Patents

Literature

481results about How to "With high and low temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

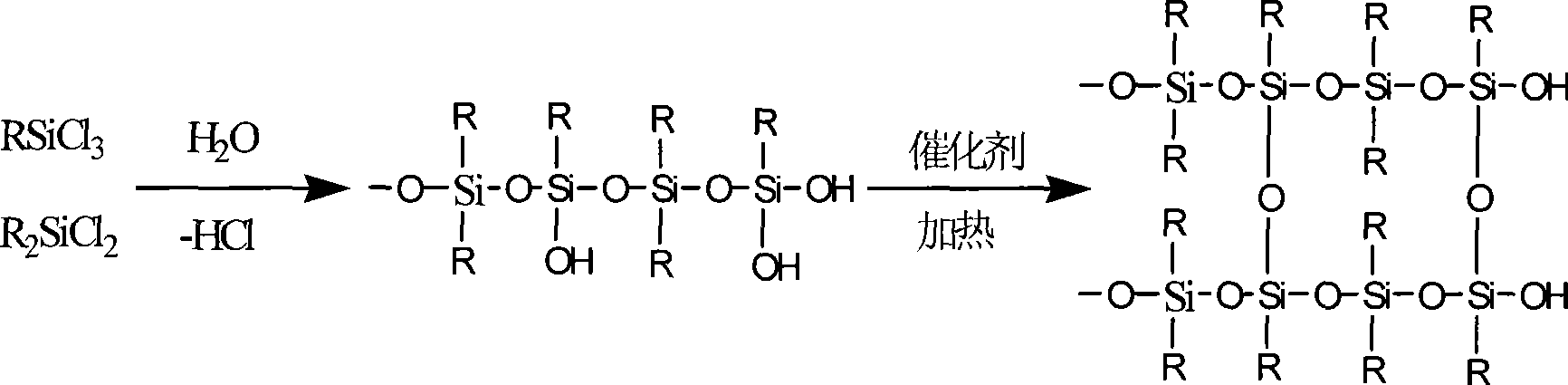

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

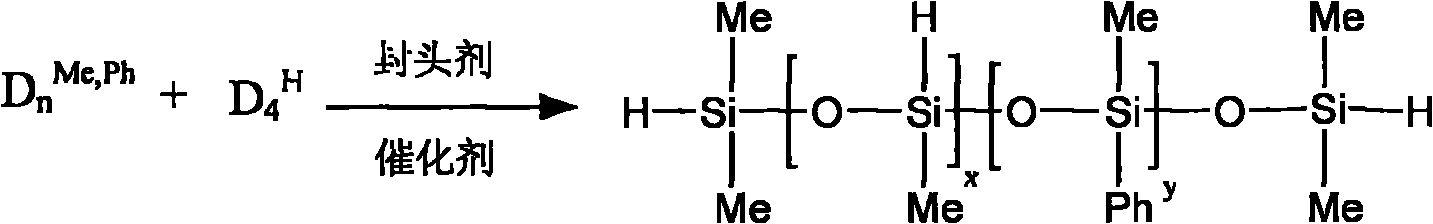

Method for preparing methyl and phenyl hydrogen-containing silicon oil for packaging LED

ActiveCN101289538AHigh refractive indexRadiation resistantChemical recyclingSemiconductor devicesHydrogenRoom temperature

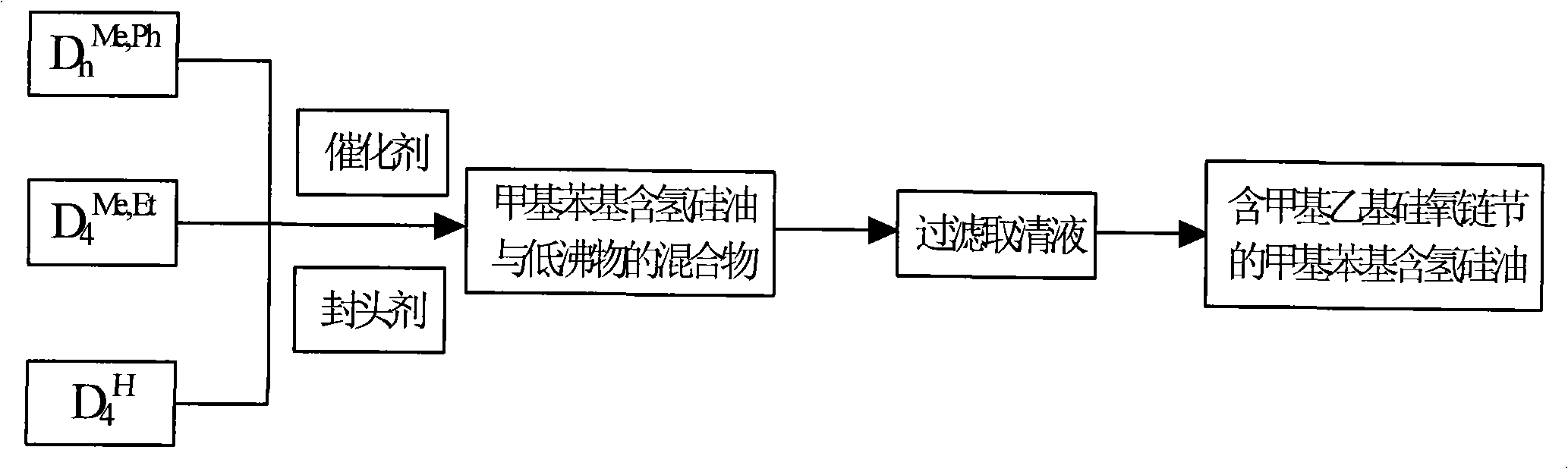

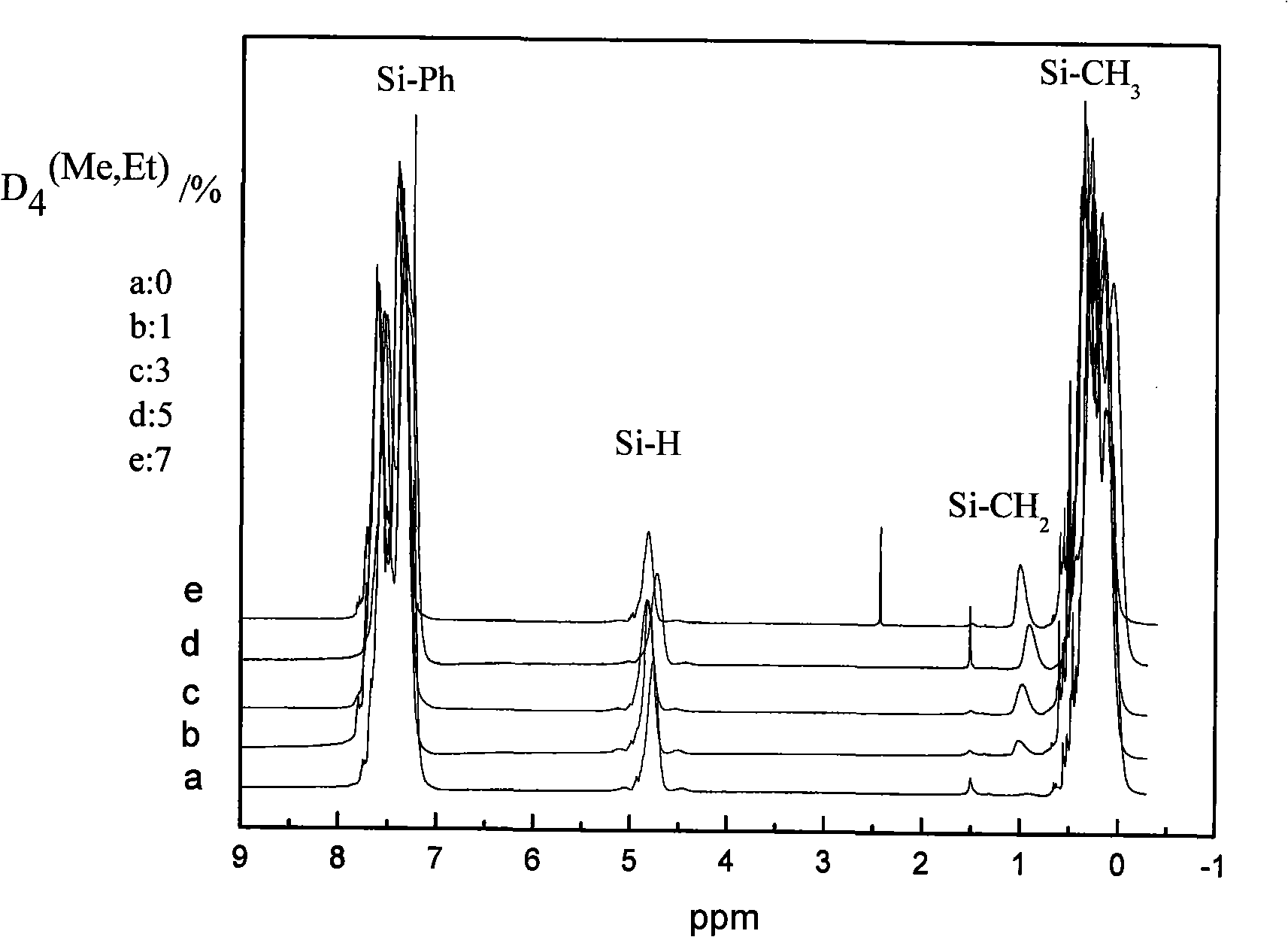

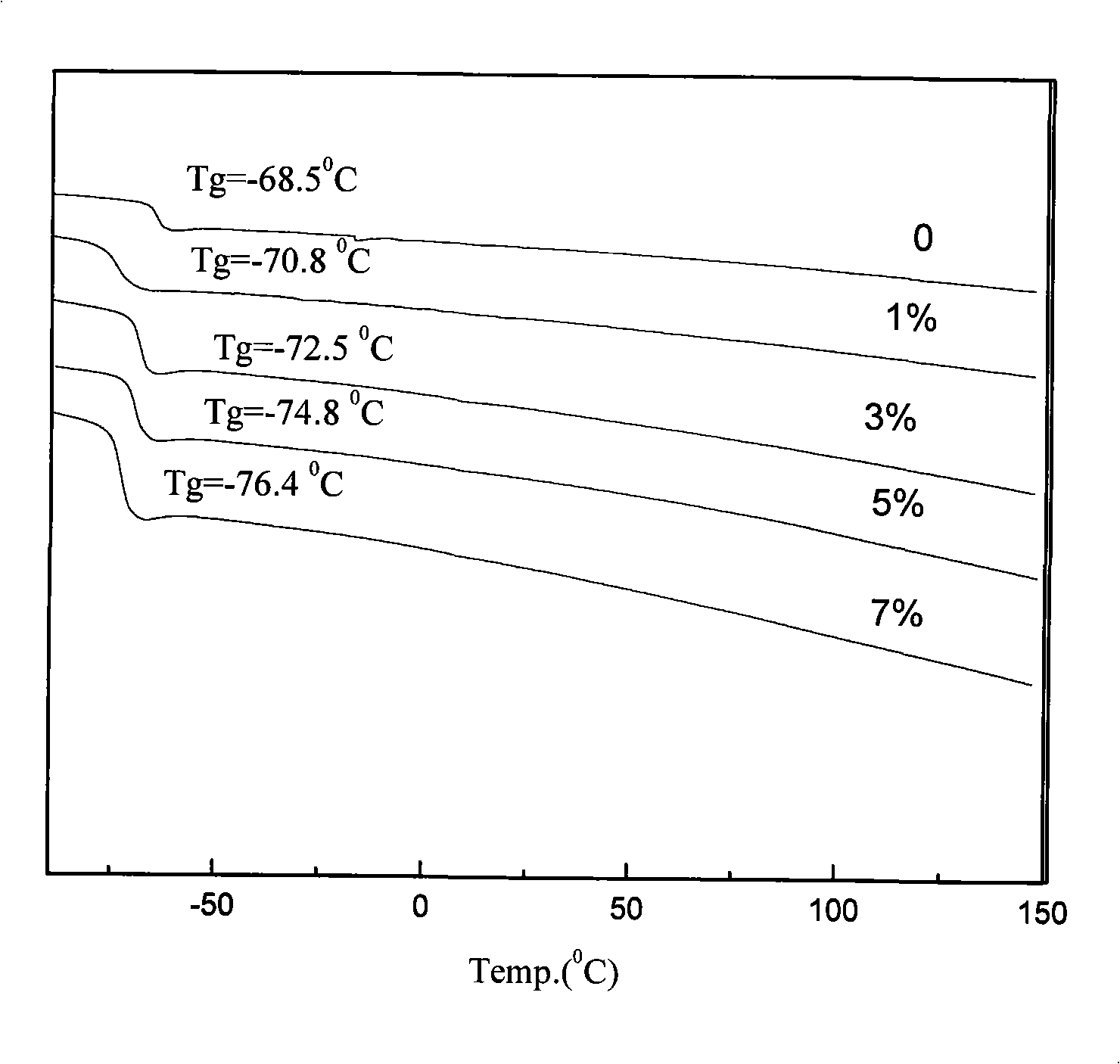

The invention relates to a method for making hydrogen-containing silicone oil, in particular to a method for making methyl phenyl hydrogen-containing silicone oil for the encapsulation of LEDs. The method is characterized in that the methyl-phenyl cyclic siloxane (Dn<Me, Ph>), the tetramethyl tetraethyl cyclic tetra-siloxane (D4<Me, Et>) and hydrocyclotetrasiloxane (D4<H>) are taken as monomers; under the protection of N2, right amount of an end capping agent is added into the monomer mixture to be copolymerized under the action of a catalyst, after the polymerization, the catalyst is filtered and recycled, the low molecular compound of the obtained clear solution is removed in decompression and high temperature conditions, the clear solution without low molecular compound is cooled to the room temperature, and the target product is obtained. The method has the advantages of available raw materials, low cost, moderate conditions, simple technique, simple operation, environmental protection and convenient industrialization. The product made by the method can be widely applied to the enterprises which manufacture and use the LEDs, etc.

Owner:XINYAQIANG SILICON CHEM JIANGSU

Power cable insulating layer material and preparing method thereof

InactiveCN104140613AGood weather resistanceGood solvent resistancePlastic/resin/waxes insulatorsEpoxyPolyvinyl chloride

The invention relates to a power cable insulating layer material and a preparing method thereof. The material comprises, by weight, 70 parts of polyvinyl chloride, 3 parts of ethylene-vinyl acetate copolymer, 10 parts of polyvinylidene chloride, 10 parts of methyl vinyl silicone rubber, 15 parts of GNA type chloroprene rubber, 5-6 parts of epoxy fatty acid essien ester, 1 part of barium stearate, 10 parts of aluminum hydroxide, 5 parts of compatilizer, 8-10 parts of fire resistant systems and 0.1 part of antioxygen. The prepared fire resistant cable material is obvious in synergistic effect, good in antioxidant effect, high in stability and obvious in fire resistant effect, and has wide application prospects.

