Patents

Literature

10490results about How to "Reduce moisture content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

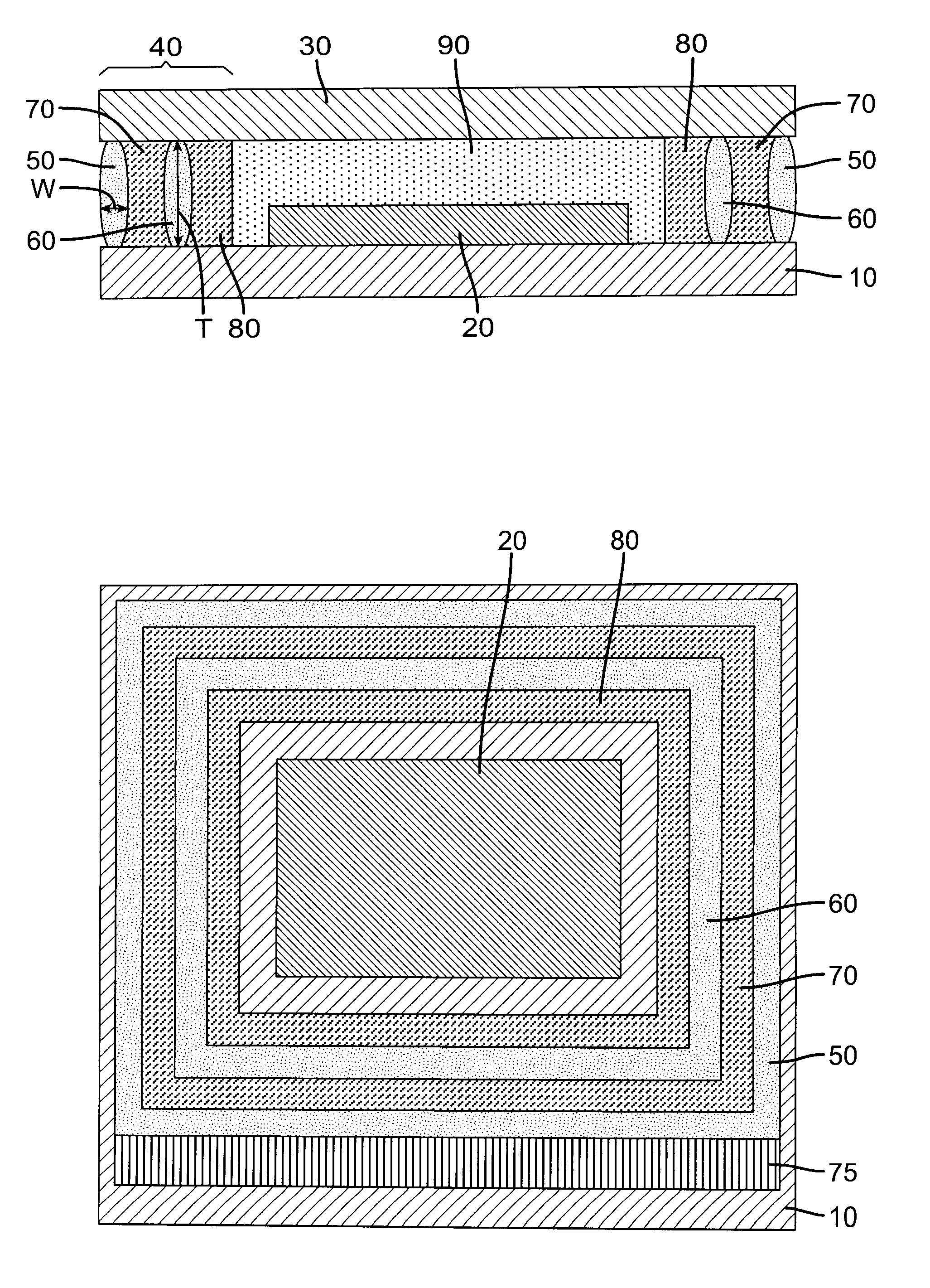

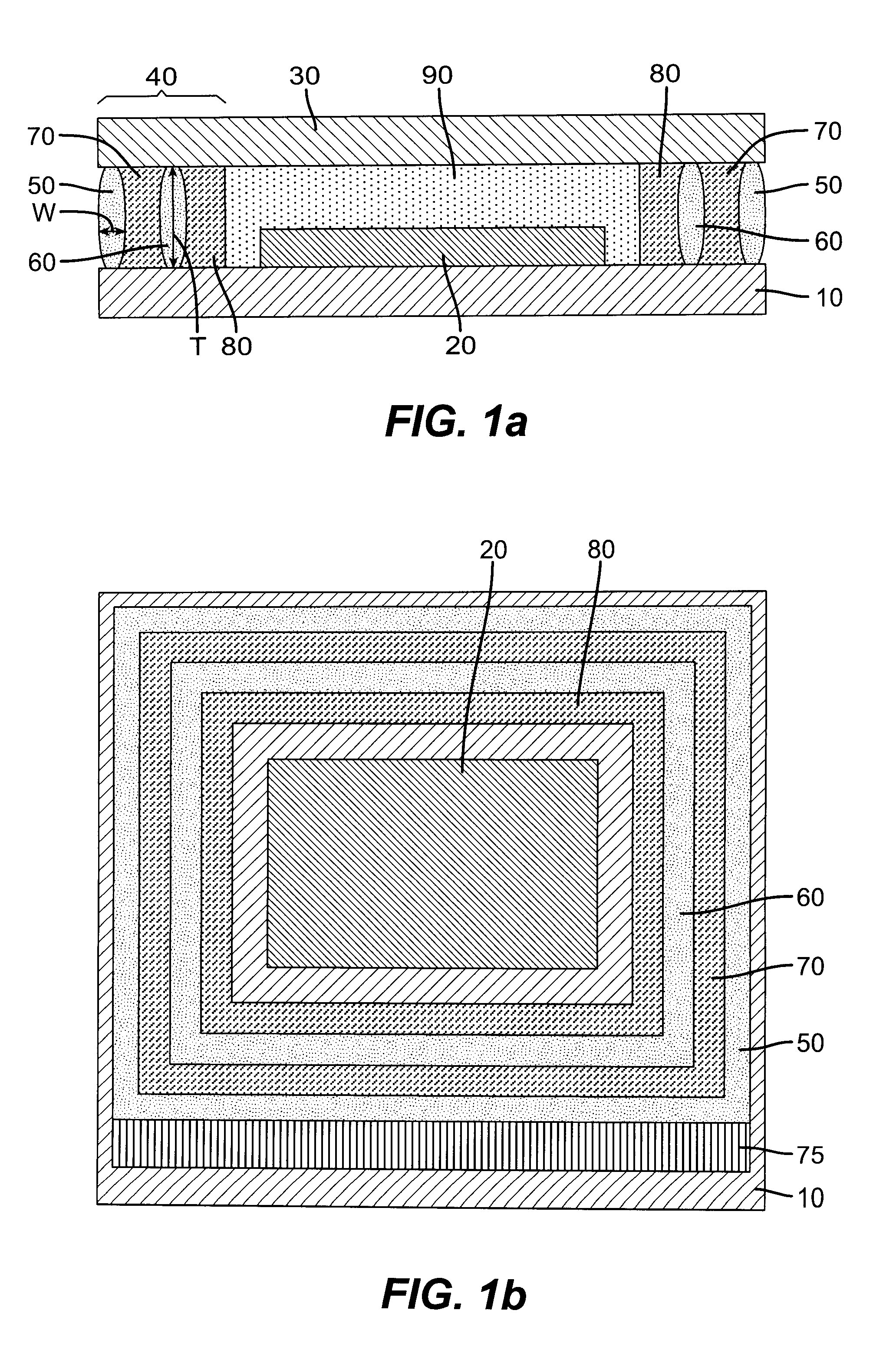

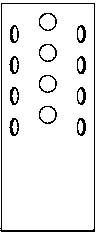

Desiccant sealing arrangement for OLED devices

InactiveUS20070172971A1Reduce penetrationLow moisture permeabilitySolid-state devicesSemiconductor/solid-state device manufacturingDesiccantEngineering

A method of encapsulating an OLED device, comprising: providing a substrate; forming an OLED device over the substrate, and a cover over the OLED device; and providing a desiccant sealing arrangement between the cover and the substrate, with the desiccant sealing arrangement provided by forming a perimeter seal and a spaced interior seal; a first desiccant material placed between the perimeter seal and the spaced interior seal; and a second desiccant material placed interior of the spaced interior seal.

