Patents

Literature

16927results about How to "No secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

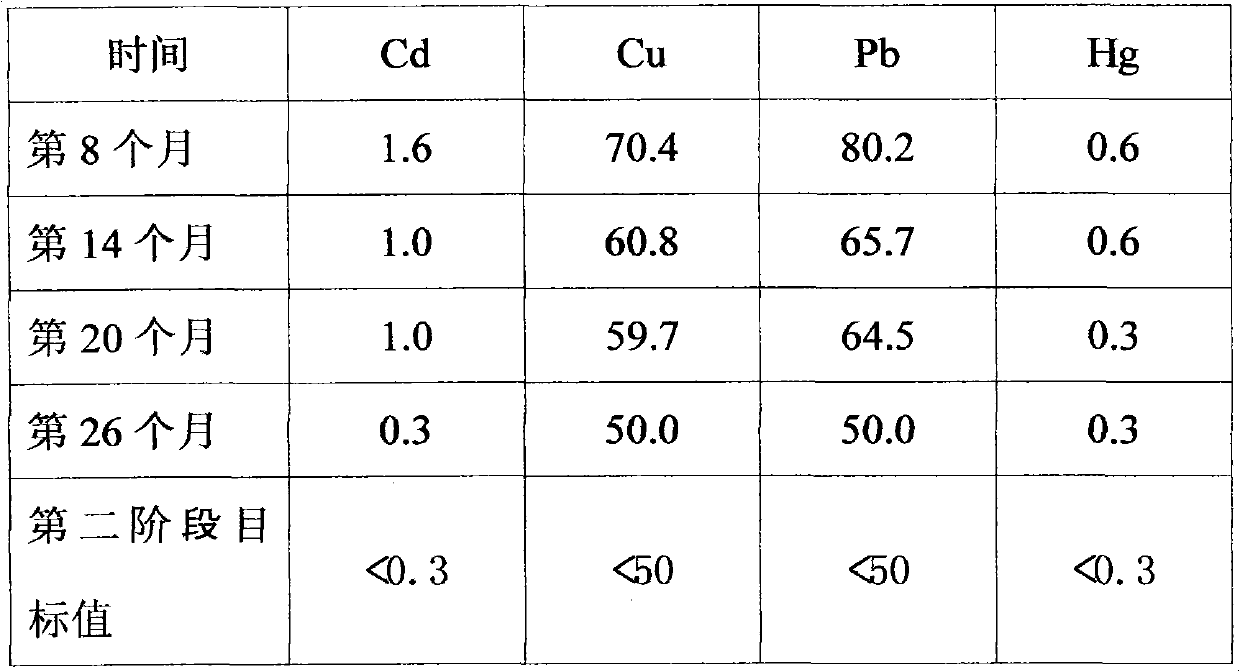

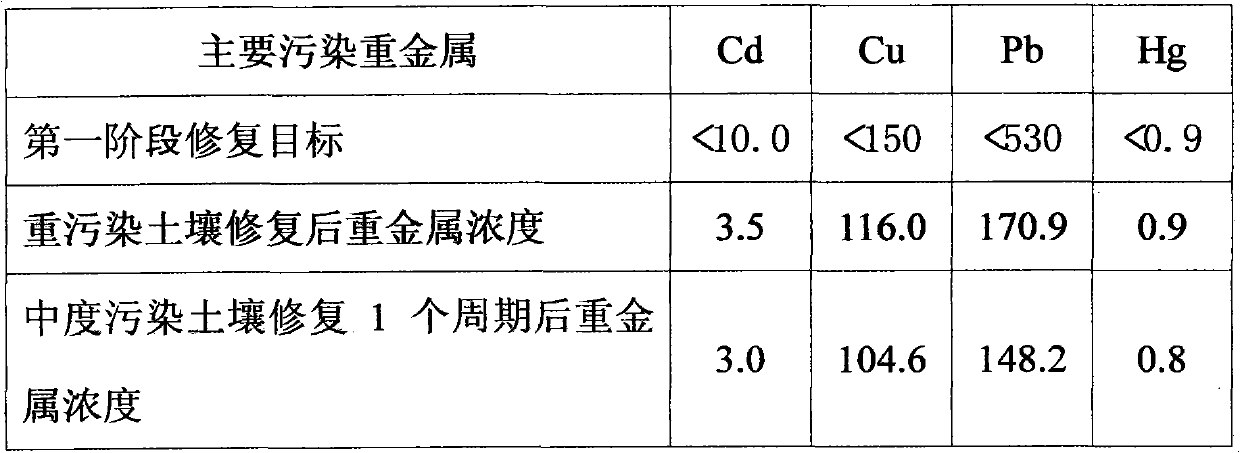

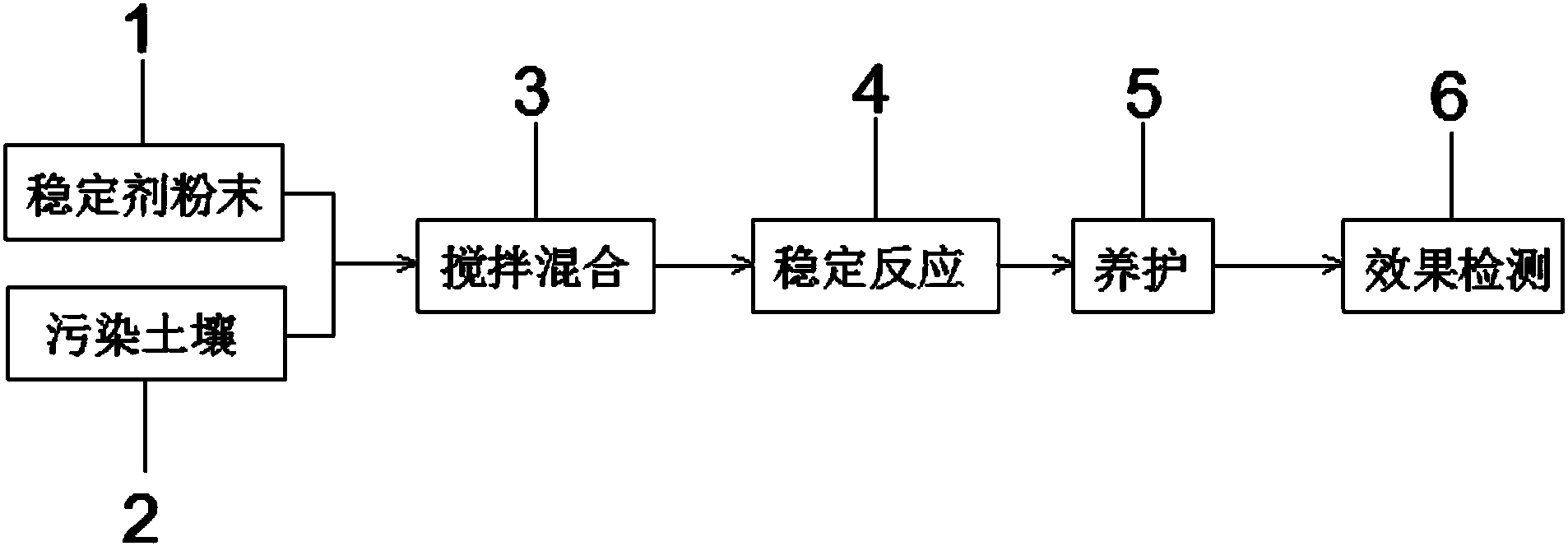

Soil remediation method for treating heavy metal pollutants

ActiveCN101947539AReduce the amount requiredNo secondary pollutionContaminated soil reclamationSoil scienceSoil remediation

Owner:浙江博世华环保科技有限公司

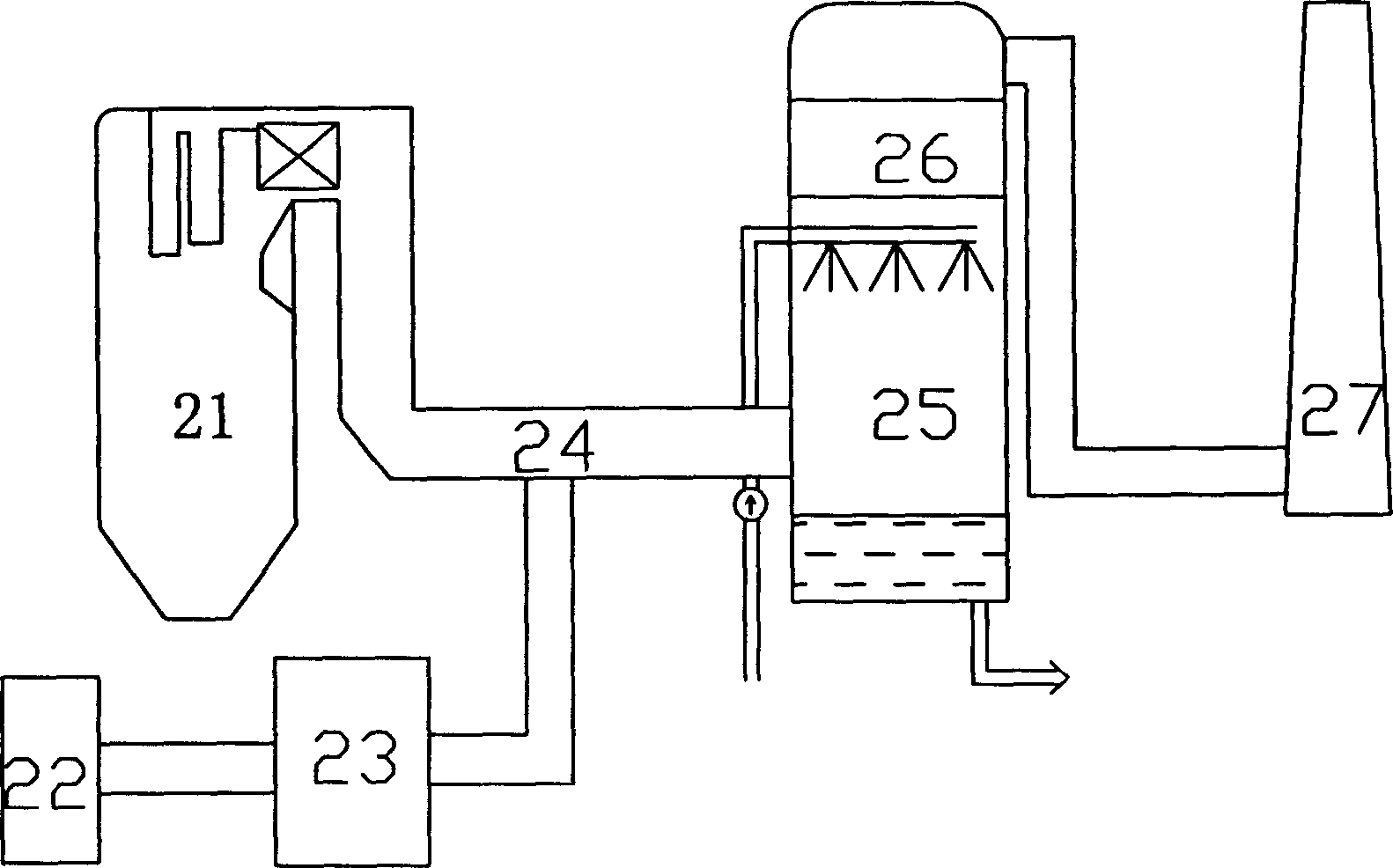

Ozone oxidation and denitration method of boiler flue gas

The invention provides a method for processing de-nitration on the boiler smoke, belonging to the environmental protective technique. The method comprises: ejecting ozone O3 into the low-temperature section of smoke channel of boiler whose temperature ranges from 110-150Deg. C; oxygenizing the nitric oxide NO into high-state nitrogen oxide as NO2, NO3 or N2O5; washing the smoke with alkali liquor to remove the nitrogen oxide in the smoke. Compared to other de-nitration method, said invention has higher efficiency, lower cost, and non-secondary pollution, while the absorption effect combined with alkali liquor can reach more than 80%. In addition, the invention can apply variable boiler devices, which is not relative to the burning condition of boiler.

