Patents

Literature

1015 results about "Water in oil emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

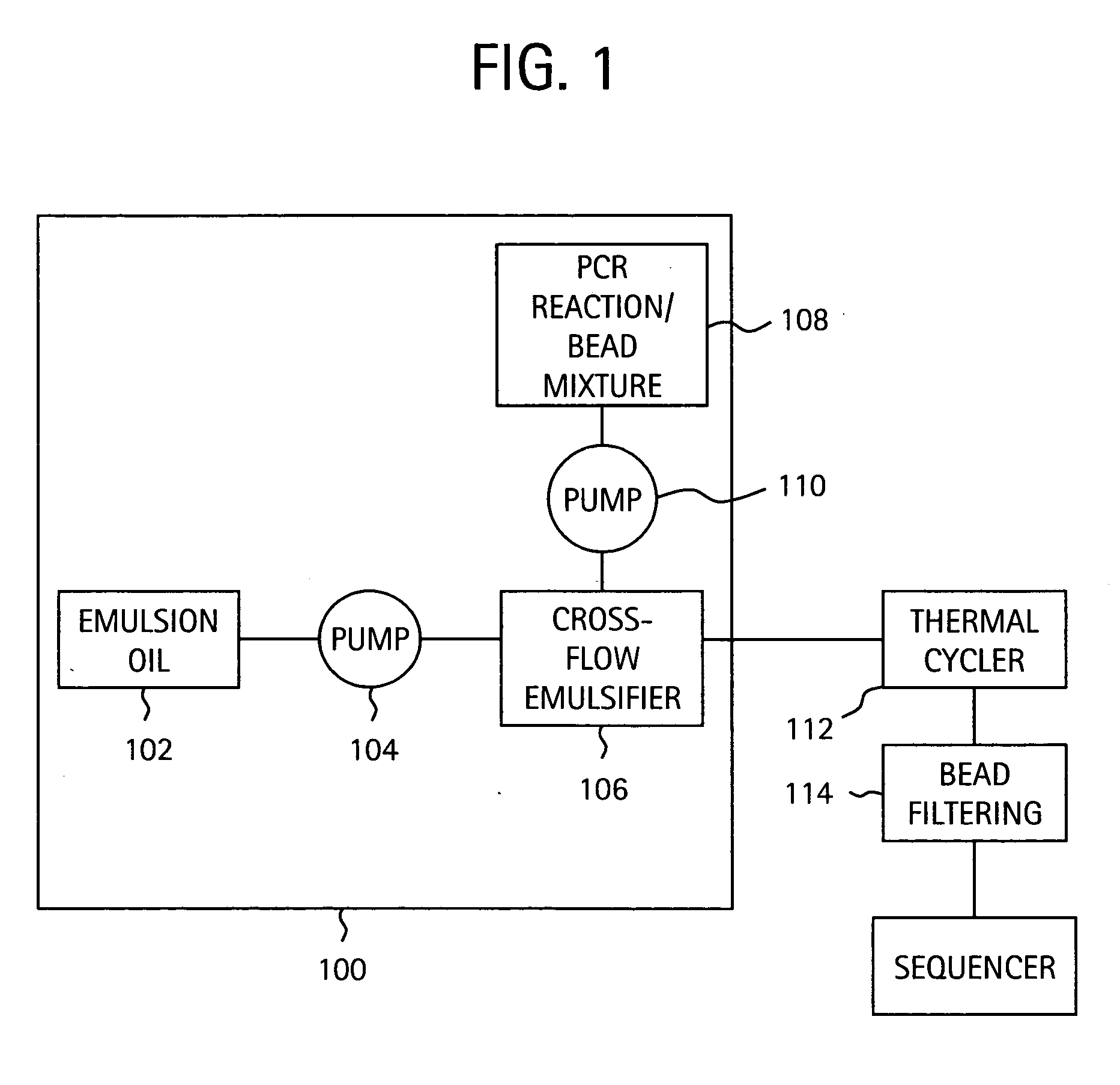

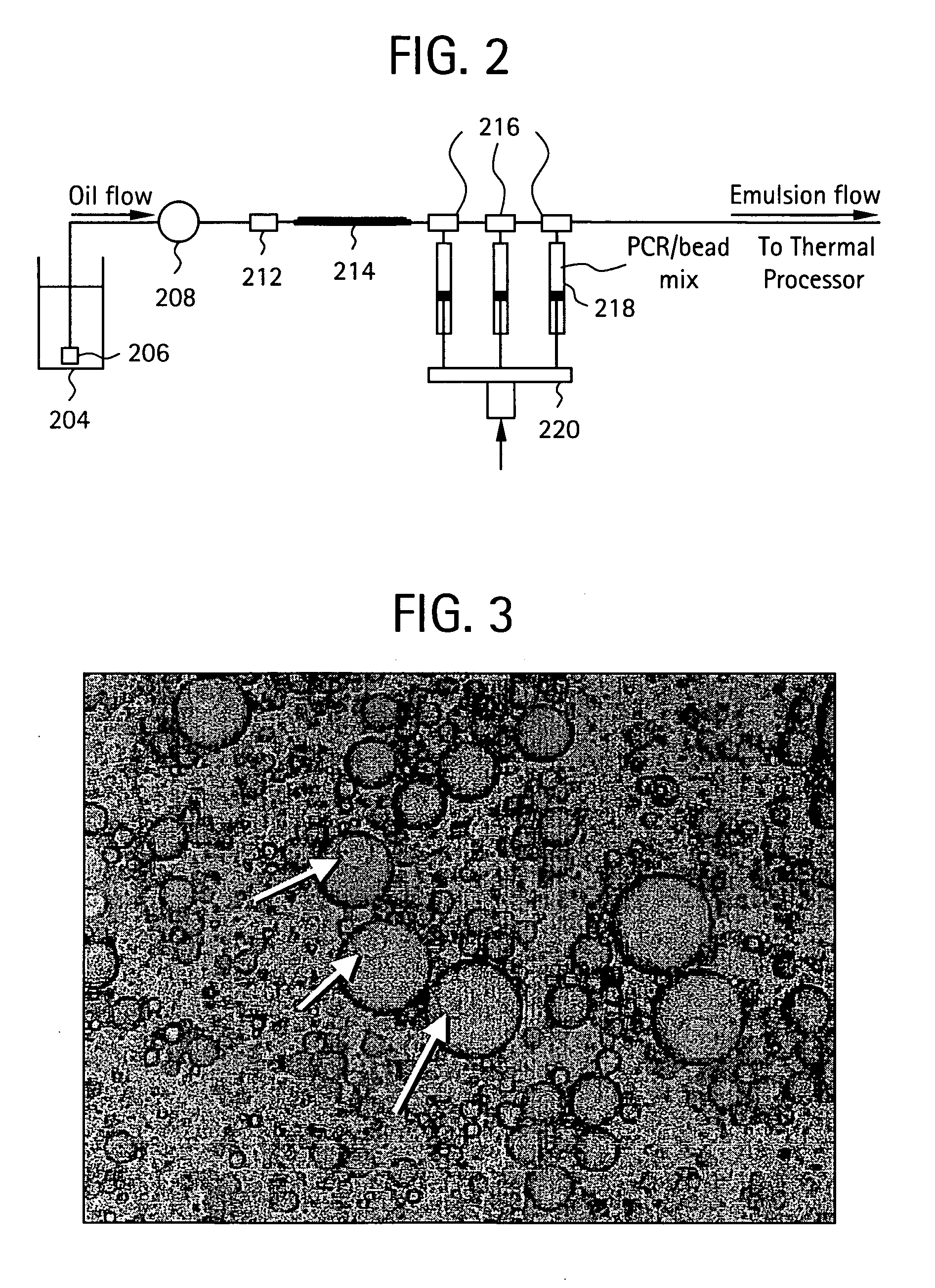

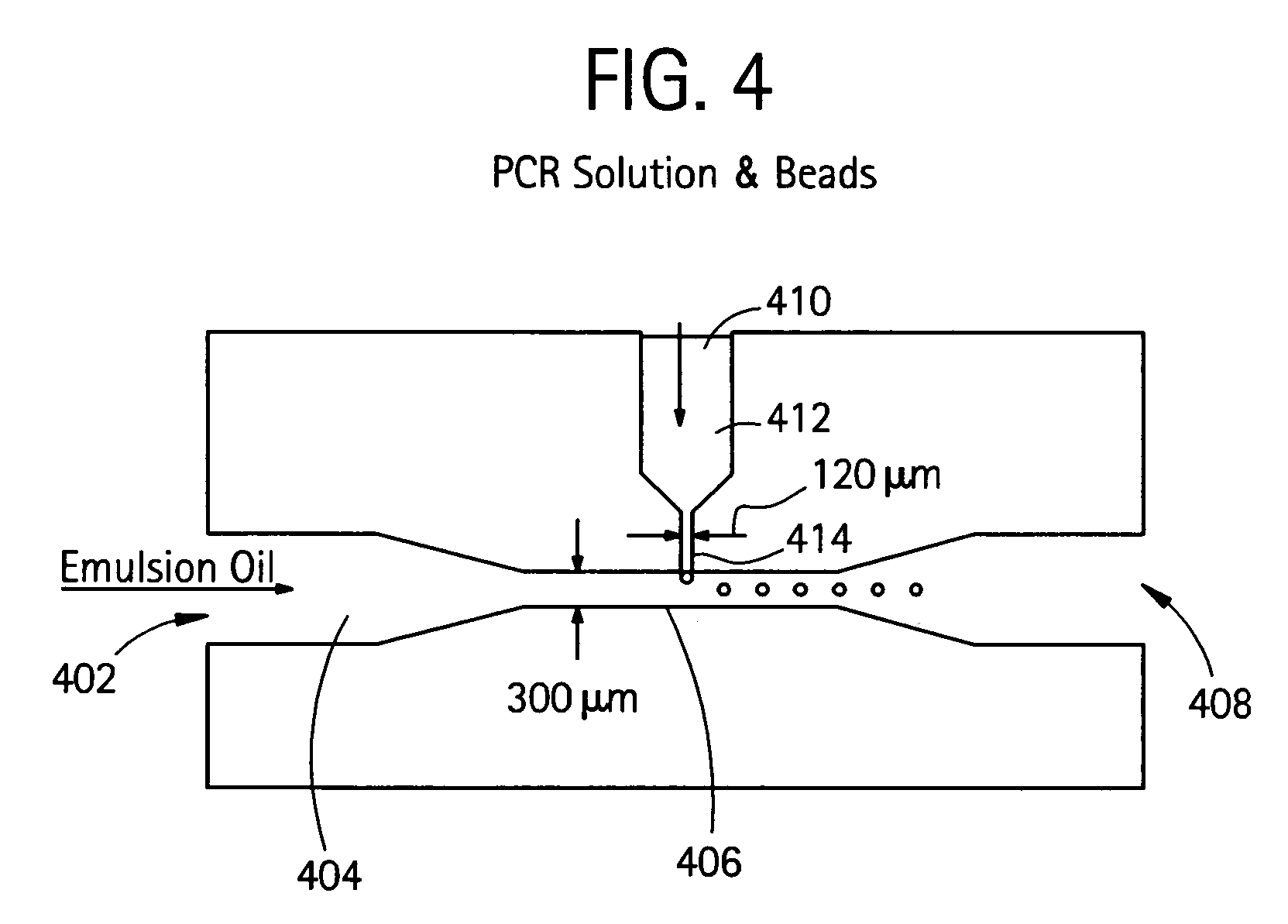

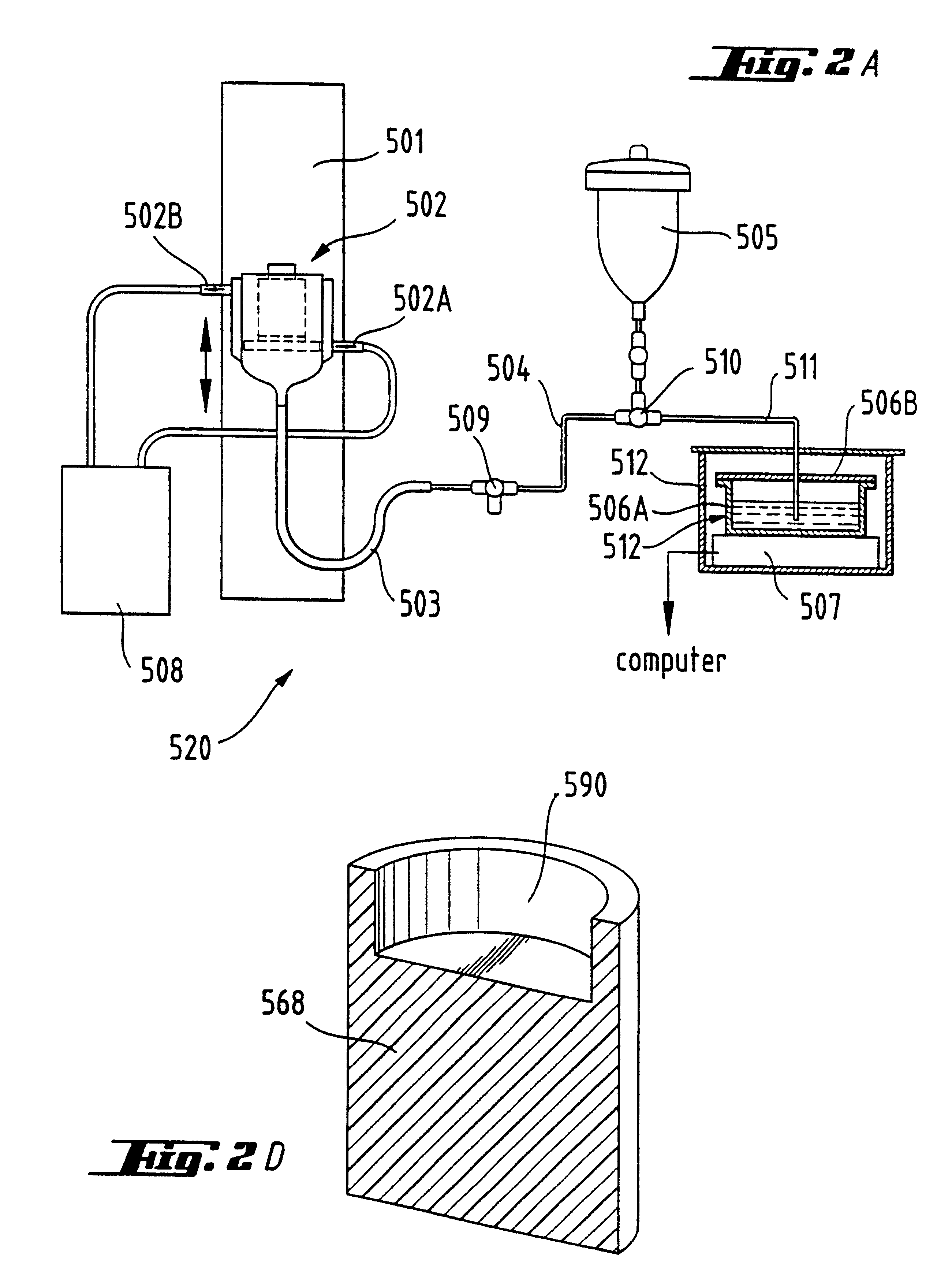

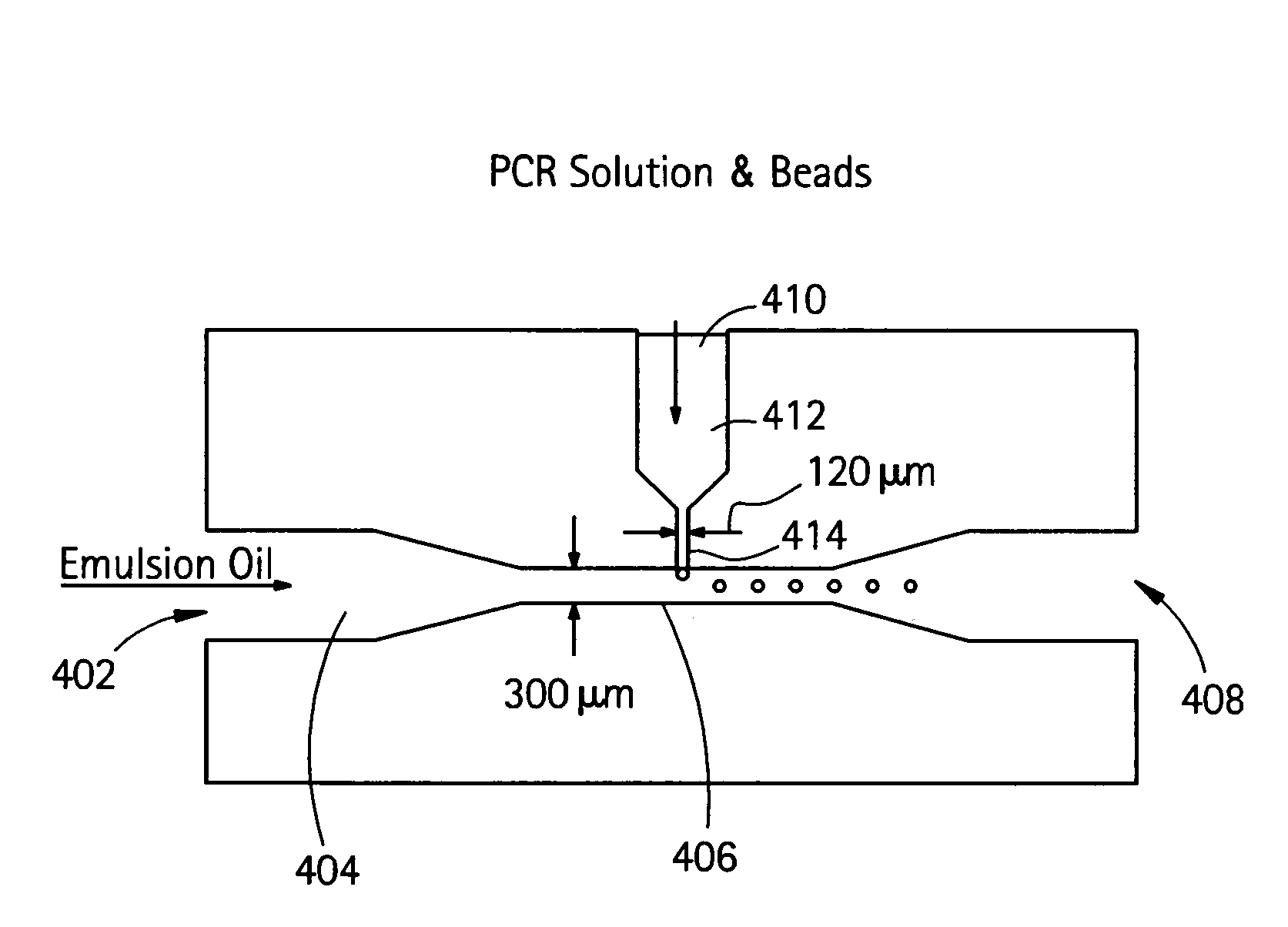

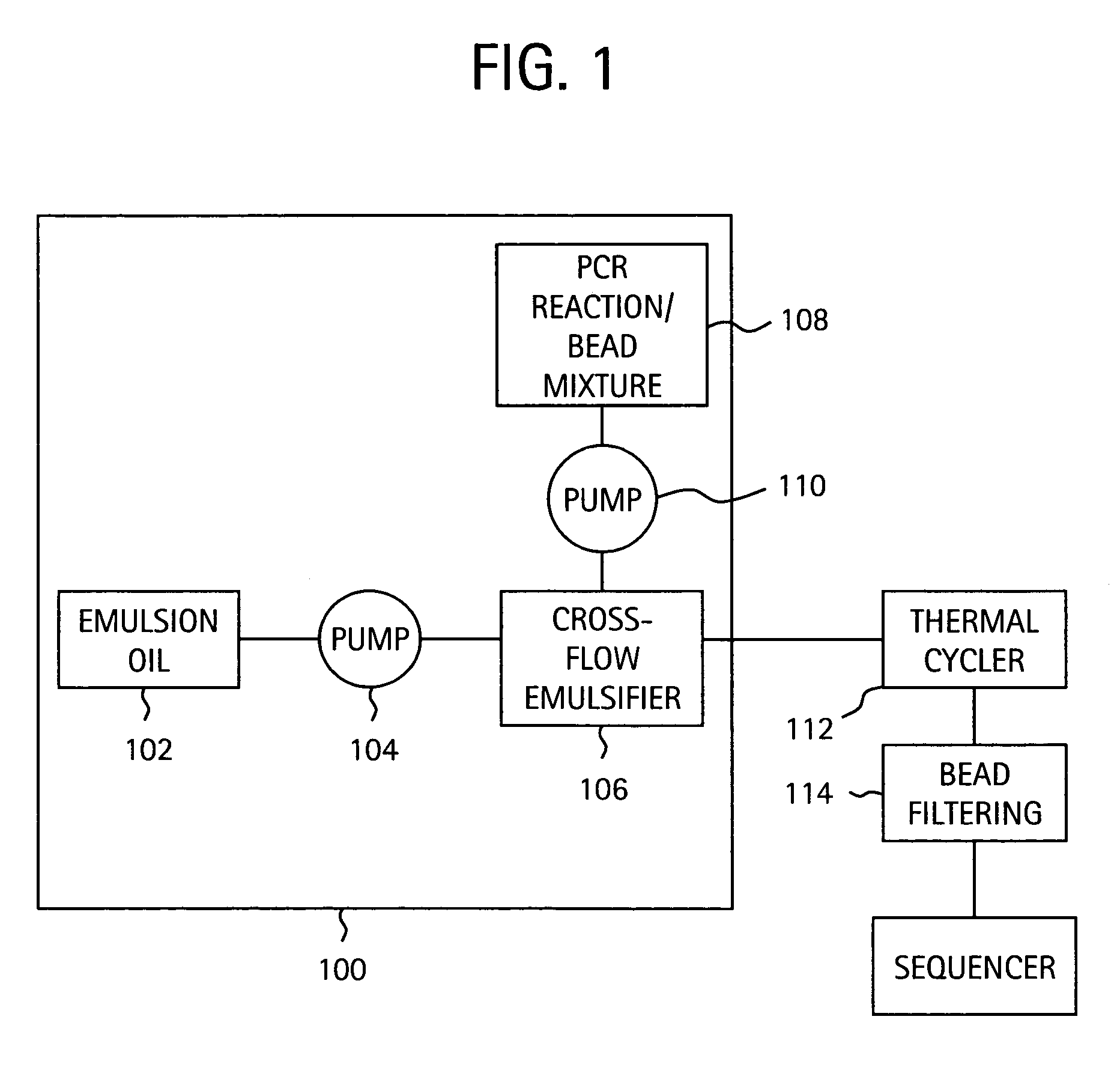

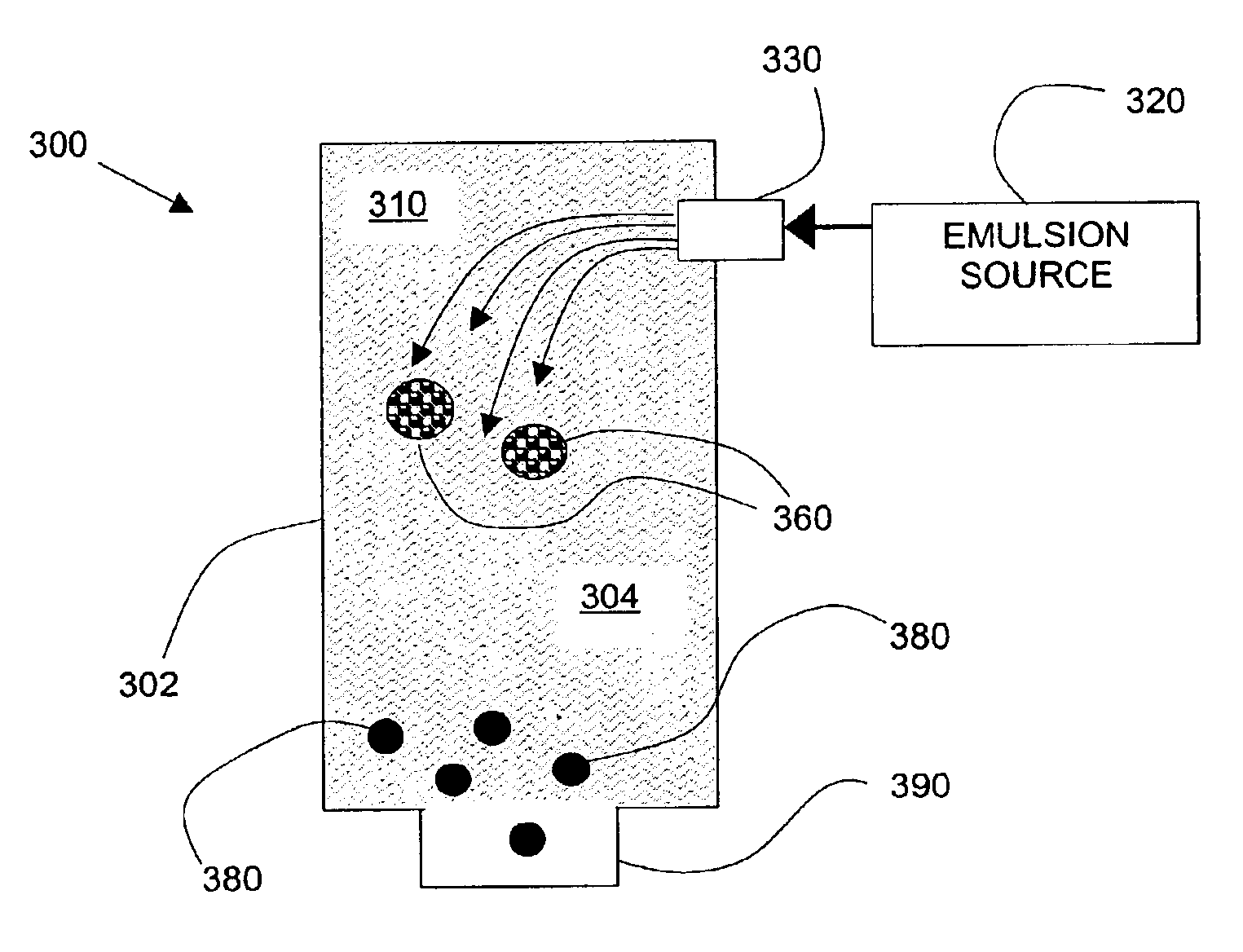

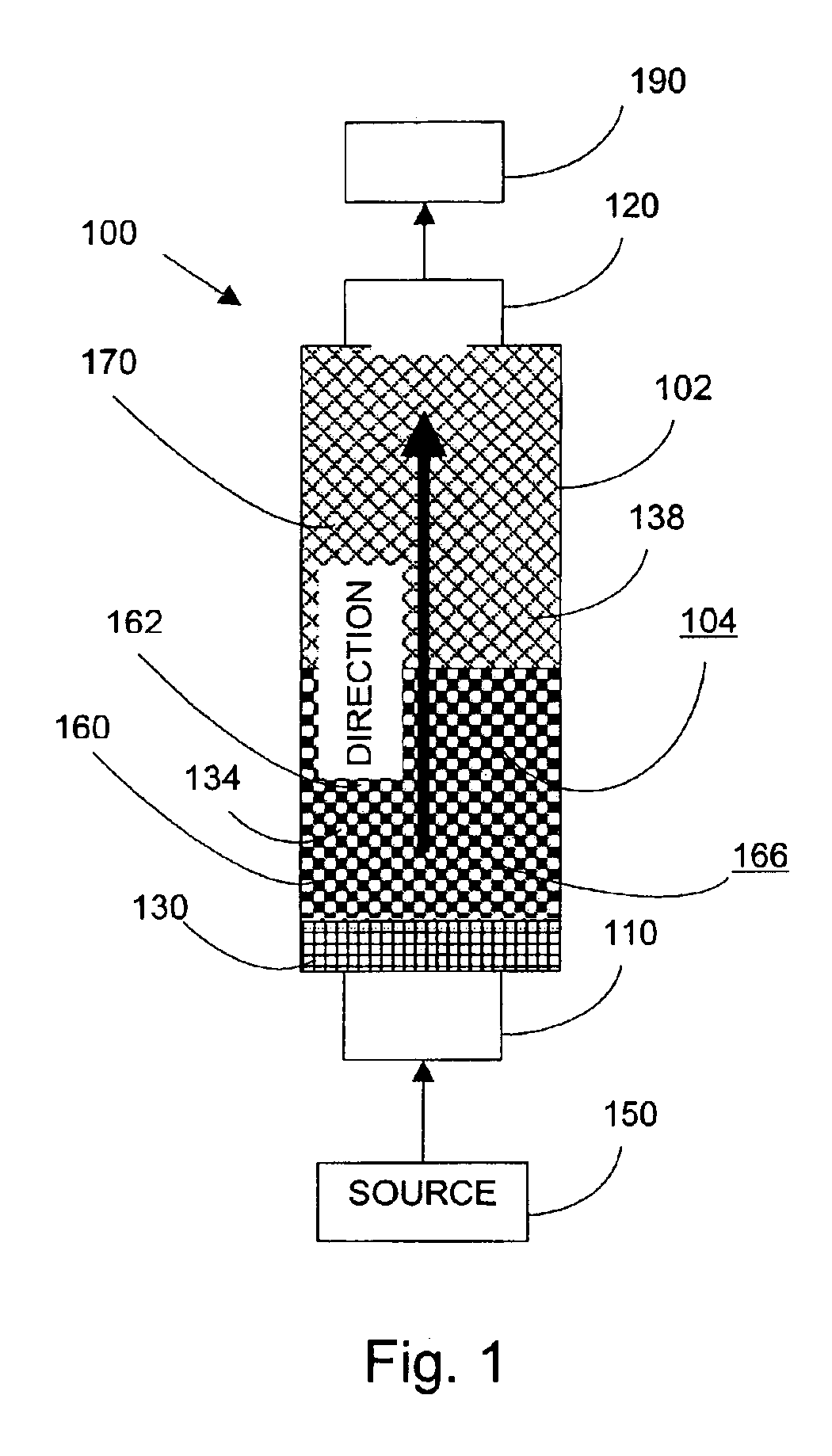

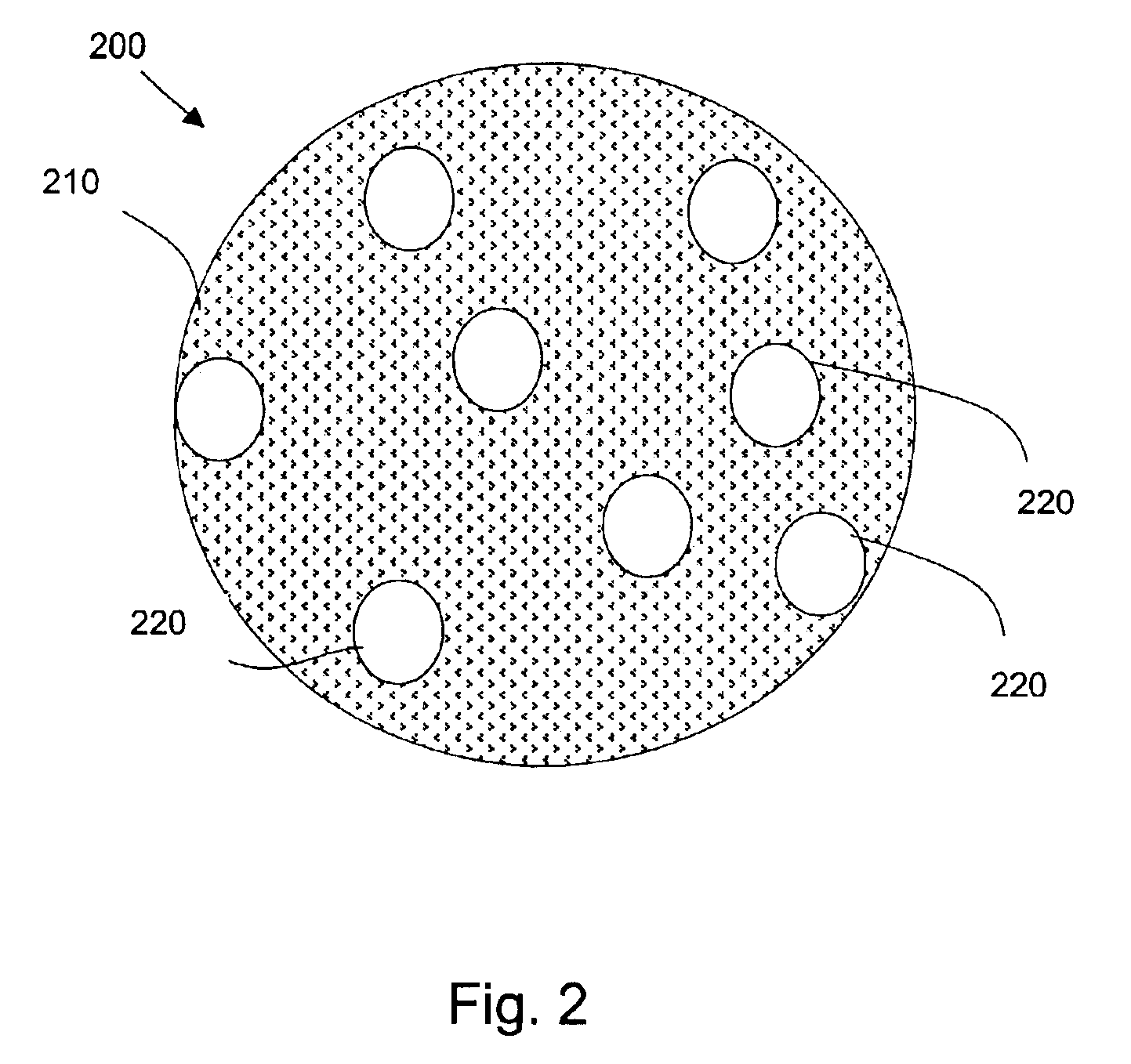

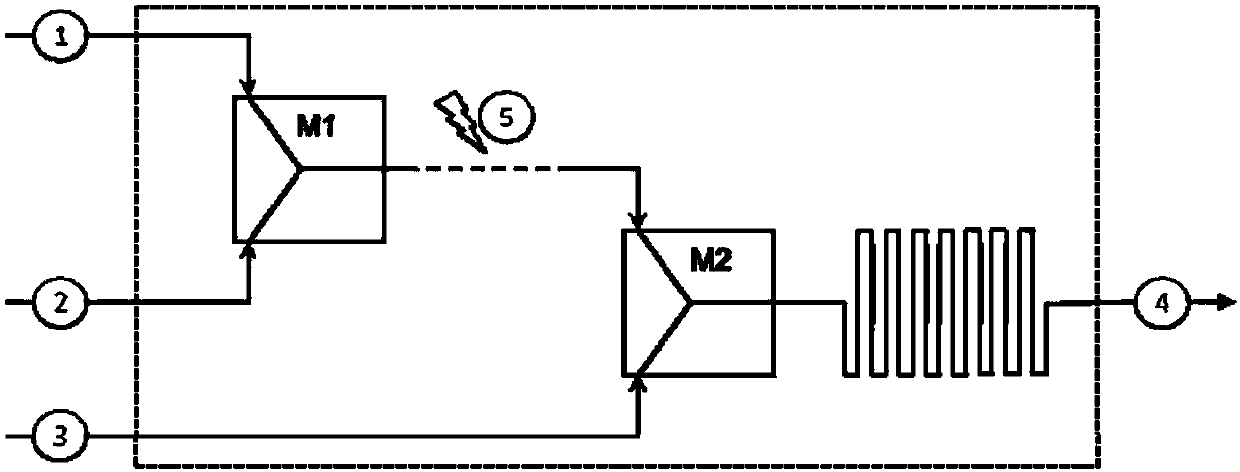

