Patents

Literature

142results about How to "Improve pressure distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

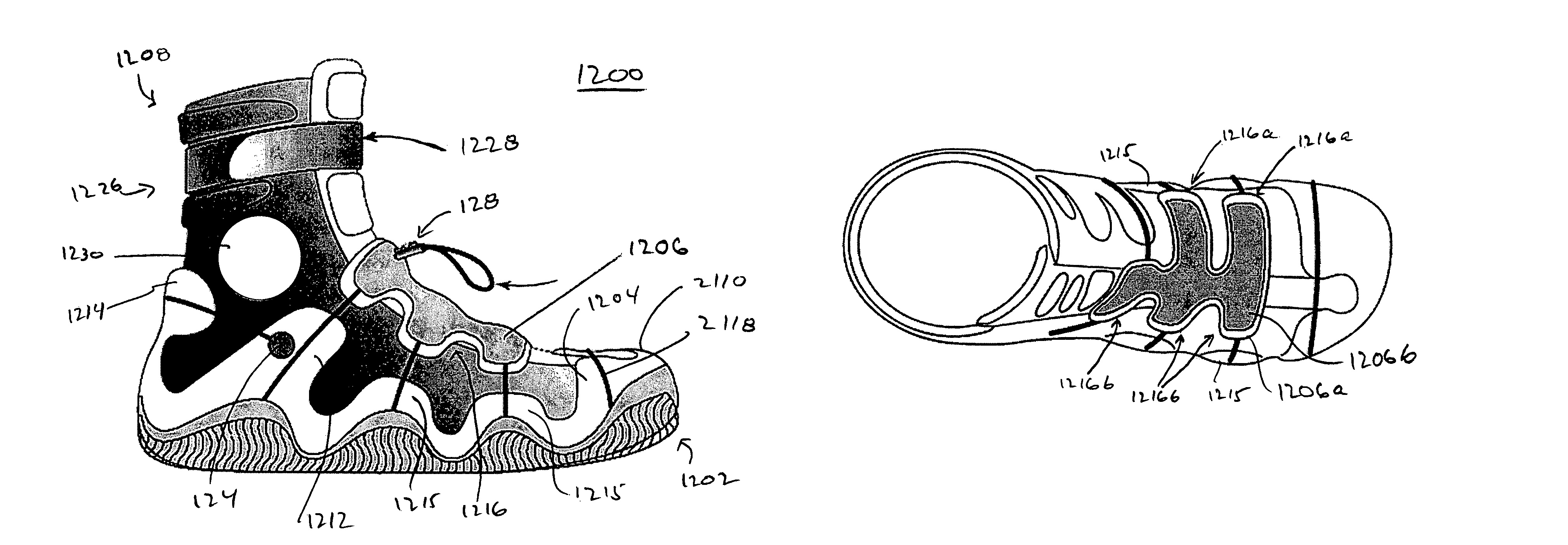

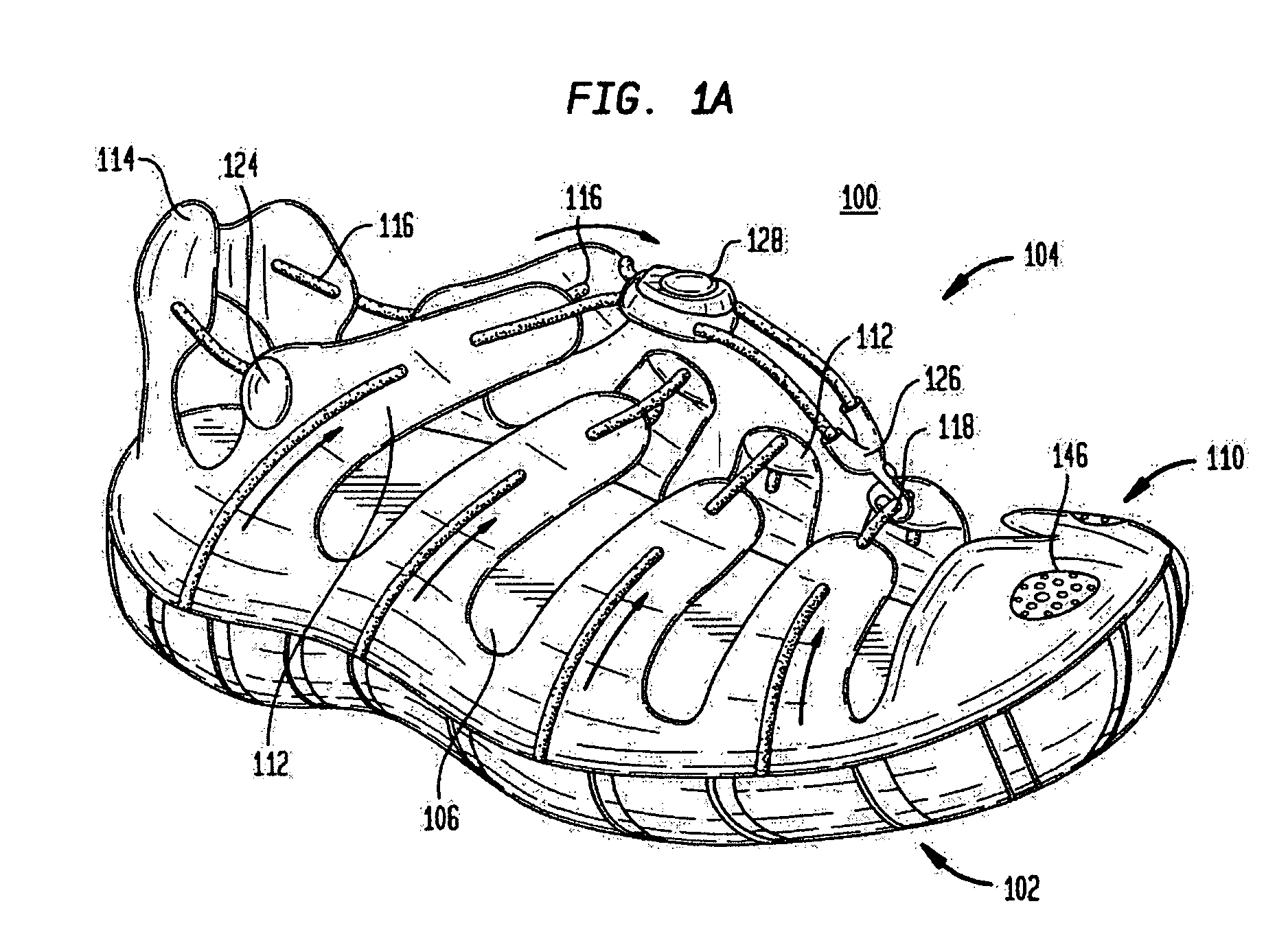

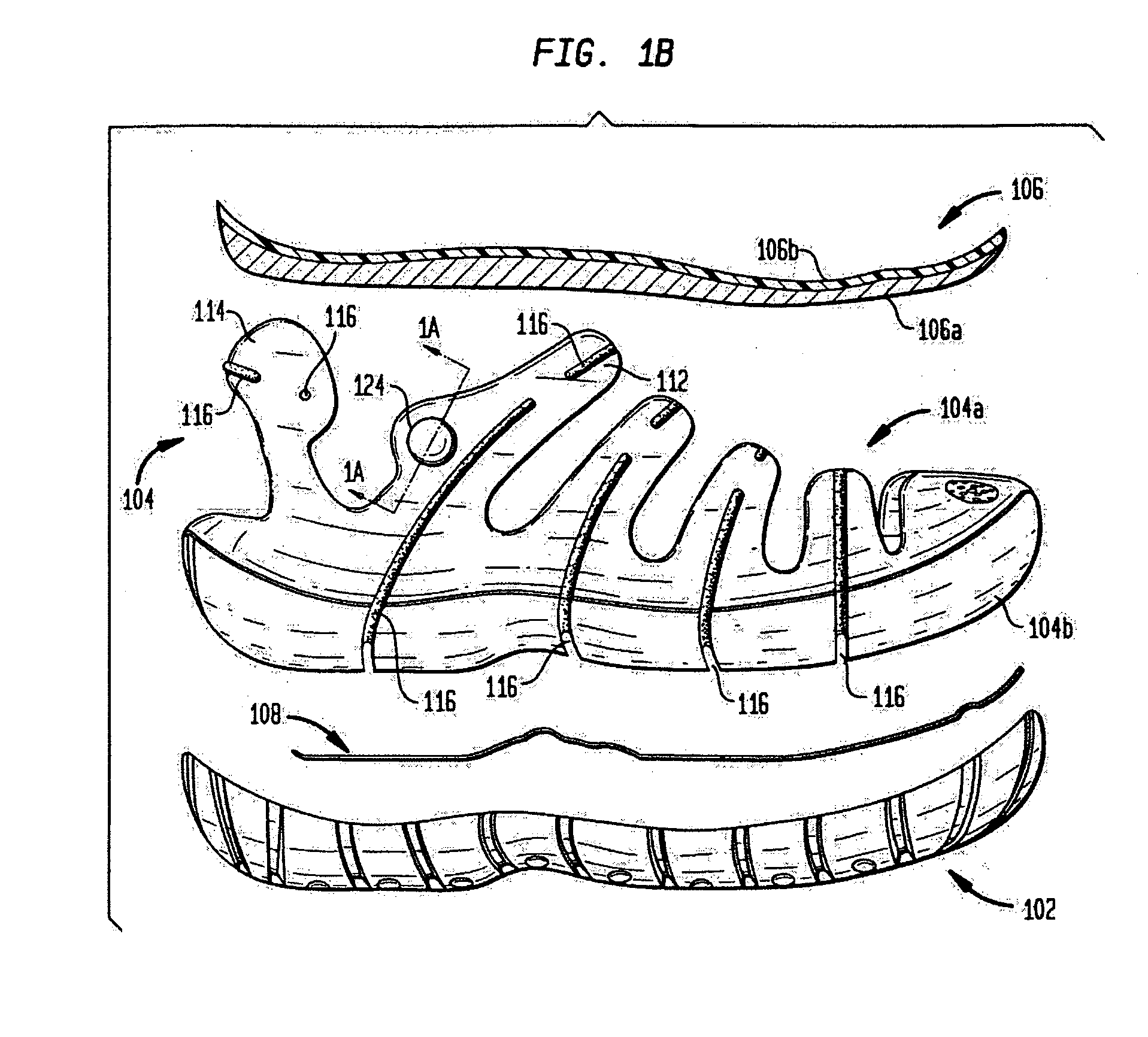

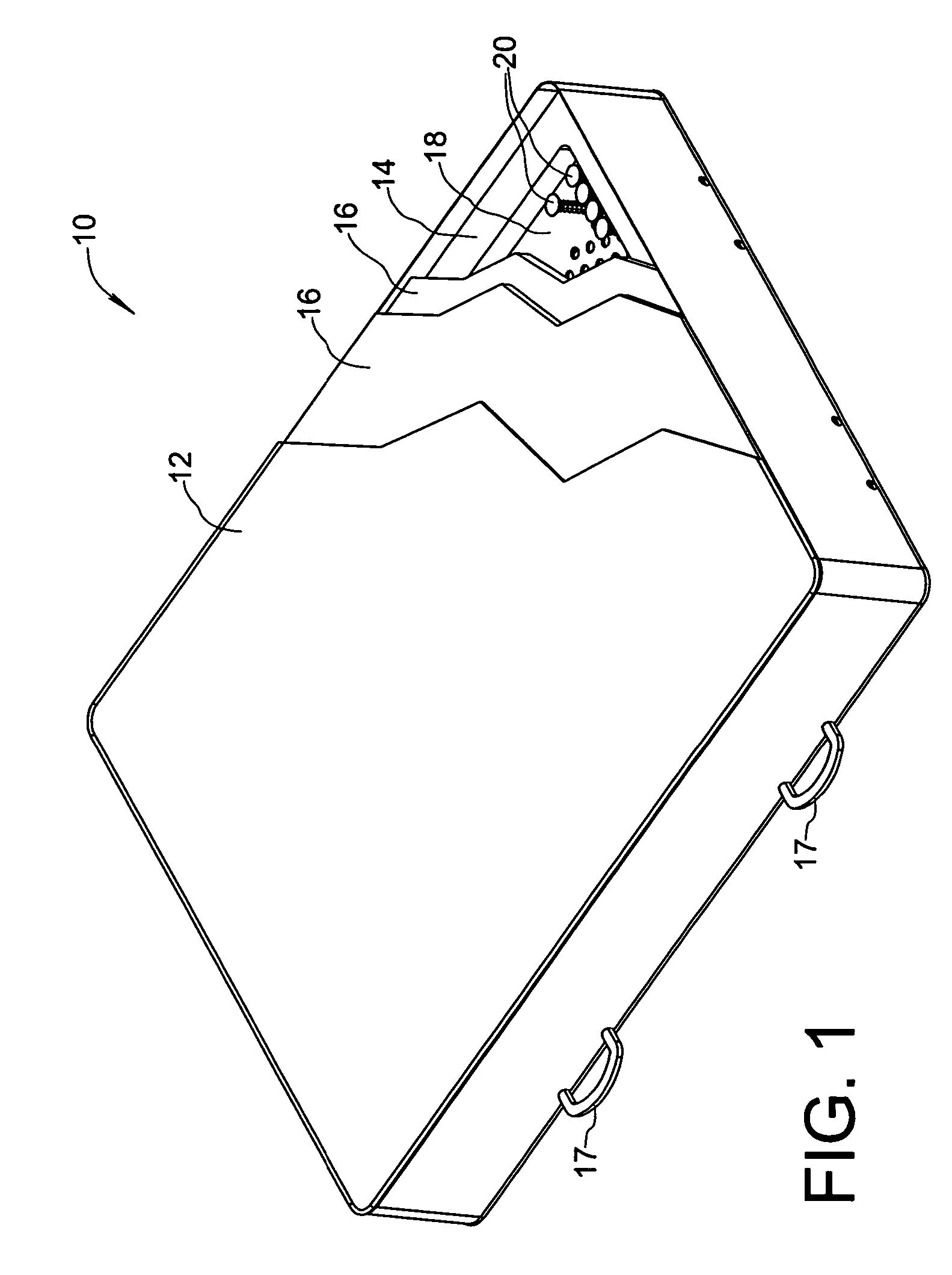

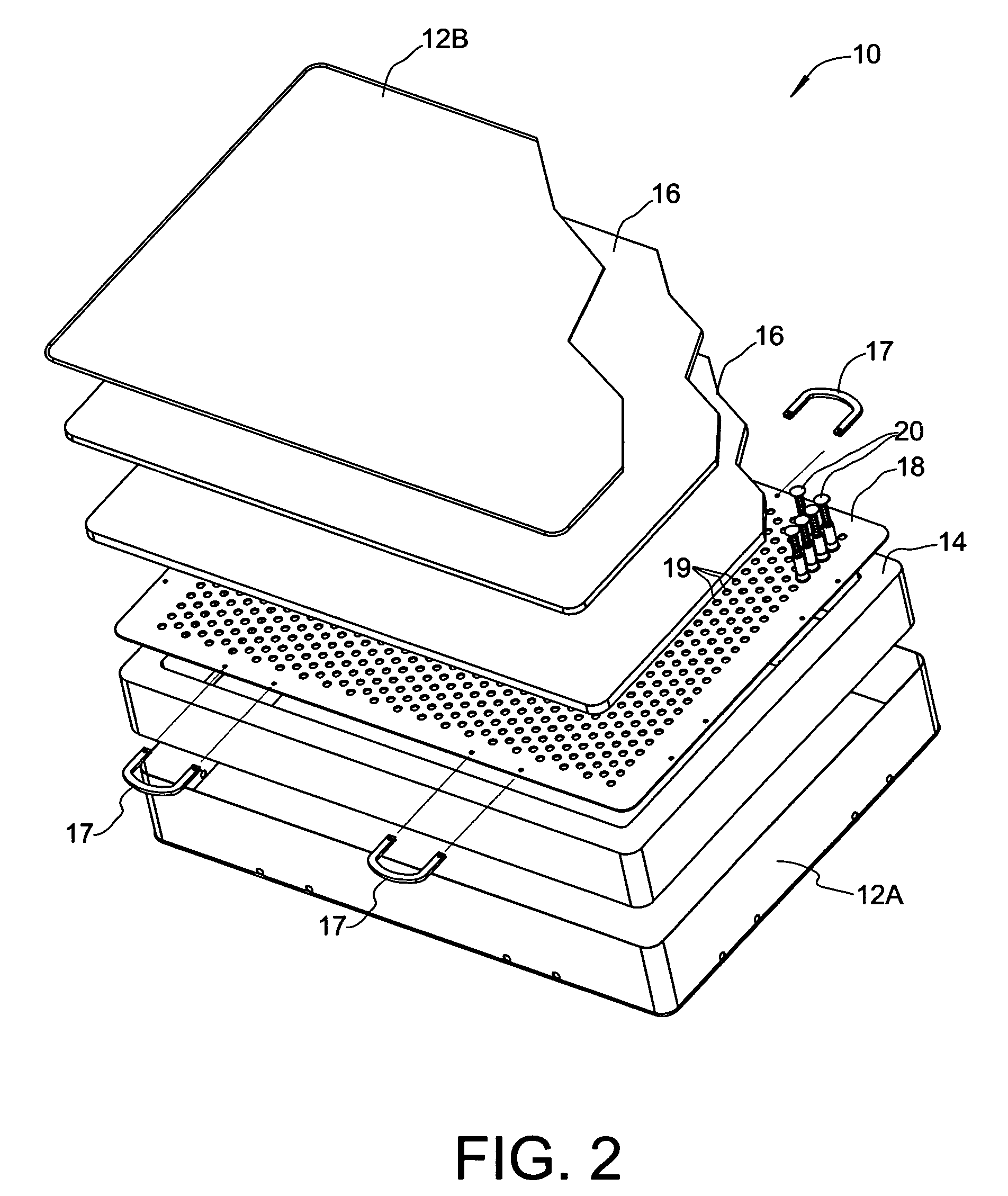

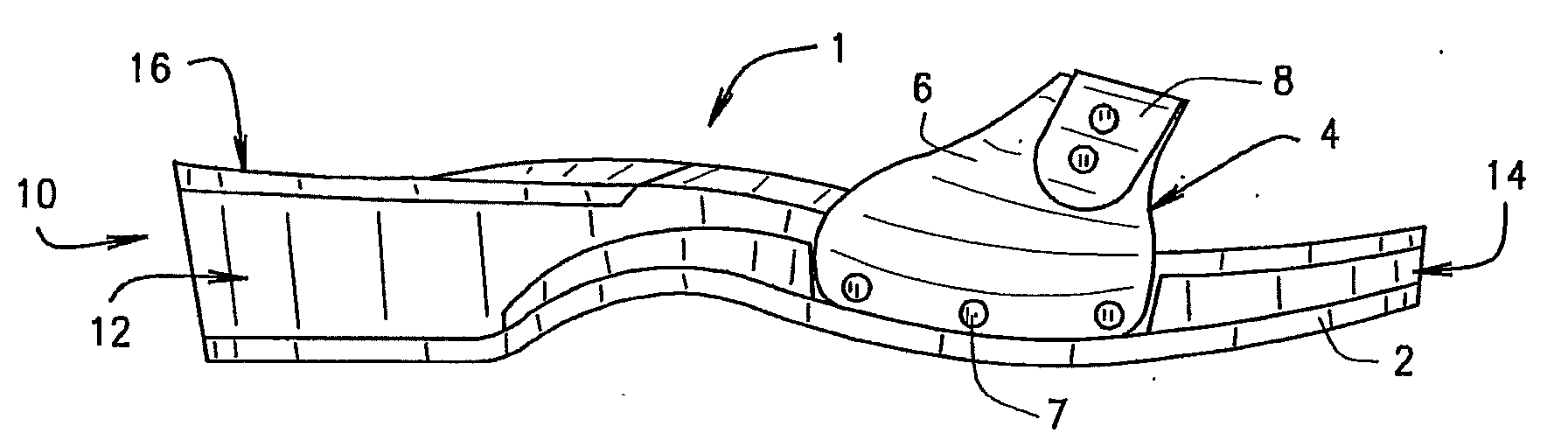

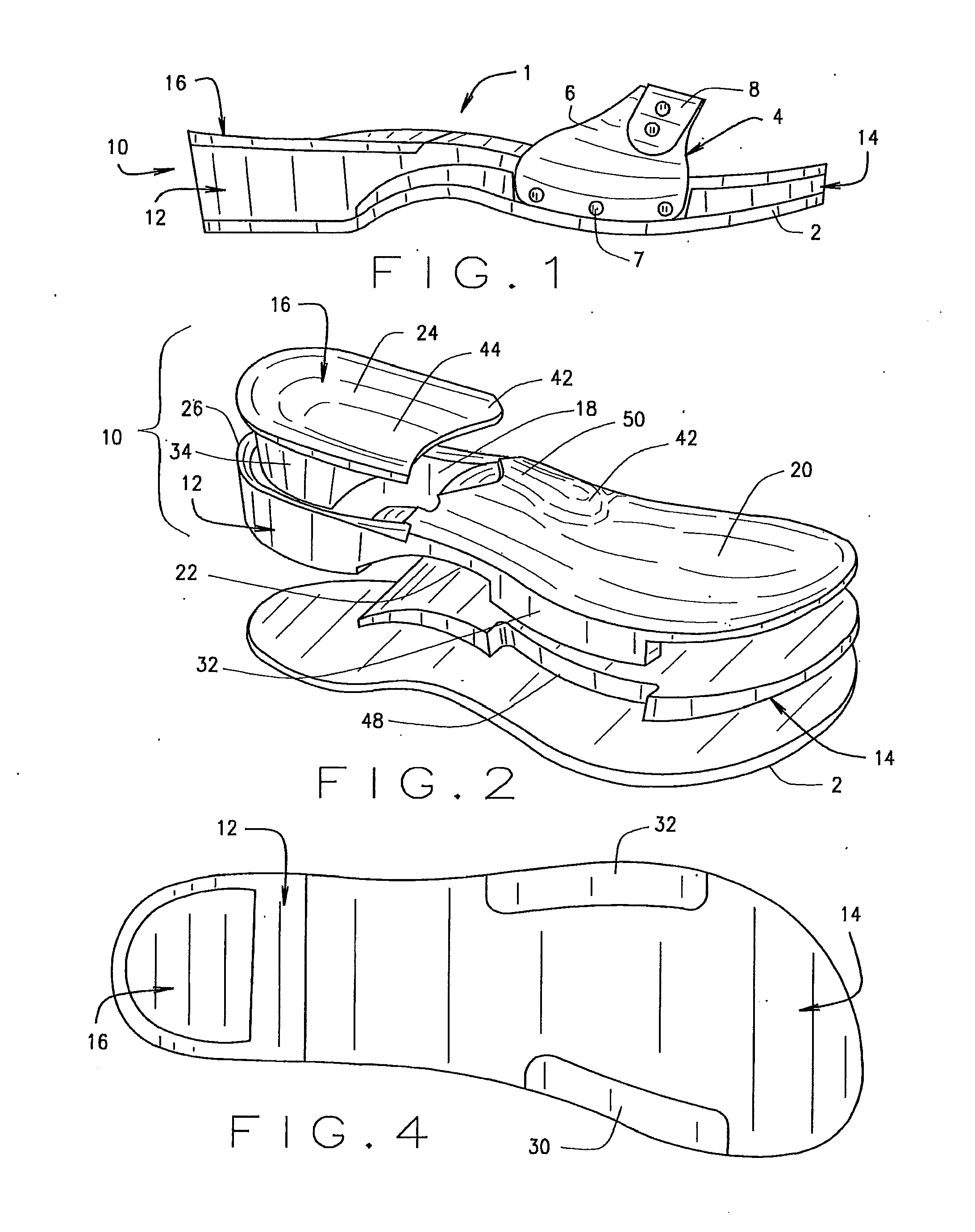

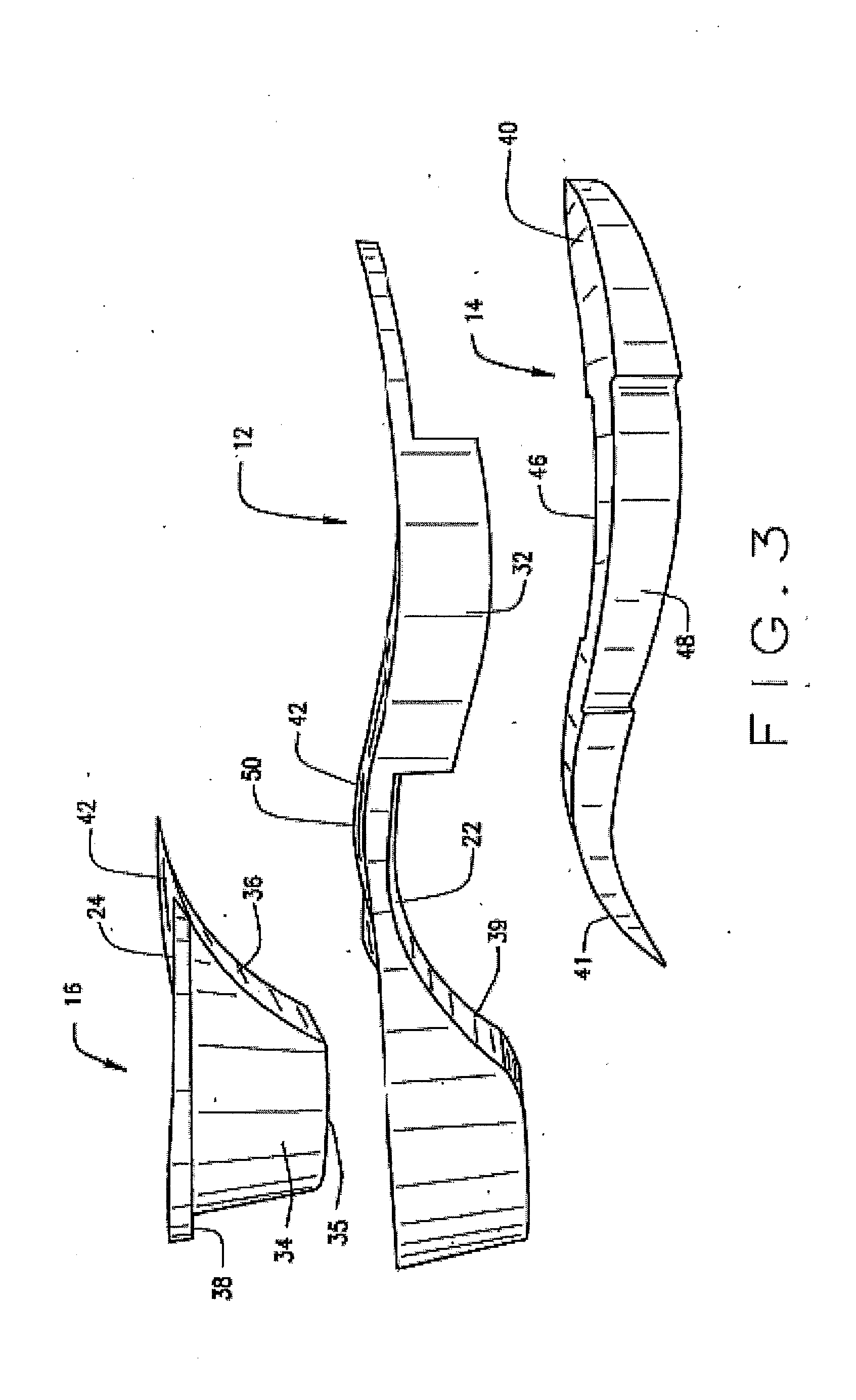

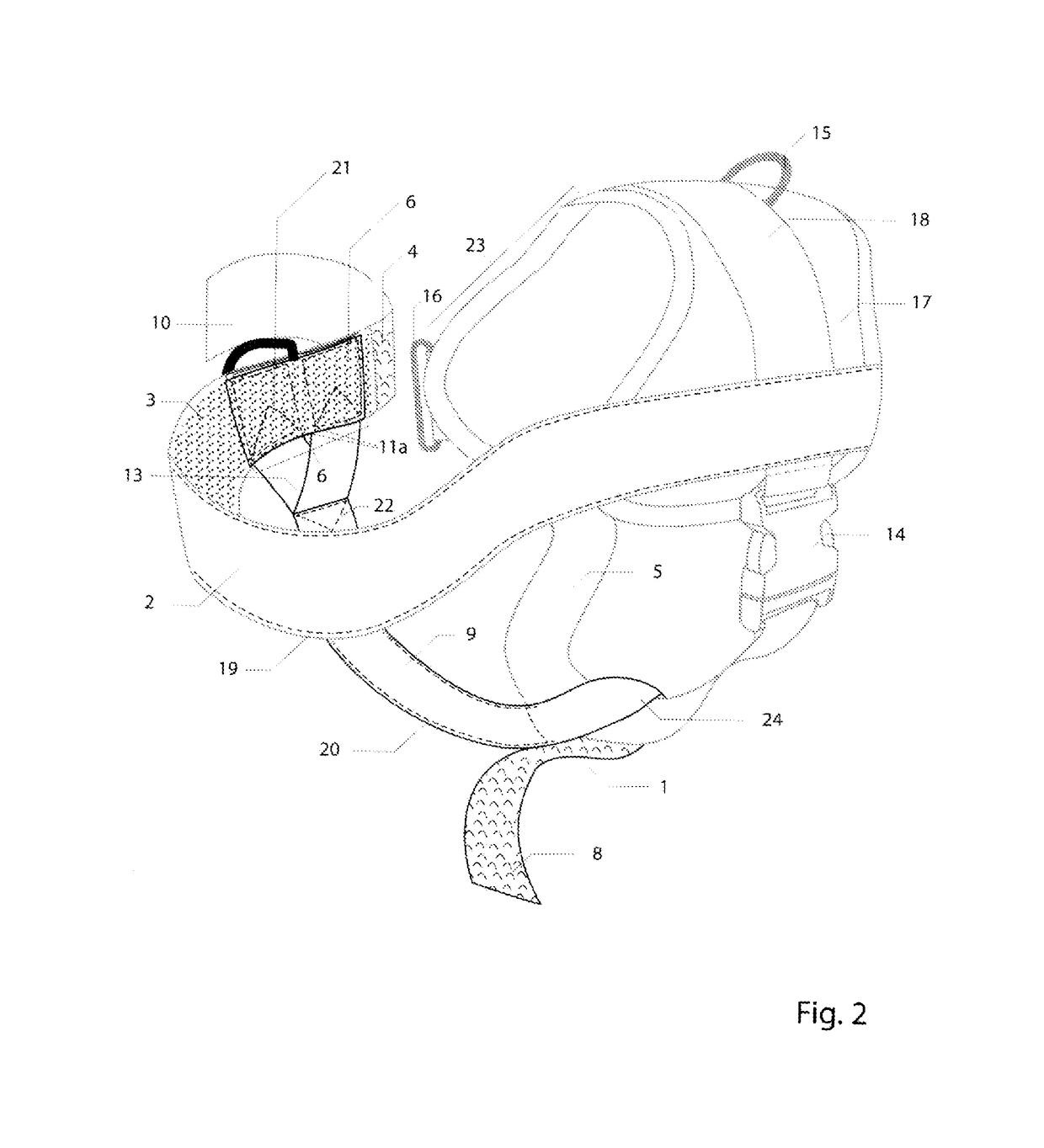

Shoe with anatomical protection

ActiveUS20070011914A1Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

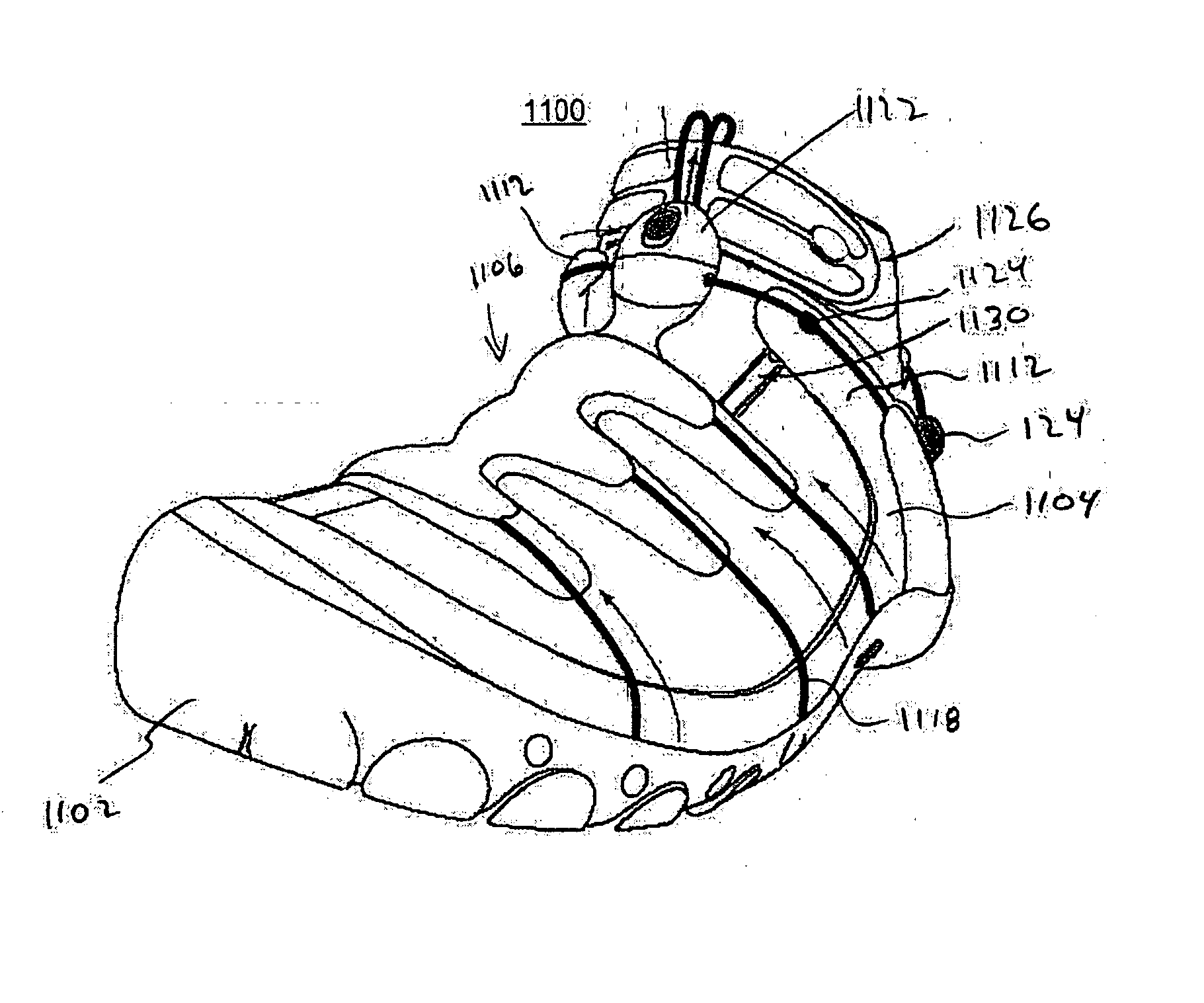

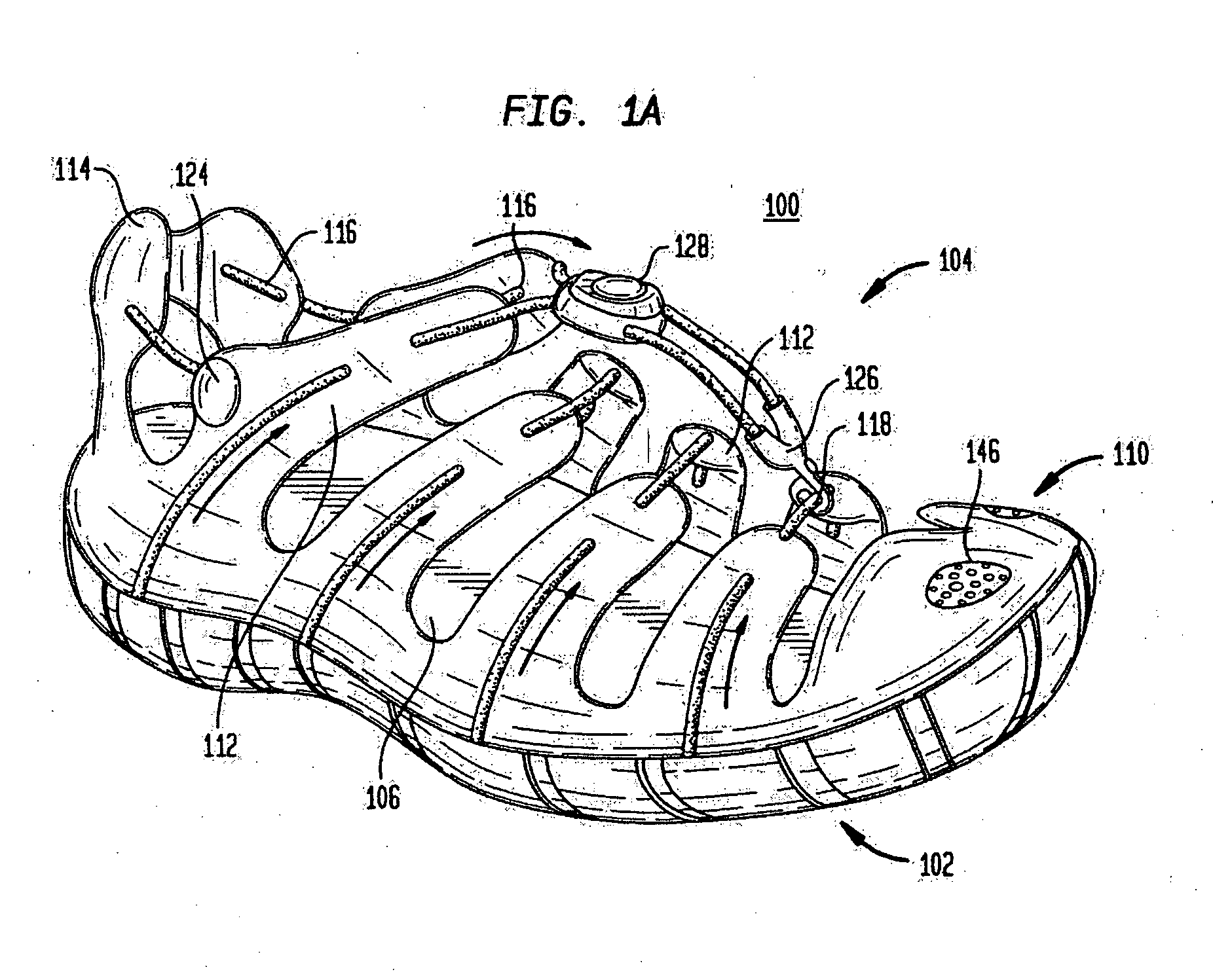

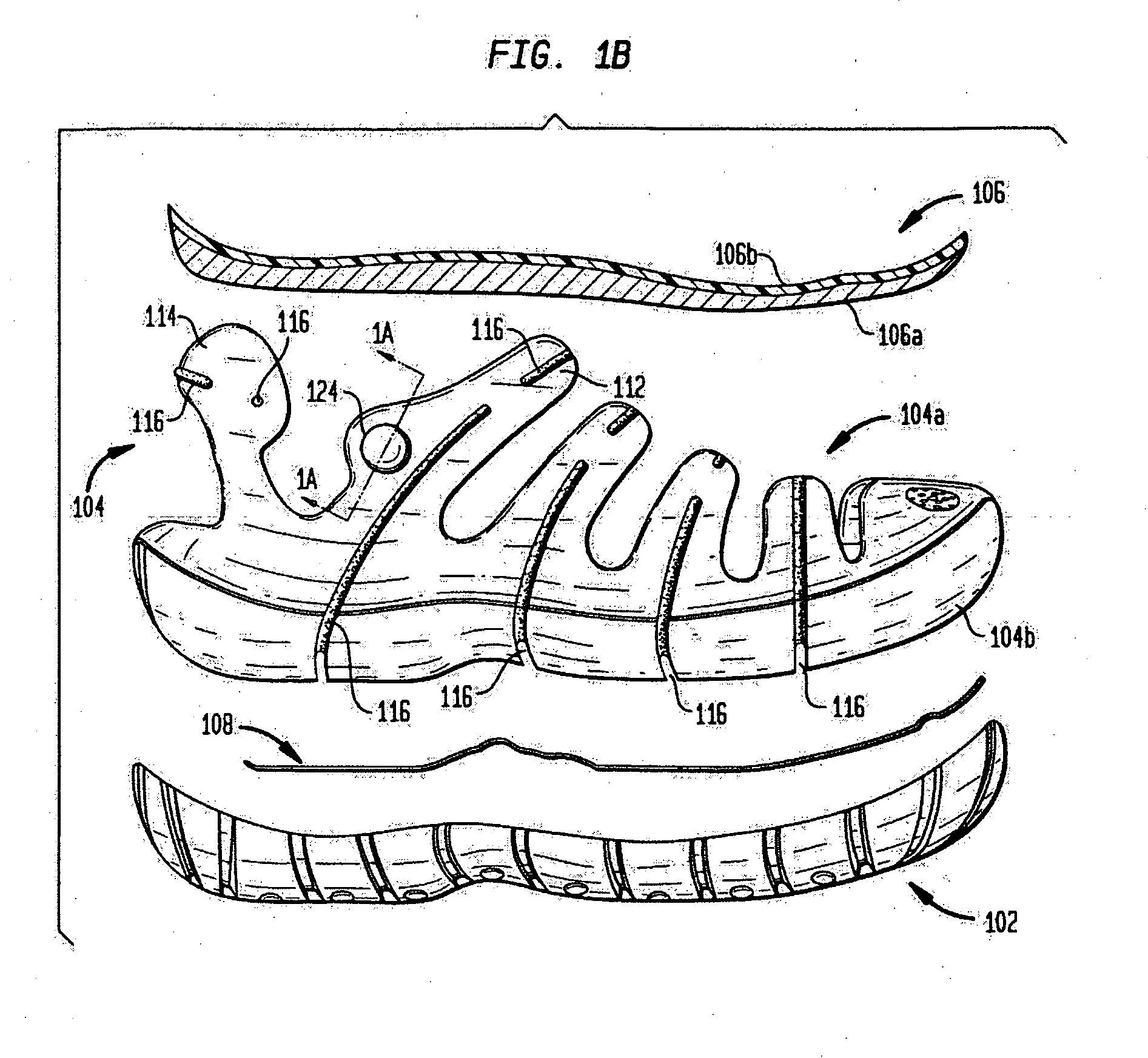

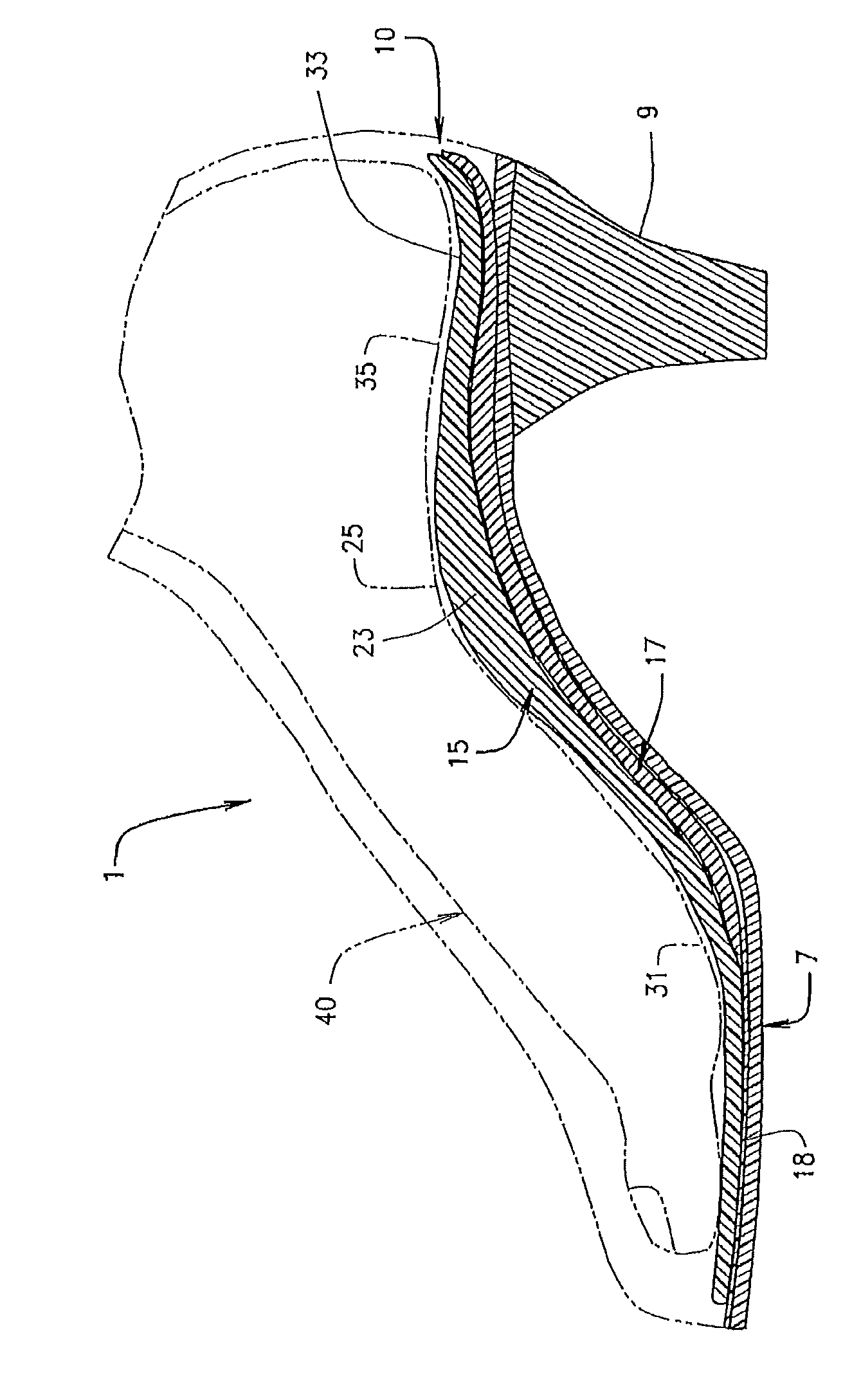

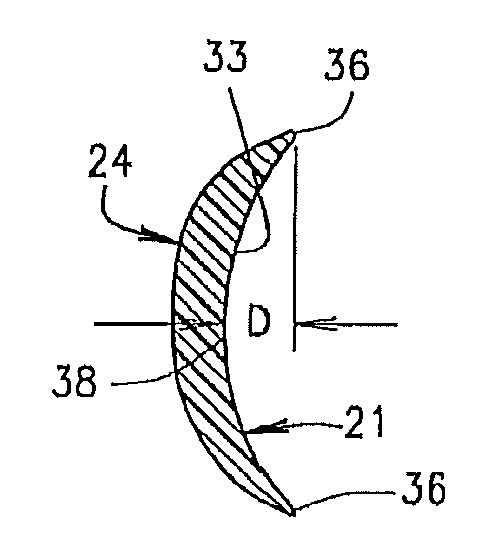

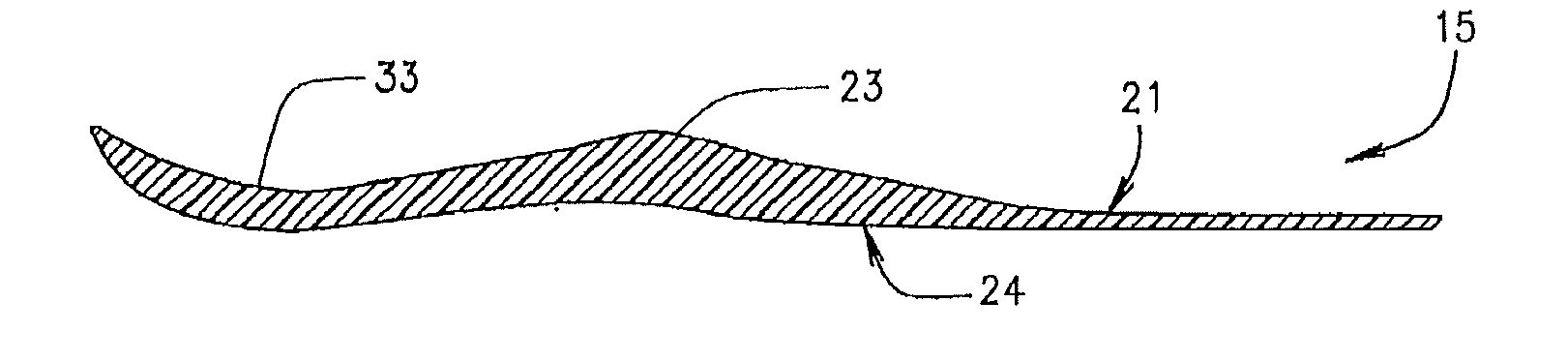

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

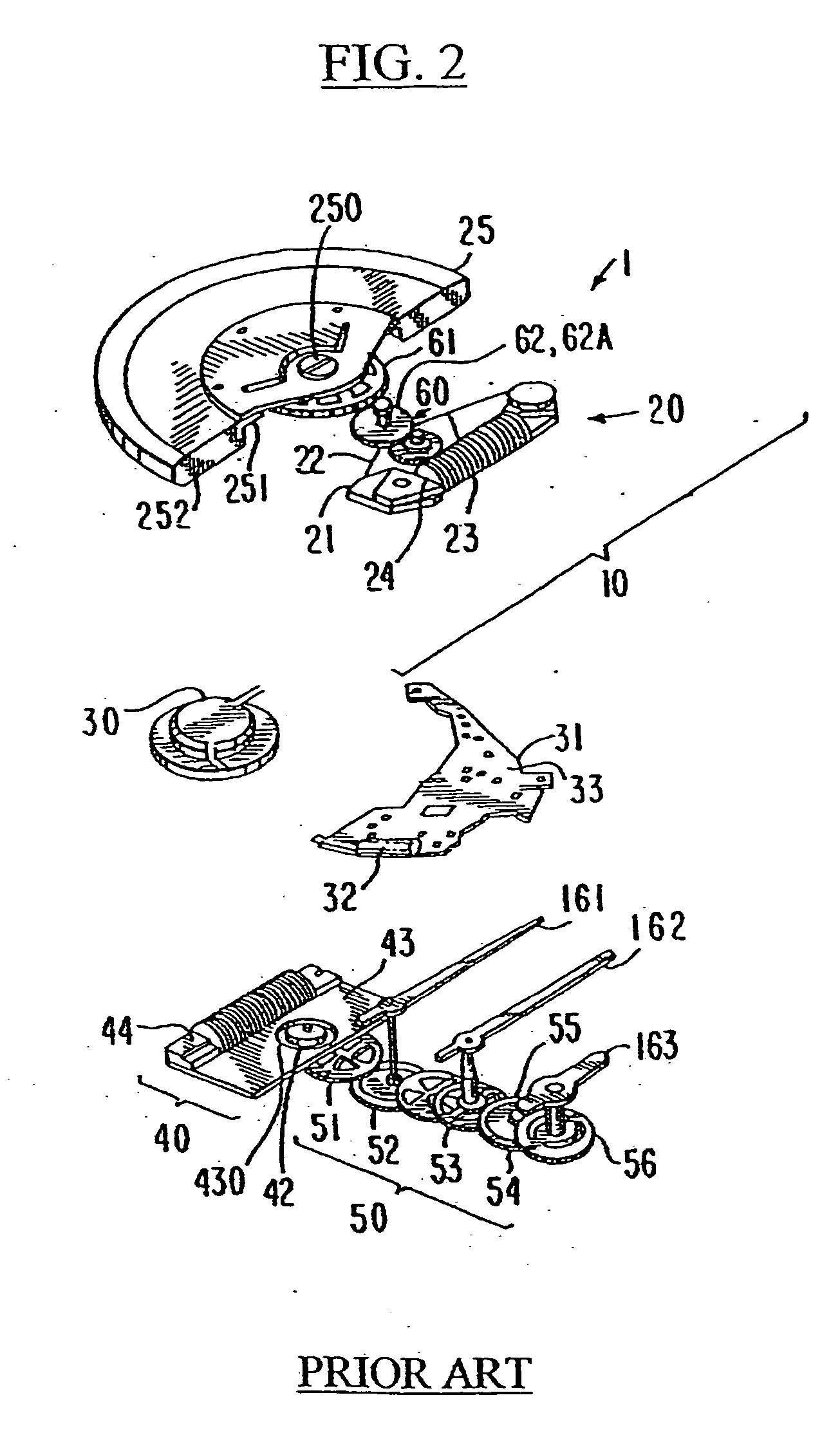

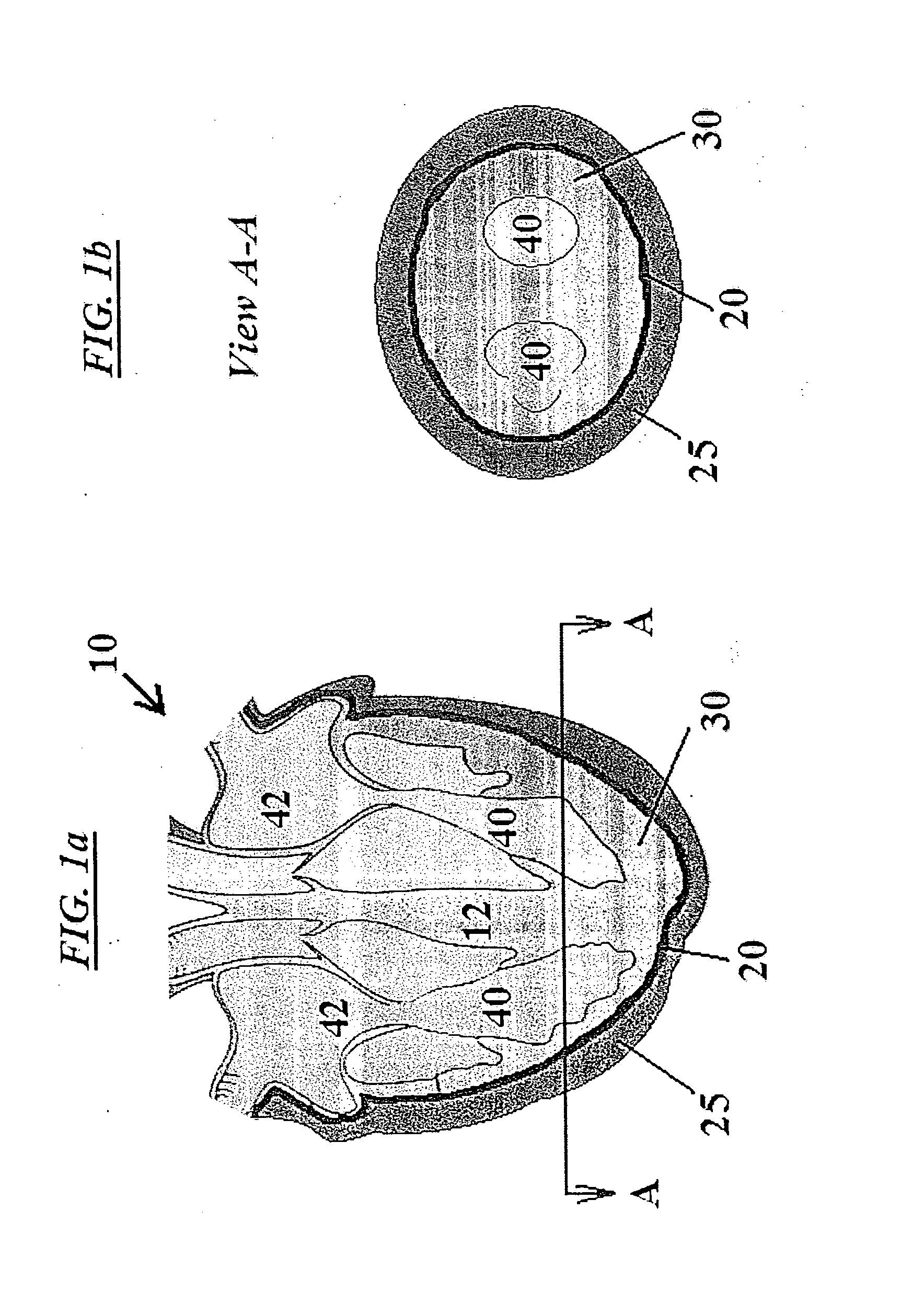

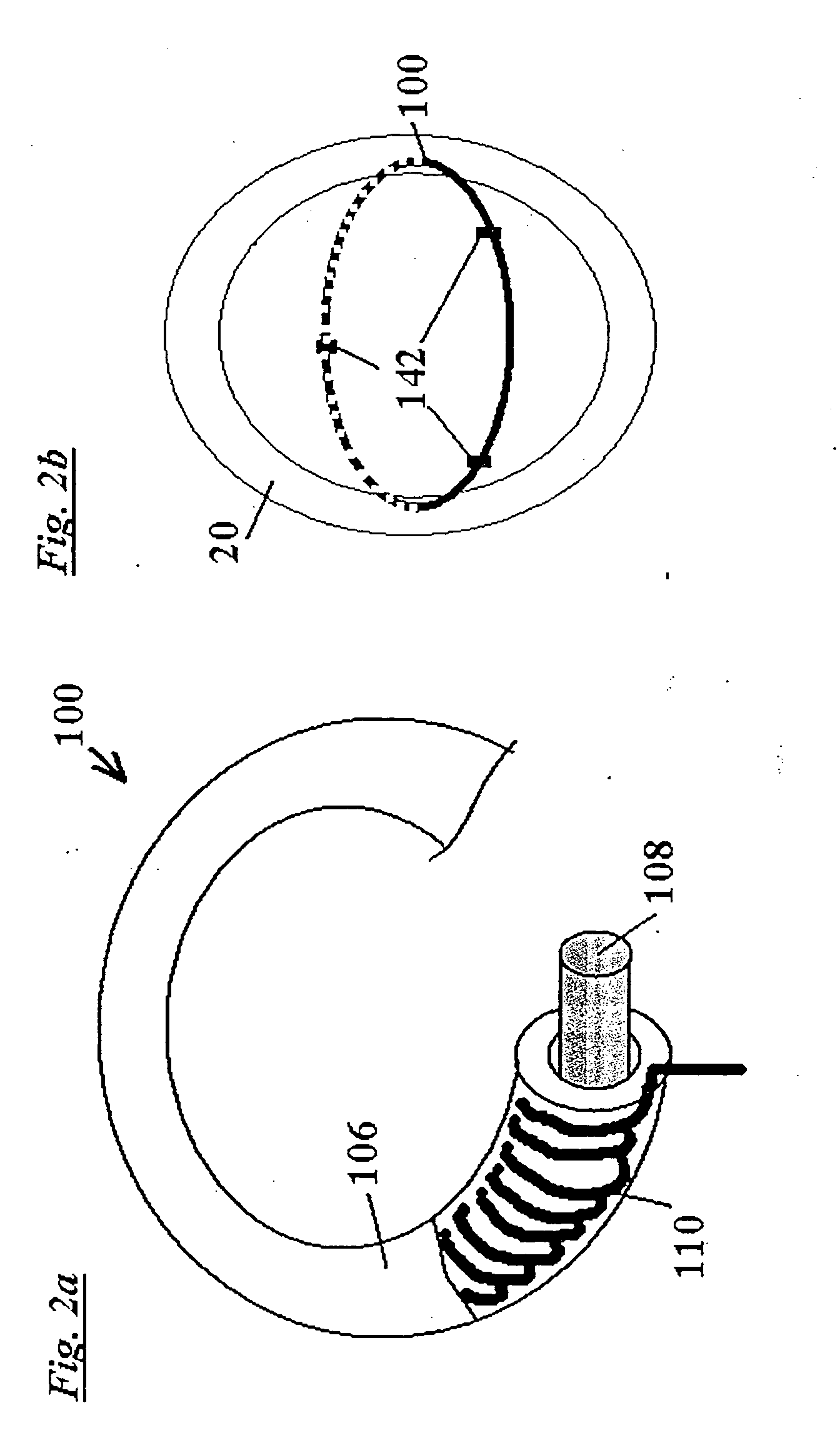

Micro-generator implant

InactiveUS20050256549A1Minimized in sizeSmall sizeEpicardial electrodesMechanical energy handlingMechanical energyEngineering

A micro-generator implant device including (a) a micro-generator, disposed within a living body, the micro-generator including: (i) a first mechanism for harnessing mechanical energy from a natural body movement, and (ii) a second mechanism for converting the mechanical energy to electrical energy, the electrical energy for providing power within the living body.

Owner:SIRIUS IMPLANTABLE SYST

Shoe with anatomical protection

ActiveUS7631440B2Overcome deficienciesEnhanced protection and flexibility and comfortSolesInsertsTibiaShoe laces

The present invention provides a floating anatomical protector for use in articles of footwear, and is particularly suited for footwear employing a wraparound lacing system. The floating anatomical protector preferably does not directly contact the superstructure of the article of footwear when worn. Instead, the lacing or other fastening system retains the floating anatomical protector in place over the wearer's foot and / or leg. For instance, the instep region of the foot, the shin, Achilles heel, calf, etc. may be covered by the floating anatomical protector. Multiple segments or separate protectors may be used. The lace may run between different layers of the floating anatomical protector. Also, the floating anatomical protector may directly contact the wearer's skin, or it may be used in conjunction with a bootie, sock or other intermediate material.

