Patents

Literature

186results about How to "Process operation is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

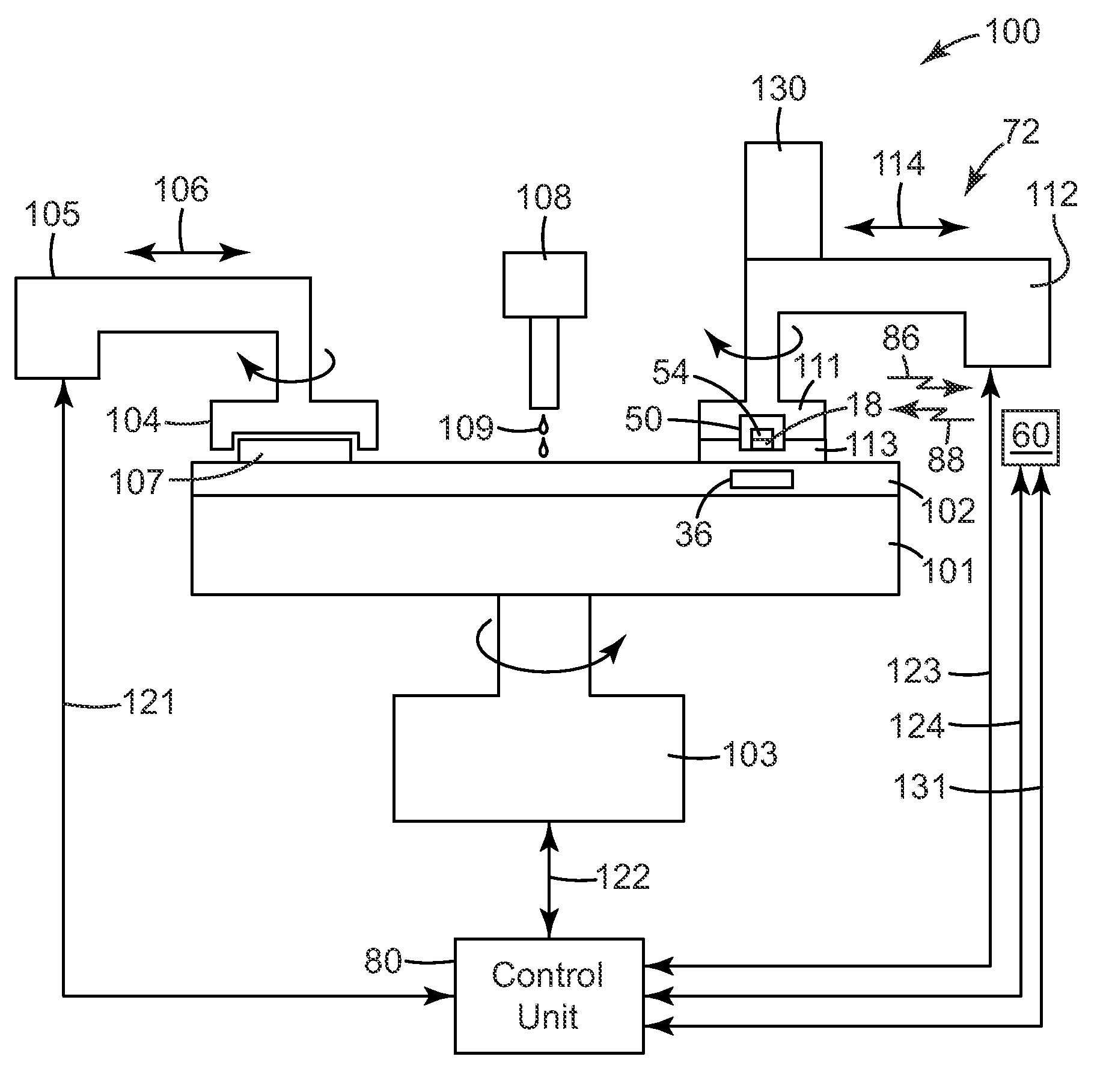

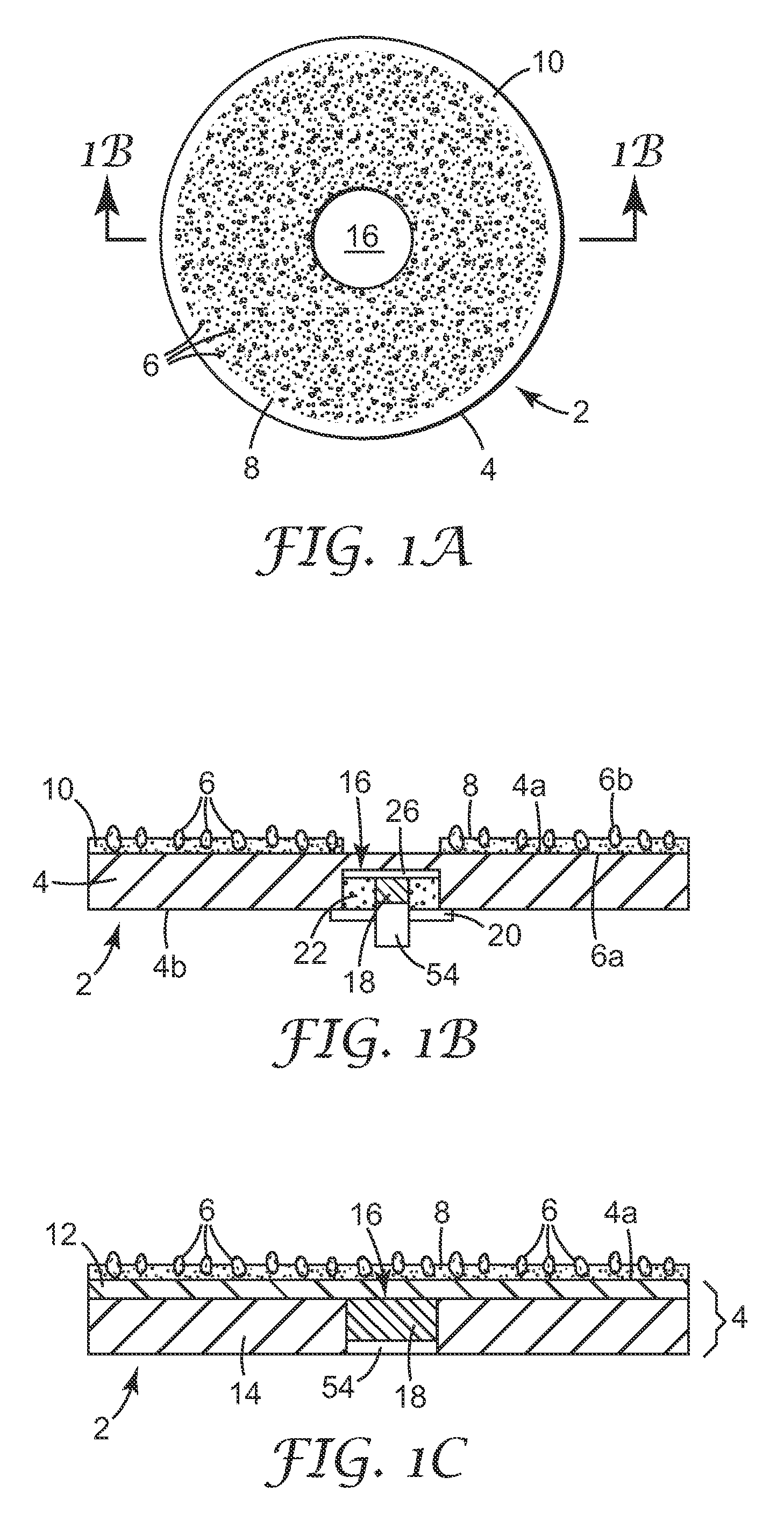

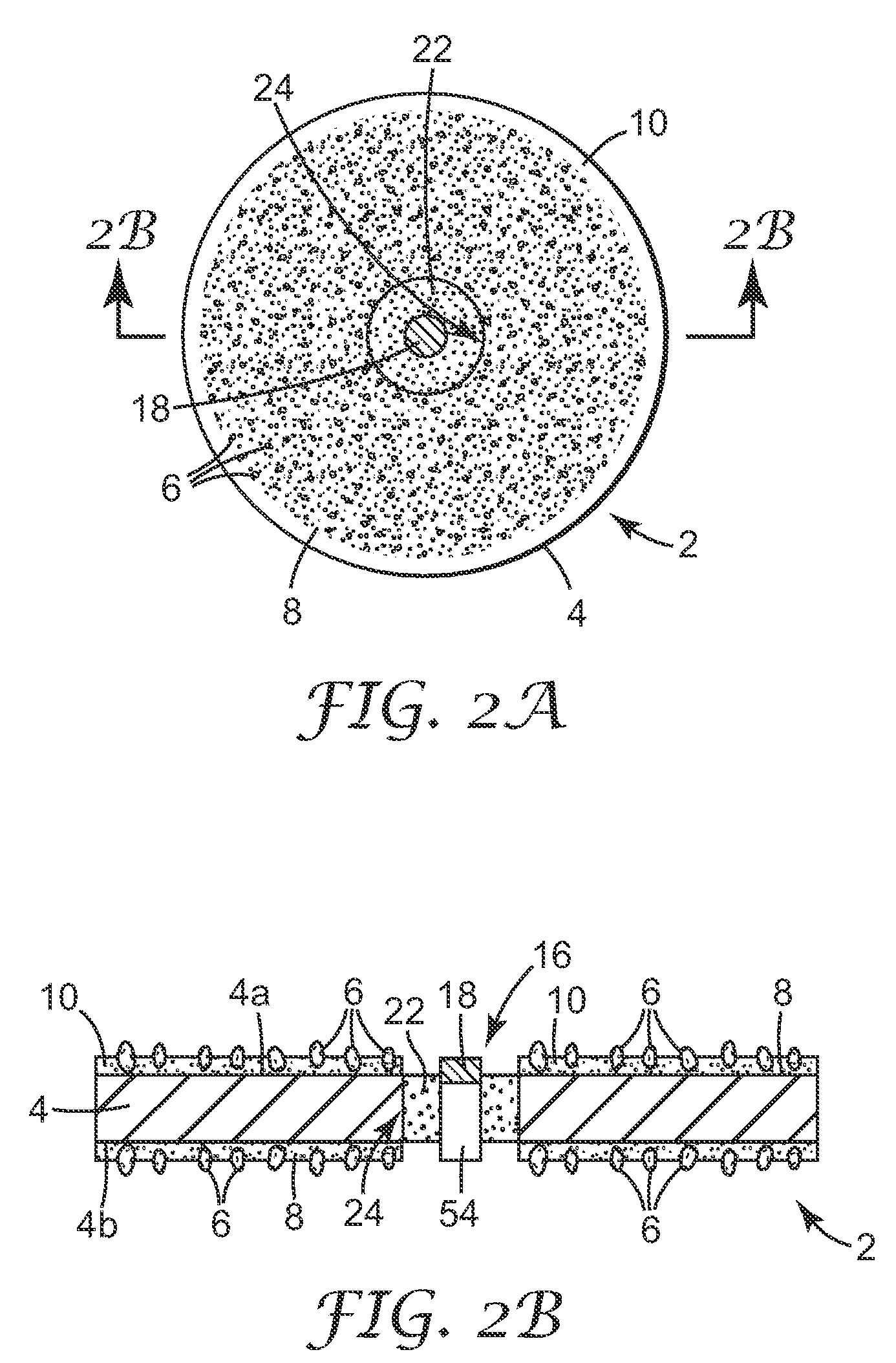

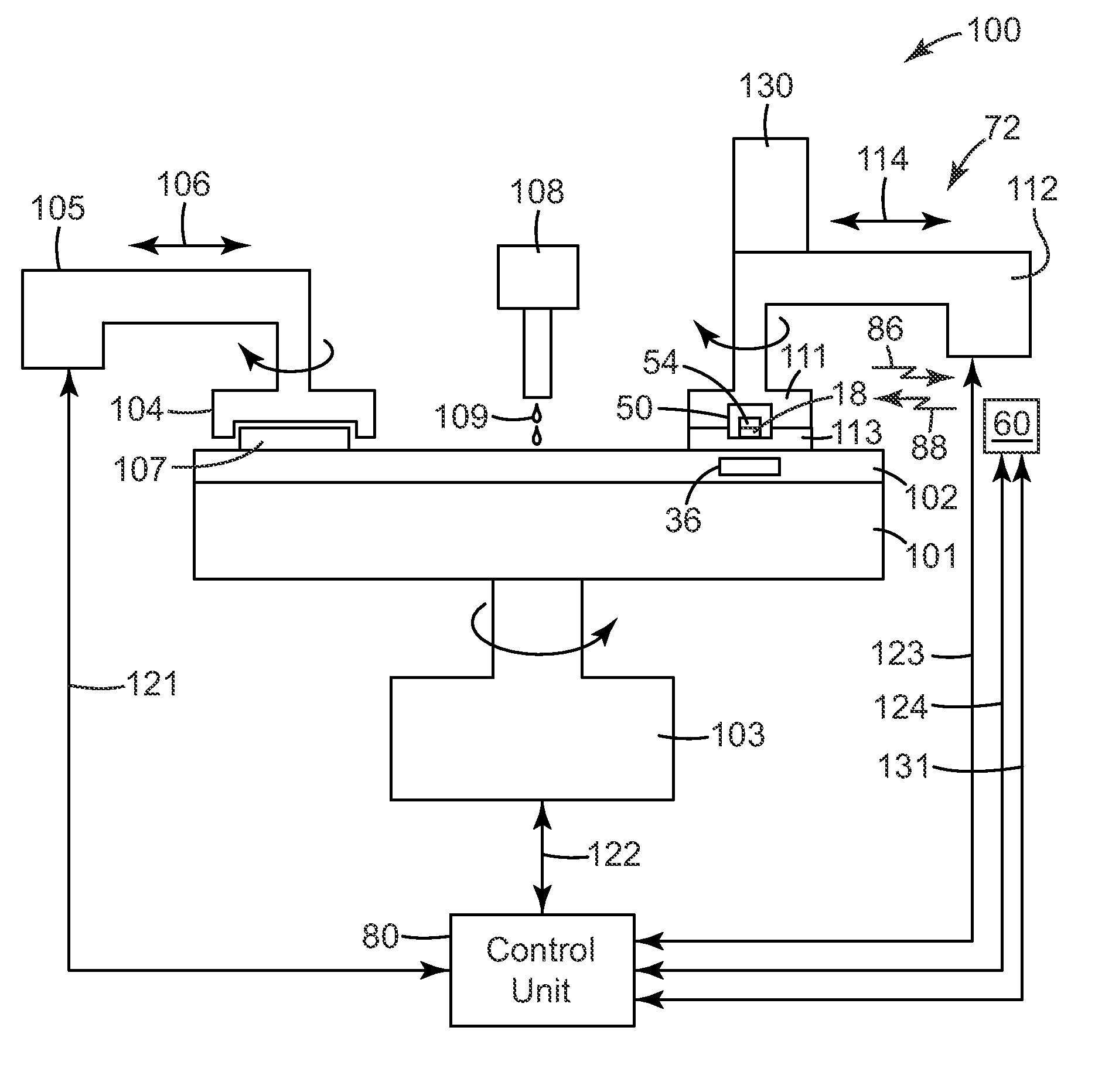

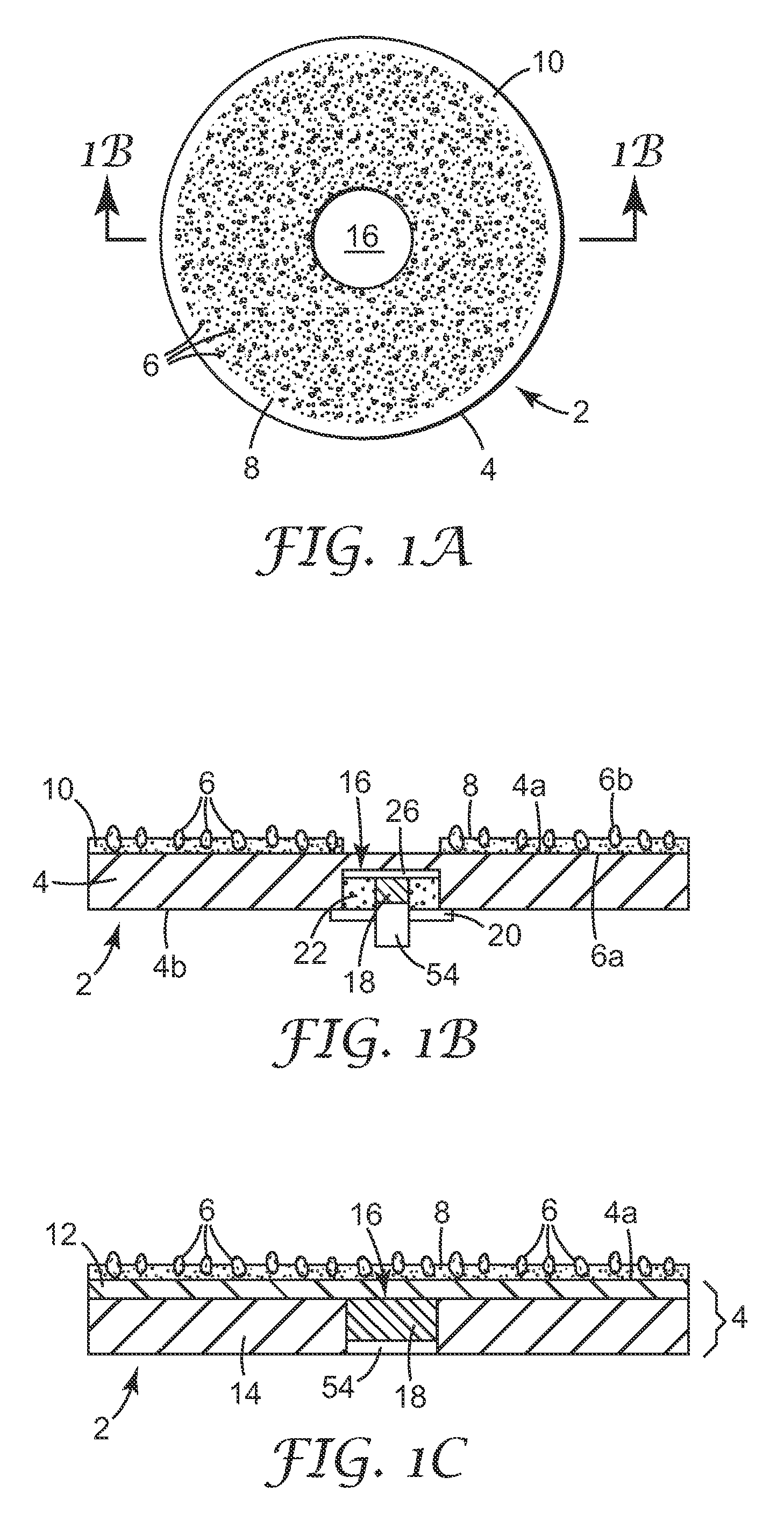

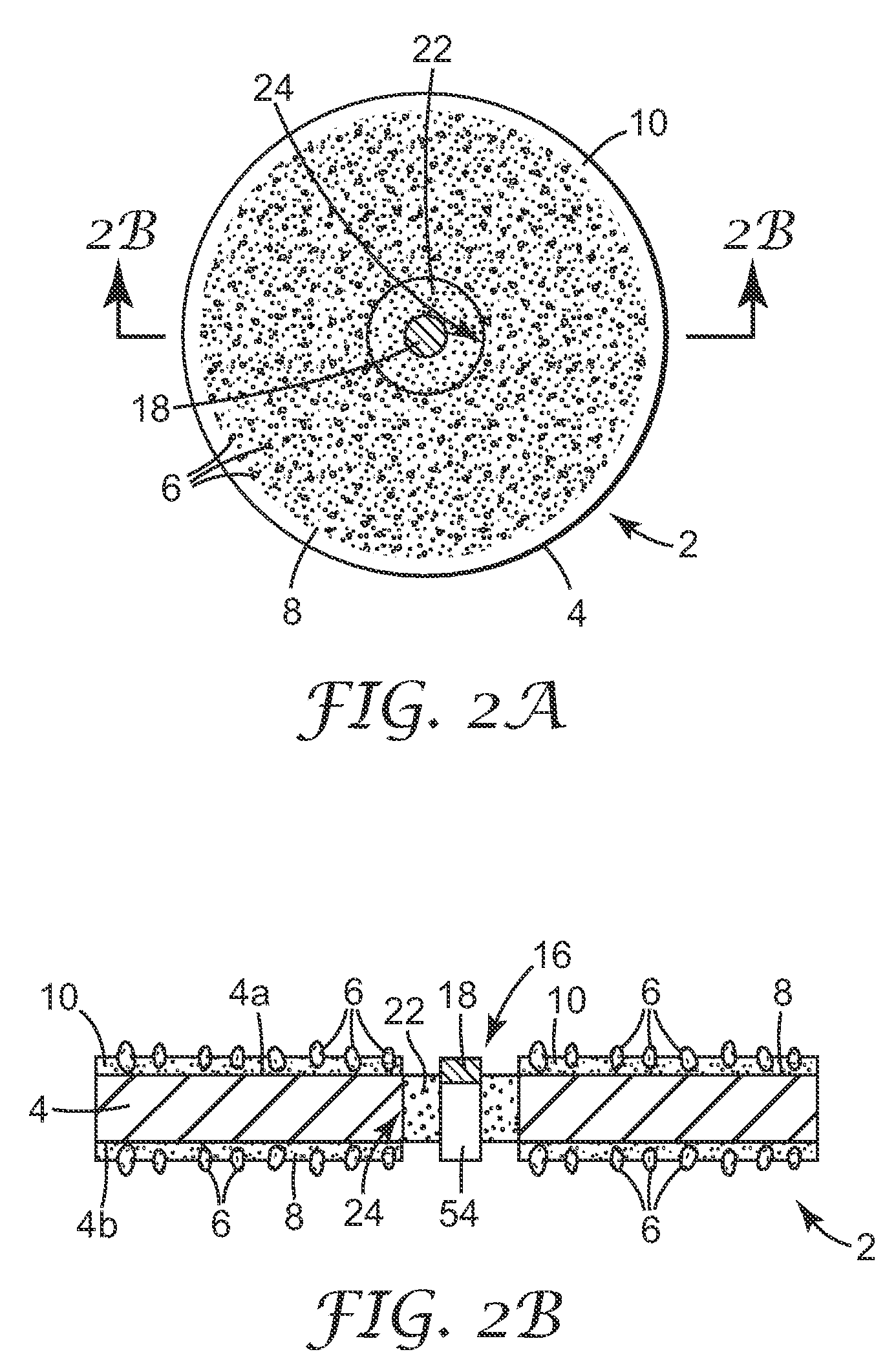

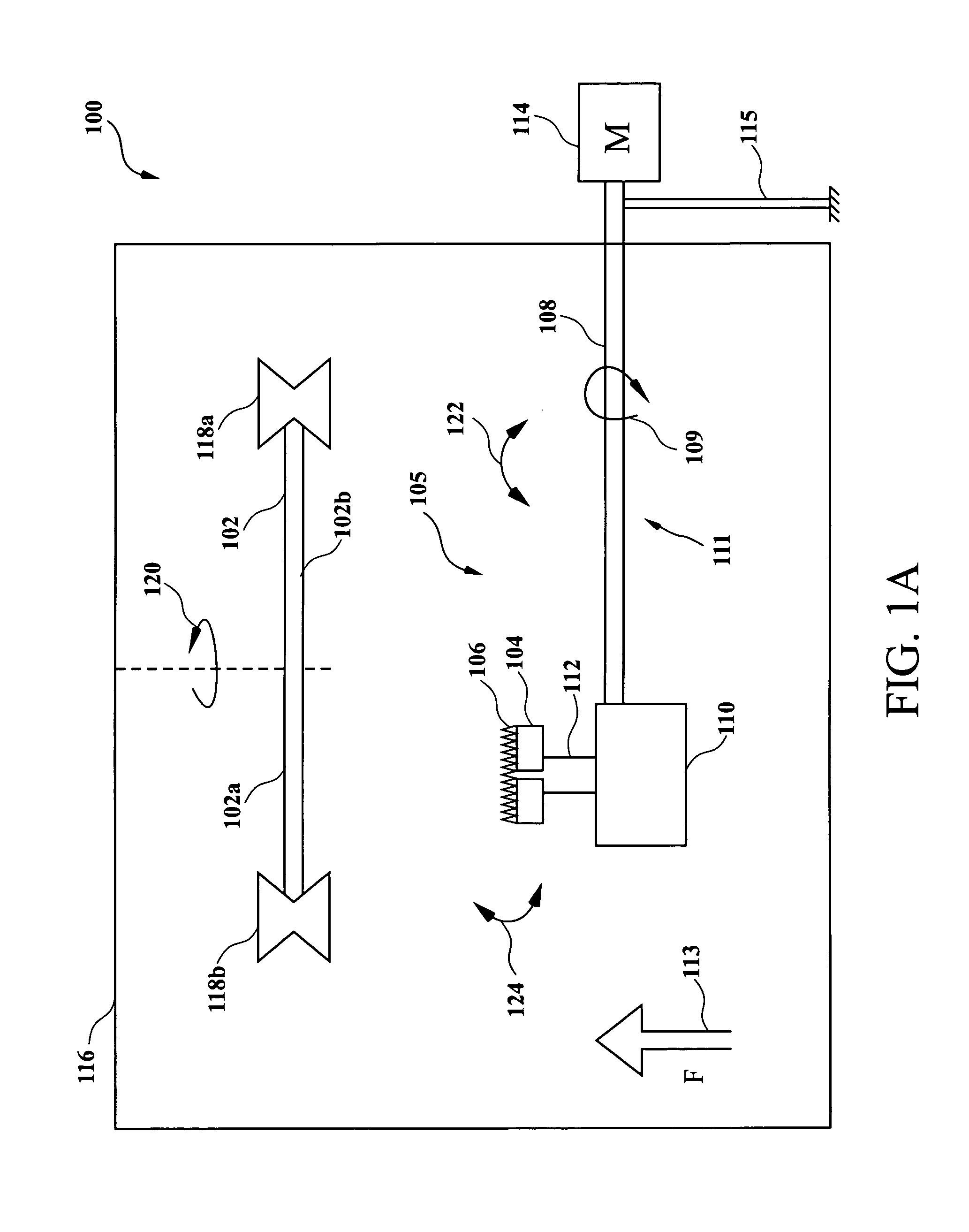

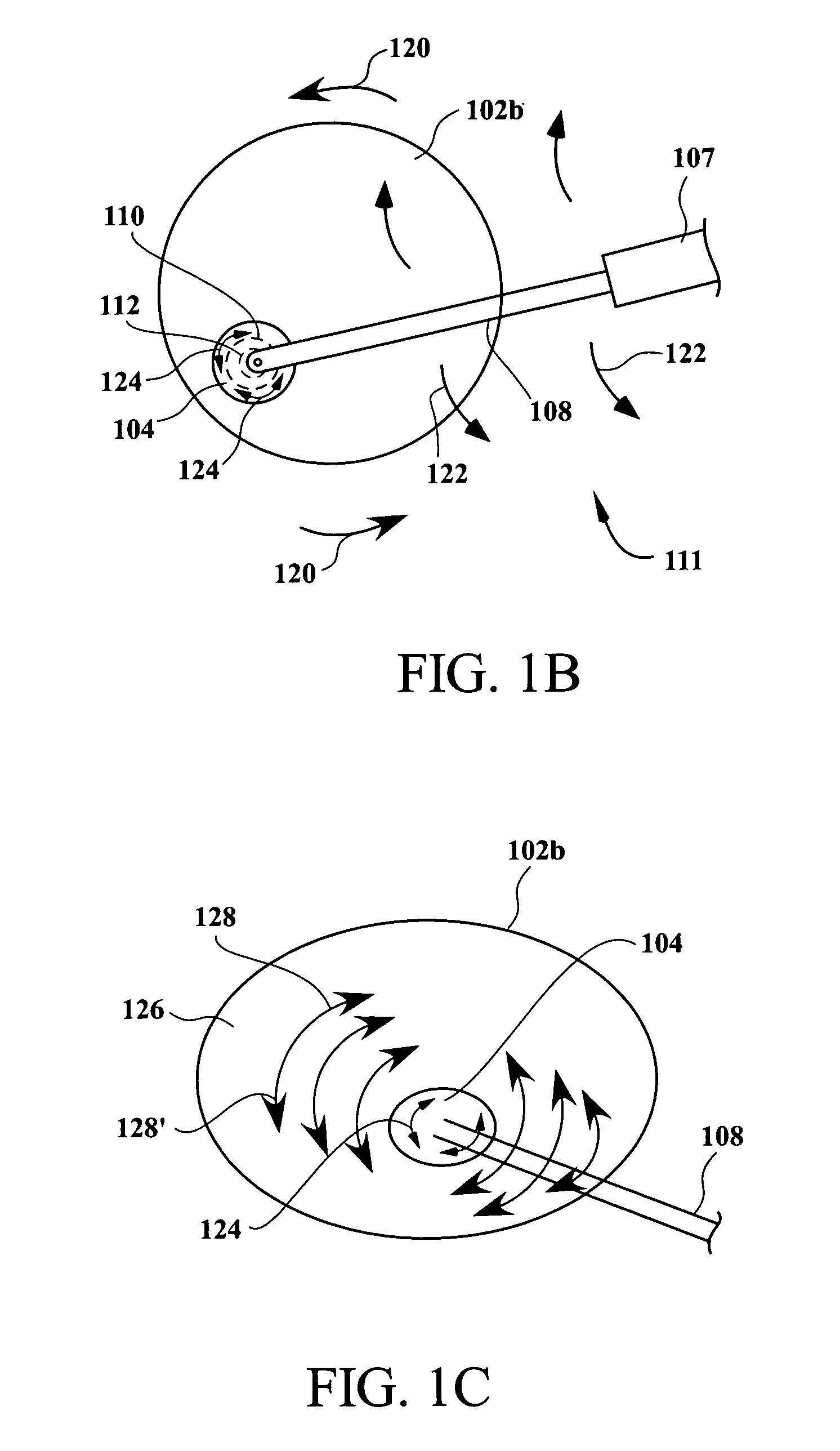

Abrasive Articles, CMP Monitoring System and Method

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

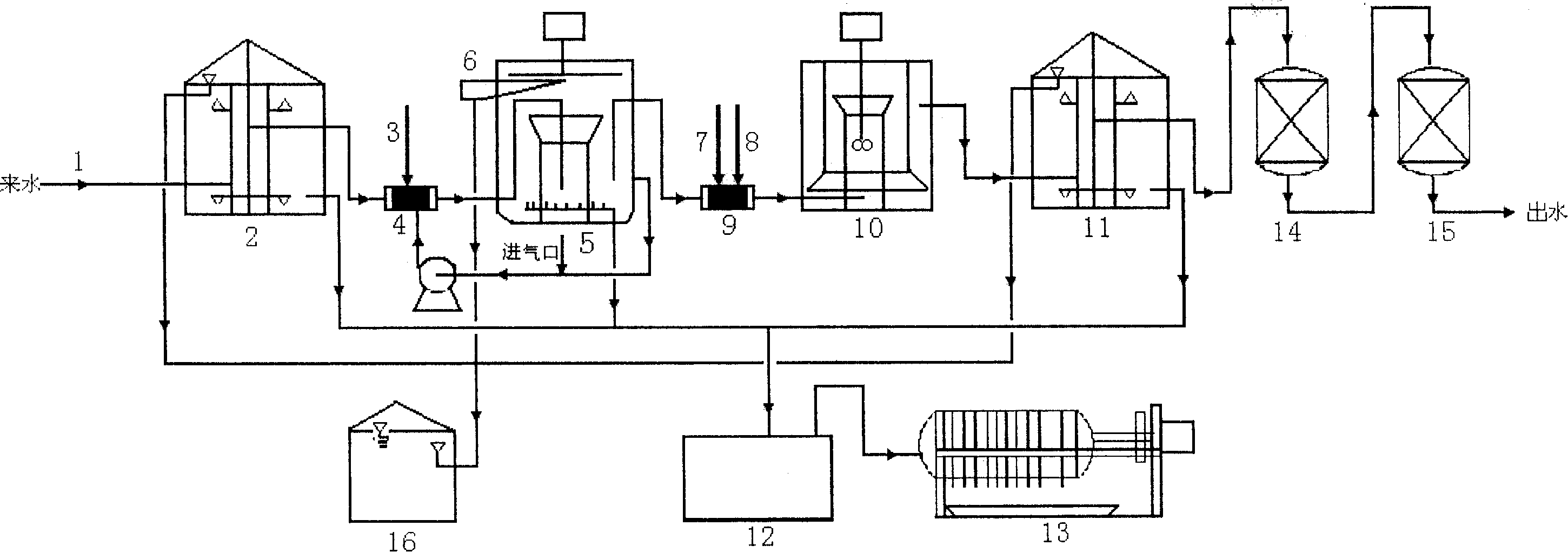

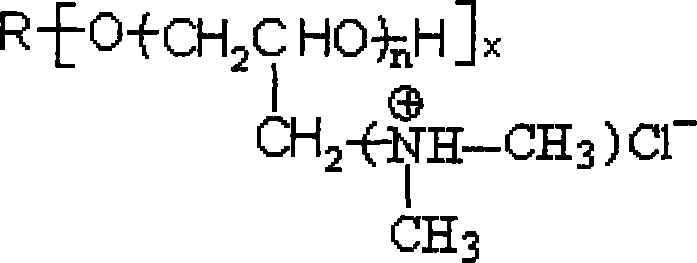

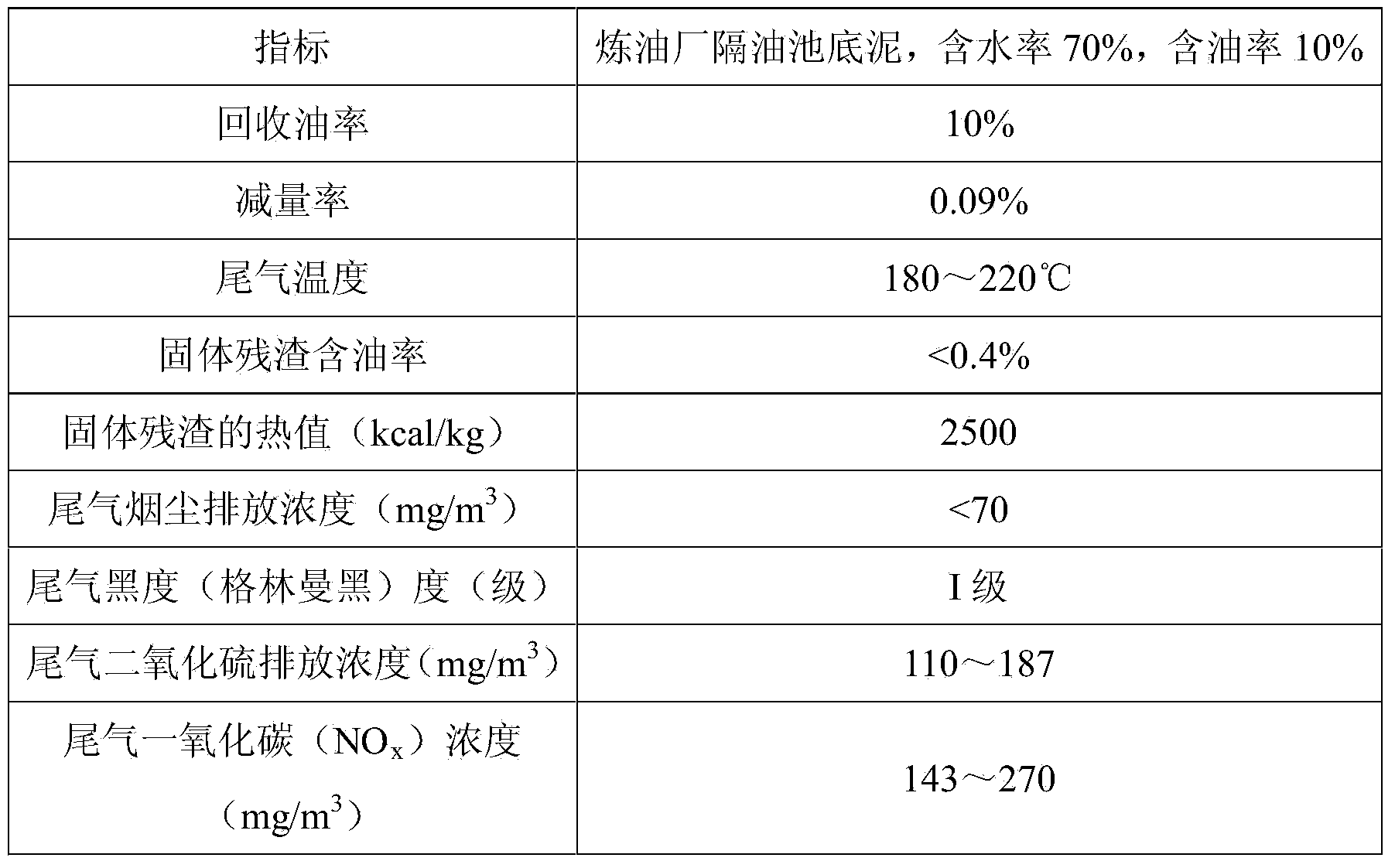

Ternary combination flooding produced liquid oil-containing sewage treatment technique

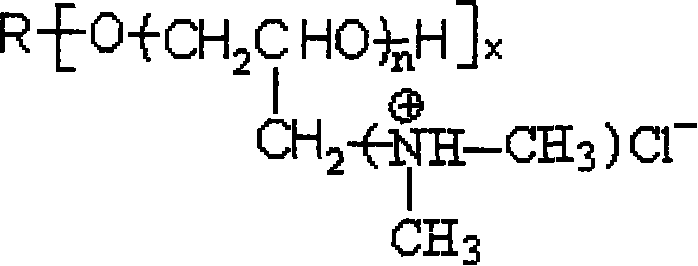

ActiveCN101125717AImprove processing efficiencyReduce processing costsFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFiltrationPolymer

The invention discloses a treatment technique for oil sewage in produced liquid in 3-dimension complex drive in oil fields. The produced liquid in 3-dimension complex drive in oil fields contains a mass of polymers, alkali and surfactant, thus water-in-oil emulsion formed in the sewage is quite stable and treatment of the oil and suspended substances is quite difficult. The technique uses methods of natural sedimentation, oil removal by floatation, coagulation sedimentation and mechanical filtration by adding oil removal agent, flocculant and coagulant aid to treat the oil sewage in the produced liquid in 3-dimension complex drive, so as to realize that oil content in the water after the treatment of the sewage is less than 20 mg / L and the content of the suspended substances is less than 20 mg / L to meet the standards of injection water of the 3-dimension complex drive in the oil fields. The technique solves the problems of the oil sewage treatment in the produced liquid in 3-dimension complex drive in the oil fields and has effective economic and social benefits for saving water resource, reducing tertiary recovery cost and protecting the environment.