Nucleic acid amplification with continuous flow emulsion

InactiveUS20050227264A1Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

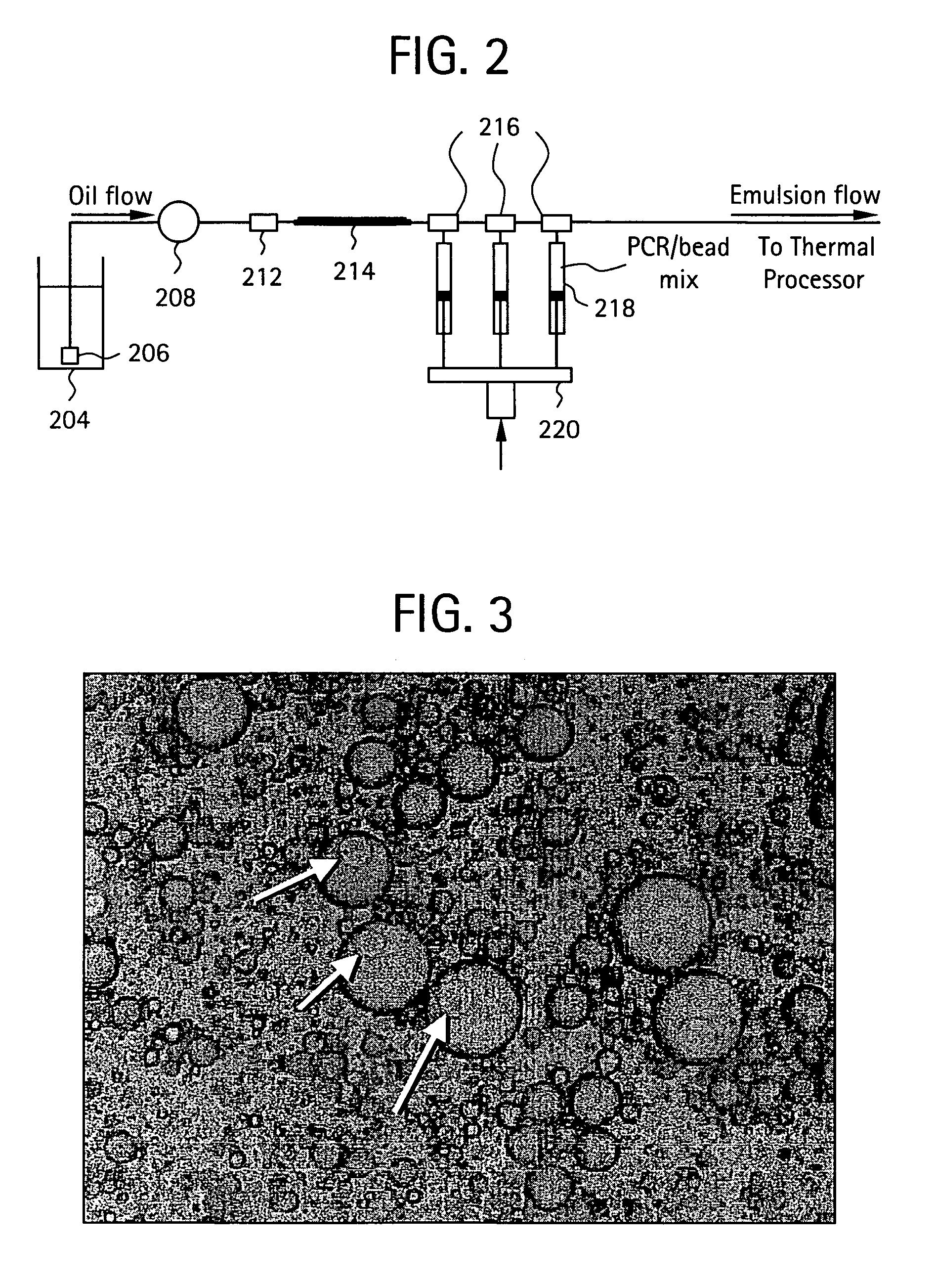

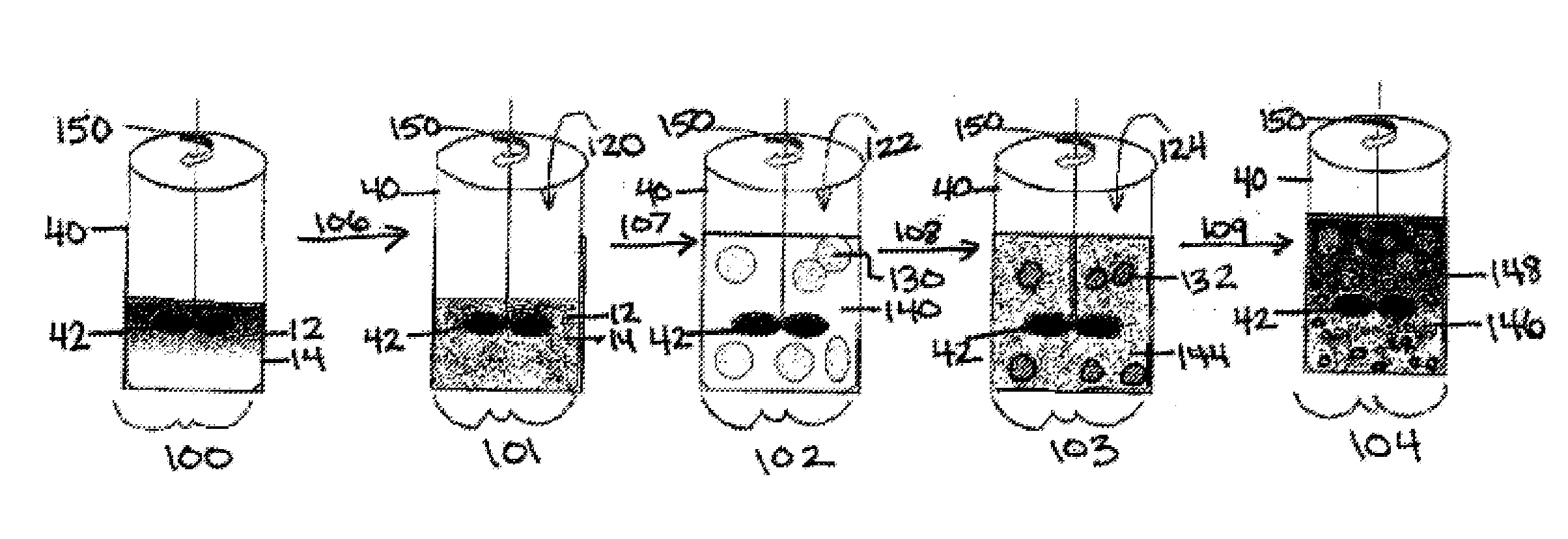

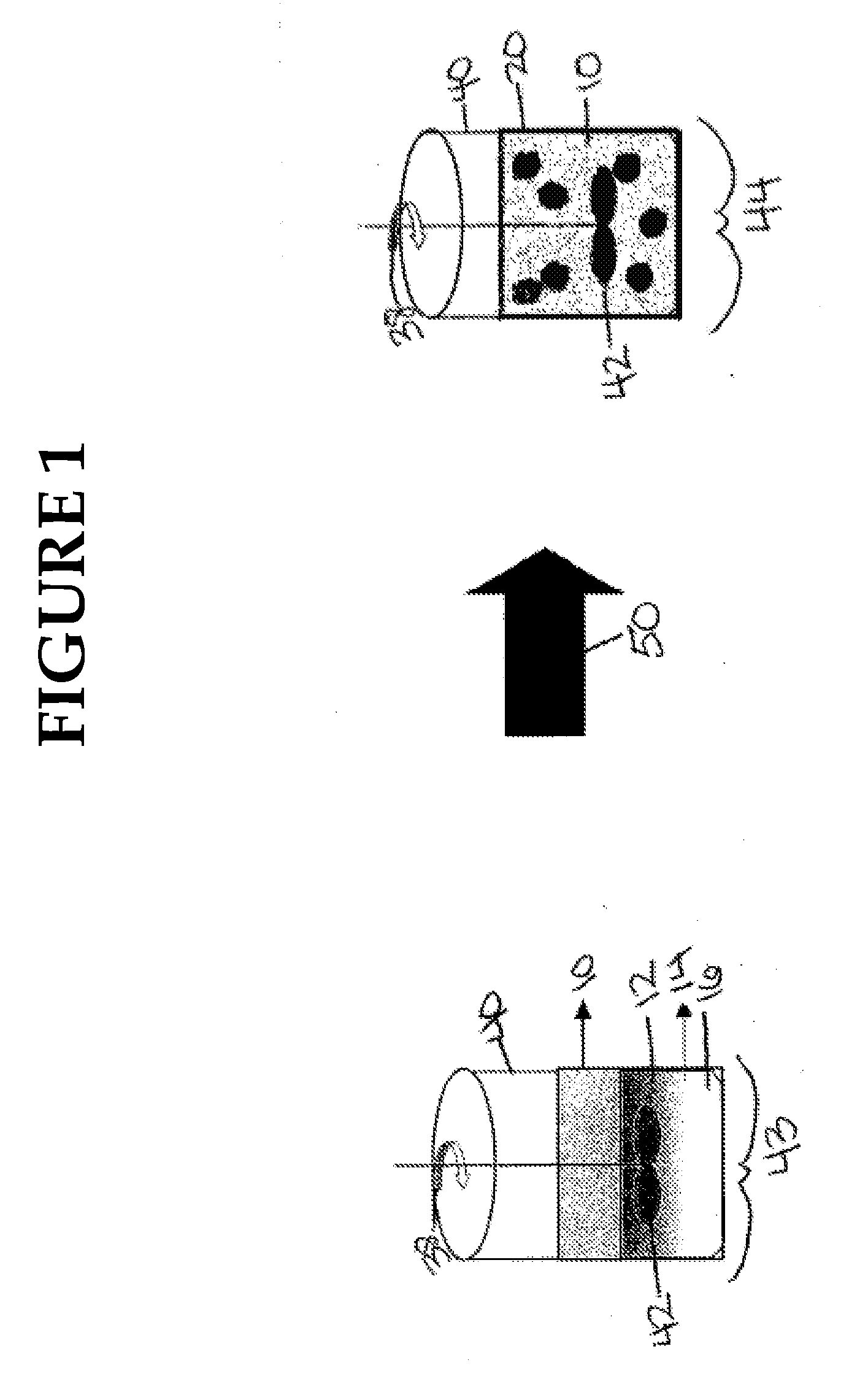

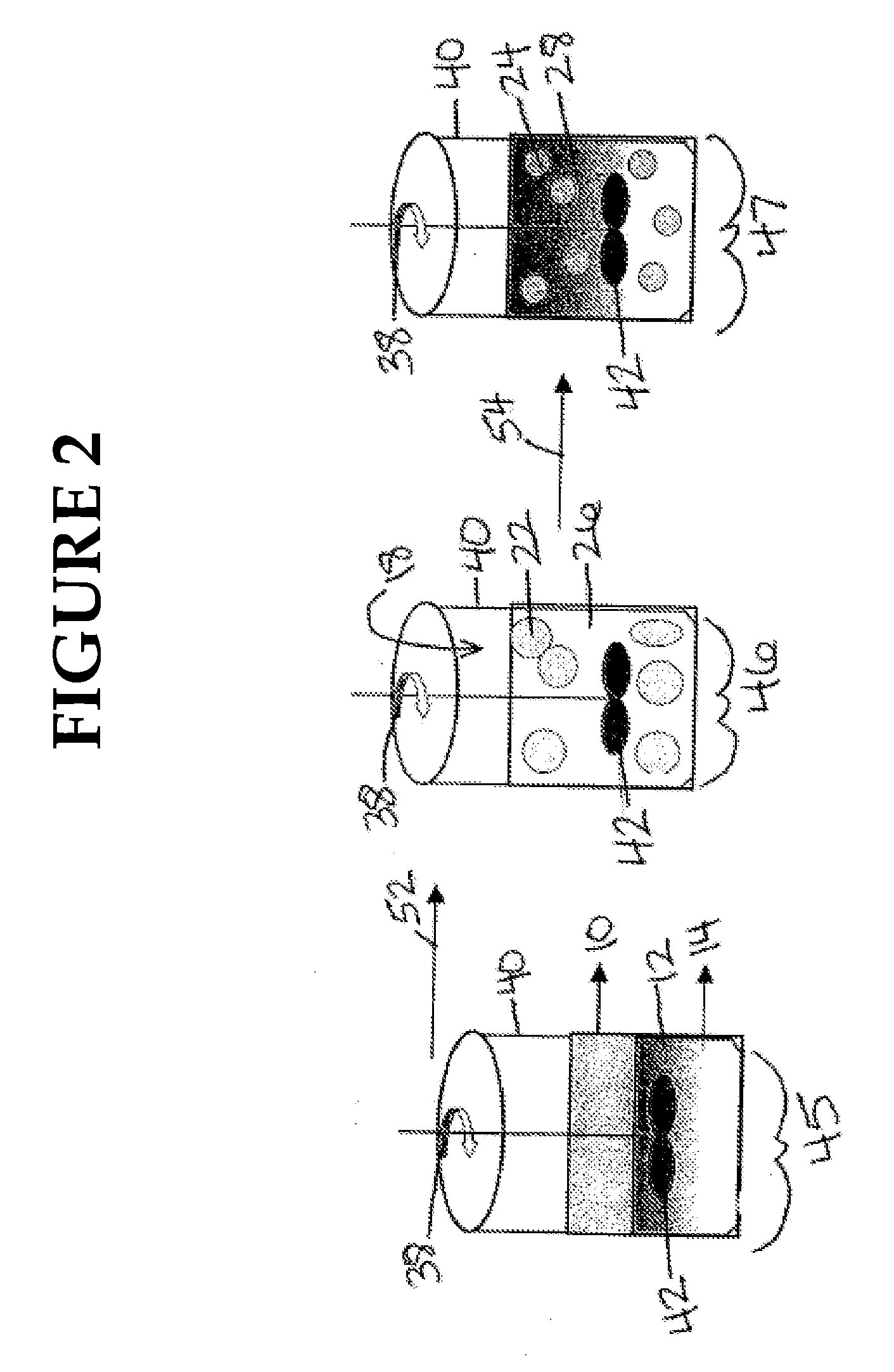

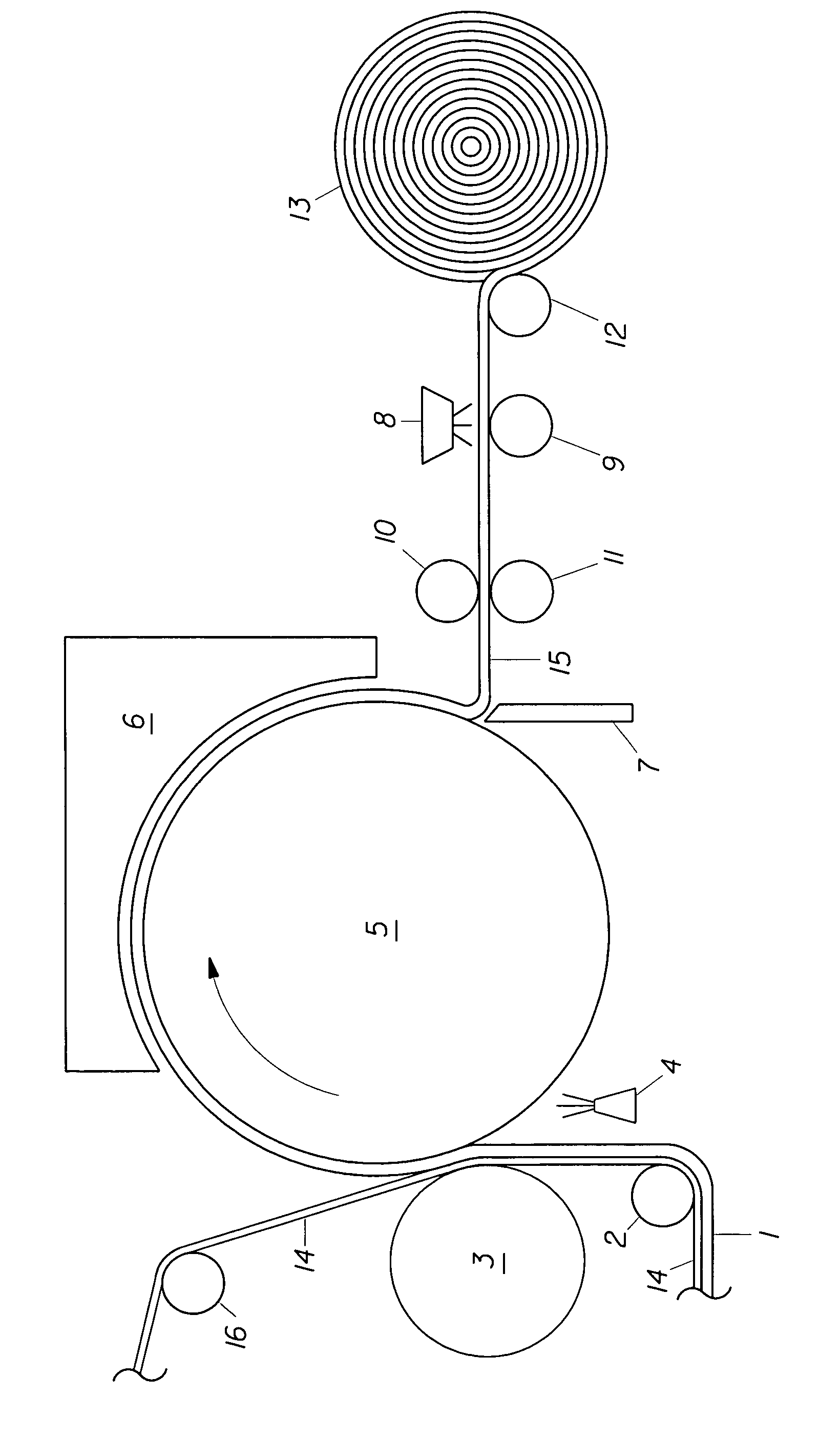

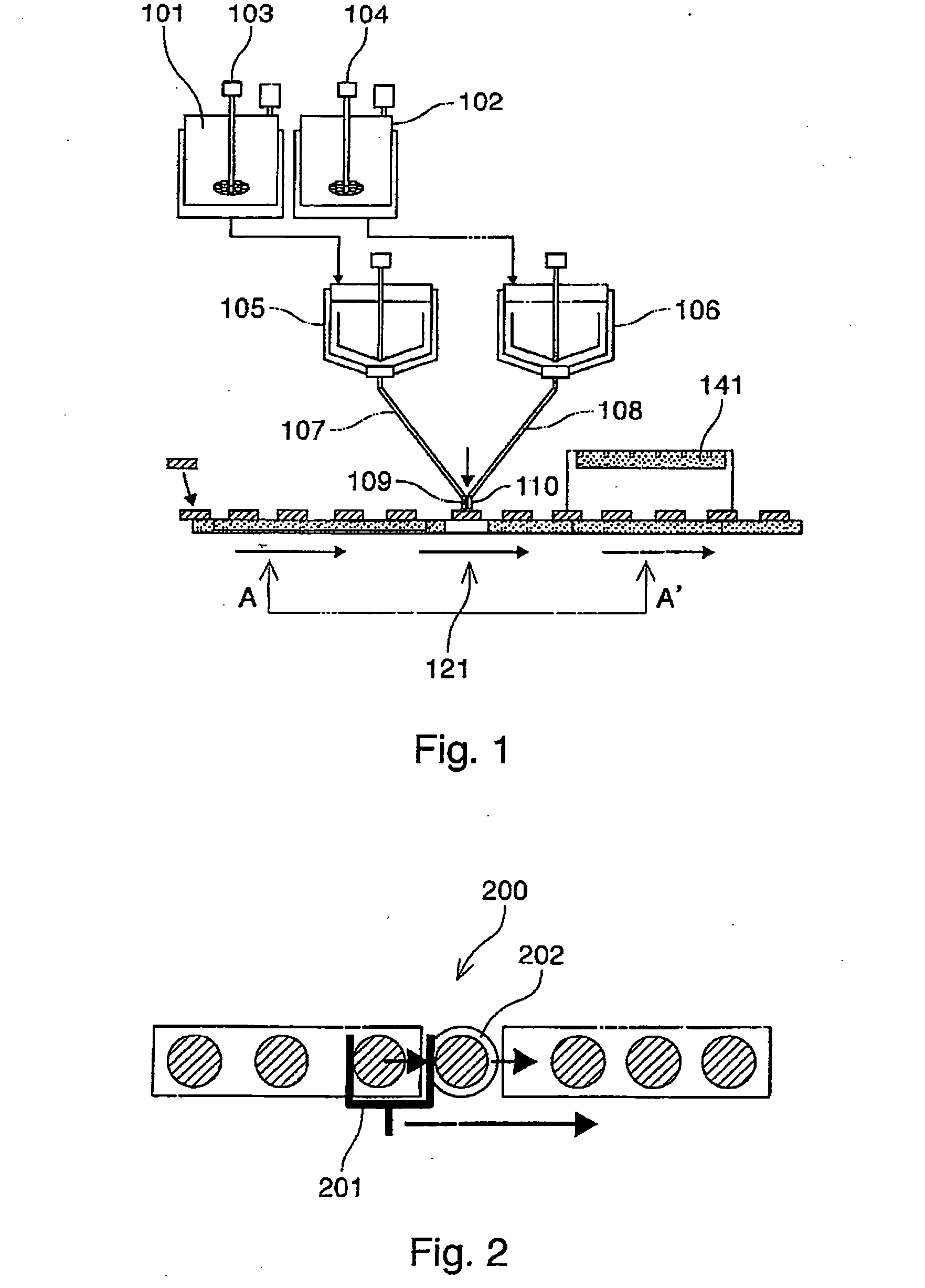

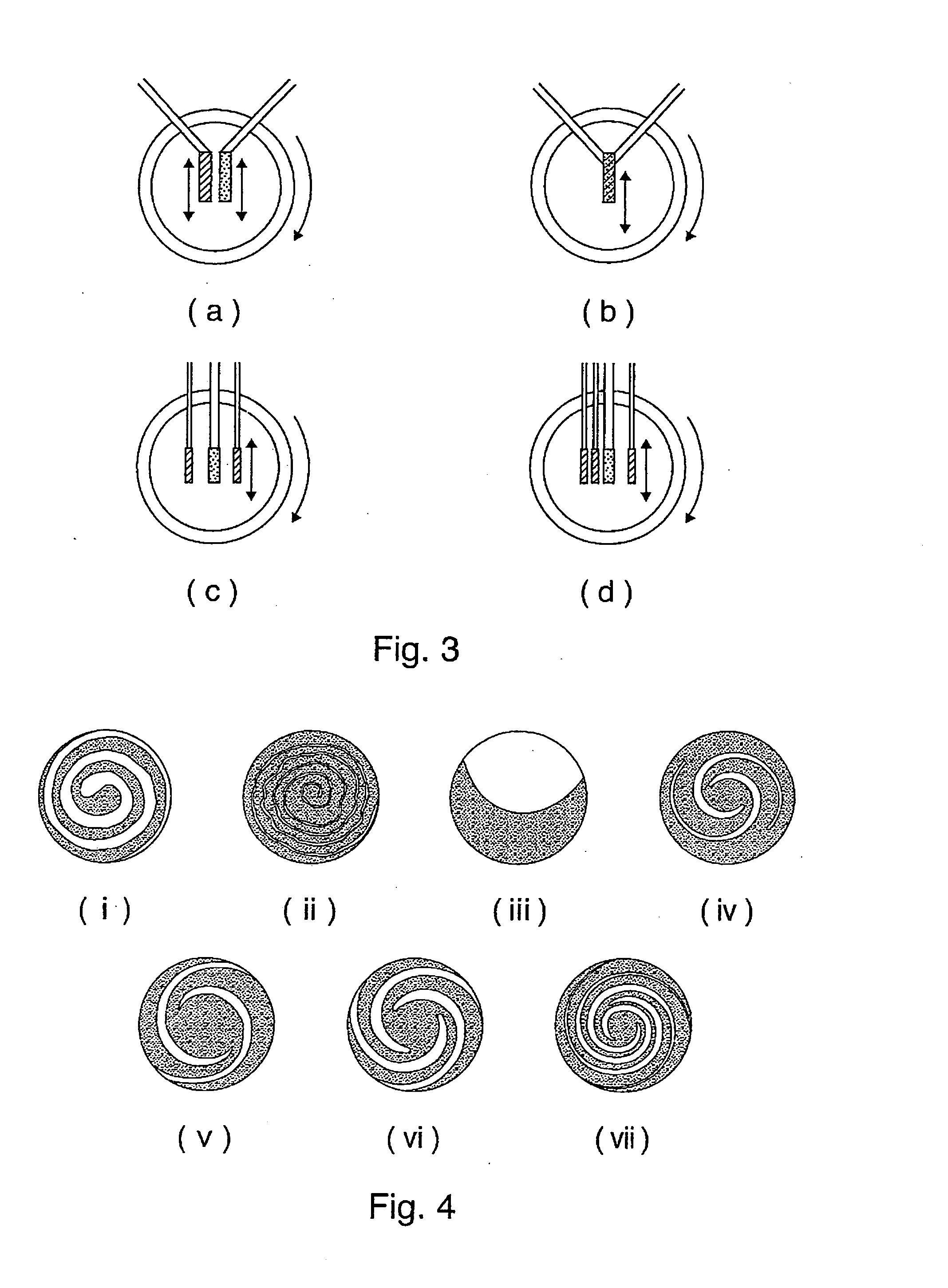

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

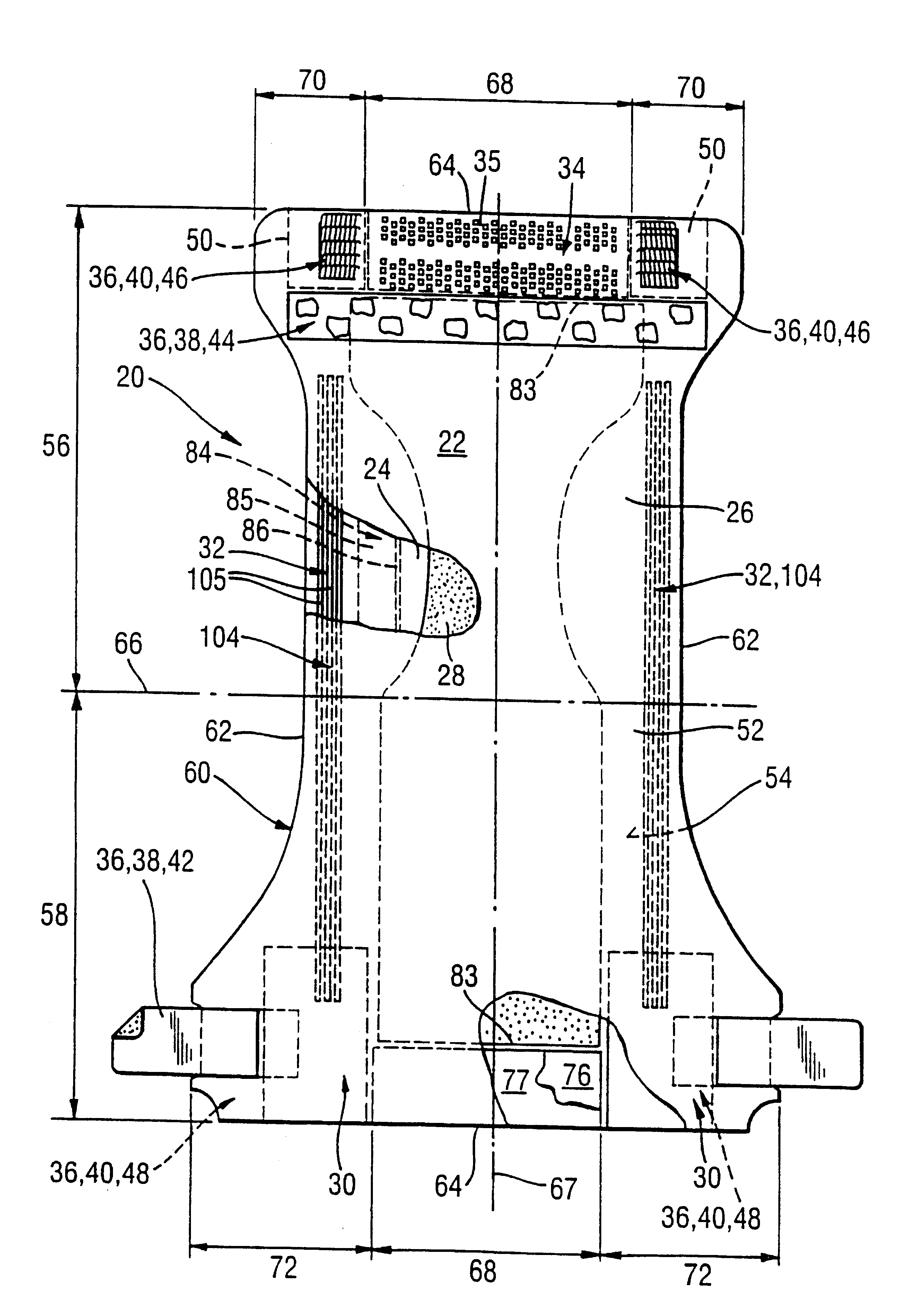