Owner:ZHEJIANG UNIV

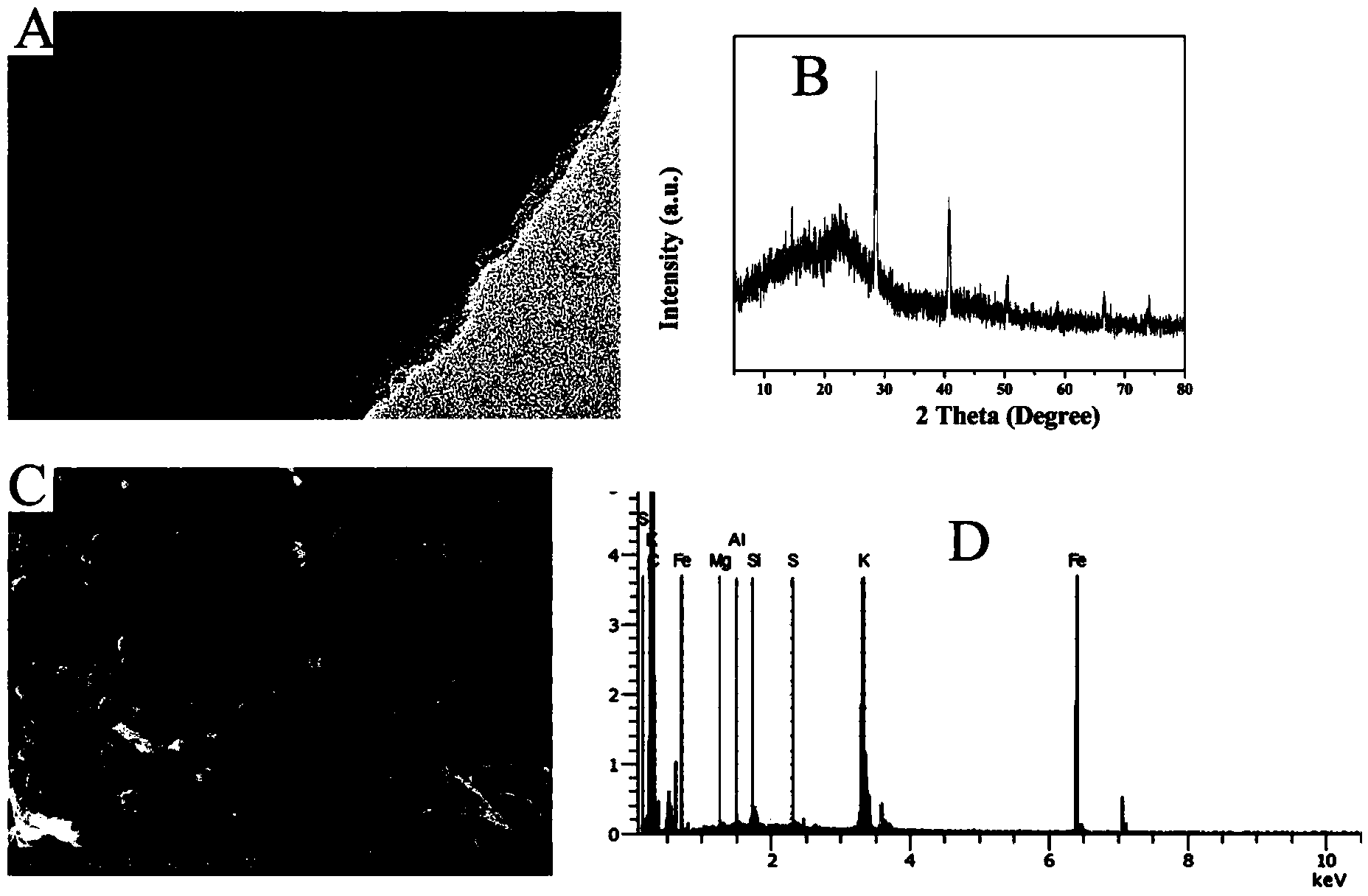

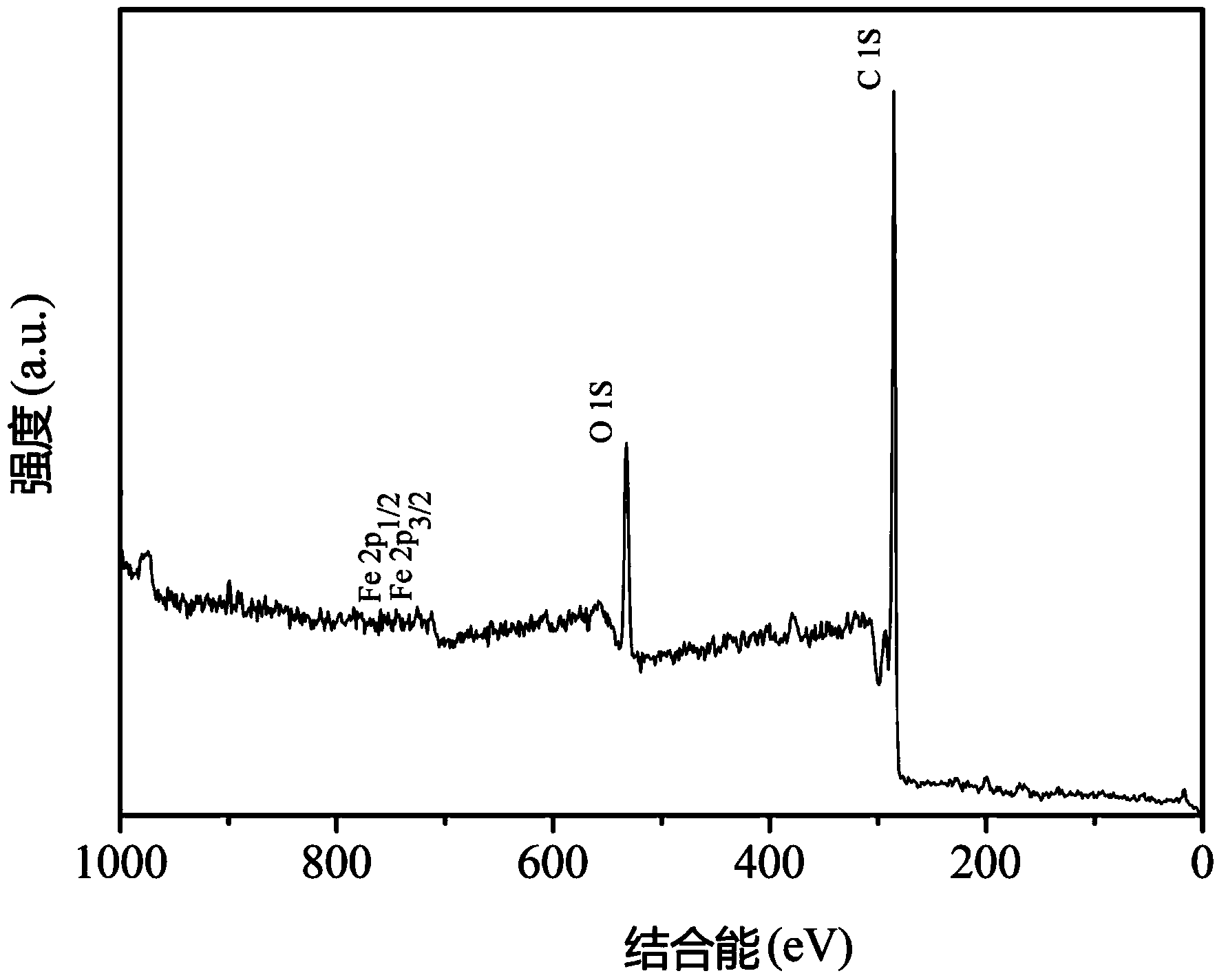

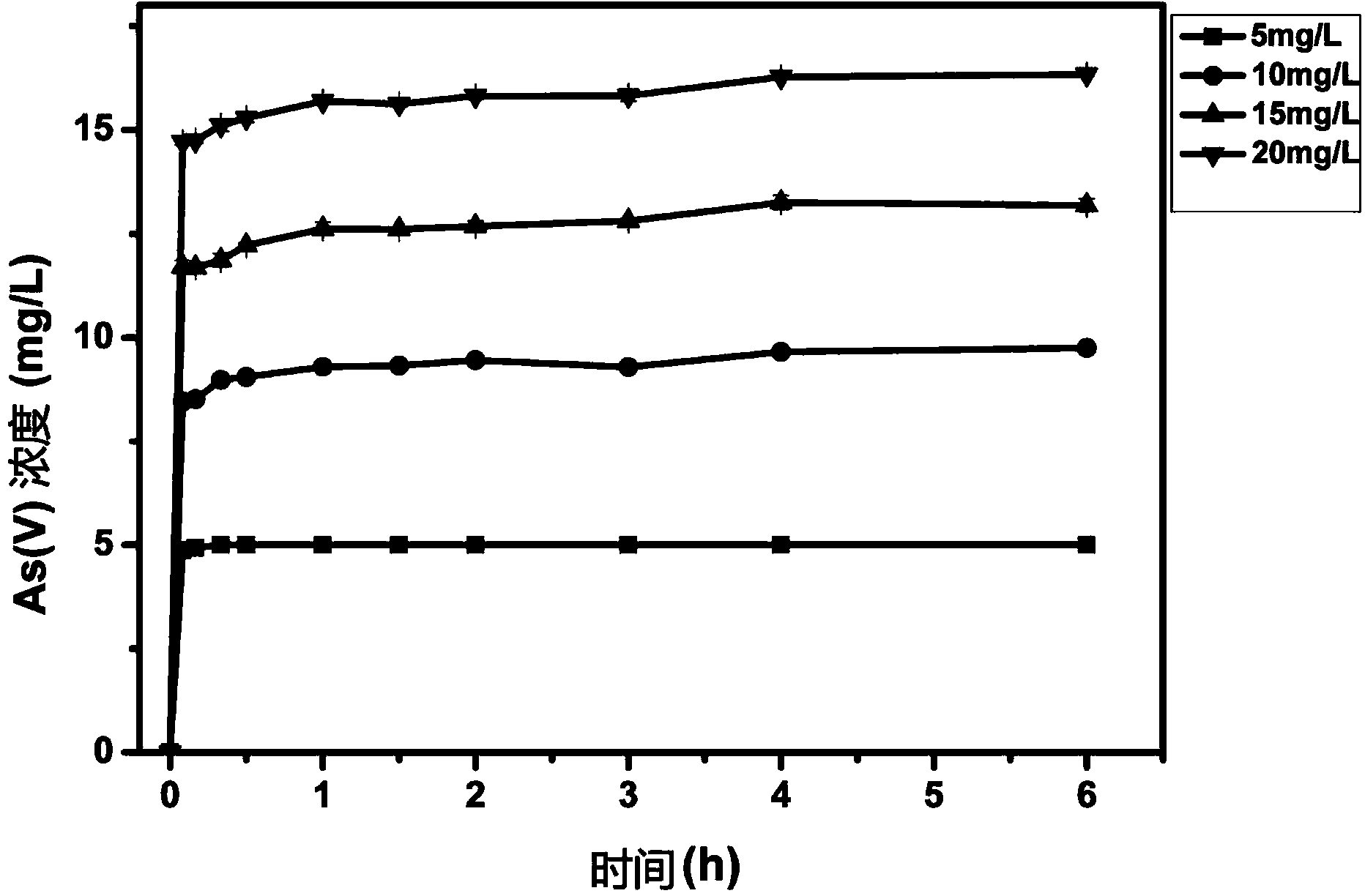

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

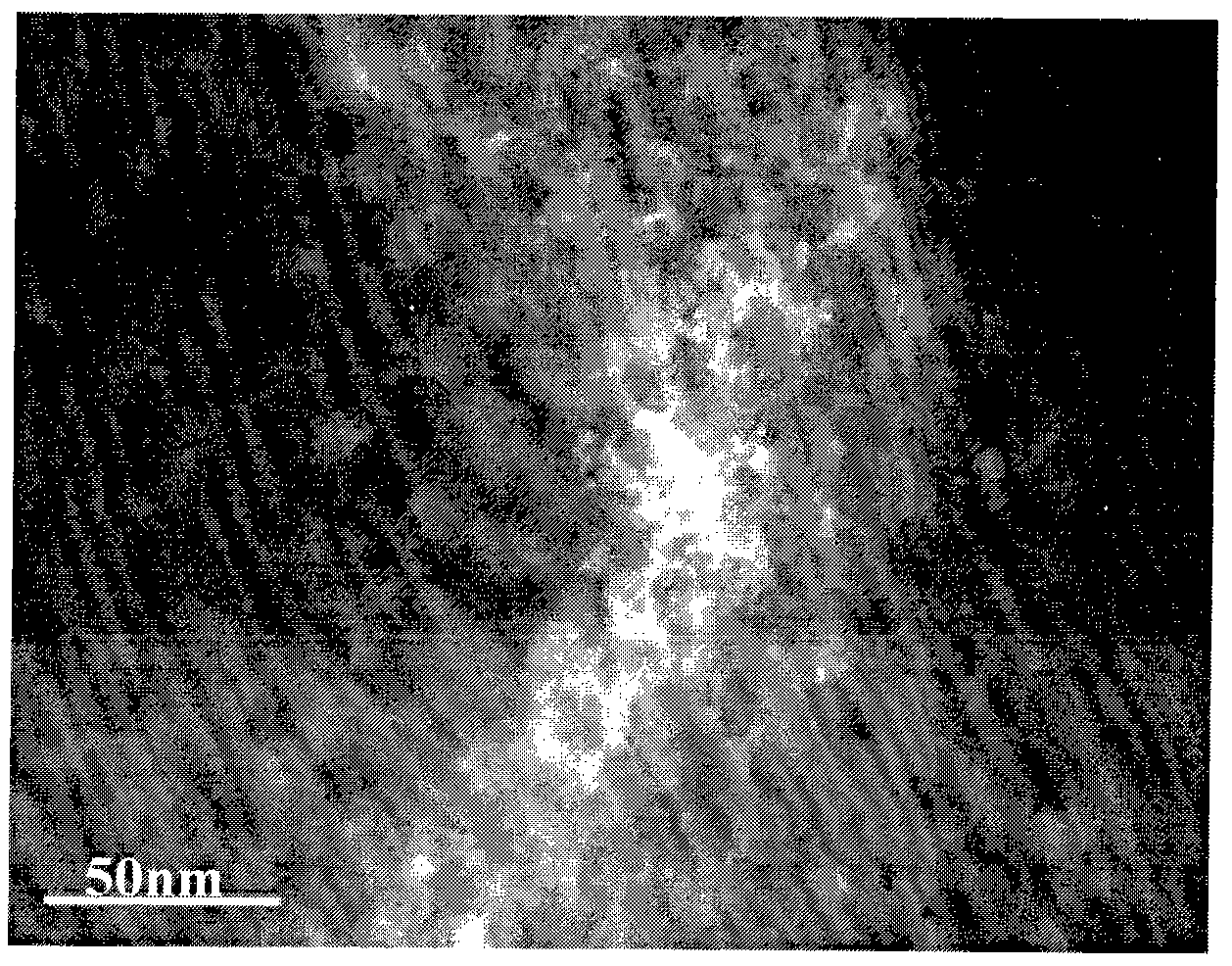

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

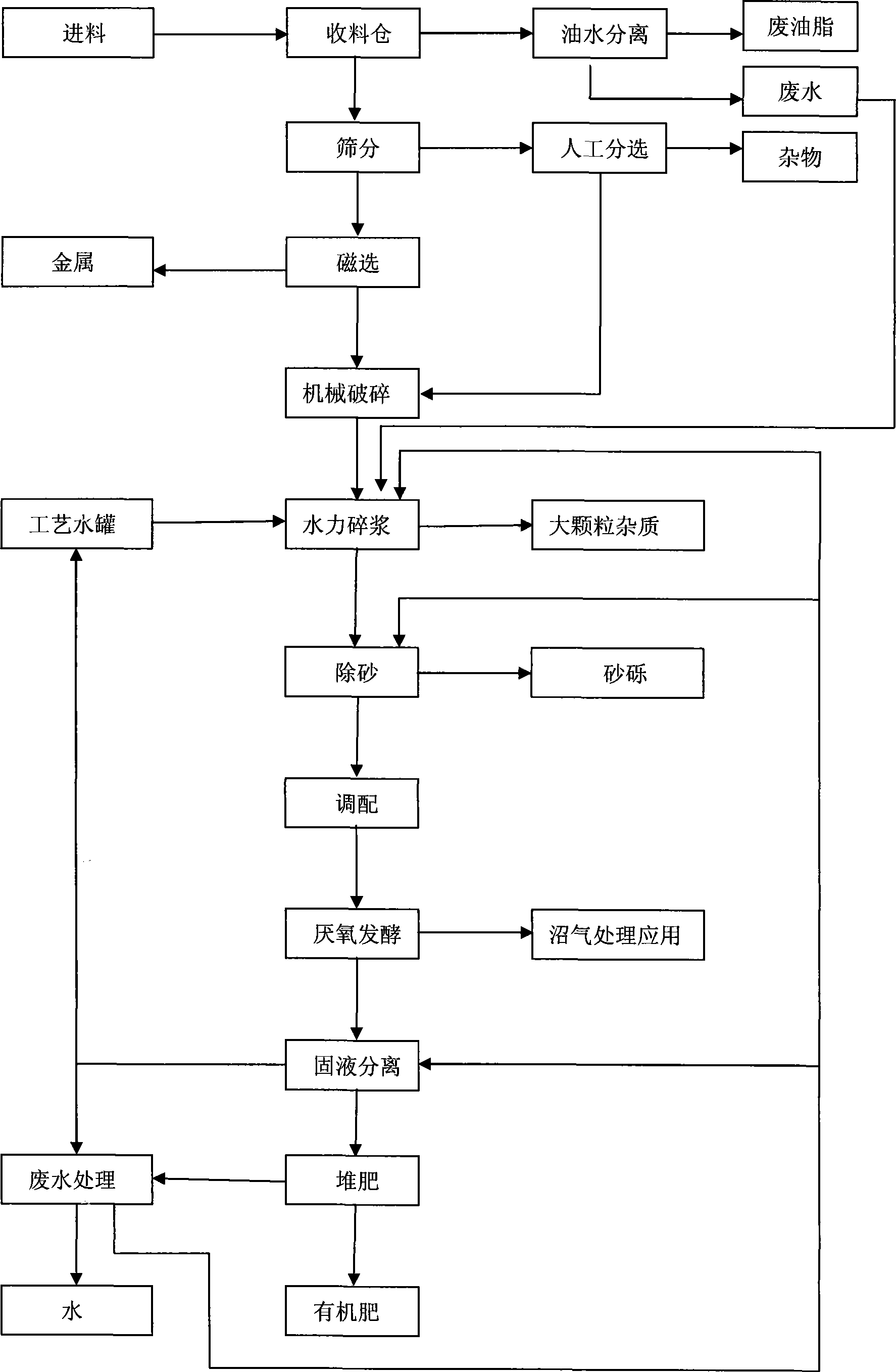

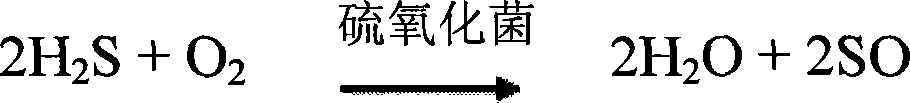

Anaerobic digestion handling method for restaurant garbage

ActiveCN101224999AHarmlessRealize resource processingBio-organic fraction processingClimate change adaptationSlurryOxygen

The invention provides a method for resourceful treatment of restaurant garbage, which is characterized in that the restaurant garbage is completely degraded after treatment with the working procedures of oil separating, preliminary selecting, mechanical crushing, hydraulic pulping, slurry blending, anaerobic fermentation and oxygen-control composting, finally the marsh gas is decomposed via anaerobic digestion and is utilized as energy after desulfurization treatment; the high-quality organic manure is produced from the biogas residues via oxygen-control composting; the separated oil can be recycled as the regenerated industrial raw oil; the wastewater generated in the treatment process can be recycled, and finally the redundant wastewater reaching the standard is discharged after biochemical treatment; and the odor generated by the garbage in the treatment process is directly discharged after reaching the standard via biofiltration treatment, thus the restaurant garbage can be transformed into the clean regenerated energy of electric power and the pollution-free organic manure to completely realize resourceful treatment of restaurant garbage. The resourceful treatment of restaurant garbage has the advantages of innocuity, no peculiar smell, no secondary pollution during the treatment process and realization of harmless and resourceful treatment of restaurant garbage.

Owner:宝林

Extensive wastewater treatment capture agent

InactiveCN104071880ASimple application processQuick resultsWater/sewage treatment by flocculation/precipitationChemical adsorptionSewage

The invention discloses an extensive wastewater treatment capture agent. The capture agent is prepared from an organic coagulant, an inorganic coagulant, a coagulant aid, a binder and a modifier. The colloid charge balance in sewage is broken by ionization of the capture agent in water, and pollutants are subjected to physical and chemical adsorption and subjected to consolidation settlement, so as to achieve the target of reducing chemical oxygen demand (COD), biochemical oxygen demand (BOD) and storativity (SS). The extensive wastewater treatment capture agent is simple in application process, quick to take effect, wide in adaptability and broad in market prospect.

Owner:NANCHANG GERUN ENVIRONMENTAL PROTECTION SCI &TECH CO LTD

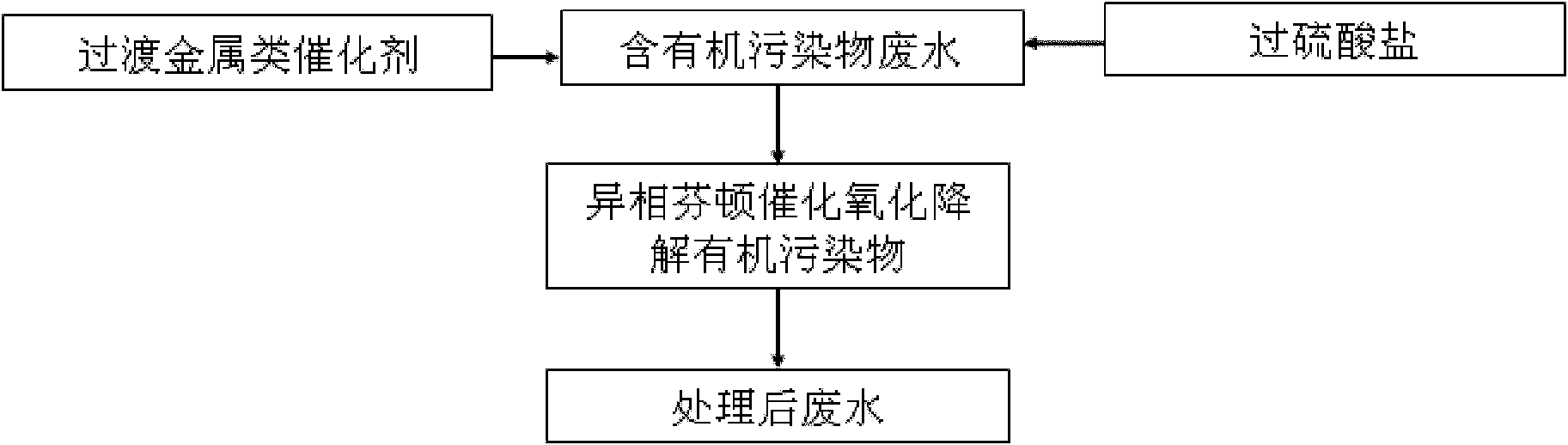

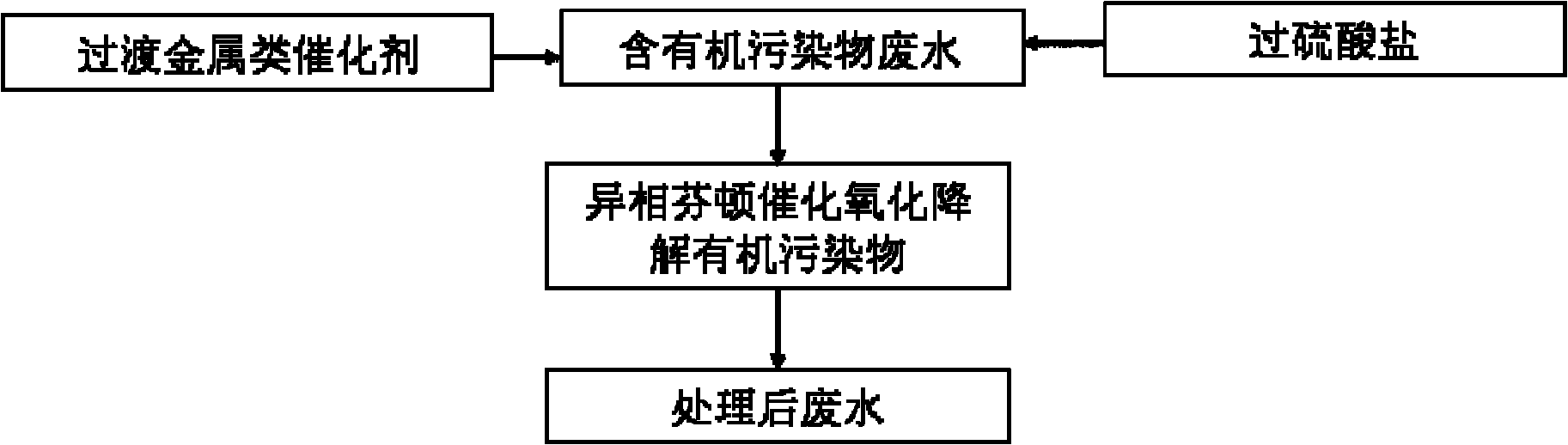

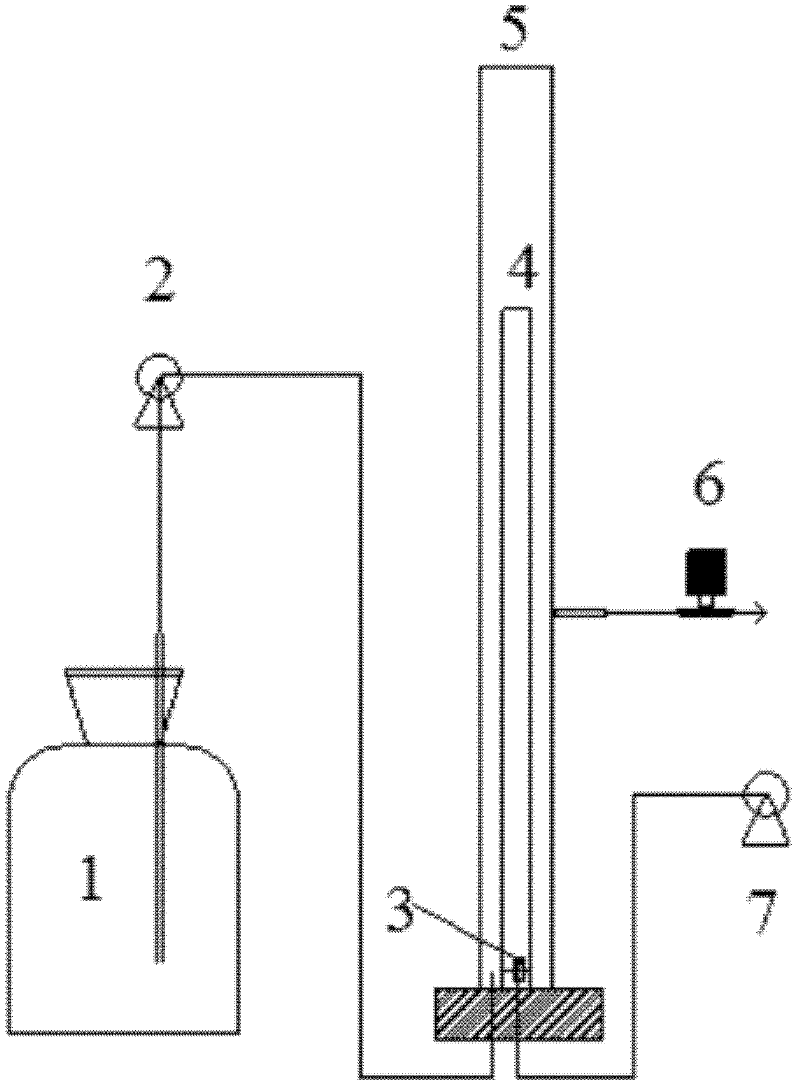

Processing method of heterocatalysis persulfate Fenton oxidation water

InactiveCN102020350ALong-lasting and efficient purificationImprove durabilityWater/sewage treatment by oxidationPersulfateFenton reagent

The invention proposes a processing technology of heterocatalysis persulfate Fenton oxidation water. In the method, transitional metal, transitional metallic oxide and a transitional metal / transitional metallic oxide composite material are used as out-phase Fenton reagents; and persulfate is catalyzed and decomposed to generate hydroxyl radical free radical, thus oxidizing to remove the organic matters in the waste water. Compared with the water treatment technique of homogeneous phase persulfate, the out-phase transitional metal and the transition metal oxide catalyst can slowly release transitional metal icons, thus ensuring that the organic matters in the water are purified lastingly and efficiently by the processing method of the heterocatalysis persulfate Fenton oxidation water. The processing technology of heterocatalysis persulfate Fenton catalyzed oxidation water built by the invention is suitable for processing various organic wastewater, has the advantages of good durability, high efficiency, environmentally friendliness, and no secondary pollution, is easy to operate, conforms to the requirements of actual water treatment units, and has great application potential in the field of environmental pollution regulation.