Owner:THE TIMBERLAND COMPANY

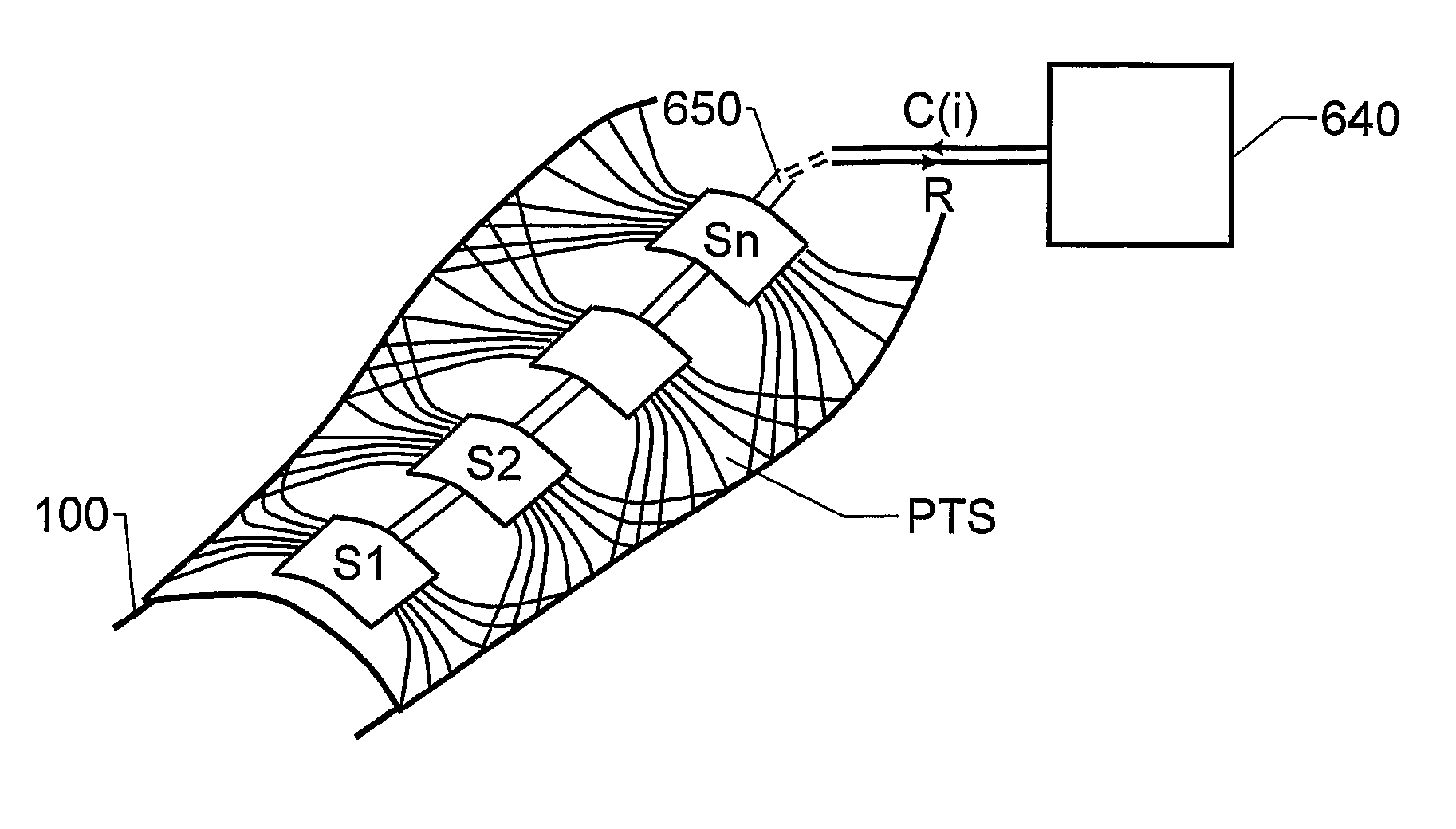

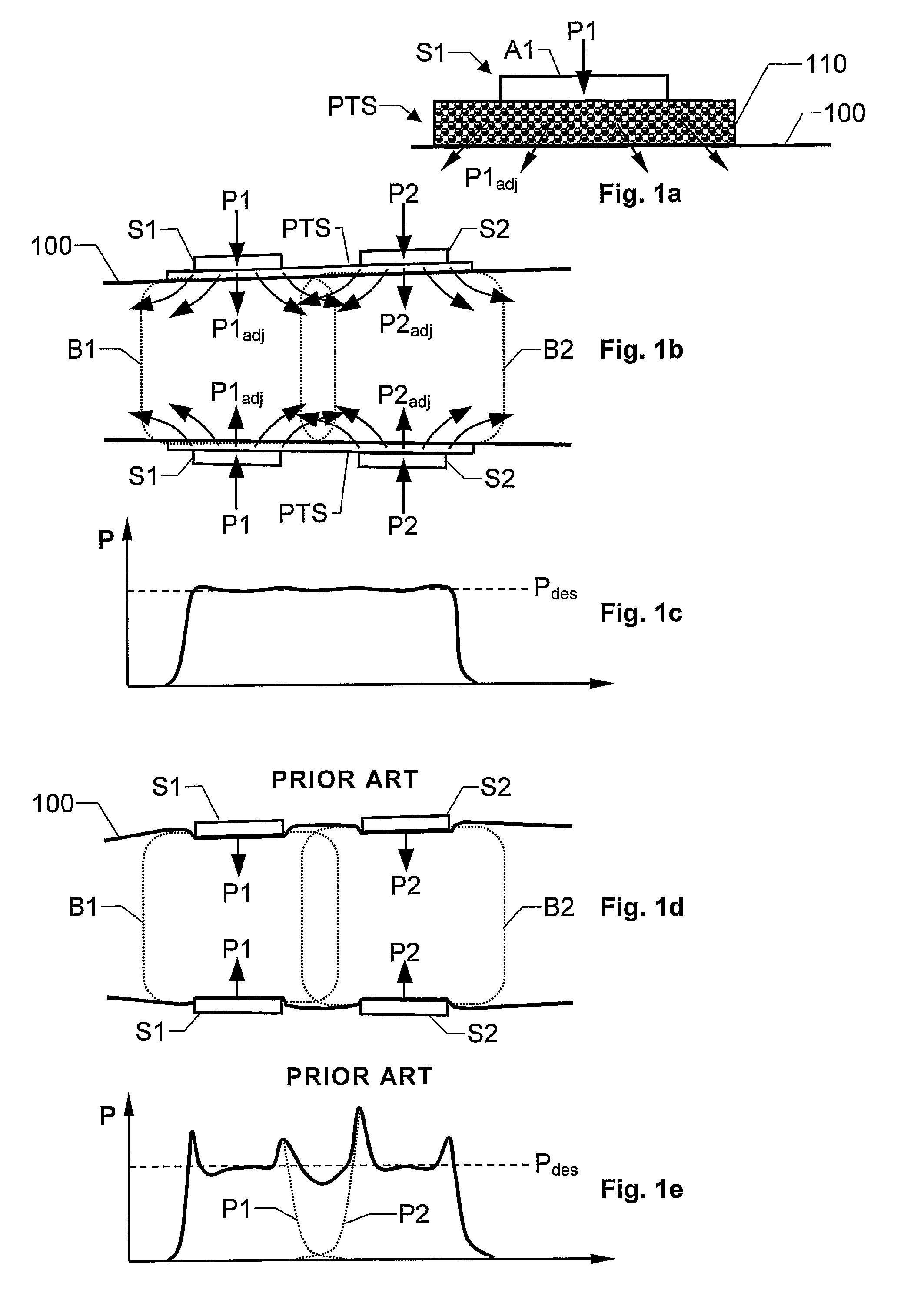

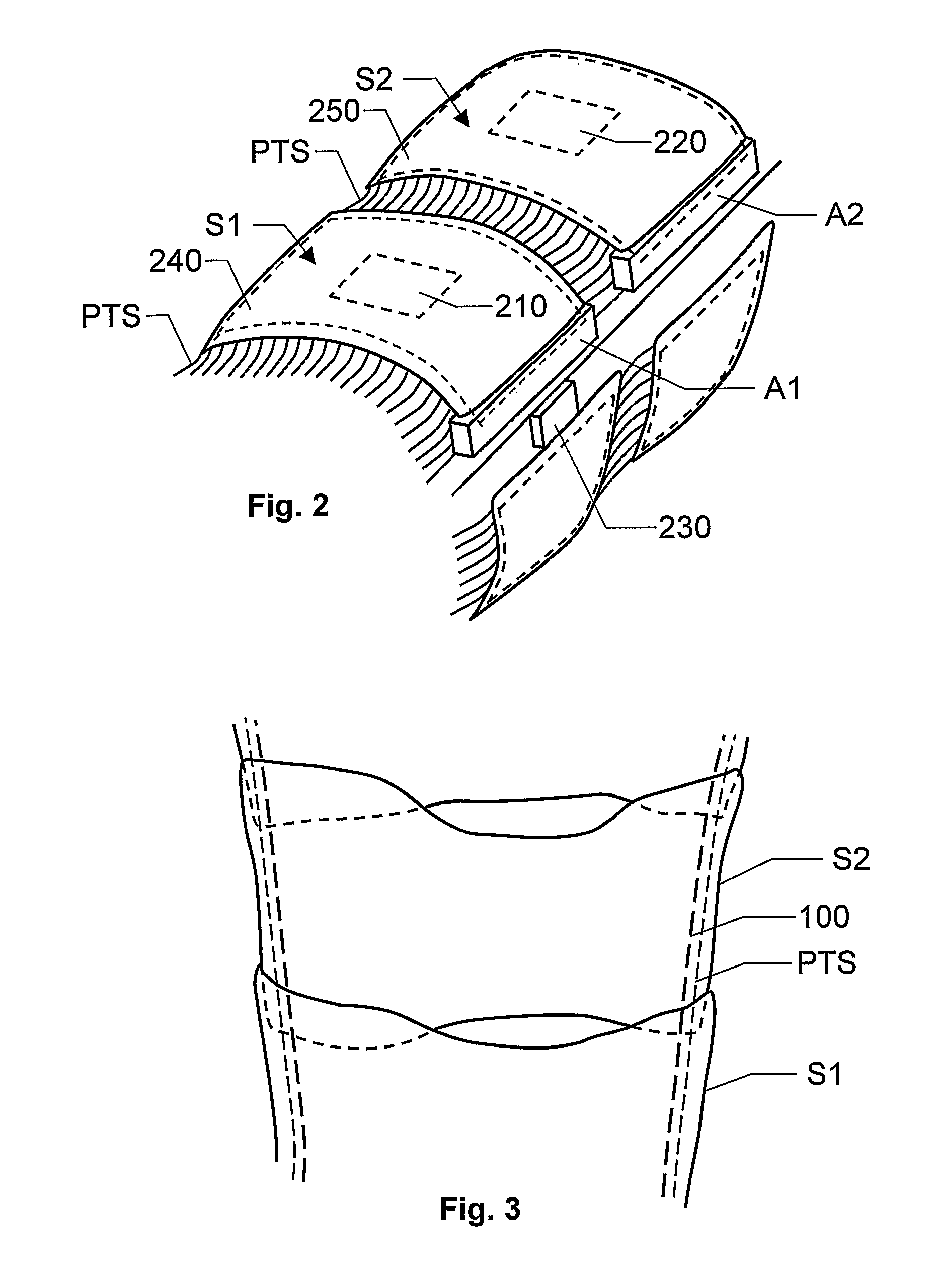

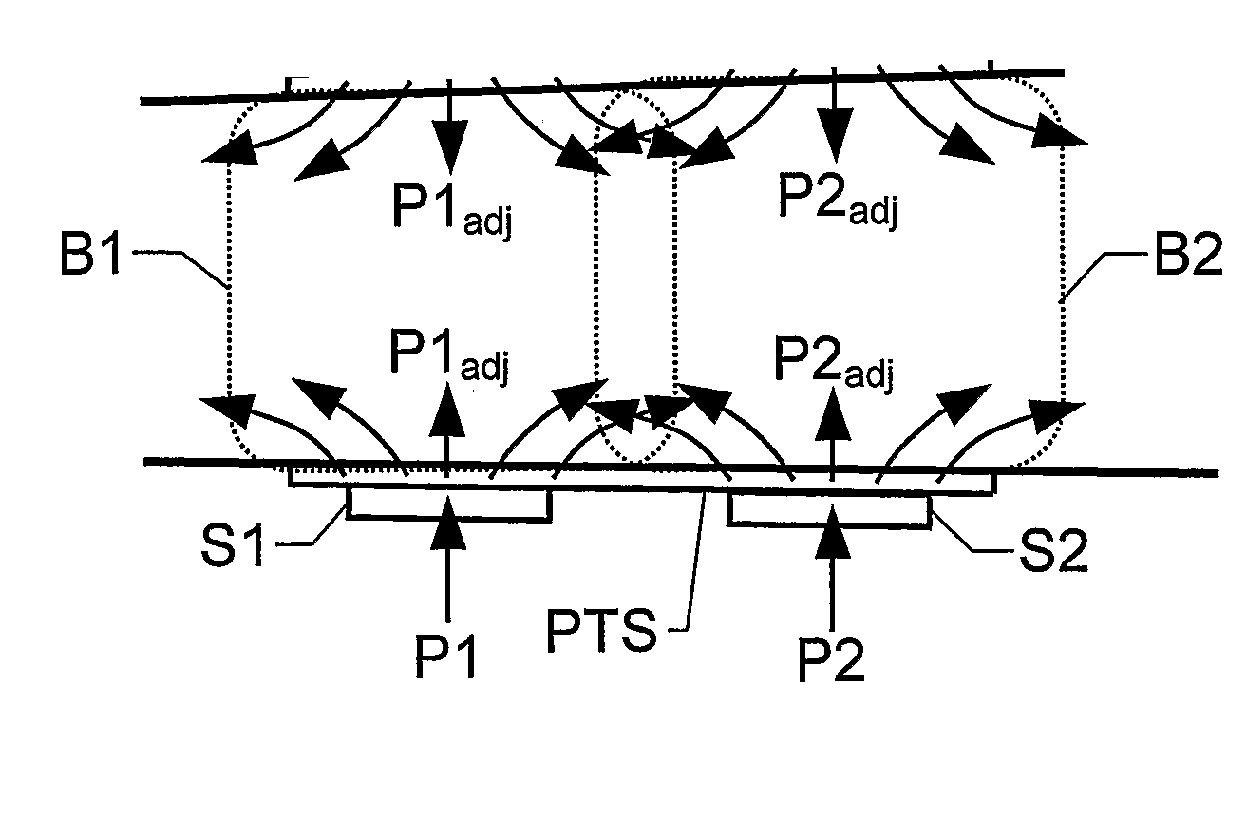

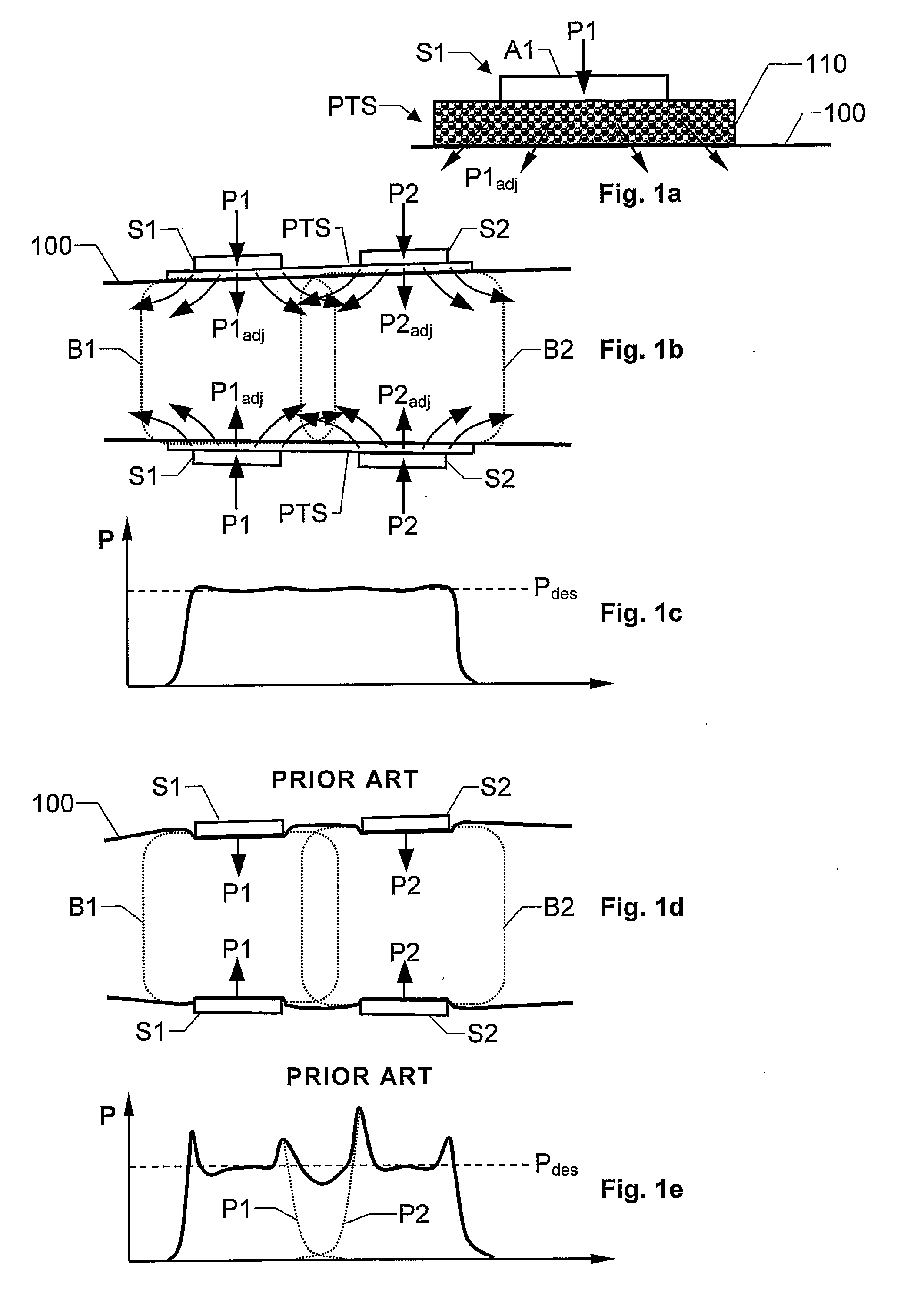

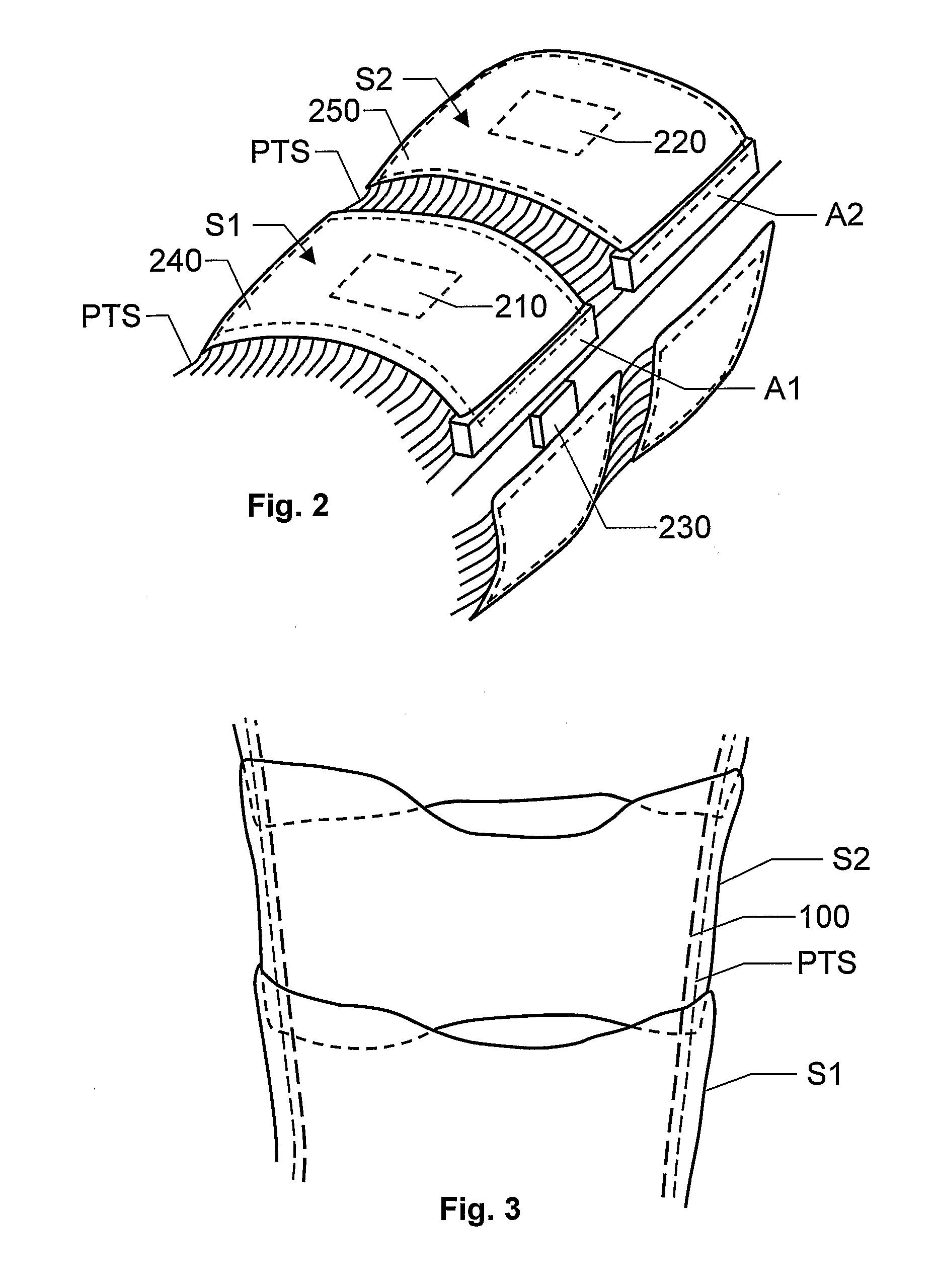

Electro active compression bandage

ActiveUS7857777B2Improve pressure distributionMassage combsElectrotherapyControl signalElectrical control

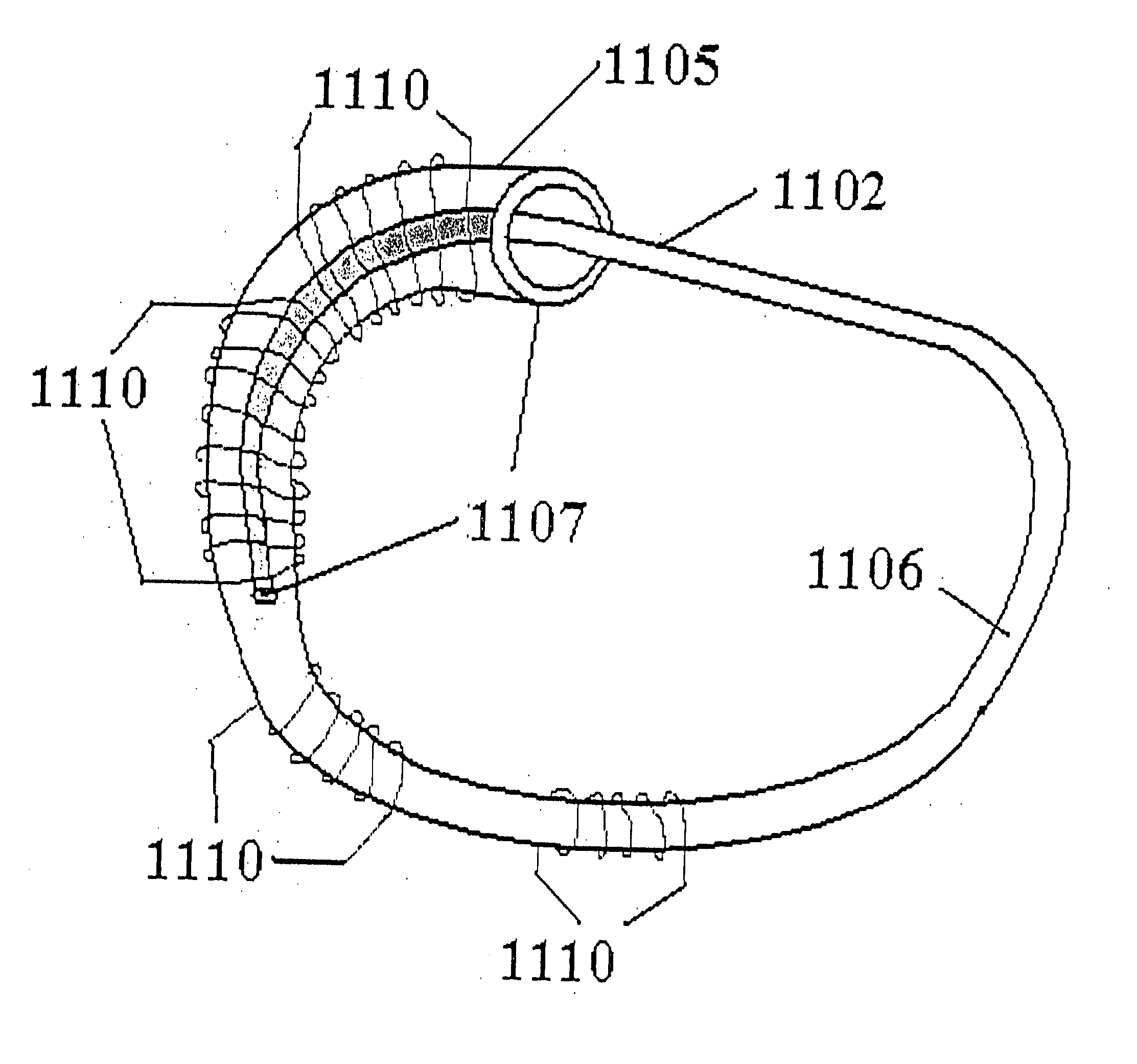

The proposed device includes two segments adapted to enclose a body part in a form-fitting manner. Each segment contains an electroactive-material-based actuator, which is adapted to receive an electrical control signal and in response thereto adjust the actuator's morphology, so as to cause the segment to apply a basic pressure profile to the body part. A pressure transition is adapted to redistribute the basic pressure profiles between the first and second segments. A control signal in respect of the first segment causes the pressure transition system to apply a first adjusted pressure profile to at least part of the second portion of the body part, and vice versa, a control signal in respect of the second segment causes the pressure transition system to apply a second adjusted pressure profile to at least a part of the first portion of the body part.

Owner:SWELLING SOLUTIONS

Electro Active Compression Bandage

ActiveUS20080195018A1Improve pressure distributionMassage combsElectrotherapyControl signalElectrical control

The proposed device includes two segments adapted to enclose a body part in a form-fitting manner. Each segment contains an electroactive-material-based actuator, which is adapted to receive an electrical control signal and in response thereto adjust the actuator's morphology, so as to cause the segment to apply a basic pressure profile to the body part. A pressure transition is adapted to redistribute the basic pressure profiles between the first and second segments. A control signal in respect of the first segment causes the pressure transition system to apply a first adjusted pressure profile to at least part of the second portion of the body part, and vice versa, a control signal in respect of the second segment causes the pressure transition system to apply a second adjusted pressure profile to at least a part of the first portion of the body part.

Owner:SWELLING SOLUTIONS

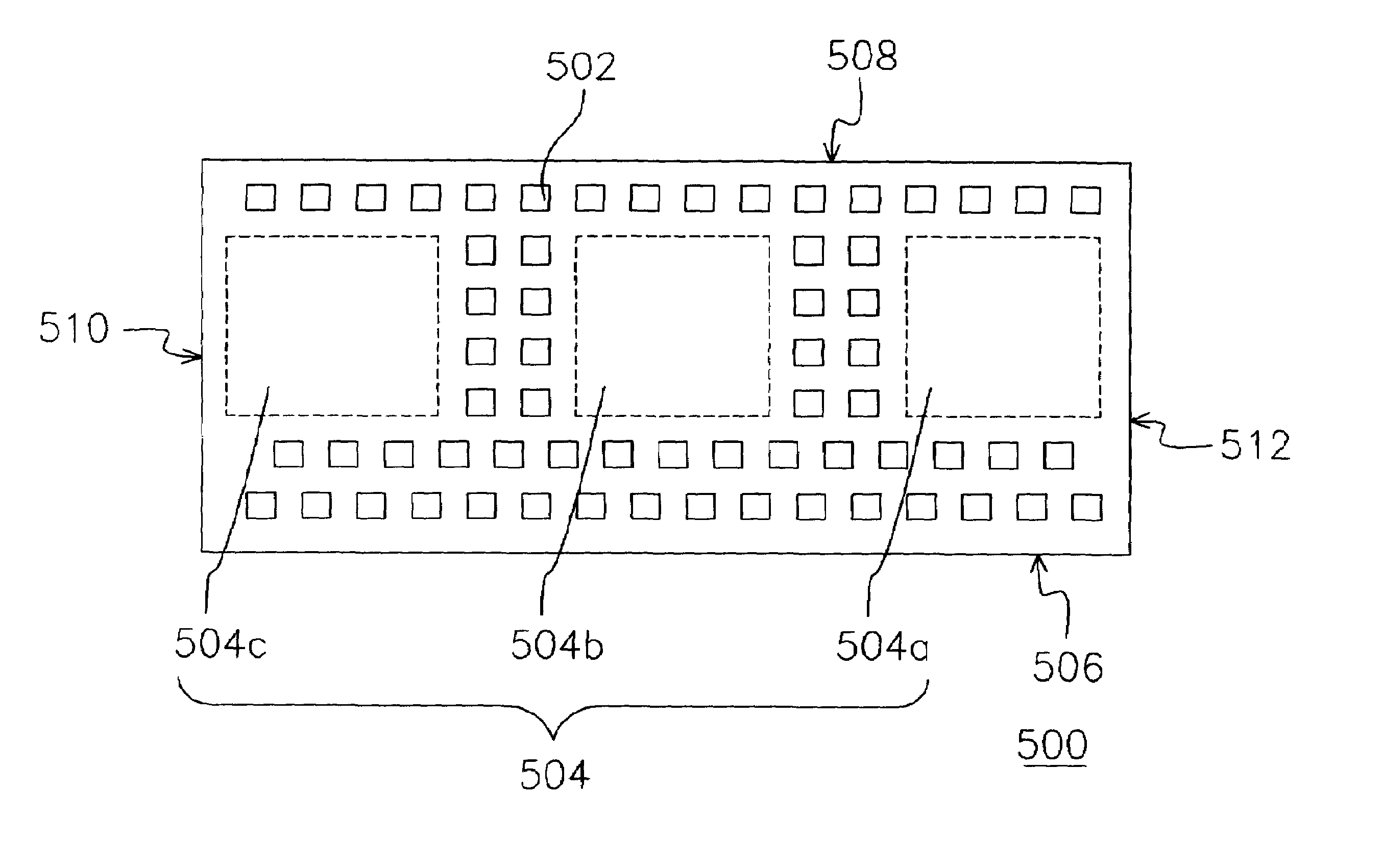

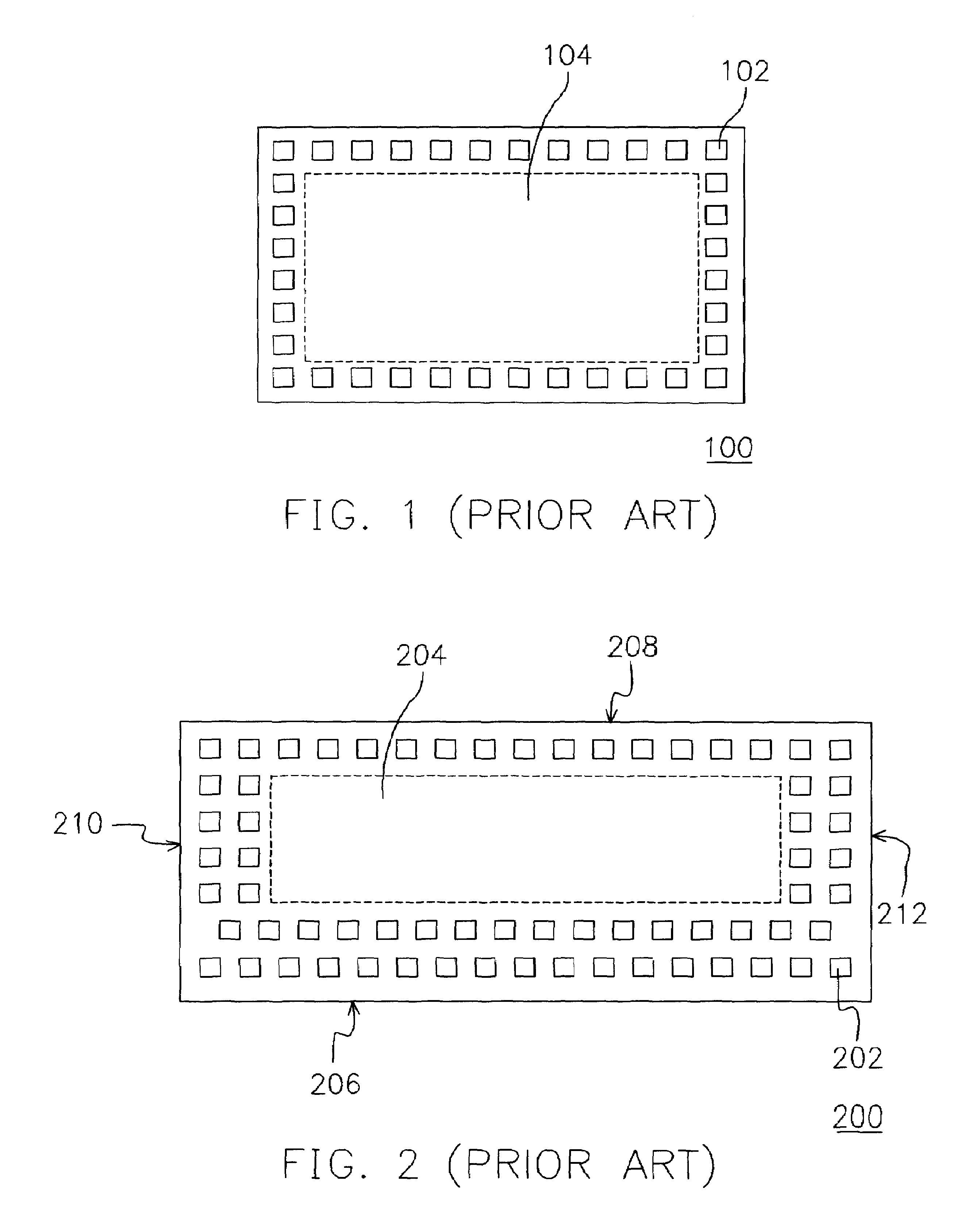

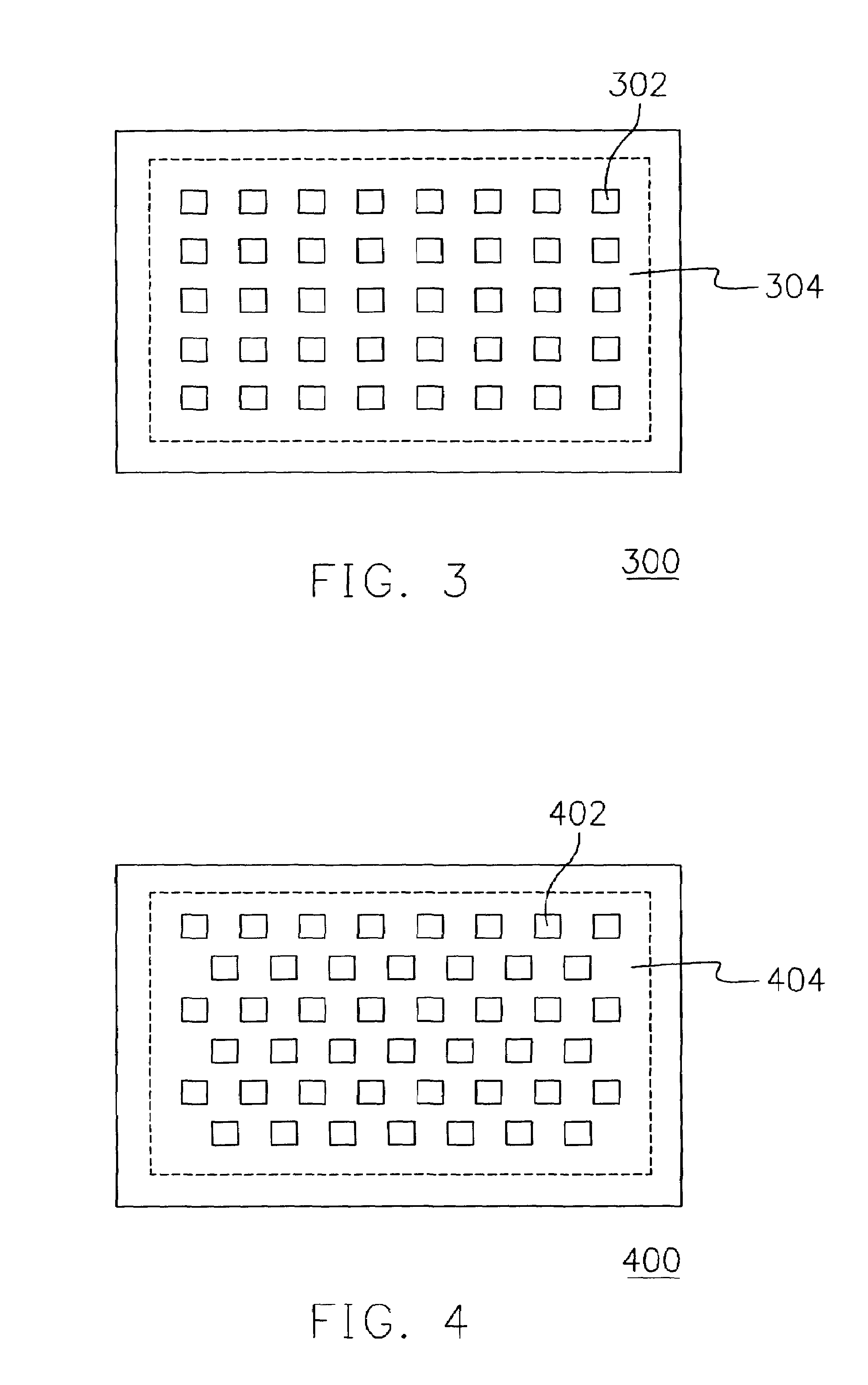

Bump layout on silicon chip

InactiveUS7061117B2Easy to installLighter marks on the shorter sides of a conventional rectangular drive chip are preventedSemiconductor/solid-state device detailsSolid-state devicesSilicon chipMechanical engineering

A bump layout on the active region of a driver IC for increasing overall bump count. The layout fits IC packages that have a narrow and long body profile. Bumps are positioned close to the long side and central regions of the active region so that low marking pressure on the shorter sides of the package during chip-glass bondage is avoided. Dummy bumps may also be positioned close to the shorter sides of the package so that pressure distribution is optimized during chip-glass bondage.

Owner:AU OPTRONICS CORP

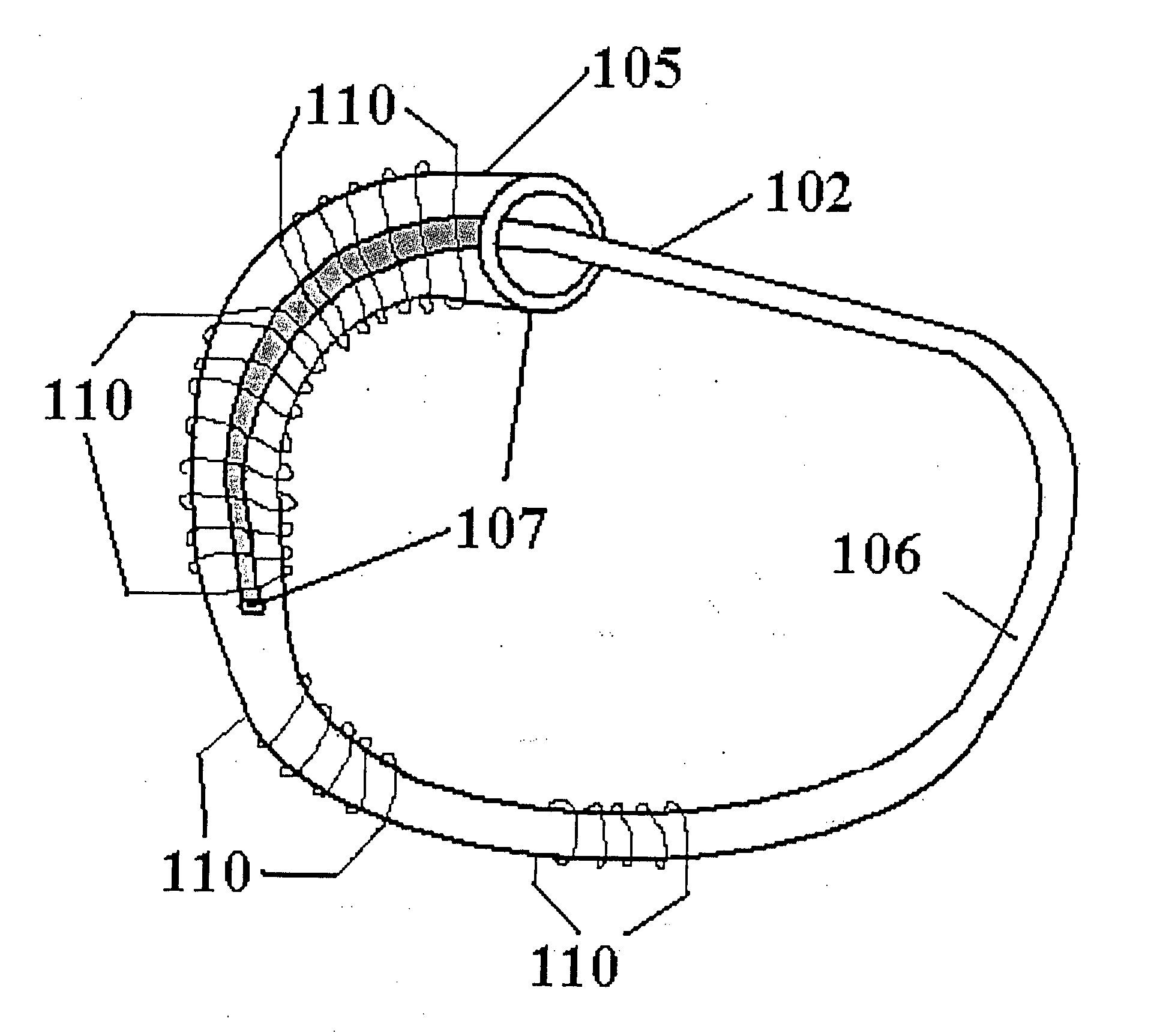

Cardiac implant device

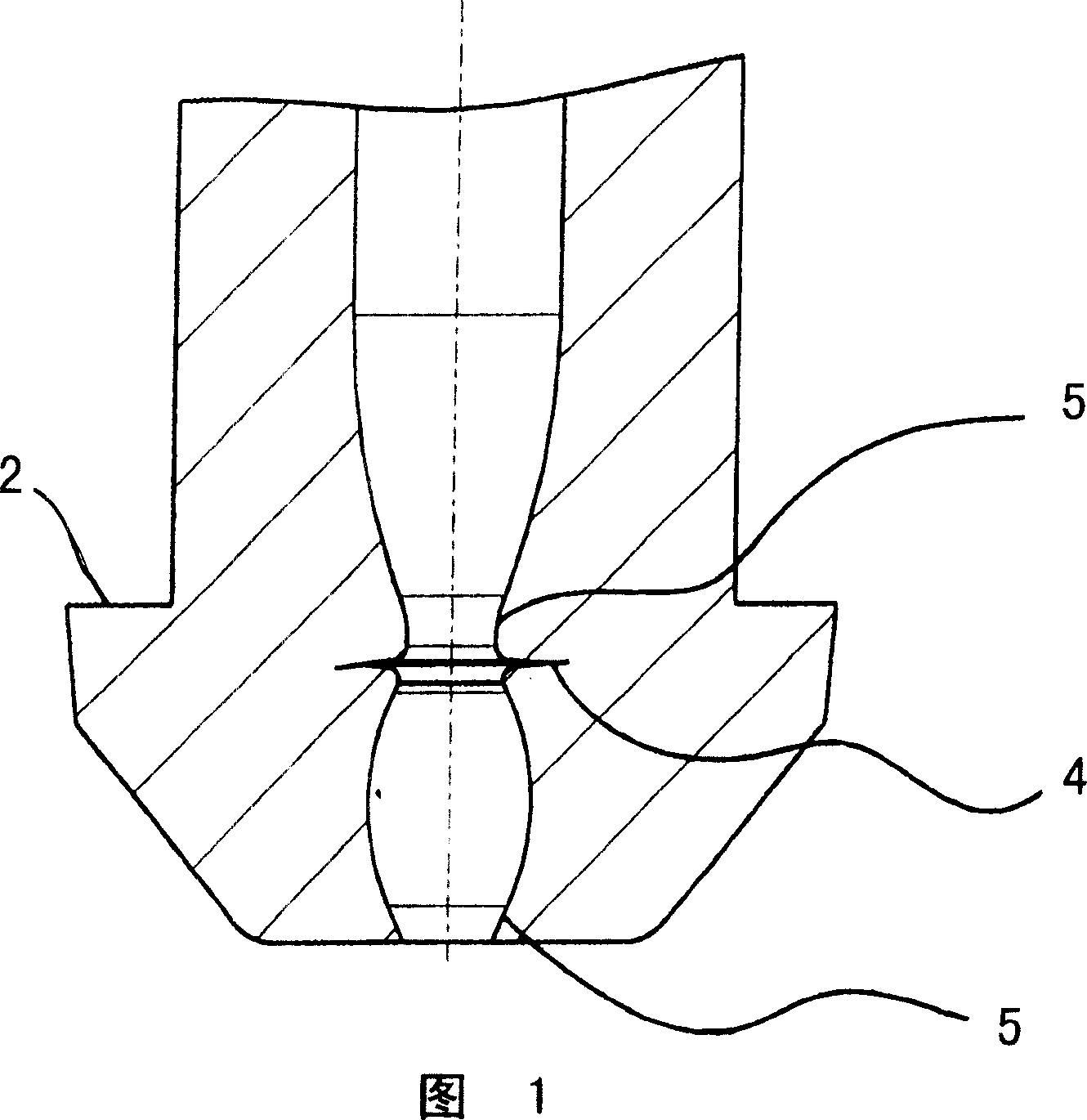

InactiveUS20050055061A1Increase surface areaImprove pressure distributionEpicardial electrodesHeart stimulatorsLiving bodyBiomedical engineering

A heart implant device for associating with a heart of a living body, the device including: (a) a housing for securely associating with heart tissue, the housing encompassing a space, the housing including a conductive coil, and (b) a ferromagnetic element disposed within the space, the element for moving relative to the coil so as to produce electrical energy within the living body.

