Process for treating wastewater generated in solar silicon wafer production process

A solar silicon wafer, production process technology, applied in the fields of energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of moderate pressure reaction conditions and short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments.

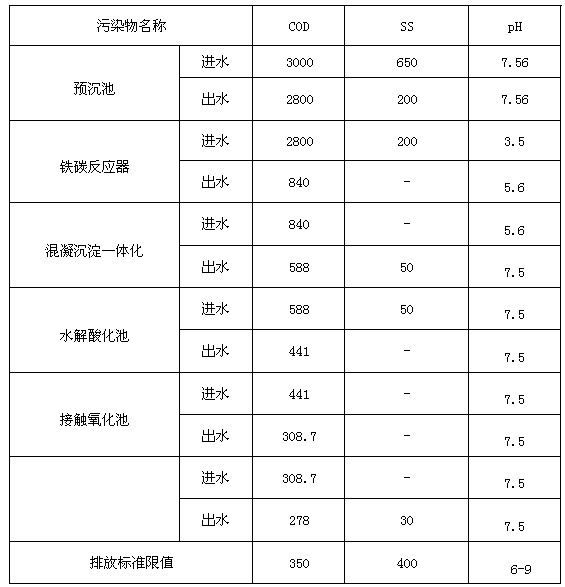

[0030] Water quality indicators of wastewater discharged from a solar energy production plant: pH: 7.56; CODcr: 3000 mg / l; SS: 650mg / l.

[0031] Treatment process of the present invention is:

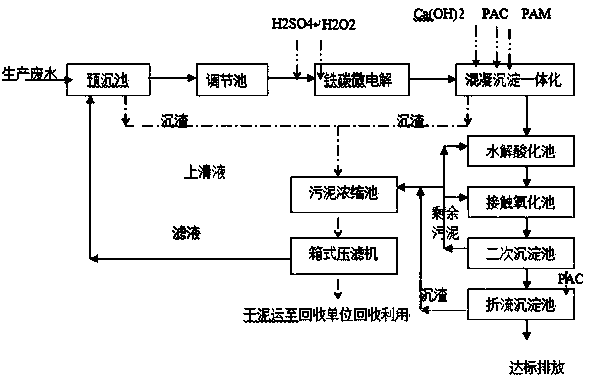

[0032] like figure 1 As shown, the production wastewater flows into the pre-sedimentation tank by itself, and the particles with a larger specific gravity than water are pre-sedimented. Then the wastewater is pumped into the regulating tank at the outlet of the pre-settling tank. After the wastewater is homogenized in the regulating tank, it is lifted by the pump. After entering the iron-carbon micro-electrolysis reactor through the tubular mixer, add sulfuric acid with a concentration of 50% at the front end of the tubular mixer and adjust the pH value to about 3.5 through the online digital display pH meter, and add a concentration of 30% at the rear end. % H2O2, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com