Owner:PETROCHINA CO LTD

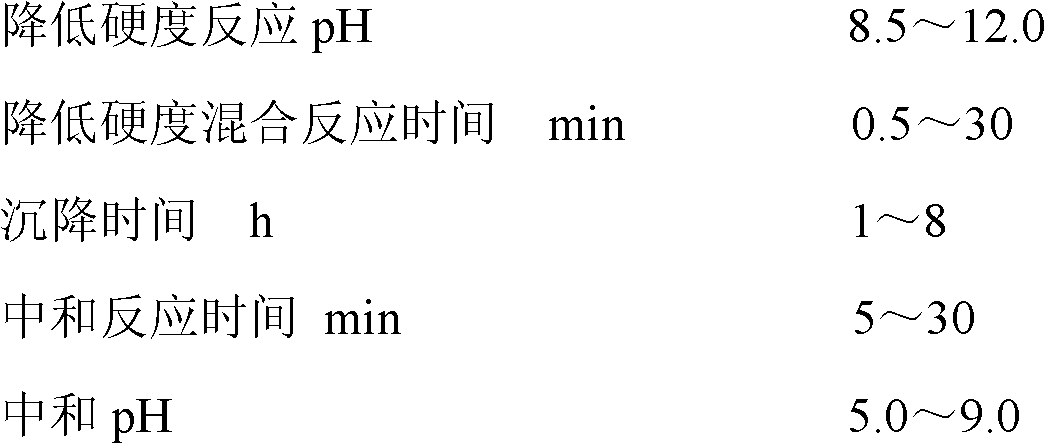

Method of deep desalting and recycling of industrial effluent

ActiveCN102452751AGuaranteed uptimeAvoid the problem of susceptibility to incoming water organic contaminationGeneral water supply conservationMultistage water/sewage treatmentElectricityIndustrial effluent

The invention provides a method of deep desalting and recycling of industrial effluent. The method is characterized in that industrial effluent to be treated is treated with a hardness reducing operating unit, an efficient filtering operating unit and an electro-adsorption desalting operating unit to reach a standard of recycling water. The method comprises specific steps of: a. hardness reduction, precipitation and neutralization; b. efficient filtering; and c. electro-adsorption desalting. The provided method of deep desalting and recycling of industrial effluent requires no equipment of electroosmosis or reverse osmosis membrane, or ion exchange resin, keeps stable operation of the system under a condition of water quality conductivity higher than 2500 muS / cm and does not scale; and an outlet water quality satisfies water quality requirements on recycling water replenishment. Discharge secondary industrial effluent with water quality conductivity lower than 4500 muS / cm can be treated to reach water replenishment requirements of an industrial recycling water system. The method is suitable for chemical effluent, printing and dyeing effluent, spinning effluent and oil refining effluent and has wide water quality scope of application, stable technology operation and high desalting efficiency.