Owner:EASTMAN KODAK CO

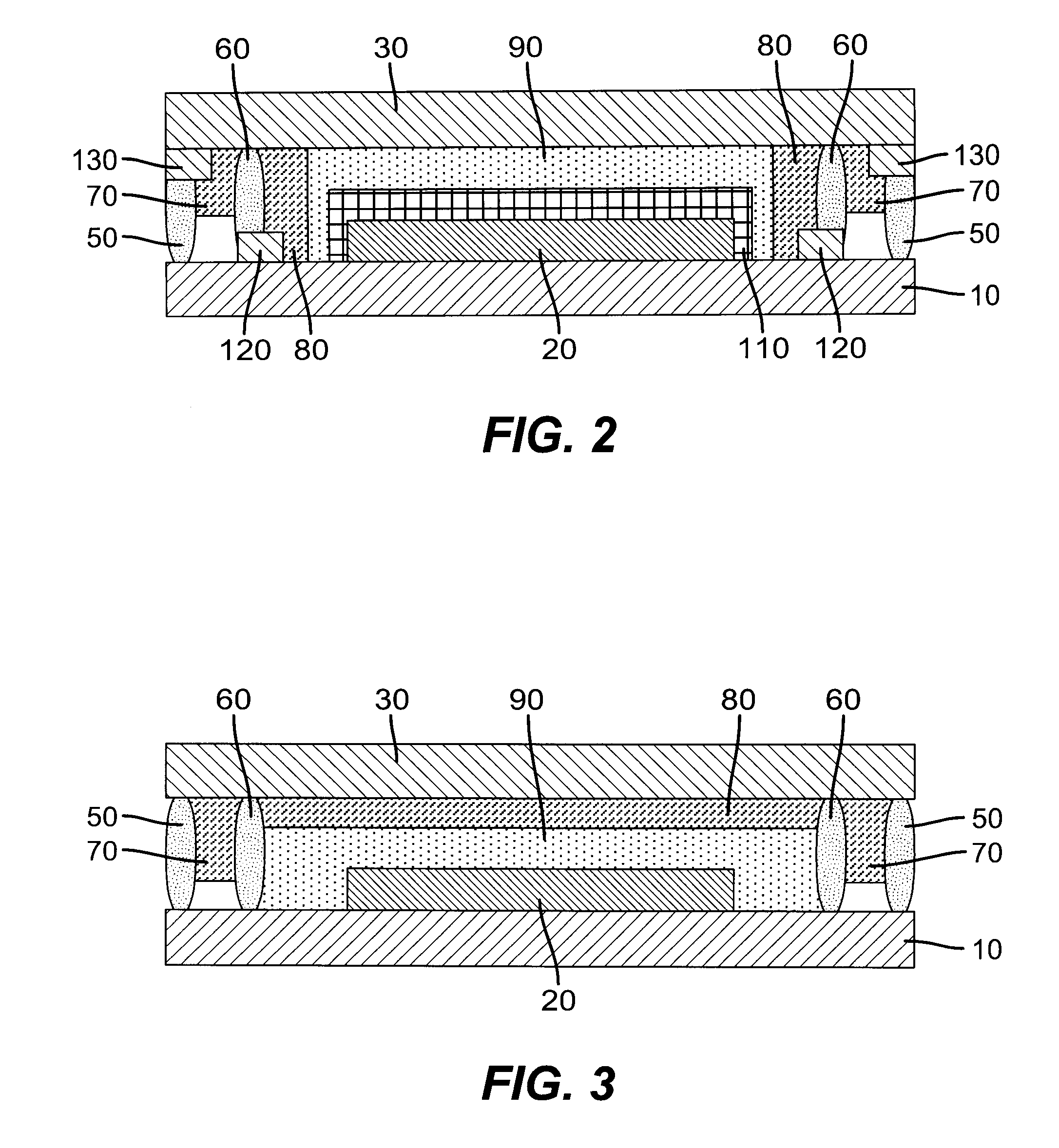

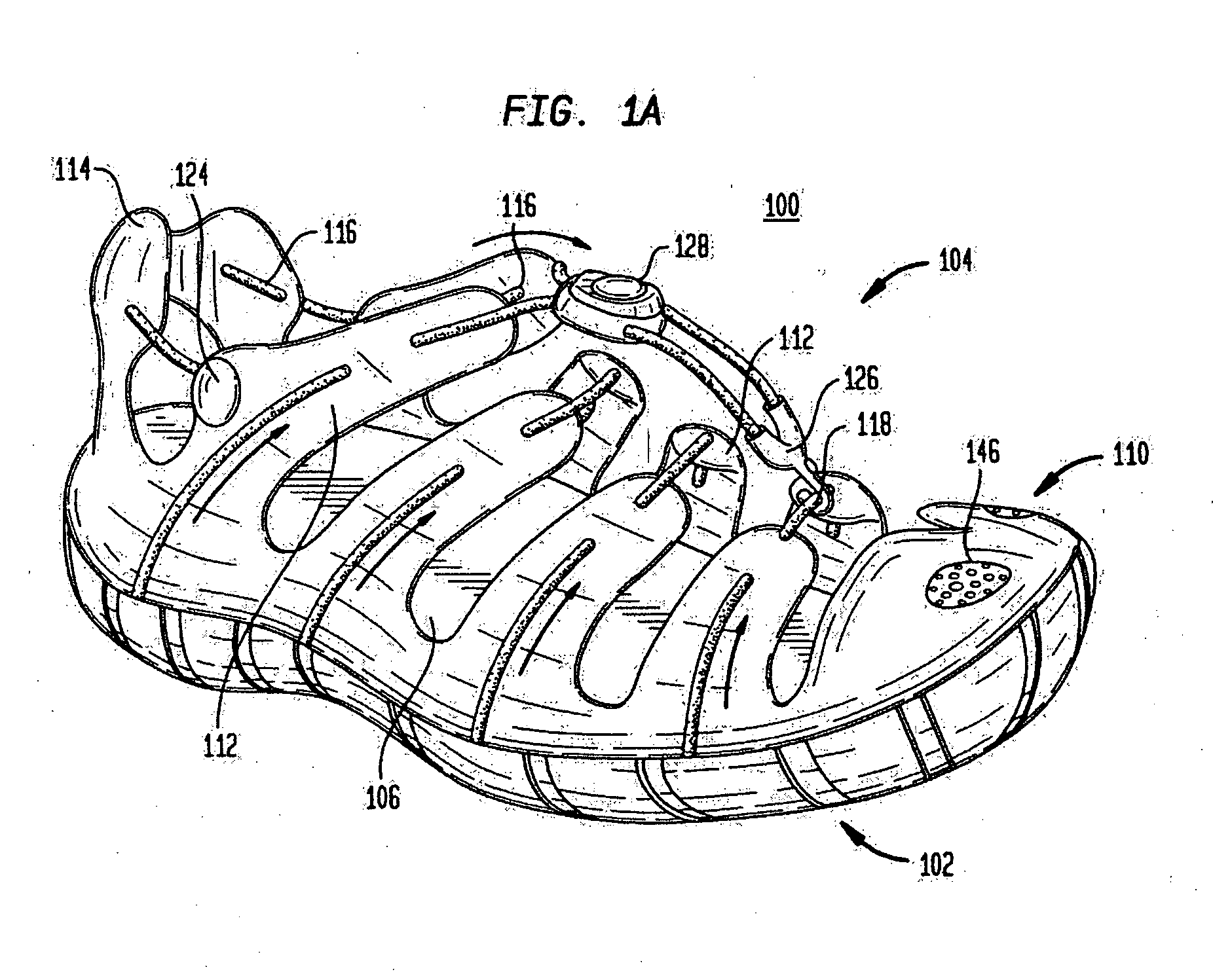

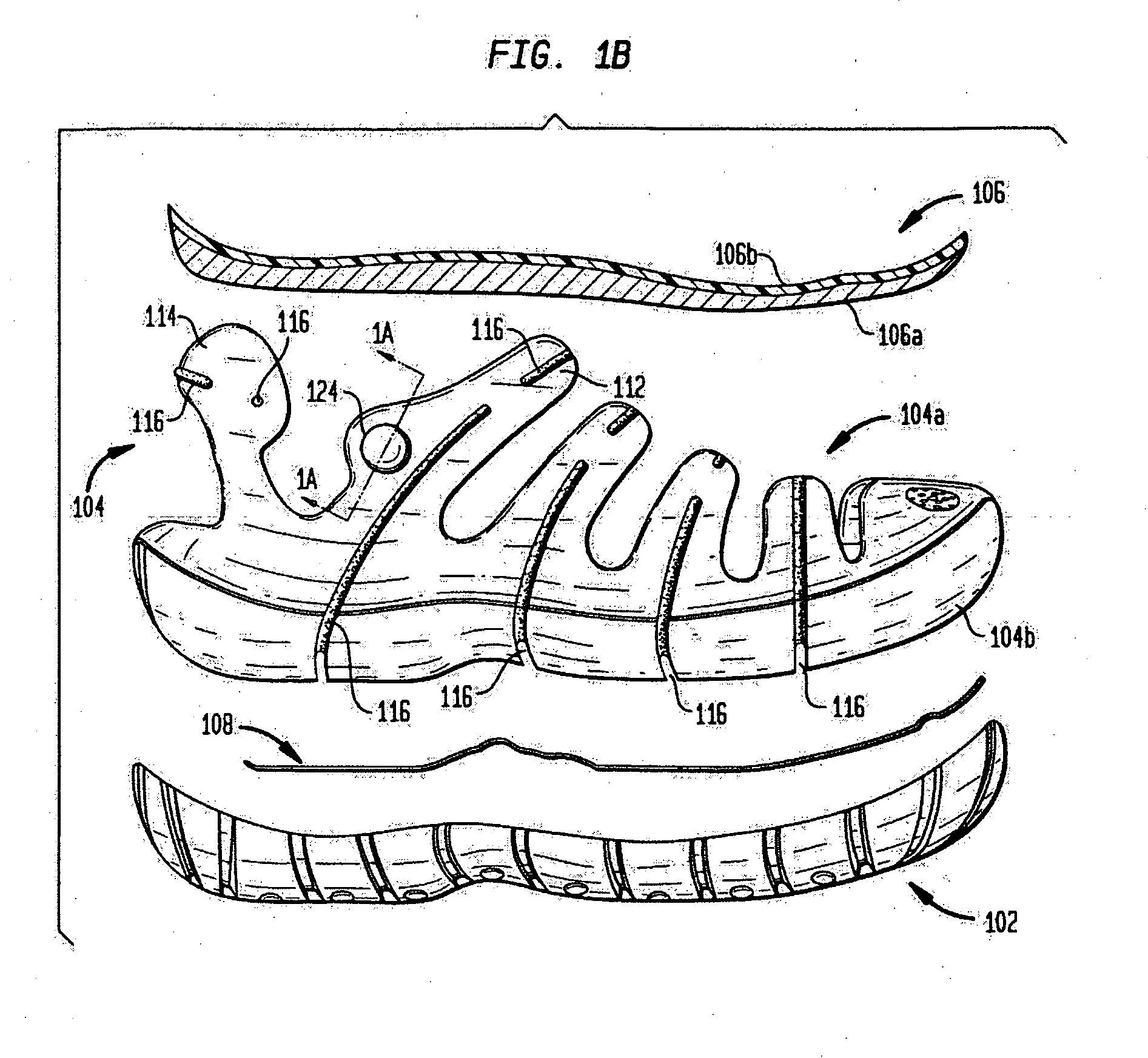

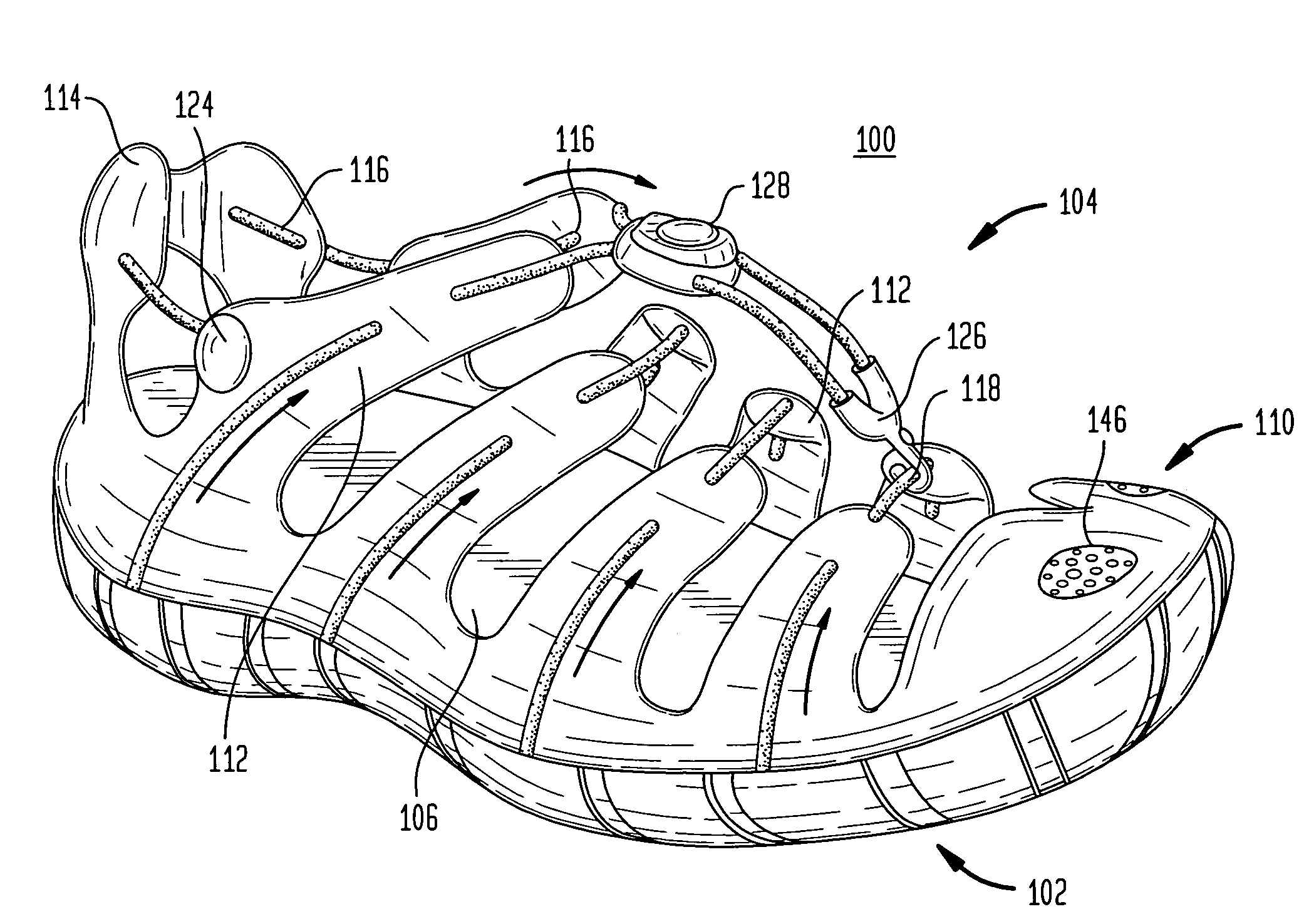

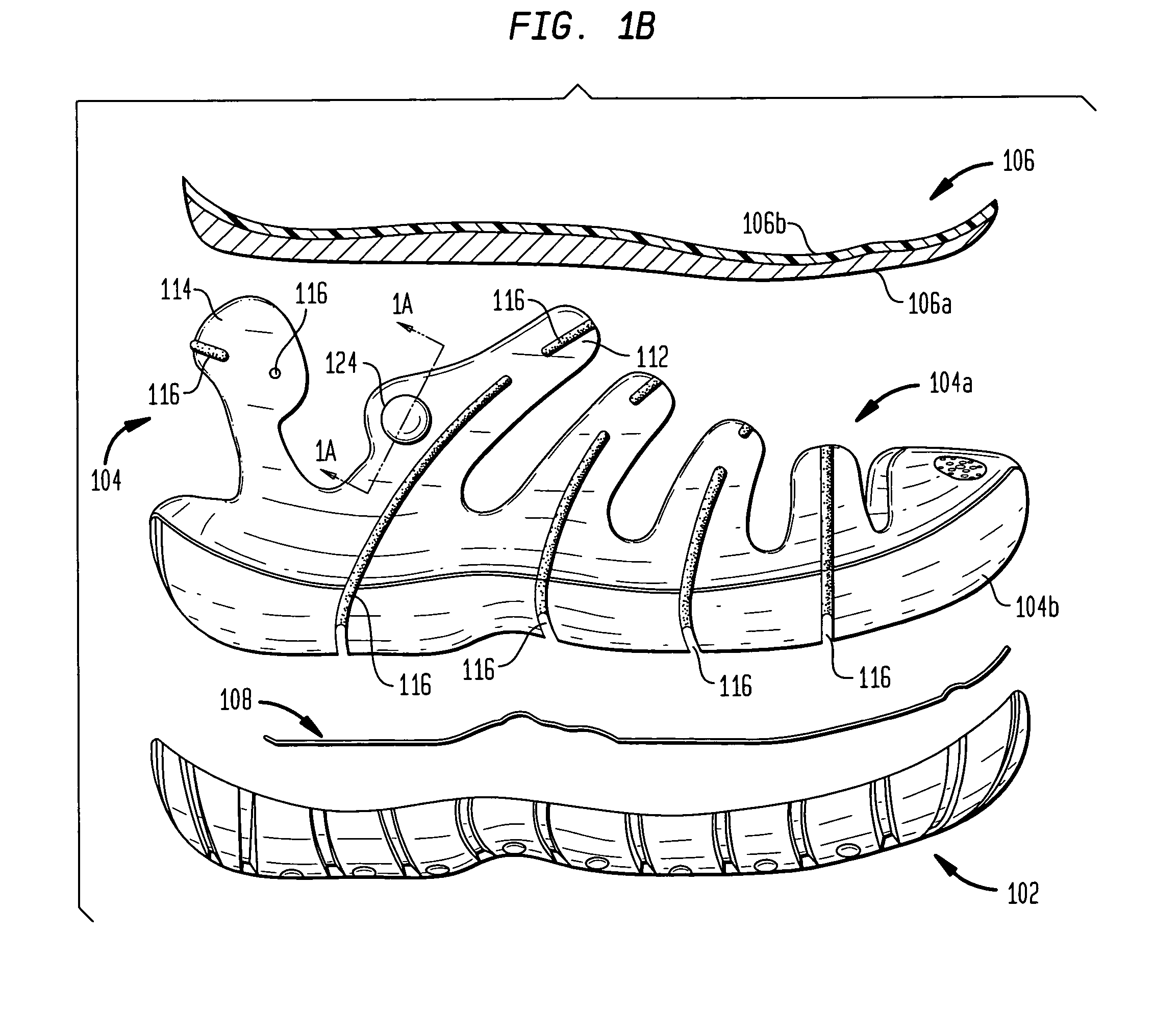

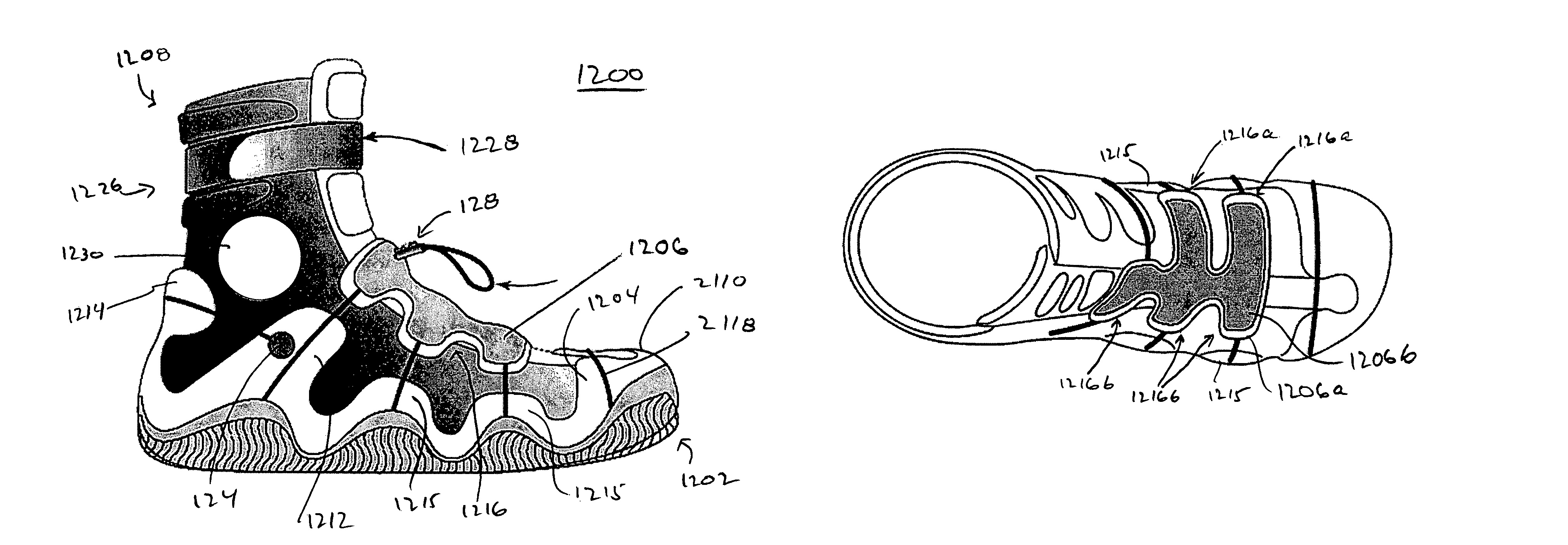

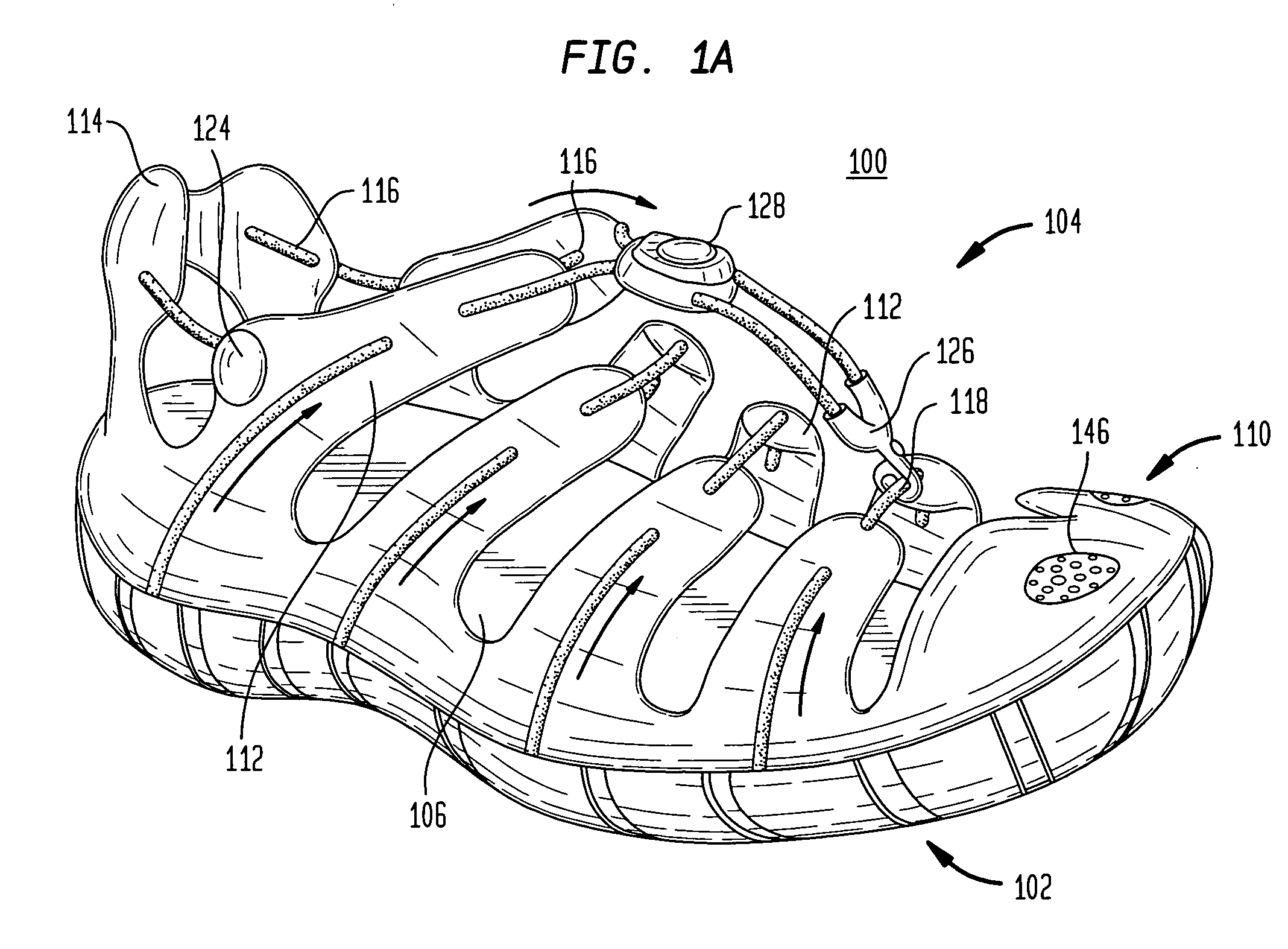

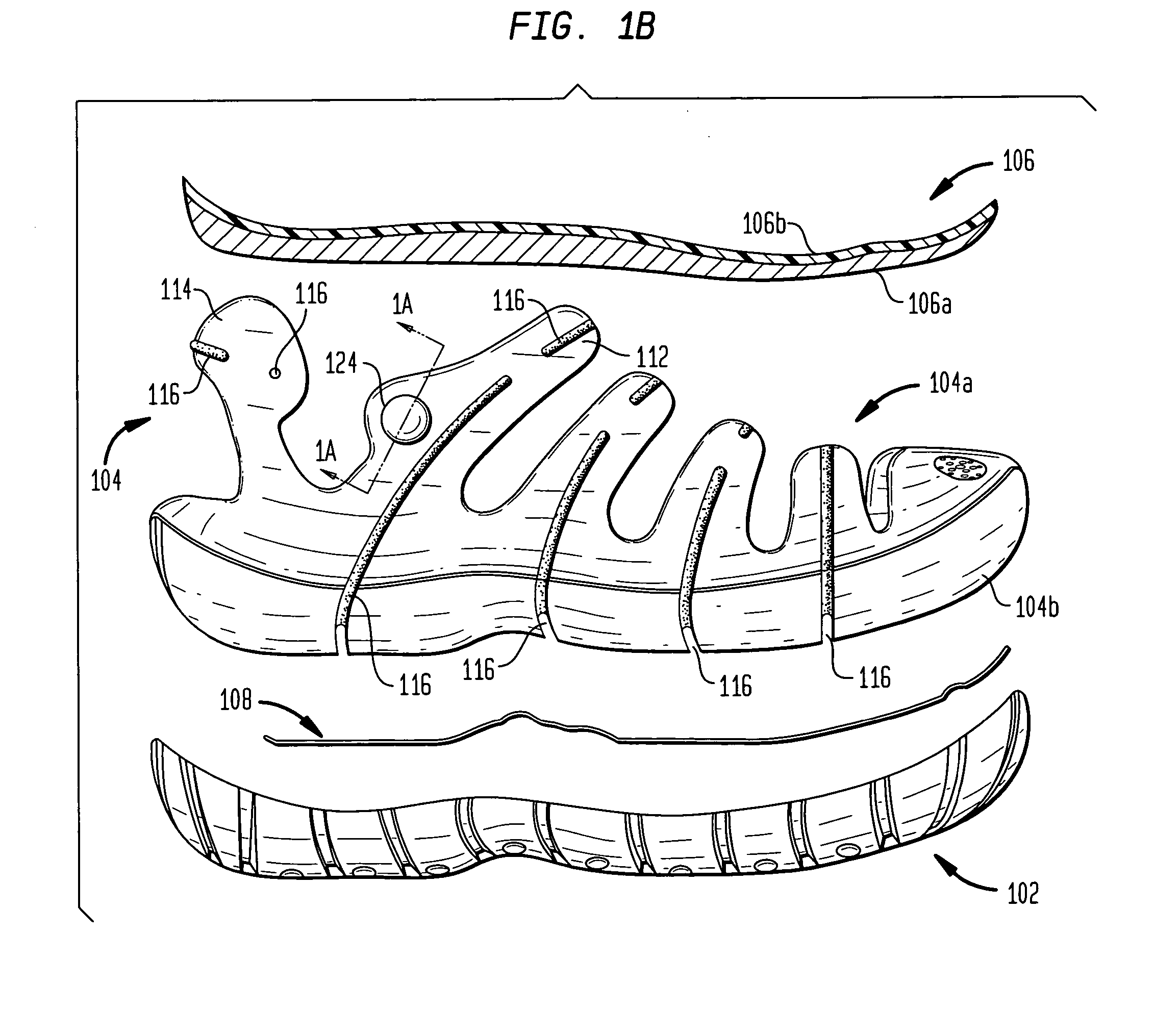

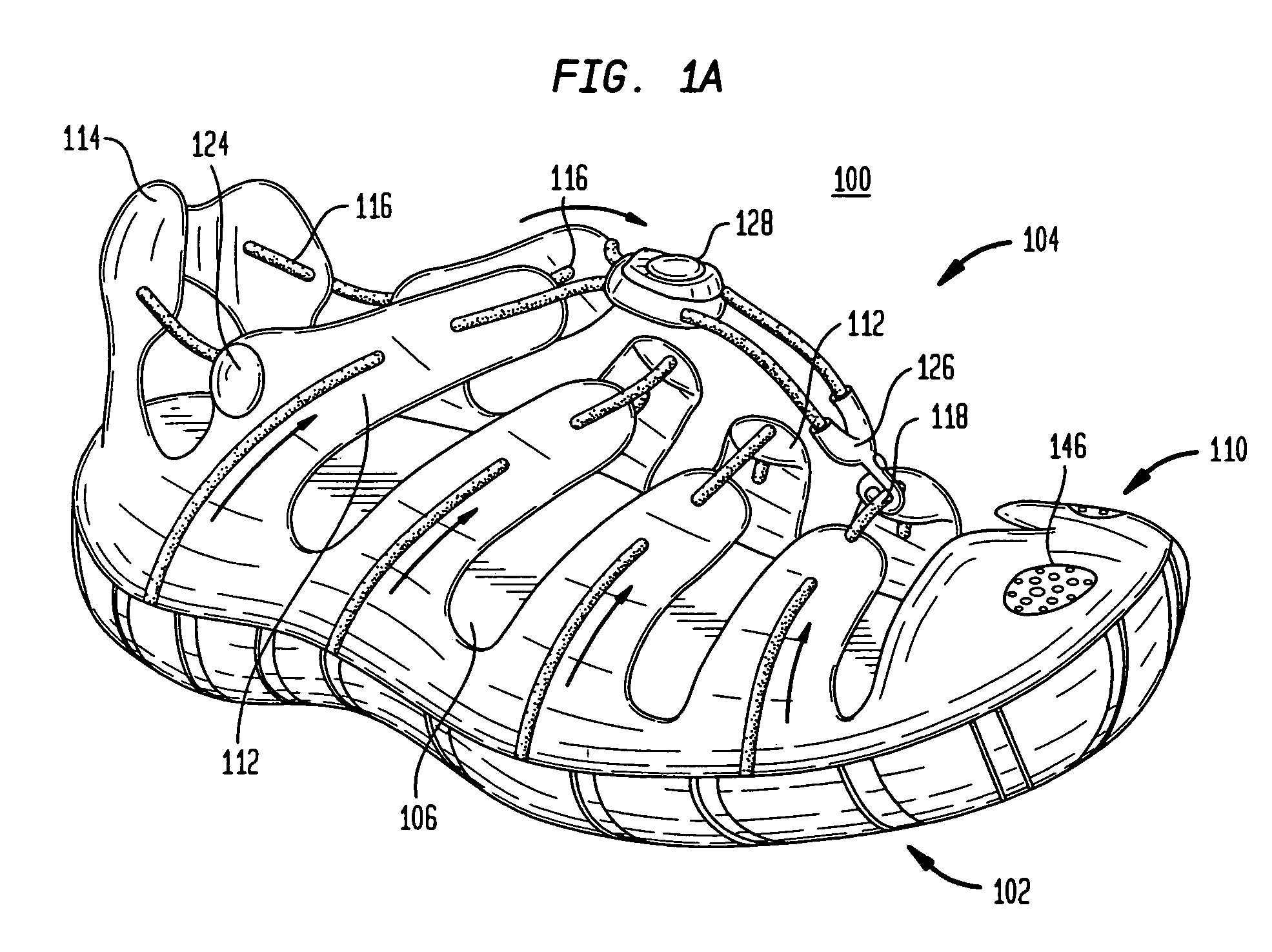

Shoe with anatomical protection

ActiveUS20070011914A1Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

Petroleum Coke Compositions for Catalytic Gasification

InactiveUS20090166588A1Improve efficiencyReduce moisture contentOther chemical processesMixing methodsPtru catalystThermodynamics

Particulate compositions are described comprising an intimate mixture of a petroleum coke, coal and a gasification catalyst, where the gasification catalyst is loaded onto at least the coal for gasification in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