Owner:STATE GRID CORP OF CHINA +1

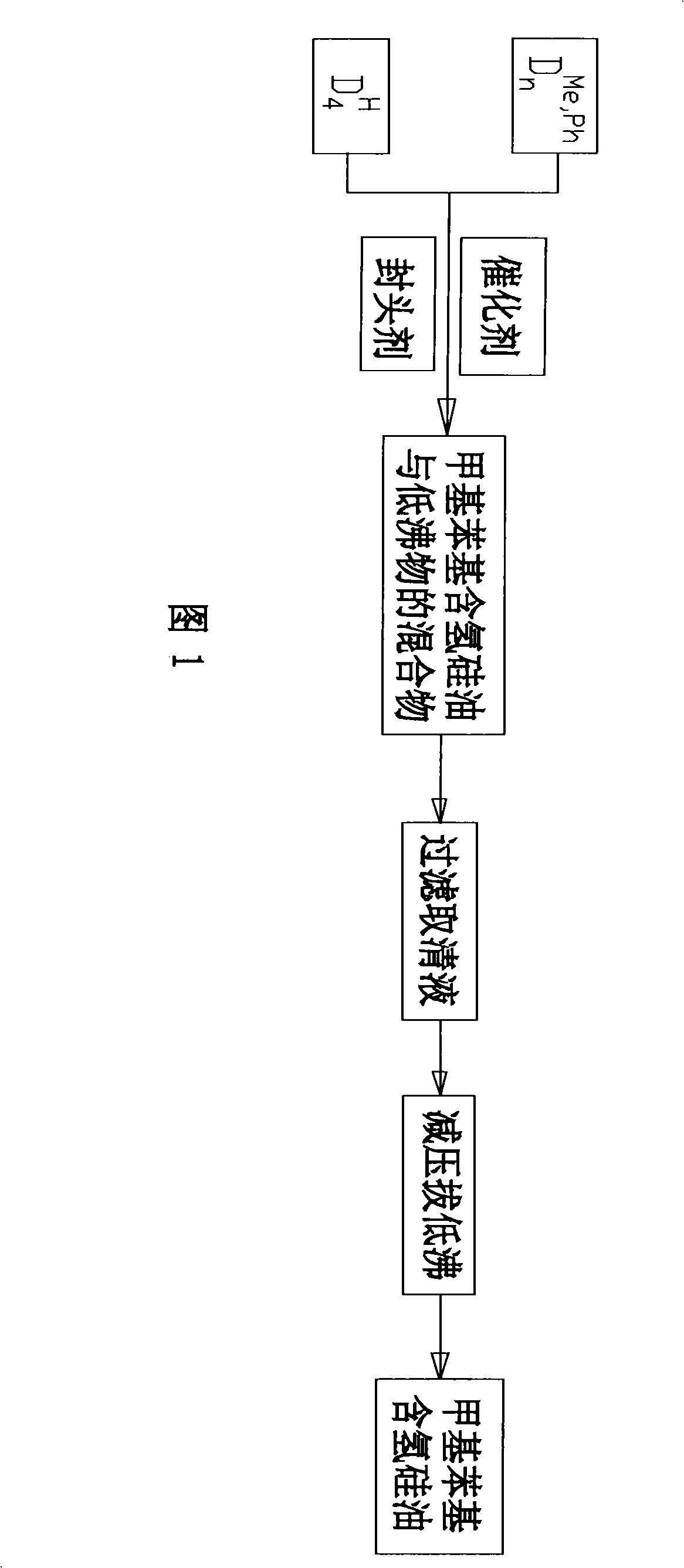

Preparation of methyl phenyl hydrogen-containing silicone oil for LED encapsulation

InactiveCN101328268ALow costMild conditionsOther chemical processesSemiconductor/solid-state device detailsLed packagingChemistry

The invention discloses a method for preparing an organic substance, in particular to a method for preparing methyl phenyl cyclosiloxane for LED packaging. The method takes methyl phenyl cyclic siloxane (Dn<Me, Ph>, n is equal to 3 and 4) and tetramethyl tetrahydric cyclotetrasiloxane (D4<H>) as monomers; under the protection of N2, an end-capping agent is added into the cyclosiloxane monomer which is subjected to pressure reduction and water removal to copolymerize under the action of a catalyst, then the filtration is performed to recover the catalyst, and the a low molecular compound in clear solution is removed under the condition of pressure reduction and high temperature and then is cooled to room temperature to produce a target product. The method has the advantages of easily-obtained raw materials, low cost, mild conditions, simple process, simple and convenient operation, no pollution, and easiness for industrialization. A product prepared by the method has good effect in the packaging process of LEDs.

Owner:HANGZHOU NORMAL UNIVERSITY

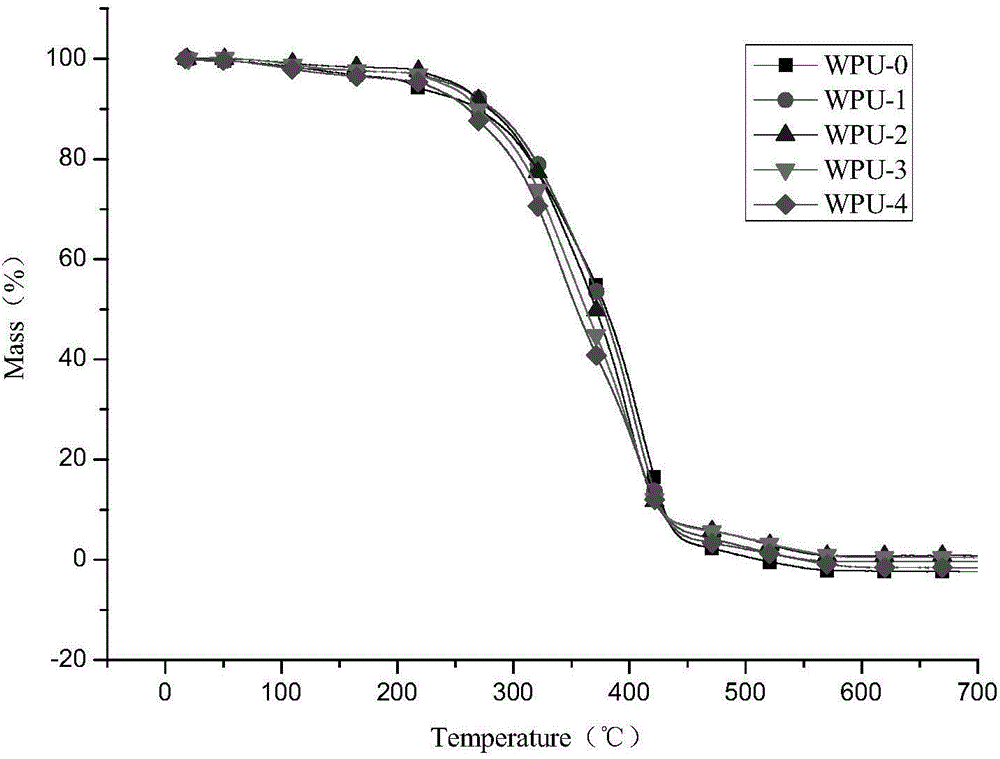

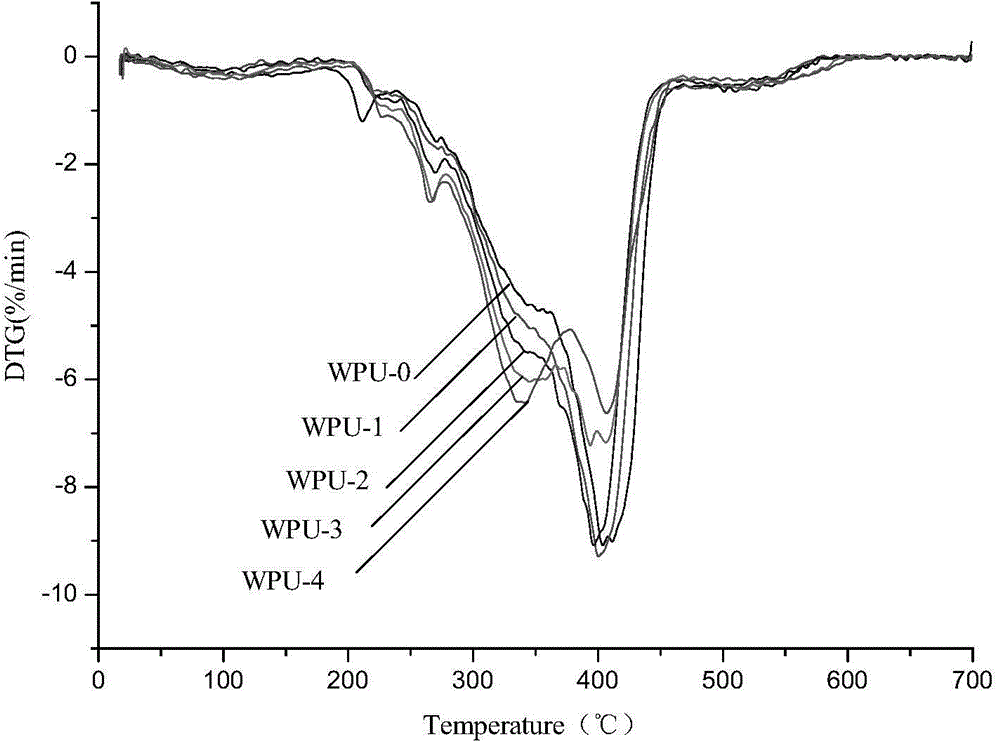

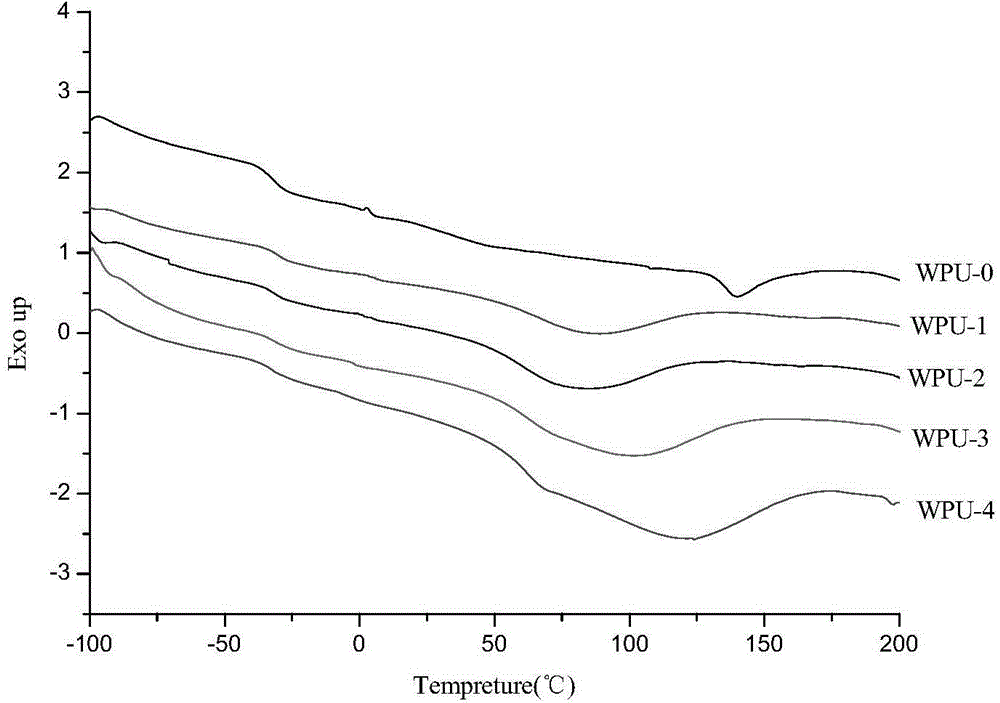

Waterborne polyurethane emulsion and preparation method thereof

InactiveCN104974327AImprove performanceKeep hydrophilicPolyurea/polyurethane coatingsLeather surface finishingPolymer scienceEmulsion

The invention discloses a waterborne polyurethane emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly carrying out vacuum dehydration on polymer polyol, a hydrophilic chain extender, isosorbide and N-methyl pyrrolidone at 90 DEG C for 1-2 hours, reducing the temperature to 80-90 DEG C, adding diisocyanate and reacting for 2.5-3 hours until NCO% reaches the theoretical value; then reducing the temperature, adding a neutralizer to an NCO-terminated polyurethane prepolymer and reacting at 60 DEG C for 0.5 hour until the neutralization degree is 95-100%; finally dispersing the polyurethane prepolymer containing isosorbide into deionized water under the high-speed shearing action of an agitator and dropwise adding a mixture of diamine and water after dispersing for a period of time, thus obtaining the waterborne polyurethane emulsion. Isosorbide is successfully introduced into the waterborne polyurethane emulsion, thus obviously improving the glossiness of waterborne polyurethane films.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