Owner:CHINA PETROLEUM & CHEM CORP

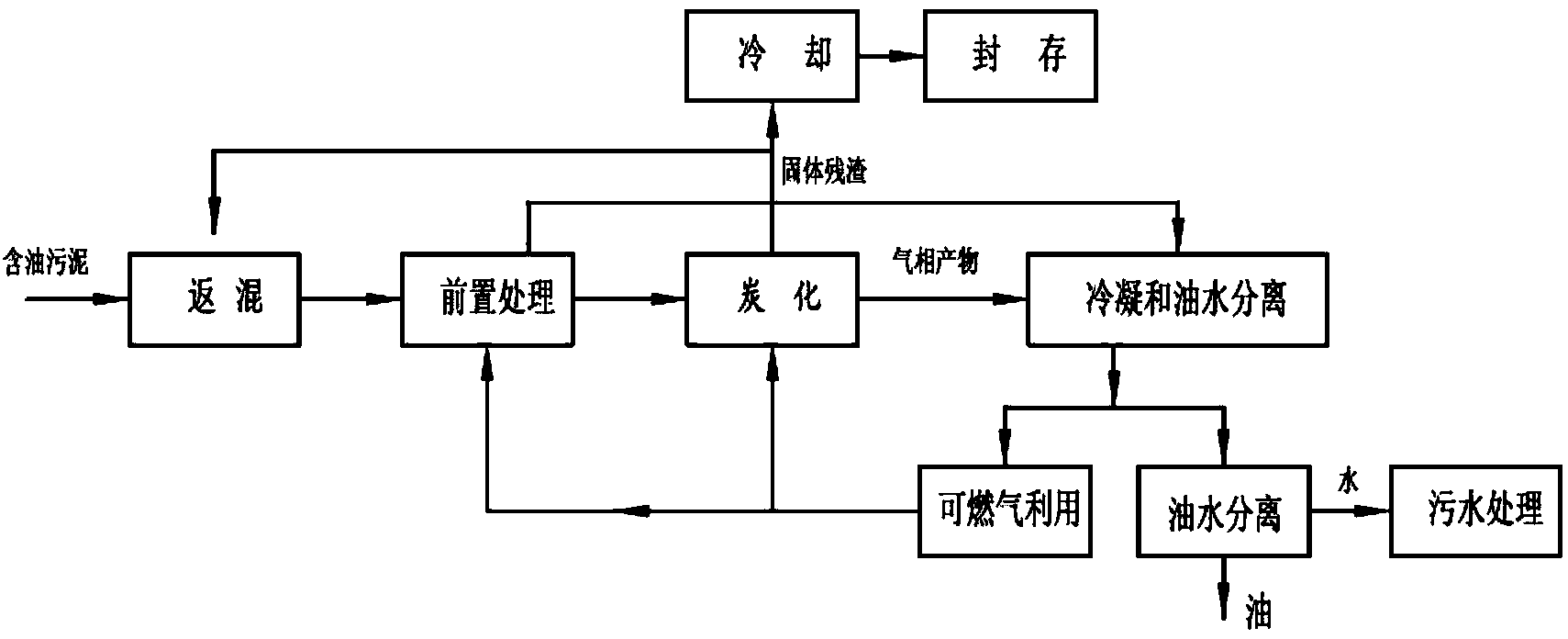

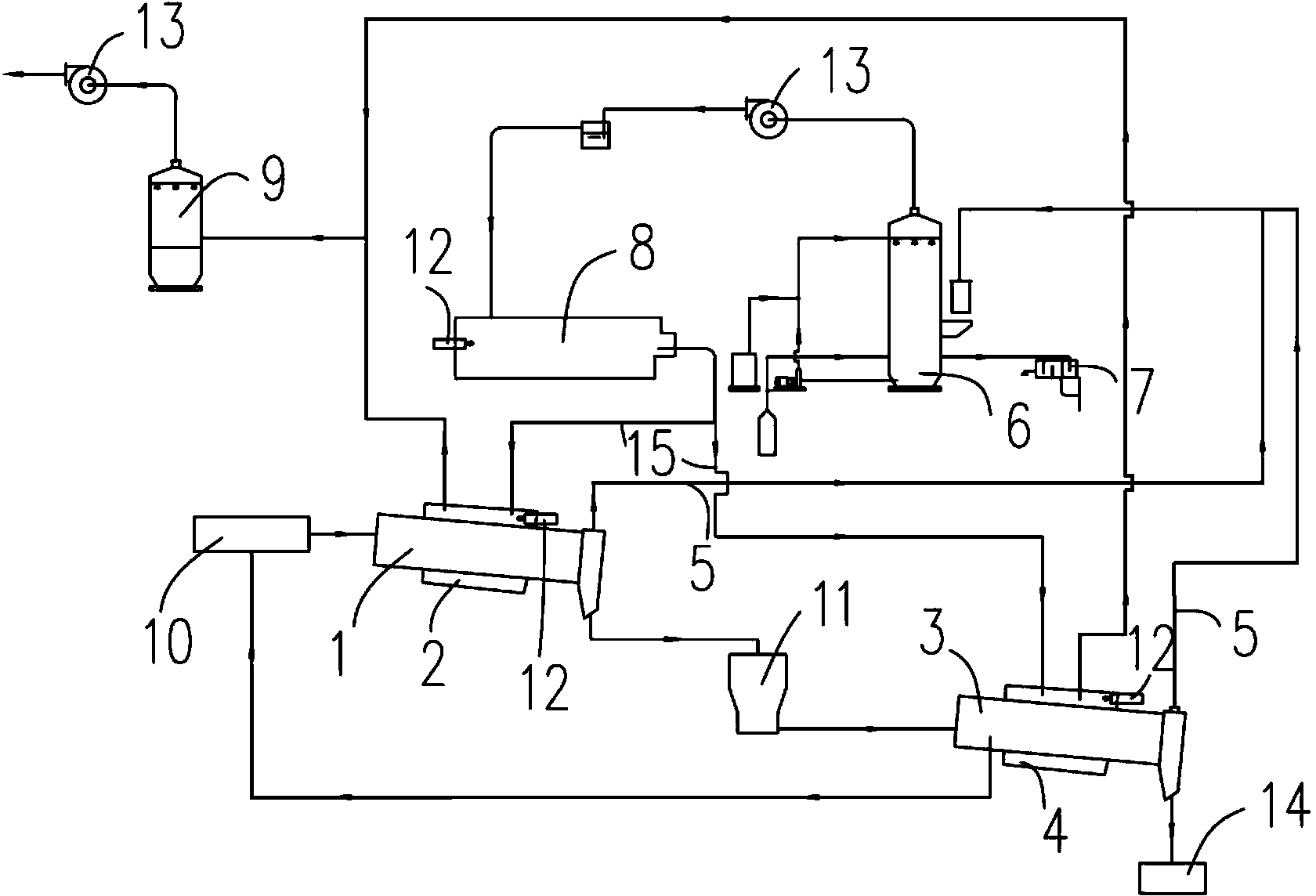

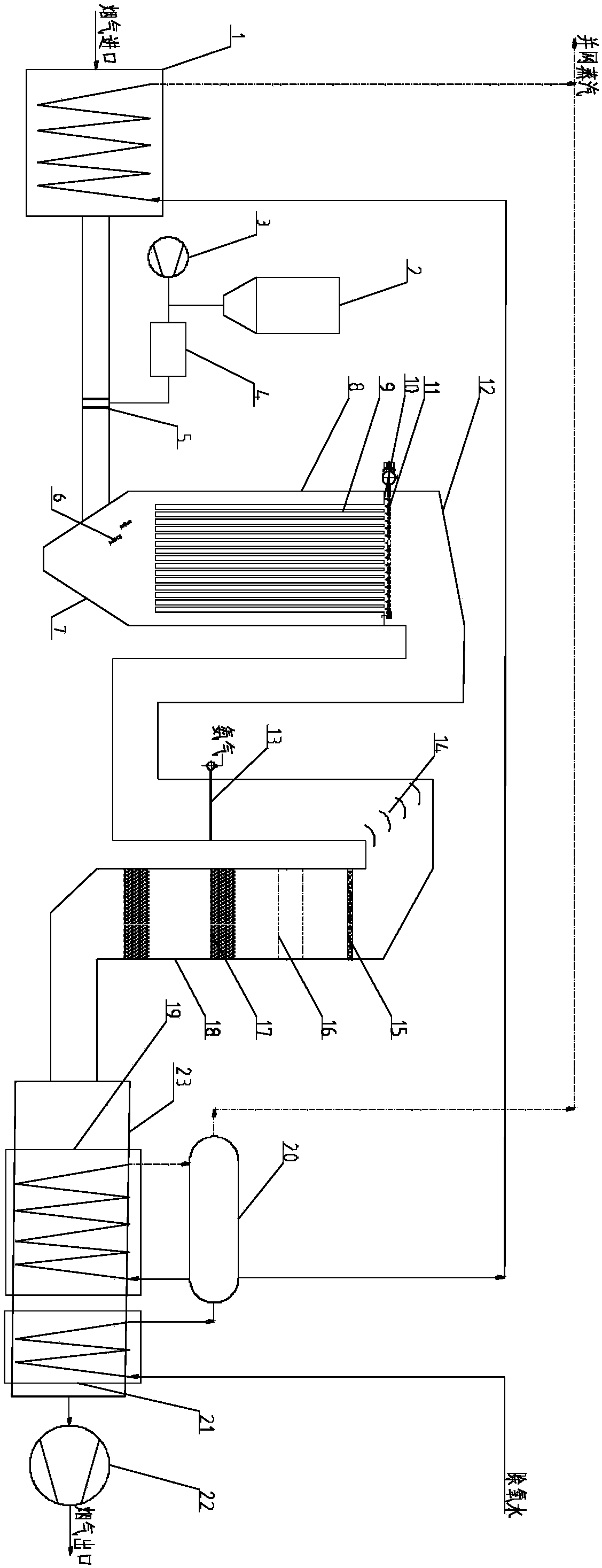

Method and device for refinery sludge carbonization treatment and carbon recovery

ActiveCN103449701AReduce the difficulty of process controlEfficient process operationSludge treatment by thermal conditioningCarbon preparation/purificationSludgeGas phase

The invention relates to a method and device for refinery sludge carbonization treatment and carbon recovery. The method comprises the following steps: pre-treatment: heating oil-containing sludge to 160-180 DEG C in an external heating manner while isolating air, and ensuring that the water content of the oil-containing sludge is controlled at 20% or below; carbonization: carbonizing the oil-containing sludge at 600-650 DEG C for 30-45 minutes, and recovering the solid residue generated by carbonization; condensation and oil-water separation: collecting gas-phase products generated by pre-treatment and carbonization, condensing in a water spray manner to obtain carbonization liquid and non-condensable gas, and performing oil-water separation on the carbonization liquid to obtain carbonization oil; utilization of combustible gas: performing combustion treatment on the non-condensable gas, enabling high temperature generated by combustion to provide heat energy for pre-treatment and carbonization, and performing purification treatment on the tail gas before discharging. The invention also provides a device for realizing the method. According to the invention, the advantages of high oil content recovery rate and stable and reliable process operation are achieved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

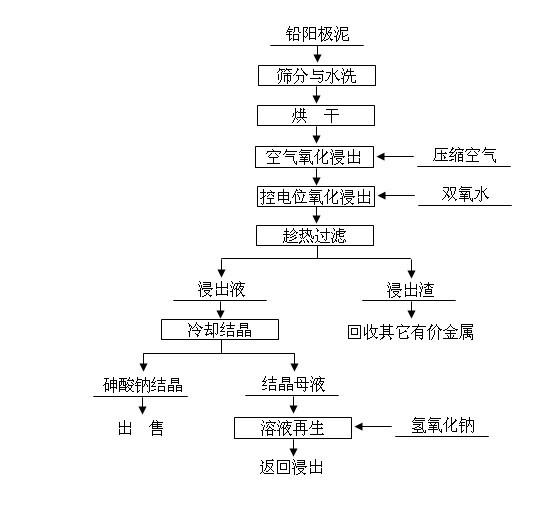

Method for removing and recovering arsenic from lead anode slime

ActiveCN101928838AHigh removal rateAvoid secondary pollutionProcess efficiency improvementArsenic pollutionSodium hydroxide

The invention discloses a method for removing and recovering arsenic from lead anode slime, which comprises the following steps of: performing screening, hot water washing and baking on the lead anode slime, performing oxidation leaching by controlling potential in sodium hydroxide solution, oxidizing the arsenic by using compressed air and hydrogen peroxide as oxidants respectively, adding the oxidized arsenic into alkaline leachate, and ensuring metals such as bismuth, lead, stibium and copper are oxidized and then enter alkaline leaching residue together with noble metals; and after alkaline oxidization leaching process is finished, filtering while hot, performing cooling crystallization on the leachate to generate sodium arsenate crystals, supplementing certain sodium hydroxide to crystallization mother liquor, returning the crystallization mother liquor to the leaching process, and separating and recovering the arsenic and other valuable metals from the lead anode slime. The arsenic leaching rate is over 98.0 percent and the secondary arsenic pollution is free; and the method has the advantages of low requirement on equipment materials, safe operation, low labor intensity, short treatment time and good operating environment.

Owner:YONGZHOU FUJIA NON FERROUS METALS

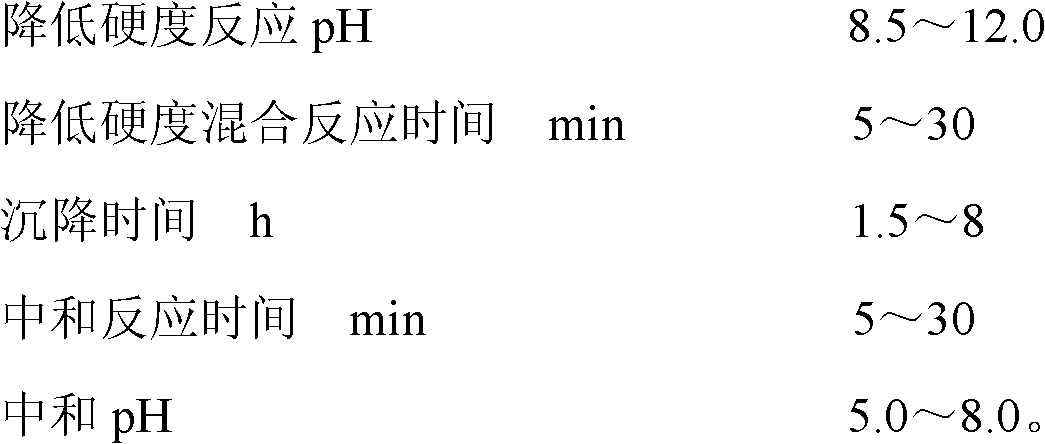

Deep stage treatment method for industrial wastewater

ActiveCN102616962AInfluent water quality requirements are lowReduce energy consumptionDispersed particle separationWater softeningWater qualityReverse osmosis

The invention discloses a deep stage treatment method for industrial wastewater. The method comprises the following steps of: 1, primarily reducing hardness, settling, and neutralizing; 2, filtering; 3, performing electro-adsorption to appropriately remove salt; and 4, performing reverse osmosis to deeply remove salt. According to deep stage treatment method for the industrial wastewater, the water quality application range is wide, a process can run stably, salt can be deeply removed by the method, and a small amount of sewage which is produced by a treatment system and meets the standard is discharged, and secondary pollution is avoided; and the treated industrial wastewater can be used as industrial circulating water, industrial circulating cooling water, and boiler water. The problems that a reverse osmosis membrane is easy to pollute, and reverse osmosis concentrated water which does not meet standard is discharged, and the problem of low running stability are solved; all the discharged sewage which is discharged meets the standard; and the produced water has various water qualities, and the recycling range is widened.

Owner:CHINA PETROLEUM & CHEM CORP

Ozone low-temperature oxidation denitration technology and system

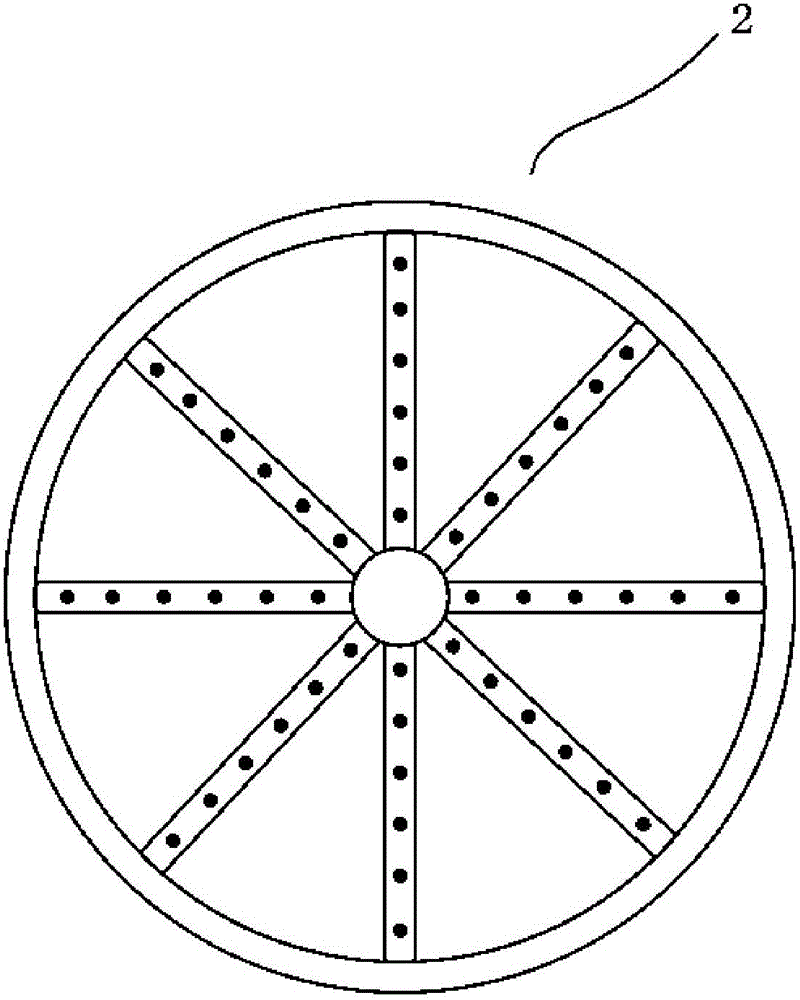

ActiveCN105854554AHigh removal rateCompact layoutGas treatmentDispersed particle separationDistributorPollution

The invention discloses an ozone low-temperature oxidation denitration system which comprises a flue, an ozone generator and a washing tower. The ozone low-temperature oxidation denitration system is characterized in that an ozone distributor is mounted in the flue; the ozone is supplied to an ozone channel of the ozone distributor through a pipeline at an outlet of the ozone generator; the ozone is jetted into the flue by the ozone distributor; the outlet of the flue is connected with the washing tower; the mixture of the ozone and exhaust gas in the flue enters into the washing tower. Compared with the prior art, the ozone low-temperature oxidation denitration system has the beneficial effects that the investment and running cost is lower than that of SCR (Selective Catalytic Reduction) technology; NOx removal rate is high and can reach 95% or more; the technique is simple, the expandability is excellent and the technological operation is simple, stable and reliable; the adaptation of the technical condition is wide; operation at low temperature is carried out and no high-temperature window is required; the system is free from ammonia escape secondary pollution and ammonium sulfate corrosion. The invention also discloses an ozone low-temperature oxidation denitration technology.

Owner:山东普莱斯玛环保设备有限公司

Technique for smelting vanadium iron from calcium vanadate

A production of ferrovanadium concerned with calcium vanadate is carried out by smelting calcium vanadate, Al and ferrous powder at weight ratio of 100: (23-28): (23-27). The said calcium vanadate is selected from m-calcium vanadate, p-calcium vanadate or o-calcium vanadate, one of them at least, with V content of 24-43%. It has high recovery rate and no wastewater pollution.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

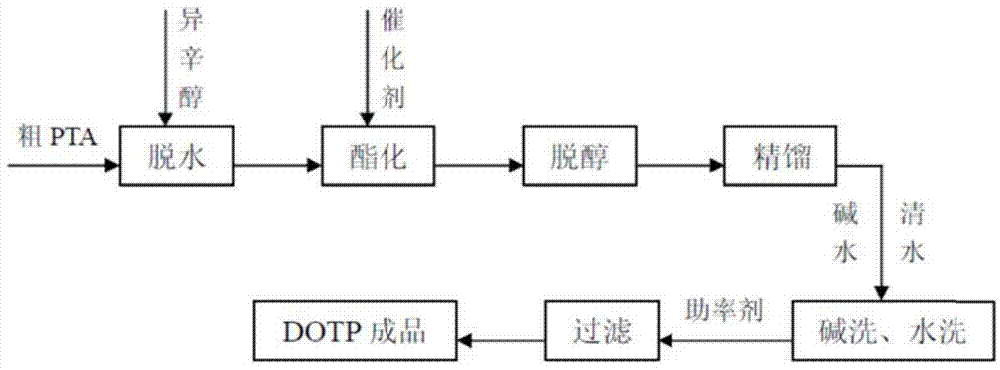

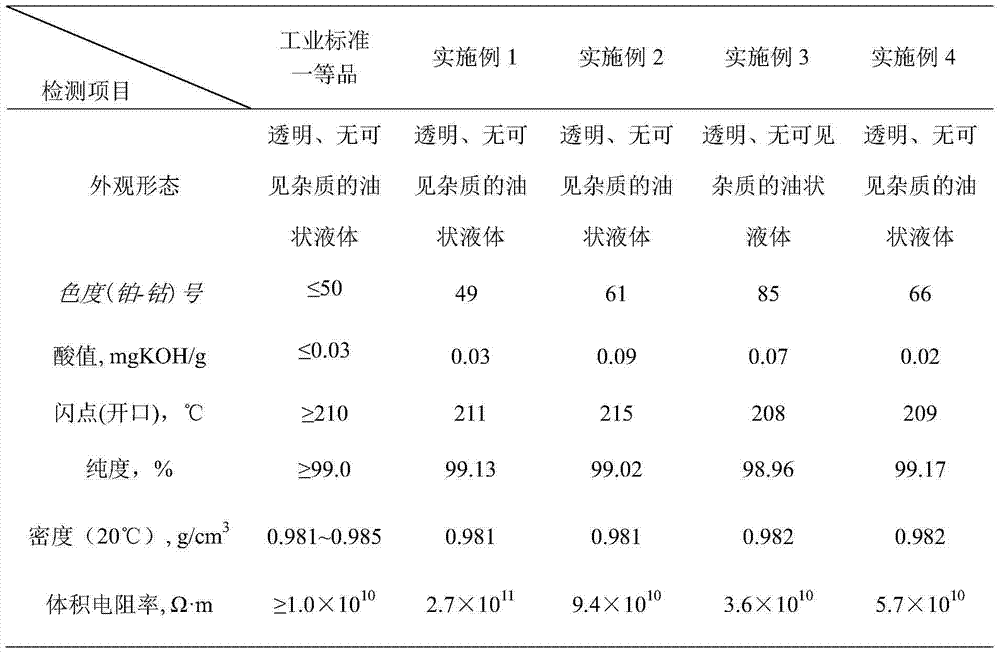

Method for preparing environment-friendly plasticizer by recycling waste resources