Owner:HUAZHONG NORMAL UNIV

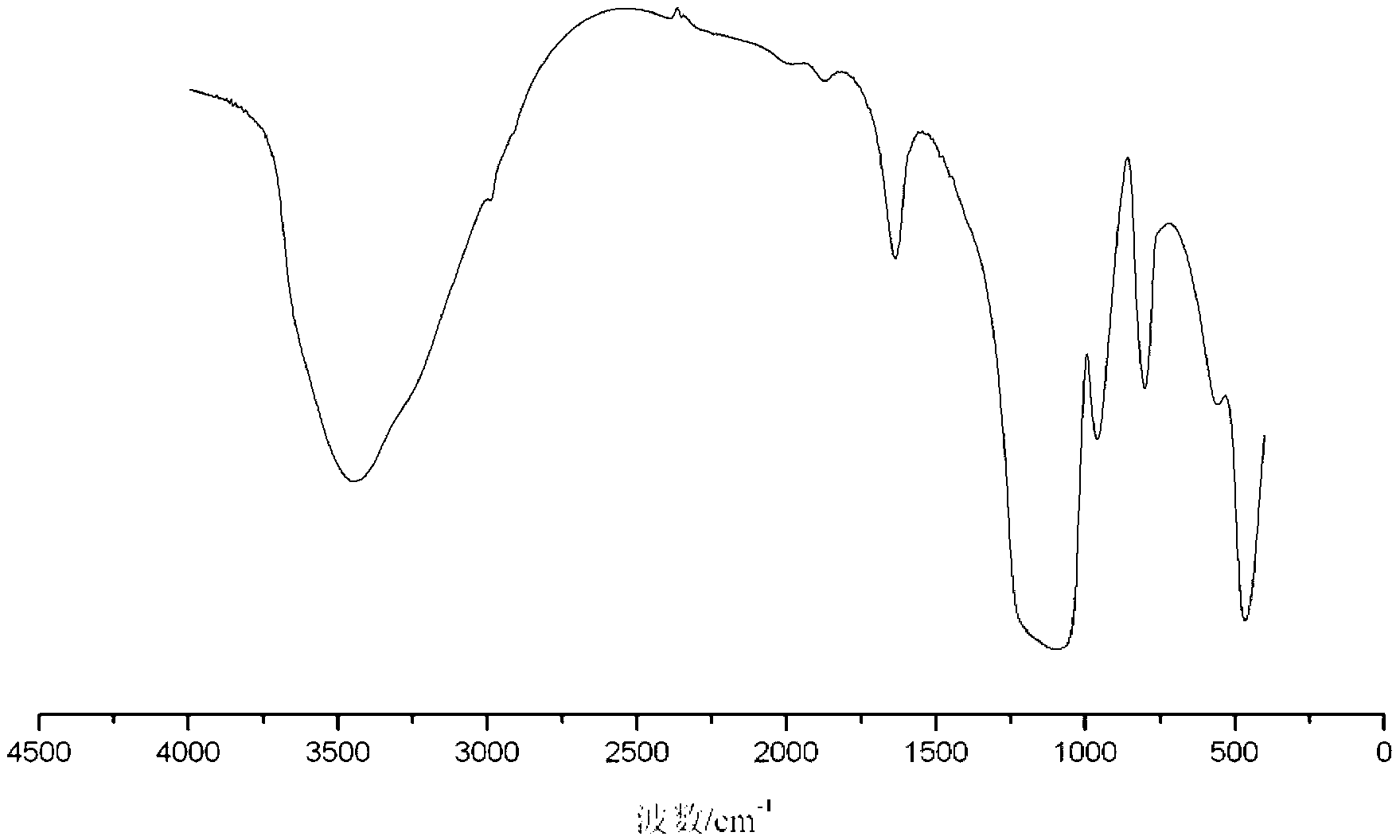

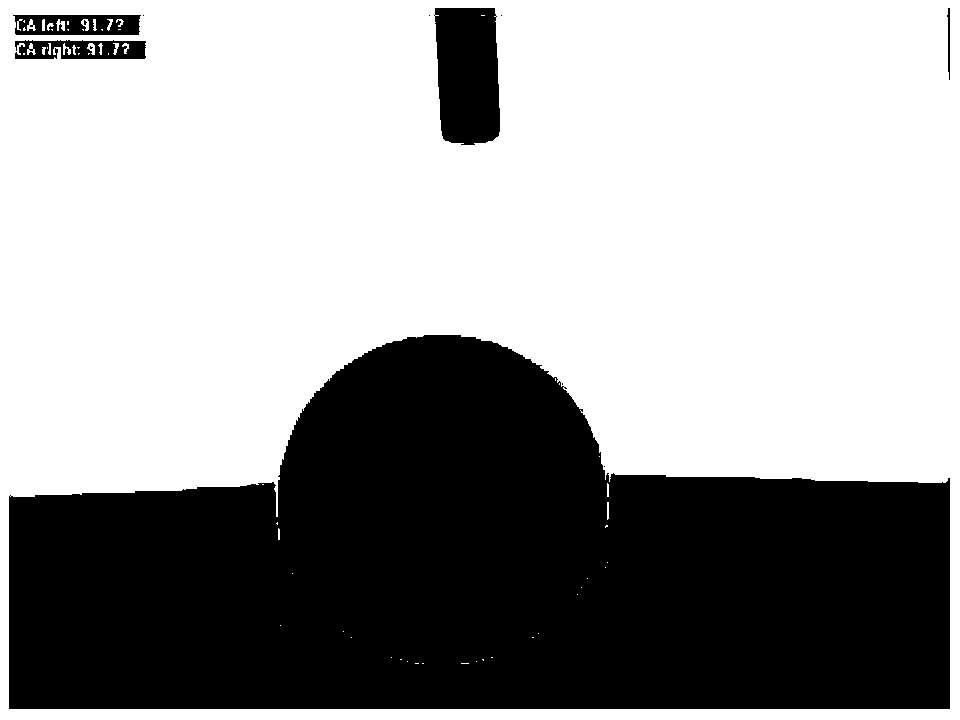

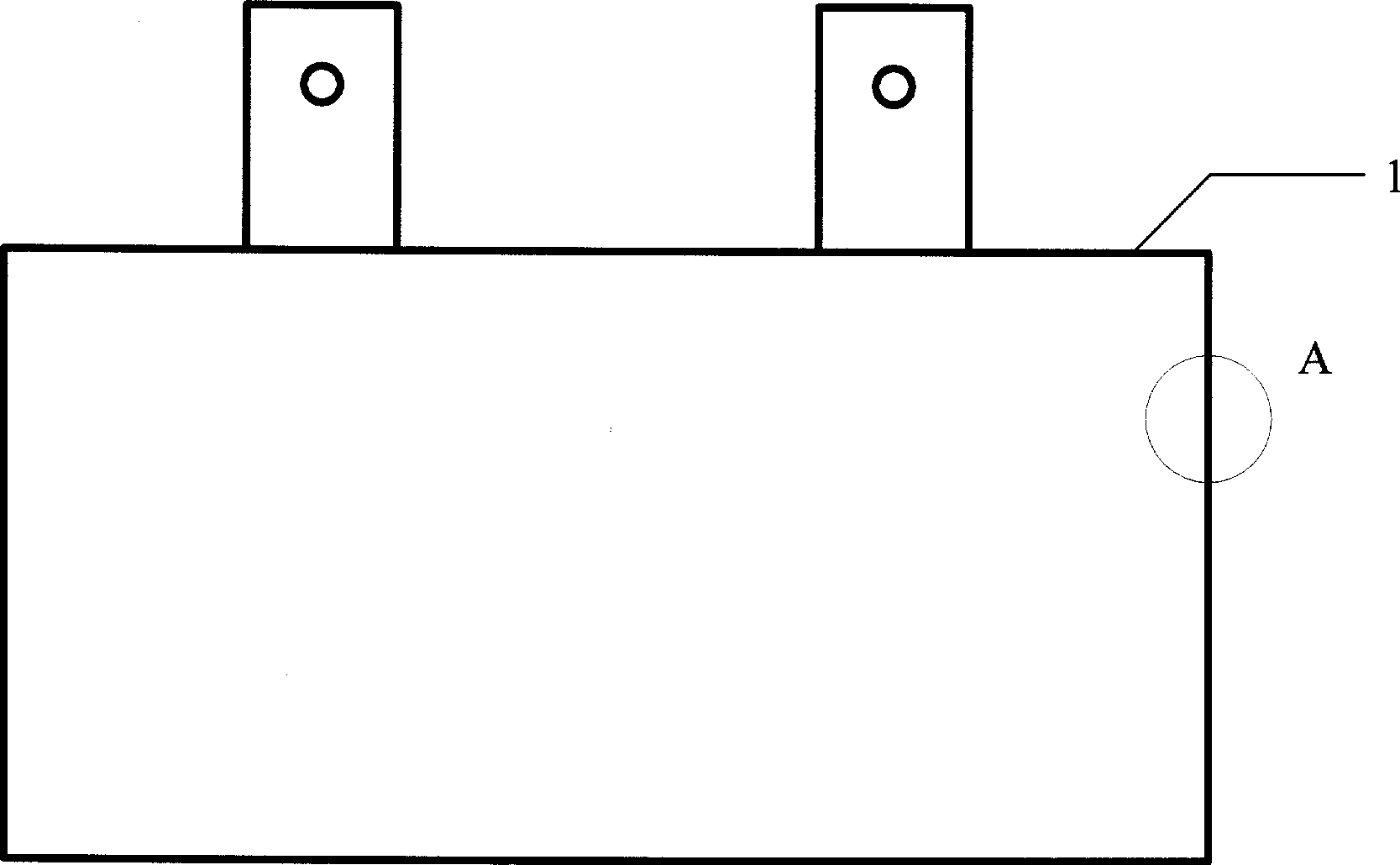

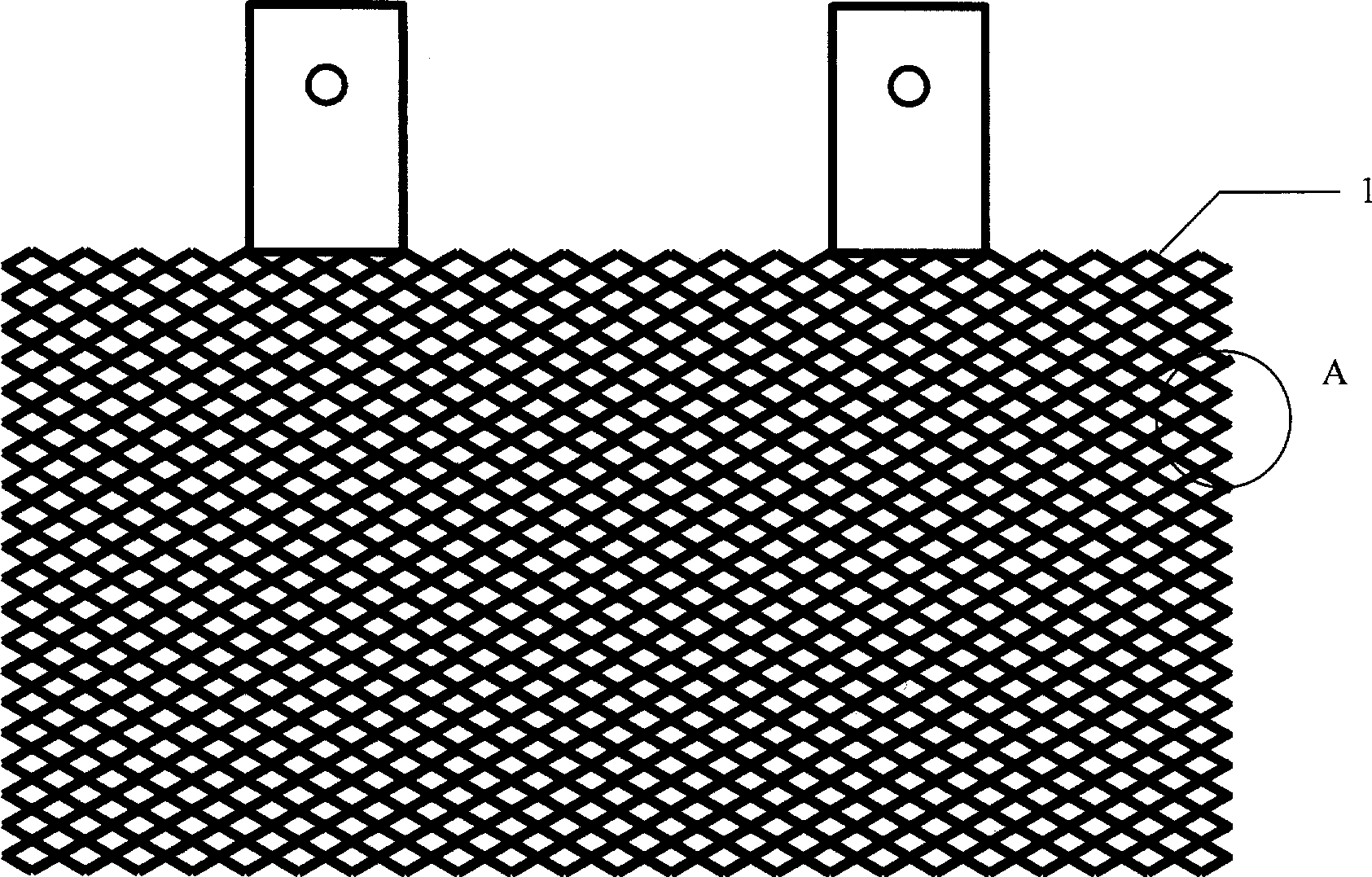

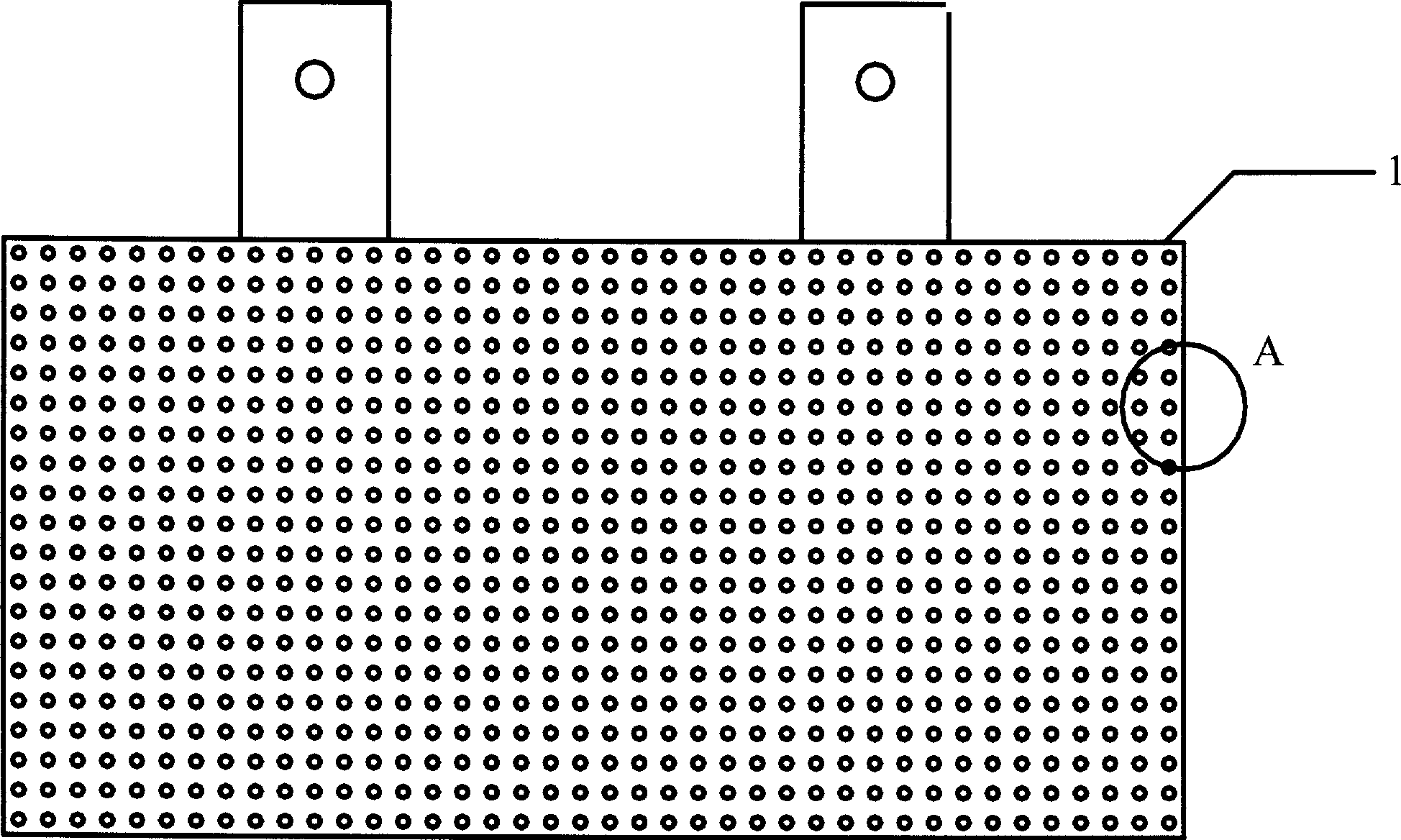

Super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and preparation method and application thereof

InactiveCN103316507AHas super oleophobic propertiesLow costFatty/oily/floating substances removal devicesLiquid separationHydrophilic polymersSewage

The invention discloses a super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and a preparation method and an application thereof. According to the method, fabric mesh with a specification of 100-300 meshes is subjected to ultrasonic cleaning, and is air-dried under normal temperature; a hydrophilic polymer water-sensitive agent and a cross-linking agent are dissolved in water according to a ratio of 1:9-9:1; the mixture is well mixed by magnetic stirring, such that a solution with a concentration of 1-99% is prepared; nano-sol is prepared with a sol-gel method; the solution and the nano-sol are prepared into a mixed solution with a concentration of 1-99%, and the solution is well dispersed through ultrasonic dispersion; the mesh is soaked in the mixed solution and is vertically lifted, or the mesh is directly sprayed by using a high-pressure spraying gun; and the mesh is bake-dried, such that the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane is obtained. Contact angles of the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane with water and oil in air are both 0 DEG, and the membrane is super-hydrophilic. Under water, the contact angle of the membrane with oil drops is larger than 150 DEG, and the membrane has an oil drop low adhesion characteristic. The mesh membrane provided by the invention can be used in oil-water mixture separation and oil-containing sewage processing.

Owner:SOUTH CHINA UNIV OF TECH

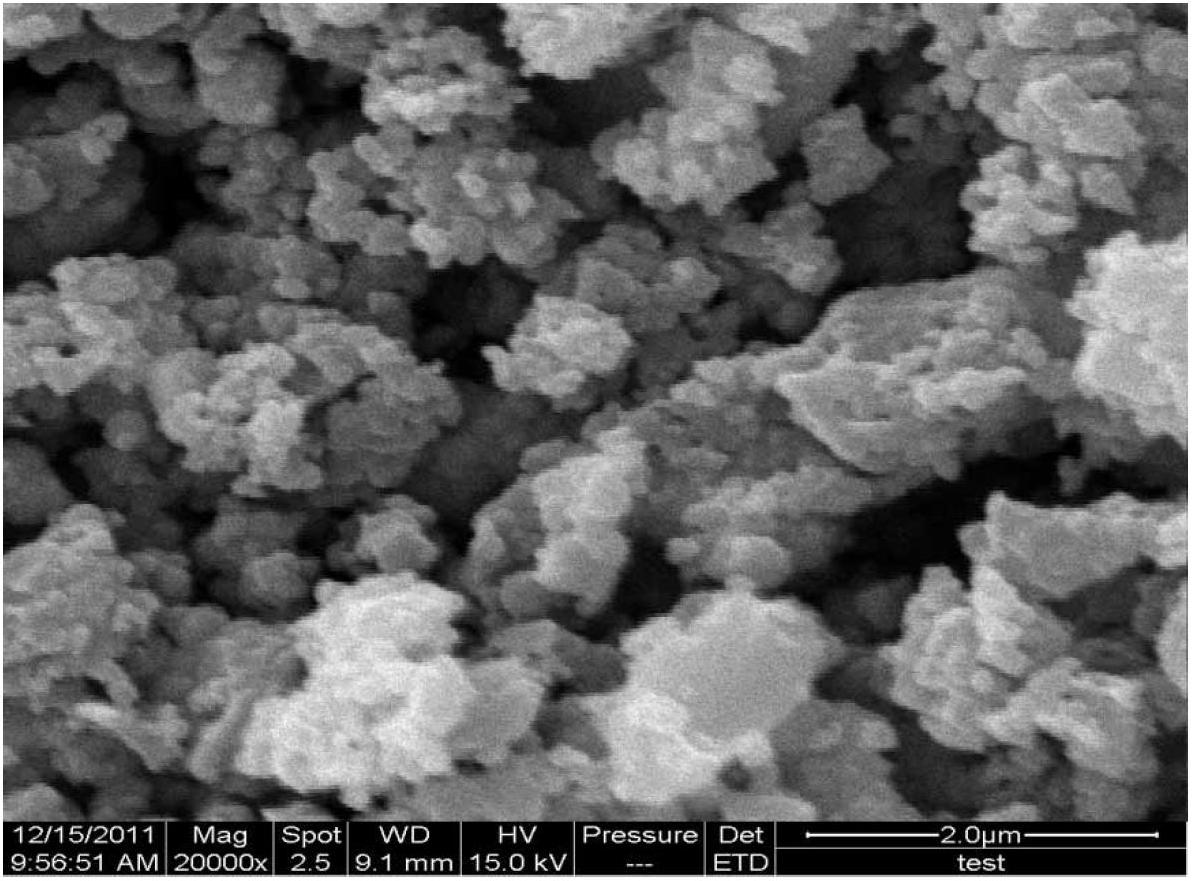

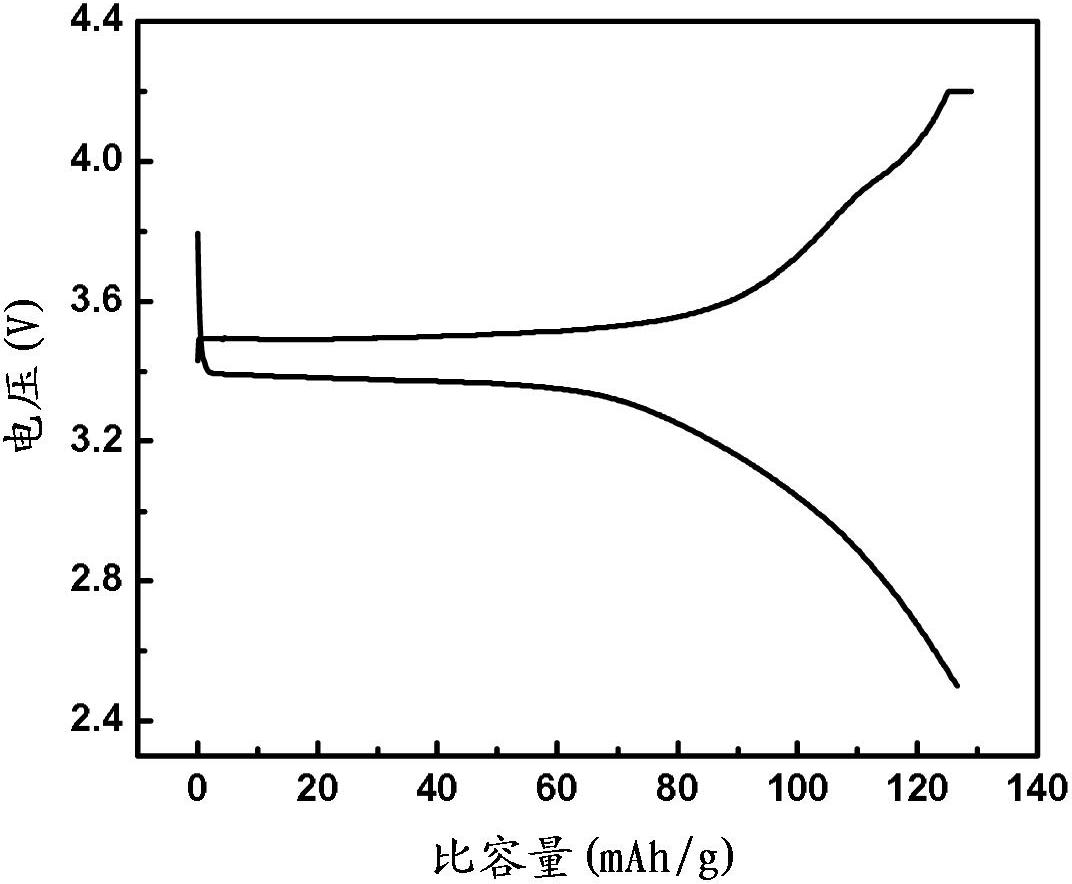

Synthetic recovering method for positive pole waste tablet from ferric phosphate lithium cell

ActiveCN101383441AReduce manufacturing costAchieve recyclingElectrode manufacturing processesSolid waste disposalRecovery methodPhosphate

The invention relates to a synthesized recovery method for waste positive plates of iron phosphate lithium batteries. The method comprises the following steps: collected waste positive plate material is mechanically crashed into fragments; the fragments are positioned in a welding furnace which is protected by vacuum atmosphere, inert gases and / or reducing gases and / or nitrogen and are heat processed in the temperature of 150-750 DEG C; aluminum foil basal bodies are separated from the fragments after heat process by adopting mechanical separation or ultrasonic concussion to obtain a mixture of iron phosphate lithium positive material, conduction agent and caking agent giblets; the mixture of iron phosphate lithium anode material, conduction agent and caking agent giblets is roasted for 8-24 hrs in 80-150 DRG C; the mixture after roasting is classified to control the grain diameter of the powder material to be not more than 20 microns, and the D50 is controlled to be 3-10 microns so as to obtain iron phosphate lithium positive recovery material. The method has simple technique, takes effect fast and reduces the material consumption and production cost of a manufacturer.

Owner:ZHENGZHOU BAK BATTERY CO LTD

Production method of concave convex stick ceramic grain filter

InactiveCN100423808CGood film-hanging performanceImprove stabilityFiltration separationClaywaresRough surfaceWater quality

The invention discloses a produce method for concavo-convex bar ceramsite filtering material. Wherein, the said filter material comprises concavo-convex bar clay, coal gangue and volcanic ash, and is produced by burdening, milling, granulating, baking, screening and packaging. The filter material has rough surface, well bonding film property, small flow resistance, and well stability and adsorption properties. This invention needs low cost and baking temperature, can save much energy, has no secondary pollution and fit to water purification treatment.

Owner:许盛英

Method for treatment and in-situ ecological restoration of black and stink riverway by using microorganism

InactiveCN102050523AReduce organic matterGood governanceWater resource protectionBiological water/sewage treatmentMicroorganismWater treatment system

The invention discloses a method for treatment and in-situ ecological restoration of a black and stink riverway by using microorganism. The invention is characterized in that target strains with pertinence are selected from sewage and then matched and combined with the existing strains to form compound microbial agents; and the sewage in the riverway is treated by using the matched compound microbial agents. In the invention, according to the specific pollution conditions of the riverway, the selected strains which are grown in the sewage are used to treat the sewage in the riverway, and the strains are matched and combined with the existing strains aiming at the pollution conditions of the water body in the riverway, so that the strains can exert synergistic effects in a microorganism sewage treatment system, thereby rapidly forming superior floras so as to decompose, absorb and transfer pollutants in the riverway and then achieving the optimum treatment efficiency. In the invention, the microorganism is firstly used to treat the water body, and then the water body is treated through the self-cleaning capability of the water body, thereby reaching the purpose of curing the exterior and the inherence and not generating secondary pollution. The method has the characteristics of safety, high efficiency, low cost, small investment and the like, and is simple to operate.