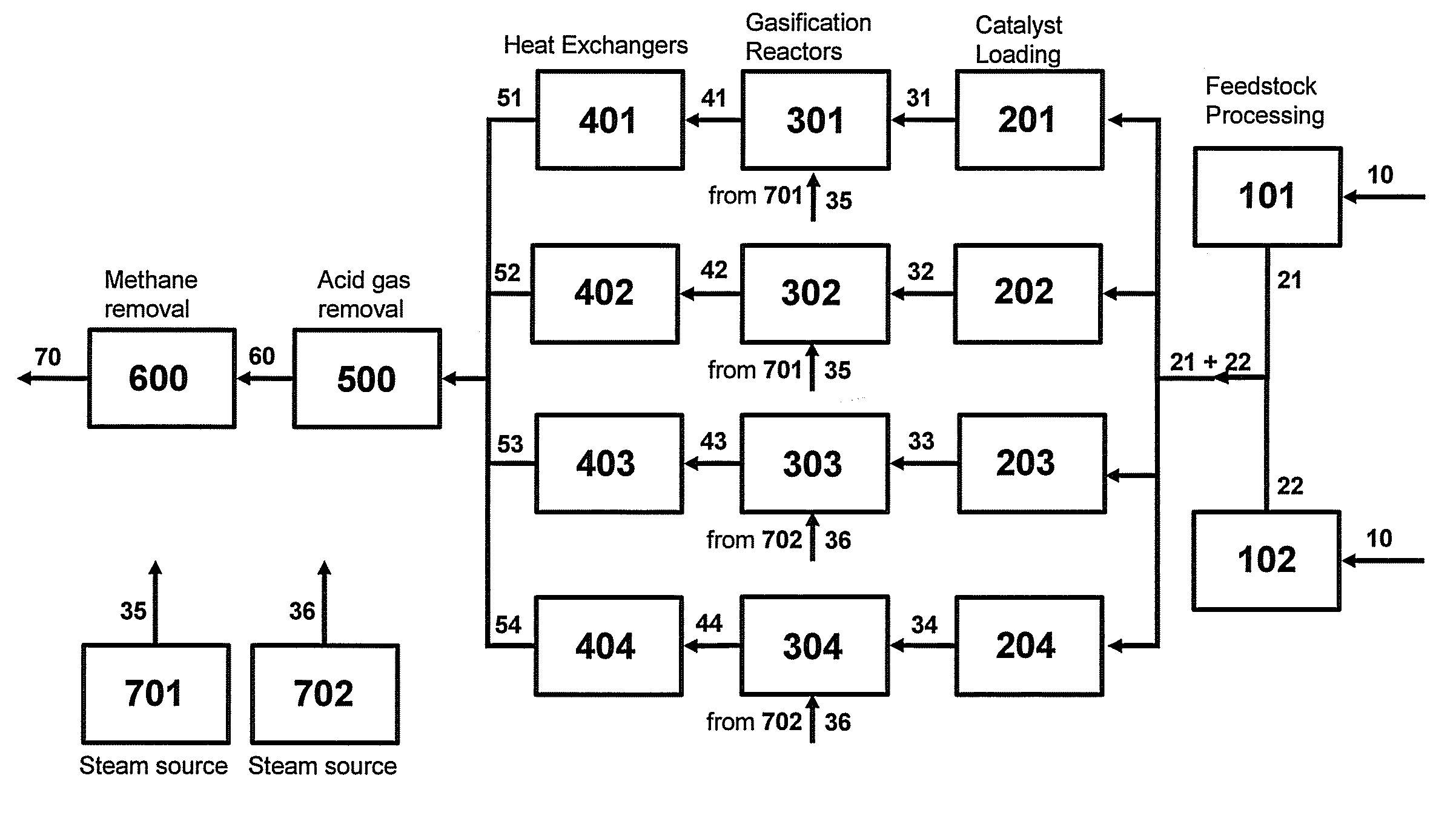

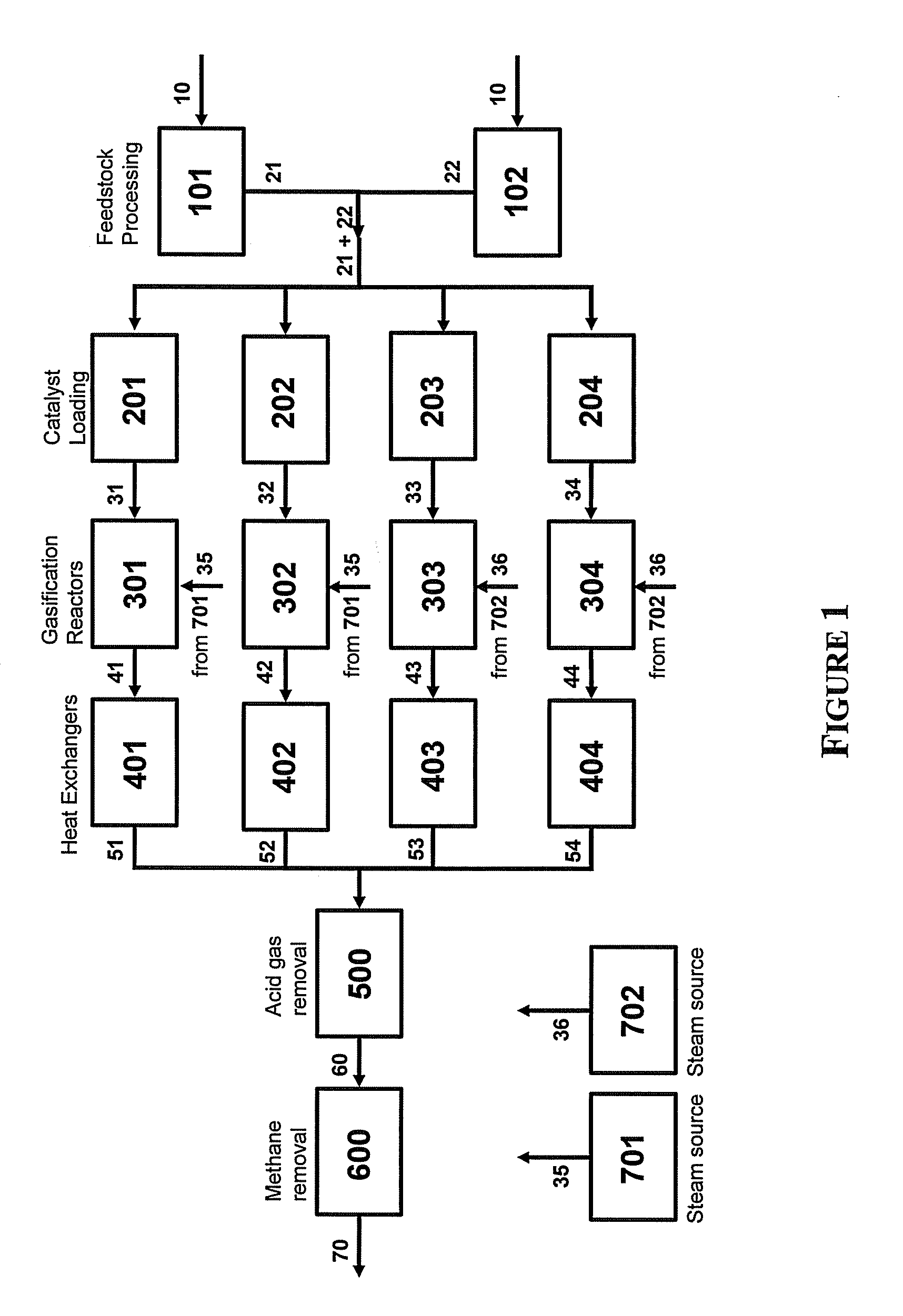

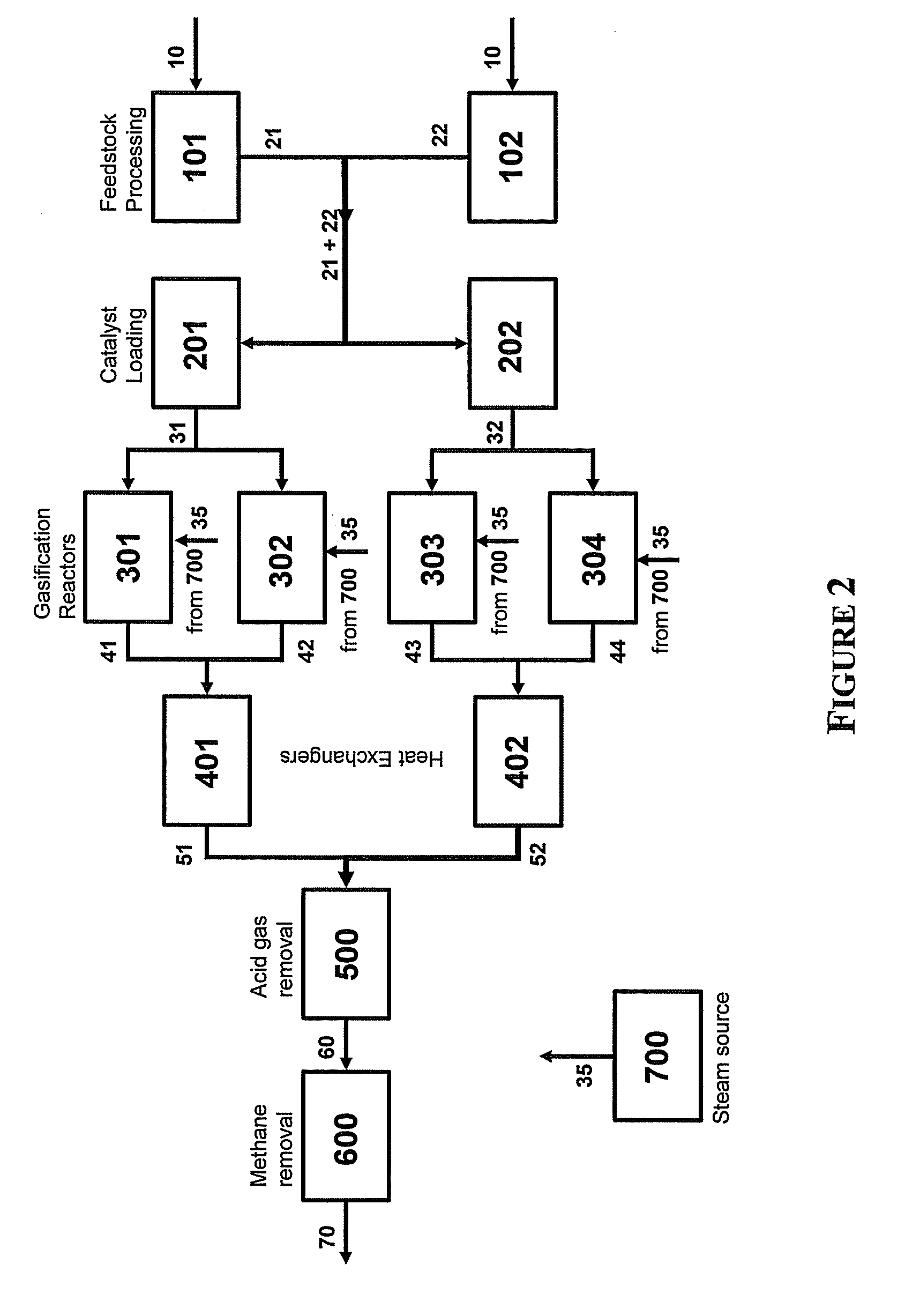

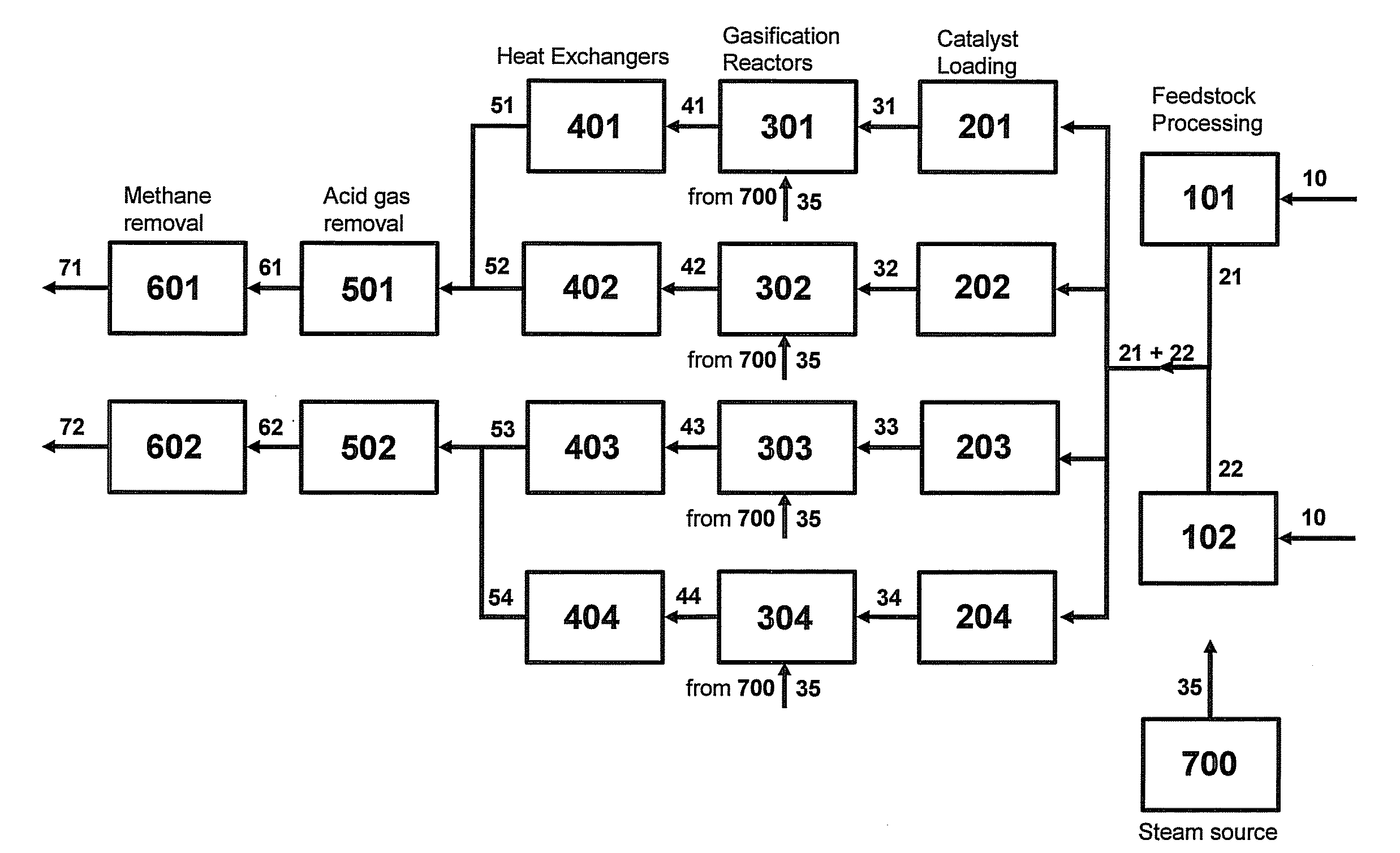

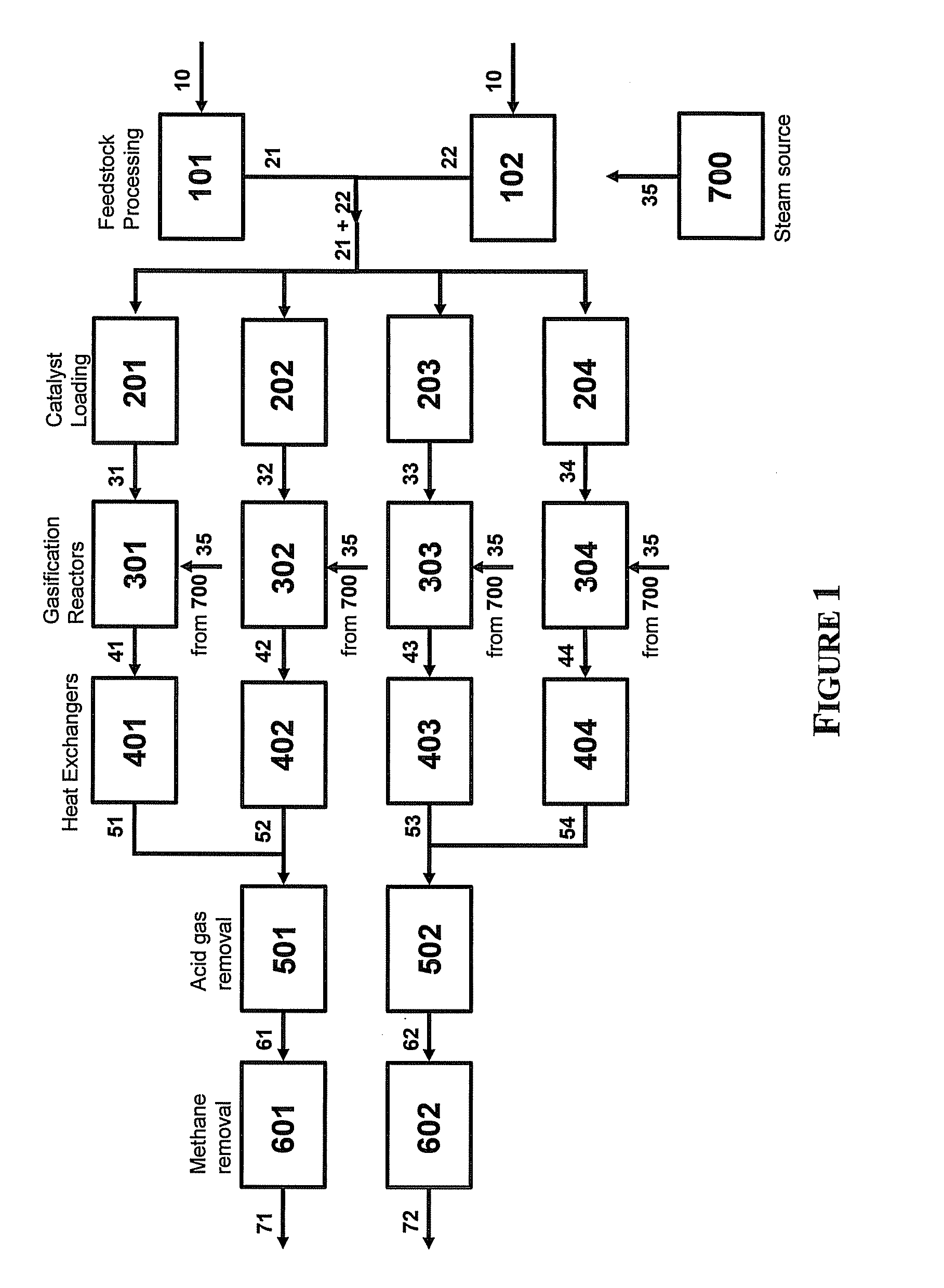

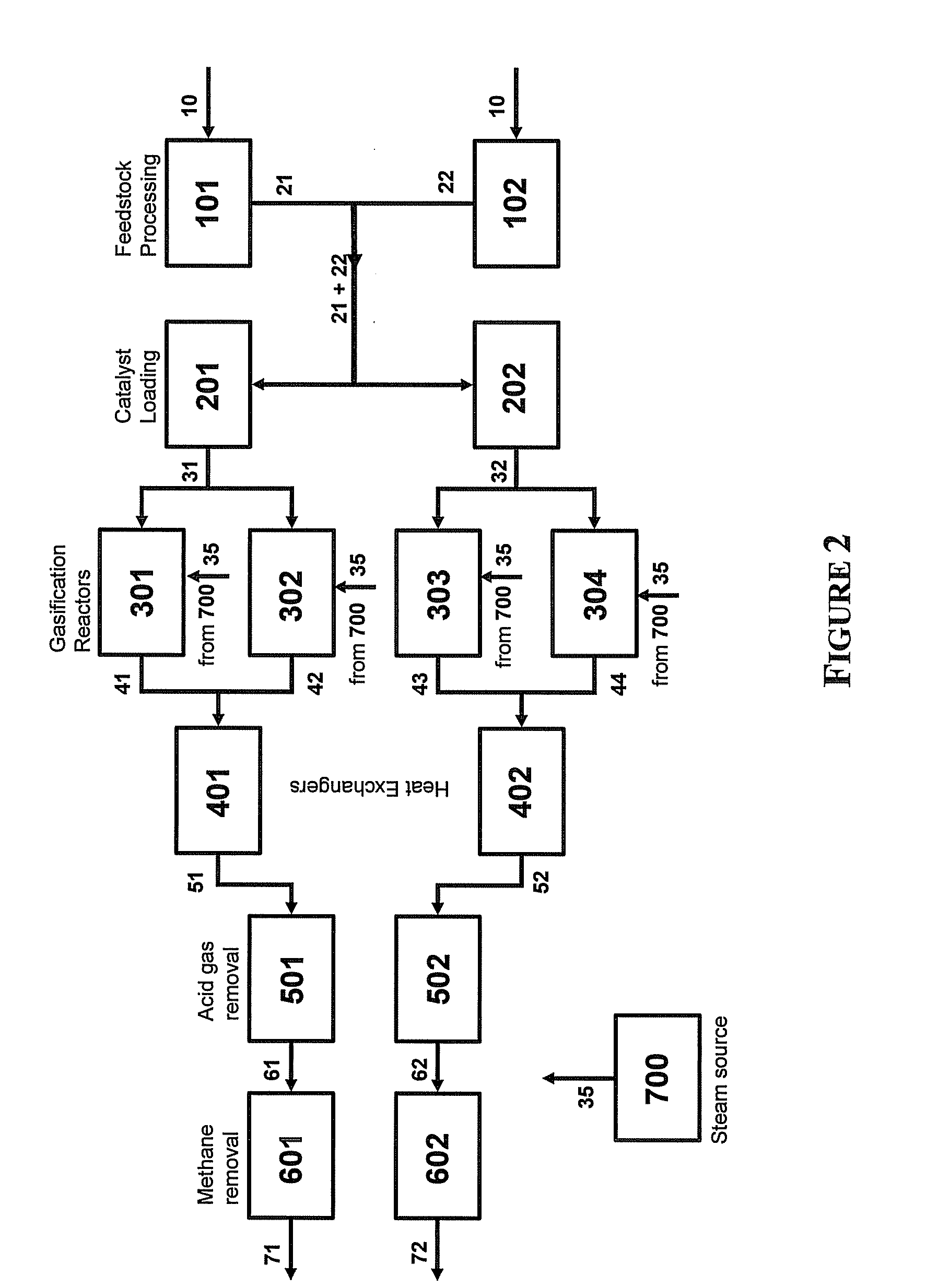

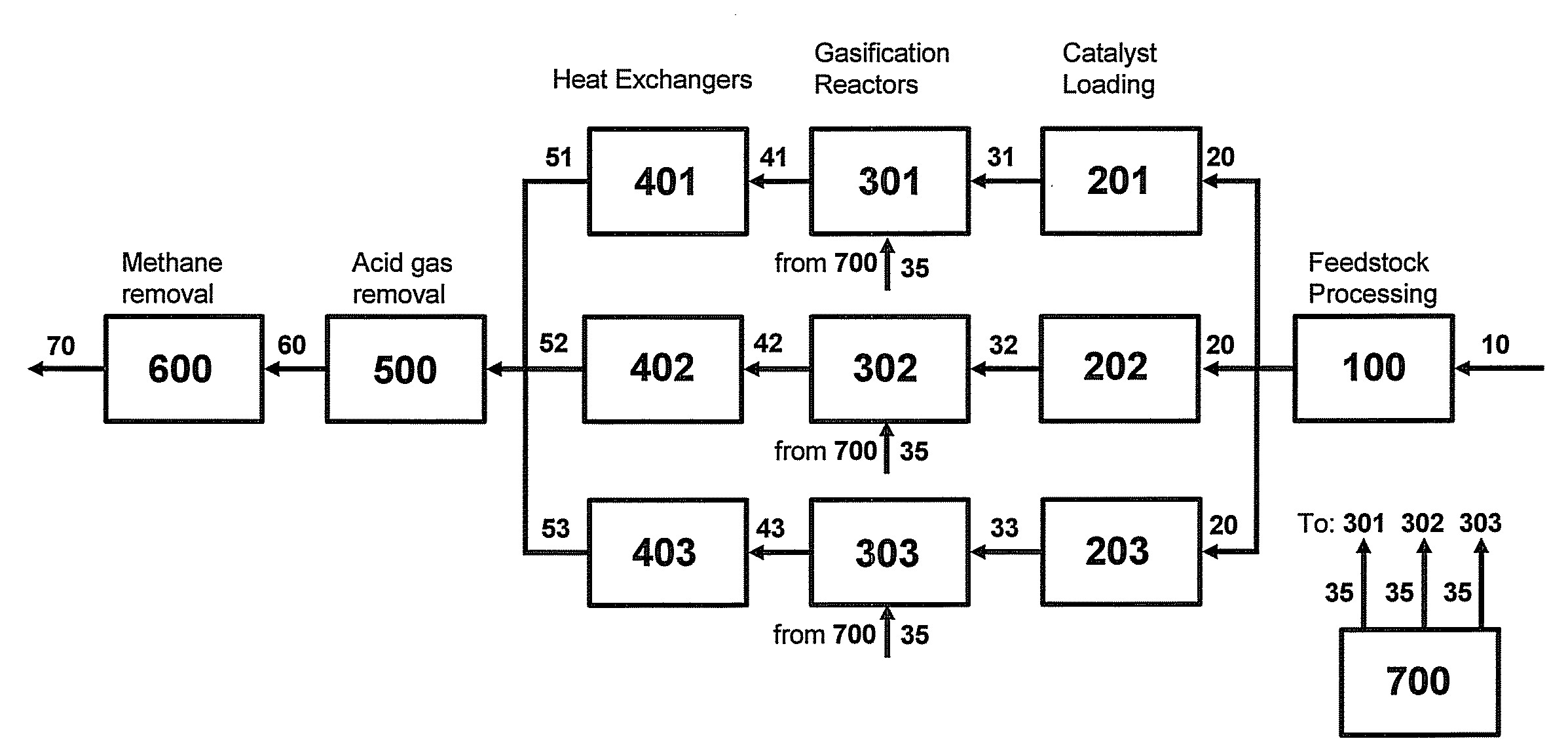

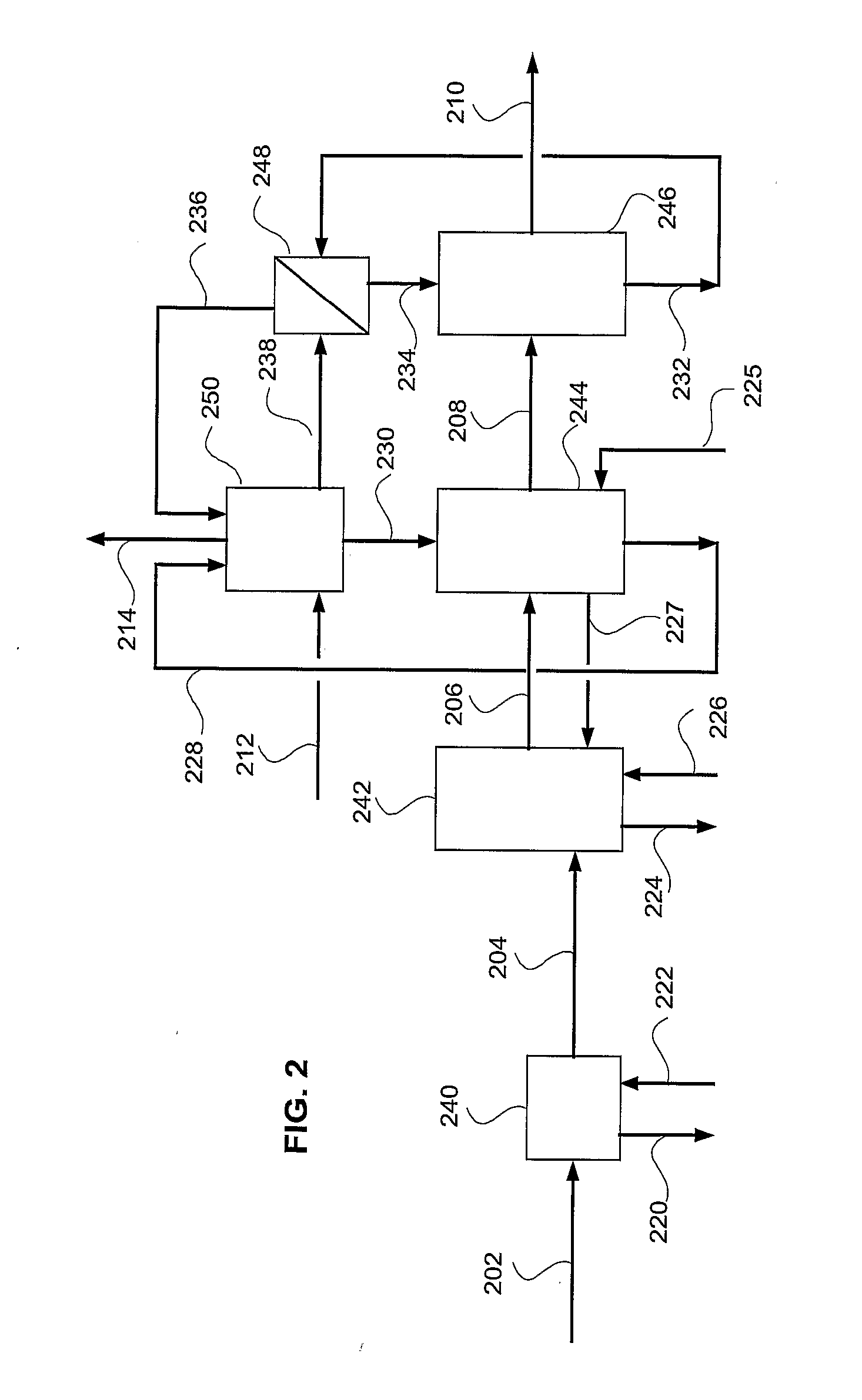

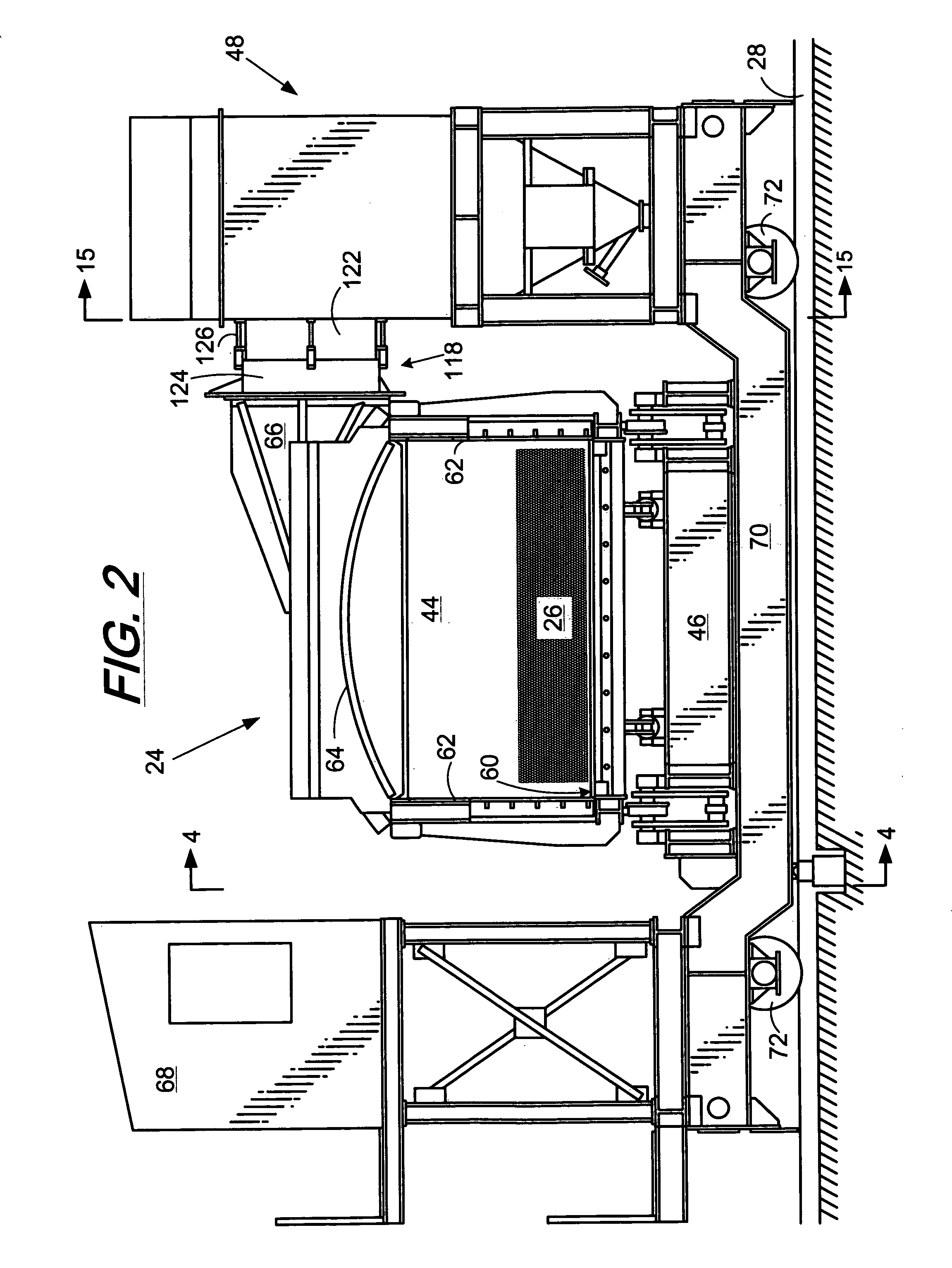

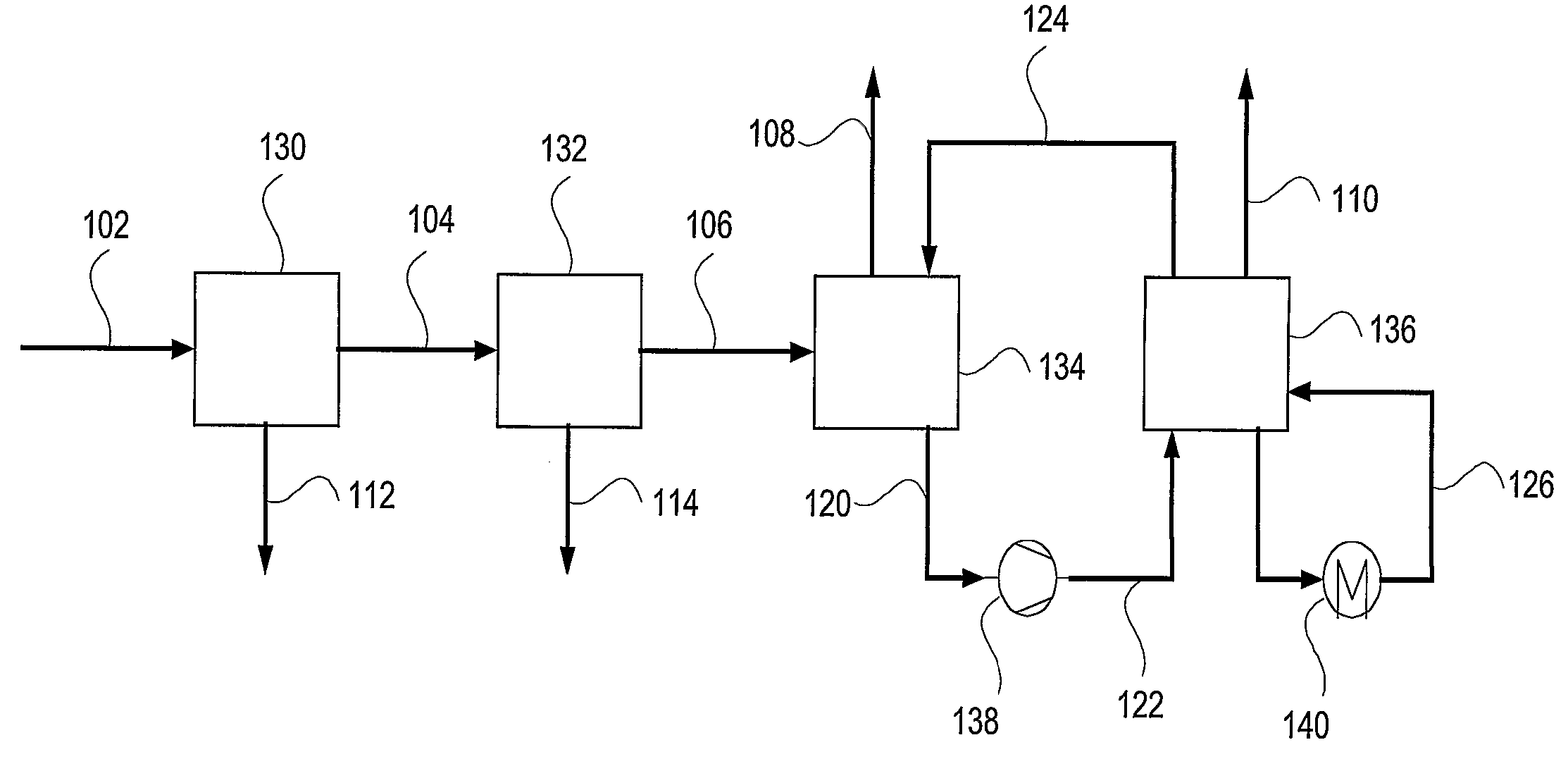

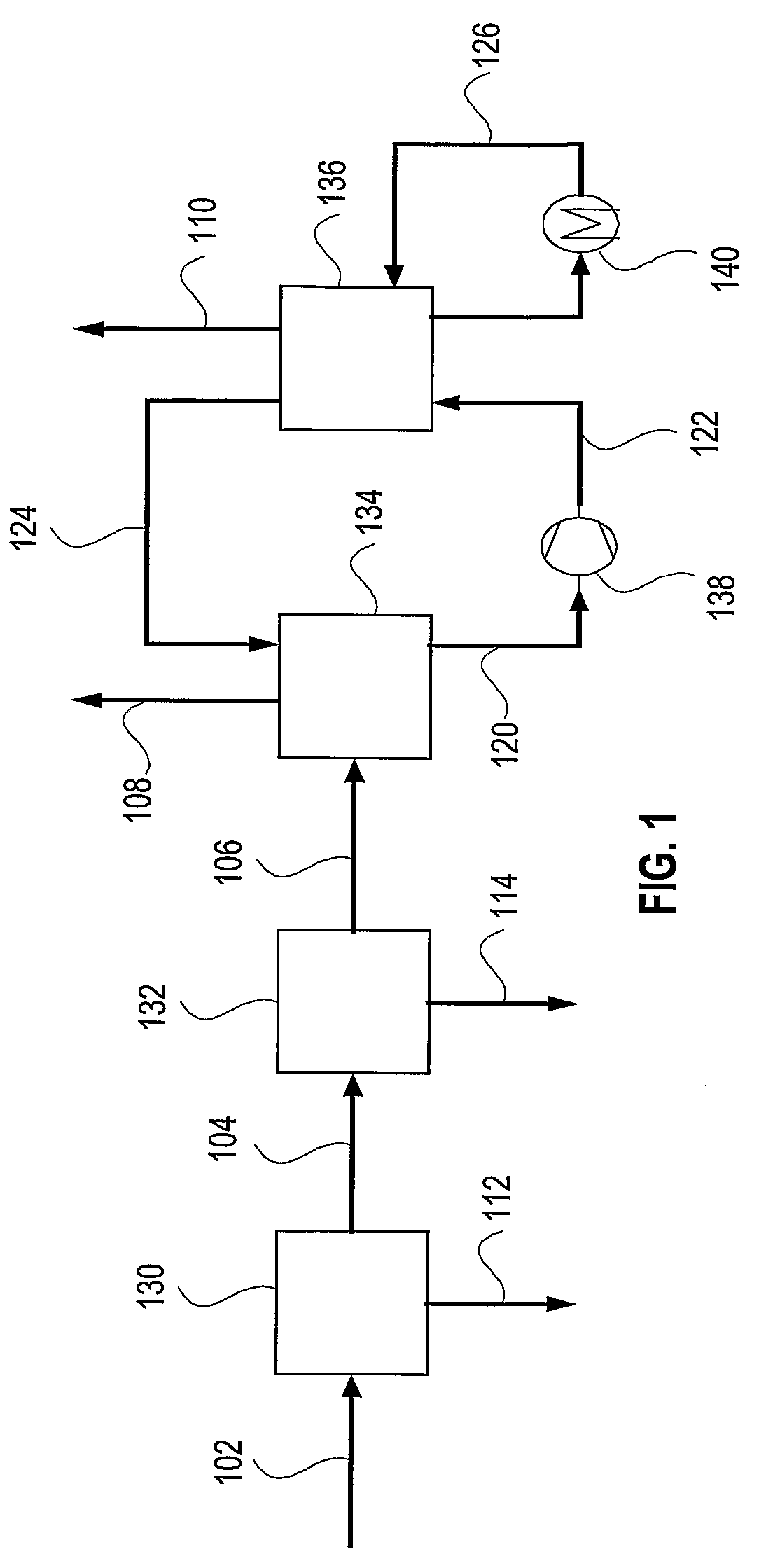

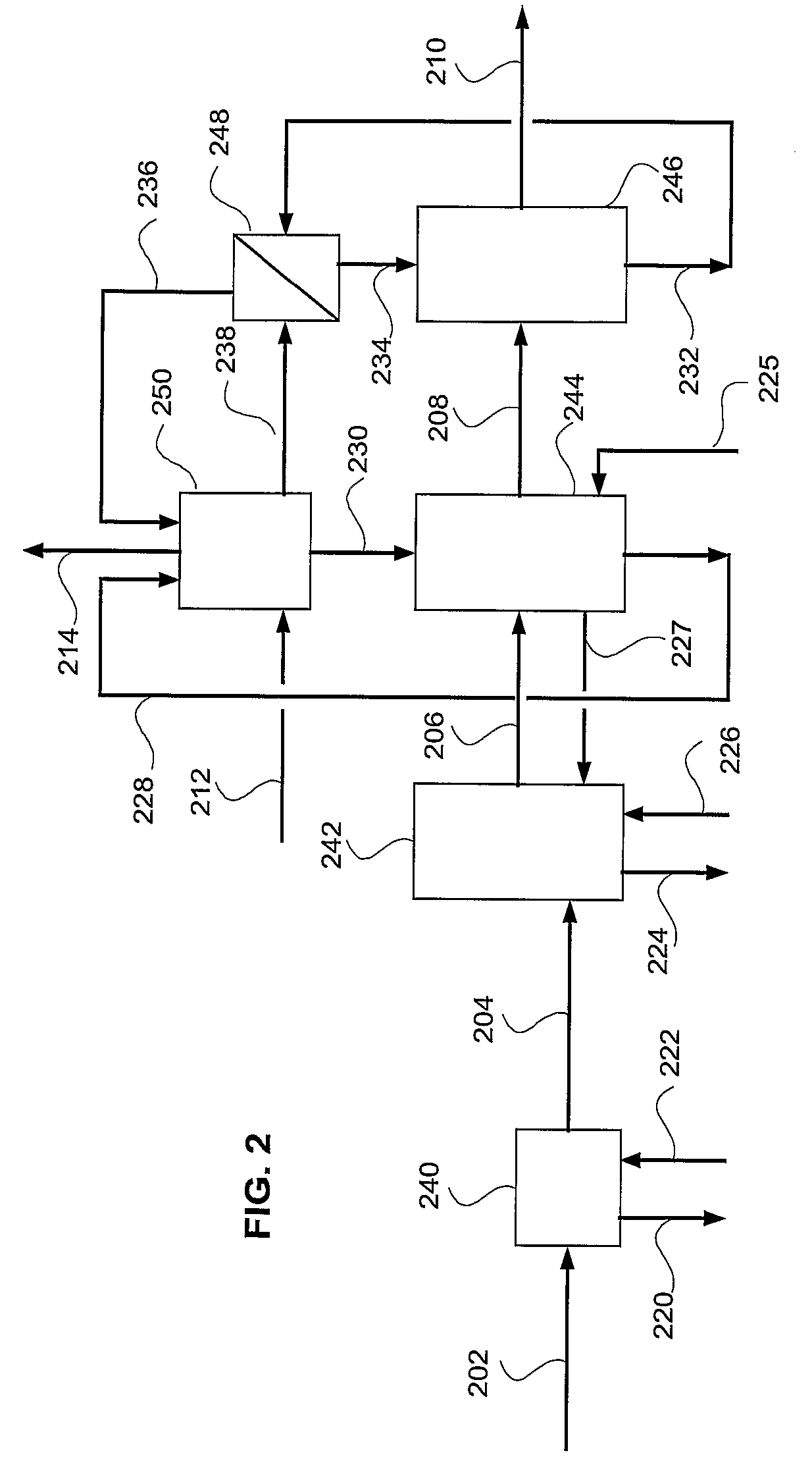

Four-Train Catalytic Gasification Systems

InactiveUS20090324462A1Reduce moisture contentCombustible gas catalytic treatmentGaseous fuelsUnit operationChemistry

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

Four-Train Catalytic Gasification Systems

InactiveUS20090324461A1Reduce moisture contentGaseous fuelsGasification processes detailsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, four separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal, or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