ActiveCN104496819AImprove qualityAvoid wastingOrganic compound preparationCarboxylic acid esters preparationFiltrationOctanol

The invention relates to a method for preparing an environment-friendly plasticizer by recycling waste resources. The method comprises the following steps of transferring alkali-reduction wastewater containing sodium terephthalate into an acid precipitation tank with a stirring device and adding sulfuric acid to further precipitate terephthalic acid (PTA) solids; carrying out plate-frame filtration on the mixed solution to obtain a crude PTA material; adding the recovered crude PTA material into an esterification reactor with an alcohol-water separation device, adding iso-octanol, heating and dehydrating, adding tetrabutyl titanate as a catalyst and carrying out esterification reaction; after water is no longer produced, stopping reaction and dealcoholizing to obtain a crude DOTP (Dioctyl Terephthalate) product; rectifying the prepared crude DOTP product in a packing-type rectifying tower to obtain a rectified product, adding the rectified product into a neutralization reaction kettle, adding sodium hydroxide lye, stirring and washing with alkali; standing, precipitating and discharging the aqueous solution in the lower layer, adding hot water, stirring and washing with water, standing, precipitating and discharging the moisture in the lower layer, carrying out temperature-raising dehydration, adding an inorganic filter aid and filtering to obtain the pure DOTP product. By the method, the recycling of the waste resources is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

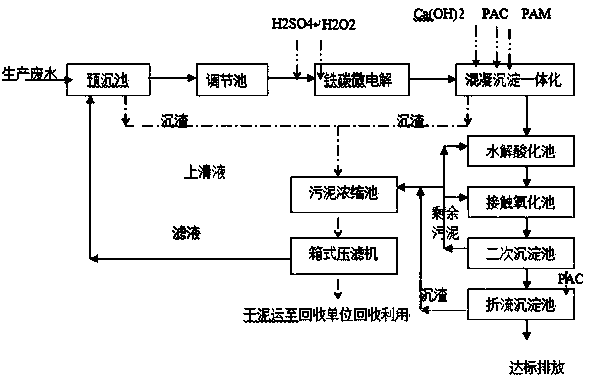

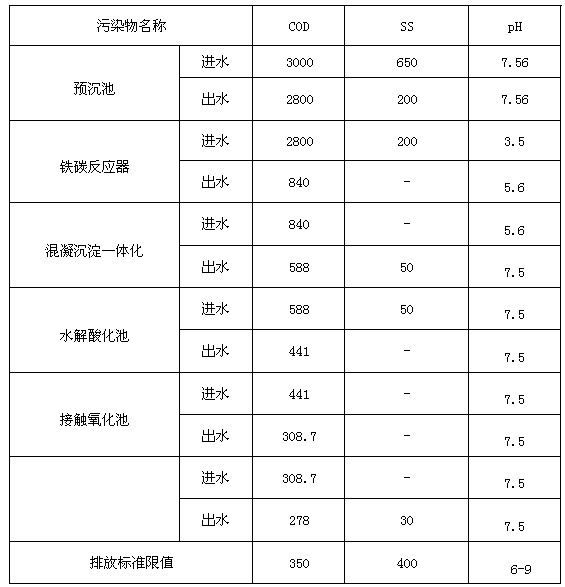

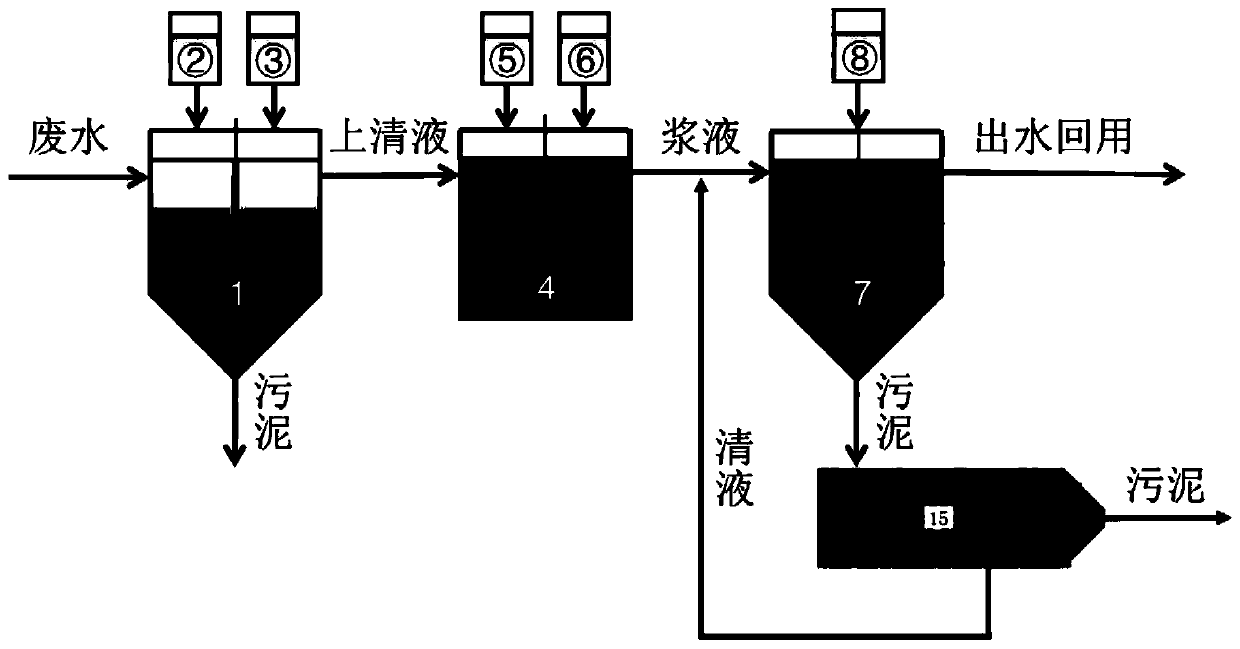

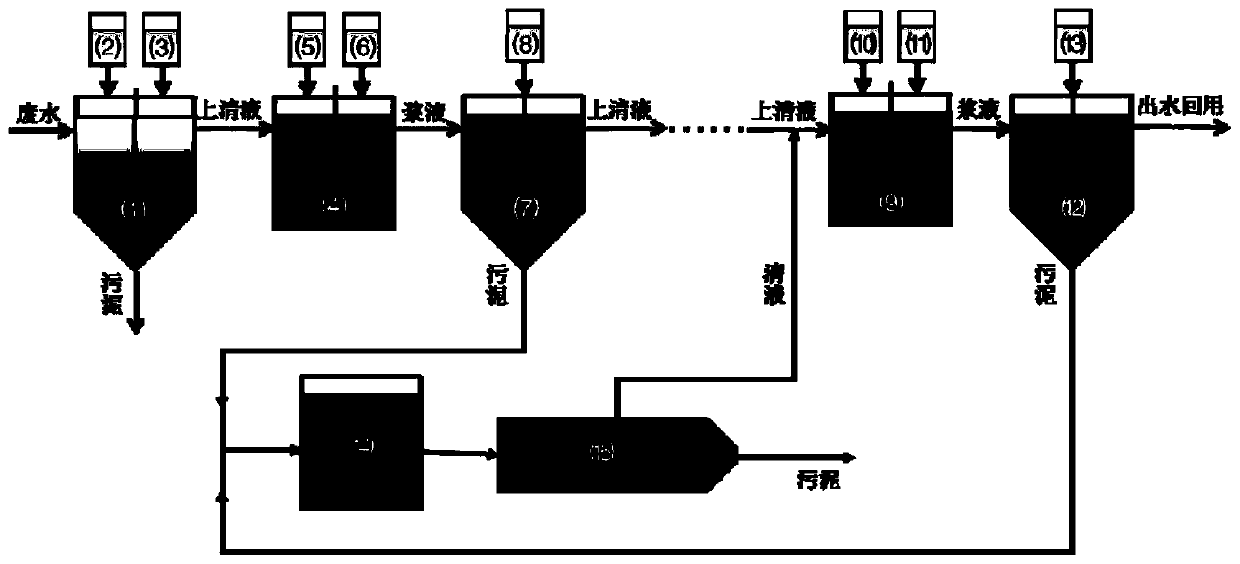

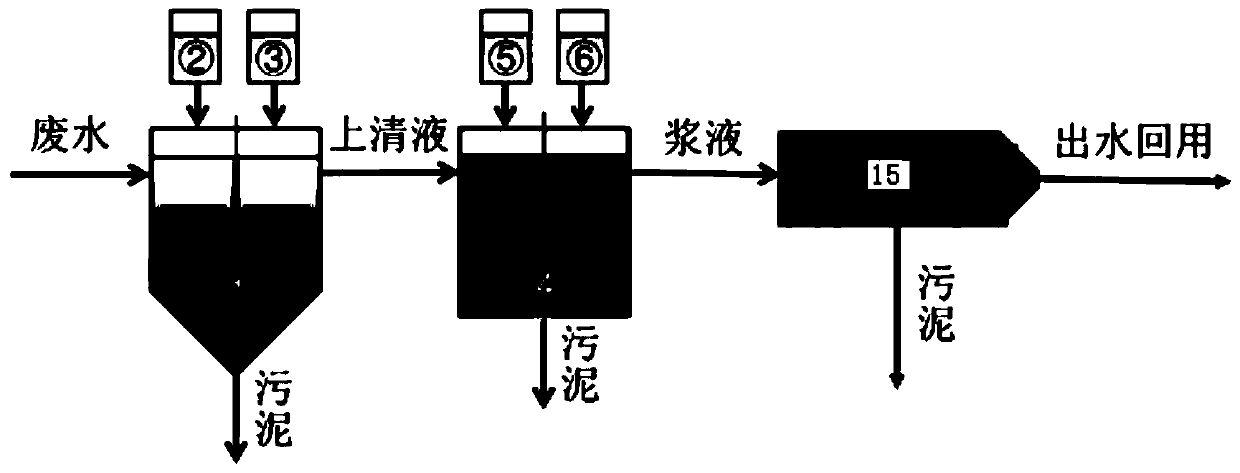

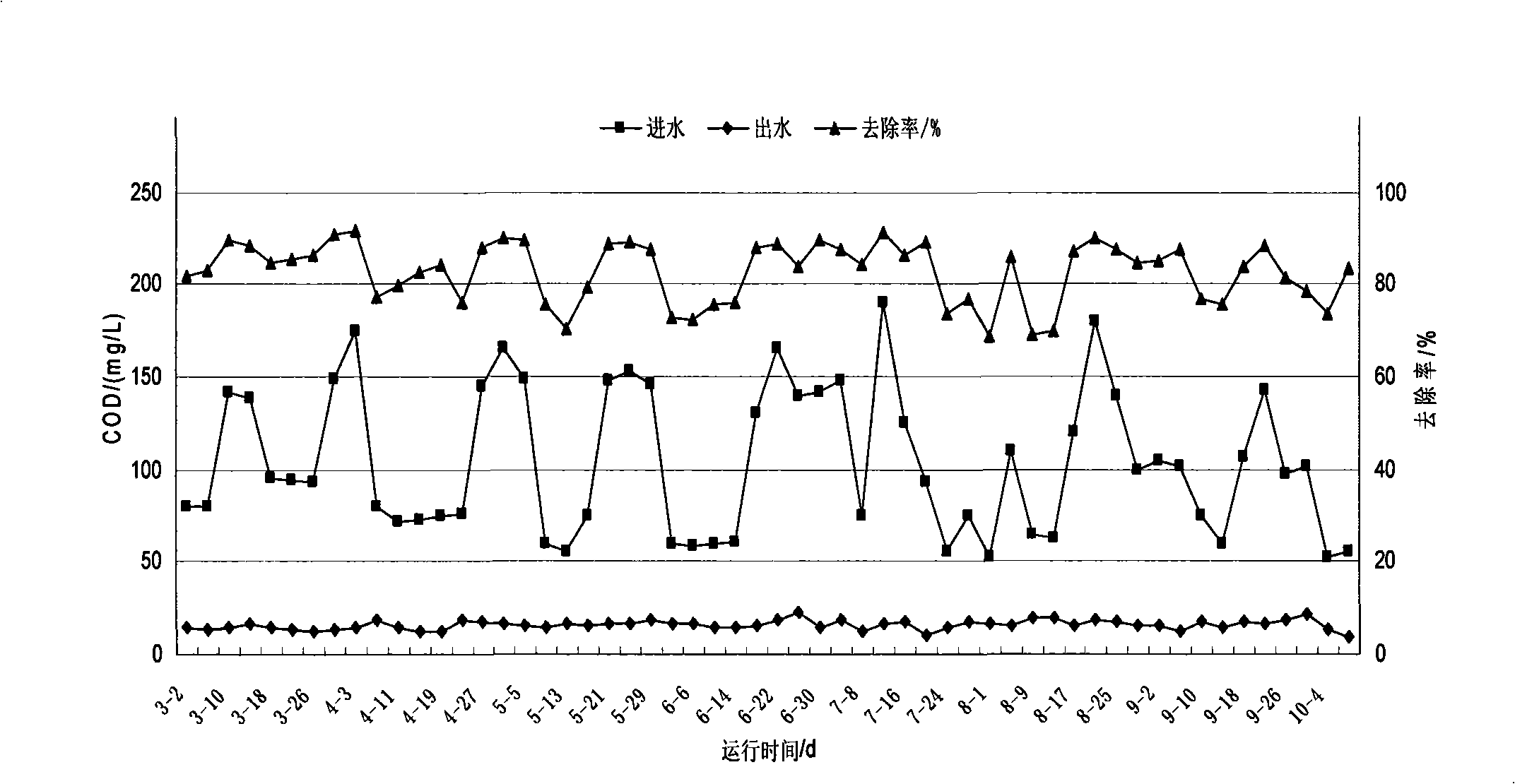

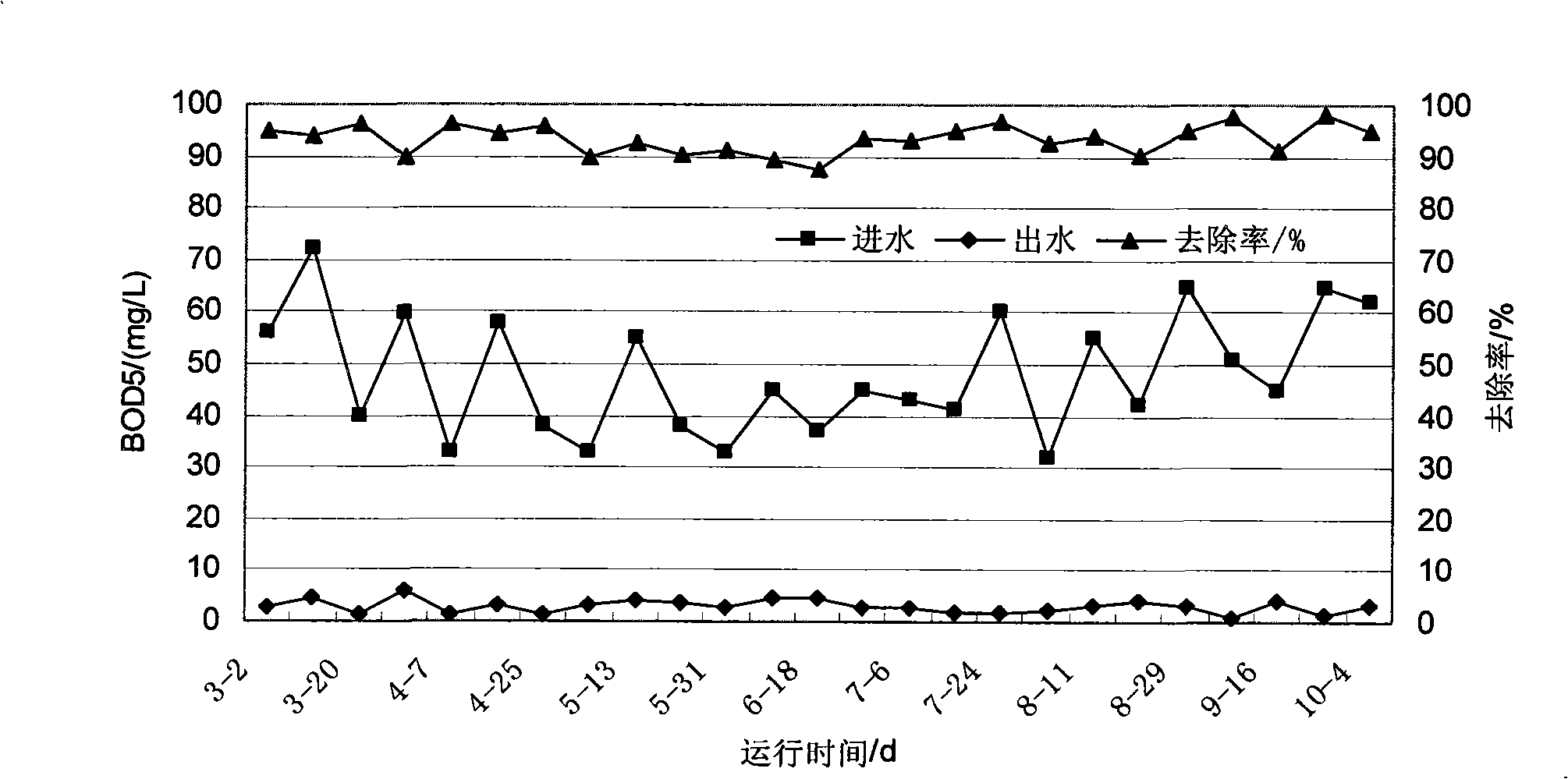

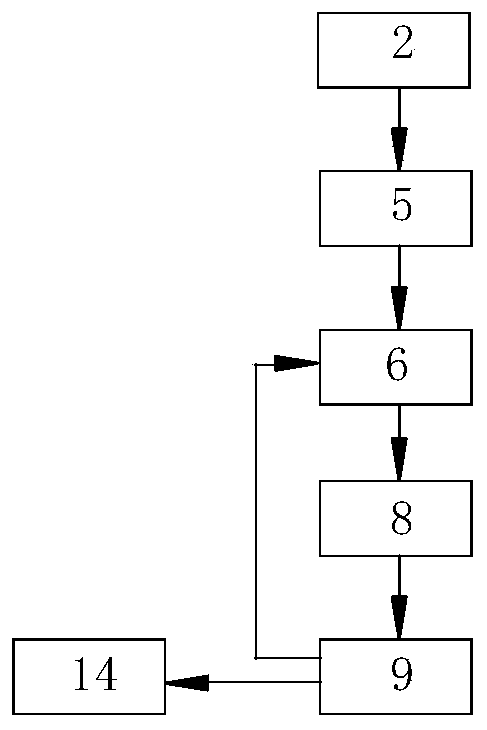

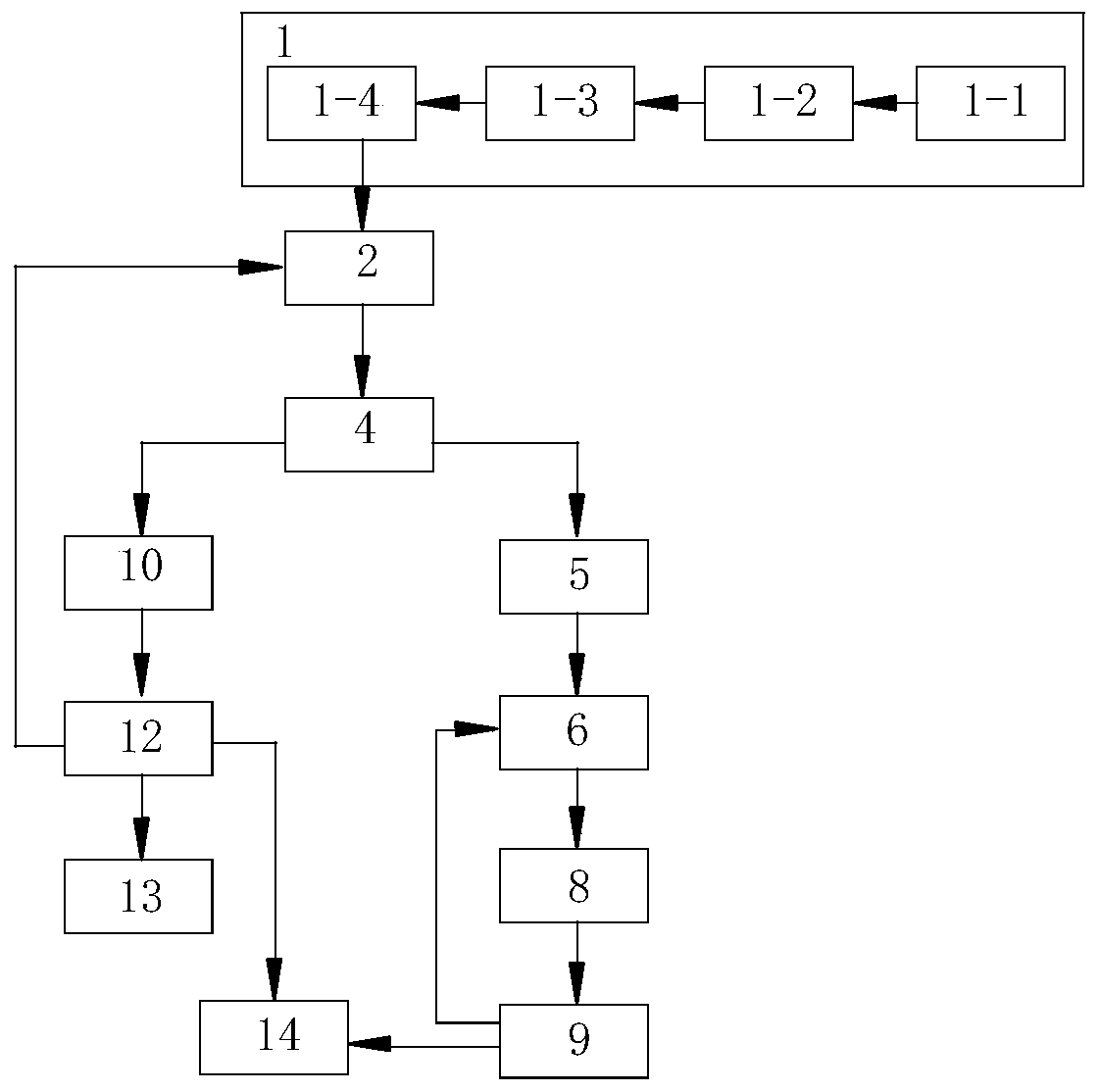

Process for treating wastewater generated in solar silicon wafer production process