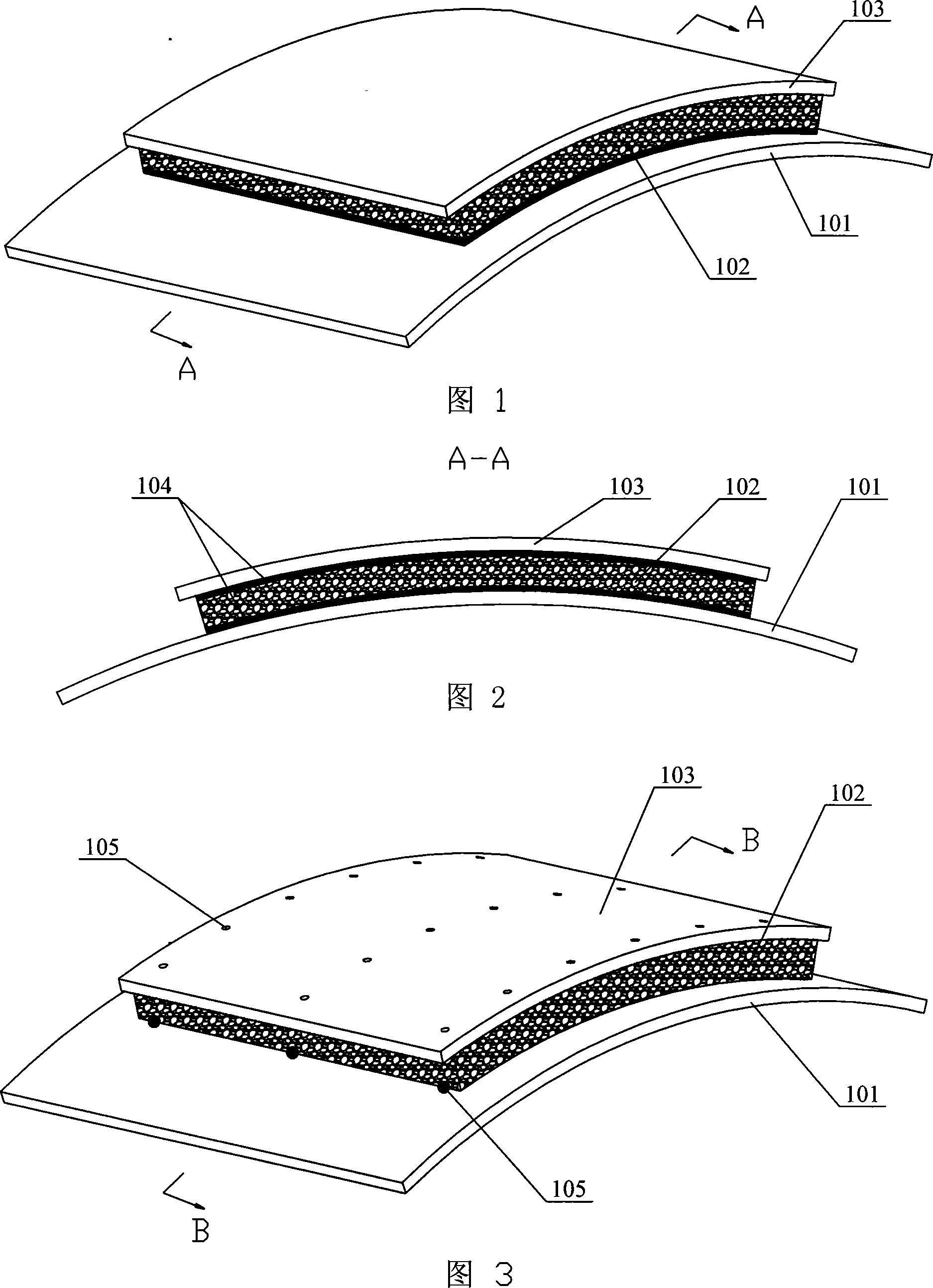

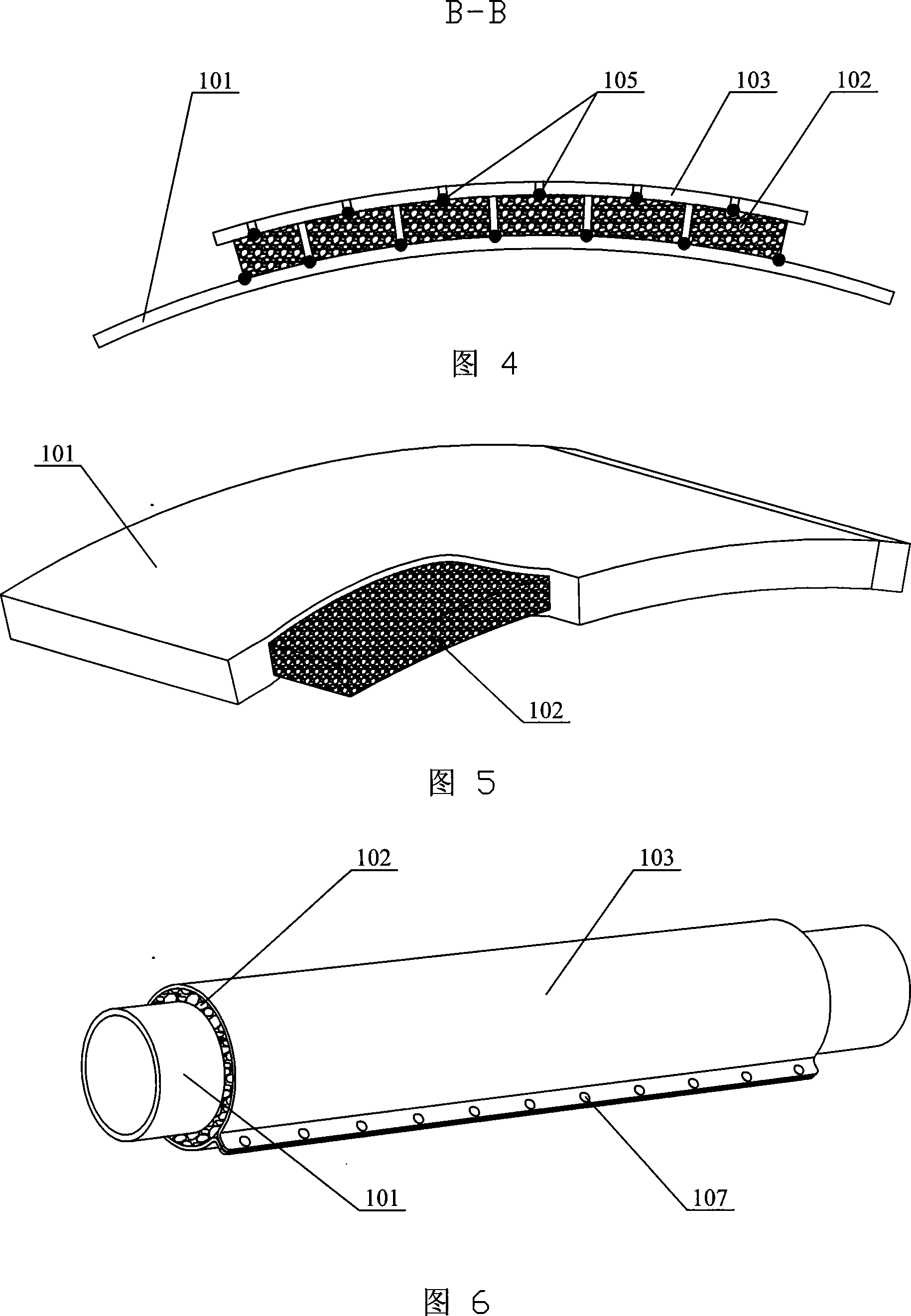

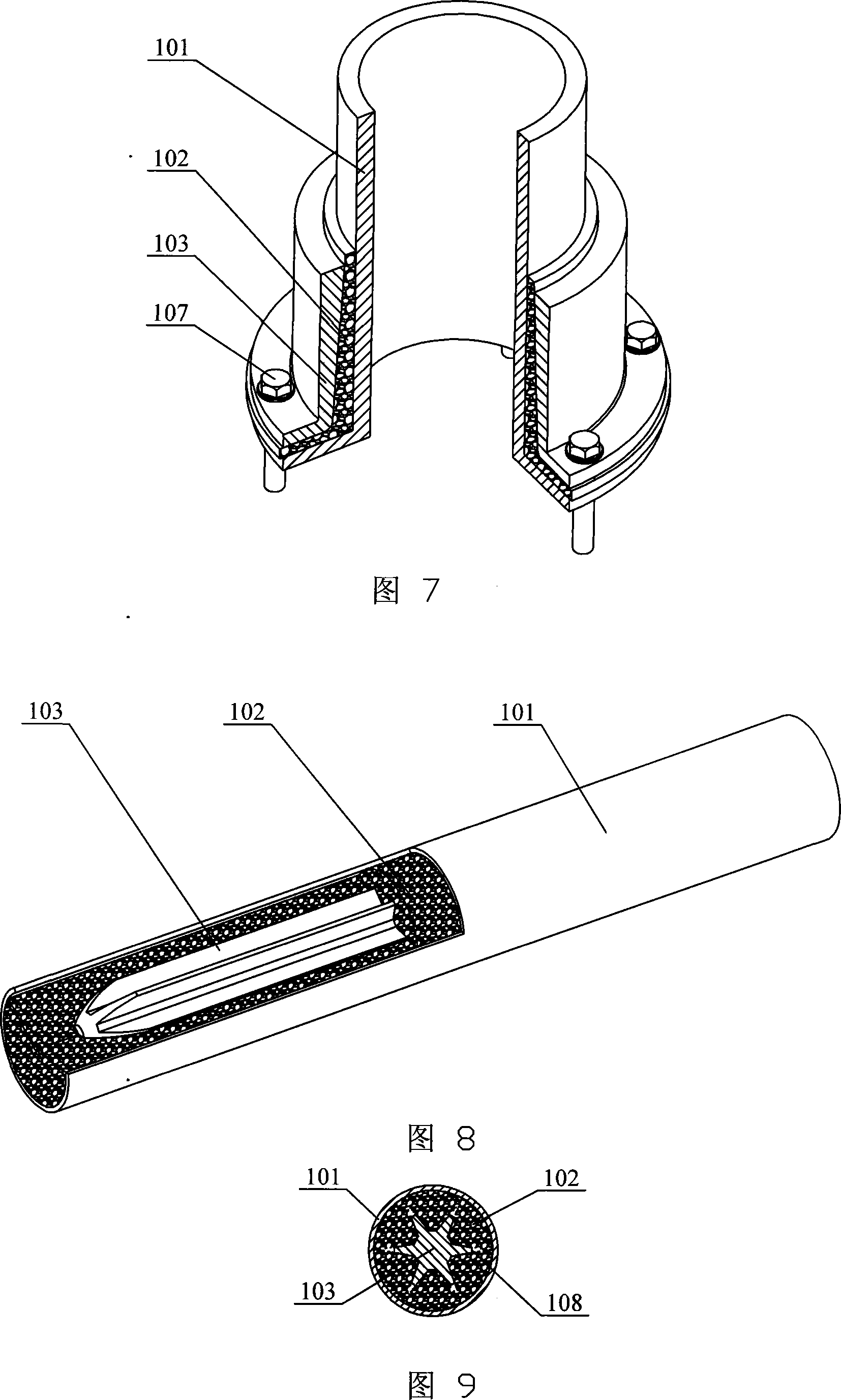

Composite damping material with interlayer being as metal rubber

InactiveCN101093008ACorrosion resistantVarious application methodsHigh internal friction springsRubber materialMetal rubber

This invention relates to a composite damp material with a metal rubber interlayer, in which a metal rubber layer is clamped between a base layer and a restriction layer, the lower surface of the metal rubber layer and the top surface of the base layer, the top surface of the rubber layer and the lower surface of the restriction layer are glued together by adhesives to prepare a composite damp material with a metal rubber interlayer, which replaces traditional rubber materials with metal rubber material having the advantages of anti-corrosion, anti-aging, high and low temperature resistant and not volatile in vacuum.

Owner:郑钢铁 +5

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

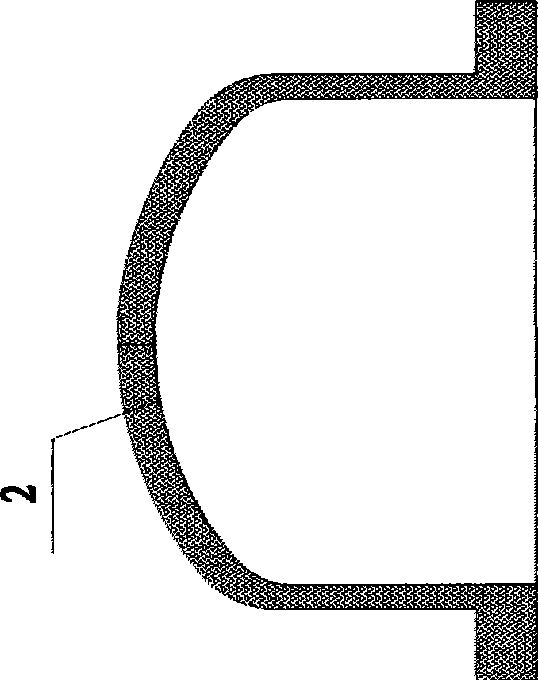

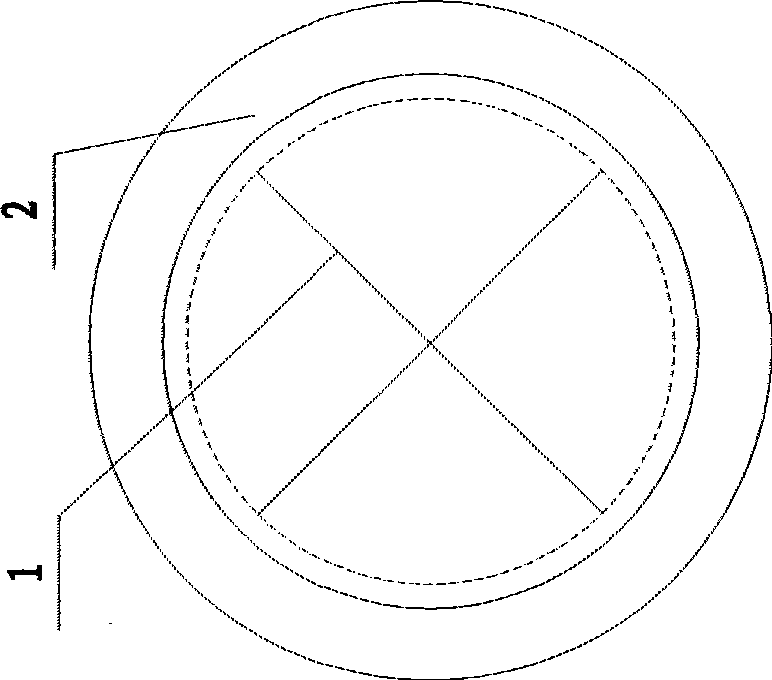

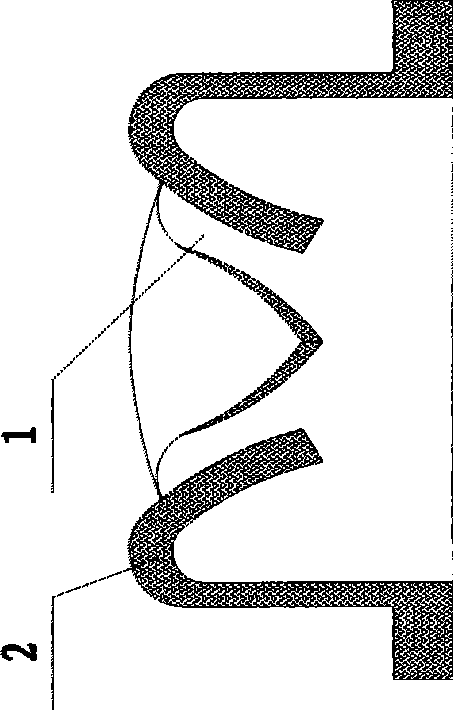

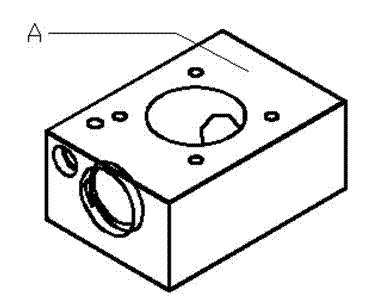

Multipurpose thimbleshaped valve respiration valve

The invention discloses a multipurpose cap-shape valve respiratory valve, comprising a valve seat, a valve core and a fixed sleeve; the valve core is of cap shape and made of elastic rubber; the cap rim of the valve core is fixed between the valve seat and the fixed sleeve; the cap body is sheathed in the central hole of the valve seat or the fixed sleeve; furthermore, the top of the cap of the valve core is provided with at least two lancings so that at least one valve clack is formed at the top of the cap. the lancings are distributed all around in a radial pattern from the axle center projected at the top of the cap to form a taper angle shape valve clack, or a C shape, V shape, U shape or opening polygon shape valve clack to cause the end part projected at the top of the cap to form a flip-shell valve clack or cause the lateral side projected at the top of the cap to form at least two valve clacks. The invention has the advantages of simple structure, few faults, long service life, low manufacturing cost, multiple functions and extensive usage, is favorable for environment protection, and has good social and economical benefits.

Owner:刘景福

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Special insulating material for electrical equipment and preparation method for special insulating material

InactiveCN105348739AGood compatibilityGood dispersionPlastic/resin/waxes insulatorsEpoxyPower equipment

The invention discloses a special insulating material for electrical equipment and a preparation method for the special insulating material. The special insulating material for the electrical equipment comprises the following components in parts by weight: 90-100 parts of epoxy resin, 15-25 parts of methyl vinyl silicone rubber, 20-25 parts of fluorosilicon resin, 15-20 parts of polytetrafluoroethylene, 10-15 parts of glass fiber, 15-20 parts of nano inorganic powders, 0.2-1 part of butyl titanate, 20-40 parts of distilled water, 1-6 parts of a compatilizer, 1-5 parts of a flame retardant, 0.3-1.2 parts of an antioxidant and 1-10 parts of a crosslinking agent. The special insulating material for the electrical equipment prepared by the invention can inhibit the space charge accumulation in the cable insulating material, improve the anti-aging property, the anti-flashover property and the anti-acidic and alkaline water-resistent property of the material, has good mechanical properties, electrical property and thermal property, and is excellent in comprehensive properties.