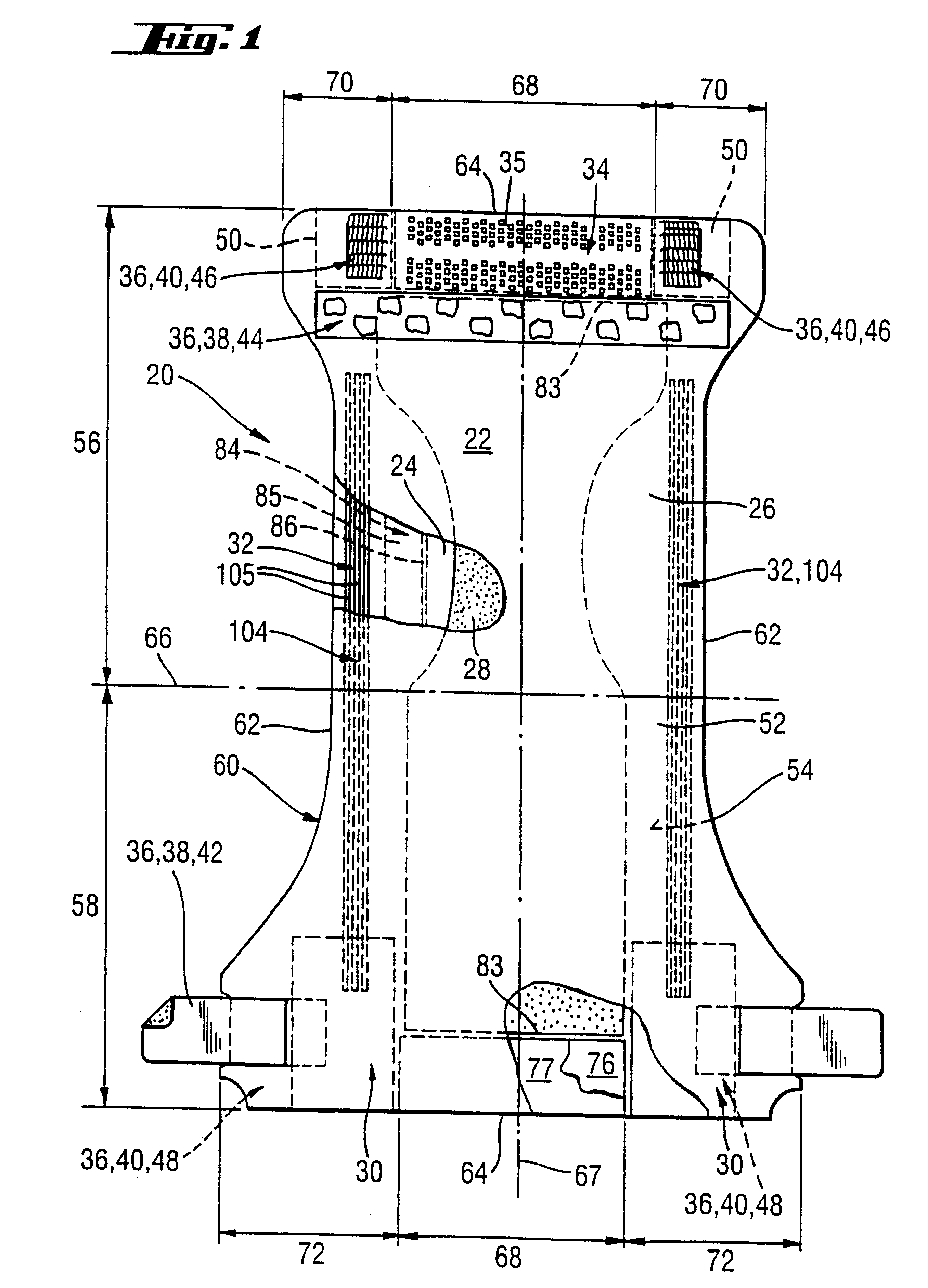

Absorbent articles with distribution materials positioned underneath storage material

An absorbent article having an ultimate fluid storage region and a fluid distribution region, positioned between the ultimate storage region and the garment oriented surface of the article, in fluid communication with the ultimate fluid storage region, the ultimate fluid storage region includes a material which has: (1) a Capillary Sorption Desorption Capacity at 100 cm (CSDC 100) of at least 10 g / g; (2) a Capillary Sorption Desorption Capacity at 0 cm (CSDC 0) higher than the CSDC 100; (3) a Loosely Bound Liquid Capacity (LBLC); and (4) a Capillary Sorption Desorption Release Height when 50% of the LBLC are released (CSDRH 50) less than 60 cm. Further, the liquid distribution layer material has a Capillary Sorption Absorption Height at 30% of its maximum capacity (CSAH 30) of at least 35 cm. Distribution material can be foam materials, particularly those derived from high internal phase water-in-oil emulsions.