InactiveCN103466885ARapid responseEase of conditionsGeneral water supply conservationEnergy based wastewater treatmentAluminium chlorideChemical oxygen demand

The invention discloses a process for treating wastewater generated in a solar silicon wafer production process and relates to wastewater treatment in the field of the electronic semiconductor industry. The process comprises the following steps of: pretreating wastewater in a preliminary sedimentation tank; carrying out Fenton and iron-carbon micro-electrolysis combined oxidization reaction on the wastewater in an iron-carbon micro-electrolysis reactor; after the reaction, feeding the wastewater into a coagulation-sedimentation integrated pool, feeding PAC (Poly Aluminium Chloride) and PAM (Poly Acryl Amide) to arouse the coagu-flocculation reaction of the wastewater, and after the reaction, performing sludge-water separation on the wastewater; causing the supernate to flow to a hydrolysis acidification pool, and then causing the wastewater to flow to a contact oxidation tank; causing the mixed liquid to flow to a secondary sedimentation tank for sludge-water separation, while causing the supernate to flow to a deflection sedimentation pool, and feeding PAC for purifying water so that the supernate is up to the stand and can be discharged after sedimentation; finally, performing concentration treatment on sludge. After non-degradable organic wastewater is treated by the process provided by the invention, the BOD5 (Biological Oxygen Demand) / CODcr (Chemical Oxygen Demand) ratio of the wastewater is obviously increased.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

Precipitating and desalting high-salt wastewater recycling process

PendingCN110668540AAchieving zero emissionsEfficient removalWater contaminantsWater/sewage treatment by flocculation/precipitationSulfate radicalsDivalent metal

The invention relates to a high-salt wastewater precipitation desalting recycling process, which is a two-stage process and comprises the following steps: a first stage: removing sulfur by a calcium sulfate method, to be more specific, synchronously removing sulfate radicals and divalent metal salts by adding lime to a calcium sulfate method sulfur removal unit; and a second stage: performing deepsulfur removal and chlorine removal, to be more specific, simultaneously deeply removing the sulfate radicals and chloride ions by adding lime and aluminum salt in a deep sulfur removal and chlorineremoval unit. Compared with the prior art, the multi-stage precipitation desalting process provided by the invention considers the problem of efficient sludge dewatering while treating sewage, improves the removal efficiency and reduces the treatment cost.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

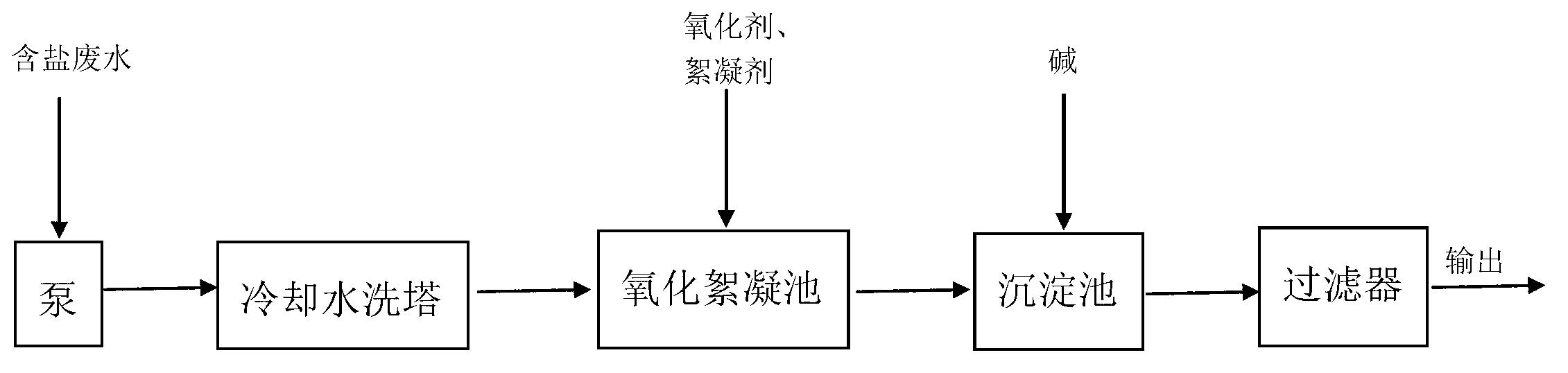

Treatment method for salt-containing wastewater

ActiveCN103288236AReduce hardnessReduce turbidityMultistage water/sewage treatmentChemical oxygen demandTurbidity

The invention relates to a treatment device and a treatment method for salt-containing wastewater. The treatment device comprises a pump, a cooling and water-washing tower, an oxidation and flocculation pool, a precipitation pool, and a filter, wherein the salt-containing wastewater enters in the cooling and water-washing tower of a wet-method flue gas desulfurization device and adequately contacts with sulphur dioxide-containing flue gas to react at first, and then is subjected to the subsequent treatments of oxidation, flocculation, neutralization, precipitation, filter and the like; the treated wastewater can be used as replenishing water for circulation water or be discharged up to the standards. Compared with the prior art, the method disclosed by the invention is wider in sewage application range, as well as capable of effectively reducing the hardness, COD (chemical oxygen demand) and turbidity of the salt-containing wastewater, reducing industrial water, increasing the utilization rate of the industrial water, and achieving the effects of saving water and reducing discharge.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

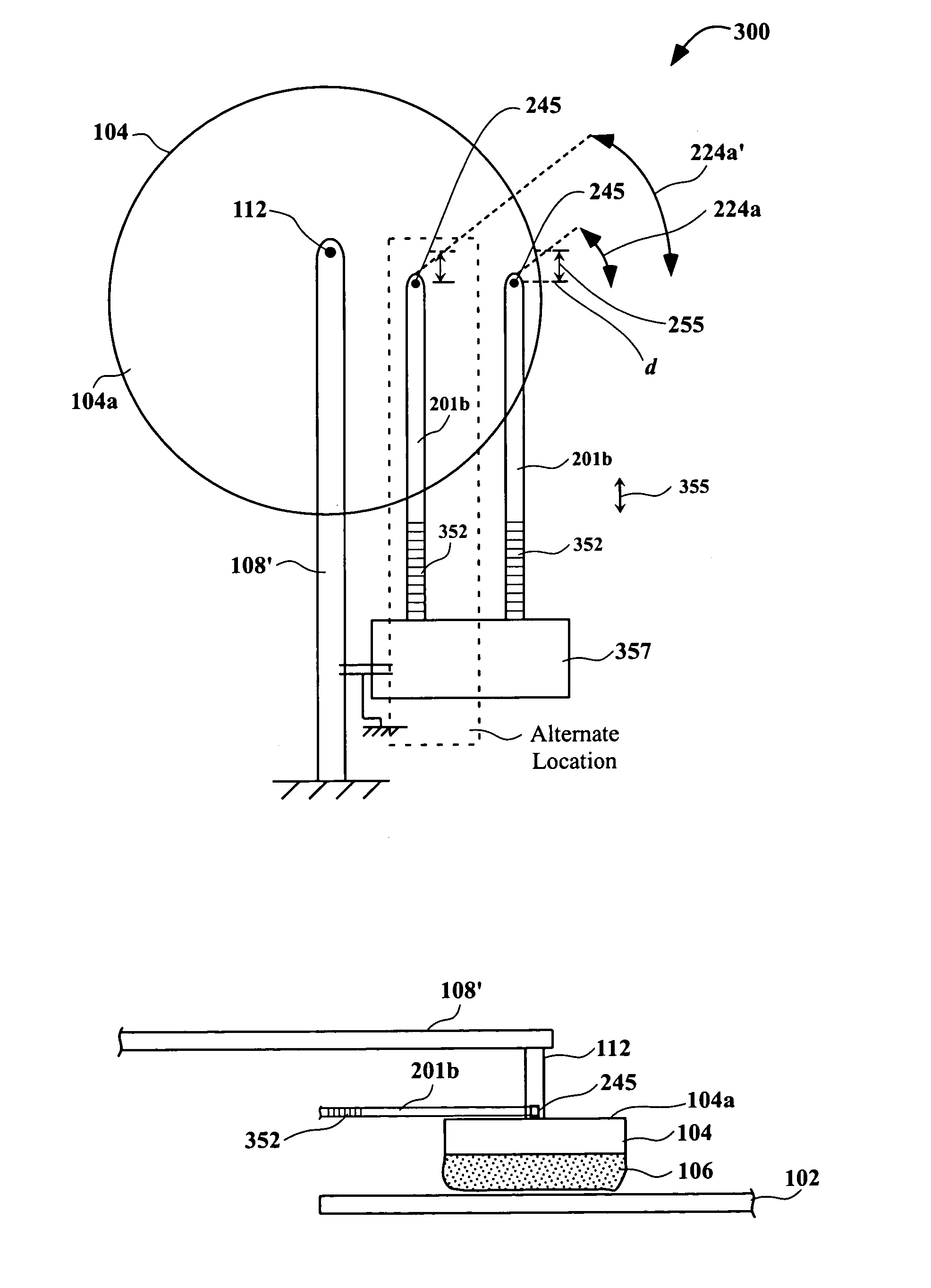

Apparatus for oscillating a head and methods for implementing the same

InactiveUS7170190B1Improve efficiencyImproving local mass transportEdge grinding machinesPolishing machinesEngineeringAngle of rotation

An apparatus for brushing a surface of a substrate is provided. The apparatus includes a brush for scrubbing the surface of the substrate, a head for holding the brush, and an arm. The arm is configured to hold the head about a connection point. The arm is connected to an oscillating mechanism configured to cause the head to oscillate at an angle of rotation about the connection point.

Owner:LAM RES CORP

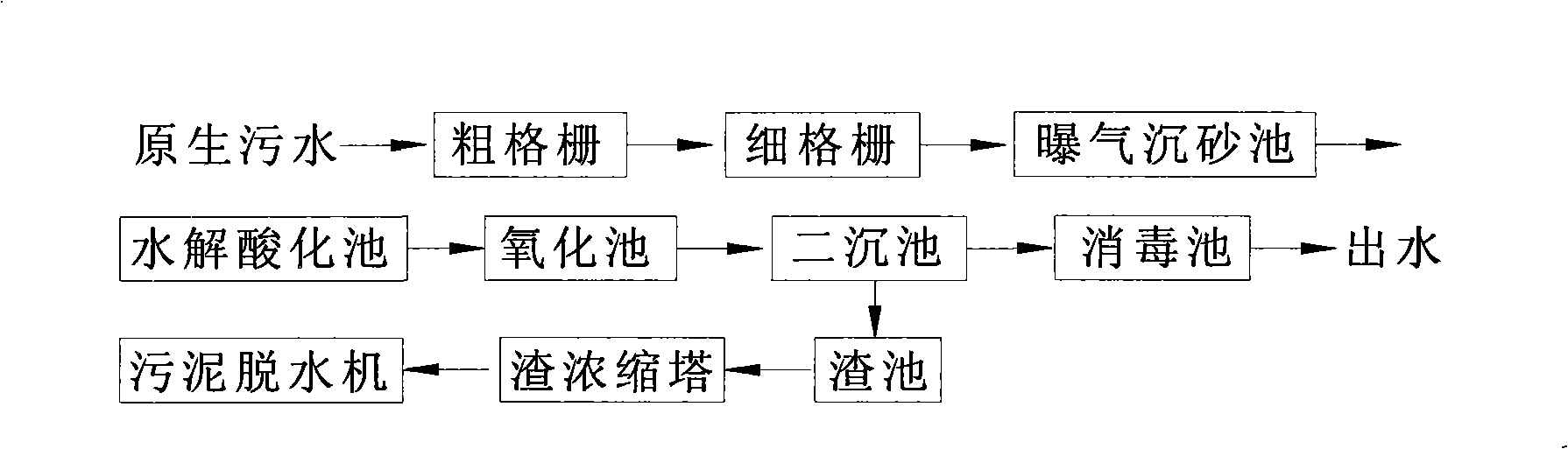

Treatment system for wastewater without sewage sludge

InactiveCN101402504AImprove processing efficiencyEasy to handleMultistage water/sewage treatmentSustainable biological treatmentWater treatment systemSlag

The invention relates to a wastewater and sludge treatment technique, which particularly provides a sludge and wastewater free treatment system. The system comprises grilles, an aerated grit chamber, a hydrolysis acidification pond, an oxidation pond and a secondary sedimentation pond which are orderly connected, and the system also comprises a disinfection pond, a slag pond, a slag concentration tower and a sludge dewatering machine. When the system is operated, the wastewater passes through wide and narrow grilles to remove large impurities and enters the aerated grit chamber for sedimentation treatment, the discharged water enters the hydrolysis acidification pond; by a sludge bed in the hydrolysis acidification pond, the wastewater and reflux slag sludge are captured and the slag sludge is decomposed; the wastewater after the sedimentation treatment passes through a fixed type biological bed in the oxidation pond for biological treatment, the discharged water enters the secondary sedimentation pond for slag sedimentation, the discharged water after the slag sedimentation enters the disinfection pond for disinfection treatment, the water after the disinfection treatment can be discharged or reutilized, and the sedimentation slag is sent to the slag pond, and is concentrated by the slag concentration tower and is sent to the sludge dewatering machine for dewatering treatment. The sludge and wastewater free treatment system has the advantages of low equipment investment, low operating cost and good effect of wastewater treatment.

Owner:李波

Glyphosate-producing wastewater treatment integration technology

InactiveCN104609665ATo achieve the purpose of precipitation removalPrevent subsidenceMultistage water/sewage treatmentNature of treatment waterTreatment effectElectrolysis

The invention discloses a gyphosate-producing wastewater treatment integration technology. The technology comprises steps as follows: micro-electrolysis treatment is performed under the aeration condition, toxic and degradation-resistant organic matters in wastewater are oxidized by a Fenton regent comprising hydrogen peroxide and ferrous ions which are by-products produced by ferric carbon filler, after lime is added to effluent and pH is regulated to 8-9, a flocculating agent is added for precipitation, suspended matters and iron-phosphorus precipitates are removed, effluent after precipitation is sent to an upflow anaerobic reactor, and degradation-resistant and toxic organic matters in wastewater are further degraded, removed and transformed, the effluent enters a multi-stage contact oxidation pond and a primary aeration sedimentation tank for biochemical treatment, the treated wastewater is emitted up to standard, and the organic matter removal rate in a pretreatment combination physicochemical technology can be up to 50%. The technology is stable in operation and good in treatment effect, the treatment cost is reduced, and the treated effluent can meet the integrated wastewater discharge standard (GB-8978-1996).

Owner:四川省生态环境科学研究院 +2

Synergistic gas-liquid-solid pollutant treatment system based on power plant wastewater zero-discharge technology

InactiveCN105967420AImprove economyImprove operational efficiencyElectrostatic separationDispersed particle separationDevice failureEconomizer

The invention provides a synergistic gas-liquid-solid pollutant treatment system based on a power plant wastewater zero-discharge technology and belongs to the technical field of coal-fired boiler pollutant control. The synergistic gas-liquid-solid pollutant treatment system includes a desulfurized wastewater zero-discharge treatment system, an SNCR + SCR united denitration system and a high-temperature electric dust removal system, wherein the desulfurized wastewater zero-discharge treatment system performs desulfurized wastewater pretreatment and pre-concentration, the SNCR + SCR united denitration system absorbs dissolved ammonia or urea of the treated desulfurized wastewater, uses the dissolved ammonia or urea as a reducing agent to be sprayed into an outlet of a boiler and a flue behind a coal economizer to complete denitration reaction, and the high-temperature electric dust removal system is arranged behind the coal economizer to collect and remove evaporated crystal substances of the wastewater. The synergistic gas-liquid-solid pollutant treatment system has excellent properties, is stable in process operation, achieves zero discharge of wastewater while achieving synergistic and coupled gas-liquid-solid pollutant treatment, reduces equipment investment by 10%-50% and the operation costs by 75%-90%, greatly reduces the equipment failure rate and maintains the working amount.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

Method for extracting capsicum red pigment and capsaicin

InactiveCN102516802AHigh yieldReduce consumptionCarboxylic acid amide separation/purificationNatural dyesSolventChemistry

The invention discloses a method for extracting capsicum red pigment and capsaicin, comprising the following steps of: extracting capsicum particles in a case chain type extractor by the use of a mixed solvent of hexane and acetone; allowing the extracted capsicum residue to enter into a vertical faceplate evapo-separated machine for desolvation; allowing the extracted mixed solvent containing capsicum red pigment and capsaicin to enter into a filtration and evaporation system to obtain a mixture of capsicum red pigment and capsaicin; and allowing the mixed solvent which has undergone condensation recovery to enter into a separator for separation. By the adoption of the method, the yield of capsicum red pigment is raised, capsaicin is fully extracted and the extraction effect is good; desolvation is thorough and there is no agglomeration and obstruction phenomenon; a negative pressure technology is adopted to reduce steam consumption, the yield of capsicum red pigment and capsaicin is increased, and the process operation is stable.

Owner:山东凯斯达机械制造有限公司

Coke oven flue gas multi-pollutant dry purification device and process

InactiveCN107854997AAvoid waste heat to maximize utilizationGuaranteed safe operationDispersed particle separationSteam generation using hot heat carriersPtru catalystFlue gas

The invention relates to a coke oven flue gas multi-pollutant dry purification device. The device consists of an evaporator I, a desulfurizer adding apparatus, a cloth bag dust collector, and a mediumand low temperature SCR denitration reactor. The evaporator I is a heat pipe type evaporator, the desulfurizer adding apparatus is connected to a desulfurizer grinding and conveying system, and the desulfurizer grinding and conveying system consists of a desulfurizer powder bin, a Roots blower and a desulfurizer pulverizer. The cloth bag dust collector includes a filter bag chamber, the filter bag chamber includes a dust remover ash hopper, a dust remover middle box and a purified air chamber that are disposed from the bottom up in order, the dust remover middle box is internally equipped with a tubesheet, a filter bag is disposed on the tubesheet, and a pulse dust-cleaning apparatus is disposed above the filter bag. An air outlet of the cloth bag dust collector is connected to an air inlet of the medium and low temperature SCR denitration reactor, an air inlet pipeline of the medium and low temperature SCR denitration reactor is internally equipped with an ammonia injection grid anda guide plate II, and a flue gas current equalizer, a catalyst reservation layer and a catalyst layer are disposed below the guide plate II in order.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