Owner:SIRIUS IMPLANTABLE SYST

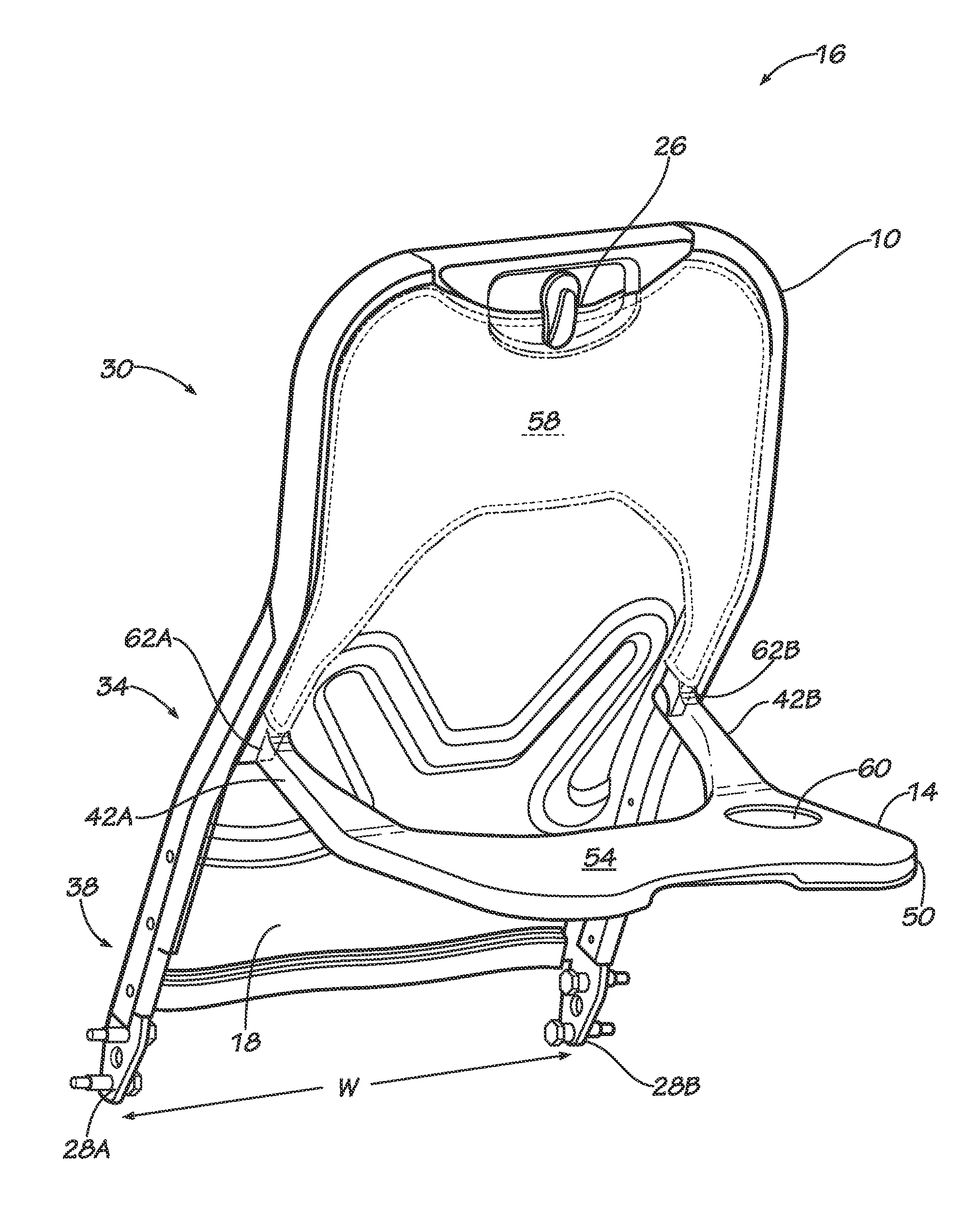

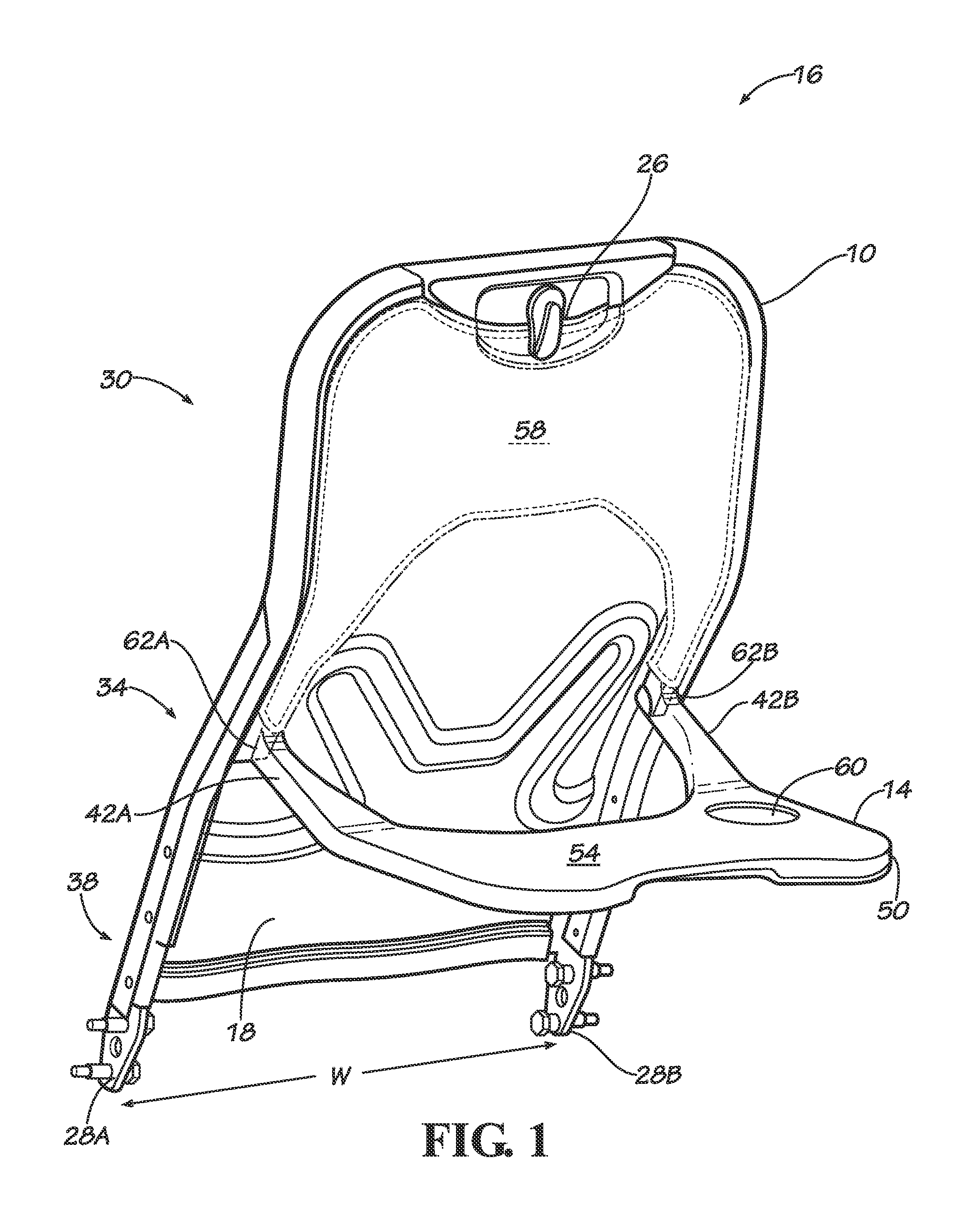

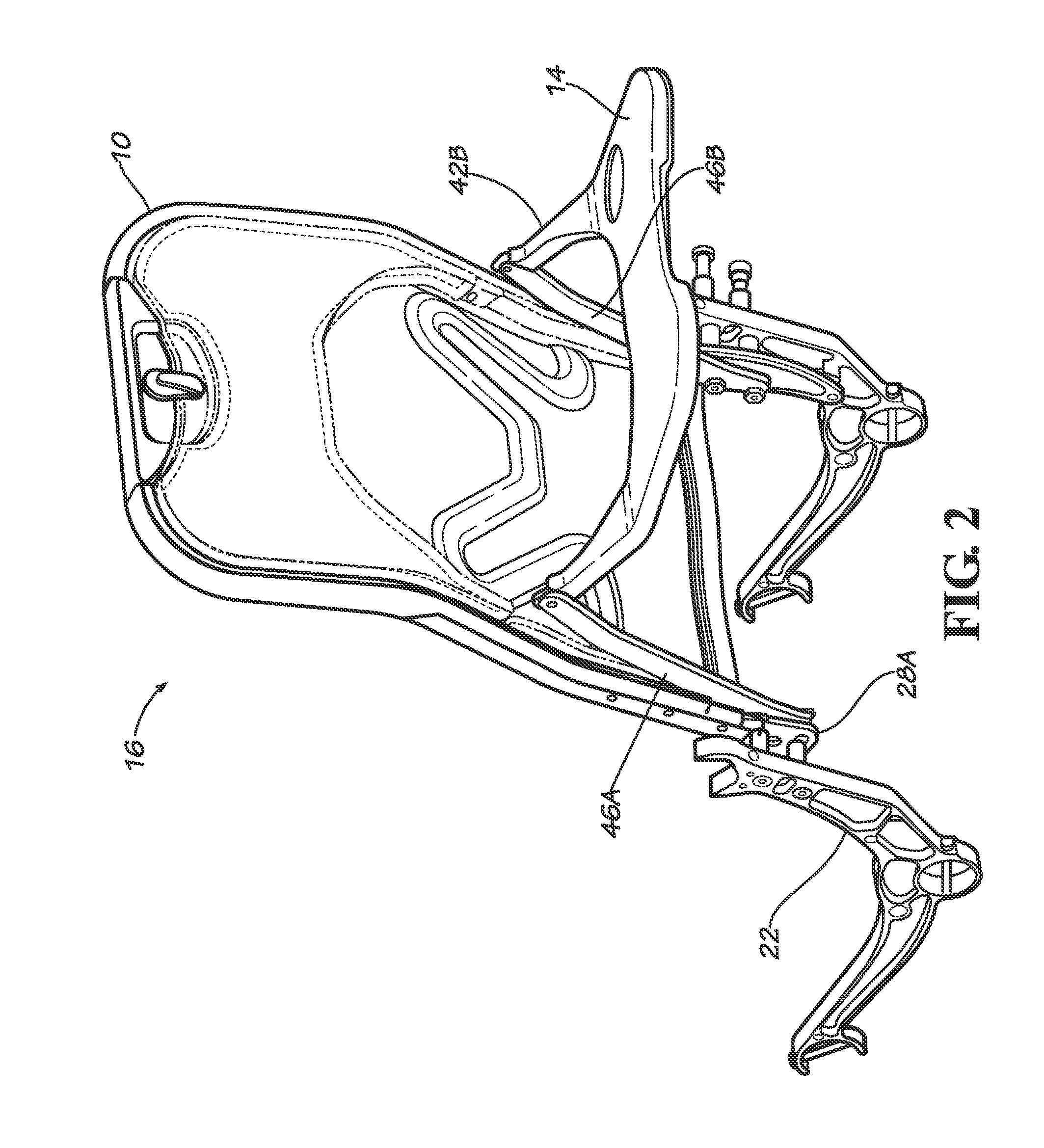

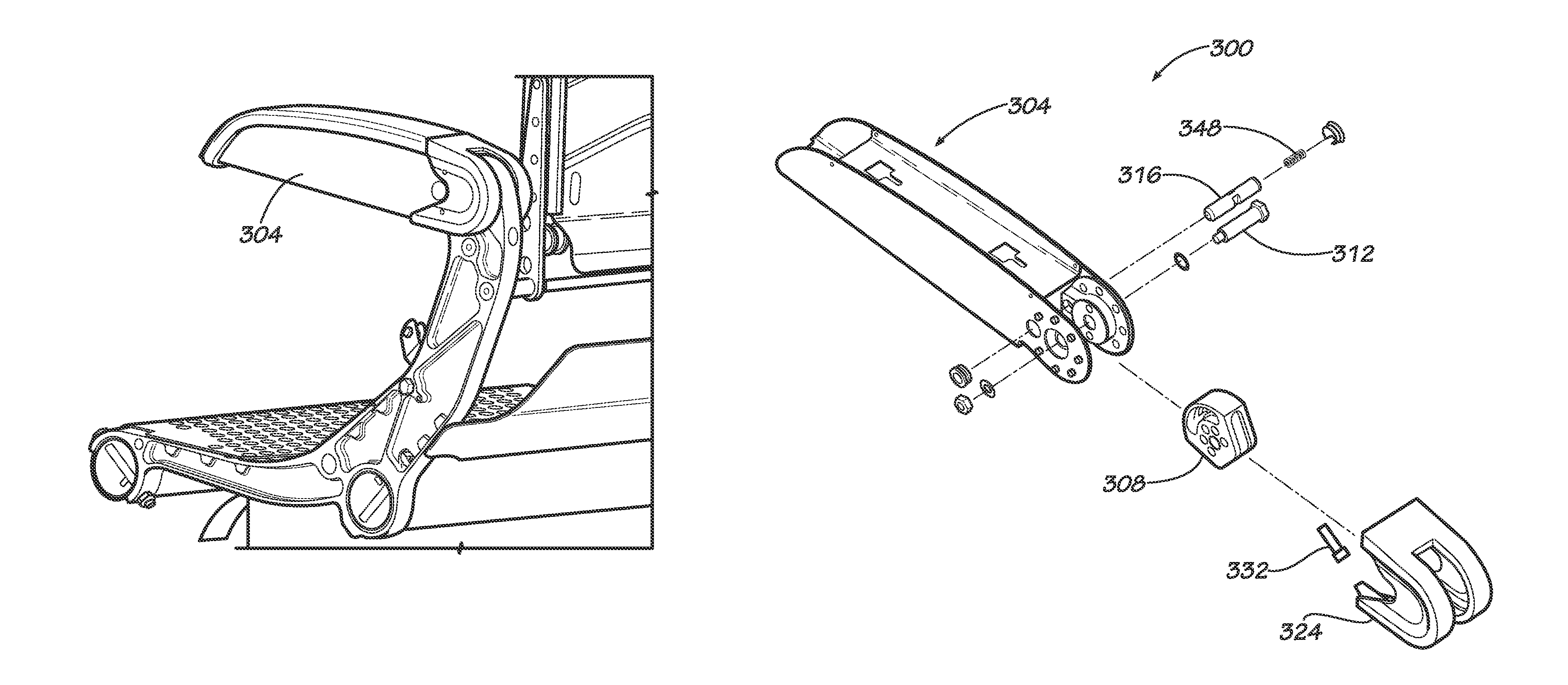

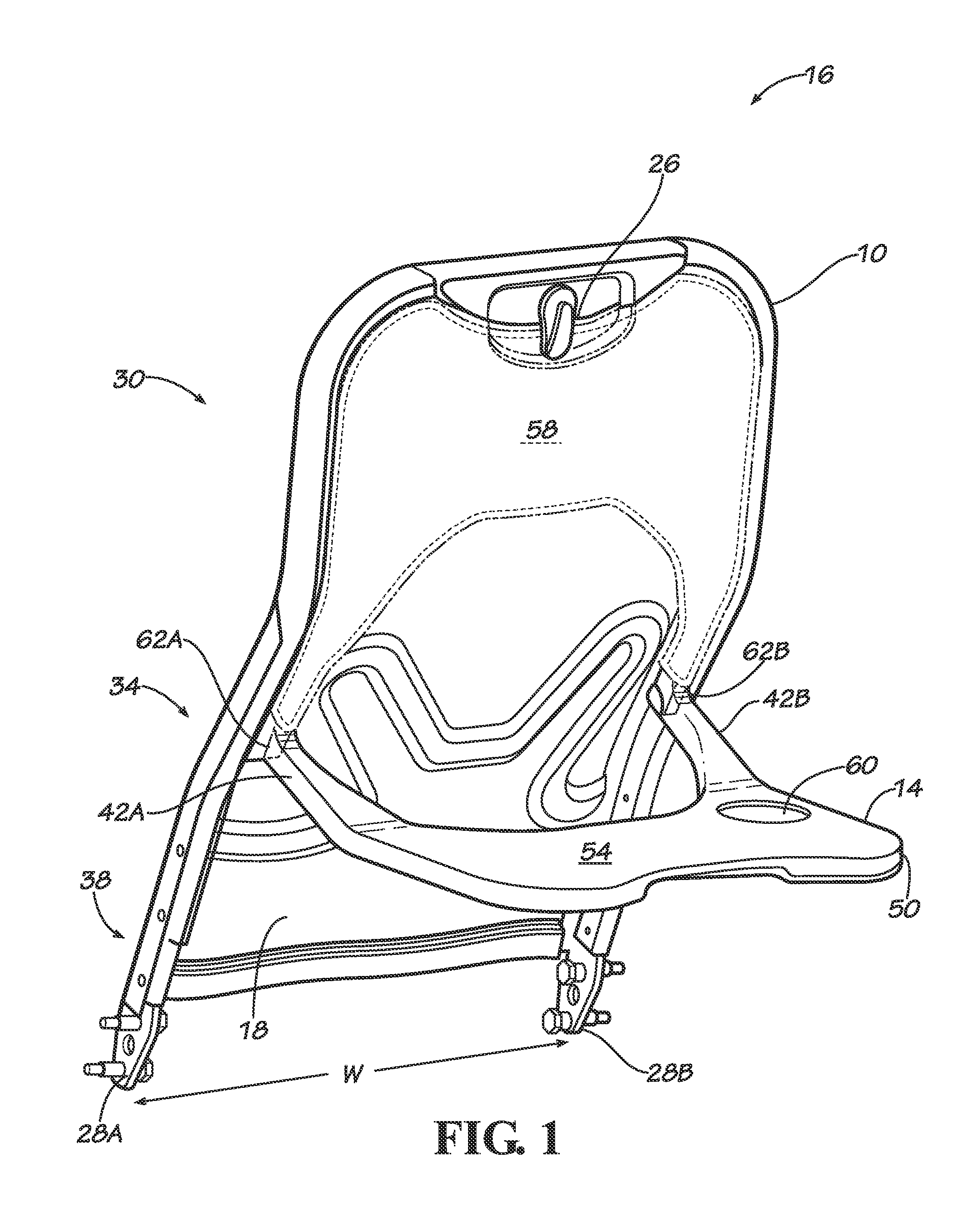

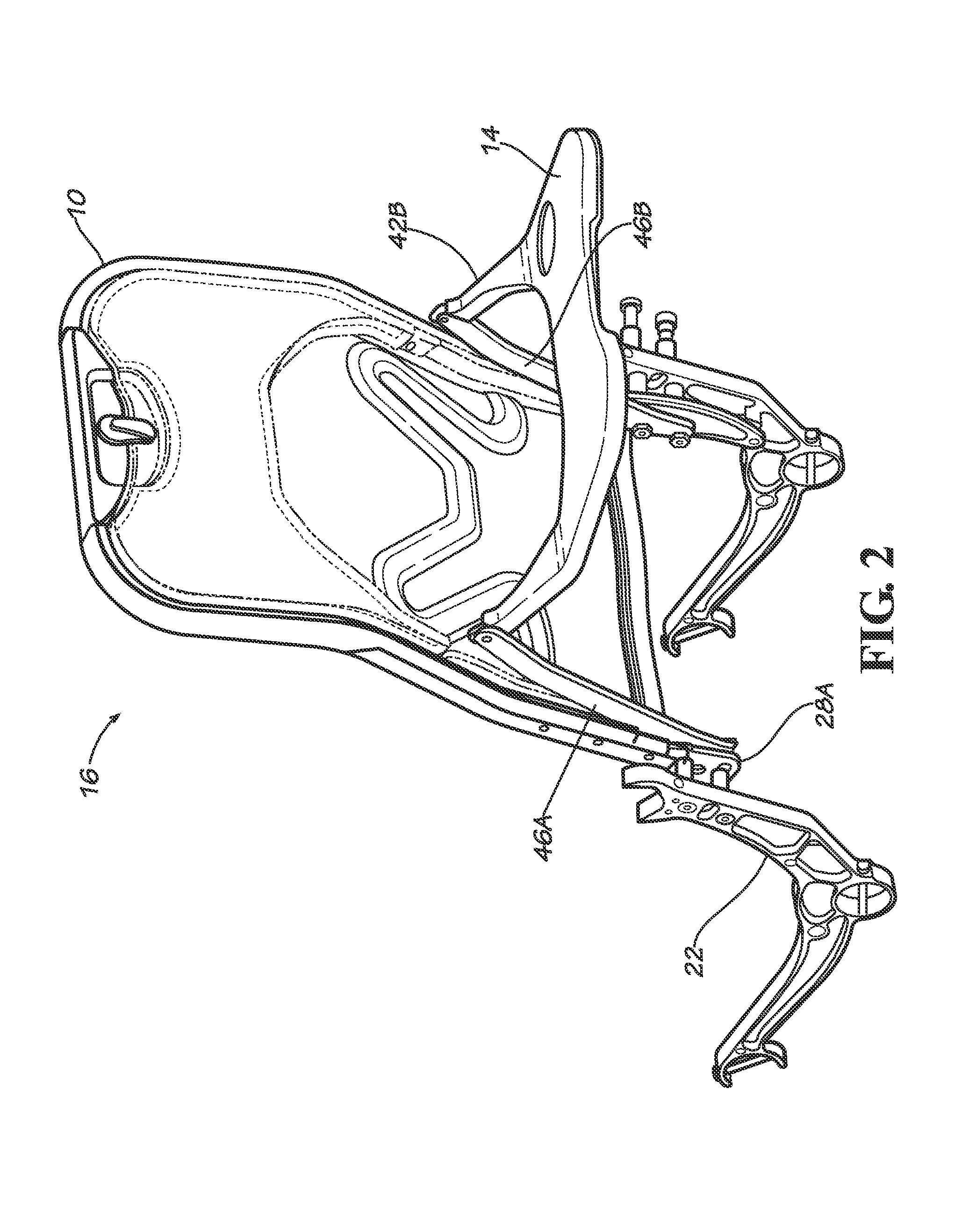

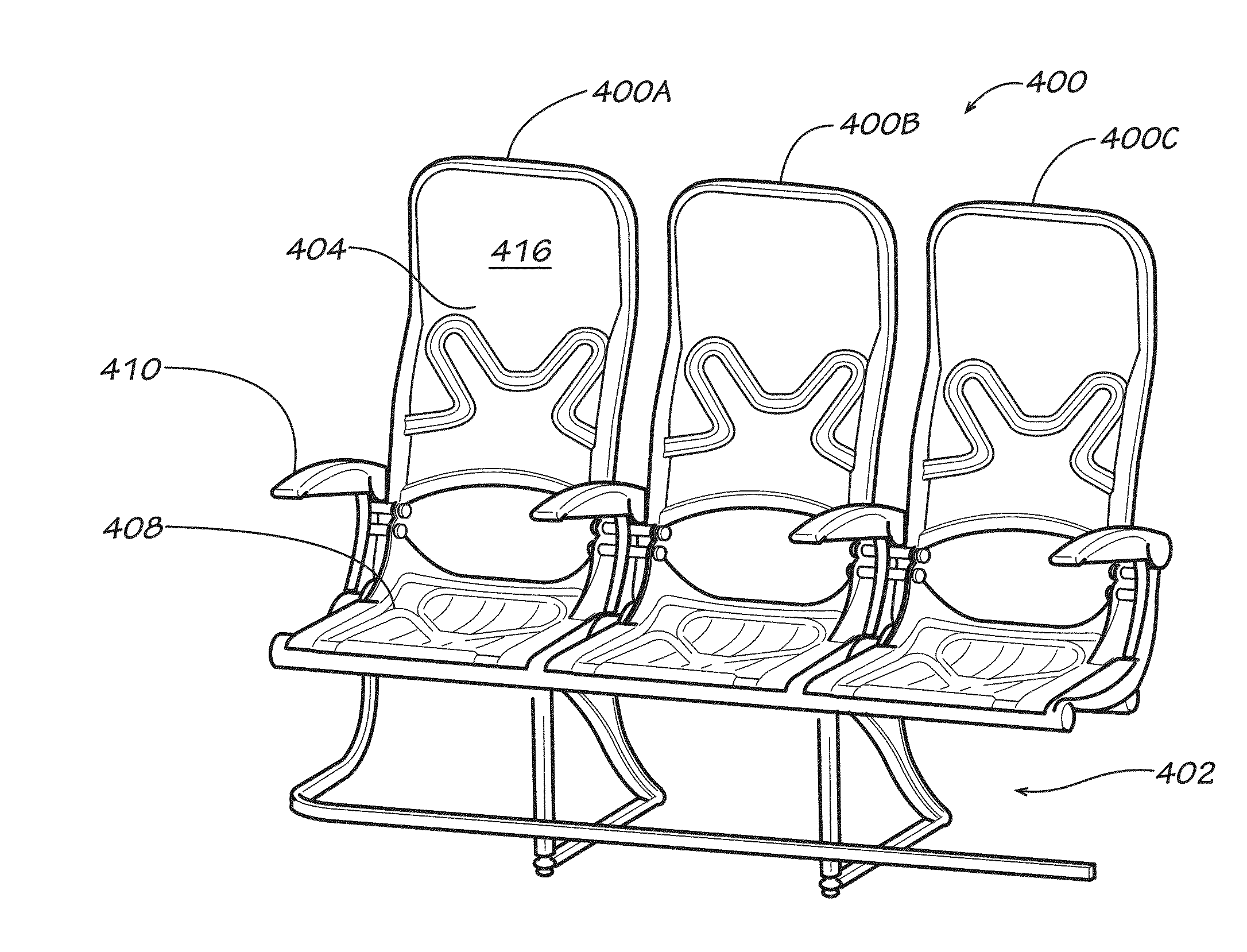

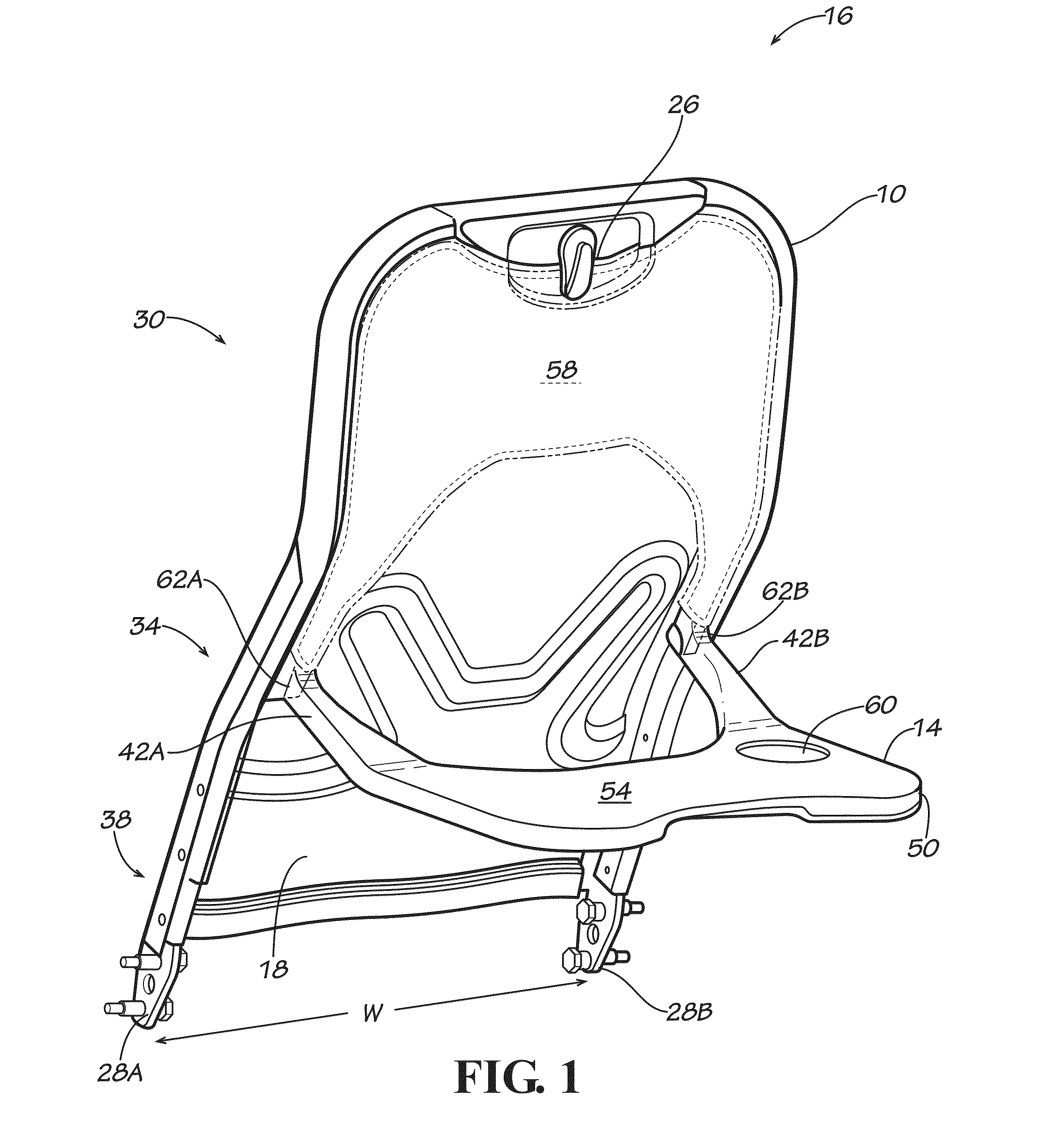

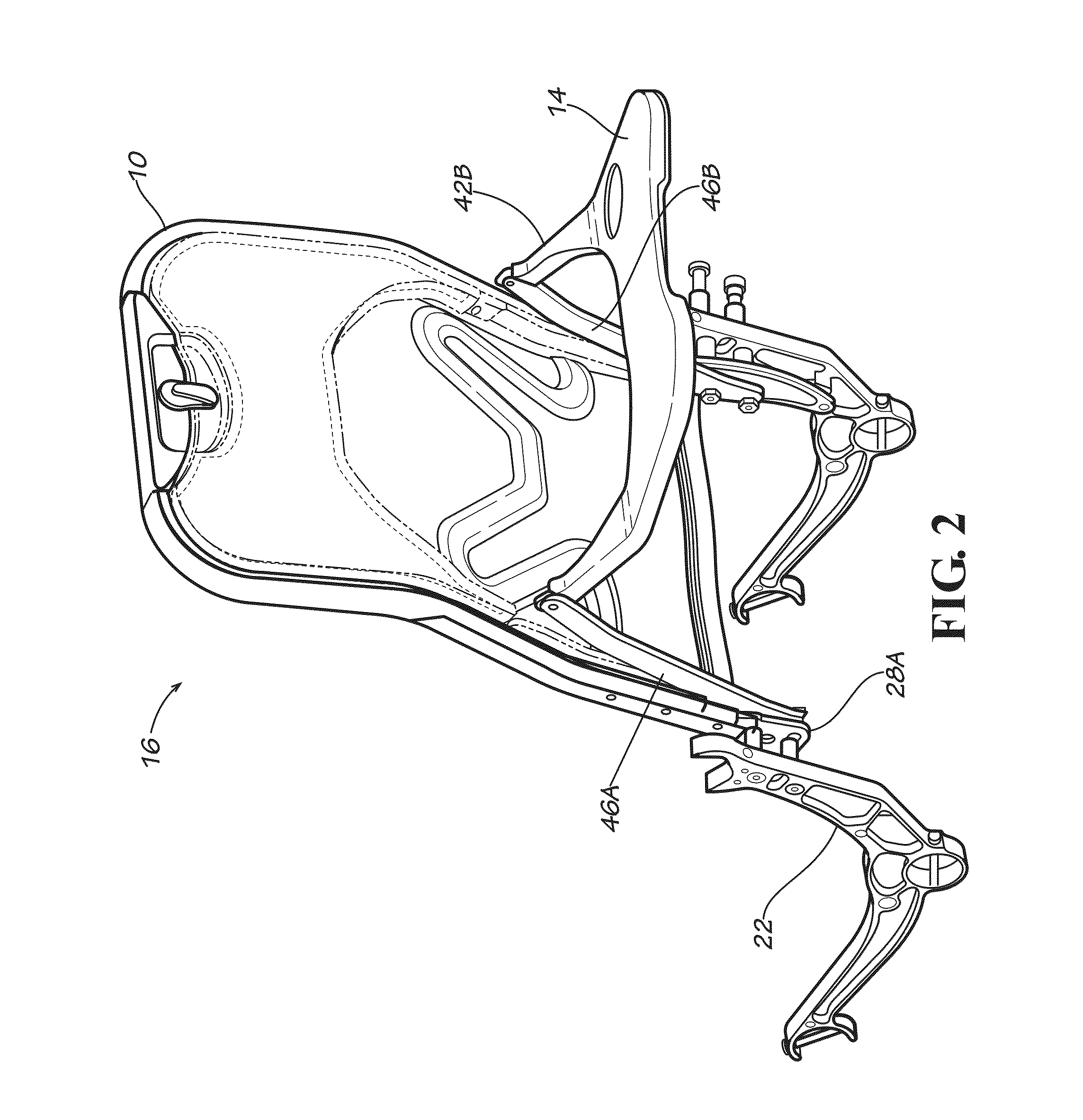

Passenger seating assemblies and aspects thereof

ActiveUS20120091764A1Improve pressure distributionPrevent reclineSeating arrangementsArm restsEngineeringMechanical engineering

Owner:SAFRAN SEATS

Passenger seating assemblies and aspects thereof

ActiveUS8931847B2Improve pressure distributionPrevent reclineSeating arrangementsArm restsEngineeringMechanical engineering