Owner:THE PROCTER & GAMBLE COMPANY

Nucleic acid amplification with continuous flow emulsion

InactiveUS7927797B2Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

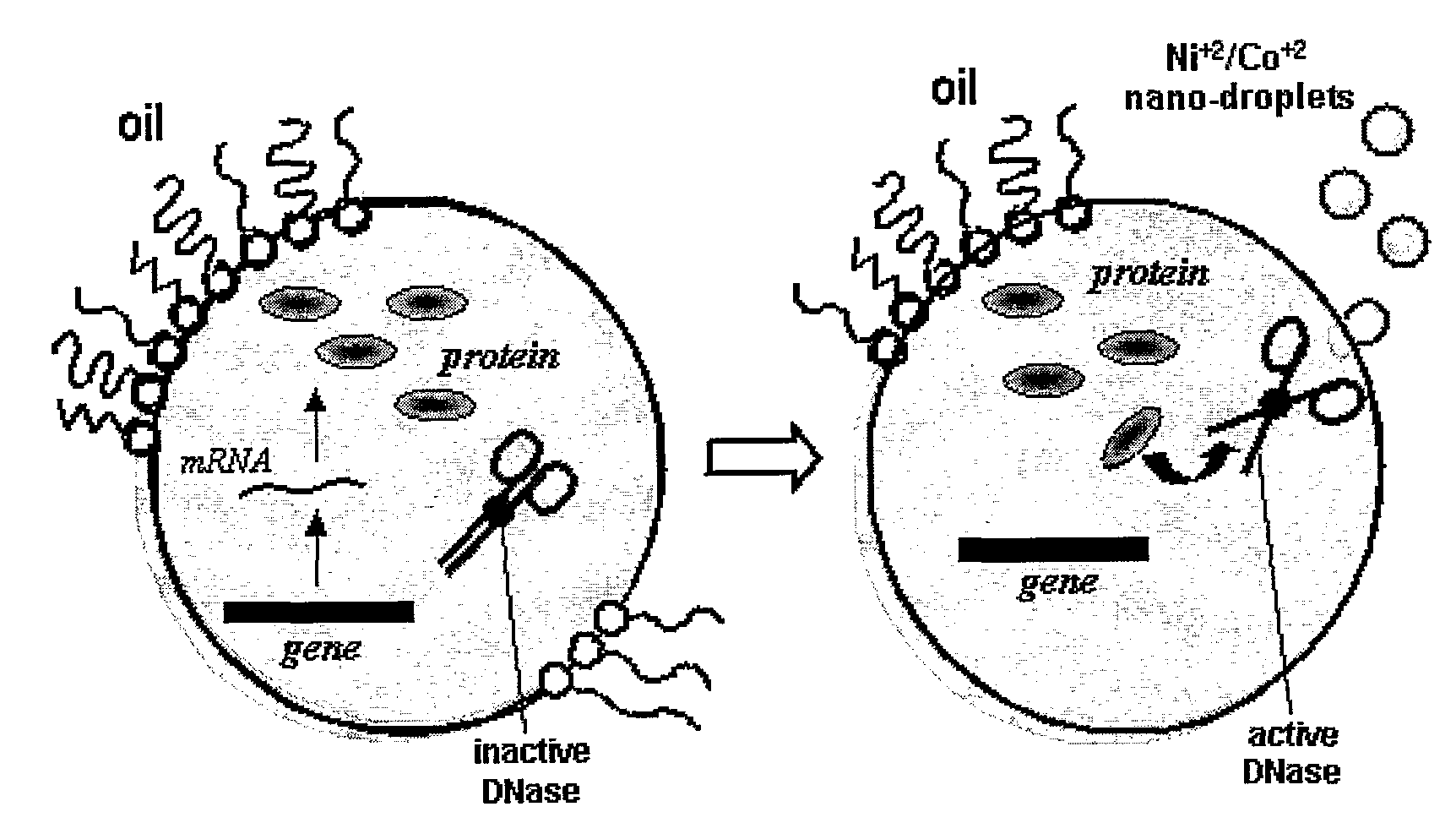

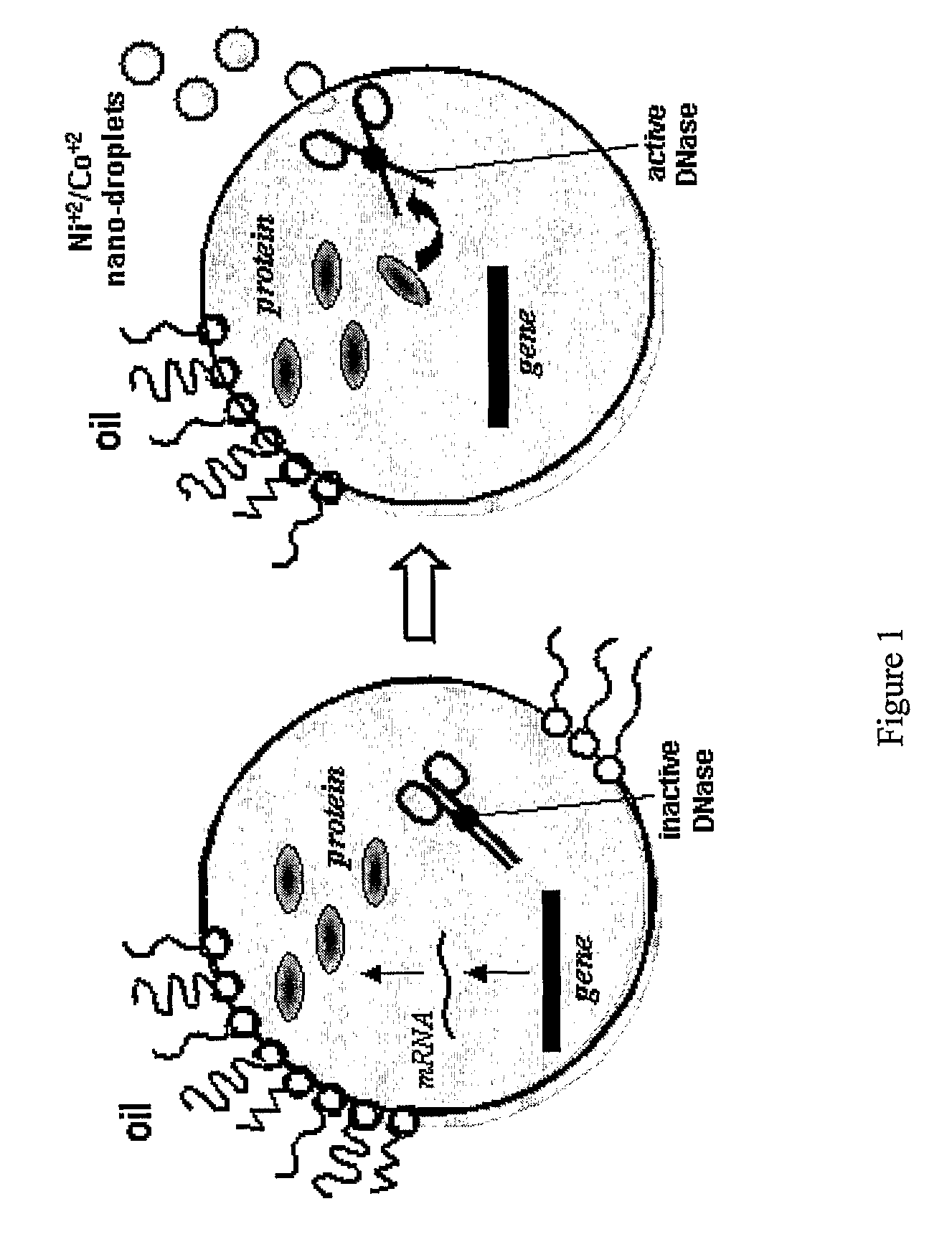

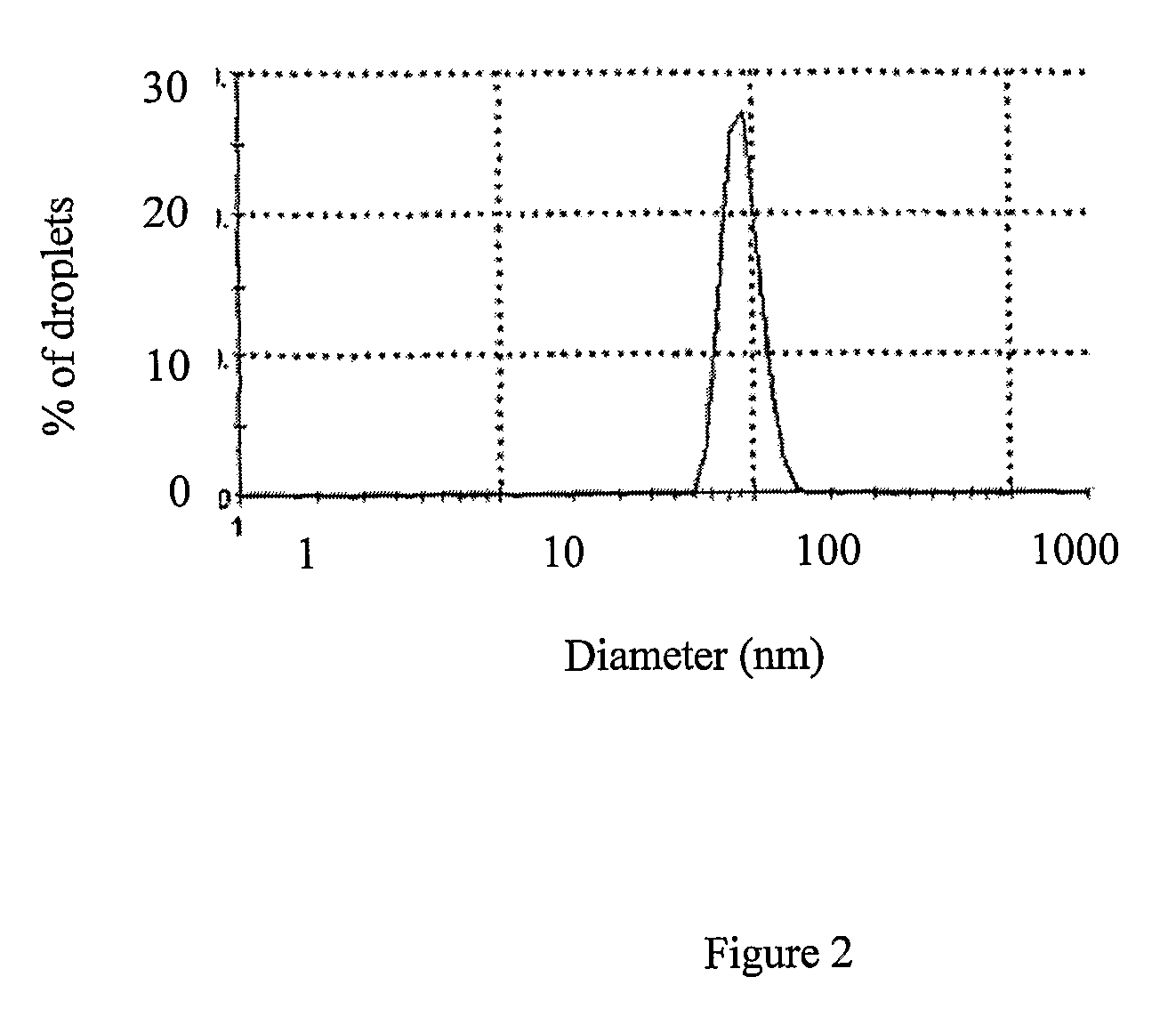

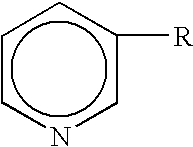

Directed Evolution and Selection Using in Vitro Compartmentalization

InactiveUS20080004436A1Easy to adjustImprove concentrationSugar derivativesDNA preparationWater in oil emulsionGenetic element

The present invention is related to the field of compartmentalized libraries of genetic elements and the selection of biologically active molecules and the genes encoding same from said libraries. The selection assay of the invention utilizes water-in-oil emulsions and is particularly advantageous in applications in the field of directed-evolution, as exemplified herein for selection of protein inhibitors of DNA nucleases.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