Owner:赵亚勋 +3

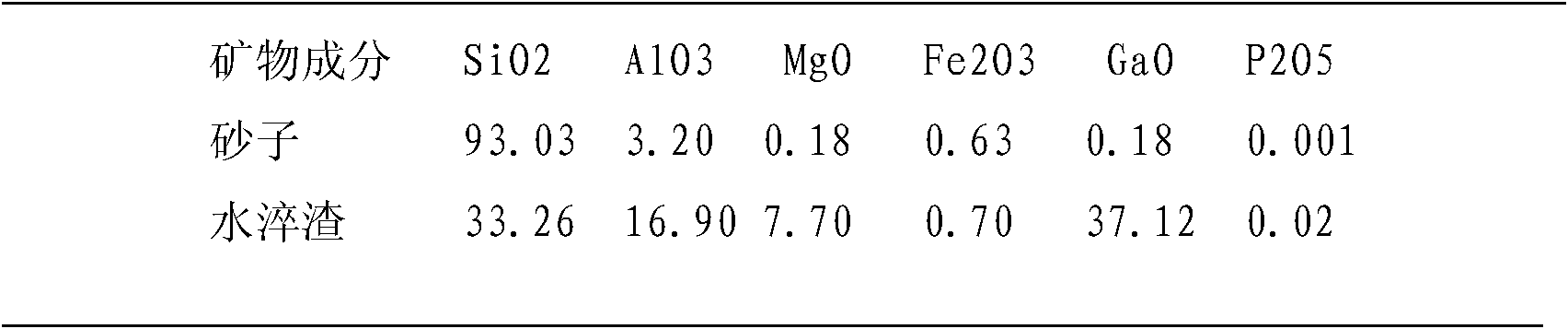

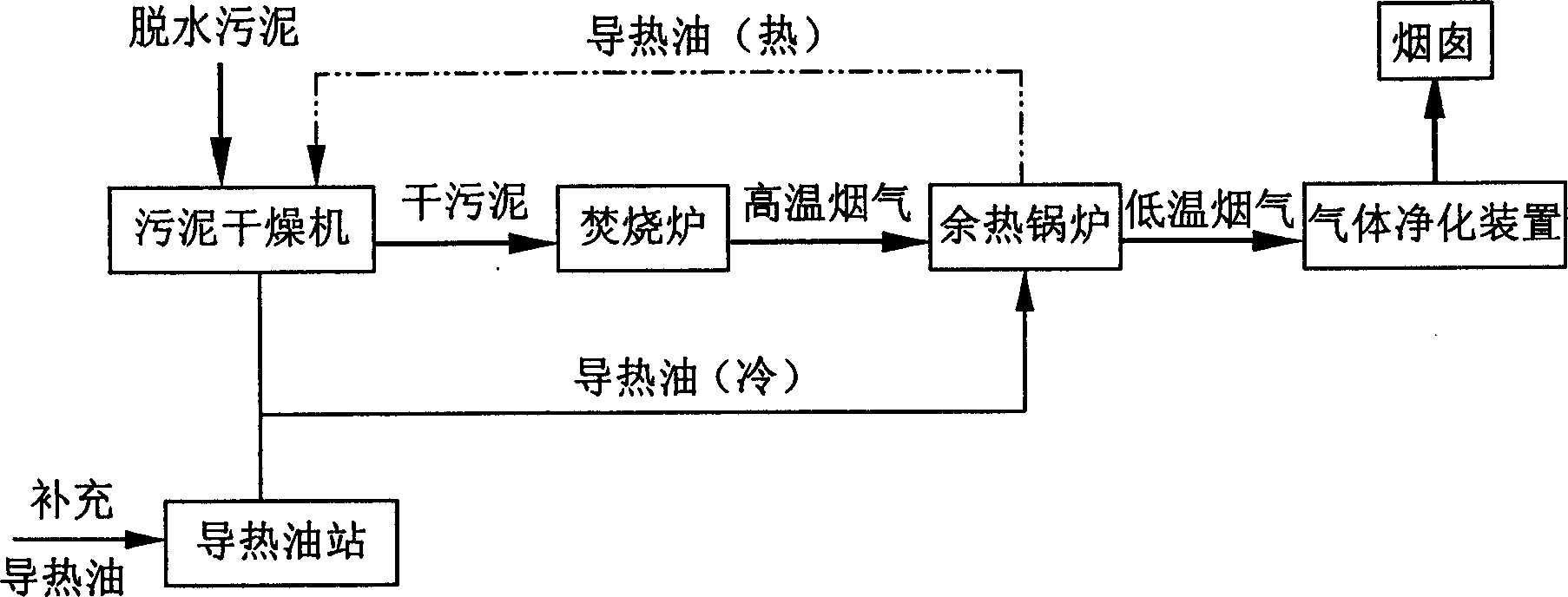

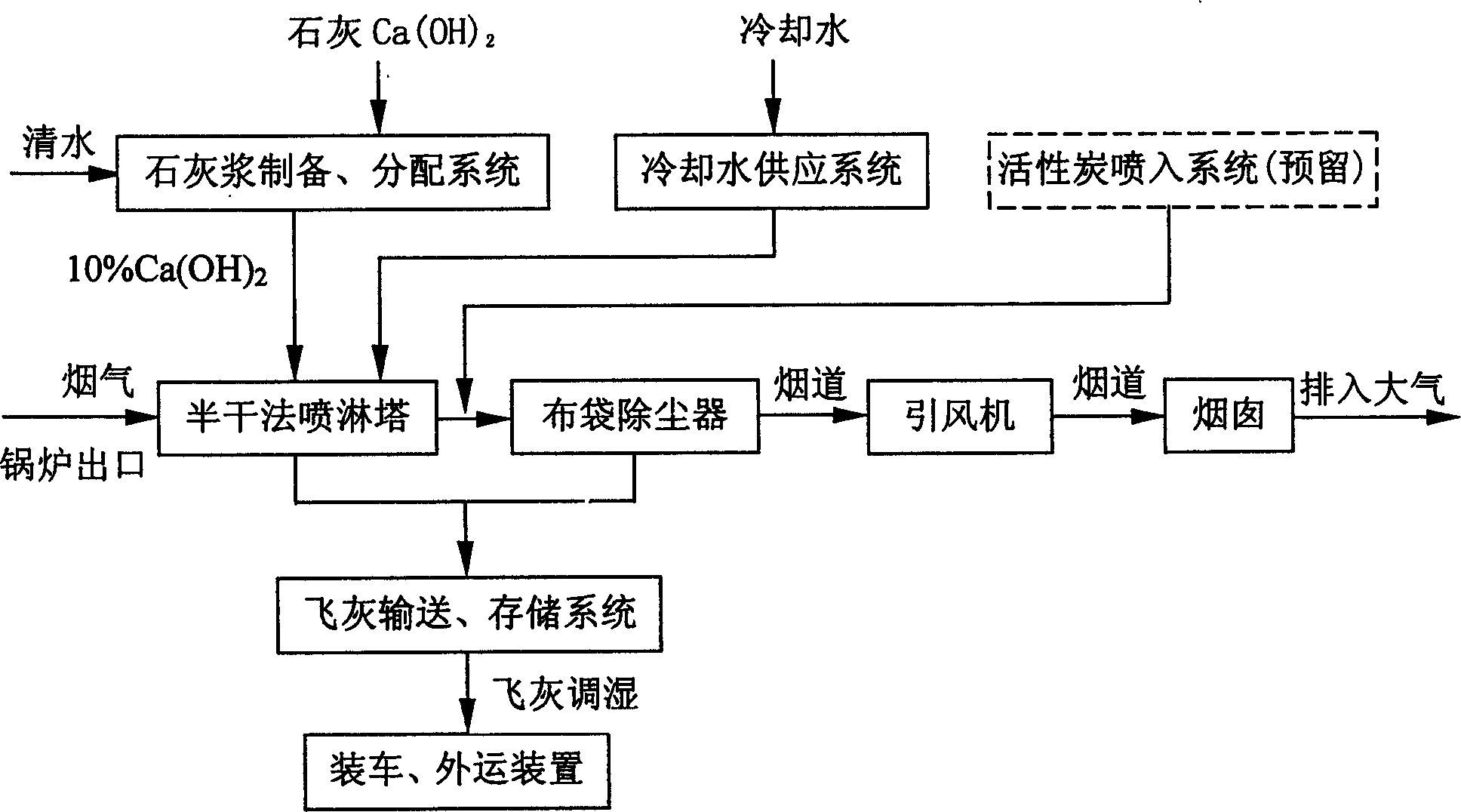

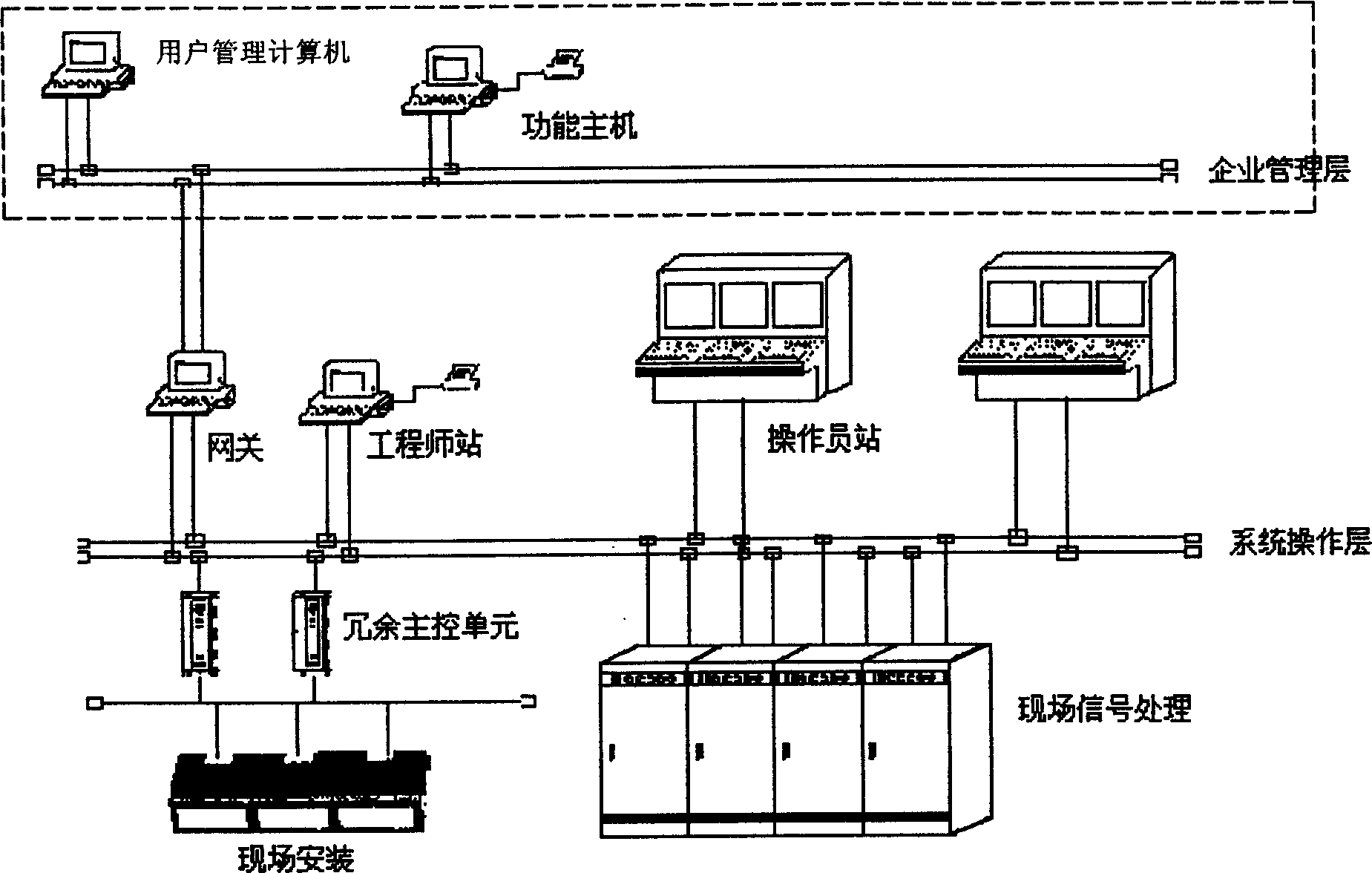

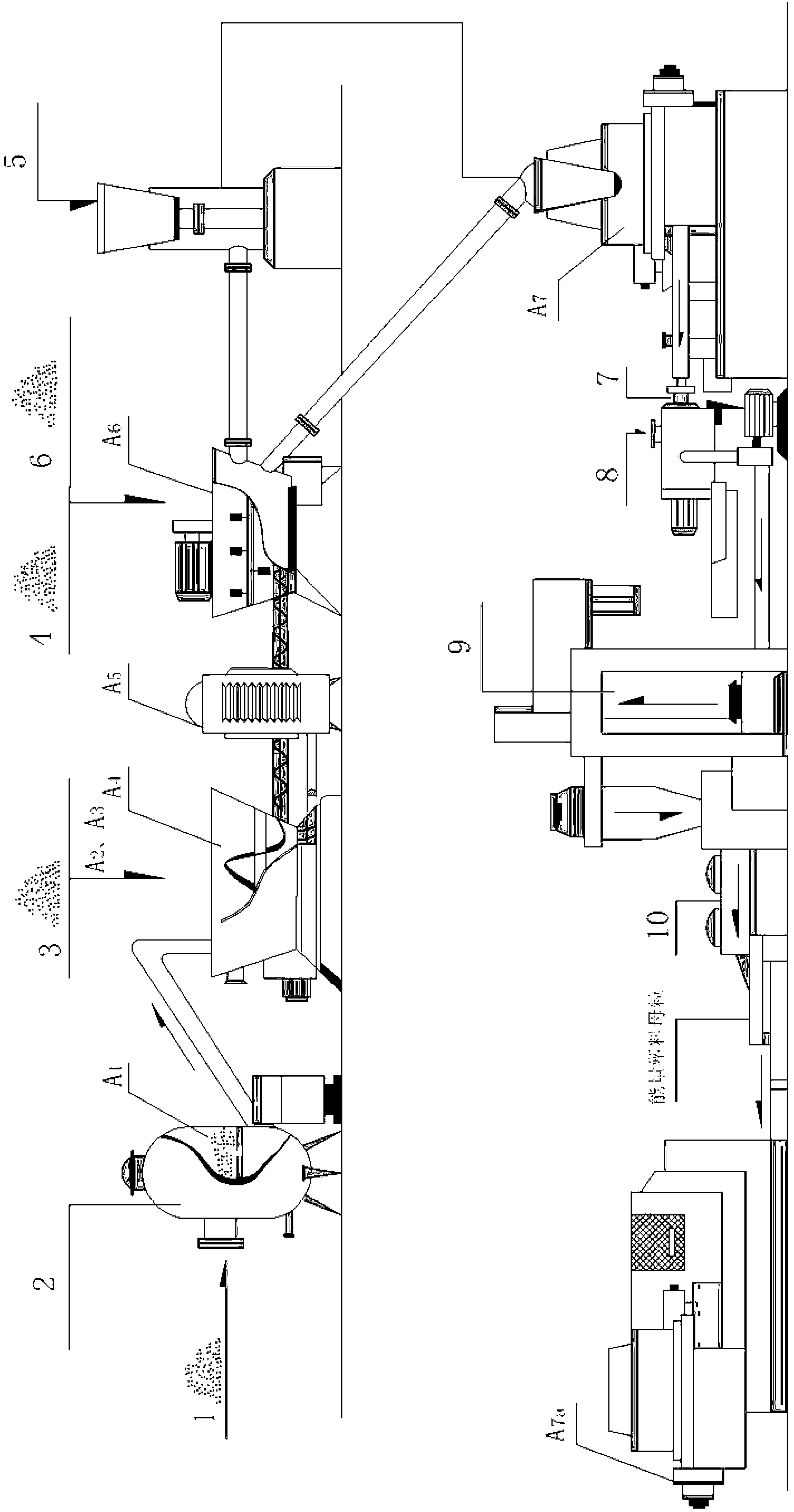

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

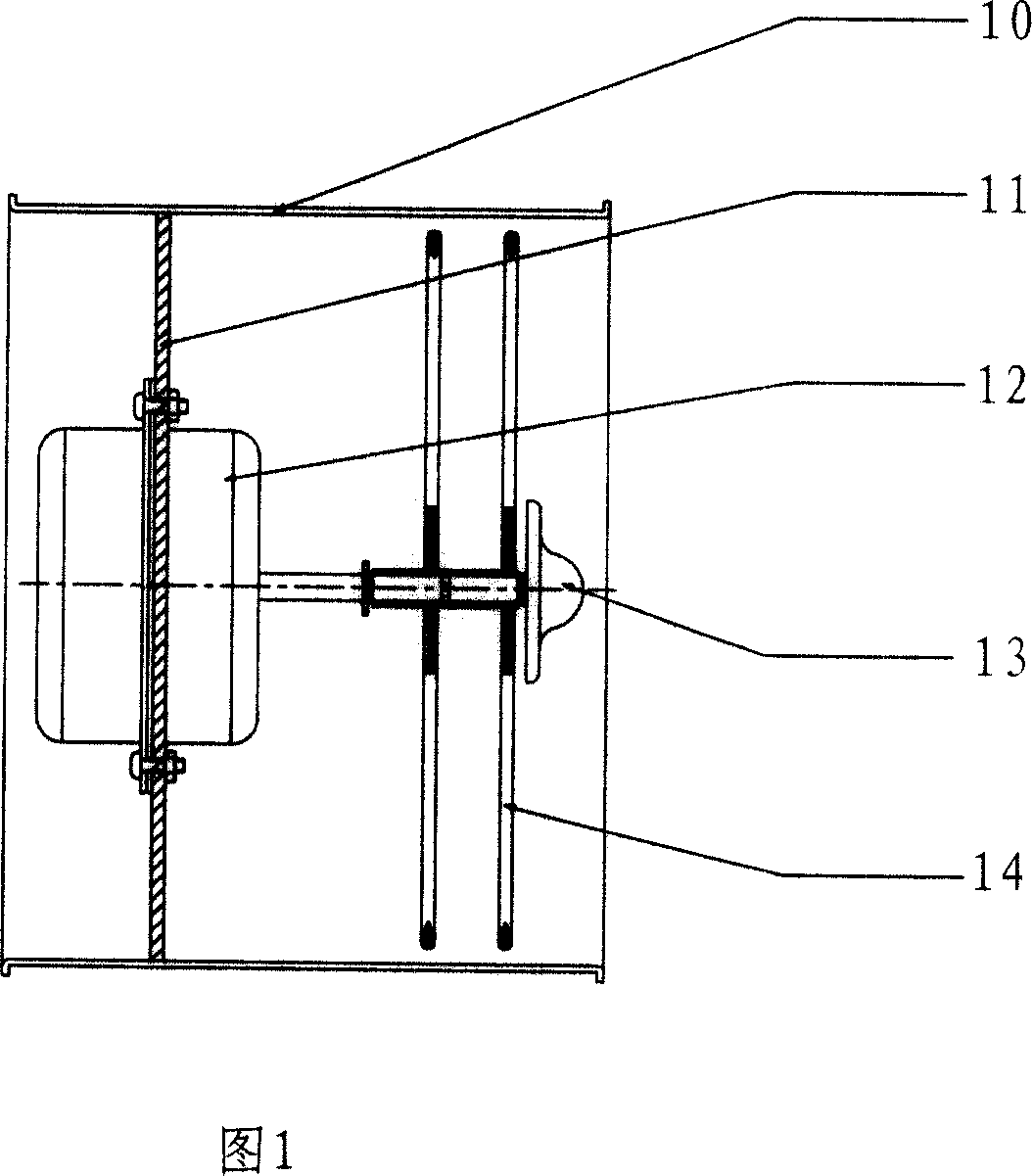

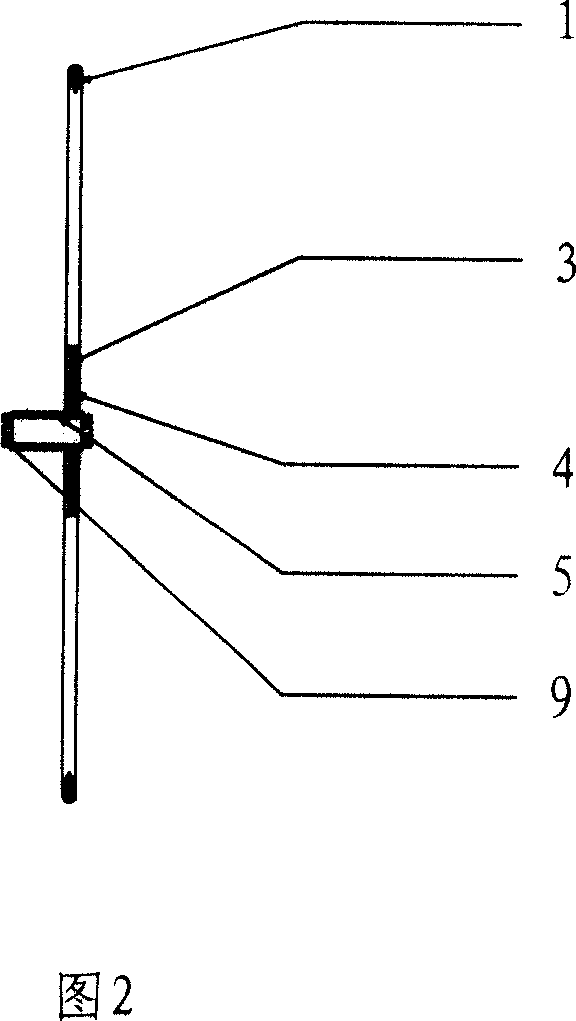

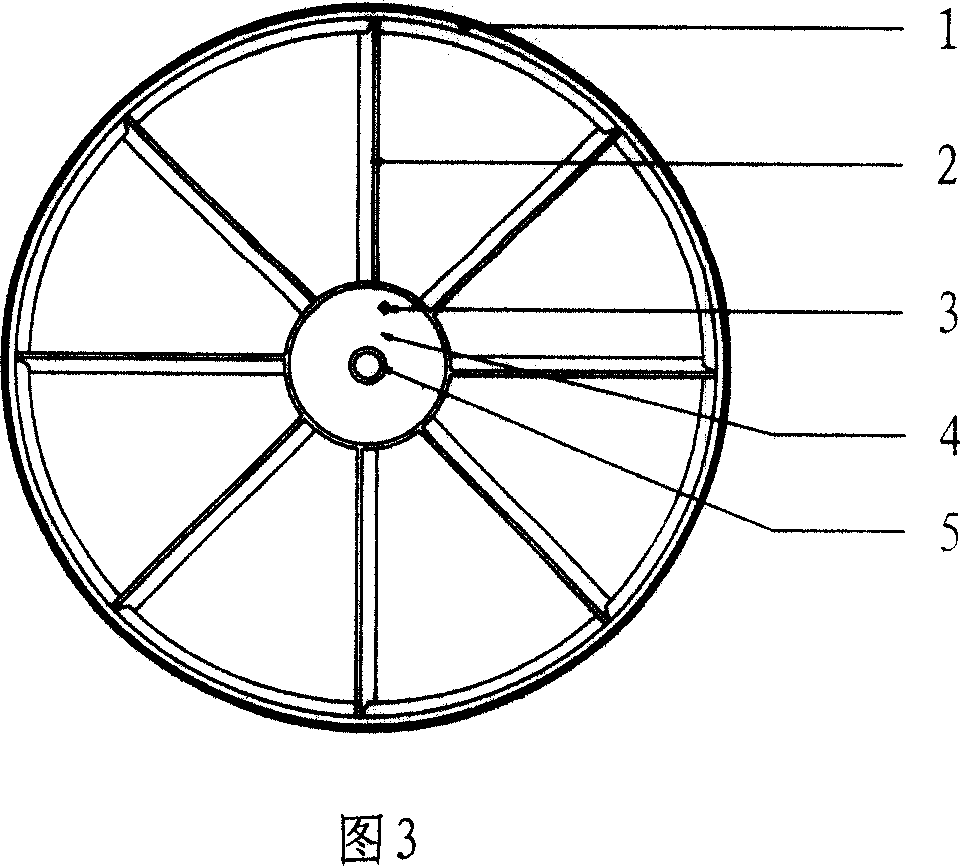

Air dust centrifugal purifier and method for making rotary filter net disk

ActiveCN101028575AEasy to recycleSimple structureDispersed particle filtrationEngineeringMechanical engineering

A centrifugal cleaning apparatus for the air or fume, such as treating oil soot, exchanging air, and desulfurizing fume, features that at least one rotary netted filter disc is arranged to the axle of a motor in an air guiding cylinder. Said rotary netted filter disc is composed of a disc skeleton and a radiant filtering net wound uniformly on said disc skeleton. A method for preparing said rotary netted filter disc is also disclosed.

Owner:武汉创新环保工程有限公司

Novel method for innocent treatment and utilization of dead livestock and poultry

InactiveCN101182247ASave energyNo secondary pollutionBio-organic fraction processingInternal combustion piston enginesSlagSludge

The invention discloses a novel method of the harmless treatment and utilization of livestock and poultry which died of disease according to the steps as follows: firstly, various kinds of the animal bodies of the livestock and the poultry which died of disease are collected; secondly, the animal bodies are crushed; thirdly, the crushed animal bodies are sterilized under high temperature and highpressure and separated for filtering, the material of oil and fat flows into a cooling pool, and the material of hair and bone is dried; fourthly, the material of hair and bone after drying is carbonized; fifthly, the material of oil and fat after cooling is added with catalyst, high-efficiency compound microorganism, trash, organic wastewater and sludge; sixthly, the mixed organic material is put into an anaerobic tower to be fermented, and then biogas, biogas slurry and biogas slag are processed for three-phase separation; seventhly, the biogas is used for burning and generating electricity; eighthly, the biogas slurry inside a fertilizer storing pool is used as farmland fertilizer; ninthly, the biogas slag is added with the high-efficiency compound microorganism and the catalyst for secondary ferment; tenthly, the material after the secondary ferment is made into agricultural high-efficiency organic fertilizer. The invention solves the problem of the environmental pollution caused by the livestock and poultry which died of disease and change the waste livestock and poultry which died of disease into valuables.