Owner:国网河南唐河县供电公司

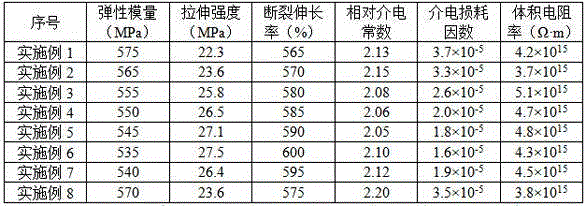

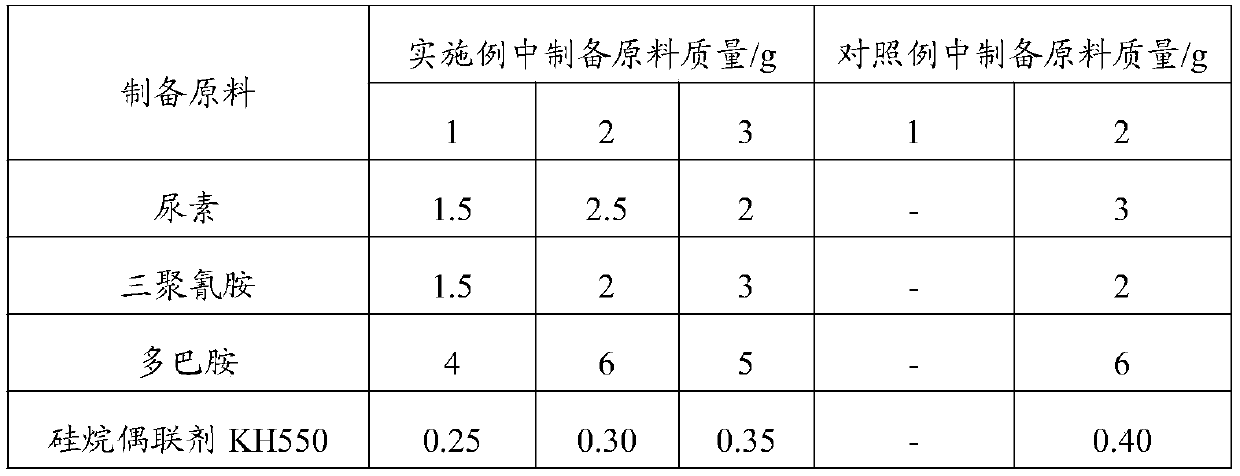

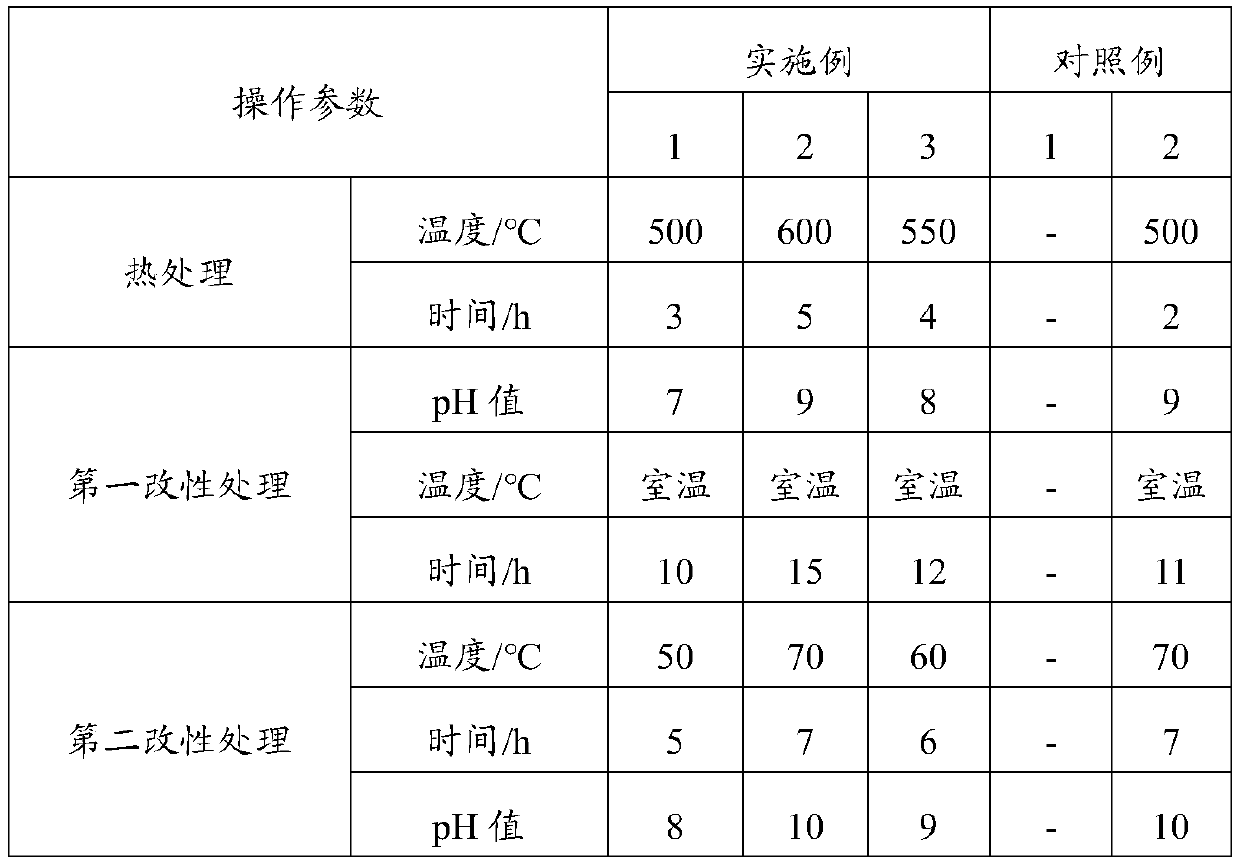

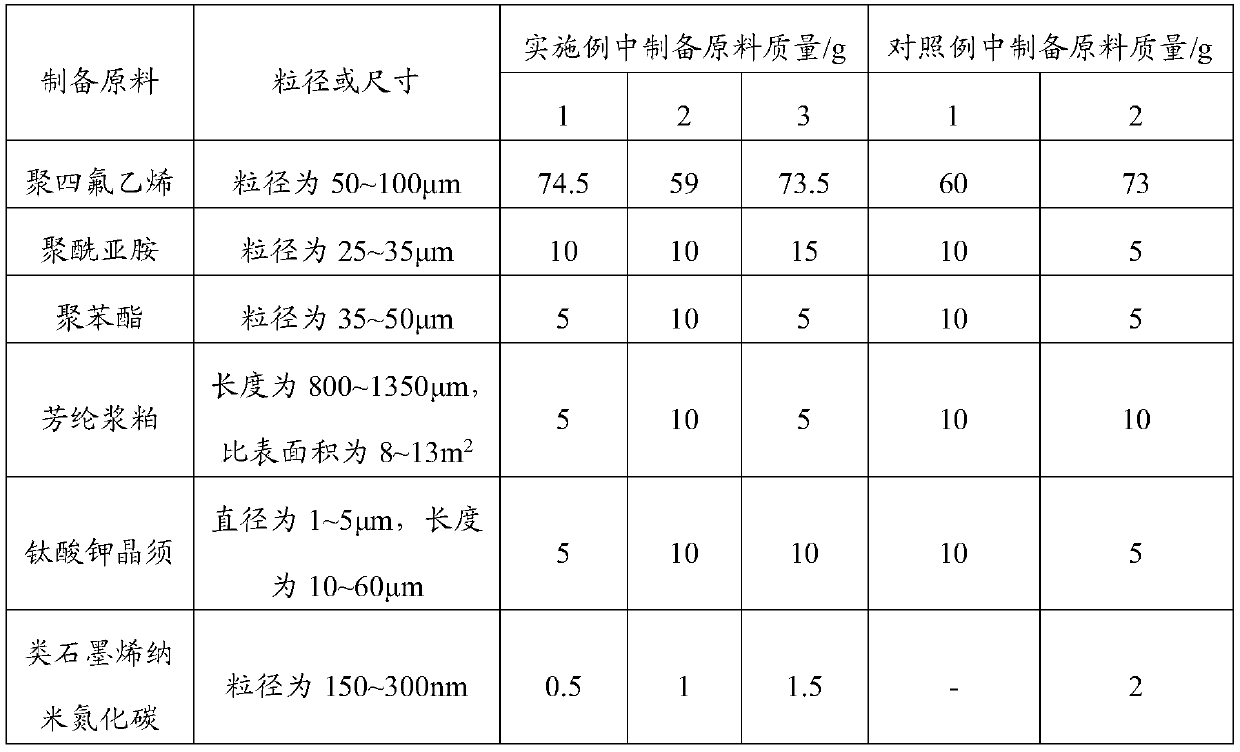

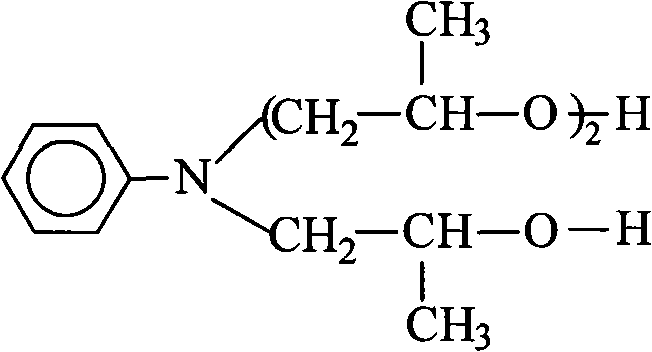

Graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as preparation method and application thereof

ActiveCN109851962AStable coefficient of frictionHigh modulus of elasticityOther chemical processesAramidUltrasonic motor

The invention relates to the technical field of composites and specifically relates to a graphene-like nano carbon nitride modified polytetrafluoroethylene friction material as well as a preparation method and application thereof. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material provided by the invention comprises the following preparation raw materials in parts by mass: 50-80 parts of polytetrafluoroethylene, 5-15 parts of polyimide, 5-10 parts of polybenzoate, 5-20 parts of aramid pulp, 5-15 parts of potassium titanate whiskers and 0.5-1.3 parts of graphene-like nano carbon nitride. The graphene-like nano carbon nitride modified polytetrafluoroethylene friction material prepared by adopting the raw materials with the proportions also has relativelylow mass wear rate and relatively high conversion efficiency on the basis of stable friction coefficient and is capable of meeting the demand for the friction material in an ultrasonic motor.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing high performance urethane elastomer for thermal barrier coating

ActiveCN101358030AIncrease elasticityFriction-resistantPolyurea/polyurethane coatingsPolymer scienceThermal insulation

The invention provides a preparation method of a thermal insulation coating high-performance polyurethane elastomer. After the reaction of terminal hydroxyl polybutadiene liquid rubber and polyisocyanate, polyurethane is added for reaction for 3 to 4.5 hours at 85 to 90 DEG C to produce isocyanate-terminated prepolymer; a certain amount of heat insulating filler is added in the prepolymer and is mixed evenly to produce component A; chain extender, antioxidant, curing agent and solvent are mixed evenly according to a certain portion to produce component B; the component A and the component B with the weight portion of 3: 1 to 6: 1 are mixed, stirred evenly, cured at room temperature to produce the thermal insulation coating high-performance polyurethane elastomer. The process of the invention used to synthesize the thermal insulation coating high-performance polyurethane elastomer is more reasonable, the product has higher quality and better comprehensive properties. The test date shows that the tensile strength is 3.50 to 5.80MPa, the elongation at break is more than 220 percent, the bond strength is more than 10.0MPa, the glass transition temperature is less than 60 DEG C below zero, the solidification shrinkage rate is less than 0.1 percent. The product is mainly applicable to aerospace industry.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

