Ternary combination flooding produced liquid oil-containing sewage treatment technique

A ternary compound and treatment process technology, which is applied in the fields of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Solve problems such as improving the economic and social benefits of the oil field, increasing the formation pressure, and reducing the amount of chemical added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

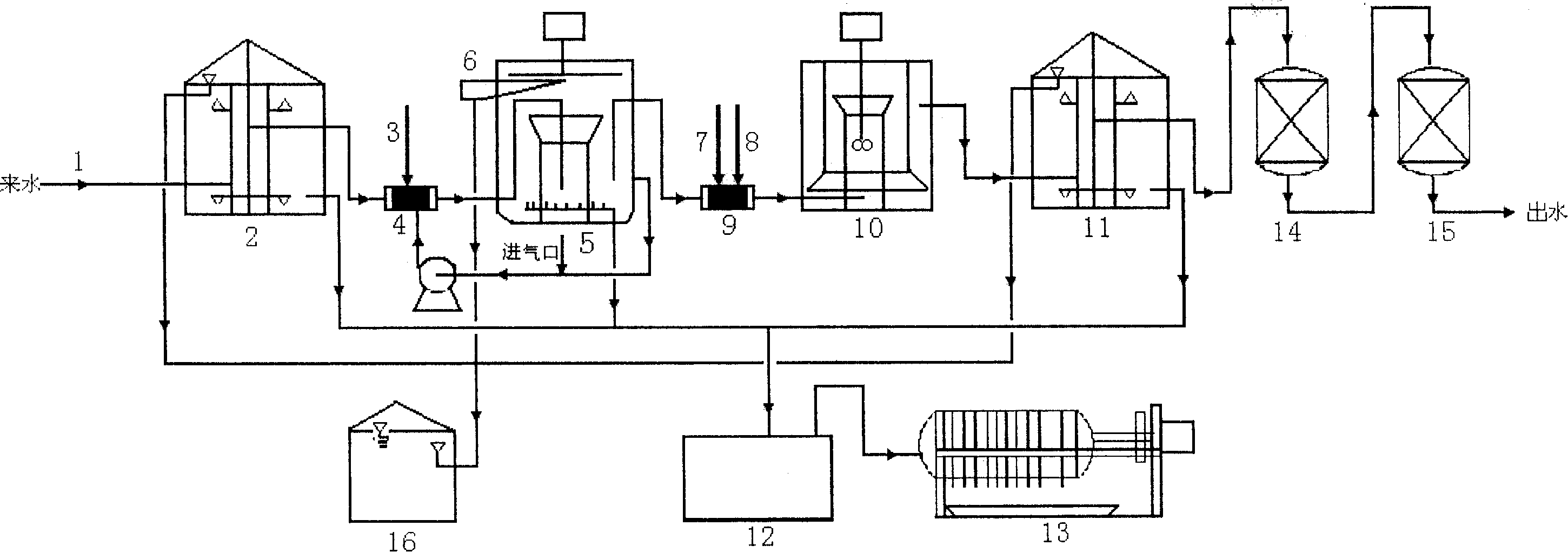

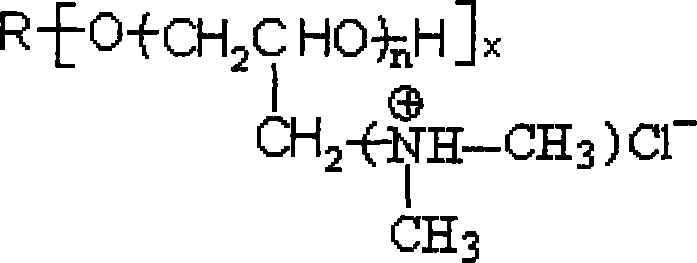

[0031] Embodiment 1: refer to accompanying drawing. Wastewater produced by ASP flooding 1 (flow 1m 3 / h) First enter the settling tank 2 (tank volume 4m 3 ), the residence time in the sewage tank is 4h. Add degreaser 3 (AM and trimethyl monoallyl ammonium chloride copolymer) to the pipeline, adjust the flow rate of the metering pump to control the dosing concentration of degreaser 3 to 80mg / L. The degreasing agent 3 is mixed with the effluent of the settling tank 2 through the static mixer 4, and then enters the air flotation device 5 to remove oil, and then enters the next stage of treatment. Add flocculant 7 polymerized ferric sulfate and coagulant 8 anionic polyacrylamide (molecular weight 6 million) to the pipeline, adjust the metering pump flow to control the dosing concentration of flocculant 8 and coagulant 9 to 200mg / L and 10mg / L respectively . The flocculant 8, the coagulant 9 and the effluent after air flotation are mixed by the static mixer 9 and then enter the ...

example 1

[0032] Example 1 data table Table 1

[0033] transport

Embodiment 2

[0034]Embodiment 2: refer to accompanying drawing. Wastewater produced by ASP flooding 1 (flow rate 2m 3 / h) First enter the settling tank 2 (tank volume 10m 3 ), the residence time in the tank is 5h. Add the polyether degreasing agent 3 produced by the reaction of epichlorohydrin and polyhydric fatty alcohol into the pipeline, and adjust the flow rate of the metering pump to control the dosing concentration of the degreasing agent 3 to 60mg / L. The degreasing agent is mixed with the effluent of the settling tank 2 through the static mixer 4, and then enters the air flotation device 5 to remove oil, and then enters the next stage of treatment. Add flocculant 7 aluminum sulfate and coagulant 8 anionic polyacrylamide (molecular weight 6 million) to the pipeline, adjust the flow rate of the metering pump to control the dosing concentration of flocculant 7 and coagulant 8 to 400mg / L and 15mg / L respectively. The flocculant 7, the coagulant 8 and the effluent after air flotation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com