Owner:浙江威尔斯生物能源开发有限公司

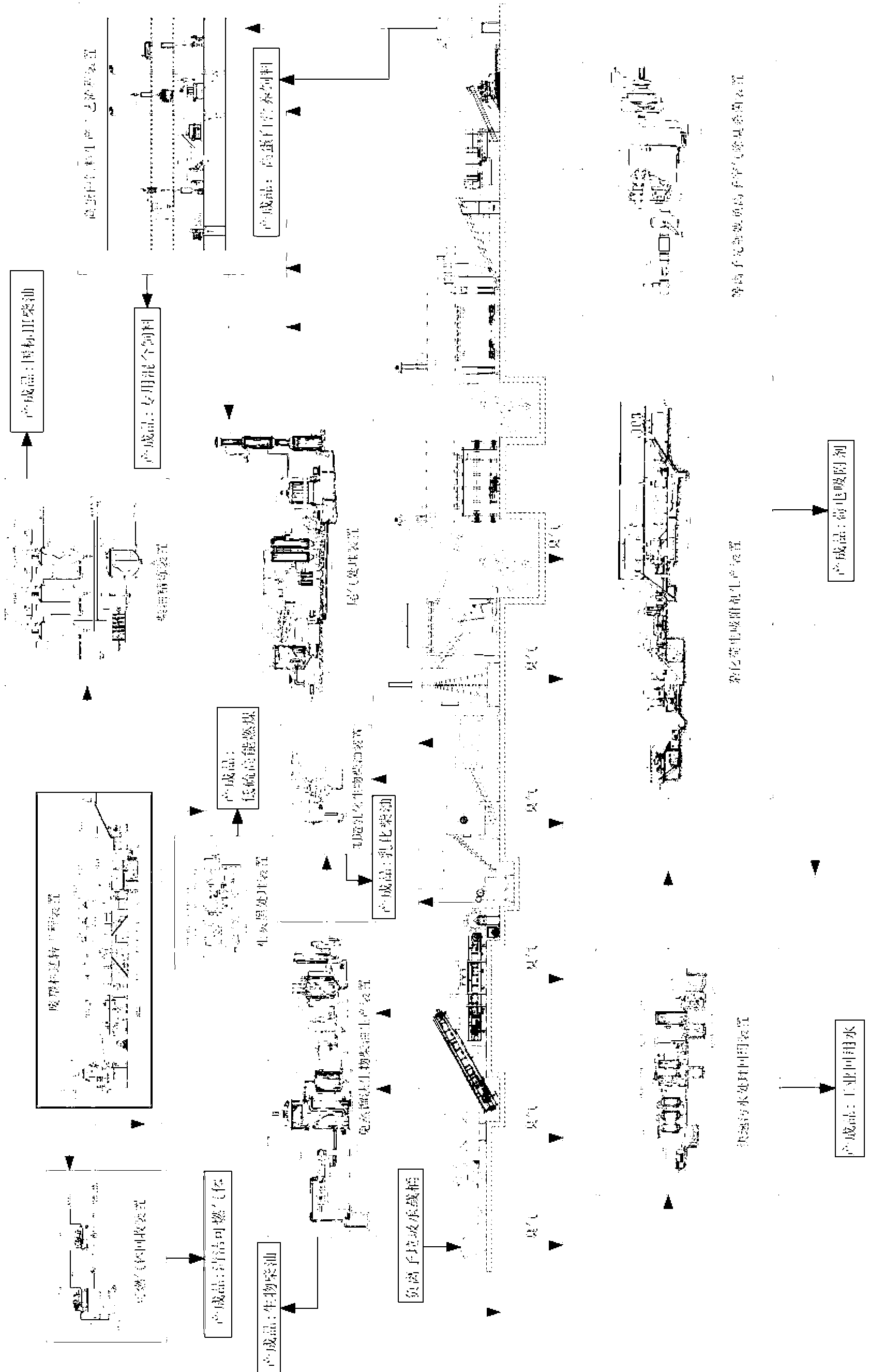

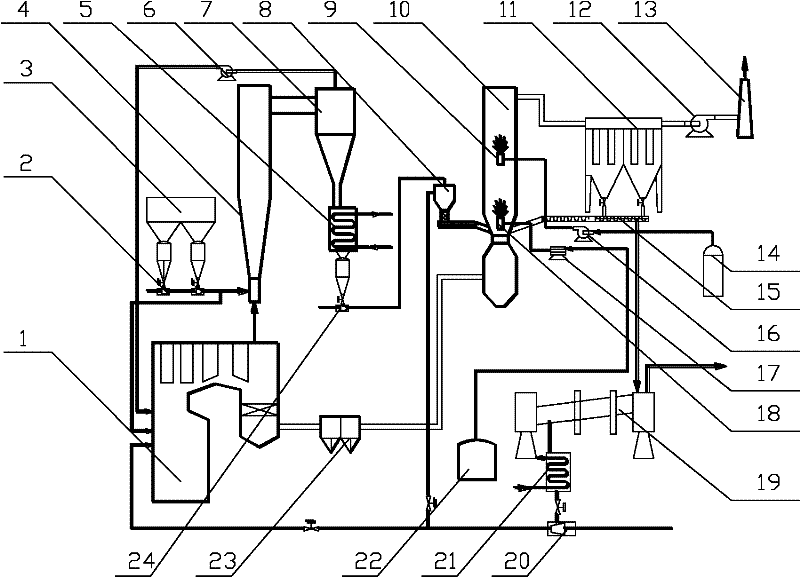

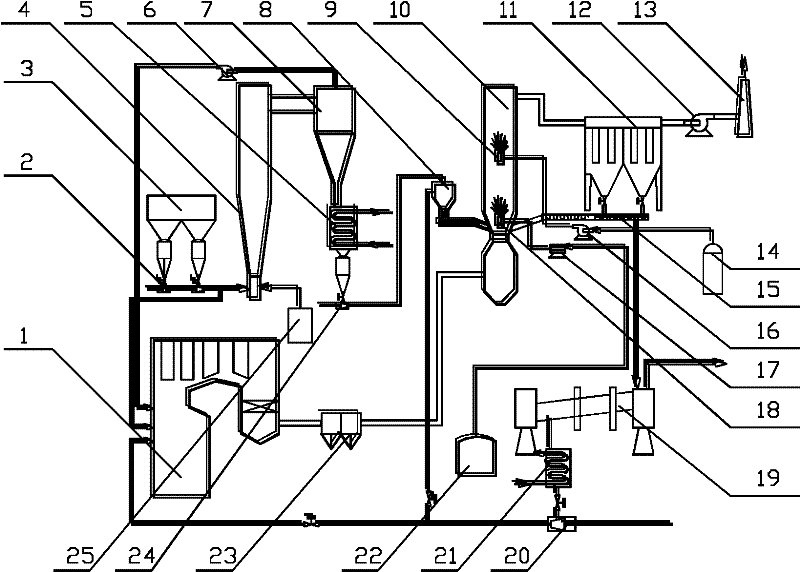

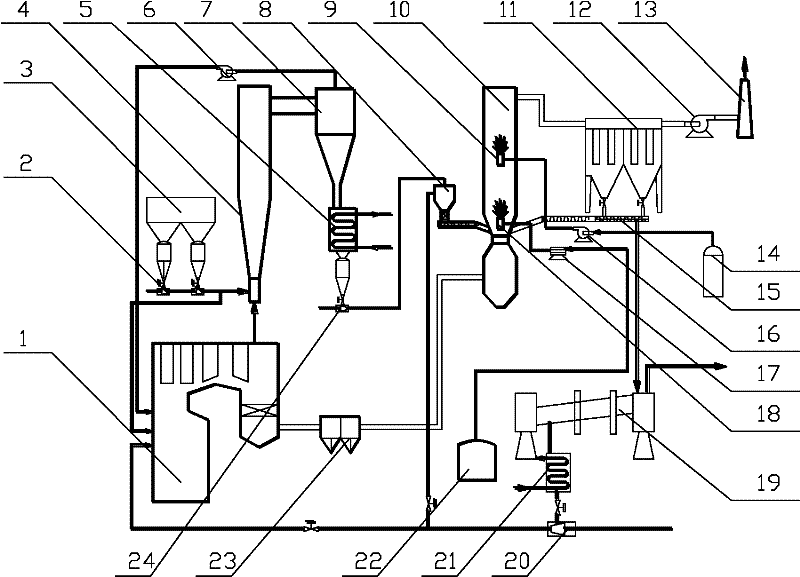

Integrated equipment for omnibearing treatment of kitchen garbage and production method of products

InactiveCN103071666ANo secondary pollutionIncrease added valueSolid waste disposalBiofuelsAutomatic controlBiodiesel

The invention discloses integrated equipment for omnibearing treatment of kitchen garbage and a production method of products. The equipment comprises a central intelligent automatic control system, an air treatment system, a straw biochemical system, an advanced oxidization artificial forced inactivation system, a combined screening and impurity removal system, a compound biochemical system, an automatic drying system, a combined conveying system, a waste plastic reversion engineering system, a sludge treatment system, a sewage treatment system, an oil treatment system and a hot smoke combined treatment system. Produced finished products comprise high-nutrition microbial protein feed, mineral state III diesel, biodiesel, emulsification diesel, low-sulfur clean fire coal, hybrid charge adsorbents and industrial recycle water. A recycling rate of the kitchen garbage reaches above 95%; basically no waste water is discharged, no sludge is transferred, no room temperature discharge exists, no peculiar smell or smoke is discharged and no residue is transferred during production; and the environment-friendly, safe and reliable highly-integrated production equipment and the production method are provided for the treatment of the kitchen garbage.

Owner:SOUTH CHINA REBORN RESOURCES ZHONGSHAN

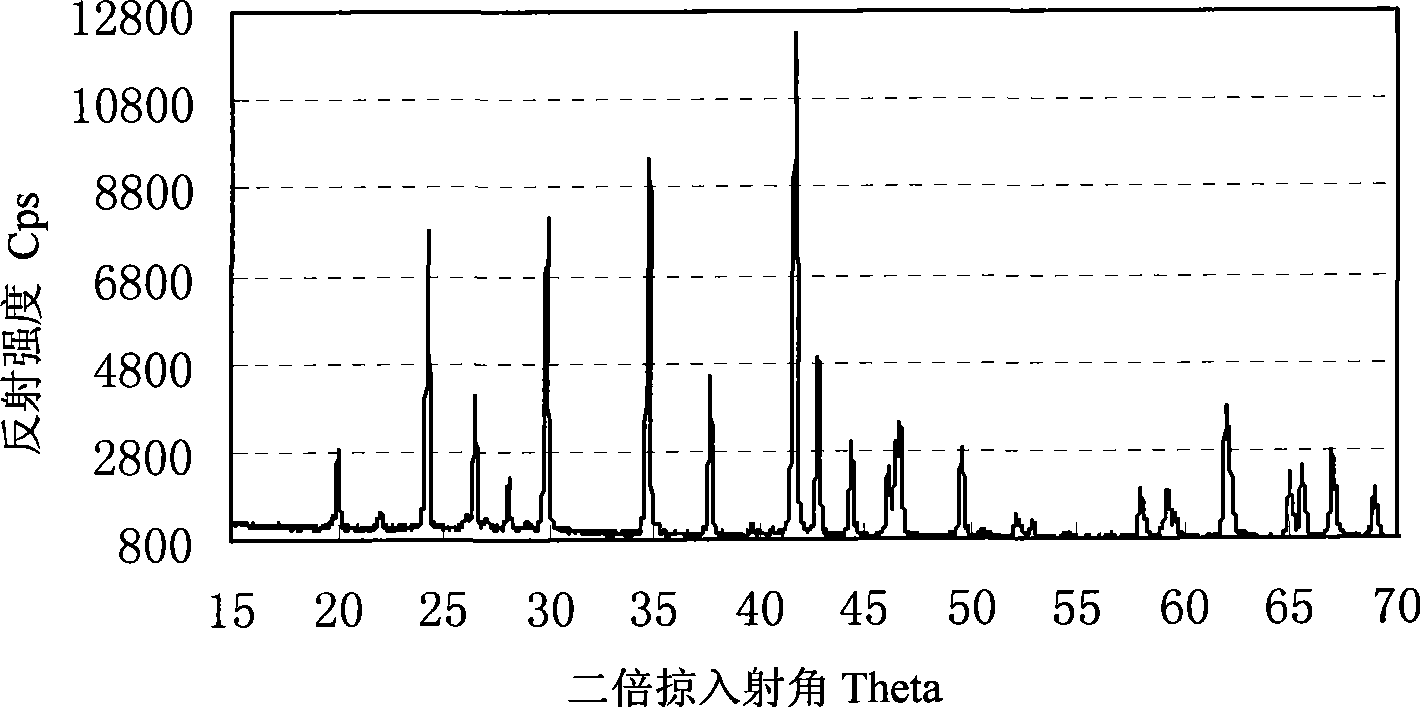

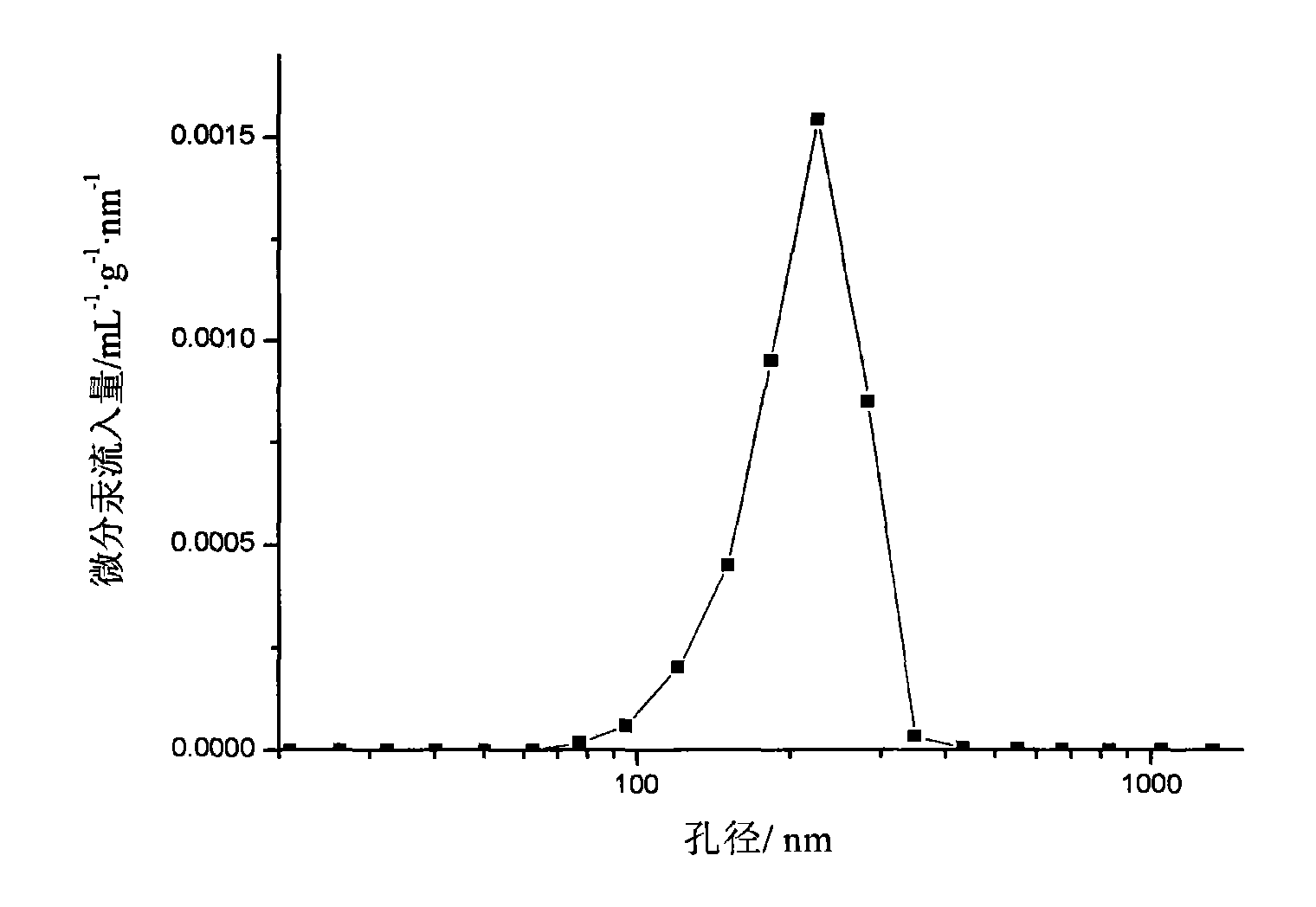

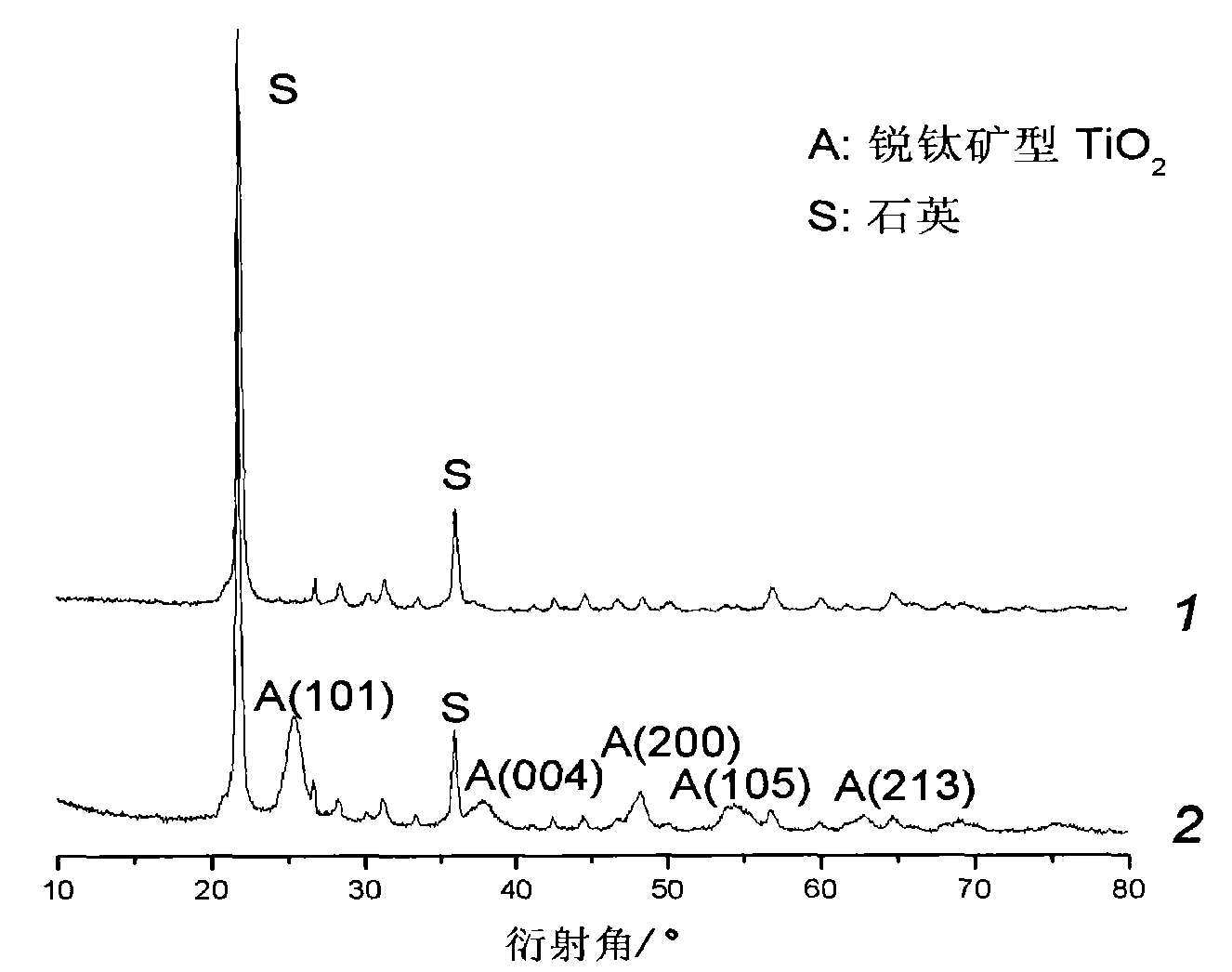

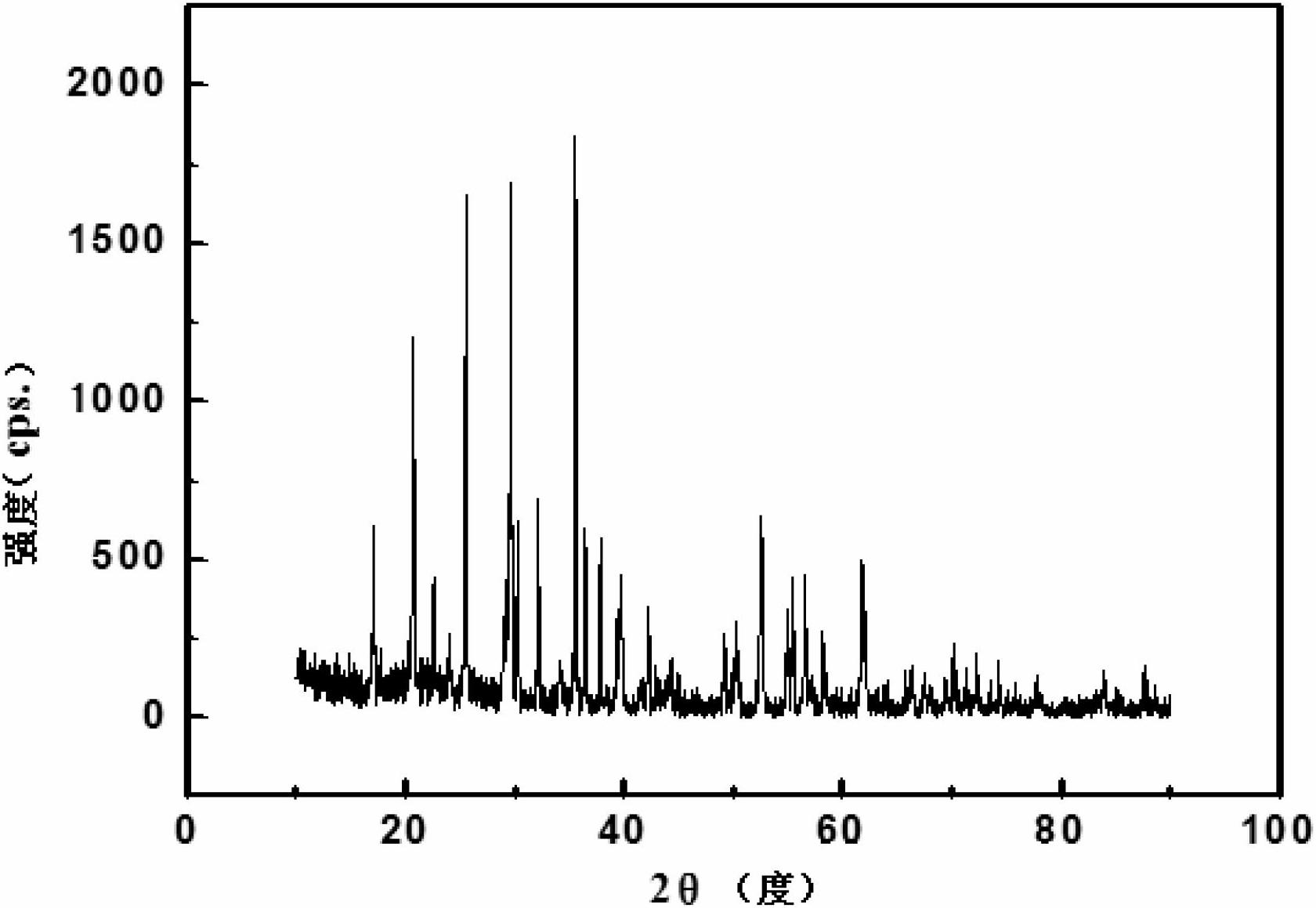

Kieselguhr-based porous ceramics and method for loading Ag doped with nano TiO2 on same

The invention relates to a kieselguhr-based porous ceramics, a preparation method thereof and a method for loading Ag doped with nano TiO2 on the same, belonging to the technical field of a kieselguhr inorganic material. The kieselguhr-based porous ceramics is made from kieselguhr, a sintering auxiliary agent, a dispersing agent, a binder and water in the weight ratio of 60-92:8-40:0.01-2:0:001-1:100-450. The kieselguhr-based porous ceramics has functions of absorption and filtration, and can absorb granules in fluid when the fluid passes through the lieselguhr-based porous ceramics. Ag doped with nano TiO2 is loaded on the kieselguhr-based porous ceramics to generate kieselguhr-based porous ceramics loading the Ag doped with TiO2. The laden anatase-type nano TiO2 has large specific surface area. The effects of filtration, photochemical catalysis and sterilization of the kieselguhr-based porous ceramics loading the Ag doped with nano TiO2 are greatly increased.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

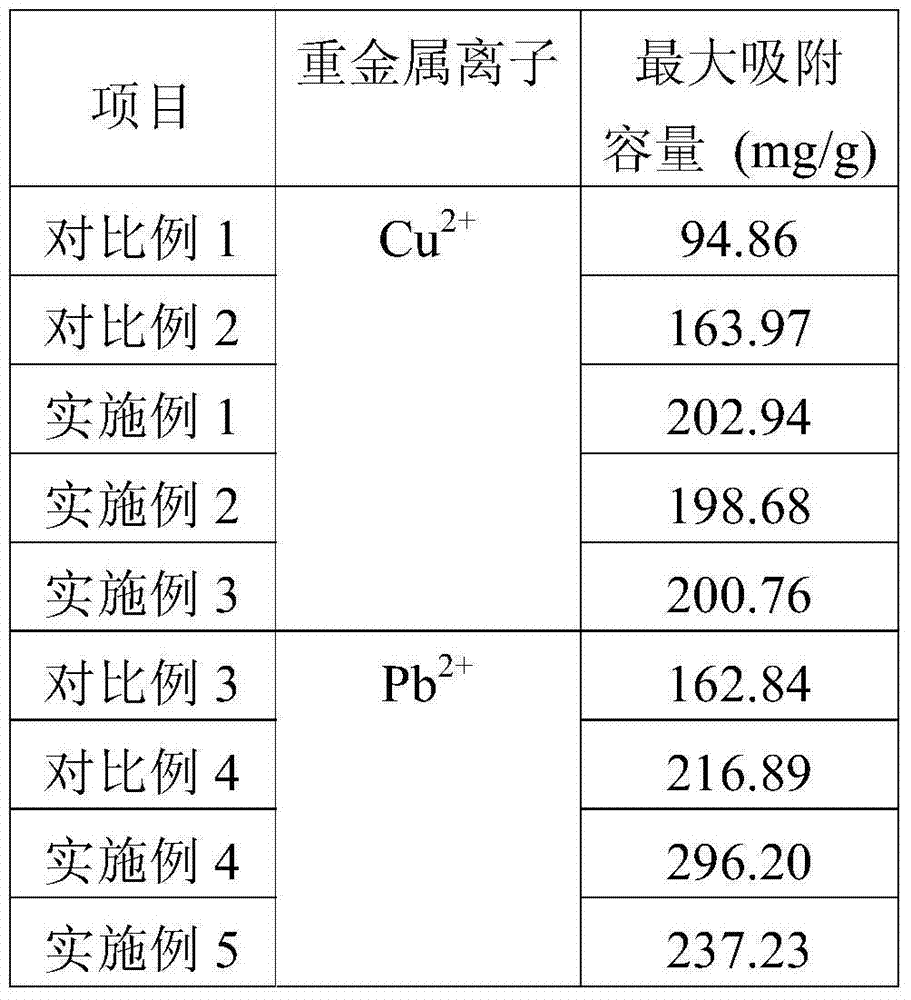

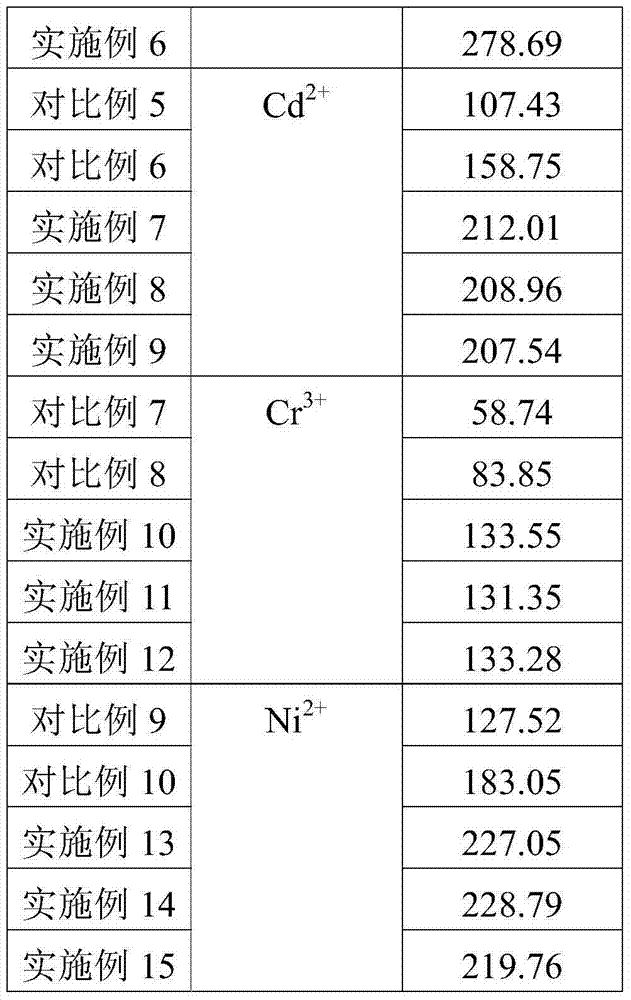

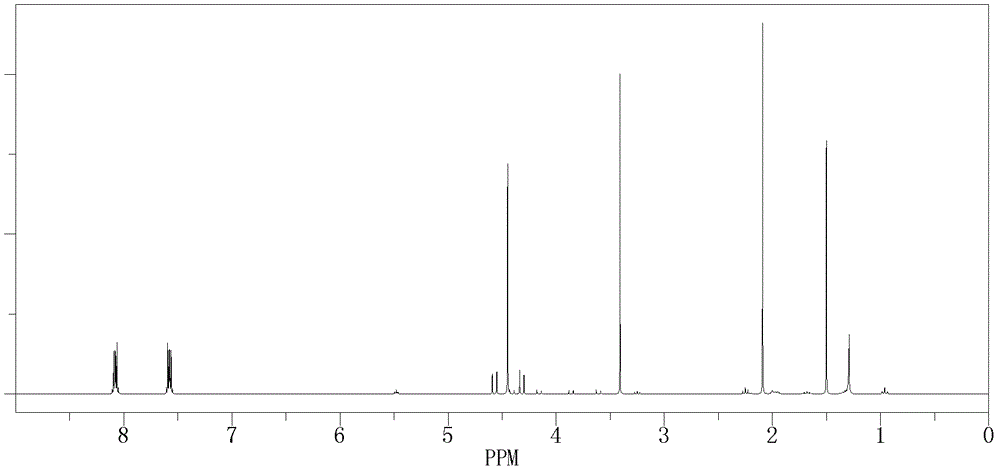

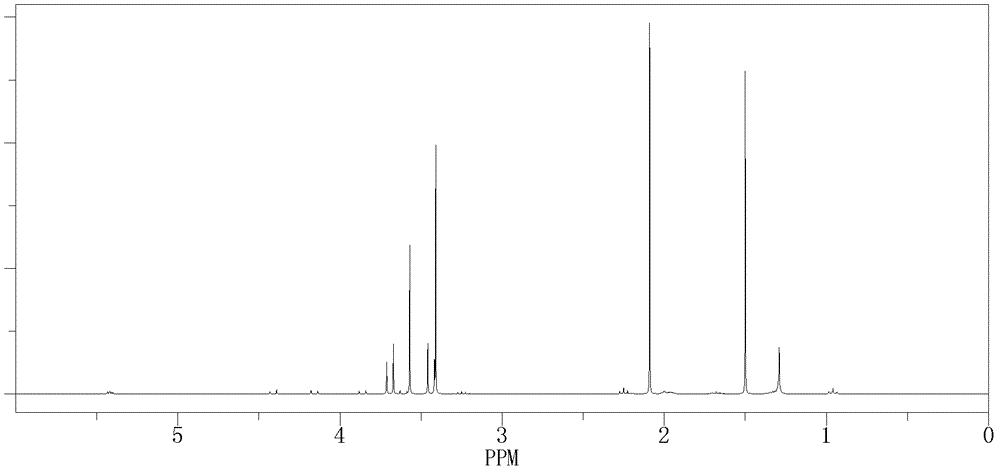

Composite hydrogel for adsorption of heavy metal ions and preparation method thereof