Owner:SAFRAN SEATS

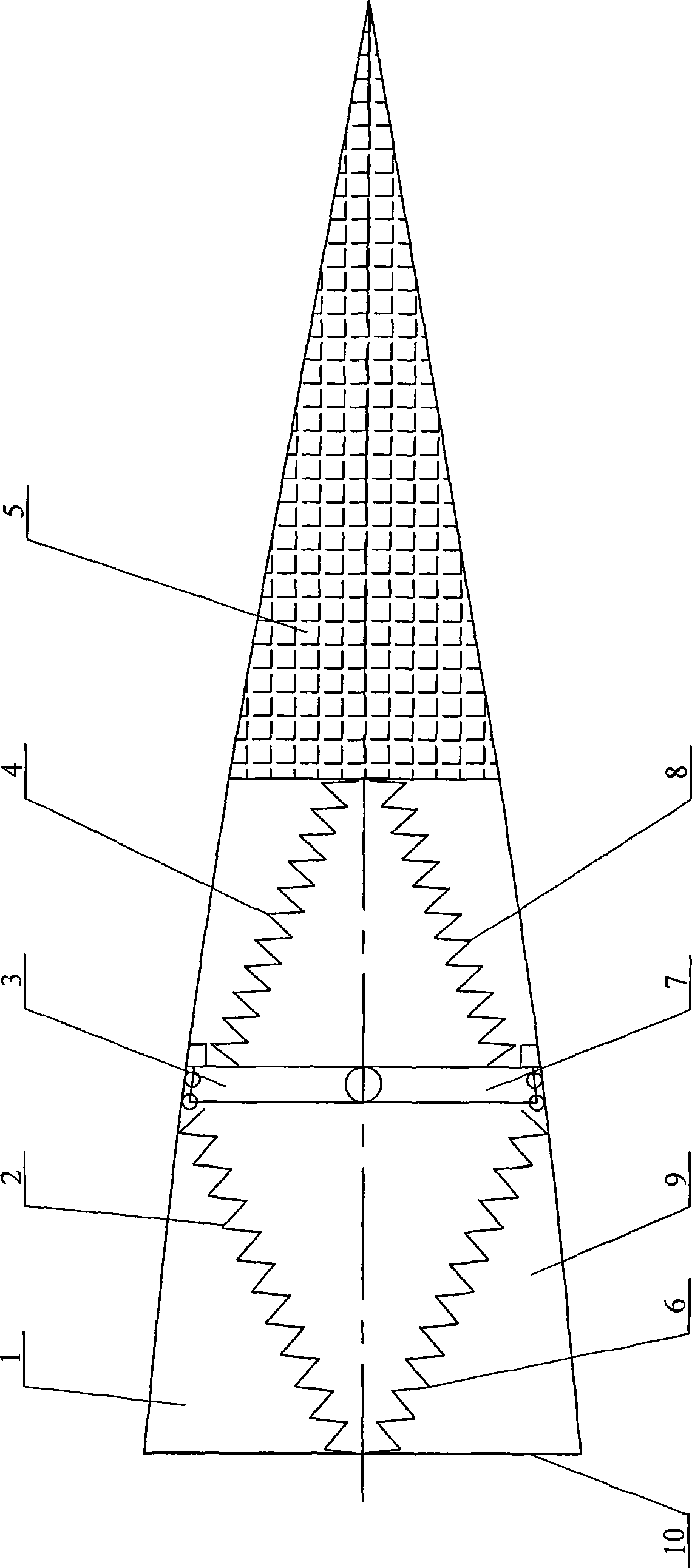

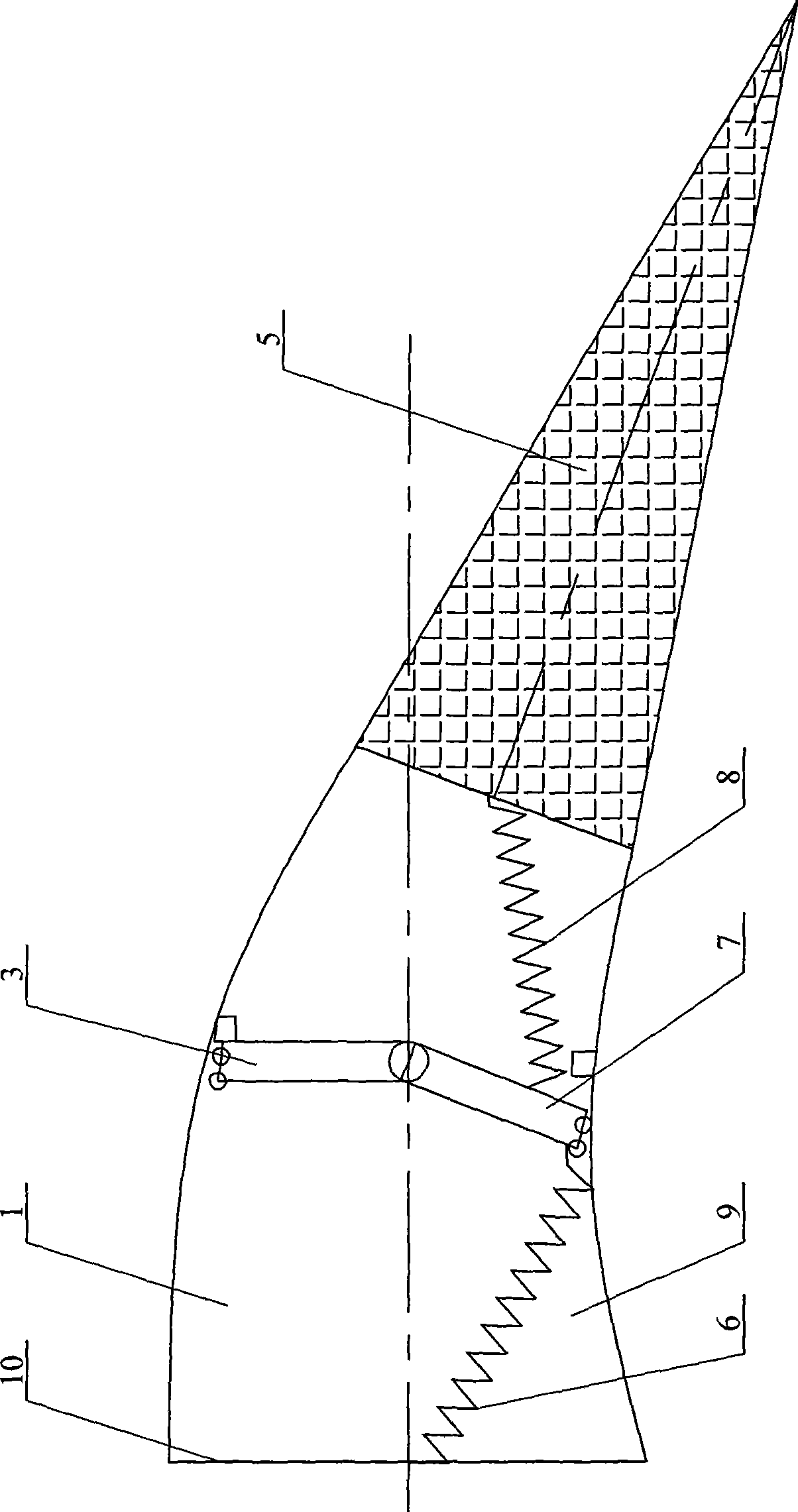

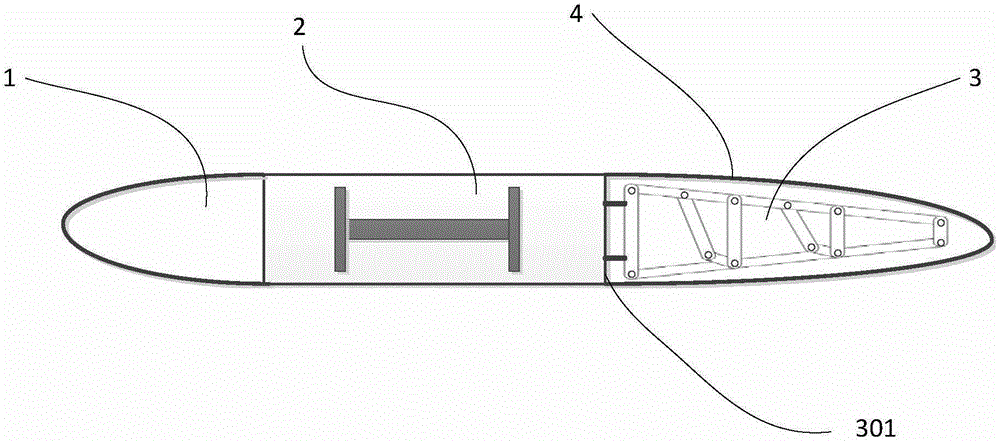

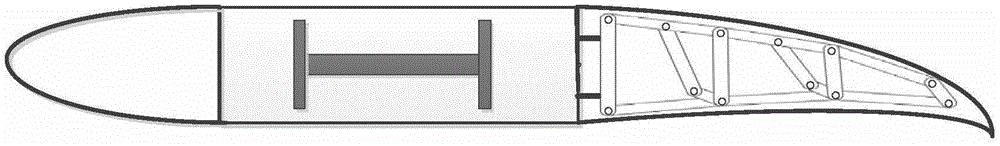

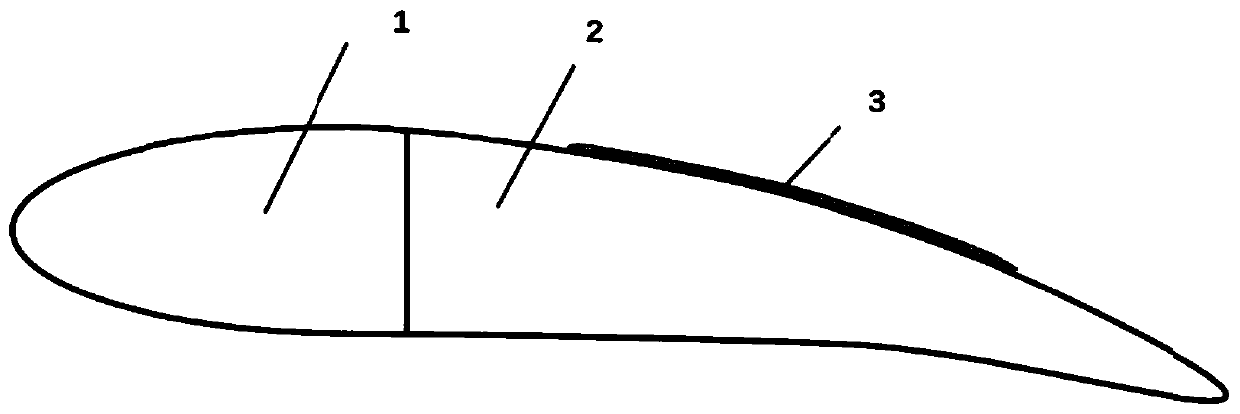

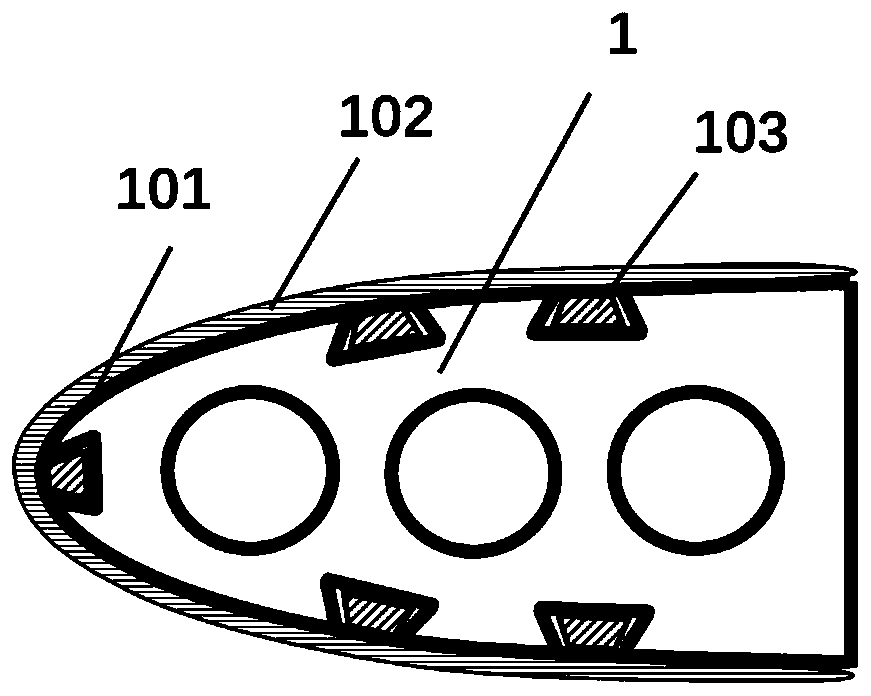

Shape memory spring driven hinder margin camber variable wing

InactiveCN101503113AImprove pressure distributionIncrease lift coefficientWing adjustmentsEngineeringMetal sheet

The invention provides a wing with changeable trailing edge camber driven by a shape memory spring, relating to a wing with a changeable trailing edge camber, and aiming at the problems of traditional airplanes that a mechanism is complex and heavy, airflow breakaway is quite early and aerodynamic efficiency is low. The front end face and the back end face of an upper metal plate are fixedly connected with the front end faces of a connecting plate and the trailing edge; the front end face and the back end face of the lower metal plate are fixedly connected with the front end face of the connecting plate and the trailing edge; the same side surface of the upper metal plate and the lower metal plate are fixed with an upper prop stay and a lower prop stay; the two ends of a first shape memory spring are fixedly connected with a fixed plate and the upper metal plate; the two ends of a second shape memory spring are fixedly connected with the front end faces of the upper prop stay and the trailing edge; the two ends of a third shape memory spring are fixedly connected with the fixed plate and the lower metal plate; and the two ends of a fourth shape memory spring are fixedly connected with the front end faces of the lower prop stay and the trailing edge. The invention has the advantages of light weight, simple structure and high aerodynamic efficiency.

Owner:HARBIN INST OF TECH

Heat pipe sealing structure, and its pressing method and special mould

InactiveCN1891374AImprove the pressing strengthImprove pressure distributionShaping toolsIndirect heat exchangersStress concentrationHeat conducting

This invention relates to a sealing and stitching method for heat conducting pipes including: providing a die with a first and a second moulds and at least a surface of one is processed with die stamping to form multiple convexes and concaves, putting the open-end of a heat conduction pipe between the two moulds to apply pressure onto the open-end to close it simultaneously when passing through the concaves and convexes and let the extruded metal of the pipe extend to the multiple concaves and convexes to form an embossing closing part at the open-end, the embossing part is set on the special die and the sealing structure.

Owner:郑坚地

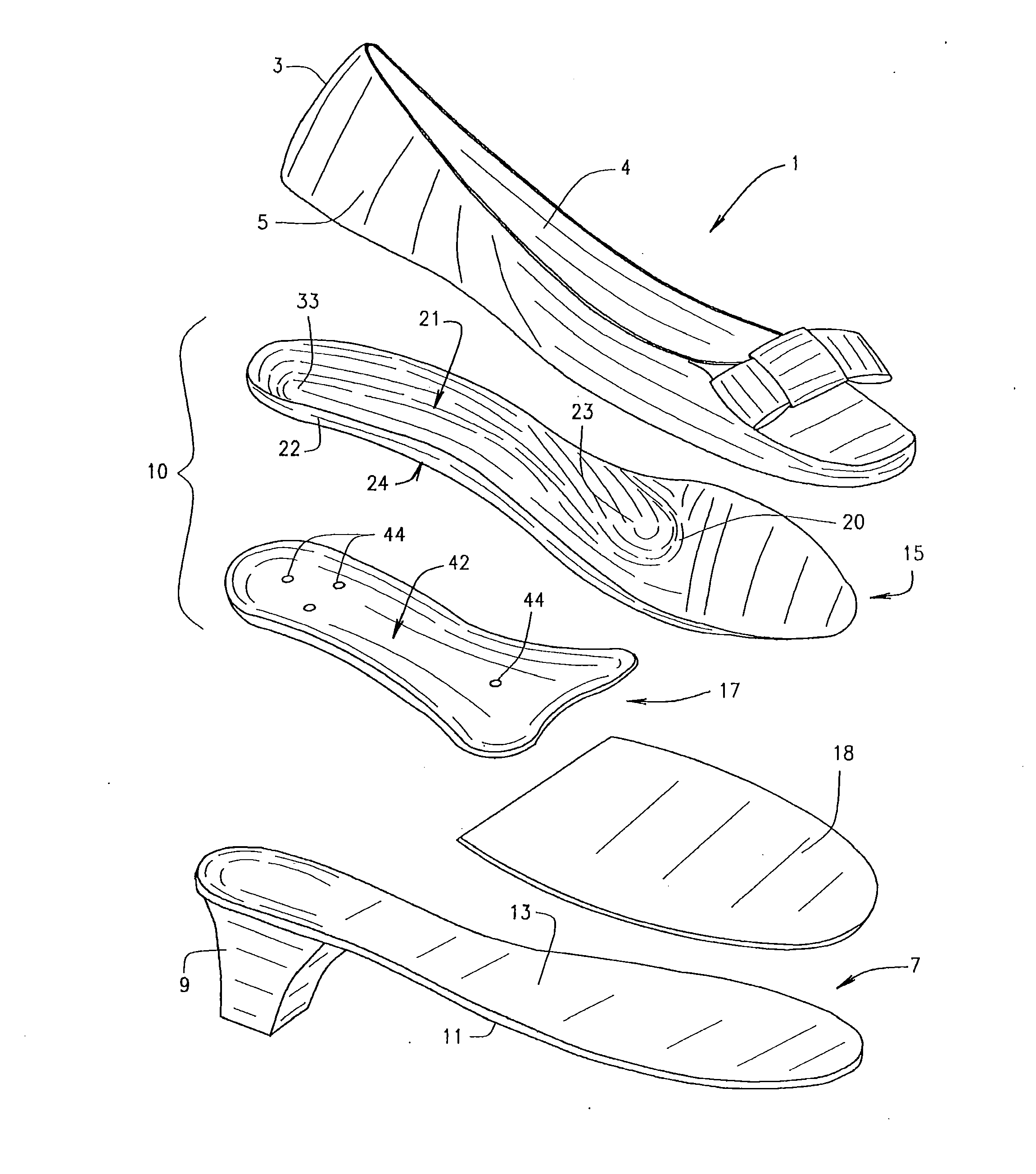

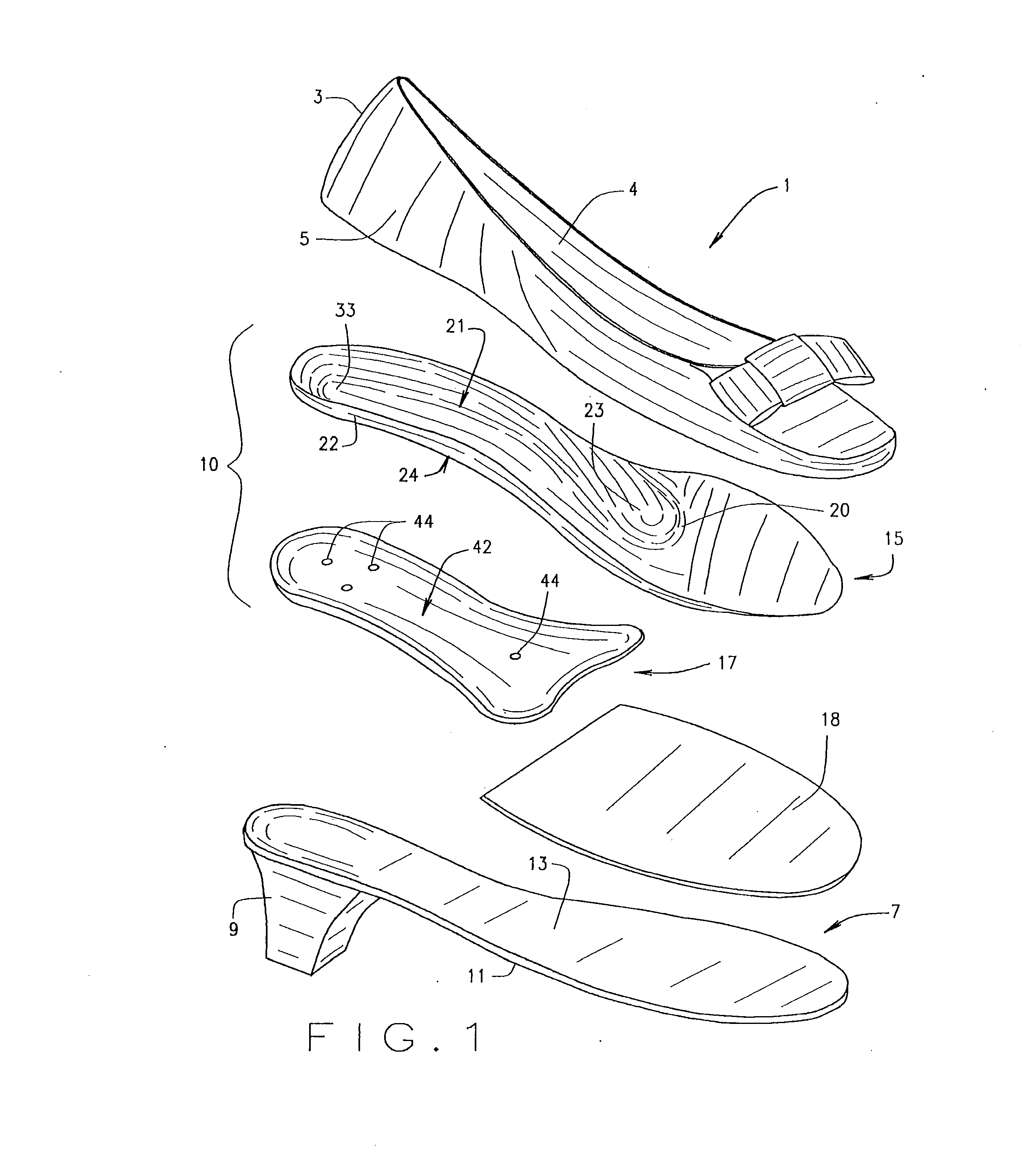

Anatomical shoe insert assembly

InactiveUS20120047767A1Effectively locks in anatomical shape within shoeAvoid inconsistenciesSolesInsolesEngineeringMechanical engineering

A shoe construction including a shoe upper, an intermediate insert assembly and at least an outsole, the insert assembly including a sockliner having a raised area positioned to underlie an arch of a wearer's foot and a recessed area positioned to underlie a heel of a wearer's foot, and a relatively rigid board member having recessed areas underlying the sockliner in the heel and arch areas.

Owner:BROWN SHOE

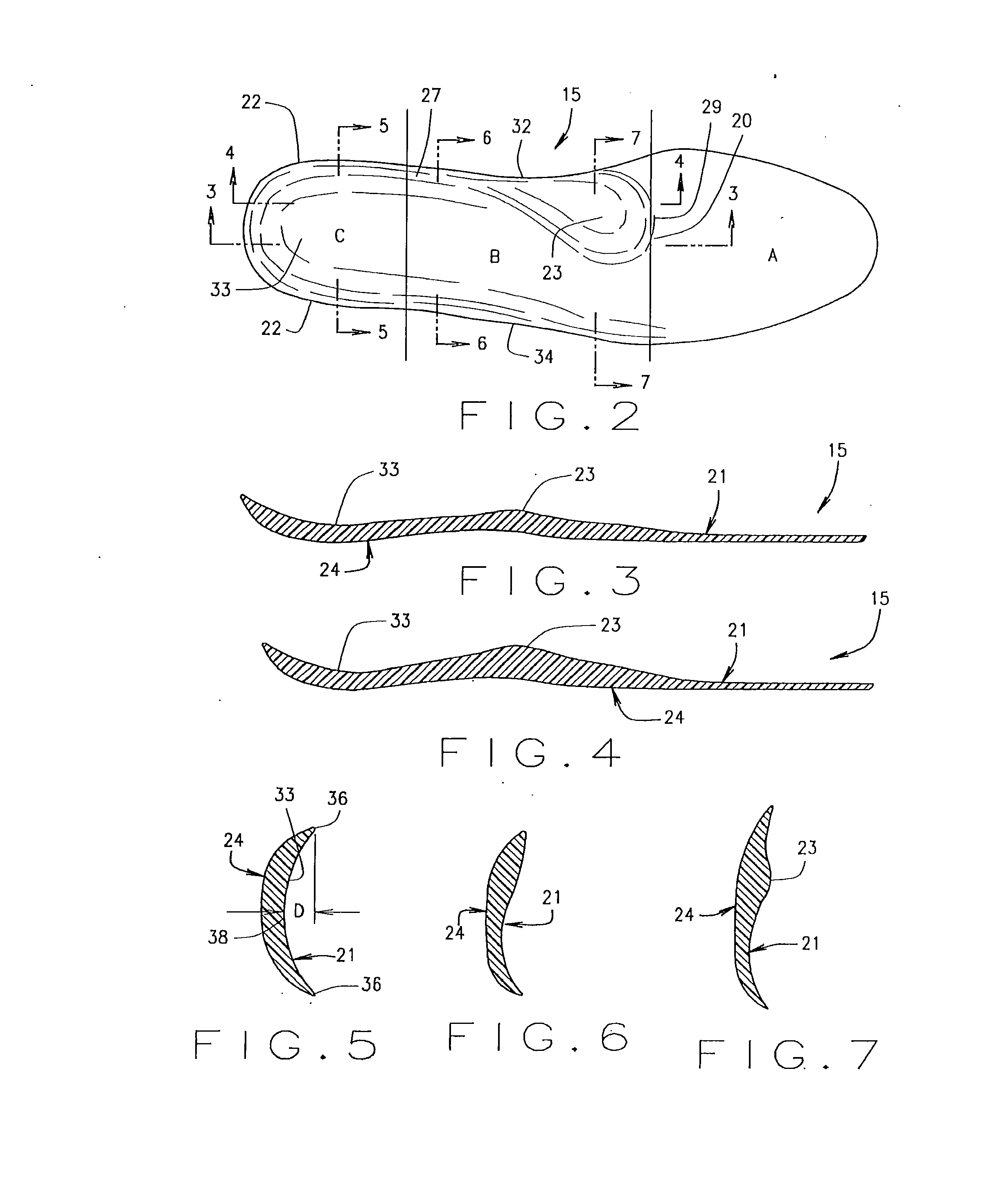

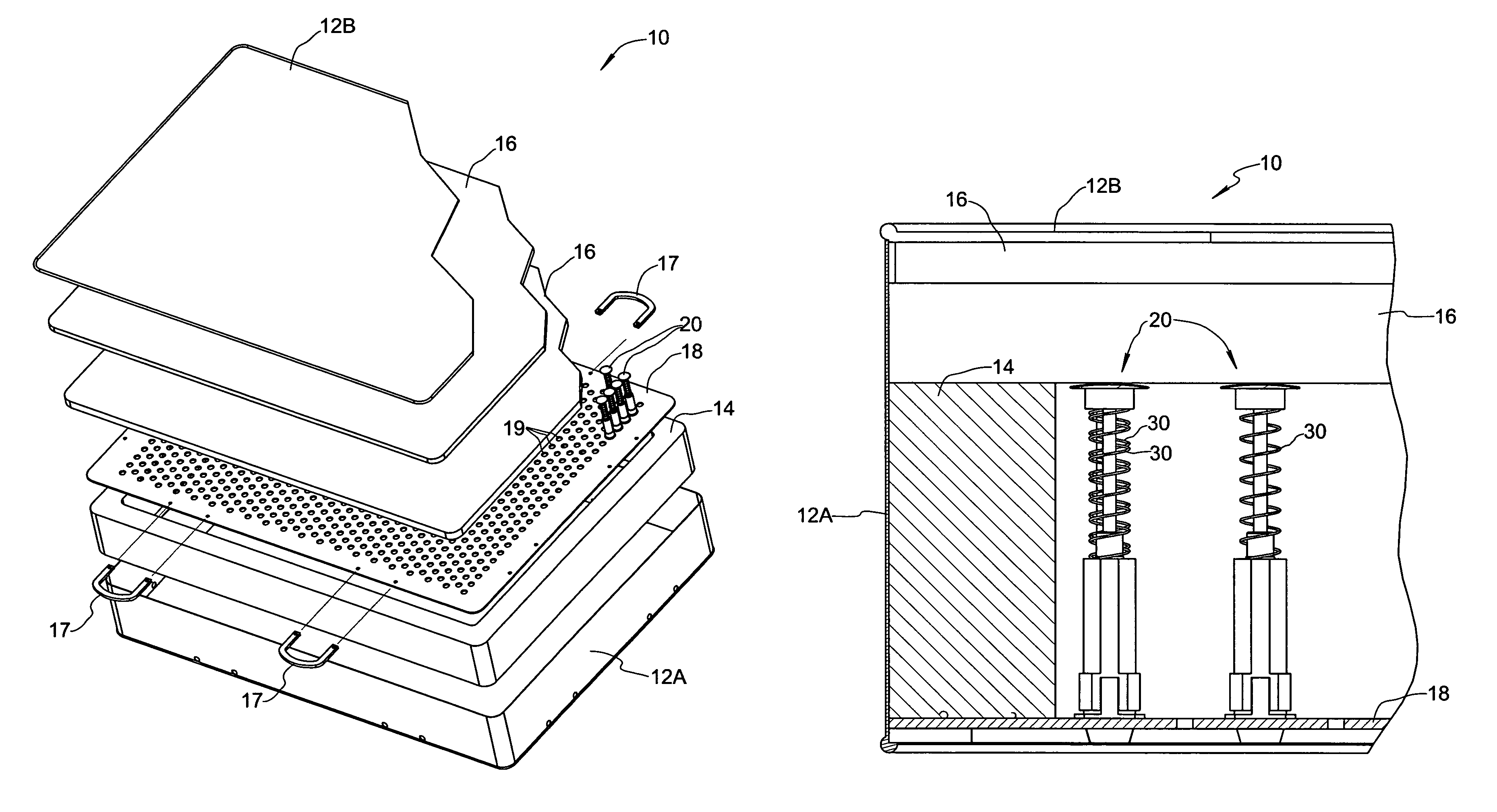

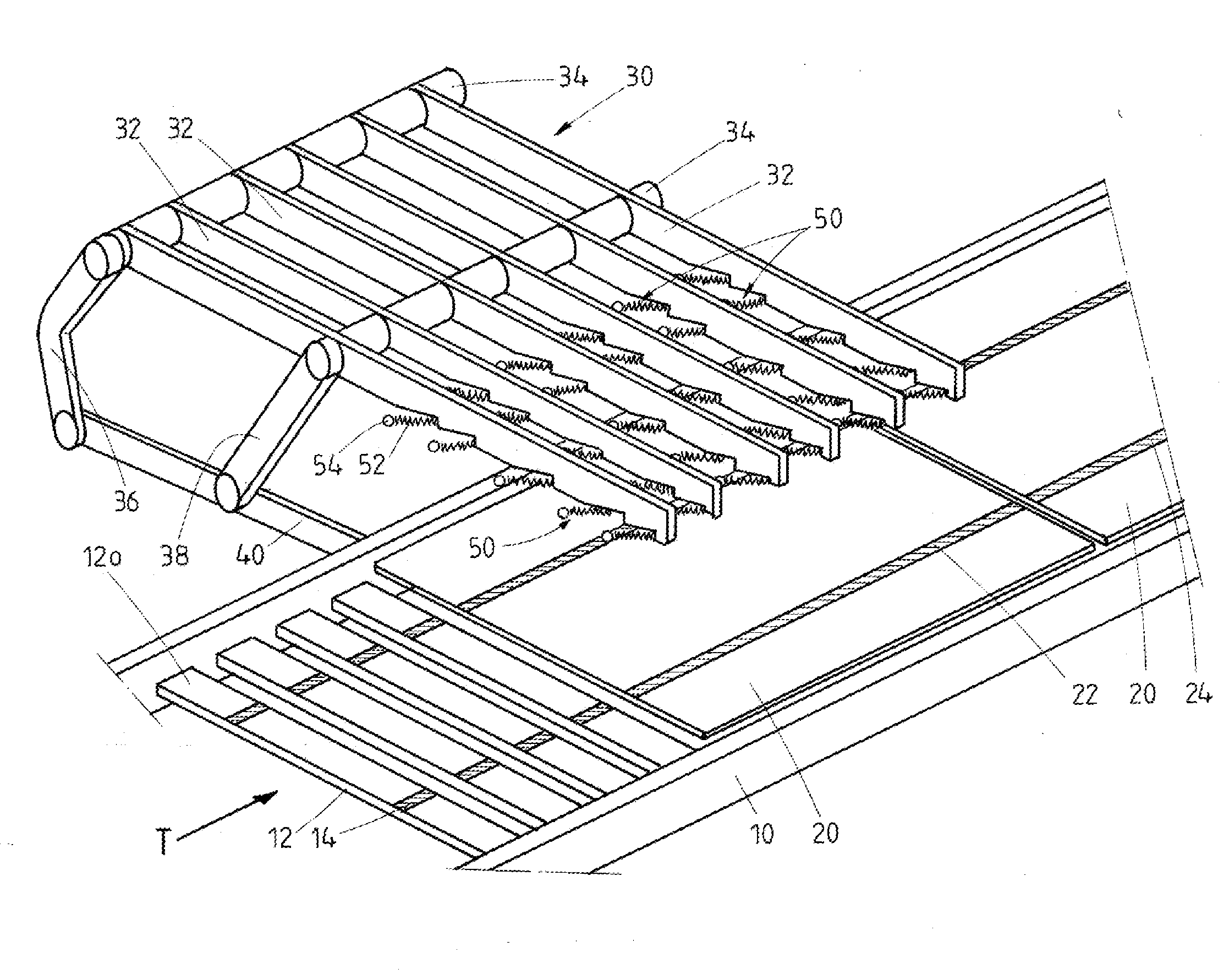

Mattress structure

ActiveUS6996865B2Improve pressure distributionBetter conformsStuffed mattressesMultiple spring combinationsEngineeringBellows

A mattress comprises a support plate having a plurality of mounting holes, a plurality of independent spring assemblies individually mounted to the support plate, and a cover enclosing the support plate and the plurality of spring assemblies. Each of the spring assemblies includes a tubular mounting member fixed to the support plate preferably by snap-fit through a mounting hole in the support plate, a sliding cap axially movable relative to the mounting member, and a spring acting between the mounting member and the sliding cap, wherein the spring is axially compressible when the sliding cap is forced in an axial direction toward the support plate. A spacer of chosen length can be provided to set preload on the spring. In a “flippable” embodiment, the mounting member includes a mid-portion snap-fitted to the support plate and upper and lower portions each having a sliding cap associated therewith, wherein the spring acts between the two sliding caps. In yet another embodiment, the sliding cap is replaced by a bellows attached to the mounting member.

Owner:SABIN JEFFREY M

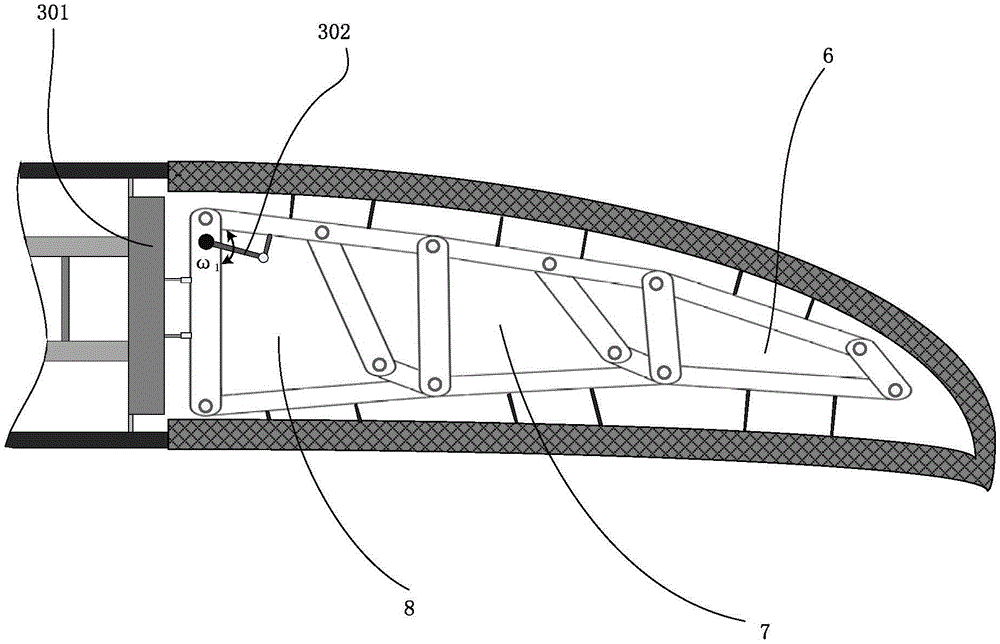

Complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units

ActiveCN106275388AImprove pressure distributionImprove aerodynamic characteristicsWing adjustmentsControl systemClosed loop

The invention provides a complex-hinge transformable trailing edge mechanism based on planar linkage closed-loop units. The complex-hinge transformable trailing edge mechanism comprises at least three closed-loop linkage units and a drive mechanism. Each closed-loop linkage unit is a planar linkage structure based on a 6R closed-loop unit and has one freedom degree. The closed-loop linkage units include a tail-end unit, at least one middle unit and a starting-end unit which are parallelly arranged, and the middle units are arranged between the starting-end unit and the tail-end unit. Compared with the prior art, the complex-hinge transformable trailing edge mechanism has the advantages that the basic units of the complex-hinge transformable trailing edge mechanism are independent 6R closed-loop units, the units influence on another, and the output of the previous unit is the input of the next unit; the whole mechanism contains few linkages and is lightweight; the freedom degree of the whole mechanism is 1, the mechanism can be driven by only one drive motor, the weight of the mechanism is reduced, system control difficulty is lowered, and the gradual bending effect of a transformable wing is good due to the fact that multiple basic unit modules are used.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

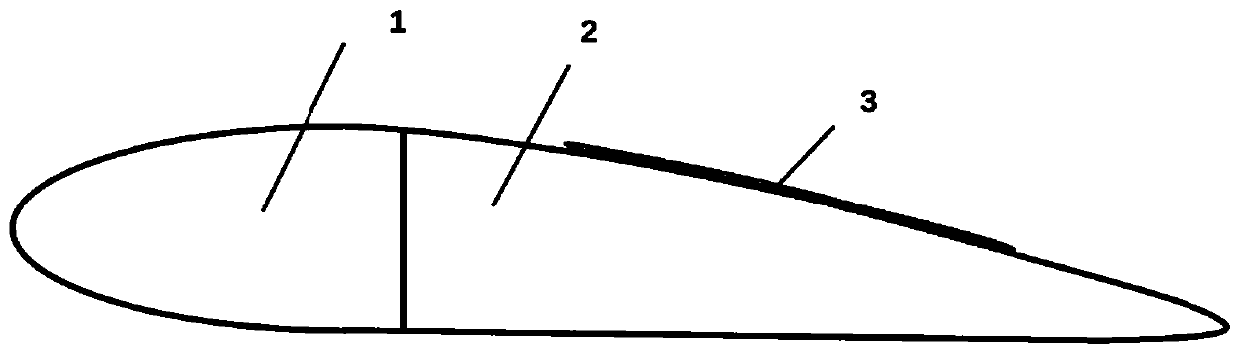

Trailing edge variable camber wing driven by piezoelectric fiber materials

ActiveCN111232186AImproved stall characteristicsReduce structural weightWing adjustmentsFiberLeading edge

The invention provides a trailing edge variable camber wing driven by piezoelectric fiber materials. The wing comprises a leading edge fixing section with the invariable camber, a trailing edge flexible deformation section with the variable camber and a piezoelectric fiber composite material driver used for adjusting the change degree of the trailing edge flexible deformation section. The trailingedge flexible deformation section comprises a flexible wing rib, a stringer, a deformation skin, a segmented deformation skin and a segmented deformation skin fixing device. Voltage excitation is applied to the piezoelectric fiber composite material drivers, generated torque is transmitted to the flexible wing rib structure through the skin, and continuous and smooth change of the shape of the trailing edge of the wing is achieved. The wing structure mass can be greatly reduced, noise is reduced, the stealth characteristic is improved, the corresponding deformation control system is combined,accurate control over wing camber changes in the flight process can be achieved, the maneuvering and stall characteristics of an airplane are improved, and the task adaptability of the airplane is greatly enhanced.

Owner:DALIAN UNIV OF TECH

Composite sole assembly

A composite sole assembly for attachment to an outsole of suitable material, the sole assembly including a chassis, a forefoot pad and a heel pad. The chassis includes an opening for receiving the heel pad and further includes two peripheral flanges for securing attachment with the shoe upper. A cushioning forefoot pad is positioned between the chassis and the outsole and between the two peripheral flanges and is formed of a soft cushioned foam material. The top surface of the chassis and the heel pad define a raised area in the midfoot region and a recessed area in the heel region of the assembly to better conform to the anatomical shape of a wearer's foot. The combination of the raised and recessed areas along with the positioning of the heel and forefoot pads improves comfort and provides for a better distribution of foot pressure during a normal gait.

Owner:BROWN SHOE

Device for fixing conductor tracks on a solar cell

InactiveUS20110147437A1Shorten speedIncrease clock frequencyWelding/cutting auxillary devicesAuxillary welding devicesElectrical conductorElectrical battery

The invention concerns to a device for fixing conductor tracks on at least one first main-surface of at least one solar cell.