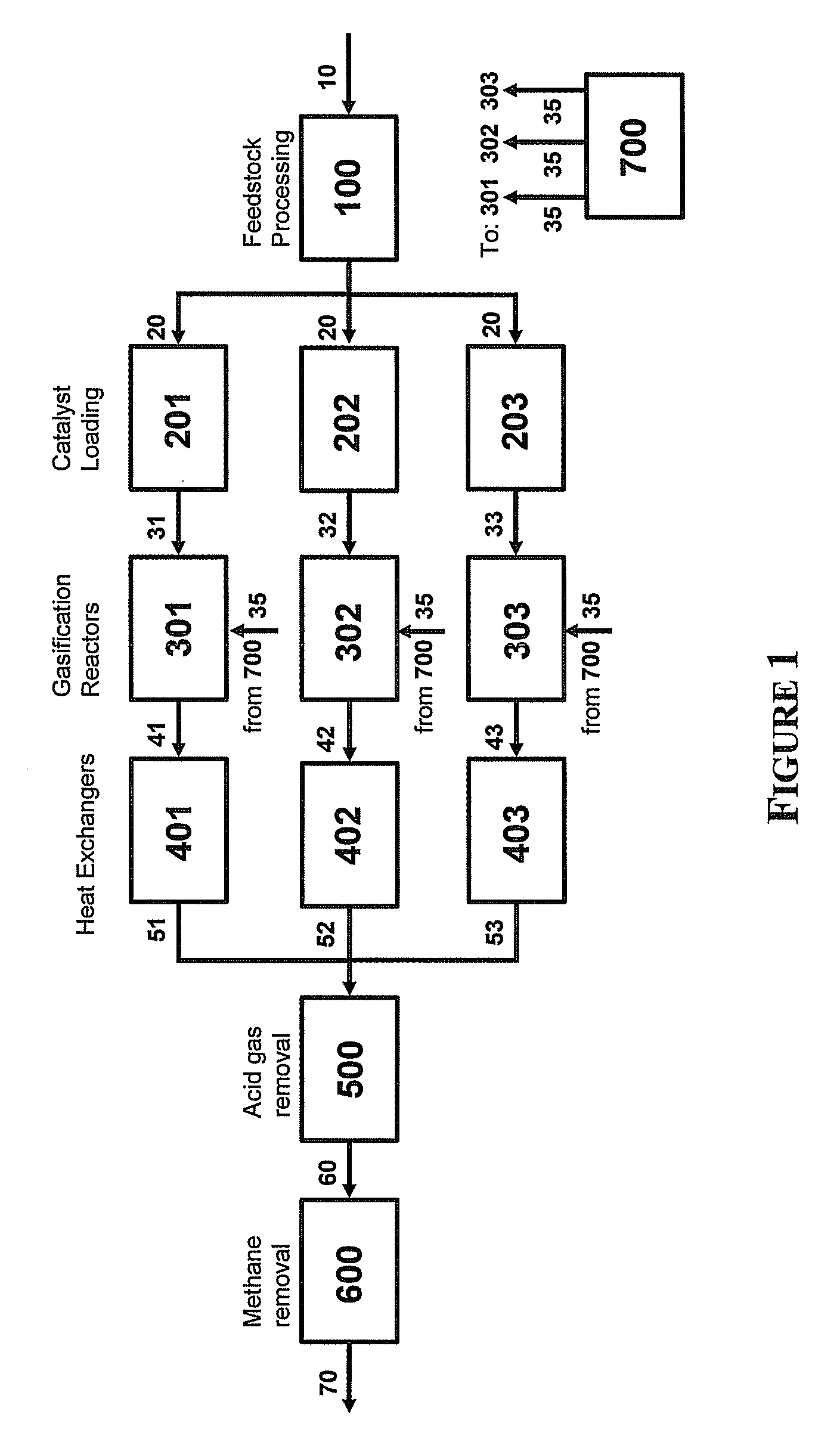

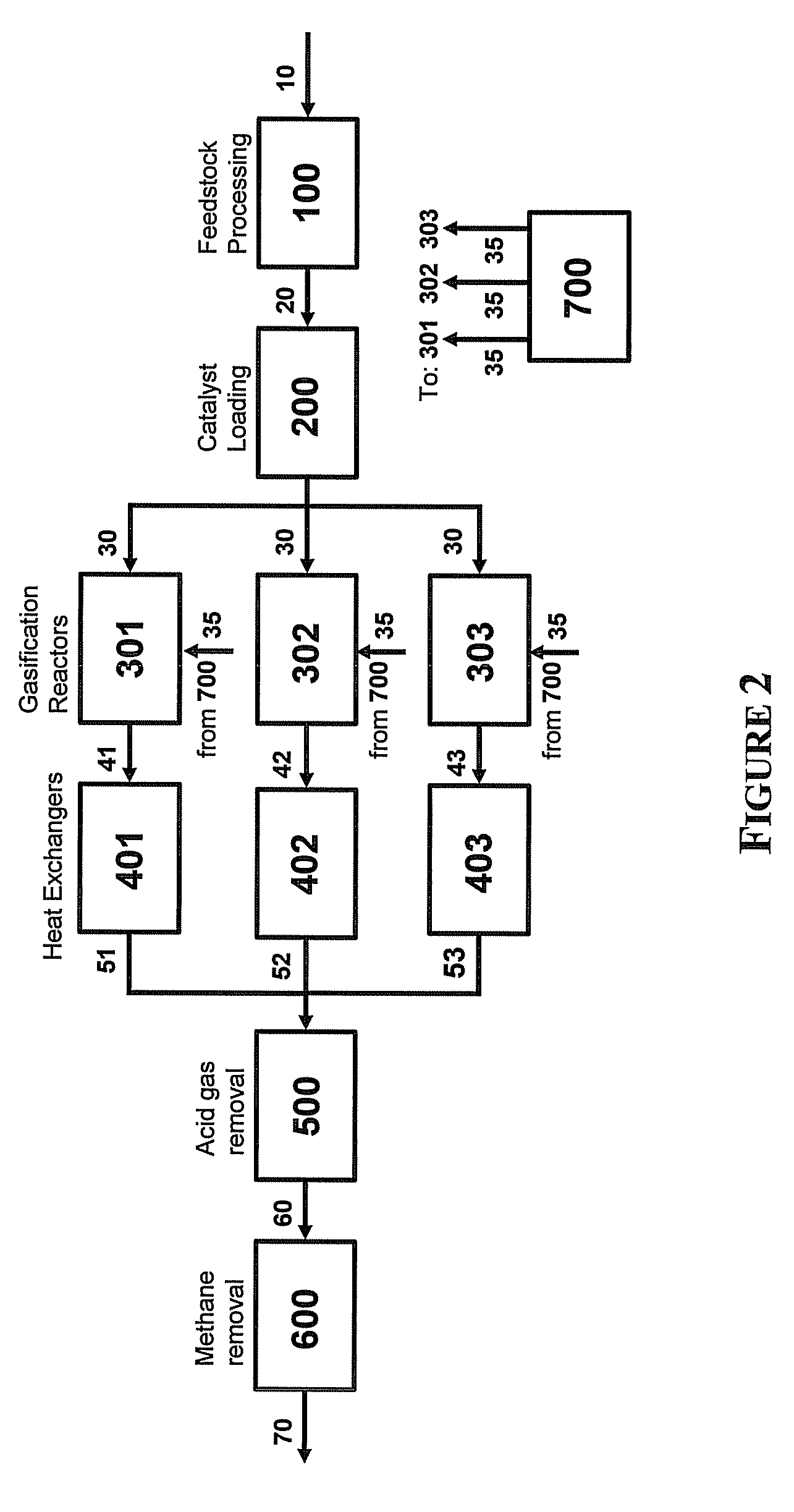

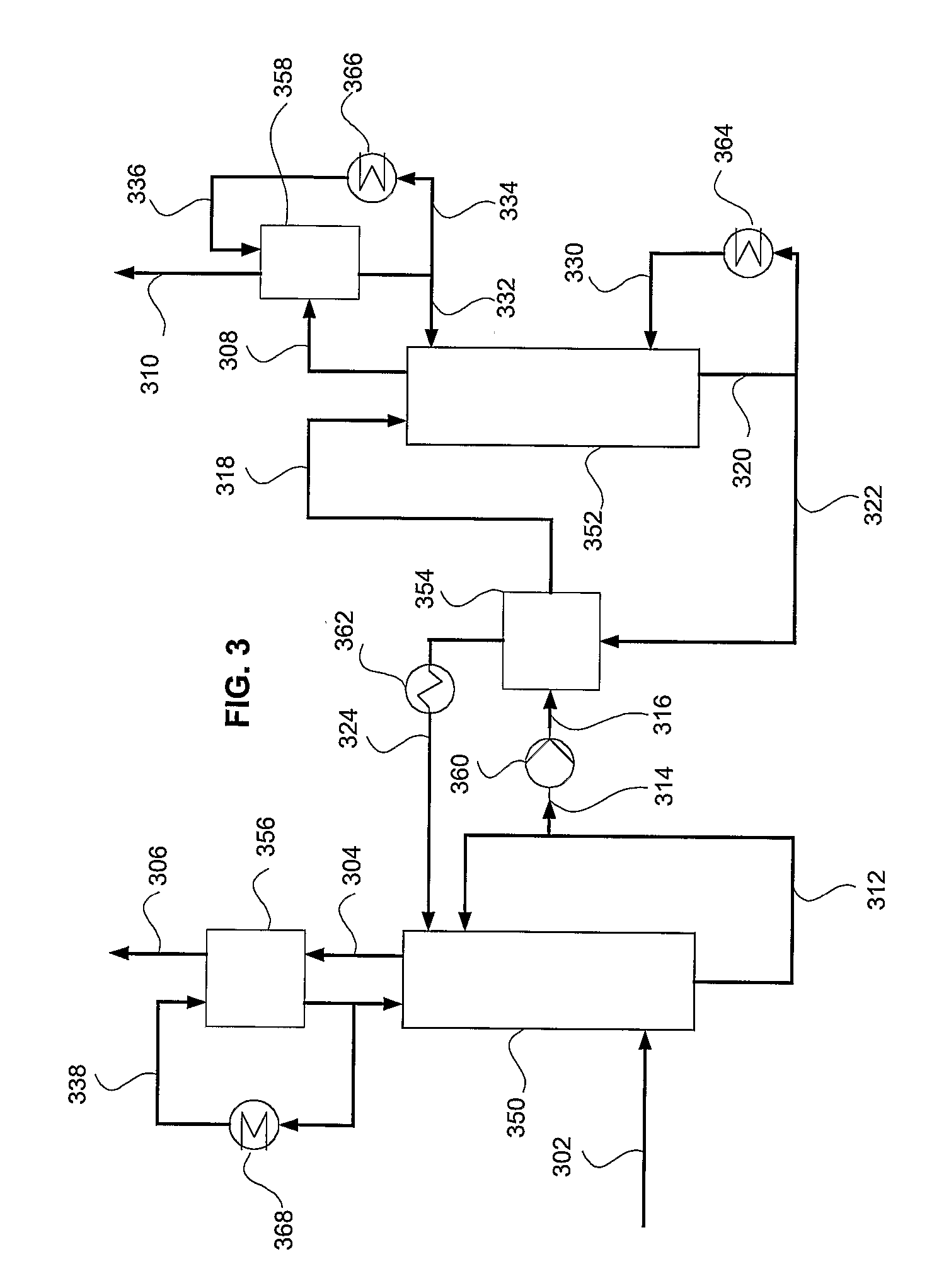

Three-Train Catalytic Gasification Systems

InactiveUS20090324459A1Reduce moisture contentCombustible gas catalytic treatmentGaseous fuelsUnit operationAmmonia

Systems to convert a carbonaceous feedstock into a plurality of gaseous products are described. The systems include, among other units, three separate gasification reactors for the gasification of a carbonaceous feedstock in the presence of an alkali metal catalyst into the plurality of gaseous products including at least methane. Each of the gasification reactors may be supplied with the feedstock from a single or separate catalyst loading and / or feedstock preparation unit operations. Similarly, the hot gas streams from each gasification reactor may be purified via their combination at a heat exchanger, acid gas removal or methane removal unit operations. Product purification may comprise trace contaminant removal units, ammonia removal and recovery units, and sour shift units.

Owner:SURE CHAMPION INVESTMENT LTD

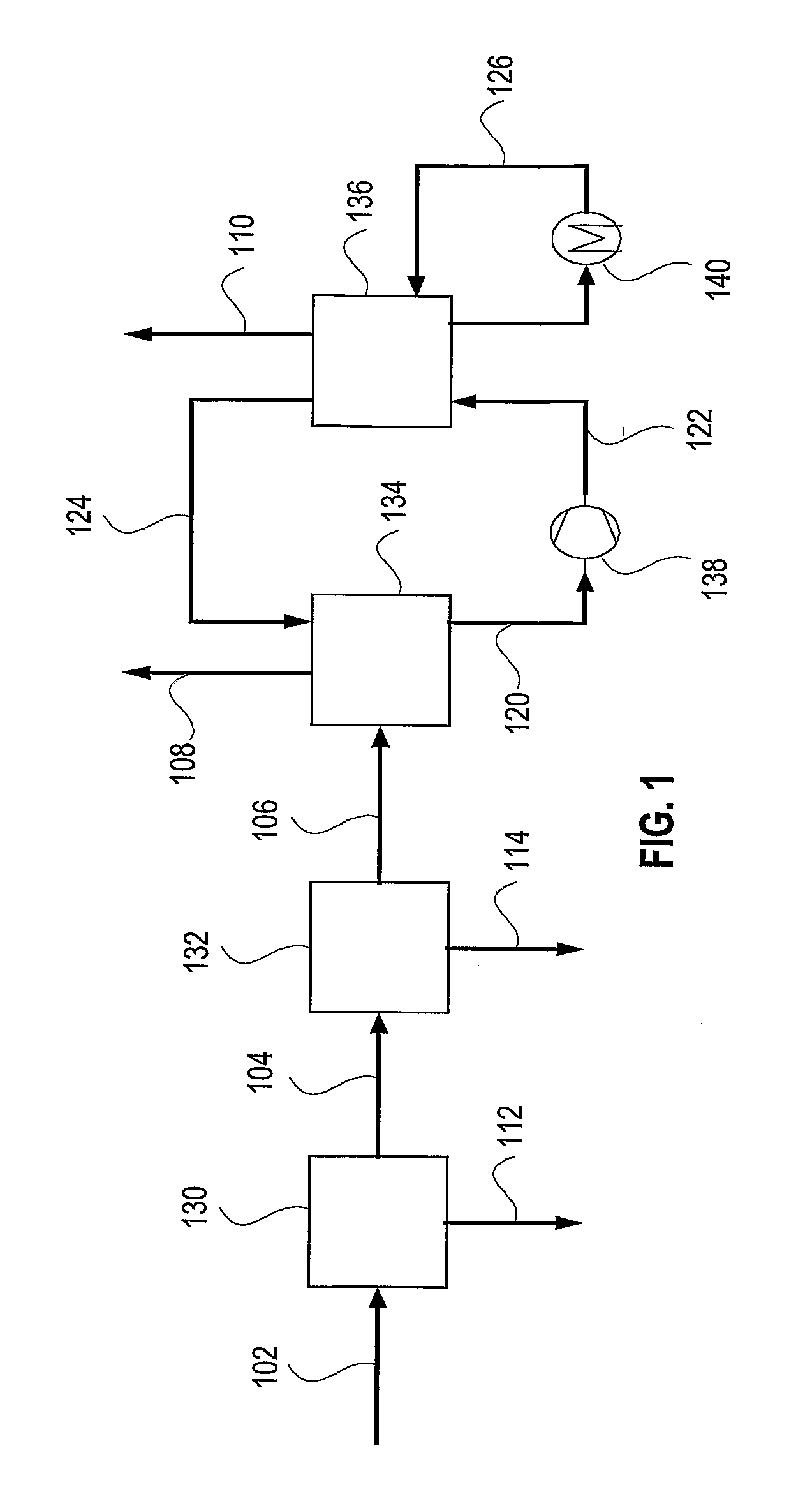

Ultra Cleaning of Combustion Gas Including the Removal of Co2

ActiveUS20080072762A1Reduce evaporationMinimize energy consumptionUsing liquid separation agentEmission preventionCo2 removalCombustion

Ultra cleaning of combustion gas to near zero concentration of residual contaminants followed by the capture of CO2 is provided. The high removal efficiency of residual contaminants is accomplished by direct contact cooling and scrubbing of the gas with cold water. The temperature of the combustion gas is reduced to 0-20 degrees Celsius to achieve maximum condensation and gas cleaning effect. The CO2 is captured from the cooled and clean flue gas in a CO2 absorber (134) utilizing an ammoniated solution or slurry in the NH3—CO2H2O system. The absorber operates at 0-20 degrees Celsius. Regeneration is accomplished by elevating the pressure and temperature of the CO2-rich solution from the absorber. The CO2 vapor pressure is high and a pressurized CO2 stream, with low concentration of NH3 and water vapor is generated. The high pressure CO2 stream is cooled and washed to recover the ammonia and moisture from the gas.

Owner:GENERAL ELECTRIC TECH GMBH

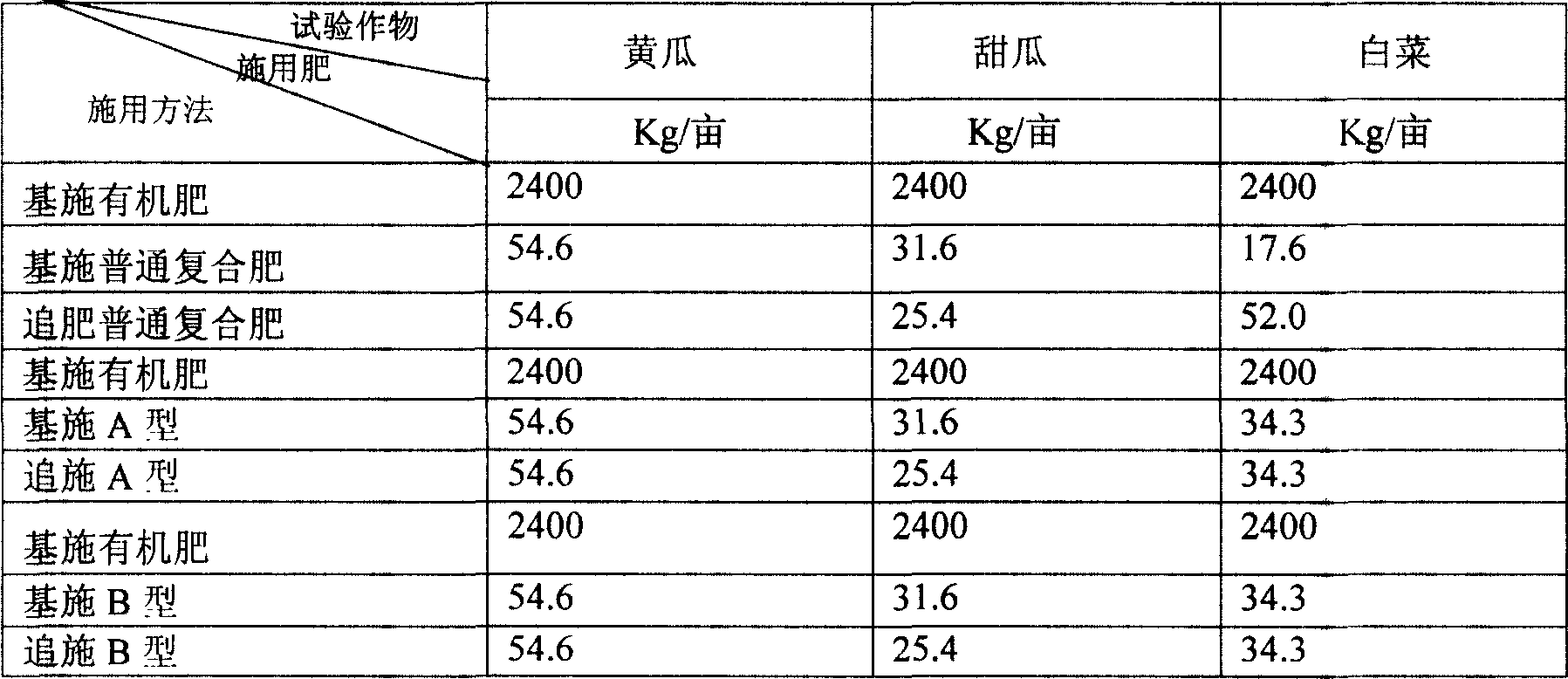

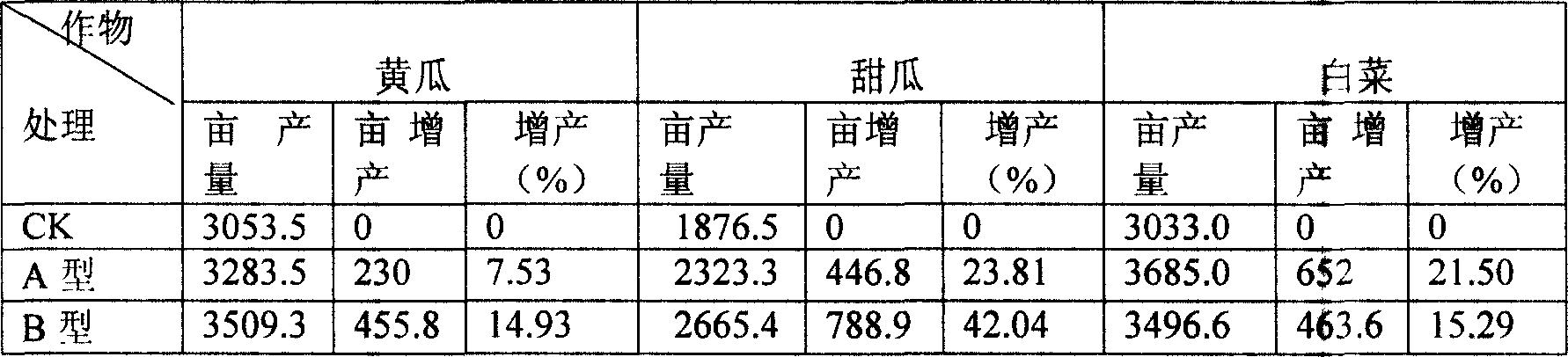

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

Processes for the production of solid dressings for treating wounded tissue

ActiveUS20080031934A1Reduce the temperatureAvoid componentsNon-adhesive dressingsPeptide/protein ingredientsFibrinogenBiomedical engineering

Disclosed are processes for preparing solid dressings for treated wounded tissue in mammalian patients, such as a human, comprising a haemostatic layer consisting essentially of a fibrinogen component and a fibrinogen activator. Also disclosed are methods for treating wounded tissue using these dressings and frozen and liquid compositions useful for preparing the haemostatic layer(s) of these dressings or for treating wounded tissue in a mammal.