ActiveCN104226281ASimple preparation processGood biocompatibilityOther chemical processesAlkali metal oxides/hydroxidesIonHeavy metals

The invention discloses composite hydrogel for adsorption of metal ions and a preparation method thereof. The hydrogel comprises, by weight, 5-95 parts of polyvinyl alcohol, 5-95 parts of chitosan, 0.1-20 parts of modified graphene oxide and 2-6 parts of sodium alginate, the weight ratio between the polyvinyl alcohol and the chitosan is (5: 95)-(95: 5), modified graphite oxide includes modified graphene oxide modified by dopamine and / or modified graphene oxide modified by ferroferric oxide, all components are uniformly mixed in a certain sequence, and the composite hydrogel is obtained under special conditions. The composite hydrogel for adsorption of the heavy metal ions and the preparation method thereof have the advantages that high speed, high efficiency, high adsorption capacity and high selectivity are achieved, the adsorption effect on the heavy metal ions is remarkable, meanwhile, the preparation process is simple, and the operability is high.

Owner:JIANGNAN UNIV

Formaldehyde scavenging agent with oil solubility and preparation method

InactiveCN103055465AImprove purification efficiencyImprove practicalityPreparation by ester-hydroxy reactionPolyester coatingsSocial benefitsSolubility

The invention relates to the chemical technology field, and concretely relates to a formaldehyde scavenging agent with oil solubility and a preparation method and a usage method. The formaldehyde scavenging agent with oil solubility can be prepared to paint, and can be used for coating on the furniture, floor or other decoration sheet materials, and has good purification efficiency on indoor free formaldehyde, and no secondary pollution can be generated. On the premise of no change of the sheet material application and construction technology in the prior art, and the release of indoor formaldehyde can be fundamentally controlled. The preparation method is simple, the usage is convenient, and the formaldehyde scavenging agent is suitable for large-scale production and business application for enterprises, has good application prospect, and has obvious economy and social benefit.

Owner:上海格伦化学科技有限公司

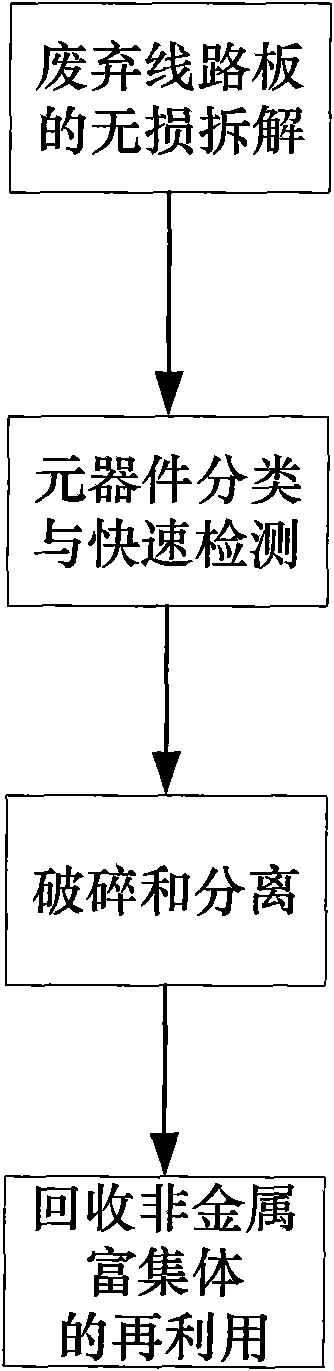

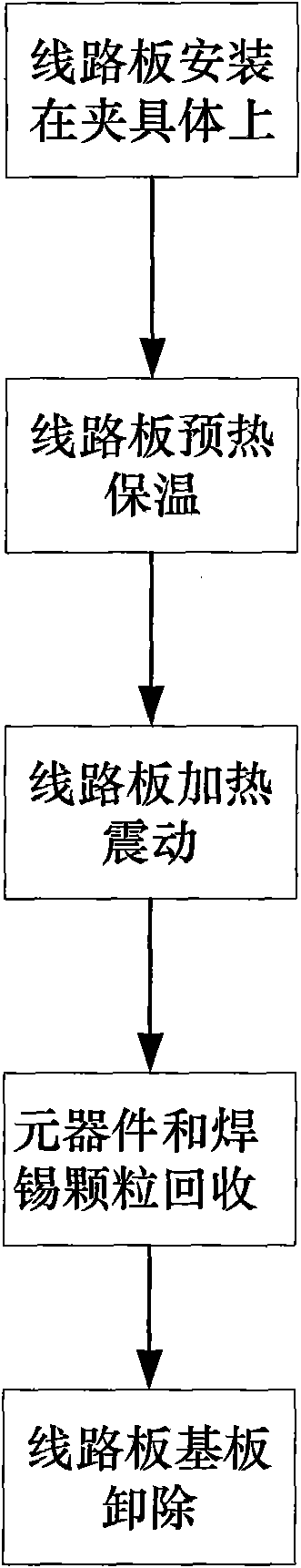

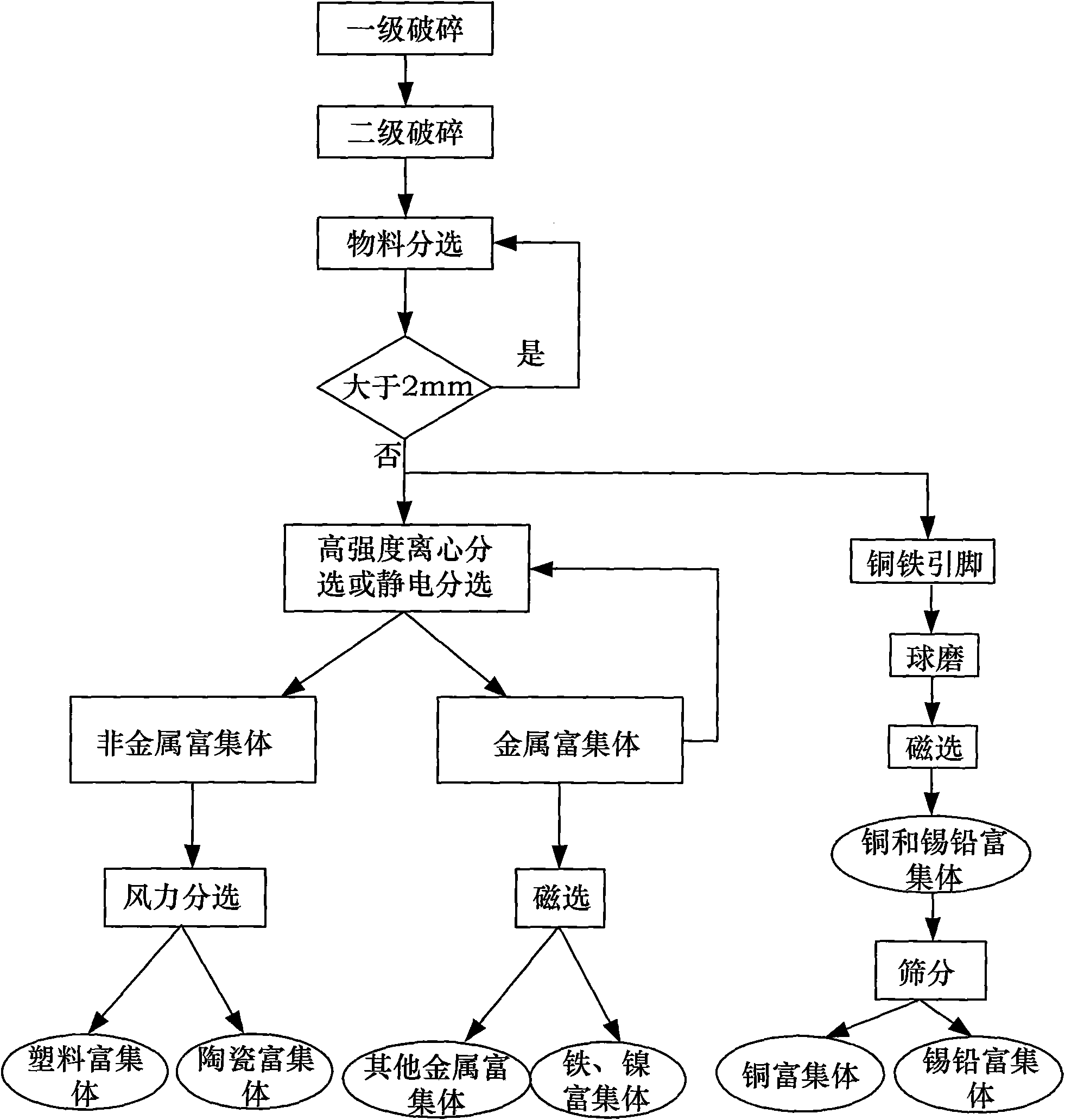

Recycling method of discarded circuit board

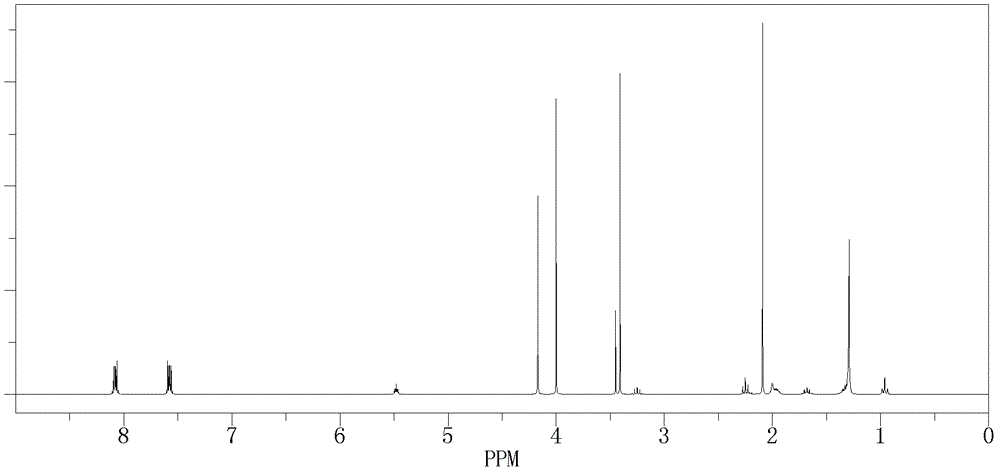

InactiveCN101642765ARealize separation and recoverySimplified brokenSolid waste disposalSoldering apparatusEngineeringMetal powder

The invention discloses a recycling method of discarded circuit boards, comprising the following steps: disassembling a discarded circuit board into three parts: a base plate, components and solder, then carrying out sorting and rapid detection on disassembled components; respectively crushing and separating the base plates and various loss-of-function components, and recycling the crushed and separated various powders, wherein the metal powder can be directly reused, and the recycled non-metal powder is used for being prepared into compound material. The method provided by the invention can realize sorting recycling of all resources of the discarded circuit boards; the recycled material can be reused, and therefore, the secondary pollution can not be generated.