Owner:KIOTO PHOTOVOLTAICS

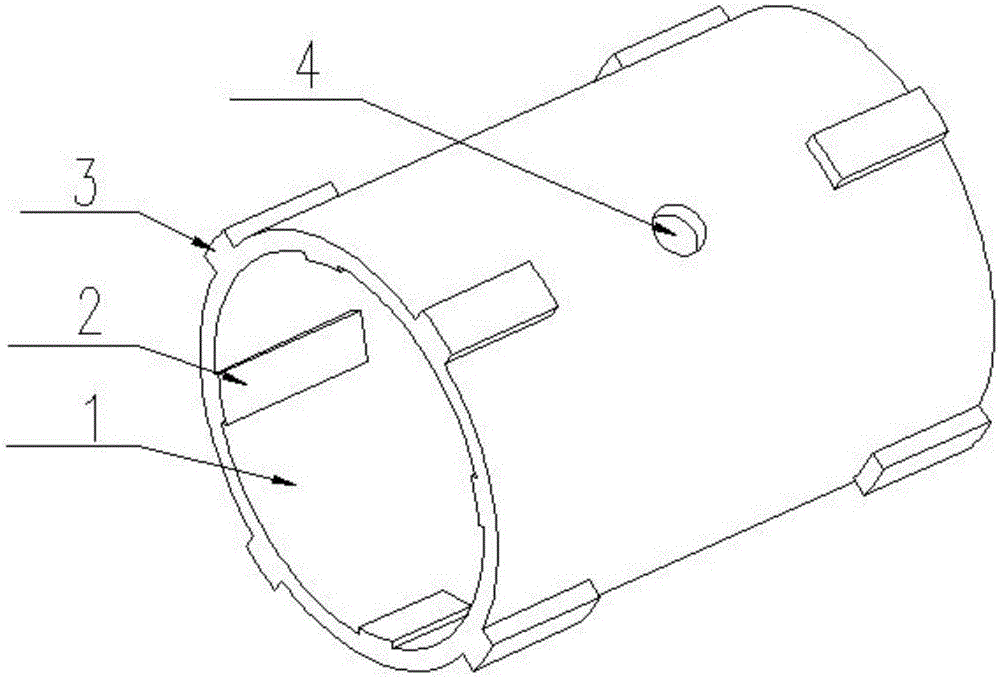

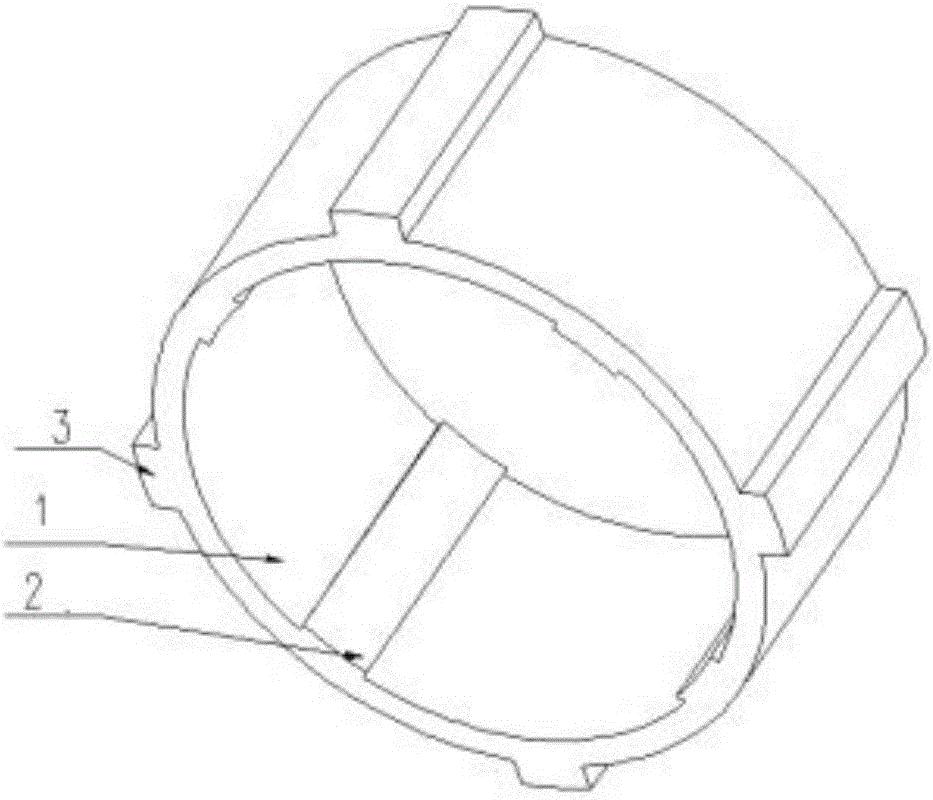

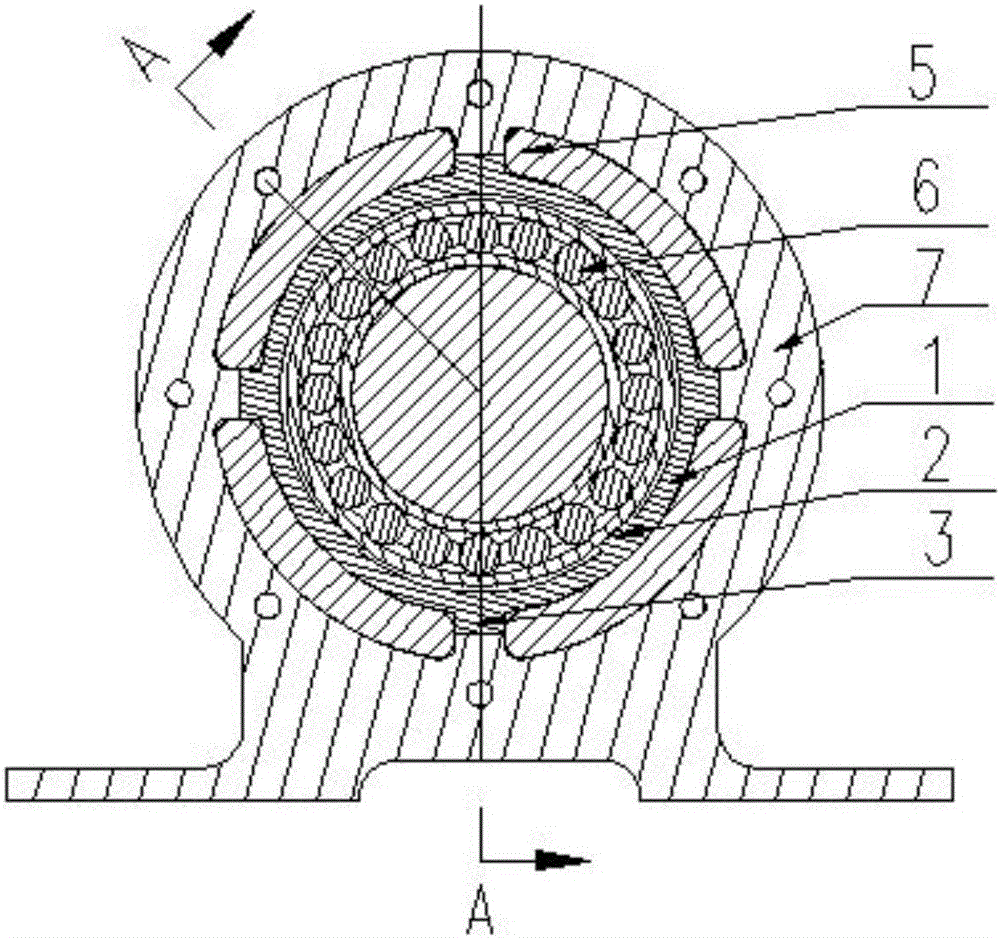

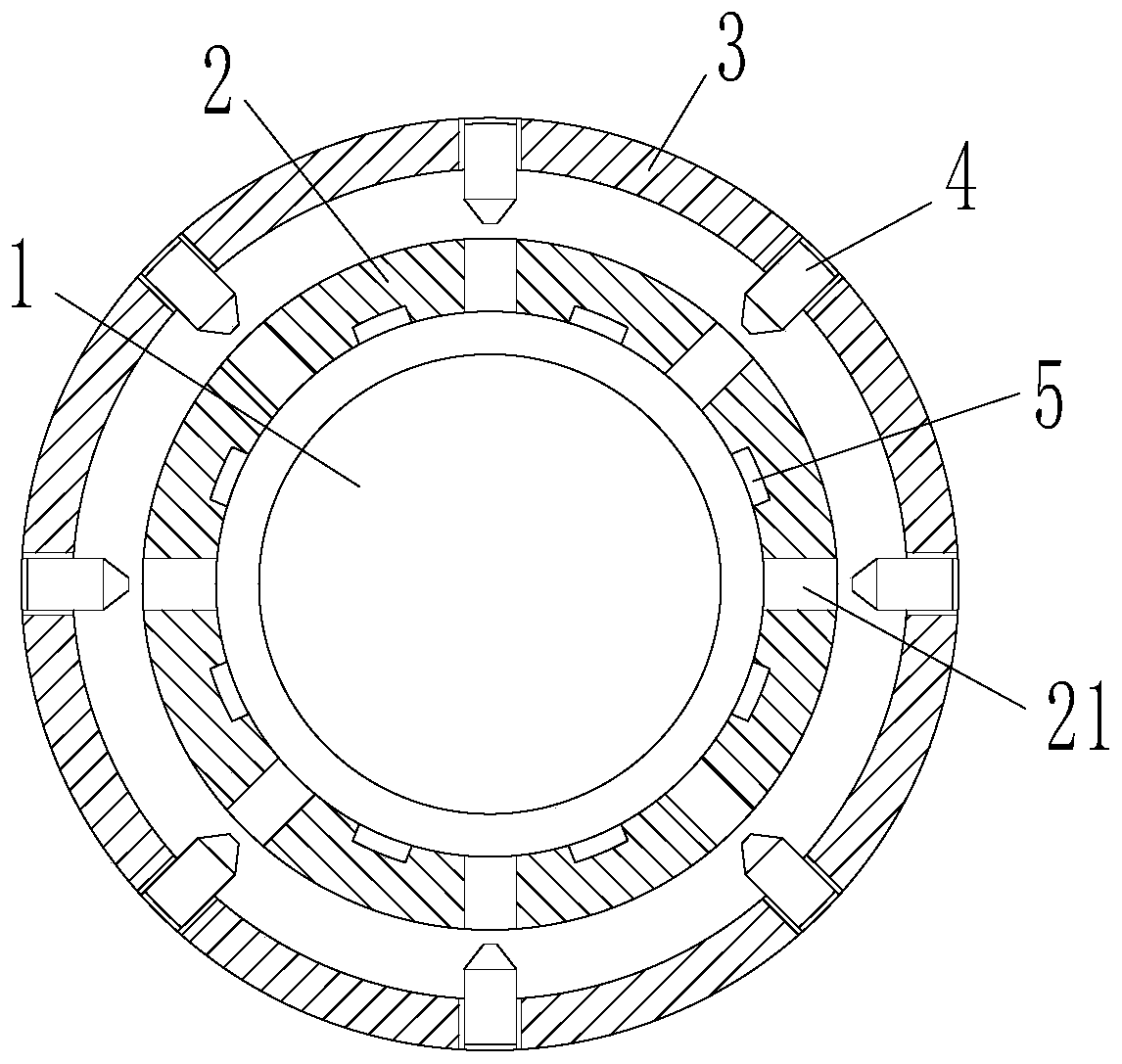

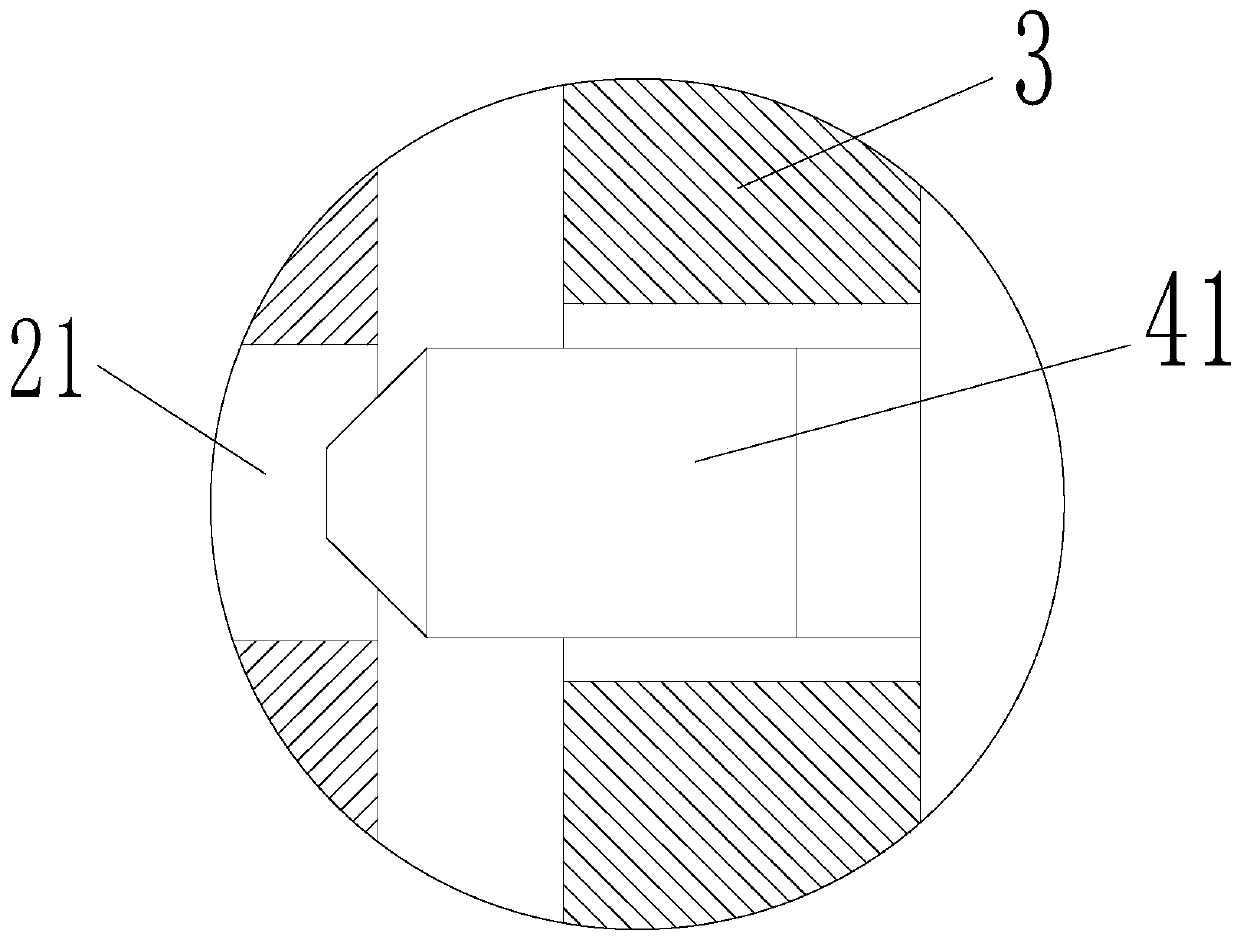

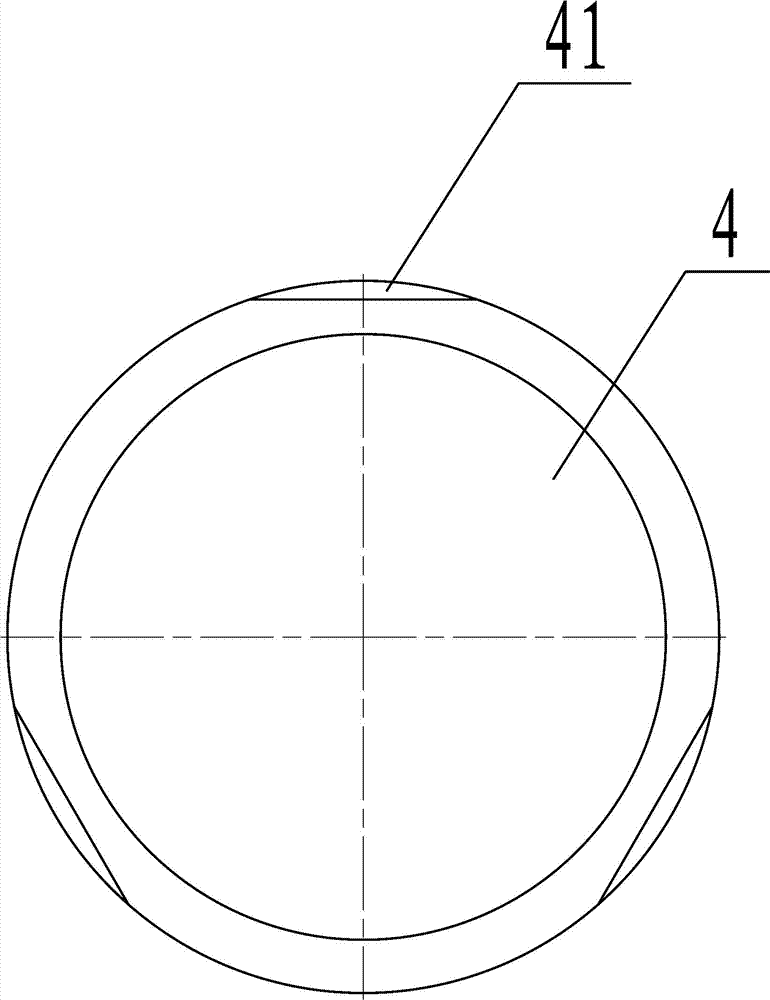

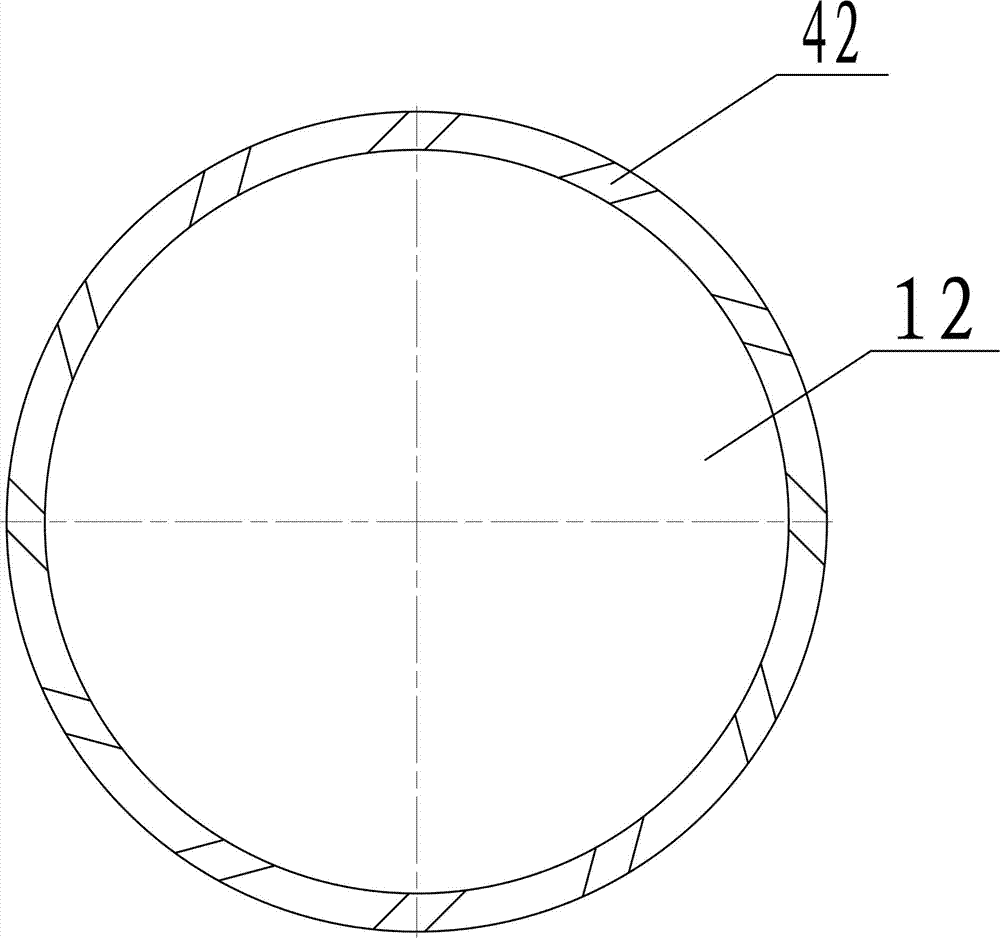

Elastic ring type damper with metal rubber

InactiveCN106286701AWith high and low temperature resistanceSolution to short lifeRotating vibration suppressionMetal rubberCoupling

An elastic ring type damper with metal rubber comprises an elastic ring connected to the outer side of rolling bearings, wherein the elastic ring adopts a thin-walled cylinder structure; inner convex plates and outer convex plates, which are regular rectangular bulges, are respectively arranged on the inner wall and the outer wall of the elastic ring, and are respectively uniformly distributed along the elastic ring in the circumferential direction; parts between every two outer convex plates are filled with metal rubber; the metal rubber is limited by the elastic ring, the outer convex plates, a casing and bearing flanges; the elastic ring is large in rigidity and less in damping; the metal rubber is small in rigidity and large in damping; the elastic ring and the metal rubber have a mutual coupling function. The damper can be used in a high-speed rotor system supported by the oil-air lubricated and oil-mist lubricated rolling bearings, can adjust the supporting rigidity of the system and inhibit the vibration of a rotor, and is simple in structure and easy to assemble.

Owner:XI AN JIAOTONG UNIV

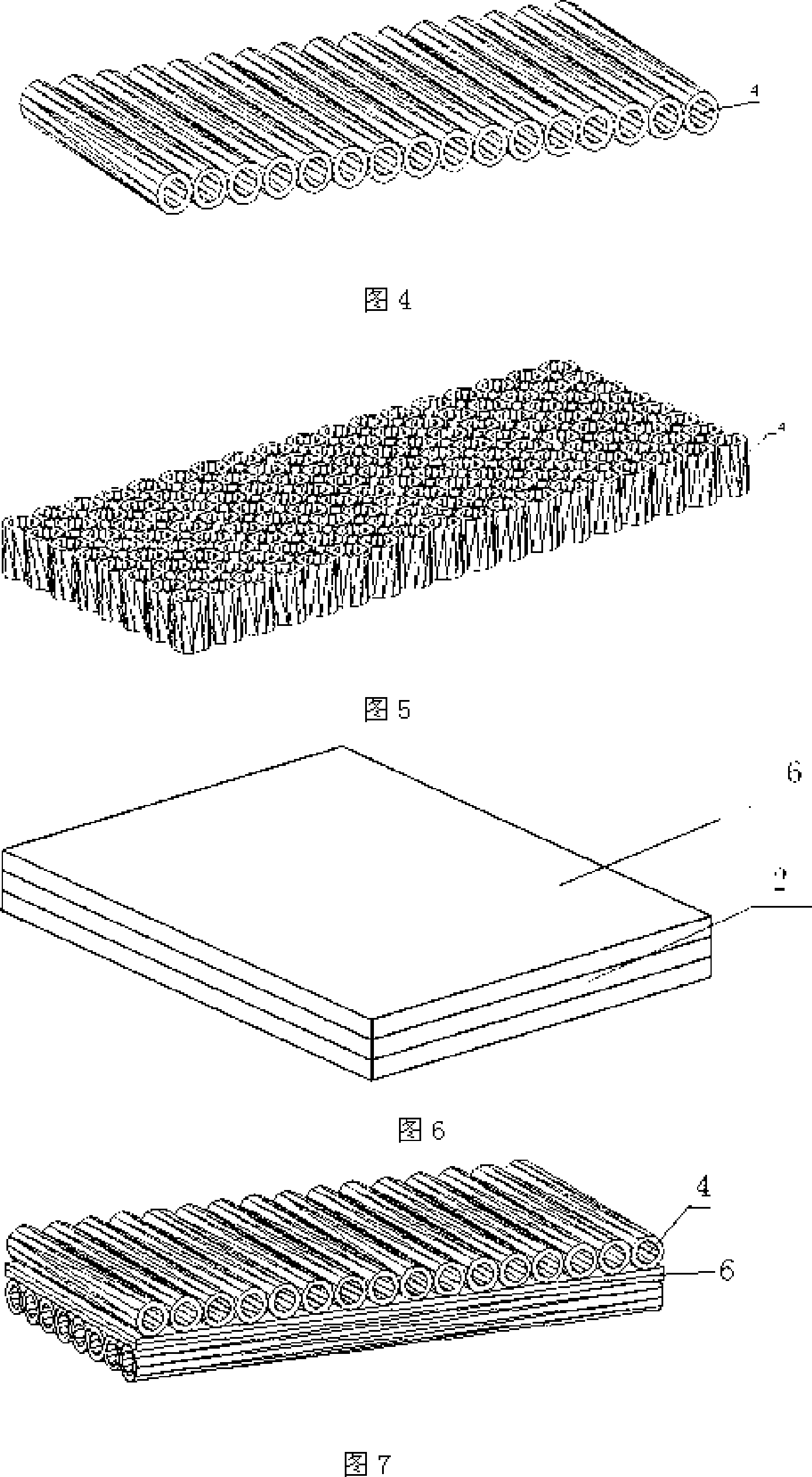

Plant-fiber elastic cushion and mfg. method

The invention discloses a plant fiber cushion and the preparation method which includes the fiber flexible sheet material which is made to the fiber flexible reel, then the reel is fixed together to form the flexible reel layer; then the flexible reel layer is fixed with the fiber flexible sheet material to sulfur forming. The advance of the invention is: the density of the invention has decreased by 15%-30% compared to the present plant fiber cushion and the amenity has improved such as: the human body pressure distribution is increases and the pressure is decreased to 10%-20%; the density is uniform without hollow or prominence on surface.

Owner:GUIZHOU DAZIRAN TECH

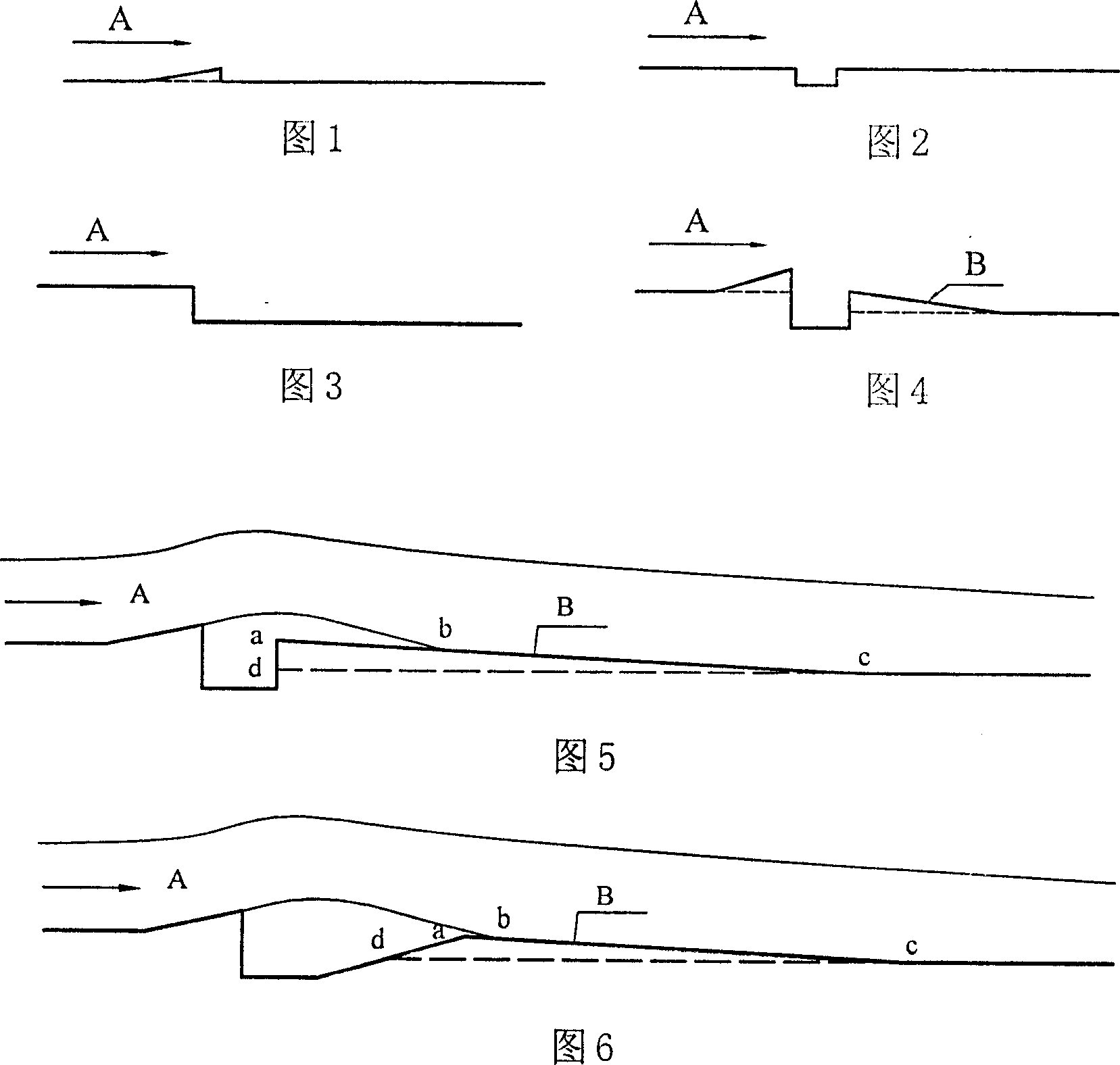

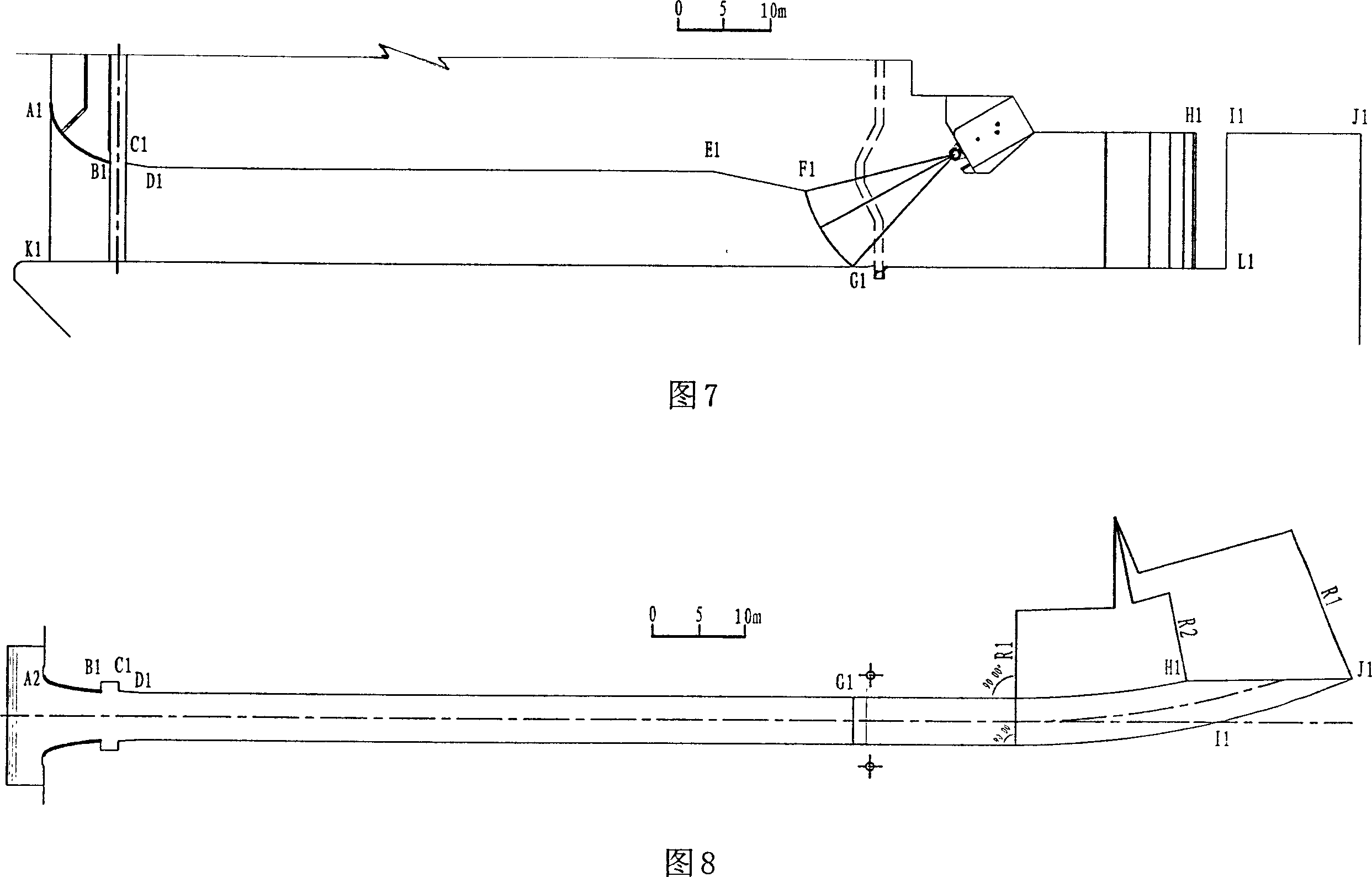

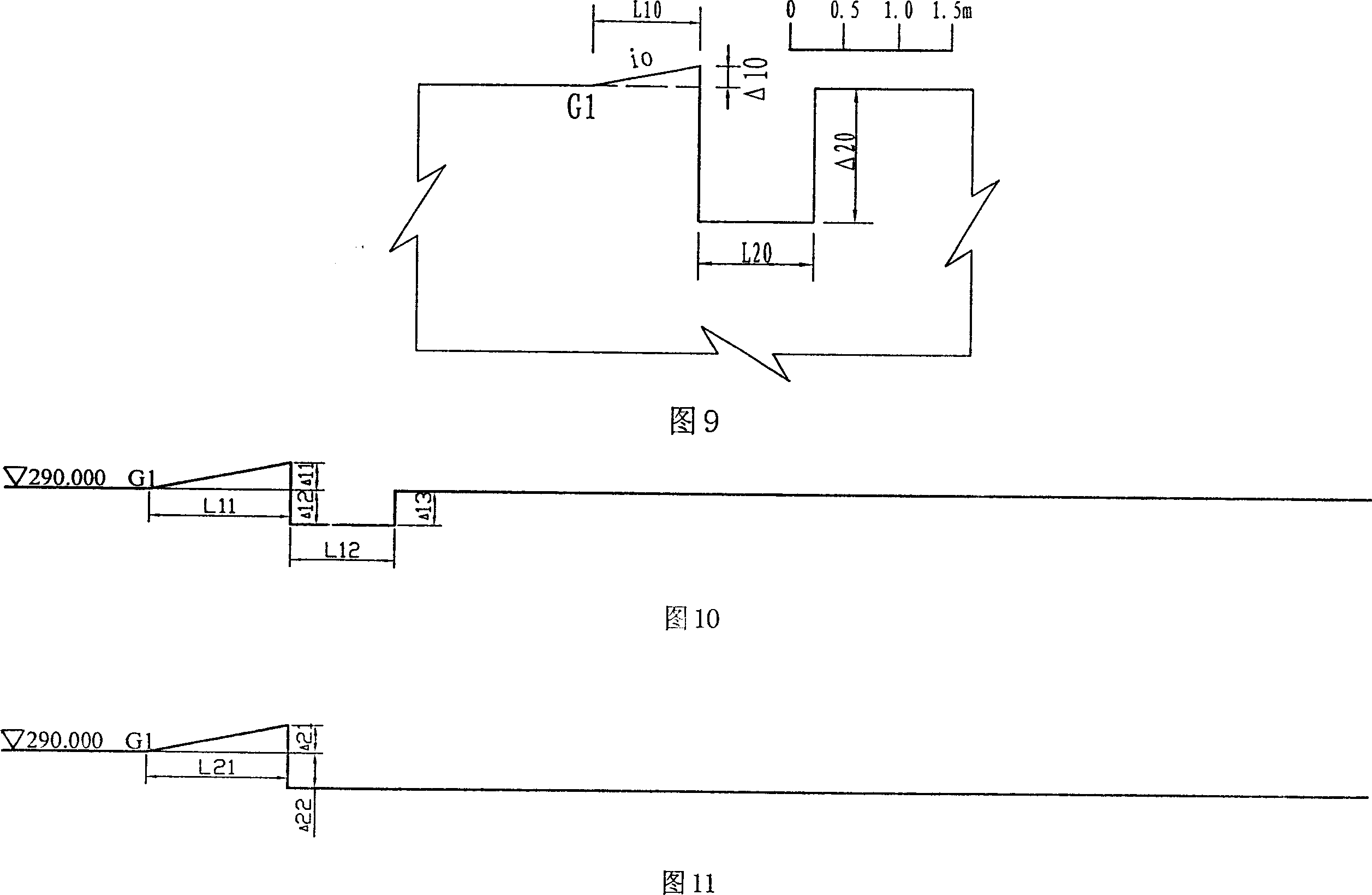

Aerator for flat-bottomed water release structure

This invention relates to an aeration device of a flat-bottomed building to aerate with a combined way of raised ridge, aeration tank and a drop ridge and sets a paste ridge at the back of the tank, in which the profile line of the top of the paste ridge extends to the bottom from the top gradually along the counter flow direction in a cavity sphere, the profile line on top of the paste ridge along the current direction extends to the bottom from the top gradually at the bump section of the current and the paste ridge at the back of the cavity. Advantage: obliquity of the jet with the paste ridge is small across a ventilation tank, it's not easy to generate back flow to block the cavity, a stable cavity is formed at the flow surface of the building to reduce back flow and increase aeration efficiency, extra part is removed to improve distribution of pressure in the cavity to increase contact area of water and gas.