Owner:HDG

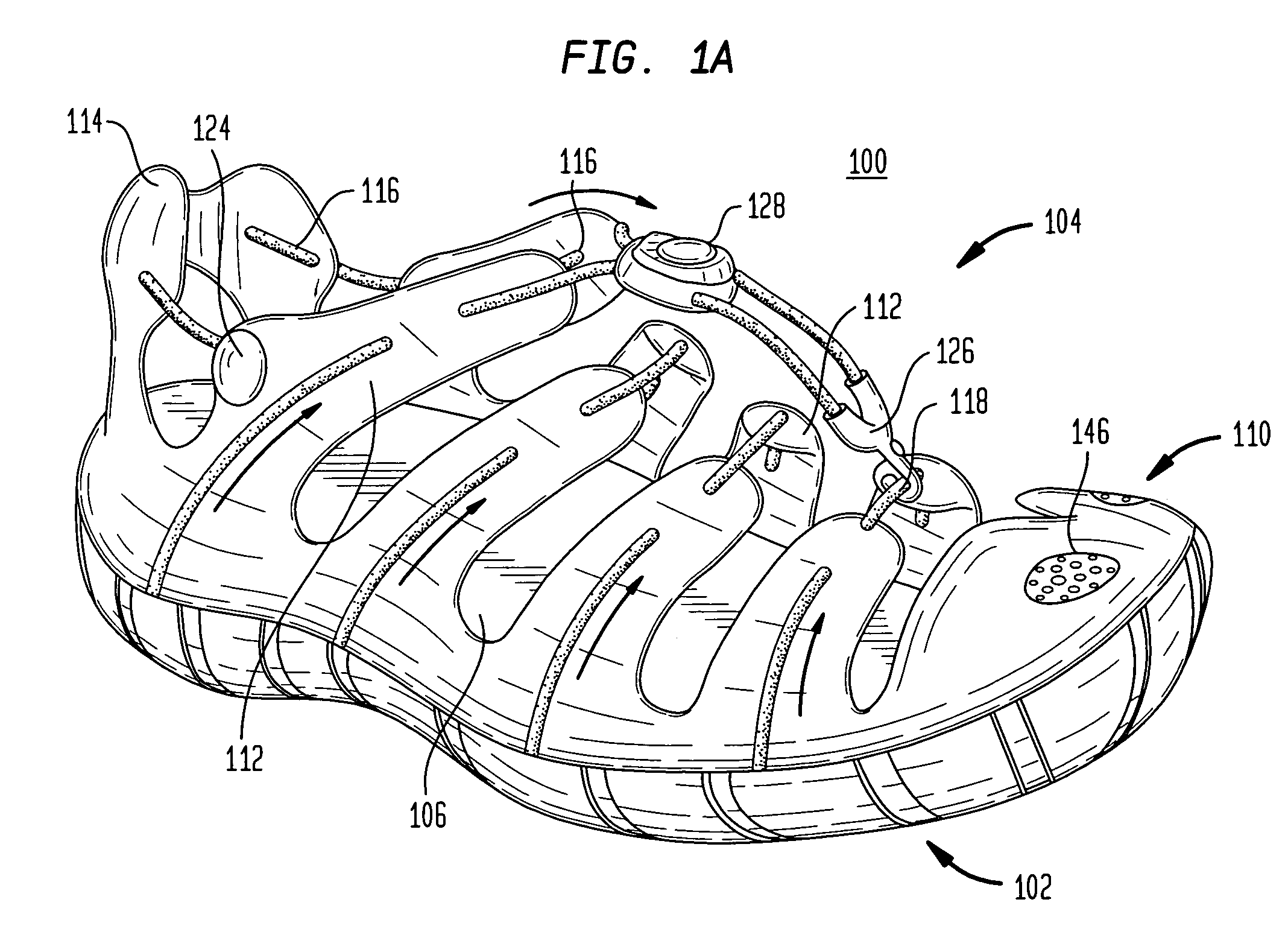

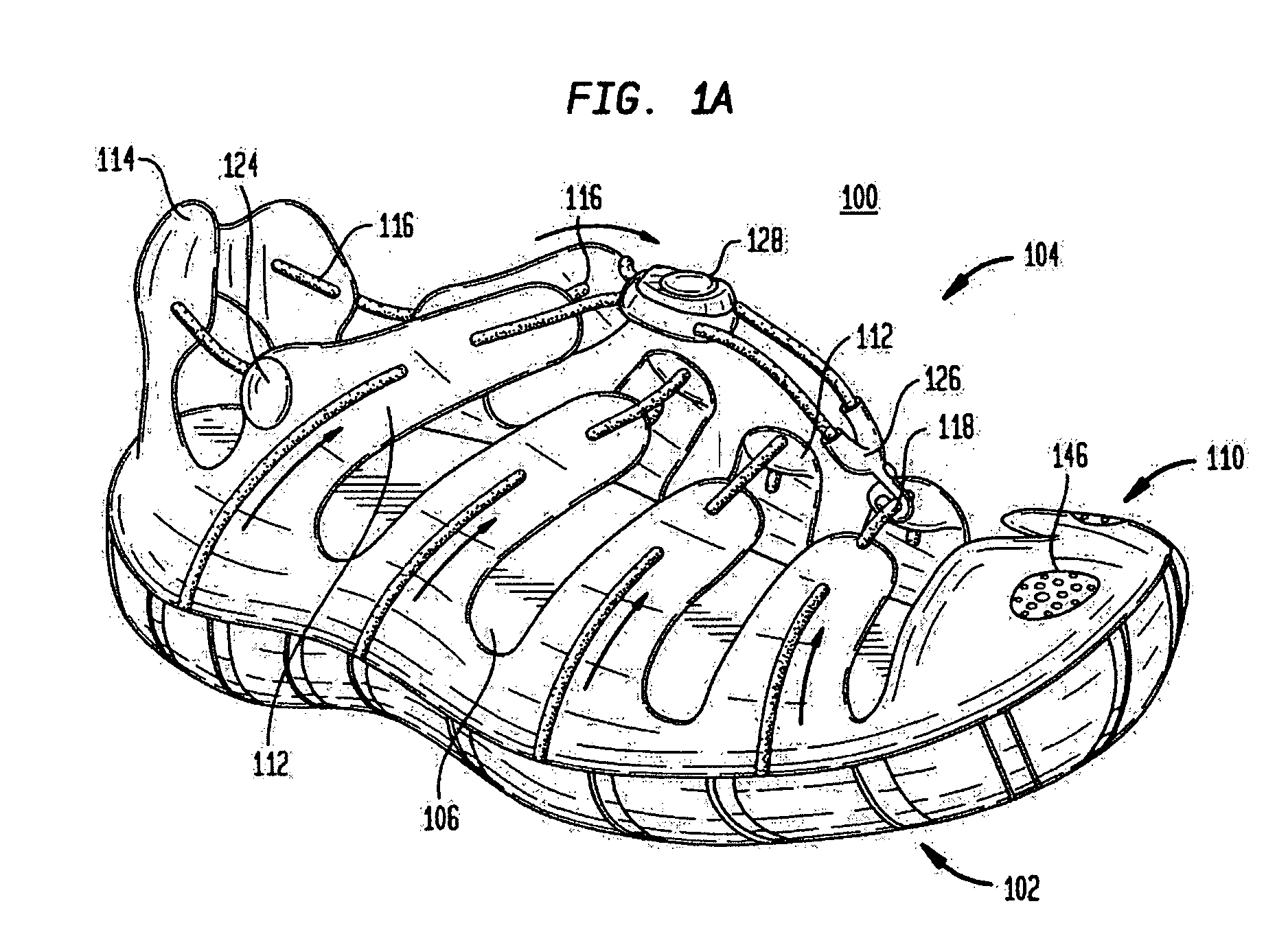

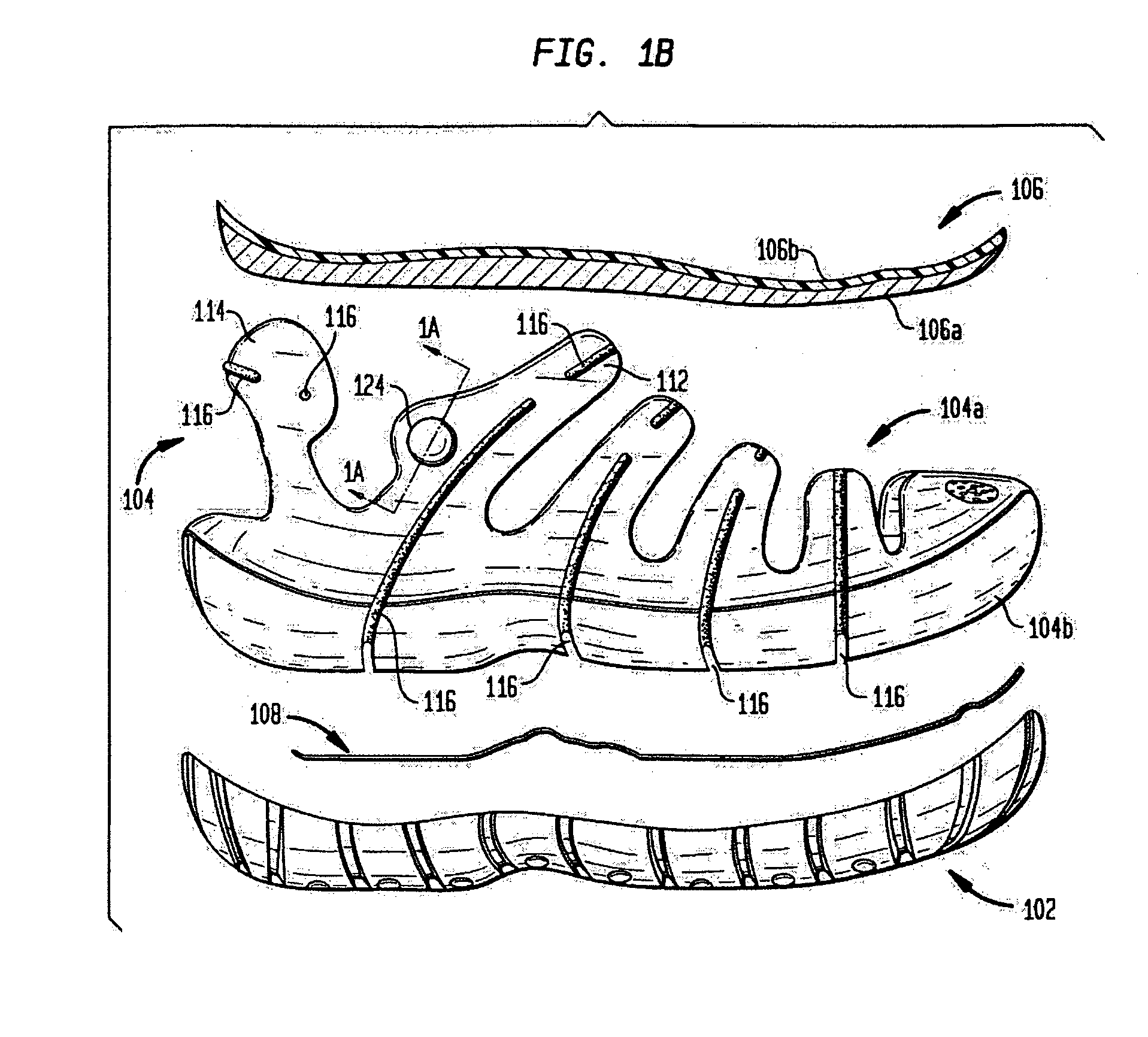

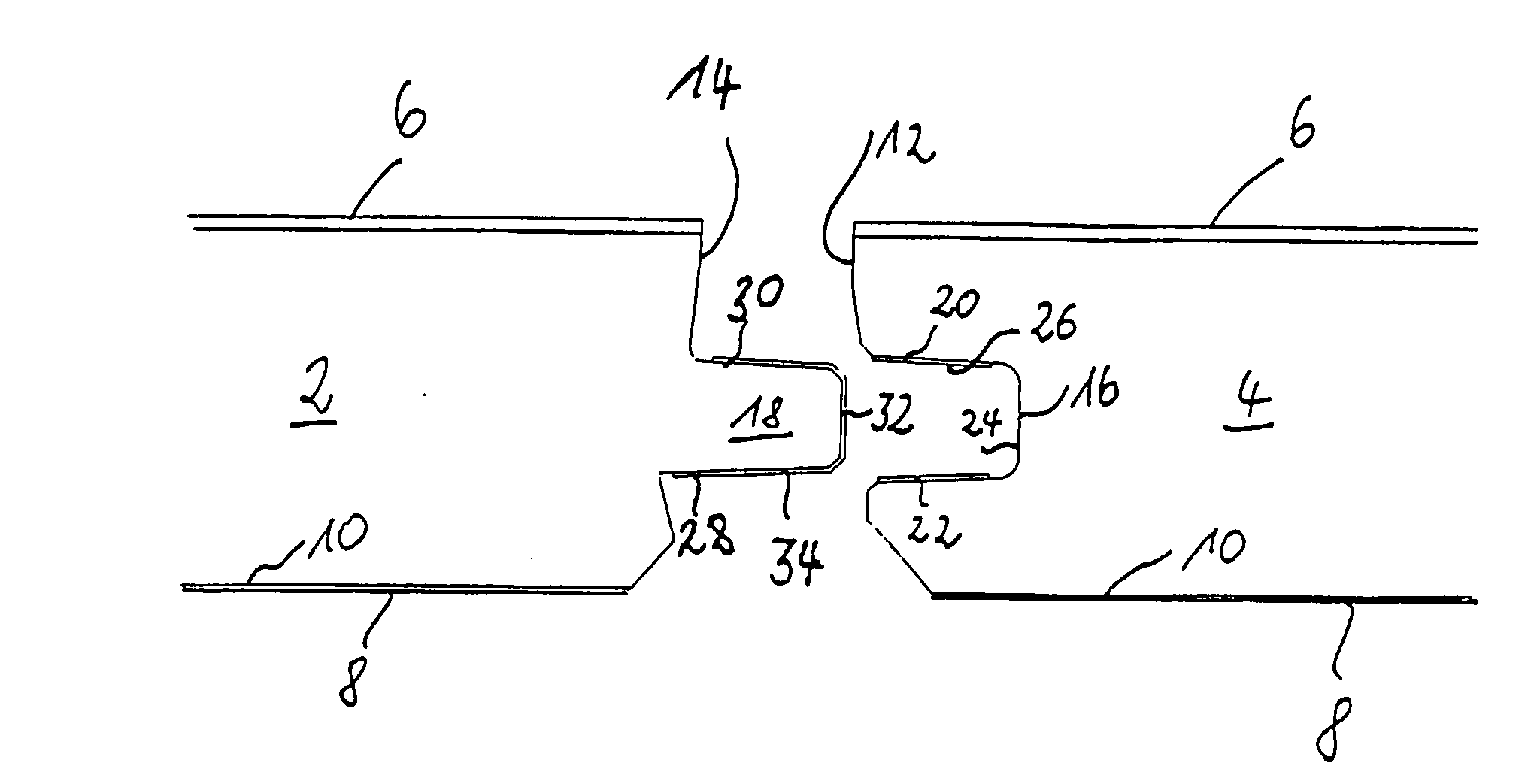

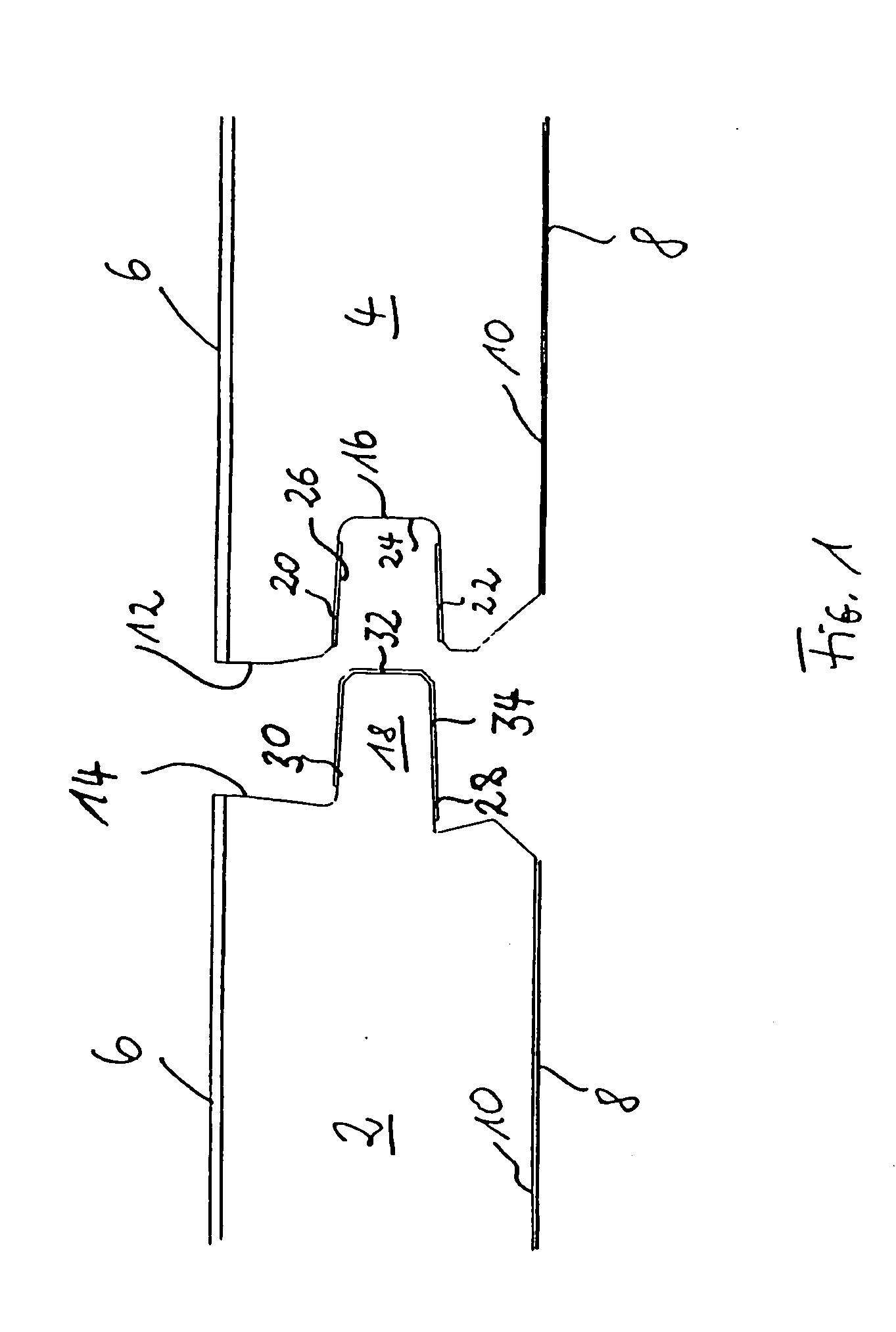

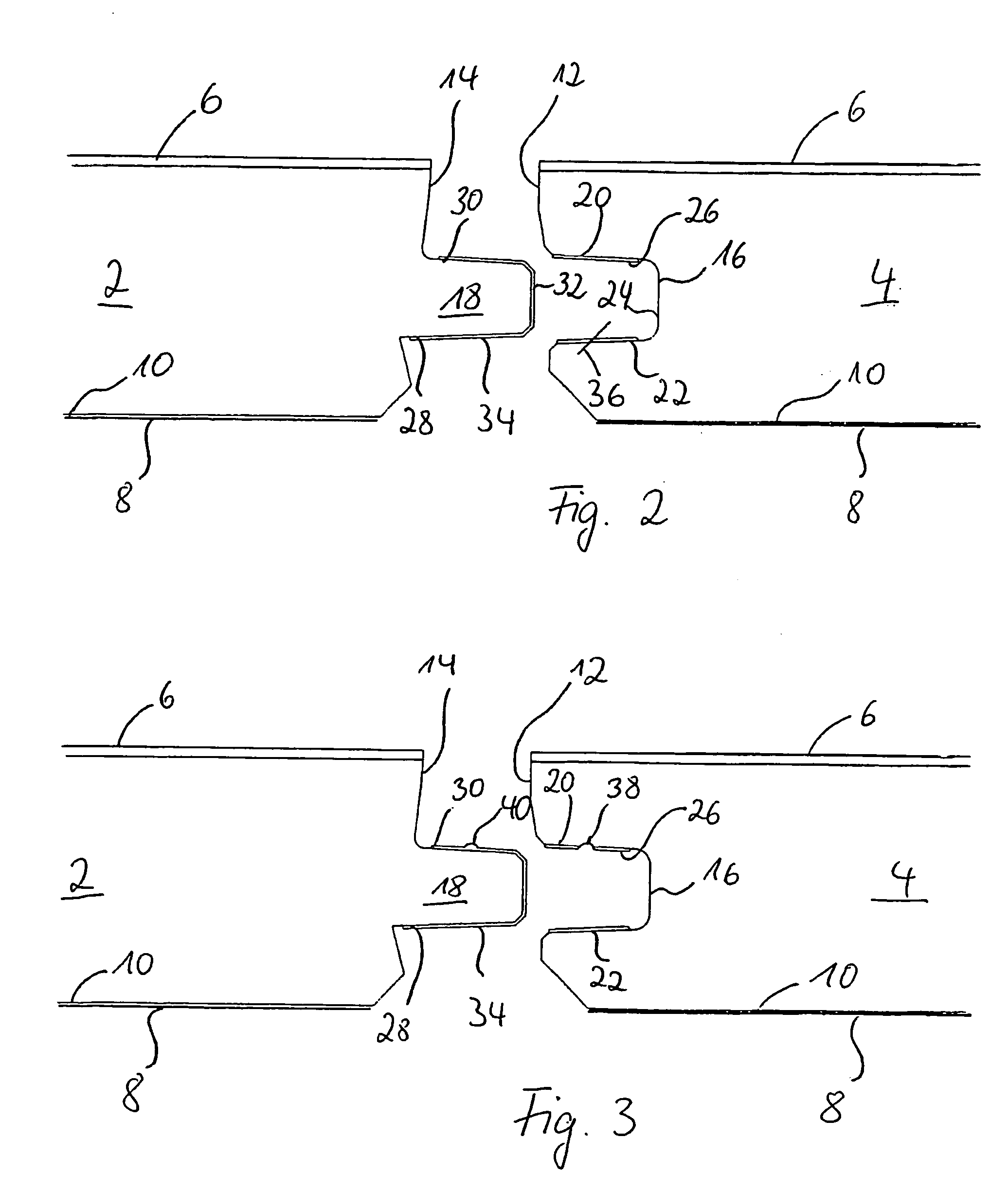

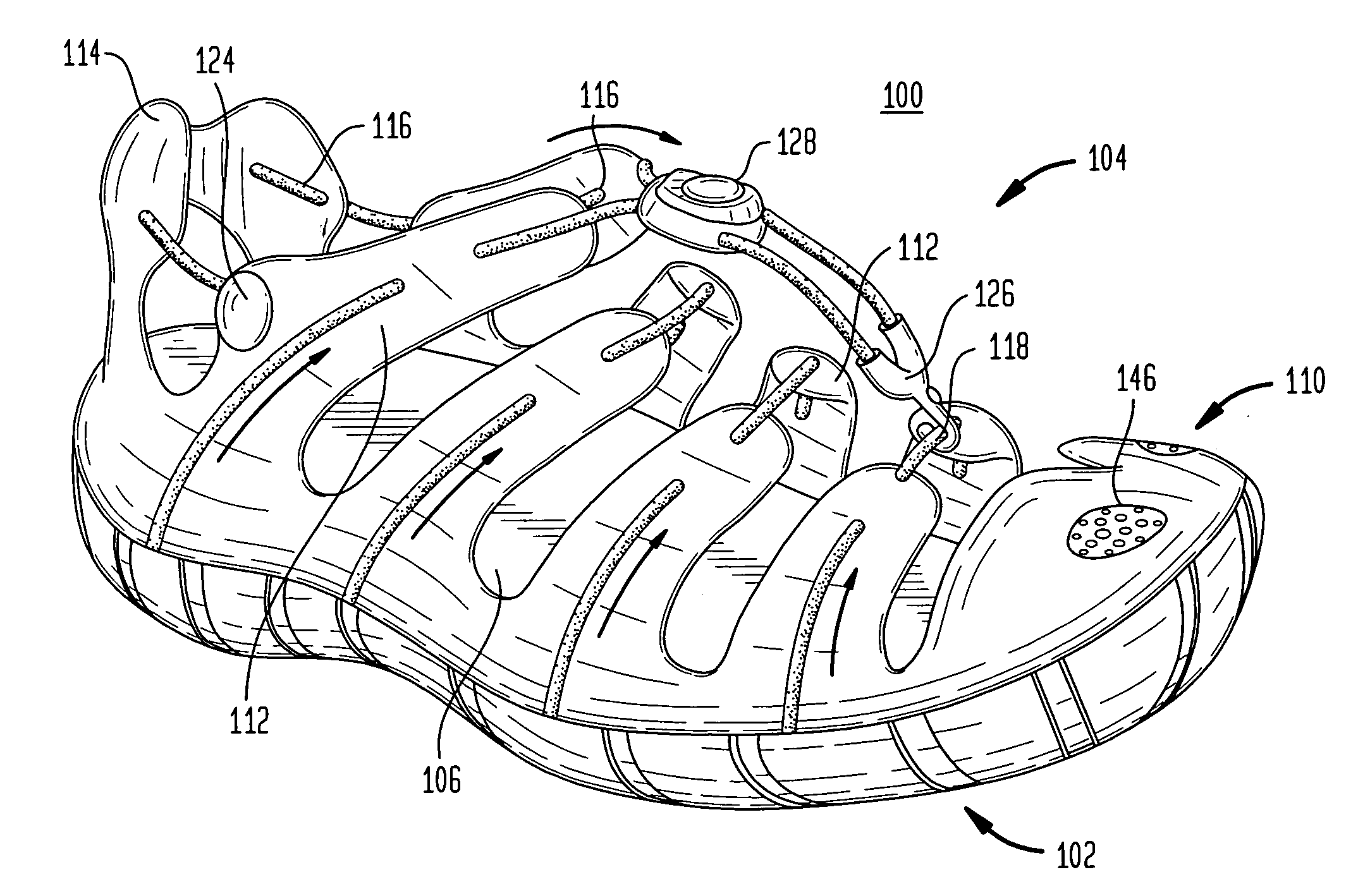

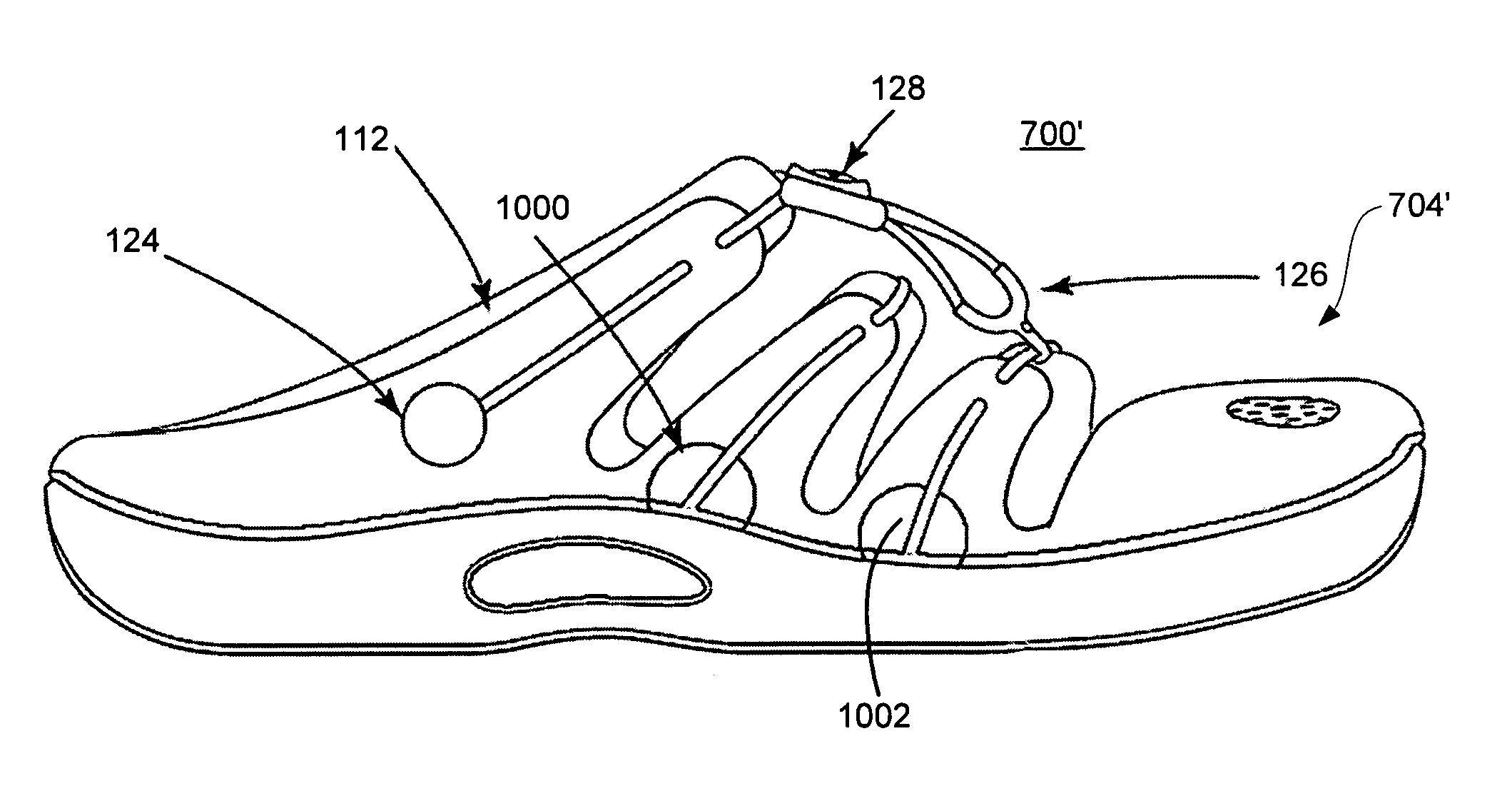

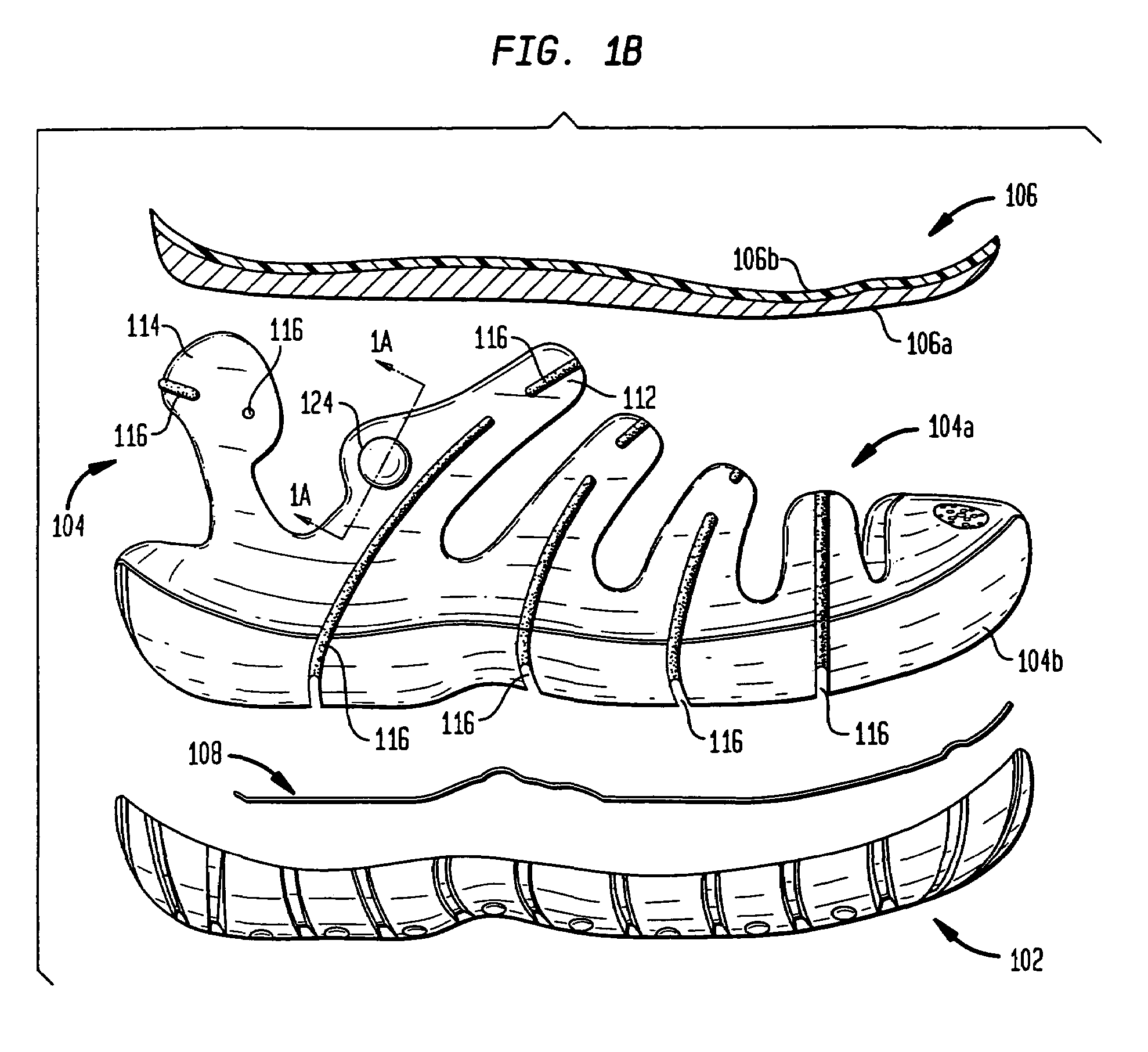

Shoe with lacing

ActiveUS7287342B2Overcome deficienciesReduce moisture contentShoe lace fasteningsUpperShoe lacesEngineering

The present invention provides a wraparound lacing system for use in all manner of footwear. The lacing system includes a lace which encircles the upper and midsole of the article of footwear in a spiral, helical, coiled or similar wound wraparound pattern. The upper includes finger members which independently adjust to the contours of the wearer's foot while providing a snug and secure fit. The upper and midsole are integrally formed as a unitary structure. The housing of the upper and the midsole includes channels therein which receive the wraparound lace. The lace can be affixed at one or both ends to the midsole or to the upper. Removable lace end keepers on the upper permit the user to adjust the length of the lace.

Owner:THE TIMBERLAND COMPANY

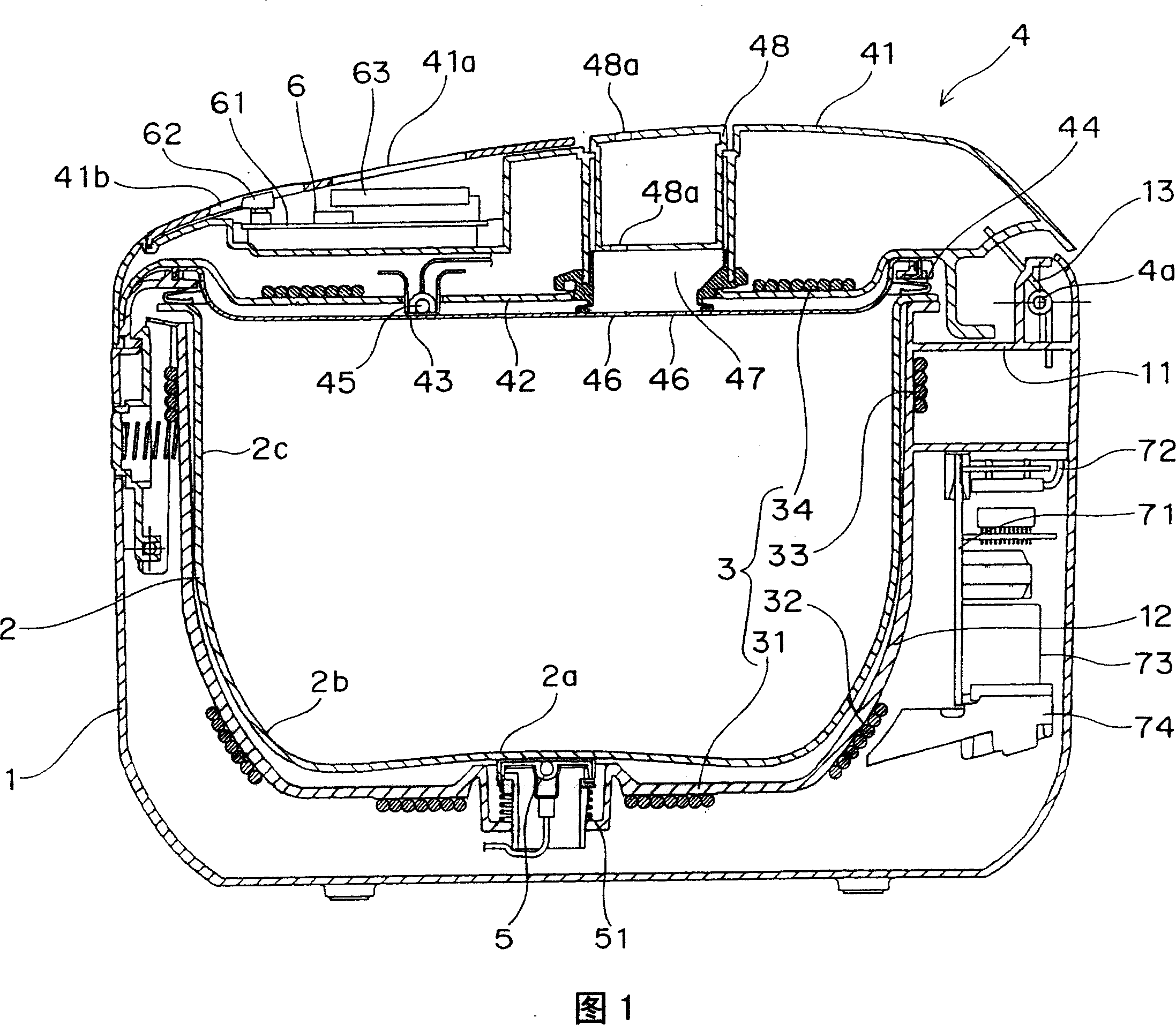

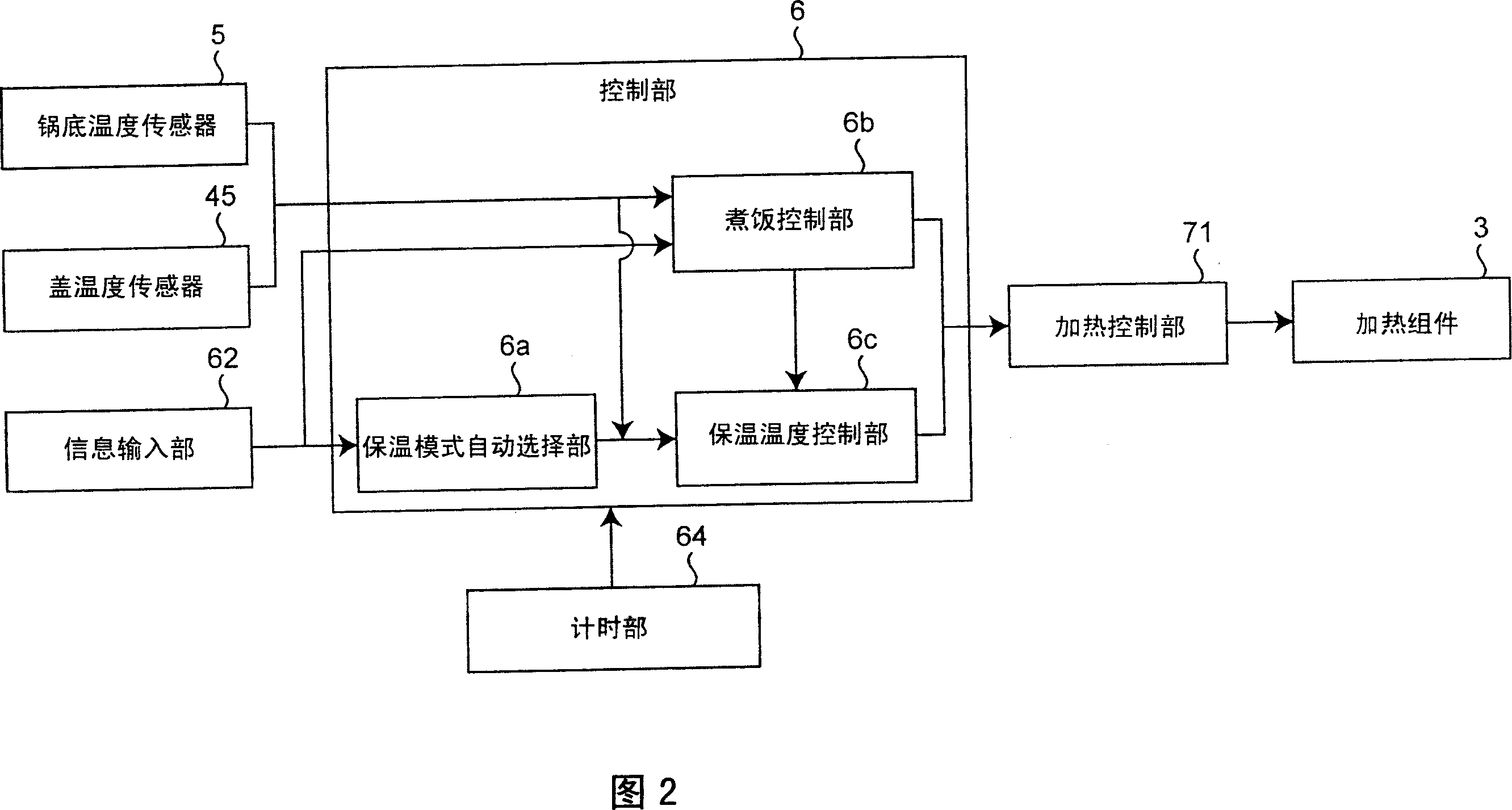

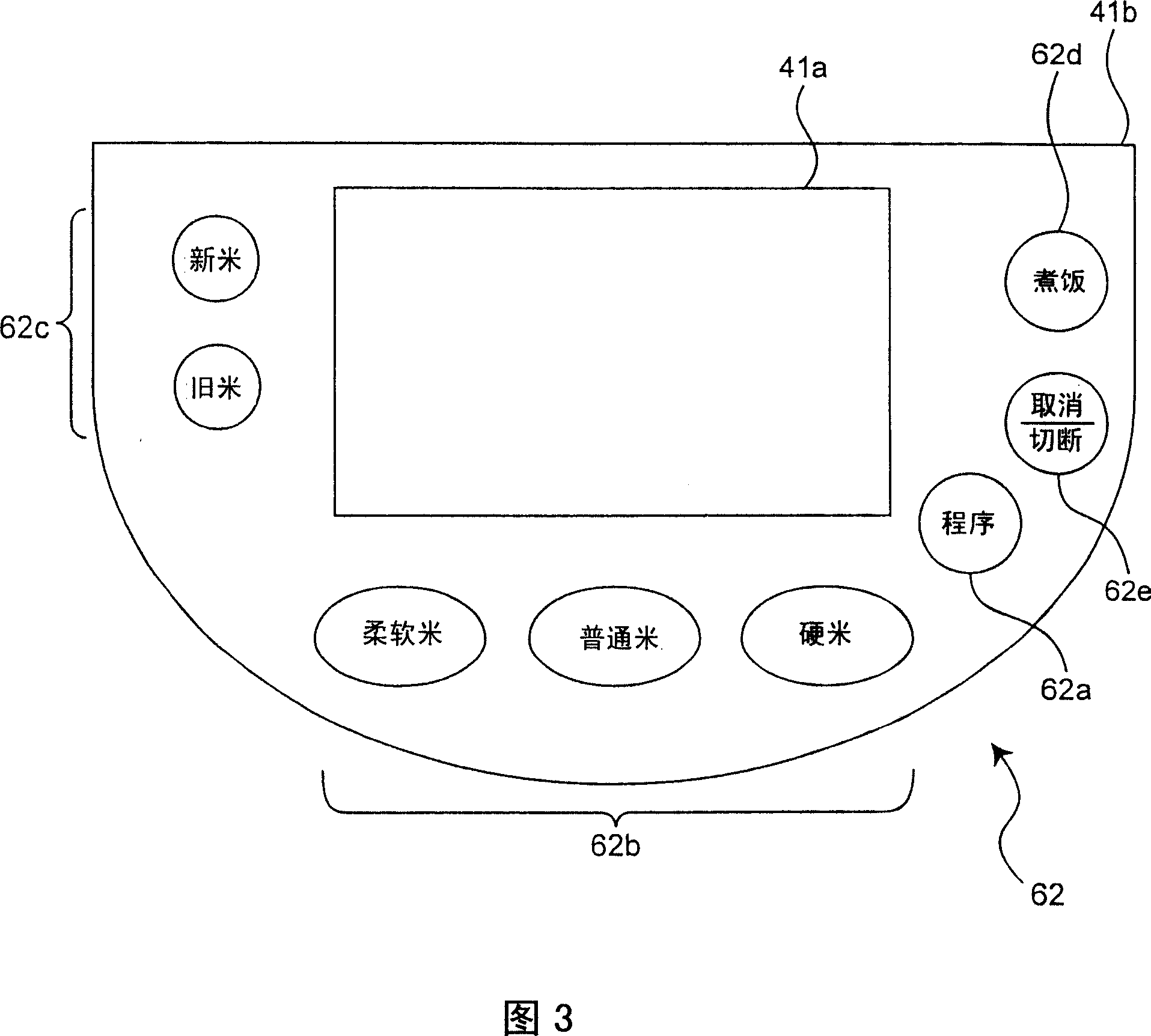

Electric cooker

ActiveCN101023842AReduce the burden onReduce rotBoiling over preventionCooking insertsTemperature controlThermal insulation

The invention provides an electric cooker capable of relieving the burden of user and more effectively depressing the decay of rice and deterioration of edible flavour induced by heat preservation. The electric cooker comprises boiler holding rice inside the electric cooker body; cover easily openned and closed for covering the peristome of upside of the cooker; heating arrangement for heating the pan bottom; cooker temperature test sensor for detecting temperature; heat control section for controlling the heating action of heating arrangement of the pan bottom; cook information input part for inputting the cook information related with cooking rice; automatic selection part of thermal insulation mode for automatically selecting the corresponding thermal insulation mode from many thermal insulation modes based on the cook information input by cook information input part before cooking; holding temperature control section for controlling temperature, based on thermal insulation mode selected by the automatic selection part of thermal insulation mode and controlling the heat control section by temperature detected by cooker temperature test sensor.