Owner:BEIHANG UNIV

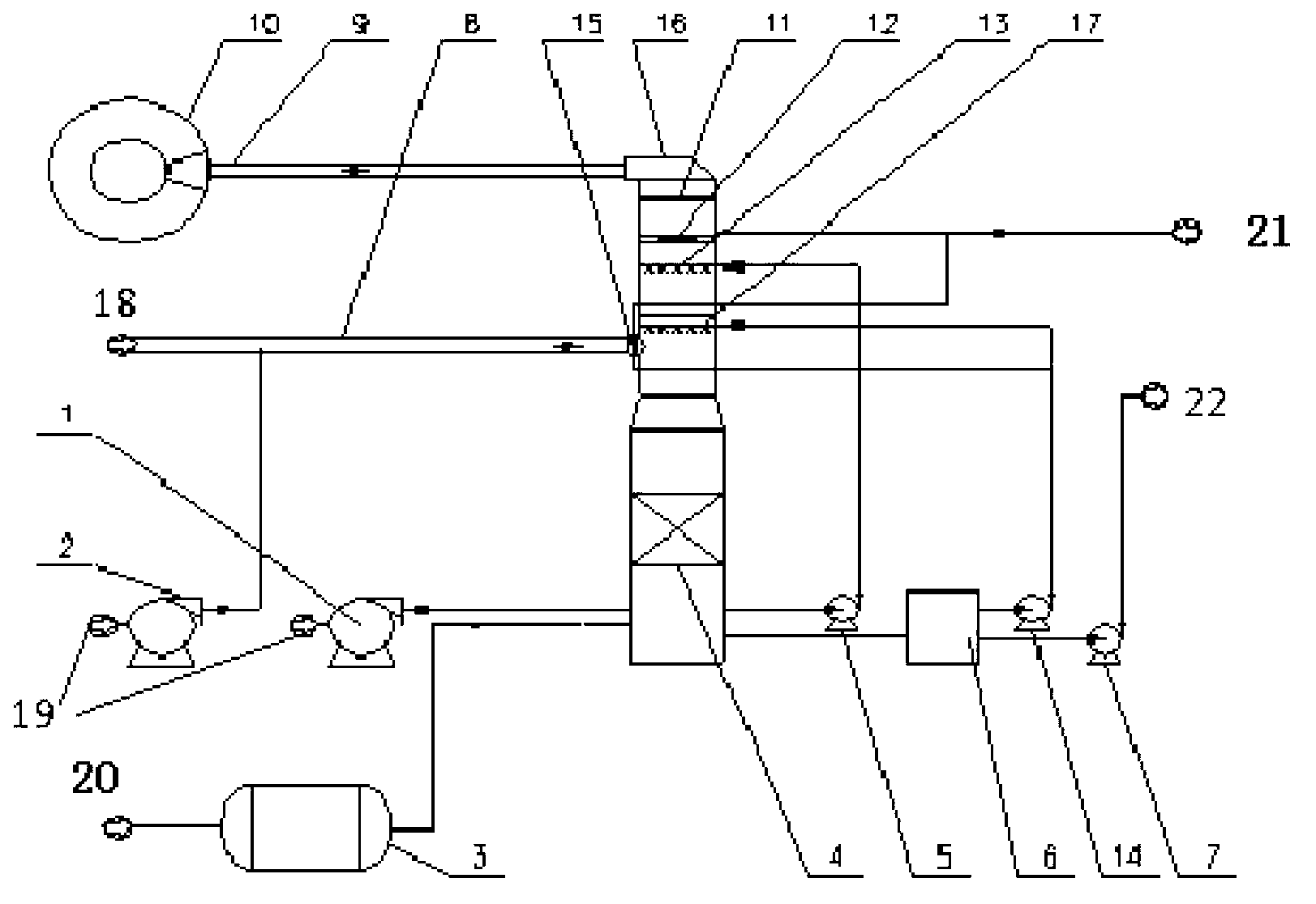

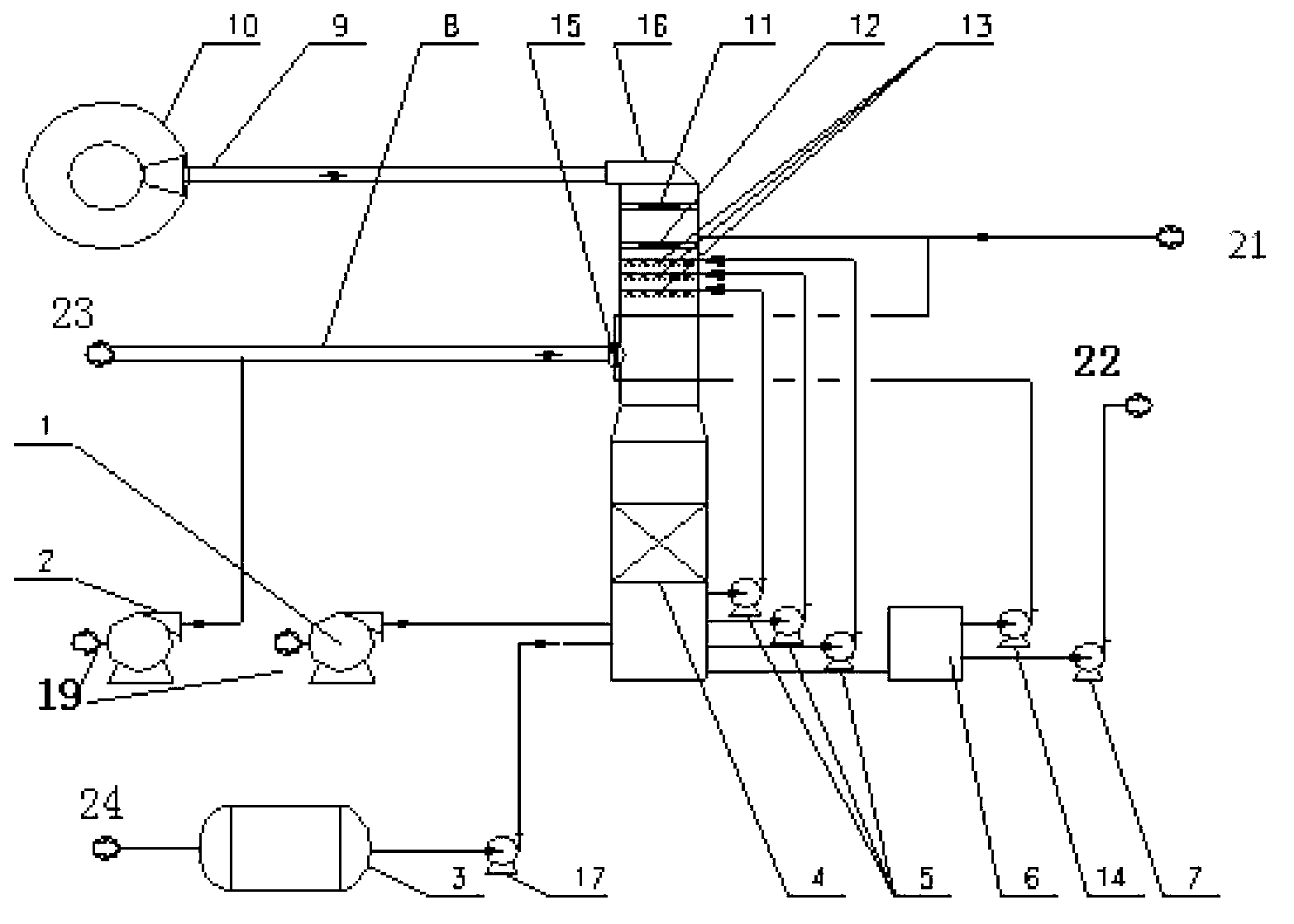

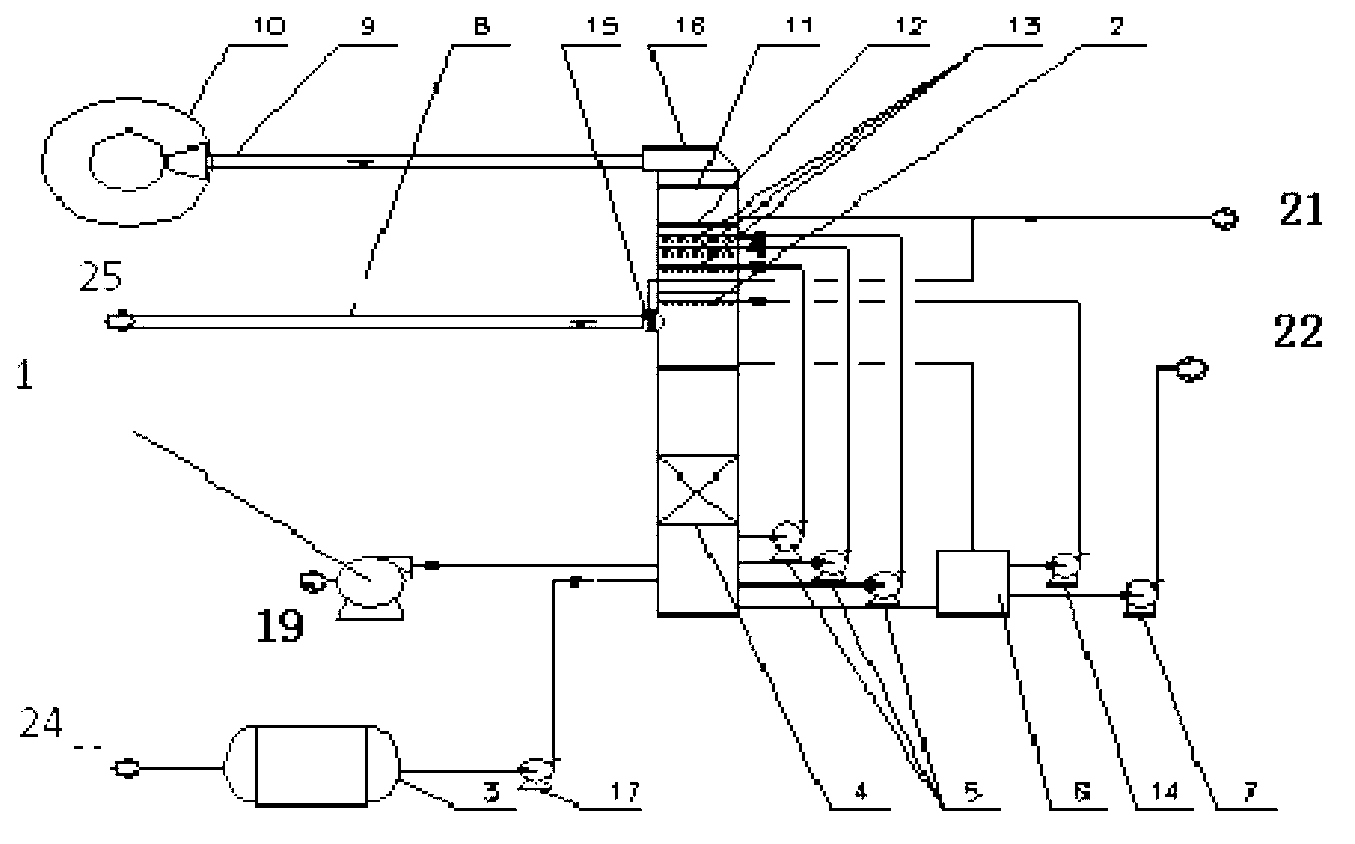

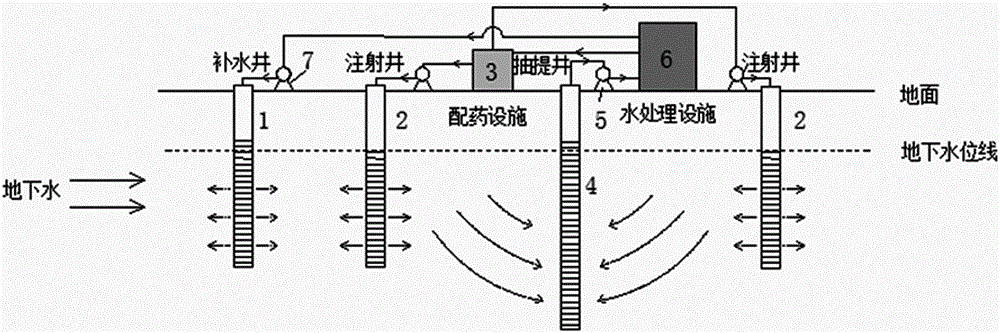

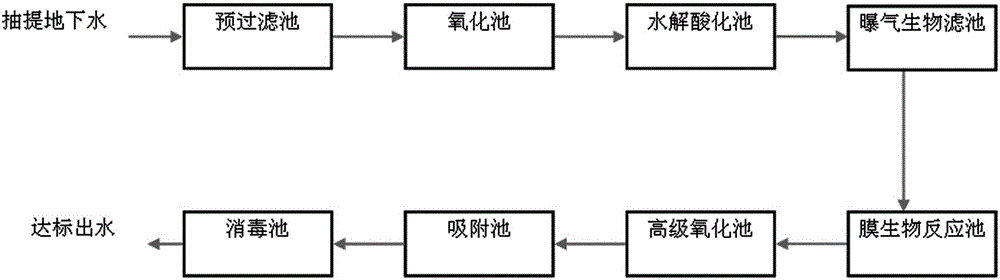

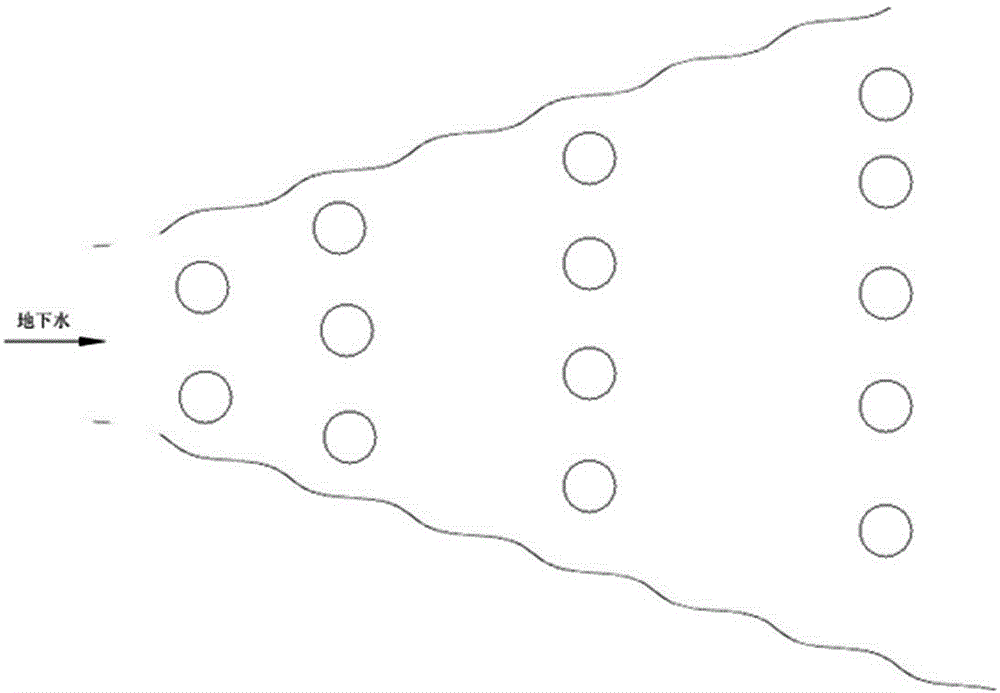

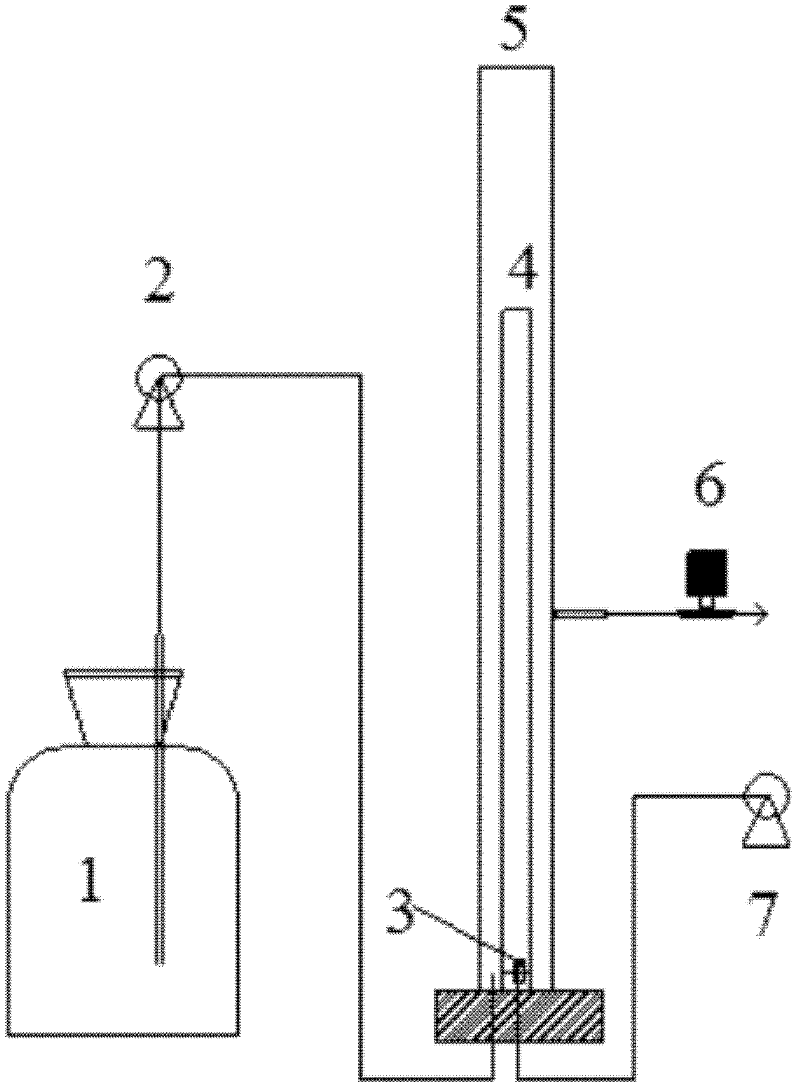

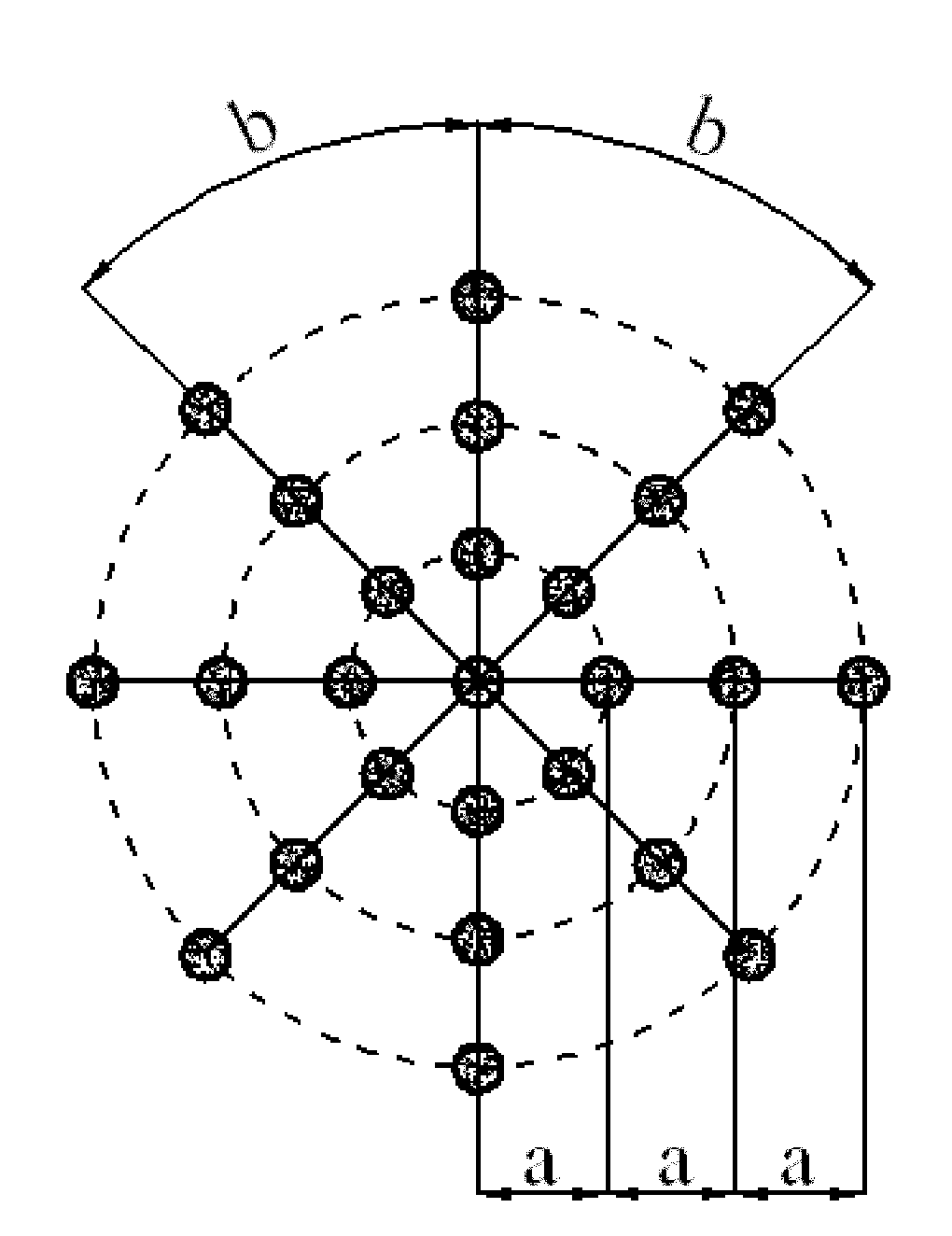

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

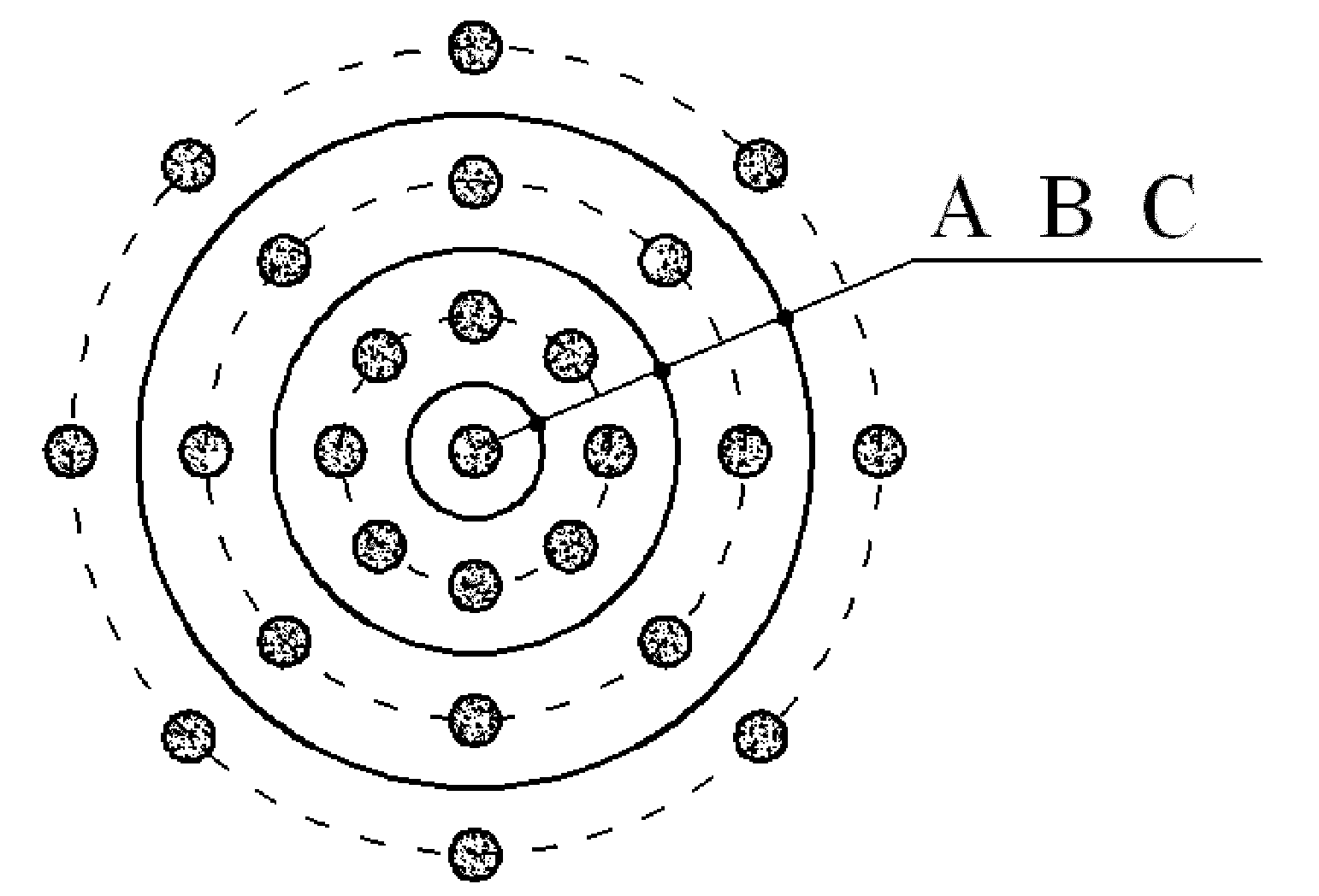

Culture method of short-cut nitrification and denitrification granular sludge

InactiveCN102417238ANo secondary pollutionNO increaseTreatment with aerobic and anaerobic processesSelective inhibitionChemistry

The invention which relates to a culture method of short-cut nitrification and denitrification granular sludge belongs to the technical field of water processing. The culture method is characterized in that: hydroxylamine with the concentration of 5-15mg / L is regularly added to gradually improve COD, ammonia nitrogen, and the phosphorous load in water to culture aerobic granular sludge. The effect of the culture method of the invention is the selective inhibition of hydroxylamine to NOB, so AOB and denitrifying bacteria are enriched. High waterpower shearing force (completed in an aeration mode) is needed to form the granular sludge, so an over-high aeration level allows DO in water to be improved, but low DO is needed by the short-cut nitrification, thereby above problem is solved through the intermit hydroxylamine addition. Hydroxylamine is an intermediate product of a nitration reaction, so the addition of a small amount of hydroxylamine generates no secondary pollution, thereby the culture method of the short-cut nitrification and denitrification granular sludge has a wide market application prospect.

Owner:DALIAN UNIV OF TECH

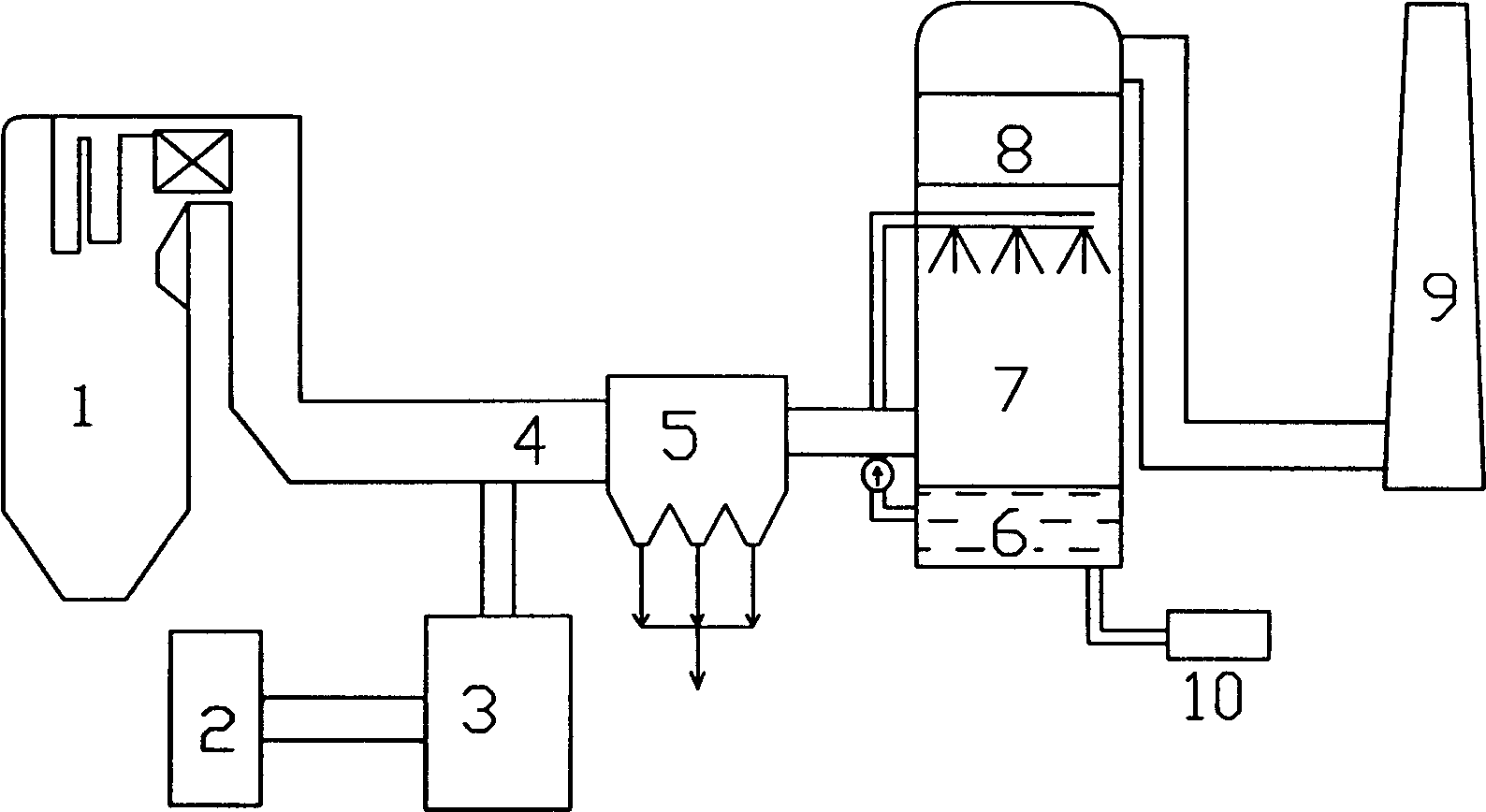

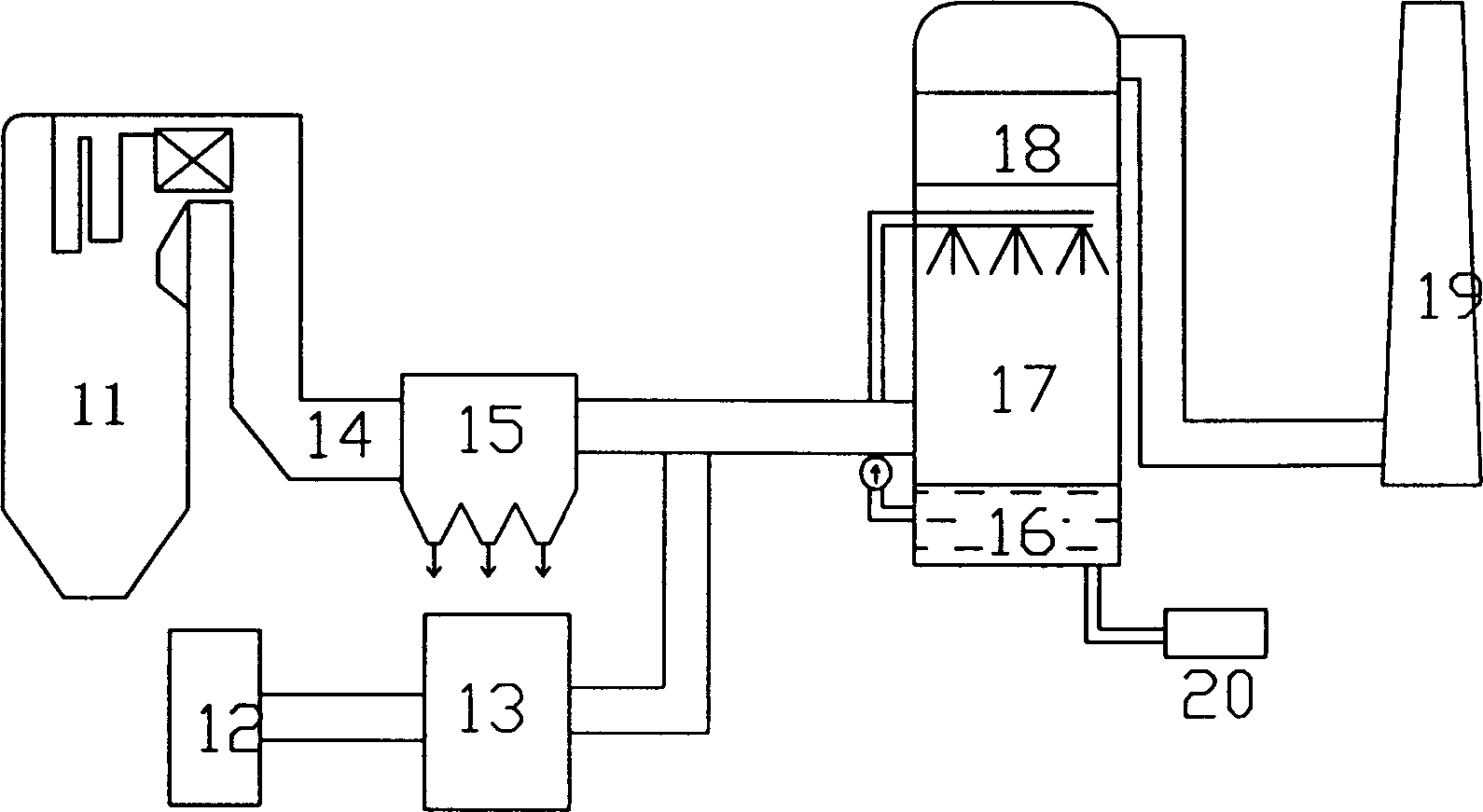

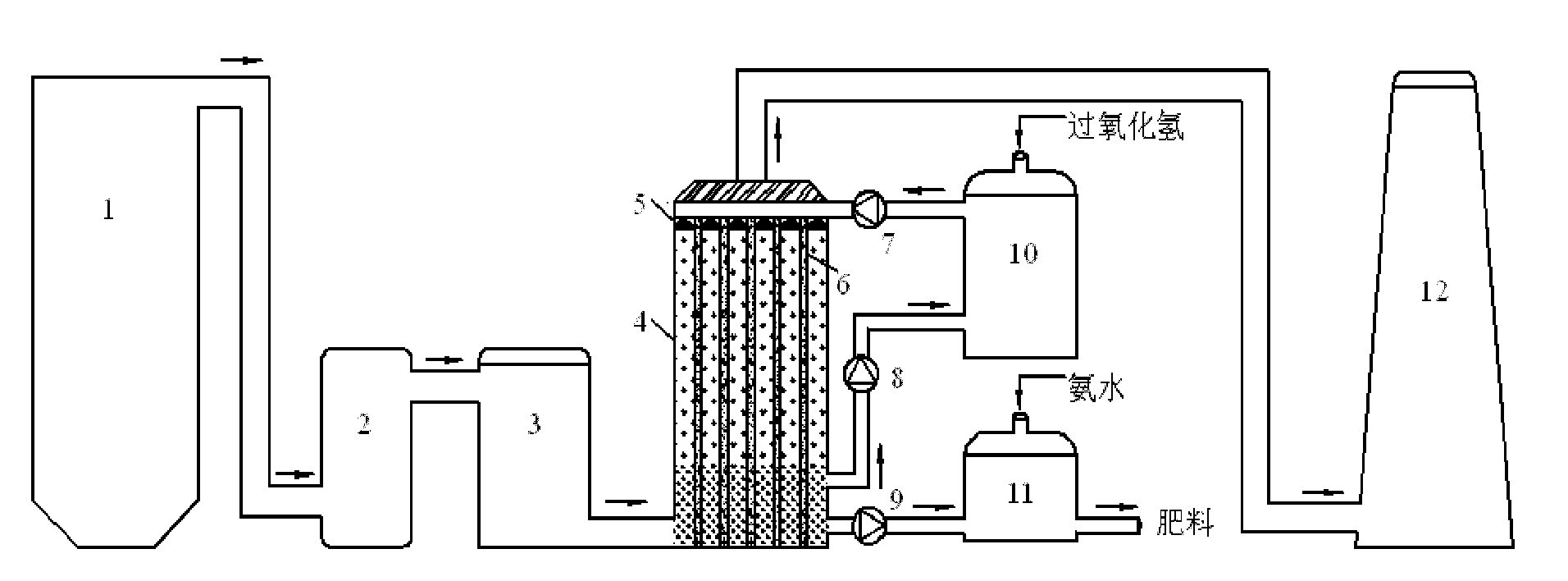

Photochemical advanced oxygenation-based simultaneous desulfuration and denitration system

InactiveCN101940871AThe process is simple and reliableSmall footprintDispersed particle separationAir quality improvementFertilizerAmmonium sulfate

The invention discloses a photochemical advanced oxygenation-based simultaneous desulfuration and denitration system. The system is provided with a burning and exhausting system consisting of a burner, an electrostatic dust collector, a heat exchanger, a spray tower, a liquid adding tower and a chimney, wherein fume generated by the burner enters the electrostatic dust collector, fume particles are removed from the fume by the electrostatic dust collector, the fume enters the heat exchanger and is cooled by the heat exchanger, and then the fume enters the spray tower; an UV light tube is arranged in the spray tower; hydrogen peroxide solution from the liquid adding tower is pumped by a circulating pump, sprayed into the spray tower through an atomizing nozzle and is activated by ultraviolet light to decompose hydrogen peroxide and then generate hydroxyl radicals (.OH) with strong oxidizing property; after being contacted with the fume in the spray tower, the hydroxyl radicals undergoes a gas-liquid absorption reaction with the fume to oxidize and remove NOx and SO2 in the fume; the fume, after being absorbed and washed, enters the chimney from the top of the spray tower and is exhausted; and sulfuric acid solution and salpeter solution generated in the spray tower are pumped into the separating column by the circulating pump and are reacted with added ammonia water to generate agricultural fertilizers including ammonium sulfate and ammonium nitrate.