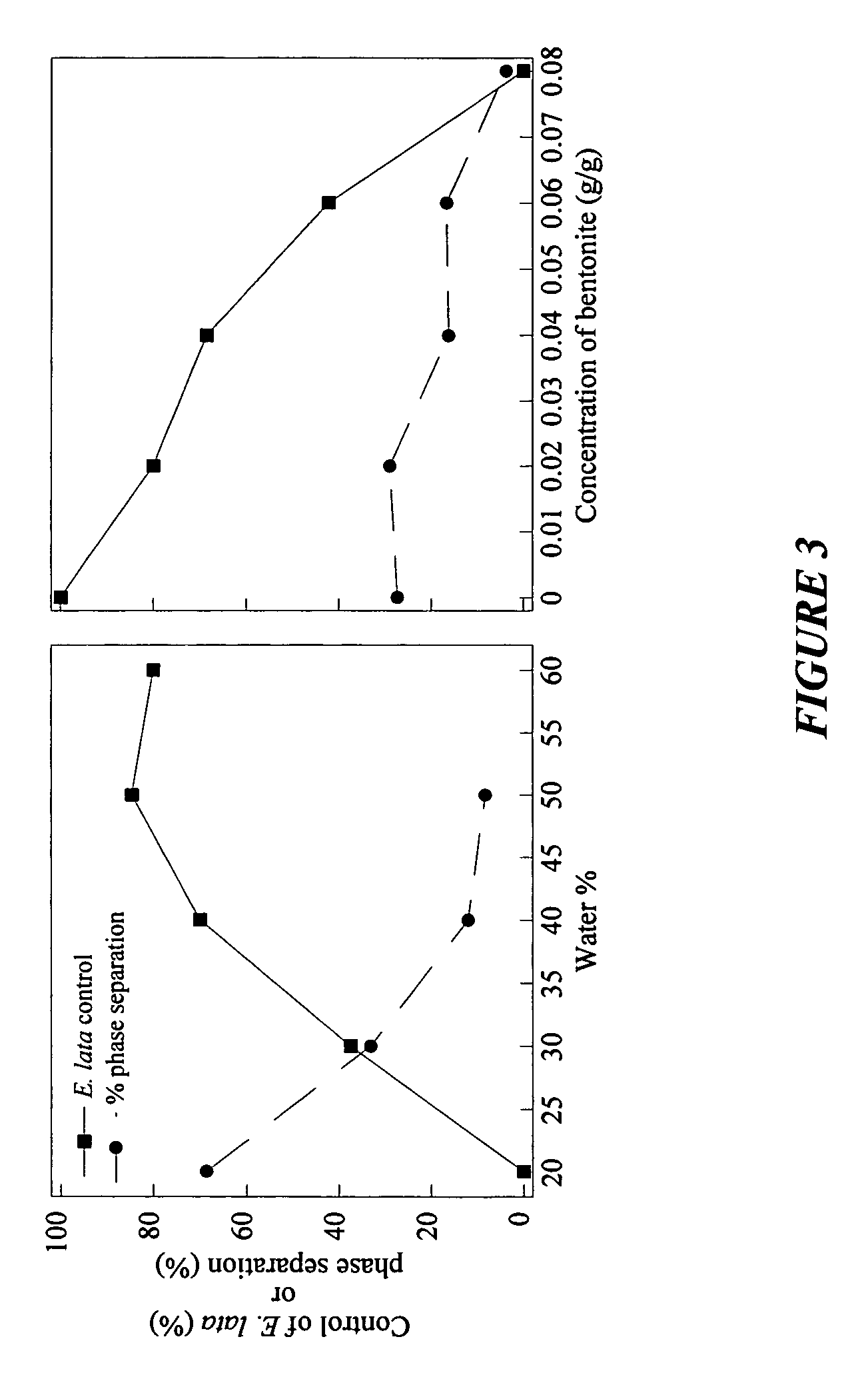

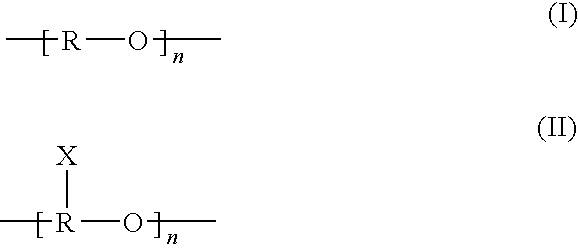

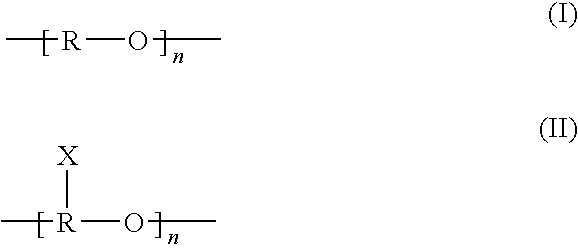

Storage stable compositions of biological materials

Storage stable compositions of biological materials, including bioactive biological materials are provided in the form of a water-in-oil emulsion, comprising:(a) cellular material selected from living and / or dormant prokaryotic and / or eukaryotic cells and tissues, the cellular material being compatible with water-in-oil emulsions;(b) one or more oils selected from vegetable oils and fish oils;(c) an oil-soluble nonionic polymeric surfactant having a molecular weight of from about 2500 to about 15000; and(d) water.The compositions may also contain a thickener such as a hydrophobic fumed silica or bentonite.Compositions may be used for various purposes, depending on the contained biological material. Specific examples include compositions containing Fusarium lateritium control of Eutypa lata in plant wounds made by cutting or pruning, and compositions containing Lagenidium giganteum for control of mosquitoes.

Owner:RGT UNIV OF CALIFORNIA

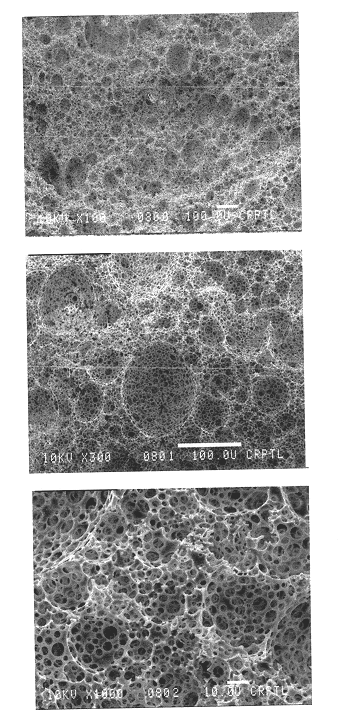

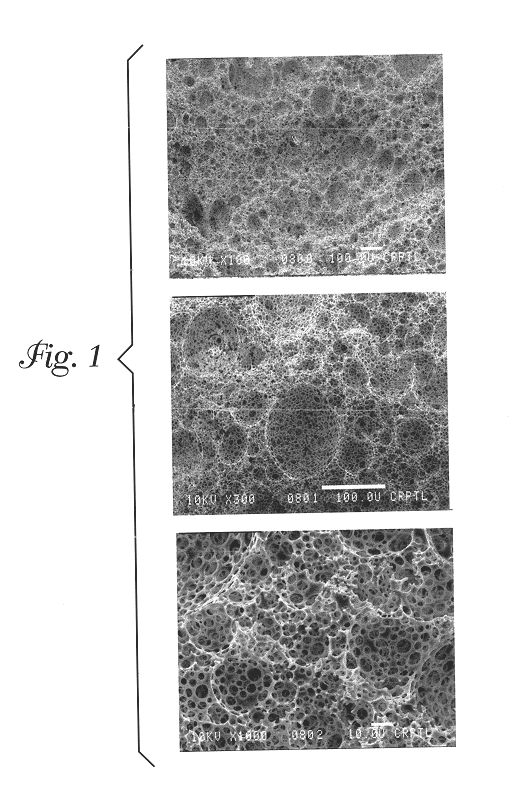

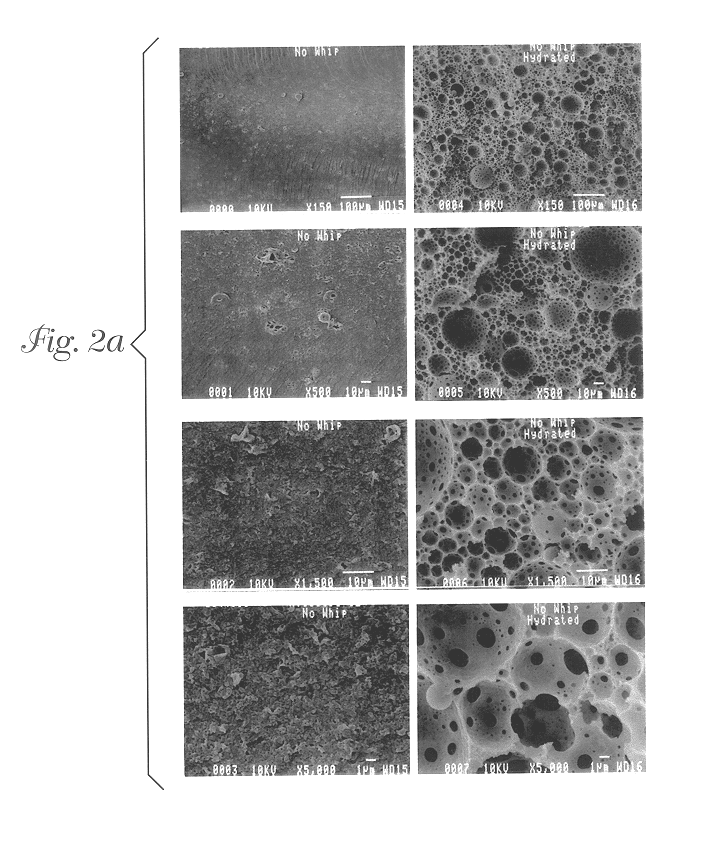

Foams made by photopolymerization of emulsions

InactiveUS6573305B1High mechanical strengthFilm/foil adhesivesOptical articlesWater in oil emulsionPolymer chemistry

Owner:3M INNOVATIVE PROPERTIES CO

Method of fracturing subterranean formations utilizing emulsions comprising acrylamide copolymers

InactiveUS7482310B1Predictable and convenient and efficient preparationSufficient amountOther chemical processesMixing methodsPolymer scienceFracturing fluid

A method of treating a subterranean formation penetrated by a well bore including:(a) preparing a fracturing fluid containing a mixture resulting from:(I) providing a water-in-oil emulsion composition that includes:(i) 5% to 99% by weight of a water-in-oil emulsion polymer comprising a polymer or copolymer containing repeat units from an acrylamide monomer;(ii) 0.5% to 90% by weight of a carrier solvent; and(iii) 0 to 90% by weight of a fluidizing agent; and adding(iv) 0.1% to 10% by weight of one or more inorganic microparticles, where the total of all components is 100% by weight; and(II) adding the water-in-oil emulsion composition to water; and(b) contacting the subterranean formation with the fracturing fluid.

Owner:KROFF CHEM +1

Resilient personal care composition comprising polyalkyl ether containing siloxane elastomers

InactiveUS20100092408A1Improve stabilityGood flexibilityCosmetic preparationsToilet preparationsPersonal careEther

A stable personal care composition in the form of a water-in-oil emulsion may comprise a silicone elastomer comprising a polyalkyl ether pendant or a polyalkyl ether crosslink, wherein the alkyl group contains three or more carbon atoms; a non-emulsifying silicone elastomer; an emulsifier; a polar oil; and water. The personal care composition allows for previously unattainable levels of polar oils and / or aqueous phase within a water-in-oil emulsion.