Owner:HOHAI UNIV

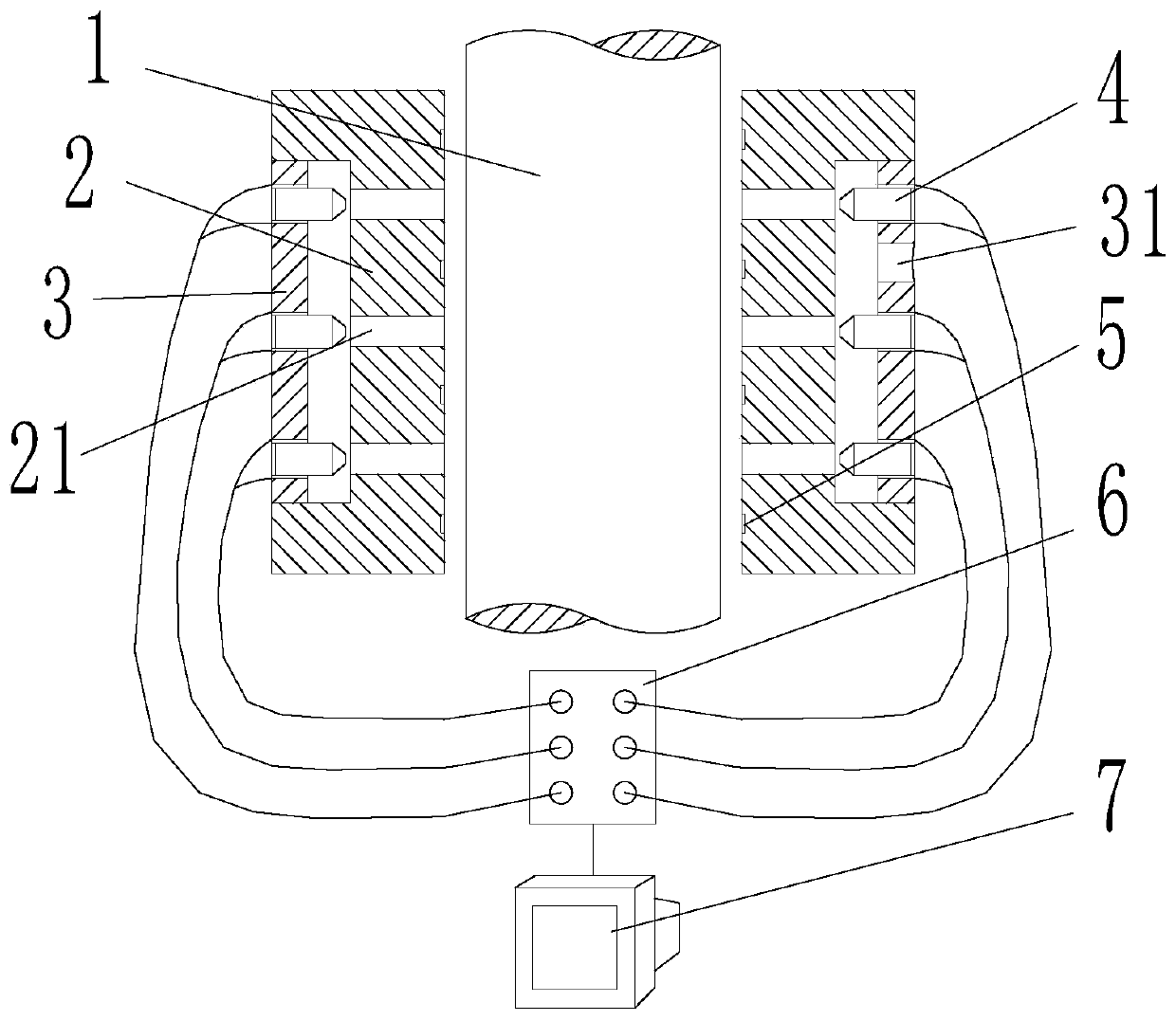

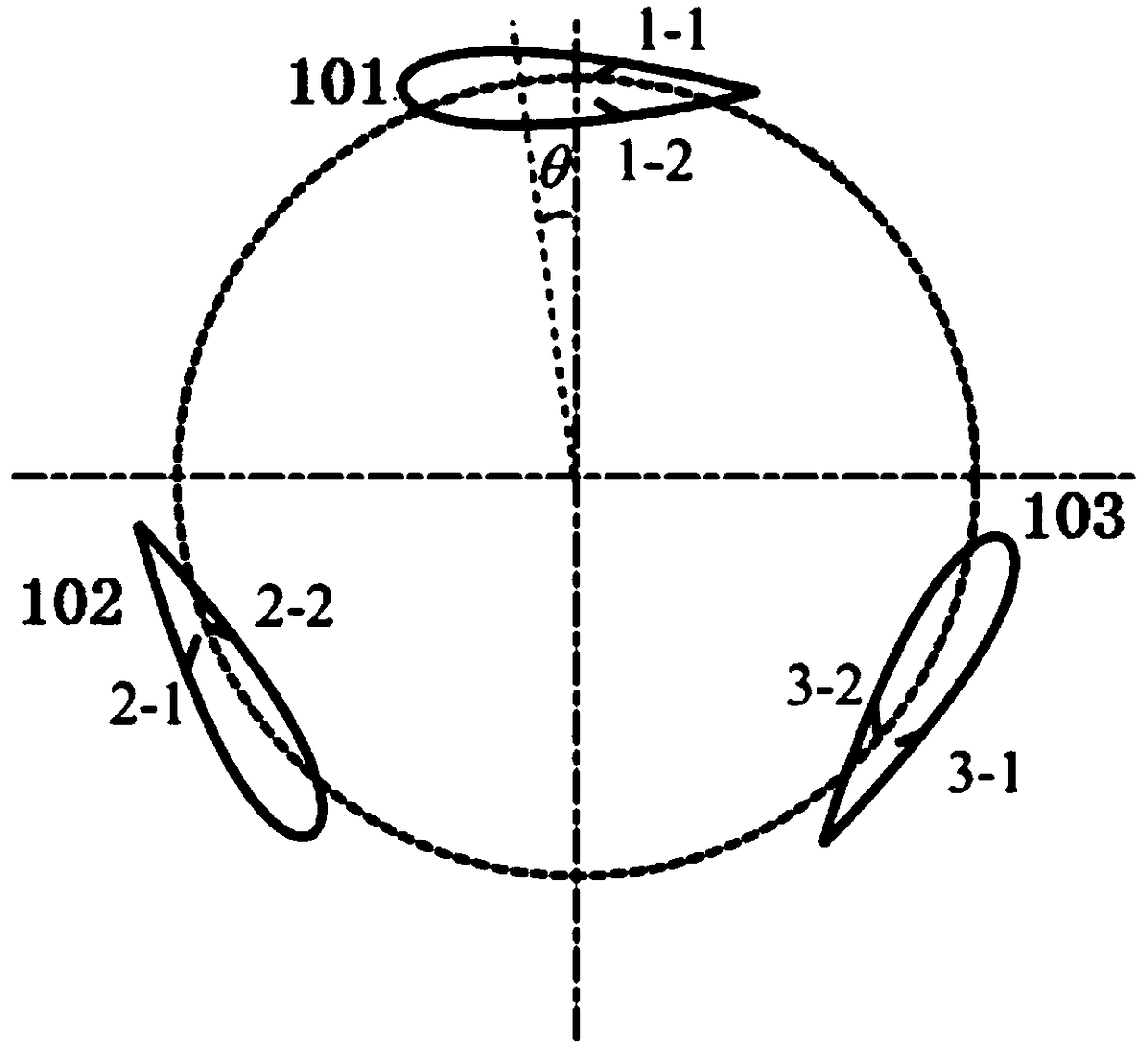

Gas film pressure vector control device for aerostatic bearing

PendingCN110030266AControllable outlet pressureRealize vector controlHydrostatic bearingsControl vectorEngineering

The invention provides a gas film pressure vector control device for an aerostatic bearing. The control device comprises a main shaft and a bearing, wherein the bearing is arranged outside the main shaft, an air film is formed in a gap area between the main shaft and the bearing, and throttling holes are uniformly distributed in the bearing; an air chamber coat sleeves outside the bearing, a closed area formed between the air chamber coat and the bearing is the air chamber, and the throttling holes communicate the air film and the air chamber; a flow control valve is arranged on the wall surface of the air chamber coat opposite to the throttling holes in a penetrating mode, the flow control valve is coaxially arranged with the throttling holes, and the valve element of the flow control valve is used for adjusting the opening degree of the throttling holes; an air inlet hole penetrates through the wall surface of the air chamber coat and is externally connected with an air inlet pipe; awireless pressure sensor is arranged in a groove formed in the inner wall of the bearing, the shape, close to one side of the main shaft, of the wireless pressure sensor is consistent with the shapeof the inner wall surface of the bearing, and namely the wireless pressure sensor and the gas film flow field do not interfere with each other; the flow control valve is connected with a wire collecting terminal through a wire harness; the control device is connected with the wire collecting terminal through an anti-interference bus; and the vector control of the gas film pressure of the aerostatic bearing can be realized.

Owner:ZHEJIANG UNIV OF TECH

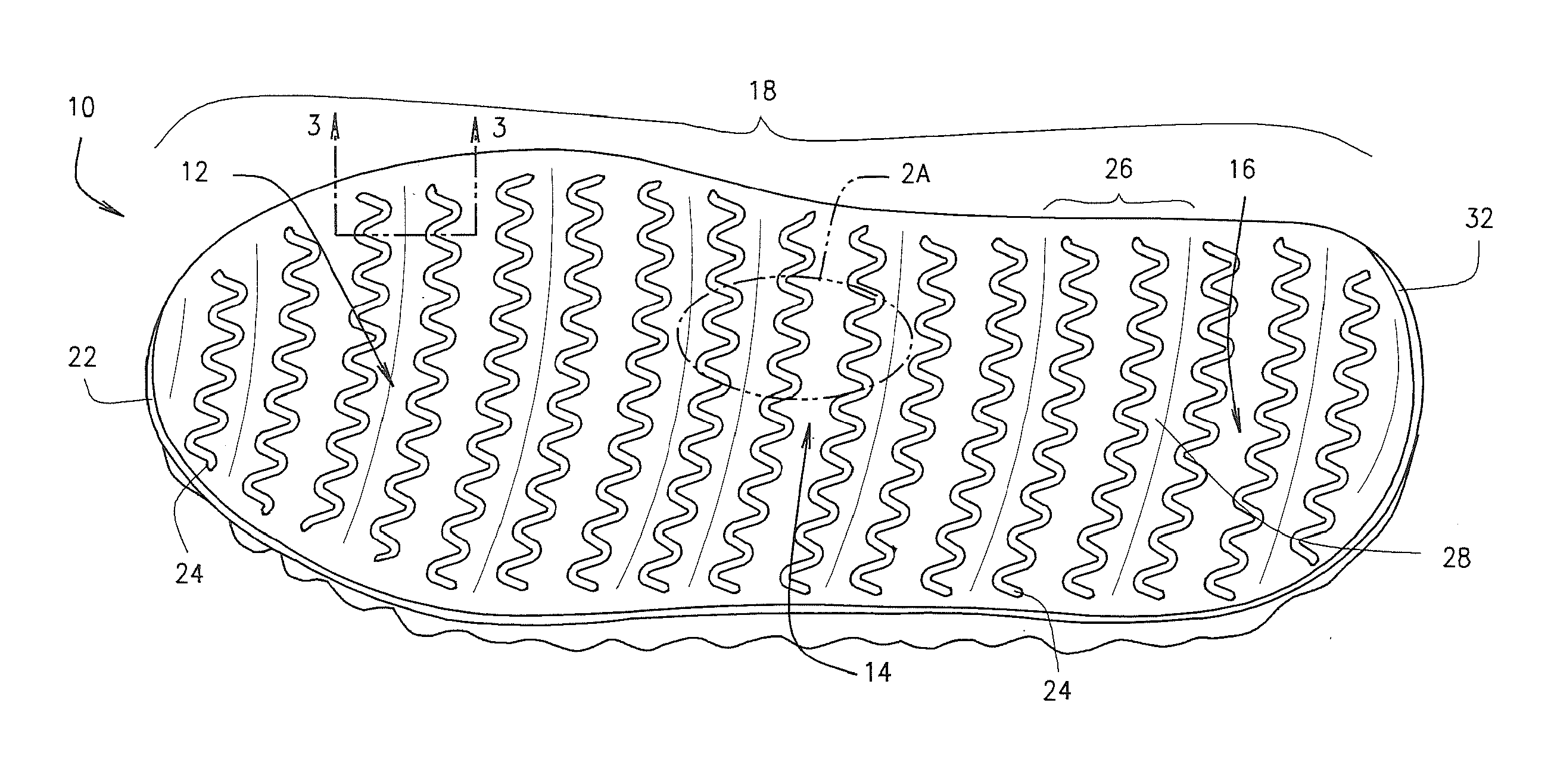

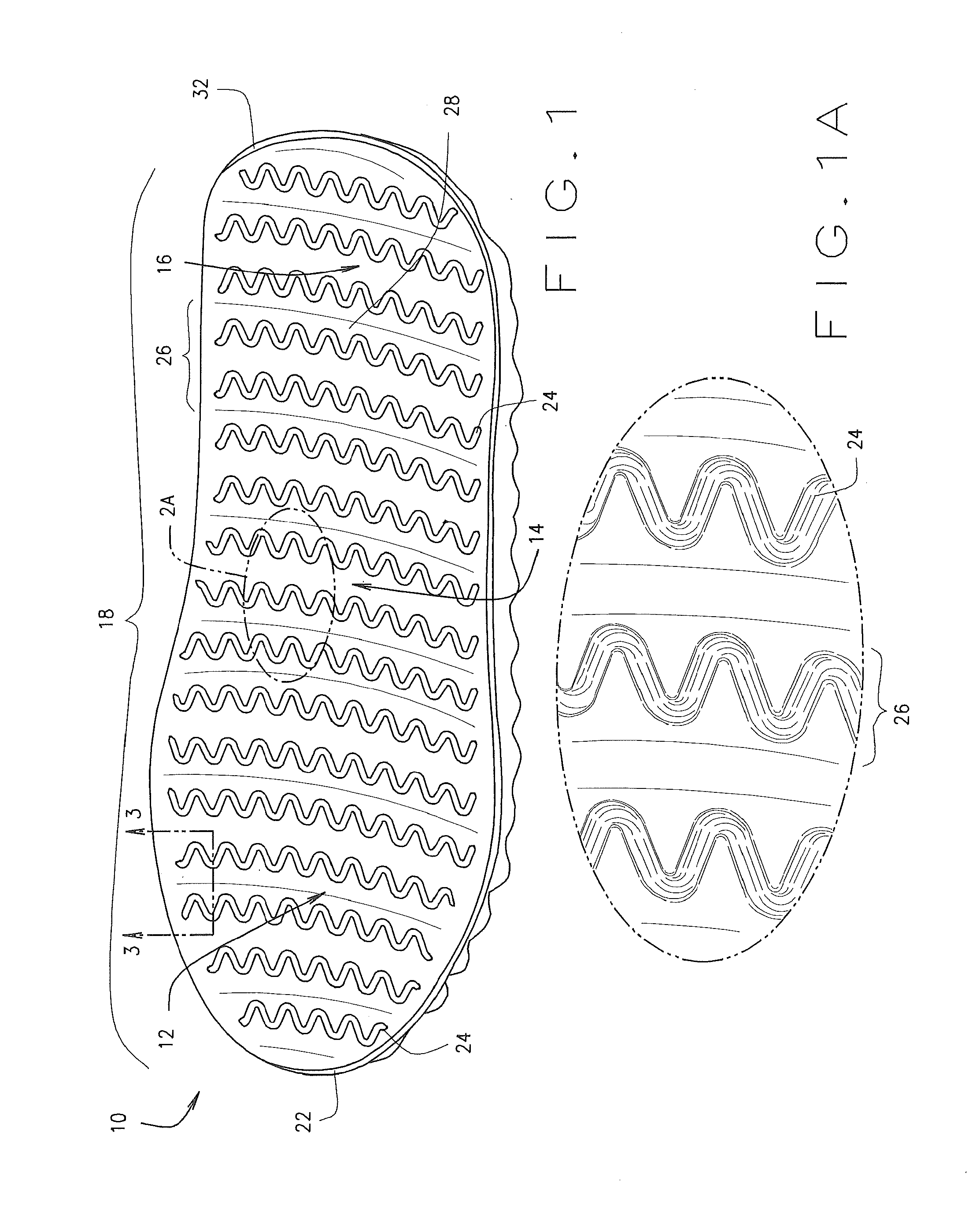

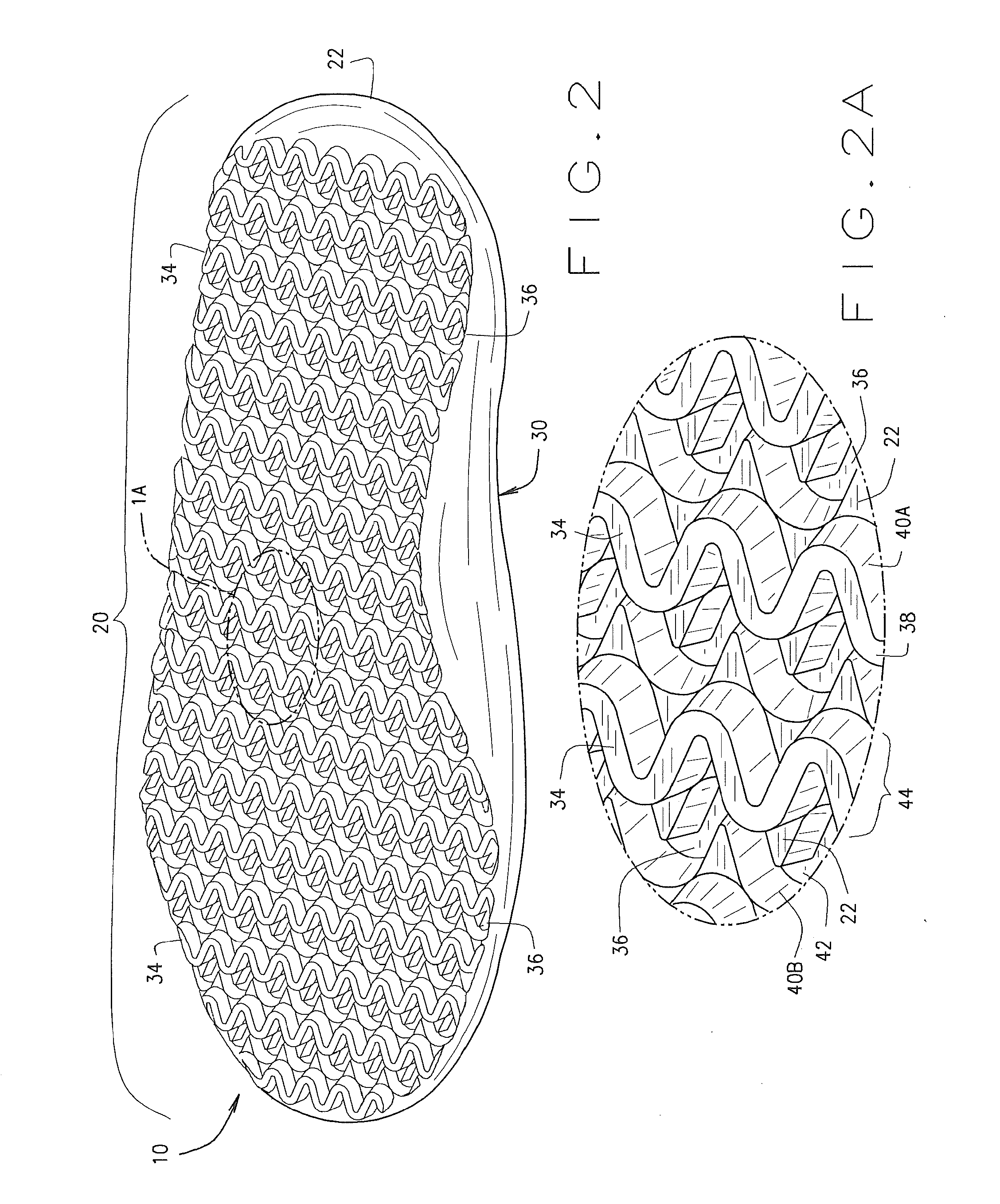

Energy wave sockliner

InactiveUS20130326905A1Effective lockingMaximize surface contactSolesInsolesEngineeringMechanical engineering

A sockliner for integration into a shoe assembly including a top face and a bottom face, each having a generally planar surface, extending along a base plane. On the top face, a plurality of grooves extend across the base plane in a generally undulating pattern for engagement with the sole of the foot. On the bottom face, a plurality of alternating ridges and / or valleys extend from the inside of the foot to the outside of the foot in a generally sinusoidal pattern for engagement with the outsole. The bottom face having a plurality of ridges positioned parallel and above the base plane, extend downwardly and a plurality of valleys positioned parallel and below at the base plane, extend upwardly. The combination of the generally undulating geometry of the top face and the generally sinusoidal geometry of the bottom face built into the structure of the sockliner for providing support and cushioning integrated into a shoe assembly.

Owner:BROWN SHOE

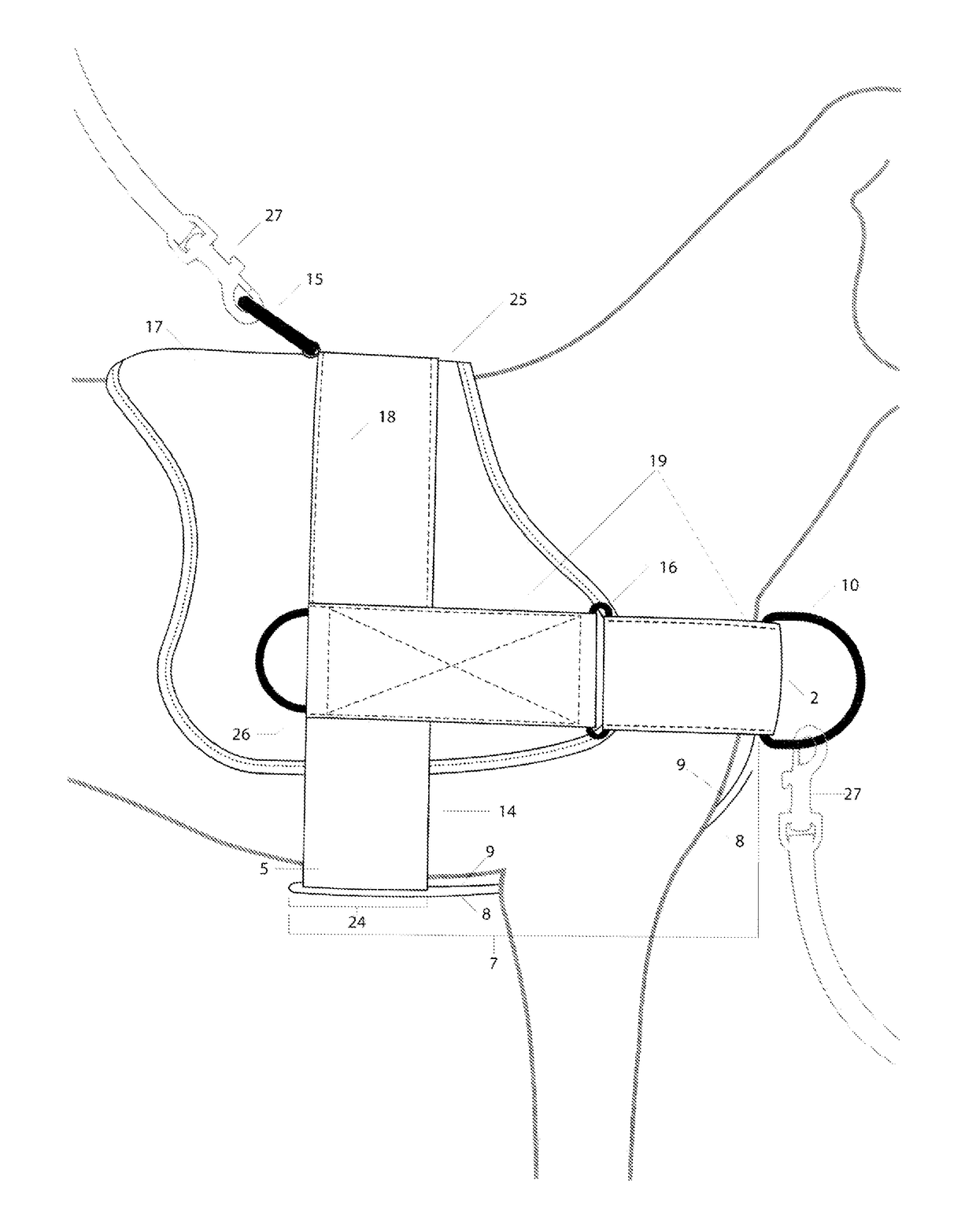

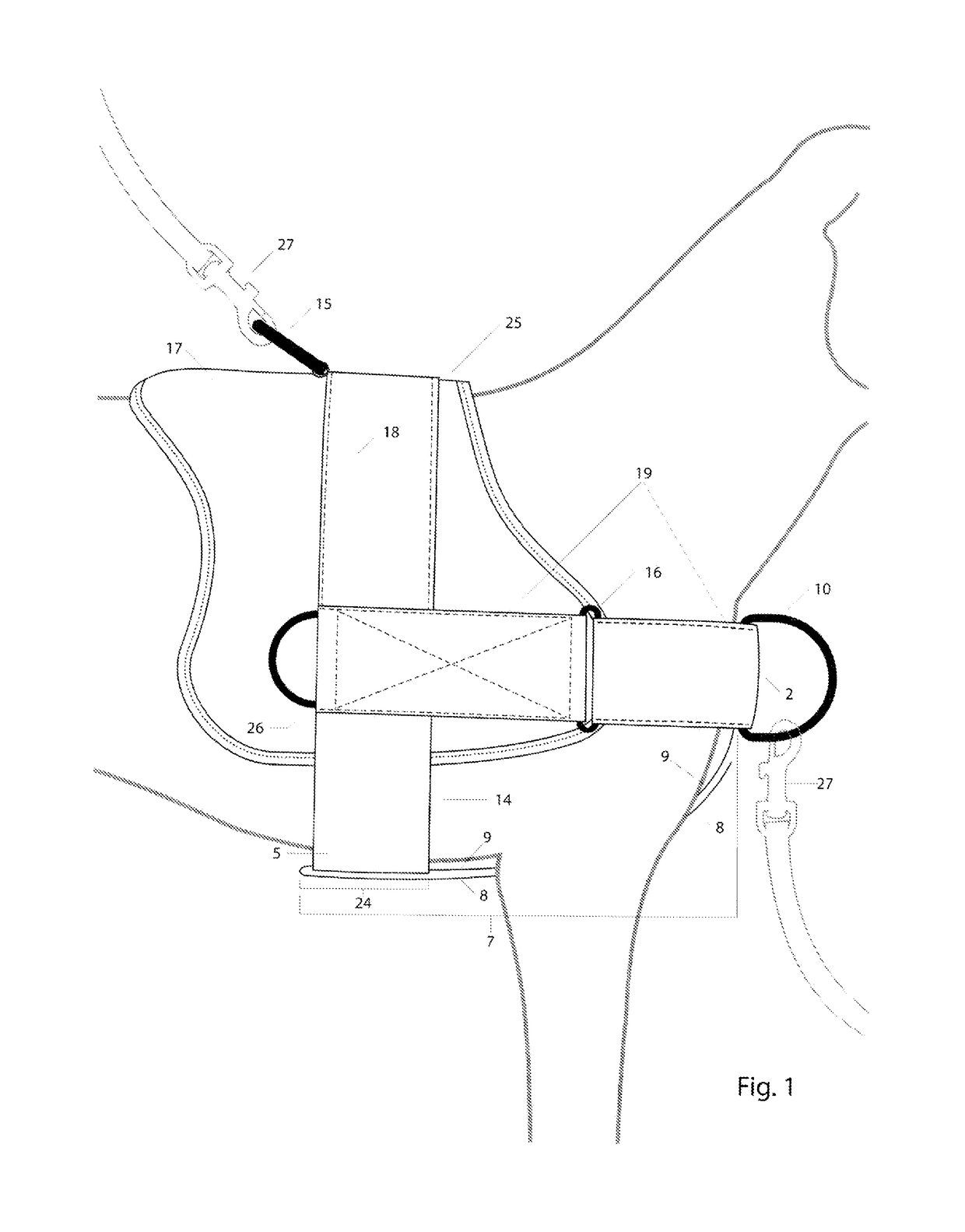

Pressure distribution element holding a ring for chest harnesses

InactiveUS9655344B1Improve carrying capacityConnection securityTaming and training devicesEngineeringMechanical engineering

A pressure distribution element holding a ring, attachable to the horizontal chest strap of a chest harness which is closable-openable by a hook-and-loop fastener, by connecting the chest strap loop section and the chest strap hook section comprising a chest strap connecting portion, and a vertical connecting element connecting the horizontal chest strap of the dog harness to the belly strap, forming a loop around the belly strap by folding back on itself, comprising at least a loop section, continued in a lower loop portion resting on the belly strap of the dog harness.

Owner:JULIUS K9

Passenger seating assemblies and aspects thereof

InactiveUS20150091342A1Improve pressure distributionPrevent reclineSeating arrangementsArm restsEngineeringMechanical engineering

Owner:ZODIAC SEATS FRANCE

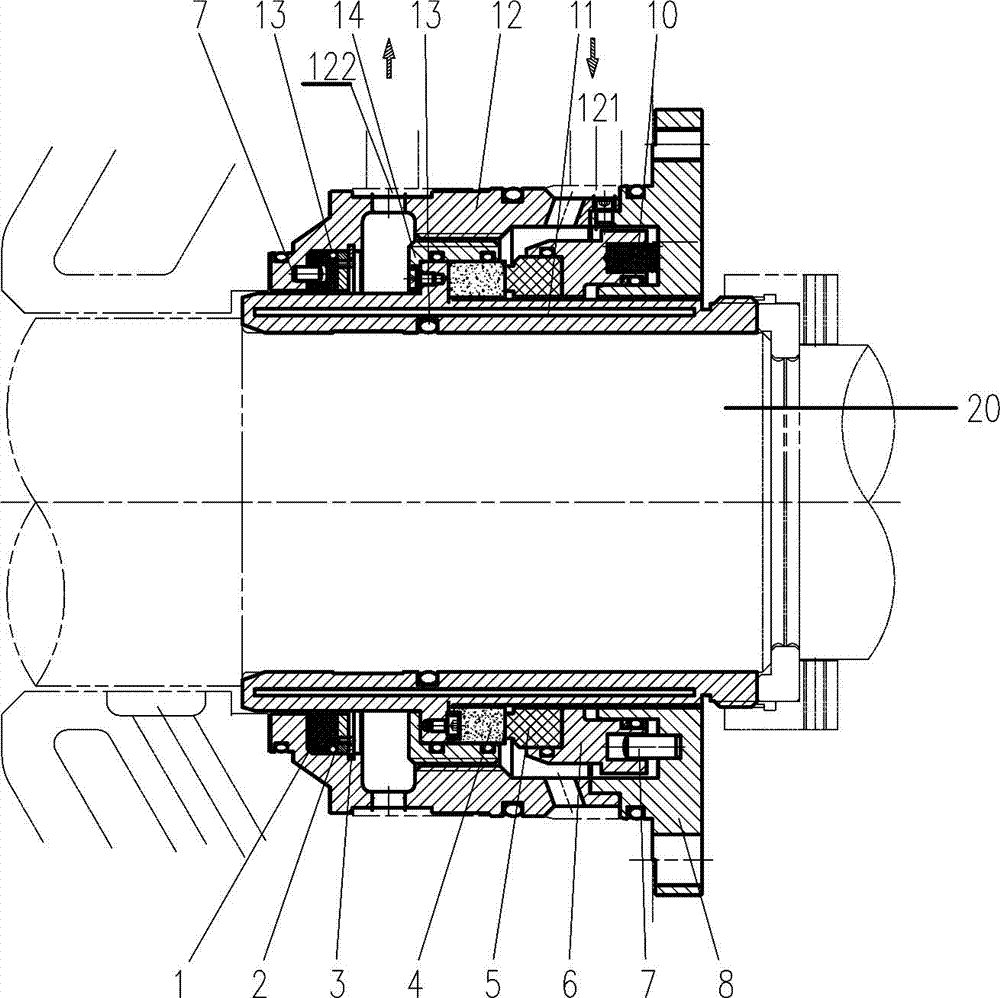

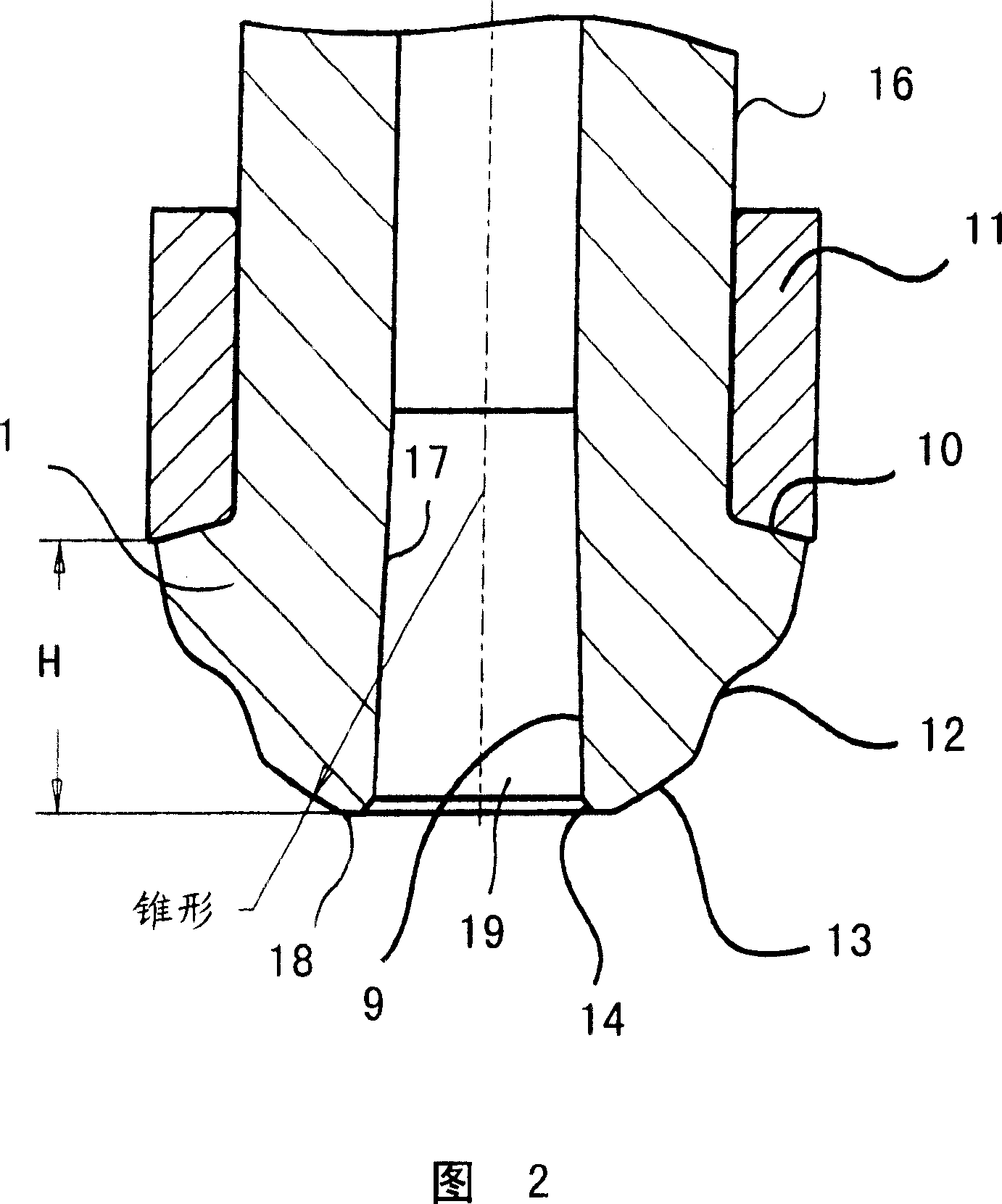

High-temperature-resistant mechanical sealing device

ActiveCN104329466AReduced mechanical propertiesReduce thermal deformationEngine sealsEngineeringRunning time

The invention relates to the field of sealing devices for fluid medium conveying pipelines, in particular to a high-temperature-resistant mechanical sealing device. The high-temperature-resistant mechanical sealing device comprises a movable ring (4), a static ring (5) and a revolving shaft (20), and is characterized by further comprising a vacuum shaft sleeve (11) and an O-shaped ring (13), wherein the inner cavity of the vacuum shaft sleeve (11) is in a high-vacuum state; the vacuum shaft sleeve (11) is fixed on the revolving shaft (20) in a sleeving manner; the movable ring (4) is fixed on the vacuum shaft sleeve (11) in the sleeving manner; the static ring is rotationally arranged on the vacuum shaft sleeve (11) in the sleeving manner; the static ring (5) and the movable ring (4) are jointed together and rotate relatively; the O-shaped ring (13) is lined between the vacuum shaft sleeve (11) and the revolving shaft (20). The high-temperature-resistant mechanical sealing device has high sealing performance, low medium leakage, long running time and long service life.