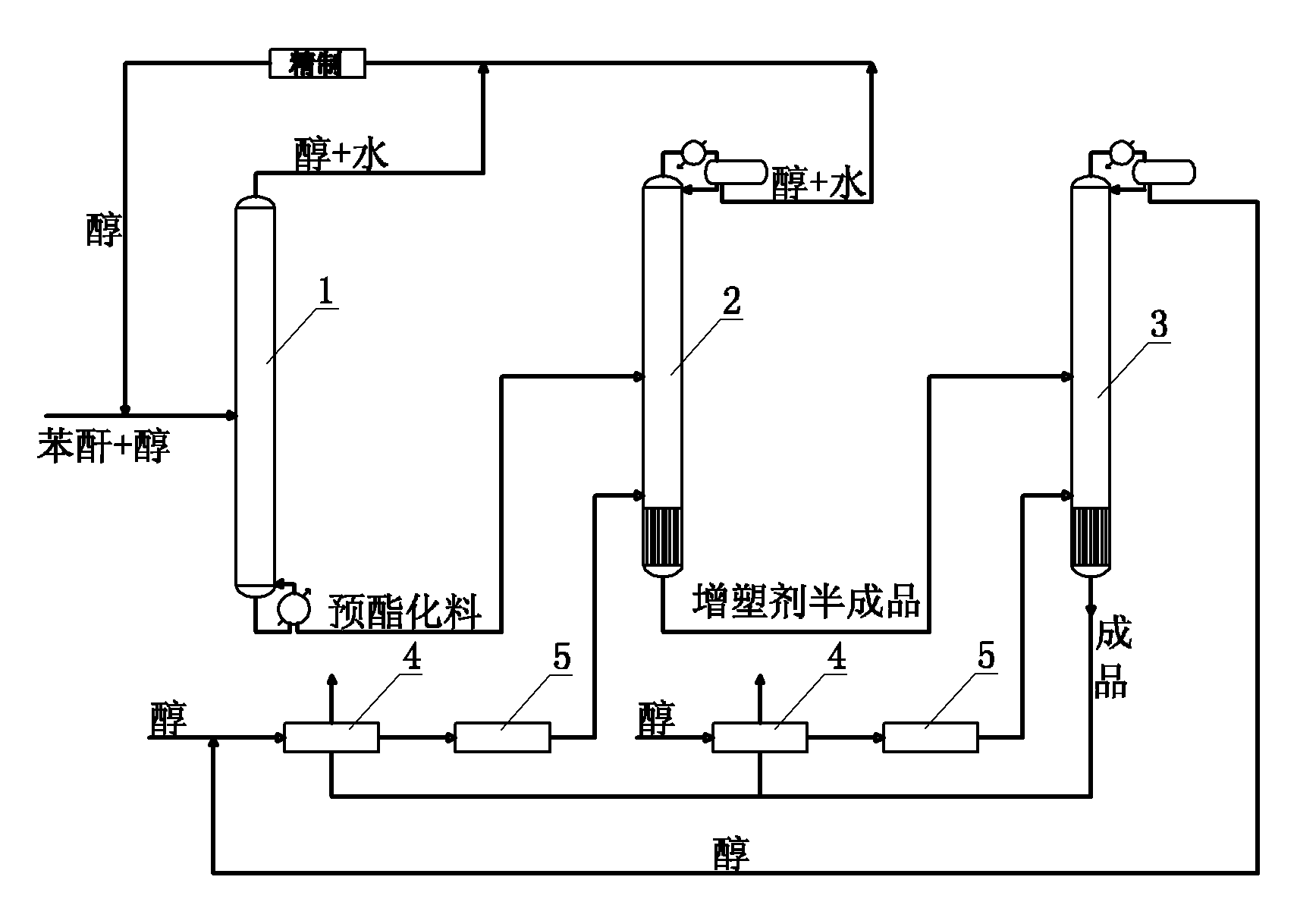

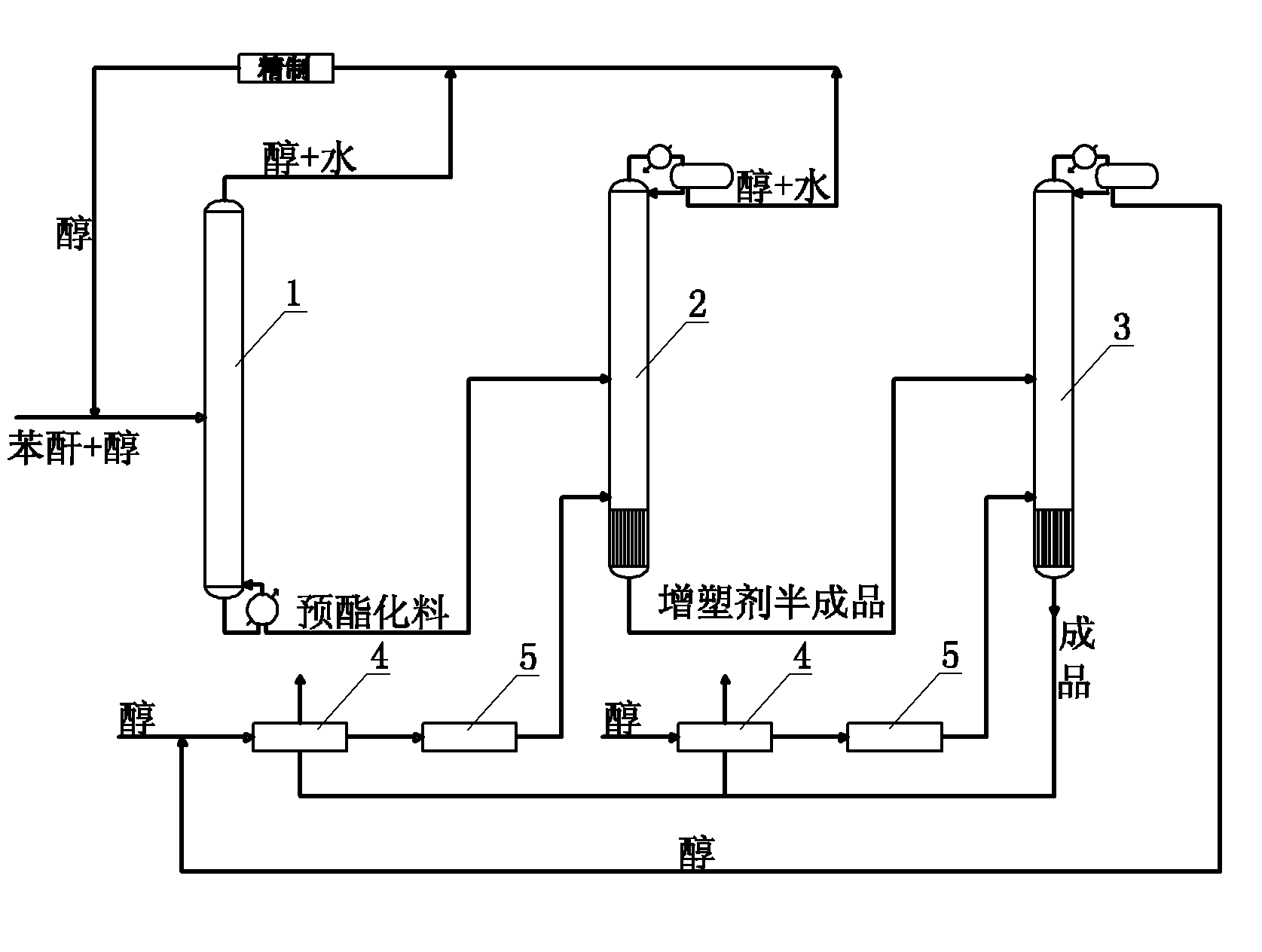

Continuous esterification production method for plasticizer

InactiveCN102503831AImprove conversion rateHigh conversion rate, product purityOrganic compound preparationCarboxylic acid esters preparationPtru catalystAlcohol

The invention discloses a continuous esterification production method for a plasticizer. The method comprises the following steps of: mixing phthalic anhydride and an alcohol raw material according to the molar ratio of 1:(2.5-3.0), removing water at the temperature of between 150 and 180 DEG C, and thus obtaining a pre-esterification material; heating the alcohol raw material to obtain overheating alcohol gas; and allowing the pre-esterification material to continuously pass through at least two continuous esterification reactors which are connected in series with each other and are provided with catalyst reaction beds, continuously introducing the overheating alcohol gas into the continuous esterification reactors, and taking the plasticizer out of the bottom of the continuous esterification reactor at the tail end continuously. By the continuous esterification production method for the plasticizer, production time is greatly shortened, production efficiency is improved, a large quantity of labor power and material resources are saved, the conversion efficiency of raw materials is improved, the purity of a product is improved, energy consumption is reduced, and the raw materials are saved; and the method is environment-friendly.

Owner:WEIFANG YUANLI CHEM

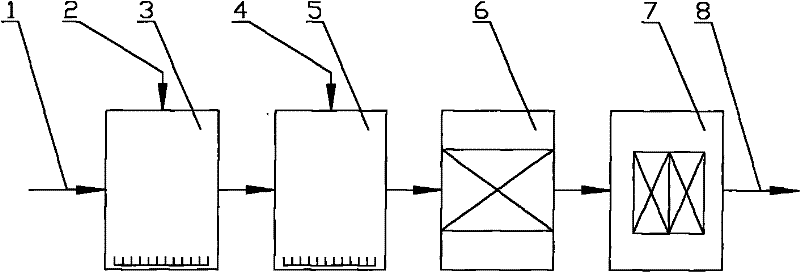

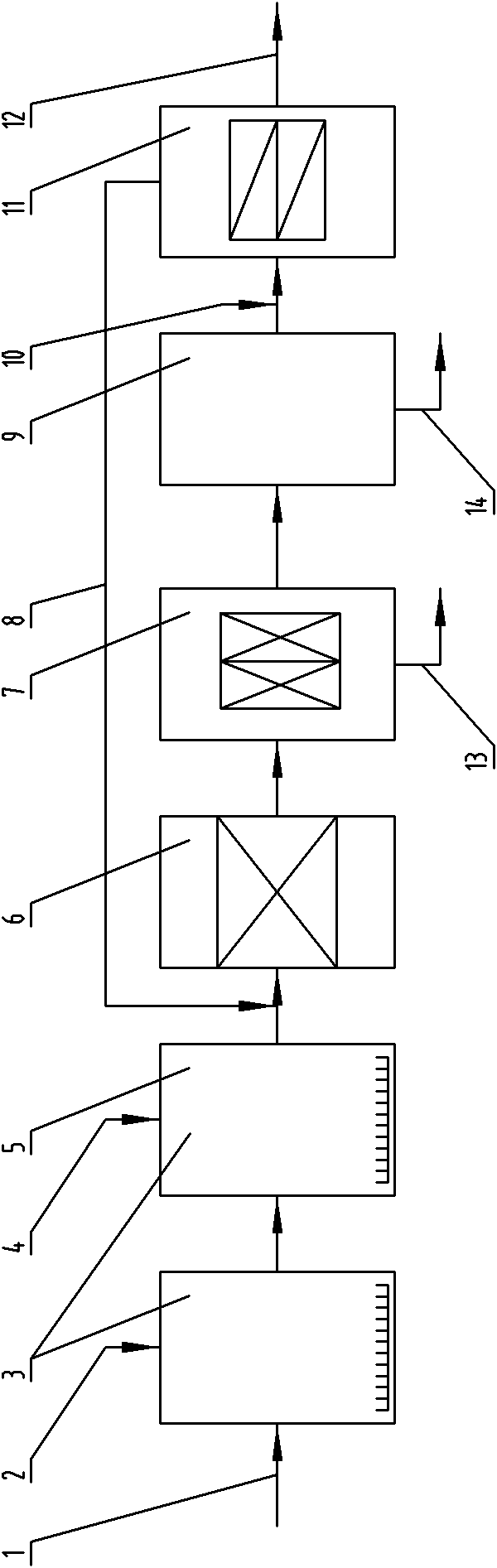

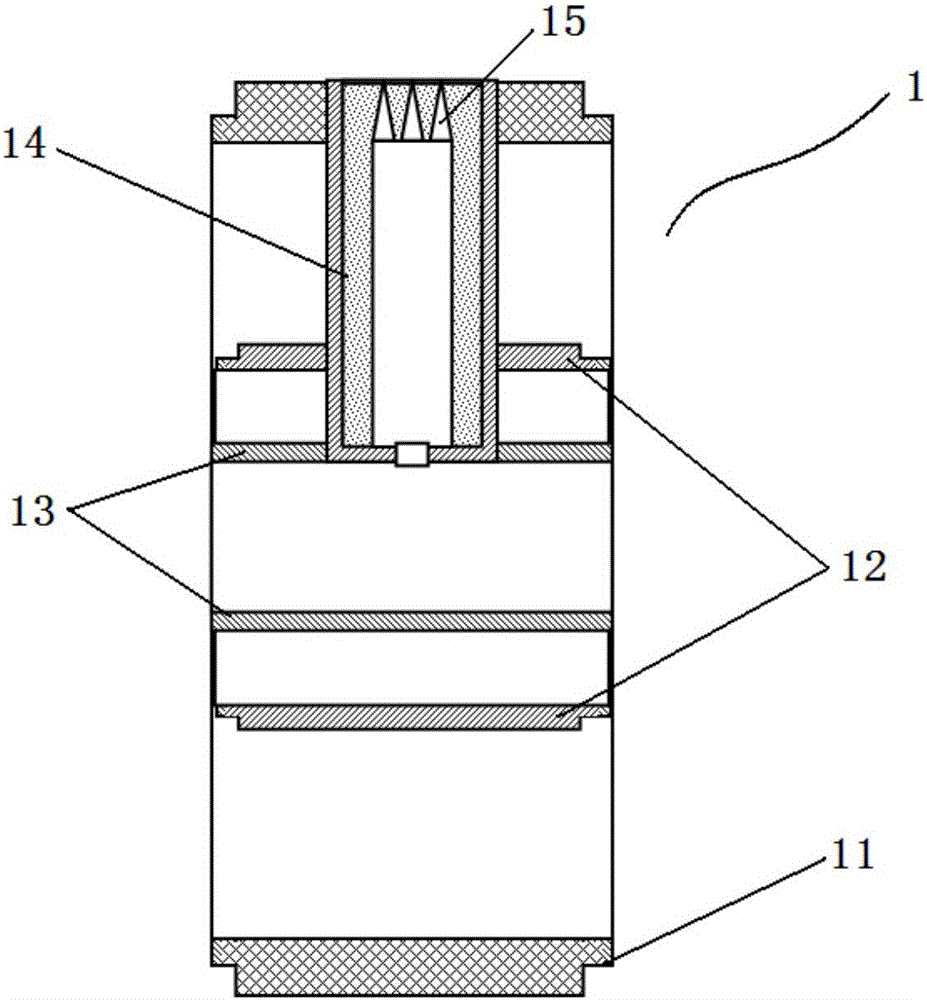

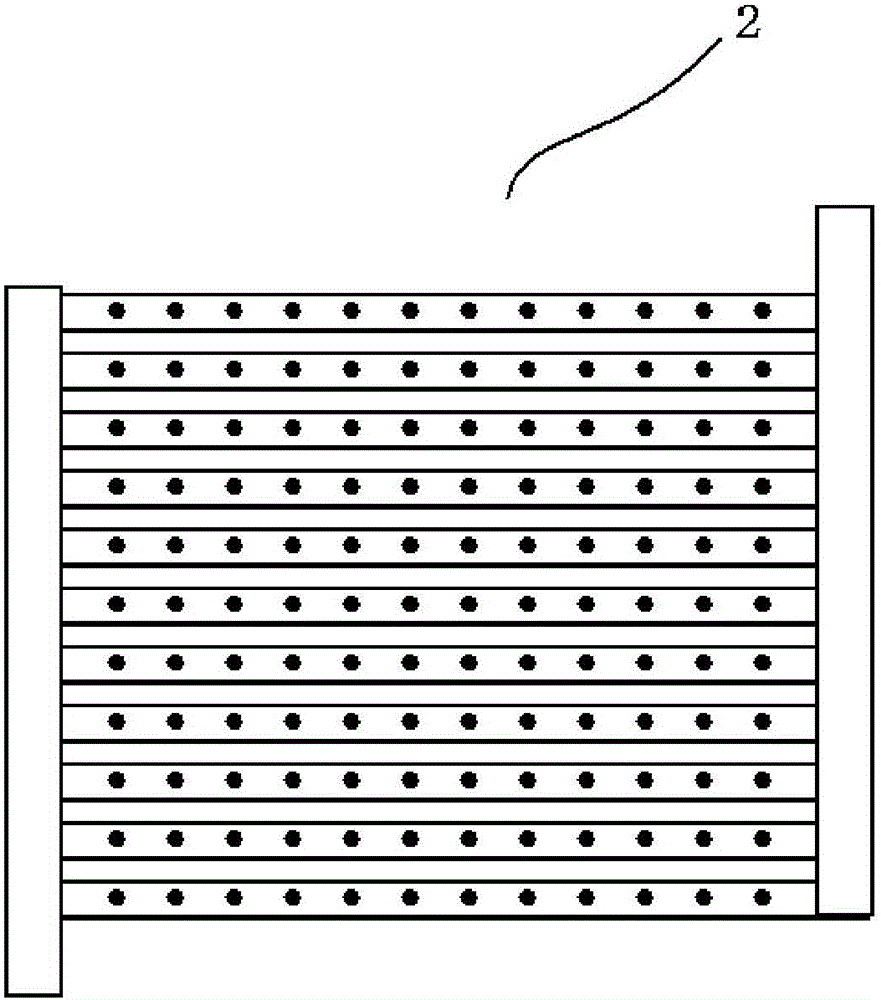

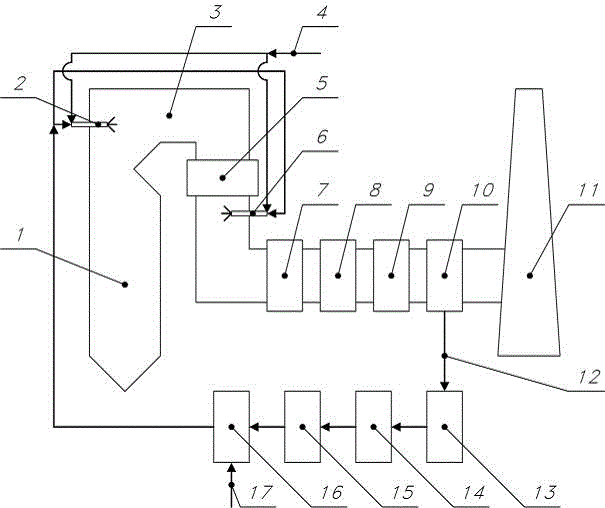

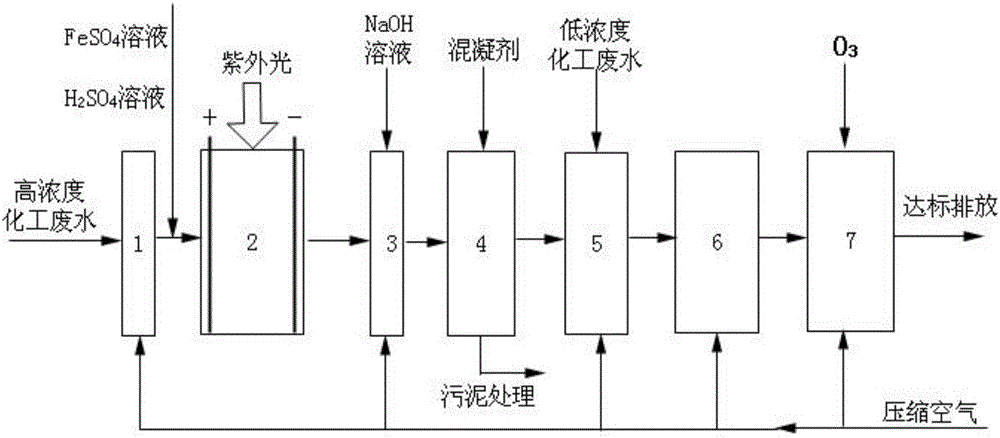

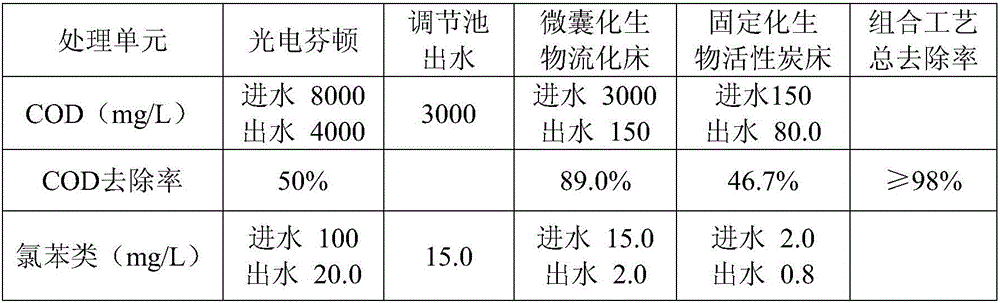

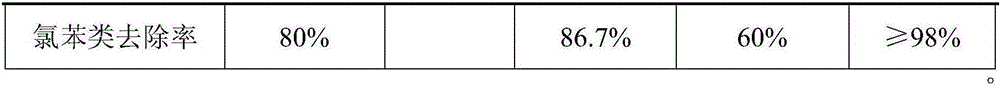

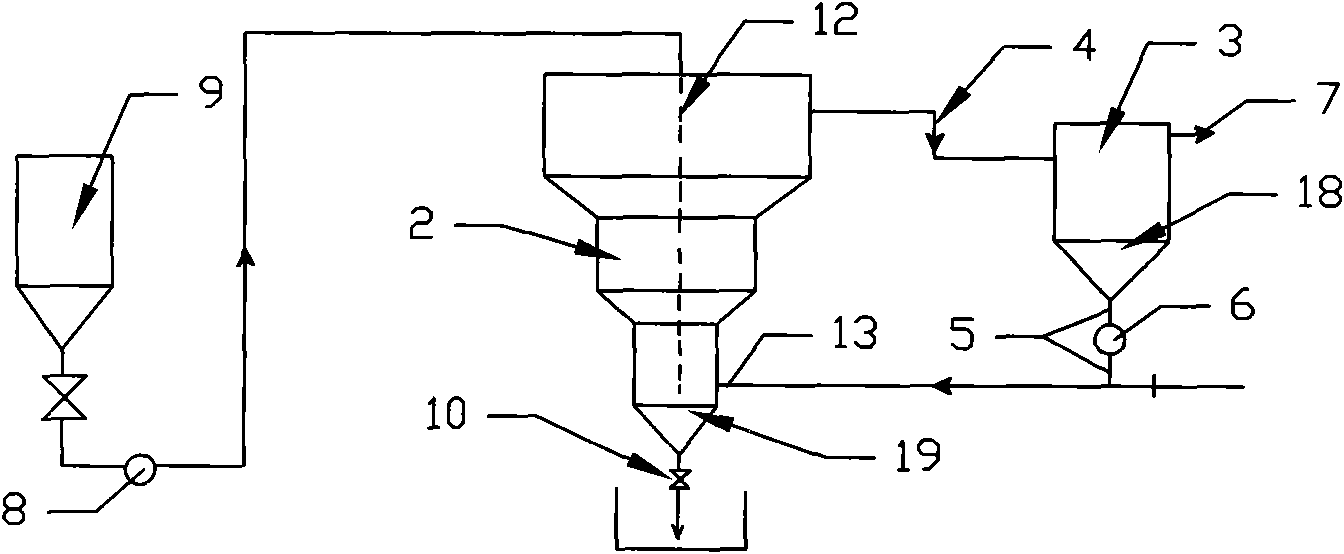

Wastewater treatment system and wastewater treatment method based on photoelectric Fenton-biological enhancement

PendingCN106830563AReasonable process routeThe processing mechanism is clear and orderlyWater treatment compoundsWater aerationWater pipePrecipitation

The invention discloses a wastewater treatment system and a wastewater treatment method based on photoelectric Fenton-biological enhancement. The system comprises a preaeration tank (1), a photoelectric Fenton reactor (2), a degassing neutralizing tank (3), a coagulative precipitation tank (4), an adjustment tank (5), a microencapsulation biological fluidized bed (6) and an immobilization biological active carbon bed (7) which are connected in sequence through water pipes. The photoelectric Fenton-biological enhancement-based wastewater treatment system is reasonable in structural design, convenient to operate, high in working efficiency, low in cost and good in wastewater treatment effect and orderly, and organically combines physical and chemical treatment, biochemical treatment and guarantee treatment; the photoelectric Fenton reactor, the microencapsulation biological fluidized bed and the immobilization biological active carbon bed support and promote one another functionally, so that the removal efficiency for refractory characteristic organic pollutants is over 98 percent, the sludge yield is low, the sludge treatment cost is low, the sewage treatment effect is good, and the wastewater treatment system based on photoelectric Fenton-biological enhancement has important significance for environmental protection.