Owner:THE PROCTER & GAMBLE COMPANY

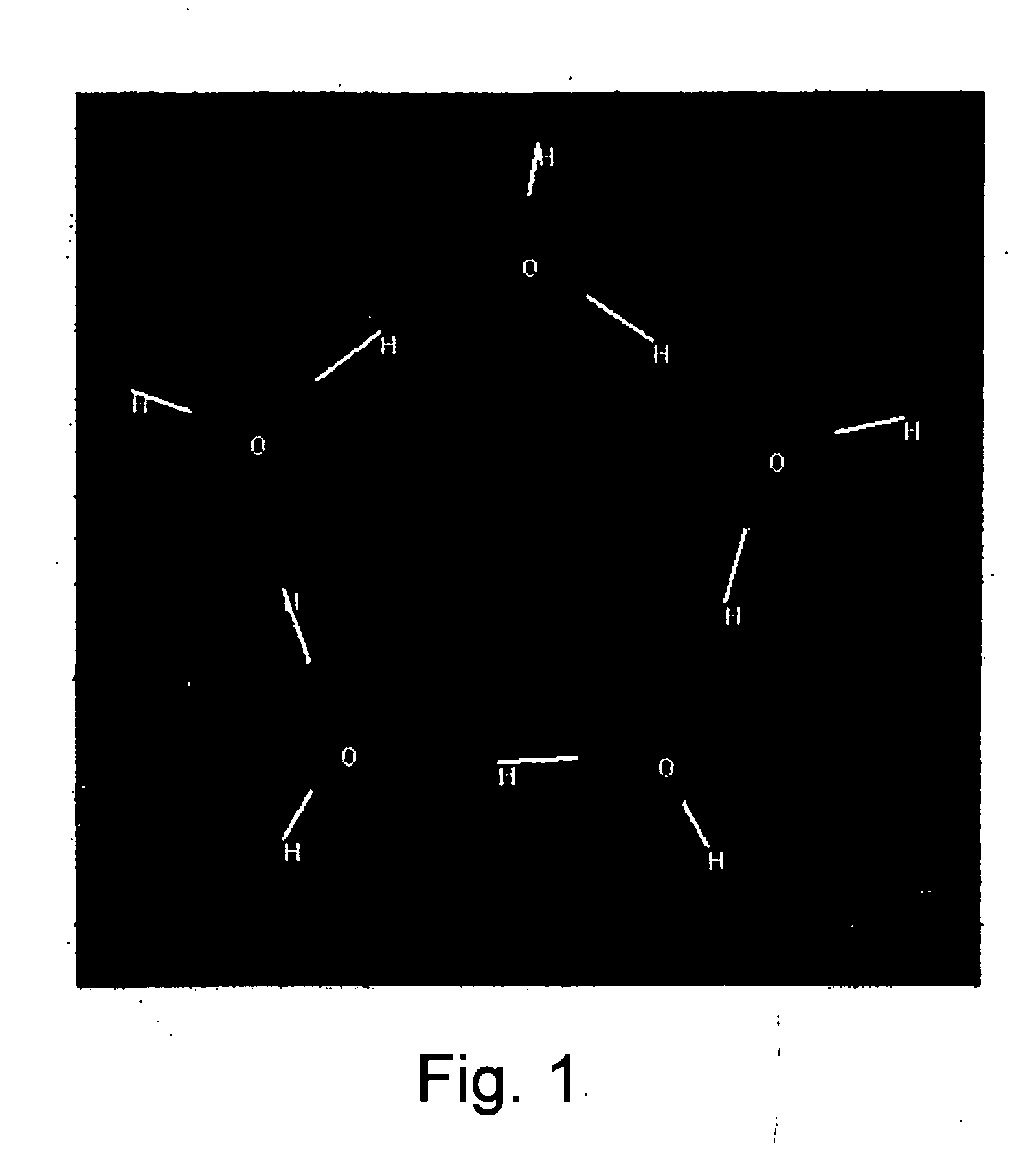

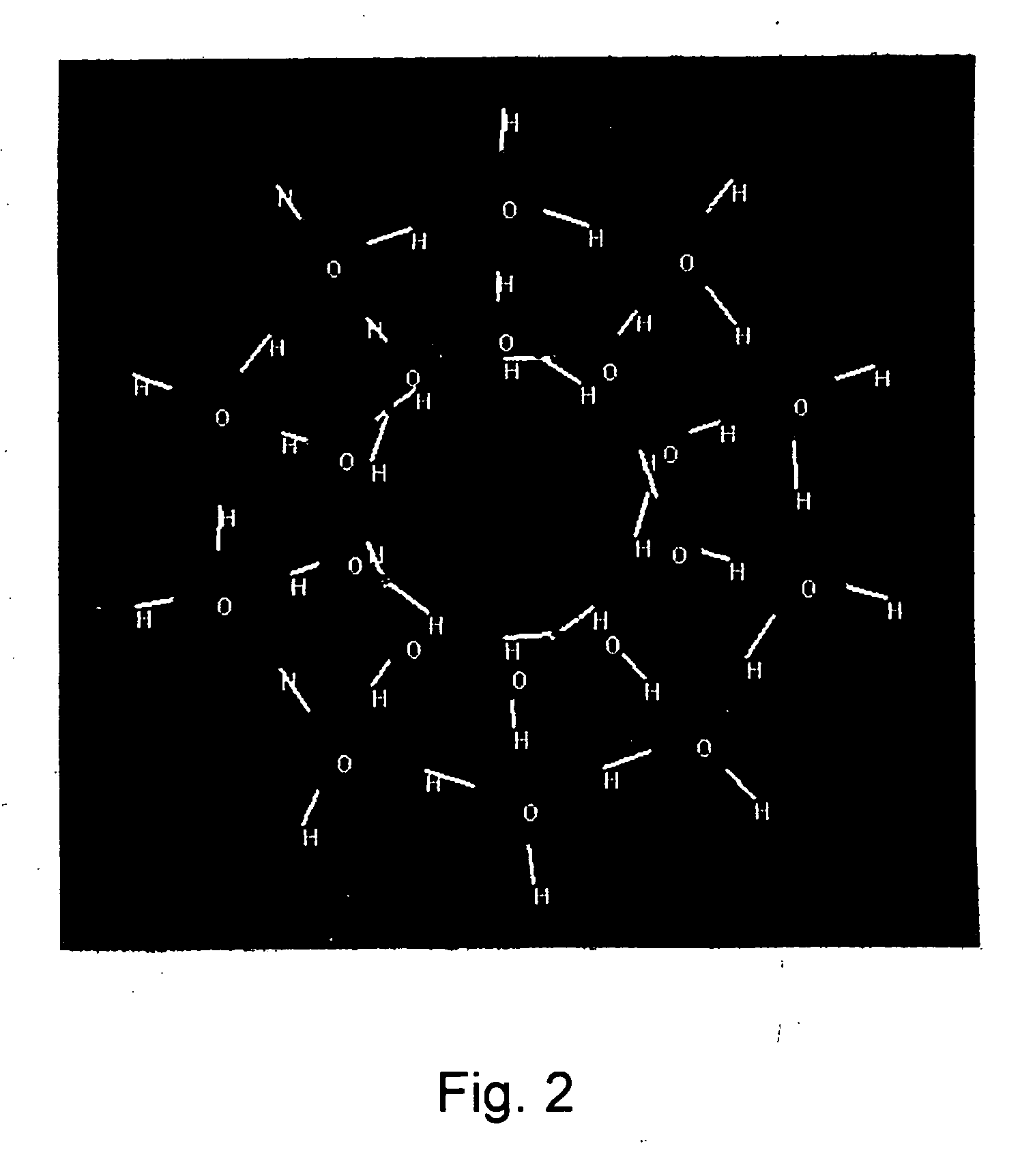

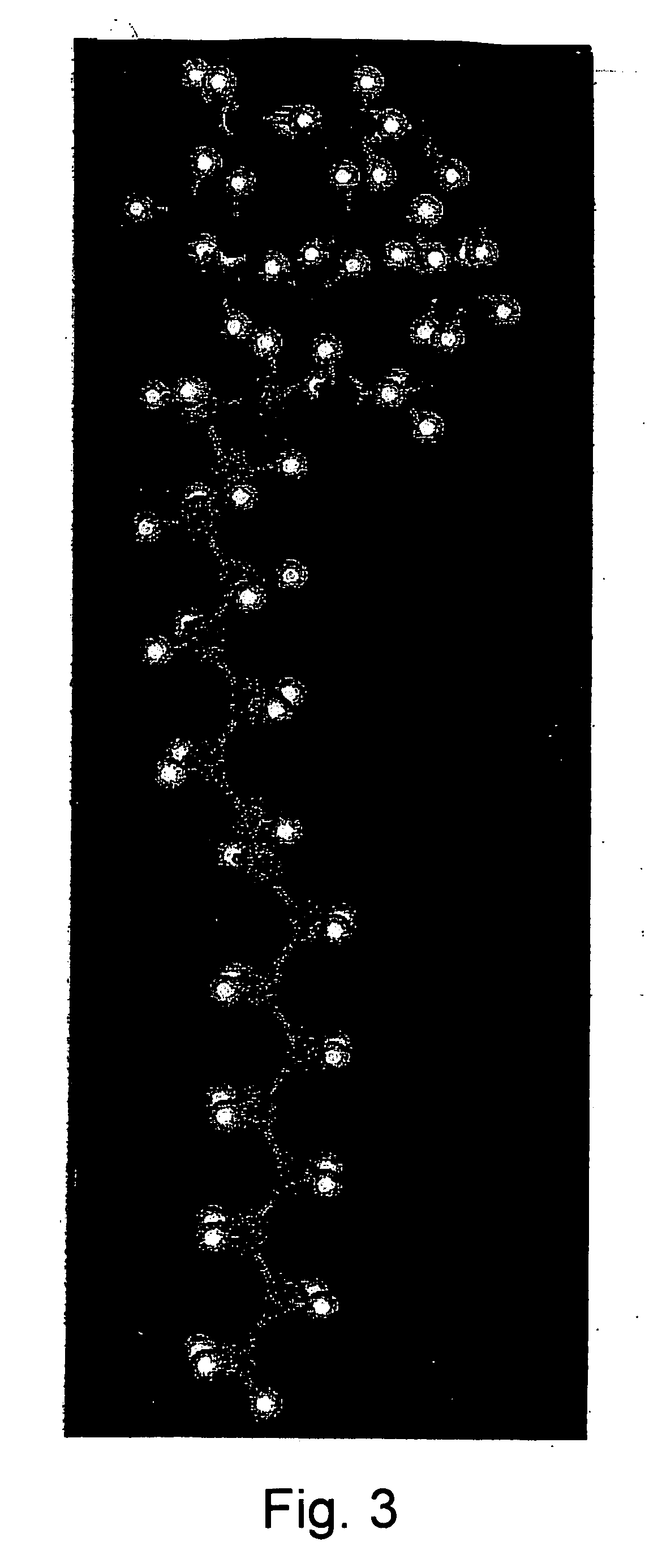

Water-in-oil emulsions and methods

The present invention provides a process for delivery of water nanoclusters of diameter less than about one nanometer to the skin to yield high epidermal permeability and improved delivery of water to within the outer layer of human skin. This invention provides effective water-cluster-based formulations for a broad range of stable water / oil nanoemulsion configurations.

Owner:HYDROELECTRON VENTURES

Method of using water-in-oil emulsion to remove oil base or synthetic oil base filter cake

ActiveUS7481273B2Improve breathabilityHighly efficient in breakingCleaning apparatusScale removal and water softeningParticulatesParaffin wax

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

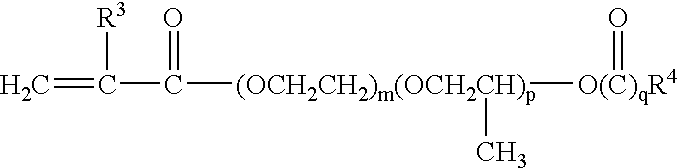

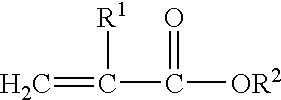

Water-in-oil emulsions with ethylene oxide groups, compositions, and methods

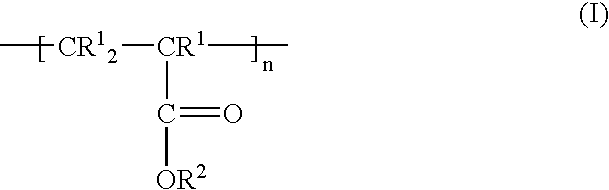

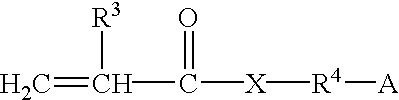

Water-in-oil emulsions, compositions, and methods that include a vinyl polymer that includes ethylene oxide-containing side chains and alkyl-Y-containing side chains, wherein Y is O or NR, wherein R is H or CH3, and wherein the alkyl group of the alkyl-Y-containing side chain has at least 4 carbon atoms on average in a cyclic, branched-, or straight-chain configuration and optionally including one or more heteroatoms.

Owner:3M INNOVATIVE PROPERTIES CO

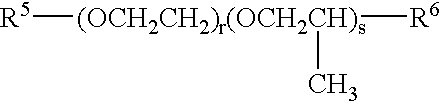

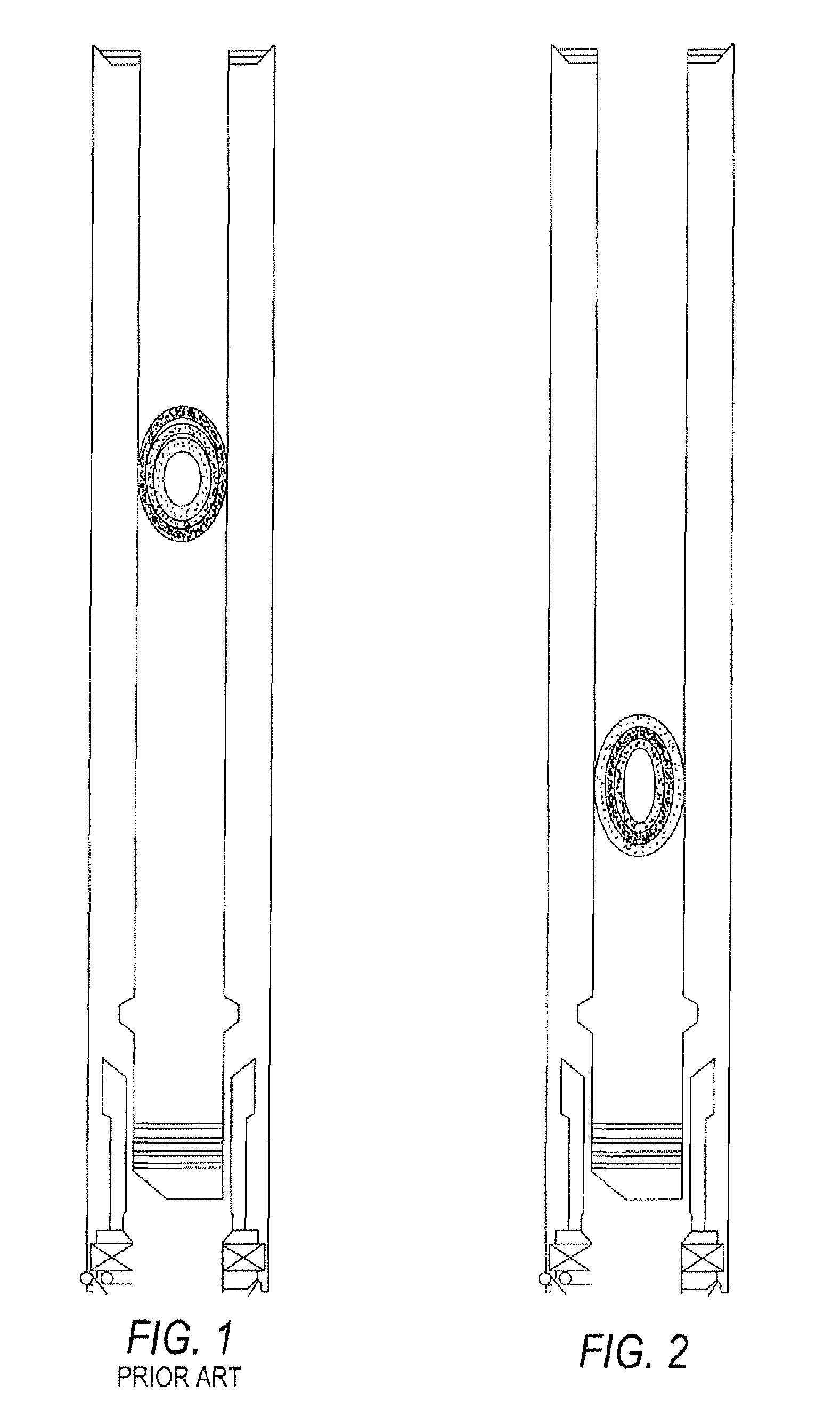

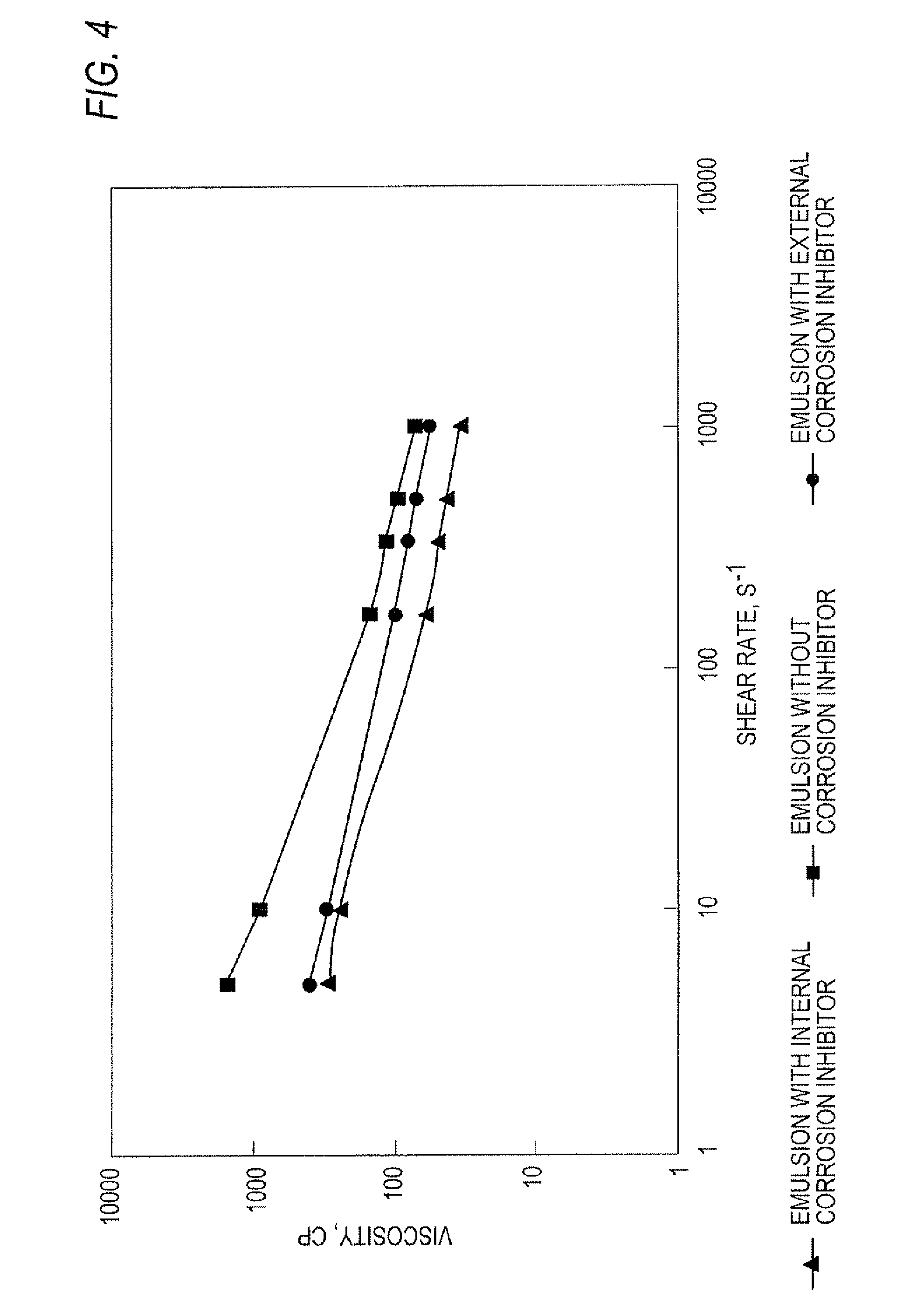

Method of mixing a corrosion inhibitor in an acid-in-oil emulsion

ActiveUS8039422B1Avoid corrosionPromote recoveryOther chemical processesMixing methodsOil emulsionWater in oil emulsion

An acid-in-oil emulsion having a corrosion inhibitor as the external phase has been found to prevent downhole corrosion when acidizing carbonate formations to enhance hydrocarbon recovery.

Owner:SAUDI ARABIAN OIL CO

Stability enhanced water-in-oil emulsion and method for using same

InactiveUS7186673B2Improve stabilityImprove emulsion stabilityOther chemical processesMixing methodsWater in oil emulsionPre treatment

A method for enhancing the stability of a water-in-oil emulsion pretreating at least a portion of the oil prior to emulsification. The pretreatment step may consist of adding polymers to the oil, biotreating the oil, photochemically treating the oil, or combinations thereof. The emulsion may be used in various enhanced oil recovery methods including using the emulsion as a flooding agent to displace hydrocarbons in a subterranean formation, and using the emulsion as a barrier fluid for diverting flow of fluids in the formation.

Owner:EXXONMOBIL UPSTREAM RES CO

Antiperspirant emulsion products with improved efficacy and processes for making the same

InactiveUS20110038823A1Improved antiperspirant efficacySimple processCosmetic preparationsToilet preparationsWater in oil emulsionOil phase

Antiperspirant emulsion products with improved antiperspirant efficacy and processes for making them are provided. In one embodiment, an antiperspirant emulsion product comprises a water-in-oil emulsion having a water phase and an oil phase. The water phase comprises an activated aluminum sesquichlorohydrate active system and the oil phase comprises cetyl PEG / PPG-10 / 1 dimethicone and a hydrophobic carrier.

Owner:DIAL CORPORATION

Composite particles and method for preparing

A method for producing composite particles using a supercritical fluid extraction technique on an emulsion. First and second materials (for example; a polymer and a biologically active material) are dissolved or suspended in a preferably solvent to form a solution or dispersion. The solution or dispersion is emulsified in a polar solvent to form an oil-in-water or water-in-oil-in-water emulsion. The emulsion is contacted with a supercritical fluid to extract the solvent. Removal of the solvent by the supercritical fluid from the emulsion supersaturates at least the first material in the solution causing the first material to precipitate out of the solution as composite particles that include both the first and second materials.

Owner:FERRO CORP

Preparation of porous particles with multiple markers

Porous particles are prepared using a first water-in-oil emulsion comprising a first marker material in a first aqueous phase that is dispersed in a first oil phase containing a polymer and a first organic solvent, and a second water-in-oil emulsion comprising a second marker material in a second aqueous phase that is dispersed in a second oil phase. The first and second marker materials are detectably different. The two water-in-oil emulsions can be used to form a third water-in-oil emulsion containing distinct droplets of the first and second aqueous phases. This third water-in-oil emulsion is dispersed in a third aqueous phase containing a surface stabilizing agent to form a water-in-oil-in-water emulsion containing droplets of the third water-in-oil emulsion. The organic solvents are removed from the water-in-oil-in-water emulsion to form porous particles comprising first and second discrete pores that are isolated from each other. The first marker material is present within the first discrete pores, and the second marker material is present within the second discrete pores.

Owner:EASTMAN KODAK CO

Water-in-oil polymer emulsion containing microparticles

InactiveUS7531600B1Predictable and convenient and efficient preparationEasily metered into the fluid.Sludge treatment by de-watering/drying/thickeningWater treatment compoundsPolymer scienceFracturing fluid

A storage stable water-in-oil emulsion composition that includes 5% to 99% by weight of a water-in-oil emulsion polymer including a polymer or copolymer containing repeat units from an acrylamide monomer; 0.1% to 10% by weight of one or more inorganic microparticles; 0.5% to 90% by weight of a carrier solvent; and 0 to 90% by weight of a fluidizing agent. The compositions can be used to treat aqueous systems including paper processing, sludge dewatering and for fracturing fluids for subterranean formations.