Owner:SOUTHEAST UNIV

Environmental-friendly heavy metal stabilizer and application method thereof

ActiveCN104004524AStable, fast and effectiveLow toxicityContaminated soil reclamationOrganic fertilisersClay mineralsHeavy metal chelation

The invention relates to the field of environmental protection and restoration and in particular relates to an environmental-friendly heavy metal stabilizer used for soil restoration of an industrial pollution site and an application method thereof. The environmental-friendly heavy metal stabilizer is prepared from the following material components in parts by weight: 40-50 parts of clay mineral, 17-24 parts of adsorbing material, 10-18 parts of heavy metal chelating agent, 4-8 parts of heavy metal precipitating agent and 10-15 parts of alkaline modifier. Main ingredients of the adopted stabilizer are natural materials, heavy metal pollutant in soil can be rapidly and effectively stabilized through composite action such as chelating, precipitation and adsorption; the heavy metal pollutant is stabilized for a long time, toxicity and biological availability of the heavy metal pollutant can be reduced, risk of the heavy metal polluted soil to the environment and human health is reduced, and the heavy metal polluted soil is restored; besides, a soil texture improving ingredient is contained, so that soil is restored while tillability of the soil is improved.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

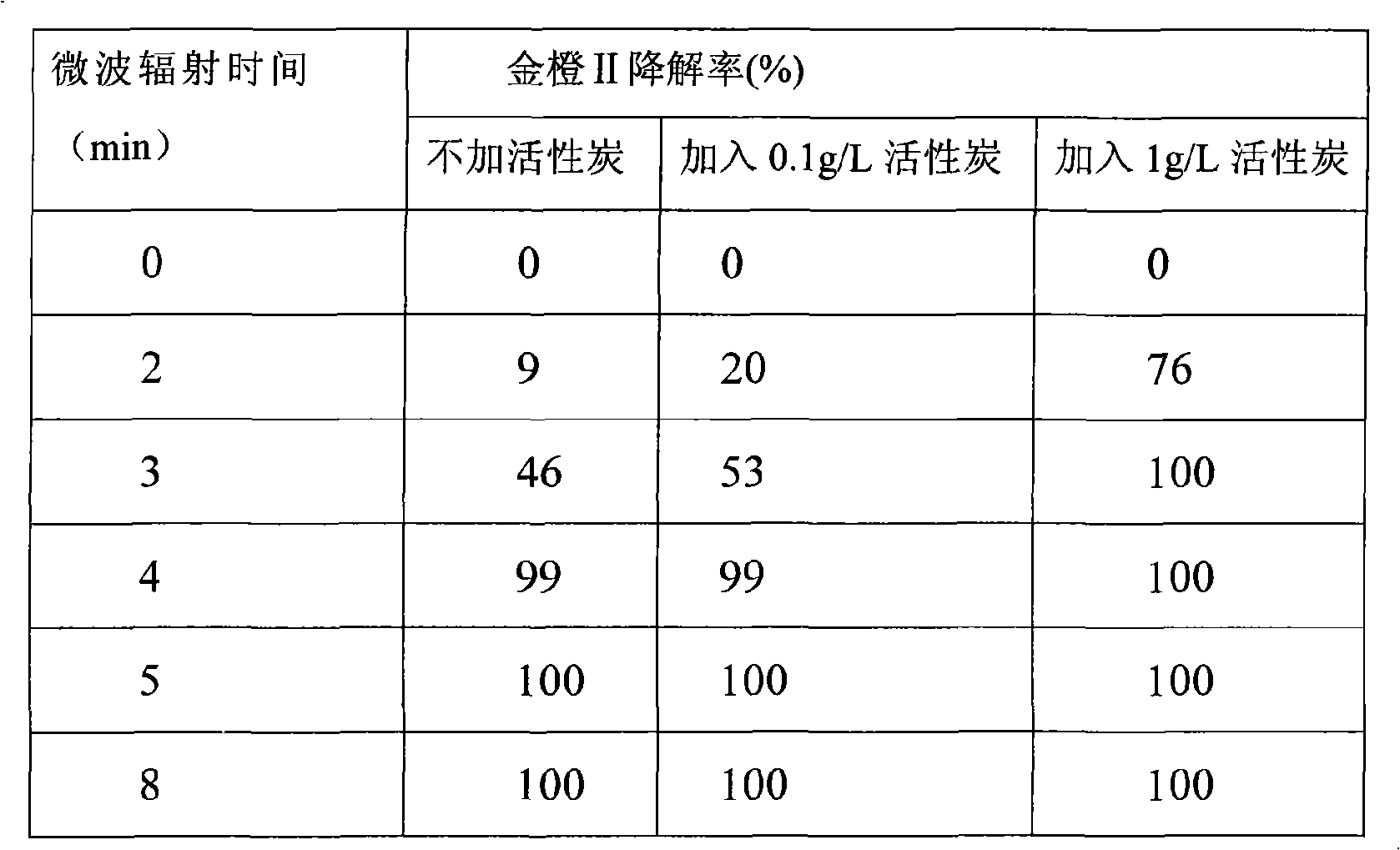

Method of using active persulphate for processing difficult-biodegradability organic waste water

InactiveCN101525177AShort processing timeHeating evenlyWater/sewage treatment by irradiationWater/sewage treatment by oxidationSmall footprintPollution

The invention relates to a method of using active persulphate for processing difficult-biodegradability organic waste water, which is characterized in that persulphate is firstly thrown into a reaction container containing organic waste water, after mixing and dissolving, the mixture is placed into a microwave generator with the frequency of 2450 MHz and the power of 800 W to be radiated for several minutes to be completed, wherein the biodegradability index BOD5 / COD of the organic waste water is lower than 0.2, and the mol ratio of the throwing amount of the persulphate and the organic matter in the organic waste water is 10:1 to 50:1. The persulphate includes peroxy-monosulphate and peroxydisulphate. To improve the degrading efficiency of the organic waste water, before using the microwave active persulphate for processing the difficult-biodegradability organic waste water, a catalyst is added, wherein the ratio of the weight of the catalyst and the volume of the organic waste water is 0.1 to 1, and the added catalyst is active carbon, and the like. The invention has the characteristics of short processing time, no secondary pollution and small occupied land area of the equipment, and can obtain an excellent processing effect on the difficult-biodegradability organic waste water.

Owner:OCEAN UNIV OF CHINA

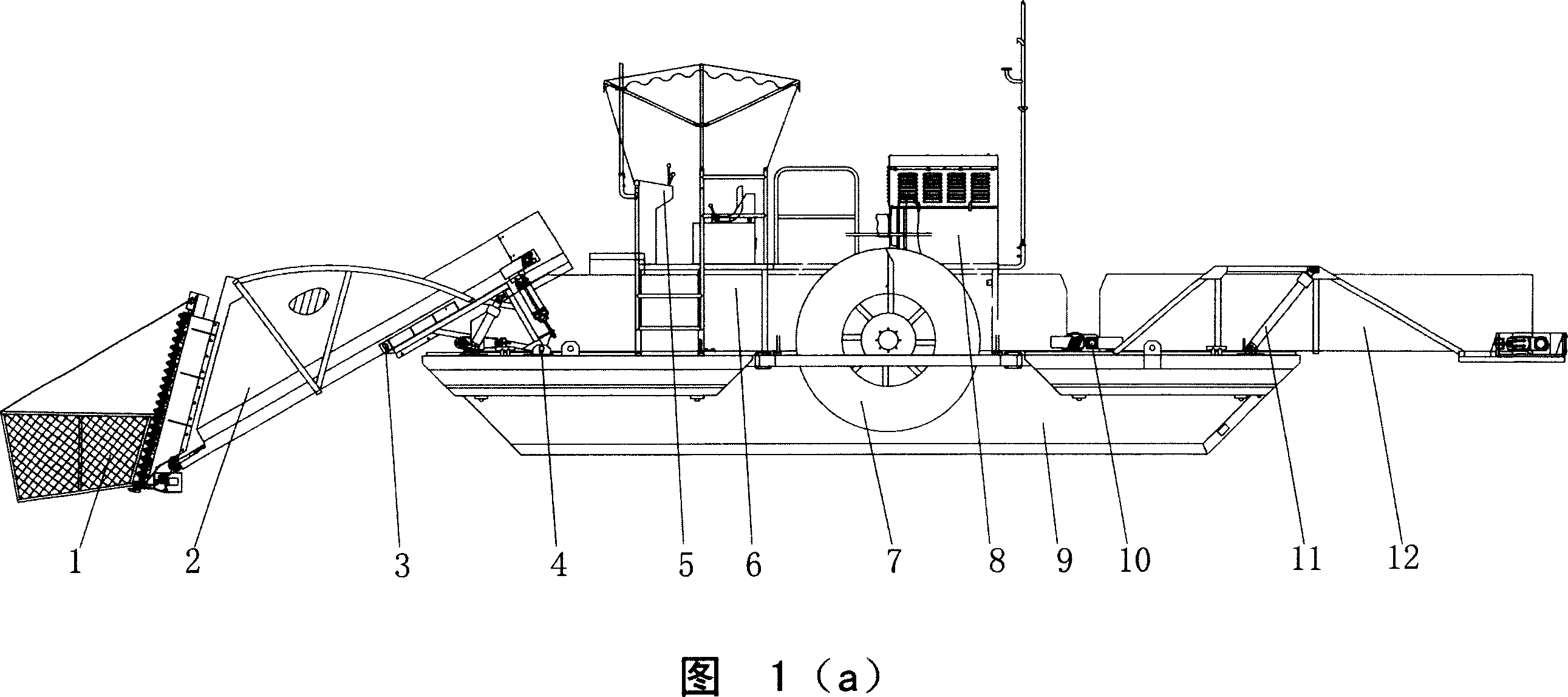

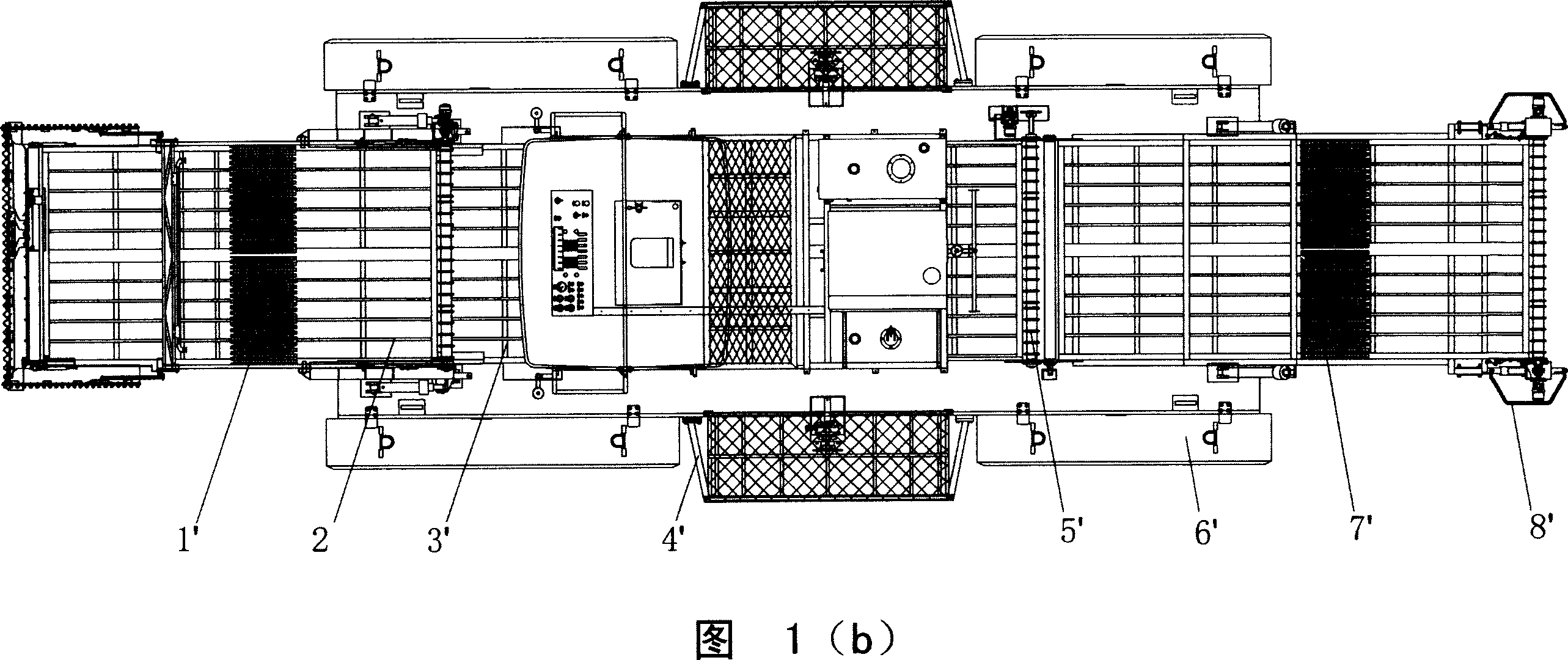

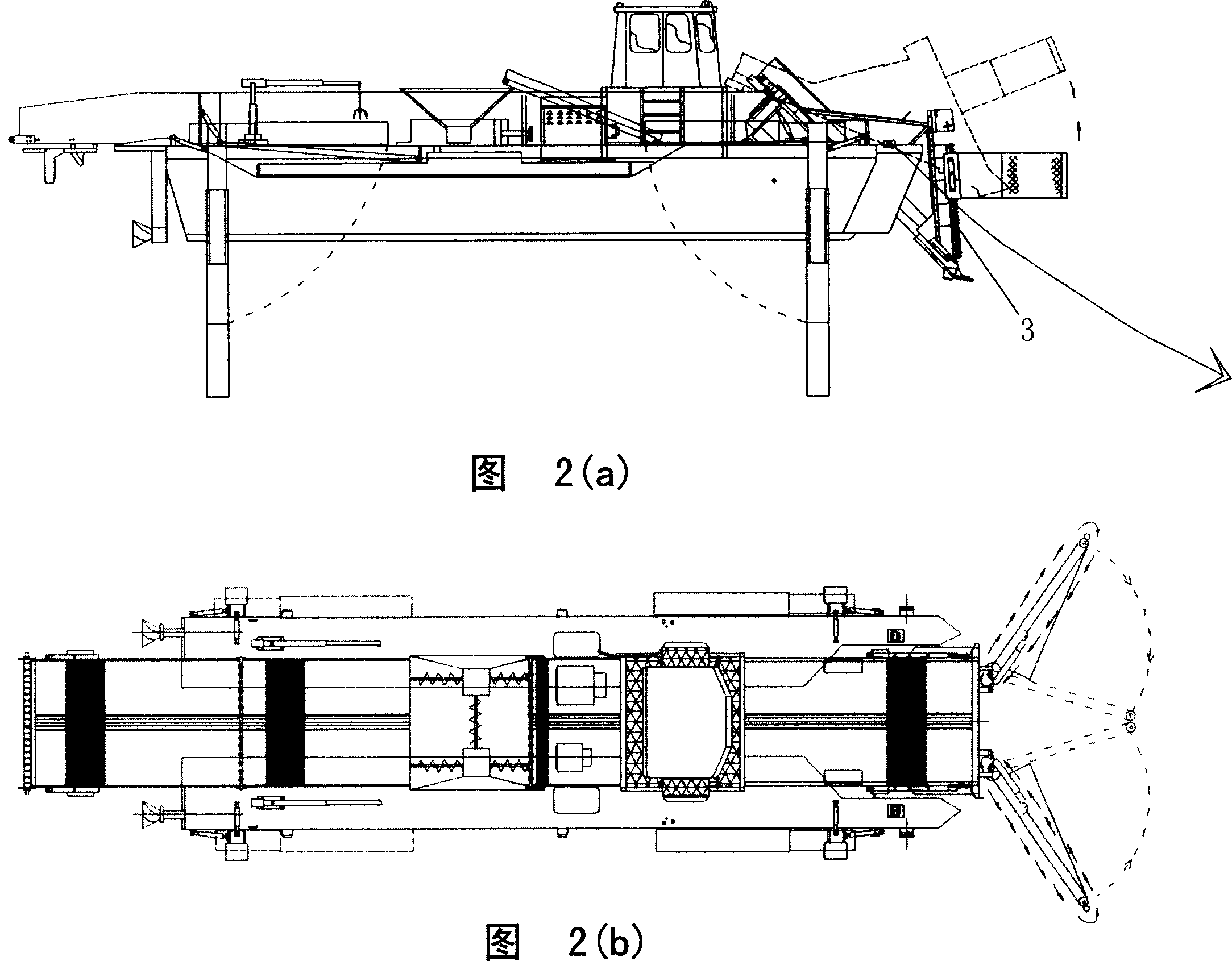

Chain-net type mechanical device for mowing and cleaning operation

InactiveCN101088856AImprove continuityAchieve separationWater cleaningWaterborne vesselsControl systemEnvironmental engineering

The chain-net type solid-liquid separating mechanical apparatus for cutting aquatic weed and cleaning river includes one aquatic weed cutting mechanism, one aquatic weed and waste fishing mechanism, one compressing and conveying mechanism, one flow forming mechanism, one anchor locating mechanism, one intercepting and driving mechanism and one control system. It is used to cut, collect, solid-liquid separate, pile, etc for maintaining clean river.

Owner:SHANGHAI LIXIN HYDRAULIC +1

Coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and technology

InactiveCN102350214ARealize reburning and denitrificationFull joint removalDispersed particle separationResource utilizationCoal dust

The invention relates to a coal-fired power plant coal dust prepared activated coke flue gas comprehensive purification system and a technology. The technology provided by the invention comprises the following steps of: using coal dust in a coal-fired power plant as a raw material, simultaneously carrying out carbonization and activation on coal dust in an activated coke preparation reactor to obtain powdered activated coke, using pyrolysis gas obtained during the preparation process as reburning fuel and sending it into a boiler so as to remove part of NOx; sending the powdered activated coke into a flue gas adsorption tower, adsorbing pollutants such as sulfur dioxide, mercury and the like at an appropriate temperature, injecting ammonia gas and nitrogen oxide to perform a catalytic reduction reaction so as to remove nitrogen oxide; reusing the adsorbed activated coke after regeneration; sending the activated coke into the boiler for combustion after multiple adsorption / regeneration; regenerating the activated coke after adsorbing sulfur dioxide to obtain high-density sulfur dioxide gas to realize resource utilization. By the utilization of coal resources in a coal-fired power plant, the comprehensive purification of flue gas and the resource utilization of sulfur dioxide are realized without discharge of waste water, exhaust gas and solid waste.

Owner:SHANDONG UNIV

Electric pole material of high efficiency electrocatalysis high-grade oxidation technology

ActiveCN101423270ALarge specific surface areaHigh catalytic activityWater/sewage treatment using germicide/oligodynamic-processCatalytic effectHypochlorous acid

The invention relates to a set of electrocatalytic strong oxidizer materials, comprising a nano-function anode material which compounds nano oxide particles and catalyzes metal nano particles on a titanium substrate, and a nano-function cathode material which takes titanium or stainless steel as a substrate and introduces transition metal nano-particles on the surface thereof. By the electro-catalytic advanced oxidation technology, under the catalytic action of electrocatalytic strong oxidizer materials, water body can generate a hydroxyl radical with strong oxidizing performance and an oxygen radical; and if a chloride ion exists in water, hypochlorite can be generated. Under the joint action of a plurality of types of strong oxidizers, the algae cells in the water body and various harmful bacteria can be killed; and simultaneously the ammonia in water and the water-soluble organic matters can be degraded, so the goal of purifying water is achieved. According to the electrocatalytic advanced oxidation theory, the electrocatalytic strong oxidizer materials does not need to add any chemical agent when in application, does not have secondary pollution, and has good safety, high efficiency and low energy consumption.

Owner:苏州盖依亚生物医药有限公司

Method for recycling waste lithium iron phosphate batteries

InactiveCN102664294AAchieve recyclingImprove electrochemical performanceWaste accumulators reclaimingBattery recyclingLithium iron phosphateEngineering

A method for recycling waste lithium iron phosphate batteries relates to a battery recycling method. The method provided by the invention aims to provide a battery recycling method which is simple in process and low in cost. The method comprises the following steps of: removing residual electric quantity of a waste lithium iron phosphate battery, taking out the cell of the battery and crashing the cell into fragments, soaking the cell fragments in sodium hydroxide solution and stirring; and then performing filtering, washing, drying and vibratory screening so as to obtain pure alumium, pure copper and a diaphragm on a screen, recycling alumium and copper through smelting so as to obtain mixed powder under the screen, cleaning the mixed powder by using acidic solution, performing drying and thermal treatment, adjusting the mol ratio of lithium to iron to phosphorus to carbon, and then performing ball milling, drying and roasting, thereby obtaining a lithium iron phosphate anode material. The method for efficiently recycling the waste lithium iron phosphate batteries provided by the invention is simple in process, low in production cost and quick in taking effect.

Owner:HARBIN INST OF TECH

Preparation method of micro-emulsion absorption liquid used for processing organic exhaust gas

The invention relates to a preparation method of an organic exhaust gas micro-emulsion absorption liquid, and a method for applying the micro-emulsion absorption liquid for cleaning industrial organic exhaust gas comprising benzene, toluene, xylene, and the like. The invention belongs to the technical field of atmosphere pollution control. The absorption liquid is prepared from the components of, by mass, 80-90% of water, 0.5-3% of a surfactant, 7-19.5% of a coupling agent, and 0.02-0.06% of an auxiliary agent. The surfactant is sufficiently mixed with water, such that a surfactant solution is obtained; the auxiliary agent is dissolved in water, such that an auxiliary agent solution is obtained; the two solutions are combined and uniformly mixed; and the coupling agent is added, and the obtained solution is stirred, such that the organic exhaust gas micro-emulsion absorption liquid is obtained. The organic exhaust gas micro-emulsion absorption liquid is suitable to be used for controlling exhaust gas containing benzene-series volatiles, and has the advantages of convenient raw material source, low cost, mild and stable property, low toxicity, environment-friendliness, no absorption tower corrosion or blocking phenomena, no severe influence to human health, high removal rate to organic exhaust gas, no need of pretreatment upon exhaust gas, and low investment and running cost. Saturated absorption liquid and absorbed organics can be recycled, such that waste can be turned useful.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com