Owner:YANCHENG INST OF TECH

Method for using ozone-immobilized biological activated carbon for realizing deep treatment of industrial wastewater

InactiveCN101786686ADepth processing worksExtended service lifeWater/sewage treatment by sorptionWater/sewage treatment by oxidationUltrafiltrationWater quality

The invention discloses a method for using ozone-immobilized biological activated carbon for realizing the deep treatment of industrial wastewater and relates to a deep treatment method of the industrial wastewater. The method can solve the problems that the existing industrial wastewater deep treatment processes have the common defects of greater investment, unstable process operation, unstable treatment effect and incapability of meeting environmental protection requirements, thereby causing difficult deep treatment of the industrial wastewater; and the method can also solve the problem that the adoption of the ozone-immobilized biological activated carbon technology is not applicable to the industrial wastewater deep treatment. The method comprises the following steps: 1) leading outlet water of pre-treatment to enter into a contact oxidation tower, and carrying out ozone aeration; 2) injecting the outlet water from the contact oxidation tower into an immobilized biological activated carbon tank; and 3) leading the outlet water from the immobilized biological activated carbon tank to enter into an ultrafiltration water tank for completing the method. The method can effectively carry out the deep treatment of the wastewater, reduce the cost, stabilize the process operation and stabilize the treatment effect, thereby being applicable to the deep treatment processes of petrochemical wastewater, printing and dyeing wastewater, coking wastewater and other types of wastewater and leading the water quality COD of the outlet water to be lower than 50mg / L.

Owner:HARBIN INST OF TECH

Softening process for industrial raw water

The invention discloses a softening process for industrial raw water, and the process comprises the following steps of: A. industrial raw water input; B. softening reagent injection; C. precipitation and collection of a natural crystal grain which mainly comprises CaCO3; D. cyclic reinjection of the natural crystal grain which mainly comprises CaCO3; E. crystal grain growth to become a circulating fluidized-suspended bed; F. softened water output; G. sand discharge. Compared with traditional clarifier process, the invention has the advantages of both a fluidized bed and a suspended bed, so the filtration rate is high and the volume is small; and the resultant is sand which is easy for dehydration. According to the process of the invention, the crystal nucleus is generated naturally and grows circularly by itself; no artificial processing of the crystal nucleus is necessary; and the cost for the processing and the addition of an artificial crystal nucleus is saved; the particle size and the flow velocity of the suspended crystal grain in the process of the invention are self-matched without strict requirements to the particle size of the initial crystal nucleus, and are self-adjusted, so the process condition is quite wide; no accurate matching with the filtration rate of raw water is necessary; and the process operation becomes more simple and reliable.

Owner:白连福

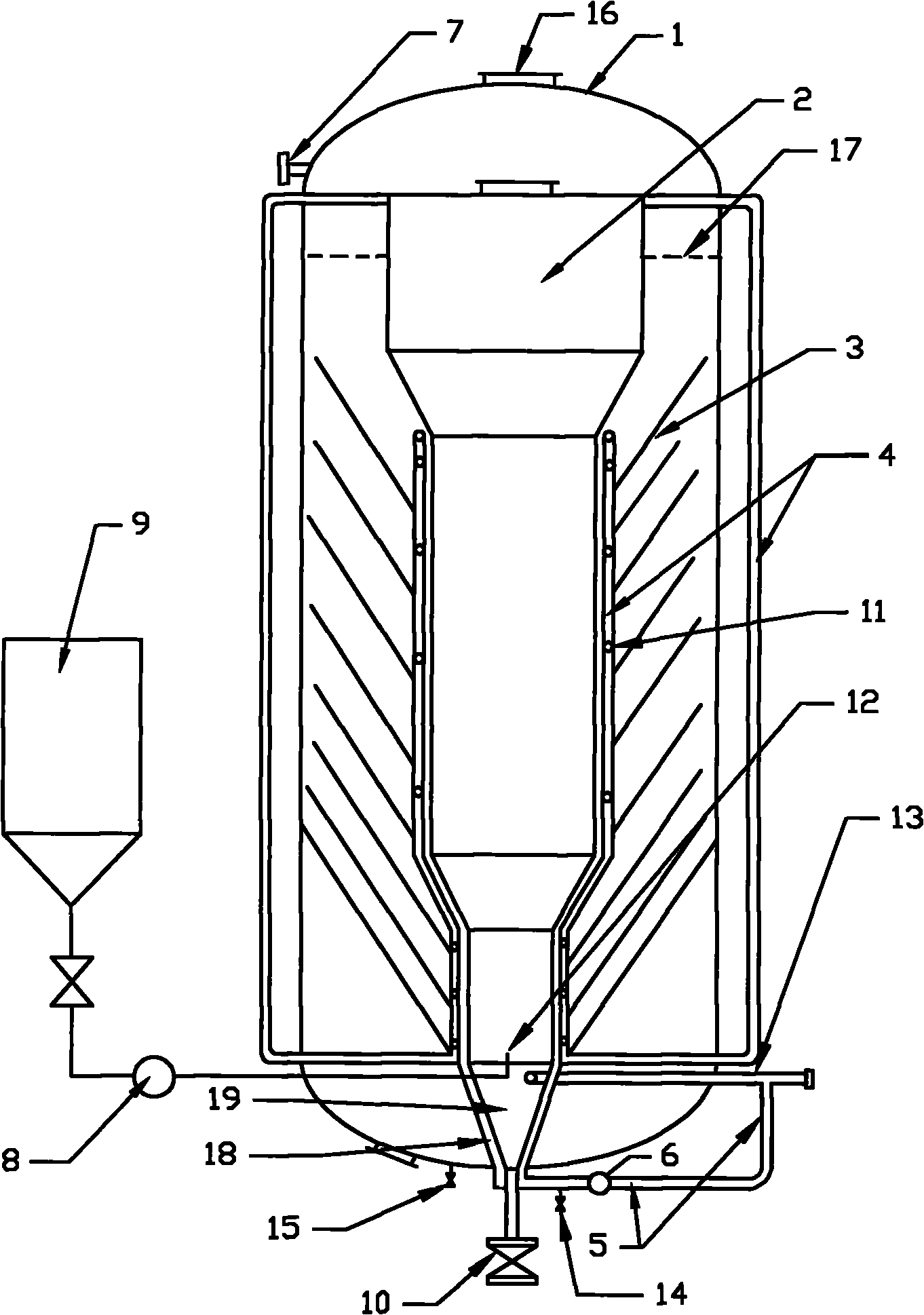

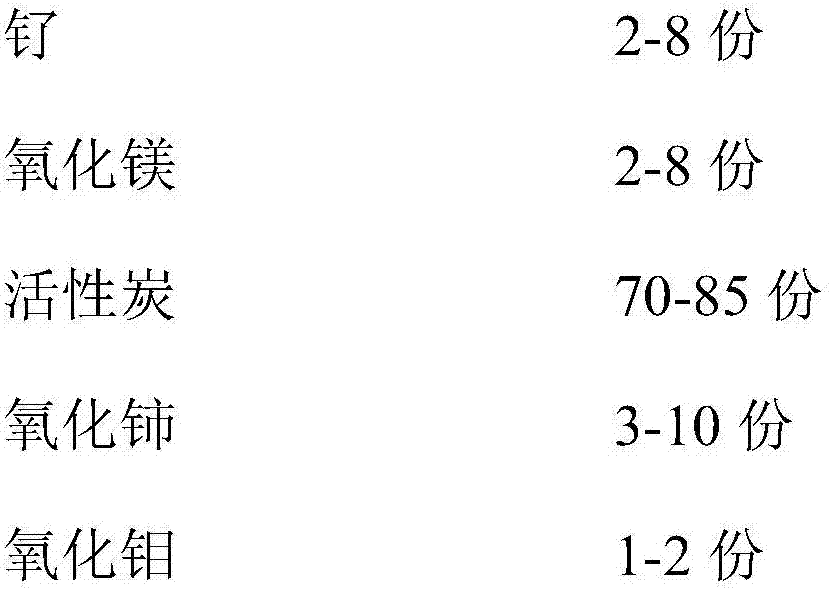

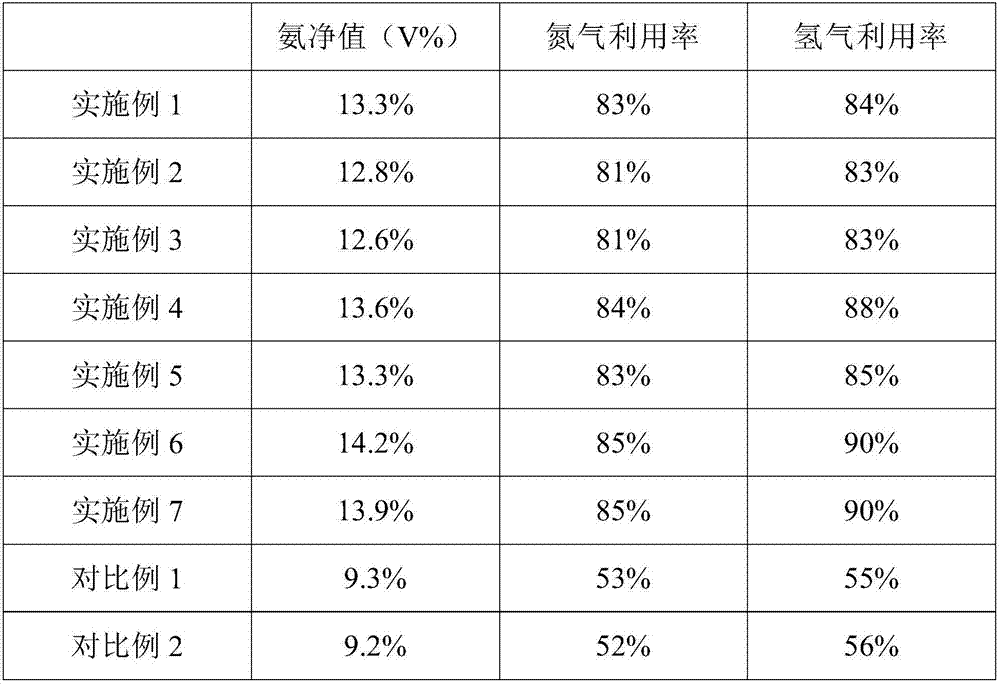

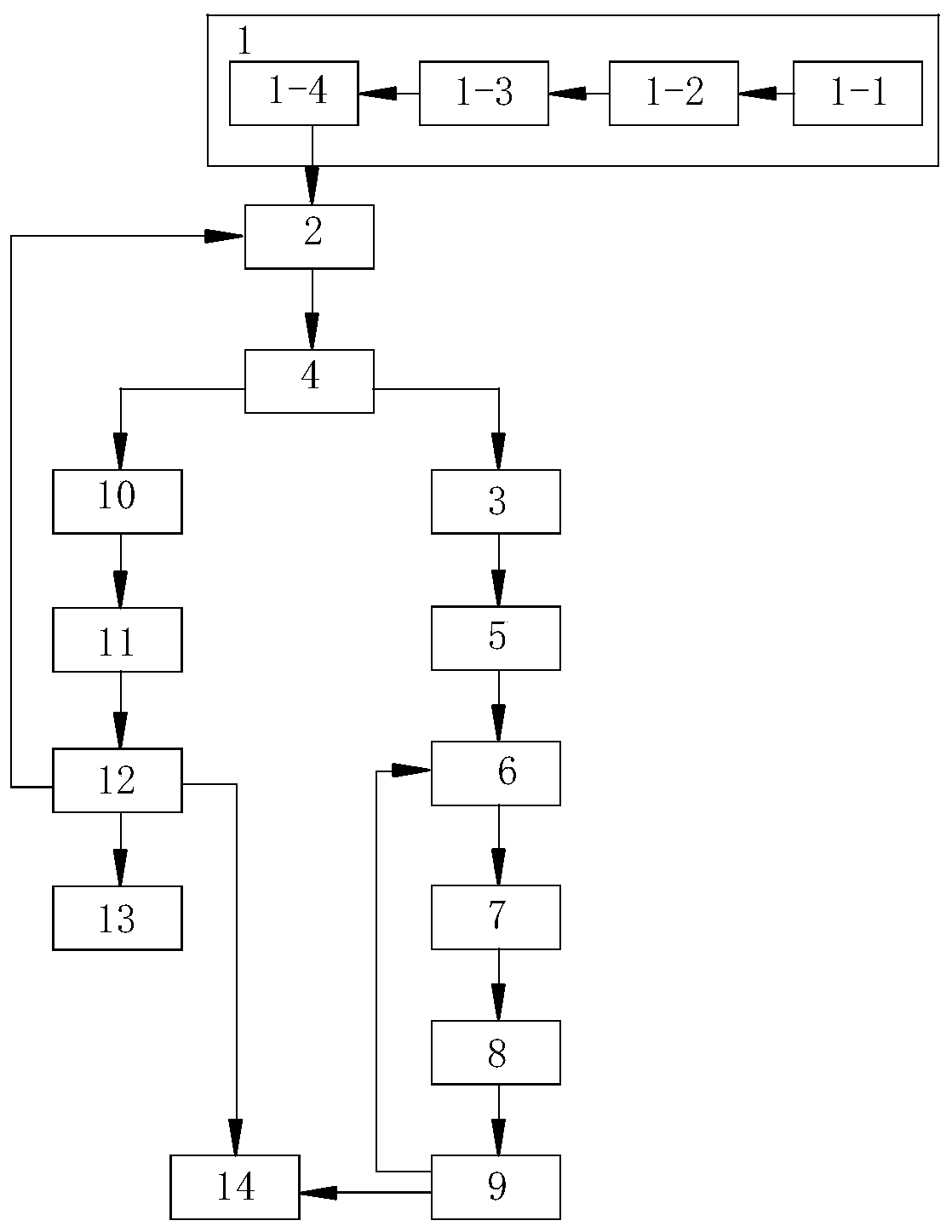

Low-pressure ammonia synthesis process

ActiveCN107117628AGuaranteed uptimeProcess operation is stableMetal/metal-oxides/metal-hydroxide catalystsAmmonia preparation/separationElectrolysisNitrogen gas

The invention provides a low-pressure ammonia synthesis process which comprises the following steps: 1) performing deep cooling air separation on air so as to obtain nitrogen and oxygen, and performing pure oxygen self-heat conversion on the oxygen with a natural gas so as to obtain a mixed gas with CO and H2; ) performing electrolysis water separation so as to obtain hydrogen; 3) mixing the hydrogen with the nitrogen so as to obtain an ammonia synthesis raw material gas, and performing primary ammonia synthesis in a first ammonia synthesis tower filled with an iron-based catalyst, wherein the synthesis pressure is 5-7MPa; 4) feeding the mixed gas discharged from the first ammonia synthesis tower into a second ammonia synthesis tower filled with a ruthenium-based catalyst, and performing secondary ammonia synthesis, wherein the synthesis pressure is 4-6MPa. By adopting the process, the ammonia synthesis process is divided into two sections which are implemented at specific pressure in the presence of specific types of catalysts and raw material gases of specific hydrogen to nitrogen ratios, ammonia synthesis process requirements are met, stable process operation is ensured, and the net value of ammonia at the outlets of the ammonia synthesis towers and the utilization rates of nitrogen and hydrogen are increased.

Owner:绿氨(北京)技术有限公司

System and method for high-salt wastewater grading crystallization treatment

PendingCN111153456AAvoid boiling pointEfficient separationAlkali metal nitrate preparationWater/sewage treatment by heatingPotassium nitrateSodium sulfate

The invention discloses a system and a method for high-salt wastewater grading crystallization treatment. The system comprises an adjusting tank, a first sodium chloride evaporative crystallization system, a sodium chloride mother liquor buffer tank, a potassium nitrate freezing crystallization system, a second sodium chloride evaporative crystallization system and a miscellaneous salt evaporativecrystallization system. The method comprises the following steps: (1) homogenizing and averaging treatment of wastewater; (2) primary evaporative crystallization of sodium chloride; (3) addition of potassium chloride into a sodium chloride mother liquor to obtain a mixed solution; (4) freezing to separate out potassium nitrate; and (5) evaporative crystallization of a potassium nitrate frozen mother liquor. The method has the advantages of low wastewater treatment cost, multiple product types and small impurity salt amount, the purity of produced sodium chloride is greater than 99%, the purity of sodium sulfate is greater than 99%, the purity of potassium nitrate is greater than 99%, and the yield of impurity salt is less than or equal to 10%.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

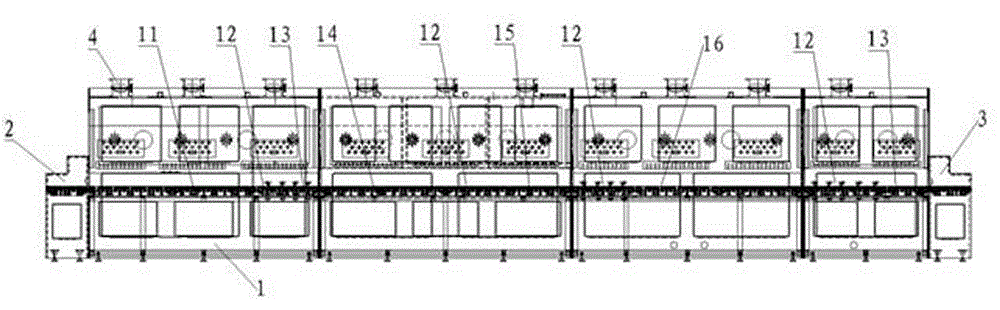

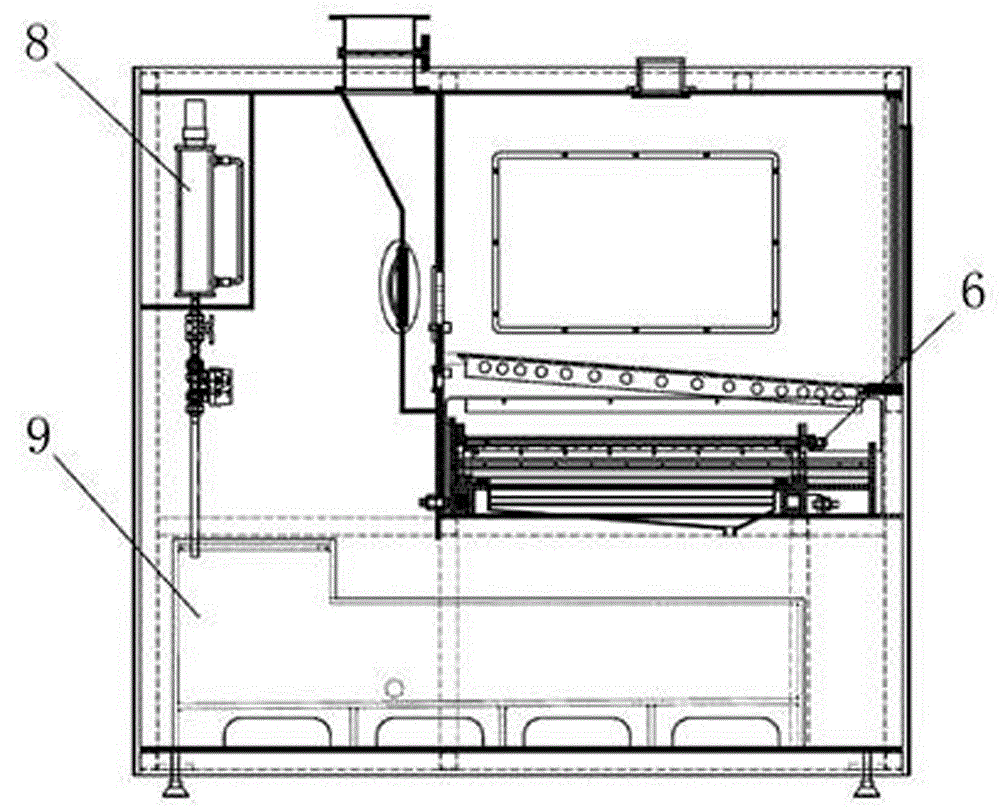

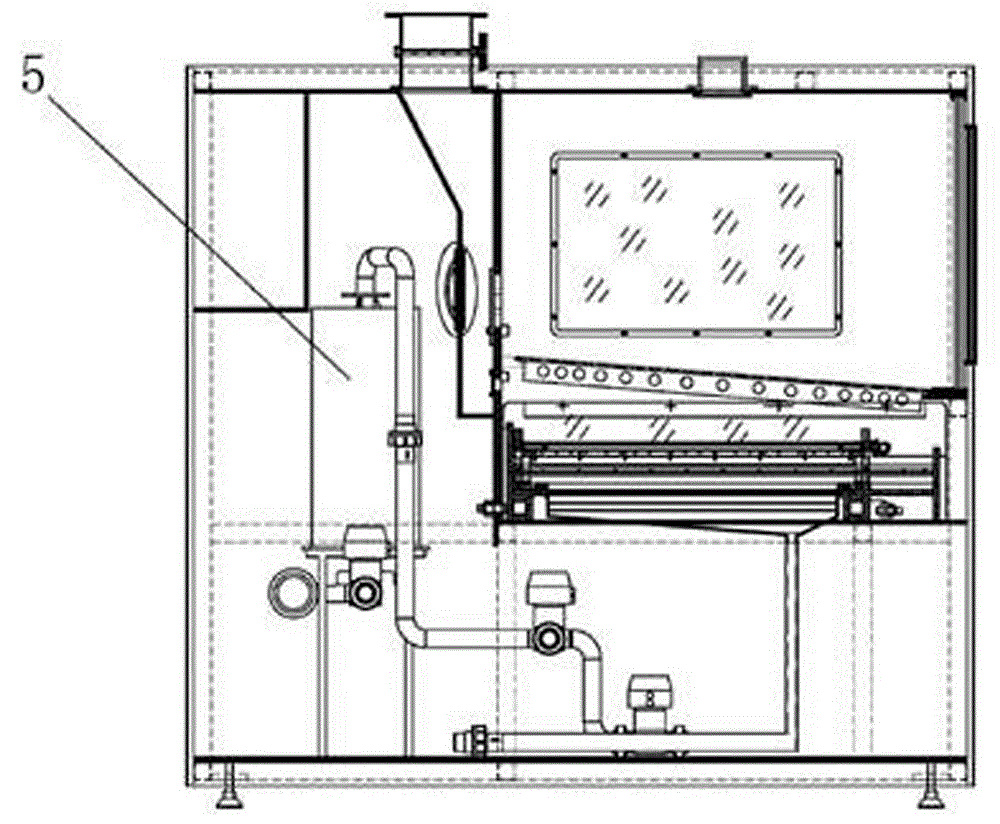

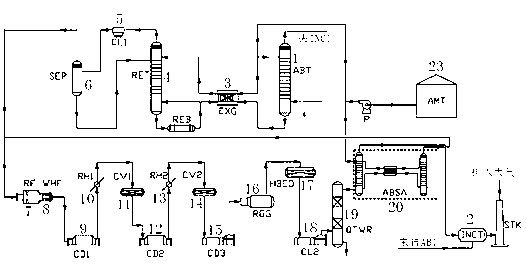

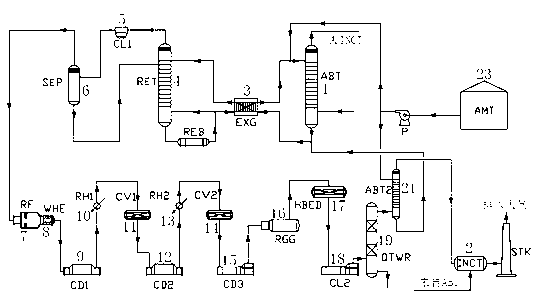

Single-crystal and poly-crystal flocking equipment

ActiveCN105133039AProcess operation is stablePolycrystalline material growthAfter-treatment detailsControl systemSingle crystal