Owner:KROFF CHEM

Method for displacing oil base drilling muds and/or residues from oil base drilling mud using water-in-oil emulsion

ActiveUS7188676B2Improve breathabilityEfficacious in displacingCleaning apparatusFluid removalParticulatesParaffin wax

Fluid producing wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted solid particulates, including pipe dope, asphaltenes and paraffins. Such emulsions are of particular applicability in the displacement of oil base drilling muds and / or residues from such muds from producing wells. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES INC

Process for preparing thermally stable oil-in-water and water-in-oil emulsions

InactiveUS20100022421A1Improve thermal stabilityEnhanced saline stabilityTransportation and packagingMixingAlcoholWell drilling

A method for preparing a thermally stable well servicing fluid in the form of an oil-in-water (O / W) macroemulsion, a water-in-oil (W / O) macroemulsion or a water-in-oil (W / O) microemulsion at the well drilling location is provided. The servicing fluid is prepared by mixing a hydrocarbon phase, a water phase and a surfactant phase to obtain either an O / W macroemulsion, a W / O macroemulsion or a W / O microemulsion. The surfactant phase comprises a first surfactant and / or a second surfactant. The first surfactant comprises a fatty acid mixture and a hygroscopic first additive. The second surfactant comprises a C4-C6 alcohol. Whether or not an O / W macroemulsion, W / O macroemulsion or a W / O microemulsion is produced is determined by the concentration of the phases, the first surfactant, the second surfactant and the timing upon which the first additive, water phase and second surfactant are introduced to the mixture.

Owner:INTREVEP SA

Paper softening compositions containing low levels of high molecular weight polymers and soft tissue paper products comprising said compositions

Disclosed is a composition suitable for atomizing without excessive aerosolization in the form of an oil-in-water emulsion comprising: a) a continuous aqueous phase, and b) a discontinuous oil phase wherein the rheology of the aqueous phase is modified by the addition of a water-in-oil emulsion comprising: i) a high molecular weight polymer in a discontinuous aqueous phase, and ii) a continuous organic solvent phase. Preferred embodiments of the present invention relate to compositions for softening an absorbent paper tissue comprising a) a quaternary ammonium softening active ingredient; b) an electrolyte; c) a high molecular weight polymer emulsion comprising: i) from about 20% to about 40% by weight of the premix of a high molecular weight polymer; ii) from about 40% to about 60% of water; and iii) from about 20% to about 40% of an organic solvent; and d) a vehicle in which said softening active ingredient is dispersed.

Owner:THE PROCTER & GAMBLE COMPANY

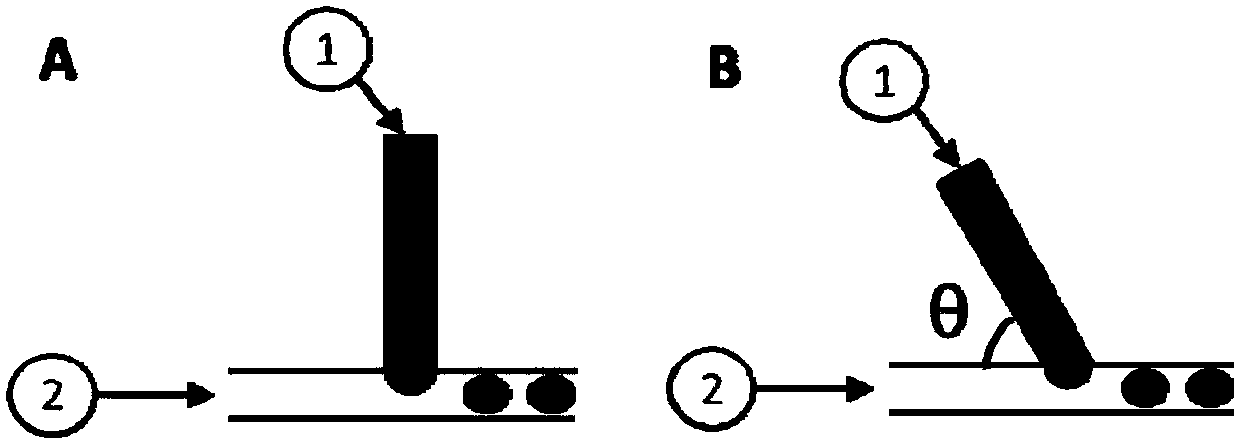

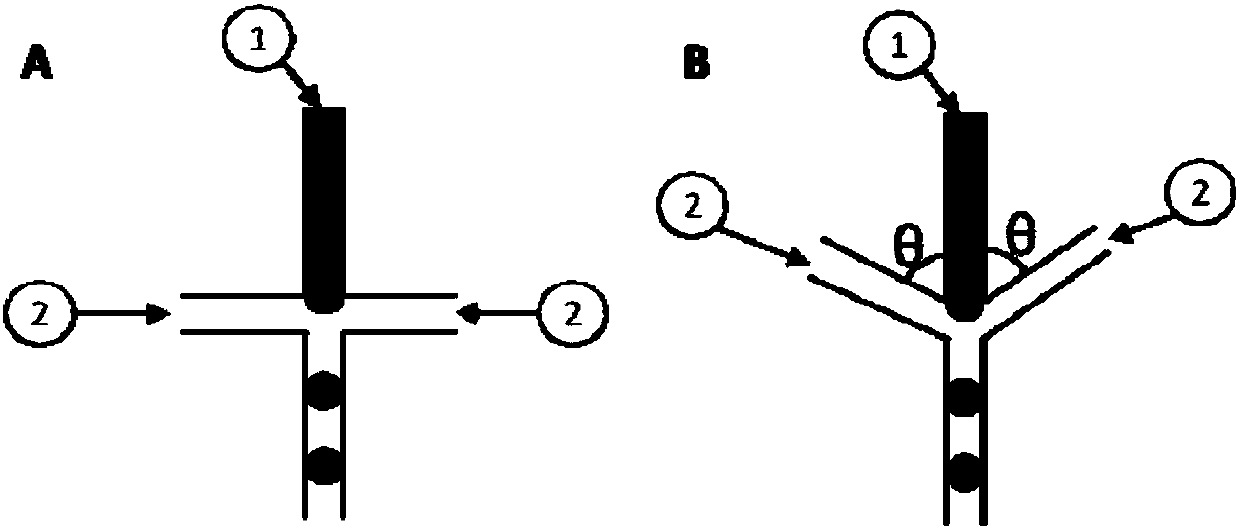

Microfluidic technology for one-step continuous preparation of calcium alginate microgel

ActiveCN107930542AFast shippingMaintain biological activityLaboratory glasswaresGel preparationOil phaseWater in oil emulsion

The invention relates to a microflow droplet technology-based method for one-step continuous preparation of multi-chamber calcium alginate microgel for immobilization of bioactive substances. The method realizes high-throughput continuous production of a microgel material. The method comprises forming a parallel and stable flow field through different hydrogel prepolymer solutions in a microfluidic channel, pouring the hydrogel prepolymer solutions for forming different chambers of the microgel into a microfluidic chip to form water phase solutions of multiple phase parallel fluids, mixing thewater phase solutions and an immiscible fluid (oil phase) through a T-shaped channel or a fluid focusing design to obtain water-in-oil emulsion drops and then alginic acid in the drops is linked immediately so that multi-chamber microgel is prepared, and cleaning the emulsion drops on the microfluidic chip so that the microgel is fast conveyed into a water phase. The method realizes one-step preparation of the calcium alginate microgel immobilized with bioactive substances and is suitable for industrial application.

Owner:SHENZHEN HUA NOVA BIOTECH LTD

Oil-in-oil emulsions

ActiveUS20070189998A1More predictable behaviorLow settling rateBiocideCosmetic preparationsPhosphateOil emulsion

An stable oil-in-oil emulsion is disclosed containing a first oil phase dispersed as droplets in a continuous second oil phase, which droplets have a number median diameter of 10 nm to 1000 nm, wherein the first oil phase is substantially immiscible in the second oil phase and wherein the first oil phase comprises a liquid organic phosphate compound. In one preferred embodiment, the first oil phase comprises colorants, polymers, and / or other additives, depending on the particular use of the emulsion.

Owner:EASTMAN KODAK CO

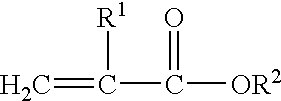

Water-in-oil emulsions with anionic groups, compositions, and methods

Water-in-oil emulsions, compositions, and methods that include a vinyl polymer having a pKa of less than 4 that includes anionic group-containing side chains and alkyl-Y-containing side chains, wherein Y is O or NR, wherein R is hydrogen or methyl, and wherein the alkyl group of the alkyl-Y-containing side chain has at least 4 carbon atoms on average in a cyclic, branched-, or straight-chain configuration and optionally including one or more heteroatoms.

Owner:3M INNOVATIVE PROPERTIES CO

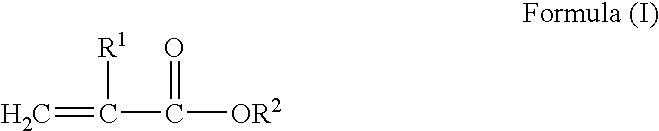

Method for preparing molecular cloning chip for high-throughput cloning of nucleic acid molecule

InactiveCN101413034AEasy to manufactureMiscellaneous transactionsMicrobiological testing/measurementDNA preparationOil phaseWater in oil emulsion

The invention provides a method for preparing a molecular cloning chip by cloning high flux nucleic acid molecule. The method comprises the following steps: a. a cloning nucleic acid molecule template is mixed with a nucleic acid amplification reaction system reagent to obtain an amplification mixture solution; b. the amplification mixture solution is added with a high molecular compound; c. the solution is added with oil phase, of which the volume is two times of the volume of the solution for emulsification to obtain water-in-oil emulsion; d. the emulsion is placed in a PCR meter or a thermostat to undergo a nucleic acid amplification reaction; e. after the nucleic acid amplification reaction, the emulsion is cooled down to form nucleic acid molecule cloning grains; f. the nucleic acid molecule cloning grains are separated; and g. the nucleic acid molecule cloning grains are randomly dispersed on a solid phase carrier to fix the nucleic acid amplification products in the solution on the solid phase carrier and form a nucleic acid molecule cloning array on the surface of the solid phase carrier and thus the cloning chip is obtained. The method has the advantages of improving preparation sequencing template, ensuring high flux of sequencing and lowering sequencing cost.

Owner:SOUTHEAST UNIV

Method of treating a formation

A method of treating a portion of a subterranean formation that includes: providing a water-in-oil emulsion, inverting the water-in-oil emulsion to form a friction reducing treatment solution, and introducing the treatment solution into the portion of the subterranean formation. The water-in-oil emulsion has an oil phase, an aqueous phase and surfactants. The oil phase (O) and an aqueous phase (A) are present at an O / A ratio of from about 1:8 to about 10:1. The oil phase is present as a continuous phase and contains an inert hydrophobic liquid. The aqueous phase is present as a dispersed phase of distinct particles in the oil phase and includes water and a water soluble polymer. The water soluble polymer makes up from 10 to 25 weight percent of the water-in-oil emulsion. The water-in-oil emulsion is inverted by adding it to water to form a friction reducing treatment solution.

Owner:SOLVAY USA

Cold-mix water-in-oil emulsions comprising quaternary ammonium compounds and process for producing same

The present invention relates to stable cold-mix water-in-oil emulsions and methods for preparing such emulsions. The cold-mix water-in-oil emulsions comprise oil (i.e., an emollient), water and an emulsification system comprising a quaternary ammonium-based low HLB emulsifier and optional co-emulsifiers. The emulsions are useful in preparing finished cosmetic compositions in the form of lotions, gels, or sprays, which provide improved moisturization, skin feel, skin care, and / or appearance benefits and / or reduced greasiness, with excellent rub-in and absorption characteristics. Also disclosed are cold-mix water-in-oil sunscreen emulsions and methods for preparing such sunscreen emulsions. The emulsions of the instant invention are generally capable of being substantially completely emulsified and stable at about 25° C.

Owner:STEPAN COMPANY

Cosmetic composition

A finisher composition that provides improved look and feel benefits to an underlying skin care product. The finisher composition is an oil-in-water emulsion that includes from 10 to 25 wt % of substantially spherical starch particles having a mean particle size of from 5 to 30 microns. The oil phase of the finisher includes a non-volatile oil present at an amount to provide a weight ratio of non-volatile oil to starch particles of from 1:10 to 3:2. The aqueous phase of the finisher includes from 20 to 85 wt % of water.

Owner:PROCTER & GAMBLE CO

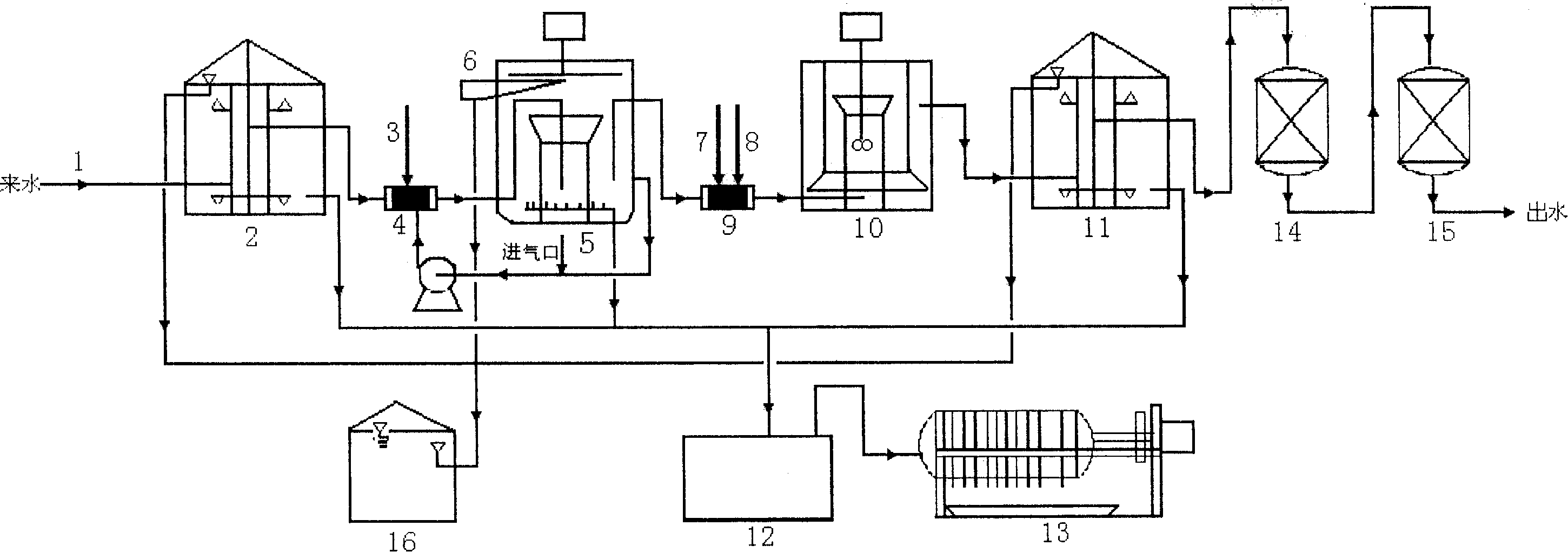

Ternary combination flooding produced liquid oil-containing sewage treatment technique

ActiveCN101125717AImprove processing efficiencyReduce processing costsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFiltrationPolymer

The invention discloses a treatment technique for oil sewage in produced liquid in 3-dimension complex drive in oil fields. The produced liquid in 3-dimension complex drive in oil fields contains a mass of polymers, alkali and surfactant, thus water-in-oil emulsion formed in the sewage is quite stable and treatment of the oil and suspended substances is quite difficult. The technique uses methods of natural sedimentation, oil removal by floatation, coagulation sedimentation and mechanical filtration by adding oil removal agent, flocculant and coagulant aid to treat the oil sewage in the produced liquid in 3-dimension complex drive, so as to realize that oil content in the water after the treatment of the sewage is less than 20 mg / L and the content of the suspended substances is less than 20 mg / L to meet the standards of injection water of the 3-dimension complex drive in the oil fields. The technique solves the problems of the oil sewage treatment in the produced liquid in 3-dimension complex drive in the oil fields and has effective economic and social benefits for saving water resource, reducing tertiary recovery cost and protecting the environment.

Owner:PETROCHINA CO LTD

Solid skin care composition comprising multiple layers

Disclosed is a solid skin care composition comprising: (a) a first layer which is solid at 45° C. and which is a water-in-oil emulsion; and (b) a second layer which is solid at 45° C. and which is a water-in-oil emulsion comprising a benefit agent; wherein the first layer and the second layer have a different composition; and wherein the first layer and the second layer are provided in the same package in a manner such that the first layer and the second layer can be simultaneously applied.

Owner:THE PROCTER & GAMBLE COMPANY

Method of Using Water-in-Oil Emulsion to Remove Oil Base or Synthetic Oil Base Filter Cake

InactiveUS20090114394A1Improve permeabilityImprove effectivenessCleaning apparatusFluid removalParaffin waxOil emulsion

Fluid producing or injecting wells may be treated with a water-in-oil emulsion for the removal or inhibition of unwanted particulates, including pipe dope, asphaltenes and paraffins. In addition, such emulsions are effective in the displacement of oil base drilling muds and / or residues from such muds from wells. The emulsion may also be used to break the interfacial and / or rheological properties of oil base mud and synthetic oil base mud filter cakes, and act as a demulsifier to break the water-in-oil emulsion present in such oil base and synthetic oil base muds. The water-in-oil emulsions may optionally contain a dispersing agent as well as a surfactant.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com