Owner:PANASONIC CORP

Organic/inorganic drought resisting compound fertilizer and preparation method thereof

InactiveCN102503723AImprove problems such as hardeningIncrease heatFertilizer mixturesSoil sciencePeat

The invention provides an organic / inorganic drought resisting compound fertilizer and a preparation method thereof. The preparation method comprises the following special steps of: at first, carrying out harmless treatment on raw materials of an organic fertilizer, such as livestock excrement, crop straws, kitchen garbage, fallen leaves, turf and peat, humic acid and the like, so as to obtain the organic fertilizer; then adding a macromolecule moisture retention material and an inorganic fertilizer at a certain ratio and uniformly stirring; and finally obtaining the organic / inorganic drought resisting compound fertilizer by extruding granulation. The organic / inorganic drought resisting compound fertilizer disclosed by the invention has functions of drought resistance and moisture retention, nutrient slow release and soil fertilization, so that the effects of increasing production and income of the crops are achieved. Furthermore, the organic / inorganic drought resisting compound fertilizer can effectively solve the environment pollution caused by the livestock excrement, straw burning and domestic garbage.

Owner:ANHUI AGRICULTURAL UNIVERSITY

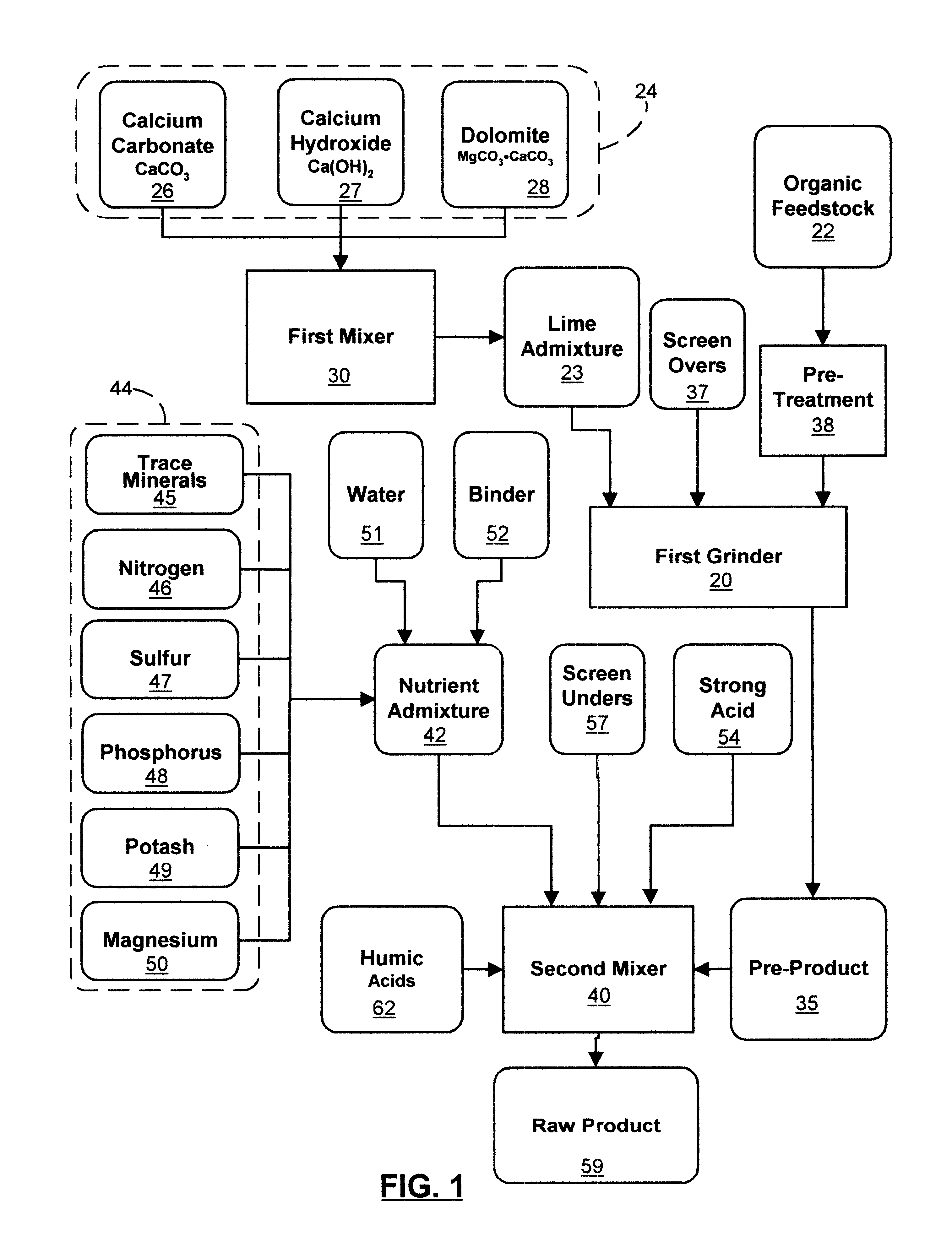

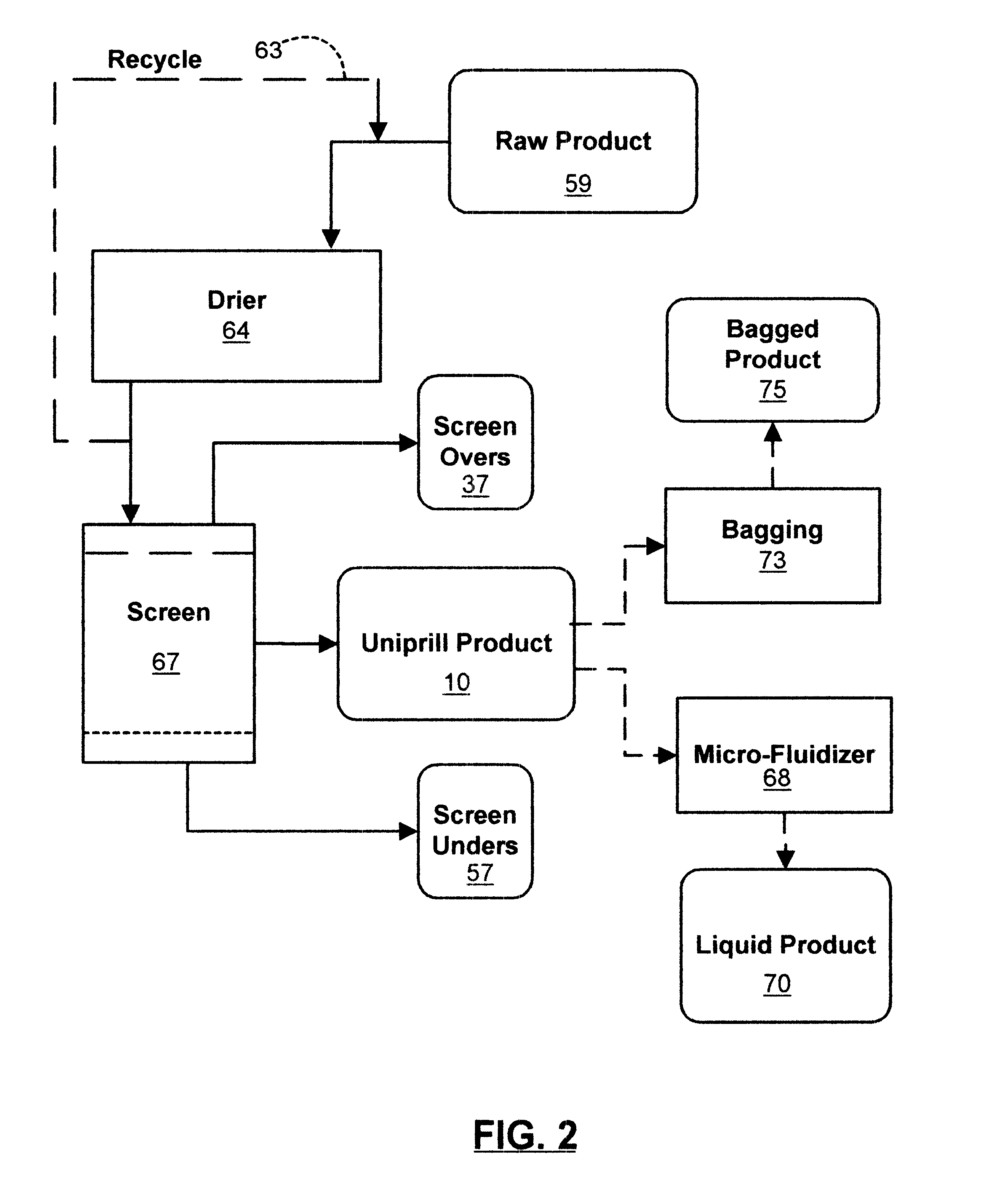

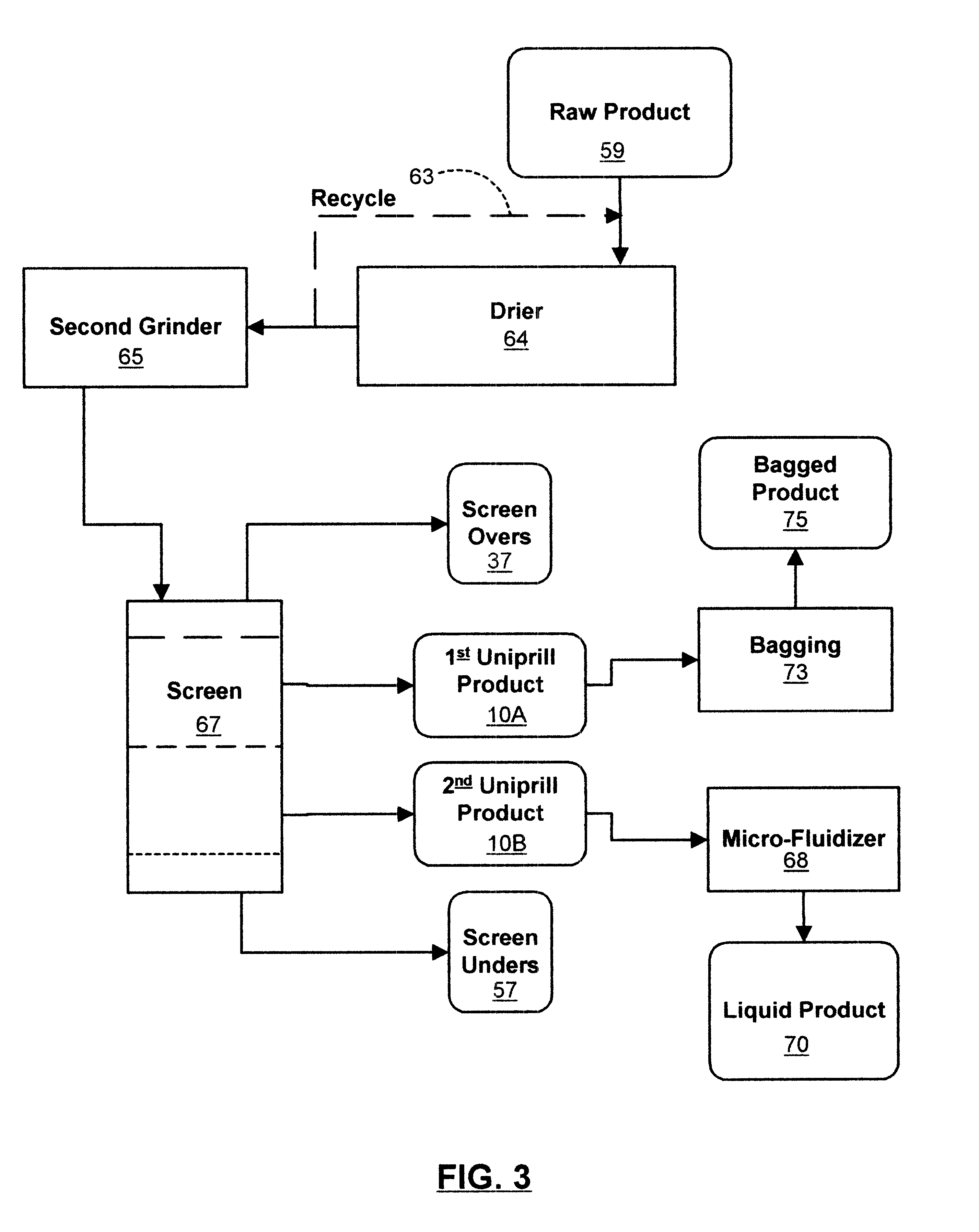

Organic material based uniprill fertilizer

InactiveUS6461399B1Reduce moisture contentIncrease speedCalcareous fertilisersBiocideOrganic basePhosphoric acid

An organic-based uniprill fertilizer is provided. To produce the fertilizer, organic matter is sequentially pre-treated by first mixing it in a first grinder with a lime admixture, then adding a slurry of reagents and binders, followed by a mixture of acids. The acids can include sulfuric and phosphoric acids, in addition to nitric acid and various organic acids such as citric and fulvic acid, depending on the end requirements of the fertilizer product. Following the mixing of the pre-product with the mixture of acids and reagents, the resultant raw product is preferably processed through a second grinder. This grinding further dries, mixes and granulates the raw product. The particle size of the completed fertilizer is reduced into a flowable, user safe uniprill product that can be further ground to reduce its moisture. Further drying may be necessary for bag or bulk product, or it can be liquified by high speed blending or micro-fluidized for sprinkler or drip applications. The uniprill fertilizer comprises small, preferably microscopic particles that are homogenous in nature, in that any single particle is substantially identical in composition to all other particles of the fertilizer. Additionally, each uniprill particle contains substantially all sixteen nutriments and minerals required for the growth of healthy plants.

Owner:GREEN TRIANGLE

Shoe with anatomical protection

ActiveUS7631440B2Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

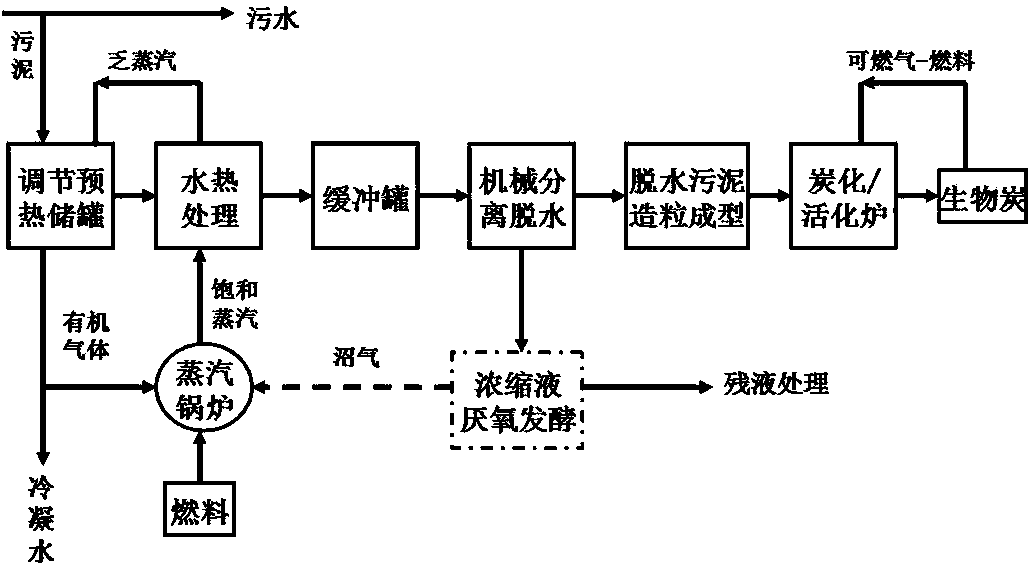

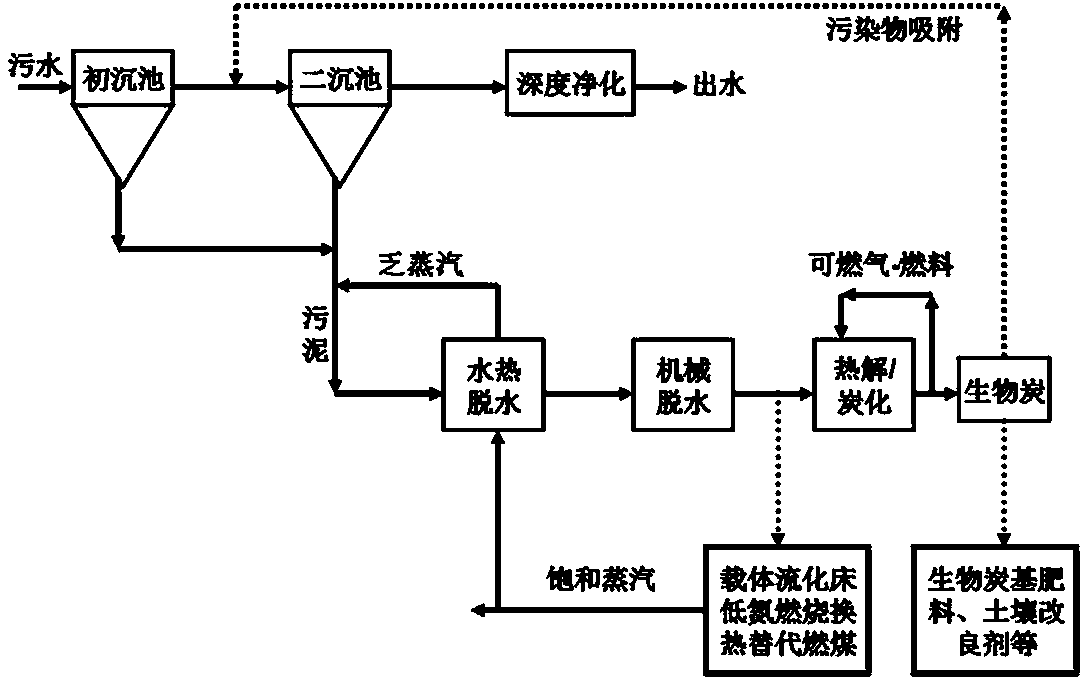

Method for preparing carbon materials by use of sludge

ActiveCN103396815AReduce moisture contentEasy to separateSludge treatment by de-watering/drying/thickeningOther chemical processesEnvironmental chemistryDewatered sludge

The invention provides a method for preparing carbon materials by use of sludge. The method comprises the following steps: preheating of high-water-content sludge to obtain preheated sludge; primary separation of water and solid particles: viscous organic matters in the preheated sludge are hydrolyzed, colloid structures and cell membrane walls of the sludge are destroyed, so that the bound water and the solid particles can be effectively separated; secondary separation of the water and the solid particles; dewatering to obtain dewatered sludge with the water content down to about 40%; and carbonization: preparation of biological carbon. The method also comprises further modification treatment of the biological carbon to prepare adsorption carbon materials. The method also comprises anaerobic fermentation of the dewatered sludge to produce biogas. The adsorption carbon materials prepared by the method can be recycled to a wastewater treatment plant for the adsorption of heavy metals, nitrogen and phosphorus and the organic matters in sewage, and cyclic utilization of the sludge in the wastewater treatment plant can be realized; and the combustible gas generated in the process can be used as a supplementary fuel of a pyrolysis carbonization furnace. The method has the advantages of cyclic utilization, recycle of waste materials and ecological environmental friendliness.

Owner:中科核润(陕西)生态环境有限公司

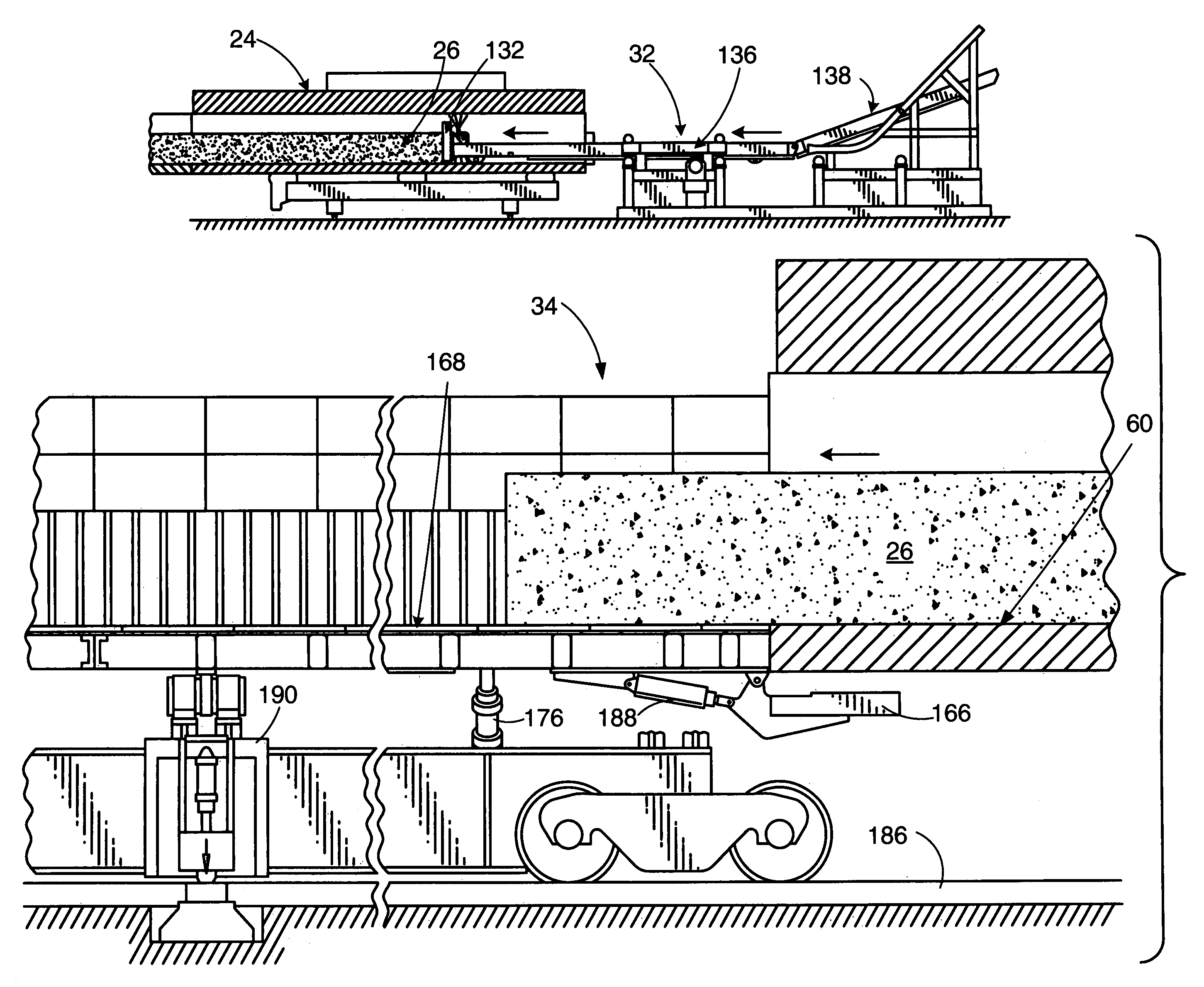

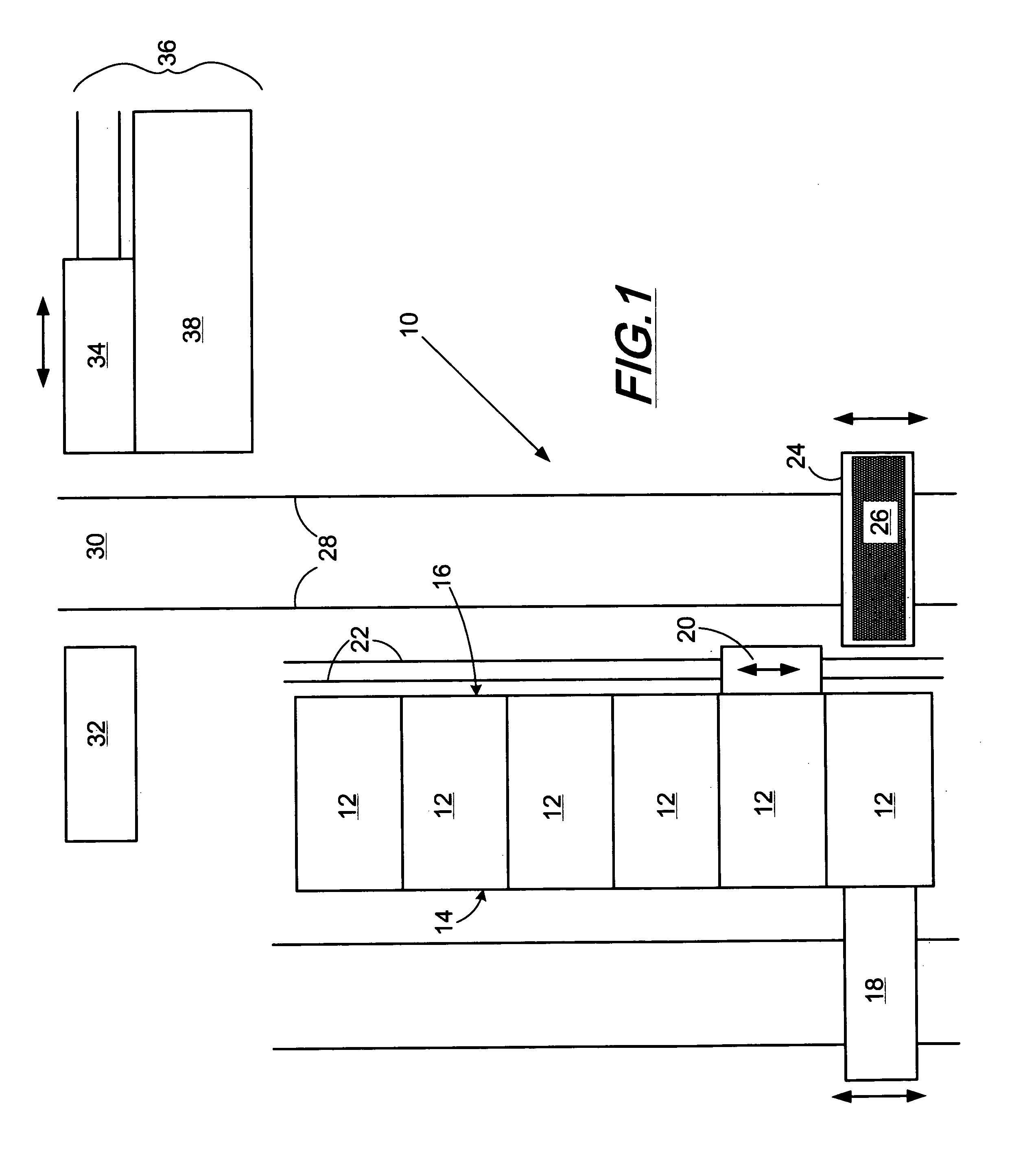

Method and apparatus for producing coke

ActiveUS8152970B2Reduce the amount requiredReduce moisture contentSpeed controllerCoke quenchingMetallurgyMetallurgical coke

A method and apparatus for quenching metallurgical coke made in a coking oven. The method includes pushing a unitary slab of hot coke onto a substantially planar receiving surface of a hot car. The hot car containing the coke is then transported to a quench car station. The unitary slab of hot coke is pushed onto a substantially planar receiving surface of a quench car at the quench car station. Quenching of the slab of hot coke is conducted in the quench car with a predetermine amount of water. After quenching, the quenched coke is dumped onto a receiving pad for collection thereof.

Owner:SUNCOKE TECH & DEV LLC

Method for coating an element with glue

InactiveUS20060053724A1Reduce moisture contentCarry out quicklyAdhesive processesCovering/liningsEngineeringAdhesive

The invention relates to a method for producing a glue-coated element, to the glue-coated element, to an adhesive compound and to a method for producing glue-coated derived timber panels, as well as to panels produced according to the method. The method for producing a glue-coated element that can be glued with other similarly glue-coated elements, comprises the steps of applying a one-component adhesive to at least one surface section of the element and drying the applied one-component adhesive. According to a preferred embodiment of the invention, draw-out resistance elements are provided on the glue-covered element.