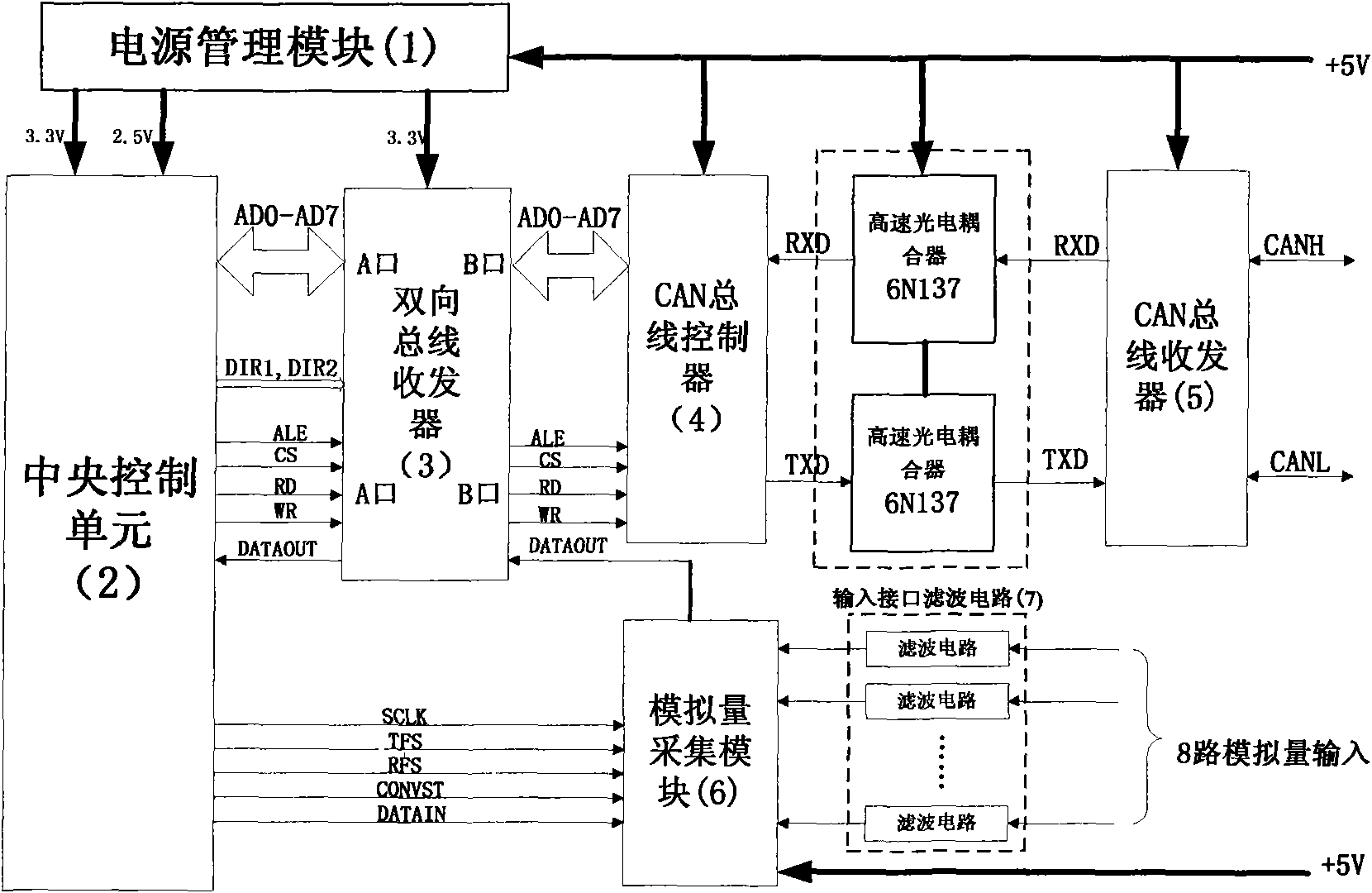

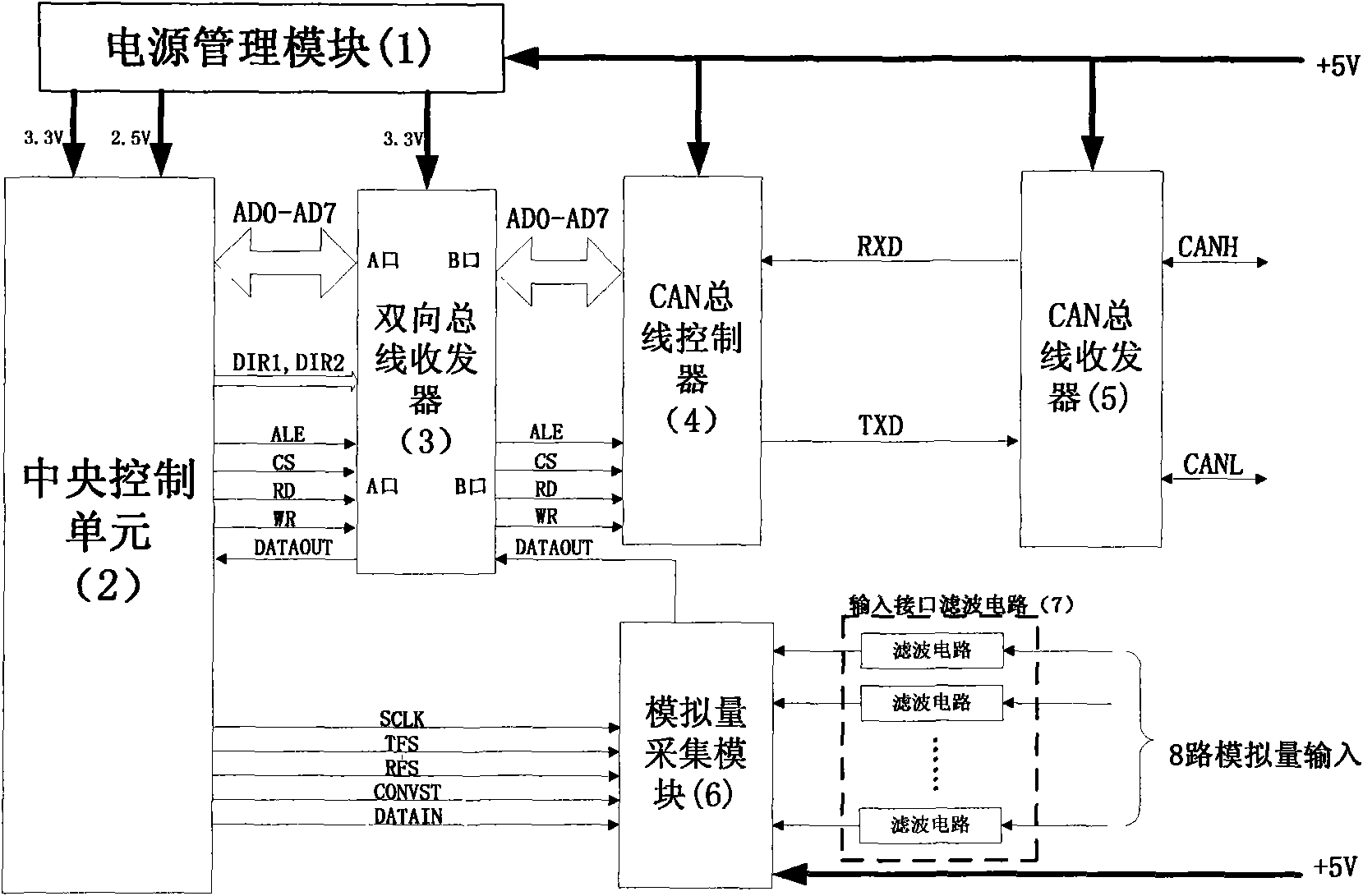

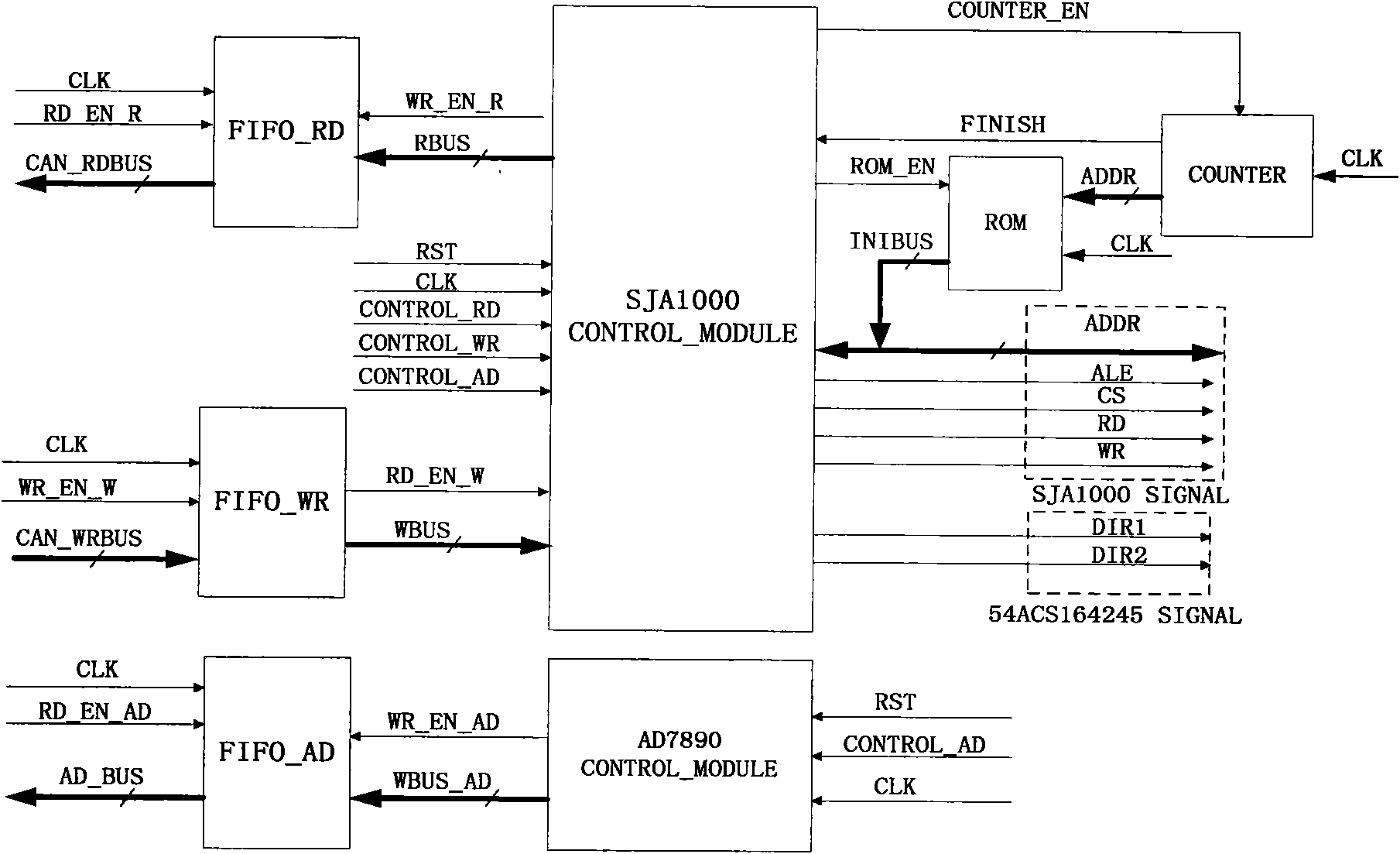

Data acquisition and communication system suitable for small satellite controller local area network

The invention relates to a data acquisition and communication system suitable for a small satellite controller local area network. The system comprises a power management module, a central control unit, a bidirectional bus transceiver, a control area network (CAN) bus controller and a CAN bus transceiver, and further comprises an analog / digital (A / D) acquisition module and an input interface filter circuit, wherein the power management module is used for supplying power to the whole system; the central control unit is used for controlling the bidirectional bus transceiver, the CAN bus controller and the A / D acquisition module; the bidirectional bus transceiver is used for performing chip level conversion; the CAN bus controller supports CAN bus technical regulations; the CAN bus transceiver is directly and electrically connected with a physical bus; the CAN bus controller and the CAN bus transceiver realize data communication through two data transceiving wires; the A / D acquisition module is used for acquiring analog data, converting the analog data into digital data and inputting the digital data to the central control unit; and the input interface filter circuit performs analog filtering. The A / D acquisition module is used for performing satellite analog acquisition to obviously extend a dynamic acquisition range and reduce energy consumption. The system has the advantages of the realization of the satellite digital and analog acquisition and communication, and high extendibility and reliability.

Owner:NAT SPACE SCI CENT CAS

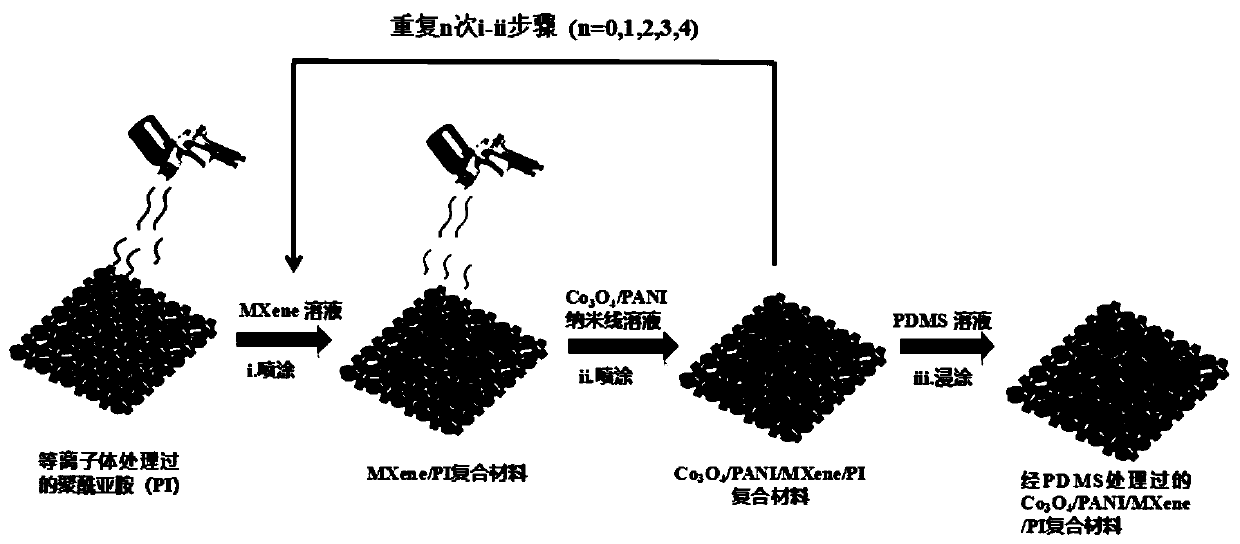

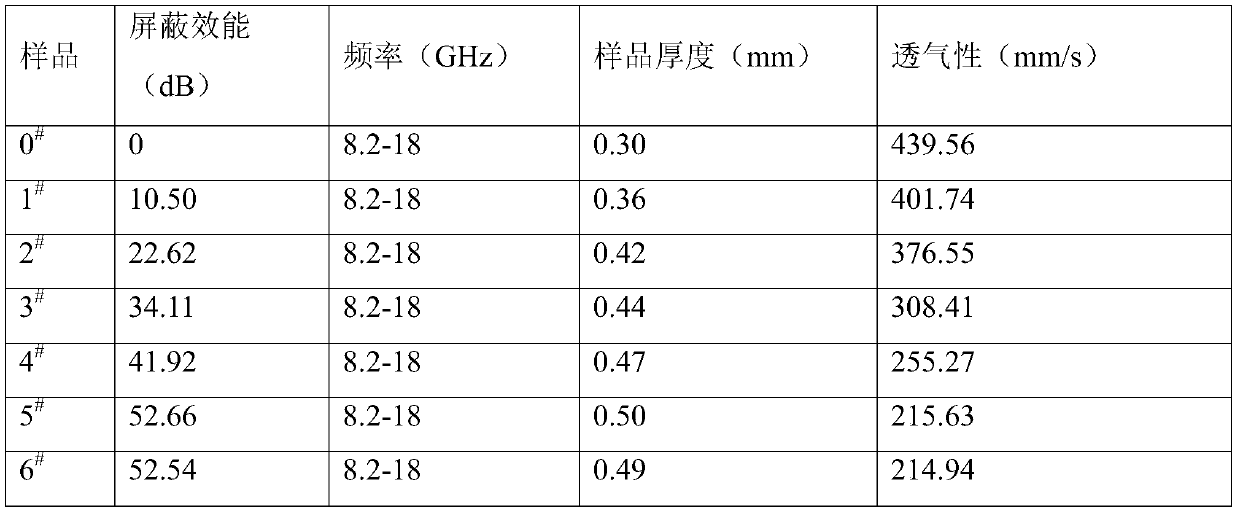

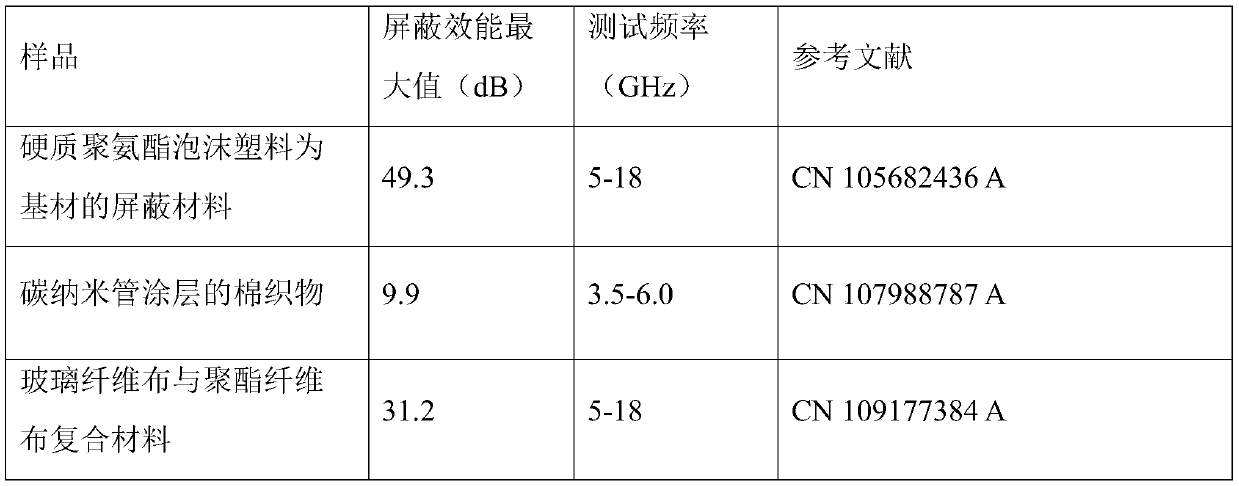

Preparation method of Co3O4/PANI/MXene/PI electromagnetic shielding fabric

ActiveCN110846881AGood shielding performanceBroad application prospectsUltrasonic/sonic fibre treatmentLiquid repellent fibresPlasma treatmentPolymer chemistry

The invention relates to a preparation method of a Co3O4 / PANI / MXene / PI electromagnetic shielding fabric. The preparation method comprises the steps: pretreating a PI fabric, and then carrying out plasma treatment; spraying MXene solution to the surface of the treated PI fabric for reaction; spraying Co3O4 / PANI nanowire solution on the obtained MXene / PI composite for reaction; treating the obtainedCo3O4 / PANI / MXene / PI composite in a PDMS (polydimethylsiloxane) solution. The preparation method is simple and has mild conditions, and the obtained electromagnetic shielding fabric has excellent conductivity and electromagnetic shielding performance.

