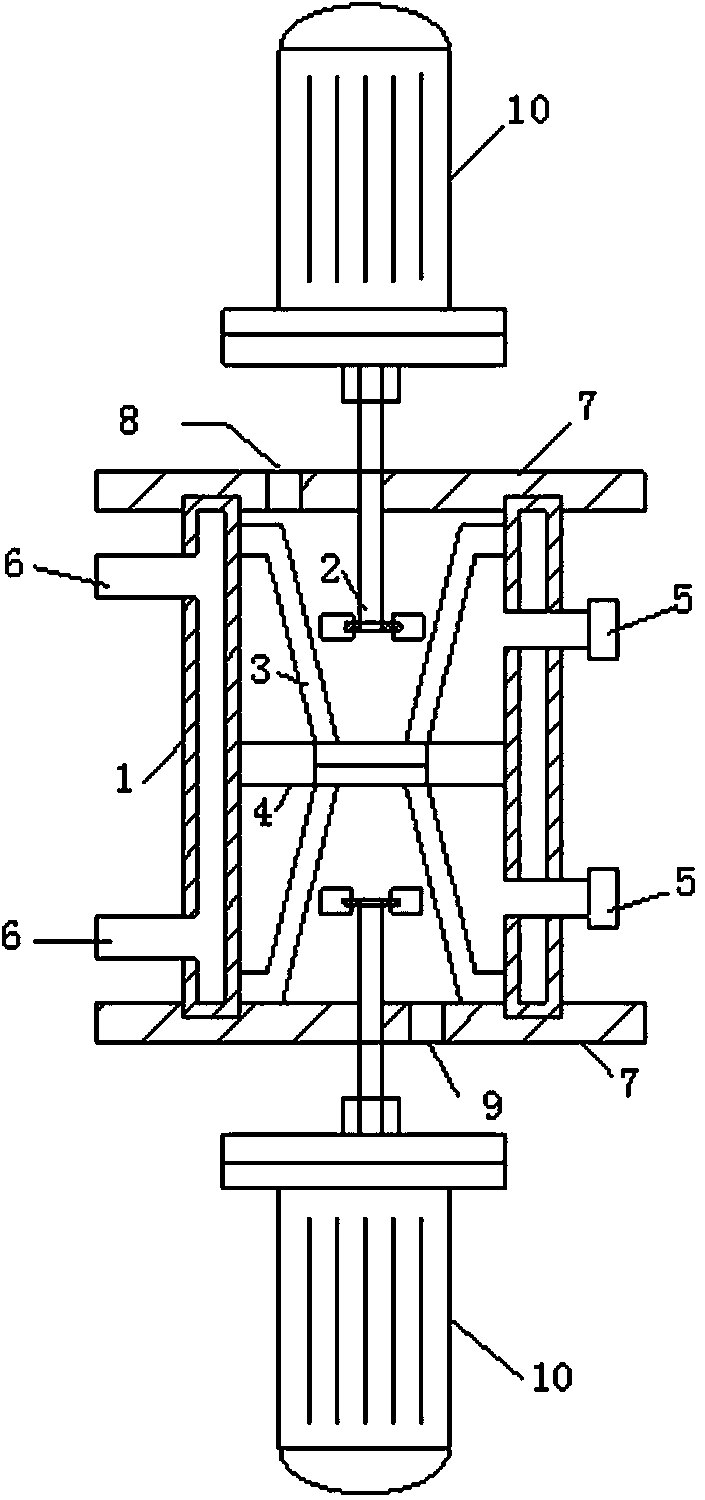

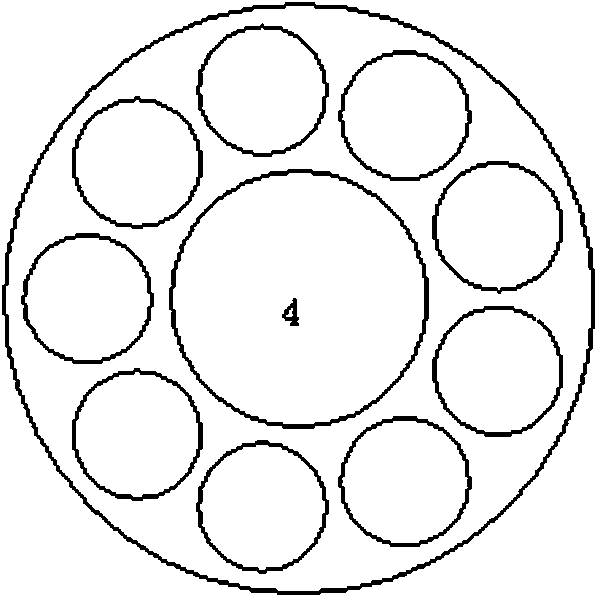

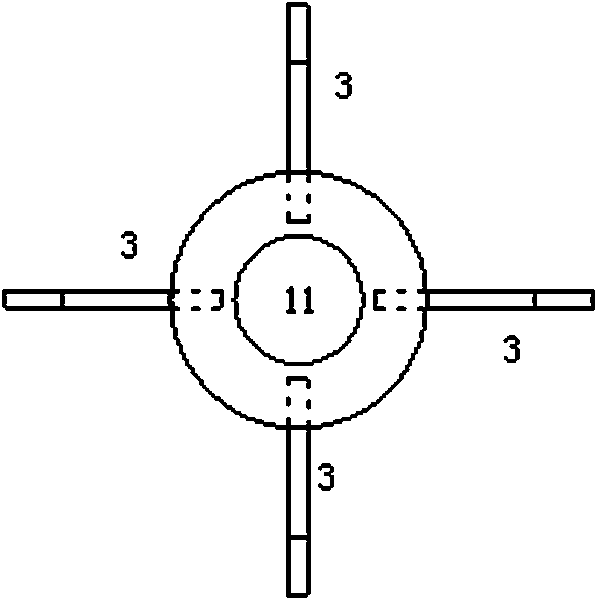

[0019] Such as figure 1 As shown, the experimental device for measuring the liquid-liquid mass transfer coefficient of the present invention includes a jacketed glass kettle 1 with upper and lower flanges 7 fixed on the upper and lower ends of the glass kettle, and installed at half the height of the inner cavity of the glass kettle. Interface ring 4 (see figure 2 ), the upper and lower agitating paddles 2 driven by the motor 10 are respectively arranged in the upper and lower chambers of the glass kettle divided by the interface ring 4 in a coaxial manner with the glass kettle; a number of central holes are arranged around the interface ring 4 The number of through holes can be set according to experimental needs. The two-phase mass transfer area can be con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com