Owner:SHANGHAI LEHE FLUID MACHINERY

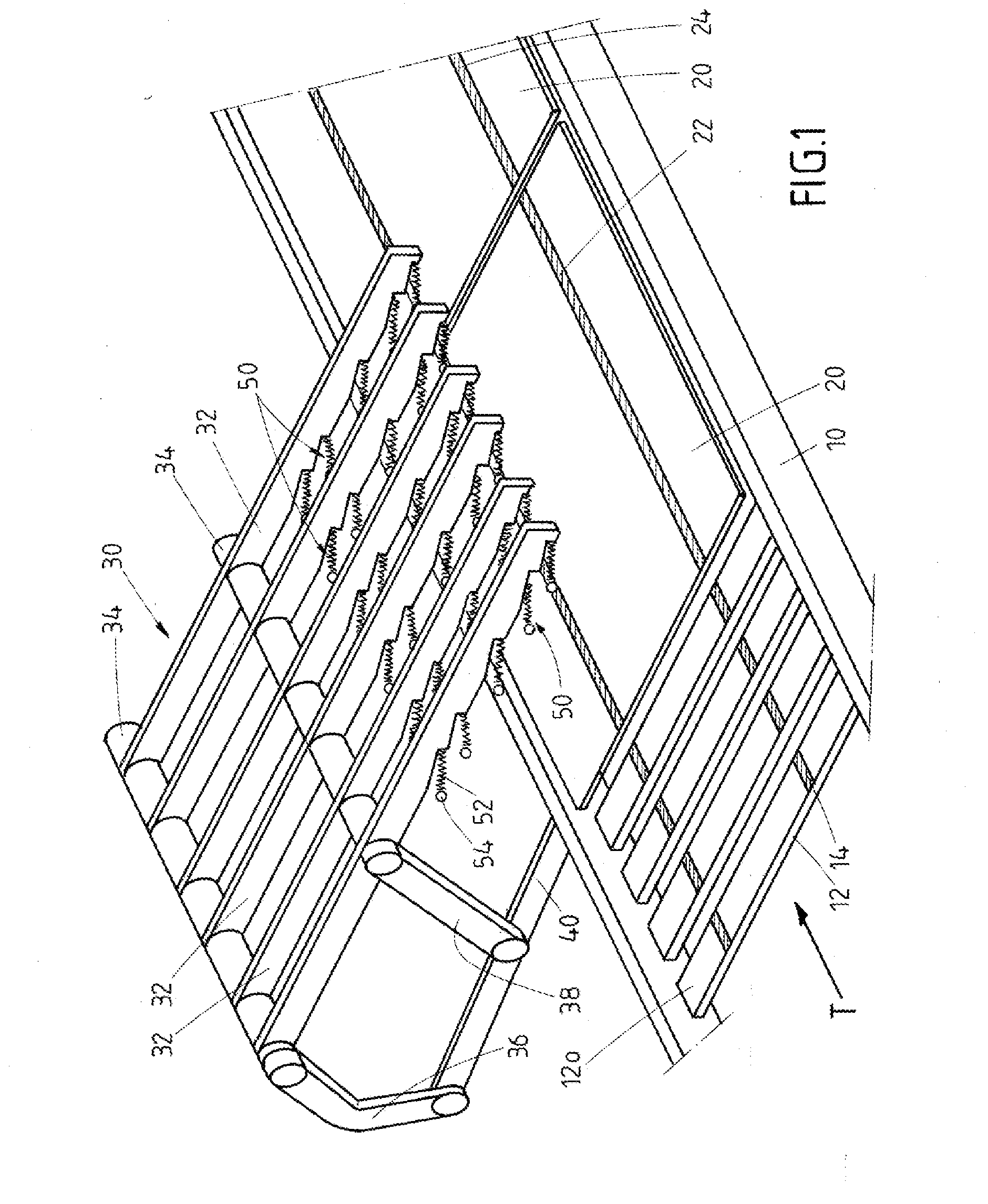

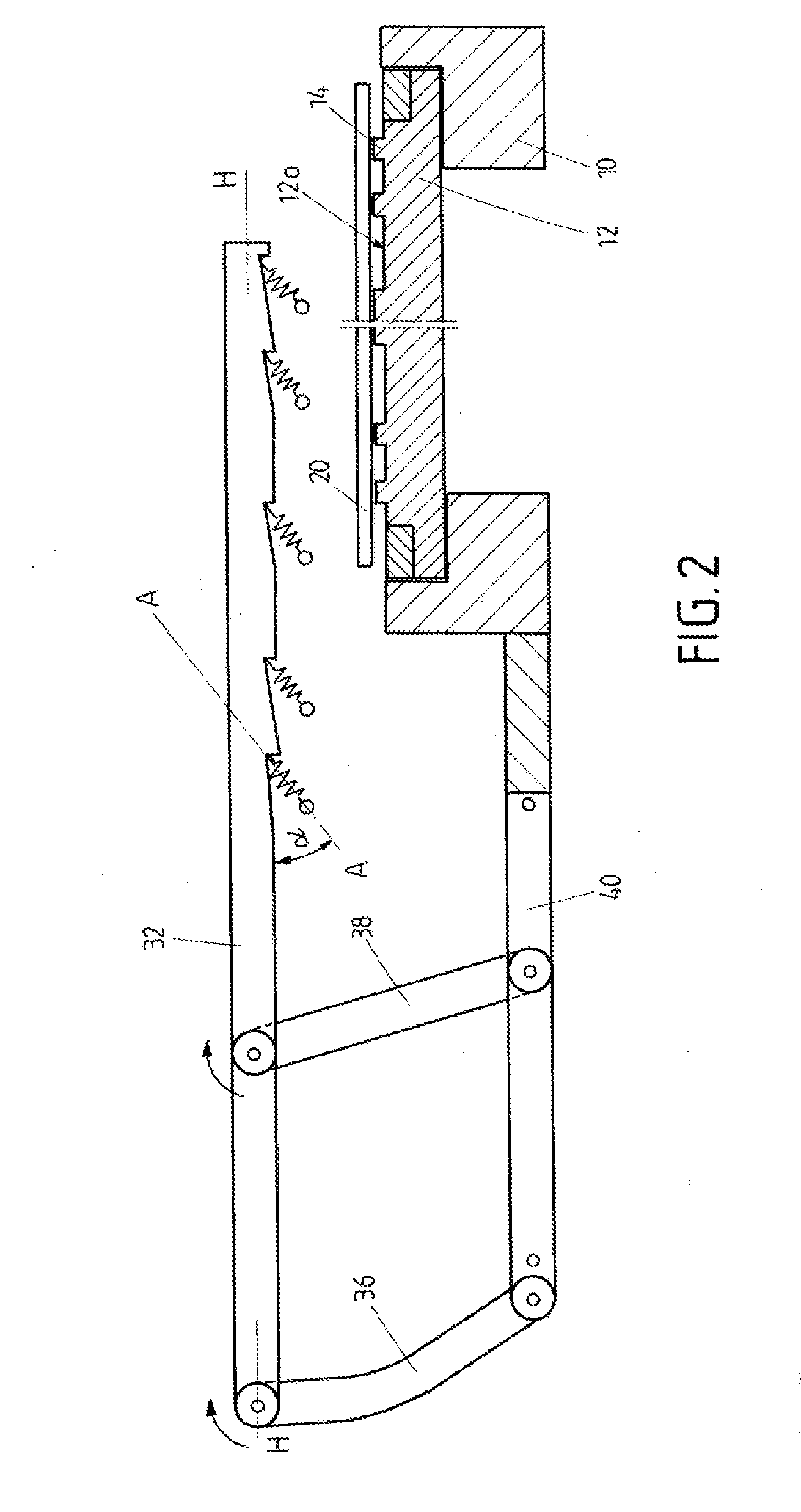

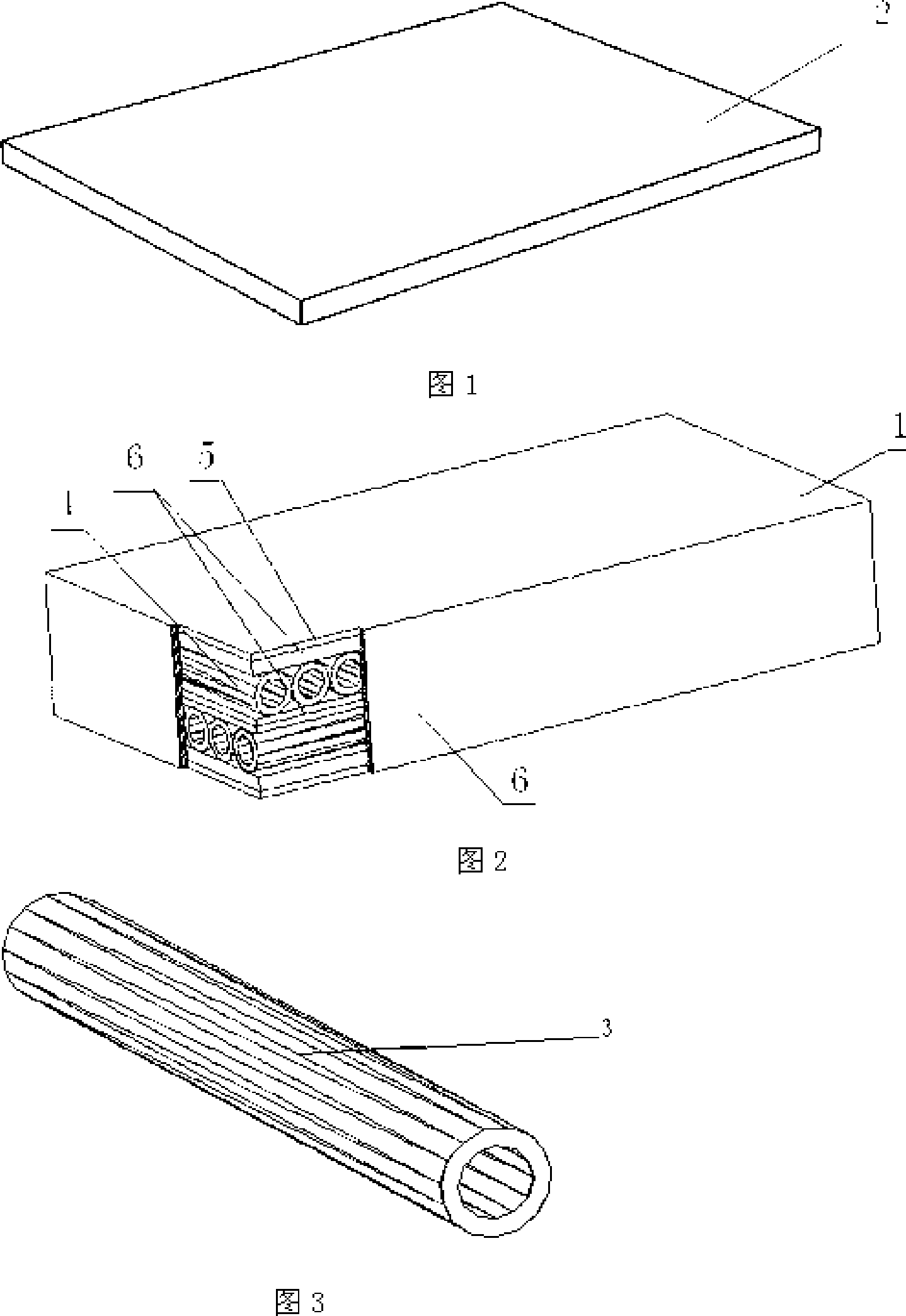

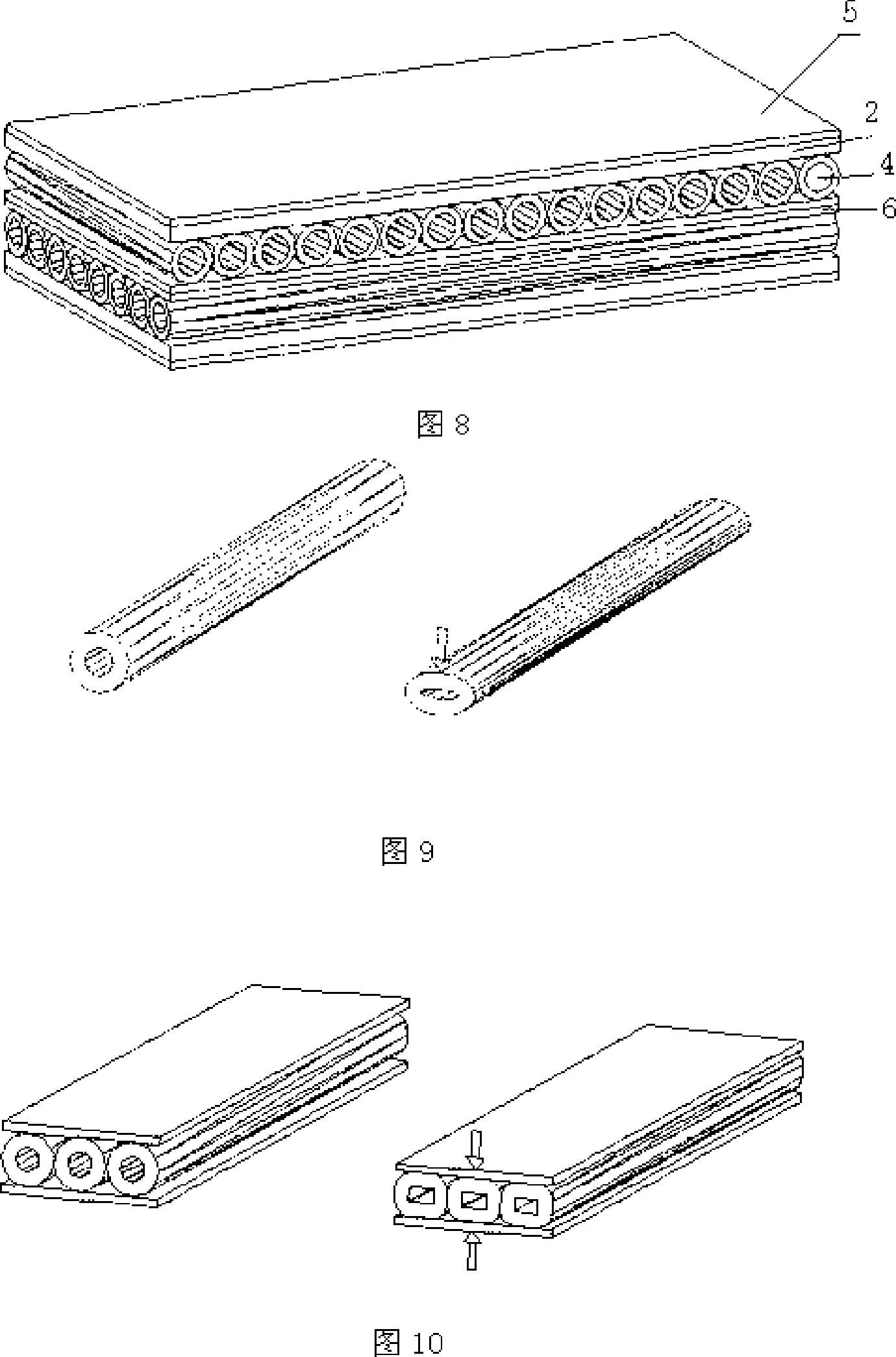

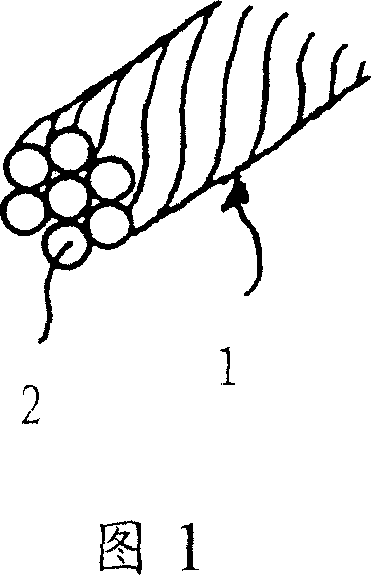

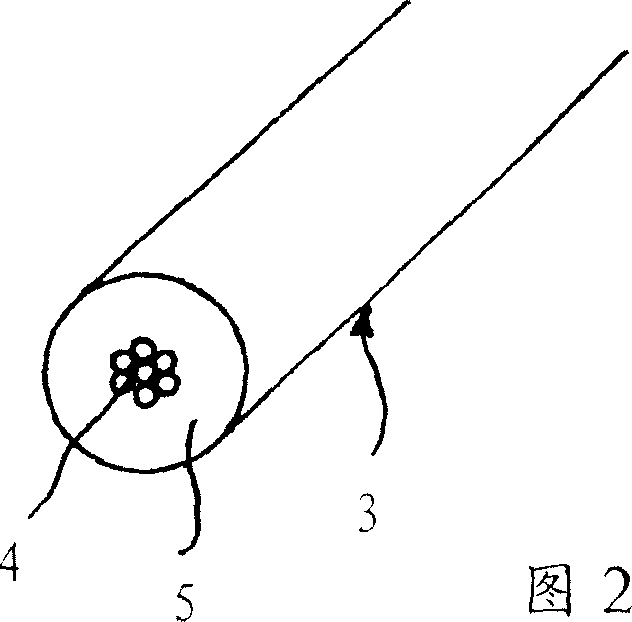

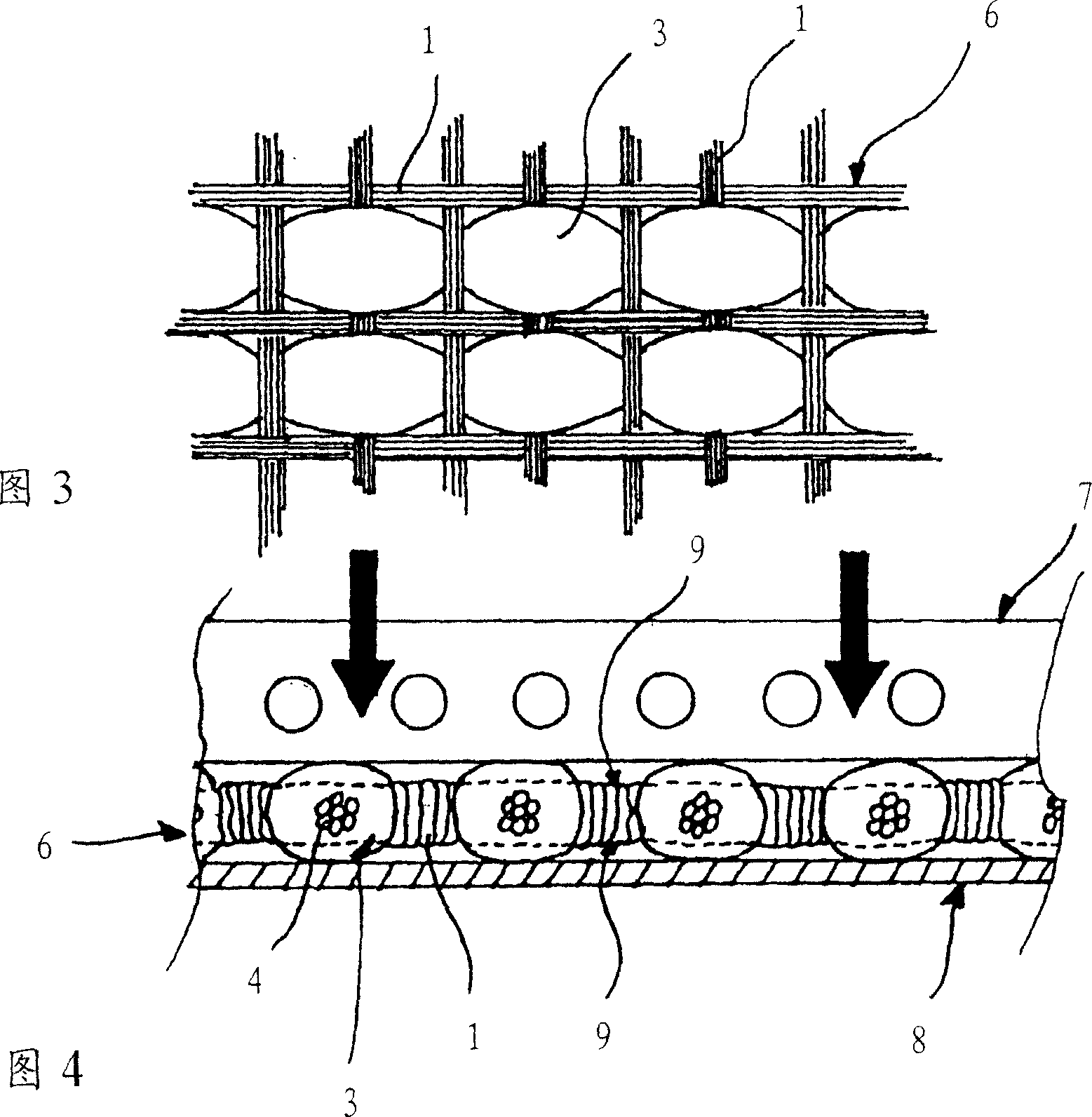

Pressure equalizing fabric for hydraulic hot pressing installation

The present invention relates to a pressure equalization fabric ( 6 ), particularly a pressing cushion, for use in hydraulic hot pressing facilities, comprising metal threads ( 1 ), both as warp threads and also as weft threads of the pressing cushion, and high-temperature-resistant elastomer threads ( 3 ), preferably having stabilizing core threads ( 4 ), which are situated alternating with the metal threads ( 1 ) either as warp threads or as weft threads. To ensure better diffusion of the vapor bubbles during the pressing procedure and thus achieve a transparent and closed melamine resin surface, the pressing cushion is characterized in that the thickness in the uncompressed state of the pressing cushion is determined by the elastomer threads ( 3 ) and thus the contact points pressing cushion with parts of the hot pressing facility at moderate pressure buildup are first formed by the elastomer threads ( 3 ), the elastomer threads being compressible in such a way that upon further pressure increase up to the total pressing pressure, further contact points ( 9 ) are formed by the metal threads ( 1 ).

Owner:RHEINISCHE FILZTUCHFAB

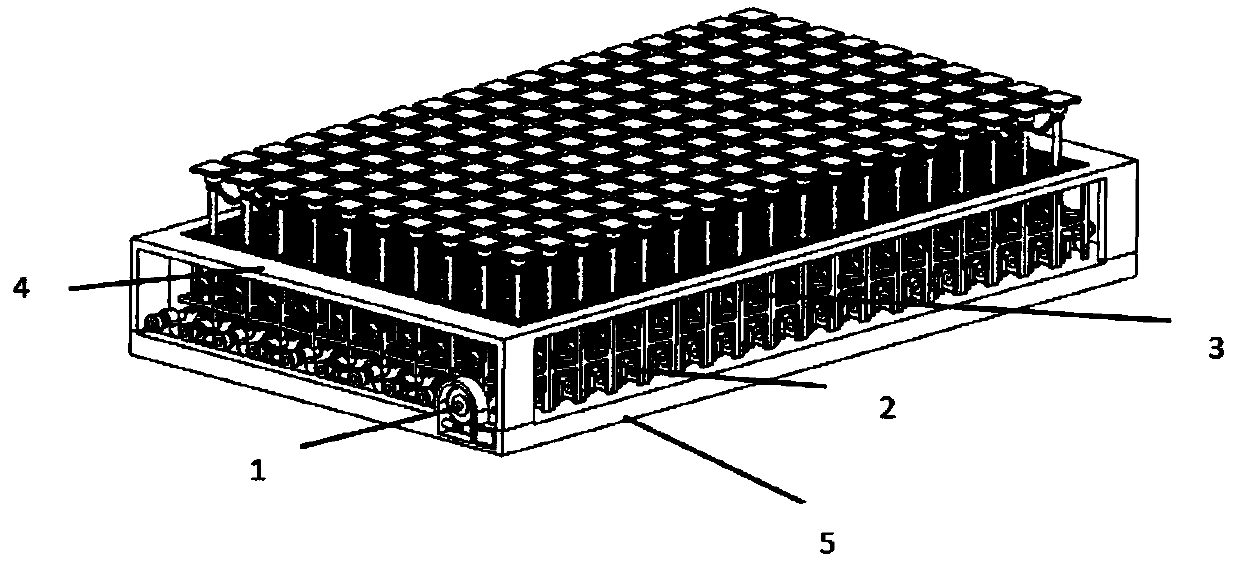

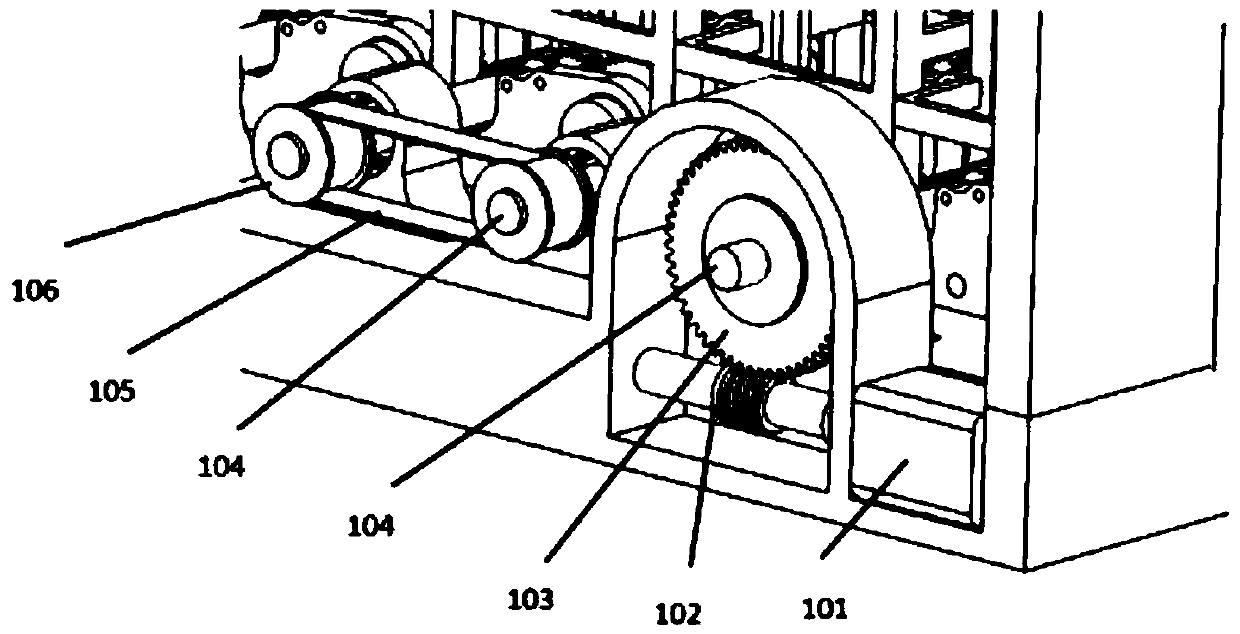

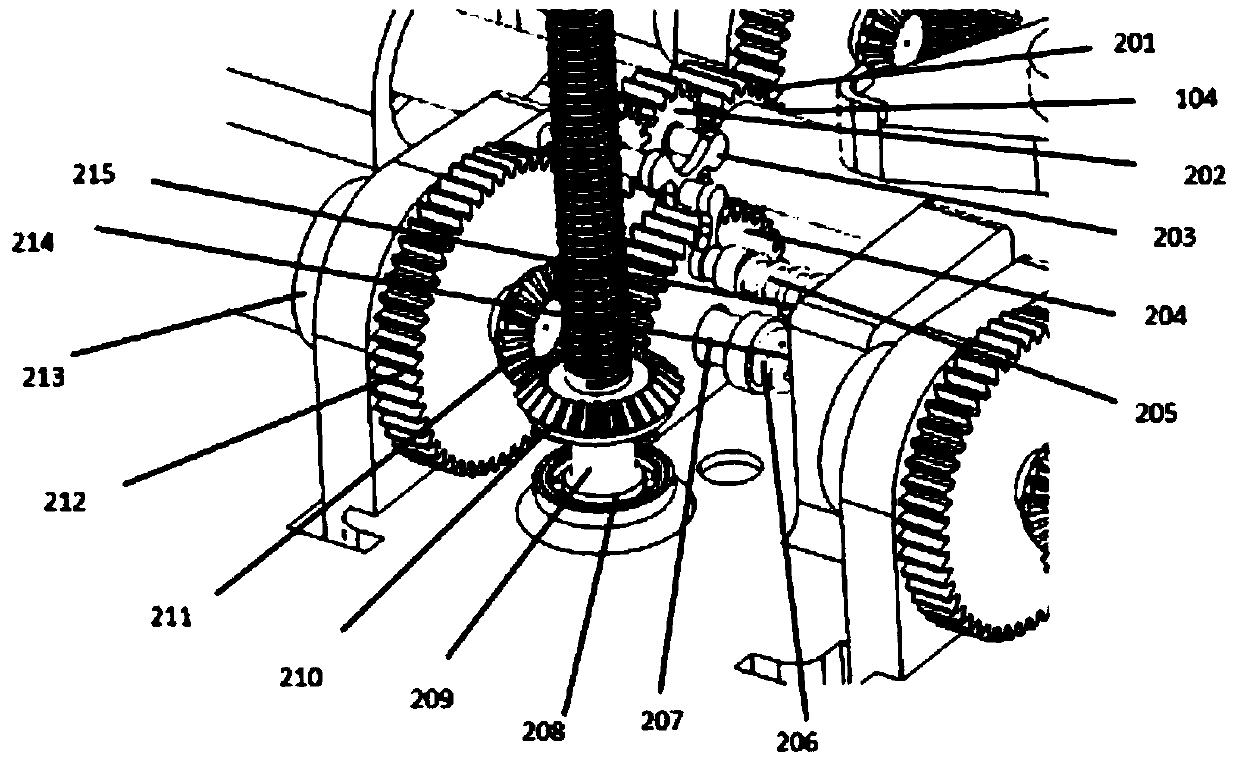

Flexible intelligent nursing bed with adjustable bed top

A flexible intelligent nursing bed with an adjustable bed top comprises a power and transmission mechanism, a plurality of reserving mechanisms, a plurality of lifting mechanisms, a frame and a base;the power and transmission mechanism, the reversing mechanisms, and the lifting mechanisms are mounted on the frame and the base; the power and transmission mechanism and the reversing mechanisms enable the lifting mechanisms to move up and down so as to adjust the change of the bed top, so that a body posture adjusting function and a massaging function are achieved. The flexible intelligent nursing bed herein allows adjustment for complex postures; posture adjustment is highly flexible, and good comfort is provided.

Owner:西安佰优智能科技有限责任公司

Anatomical shoe insert assembly

InactiveCN103347413AEffective lockingEnsure maximum contactSolesInsolesMechanical engineeringFoot orthosis

Owner:布朗鞋业公司

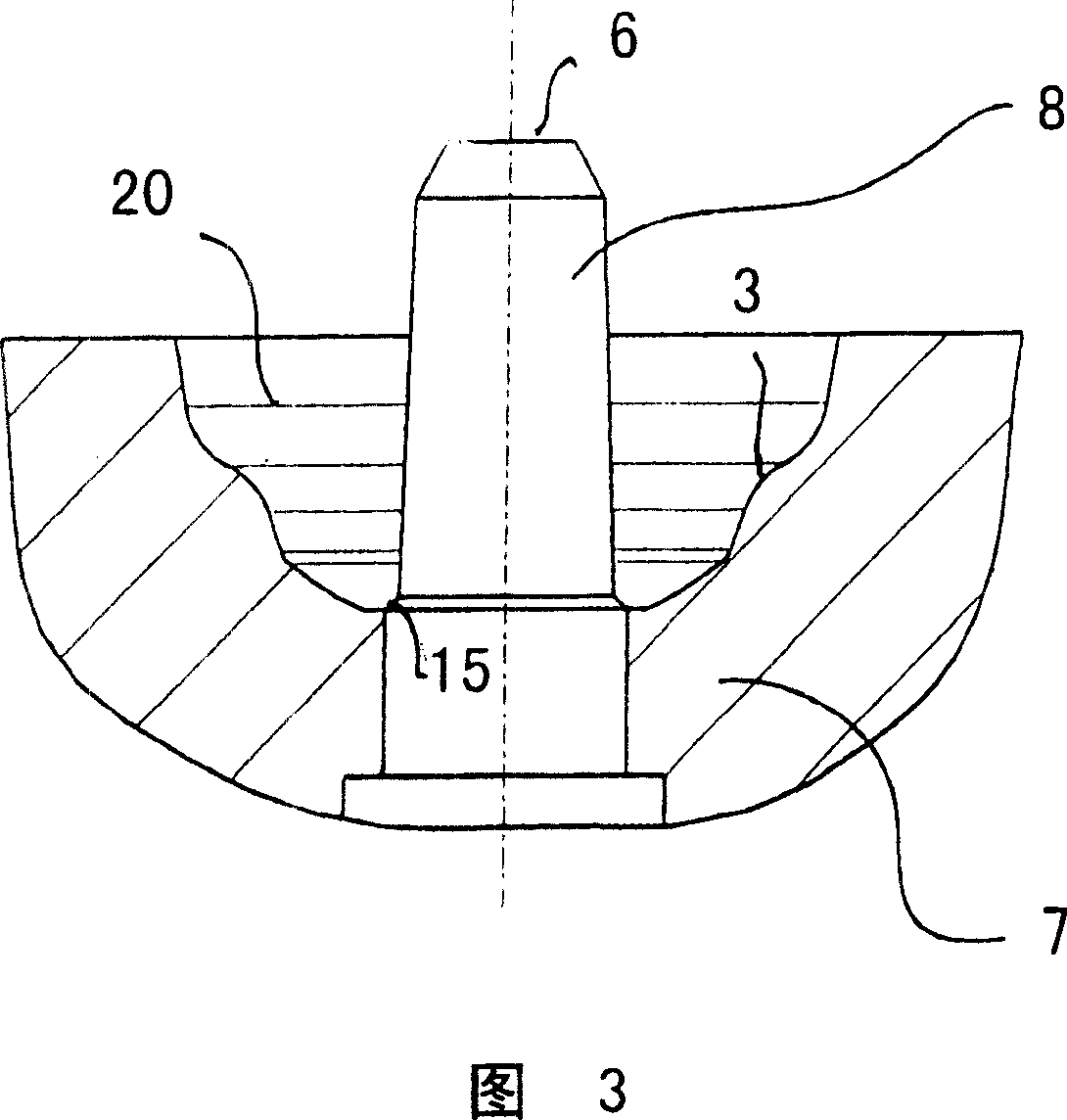

Pressure pipe with formed connecting head

ActiveCN1959174AGood use strengthImprove surface qualityFluid pressure sealed jointsJoints with sealing surfacesEngineeringHigh pressure

The pressure line, for example as a high-pressure fuel injection line, has a cold-worked connection (1) at the end of the line (16). The joint (1) is frustoconical and has a surrounding sealing surface on its enveloping surface, which is pressed against the connection part with a corresponding fit by means of a preload transmitted via the pressure shoulder (10). Wherein the outer surface of the pipe (16) encloses an angle greater than 90° with a surface of the pressure shoulder (10).

Owner:MAN ENERGY SOLUTIONS SA

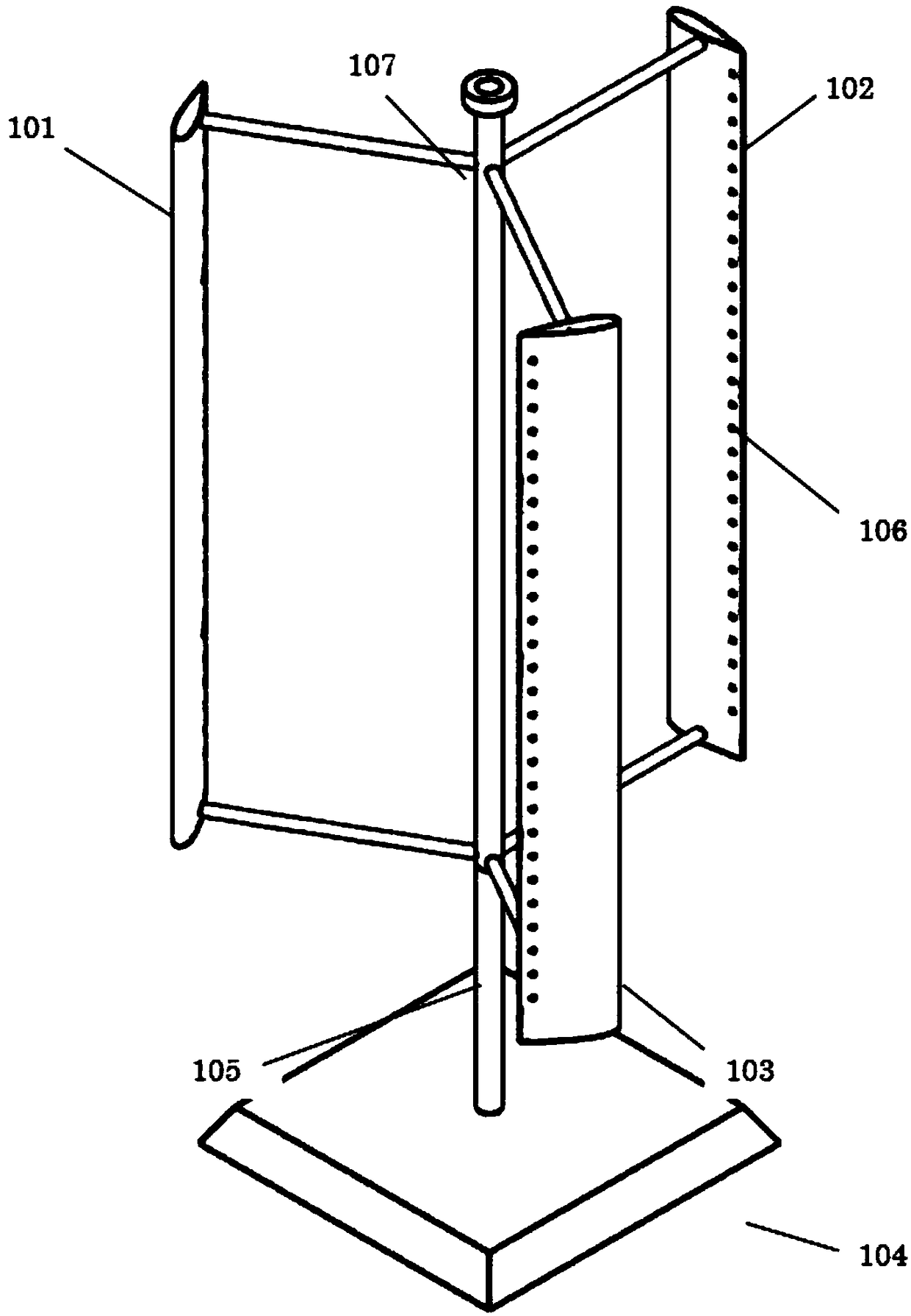

Vertical axis wind turbine blade module and synthesized jet control method thereof

ActiveCN108150348AReduce vibration amplitudeReduce vibration frequencyWind motor controlMachines/enginesElectricityVertical axis wind turbine

The invention discloses a vertical axis wind turbine blade module and a synthesized jet control method thereof. The vertical axis wind turbine blade module is arranged on a base of a vertical axis wind turbine, and comprises multiple blade bodies, synthesized jet exciters and multiple jet holes, wherein the upper and lower ends of each blade body are fixed on a rotating shaft of the vertical axiswind turbine through fixed rod pieces; the synthesized jet exciters are uniformly and serially arranged in the blade bodies in the blade height directions of the blade bodies; the multiple jet holes are formed in the tail edges of the blade bodies; the synthesized jet exciters comprise shells, piezoelectric films, jet channels, piezoelectric drivers and control boxes, wherein the shells are squares, and are provided with upper openings and the lower openings; the piezoelectric films are squares, and cover the lower openings; the jet channels communicate with the upper openings; the piezoelectric drivers are arranged below the piezoelectric films, and are driven by rectangular pulse signals to generate a reverse piezoelectric effect so as to drive the square piezoelectric films to periodically vibrate up and down; and the control boxes are arranged above rotating shafts, are electrically connected with the piezoelectric drivers, and are used for inputting the rectangular pulse signals to the piezoelectric drivers.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com