Owner:DONGHUA UNIV

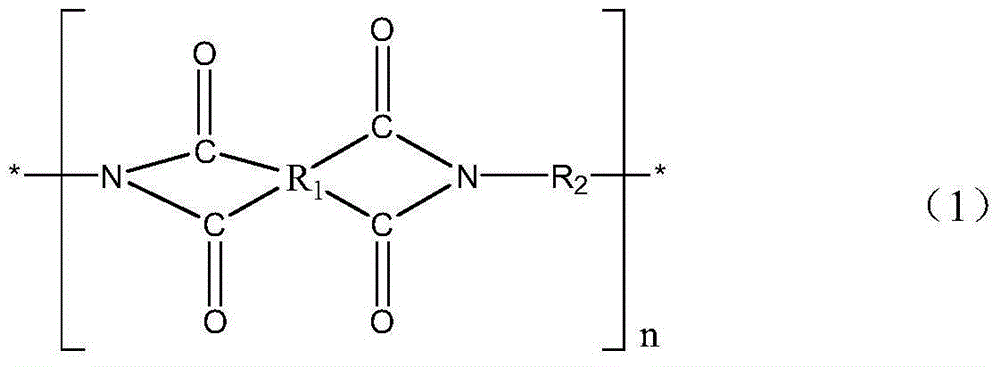

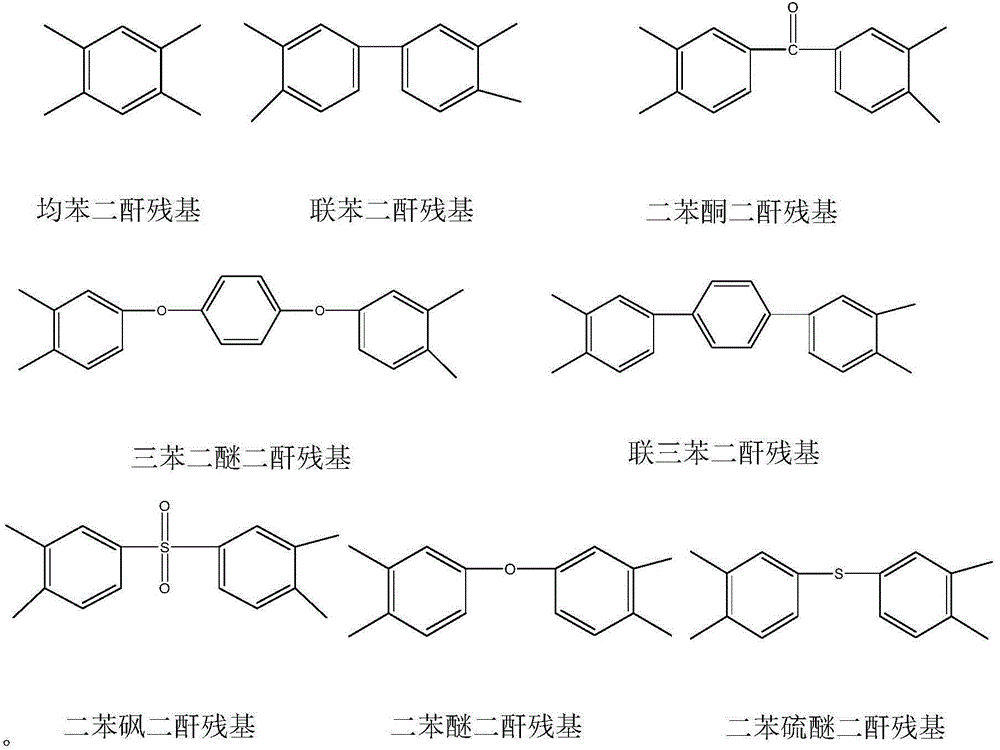

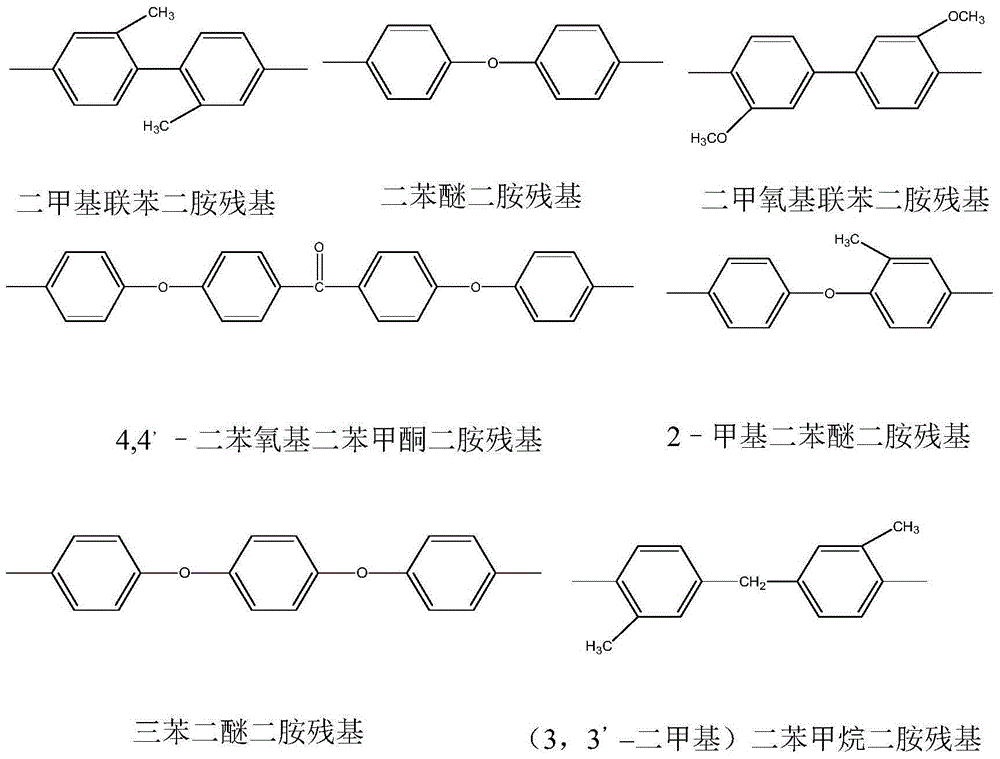

Polyimide nanofiber flocculus, preparation method and application thereof

InactiveCN105019141AImprove filtration efficiencyImprove breathabilityHeating/cooling textile fabricsFiltration separationAir filtrationFiber

The invention provides a polyimide nanofiber flocculus, a preparation method and application thereof. The structure of the polyimide nanofiber flocculus is described in the following formula (1). In the formula (1), R1 denotes dianhydride residues of aromatic-containing rings. R2 denotes diamine residues of romatic-containing rings. N is an integer larger than 100. The polyimide nanofiber flocculus provided by the invention is featured by being high in filtration efficiency, good in air permeability, permanent in flame retardance and endurable in high temperature and is less susceptible to deformation and has anti-bacteria, mould-proof and electrostatic adsorption functions and has an extensive application prospect in air filtrations fields such as high-temperature filtration, high-end filtration and sterile filtration.

Owner:JIANGXI ADVANCED NANOFIBER S&T CO LTD

Polyimide ultra-short fiber and preparation method thereof

ActiveCN107675288AGood insulationAchieve decentralizationHeating/cooling textile fabricsMonocomponent synthetic polymer artificial filamentTemperature treatmentSlurry coating

The invention discloses a polyimide ultra-short fiber and a preparation method thereof and relates to the field of fiber preparation. According to the preparation method disclosed by the invention, batch preparation of polyimide fiber products with a fiber diameter nanoscale and a length micro scale can be realized. For the polyimide ultra-short fiber disclosed by the invention, the length of thefiber is 2 to 500mu m, the diameter of the fiber is 0.1 to 50mu m, and specific area is 2 to 30m<2> / g. By utilizing the physical and chemical properties at different heat treatment temperatures in thepreparation process of the polyimide fiber, dispersion and ultrashort properties of the fiber are realized more easily by adopting physical and mechanical methods in a state that the polyimide fiberis incompletely imidized; then complete imidization of the polyimide fiber is realized by high-temperature treatment; finally, the polyimide ultra-short fiber is obtained by a method of mechanical pulverization, lapping and shifting. The polyimide ultra-short fiber obtained by the preparation method disclosed by the invention has the characteristics of high and low temperature resistance, ultraviolet irradiation resistance, good insulating property and the like, and can be used for preparing a slurry coating solution, reinforcing resin, rubber and the like, forming pulp and the like.

Owner:JIANGXI XIAN CAI NANOFIBERS TECH

Modified composite type surface active agent

InactiveCN106693829AImprove performanceWeather resistantTransportation and packagingMixingBetaineAlpha-olefin

The invention discloses a modified composite type surface active agent. The raw materials is prepared from modified organosilicone surface active agent, polyether polyamine organosilicone surface active agent, fluorine silicon surface active agent, triethanolamine, ethylene diamine tetraacetic acid, sodium dodecyl benzene sulfonate, sodium oxalate, sodium dodecyl sulfate, cetyl trimethyl ammonium bromide, sodium di(2-ethyl-hexyl)sulfosuccinate, Tween 40, polysorbate 40, sodium alpha-olefin sulfonate, dodecyloxy hydroxypropyl betaine, dodecylbenzene sulfonic acid triethanolamine salt, tetraalkyl ammonium chloride and ethyl alcohol. The prepared modified composite type surface active agent has excellent high and low temperature resistance, corrosion resistance and weather resistance, and has excellent chemical stability and waterproof oil repellency at the same time.

Owner:柏青龙

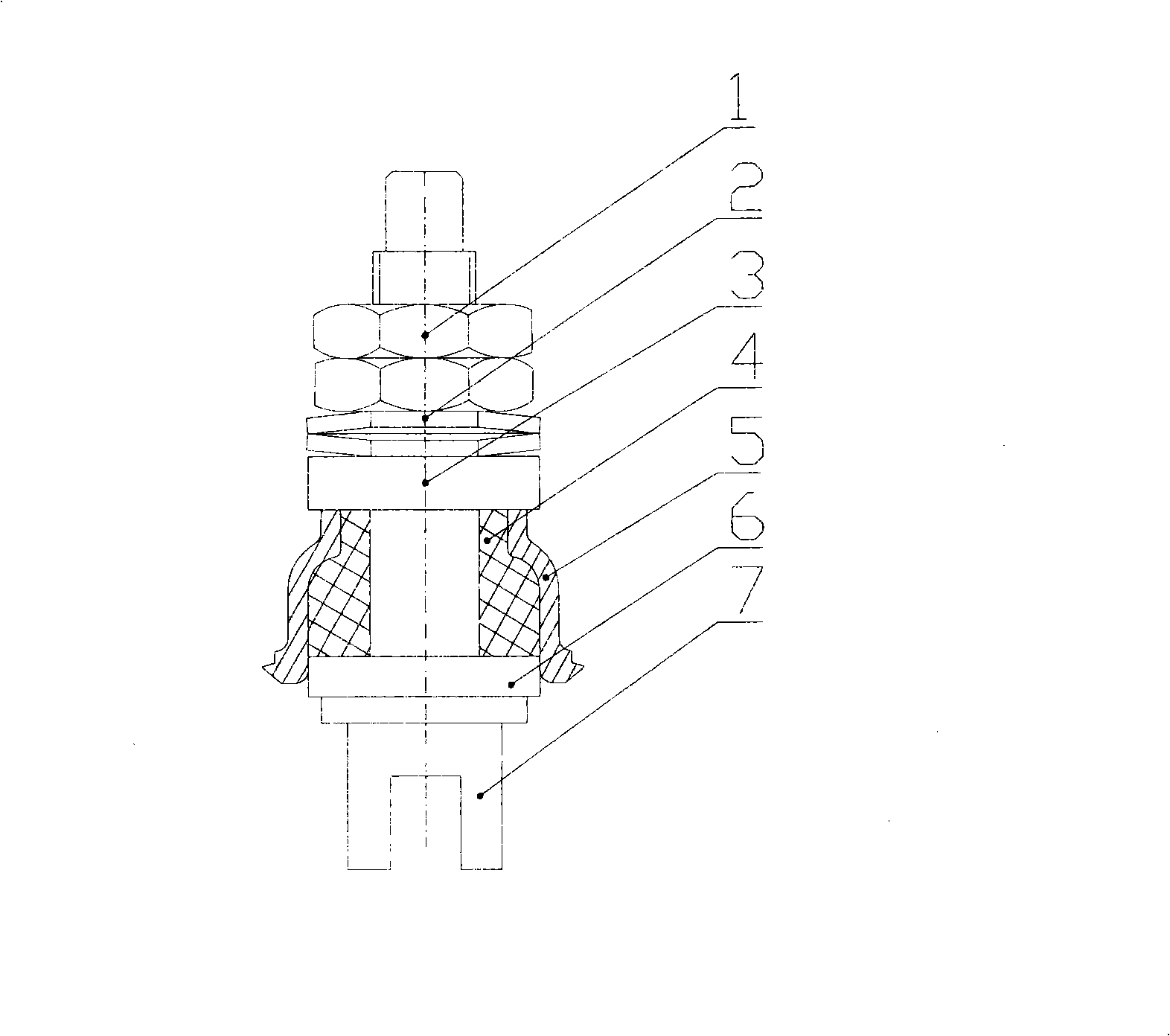

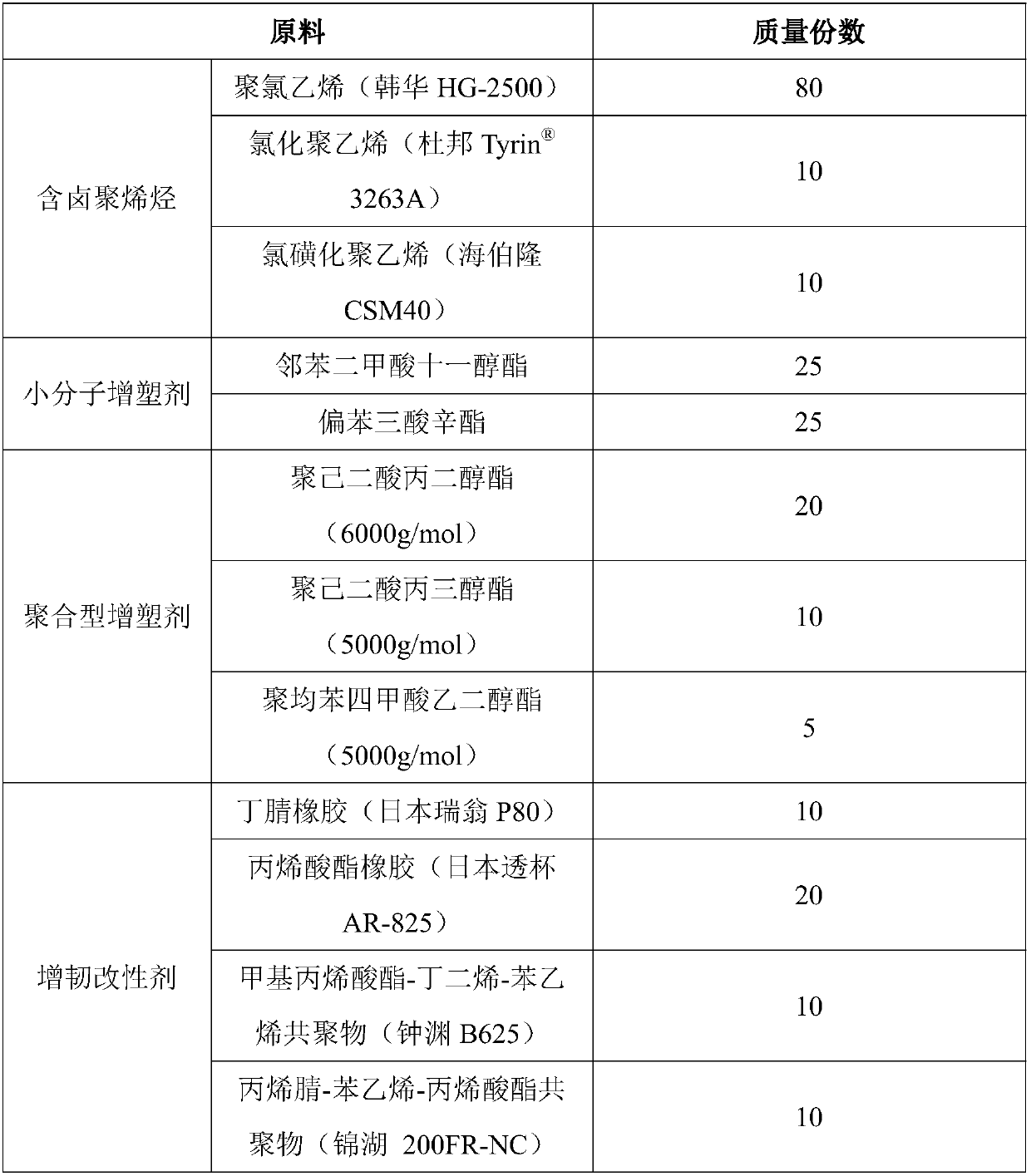

Apparatus for sealing pole post of hydrogen nickel accumulator

InactiveCN101350403ACorrosion-resistant service lifeSimple processSmall-sized cells cases/jacketsCell sealing materialsNickelElectron beam welding

The invention relates to a pole sealing device for a MH / Ni battery, comprising a pole (7). A nut (1), a disc gasket (2) coated by round structures in turn from top down, a ceramic gasket A (3), a sealing member (4), a pole sleeve (5), a ceramic gasket B (6) are coated on the surface of the pole (7). The pole (7), the ceramic gasket B (6) and the sealing member (4) are inserted into the pole sleeve (5) through the sealing member (4); the ceramic gasket A (3) is coated on the periphery of the pole sleeve (5), and fastened by the nut (1) and the disc gasket (2); the pole sleeve (5) is integrated with the battery shell by vacuum electron-beam welding. The invention settles the problem of pole sealing of MH / Ni batteries, and has the advantages of simple process, easy assembly, low cost and sound sealing performance, etc.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Thermal insulation material

The invention discloses a novel thermal insulation material, and the composition comprises expanded perlite, cement, gypsum powder, fibers, redispersible rubber powder, casein glue, and the like. The thermal insulation material has the advantages of high strength, aging resistance, excellent thermal insulation effect, energy conservation, environmental protection, fire protection, sound insulation, low cost, convenient use, and the like. The novel thermal insulation material can be directly applied on buildings, containers, pipelines, reactors, household appliances and the like through a plurality of construction methods, thereby achieving the effects of thermal insulation and energy conservation.

Owner:ORDOS DONGRONGCI TECH DEV

Preparation method and application of polyhedral oligomeric silsesquioxane skeleton containing vinyl silicone oil

ActiveCN103289096AEasy to prepareMeet packaging requirementsSemiconductor devicesMethyl phenyl polysiloxaneMechanical property

The invention relates to an organic silicon rubber for LED packaging. In order to solve the problems that during direct physical blending of POSS (polyhedral oligomeric silsesquioxane) with vinyl silicone oil and hydrogen containing silicone oil, POSS has poor compatibility with vinyl silicone oil and hydrogen containing silicone oil and is very easy to precipitate, so that the light transmittance and mechanical properties of the product can be affected, the invention provides a preparation method of a POSS skeleton containing vinyl silicone oil. The method includes: mixing POSS with one or two of dimethyl polysiloxane and methylphenyl polysiloxane at any proportion to obtain a mixture, in the presence of a catalyst, carrying out end-capping with a vinyl end-capping reagent, and performing a polymerization reaction to obtain the POSS skeleton containing vinyl silicone oil. The preparation method is simple. The invention also provides application of the POSS skeleton containing vinyl silicone oil in LED packaging materials.