Owner:KRONOTEC

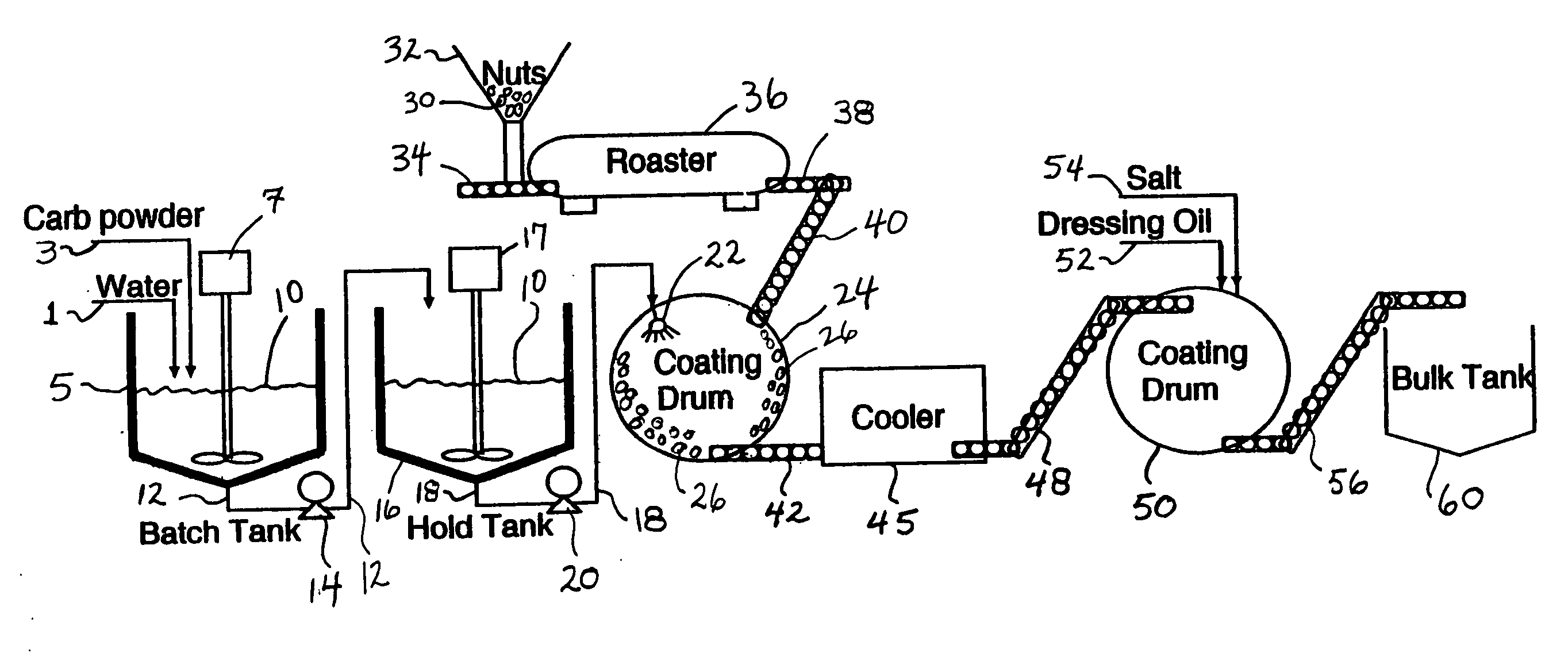

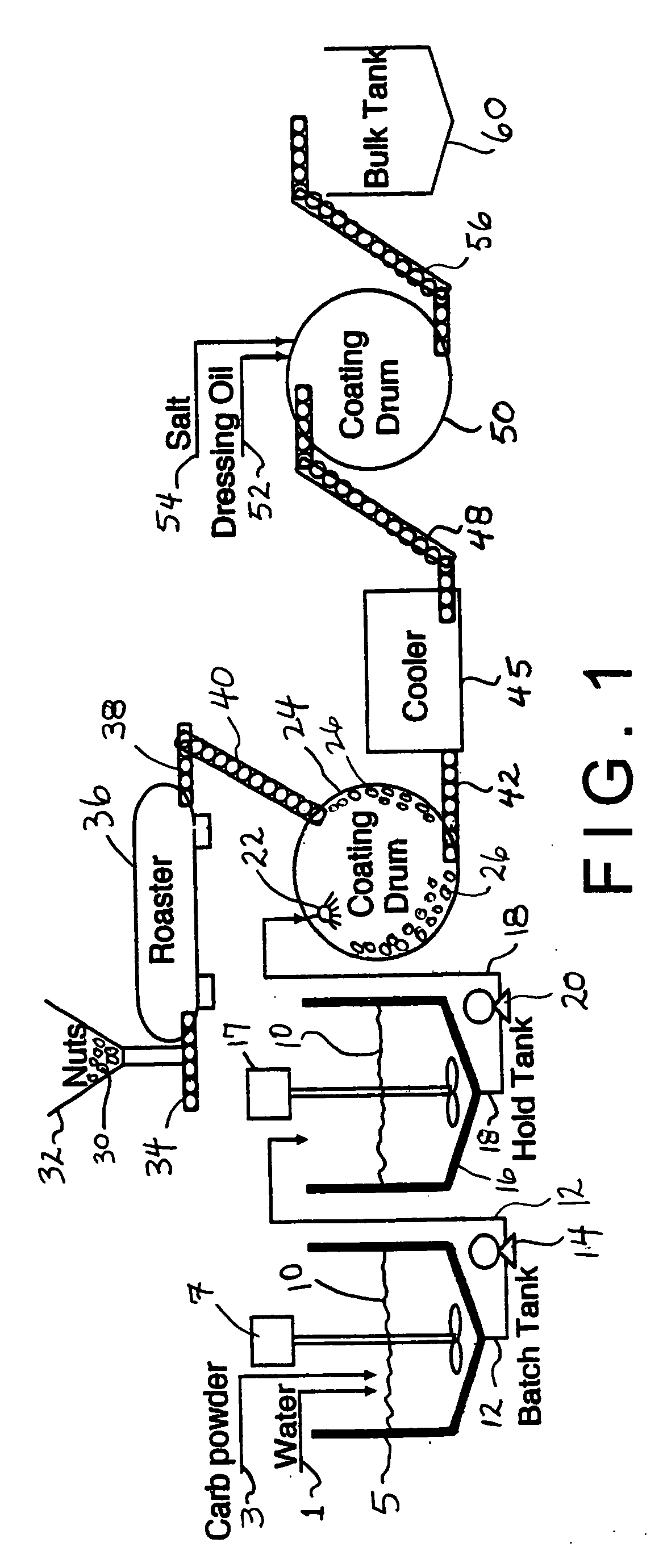

Method and apparatus for applying aqueous coating to cooked foods

A cooked snack food or cooked edible core material, such as roasted nuts, or baked snack chips, while still hot from the cooking step, is tumbled and sprayed with an aqueous solution of a water-soluble, film-forming coating component, such as a maltodextrin. The tumbling and spraying is performed immediately after cooking so that latent heat from the cooked edible core material, reduces the moisture content of the applied aqueous solution to form a dry, thin film coating of the coating component on the edible core material. The need for a separate, subsequent drying step or forced air drying equipment to reduce the moisture content is eliminated by evaporative cooling of the hot cooked snacks and flashing of the applied aqueous coating solution. The dry, coated cooked snack may be cooled to obtain a snack food having a thin, uniform coating which enhances appearance, texture, taste and shelf life.

Owner:KRAFT FOODS GRP BRANDS LLC

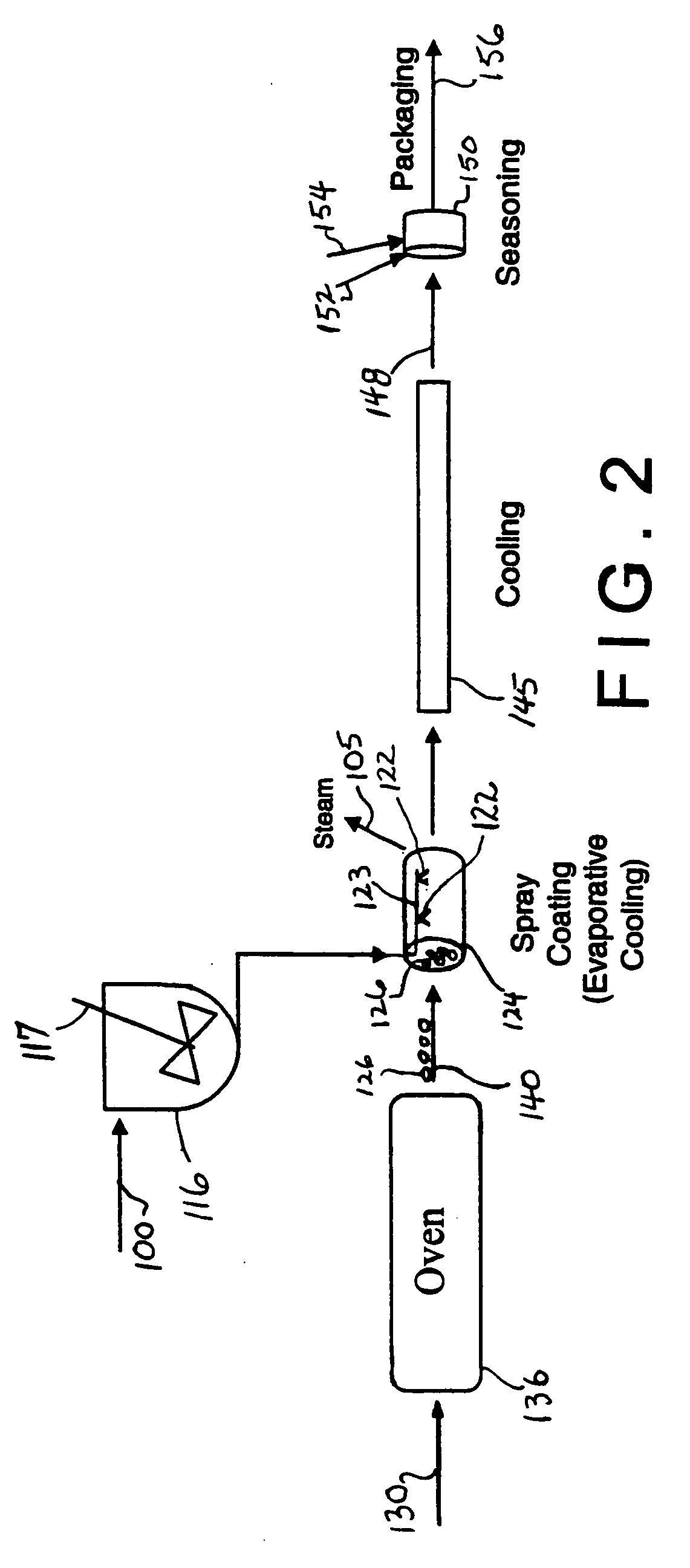

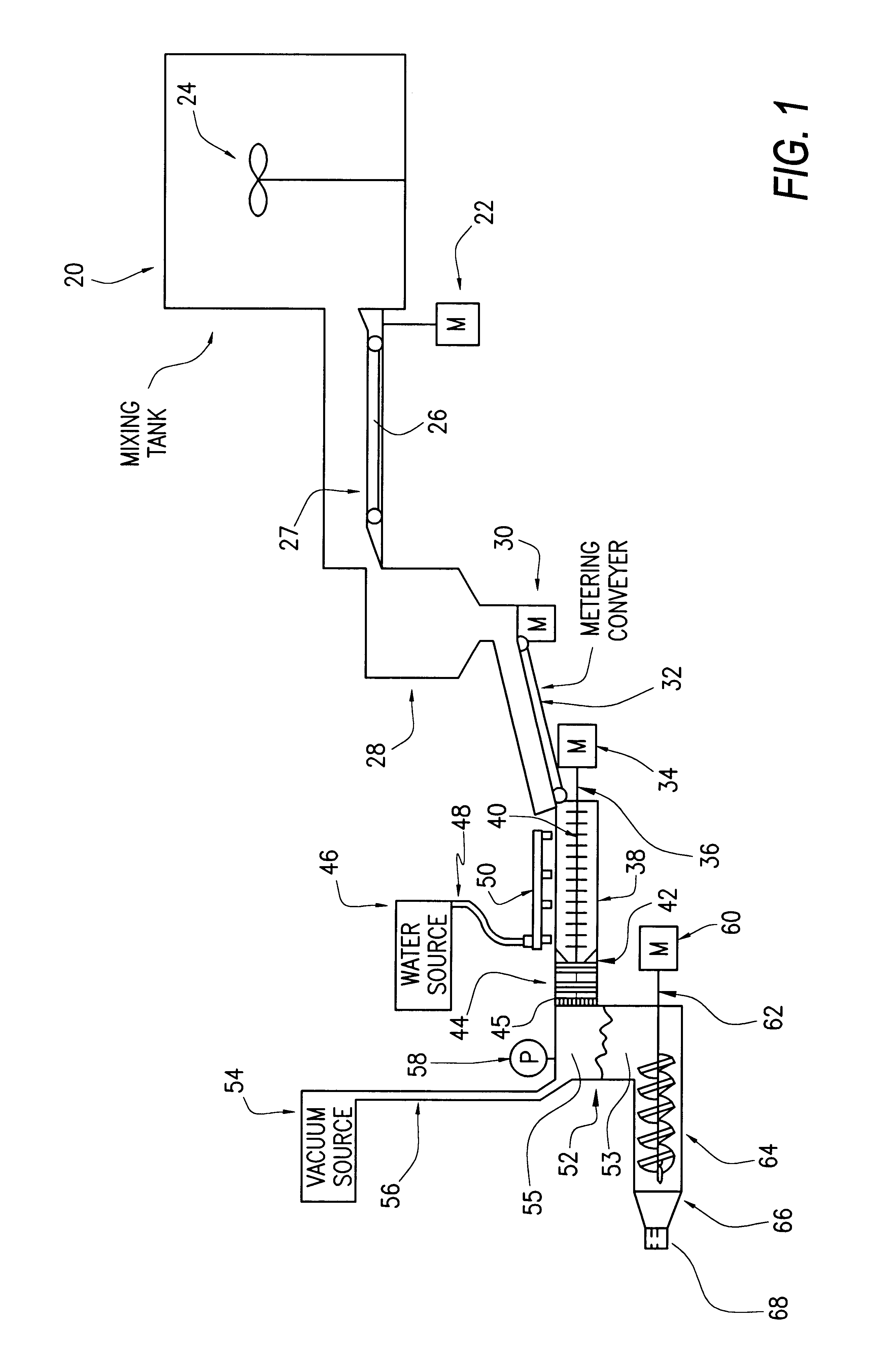

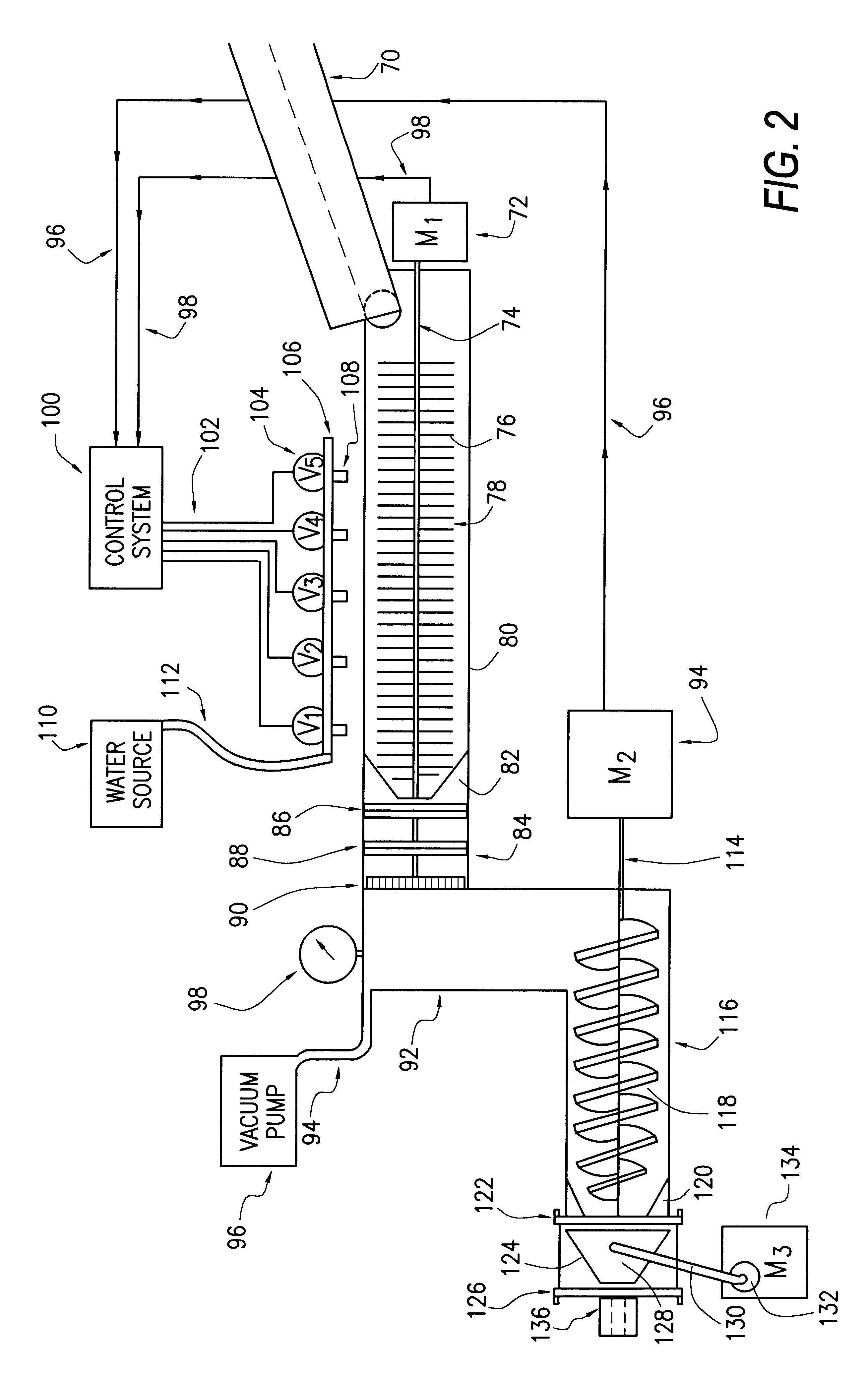

Vacuum extrusion system for production of cement-based articles

InactiveUS6309570B1Reduce frictionReduce the amount requiredFrozen sweetsConfectioneryMaterials scienceExcess water

A system for making extruded cement-based articles. The process can include forming a cement-based feed mixture including water, aggregate and binder and directing the feed mixture to a vacuum zone, wherein sufficient vacuum is maintained in the vacuum zone to remove entrained air and, preferably, excess water, from the feed mixture. The feed mixture is held in the vacuum zone at a negative pressure for a time sufficient to form a vacuum-treated or densified mixture. The vacuum-treated or densified mixture is passed through an extruder at an elevated pressure to provide an extruded cement-based article.

Owner:BLEECKER LEE M

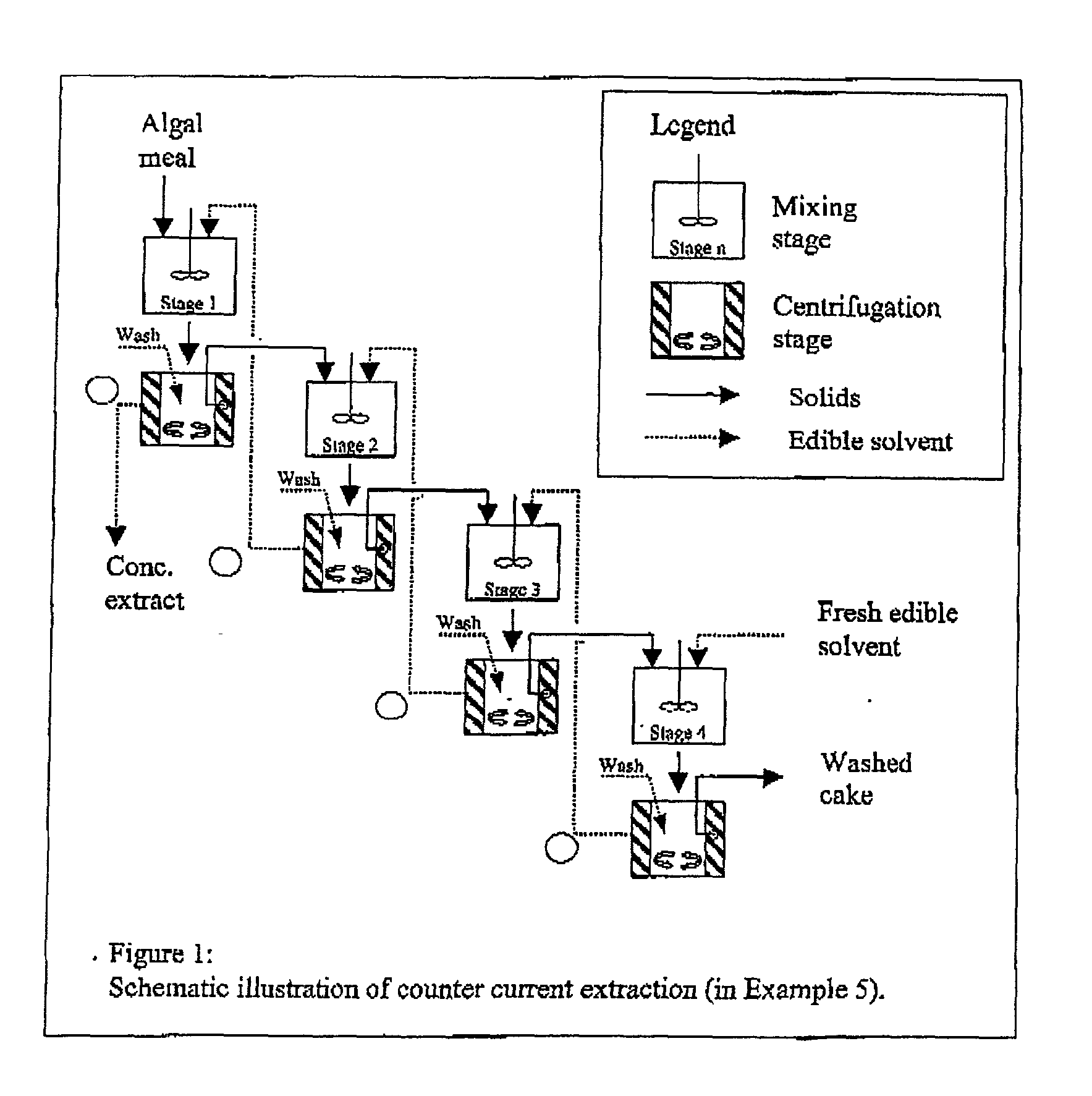

Edible solvent extraction of carotenoids from microorganisms

InactiveUS20030054070A1Efficient extractionEnriching carotenoid contentLiquid hydrocarbon mixture productionHydrocarbonsParticulatesAnimal food

A process for extracting carotenoids from a carotenoid-containing starting material produced by microorganisms is described. Said starting material is admixed with edible solvent to effectuate the transfer of carotenoids. Separation of the carotenoid-enriched edible solvent is improved by the formation of a "cake", composed of said carotenoid-containing particulate solids, and, as required, a certain quantity of suitable filtration aid to modify the cake's consistency. Mechanical aids accelerate the separation of the carotenoid-enriched edible solvent. Said mixture may be hydrated to aid the removal of solids and gums from the carotenoid containing edible solvent. The carotenoid-enriched edible solvent is filtered though said cake to reduce the particulate load including any undesirable microbial load. A counter-current process increases the carotenoid concentration of the extract. The carotenoid-enriched edible solvent can be used as an ingredient in human and animal foodstuffs and dietary supplements for the possible prevention and treatment of illnesses and diseases.

Owner:AQUSRCH

Method for resource circulating treatment of dining-kitchen organic waste using compound bacteria

ActiveCN1850965AShorten fermentation timeDegradation of organic matterFungiBacteriaWater contentEnvironmental chemistry

The invention relates to a method to take kitchen organic waste recycling process by compounding bacterium that includes the following steps: collecting the organic waste, adding water content adjusting material, taking high temperature fermenting process, taking drying process to gain biology albumen feedstuff raw material. The invention could effectively kill the noxious bacterium and shorten the fermenting time. It realizes effective reusing to the kitchen organic waste materials.

Owner:BEIJING GOLDENWAY BIO TECH

Shoe with lacing

ActiveUS20070011910A1Overcome deficienciesReduce moisture contentShoe lace fasteningsUpperShoe lacesEngineering

The present invention provides a wraparound lacing system for use in all manner of footwear. The lacing system includes a lace which encircles the upper and midsole of the article of footwear in a spiral, helical, coiled or similar wound wraparound pattern. The upper includes finger members which independently adjust to the contours of the wearer's foot while providing a snug and secure fit. The upper and midsole are integrally formed as a unitary structure. The housing of the upper and the midsole includes channels therein which receive the wraparound lace. The lace can be affixed at one or both ends to the midsole or to the upper. Removable lace end keepers on the upper permit the user to adjust the length of the lace.

Owner:THE TIMBERLAND COMPANY

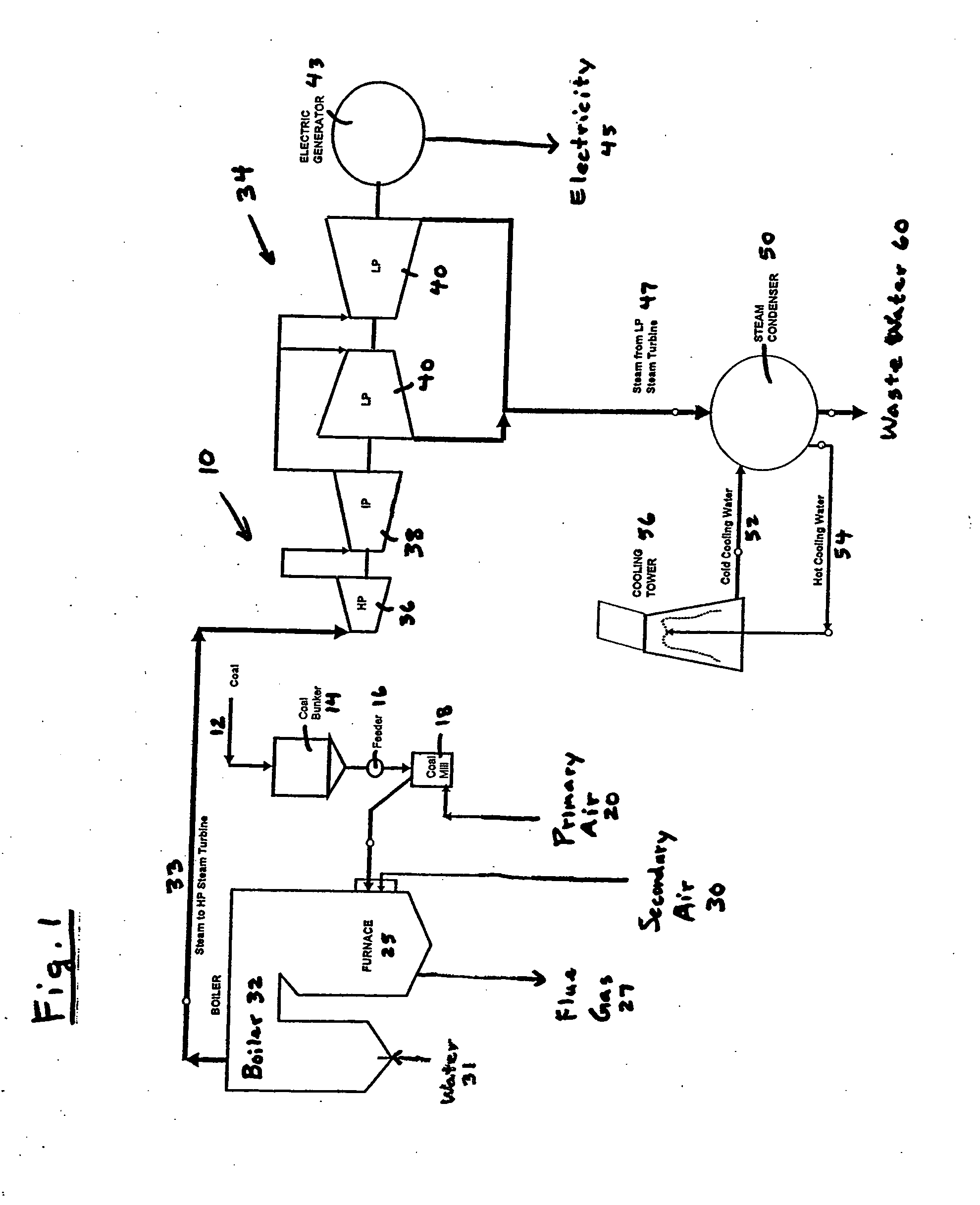

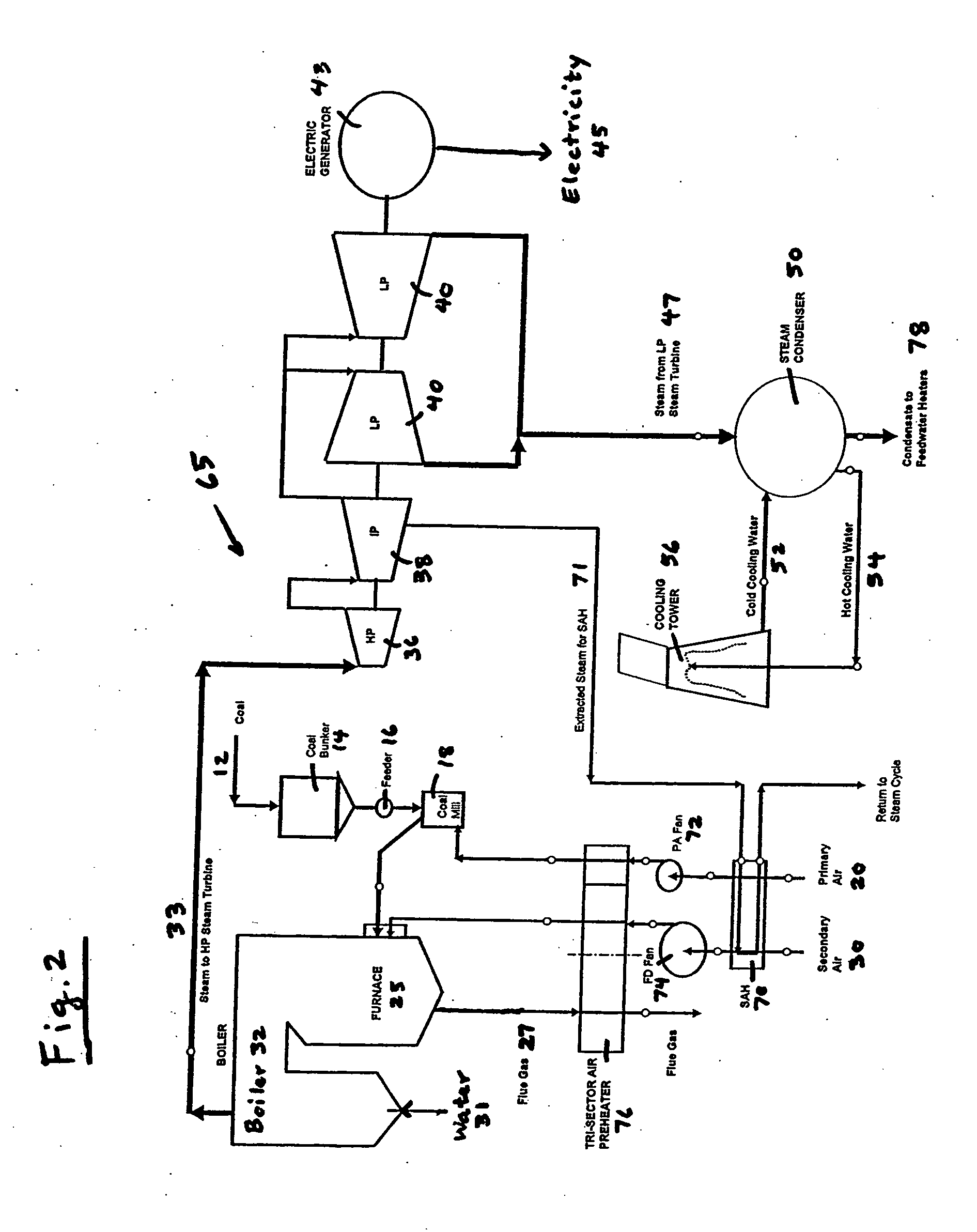

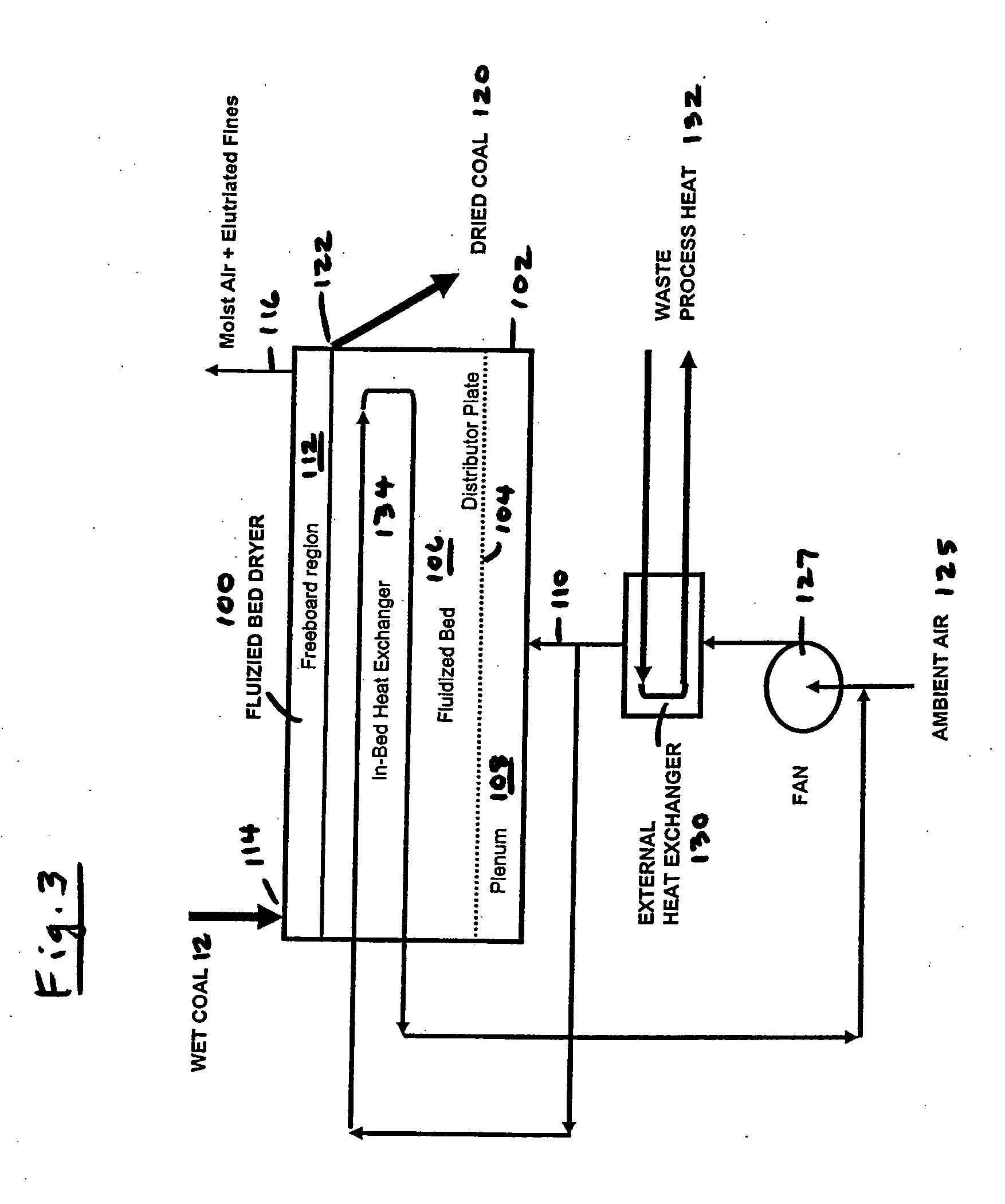

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

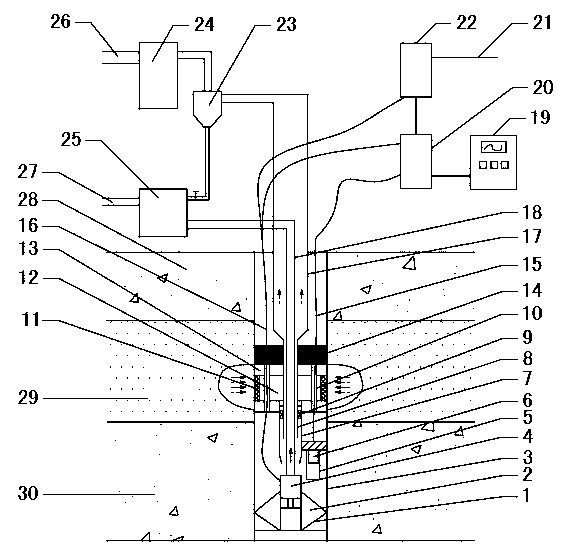

Natural gas hydrate water discharge gas production exploitation device and exploitation method of natural gas hydrate water discharge gas production exploitation device