The invention discloses single-crystal and poly-crystal flocking equipment. The single-crystal and poly-crystal flocking equipment comprises an equipment body, stations arranged on the equipment body, a transmission device and a control system, wherein the stations are the acid soaking flocking station, the spray-washing station, the drying station, the alkali spraying flocking station, the spray-washing station, the alkali soaking treatment station, the spray-washing station, the acid treatment station, the spray-washing station and the drying station which are arranged in sequence, the transmission device is used for transmitting a silicon wafer to the stations in sequence, and the control system controls the working states of the stations; the alkali spraying flocking station is connected with a heating device, and the working state of the heating device is also controlled by the control system. The single-crystal and poly-crystal flocking equipment is stable, efficient and reliable in technological operation and capable of achieving seamless switching between poly-crystal acid flocking, poly-crystal alkali flocking, single-crystal acid flocking and single-crystal alkali flocking.

Owner:CHANGZHOU S C EXACT EQUIP

Method for manufacturing flexible circuit board

InactiveCN101945544APrevent interdiffusionReduce tin whisker generationConductive pattern reinforcementEtchingTinning

The invention discloses a method for manufacturing a flexible circuit board, which comprises processes of oil removal, washing, micro etching, acid dipping, tinning and drying of the flexible circuit board. The method is characterized in that: after the acid dipping of the flexible circuit board and before tinning, chemical tin deposition is performed. Because the chemical tin deposition is performed before tinning, a chemical tin deposition layer serving as a barrier layer is increased between the copper of the flexible circuit board and the tin of the plating layer so as to effectively prevent mutual diffusion of the copper of the flexible circuit board and the tin of the tinning layer and reduce the generation of tin whiskers without changing the properties and purposes of the flexible circuit board; and the method is convenient in process operation, simple, reliable and easy to control.

Owner:XIAMEN DIAL ELECTRONICS

Integrated sour gas treating process

ActiveCN102838088AEasy to recycleHigh recovery rateHydrogen sulfidesSulfur preparation/purificationProcess engineeringEnvironmental engineering

The invention discloses an integrated sour gas treating process, and aims at the sour gas which contains light concentration H2S and is generated in a desulfuration decarburization device. The integrated sour gas treating process comprises the following steps of: adding a sour gas concentrating segment before a two-level Claus sulfur recovery segment, concentrating the H2S concentration in sour gas to more than 50%, and enabling the sour gas after concentrating to enter the two-level Claus sulfur recovery segment to carry out reaction, wherein the sulphur recovery rate of a sour gas concentrating + sulfur recovery segment is improved by 1%-2% compared with the general two-level Claus sulfur recovery segment, thereby being beneficial for sulfur recovery to obtain high sulfur recovery ratio. The integration sour gas treating process provided by the invention has the advantages that the technological operation is flexible and reliable, the investment is saved, the energy consumption is low, the total sulfur recovery ratio can achieve more than 99.8%, and the strict environmental standard requirements are met.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

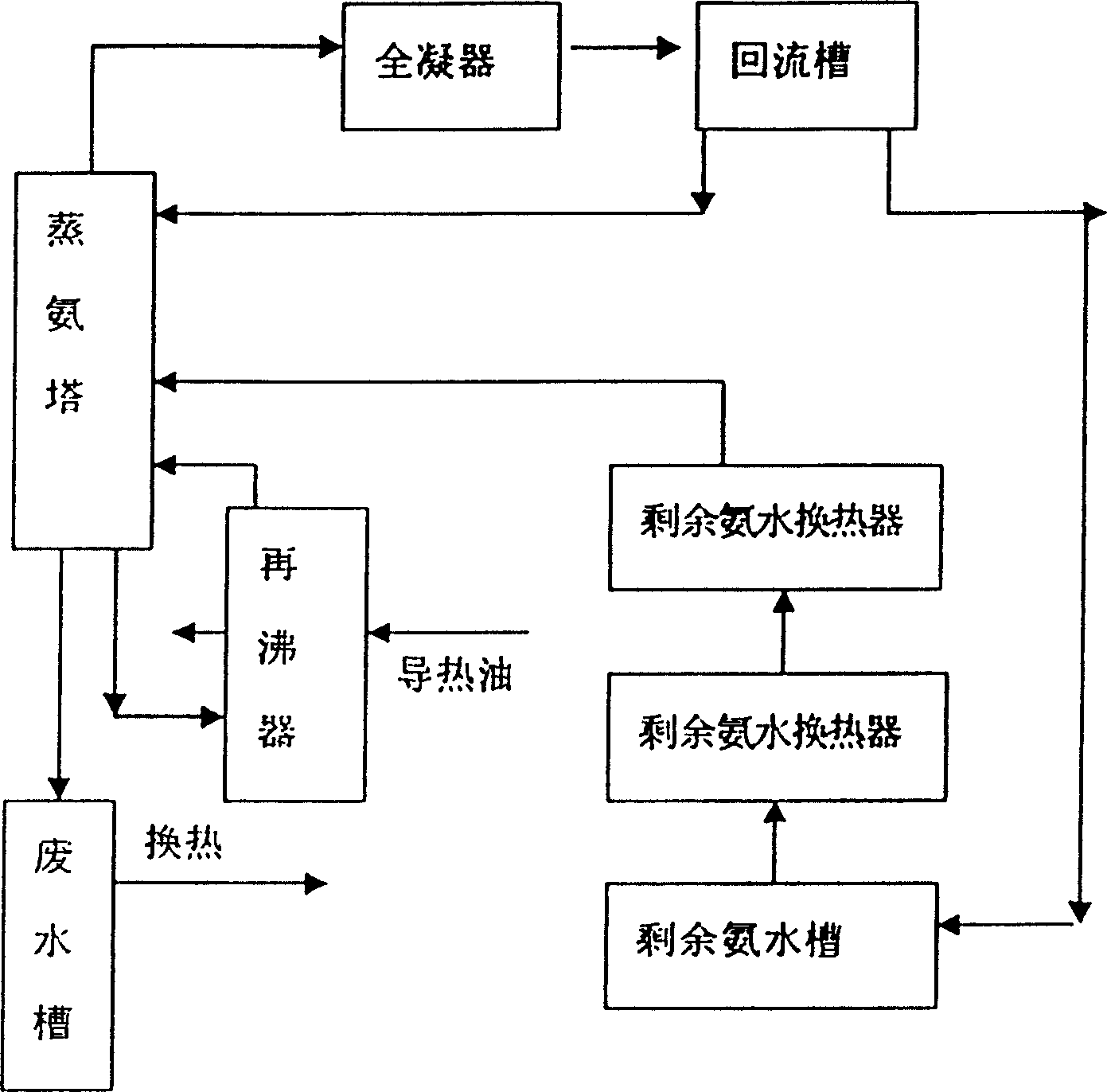

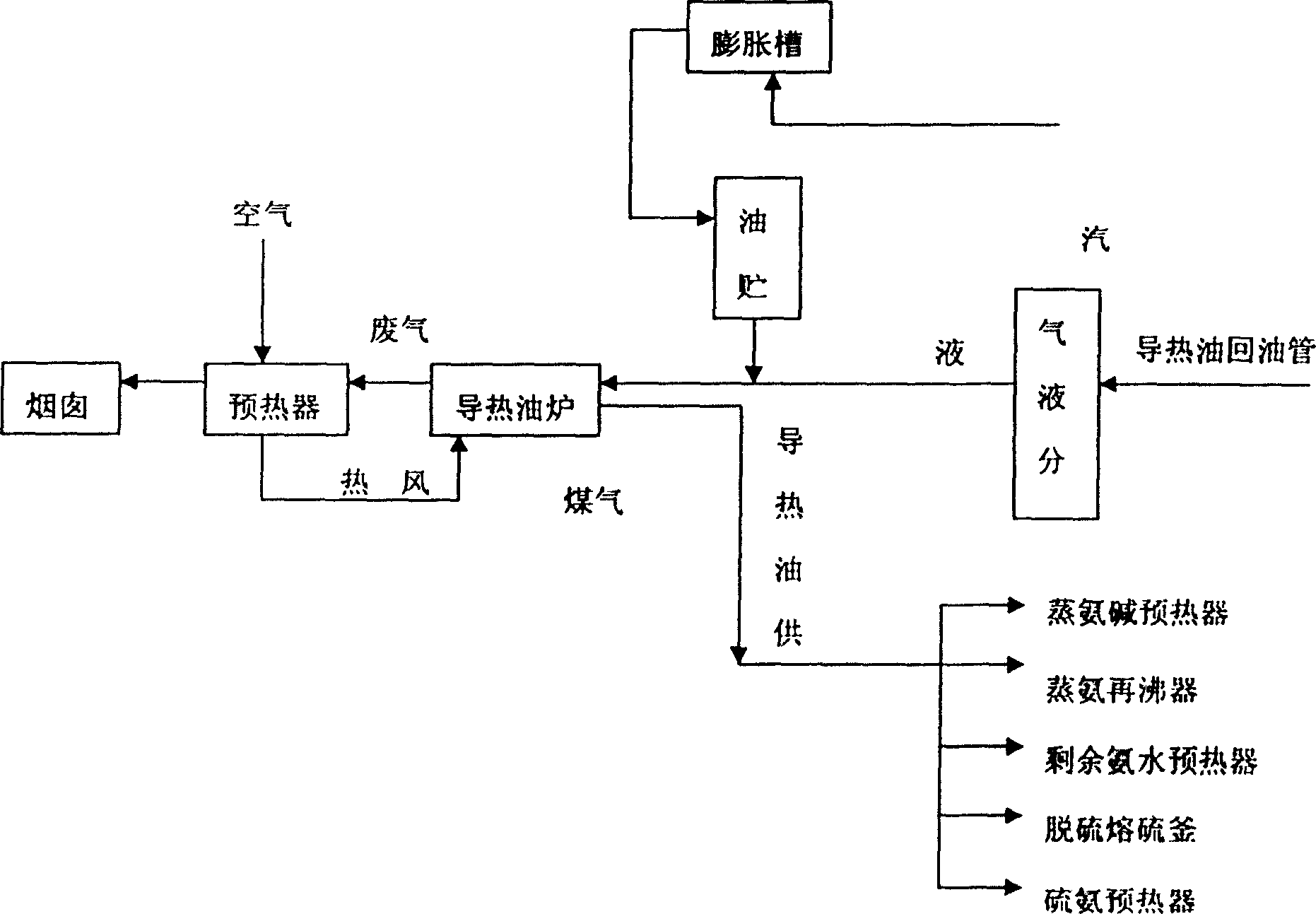

Process for treating residual ammonia water of coking

InactiveCN1631810ASolve puzzlesSolve pollutionFatty/oily/floating substances removal devicesWater/sewage treatment by heatingHeat conductingReboiler

The invention has supplied a processing technique for remained ammonia water, the remained ammonia water enters into ammonia still after heat exchange in heat exchanger, the ammonia gas enters into the condenser on the top of the tower to be cooled and flows back, its characteristics are: use the world-famous software package to do simulating optimal design, the ammonia still has multi-channel compound plate with declined holes, the hot waste water at the bottom enters into the reboiling device, the steam comes back from which to the ammonia still after being heated by heat conducting oil, for supplying heat to ammonia. The invention has advanced the conventional technique direct steam distillation technology for processing remained has stable operation, remarkable effect of energy-saving, decreasing the cost, increasing the products quality as well as the economic income, more importantly, the environmental pollution is reduced greatly by eliminating the direct steam and reducing the quantity of waste water generated.

Owner:JIGANG GRP

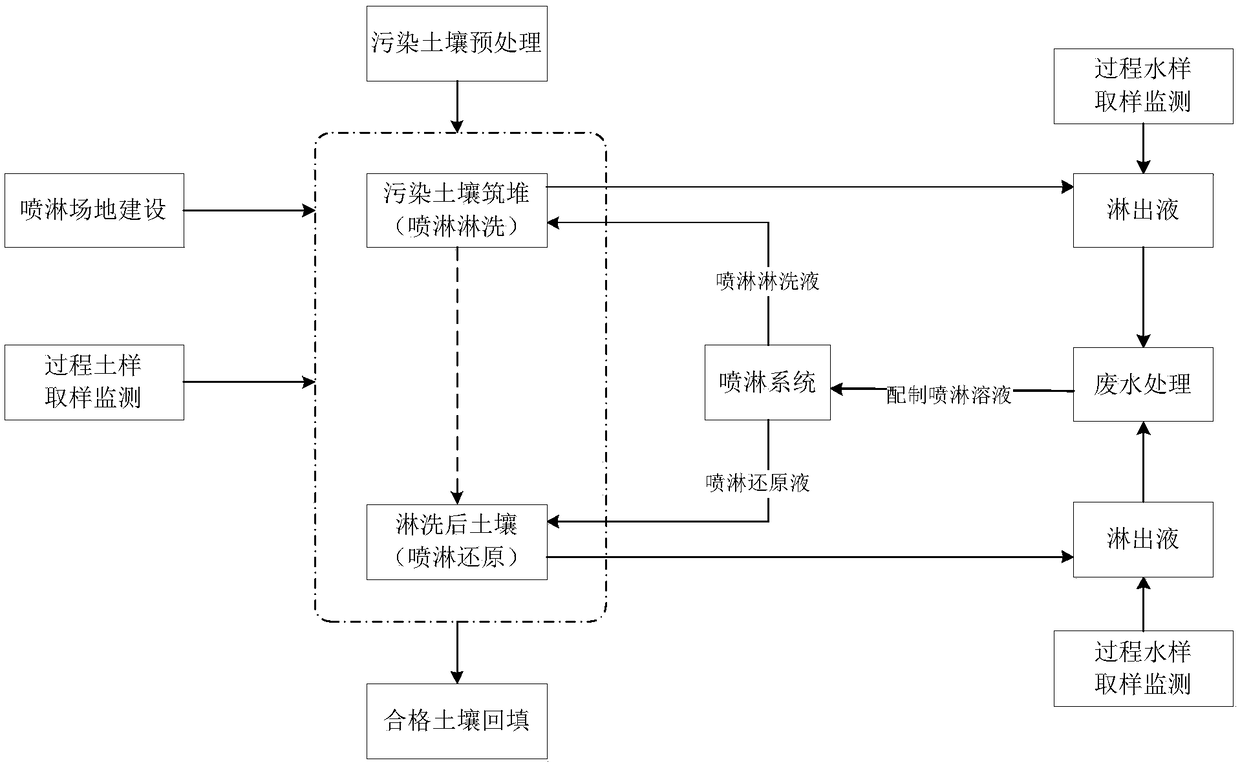

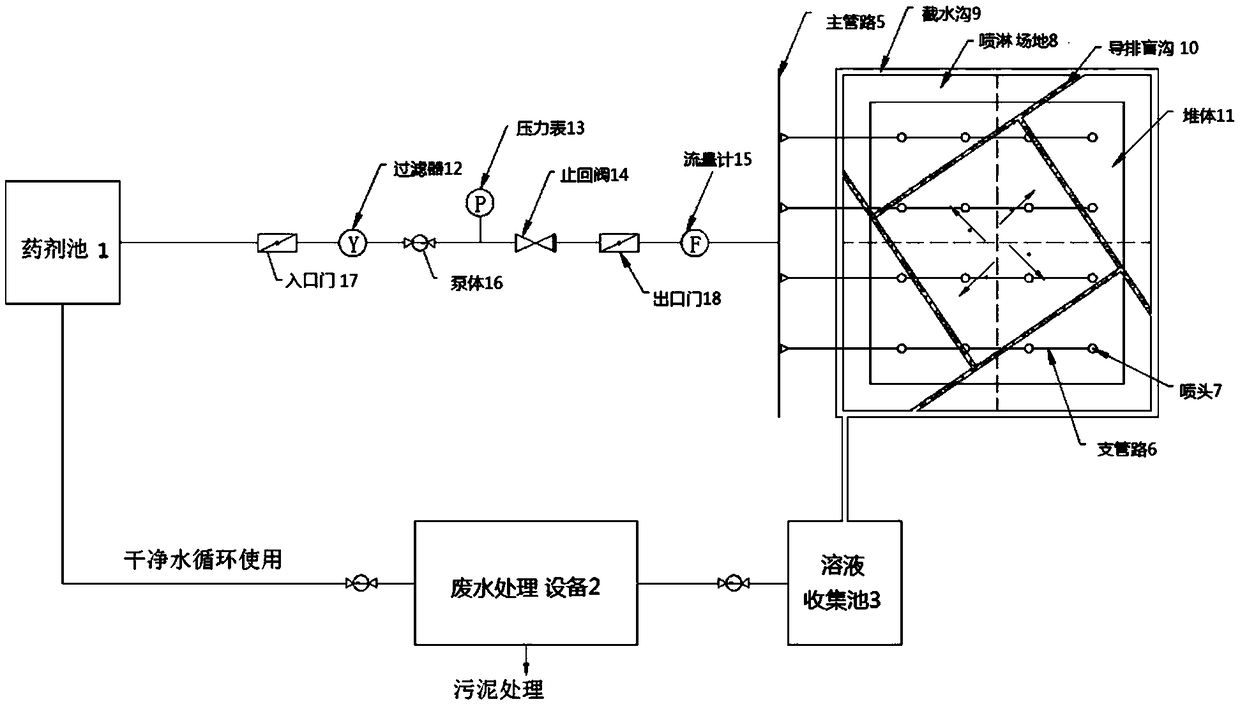

Process of repairing polluted soil by combined use of chemical elution and chemical reduction

ActiveCN108787726AAvoid destructionEasy to operateContaminated soil reclamationPollution soilCompound (substance)

The invention discloses a process of repairing polluted soil by combined use of chemical elution and chemical reduction. The process comprises the following steps: constructing a spraying site; pre-treating and stacking the polluted soil; arranging a spraying device; preparing an eluting solution in a reagent pond; implementing a spraying process taking acid, alkali and salt as the eluting solution and judging whether the pollutant concentration in a soil lixivium meets a repair target or not; and implementing a spraying process taking a reducer as the eluting solution and judging whether thepollutant concentration in the soil lixivium meets the repair target or not, wherein the spraying process taking water as the eluting solution is executed before the spraying process taking acid, alkali and salt as the eluting solution is executed. By adopting a stacking and spraying process, the process integrates the advantages of a chemical reduction stabilization technology and a chemical elution technology, and solves inevitable problems of the two technologies. The pollutants are reduced more thoroughly by adopting the reducer solution circular spraying process, and meanwhile, pollutioncaused by a lot of pollutants is reduced, use of the reducer is reduced greatly, and the environmental risk is reduced.

Owner:BEIJING GEOENVIRON ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com