Owner:HANGZHOU NORMAL UNIVERSITY

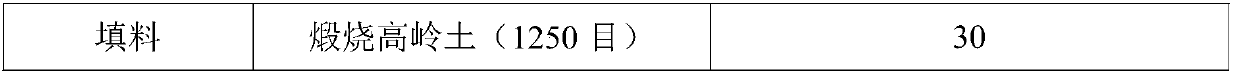

Elastomer-based insulating cladding material for charging pile cable and preparation method of elastomer-based insulating cladding material

ActiveCN107556645AGood high and low temperature resistanceExcellent resistance to solvent extractionPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an elastomer-based insulating cladding material for a charging pile cable and a preparation method of the elastomer-based insulating cladding material. The insulating claddingmaterial is prepared from the following raw materials in parts by mass: 100 parts of halogen-containing polyolefin, 35-85 parts of a small-molecule plasticizer, 15-45 parts of a polymeric plasticizer,30-80 parts of a toughening modifier, 10-25 parts of a flame-retardant compatible agent, 3-9 parts of a flame retardant, 3-9 parts of a lubricant, 5-25 parts of a heat stabilizer, 3-9 parts of an antioxidant, 3-9 parts of an ultraviolet stabilizer, 3-9 parts of a smoke suppressant and 15-45 parts of filler. The preparation method of the elastomer-based insulating cladding material is simple, thematerials are mixed uniformly and subjected to melting mixing and extrusion pelletizing, and the insulating cladding material can be obtained. The elastomer-based insulating cladding material for thecharging pile cable has the excellent properties of high and low temperature resistance, solvent extraction resistance, tear resistance, heat resistance, weather resistance, aging resistance and the like, and has advantages of high strength, high toughness, excellent flame retardancy and insulation performance and low smoke; the preparation process is simple, and the preparation cost is low.

Owner:东莞海铂新材料科技有限公司

Local anodic oxidation method for surface of workpiece

The invention discloses a local anodic oxidation method for the surface of a workpiece. The method comprises the following steps of: putting the workpiece into a pretreatment solution, and treating the workpiece for 20 to 30 seconds; washing and drying the pretreated workpiece; firmly sticking a polyimide adhesive tape to the oxidation-free surface of the workpiece, and removing bubbles on the adhesive tape and the surface of the workpiece; performing anodic oxidation treatment according to the conventional oxidation flow; and tearing down the adhesive tape on the surface of the oxidized workpiece, and wiping the residual adhesive on the surface of the workpiece by using an organic solvent. The local anodic oxidation method has the advantages of reducing the machining frequency, reducing the machining cost of the workpiece and avoiding the defects of poor repeated positioning precision and low product qualification rate; and the oxidation-free surface of the workpiece is effectively shielded by the polyimide adhesive tape.

Owner:SHANGHAI REAL INDAL

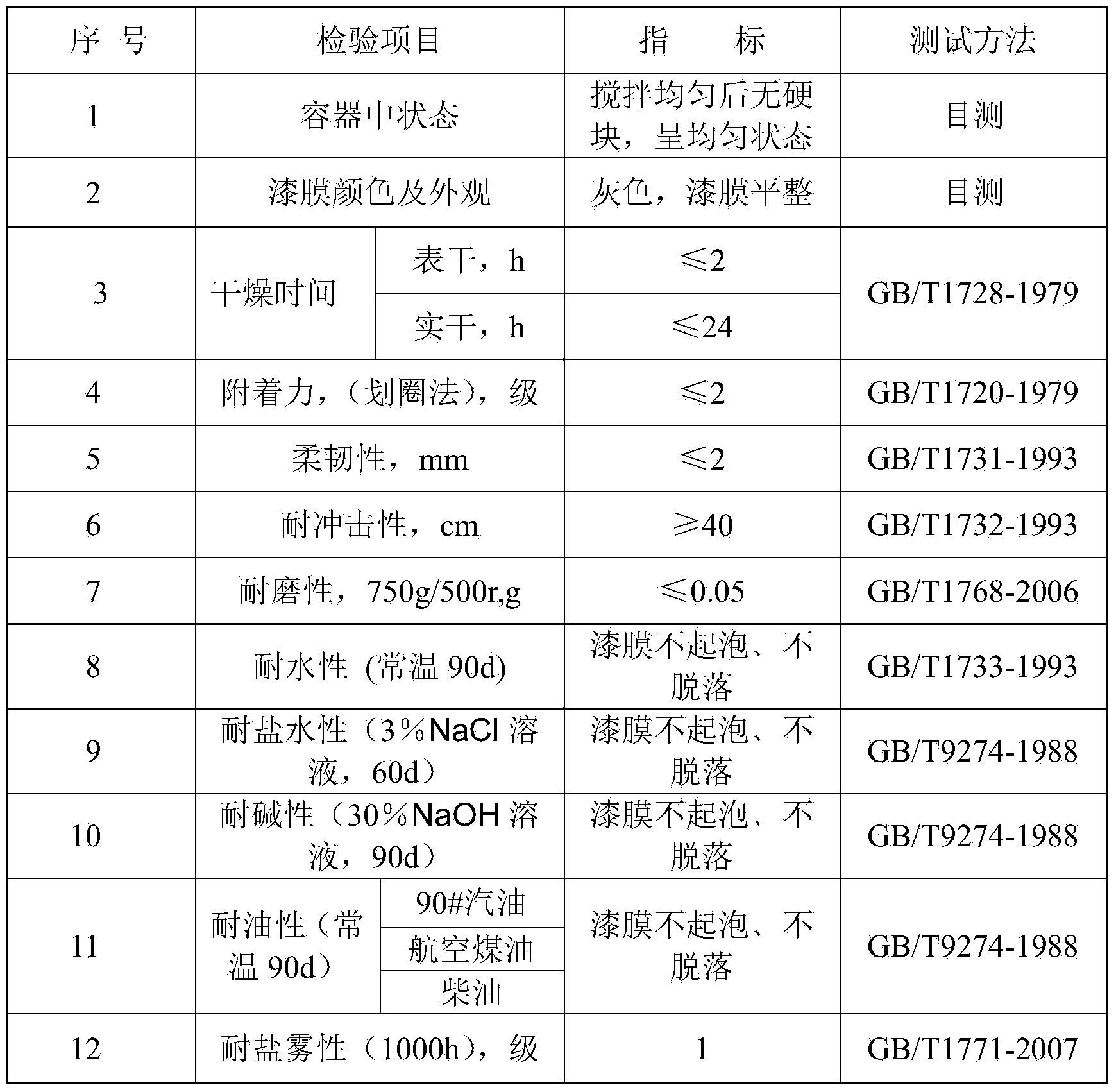

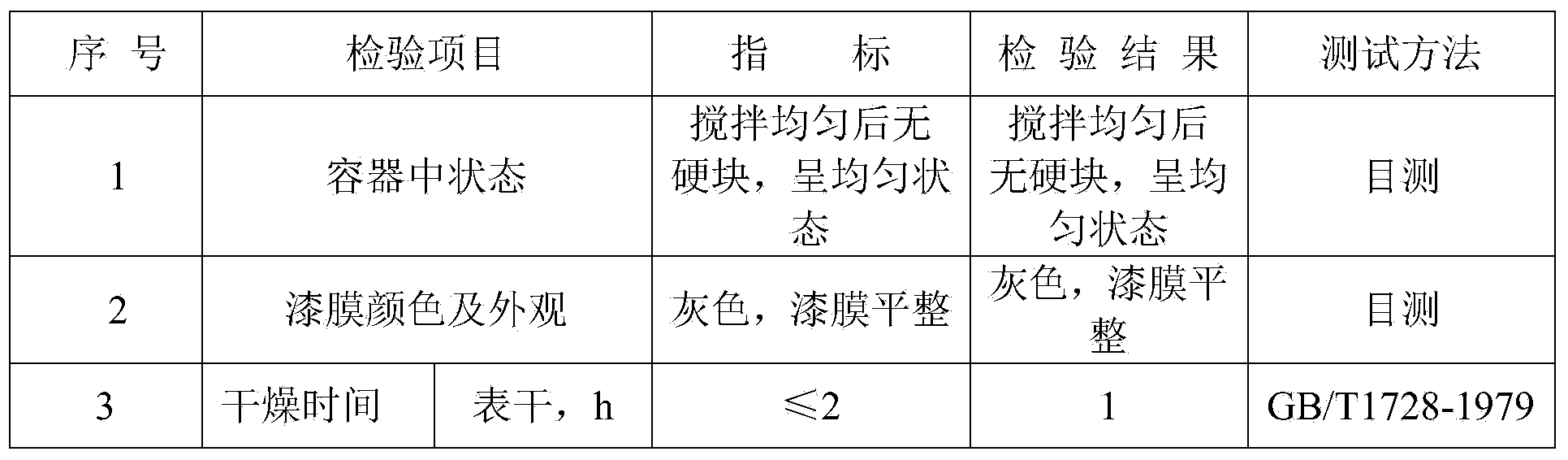

Aqueous anticorrosive epoxy coating for steelworks

InactiveCN103666197AImprove wear resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention relates to an aqueous anticorrosive epoxy coating for steelworks. The coating is composed of a component A and a component B, a weight ratio of the component A to the component B is 100:30, the component A is composed of 50-65 parts of an aqueous epoxy resin, 5-13 parts of deionized water, 0.4-0.9 parts of a dispersant, 0.1-0.6 parts of an antifoaming agent, 0.3-0.6 parts of a wetting agent, 4-10 parts of ultrafine zinc phosphate, 5-12 parts of titanium ash, 9-22 parts of hollow glass bead, 6-12 parts of silicon micro-powder, 3-6 parts of precipitated barium sulfate, 0.3-0.6 parts of a thickening agent, 1.2-2.5 parts of a metal corrosion inhibitor, and 0.1-0.2 parts of an in-tank bactericide; and the component B is an aqueous epoxy hardener. The coating is a completely-aqueous environmentally-friendly coating, contains no chemical solvents, has better wear and corrosion medium resistances than like coatings after film solidification, and can effectively reduce the product cost.

Owner:CHANGZHOU CITY LATE COATINGS

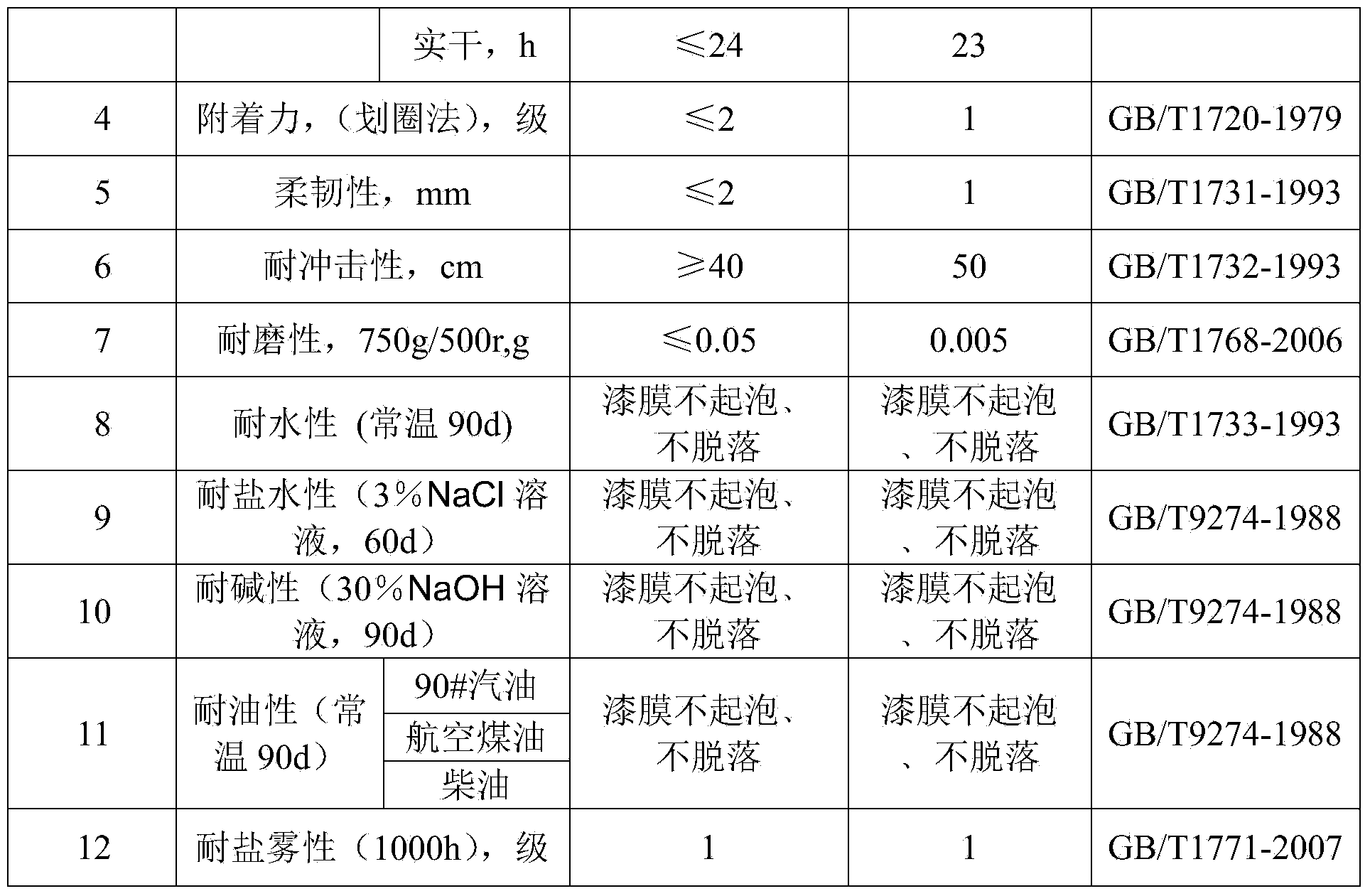

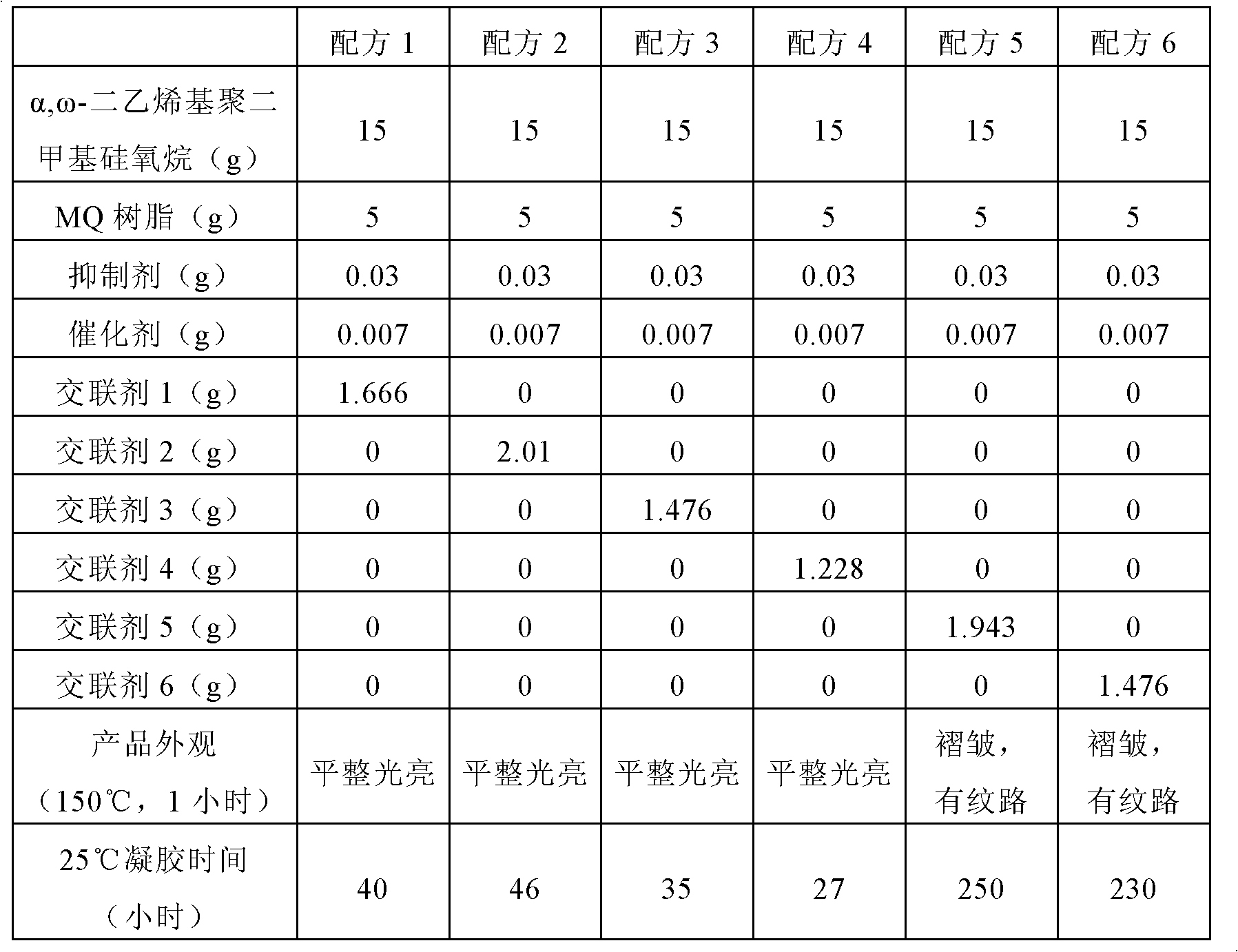

Hydrogen-based silicone resin containing trifunctional group chain element and preparation method thereof