ActiveCN103410488ASpeed up decompositionReduce moisture contentConstructionsFluid removalElectricityVapor–liquid separator

The invention provides a natural gas hydrate water discharge gas production exploitation device and an exploitation method of the natural gas hydrate water discharge gas production exploitation device, and belongs to the technical field of natural gas hydrate exploitation. A feeding cavity (12) communicated with a natural gas hydrate layer (29) is connected with an in-well gas-liquid separator (7), an exhaust cavity (8) of the in-well gas-liquid separator (7) is communicated with a gas production sleeve pipe (17), and a water discharge opening of the in-well gas-liquid separator (7) is communicated with a liquid storage cavity (2) arranged at the lower part. According to the exploitation method adopting the device, the natural gas hydrate layer (29) is firstly heated, the in-well gas-liquid separator (7) is utilized for separating gas-water mixture generated in the natural gas hydrate decomposition process, meanwhile, a liquid level monitoring device is utilized for regulating the water discharge speed of an electric submersible pump (4), and the decomposition speed of the natural gas hydrate is controlled. The device and the method have the advantages that the natural gas hydrate exploitation well liquid accumulation can be effectively prevented, the gas production efficiency is improved, the work is safe and reliable, the environment is protected, the service life is long, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Alkali activated solidification and stabilization treatment method of refuse incineration fly ash

ActiveCN102303036ASimple and efficient operationSimple processSolid waste disposalChemistryPre treatment

The invention relates to an alkali activated solidification and stabilization treatment method of refuse incineration fly ash. The method comprises the following steps of: A: carrying out a pretreatment on the refuse incineration fly ash; B, then adding water and heavy metal stabilizing agents and fully stirring so as to fully integrate soluble heavy metals in the fly ash with the heavy metal stabilizing agents and then realizing a mineralization stability; C, adding alkali activating agents into fly ash slurry after finishing the B step and fully stirring; D, carrying out a heating treatment on a water bath after finishing the C sep, controlling a heating temperature and a heating time, and aperiodically stirring so as to uniformly heat the fly ash slurry materials; and E, finally shaping and maintaining the mixed materials so as to further blockade mineralized heavy metals in the fly ash and simultaneously solidify dioxin in the fly ash, and finally realizing the harmless solidification and stabilization of the fly ash. According to the method provided by the invention, the gelling reaction of the fly ash is generated by using the alkali activating agents to activate the fly ash activity only on a base of regulating the fly ash activity, and the double-effect stabilization of the fly ash is obtained by simultaneously supplementing the heavy metal stabilizing agents; moreover, the method has the advantages of low cost, good effect, low increase-volume rate and no secondary pollution.

Owner:深圳市龙岗区东江工业废物处置有限公司

Shoe with lacing

The present invention provides a wraparound lacing system for use with footwear. The lacing system includes a lace which encircles the housing of the article of footwear in a spiral, helical, coiled or similar wound wraparound pattern. The housing includes finger members which independently adjust to the contours of the wearer's foot while providing a snug and secure fit. The housing of the upper and the midsole includes channels therein which receive the wraparound lace. The lace can be affixed at one or both ends to the midsole or to the upper. Removable lace end keepers on the upper permit the user to adjust the length of the lace. Recessed cavities may be positioned along the lacing channels to promote easy adjustment of the lace. The lace may run along channels formed between fingers and an overlying shell structure. The lace may run through a tube structure within the channels.

Owner:THE TIMBERLAND COMPANY

Ultra cleaning of combustion gas including the removal of CO.sub.2

ActiveUS7641717B2Efficiently and emissionLow costUsing liquid separation agentEmission preventionCombustionCelsius Degree

Owner:GENERAL ELECTRIC TECH GMBH

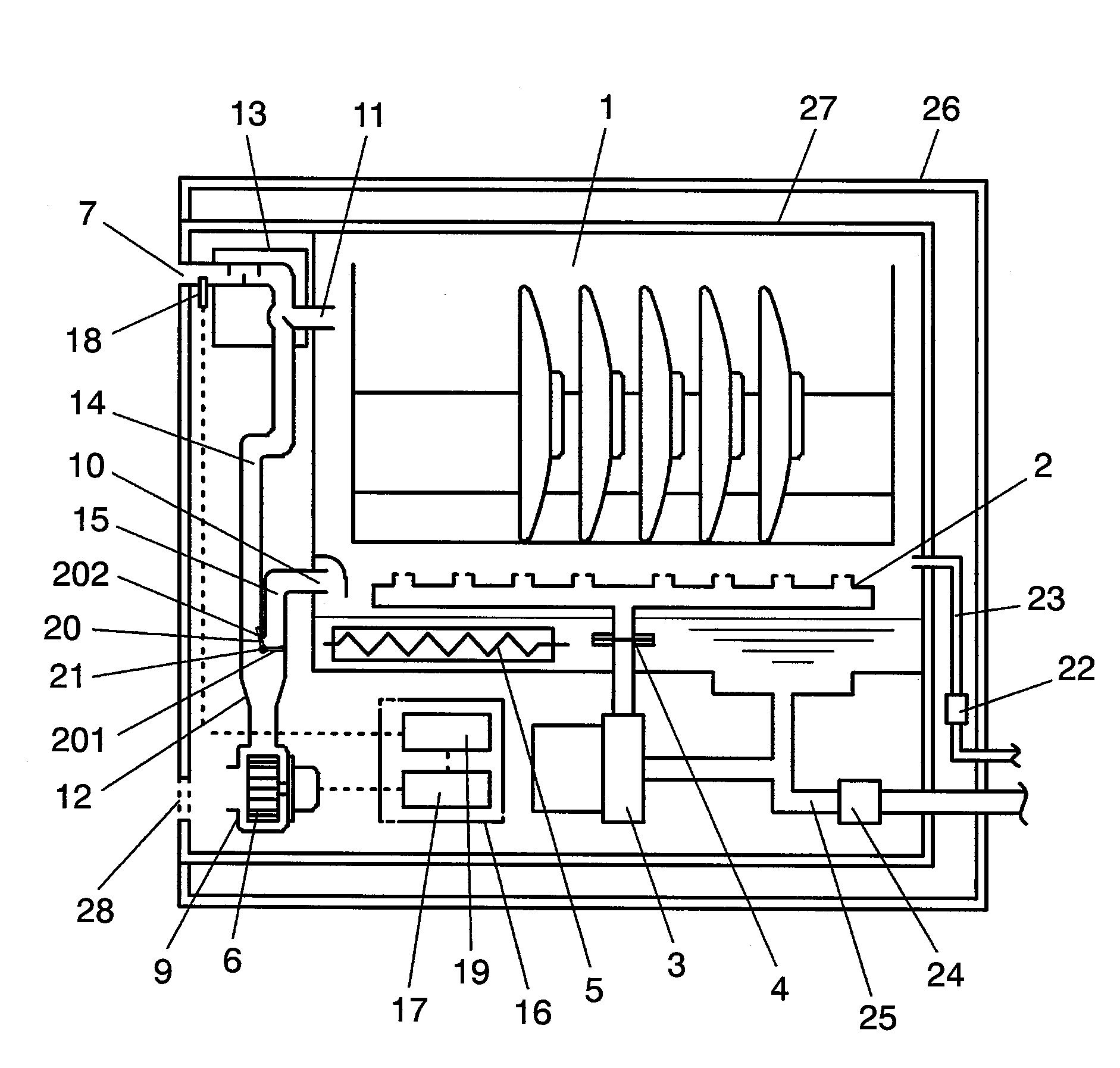

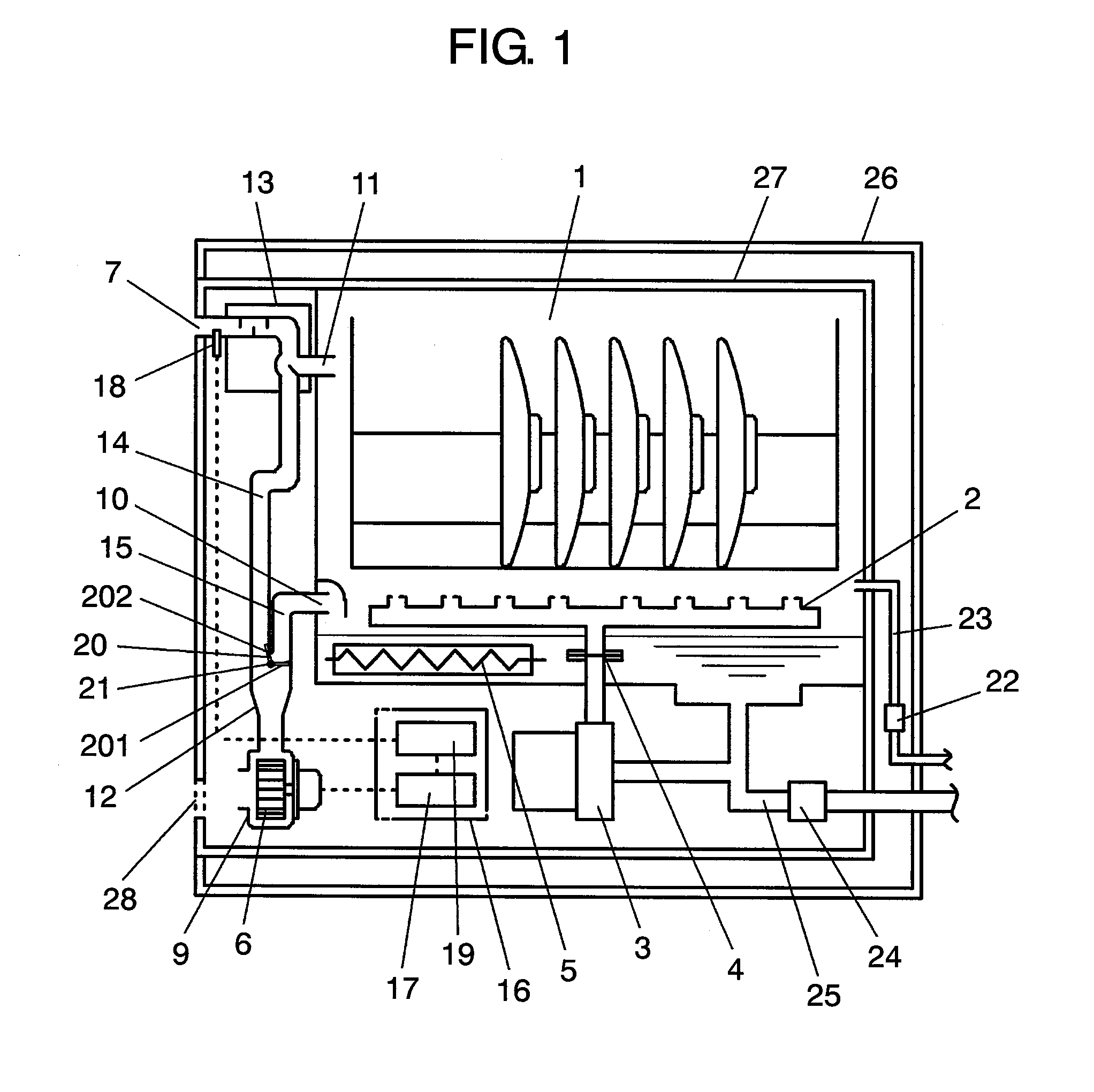

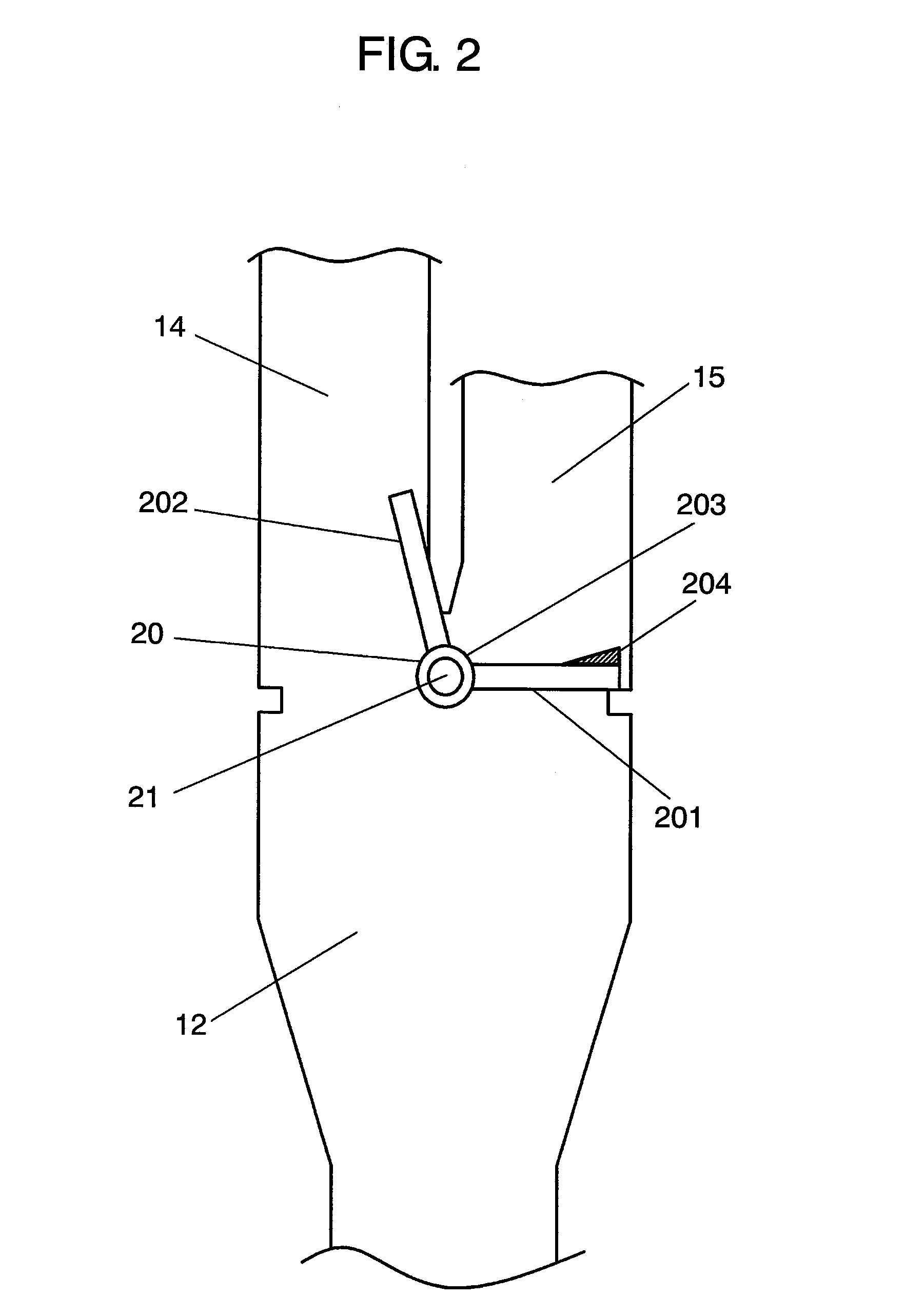

Dish washer/dryer

ActiveUS20090095330A1Reliable preventionReduce humidityTableware washing/rinsing machine detailsMultiple way valvesAir volumeAir blower

A dish washer / dryer includes a washing tub for accommodating an object to be washed, a washing section for washing the object to be washed, a heater for heating washing water, an exhaust port for discharging moisture inside the washing tub, an air blower for blowing outside-air, a mixing section disposed at an upstream side of the exhaust port and mixing the outside-air with washing-tub-inside-air, and an air volume distribution section for changing the feeding ratio of outside-air into the washing tub and the mixing section. This configuration provides a dish washer / dryer, in which a sufficient amount of outside-air is mixed with exhaust air in the washing tub so as to promote the temperature reduction of the exhaust air and the reduction of the moisture content in the exhaust air during drying operation, thereby enhancing the comfort of the exhaust air.

Owner:PANASONIC CORP

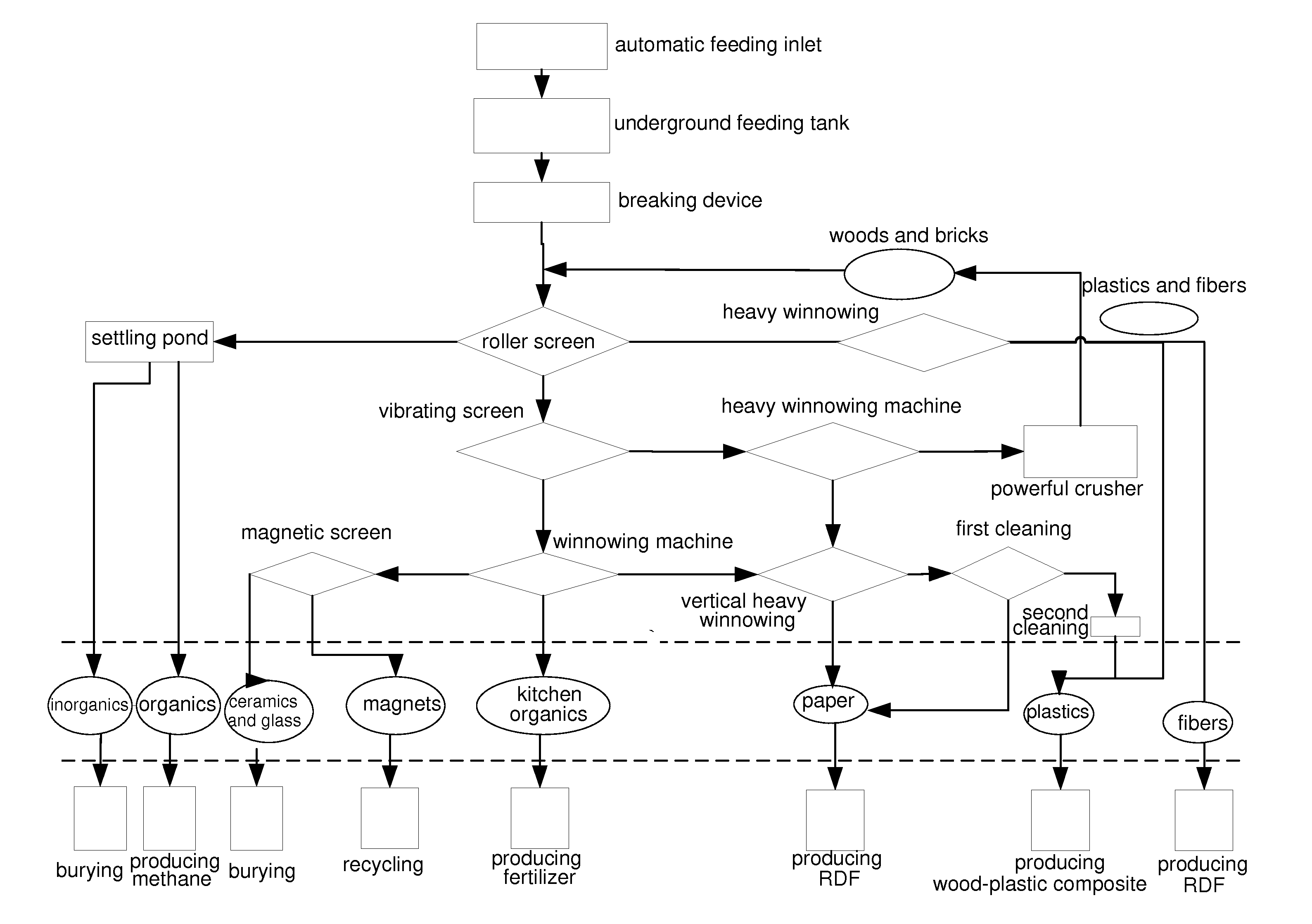

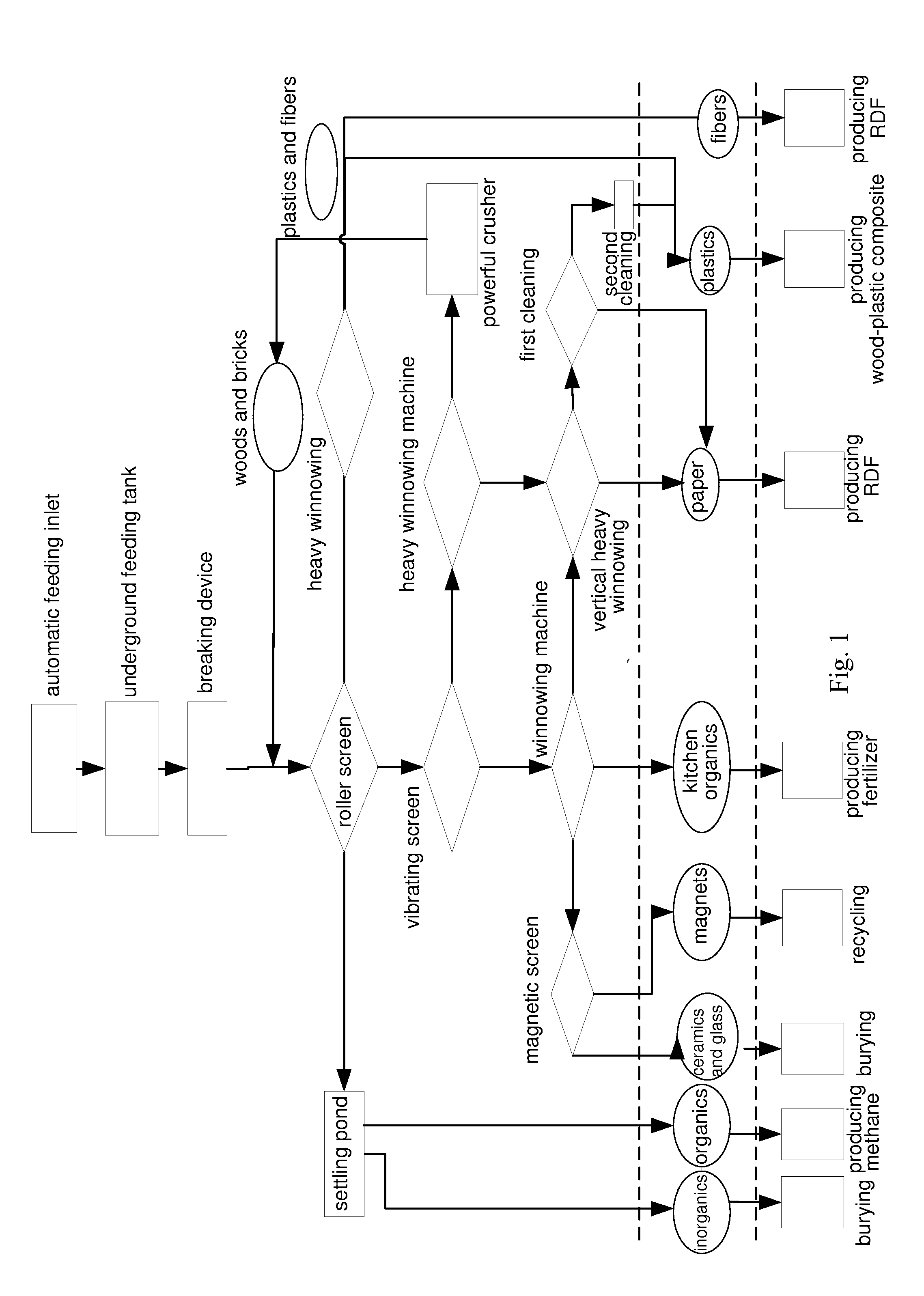

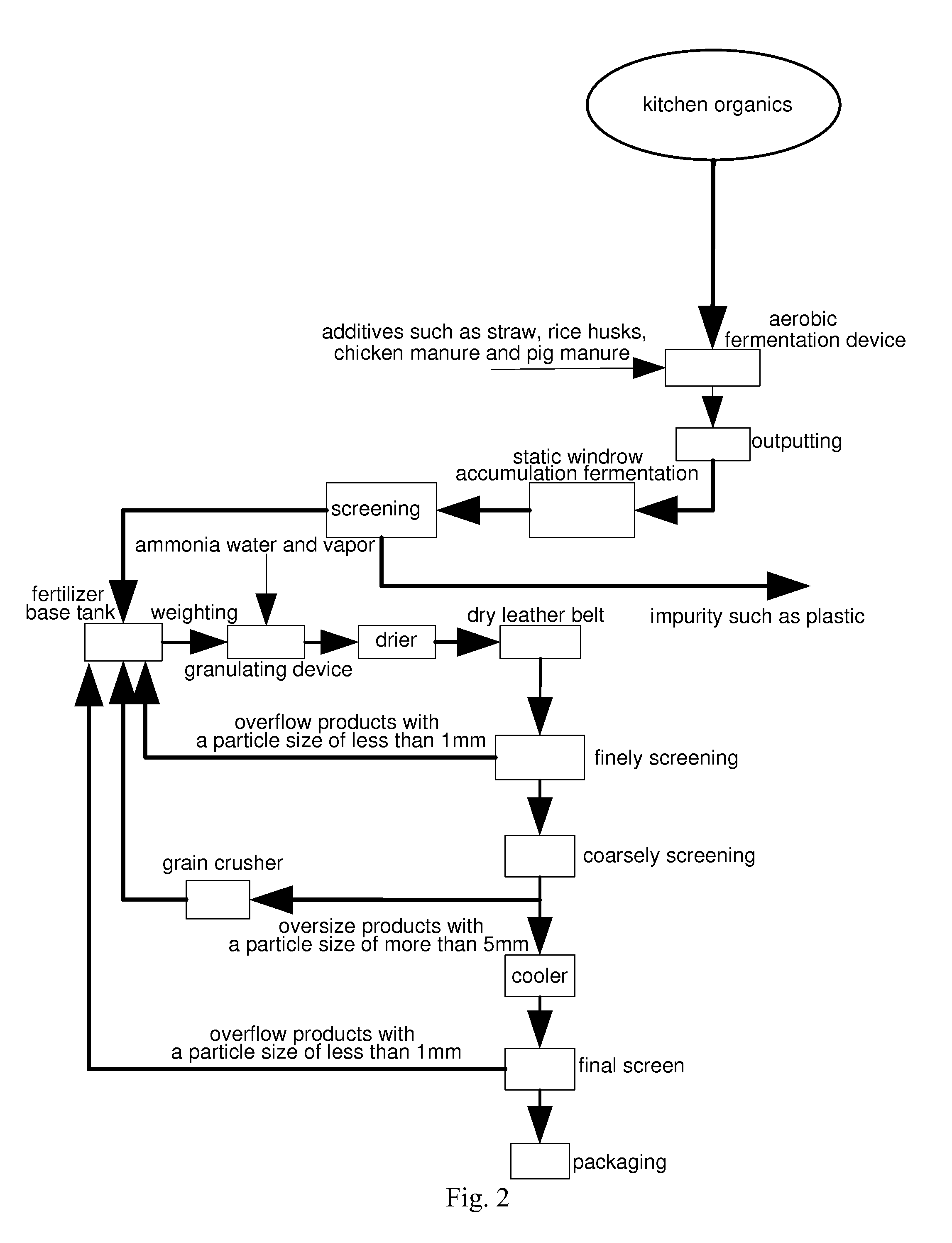

Method for sorting and comprehensively utilizing municipal solid waste

InactiveUS20150135785A1Maximize resource utilizationEfficient combinationBio-organic fraction processingSolid waste disposalRefuse-derived fuelFiber

A method for sorting and comprehensively utilizing municipal solid waste includes steps of: 1) feeding the municipal solid waste into a feeding tank through a feeding inlet, then outputting into a breaking device; 2) breaking refuse bags and large blocks by the breaking device; 3) transporting broken refuse into a two-stage roller screen for screening out dusts with a particle size of less than 3 mm, and hanging strips; and 4) transporting mixed refuse screened by the two-stage screen into a vibrating screen; screening oversize products by a heavy winnowing machine for separating inorganic blocks, large plastics and paper; transporting underflow products into a two-room multi-functional winnowing machine for dividing into heavy materials, light materials and medium materials. By effectively combining sorting devices, effective sorting and reutilization of mixed refuse are achieved. Thereafter, paper, fibers, plastics and kitchen organic refuse are respectively for producing refuse derived fuel, wood-plastic composite and fertilizer.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com