The invention relates to hydrogen-based silicone resin containing a trifunctional group chain element and a preparation method thereof. The hydrogen-based silicone resin containing the trifunctional group chain element has the following structural general formula: (R12HSiO1 / 2) a (R2SiO3 / 2) b, wherein a is not less than 3 and is of an integer, b is not less than 1 and is of an integer, the relation between a and b meets the condition that b / a is not less than 0.33 and not more than 4, R1 is of alkyl with 1-3 carbon atoms, and R2 is of phenyl or alkyl with 1-3 carbon atoms. The preparation method sequentially comprises the following steps of: 1) mixing trifunctional alkoxy silane, tetra-alkyl-dihydro-disiloxane, an organic solvent and an acid catalyst; 2) adding water to perform hydrolysis on the trifunctional alkoxy silane; and 3) evaporating out byproducts so as to get the hydrogen-based silicone resin disclosed by the invention. The hydrogen-based silicone resin disclosed by the invention can be used for cross-linking and curing reaction of LED (light-emitting diode) packaging materials and other addition type polysiloxane, and has the characteristics of high curing speed and smooth appearance of the obtained product.

Owner:BEIJING KMT TECH

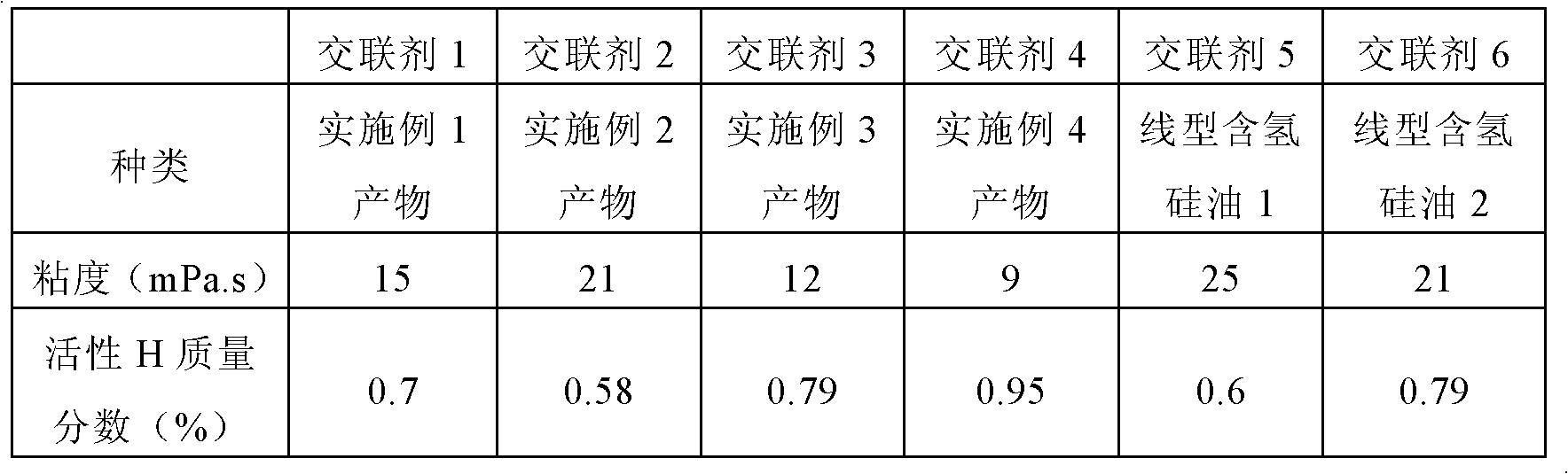

Anti-torsion data power composite cable and manufacturing method thereof

ActiveCN101562062ASimple structureAdvanced technologyPlastic/resin/waxes insulatorsInsulated cablesCapacitanceEngineering

The invention discloses an anti-torsion data power composite cable and a manufacturing method thereof. The composite cable comprises a cable core, an outer jacket, and is provided with a data line core and a power control line core; wherein, the data line core is formed by stranding of quad and positioned in the center of cable, the quad is provided with two insulated cores and drainage lines, and wounded and wrapped with a plastic-aluminum composite strip sub-shielding layer, the data line core is provided with a main shielding layer, the power control line core is formed in a manner that multi-assemble reinforced cores are mounted on the periphery of the data line core, the data line core and the cable core are provided with a composite cushion layer respectively. The invention has the advantages of simple and reasonable structure, advanced technique, high mechanical strength of products, low capacity and low attenuation. The invention is also characterized by strong anti electromagnetic interfere property, shock resistance, fine torsion bending resistance property, oil proofness, chemical solvent resistance, hard wearing, high / low temperature resistance, water erosion resistance, environmental leaching and loss resistance, ensuring stable property of cables in various severe environments so that cable property is reliable and safe.

Owner:BAOSHENG SCI & TECH INNOVATION

Carbon nanotube in situ reinforced LED packaging silica gel and preparation method thereof

InactiveCN103045156AHigh light transmittanceGood adhesionNon-macromolecular adhesive additivesSemiconductor devicesIn situ polymerizationCarbon nanotube

The invention discloses a carbon nanotube in situ reinforced LED packaging silica gel and a preparation method of the carbon nanotube in situ reinforced LED packaging silica gel and relates to an LED packaging silica gel and the preparation method of the LED packaging silica gel. The carbon nanotube in situ reinforced LED packaging silica gel comprises the preparation steps of: 1, carrying out plasma treatment on carbon nanotubes for 1 to 2hours; 2, adding a certain amount of treated carbon nanotubes into an appropriate amount of dimethyl polysiloxane monomer, carrying out in-situ polymerization under the action of an acidic catalyst, after the polymerization is finished, adding an alkaline neutralizing agent to be neutralized in a neutral state, or carrying out water washing to be neutral, and removing residual moisture and obtaining simethicone which is modified by carbon nanotubes and of which the tail end is hydroxyl; and 3, uniformly mixing the product obtained in the step 2 with a crosslinking agent and a catalyst to prepare a potting silica gel which comprises a component A and a component B. With the adoption of the carbon nanotube in situ reinforced LED packaging silica gel, the mechanical property of the silica gel is improved, simultaneously, the silica gel is ensured to have high light transmittance.

Owner:HANGZHOU COLORICH CHEM MATERIALS

Thermal insulation sheet material and preparation method thereof

The invention, belonging to the field of building materials, particularly relates to a lightweight thermal insulation sheet material for building walls. The thermal insulation sheet material comprises the following ingredients: 8.5-10.5 weight portions of fly ash floating bead, 30-38 weight portions of closed cell perlite, 43-52 weight portions of cement, 7-8.5 weight portions of bentonite, 0.04-0.06 weight portions of cellulose ether, 0.07-0.09 weight portions of short fiber, 0.04-0.06 weight portions of wood fiber, and 0.3-0.4 weight portions of gelatine powder. The thermal insulation sheetmaterial is prepared by using organic materials, and has the characteristics of no toxicity, good thermal insulation property, high temperature resistance, low temperature resistance, non-inflammableproperty, high efficiency, and aging resistance. When the thermal insulation sheet material is used for building walls, the thermal insulation property of the sheet material can not be reduced with time, and the sheet material has the same service life with the building.

Owner:安徽瑞蒙科技有限公司

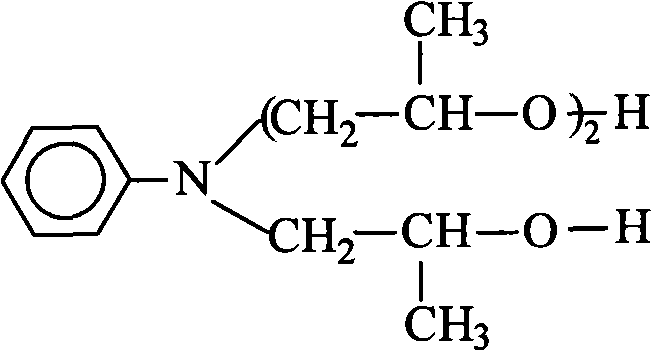

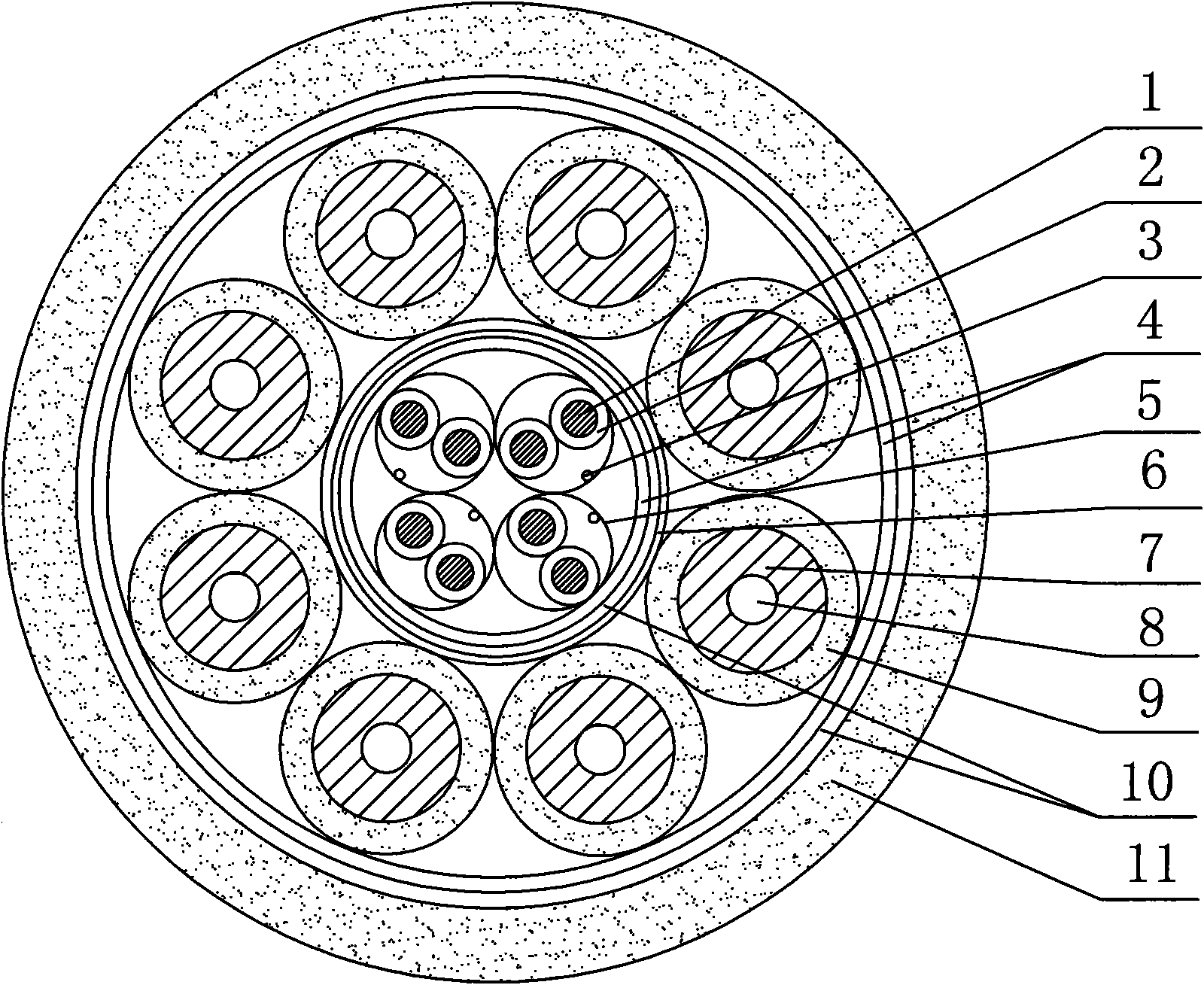

Preparation method of intrinsic flame retardant polyphosphazene resin with high/low-temperature resistance and high performance

InactiveCN108359101AControllable thermal performanceWide operating temperature rangePolyphosphazeneThermal stability

The invention discloses a preparation method of intrinsic flame retardant polyphosphazene resin with high / low-temperature resistance and high performance. According to the method, linear polydichlorophosphazene is subjected to co-substitution with two specific nucleophilic substitution reagents in the aspect of molecular design, separation, washing, purification, drying and other treatment are performed, and the intrinsic flame retardant polyphosphazene resin with high-temperature thermal stability and low-temperature flexibility is prepared. The high / low-temperature stability and elasticity of the intrinsic flame retardant polyphosphazene resin can be regulated by regulating the ratio of functionalized side groups. The scheme is as follows: phenoxyl and aliphatic straight-chain alkoxy indifferent molar ratios are used as the nucleophilic substitution reagents, tetrahydrofuran is taken as a reaction solvent, a reflux reaction is conducted at 60-70 DEG C for 36-48 h, a reaction mixtureis washed with deionized water and n-heptane 2-3 times, drying treatment is performed, and the intrinsic flame retardant polyphosphazene resin with high / low-temperature resistance and high performance is obtained. The resin has the Tg range of subzero 71.3 DEG C to subzero 7.1 DEG C, the maximum thermal weight loss temperature up to 530 DEG C and the residual rate up to 59.25%.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing phenyl silicone resin with high-refractive index

ActiveCN103232600ARadiation resistantWith high and low temperature resistanceSilanesRefractive index

The invention discloses a method for preparing phenyl silicone resin with high-refractive index. The method orderly comprises the following steps of (1) by taking silicone-alcohol and alkoxy silane as monomers, carrying out polycondensation under effect of a solid catalyst; (2) filtering out the solid catalyst in obtained reaction liquid after polycondensation is finished, and removing low-boiling-point substance to the reaction liquid to obtain the phenyl silicone resin with high refractive index. Compared with the prior art, the method has the advantages that 1, the method is simple in reaction process condition, easy to control and convenient to industrialize; 2, no solvent is added in the preparation process; and the method is environment-friendly and free of pollution; 3, the reaction process does not need hydrolysis reaction; and the reaction time is short; 4, the catalyst can be directly filtered after the reaction is finished; neutralization is not needed; the catalyst is removed by washing; the process is simplified; and wastewater discharge is also reduced; and 5, the refractive index of the prepared phenyl silicone resin is between 1.56 and 1.60; and the phenyl silicone resin has excellent performances such as high refractive index, high light transmittance, radiation resistance and high and low temperature resistance.

Owner:NICHE TECH KAISER SHANTOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com